Patents

Literature

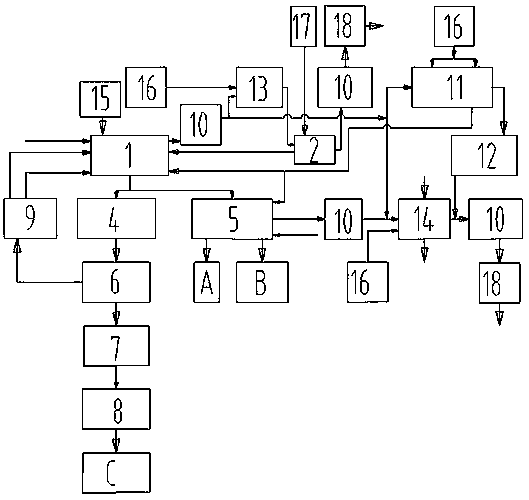

169results about How to "Restore fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

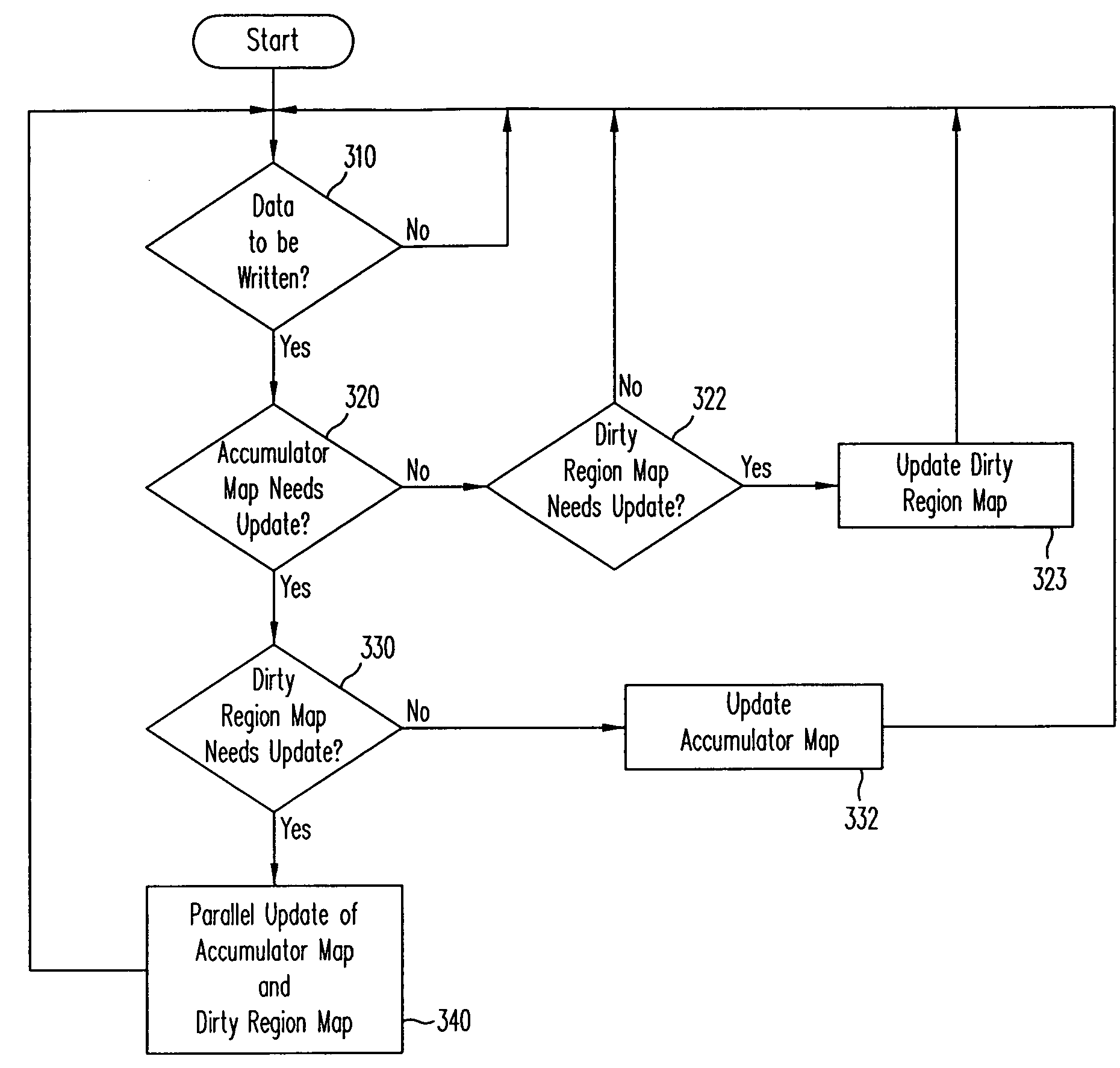

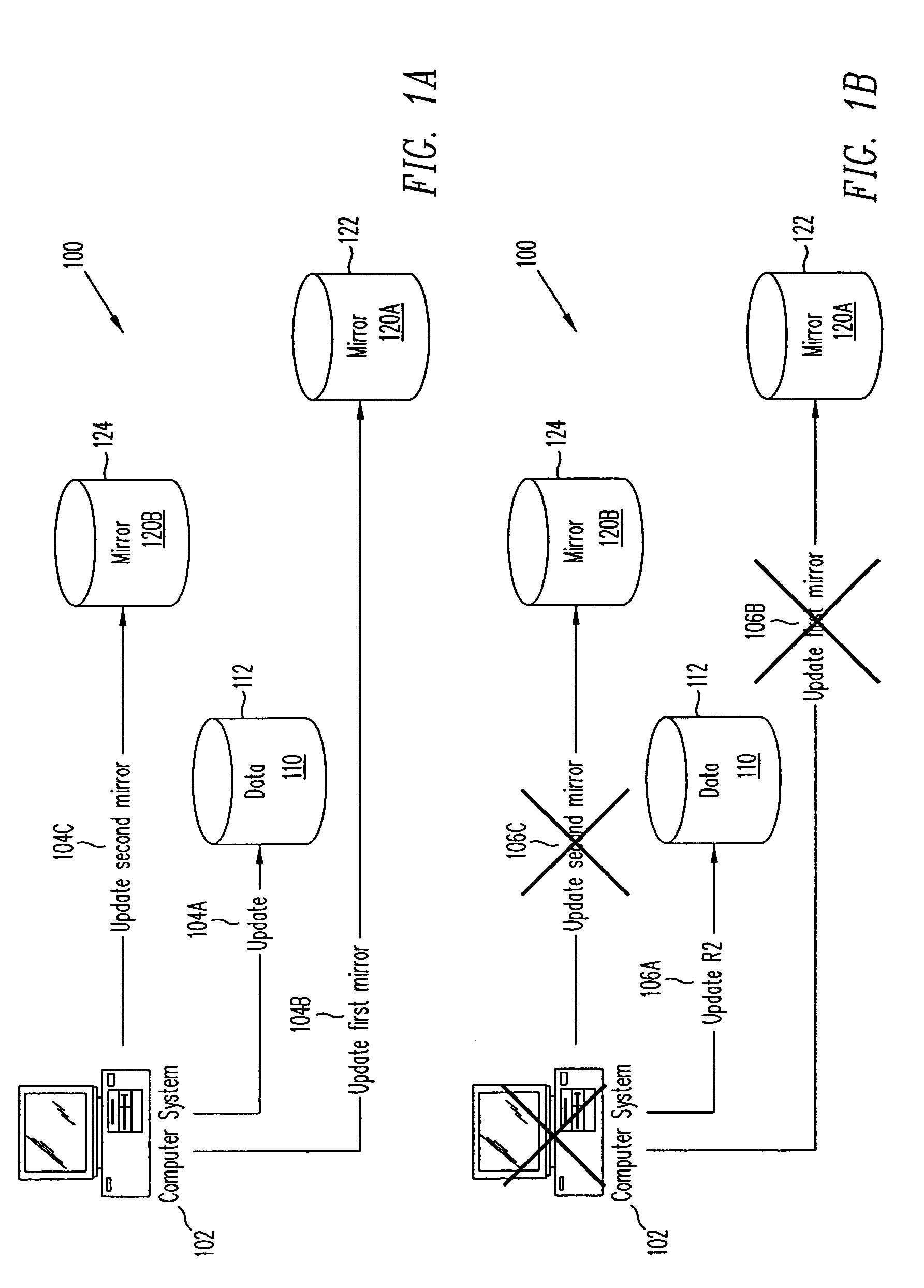

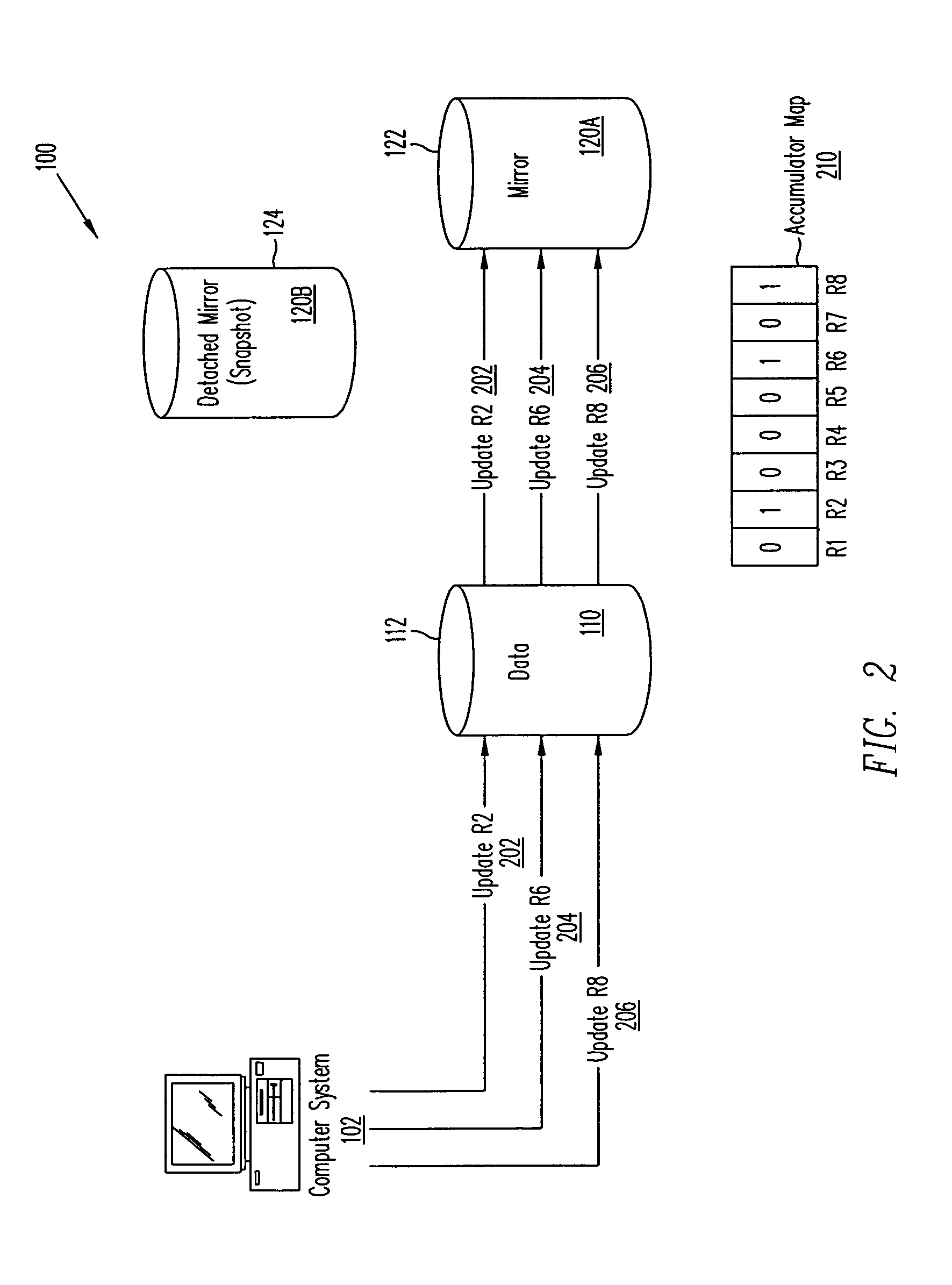

Parallel data change tracking for maintaining mirrored data consistency

ActiveUS7103796B1Reduce overheadReduce processing timeError detection/correctionComputerized systemSystem failure

A method, system, computer system and computer program product to maintain consistency between mirrored copies of data. A first data change map identifies regions that are about to be updated. If a system failure occurs during the update, the first data change map identifies regions that were being changed so that only those regions can be synchronized to restore consistency between the mirrored copies of data. A second data change map tracks changes made to data after a snapshot of the mirrored data is taken. This second data change map enables the mirrored copies of data to be synchronized without copying all data from one mirrored copy to another. The first and second data change maps are updated in parallel to reduce processing time and overhead. This parallel processing enables fast restoration and synchronization of mirrored copies of data, while having minimal effect on performance of applications using the data.

