Patents

Literature

90results about How to "Reduce production process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing lithium ion battery anode material LiNi0.5Mn1.5O4

InactiveCN102531071AReduce production process stepsShort synthesis timeNickel compoundsMass ratioNickel compounds

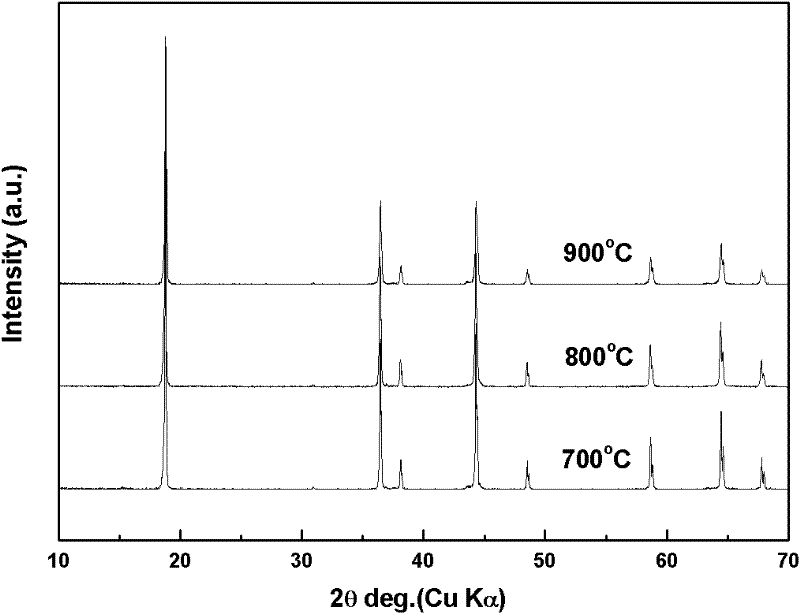

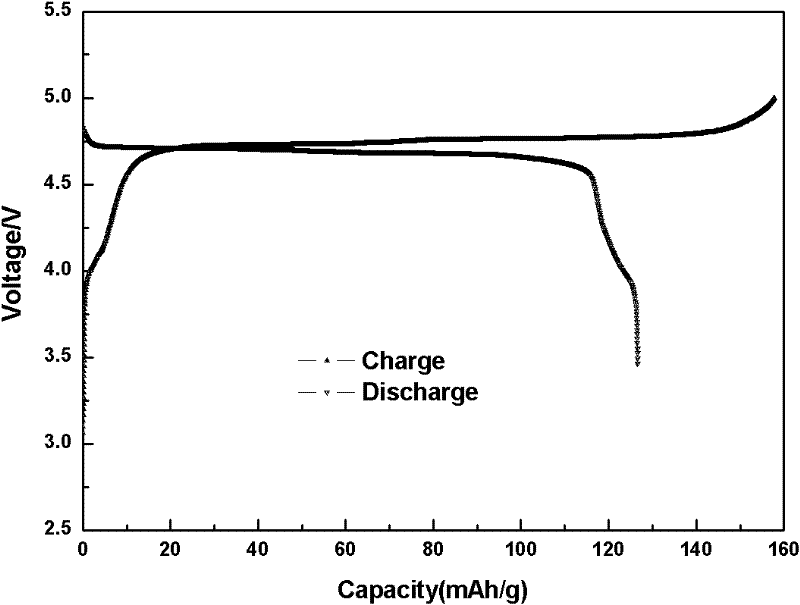

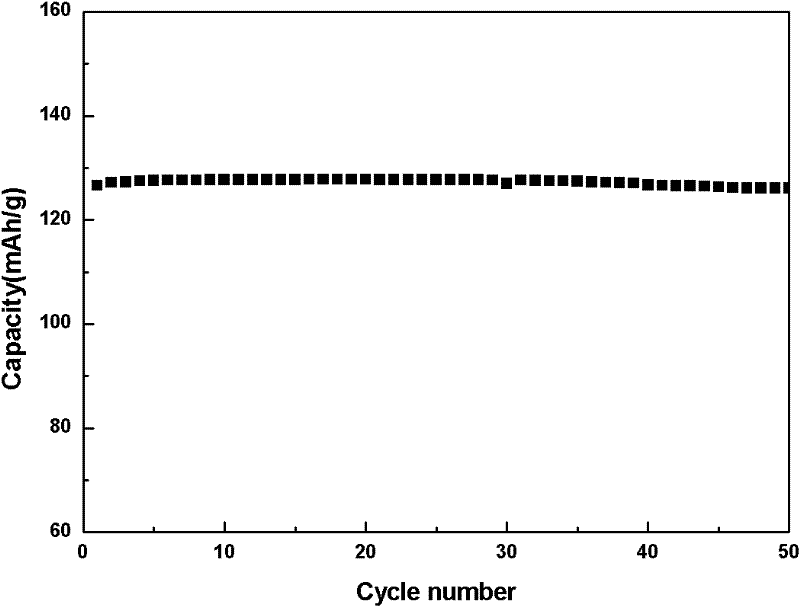

The invention relates to a method for preparing a lithium ion battery anode material LiNi0.5Mn1.5O4. The method comprises the following steps of: (1) liquid phase ball milling: performing liquid phase ball milling on a lithium-containing compound, a nickel-containing compound and a manganese-containing compound in a mass ratio of 1: (1-1.5): (2-5) in a solvent; (2) spray drying: performing spray drying on the ball-milled product in a high-speed spray drying machine; and (3) sintering: performing high-temperature sintering on the spray-dried product in a furnace, cooling the product to room temperature, crushing and grading, and thus obtaining the lithium ion battery anode material LiNi0.5Mn1.5O4. By adopting the preparation process of liquid phase ball milling, spray drying and sintering, the production process is greatly reduced, the synthesis time is short, and the production cost is reduced; and the method is easy to operate, and can realize continuous and large-scale commercial production. The lithium ion battery anode material LiNi0.5Mn1.5O4 has the characteristics of stable structure, high specific capacity and circular, stable and excellent electrochemical performance.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

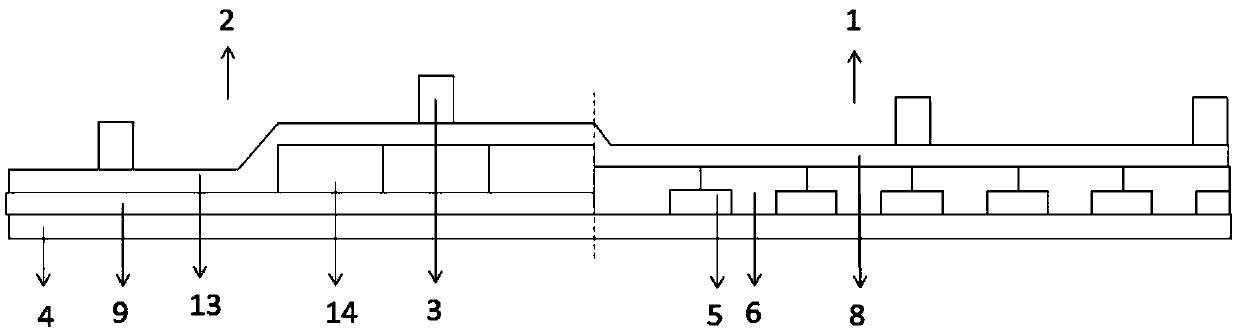

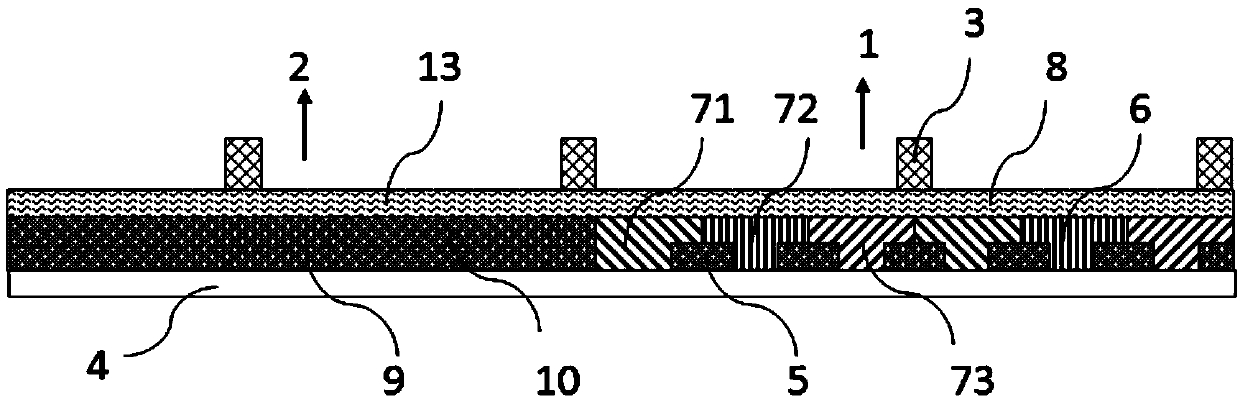

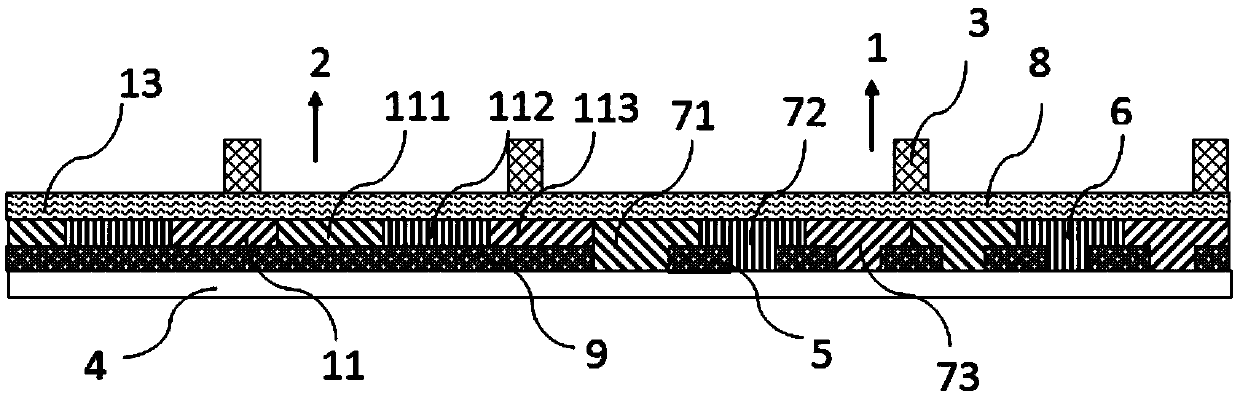

Color film substrate and manufacturing method thereof

ActiveCN109557709ASolve the problem of poor peripheral displayReduce production process stepsNon-linear opticsLiquid-crystal displayColor film

The invention discloses a color film substrate, and belongs to the field of the liquid crystal display. The color film substrate comprises a display area and a non-display area located surrounding thedisplay area; the display area comprises a first black matrix, pixel areas limited through the first block matrix, a color resistance layer located at each pixel area, and a first planarization layercovering the color resistance layer; the color resistance layer partially covers the first black matrix; the non-display area comprises a second black shading layer in whole surface laying, a cushionlayer covering the second black shading layer and a second planarization layer covering the cushion layer; the total height of the cushion layer and the second black shading layer is equal to the height of the color resistance layer. The color film substrate for flattening the display area and the non-display area can solve the problem that the periphery display is bad under the condition of notincreasing the thickness of the display area.

Owner:NANJING CEC PANDA FPD TECH CO LTD

Water column forming method of spherical molecular sieve

ActiveCN104383967AImprove adhesionReduce production process stepsCatalyst carriersCatalyst activation/preparationNano al2o3Manganese

The invention relates to a water column forming method of a spherical molecular sieve. The water column forming method is characterized by comprising the following steps: 1, beating a molecular sieve, a binding agent and water uniformly; 2, adding an alginate solution, and stirring uniformly at high speed to prepare a suspended sizing agent; 3, dropping the suspended sizing agent to a polyvalent metal cation water solution to form gel particles; and 4, taking the gel particles out, drying and roasting to obtain the product, wherein the dry-basis mass rate of the molecular sieve to the binding agent in the step 1 is (0.2-3):1, and the binding agent is alumina hydrogel, nanometer aluminum oxide sol or silica sol; the soluble alginate in the step 2 is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, the content of alginate in the suspended sizing agent is 0.3-5w%, and total dry-basis content of the molecular sieve and the binding agent in the suspended sizing agent is 5-30w%; the polyvalent metal cation water solution in the step 3 is a saline solution containing aluminum, zinc, calcium, copper, ferrum, ferrous, cobalt, manganese or nickel ions, with the saturation concentration being 0.1mol / L.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Preparing method of spherical titanium-aluminum composite carrier

ActiveCN104353504AImprove adhesionReduce production process stepsCatalyst carriersAluminum IonNano al2o3

The invention relates to a preparing method of a spherical titanium-aluminum composite carrier. The preparing method is characterized by comprising the following steps: adding deionized water and titanium oxide into alumina gel and uniformly mixing; slowly adding an alginate solution, and stirring at high speed to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form spherical composite gel particles; and drying and roasting the gel particles to obtain the spherical titanium-aluminum composite carrier, wherein aluminum oxide hydrogel or nano aluminum oxide gel is adopted as the alumina gel; the adding amount of titanium oxide is 0.1-4 times the mass of alumina gel based on Al2O3, and the crystalline phase of titanium oxide is selected as anatase phase; the solid content of the suspension slurry is 5%-25%, and the content of alginate is 0.3%-5%; alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate; the multivalent metal cation solution is saline solutions containing aluminum ions, zinc ions, calcium ions, copper ions, iron ions, ferrous ions, cobalt ions, manganese ions or nickel ions, with the saturation concentration being 0.1mol / L.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

