Patents

Literature

78results about How to "Increase the stretch ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Matte BOPP (Biaxially-oriented Polypropylene) film for leather transferring and preparation method thereof

ActiveCN103709517AImprove rigidityIncrease the stretch ratioSynthetic resin layered productsCoatingsAnti adhesivePolypropylene

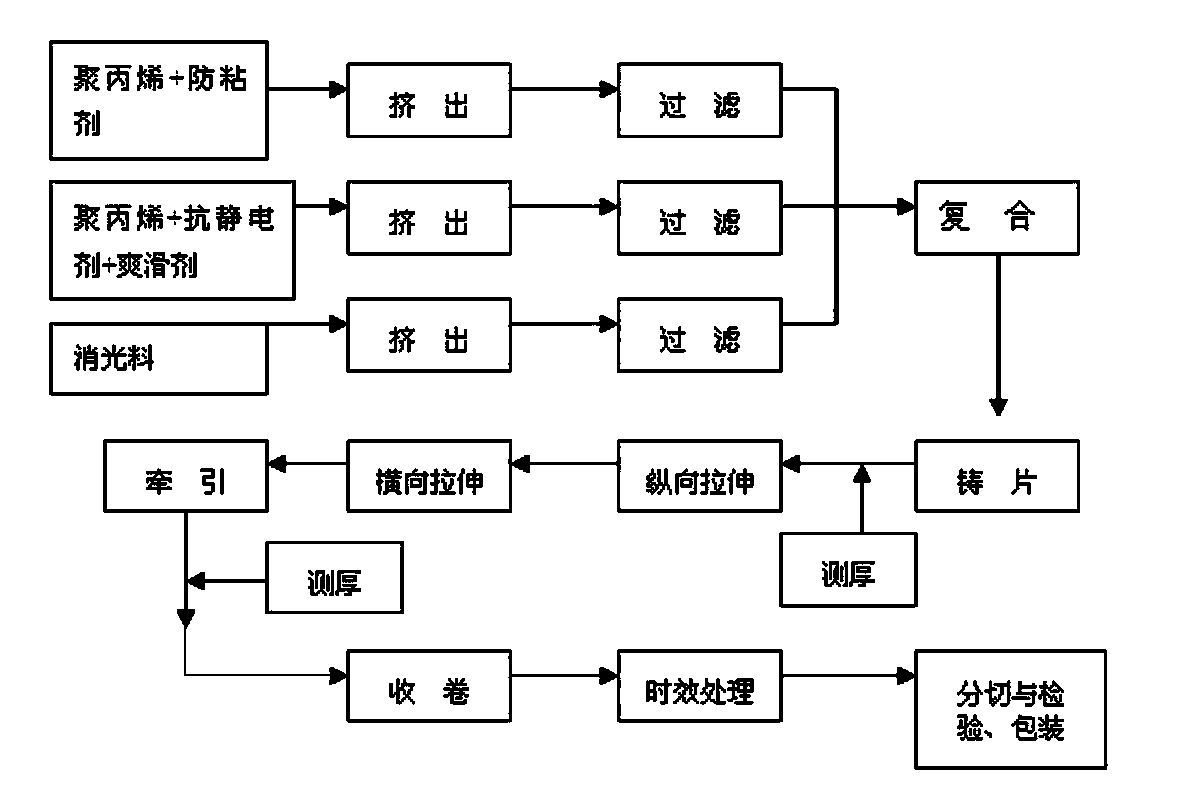

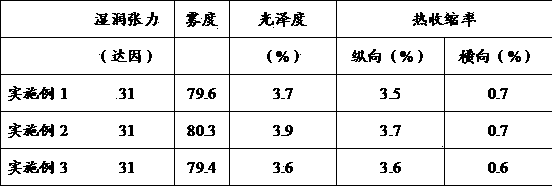

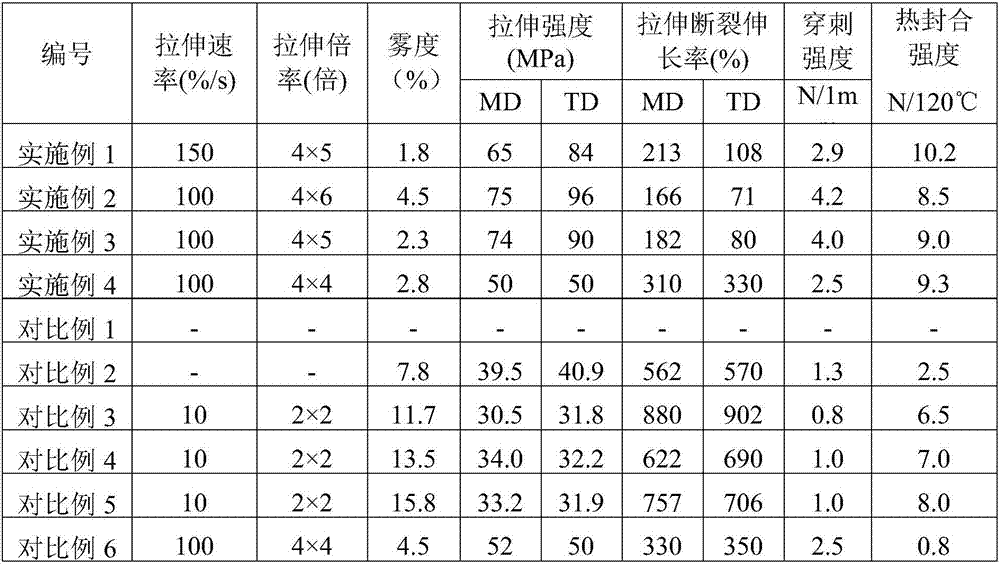

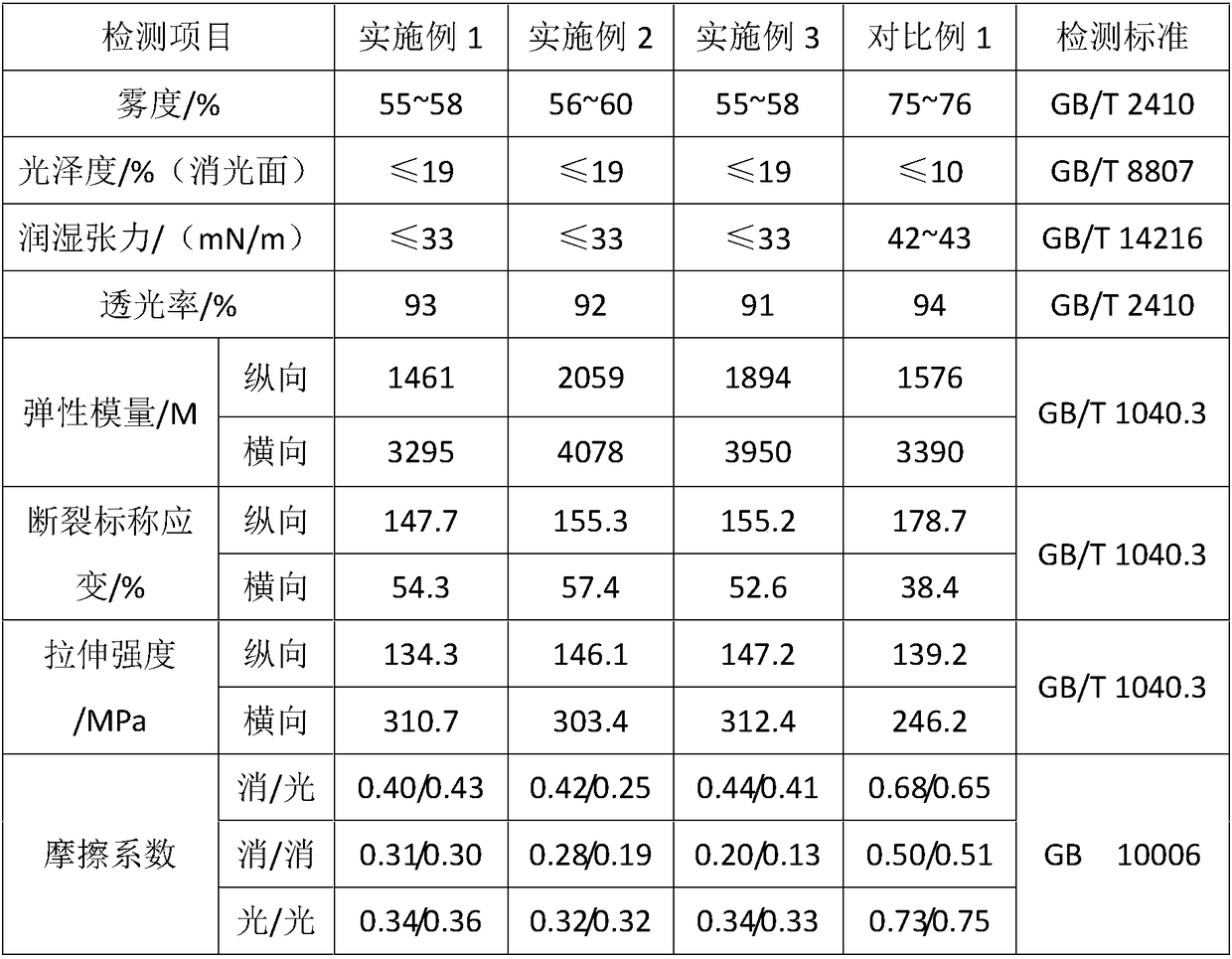

The invention relates to a matte BOPP (Biaxially-oriented Polypropylene) film for leather transferring and a preparation method thereof. The matte BOPP film consists of an inner surface layer, a core layer and an outer surface layer, and is prepared by coextrusion and two-way stretching of the inner surface layer, the core layer and the outer surface, wherein the inner surface layer comprises the following components in percentage by weight: 97.5-98.5% of polypropylene and 1.5-2.5% of adhesive; the core layer comprises the following components in percentage by weight: 98.0-98.4% of polypropylene, 1.0-1.2% of antistatic agent and 0.4-1.0% of slipping agent; the outer surface layer adopts a delustering material which comprises the following components in percentage by weight: 54-56% of polyethylene, 43.7-45.7% of high-density polyethylene and 0.3% of antioxidant. The matte BOPP film and the preparation method have the advantages that the selection and matching of the materials are reasonable, the selected polypropylene material is good in processing performance and high in mechanical strength; the prepared BOPP film is large in elastic modulus and low in heat shrinkage rate; the performance indexes such as haze and glossiness of the outer surface layer are excellent.

