Production process of aluminum-plastic plate

A production process and technology of aluminum-plastic panels, applied in applications, household appliances, adhesives, etc., can solve the problems of falling off, glue opening, poor bonding of the alloy layer and the lower aluminum alloy layer, etc., to prevent glue opening or falling off, simple steps, Guaranteed good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

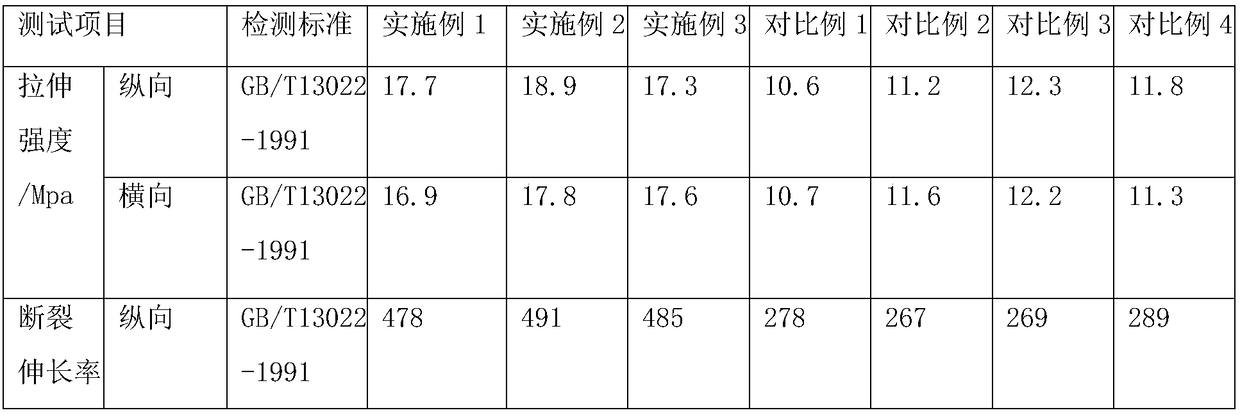

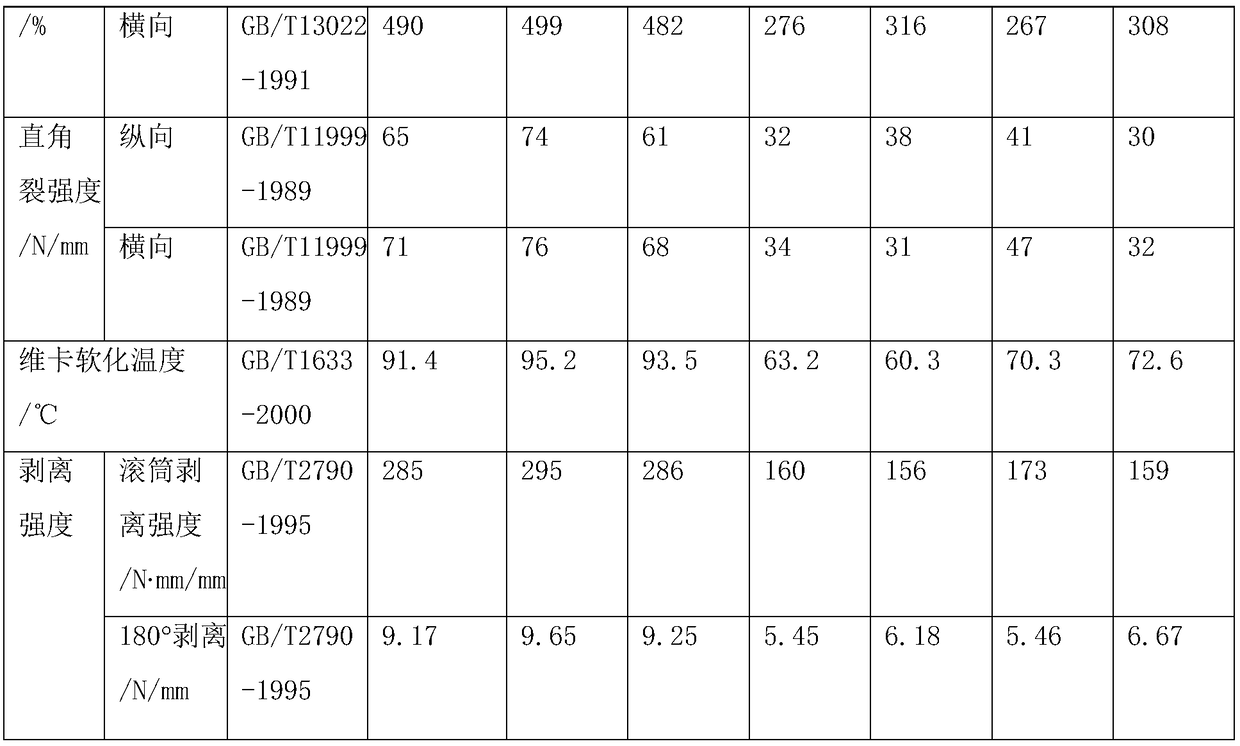

Examples

Embodiment 1

[0031] Embodiment 1: A kind of production technology of aluminum-plastic panel, comprises the following steps:

[0032] (1) Mixing and stirring: Weigh 100kg and have a density of 0.91g / cm 3 After the polyethylene was stirred in the mixer for 5 minutes, 0.3kg of azodicarbonamide, 2kg of talcum powder, 3kg of calcium carbonate, and 10kg of barium sulfate were poured in order, and after stirring for 1 minute again, it was sucked into the exhaust type by a vacuum suction machine. in the hopper of the extruder;

[0033] (2) Extrusion and sheeting: control the extrusion temperature of the exhaust extruder to 140°C, plasticize and extrude each raw material, exhaust during extrusion, and utilize the extruded molten state raw materials The water-cooled roll is extruded to form a plastic core material, and the temperature of the water-cooled roll is controlled at 15°C, and the plastic core plate is dedusted by an electrostatic precipitator;

[0034] (3) Degreasing of the aluminum plat...

Embodiment 2

[0041] Embodiment 2: a kind of production technology of aluminum-plastic panel, comprises the following steps:

