Carbon fiber prepreg and preparation method thereof

A carbon fiber prepreg, carbon fiber technology, applied in the field of polymer materials and their preparation, can solve the problems of increased production difficulty, non-uniform materials, complex production processes, etc., and achieves suitable temperature control, simple production process steps, and product mechanical properties. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

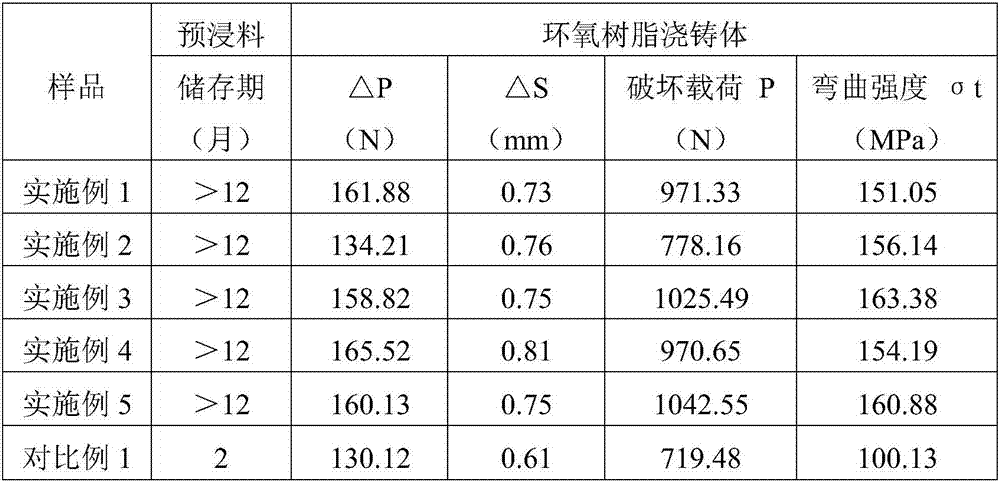

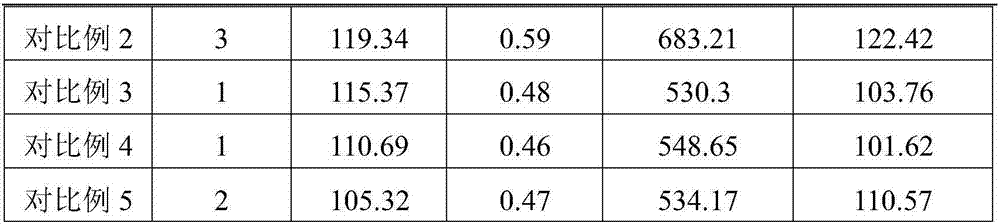

Embodiment 1

[0026] Example 1: Stir 10kg each of novolac epoxy resin NPCN-704, liquid bisphenol A epoxy resin NPEL-128 and solid bisphenol A epoxy resin NPES-901 at 80°C, and after mixing completely, a mixed solution A is obtained ; Add 0.9kg of curing agent dicyandiamide 100S to the mixed solution A, and stir evenly at 70°C to obtain the mixed solution B, add 0.15kg accelerator UR700 to the mixed solution B, and stir evenly at 70°C to obtain Mixed solution C, the viscosity of mixed solution C is 10000cps, take 2kg of mixed solution C and solidify at 150°C for 2 hours to obtain an epoxy resin cast body, and measure the performance of the epoxy resin cast body. Put the remaining mixed liquid C in the glue coating machine, check the weight per square meter of the film with an infrared instrument, and lower the temperature of the film to room temperature through the cooling plate to obtain the film, and put the film from the prepreg machine up and down Lead out from the rubber film roll, and ...

Embodiment 2

[0027] Example 2: Stir 10kg of novolac epoxy resin 638S, 20kg of liquid bisphenol A epoxy resin NPEL-128 and 10kg of solid bisphenol A epoxy resin NPES-901 at 90°C, and after mixing completely, a mixed solution A is obtained; Add 1.5kg of curing agent dicyandiamide 100SF to mixed solution A, and stir evenly at 80°C to obtain mixed solution B, add 0.83kg accelerator modified imidazole PN40 to mixed solution B, and stir evenly at 80°C , to obtain the mixed solution C, the viscosity of the mixed solution C is 20000cps, take 2kg of the mixed solution C and cure it at 150°C for 2h to obtain the epoxy resin cast body, and measure the performance of the epoxy resin cast body. Put the remaining mixed liquid C in the glue coating machine, check the weight per square meter of the film with an infrared instrument, and lower the temperature of the film to room temperature through the cooling plate to obtain the film, and put the film from the prepreg machine up and down Lead out from the ...

Embodiment 3

[0028] Example 3: Stir 10kg of novolac epoxy resin 638S, 15kg of liquid bisphenol A epoxy resin NPEL-128 and 10kg of solid bisphenol A epoxy resin NPES-901 at 85°C. After mixing completely, a mixed solution A is obtained; Add 2.8kg of curing agent dicyandiamide DDA-5 to mixed solution A, stir evenly at 75°C to obtain mixed solution B, add 1.1kg accelerator modified imidazole PN50 to mixed solution B, and stir at 75°C After uniformity, the mixed solution C was obtained. The viscosity of the mixed solution C was 40,000 cps. Take 2kg of the mixed solution C and cure it at 150°C for 2 hours to obtain an epoxy resin cast body, and measure the performance of the epoxy resin cast body. Put the remaining mixed liquid C in the glue coating machine, check the weight per square meter of the film with an infrared instrument, and lower the temperature of the film to room temperature through the cooling plate to obtain the film, and put the film from the prepreg machine up and down Lead out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com