Patents

Literature

65results about How to "Easy to realize industrialized continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for drying fresh wolfberry fruits

ActiveCN103005452AAvoid astringencyBactericidalFood preservationFood preparationBiotechnologyLycium barbarum fruit

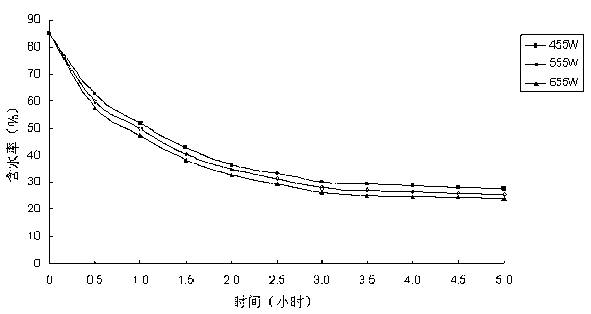

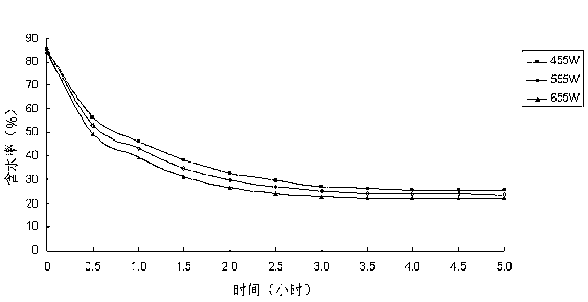

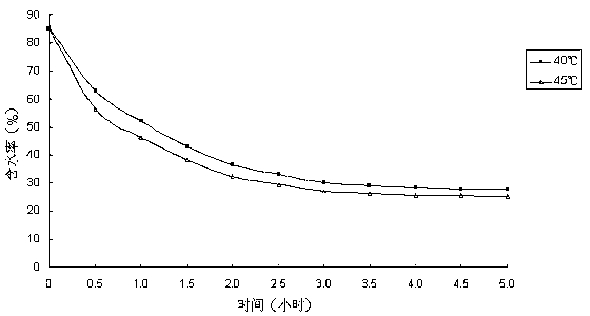

The invention relates to a method for drying fresh wolfberry fruits. The method comprises the following steps of: (1) selecting a material: picking fresh wolfberry fruits without pest and disease damage or mildew as a raw material; (2) cleaning: cleaning the picked fresh wolfberry fruits by using clean water, and then randomly sampling and measuring the initial water content of the fresh wolfberry fruits by a conventional method; (3) pricking: pricking the fresh wolfberry fruits obtained in the step (2) by using a needle or laser; (4) drying: uniformly spreading the pricked fresh wolfberry fruits on a turntable of a microwave vacuum drying box, performing vacuum drying, and performing forced air drying till constant weight to obtain dried wolfberry fruits; (5) measuring the dried water content: randomly sampling and measuring the water content of the dried wolfberry fruits by the conventional method, wherein if the water content is less than or equal to 13 percent, the dried wolfberry fruits are qualified; and (6) obtaining a finished product: grading and packing the qualified dried wolfberry fruits according to the quality requirements by adopting the conventional methods, and thus obtaining the finished product. The method is quick in drying, remarkable in effect and strong in operability, and easily realizes industrialized continuous production of wolfberry drying.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

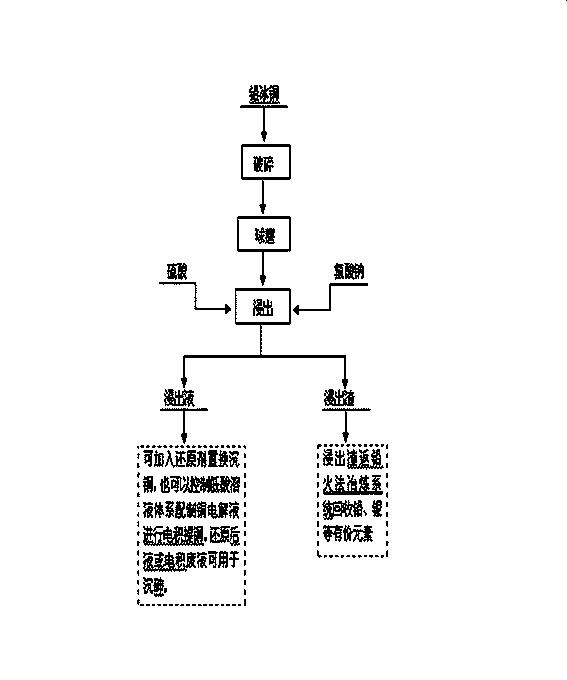

Process for efficiently and selectively separating copper in lead copper matte

InactiveCN104017991AAdaptableHigh recovery ratePhotography auxillary processesProcess efficiency improvementPregnant leach solutionLead smelting

The invention discloses a process for efficiently and selectively separating copper in lead copper matte. The process comprises the following steps: smashing and grinding the lead copper matte taken as a raw material and screening to reach below 80 meshes; sending the lead copper matte which is ground and screened into a leaching tank and leaching by using a sulfuric acid; reacting for 3 to 5 hours at a normal pressure under the conditions that the oxidation potential of the solution is controlled within 450mV to 800mV, the concentration of sodium chlorate is controlled within 200g / L to 500g / L, the liquid-solid ratio is controlled within (5-15):1, the temperature is controlled within 70 DEG C to 100 DEG C and the concentration of the sulfuric acid is controlled within 1.0mol / L to 1.5mol / L; and leaching the copper under an acid condition by taking the sodium chlorate as an oxidizing agent. During the oxidizing and leaching process, sulfur in the lead copper matte is oxidized into elemental sulfur which is transferred into slags, wherein copper which is oxidized enters the solution in a form of copper ions while lead remains in the slags in a form of lead sulfate together with gold and silver. After the leaching process is finished, the solid-liquid separation is carried out, so that the primary separation of the copper and other valuable elements is realized; a certain amount of scrap iron is added into the leaching solution rich in the copper so as to replace the deposited copper, so that the spongy copper, which is a primary product, can be obtained; the leaching slags are sent into a pyrogenic lead smelting system, so that the valuable elements such as Pb and Ag are comprehensively recycled.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

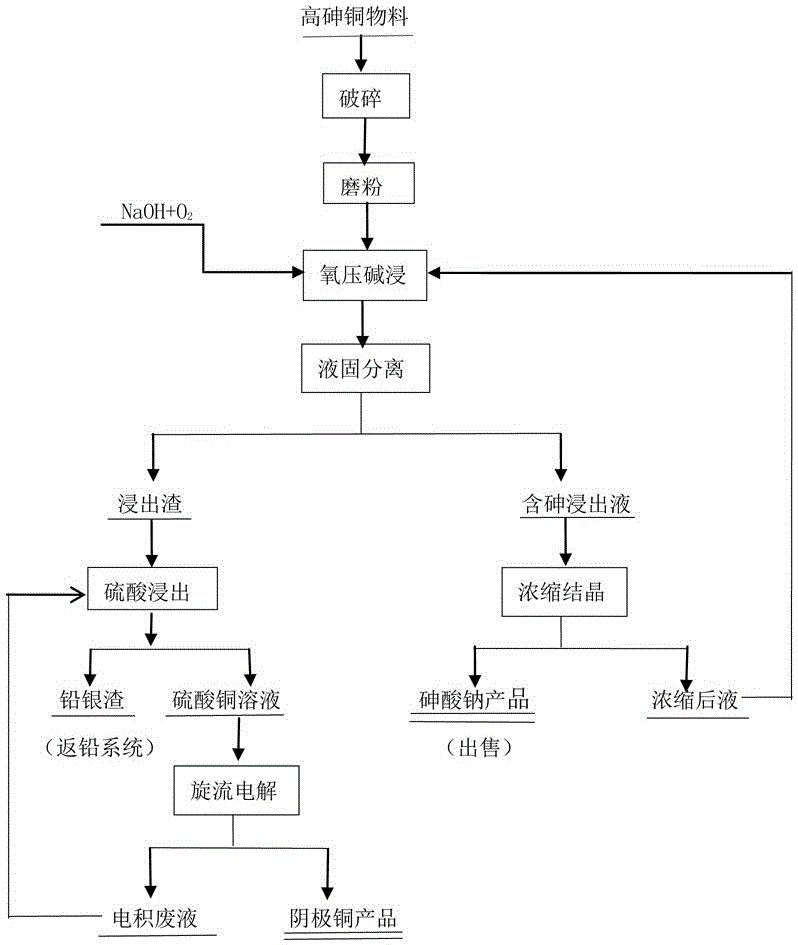

Technology for treating high-arsenic copper material

ActiveCN106555058AEnvironmental pollutionNo pollution to the environmentPhotography auxillary processesProcess efficiency improvementElectrolysisCopper sulfate

The invention discloses a technology for treating a high-arsenic copper material. The technology comprises the steps that the high-arsenic copper material is subjected to crushing, grinding, sodium hydroxide mixing and oxidizing leaching, copper in the high-arsenic copper material is oxidized and left in residues in a residual mode along with lead and noble metal of gold, silver and platinum, arsenic enters a solution in a sodium arsenate mode, leachate is subjected to concentration and crystallization, a sodium arsenate product is obtained, and a concentrated solution returns to be subject to oxygen-pressure alkali leaching; leached residues are subjected to sulfuric-acid atmospheric pressure leaching, copper enters the solution in a copper sulfate mode, acid adjustment is conducted, and vortex electrolysis is directly conducted for extracting copper; electrodeposited waste liquid is recycled; and lead and the noble metal enter lead and silver residues, and valuable elements of Pb, Ag and Au are comprehensively recycled. The technology belongs to a clean metallurgy process, is low in equipment corrosion-resistant requirement, free of pollution to environment, easy to operate and high in comprehensive recycling degree of metal and has the advantages of being higher in practicability and adaptability to raw materials and the like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Water column forming method of spherical molecular sieve

ActiveCN104383967AImprove adhesionReduce production process stepsCatalyst carriersCatalyst activation/preparationNano al2o3Manganese

The invention relates to a water column forming method of a spherical molecular sieve. The water column forming method is characterized by comprising the following steps: 1, beating a molecular sieve, a binding agent and water uniformly; 2, adding an alginate solution, and stirring uniformly at high speed to prepare a suspended sizing agent; 3, dropping the suspended sizing agent to a polyvalent metal cation water solution to form gel particles; and 4, taking the gel particles out, drying and roasting to obtain the product, wherein the dry-basis mass rate of the molecular sieve to the binding agent in the step 1 is (0.2-3):1, and the binding agent is alumina hydrogel, nanometer aluminum oxide sol or silica sol; the soluble alginate in the step 2 is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, the content of alginate in the suspended sizing agent is 0.3-5w%, and total dry-basis content of the molecular sieve and the binding agent in the suspended sizing agent is 5-30w%; the polyvalent metal cation water solution in the step 3 is a saline solution containing aluminum, zinc, calcium, copper, ferrum, ferrous, cobalt, manganese or nickel ions, with the saturation concentration being 0.1mol / L.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Preparing method of spherical titanium-aluminum composite carrier

ActiveCN104353504AImprove adhesionReduce production process stepsCatalyst carriersAluminum IonNano al2o3

The invention relates to a preparing method of a spherical titanium-aluminum composite carrier. The preparing method is characterized by comprising the following steps: adding deionized water and titanium oxide into alumina gel and uniformly mixing; slowly adding an alginate solution, and stirring at high speed to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form spherical composite gel particles; and drying and roasting the gel particles to obtain the spherical titanium-aluminum composite carrier, wherein aluminum oxide hydrogel or nano aluminum oxide gel is adopted as the alumina gel; the adding amount of titanium oxide is 0.1-4 times the mass of alumina gel based on Al2O3, and the crystalline phase of titanium oxide is selected as anatase phase; the solid content of the suspension slurry is 5%-25%, and the content of alginate is 0.3%-5%; alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate; the multivalent metal cation solution is saline solutions containing aluminum ions, zinc ions, calcium ions, copper ions, iron ions, ferrous ions, cobalt ions, manganese ions or nickel ions, with the saturation concentration being 0.1mol / L.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