Owner:SYMANTEC OPERATING CORP

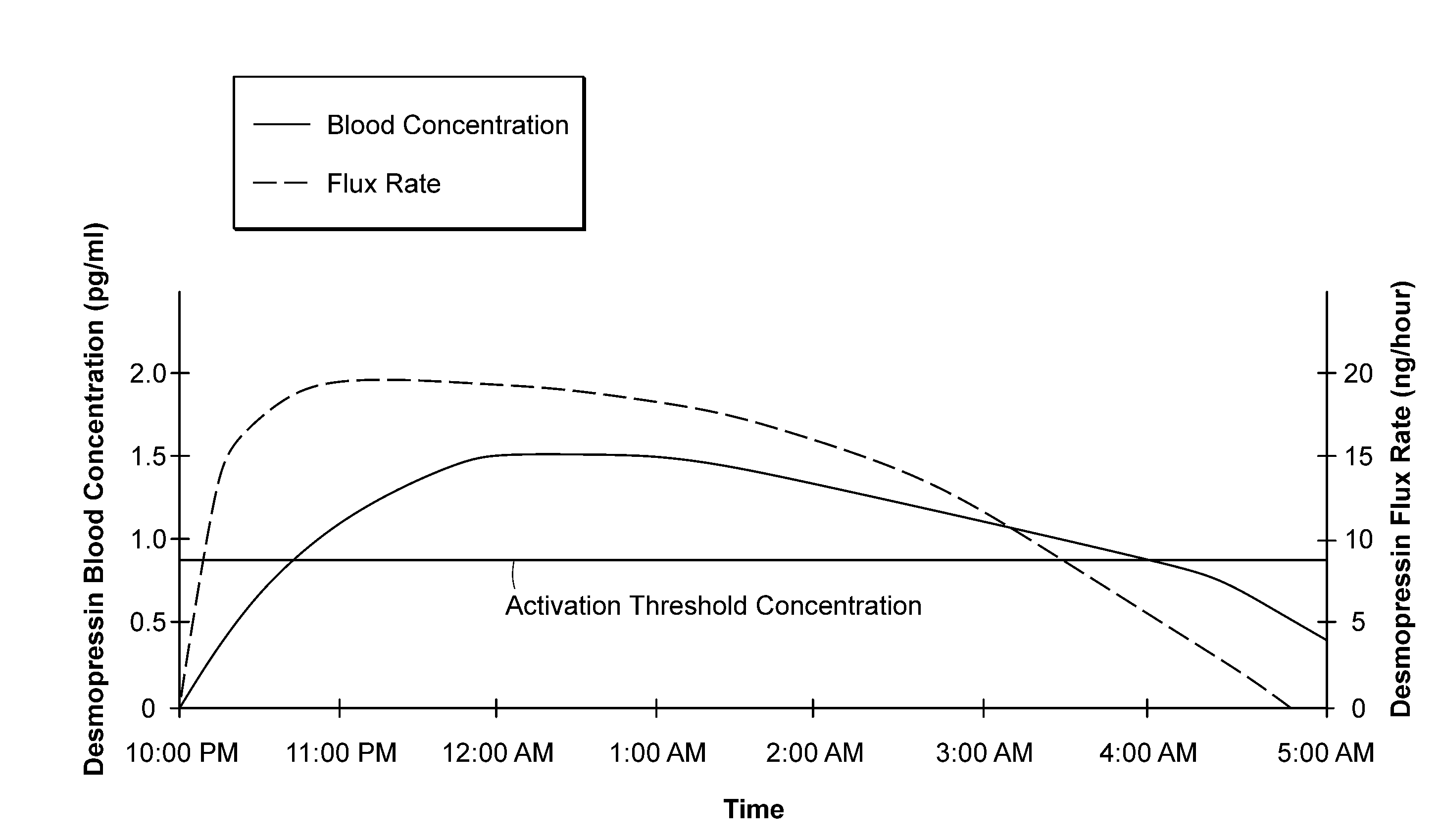

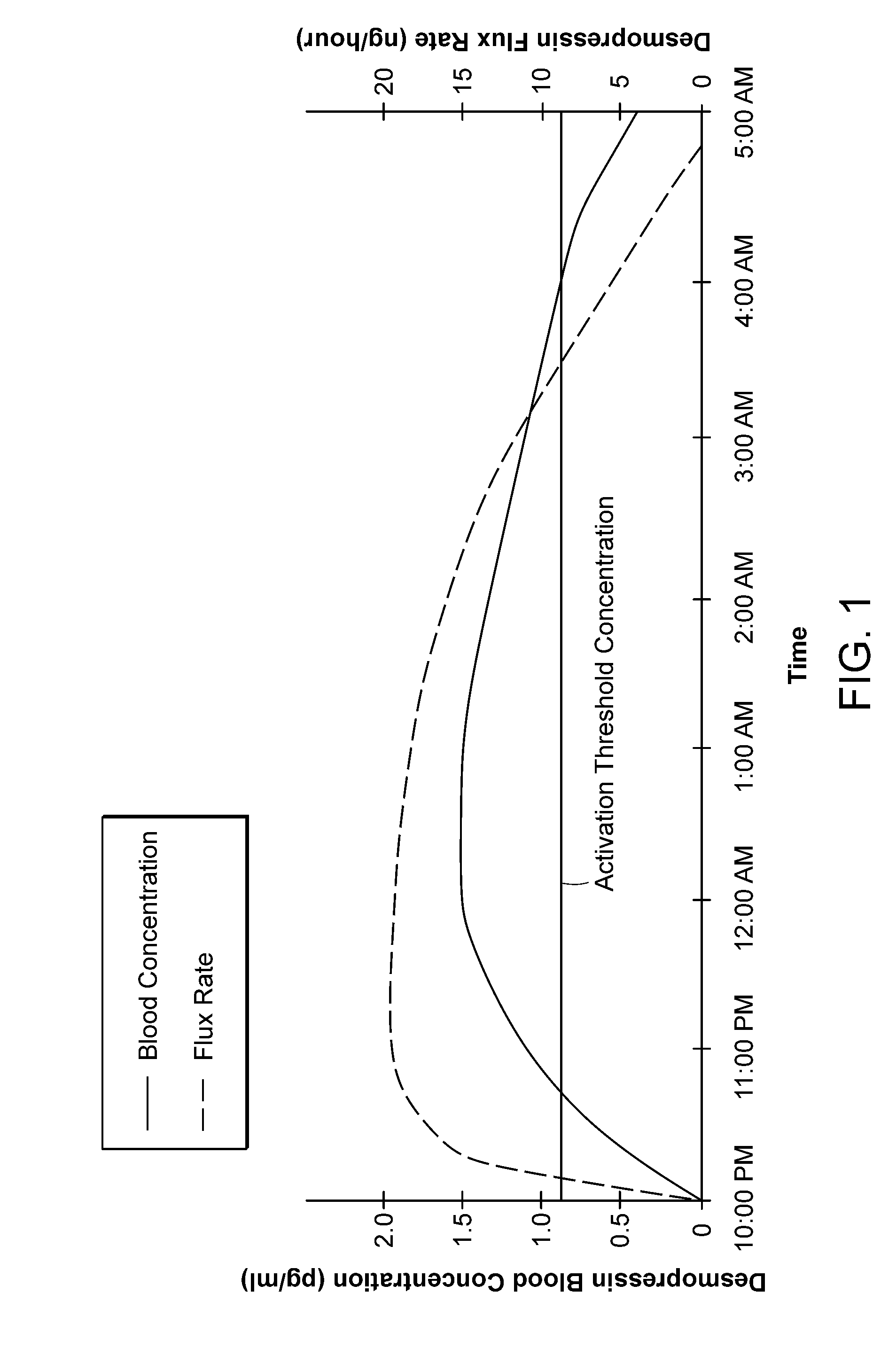

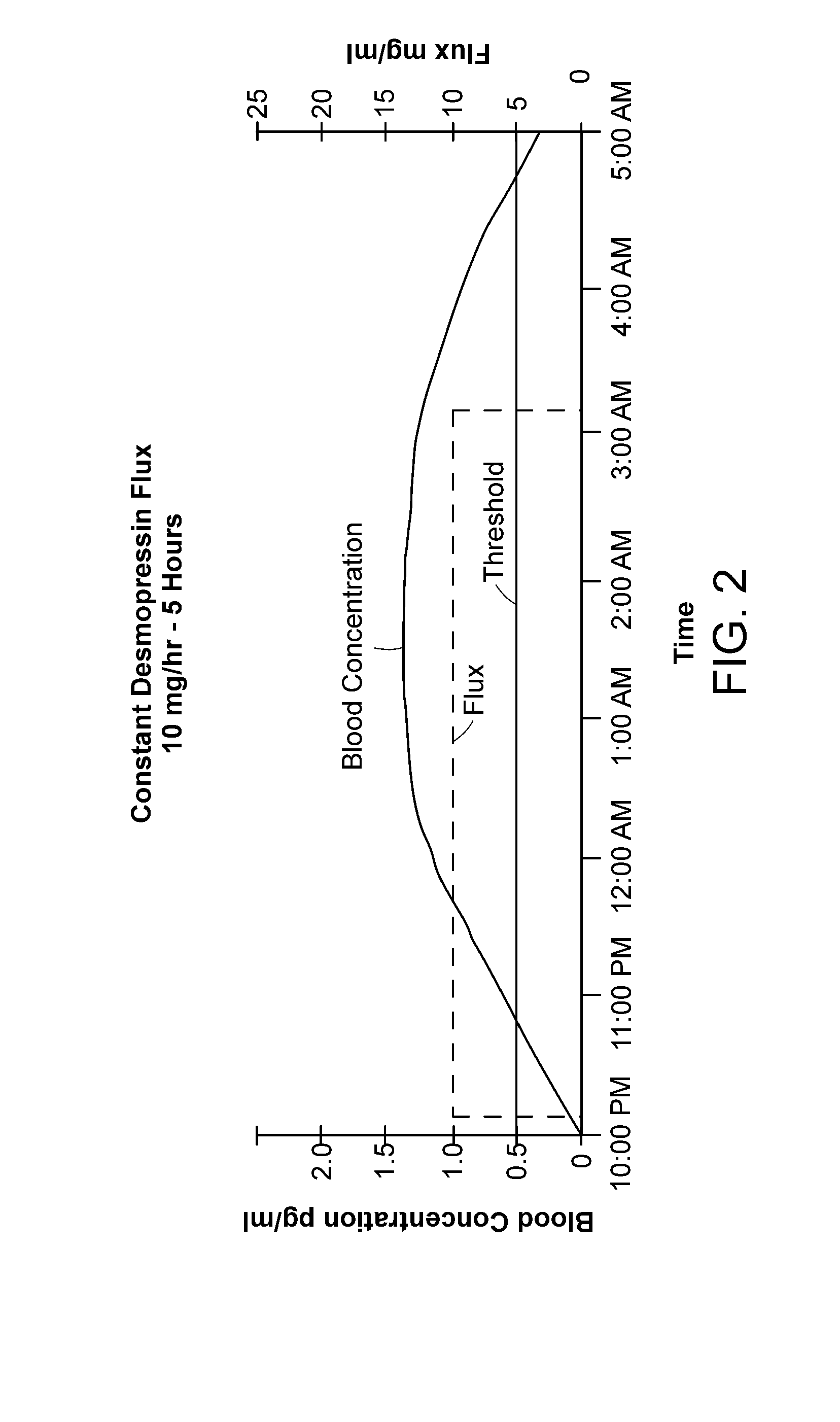

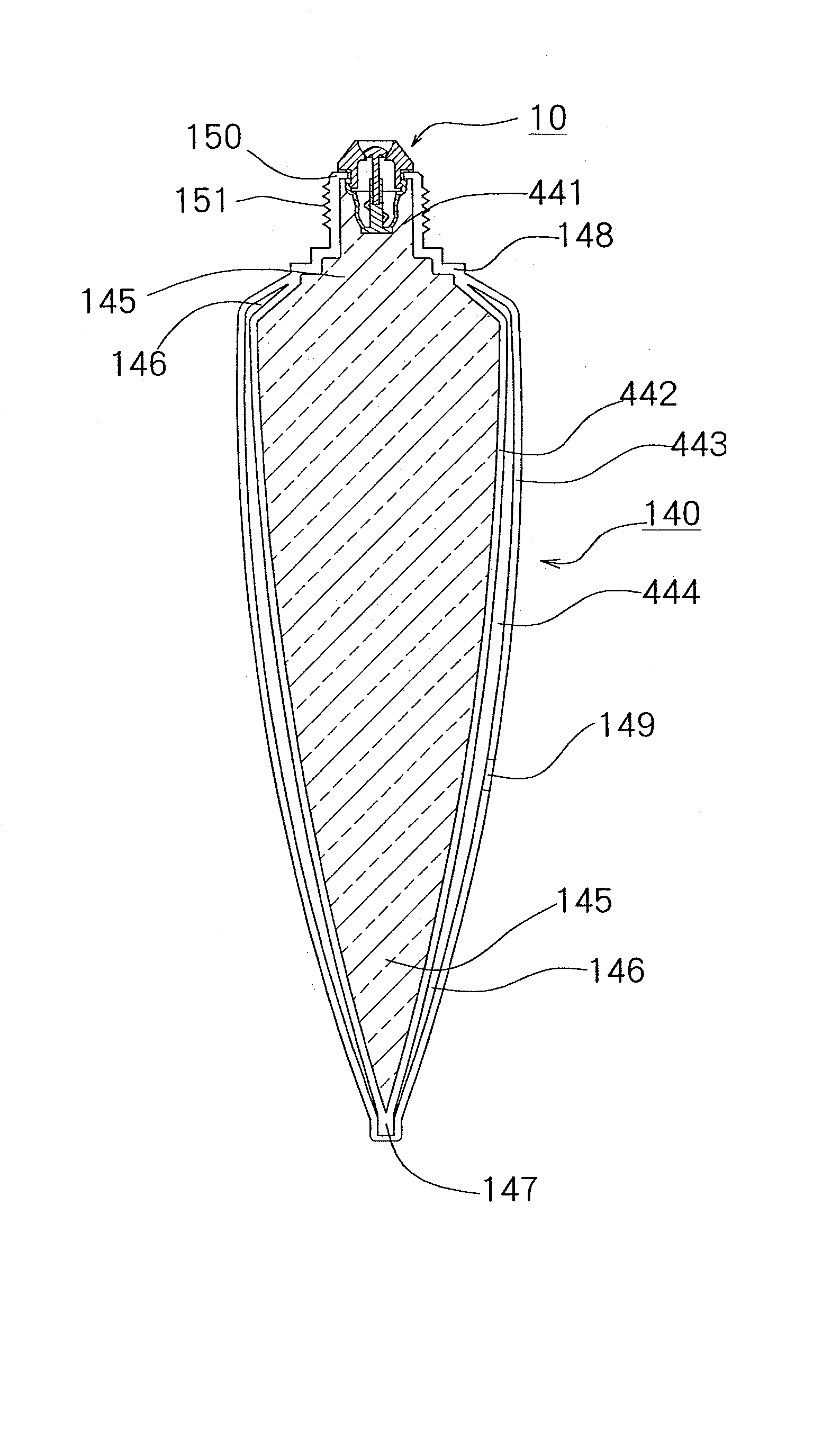

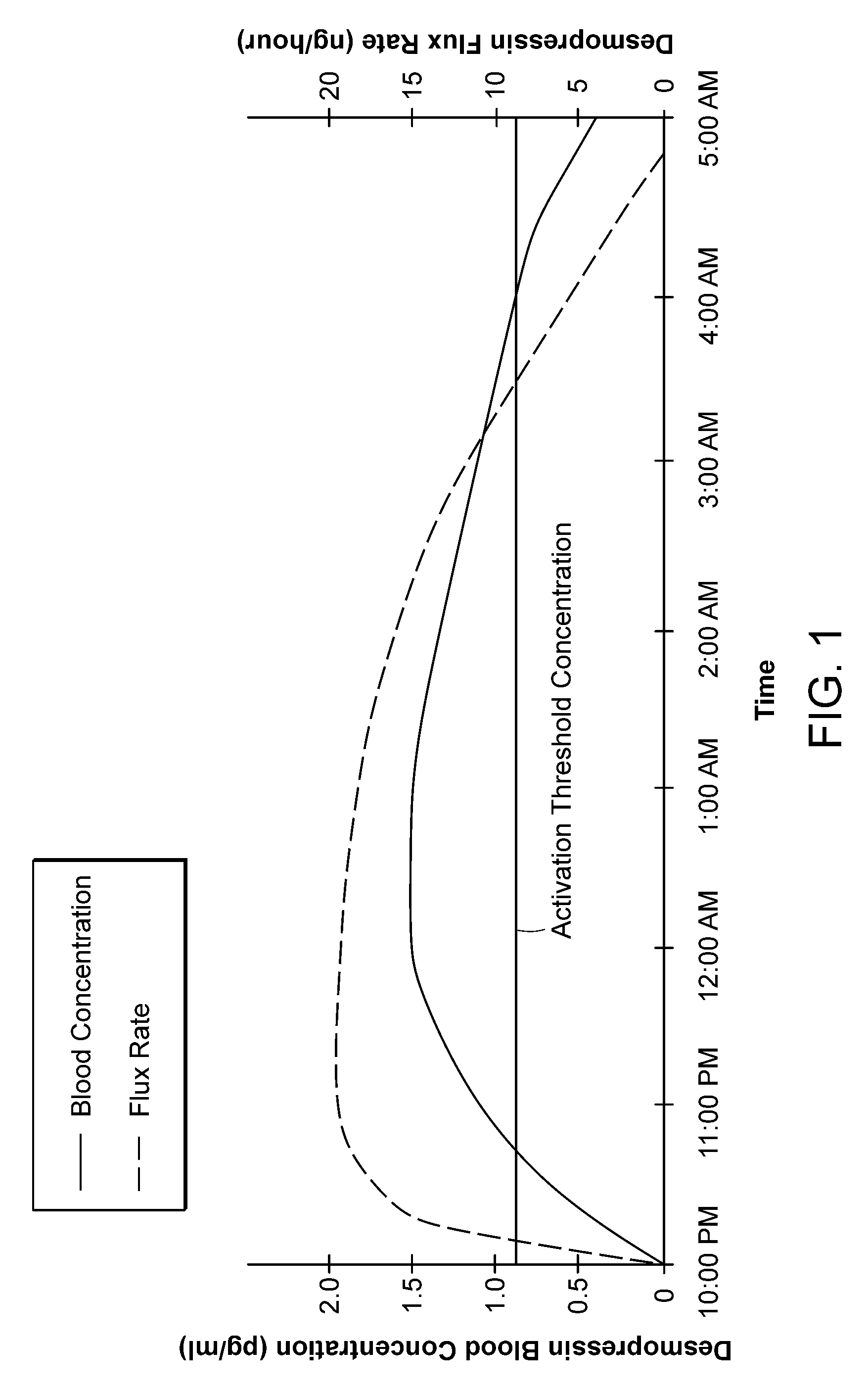

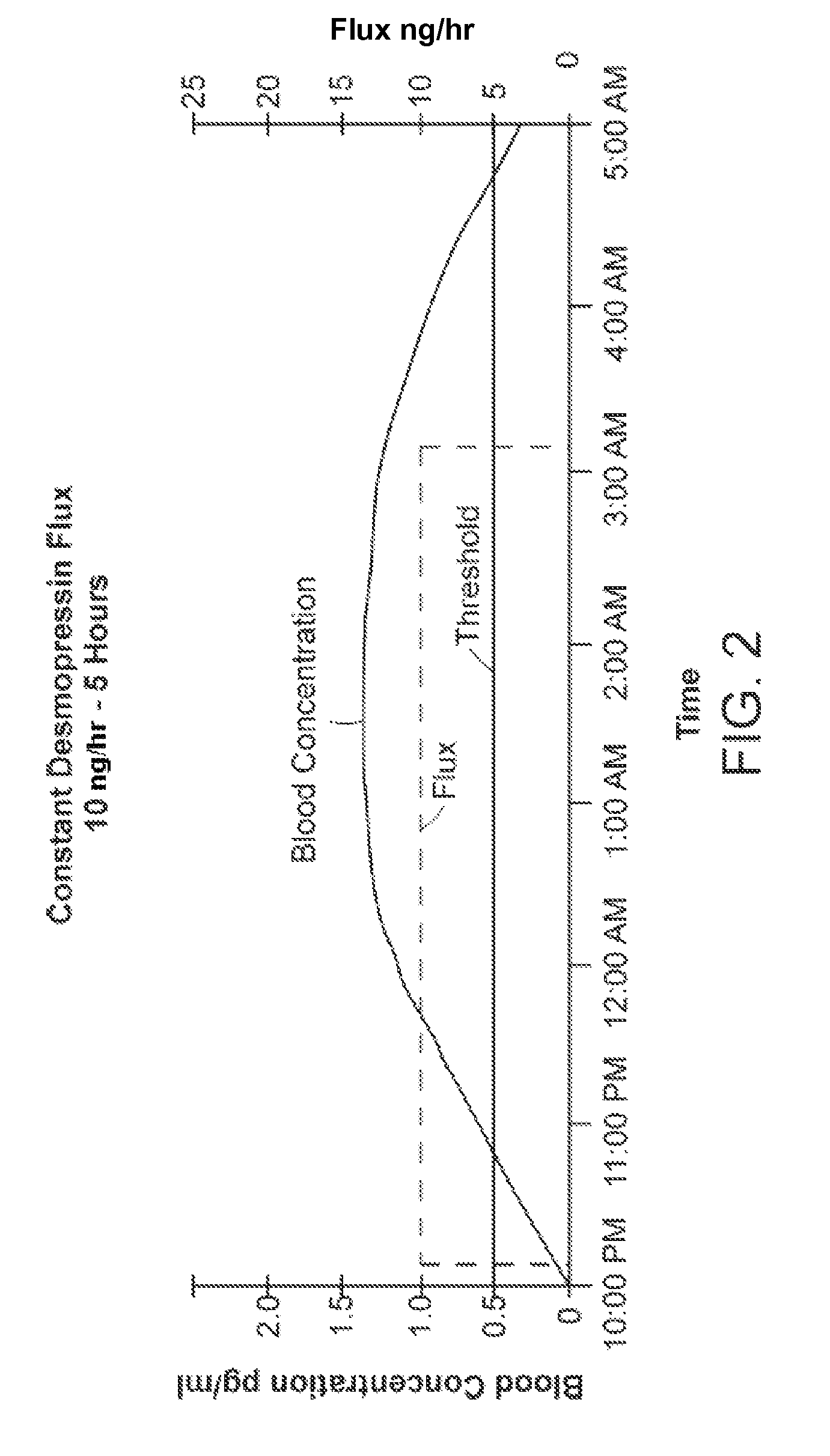

Methods and devices for desmopressin drug delivery

InactiveUS20090042970A1Reduce urine productionRestore normal urine productionBiocidePowder deliveryDecreased sodiumSide effect

Disclosed are devices for urine voiding postponement, and methods for treating conditions such as central diabetes insipidus, enuresis, nocturia, urinary frequency or incontinence. The devices deliver a desmopressin flux through the skin of a patient in a low dose amount just necessary to achieve a desired anti-diuretic effect without undesirable side effects such as hyponatremia. The devices are designed to permit a state of normal urinary production to return quickly after the desmopressin flux is terminated.

Owner:SERENITY PHARMA CORP

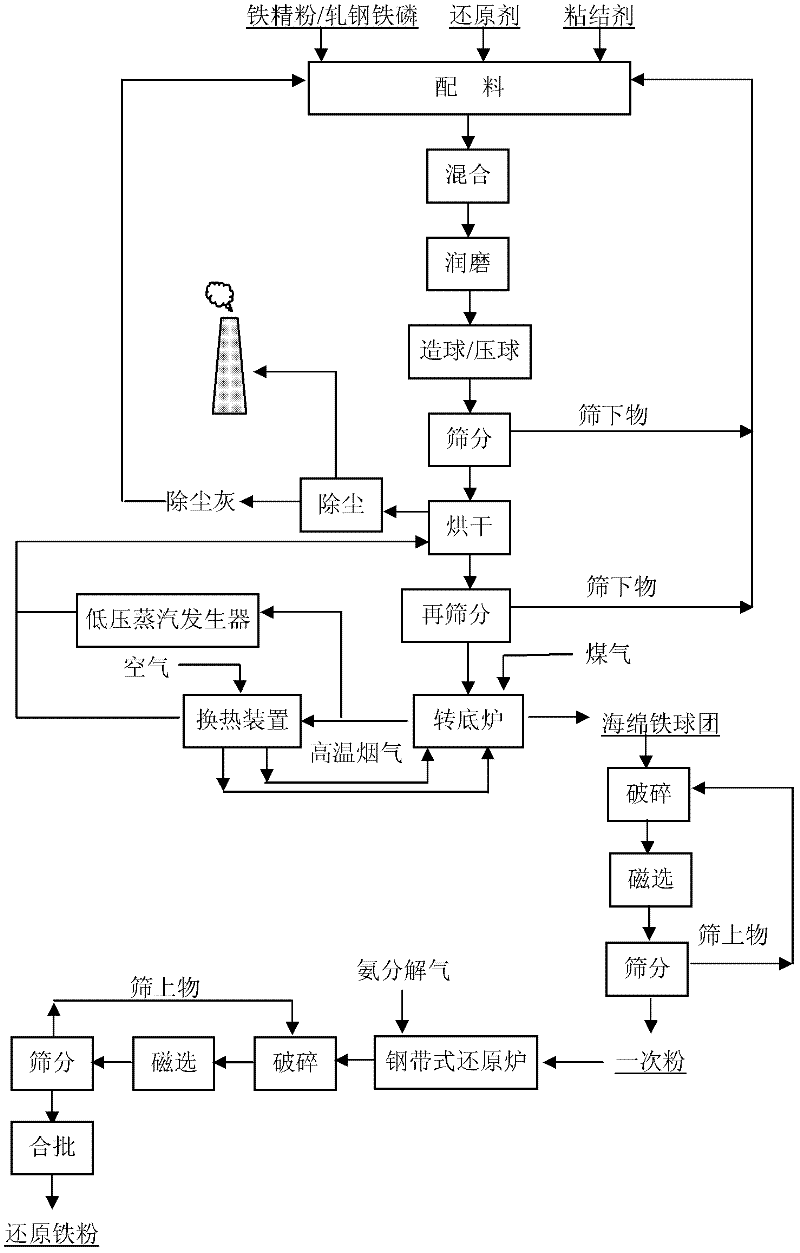

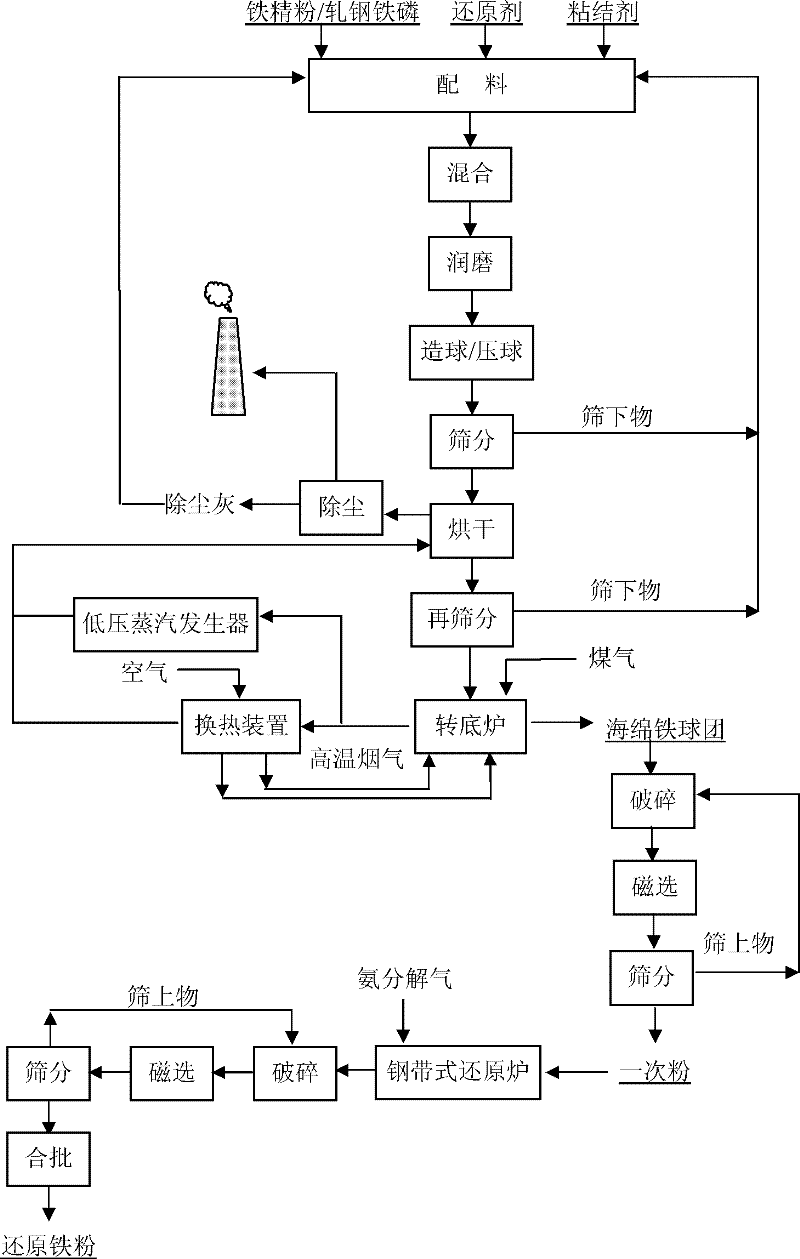

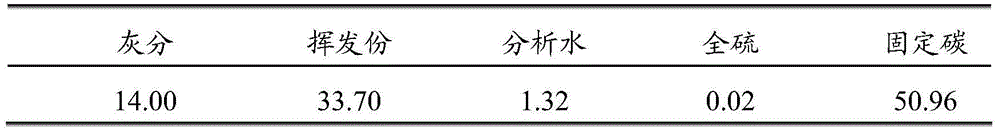

Process for producing reduced iron powder

An efficiency energy-saving process for producing reduced iron powder is implemented through the technical scheme as follows: firstly, the process comprises the following steps of: 1) dosing high-purity iron concentrate fines / mill scales, a reducing agent and an adhesive according to certain proportions, mixing all the materials together and subjecting the mixture to wet grinding treatment, and forming the ground mixture into green balls through pelletizing / pressing into ball; 2) after the green balls are screened and dried, putting the green balls in a rotary hearth furnace for primary reduction, thereby obtaining sponge iron, wherein as the iron core powder is in direct contact with the reducing agent, the reducing speed is high, the time consumed is short and the production efficiency is high; and the high temperature smoke at 1000-1100 DEG C of the rotary hearth furnace enters a smoke waste heat recovery system, thereby realizing efficiency utilization of heat energy; and 3) after performing crashing, magnetic selection and screening on the sponge iron, performing secondary reduction in a steel strip type reducing furnace, and performing crashing, screening and blending on the obtained powder cake, thereby obtaining the reduced iron powder; and 4) the process for producing the reduced iron powder effectively solves the problems of low reduced iron powder productivity, poor quality stability, low heat utilization ratio, high working intensity, bad working environment and the like.

Owner:LAIWU IRON & STEEL GRP

Iron-containing zinc powder recycling process

InactiveCN104073649AComplete restorationImprove thermal efficiencyProcess efficiency improvementShaft furnaceSteelmakingHigh energy

The invention discloses a recycling process of iron-containing zinc powder generated in an iron and steel process. The process comprises the following steps: mixing dried iron-containing zinc powder with a binder, and pelletizing by a pelletizer to obtain green balls; feeding the green balls into a shaft furnace and heating to 1100-1300 DEG C; reducing iron in the shaft furnace to sponge iron; converting reduced zinc at high temperature into zinc steam which is discharged out of the shaft furnace with coal gas and enters into a two-stage dedustor; and feeding dedusting mud obtained from the dedustor into a settling pond, and filtering, settling, thickening and drying to obtain zinc powder. The iron-containing zinc powder mainly comprises blast furnace gas ash, gas mud, dedusting ash, converter steelmaking dust and continuous casting steel rolling scrap iron generated in the iron and steel production. By adopting a treatment mode of the shaft furnace, the problem such as large rotary kiln equipment, low utilization ratio of in-kiln volume and high energy consumption is solved. Coal base is directly reduced at a high speed, and meanwhile, zinc in dust is further recovered.