Owner:ZHEJIANG KINLEAD PACKAGING MATERIAL

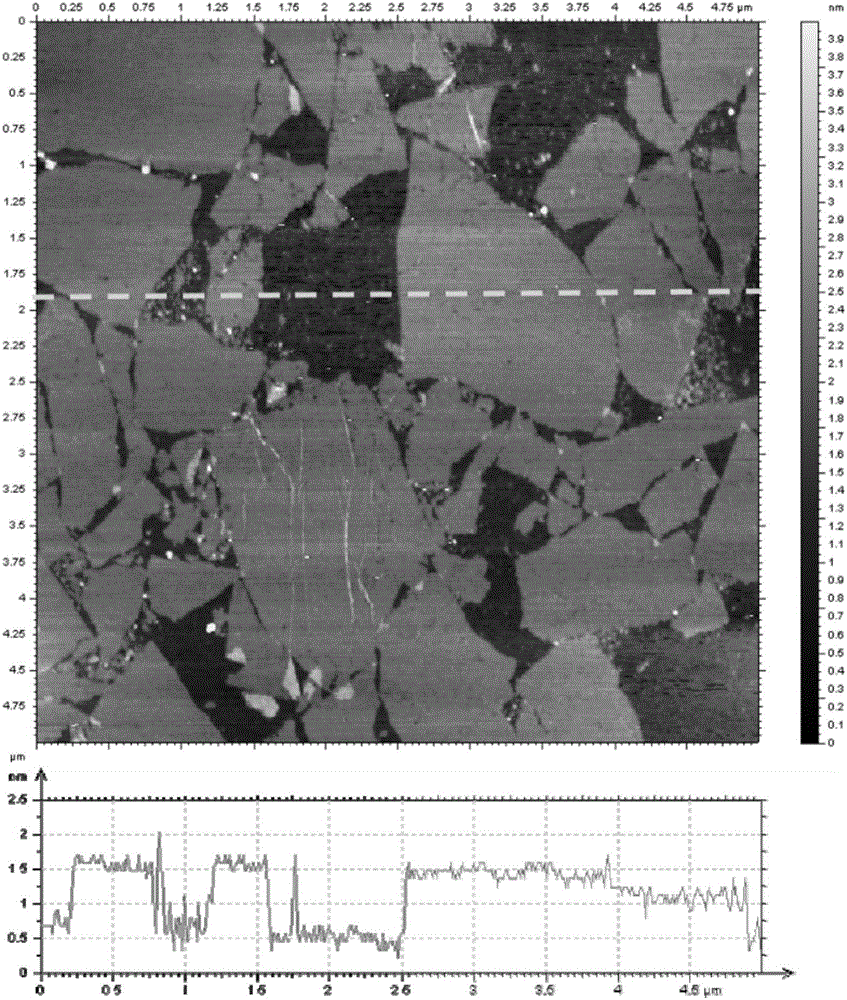

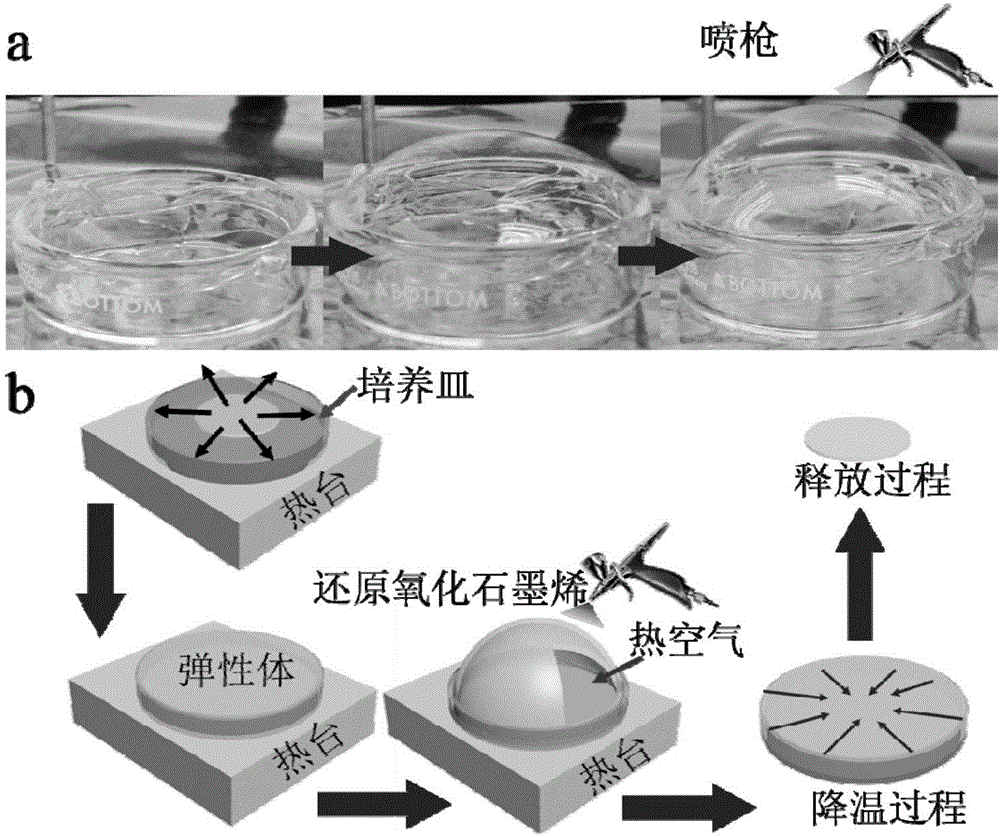

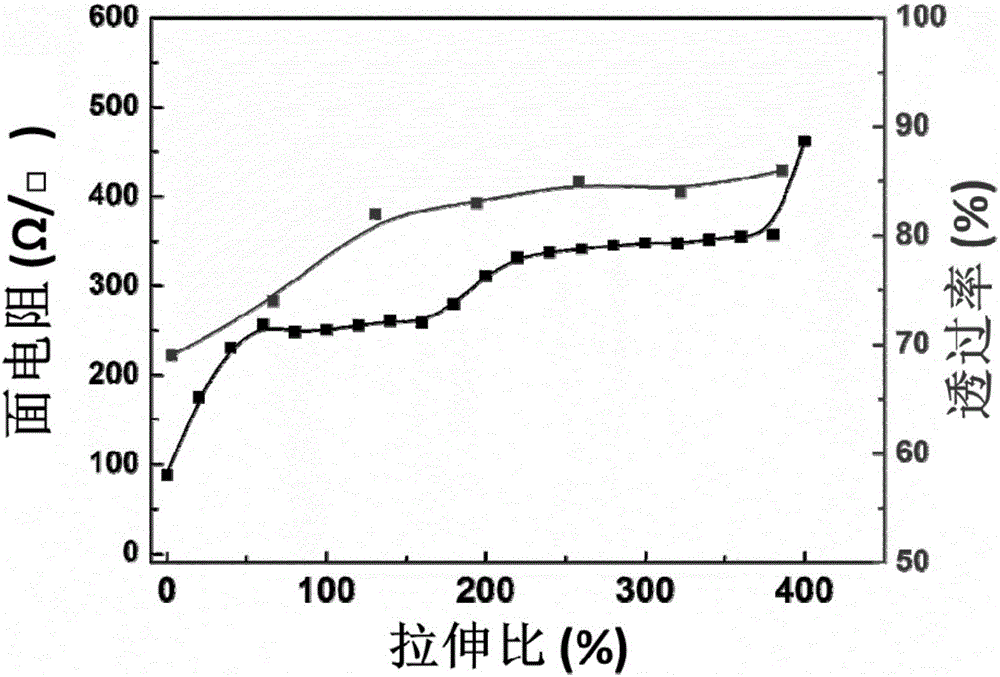

Hierarchical structure gaphene-based tensile tansparent conductive elastomer preparation method

ActiveCN106229038AEasy to prepareMild reaction conditionsConductive layers on insulating-supportsCable/conductor manufactureElastomerPolymer science

The invention relates to a hierarchical structure gaphene-based tensile tansparent conductive elastomer preparation method. The method comprises steps: after being stretched, the polymer elastomer is applied to an opening outer edge of an open container to form closed space, the container is heated, and the polymer elastomer is expanded; a reduced graphene oxide solution coats the expanded elastomer surface, cooling to room temperature is carried out, after restoring the initial morphology, the polymer elastomer is taken down, and thus, the hierarchical structure gaphene-based tensile tansparent conductive elastomer is obtained. The method of the invention is simple, the reaction condition is mild, no special equipment requirements is required, and mass production is facilitated; and the prepared hierarchical structure gaphene-based tensile transparent conductive elastomer presents excellent tensile performance while high transmittance and high conductivity are ensured, and experiments prove that the conductivity can still be smaller than 500 omega per square while the tensile ratio is larger than 400%.

Owner:DONGHUA UNIV

Iodine polarizing film manufacturing method, polaroid manufacturing method and optical laminate manufacturing method

ActiveCN1629660AReduce wrinklesReduce tensionLayered productsPolarising elementsWrinkle skinPolyvinyl alcohol

PROBLEM TO BE SOLVED: To provide a manufacturing method of polarizing film which hardly causes dyeing irregularity and permits the reduction of frequency of wrinkle generation and the reduction of tension during processes after dyeing, and to provide a polarizing plate and an optical laminate using the polarizing film. SOLUTION: In the manufacturing method of polarizing film, uniaxial stretching is performed before and / or during a process of treating a polyvinyl alcohol base film in order of swelling, iodine dyeing and borating. Prior to the borating process, the iodine dyeing is performed in dyeing baths of two steps or more and, further, uniaxial stretching is performed in dyeing baths of two steps or more. Therein, the uniaxial stretching is performed in such a manner that (1) the stretching ratio in the initial dyeing bath is set to be higher than the sum stretching ratio in dyeing baths on and after the second step or (2) the stretching ratio in the last dyeing bath is set to be higher than the sum stretching ratio in the dyeing baths prior to the last dyeing bath.

Owner:SUMITOMO CHEM CO LTD

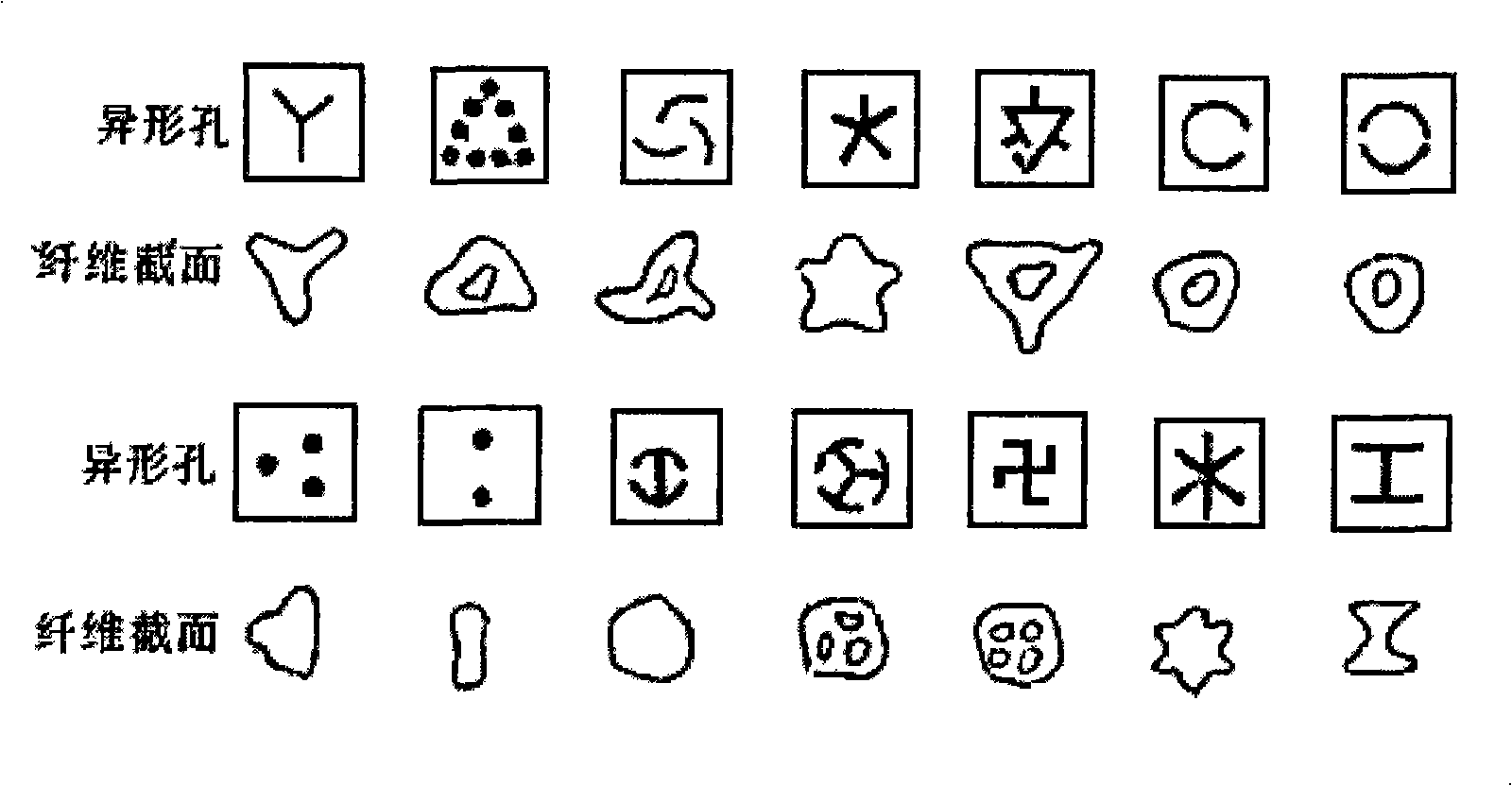

Colored profiled polyester multifilament fiber with stable dimension and preparation method thereof

ActiveCN101525786AFine and uniform meshGeometrically stableMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterYarn

The invention relates to a colored profiled polyester multifilament fiber with stable dimension and a preparation method thereof. The preparation method comprises the following steps: adjusting contents of polyester, pigment masterbatch and an additive in a fusant according to a certain proportion, drying and dehydrating, forming after melting, extrusion, spinning and cooling, and obtaining finished filament after oiling, coiling, heating, tensioning, heat setting, inspection and grading. The fiber can be prepared with conventional spinning equipment, has even multifilament bundle yarn and even color distribution, can be widely applied to fields of clothing, decoration and industry. Fabric is smooth, is characterized by soft luster, high breaking strength and low breaking elongation, can ensure stable geometric dimension of the fabric without easy deformation; and the fiber has the advantages of good fabric elastic resilience, less creep and relaxation and low boiling water shrinkage, and can improve the stability due to hard deformation at high temperature.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Colored non-conventional type polyester monofilament with stable size and preparing method thereof

ActiveCN101586266AFine and uniform meshGeometrically stableMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention relates to a colored non-conventional type polyester monofilament with stable size and preparing method thereof. The method comprises drying, de-watering, melting, squeezing, spinning, cooling to form, oiling, rolling, heating to extend and heat forming the polyester slice cospun master batch slice, checking to form product filament. Advantages of the invention lie in that preparation process is simple; filaments are even; leveling shade is even; fiber thickness is even, which can be widely applied in fiber window screen preparation and industrial field. The fabric is flat, which is lucidus and flexible, high is rupture strength, low rupture extension to ensure stable size of the fabric. It is not easy to deform. Fabric rebound resilience is great. Creep deformation and relaxation phenomenon are fewer. Waste water has low volume shrinkage ratio. The invention is not easy to deform at high temperature, which improves stable performance. Surface of fabric is clean with no polyester nonomer deposit builder.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Polyethylene film and preparation method thereof

ActiveCN107312229AHigh standardIncrease the stretch ratioSynthetic resin layered productsFlat articlesLinear low-density polyethylenePolymer science

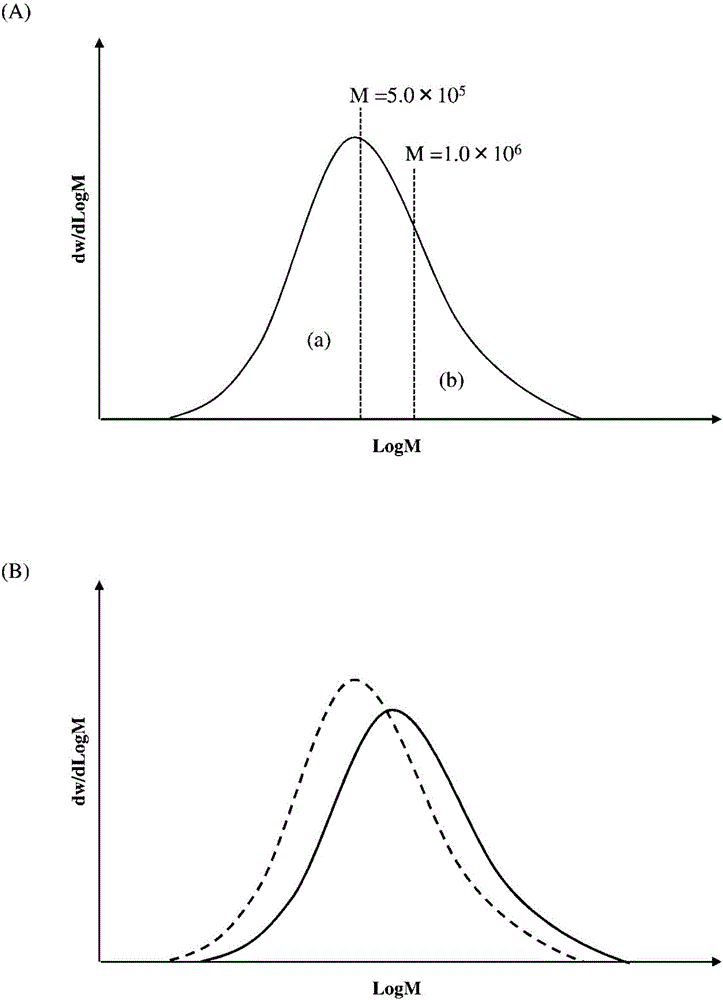

The present invention relates to the field of polymers, and provides a polyethylene film and a preparation method thereof. The polyethylene film comprises a polyethylene core layer and a polyethylene surface layer attached to at least one side surface of the polyethylene core layer, wherein the polyethylene core layer is formed from a first polyethylene composition containing a component A, a component B and a component C, the polyethylene surface layer is formed from a second polyethylene composition containing a component D, the components A, B, C and D respectively are ethylene / alpha olefin copolymerized linear low density polyethylene, the melt indexes of the components A, B, C and D at a temperature of 190 DEG C and a load of 2.16 kg respectively are 0.01-3.5 g / 10 min, 3.6-9.9 g / 10 min, 10-80 g / 10 min and 0.5-50 g / 10 min, and the densities of the components A, B, C and D respectively are 0.915-0.936 g / cm<3>, 0.915-0.930 g / cm<3>, 0.915-0.930 g / cm<3> and 0.880-0.910 g / cm<3>. The polyethylene film of the present invention has advantages of excellent mechanical property, excellent optical property, excellent heat sealing strength, and great industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

BOPP matting transfer film for coating transfer and preparation method thereof

InactiveCN109228591AAvoid stickingGuaranteed stabilitySynthetic resin layered productsLaminationMasterbatchSurface layer

The invention discloses a BOPP matting transfer film for coating transfer. The BOPP matting transfer film for coating transfer sequentially comprises an upper surface layer, an upper core layer, a lower core layer and a lower surface layer, wherein the upper surface layer is an anti-adhesive layer; the upper core layer is a polypropylene layer; both the lower core layer and the lower surface layerare transfer layers; each transfer layer comprises the following components in percent by weight: 80-88% of matting transfer masterbatch, 4.0-8.0% of an antistatic agent, 4.0-6.0% of a slipping agentand 4.0-6.0% of an anti-adhesion agent. The BOPP matting transfer film is directly prepared by a four-layer coextrusion and biaxial stretching method. The BOPP matting film for coating transfer is uniform in matting layer surface roughness, stable in matting effect and good in transfer effect, and can be applied to transfer of leather textiles.

