Patents

Literature

131results about How to "No special equipment required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

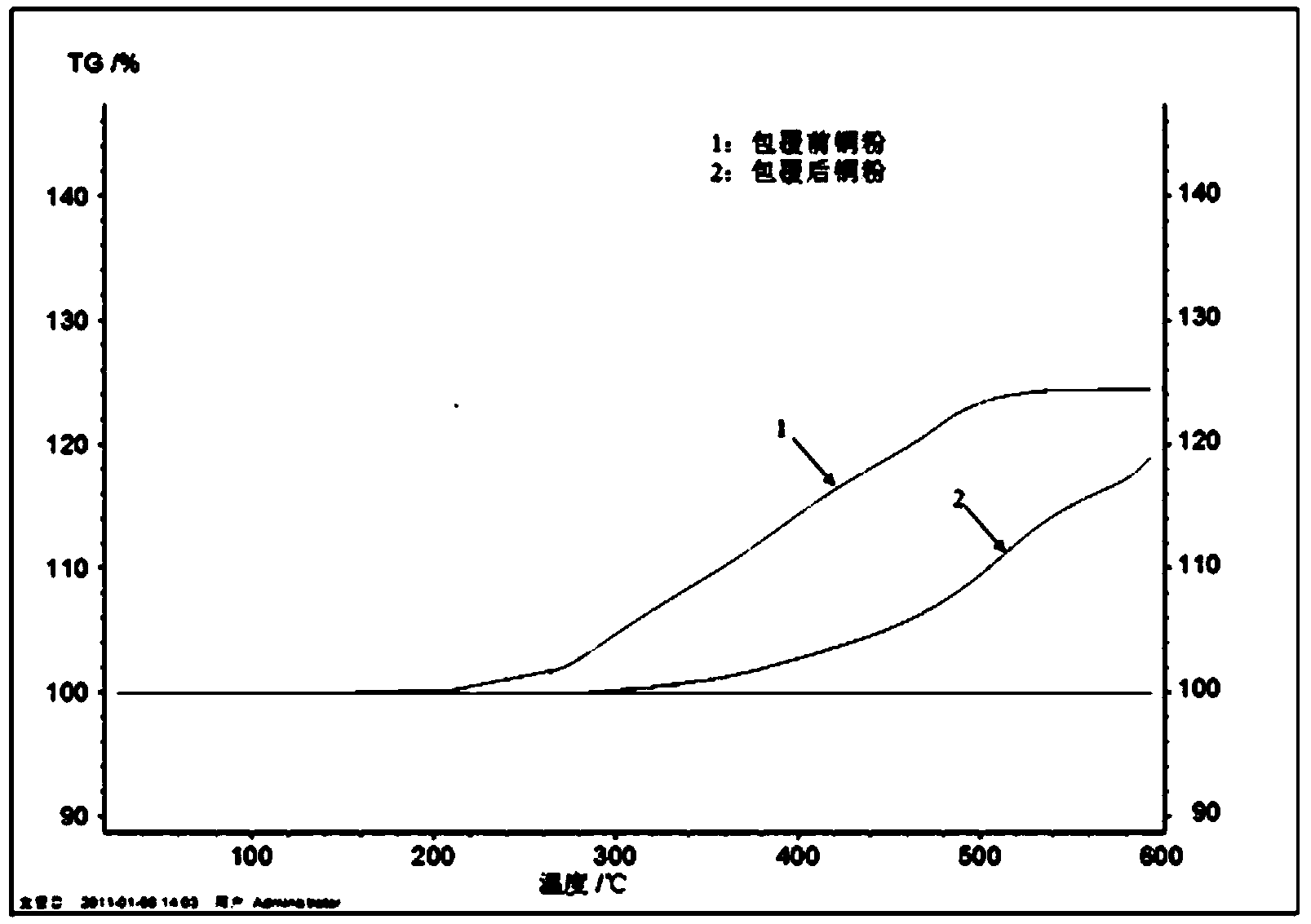

Surface modification method of copper powder for conductive paste

The invention provides a method for decorating the surface of copper powder used in conductive paste, which relates to the processing of metal powder, in particular to the characteristic improvement and the coating of the metal powder. The method is characterized in that: the copper powder is dispersed into a water solution that contains a dispersing agent, an organic mixed acid is added, and the mixture is stirred and mixed for 30 to 90 min; a reductant is added, temperature is increased to 50 to 90 DEG C and heat preservation reaction occurs for 60 to 120 min; a coating agent is added for carrying out the heat preservation reaction for 60 to 150 min; then liquid-solid separation, washing and vacuum drying are carried out to finish the method. The adding amount of additional substances is as follows: the copper powder : the dispersing agent : the organic mixed acid : the reductant : the coating agent is equal to 1 : 0.05 to 0.25 : 0.05 to 0.5 : 0.1 to 1 : 0.05 to 0.5, and the ratio of liquid to solid is 4 to 8 : 1. The antioxidant capability of the copper powder is improved by the two processes of recrystallization and organic coating, thereby solving the problem of the serious oxidation of copper during the sintering process of the paste and greatly improving the stability of the conductive paste due to the existence of an organic-inorganic interface.

Owner:CENT SOUTH UNIV +1

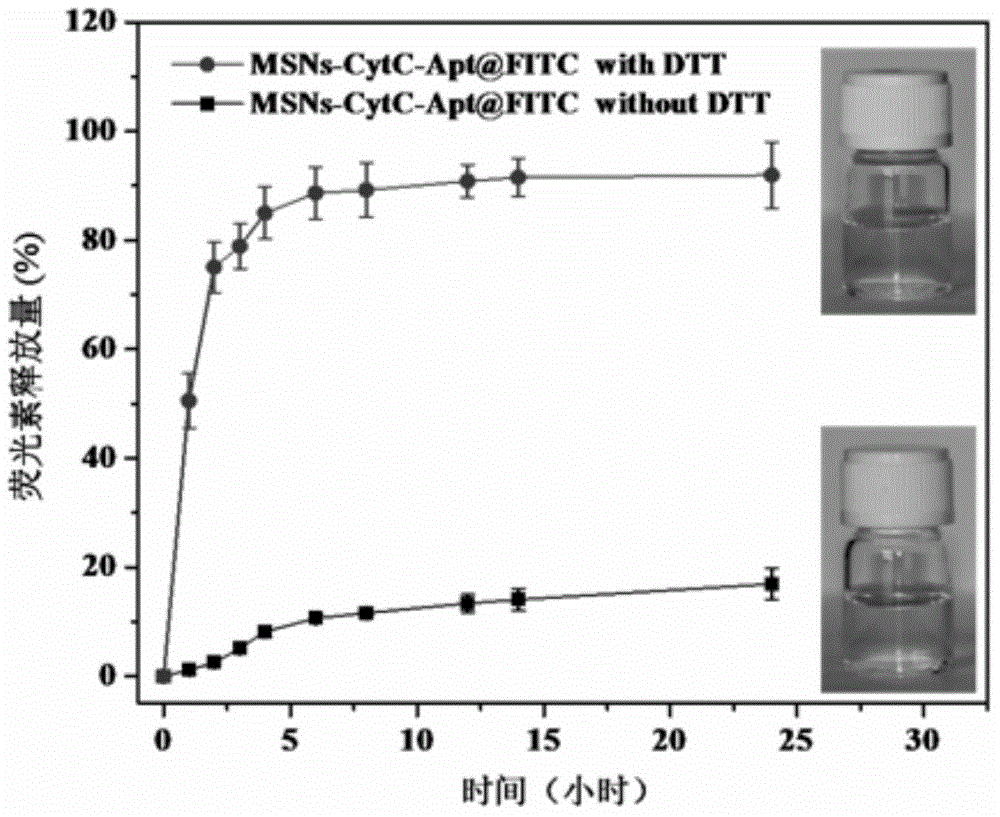

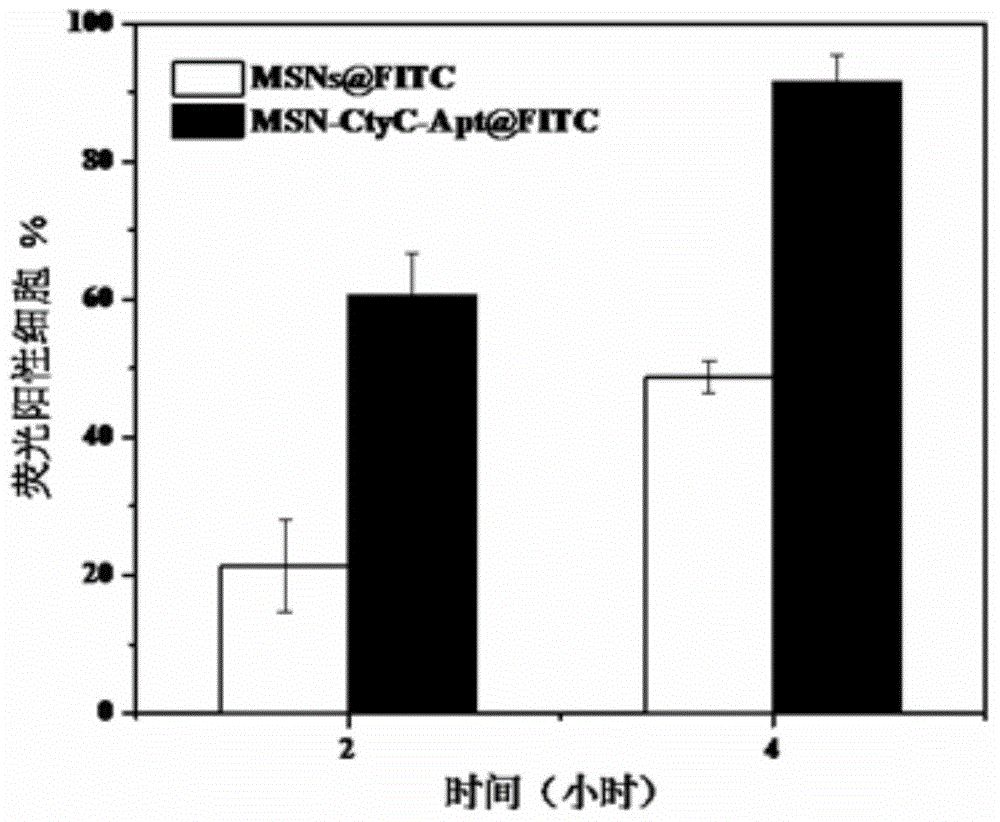

Method for preparing meso-porous silicon nano medicine carrier with cell specificity target, reduction responsiveness and triple anticancer treatment effects

InactiveCN104013965AOvercome toleranceEasy to operatePowder deliveryMacromolecular non-active ingredientsCell membraneCarrier system

The invention discloses a method for preparing a meso-porous silicon nano medicine carrier with cell specificity target, reduction responsiveness and triple anticancer treatment effects. The method comprises the following steps: firstly, synthesizing meso-porous silicon nano particles by using a gel dissolution method, subsequently, introducing a disulfide bond onto the surface of a meso-porous silicon nano reservoir by using a chemical modification method, innovatively fixing cytochrome C with an apoptosis-inducing function onto the surface of the meso-porous silicon nano reservoir, blocking meso-porous channels with medicines, finally modifying DNA (Deoxyribose Nucleic Acid) aptamer single chain molecules (AS1411, with a cancer cell apoptosis-inducing function) onto the surface of a meso-porous silicon / cytochrome C nano composite system, and taking the system as specificity ligand of a receptor (nucleolin protein) which is overexpressed on the surface of liver cancer cytomembrane, thereby establishing a multifunctional composite type nano medicine carrier system for achieving triple anticancer treatment under combined action of medicines, blocking substances and target molecules inside meso-pores.

Owner:CHONGQING UNIV

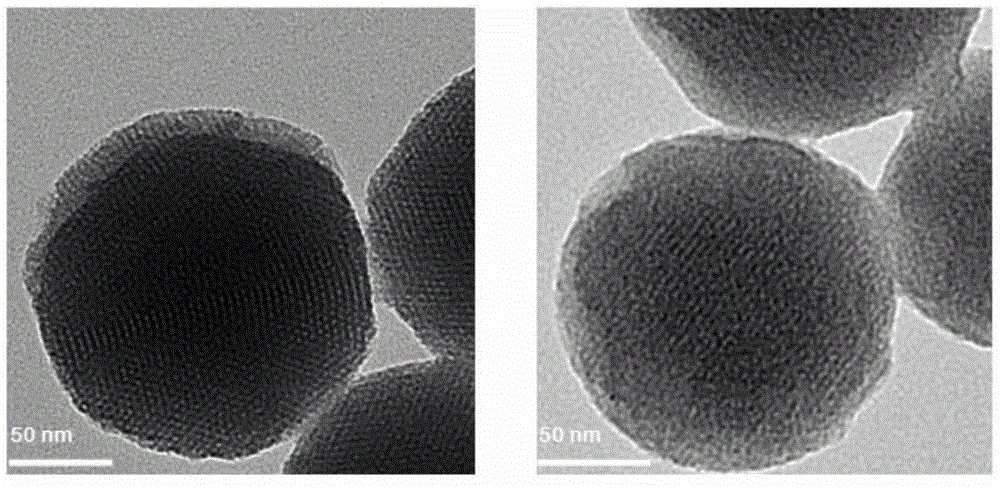

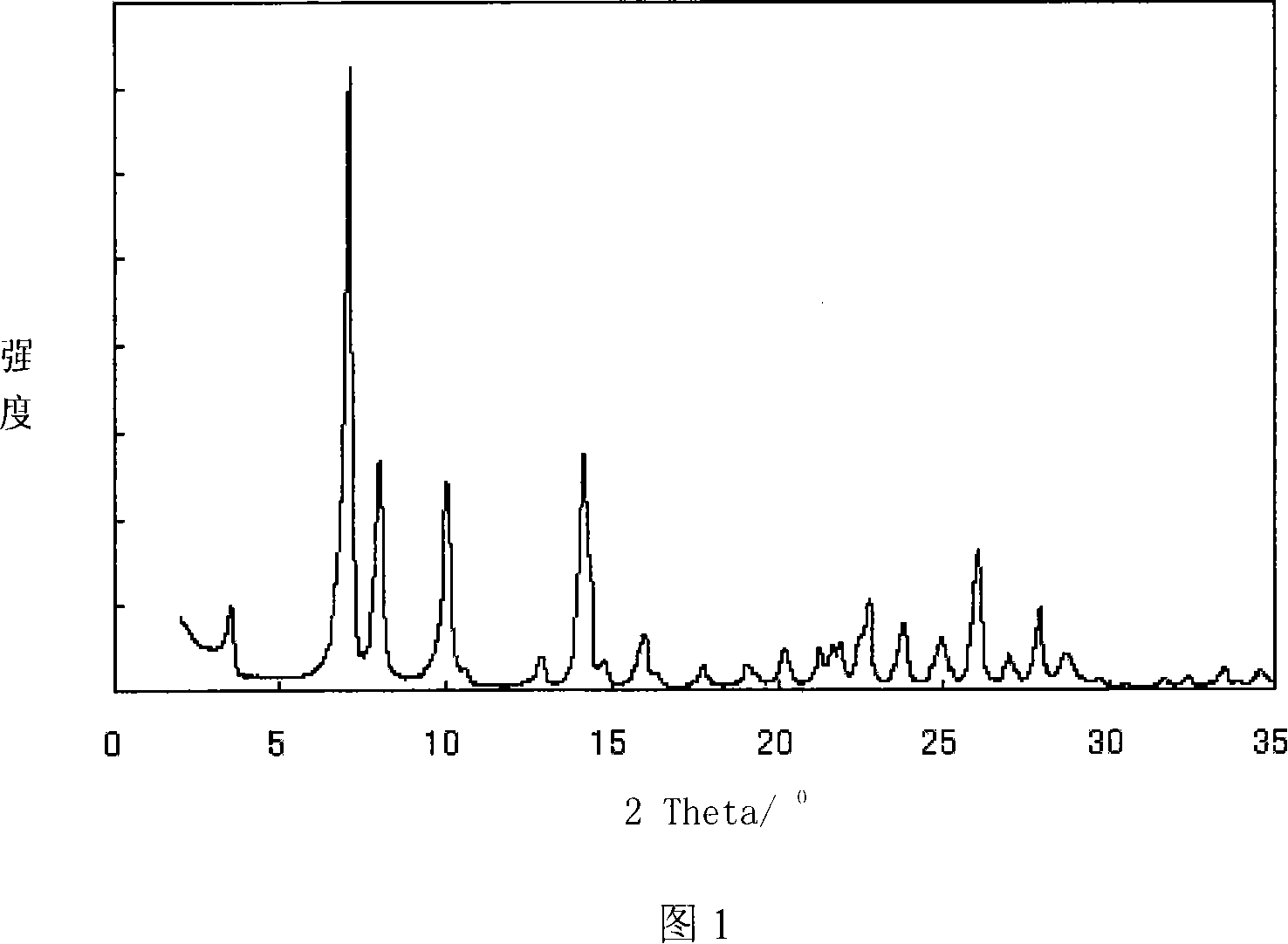

Titanium-silicon molecular screen with MWW structure and its synthesis and application

InactiveCN101148260AReduce surface defectsImprove catalytic performanceMolecular sieve catalystsOximes preparationMolecular sieveInorganic Chemical

The present invention is one kind of Ti-Si molecular sieve in MWW structure and its synthesis and application, and belongs to the field of inorganic chemical technology. The Ti-Si molecular sieve in MWW structure with Ti, Si and O as the skeleton elements and without B adverse to selective catalytic oxidation is prepared through synthesizing intermediate crystal material and roasting directly or after acid treatment. It is suitable for use as the catalytic oxidation catalyst, and has less surface faults, great specific surface area up to 450 sq m / g, high catalytic oxidation performance and other advantages.

