Patents

Literature

170results about How to "The production process steps are simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid wood bending technological method for curve-shaped structural member of redwood furniture

ActiveCN104802247AImprove the level of production technologyHigh strengthWood compressionWood treatment detailsSolid woodColor effect

The invention discloses a solid wood bending technological method for a curve-shaped structural member of redwood furniture. The solid wood bending technological method comprises the following steps: (1) wood type selection and lumber processing; (2) boiling or steaming for thermal treatment for softening; (3) longitudinal compression; (4) die bending forming; (5) drying sizing; (6) aging for life nourishing; (7) later processing and bending to manufacture the curve-shaped structural member of the redwood furniture. The solid wood bending technological method has the advantages that the generally conventional lineation sawing processing method can be replaced; a redwood type solid wood lumber can be directly bent into a curve-shaped part; the production technological level for the curve-shaped part of the redwood furniture can be increased, and the production technological steps can be simplified; the utilization rate of redwood type woods can be increased, the intensity of the curve-shaped part is enhanced, and the texture and color effect and the paint decoration quality on the surface of a product are guaranteed.

Owner:ZHONGSHAN TAIXING FURNITURE CO LTD

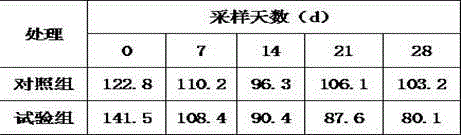

Biological deodorant for animal feeding

ActiveCN104814276AIncrease profitPromote Microecological BalanceFood processingAnimal feeding stuffSynbioticsHuman waste

The invention discloses a biological deodorant for animal feeding and belongs to the field of feed additives. The biological deodorant for animal feeding is composed of an active ingredient and an auxiliary protection carrier, wherein the active ingredient comprises synbiotics, the weight proportion of the synbiotics to the auxiliary protection carrier is (25-35): (50-65), the synbiotics are compounds of probiotics and prebiotics, and the mass fractions of the probiotics and the prebiotics are 65-80% and 20-35% respectively. After the biological deodorant for the animal feeding is used for feeding animals, all the active ingredients are synergistic in animal intestinal tracts, and finally the aim of reducing or eliminating odour of animal excrements is foundationally achieved, so that the biological deodorant for the animal feeding has good popularization and application values.

Owner:山东君德生物科技有限公司

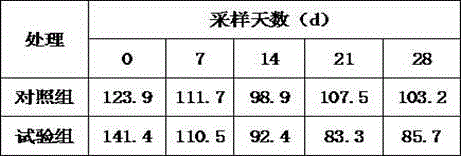

High-conductivity heat-resistance aluminum alloy wire and preparation method thereof

InactiveCN104831127AImprove heat resistanceImprove conductivityMetal/alloy conductorsSilicon alloyChemical element

The invention relates to a high-conductivity heat-resistance aluminum alloy wire and a preparation method thereof. The high-conductivity heat-resistance aluminum alloy wire comprises the chemical elements by weight percent: 0.03-0.06% of zirconium, 0.07-0.10% of silicon, 0.14-0.25% of iron, 0.03-0.06% of ytterbium, 0.01-0.04% of boron, not more than 0.02% of total amount of titanium, manganese, chromium and vanadium, and the balance of aluminum. The preparation method comprises the following steps: respectively weighing raw materials including aluminum ingots, aluminum-silicon alloy, aluminum-iron alloy, aluminum-ytterbium alloy and aluminum-boron alloy at a mass ratio of (6000-7000): (50-95): (15-55): (18-20): (40-85): (35-90); melting each raw material, performing purification regulating elements of an aluminum solution, slagging off, preserving the heat, standing, filtering the aluminum solution, casting and crystallizing; rolling ingot-casting-formed aluminum alloy ingots to form aluminum alloy wires, drawing the rolled aluminum alloy wires to form high-conductivity heat-resistance aluminum alloy wires. According to the prepared high-conductivity heat-resistance aluminum alloy wire, the electric conductivity is larger than 61% IACS, the tensile strength is larger than 160MPa, and the heat resistance is good; furthermore, the production technical steps are simple; by utilizing electric wires and cables produced by the aluminum alloy wires, the operation speed of a circuit can be improved, and the carrying capacity is improved.

Owner:WUXI HUANENG ELECTRIC CABLE

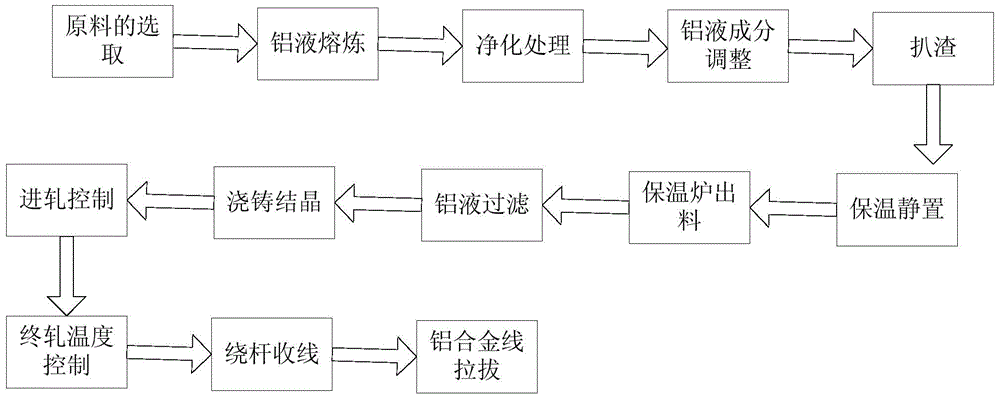

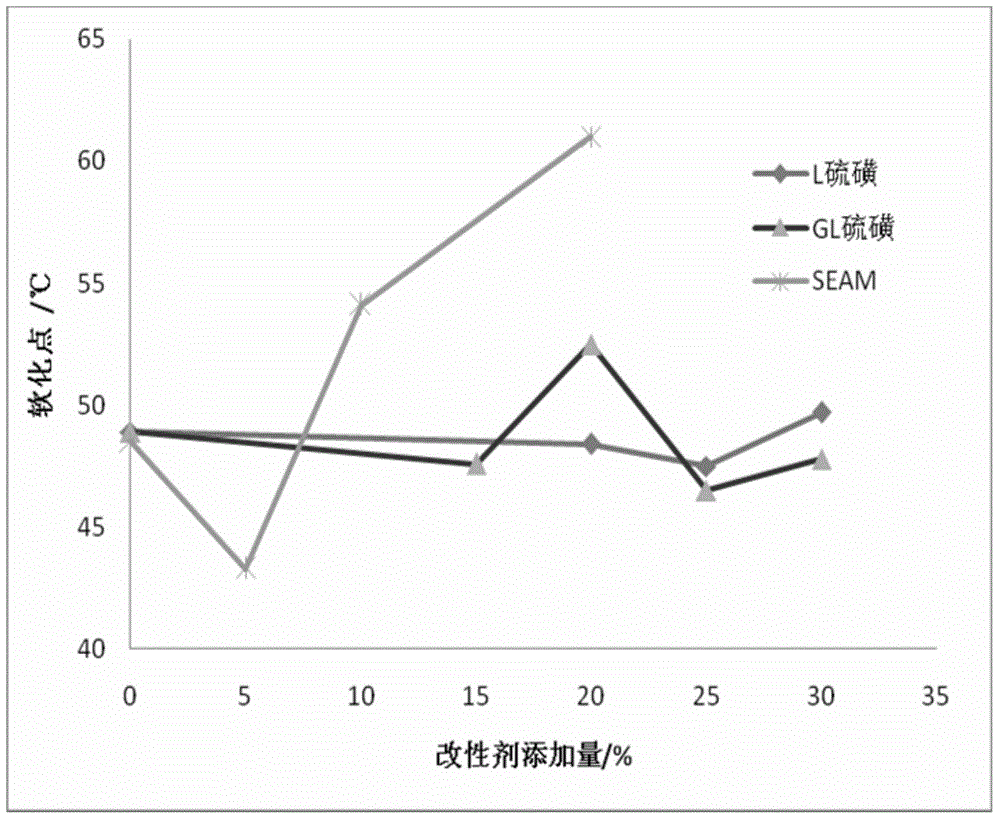

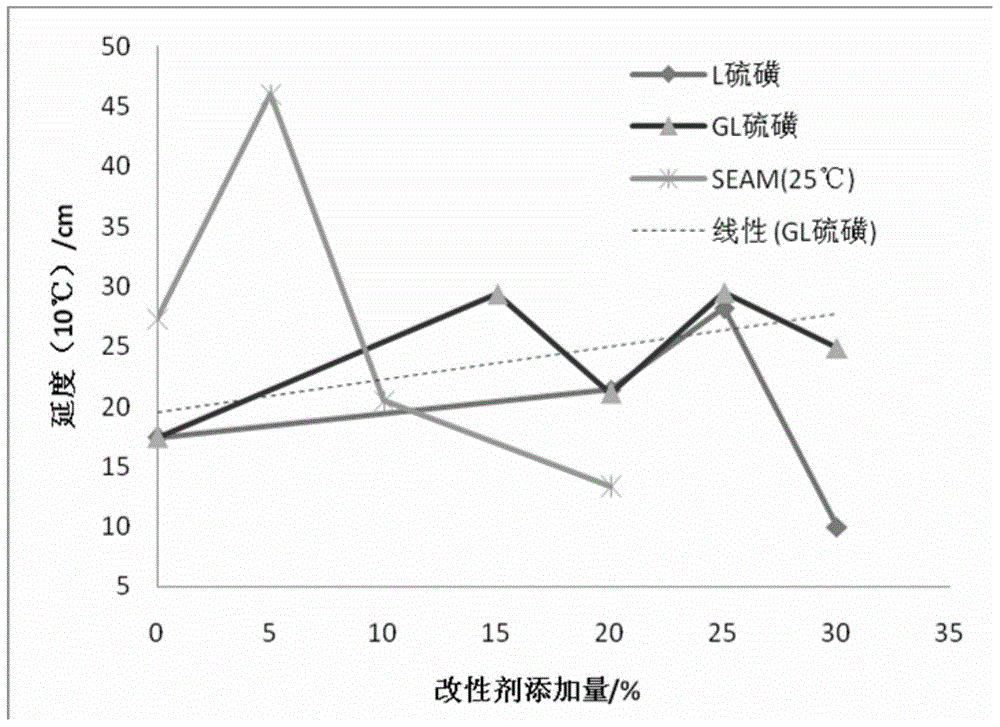

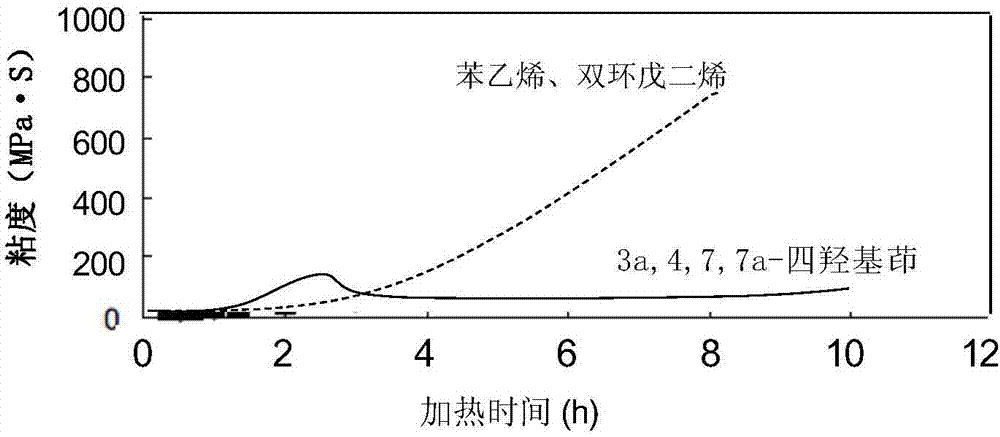

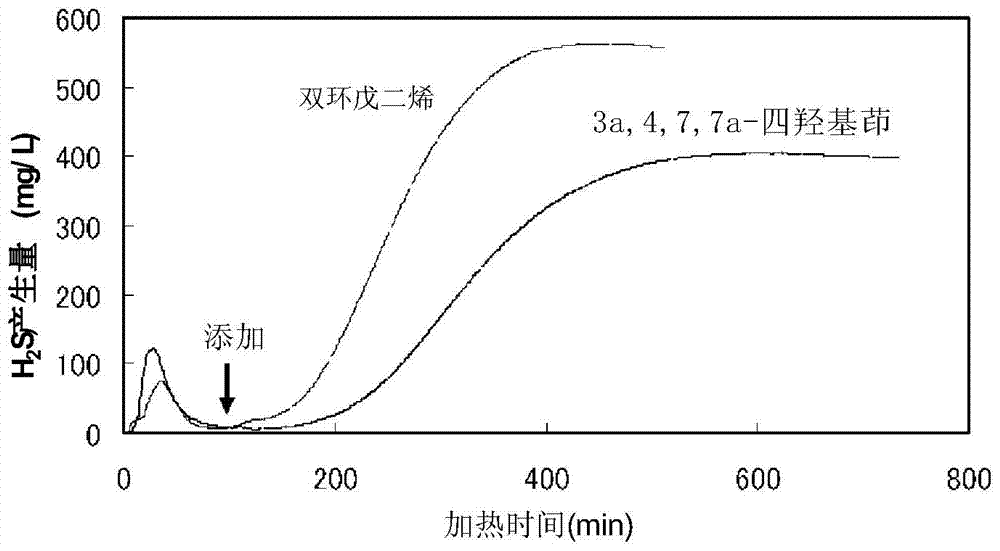

Asphalt modifier and industrial production method and application thereof

The invention discloses an asphalt modifier and an industrial production method and application thereof. The asphalt modifier is prepared by uniformly mixing modified sulfur and red mud particles. The industrial production method comprises the following steps: 1, preparing the modified sulfur, namely performing sulfur fusion and sulfur modification; and 2, adding the red mud particles. In the industrial production method, the modified sulfur is prepared in a way that an olefin modifier and a sulfur modification additive are added into sulfur for modifying sulfur; a weight ratio of the olefin modifier to sulfur is 2-6:100, and a weight ratio of the red mud particles to the sulfur is 10-30:100. The application process of the asphalt modifier comprises the following steps: I, preheating raw materials; and II, mixing, namely mixing the preheated asphalt modifier, mineral aggregate and matrix asphalt. The asphalt modifier adopted in the production method is simple in production process, low in construction cost, incombustible, safe to use and excellent in performance, the amount of discharged atmospheric pollutants in the production and application process is small, comprehensive performance of the modified asphalt concrete is excellent, and industrial waste red mud can be effectively utilized.