Owner:ANHUI GUOFENG PLASTIC

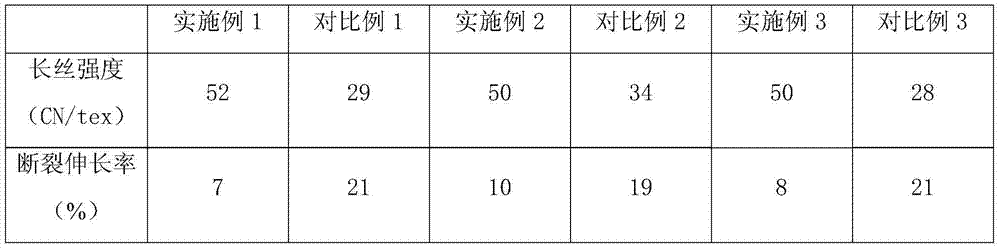

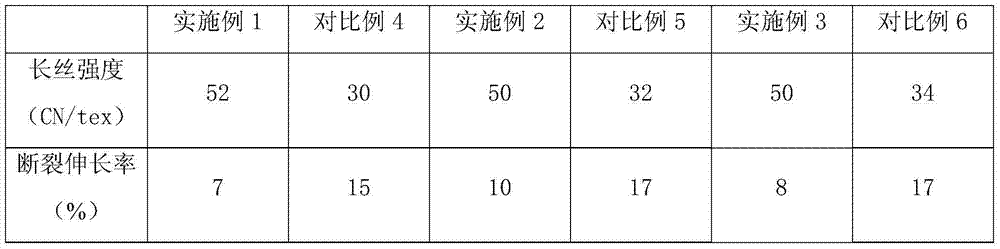

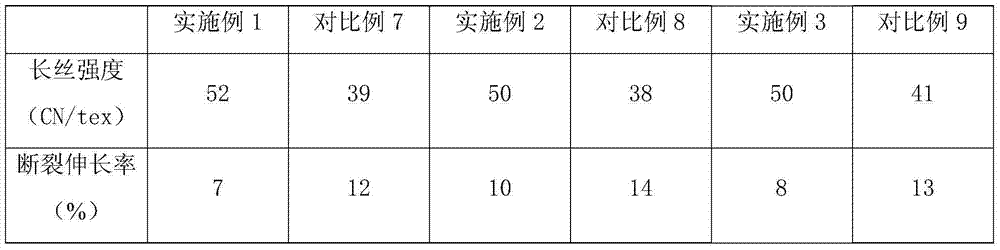

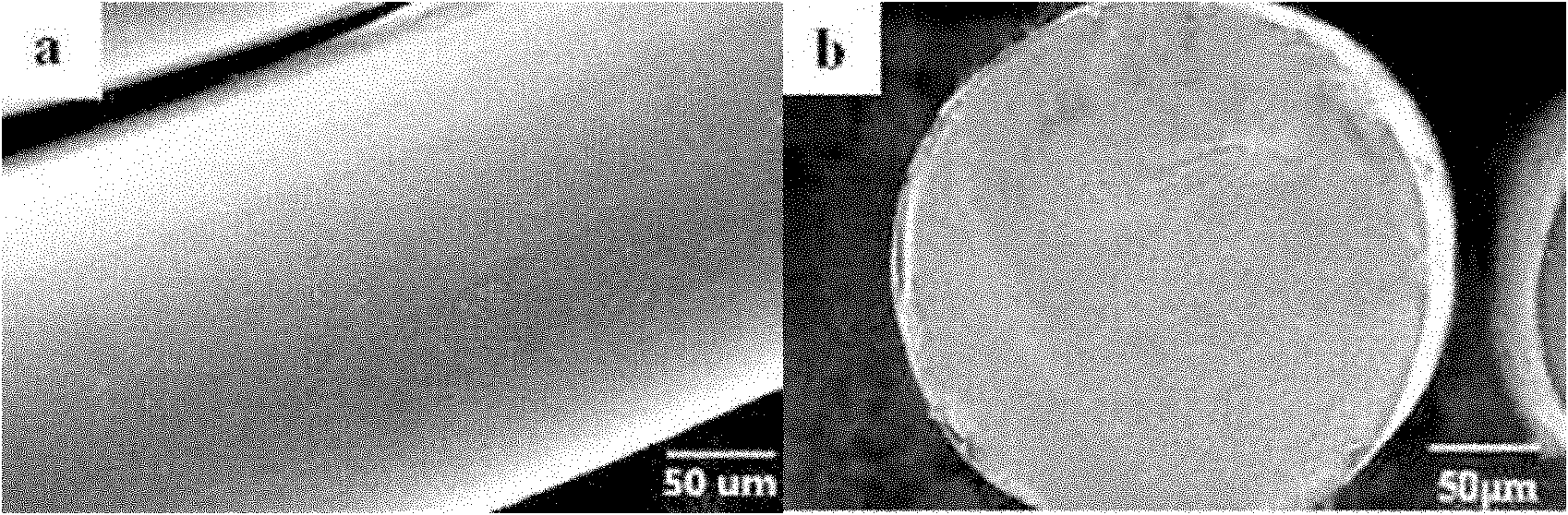

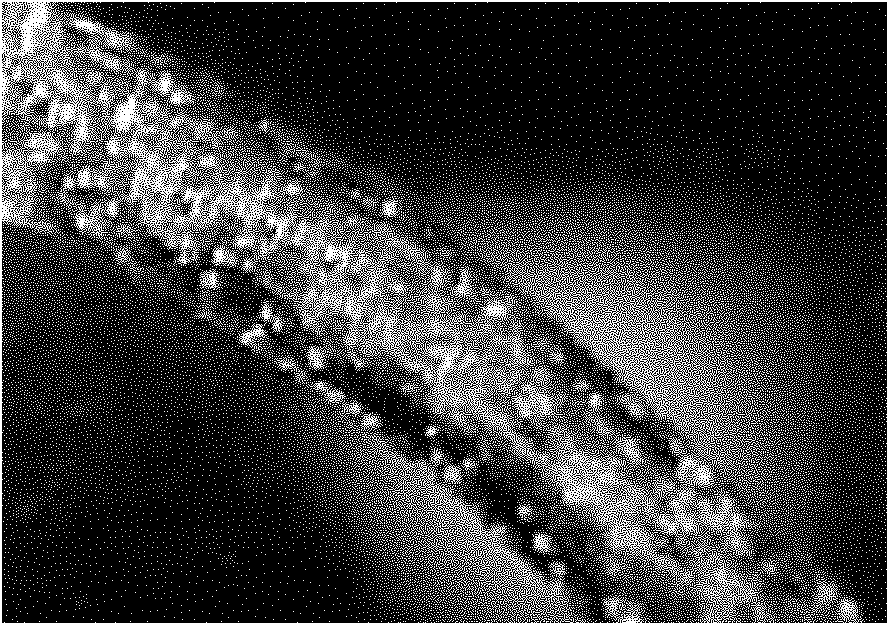

Process for manufacturing high-strength low-elongation polytetrafluoroethylene filaments

ActiveCN104294382AHigh strengthFilament quality improvement and breakthroughStretch-spinning methodsCompression moldingPolymer science

The invention belongs to the field of polytetrafluoroethylene functional material manufacturing, and particularly relates to a process for manufacturing high-strength low-elongation polytetrafluoroethylene filaments. The process comprises the steps that disperse polytetrafluoroethylene granules are processed in a low-temperature oil supply mode, cured and subjected to vacuum compression molding, material strips are extruded in a pushing and pressing mode, a thin film is obtained through compression, longitudinal heating stretching is conducted twice, the thin film is slit into flat filaments, the flat filaments are twisted into round filaments, heating stretching and forming are conducted on the round filaments, and the PTFE filaments of different specifications are manufactured. The filaments manufactured through the process meet the ideal indexes of high strength and low elongation, thereby being an improvement and breakthrough in the quality of polytetrafluoroethylene filaments.

Owner:常州华福环境科技股份有限公司

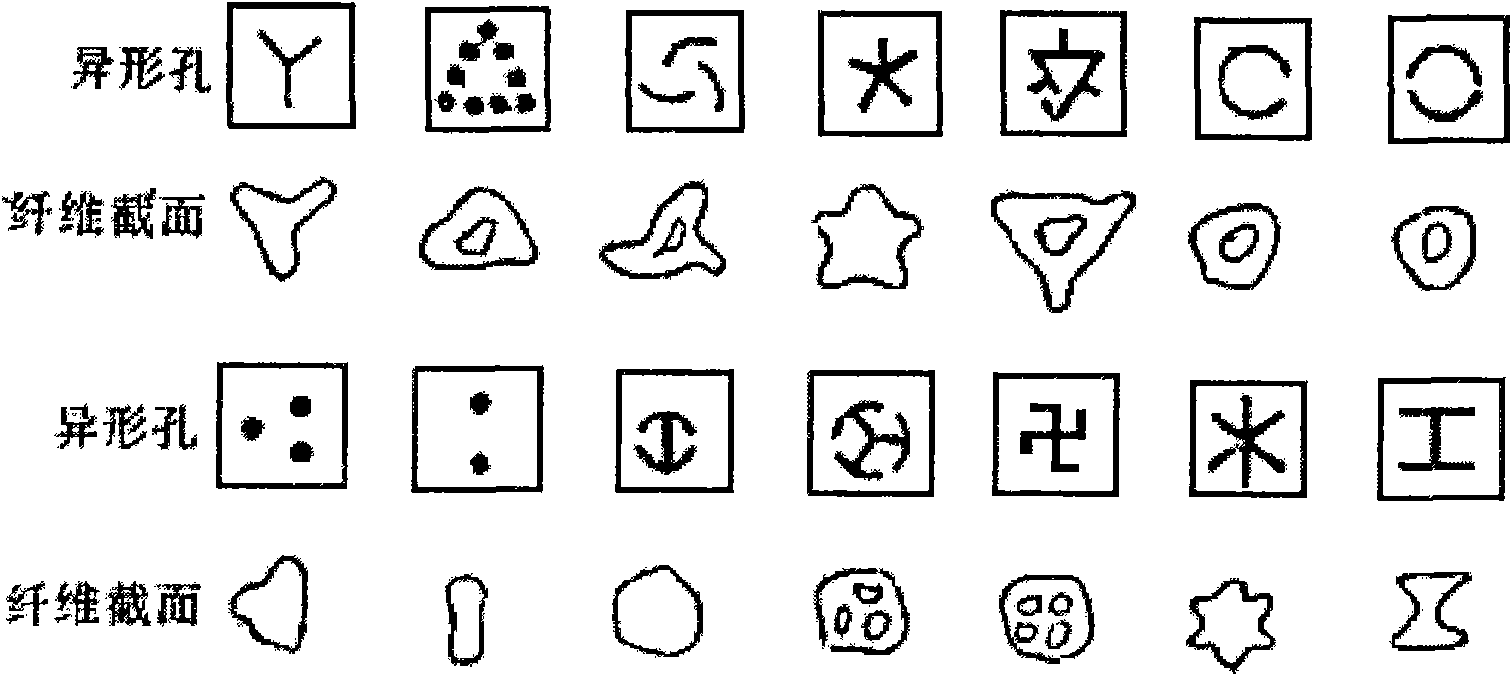

Colored special-shaped size-stabilized type polyester monofilament and preparation method thereof

InactiveCN104532388AImprove heat resistanceGood dimensional stabilityArtificial thread manufacturing machinesFilament/thread formingPolyesterPolyethylene terephthalate glycol

The invention relates to a colored special-shaped size-stabilized type polyester monofilament and a preparation method thereof. The colored special-shaped size-stabilized type polyester monofilament is composed of, by weight, 84.5 parts to 99.75 parts of polyethylene terephthalate (PET), 0.2 part to 5 parts of color master batches, 0.1 part to 10 parts of poly(ethylene 2,6-naphthalate) (PEN) and 0.05 part to 1 part of barium sulfate powder. By adding the PEN, the thermal resistance of fiber is improved, and no roller sticking phenomenon can occur even when the heat setting temperature is above 245 DEG C; nanometer barium sulfate plays a role of plasticizer, the slippage among high polymers is improved, the drawing ratio is increased, the fiber contraction rate is decreased, and meanwhile the colored fiber can be more uniform and brighter in color and luster; the high drawing ratio is achieved in the fiber drawing process, induced crystallization produced in the fiber drawing process is improved, and the boiling water shrinkage is decreased; the fiber preparing process is simple, dry strands are uniform, fiber is uniform in thickness, woven fabric is smooth, grids are exquisite and uniform, and a colored special-shaped filament is softer and richer in color so that stylized reflection can be facilitated.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD +1

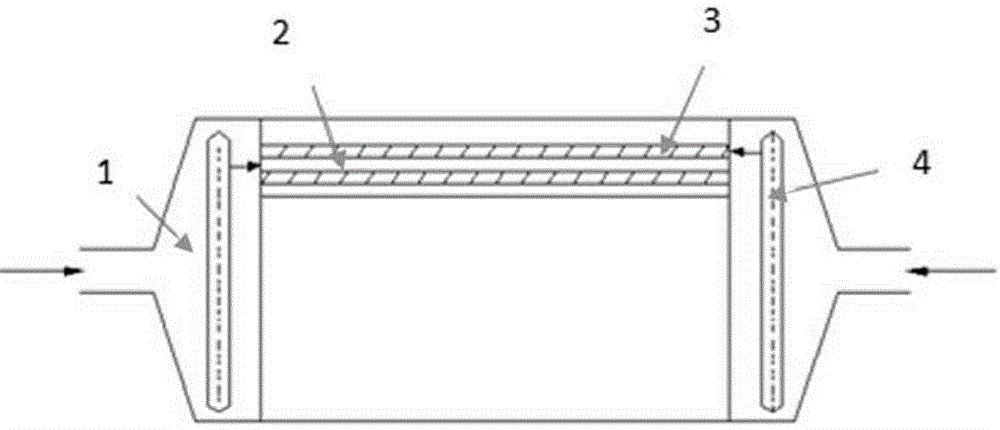

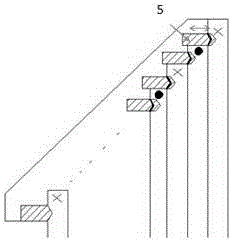

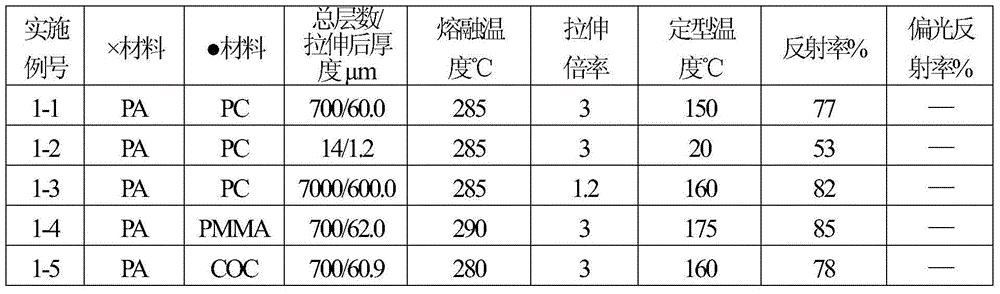

Multilayer optical thin film and manufacturing method thereof

InactiveCN104459834AGood optical performancePolarization effect is obviousOptical elementsCompound aReflecting telescope

The invention discloses a multilayer optical thin film and a manufacturing method of the multilayer optical thin film. The multilayer optical thin film is characterized in that the thin film is formed by compounding one to 10,000 optical thin film units, and the thickness is 0.11 micron to 5,000 microns; each optical thin film unit is formed by compounding a layer of * material thin film and a layer of . material thin film, the thickness speciation of the * material thin films is 0.053 micron to one micron, and the thickness speciation of the . material thin films is 0.053 micron to one micron; the * material thin film and the . material thin film in the same optical thin film unit are different in refractive index. The multilayer optical thin film is manufactured in the mode of carrying out multilayer coextrusion through two extruders and then carrying out unidirectional or bidirectional stretching. The multilayer optical thin film has the functions of totally reflecting visible light and ultraviolet light, filtering 550nm green light and the like, and can be applied to manufacturing of building curtain wall reflecting thin films, automobile glass sticker thin films and reflecting telescopes.