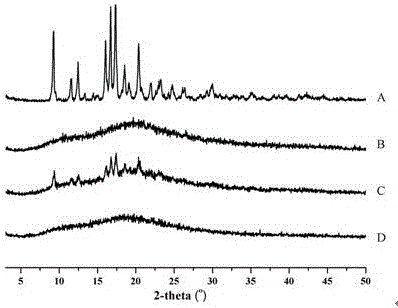

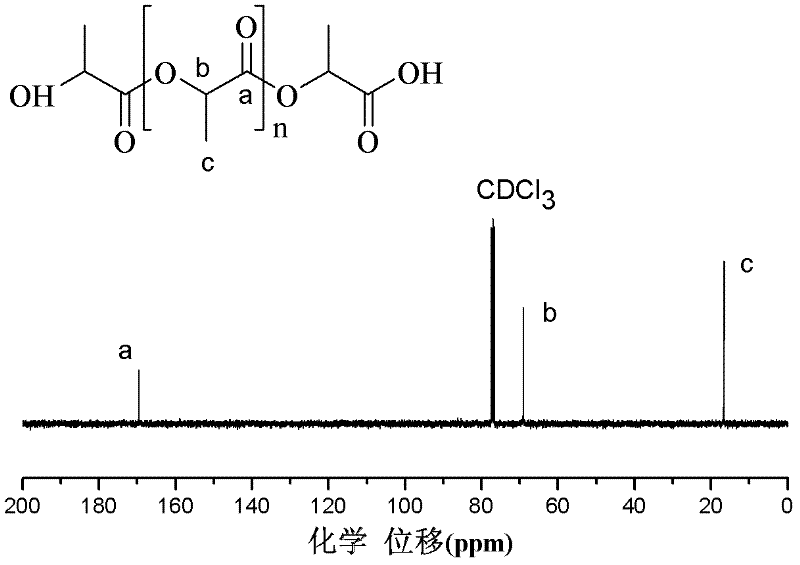

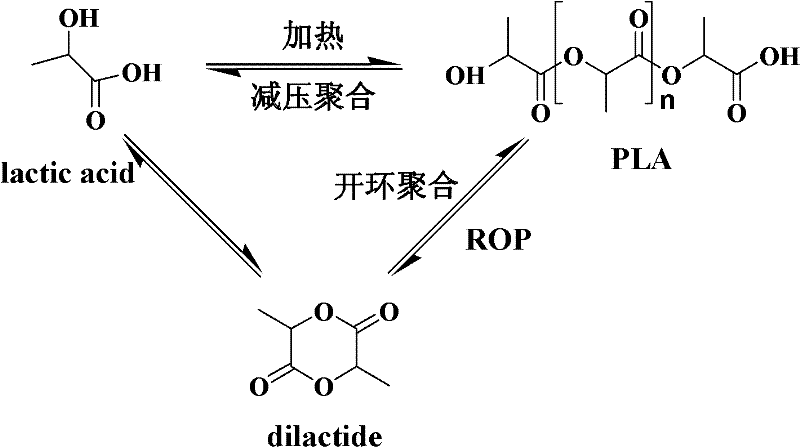

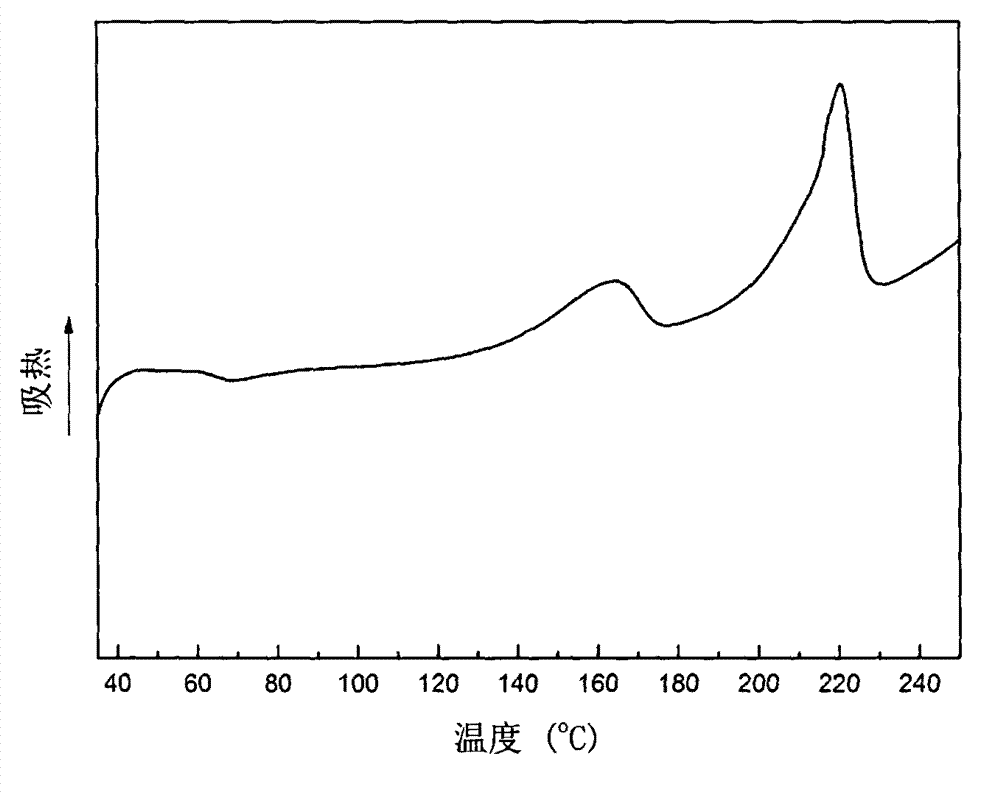

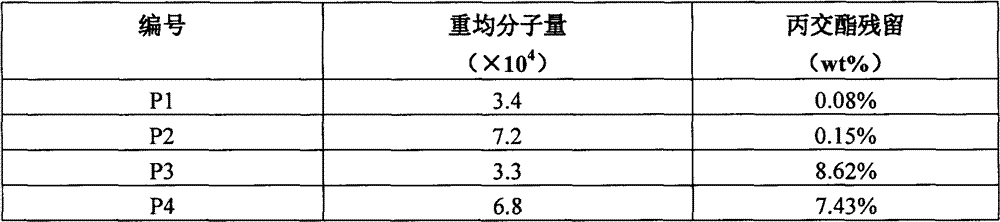

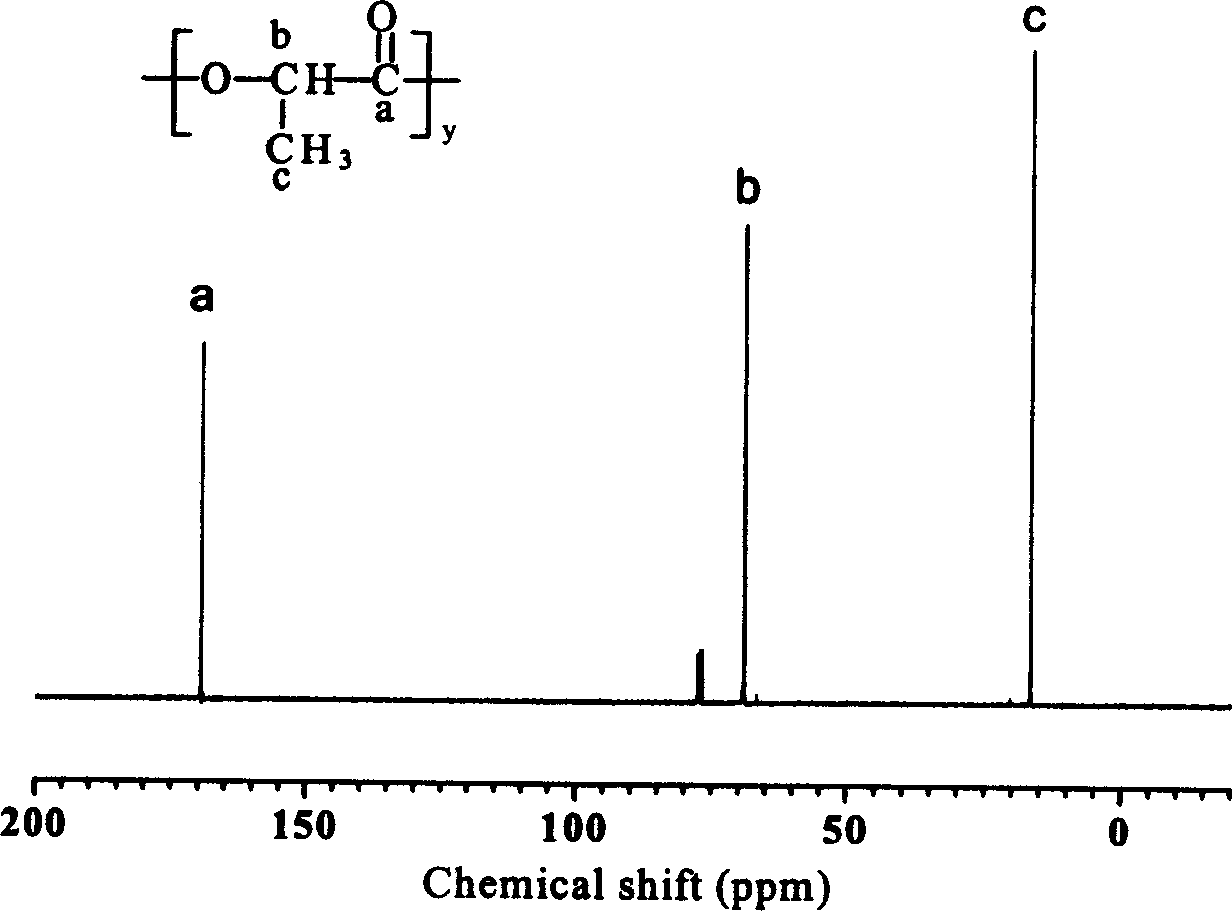

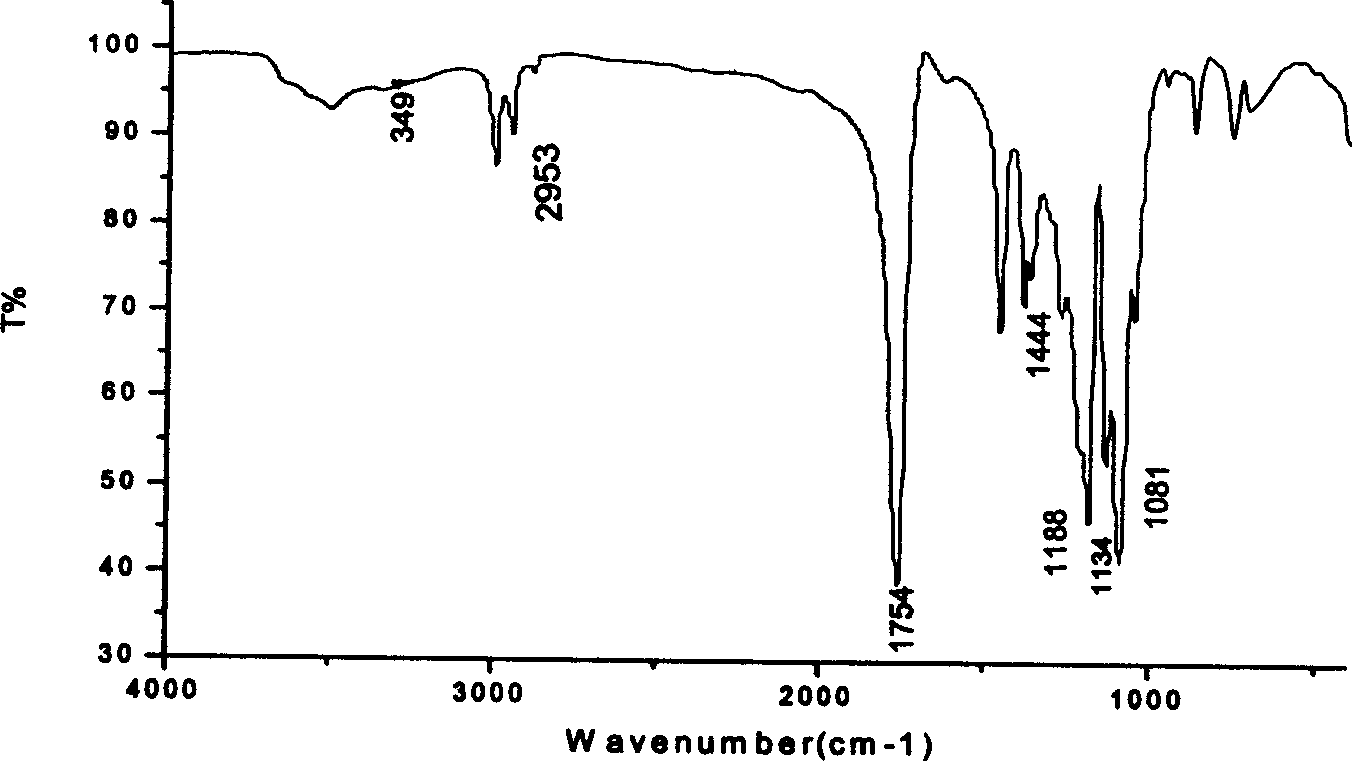

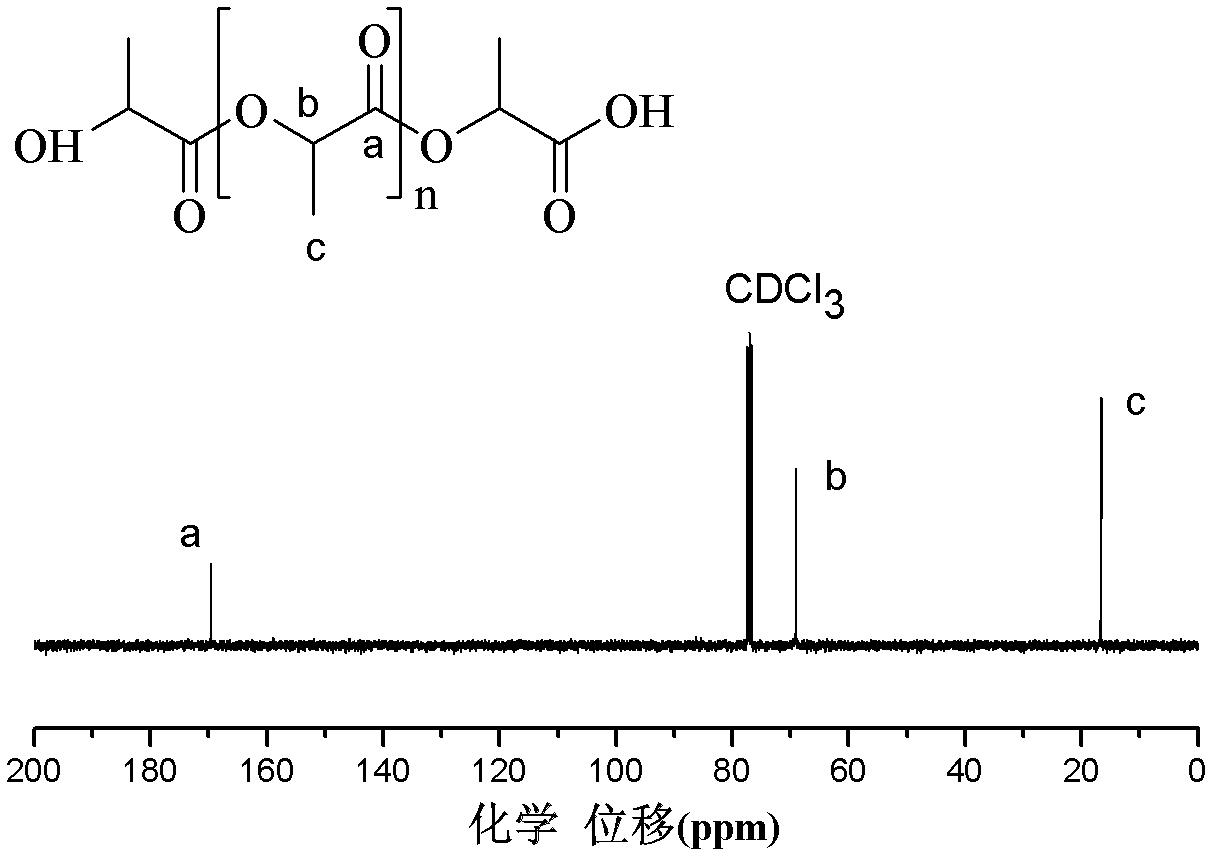

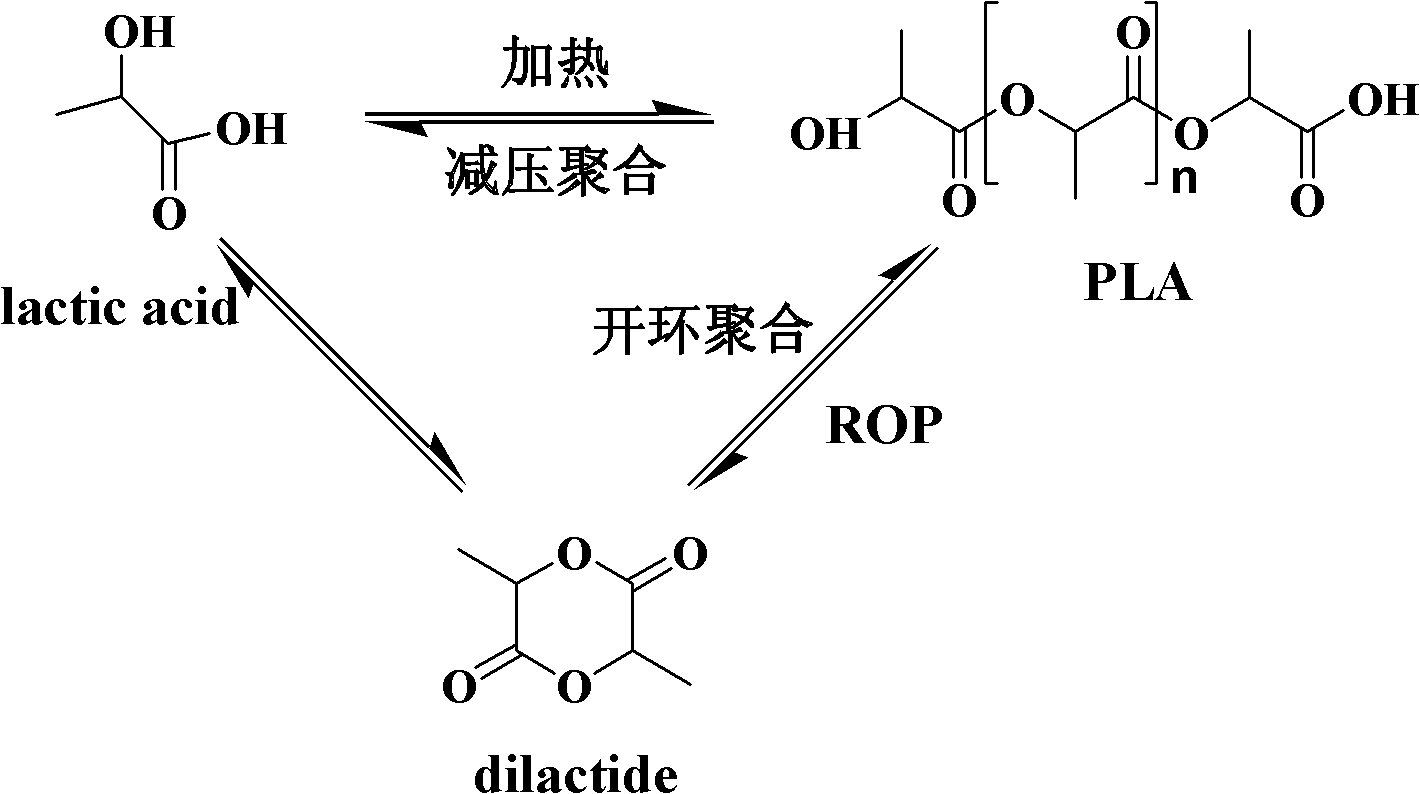

Melt polycondensation method for preparing high molecular weight polylactic acid

The invention discloses a melt polycondensation method for preparing high molecular weight polylactic acid. The method is characterized by comprising the steps of: (1) pre-polymerizing, namely adopting a heating decompression dehydration process to remove free water and partial bound water in a raw material, namely lactic acid, to obtain a prepolymer, wherein the temperature of a reaction system is between 100 and 200 DEG C, and the pressure of the reaction system is between 0 and 30kPa; and 2) performing azeotropic water removal polycondensation by lactide, namely taking the prepolymer prepared in the step (1) as a raw material for polycondensation under the condition of adding a catalyst, a cocatalyst and an azeotropic water removal agent, namely the lactide, wherein the temperature of the reaction system is between 150 and 250 DEG C, the pressure of the reaction system is between 0 and 20kPa, the reaction time is between 1 and 45 hours, the adding amount of the catalyst is between 0.001 and 5 weight percent, the adding amount of the cocatalyst is between 0.001 and 5 weight percent, and the adding amount of the azeotropic water removal agent, namely the lactide is between 0.01 and 50 weight percent.

