Patents

Literature

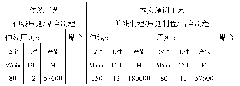

285results about "Manufacturing extensible conductors/cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

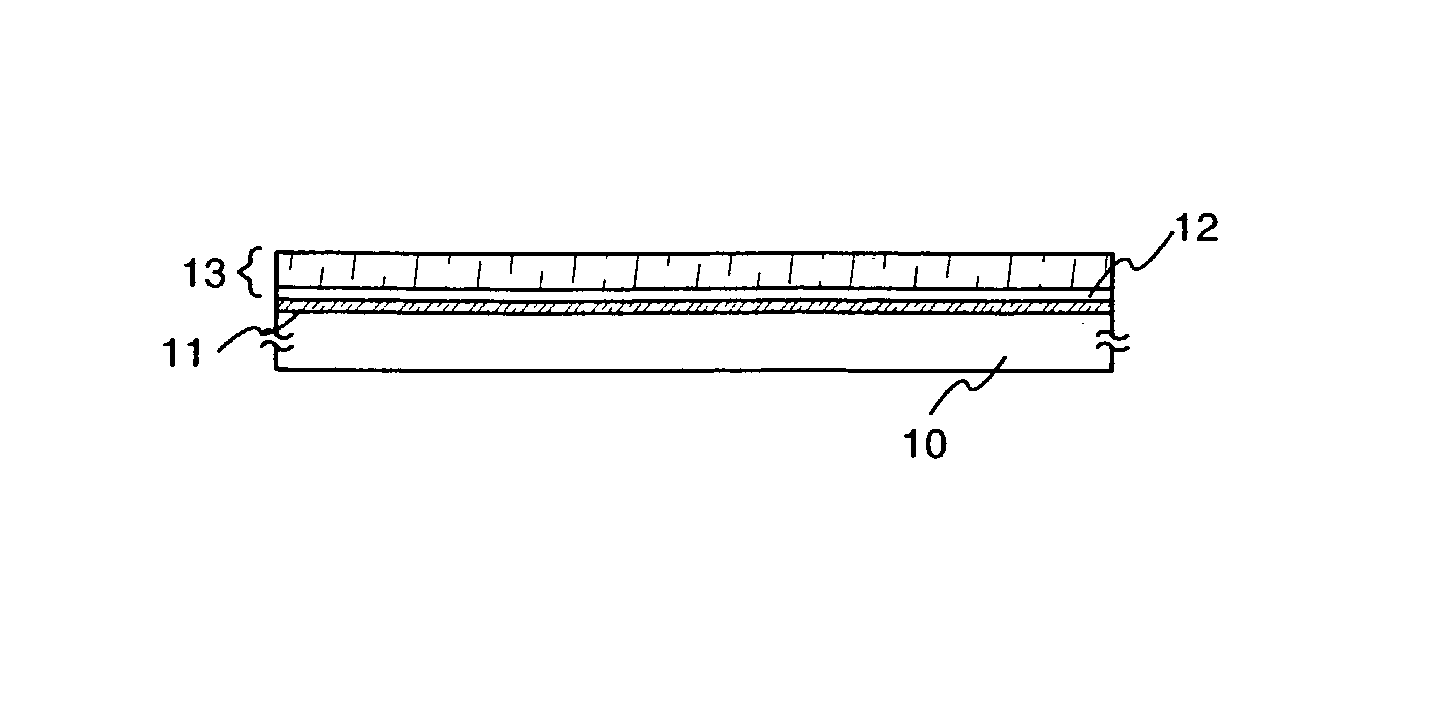

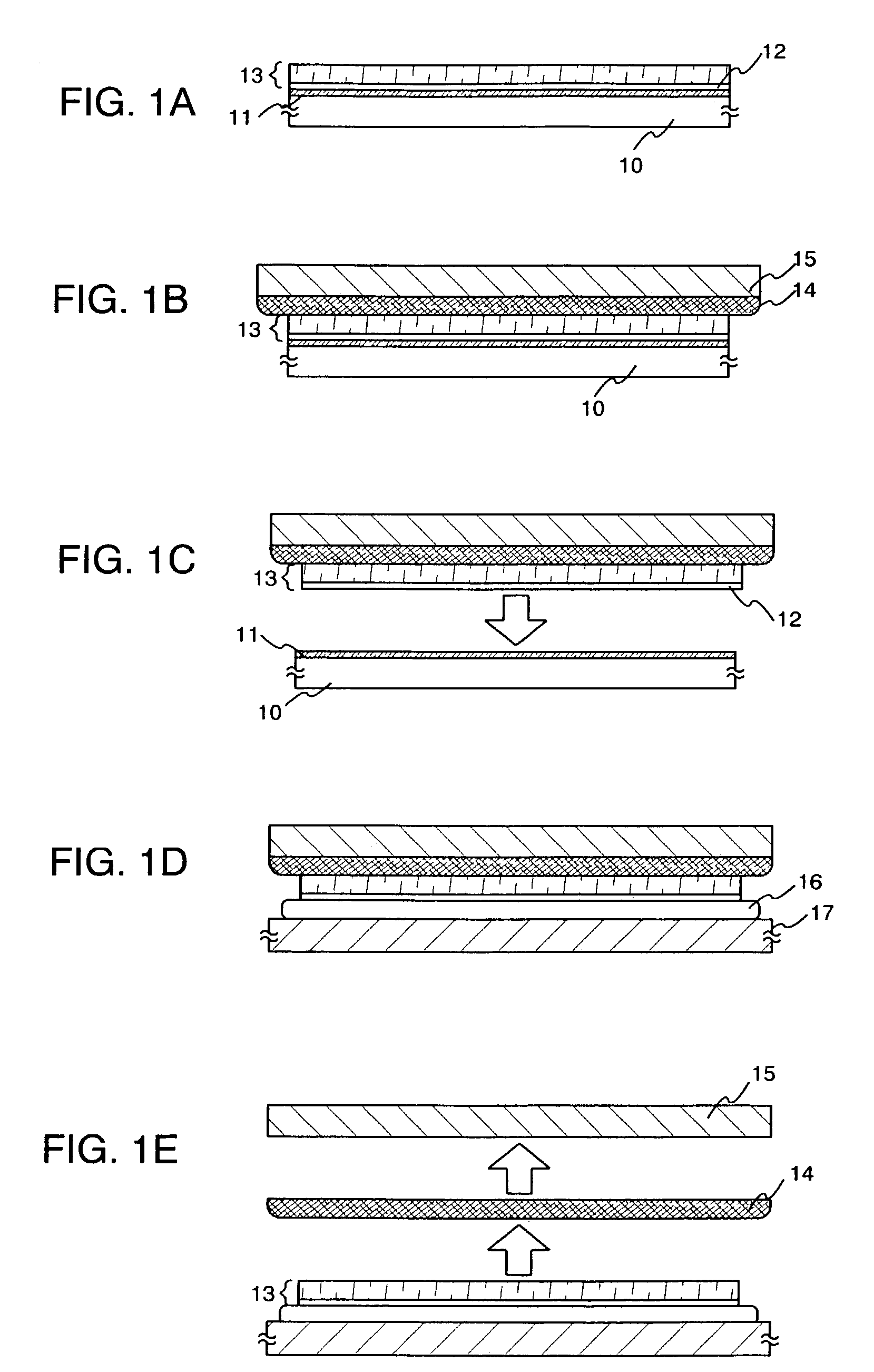

Method of transferring a laminate and method of manufacturing a semiconductor device

InactiveUS7147740B2Lamination ancillary operationsDecorative surface effectsSemiconductor deviceSemiconductor components

An object of the present invention is to provide a method of transferring an object to be peeled onto a transferring member in a short time without imparting damage to the object to be peeled within a laminate. Also, another object of the present invention is to provide a method of manufacturing a semiconductor device in which a semiconductor element manufactured on a substrate is transferred onto a transferring member, typically, a plastic substrate. The methods are characterized by including: forming a peeling layer and an object to be peeled on a substrate; bonding the object to be peeled and a support through a two-sided tape; peeling the object to be peeled from the peeling layer by using a physical method, and then bonding the object to be peeled onto a transferring member; and peeling the support and the two-sided tape from the object to be peeled.

Owner:SEMICON ENERGY LAB CO LTD

Biosensor and method of making

Owner:ROCHE DIABETES CARE INC +1

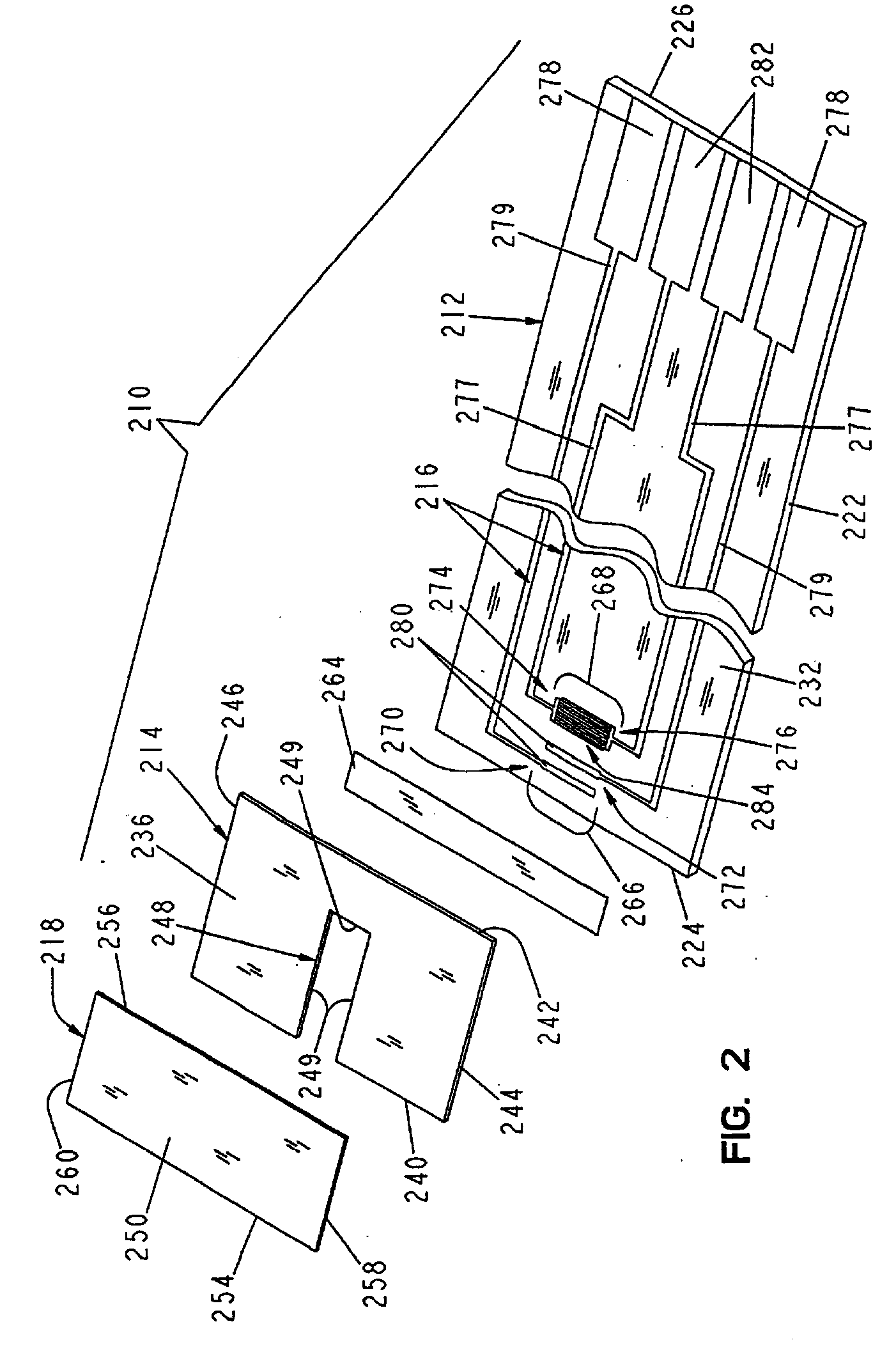

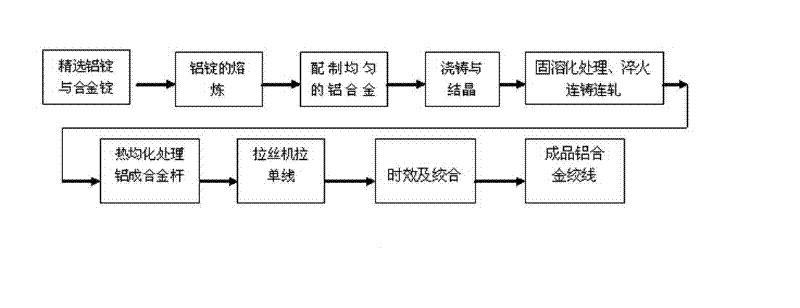

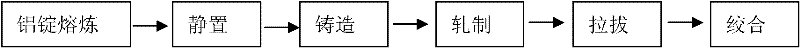

Method for manufacturing medium-strength aluminum alloy wire with electric conductivity of 59 percent

ActiveCN102162050AQuick checkControl contentManufacturing extensible conductors/cablesMetal/alloy conductorsAluminium matrixIngot

The invention discloses a method for manufacturing a medium-strength aluminum alloy wire with the electric conductivity of 59 percent (International Annealed Copper Standard, IACS), and relates to a method for manufacturing a medium-strength aluminum alloy wire with high conductivity. The method is characterized by comprising the following steps of: (1) selecting an aluminum matrix and an aluminum intermediate alloy ingot; (2) performing on-the-spot sample analysis and adjustment, namely putting the selected aluminum ingot into a shaft furnace, melting to form molten aluminum, and refining by using a refining agent; (3) casting and crystallizing, namely allowing molten aluminum alloy in a kettle furnace to pass through a runner and filtering by using a ceramic filtering plate, adding rare earth to ensure that the content of the rare earth is 0.05 to 0.15 percent, feeding into an aluminum alloy continuous casting machine, performing continuous casting to form an aluminum alloy cast ingot, and rolling a medium-strength alloy rod by using an aluminum alloy continuous mill; (4) performing solid solution treatment and quenching, namely performing thermal homogenization treatment on the aluminum alloy rod; and (5) drawing, aging and twisting, namely drawing the aluminum alloy rod treated in the previous working procedure into an aluminum alloy wire with the required diameter on an aluminum alloy wire drawing machine, and twisting on a frame type wire twisting machine to obtain the medium-strength aluminum alloy wire with the electric conductivity of 59 percent IACS.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +1

