Patents

Literature

2061results about "Charge treatment type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

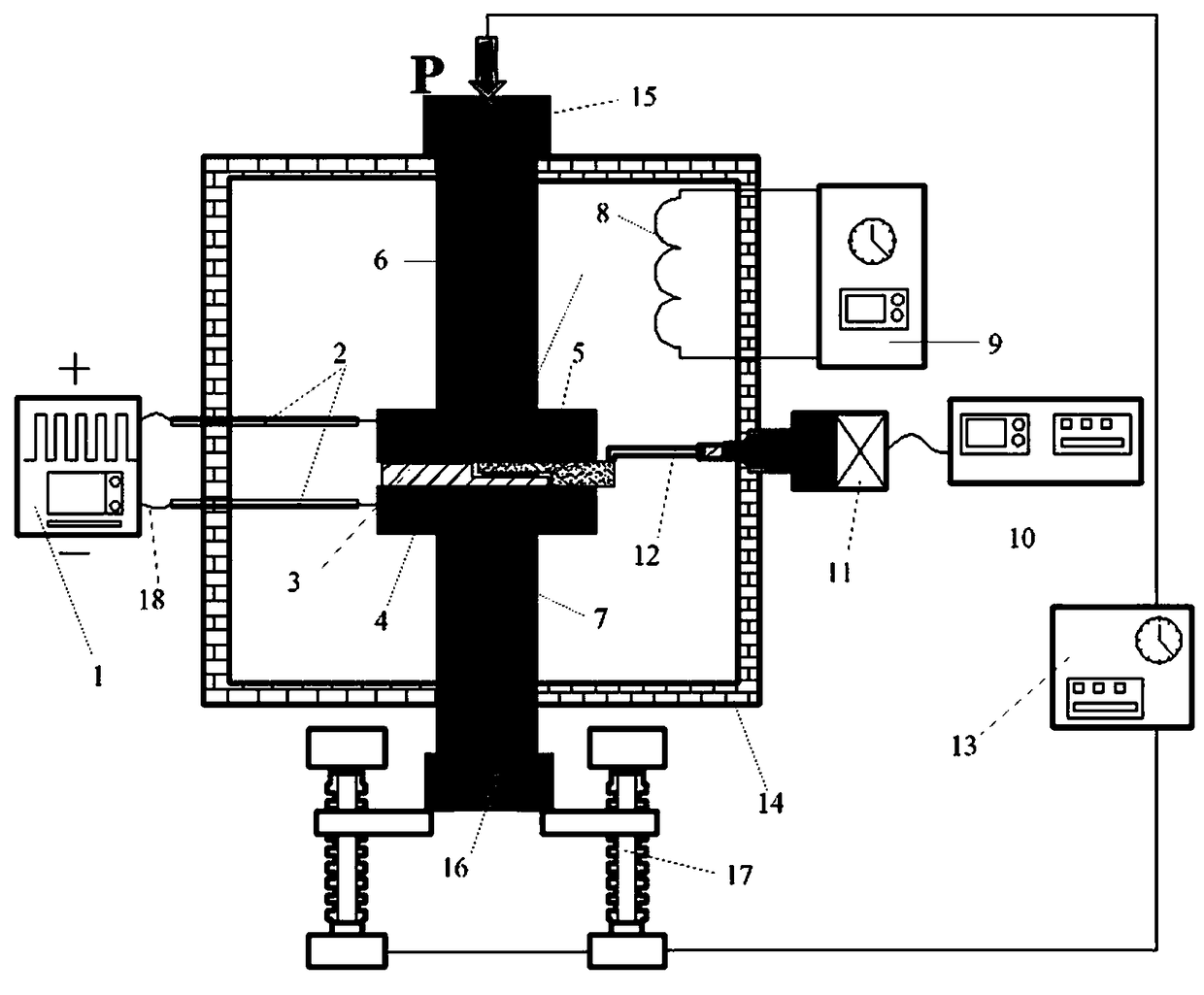

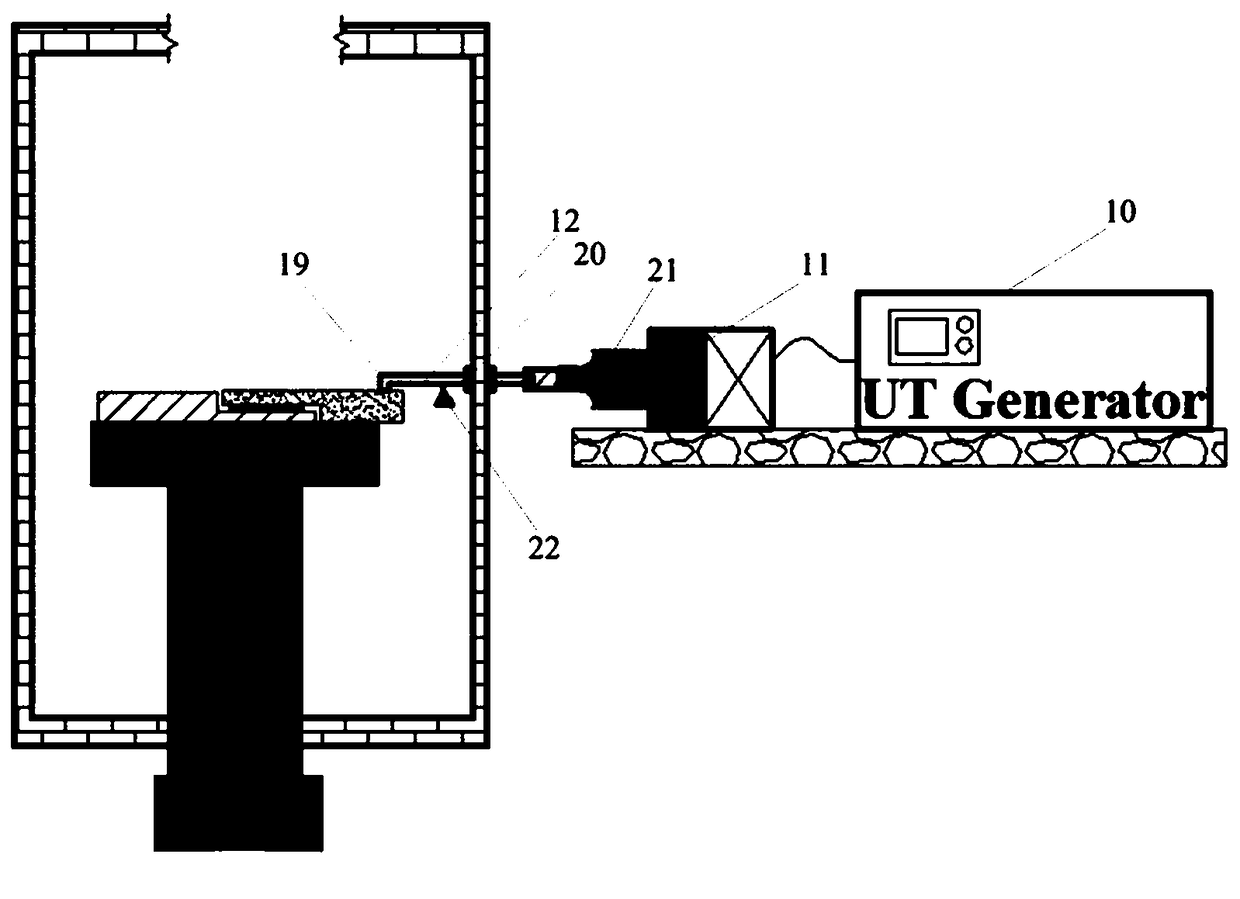

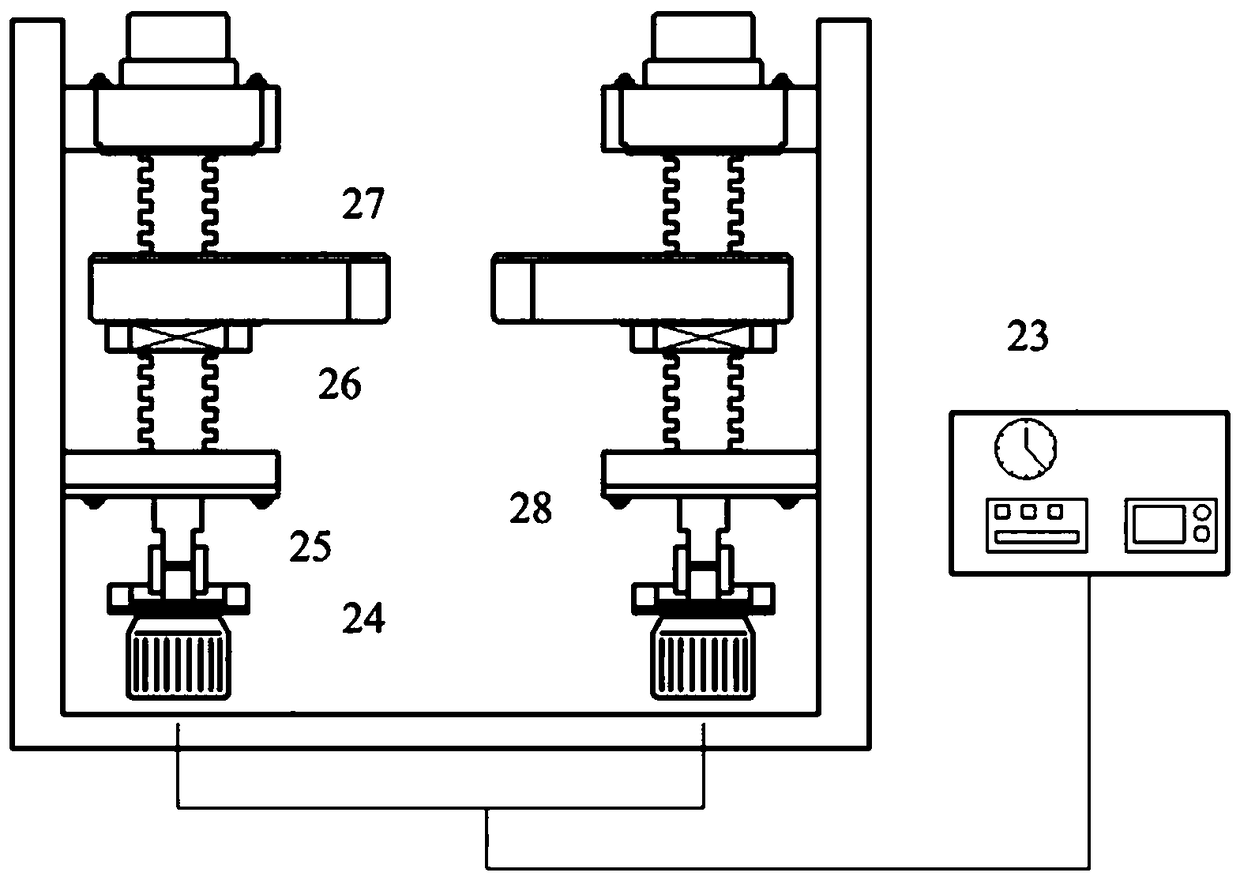

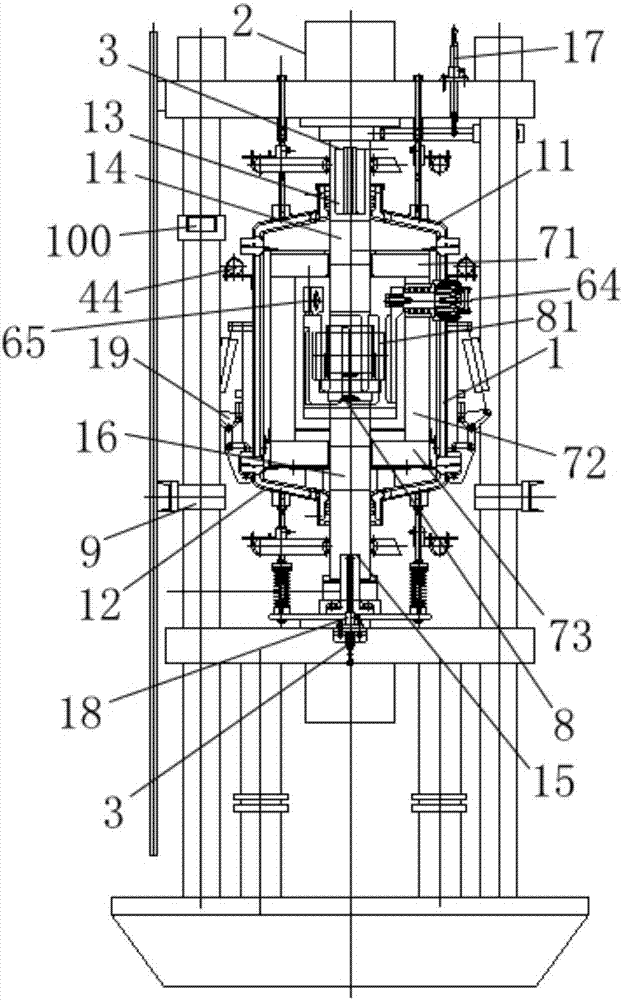

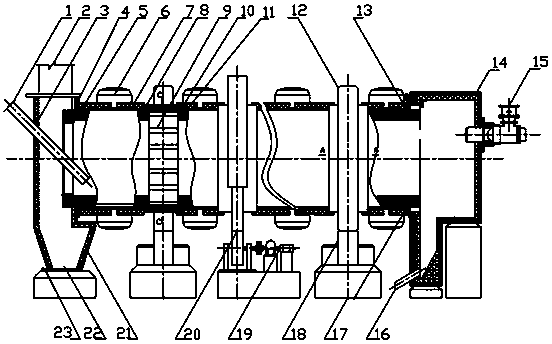

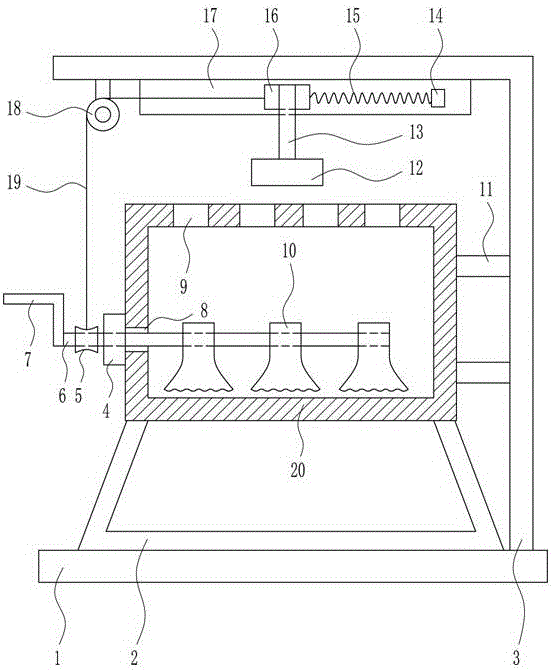

Synchronous bonding method for metal matrix composite material sintering assisted by pulsed electric field and ultrasonic field and device thereof

ActiveCN108890114ASevere thermal expansion effectChange growth characteristicsCharge treatment typeFurnace typesBond interfaceRadiant heat