Owner:WISDRI ENG & RES INC LTD

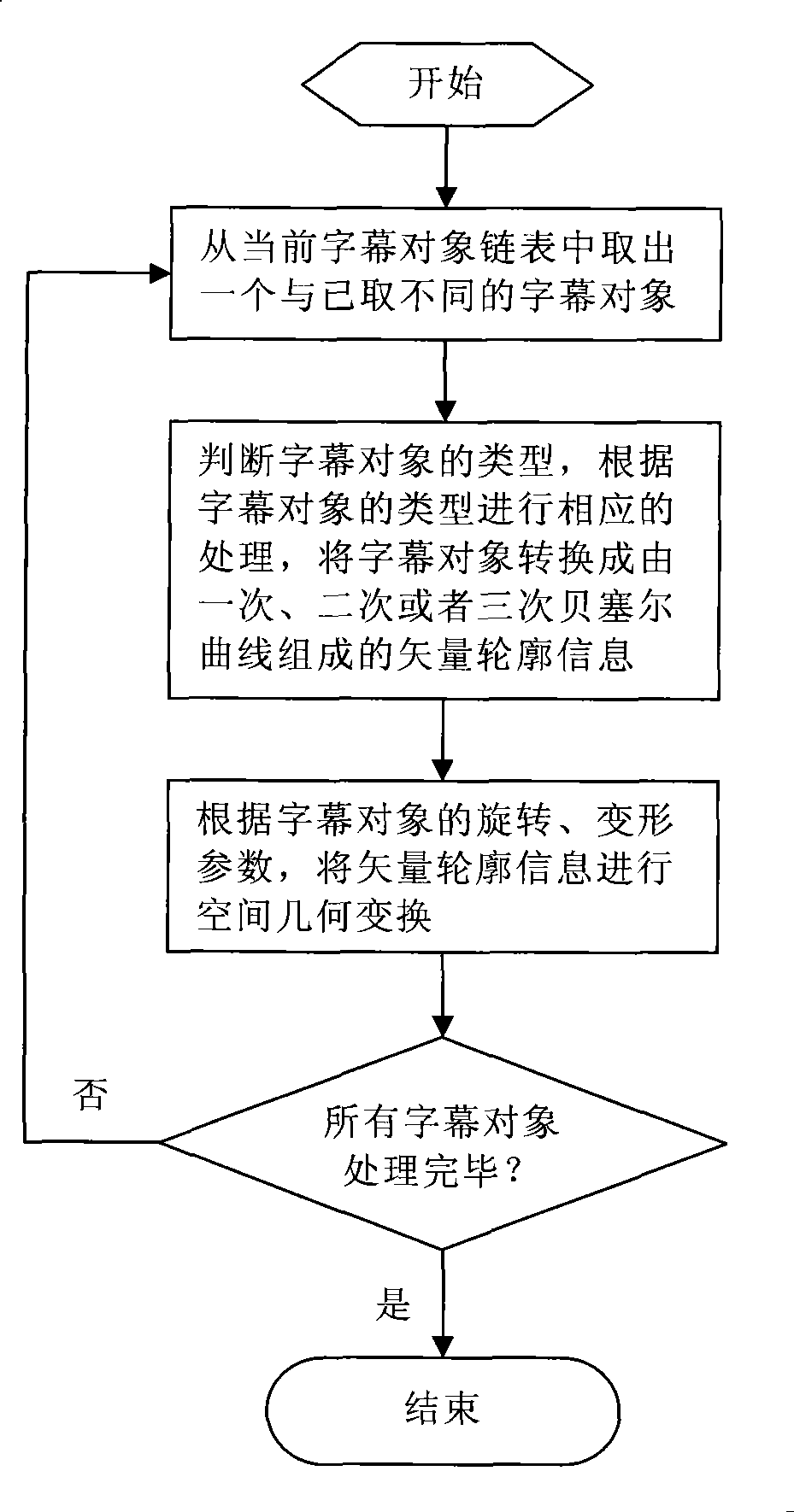

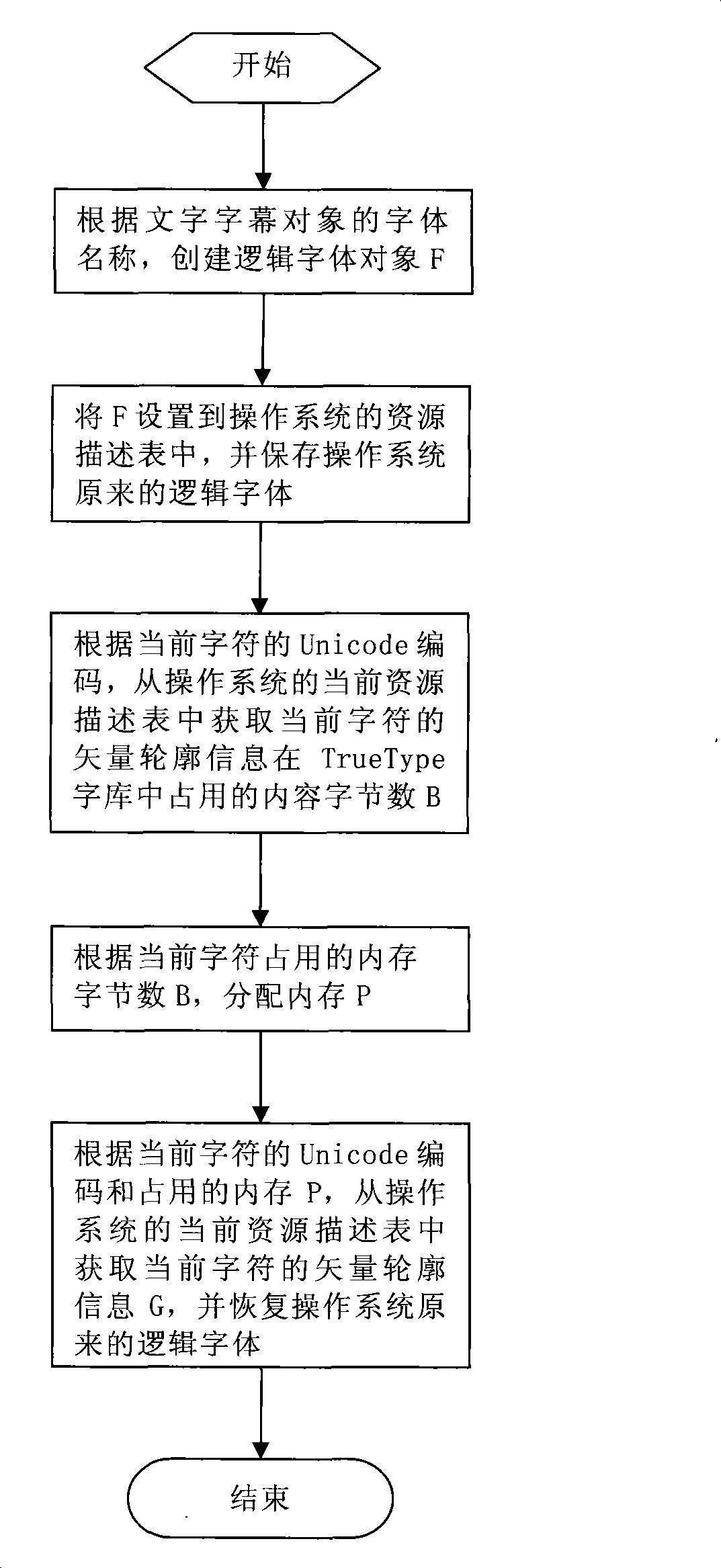

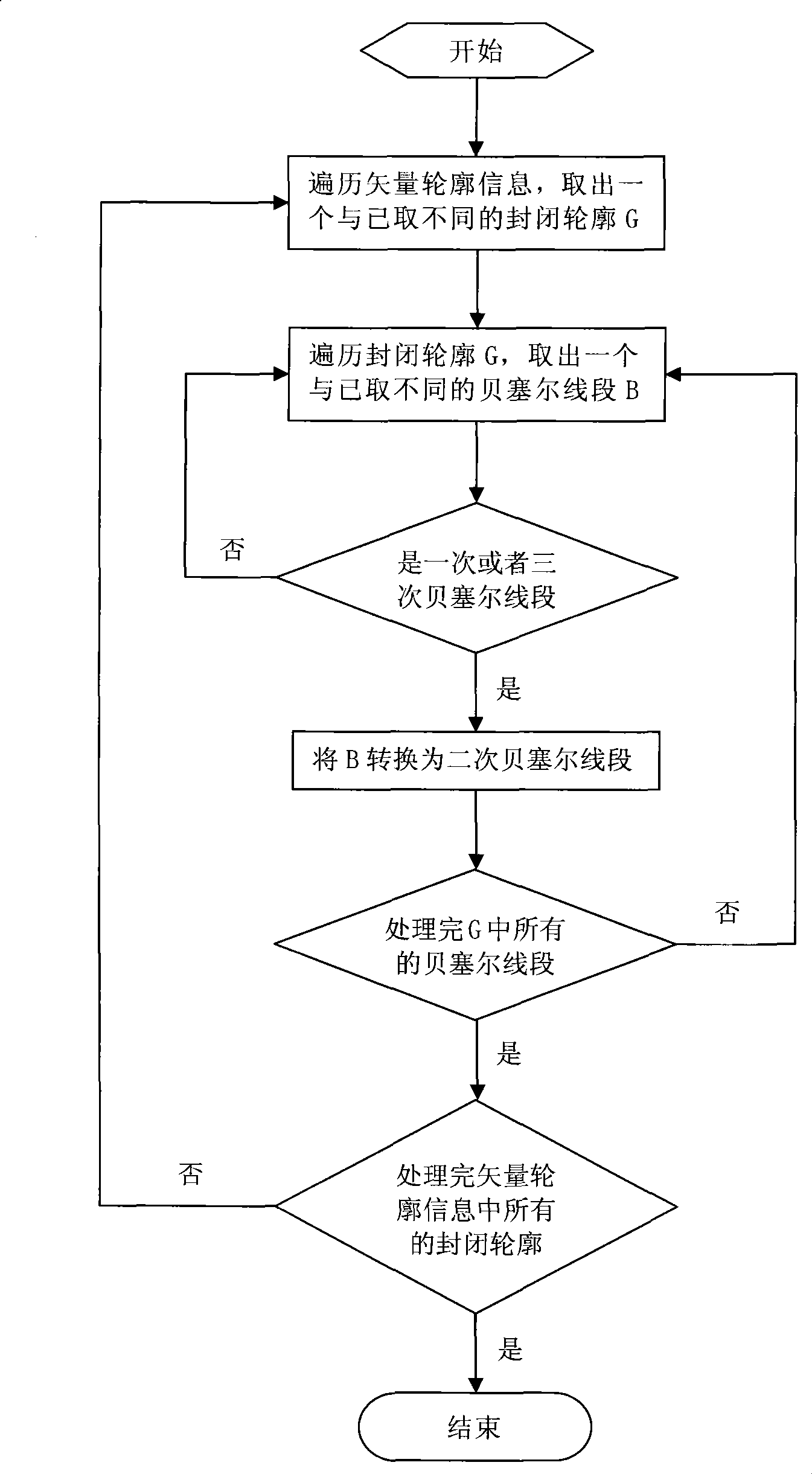

Method for transforming subtitling object into Bessel curve

InactiveCN101415079AAny zoomShrink arbitrarilyTelevision system details2D-image generationBroadcastingComputer science

The invention discloses a method for converting a caption object into a Bezier and belongs to the technical field of caption editing and broadcasting in the TV program producing and broadcasting mechanism of broadcasting and TV industries. The method aims at different processing methods for the caption objects with different types and the caption objects with all types are converted to vector profile information which is formed by a primary Bezier, a secondary Bezier or a third Bezier and comprises one or a plurality of closed profiles; then the primary Bezier and the third Bezier in the vector profile information are converted into the second Bezier. The method leads the caption object to be freely amplified, minified, rotated and deformed without affecting the quality, leads the romancing effects of the captions to be smooth and distortionless and has stepless zooming, realizes the functions of word formation, character deformation, character reflection, character reversing, curve swinging and the like, and meets the high-grade caption application demands.

Owner:CHINA DIGITAL VIDEO BEIJING

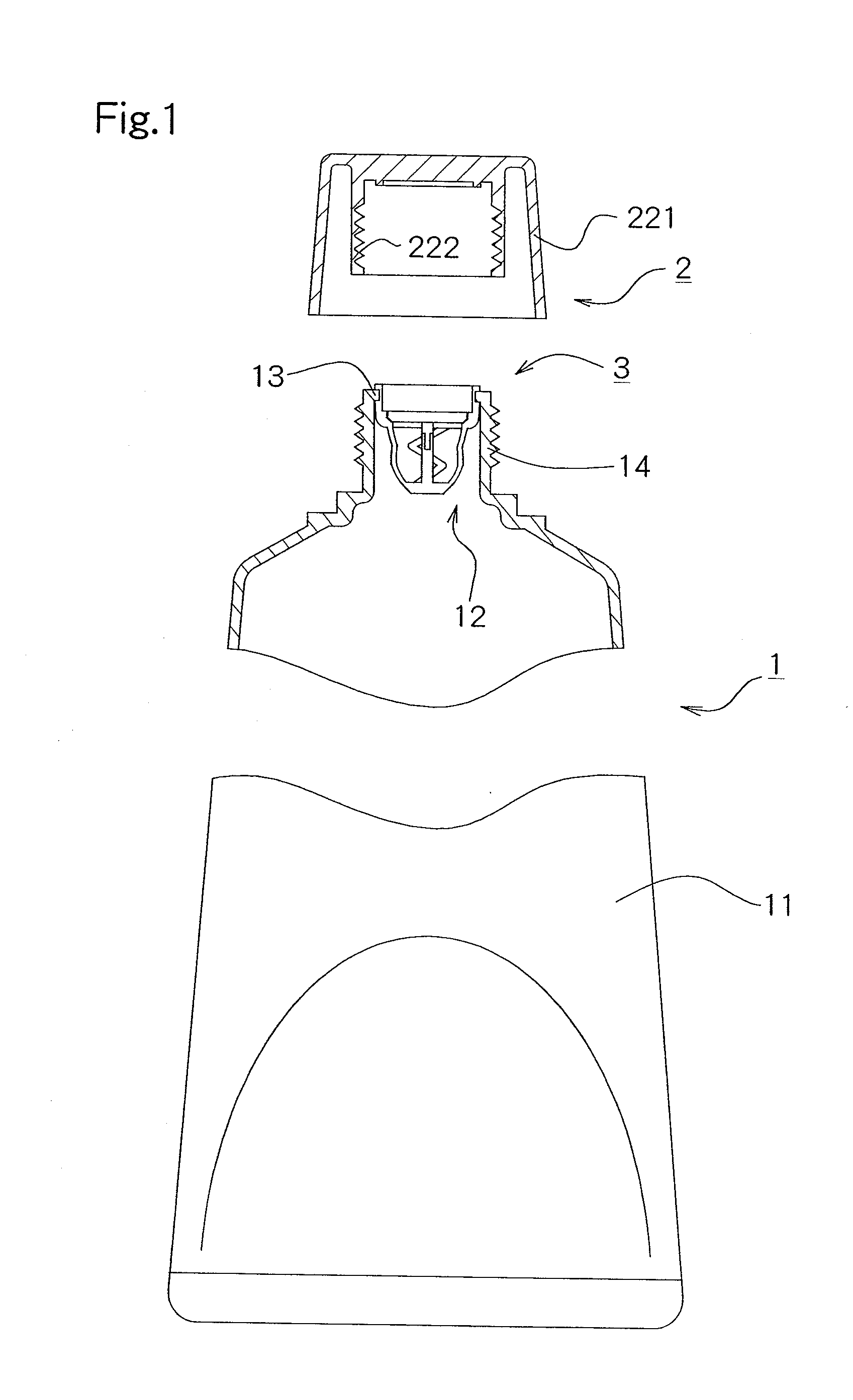

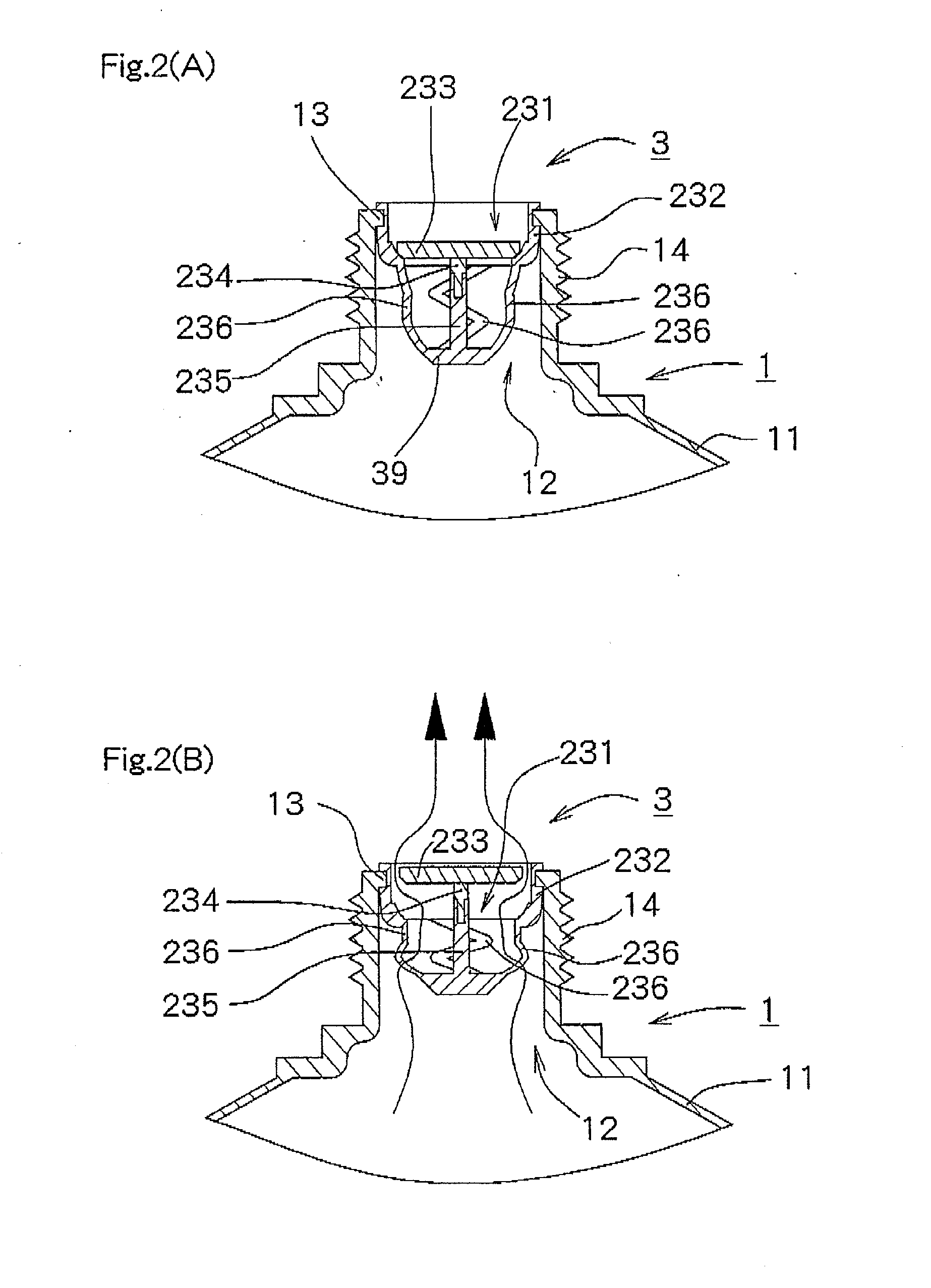

Valve mechanism for tube-type fluid container

InactiveUS20080041890A1Close reliableSimple configurationClosuresDischarging meansEngineeringValve seat

A valve mechanism adapted for a fluid-discharging port of a tube-type fluid container includes: a valve seat portion having a valve seat surface with an opening for passing a fluid therethrough; a valve portion comprising a valve body having a shape corresponding to the valve seat surface with the opening, and a shaft connected to the valve body and extending downward from the valve body, and a valve support portion for elastically urging the valve body downward to close the opening. An annular convex portion is further formed between the valve seat surface and the valve body on the valve seat surface or the valve body for closing the opening with the valve body at the annular convex portion.