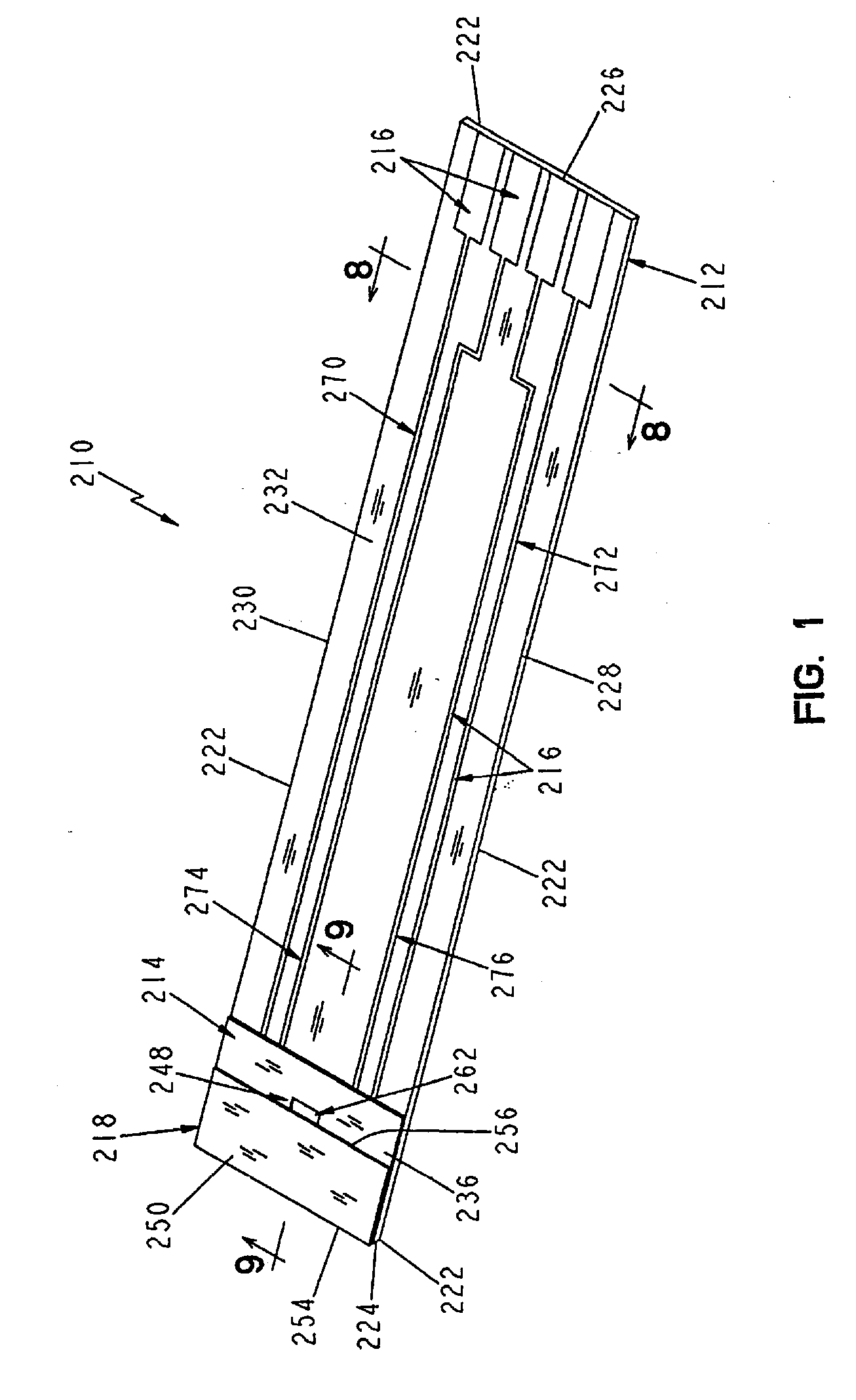

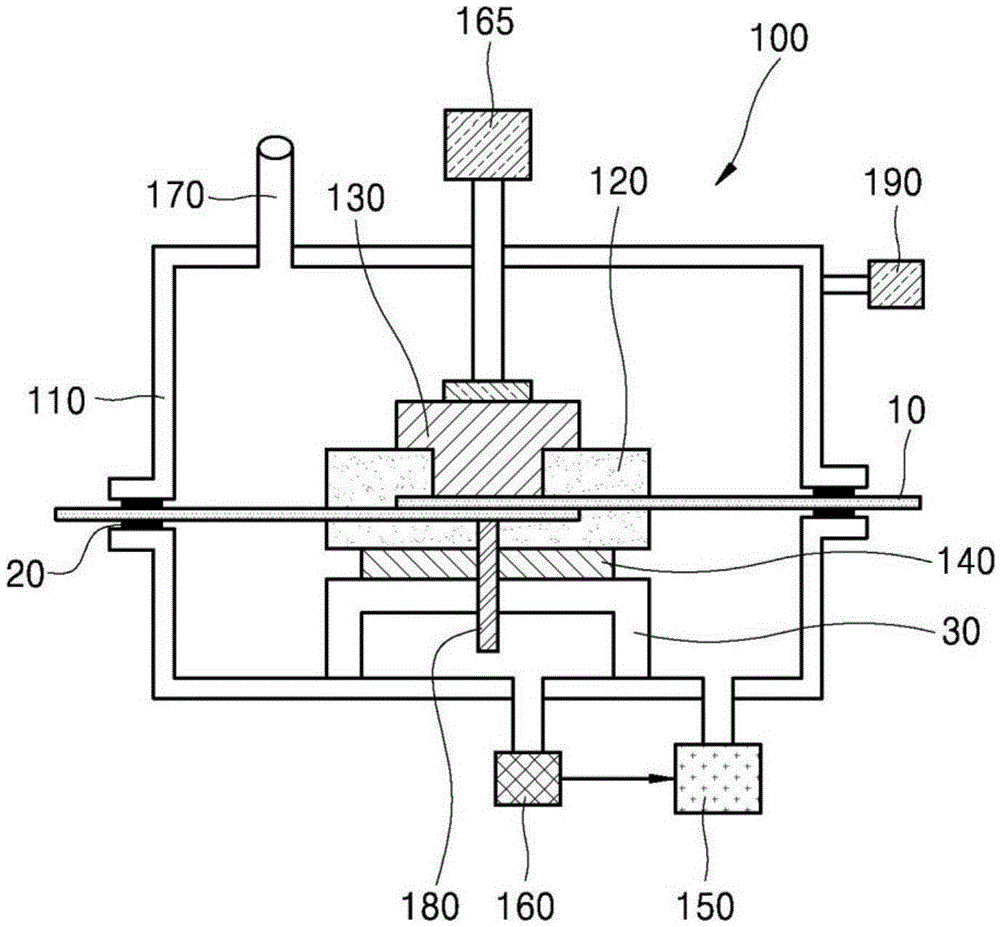

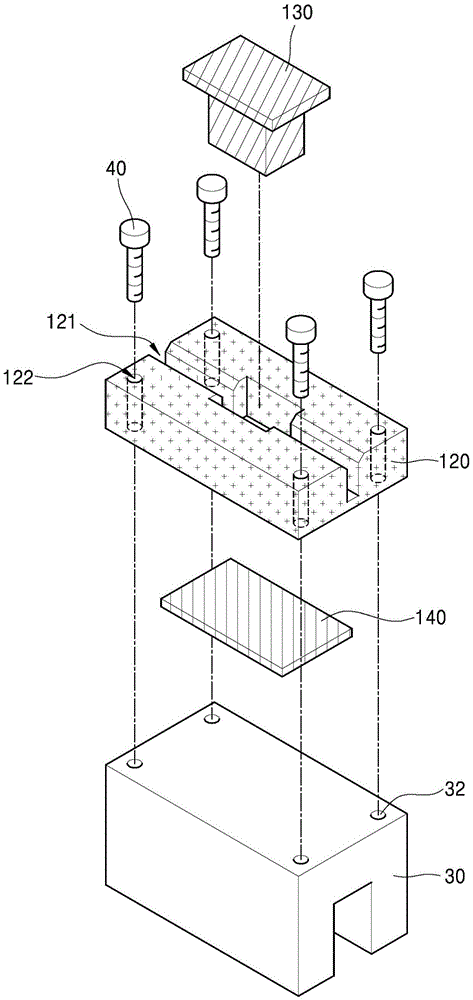

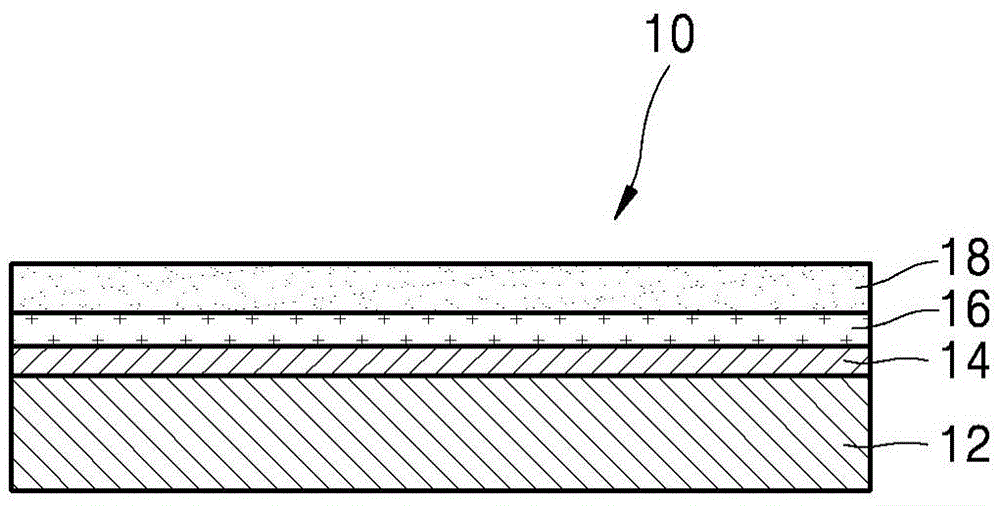

Apparatus and method for manufacturing elastic cable and electronic device using the same

InactiveUS20110026233A1Increased durabilityDigital data processing detailsInsulated cablesElectrical conductorEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

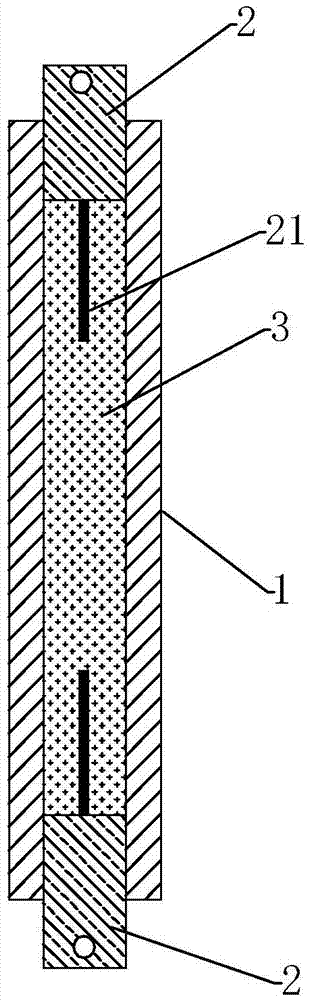

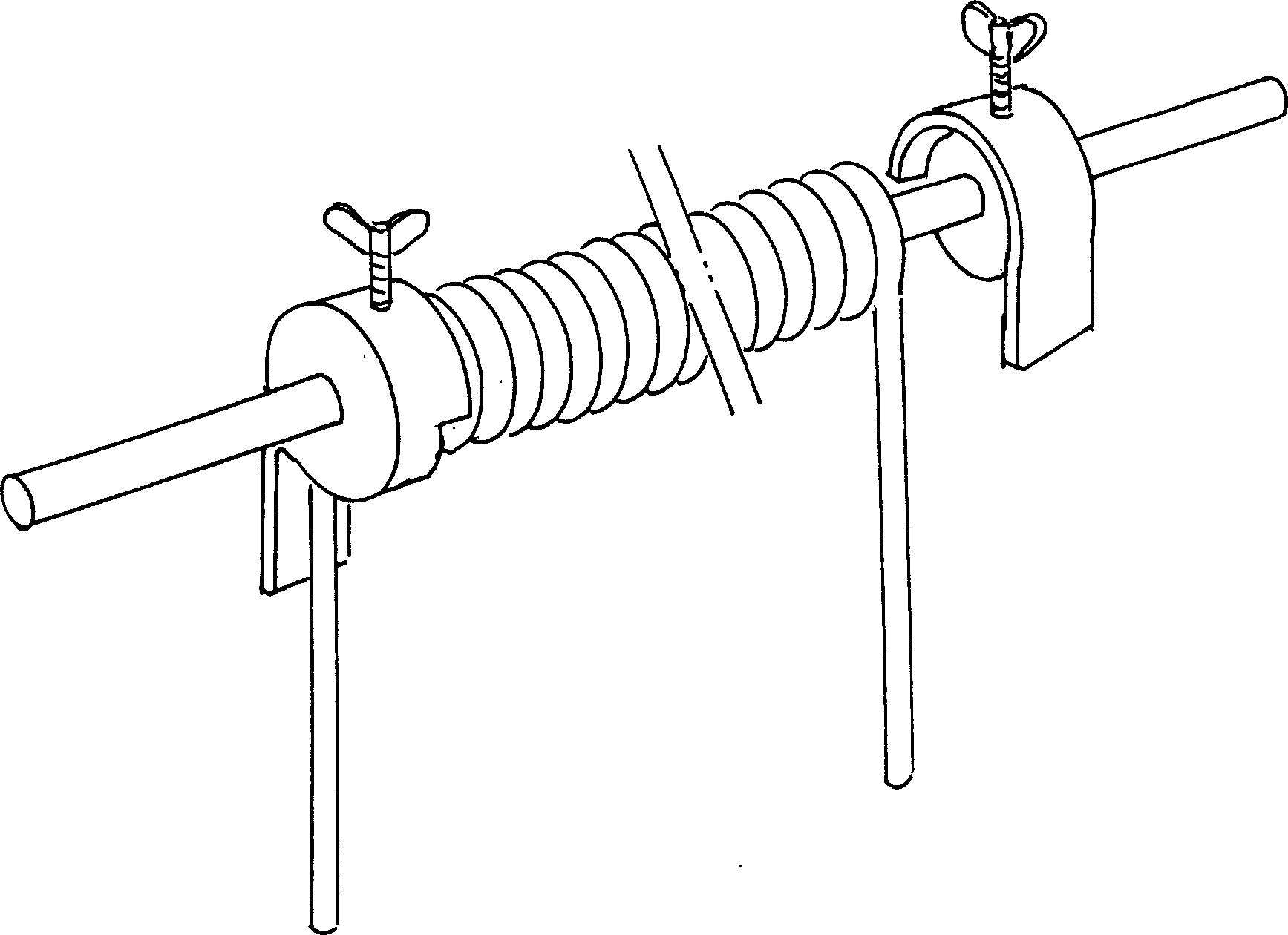

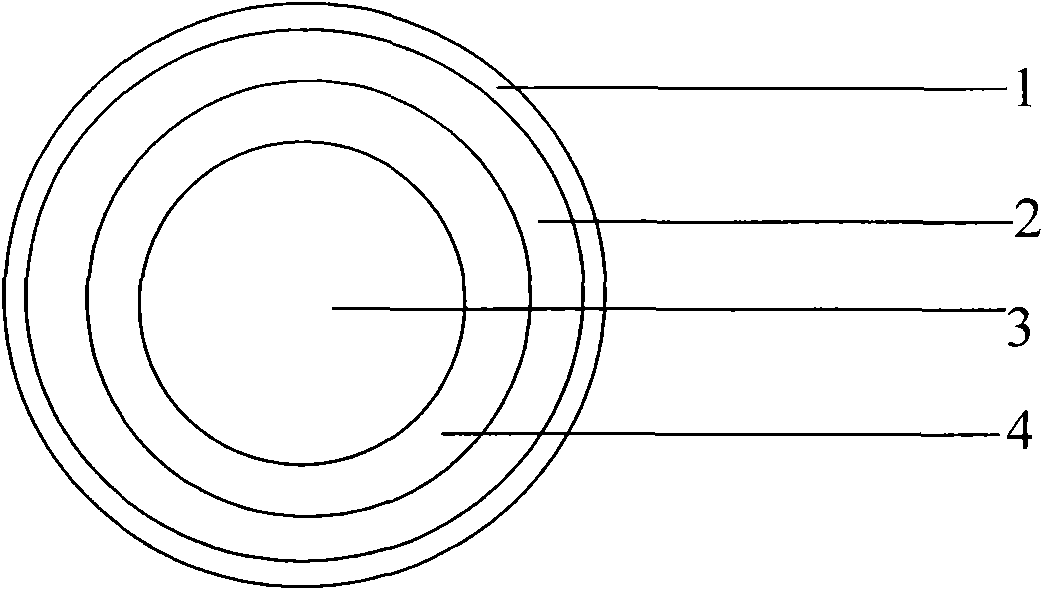

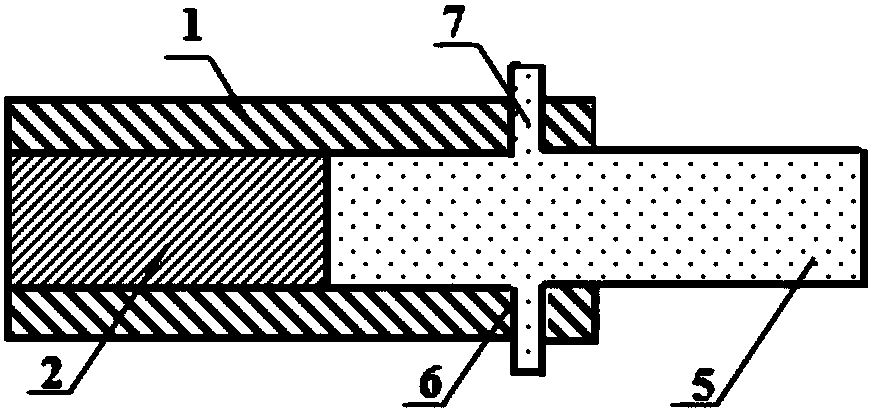

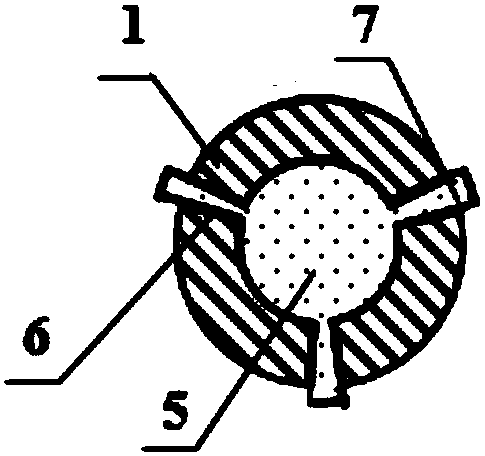

Liquid metal electric wire and manufacturing method therefor

InactiveCN105449380AIncrease the length of useSimple structureCoupling device connectionsLine/current collector detailsLiquid stateLiquid metal

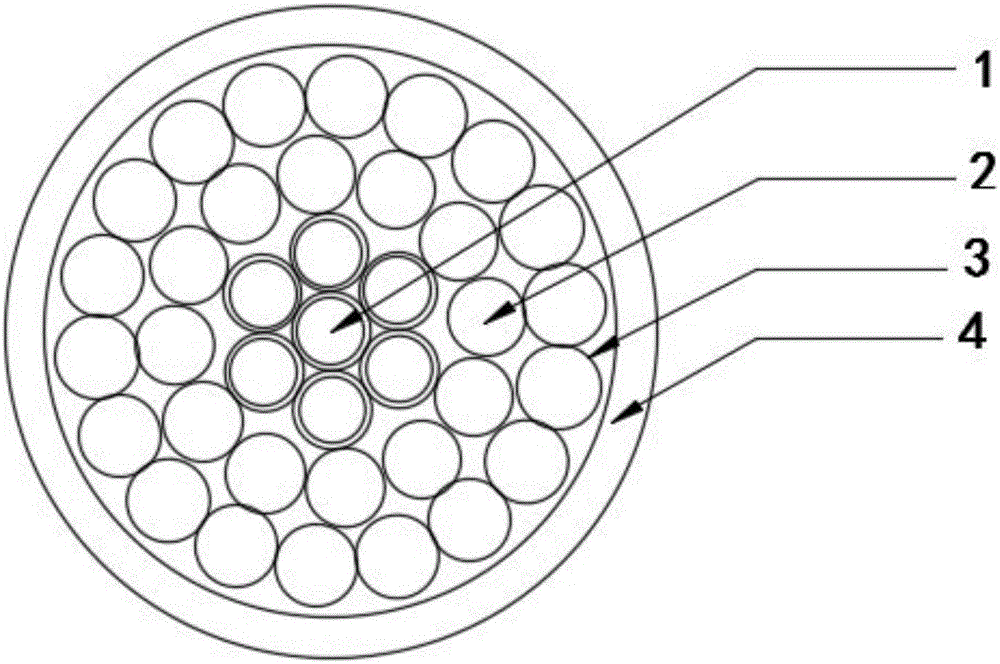

The invention discloses a liquid metal electric wire and a manufacturing method therefor. The liquid metal electric wire comprises an elastic silicone tube (1); conductive terminals (2) are fixed in tube orifices in the two ends of the elastic silicone tube (1); the tubes are filled with liquid conductive metal liquid (3); the liquid conductive metal liquid (3) is in contact with the conductive terminals (2) extending into the inner end of the tube; and the liquid conductive metal liquid (3) enables the conductive terminals (2) at the two ends of the elastic silicone tube (1) to be conductive. The liquid metal electric wire is simple in structure; the liquid metal electric wire can be stretched on the basis of the inherent length; the stretched liquid metal electric wire is retractable due to the inherent attribute of the elastic silica gel, so that the length of the liquid metal electric wire can be adjustable; and therefore, the liquid metal electric wire is applicable to various domestic appliances, industrial appliances and the like.

Owner:林永勤

Copper bus bar with high strength, high conductivity and high toughness and preparation method thereof

InactiveCN102034563AImprove conductivityImprove equipment technologySingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesLiquid cathodeLiquid copper

The invention relates to a copper bus bar with high strength, high conductivity and high toughness and a preparation method thereof. The copper bus bar is characterized in that the material comprises 99.96-99.998% of copper and silver, 0.002-0.02% of yttrium rare earth and 0-0.038% of impurities, wherein silver accounts for 0.0005-0.01% of copper and silver; and the copper master alloy containing the yttrium rare earth is used as a modifier. The preparation method comprises the following steps: (1) melting a copper material: heating the cathode copper in a mains frequency core induction furnace to melt the cathode copper into liquid cathode copper; (2) modifying liquid copper: melting the modifier in the liquid cathode copper and fully mixing the modifier with the liquid cathode copper; (3) drawing a continuously cast copper bar upwards: causing a crystallizer of a continuous casting machine to stretch into the liquid cathode copper, condensing the liquid cathode copper into the copper bar in the crystallizer and drawing the copper bar upwards by means of two pairs of drawing roll mechanisms in the continuous casting machine to lead the copper bar to a take-up machine via a wheel frame; (4) continuously extruding the copper bar at medium temperature and carrying out anti-oxidation cooling; and (5) carrying out draw forming: putting copper bus bar blanks on a drawing machine, carrying out draw forming on the copper bus bar blanks.

