Patents

Literature

886results about "Granular material drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

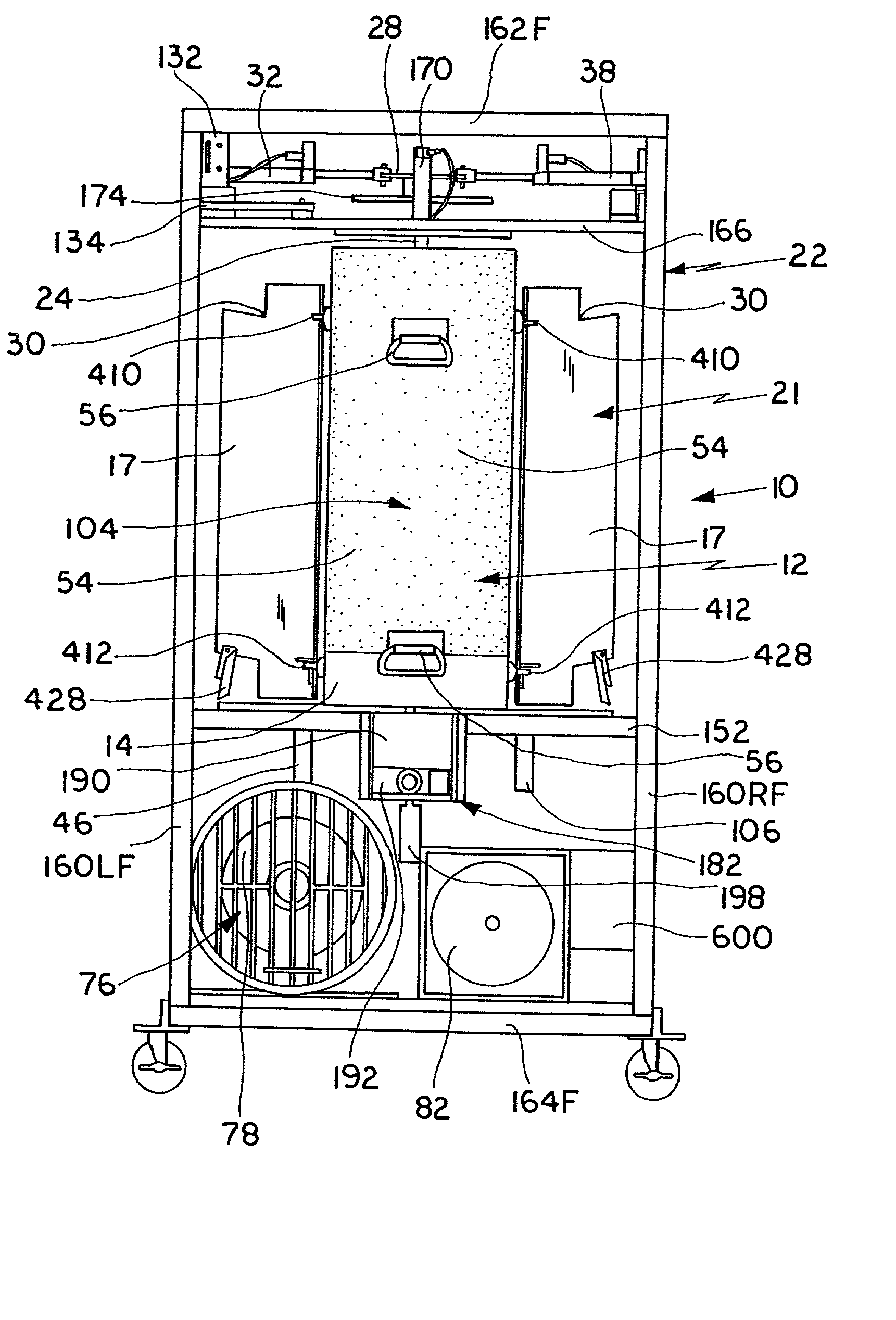

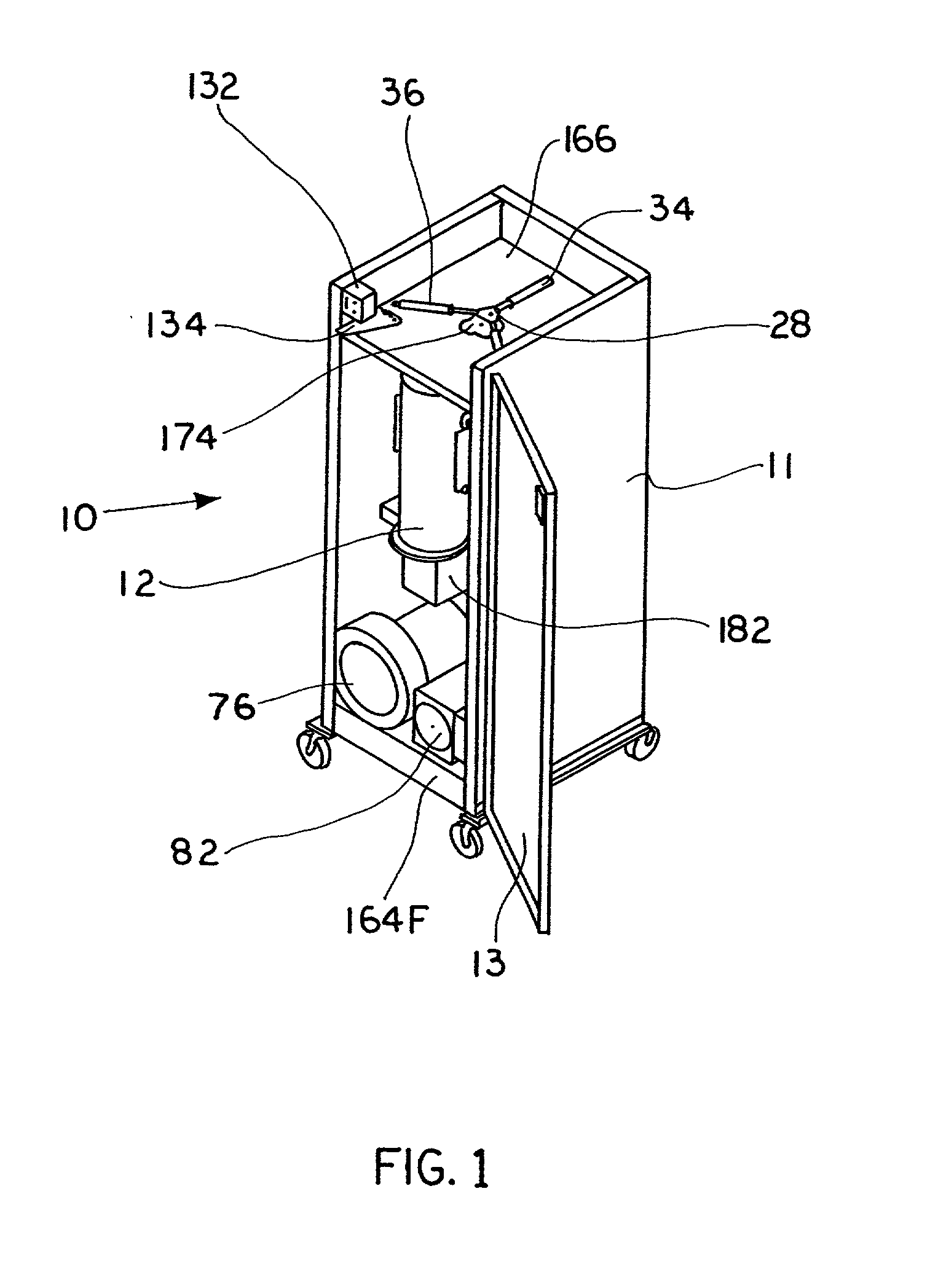

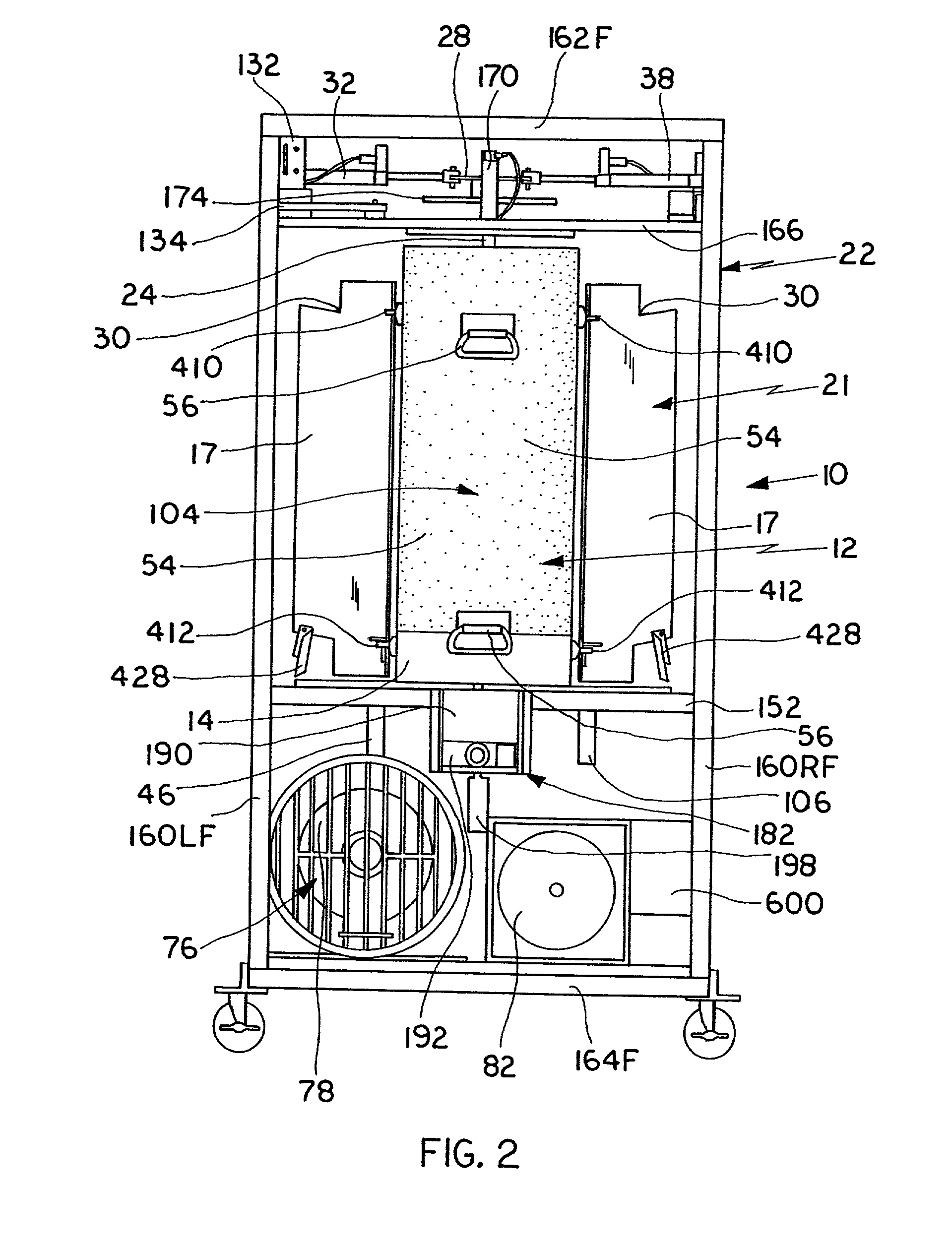

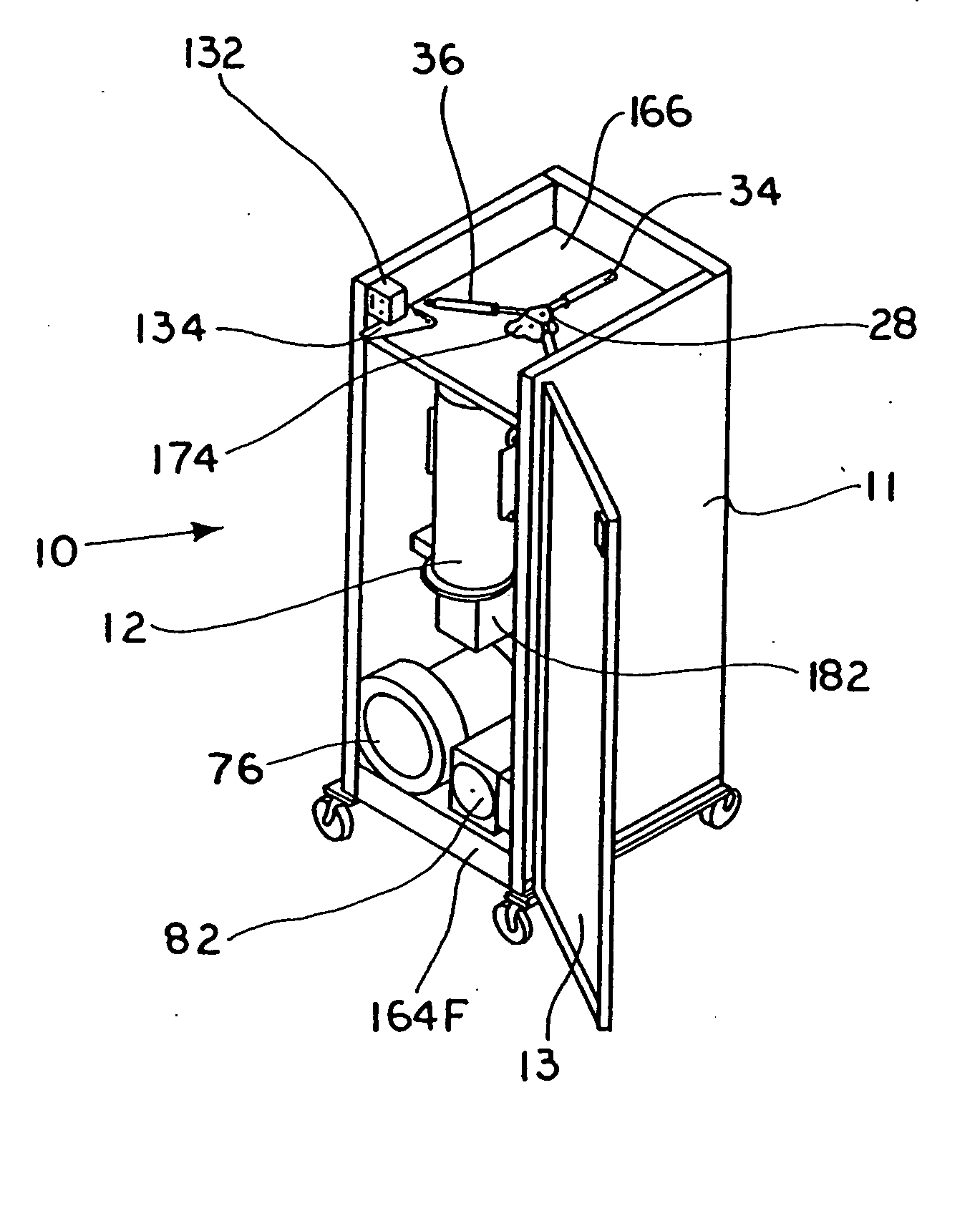

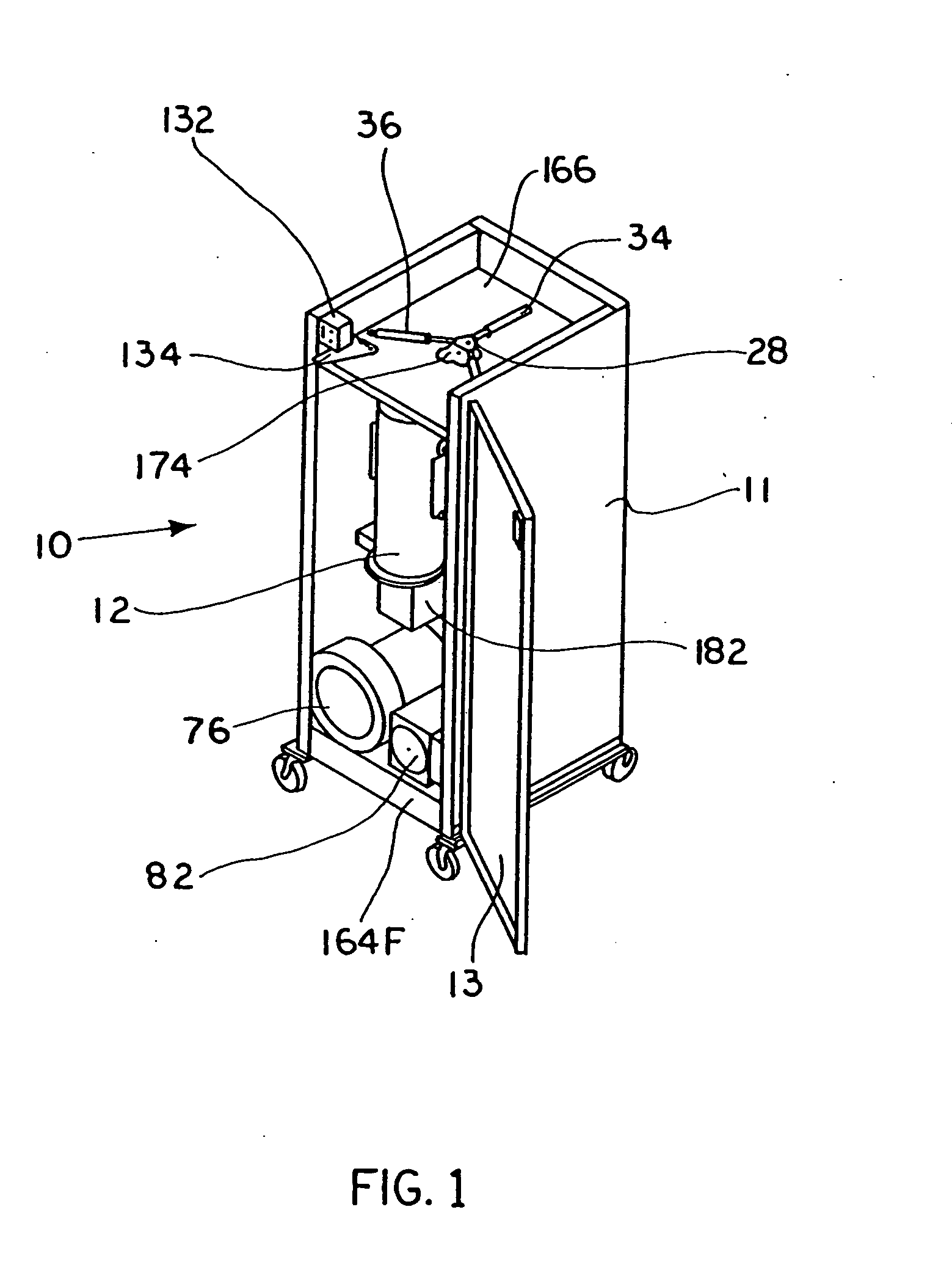

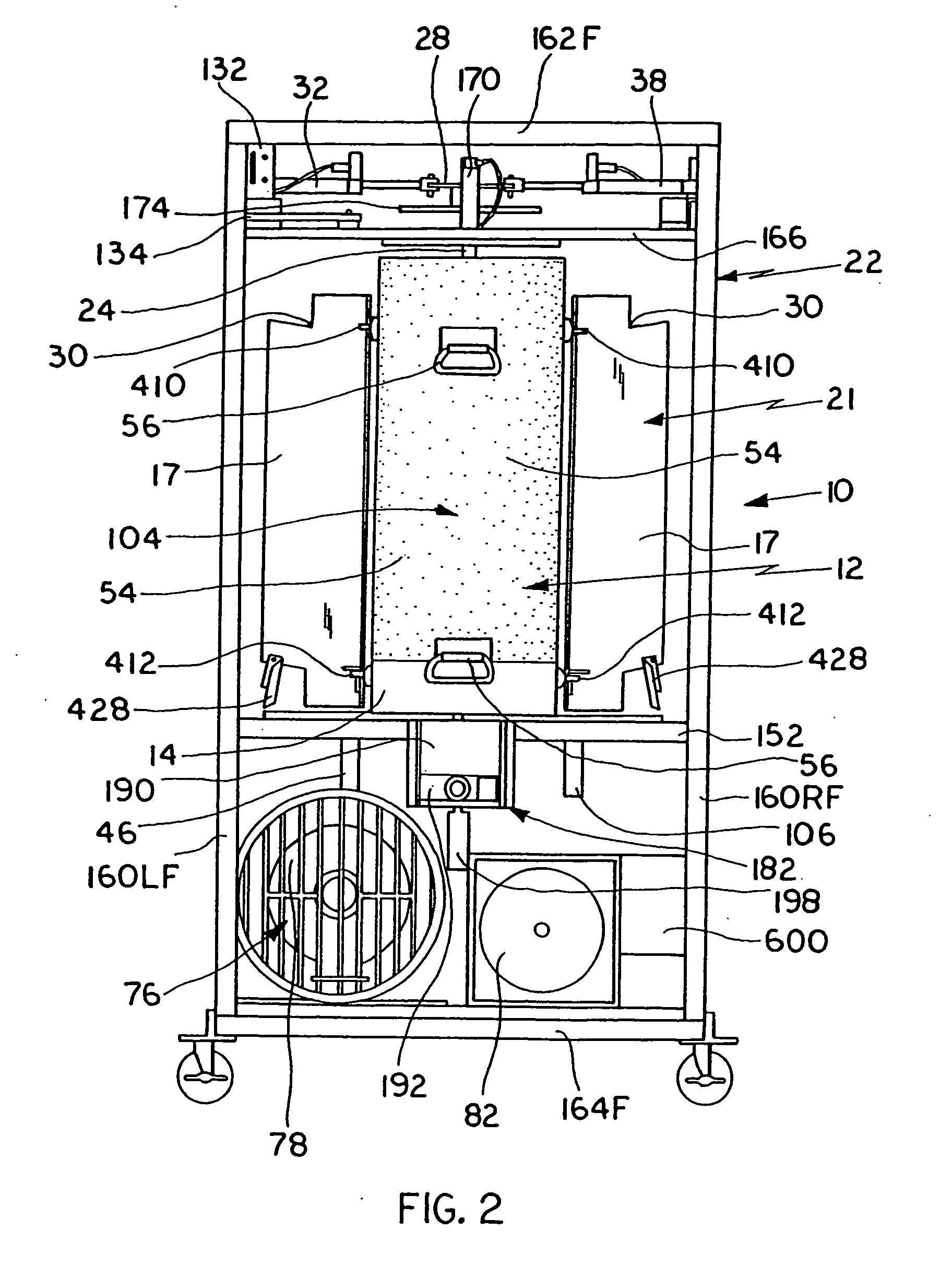

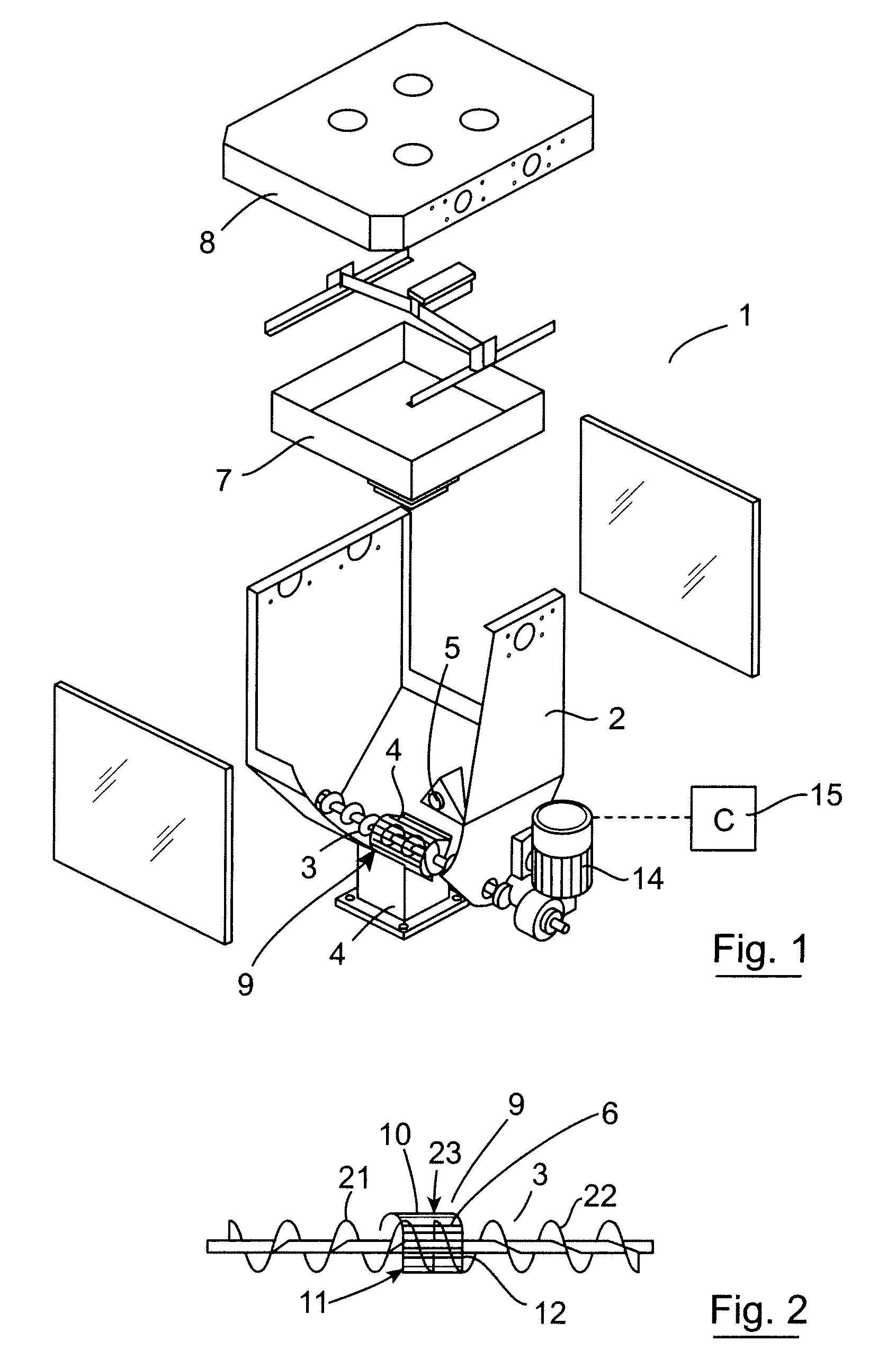

Low pressure dryer

InactiveUS20020024162A1Granular material dryingDough-sheeters/rolling-machines/rolling-pinsThermodynamicsEngineering

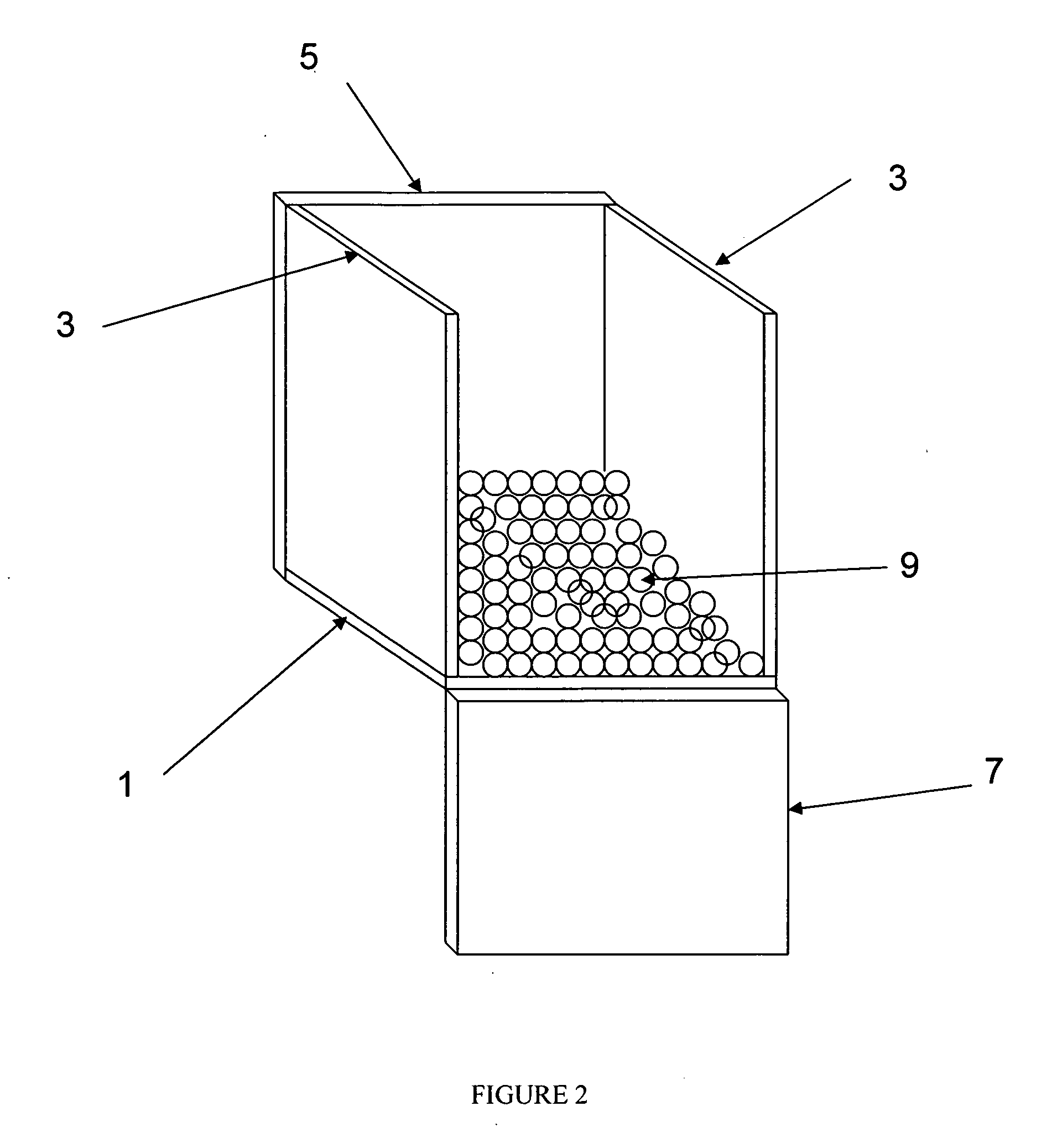

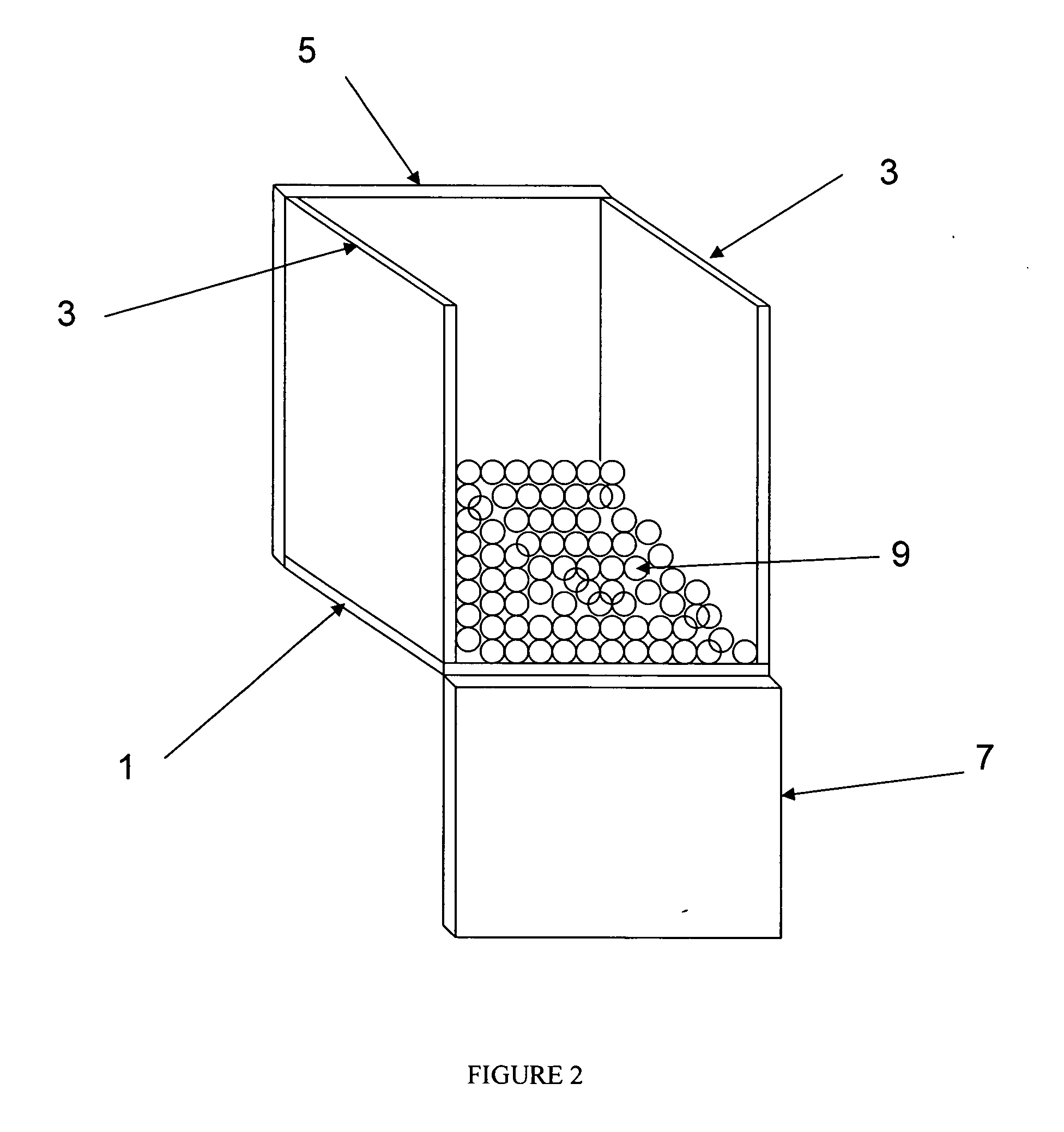

A low pressure dryer for granular or powdery material includes a plurality of canisters rotatable about a common vertical axis serially among material heating, vacuum drying and material inventory discharge positions; pneumatic piston-cylinder means for rotating the canisters about said axis among said heating, vacuum drying and inventory discharge positions; means for heating contents of a canister at said heating position; means for sealing and drawing vacuum within a canister at said vacuum drying position and means for selectably permitting downward flow of dried granular or powdery material out of a canister at said discharge position where said canisters move collectively and unitarily one with another.