Owner:EAST CHINA NORMAL UNIV

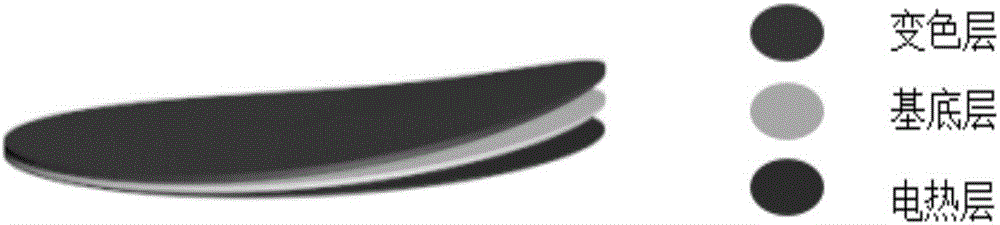

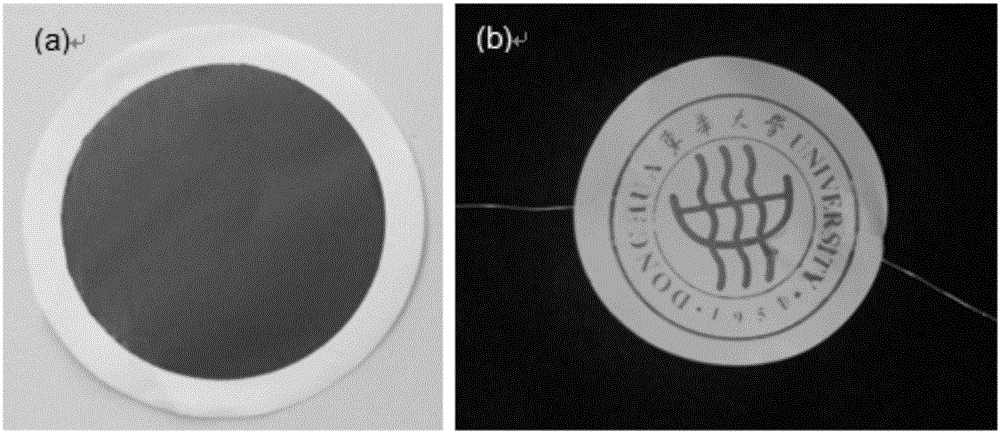

Reversible thermochromatic film based on graphene electrothermal driving, preparation and application of reversible thermochromatic film

The invention relates to a reversible thermochromatic film based on graphene electrothermal driving, preparation and application of the reversible thermochromatic film. The reversible thermochromatic film comprises a heat source layer, a substrate layer and a chromatic layer. The preparation comprises the following steps: mixing reversible chromatic ink and water, obtaining reversible chromatic ink solution, then loading on the surface of a carrier film, drying to obtain reduced graphene oxide / carrier film / reversible thermochromatic film, connecting with a loop and obtaining the reversible thermochromatic film. The reversible thermochromatic film has the advantages of simple structure, higher sensitivity and better cycling stability.

Owner:DONGHUA UNIV

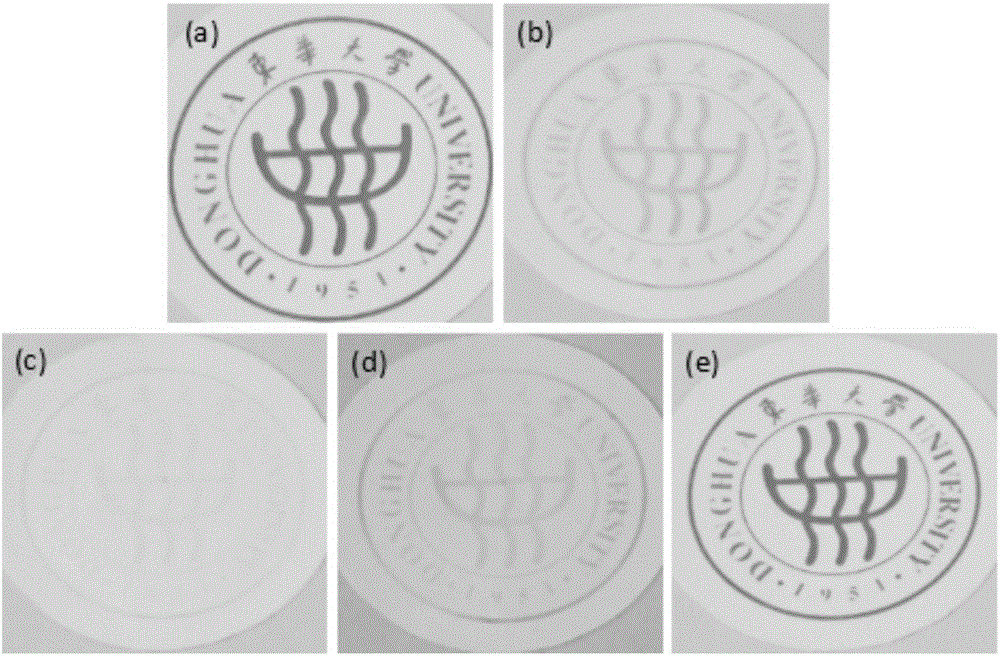

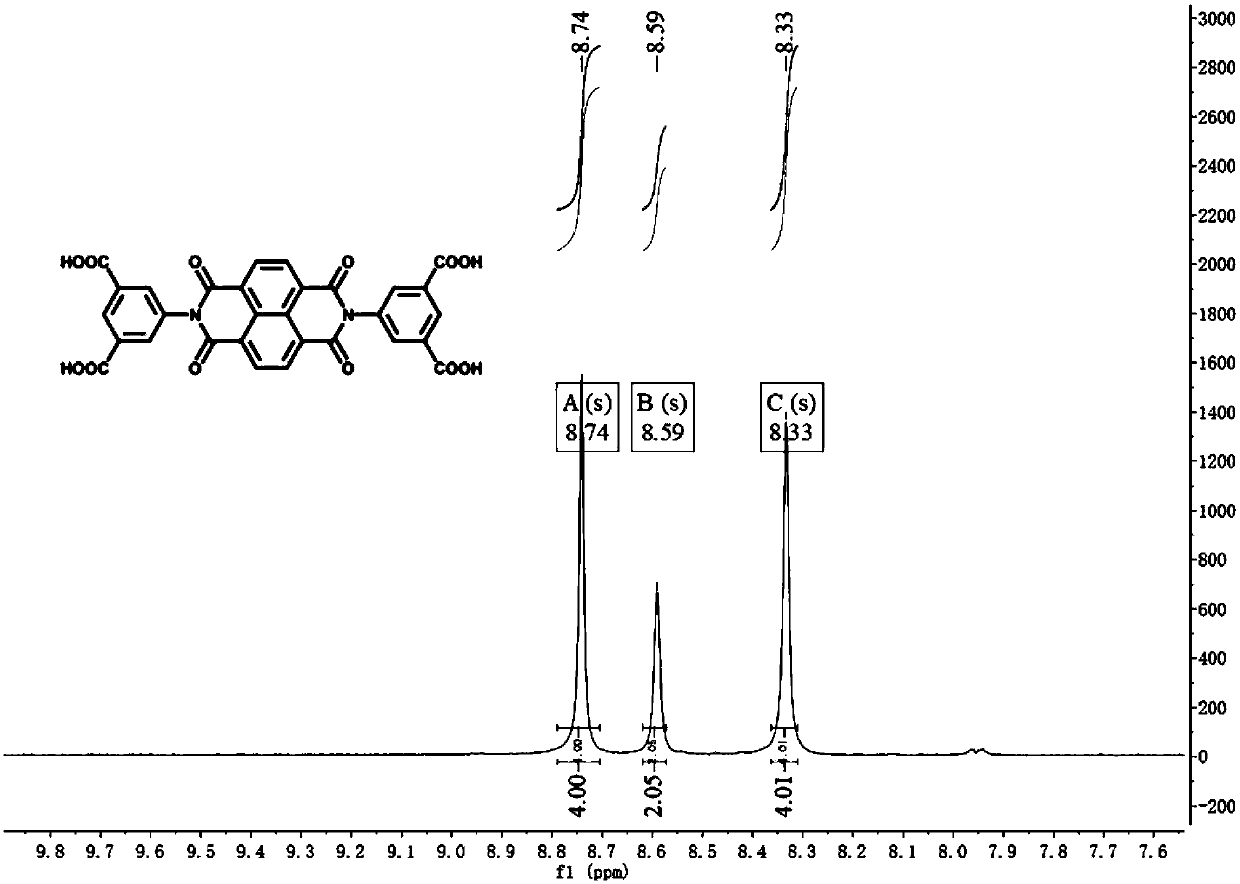

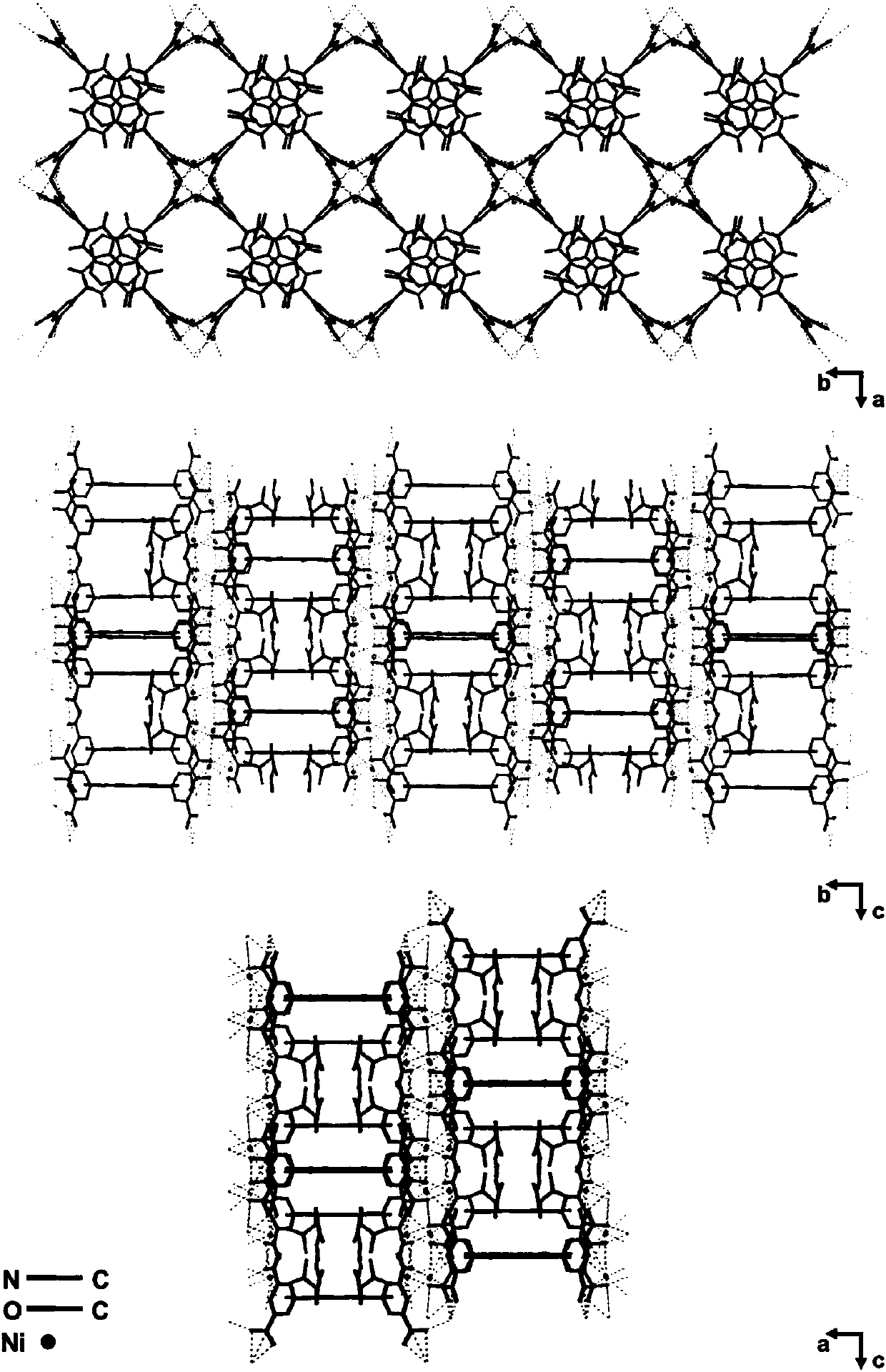

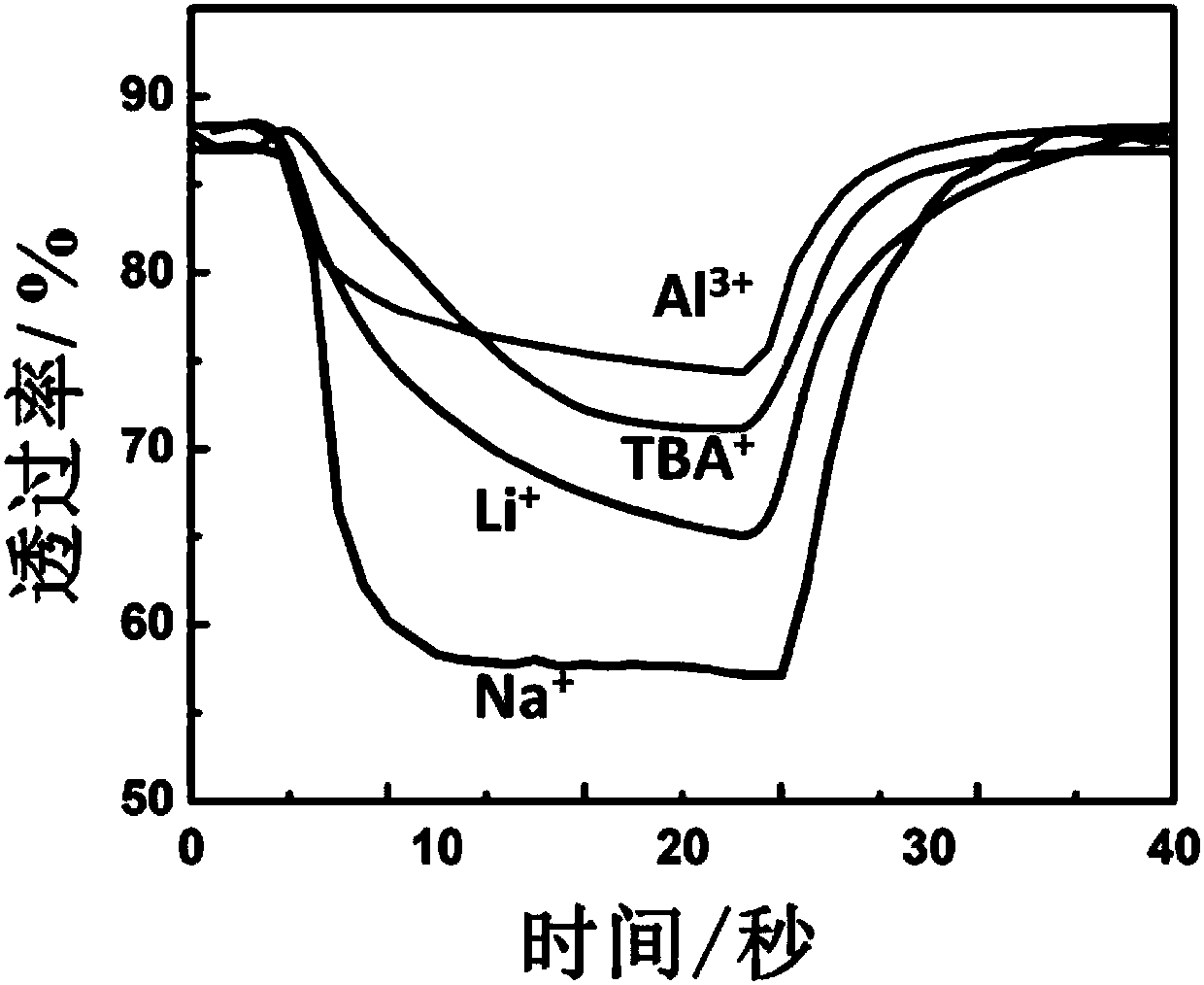

Preparation method of MOFs-based colorful electrochromic intelligent display device

ActiveCN108051970AIncrease surface areaImprove electrochemical performanceTenebresent compositionsNon-linear opticsNickel saltDisplay device

The invention relates to a preparation method of a MOFs-based colorful electrochromic intelligent display device. The device comprises the steps of dissolving 1,4,5,8-naphthalene tetracarboxylic anhydride and 5-aminoisophthalic acid in toluene for reaction under an inert atmosphere to obtain naphthalene tetracarboxylic anhydride-based ligands; dissolving the ligands and nickel salt in DMF / water toobtain a mixed solution; placing pretreated FTO glass into the mixed solution to be subjected to a hydrothermal reaction to obtain a FTO electrode with a MOFs membrane attached on the surface of theFTO electrode; sculpturing the FTO electrode into an electrochromic working electrode for displaying predetermined patterns, using the other FTO glass as a counter electrode, injecting gel electrolyte, and packaging to obtain the device. When voltages ranging from low to high are gradually imposed on the electrochromic device, the device exhibits various colors such as yellow, red, green, blue andblack, efficiently transmits various electrolytes, has good electrochromic performance, and has a wide range of application prospects in the fields such as intelligent display, intelligent wearable articles and the like.