Owner:江西省科院生物技术有限责任公司 +1

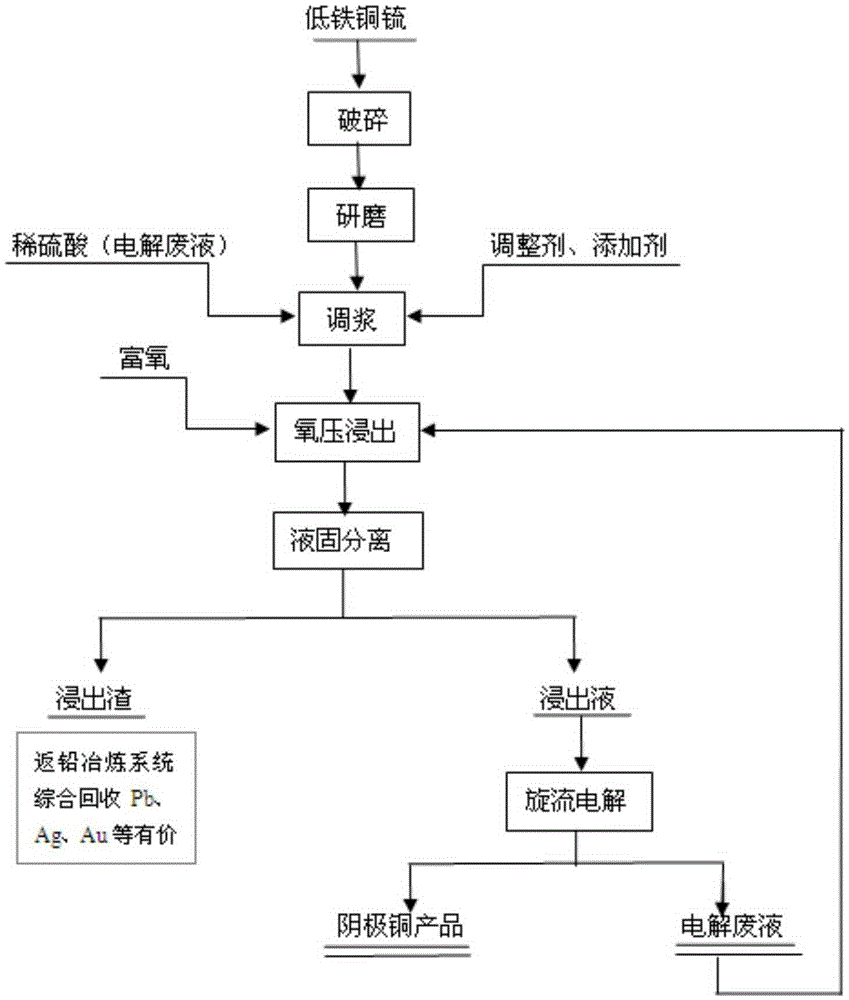

Method for selectively extracting copper from iron-copper-matte materials

ActiveCN105349791AImprove electrolysis efficiencyIncrease current densityProcess efficiency improvementElectrolysisHydrometallurgy

The invention relates to the field of hydrometallurgy of nonferrous metals, in particular to a method for selectively extracting copper from iron-copper-matte materials. The method for selectively extracting the copper from the iron-copper-matte materials comprises the following steps that after being subjected to crushing grinding and sulfuric acid adding size mixing, the iron-copper-matte materials are subjected to oxidizing leaching by pumping enriched oxygen into a high-pressure kettle; after oxidizing leaching of the iron-copper-matte materials is completed, solid-liquid separation is carried out to obtain leaching liquid and leaching residues; and after the leaching liquid is subjected to acid adjusting, a rotational flow electrolysis technology is adopted for obtaining a cathode copper product. The iron-copper-matte materials comprise, by weight percentage, 15%-45% of Pb, 35%-60% of Cu, 2%-18% of S, 0.2%-0.8% of Ag, 5%-20% of As and 0.05%-0.6% of Fe. The method is especially suitable for selectively extracting the copper from the iron-copper-matte materials with the low iron content, the rotational flow electrolysis technology is adopted in the copper leaching liquid for electrolysis of settled copper, the yield is higher, and the obtained cathode copper product is few in impurity and high in purity.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

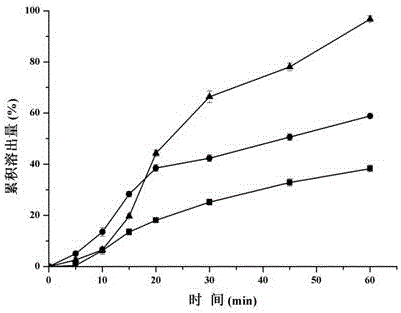

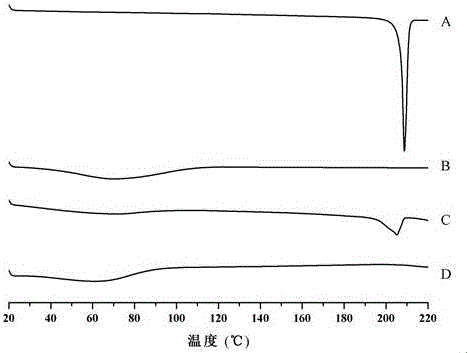

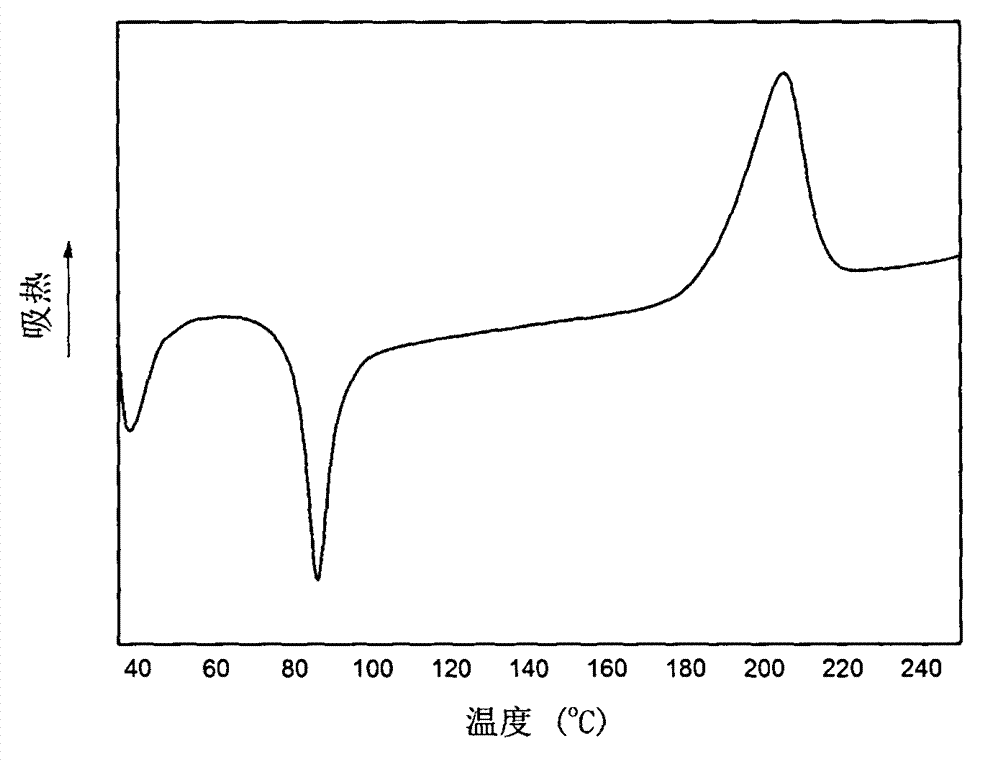

Pharmaceutical composition for improving in-vitro dissolution and liquidity of spironolactone

ActiveCN105832680AImprove in vitro dissolutionImprove liquidityOrganic active ingredientsPill deliveryOrganic solventMass ratio

The invention belongs to the field of pharmaceutical preparations, and relates to a pharmaceutical composition for improving in-vitro dissolution and liquidity of spironolactone and a preparation method of the pharmaceutical composition. The pharmaceutical composition is mainly characterized by being prepared from an indissolvable drug spironolactone and a carrier material, wherein the mass ratio of the drug to the carrier is 1:3-1:10, the pharmaceutical composition prepared through a hot-melt extrusion technique is solid dispersion, the spironolactone is dispersed into the carrier in a molecular or amorphous mode, and therefore the in-vitro dissolution of the spironolactone is significantly improved. After the spironolactone is smashed, the liquidity of the spironolactone is significantly improved, and the smashed spironolactone can be directly filled into capsules or directly subpackaged by serving as powder and granules or used by being mixed with other pharmaceutical auxiliary materials to prepare tablets. Compared with traditional methods such as the solvent method and the solvent-melt method, the adopted hot-melt extrusion technique has the advantages of being capable of not using an organic solvent, safe, free of pollution, stable in technology, capable of achieving continuous operation, easily achieving industrialized enlarged production and improving the liquidity without needing to add a flow aid and the like.

Owner:SHENYANG PHARMA UNIVERSITY

Preparation method of spherical silicon-aluminum composite carrier

ActiveCN104353503AImprove adhesionReduce production process stepsCatalyst carriersManganeseNano al2o3

The invention relates to a preparation method of a spherical silicon-aluminum composite carrier. The preparation method is characterized by comprising the following steps: adding silicon dioxide to an alumina gel, and uniformly mixing; slowly adding to an alginate solution, and uniformly stirring to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form a spherical composite gel granule; taking out the spherical composite gel granule, and drying and calcining to obtain the spherical silicon-aluminum composite carrier, wherein the alumina gel is an alumina hydrogel or a nano-alumina sol, the addition amount of the silicon dioxide is 0.1-0.3 time more than the weight of the alumina gel in terms of Al2O3, the suspension slurry contains 5%-25% by weight of solids and 0.3%-5% by weight of alginate, the soluble alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, and the multivalent metal cation solution is an aluminum, zinc, calcium, copper, iron, ferrous iron, cobalt, manganese or nickel ion salt solution with the saturation concentration of 0.1 mol / L. The spherical silicon-aluminum composite carrier obtained through the preparation method disclosed by the invention has the advantages of high strength, large pore volume and low bulk density.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Method for preparing polylactic acid from lactic acid under catalysis of titanium composite catalyst

The invention relates to a method for preparing polylactic acid from lactic acid under catalysis of a titanium composite catalyst, belonging to the technical field of polymer materials. The method comprises the steps of: removing water from a raw material under normal pressure by an inert gas blowing method; gradually reducing pressure for pre-polycondensing: pre-polycondensing under low vacuum degree of 1000-10000Pa and high vacuum degree of 20-1000Pa at the temperature of 60-160 DEG C for 1-10h to obtain a lactic acid prepolymer; and carrying out melt polycondensation on the lactic acid prepolymer as a raw material in the presence of the titanium composite catalyst to finally prepare polylactic acid. The method has the advantages that any organic solvent is not used, the production equipment is simple, operation is convenient, industrialized continuous production is easy to realize, and the obtained product namely polylactic acid has higher molecular weight.

Owner:BEIJING UNIV OF CHEM TECH

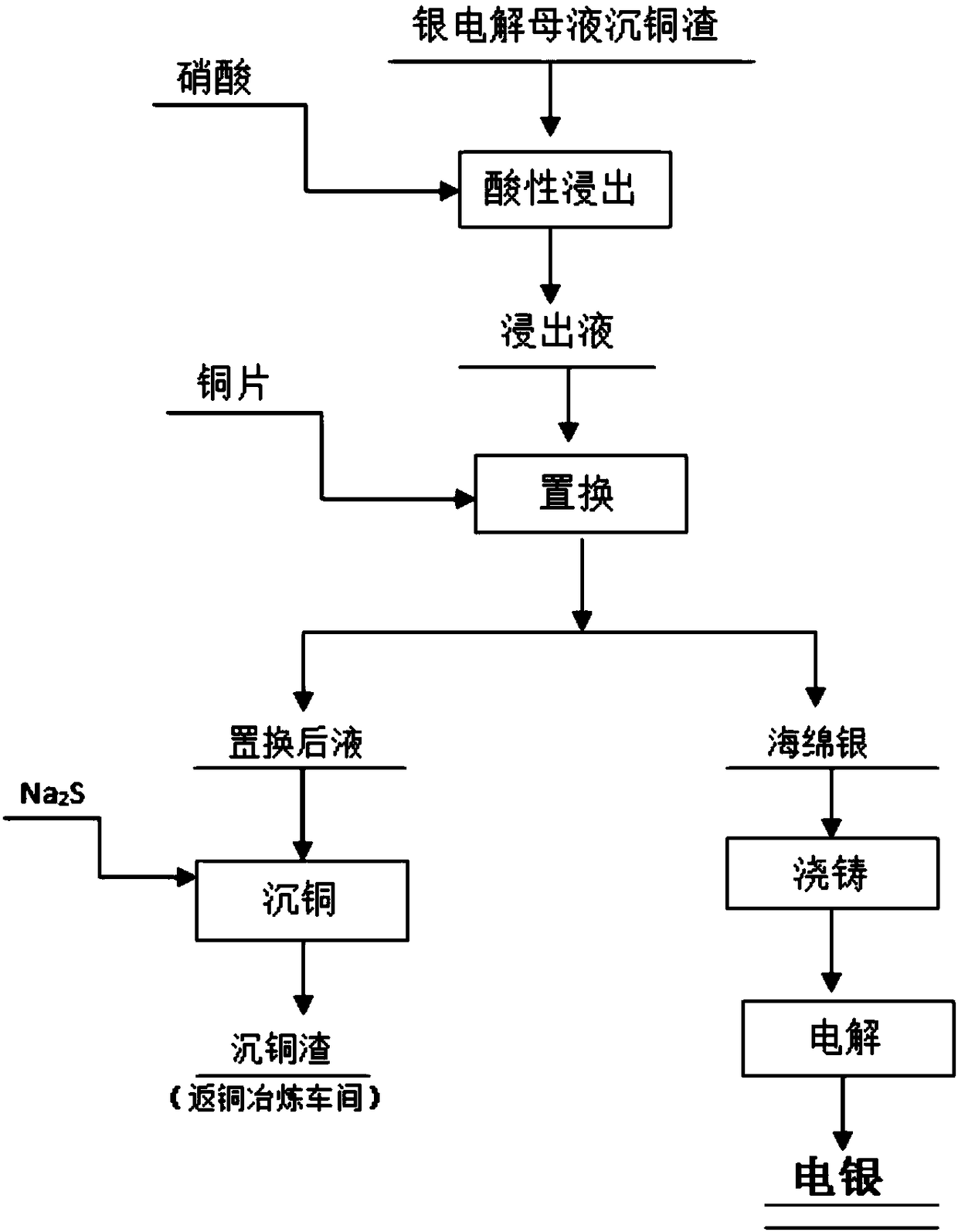

Method for recycling valuable metal from silver electrolysis mother liquor copper deposition drags

ActiveCN108070722AHigh recovery rateReduce pollutionPhotography auxillary processesProcess efficiency improvementPregnant leach solutionElectrolysis procedure

The invention discloses a method for recycling valuable metal from silver electrolysis mother liquor copper deposition drags. The method comprises the steps of (1) nitric acid leaching, wherein nitricacid is added into the silver electrolysis mother liquor copper deposition drags, and leachate is obtained; (2) silver replacing with copper sheets, wherein the thoroughly cleaned copper sheets are taken and inserted into the leachate, the pH is controlled to be equal to 0.5 to 1.5, and sponge silver powder and displacement liquid are obtained; (3) valuable metal deposition, wherein Na2S is addedinto the displacement liquid for deposition of copper, bismuth, lead and other valuable metal, and metal residues are obtained; (4) valuable metal recycling, wherein the obtained metal residues are returned into a smelting system, and copper, bismuth and lead are recycled; and (5) silver recycling, wherein the sponge silver powder is cast, then a silver electrolysis procedure is carried out, andsilver is obtained. The method has the beneficial effects of being good in environmental friendliness performance, simple in process, convenient to operate, high in comprehensive recycling degree andthe like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for preparing ceramic fiber precursor

The invention relates to a preparation method of a ceramic fibre precursor. The steps comprises that (1) the preparation of a small molecular monomer: under the oxygen-free dry atmosphere under subzero 80 DEG C to 0 DEG C, the mol ratio of boron trichloride and aliphatic secondary amine is 1 to 0.2 to 1 to 1 to 5, the boron trichloride is slowly condensed into aliphatic secondary amine triethylamine solution to react for 1 to 20 hours under magnetic force mixing and then reacts for 1 to 20 hours under the room temperature to produce yellow sedimentation for filtering; then the mol ratio of anhydrous toluene solution and aliphatic primary amine is 1 to 1 to 5 to 1, the anhydrous toluene solution is added into the filtrate by dropping to react for 1 to 20 hours under subzero 80 DEG C to 0 DEG C along with magnetic force mixing and then reacts for 5 to 30 hours under the room temperature to produce the yellow sedimentation again for filtering and reduced pressure distillation;(2) the preparation of a BN precursor: the light yellow liquid is treated for multiple-stage linear heating under magnetic force mixing, the heating speed is 0.5 to 20 DEG C per minute, the liquid is heated till 150 DEG C to 180 DEG C for 15 to 25 hours and then cooled to obtain the yellow solid precursor. The technology of the method is simple, and the continuous industrialized production can be easily realized.