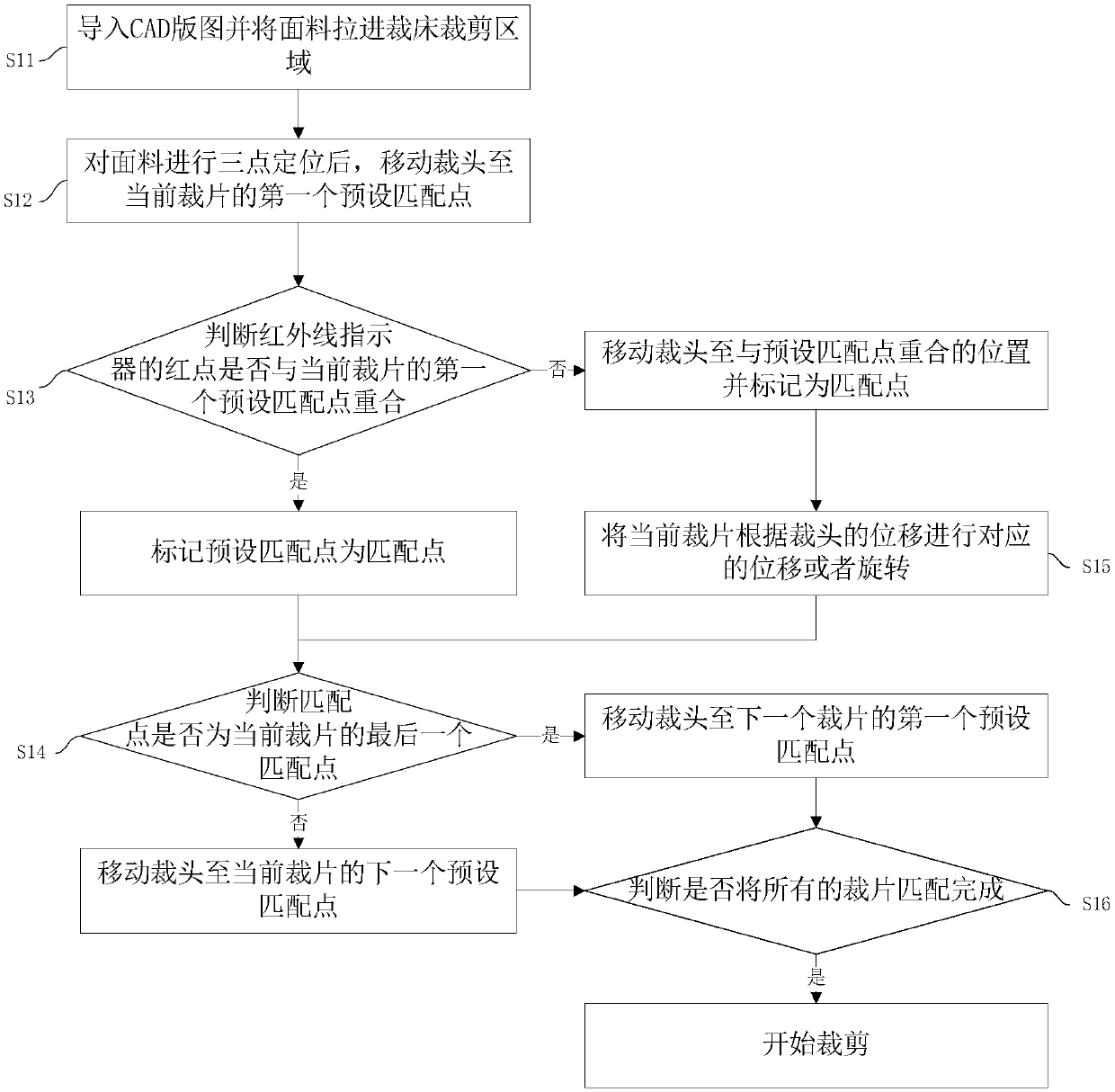

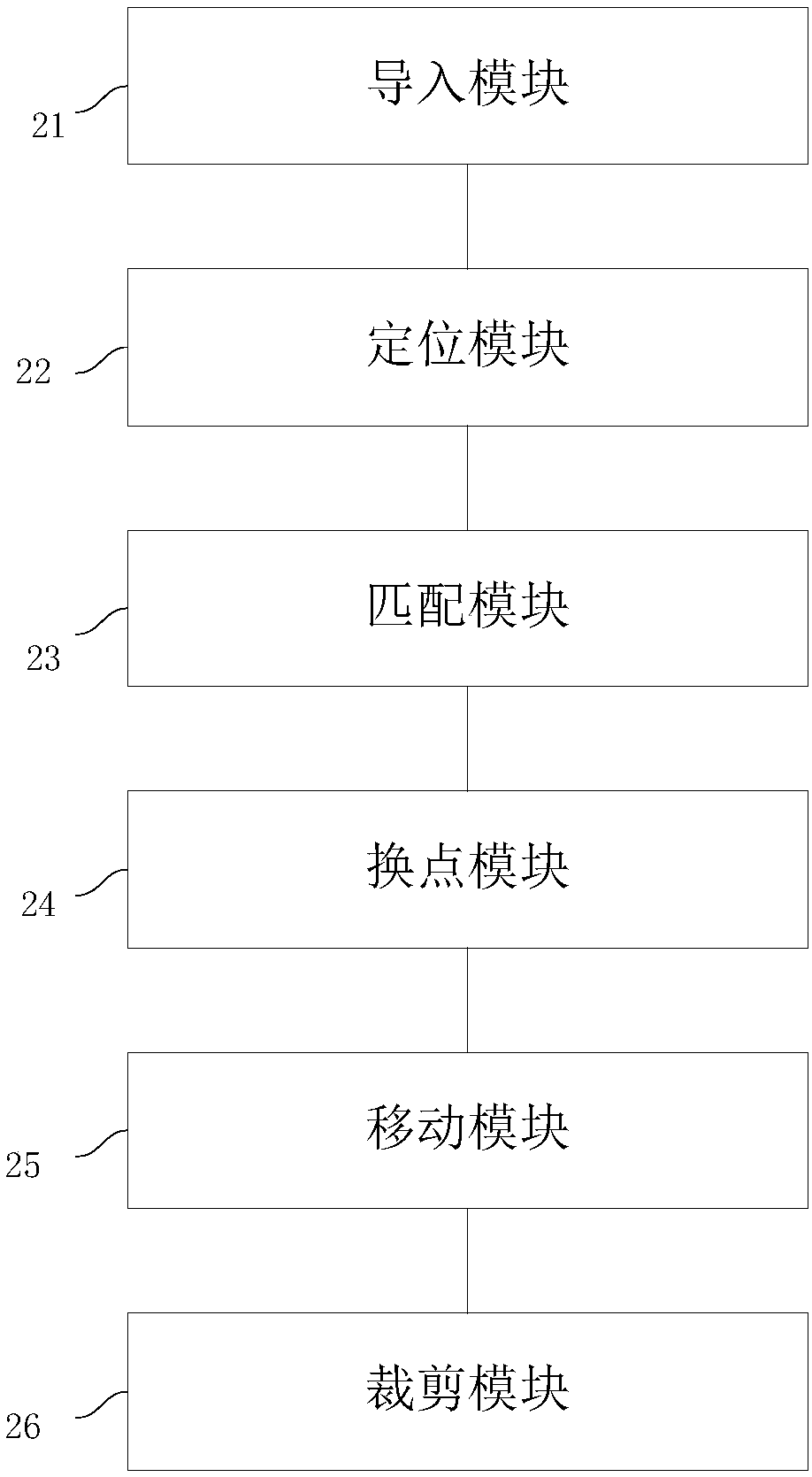

Symmetrical-stripe-and-check cutting method and system

The invention discloses a symmetrical-stripe-and-check cutting method and system. The method and system are used for solving the problems that in existing stripe-check clothing production, the cuttingefficiency is low and the precision is poor. The method comprises the steps of importing a CAD map and drawling fabric into a cutting bed cutting area; moving a cutting head to a first preset matching point of a current cutting part after conducting three-point locating on the fabric; judging whether a red point of an infrared indicator of the cutting head coincides with the first preset matchingpoint of the current cutting part or not, and if yes, labeling the preset matching point as a matching point; if not, moving the cutting head to the position coinciding with the preset matching pointand labeling the position as the matching point. By means of the symmetrical-stripe-and-check cutting method and system, before cutting, the position of the cutting part in a cutting bed computer isadjusted through a matching stripe and check point method, the operation is simple and the time is saved. Besides, after cutting is conducted, manual cutting is not needed anymore, the production process steps are reduced, the efficiency is improved, and the production cost is reduced.

Owner:BULLMER ELECTROMECHANICAL TECH

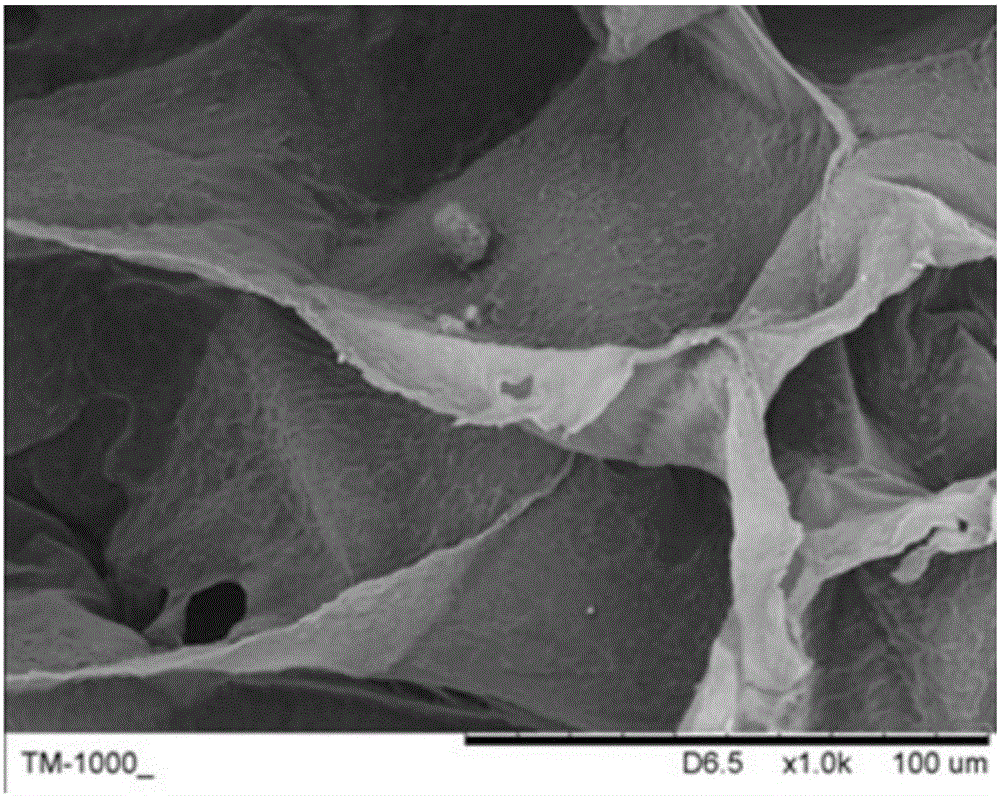

Aroma-emitting underwear chest pad containing essential oil and preparation method thereof

InactiveCN101897480AQuality is not affectedReduce production process stepsBrassieresCorsetsPolyolSilicone oil

The invention relates to the technical field of female life daily necessities, in particular to an aroma-emitting underwear chest pad containing essential oil and a preparation method thereof. The formula of the chest pad comprises the following components by weight percent: 54-77% of polyether polyol, 20-35% of organic isocyanate, 1-5% of plastic flavoring particles (matrix resin is polyurethane), 1-4% of water, 0.2-0.4% of catalyst and 0.8-1.6% of silicon oil. Compared with the prior art, the chest pad is applicable to all the existing sponge production processes, and the flavoring master batches are added for achieving the technical effects of producing the aroma-emitting underwear chest pad, leading a product to emit aroma in a lasting manner, and producing the diversity by using the different flavoring master bathes; and the chest pad can be taken out when washing underwear at each time, thereby preventing the deformation of sponge, leading a woman to fill different chest pads into the underwear according to different moods during the daily life, leading the woman to be more charming, and further having a plurality of health care roles.

Owner:BESTSCENT SHANGHAI FINE CHEM

Release-free laser electrochemical aluminum hot-stamping foil imaging layer coating and preparation method thereof

InactiveCN101921523AReduce production process stepsMeet the use requirementsPolyurea/polyurethane coatingsPolyester coatingsHot stampingSolvent

The invention discloses a release-free laser electrochemical aluminum hot-stamping foil imaging layer coating and a preparation method thereof, and mainly solves the technical problems of harsh production field environment requirement of the conventional laser electrochemical aluminum hot-stamping foil imaging layer coating in a coating process, short service life of the coating, complex production process flow and the like. The invention adopts the technical scheme that the electrochemical aluminum hot-stamping foil imaging layer coating is prepared from the following raw materials in part by weight: 5 to 10 parts of polyurethane resin, 3 to 8 parts of nitrocellulose, 5 to 15 parts of polyacrylate resin, 1 to 8 parts of dehydrated malic acid resin, 0 to 10 parts of polyester resin, 0.1 to 5 parts of auxiliary agent and 50 to 85 parts of solvent. The coating can be directly coated on a PET carrier film, and the PET carrier film is prepared into a laser electrochemical aluminum hot-stamping foil product by laser die pressing, vacuum aluminizing, gum coating, slitting and rewinding; and the coating has no over harsh requirements for relative humidity of a production field and the like in the coating process, and the coating product has the properties of long service life and the like.