Owner:MASUDA MASATOSHI

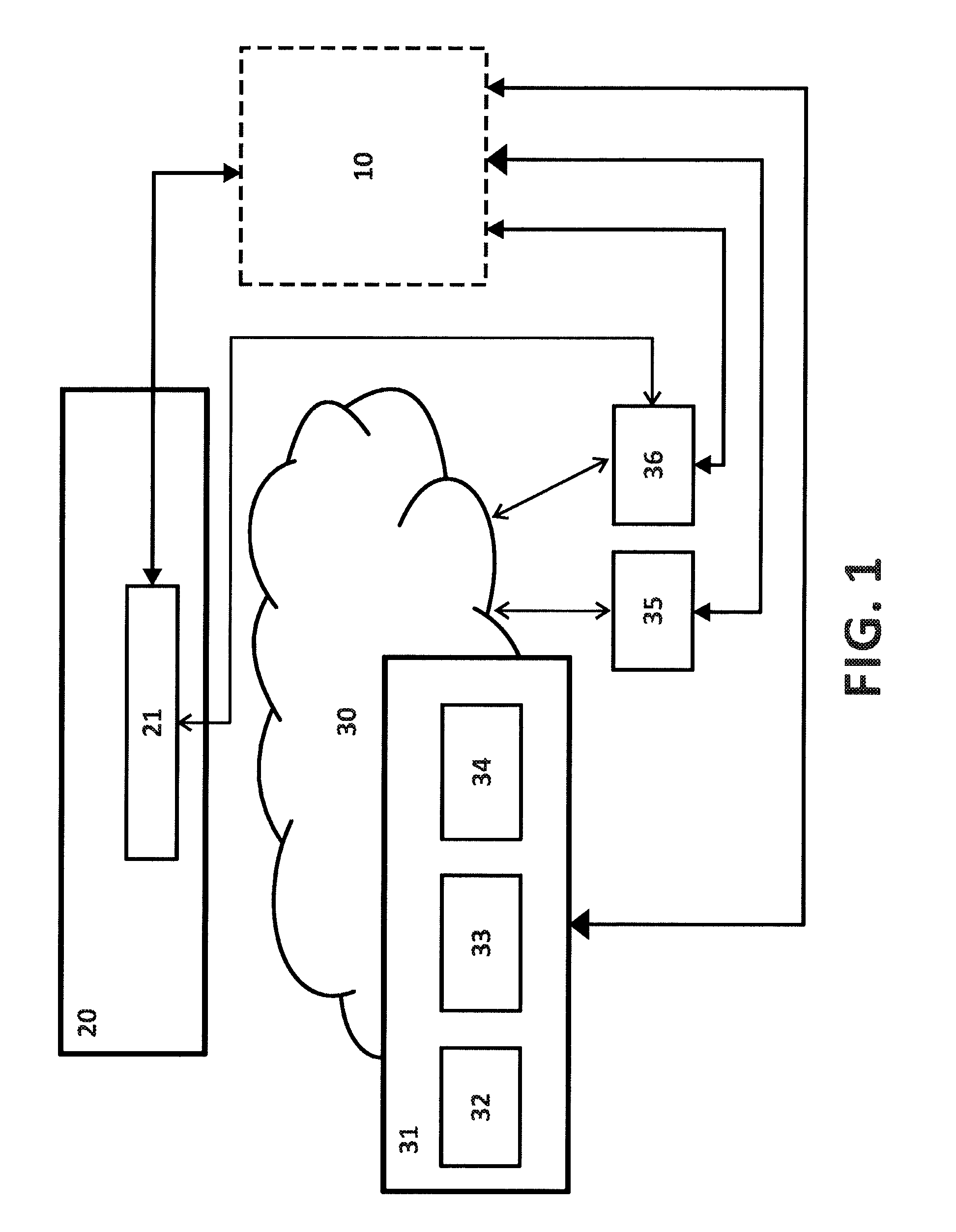

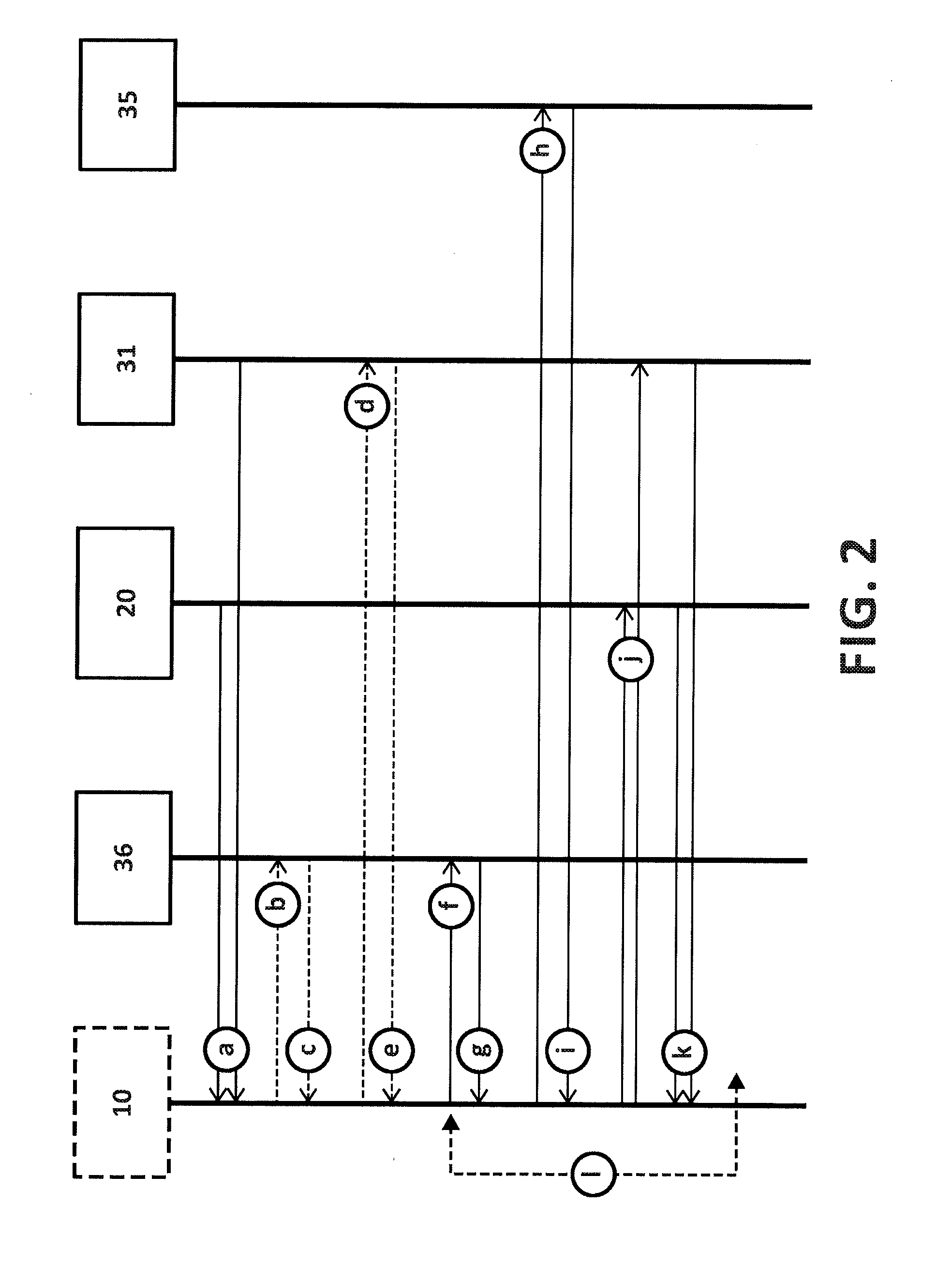

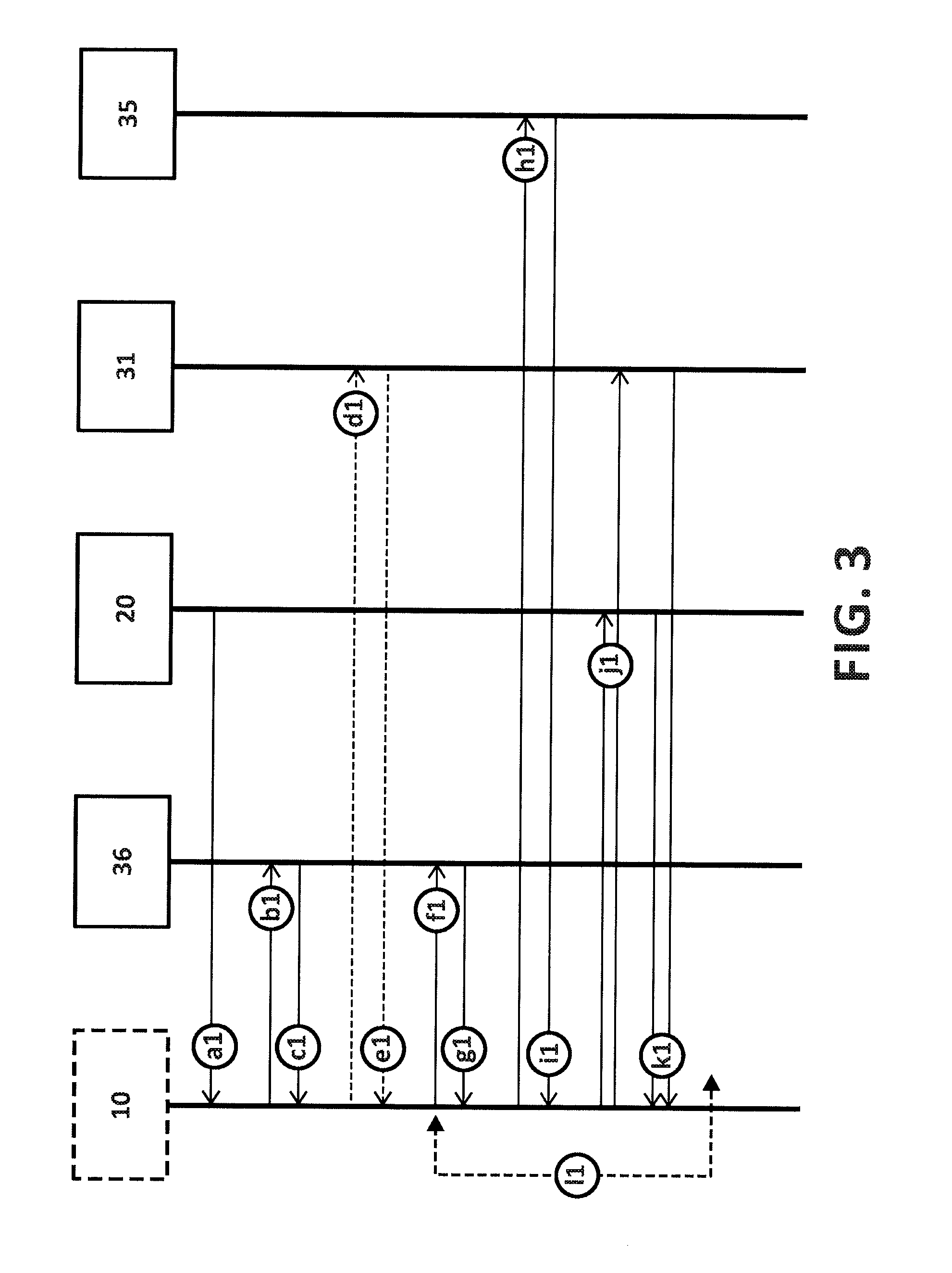

Method and system for restoring QOS degradations in mpls networks

InactiveUS20160308709A1Reduce monitoring loadReduce bandwidth consumptionHybrid transportTraffic capacityPhysical layer

A system implementing a method for determining QoS degradations comprises:receiving alarms (a) from application layer or from network nodes of a MPLS network, including Passive Traffic Analyzer, Physical Layer Monitoring and MPLS OAM nodes,depending on the alarm, the system requests testing (d) for location and the network nodes answer back with location (e),once the fault is located, the system starts traffic restoration (h) via MPLS Signaling and receives the result (i),the system may need to consult the System Database, optionally query (b)—reply (c) step before requesting location, while query (f)—response (g) step is mandatory before restoration (h),once traffic restored, further testing by the network nodes and / or the application layer are triggered (j) by the system to ensure the correct overall QoS within the new network situation,a loop (i) of further restoration can be triggered by the system until a global stable non-degraded behavior is declared.

Owner:TELEFONICA SA

Vanadium-nitrogen microalloy additive and preparation method thereof

ActiveCN103388101ARestore fastConducive to primary and secondary recovery timeVanadium CompoundsReduction rate

The invention discloses a vanadium-nitrogen microalloy additive and a preparation method thereof. The preparation method comprises the following steps of 1, grinding a vanadium compound by a flour mill, 2, mixing a composite reducing agent and the grinded vanadium compound, adding a density enhancer, a binder and water into the mixture, and carrying out uniform mixing, 3, molding the mixture obtained by the step 1 by pressing, carrying out drying in air in a ordinary state, adding a curing agent into the molded mixture for a curing reaction, and carrying out a drying, reduction, carbonization, nitridation, sintering and cooling integrative continuous sintering process by a full-automatic one-step nitrogen atmosphere-protected double-push plate kiln to obtain the vanadium-nitrogen microalloy additive. The preparation method adopts a composite graphite raw material, improves a reduction rate and a product output, adopts the full-automatic one-step nitrogen atmosphere-protected double-push plate kiln, has simple processes, greatly improves production efficiency, greatly reduces a production cost and can produce the vanadium-nitrogen microalloy additive having good market competitiveness.

Owner:陕西丰源钒业科技发展有限公司

Pure cotton fabric reduced dye dyeing method

InactiveCN104047186AImprove reducibilityMaintain resilienceBleaching apparatusDyeing processPolymer scienceDioxyethylene Ether

The invention relates to a pure cotton fabric reduced dye dyeing method which comprises the following steps: (1) textile preparation; (2) textile pretreatment; (3) preparation of reduced dye leuco body solution; (4) dip dyeing of reduced dye; (5) soap boiling and (6) after-finishing. The reduced dye leuco body solution is prepared by the following raw materials: 1-10g / L thiourea dioxide, 2-5g / L of iso-tridecanol polyoxyethylene ether, 1-2g / L of glucose, 2-5g / L of sodium silicate, and 1-2g / L of sodium sulfide. The K / S value of the dyed textile is obviously improved.

Owner:福建金苑服饰有限公司

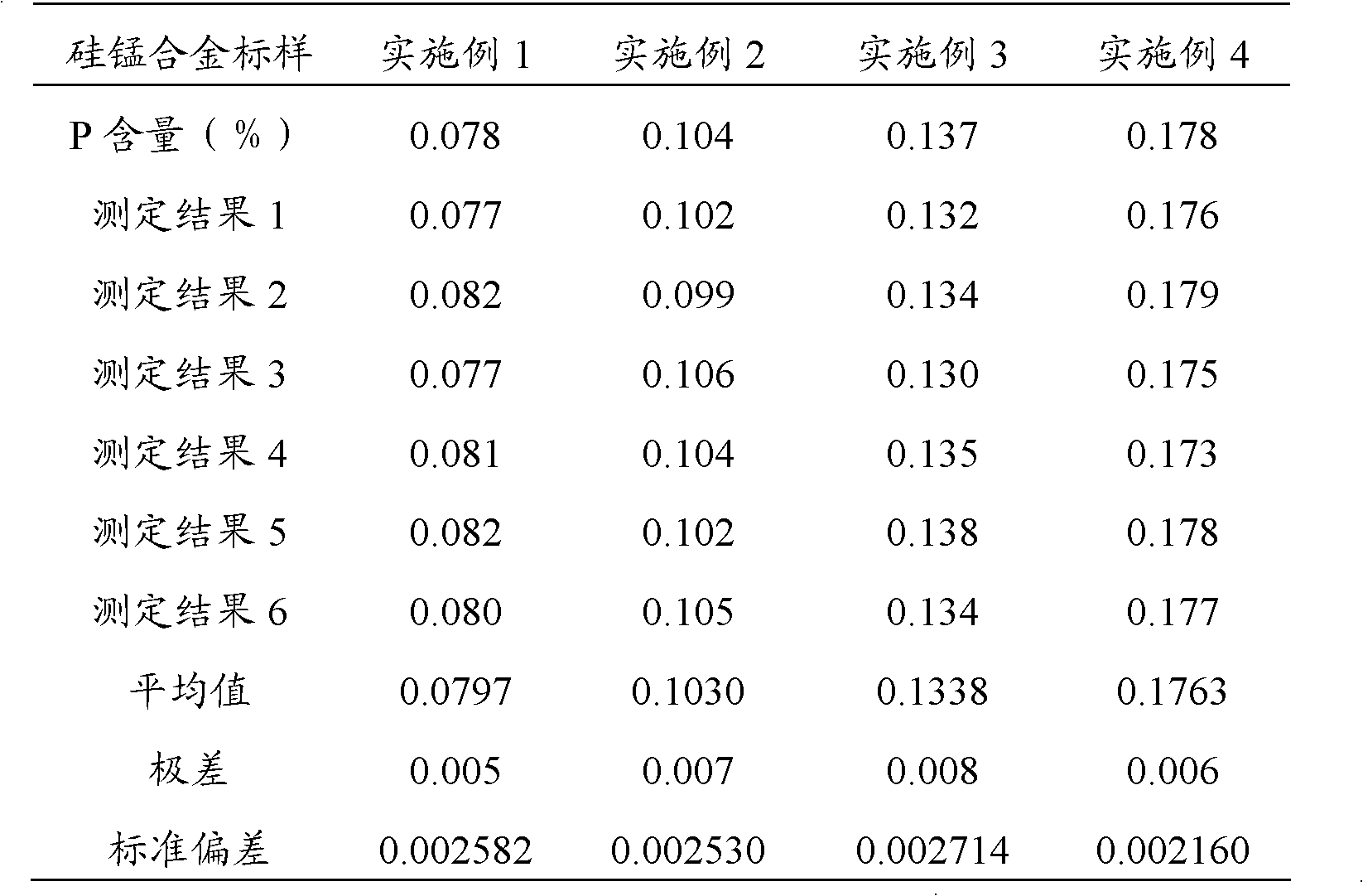

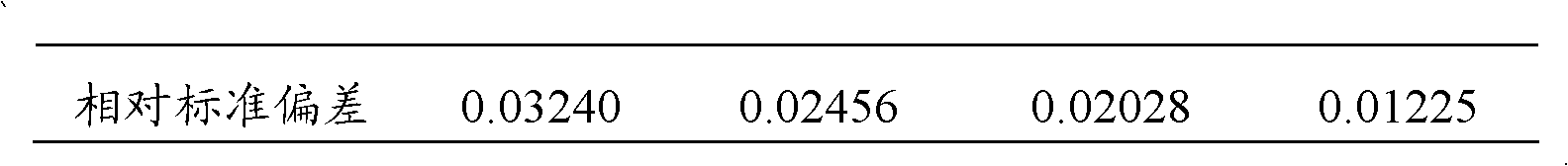

Method for determining phosphorus in silicon-manganese alloy

InactiveCN102539426AShort analysis timeImprove accuracyMaterial analysis by observing effect on chemical indicatorFistHeteropoly acid

The invention discloses a method for determining phosphorus in silicon-manganese alloy, which comprises the steps of: dissolving a test sample by using nitric acid and hydrofluoric acid and adding perchloric acid to convert phosphorus in the test sample into orthophosphoric acid to obtain fist mixed solution; adding sodium sulfite into the first mixed solution to reduce manganese in the silicon-manganese alloy to obtain second mixed solution; and adding bismuth nitrate solution, ammonium molybdate solution, potassium sodium tartrate solution, sodium fluoride and stannous chloride into the second mixed solution, wherein ammonium molybdate can convert the orthophosphoric acid in the first mixed solution into phosphorus-molybdenum heteropoly acid, using stannous chloride to reduce the formed phosphorus-molybdenum heteropoly acid into blue phosphomolybdenum blue and finally using a spectrophotometric method to determine the content of the phosphorus. Compared with the prior art, by using the stannous chloride as the reducing agent, since the stannous chloride has the characteristics of high reducing speed, good reducing effect and the like, the analysis time of the determination method is shorter, the accuracy and the stability of the determination result are improved and the method is suitable for field mass production analysis.

Owner:吉林建龙钢铁有限责任公司

Method for zero-valent metal and carbon combination internal electrolysis catalysis reduction of nitrate nitrogen in water zero-valent metal and carbon combination

InactiveCN103193298APromote reductionIncrease corrosion rateWater contaminantsWater/sewage treatment by reductionWater processingPollution

The invention belongs to the water processing technology application field, relates to a method for removing nitrate nitrogen in water, and especially relates to a method for the zero-valent metal and carbon combination internal electrolysis catalysis reduction of a pollutant nitrate nitrogen in water. A technological principle of the method is characterized in that the reductibility of a zero-valent metal elementary substance and the internal electrolysis effect of the zero-valent metal elementary substance and conductive substances comprising active carbon and the like are utilized to accelerate the transfer of electrons in a solid-liquid phase interface, so nitrate nitrogen is rapidly reduced and removed, and the zero-valent metal can prolong the service life because of the internal electrolysis effect, thereby the reaction efficiency is improved. The method is characterized in that the granular or powdery zero-valent metal and a carbon material are directly added to or are mixed and then added to water containing nitrate nitrogen, stirring is carried out in a certain strength under reacting, and nitrate is directly reduced on the surface of the metal, and is reducibly degraded under the action of nascent state hydrogen [H] generated by an electrode reaction in the internal electrolysis process. The method has the advantages of simple operation, convenient management, less secondary pollution and high reaction time and space efficiency.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

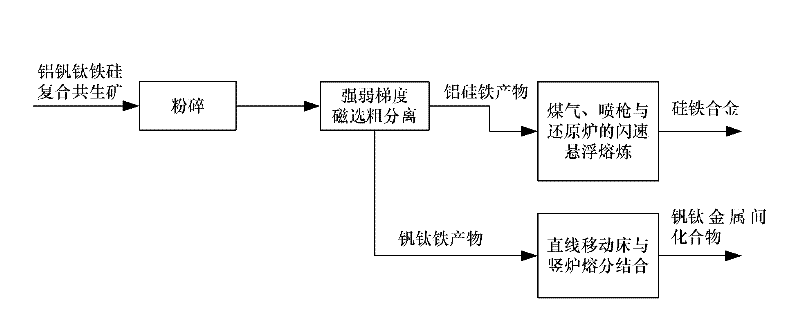

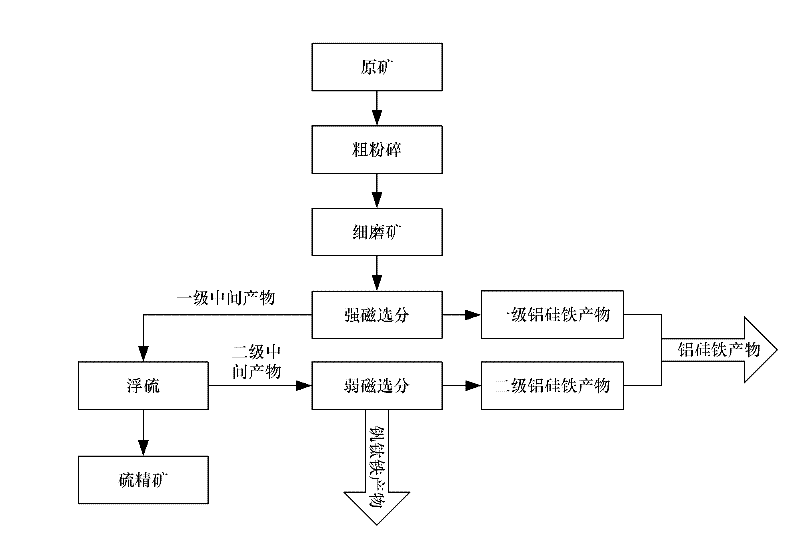

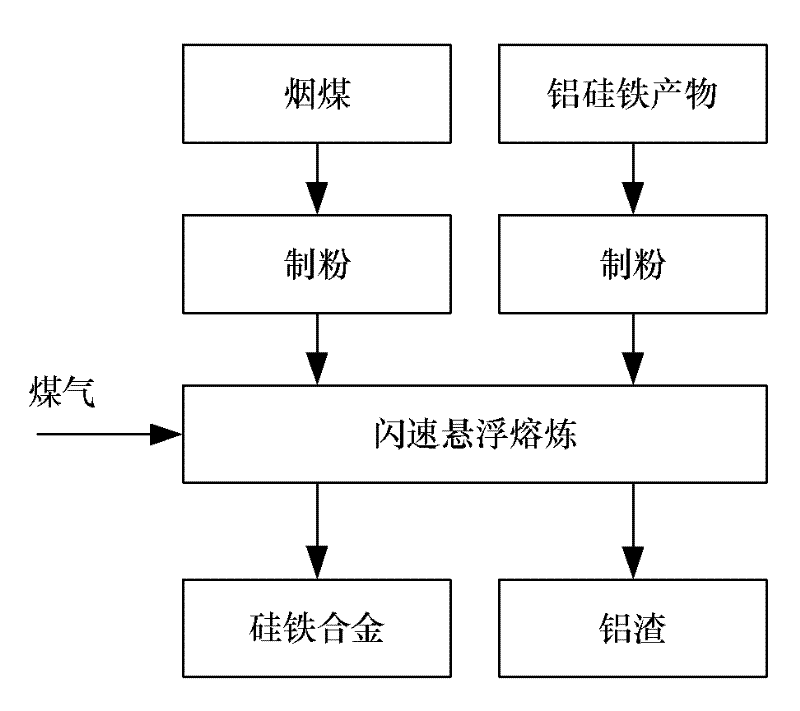

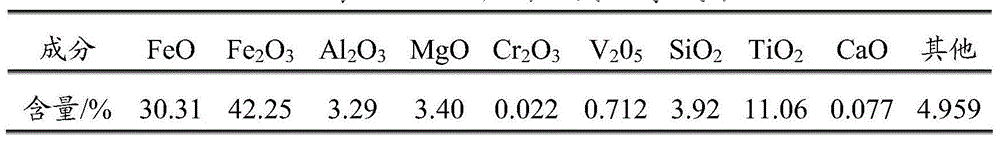

An industrial production method for separating valuable elements from aluminum-vanadium-titanium-iron-silicon composite symbiotic ore for recovery and utilization

The invention discloses an industrial production method of separating valuable elements from composite paragentic mineral of aluminum-vanadium-titanium-iron-silicon for cyclic utilization. The method comprises the following steps: employing the technique of gradient magnetic separation to separate aluminum-silicon-iron products, vanadium-titanium-iron products and sulfur concentrate from composite paragentic mineral of aluminum-vanadium-titanium-iron-silicon; carrying out flash suspension smelting on the aluminum-silicon-iron products to obtain ferrosilicon alloy and aluminum slag which is used as a raw material for production of alundum; employing the technique of rectilinearly movable bed prereduction-shaft furnace smelting to prepare the vanadium-titanium-iron products into vanadium iron intermetallic compounds and titanium slag. Smelting separation and flash suspension smelting and rectilinearly movable bed prereduction-shaft furnace smelting are combined in the method provided inthe invention, which enables the recovery rate of raw ores to be enhanced.