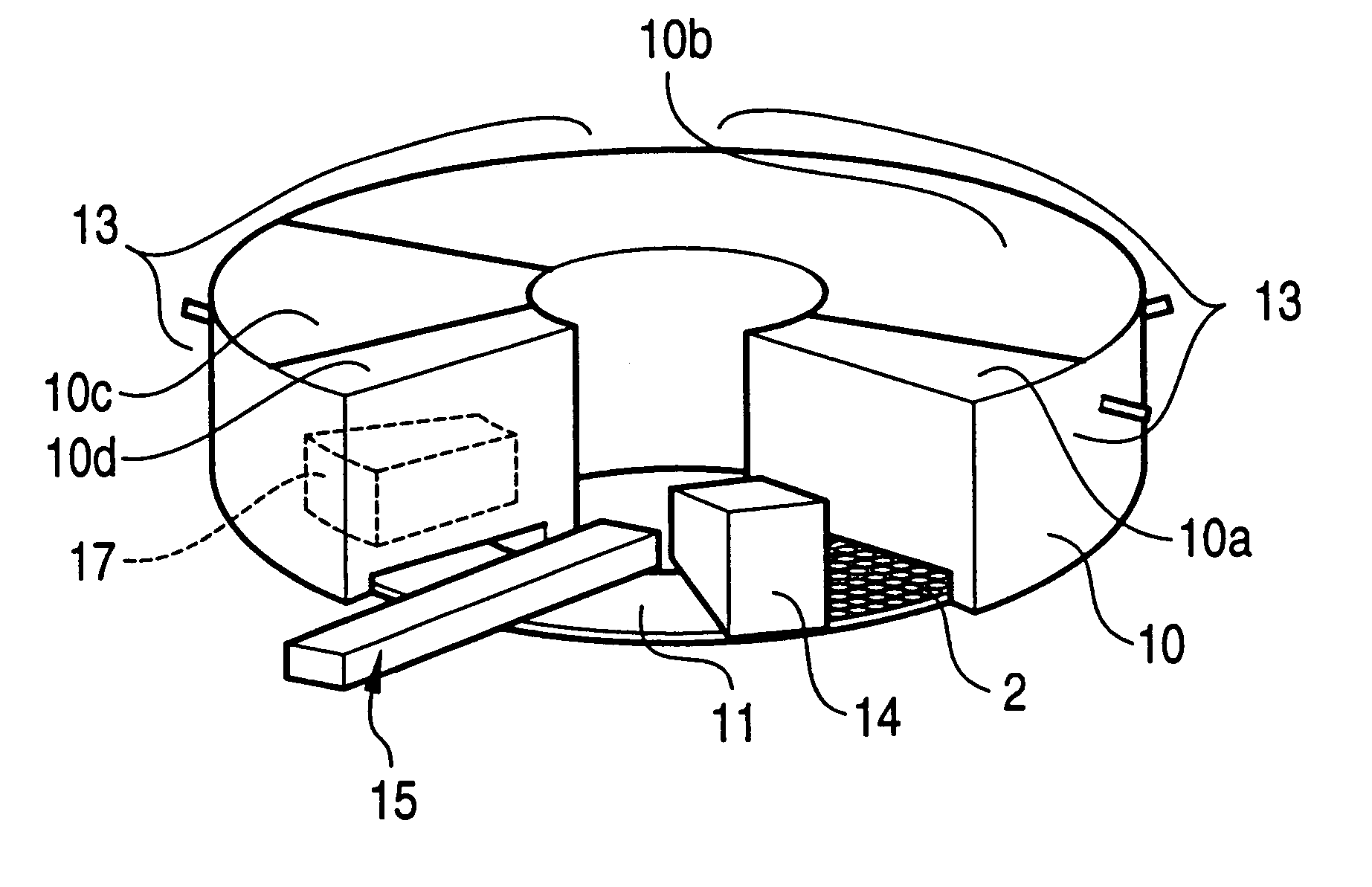

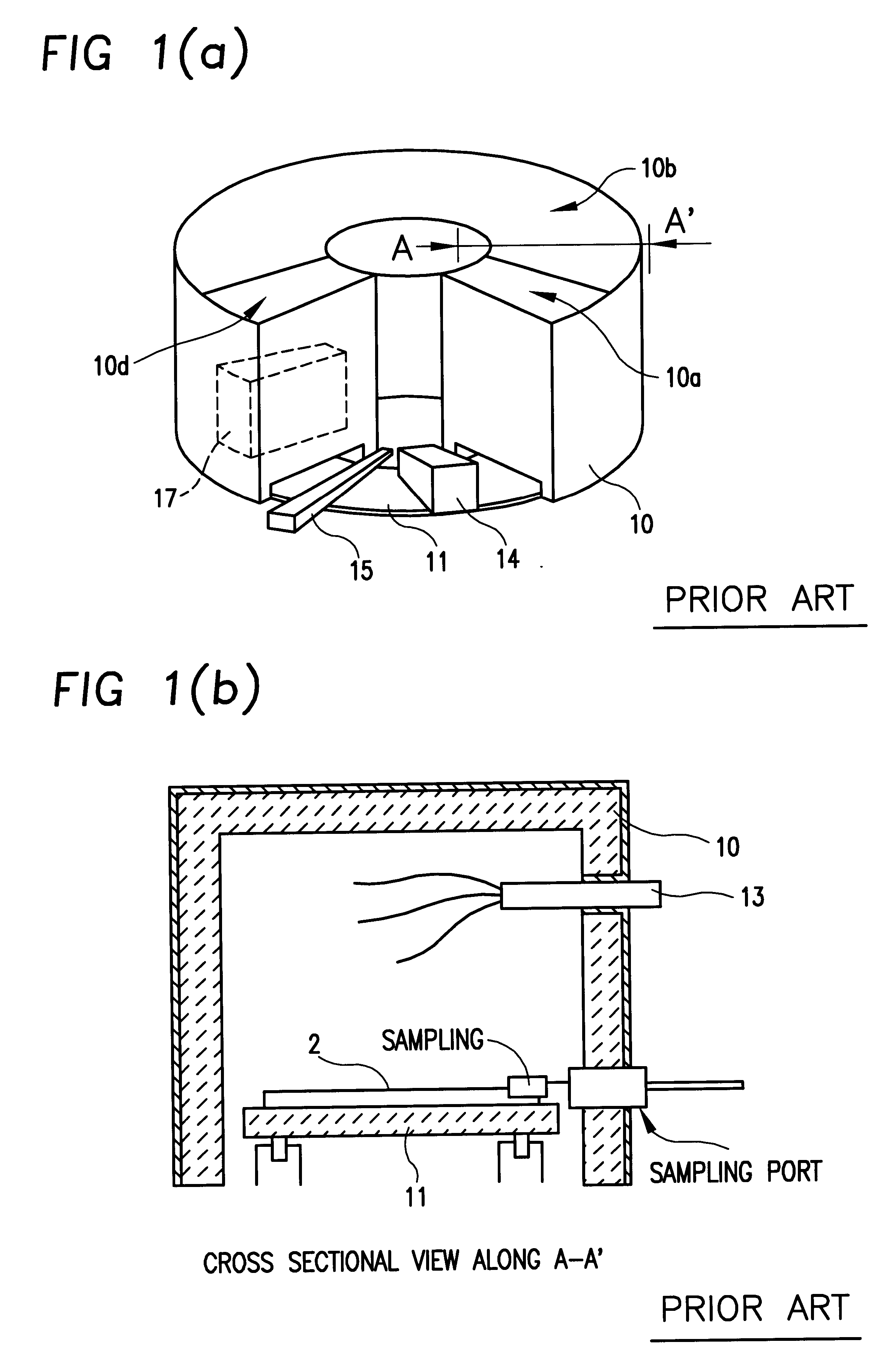

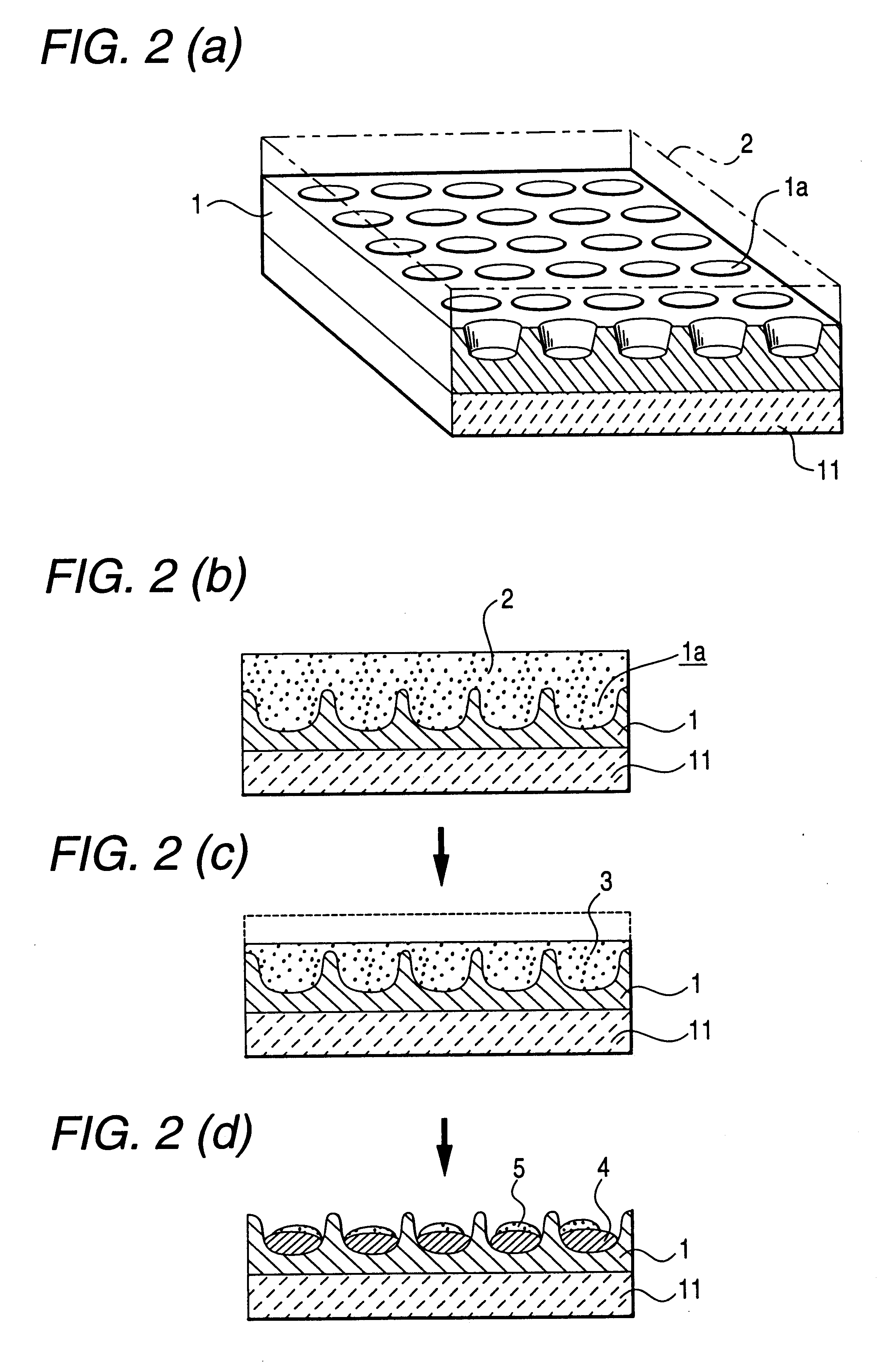

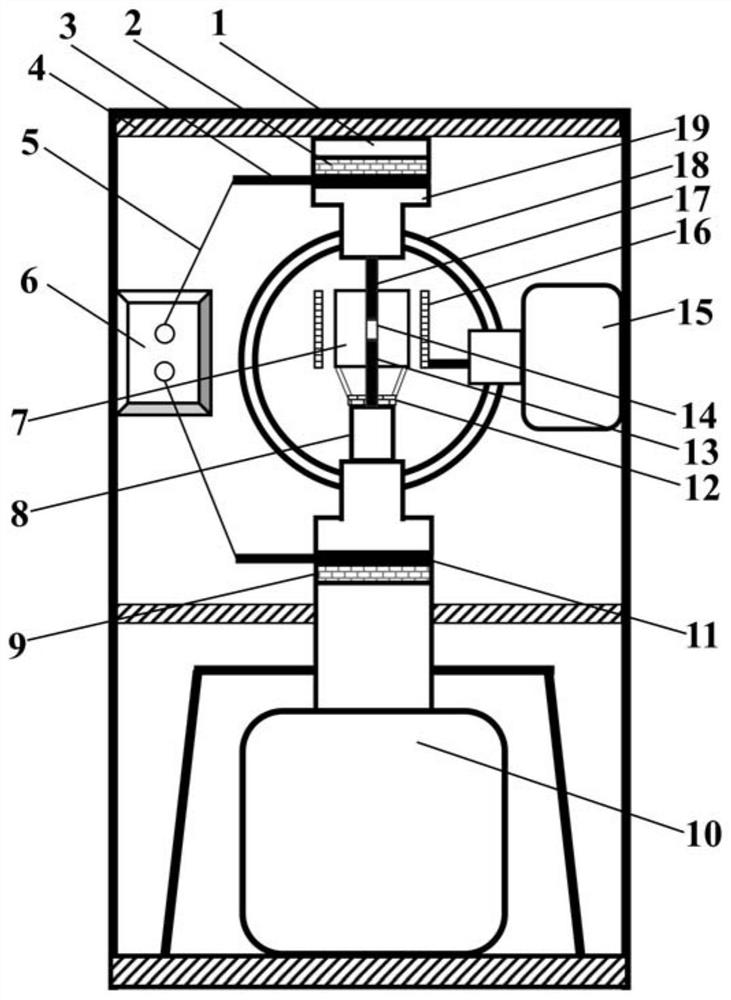

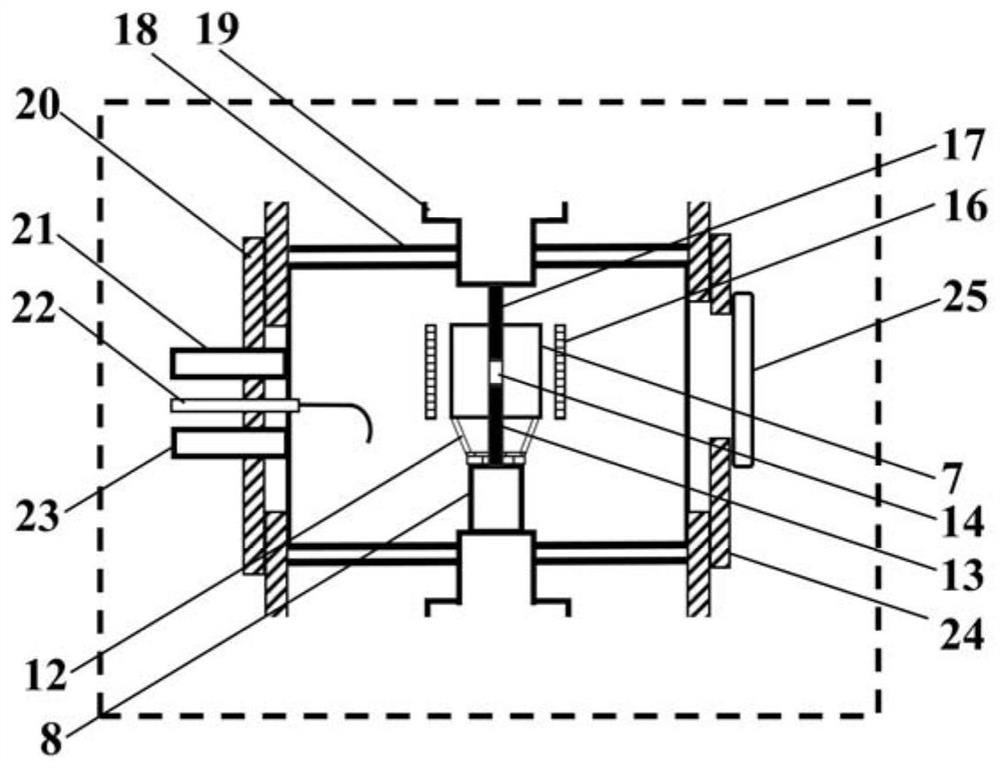

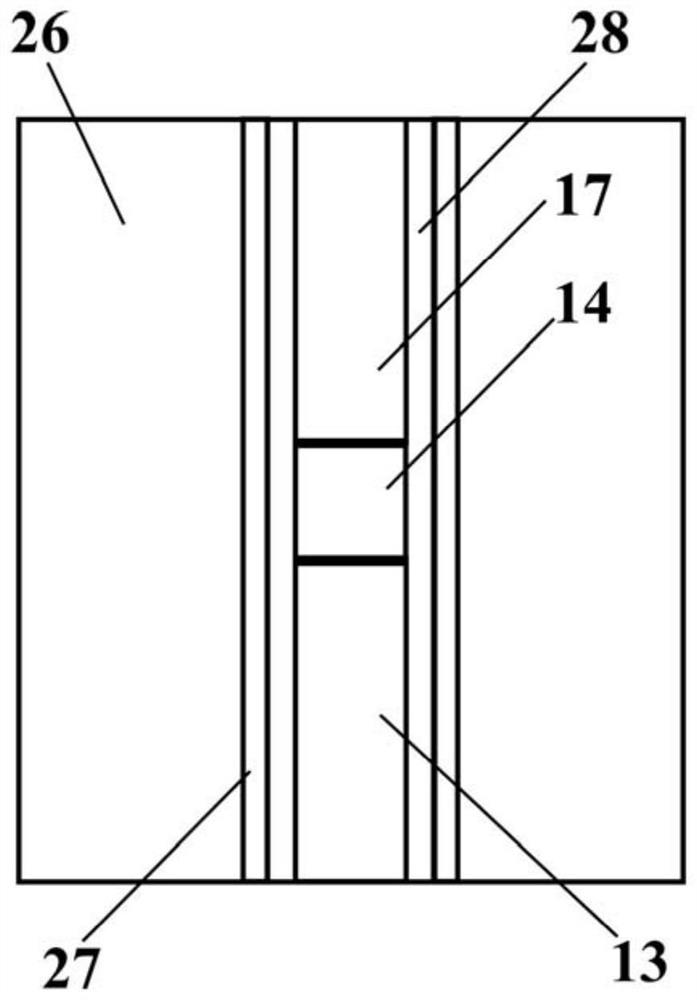

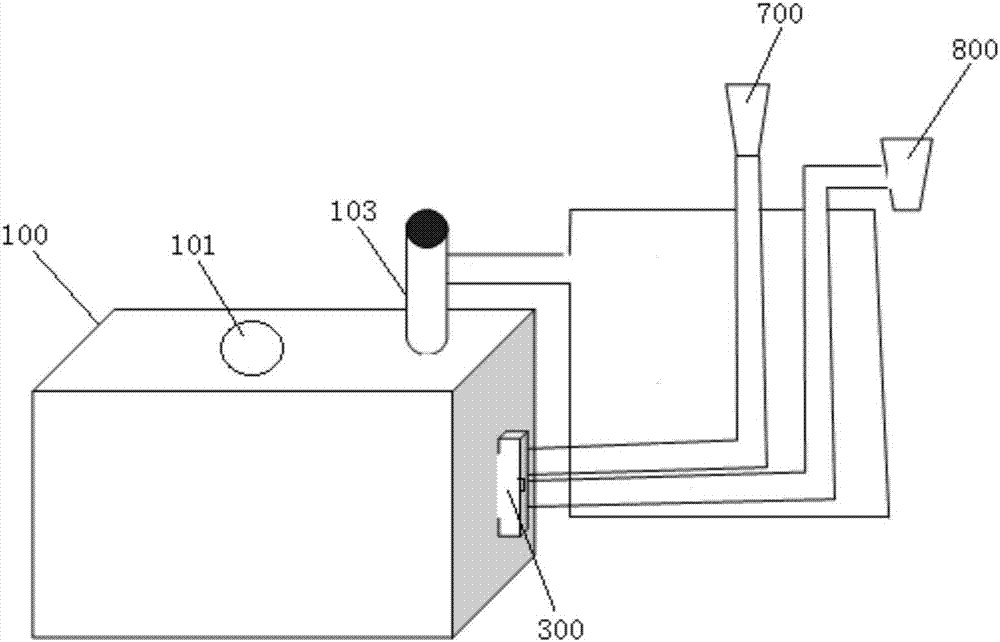

The invention provides a synchronous bonding method for metal matrix composite material sintering assisted by pulsed electric field and an ultrasonic field and a device thereof. The invention discloses a method for connecting magnesium (or copper) matrix composite material with stainless steel while sintering, which is assisted by pulsed electric field and ultrasonic field, and a device for simultaneously sintering metal matrix composite material. The device of the method comprises an airtight heating furnace, a pulse current loading system, an ultrasonic load applying system, a pressure and lifting system, a sealed insulating pipe and other auxiliary devices. The remarkable advantage of the invention is that the sintering of the metal matrix composite material and the joining of the different materials are carried out simultaneously; Pulse current flowing through the experimental material induces interface resistance heat plasma spark heat sintering and bonding interface heating and cooling speed fast reducing external radiant heat reducing residual stress of the joint. Using the coupling function of pulsed electric field- ultrasonic field-pressure field, breaking the oxide film on the surface of reinforcing phase, sintering under atmospheric conditions, reducing the activation energy of atomic diffusion, promoting the interfacial metallurgical reaction, controlling the particle morphology and size, refining the interfacial grains and improving the quality stability of joints are conducive to the preparation of metal matrix composite / alloy joints with high comprehensive properties.

Owner:李纲

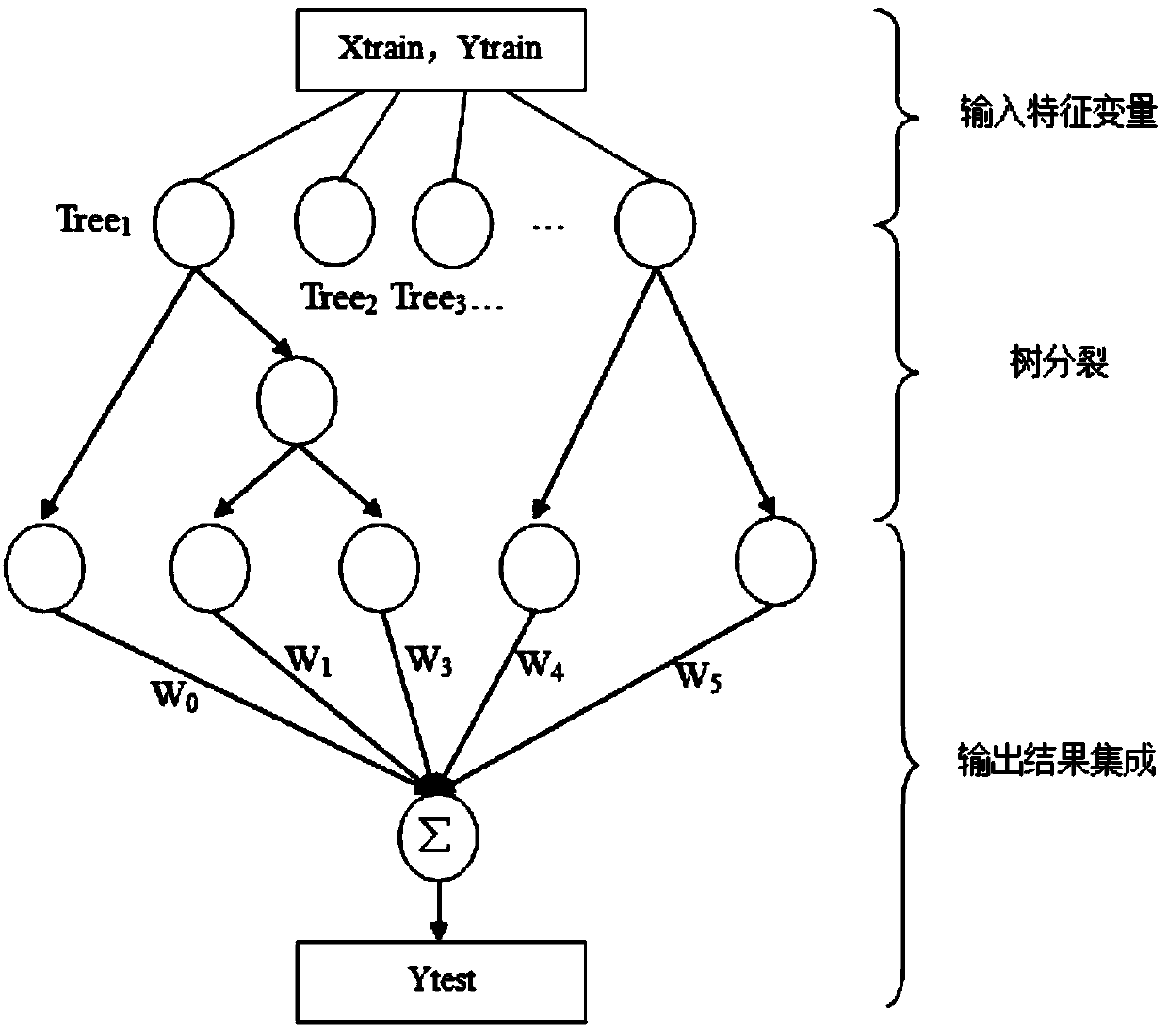

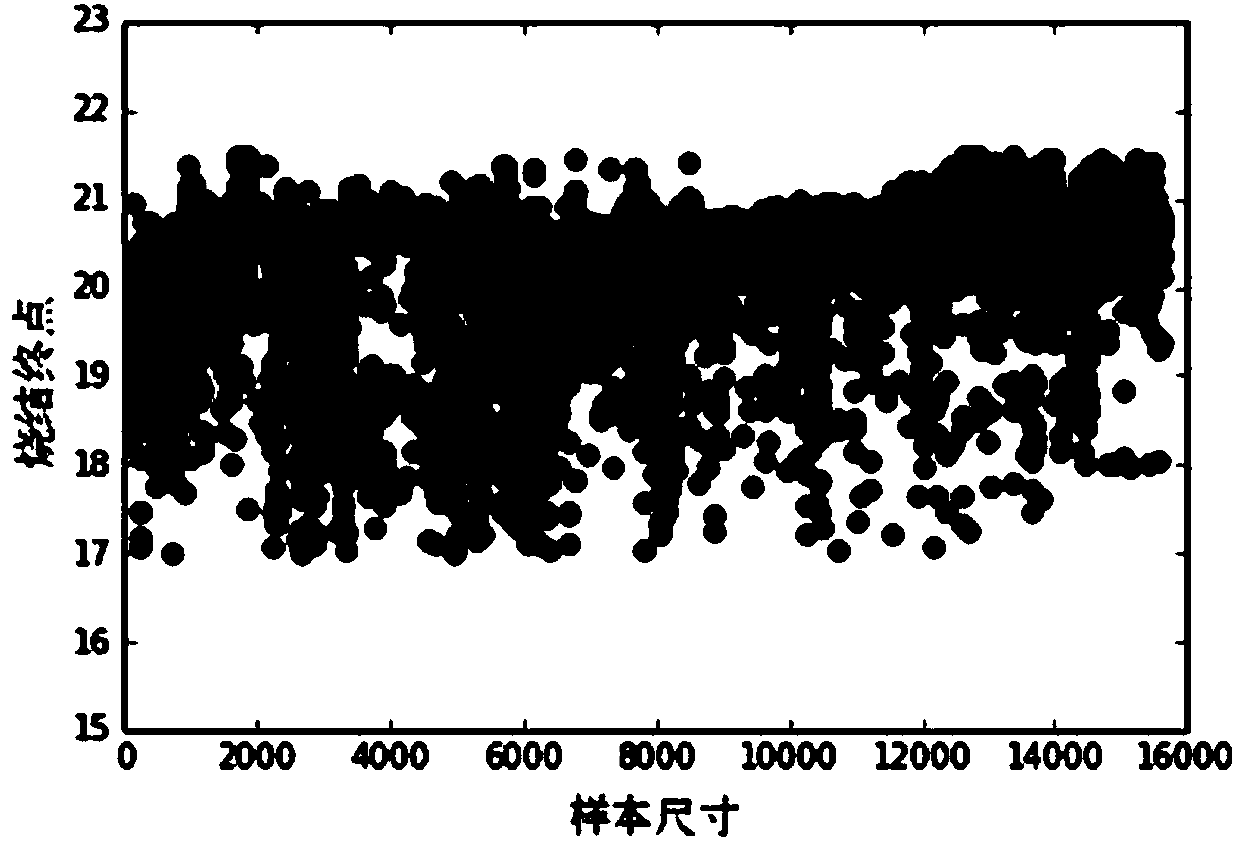

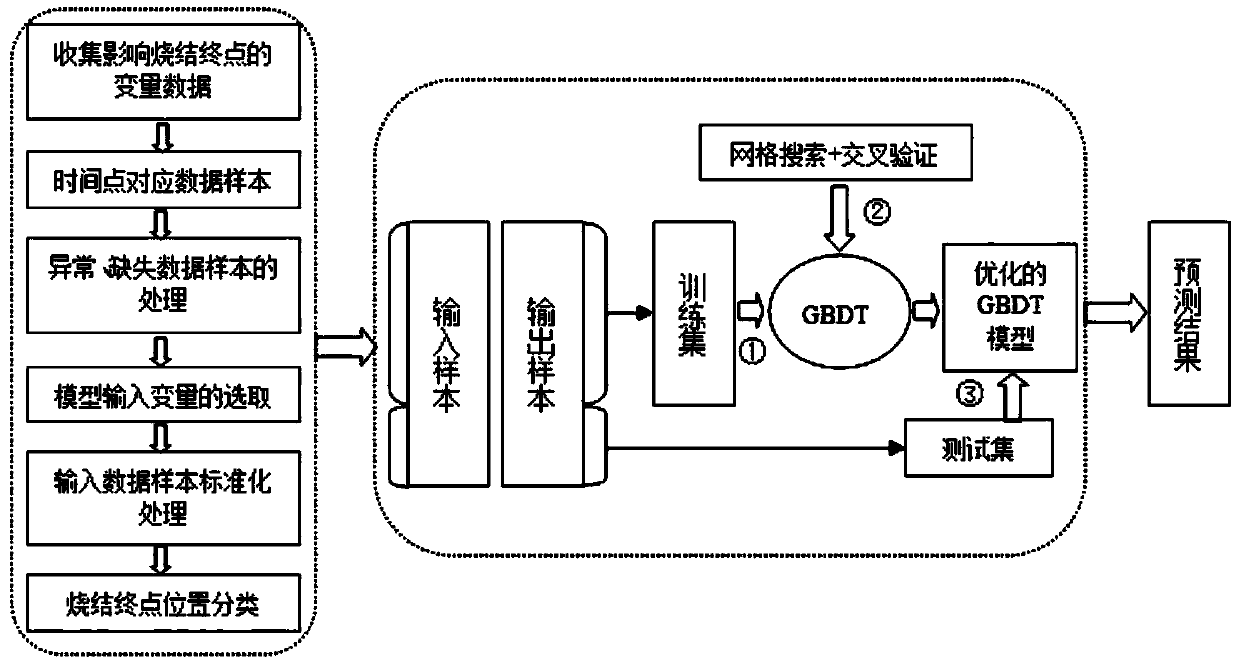

Establishment method for sintering end point prediction system based on big data and machine learning

ActiveCN108469180AHigh precisionImprove guidanceCharge treatment typeFurnace typesVisual presentationProcess engineering

The invention discloses an establishment method for a sintering end point prediction system based on big data and machine learning, and belongs to the field of sintering technological process control.The model establishment method comprises the steps that historical data are collected; data pre-processing is carried out; the model input variable and output variable are determined; an output sample is subject to visual presentation according to a drawing method, the data distribution characteristic and the equipment control accuracy are comprehensively considered, and sintering end point position classification is determined according to technological experience; and a GBDT is used for building a prediction model for sintering end point trend change states. The model established through the method can obtain the trend change range, it can be obtained that current ignition sintering mixture sintering end point positions are six classification trend change conditions including undersintering+++, undersintering++, undersintering+, undersintering, normality and oversintering. Well guidance is provided for a sintering process operator to judge sintering end point in advance and taking measures including fine adjustment, early adjustment and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