Owner:DONGHUA UNIV

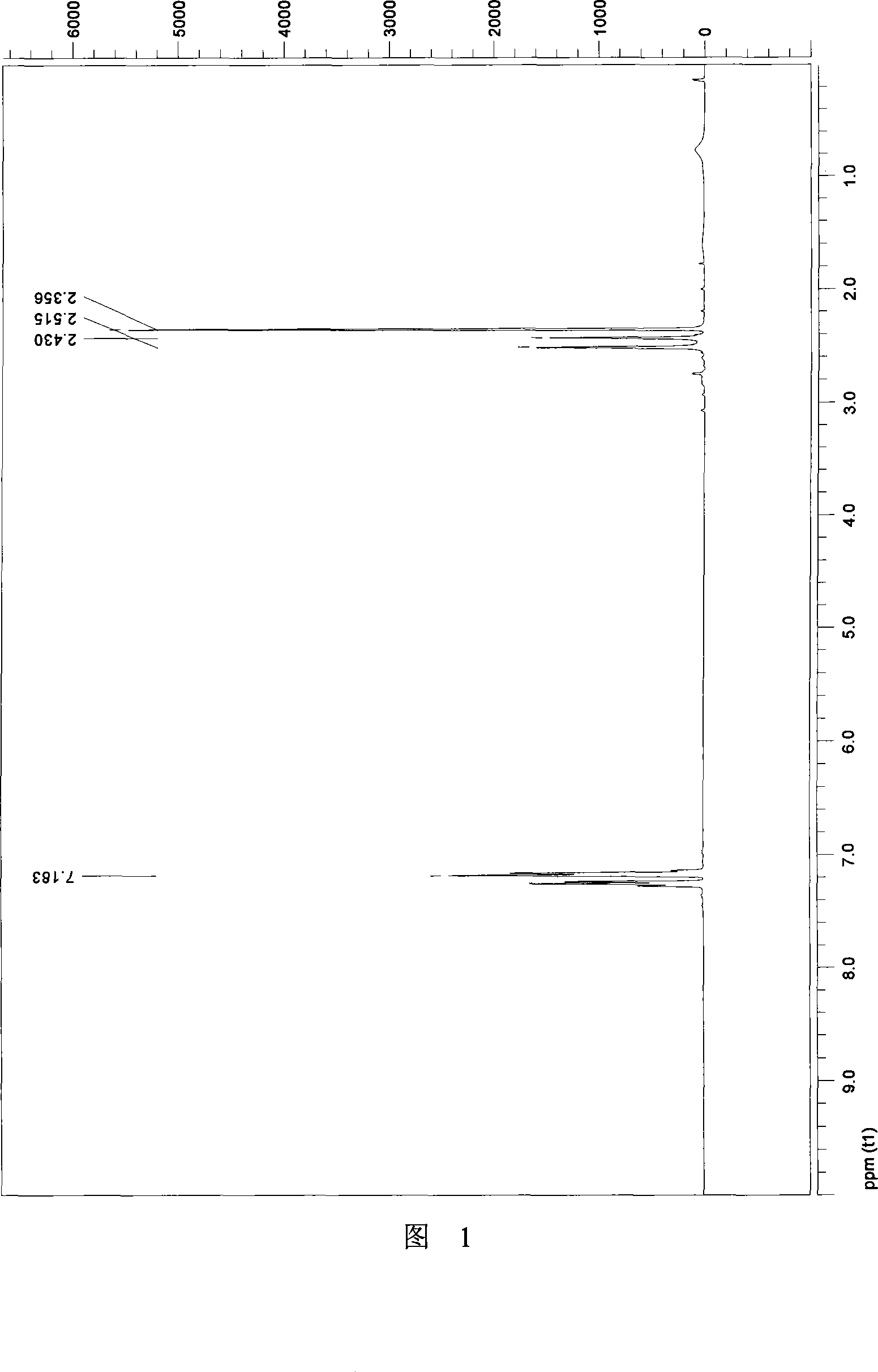

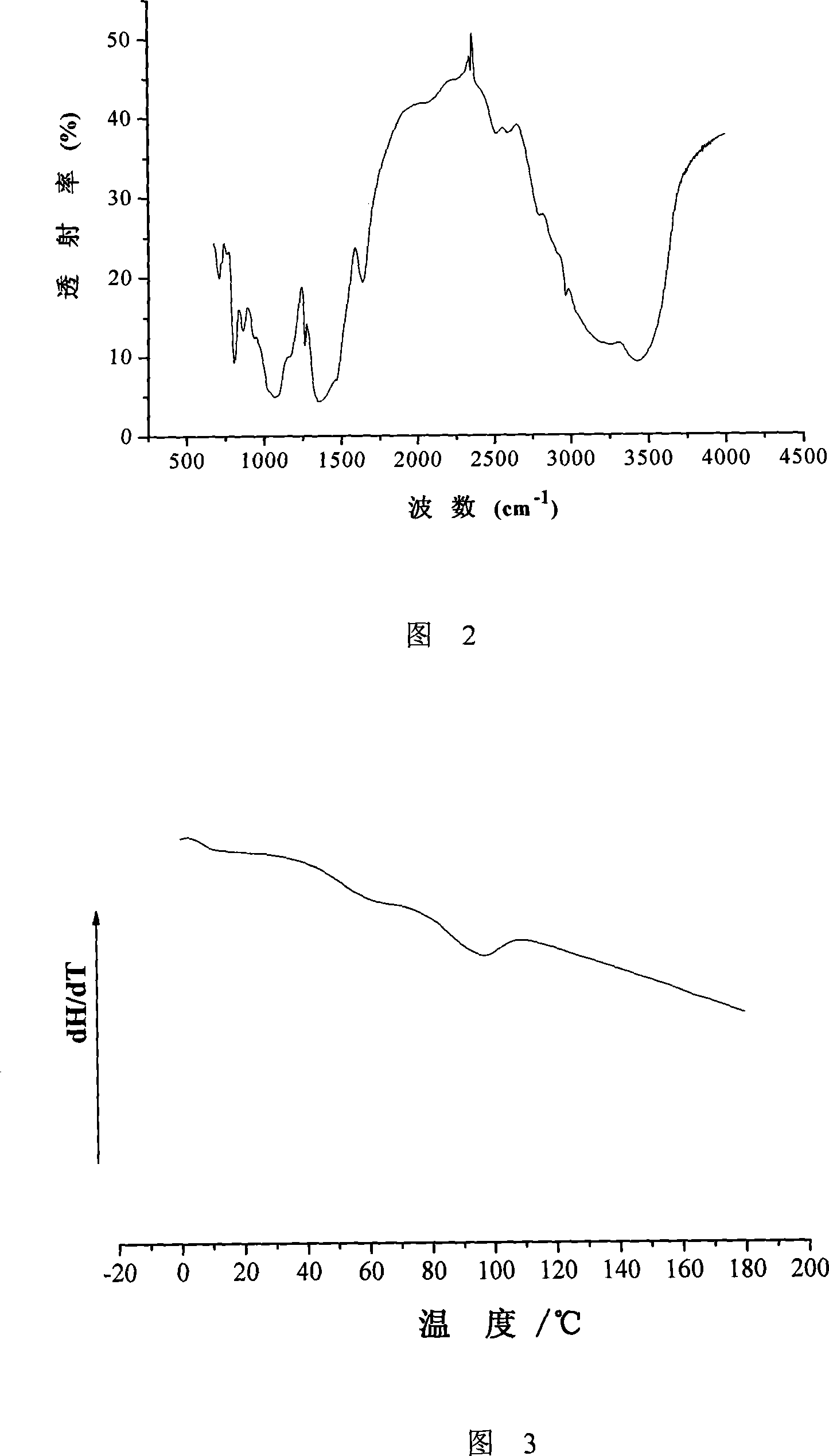

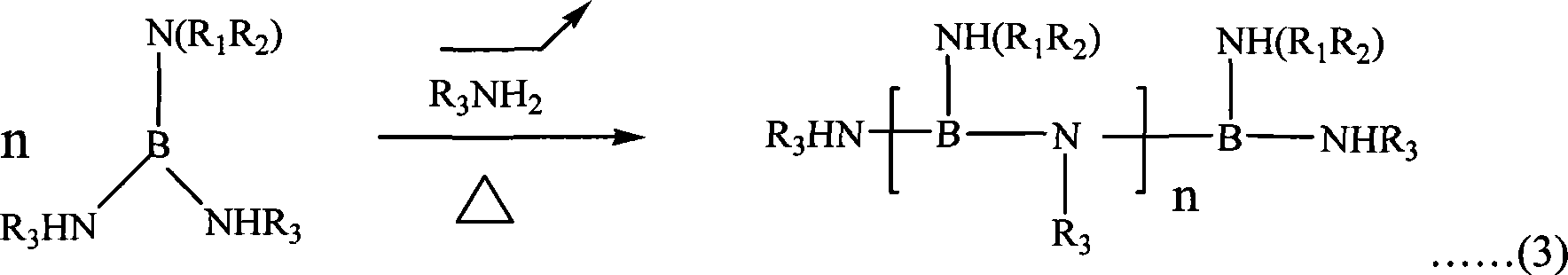

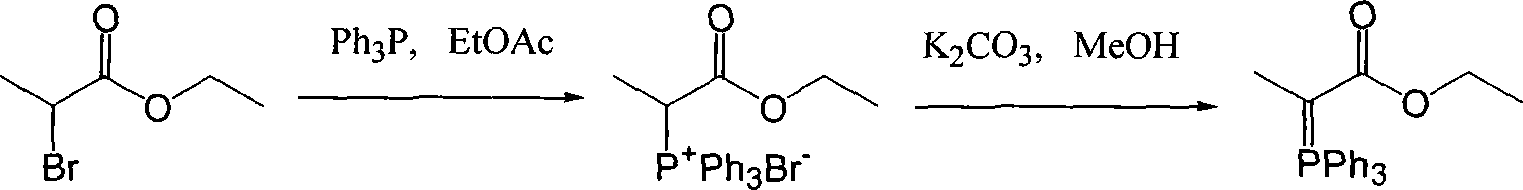

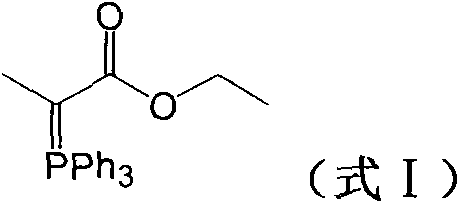

Preparation method of (carbethoxyethylidene)triphenylphosphorane

ActiveCN103910759ASimple preparation stepsShorten the production cycleGroup 5/15 element organic compoundsState of artEthyl ester

The invention relates to a preparation method of (carbethoxyethylidene)triphenylphosphorane. According to the method, after a reaction of triphenyl phosphine and ethyl 2-bromopropionate is completed in a solvent, the reaction products are not required to be separated, the pH value of a static separated water layer is directly regulated to 7.5-8.5, and the precipitate is collected to obtain the product. The method improves a two-step reaction of the prior art into a way that the intermediate products are not separated and a next-step reaction is directly carried out, simplifies the preparation steps, shortens the production cycle, and has the advantages of mild reaction conditions, simplified preparation steps, short production cycle, low manufacturing cost (reduced by about 40%), less three wastes, environmental protection, solvent recycling and reutilization, easily realized industrialized continuous production and the like.

Owner:ANHUI BIOCHEM BIO PHARMA

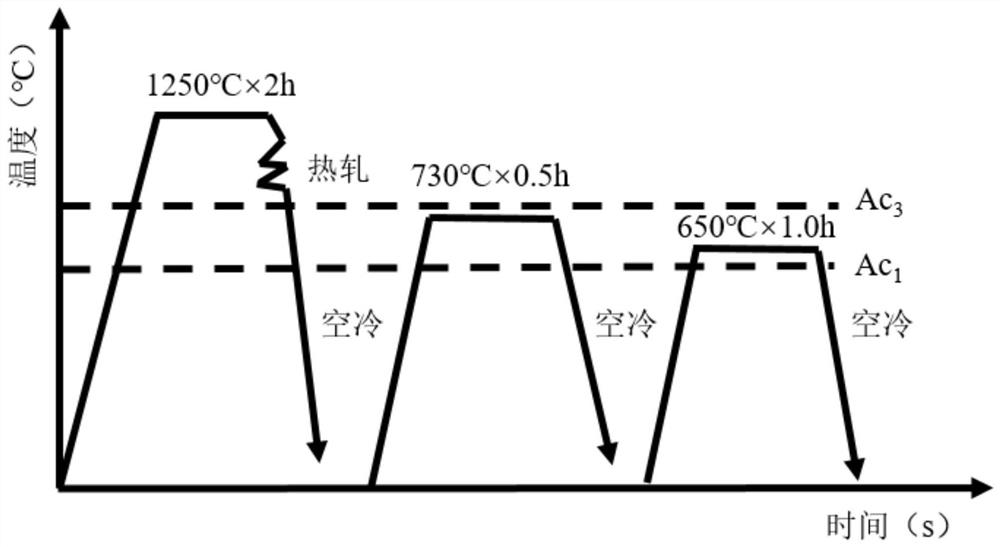

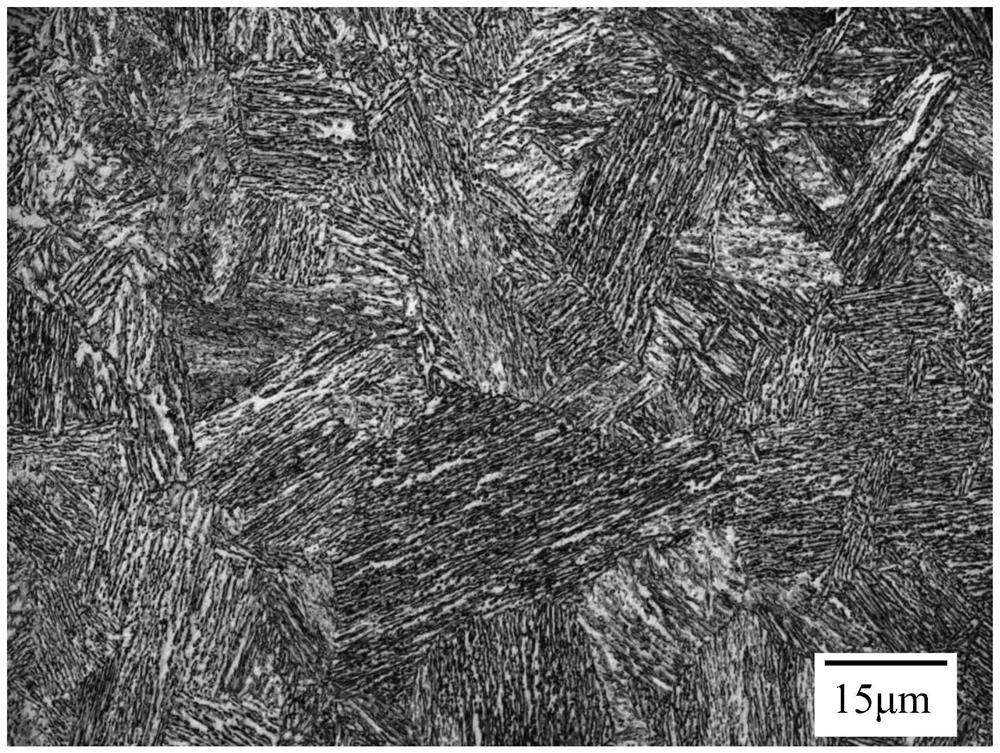

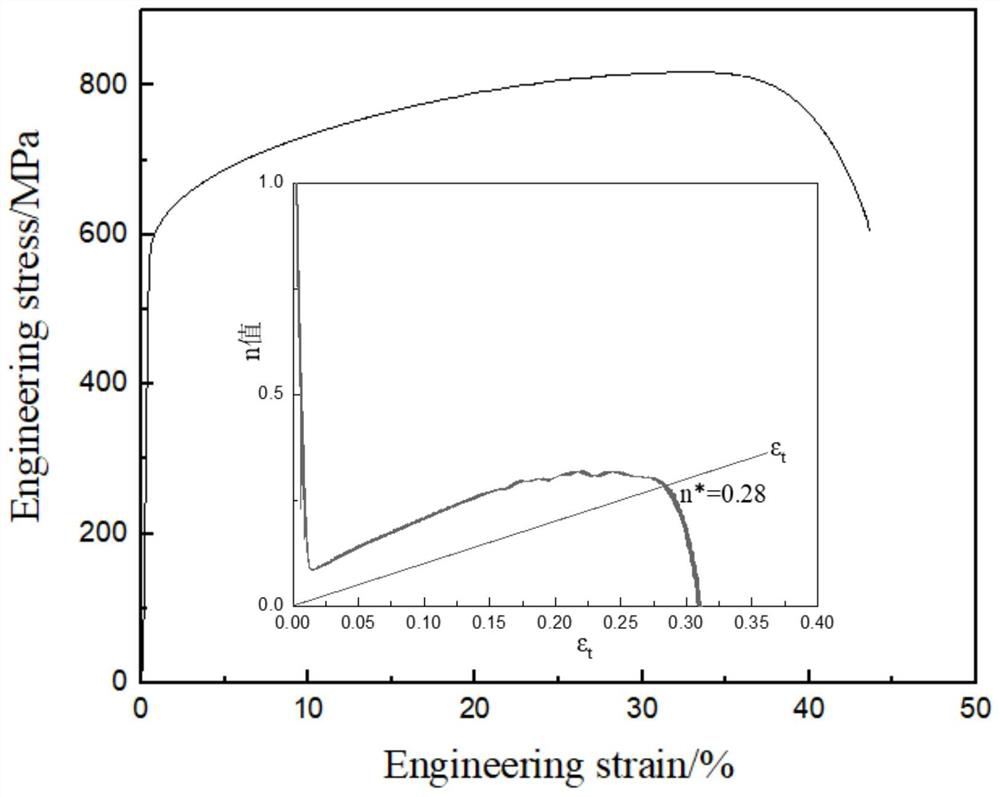

High-strength, high-plasticity, low-carbon and medium-manganese TRIP steel and preparation method thereof

ActiveCN112853224AHigh strengthImprove plasticityFurnace typesHeat treatment process controlPlasticityContinuous production

The invention discloses high-strength, high-plasticity, low-carbon and medium-manganese TRIP steel and a preparation method thereof, and belongs to the technical field of high-strength and high-plasticity steel. The high-strength, high-plasticity, low-carbon and medium-manganese TRIP steel comprises the following components in percentage by mass: 0.08%-0.16% of C, 2.9%-4.0% of Mn, 0.1%-1.5% of Si, 0.01%-0.08% of Al, 0.005%-0.04% of Ti, less than 0.015% of P, less than 0.003% of S, and the balance of Fe and inevitable impurity elements. According to the preparation method, the raw materials with the chemical components are subjected to smelting, casting, forging, hot rolling and two-step annealing treatment in a two-phase region, the high-strength, high-plasticity, low-carbon and medium-manganese TRIP steel is high in strength, high in plasticity and good in impact toughness, the components of the high-strength, high-plasticity, low-carbon and medium-manganese TRIP steel and the heat treatment process are simple and feasible, and industrial continuous production is easy to achieve.