Owner:张学毅

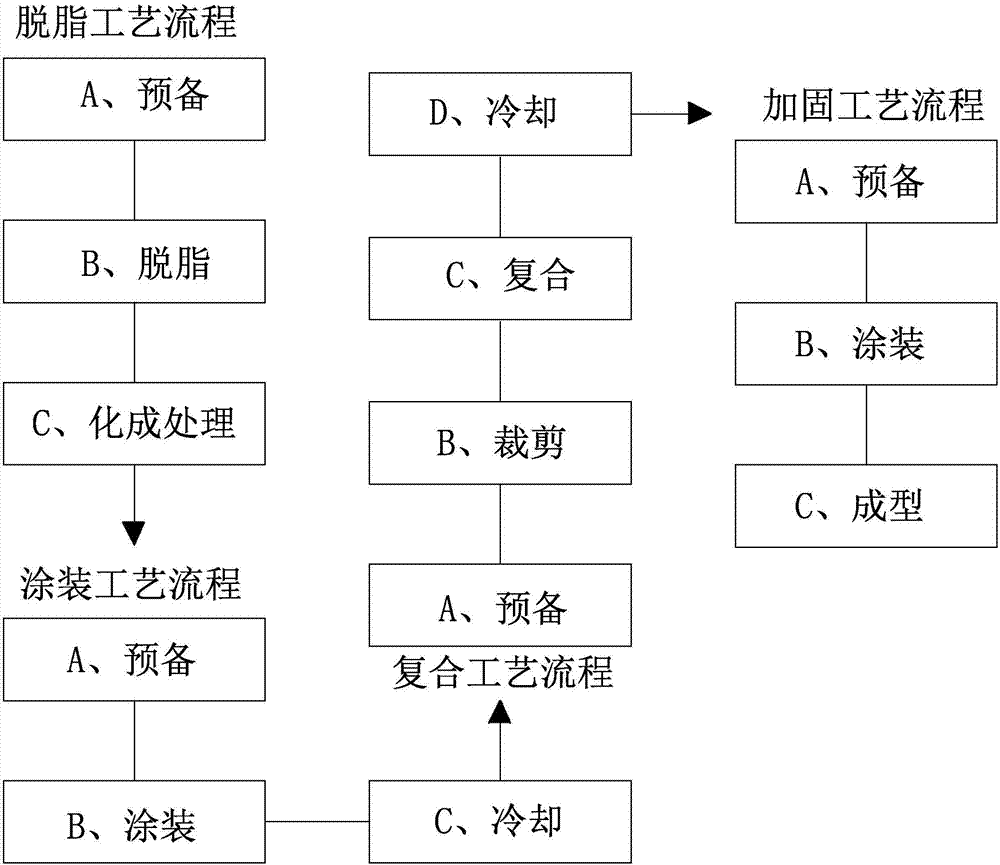

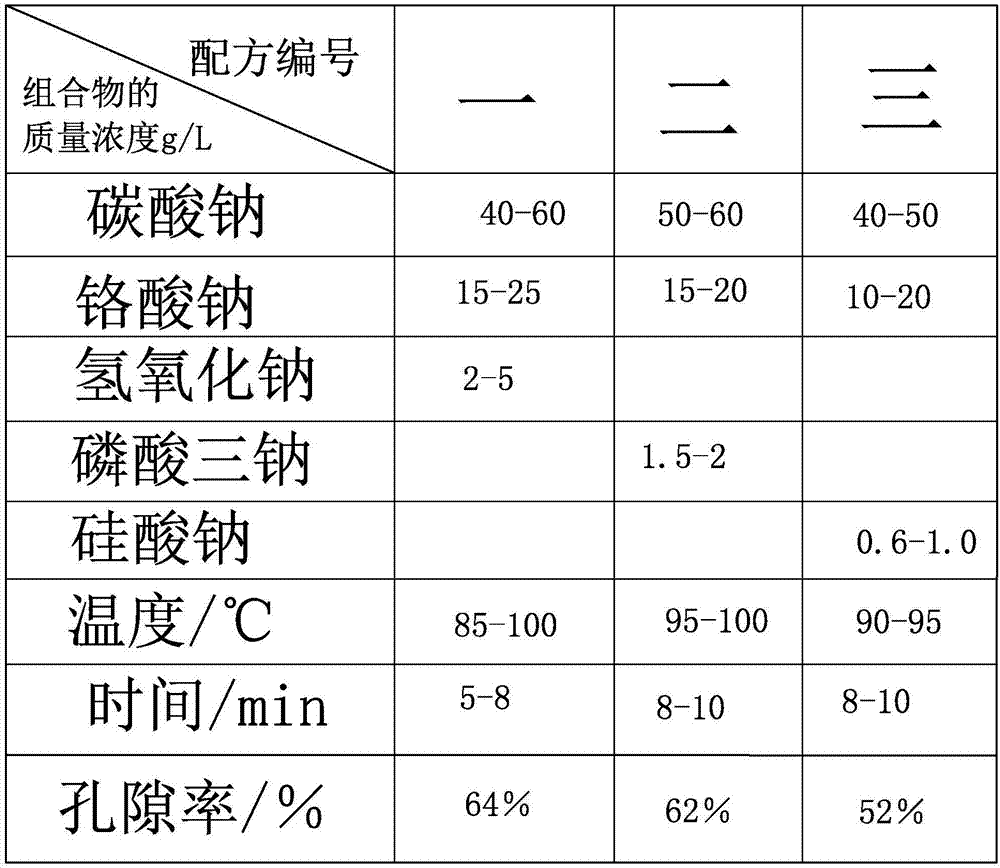

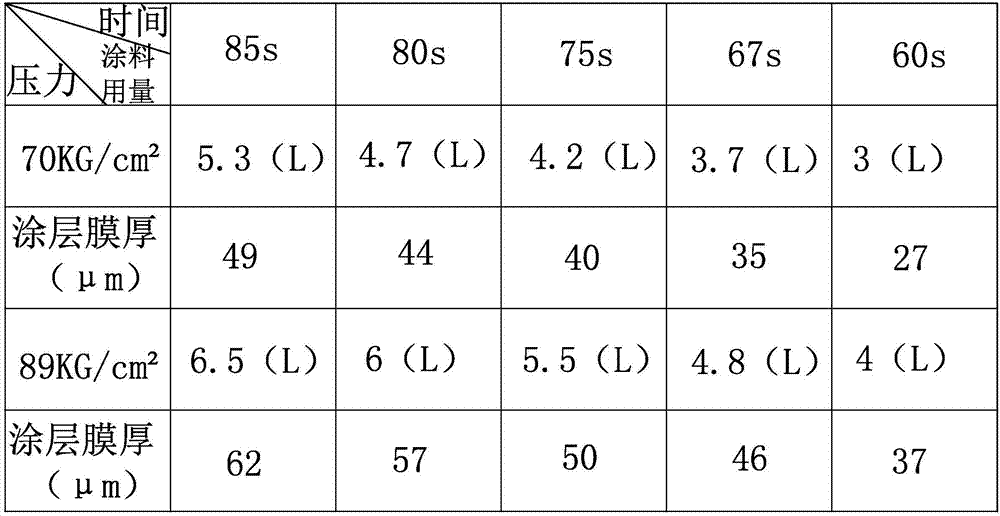

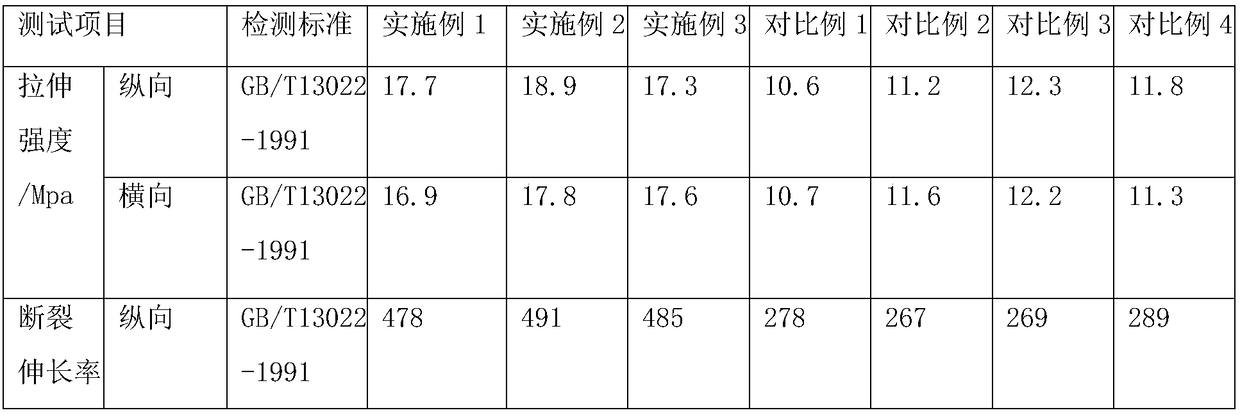

Production method of aluminum-plastic plate

InactiveCN107471807AReduce production process stepsSimple stepsCovering/liningsLamination ancillary operationsCorrosionMaterials science

The invention discloses a production method of an aluminum-plastic plate. The aluminum-plastic plate produced by the method has the effects of being good in corrosion resistance effect and plastic coating effect, and high in tensile strength. The aluminum-plastic plate is characterized by comprising an upper aluminum alloy layer, a middle layer and a lower aluminum alloy layer which are sequentially connected with one another, wherein the middle layer is prepared from flame-retardant material polyethylene (PE) plastic profiles; the upper aluminum alloy layer and the lower aluminum alloy layer are respectively sprayed with a flame-retardant coating; a filling ring groove is formed at the peripheral side of the middle layer and is positioned between the upper aluminum alloy layer and the lower aluminum alloy layer; the filling ring groove is internally filled with thermosetting resin. The production process comprises the following steps: (1) a degreasing process; (2) coating process; (3) compounding process; (4) strengthening process. The production method of the aluminum-plastic plate is suitable for the technical field of aluminum-plastic plate production.

Owner:台州港邦建材有限公司

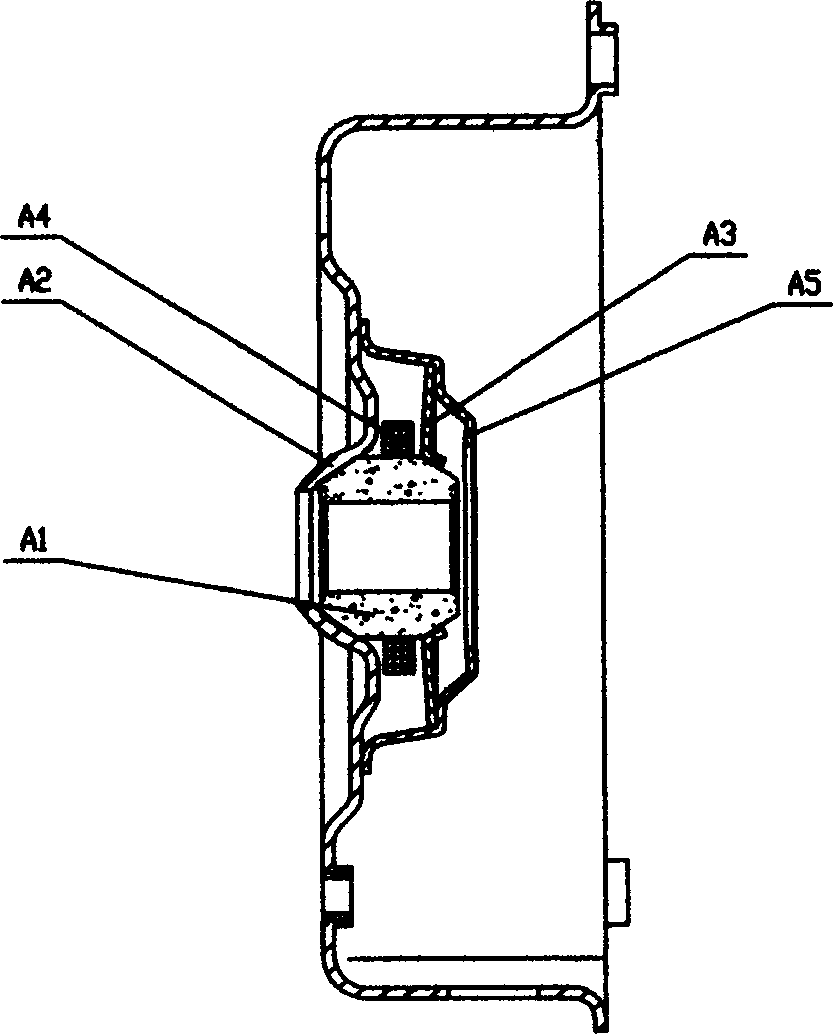

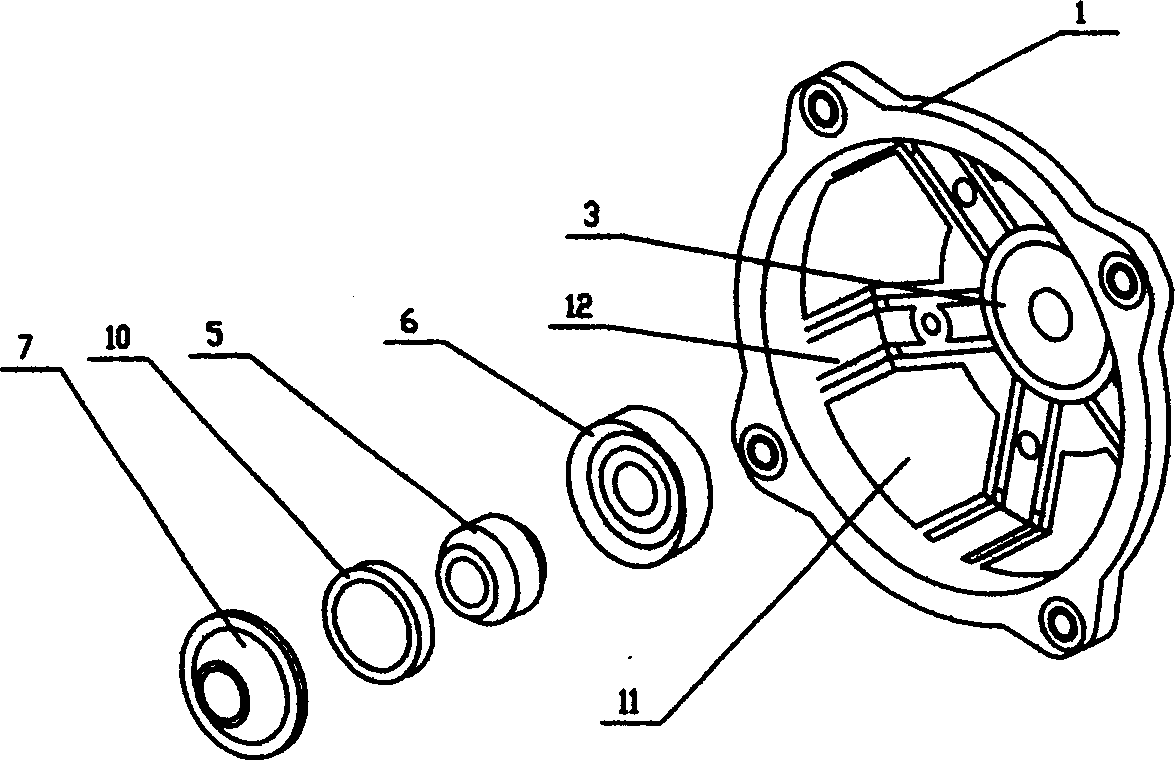

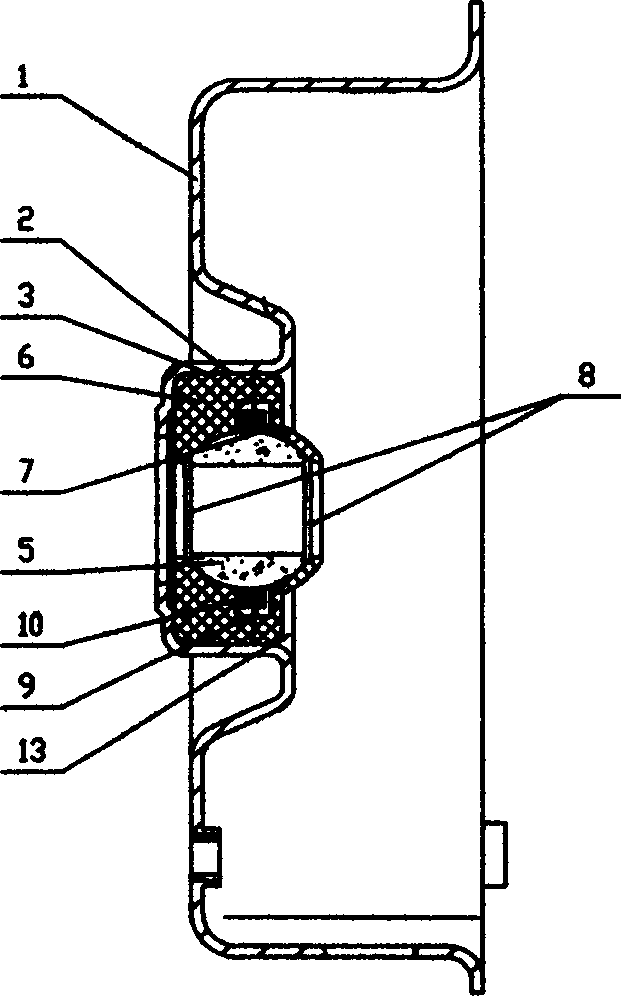

A motor cover with bearing arrangement

InactiveCN1700565AHigh positioning accuracyImprove work performanceSupports/enclosures/casingsEngineeringDevice Motor

This invention discloses one plastic sealed axis device motor cover, which is characterized by the following: comprising shell with axis fixing socket, plastic axis device connected to the shell; the sealed axis device is fixed inside the axis device fixing socket; the axis device is fixed on the socket connected to the axis socket of the plastic axis device.