Owner:XIAN UNIV OF SCI & TECH

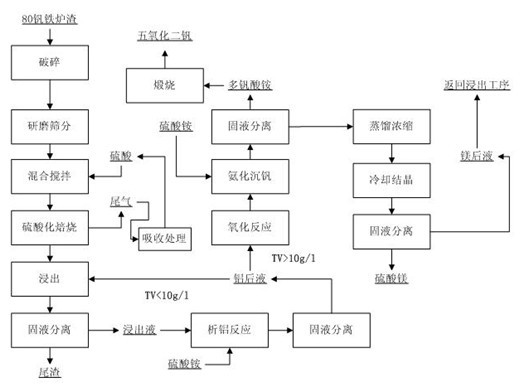

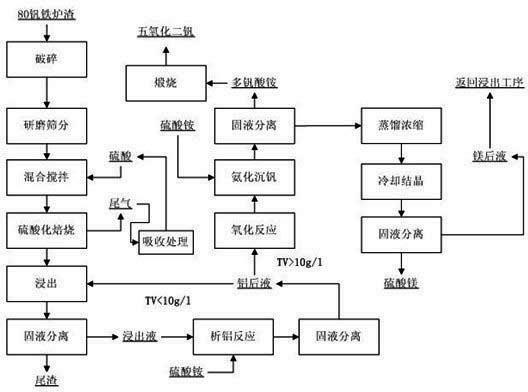

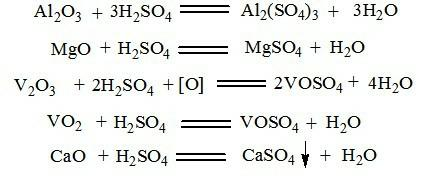

Resource recycling method for 80 ferrovanadium slag

ActiveCN102616851AFewer separation stepsEfficient recyclingSolid waste disposalMagnesium sulfatesSlagAluminum ammonium sulfate

The invention discloses a resource recycling method for 80 ferrovanadium slag, which adopts the following steps: (1) sulfating roasting: mixing the ferrovanadium slag and sulfuric acid, stirring, and then conducting sulfating roasting to obtain roasting slag; (2) leaching: mixing the roasting slag and deionized water or diluted acid, stirring and leaching, and then filtering to obtain leaching liquid; (3) enriching vanadium: adding ammonium sulfate into the leaching liquid, heating and dissolving, and then cooling, crystallizing, and filtering to obtain aluminum ammonium sulfate crystal and crystallization post liquid; (4) oxidizing and sinking vanadium: adding oxidant into the crystallizing post liquid to conduct oxidizing, converting all V3+ and V4+ in the crystallizing post liquid into V5+, then dropwise adding ammonia water, stirring and filtering to obtain ammonium polyvanadate sediment and filtrate, and roasting ammonium polyvanadate to obtain vanadium pentoxide; and (5) magnesium separating reacting: distilling and concentrating the filtrate, cooling, and filtering to obtain magnesium sulfate crystal. The method has the advantages of being simple in technology process, low in energy consumption and friendly in environment.

Owner:HEBEI IRON AND STEEL

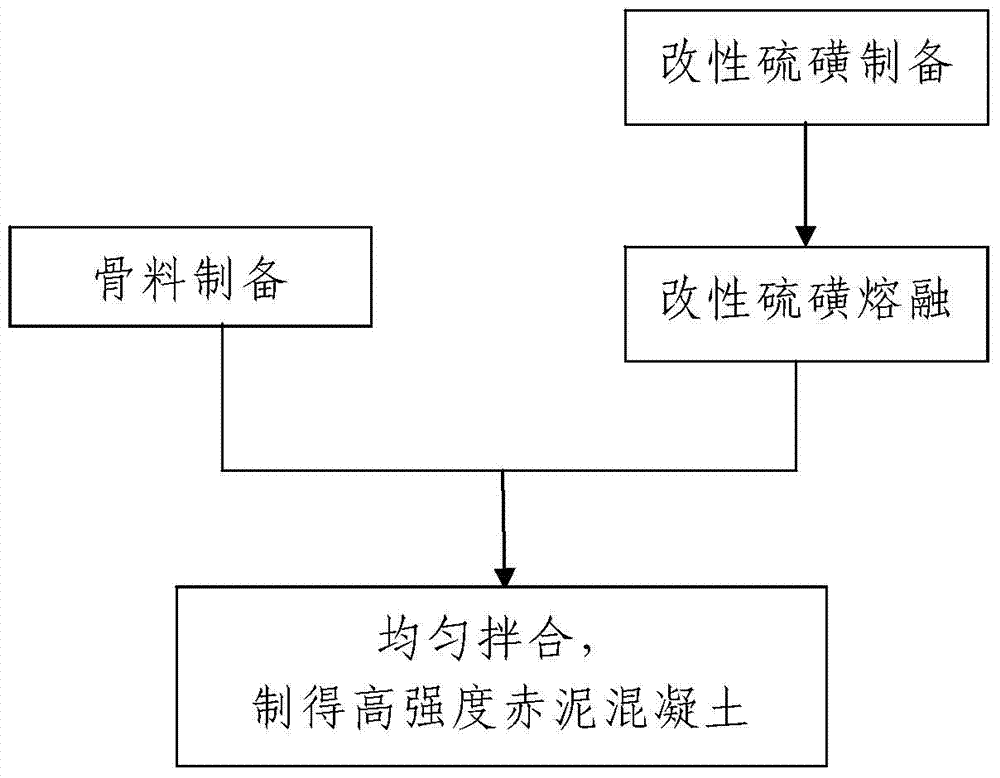

Low-emission high-strength red-mud concrete, and industrial production method and application thereof

The invention discloses a low-emission high-strength red-mud concrete and an industrial production method and application thereof. The high-strength red-mud concrete comprises, by weight, 21 to 40% of modified sulphur, 25 to 60% of red mud particles and 54 to 0% of steel slag, is prepared through uniform blending of the modified sulphur, the red mud particles and steel slag particles and has compressive strength of no less than 50 MPa. The industrial production method comprises the following steps: 1, preparation of the modified sulphur; 2, preparation of aggregate and fusion with the modified sulphur; and 3, uniform blending. Application of the high-strength red-mud concrete is as follows: the high-strength red-mud concrete is poured into a casting molding die so as to obtain molded red mud stone. The industrial production method has the advantages of simple process steps, short production flow, low investment cost, easy operation, convenient implementation, capacity of effective utilization of the waste material red mud in the aluminum industry and discharge of low concentration sulfur-containing gas during production and casting; and a produced red mud concrete structural member has excellent performance.

Owner:嘉兴如运建筑科技有限公司

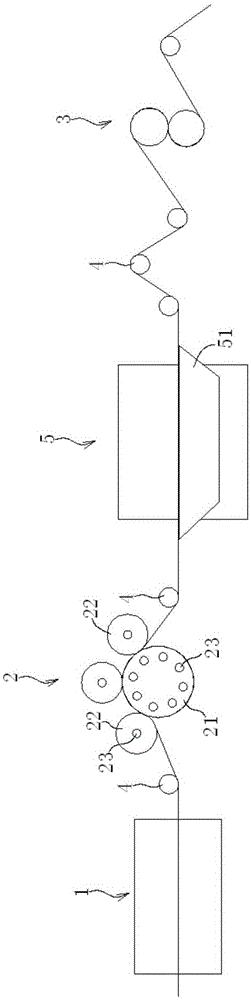

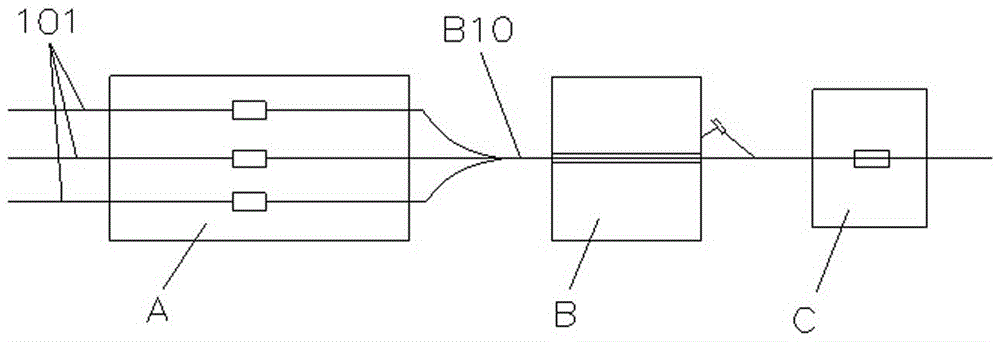

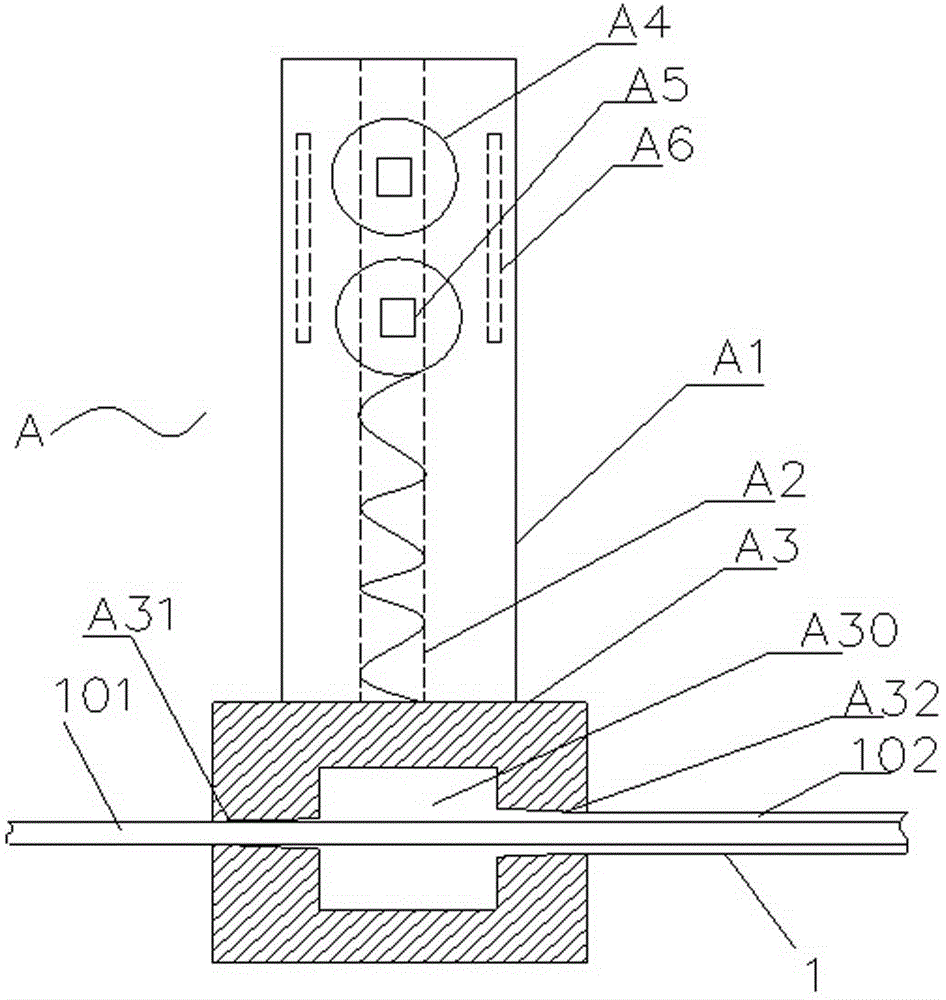

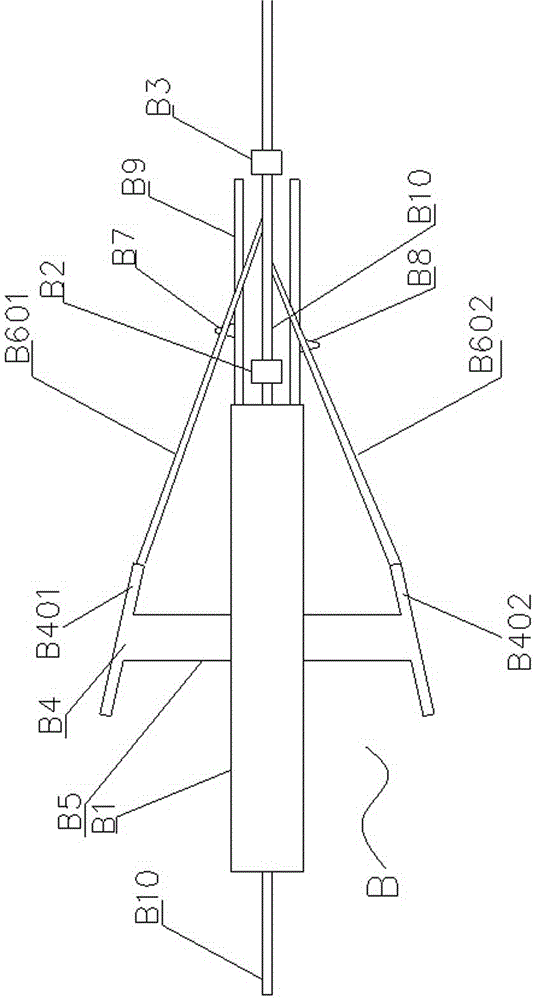

Production device and process for 3D flexible knurling nonwoven fabric

The invention discloses a production device for a 3D flexible knurling nonwoven fabric. The production device comprises a preheating device, a knurling device and a cooling device. The knurling device comprises a knurling roll and multiple soft rubber rolls which abut against the knurling roll. The nonwoven fabric passes through the preheating device, the knurling device and the cooling device in sequence. Accordingly, the invention also provides a production process for the 3D flexible knurling nonwoven fabric. According to the production device for the 3D flexible knurling nonwoven fabric, the soft rubber rolls abut against the knurling roll for knurling, the softness of the nonwoven fabric is not affected while a stable concave-convex pattern is formed, the 3D flexible knurling nonwoven fabric with high softness is obtained, and the comfort level of a sanitary product is enhanced; the preheating device and a hot wind blowing device further improve the softness of the knurling nonwoven fabric. According to the production process for the 3D flexible knurling nonwoven fabric, steps are simple, and process conditions are easy to control.