Owner:福州市广福有色金属制品有限公司

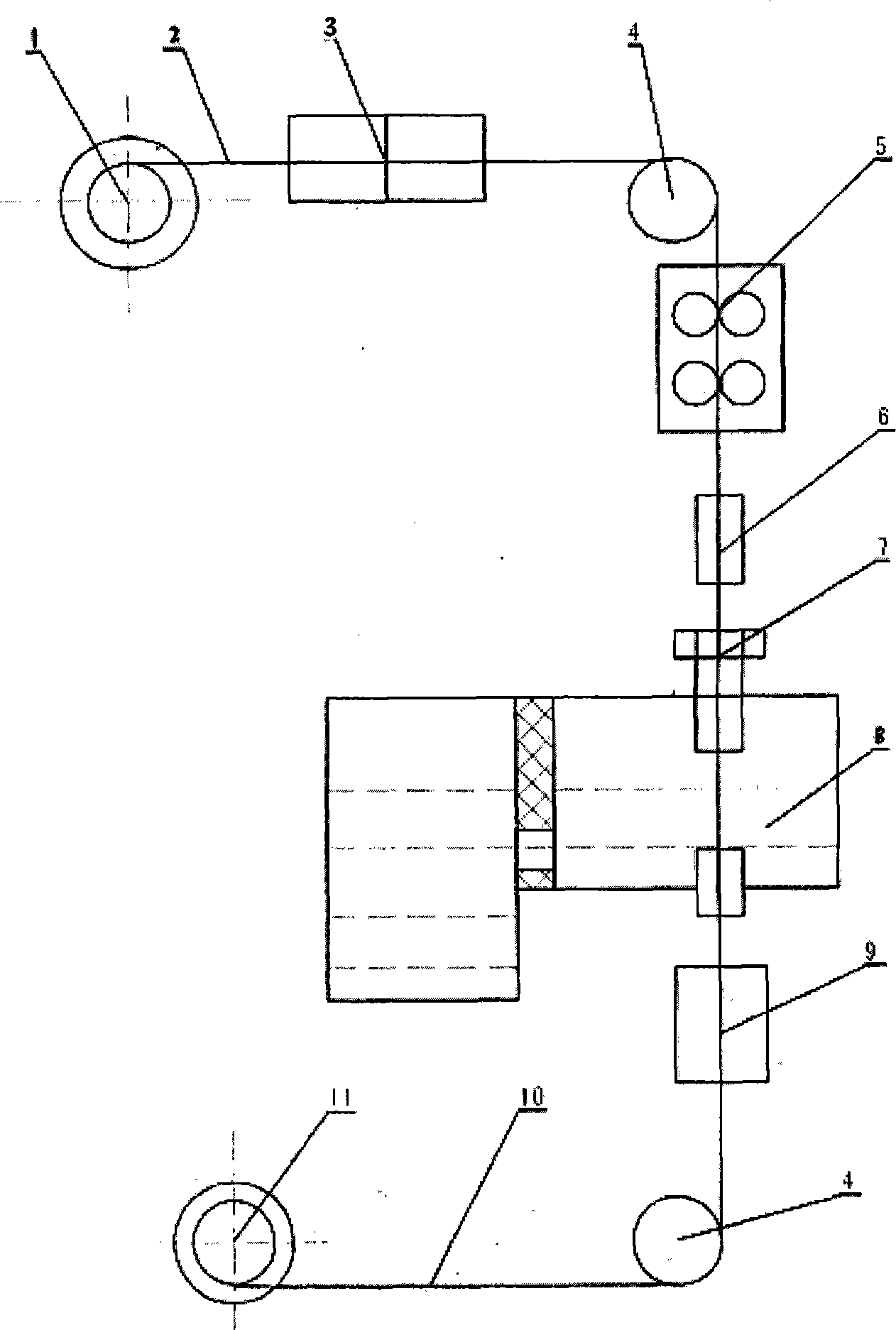

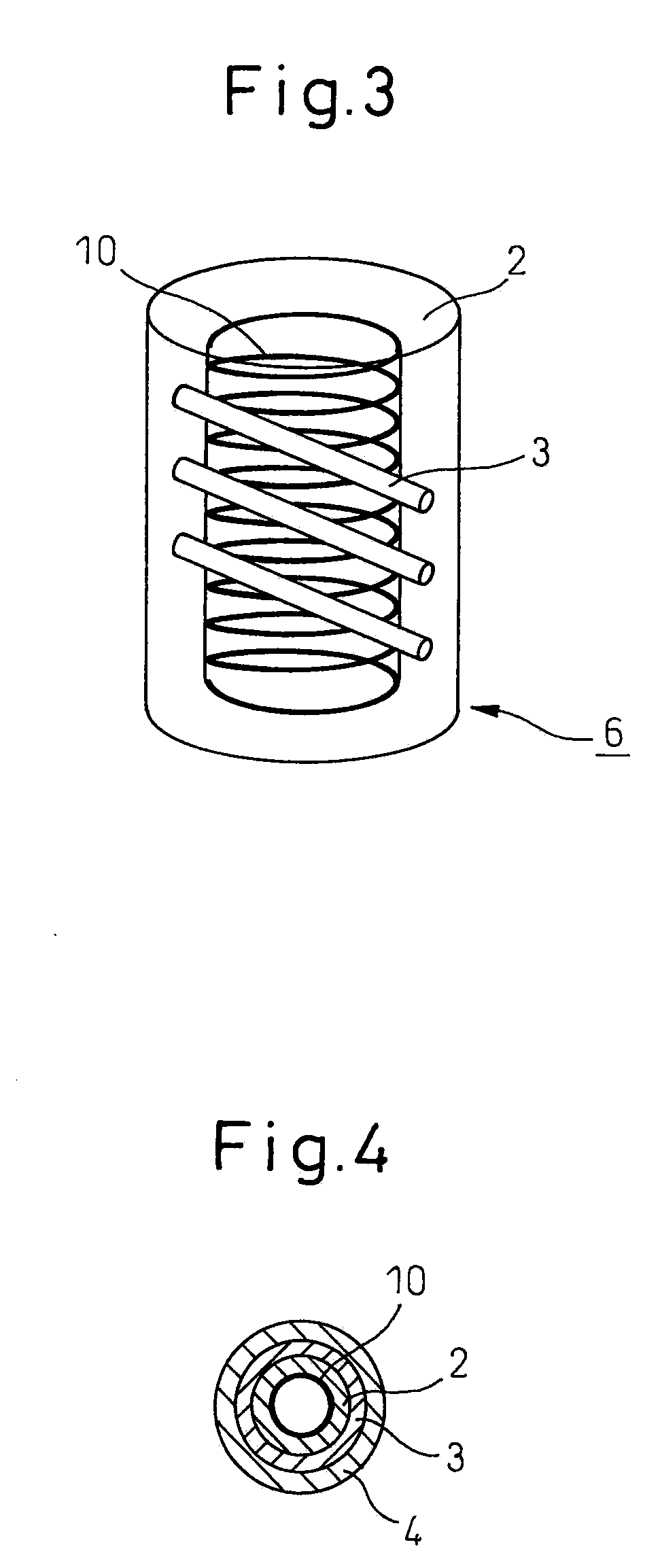

Method and device for downwards leading and continuously casting copper wire covering steel core

ActiveCN101546631AProlong clotting timeGuaranteed solidification thicknessSingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesCopper wireGraphite

The invention relates to a method and a device for downwards leading and continuously casting a copper-wrapped steel core wire. The method for downwards leading and continuously casting a copper wire covering steel core wire comprises the following steps: a continuous casting furnace (8) with an inner cavity is used, the bottom of the continuous casting furnace (8) is provided with a graphite crystallizing mold (19) communicated with the inner cavity of the continuous casting furnace (8), the graphite crystallizing mold (19) comprises a cooling device and a basically vertical mold cavity (20), a steel core wire (2) inside the continuous casting furnace (8) penetrates through the basically vertical mold cavity (20) from top to bottom, copper liquid inside the continuous casting furnace (8) flows into a gap between the steel core wire (2) and the graphite crystallizing mold (19) and is congealed to wrap the steel core wire (2), and then a copper-wrapped steel core wire (10) is pulled out of the graphite crystallizing mold (19) in an interval way. Compared with the prior art, the method for downwards leading and continuously casting a copper-wrapped steel core wire can increase the thickness of copper wrapped on steel core wires, thereby enhancing the concentricity of the steel core wires and wrapping copper layers.

Owner:江苏金合益复合新材料有限公司

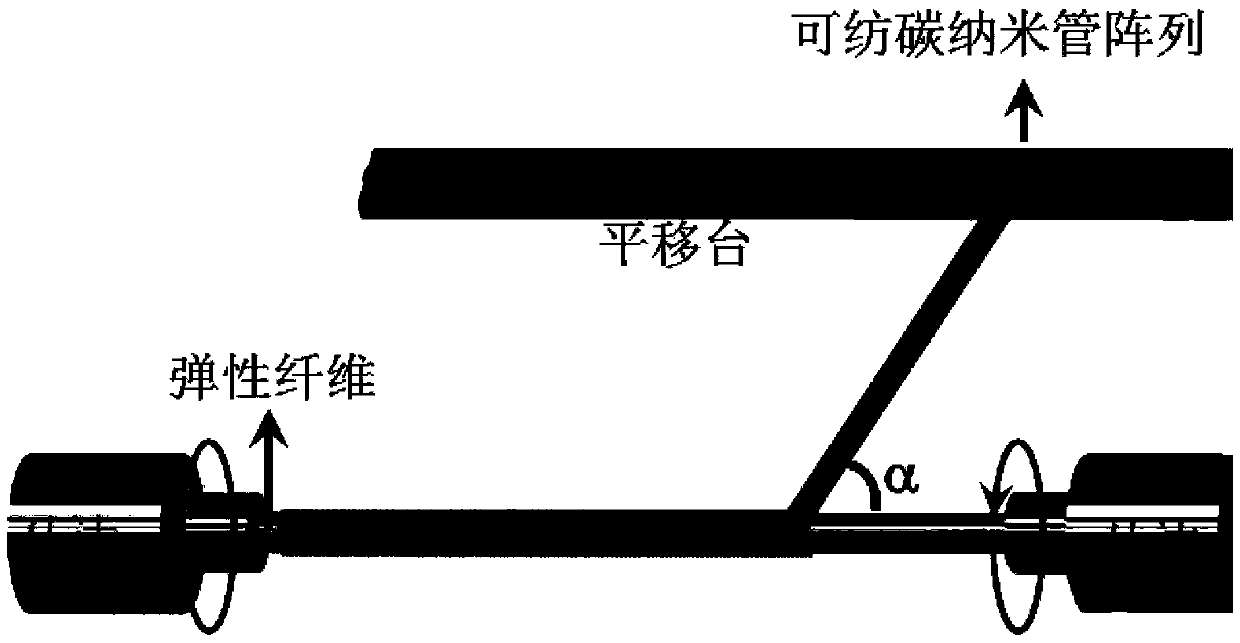

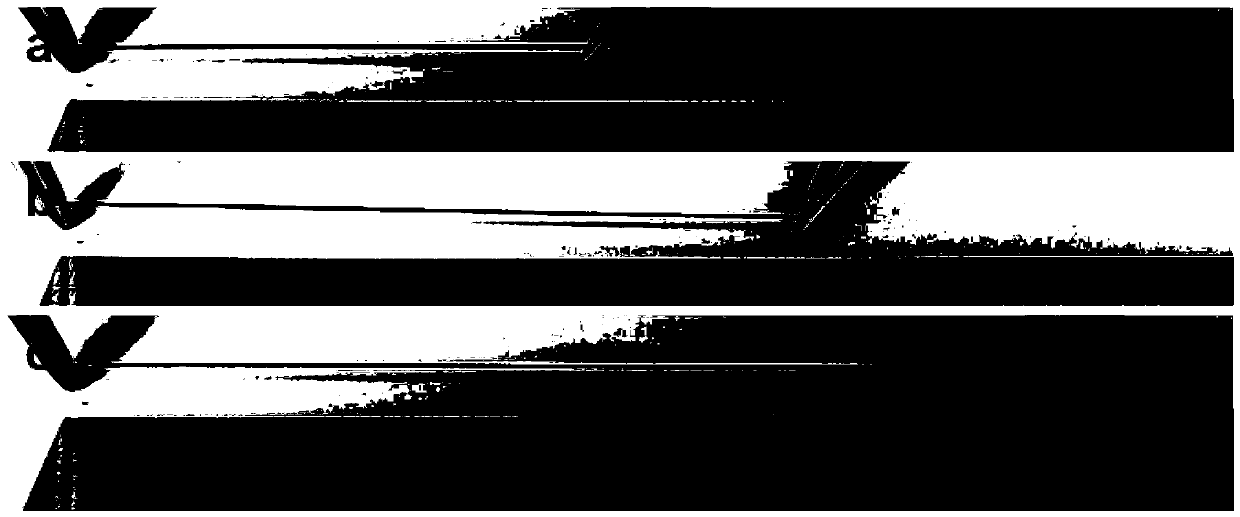

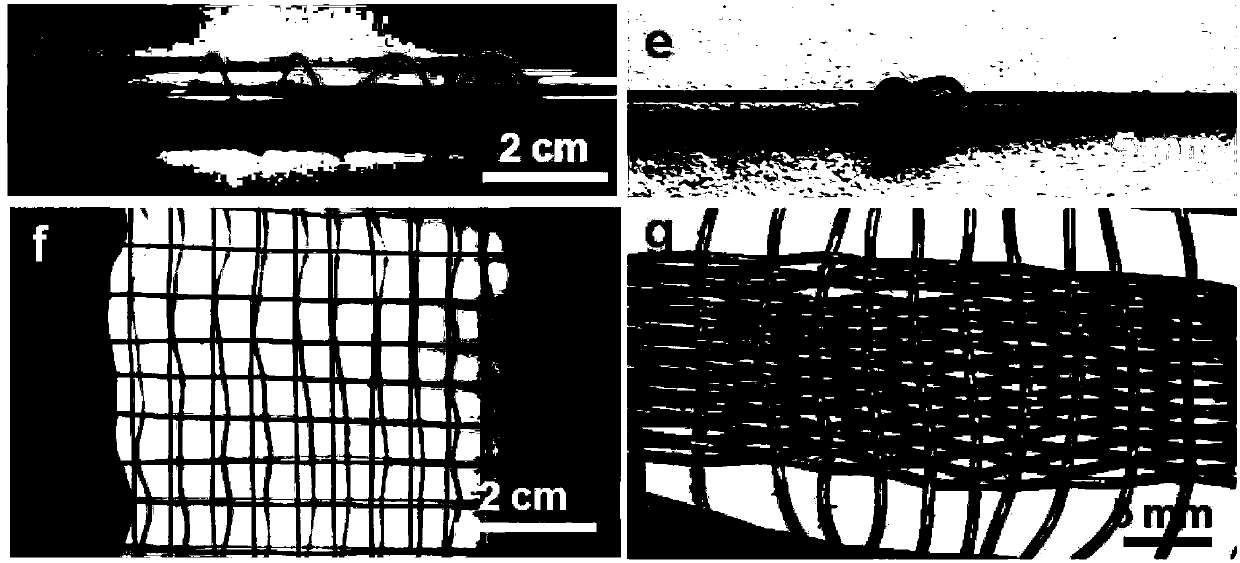

Elastic conductive fiber manufacturing method

InactiveCN103390467AAny bendRandom weaveNon-insulated conductorsManufacturing extensible conductors/cablesFiberManufacturing technology

The invention belongs to the field of electrode manufacturing technologies and particularly relates to an elastic conductive fiber manufacturing method. The elastic conductive fiber manufacturing method comprises utilizing two motors and a translation stage, fixing two ends of an elastic fiber onto the two motors, and fixing a spinnable carbon nanotube array on the translation stage; pulling out a carbon nanotube thin film from the array and putting the carbon nanotube thin film on the elastic fiber at a preset angle; starting the two motors synchronously to enable the elastic fiber with two ends fixed onto the two motors to rotate along the two motors, continuously winding the continuous carbon nanotube thin film onto the elastic fiber at a preset angle, namely, a helical angle, and enabling the helical angle of the elastic fiber to remain unchanged by setting the movement speed of the translation stage; continuously performing the above process to manufacture and obtain an elastic conductive fiber. The resistance of the elastic conductive fiber can basically remain unchanged under the condition that the stretch rate is 100%. The elastic conductive fiber provides novel materials for manufacturing elastic leaner electronic devices.

Owner:宁国市龙晟柔性储能材料科技有限公司

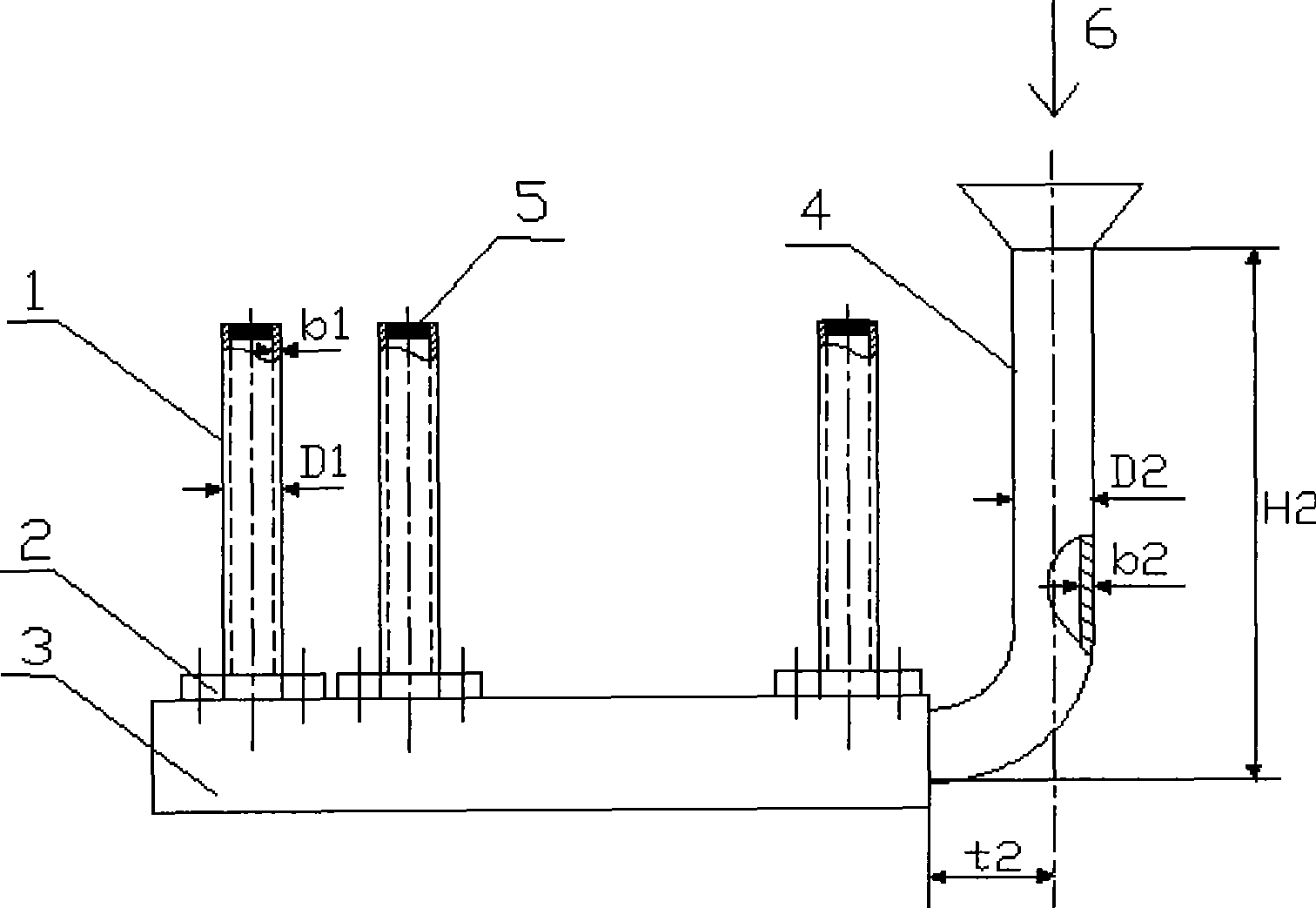

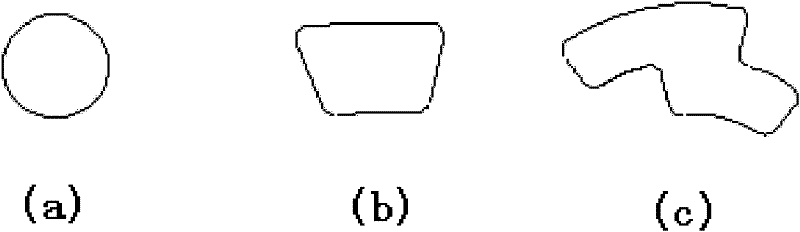

Technology and apparatus for manufacturing shaped conductor

InactiveCN101510455AMeet the requirements of flow productionOut of line fastDrawing diesSingle bars/rods/wires/strips conductorsFiberEngineering

The invention relates to a shaped conductor manufacturing technique and a device thereof, wherein, the manufacturing technique comprises payingoff step, lead-forming step and lead-drawing step and is characterized in that the lead-forming step adopts the technique of combing drawing and rolling; the section of a lead is shaped by rolling; the sectional area of the lead meets requirement by drawing; the device comprises a payingoff device, a shaped conductor forming device and a lead-drawing device which are sequentially arranged, wherein, the shaped conductor forming device is provided with a shaped groove roller device. The technique ensure the quality of products, greatly improves producing efficiency and meets the production requirement of compound carbon fiber aluminum stranded conductors required by ultra-high and super-high power transmission.