Owner:陕西延长石油中陕金属矿业有限公司 +1

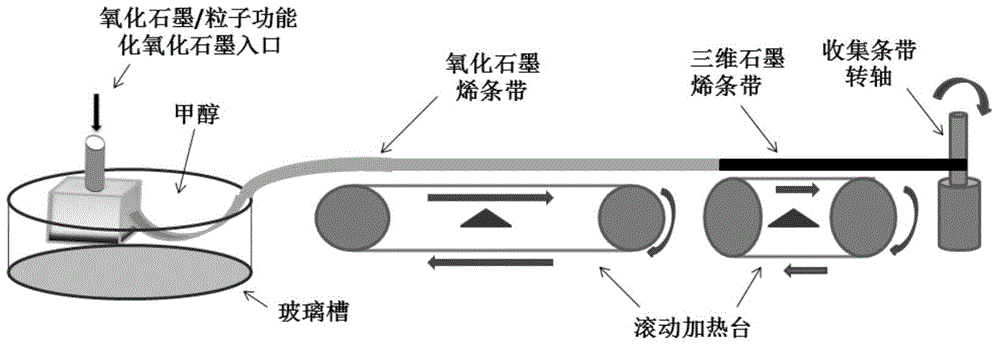

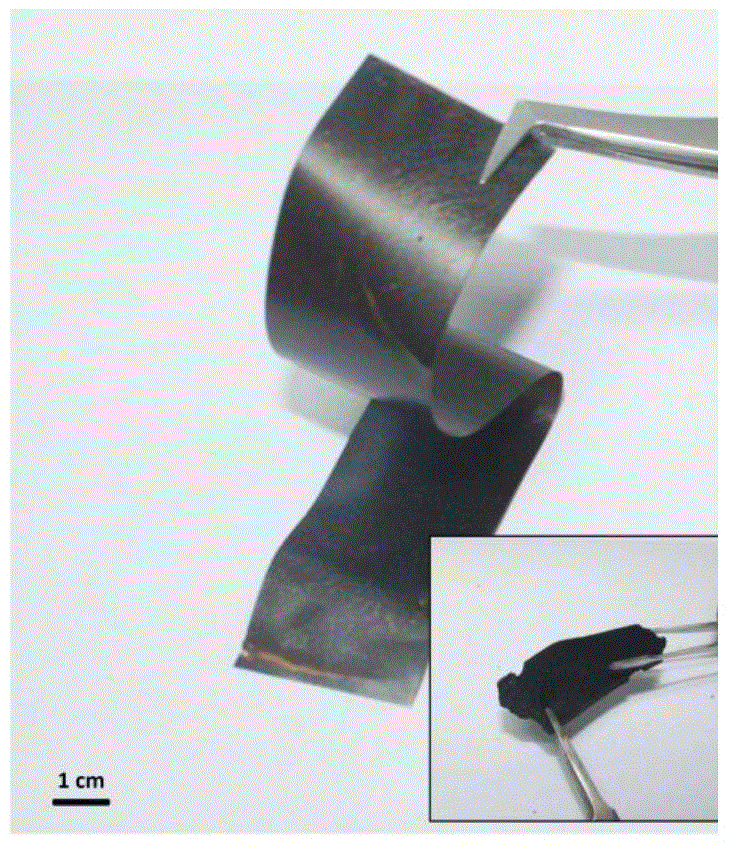

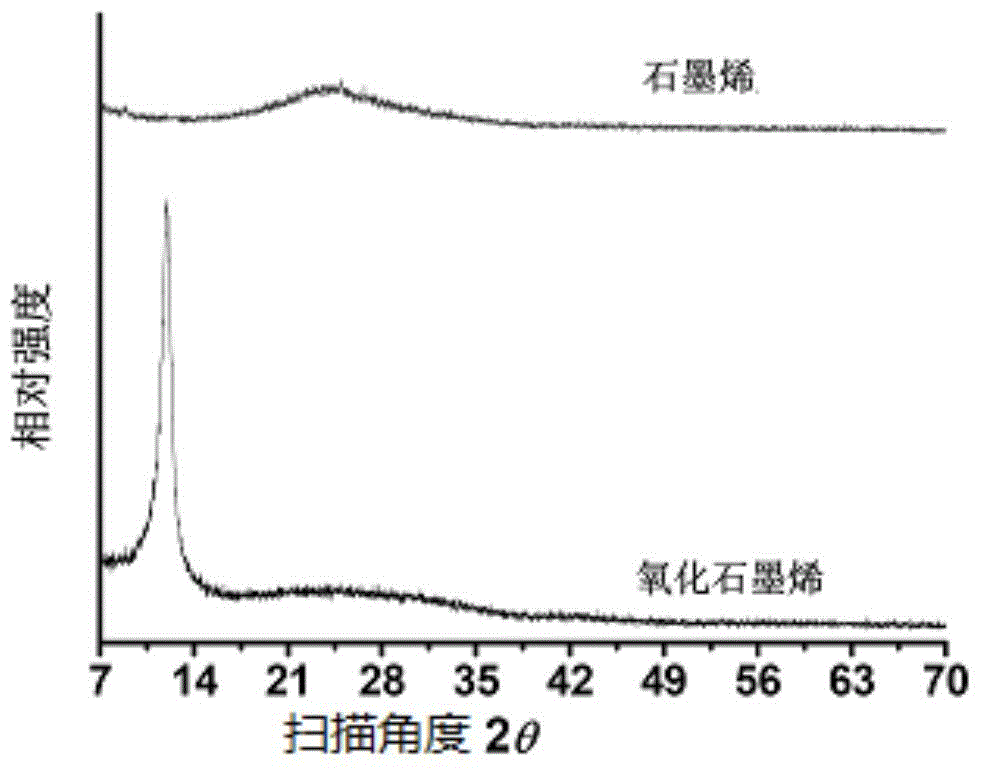

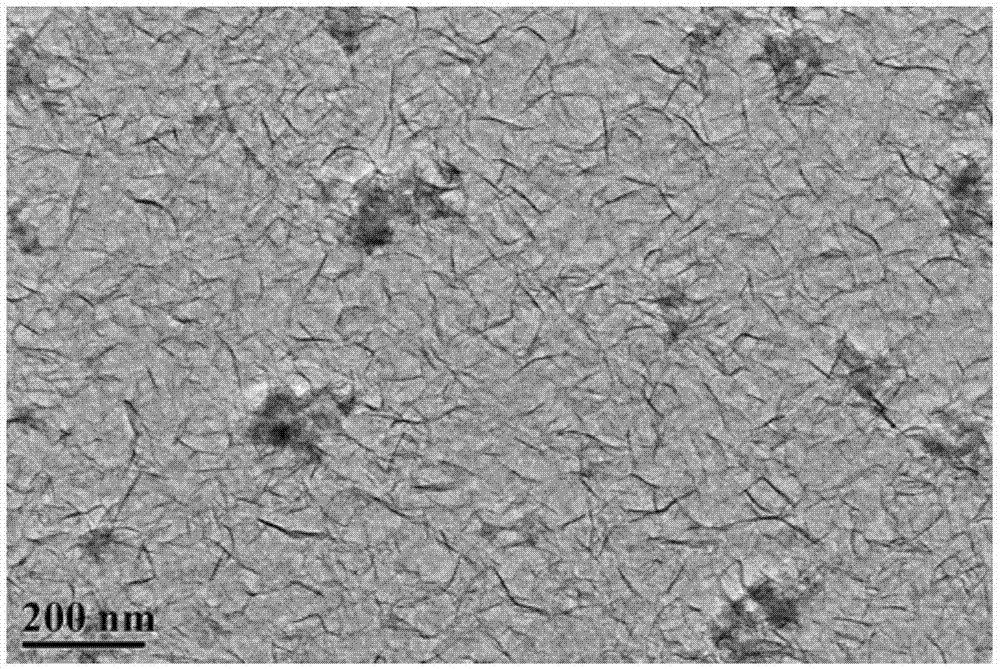

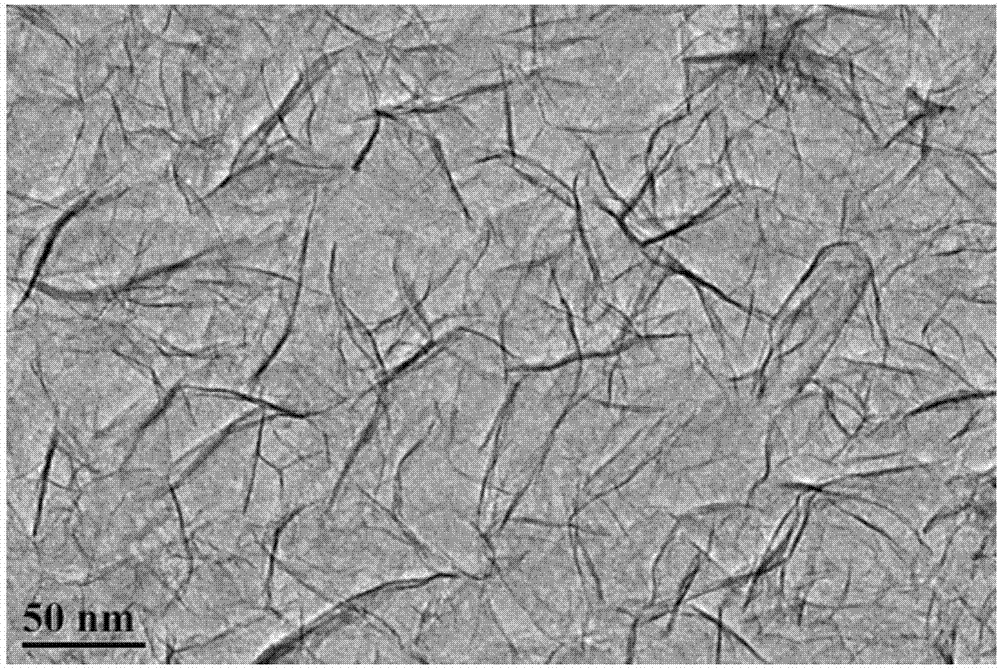

Method for on-scale continuous production of three-dimensional graphene membrane and application

ActiveCN104310381ALow costSynthetic technology is matureMaterial nanotechnologyFerroso-ferric oxidesNanoparticleCvd graphene

The invention discloses a method for on-scale continuous production of a three-dimensional graphene membrane and application, belonging to the field of functional materials. The method comprises the following steps: 1, preparing a graphene oxide solution; 2, stirring and concentrating; 3, soaking a polytetrafluoroethylene bath into methanol; 4, filling the concentrated graphene oxide solution into the polytetrafluoroethylene bath, thereby obtaining graphene oxide strips; 5, leading out the graphene oxide strips from the methanol solution, firstly drying, and further performing reduction expansion, thereby obtaining the three-dimensional graphene membrane; and 6, collecting the three-dimensional graphene membrane, and coiling. The graphene oxide solution and functional nanoparticles are mixed, and the functional three-dimensional graphene membrane can be prepared by performing the above preparation steps. The method is simple in preparation process, environment-friendly, low in cost and applicable to on-scale production, and the three-dimensional graphene membrane prepared by using the method is three-dimensional and porous and has the characteristics of light mass, large specific surface area and good flexibility.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for directly reducing laterite-nickel into nickel-bearing ball iron in tunnel kilns

InactiveCN101538628AImprove heat transfer performanceRestore fastFluidised-bed furnacesTunnel kilnDesiccant

The invention relates to a method for directly reducing laterite-nickel into nickel-bearing ball iron in tunnel kilns, which is completed according to the following steps: firstly, laterite-nickel containing absorption water is added with dryers, then stirred uniformly and dewatered and dried; secondly, the mixture is broken up and added with reducing agents and particle ferronickel aggregation agents, mixed uniformly and sent onto a tunnel kiln trolley spread with coke powder, and then covered with a layer of coke powder for reducing roasting; the materials after reducing roasting are cooled and hardened by water, broken up, ball ground and subjected to magnetic separation, and then high-quality nickel-bearing ball iron alloy is obtained. The method does not use the traditional reduction pot, has the advantages of simple production, short reduction time, high yield, convenient operation, low energy consumption, low cost and high recovery ratio of nickel, and the produced nickel-bearing ball iron alloy particles can be directly used as the high-quality raw material for smelting stainless steel; and the method is applicable to laterite-nickel of various grades and various types.

Owner:毛黎生

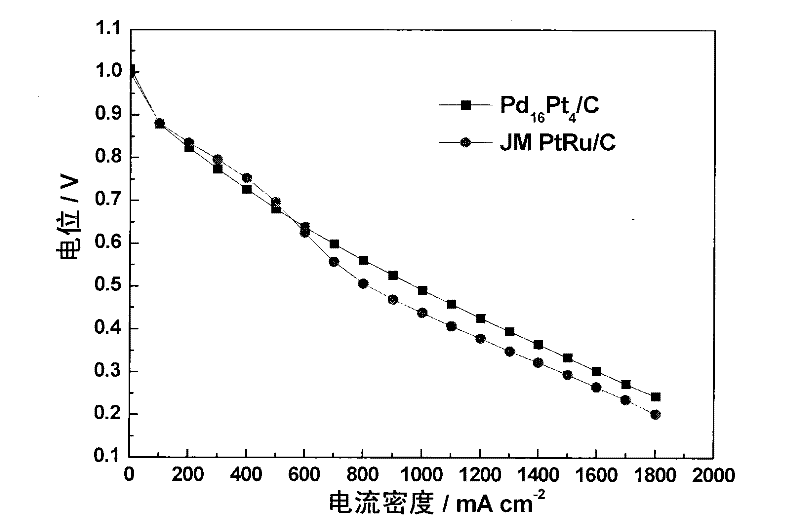

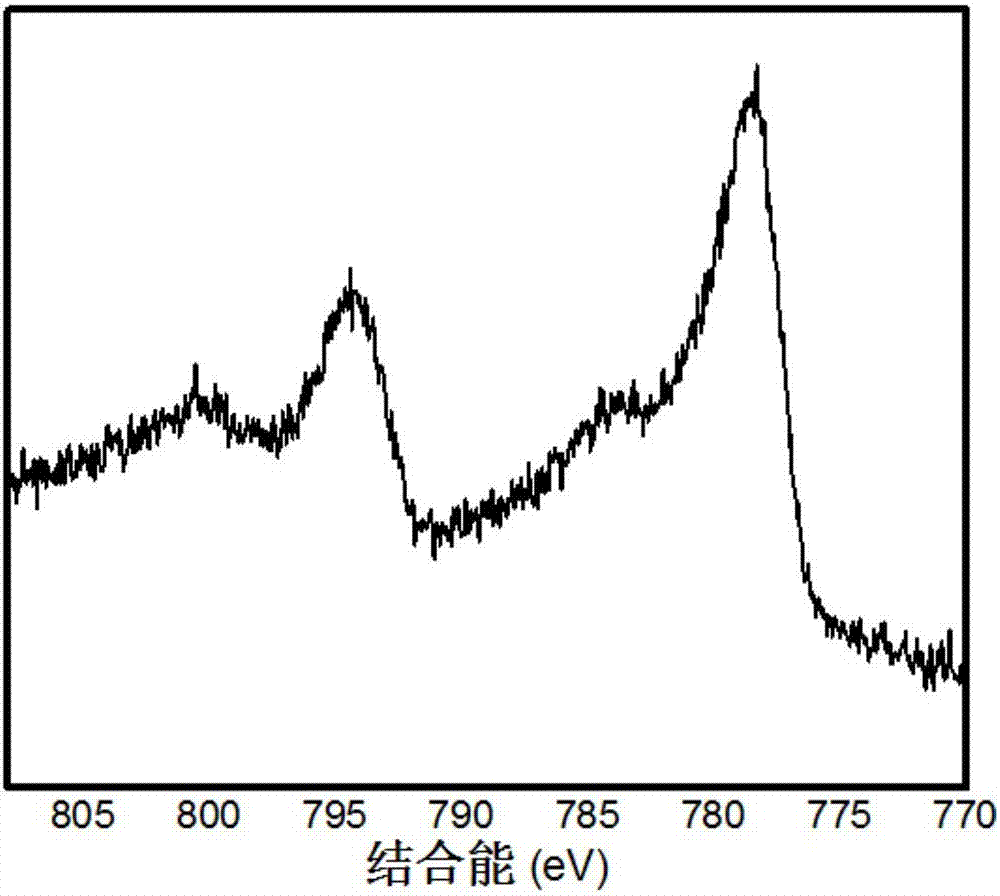

Application of an electrocatalyst in the anode of proton exchange membrane fuel cell

ActiveCN102299346AHigh degree of alloyingRestore fastCell electrodesMetal/metal-oxides/metal-hydroxide catalystsElectrical conductorAlloy

The application of an electro-catalyst in an anode of a proton exchange membrane fuel cell is the application of the electro-catalyst in the anode of the proton exchange membrane fuel cell. The catalyst has the following characteristics: taking PdxPty alloy and the added one or more types of IIIB, IVB, VB, VIB, VIIB, VIII and IB group as active ingredient, wherein the content of the active ingredients accounts for 5%-70% of the weight of the catalyst, the rest is conductive carrier, the content of the Pd metal accounts for 50%-95% of the total weight of the metal. In the preparation method, a liquid phase reduction method is adopted, the main active ingredient Pd metal precursor is dissolved in a mixture solution of water and alcohol, ammonia water to be used as a complexing agent is added, and then other active ingredient precursors and conductive carriers are added; and the active ingredients can be reduced by a strong reducing agent and then the electro-catalyst is loaded on the conductive conductor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