Owner:FOSHAN GOOD FEELING EISAI TECH CO LTD

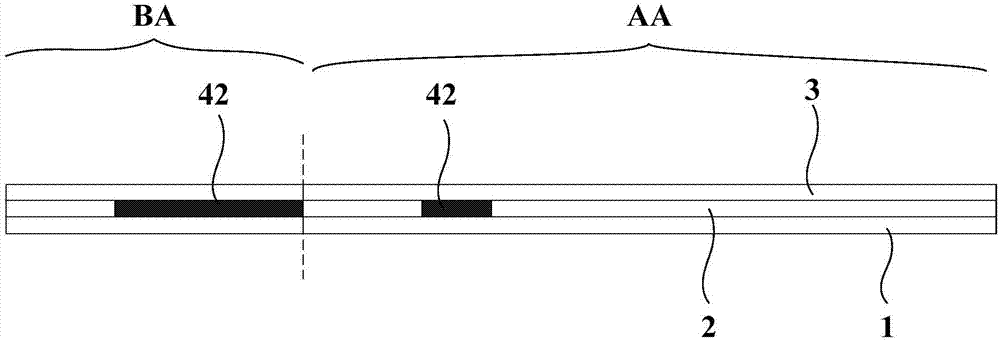

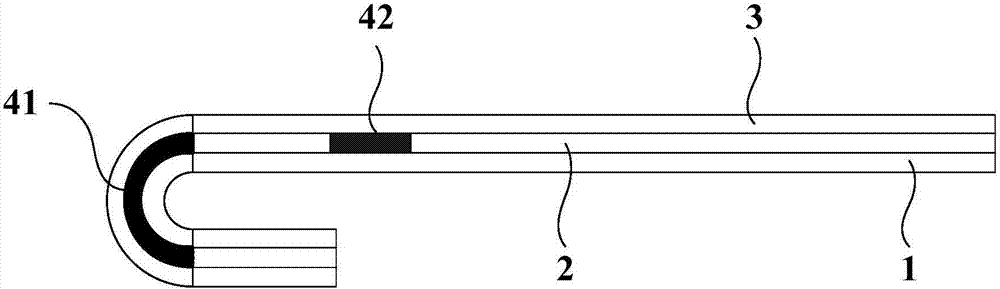

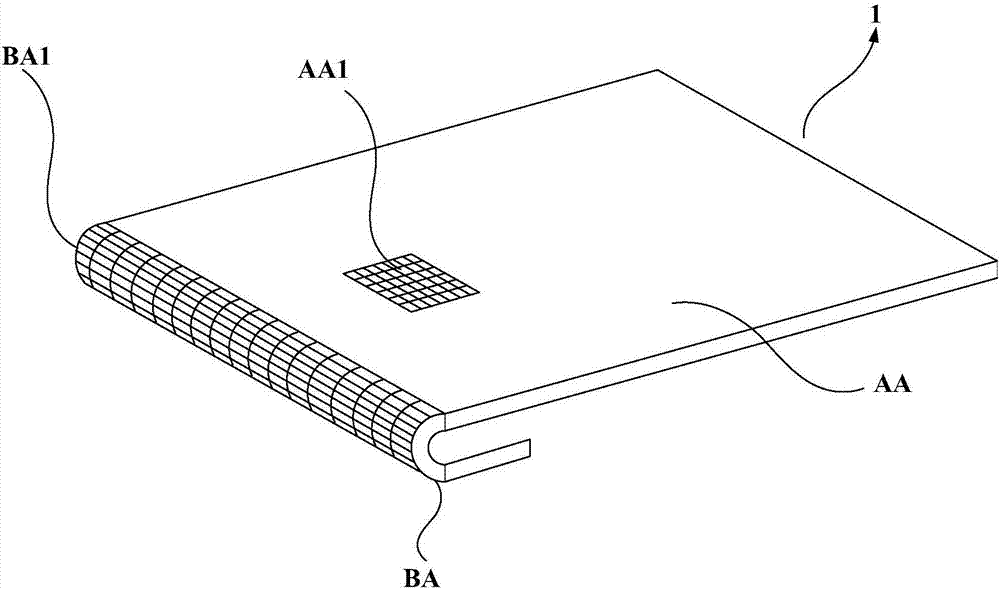

Fingerprint identification flexible display panel and manufacturing method thereof

ActiveCN107579104AThe production process steps are simpleReduce thicknessFinal product manufactureSolid-state devicesFingerprintEngineering

The invention discloses a fingerprint identification flexible display panel and a manufacturing method thereof. The fingerprint identification flexible display panel and the manufacturing method thereof can reduce the thickness of the display panel, simplify the production processes and improve the finger identification function and the wear-resisting performance of the flexible display panel. Thefingerprint identification flexible display panel comprises a flexible substrate, an inorganic layer and flat layers, wherein the flexible substrate comprises a display area and a boundary area, theinside of the display area is provided with a fingerprint identification area, and the inside of the boundary area is provided with a bent area; the inorganic layer is adhered to one surface of the flexible substrate, the area of the inorganic layer, which corresponds to the fingerprint identification area, is hollowed out and provided with a black filter flat layer, and the area of the inorganiclayer, which corresponds to the bent area, is hollowed out and provided with a black flat layer; one sides of the inorganic layer, the black filter flat layer and the black flat layer, which back to the flexible substrate, are provided with the flat layers through adhesion.

Owner:BOE TECH GRP CO LTD +1

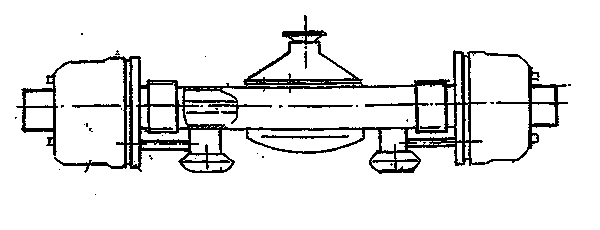

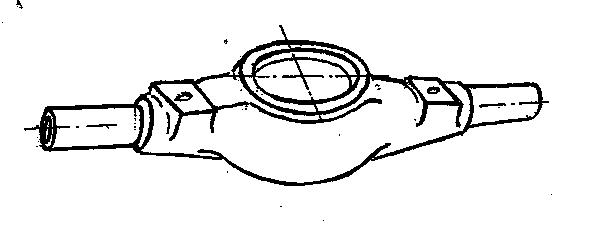

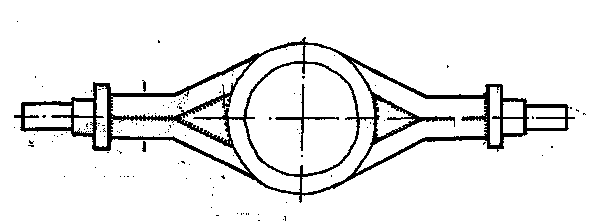

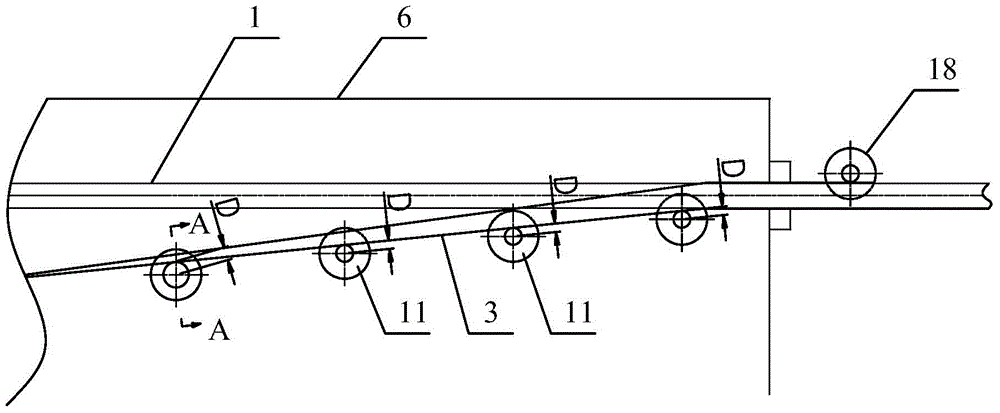

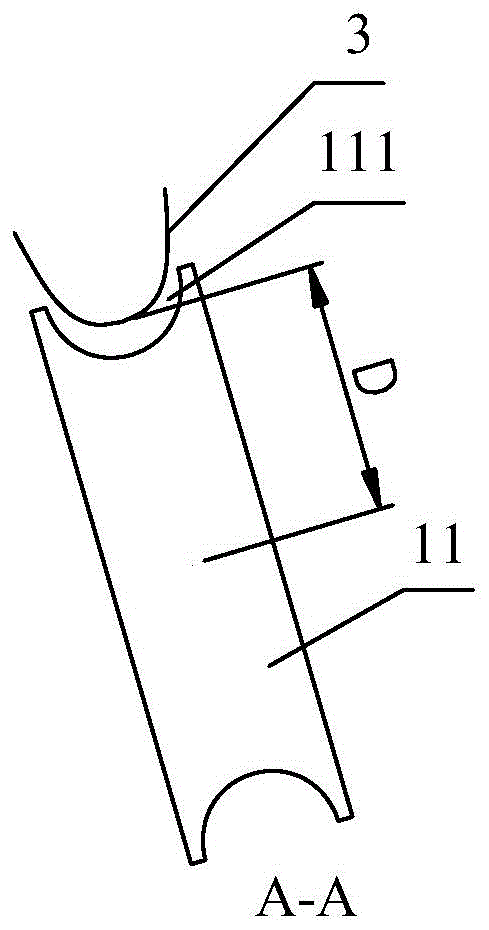

Method for forming whole axle housing of automobile drive axle

ActiveCN103624482ASolve the deformationHigh strengthFurnace typesAxle unitsAxial pressureMedium frequency

The invention discloses a method for forming a whole axle housing of an automobile drive axle. The method comprises the steps that a steel tube processed through medium-frequency non-oxidation induction heating is squeezed, upset and pulled to reach the size and shape needed by a spindle nose; a groove is formed in the middle of the steel tube; the steel tube is placed into a lead groove in a drive axle housing Pipa hole forming device and locked; two hydraulic pumps are started to exert axial pressure to the two ends of the steel tube, so that the middle (with the smaller section) of the axle tube is in the deformation critical state; a guide column moves downwards and damages the balance of the axial force of the middle of the axle tube, and radial component force is generated and enables materials of the middle of the axle tube to expand and extend outwards to reach the preset size. According to the method for forming the whole axle housing of the automobile drive axle, the production process is simple and easy to operate, the axle housing does not directly penetrate through a weld joint and does not need spindle nose welding, the problems of axle housing deformation and oil leakage are solved, the heat treatment hardening and tempering technology is adopted, the general mechanical performance of the axle housing materials is improved, the strength and stiffness of the axle housing are improved, and the bearing property, reliability and fatigue durability of the axle housing are improved.

Owner:李迎春

Production technology of flock tipping paper for cigarettes

InactiveCN105882176AEnhanced tactile experienceThe production process steps are simpleOther printing apparatusPrinting after-treatmentProcess engineeringIndustrial engineering

The invention belongs to the technical field of tipping paper for cigarettes, and relates to preparation of tipping paper for cigarettes, in particular to a production technology of flock tipping paper for cigarettes. The production technology comprises the steps of uniformly printing a plurality of ink layers on the surface of raw tipping paper through utilizing a printing wire roll, wherein the dry coating amount of the ink layers is 0.1 to 2.0 g / m<2> per color, and the printing wire roll is a steel roll with 150 to 200 wires and the depth of 40 to 55 microns; drying; uniformly smearing flock gloss oil through utilizing the wire roll; continuously drying; and cutting an obtained semi-finished product, and carrying out gold blocking or punching in the follow-up procedure, wherein the raw tipping paper is in the ordinary type, silver white transferring type, transparent type, highlight type, laser type, or direct plating type, and the like. According to the production technology, the steps are simple, the production cost is low, environmental protection is achieved, production devices do not require any auxiliary device, a product can have a duck down touch feeling effect through only coating the raw paper or the raw paper ink layers with a layer of flock gloss oil, the decoration quality of the product is effectively improved, the touch feeling experience of consumers is improved, the product selling points of the tipping paper for cigarettes are increased, and the distinguishing degree of the tipping paper for cigarettes is improved.

