Patents

Literature

609results about How to "Guaranteed drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

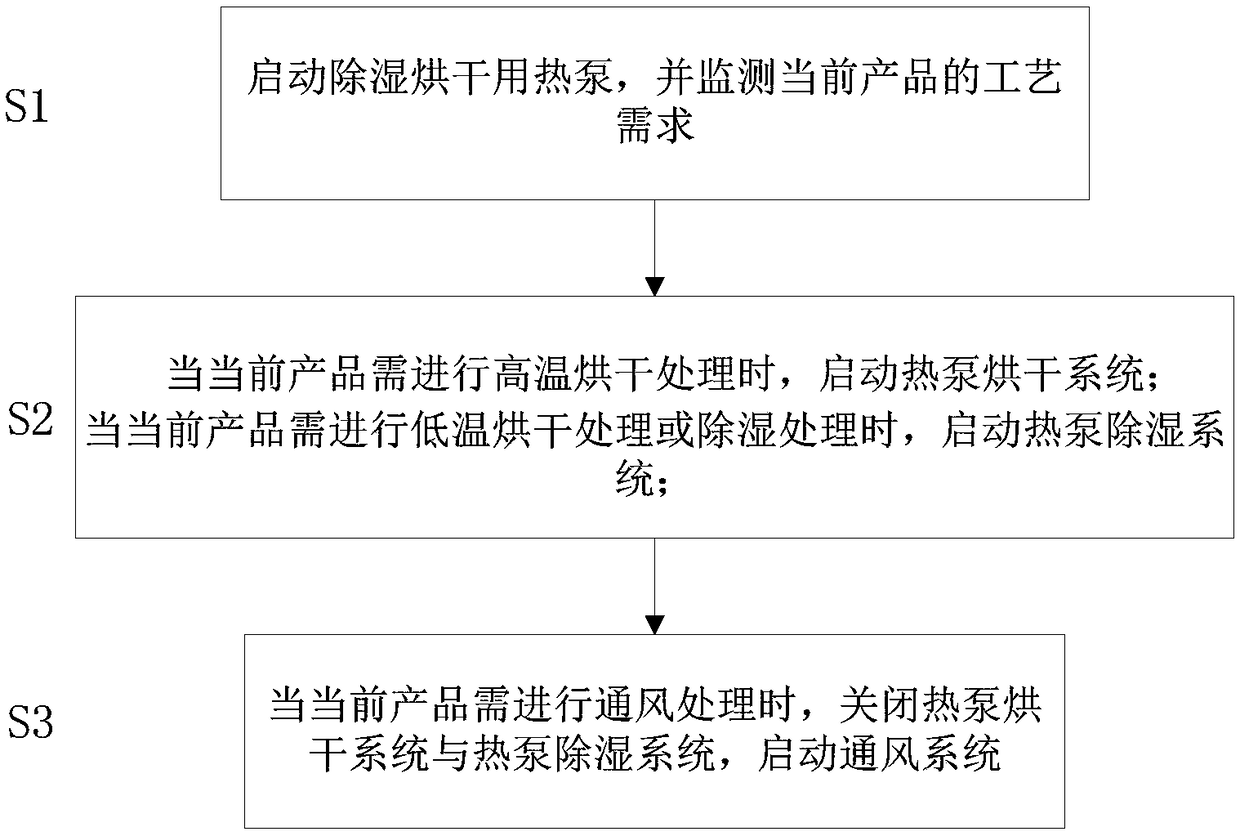

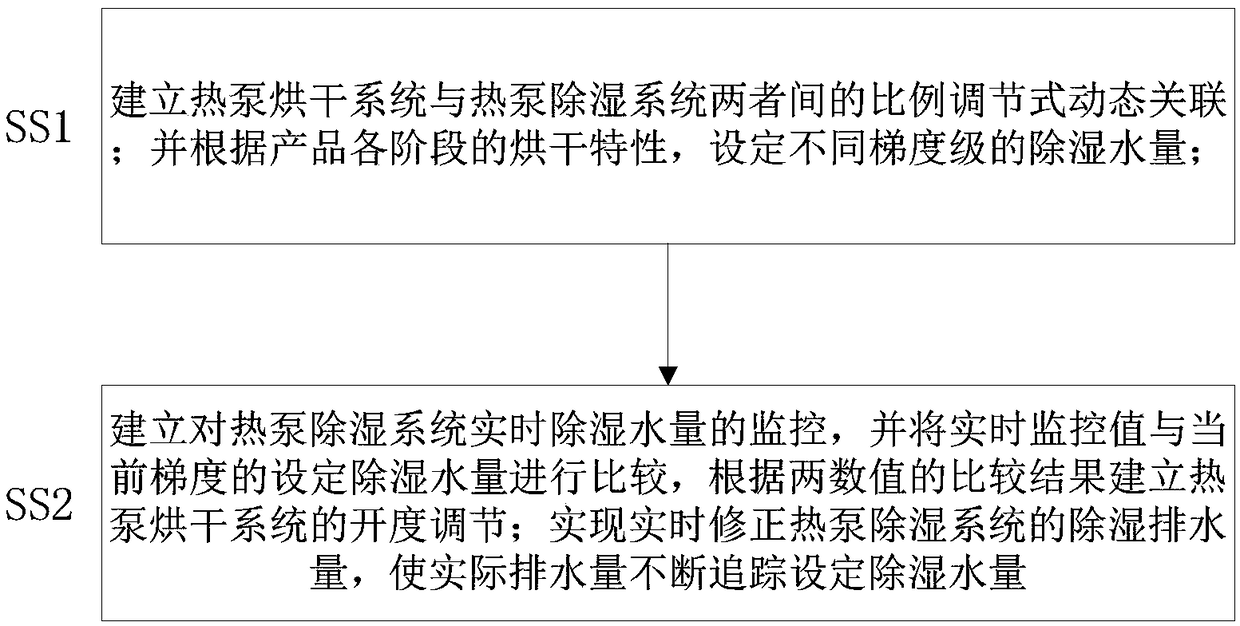

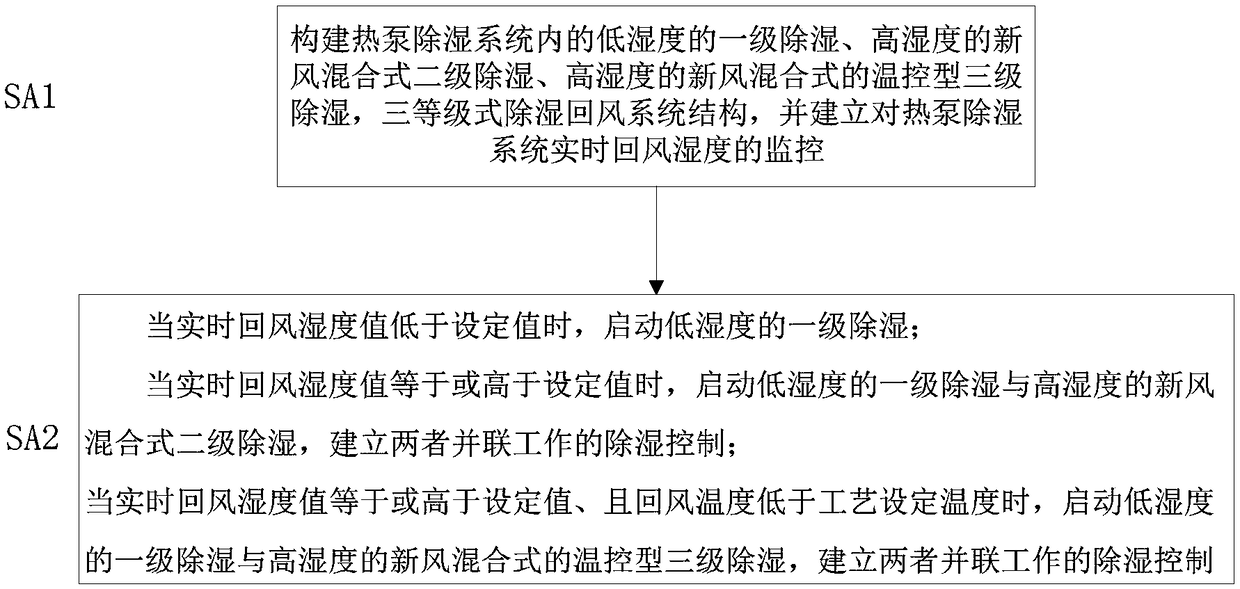

Heat pump control method for dehumidification and drying

ActiveCN109489402AAvoid lostMeet the requirements of dehumidificationHeat pumpsDrying gas arrangementsProcess engineeringEngineering

The invention relates to a heat pump control method for dehumidification and drying. A heat pump drying system, a heat pump dehumidification system and a ventilation system are established according to three factors of drying, dehumidification and ventilation, and according to the process requirements of current products, the heat pump control method for dehumidification and drying based on the heat pump drying system, the heat pump dehumidification system and the ventilation system is established. The heat pump control method for dehumidification and drying includes the steps that air sourcemulti-dimensional treatment type dehumidification and drying control is established, and according to the requirements of different process working conditions, air from a drying room can be simultaneously dehumidified and heated to meet the requirement of dehumidification; heat can be also absorbed from the external environment space, the heat is transferred to the drying room, and the requirementof the high temperature environment is met; and when the humidity of a unit is high, dehumidification and fresh air entering are conducted, total heat recovery is conducted on fresh air and dehumidification , and the heat loss during dehumidification is effectively avoided. Not only is the requirement of dehumidification under the low temperature working condition met, but also the requirements of dehumidification and drying at high temperature are ensured, the drying effect of the products is ensured, and the operating costs of the products are reduced.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

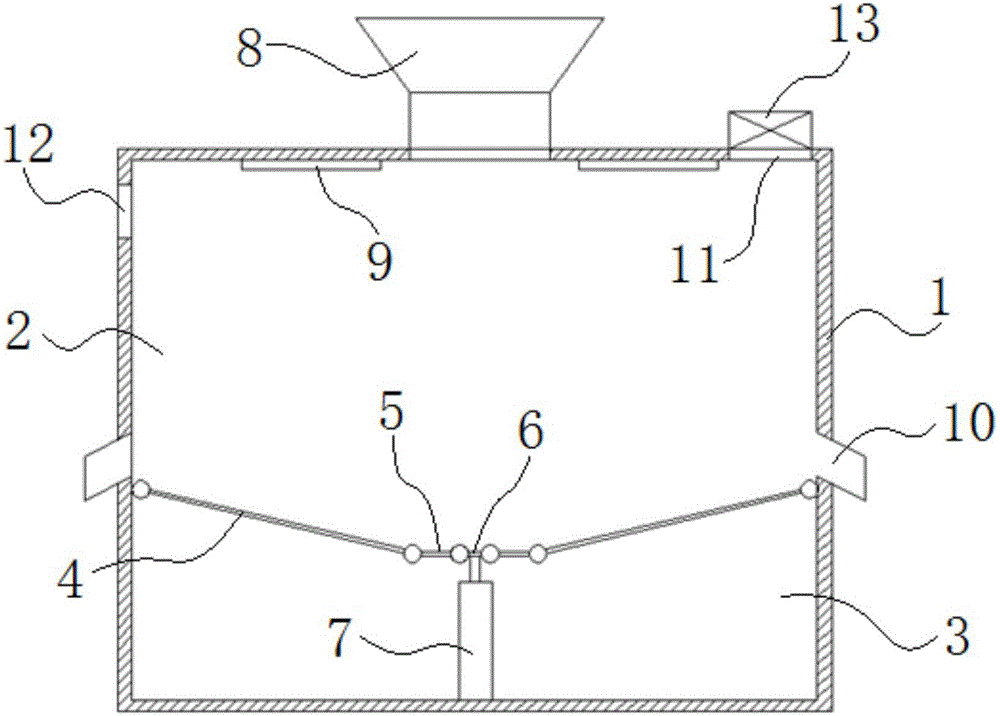

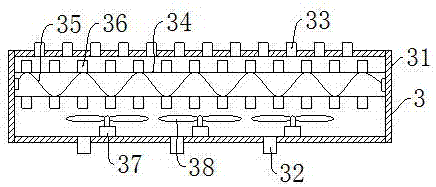

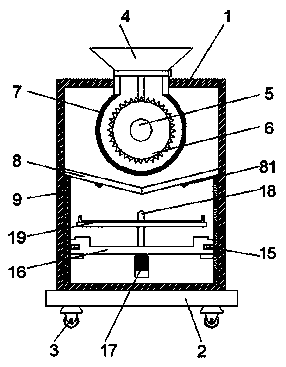

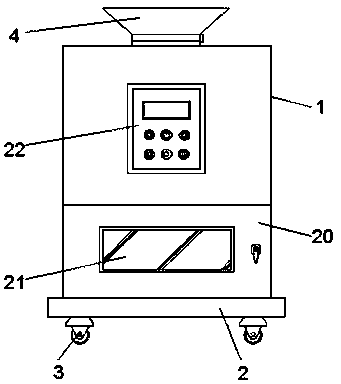

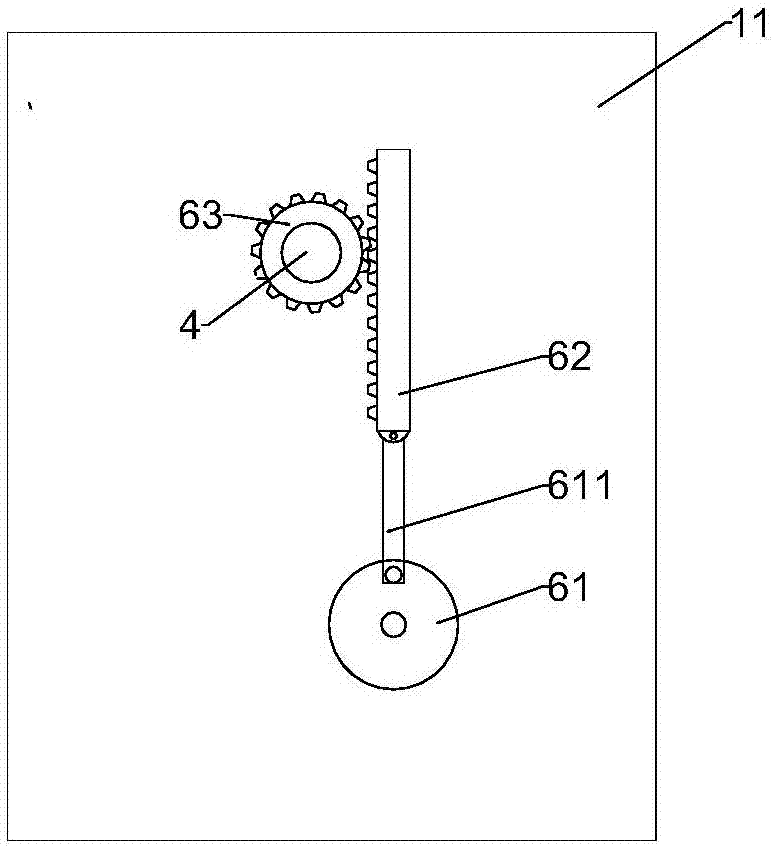

Fodder drying device

InactiveCN106568301ASimple structureReduce volumeDrying gas arrangementsDrying solid materialsEngineeringFodder

The invention discloses a fodder drying device. The fodder drying device comprises a machine shell, a swing plate, two connection plates, a lifting plate, a lifting drive mechanism, a feeding hopper, heating devices and discharge chutes, wherein the swing plate separates an inner cavity of the machine shell into an upper chamber and a lower chamber, and the upper cavity serves as a driving chamber; the swing plate comprises two side plates, and one end of each of the two side plates is hinged to the inner wall; one end of each of the two connection plates is hinged to the other end of the corresponding side plate; the two ends of the lifting plate are hinged to the other end of the corresponding connection plate; the lifting drive mechanism is used for driving the lifting plate to ascend and descend; the feeding hopper is arranged at the top of the machine shell; the heating devices are arranged in the drying chamber; the left side and the right side of the drying chamber are provided with the discharge chutes respectively, and each discharge chute is higher than or equal to the hinge position of the side plate on the same side and the inner wall of the machine shell. According to the fodder drying device, fodder is turned through vertical swing of the swing plate so that the fodder can be dried uniformly; the fodder can also be discharged out of the two discharge chutes by lifting the swing plate; and the fodder drying device is simple in structure, small in size and low in weight.

Owner:南宁市美嘉农饲料有限责任公司

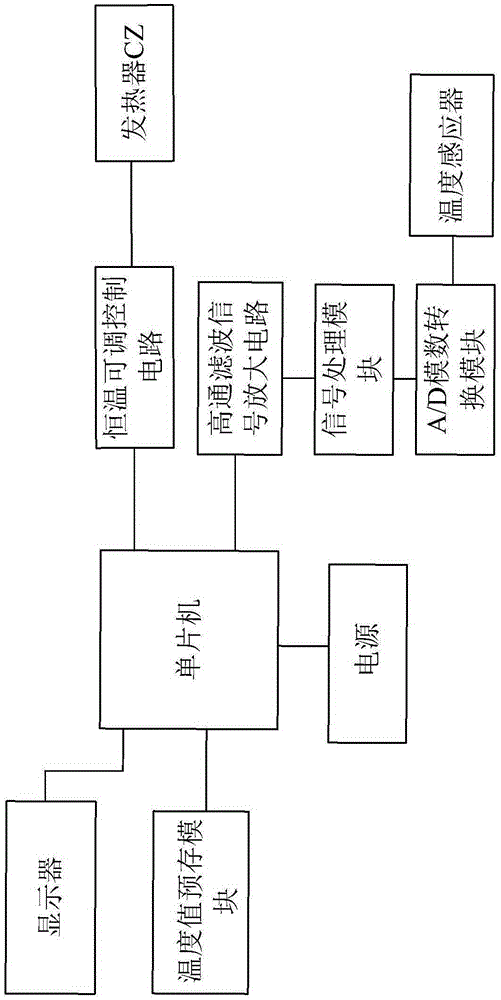

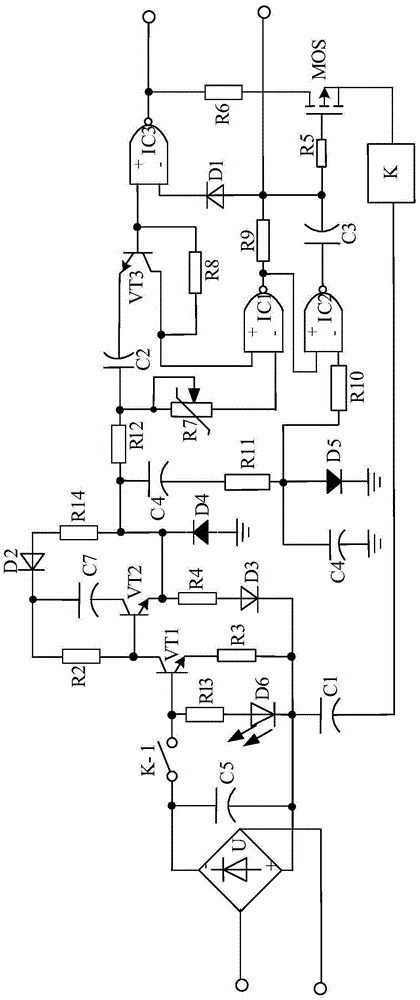

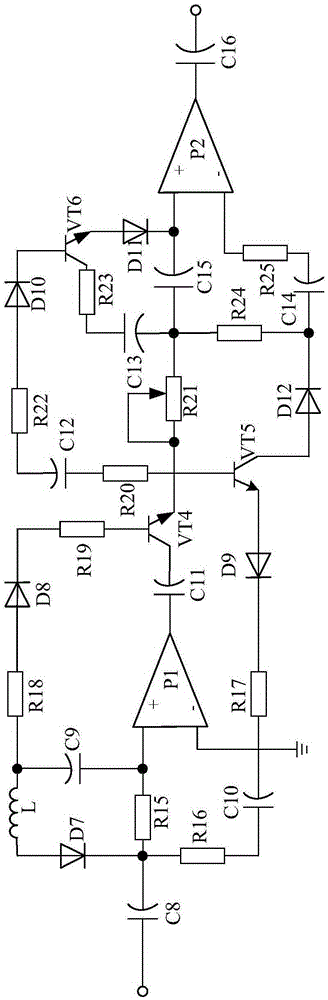

Dryer temperature control system based on high-pass filter and amplification circuit

InactiveCN105404334AGuaranteed accuracyStable jobAuxillary controllers with auxillary heating devicesMicrocontrollerSynchronous motor

Disclosed in the invention is a dryer temperature control system based on a high-pass filter and amplification circuit. The system comprises a single-chip microcomputer, a display device, a temperature value pre-storage module, a signal processing module, a heater CZ, a power supply, an A / D analog-digital conversion module, and a temperature inductor, wherein the display device, the temperature value pre-storage module, the signal processing module, the heater CZ, the power supply, the A / D analog-digital conversion module, and the temperature inductor are connected with the single-chip microcomputer. The heating unit includes a synchronous motor, a fan arranged at an end portion of an upper end of a transmission shaft of the synchronous motor, and the heater CZ arranged at an air outlet of the fan. The system is characterized in that a high-pass filter and signal amplification circuit is connected in series between the signal processing module and the single-chip microcomputer; and a constant-temperature adjustable control circuit is connected between the single-chip microcomputer and the heater CZ. According to the invention, the system has the stable performances, so that the temperature stability of the hot-air dryer can be guaranteed effectively.

Owner:CHENGDU JUHUICAI TECH

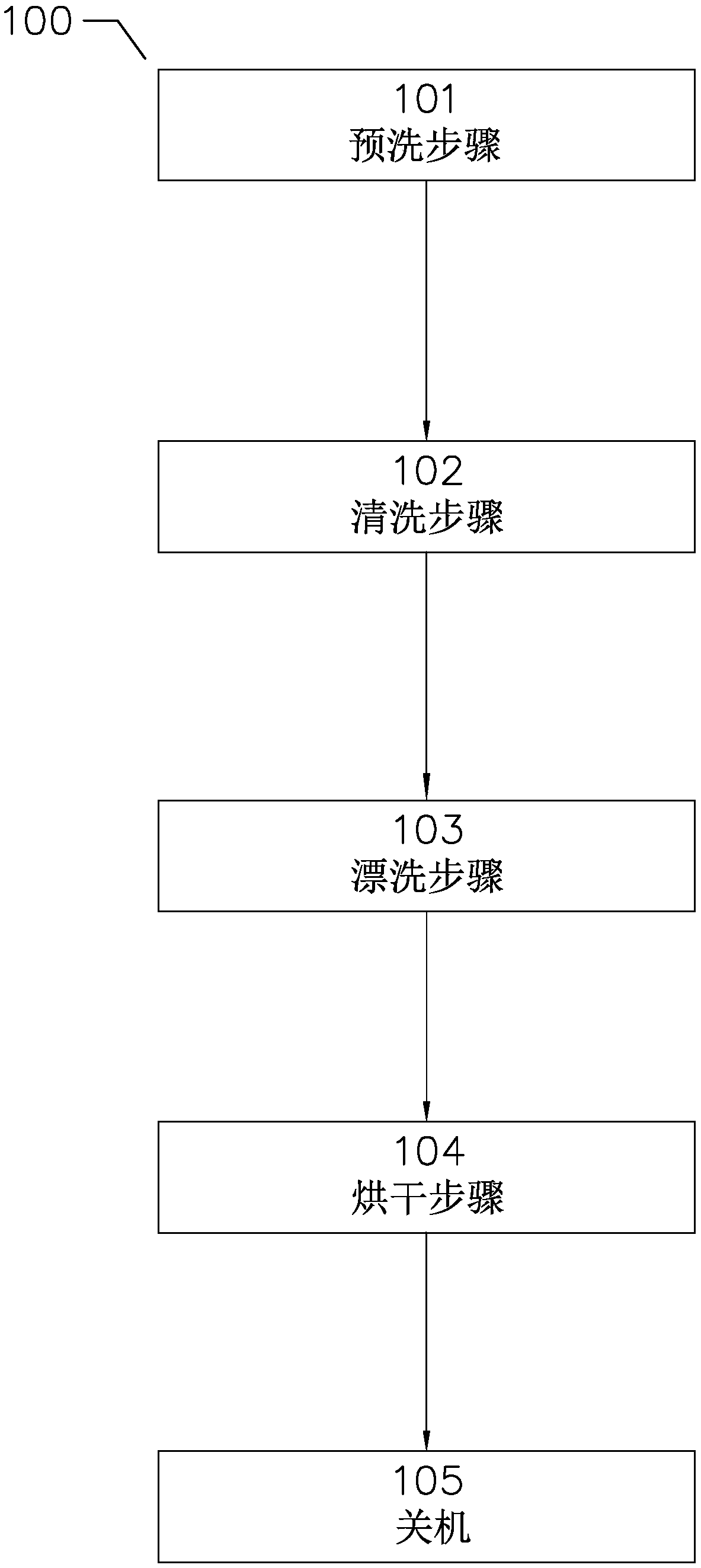

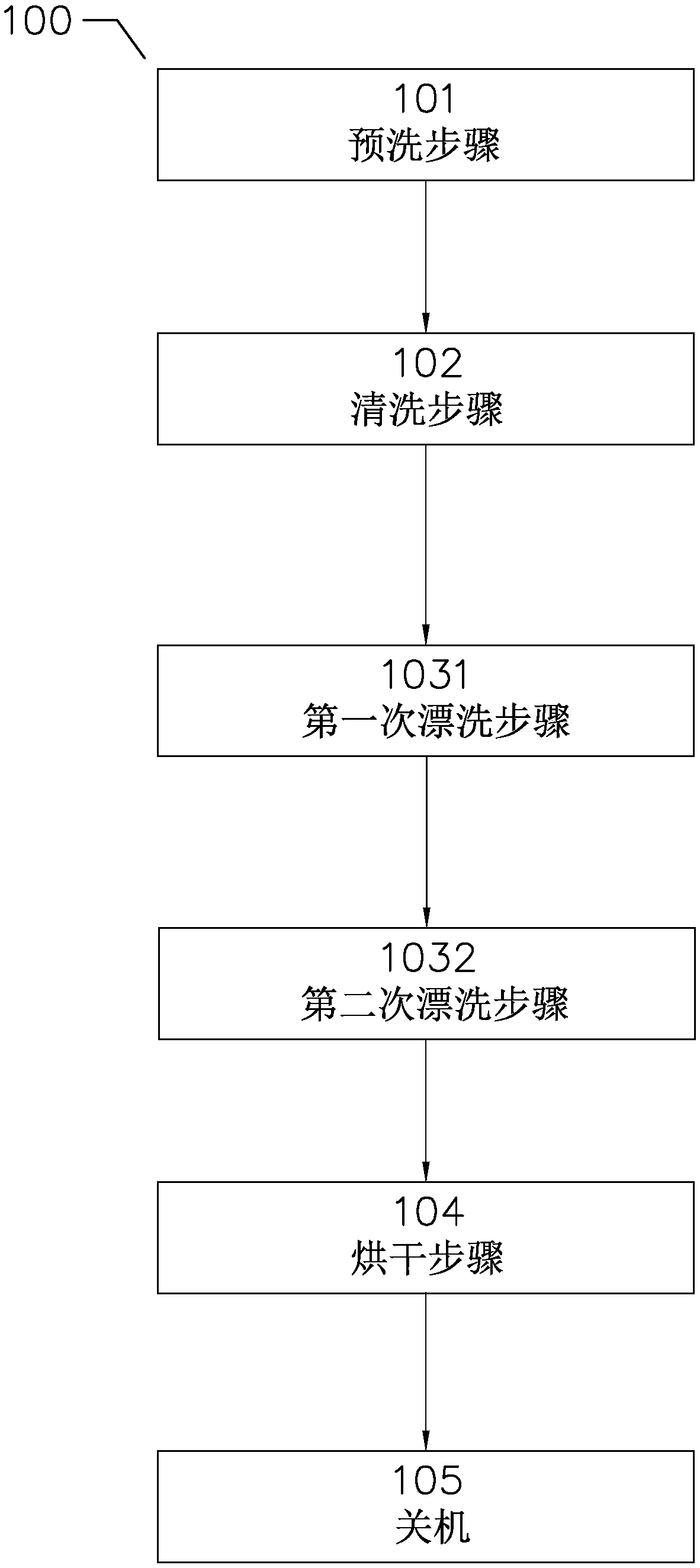

A Dishwasher Washing Method and a Dishwasher

InactiveCN108968861AImprove intelligenceGuaranteed washing effectWashing processesTurbidityProcess engineering

The invention provides a dishwasher washing method and a dishwasher, comprising a washing step, a rinsing step and a drying step. The dishwasher sets a pre-washing step before the washing step by adding water of capacity C1 to the sink and heating the water until the temperature reaches temperature T1. The washing pump works for time t1 and then suspends for time t2; the dishwasher determines thewashing mode according to the turbidity of the water detected by the turbidity sensor. The dishwasher determines the washing mode by adding a certain capacity of water, heating the water to a certaintemperature, washing for a period of time and then suspending for a period of time, and finally detecting the turbidity of the water through the turbidity sensor. This method adds a fast, accurate andefficient pre-washing process, and then determines the washing mode according to the detection of the turbidity sensor. Compared with the existing method of continuously detecting the turbidity of the water during the cleaning process, the method is more efficient for ensuring the washing effect by prolonging the cleaning time.

