Elastic lead and preparation method thereof

A wire and elastic technology, applied in the field of elastic wire and its preparation, can solve the problems of poor electrical conductivity, poor tensile performance and poor electrical conductivity of ionic conductors, and achieve the effects of stable performance, high tensile performance and reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

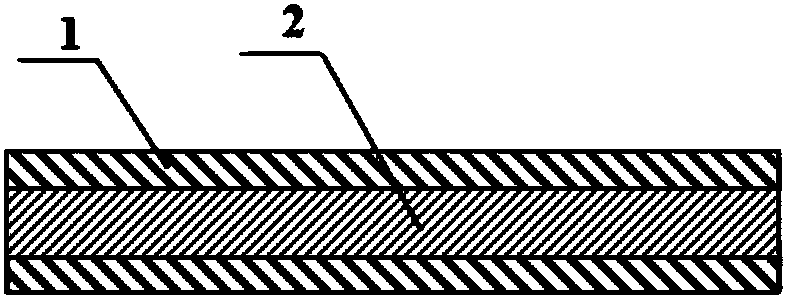

[0042] In this embodiment, the elastic wire adopts liquid metal and elastic body, the elastic body is thermoplastic elastomer TPE, and the liquid metal is GaInSn alloy.

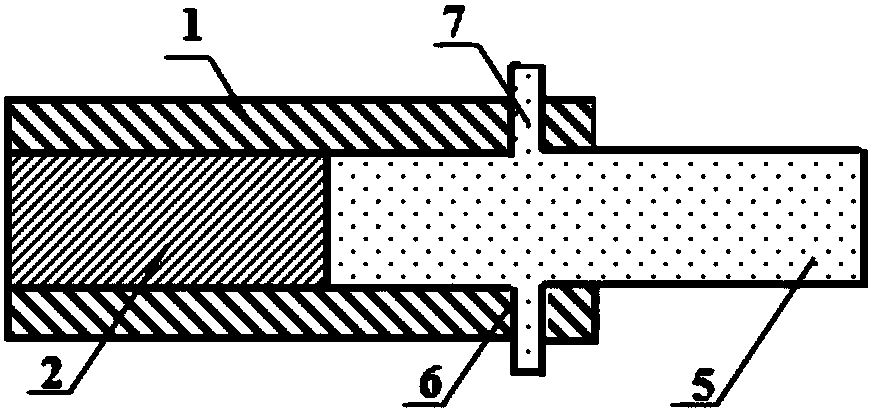

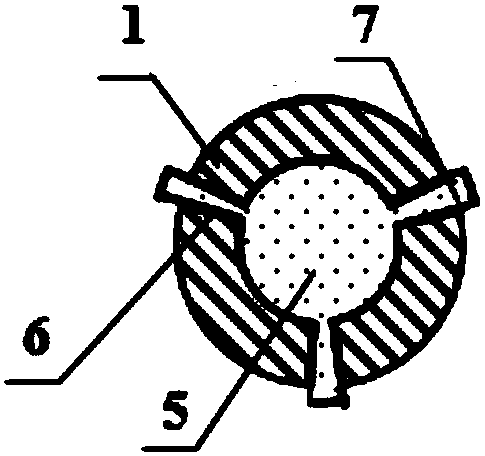

[0043] Such as figure 1 As shown, the elastic body 1 is a hollow tube structure with openings at both ends, and the liquid metal 2 is filled in the hollow part of the tube body. Such as figure 2 and 3 shown (for clarity, figure 2 and image 3 compare figure 1 Slightly enlarge the size ratio of the pipe body), seals are arranged at both ends of the pipe body. In this embodiment, the seal is composed of a metal seal head 5 matching the structure of the inner wall of the pipe, and a protrusion 7 arranged around the seal head. The head 5 is in electrical contact with the liquid metal 2, and the protrusions 7 protrude through the elastic tube holes 6 at both ends of the elastic tube.

[0044] In this embodiment, the specific steps for preparing the above-mentioned elastic wire are:

[0045] (1) Prepare th...

Embodiment 2

[0051] In this embodiment, the elastic wire adopts liquid metal and elastic body, the same as in embodiment 1, the elastic body is thermoplastic elastomer TPE, and the liquid metal is GaInSn alloy.

[0052] In this embodiment, the structure of the elastic wire is basically the same as in Embodiment 1, the difference is that, as Image 6 As shown, the liquid metal adheres to the inner wall of the pipe body, and the middle part 3 of the pipe body is hollow.

[0053] In this embodiment, the specific steps for preparing the above-mentioned elastic wire are:

[0054] (1) Prepare the elastic tube by melt extrusion, the elastic tube is a hollow tube body with openings at both ends, and its inner wall is smooth, choose a 10 cm long elastic tube, and punch holes at both ends of the elastic tube to form the elastic tube hole 6;

[0055] (2) if Figure 7 As shown, select a glass container 8, pour sodium hydroxide solution 9, put a 10 cm long elastic body 1 and liquid metal 2 in the sol...

Embodiment 3

[0058] In this embodiment, the elastic wire adopts liquid metal and elastic body, the same as in embodiment 1, the elastic body is thermoplastic elastomer TPE, and the liquid metal is GaInSn alloy.

[0059] In this embodiment, the structure of the elastic wire is basically the same as in Embodiment 1, the difference is that, as Figure 8 As shown, the hollow inner wall surface of the elastic body 1 contains several protrusions.

[0060] In this embodiment, the specific steps for preparing the above-mentioned elastic wire are:

[0061] (1) A method in which an extruder is used to simultaneously extrude the elastic tube and the liquid metal. Design extrusion dies such as Figure 9 As shown, the head of the extrusion die is two hollow tubes 13 and 14 coaxially socketed together. The inner tube 14 forms an extrusion channel for liquid metal, and the liquid metal 2 is injected into the inner tube by air pressure. 14, at the same time, the outer pipe body 13 and the inner pipe bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com