Owner:MAGUIRE STEPHEN B

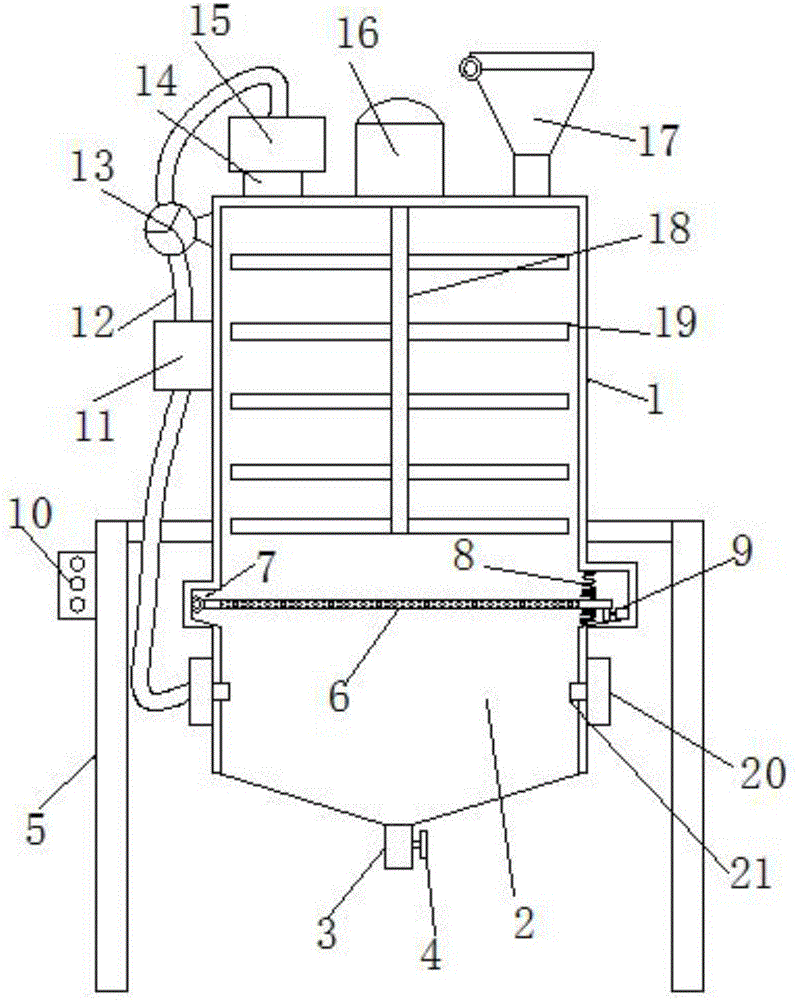

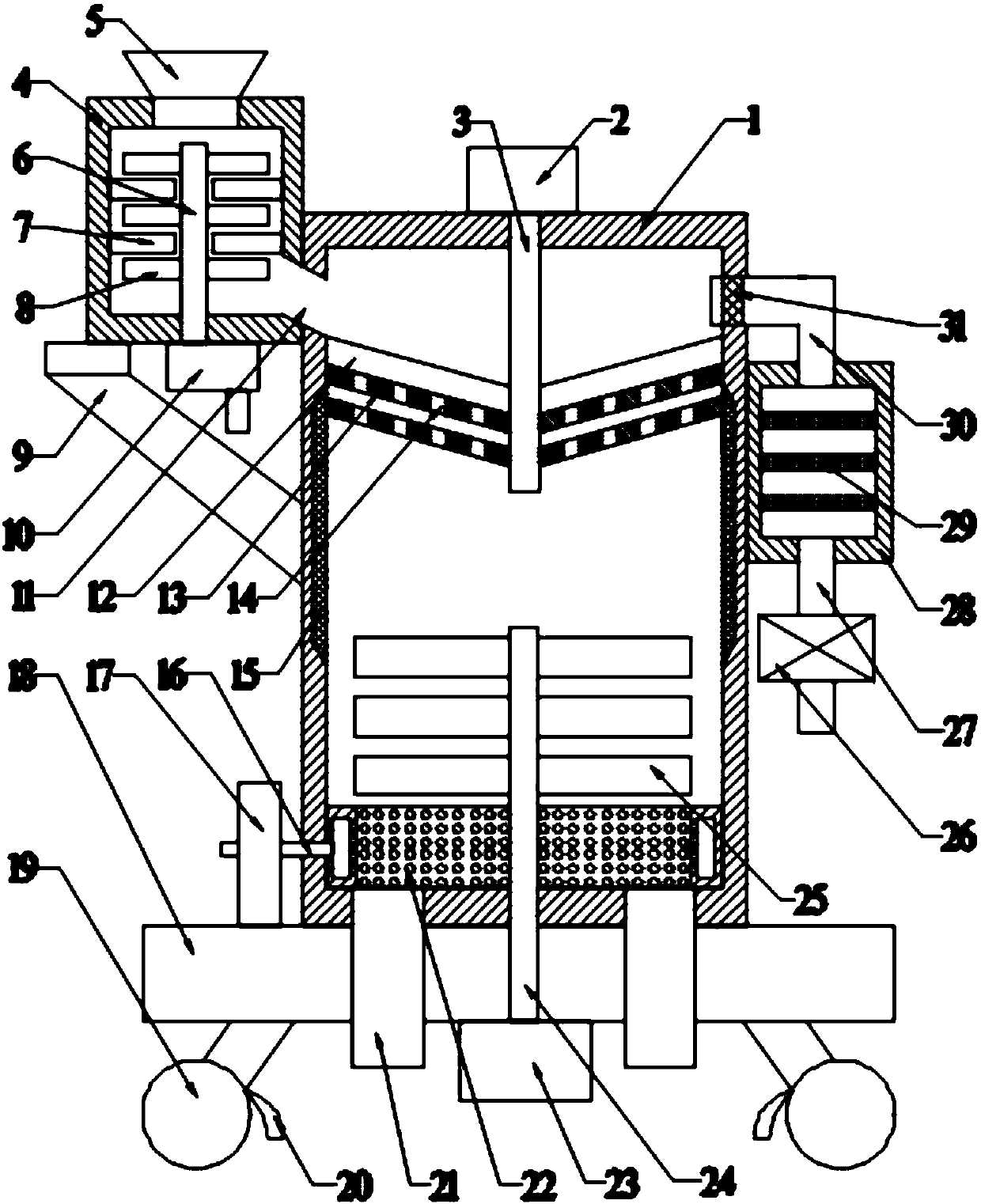

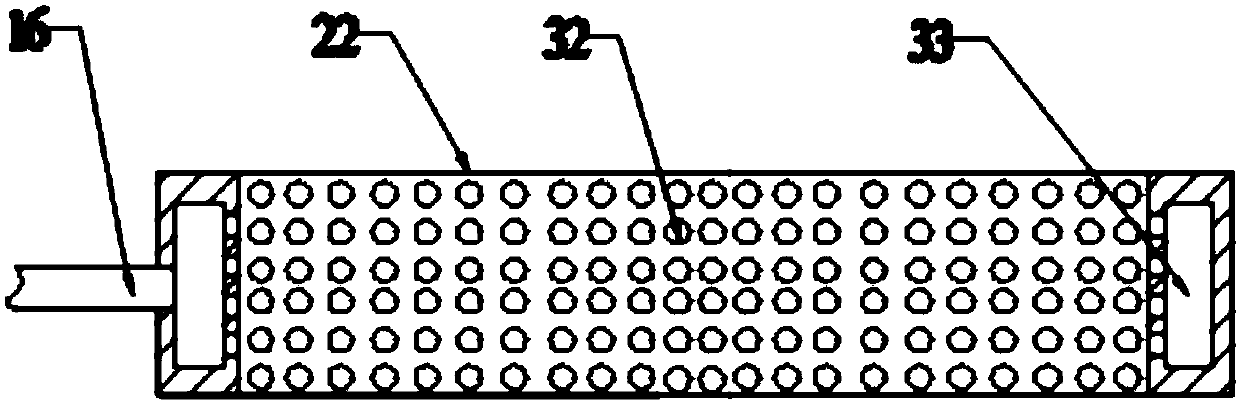

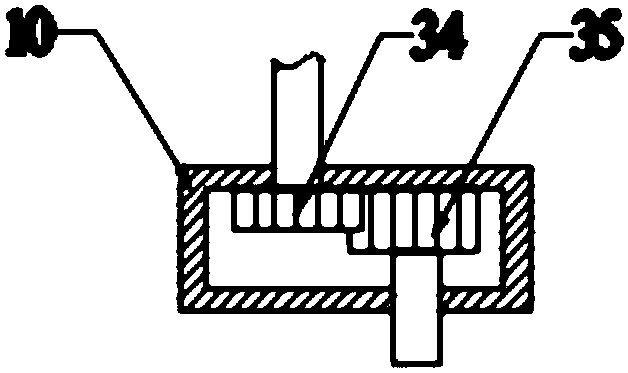

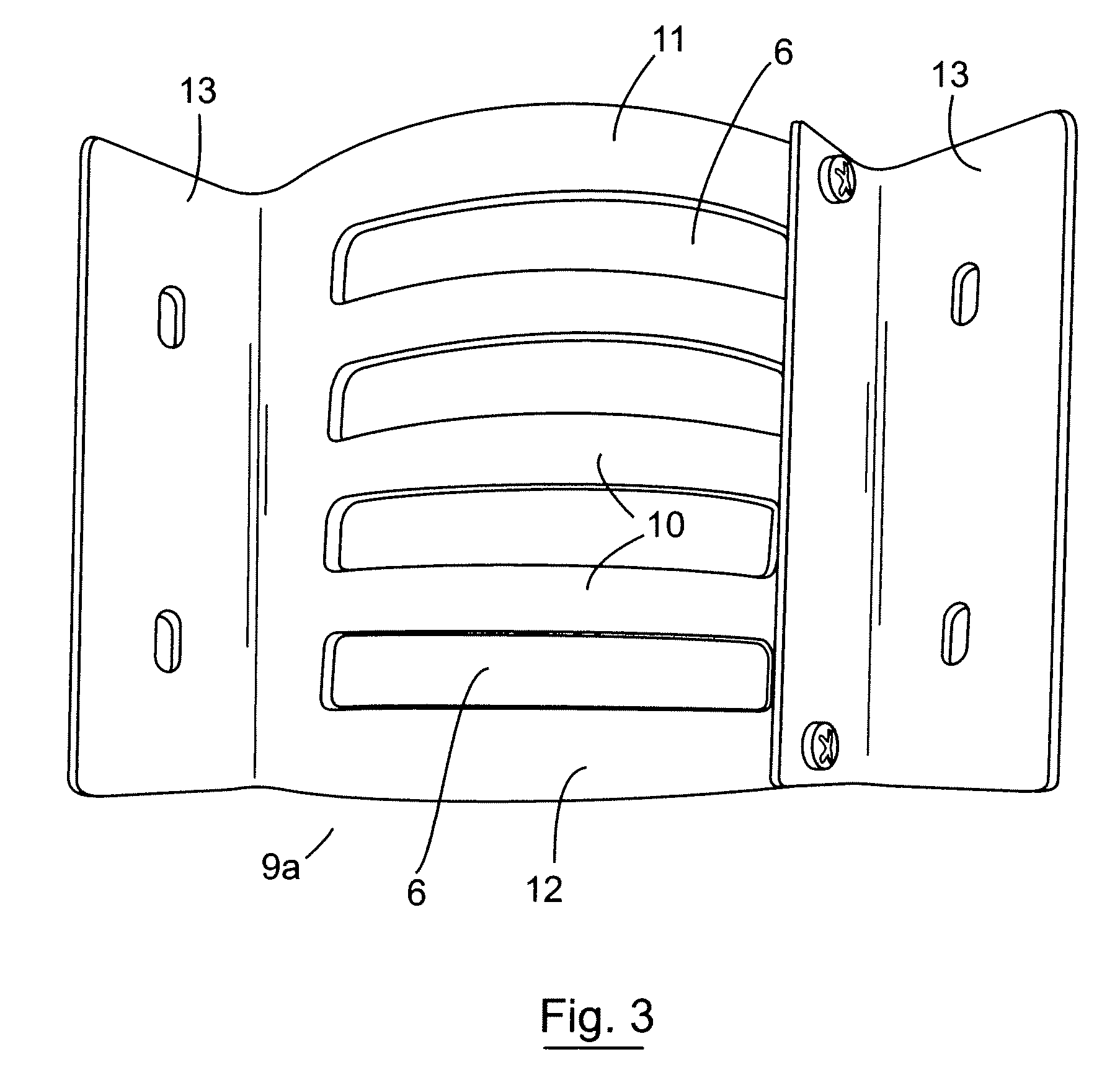

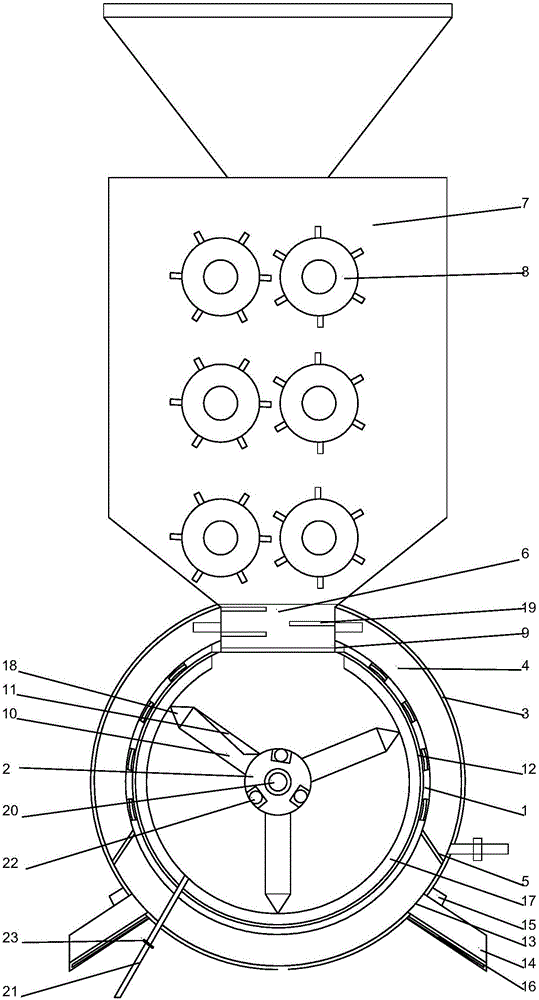

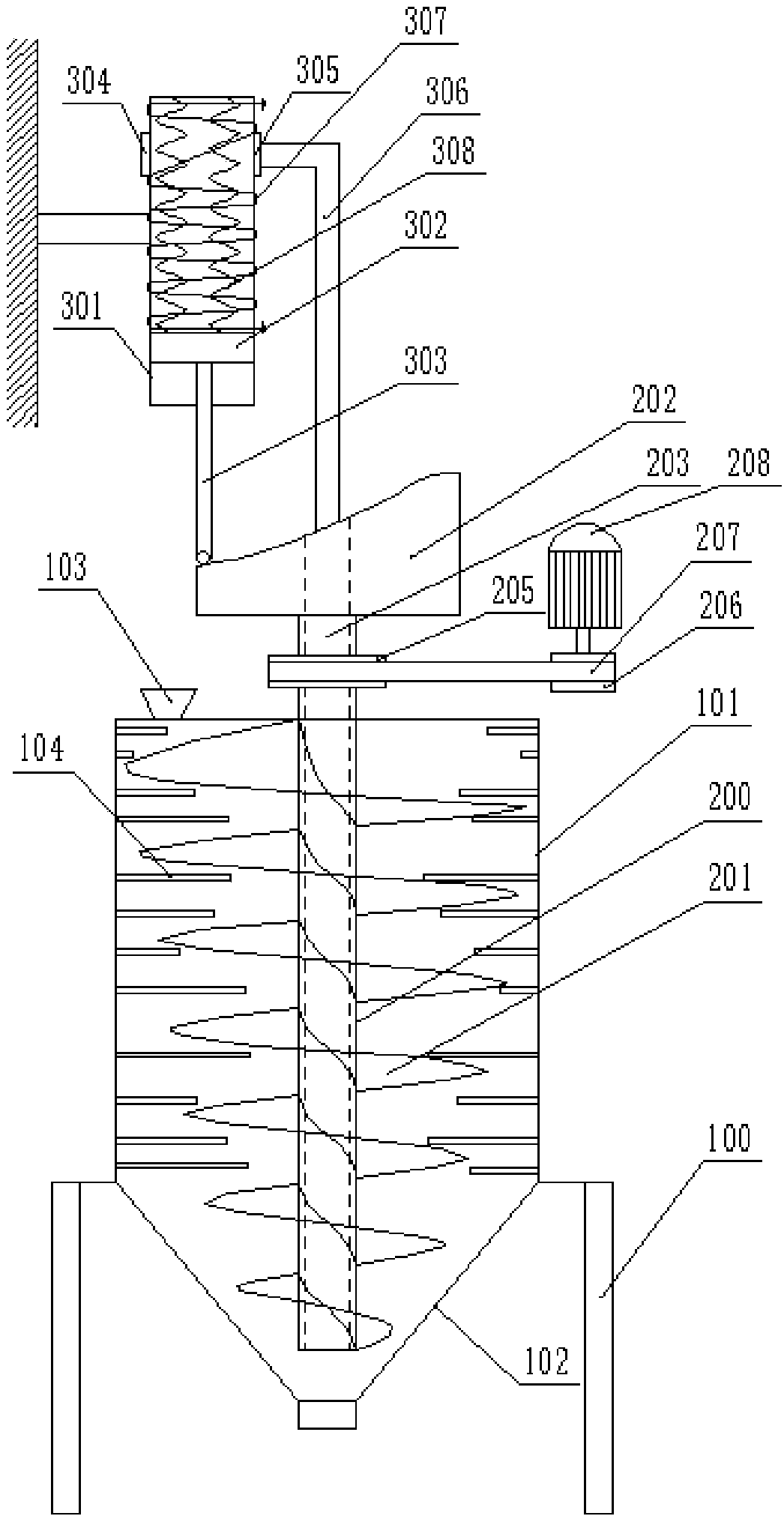

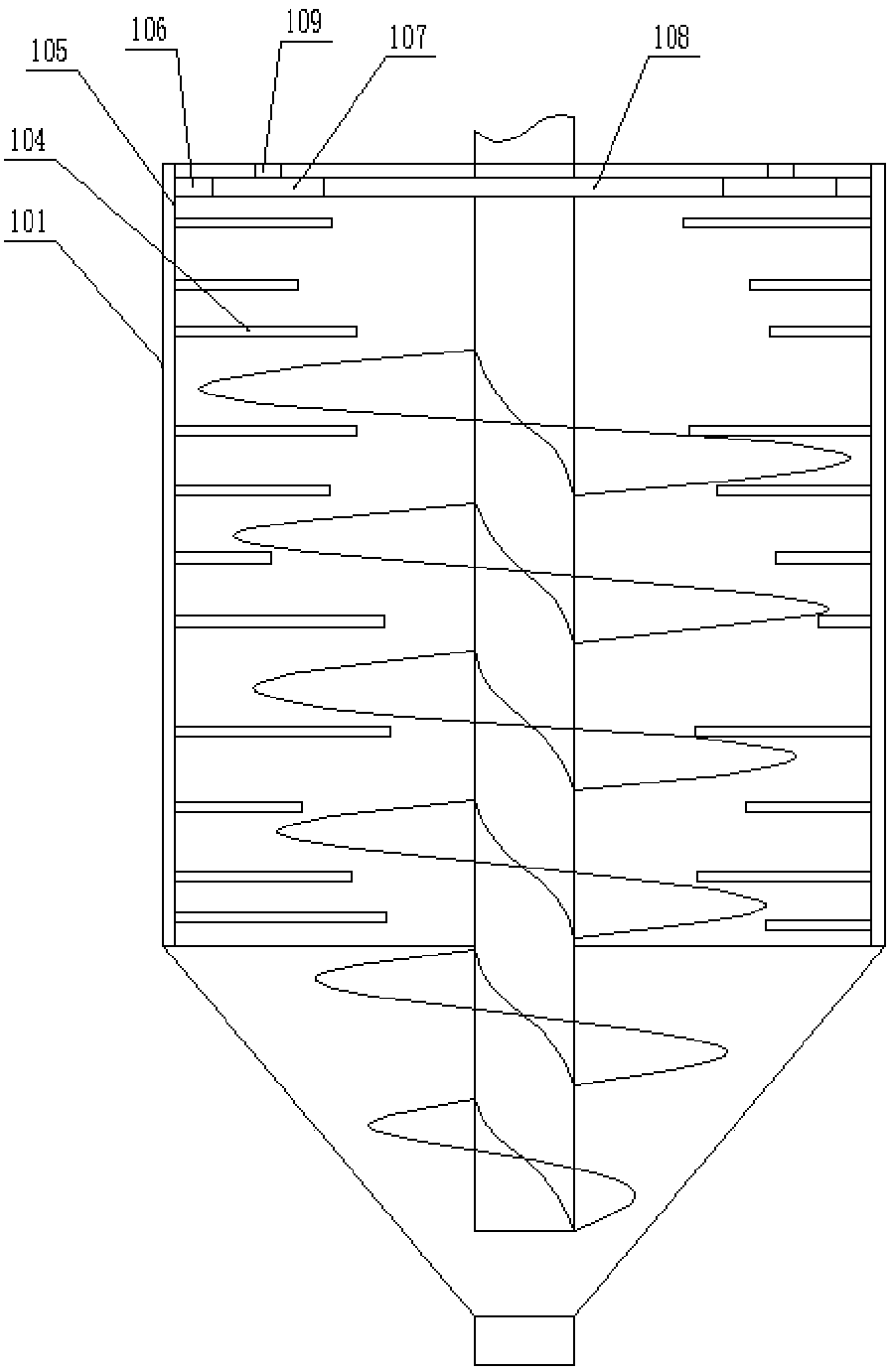

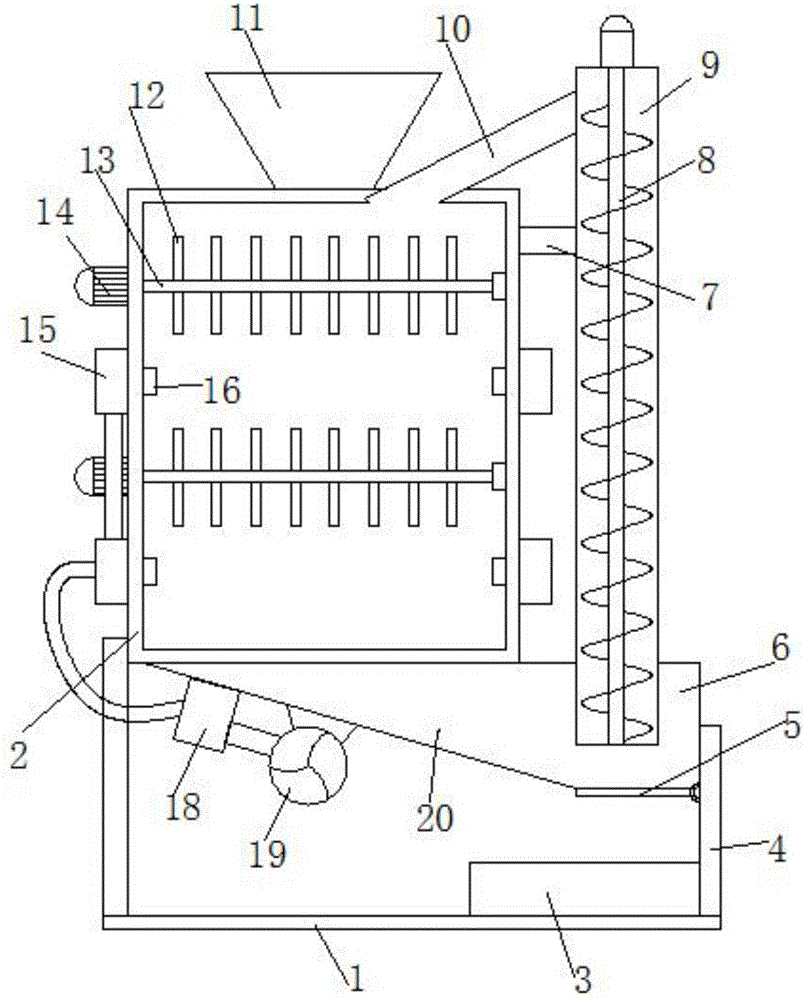

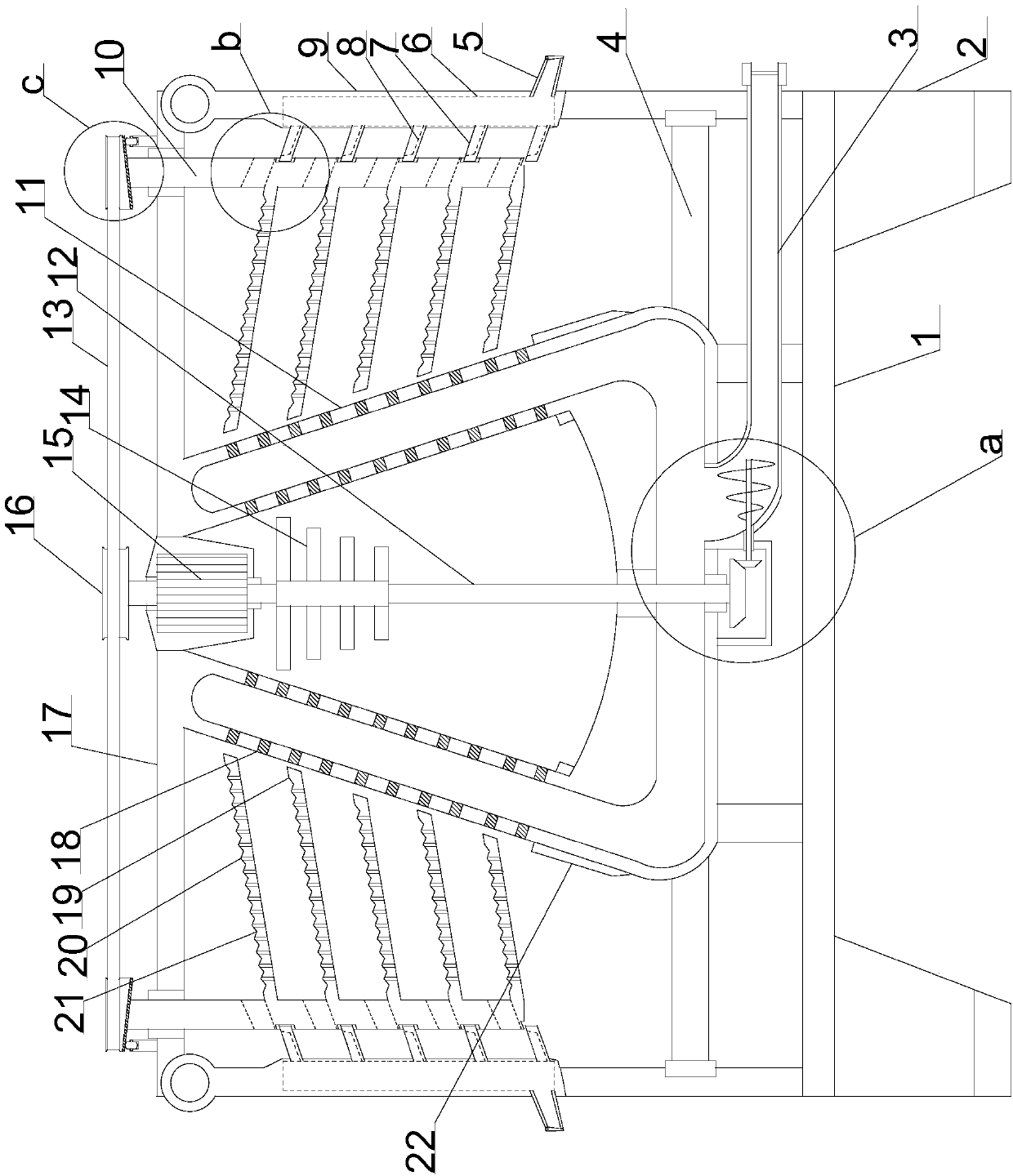

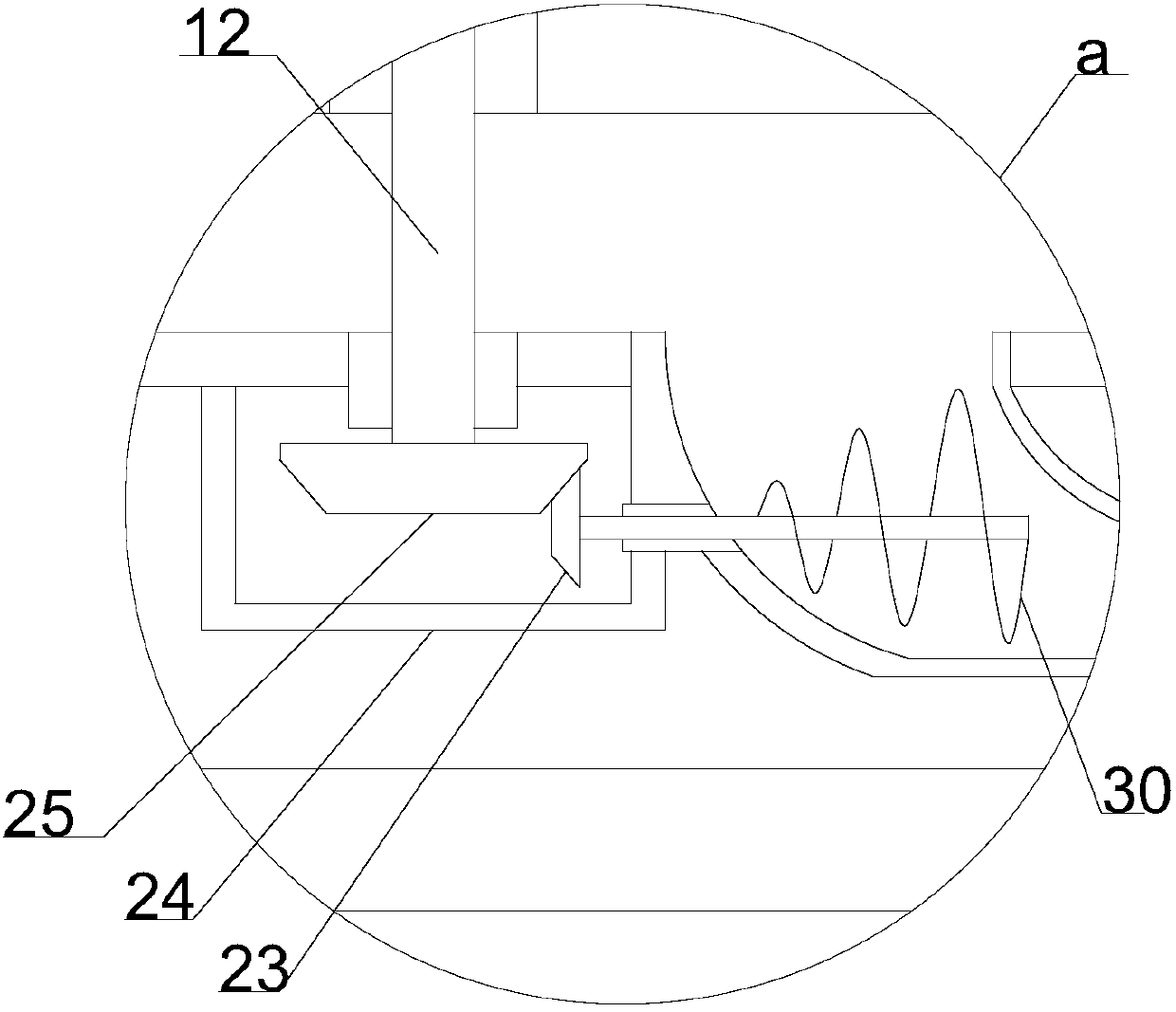

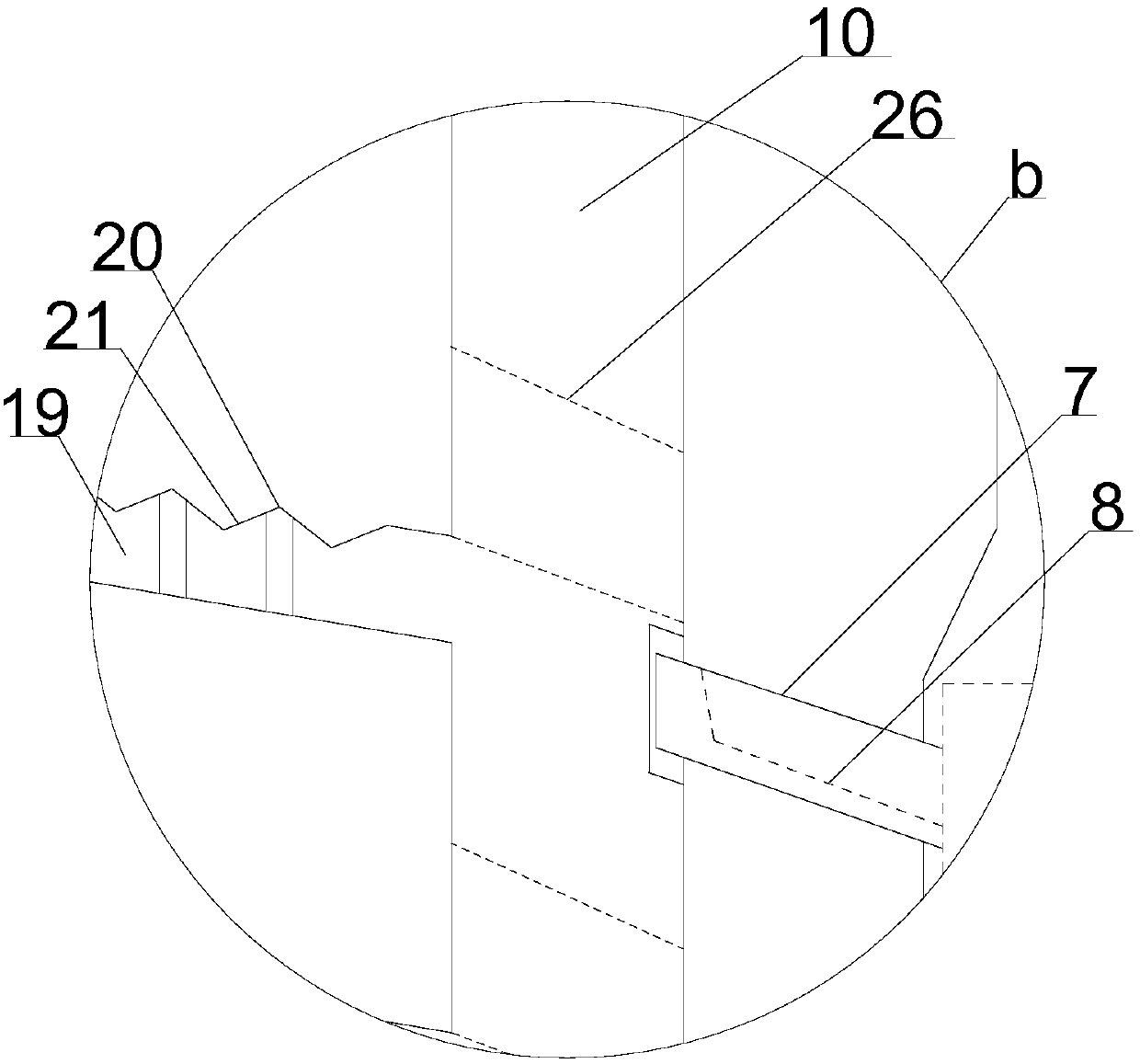

Improved traditional Chinese medicine smashing and drying device

InactiveCN106311415AAchieve recyclingHelp break upSievingDrying solid materials with heatDrive shaftEngineering

The invention discloses an improved traditional Chinese medicine smashing and drying device which comprises a smashing box and a drying box, and is characterized in that the smashing box and the drying box are cylindrical barrel bodies; supporting legs are symmetrically arranged on the left and right sides of the smashing box; a lower end opening of the smashing box is connected with the drying box; a conical hopper is arranged at the lower end of the drying box; a smashing motor is arranged at the middle position of the top of the smashing box; a driving shaft is arranged at the output end of the smashing motor; a smashing knife is arranged on the driving shaft; a mounting cavity is arranged on the outer side of the smashing box below the driving shaft; a screen plate with screening holes in the surface is horizontally arranged in the mounting cavity; the left end of the screen plate is fixed on the inner wall of the mounting cavity in a rotatable manner; the right end of the screen plate is fixed in the mounting cavity on the right side through a reset spring; and a driving motor is arranged in the mounting cavity where the right end of the screen