[0042] (1) Mixing and stirring: Weigh 100kg and have a density of 0.915g / cm 3 After the polyethylene is stirred in the mixer for 10 minutes, pour 0.5kg of azodicarbonamide, 4kg of talcum powder, 4kg of calcium carbonate, and 15kg of barium sulfate in sequence, and after stirring again for 3 minutes, it is sucked into the exhaust type by a vacuum suction machine. in the hopper of the extruder;

[0043] (2) Extrusion and sheeting: control the extrusion temperature of the exhaust extruder to 210°C, plasticize and extrude each raw material, exhaust during extrusion, and utilize the extruded molten state raw materials The water-cooled roll is extruded to form a plastic core material, and the temperature of the water-cooled roll is controlled at 18°C, and the plastic core plate is dedusted by an electrostatic precipitator;

[0044] (3) Degreasing of the aluminum plate: ...

Embodiment 3

[0051] Embodiment 3: a kind of production technology of aluminum-plastic panel, comprises the following steps:

[0052] (1) Mixing and stirring: Weigh 100kg and have a density of 0.92g / cm 3After the polyethylene was stirred in the mixer for 15 minutes, 0.6kg of azodicarbonamide, 7kg of talcum powder, 6kg of calcium carbonate, and 20kg of barium sulfate were poured in order, and after stirring again for 6 minutes, the vacuum suction machine was sucked into the exhaust in the hopper of the extruder;

[0053] (2) Extrusion and sheeting: control the extrusion temperature of the exhaust extruder to 280°C, plasticize and extrude each raw material, exhaust during extrusion, and utilize the extruded molten state raw materials The water-cooled roll is extruded to form a plastic core material, and the temperature of the water-cooled roll is controlled at 20°C, and the plastic core plate is dedusted by an electrostatic precipitator;

[0054] (3) Degreasing of the aluminum plate: send t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com