Owner:NORTHEASTERN UNIV

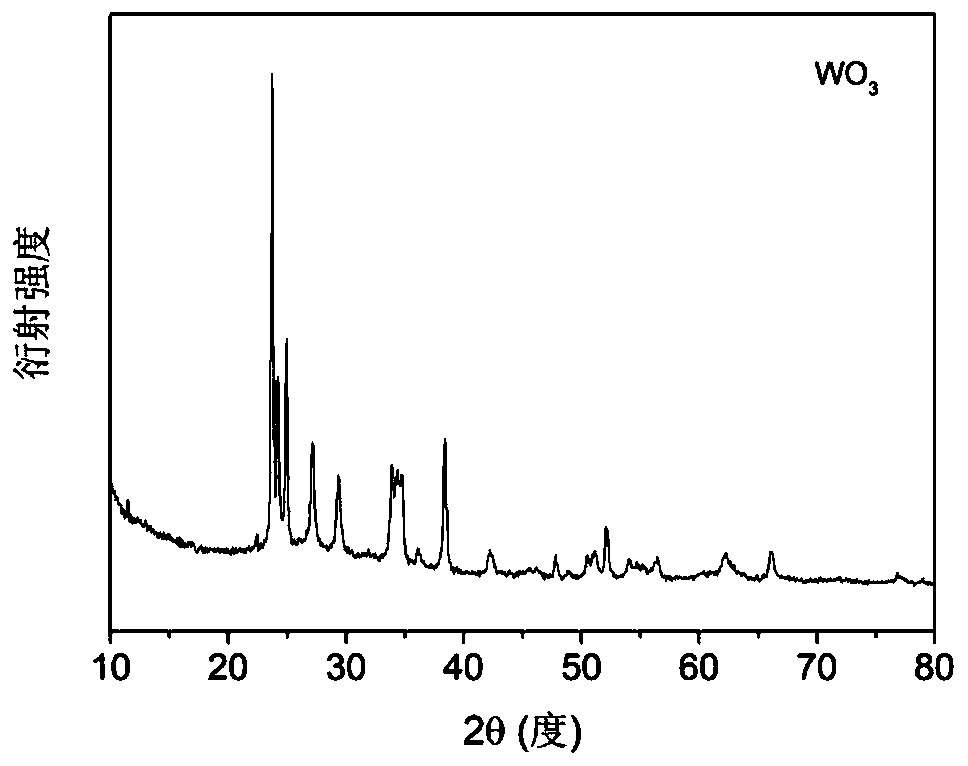

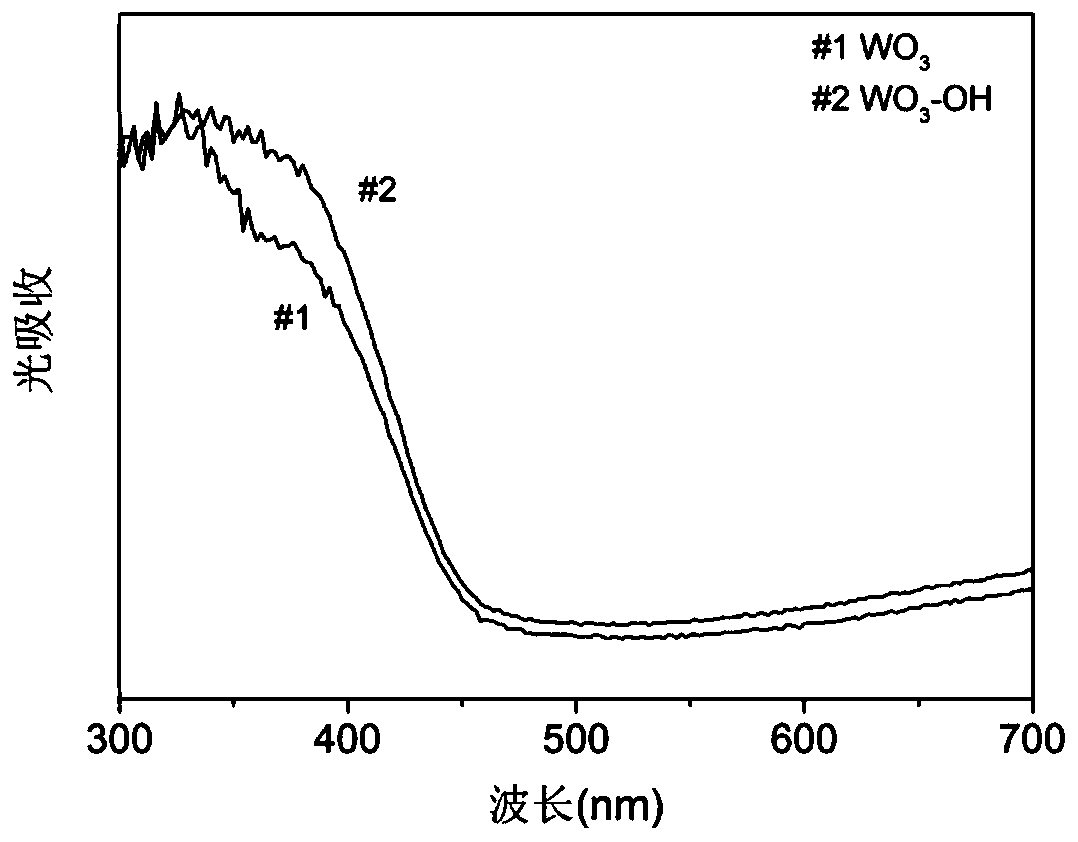

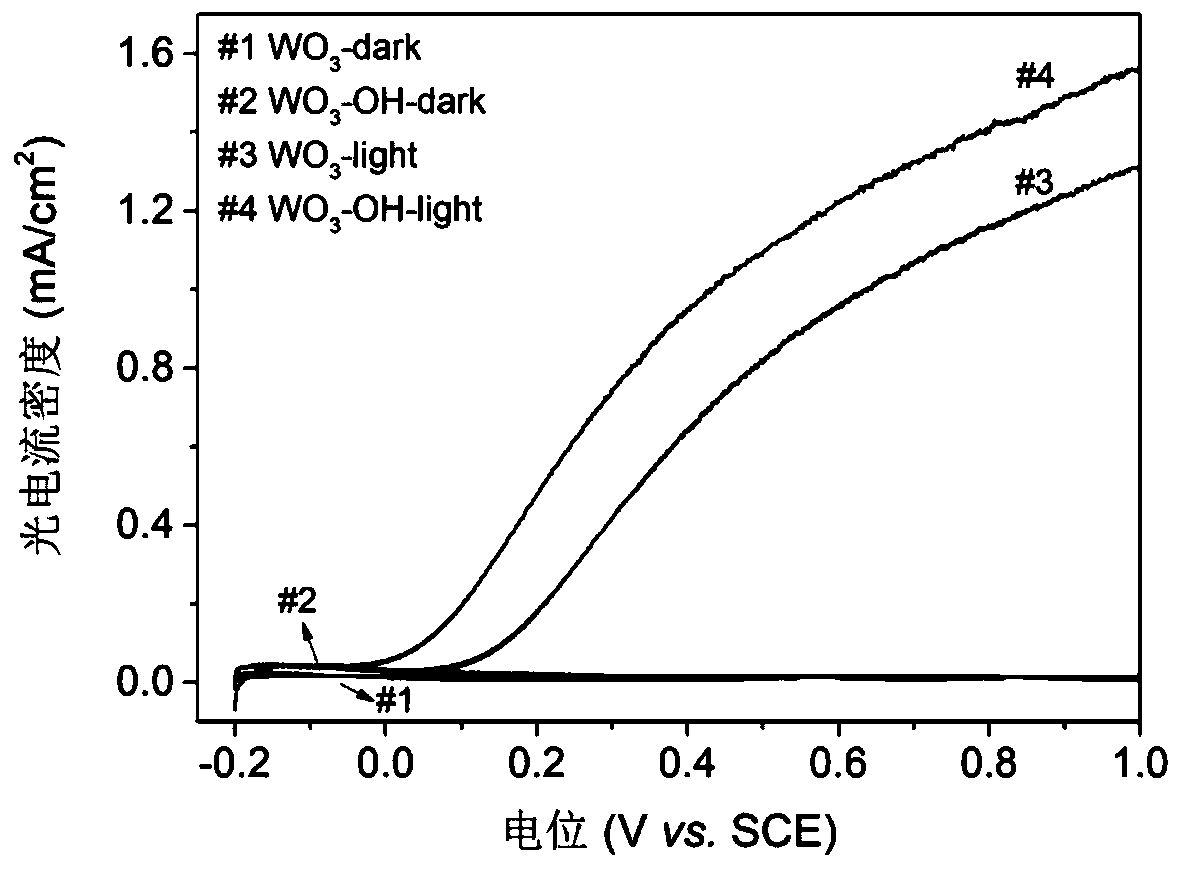

Method for preparing surface hydroxylated WO3 film photoelectrode material through plasma treatment

ActiveCN110241439AExcellent photoelectrocatalytic water splitting performanceImprove hydrophilicityLiquid/solution decomposition chemical coatingElectrodesOxalateDecomposition

The invention relates to a method for preparing a surface hydroxylated WO3 film photoelectrode material through plasma treatment. The specific steps comprise: preparing a WO3 seed crystal on the surface of a FTO electric-conduction glass, and hydrothermally growing nano-sheet-like WO3 on the surface of the WO3 seed crystal by using the H2O2 solution of H2WO4, acetonitrile, oxalic acid and a hydrochloric acid solution as raw materials; and treating the surface of the WO3 film electrode by using a low temperature plasma technology to obtain the surface hydroxylated WO3 film. According to the present invention, the prepared surface hydroxylated WO3 film has characteristics of good wettability with water, increased bulk phase carrier concentration and accelerated interface charge transfer, and can effectively promote the photoelectrocatalytic water decomposition performance; and the process for the plasma treatment of the WO3 film has characteristics of simpleness, energy saving, environmental protection, no pollution, high efficiency and short time, and provides the important way for the large-scale treatment of the WO3 photoelectrode.

Owner:TAIZHOU UNIV

Method for preparing three-dimensional block polylactic acid at high efficiency

The invention provides a method for preparing three-dimensional block polylactic acid at high efficiency. The method is characterized by comprising the following steps of: (1) pre-polymerizing: adding polymerization-stage D type (or L type) lactide, a catalyst and an initiator into a polymerization reactor, heating to the first reaction temperature of 160-200DEG C under the protection of inert gas, reacting for 0-1hour after a set temperature is achieved, cooling to the second reaction temperature of 100-150 DEG C, and reacting for 0.5-5hours to obtain a prepolymer; and (2) carrying out block copolymerization: taking the prepolymer prepared by the step (1) as a raw material, adding the polymerization-stage L type (or D type) lactide into the polymerization reactor, wherein the mass ratio is (1:9)-(3:7), the reaction temperature is 190-230DEG C under the protection of inert gas, and the reaction time is 0.5-5hours after the set temperature is achieved, so that the three-dimensional block polylactic acid can be obtained.

Owner:SHANGHAI KEYUAN BIO MATERIAL

Method for synthesizing high molecular weight polylactic acid

The invention relates to a novel method for preparing high molecular weight polylactic acid through direct-melting polycondensation. The method has the key that a certain amount of low molecular weight polylactic acid serving as base material is added to a reaction system for participating in the polycondensation of lactic acid, and the addition of the base material can reduce the concentration of the lactic acid in the system so as to reduce the ring formation probability in the polycondensation of lactic acid, promote the proceeding of polycondensation, raise polymerization rate, greatly increase the molecular weight of polylactic acid products and overcome the disadvantages that the direct polycondensation method of lactic acid is long in reaction time, low in molecular weight of products and the like. Change in the polymerization process ensures simple process of lactic acid polymerization, single product structure and high molecular weight.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Method for preparing dried medlar after secondary cleaning

ActiveCN104012901ASolve the problem of drying after secondary cleaningImprove qualityGranular material dryingDrying gas arrangementsChemistryEngineering

The invention provides a method for preparing dried medlar after secondary cleaning, which is implemented by using a belt dryer through a specific multi-stage drying process. According to the method for preparing the dried medlar after the secondary cleaning, the problem about preparing the dried medlar after the secondary cleaning is effectively solved by adopting the multi-stage drying process; the obtained product has bright color and loose particles, and is clean, sanitary and safe; the quality of the dried medlar is improved; a novel way is developed for preparing the high-quality dried medlar.

Owner:青海新泰行生物科技有限公司

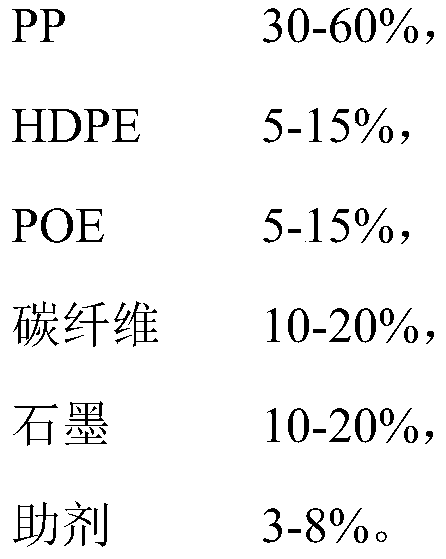

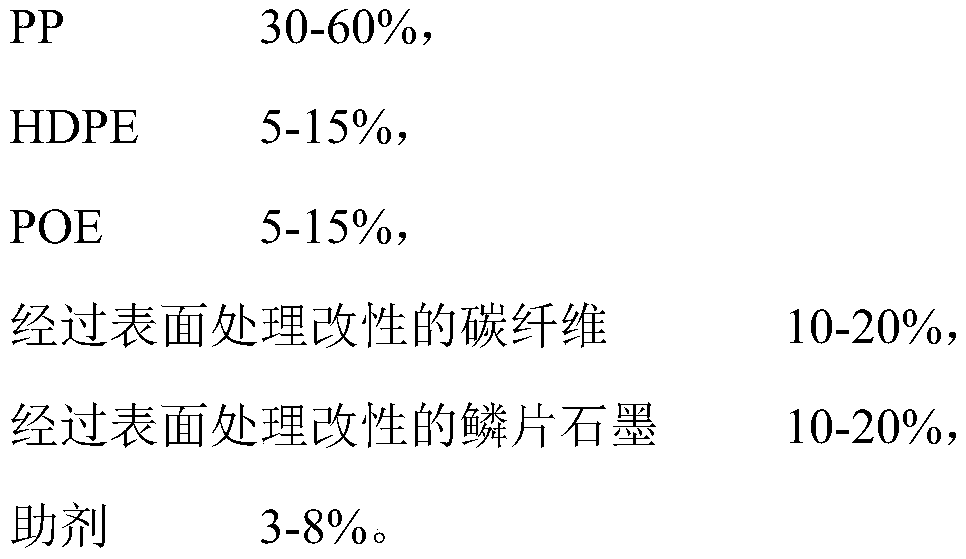

PP/HDPE/POE composite thermal-conduction polymer material, preparation method and applications thereof

The invention discloses a PP / HDPE / POE composite thermal-conduction polymer material, a preparation method and applications thereof, wherein the PP / HDPE / POE composite thermal-conduction polymer material comprises, by weight, 30-60% of PP, 5-15% of HDPE, 5-15% of POE, 10-20% of carbon fiber, 10-20% of graphite, and 3-8% of an auxiliary agent. According to the present invention, the filling type PP / HDPE / POE composite thermal-conduction polymer material with excellent mechanical property, excellent fluidity, excellent thermal property, excellent thermal conductivity and the like is prepared by carrying out same-direction asymmetric extrusion and mixing on the components, and can be used in illumination lampshades, heat dissipating devices, household appliance shells and massage pump shells.