plate is placed. The improved traditional Chinese medicine smashing and drying device is simple and reasonable in structure and good in drying effect, and can save energy and reduce discharge; and the shortcomings of the existing device are eliminated, and the practicability of the device is improved.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

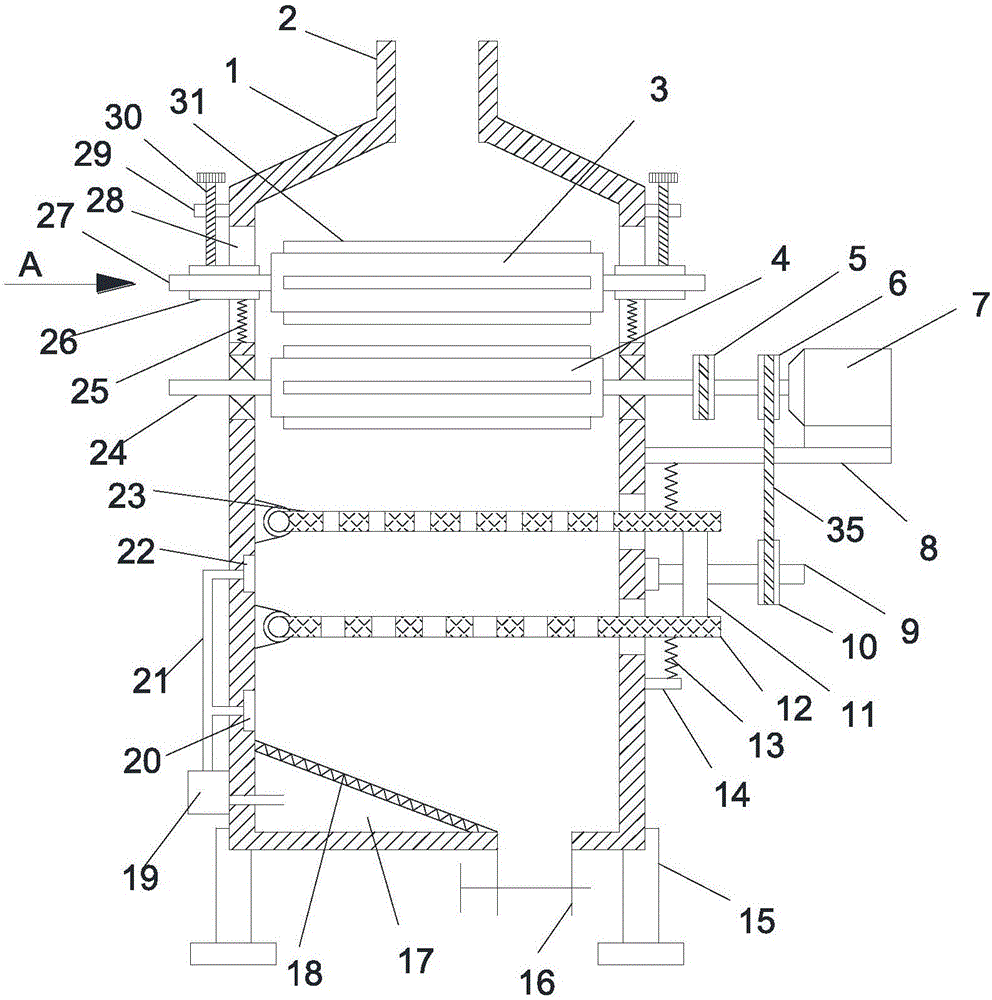

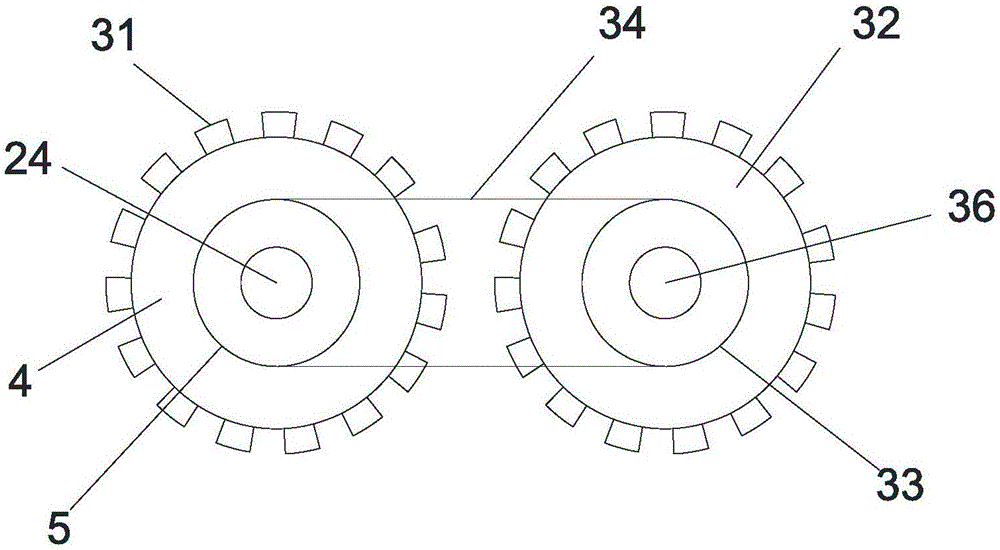

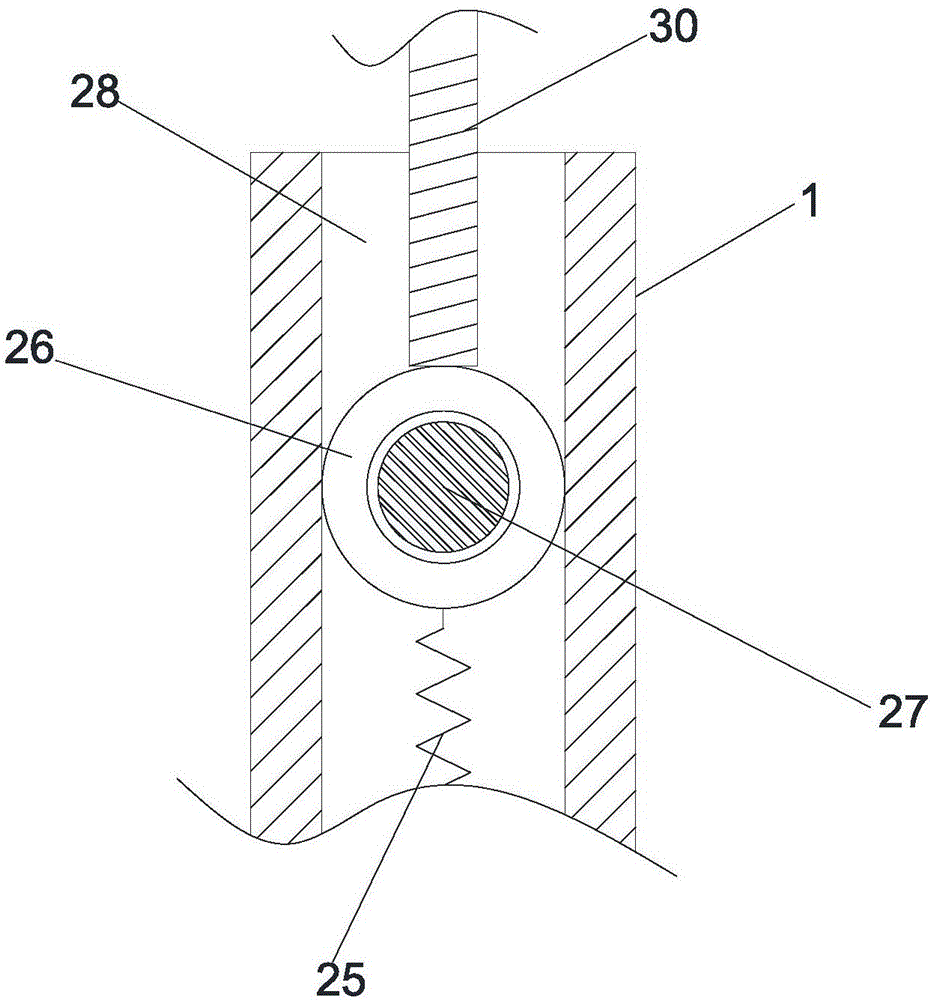

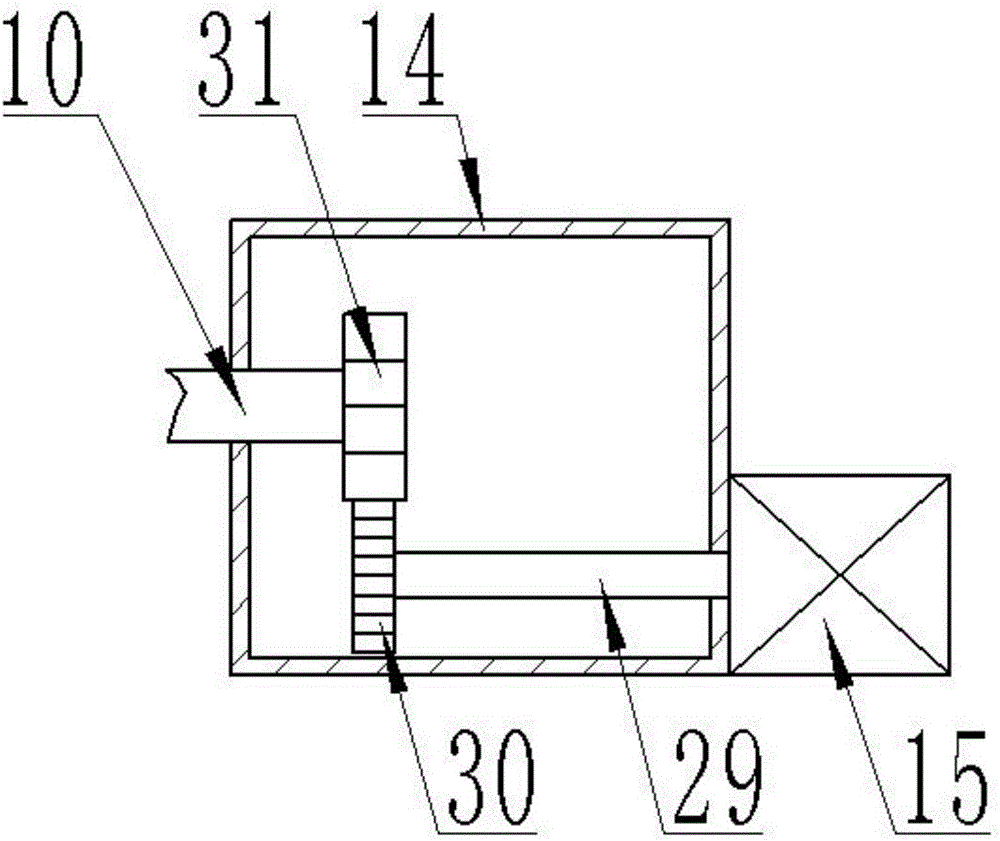

Rice hulling device with screening function

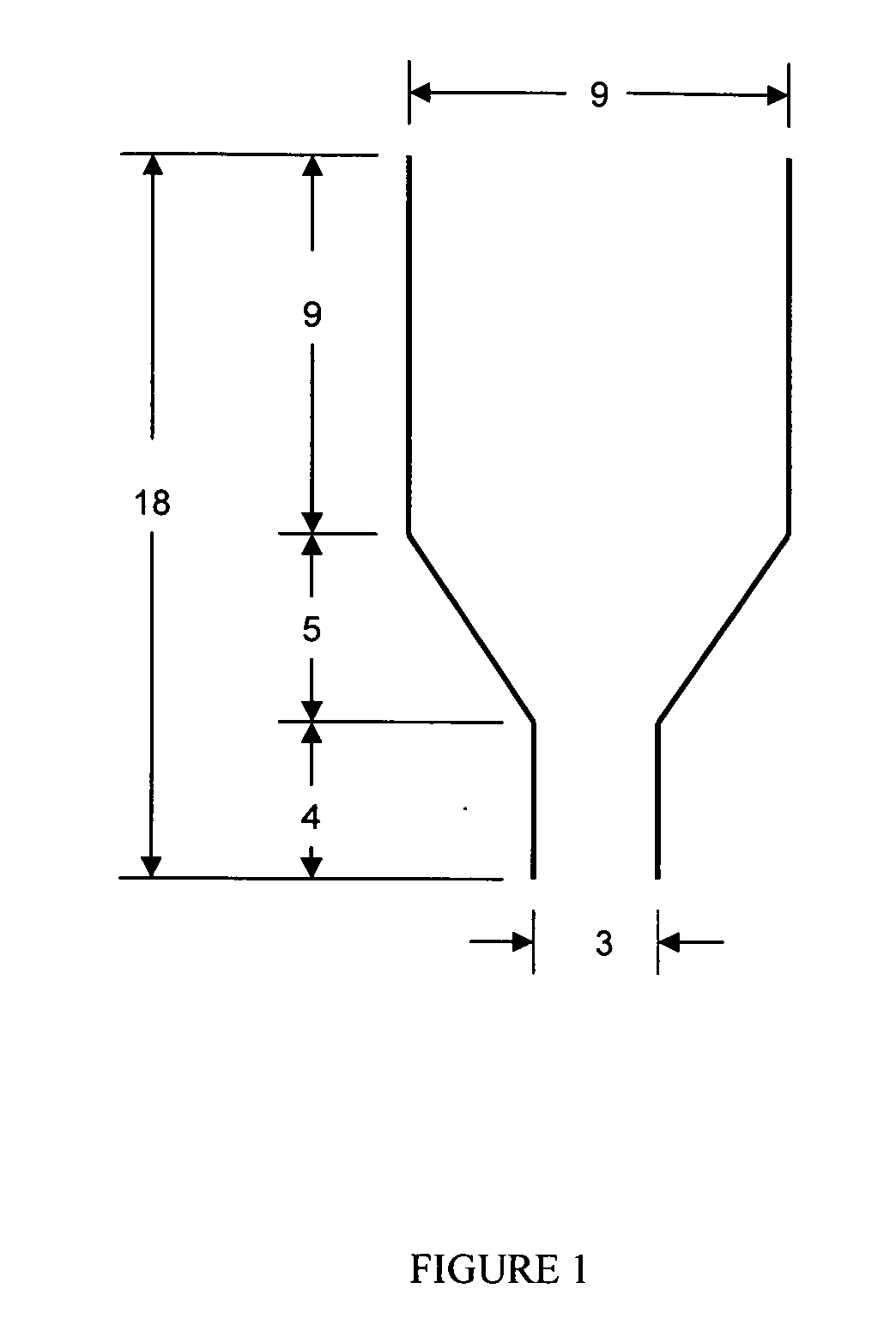

The invention discloses a rice hulling device with a screening function. The device comprises a hulling box; a feeding pipe is fixedly mounted at the top of the hulling box; a limiting plate is arranged on the side wall of the hulling box, and is in vertical threaded connection with a lead screw; a support plate is fixedly mounted on the right side wall of the hulling box; a driving motor is fixedly mounted on the support plate; a driven shaft parallel to a driving shaft is rotationally arranged in the hulling box; and a second driving belt wheel is fixedly mounted on the driving shaft. The device is convenient to hull and screen rice, low in workload and high in efficiency, rotationally hulls the rice through rotation of an adjusting pressure roller, a first hulling rotating roller and a second hulling rotating roller, greatly improves the rice hulling efficiency, and realizes quick hulling of the rice; and the up-down position of the adjusting pressure roller can be adjusted through a rotating lead screw, so that the position adjustment of the adjusting pressure roller and the first hulling rotating roller and the second hulling rotating roller is realized, the hulling extrusion acting force is increased, and the rice hulling is more thorough.