Owner:四川东方绝缘材料股份有限公司

Manufacturing technology of high-strength low-elongation polytetrafluoroethylene filaments

InactiveCN104894675AHigh strengthReduce airArtificial thread manufacturing machinesFilament/thread formingCompression moldingState of art

The invention belongs to the field of preparation of polytetrafluoroethylene functional materials and provides a manufacturing technology of high-strength low-elongation polytetrafluoroethylene filaments to solve the problems that the PTFE (polytetrafluoroethylene) filaments produced in the prior art generally are of low strength and excessively high elongation. The manufacturing technology includes: low-temperature oil treatment, curing treatment, compression molding, strip extruding, thermal elongating, slitting, filament manufacturing, and drawing and setting. The high-strength low-elongation polytetrafluoroethylene filaments are of strength up to 48-52 CN / tex and elongation at break, only 6% to 10%, the ideal indexes, high strength and low elongation, are achieved, and improvement and breakthrough on the quality of the polytetrafluoroethylene filaments are made; by the use of vacuum compression molding, the air in formed plastic is greatly reduced, the semi-finished products are higher in density and uniformity, and the manufacturing technology plays a key role in improving the quality of products made by the following pushing and rolling process.

Owner:常州万容新材料科技有限公司

Method for preparing polyacrylonitrile-based carbon fiber precursors without skin-core structure

InactiveCN102154723AIncreased stretch ratioReduce energy consumptionMonocomponent synthetic polymer artificial filamentSpinning solutions preparationChemistrySkin core

The invention provides a method for preparing polyacrylonitrile-based carbon fiber precursors without a skin-core structure and belongs to the technical field of carbon fiber precursors. The method comprises the followings steps of: evenly mixing water or alcohol compounds and an organic solvent, adding polyacrylonitrile resin in the mixed solution, performing the heated swelling dissolution treatment, and filtering the mixed solution to obtain polyacrylonitrile spinning solution; and ageing the polyacrylonitrile spinning solution, performing spraying and extrusion to obtain primary precursors, and performing water-washing stretching, second-level hot water stretching, drying densification and saturated steam stretching of the primary precursors in sequence to obtain the polyacrylonitrile-based carbon fiber precursors. By the method, the good-quality polyacrylonitrile-based carbon fiber precursors having the advantages of no skin-core structure, less defects, small fiber number and high strength can be mass produced in large scale in the conventional industrialized spinning equipment, and the production cost can be effectively lowered.