Owner:DONGHUA UNIV

Preparation method of porous carbon microsphere

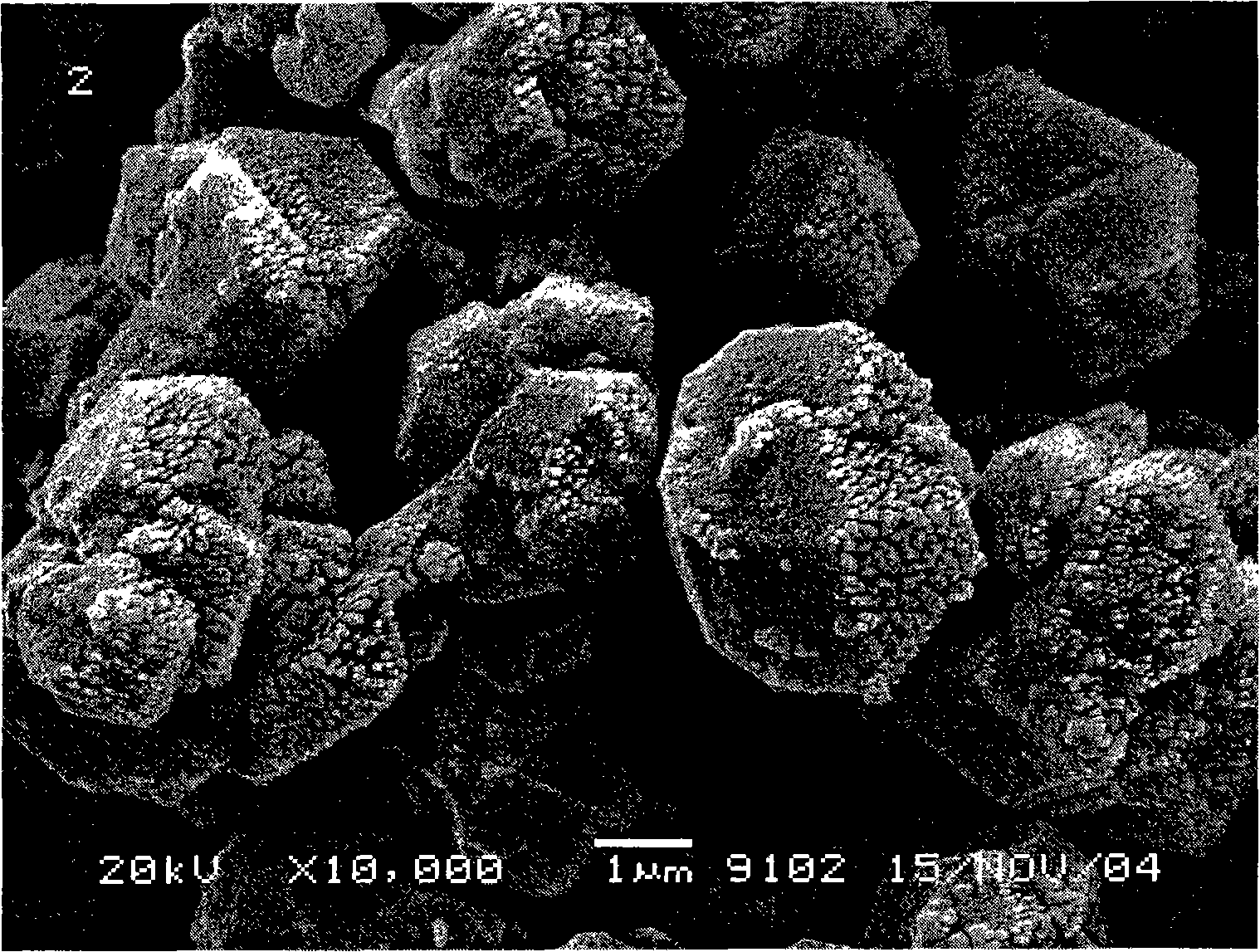

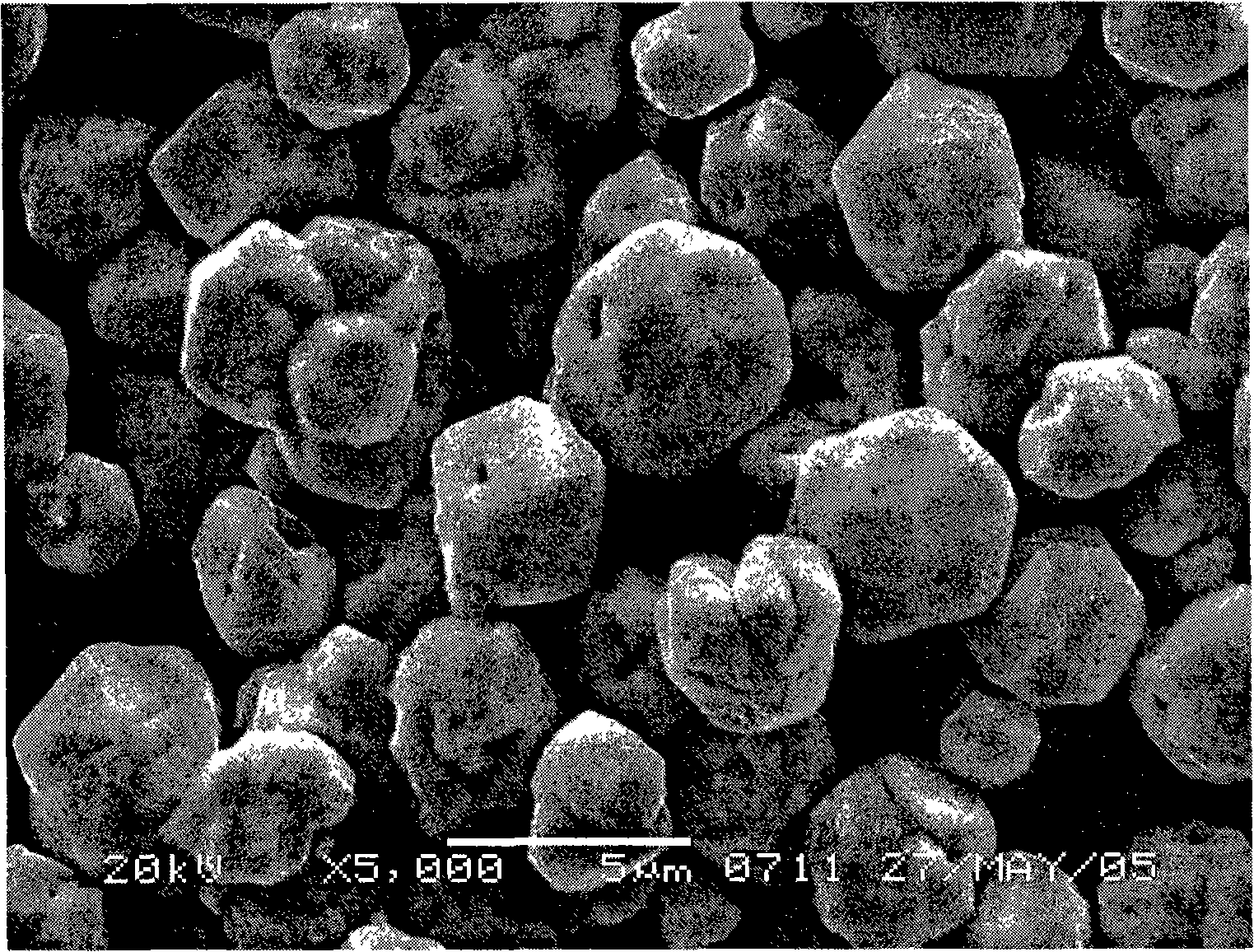

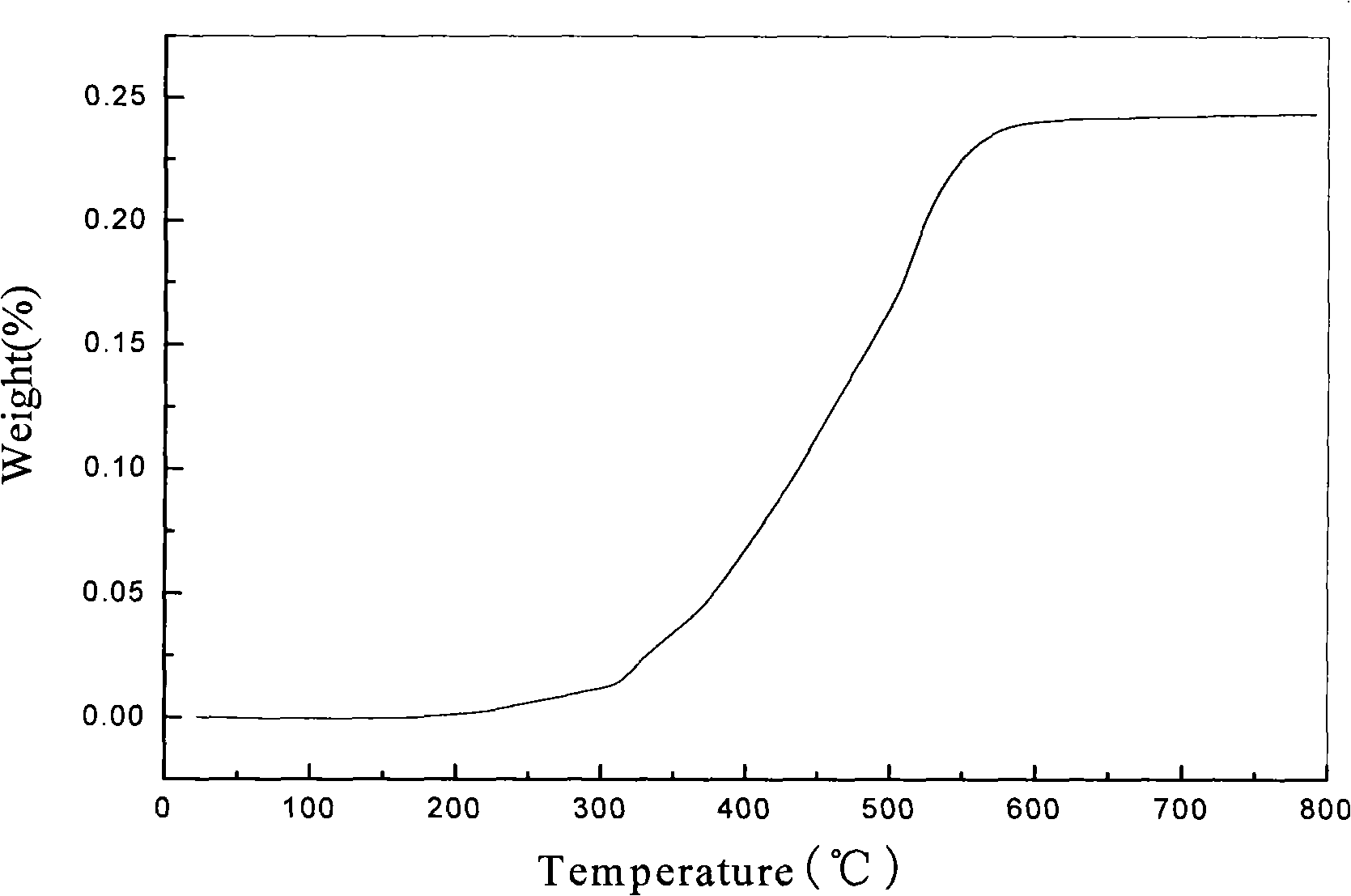

InactiveCN103569995APreparation raw materials are cheapRaw materials are readily availableCarbon preparation/purificationRough surfaceMicron scale

The invention discloses a preparation method of a porous carbon microsphere. The preparation method comprises the following steps: subjecting o-dihydroxybenzene and formaldehyde to carry out polymerization reactions in a silica sol solution under the catalytic action of acid so as to obtain compound microspheres of o-dihydroxybenzene-formaldehyde resin-oxidized nano particles, and then subjecting the compound microspheres to the processes of carbonization and silicon oxide removing so as to obtain porous carbon microspheres with a even particle size. The size of the porous carbon microsphere is in a micron scale range; the porous carbon microsphere has a good spherical shape and a rough surface, is rich in medium holes with a size of 10 to 40 nanometers, integrally has two hole structures, namely the medium hole and the micro hole, and has a large specific surface area. The porous carbon microsphere has a high purity, and the carbon content can reach 95% or more.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

