Patents

Literature

46results about How to "The taste is mellow and fresh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fragrant white peony tea and production process thereof

ActiveCN101664082AThe taste is mellow and freshImprove qualityPre-extraction tea treatmentFlavorTea leaf

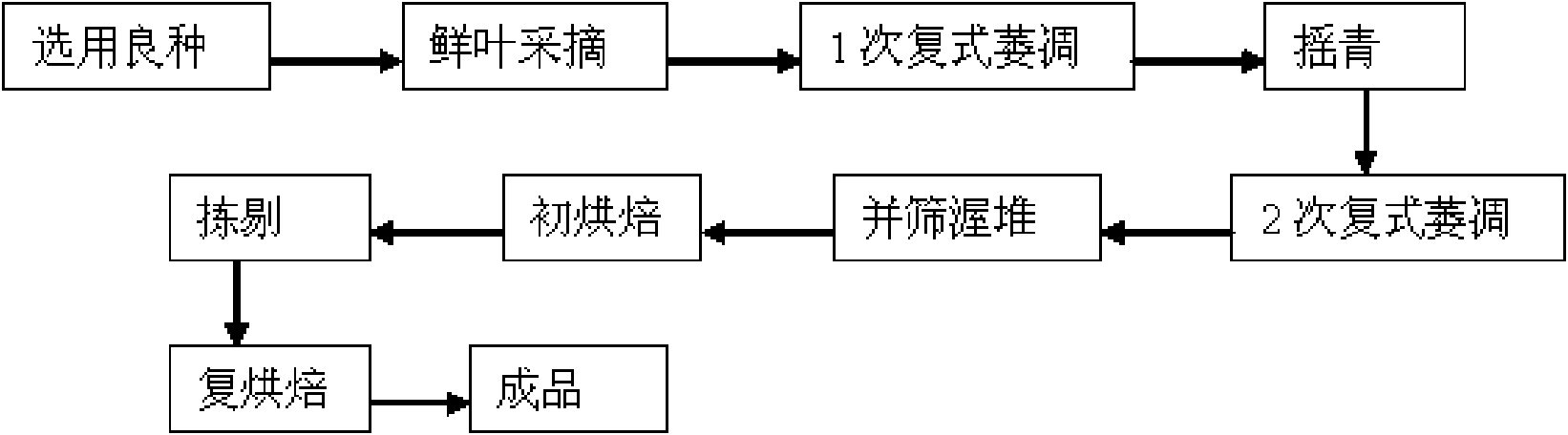

The invention provides a fragrant white peony tea and a production process thereof, which belongs to the technical field of white tea production, solves the problems that in the prior art, the appearance of white tea is deep green, pekoe is exposed without luster, endosarc has flavor but has obvious pekoe flavor, the liquor color is deep yellow, taste is pure and mild but thin, and the like, and improves external shape and endosarc of the white peony tea. The production process of the white peony tea takes tea suitable for preparing white tea as raw material, and prepares the white peony tea through the following steps: first combined withering, rocking green, secondary combined withering, screening and piling, primary curing, stalk extraction and after-curing. The white peony tea is beautiful in appearance, sage green in color and luster, obvious in endosarc pekoe flavor, apricot yellow in liquor color and full-bodied answer pleasant after taste, and naturally droops for leaf margin;and more importantly, the white peony tea can complement wateriness fragrance of white tea and have no defect of any fragrance. The white peony tea prepared by the production process has high-acuity fragrance, both pekoe flavor and obvious fleur, is very popular among consumers and vast tea lovers, and has obvious economical benefits; and the taste of the white peony tea is also with fleur.

Owner:福建品品香茶业有限公司

Production process of angelica keiskei koidzumi tea

The invention relates to the field of tea, in particular to a production process of angelica keiskei koidzumi tea, mainly comprising the steps of picking and washing fresh leaves of angelica keiskei koidzumi, and then spreading, fixing, rolling, drying, fried rolling, screening, drying, and finally obtaining the finished angelica keiskei koidzumi tea. The angelica keiskei koidzumi tea which is prepared by adopting the production process has the advantages of black and lubricant appearance, tightly knotted rope shape, prominent angelica keiskei koidzumi aroma, rich inclusion, darkbrown liquor color, dark green bottom of leaves, mellow taste and sweet aftertaste, retains a large number of beneficial health ingredients, and can resist brewing.

Owner:HUANGSHAN DUOWEI BIOLOGICAL GRP

Processing technique of fragrant Bailin Kongfu black tea

ActiveCN101664084AShorten withering timeAvoid the impact of low temperature and high humidity in springPre-extraction tea treatmentBlack teaSweetness

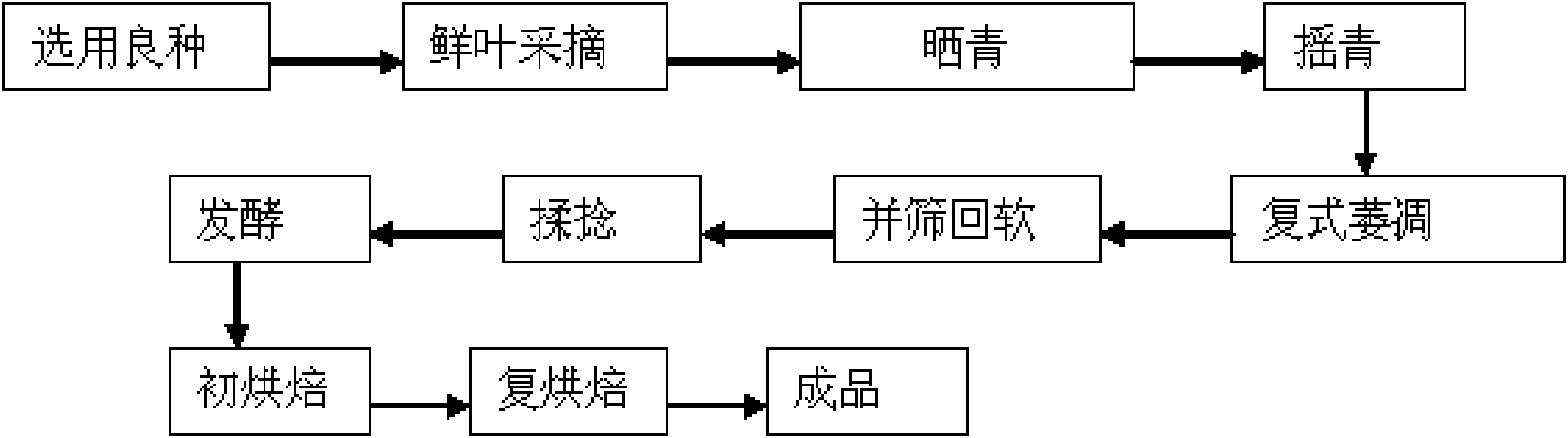

The invention provides a processing technique of a fragrant Bailin Kongfu black tea, belonging to the technical field of Kongfu black tea processing and solving the problem of Kongfu black tea in the prior art. The fragrant Bailin Kongfu black tea takes tea leaves appropriate for preparing black tea as raw materials, and the finished product is prepared by the following steps of green drying, green rotating, combined withering, screening and conditioning, rolling, fermentation, primary curing and combined curing. The processing technique improves the endoplasm feature of Bailin Kongfu, leads the endoplasm aroma to be with keen sweetness and with obvious flower and fruit fragrance; tea soup has charming red color and brightness; and taste is mellow and sweet and has fruity fragrance. The Bailin Kongfu black tea prepared by the processing technique has keen fragrance, sweetness and obvious fleur in taste, is very popular among consumers and vast tea lovers, and has obvious economical benefits.

Owner:福建品品香茶业有限公司

Processing method of Guanyin black tea having aroma

ActiveCN107865125AReduce color changeImprove distributionPre-extraction tea treatmentClimate change adaptationTemperature controlBlack tea

The invention provides a processing method of Guanyin black tea having aroma, and belongs to the technical field of processing of tea leaves. The processing method comprises the following steps of selecting Tieguanyin tea trees, picking fresh leaves, performing sunning with soft sunlight, performing cooling, rocking the cooled leaves for the first time, shining the rocked leaves, and performing rocking for the second time; and performing temperature-controlled withering in an air conditioning room, performing rolling, performing deblocking, performing fermentation, performing drying with a first fire, performing drying with a full fire, performing aroma increasing and performing packing. The made Guanyin black tea is tight and thin in strips, the soup color is red and bright, the taste ismellow, fresh and brisk, the Guanyin black tea has special aroma of Guanyin tea, and sweet aroma of black tea, and the Guanyin black tea is long in fragrance and rich in Guanyin tea fragrance.