Owner:德阳东佳港智能装备制造股份有限公司

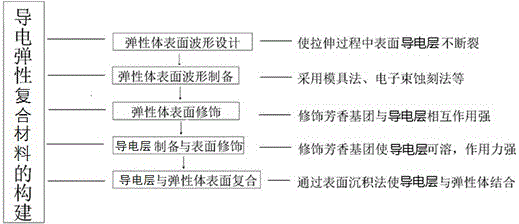

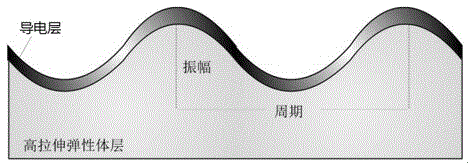

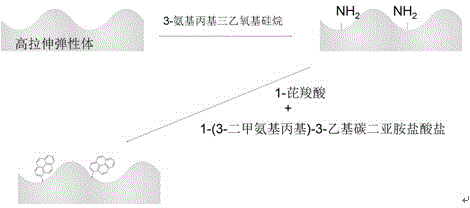

Constructing and preparation scheme of conductive elastic composite material

InactiveCN104538088AConductiveStable resistanceConductive layers on insulating-supportsManufacturing extensible conductors/cablesElastomerStretchable electronics

The invention belongs to the field of stretchable electronics and relates to a constructing and preparation scheme of a conductive elastic composite material, in particular to a constructing and preparation scheme of a conductive elastic body which keeps high resistance stability when stretches out and draws back. The high-stretching conductive elastic body comprises two main parts including an elastic main body and a conductive layer. The conductive layer adopts graphene, a carbon nano tube and other conductive materials as a basic conductive unit, and the elastic main body serves as a basic structural unit. An experiment result shows that the whole conductivity of the material can reach 10 Scm-1, elastic strain can reach 600-1000%, and the resistance change is smaller than 10% after 10000 times of repeated stretching. The conductive elastic composite material serves as the basic material of a flexible stretchable electronic device, and can be widely used for medical transplanting, intelligent clothes, artificial intelligence, biomimetic materials and the like.

Owner:JIANGNAN GRAPHENE RES INST +1

Method for manufacturing copper-clad aluminum composite panel belt

InactiveCN101447258AControl Section ShapeIncrease the amount of deformationSingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesProcess equipmentComposite plate

The invention belongs to the manufacturing field of duplex metal composite panel belt, and discloses a method for manufacturing a copper-clad aluminum composite panel belt. The manufacturing method comprises two steps of the preparation of copper-clad and aluminum-clad core casting blank and the manufacture of the copper-clad aluminum composite panel belt. The method has simple processing technique, firm combination of copper-aluminum duplex metals, and low requirements for the carrying capacity of the process equipment, thereby being easy to realize continuous production and automation production, better improving the quality and the production efficiency of the products, reducing the production cost, and meeting the application needs.