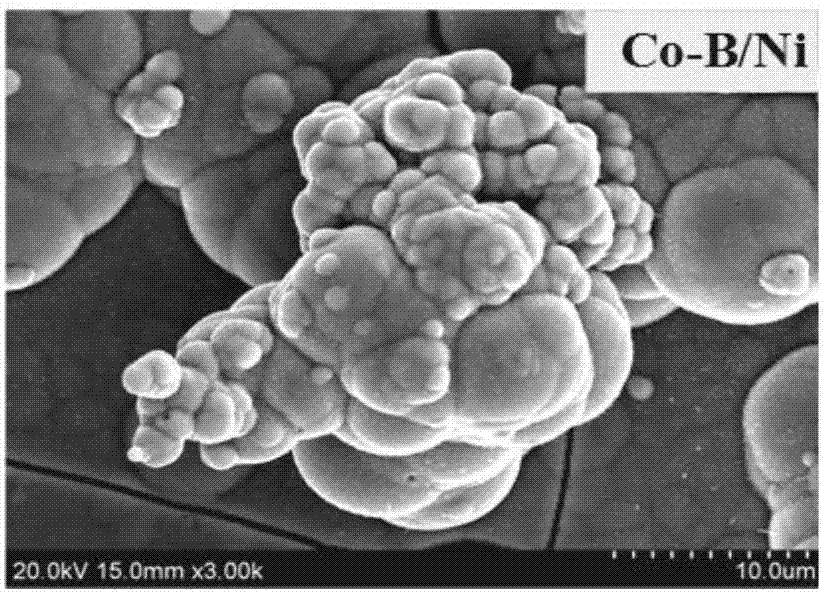

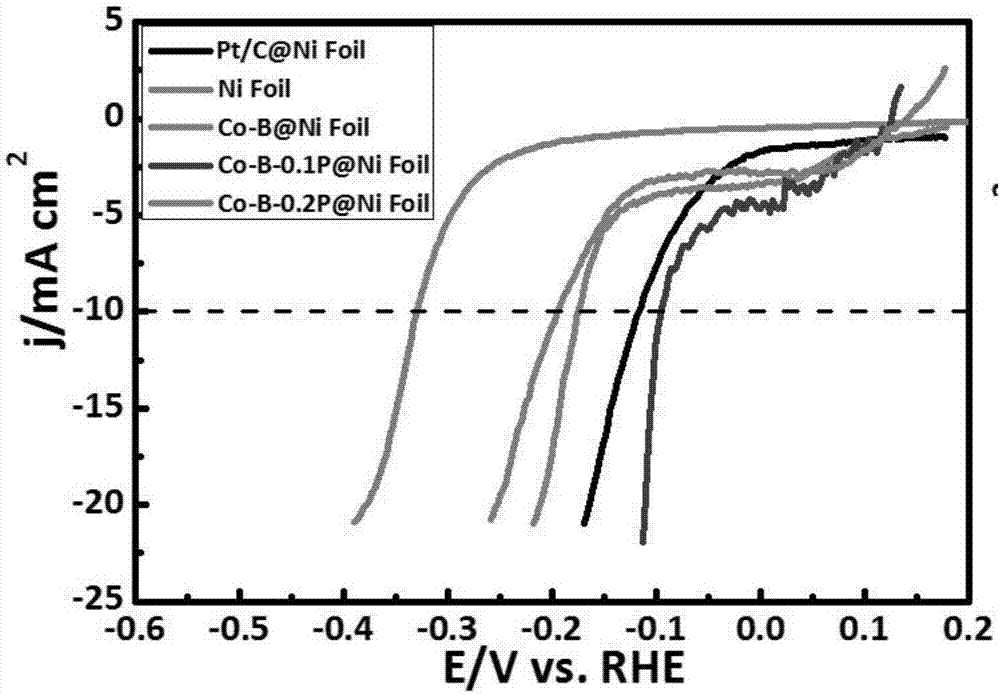

Water electrolysis efficient and double-function catalysis electrode and preparation method thereof

InactiveCN107988617AReduce overpotentialExtended service lifeLiquid/solution decomposition chemical coatingElectrodesChemical industryChemical plating

The invention belongs to the technical field of electrochemical catalysis electrodes, and particularly relates to a water electrolysis efficient and double-function catalysis electrode and a preparation method thereof. A chemical plating method is adopted, a pre-treated substrate is soaked into chemical plating liquid, and the catalysis electrode covered with metal boride or metal boron-phosphorous compound is obtained after reaction. The catalysis electrode can also serve as a hydrogen evolution electrode and an oxygen evolution electrode of water electrolysis, and has the characteristics ofbeing low in overpotential, chemically stable, and long in service life. According to the preparation method of the catalysis electrode, the process is simple, reaction conditions are mild, equipmentrequirements are low, and an electro-catalysis function film is compact and firm in combination with the substrate. The method is not only suitable for preparation of the efficient catalysis electrode, but also suitable for upgrading and reconstruction of assembled electrodes, and has industrial practical value in the fields such as water electrolysis and chlorine-alkali chemical industry hydrogenevolution.

Owner:FUDAN UNIV

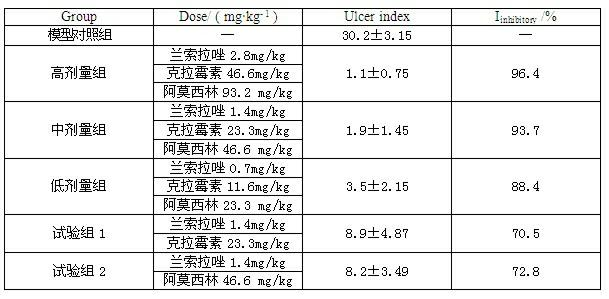

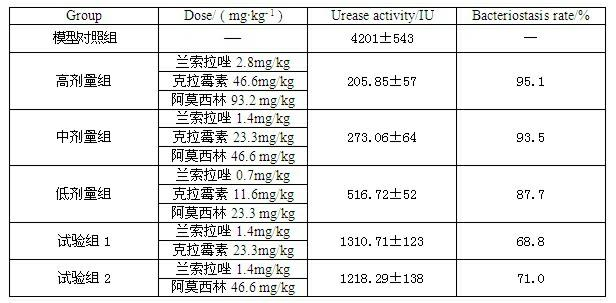

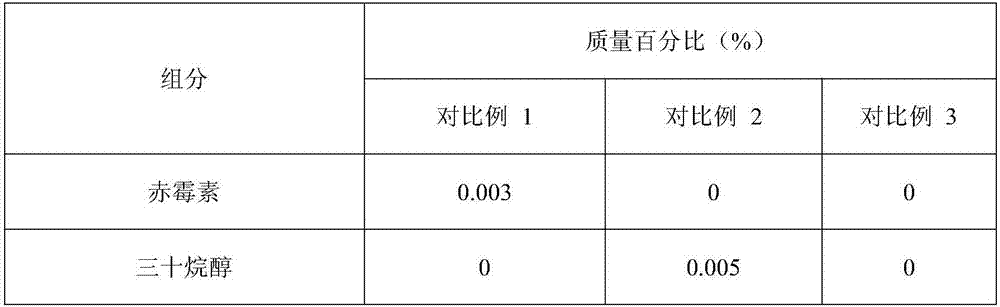

Compound capsule and preparation method thereof

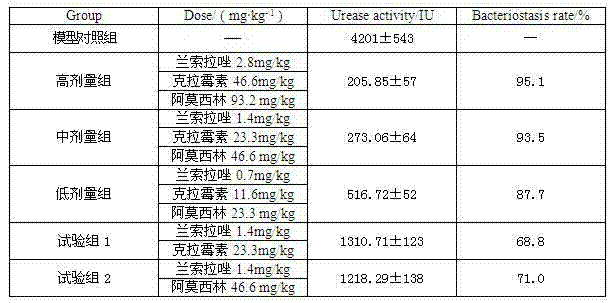

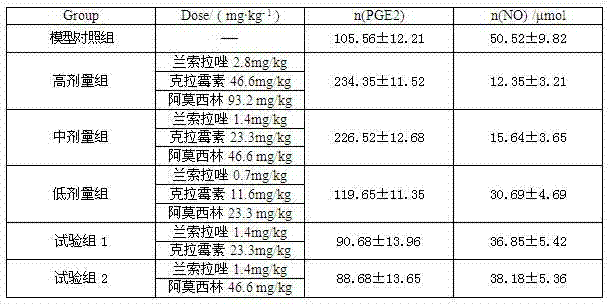

InactiveCN102091084AQuick effectReduce adverse reactionsAntibacterial agentsDigestive systemLansoprazolePeptic ulcer

The invention relates to a compound capsule and a preparation method thereof. The capsule comprises lansoprazole enteric coated pellets, clarithromycin stomach-soluble pellets and amoxicillin stomach-soluble pellets. The compound capsule is administered twice one day based on the following dose each time: lansoprazole 20-40 mg, clarithromycin 400-600 mg, and amoxicillin 900-1100 mg. The capsule provided by the invention has a distinct effect on peptic ulcer, is used for thoroughly killing helicobacter pylori, and has the advantages of quick action, strong effect, improved bioavailability, convenience in administration and low cost.

Owner:王勇

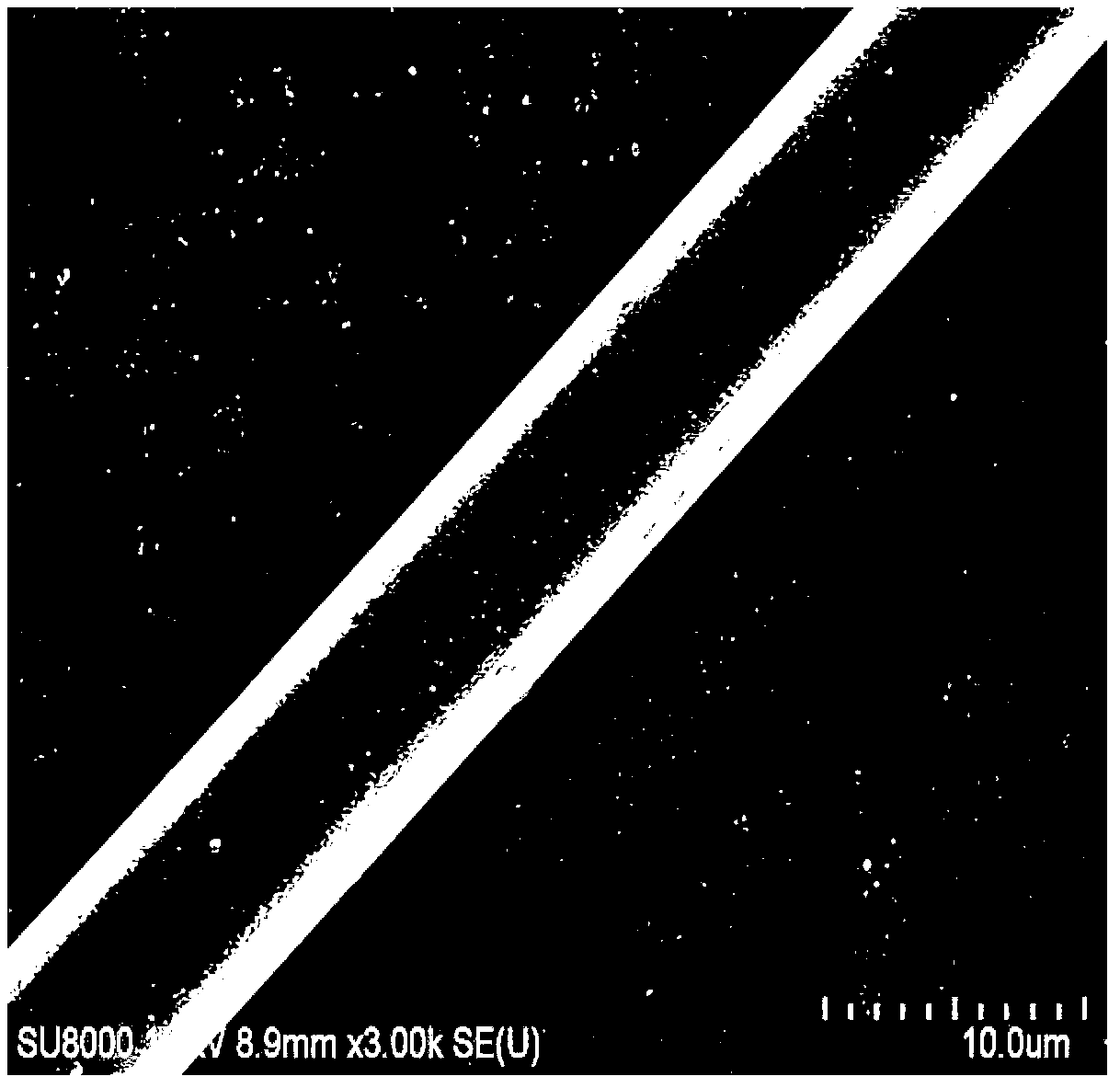

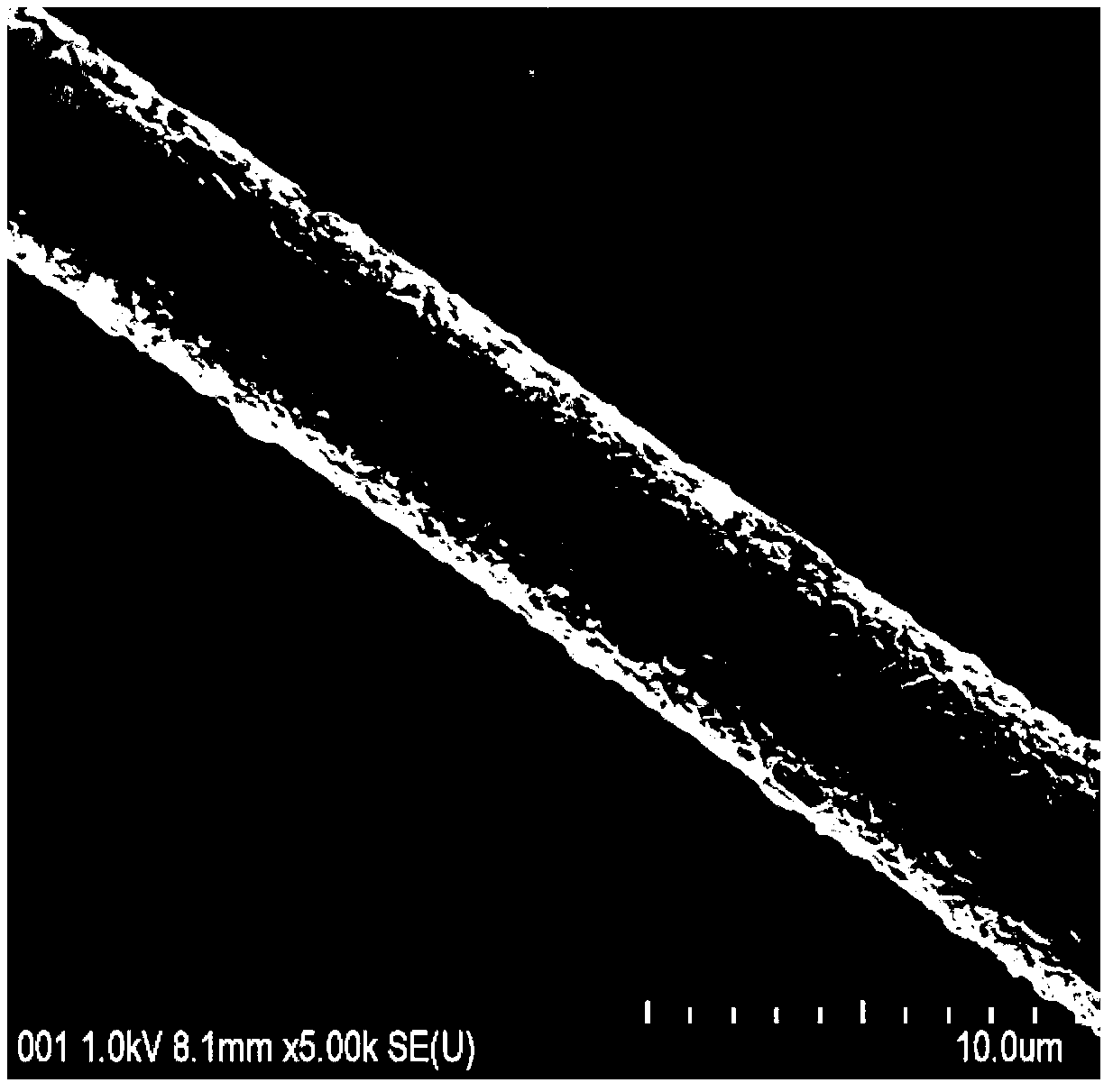

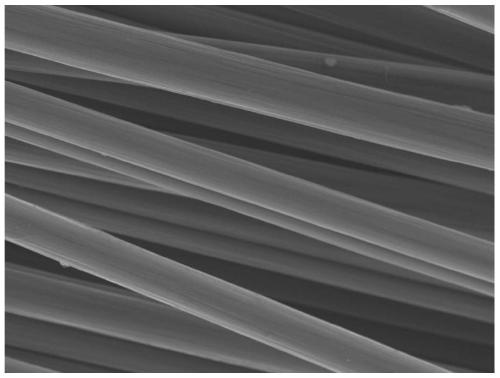

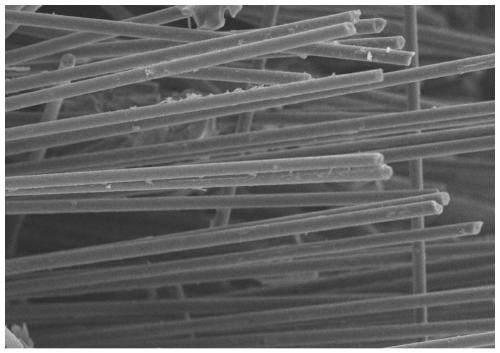

Preparation method of high-temperature-resistant SiBN(C) carbon fiber coating

InactiveCN103243548ANo special equipment requiredHigh implementabilityCarbon fibresCarbon fibersNitrogen

The invention relates to a preparation method of high-temperature-resistant SiBN(C) carbon fiber coating. The preparation method comprises the following steps of: (1) preparing polyborosilazane anhydrous toluene solution; (2) performing glue-removing treatment on the carbon fiber at 100 to 600 DEG C and soaking the carbon fiber into 40 to 70 percent nitric acid to obtain the treated carbon fiber; (3) under the protection of nitrogen, soaking the treated carbon fiber into the polyborosilazane anhydrous toluene solution for 0.1 to 5 hours and standing; and (4) under the atmosphere of nitrogen flow, crosslinking the soaked carbon fiber obtained in the step (3), heating to 1,000 to 1,600 DEG C at the rate of 0.05 to 5 DEG C / min, cracking and cooling to obtain the high-temperature-resistant SiBN(C) carbon fiber coating. The preparation method is simple and has strong actionability; and the surface of the obtained SiBN(C) carbon fiber coating is uniform and compact, the original mechanical property of the carbon fiber is maintained, and the high-temperature oxidation resistance is improved.