Owner:罗世明

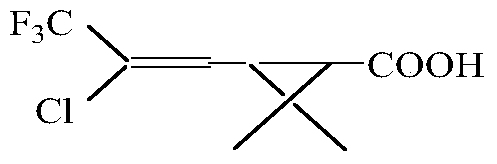

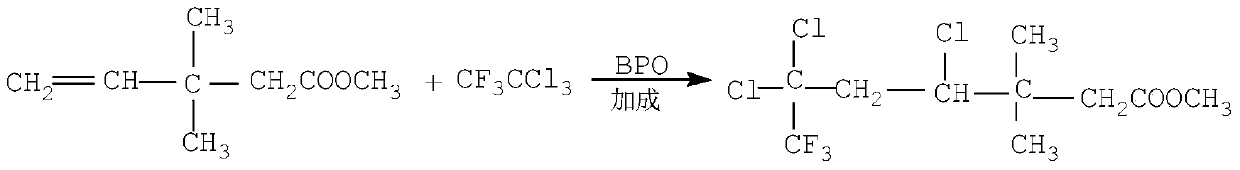

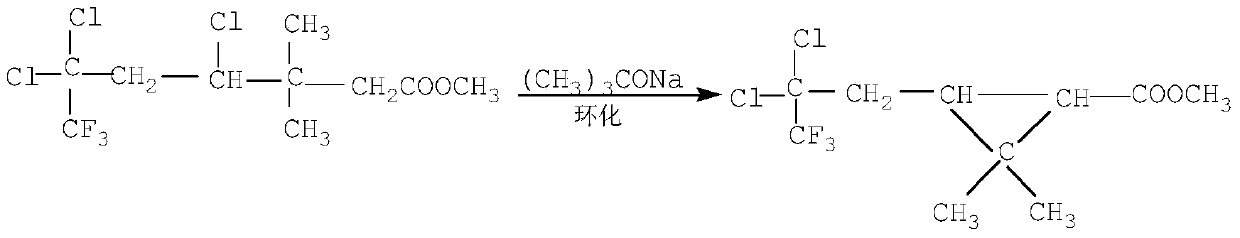

Continuous production method for trifluoro monochloro chrysanthemic acid

InactiveCN105503582ABest production methodQuality improvementOxygen-containing compound preparationOrganic compound preparation4-pentenoic acidChrysanthemic acid

The invention discloses a continuous production method for trifluoro monochloro chrysanthemic acid. The method includes the steps of (1) performing an addition reaction to prepare 3,3-dimethyl-4,6,6-trichloro-7,7,7-trifluoro heptylic acid ester with 3,3-dimethyl-4-pentenoic acid methyl ester and trifluorotrichloroethane as initial raw materials; (2) performing a cyclization reaction with sodium tert-butoxide to generate cis(trans)-3-(2,2-dichloro-3,3,3-trifluoropropyl)-2,2-dimethyl cyclocarboxylate; and (3) performing a saponification reaction to prepare 3-(2-chloro-3,3,3-trifluoro-propylene-1-yl)-2,2-dimethylcyclopropane carboxylic acid, namely, the trifluoro monochloro chrysanthemic acid. In the invention, continuous control is employed in the production method, so that the method is simple in process, is high in equipment utilization, is high in yield and stable in quality of products, is low in production cost and has a wide application prospect.

Owner:LIANYUNGANG CCA CHEM CO LTD

Preparation method of spherical silicon-aluminum composite carrier

ActiveCN104353503AImprove adhesionReduce production process stepsCatalyst carriersManganeseNano al2o3

The invention relates to a preparation method of a spherical silicon-aluminum composite carrier. The preparation method is characterized by comprising the following steps: adding silicon dioxide to an alumina gel, and uniformly mixing; slowly adding to an alginate solution, and uniformly stirring to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form a spherical composite gel granule; taking out the spherical composite gel granule, and drying and calcining to obtain the spherical silicon-aluminum composite carrier, wherein the alumina gel is an alumina hydrogel or a nano-alumina sol, the addition amount of the silicon dioxide is 0.1-0.3 time more than the weight of the alumina gel in terms of Al2O3, the suspension slurry contains 5%-25% by weight of solids and 0.3%-5% by weight of alginate, the soluble alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, and the multivalent metal cation solution is an aluminum, zinc, calcium, copper, iron, ferrous iron, cobalt, manganese or nickel ion salt solution with the saturation concentration of 0.1 mol / L. The spherical silicon-aluminum composite carrier obtained through the preparation method disclosed by the invention has the advantages of high strength, large pore volume and low bulk density.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

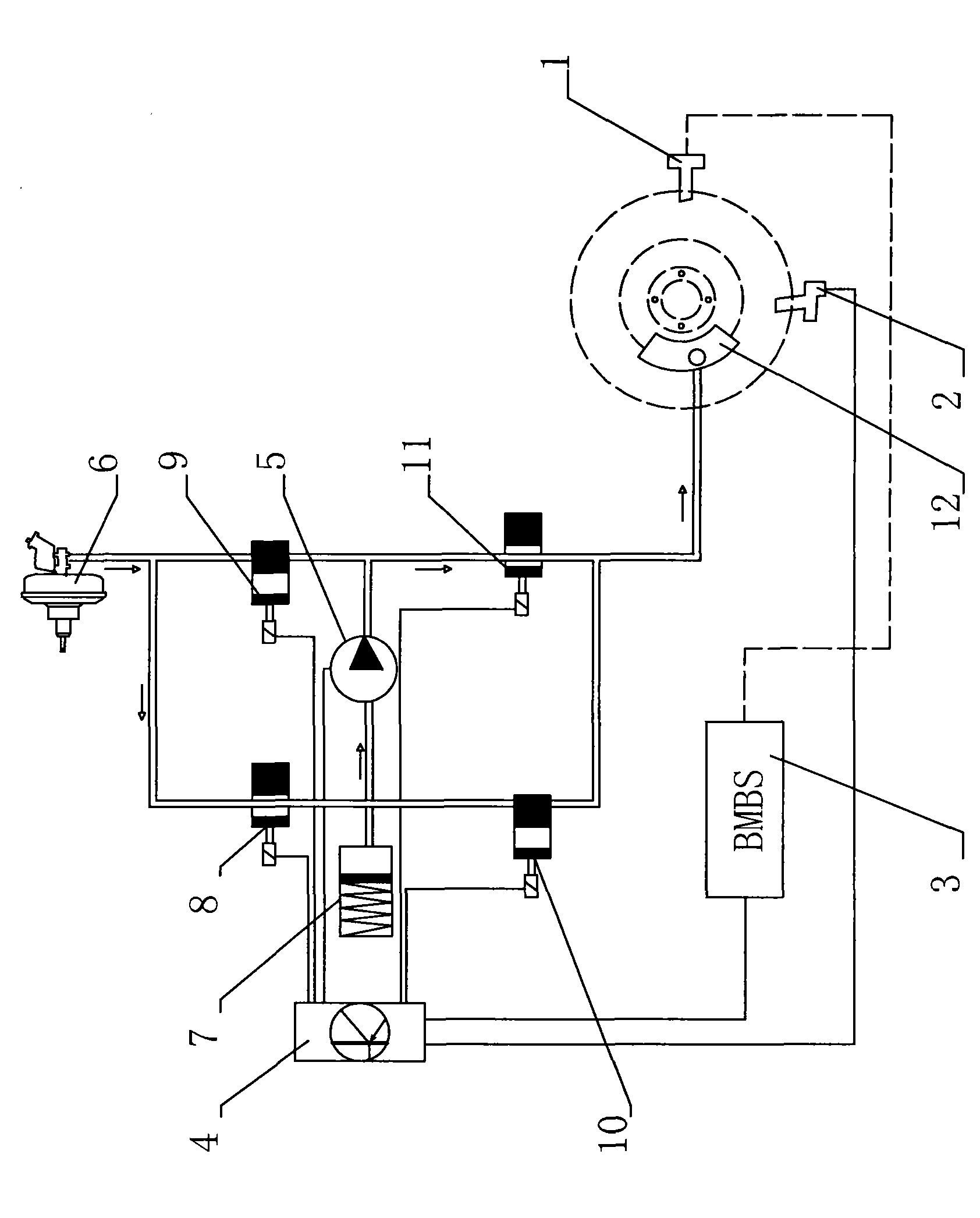

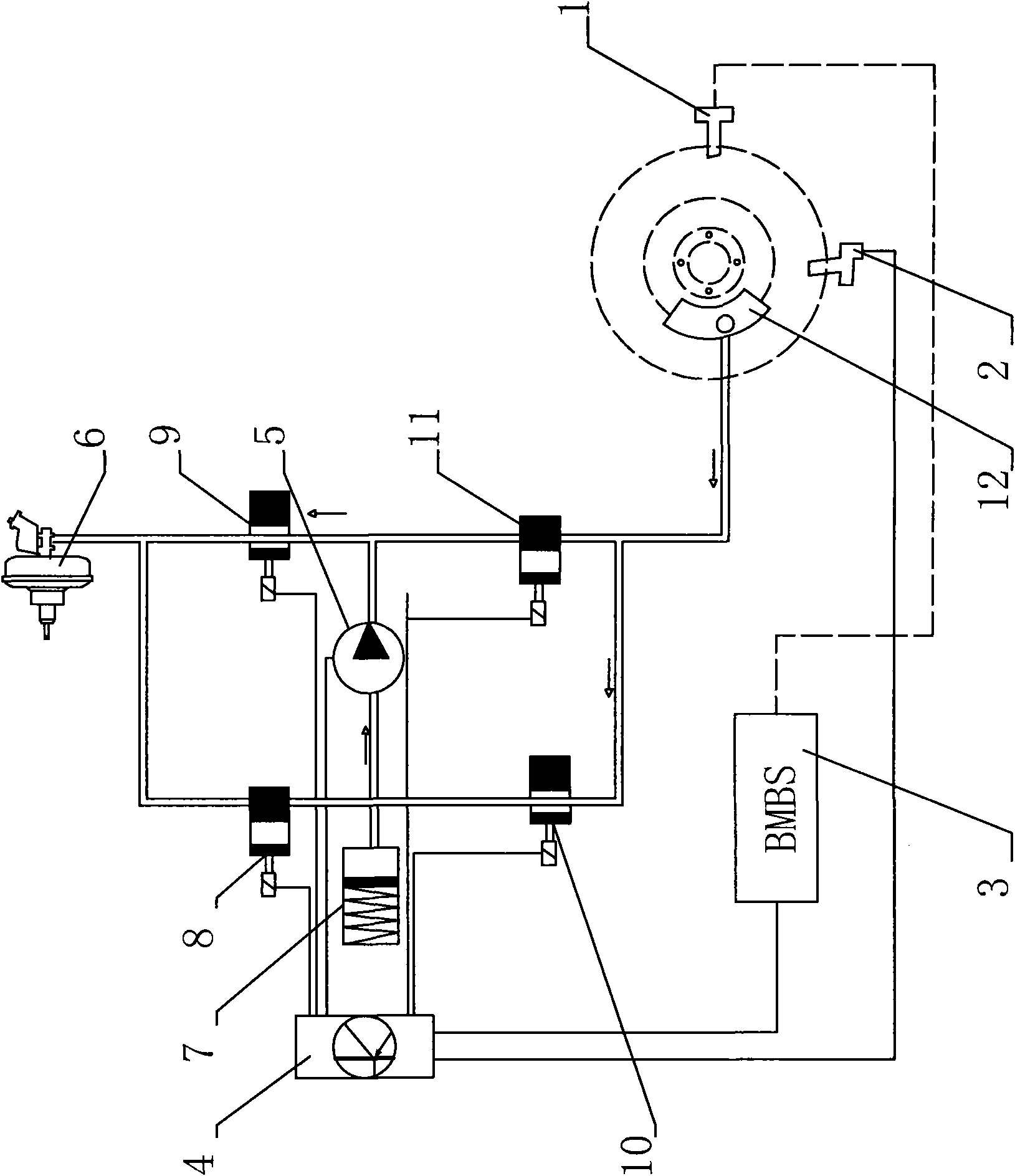

Anti-lock system-based tyre burst braking system

InactiveCN101643006AHigh control precisionImprove flexibilityTyre measurementsBraking systemsExecution unitControl theory

The invention discloses an anti-lock system-based tyre burst braking system, which avoids using an oil pump as an execution unit or a remanufactured vacuum booster. By combining a braking system with ABS / EPS, the tyre burst braking system directly serves as the execution unit and greatly simplifies the structure of the tyre burst braking system, so that rearrangements are not required in an engine compartment, the production process steps are reduced, and the production cost is reduced. Comparing the time from the sending of a command by a BMBS controller to the work start of the braking system with the ABS / ESP with the time for the prior structure to achieve braking, the time from the sending of a command by a BMBS controller to the work start of the braking system with the ABS / ESP is shorter, so the anti-lock system-based tyre burst braking system has a quick response speed.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

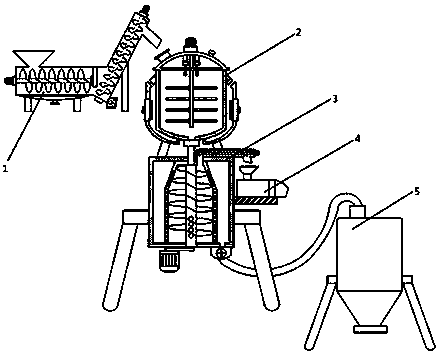

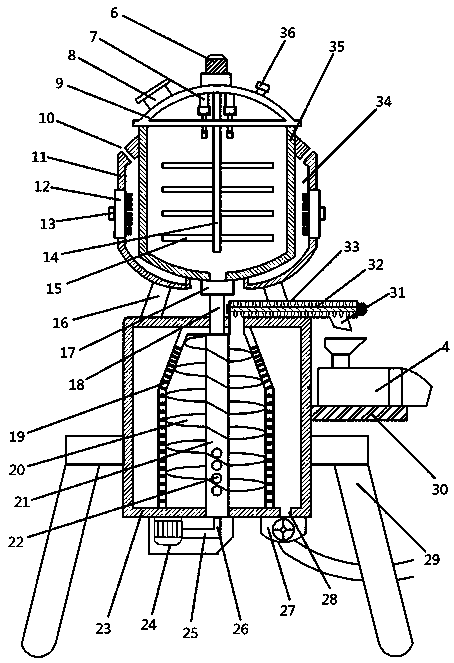

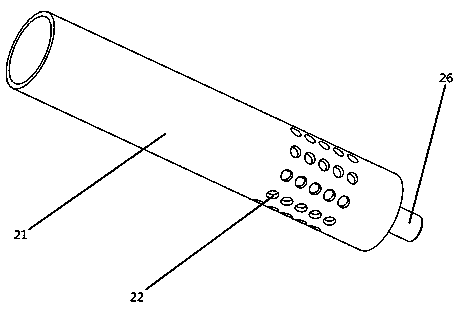

Equipment for extracting dietary fiber from wheat bran

InactiveCN109198654AAvoid security issuesRapid solid-liquid separationFood ultrasonic treatmentDietary fiberResource utilization