Owner:SHANGHAI UNIV OF ENG SCI

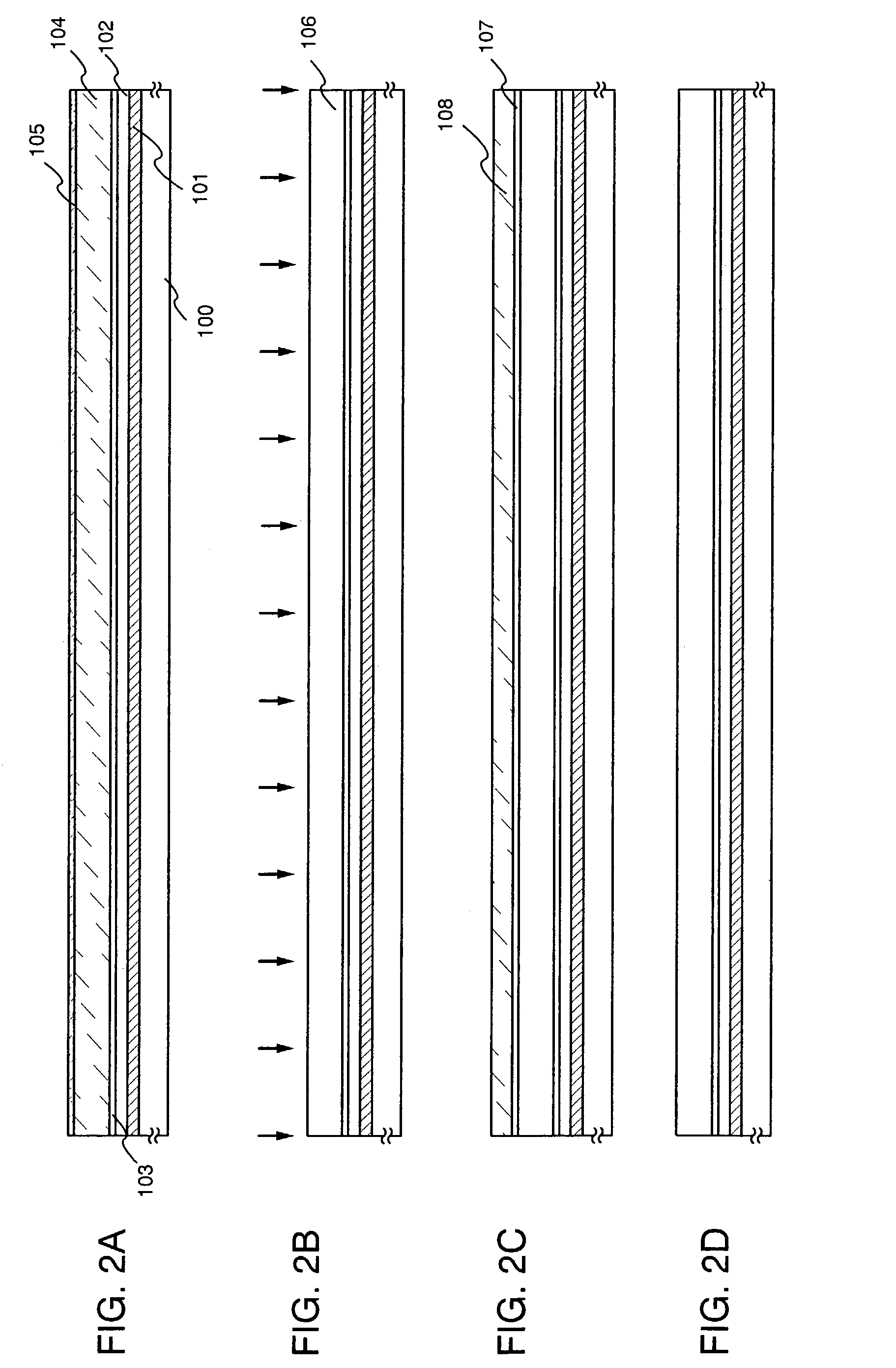

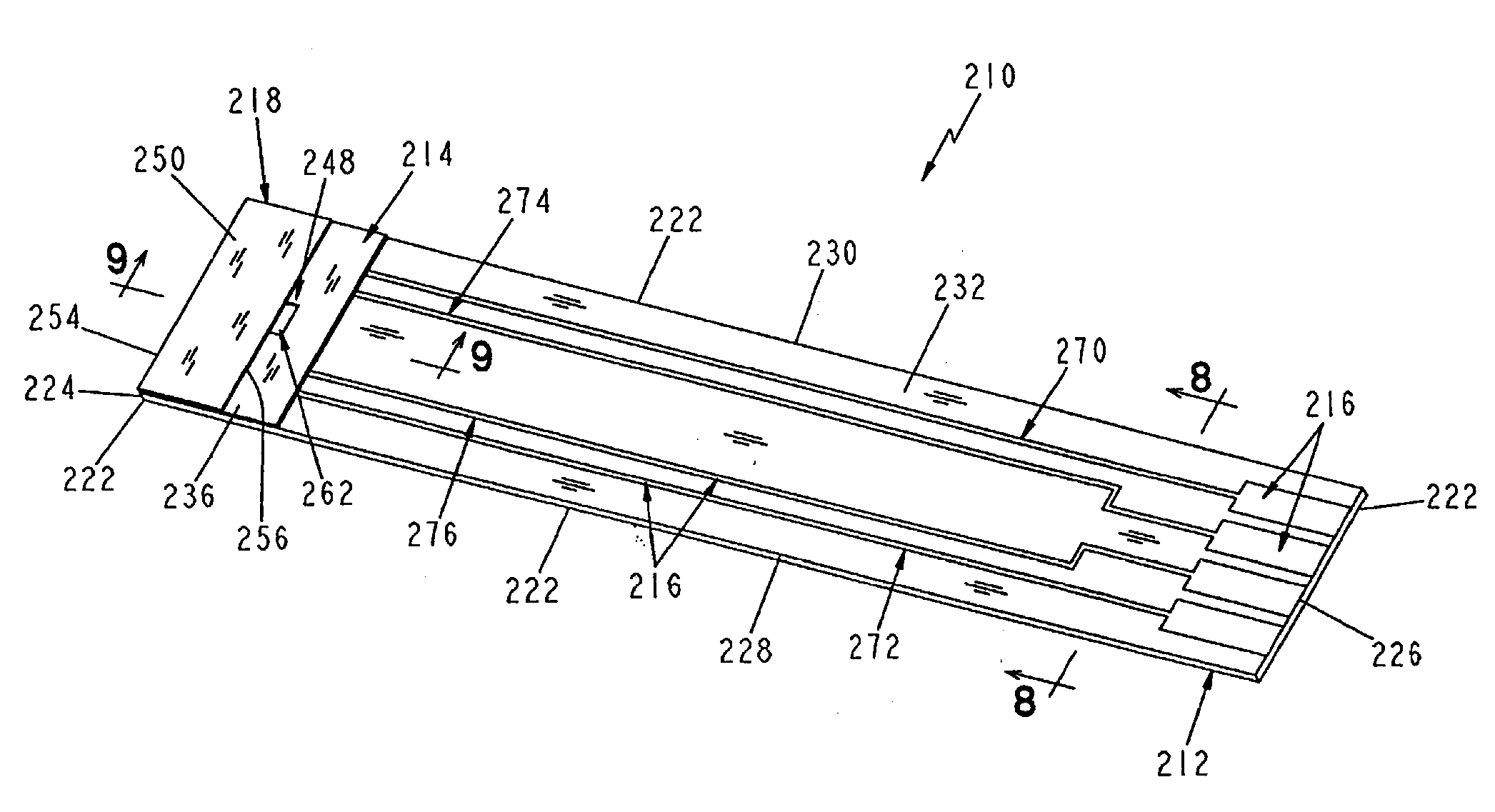

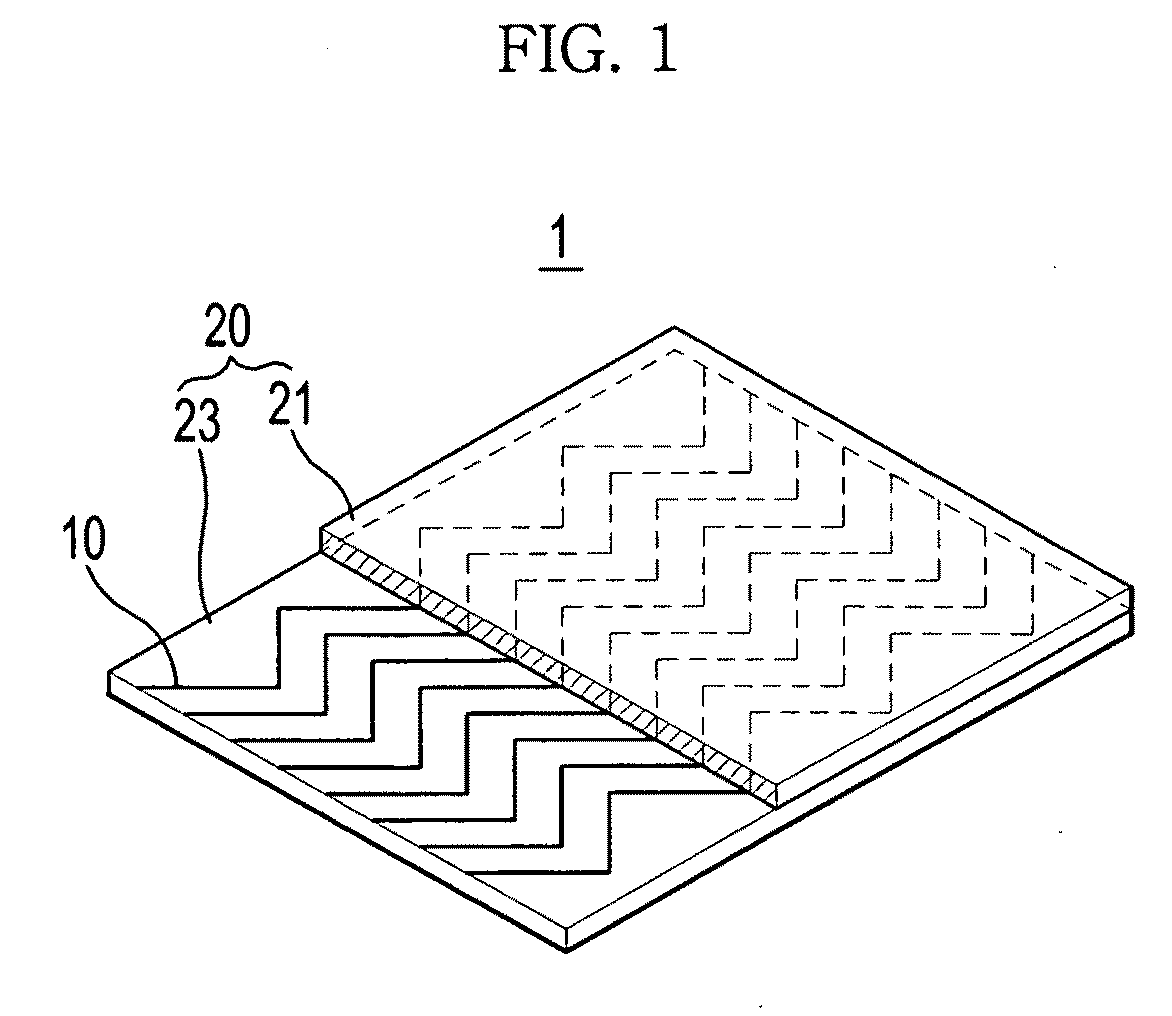

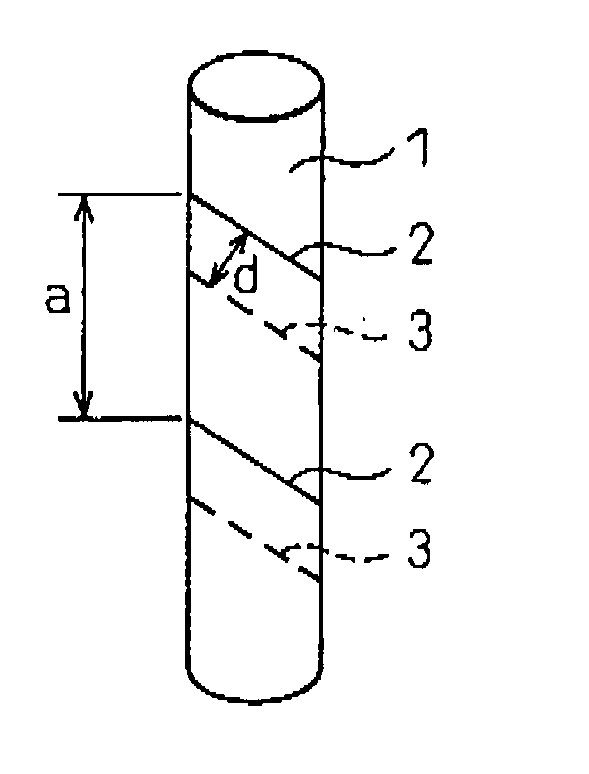

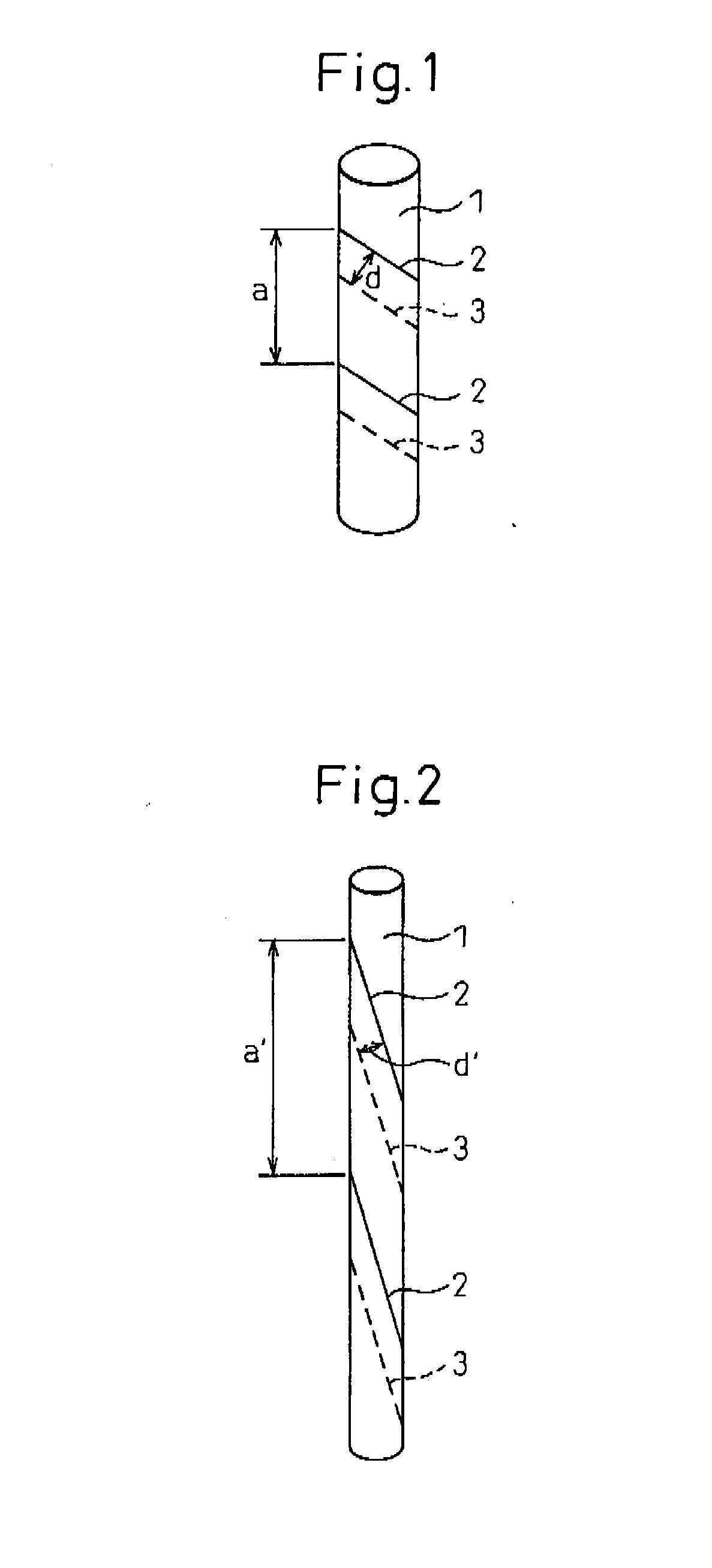

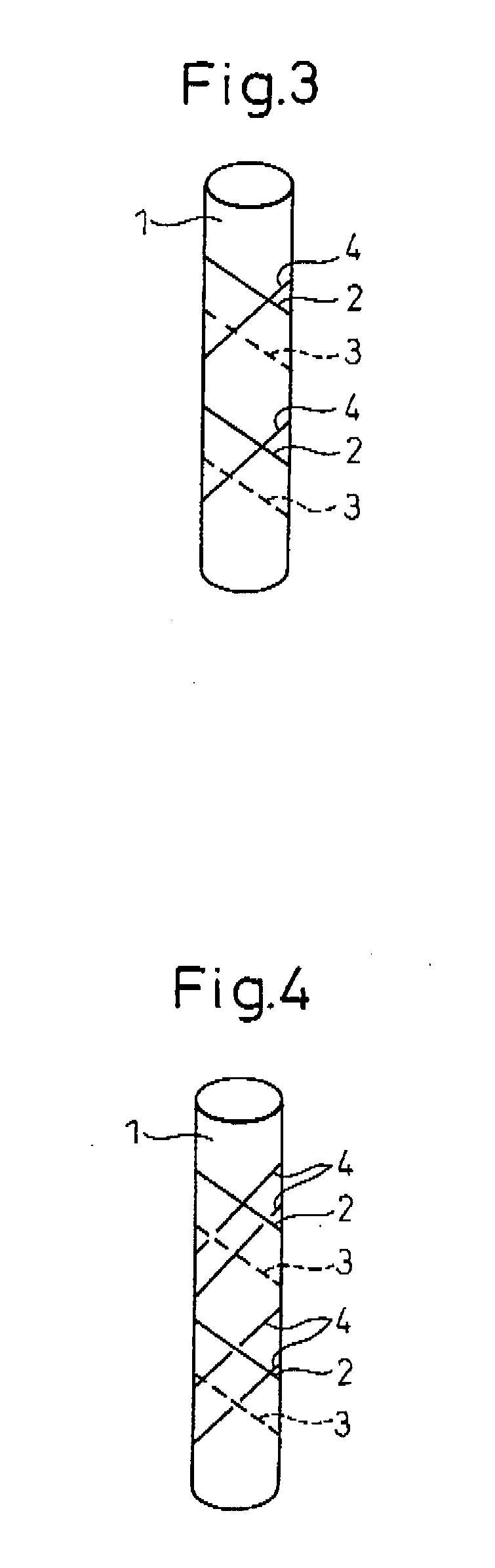

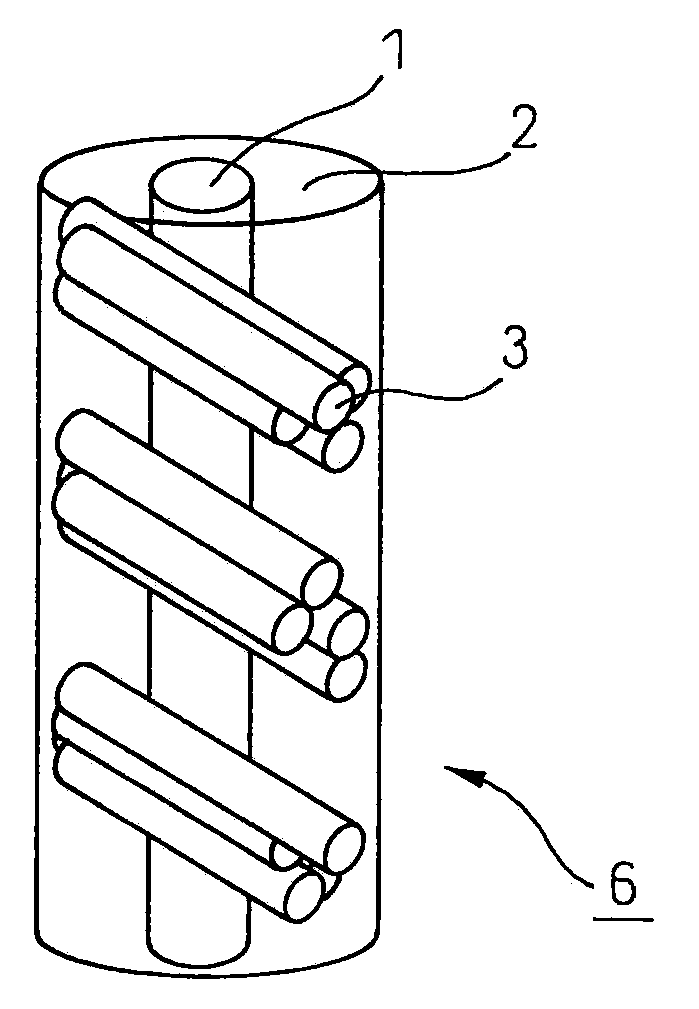

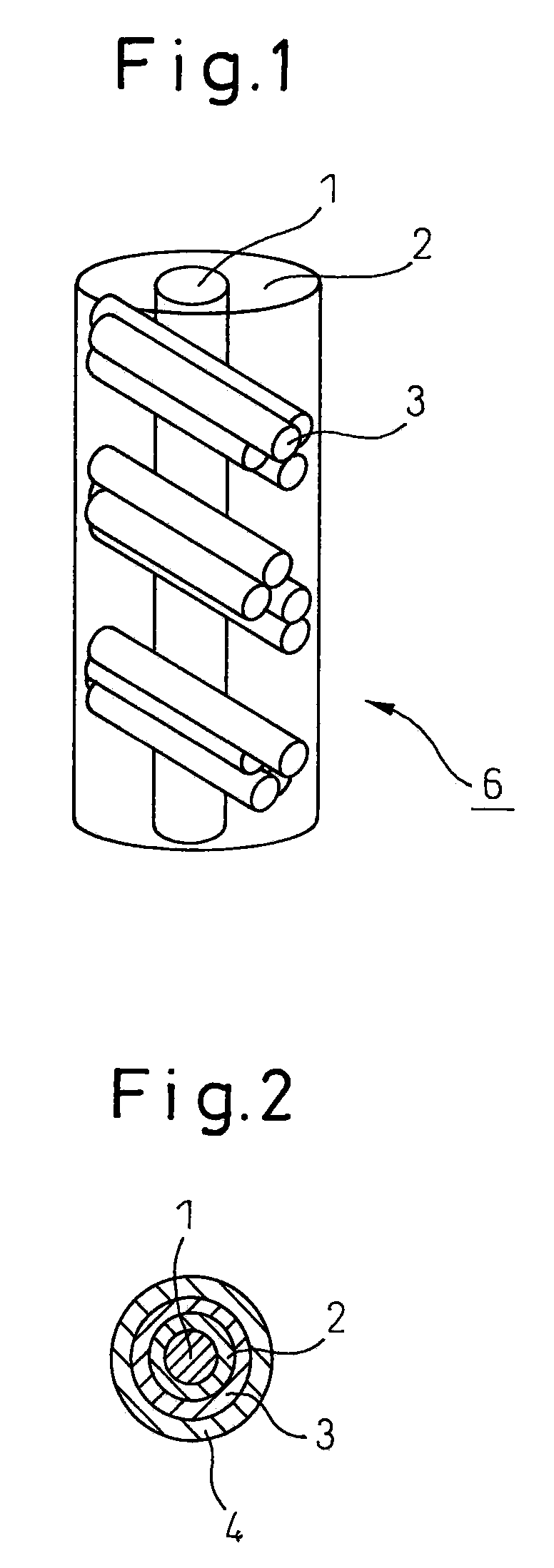

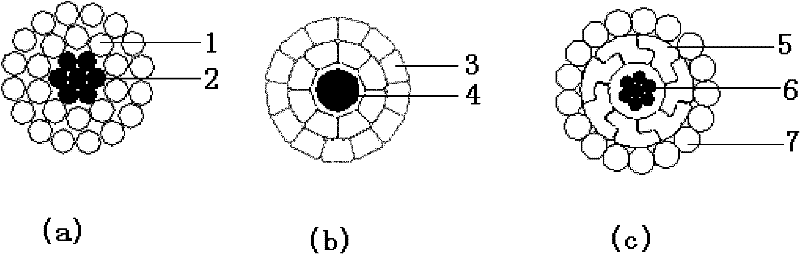

Elastic signal transmission cable

ActiveUS20110088925A1Coaxial cables/analogue cablesLine/current collector detailsElectrical conductorEngineering

An object of the present invention is to provide an elastic signal transmission cable having a length of several centimeters to several meters that has a shape deformation tracking ability and enables high-speed signal transmission. The inventive elastic signal transmission cable has an elasticity of 10% or more and transmission loss of 10 dB / m or less in a relaxed state at 250 MHz, and comprises an elastic cylindrical body having an elasticity of 10% or more and a conductor portion containing at least two conductor wires wound in the same direction around the elastic cylindrical body.

Owner:ASAHI KASEI FIBERS CORPORATION

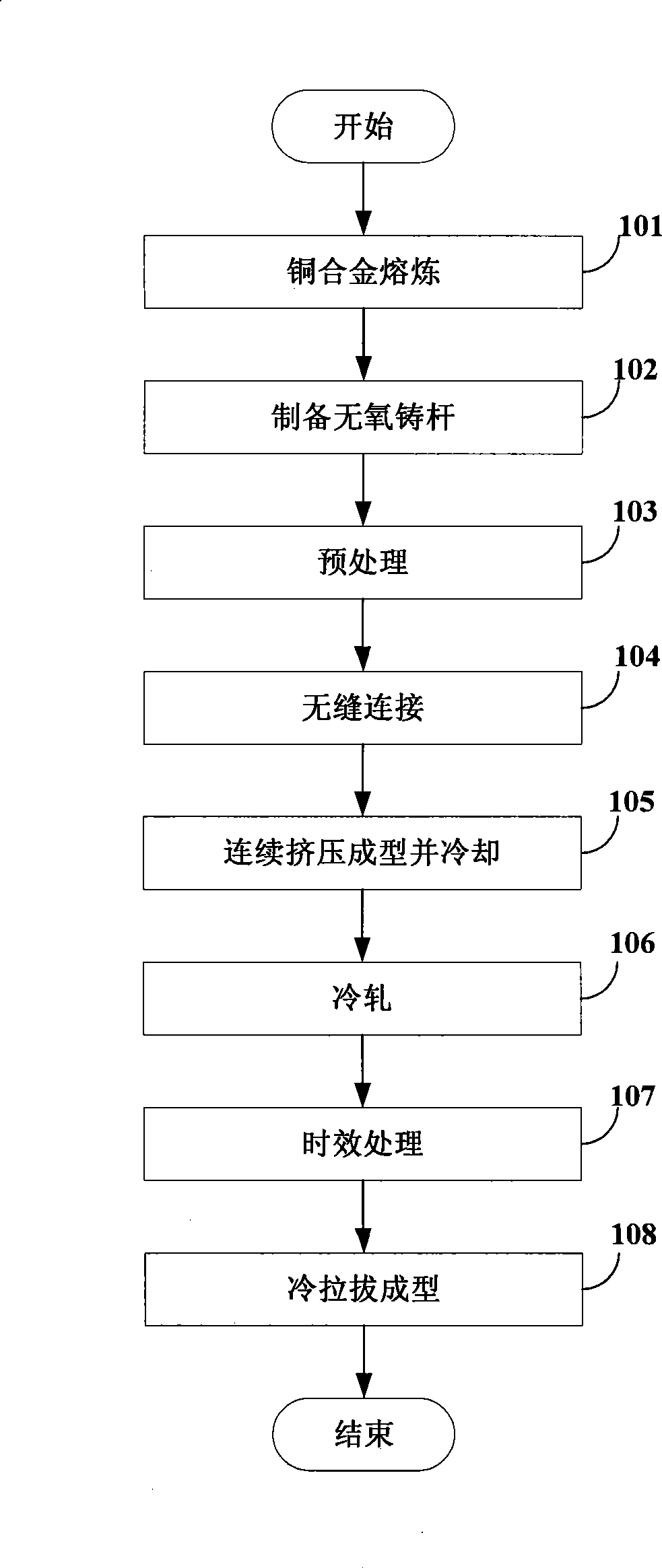

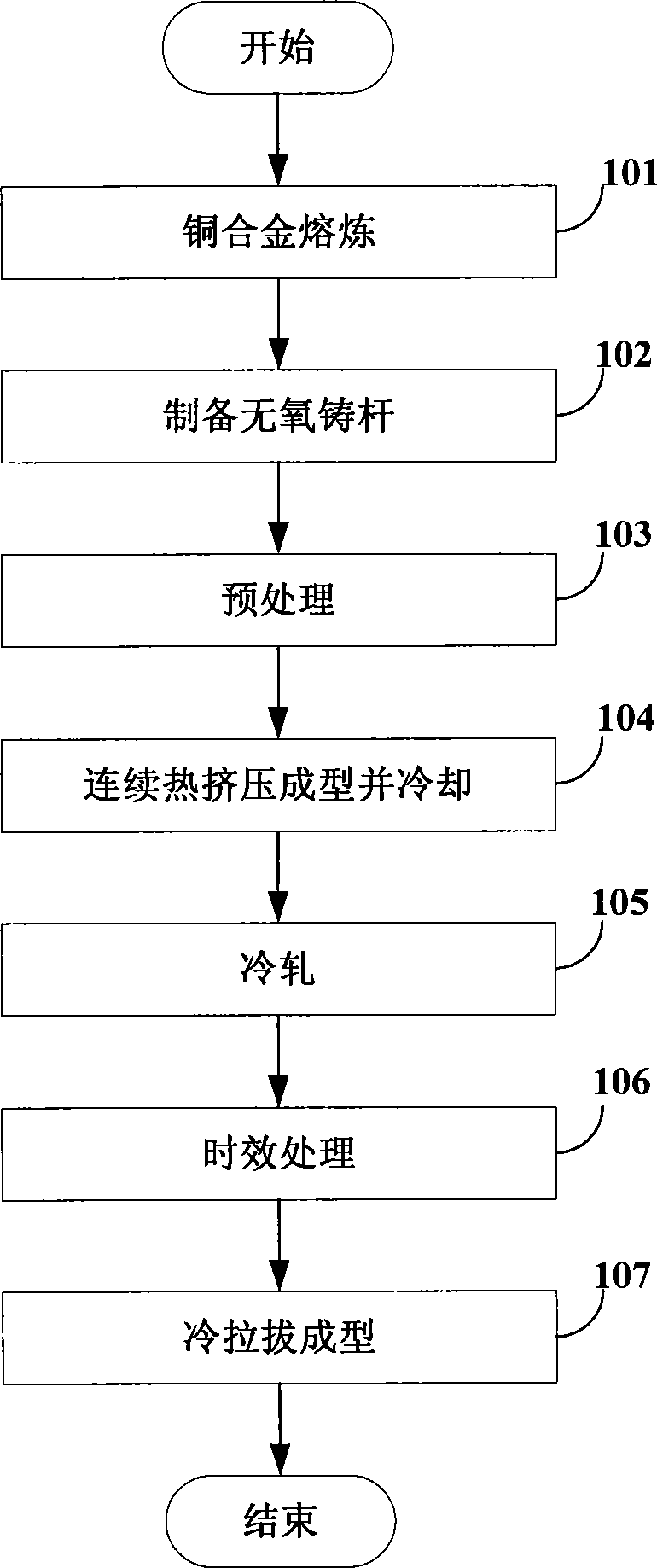

Manufacture methods of contact wire and rod blank

ActiveCN101447259AFine grainHigh mechanical strengthSingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesOxygenThermal treatment

The invention discloses the manufacture methods of a contact wire and a rod blank. The manufacture method of the contact wire comprises the following steps: manufacturing a plurality of precipitation-strengthened copper alloy oxygen-free cast rods by smelting; preprocessing the oxygen-free cast rods to obtain a plurality of blank rods; connecting the plurality of blank rods seamlessly; feeding the connected blank rods to an extruder for continuous extrusion, and cooling the extruded contact wire rod blanks; cold-rolling the contact wire rod blanks, and subjecting to aging treatment; and cold-drawing the contact wire rod blanks for multiple times according to the predetermined section size of the contact wire to obtain the contact wire. The method can simplify the smelting and thermal treatment of the precipitation-strengthened copper alloy contact wire material. The manufactured contact wire has the advantages of fine and dense grains, higher mechanical strength, good conductivity, and better physical performance, and can meet the length requirement for railway construction.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAUGRP +1

Production technology of copper-clad steel wire in soft state

ActiveCN102254629AAvoid crackingGuaranteed elongationCommunication cablesManufacturing extensible conductors/cablesElectricityElectrolysis

The invention relates to a production technology of a copper-clad steel wire in a soft state. The production technology successively comprises the following steps: drawing; tempering under high temperature; carrying out electro-deposition pretreatment; carrying out acid electrolysis; washing; carrying out pretreatment of electro-deposition; washing; carrying out electrodeposition thick treatment; washing; carrying out anti-oxidation processing; drying; drawing; washing; carrying out anti-oxidation processing; tempering under high temperature; polishing; carrying out anti-oxidation processing; and spooling to obtain a finished product. An advantage of the production technology of the copper-clad steel wire in the soft state is that an elongation rate of the produced copper-clad steel wire is greater than or equal to 8%, wherein the elongation rate, which is compared with an elongation rate of a copper-clad steel wire produced by a traditional tempering technology, can be enhanced by at least more than one time..

Owner:ZHEJIANG PUJIANG BAICHUAN IND

Expandable electric cord and production method thereof

ActiveUS20100006320A1High currentPractical to usePlastic/resin/waxes insulatorsDetails of conductive coresElastomerElectrical resistance and conductance

An object of the present invention is to provide an expandable electric cord not requiring a large force (energy loss) for expansion and contraction, able to carry a large current for driving electric power, and having expandability under a small load and low electrical resistance.The inventive expandable electric cord has a structure at least comprised of a core portion, a conductor portion and a sheath portion; wherein, the core portion is an elastic cylinder comprised of an elastic body and an intermediate layer covering the outer periphery thereof, the conductor portion contains a conductor wire comprised of narrow stranded wires, with the conductor wire being coiled and / or braided around the outer periphery of the elastic cylinder, and the sheath portion is an outer sheath layer comprised of an insulator that covers the outer periphery of the conductor portion.

Owner:ASAHI KASEI FIBERS CORPORATION

Round compressing process of stranded aluminum conductor

ActiveCN101976601AReduce the incidence of breakageSafe and effective lubrication processShaping toolsManufacturing extensible conductors/cablesElectrical conductorSurface layer

The invention relates to a round compressing process of a stranded aluminum conductor. Two round compressed stretching dies are continuously adopted on the same stranded layer without speed-change traction between, the wire-cable stranded aluminum conductor is roundly and basically compressed, stretched and deformed on aluminum filaments on a surface layer, and the aluminum filaments on the outerlayer subjected to primary stretching and deforming have smaller cross sections and are slightly longer than aluminum wires on an inner layer so that a lightly loosening phenomenon occurs in the filaments on the surface layer between the stretching dies, which is convenient to repair broken filaments. In addition, because of hard aluminum filaments, the aluminum filaments on the outer layer are loose and have weak tension compared with the aluminum filaments on the inner layer, the aluminum filaments on the outer layer and the inner layer can slightly slide, the lightly loosening phenomenon disappears after the aluminum filaments pass through the secondary stretching die, and stranded aluminum wires are compact and round.

Owner:江西南缆集团有限公司

Semihard aluminum wire, overhead wire and preparation method of semihard aluminum wire

ActiveCN102682872AImprove performanceReduce power consumptionSingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesElectrical conductorMetallurgy

The invention belongs to the field of electrotechnics, relates to an aluminum rod with a specific state, a semihard aluminum single wire, an overhead electric transmitting wire with the semihard aluminum single wire serving as a conductor layer and a preparation method of the semihard aluminum single wire. The aluminum rod with the specific state is prepared by controlling a casting process of the aluminum rod, and an aluminum single wire conductor which has the semihard characteristic and is stable in performance is directly prepared by controlling a drawing process. The preparation method of the semihard aluminum single wire has the advantages of being short in flow and simple to operate and the like. The prepared semihard aluminum single wire conductor consumes little electric energy and is stable in performance. The overhead electric transmitting wire made by enabling the semihard aluminum single wire to serve as a conductor material has the advantages of being energy-saving and good in construction characteristic and the like.