Owner:DONGHUA UNIV

Tellurobismuthite leaching method

InactiveCN106987706AFully leachedSimple processSelenium/tellurium compundsProcess efficiency improvementIndustrial scaleMaterials science

The invention discloses a tellurobismuthite leaching method. The method comprises the steps that crude tellurobismuthite is subjected to crushing treatment, and grinding is conducted to enable the particle size to meet the requirement that 90% of ore powder can pass through a 200-mesh sieve; treated tellurobismuthite is put into a roasting furnace, roasting is conducted for 4 h to 6 h at the temperature ranging from 400 DEG C to 450 DEG C, and tellurobismuthite subjected to roasting is collected; grinding is continuously conducted to enable the particle size to meet the requirement that 90% of ore powder can pass through the 200-mesh sieve, pretreated tellurobismuthite is put into a sulfuric acid medium, ozone with the concentration ranging from 10 mg / h to 50 mg / h is introduced, an appropriate amount of surfactant is added, leaching is conducted at 70 DEG C to 80 DEG C, and leachate is obtained, wherein 100 r / min to 200 r / min mechanical stirring is conducted in the leaching process, and the leaching stirring time ranges from 3 h to 4 h. According to the tellurobismuthite leaching method, the technological process is simple, operation is convenient, no special equipment requirement exists, the cost is low, the method is suitable for industrial scale production, the leaching rate of tellurium is 98% or above, the leaching rate of bismuth is 97% or above, and tellurium and bismuth in tellurobismuthite are fully leached; meanwhile, leached leachate provides a good condition for extraction of downstream tellurium and bismuth.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of self-healing silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material

InactiveCN104529499AImprove high temperature stabilityHigh resistance to crystallization temperatureCarbon compositesSelf-healing

The invention relates to a preparation method of a self-healing silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material, which comprises the following steps: (1) preparing a polyborosilazane (PBSZ) precursor; dissolving the PBSZ precursor in a toluene solution under the protection of N2 to obtain a PBSZ toluene solution; transferring into a pipe furnace, crosslinking under the protection of N2, grinding and screening to obtain SiBNC precursor powder; (2) preparing SiC fibers into a prefabricated part, carrying out hot pressing on the SiBNC precursor powder and SiC fiber prefabricated part, cooling and demolding to obtain a composite material; and transferring into a pipe furnace in an N2 protective atmosphere to perform ceramization, and finally, sintering. The method is simple in technique, easy to operate and low in cost; and the prepared silicon-carbide-fiber-reinforced silicon-boron-nitrogen-carbon composite material is uniform and compact, has the advantages of favorable high-temperature stability and excellent oxidation resistance, and especially has self-healing performance.

Owner:DONGHUA UNIV

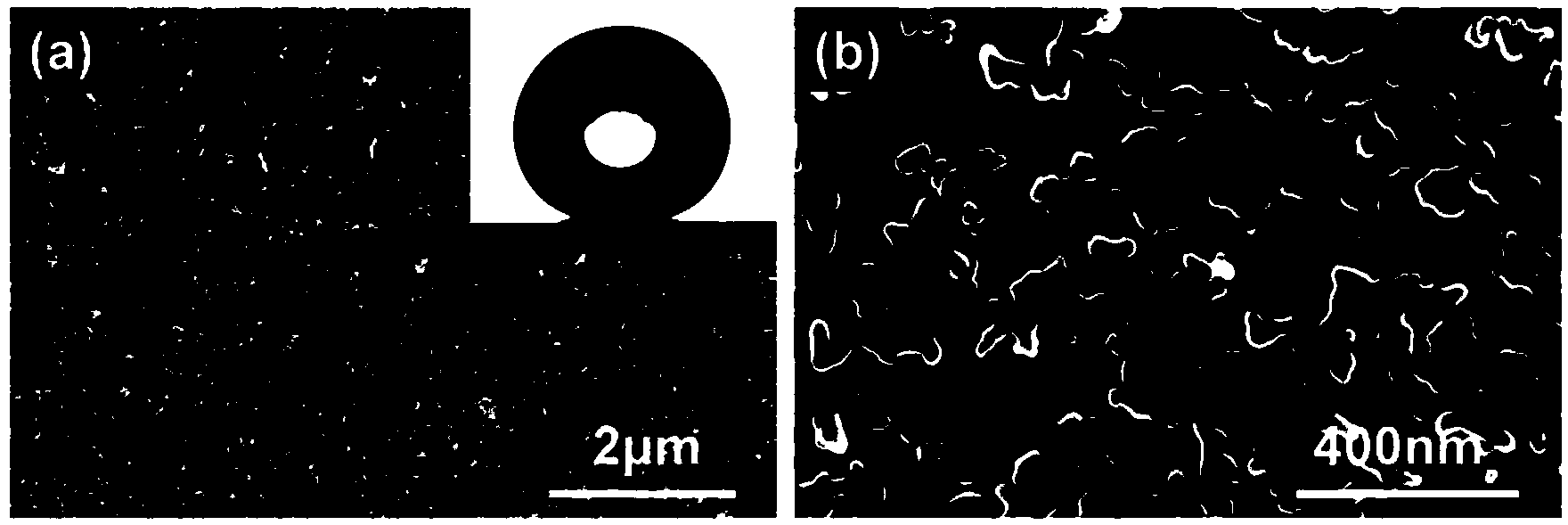

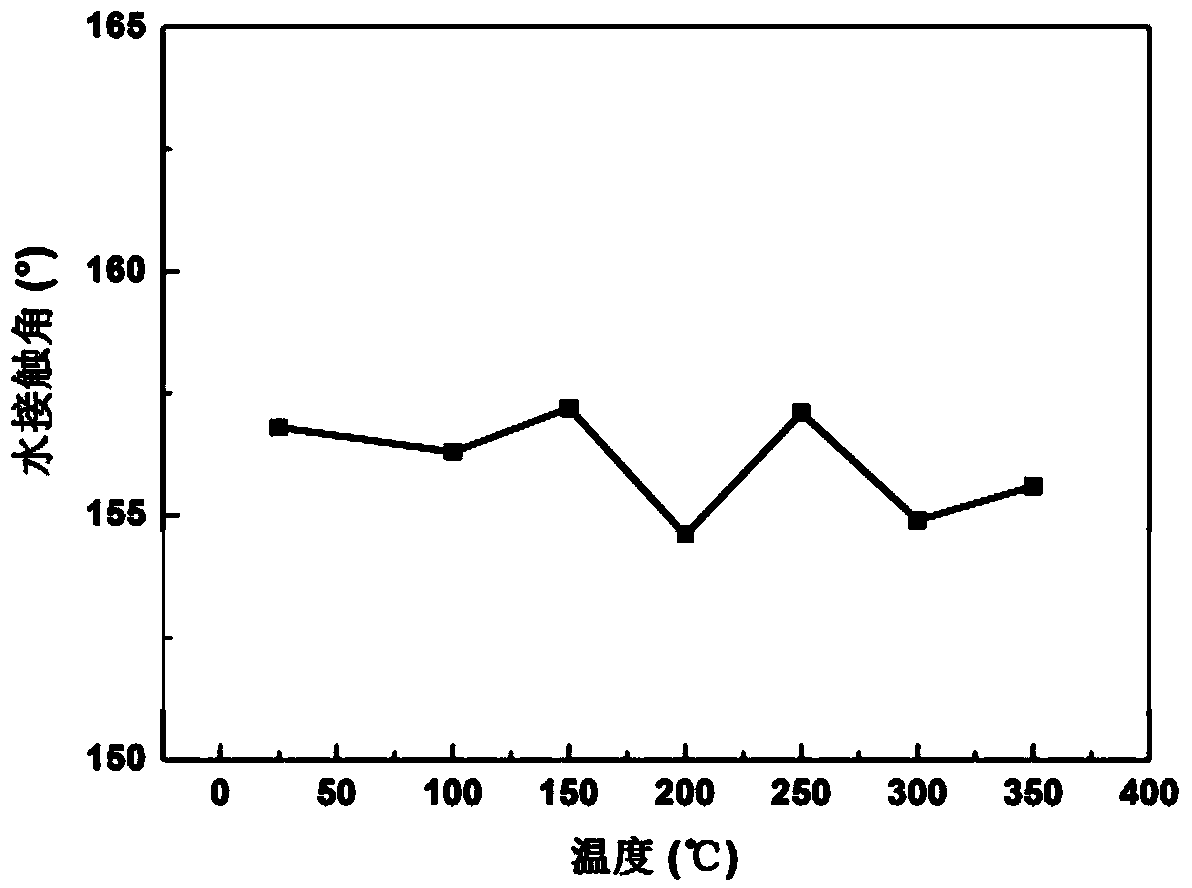

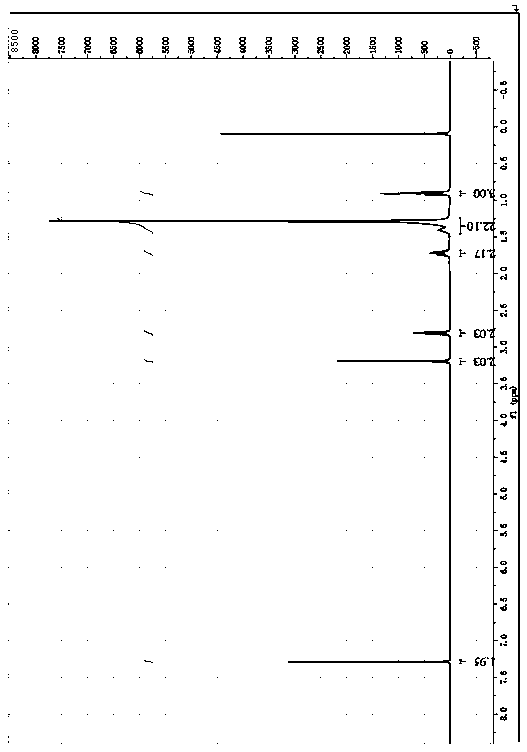

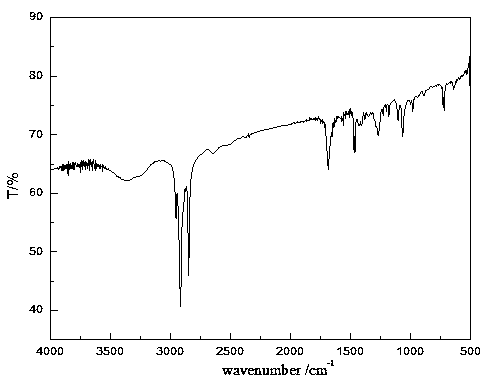

Method for hydrophobically modifying surface of polymer

The invention discloses a method for hydrophobically modifying the surface of a polymer. The method comprises the following steps: firstly, performing ultraviolet oxidation treatment on the cleaned surface of the polymer; secondly, performing hydrophobic substance modification on the surface of the polymer, subjected to the ultraviolet oxidation treatment, through a soaking method or a vapor deposition method. The method has the advantages that the process is simple; special equipment and vacuum or special atmosphere conditions are not needed; a template is not needed to be additionally used; large-scale implementation is facilitated. Particularly, the surface of the polymer, modified through the method, has super-hydrophobic characteristic, can still keep the super-hydrophobic characteristic after being treated at high temperature of 350 DEG C, and can meet requirements of application to severe environments such as high temperature.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Selenium-containing surfactant as well as preparation method and application thereof

ActiveCN105498622AImprove surface activityEasy to prepareCosmetic preparationsHair cosmeticsChemical industryAcute toxicity testing

The invention discloses a selenium-containing surfactant as well as a preparation method and application thereof and belongs to the technical field of a daily chemical industry. The surfactant is long-chain alkyl selenium base acetate, and a structural character of the surfactant is shown as a formula (1) as shown in the specification; in the formula (1), n is an integer from 11 to 15; M<+> is one of a sodium ion, a potassium ion or an ammonium ion. The preparation method of the selenium-containing surfactant is simple, and has moderate synthesis conditions, no special requirements on equipment and relatively low energy consumption; raw materials are easy to obtain and the product does not contain hydroxyl acetate and chloroacetate; the selenium-containing surfactant has relatively high surface activity, excellent foaming and foam stabilization performance, unique hard water resistance and oxidation resistance and free radical removing capability, and relatively low cytotoxicity, aquatic organism acute toxicity and skin irritation.

Owner:JIANGNAN UNIV

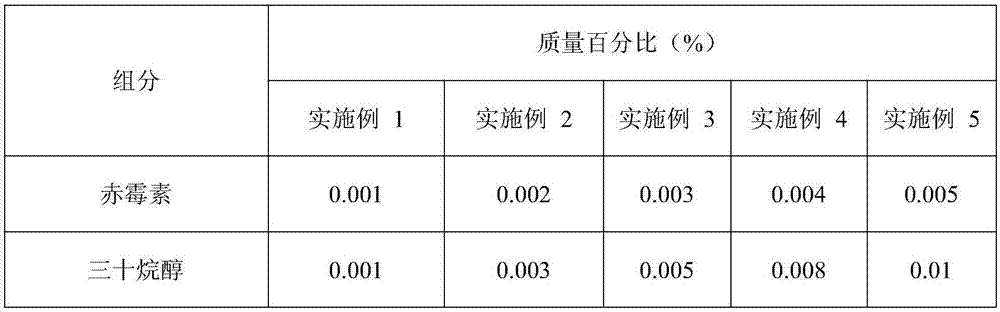

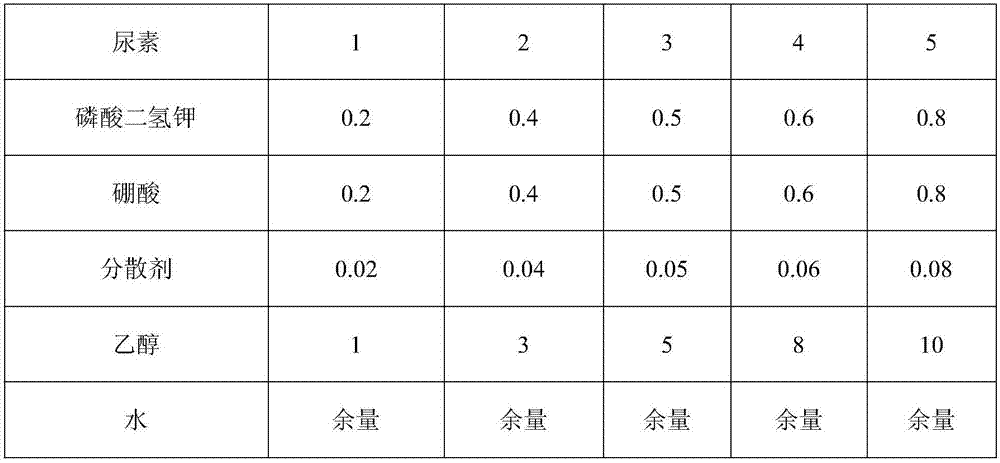

Rice growth regulator and preparation method thereof

InactiveCN107372602APromote growth and developmentImprove result rateBiocidePlant growth regulatorsGibberellic acidPhosphate

The invention discloses a rice growth regulator. The rice growth regulator is composed of 0.001 to 0.005% of triacontanol, 0.001 to 0.01% of gibberellin, 1 to 5% of urea, 0.2 to 0.8% of potassium dihydrogen phosphate, 0.2 to 0.8% of boric acid, 0.02 to 0.08% of a dispersing agent, 1 to 10% of ethanol and the balance of water. The rice growth regulator is sprayed to leaf surfaces in rice tillering, jointing and full heading periods. Triacontanol and gibberellin produce synergism so that the lodging resistance of rice is improved. The regulator and the chemical fertilizer are used together so that the absorption of the chemical fertilizer and dry matter accumulation of the rice are promoted and a rice yield and quality are improved.