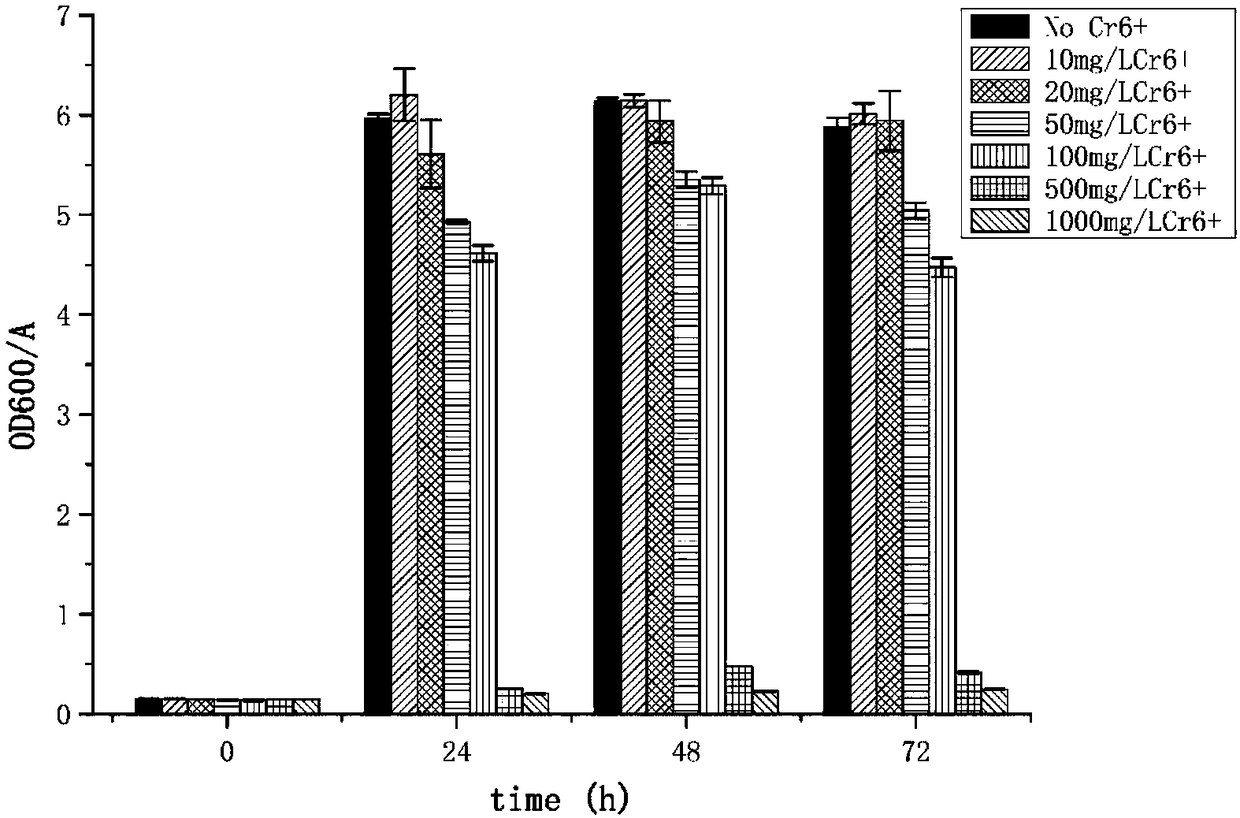

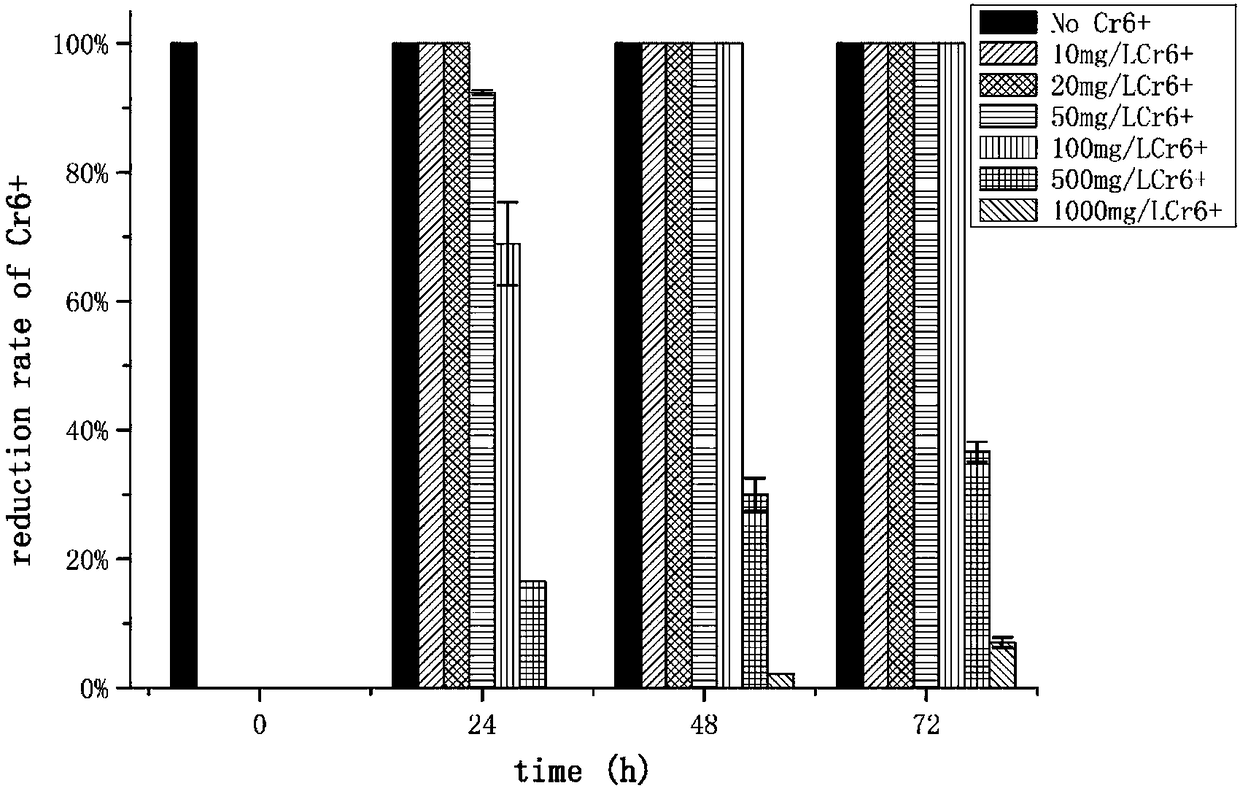

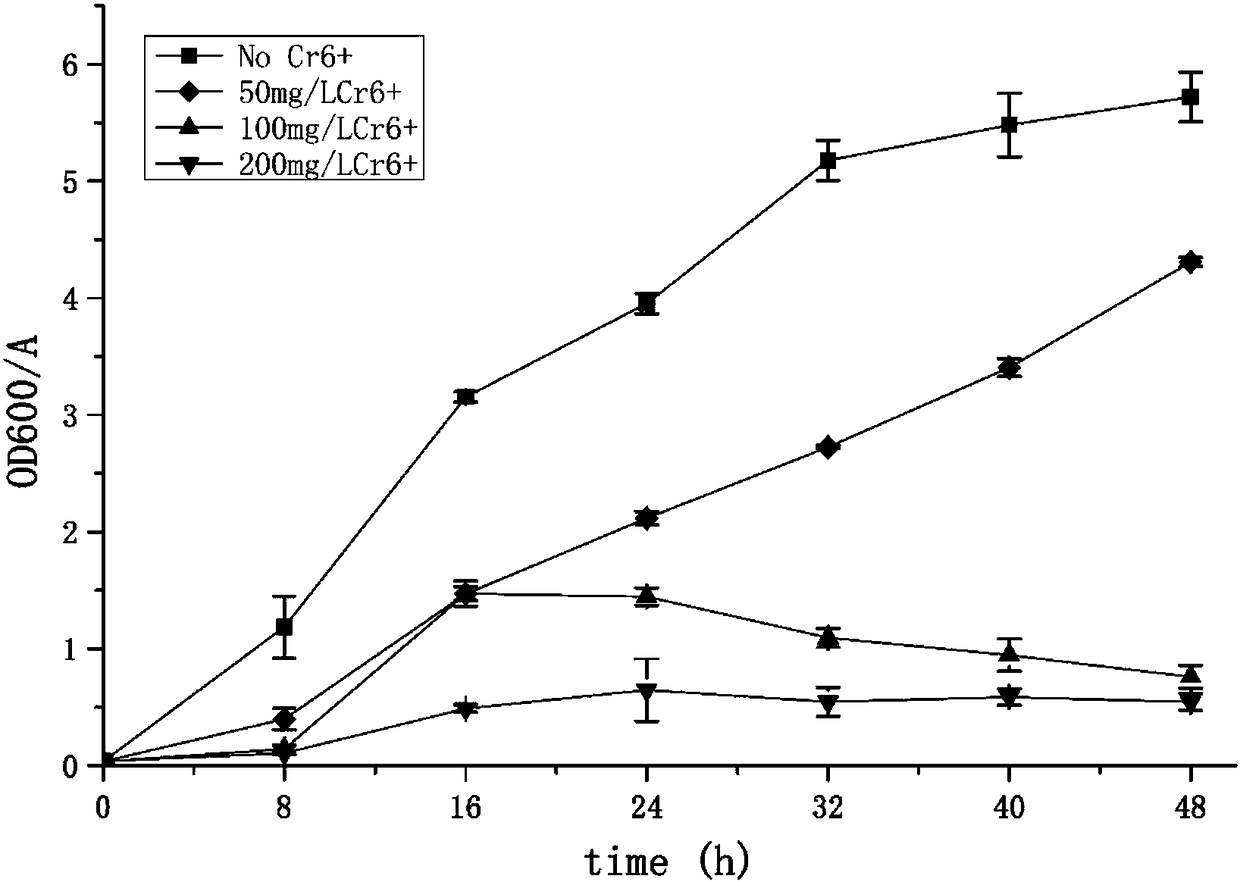

Application of Stenotrophomonas rhizophila DSM14405 in reduction of hexavalent chromium

ActiveCN108251327ALow toxicityReduce contentBacteriaWater contaminantsReduction rateStenotrophomonas rhizophila

The invention discloses application of Stenotrophomonas rhizophila DSM14405 in reduction of hexavalent chromium. The Stenotrophomonas rhizophila DSM14405 survives in an alkaline environment for reducing the hexavalent chromium to trivalent chromium, and the trivalent chromium is bonded with hydroxide to produce a chromium hydroxide precipitate. The Stenotrophomonas rhizophila DSM14405 has a fasterreduction rate of the hexavalent chromium, the reduction rate of the hexavalent chromium of 50 mg / L is up to 100% within 32 h, and the concentration tolerance to the hexavalent chromium is high. Whenthe concentration of the hexavalent chromium reaches 200 mg / L, thallus can also grow, and the reduction rate reaches 47.6% within 48 hours.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Iron ore rotary kiln coal-based hydrogen metallurgy process and device thereof

PendingCN110195156AEasy accessAchieving Hot State IntersectionRotary drum furnacesProcess efficiency improvementReaction temperatureCoal

The invention discloses an iron ore rotary kiln coal-based hydrogen metallurgy process and a device thereof. The process comprises the steps of material pelletizing, pellet drying and preheating, feeding materials into a kiln, material hydrogen metallurgy roasting, material melting-separating and cooling to obtain a product. According to the process, iron ore reduction takes H2 which is easy to obtain as the main material, and the hot-state intersection of the coal sufficient pyrolysis and iron oxide reduction process is realized; the reaction temperature point of hydrogen metallurgy is low, under the same combustion space temperature, more heat is introduced into a material layer, so that the reduction speed of pellets is accelerated, and the energy consumption of the process is low; theproductivity is greatly improved on the premise of the same heat transfer amount, the reduction speed is high, the productivity is high, and the intrinsic energy conservation, the intrinsic emission reduction and the intrinsic safety are effectively realized.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Method for smelting magnesium through vacuum thermal reduction of precast pellets

The invention belongs to the field of metallurgy, and in particular relates to a method for smelting magnesium through vacuum thermal reduction of precast pellets. The method comprises the steps of: uniformly mixing dolomite, a reducing agent and fluorite by mass, and then adding a binding agent; preparing raw pellets with diameters of 5-20mm by using a disk pelleting machine; calcining the raw pellets under a nitrogen or argon protection atmosphere to obtain calcined cured pellets; and carrying out vacuum thermal reduction for 0.5-2 hours on the calcined cured pellets at a temperature of 1150 DEG C under the vacuum degree of 10 Pa to obtain the magnesium. The method has the advantages of high raw material utilization rate, high reduction rate, short reduction period, low energy consumption and the like; and compared with the traditional ferrosilicon process for smelting the magnesium, the method realizes the technical upgrading of the ferrosilicon process for smelting.

Owner:LIAONING DONGYU MAGNESIUM RES TECH CO LTD

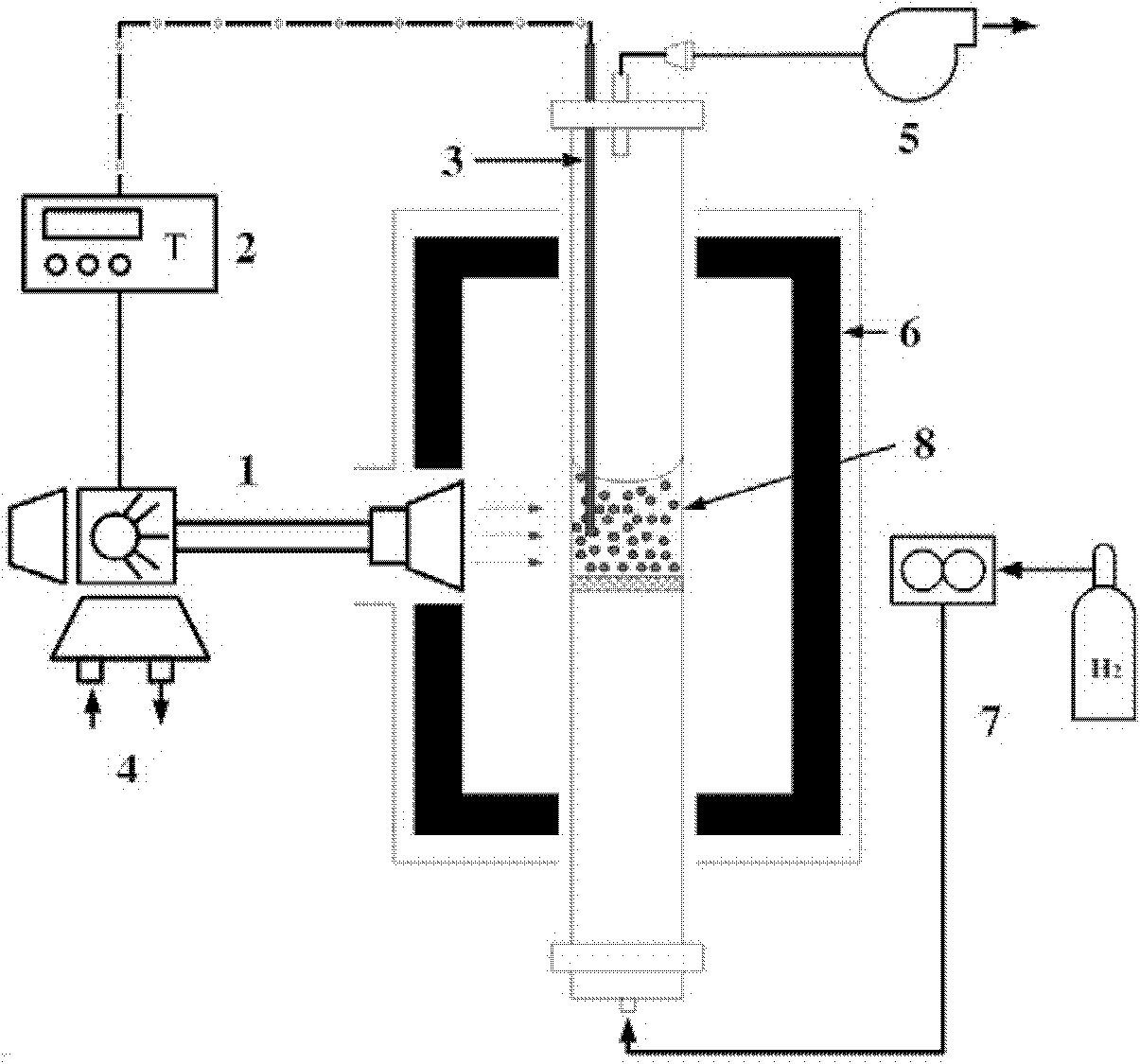

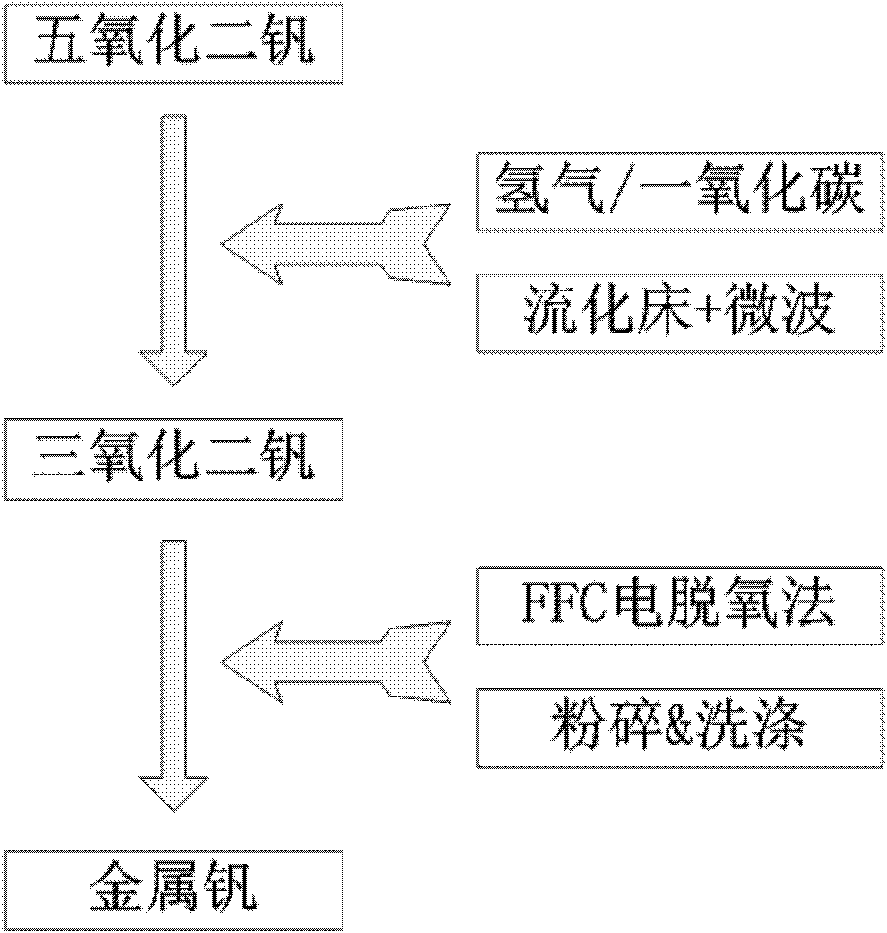

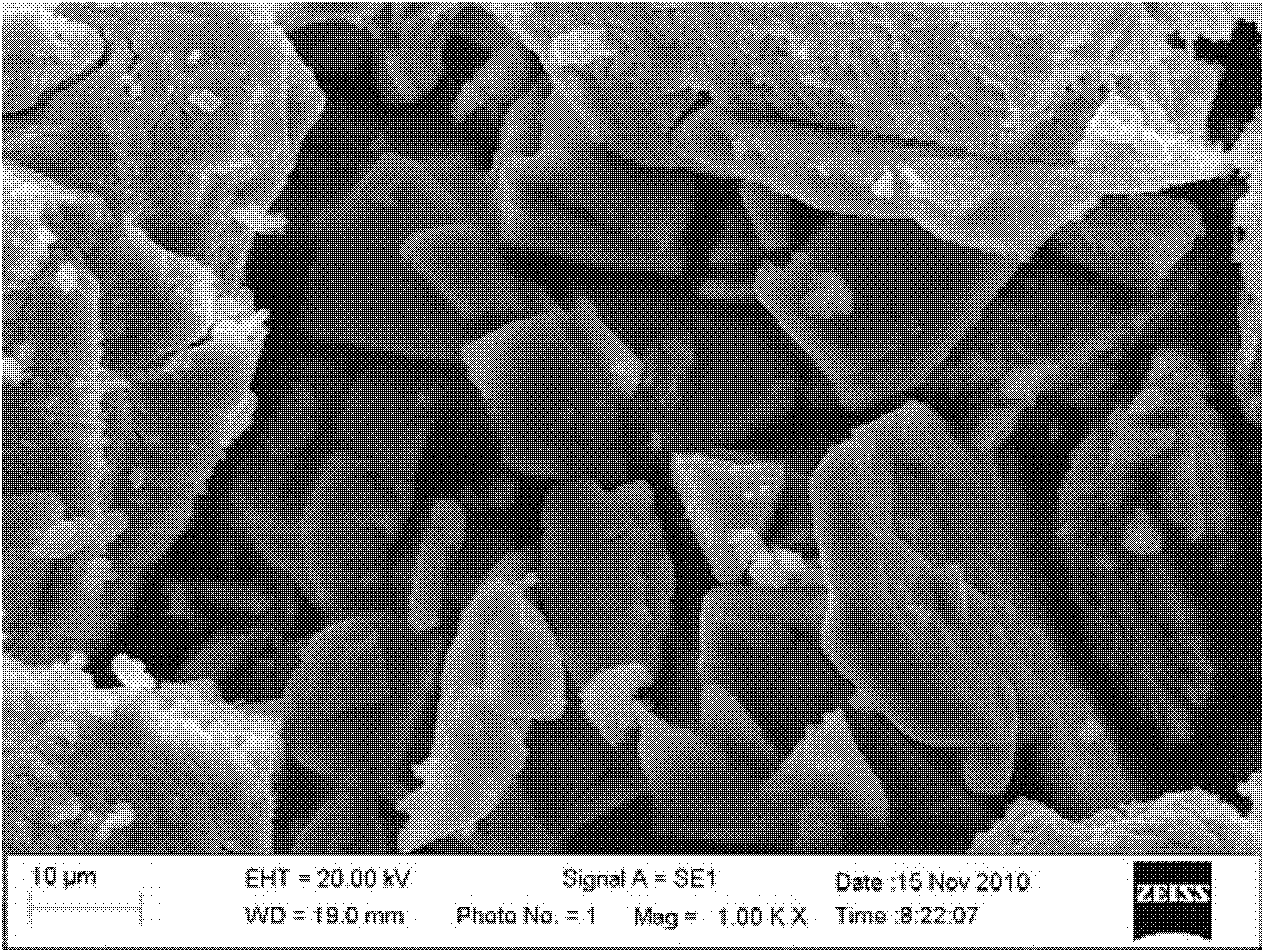

Vanadium metal smelting process

The invention discloses a vanadium metal smelting process. The process prepares vanadium metal by combining a microwave fluidized bed technology and a flexible flat cable (FFC) electric deoxidation technology and using vanadium pentoxide as a raw material. The method comprises the following steps of: directly reducing the vanadium pentoxide with low melting point (the melting point is 690 DEG C) into vanadium trioxide in short time at the temperature of between 600 and 650 DEG C by using the characteristics of high heating efficiency, quick temperature rise and gas-solid contact of a microwave fluidized bed and adopting hydrogen and / or carbon monoxide as reducing gas; directly preparing the vanadium trioxide which has high melting point into an oxide cathode by molding and sintering processes; and performing FFC electric deoxidation on the oxide cathode in molten salt of calcium chloride or mixed molten salt of calcium chloride and sodium chloride, crushing the electrolyzed cathode by using ultrasonic wave, then performing water washing, acid washing and alcohol washing to remove impurities, and finally obtaining the vanadium metal with purity of over 99 percent, wherein the current efficiency is kept over 70 percent, the energy utilization rate of microwave heating equipment is over 80 percent, and the electrolysis energy consumption is 10kwh to 13kwh / kg.

Owner:UNIV OF SCI & TECH BEIJING

Reducing roasting method for powdered iron ores in tunnel kiln

The invention discloses a reducing roasting method for powdered iron ores in a tunnel kiln, which is designed for solving the problems of low heat transfer efficiency, long reducing time, non-uniform material reduction quality, and the like when powdered iron ores are subjected to reducing roasting in a tunnel kiln. According to the invention, by reasonably selecting the particle size range and distribution of iron ores, iron ores with different particle sizes and reducing coal are mixed and distributed in layers, and then the obtained object is subjected to reducing roasting, so that the iron ores with different particle sizes achieve a same roasting effect, thereby increasing the metal recovery rate of roasted iron ores, improving the quality of roasting, shortening the roasting time, reducing the roasting temperature, and lowering the production cost.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

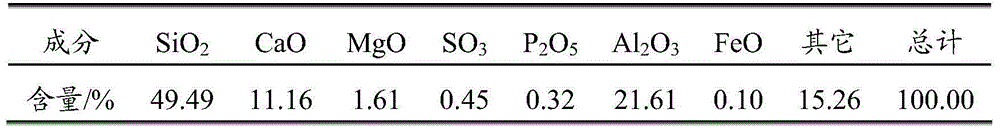

Method of directly reducing vanadium-titanium ore hot-pressing blocks in rotary hearth furnace and melting in electric furnace

InactiveCN104131179AImprove reducibilityShorten the smelting processRotary drum furnacesGas emission reductionTitanium dioxideHot press

The invention belongs to the technical field of comprehensive utilization of metallurgical resources, and in particular relates to a comprehensive utilization method of directly reducing vanadium-titanium ore hot-pressing blocks in a rotary hearth furnace and melting in an electric furnace. The method comprises the following steps: (1) blending vanadium-titanium ore mineral powder with bituminous coal powder, heating mixed powder and carrying out hot-press molding so as to obtain the vanadium-titanium ore hot-pressing blocks; (2) putting the vanadium-titanium ore hot-pressing blocks into the rotary hearth furnace by covering multiple layers of materials on the vanadium-titanium ore hot-pressing blocks and carrying out direct reduction via thick material layers; (3) melting products obtained by reducing the vanadium-titanium ore hot-pressing blocks in the rotary hearth furnace so as to obtain vanadium-containing molten iron and titanium slag; and (4) carrying out vanadium blowing and steelmaking on the vanadium-containing molten iron so as to obtain vanadium slag and a steel ingot, wherein the vanadium slag can serve as a raw material for preparing titanium dioxide. The method which is used for preparing the vanadium-titanium ore hot-pressing blocks has the advantages of low production cost, high production efficiency, low energy consumption, good quality of the vanadium titanium ore hot-pressing blocks and the like. Thus, the economy of the process of directly reducing vanadium-titanium ores in the rotary hearth furnace and melting in the electric furnace is obviously improved.

Owner:NORTHEASTERN UNIV

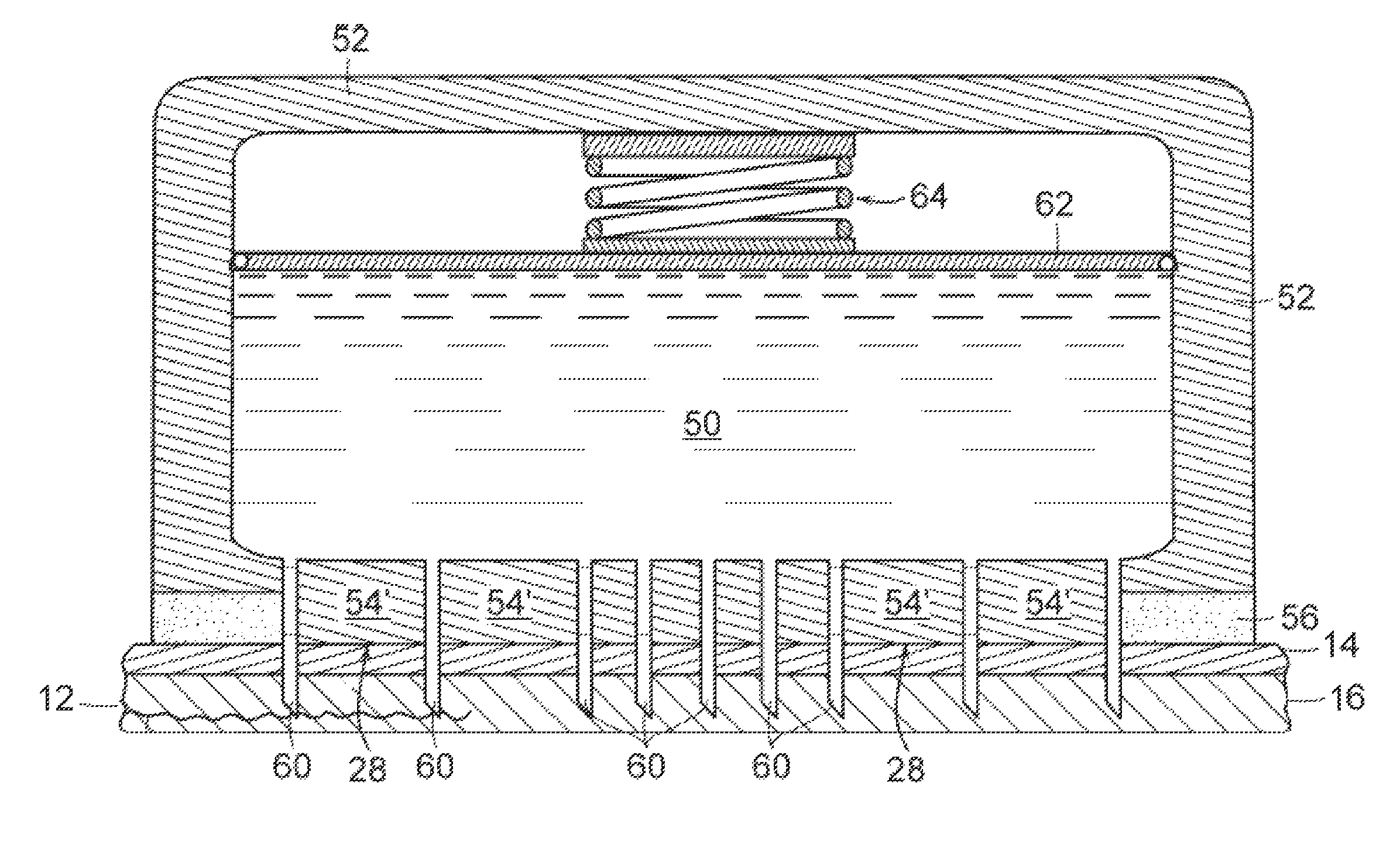

Methods and devices for desmopressin drug delivery

InactiveUS8399410B2Prevent adverse side effectsReduce productionElectrotherapyMicroneedlesDecreased sodiumSide effect

Disclosed are devices for urine voiding postponement, and methods for treating conditions such as central diabetes insipidus, enuresis, nocturia, urinary frequency or incontinence. The devices deliver a desmopressin flux through the skin of a patient in a low dose amount just necessary to achieve a desired anti-diuretic effect without undesirable side effects such as hyponatremia. The devices are designed to permit a state of normal urinary production to return quickly after the desmopressin flux is terminated.