Owner:SHANGHAI JIAO TONG UNIV

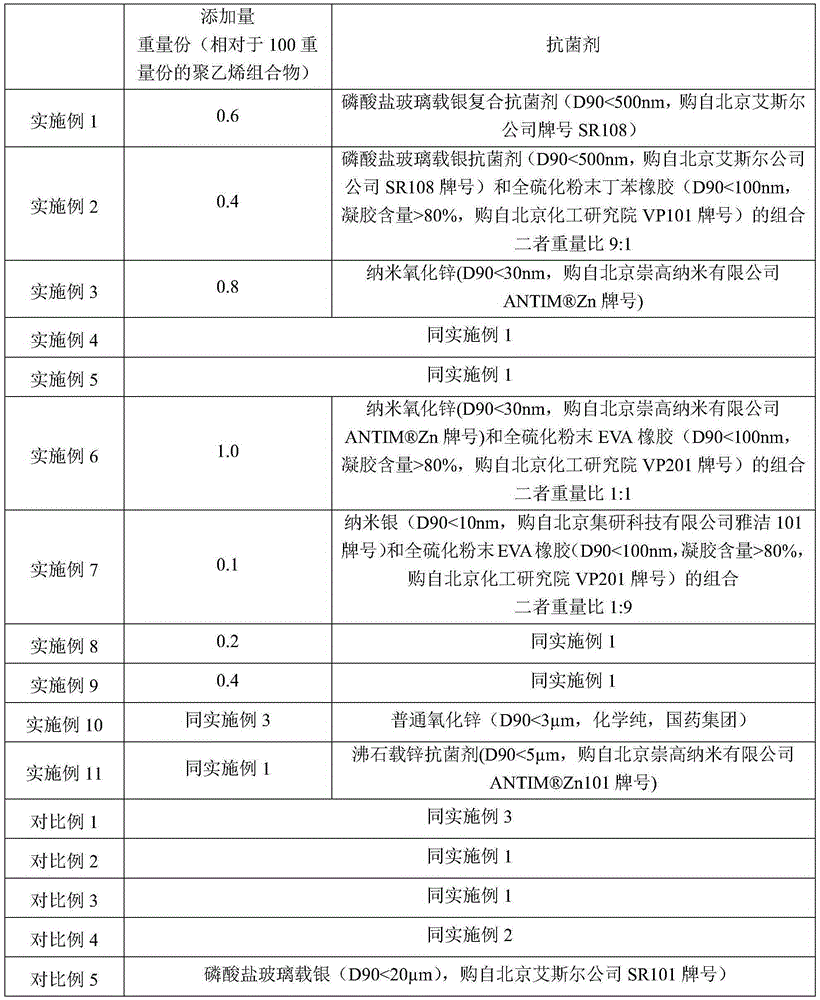

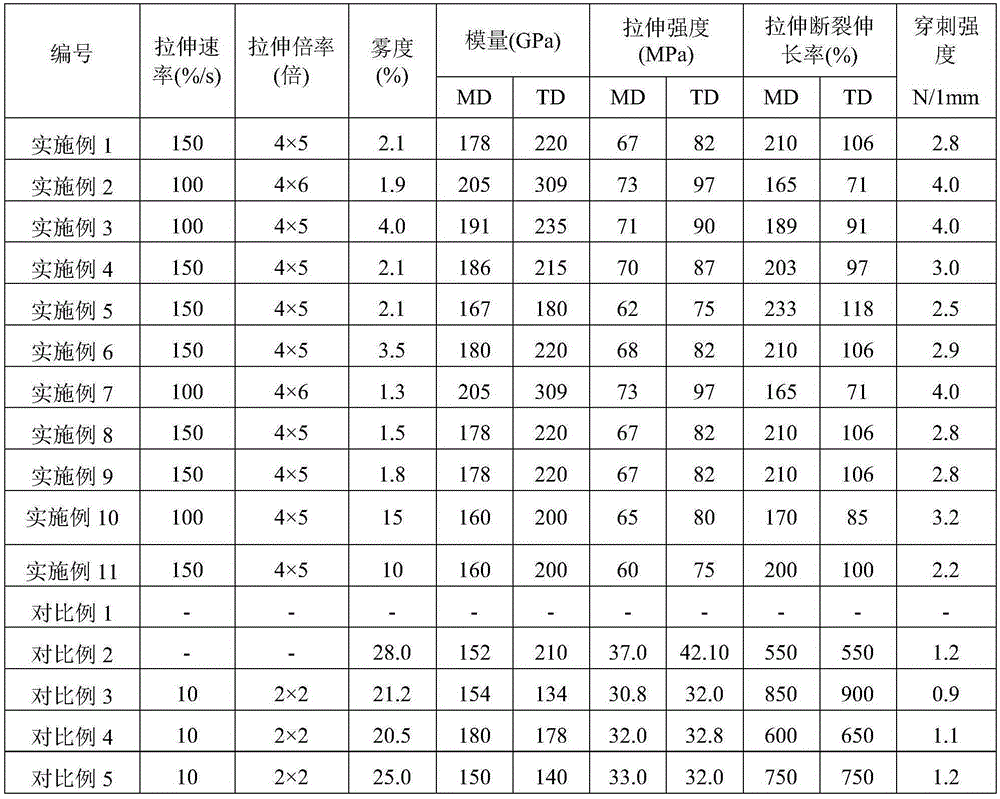

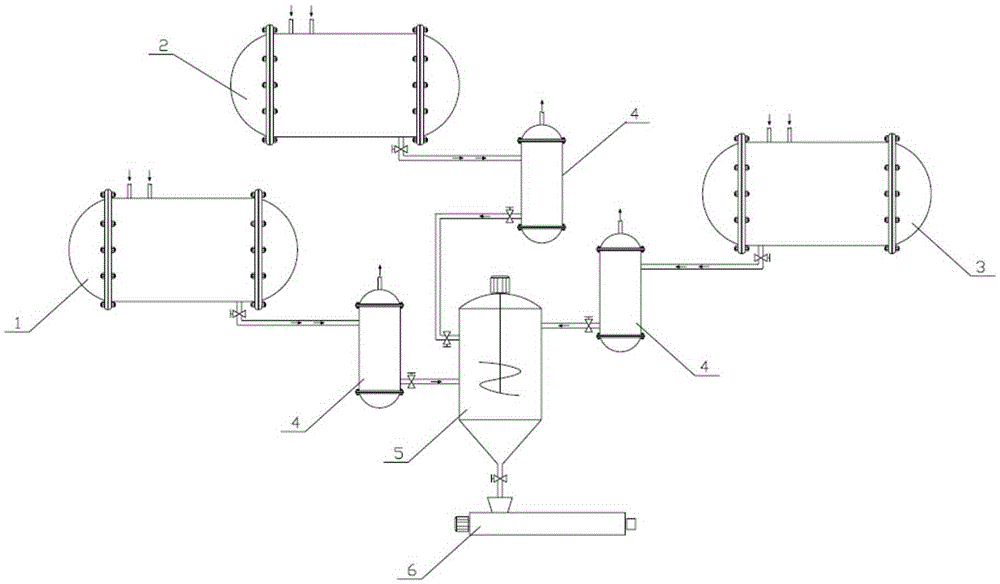

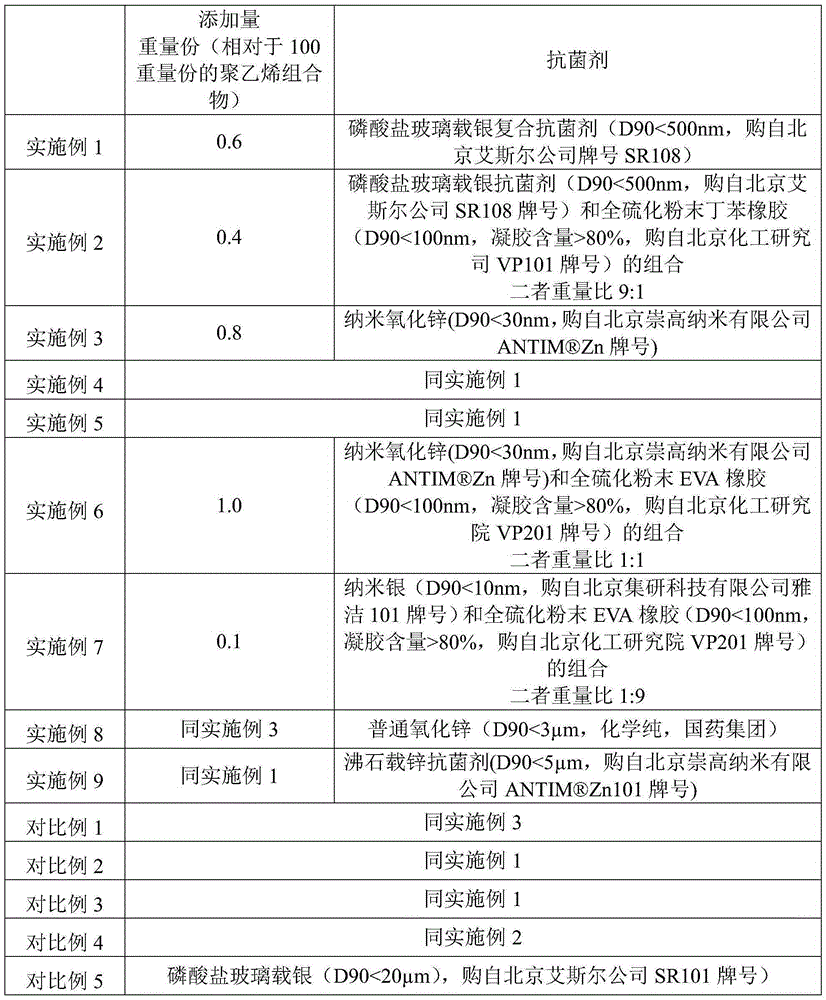

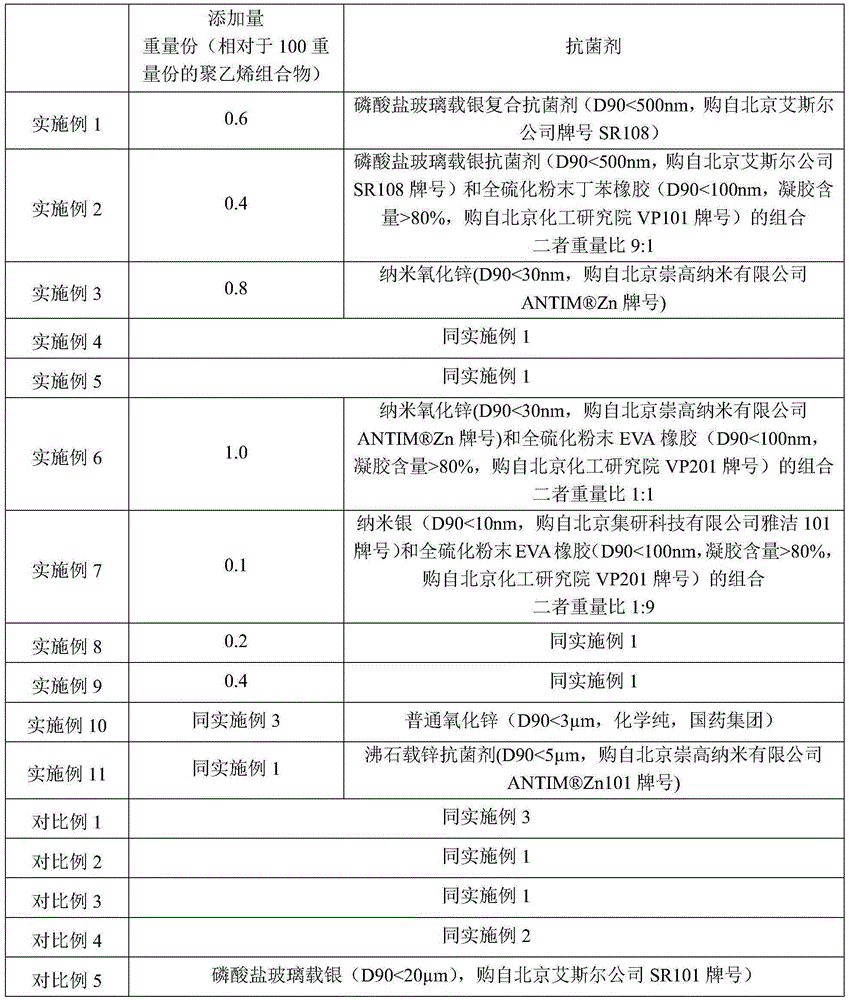

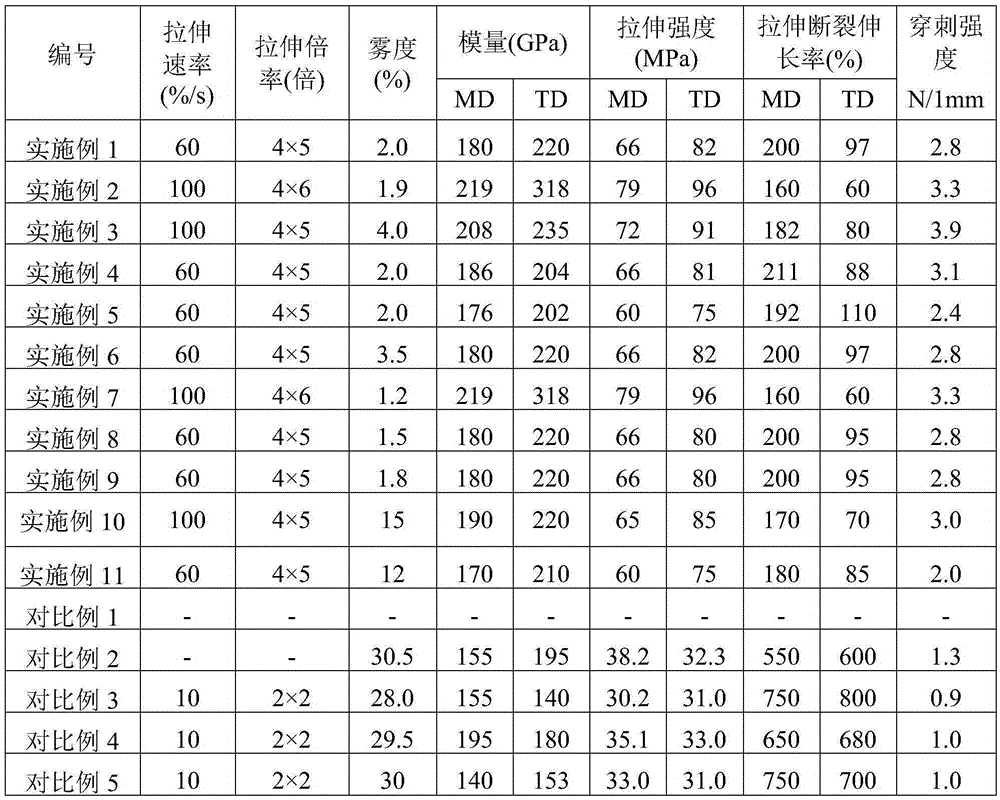

Antibacterial composition and film thereof

InactiveCN106674701AHigh standardAdapt to economic needsSynthetic resin layered productsLinear low-density polyethylenePolymer science

The present invention relates to an antibacterial composition, which contains a polyethylene composition and an antibacterial agent, wherein the polyethylene composition contains a component A, a component C and an optional component B, the component A is ethylene / alpha olefin copolymerized linear low density polyethylene and has a melt index MIA of 0.01-3.5 g / 10 min, the component B is ethylene / alpha olefin copolymerized linear low density polyethylene and has a melt index MIB of 3.6-9.9 g / 10 min, and the component C is ethylene / alpha olefin copolymerized linear low density polyethylene and has a melt index MIC of 10-80 g / 10 min. The present invention further provides a film, which comprises at least a layer of a polyethylene layer formed from the antibacterial composition. According to the present invention, the film achieves good antibacterial property while has advantages of high elongation ratio and high film-forming rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antibacterial composition and thin film thereof

The invention relates to an antibacterial composition. The antibacterial composition contains a polyethylene composition and an antibacterial agent, wherein the polyethylene composition contains a component A, a component C and an optional component B; the component A is linear low-density polyethylene copolymerized with ethylene / alpha olefins, and the melt index MIA is 0.01-3.5 g / 10 min; the component B is linear low-density polyethylene copolymerized with ethylene / alpha olefins, and the melt index MIB is 3.6-14.9 g / 10 min; the component C is linear low-density polyethylene copolymerized with ethylene / alpha olefins, and the melt index MIC is 15-150 g / l0 min. The invention further provides a thin film; the thin film at least comprises a polyethylene layer formed by the antibacterial composition. The thin film provided by the invention has the advantages of being large in draft ratio and high in film forming rate while obtaining better antibacterial property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metallizable double-sided corona BOPP extinction heat sealing film and preparation method thereof

InactiveCN110920192AReasonable choiceAvoid stickingSynthetic resin layered productsMasterbatchPolypropylene

The invention discloses a metallizable double-sided corona BOPP extinction heat sealing film and a preparation method thereof. The metallizable double-sided corona BOPP extinction heat sealing film issequentially composed of an upper surface layer, an upper core layer, a lower core layer and a lower surface layer. The corona treatment is conducted on the upper surface layer and the lower surfacelayer, the upper surface layer is a heat sealing layer, the upper core layer is a polypropylene layer, and the lower core layer and the lower surface layer are extinction layers. The heat sealing layer is prepared from the following raw materials in percentage by weight: 96-98% of ternary polymerization heat sealing master batch and 2-4% of anti-blocking master batch. The BOPP film prepared by themethod has high elasticity modulus and low thermal shrinkage rate, and the performance indexes such as haze and glossiness of the extinction layerd are excellent.

Owner:ANHUI GUOFENG PLASTIC

Polypropylene self-reinforced composite and preparation method thereof

ActiveCN105563976AOvercome the defect of incomplete infiltrationStable mechanical propertiesSynthetic resin layered productsLaminationPolymer scienceSelf reinforced

The present invention discloses a polypropylene self-reinforced composite and a preparation method thereof, wherein the method comprises the following steps: (1) high melting point polypropylene and a beta crystal form nucleating agent are mixed as core layer polypropylene; (2) low melting point polypropylene is used as outer layer polypropylene; (3) the core layer polypropylene and the outer layer polypropylene are coextruded for molding to obtain a coextruded polypropylene strip; (4) the coextruded polypropylene strip is stretched, and weaved into a plain, twill, satin-line or three-dimensional polypropylene fabric; and (5) a first polypropylene sheet, an interlayer sheet and a second polypropylene sheet are in turn laminated and hot-pressed, and a polypropylene fabric is used as the interlayer sheet. The beta crystal form nucleating agent is added into the production process, so that the stretching is stretch, the polypropylene self-reinforced composite is not easy to fracture, the stretching ratio is higher, and the material mechanical performances are more stable.

Owner:CHINA PETROLEUM & CHEM CORP +1

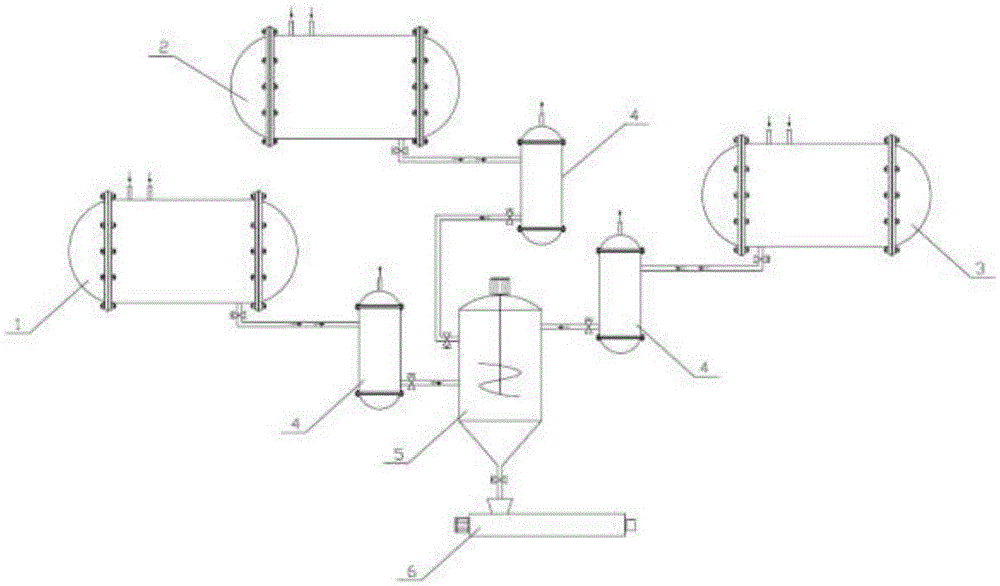

Polyperfluorinated ethylene propylene hollow fiber membrane preparation formula and preparation method

InactiveCN109351209AHigh porosityImprove permeabilitySemi-permeable membranesMembranesPolymer scienceDecomposition

The invention discloses a polyperfluorinated ethylene propylene hollow fiber membrane preparation formula and preparation method. The formula comprises 50-75wt% of polyperfluorinated ethylene propylene, 20-40wt% of a pore-forming agent, 5-15wt% of a plasticizer and 0-10wt% of auxiliary additives, wherein the sum of the components is 100wt%, and the pore-forming agent refers to calcium carbonate. The method includes: well mixing the components in the formula, granulating, quantitatively extruding particles, and after curing of spinning melt in an air bath, performing online stretching and winding to obtain a primary hollow fiber membrane; subjecting the primary hollow fiber membrane to after stretching and heat setting, and soaking membrane fibers into acid solution to leach out calcium carbonate; sequentially performing extraction washing and water washing to obtain a polyperfluorinated ethylene propylene hollow fiber membrane in a multi-hole structure with a stretching hole, a dissolution hole and an interface hole. By adoption of calcium carbonate as the pore-forming agent in the formula, decomposition in a high-temperature spinning process is avoided, and the calcium carbonate can be completely leached out by the acid solution after spinning forming is finished.

Owner:TIANJIN POLYTECHNIC UNIV

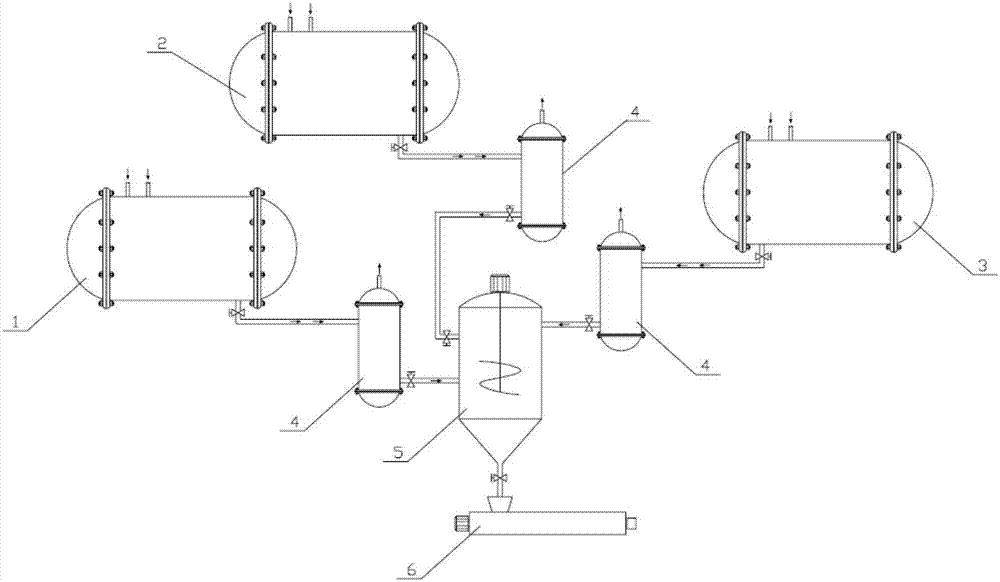

Manufacturing method for low-shrinkage high-strength PET industrial yarn

The invention relates to a manufacturing method of low-shrinkage and high-strength polyester industrial yarn. The process flow is high-viscosity molten polyester raw material—measurement—spraying—cooling—oiling—stretching—heat setting—winding; the polyester slices used are It is a high-viscosity chip obtained by solid-phase viscosification. The cooling process includes four parts: slow cooling, pre-cooling, windless zone cooling and blowing cooling. The pre-cooling adopts the method of active outer ring sequential pre-cooling. The hot air is conveyed through the active outer ring sequencer to cool the filaments. Through the introduction of the pre-cooling device, not only the disturbance of the tow caused by the downward movement of the fiber solidification point is reduced, the deviation rate of the linear density of the tow is controlled, but also the orientation and crystallization of the primary fibers are reduced, and the deviation rate of the linear density is ≤ 1.5%, breaking strength > 7.5cN / dtex, polyester industrial yarn with dry heat shrinkage rate of 1.8±0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

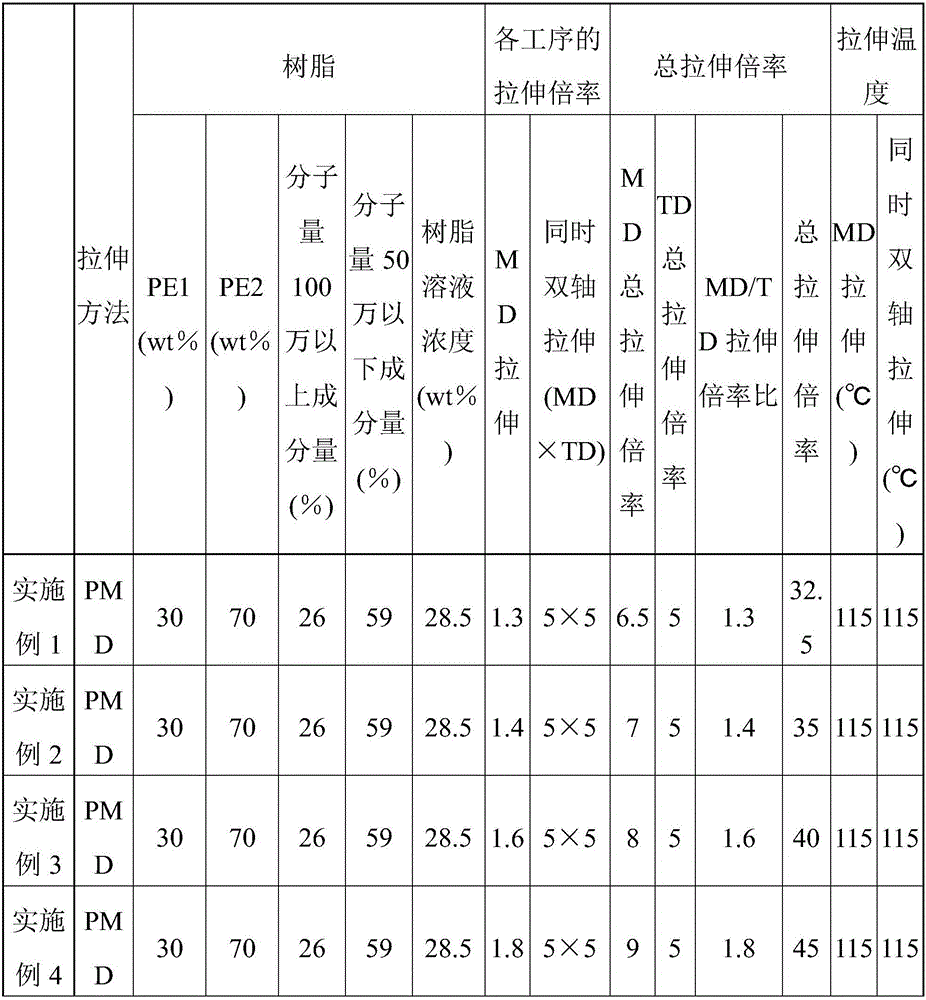

Polyolefin microporous film and method for manufacturing same, separator for nonaqueous electrolyte secondary cell, and nonaqueous electrolyte secondary cell