The invention discloses equipment for extracting dietary fiber from wheat bran. The equipment comprises a reaction device and a separation device, wherein the reaction device can be used for performing steaming boiling heating and modification on the wheat bran; the wheat bran mixed liquid after modification is completed enters the separation device to be subjected to centrifugal separation; water-soluble dietary fiber and water-insoluble dietary fiber are respectively obtained and are respectively fed into a spray drying machine and an ultrafine crushing machine to be made into dietary fiberpowder. The device provides a set of complete extraction equipment; the production process from raw materials to finished product has few steps; the efficiency is high; the fast industrial productionis facilitated; a novel path is provided for the further resource utilization of the wheat bran.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Environment-friendly and energy-saving laser hot stamping foil imaging layer paint and preparation method thereof

InactiveCN101921524AReduce production process stepsMeet the use requirementsCoatingsHot stampingShort duration

The invention relates to an environment-friendly and energy-saving laser hot stamping foil imaging layer paint and a preparation method thereof. The invention mainly solves the technical problems of rigorous environmental requirements for production sites, short duration of usage of the paint, complicated production processes and the like in the coating process of the existing laser hot stamping foil imaging layer paint. The technical scheme of the invention as follows: the hot stamping foil imaging layer paint is prepared by mixing the following raw materials in parts by weight: 5-15 parts of polyacrylate resin, 1-8 parts of dehydrated malic acid resin, 0.1-5 parts of assistants and 50-85 parts of solvent. The paint of the invention can be directly coated on a PET carrier film to be slit and rewound after laser molding, vacuum aluminizing and gum coating to obtain a laser hot stamping foil product; the invention does not have too rigorous requirements for relative humidity and the like of production sites in the coating process; and the paint product has the properties of long duration of usage and the like.

Owner:张学毅

Preparation method of roselle antifatigue buccal tablet

ActiveCN104738641ASweet and sour smellImprove stabilityAntinoxious agentsPill deliveryWork periodMedicine

The invention relates to a preparation method of a roselle antifatigue buccal tablet, and relates to the preparation method of the tablet with the function of relieving physical fatigue. The invention aims to solve the problems that in the prior art, as extracts crudely extracted from medicinal material fine powders or raw medicinal materials are mostly used for preparing antifatigue preparations, and the adopted dosage forms are mostly capsules, medicinal liquor, oral liquid, particles, common tablets, beverage and the like, the medicine cannot carried or taken conveniently, the dosage is large, the taste is bad, the oral bioavailability is low, the medicinal liquor cannot be used conveniently during the work period and the like. The preparation method comprises the following steps of (1) sieving raw and auxiliary materials; (2) weighing the raw and auxiliary materials; (3) uniformly mixing the raw materials; (4) uniformly mixing the auxiliary materials; (5) uniformly mixing the raw materials and the auxiliary materials; (6) directly compressing to obtain the tablet. The roselle antifatigue buccal tablet prepared by refined extracts is fragrant, sour and sweet, and good in taste, has no gritty texture when being taken, is not adhered to gingival or teeth, is fresh and cool, does not easily induce decayed teeth, is high in oral bioavailability and quick in effect, and can quickly relieve the state of fatigue.

Owner:哈药集团中药有限公司

Method for preparing collagen sponge under acid condition

InactiveCN106367460ASimple production processReduce manufacturing costConnective tissue peptidesPeptide preparation methodsNeutral phFreeze-drying

The invention discloses a method for preparing a collagen sponge under an acid condition. The method comprises the following steps: mixing a corium layer of mammal skin, quicklime and water, and conducting oscillating at room temperature; conducting eluting by virtue of an eluent; conducting freeze-drying and crushing the freeze-dried material into particles; mixing the particles with an acetic acid solution containing pepsase, conducting stirring and centrifuging, and taking the supernatant; conducting salting out so as to precipitate collagen and purifying the collagen; and then, dissolving the collagen in an acetic acid solution, regulating pH to 1-5, injecting the obtained material into a mould, conducting freeze-drying and cross-linking treatment, and conducting packaging and sterilizing, so that the finished collagen sponge product is obtained. According to the preparation method provided by the invention, a high-purity raw material can be directly extracted by virtue of a two-step method, and in a process of preparing the collagen sponge, rather than a rigid requirement on neutral pH of a collagen solution, the ideal collagen sponge is prepared under a low-pH condition, so that a production process is effectively simplified and preparation cost is reduced.

Owner:HANGZHOU S EVANS KETUO STEM CELL TECH RES CO LTD

Production process of aluminum-plastic plate

The invention discloses a production process of an aluminum-plastic plate, and relates to the technical field of production and manufacturing of the aluminum-plastic plates. According to the technicalscheme, the production process is characterize by comprising the following steps that (1) mixing and stirring are performed; (2) extruding and piece making are performed; (3) aluminum plate degreasing is performed; (4) aluminum plate formation treatment is performed; (5) adhesive coating and compounding are performed; and (6) a protection film is compounded. According to the production process, the problem that the phenomenon of glue failure or falling off of an aluminum plate and a plastic core material due to poor bonding of the aluminum plate and the plastic core material is prone to occurrence during compounding of the aluminum plate and the plastic core material by using a polymer film is solved, the aluminum plate and the plastic core material are bonded and compounded by using adhesives, and air exhaust and dust removal operation is carried out so that the aluminum plate and the plastic core material can be tightly bonded, and glue failure or falling off of the aluminum plate and the plastic core material can be prevented.

Owner:台州市佳信新材料科技有限公司

Method for safely producing nitrogen-containing super activated carbon

InactiveCN106629721AReduce production process stepsAvoid side effectsCarbon compoundsChemistryActivated carbon

The invention discloses a method for safely producing nitrogen-containing super activated carbon. The method comprises the step of feeding ammonia gas in a KOH activation process for activation; reaction between the ammonia gas and carbon at high temperature can be used for producing a developed pore structure; furthermore, reaction between the ammonia gas and potassium can be used for solving the problem of difficult release of the potassium in the KOH activation process, and the aim of doping a nitrogen element into the surface of activated carbon is fulfilled. By the adoption of the method, the nitrogen-containing activated carbon with a high specific surface area can be prepared, and the severe production safety problem caused by production and release of elemental potassium in the process of activating KOH to produce the super activated carbon can be solved; a new technical way is supplied to industrial production of the super activated carbon through a KOH activation method.

Owner:NANJING FORESTRY UNIV

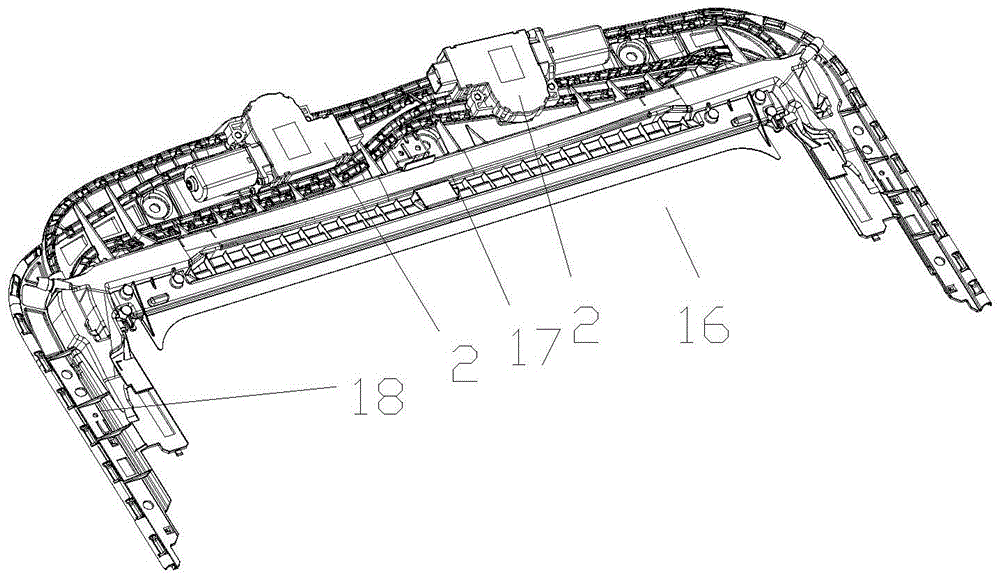

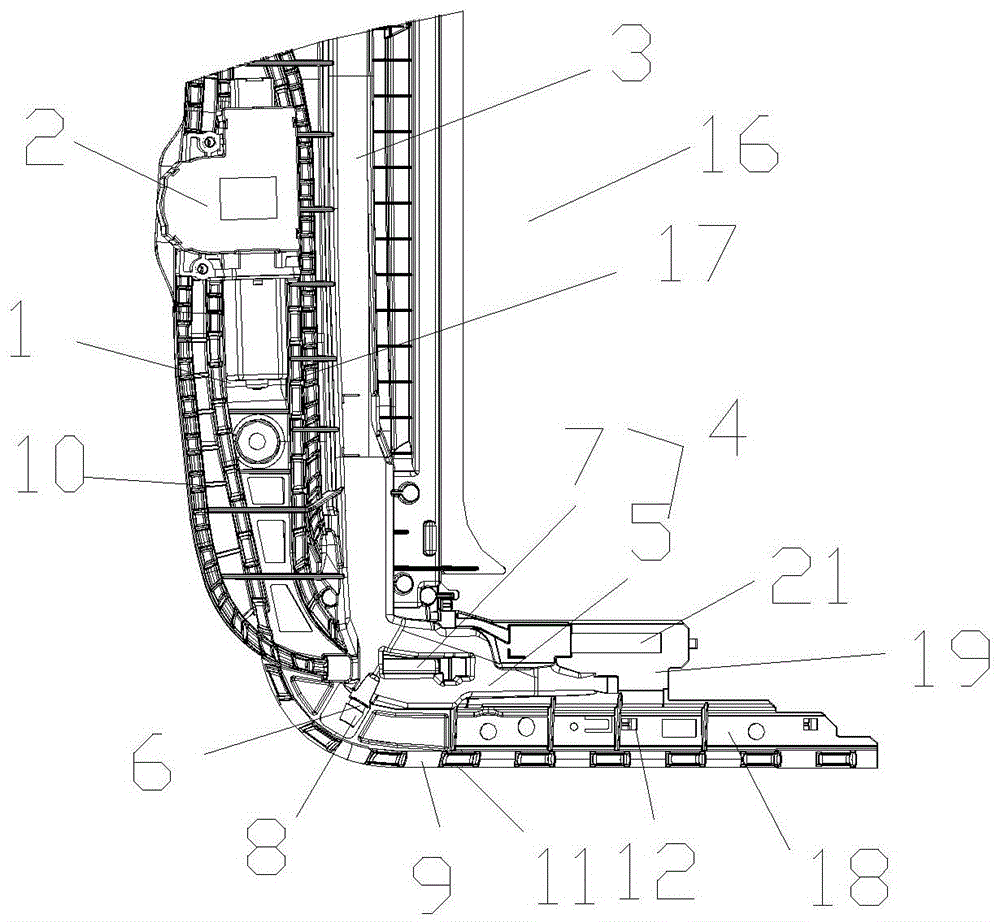

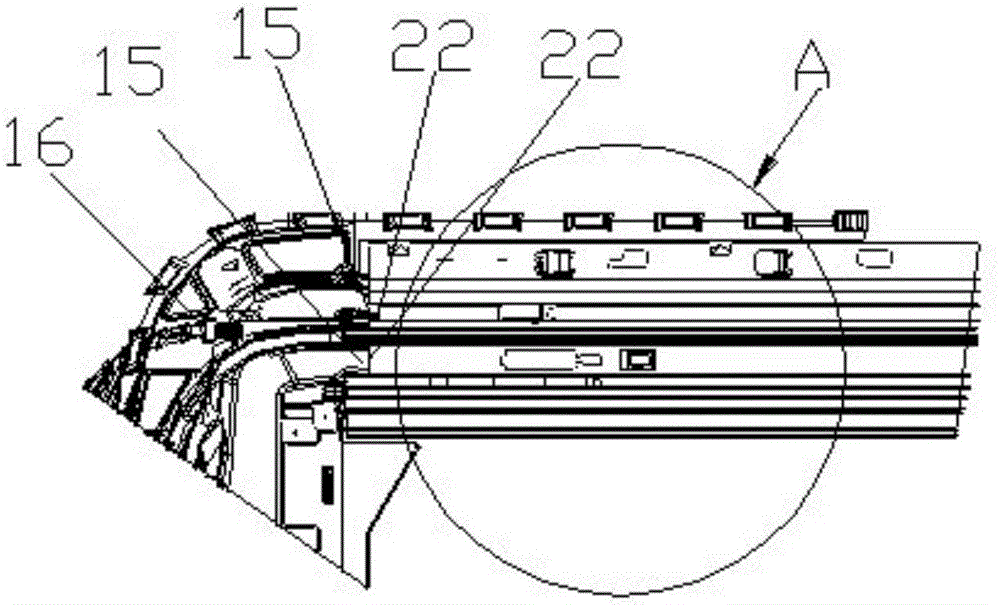

Front beam device of automobile skylight

The invention provides a front beam device of an automobile skylight.The front beam device comprises a U-shaped front beam.The U-shaped front beam is composed of a main beam and branch beams on the rear sides of the two ends of the main beam.A pair of motor installation grooves are formed in the upper end face of the main beam of the U-shaped front beam.Motors are arranged inside the motor installation grooves.The rear portion of the upper end face of the main beam is provided with a pressing rod groove.According to the front beam structure, the integral casting technology is adopted, and the production technology steps are reduced, so that the production efficiency is improved, the production time is shortened, an outer layer is an electrophoretic coating formed through electrophoresis, rust and corrosion can be resisted, drainage is more convenient, corrosion is also avoided, the service life is prolonged, space is saved, and noise is lowered.