Owner:南宁茗韵茶业有限公司

Baking and drying method of strong-flavor green tea leaves

InactiveCN106720527AImprove thermal efficiencyPrevent oxidationPre-extraction tea treatmentCooking & bakingAdditive ingredient

The invention discloses a baking and drying method of strong-flavor green tea leaves. The method comprises the steps of putting the tea leaves into a heat-pump drying oven to dehumidify and dry the tea leaves; putting the tea leaves into a dryer after the tea leaves are cooled down, baking the tea leaves for 30-40 min at the temperature of 125-132 DEG C, cooling the tea leaves to 60 DEG C, then heating the tea leaves to raise the temperature to 105-115 DEG C to bake the tea leaves for 3-5 h, and then cooling the tea leaves to the room temperature; then conducting far-infrared baking, wherein the far-infrared heating temperature is 90-100 DEG C, the wavelength is 35-60 micrometers, and the heating duration is 1-2 h. According to the baking and drying method of the strong-flavor green tea leaves, a heat pump is firstly chosen to conduct drying and dehumidification, the thermal efficiency of the heat pump is high, and nutritional ingredients can be effectively prevented from being oxidized after the heat pump is filled with nitrogen to dry the tea leaves; meanwhile, consumed energy is little, moisture and foreign flavor are removed through high-temperature baking, the fragrance is pure, low-temperature baking is conducted so that the tea leaves can slowly and sufficiently absorb heat, the substances in the leaves change steadily, through far-infrared baking, a thermalization effect is further achieved, and the fragrance is further improved. The fragrance of the tea leaves baked through the baking and drying method of the strong-flavor green tea leaves is obviously improved, the taste is more mellow and fresher, and the tea liquor color is golden yellow and bright.

Owner:六安市笑春堂农业开发有限公司

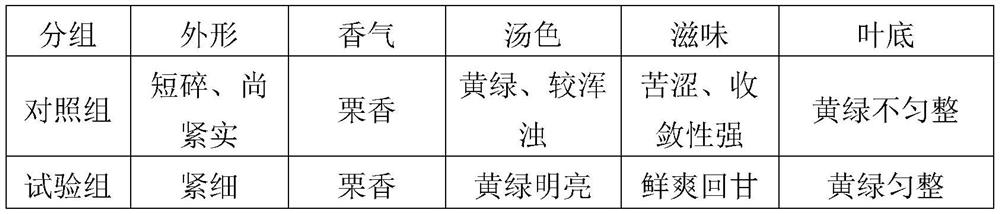

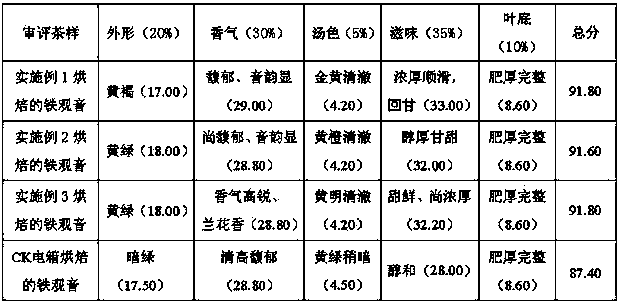

Microwave and far-infrared composite baking method for improving quality of Tieguanyin fresh tea

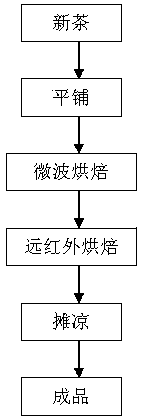

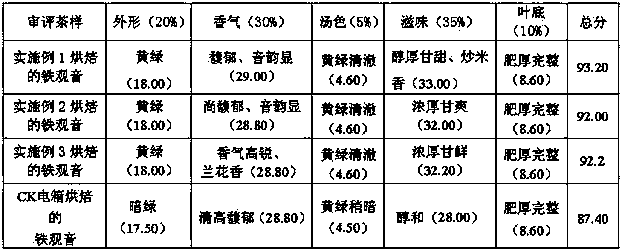

The invention discloses a microwave and far-infrared composite baking method for improving the quality of Tieguanyin fresh tea, belonging to the technical field of tea processing. The method comprises the steps of performing microwave and far-infrared composite baking on the Tieguanyin fresh tea, wherein the heating temperature of microwave baking is 50-60 DEG C, and the microwave frequency is 2,450-4,000MHz; performing intermittent heating baking for 2-3 hours; performing far-infrared baking, wherein the far-infrared heating temperature is 90-100 DEG C, the wavelength is 40-100 microns, and the baking time is 1-2 hours. After the microwave and far-infrared composite baking, the aroma of the Tieguanyin fresh tea is mixed with flower aroma or stir-fried rice aroma, and the taste becomes fresh and mellow without bitter, so that the quality is remarkably improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

Preparation method of jasmine tea

ActiveCN111919946ANo pollution in the processMix flowers evenlySievingPre-extraction tea treatmentEngineeringTea leaf