Owner:杭州小月亮科技有限公司

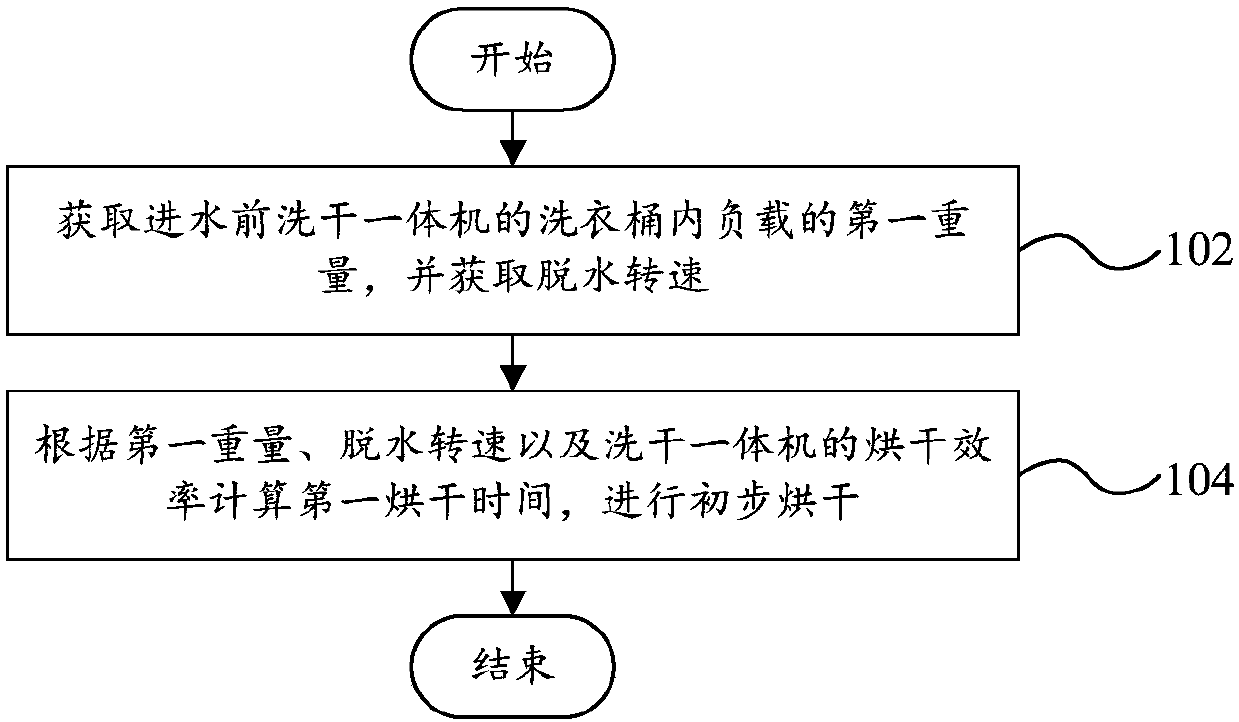

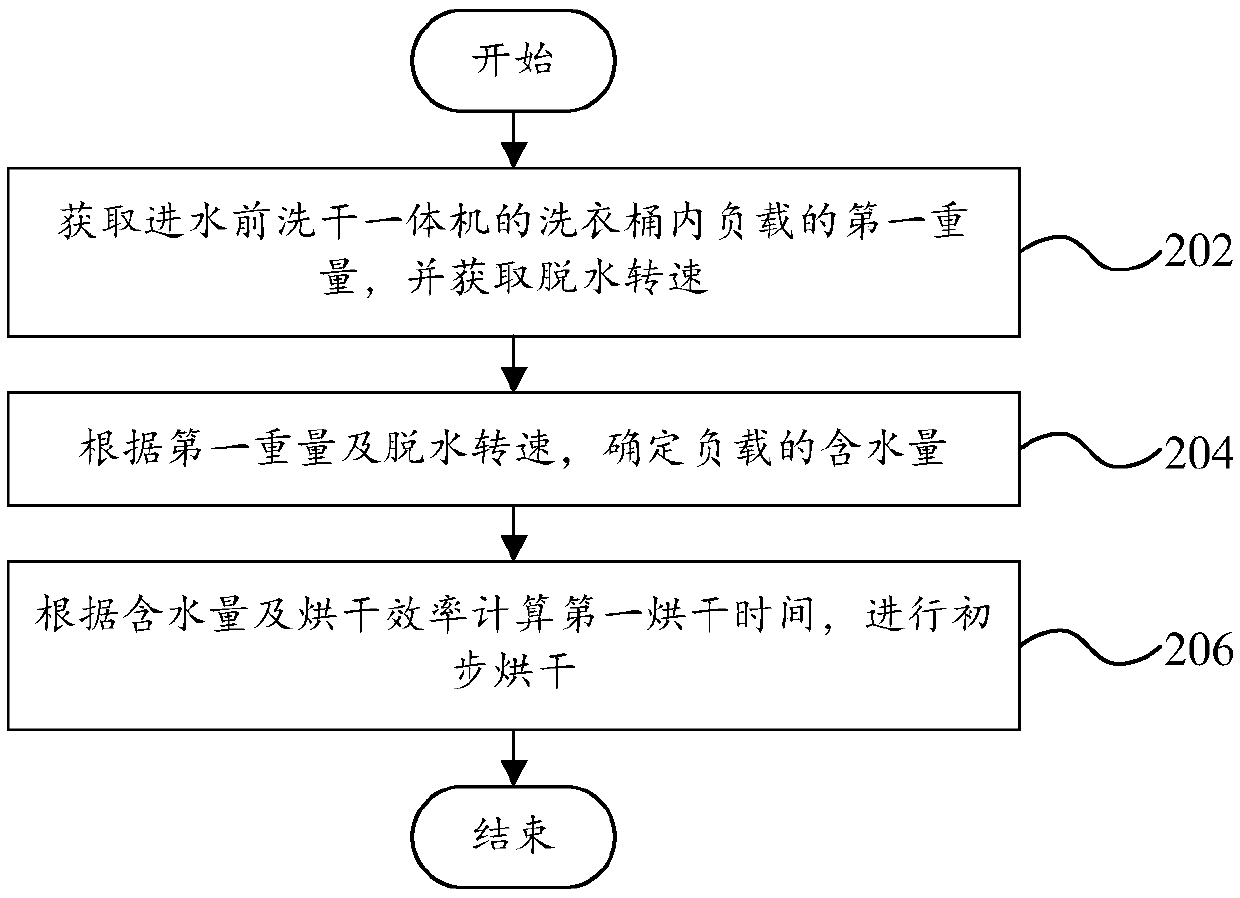

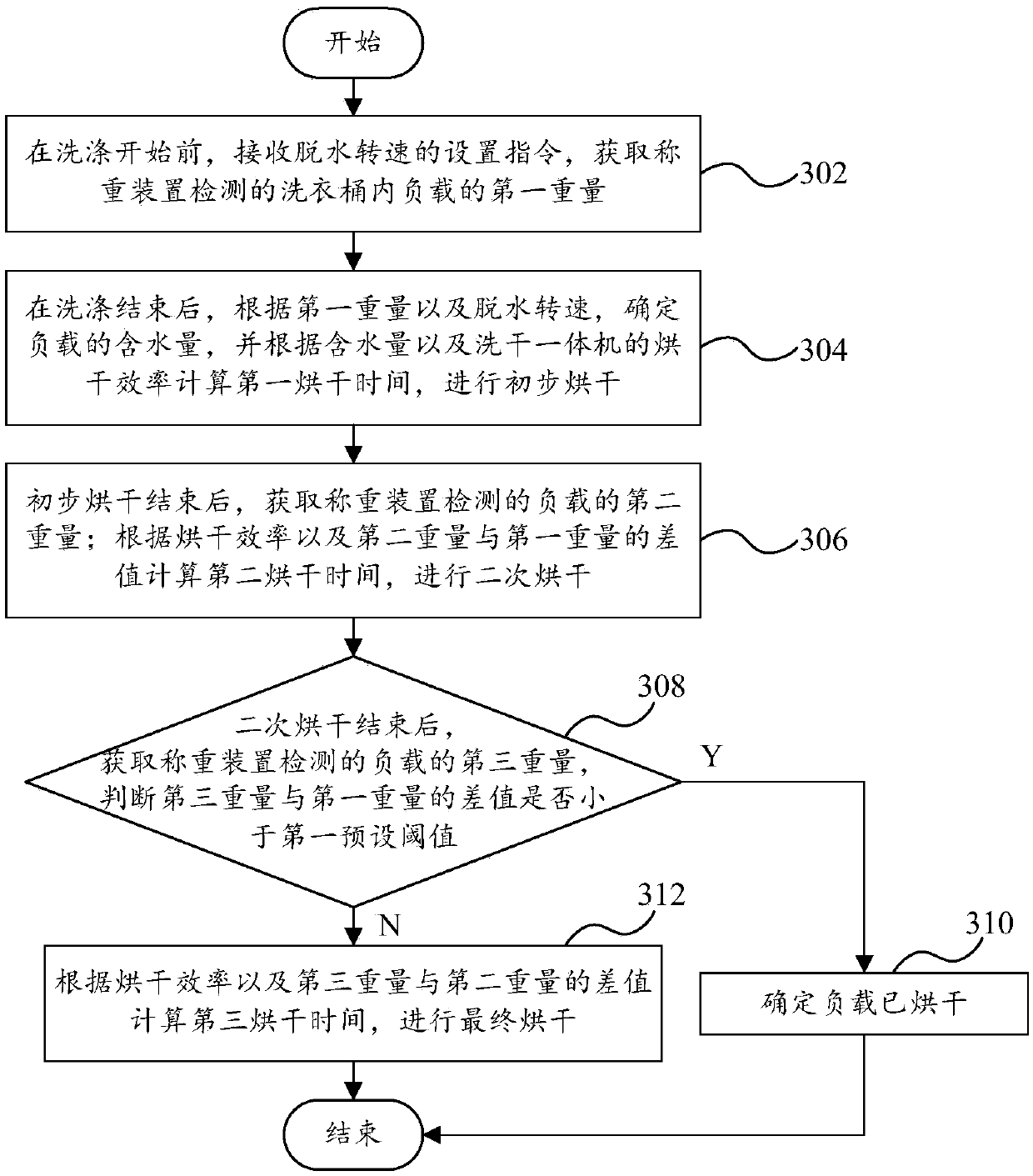

Control method of washing and drying all-in-one machine, control device for washing and drying all-in-one machine, and washing and drying all-in-one machine

ActiveCN109957955ASolve the problem that it is impossible to distinguish the difference in weighing of small loads before and after washingAvoid overbakingControl devices for washing apparatusTextiles and paperWater savingPulp and paper industry

The invention provides a control method of a washing and drying all-in-one machine, a control device for the washing and drying all-in-one machine, and the washing and drying all-in-one machine. The control method comprises the following steps: acquiring a first weight of a load in a washing drum of the washing and drying all-in-one machine before water enters the washing and drying all-in-one machine, and acquiring a spinning speed; calculating first drying time according to the first weight, the spinning speed and the drying efficiency of the washing and drying all-in-one machine, and carrying out preliminary drying. By adopting the technical scheme provided by invention, the water content of clothing can be accurately known, and the drying time can be initially determined, so that the problem that a motor can not discriminate the weighing difference before and after washing of the micro load is solved, and the problem that when a user puts wet clothes into the machine, the drying program is not performed due to a small weighing difference value before and after washing is also solved; therefore, the situation of over-baking or not baking to dryness is avoided, and the drying effect is effectively improved. Compared with related washing and drying all-in-one machines, the washing and drying all-in-one machine provided by the invention is more intelligent, water-saving and power-saving.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

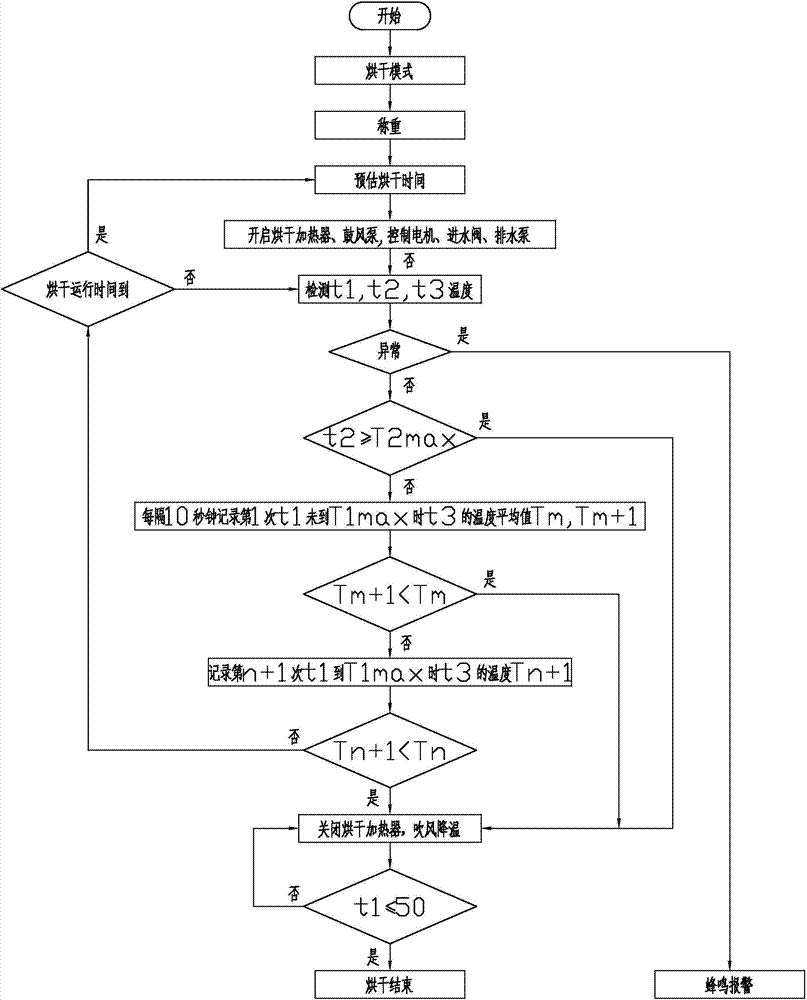

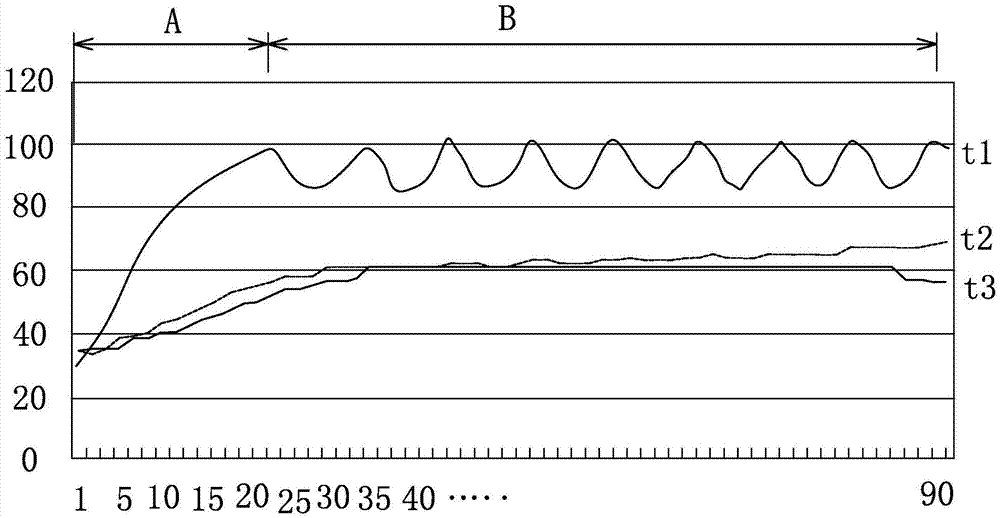

Method for drying through temperature sensor of roller washing machine

ActiveCN104762799AReduce frequent movementsEasy to judgeTextiles and paperLaundry driersPulp and paper industryWater content

The invention provides a method for drying through a temperature sensor of a roller washing machine. The method is that three temperature sensors are arranged to operate. The method comprises the steps of 1, presetting T1max, T2min and T2max; 2, drying, namely, synchronously starting a condenser, a water feeding valve, a draining pump, a condenser, a blower pump and a heater, or starting to circulate hot water, and determining that the clothes are dried after any one of the two necessary conditions is met during drying; 3, dynamically detecting t1, and finishing drying when the t1 is less than 50 DEG C. According to the method, the three temperature sensors are matched to monitor and determine the state, and the determining method is the same and free of influence of the clothes load in the washing machine and the water content rate of the clothes, so that the drying effect can be accurately determined; a certain fuzzy artificial intelligence function is achieved.

Owner:SHANDONG XIAOYA GROUP HOUSEHOLD APPLIANCES CO LTD

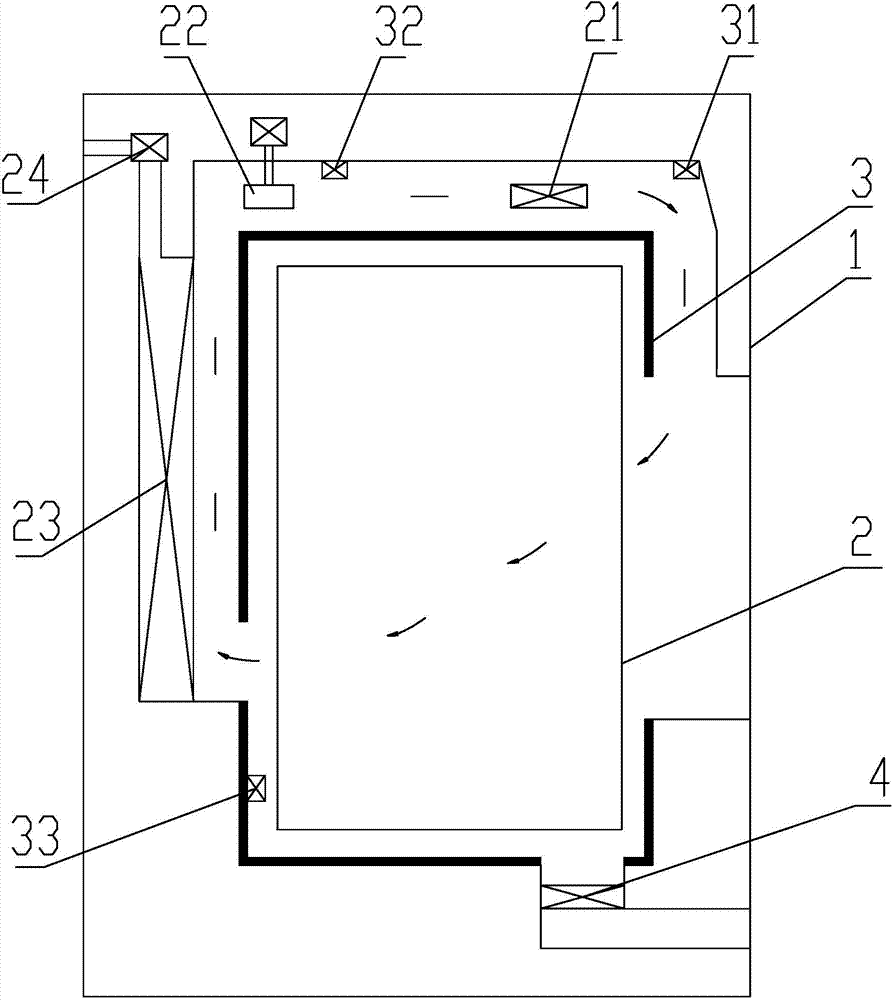

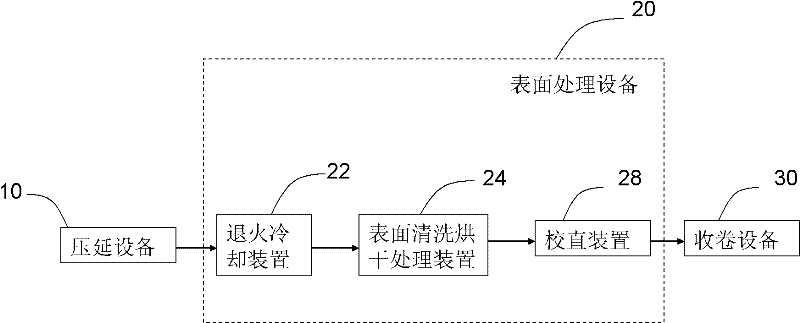

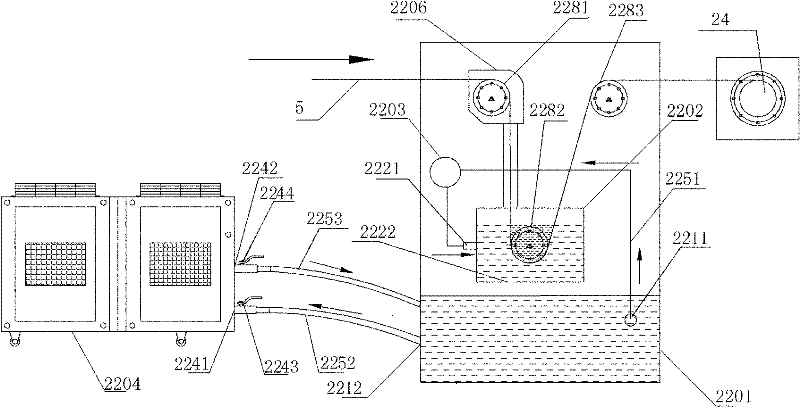

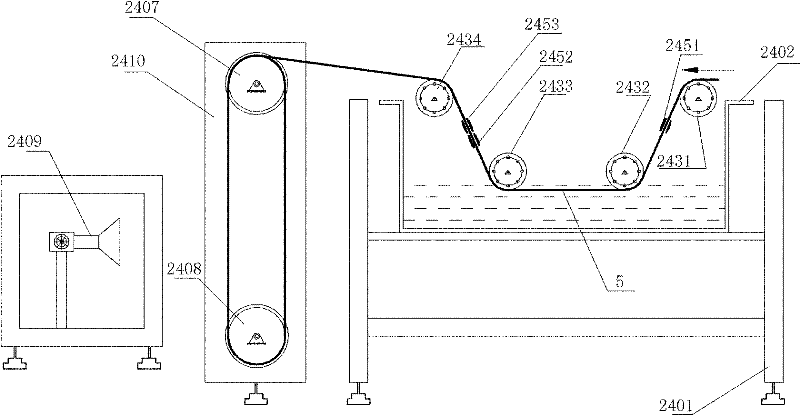

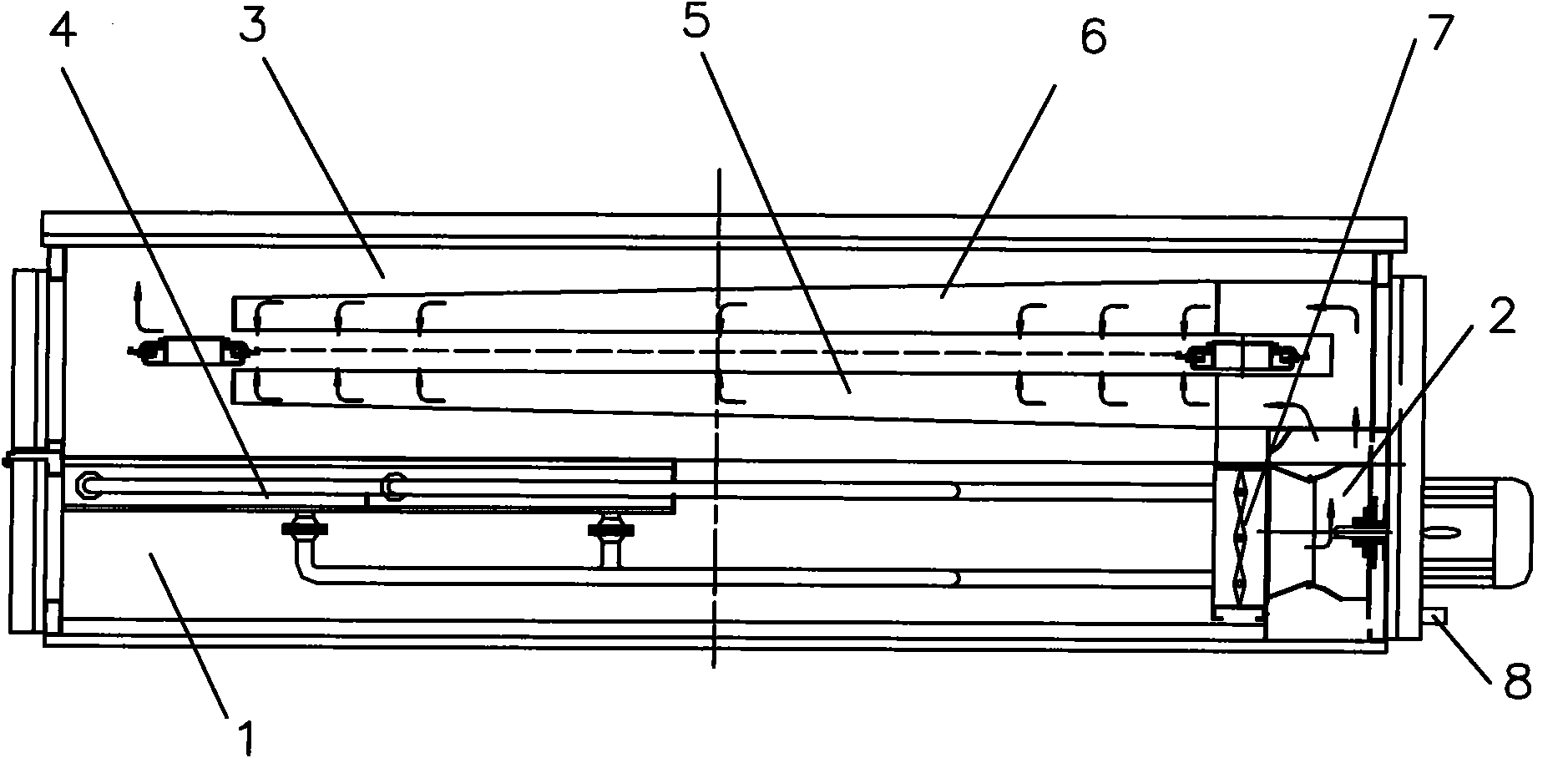

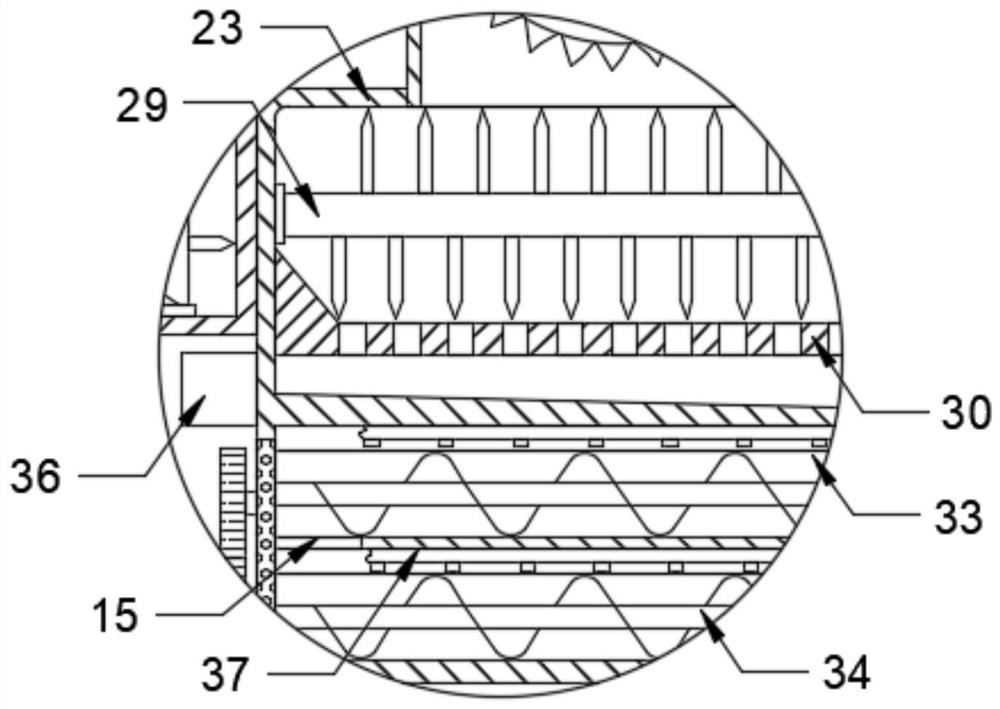

Copper base belt surface treatment device of solar photovoltaic welding belt and processing method thereof

InactiveCN102479880AAchieve cleaningSimple structureFinal product manufactureSemiconductor devicesProduction lineSurface cleaning

The invention discloses a copper base belt surface treatment device of a solar photovoltaic welding belt. The device can be used in a solar photovoltaic welding belt production line and installed behind rolling equipment and in front of rolling-up equipment. The device comprises an annealing and cooling device, a surface cleaning and drying processing device and a straightening device. The invention also discloses a processing method using the copper base belt surface treatment device. According to the processing method, the copper base belt is rolled by the rolling equipment and then annealed and cooled by the annealing and cooling device; the copper base belt after being annealed and cooled enters into the surface cleaning and drying processing device for surface cleaning and drying; the copper base belt after being cleaned and dried enters into the straightening device for improving the straightness; and the copper base belt after being straightened enters into the rolling-up equipment for rolling up. By adopting the device and the method, wires can be cleaned in real time, weldability of the copper base belt can be improved, tinplating rejection rate caused by the poor surfacequality of the copper belt can be reduced and the problems such as the poor straightness of the copper base belt and the like can be solved.