Owner:JIANGSU DAYA NEW PACKAGING MATERIALS

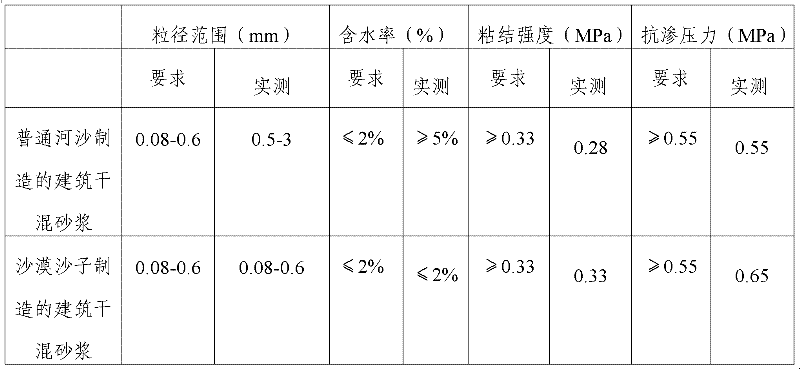

Desert sand compound type building dry-mixed mortar and manufacturing method thereof

ActiveCN102390962ASolve the use problemChange the status quo of lack of resourcesPlasticizerMaterials science

The invention relates to a desert sand compound type building dry-mixed mortar and a manufacturing method thereof. The dry-mixed mortar comprises the following raw materials by weight percent: 30%-60% of desert sand, 0.1%-2% of intensifier, 0.01%-2% of water-retaining agent, 0.1%-5% of plasticizer, 0.01%-2% of anti-cracking agent, 0.001%-2% of permeability admixture, 30%-60% of curing agent, 0%-10% of mineralizing agent and 0%-10% of flatting agent. The manufacturing method comprises the following steps: screening the desert sand; crushing, drying and screening the mineralizing agent; and dosing, mixing and stirring the raw materials, thereby obtaining the dry-mixed mortar. A long-term existing problem that the desert sand cannot be used as the sand for building because the desert sand contains superfine grains and is high in silt content is solved. The present problem of utilizing the large amount of desert sand is also solved. A novel method for manufacturing the dry-mixed mortar isprovided. The current situation that the resource of the sand for building is in insufficient is changed. Meanwhile, the production process is simple and the operation is convenient.

Owner:XIAN HONGFENG INDAL

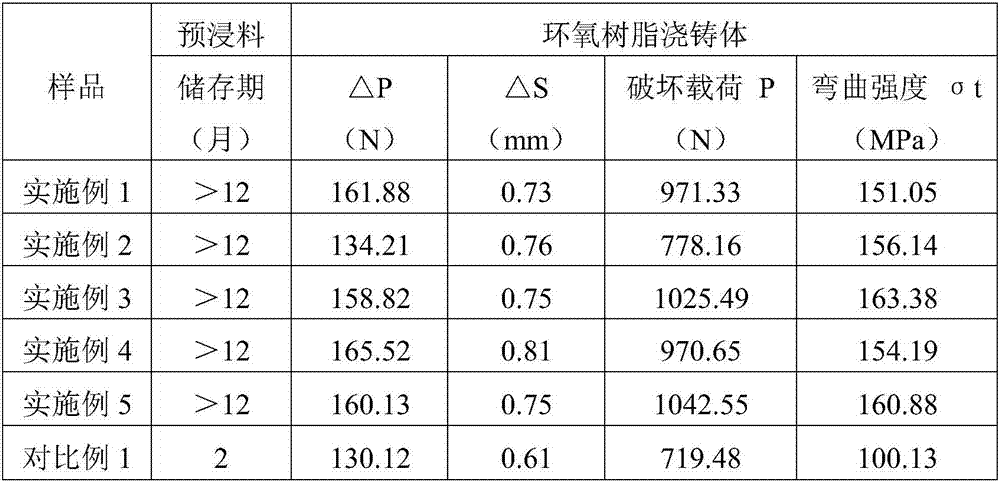

Carbon fiber prepreg and preparation method thereof

InactiveCN107118518AThe production process steps are simpleGood mechanical propertiesFiberCarbon fibers

The invention discloses carbon fiber prepreg and a preparation method thereof. The carbon fiber prepreg is mainly prepared from components as follows: epoxy resin, a curing agent, an accelerant and carbon fibers, wherein epoxy resin is prepared from novolac epoxy resin, liquid bisphenol A epoxy resin and solid bisphenol A epoxy resin in a mass ratio being 1:(1-2):1. The carbon fiber prepreg can be stored for more than 12 months at the normal temperature and can be widely applied to the fields of fishing tackles, sports apparatus, sporting goods, aerospace and the like.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Surface modification preparation method of flaky metal powder.

ActiveCN104070162AImprove stability and storage and transportation resistanceThe production process steps are simpleCoatingsSolventSurface modification

The invention discloses a surface modification preparation method of flaky metal powder and belongs to the technical field of metal powder material preparation. The method comprises the steps that spherical metal powder, a metal chelating agent, a surface treating agent, solvent oil and a grinding medium are placed in a ball grinding mill, ball grinding is conducted for 5-18 hours at the ball-milling rotation speed of 5-40 Hz, slurry obtained after ball milling is taken out, soil-liquid separation is conducted, so that paste metal powder is obtained, the paste metal powder is dried and graded, and then the modified flaky metal powder coated with the metal chelating agent and the surface treating agent is obtained. According to the surface modification preparation method, flaking and surface modification of the metal powder are completed at the same time, the process steps are simple, the efficiency is high, the product stability is high, and the surface modification preparation method is suitable for industrial production.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

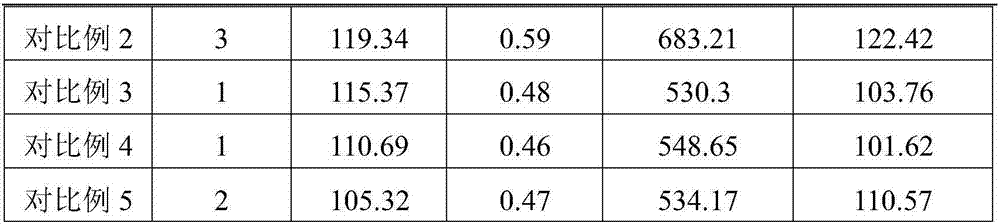

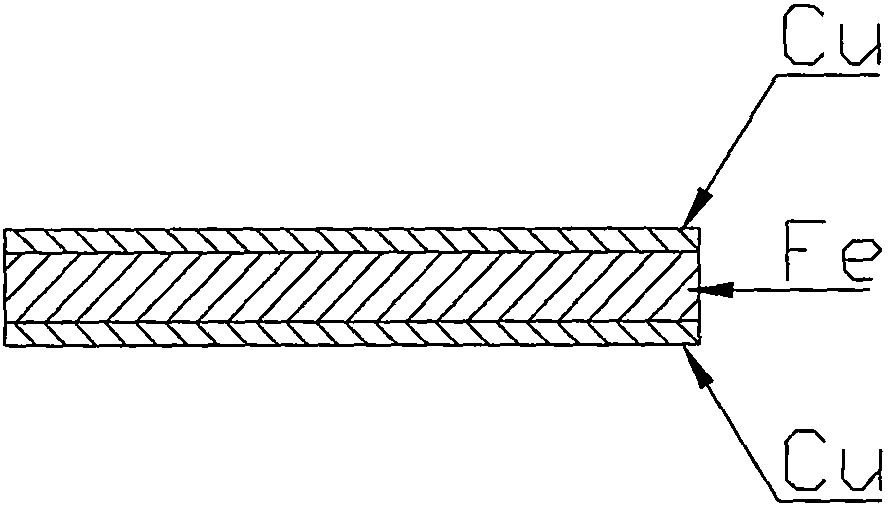

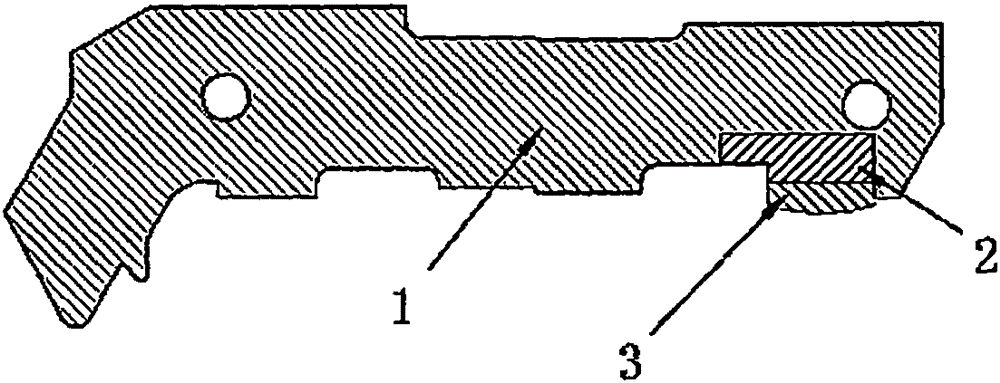

Circuit breaker electrical contact support member and preparation method thereof

InactiveCN105161380AReduce usageAvoid unstable contactEmergency protective device manufactureCircuit-breaking switch contactsPunchingMaterial consumption

The invention discloses a circuit breaker electrical contact support member and a preparation method thereof. The support member comprises a support member body made of a Cu / Fe / Cu material strip. One side of the support member body is provided with a built-in groove; the groove is embedded by a conductive insert block; and the insert block is provided with a contact point. The method is characterized by, carrying out thermal treatment on the Cu / Fe / Cu material strip, and rolling the Cu / Fe / Cu material strip obtained after thermal treatment; carrying out punching on the Cu / Fe / Cu material strip obtained after rolling to prepare the support member body; preparing the insert block, and inserting and welding the insert block to one side of the obtained support member body; and welding the contact point to the other side of the insert block. The support member is prepared by inserting the Cu block or other conductive metal blocks into the Cu / Fe / Cu composite strip, thereby improving the strength of the contact support member, ensuring stability of the current conduction when an electrical contact is contacted, and meanwhile, reducing copper material consumption and saving cost.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Preparation method of amide copolymer hydrate kinetic inhibitor

InactiveCN106380541AThe production process steps are simpleLow injection doseDrilling compositionDispersed mediaKinetic Inhibitor

The invention discloses a preparation method of an amide copolymer hydrate kinetic inhibitor, and belongs to the technical field of preparation of chemical engineering reagents. The preparation method is concretely characterized in that the AM / AN / VCL ternary copolymer hydrate kinetic inhibitor with the molecular weight reaching 300,000-500,000 is synthesized from acrylamide (AM), acrylonitrile (AN) and vinyl caprolactam (VCL) in anoxic environment with azodiisobutyronitrile as an initiator and nonionic surfactant-containing deionized water as a disperse medium. The method has the characteristics of simple production process and low production cost, and the prepared inhibitor has the advantages of low injection dosage and long inhibition time.

Owner:路术松

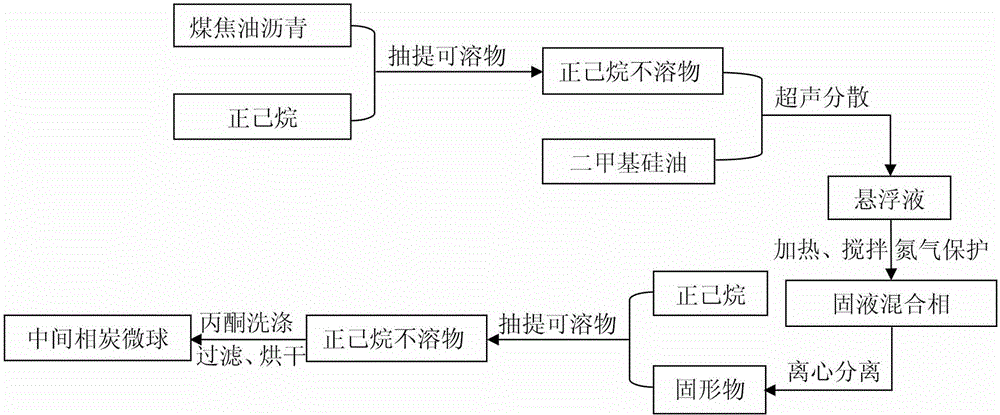

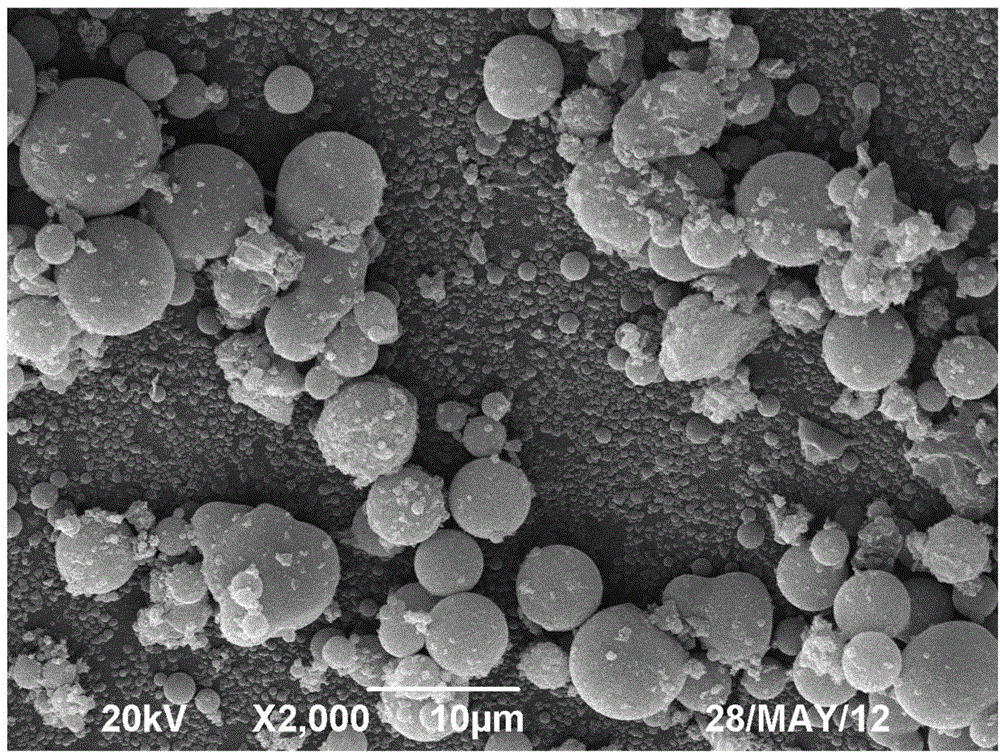

Raw material composition capable of being used for preparing mesocarbon microbeads (MCMB), preparation method thereof and preparation method of MCMB anode material