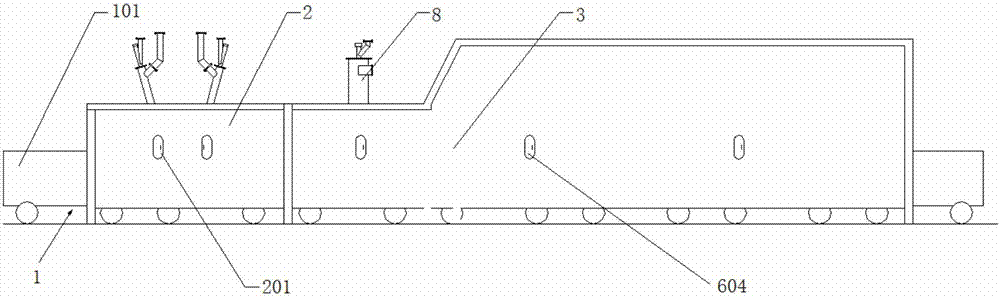

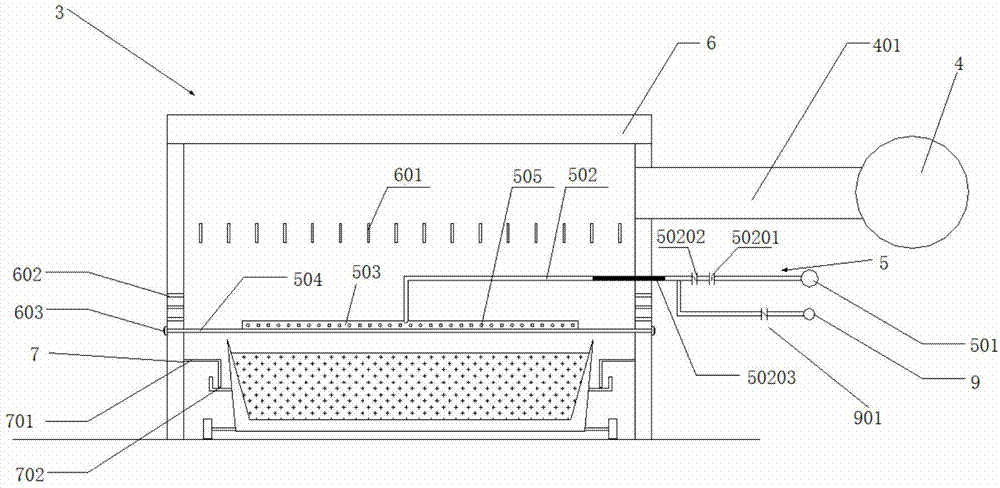

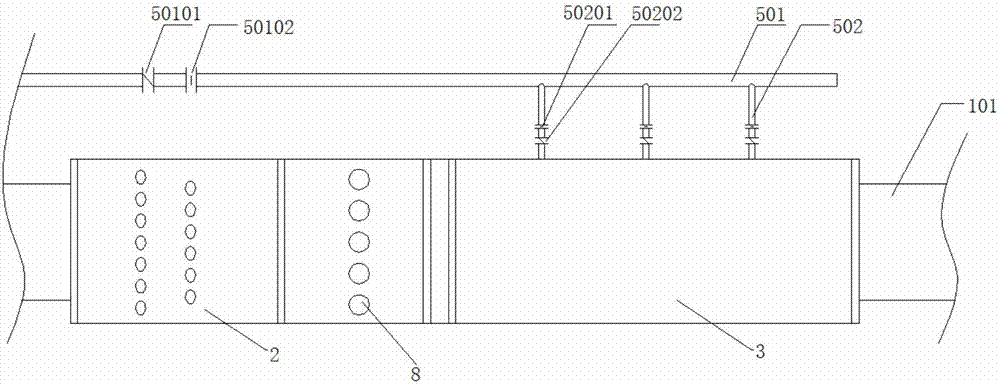

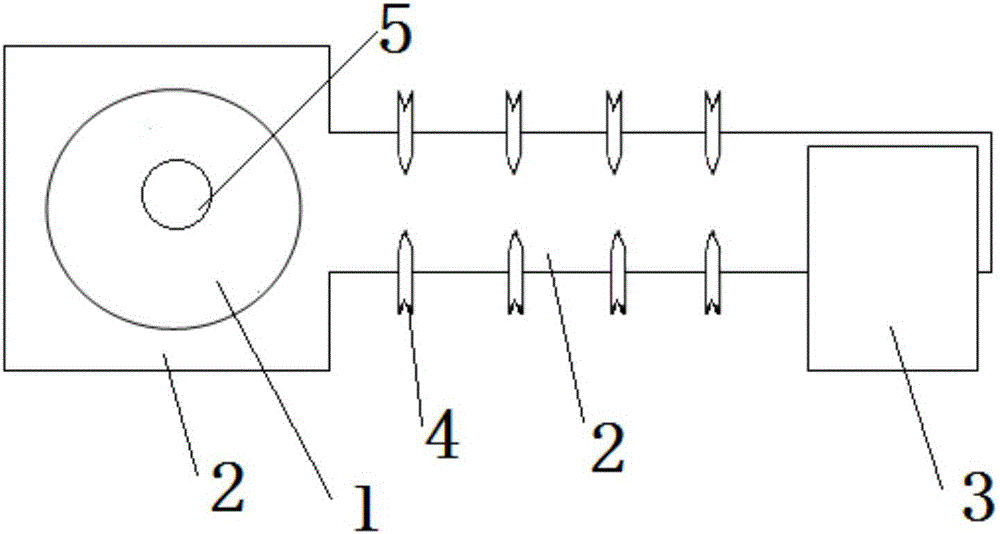

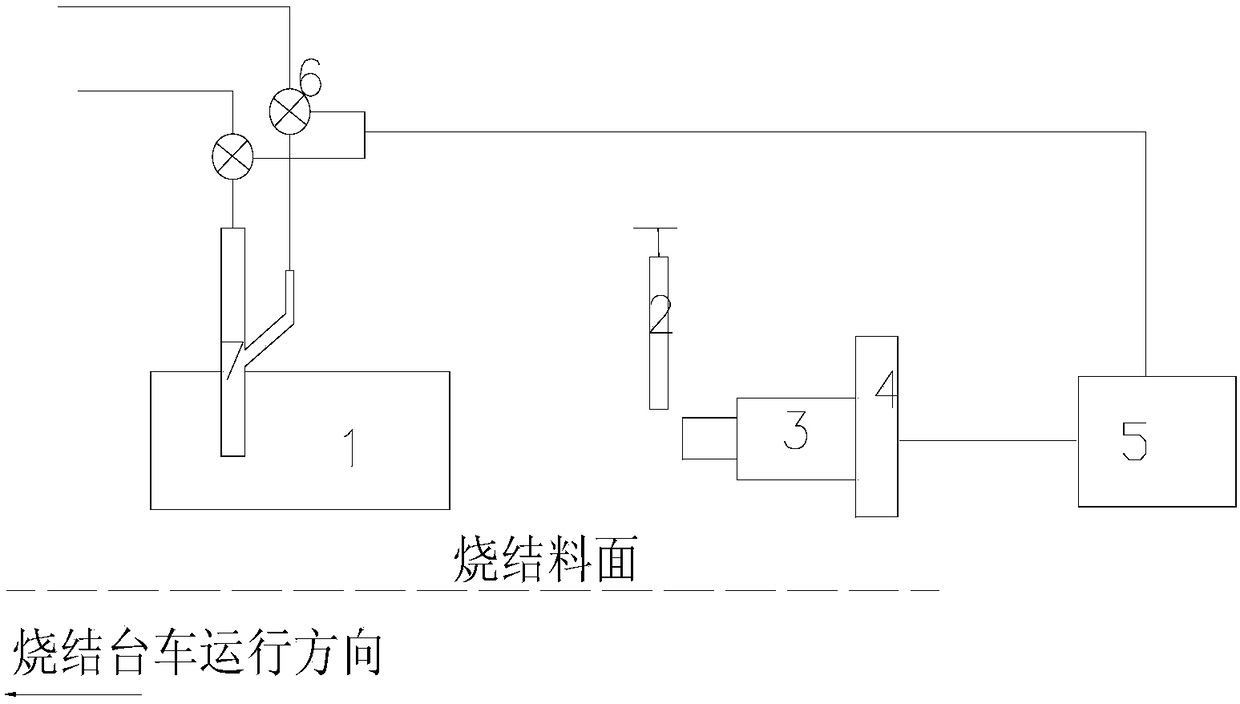

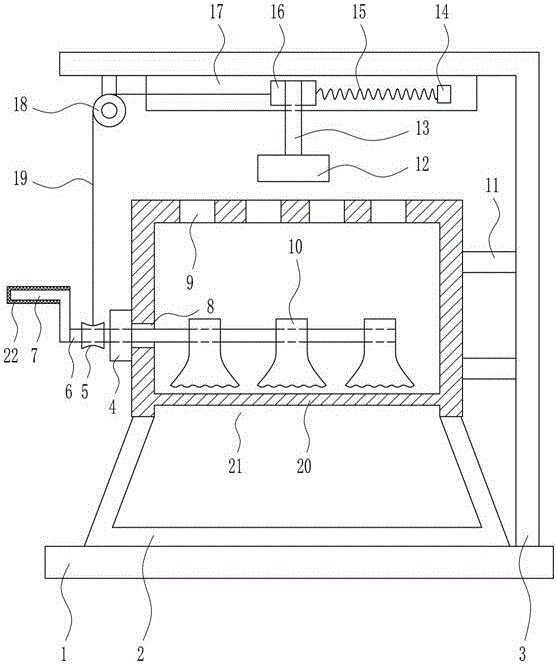

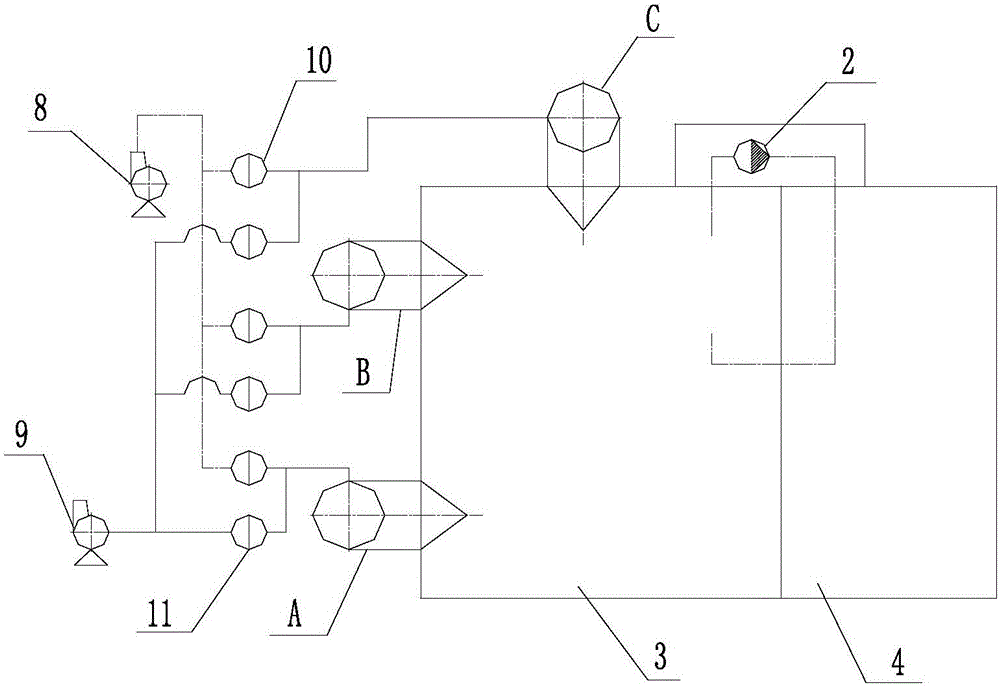

Multi-stage intensifying auxiliary sintering type ignition holding furnace and use method of same

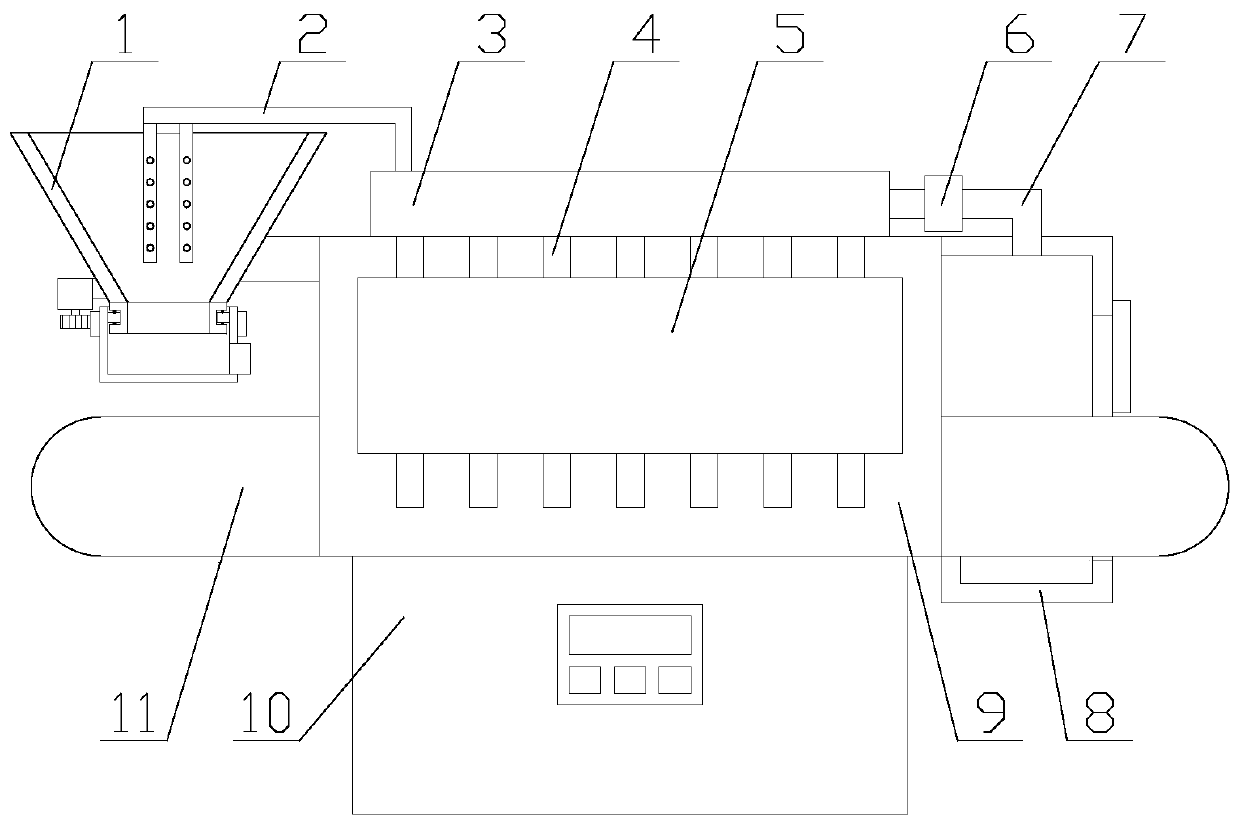

PendingCN107356119AIncrease freedomEnsure the effect of auxiliary sinteringCharge treatment typeFurnace typesPhase conversionEngineering

A multi-stage intensifying auxiliary sintering type ignition holding furnace comprises a sintering machine (1), an ignition device (2) and an auxiliary combustion device (3), wherein the sintering machine (1) has a trolley (1); the ignition device (2) and the auxiliary combustion device (3) are orderly arranged on the trolley (1); the auxiliary combustion device (3) has a hot air device (4), a blow-injection device (5) and an auxiliary combustion cover (6); the hot air device (4) has a hot air pipeline (401); and the blow-injection device (5) has a fuel gas total pipe (501), a fuel gas branch pipe (502), a blow-injection pipe (503) and a rack (504). The multi-stage intensifying auxiliary sintering type ignition holding furnace can replace coke by partial fuel gas and hot smoke and achieves sintering bed segregation coke distribution effect via phase conversion; blow-injection device adjustability and freedom can be enhanced; multi-procedure multi-medium coupling blow-injection can be achieved; and the multi-stage intensifying auxiliary sintering type ignition holding furnace has great safety performance and high sintering quality.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

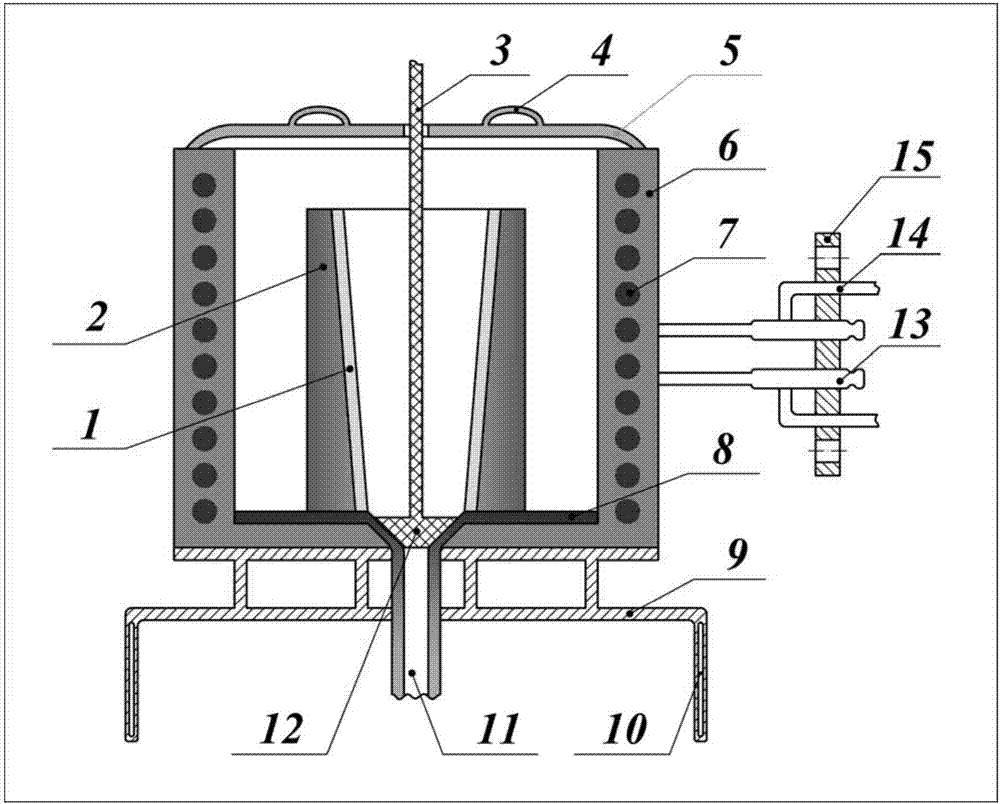

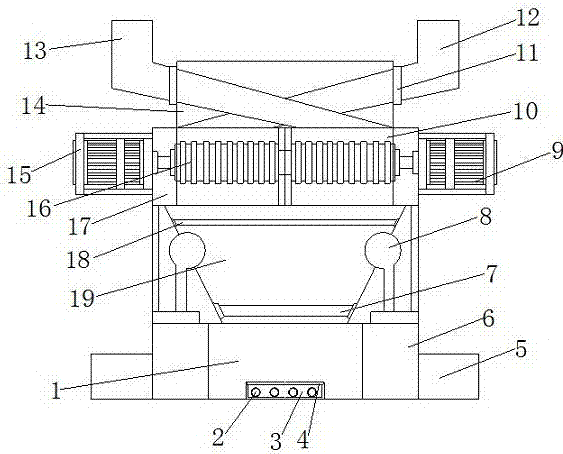

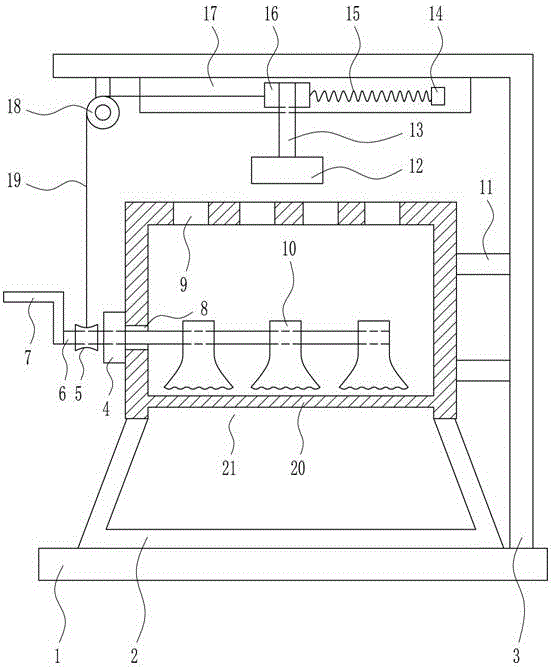

Oscillating hot press sintering furnace

InactiveCN107062891AUniform densityShort sintering timeMuffle furnacesCharge composition/stateVibration amplitudeMaterials preparation

Owner:ZHUZHOU XINRONGLI IND

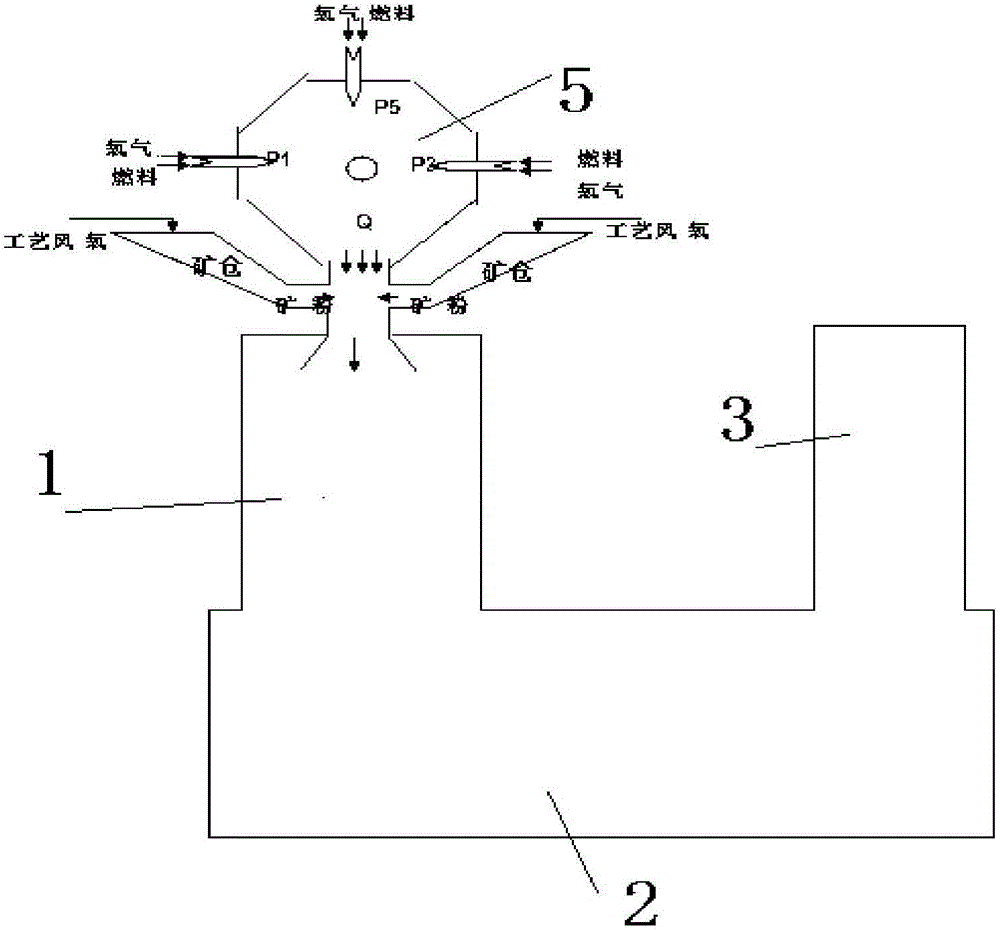

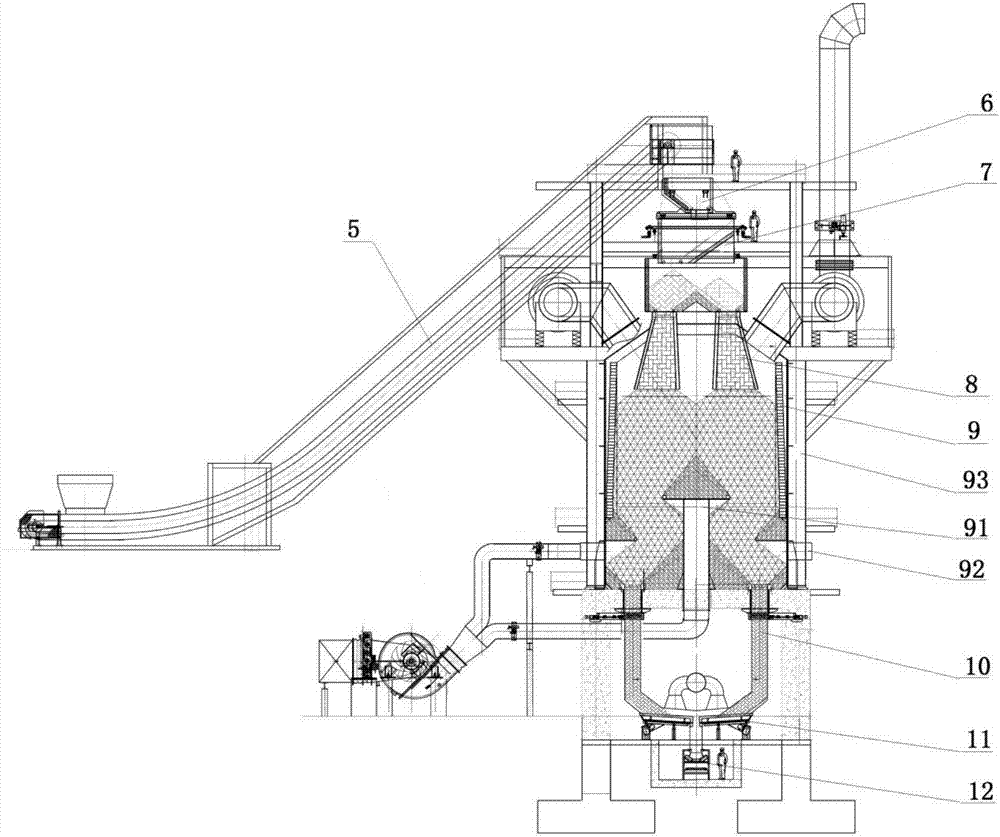

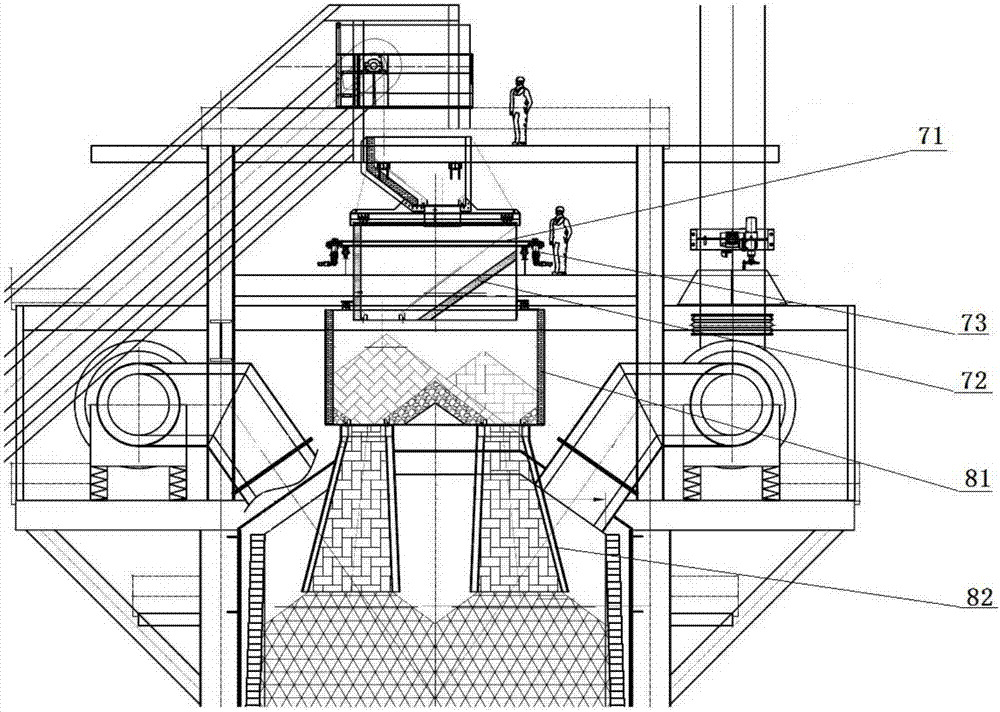

Connection-in-series flash furnace and smelting method

ActiveCN105925809ARestore fastExtend smelting timeMaintainance of heating chambersCharge treatment typeFlue gasSlag

The invention relates to a connection-in-series flash furnace. The connection-in-series flash furnace comprises an upper reaction body (5), a lower reaction body (1), and a connecting passage (7) through which the upper reaction body (5) and the lower reaction body (1) are connected, wherein the upper reaction body (5) is positioned at the upper part of the lower reaction body (1), so that a connection-in-series structure is formed; one or more molten pools (2) are arranged at the lower part of the lower reaction body (1); the flash furnace further comprises a lifting flue (3) through which flue gas is exhausted, the lifting flue (3) communicates with the lower reaction body (1) through the molten pools (2), and a slag-off outlet is formed in each of the molten pools (2). The connection-in-series flash furnace disclosed by the invention provides heat and reducing atmosphere for the lower reaction body through the upper reaction body, so that the purpose that mineral fines of metal oxidized ore are rapidly reduced and melted through the lower reaction body is achieved.