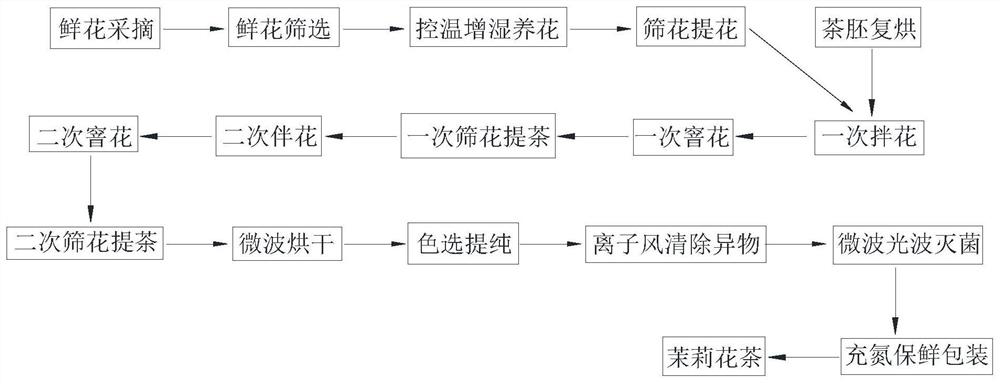

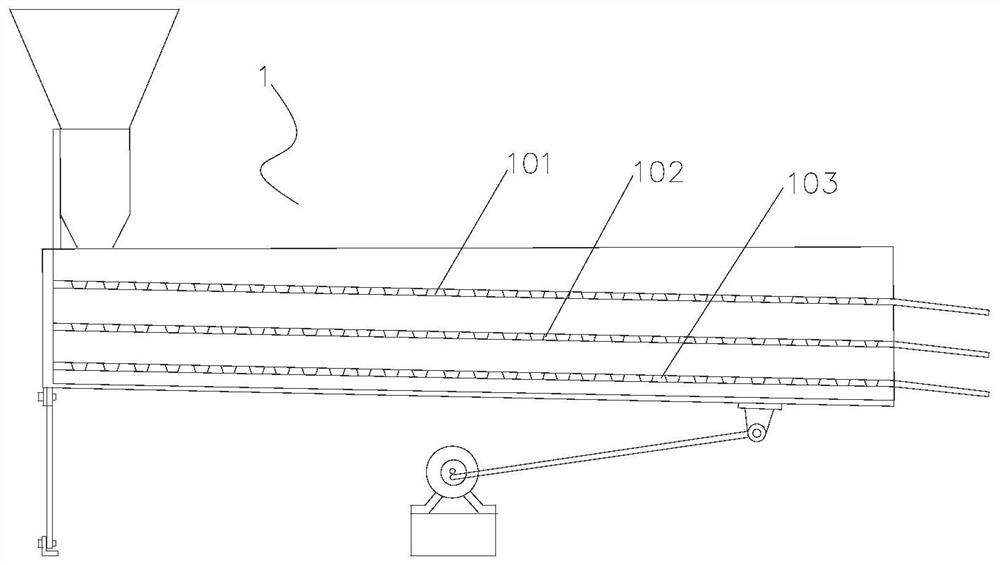

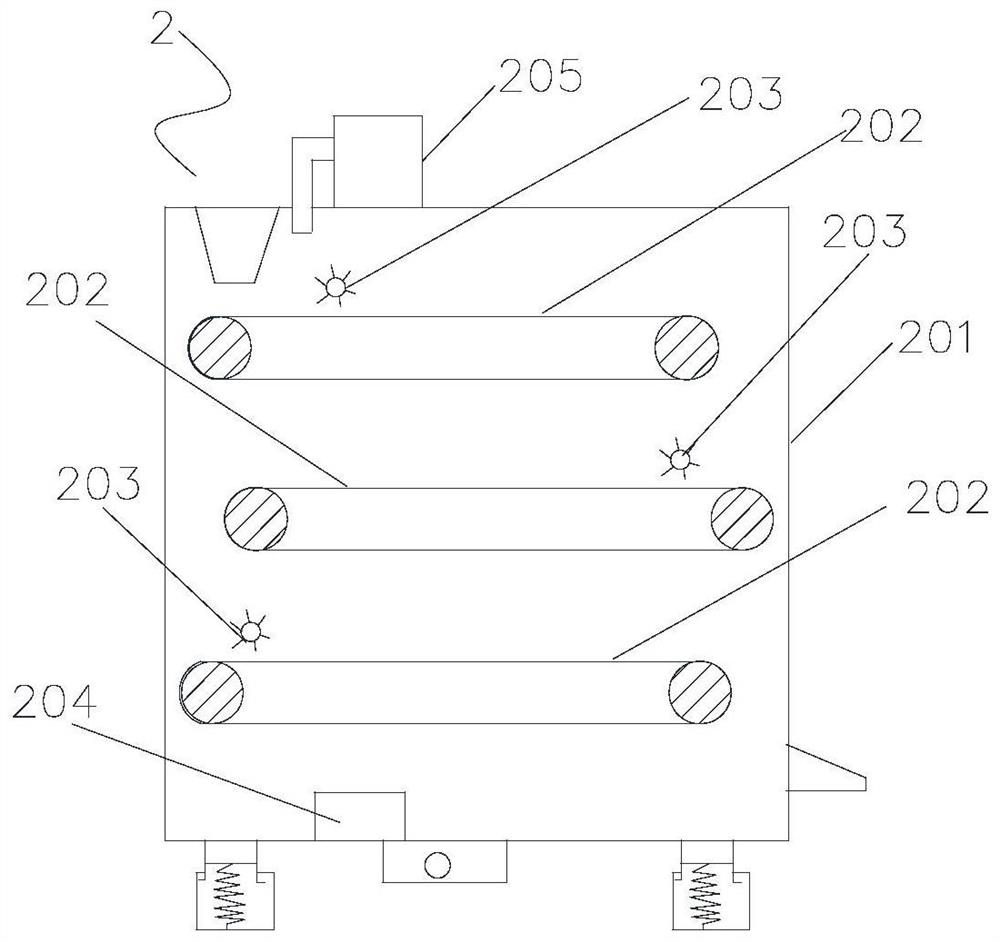

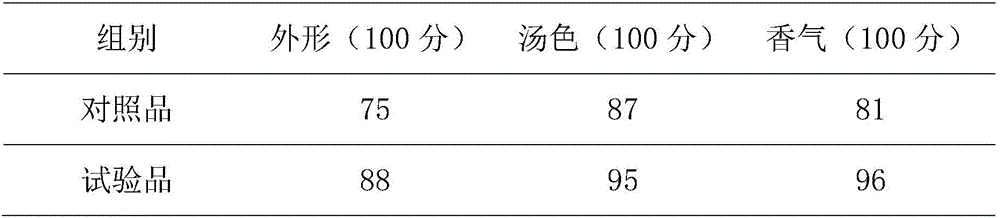

The invention discloses a preparation method of small-pot jasmine flowers. The preparation process of the jasmine tea comprises the following steps of: picking fresh flowers, screening and selecting flowers, controlling temperature, humidifying, growing flowers, screening flowers, extracting flowers, primarily preparing and re-drying a tea base, mechanically stirring flowers, scenting for the first time, screening flowers and extracting tea for the first time, accompanying for the second time, scenting for the second time, screening flowers and extracting tea for the second time, conducting microwave drying, sorting color and purifying, removing foreign matters, sterilizing by microwave light waves, and filling nitrogen for preservation and packaging. The jasmine tea prepared by the methodis few in impurities and high in cleanliness, the tea leaves can fully absorb the fragrance of jasmine, the use amount of jasmine can be effectively reduced while the fragrance of the tea leaves is ensured, and the jasmine tea can be widely applied to the field of jasmine tea processing.

Owner:黄山小罐茶业有限公司

Preparation method for jasmine scented tea

InactiveCN106889231AFresh and lasting aromaStrong aromaPre-extraction tea treatmentGreen teaTea leaf

The invention discloses a preparation method for jasmine scented tea. The method comprises the following steps: 1) finely selecting jasmine flowers: picking in sunny days at the temperature of 25-35 DEG C at 12 p.m. to 16 p.m. at the beginning of August and selecting variety jasmine sambac; 2) treating a tea re-firing the tea base of green tea till the water content is reduced to about 5%, reducing the temperature to about 40 DEG C after re-firing and then scenting; 3) stirring the tea flowers: using a screen machine for screening the jasmine sambac flowers and then alternately stacking the jasmine flowers and the re-fired tea base of green tea layer by layer; 4) taking out the flowers and re-firing: taking out the jasmine flower residue in the jasmine scented tea after stirring, and then re-firing the jasmine scented tea till the water content of the tea leaves is 6.5%-7%; 5) extracting flowers: adding the jasmine flowers into the jasmine scented tea after re-firing, extracting flowers and then taking out the jasmine flower residue. In such a manner, the jasmine scented tea provided by the invention has higher quality, better taste, long-lasting fresh fragrance and strong fragrance, and is suitable for all the people.

Owner:毛少云

Processing method of selenium-copper-rich green tea

InactiveCN106260201AEmerald green colorLong-lasting fragranceBio-organic fraction processingPre-extraction tea treatmentAdditive ingredientEmerald

The invention discloses a processing method of selenium-copper-rich green tea, and belongs to the technical field of tea processing. The processing method of selenium-copper-rich green tea provided by the invention has the advantages that according to the growth characteristics of a tea tree, an organic selenium copper nutrient solution is fully supplemented in the growth period of the tea tree; after being harvested, tea leaves are subjected to a series of simple processing such as spread drying, water removing and fumigating, so that after the tea leaves are brewed; tea buds are upright; the effect that as one falls, another rises is achieved; the color and luster are emerald green; the fragrance is aromatic and durable; the soup color is clear and bright; the taste is fresh, cool and mellow; the leave bottom is tender green and complete; the ornamental value is realized; in addition, the organic selenium copper content is obvious; no any injury is caused on the human body; meanwhile, the effective ingredients of tea polyphenol, amino acid and theine in the tea leaves are remained to the great degree; the tea leaf quality is improved, so that the commodity property of the tea leaves is greatly improved.

Owner:文县科学技术局

Tea extraction liquid, tea beverage, and preparation methods of tea extraction liquid and tea beverage

The present invention belongs to the technical field of food processing, and particularly relates to a tea extraction liquid, a tea beverage, and preparation methods of the tea extraction liquid and the tea beverage. The tea extraction liquid preparation method comprises: 1) double temperature extraction: dividing tea leaves into a first part of tea leaves and a second part of tea leaves, adding the first part of the tea leaves to water, extracting at an extracting temperature of 10-40 DEG C, carrying out solid-liquid separation to obtain a first part tea leaf extraction liquid, adding the second part of the tea leaves to water, extracting at an extracting temperature of 60-90 DEG C, and carrying out solid-liquid separation to obtain a second part tea leaf extraction liquid; and 2) mixing clarifying: mixing the first part tea leaf extraction liquid obtained in the step 1) and the second part tea leaf extraction liquid obtained in the step 1), and clarifying to obtain the tea extraction liquid. According to the preparation method of the present invention, the tea leaves are divided into the two parts, the two parts are respectively extracted at different temperatures, and the obtained extraction liquids are mixed, such that the aroma substance and the taste substance in the tea leaves are completely retained; and the tea beverage produced by using the extraction process has characteristics of rich aroma, mellow, refreshing and delicious taste, enough tea taste, and good sweet aftertaste.