Owner:SERENITY PHARMA CORP

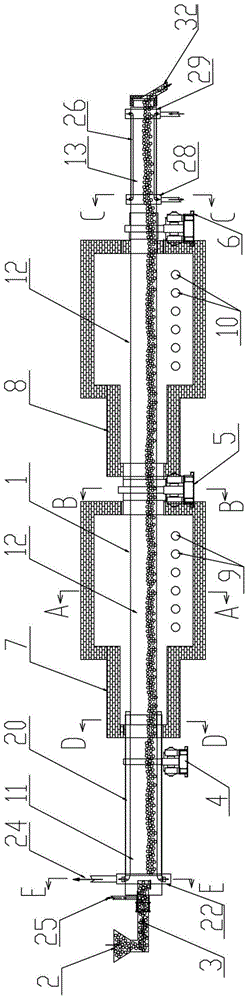

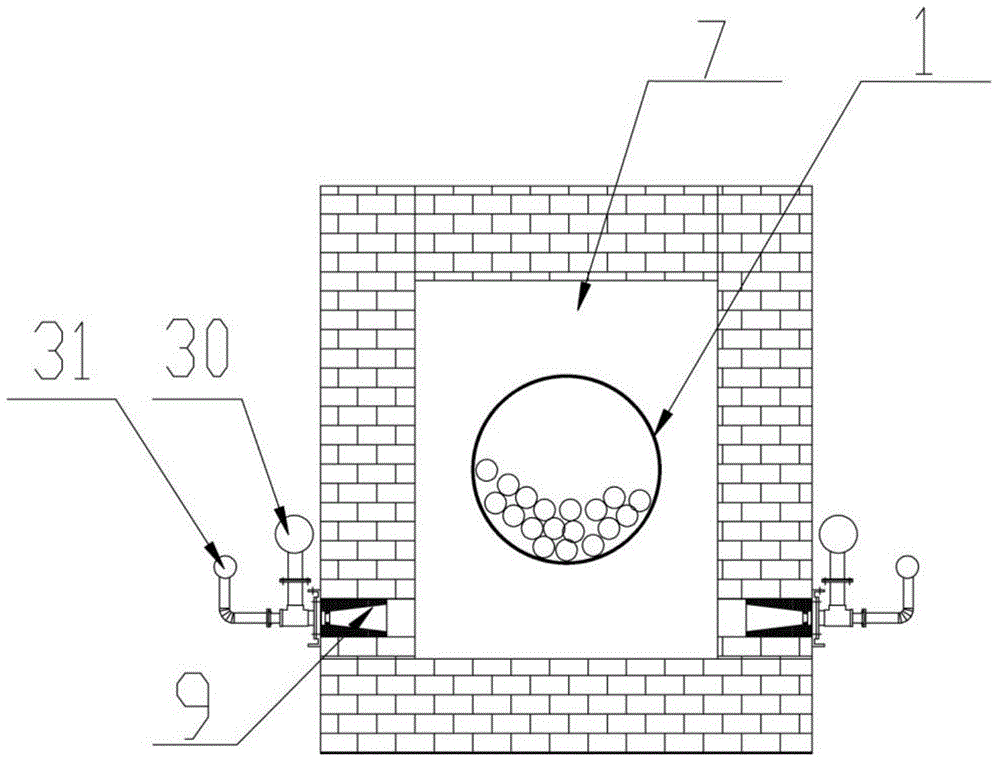

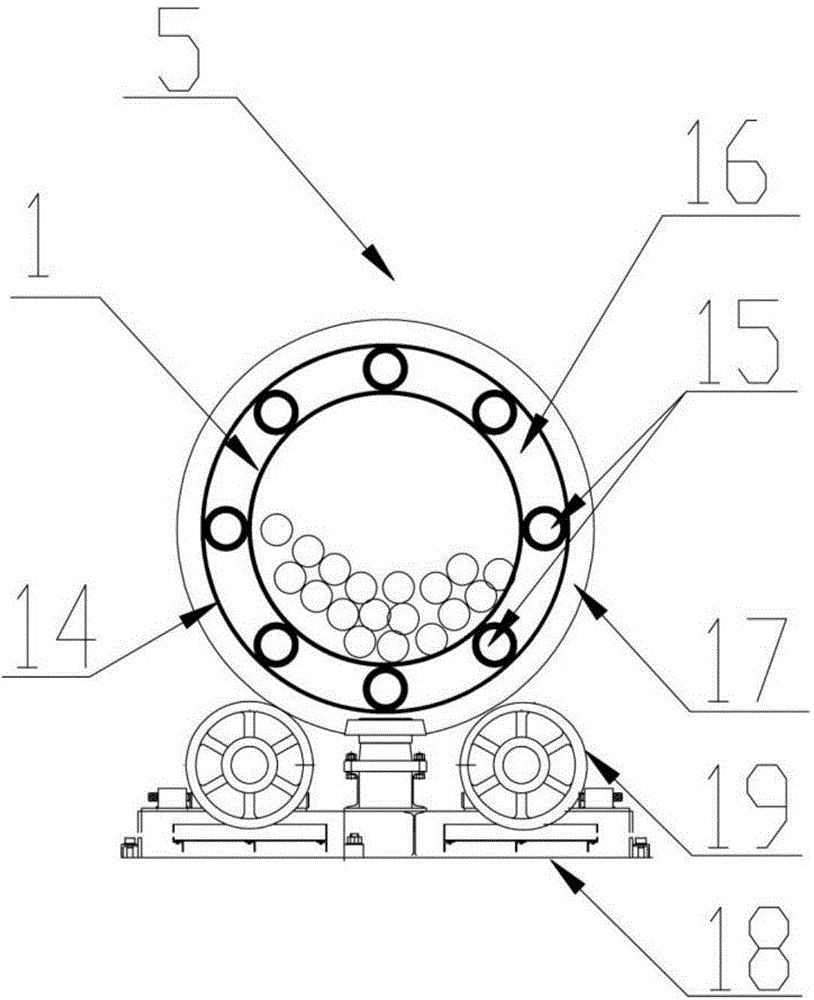

Whole-body type external-heating muffle type rotary kiln

InactiveCN104630407AContinuously stable temperatureReduced temperature required for reductionRotary drum furnacesRotary kilnLow graded

The invention belongs to the field of metallurgical equipment, and in particular relates to a whole-body type external-heating muffle type rotary kiln. A whole-body type continuous external heating muffle type coal-based rotary kiln device with a preheating section and a high-temperature section is adopted, the continuous stabilization of the temperature in a high-temperature area is realized, and a strict requirement on a reduction condition of reduced iron is met. By adopting a muffle-type heating mode, a reduction atmosphere in the rotary kiln is very full, the volatile gas is totally recycled, and the afterheat is fully utilized, so that the required reduction temperature of reduced materials can be greatly reduced, the reduction speed is greatly increased, the energy consumption is greatly reduced, and the carbon emission is reduced; by using non-caking coals with high granularity and high quality as reducing coals, the device is suitable for various iron raw materials with high grade, low grade and varieties, the reduction process is flexible, and the device has many advantages. According to a single production line of the device, the annual reduction treatment ore quantity can reach the maximum scale of 1,800,000-2,100,000 tons.

Owner:泉州寰锋冶金技术有限责任公司

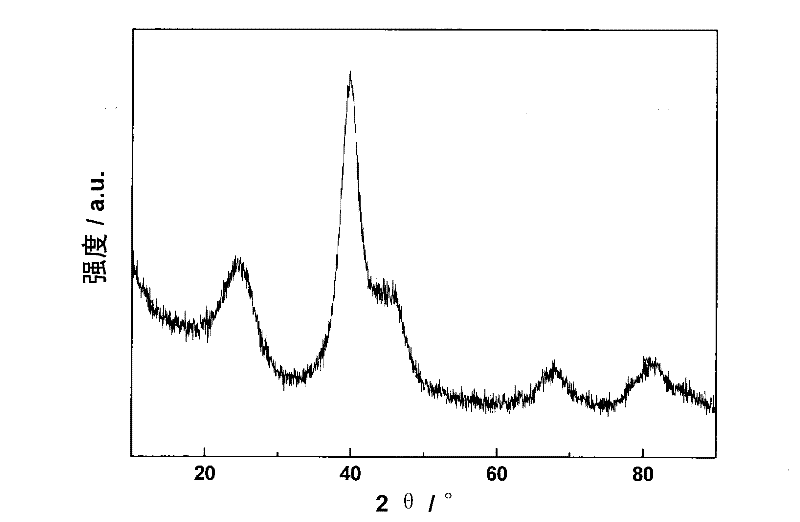

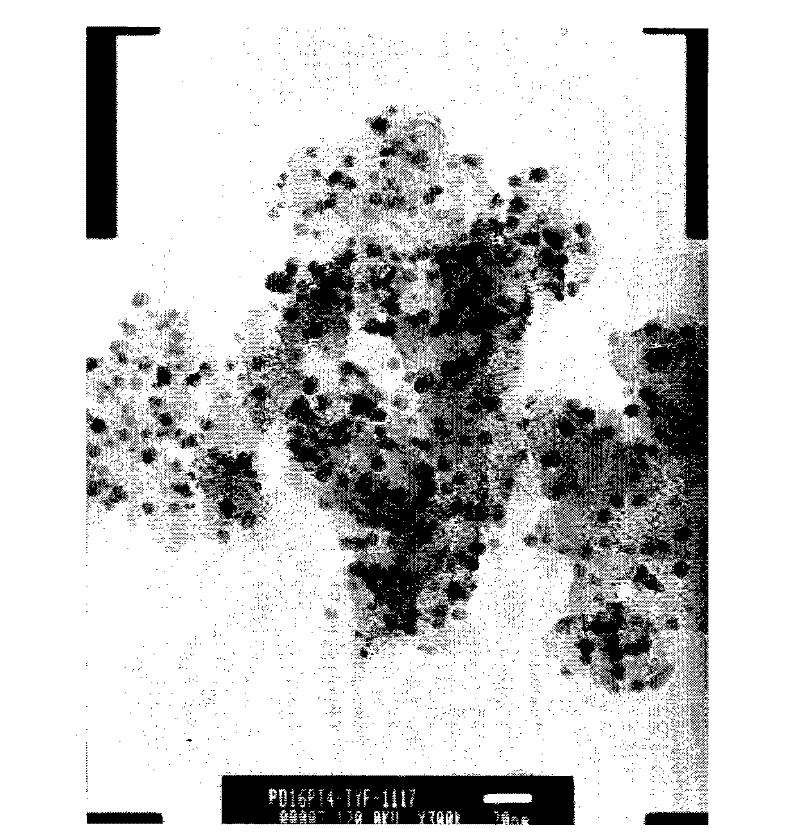

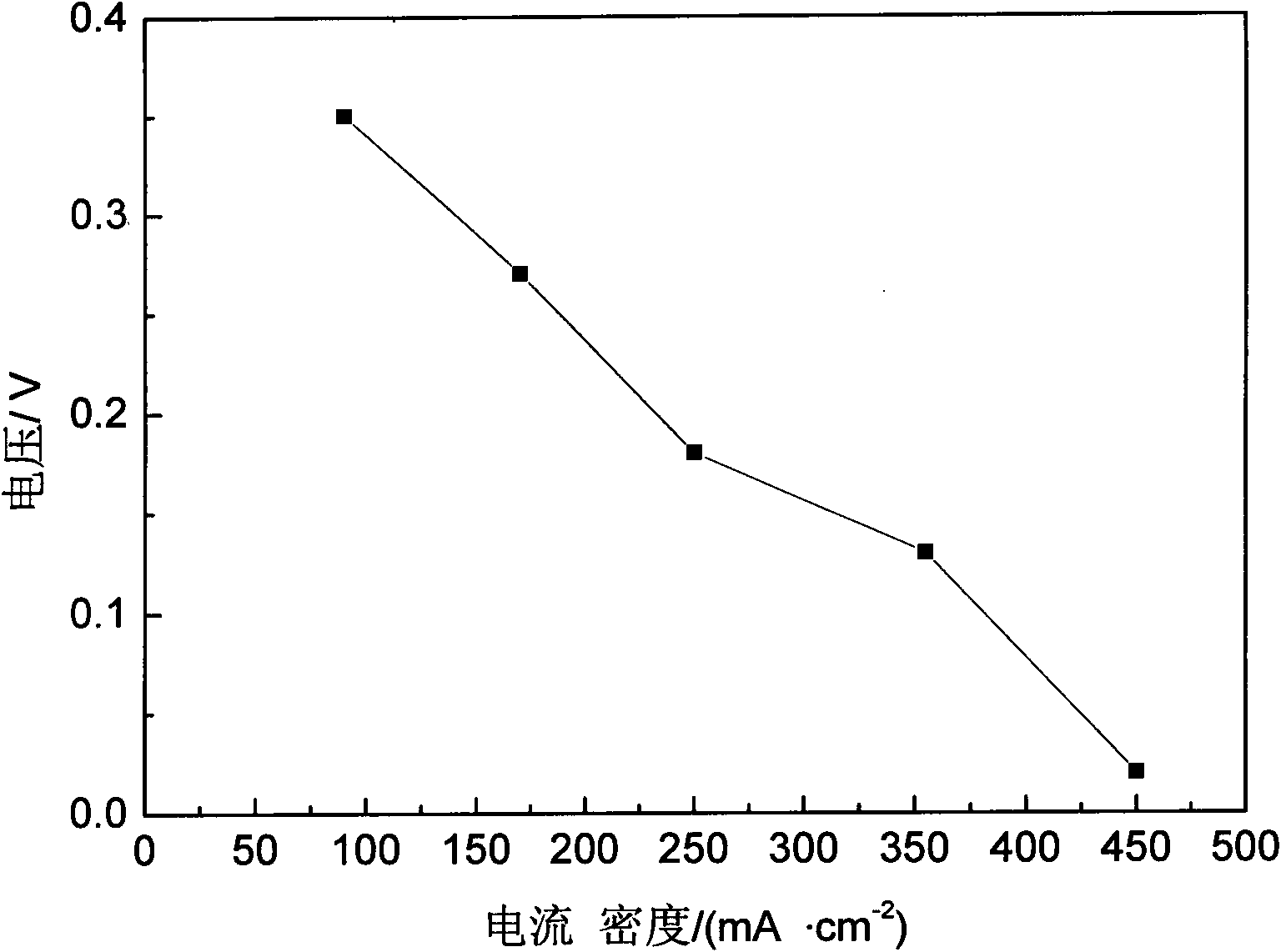

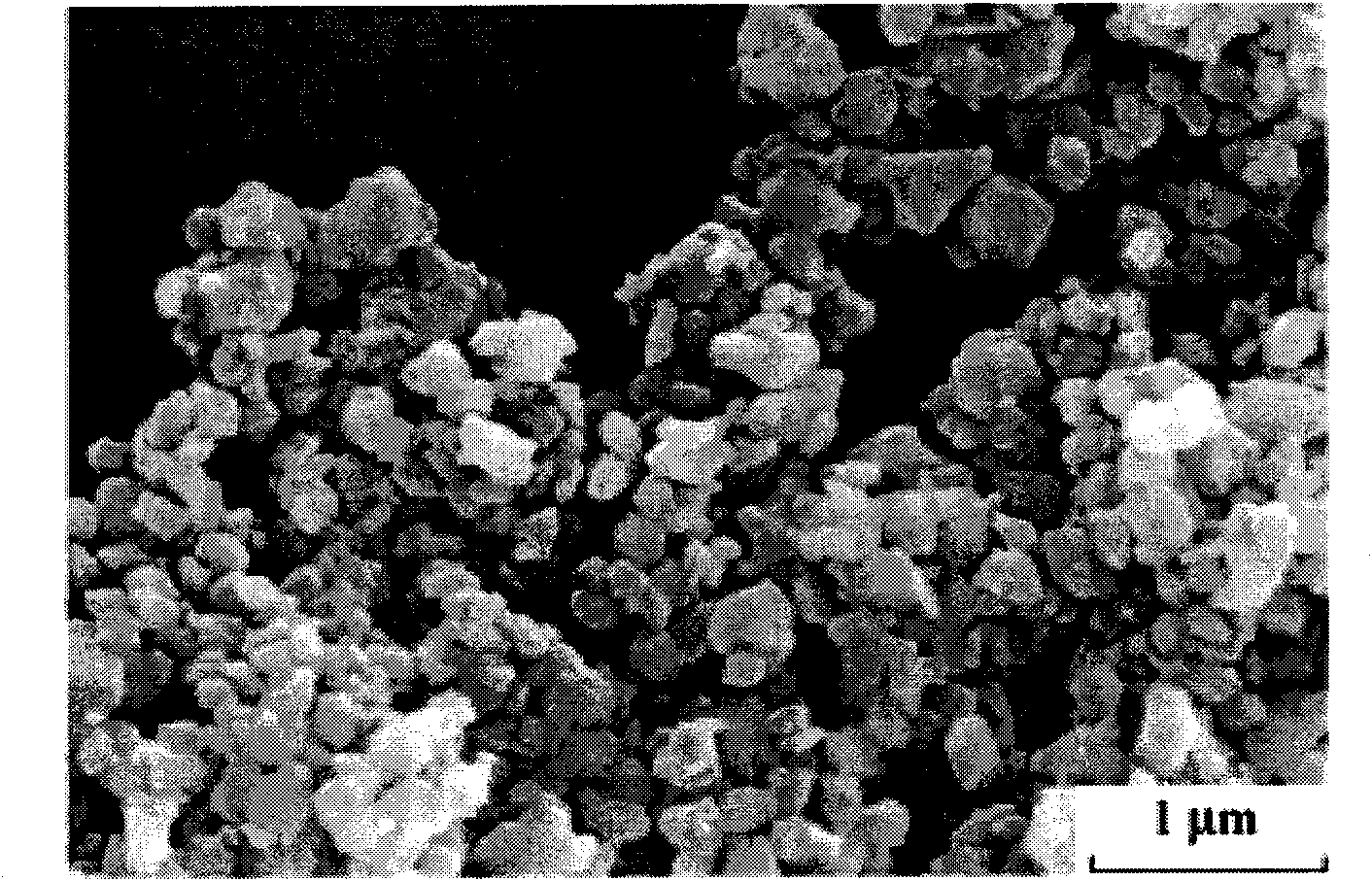

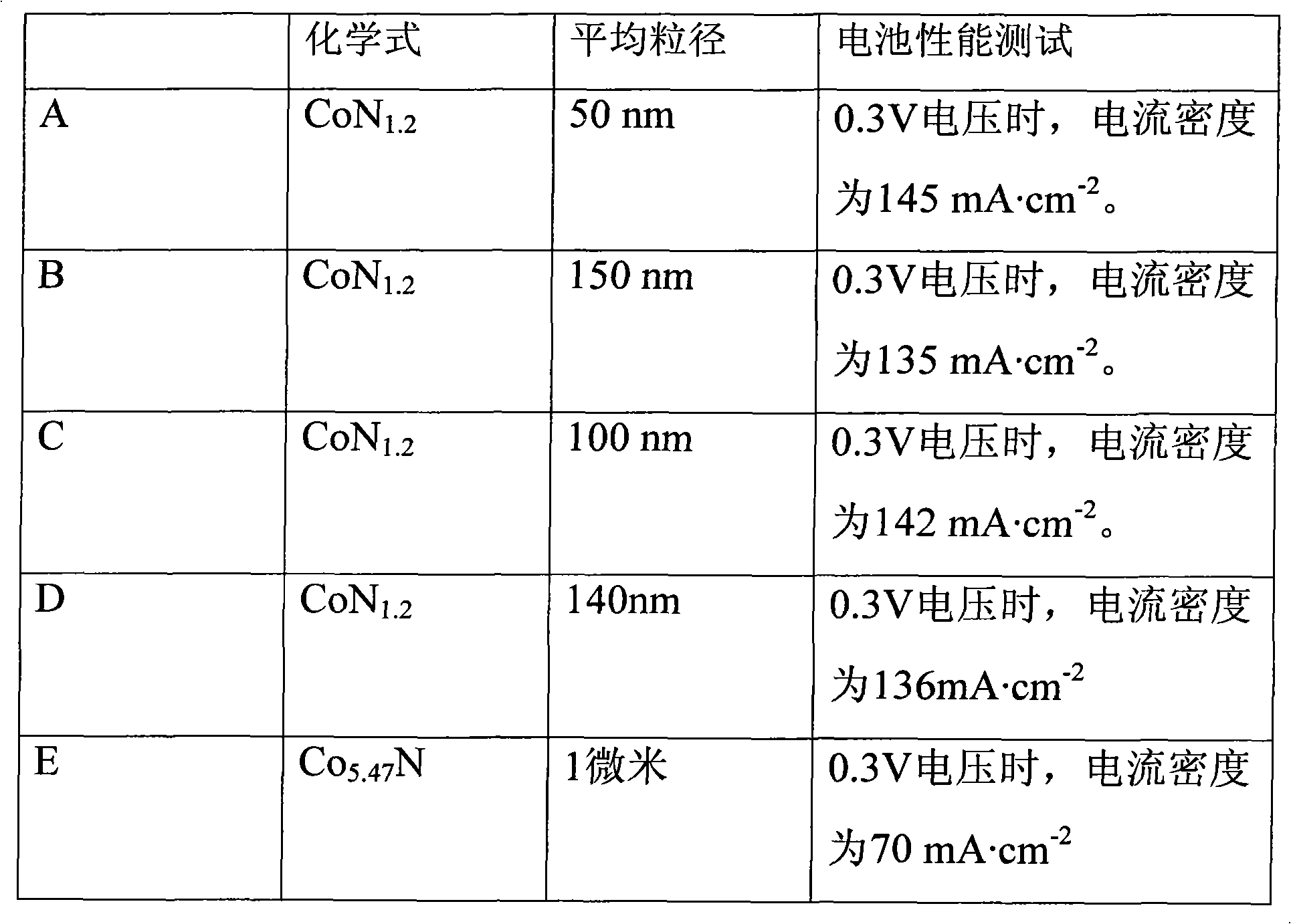

Cobalt nitride compound and preparation method thereof as well as methanol fuel cell catalyst and preparation method thereof

InactiveCN101885476AIncrease element contentRestore fastNitrogen-metal/silicon/boron binary compoundsCatalyst activation/preparationCobalt acetateMethanol fuel

The invention provides a cobalt nitride compound. The chemical formula of cobalt nitride is CoN1.2. The invention also provides a preparation method of the cobalt nitride compound, wherein the average grain size of a reaction raw material namely cobalt acetate is 300 to 500 nanometers, and the cobalt acetate is sintered at a high temperature in the presence of a nitrogen source atmosphere to obtain the cobalt nitride compound. The invention also provides a methanol fuel cell catalyst and a preparation method thereof, wherein the catalyst comprises the cobalt nitride compound and a carrier for loading the cobalt nitride compound. The preparation method of the methanol fuel cell catalyst comprises the following steps of: performing ball milling on the reaction raw material cobalt acetate and the carrier for loading the cobalt nitride compound to ensure that the average grain size is 300 to 500 nanometers; and performing high temperature sintering in the presence of the nitrogen source atmosphere to obtain the catalyst.