Owner:TIANJIN FLASH IRONMAKING TECH CO LTD

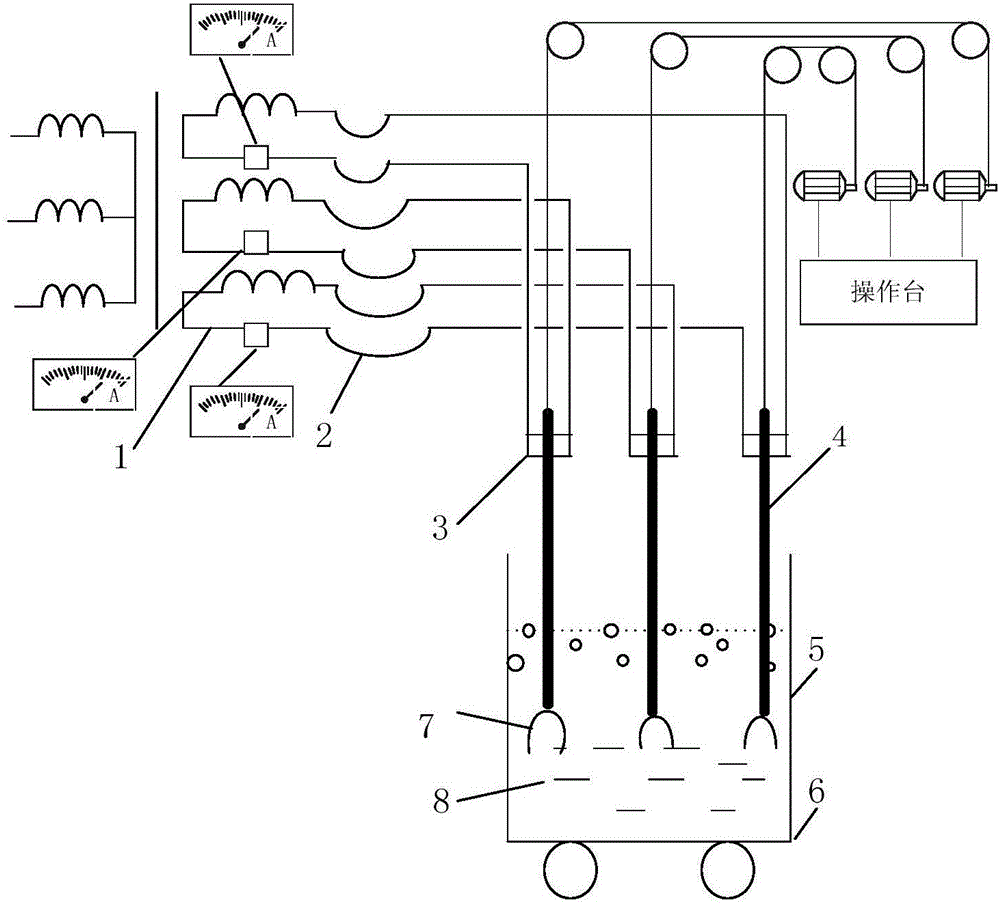

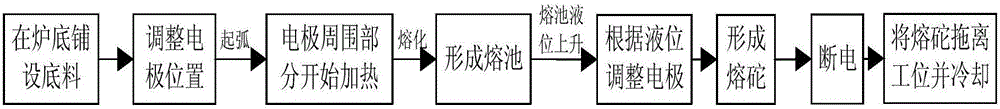

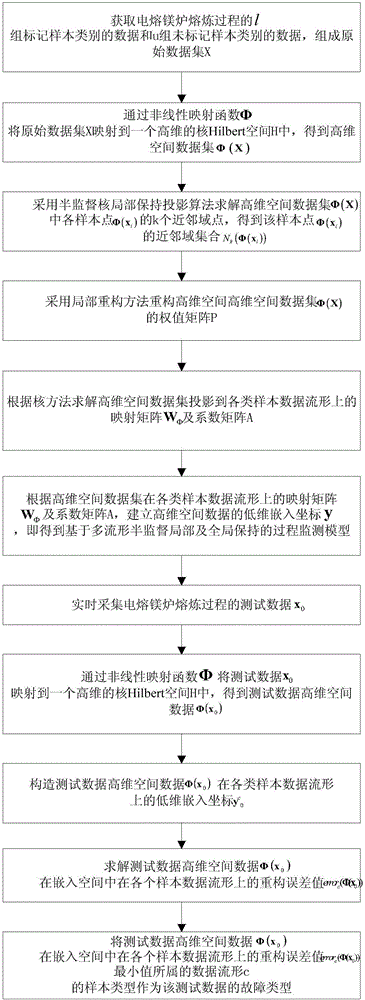

Electrical smelting furnace for magnesia fault monitoring method based on multi-manifold semi-supervised local-overall situation

ActiveCN106839769AReduce distanceIncrease distanceCharge composition/stateCharge treatment typeOriginal dataSmelting process

The invention provides a electrical smelting furnace for magnesia fault monitoring method based on a multi-manifold semi-supervised local-overall situation. The method comprises the steps of acquiring an original data set X during a smelting process of a electrical smelting furnace for magnesia, building a process monitoring model based on multi-manifold semi-supervised local-overall situation maintaining according to the original data set of the smelting process of the electrical smelting furnace for magnesia, acquiring test data x0 during the smelting process of the electrical smelting furnace for magnesia in real time, and carrying out fault type diagnosis on the test data x0 by adopting the process monitoring model based on multi-manifold semi-supervised local-overall situation maintaining. The method provided by the invention takes local and overall structures of data into consideration at the same time, and considers local diversity information among homogeneous data in order to prevent the occurrence of local overfitting, finally builds an optimal object function for multi-manifold semi-supervised fault diagnosis, and has a favorable monitoring effect.

Owner:NORTHEASTERN UNIV

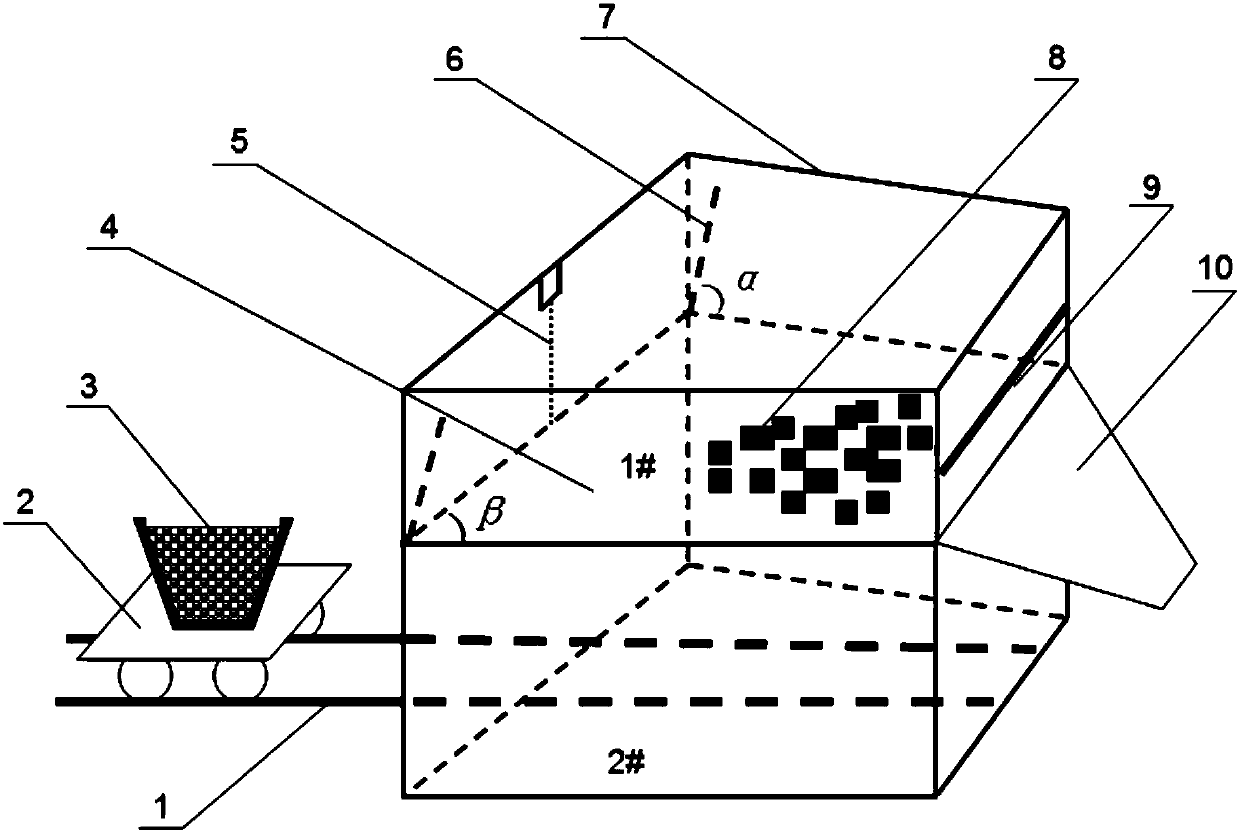

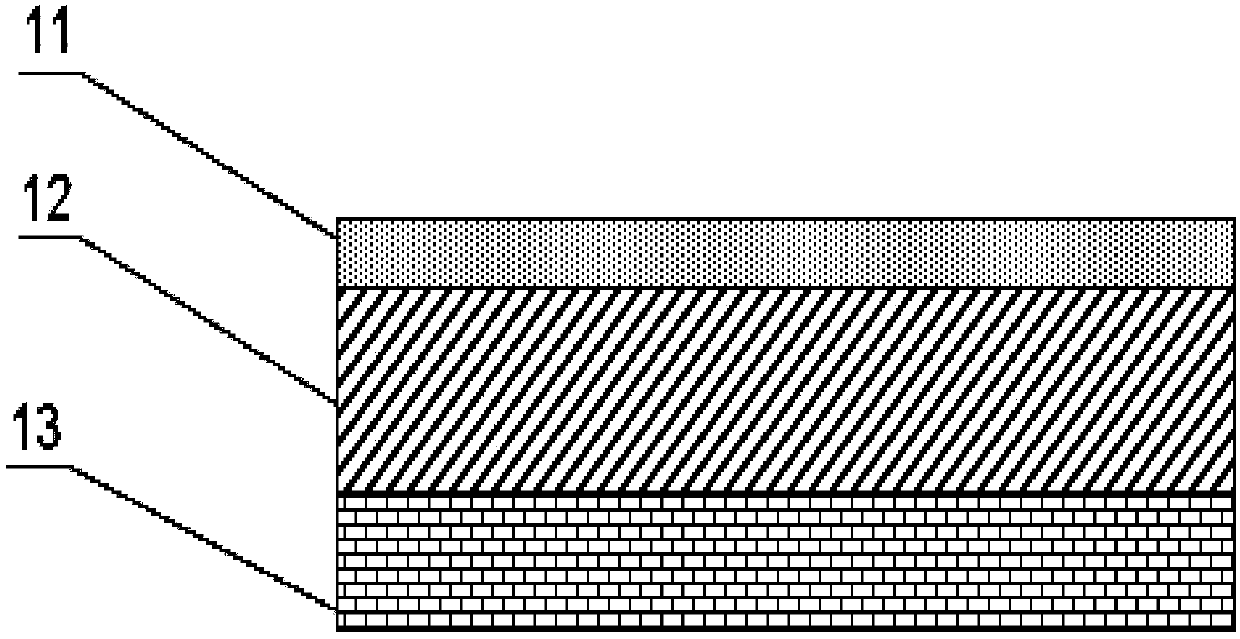

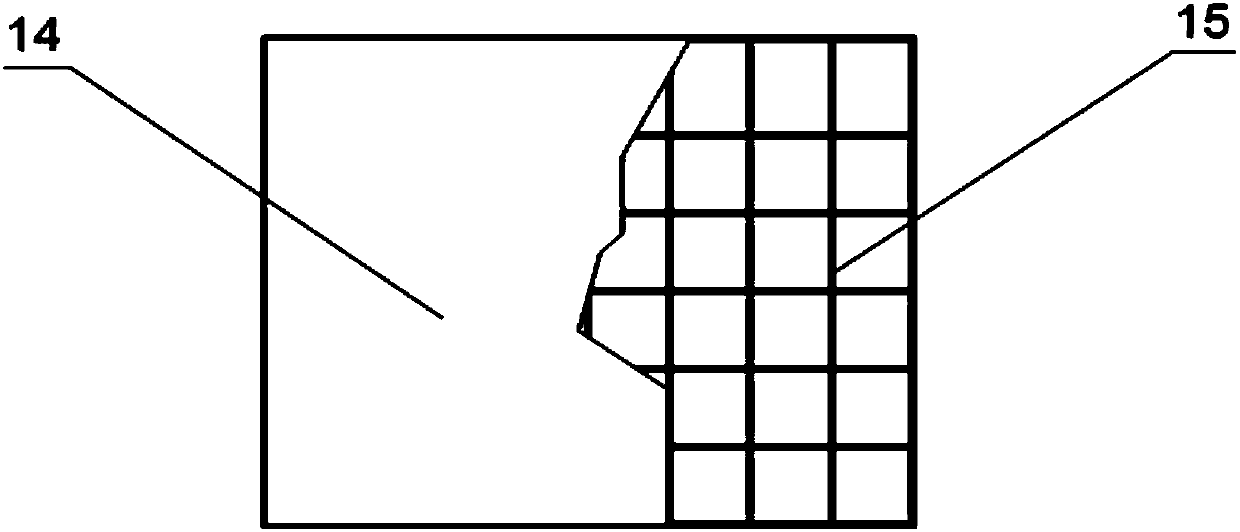

Device for preheating waste steel and alloys by using converter steel slag afterheat and application method

ActiveCN107779543ATo achieve the effect of recyclingIncreased hydrogen and nitrogen contentCharge treatment typeIncreasing energy efficiencySlagAlloy

The invention discloses a device for preheating waste steel and alloys by using converter steel slag afterheat and an application method. The device mainly consists of a waste steel and alloy adding chamber 1# chamber and a high-temperature furnace slag storage chamber 2# chamber. An insulation cover plate covers the top of the 1# chamber; the lower part of the 1# chamber is a baking chamber baseplate with a double-layer structure; a baseplate overturning driving hydraulic lifting chain is arranged above the top edge of the baseplate; overturning guide rails forming included angles alpha withthe baseplate are arranged on two side walls; and a discharge door is arranged on the back side wall. A slag tank car rail is arranged in the 2# chamber; and the top is the baseplate of the 1# chamber. In the use process, the cover plate at the top of the 1# chamber is opened to put the waste steel or the alloys on the baseplate; the insulation cover plate is covered; and then, a high-temperatureslag tank is conveyed to the 2# chamber through a slag tank car to finish baking heating of the waste steel or the alloys. Through use of the device, the converter high-temperature furnace slag afterheat can be recycled, and meanwhile, the effects of increasing the converter waste steel ratio, reducing the cost and improving the efficiency are achieved.

Owner:ANGANG STEEL CO LTD

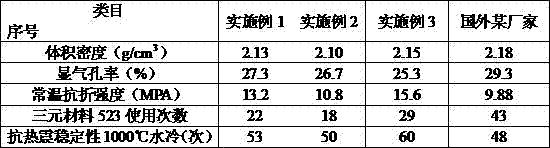

Sagger for calcining battery material and preparation method thereof

InactiveCN107382298ALower firing temperatureLow melting pointCharge supportsCharge treatment typeCordieriteAssembly line

The invention relates to a sagger for calcining a battery material and a preparation method thereof, and belongs to the technical field of lithium batteries. The sagger comprises the following raw materials in parts by weight: 10-50 parts of cordierite with a particle size of 2 to 1, 10-40 parts of cordierite with a particle size of 1 to 0, 1-20 parts of 200-mesh cordierite fine powder, 1-25 parts of 325-mesh fused magnesia-alumina spinel fine powder, 1-5 parts of sintering-promoting micro powder, 1-30 part of clay and 0.1-2 parts of an organic binding agent. The sagger uses the sintering-promoting micro powder, the sintering-promoting micro powder comprises of a plurality of kinds of lithium fine powder, and has low melting point and small thermal expansion coefficient so as to reduce the firing temperature of the saggar; and a roller kiln is used for firing, after forming, the saggar is spread out and put into the roller kiln for sintering, after the firing, the bottom flatness effect of the sagger is better than that of the sagger which is sintered by vertically placed in a shuttle kiln, and a fully automated assembly line production mode of a user can be met.

Owner:宜兴市锦泰耐火材料有限公司

Multi-purpose electromagnetic induction melting device and method

InactiveCN107388823AAvoid pollutionPrevent oxidationCharge treatment typeCrucible furnacesEddy currentElectromagnetic induction

A multi-purpose electromagnetic induction melting device and a method are disclosed. The multi-purpose electromagnetic induction melting device comprises a zirconia crucible, a graphite crucible, an electromagnetic induction coil, a upper-portion top cover, a conical funnel, a ceramic flow guide pipe, a ceramic plug, a supporting mechanism, power-line terminals and cooling pipelines; the zirconia crucible is arranged in the graphite crucible and serves as a place for material melting, and the graphite crucible has magnetic conductivity and emits heat under the effect of eddy currents; the electromagnetic induction coil is placed at the outer portion of a double-layer crucible and subjected to sintering protection by adopting magnesite, and can be used in a corrosion environment; the power-line terminals and the cooling pipelines of the electromagnetic induction coil are all welded to a flange plate, and seamless connection with a sealed container can be achieved; the zirconia crucible is connected with the ceramic flow guide pipe through the conical funnel at the bottom and cooperates with the ceramic plug to control opening and closing of a crucible bottom hole; and the whole device is fixedly connected with a base or the inner wall of a container through the supporting structure at the bottom of the device. The multi-purpose electromagnetic induction melting device can be used in severe environments such as the corrosion environment, and electromagnetic induction melting and casting of materials are achieved.

Owner:XI AN JIAOTONG UNIV

Microwave-assisted dynamic continuous calcining device and method for lithium-ion battery material

PendingCN108759459AExcellent consistency of propertiesImprove production efficiencyRotary drum furnacesCharge treatment typeMicrowave powerLithium-ion battery

The invention relates to microwave-assisted dynamic continuous calcining device and method for a lithium-ion battery material. The device comprises a rotary kiln body, a transmission device and a power device, wherein the power device is connected with the rotary kiln body through the transmission device; the rotary kiln body comprises a rotary kiln tube body; independent microwave emitters are continuously arranged on a rotary kiln body shell; waveguide tubes are connected onto the microwave emitters and are connected with the rotary kiln tube body; the temperatures of different temperature areas of the rotary kiln body are controlled through adjusting microwave powers of the microwave emitters; a discharging device is arranged on a kiln head of the rotary kiln body; a feeder is arrangedon a kiln tail of the rotary kiln body; an air supply gun is arranged on the kiln head of the rotary kiln body and communicates with the rotary kiln tube body; an air discharge flue is arranged on thekiln tail of the rotary kiln body; and a sintering atmosphere in the rotary kiln body is controlled through the air supply gun on the kiln head. The microwave-assisted dynamic continuous calcining device and the method for the lithium-ion battery material provided by the invention have high heat utilization ratio, and is particularly good for preparing a nanometer material; continuous feeding anddischarging can be realized, so that the preparation efficiency of the lithium-ion battery material is greatly improved; and the generated greenhouse gas is less so as to have low effect on the environment.

Owner:CENT SOUTH UNIV

Apparatus for producing a reduced metal, and traveling hearth furnace for producing the same

InactiveUS6224820B1Low gangueLow ash contentRotary drum furnacesCharge composition/stateHearthFireplace

A traveling hearth for producing reduced metal by charging and stacking a raw material containing a metal-containing material and a solid-reducing material on a horizontally moving hearth, arranged for disposing a solid-reducing material layer on the hearth, forming concave portions at the solid-reducing material surface, stacking the raw material on the surface of the solid-reducing material layer, reducing the raw material by at least once heating and melting the material on the hearth to separate metal and gangue and ash ingredients, and discharging metal from the hearth.