Owner:SHANGHAI ELECTRIC CABLE RES INST

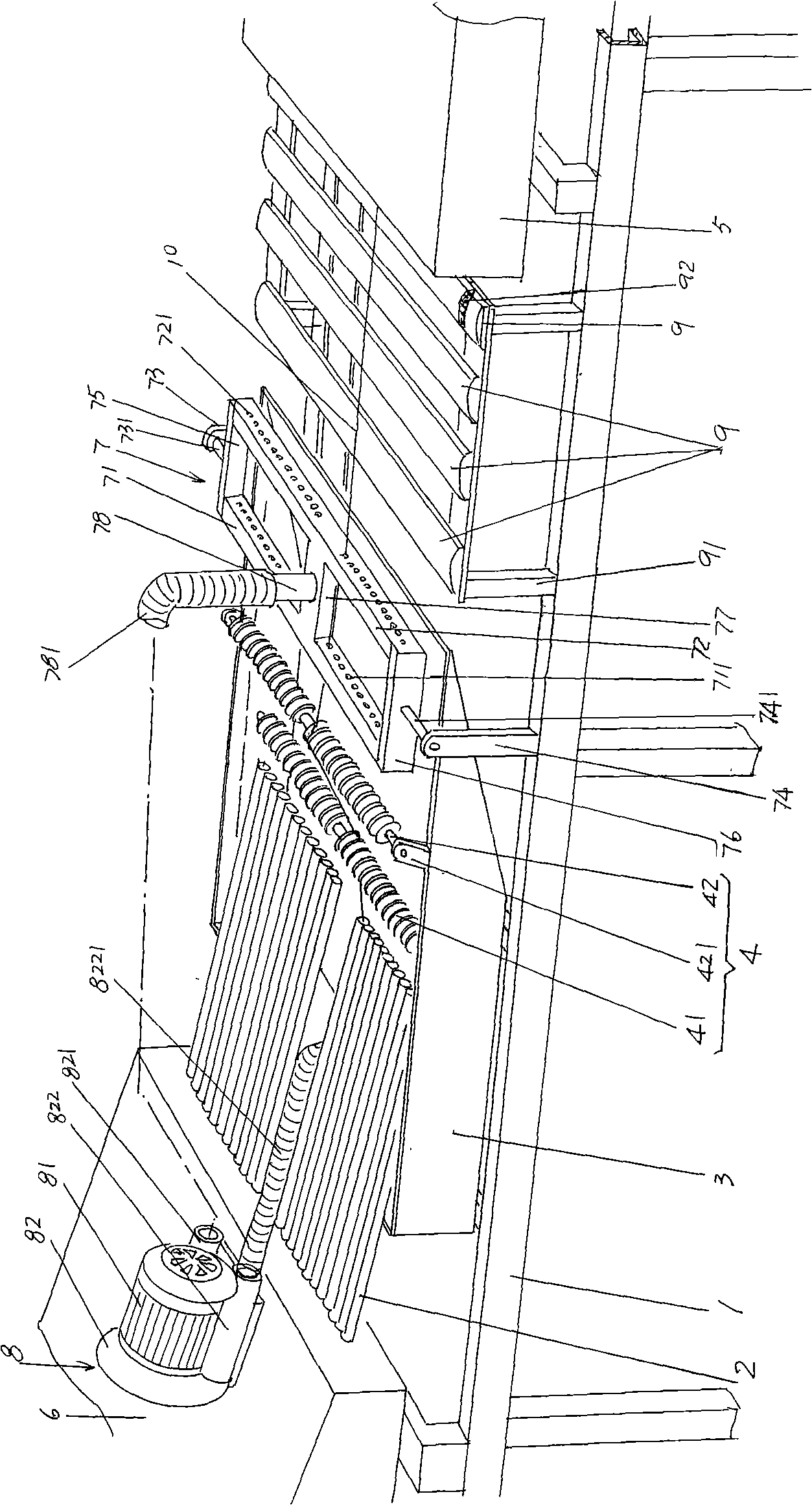

Annealing and cooling device for conductive wire

ActiveCN101290823AReduced transit timePrevent oxidationFurnace typesManufacturing extensible conductors/cablesButt jointSurface oxidation

A conducting wire annealing cooling device belongs to the electric wire-cable manufacturing device technical field. The device comprises a frame, an annealing furnace, a trough arranged on the upper part of the frame, a set of wire guide tubes in butt joint with the outlet of the annealing furnace and extending into the trough, a wire guide device arranged inside the trough and a drying box arranged at the other end of the frame. The device is characterized in that: the device also comprises a negative pressure water absorption mechanism and a negative pressure generating mechanism; the negative pressure water absorption mechanism is arranged on the upper part of the frame and is positioned between the wire guide device and the drying box and above the trough; the negative pressure generating mechanism is arranged on either the annealing furnace or the frame, and is also connected with a negative pressure pipe of the negative pressure water absorption mechanism. Moreover, the device has the advantages that: the device not only can shorten the time during which a conducting wire passes through the drying box so as to save the energy sources supplying heat for the drying box, but also can increase production efficiency; in addition, the device can also ensure drying effect, prevent surface oxidation of the conducting wire and improve electric wire-cable quality after cabling.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +2

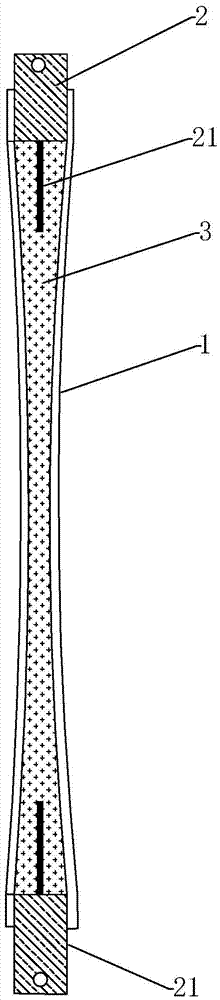

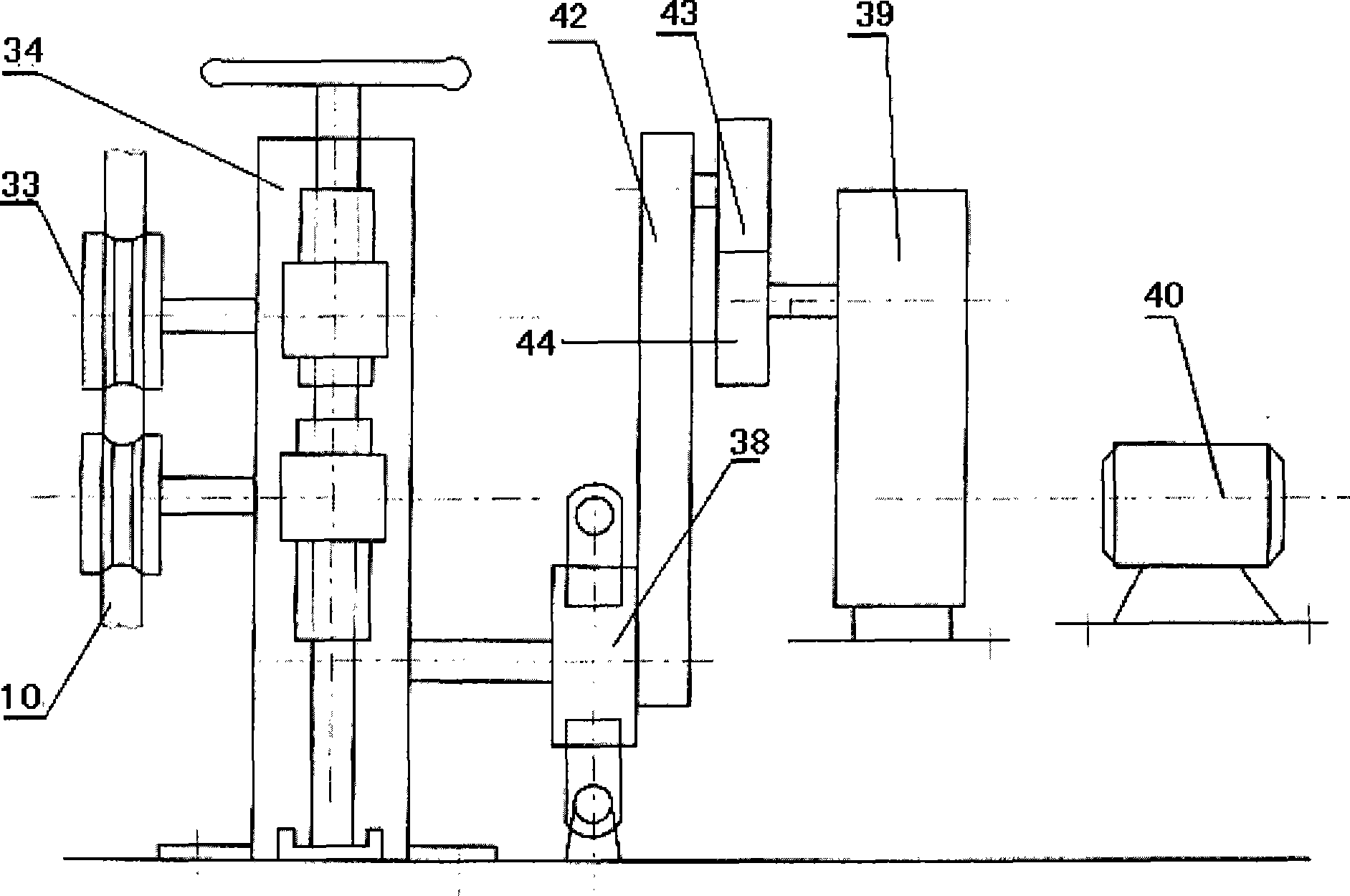

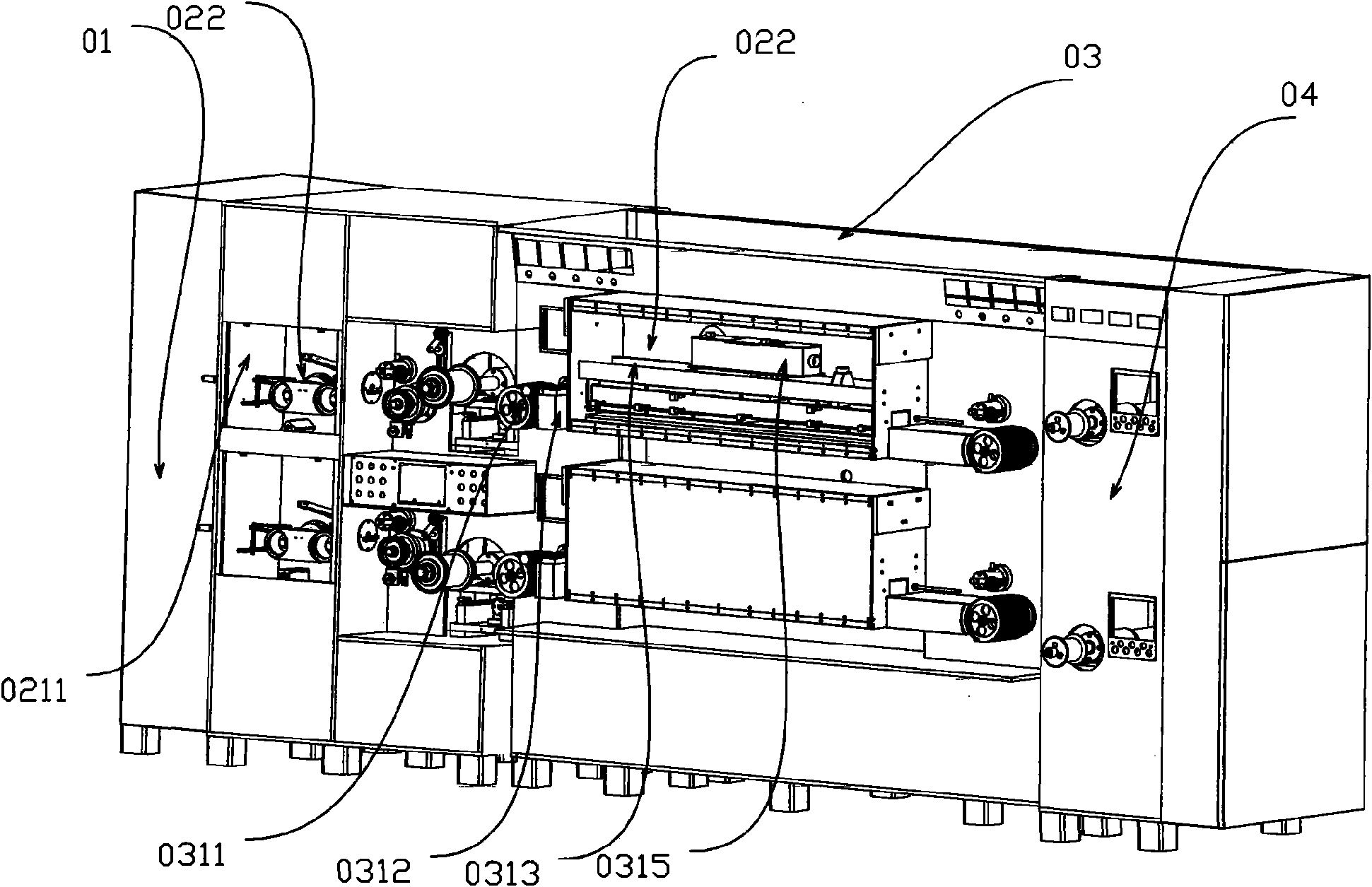

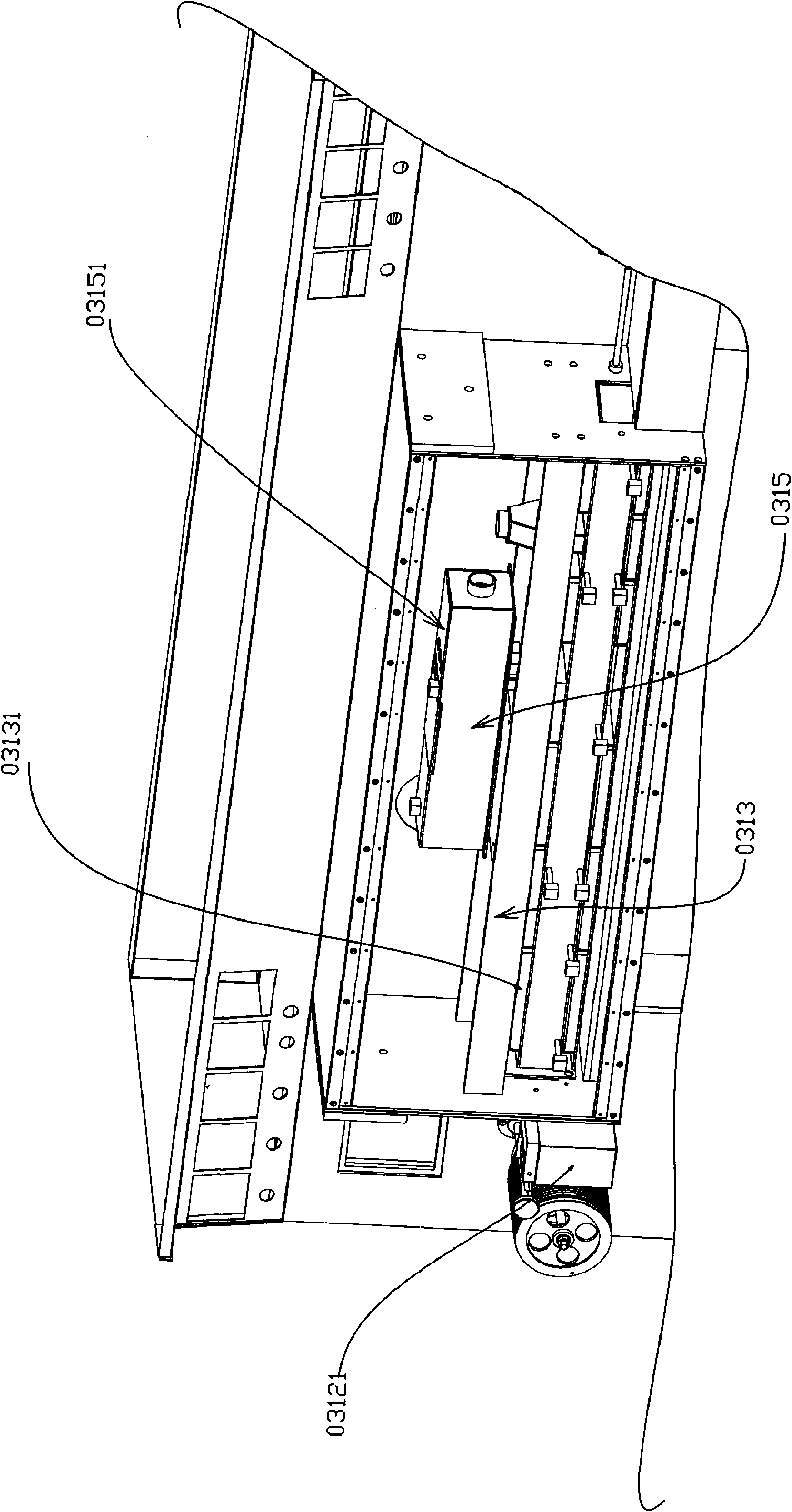

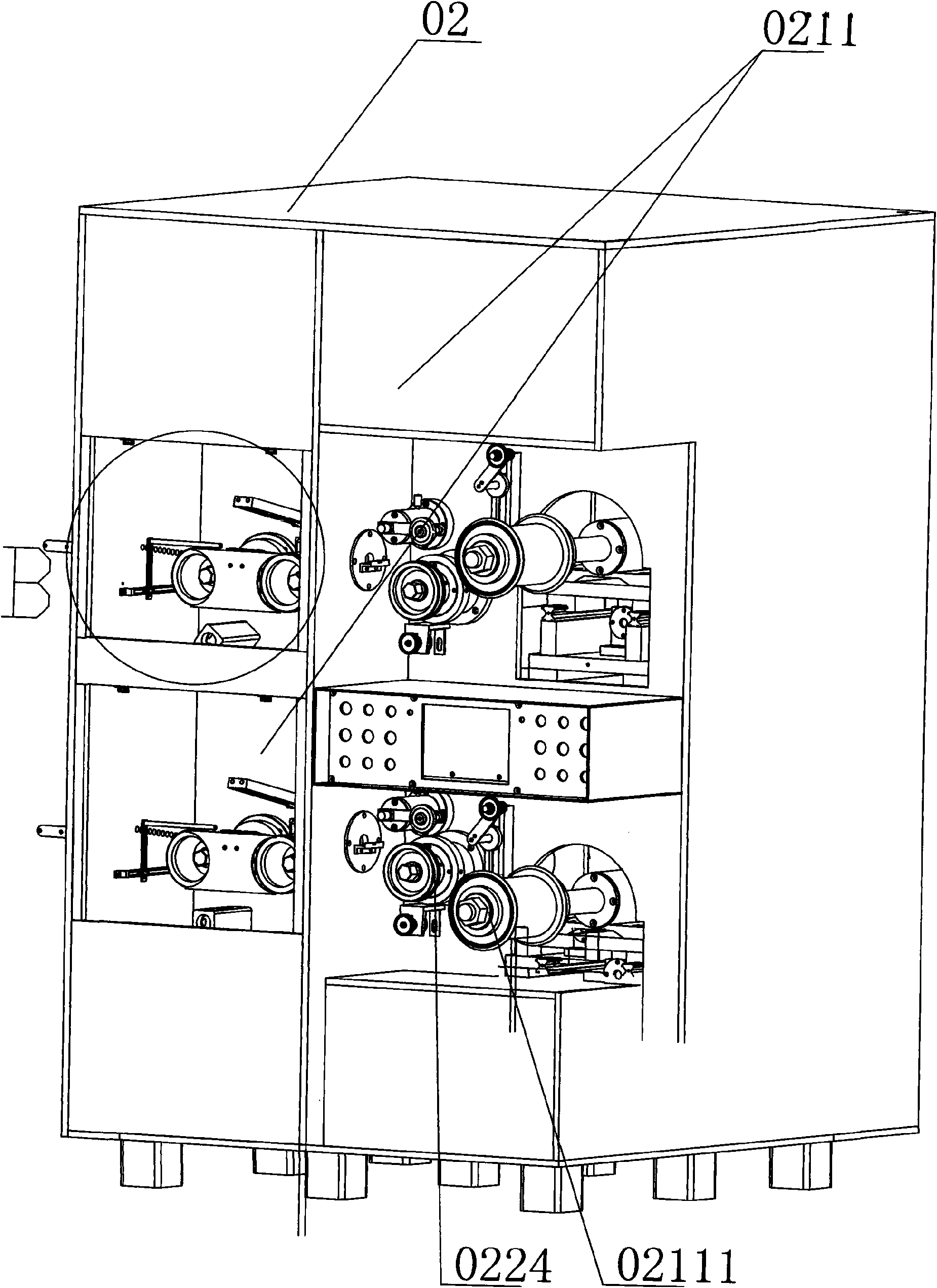

Equipment for producing bonding wire for packaging semiconductor

InactiveCN101572135AReduce volumeCompact structureLine/current collector detailsSemiconductor/solid-state device manufacturingThin metalSemiconductor package

The invention discloses equipment for producing a bonding wire for packaging a semiconductor, which comprises a wire releasing device, a wire-drawing machine, a quenching and tempering device and a take-up device, wherein a metal wire in the wire releasing device is sent to the wire-drawing machine through a leading mechanism; the wire-drawing machine is arranged on one side of a wire outlet of the wire releasing device and comprises a wire-drawing component; the metal wire led out of the leading mechanism of the wire releasing device is connected to a wire-drawing component capable of gradually drawing the outer diameter of the metal wire small; the quenching and tempering device is arranged on one side of a wire outlet of the wire-drawing machine and comprises a wire sending device, a washing device, a coating device, an annealing device and a roasting oven; a thin metal wire conforming to specifications and pulling out of the wire-drawing machine is sent to the washing device through the wire sending device; the washed metal wire enters the annealing device for annealing; the annealed metal wire enters the coating device for coating; the coated metal wire enters the roasting oven for drying and then enters a cooling device for cooling; the wire take-up device is provided with a wire containing tray for collecting a finished wire, and the wire containing tray is connected with a driving device and driven by the driving device.