Owner:ANHUI DIKUN AUTO SKYLIGHT TECH CO LTD HEFEI

Method for manufacturing two-part type solar cell

InactiveCN101771103AOmit the growth stepReduce cleaningFinal product manufactureSemiconductor devicesHigh concentrationDiffusion

The invention provides a method for manufacturing a two-part type solar cell, comprising the following steps of: manufacturing a substrate; implanting impurity before diffusing; or diffusing before implanting impurity. The step of implanting purity comprises the steps of: setting an obstruction on the substrate, wherein the obstruction is provided with a preset pattern opening for perforating the obstruction; implanting purity below the obstruction and enabling the concentration of the purity at the opening to be higher than that of the purity at the non-opening; and forming a reflective protection film as well as electrode on the surface. The invention ensures that doped ion with different concentrations can be implanted in different areas by adopting the obstruction so that a high-concentration layer is formed below the electrode and a low-concentration layer is formed in other areas. The method provided in the method can adopt implantation and diffusion in one step to realize the technical parameter the same as the two-part type solar cell, has better contact resistance as well as higher conversion efficiency, reduces the production process and lowers the cost.

Owner:HEJIAN TECH SUZHOU

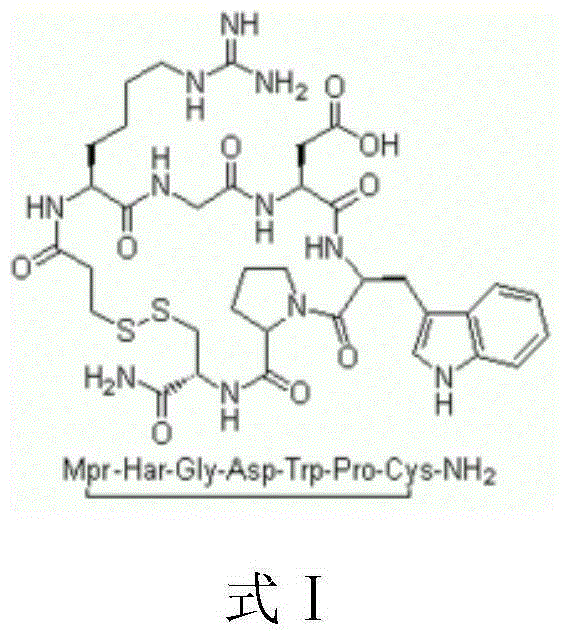

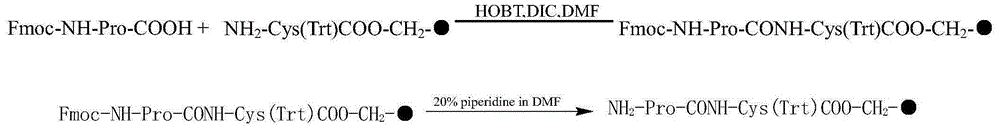

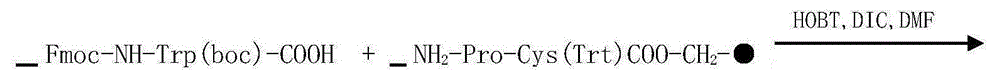

Preparation method for eptifibatide

ActiveCN105037496AAvoid it happening againReduce the difficulty of purificationPeptide preparation methodsFreeze-dryingAcetonitrile

The invention discloses a preparation method for eptifibatide. The method includes the steps of sequentially coupling and connecting Fmoc-protected amino acid and a protected amino acid tripeptide section with Fmoc-Cys(Trt) resin as a coupling resin carrier, splitting eptifibatide resin through a split agent, oxidizing reduced type eptifibatide in an acetonitrile aqueous solution, conducting condensation after oxidation, and conducting purification, salt transfer and freeze drying on crude eptifibatide product concentrated liquor to obtain a fine eptifibatide product. By means of the preparation method, production cost can be effectively reduced, yield is increased, and the content of impurities in the finished product is reduced.

Owner:SICHUAN JISHENG BIOPHARM CO LTD

Grinder processing technology improving surface finish of die

InactiveCN107350903AReduce processing costs for high-quality finishesEliminate manual polishing processGrinding/polishing apparatusSurface finishEngineering

The invention relates to a grinder processing technology improving the surface finish of a die. The technology particularly comprises the following steps of die workpiece coarse grinding, die workpiece semi-finish machining and die workpiece finish machining, the surfaces of a 46 # grinding wheel and a 220 # grinding wheel which are used for semi-finish machining and finish machining are subjected to polishing finishing, and then the grinding wheels are used; the surface of the 220 # grinding wheel obtained after finishing is smeared with abrasive, gaps between air holes formed in the surfaces of the grinding wheels and a grinding material are filled with the abrasive, the grinding cutting edge of the grinding material is weakened, the polishing effect of the grinding wheels on the surface of a die workpiece is improved, and the surface finish of the die workpiece meets the expected requirements; meanwhile, manual polishing operation is omitted, the grinding and polishing steps are reduced, and the finished product rate is increased.

Owner:苏州沃思诺自动化科技有限公司

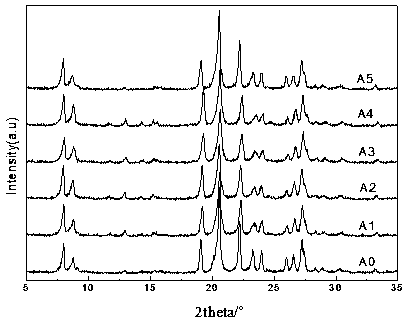

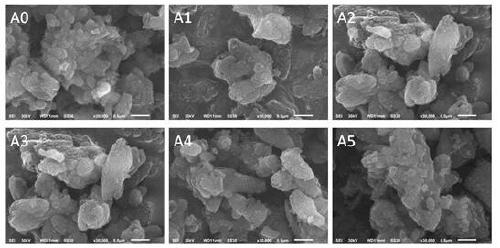

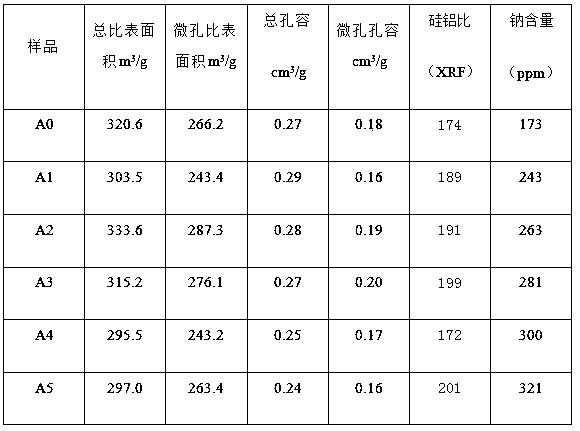

Green preparation method of high silica-alumina ratio hydrogenous molecular sieve

InactiveCN109485059AHigh utilization rate of raw materialsReduce production process stepsMolecular-sieve silicatesCrystalline aluminosilicate zeolitesQuaternary ammonium surfactantChemistry

The invention relates to the technical field of molecular sieve preparation, and discloses a green preparation method of a high silica-alumina ratio hydrogenous molecular sieve, comprising the following steps: mixing and crystallizing a silicon source with Na2O less than 100ppm, an aluminum source, water and hexamethonium hydroxide, then cooling, and performing suction filtration to obtain an EU-1molecular sieve semi-finished product and molecular sieve crystallization mother liquor, and drying and roasting the EU-1 molecular sieve semi-finished product to obtain the hydrogenous EU-1 molecular sieve. According to the invention, in a sodium-free system, a hydrogenous zeolite molecular sieve is obtained by high temperature roasting at 400-600 DEG C, production process steps are reduced, water consumption and energy consumption are saved, and production time is saved; compared with a sodium-containing ion synthesis system, in the system, low-positive-charge-density quaternary ammonium cation is easier to match with a high silica-alumina molecular sieve framework with low negative charge, and a molecular sieve with high silica-alumina ratio phase region SiO2 / Al2O3 being equal to 100-500 and sodium oxide content being lower than 500ppm is synthesized.

Owner:TAIYUAN UNIV OF TECH

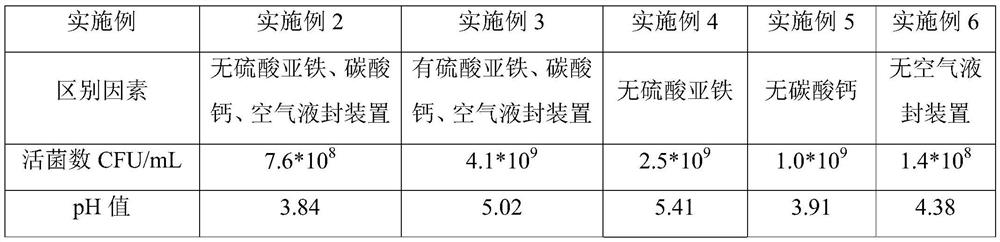

Clostridium butyricum liquid fermentation preparation method and liquid culture medium

ActiveCN112795524ALow costImprove concentrationBacteriaMicroorganism based processesDextrose MonohydrateDipotassium phosphate

The invention discloses a clostridium butyricum liquid fermentation preparation method which comprises the following steps: taking clostridium butyricum as a fermentation strain, inoculating the strain taken out from a refrigerator at the temperature of -80 DEG C into a 3L seed culture medium, and standing and culturing at the temperature of 37 DEG C for 18 hours; inoculating the seed solution into 150L of fermentation culture medium of a 200L fermentation tank according to the inoculum size of 2%, performing anaerobic culture at 37 DEG C, starting a motor for stirring, and opening a valve of an air liquid sealing device; the seed culture medium and the fermentation culture medium comprising the following components: 3-5g / L of dextrose monohydrate, 5-10g / L of soluble starch, 5-10g / L of yeast extract, 1-3g / L of dipotassium phosphate, 6-10g / L of ferrous sulfate, 5-10g / L of calcium carbonate and 0.2-0.8 g / L of tomato powder, and the pH value is 6.5-7.0. Ferrous sulfate, calcium carbonate and an air liquid sealing device supplement one another and have a synergistic effect, so that the interior of a fermentation tank and a fermentation culture medium rapidly reach an anaerobic environment, the inhibition effect of oxygen on the growth of clostridium butyricum is relieved, the clostridium butyricum is promoted to rapidly grow and propagate, the viable count of the clostridium butyricum can be increased from 7.6 * 10<8> CFU / mL to 4.1 * 10<9> CFU / mL, and the production cost is reduced.