Owner:KAWASAKI STEEL CORP

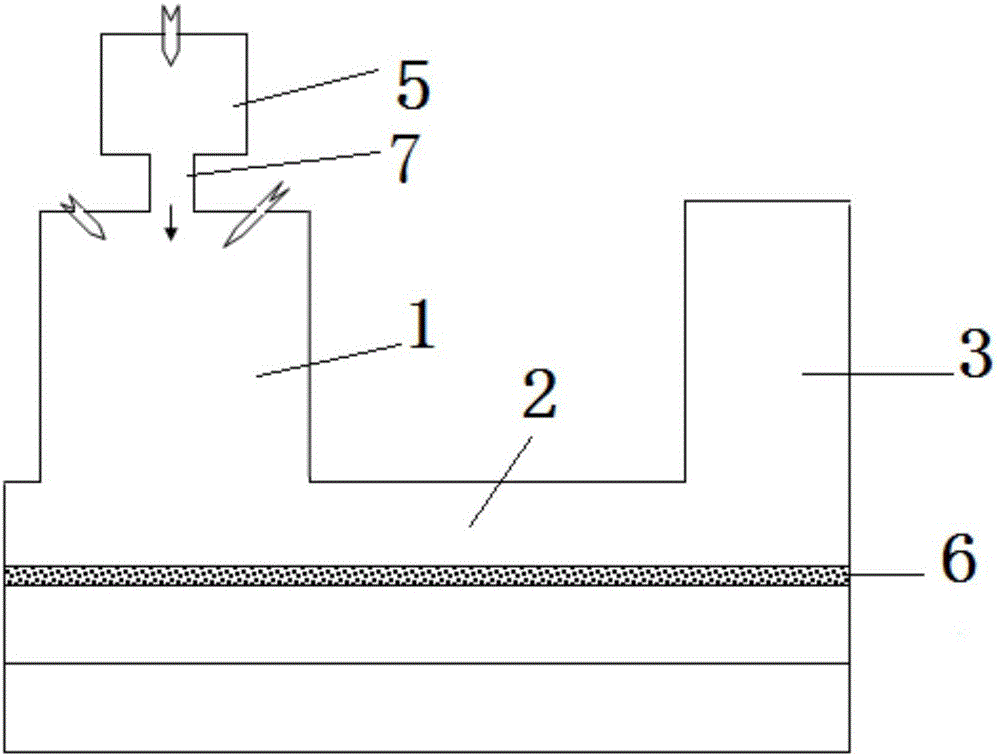

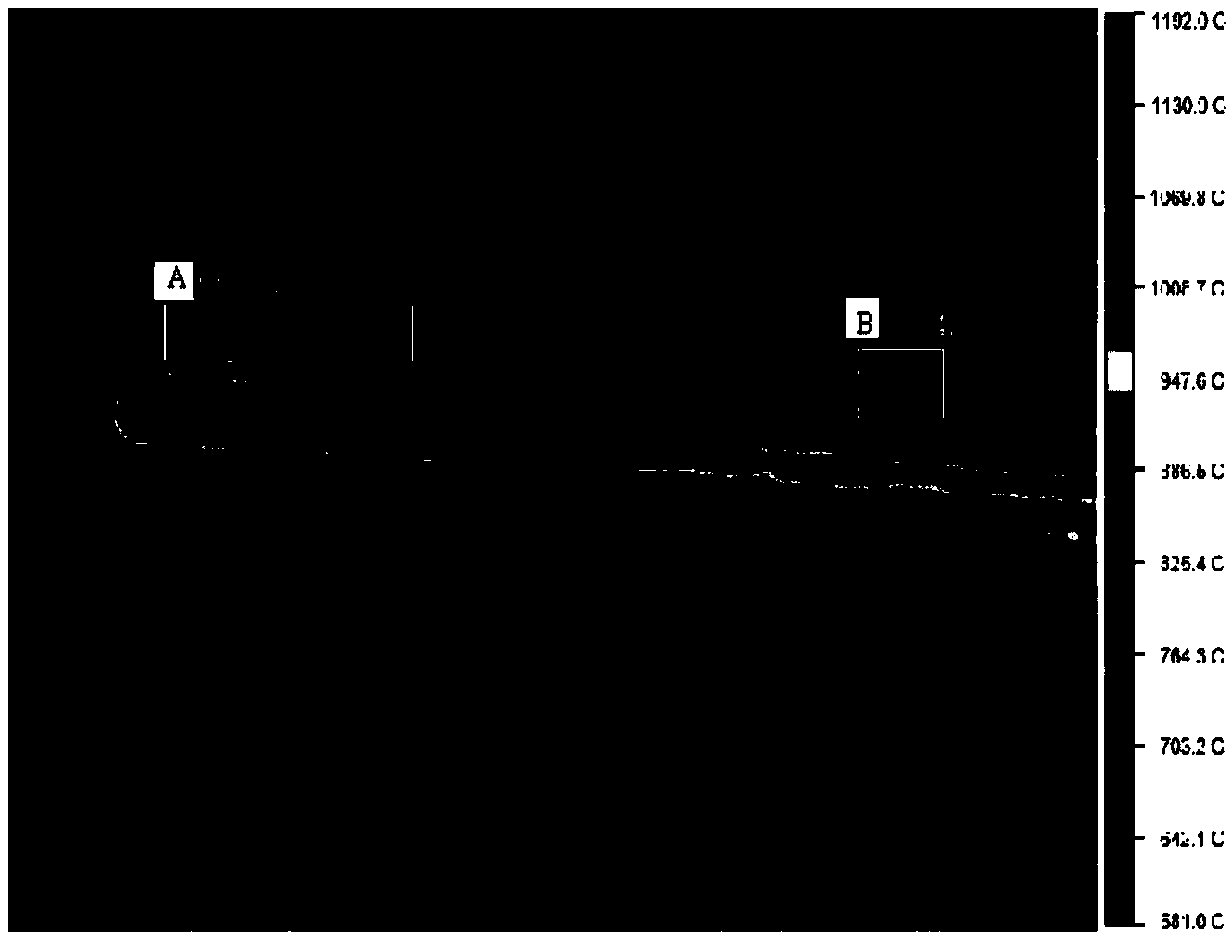

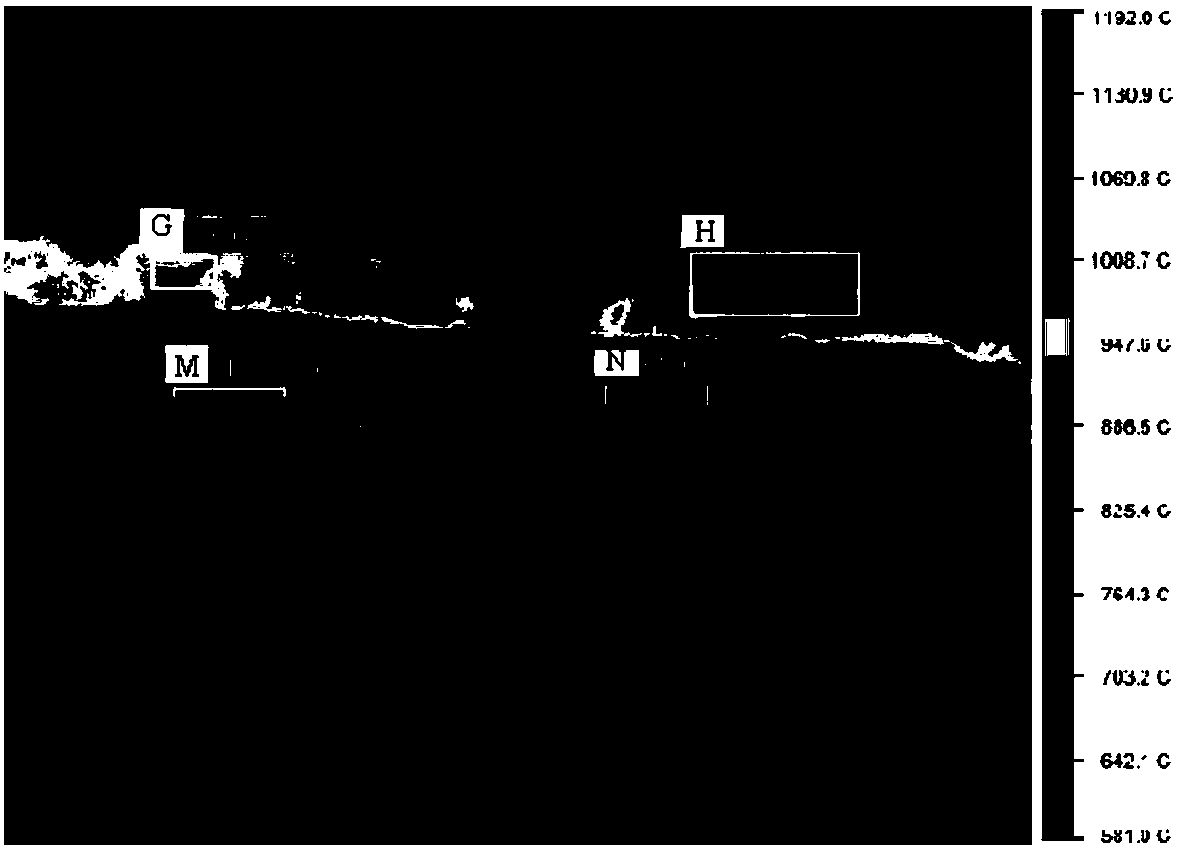

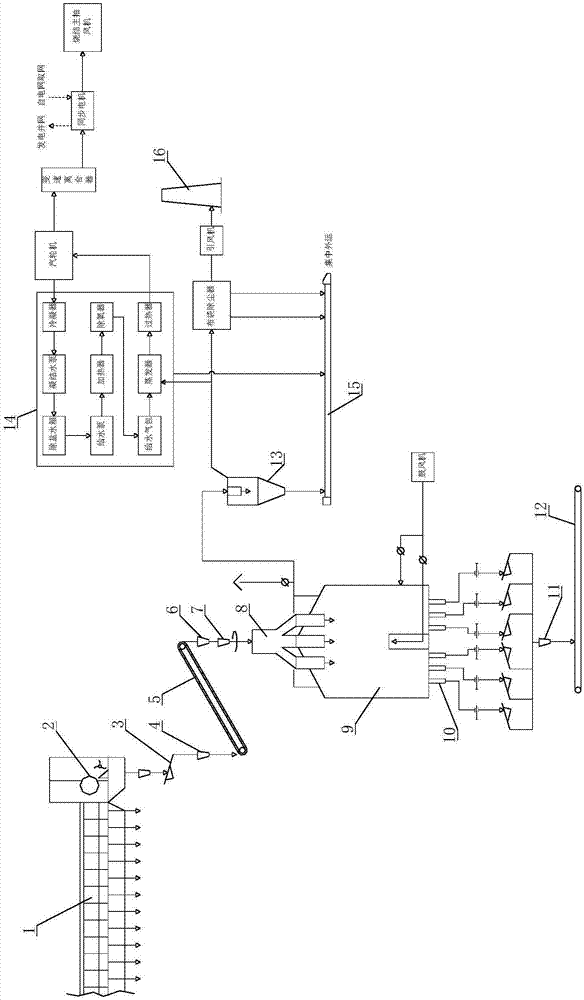

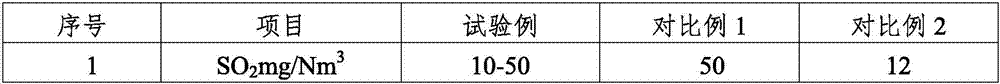

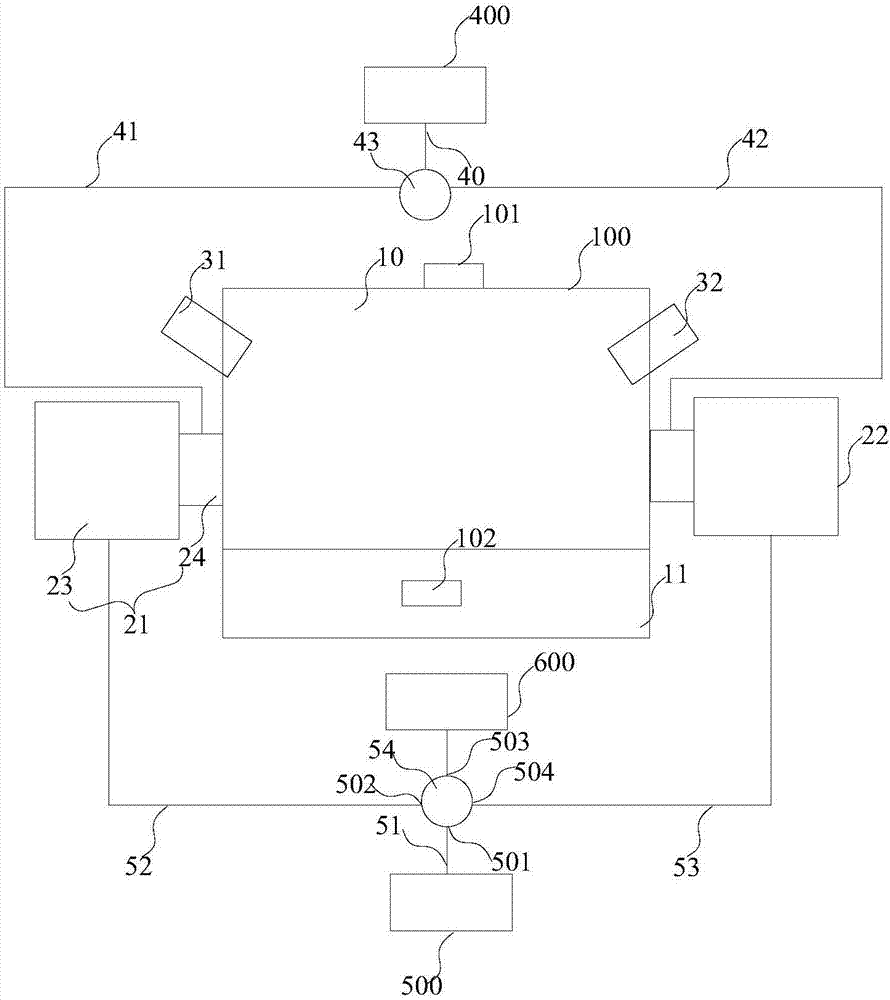

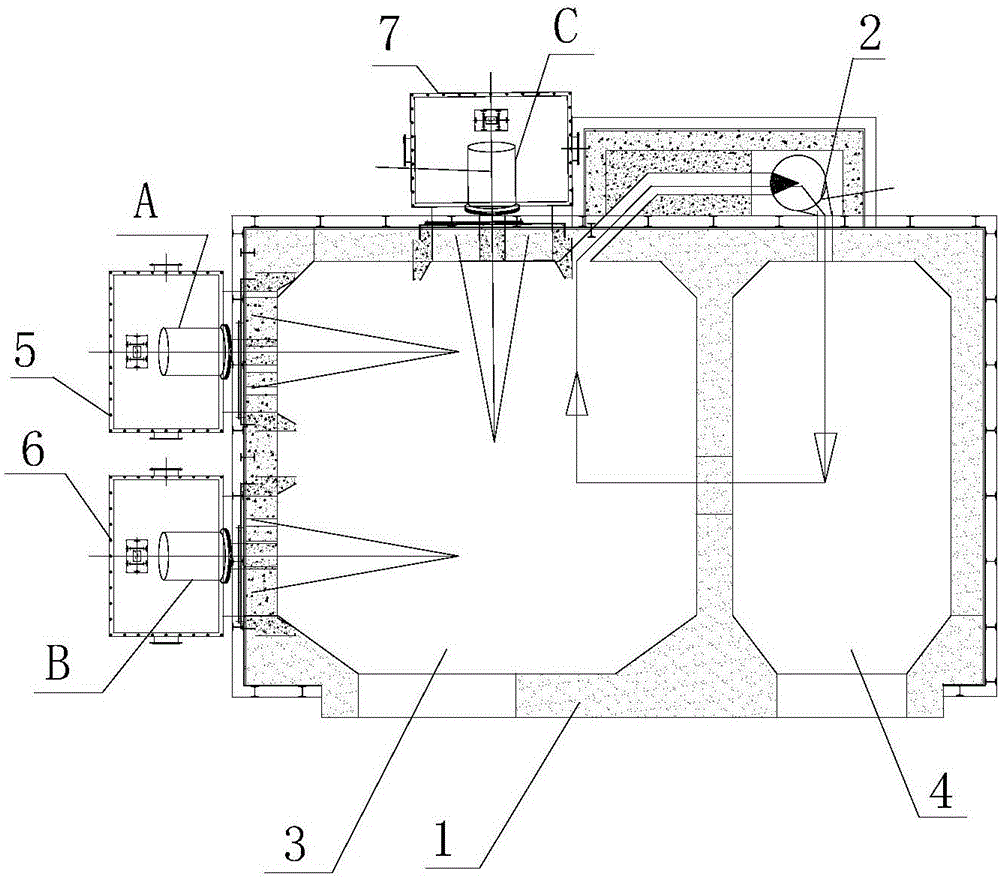

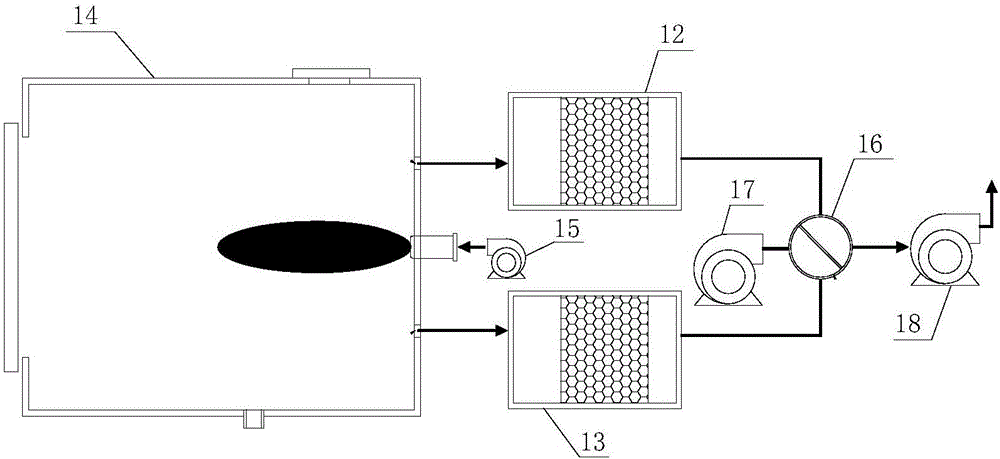

Online detection and control system for flame combustion uniformity in sintering ignition furnace

ActiveCN109114985AAdjustable temperatureGuaranteed temperatureCharge treatment typeFurnace typesCombustionControl system

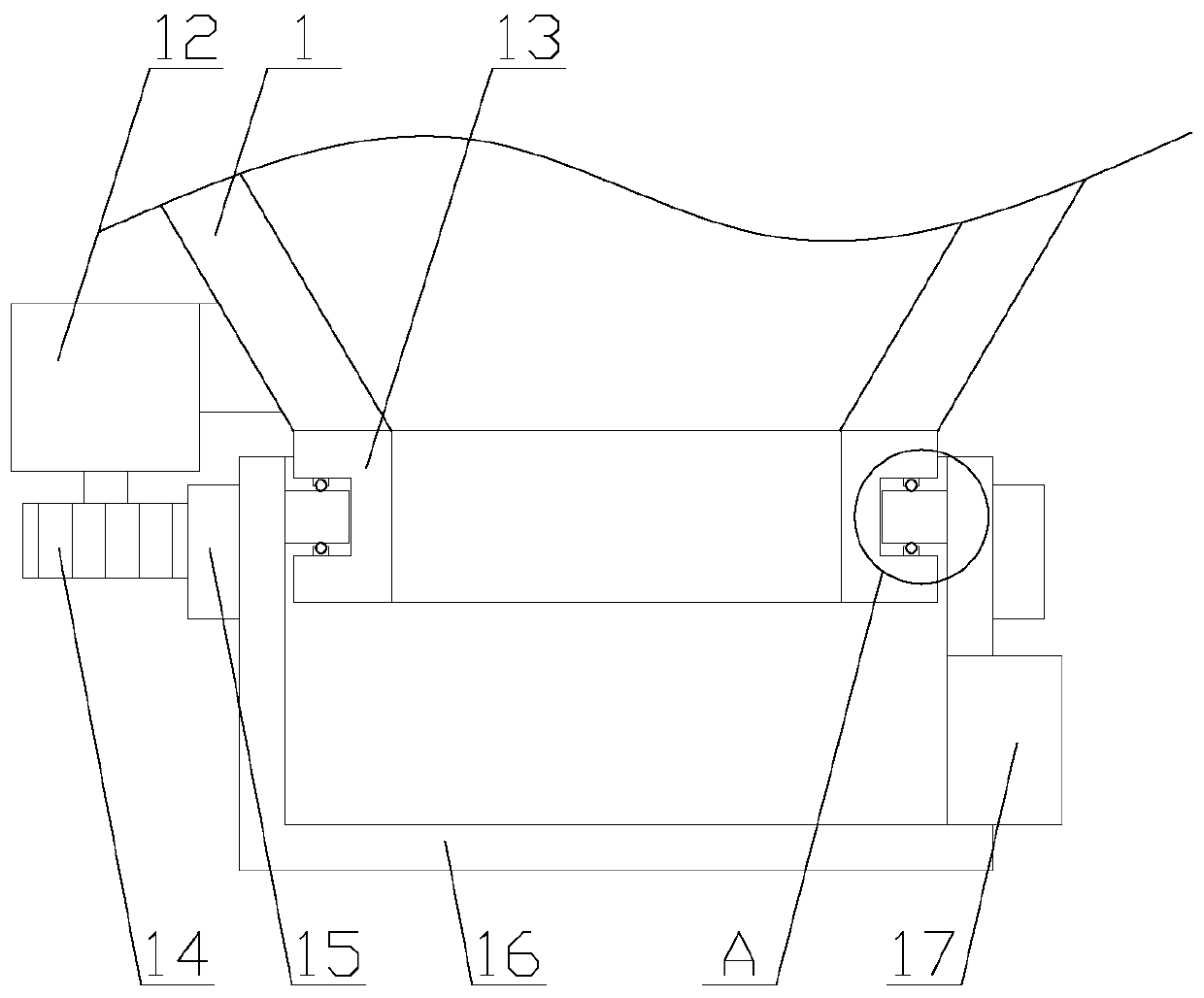

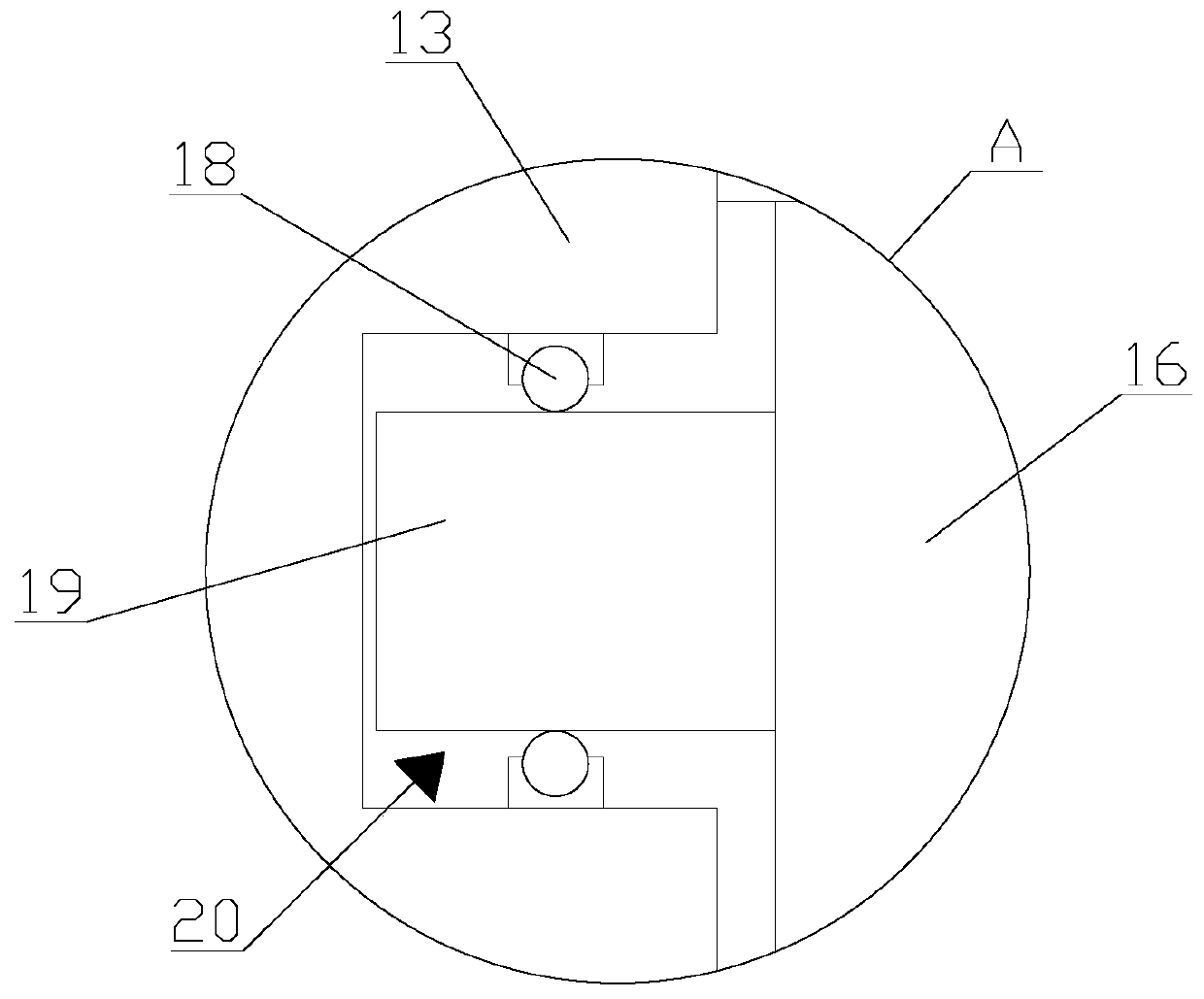

The invention provides an online detection and control system for flame combustion uniformity in a sintering ignition furnace. The system comprises a dust removal and blowing system, a high-temperature infrared thermal imager, a swing system and burners; the swing system is arranged above a furnace charge, the high-temperature infrared thermal imager is installed on the swing system, the dust removal and blowing system is installed in front of and above the high-temperature infrared thermal imager, and the high-temperature infrared thermal imager is used for detecting temperature data and transmitting the temperature data to an industrial control machine; the burners are uniformly installed inside the sintering ignition furnace, the burners are connected to an air pipeline and a coal gas pipeline through electric adjusting valves, and the electric adjusting valves are correspondingly connected to the industrial control machine through power lines; and the industrial control machine adjusts the internal specific temperature of the ignition furnace by adjusting the coal gas flow and the air flow through the electric adjusting valves. According to the system, the problem that the adjustment cannot be carried out in a targeted mode is overcome, the flame combustion uniformity can be timely adjusted on line, the necessary temperature of a sintered material surface is ensured, the sintering and ignition energy consumption is reduced, the surface quality of a sintered ore is improved, and the productivity of the sintered ore is improved.

Owner:ANGANG STEEL CO LTD

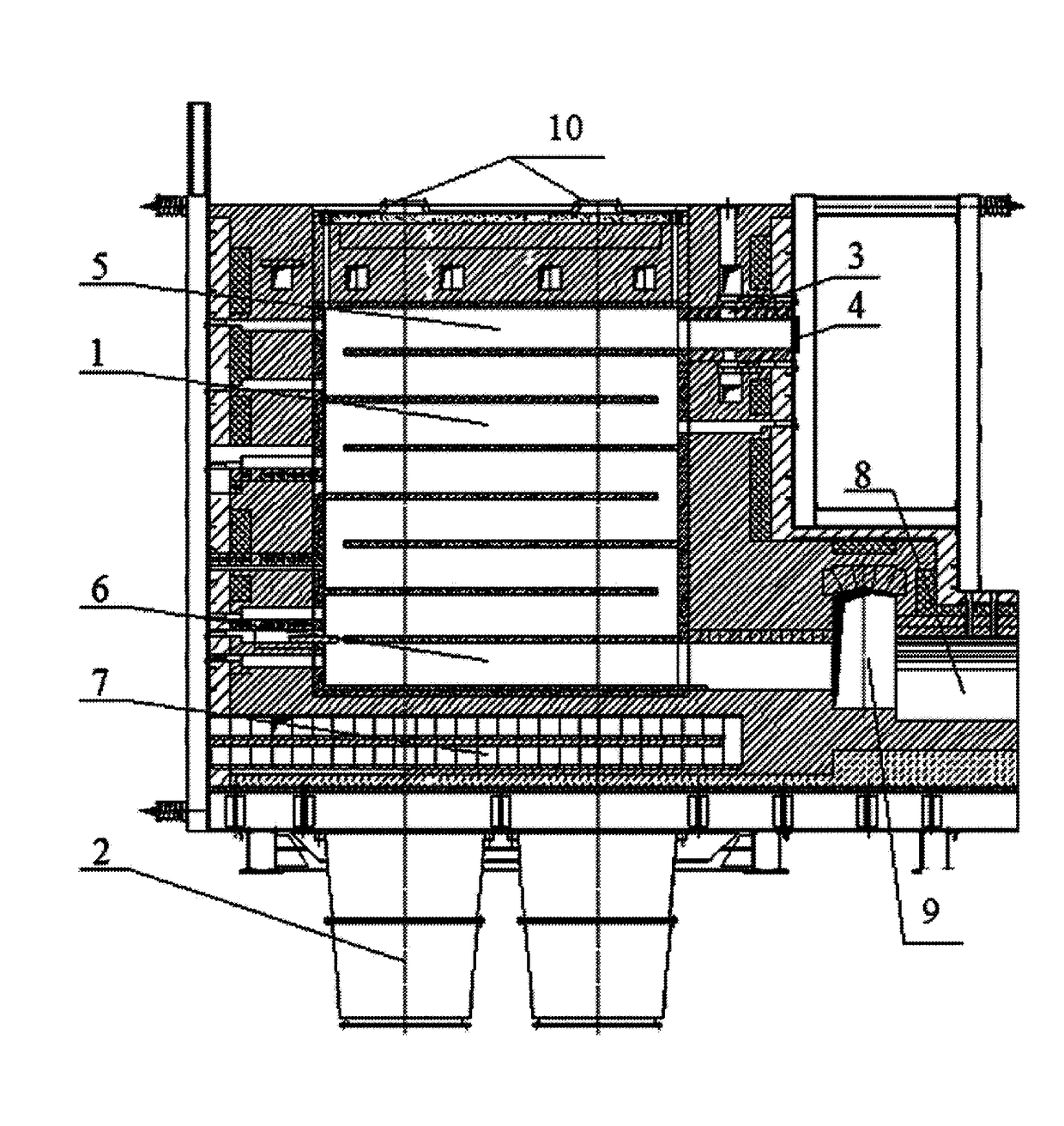

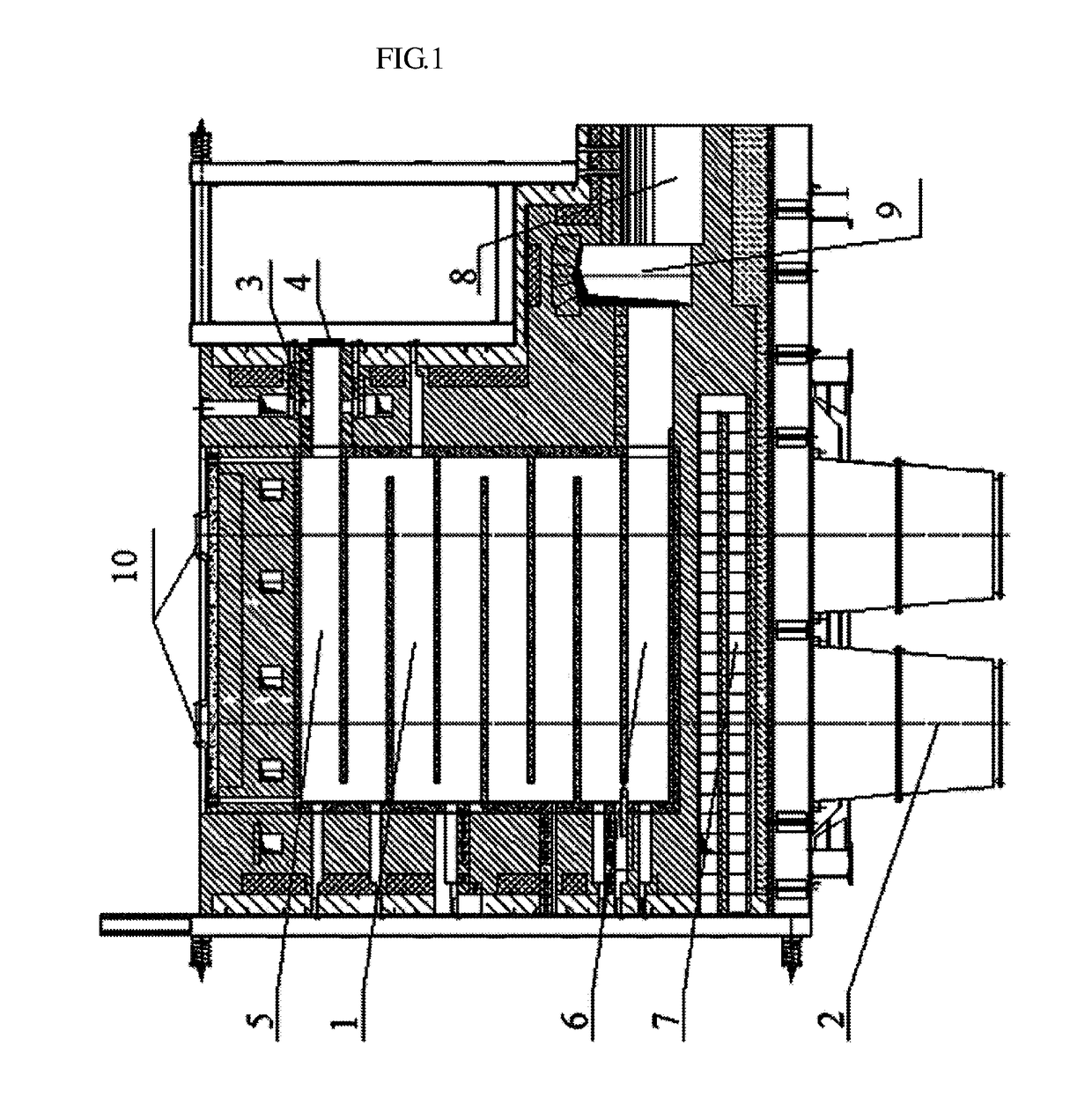

Technological method and system for driving main exhaust fan by using vertical cold kiln to recover waste heat of sintered ore

PendingCN106907931AImprove waste heat recovery rateEvenly distributedCharge manipulationCharge treatment typeSynchronous motorMechanical energy

The invention relates to a technological method and system for driving a main exhaust fan by using a vertical cold kiln to recover waste heat of sintered ore. The hot sintered ore is subjected to heat exchange with cold air in the vertical cold kiln, waste gas is conveyed to a waste heat boiler after being subjected to dedusting, and generated superheated steam is conveyed to a steam turbine; and the steam turbine directly drives the sintering main exhaust fan to operate through a variable-speed clutch and a synchronous motor. By the adoption of the vertical cold kiln of a novel structure, the recovery rate of the waste heat of the sintered ore can be increased to the maximum extent; complementation between electricity generation of the steam turbine and electric energy of a power grid is achieved through the synchronous motor, and normal operation of the sintering main exhaust fan is guaranteed; and the complete sintering plant energy utilization technological system is composed of the vertical cold kiln, the waste heat boiler, the steam turbine and the sintering main exhaust fan, the steam turbine directly provides power for the main exhaust fan, electricity obtained from the power grid is reduced, secondary efficiency loss occurring due to the fact that in the conventional technique, when electricity is generated by the steam turbine and incorporated into the power grid and the sintering main exhaust fan obtains electricity from the power grid, mechanical energy is converted into electric energy and the electric energy is reconverted into the mechanical energy can be avoided, and great significance is brought to energy saving and value creating.