InactiveCN106661264ASmall apertureSuppress generationFinal product manufactureSecondary cellsPolymer sciencePolyolefin

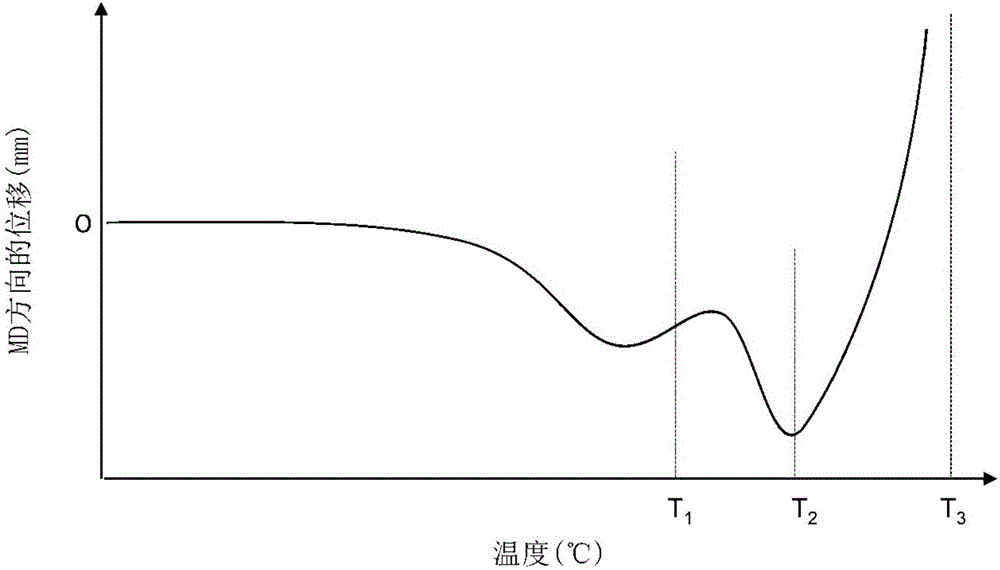

Provided is a polyolefin microporous film having pores with small diameters and excellent shutdown characteristics, and which is suitable for a separator for a nonaqueous electrolyte secondary cell. The polyolefin microporous film is characterized in that the difference between the shutdown start temperature in the MD direction and the temperature at maximum shrinkage in the MD direction is 8.6 DEG C or greater, and the maximum pore diameter thereof is less than 0.036 [Mu]m. Also provided is a method for manufacturing the polyolefin microporous film, characterized by comprising melt-kneading and molding into a sheet shape a plasticizer and a polyolefin resin including an ultrahigh-molecular-weight polyolefin, stretching the resultant sheet in the MD direction and performing simultaneous biaxial stretching thereof, and then drying the stretched sheet.

Owner:TORAY IND INC

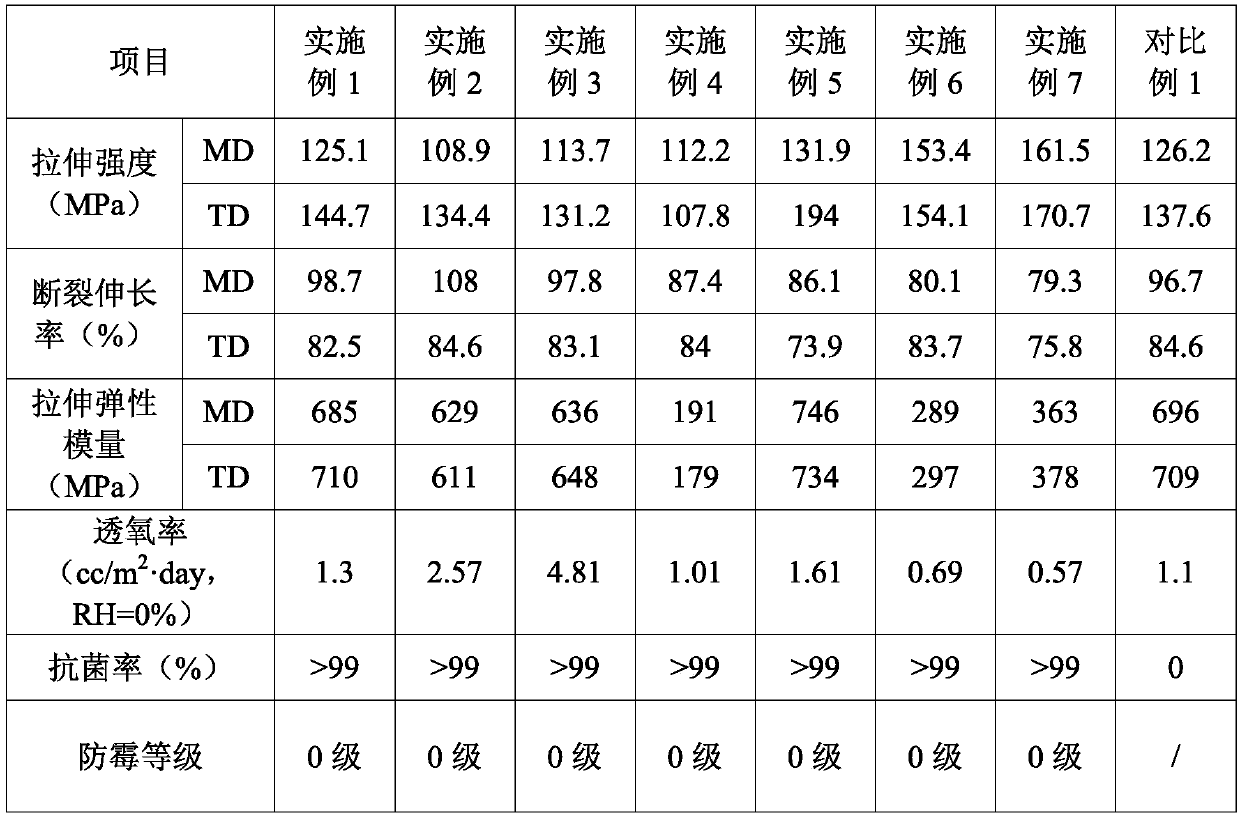

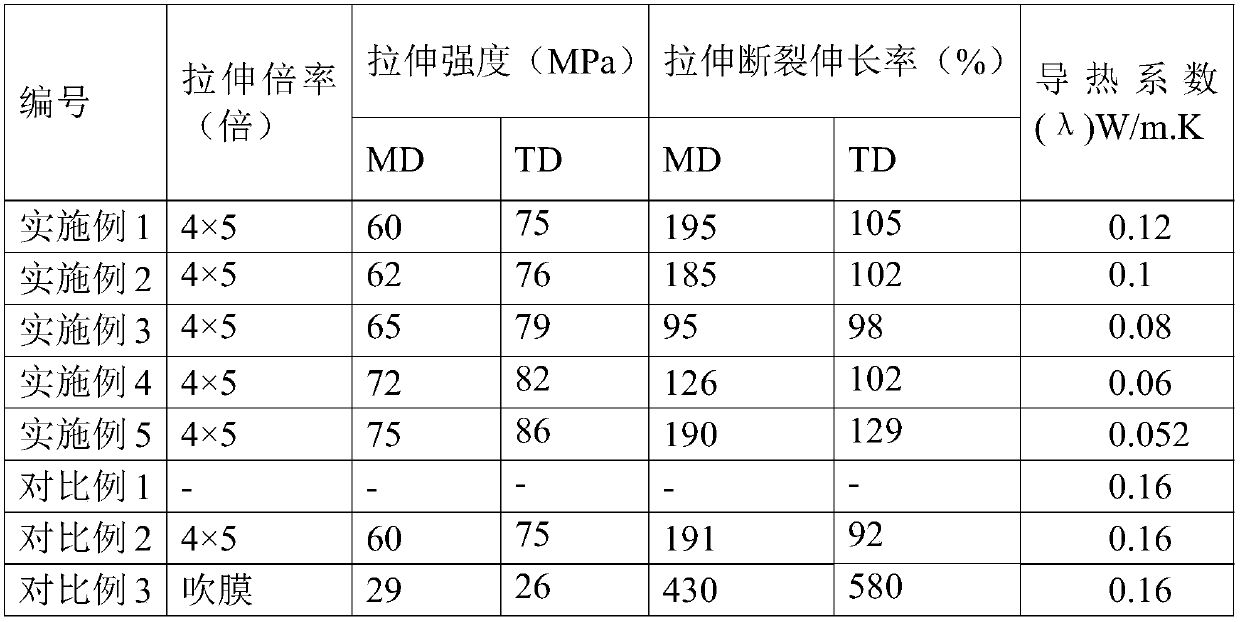

Antibacterial mildew-proof polyvinyl alcohol composition, biaxially oriented polyvinyl alcohol film and preparation method thereof

ActiveCN111087727AHigh tensile strengthImprove barrier propertiesSynthetic resin layered productsPolymer sciencePolyvinyl alcohol

The invention belongs to the field of polyvinyl alcohol film materials, and discloses an antibacterial mildew-proof polyvinyl alcohol composition, a biaxially oriented polyvinyl alcohol film and a preparation method thereof. The antibacterial mildew-proof polyvinyl alcohol composition contains polyvinyl alcohol, a plasticizer, a guanidine salt composite antibacterial agent, a mildew-proof agent and an auxiliary agent, wherein based on 100 parts by weight of polyvinyl alcohol, the content of the plasticizer is 10 to 30 parts by weight, the content of the guanidine salt composite antibacterial agent is 0.05 to 1.5 parts by weight, the content of the mildew-proof agent is 0.05 to 5.0 parts by weight, and the content of the auxiliary agent is 0.05 to 10 parts by weight. The polyvinyl alcohol film prepared by the invention has high tensile strength and barrier property, and also has good antibacterial and mildew-proof properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

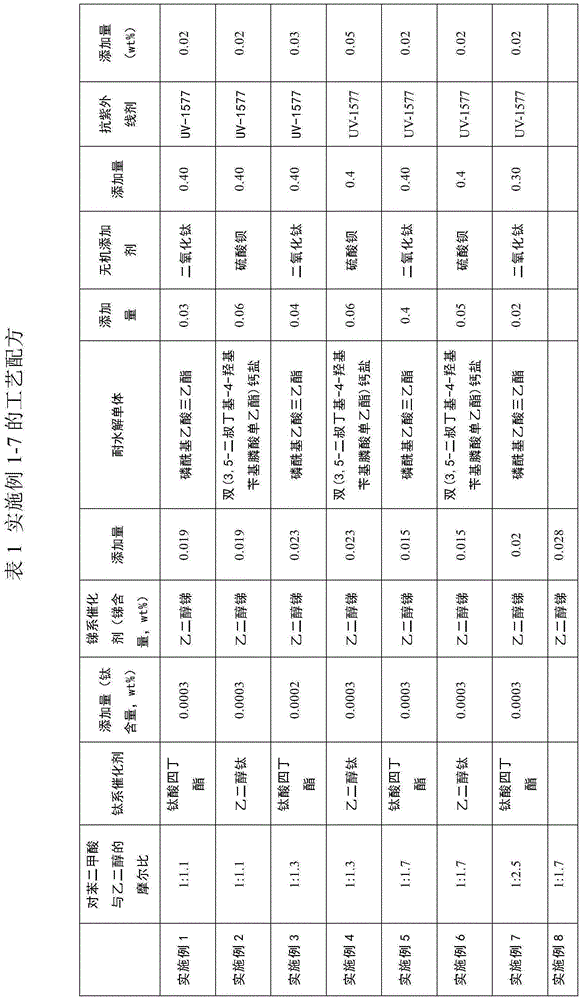

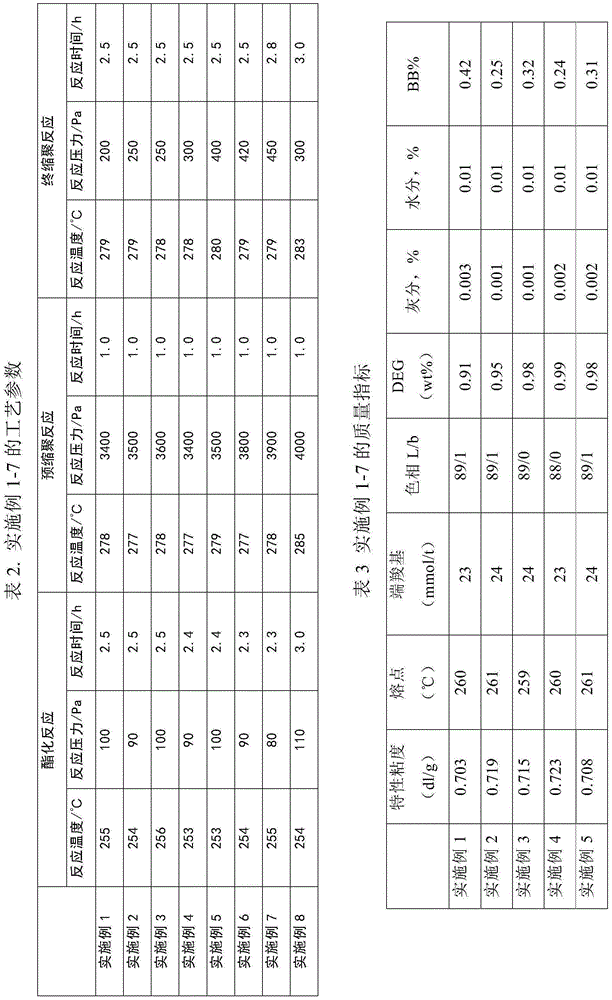

Polyester for hydrolysis-resistant high-speed-spun spunbonded non-woven fabric and synthesis method thereof

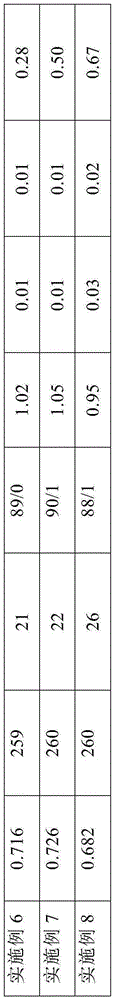

The invention discloses polyester for a hydrolysis-resistant high-speed-spun spunbonded non-woven fabric and a synthesis method thereof. The polyester for the hydrolysis-resistant high-speed-spun spunbonded non-woven fabric is prepared by PTA and EG low temperature esterification by using a Ti-Sb composite catalyst, adding a hydrolysis-resistant monomer and an inorganic additive for supplementing spun-bonding high-speed high-ratio stretching, and adding an anti UV agent for pre polycondensation and final polycondensation reaction, and the polyester for the hydrolysis-resistant high-speed-spun spunbonded non-woven fabric has the intrinsic viscosity of 0.68-0.72 dl / g, the end carboxyl group content of 28-34 mmol / t, the DEG content of less than 0.8%, the melting point of higher than 260 DEG C, the water content of less than 0.1%, the powder content of less than 0.01%, the ash content of less than 0.01% and the suitable spinning stretching speed of 5000-6000 m / min.