ActiveCN102942172AThe production process steps are simpleReduce manufacturing costCell electrodesCarbon preparation/purificationSilicone fluidCoal Tar Pitches

The invention discloses a raw material composition capable of being used for preparing MCMB. The composition is a suspension formed by coal tar pitch extracts after dispersed on dimethicone, and the coal tar pitch extracts are insoluble substances obtained by coal tar pitch powder after dissolution and impurity removal by n-hexane or toluene. The preparation method of the raw material composition includes filling the coal tar pitch powder into a Soxhlet extractor, performing repeated extracting, dissolving and impurity removing to obtain the insoluble substances through n-hexane or toluene; and then drying and grinding, and subjecting the substances to ultrasonic dispersion on the dimethicone. The method for preparing the MCMB anode material through the raw material composition includes heating the raw material composition to subject the material to a thermal condensation reaction to form micron-sized spherulite; and then subjecting the solid-liquid mixed phase after the thermal condensation to centrifugation, n-hexane extraction, repeated scrubbing and drying sequentially to obtain the MCMB anode material. The material and the methods are simple in process steps, low in cost and capable of being used for preparing high-quality MCMB.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Dried beef by roasting whole cattle and preparing technique thereof

The invention discloses the beef jerky of roast whole cattle and a production technique thereof. The beef jerky at least consists of raw caw meat and vegetable protein powder, wherein, the weight of the raw cattle meat makes up 30 percent to 70 percent and the weight of the vegetable protein powder makes up 29 percent to 69 percent of per 100g of the beef jerky and the others are flavorings. Except bones, all cattle muscle, cattle harslet and / or cowhells serve as raw materials to produce the beef jerky; the raw meat is cleaned and minced into muddy flesh by a meat chopper, and then vegetable protein powder is added according to weight ratio to be cut into pieces after mixed evenly and then the pieces are put into an oven to be roasted for 2 hours to 10 hours; the roasting temperature is not higher than 100 DEG C; the meat pieces are cut into strips of 2cm multiplied by 4cm and finally stir-fried after adding flavorings for 8 minutes to 15 minutes. The beef jerky of the invention is easily chewed, which has good taste, simple production technique, low production cost and easy popularization.