Owner:鞍钢集团工程技术有限公司 +1

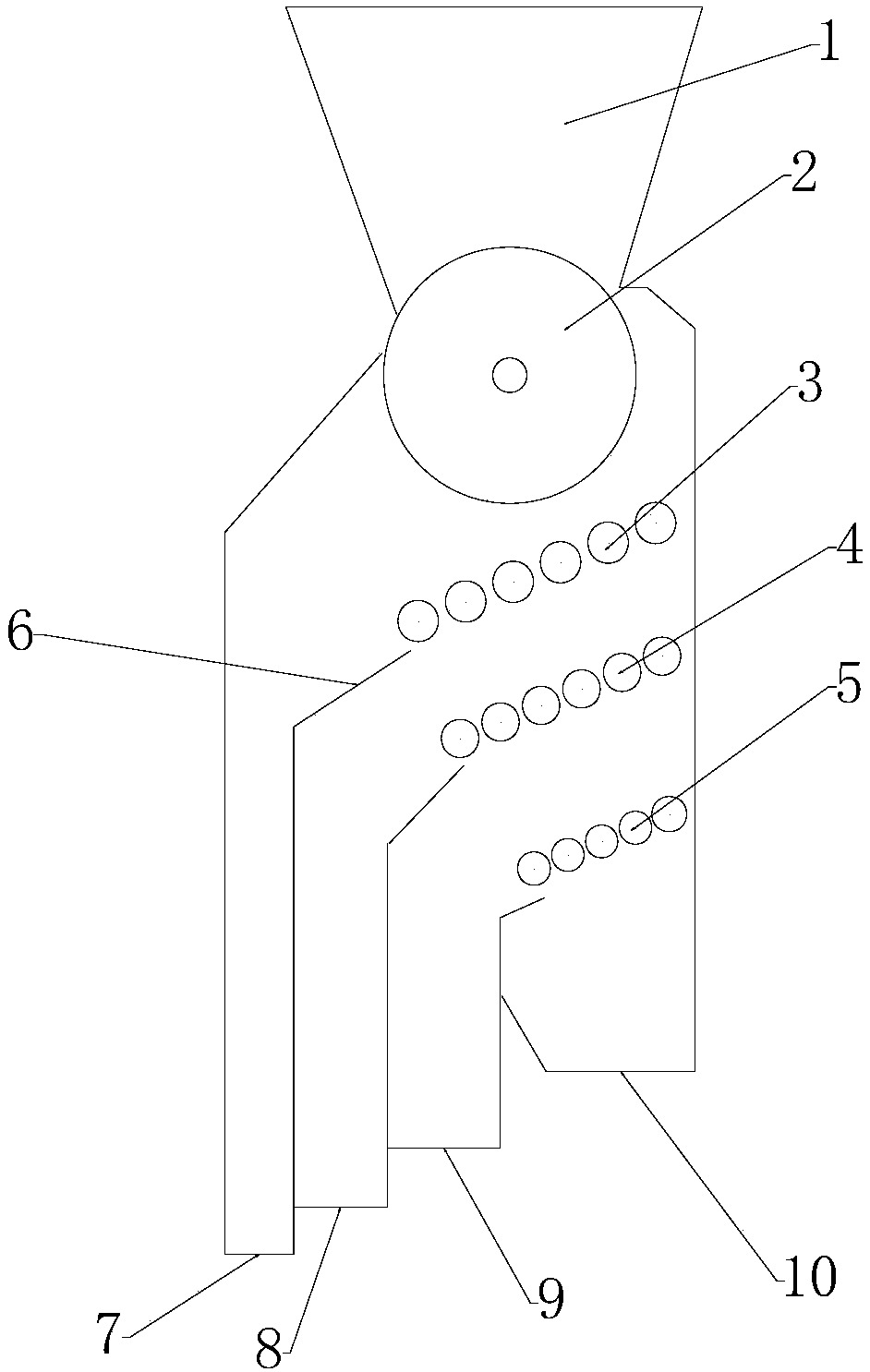

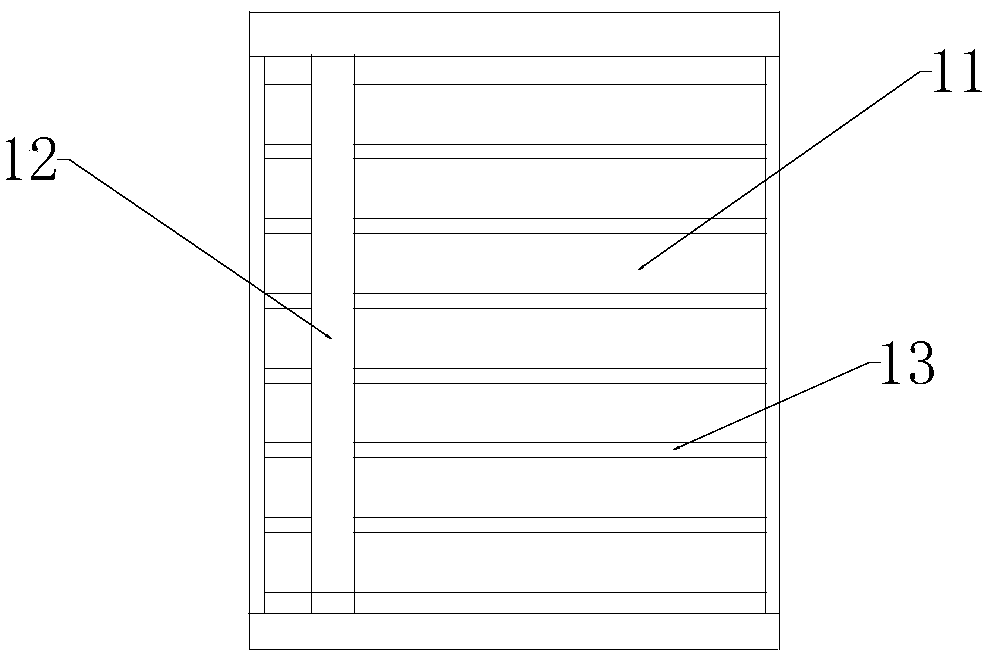

Sintered mixture preparation method, sintered mixture distribution apparatus and sintered mixture distribution method

ActiveCN108396136AEnhanced granulationIncrease the ratio of reasonable granularityCharge composition/stateCharge manipulationMaterial distributionDistributor

The invention relates to a sintered mixture preparation method, a sintered mixture distribution apparatus and a sintered mixture distribution method, wherein the raw materials of the sintered mixturecomprise iron ore powder, coke powder, return ore, quicklime and limestone. The sintered mixture preparation method comprises: placing iron ore powder, quicklime, return ore with a particle size of less than 3 mm after wetting, coke powder with a particle size of less than 3 mm, limestone and water to a primary mixer, and uniformly mixing to obtain a primary mixture; and placing the primary mixture, return ore with a particle size of 3-5 mm after wetting, coke powder with a particle size of more than 3 mm, limestone with a particle size of greater than 3 mm and water to a secondary intensive mixer, and uniformly mixing to prepare the sintered mixture. The sintered mixture distribution method comprises: distributing the sintered mixture onto a sintering machine in layers through the sintered mixture distribution apparatus comprising three sets of multi-roller material distributors, wherein the particle sizes of the layers are sequentially reduced from bottom to top, the particle size ofthe first layer is more than 8 mm, the particle size of the second layer is 5-8 mm, the particle size of the third layer is 3-5 mm, and the particle size of the uppermost layer is less than 3 mm. According to the present invention, the particle size ratio of the sintered mixture is improved, the precise segregation multi-layer material distribution is achieved, and the gas permeability and the sintering utilization coefficient of the sintered mixture are improved.

Owner:ANGANG STEEL CO LTD

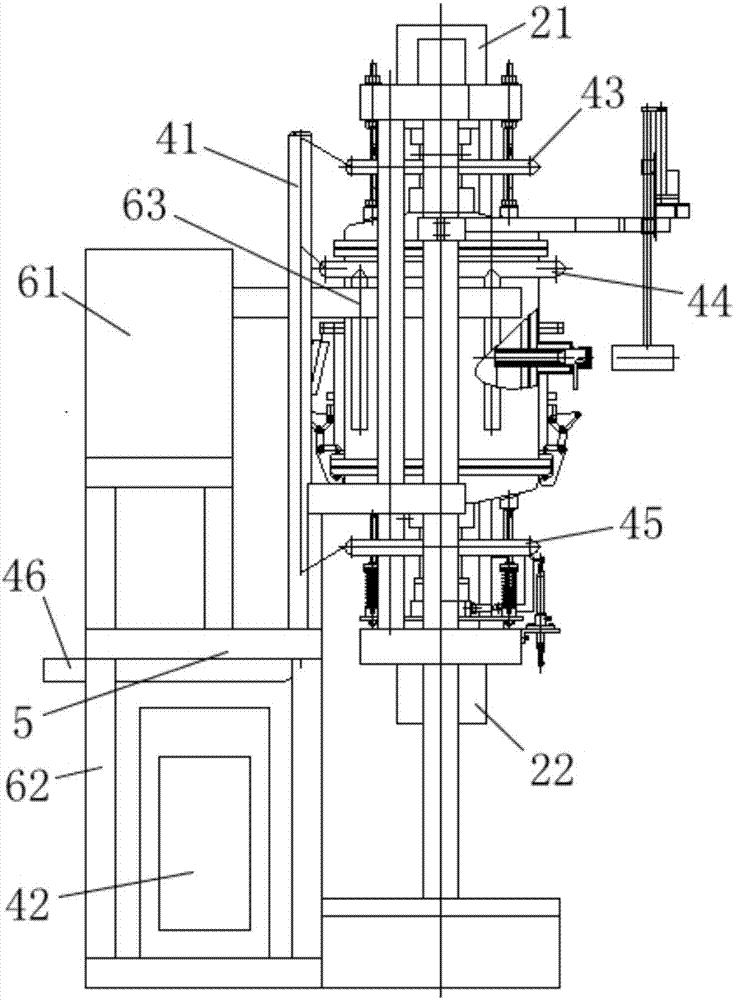

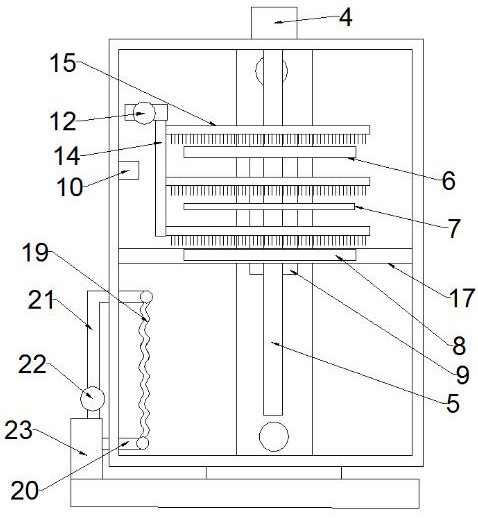

Pressure-assisted induction heating vacuum atmosphere flash sintering device

InactiveCN111981847AGood conductivity at room temperatureOvercome inherent shortcomingsMaintainance of heating chambersCharge treatment typeSystem pressurePumping vacuum

The invention relates to the field of new material preparation, and provides a pressure-assisted induction heating vacuum atmosphere flash sintering device. The pressure-assisted induction heating vacuum atmosphere flash sintering device comprises a furnace body, a pressure system, a flash sintering system, an induction heating system, a cooling system and a vacuum system. The pressure system comprises an upper pressing head and a movable lower pressing head. An upper electrode and a lower electrode are arranged on the end portions of the upper pressing head and the lower pressing head correspondingly and provide pressure for flash sintering samples. The flash sintering system provides a flash sintering circuit. The induction heating system provides heating and heat preservation. The furnace body is cooled by the cooling system. The furnace body is vacuumized by the vacuum system. The inherent defects in a traditional flash sintering technology are overcome, flash sintering power sources can be flexibly selected according to the electrical properties of materials obtained after flash sintering to cause thermal runaway, thus, the density level and microstructures of the samples arefinely adjusted and controlled to the maximum degree, and the device has universality for metal and ceramic materials; and pressure assisting of the flash sintering process can be easily achieved, andnew preparation means can be provided for the research field.

Owner:UNIV OF SCI & TECH BEIJING

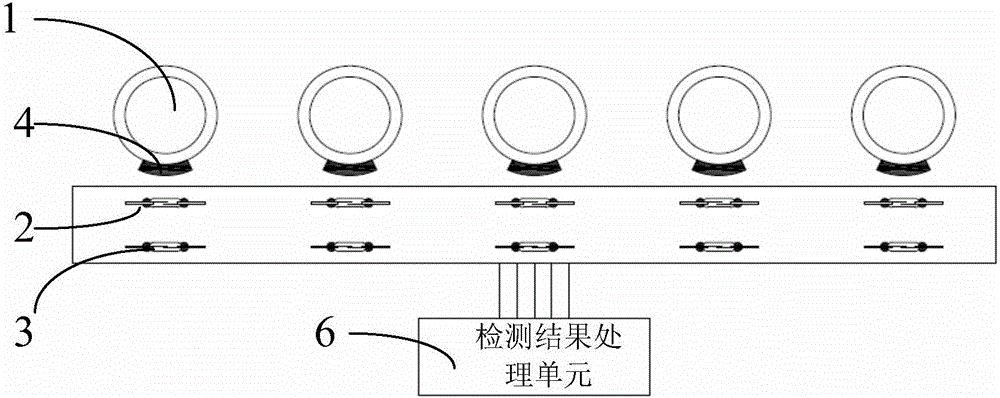

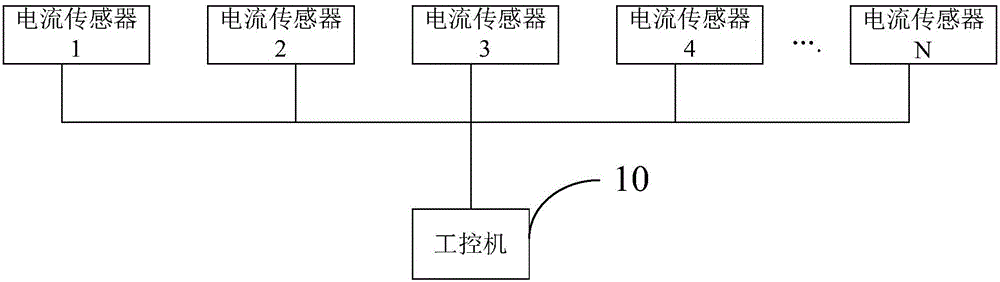

Roller kiln subarea broken roller detection method and system

ActiveCN106440778ARealize precise alarmAvoid inaccurate test resultsCharge treatment typeFurnace typesKilnComputer engineering

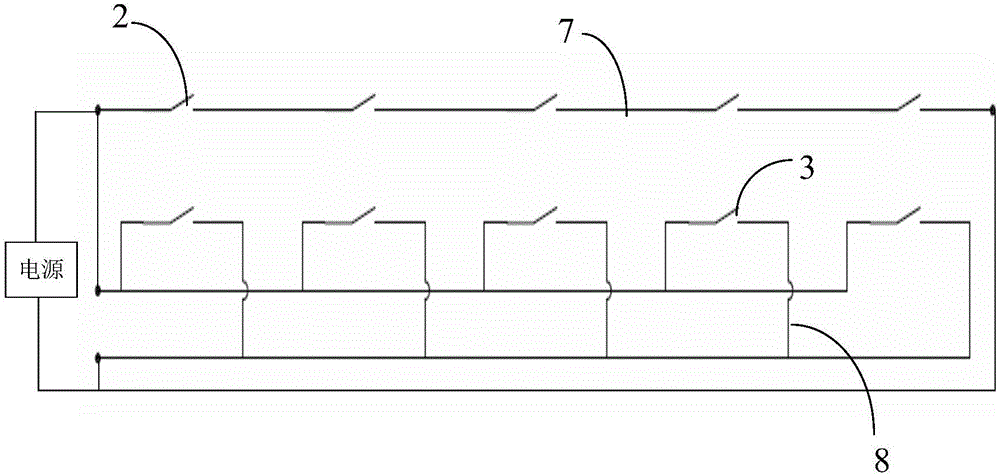

The invention discloses a roller kiln subarea broken roller detection method and system and belongs to the field of lithium battery material sintering. The roller kiln subarea broken roller detection method comprises the steps that two inductive switches are arranged in an induction area which is arranged below the driven side of any roller bar and can induct a follow-up element, and the two inductive switches are denoted as the first inductive switch and the second inductive switch; a series circuit is built so that all the first inductive switches in subareas can be connected in series, and a parallel circuit is built so that all the second inductive switches in the subareas can be connected in parallel; whether connection and disconnection of the series circuit and the parallel circuit are in a periodical change mode is detected at the same time; and when connection and disconnection of the series circuit and the parallel circuit in any subarea are detected to be not in the periodical change mode, the situation that a roller in the subarea is broken is judged. The corresponding detection system is built based on the detection method, accordingly, an alarm is given timely and accurately, and the subarea where the broken roller is located is fed back; and a maintenance man can go to the subarea where the broken roller is located to find out the broken roller and replace the broken roller in time, meanwhile, overall monitoring of multiple roller kiln roller bars can be achieved advantageously, and the whole operating efficiency is improved.

Owner:HUNAN JINLU TECH CO LTD

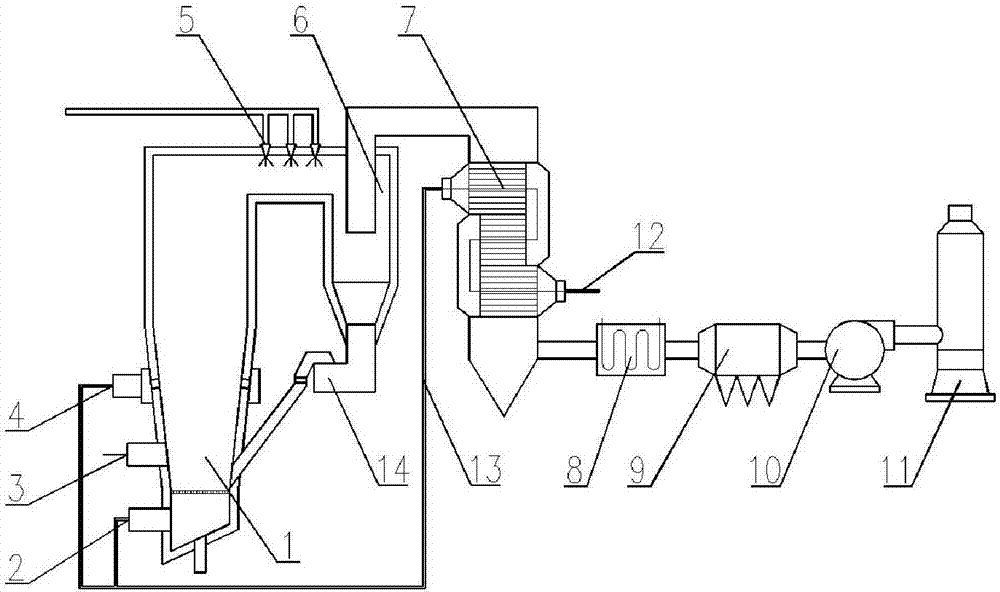

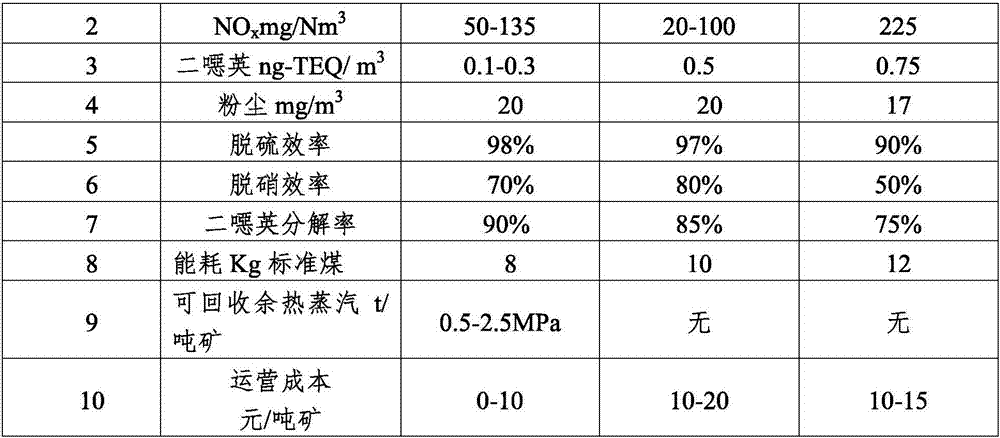

System and method for combustion support of sintering flue gas, dioxin decomposing, desulfurization, denitrification and residual heat recovery

InactiveCN106969641AReduce consumptionStable combustionCharge treatment typeIncreasing energy efficiencyFluidized bedFlue gas