Owner:BRUKER SPALECK SOLAR TECH TAICANG

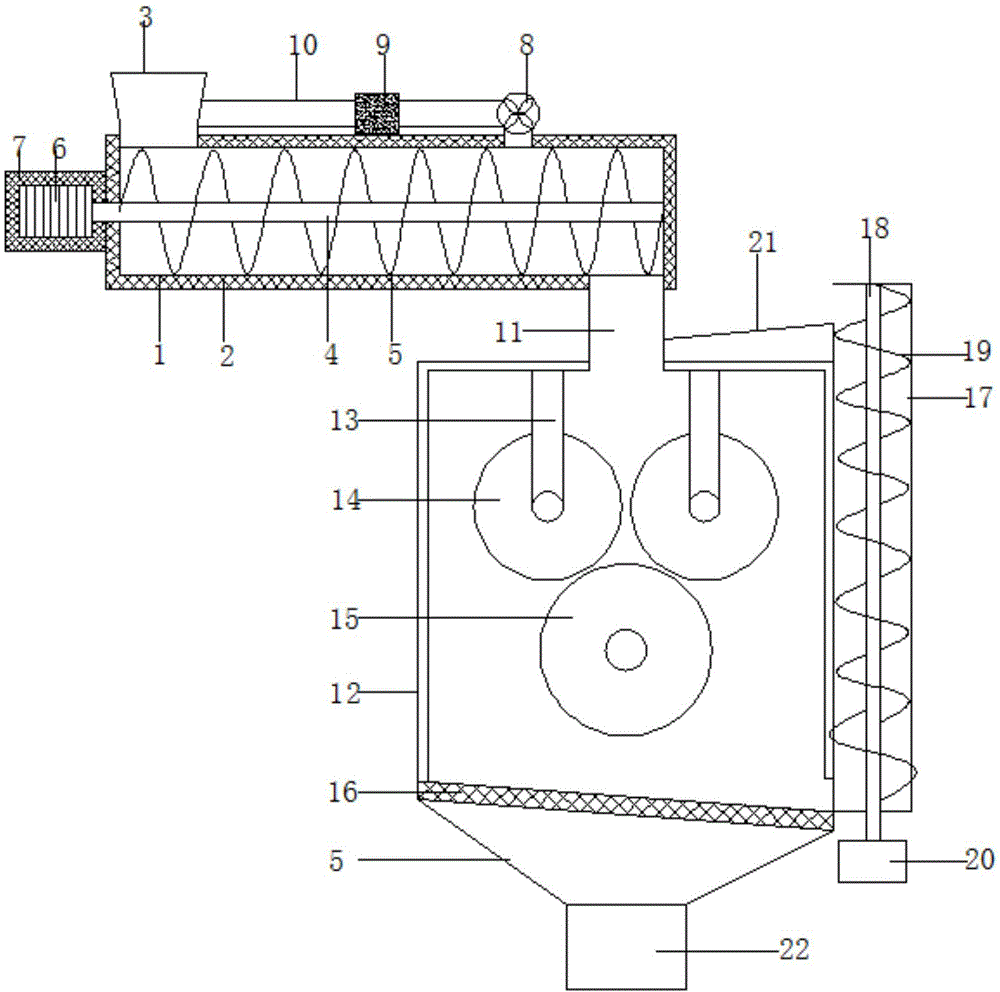

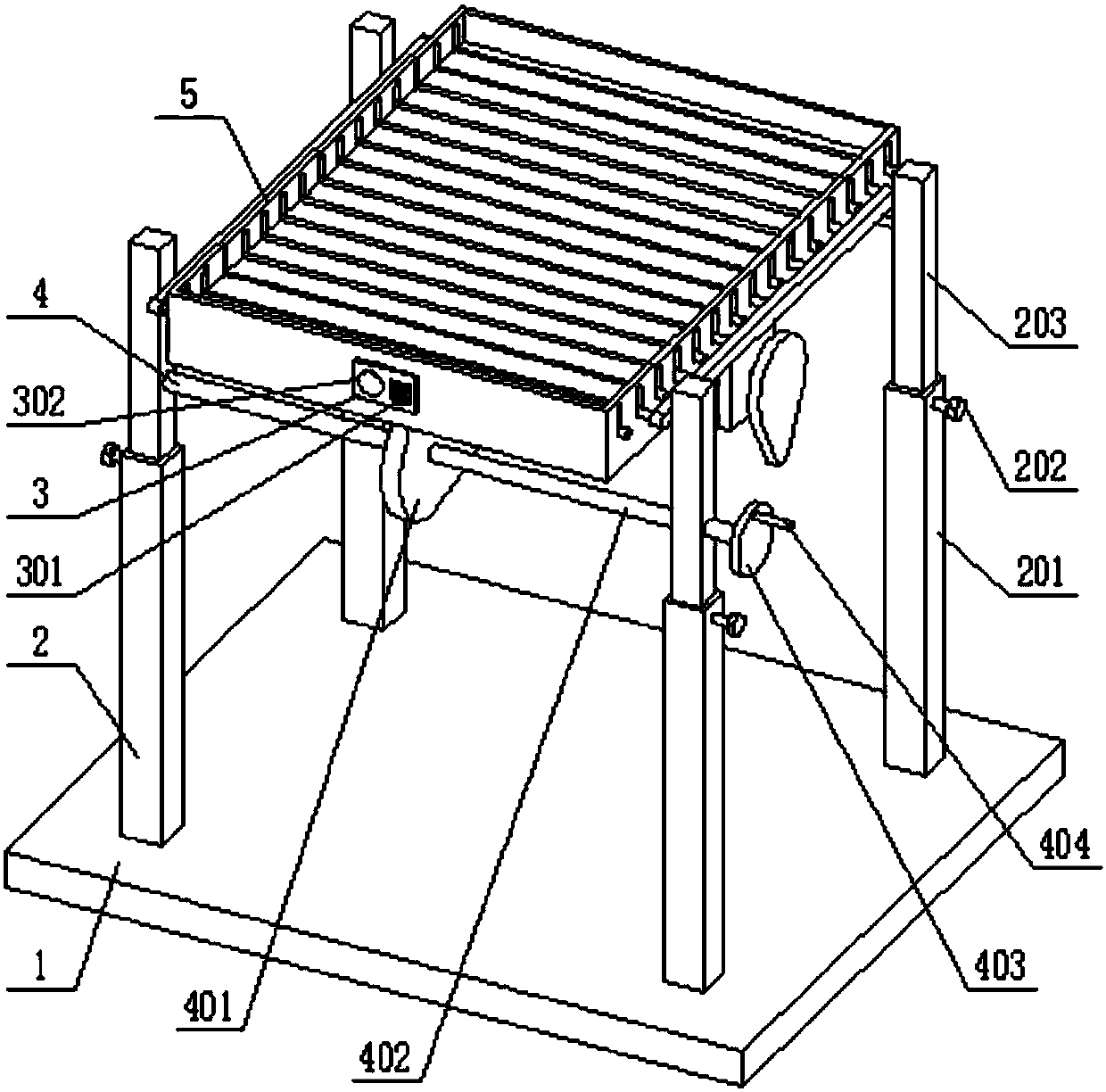

Efficient energy-saving crusher for ceramic production

InactiveCN104941758AReduce noiseImprove crushing effectGrain treatmentsElectric machineryEngineering

The invention discloses an efficient energy-saving crusher for ceramic production, which comprises a material conveying barrel, a drying device and a preheating pipe, wherein an outer wall of the material conveying barrel is covered with an electric heating layer; a material feeding hopper is arranged on the upper side of the left end of the material conveying barrel; a first rotating shaft is arranged at an axis of the interior of the material conveying barrel; a plurality of screw blades are uniformly arranged on the first rotating shaft from left to right; the left end of the first rotating shaft stretches out of the material conveying barrel and is connected with a first rotating motor. The efficient energy-saving crusher for the ceramic production can crush and dry raw materials for producing ceramics, and adopts two crushing modes, namely the screw blades and crushing rolls, so that the crushing efficiency of the crusher is improved; the materials with unqualified sizes can be screened and conveyed to a crushing cavity to be crushed circularly, so that a crushing effect and the quality of a finished product are ensured; in addition, the crusher can perform moisture removal on the interior of a material conveying pipe; waste heat is used to preheat the materials, so that the drying efficiency is improved; and energy sources are saved.

Owner:顾广才

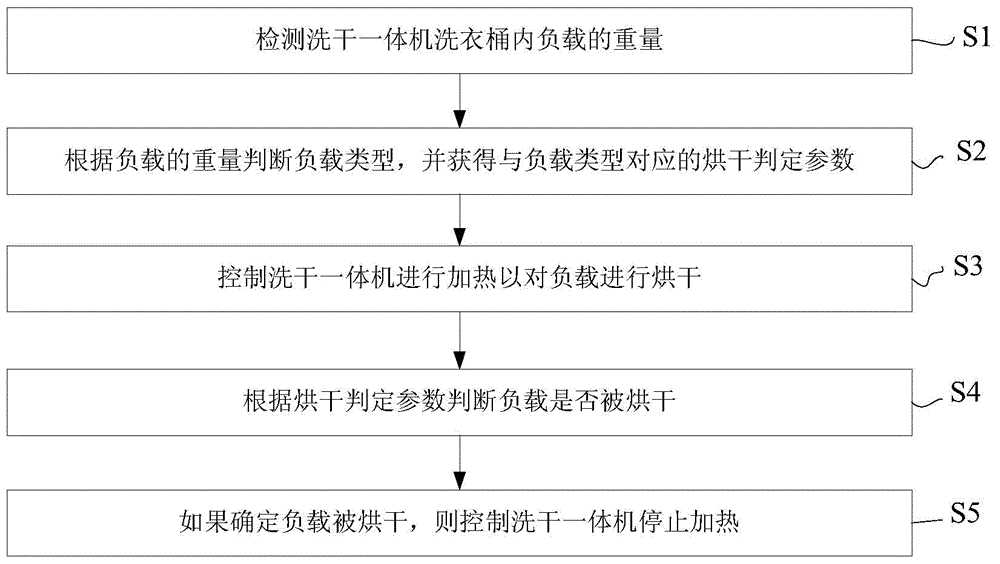

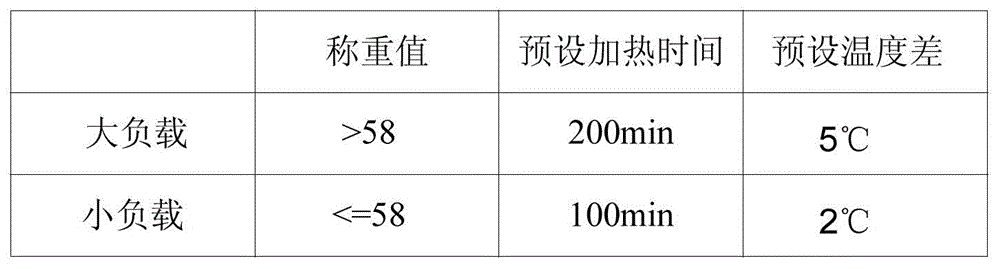

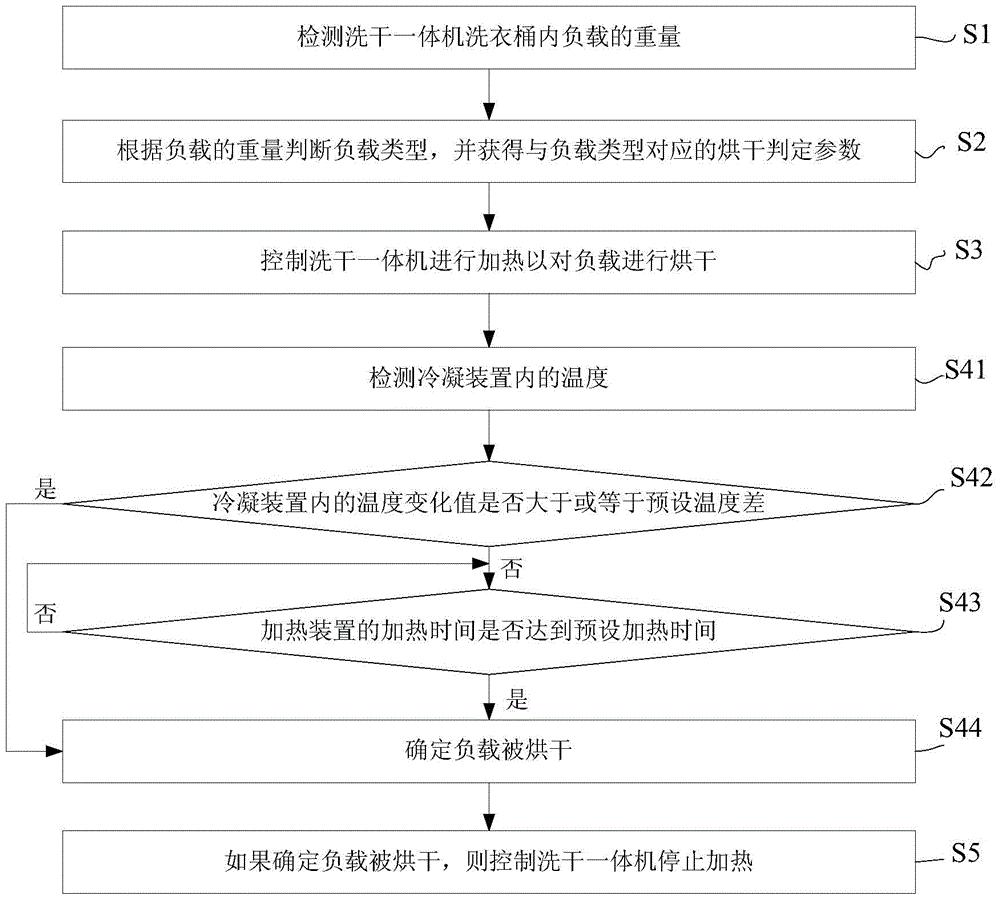

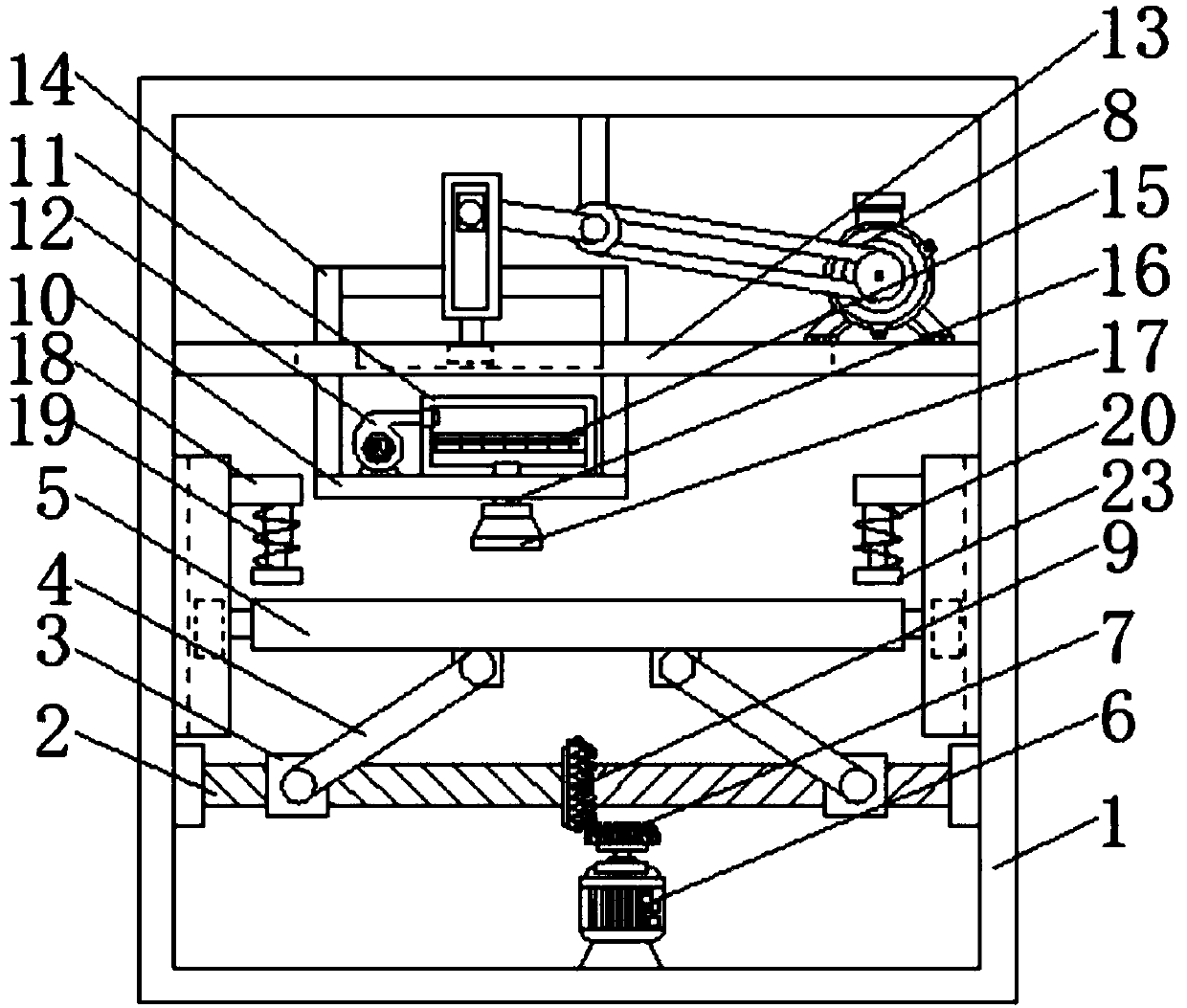

Washing-drying all-in-one machine and drying control method thereof

ActiveCN104805664AImprove accuracyGuaranteed drying effectWashing machine with receptaclesTextiles and paperEngineering

The invention discloses a drying control method of a washing-drying all-in-one machine. The method comprises the following steps: detecting the weight of a load in a washing barrel of the washing-drying all-in-one machine; judging the type of the load according to the weight of the load, and acquiring the drying determination parameter corresponding to the type of the load; controlling the washing-drying all-in-one machine to be heated so as to dry the load; judging whether the load is dried or not according to the drying determination parameters; and controlling the washing-drying all-in-one machine to stop heating if the load is dried. By adopting the drying control method, the load drying judgment accuracy can be improved, and the drying effect of the load can be guaranteed. The invention also discloses a washing-drying all-in-one machine adopting the drying control method.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

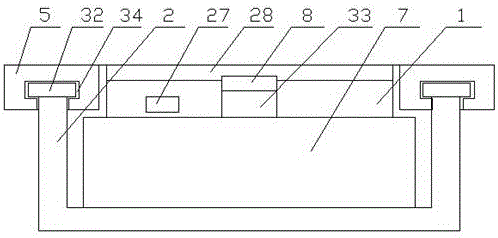

Drying device uniform in heating for garment processing

InactiveCN107747200AHeating evenlyDry evenlyTextiles and paperLaundry driersEngineeringControl effect

The invention discloses a drying device uniform in heating for garment processing, and relates to the technical field garment processing. The device comprises a shell, a lead screw is rotationally connected between the two sides of the inner wall of the shell, movable blocks are rotationally connected to the two sides of the surface of the lead screw, connecting rods are rotationally connected tothe tops of the movable blocks, a movable plate is rotationally connected to the tops of the connecting rods, a transverse plate is fixedly connected between the two sides of the inner wall of the shell, a motion device is fixedly connected to the top of the transverse plate, vertical rods are fixedly connected to the two sides of the motion device, and the bottoms of the vertical rods penetrate through the transverse plate and extend to the bottom of the transverse plate. According to the drying device uniform in heating for garment processing, clothes are dried uniformly, the phenomenon thatdue to the fact that the temperature is too high or too low, the drying effect is affected is avoided, the processing quality is improved, the height of the movable plate is adjusted conveniently, the clothes drying temperature is controlled conveniently, the control effect is good, and the quality of finished clothes products is improved.

Owner:界首市永顺服饰有限公司

Tea drying box capable of conducting drying uniformly

The invention discloses a tea drying box capable of conducting drying uniformly. The tea drying box comprises a box body. A feeding pipe is connected to the top of the box body. A movable piston is arranged at the position, below the feeding pipe, inside the box body. Overturning plates are hinged to the positions, below a dispersing plate, of the inner walls of the left side and the right side ofthe box body, wherein the overturning plates are distributed in a staggered manner. A discharging plate is arranged below the overturning plates. According to the tea drying box, by means of the dispersing plate and the overturning plates with the surfaces being provided with protruding strips, tea is dispersed and then shaken to fall; the tea is uniformly dried by hot air through mesh holes in the overturning plates; meanwhile, the overturning plates ceaselessly shakes the tea, so that nonuniform heating is avoided; the tea drying box is provided with the movable plug, the movable plug movesup and down, so that intermittent discharging is achieved, and the drying effect is guaranteed; and the tea drying box is provided with the discharging plate which moves up and down, so that discharging is conducted uniformly.