Owner:安徽林胜农业科技有限公司

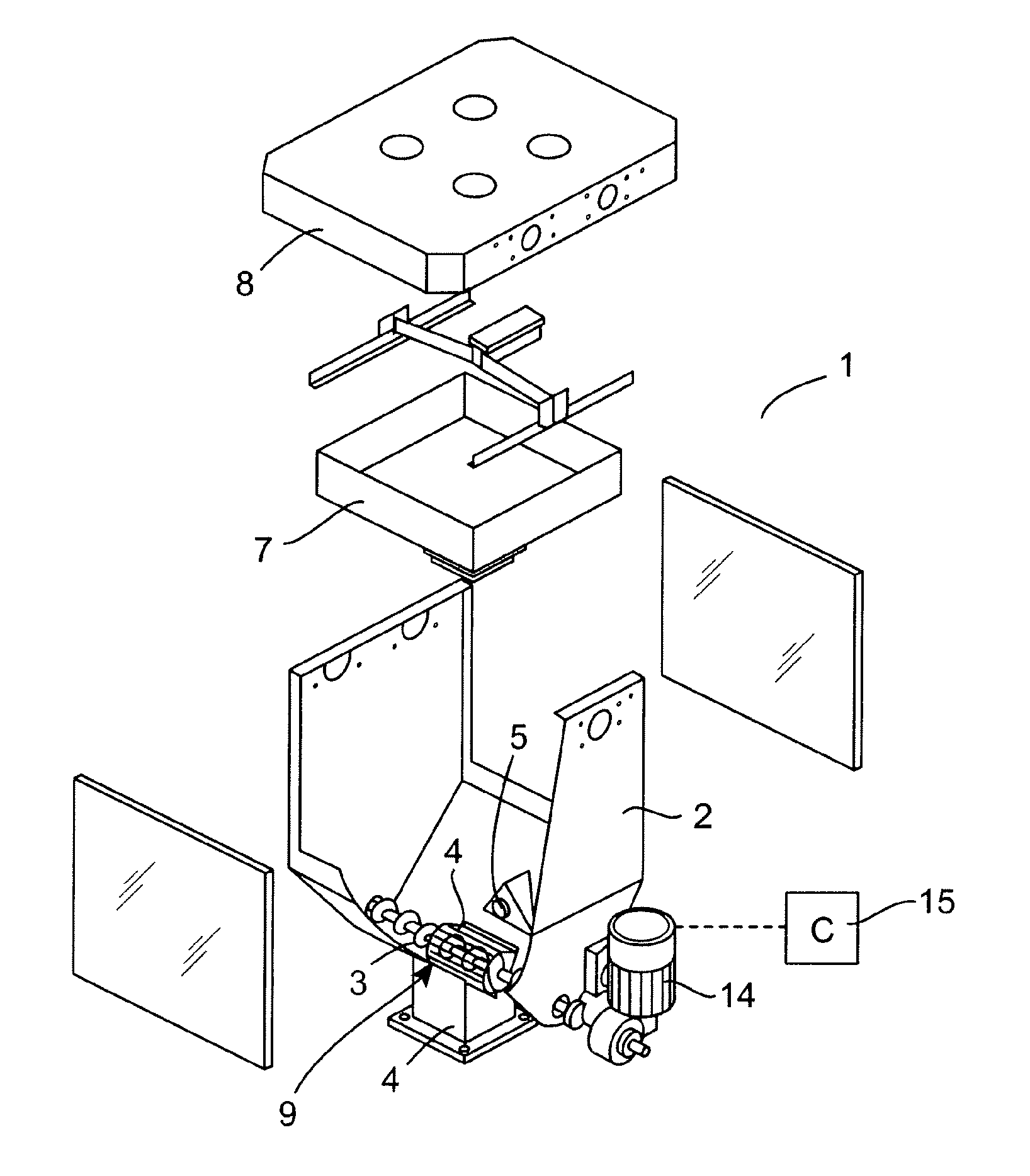

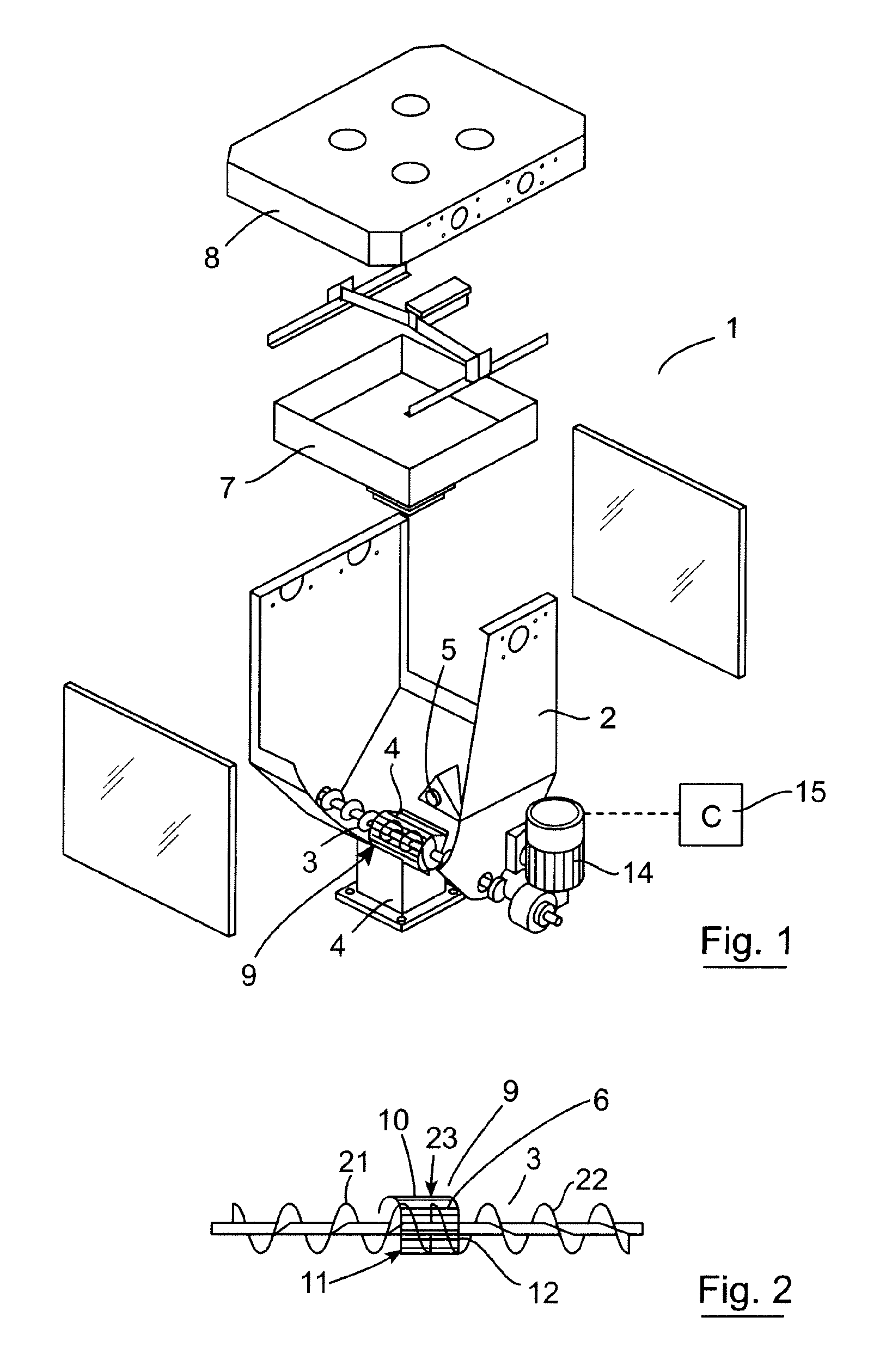

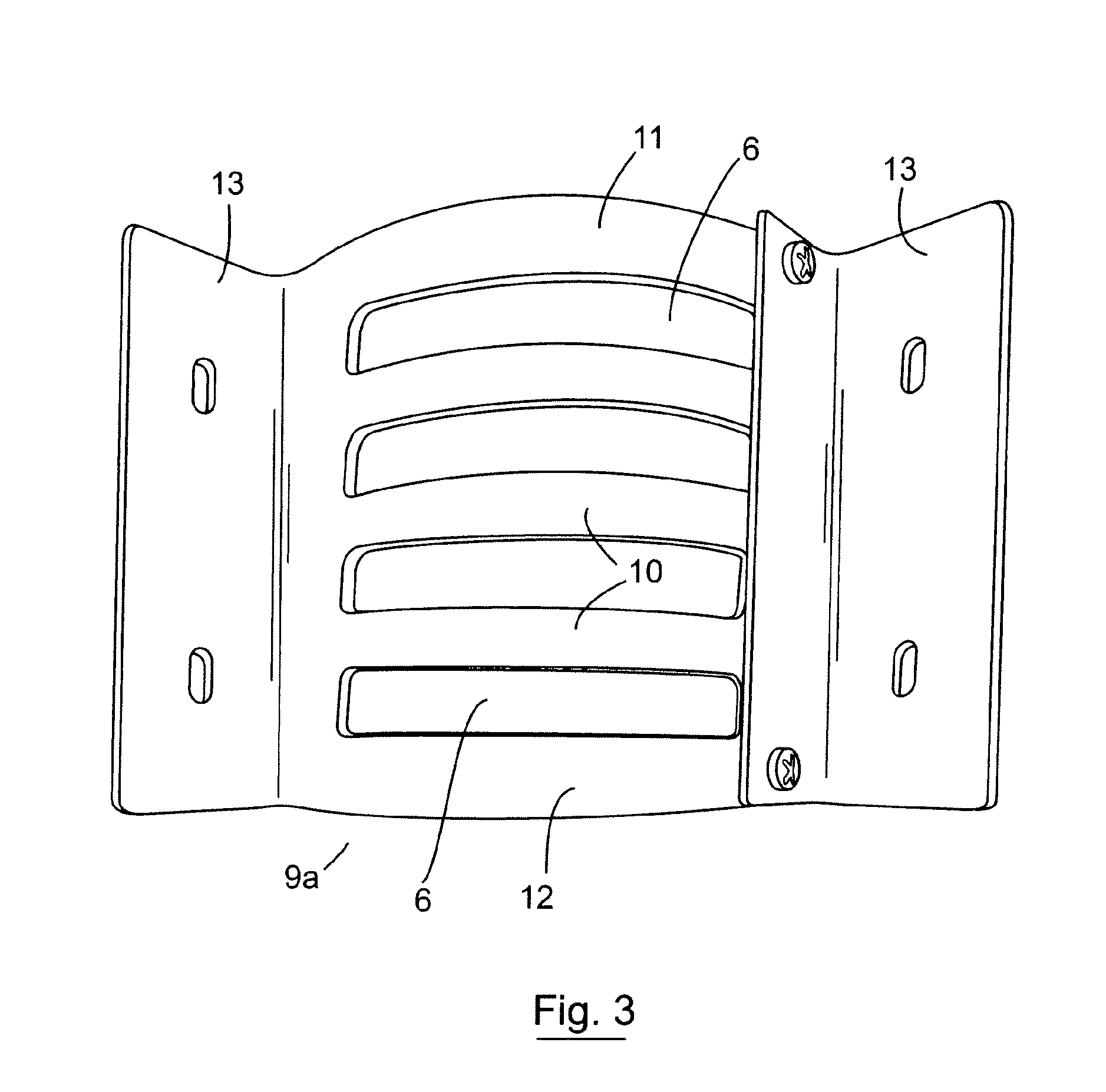

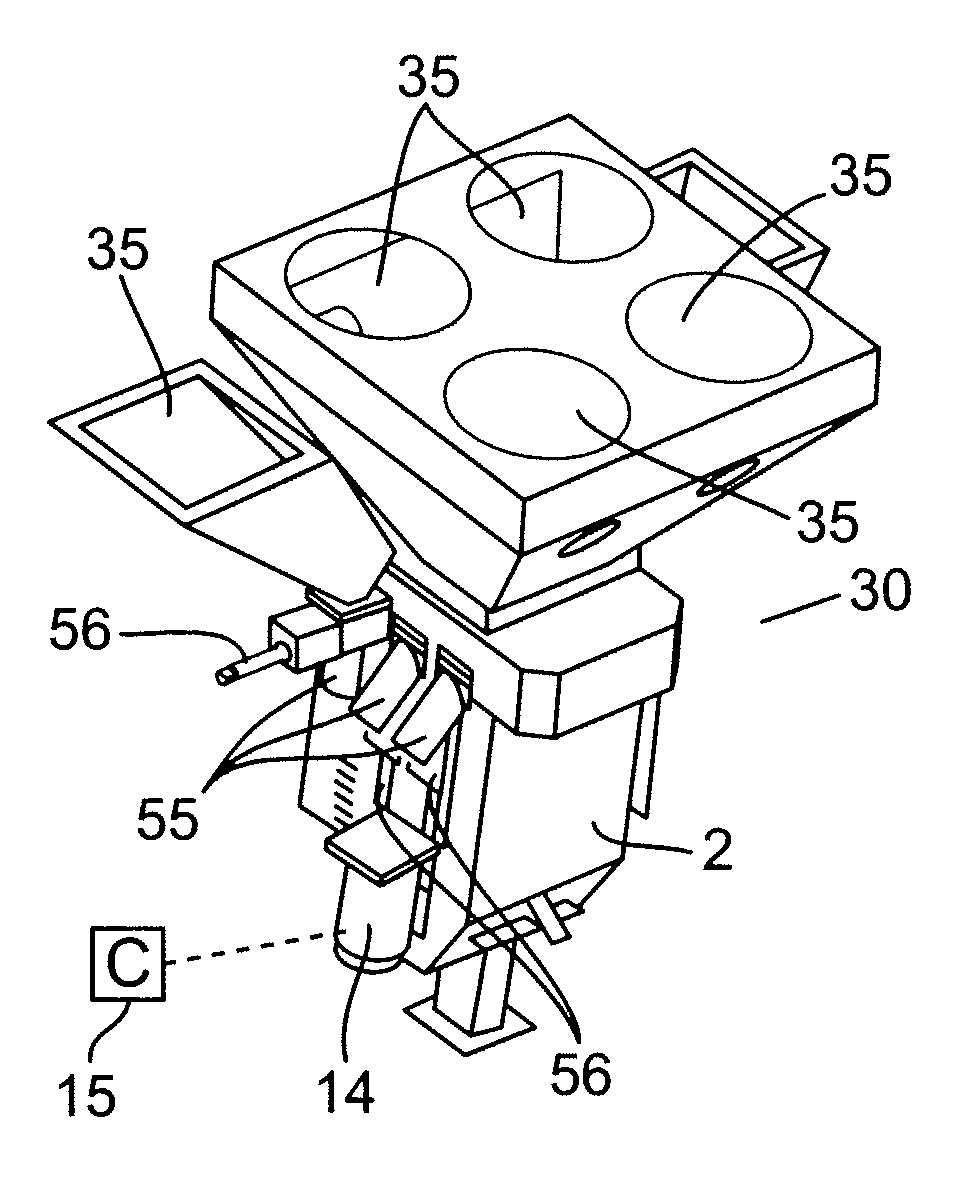

Blenders

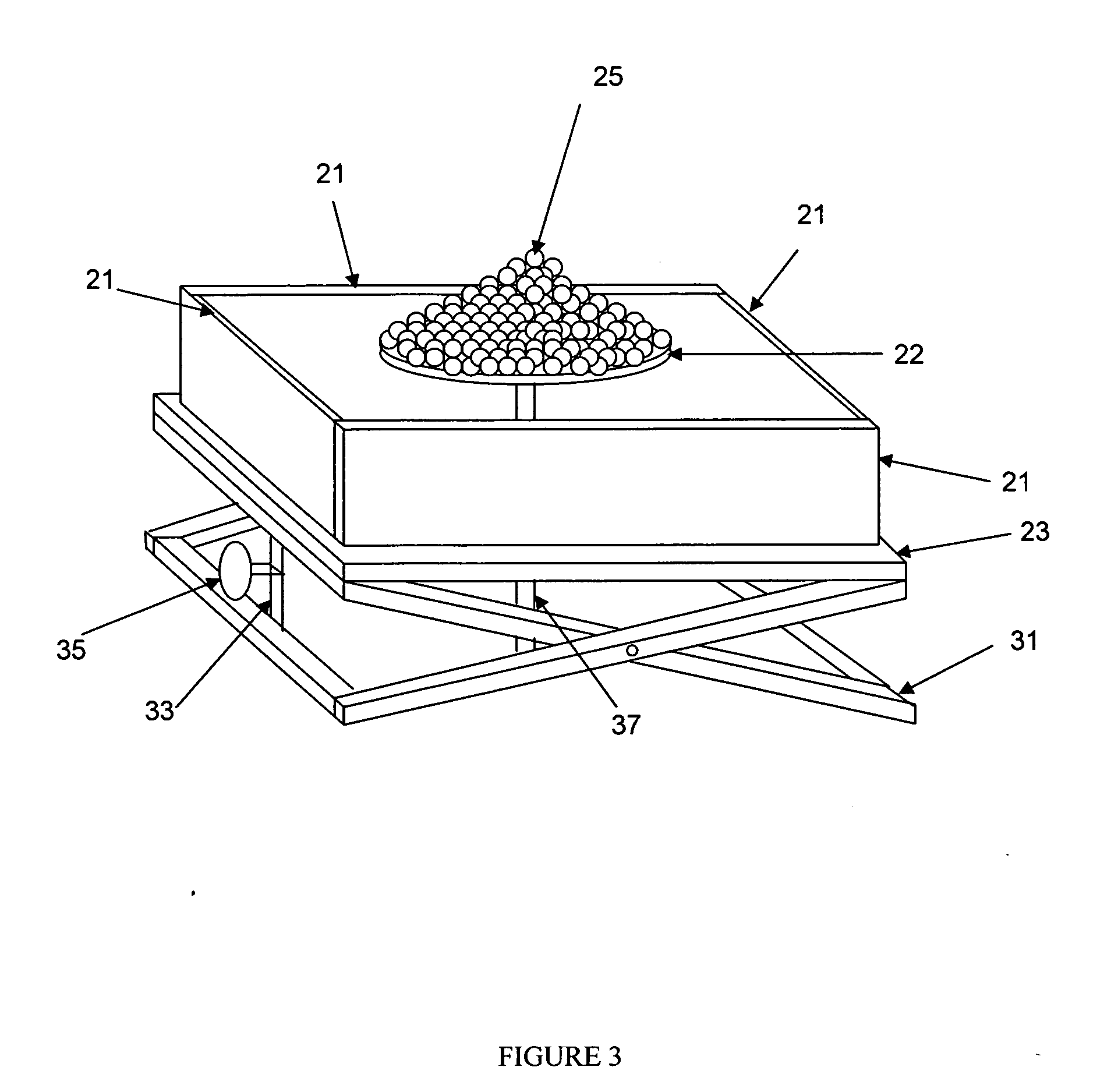

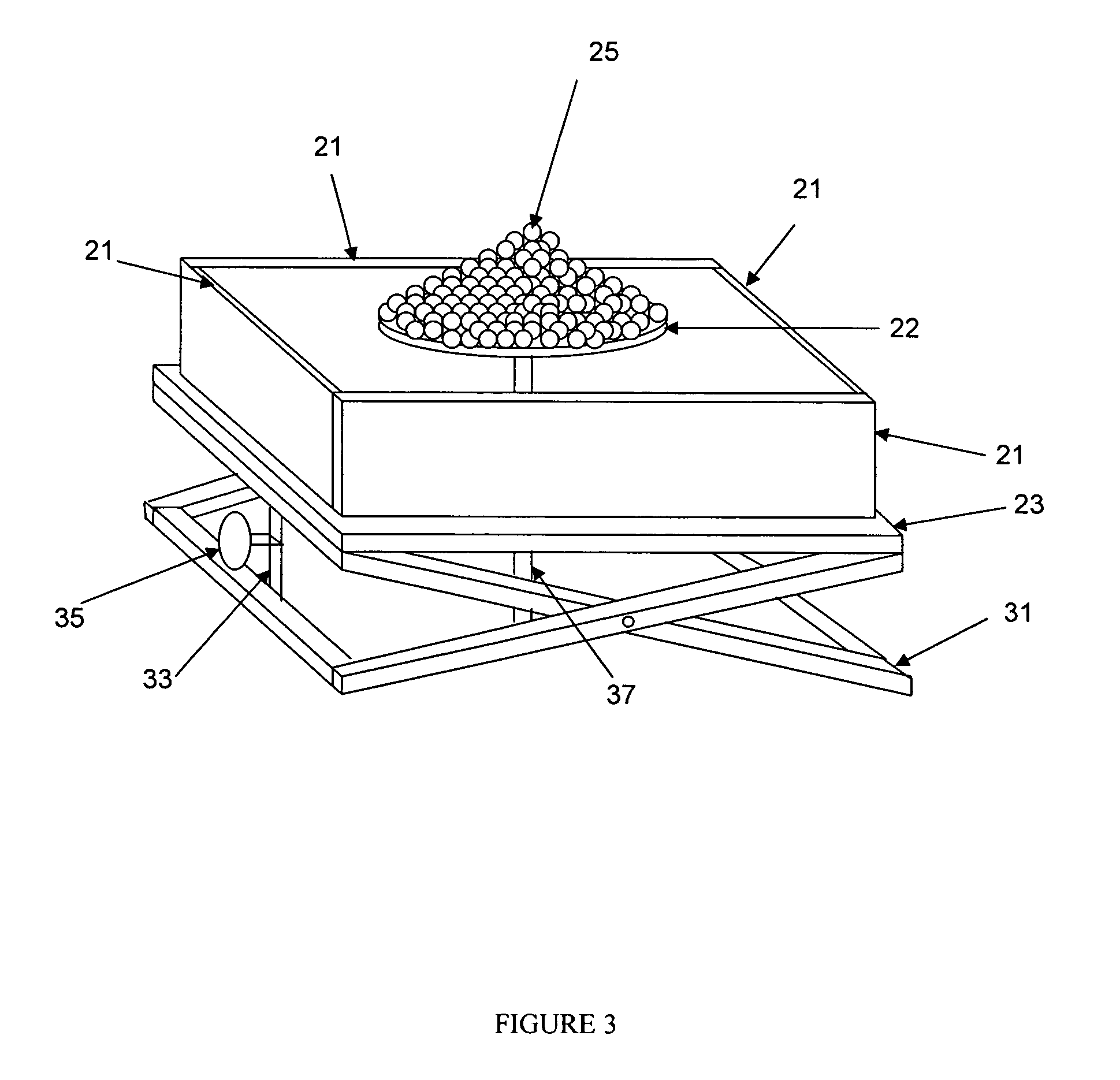

ActiveUS20130135958A1Clean thoroughlySand dryingDrying solid materials with heatMixed materialsEngineering

A blender has a mixing chamber for reception of materials to be blended. A mixing screw is mounted at a bottom of the mixing chamber for mixing materials within the mixing chamber and delivering mixed materials to an outlet feeding a processing line. A baffle is mounted at the outlet extending about the mixing screw. The baffle inhibits upward movement of material at the outlet tending to cram material into the outlet.

Owner:VERVANT

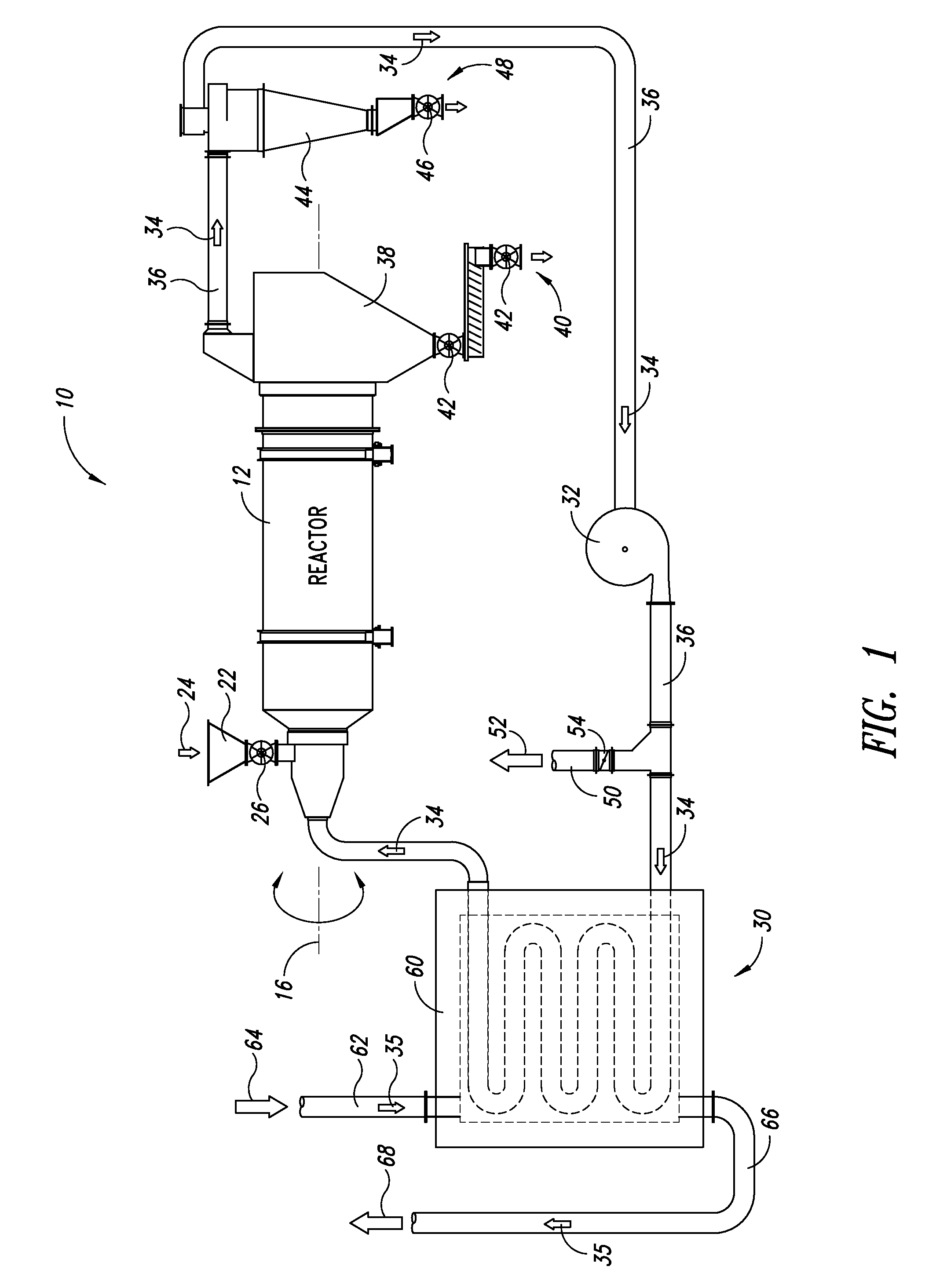

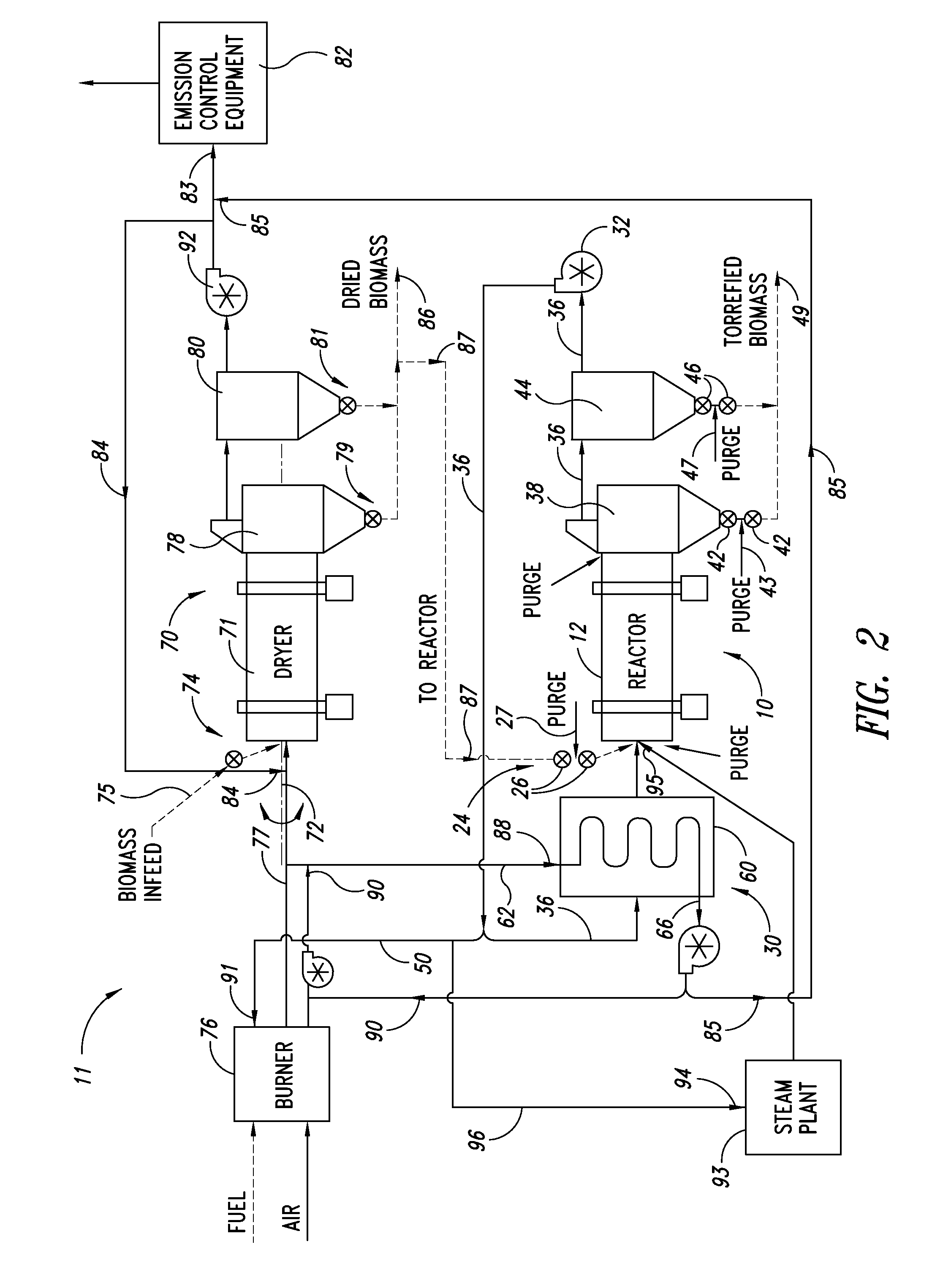

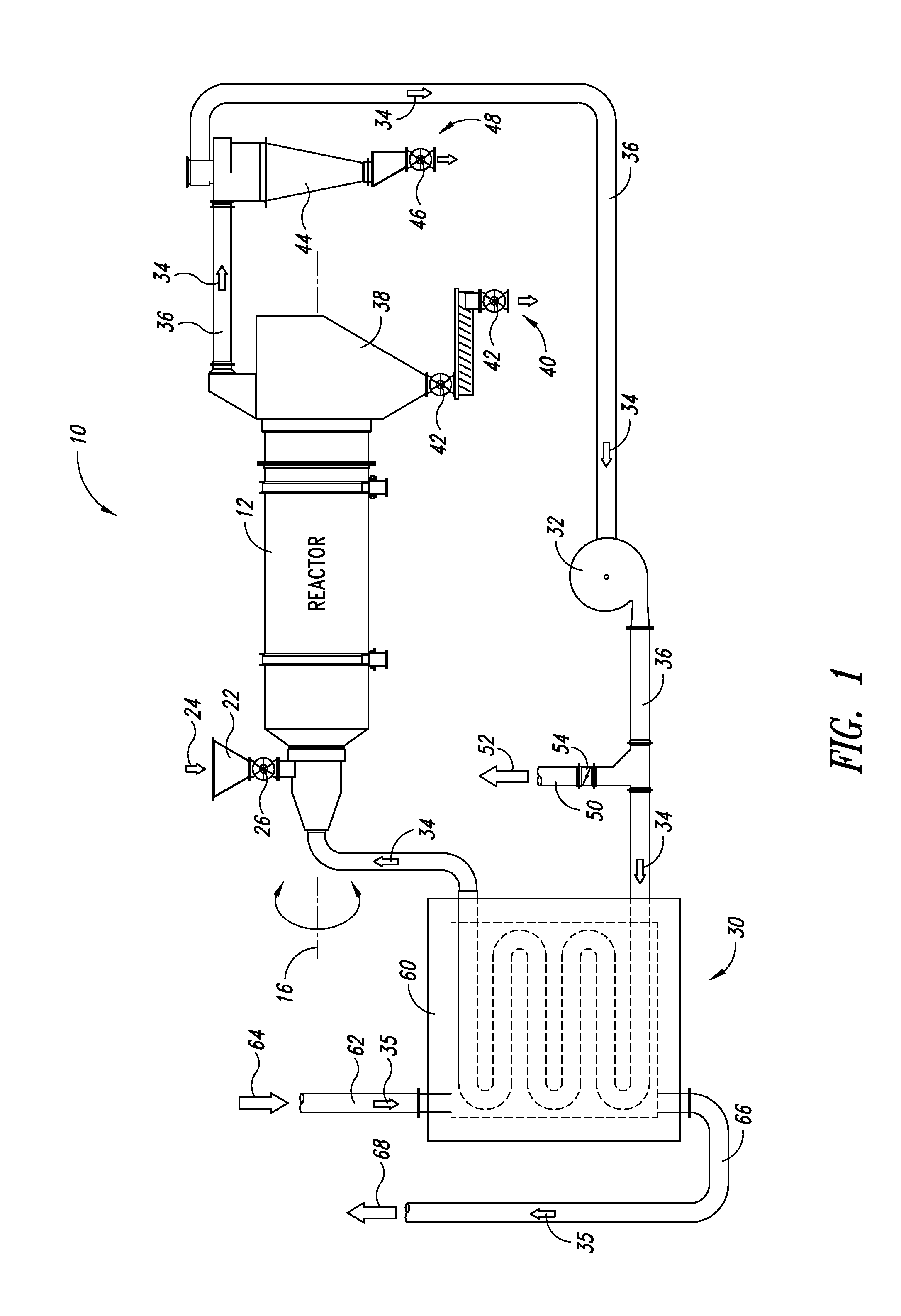

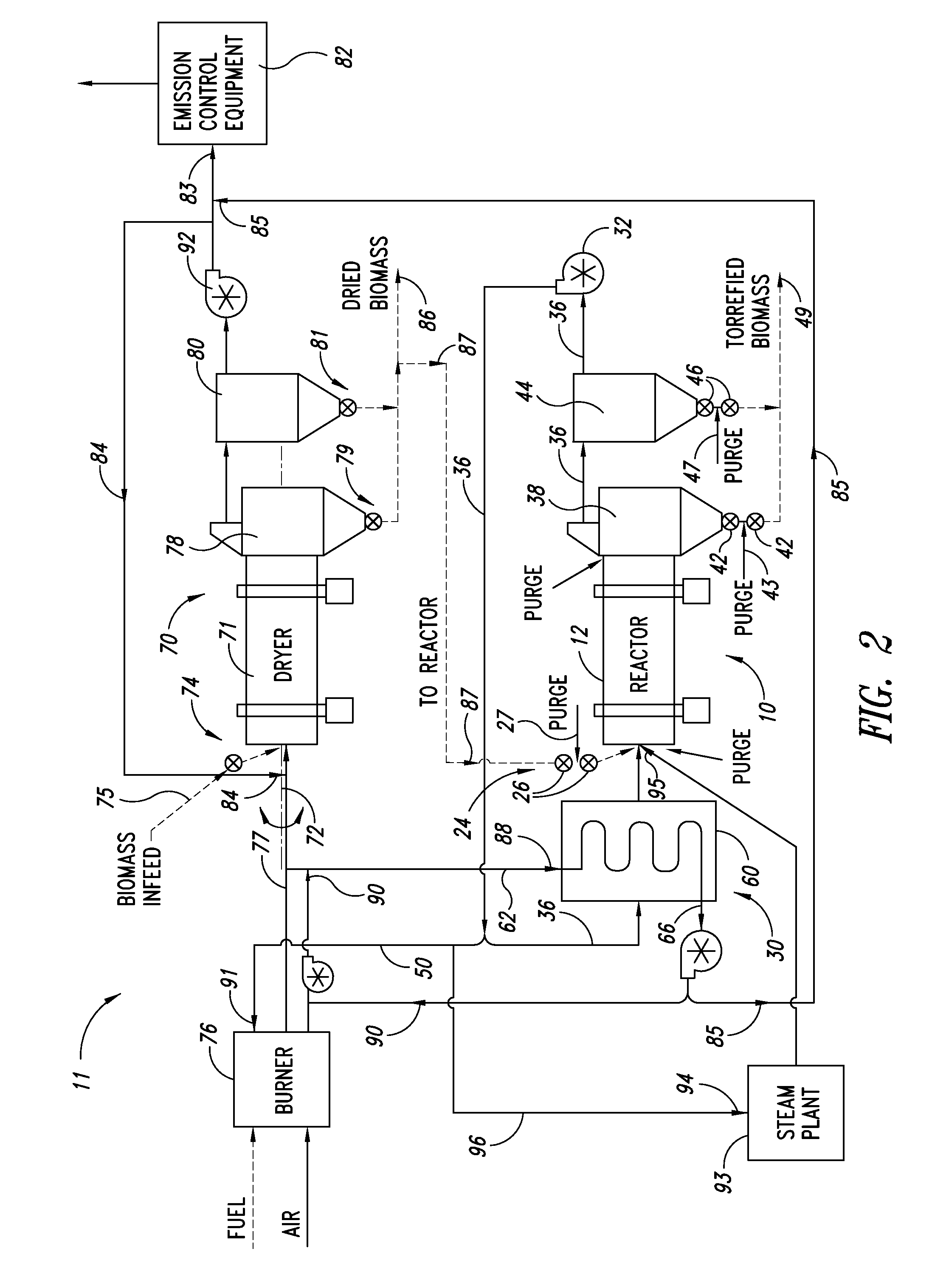

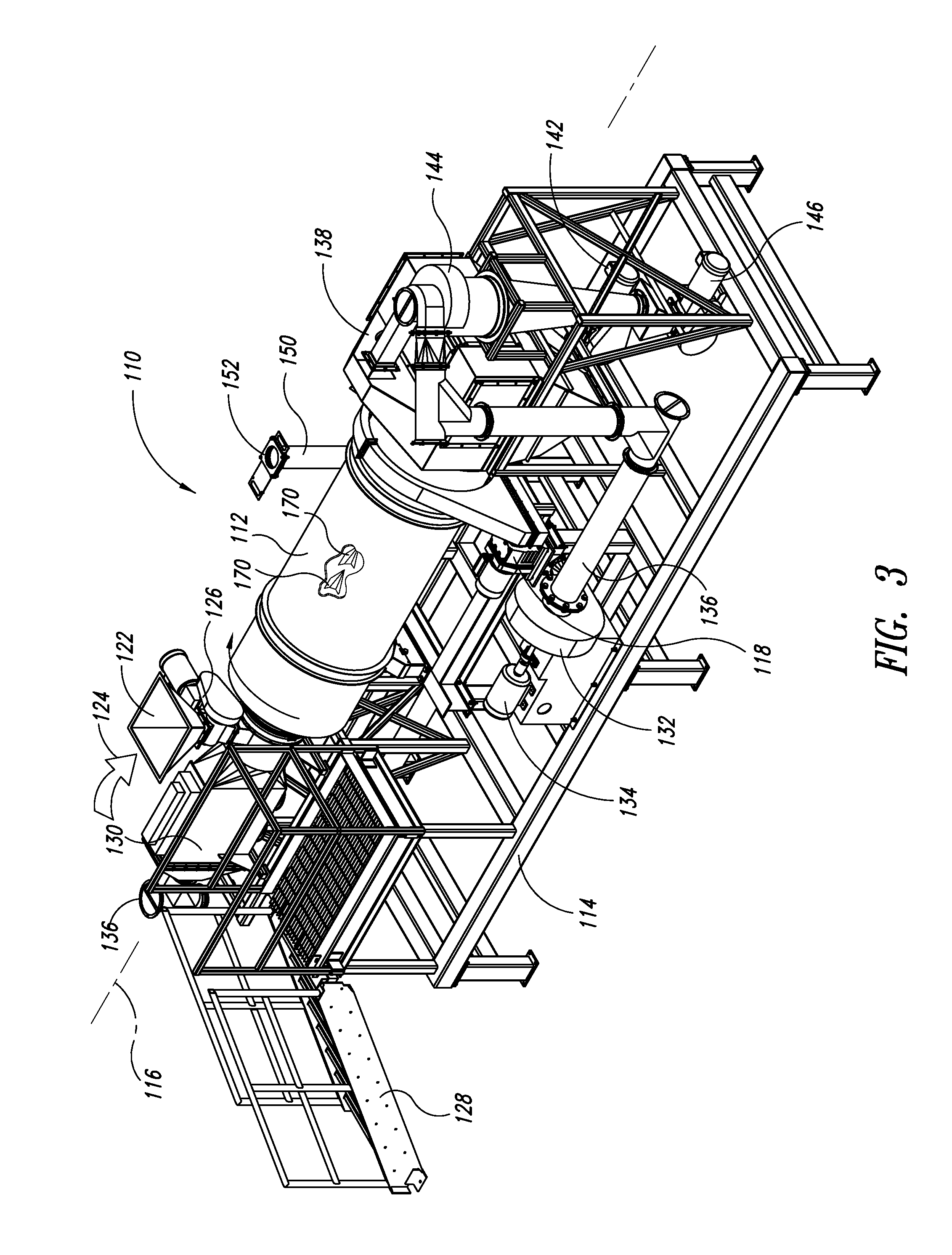

Biomass torrefaction system and method

ActiveUS8246788B2Improve scalabilityEasy to controlCombustible gas coke oven heatingDrying solid materials with heatProcess engineeringTorrefaction

A biomass torrefaction system is provided which enables a continuous torrefaction process that involves the introduction of biomass particles into a rotating reactor drum having a low oxygen environment. The particles are conveyed through the drum by a heated gas stream and simultaneously torrefied thereby. Gas exiting the drum is recirculated back to a heat source for reheating the gas prior to reentering the drum. A method of biomass torrefaction is also provided.