Owner:FOSHAN SANSHUI JIAXIN AGRI TECH RES INST GENERAL PARTNERSHIP

Mullite raw material adopting alumina-chrome slag as main ingredient and preparation method thereof

The invention relates to a mullite raw material adopting alumina-chrome slag as a main ingredient and a preparation method thereof. According to the technical scheme, the method comprises the steps that the alumina-chrome slag is placed into a muffle furnace, and calcination is performed under the temperature of 700-750 DEG C for 3-5 h to obtain calcined alumina-chrome slag; the calcined alumina-chrome slag, silica powder and aluminite powder are mixed on the basis that the mass ratio of the calcined alumina-chrome slag to the silica powder to the aluminite powder is 100:(16.0-16.5):(2.0-4.5) for 15-20 min, and a mixed material is obtained; the mixed material is placed into an electromagnetic induction furnace, the temperature is increased to 1,800-1,840 DEG C and kept constant for 2-3 h; then, an upper scum layer is separated out, furnace cooling is performed to the room temperature, and crushing is performed to obtain the synthesis mullite raw material adopting the alumina-chrome slag as the main ingredient. The alumina-chrome slag contains main chemical components: 80-85 wt% of Al2O3, 10-15 wt% of Cr2O3 and not larger than 1 wt% of Fe2O3. The technology is simple, the production cost is low, and no special requirement for equipment is needed; the prepared mullite raw material adopting the alumina-chrome slag as the main ingredient is high in refractoriness, good in sintering performance and high in mullite conversion rate.

Owner:锦州集信高温材料有限公司

Method for preparing nanometer silicon powder by sol-microemulsion-hydro-thermal system

InactiveCN102659124ASimple processEasy to operateNanotechnologySilicon compoundsSodium silicateChemistry

A method for preparing a nanometer silicon powder by a sol-microemulsion-hydro-thermal system comprises technological processes of: preparation of sodium silicate, preparation of a silicic acid sol system, preparation of a four-phase microemulsion system, hydro-thermal system reaction, washing treatment and the like. The method provided by the invention has a simple technology, requires no special equipment, is convenient to operate and easy to control, and requires low production cost and low reaction temperature, and can be popularized for the preparation of nanometer silicon powder with natural powder quartz as a raw material.

Owner:NANCHANG UNIV

Compound capsule and preparation method thereof

InactiveCN102091084BQuick effectReduce adverse reactionsAntibacterial agentsDigestive systemLansoprazolePeptic ulcer

The invention relates to a compound capsule and a preparation method thereof. The capsule comprises lansoprazole enteric coated pellets, clarithromycin stomach-soluble pellets and amoxicillin stomach-soluble pellets. The compound capsule is administered twice one day based on the following dose each time: lansoprazole 20-40 mg, clarithromycin 400-600 mg, and amoxicillin 900-1100 mg. The capsule provided by the invention has a distinct effect on peptic ulcer, is used for thoroughly killing helicobacter pylori, and has the advantages of quick action, strong effect, improved bioavailability, convenience in administration and low cost.

Owner:王勇

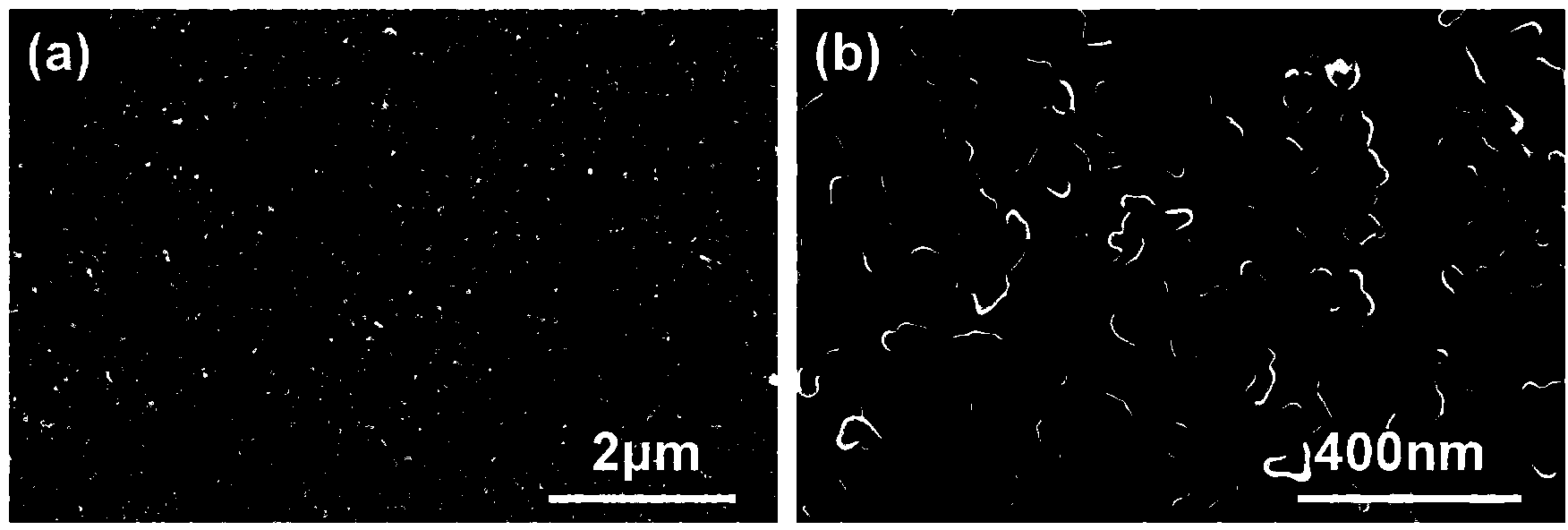

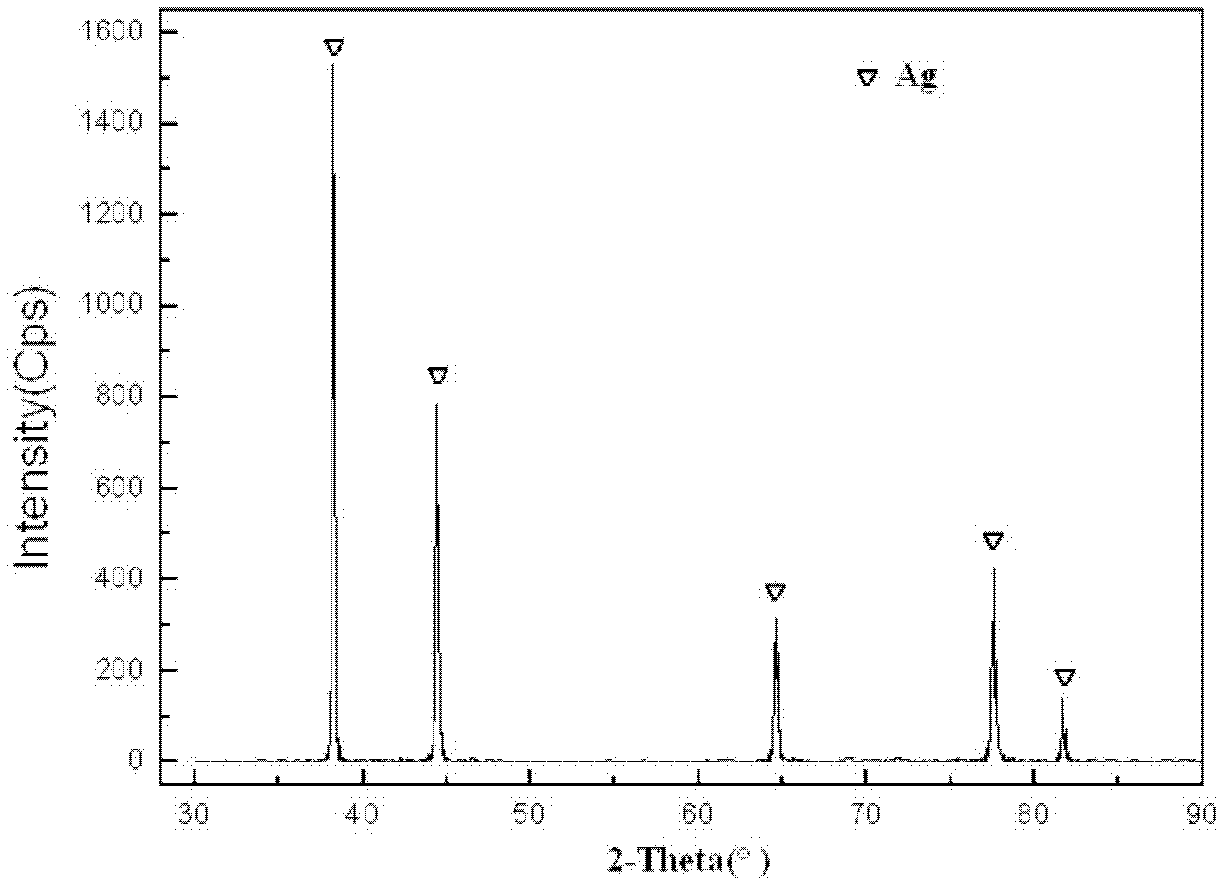

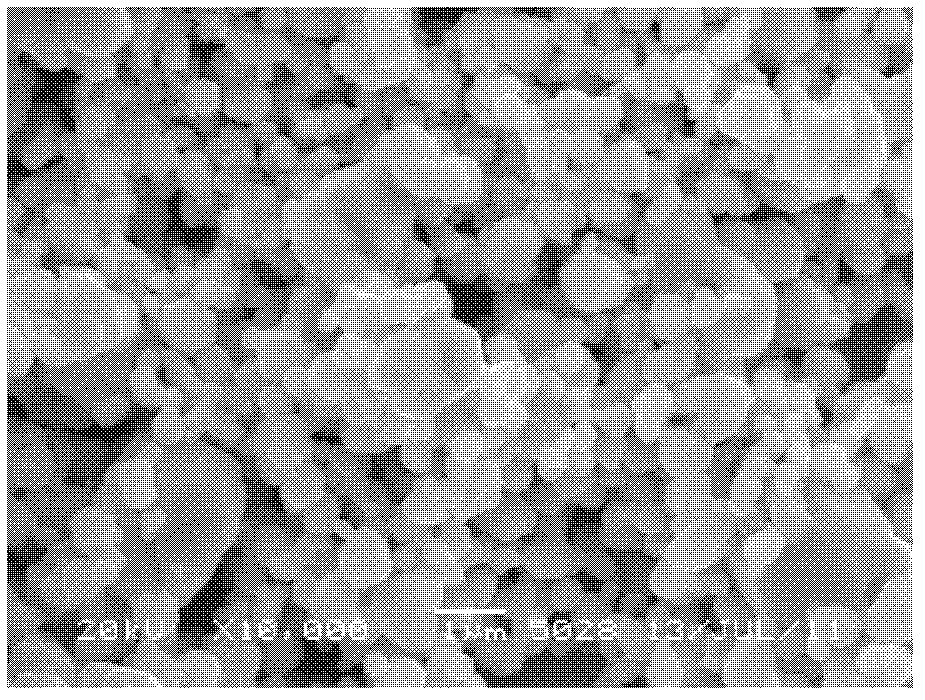

Method for preparing ultrafine silver powder by directly performing thermal decomposition on silver nitrate

The invention discloses a method for preparing ultrafine silver powder by directly performing thermal decomposition on silver nitrate. The method comprises the following steps of: putting a crucible with a silver nitrate solid into a tubular furnace, heating to temperature of between 400 and 550 DEG C at heating speed of between 5 and 50 DEG C / min, and introducing air with the relative humidity of between 80 and 100 percent, wherein the air flow is of between 200 and 800 ml / min; calcining for 2 to 8 hours, stopping heating and introducing the air; and cooling to room temperature, collecting solid products in the crucible, and thus obtaining the ultrafine silver powder with the average particle size of between 0.5 and 2 mu m. According to the method, reducing agents and aids are not required. The process is simple, and is low in cost; and the obtained silver powder is similarly spherical particles, has high purity, high crystallinity and relatively high compaction density, and is suitable for conductive slurry industries.