Owner:唐应佳

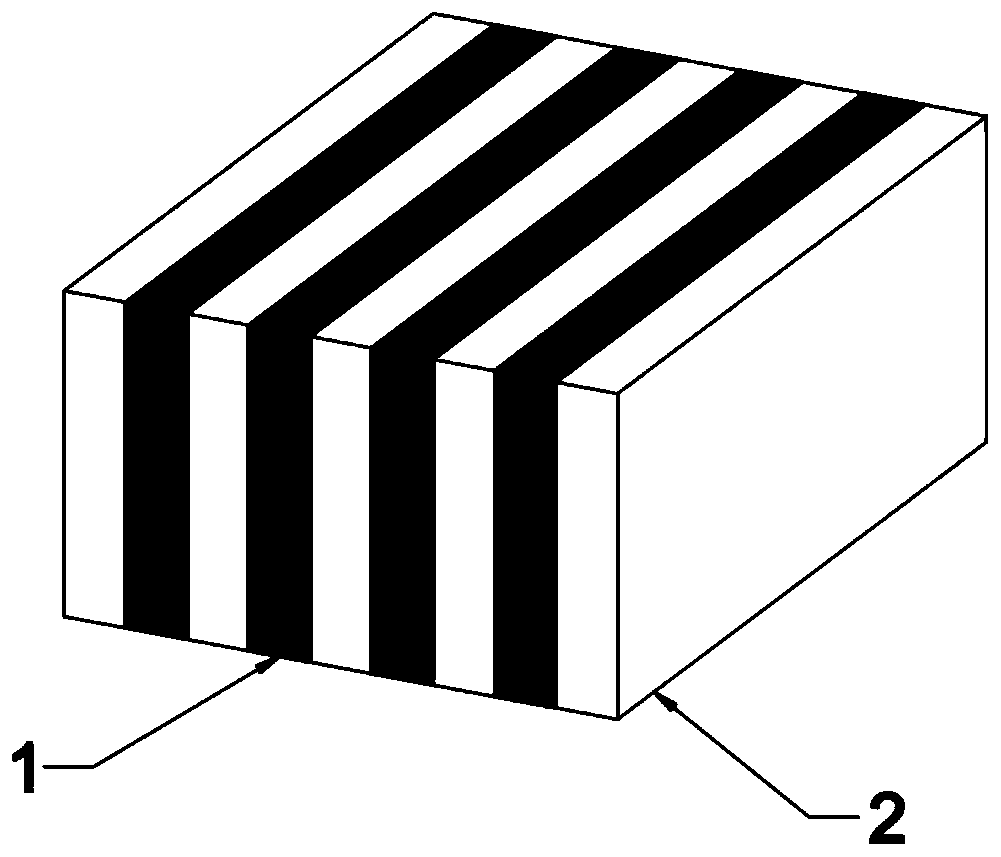

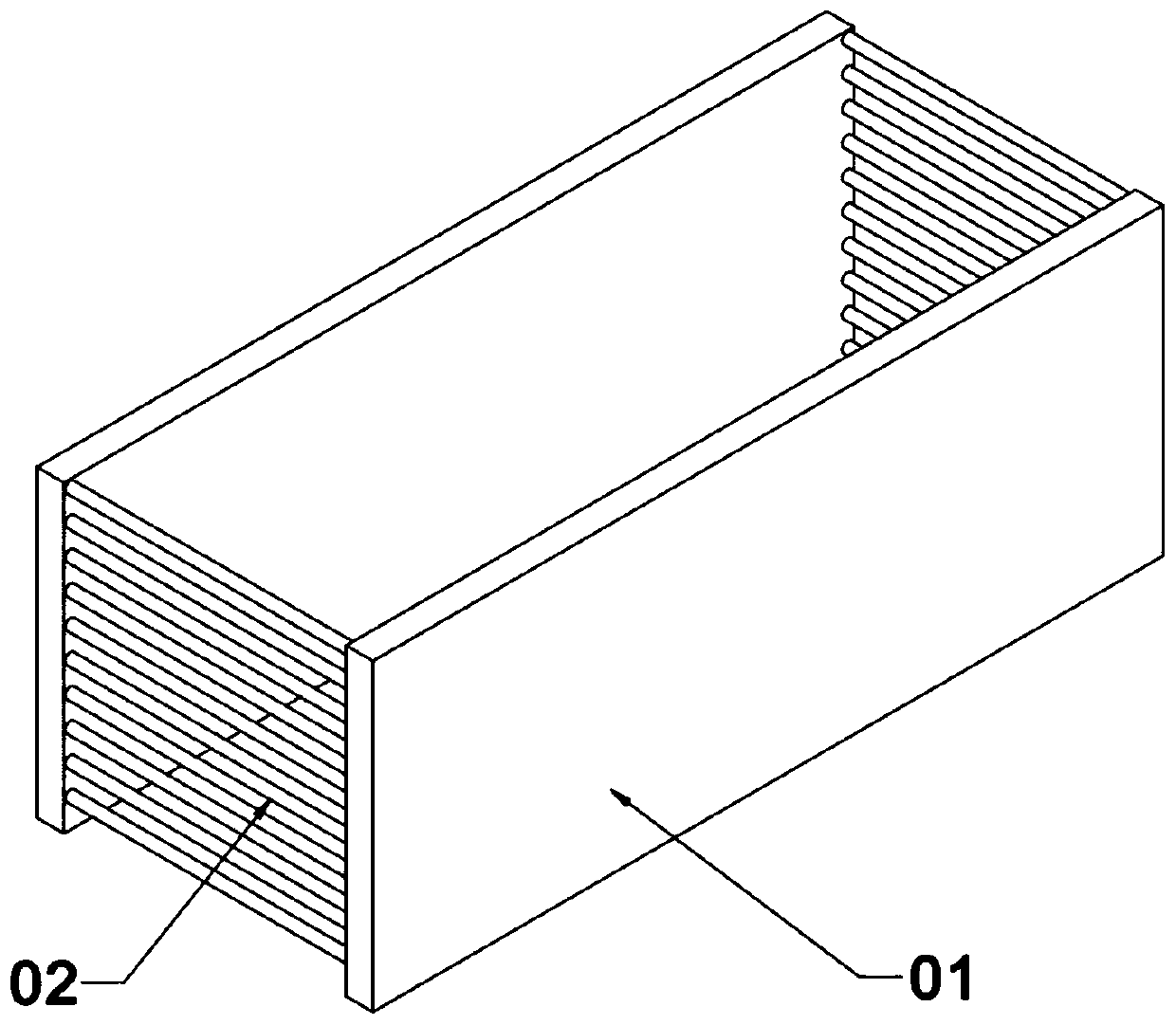

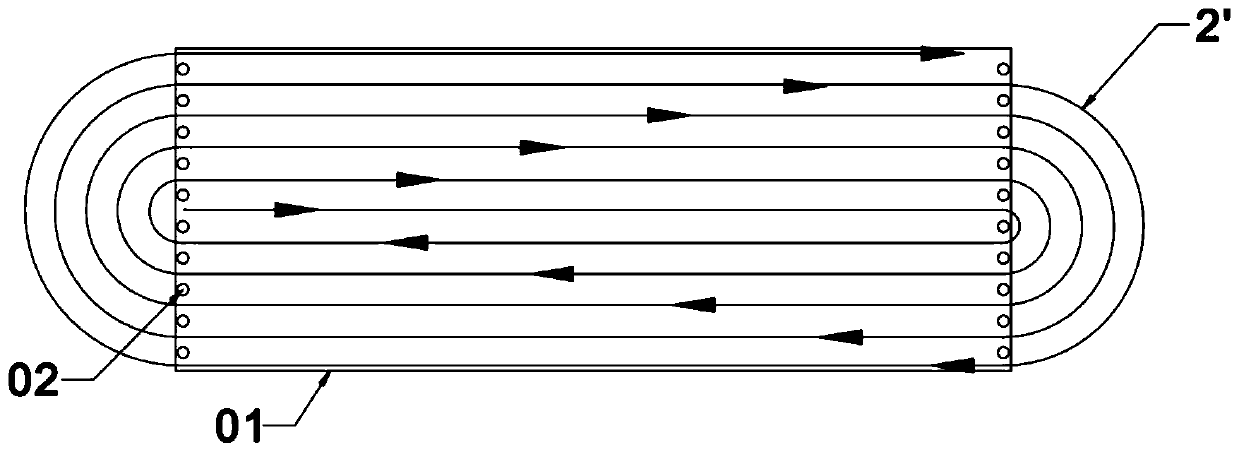

Anisotropic composite profile and preparation method thereof

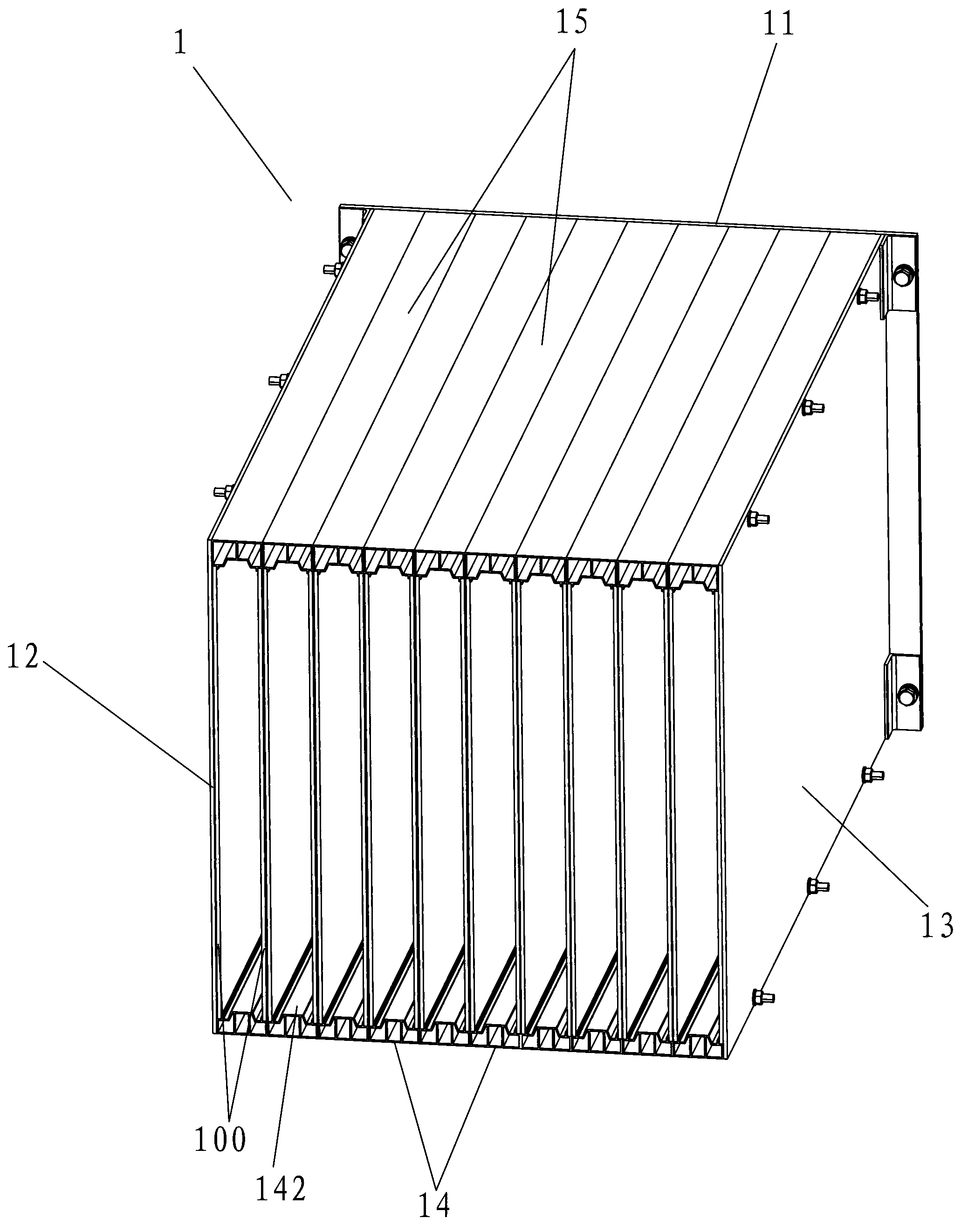

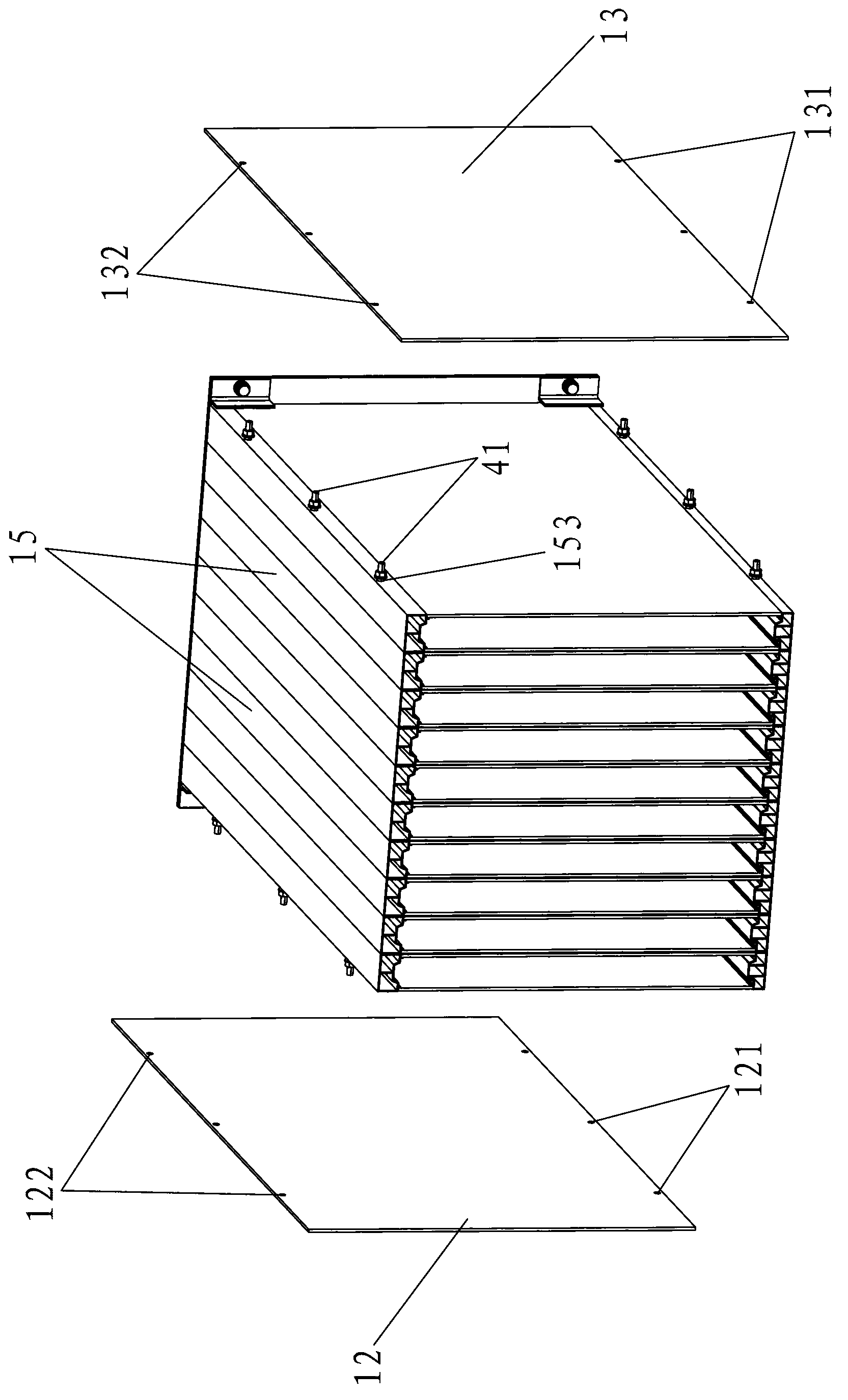

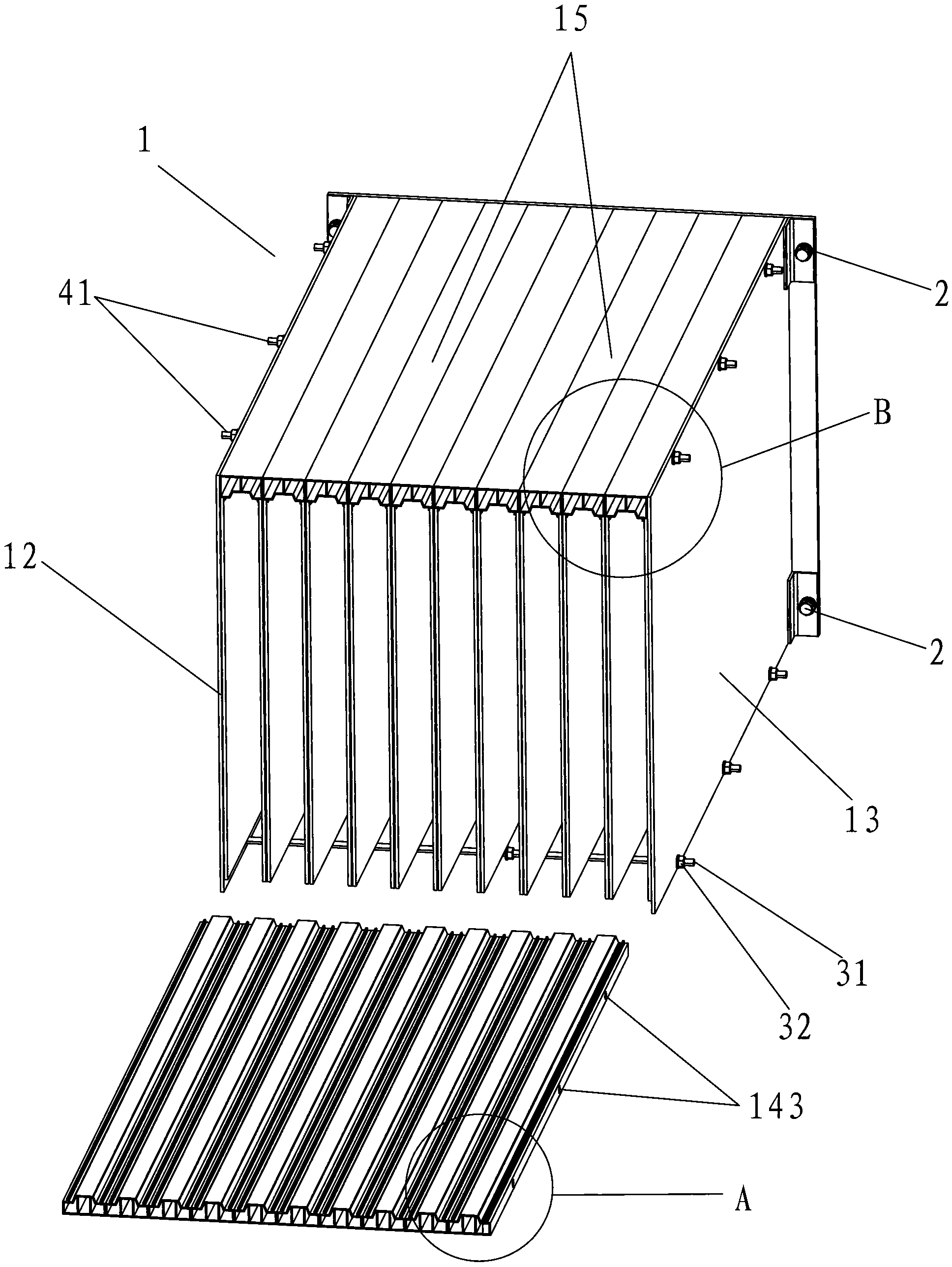

The invention discloses an anisotropic composite profile, which comprises heat conduction silica gel and heat conduction sheets. The heat conduction sheets are arranged layer by layer at intervals, and the heat conduction silica gel fills a gap between every two adjacent layers of heat conduction sheets to form a heat conduction silica gel layer. The structure is novel, the method is innovative, the attaching performance of the anisotropic heat conduction material is optimized, the application range of the anisotropic heat conduction material is expanded, the production process steps are simple, the production efficiency is improved, and the production cost is reduced.

Owner:东莞市高酷纳米科技有限公司

Potato spirit and manufacturing technology thereof

InactiveCN104694367AThe production process steps are simpleIncrease yieldAlcoholic beverage preparationBudFlavor

Provided is a potato spirit and a manufacturing technology thereof. After a fermentation substrate prepared by fermenting of potato powder, maize buds and wheat malt is evenly mixed according to a weight ratio of 0.65 - 0.85 : 0.35 - 0.15, the fermentation is carried out, the potato spirit is prepared by steam-in distillation, the fermentation substrate prepared by fermenting of the potato powder, the maize buds and the wheat malt is used for improving the liquor yield. The manufacturing technology is simple in step and high in liquor yield, brewed white spirit is not prone to oxidation and browning, the sedimentation is few, the aroma is unique, the taste is smooth, the flavor is excellent, the functions of improving the mental state, matching with the spleen and invigorating the stomach, and maintaining beauty and keeping young are provided.

Owner:YUNLONG QIMIN AGRI TECH

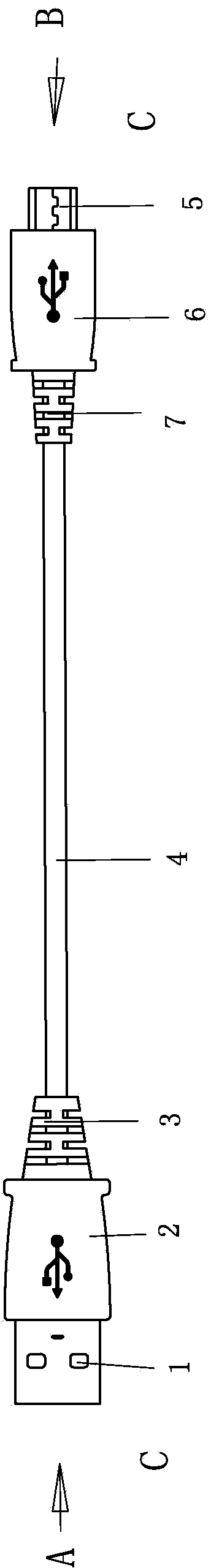

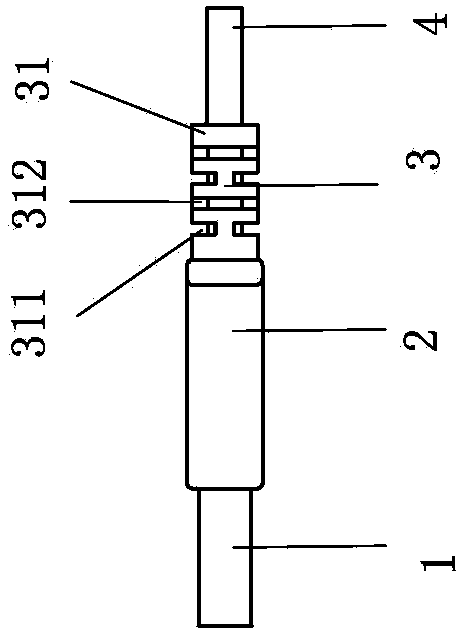

Signal wire with plugs at two ends and manufacturing method of signal wire with plugs at two ends

ActiveCN103855568AAvoid the risk of sheddingReduce manual operationsLine/current collector detailsCouplings bases/casesEngineeringCopper

The invention discloses a signal wire with plugs at the two ends and a manufacturing method of the signal wire with the plugs at the two ends, and relates to a signal adapter wire and a manufacturing method of the signal adapter wire. The two ends of four core wires of a four-core cable of the signal wire and copper contacts corresponding to the USB-A type plug and the USB-Micro type plug are welded together respectively. In a USB-A type plug part, a first lining in a first outer shell wraps the rear portion of a core of the USB-A type plug and the first end of the four-core cable, and a first wire clamp is arranged on the first end side of the four-core cable in a penetrating and sleeved mode and penetrates through a via hole in the rear end of the first outer shell to extend out towards the second end side of the four-core cable; in a USB-Micro type plug part, a second lining in a second outer shell wraps the rear portion of a core of the USB-Micro type plug and the second end of the four-core cable, and a second wire clamp is arranged on the second end side of the four-core cable in a penetrating and sleeved mode and penetrates through a via hole in the rear end of the second outer shell to extend out towards the first end side of the four-core cable; the first lining and the first wire clamp are integrated, and the second lining and the second wire clamp are also integrated. The outer shells and the linings of the plugs at the two ends can not be separated.