Owner:秦皇岛合达能源科技开发有限公司

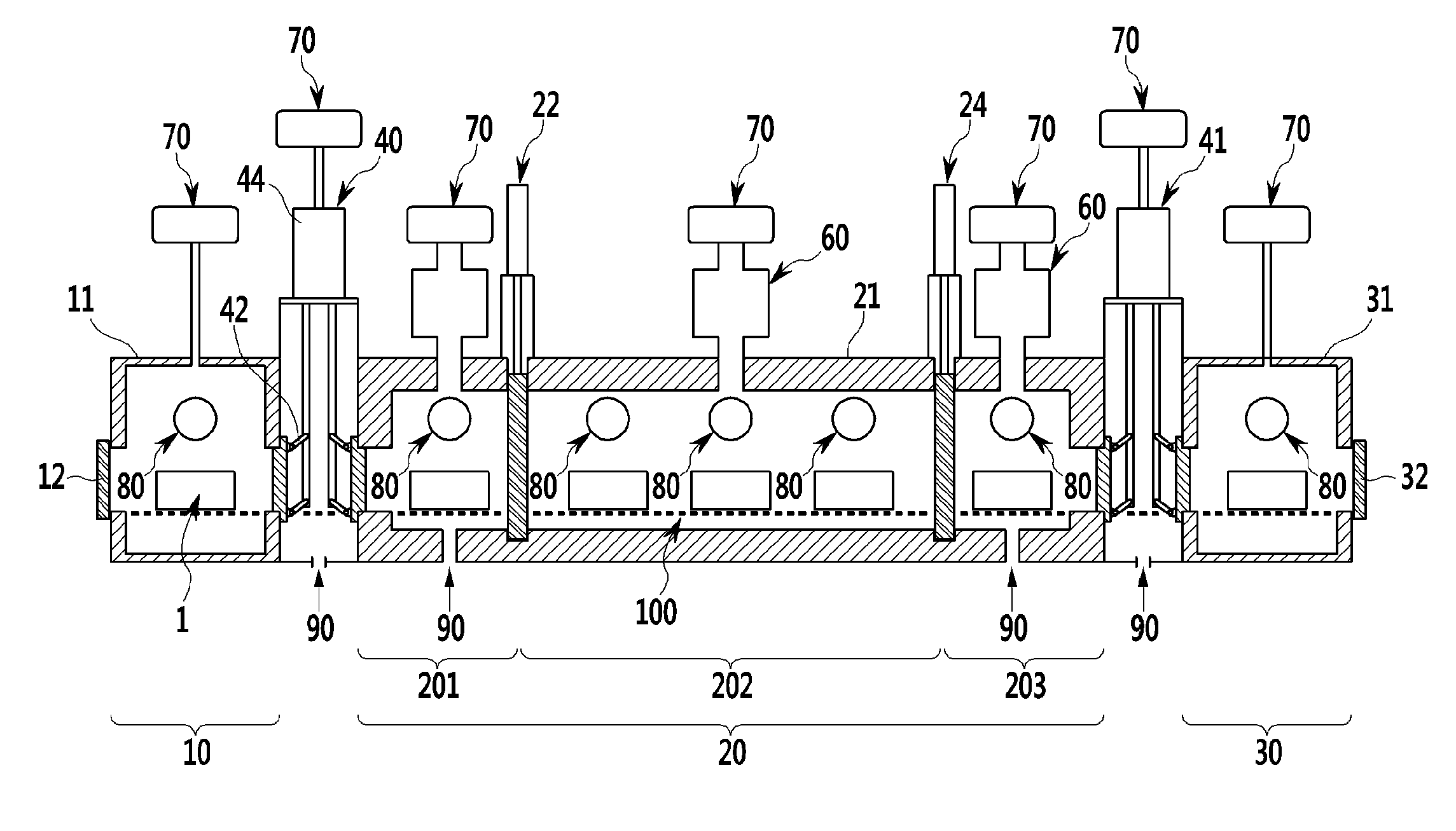

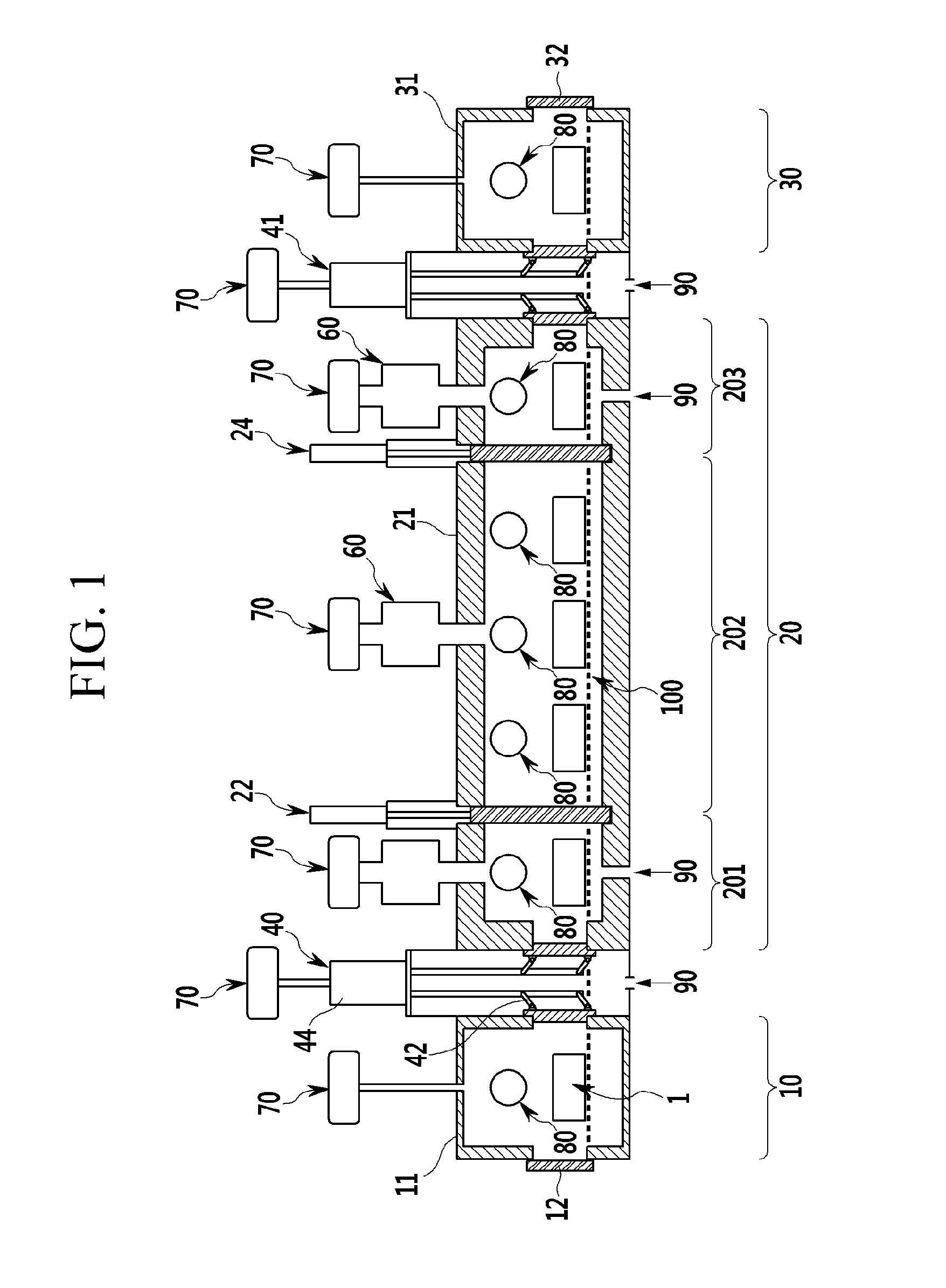

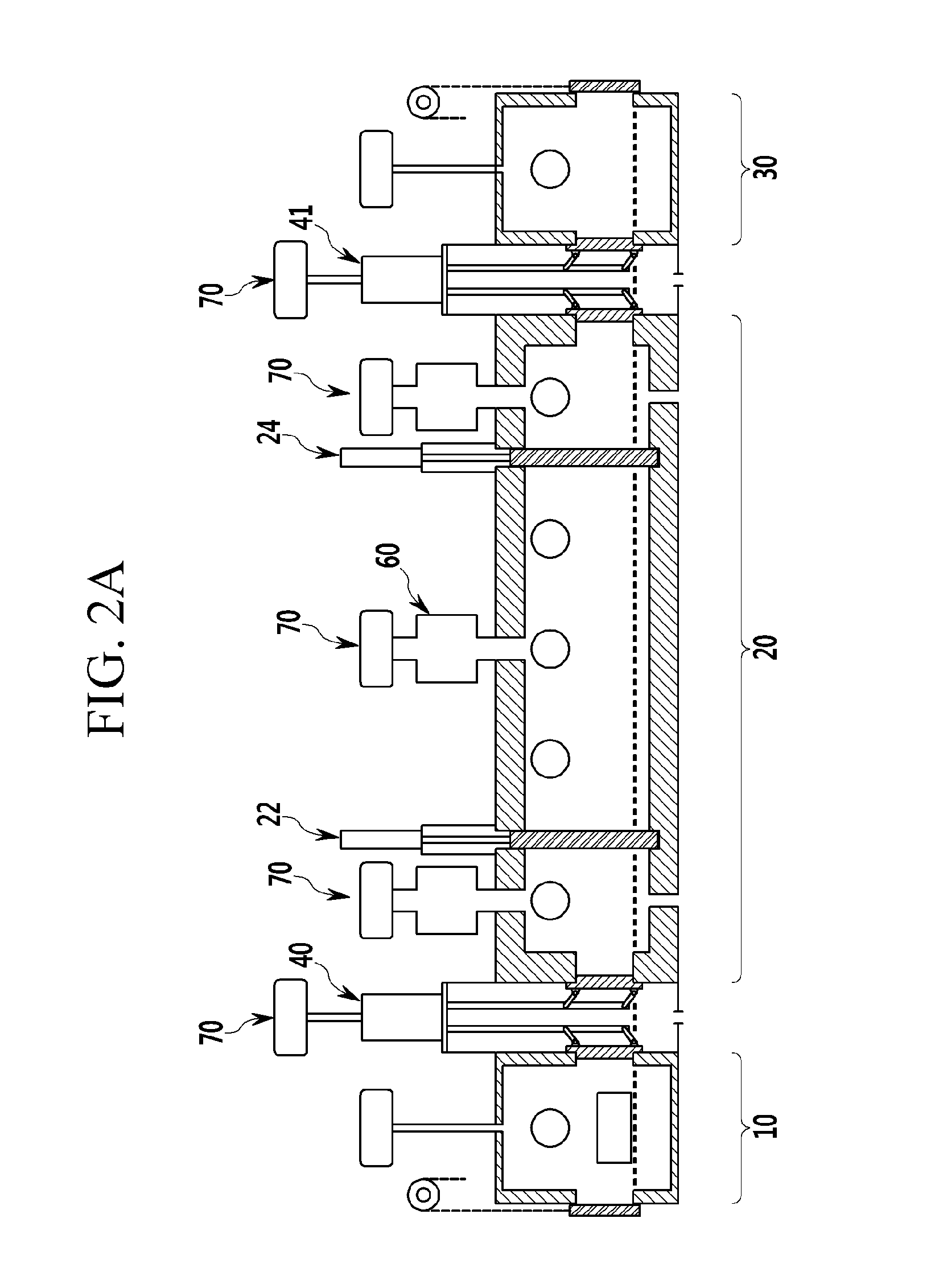

Thermal reduction apparatus for metal production, gate device, condensing system, and control method thereof

ActiveUS20160069615A1Maximize productivityContinuously and thermally reducedMaintainance of heating chambersCharge manipulationEngineeringMetal

Disclosed is a thermal reduction apparatus. The thermal reduction apparatus according to the exemplary embodiment includes: a preheating unit which preheats a to-be-reduced material and loads the to-be-reduced material into a reducing unit; the reducing unit which is connected to the preheating unit and in which a thermal reduction reaction of the to-be-reduced material occurs; a cooling unit which is connected to the reducing unit and from which the to-be-reduced material flowing into the cooling unit is unloaded to the outside; a gate device which is installed between the preheating unit and the reducing unit; a gate device which is installed between the reducing unit and the cooling unit; a condensing device which is connected to the reducing unit and condenses a metal vapor; a first blocking unit which is installed in the reducing unit; and a second blocking unit which is installed in the reducing unit so as to be spaced apart from the first blocking unit.

Owner:RES INST OF IND SCI & TECH

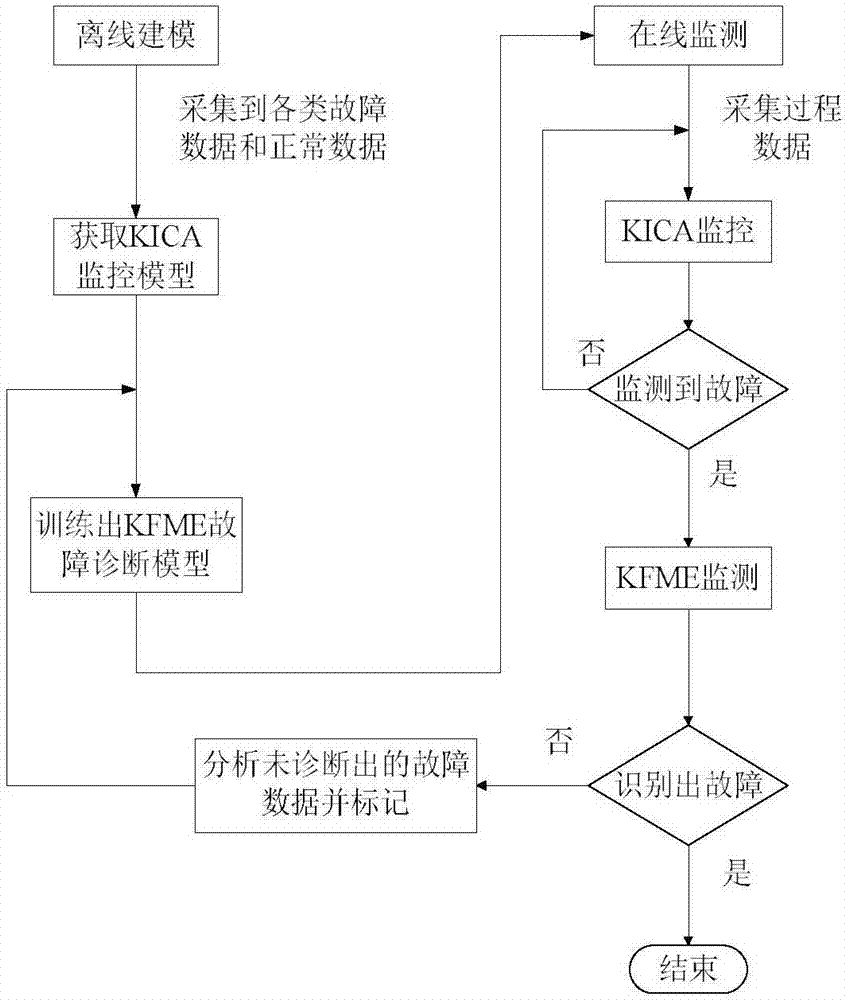

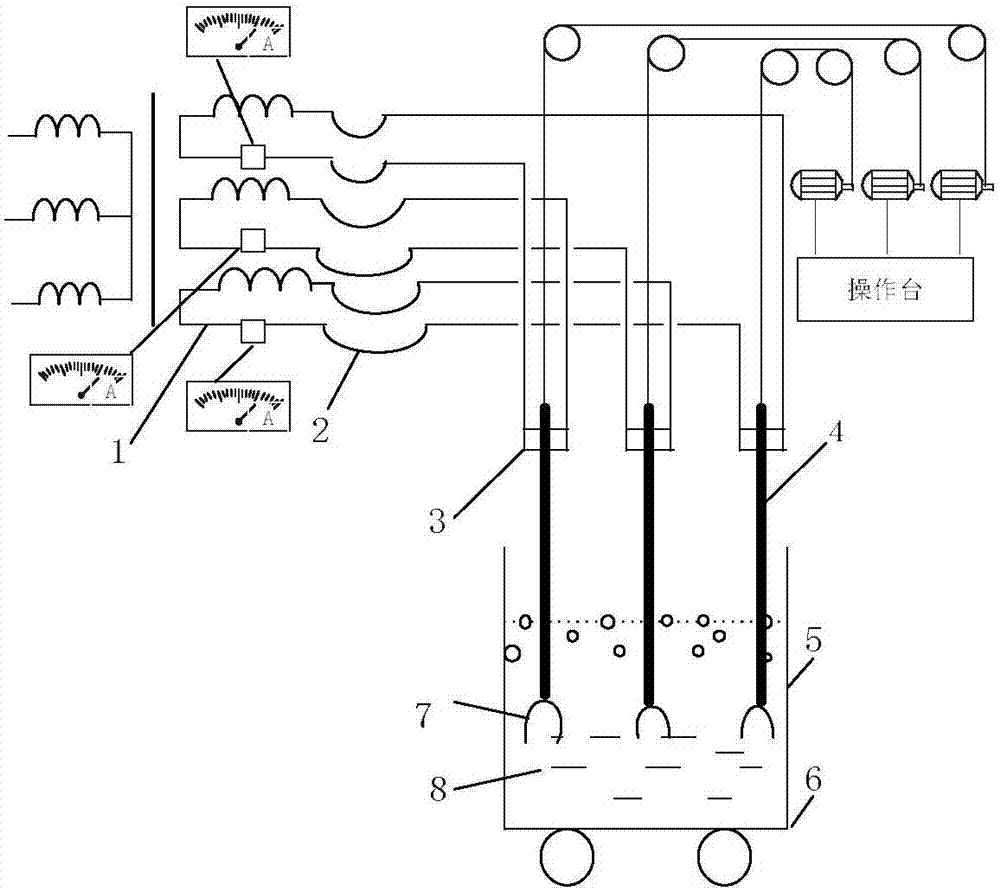

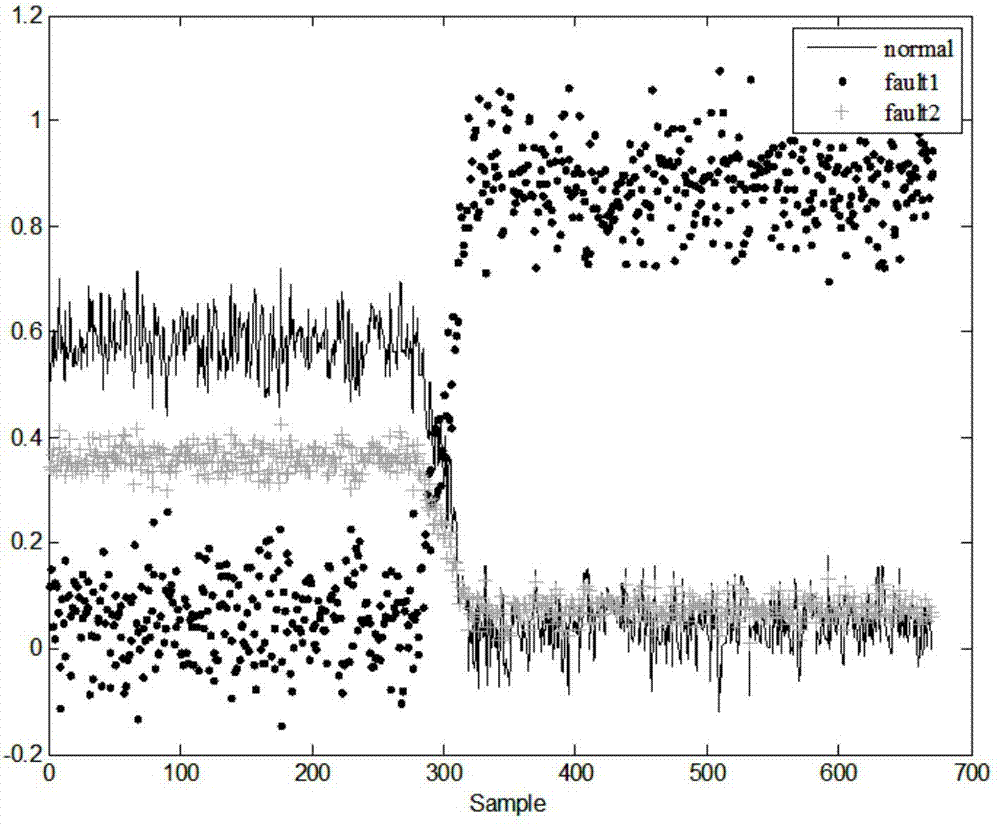

Nuclear flexible manifold embedding electric smelting magnesium furnace fault monitoring method

ActiveCN106907927AImprove monitoring effectReduce computing costCharge composition/stateCharge treatment typeElectricityOriginal data

The invention relates to a nuclear flexible manifold embedding electric smelting magnesium furnace fault monitoring method. The method comprises the steps that various kinds of fault data and normal data are collected; offline modeling is carried out, a KICA monitor model is acquired according to the collected data, and a KFME fault diagnosis model is trained; online monitoring is carried out, the KICA monitor model is utilized for carrying out real-time online monitoring, and process data are collected; if faults are monitored, a KFME monitor model is used for carrying out fault recognition; if faults are recognized, a one-time fault monitoring process is finished; and if no fault is recognized, non-diagnosed fault data are analyzed and marked, and the step of training the KFME fault diagnosis model is executed through jump. By means of the method, a small quantity of marked data and a large quantity of non-marked data are utilized for building a process monitoring model, the model is more accurate, data dimension reduction and original data information retention can be achieved well, the accuracy and antijamming capability of the fault diagnosis model are improved, and unknown faults are monitored.

Owner:NORTHEASTERN UNIV

Crushing smelter with better smelting effect

ActiveCN106871644AEasy to reinforcePromote meltingCharge treatment typeFurnace typesCombustorEngineering

The invention discloses a crushing smelter with a better smelting effect. The crushing smelter comprises a smelter body, discharging holes are formed in the obverse side of the smelter body, and burning cavities are formed in the two sides of the smelter body. Burning devices are connected to the outer sides of the burning cavities, a discharging cavity is connected to the top of the smelter body, and a crushing cavity is connected to the top of the discharging cavity. A crushing idler wheel is arranged in an inner cavity body of the crushing cavity and connected with a rotary motor arranged outside the crushing cavity through a wheel shaft, a feeding cavity is connected to the top of the crushing cavity, and a left feeding pipe and a right feeding pipe which are connected with the top of the crushing cavity are installed on an inner cavity of the feeding cavity in a staggered mode. The crushing smelter with the better smelting effect is provided with the crushing cavity and the crushing idler wheel on the whole so that input large metal waste materials can be crushed and pressed, and the large metal waste materials are changed into small metal waste materials, so that smelting operation is convenient to conduct, and the metal waste materials are quickly and conveniently smelted.

Owner:XINGHUA SANQIANG MACHINERY MFG CO LTD

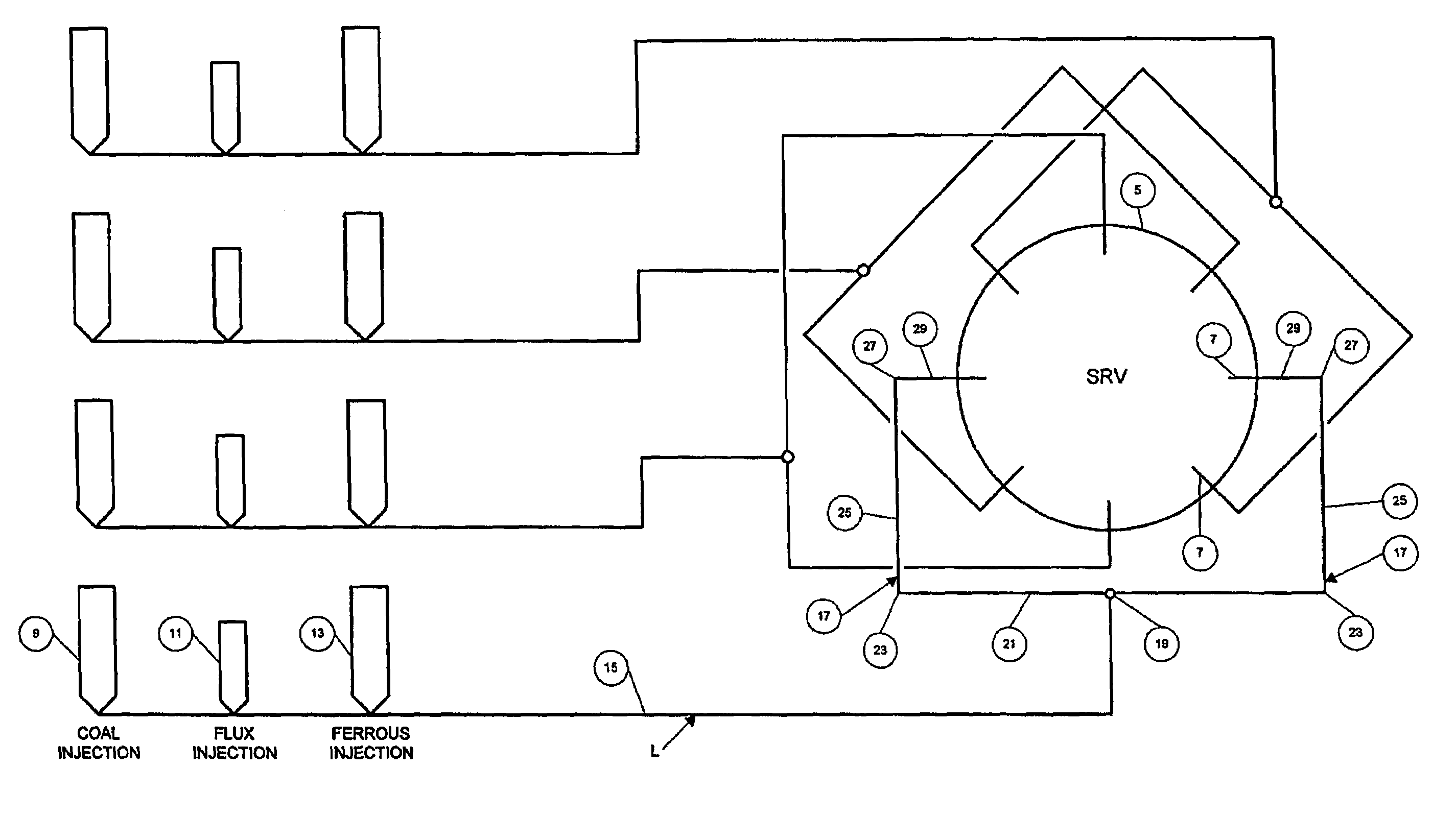

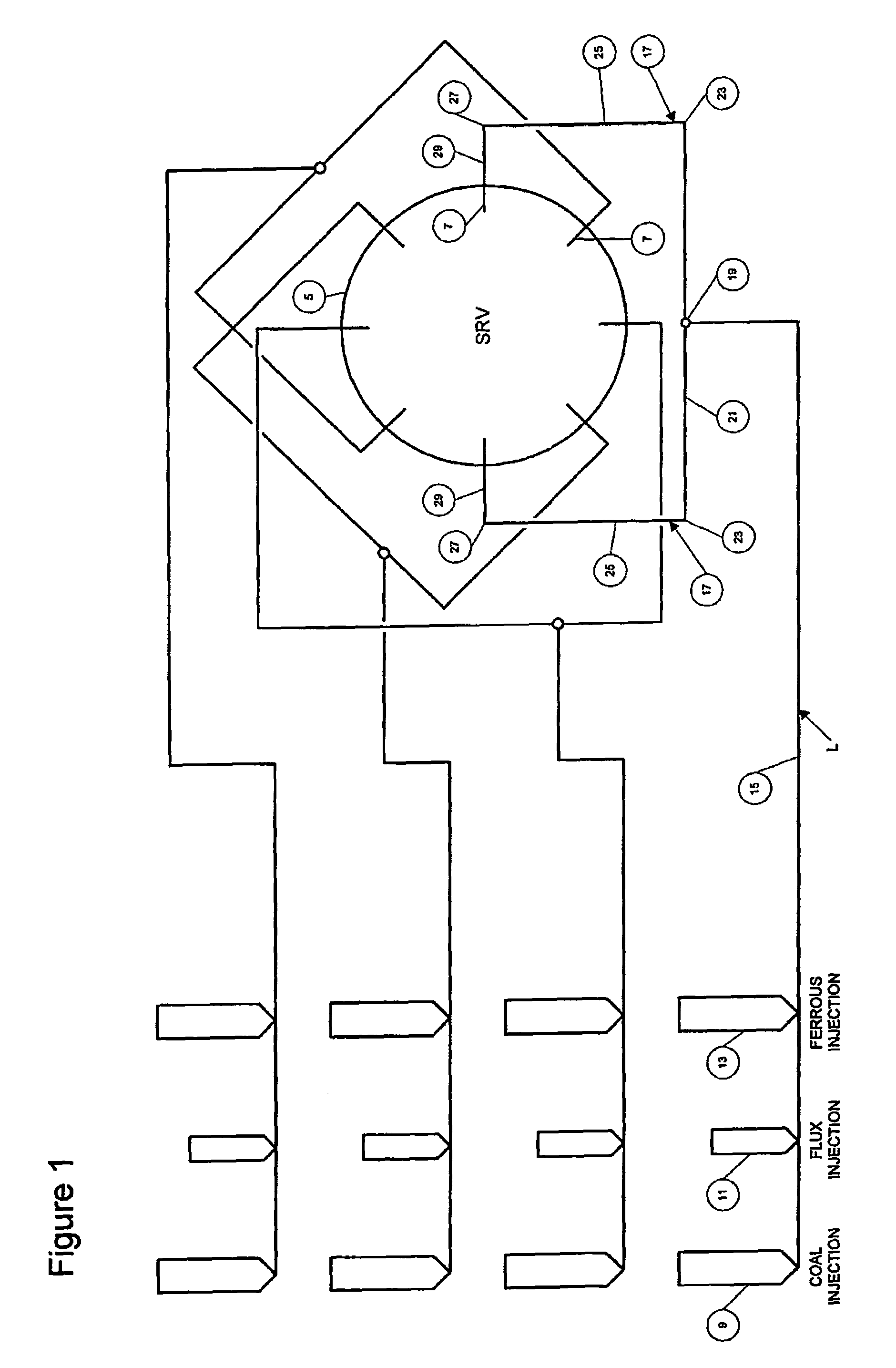

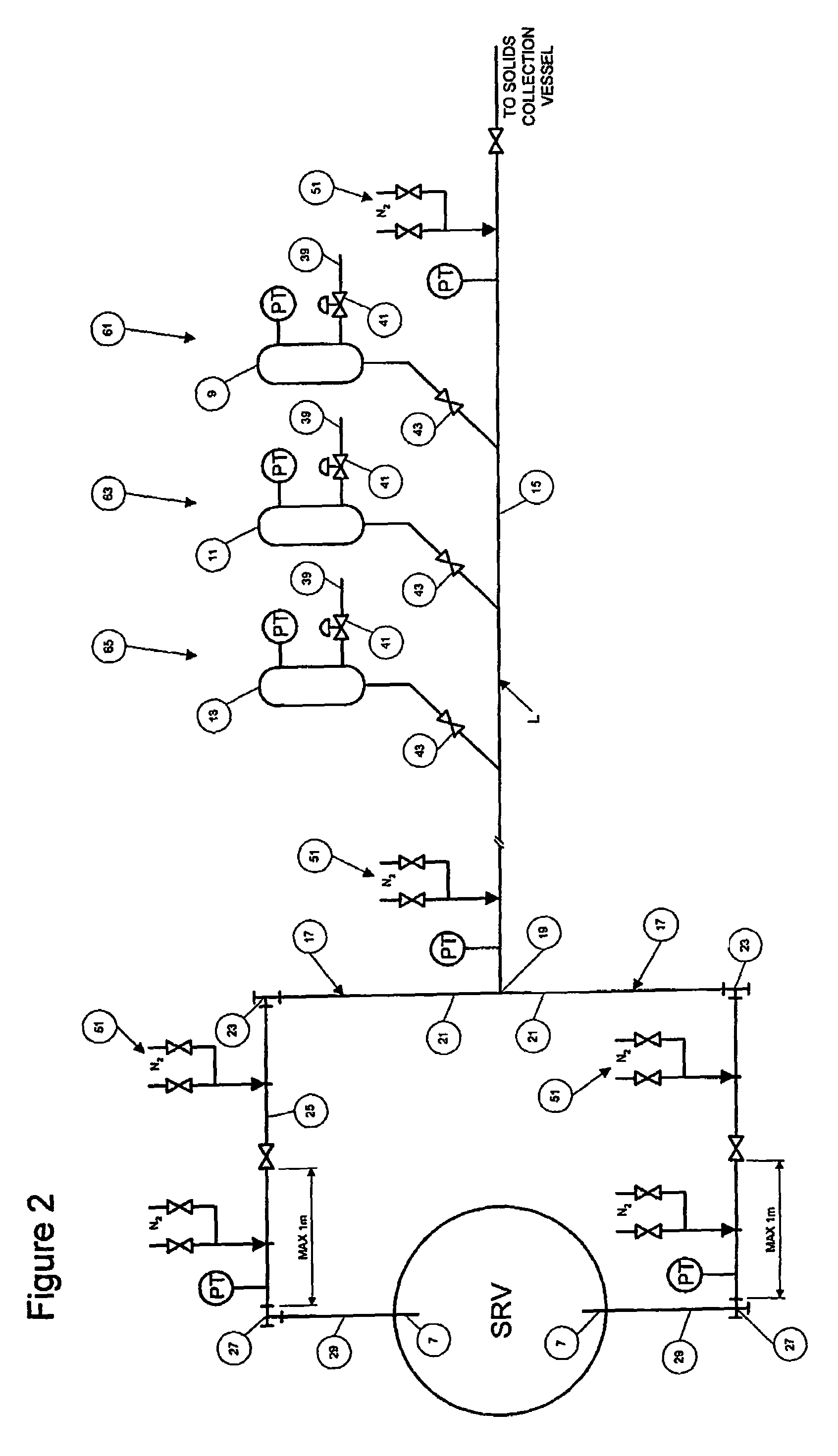

Supplying solid feed materials for a direct smelting process

InactiveUS7422622B2Effective and reliable processEffective and reliable and apparatusCharge composition/stateTuyeresSmelting processMaterial supply

A process and apparatus for supplying solid feed materials for a direct smelting process to solids injection lances of a direct smelting vessel is disclosed. The feed materials supply apparatus includes a supply line (L) for conveying iron-containing material and solid carbonaceous material under pressure to solids injection lances (7), and the supply line includes a main feeder line section (15) and a plurality of branch line sections (17) extending from the main feeder line section. Each branch line section is connected to one solids injection lance for supplying iron-containing material and carbonaceous material to that lance. The apparatus further includes an assembly for dispensing iron-containing material under pressure into the main feeder line section of the supply line and an assembly for dispensing carbonaceous material under pressure into the main feeder line section of the supply line.