Owner:XIAMEN HUIYING ANIMAL TECH

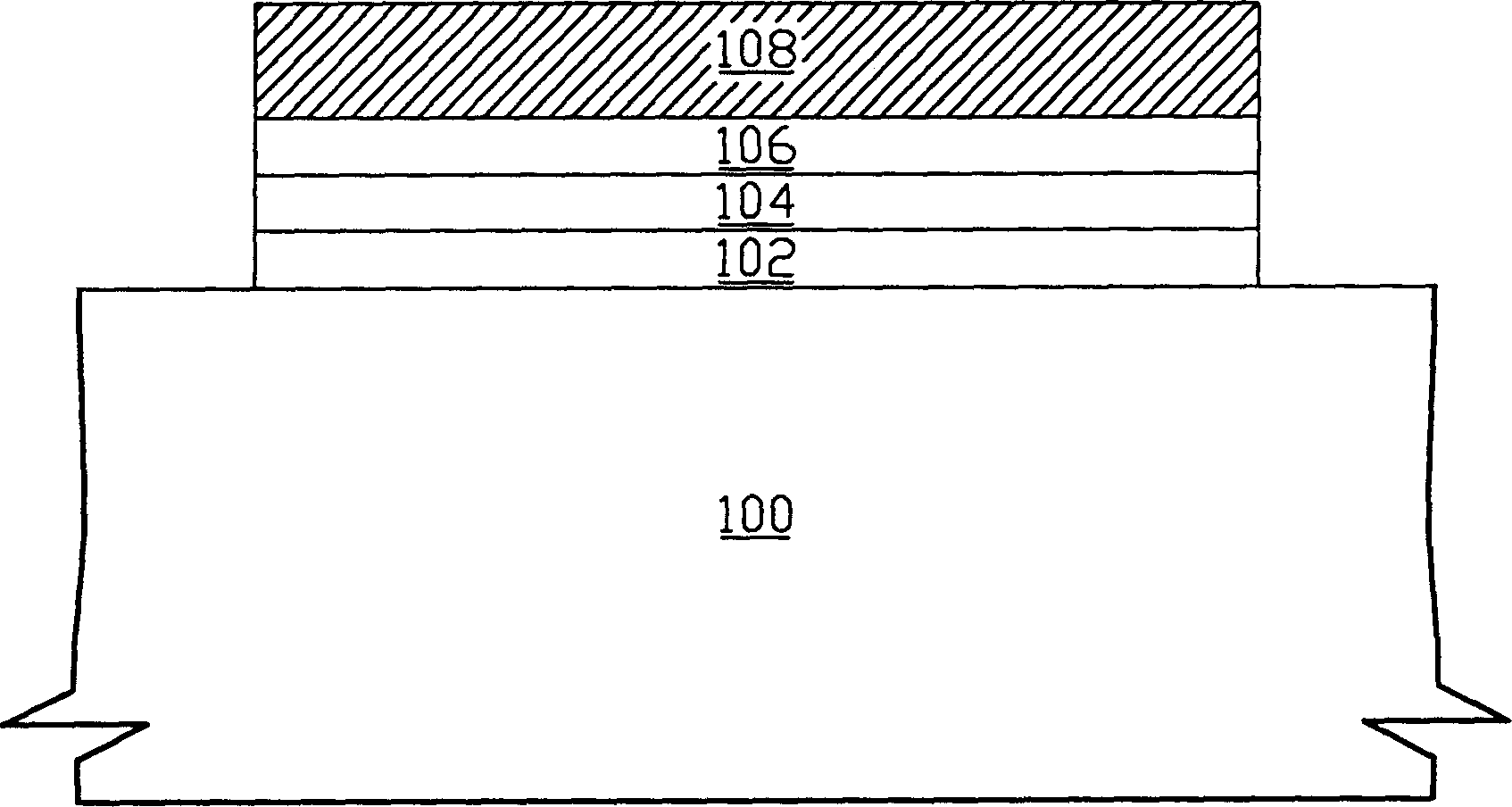

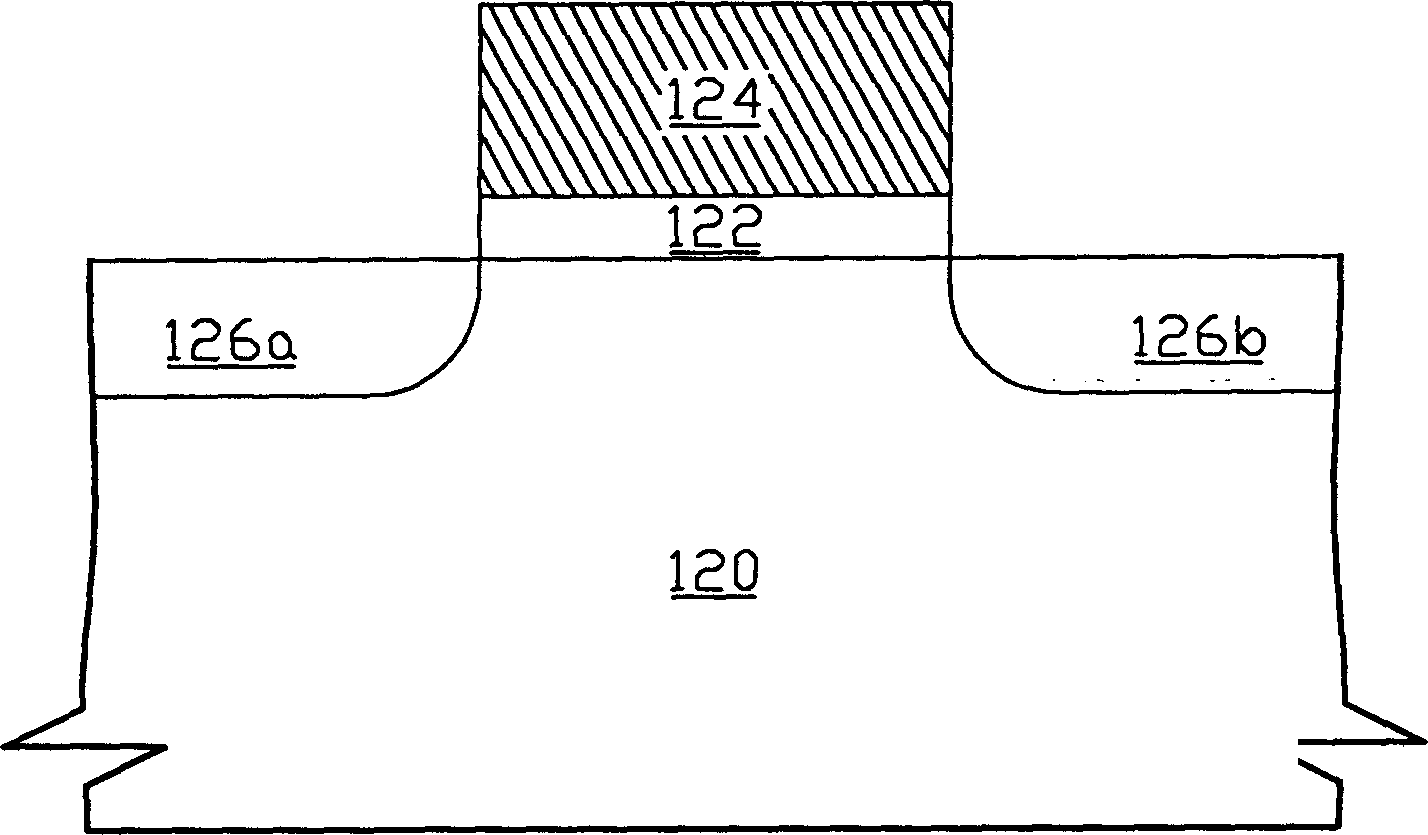

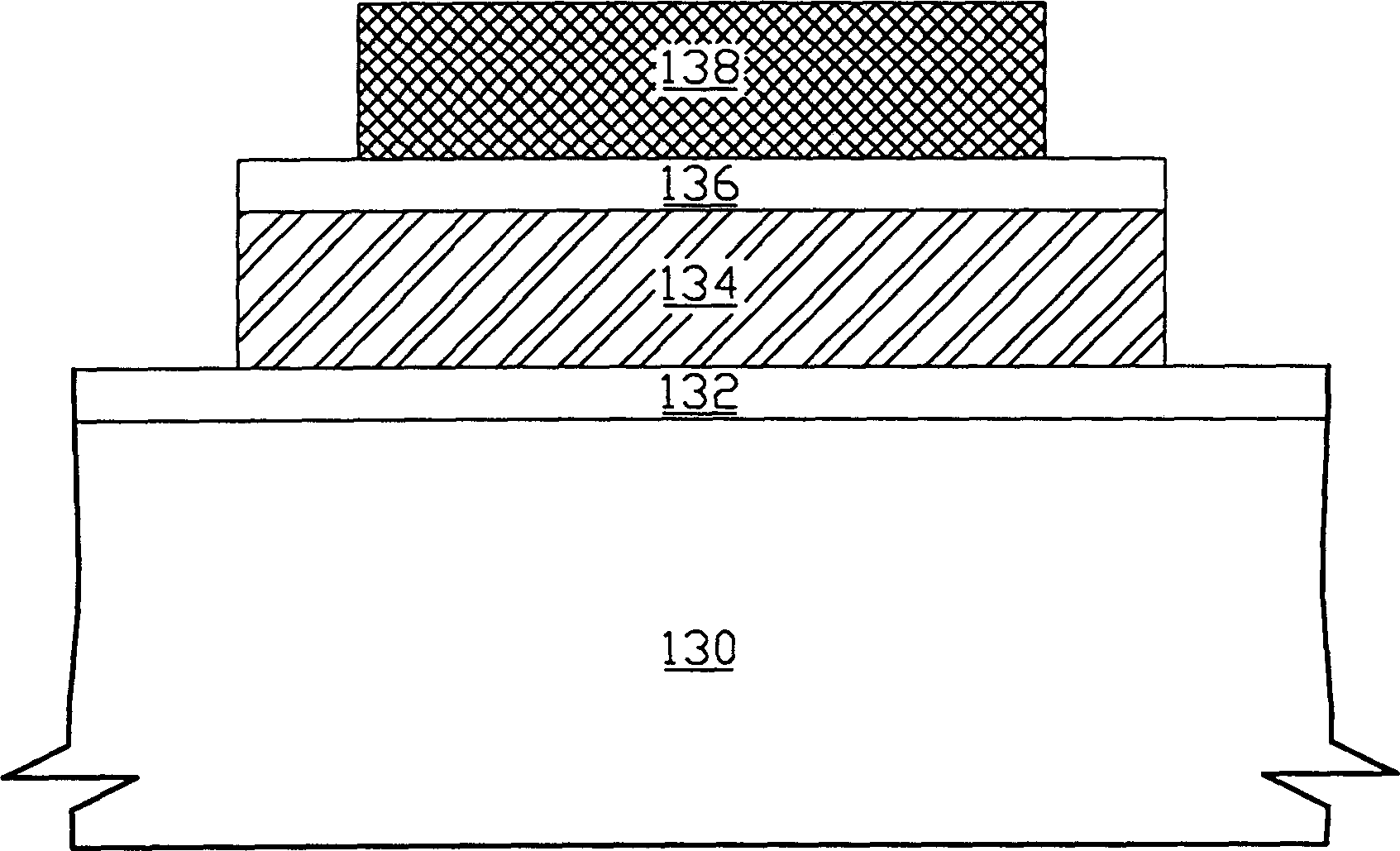

Method for forming integrated circuit with MONOS element and mixed signal circuit

InactiveCN1405876AReduce production process stepsAvoid reliabilitySemiconductor/solid-state device manufacturingIntegrated circuitEngineering

The invention relates to a method for forming integrate circuit with and mixed signal, which integrates the non-volatile component such as MONOS storage and logic unit, for example MOS transistor and the PIP capacitor into the single chip of the system by using lesser manufacturing procedure steps.