Owner:康师傅饮品控股有限公司

Collagen milk tea and preparation technology thereof

InactiveCN107173442ABiodegradableHigh nutritional valueMilk preparationPre-extraction tea treatmentBiotechnologyHealthy diet

The invention discloses collagen milk tea and a preparation technology thereof. The milk tea consists of the following components in parts by weight: 2-6 parts of tea powder, 40-60 parts of collagen fat powder, and 8-12 parts of whole milk powder, wherein the collagen fat powder contains collagen, has biodegradability, is rich in amino acids including amino acids, proline, hydroxyproline and the like required by human bodies, has the effect of protecting the skin, can prevent calcium in skeleton from running off, can prevent osteoporosis, beside, can also enable cornea to keep transparent, and has favorable health-care efficacy. Compared with common milk tea in the market, the collagen milk tea has higher nutrient value, the milk fragrance and the tea fragrance are richer, the taste is mellow, fresh and refreshing, the milk tea is sweet after taste after being drunk, and the collagen being high in protein content and easy to digest and absorb by human bodies is matched with the milk tea, so that the collagen milk tea not only meets the pursuit of consumers, particularly young consumers for mouth feel, but also meets the requirements of people for healthy diets in modern society.

Owner:阳江喜之郎果冻制造有限公司

Processing method for strong-fragrance straight-strip green tea, as well as product thereof

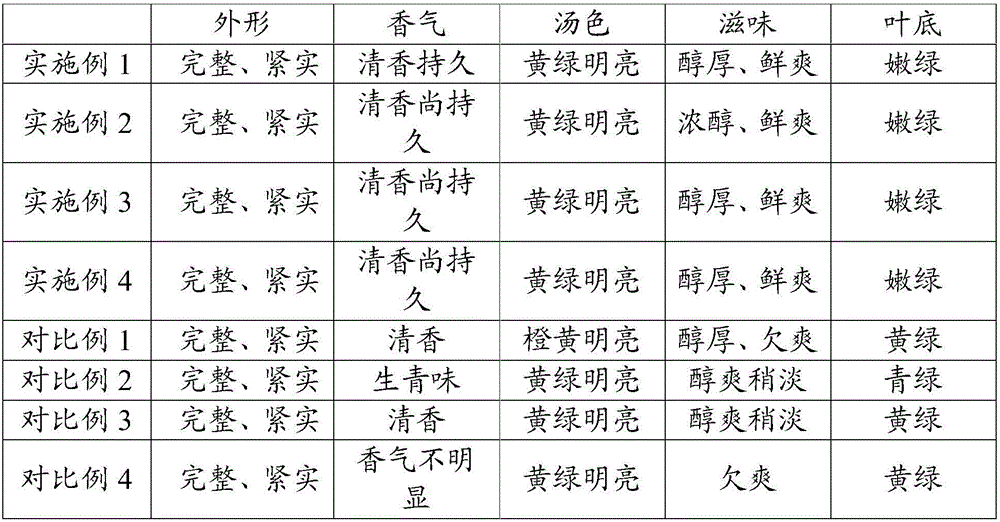

PendingCN107771980ASolve the shape and colorSolve the technical problem of incompatibility of aromaPre-extraction tea treatmentRoom temperatureGreen tea

A processing method for strong-fragrance straight-strip green tea as well as a product thereof. The invention relates to a green tea processing method and a product thereof. The method includes, but is not limited to the steps of: picking fresh tea leaves, tedding the fresh leaves, performing enzyme deactivation, spreading the tea leaves, rolling the tea leaves, re-wetting the tea leaves, pressuring the tea leaves to shape the tea leaves, and drying the tea leaves for enhancing fragrance. After the spreading step, the tea leaves are subjected to primary drying and heating, temperature being 80-100 DEG C; the tea leaves are rolled in a manual hot-rolling manner, wherein the tea leaves, after the primary drying and heating, are rubbed in the same direction by hands according to the force sequence of light-heavy-light for 3-7 min, and when the tea leaves has a slight stabbing hand feel, moving the tea leaves out from the pot; after the pressuring and shaping step, the tea leaves are rapidly cooled and re-wetted; the shaped primary tea leaves are placed in a ventilated tea plate according to the thickness of 2-6 cm, so that the tea leaves are quickly cooled to room temperature within 10 sec; finally the tea leaves are spread and are re-wetted. The product has stiff texture, has a bright green color of tea residues and tea soup and has mellow fragrance. Dry tea leaves have strong fragrance and the tea has a refreshing and mellow taste. The tea product brings enjoyment of color, fragrance and smell, even physical and mental pleasure.

Owner:湖南省千秋界茶业股份有限公司

Method for processing organic fragrant tea

InactiveCN102370013AEmerald green colorSoup is clear and brightPre-extraction tea treatmentChemistryWinnowing

The invention relates to a method for processing tea, in particular to a method for processing organic fragrant tea. The method for processing the organic fragrant tea comprises the processing steps of selecting materials, slightly withering, removing green, cooling, kneading and twisting, drying, winnowing and the like. In the method, processing machines are adopted in the process of processing the tea, so a flow line is formed integrally and yield is increased. The tea processed according to the steps has high quality, durable fragrance, faint fragrance slightly with orchid fragrance, strip-shaped, curled and attractive appearance, jade green color, flowers at the bottom of the tea, clear and bright soup color, and fresh and mellow taste.

Owner:浙江银奥茶业发展有限公司

Production method of high-nutrition good-taste green tea

InactiveCN106387125AIncrease contentOptimizing Process ParametersPre-extraction tea treatmentMicrowaveNutrition