Owner:南安市科联专利应用服务有限公司

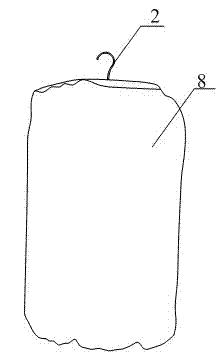

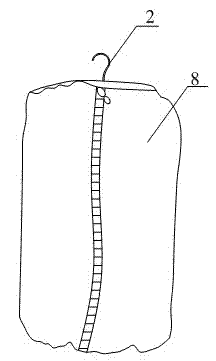

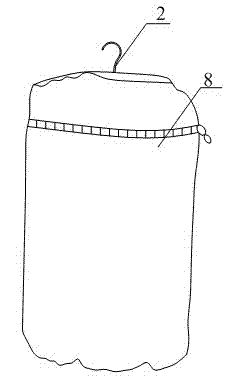

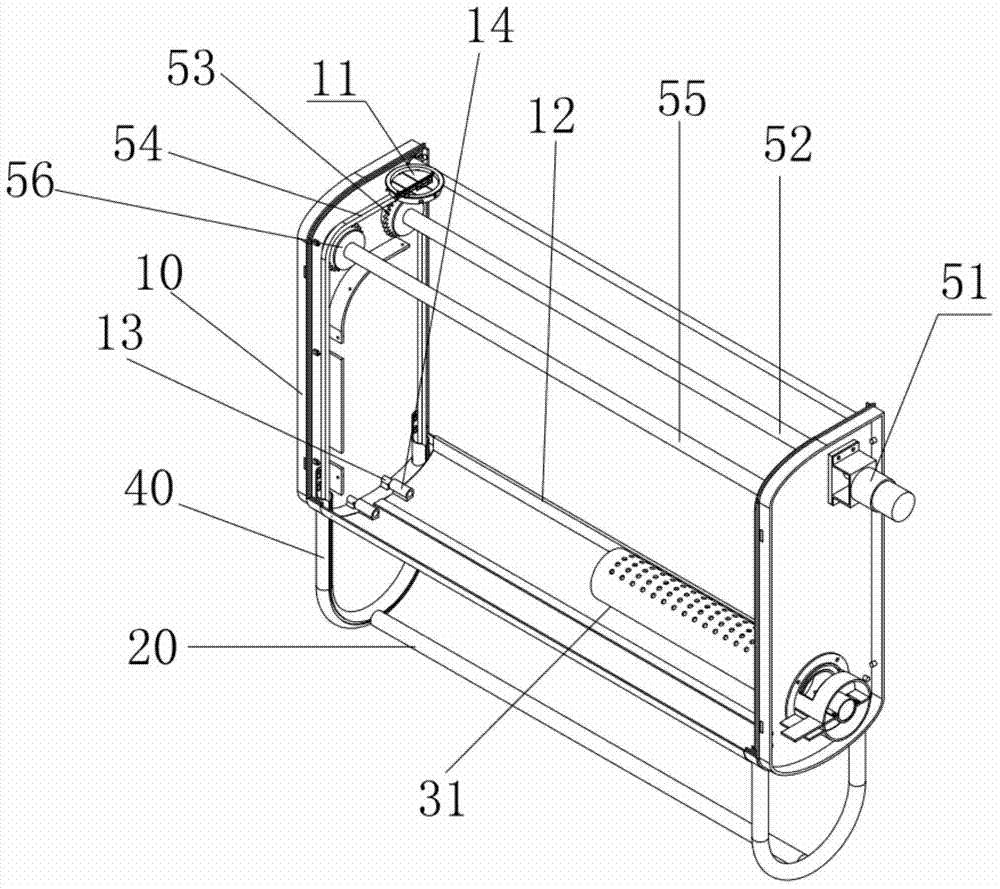

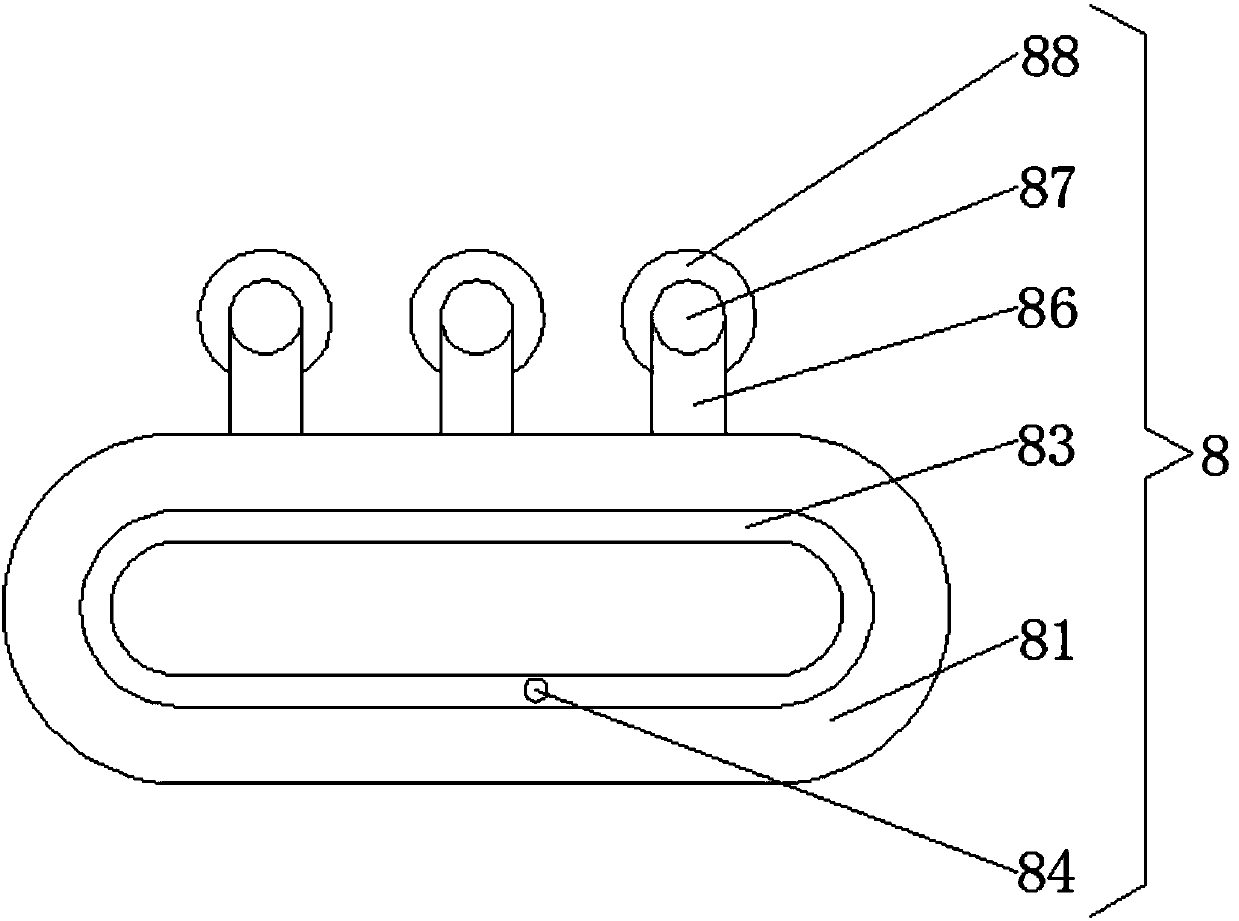

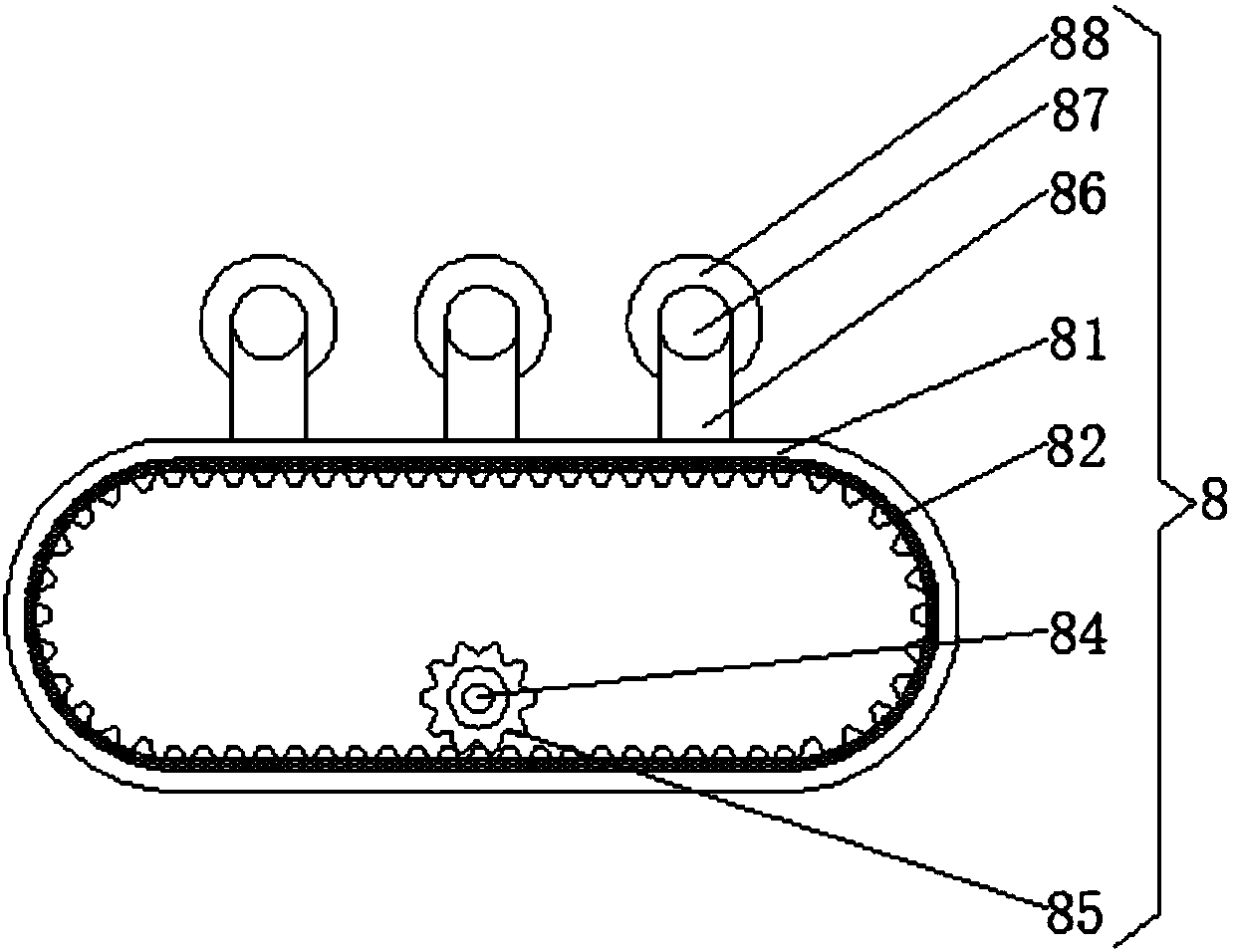

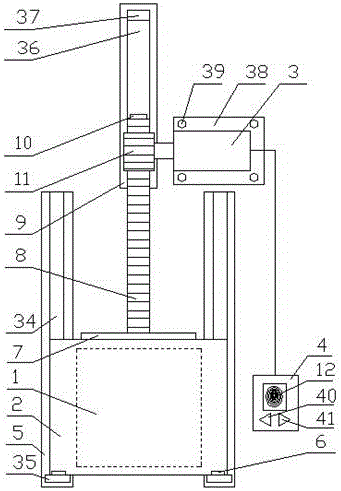

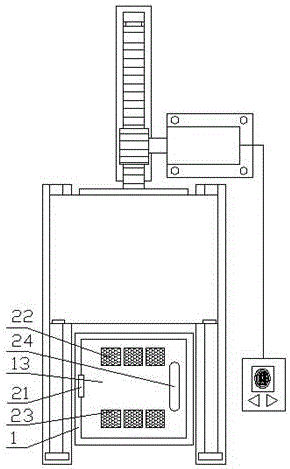

Portable clothes drying device

InactiveCN102926177ASave spaceFast fillOther drying apparatusTextiles and paperEngineeringClothes hanger

The invention discloses a portable clothes drying device, and solves the problems of large volume and inconvenience in carry of the clothes drying device in the prior art. The portable clothes drying device comprises a clothes drying device skeleton and a clothes drying cover (8) covering the outer side of the clothes drying device skeleton, and is characterized in that the clothes drying device skeleton comprises a supporting mechanism and a clothes hanger (1), wherein the top end of the supporting mechanism is provided with a hook (2), and the bottom end of the supporting mechanism is provided with a heating device (3); and the clothes hanger (1) is arranged at the upper end of the supporting mechanism, is movably connected with the upper end of the supporting mechanism and is umbrella-rib-shaped. The portable clothes drying device disclosed by the invention has the advantages that the structure is simple, the cost is low, the implementation is convenient, and the foldable design is adopted, so that the carry of people is facilitated. Therefore, the portable clothes drying device is suitable for being promoted and applied.

Owner:周斌

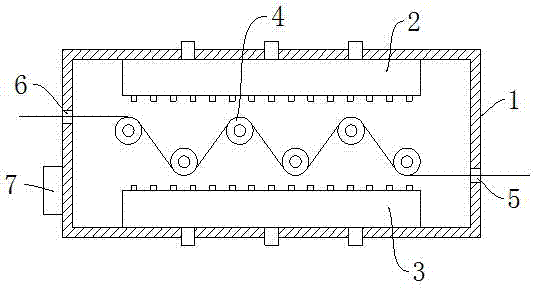

Cloth drying device for spinning

InactiveCN107289762AIncrease running trackImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsSurface mountingEngineering

The invention discloses a cloth drying device for spinning. The cloth drying device comprises a drying box, an upper hot air box, a lower hot air box and conveying rolls, wherein the upper hot air box is fixedly erected on the lower surface of a top plate of an inner cavity of the drying box; the lower hot air box is fixedly erected on the upper surface of a bottom plate of the inner cavity of the drying box; the conveying rolls are arranged in the middle inner cavity of the drying box; and the three adjacent conveying rolls form a V shape. According to the cloth drying device, structure is simple, design is reasonable, the conveying rolls are arranged in a V shape, the travelling path of textile cloth in the inner cavity of the drying box is increased under the condition that size is not changed, drying efficiency is improved, floor space is decreased, hot air blown from exhaust pipes on the upper hot air box dries the upper surface of textile cloth, hot air blown from exhaust pipes on the lower hot air box dries the lower surface of textile cloth, the double surfaces of textile cloth are dried at the same time, the drying effect is guaranteed, and drying efficiency is high.

Owner:黄忠南

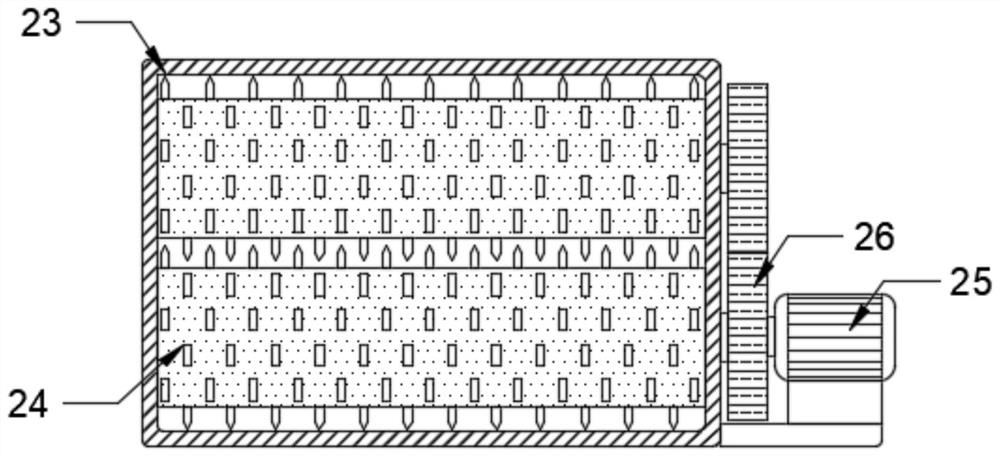

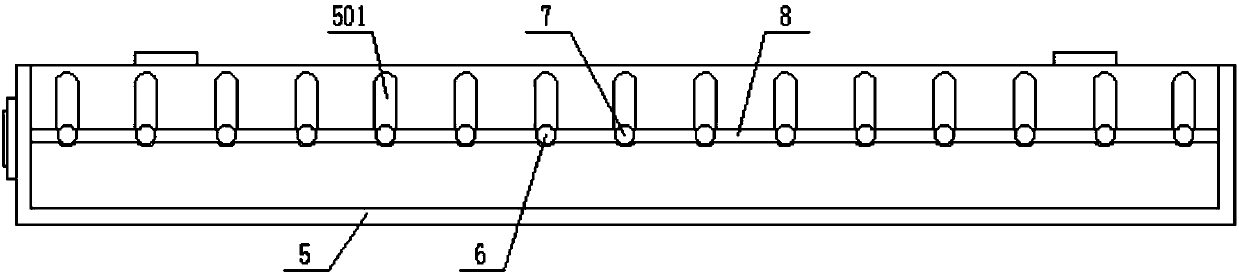

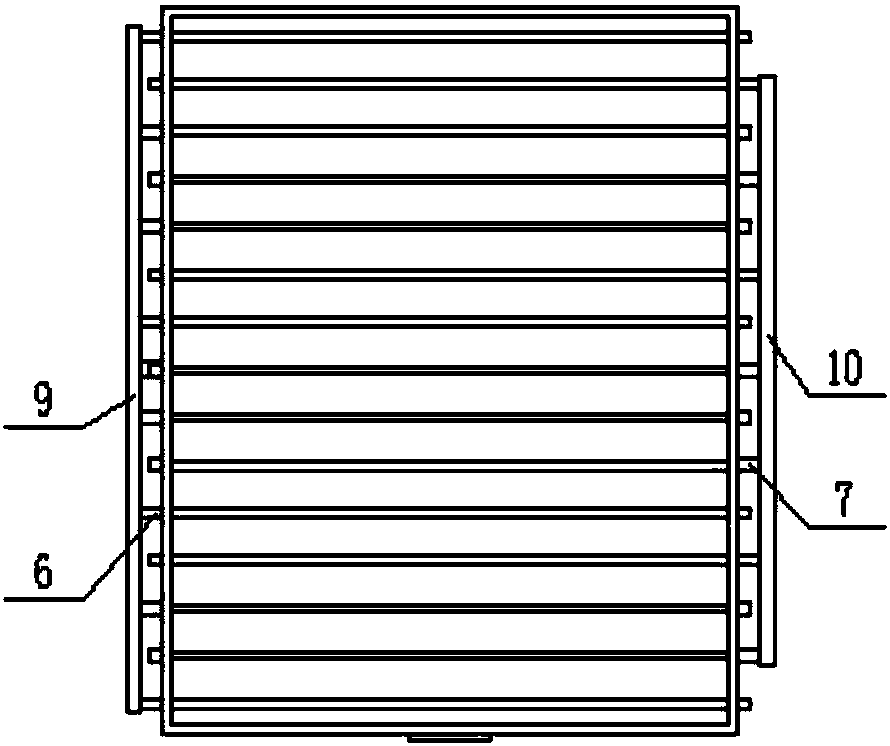

Drying room for tentering forming machine

InactiveCN101899757AGuaranteed drying effectHeating/cooling textile fabricsStretchingAir volumeTuyere

The invention discloses a drying room for a tentering forming machine, comprising a heat source box, two circulating fans and a drying oven. The heat source box is internally provided with a heater, and the drying box is internally provided with a jet pipe. The drying room is characterized in that the jet pipe comprises an upper jet pipe and a lower jet pipe, a blade outlet of one of two circulating fans is connected with the upper jet pipe, and a blade outlet of the other circulating fan is connected with the lower jet pipe; and motors of the two circulating fans on the jet pipe are variable frequency motors. Compared with the prior art, the upper jet pipe and the lower jet pipe of the drying room are respectively and independently controlled by the independent circulating fans; because the motor of the circulating fan is a variable frequency motor, air jetting proportion and air jetting time of the upper jet pipe and the lower jet pipe can be adjusted according to different requirements of textile fabric, such as different thicknesses of the textile fabric; and when the textile fabric is thin, and the compactness of the textile fabric is different, the air quantity can be adjusted by each circulating fan so as to guarantee the drying effect of the textile fabric.

Owner:JIANGSU HAIDA DYEING & PRINTING MACHINERY

Diatomite crushing and drying device

The invention discloses a diatomite crushing and drying device which comprises an air duct, a crusher, a roll crusher, a hearth, a primary vibrating screen, a secondary vibrating screen, a turbofan, a classification device and a dust collection warehouse, wherein the crusher comprises two crushing rollers which rotate opposite to each other and have a plurality of rows of wolf tooth structures distributed uniformly on the surface; and the roll crusher comprises two rollers which rotate opposite to each other and are provided with a plurality of convex structures on the surface. During crushing and drying, the diatomite is crushed twice through the crusher and the roll crusher and is dried at the drying temperature of 400-600 DEG C for 30-60 seconds, dust collection and screening are performed through the classification device and the primary vibrating screen after drying, and the required particles are screened. The device has the beneficial effects that the whole device can integrate the functions of feeding, crushing, drying, screening and dust removing into a whole, the operation is convenient, the production efficiency is high, and the manual and material cost is greatly reduced. The crushed and dried diatomite is low in moisture content, and the yield of particles of which the particle size is in the required range is high.

Owner:嵊州宝钒硅藻土股份有限公司

Automatic disinfecting and drying device

ActiveCN103789983AImprove convenienceIncrease wind pressureOther drying apparatusTextiles and paperElectrical controlElectric heating

The invention discloses an automatic disinfecting and drying device which is used for disinfecting and drying towels and clothes. The automatic disinfecting and drying device comprises a box body, a power module, an electrical control system and a heating system, wherein the towels and clothes are placed in the box body, the electrical control system controls high-temperature disinfecting and drying performed by the heating system on the towels and clothes. The heating system comprises an outer air pipe, an inner air pipe, an electric heating wire and a fan, wherein the electric heating wire is arranged in the outer air pipe, the outer air pipe is arranged in the box body and provided with a first opening, the inner air pipe is respectively provided with a first end and a second end respectively located inside and outside the outer air pipe, the first end is open, an air blocking plate is arranged at the second end, and the inner air pipe is provided with a second opening. The electrical control system control relative motion of the inner air pipe and the outer air pipe to form two working stations, when the relative motion enables the first opening to be coincide with the second opening, air circulation passing through the electric heating wire is formed inside the box body, and the temperature in the box body can be improved for disinfection. When the relative motion enables the openings to be staggered, air circulation passing through the electric heating wire is formed inside and outside the box body, and the inside of the box body can be quickly dried for drying.

Owner:新疆北辰高新电子科技有限公司

Quick dehydration and drying device for textile fabric

ActiveCN107815805AReduce moisture contentReduce energy wasteLiquid/gas/vapor removal by squeezingLiquid/gas/vapor removal by gas jetsElectric machineryLeather belt

The invention discloses a quick dehydration and drying device for a textile fabric and relates to the technical field of textile machinery and equipment. The quick dehydration and drying device for the textile fabric comprises a box body, wherein a motor is fixedly connected to the bottom of the inner wall of the box body, the surface of a motor output shaft is sleeved with a first belt wheel, a first supporting rod is fixedly connected to the left side of the bottom of the inner wall of the box body, the top end of the first supporting rod is in rotary connection with a first rotary rod, thesurface of the first rotary rod is sleeved with a second belt wheel, the surface of the second belt wheel is in driving connection with the first belt wheel through a belt, and an extruding device isfixedly connected to the back surface of the second belt wheel. The quick dehydration and drying device for the textile fabric achieves the textile fabric dehydration purpose and reduces the moisturecontent before textile fabric drying, the problems of longer drying time and lower working efficiency of drying devices in the market at present are solved, energy waste is reduced, and the actual service life of the drying device is prolonged.

Owner:莆田市荔城区自然家居电子商务有限公司

Electric power metering device

ActiveCN106199108APrevent slippingPlay the role of rain protectionTime integral measurementRefrigerationElectric power

The invention discloses an electric power metering device which comprises an electric power metering box, a protective shell, a gear motor and a lift controller. Protective shell sliding rails are arranged on corresponding positions on the two sides of the electric power metering box. The protective shell and the protective shell sliding rails are in sliding fit. The protective shell is provided with a rack. The rack is in sliding fit with a rack sliding rail arranged on the upper portion of the electric power metering box and is meshed with a driving gear arranged on the gear motor. A set of semiconductor refrigeration sheets, a set of air inlet fans, a set of electric energy meters, a line-in terminal, a line-out terminal, a set of switches and a radiating drying controller are arranged in the electric power metering box. The protective shell and the electric power metering box in the electric power metering device cooperate to ascend and descend, and consequently the electric power metering box can be well protected; the whole device can be arranged outdoors, has a rainproof function, can resist dampness, has a high temperature heat dissipation function and is wide in applicable range and long in service life.