Owner:TECHNOLOGICAL RESOURCES

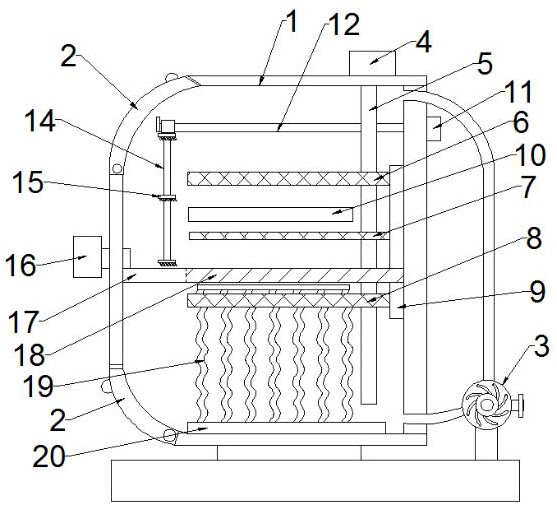

Neodymium iron boron vacuum sintering furnace

InactiveCN111795569AImprove work efficiencySave energyMuffle furnacesCharge composition/stateMetallurgyVacuum pump

The invention discloses a neodymium iron boron vacuum sintering furnace which comprises a furnace body, a vacuum pump, a sweeping device, a cooling device, a heating device and a containing device. Abaffle is transversely arranged in the furnace body and divides the interior of the furnace body into two spaces including a sintering cavity and a cooling cavity, the sweeping device and the heatingdevice are both arranged in the sintering cavity, the cooling device is arranged in the cooling cavity, the containing device is connected to the inner wall of the right side of the furnace body in sliding and clamped modes, a driving device is arranged on the containing device, the sintering cavity and the cooling cavity are each provided with a furnace cover, the furnace covers are connected tothe furnace body in a pivoted mode, and the vacuum pump is connected with the sintering cavity and the cooling cavity through air pipes. According to the neodymium iron boron vacuum sintering furnace,neodymium iron boron can be sintered in the sintering cavity and cooled in the cooling cavity, cooling and sintering are carried out separately, a large amount of energy is saved, the working efficiency of sintering and cooling procedures can be improved, neodymium iron boron residual substances in the sintering cavity can be automatically swept through the sweeping device, and a large amount oflabor cost is saved.

Owner:宁波元辰新材料有限公司

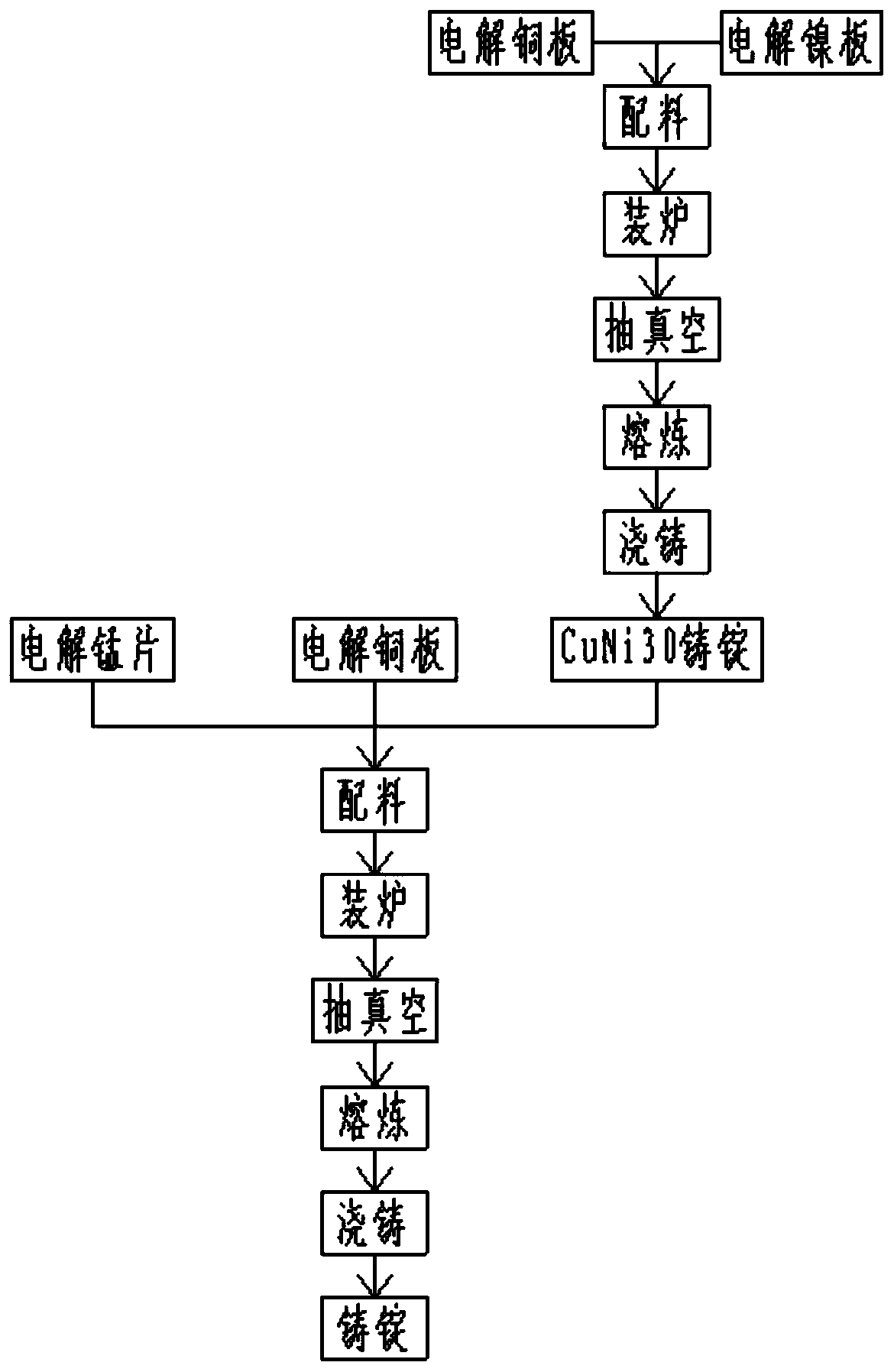

Method for preparing CuMn12Ni alloy by adopting vacuum induction melting

ActiveCN111534708ALow costReduce burning lossCharge treatment typeIncreasing energy efficiencyVacuum pressureCrucible

The invention discloses a method for preparing CuMn12Ni alloy by adopting vacuum induction melting. The method comprises the following steps that burdening is carried out, specifically, an electrolytic copper plate, an electrolytic manganese sheet and a CuNi3O intermediate alloy material are respectively weighed; charging is carried out, specifically, the prepared alloy material is charged into acrucible, a deflation valve is closed; vacuumizing is carried out, specifically, turning on a mechanical pump is carried out, a low-vacuum baffle valve is opened for vacuumizing, turning on a roots pump is carried out when the vacuum pressure p in a furnace is less than or equal to 0.08 MPa; smelting is carried out, specifically, when the vacuum degree p is smaller than or equal to 10 Pa, heatingis carried out, the heating power is increased to 60 KW, when the raw material in the crucible begins to be molten, the power is reduced to be lower than 20 KW, an argon filling valve is opened, whenthe pressure in the furnace is increased to about 0.08 Mpa, the argon filling valve is closed, the power is increased to 65 KW, refining is carried out for 2 min; casting is carried out, specifically,the power is reduced to 40KW + / -5KW, keeping for 0.2 minute is carried out, casting is started, the casting time is less than or equal to 2min; and discharging is carried out, specifically, after casting is completed, heating is stopped, and after cooling is carried out for 30 min, discharging is carried out. According to the method for preparing the CuMn12Ni alloy by adopting vacuum induction melting, the technological process is reasonable in design, and the prepared CuMn12Ni alloy is low in gas content, uniform in structure, free of segregation defects and suitable for large-scale popularization.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Efficient roasting device for rare earth waste

InactiveCN106482504AReasonable useEasy to passCharge composition/stateCharge treatment typeRare earthEngineering

The invention relates to a roasting device, in particular to an efficient roasting device for rare earth waste. The efficient roasting device for rare earth waste achieves the technical aims of being easy to operate, low in equipment cost and low in energy consumption and comprises a bottom plate, a roasting furnace, a support, a bearing pedestal, a reel, a rotating shaft, a rotating rod, shifting pieces, a first connecting rod, an exhaust fan, a second connecting rod, a baffle and the like; the top of the bottom plate is connected with the support in a welded manner, the support is located on the right of the roasting furnace, the upper portion and the lower portion of the right wall in the support are connected with the first connecting rod in a welded manner, and the left end of the first connecting rod is connected with a roasting box in a bolt connection manner. The effects of being rapid in heating, uniform in heating, low in energy consumption, simple in structure and capable of reasonably utilizing labor resources are achieved, and a groove is formed in the bottom of the roasting box.

Owner:明光智慧天顺技术转移服务有限公司

Smelting furnace

PendingCN106871641AReduce lossImprove uniformityBurnersCharge treatment typeCombustion chamberHearth

The invention discloses a smelting furnace. The smelting furnace comprises a smelting furnace body, a heat storage device, a coal powder-oxidant gas spray gun, a gas supply assembly, an air supply assembly and a smoke exhaust pipe assembly; a furnace hearth is defined in the smelting furnace body, the heat storage device comprises a first heat storage assembly and a second heat storage assembly, the first heat storage assembly and the second heat storage assembly each comprises a heat storage combustion chamber and a combustion nozzle which are connected with each other, and each heat storage combustion chamber communicates with the corresponding combustion nozzle through the furnace hearth; the coal powder-oxidant gas spray gun comprises a first spray gun assembly and a second spray gun assembly, the first spray gun assembly and the second spray gun assembly are arranged on the side walls of the smelting furnace body separately, the first spray gun assembly and the first heat storage assembly are distributed on the side wall of the smelting furnace body in a staggered manner, and the second spray gun assembly and the second heat storage assembly are distributed on the side wall of the smelting furnace body in a staggered manner; and the gas supply assembly is connected with the combustion nozzle of the first heat storage assembly and the combustion nozzle of the second heat storage assembly separately, the air supply assembly is connected with the heat storage combustion chamber of the first heat storage assembly and the heat storage combustion chamber of the second heat storage assembly separately, and the smoke exhaust pipe assembly communicates with the heat storage combustion chamber of the first heat storage assembly and the heat storage combustion chamber of the second heat storage assembly separately.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Sintering furnace with heat recovery function and uniform heating capability

ActiveCN110763010AAchieve recyclingGood energy saving effectCharge treatment typeFurnace typesElectric machineGear wheel

The invention relates to a sintering furnace with a heat recovery function and uniform heating capability. The sintering furnace comprises a sintering chamber, a conveyor belt and a base, as well as arecovery mechanism and a feeding mechanism; the feeding mechanism comprises a feeding groove, a discharging pipe, a rotating cylinder, an annular track, an annular groove, a driving assembly and a discharging port; the recovery mechanism comprises a heat absorption box, a third heat conduction pipe, a first heat conduction pipe, a heat storage box, an air pump and at least two fourth heat conduction pipes; and the driving assembly comprises a motor, a gear and an annular rack. In the sintering furnace with the heat recovery function and the uniform heating capability, part of the heat on workpieces can be recovered through the recovery mechanism, so that the recovery and utilization of the heat are realized, and the energy-saving performance of the sintering furnace is improved; and the workpieces can be uniformly spread on a conveying belt through the feeding mechanism, so that the spatial heating uniformity is improved, and the sintering quality of the sintering furnace is improved.

Owner:赣州涌金磁材有限公司

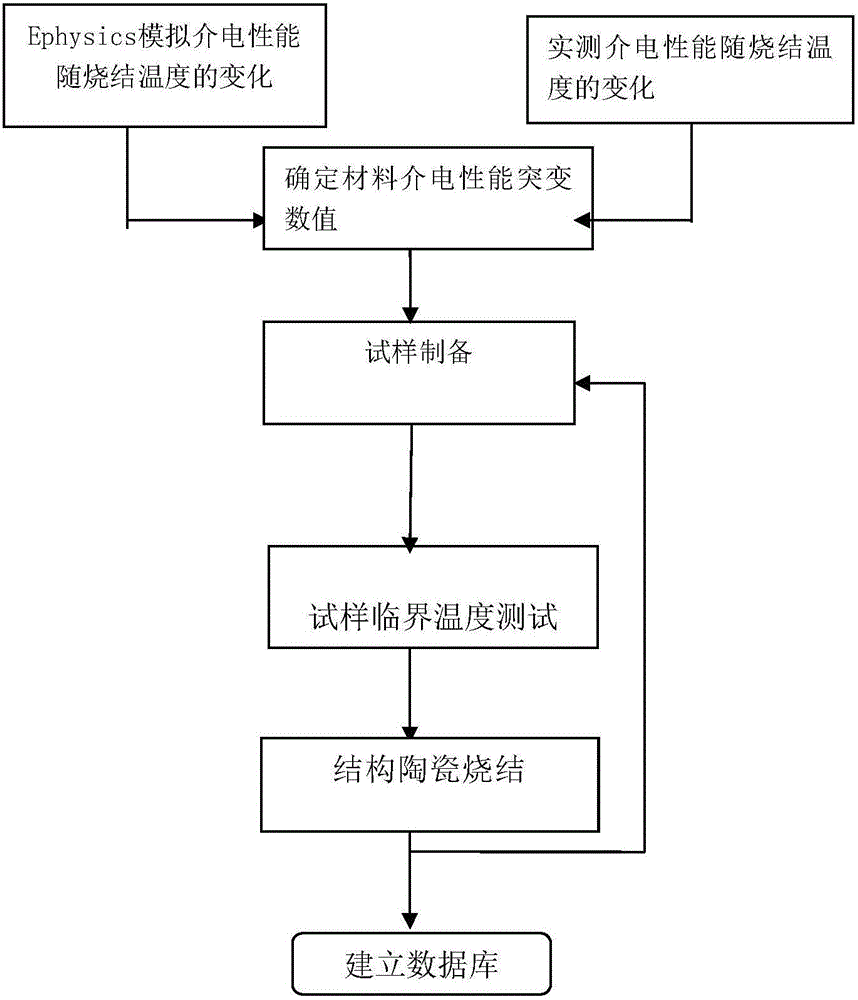

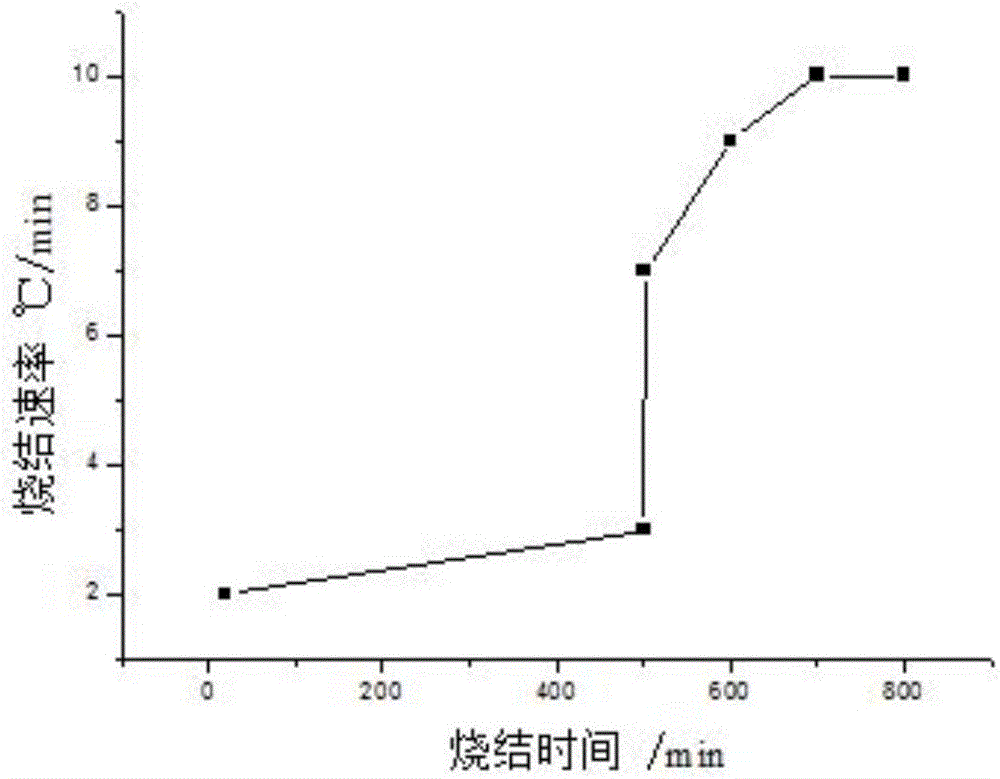

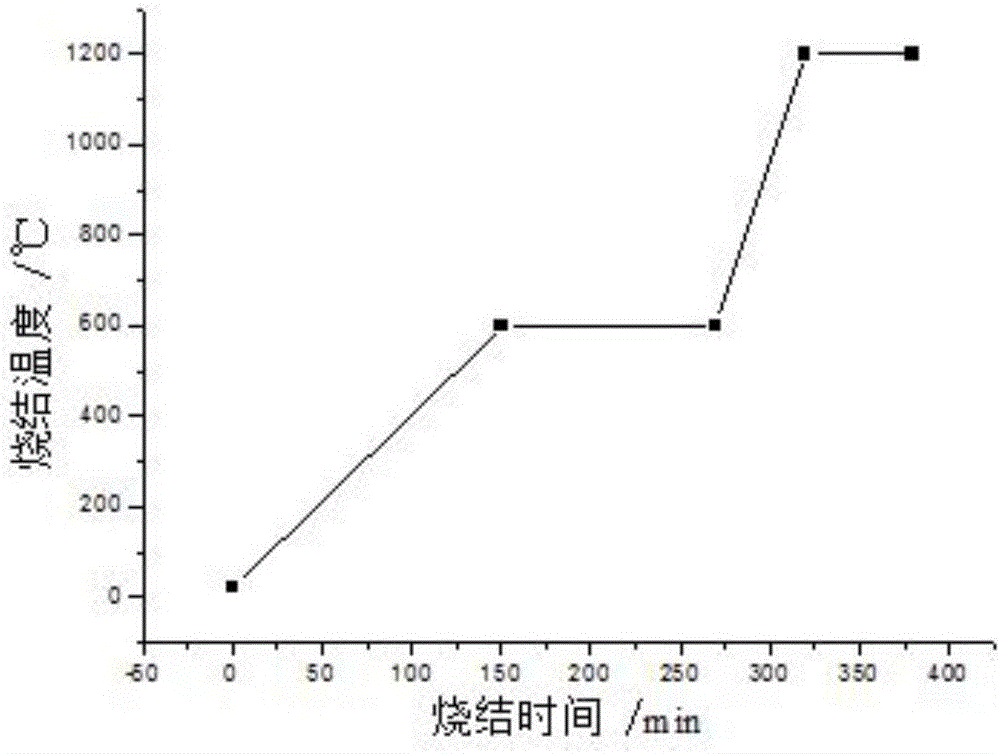

Micro-wave-regular sintering method of structural ceramic

InactiveCN106810216AAvoid crackingReduce temperature gradientCharge treatment typeFurnace typesHeating timeDielectric loss

The invention belongs to the technical field of preparation of structural ceramic, and relates to a micro-wave-regular sintering method of a structural ceramic. The method includes steps of analyzing dielectric property of a structural ceramic along with the temperature changing rule, applying an electromagnetic field distribution simulation result to temperature field simulation software to simulate change status of dielectric constant and loss tangent of Y-TZP and ZTA material in microwave sintering process along with the temperature field on the basis of study of a three-dimensional electromagnetic simulation technique on electromagnetic field distribution of the structural ceramic in the microwave sintering cavity; testing change of the dielectric properties of the Y-TZP and ZTA along with the sintering temperature, contrasting the actual measured data with the simulated data; analyzing the difference, reason and influence factors; finding out the critical temperature of Y-TZP and ZTA with sharply increased dielectric loss in sintering process; then performing micro-wave-regular sintering on the prepared Y-TZP and ZTA samples. The micro-wave-regular sintering method is simple in technique, convenient to operate, scientific in principle, uniform in material heating, short in heating time, few in energy consumption, and convenient to perform the industrial production of the structural ceramic.

Owner:QINGDAO UNIV

Novel burning and circulating system for aluminum smelting furnace

InactiveCN106766890AReduce burning lossFull recoveryCharge composition/stateCharge treatment typeFlue gasTorch

The invention discloses a novel burning and circulating system for an aluminum smelting furnace. The novel burning and circulating system comprises a mother furnace body, a melting chamber, a feeding chamber, a heat storage system and an aluminum water circulating pump. The mother furnace body is internally provided with the melting chamber and the feeding chamber, the melting chamber and the feeding chamber are separated, the bottom of the melting chamber communicates with the bottom of the feeding chamber, and the upper portions of the melting chamber and the feeding chamber are partitioned by liquid. The heat storage system comprises three heat storage chambers arranged on the mother furnace body and corresponding heat storage burning torches and burners. The novel burning and circulating system further comprises a combustion air pipeline, a combustion fan, a flue gas emission pipeline, an exhaust gas fan and a PLC system. The combustion air pipeline and the flue gas emission pipeline are each internally provided with a plurality of two-way valves which are connected in parallel. The combustion fan communicates with the corresponding heat storage type burning torches and burners through the combustion air pipeline, and the exhaust gas fan communicates with the corresponding heat storage type burning torches and burners through the smoke emission pipeline. By means of the novel burning and circulating system, the burning efficiency is greatly improved, the heat is recycled completely, the gas consumption per unit is reduced, the number of times of ash beating is increased, the melting efficiency is improved, and the burning loss is reduced.

Owner:HUANGSHI FUXING ALUMINUM

Silicon carbide saggar for calcining lithium battery positive electrode material, and production method thereof

ActiveCN108484188AImprove corrosion resistanceExtended service lifeCharge supportsCharge treatment typeSaggarTalc

The invention relates to a silicon carbide saggar for calcining a lithium battery positive electrode material, and a production method thereof. The production method comprises the following steps: using 40-55 wt% of alumina powder, 30-40 wt% of zircon and 10-20 wt% of Suzhou clay as a mixture, adding vanadium pentoxide accounting for 4-6 wt% of the mixture and water accounting for 5-8 wt% of the mixture, and performing uniform mixing to obtain a working layer mixture; using 30-45 wt% of talcum, 10-20 wt% of alumina powder and 40-50 wt% of Suzhou clay as a matrix material, adding water, performing ball milling, and drying and crushing the obtained matrix material solution to obtain a matrix powder; using 60-75 wt% of silicon carbide aggregates and 25-40 wt% of the matrix powder as raw materials, adding a binder accounting for 5-10 wt% of the raw materials, and performing uniform mixing and molding; distributing a layer of the working layer mixture on the bottom working surface of a molded saggar matrix, and performing machine pressing and drying; and performing heat insulation at 1370-1400 DEG C for 8-10 h to produce the silicon carbide saggar for calcining a lithium battery positive electrode material. The production method has the advantages of low cost, energy saving and environmental protection, and the product produced in the invention has the advantages of good thermal shock stability, excellent erosion resistance and long life.

Owner:WUHAN UNIV OF SCI & TECH

Pot Furnace for Calcining Petroleum Coke at Low Temperature

ActiveUS20170261262A1Reduce the amount requiredReduce corrosionCoke ovensCharge composition/stateFlue gasWater jacket

A pot furnace for calcining petroleum coke at low temperature may include a pot, and a cooling water jacket and a flame path below the pot. The flame path may include eight layers. An inlet of a first flame path layer may be in communication with a volatile channel in the front wall, and is provided with a first flame path layer flashboard. An eighth flame path layer may be in communication with a communication flue. Flue gas may be discharged out of the furnace body through a main flue. A furnace bottom cooling channel may be provided below the eighth flame path layer.

Owner:CHINA ALUMINUM INT ENG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com