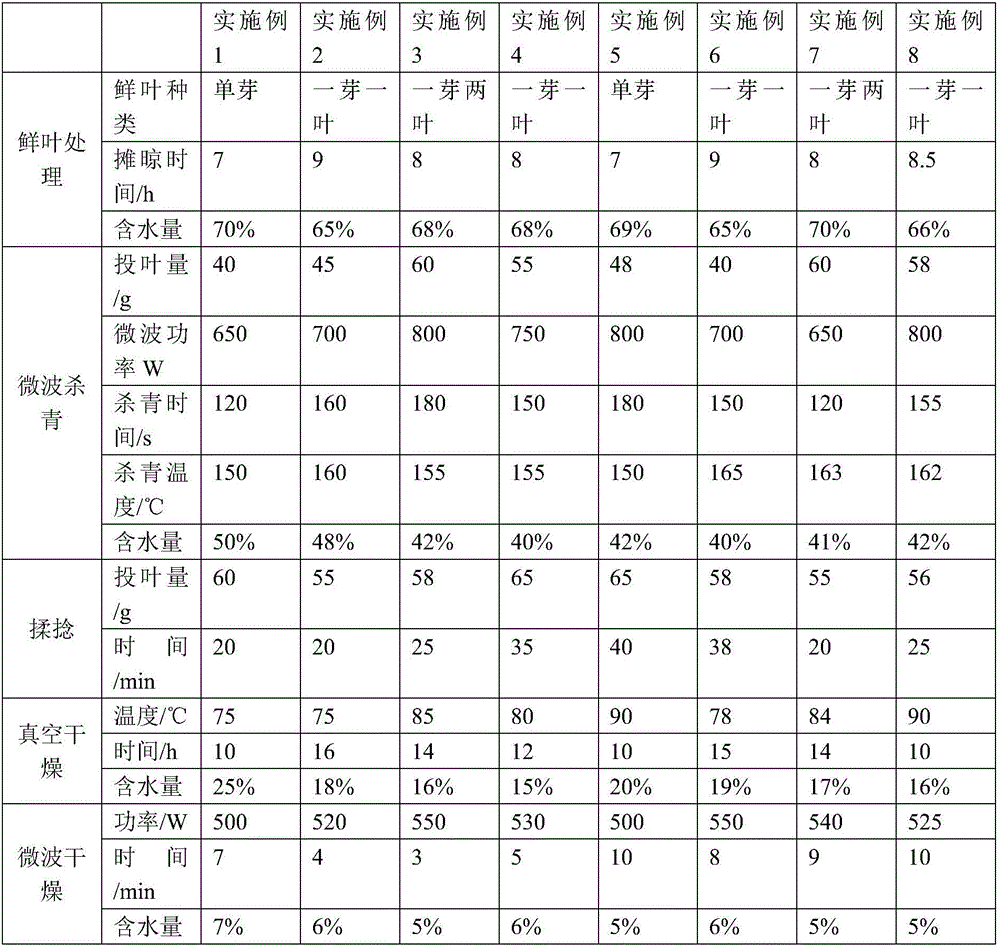

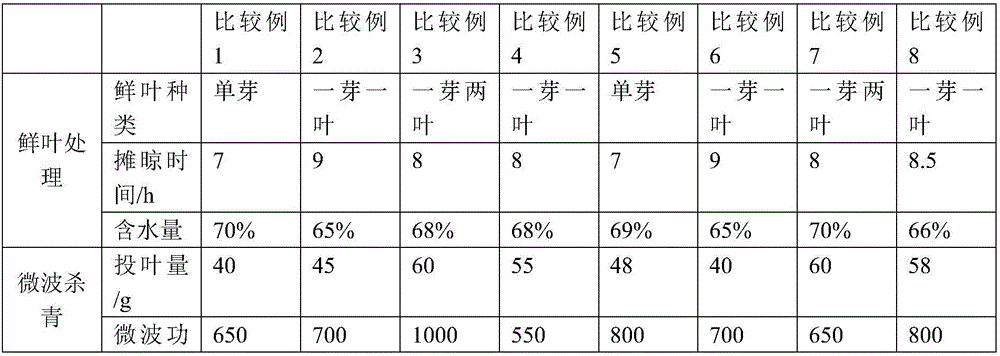

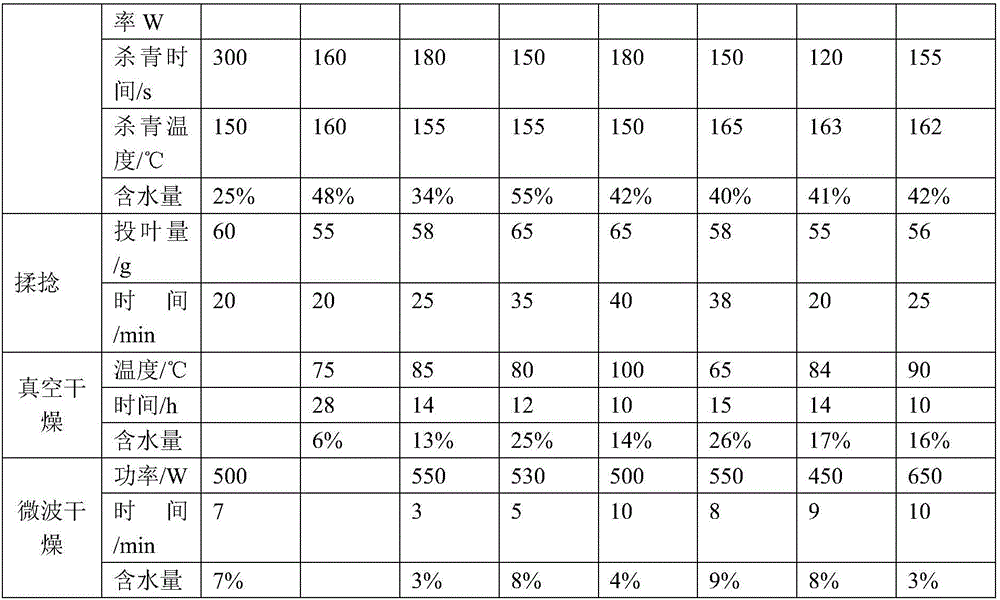

The invention discloses a production method of high-nutrition good-taste green tea. The production method comprises the following steps of (1) performing spreading for cooling: taking fresh tea leaves, and spreading the taken fresh tea leaves for cooling for 7-9 hours so that the water content is reduced to 65-70%; (2) performing microwave fixation: performing microwave fixation on the fresh leaves which are spread for cooling in the step (1) so as to obtain fixation leaves of which the water content is 40-50%; (3) performing rolling: rolling the microwave fixation leaves so as to obtain shaping leaves; (4) performing vacuum drying: performing vacuum drying on the shaping leaves after rolling so as to obtain a semi-finished green tea product of which the water content is 15-25%; and (5) performing microwave drying: performing microwave drying on the semi-finished green tea product after vacuum drying so as to obtain the green tea of which the water content is 5-7% finally. The green tea is high in content of tea polyphenols, high in content of amino acids, high in content of soluble sugar, high in content of water extracts, low in phenols / ammonia ratio, and fresh, refreshing and mellow in taste.

Owner:东莞市哥布林文化传媒有限公司

Jasmine tea lipstick

InactiveCN105919911AKeep dryEasy to crackCosmetic preparationsToilet preparationsBiotechnologyMentha spicata

The invention belongs to the field of preparation of a lipstick, and in particular relates to a jasmine tea lipstick. The jasmine tea lipstick consists of the following raw materials in parts by weight: 8-10 parts of a jasmine tea extract, 12-15 parts of peppermint, 15-20 parts of Chinese toon sprouts, 12-13 parts of honey, 19-22 parts of beeswax and 6-8 parts of apricot kernel oil. The jasmine tea lipstick is quite significant in effects on resisting bacteria and diminishing inflammation, moistening lips, resisting radiation and aging, and the jasmine tea lipstick is easy to absorb, mild in property and non-irritant.

Owner:福建春伦集团有限公司

Ilex latifolia thunb black tea and processing method thereof

ActiveCN111418668AReduce bitternessStable tastePre-extraction tea treatmentClimate change adaptationBlack teasTea leaf

The invention relates to Ilex latifolia thunb black tea and a processing method thereof, and belongs to the field of tea processing. The processing method of the Ilex latifolia thunb black tea comprises the following steps: withering fresh leaves, splicing the fresh leaves, performing primary rolling, performing primary fermentation, performing primary baking, performing secondary rolling, performing secondary fermentation and performing drying to obtain the Ilex latifolia thunb black tea. According to the ilex latifolia thunb black tea prepared by the method, the tastes of congou black tea and small-leaf ilex latifolia thunb are well fused together, the bitter tastes of the congou black tea and the small-leaf ilex latifolia thunb are reduced, and the Ilex latifolia thunb black tea has thefresh and sweet fragrance of the congou black tea and sweet aftertaste of the small-leaf ilex latifolia thunb and has a stable taste.

Owner:YIBIN SHUANGXING TEA IND

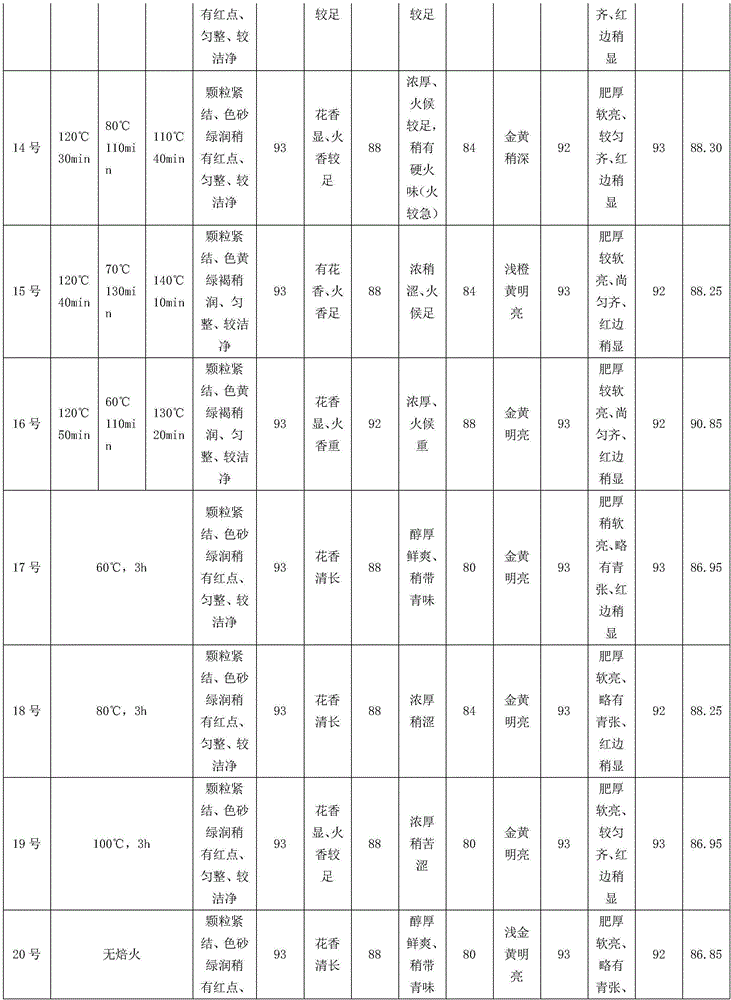

Temperature-changeable baking method of orange osmanthus oolong tea

The invention provides a temperature-changeable baking method of orange osmanthus oolong tea, and belongs to the technical field of tea leaf baking. The orange osmanthus oolong tea is granular orange osmanthus oolong tea which is obtained by removing stems and bracts after refining; the temperature-changeable baking method of the orange osmanthus oolong tea comprises the following steps: (1) removing impurities at high temperature, wherein the temperature is 110 DEG C to 120 DEG C and the lasting time is 20min to 30min; turning and stirring for one time during the process; (2) slowly baking at low temperature, wherein the temperature is 90 DEG C and the lasting time is 130min to 140min; turning and stirring for 1 to 2 times during the process; (3) improving the aroma at high temperature, wherein the temperature is 120 DEG C to 130 DEG C and the lasting time is 10min to 30min; turning and stirring for one time during the process. The method provided by the invention has the advantages that (1) the baked orange osmanthus oolong tea has relatively low water content, the aroma of tea leaves is improved, and the bitter and green tastes of the tea leaves are reduced; (2) baked tea grains are tight, have rich flower aroma, have mellow and fresh taste and have thick, soft and bright leaves after being brewed.