Owner:龙岩岳凯科技有限公司

Molding die of straight-tenon light wallboard and molding method thereof

ActiveCN102837357AThe production process steps are simplePlay a reinforcing roleDischarging arrangementMould separation apparatusEngineeringUltimate tensile strength

The invention discloses a molding die of a straight-tenon light wallboard. The molding die comprises a lower base plate, a front side plate, a rear side plate, a left side plate and a right side plate, wherein the front side plate is formed by splicing a plurality of front strip-shaped aluminum alloy molding modules which are tightly erected and arranged together side by side; the rear side plate is formed by splicing a plurality of rear strip-shaped aluminum alloy molding modules which are tightly erected and arranged together side by side; the left side plate, each front strip-shaped aluminum alloy molding module and the right side plate are integrally locked and connected by a first locking component; and the left side plate, each rear strip-shaped aluminum alloy molding module and the right side plate are integrally locked and connected by a second locking component. The invention further discloses a molding method for manufacturing the straight-tenon light wallboard by utilizing the molding die. According to the invention, a median septum is omitted, so that the process for dismounting and mounting the median septum is omitted. Therefore, the labor intensity of a worker is reduced, the production process step is simplified, the production efficiency is improved, and the problem of influence on the molding quality of a finished product caused by dismounting and mounting of the median septum is eliminated.

Owner:QUANZHOU HONGYI BUILDING MATERIAL MACHINERY

Temperature-resistant and compressive cable and production equipment and production technology thereof

ActiveCN106531297AIncrease productivityThe production process steps are simpleInsulated cablesInsulated conductorsTemperature resistanceElectrical and Electronics engineering

The invention relates to a temperature-resistant and compressive cable and production equipment and the production technology thereof. The temperature-resistant and compressive cable is characterized by comprising three twisted core wires, a mica tape layer which envelopes outside the three core wires and a galvanized iron layer which envelopes outside the mica tape layer. A cable sheath layer extrudes outside the galvanized iron layer. The temperature-resistant and compressive cable is simple in structure, reasonable in design and favorable for enhancing the temperature resistance and the compressive property of the cable.

Owner:FUZHOU YONGTONG WIRE & CABLE

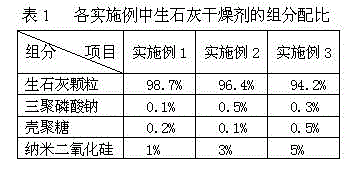

Quick lime desiccant and production process thereof

ActiveCN103055665AImprove qualityNot easy to agglomerateDispersed particle separationGranularityDesiccant

The invention discloses a quick lime desiccant, which solves the problems that a quick lime desiccant in the prior art is prone to being caked, so that the granularity of the quick lime is lowered, and a drying effect is influenced. The quick lime is prepared by mixing the following components in percentage by weight: 0.1%-0.5% of sodium tripolyphosphate, 0.1%-0.5% of chitosan, 1%-5% of nano-silicon dioxide and the balance of quick lime particles. The quick lime desiccant has the advantages of anti-caking, favorable moisture absorption and drying effects, low cost and the like. The invention also discloses a production process of the quick lime desiccant. The production process of the quick lime desiccant mainly comprises the steps of smashing lime stones, preparing calcined materials, preheating the calcined materials, carrying out calcinations on the preheated materials, outputting and crushing the materials, and packaging the mixture. The production process has the advantages of simple steps and easiness in operation, and is suitable for industrial production. Moreover, according to the production process, the under burnt or overburning phenomenon of the lime stones can be efficiently avoided, and the quality of the prepared quick lime is favorable.

Owner:ZHEJIANG JIANDE HONGXING CALCIUM

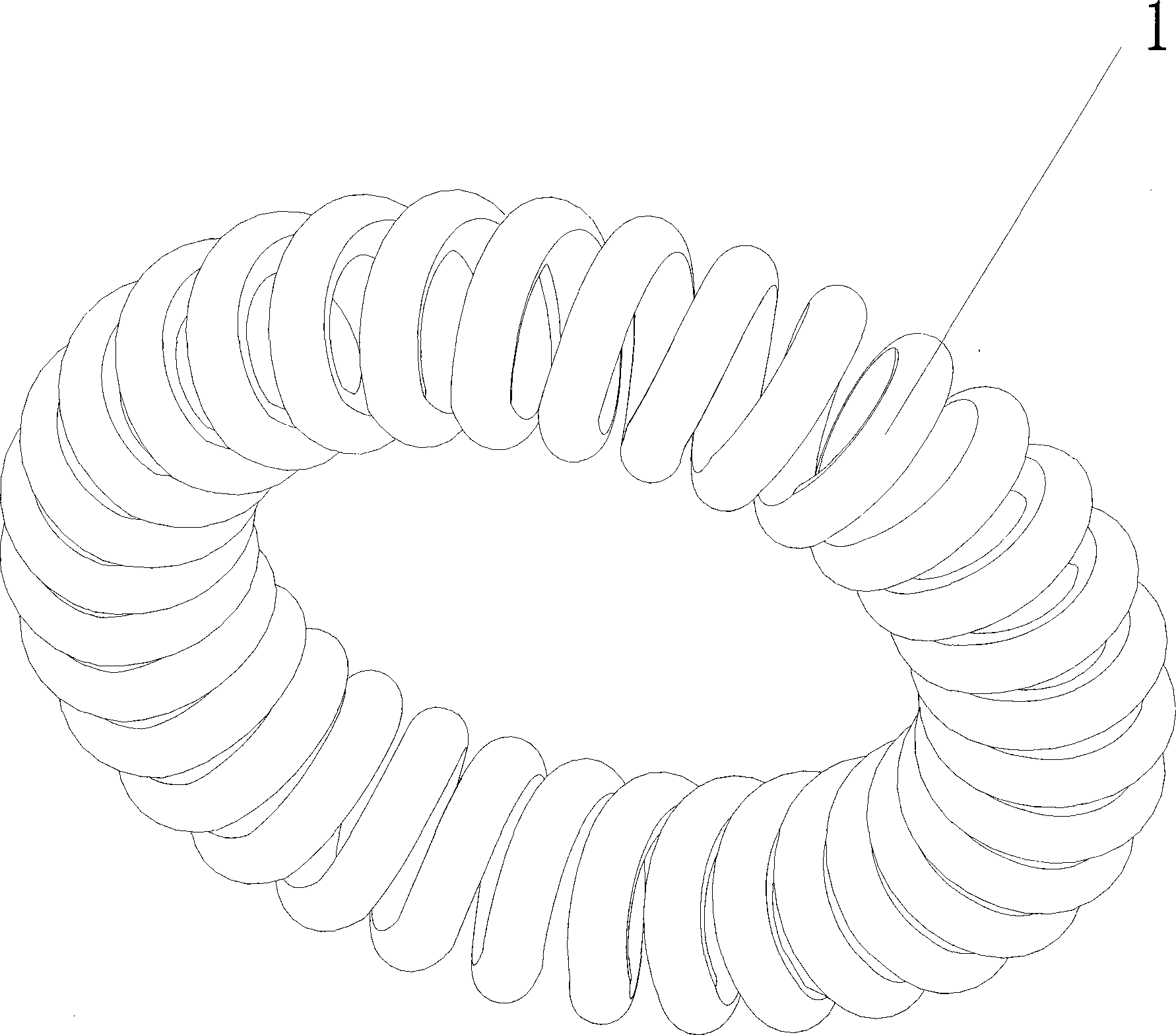

Plastic ring with mosquito-repelling function and preparing technique thereof

InactiveCN101433196AFree from painThe production process steps are simpleBiocideAnimal repellantsEngineeringBiting

The invention discloses a plastic ring with mosquito-repellent function, which is formed by winding a plastic wire in a helical shape and then connecting the plastic wire by head and tail ends. The mosquito-repellent plastic ring can be conveniently worn on a wrist, and can repel mosquitoes to avoid the pain of mosquito biting when a person goes shopping, travels and entertains. The invention also discloses a production technology for the mosquito-repellent plastic ring, which comprises the steps of material mixing, wire drawing, bending shaping, blow drying, welding and so on, and has simple steps, short period and convenient popularization.

Owner:ZHONGSHAN SHENGPAN HARDWARE PLASTIC

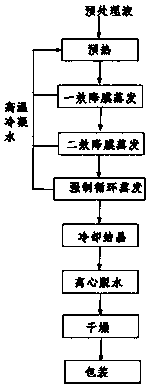

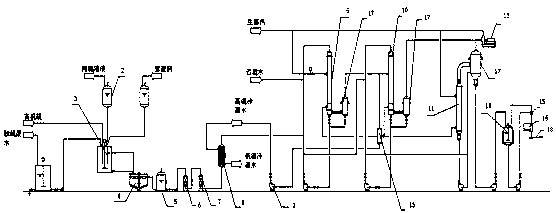

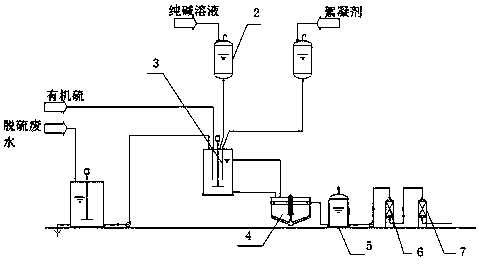

Desulfurization wastewater treatment process

InactiveCN108328835AReduce usageIncrease profitWater contaminantsTreatment involving filtrationCentrifugationSulfur

The invention discloses a desulfurization wastewater treatment process characterized by comprising the following process steps: step 1, pretreatment, namely adding organic sulfur, carbonate and a flocculant into desulfurization wastewater to carry out a reaction, and removing calcium ions and heavy metal ions in the desulfurization wastewater to obtain a pretreatment solution; step 2, evaporationand concentration, namely evaporating and concentrating the pretreatment solution until the content of sodium chloride in a feed liquid is 200-280mg / l; step 3, cooling crystallization, namely carryingout cooling crystallization on the evaporated and concentrated feed liquid to obtain slurry, wherein the crystallization temperature is 20 DEG C or below, and the crystallization time is 0.25-1h; andstep 4, centrifugation and drying, namely carrying out centrifugation and drying treatment on the slurry subjected to cooling crystallization to obtain MgSO4-7H2O. During pretreatment, excessive calcium ions cannot be introduced, and the troublesome step that calcined soda is added to remove the calcium ions is not needed, so that the use amount of a reagent is reduced; in addition, the finally obtained product is MgSO4-7H2O, so that the economic benefit of the wastewater treatment process is increased.

Owner:中国电建集团透平科技有限公司

Simple brewage method of strawberry wine

ActiveCN103555546AThe production process steps are simpleIncrease incomeAlcoholic beverage preparationFragariaBiology

The invention discloses a simple brewage method of a strawberry wine, which comprises the following steps: A. raw material preparation: screening mature fresh strawberries to obtain original strawberry fruits; B. natural fermentation: putting the original strawberry fruits and white granulated sugar into a fermentation tank in a weight ratio of 10:1-10:1.5, sealing the opening of the fermentation tank, and carrying out natural fermentation at room temperature under atmospheric pressure, thereby obtaining a strawberry juice; C. distillation: distilling the strawberry juice in a distilling apparatus to obtain a distilled unblended wine; and D. putting the distilled unblended wine in a storage tub, storing in a sealed state, and aging to obtain the strawberry wine finished product. The production procedure is simple, and is suitable for large-scale production for wineries and more suitable for domestic workshop production. The strawberry wine prepared by the method has the advantages of thick natural fragrance of strawberries, clear and transparent vinosity, sweet and soft mouthfeel, high fragrance endurance and long aftertaste.