Owner:TEAL SALES

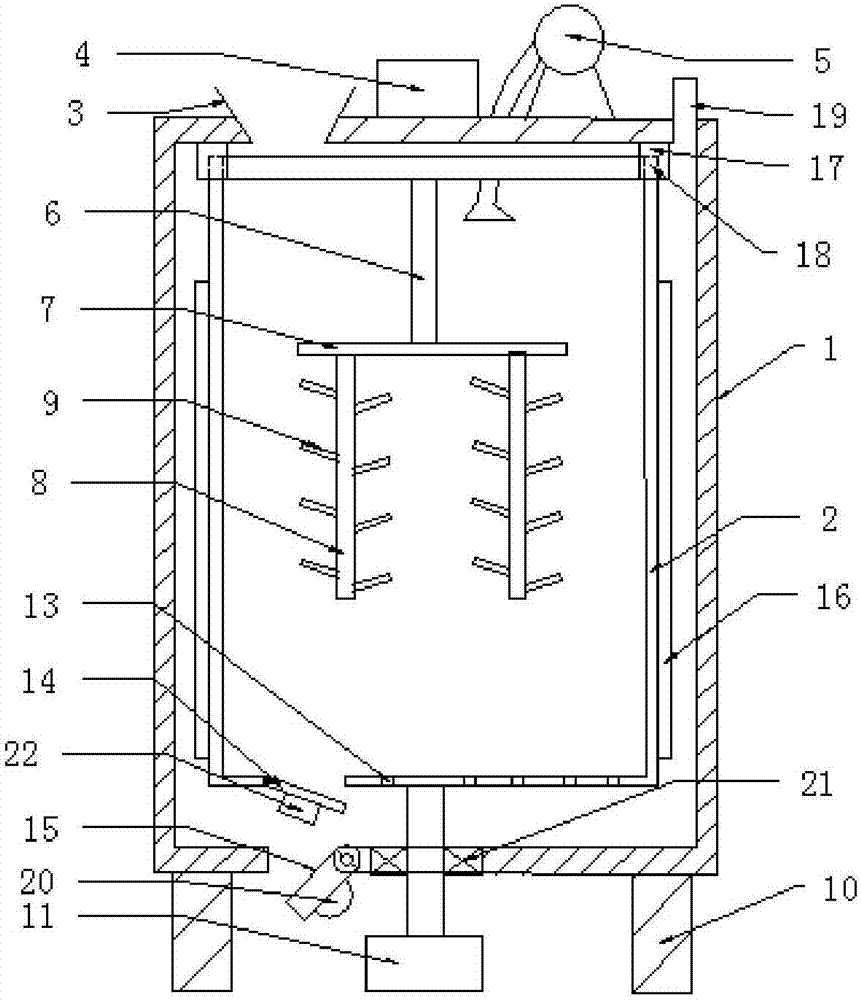

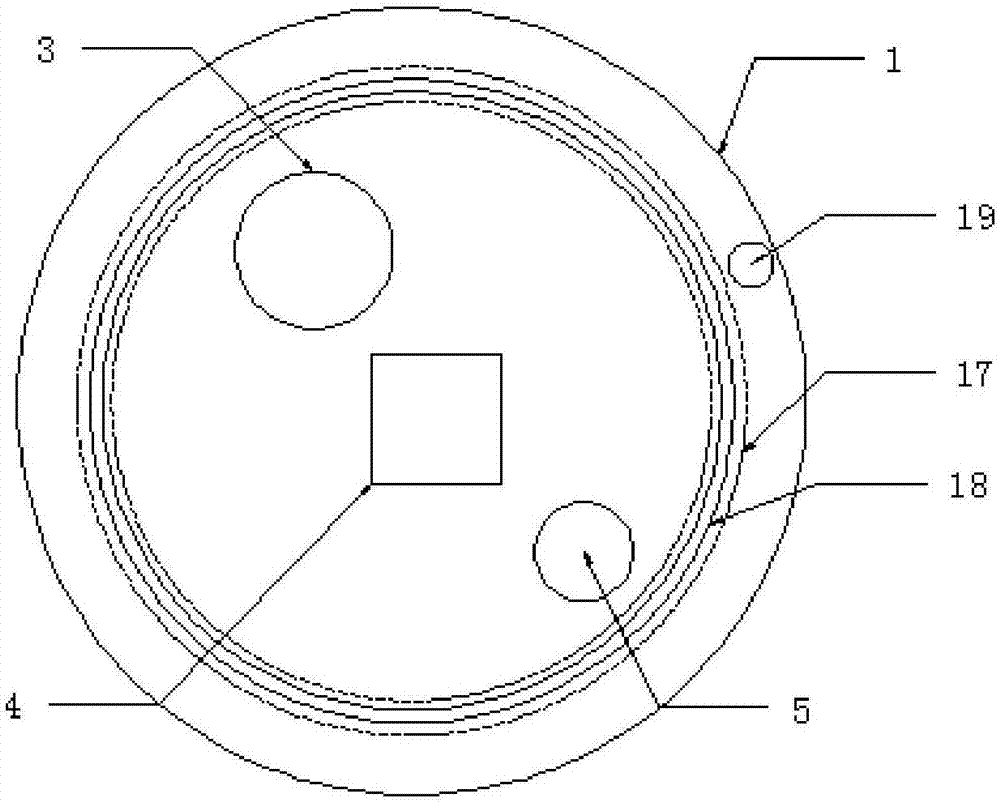

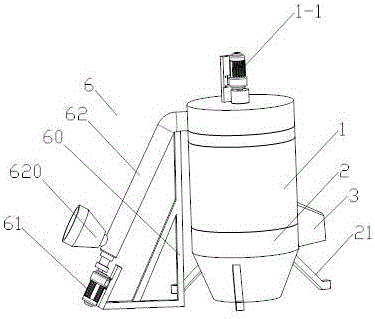

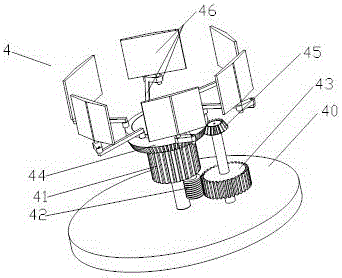

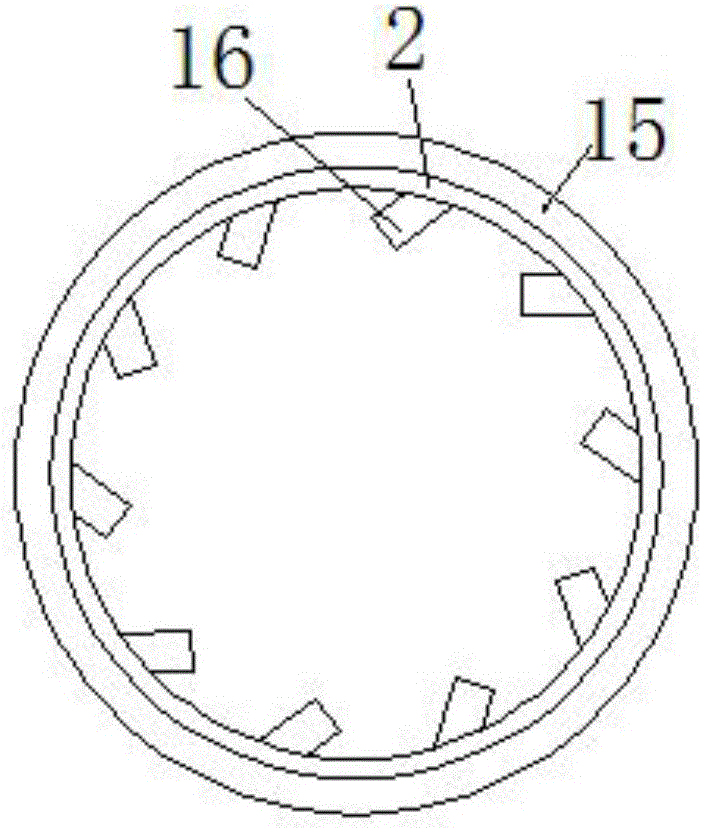

Plastic particle drying device

PendingCN107131731AImprove drying efficiencyStir wellGranular material dryingDrying gas arrangementsElectric machineryEngineering

The invention provides a plastic particle drying device. The plastic particle drying device comprises an outer cylinder, an inner cylinder and four support columns; the outer cylinder is positioned at the top ends of the support columns; the inner cylinder is arranged in the outer cylinder; an annular slide block is arranged on the top end edge of the inner cylinder; a driving motor is arranged below the outer cylinder; the end part of an output shaft of the driving motor extends into the outer cylinder, and is fixedly connected with the bottom end of the inner cylinder; the cylinder bottom of the inner cylinder is hinged with an electric opening / closing door; a feed hopper and an exhaust port are arranged at the top end of the outer cylinder; and an annular slide rail matched with the annular slide block is arranged on the lower surface of the top end of the outer cylinder. The plastic particle drying device has the beneficial effects of reasonable design and high drying efficiency. The driving motor drives the inner cylinder to rotate; and a push rod on a cylinder extends to drive blades to uniformly mix plastic particles up and down, so that the plastic particles in the inner cylinder can be fully mixed, and full contact between hot wind and the plastic particles is facilitated for drying.

Owner:TIANJIN HONGXIANG PLASTIC PROD

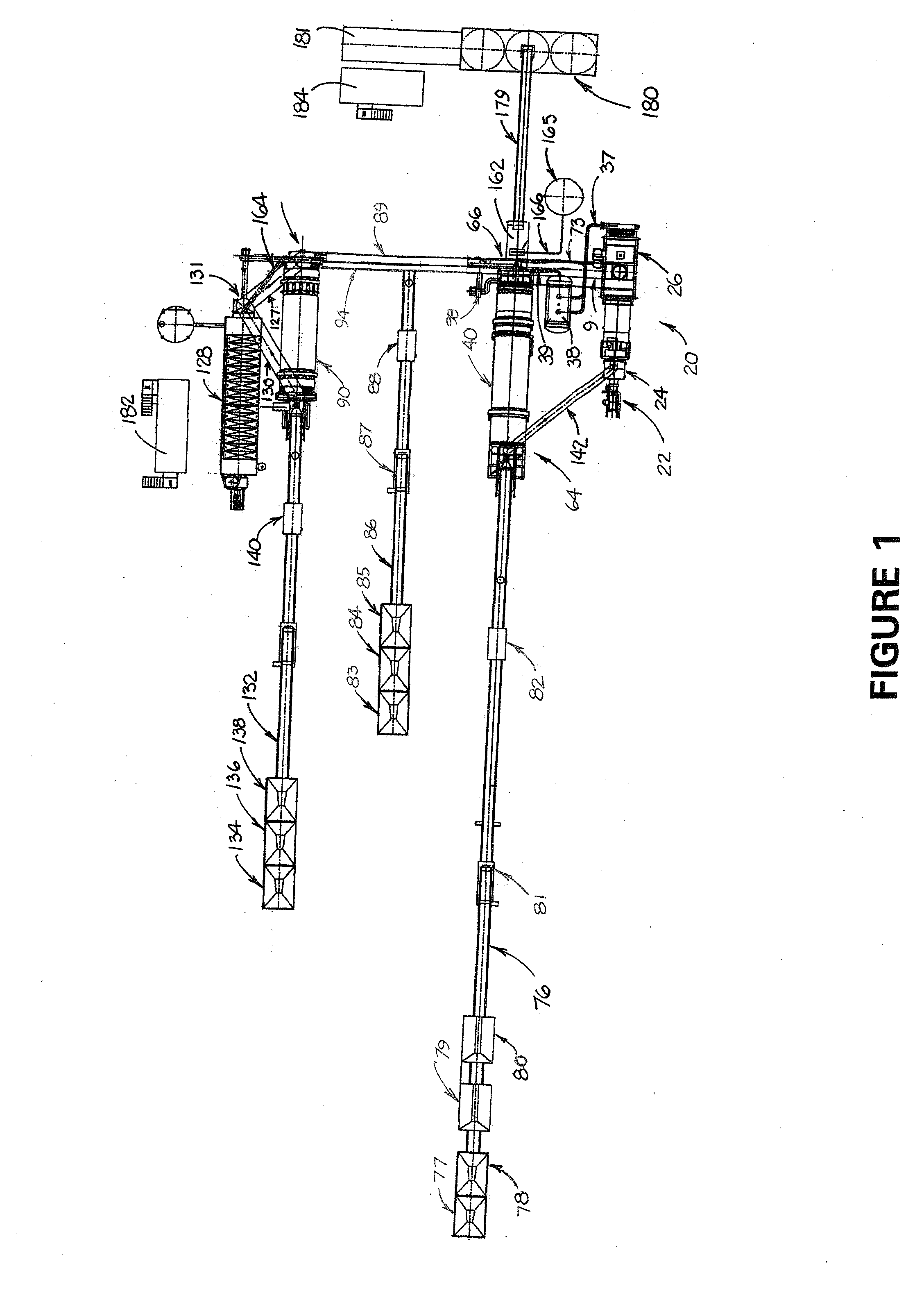

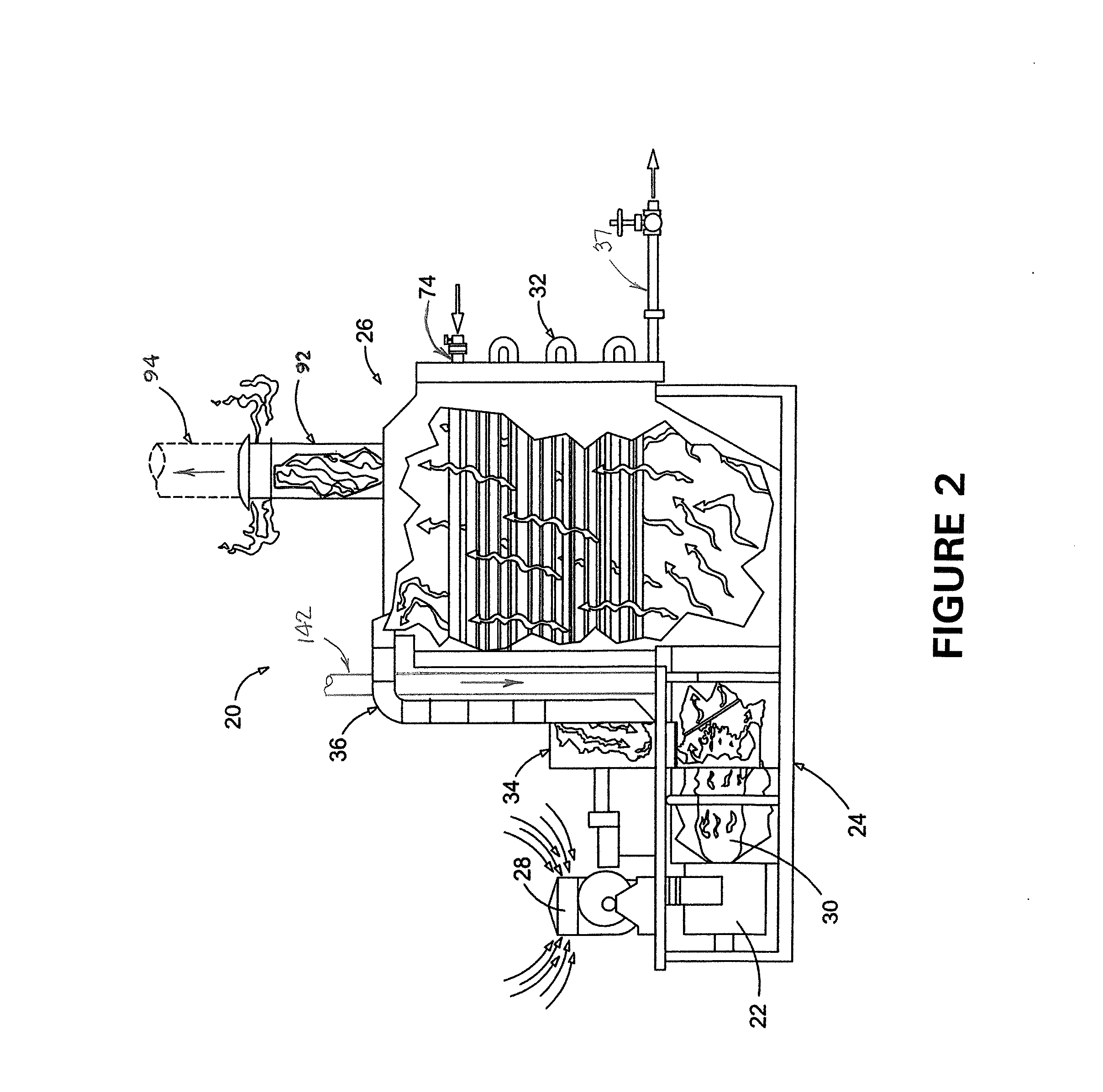

Resin drying method and apparatus

InactiveUS20060185186A1Granular material dryingDough-sheeters/rolling-machines/rolling-pinsMechanical engineeringVertical axis

Owner:MAGUIRE STEPHEN B

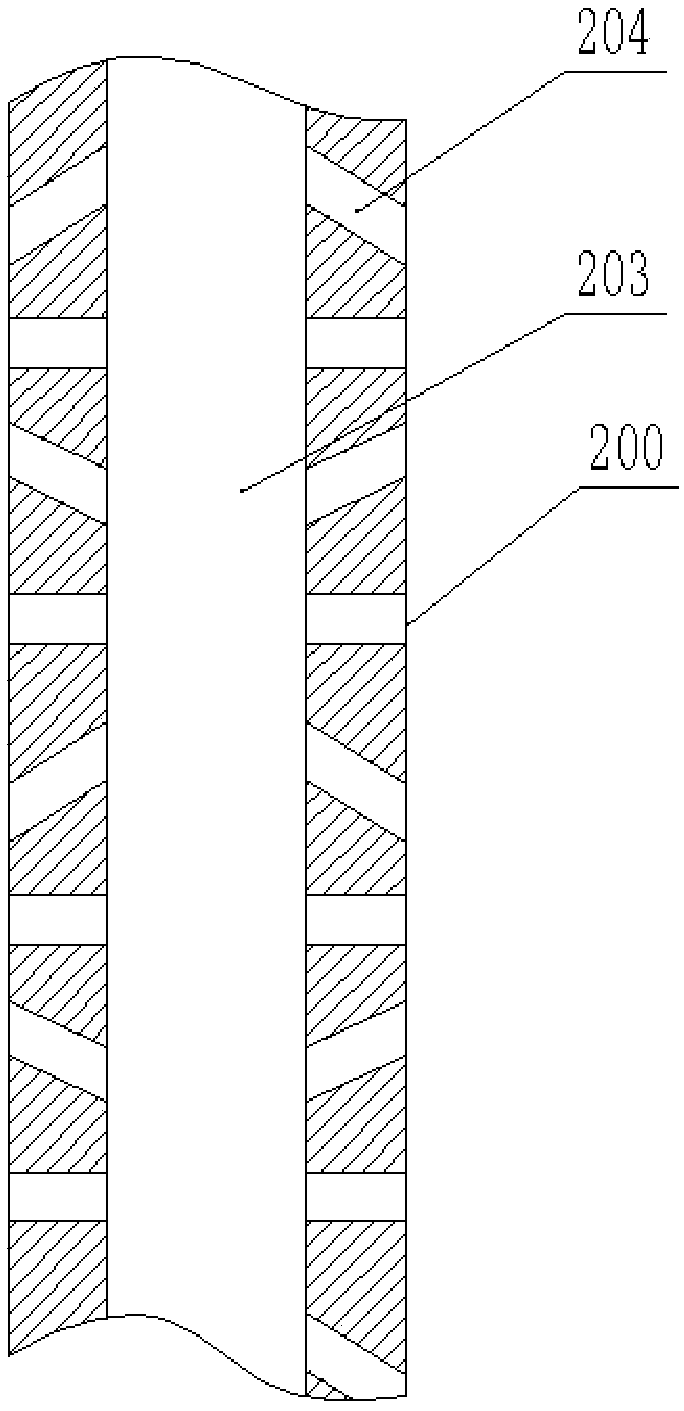

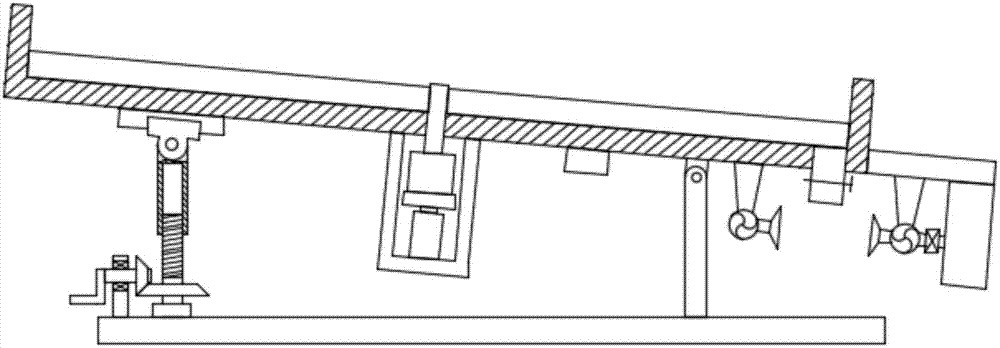

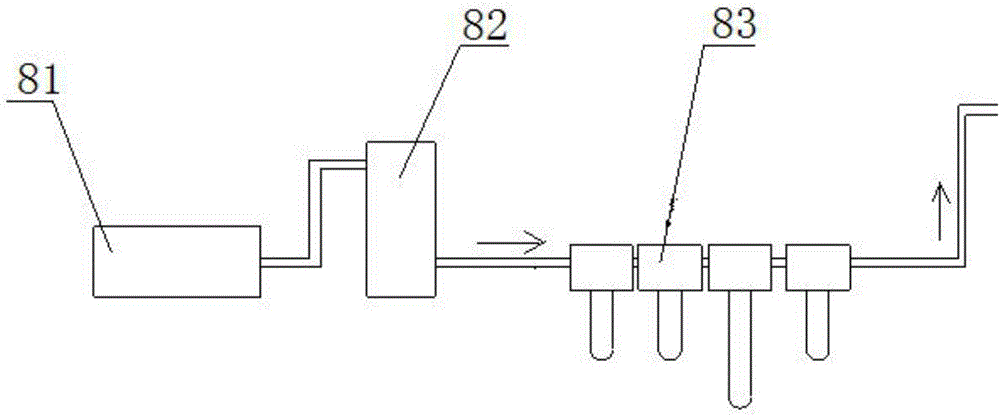

Low-air-pressure particle material drying equipment

InactiveCN107289757AImprove insulation effectEasy to addGranular material dryingDrying solid materials without heatBoiling pointHelical blade

The invention discloses a granular material drying equipment under low air pressure state, which comprises a suction pipe, a drying cylinder body and a blowing hole. Sleeve, shock-absorbing spring and T-shaped rod; both ends of the drying cylinder are welded with end sealing plates, and a closed drying chamber is formed between the drying cylinder and the end sealing plates, and the drying cylinder The top front end is welded with a material adding pipe; the heat preservation effect is good, the sealing effect is good, the spiral blade and the scraper blade stir the material in the drying cylinder to ensure the full mixing of the material in the drying cylinder, realize the circulation of hot air, and improve the heating of the material. The uniformity of the material, and in the low pressure environment in the drying cylinder, only a low heating temperature can make the water in the material reach the boiling point to evaporate and separate, which improves the efficiency of material drying, reduces the drying cost, and improves the quality of the material. Ease of drying.