Owner:国网山东省电力公司招远市供电公司

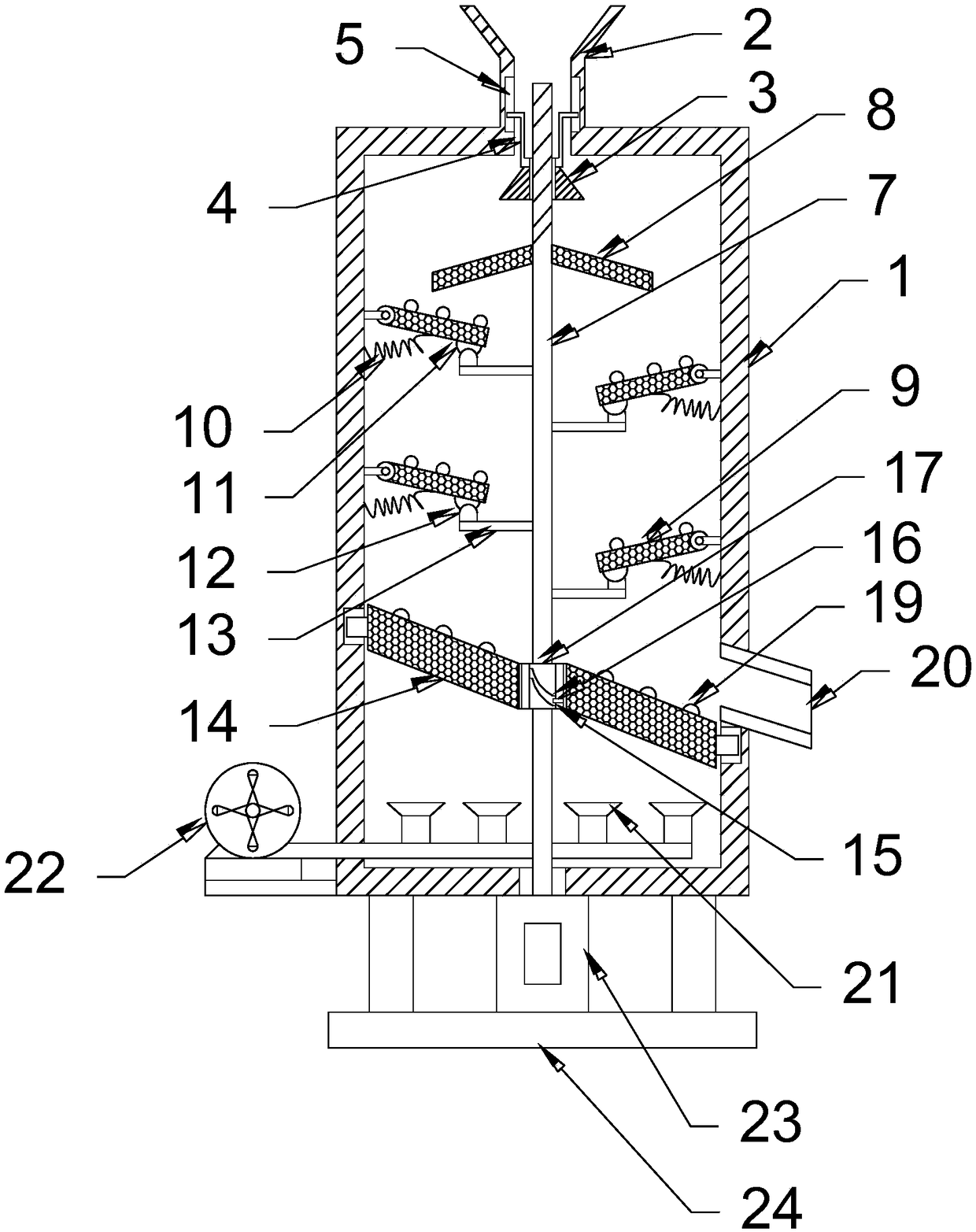

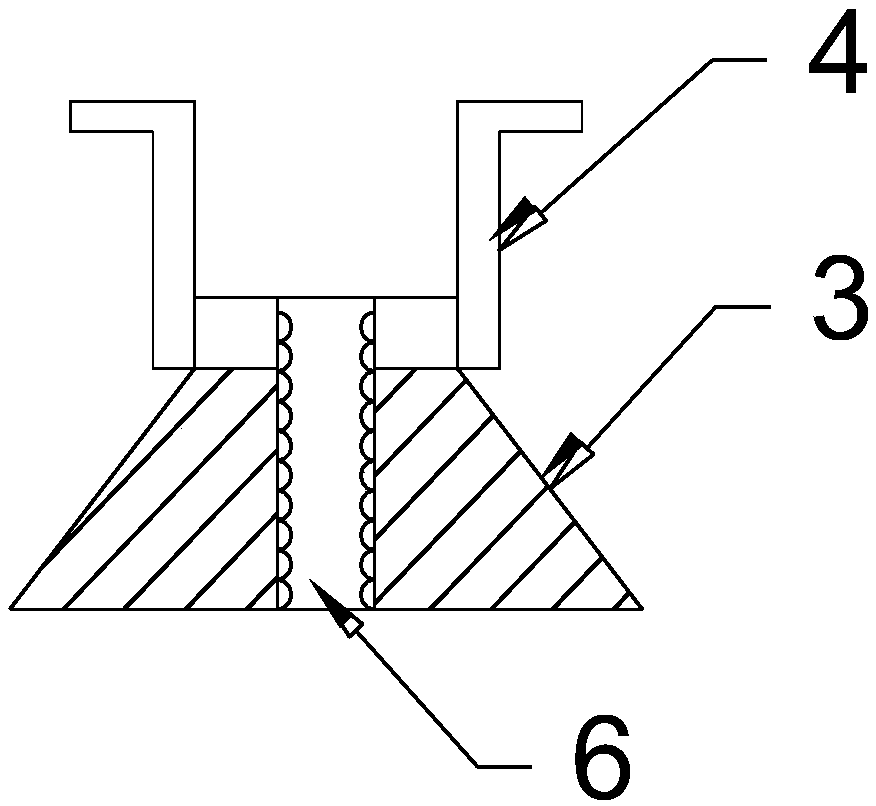

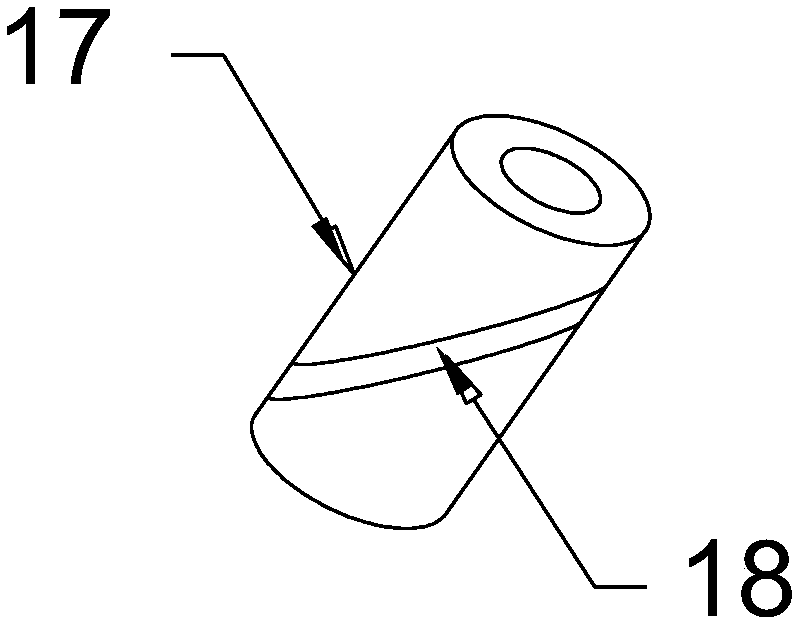

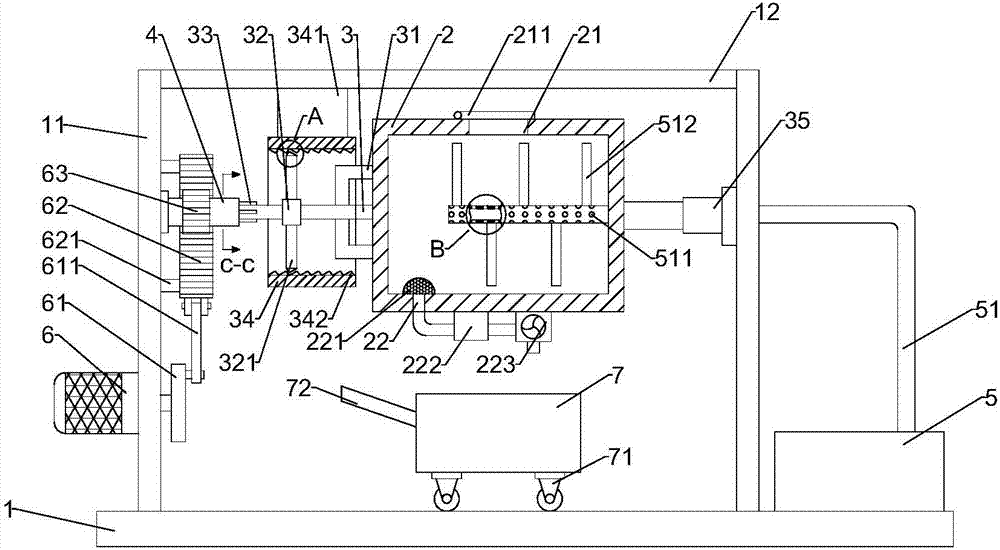

Drug-drying device for automaticpharmaceutical machinery

InactiveCN106643035AImprove efficiencyShorten drying timeDrying gas arrangementsDrying solid materialsDrugEngineering

The invention relates to a drug-drying device for automaticpharmaceutical machinery. The drug-drying device comprises a shell, a heating device, a shaking device, a separating plate device, a pushing device, a baffle device and a motor device, wherein a first through hole, a second through hole, a feeding frame and a discharging frame are arranged on the shell; the heating device comprises a radiating frame and a heating rod; the separating plate device comprises a separating plate and a concentrating block; the shaking device comprises a filter screen, a shaking frame, an idler wheel, a brush, a first fixing rod, a first spring and a second spring; the pushing device comprises an electric cylinder, a first bracket, a pushing rod and a pushing block; the baffle device comprises a first vertical plate, a second bracket, a connecting block, a baffle and a vertical rod; the motor device comprises a motor, an output shaft, a second fixing rod, a bracing wire, a connecting ring, a third spring, a second vertical plate and a triangle block. The drug-drying device for automaticpharmaceutical machinery can uniformly heat the drugs, so as to guarantee the drying effect, and meanwhile, the drugs can be uniformly spread out and shaken left and right, so that the efficiency of drying the drugs is higher.

Owner:GUANGZHOU ZHONGTAN AIR PURIFICATION TECH CO LTD

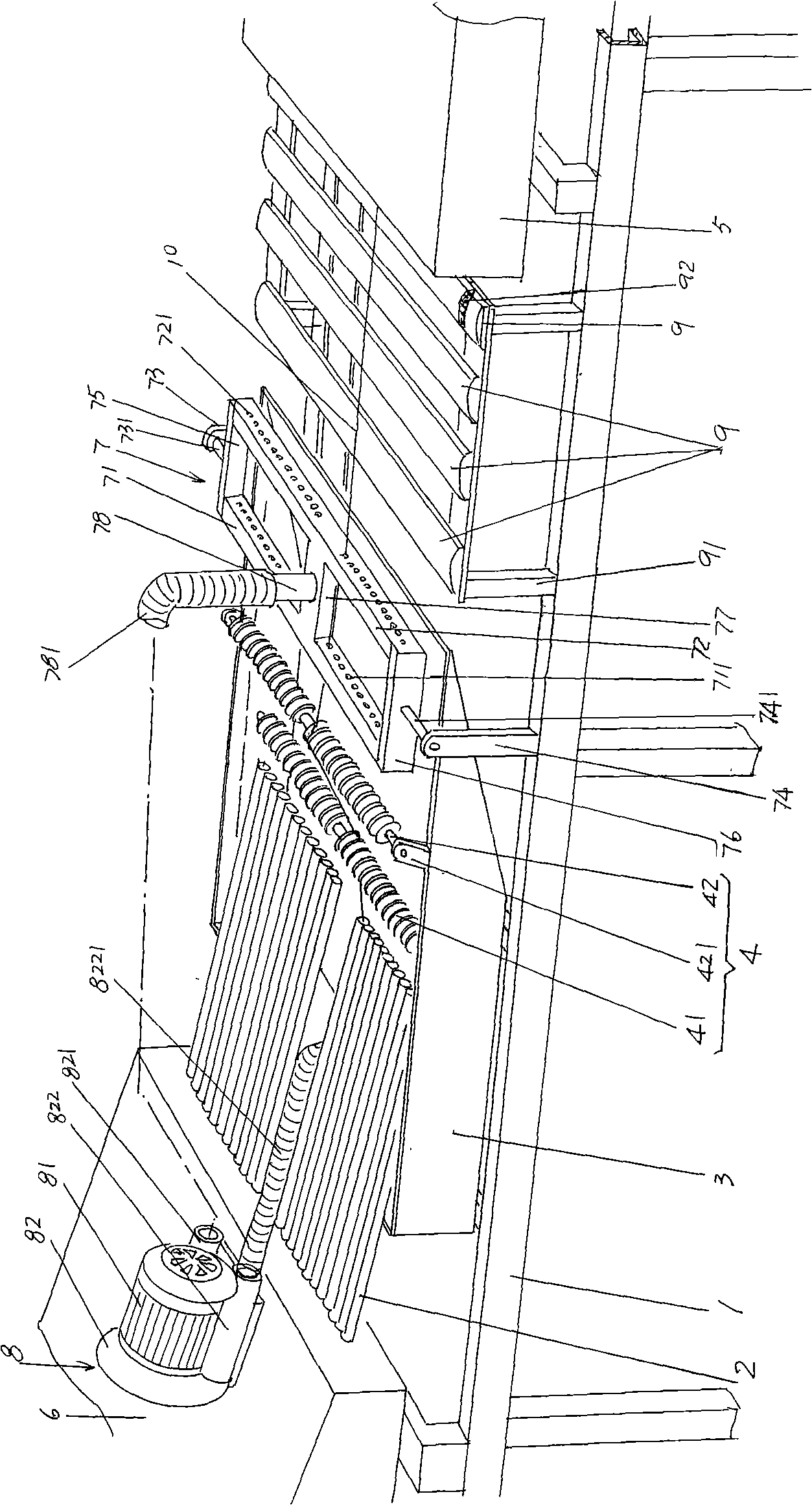

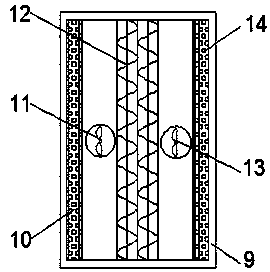

Annealing and cooling device for conductive wire

ActiveCN101290823AReduced transit timePrevent oxidationFurnace typesManufacturing extensible conductors/cablesButt jointSurface oxidation

A conducting wire annealing cooling device belongs to the electric wire-cable manufacturing device technical field. The device comprises a frame, an annealing furnace, a trough arranged on the upper part of the frame, a set of wire guide tubes in butt joint with the outlet of the annealing furnace and extending into the trough, a wire guide device arranged inside the trough and a drying box arranged at the other end of the frame. The device is characterized in that: the device also comprises a negative pressure water absorption mechanism and a negative pressure generating mechanism; the negative pressure water absorption mechanism is arranged on the upper part of the frame and is positioned between the wire guide device and the drying box and above the trough; the negative pressure generating mechanism is arranged on either the annealing furnace or the frame, and is also connected with a negative pressure pipe of the negative pressure water absorption mechanism. Moreover, the device has the advantages that: the device not only can shorten the time during which a conducting wire passes through the drying box so as to save the energy sources supplying heat for the drying box, but also can increase production efficiency; in addition, the device can also ensure drying effect, prevent surface oxidation of the conducting wire and improve electric wire-cable quality after cabling.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +2

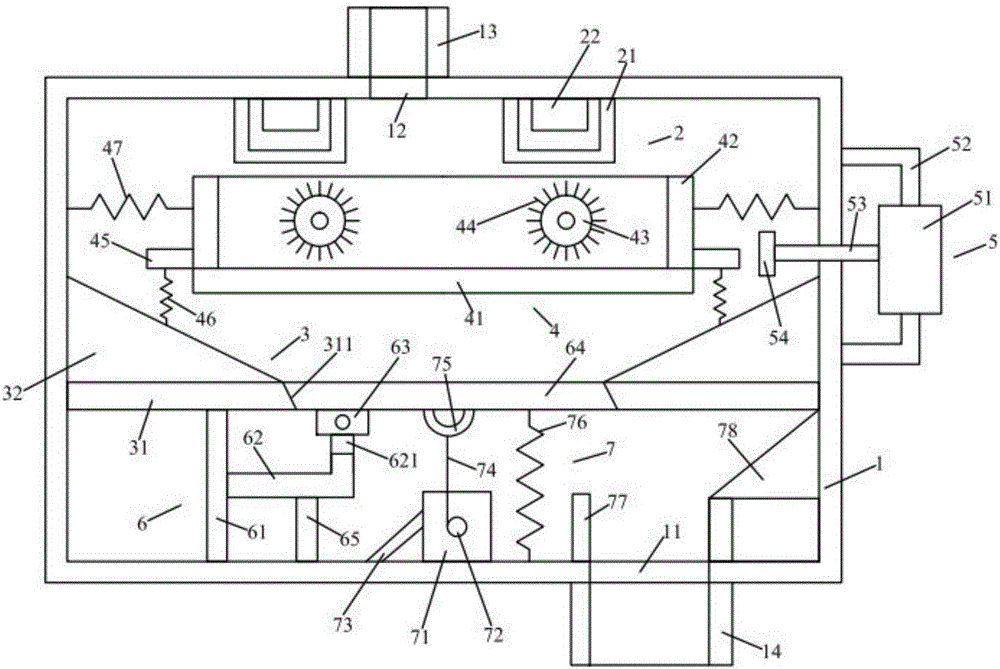

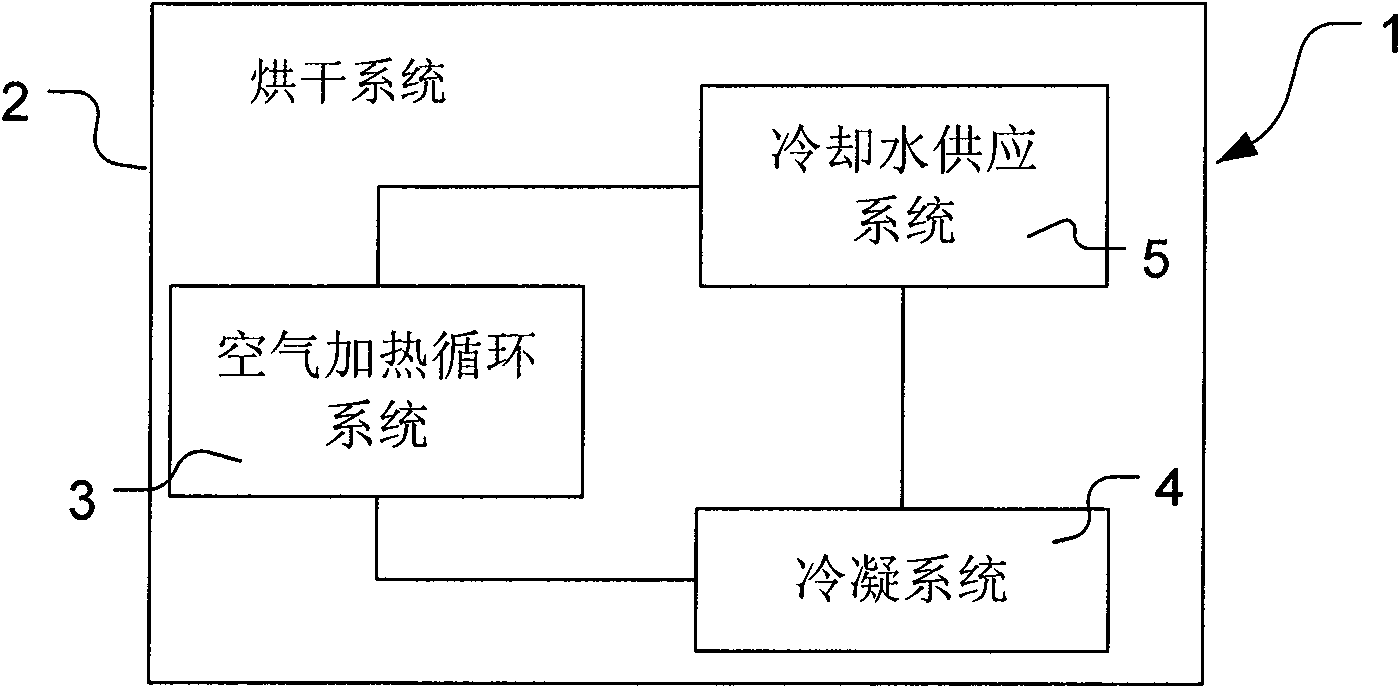

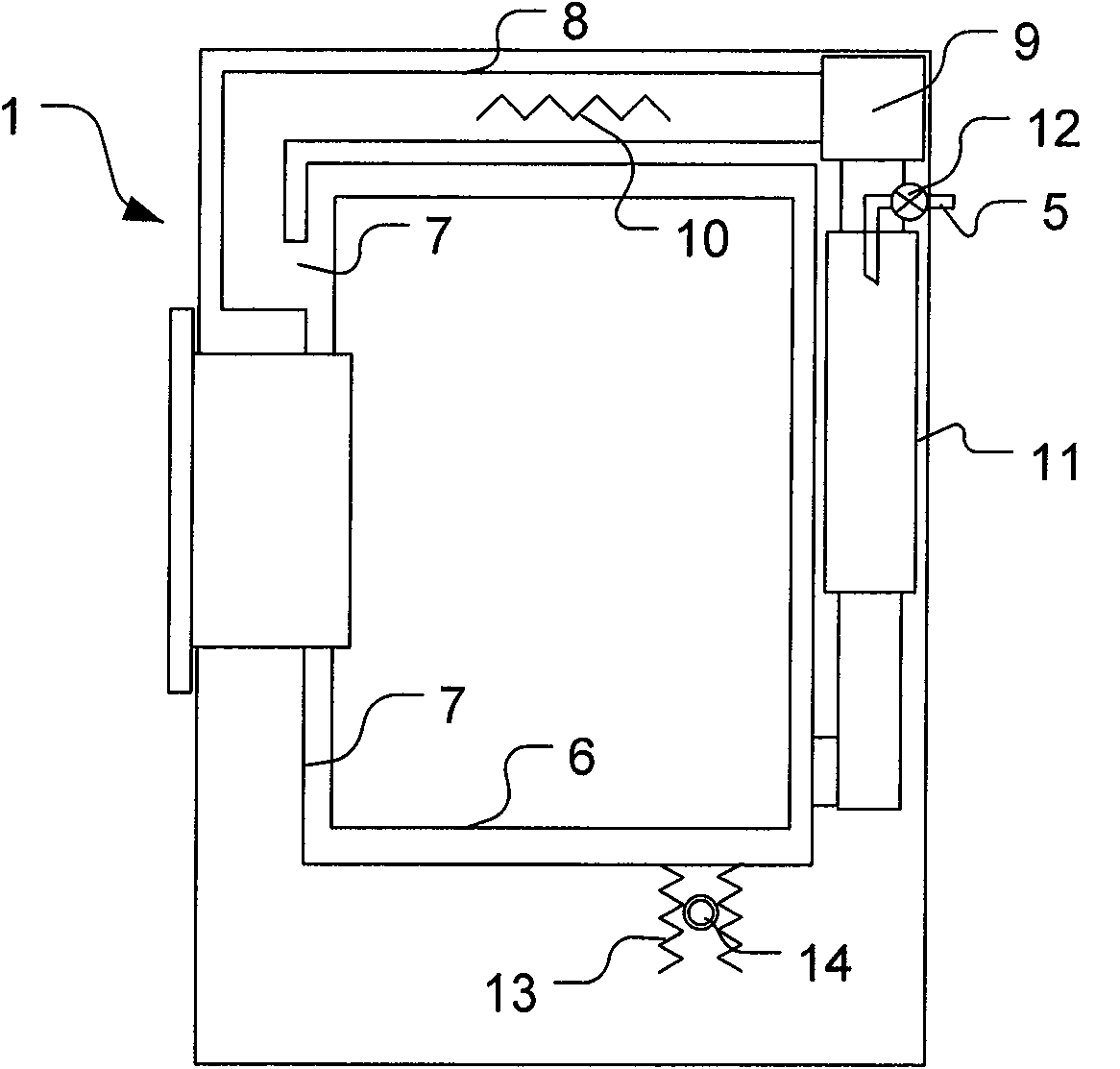

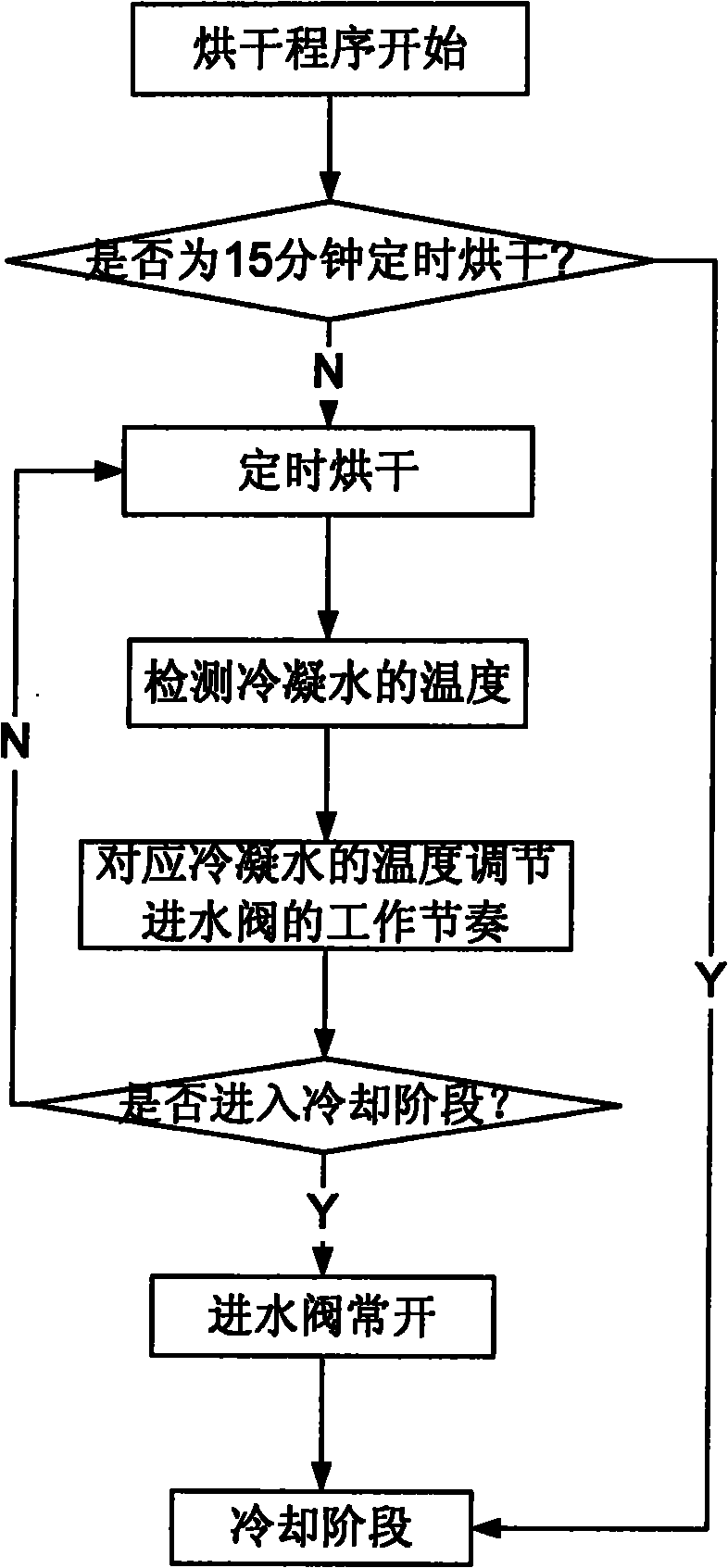

Clothes treatment equipment with drying function and control method thereof

InactiveCN102094309AOptimize water cooling drying technologySave waterTextiles and paperLaundry driersWater resourcesProcess engineering

The invention discloses clothes treatment equipment with drying function and a control method thereof. The equipment comprises a drying system for executing drying operation for clothes, wherein the drying system comprises an air circulating system for promoting heat exchange between the air and the clothes and a condensation system for condensing the heat exchanged air; and the equipment also comprises a cooling water supply system controlled according to the temperature of the condensed water formed by the condensation system and used for supplying cooling water to the condensation system. Therefore, the equipment realizes accurate control of the water inlet quantity of the cooling water, ensures the drying effect, and meanwhile, avoids unnecessary waste of water resources.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