Owner:王志岳

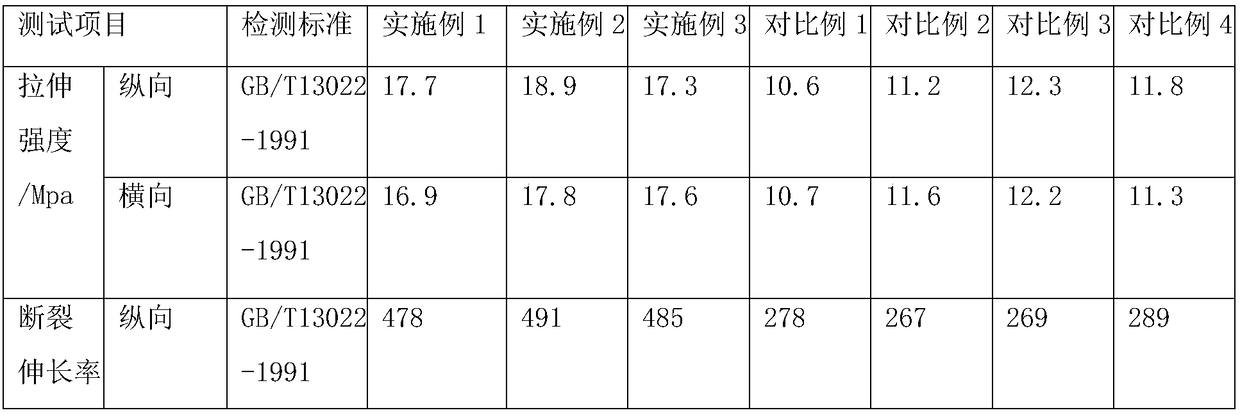

Production process of aluminum-plastic plate

The invention discloses a production process of an aluminum-plastic plate, and relates to the technical field of production and manufacturing of the aluminum-plastic plates. According to the technicalscheme, the production process is characterize by comprising the following steps that (1) mixing and stirring are performed; (2) extruding and piece making are performed; (3) aluminum plate degreasing is performed; (4) aluminum plate formation treatment is performed; (5) adhesive coating and compounding are performed; and (6) a protection film is compounded. According to the production process, the problem that the phenomenon of glue failure or falling off of an aluminum plate and a plastic core material due to poor bonding of the aluminum plate and the plastic core material is prone to occurrence during compounding of the aluminum plate and the plastic core material by using a polymer film is solved, the aluminum plate and the plastic core material are bonded and compounded by using adhesives, and air exhaust and dust removal operation is carried out so that the aluminum plate and the plastic core material can be tightly bonded, and glue failure or falling off of the aluminum plate and the plastic core material can be prevented.

Owner:台州市佳信新材料科技有限公司

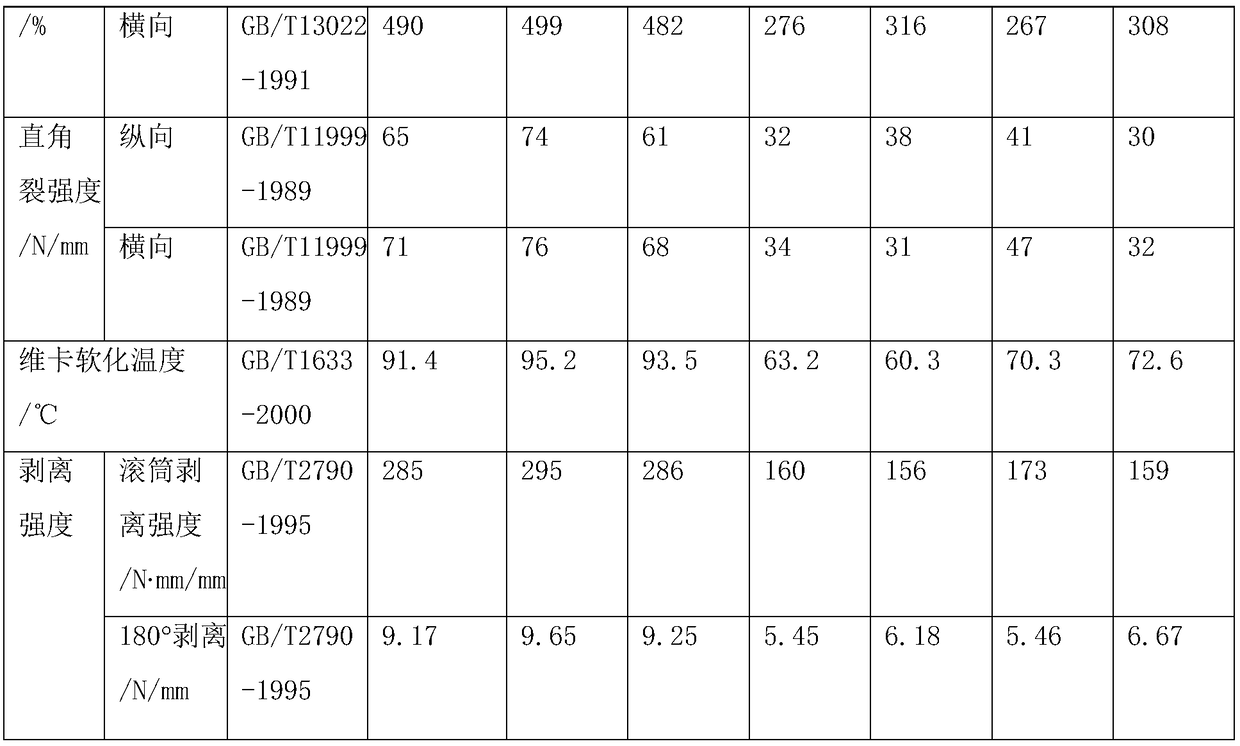

Production process for dexamethasone sodium phosphate bulk medicament

ActiveCN101623265AThe production process steps are simpleImprove stabilityPowder deliveryOrganic active ingredientsDrugDexamethasone Sodium Phosphate

The invention provides a production process for a dexamethasone sodium phosphate bulk medicament, which dissolves certain amount of dexamethasone sodium phosphate into proper amount of water for injection and performs spray drying to obtain the dexamethasone sodium phosphate bulk medicament. The dexamethasone sodium phosphate bulk medicament can be used for preparing medicaments for treating human or mammal diseases, and is preferably prepared into injection or eye drop.

Owner:TIANJIN JINYAO GRP +1

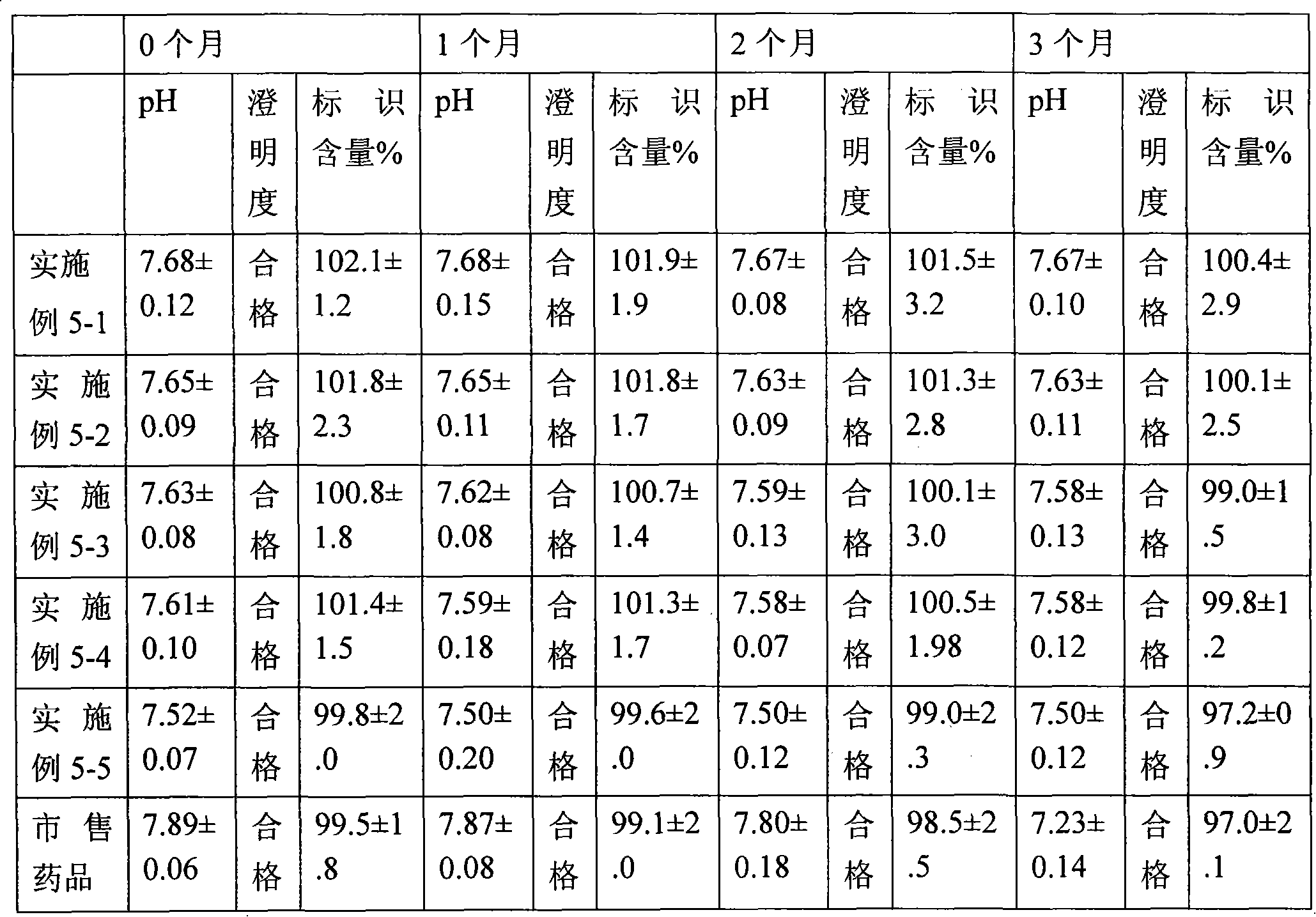

Continuous extrusion production process and production equipment of copper-coated aluminum busbar

The invention provides a continuous extrusion production process of a copper-coated aluminum busbar. The process comprises the following steps in sequence: (1) an aluminum raw material is fed into a continuous extruder; and an aluminum material is continuously extruded out in a discharge port of the continuous extruder; (2) the aluminum material is coated by a copper strip, and is welded with the copper strip to obtain a copper-coated aluminum blank; and (3) the copper-coated aluminum blank is rolled to obtain a copper-coated aluminum profile. The production process can continuously produce the copper-coated aluminum profile through a long flow, destroys a traditional short-flow preparation concept of a copper-coated aluminum composite material, and largely simplifies the steps to reduce the investment quantity and repeated investment quantity of production equipment so as to effectively reduce the production cost.

Owner:王学平 +1

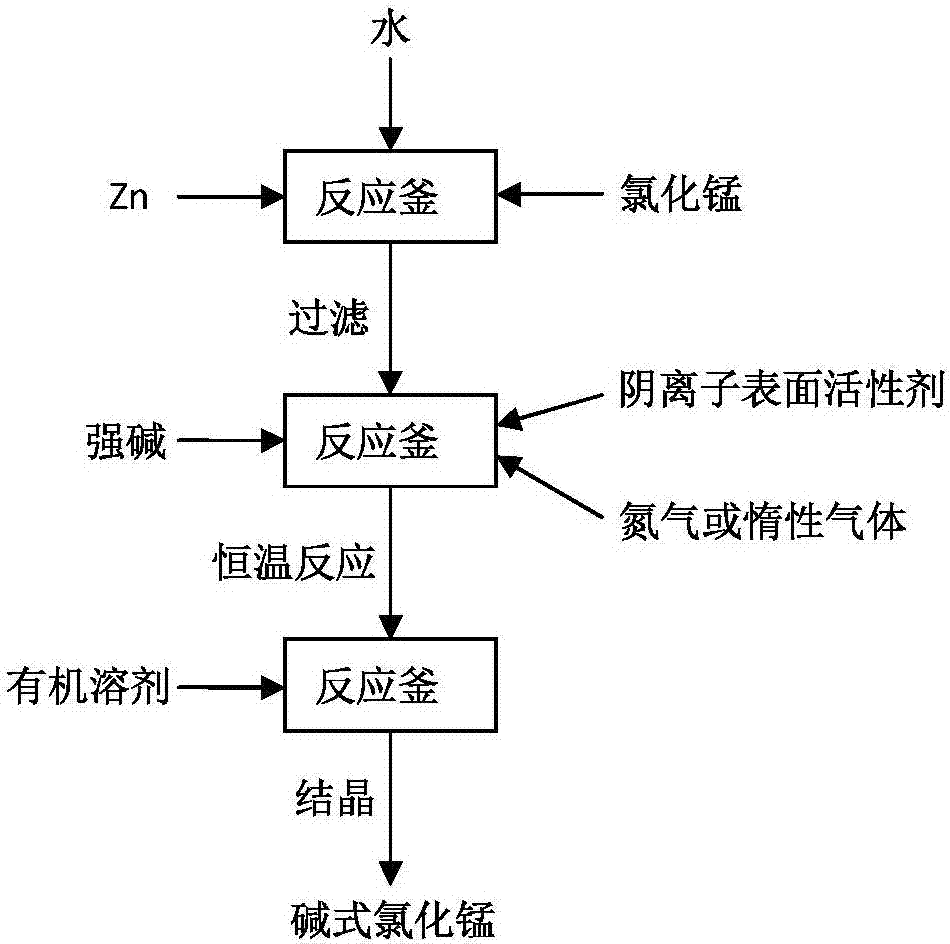

Preparation method of alkaline manganese chloride

ActiveCN106865619AThe production process steps are simpleLow costAccessory food factorsWorking-up animal fodderChemistryNitrogen gas

The invention provides a preparation method of alkaline manganese chloride capable of being used for animal feed. The preparation method comprises the following steps: (1) adjusting the pH (Potential of Hydrogen) value of a manganese chloride solution to be 6.0 to 7.5; adding manganese; stirring for a period of time and filtering; (2) sealing filtrate filtered in the step (1) and introducing nitrogen gas or inert gas for protecting; slowly adding a strong alkaline solution while stirring; raising the temperature and carrying out constant-temperature reaction after reaching reaction temperature; (3) after reacting, adding an organic solvent or an organic solvent-water mixture into a sealed reaction system and keeping the reaction temperature in the step (2); cooling to room temprature while stirring and crystallizing; (4) filtering, washing and drying to obtain the alkaline manganese chloride. The alkaline manganese chloride prepared by the preparation method has the advantages of small damages to nutrient components, high product bioavailability, low processing cost and the like.

Owner:昕嘉生物技术(长沙)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com