Owner:MACRONIX INT CO LTD

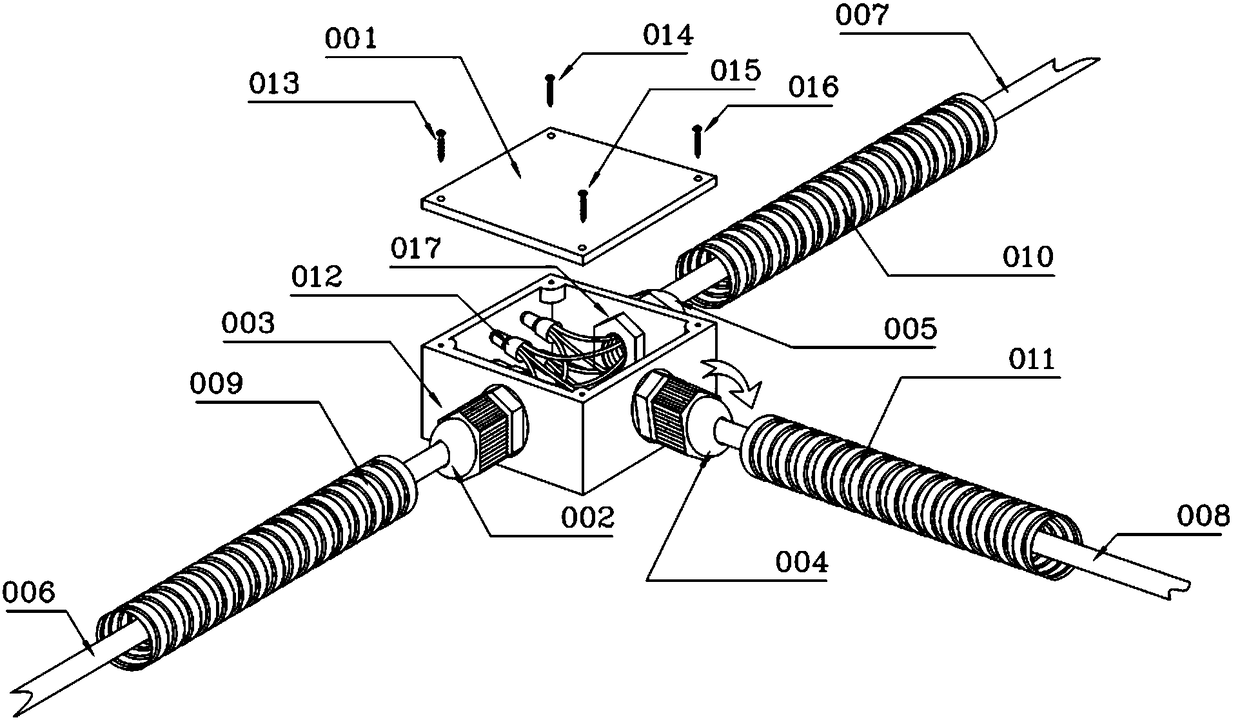

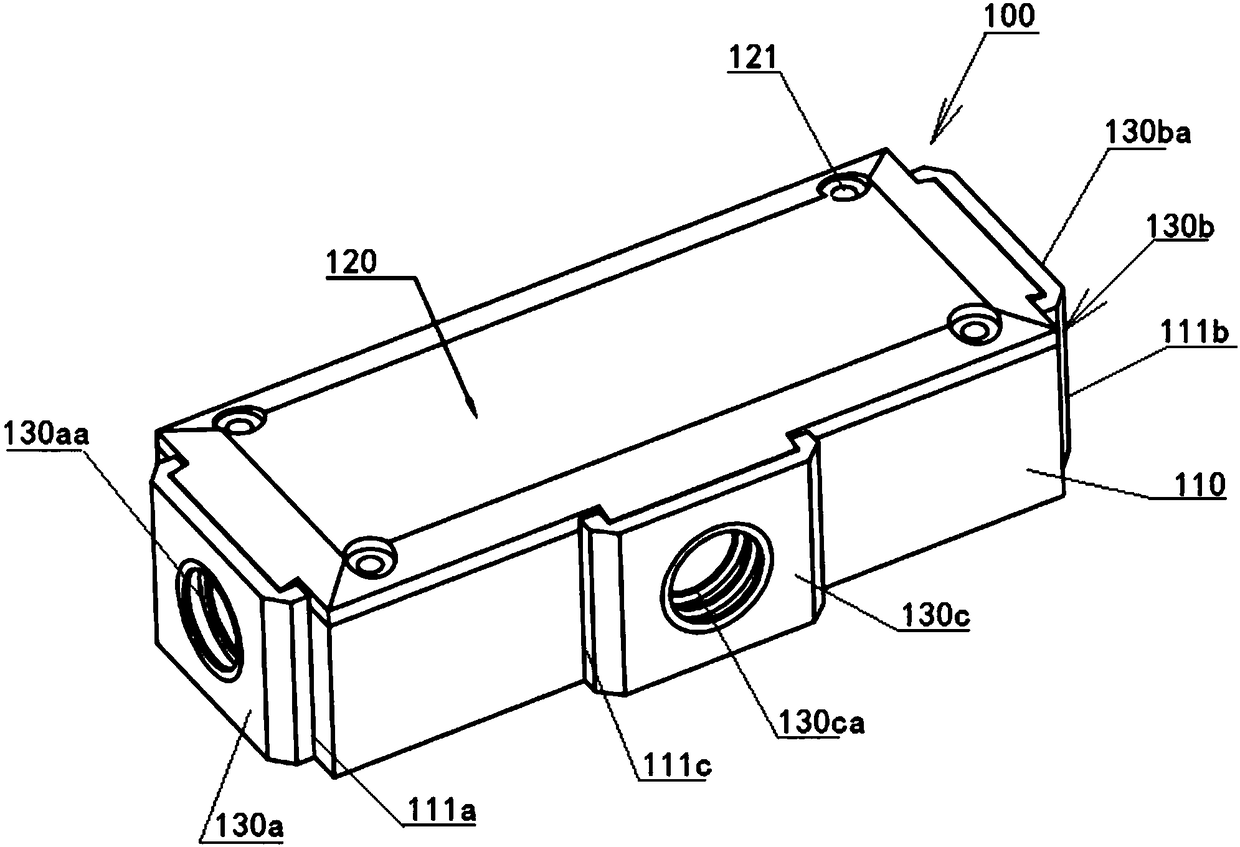

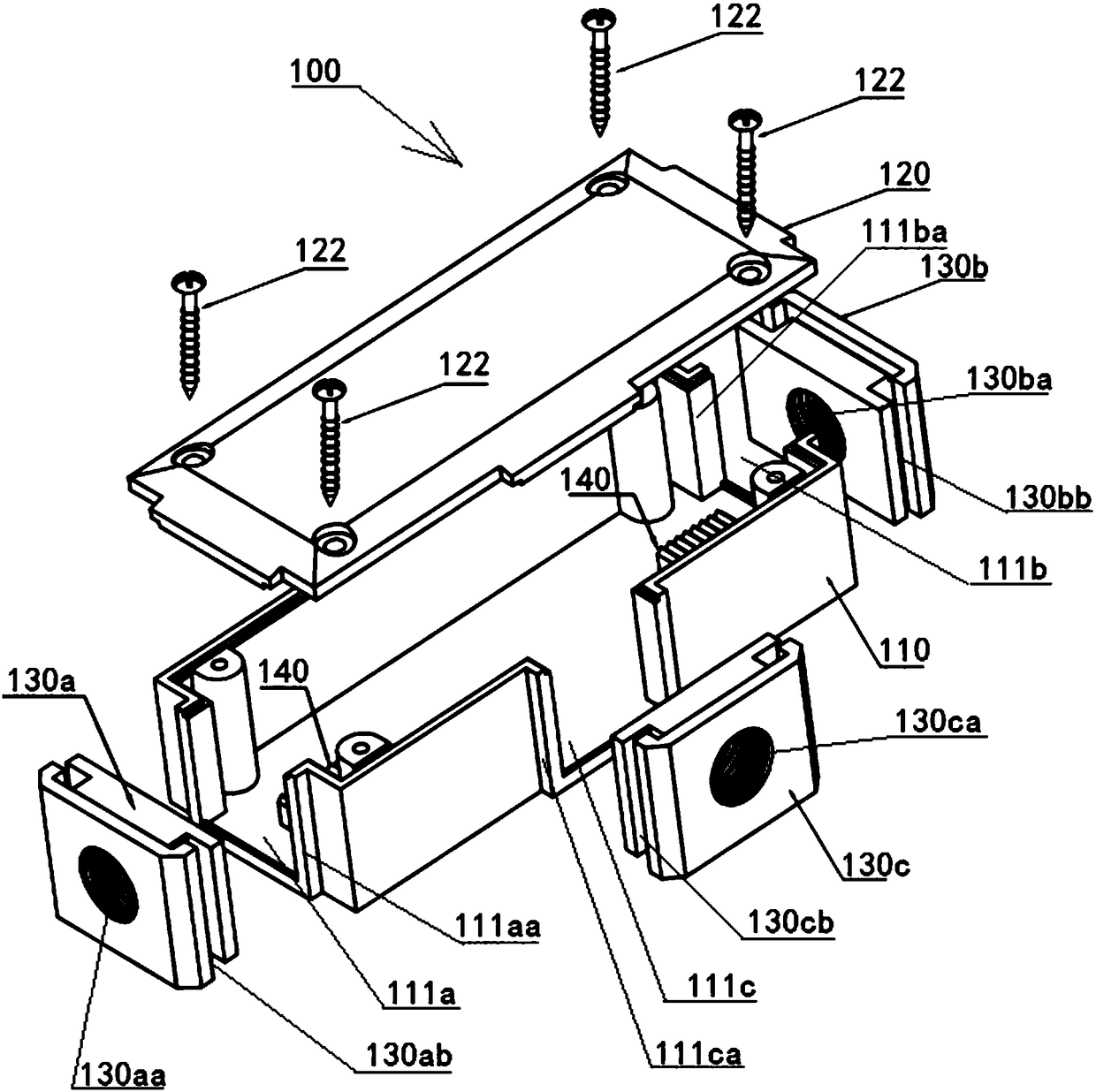

Embedded cable safety protection assembly box

PendingCN108092226AAvoid wastingReduce processing timeCable fittingsEngineeringMechanical engineering

The invention discloses an embedded cable safety protection assembly box. The embedded cable safety protection assembly box comprises an assembly box body and a top cover, wherein the assembly box body is provided with at least two main cable incoming line holes and at least one branch cable incoming line hole, and at least one limitation part is arranged in the assembly box body and is used for fixing a main cable. By the embedded cable safety protection assembly box, the main cable in the assembly box body can be rapidly limited, a ripple hose connector also can be omitted and is directly buckled, a waterproof pipe connector nut also can be omitted, and a waterproof pipe connector is directly screwed onto the assembly box. By the embedded cable safety protection assembly box, the problemof difficult threading and crimping operation is solved, waste caused by excessive usage of a cable can be prevented, and meanwhile, the processing time of a discharging through pipe due to reductionof production process step also can be saved.

Owner:上海贝恩科电缆有限公司

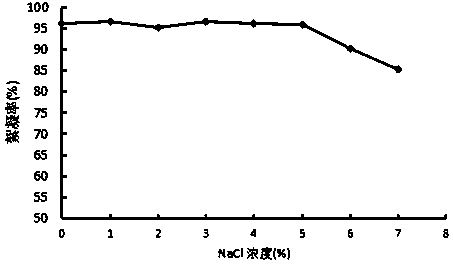

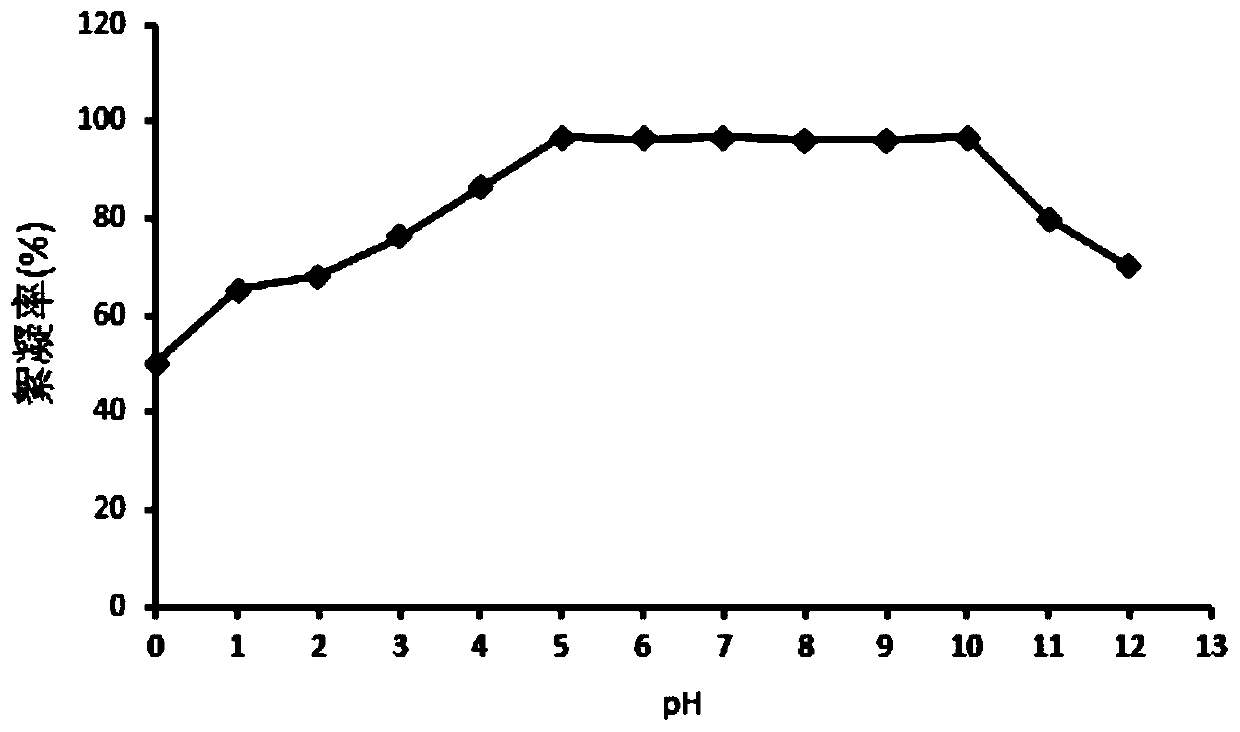

Marine microbial flocculant and preparation method thereof

ActiveCN109721141AWith flocculation effectReduce production process stepsMicroorganism based processesFermentationFlocculationMicroorganism

The invention provides a marine microbial flocculant. The marine microbial flocculant is produced through fermentation of Amylibacter lutimaris, has a flocculation effect in a wide pH and high salt concentration range, and has a wide application range. The invention provides a preparation method of the marine microbial flocculant. The marine microbial flocculant has a simple liquid medium preparation process, components have wide sources, and are easily available, and the microorganisms have low requirements for culture conditions and a short culture time; the microbial flocculant can be obtained only through fermentation after inoculation is conducted, the production process has few steps, and the dry flocculant product can be obtained through sedimentation, centrifugal separation and drying; and the purification process has simple operation, and the obtained dry flocculant product has the advantages of stable storage, convenient use and the like.

Owner:山东大湖新材料有限公司

A kind of preparation method of spherical silicon-alumina composite carrier

ActiveCN104353503BImprove adhesionReduce production process stepsCatalyst carriersManganeseNano al2o3

The invention relates to a preparation method of a spherical silicon-aluminum composite carrier. The preparation method is characterized by comprising the following steps: adding silicon dioxide to an alumina gel, and uniformly mixing; slowly adding to an alginate solution, and uniformly stirring to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form a spherical composite gel granule; taking out the spherical composite gel granule, and drying and calcining to obtain the spherical silicon-aluminum composite carrier, wherein the alumina gel is an alumina hydrogel or a nano-alumina sol, the addition amount of the silicon dioxide is 0.1-0.3 time more than the weight of the alumina gel in terms of Al2O3, the suspension slurry contains 5%-25% by weight of solids and 0.3%-5% by weight of alginate, the soluble alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, and the multivalent metal cation solution is an aluminum, zinc, calcium, copper, iron, ferrous iron, cobalt, manganese or nickel ion salt solution with the saturation concentration of 0.1 mol / L. The spherical silicon-aluminum composite carrier obtained through the preparation method disclosed by the invention has the advantages of high strength, large pore volume and low bulk density.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

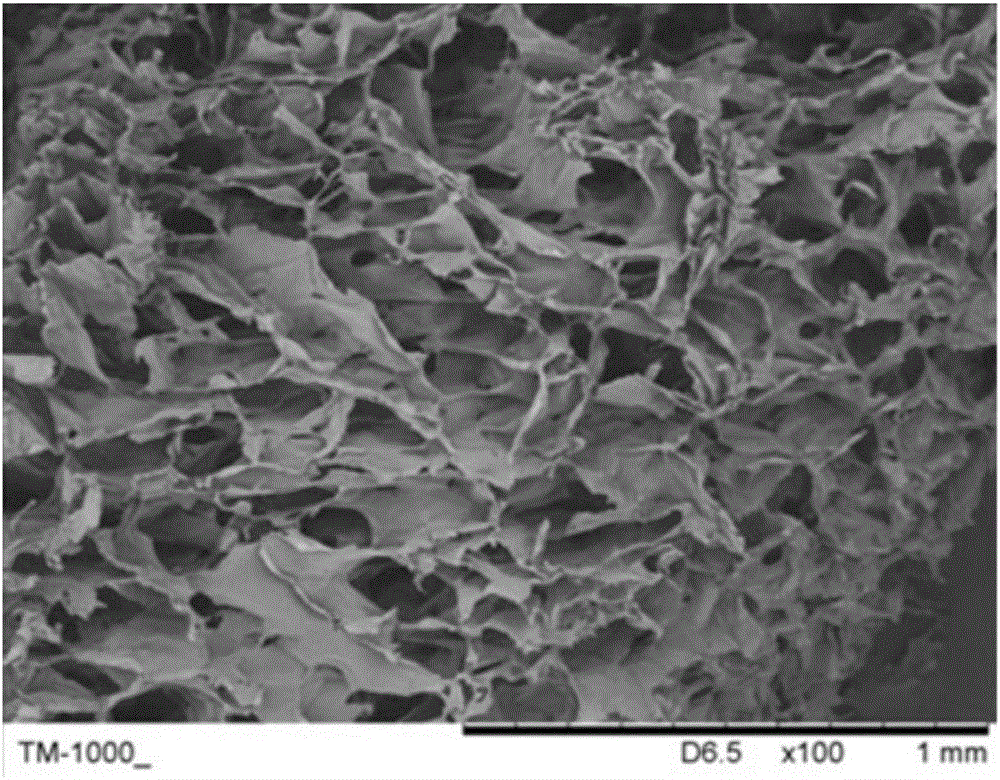

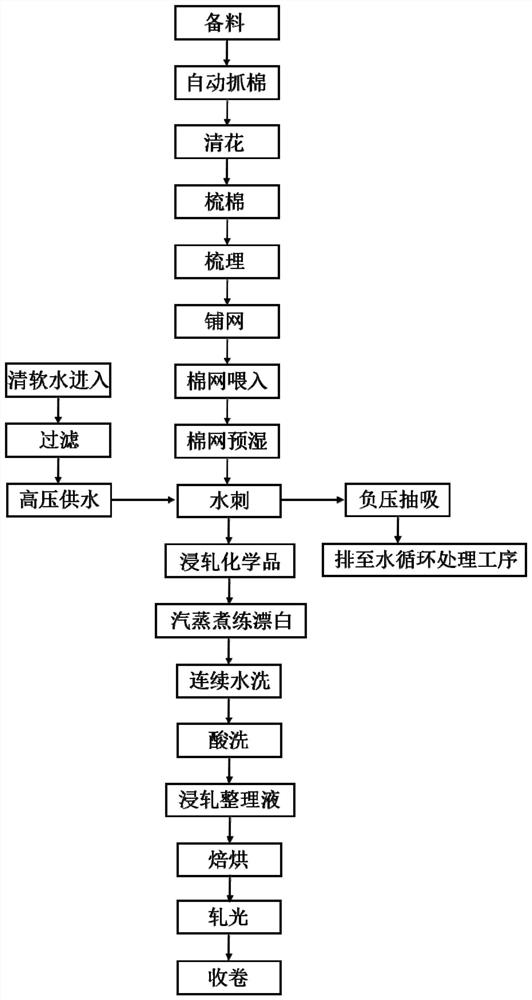

Continuous production method and application of all-cotton spunlace three-resistance non-woven fabric and three-resistance surgical gown

InactiveCN112301540AReduce production process stepsReduce labor intensityLiquid/gas/vapor removalDyeing processSurgical GownsProcess engineering

The invention relates to the technical field of non-woven fabrics, in particular to a continuous production method of an all-cotton spunlace three-resistance non-woven fabric. The continuous production method comprises the following steps that blowing, cotton carding, carding, lapping, spunlace, chemical padding, bleaching, continuous washing, acid pickling, finishing liquid padding, baking and calendering treatment are sequentially carried out on raw cotton, then a finished product is slit and wound, and thus the all-cotton spunlace three-resistance non-woven fabric can be obtained. Accordingto the continuous production method, the whole production process is continuously operated, frequent winding and roll changing are not needed, continuous production can be achieved, shutdown is avoided, and the purposes of shortening the production time, improving the production efficiency, reducing the labor intensity of workers, reducing the labor cost and the like are achieved.

Owner:稳健医疗(武汉)有限公司

Circulating iron mold coated sand production method

ActiveCN107008859AReduce production process stepsSave shot sandFoundry mouldsMoulding machinesProduction lineMaterials science

The invention discloses a circulating iron mold coated sand production method. An iron mold coated sand model used for a lower bottom plate is accomplished and transferred to the lower bottom plate so that the step of double turnover in a turnover mechanism during lower bottom plate modeling can be omitted. The turnover step after core shooting in a traditional process is omitted, precoated sand after modeling is directly placed on the lower bottom plate and then directly combined with an upper mold, the multiple turnover step of sand shooting after lower bottom plate turnover and mold recombination after another turnover is saved, and therefore production process steps of a production line can be saved, and the production efficiency is improved.

Owner:万果新材料科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com