Owner:CHINA PETROLEUM & CHEM CORP +1

Time expansion analog-digital converter based on stimulated Brillouin effect

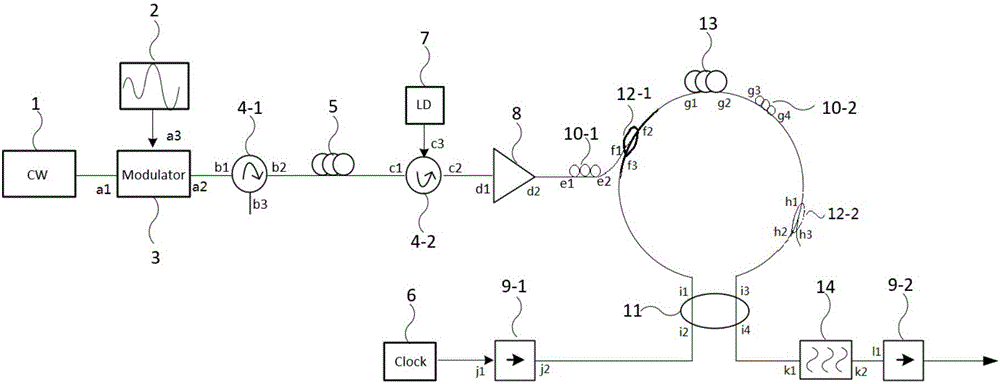

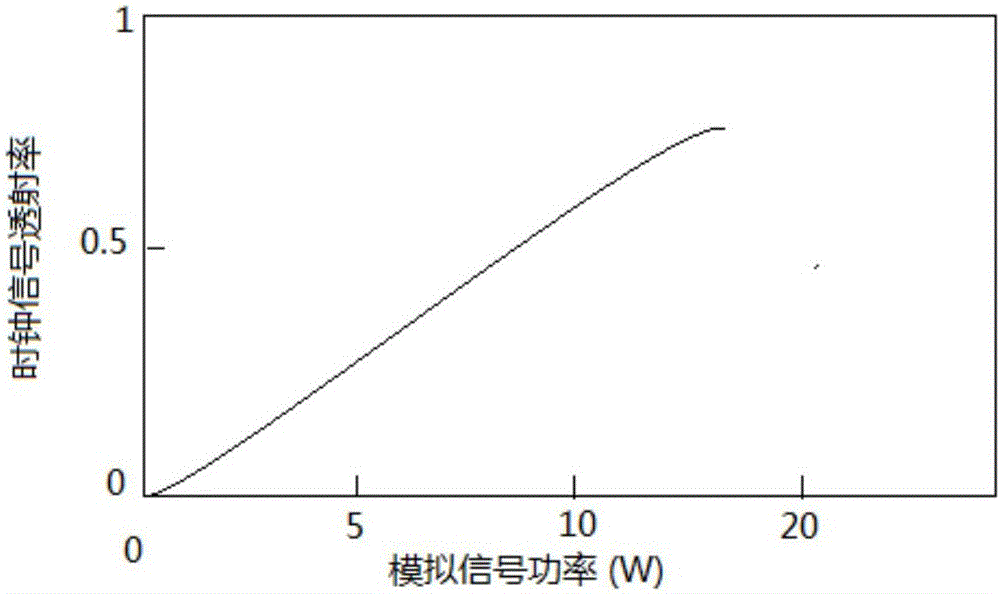

ActiveCN105938286AIncrease the stretch ratioIncrease sampling rateLaser using scattering effectsOptical analogue/digital convertersDigital down converterErbium doping

The invention discloses a time expansion analog-digital converter based on a stimulated Brillouin effect. The time expansion analog-digital converter comprises a continuous wave signal source, and the continuous wave signal source, a modulator, a first circulator, a nonlinear stimulated Brillouin effect optical fiber, a second circulator, an erbium-doped optical fiber amplifier and a first polarization controller are sequentially connected; a radio-frequency signal source modulates a continuous wave from a third port of the modulator; a pumping source enters the converter from a third port of the second circulator; a second port of the first polarization controller is sequentially connected with a first wavelength division multiplexer, a high nonlinear optical fiber, a second polarization controller and a second wavelength division multiplexer and then connected into a third port of a coupler; a third port of the first wavelength division multiplexer is connected into a first port of the coupler; a clock signal source is connected with a first isolator, and the first isolator is connected into a second port of the coupler; a second isolator is connected with a filter, and the filter is connected into a fourth port of the coupler.

Owner:INNO LASER TECH CORP LTD

Polyvinyl alcohol film and preparation method thereof

ActiveCN104085157AEasy to stretchHigh tensile strengthSynthetic resin layered productsPolarising elementsPVA - Polyvinyl alcoholPolymer chemistry

The invention provides a polyvinyl alcohol film which comprises a first polyvinyl alcohol layer, a second polyvinyl alcohol layer and a third polyvinyl alcohol layer, wherein the first polyvinyl alcohol layer is prepared from a first component comprising first polyvinyl alcohol; the polymerization degree of the first polyvinyl alcohol is 3000-4000; the second polyvinyl alcohol layer is arranged on the first polyvinyl alcohol layer and is prepared from a second component comprising second polyvinyl alcohol; the polymerization degree of the second polyvinyl alcohol is 1000-3000; the third polyvinyl alcohol layer is arranged on the second polyvinyl alcohol layer and is prepared from a third component comprising third polyvinyl alcohol; the polymerization degree of the third polyvinyl alcohol is 3000-4000. The polyvinyl alcohol film provided by the invention is formed by compounding three polyvinyl alcohol layers containing polyvinyl alcohol with different polymerization degrees, so that the polyvinyl alcohol film provided by the invention has high tensile property. The invention also provides a method for preparing the polyvinyl alcohol film.

Owner:重庆光谱新材料科技有限公司

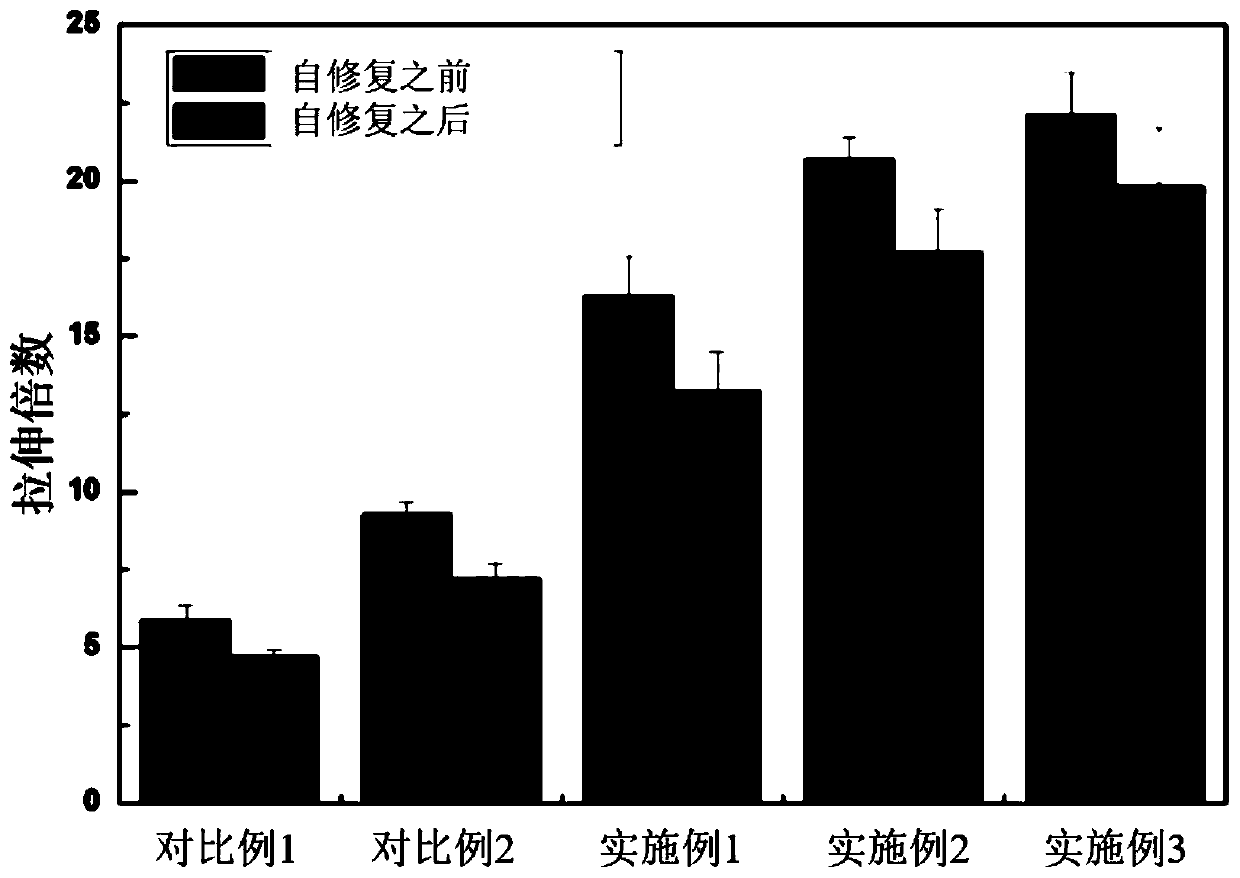

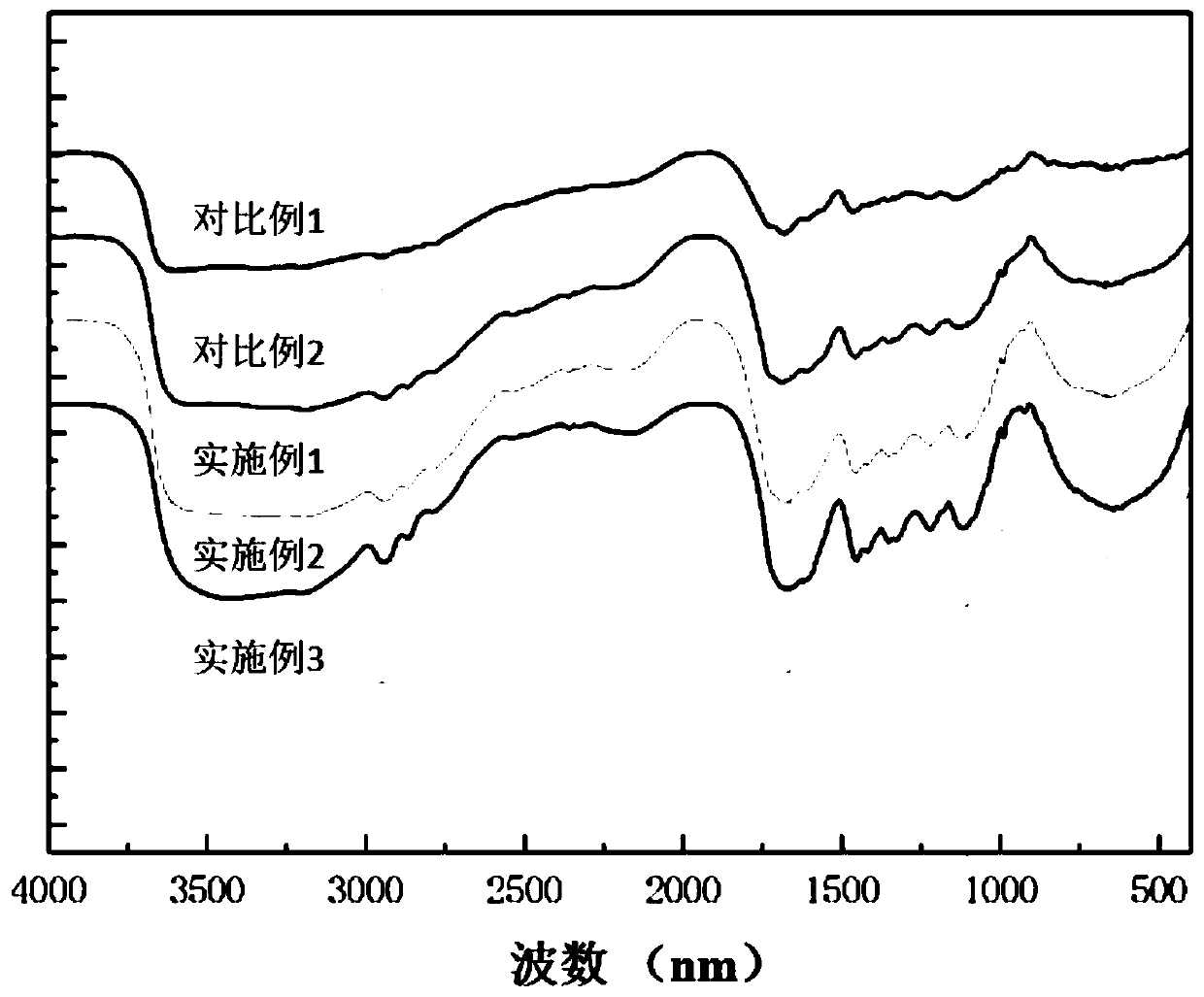

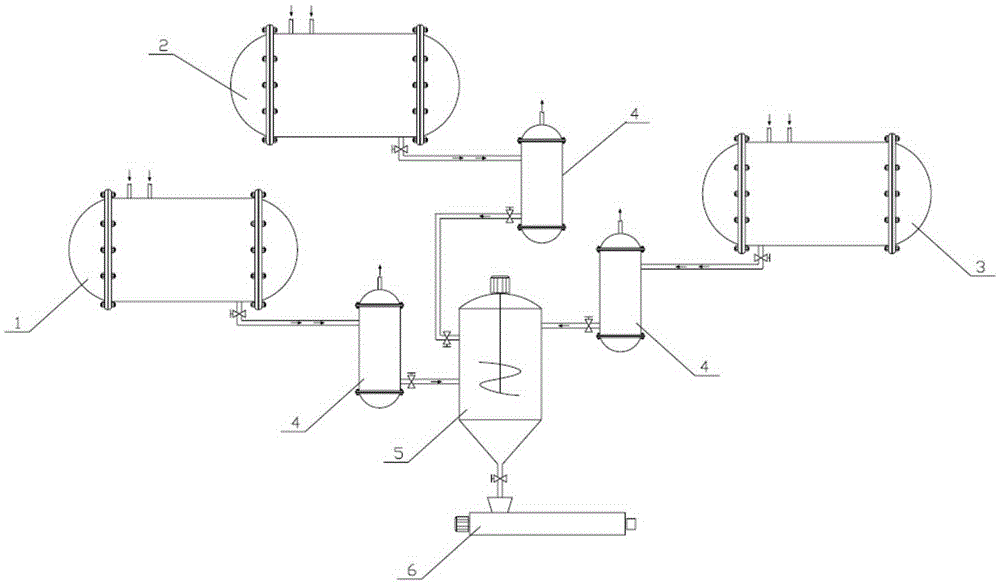

High-stretchability and self-repairing hydrogel and preparation method thereof

ActiveCN110540659AIncrease the stretch ratioShort time required for self-healingTissue regenerationProsthesisWater basedSelf-healing hydrogels

The invention discloses a hydrogel with characteristics of high stretchability and rapid self-repairing performance at a room temperature, wherein the hydrogel is prepared by carrying out free radicalpolymerization on the following raw materials by weight: 4.5-5 parts of a monomer acrylamide, 1-1.5 parts of dimethylaminoethyl methacrylate, 0.01-0.03 part of a water-based cross-linking agent, and0.001-0.01 part of an initiator in water, wherein the water-based cross-linking agent is a water-soluble hexamethylene diisocyanate tripolymer. According to the present invention, the prepared hydrogel can overcome the technical defects of low strength, poor environmental responsiveness and poor temperature resistance of the self-repairing hydrogel in the prior art, has the high stretching multiple of more than 15 times and the self-repairing rate of up to 90%, has advantages of simple preparation process, rapid molding and good light transmittance, and has wide application prospects in the fields of medicine and tissue engineering.