Owner:惠安县长信机电科技有限公司

Plastic particle feeding device of cable processing device

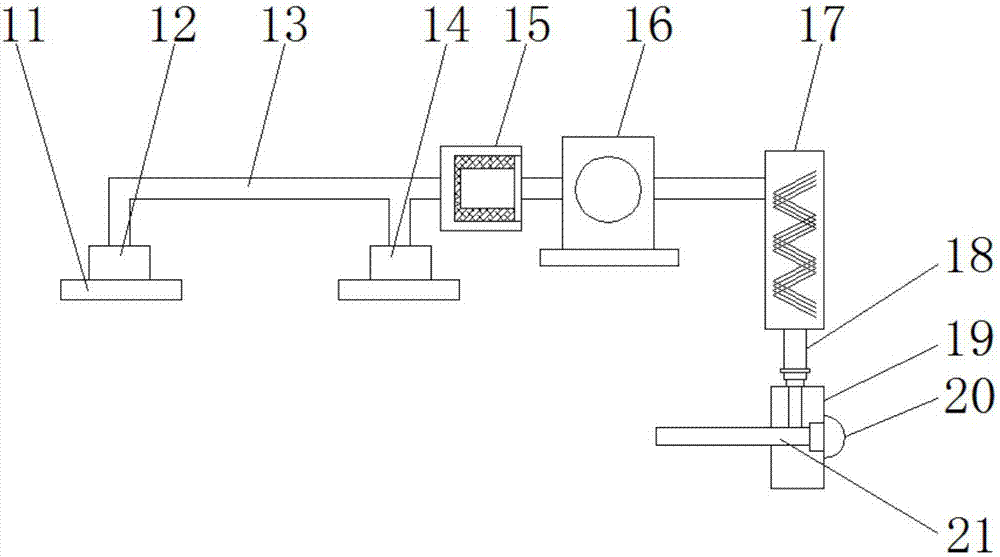

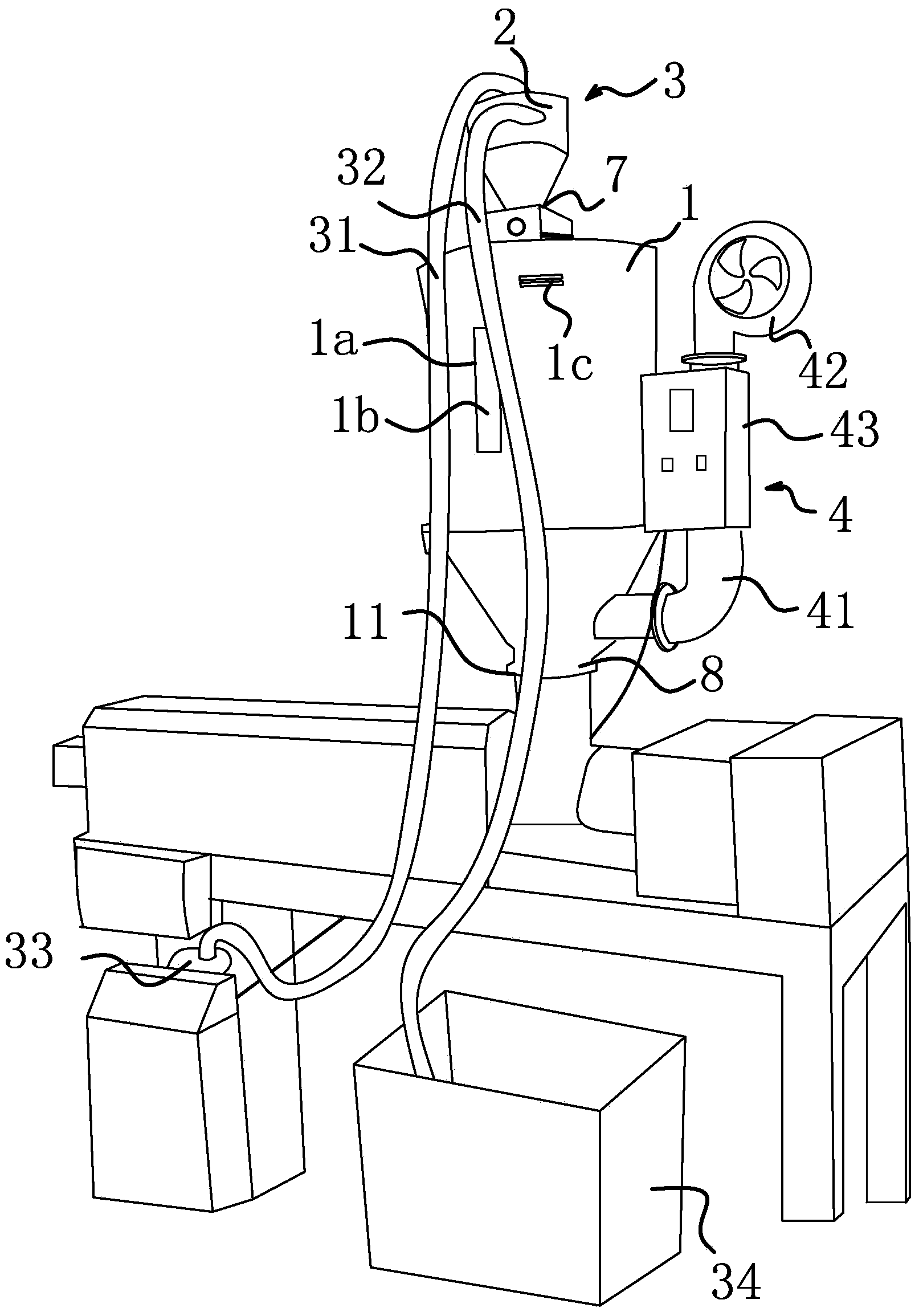

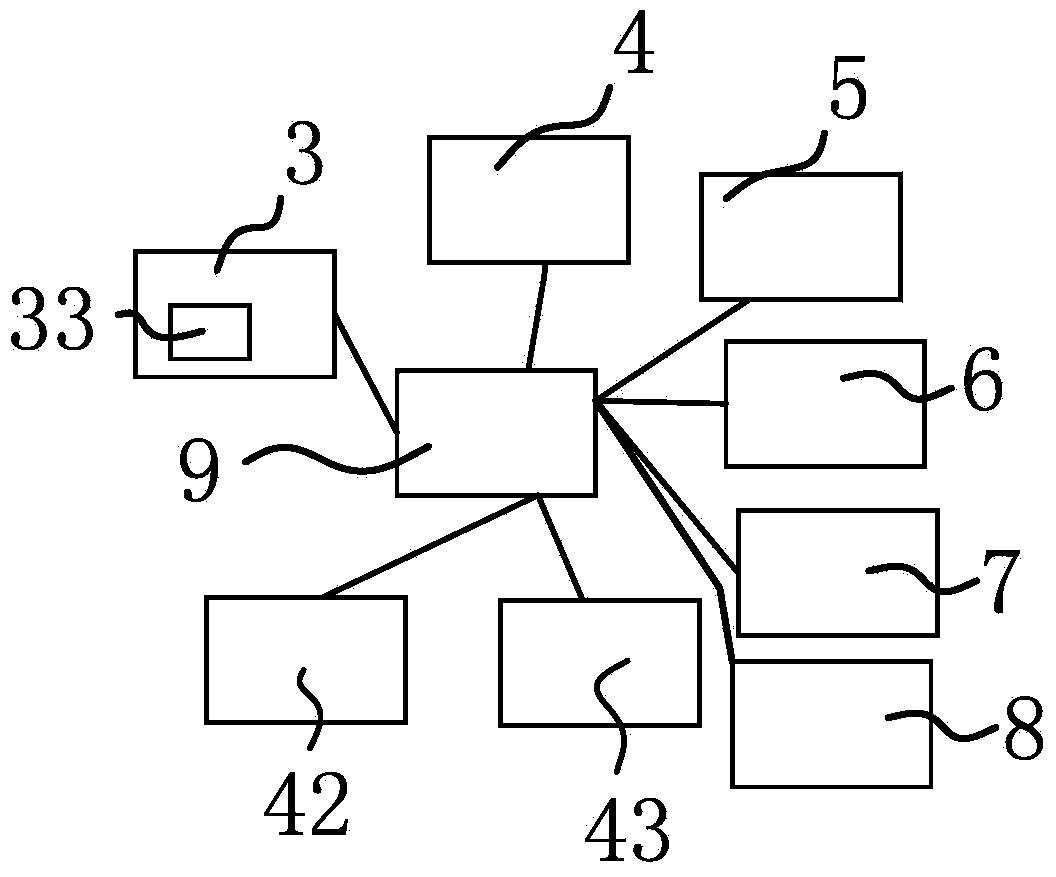

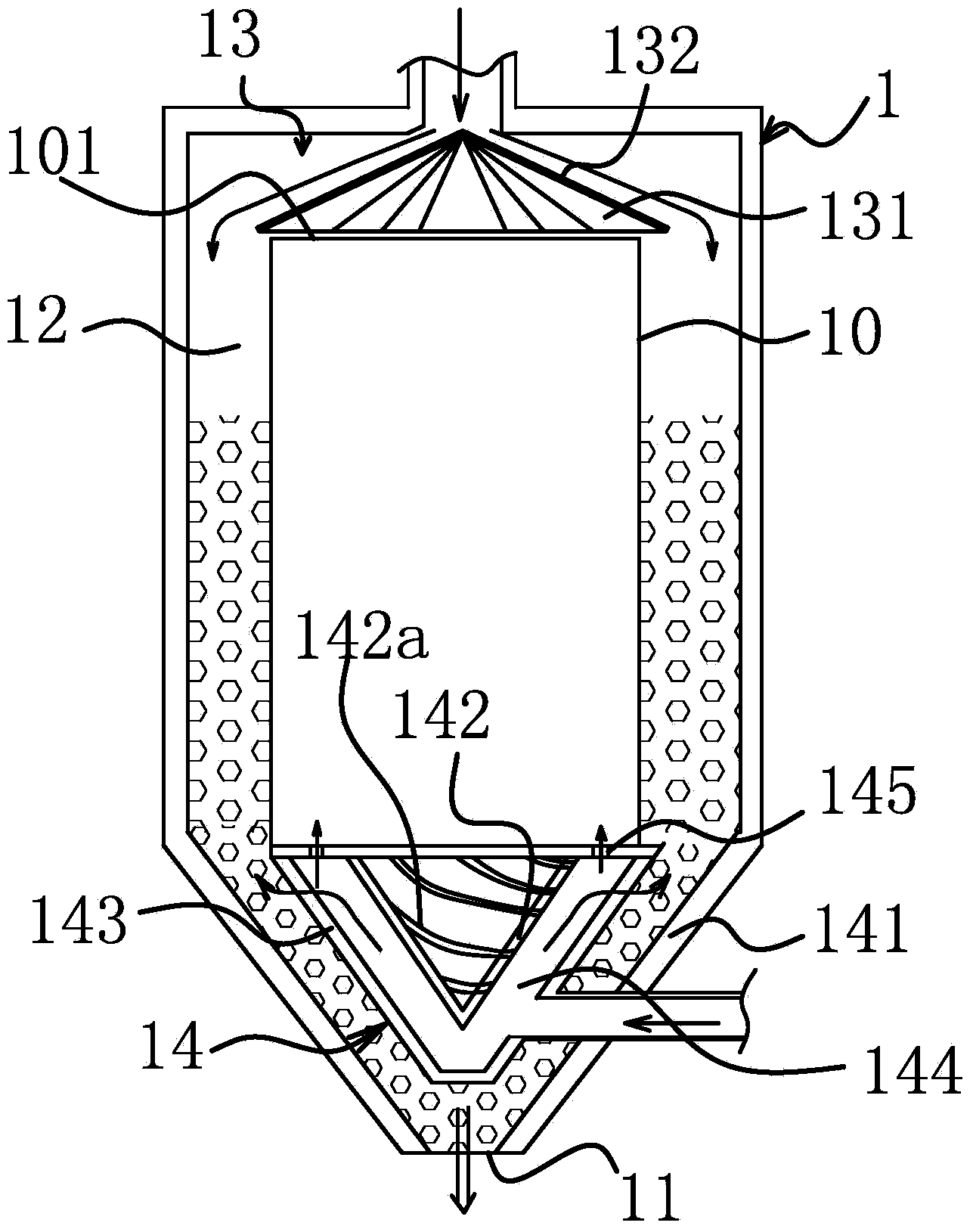

InactiveCN103862651AExtended service lifeReduce generationGranular material dryingPreliminary solid treatment for dryingElectric controlMoisture sensor

The invention belongs to the technical field of cable processing devices, particularly relates to a plastic particle feeding device of a cable processing device and solves the technical problem that the design is not reasonable enough and the like in the prior art. The plastic particle feeding device is characterized in that a negative-pressure loading mechanism is connected to a feeding bucket; a hot air drying mechanism capable of supplying hot air into a material storing cylinder is arranged at the lower part of the material storing cylinder, and a material storage quantity detector and a humidity sensor are arranged on the material storing cylinder; a first electric control valve is arranged at the bottom of the feeding bucket, a second electric control valve is arranged at a discharging hole of the material storing cylinder, and the first electric control valve, the second electric control valve, the hot air drying mechanism, the material storage quantity detector, the humidity sensor and the negative-pressure loading mechanism are all connected with a control circuit. Compared with the prior art, the plastic particle feeding device has the advantages that the design is reasonable, the structure is simple, and materials can be automatically absorbed and dehumidified; a dehumidifying effect is good, the service life of the cable processing device is prolonged, defective products are reduced, and the quality of products is guaranteed.

Owner:湖州凯博电子线缆有限公司

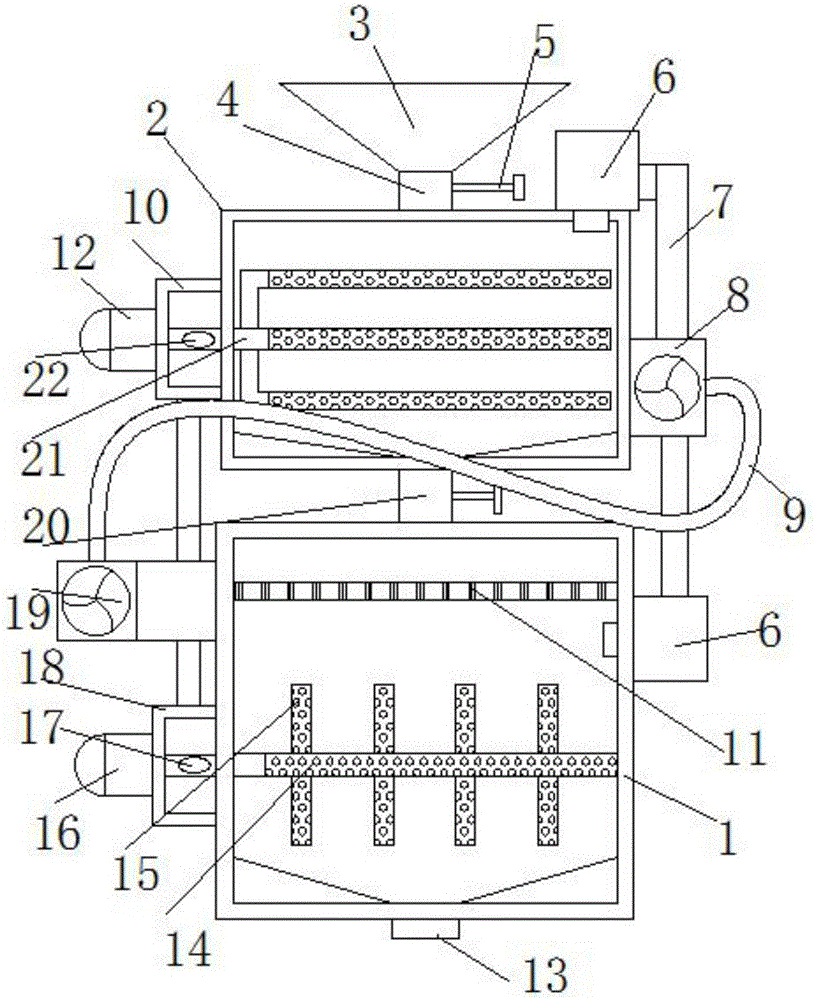

Zhongning wolfberry fruit drying device

InactiveCN106643062AImprove drying effectGuaranteed drying effectGranular material dryingDrying gas arrangementsLycium barbarum fruitDrive motor

The invention discloses a Zhongning wolfberry fruit drying device. The device comprises a drying box 1 and a drying box 2, and is characterized in that the drying box 2 is arranged above the drying box 1; the drying box 1 and the drying box 2 are communicated through a communicating pipe; an unloading pipe and an adjusting valve on the outer side of the unloading pipe are arranged in the middle position of the top of the drying box 2; a stored material is arranged at the upper end of the unloading pipe; a hollow stirring shaft 2 is inserted in the drying box 2; the right end of the stirring shaft 2 is not contacted with the drying box 2; the left end of the stirring shaft 2 penetrates through the left side wall of the drying box 2, and is connected with an output end of a driving motor 2; and a caching box 2 is arranged between the driving motor 2 and the drying box 2. The Zhongning wolfberry fruit drying device is simple and reasonable in structure, improves the wolfberry drying effect, reduces the heat waste, and is high in practicability.

Owner:郑州莉迪亚医药科技有限公司

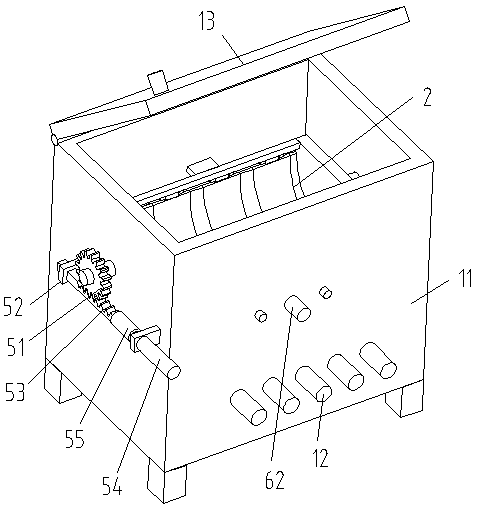

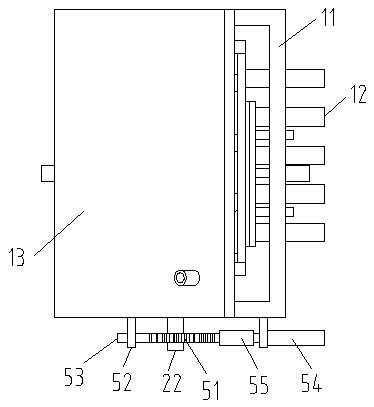

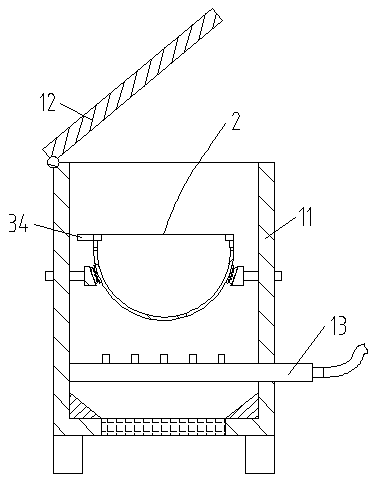

Chemical raw material drying device

InactiveCN110701896AImprove breathabilityFully contactedGranular material dryingDrying gas arrangementsRotational axisRaw material

The invention discloses a chemical raw material drying device. The chemical raw material drying device comprises a box body; the bottom of the box body is fixedly connected with a set of air conveyingpipes; the upper side of the box body is hinged with a sealing cover; a separation box is rotationally connected into the box body; the separation box comprises an upper frame; the upper frame is a square frame; rotating shafts are fixedly connected to two opposite sides of the upper frame; the rotating shafts are rotationally connected with the corresponding inner side walls of the box body; semicircular plates are fixedly connected to the two ends of the bottom of the upper frame; a set of arc plates hinged to the upper frame is alternately arranged between the two semicircular plates; oneends of the arc plates are hinged to one side of the bottom of the upper frame; and the other ends of the arc plates are fixedly connected with the other side of the bottom of the upper frame throughhanging hook springs. A gap is formed between the two connected arc plates, and is intermittently generated in continuous swinging process; and materials in the separation box fall from the generatedgap to fully contact with drying hot air on the lower side to achieve the drying uniformity.

Owner:吴燕林

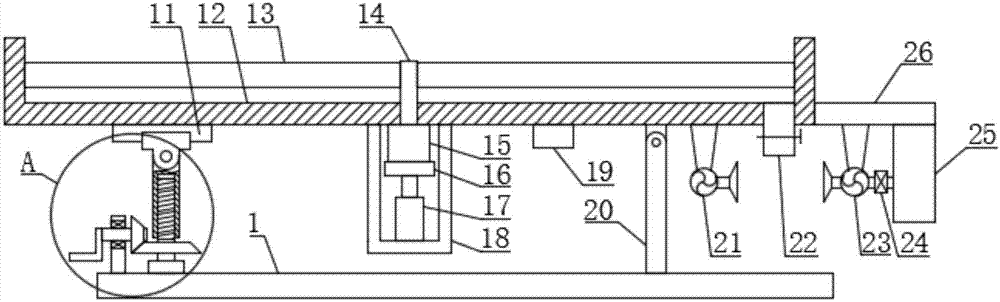

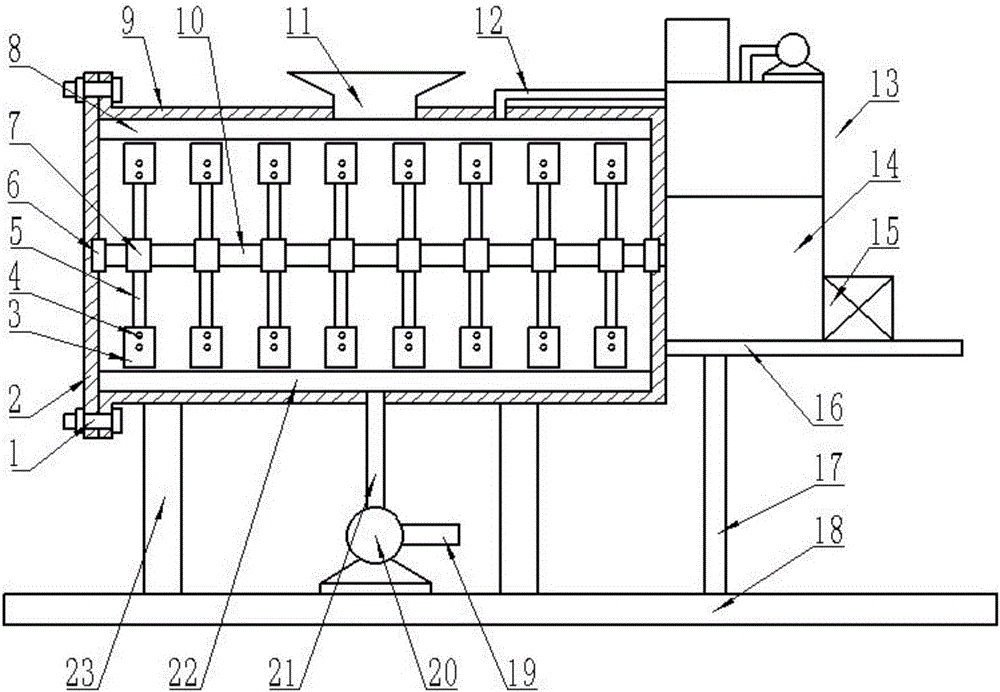

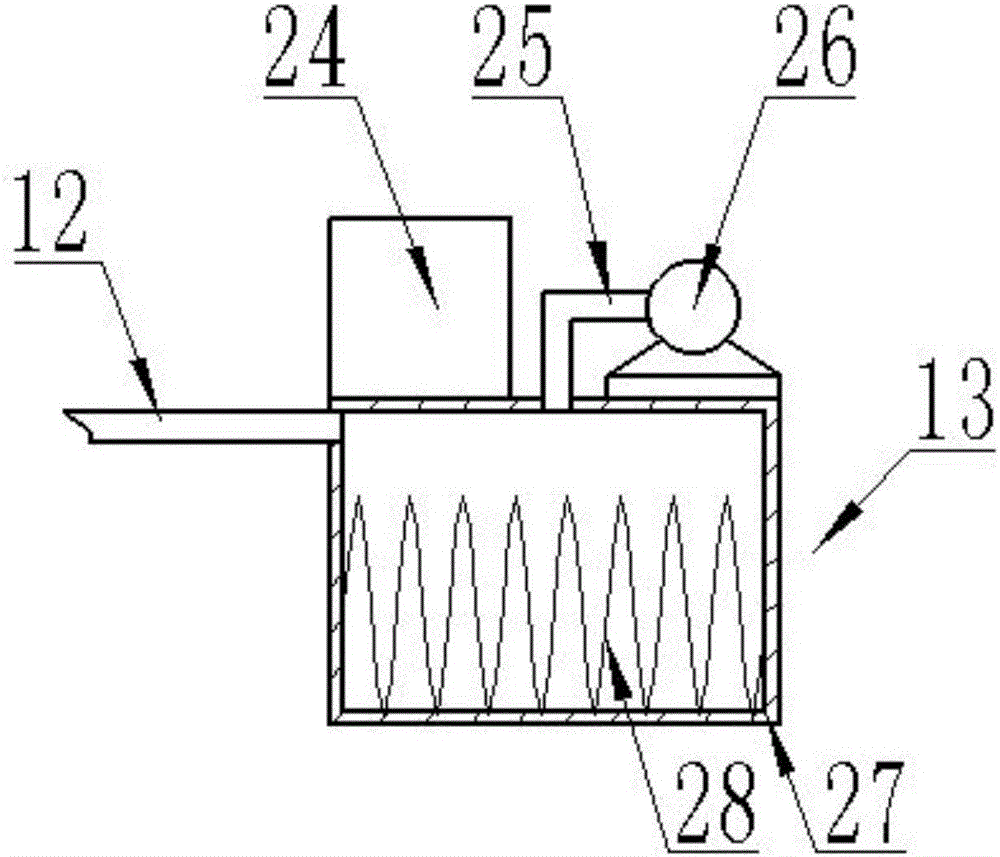

Crushing and drying device of feeds

InactiveCN107853739AImprove drying qualityImprove drying efficiencyFeeding-stuffGranular material dryingMotor driveDrive shaft

The present invention provides a crushing and drying device of feeds and belongs to the technical field of feed processing. The crushing and drying device comprises a drying box body, a crushing box body, a base seat, casters and a filtering device; a material inlet is arranged at an upper side of the crushing box body; the material inlet passes a top wall of the crushing body; and a transmissionshaft is arranged inside the crushing box body. A rotation of the transmission shaft drives rotary blades and fixing blades to rotate relative to each other to crush materials; a second motor drives arotation of a second rotary shaft and the second rotary shaft drives a rotation of stirring blades to conduct a stirring of the feeds in the drying box body, so that the crushing and drying device isconductive for heat transfer and convenient for drying; and a hot-air blower is used to introduce hot air into an air inlet pipe and the hot air is ejected from jet nozzles evenly distributed on a surface of an air jet plate, so that the crushing and drying device is conducive to expanding a spraying area of the hot air, facilitating a full contact with materials and improving drying quality of the materials.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Blenders

InactiveUS20100065149A1Clean thoroughlyLiquid fillingDrying solid materials with heatMixed materialsEngineering

A blender has a mixing chamber for reception of materials to be blended. A mixing screw is mounted at a bottom of the mixing chamber for mixing materials within the mixing chamber and delivering mixed materials to an outlet feeding a processing line. A baffle is mounted at the outlet extending about the mixing screw. The baffle inhibits upward movement of material at the outlet tending to cram material into the outlet.

Owner:VERVANT

Equipment for drying and feeding fruit juice powder

ActiveCN106643064AEfficient dryingContinuous dryingGranular material dryingDrying gas arrangementsFruit juiceControl system

The invention provides equipment for drying and feeding fruit juice powder, and belongs to the technical field of drying of fruit juice powder. The equipment disclosed by the invention has the beneficial effects that a single air-source heat pump is used for drying and heating the fruit juice powder in a bin, and the operation state of a mixing mechanism in the bin, the operation state of a material raising structure in the bin, as well as the humidity of the fruit juice powder in the bin are automatically detected through a control system, so that the shortcomings in the prior art that the energy consumption is high, the continuous working efficiency is low, the drying time is difficult to control, and drying is insufficient are overcome, and the purpose of efficient, continuous and sufficient drying of the fruit juice powder is achieved.