Owner:袁毅

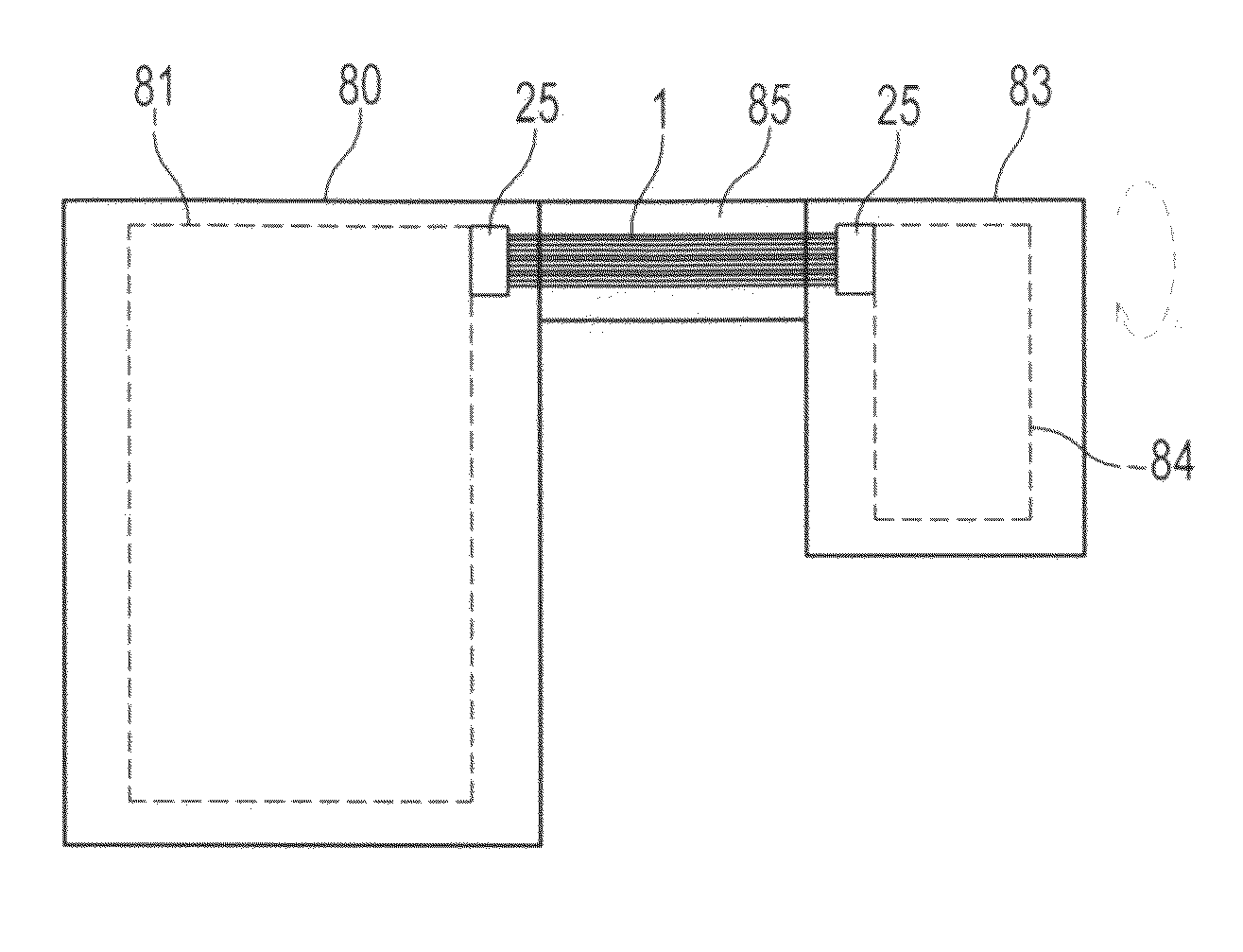

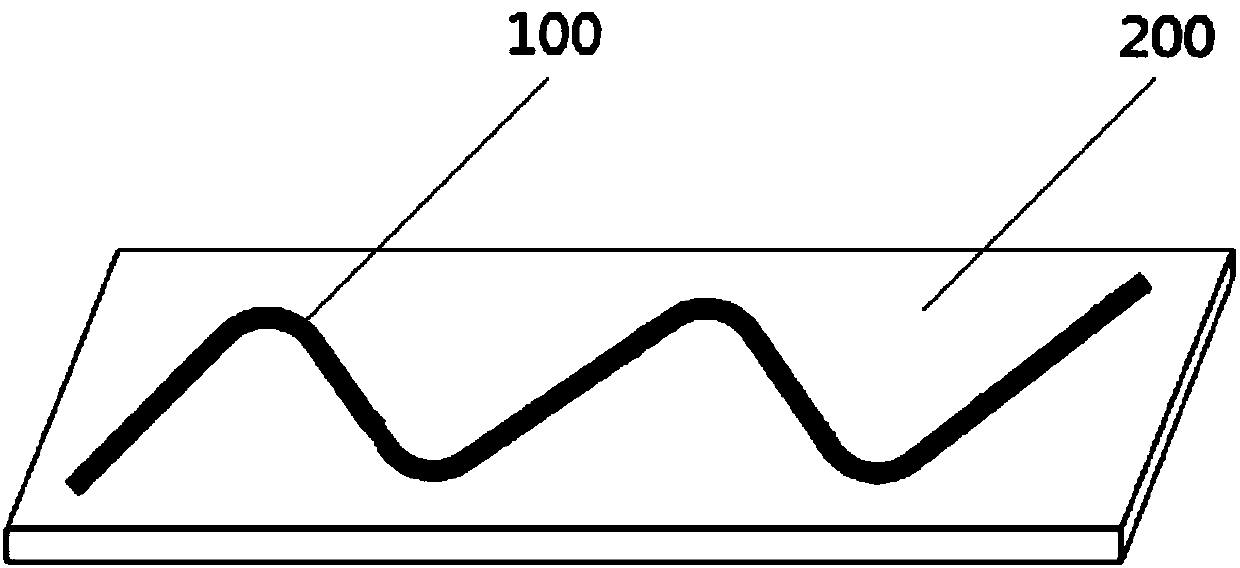

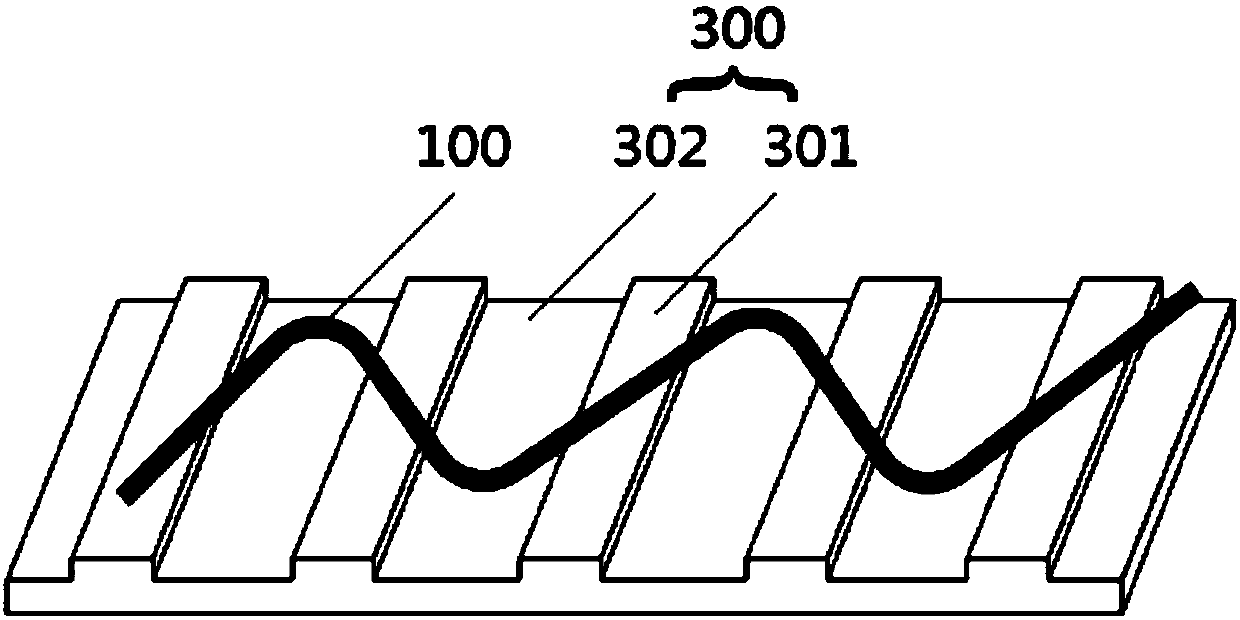

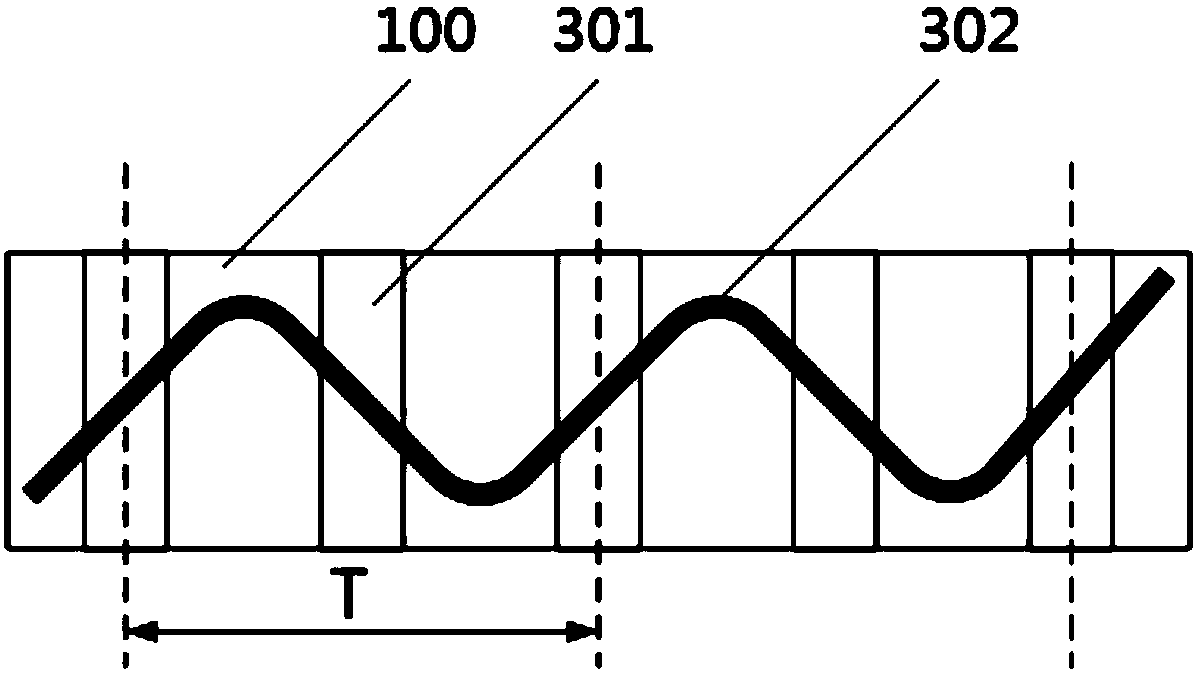

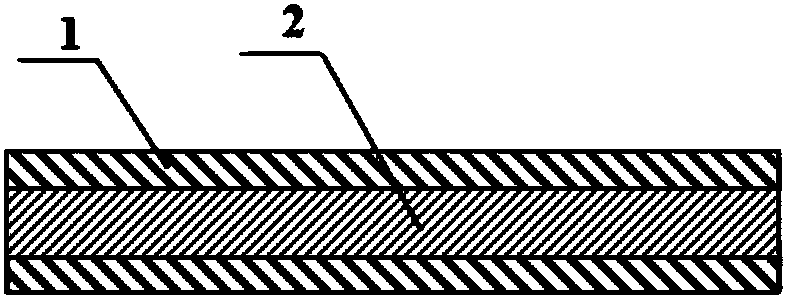

Substrate, flexible electronic component and manufacturing method of flexible electronic component

ActiveCN108520796AEasy to stretchEnsure safetyManufacturing extensible conductors/cablesExtensible conductorsInterconnectionFlexible electronics

The invention relates to a substrate used for a flexible electronic device, a flexible electronic component and a manufacturing method of a flexible electronic component. The substrate is made of stretchable flexible material and is used for holding conductors. The substrate has a surface and a plurality of bosses arranged on the surface. The plurality of bosses are arranged in a first direction,and a recessed portion is arranged between every two adjacent bosses in the first direction. When the substrate is holding the conductors, the conductors are attached to the bosses and parts of the conductors, extending in the recessed portion between every two adjacent bosses, will not touch the bottom surface of the recessed portion. According to the invention, the tensile performance of the whole flexible electronic device can be improved while the safety of the interconnection lines is guaranteed.