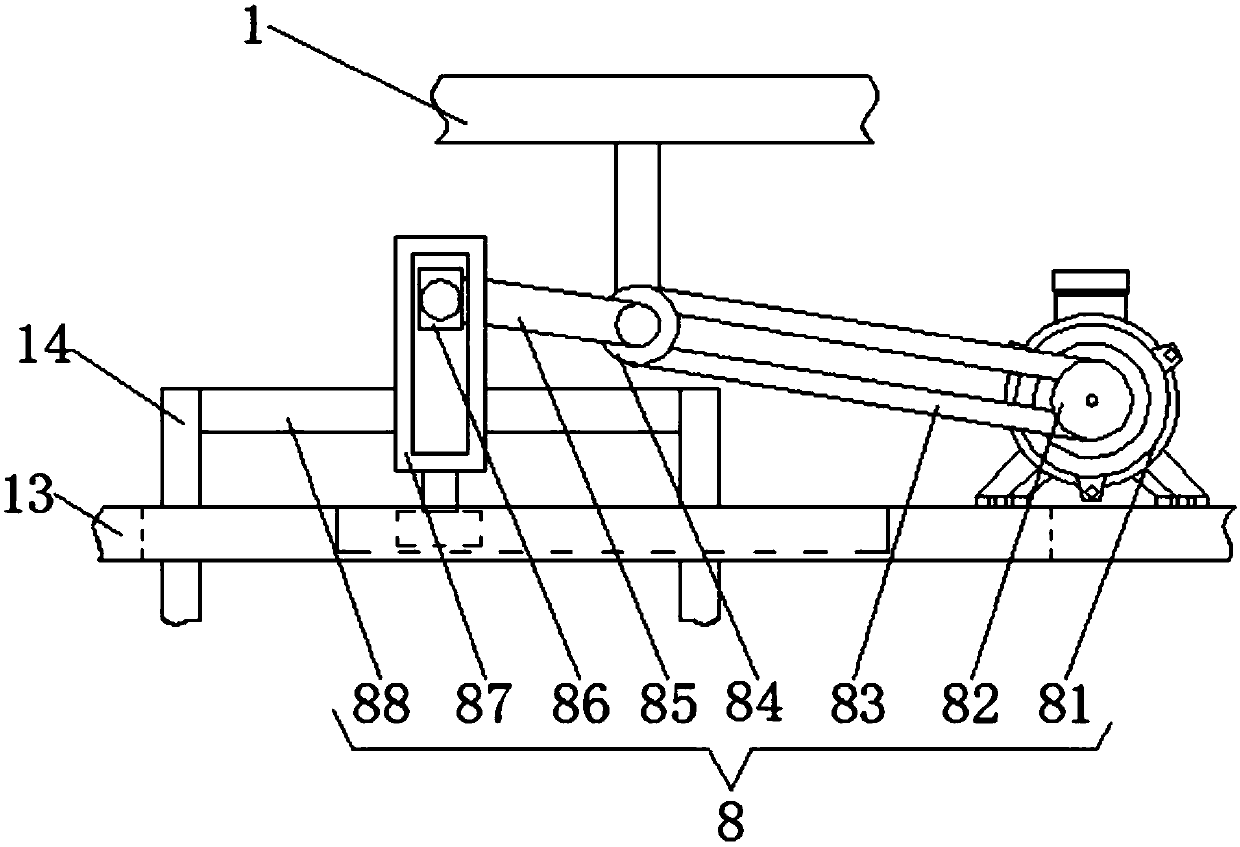

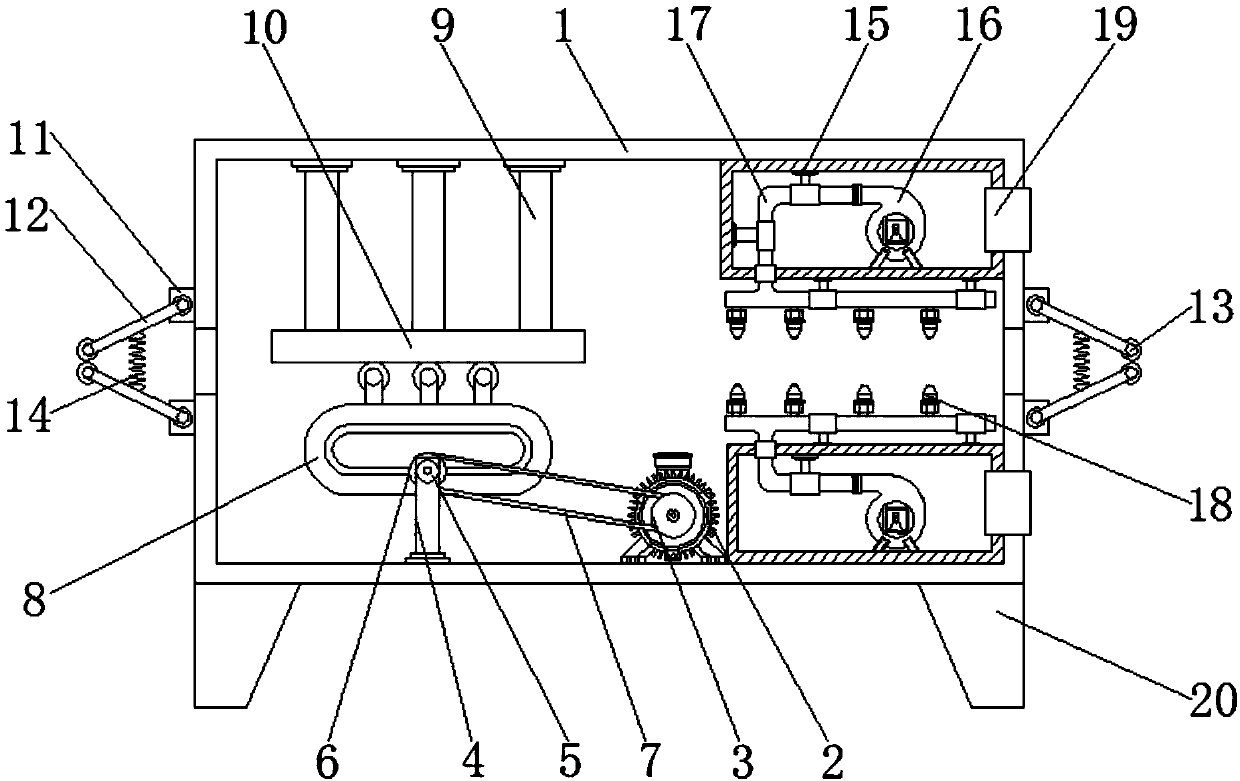

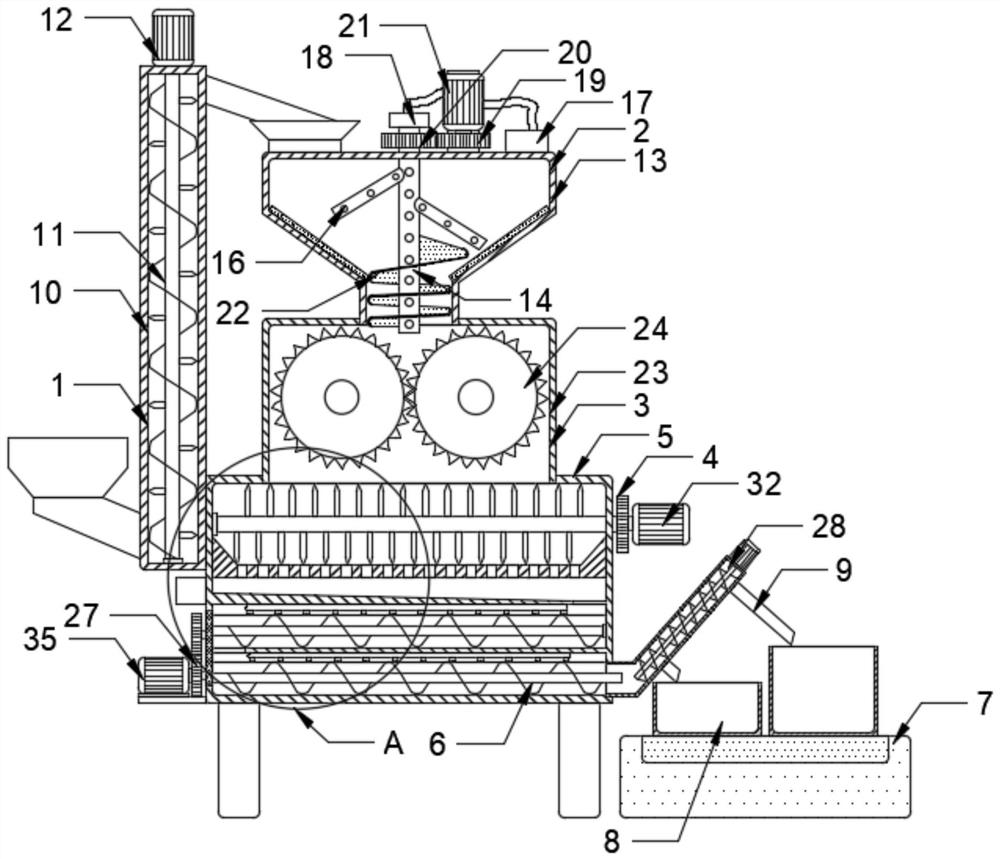

Rotary feed smashing and drying device

InactiveCN109269268ARealize synchronous processingImprove crushing efficiencyDrying gas arrangementsDrying chambers/containersEngineeringLoad cell

The invention relates to the technical field of feed processing, in particular to a rotary feed smashing and drying device. The device includes a box body, a first motor, a filtering net, pneumatic baffles, a drying apparatus and a second motor. A base is fixedly connected to the bottom of the box body, and moving wheels are fixedly installed on the two sides of the bottom of the base; a feeding hopper is arranged at the center of the top of the box body, the filtering net is arranged at the portion, at the bottom of the feeding hopper, of the top of the interior of the box body, the first motor is fixedly installed in the filtering net through a support frame, and a crushing roller is fixedly installed on an output shaft of the first motor; the pneumatic baffles are fixedly installed on the portions, close to the lower side of the filtering net, of the two sides of the inner wall of the box body, a weighing sensor is fixedly installed at the bottoms of the pneumatic baffles, and the drying apparatus is arranged at the portion, on the lower sides of the pneumatic baffles, of the inner wall of the box body. The overall device is simple in structure, convenient to operate and great in drying effect and has a certain popularization value.

Owner:潍坊正兴自动化设备科技有限公司

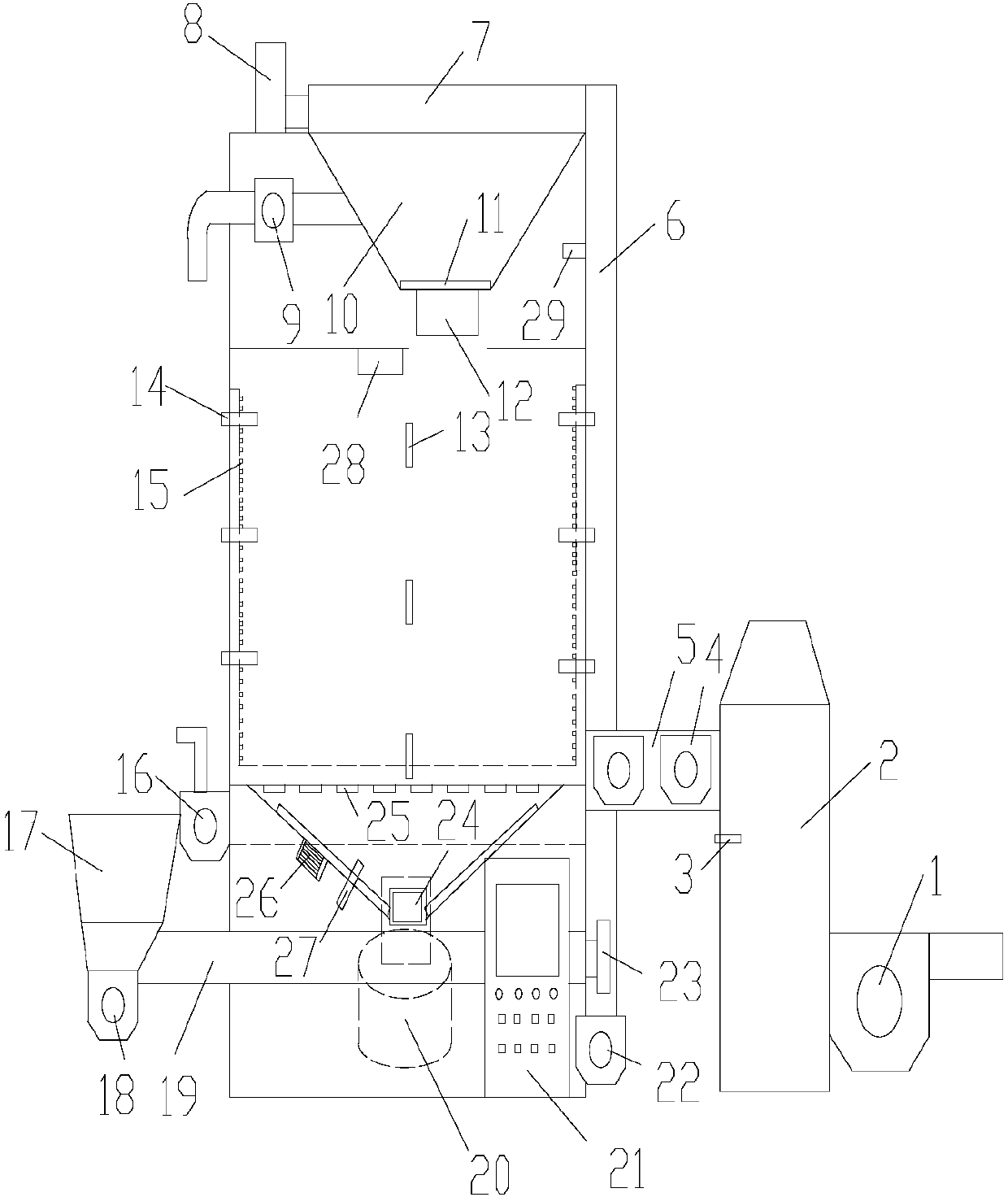

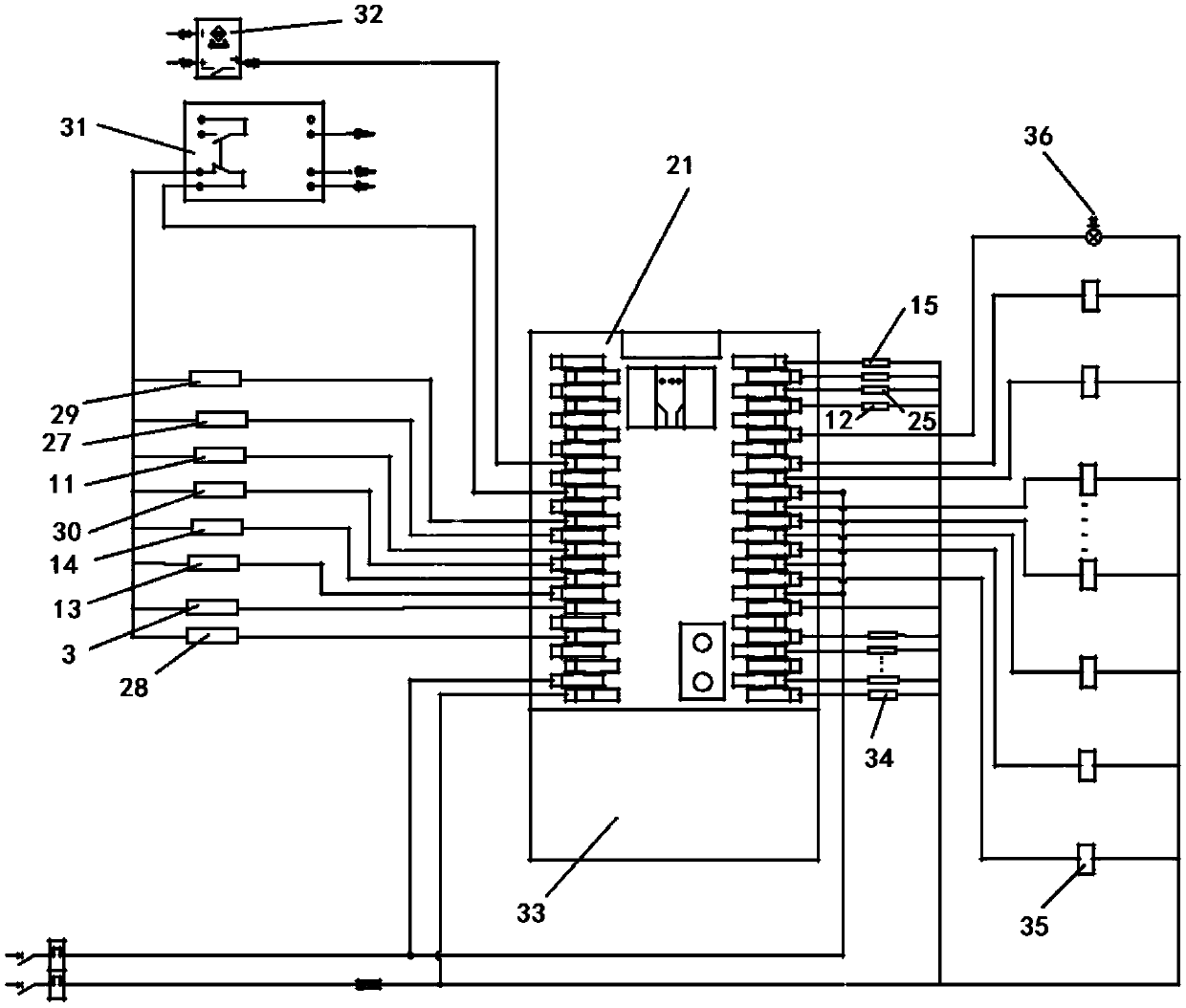

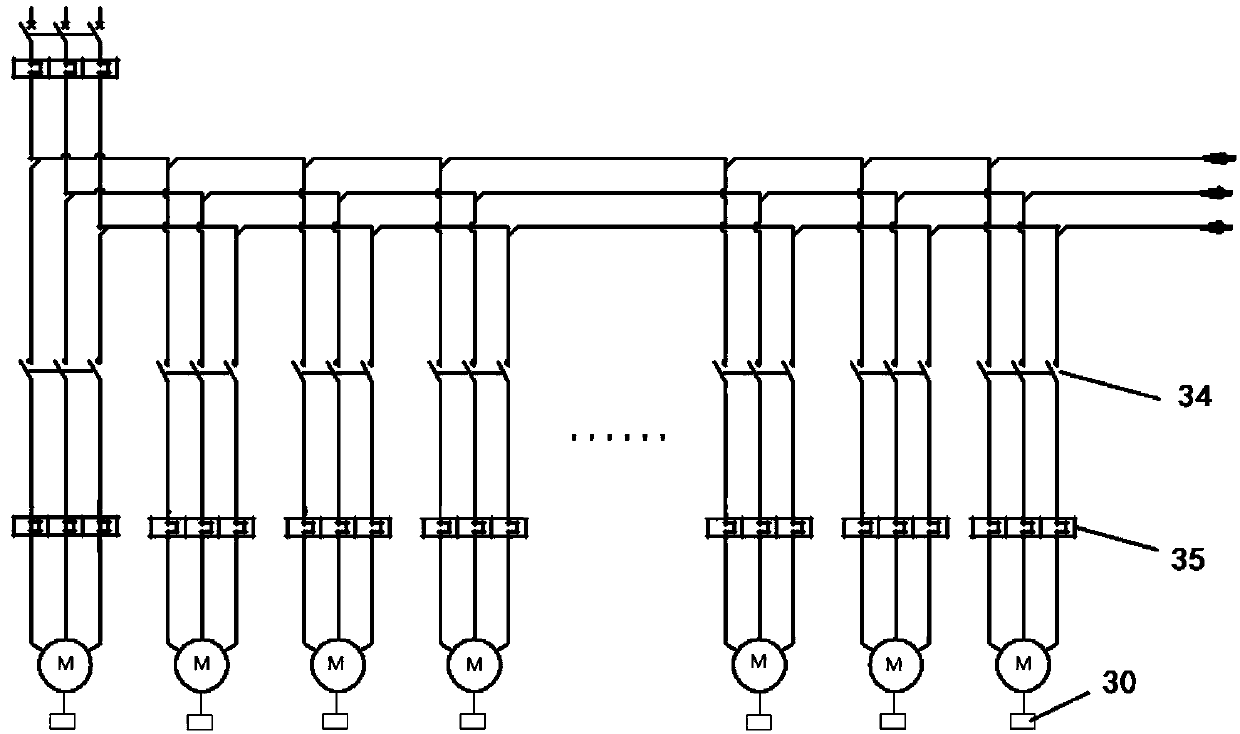

Grain dryer automatic control device and control method thereof

InactiveCN107861540AIncrease the level of automationGuaranteed drying effectTemperatue controlSeed preservation by dryingAutomatic controlInduction motor

The application discloses a grain dryer automatic control device and a control method thereof. The technical scheme adopted is as follows: a PLC controls a lifting motor, an upper auger motor and a lower auger motor, and a grain discharging motor is started to transport the grains in a feeding hopper to a drying tower until the drying tower is full; and for drying, the hot air temperature in a hotblast stove, the temperature in the drying tower and the moisture content of the grains are set first according to the process requirements, a temperature sensor collects temperature information in real time and feeds back the temperature information to the PLC, the PLC controls the speeds of a blower motor, an induction motor and an exhaust motor according to the temperature information to fullyensure the effect of drying, a moisture meter collects the moisture change of the grains in real time until the moisture content drops to a set value, a discharging hopper is opened, a transport component motor is started, and the grains are transported out through a transport component. The level of automation of the drain drying process can be improved, human intervention can be reduced, and therefore, the grain drying effect is improved.