Owner:TEA RES INST OF FUJIAN ACADEMY OF AGRI SCI

Variable-speed rolling process of curly green tea

PendingCN112602796ARich tasteThe taste is mellow and freshPre-extraction tea treatmentGreen teasEngineering

The invention discloses a variable-speed rolling process of curly green tea. The variable-speed rolling process comprises the steps of fresh leaf spreading, fixation, primary variable-speed rolling, secondary baking, secondary variable-speed rolling and drying. In the preparation process of the curly green tea, two times of variable-speed rolling are adopted, different pressurizing stages are adopted in each time of variable-speed rolling, and different rolling strengths and speeds are adopted according to different pressurizing stages, so that the finished green tea is compact and complete in appearance, light green in color, clear in soup color and fresh and sweet in taste, and the tea yield is remarkably increased; and the product value is improved.

Owner:四川省茶业集团股份有限公司

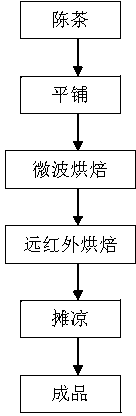

Microwave and far infrared composite baking method for improving quality of aged Tieguanyin

The invention discloses a microwave and far infrared composite baking method for improving the quality of aged Tieguanyin and belongs to the technical field of tea processing. Microwave and far infrared composite baking of the aged Tieguanyin is performed. Microwave baking heating is intermittently carried out at a temperature of 50 DEG C to 60 DEG C for 2-3h, and the microwave frequency is from 2,450 MHz to 3,000 MHz. Then, far infrared baking is adopted, the far infrared heating temperature is from 90 DEG C to 100 DEG C, the wavelength is from 40 microns to 100 microns, and the baking lasts 4-5 h. The aged Tieguanyin which is treated by microwave and far infrared composite baking has flower scent or fried rice scent, the bitter taste is changed into a fresh and mellow taste, and the quality of the aged Tieguanyin is obviously improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

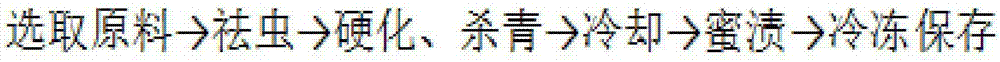

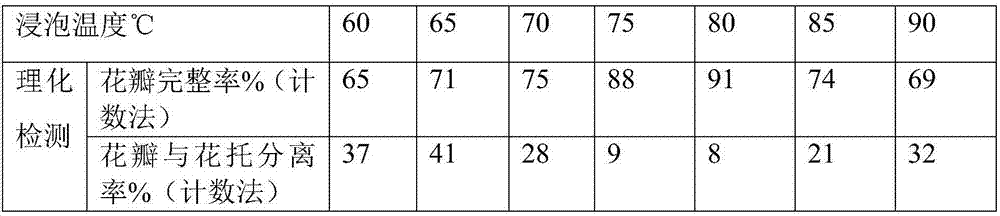

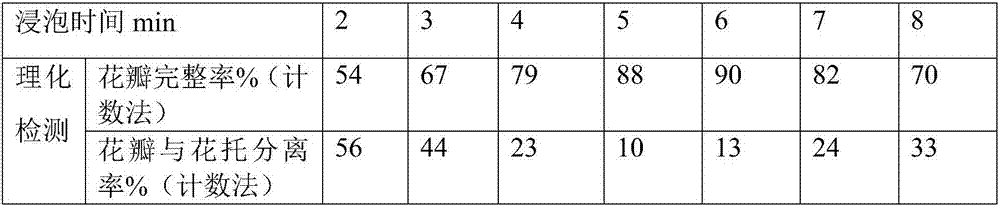

Jasmine flower beverage concentrate using fresh jasmine flowers as raw material and preparation method thereof

The invention provides jasmine flower beverage concentrate using fresh jasmine flowers as a raw material. The jasmine flower beverage concentrate comprises, by weight, 250-400 parts of candied jasmine flowers, 300-500 parts of sugar, 0.35-0.45 part of calcium chloride dihydrate, 4-5 parts of low-methoxyl pectin, 0.4-0.8 part of gluconolactone, 0.1-0.5 part of preservative, 0-1 part of antioxidant, 0-10 parts of essence and 200-300 parts of water. The jasmine flower beverage concentrate belongs to the technical field of plant beverages, is more natural in appearance and aroma, fresh and clear in aroma, high in freshness, yellowish and bright in color, high in petal integrity, mellow and fresh in taste and unique in flavor, and is high in suspension stability due to fresh flowers suspended therein.