Owner:WUYI UNIV

Preparation method of spherical aluminum oxide

ActiveCN105289756AGreen raw materialsProcess greenCatalyst carriersCatalyst activation/preparationGellan gumSphingomonas elodea

The invention relates to a preparation method of spherical aluminum oxide. The preparation method comprises the steps of dispersing gellan gum and an aluminum oxide precursor into deionized water, then heating to 70 to 90 DEG C, so that the gellan gum is fully dissolved, and homogenizing feed liquid by adopting homogeneous equipment, so as to prepare suspension slurry with good stability; adding the suspension slurry to a pill dropping machine for dropping, and curing in an organic phase to form gel beads; then further curing the gel beads with a cationic curing agent; finally, drying, and calcining to obtain a product. The forming method has the advantages of high product intensity, good degree of sphericity, large pore volume, no pollution in a preparation process, easiness in industrial production and the like, and operating steps are simple and are easy to implement.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

A kind of preparation method of spherical silicon-alumina composite carrier

ActiveCN104353503BImprove adhesionReduce production process stepsCatalyst carriersManganeseNano al2o3

The invention relates to a preparation method of a spherical silicon-aluminum composite carrier. The preparation method is characterized by comprising the following steps: adding silicon dioxide to an alumina gel, and uniformly mixing; slowly adding to an alginate solution, and uniformly stirring to prepare suspension slurry; dropping the suspension slurry into a multivalent metal cation solution to form a spherical composite gel granule; taking out the spherical composite gel granule, and drying and calcining to obtain the spherical silicon-aluminum composite carrier, wherein the alumina gel is an alumina hydrogel or a nano-alumina sol, the addition amount of the silicon dioxide is 0.1-0.3 time more than the weight of the alumina gel in terms of Al2O3, the suspension slurry contains 5%-25% by weight of solids and 0.3%-5% by weight of alginate, the soluble alginate is one or more of sodium alginate, potassium alginate, magnesium alginate and ammonium alginate, and the multivalent metal cation solution is an aluminum, zinc, calcium, copper, iron, ferrous iron, cobalt, manganese or nickel ion salt solution with the saturation concentration of 0.1 mol / L. The spherical silicon-aluminum composite carrier obtained through the preparation method disclosed by the invention has the advantages of high strength, large pore volume and low bulk density.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

A method for secondary cleaning and drying of dried wolfberry fruit

InactiveCN104013079BNot prone to breakageGood for secondary dryingFood treatmentLycium barbarum fruitWater flow

The invention provides a dried lycium barbarum secondary washing and drying method. After lycium barbarum is washed in a washing production line, and drying is then achieved. By means of the dried lycium barbarum secondary washing and drying method, impurities on the surfaces of the lycium barbarum are removed in the washing process according to the physical effect of water flow and the flotation performance of the dried lycium barbarum and the impurities, the lycium barbarum is not prone to being damaged, most of moisture on the surface of the washed dried lycium barbarum can be easily removed through a flexible water absorption rubber roller, secondary drying after dried lycium barbarum washing is easily carried out, and the dried lycium barbarum secondary washing and drying method is suitable for automatic industrial large-scale production. In addition, the multi-section type belt drying method is adopted, drying after secondary washing of the dried lycium barbarum is effectively achieved, the obtained product is bright in color, loose in particle, clean, sanitary and safe, the quality of the dried lycium barbarum is improved, and a new way is developed for making high-quality dried lycium barbarum.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Production method of automobile wear-resisting damper piston

ActiveCN104475737AReduce consumptionLow costTurbinesOther manufacturing equipments/toolsDamperMaterials science

The invention aims at providing a production method of an automobile wear-resisting damper piston. According to the method, the automobile wear-resisting damper piston is manufactured through the powder metallurgy technique and formed under relatively low pressure; a porous piston part can be obtained, then the piston part is immersed inside special lubricant, and pores can be occupied by the lubricant through the vacuum negative-pressure principles. The obtained automobile wear-resisting damper piston is low in frication force and high in wear-resistance when in work. Besides, the production method of the automobile wear-resisting damper piston is high in operating stability and repeatability, simple in equipment and application to mass production.

Owner:JIANGDU LEADER POWDER METALLURGY

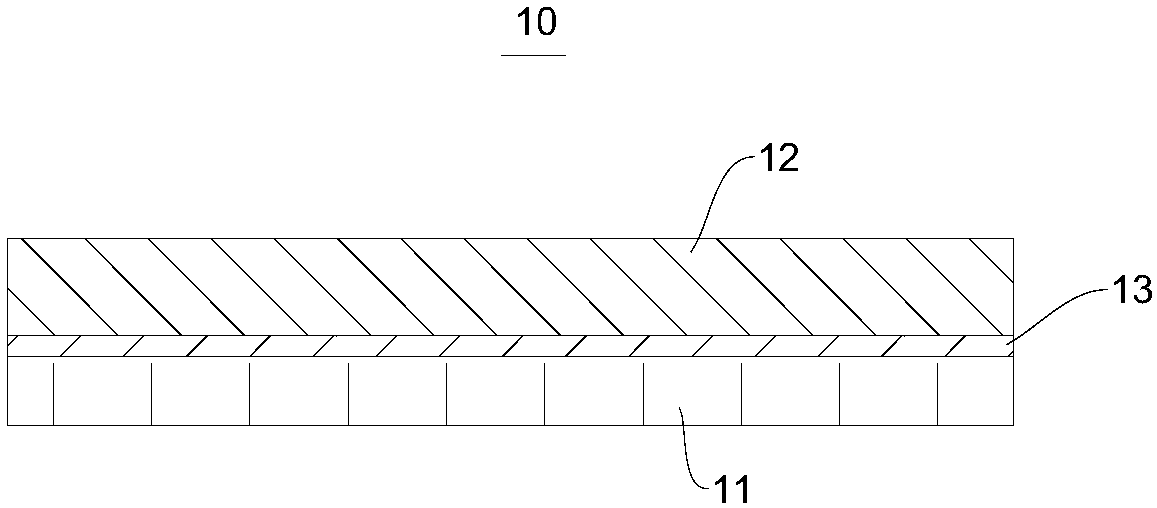

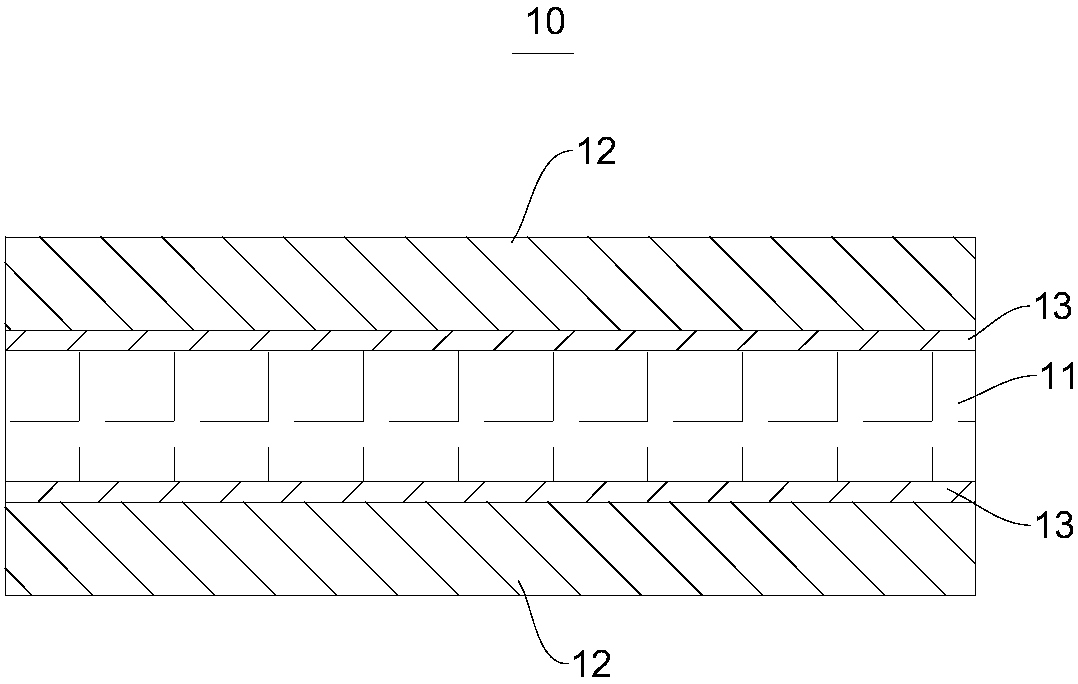

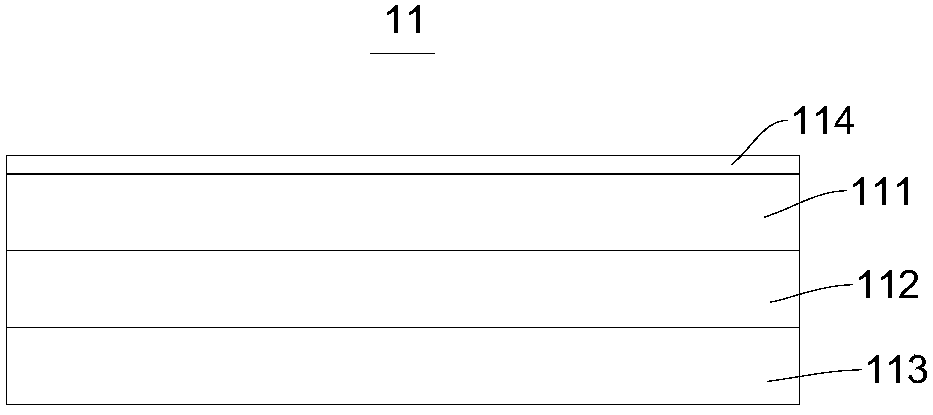

Bamboo filament decoration panel capable of adjusting humidity and preparation method and application thereof

PendingCN108454189AEasy to realize industrialized continuous productionSimple processCovering/liningsDomestic upholsterySolid woodContinuous production

The invention provides a bamboo filament decoration panel capable of adjusting humidity and a preparation method and application thereof, and belongs to the technical field of artificial boards. The decoration panel comprises a solid wood strip composite board layer, a bamboo filament decoration layer and a straw plaited paper layer, the bamboo filament decoration layer is arranged on the upper surface or the lower surface of the solid wood strip composite board layer, and the straw plaited paper layer is arranged between the solid wood strip composite board layer and the bamboo filament decoration layer. The thickness of the straw plaited paper layer is less than 1 millimeter, and the decoration panel has a better visual effect, a better mechanical property and a better humidity adjustingfunction. The preparation method comprises the steps that straw plaited paper is socked in first glue and is placed between the solid wood strip composite board layer and the bamboo filament decoration layer, and a panel blank is obtained; the panel blank is pressed, and segmented pressure relief and curing are carried out successively. The preparation method is simple, easily achieves continuousproduction of industrialization, can greatly improve production efficiency, and reduces production cost. The method can be applicable to fitment or decorative products, and improve tenacity, intensity, stereoscopic vision and environmentology performance of decorative products.