Owner:CHANGDE KEXIANG ELECTRICAL MFG

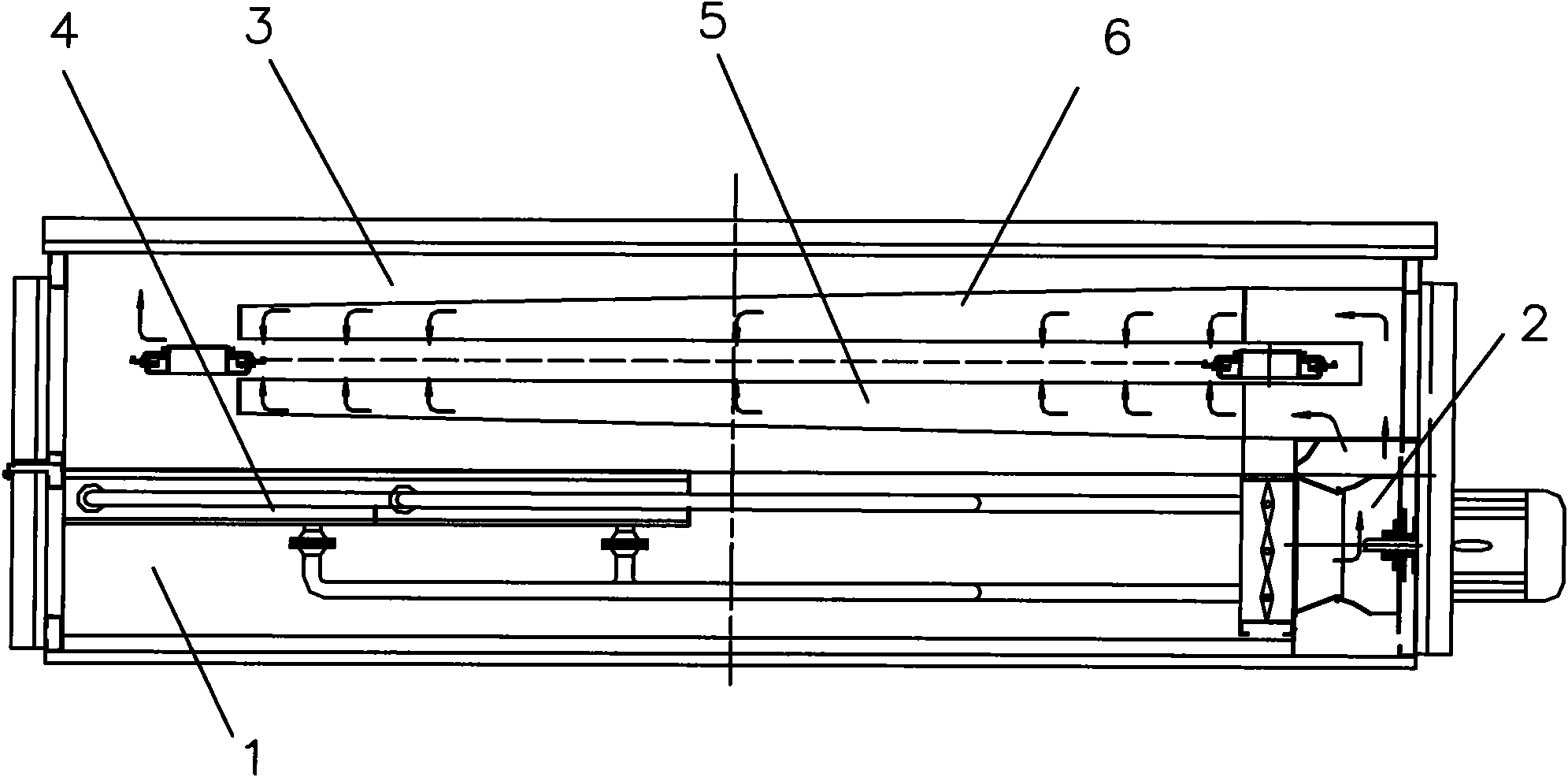

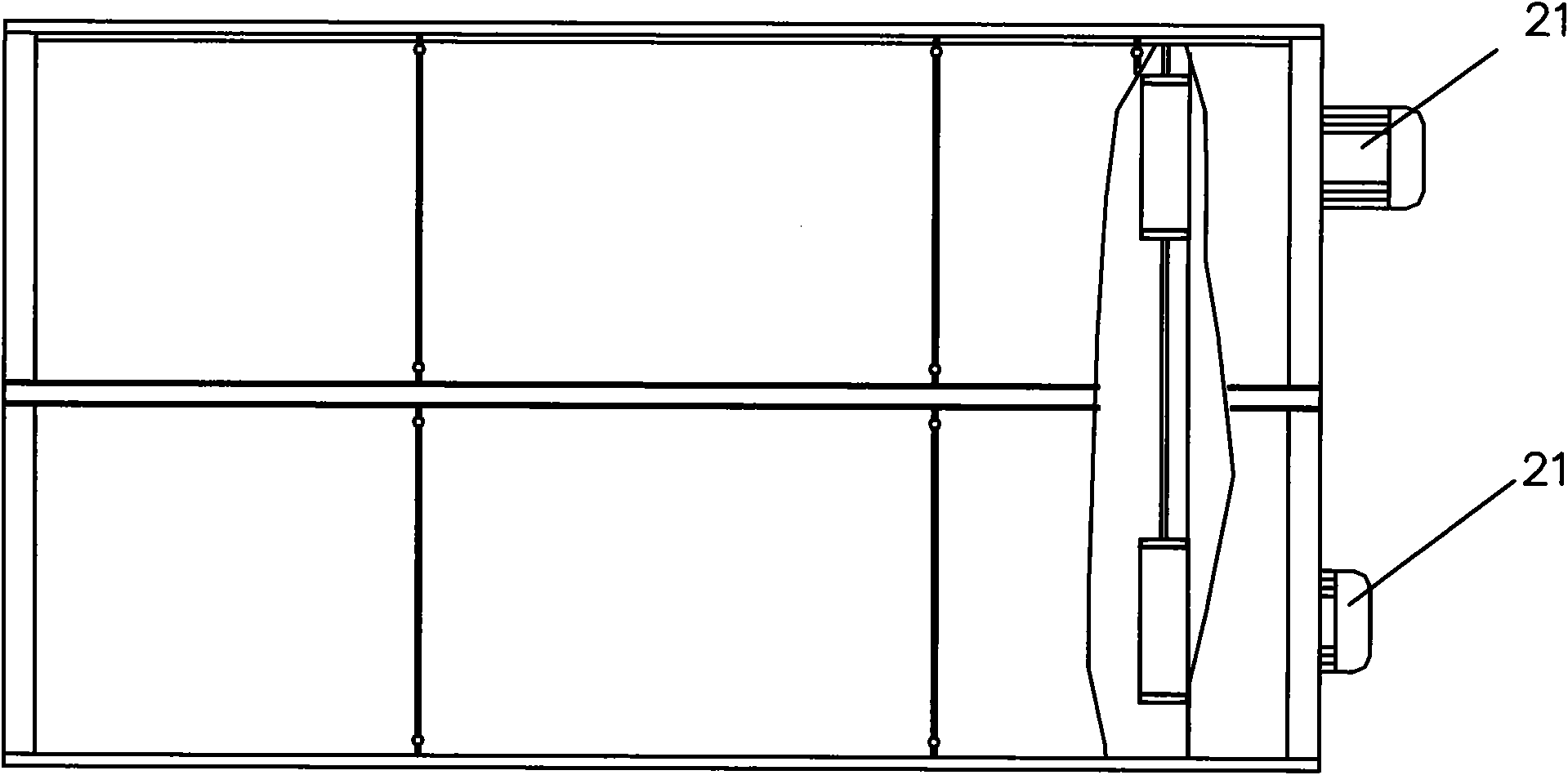

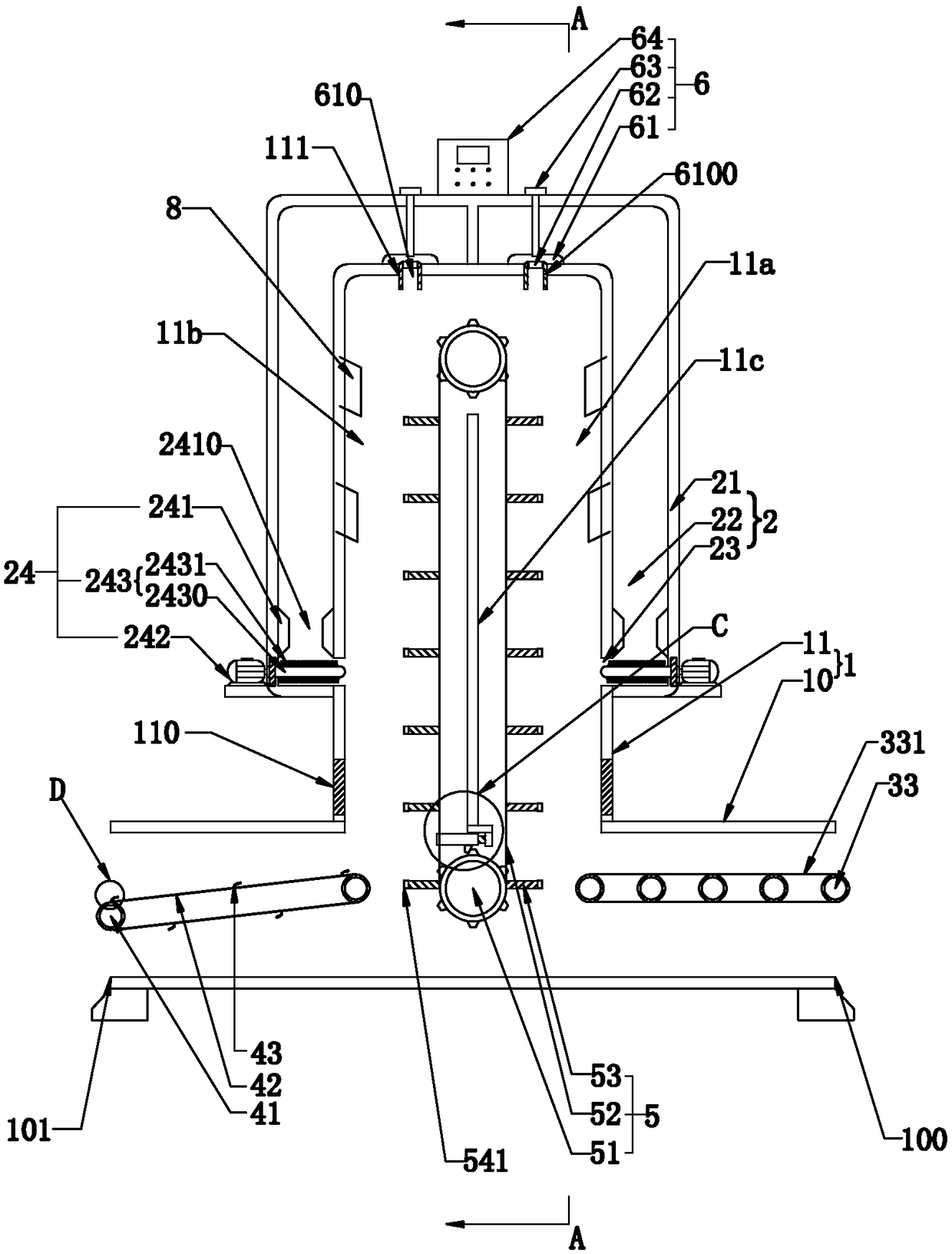

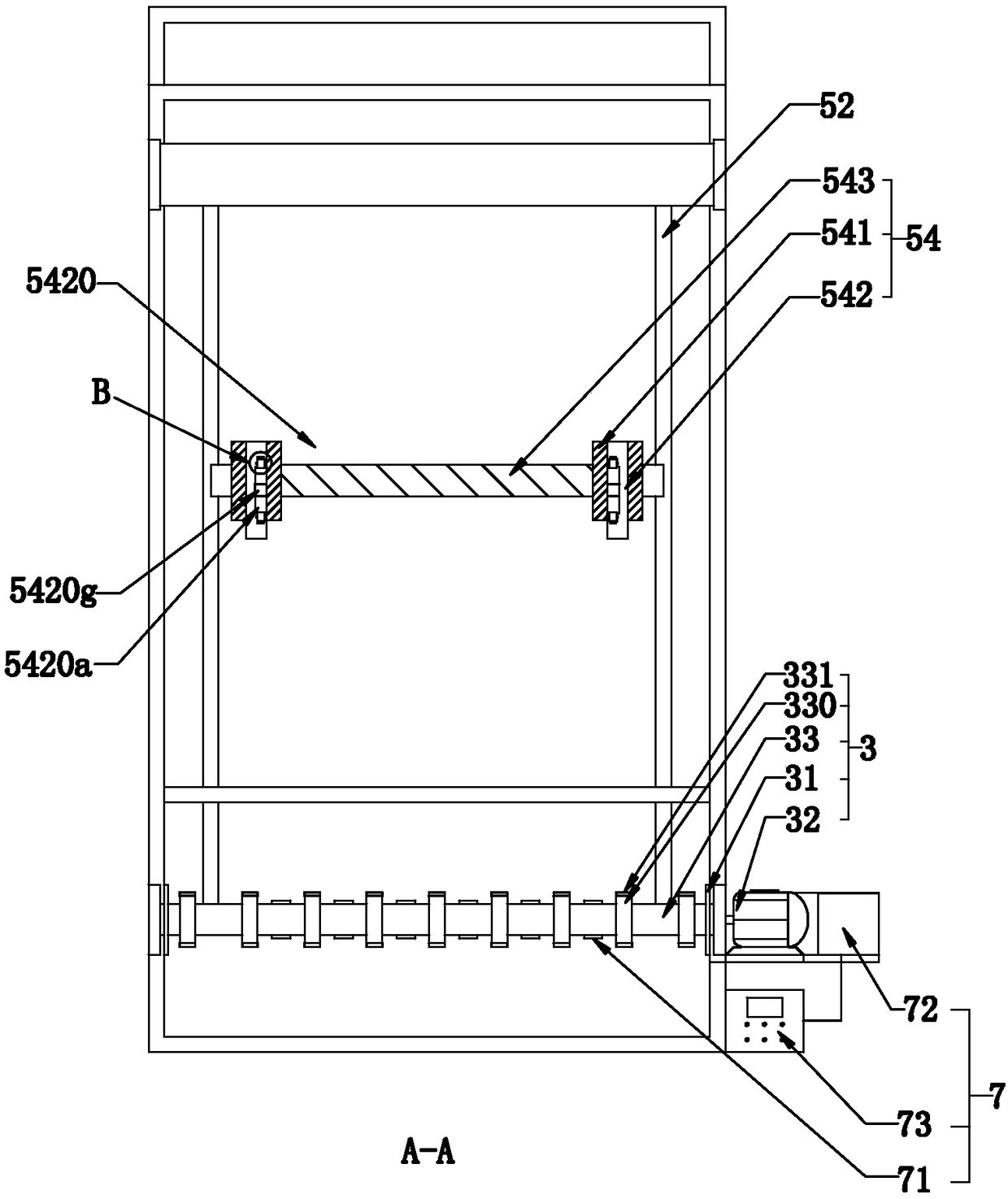

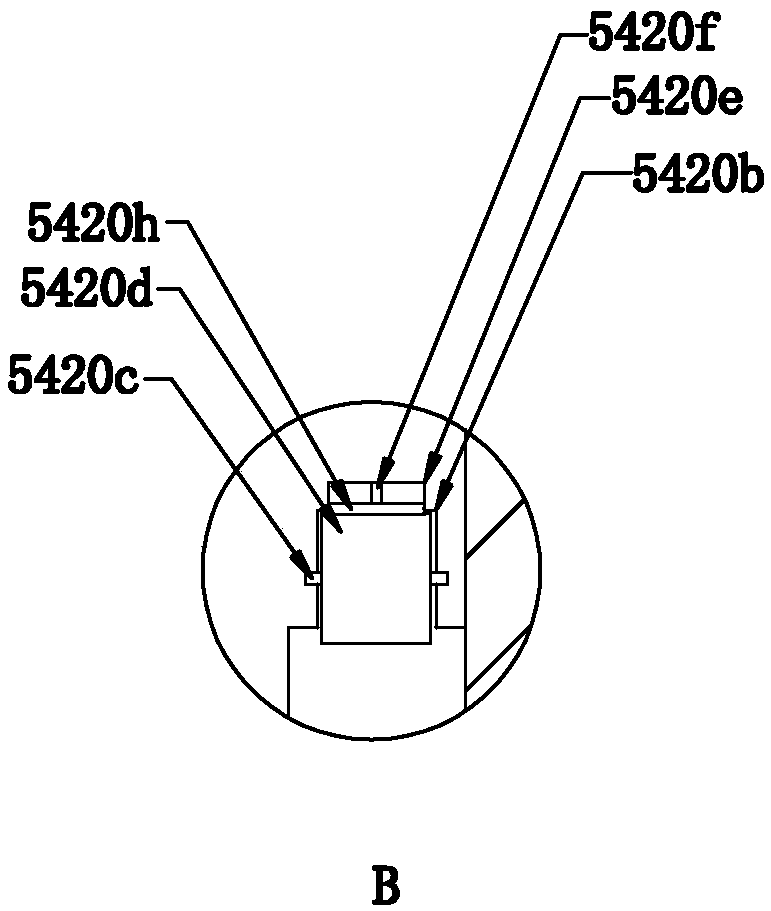

Vertical oven for circuit board and drying method thereof

ActiveCN109186233AReduce the proportion of the siteImprove drying effectDrying chambers/containersDrying machines with progressive movementsEngineeringMechanical engineering

The invention relates to a vertical oven for a circuit board and a drying method thereof. The vertical oven for the circuit board is characterized by comprising a vertical box body composed of a mainbox body and a heating box body, an insulating component arranged on the outer wall of the heating box body, and an inlet and an outlet respectively arranged in both ends of the main box body, an input assembly and an output assembly respectively arranged at the inlet and the outlet for transporting the circuit board, and a lifting assembly arranged inside the heating box body and used for transporting a circuit board frame on the input assembly to the top of the heating box body for one circle and transporting the circuit board frame to the output assembly; air inlets for supplying heat to the interior of the heating box body are arranged in the outer walls of the both sides of the junction of the heating box body and the main box body respectively, air outlets for discharging the hot airinside the heating box body into the interior of the insulating component are arranged at the top of the heating box body at intervals, and a control component is arranged at each air outlet. The vertical oven for the circuit board has the beneficial effect that the problem that the equipment occupies too much space can be solved, and the baking effect on the circuit board can be ensured.

Owner:QUZHOU CHUANTE ELECTRONICS TECH CO LTD

Pig feed grinding and drying integrated processing equipment

InactiveCN111889211ARealize the collectionRealize deliveryFeeding-stuffDrying gas arrangementsEngineeringProcess engineering

The invention discloses pig feed grinding and drying integrated processing equipment. The pig feed grinding and drying integrated processing equipment includes a feeding mechanism and a grinding mechanism. The feeding mechanism is arranged at the side edge of the fixed box, the grinding mechanism is arranged at the top of the fixed box, a material sending mechanism is arranged at the top of the grinding mechanism, a screw feeder is arranged at the lower end, away from the feeding mechanism, of the fixed box, a conveying mechanism is arranged at the position, located under the screw feeder, ofthe side edge of the fixed box, and two material collecting grooves are formed in the top of the conveying mechanism. According to the pig feed grinding and drying integrated processing equipment, thesuper strong grinding of materials is achieved through a crushing mechanism so as to ensure the grinding effect of materials, the complex process of secondary grinding caused by insufficient grindingof the materials is reduced, the strengthening drying of the materials is achieved through a drying mechanism, and the drying effect of the materials is ensured; and the overall structure is simple,grinding and drying can be integrated, moreover, the grinding and drying are relatively thorough, the complex process of subsequent processing is avoided, and the processing efficiency of pig feed isgreatly improved.

Owner:李超

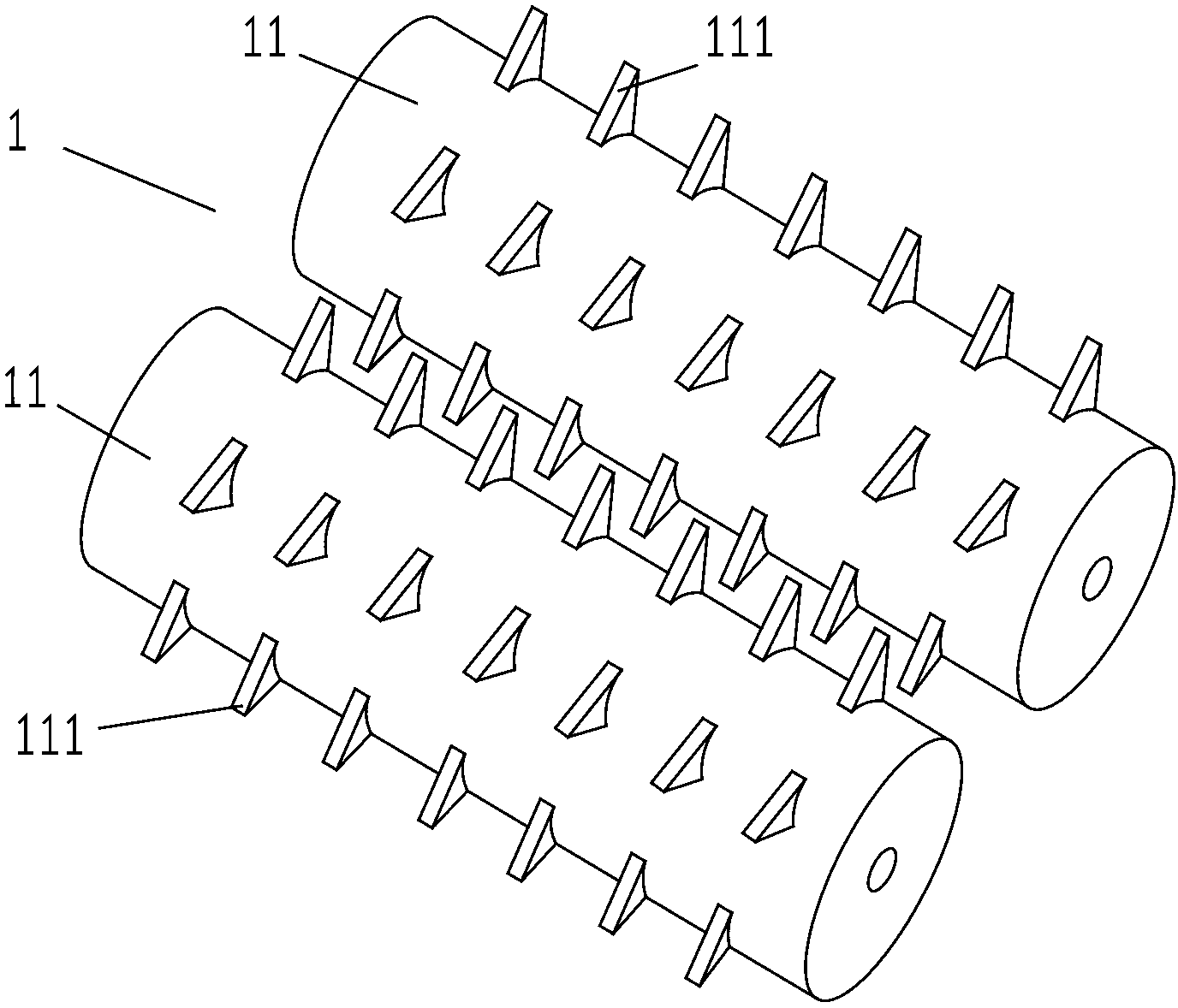

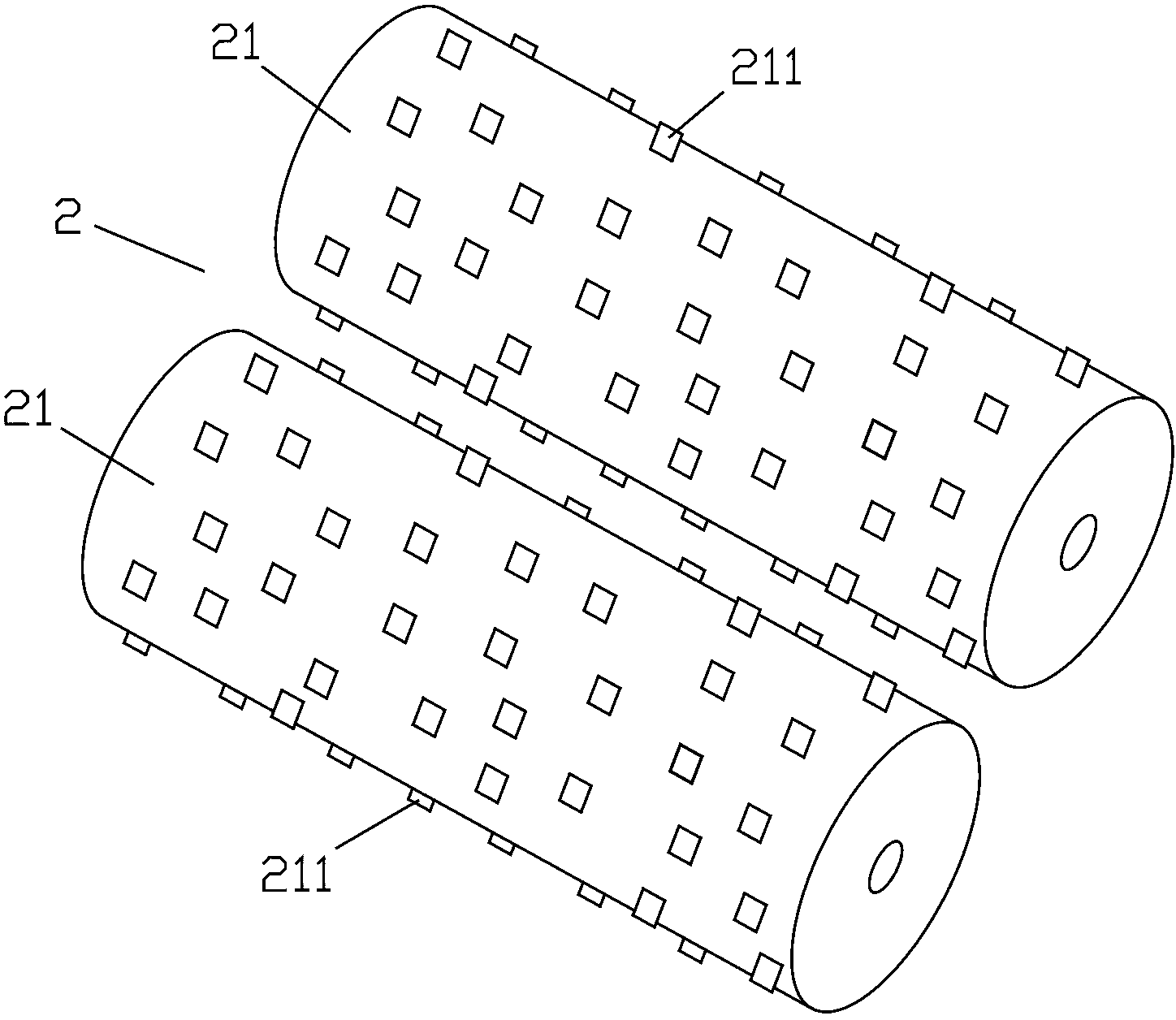

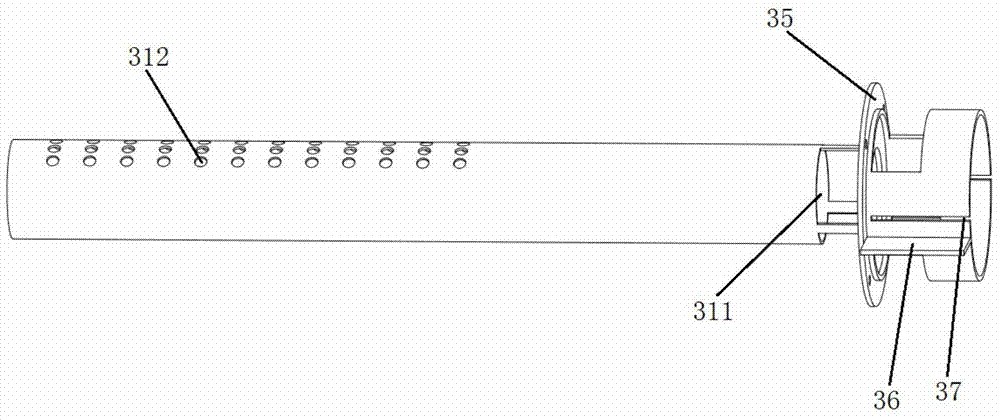

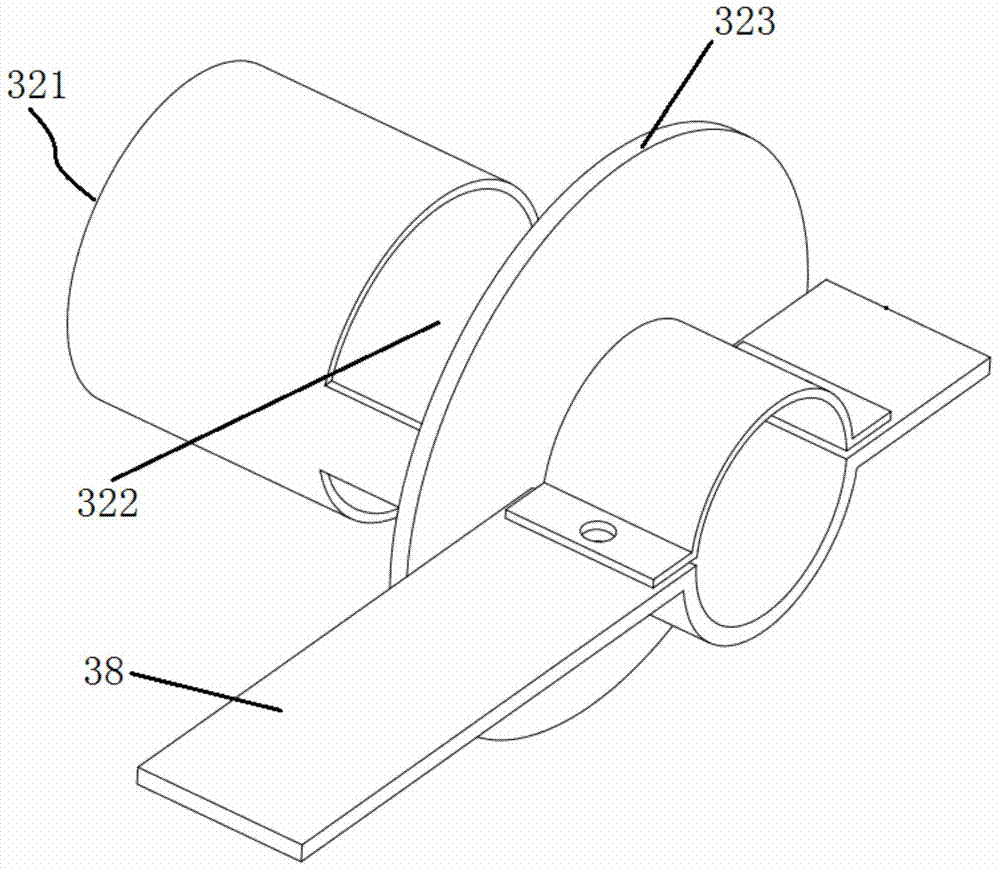

Roller type efficient mulberry leaf drying device

ActiveCN107990663AAffect nutritional valueAvoid uneven heatingDrying gas arrangementsDrying chambers/containersDrive shaftAgricultural engineering

The invention discloses a roller type efficient mulberry leaf drying device. The roller type efficient mulberry leaf drying device comprises a base, a roller, a transmission mechanism and an air heater; two stand plates are arranged on the left and right sides of the top of the base; a cross beam is connected to the tops of the stand plates on the two sides; the roller is arranged above the base;a left rotating shaft and a right rotating shaft are respectively connected to the centers of the end surfaces on the two sides of the roller; the right rotating shaft is an extension shaft with a hollow design; a transmission shaft for driving the left rotating shaft to rotate is arranged on the left side of the left rotating shaft; the transmission shaft is provided with a transmission mechanismfor driving the transmission shaft to rotate; the air heater is mounted on the right side of the base; a hot air pipe upwards extends to penetrate through the stand plate on the right side, and extends into the roller in the axis direction of the right rotating shaft; exhaust ports are densely formed in the hot air pipe; and an overturning rod is arranged at the outer periphery of a pipe body ofthe hot air pipe. The mulberry leaf drying device can effectively prevent nutrient loss of mulberry leaves to guarantee no influence on nutritional value of the mulberry leaves, and meanwhile, is uniform in heating of the mulberry leaves and excellent in drying effect to guarantee the quality grade of dried finished products.