Owner:广东鲜活果汁生物科技有限公司

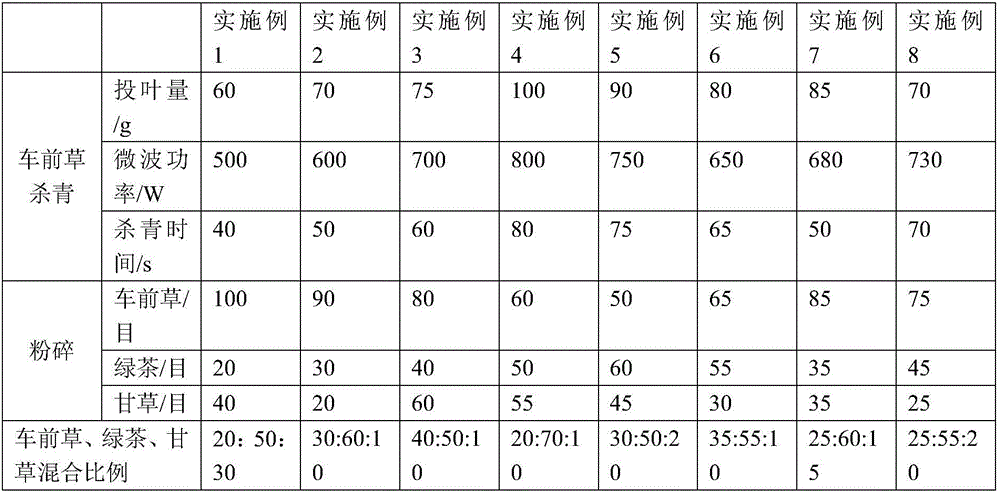

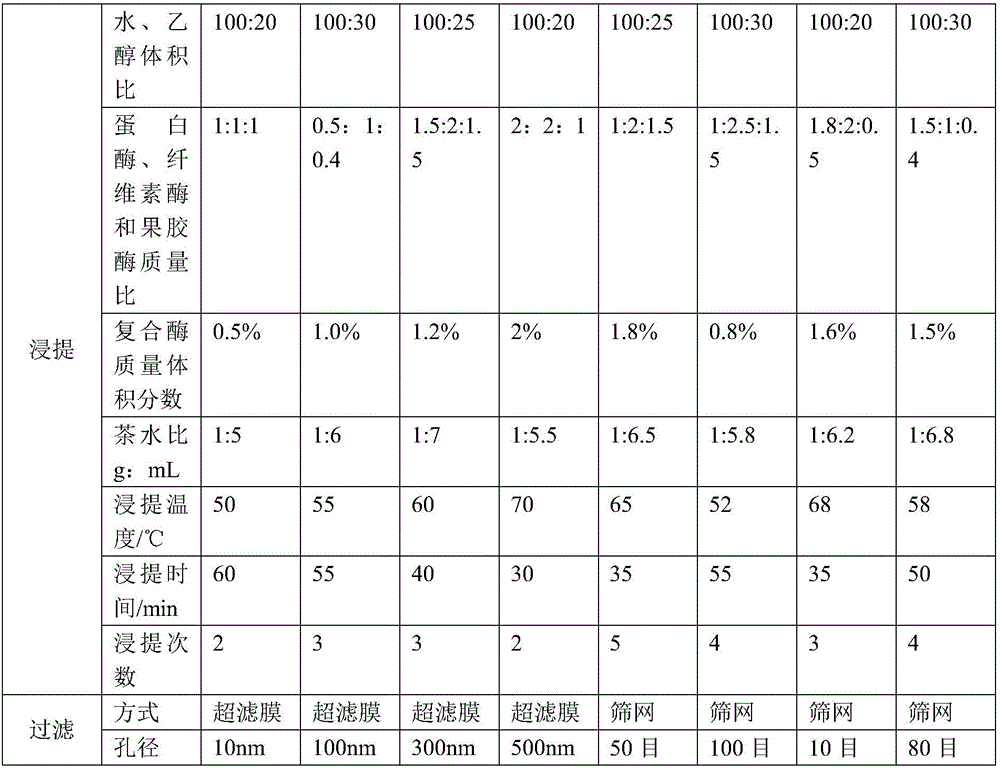

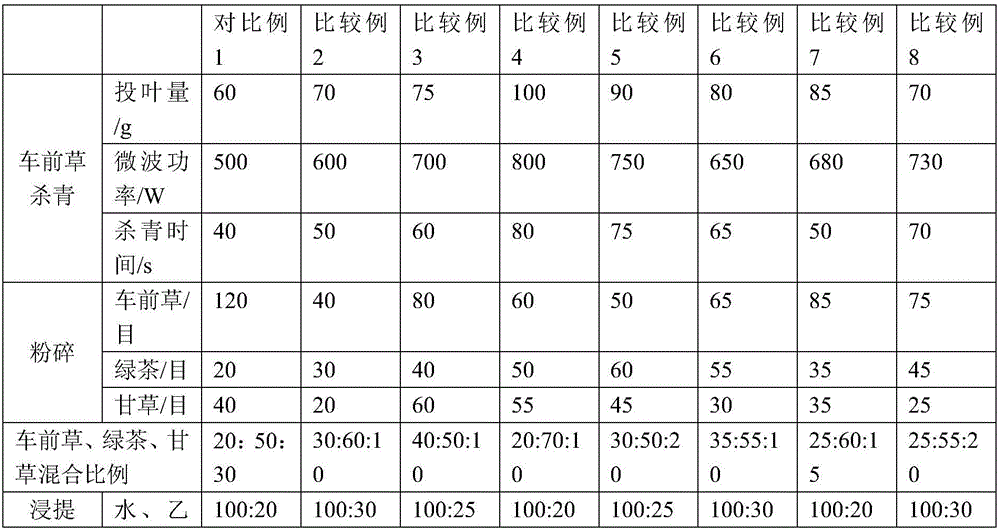

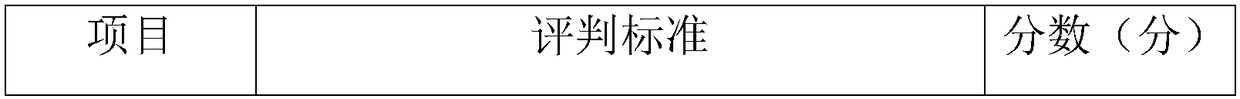

Producing method of plantain herb-green tea instant tea

InactiveCN106417772AReduce moistureKeep medicinal ingredientsTea extractionPectinaseAdditive ingredient

The invention discloses a producing method of plantain herb-green tea instant tea. The producing method includes the following steps that 1, microwave fixation and enzyme deactivation are carried out on fresh plantain herb; 2, the plantain herb obtained after fixation is smashed to 50-100 mesh, and green tea and licorice root are smashed into 20-60 mesh; 3, the smashed plantain herb, green tea and licorice root are mixed uniformly by the weight ratio of (20-40):(50-80):(10-30); 4, the mixture obtained in the step 3 is extracted through a mixed extraction liquid of water and ethyl alcohol, and compound enzymes composed of protease, cellulase and pectinase are added during extraction; 5, filtration, concentration and drying are carried out after cooling. The instant tea is high in content of the nutrient component of the green tea and the content of the medicinal component of the plantain herb and high in cold solubility.

Owner:东莞市哥布林文化传媒有限公司

Composite instant tea and preparation method thereof

PendingCN109329492AHeat-clearing and detoxifyingSoothe the nervesPre-extraction tea treatmentTea extractionMaillard reactionFreeze-drying

The invention discloses a composite instant tea and a preparation method thereof. The main materials comprise, in parts by weight, 14-16 parts of black tea, 6-8 parts of jasmine flowers, 5-7 parts oflotus leaves, 3-5 parts of Chinese wolfberry fruits, 3-5 parts of hawthorn fruits and 2-4 parts of dandelions. The auxiliary materials comprise maltodextrin, casein, carboxymethyl-beta-cyclodextrin, glucose, glycine, L-alanine and L-phenylalanine. The preparation method comprises the following steps: step 1, cleaning and weighing the main materials; step 2, adding purified water, and conducting heating and extraction; step 3, acquiring a filtrate; step 4, preparing microcapsules by adopting ultrasound; step 5, conducting vacuum concentration; step 6, carrying out a Maillard reaction; and step7, conducting pre-freezing for 30min, and conducting freeze drying to obtain the composite instant tea. According to the preparation method of the composite instant tea and the preparation method thereof, the problem of single variety of tea drink is solved, and the instant tea is not only convenient to use, but also good in fragrance, good in color and rich in nutrients.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Preparation method for jasmine flower snake gall tea

InactiveCN107232370AHighlight substantiveSignificant progressDispersion deliveryAntipyreticBile JuiceDigestion

The invention relates to a preparation method for jasmine flower snake gall tea. The preparation method is characterized by comprising the following steps: (1) taking snake galls from snakes, cleaning, placing in a shade place, shielding sunlight, naturally airing and standing by; (2) taking the dried snake galls, soaking in cold water for 30-40min or in hot water at 100 DEG C for 5min, taking out the snake galls after swelling and standing by; (3) preparing jasmine flower leaves at the ratio of 1 snake gall to 3-50g of dry flowers and standing by; placing the swelled snake galls obtained in the step (2) above the jasmine flower leaves, penetrating and uniformly dropping the outflow gall into the jasmine flower leaves prepared at an appointed ratio in the step (3); uniformly stirring and then standing by for 2-3 hours; and using a drying machine for drying for 15-20min, filling into stereoscopic tea bags, sealing, bagging according to the external packing size and volume and putting into a box, thereby obtaining the jasmine flower snake gall tea. The jasmine flower snake gall tea is characterized by the effects of refreshing, eliminating summer-heat by cooling, helping digestion, reducing phlegm, removing grease, losing weight, and the like.

Owner:广西小燕蛇业有限公司

Preparation technology of Shucheng Xiaolanhua early buds

The invention discloses a preparation technology of Shucheng Xiaolanhua early buds. The preparation technology of Shucheng Xiaolanhua early buds comprises the following step: (1), picking fresh tea leaves from west Anhui tea areas in mid-late March until mid April, wherein standards of the picked fresh tea leaves are: preliminarily developed tea leaves with one buds and one leaves, developed tea leaves with one buds and one leaves, and preliminarily developed tea leaves with one buds and two leaves; (2), sorting the freshly picked tea leaves, removing impurities, timely spreading the impurity-removed tea leaves in thin layers in ventilated, clean and dry bamboo-stripe trays indoors until moistures of the tea leaves reach 70-72% appropriately; (3), taking the tea leaves out, soaking the tea leaves in warm water for 15-20 minutes, fishing the soaked tea leaves out, draining the moisture on surfaces of the tea leaves, spreading the drained tea leaves in bamboo-stripe trays for 3-5 hours until no water is on surface of the tea leaves; (4), taking the soaked tea leaves out, treating the tea leaves in a low-temperature cold-air drying machine until moistures of the tea leaves reach 22-23%, and taking the treated tea leaves out; (5), performing manual rolling and strip-shaping on the tea leaves after cold-air drying, and sending the strip-shaped tea leaves into a drying machine so as to carry out primary drying until water contents in the tea leaves reach 6.5%; and (6), spread-airing the primarily dried tea leaves for 6-24 hours, pulling the trays of spread-aired tea leaves over big fire in turns until water contents in the tea leaves reach 4-6%, stopping baking the tea leaves, and packaging and storing the baked tea leaves when the buds and the leaves are slightly cooled.