Owner:CENT SOUTH UNIV

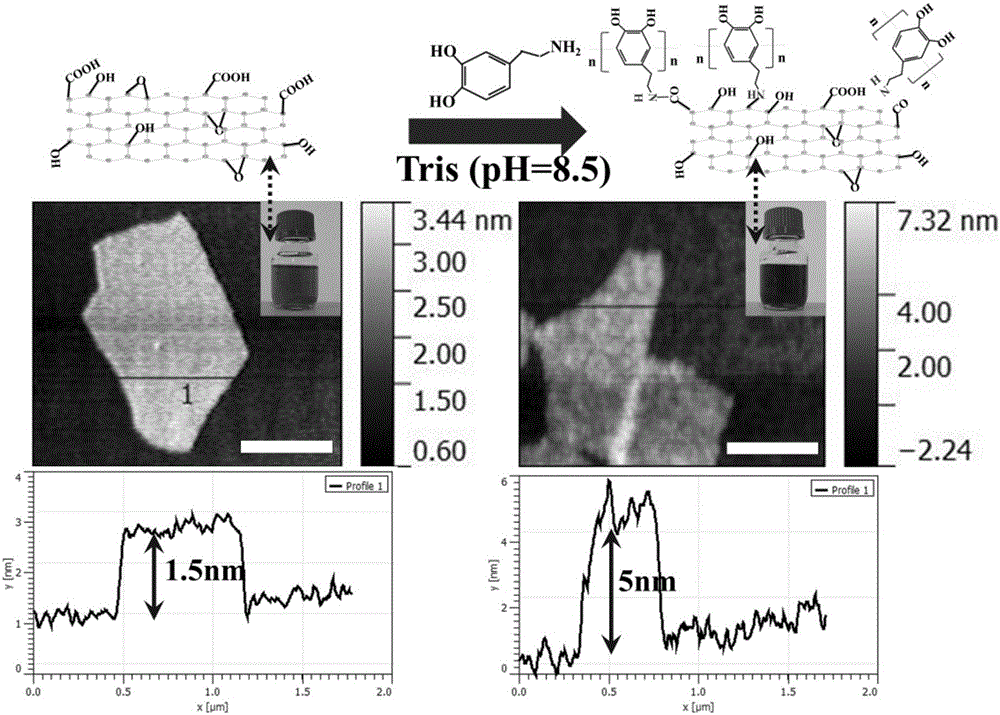

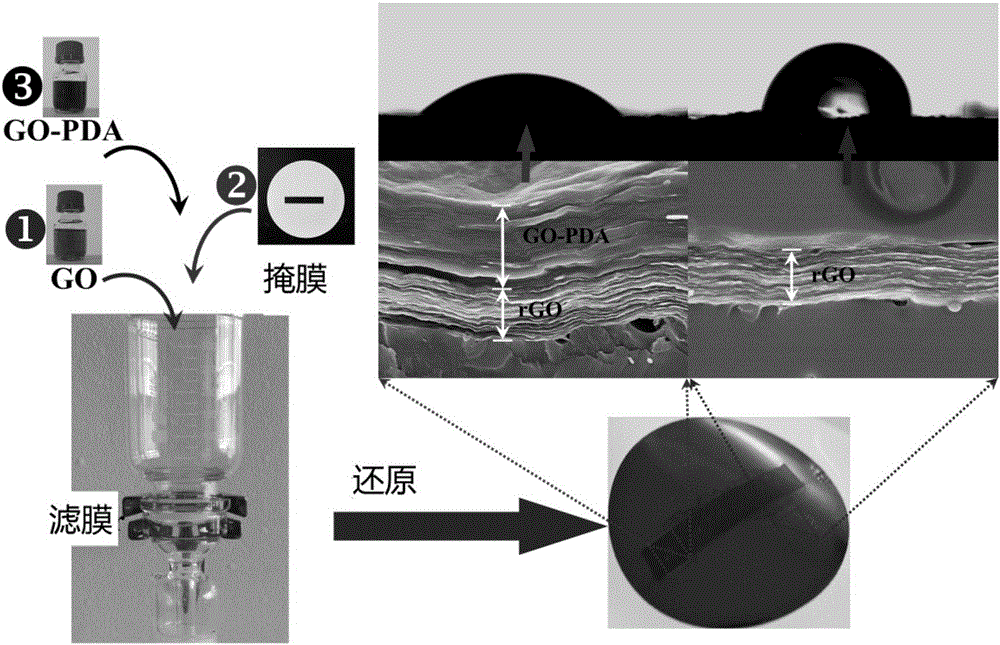

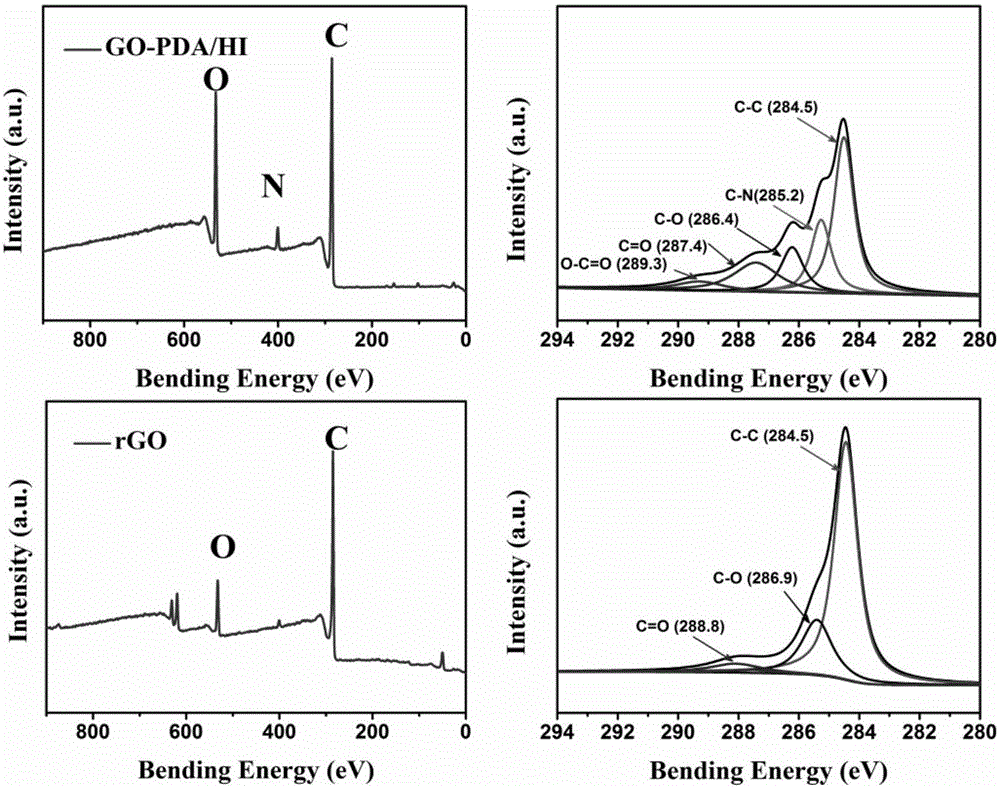

Preparation method of graphene-based actuating material for smart clothing

InactiveCN105967170AEasy to prepareMild reaction conditionsMaterial nanotechnologyGraphite oxideMaterials science

The invention discloses a preparation method of a graphene-based actuating material for smart clothing. The preparation method comprises carrying out ultrasonic treatment on graphite oxide to obtain a graphite oxide dispersion liquid, adding hydrophilic molecules into the graphite oxide dispersion liquid, adjusting pH to 7.5-9.5, carrying out stirring to obtain grafting-modified graphene oxide, washing the graphene oxide, preparing a solution or slurry with a concentration of 0.001-100mg / mL, compounding the solution or slurry and a water inert material, carrying out drying to obtain an actuating unit and carrying out graphical processing on the actuating unit. The graphene-based actuating material for smart clothing can be further used for costume designing, can be used as a pore microswitch and can realize body surface temperature and humidity self-management.

Owner:DONGHUA UNIV

Sagger for sintering positive electrode material of lithium battery based on magnesium aluminate spinel sol and preparation method of sagger

InactiveCN110207499AReduce erosionExtended service lifeCharge supportsCharge treatment typeMulliteCordierite

The invention relates to a sagger for sintering a positive electrode material of a lithium battery based on magnesium aluminate spinel sol and a preparation method of the sagger. According to the technical scheme, the preparation method comprises the steps of mixing and stirring the following components of, by weight, 20%-25% of magnesium nitrate, 15%-20% of aluminum nitrate and 60%-61% of industrial alcohol to obtain magnesium aluminate spinel sol; mixing the following components of, by weight, 25%-30% of mullite, 25%-30% of cordierite. 25%-30% of andalusite, 3%-7% of the magnesium aluminatespinel sol, 4%-7% of Guangxi white mud and 2%-7% of silicon micro powder to obtain a mixture; carrying out mechanical pressing on the mixture, drying the mixture at the temperature of 90-110 DEG C, and then carrying out heat preservation at the temperature of 1,300-1,400 DEG C for 3-4 hours to obtain the sagger for sintering the positive electrode material of the lithium battery based on the magnesium aluminate spinel sol. The preparation method has the characteristics of simple process, short production period, easy industrial production and high yield; and the prepared sagger is high in strength, long in service life, and good in thermal shock resistance and corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH +1

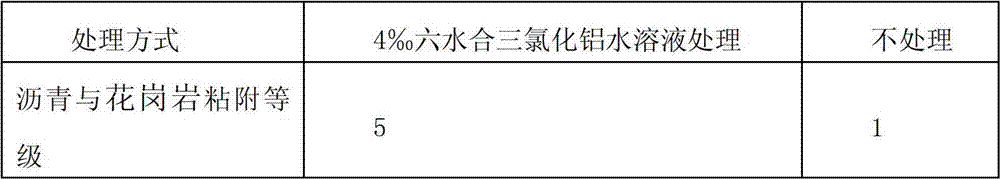

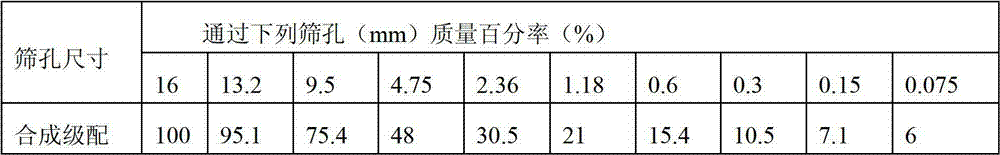

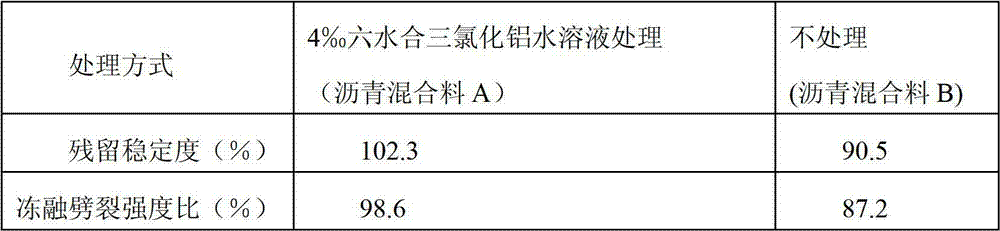

Anti-stripping agent for improving asphalt and stone adhesiveness and preparation method thereof

The invention relates to an anti-stripping agent for improving asphalt and stone adhesiveness. The anti-stripping agent is characterized by consisting of the following components in percentage by mass: 0.4-0.6 percent of aluminum chloride hexahydrate and 9.4-9.6 percent of drinking water. The anti-stripping agent for improving asphalt and stone adhesiveness is low in construction cost and simple in manufacturing, and after basalt, granite and other acidic stones are treated, the asphalt and stone adhesiveness can be obviously improved, and the water damage resistance of asphalt mixture is improved. The invention also relates to a method for preparing the anti-stripping agent for improving asphalt and stone adhesiveness. The method is characterized by comprising the following steps of: mixing 0.4-0.6 percent of aluminum chloride hexahydrate and 99.4-99.6 percent of drinking water at normal temperature, and uniformly stirring to prepare an aqueous solution. The method for preparing the anti-stripping agent for improving asphalt and stone adhesiveness is easy to operate and easy to implement and does not have special equipment requirements.

Owner:天津市市政工程研究院

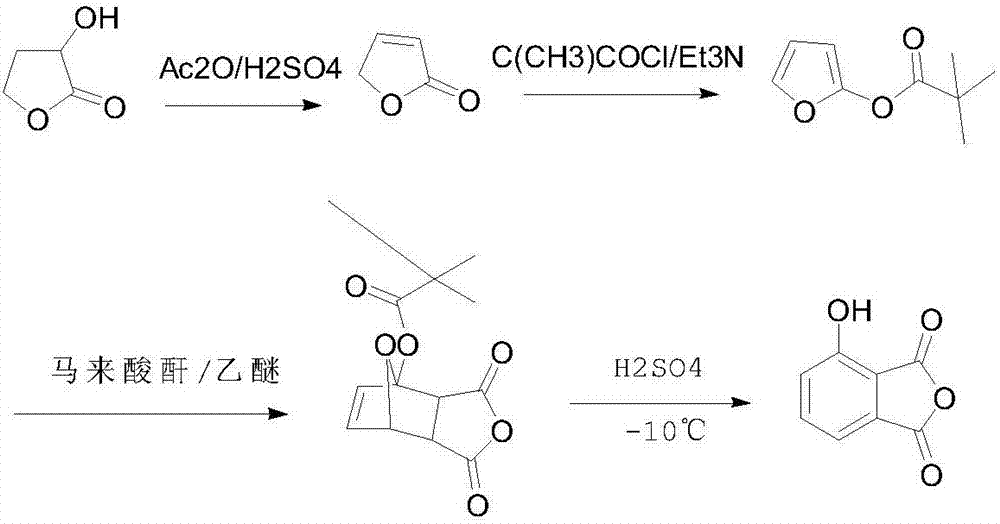

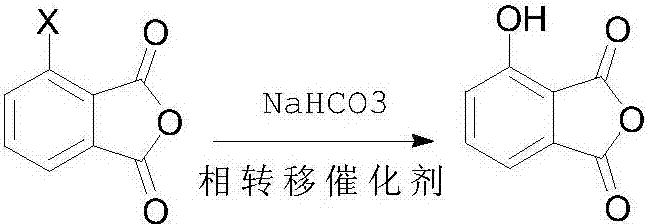

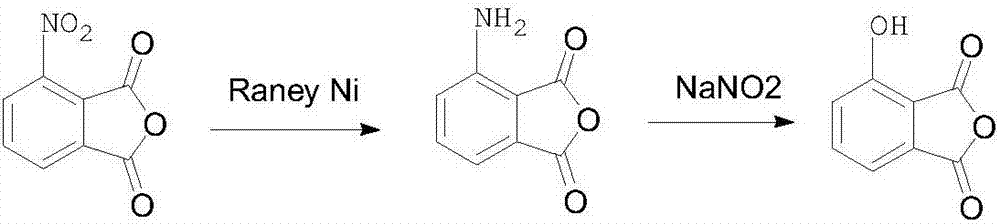

Preparation method of 3-hydroxyl phthalic anhydride

The invention belongs to the technical field of organic synthesis and in particular relates to a preparation method of a key medical intermediate, 3-hydroxyl phthalic anhydride. The method comprises the following steps: with a compound I as a raw material, oxidizing the raw material to obtain 3-methoxyl phthalic acid; performing a reaction on 3-methoxyl phthalic acid to generate 3-hydroxyl phthalic acid; and performing dehydration and condensation on 3-hydroxyl phthalic acid to generate 3-hydroxyl phthalic anhydride. 3-hydroxyl phthalic anhydride prepared by the method provided by the invention is high in yield and good in purity. The method is free of special equipment demands, has mild conditions and is safe and environmental-friendly in an industrial process, and the process technology provided by the invention can be industrially performed.

Owner:JINAN XUANHONG BIOLOGICAL PHARMA CO LTD

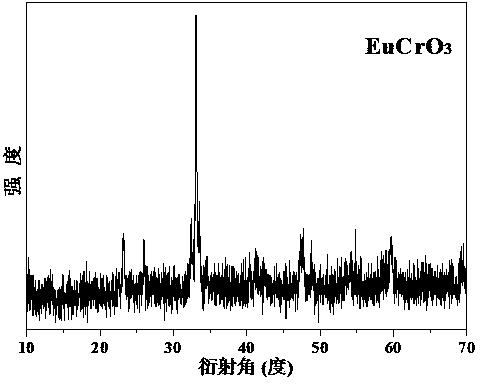

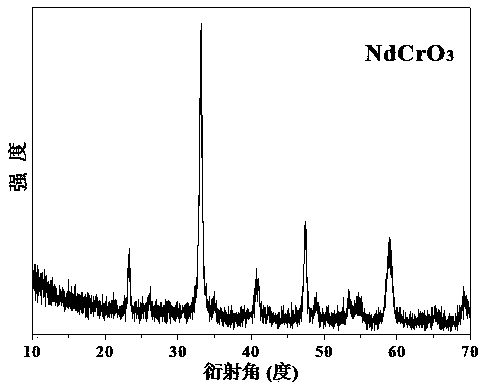

Method for preparing nano-structure of metal chromite series compound

ActiveCN103964506ASimple processEasy to operateMaterial nanotechnologyChromium compoundsNano structuringSolvent

A method for preparing a nano-structure of a metal chromite series compound is characterized by comprising the following steps: firstly using potassium chromate and soluble metal salt to composite a chromate precursor, then performing in-situ reduction on the chromate by using a glycol water solution in a solvothermal system, and washing to obtain the metal chromite. The technology of the method has the following obvious advantages that 1, the method is based on the solvothermal technology, is simple in process, convenience to operate, low in manufacturing cost, and environmental-friendly, and has no special equipment requirements; 2, the glycol in-situ reduction technology belongs to wet-chemistry methods, and an obtained product has a certain morphological character; 3, the method has excellent universality on the wide preparation of metal chromite series compounds.

Owner:江苏天园项目管理集团有限公司

Refining method capable of realizing mass production of palladium tetramine sulfate

ActiveCN110482620AHigh yieldHigh purityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsAlcoholTetramine

The invention discloses a refining method capable of realizing mass production of palladium tetramine sulfate. The method comprises the following specific steps: adding palladium sulfate solid into acertain amount of ammonia water, filtering after reaction, concentrating mother liquor to 1 / 2 of the original volume, cooling to room temperature, adding a certain amount of alcohol or ketone reagent,separating out a large amount of white solid, filtering, drying the solid for 5 hours at 50 DEG C and then drying for 3 hours at 90 DEG C by using a blast drying oven to obtain apalladium tetramine sulfate refined product. The method has the advantages of simple operation conditions, low equipment requirements, high product yield (more than 98%), high product purity (more than 99.5%), and obviouseconomic and environmental protection benefits.

Owner:SINO PLATINUM METALS CO LTD

Method for improving color fastness of polyester spandex single-sided polar fleece fabric

InactiveCN107630309AIncrease elasticityGuaranteed high elasticity of the fabricSucessive textile treatmentsHeating/cooling textile fabricsColour fastnessPolyester

The invention relates to a method for improving the color fastness of a polyester spandex single-sided polar fleece fabric. The method includes the pre-treatment process, the dyeing process, the cleaning process, the auxiliary adding process, the drawing process, the middle shaping process, the carding process, the shearing process and the post-treatment process. The whole process integrates the stability of the fabric and the high color fastness guarantee, so that the anti-pilling style is more attractive; meanwhile, the post-finishing procedure is omitted, the energy consumption is reduced,and the special requirement of equipment is avoided; the processed fabric is good in style, good in elasticity, good in hand feeling, good in fastness, good in pilling resistance and capable of achieving production stability, and technical problems in polyester spandex polar fleece fabric color fastness processing and production are solved.