Owner:HUNAN NONGYOU SHENGTAI AGRI TECH +1

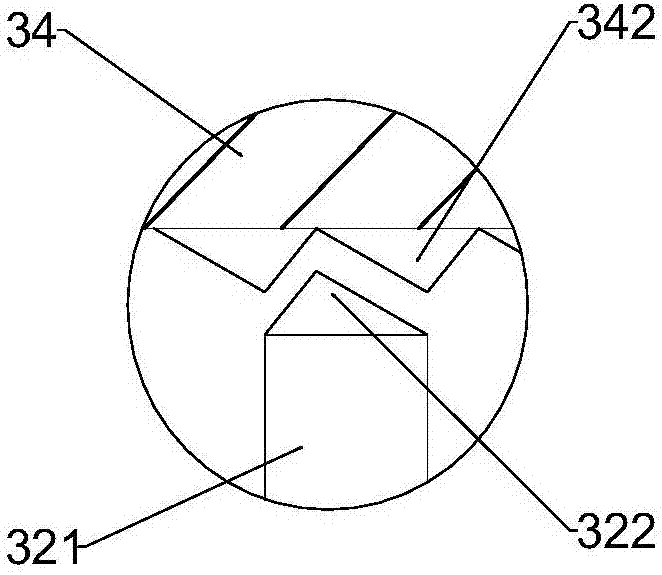

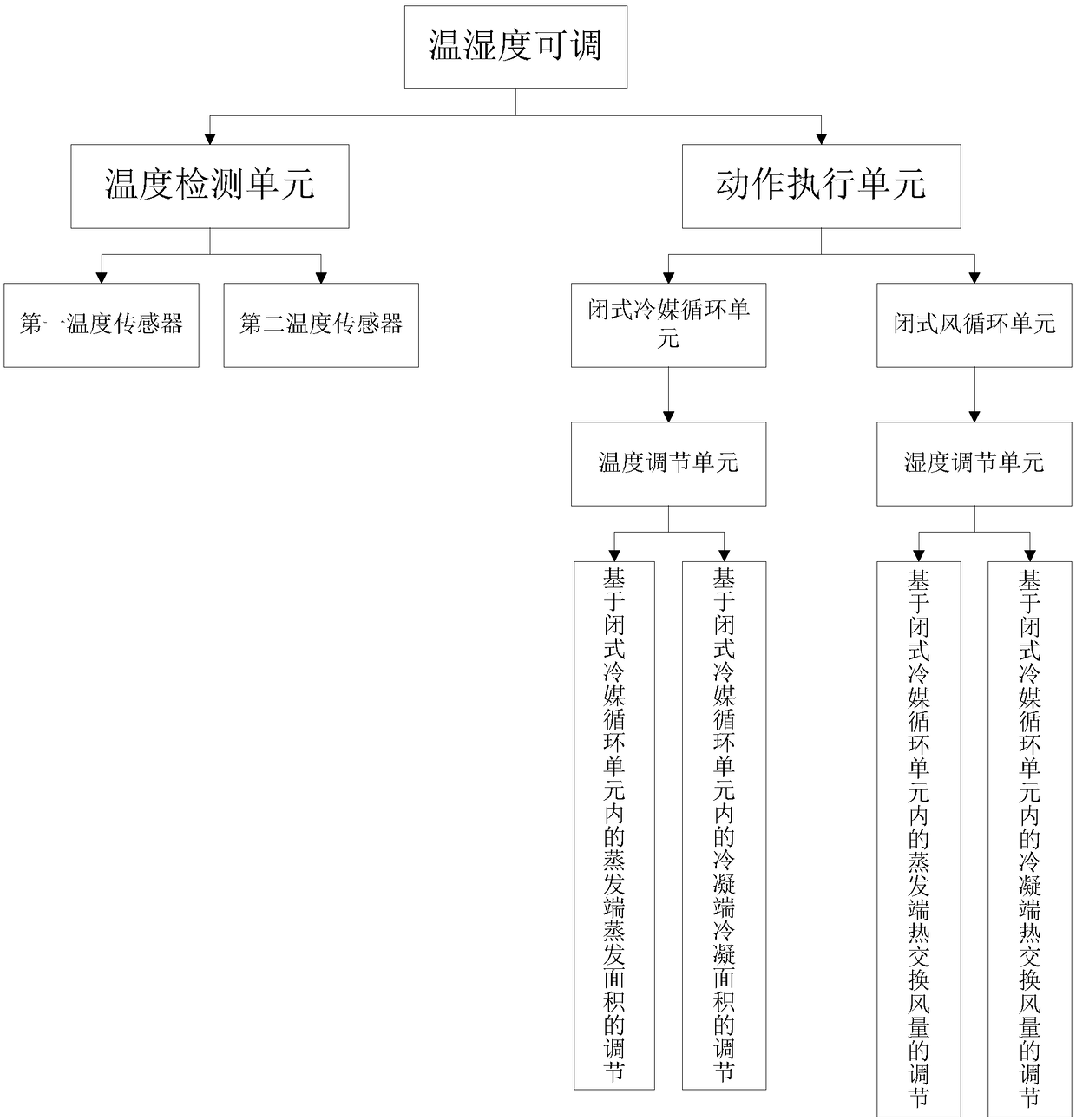

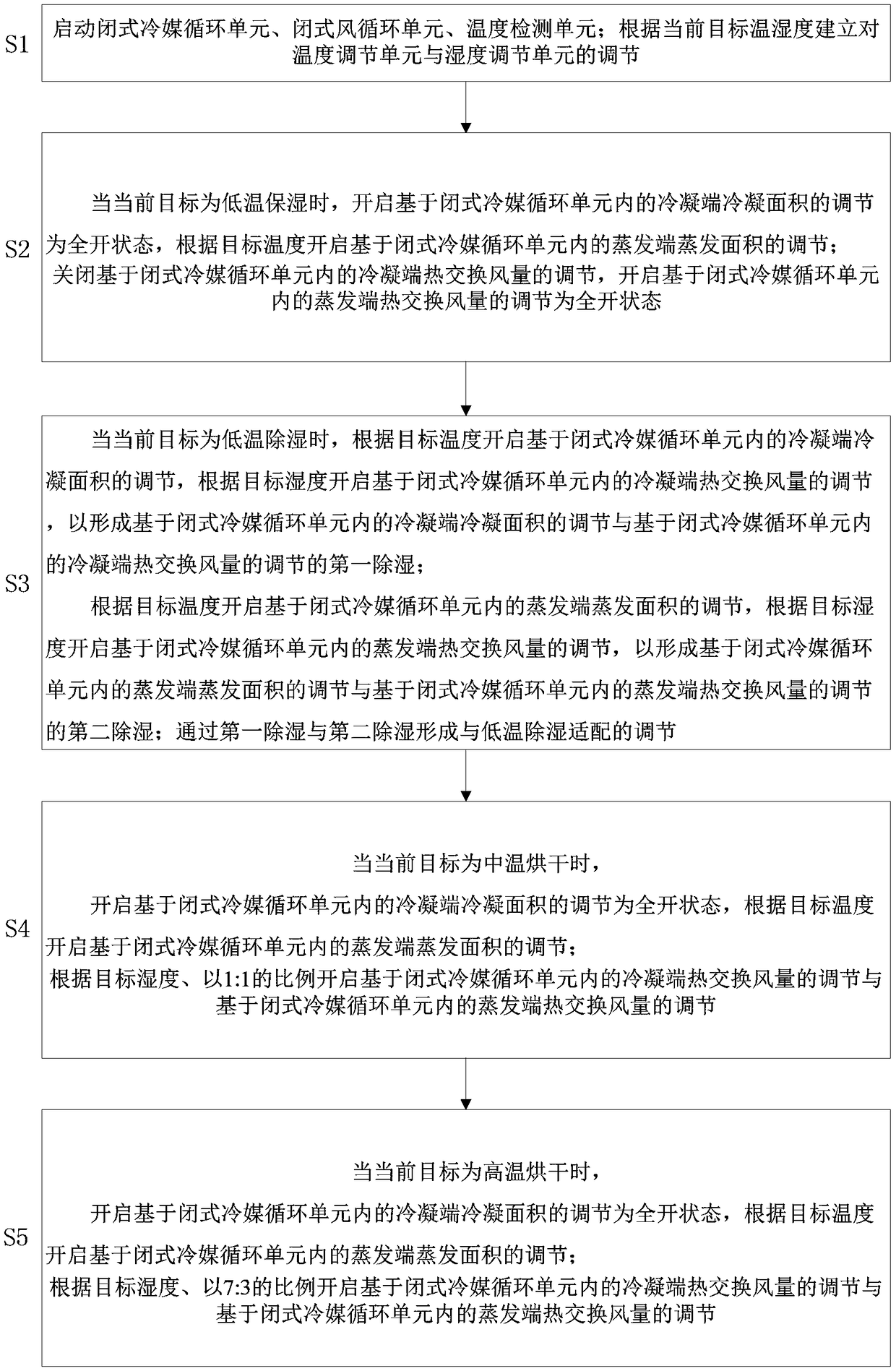

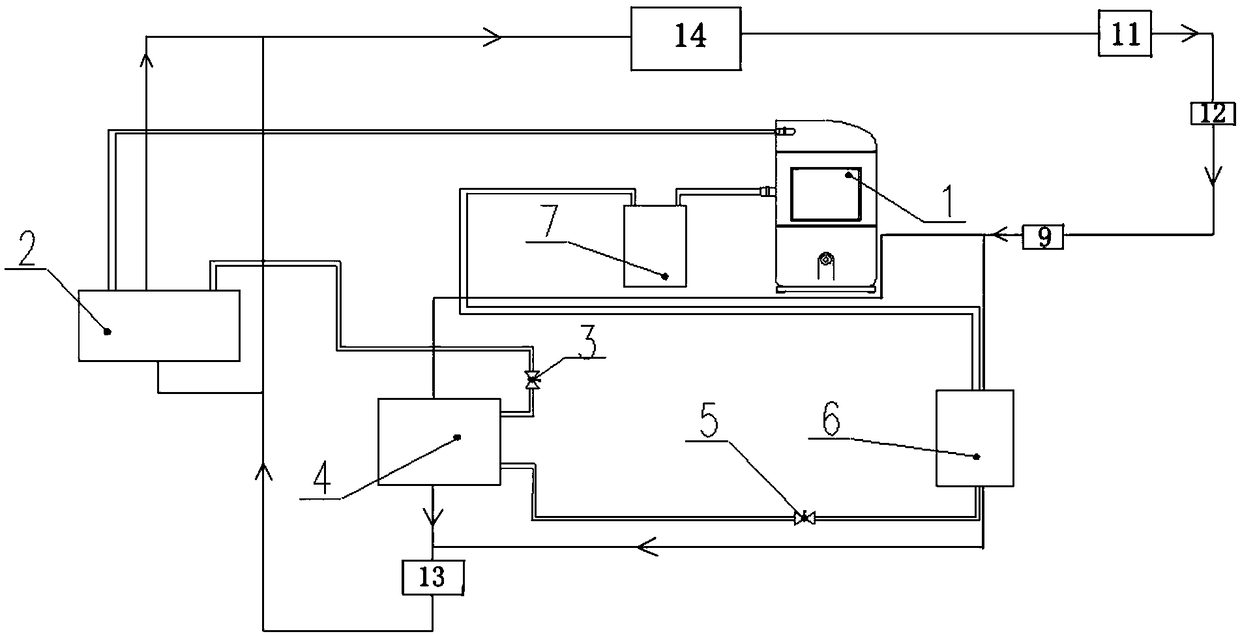

Self-adjustable dehumidification drying heat pump control system and method

ActiveCN109405526ATo achieve the purpose of high efficiency and energy savingMeet the requirements of dehumidification in low temperature conditionsHeat pumpsDrying gas arrangementsAir volumeControl system

The invention discloses a self-adjustable dehumidification drying heat pump control system and method. Through cooperation of a temperature detection unit and an action execution unit which are arranged, temperature and humidity adjustable adaptive response is formed. The action execution unit is provided with a closed refrigerant circulation unit and a closed air circulation unit. A temperature adjusting unit is arranged in the closed refrigerant circulation unit. A humidity adjusting unit is arranged in the closed air circulation unit. The temperature adjusting unit has the functions of adjusting based on the condensing area of the condensing end inside the closed refrigerant circulation unit and adjusting based on the evaporation area of the evaporation end inside the closed refrigerantcirculation unit. The functions of adjusting based on the heat exchange air volume of the condensing end inside the closed refrigerant circulation unit and adjusting based on the heat exchange air volume of the evaporation end inside the closed refrigerant circulation unit are formed in the humidity adjusting unit. By forming the four appropriate adjusting functions, self-adjustable dehumidification drying well matched with a low-temperature humidification mode, a low-temperature dehumidification mode, a medium-temperature drying mode, a high-temperature drying mode and a ventilation mode isformed.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

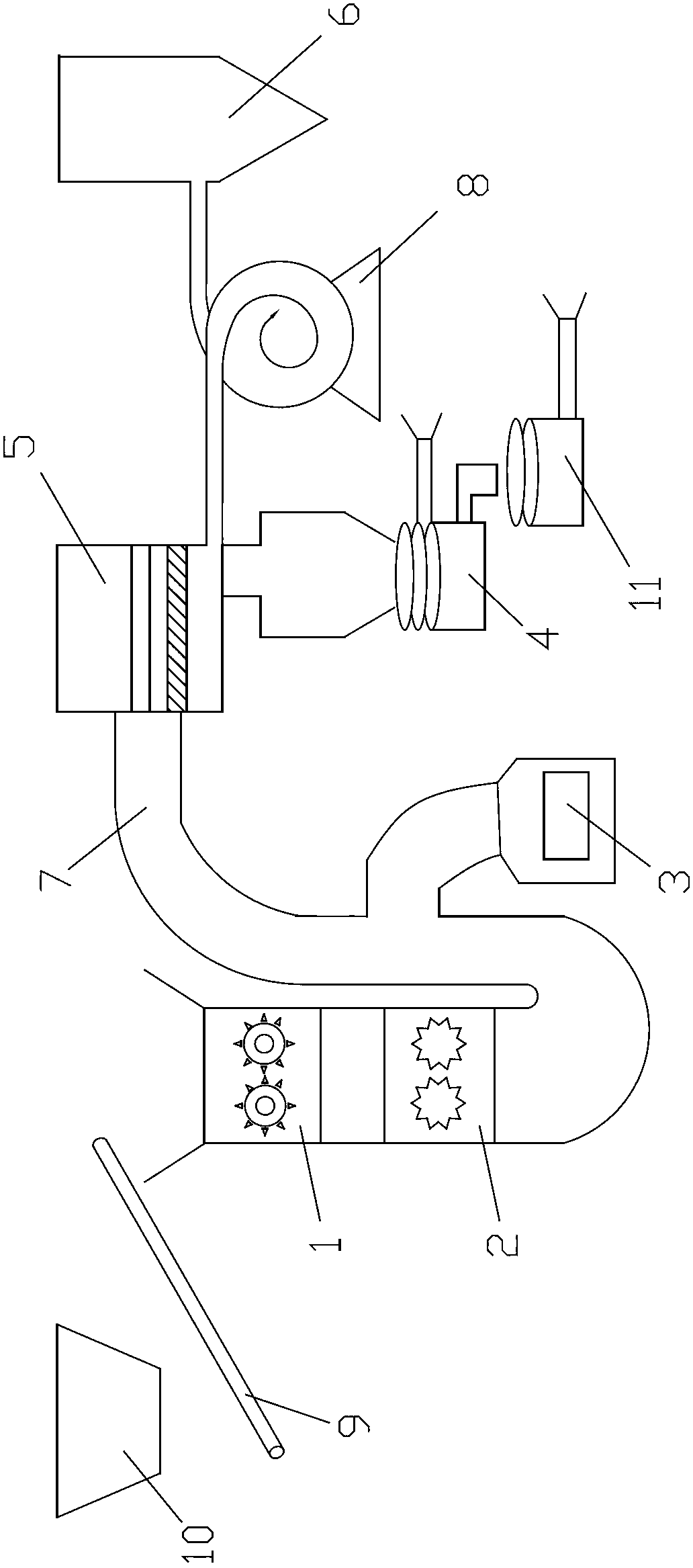

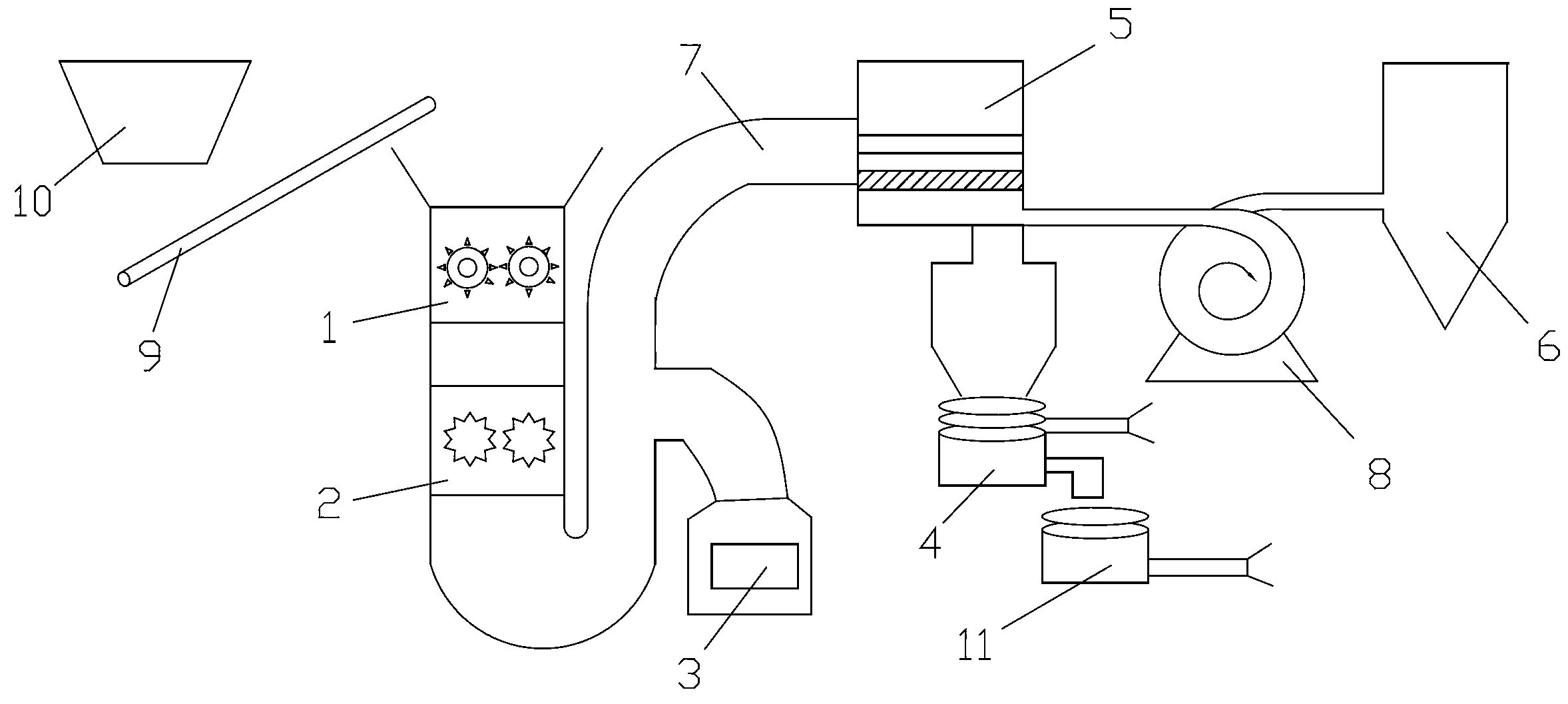

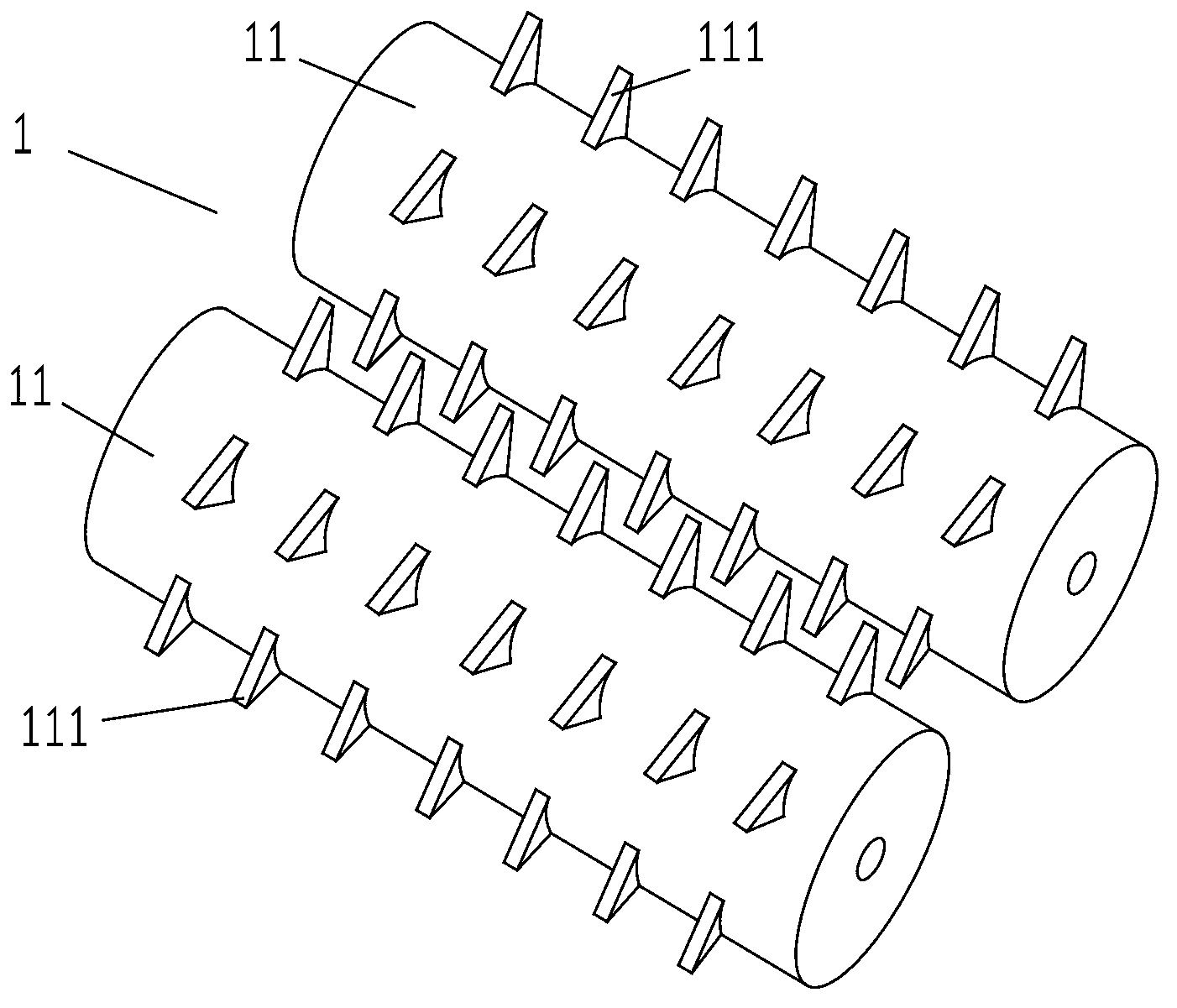

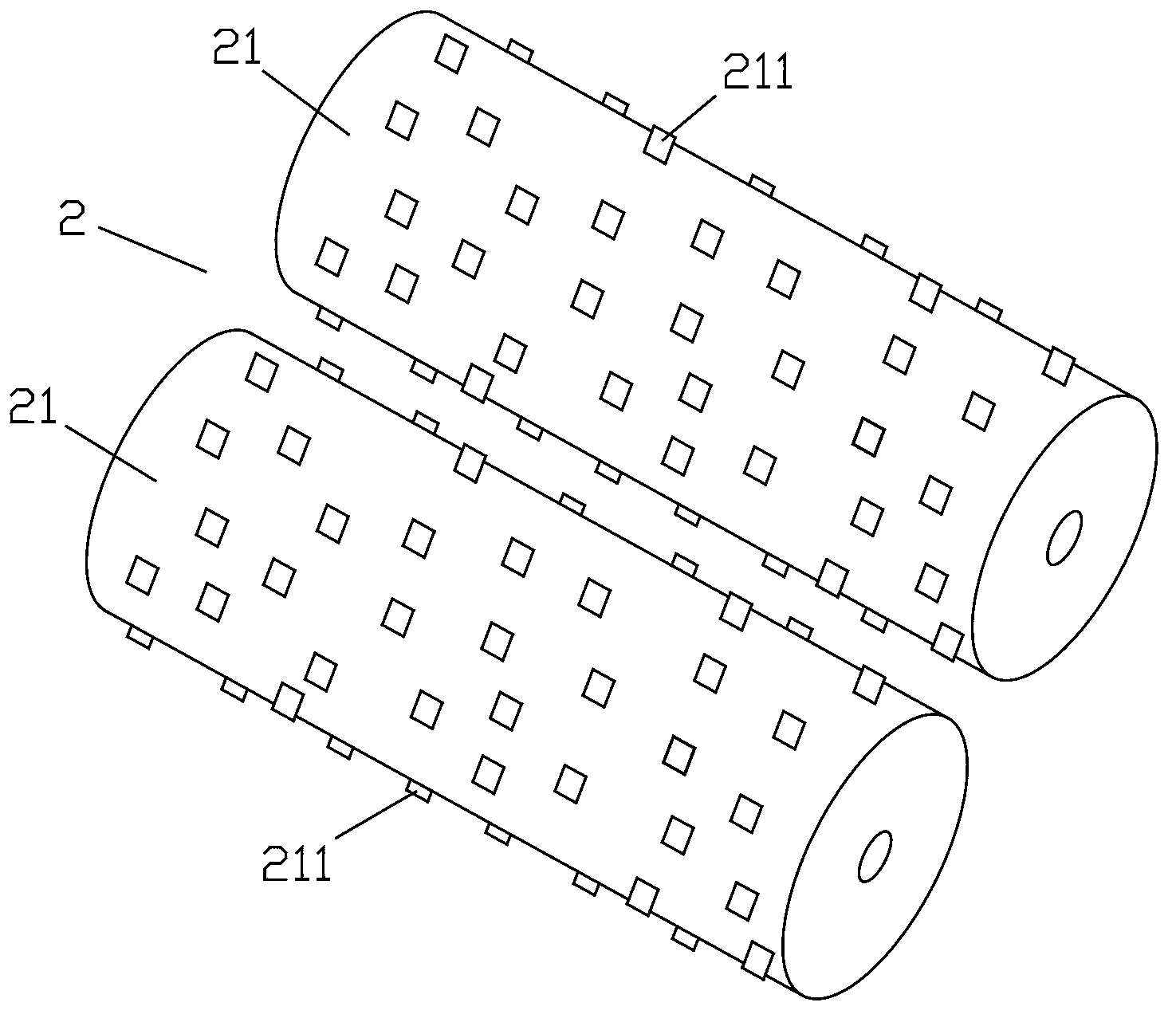

Diatomite crushing and drying apparatus and crushing and drying method

InactiveCN103263964AImprove crushing effectGuaranteed drying effectGrain treatmentsMaterial resourcesEngineering

The invention discloses a diatomite crushing and drying apparatus and a crushing and drying method. The diatomite crushing and drying apparatus comprises an air duct, a crusher, a roller machine, a primary vibrating screen, a grading device and a dust collecting chamber. The crusher comprises two crushing rollers rotating along opposite directions and uniformly provided with a plurality of rows of wolf tooth structures on their surfaces. The roller machine comprises two rollers rotating along opposite directions and provided with a plurality of projecting structures on their surfaces. During crushing and drying, diatomite successively undergoes crushing and drying twice in the crusher and the roller machine, wherein drying temperature is 400 to 600 DEG C, and drying time is 30 to 60 s; after drying, crushed diatomite enters into the grading device and the primary vibrating screen for dust collecting and screening so as to screen out desired particles. The invention has the following beneficial effects: the whole apparatus integrates feeding, crushing, drying, grading, screening and dust collecting into one, is convenient to operate, has high production efficiency and enables cost for manpower and material resources to be substantially reduced. The crushed and dried diatomite has low moisture content, and output of the particles with particle sizes in a desired range is great.

Owner:嵊州宝钒硅藻土股份有限公司

Paint for improving inner runner flaky graphite layer of austenitic nodular iron casting and method

ActiveCN105312489AImprove suspension stabilityImprove stabilityFoundry mouldsFoundry coresSodium BentonitePreservative

The invention discloses paint for improving an inner runner flaky graphite layer of an austenitic nodular iron casting. The paint comprises the following components in percentage by weight: 50-60% of zircon powder, 3-5% of sodium bentonite, 2-3% of preservative, 1-2% of defoaming agent, 0.5-2% of sodium alginate, 1-2% of alpha-starch, 1-2% of water glass binder, and 30-40% of water. The invention further provides a method for improving the inner runner flaky graphite layer of the austenitic nodular iron casting; and a sand core is dipped in the paint, and is taken out for drying and pouring. The paint and the method can prevent reducing gas in the volatilizing place in a resin from oxidizing nodular elements in molten iron, guarantee the molten iron to be effectively nodulized, and have a shielding, absorbing or replacing effect on sulfur, so that the sulfur cannot be dispersed to enter the molten iron, flaky graphite is prevented on the surface of the casting, and the surface quality of the austenitic nodular iron casting is greatly improved.

Owner:西峡飞龙特种铸造有限公司

Automatic airing device for traditional Chinese medicines

InactiveCN108020034AImplement an automatic flipRealize the second automatic flipDrying solid materialsDrying machines with local agitationEngineeringCam

The invention discloses an automatic airing device for traditional Chinese medicines. The automatic airing device comprises a fixing base plate; height adjusting supports are arranged at the upper endof the fixing base plate; a box body is hinged among the height adjusting supports; a controller is arranged on the front side of the box body; a timer is arranged on the controller; sliding groovesare formed in the two sides of the box body; first carrying shafts and second carrying shafts are arranged in the sliding grooves in a sliding mode; carrier elastic belts are hinged among the first carrying shafts and the second carrying shafts; a first lifting rod is arranged at the end parts of the first carrying shafts; a second lifting rod is arranged at the end parts of the second carrying shafts; a first turnover motor and a second turnover motor are arranged on the two sides of the lower end of the box body separately; a first turnover cam is arranged at the output end of the first turnover motor; and a second turnover cam is arranged at the output end of the second turnover motor. The automatic airing device has the advantages that the traditional Chinese medicines can be automatically and regularly turned over, the labor intensity can be lowered, and the effect of airing the traditional Chinese medicines can be guaranteed.

Owner:BOZHOU YONGGANG PIECES FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com