Owner:BYD CO LTD

Fast restore method for computer system

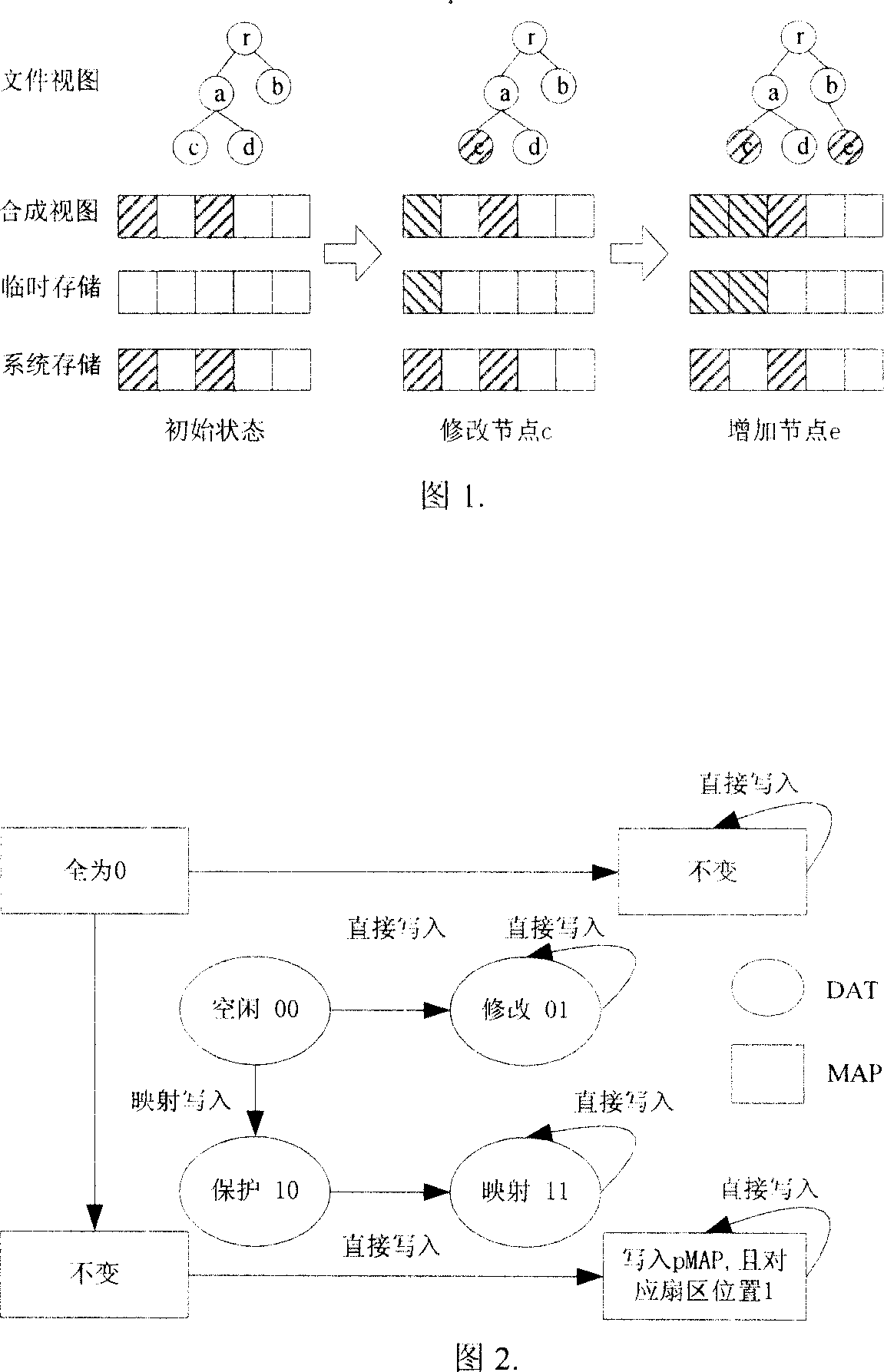

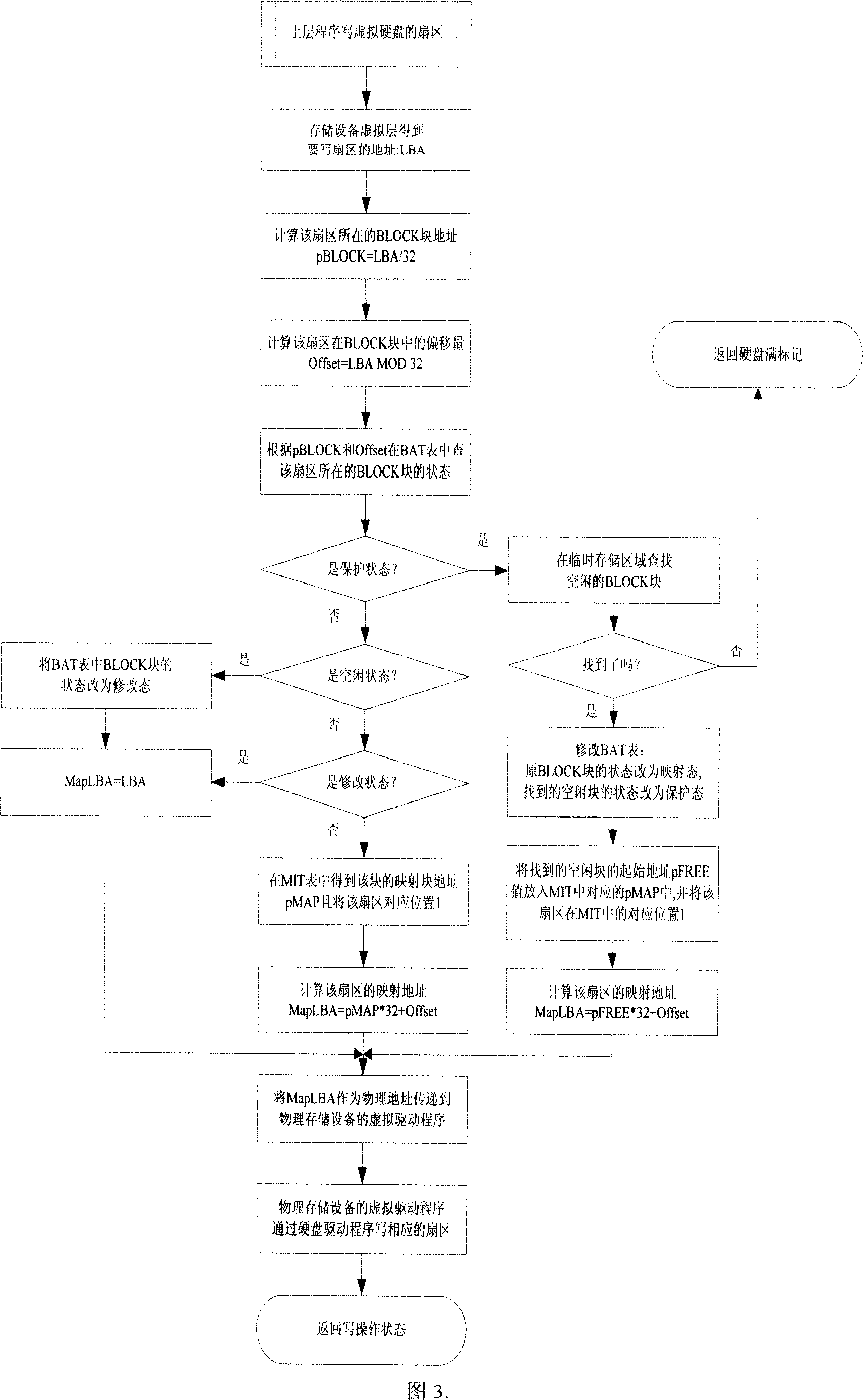

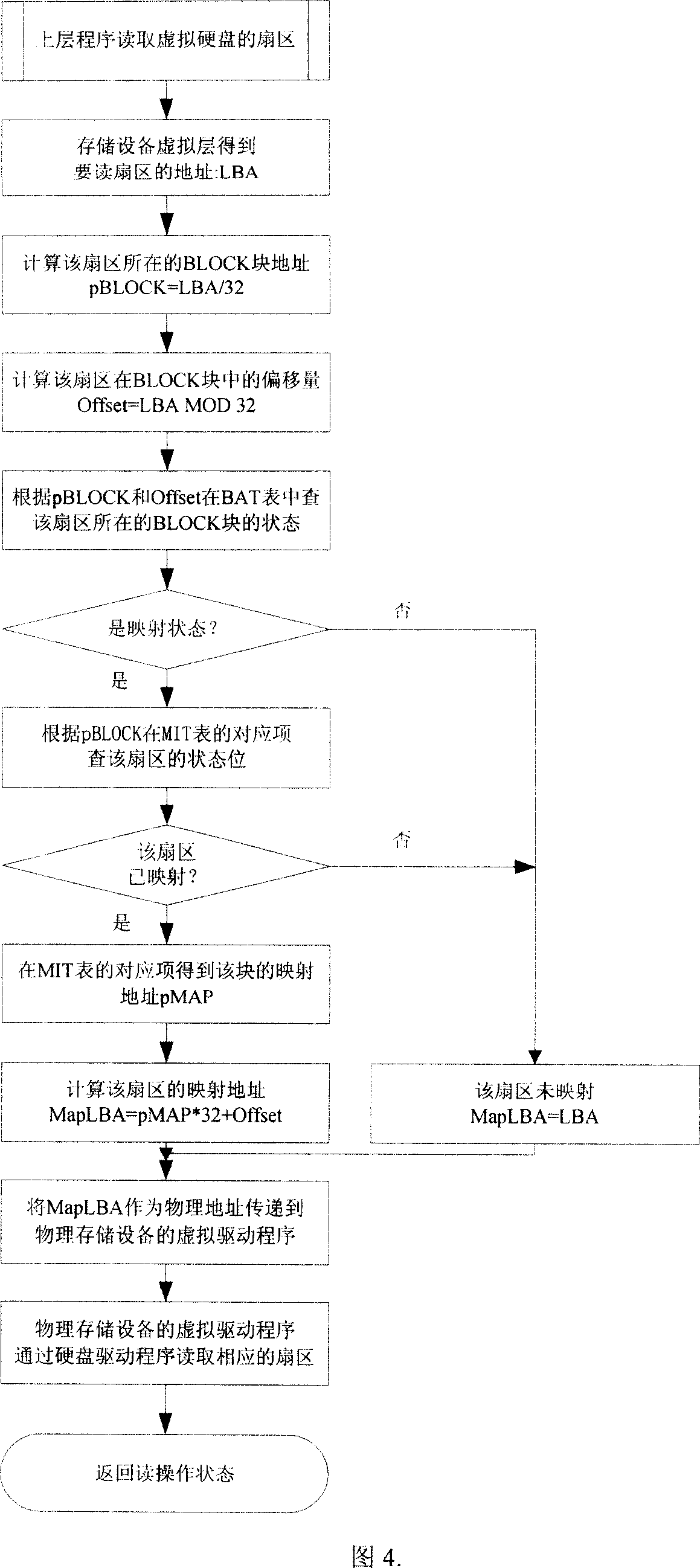

InactiveCN101004703ARestore fastSmall footprintMemory adressing/allocation/relocationRedundant operation error correctionVirtualizationFile system

A method for quickly restoring computer system includes virtualizing storage unit, utilizing mapping technique to provide a virtual storage view for said system, carrying out all operations of storage unit on said virtual view by said system and restoring said system to be real view after virtual view is removed off in order to realize quick restoration of said system. The device used for realizing said method is also disclosed.

Owner:TSINGHUA UNIV

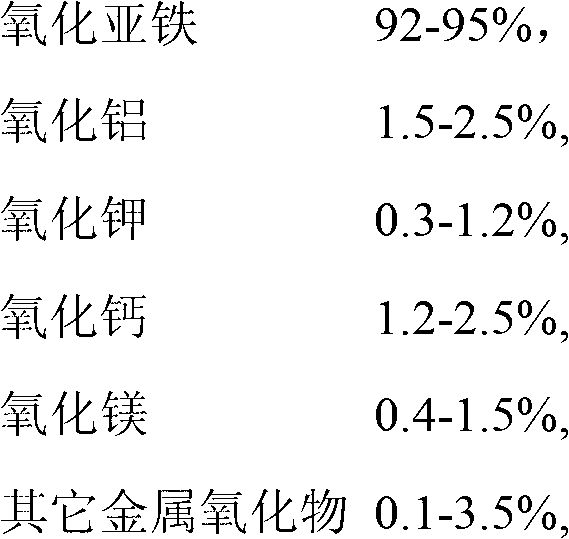

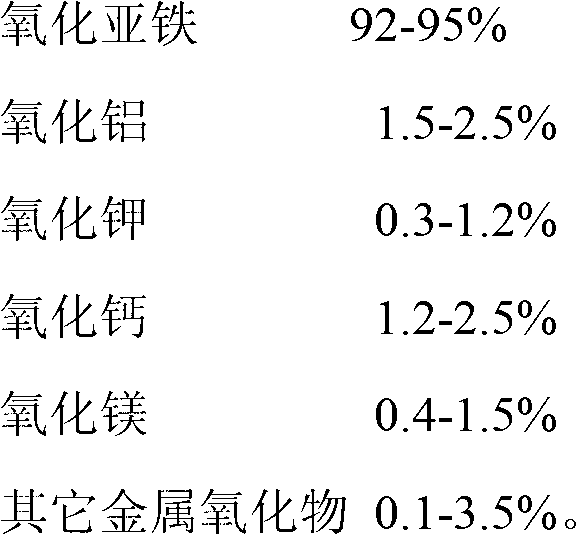

Ferrous oxide-based ammonia synthesis catalyst

ActiveCN102909030AHigh activityEnhanced adsorption and activationMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionHeat resistanceEconomic benefits

The invention discloses a ferrous oxide-based ammonia synthesis catalyst. The ferrous oxide is taken as a main phase component, and potassium oxide, calcium oxide, aluminum oxide, magnesium oxide and other metal oxides are used as auxiliary catalysts. The ferrous oxide-based ammonia synthesis catalyst is prepared by a melting method. The catalyst has high activity to catalyze nitrogen and hydrogenate to synthesize ammonia, easy to reduce, and great in heat resistance and antitoxic and has mechanical performances. The catalyst is suitable to be used in various sizes of ammonia synthesizing devices, and particularly suitable for a low-pressure and low-energy consumption ammonia synthesizing technique; and obvious energy saving, consumption reduction, efficiency increasing, cost saving and economic benefits are achieved.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of ultrathin CoNi alloy nanosheet

ActiveCN107398564ARestore syncRegular shapeTransportation and packagingMetal-working apparatusSolubilityPotassium hydroxide

The invention discloses a preparation method of an ultrathin CoNi alloy nanosheet. The method comprises the following steps: a cobalt-nickel-cyanogen glue is prepared by taking cobalt chloride and potassium tetracyanonicolate as precursors, then sodium borohydride is used as a reducing agent, and the cobalt-nickel-cyanogen glue can be reduced into the ultrathin CoNi alloy nanosheet with a regular shape and an uniform size by adopting a method of heating in an aqueous solution. The method has the advantages of being simple and economic, and is suitable for industrial large-scale production, the obtained ultrathin CoNi alloy nanosheet has good stability and water solubility, and has good OER catalytic activity and stability in an alkaline potassium hydroxide solution, so that the method has a good application prospect in the aspect of electrochemistry.

Owner:SHAANXI NORMAL UNIV

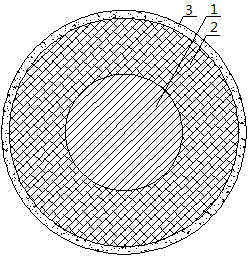

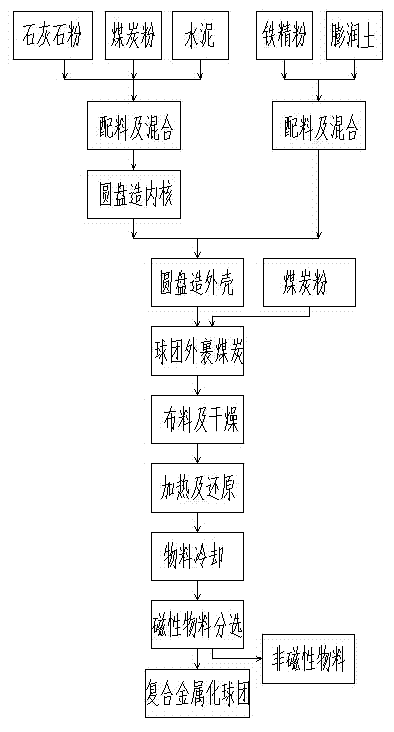

High-alkalinity composite metallized pellet for converter and production process thereof

InactiveCN104726630AEnhanced reducing atmosphereIncrease concentrationManufacturing convertersAlkalinityReduction rate

The invention relates to the technical field of metallurgical and mineral engineering and discloses a high-alkalinity composite metallized pellet for a converter and a production process thereof. The pellet comprises an inner core and a shell wrapping outside the inner core, wherein the inner core is prepared through mixing coal powder, limestone and cement according to the mass ratio of 100: (300-550): (4-7), the shell is prepared through mixing iron concentrate and bentonite according to the mass ratio of (1,500-1,800): (30-54), the granularity of the inner core is 20-25mm, and the thickness of the shell is 5-10mm; the outside of the shell is further covered with a layer of reducing agent. The production process comprises the steps of preparing the inner core, wrapping the shell to form the composite metallized pellet, wrapping the external wall of the composite metallized pellet with a reducing layer, distributing and drying the composite metallized pellet, carrying out reduction roasting on the composite metallized pellet, cooling and separating the high-temperature-reduction composite metallized pellet, and the like. According to the high-alkalinity composite metallized pellet and the production process thereof, through proportionally adding the limestone and the coal powder into the inner core, the internal reducing atmosphere of the pellet is strengthened, the reduction rate is increased, and the energy consumption is lowered.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Method for preventing directly reduced metallic pellets from bonding

Belonging to the technical field of metallurgy, the invention relates to a method for preventing directly reduced metallic pellets from bonding. The method comprises the steps of: (1) mixing anthracite carbon powder, lime powder, clay and bentonite uniformly so as to prepare peritoneal powder; (2) making a material to be reduced into mineral powder pellets; (3) placing the peritoneal powder into the pelletizing disc of a pelletizer, then putting the mineral powder pellets to be reduced on the peritoneal powder in the pelletizing disc, and initiating the pelletizer so as to prepare composite pellets; (4) subjecting the composite pellets and a pulverized coal reducing agent to a reduction reaction at a temperature of 1180-1220DEG C for 3-4h, thus obtaining metallic iron pellets. The method of the invention solves the bonding problem of directly reduced metallic pellets, and is especially suitable for producing high density metallic pellets, and also especially suitable for production of metallic pellets with high grade iron ore powder.

Owner:辽宁博联特冶金科技有限公司

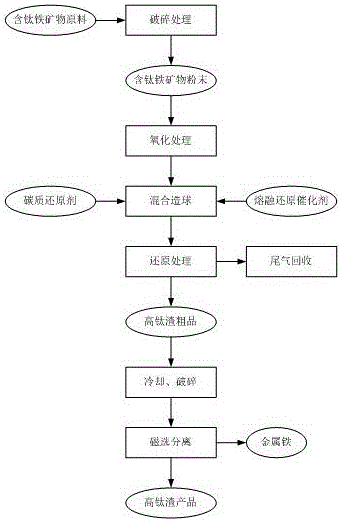

Method for preparing high titanium slag through low temperature reduction and separation of titanium-containing iron ore

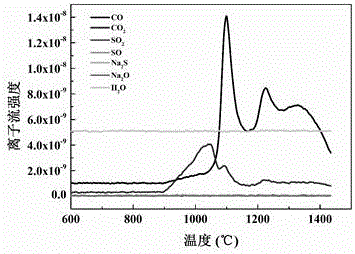

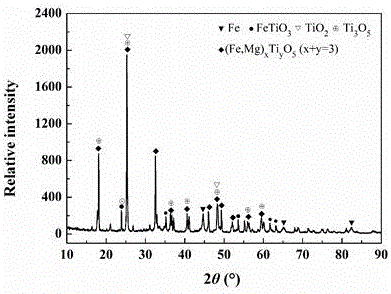

InactiveCN106521139AReduce energy consumptionRestore fastFluidised-bed furnacesEnergy consumptionReducing agent

The invention provides a method for preparing high titanium slag through low temperature reduction and separation of titanium-containing iron ore. According to the method, a pre-oxidation titanium-containing iron ore raw material is used, and a carbonaceous reducing agent and smelting reduction catalysts such as Na2SO4 and FeS are used for reduction production of pig iron and high titanium slag products; compared with a traditional electric furnace smelting titanium slag process, a product can be obtained through reduction for 20 minutes to 40 minutes at a lower temperature ranging from 1200 DEG C to 1500 DEG C, the reduction speed is higher, energy consumption is lower, cost is reduced, and the aims of separating the pig iron and the titanium slag with high efficiency, low consumption and low cost are achieved; meanwhile, the metallization recovery rate of the iron element is improved, and the grade of the obtained high titanium slag is higher; in addition, the main ingredient of tail gas in the reduction process is CO and can be recycled, and the reduction and heating energy consumption is further saved; accordingly, a new process is provided for producing the high titanium slag, and the problems that in the prior art, a high titanium slag preparing process is complex, the production efficiency is low, cost is expensive, and the energy consumption is large are solved.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com