Owner:HUBEI FORESTRY SCI INST

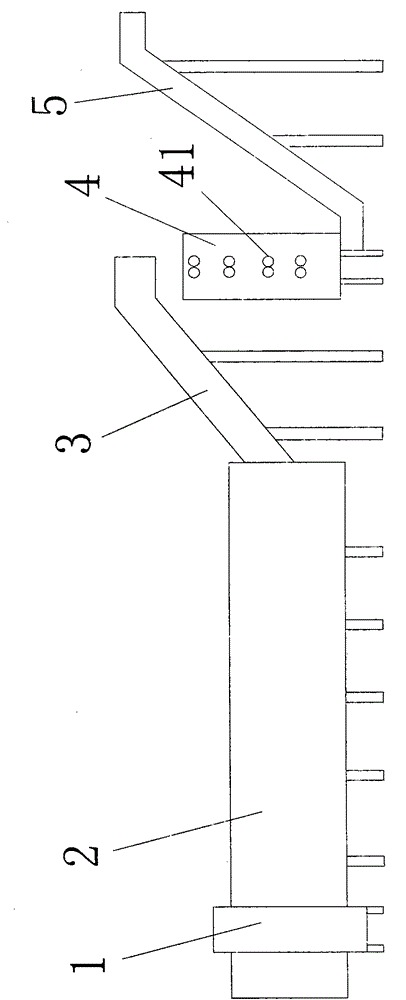

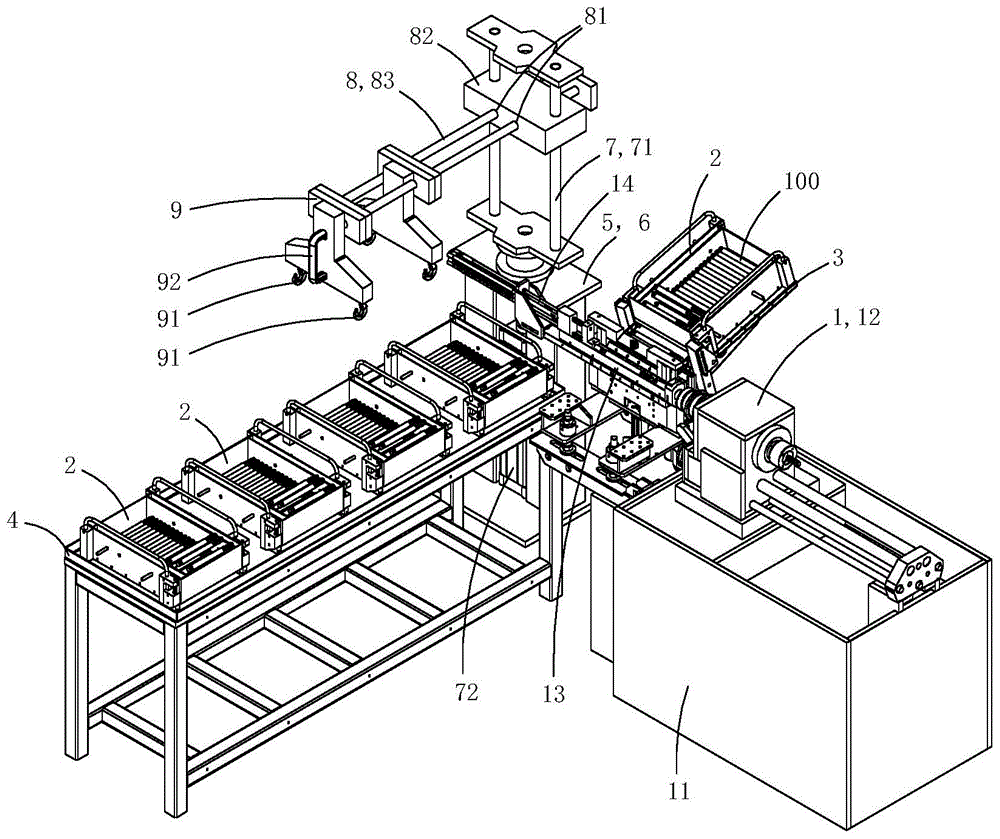

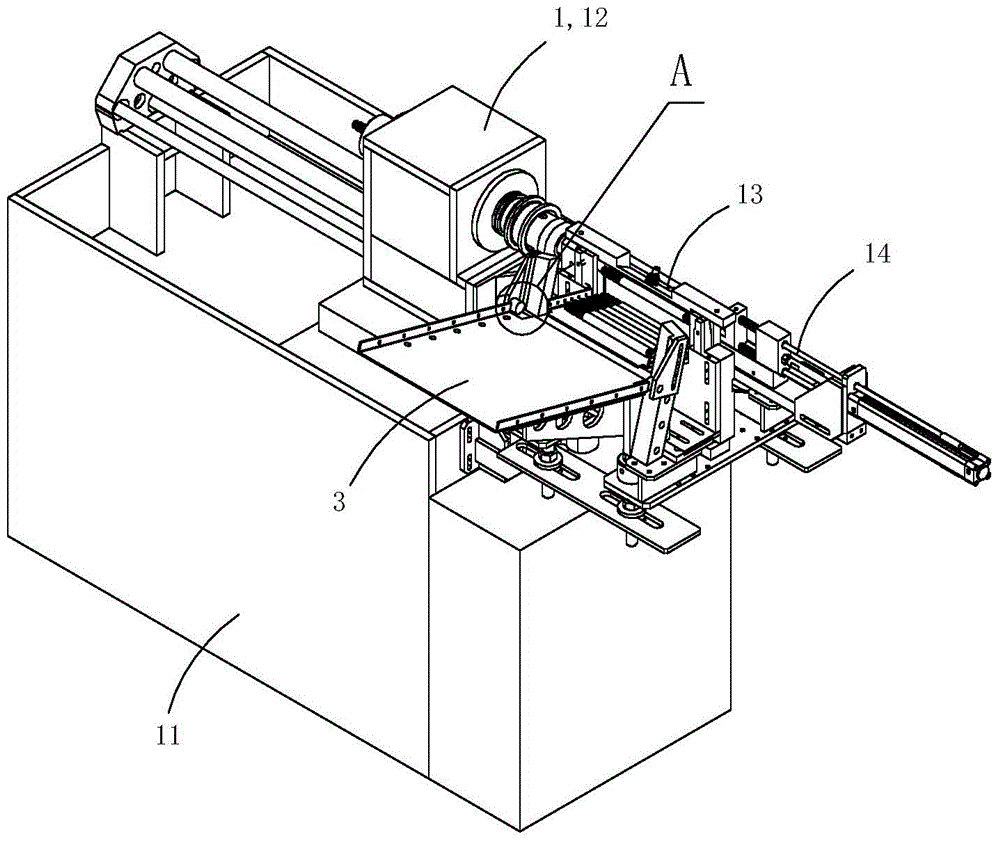

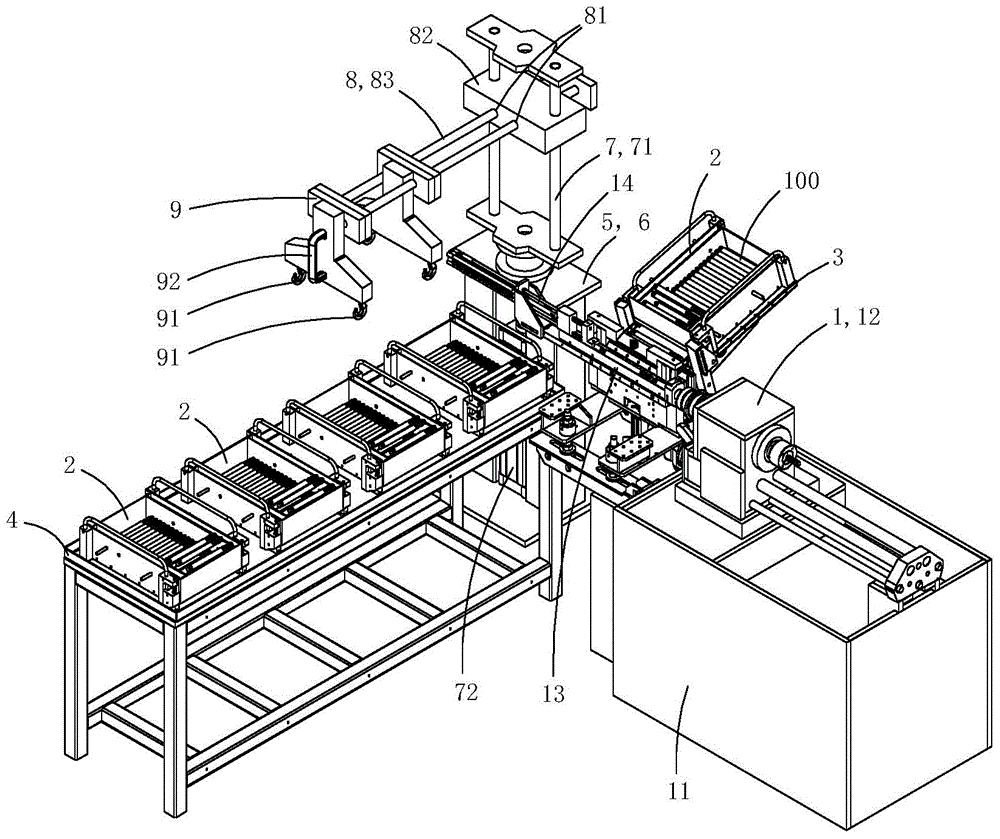

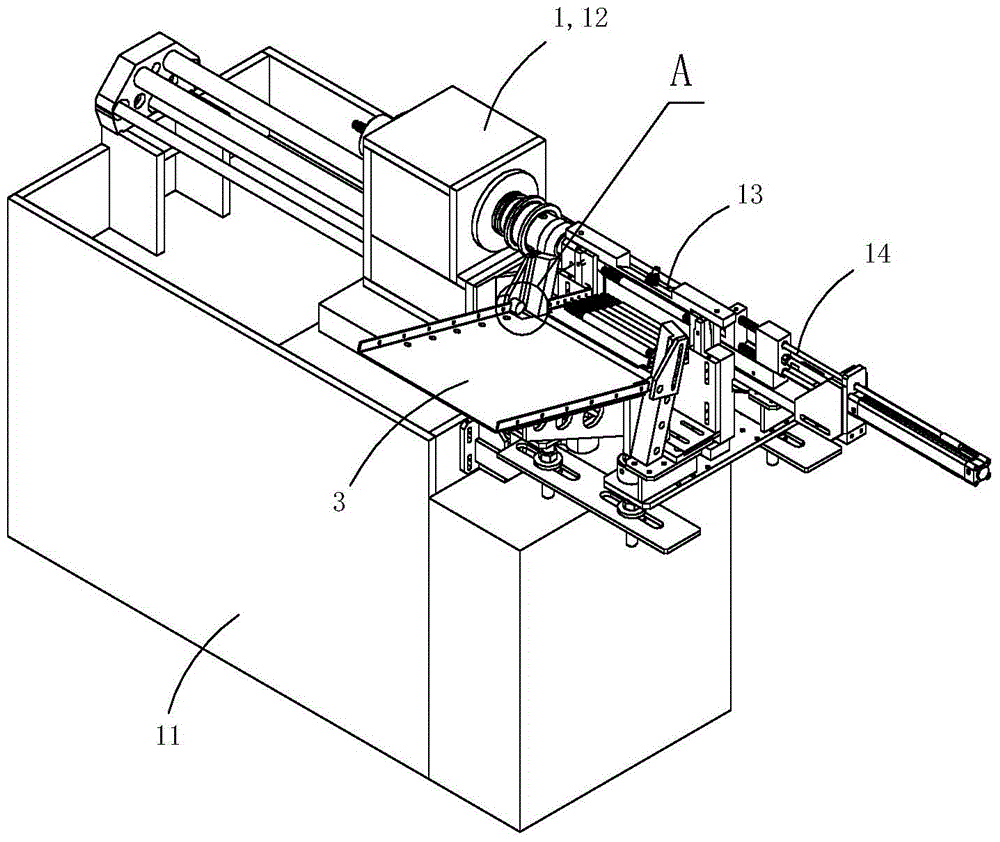

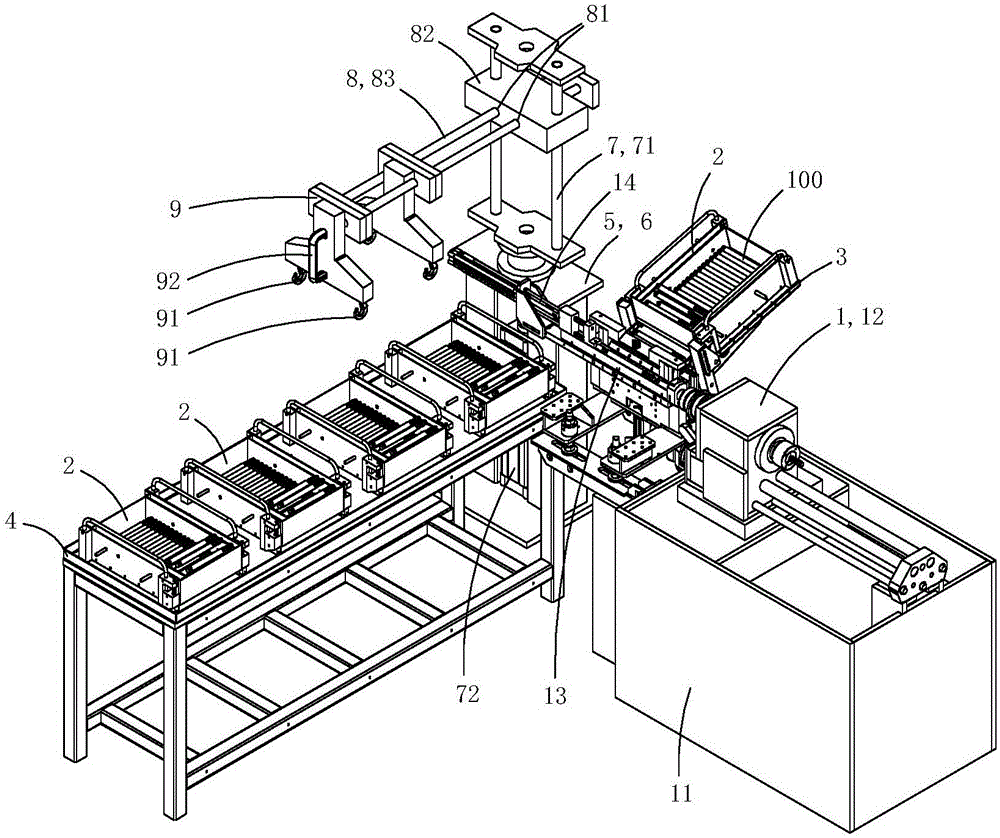

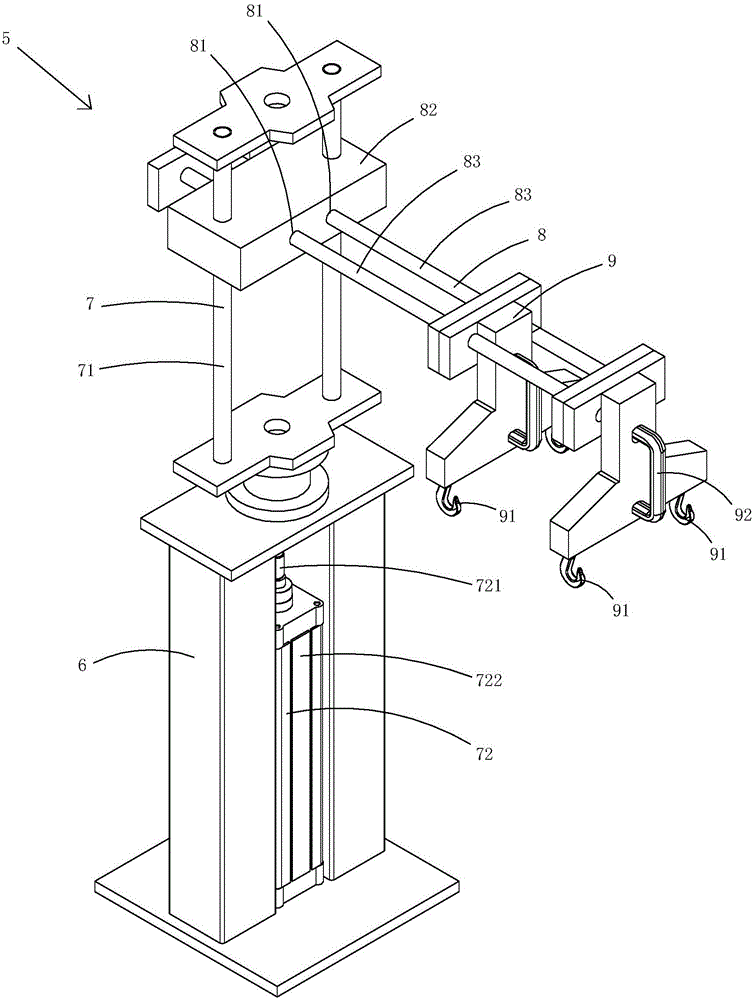

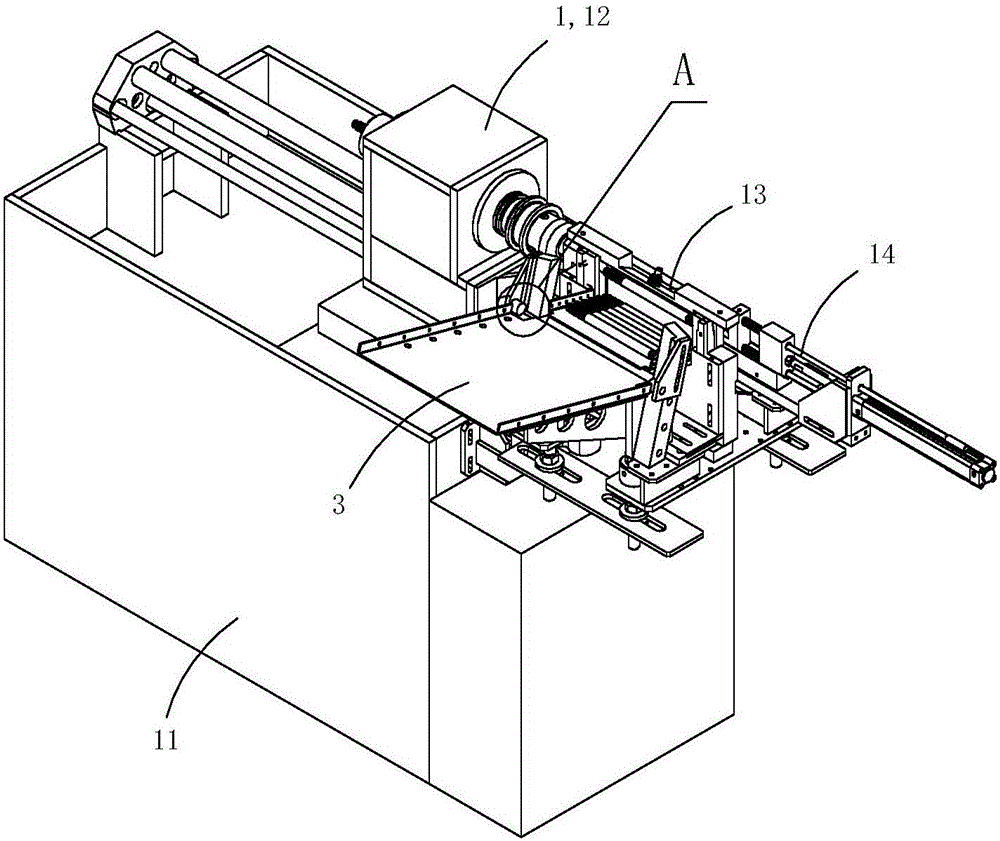

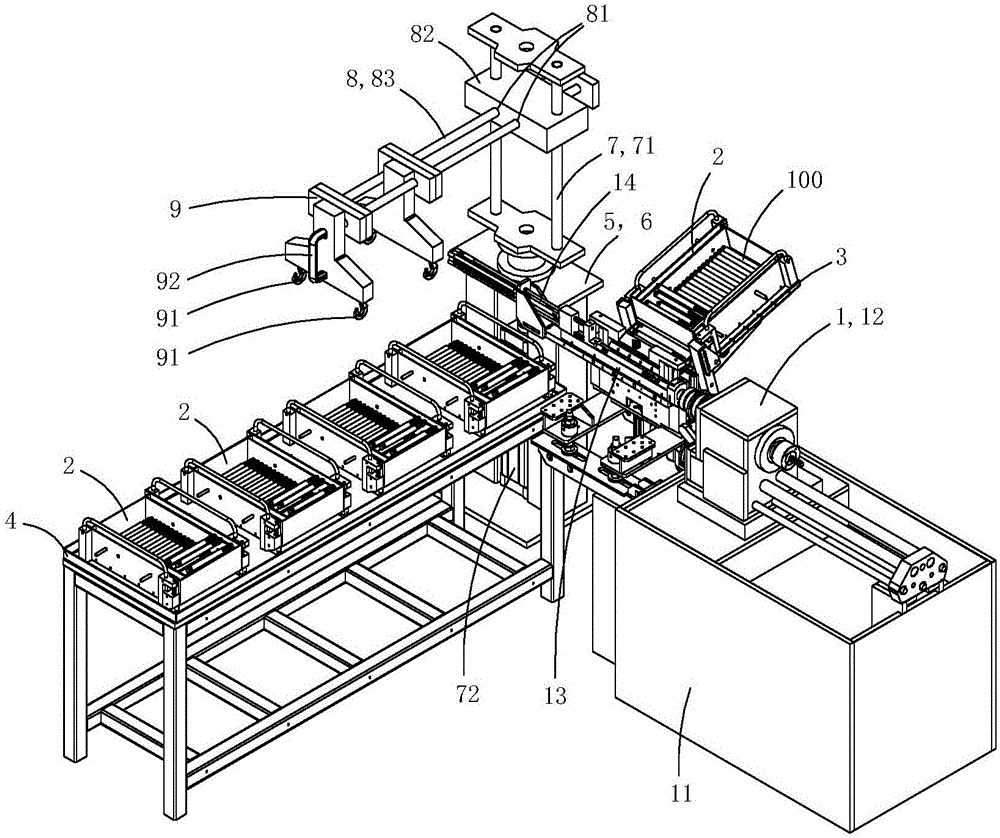

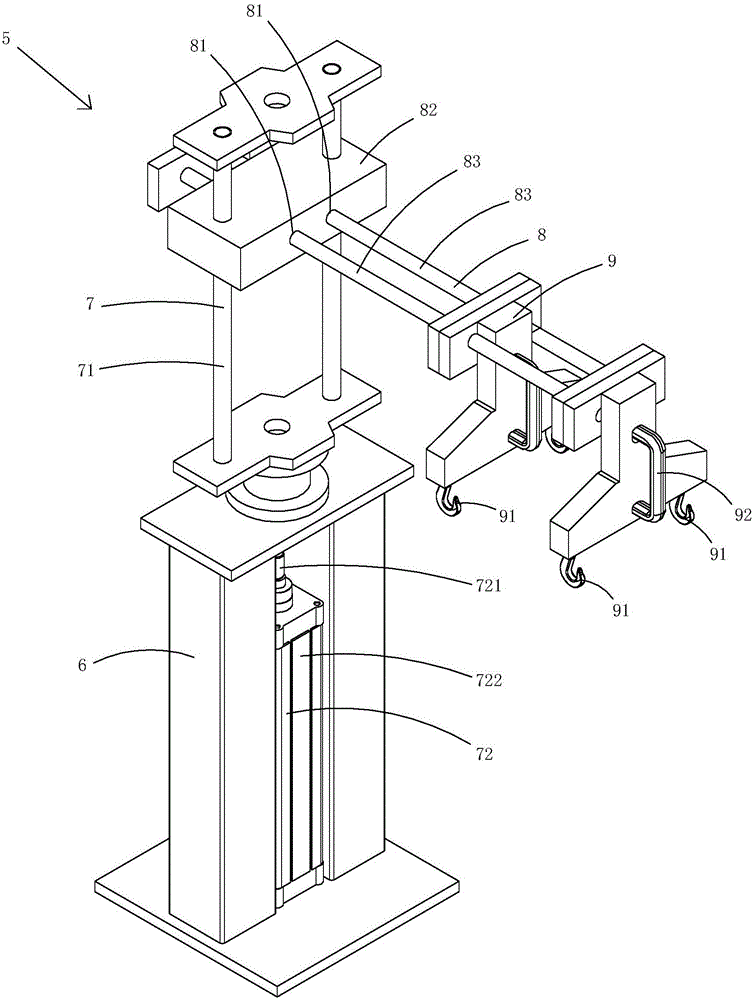

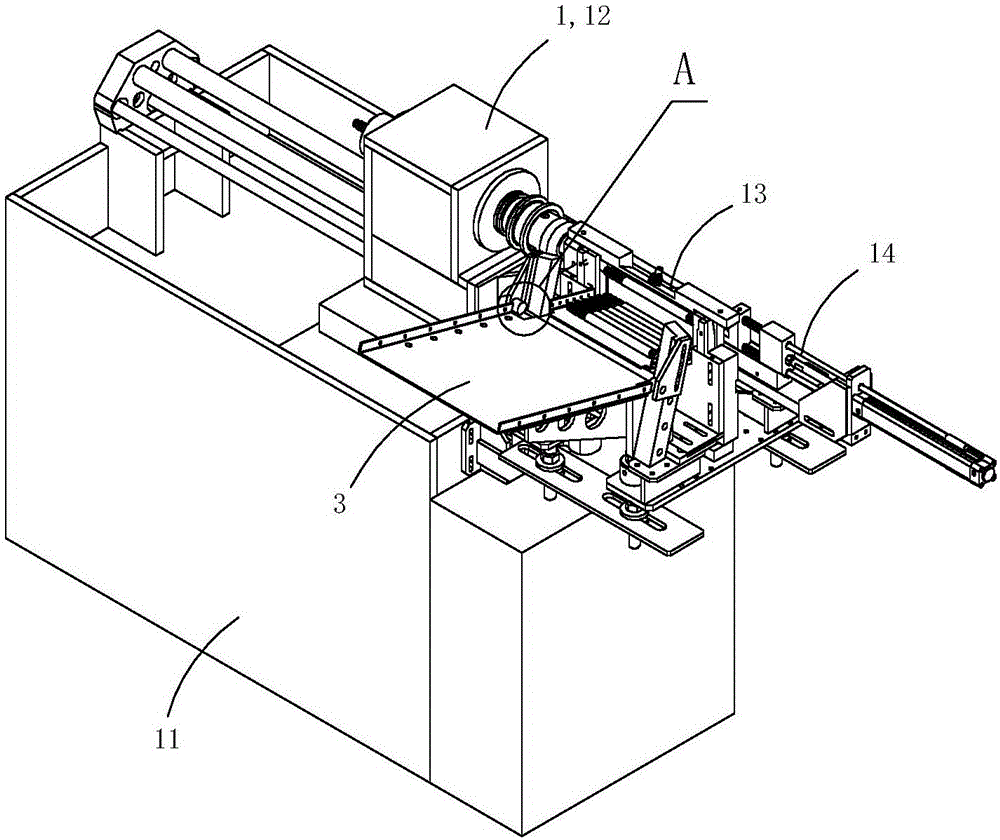

Combined type automatic feeding machine tool

InactiveCN104551831AEasy to replaceRealize industrialized continuous productionMilling machinesMetal working apparatusContinuous productionMachine tool

The invention discloses a combined type automatic feeding machine tool. The combined type automatic feeding machine tool comprises a machine tool body, a hopper, a hopper bracket arranged on the machine tool body, a discharging frame and a charging device for transferring the hopper on the discharging frame to the hopper bracket, wherein the machine tool body comprises a base, a milling head, a material clamping cavity penetrating through the milling head, a feeding positioning plate and a pneumatic material pushing mechanism; the milling head is fixedly arranged on the base; the feeding positioning plate is aligned to a discharging part of the hopper and is located between the pneumatic material pushing mechanism and the milling head. According to the combined type automatic feeding machine tool, the charging device for transferring the hopper on the discharging frame to the hopper bracket is arranged so that the hopper can be more conveniently replaced and the industrial continuous production is easy to realize.

Owner:CHUZHOU SWITCH ELECTRICAL TECH

Prepn of high molecular weight polylactic acid

The preparation process of high molecular weight polylactic acid includes the following steps: 1. decompression reflux evaporation to eliminate water from lactic acid material; 2. esterifying the dewatered lactic acid in inert gas atmosphere; 3. pre-condensating the esterified product in the presence of catalyst through gradual decompression; and 4. low vacuum polycondensing the pre-polymer through gradual decompression and in the presence of catalyst to obtain high molecular weight polylactic acid. The present invention adopts direct smelting polycondensation, and has simple production process, simple production apparatus, low cost and easy realization in industrial production.

Owner:DONGHUA UNIV

Method for preparing polylactic acid from lactic acid under catalysis of titanium composite catalyst

Owner:BEIJING UNIV OF CHEM TECH

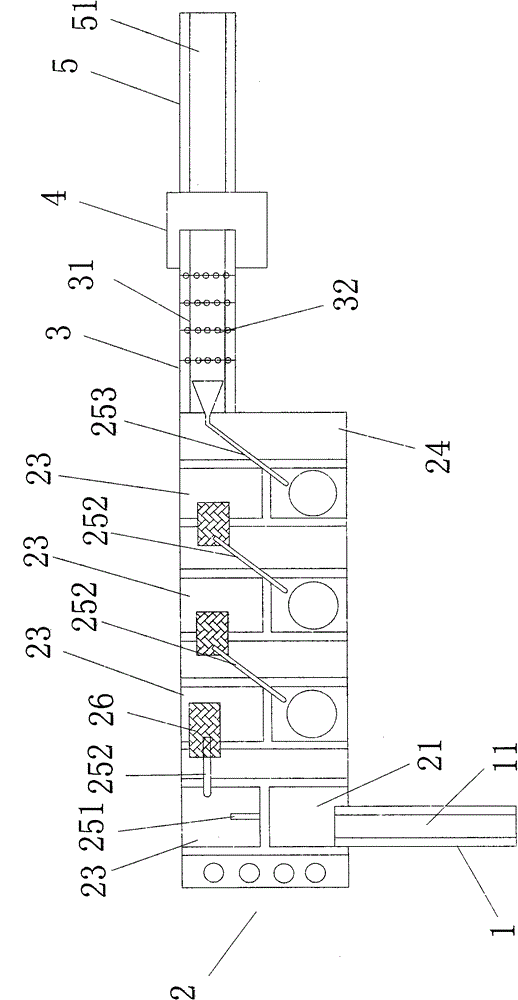

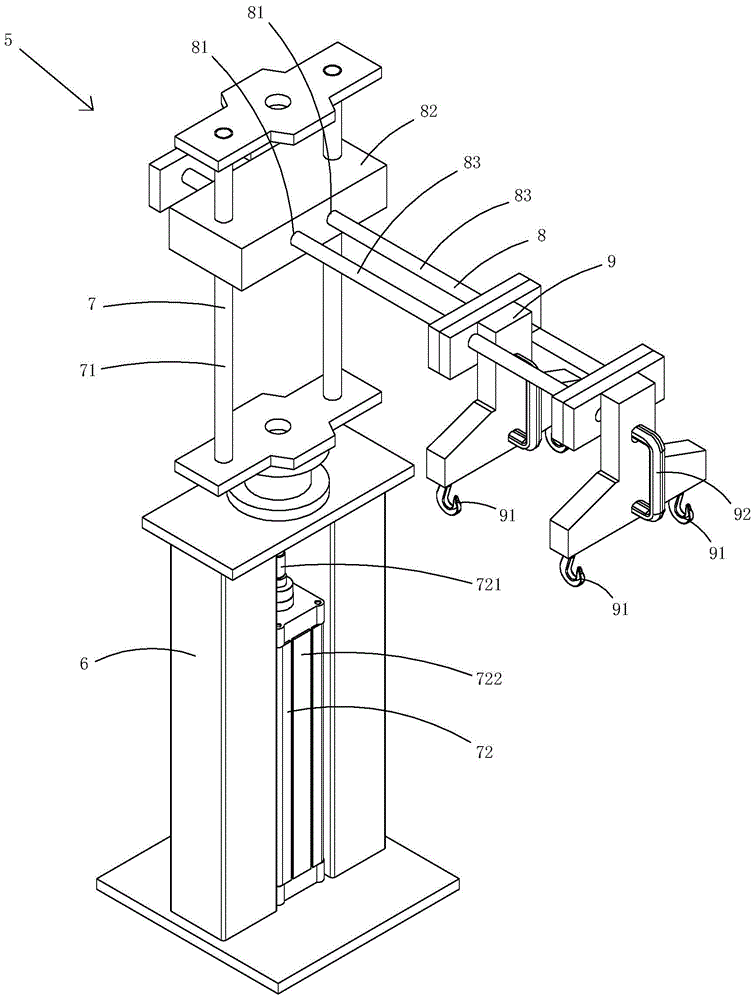

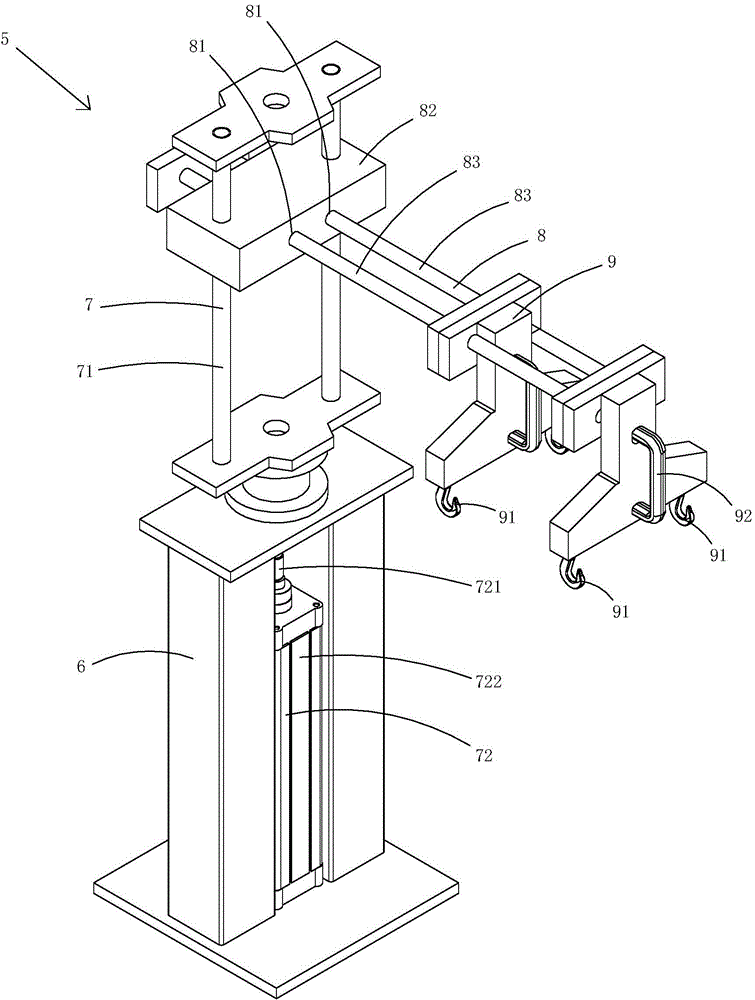

Combined automatic feeding machine tool

ActiveCN104084833AEasy to replaceEasy to realize industrialized continuous productionMilling machinesMetal working apparatusReciprocating motionEngineering

The invention discloses a combined automatic feeding machine tool comprising a machine tool body, hoppers, a hopper support arranged on the machine tool body, a material placement frame and a feeding device used for transferring the hoppers on the material placement frame to the hopper support. The feeding device comprises a feeding support, a lifting mechanism arranged on the feeding support in a rotating mode, a horizontally moving mechanism carrying out reciprocating motion in the horizontal direction, and a hooking mechanism used for hooking the hanging-connecting portion of each hopper. The lifting mechanism comprises lifting rods and a drive mechanism driving the lifting rods to move vertically, and the lifting rods are arranged on the feeding support in a rotating mode. The horizontally moving mechanism comprises a locating board and sliding rods, the locating board is provided with horizontal sliding holes and is arranged on the lifting rods, and the sliding rods can carry out reciprocating motion along the horizontal sliding holes. The hooking mechanism comprises hooks arranged on the sliding rods. As the feeding device used for transferring the hoppers on the material placement frame to the hopper support is arranged, the hoppers are replaced conveniently, and continuous industrial production is achieved easily.

