Combined type automatic feeding machine tool with loading device

An automatic feeding and combined technology, applied in milling machines, milling machine equipment, manufacturing tools, etc., can solve the problems of non-detachable hoppers, cumbersome disassembly and maintenance, and difficulty in automatic loading and unloading of materials, so as to achieve industrialized continuous production and convenient replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

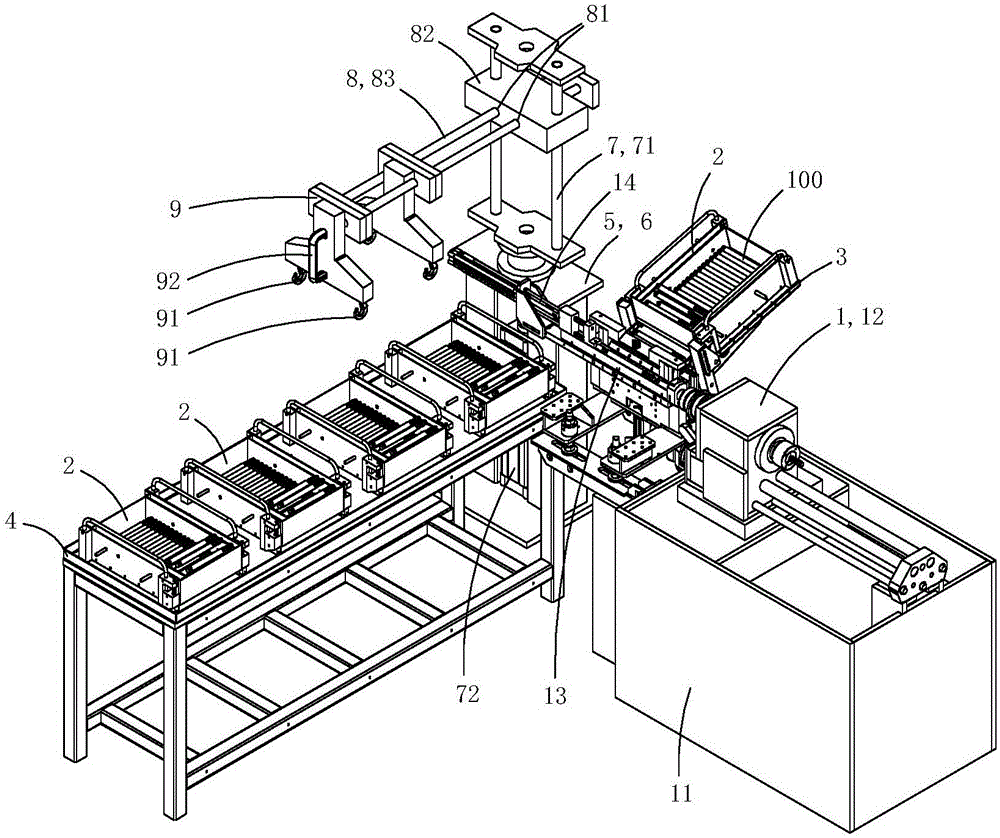

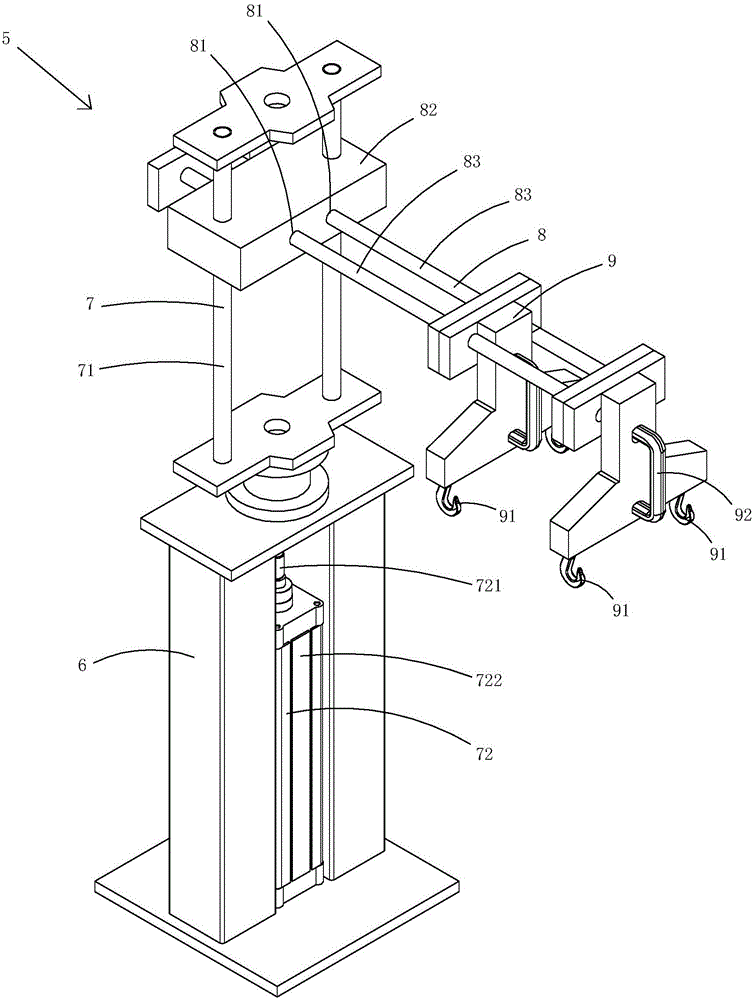

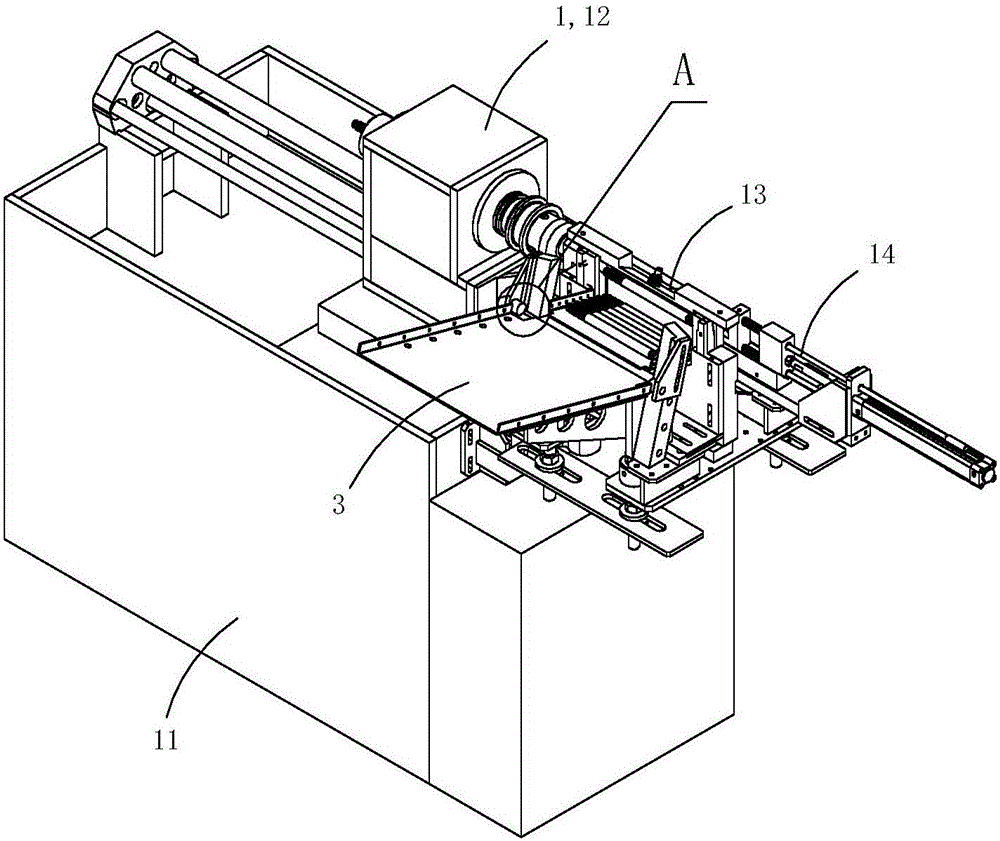

[0015] Figure 1 to Figure 8 A specific embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 A schematic diagram of a three-dimensional structure of the feeding device in the machine tool shown; image 3 for figure 1 A schematic diagram of the three-dimensional structure of the machine tool shown after removing the feeding device, unloading rack and hopper; Figure 4 for image 3 Partial enlarged schematic diagram of A; Figure 5 for figure 1 A schematic diagram of a three-dimensional structure of the hopper in the machine tool shown; Figure 6 for Figure 5 A top view of the hopper shown; Figure 7 for Figure 5 A schematic cross-sectional structure of the hopper shown; Figure 8 for Figure 7 A schematic diagram of the structure of the shown hopper resting on the hopper support.

[0016] Present embodiment is a kind of combined automatic feeding machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com