Owner:GUANGZHOU UNIVERSITY

Alginic acid fiber with high orientation degree and preparation method thereof

ActiveCN113463222AHigh strengthIncrease the stretch ratioWet spinning methodsConjugated synthetic polymer artificial filamentsPolymer scienceSpinning

The invention discloses alginic acid fiber with high orientation degree and a preparation method thereof, and belongs to the technical field of high polymer materials. The method comprises the following steps of dissolving sodium alginate with the molecular weight of 400-10000 Daltons and polyvinyl alcohol with the alcoholysis degree of 70-100 and the polymerization degree of 500-4000 as raw materials to obtain a spinning solution, performing standing, defoaming and spinning, carrying out first coagulating bath and second coagulating bath treatment, performing stretching, and performing water washing to remove the polyvinyl alcohol to finally obtain the alginic acid fiber with high orientation degree. The molecular weight of the sodium alginate and the alcoholysis degree and polymerization degree of the polyvinyl alcohol are reasonably selected; the alginic acid / polyvinyl alcohol composite fiber with high orientation degree is obtained by optimizing spinning and stretching conditions, and the essence that intermolecular or intramolecular hydrogen bonds hinder fiber super-stretching and finally influence the fiber strength is disclosed; and the purposes of weakening the hydrogen bonds, improving the fiber stretching multiple and finally improving the fiber strength are achieved by changing the conditions.

Owner:NANJING FORESTRY UNIV

Antibacterial composition and film thereof

ActiveCN106674702AHigh standardAdapt to economic needsSynthetic resin layered productsAntimicrobialLinear low-density polyethylene

The invention relates to an antibacterial composition. The antibacterial composition comprises a polyethylene composition and an antibacterial agent, wherein the polyethylene composition contains a component A and a component C, and selectively contains a component B; the component A is ethylene / alpha olefin copolymerized linear low-density polyethylene and the melt index MIA is 0.01 to 2 g / 10min; the component B is ethylene / alpha olefin copolymerized linear low-density polyethylene and the melt index MIB is 2.1 to 14.9 g / 10min; and the component C is ethylene / alpha olefin copolymerized linear low-density polyethylene and the melt index MIC is 15 to 150 g / 10min. The invention also provides a film. The film at least comprises a polyethylene layer formed by the antibacterial composition. The film provided by the invention achieves high antibacterial property and has the advantages of large stretching ratio and high film-forming speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyethylene composition and film thereof

ActiveCN111100363AIncrease the stretch ratioFast film formation ratePolymer sciencePolyethylene glycol

The invention relates to the field of polyethylene materials, and discloses a polyethylene composition, which is characterized by comprising a component A, a component B, a component C, a component Dand a component E, wherein under the conditions that the temperature is 190 DEG C and the load is 2.16 kg, the MIA of the component A is 0.01 g / 10 min to 3.5 g / 10 min, and the rho A is 0.880 g / cm < 3> to 0.936 g / cm < 3 >; the MIB of the component B is 3.6 g / 10 min to 9.9 g / 10 min, and the rho B is 0.910 g / cm < 3 > to 0.930 g / cm < 3 >; the MIC of the component C is 16 g / 10 min to 80 g / 10 min, andthe rhoC is 0.880 g / cm < 3 > to 0.930 g / cm < 3 >; the MID of the component D is 10 to 15g / 10min, and the rho D is 0.880 to 0.930 g / cm < 3 >; and the component E is obtained by performing twin-screw extrusion granulation on an ethylene-octene copolymer, polyethylene glycol and an aerogel. When a polyethylene film is prepared from the polyethylene composition prepared by matching the component A, the component B, the component C, the component D and the component E with specific melt indexes and densities by adopting a flat film stretching method, the polyethylene film has the advantages of highstretching ratio, high film forming rate, high mechanical strength and excellent barrier property, and has great industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

LaCl3 cross-linked high-strength high-modulus polyvinyl alcohol fiber and preparation method thereof

ActiveCN112095170AIncrease the stretch ratioHigh breaking strengthWet spinning methodsMonocomponent synthetic polymer artificial filamentPolyvinyl alcoholDegree of polymerization

The invention relates to a LaCl3 cross-linked high-strength high-modulus polyvinyl alcohol fiber and a preparation method thereof. The preparation method comprises the steps that polyvinyl alcohol with the polymerization degree of 1700-2600 is dissolved in DMSO, LaCl3 is added till polyvinyl alcohol is completely dissolved, a spinning solution is obtained, wet spinning is carried out to obtain nascent fibers, the nascent fibers is subjected to first-stage coagulating bath, first-time stretching, second-stage coagulating bath, second-time stretching and third-stage coagulating bath treatment insequence, and then subjected to first-time hot stretching, extraction and second-time hot stretching to obtain the high-strength and high-modulus polyvinyl alcohol fibers, wherein the temperature ofthe first-stage coagulating bath is 11 DEG C below zero-9 DEG C below zero, the temperature of the second-stage coagulating bath is 1 DEG C below zero-1 DEG C, the temperature of the third-stage coagulating bath is 9-10 DEG C, and the breaking strength of the prepared fiber is 13.6-16.3 cN / dtex, the fineness of the prepared fiber is 6.2-8.3 dtex, the elastic modulus of the prepared fiber is 325-347 cN / dtex, and the melting point of the prepared fiber is 246-253 DEG C.

Owner:DONGHUA UNIV

Beta-crystal-form polypropylene strip and preparation method thereof

The present invention discloses a beta-crystal-form polypropylene strip and a preparation method thereof, wherein the method comprises the following steps: (1) polypropylene and a beta-crystal-form nucleating agent are mixed for granulation; (2) beta-crystal-form polypropylene particles formed by the step (1) are dried and then molded by extrusion; and (3) the a beta-crystal-form polypropylene sheet molded by extrusion by the step (2) is stretched slowly at low temperature to obtain the beta-crystal-form polypropylene strip. The beta-crystal-form polypropylene strip obtained by the method is easier to stretch, not easy to break, higher in stretching ratio, and more stable in material mechanical performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

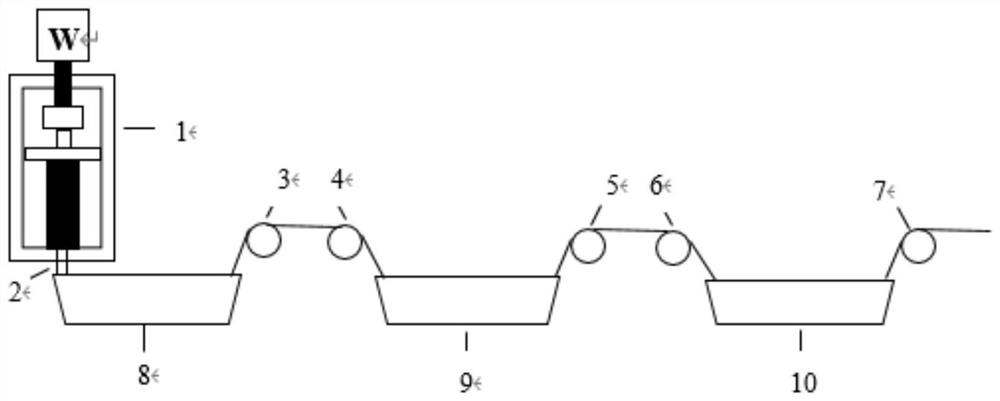

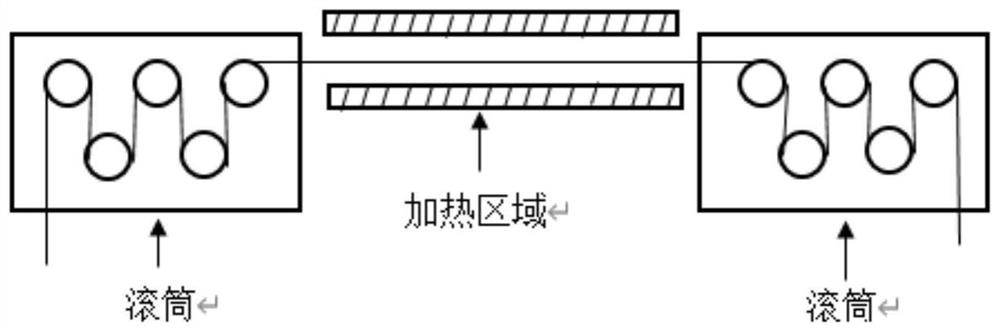

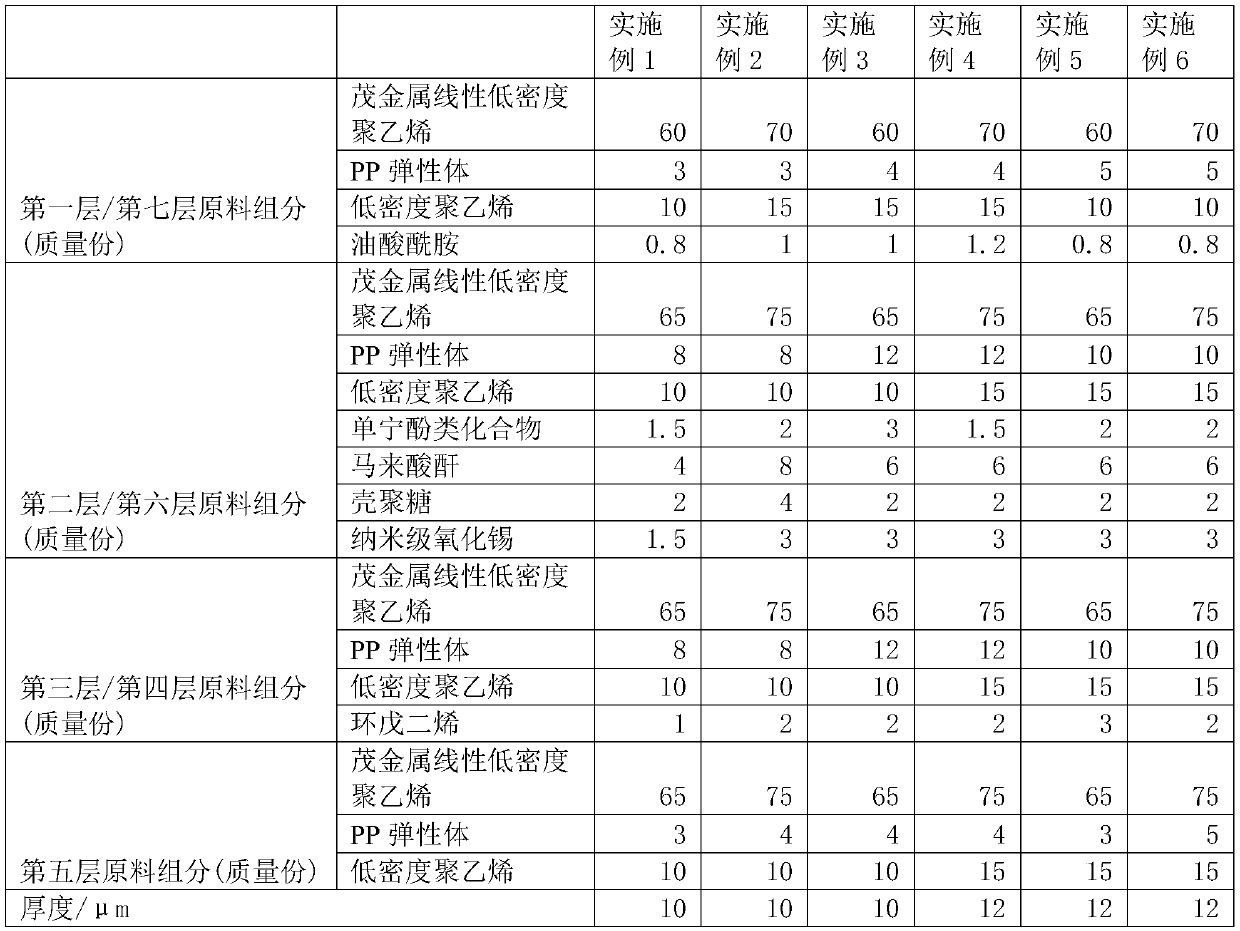

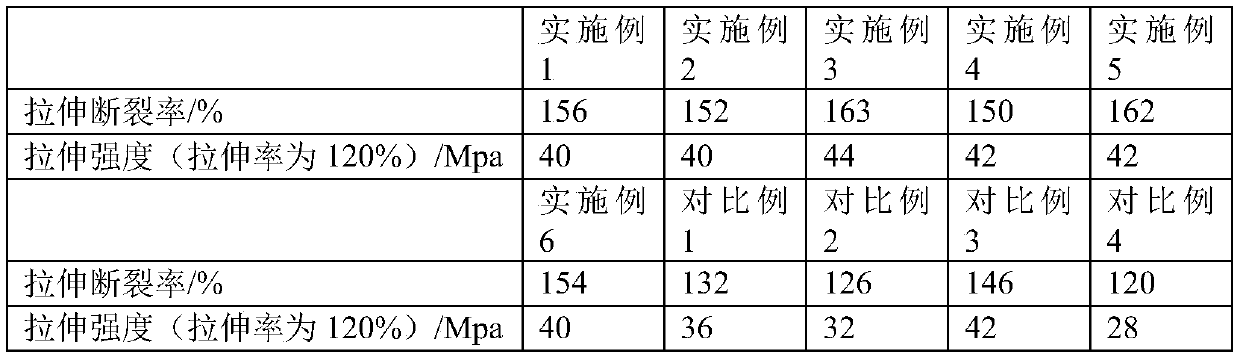

Thin packaging film with high tensile property and preparation method thereof

ActiveCN110641116AImprove bindingGuaranteed stretching effectFlexible coversWrappersLow-density polyethylenePolymer science

The invention relates to a packaging film and discloses a thin packaging film with a high tensile property and a preparation method thereof. The problem that the stretching ratio is greatly reduced after a conventional packaging film is thinned is solved in the invention. The thin packaging film is a co-extruded seven-layer composite film with a thickness of 10-12 microns; the seven-layer composite film comprises a first layer, a second layer, a third layer, a fourth layer, a fifth layer, a sixth layer and a seventh layer from one side to the other side with a cross section as a starting point; the seven film layers take metallocene linear low-density polyethylene as a matrix; maleic anhydride and tannin phenolic compounds are mixed into the second layer and the sixth layer so as to improve the binding force between the second and sixth layers and the film layers at the two corresponding sides and improve the toughness of the film layers, so change difference values of the two sides ofthe first and seventh layers located out of the second and sixth layers and the third, fourth and fifth layers located between the second and sixth layers in the stretching process are alleviated, and the layered fracture of the packaging film is delayed; and thus, the original stretching ratio and tension of the packaging film are maintained on the basis of thinning of the packaging film.

Owner:NINGBO HONGYAN PACKING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com