Owner:南通新棉锦纺织品有限公司

Combined type automatic feeding machine tool with loading device

InactiveCN106041617AEasy to replaceEasy to realize industrialized continuous productionMilling machinesMetal working apparatusReciprocating motionHooking

The invention discloses a combined type automatic feeding machine tool with a loading device. The combined type automatic feeding machine tool comprises a machine tool body, hoppers, a hopper support, an accommodating frame and the loading device. The hopper support is arranged on the machine tool body, and the loading device is used for transferring the hoppers on the accommodating frame to the hopper support; the loading device comprises a loading support, a lifting mechanism, a translation mechanism and a hooking mechanism, the lifting mechanism is rotationally arranged on the loading support, the translation mechanism can reciprocate in the horizontal direction, and the hooking mechanism is used for hooking hanging portions of the hoppers; the lifting mechanism comprises lifting rods and a driving mechanism, and the lifting rods can be driven by the driving mechanism to move up and down and are rotationally arranged on the loading support; the translation mechanism comprises a positioning plate and slide rods, the positioning plate is arranged on the lifting rods, horizontal slide holes are formed in the positioning plate, and the slide rods can reciprocate along the horizontal slide holes; the hooking mechanism comprises hooks, and the hooks are arranged on the slide rods. The combined type automatic feeding machine tool has the advantages that the combined type automatic feeding machine tool comprises the loading device for transferring the hoppers on the accommodating frame to the hopper support, accordingly, the hoppers can be conveniently replaced, and industrial continuous production can be facilitated.

Owner:申清章

Combined automatic feeding machine tool capable of achieving hopper replacement

InactiveCN106041616AEasy to replaceEasy to realize industrialized continuous productionMilling machinesMetal working apparatusReciprocating motionEngineering

The invention discloses a combined automatic feeding machine tool capable of achieving hopper replacement. The machine tool comprises a machine tool body, a hopper, a hopper support, a feeding rack and a feeding device. The hopper support is arranged on the machine tool body, and the feeding device is used for transferring the hopper on the feeding rack to the hopper support. The feeding device comprises a feeding support, a lifting mechanism rotationally arranged on the feeding support, a translation mechanism doing reciprocating motion in the horizontal direction, and a hooking mechanism for hooking the hanging portion of the hopper. The lifting mechanism comprises a lifting rod and a driving mechanism for driving the lifting rod to do vertical motion. The lifting rod is rotationally arranged on the feeding support. The translation mechanism comprises a locating plate and a sliding rod, the locating plate is arranged on the lifting rod and provided with a horizontal sliding hole, and the sliding rod can do reciprocating motion along the horizontal sliding hole. The hooking mechanism comprises a hook arranged on the sliding rod. Due to the fact that the combined automatic feeding machine tool is provided with the feeding device for transferring the hopper on the feeding rack to the hopper support, the hopper can be conveniently replaced, and industrial continuous production can be achieved easily.

Owner:申清章

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com