Owner:SHANGHAI CHALLENGE TEXTILE

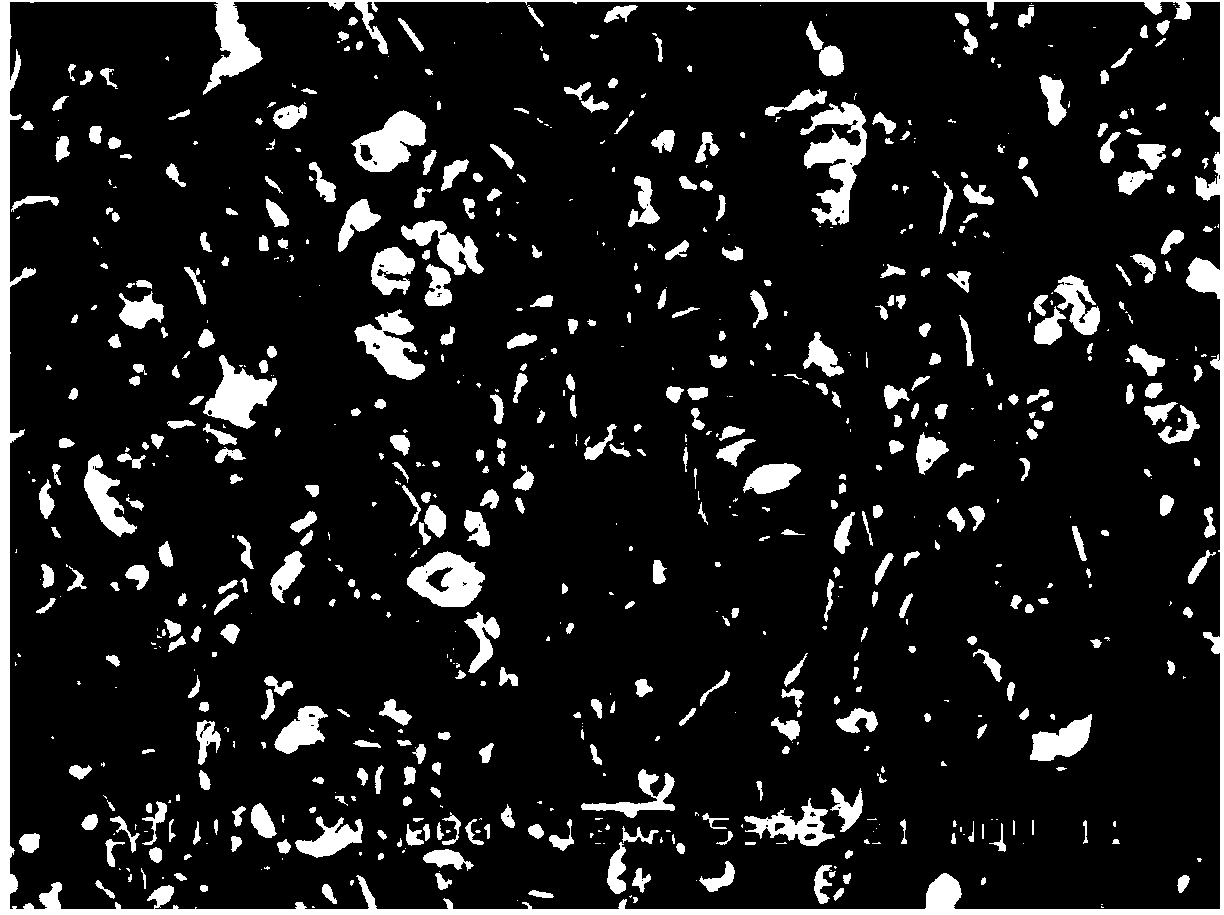

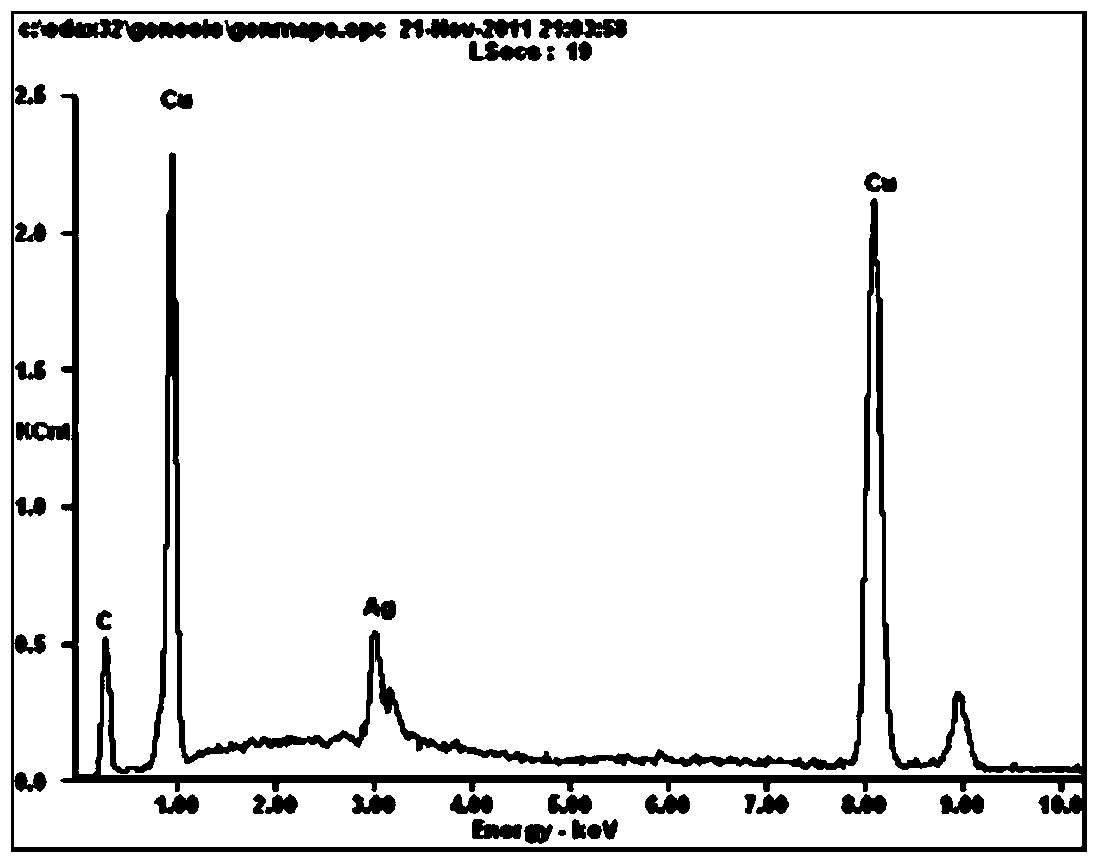

Preparation method for flaky silver coated copper powder

The invention relates to a preparation method for flaky silver coated copper powder. Under inert atmosphere, silver balls with the diameters of 0.5-10 mm are used as a milling media and the silver balls are separated through sieving after ball milling is performed on spherical copper powder in a ball milling machine for 2-8 h, so that the flaky silver coated copper powder can be obtained, and the silver balls are returned to a ball milling working procedure for being used continuously. The preparation method provided by the invention has the characteristics of simple technology, low cost and the like, compact flaky silver coated copper powder product with complete surface coating can be obtained, and the product has excellent electrical conductivity and oxidation resistance, is an ideal silver substitute product and has a good application prospect.

Owner:CENT SOUTH UNIV

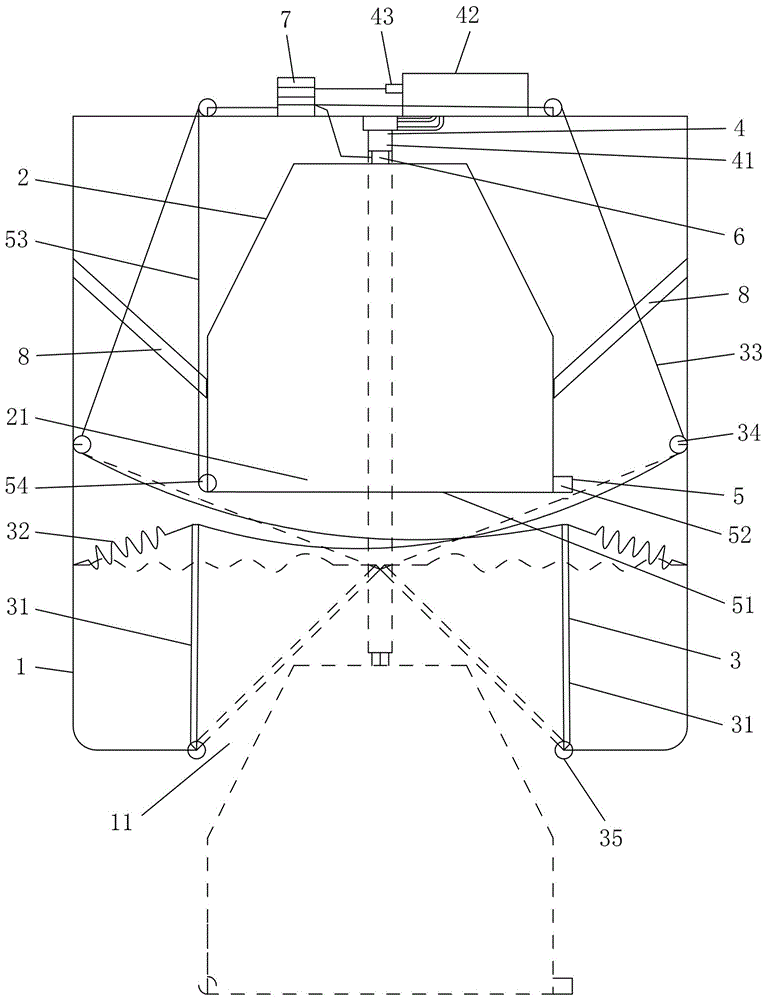

Seafloor discrete mineral particle explorer

ActiveCN106379504AReduce the impactImprove environmental adaptabilityUnderwater equipmentMineral particlesEngineering

The invention discloses a seafloor discrete mineral particle explorer. The seafloor discrete mineral particle explorer comprises a storage cabin and a detection cabin, wherein the bottom of the storage cabin is provided with an opening and an opening / closing device for opening or closing the opening; a lifting device for driving the detection cabin to stretch out of or retract into the opening is arranged on the storage cabin; the bottom of the detection cabin is provided with a material inlet / outlet and an openable / closable filter screen device for opening or closing the material inlet / outlet. The seafloor discrete mineral particle explorer also comprises an electronic scale for weighing the weight of the detection cabin. The seafloor discrete mineral particle explorer has the advantages of simple structure, good operation continuity, high efficiency, high pertinence, little influence on deep sea environments and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for testing hot shrinkage rate of knitted fabric

InactiveCN103668932ASimple test methodNo special equipment requiredInspecting textilesShrinkage rateRoom temperature

The invention relates to a method for testing the hot shrinkage rate of knitted fabric. The method for testing the hot shrinkage rate of the knitted fabric comprises the steps that (1) 3 pieces of flat and non-plicated samples are cut from the knitted fabric to be tested, 3 pairs of marks are made transversely and longitudinally on each sample; (2) the samples processed through the step (1) are laid on an ironing platform and are ironed respectively 3 times in the longitudinal and transverse directions through a steam iron, and induced draft ironing is carried out; (3) the operation step (2) is repeated two times, and the three ironed samples are obtained; (4) the three ironed samples are unfolded and dried at room temperature, and the distance between the two ends of each pair of marks in the transverse and longitudinal directions of each sample is measured after balance; the hot shrinkage rates of the three samples are calculated respectively, and the average value is obtained. The method for testing the hot shrinkage rate of the knitted fabric is easy and convenient to carry out, free of special equipment requirements, is accurate and reliable in the test result, small in error, and capable of being repeatedly implemented.

Owner:SHANGHAI CHALLENGE TEXTILE

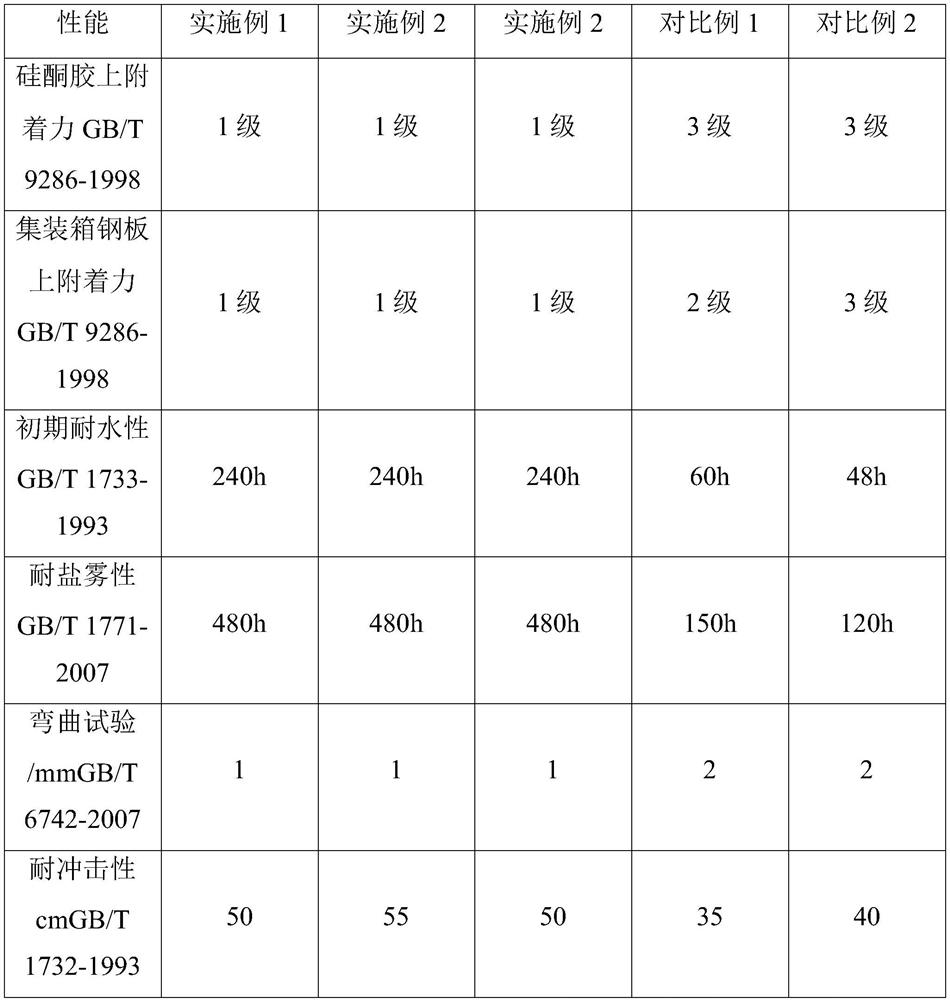

Primer-topcoat water-based paint for container and preparation method thereof

ActiveCN113372768AEasy to operateNo special equipment requiredAnti-corrosive paintsPolymer scienceSilicone adhesive

The invention relates to the technical field of water-based paint, and particularly discloses primer-topcoat water-based paint for a container and a preparation method of thereof The primer-topcoat water-based paint for the container is prepared from 45-55 parts of water-based acrylic emulsion, 15-25 parts of deionized water, 0.5-1 part of anti-freezing agent, 0.5-1 part of neutralizer, 0.8-1.2 parts of dispersing agent, 0.05-0.15 part of defoaming agent, 4-6 parts of coalescing agent, 0.05-0.15 part of sterilizing agent, 4-6 parts of pigment, 12-18 parts of anti-rust filler, 0.8-1.2 parts of anti-rust additive, 1.5-2.5 parts of an anti-flash rust agent, 0.8-1.2 parts of a wetting leveling agent, 0.1-0.3 part of a dustproof thixotropic agent and 0.4-0.8 part of a thickening agent. The primer-topcoat water-based paint for the container has good adhesive force on steel plates and silicone adhesives of the container, has excellent salt mist resistance and water resistance, and is especially suitable for living containers.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Preparation method of Cf/SiC composite material with HfB2 interface

The invention discloses a preparation method of a Cf / SiC composite material with an HfB2 interface. The preparation method comprises the steps that activating treatment is conducted on a carbon fibersurface, interfacial phase is prepared, a porous fiber preform is prepared, and a silicon carbide matrix is prepared. The preparation method of the Cf / SiC composite material with the HfB2 interface ischaracterized in that the fiber preform is filled with the silicon carbide matrix to form a carbon fiber reinforced silicon carbide ceramic matrix composite, and an interface layer coats the surfaceof carbon fiber in the composite material. According to the preparation method of the Cf / SiC composite material with the HfB2 interface, high-temperature resistant and oxidation resistant HfB2 interface phase is prepared on the surface of the carbon fiber, the original mechanical property of the carbon fiber is kept, and the oxidation resistant performance of the carbon fiber at high temperature is improved. According to the preparation method of the Cf / SiC composite material with the HfB2 interface, the technical problems that the preparation period of a traditional preparation method of silicon carbide ceramic matrix composite materials is long, the compatibility of toughened carbon fiber and the silicon carbide matrix interface in the Cf / SiC composite material occurs, and oxidizing reaction of the carbon fiber is prone to occurring in the using environment with high temperature oxidation stability are solved.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com