Owner:江山锐意科技服务有限公司

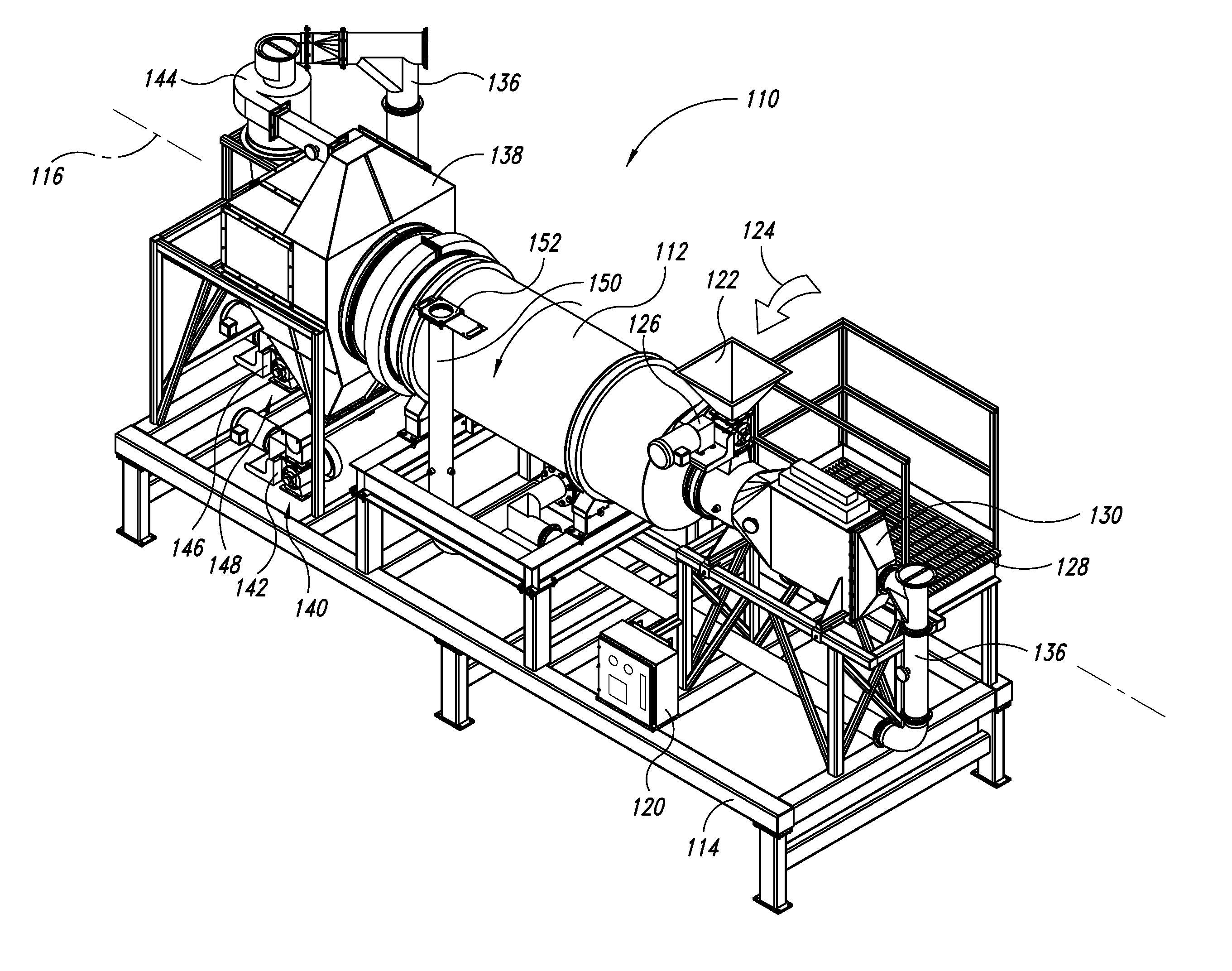

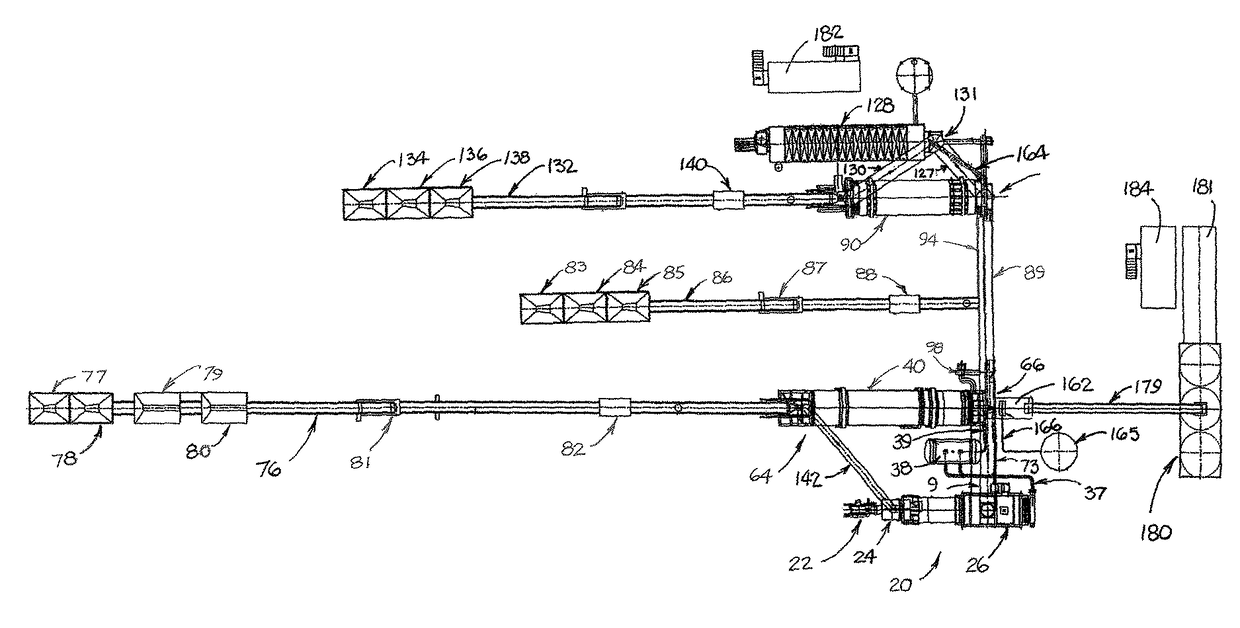

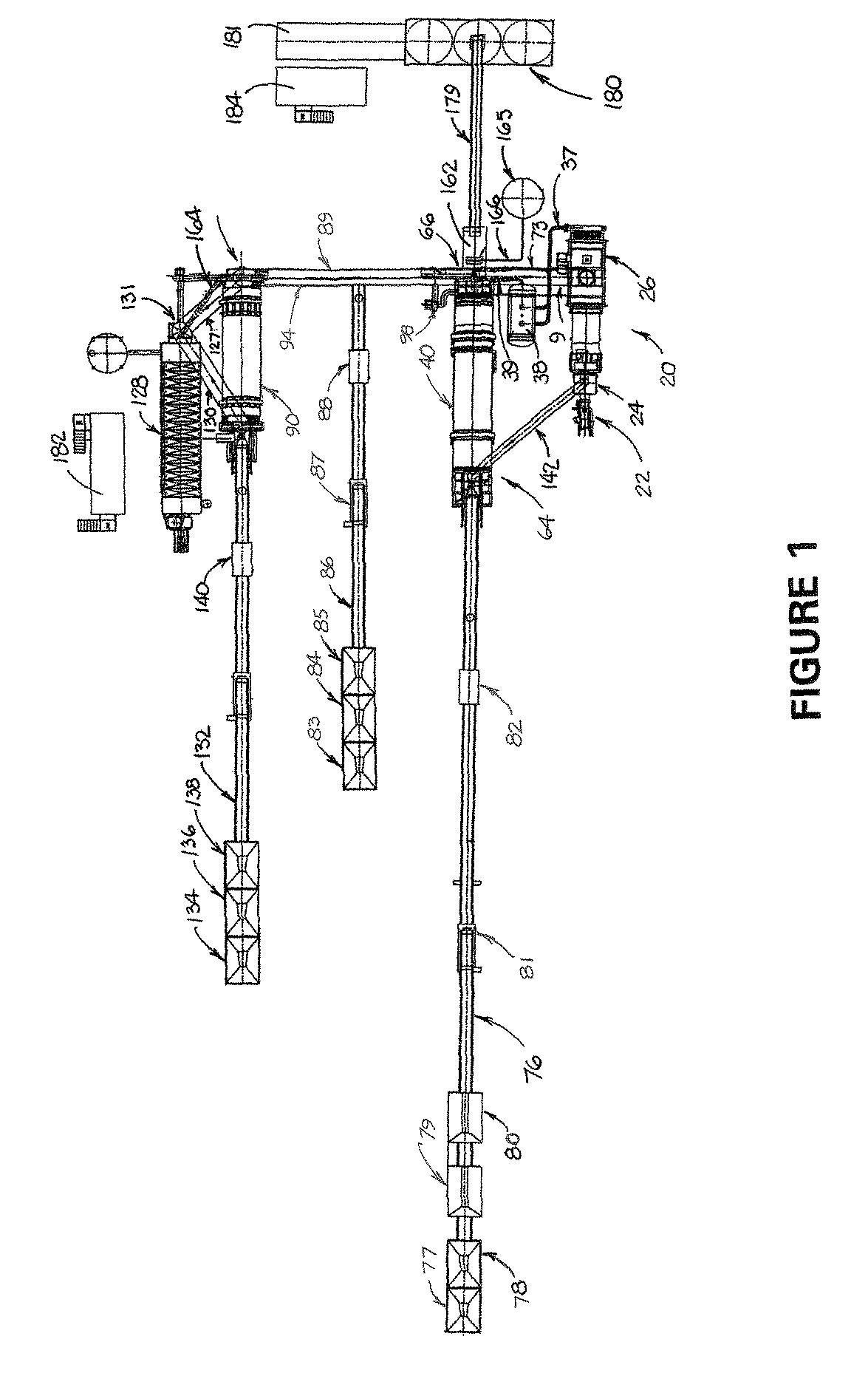

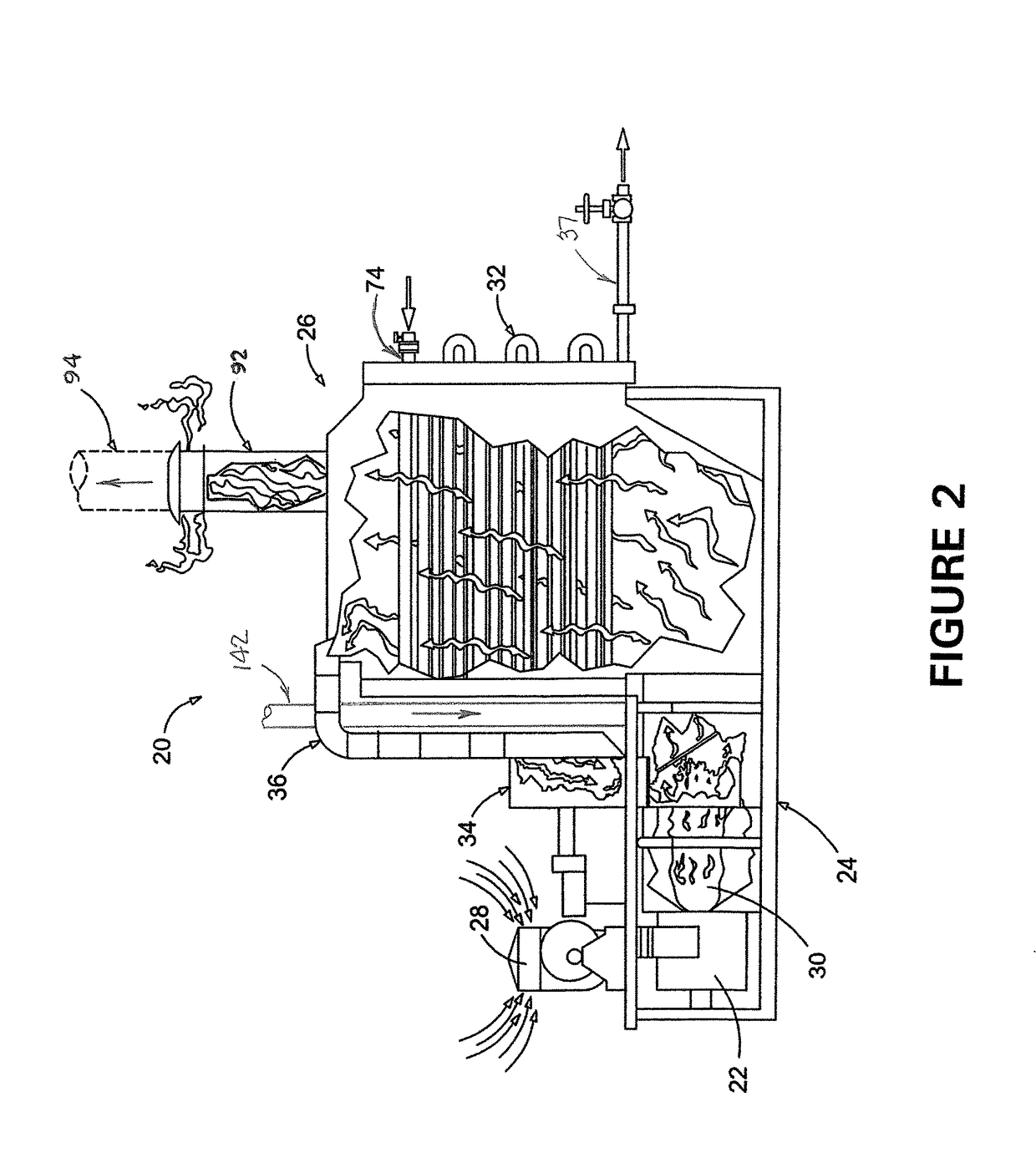

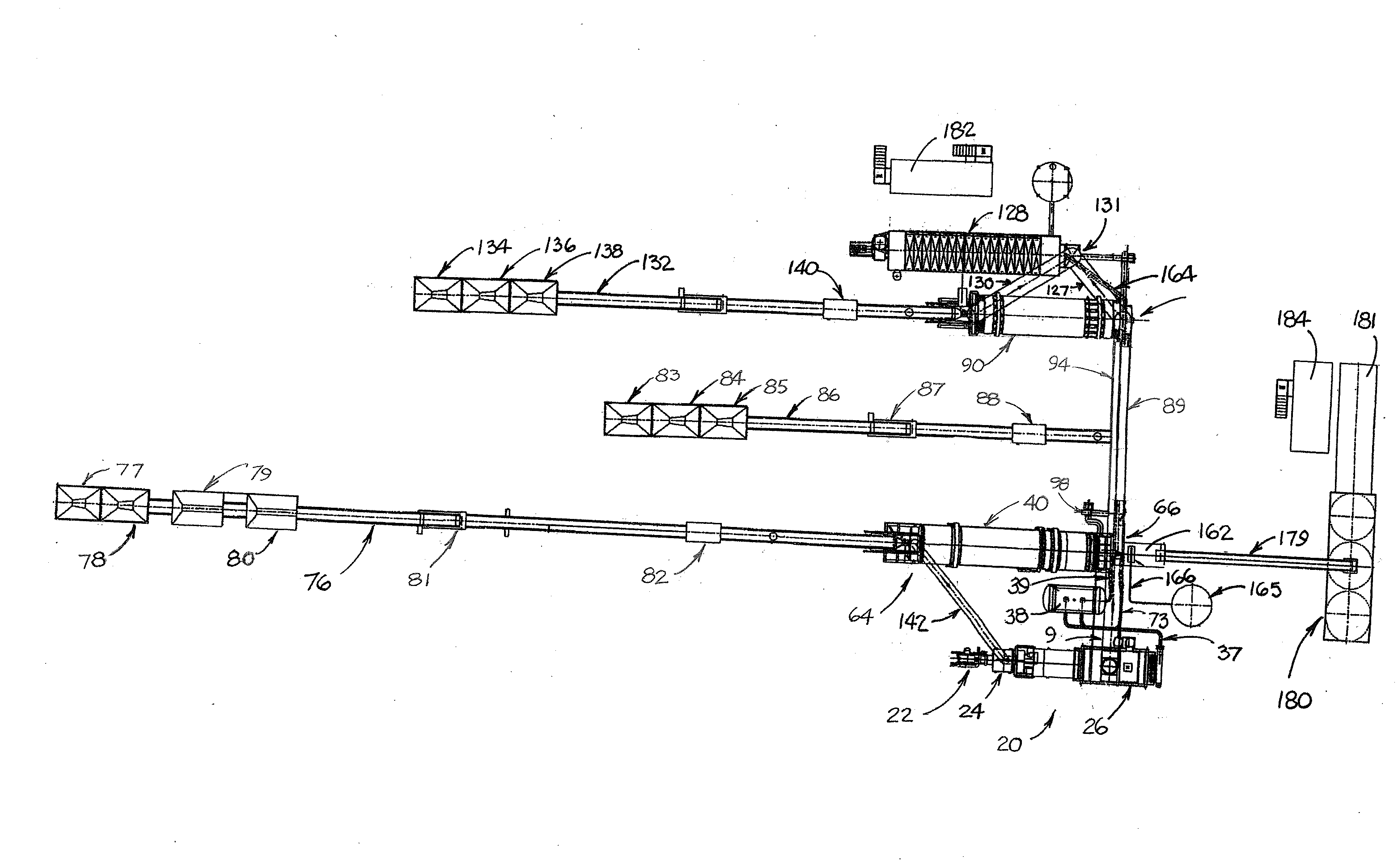

Method and apparatus for making asphalt concrete using aggregate material from a plurality of material streams

InactiveUS9855677B2Emission controlThermally efficientGranular material dryingRotary drum furnacesProcess engineeringMechanical engineering

A combination of components is provided for use in making asphalt concrete from a plurality of aggregate material streams. The combination includes an indirect dryer for heating aggregate material from a first material stream without directly exposing said first stream material to hot gases of combustion. The combination also includes a mixer for mixing aggregate material from the first material stream, aggregate material that has not been heated in the indirect dryer from a second material stream, and a binder component to produce asphalt concrete.

Owner:ASTEC

Biomass torrefaction system and method

ActiveUS20120159842A1Improve scalabilityEasy to controlDrying solid materials with heatDirect heating destructive distillationProcess engineeringTorrefaction

Owner:TEAL SALES

Smashing and drying device for straw feed for animals

ActiveCN105928322AAvoid concentrationWell mixedGranular material dryingLavatory sanitoryEngineeringFodder

The invention discloses a smashing and drying device for straw feed for animals. The smashing and drying device for the straw feed for the animals comprises a box body and a rotary shaft arranged in the middle of the box body. The box body is sleeved with a discharging cylinder. A discharging cavity is formed between the discharging cylinder and the box body. A partition plate is arranged in the middle of the discharging cavity. The portion, above the partition plate, of the inner wall of the discharging cylinder is of a corrugated structure. A discharging hole is formed in the partition plate. The discharging cavity is divided into an upper part and a lower part through the partition plate. A heater is arranged in the partition plate. A water outflow valve is arranged on the side wall of the discharging cavity and located above the partition plate. According to the smashing and drying device for the straw feed for the animals, after being smashed many times, materials are cut and smashed again through cutters in the box body, the smashing strength of the materials can be improved, and machining precision and machining efficiency are improved.

Owner:鱼台县鑫达粮机制造有限公司

Airing device for traditional Chinese medicinal materials

InactiveCN107726817AEasy to acceptSimple structureGranular material dryingDrying chambers/containersEngineeringChinese drug

The invention discloses an airing device for traditional Chinese medicinal materials. The airing device comprises a support box and an airing tank, wherein the support box is a rectangular box body; support blocks are symmetrically arranged on the two sides of the lower end of the support box; rollers which facilitate carrying of the device are arranged on the support blocks; a temporary storage cavity is formed in the support box; a guide inclined plate of which the left part is low and the right part is high is arranged in the temporary storage cavity; a lifting barrel is vertically arrangedin the position in an interpenetrating manner, on the left upper side of the guide inclined plate, of the support box; the lower end of the lifting barrel stretches into the bottom of the temporary storage cavity; and a driving motor is arranged at the upper end of the lifting barrel. According to the airing device, the structure is simple and reasonable, carrying is convenient, the height can beadjusted, the airing tank conveniently receives sunlight, the airing manner is aimed at airing of granular materials, the circular airing manner is not limited to the airing area of the airing tank,airing efficiency is improved, and practicability is high.

Owner:浙江燕思志网络科技有限公司

Spheroidal polyester polymer particles

Spheroidal polyester polymer particles, as well as preforms and stretch blow molded bottles made from the spheroidal particles, are provided which have: A) an It.V. of at least 0.72 dL / g, and either B) at least two melting peaks (on a DSC first heating scan), wherein one of said at least two melting peaks is a low peak melting point having a peak temperature within a range of 140° C. to 220° C. and having a melting endotherm area of at least the absolute value of 1 J / g, or C) a low degree of crystallinity within a range of at least 20% and a maximum degree of crystallinity Tcmax defined by the equation: Tcmax=50%−CA−OH where CA is the total mole % of all carboxylic acid residues other than terephthalic acid residues, based on 100 mole % of carboxylic acid residues in the polyester polymer, and OH is the total mole % of hydroxyl functional compound residues other than ethylene glycol residues, based on 100 mole % of the hydroxyl functional compounds residues; or both B) and C); and optionally but preferably D) 10 ppm or less of residual acetaldehyde.

Owner:EASTMAN CHEM CO

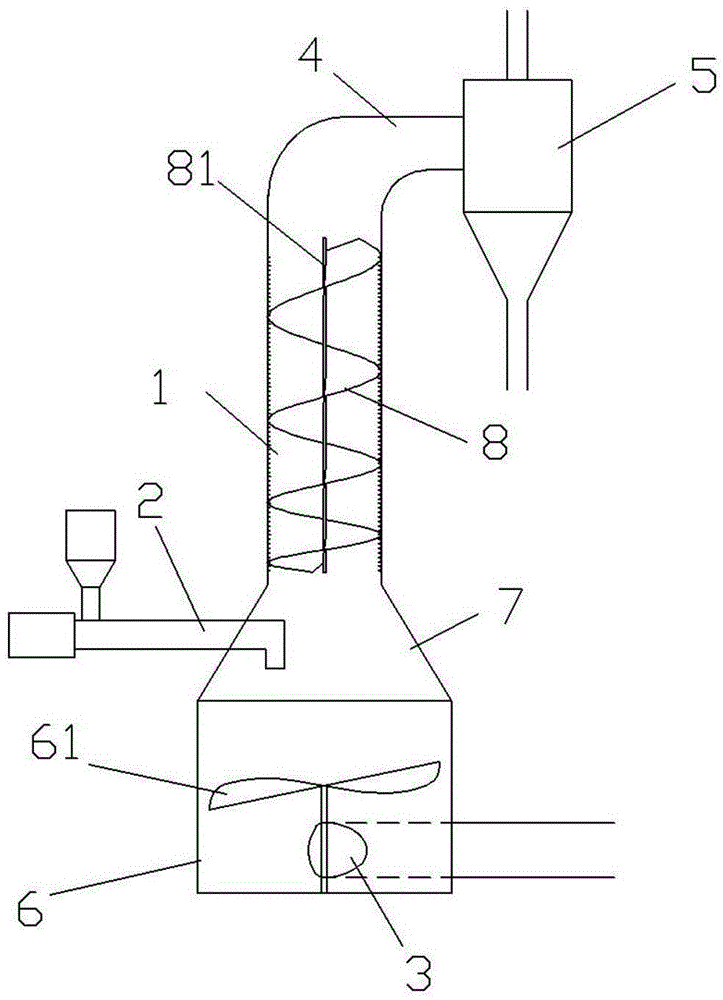

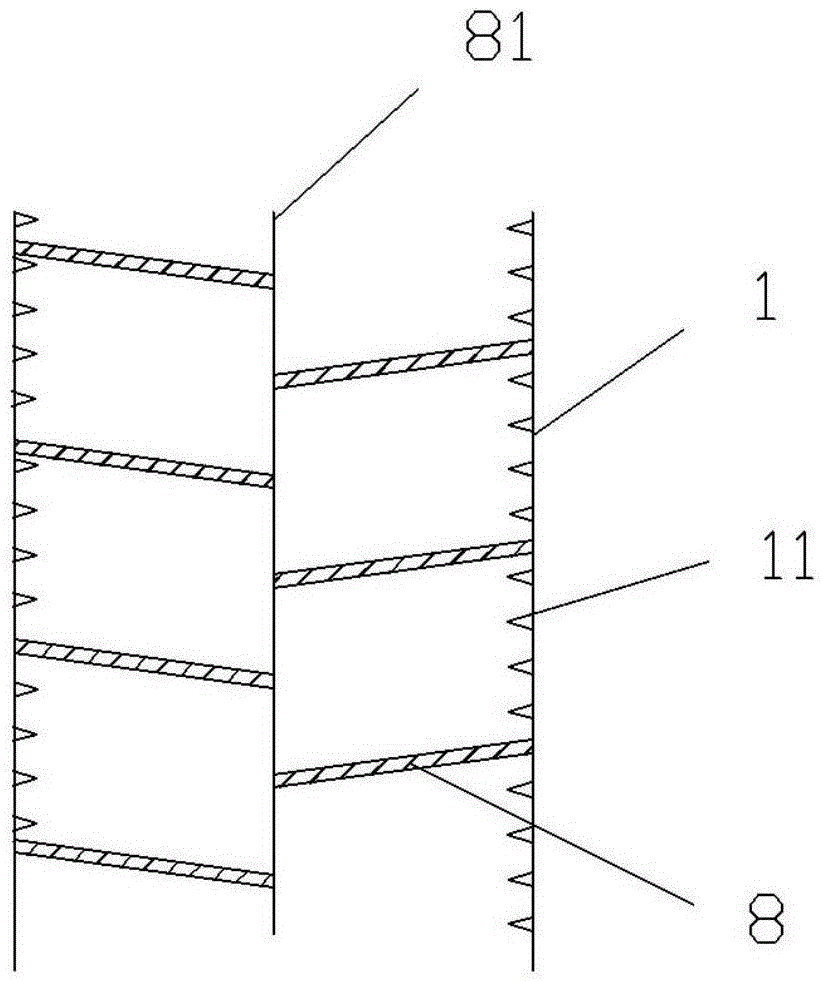

Screw type drying tower

InactiveCN105627720AGuaranteed drynessGranular material dryingDrying gas arrangementsPulp and paper industryTower

The invention discloses a screw type drying tower. The screw type drying tower comprises a tower body, a feeding pipe, a hot air nozzle and a discharging pipe, wherein the tower body is vertically arranged; the screw type drying tower is characterized in that a spiral flow guide plate is arranged inside the tower body; the spiral flow guide plate spirally rises from bottom to top and extends into the tower body from the inner wall of the tower body; a lifting cabin is arranged at the bottom of the tower body; the hot air nozzle is communicated with the lifting cabin; a lifting blade is arranged inside the lifting cabin; the feeding pipe extends into the tower body via the tower body sidewall above the lifting cabin and is arranged below the spiral flow guide plate; the discharging pipe is horizontally arranged at the top of the tower body; the tail end of the discharging pipe is connected with a cyclone separator. Compared with the prior art, the screw type drying tower disclosed by the invention has the advantages that salt particles are separated by arranging the spiral flow guide plate, the separated fine salt particles enter the discharging pipe via the tower body, and the relatively large salt particles are crushed, rapidly dried and subsequently discharged, so qualified salt particles can be screened and dried and the drying effect is guaranteed.

Owner:李书龙

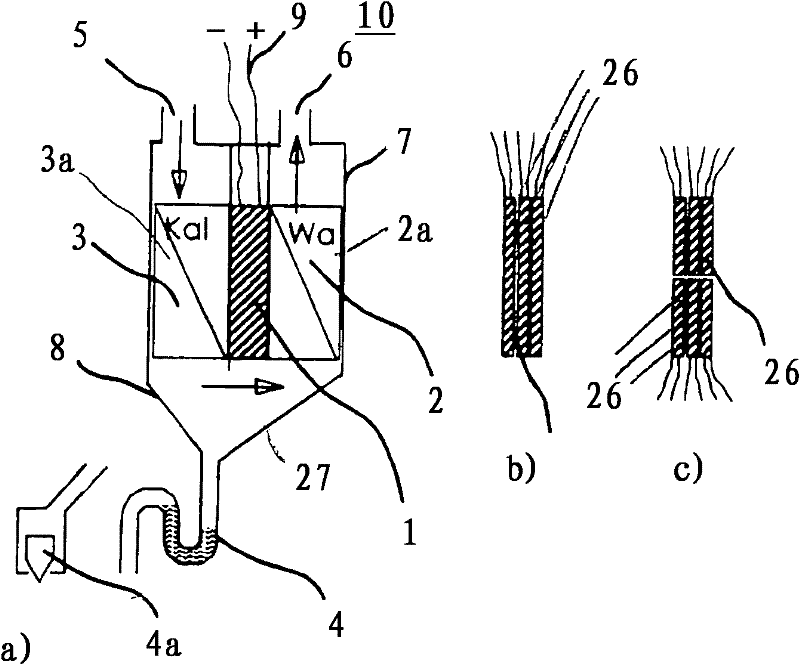

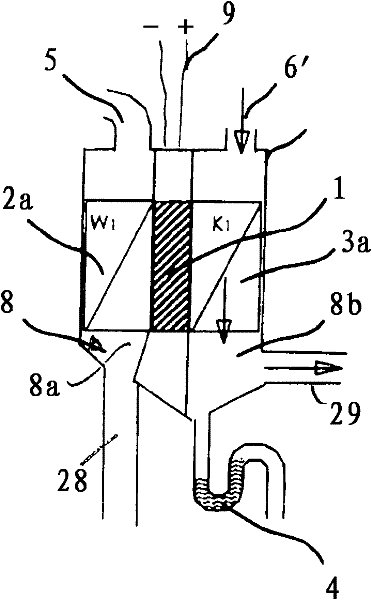

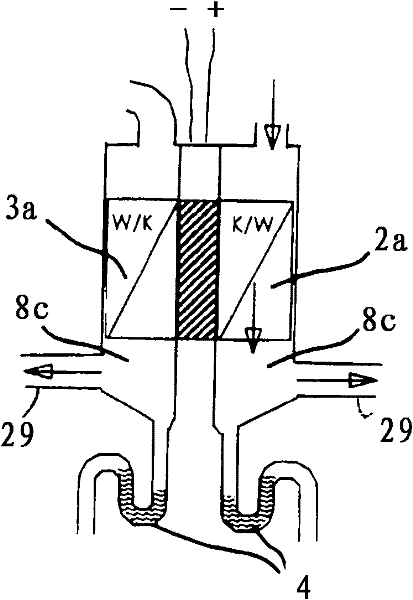

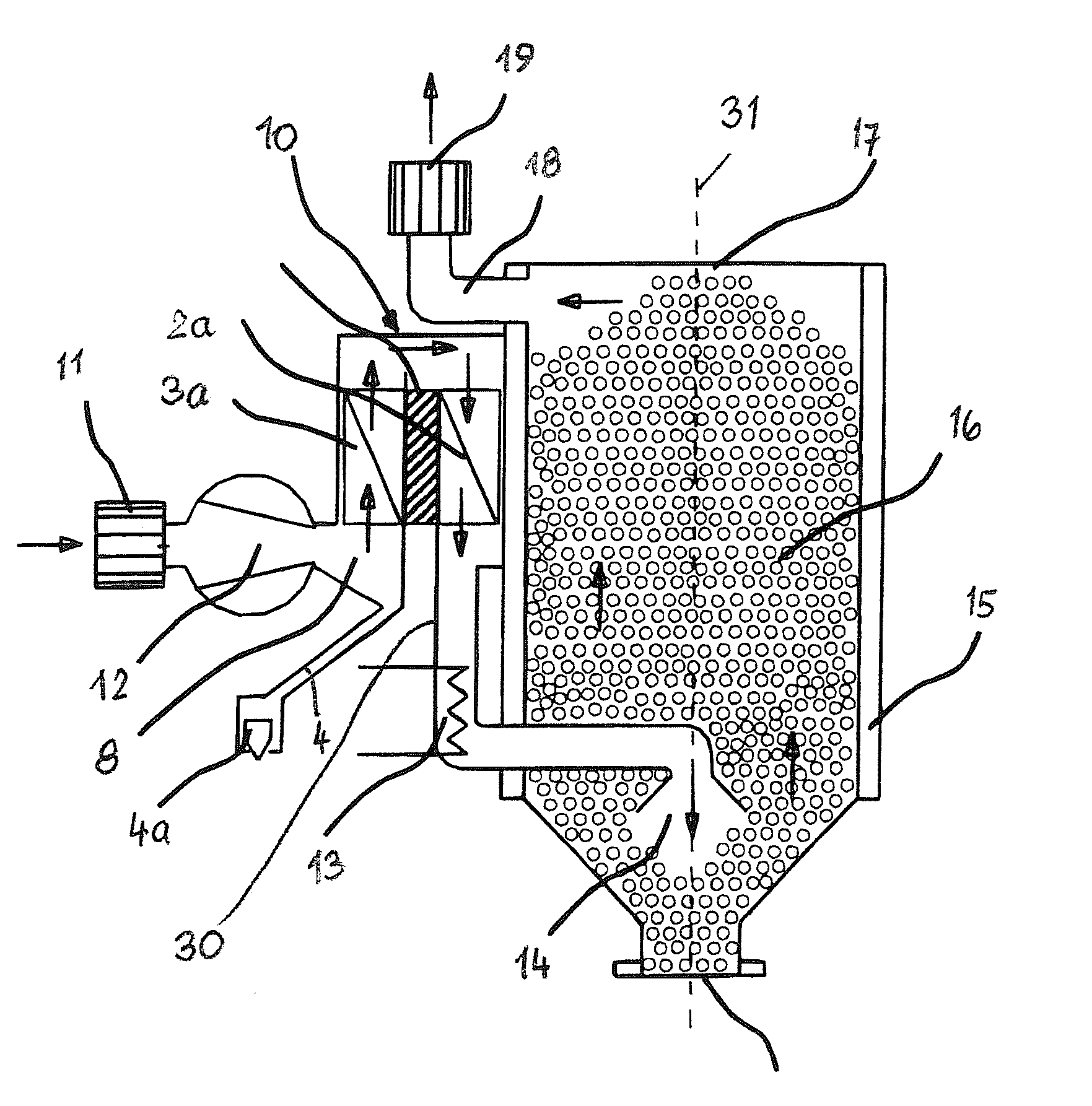

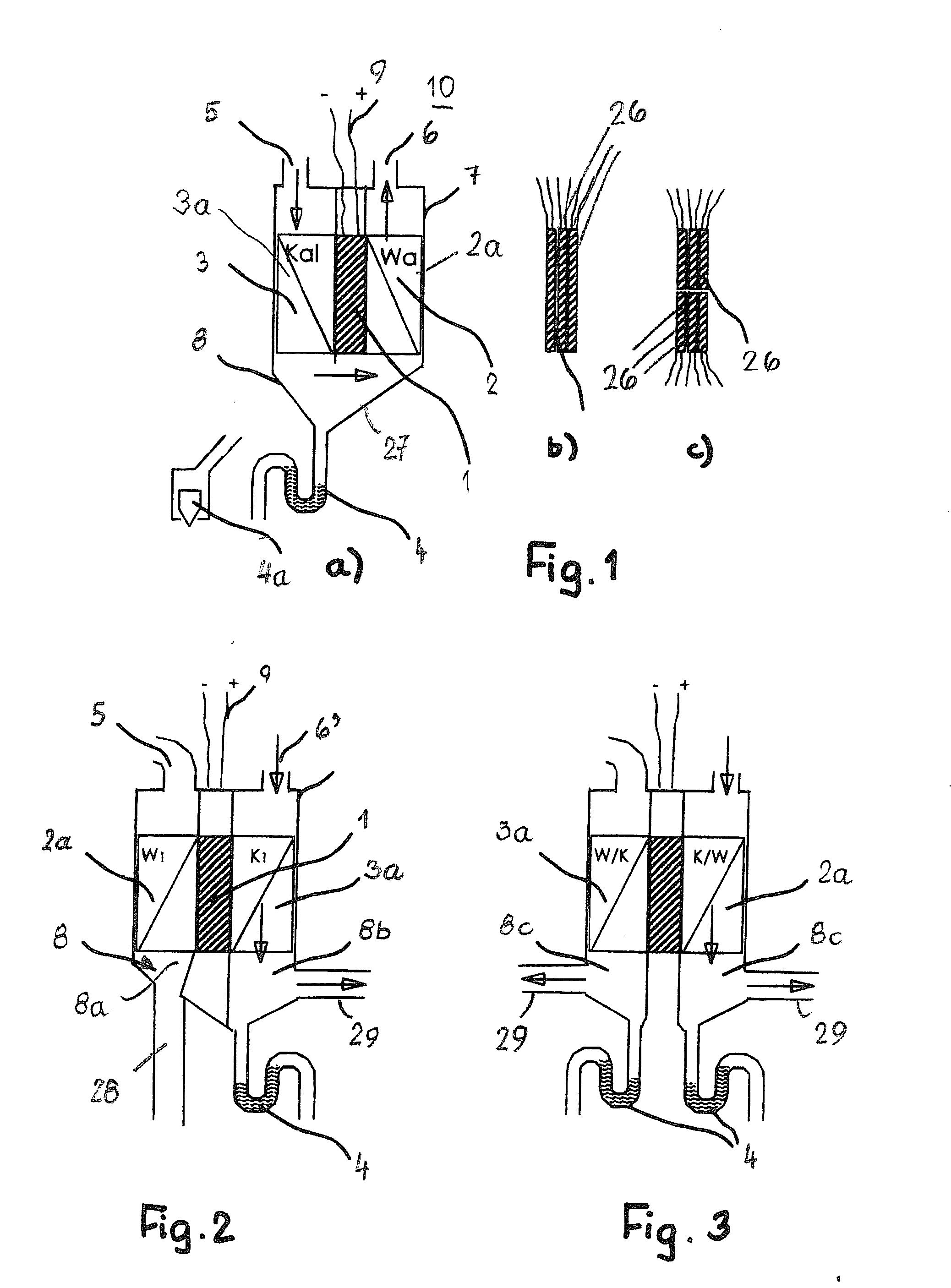

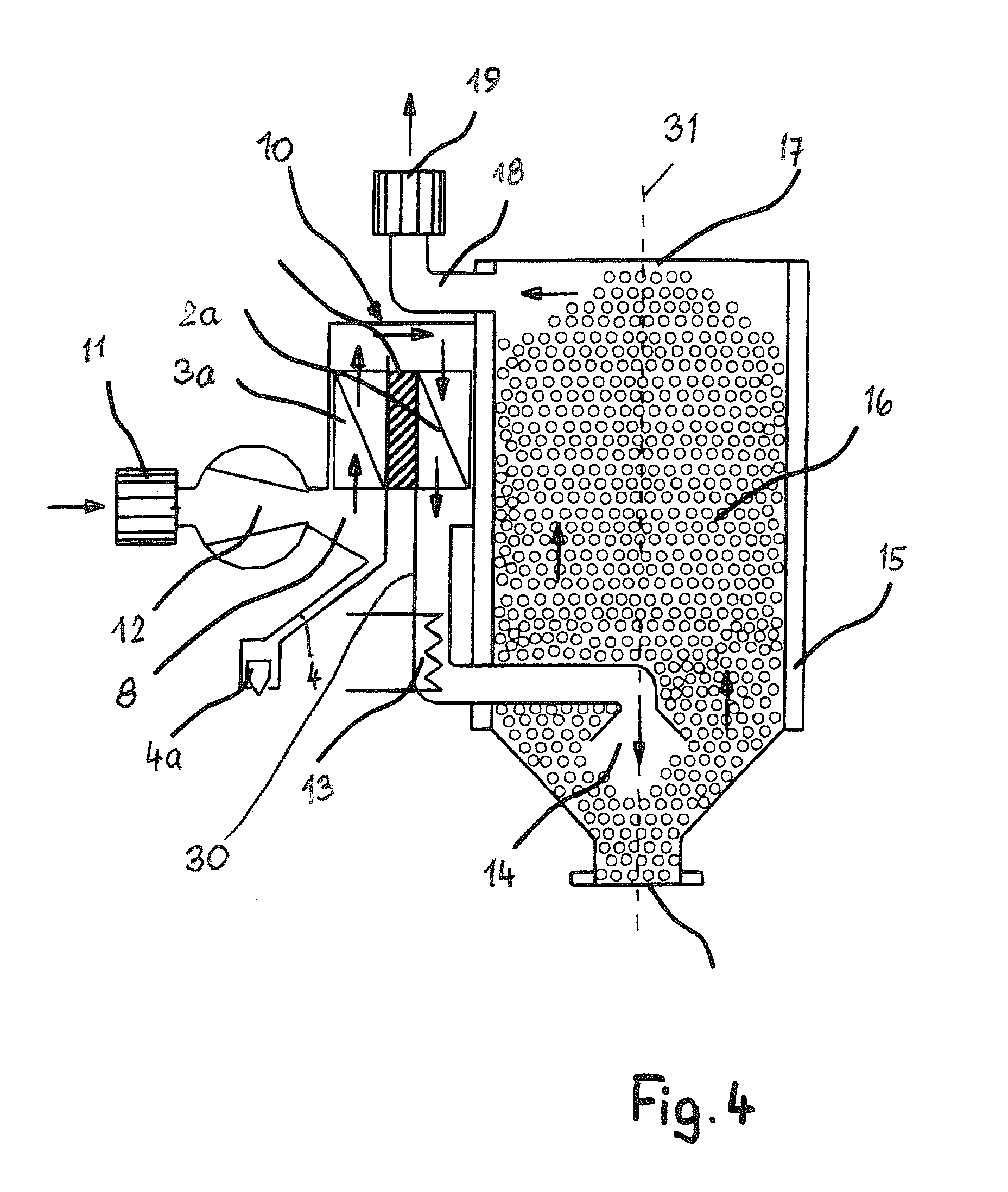

Device for drying bulk material in at least one storage container

InactiveCN102252511AReliable conductionDrying solid materials with heatGranular material dryingCold sidePulp and paper industry

Before being processed, bulk material is dried in a storage container. A drying medium such as air is passed through the bulk material for drying. The drying medium heats the bulk material and removes moisture at the same time. For dehumidifying the drying medium, a dehumidifying unit with a Peltier device is provided whose cold side and whose hot side are positioned within the flow path of the drying medium. The drying medium loaded with moisture is passed across the cold side and dehumidified. The hot side of the Peltier device is used to preheat the dehumidified drying medium.