Owner:SHUCHENG SHUCHA JIUYILIU TEA PLANTATION

Green tea early bud processing method

InactiveCN107821662AKeep active ingredientsPromote absorptionPre-extraction tea treatmentCold airWarm water

The invention discloses a method for processing early buds of green tea. The steps are as follows: 1) the standard for picking from the end of March to the middle and late April is one bud and one leaf; Put it in pure water for cleaning, then remove and drain the surface water and store it in the fresh-keeping store for 4 hours; 3) Take out the tea leaves in the fresh-keeping store, soak them in warm water for 10 minutes, then take them out and send them to the tumbler for rolling Kneading treatment; 4) Take out the tea leaves after rolling and kneading, place them in a low-temperature cold air dryer, the temperature of the cold air is 5-10°C, and take them out when the water content of the tea leaves reaches 22-23%; 5) Manually dry the tea leaves after the cold air drying. Knead and organize, and then send it to the tea dryer for initial drying. The temperature of the drying drawer of the dryer reaches 60-70°C, and the tea sticks are hand-kneaded into powder, and the water content reaches 6.5%. 6) The first-dried tea leaves Let it cool for 6-24 hours, then turn on the fire again, and dry it when the moisture content of the buds and leaves reaches 4%-6%. After a little cooling, it can be packaged and stored.

Owner:贵州绿视野绿色开发有限公司

Production process flow of single-bud Queshe tea

InactiveCN108552334AThe production process steps are simpleQuality improvementPre-extraction tea treatmentWater vaporDew

The invention provides a production process flow of single-bud Queshe tea. The production process flow comprises the following steps: firstly, picking tea leaves by manual work, and during picking, selecting one buds with one leaves with no mechanical damage, good evenness and good cleanliness rather than picking leaves with rain, leaves with dew, red or purple buds with leaves and buds with leaves with disease and pest; then placing the picked tea leaves on an airing frame, and performing airing to reduce the water content of the tea leaves to 68%-70%; placing the withered tea leaves in a steamer, and specifically, heating water vapor in the steamer to a saturated state before placing the tea leaves into the steamer; and maintaining the inside of the steamer at corresponding pressure, thereby performing fixation and softening on the tea leaves. The production process flow of the single-bud Queshe tea has simple steps and enables the tea quality to be better by selecting the mode of picking one buds with one leaves; the processed tea leaves are flat, straight and smooth in shape and jade green in color and luster; and the brewed tea liquor has mellow fragrance, clear and bright color, mellow, fresh and refreshing taste, lasting aftertaste and jade green, fresh and bright tea dregs.

Owner:黎平县侗乡永晟茶业有限责任公司

Vacuum freeze drying and microwave drying combined flower fragrance type black tea powder and preparation method thereof

PendingCN114009532AStrong floral fragranceDissolve fully and evenlyPre-extraction tea treatmentFreeze-dryingGreen teas

The invention discloses vacuum freeze drying and microwave drying combined flower fragrance type black tea powder and a preparation method thereof, and belongs to the technical field of tea preparation. The preparation method comprises the following steps: (1) picking fresh leaves; (2) sunning and withering; (3) carrying out fine manipulation of green tea leaves; (4) rolling; (5) fermenting; (6) stirring and separating; (7) carrying out freeze drying; (8) carrying out vacuum microwave drying; (9) grinding and sieving; and (10) carrying out aroma enhancement. According to a traditional black tea powder process, tea leaves are generally subjected to single fermentation. According to the invention, tea flowers and the tea leaves are subjected to mixed fermentation, so that the flower fragrance of the tea leaves is stronger, and the fragrance and taste of the tea leaves are better than those of black tea powder obtained through single fermentation; and the black tea powder can be used as auxiliary materials of instant milk tea, baked cakes, daily chemical products and the like.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Elm tree leaf tea and preparation method thereof

InactiveCN106306265ABright yellow-green soupThe taste is mellow and freshTea substituesFood dryingCooking & bakingRoom temperature

The invention relates to elm tree leaf tea and a preparation method thereof. The preparation method comprises the following steps of (1) picking fresh elm tree leaves; removing impurities; cleaning and drying the elm tree leaves; (2) performing tea seaming for 40s to 1 minute at 120 to 130 DEG C to obtain steamed green leaves; fast spreading and cooling the steamed green leaves to room temperature; (3) baking the leaves at the temperature of 100 to 110 DEG C until the water content is 65 percent; obtaining primary baked leaves; (4) kneading the primary baked leaves for 6 to 10 minutes to obtain kneaded leaves; (5) filling the kneaded leaves into a mold, and performing press forming; (6) performing baking at 75 to 85 DEG C until the leaves are fully dried; obtaining the elm tree leaf tea. The obtained elm tree leaf tea has the advantages that the soup color is yellow green and is bright; the taste is mellow, fresh and cool; the soaking is convenient; only one pressed tea block needs to be soaked in each time.

Owner:SOUTH CHINA AGRI UNIV

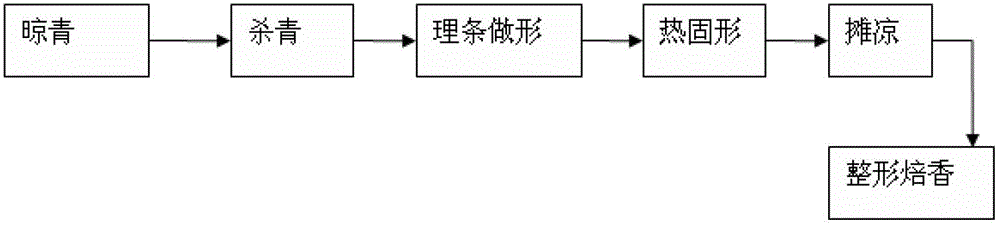

Processing process for Yungu Dafang tea

InactiveCN102742679AImprove qualityEasy to processPre-extraction tea treatmentTemperature controlAgricultural engineering

The present invention discloses a processing process for Yungu Dafang tea, which comprises the following steps: a green leaf drying and fragrance improving step, a ventilation-smothering-combined water removing step, a leaf tidying temperature-controlled shaping step, a thermal shape fixing step, a shaping and torrifying step, etc. The ventilation-smothering-combined water removing step is performed by an electrothermal roller water removing machine. The leaf tidying temperature-controlled shaping step is performed by a hot-wind leaf tidying machine and a semi-pot type tea flattening machine. The thermal shape fixing step is performed by a specific temperature-controlled heating device. The shaping and torrifying step is performed by the semi-pot type tea flattening machine. The Yungu Dafang tea which is processed by the processing process of the invention has the following advantages: strong fragrance, combination of chestnut fragrance and flower fragrance, mellow and fresh fragrance, remarkably improved quality than the traditional Dafang tea, reduced labor intensity and remarkably improved processing efficiency as a continuous water removing step is adopted in the processing process.

Owner:黄山茶业集团有限公司 +1

Processing method of Shucha early buds

The invention provides a processing method of Shucha early buds. The processing method comprises the following steps: (1) picking tea leaves in tea areas of Western Anhui from the end of March to the last ten-day period of April, wherein the standard is that one leaf has one bud in early development; (2) sorting the tea leaves which are freshly picked, then removing impurities, putting the tea leaves into purified water for washing, then fishing out the tea leaves, draining off moisture on the surfaces of the tea leaves, then putting the tea leaves into a fresh-keeping storehouse and preserving for 4 hours; (3) taking out the tea leaves in the fresh-keeping storehouse, putting the tea leaves into warm water and immersing for 10 minutes, then taking out the tea leaves and conveying the tea leaves into a rolling machine to be subjected to rolling treatment; (4) taking out the rolled tea leaves and putting the tea leaves into a low-temperature cold air dryer, wherein the temperature of cold air is 5-10 DEG C; treating the tea leaves until the moisture of the tea leaves reaches 22%-23% and taking out the tea leaves; (5) carrying out manual rolling and carding on the tea leaves dried by the cold air, conveying the tea leaves into a tea leaf drying machine and carrying out primary drying, and pinching the tea strips into powder by hands when the temperature of a drying drawer of the drying machine reaches 60-70 DEG C, wherein the moisture content is 6.5%; and (6) spreading and cooling the tea leaves, which are subjected to the primary drying, for 6-24 hours, and drying for one time until the moisture content of bud leaves reaches 4%-6%, then stopping drying and packaging and storing after the tea leaves are slightly cooled.

Owner:SHUCHENG SHUCHA JIUYILIU TEA PLANTATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com