Fragrant white peony tea and production process thereof

A technology of peony tea and floral fragrance, applied in the direction of tea treatment before extraction, can solve the problems of flat, dull and thin white tea aroma, achieve the effect of fresh and mellow taste, and change the lack of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

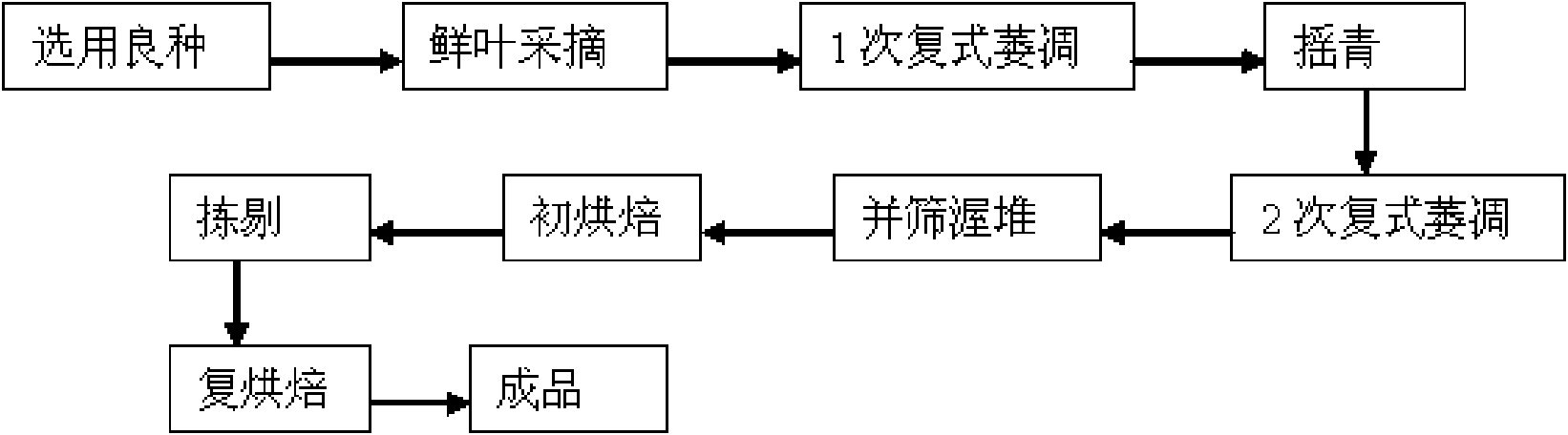

Image

Examples

Embodiment 1

[0045] Selection of fine varieties, fresh leaf standards and picking techniques, double withering, sieving and stacking, initial baking, picking, and re-baking are the same as described above.

[0046] 1. Select fine varieties: choose Fuding Dabaicha, Fuding Dahaocha or Zhenghe Dabaicha.

[0047] 2. Picking and protection of fresh leaves: The standard for picking fresh leaves is the young shoots with one bud and one and two leaves,

[0048] 3. Compound withering: The method of compound withering is adopted, and the rate of dehydration and weight loss of fresh leaves is used as the main index, and the degree of withering is grasped in combination with withering time and characteristics of withered leaves. Concretely grasp the water content of the withered leaves at 30%, the natural withering lasts 10-15 hours, and the sunlight withering lasts 4-7 hours. Carry out indoor heating and withering, the temperature is about 15°C, the relative humidity is 40%, and it lasts 3-6 hours. ...

Embodiment 2

[0054] Selection of fine varieties, fresh leaf standards and picking techniques, one double withering, shaking green, two double withering, and sifting and stacking, initial baking, picking, and re-baking are the same as above.

[0055] 1. Select fine varieties: choose Fuding Dabaicha, Fuding Dahaocha or Zhenghe Dabaicha.

[0056] 2. Picking and protection of fresh leaves: The standard for picking fresh leaves is the young shoots with one bud and one and two leaves,

[0057] 3. One-time compound withering: Withering of fresh leaves is affected by factors such as tea tree species, water content of fresh leaves, withering environment temperature, humidity and ventilation conditions, withering time, method, and leaf thickness. The present invention adopts the method of compound withering, that is, the combination of indoor natural withering, indoor heating withering and sunlight withering. The dehydration and weight loss rate of fresh leaves is used as the main index, combined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com