Owner:MOTAN HLDG

Plastic particle mixing dryer

InactiveCN108204732AStir wellAchieving stirringGranular material dryingDrying gas arrangementsHelical bladeReciprocating motion

The invention belongs to the technical field of plastic manufacturing, and specifically discloses a plastic particle mixing dryer comprising a material barrel and a discharging hopper. The inner wallof the material barrel is provided with a plurality of columnar bulges, and a rotating shaft is provided with helical blades; the top of the rotating shaft is provided with an end cam, and the rotating shaft and the end cam are internally provided with through holes which communicate with each other; the side wall of the rotating shaft in the material barrel is provided with air outlets which communicate with the through holes; a support frame is provided with a cylinder, and the lower end face of an ejector rod in the cylinder abuts against the concave side of the end cam; a coil is wound onthe outer wall of the cylinder, and connected to an AC motor; and the outer wall of the cylinder is provided with a one-way air inlet valve and a one-way air outlet valve, and a hot air pipe communicating with the through holes is installed between the one-way air outlet valve and the end cam. According to the technical scheme, hot air is intermittently discharged into a drying oven through the quick reciprocating motion of a cylinder piston, so that plastic particles are switched between two motion states, namely irregular movement and falling-down, and the plastic particles are mixed thoroughly.

Owner:重庆市中塑新材料有限公司

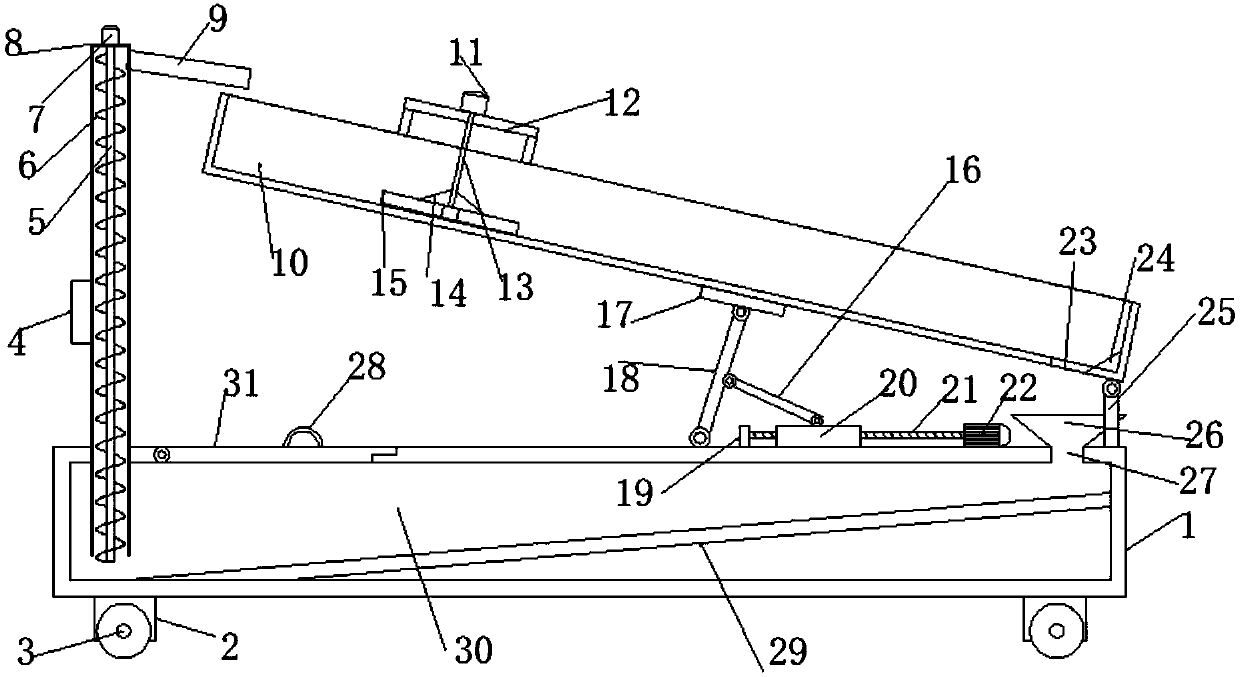

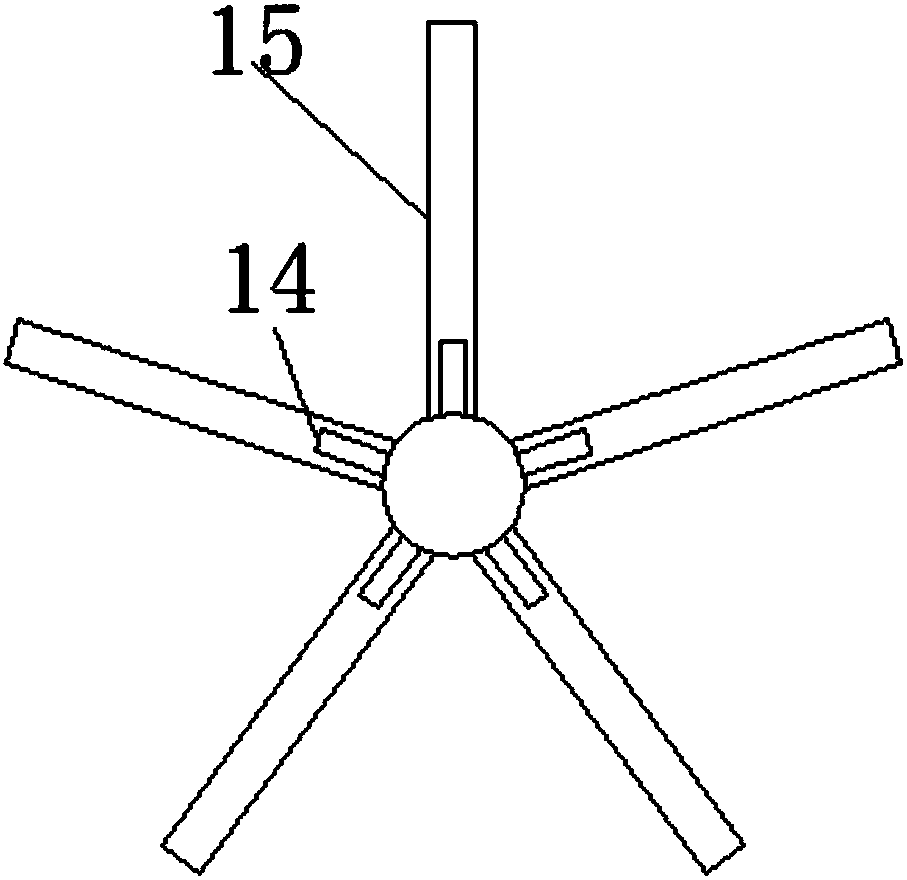

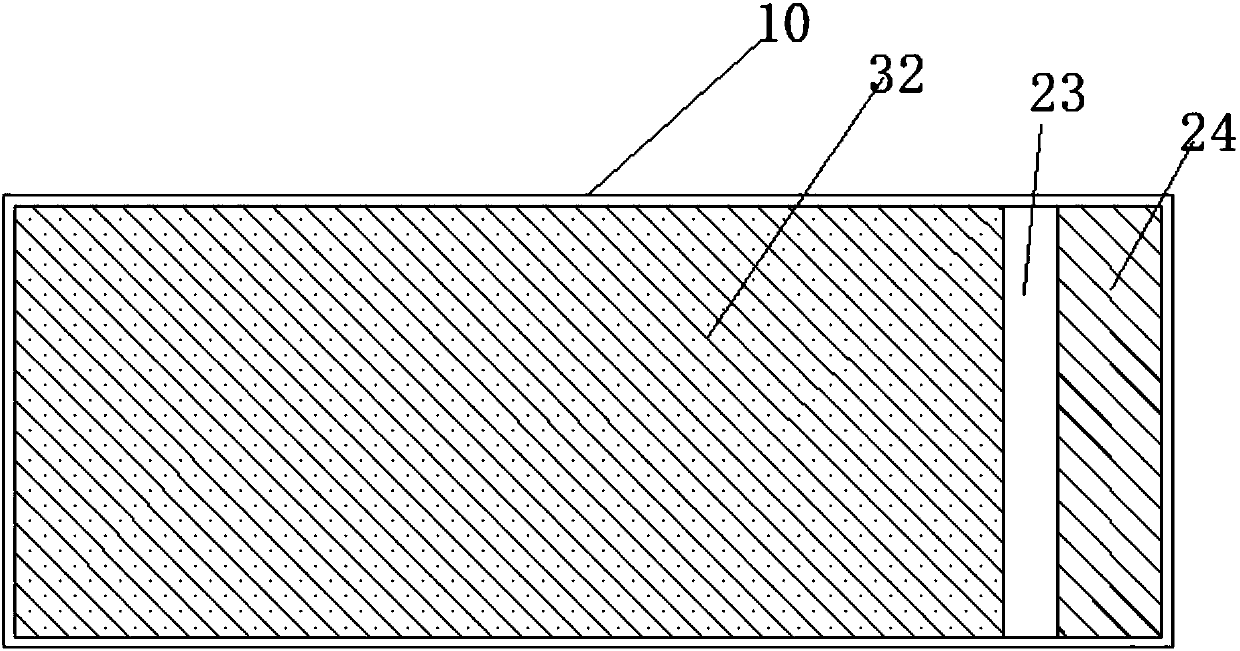

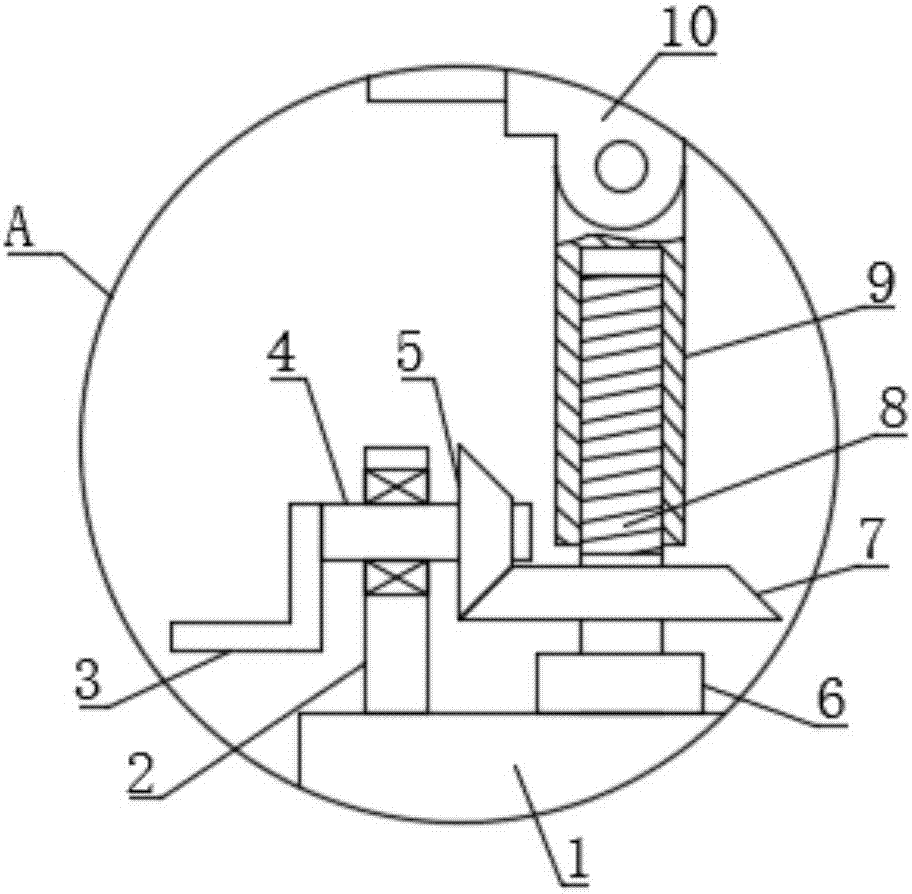

Efficient rapeseed drying and impurity removing device with convenient collecting function

InactiveCN107490271AImprove qualityConvenient for subsequent oil extractionGas current separationGranular material dryingPulp and paper industryRapeseed

The invention discloses a high-efficiency rapeseed sun-drying and impurity removal device for convenient collection, which comprises a base, a support rod is arranged on the top of the base, a drying plate is hinged on the top of the support rod, a slide rail is arranged on the left side of the bottom of the drying plate, and the slide rail slides below A sliding seat is connected, the left side of the top of the base is connected with a screw through the second bearing with a seat, the screw thread is connected with a lifting helical sleeve matched with it, and the top of the lifting helical sleeve is hinged with the sliding seat; the center of the bottom of the drying tray is provided with a fixed frame, an electric push rod is arranged in the fixed frame, the top of the electric push rod push rod is connected with a motor base, the top of the motor base is provided with a decelerating motor, the motor shaft at the top of the decelerating motor is connected with a second rotating shaft, and the top of the second rotating shaft is equipped with rotating blades. The invention can automatically flatten the rapeseed by rotating the rotating blade, so that the drying effect is better; by reducing the height of the rotating blade and then rotating the rotating blade, the rapeseed can be turned over, which effectively improves the working efficiency.

Owner:宋若梅

Efficient drying device for biofuels

InactiveCN106440718AImprove discretenessKeep dryGranular material dryingDrying gas arrangementsBiofuelDrive motor

The invention discloses an efficient drying device for biofuels. The efficient drying device comprises a base and a drying box, wherein the drying box is arranged above the base; the drying box is a cylindrical barrel; a collection box is arranged at the lower end of the drying box; the left side surface of the collection box is a guide oblique surface; supporting legs are arranged among the drying box, the collection box and the base; a discharge baffle plate is arranged at the bottom of the collection box; a lifting barrel is embedded on the upper end face of the collection box where the discharge baffle plate is positioned; a fixed rod is arranged between the left upper side of the lifting barrel and the drying box; a screw conveyer is arranged inside the lifting barrel; a material return pipeline is arranged between the left upper side of the lifting barrel and the top of the drying box; a feeding pipe is arranged on the upper end face of the lifting barrel; a feed hopper is arranged in the middle position of the top of the drying box; stirring shafts are horizontally arranged inside the drying box under the feed hopper; a plurality of stirring rods are arranged on the stirring shafts; and the left ends of the stirring shafts penetrate through the left side wall of the drying box, and are connected with driving motors. According to the efficient drying device, the structure is simple and reasonable, circular drying of materials is achieved, the drying effect is good, and the practicability is high.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

Method and apparatus for making asphalt concrete using aggregate material from a plurality of material streams

InactiveUS20150029809A1Emission controlThermally efficientGranular material dryingRotary drum furnacesCombustionMaterials science

A combination of components is provided for use in making asphalt concrete from a plurality of aggregate material streams. The combination includes an indirect dryer for heating aggregate material from a first material stream without directly exposing said first stream material to hot gases of combustion. The combination also includes a mixer for mixing aggregate material from the first material stream, aggregate material that has not been heated in the indirect dryer from a second material stream, and a binder component to produce asphalt concrete.

Owner:ASTEC

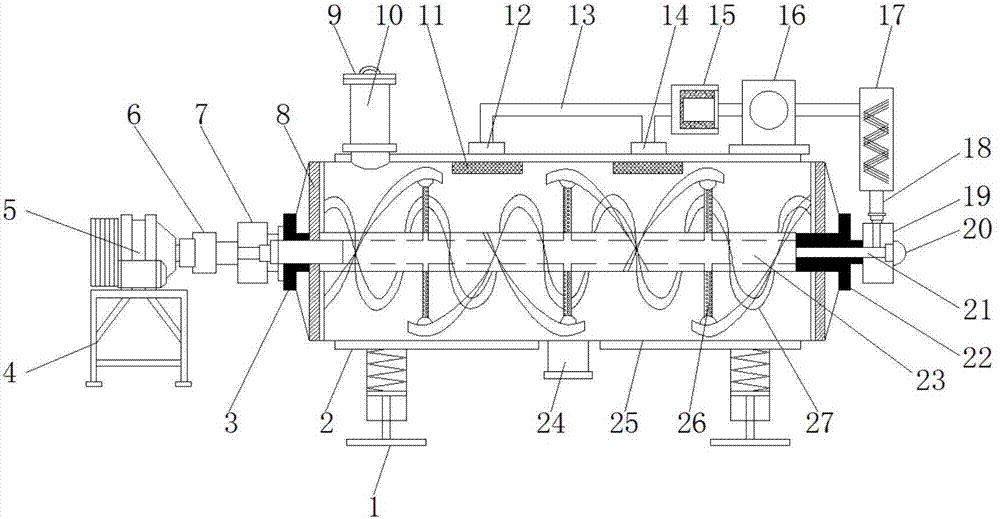

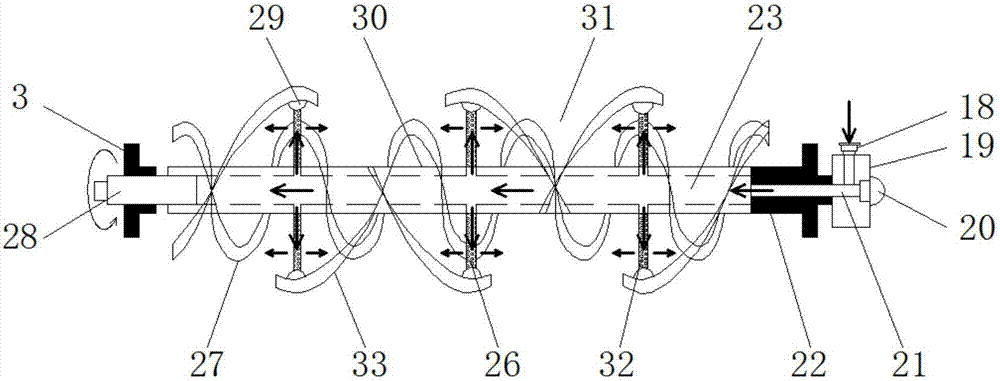

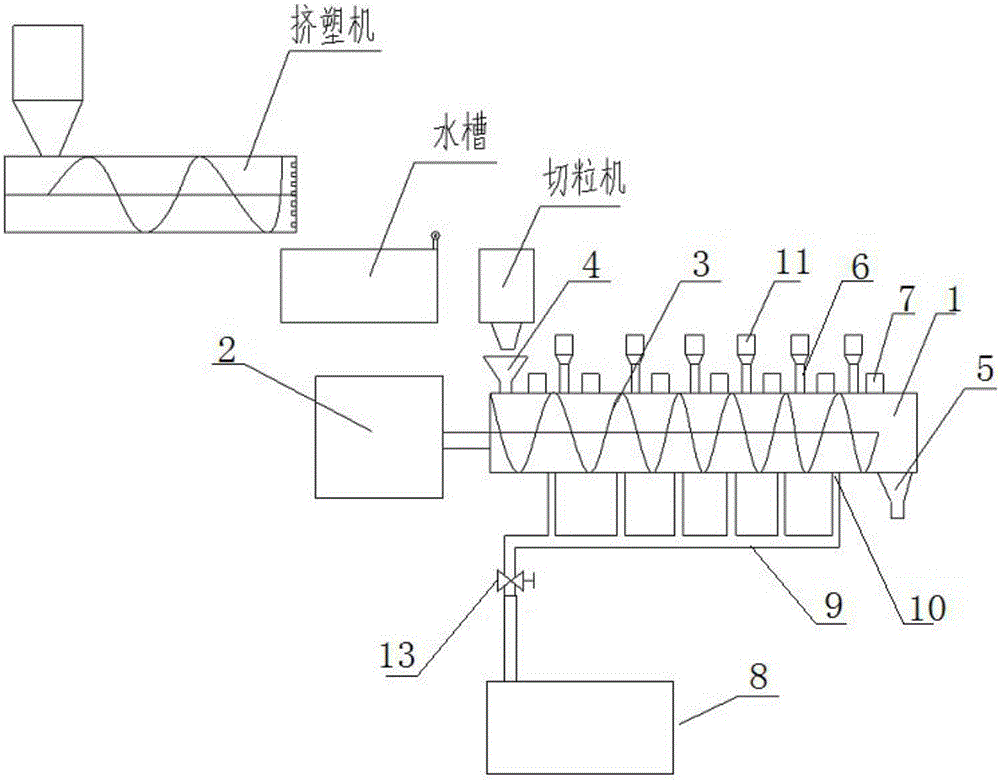

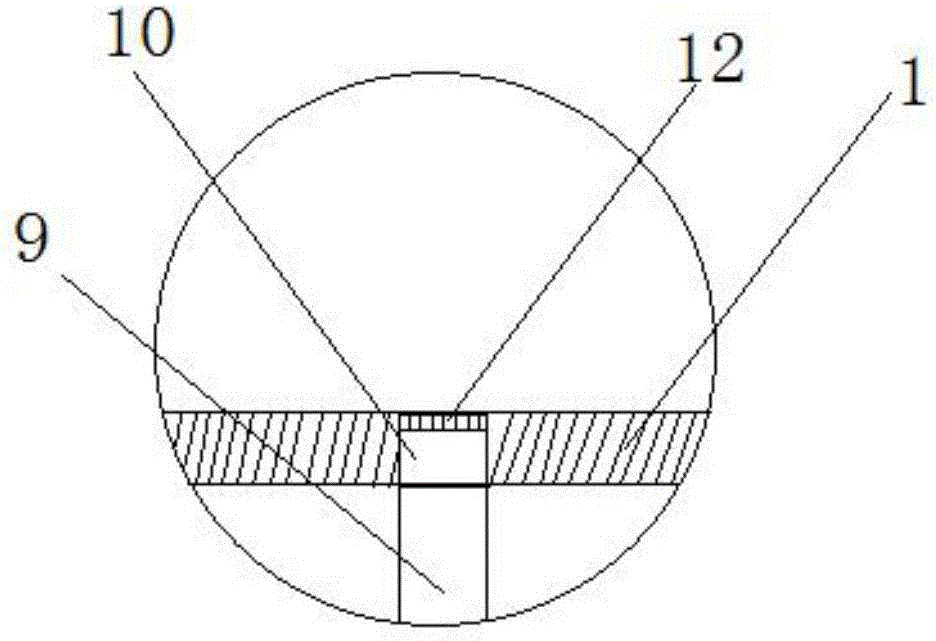

Device and method for fast drying after plastic extrusion pelletizing

InactiveCN106738435AReduce water temperatureReduce energy consumptionDrying solid materials with heatGranular material dryingMicrowaveSilanes

The invention discloses a device and method for fast drying after plastic extrusion pelletizing. A drying chamber is a transversely-arranged cylinder with two closed ends. A spiral conveying blade is arranged in the drying chamber. A driving device used for driving the spiral conveying blade to rotate is arranged outside the drying chamber. A feeding port hopper is arranged at the upper portion of one end of the drying chamber, and a drying terminal discharging port is formed in the lower portion of the other end of the drying chamber. Multiple microwave sources and multiple air outlet pipes are arranged at the upper end of the drying chamber in the length direction of the drying chamber. Multiple air supply openings are formed in the lower end of the drying chamber in the length direction of the drying chamber. The air supply openings are connected with a dry air producing device through an air supply pipe. A micro drying method is adopted for silane crosslinking polyethylene particles through the above micro drying device, so that the total energy consumption is reduced by 80% or above, and the production cost is reduced; the drying time is short, and the drying performance is good; no noise is generated in the drying process; and the quality is stably controlled and is not affected by environment weather changes.

Owner:TIANJIN LAIWO VACUUM DRYING EQUIP MFG CO LTD

Device for Drying Bulk Material in at least one Storage Container

InactiveUS20110283554A1Increase temperature differenceSave energyDrying solid materials with heatGranular material dryingCold sidePulp and paper industry

Before being processed, bulk material is dried in a storage container. A drying medium such as air is passed through the bulk material for drying. The drying medium heats the bulk material and removes moisture at the same time. For dehumidifying the drying medium, a dehumidifying unit with a Peltier device is provided whose cold side and whose hot side are positioned within the flow path of the drying medium. The drying medium loaded with moisture is passed across the cold side and dehumidified. The hot side of the Peltier device is used to preheat the dehumidified drying medium.

Owner:MOTAN HLDG

Quick drying and discharging device for feed granulation

InactiveCN107940969ANovel structural designSmooth drying processFeeding-stuffGranular material dryingDrive motorEngineering

The invention discloses a quick drying and discharging device for feed granulation. The quick drying and discharging device for feed granulation comprises a supporting mounting plate, a supporting mounting barrel is vertically arranged at the upper end of the supporting mounting plate, and a distribution mounting barrel is vertically upward fixed to the middle of the lower end of the supporting mounting barrel through a horizontally arranged supporting mounting frame. A motor mounting barrel fixed in the middle of the upper end of the supporting mounting barrel in a vertically inlaid mode is provided with a driving motor, a plurality of sets of flow guide heat dissipation pipes inclined at the same angle are arranged on the outer sides of the distribution mounting barrel in cooperation with the driving motor upwards, the upper ends of the flow guide heat dissipation pipes are all connected with the top end of the supporting mounting barrel, a plurality of heat dissipation flow guide holes are evenly formed in the outer side of each flow guide heat dissipation pipe in a penetrating mode, and a transmission rotating shaft penetrating through the distribution mounting barrel is arranged at the lower end of the driving motor vertically downwards. The quick drying and discharging device for feed granulation has the advantages of novel design, multilayer movable drying, circulation turbulent flow blowing, smooth drying process, quick drying and discharging, good quality and the like.

Owner:季梅

Spheroidal polyester polymer particles

Spheroidal polyester polymer particles, as well as preforms and stretch blow molded bottles made from the spheroidal particles, are provided which have: A) an It.V. of at least 0.72 dL / g, and either B) at least two melting peaks (on a DSC first heating scan), wherein one of said at least two melting peaks is a low peak melting point having a peak temperature within a range of 140° C. to 220° C. and having a melting endotherm area of at least the absolute value of 1 J / g, or C) a low degree of crystallinity within a range of at least 20% and a maximum degree of crystallinity Tcmax defined by the equation: Tcmax=50%−CA−OH where CA is the total mole % of all carboxylic acid residues other than terephthalic acid residues, based on 100 mole % of carboxylic acid residues in the polyester polymer, and OH is the total mole % of hydroxyl functional compound residues other than ethylene glycol residues, based on 100 mole % of the hydroxyl functional compounds residues; or both B) and C); and optionally but preferably D) 10 ppm or less of residual acetaldehyde.

Owner:ALPEK POLYESTER SA DE CV

Plastic particle heating and drying device

InactiveCN106440717AEfficient DryingSimple structureGranular material dryingDrying gas arrangementsEngineeringMoisture

The invention provides a plastic particle heating and drying device. The plastic particle heating and drying device comprises a material stirring device and a dehumidifying and drying device; the material stirring device comprises material overturning plates, a treatment barrel, a charging barrel, a transmission case and a motor; the treatment barrel is welded to two supporting plates; the transmission case is fixedly arranged on a fixing plate; the motor is fixedly arranged on the fixing plate and on the right side of the transmission case; the material overturning plates are fixedly connected with fixing rods through screws; the charging barrel is welded to the treatment barrel; the dehumidifying and drying device comprises a drying box for drying, a drying device, a dehumidifier and a moisture extracting box; the drying box for drying is welded to the upper portion in the treatment barrel; the dehumidifier is fixedly arranged on a base; the moisture extracting box is welded to the bottom face in the treatment barrel; and the drying device is arranged on the transmission case. The plastic particle heating and drying device is simple in structure, by means of cooperation of a dehumidifying device and the drying device, plastic particles can be efficiently subjected to drying treatment, and the requirements of production and use are met.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com