Owner:浙江荷清柔性电子技术有限公司

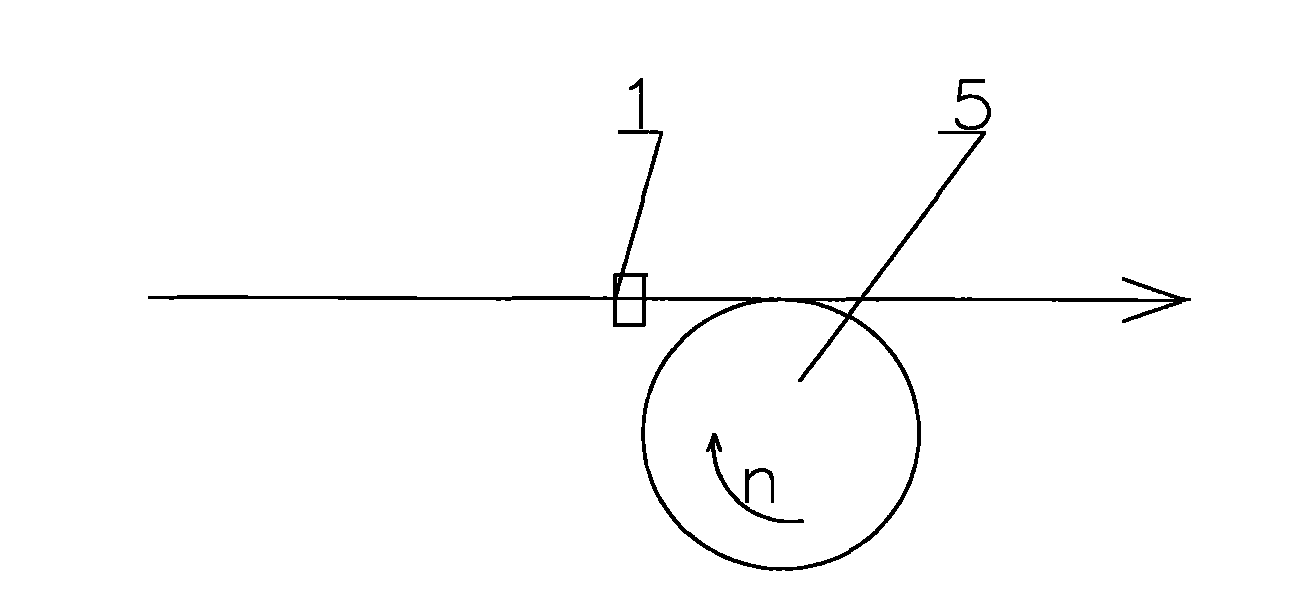

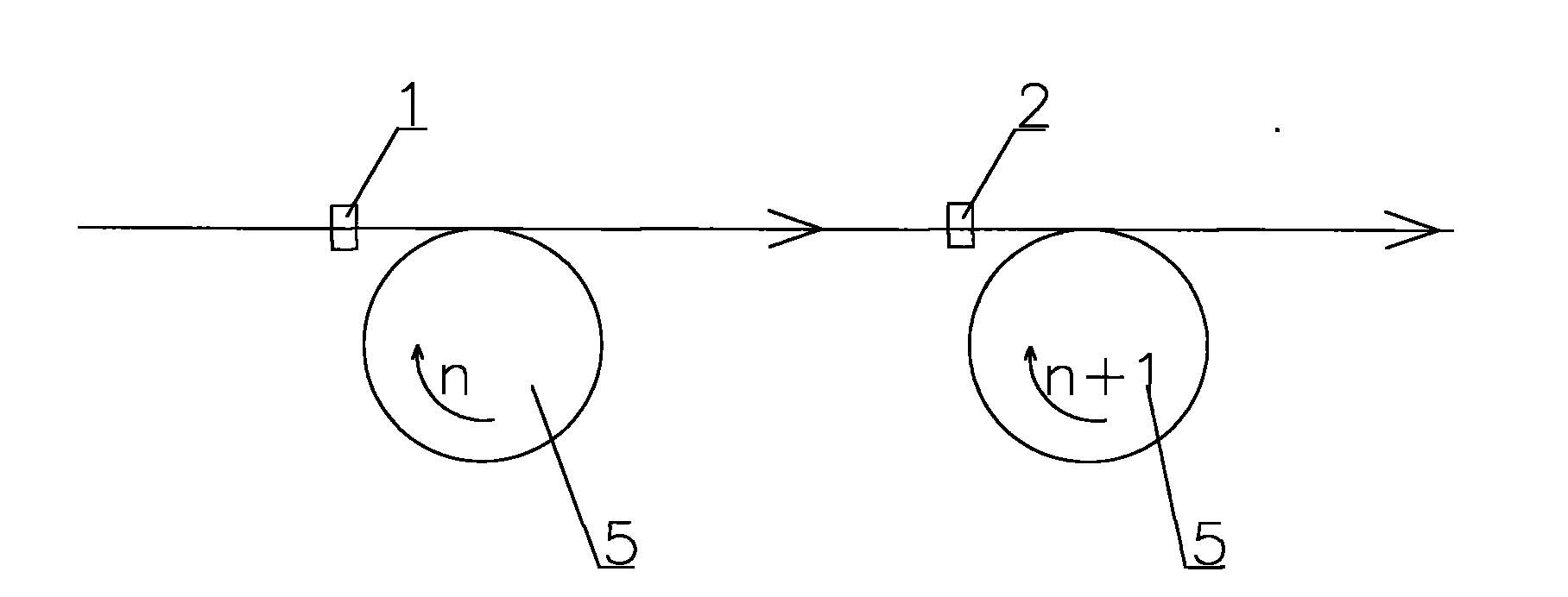

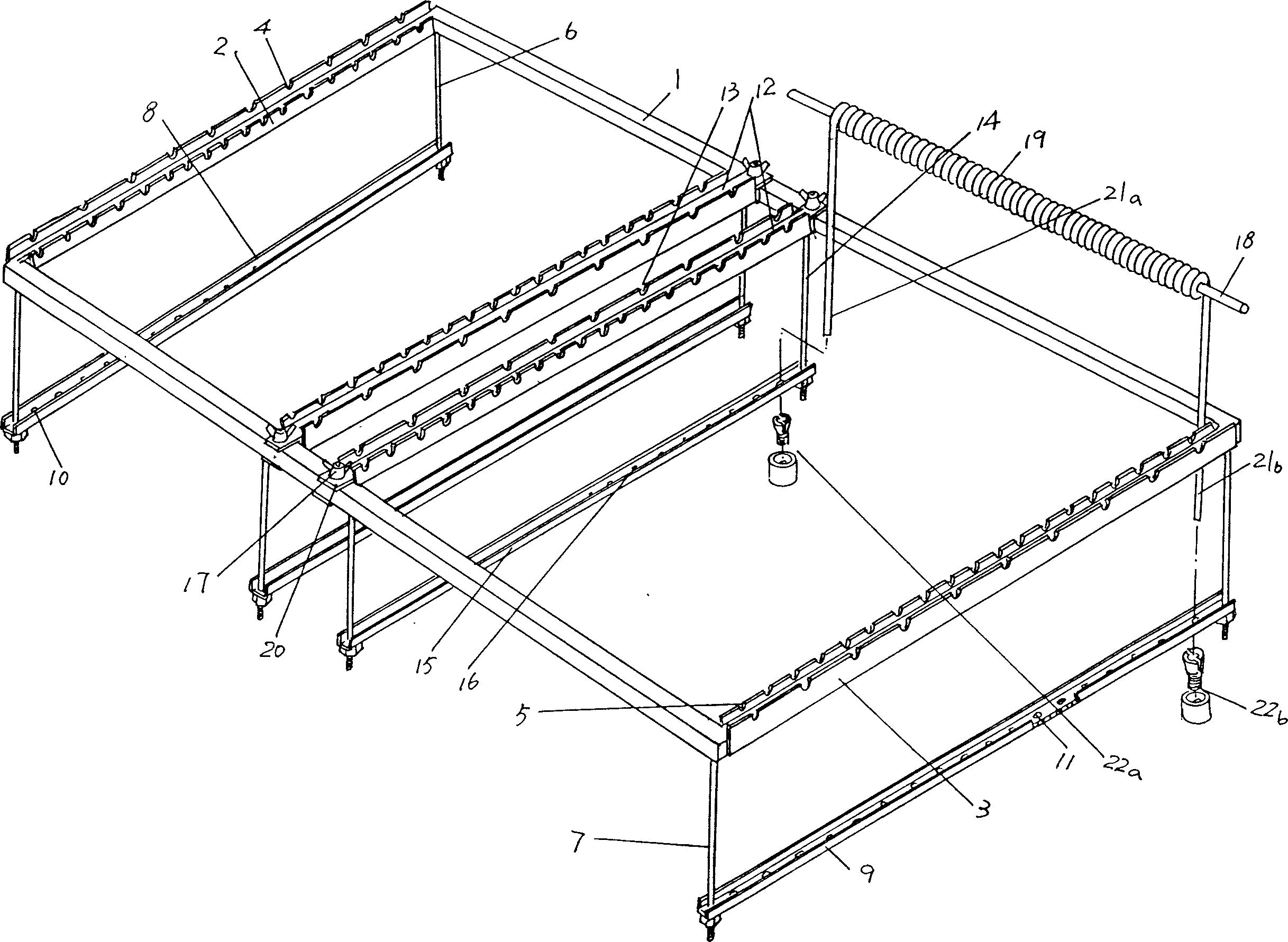

Spring wire processing device

InactiveCN1877749AEnsure the quality of the thread bodyManufacturing extensible conductors/cablesExtensible conductorsEngineeringElectric wire

The invention discloses a manufacturing device of spring line in the specific device technological domain of wire cable manufacturing, which comprises the following parts: one rack, at least one couple of first and second bar-winding locating boards on two ends of rack, first and second locating grooves on the first and second locating boards intervally and separately, one couple of first and second booms corresponding to two end parts of first and second bar-winding locating boards extended on the rack, one couple of first and second clamps with two ends fixing on one couple of first and second booms, first and second line holes on the floor of first and second clamps intervally and separately. The invention can't destroy any line bulk of spring through cutting the limit touching part of second rear part and clamp, which guarantees the line quality of spring line.

Owner:SUZHOU CABLEPLUS PHOTOELECTRIC TECH

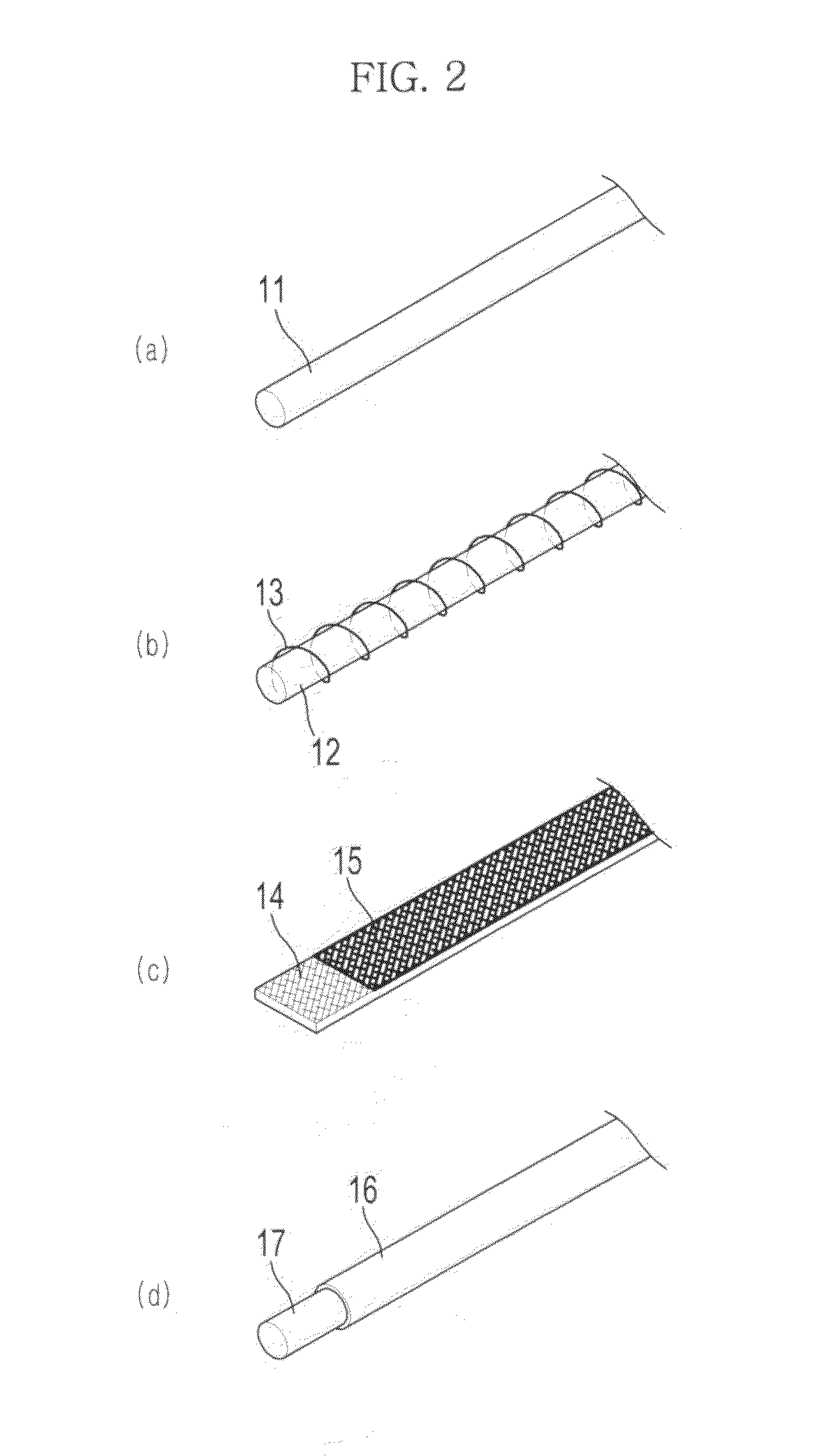

Method for producing DC variable frequency enameled wire

ActiveCN101540223ANot easy to scratchGuaranteed insulation performancePlastic/resin/waxes insulatorsInsulated cablesEngineeringWear resistance

The invention provides a method for producing a DC variable frequency enameled wire which is called as a DC enameled wire for short. The method comprises the steps: selection of raw materials and production process of the DC enameled wire: (1) drawing; (2) annealing; (3) painting; (4) detecting solidification degree. The invention has the advantages that compared with the conventional enameled wire, the DC enameled wire is greatly improved in the aspects such as flexibleness, surface lubricity and the like, and especially has good wearing resistance; when the DC enameled wire is used for winding on winding equipment, the outside film of the DC enameled wire is not easy to scratch by parts contacting with the film, so that the insulating property of a winding coil of a compressor can be ensured, and the phenomenon of interturn discharge breakdown can be avoided.

Owner:天津精达里亚特种漆包线有限公司

Method for preparing contact wires and pole blanks

ActiveCN101447260AFine grainHigh mechanical strengthSingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesOxygenPhysical property

The invention discloses a method for preparing high-strength high-conductivity contact wires and rod blanks. The method for preparing the contact wires comprises the following steps: melting and continuously casting to obtain precipitation strengthening type copper alloy oxygen-free wire rods; pre-treating the oxygen-free wire rods to obtain blank rods; loading the blank rods into an extruding machine to carry out continuous hot extrusion to obtain contact wire rod blanks, and cooling the extruded contact wire rod blanks; cold-rolling the contact wire rod blanks, and carrying out the aging treatment; and carrying out the multi-pass cold rolling to the contact wire rod blanks according to the pre-determined sectional dimension of the contact wires to obtain the contact wires. The method simplifies the problem of the heat treatment of the precipitation strengthening type copper alloy contact wire materials, the prepared contact wires have the advantage of fine grains, thereby not only ensuring higher mechanical strength, but also retaining ideal conductivity and good physical properties, and the length of the contact wires can meet the requirements for railway construction.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAUGRP

Elastic lead and preparation method thereof

ActiveCN107622818AImprove conductivityExcellent "flexibilityClimate change adaptationManufacturing extensible conductors/cablesElastomerLiquid state

The invention provides an elastic lead. Liquid metal and an elastomer are adopted. The elastomer is designed into a hollow tube structure, the liquid metal fills in the hollow part and the two ends ofthe tube body are provided with conductive sealing members to act as the two electrode ends of the lead. The elastic lead has high conductivity and high tensile performance and is easy to prepare andstable in performance and can be applied to various types of electronic products so that miniaturization of the electronic product can be realized and carrying and use convenience can be enhanced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

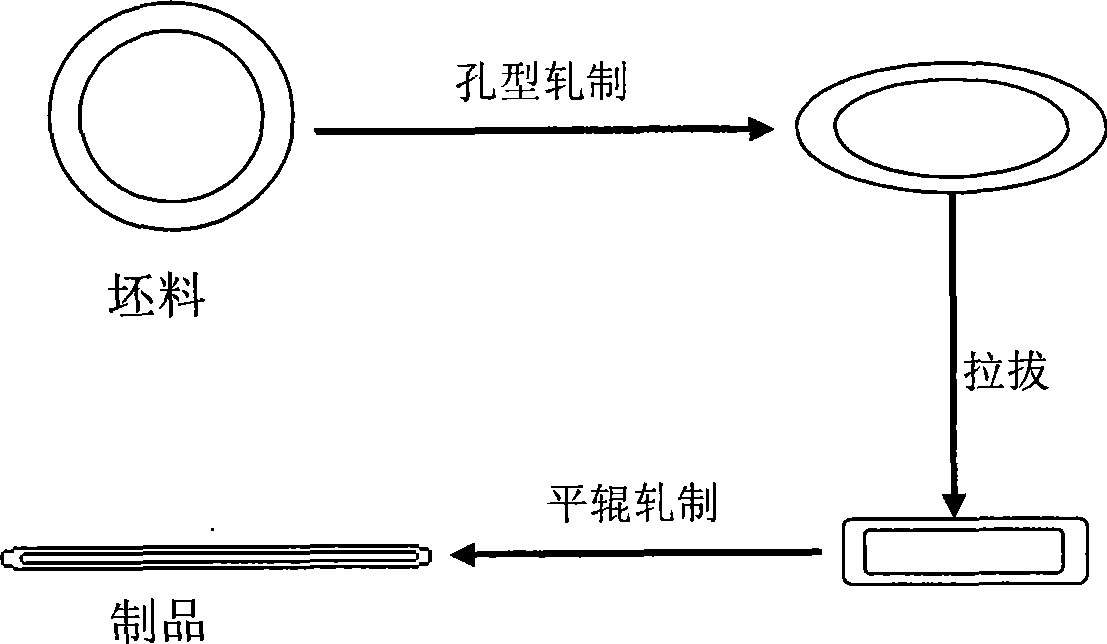

Flexible flat cable manufacturing process

ActiveCN102194552AIncrease productivityReduce labor costsFlat/ribbon cablesManufacturing extensible conductors/cablesElectrical conductorBobbin

The invention discloses a flexible flat cable manufacturing process which is characterized by comprising the following steps of: (1) a wire stretching procedure: stretching a tinned round copper wire into a preparation conductor original wire conforming to size requirements by using a wire stretching device as required; (2) a calendaring procedure: calendaring the preparation conductor original wire obtained in the step (1) to form a tinned flat conductor conforming to size requirements through a calendaring device by using a rolling method, and coiling the wire by using a bobbin; and (3) an attaching procedure: pressing an insulating adhesive film and the tinned flat conductor together by using an attaching device to form a data cable, namely a flexible flat cable. Through splitting, the yields of the wire stretching device and the calendaring device can be maximized respectively, i.e. the production efficiency of the wire stretching device after splitting process is 3 times greater than that of the traditional process, so that the production efficiency is increased, and the manpower cost and the material cost in production are reduced.

Owner:今皓光电(昆山)有限公司

Preparation method of Cu/C composite wire rod

ActiveCN108320834AImprove performanceEvenly dispersedSingle bars/rods/wires/strips conductorsConductive materialWater bathsCopper wire

The invention provides a preparation method of a Cu / C composite wire rod. The method includes the following steps that: first, an oxygen-free copper block is arranged in a vacuum induction furnace soas to be subjected to high-temperature melting; second, a high-temperature copper liquid is slowly and uniformly poured into a crucible filled with graphene oxide colloid, so as to form a cylindricalCu / C alloy ingot by means of cooling in water bath; third, the Cu / C alloy ingot is polished and is subjected to acid pickling, and the treated Cu / C alloy ingot is arranged in an oxygen-free copper sheath so as to be subjected to hot extrusion, and a Cu / C alloy rod can be obtained; and fourth, the Cu / C alloy rod is plastically drawn on the basis of a heat treatment technology, so that the Cu / C composite wire rod can be obtained finally. The microstructure distribution of the prepared Cu / C composite wire rod is uniform; the Cu / C composite wire rod has the excellent characteristics of high strength and high conductance of graphene; and the conductivity and strength of the copper wire rod are significantly improved. With the preparation method adopted, the defects of failure to realize diffusion of Cu and C, failure to realize the combination of the Cu and C, low interfacial strength and low strength of a traditional Cu / C composite material can be eliminated; a processing cycle is greatlyshortened; and cost can be saved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Aluminum-coated steel high-conductivity overhead insulated cable and production process thereof

InactiveCN106653199AAnti-galvanic corrosionHas fog corrosion resistanceInsulated cablesManufacturing extensible conductors/cablesPolyvinyl chlorideAluminum can

The invention discloses an aluminum-coated steel high-conductivity overhead insulated cable and a production process thereof. The cable sequentially comprises a 20.3% IACS aluminum-coated steel core, a 62.5% IACS hard aluminum wire, a conductor shielding layer and a weather-resistant insulated layer from inside to outside, wherein the 20.3% IACS aluminum-coated steel core is a stranded wire formed by coating the surface of a patented steel wire with an aluminum rod with the purity of 99.70%; the 62.5% IACS hard aluminum wire is formed by stranding a hard aluminum wire with the conductivity of 62.5% IACS, the tensile strength higher than 160MPa and the strength uniformity lower than 25MPa; the shielding layer is made from a crosslinked polyethylene or non-crosslinked polyethylene material; and the weather-resistant insulated layer is made from a polyethylene, polyvinyl chloride or crosslinked polyethylene material. According to the cable, a conductor adopts an aluminum-coated steel core high-conductivity aluminum stranded wire structure; the aluminum-coated steel core has electrochemical corrosion resistance and fog corrosion resistance in comparison with a general steel core; the conductor life is prolonged; and high-conductivity aluminum can effectively reduce line loss and improve power transmission efficiency.

Owner:FAR EAST CABLE +2

Method for processing novel environmental-protection spiral cable with high elasticity

ActiveCN102024526AImprove shrinkageImprove tensile propertiesManufacturing extensible conductors/cablesElectrical conductorCopper wire

The invention provides a method for processing a novel environmental-protection spiral cable with high elasticity, which comprises the following steps of: 1, using a copper wire conductor to twist to make the internal core of the cable; 2, using TPU as raw material to process the cable; 3, rolling the cable wire with a reeling rod; 4, forming the reeled cable wire into a spiral cable by using a high temperature oven, wherein the temperature of the oven is 145 DEG C and the time is 20 minutes; and 5, cooling the formed spiral cable with cooling water to prepare the novel environmental-friendly spiral cable. The invention improves the temperature resistance and resillence of the product via improvement of the process.

Owner:ZHENJIANG HUAYIN INSTR & ELECTRICAL EQUIP

Production technology of soft-state copper-clad steel wire

ActiveCN102254630AEliminate work hardeningGrain refinementCommunication cablesManufacturing extensible conductors/cablesElectricityMetallurgy

The invention relates to a production technology of a soft-state copper-clad steel wire. The production technology of the soft-state copper-clad steel wire successively comprises the following steps: drawing; high temperature tempering; electrodeposition pretreatment; acid electrolyzation; washing; pretreatment electrodeposition; washing; thick processing electrodeposition; washing; anti- oxidization; drying; drawing; washing; anti- oxidation treatment and ammonia-decomposition high temperature tempering. By using the production technology of the soft-state copper-clad steel wire of the invention, an elongation rate of the copper-clad steel wire is greater than or equal to 10%, which is more than one time of the elongation rate of the copper-clad steel wire produced by a traditional tempering technology.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

ReBCO high temperature superconducting wire bonding device and bonding method using same

InactiveCN105636719ALong superconducting wireSuperconductors/hyperconductorsApparatus for heat treatmentPower flowElectrical conductor

Owner:K·约恩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com