Patents

Literature

41results about How to "Synthetic technology is mature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bursa of Fabricius heptapeptide with immune regulation effect

InactiveCN101830968ASynthetic technology is matureImprove efficiencyPeptide preparation methodsAntibody medical ingredientsSide effectImmunologic Competence

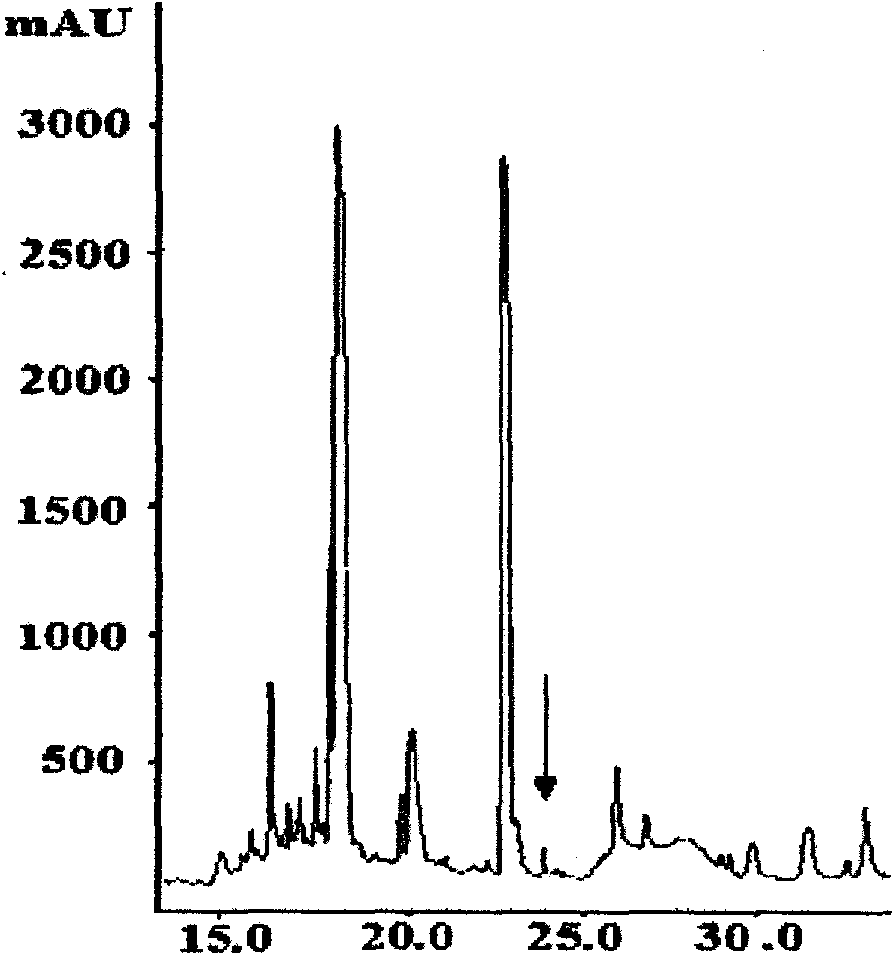

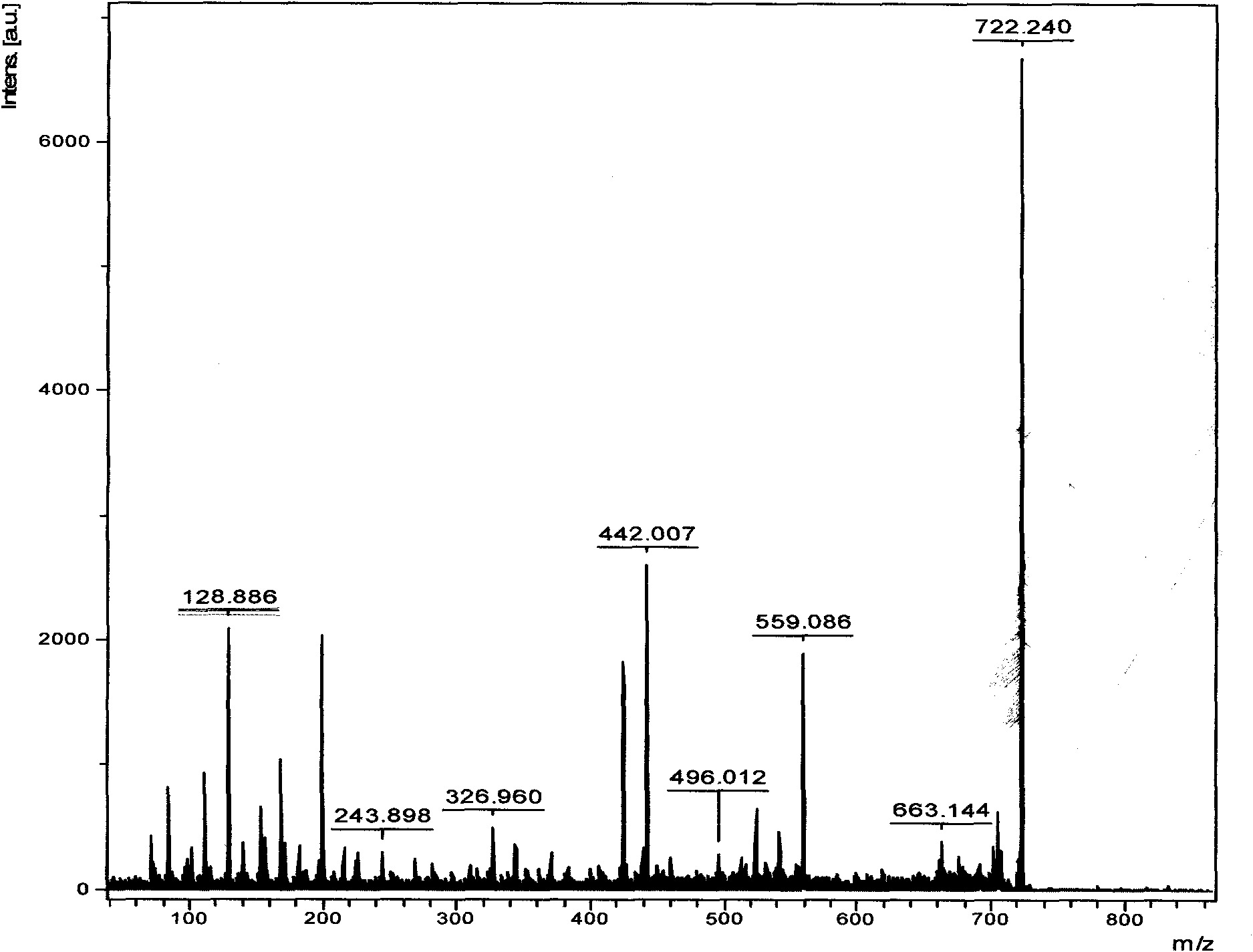

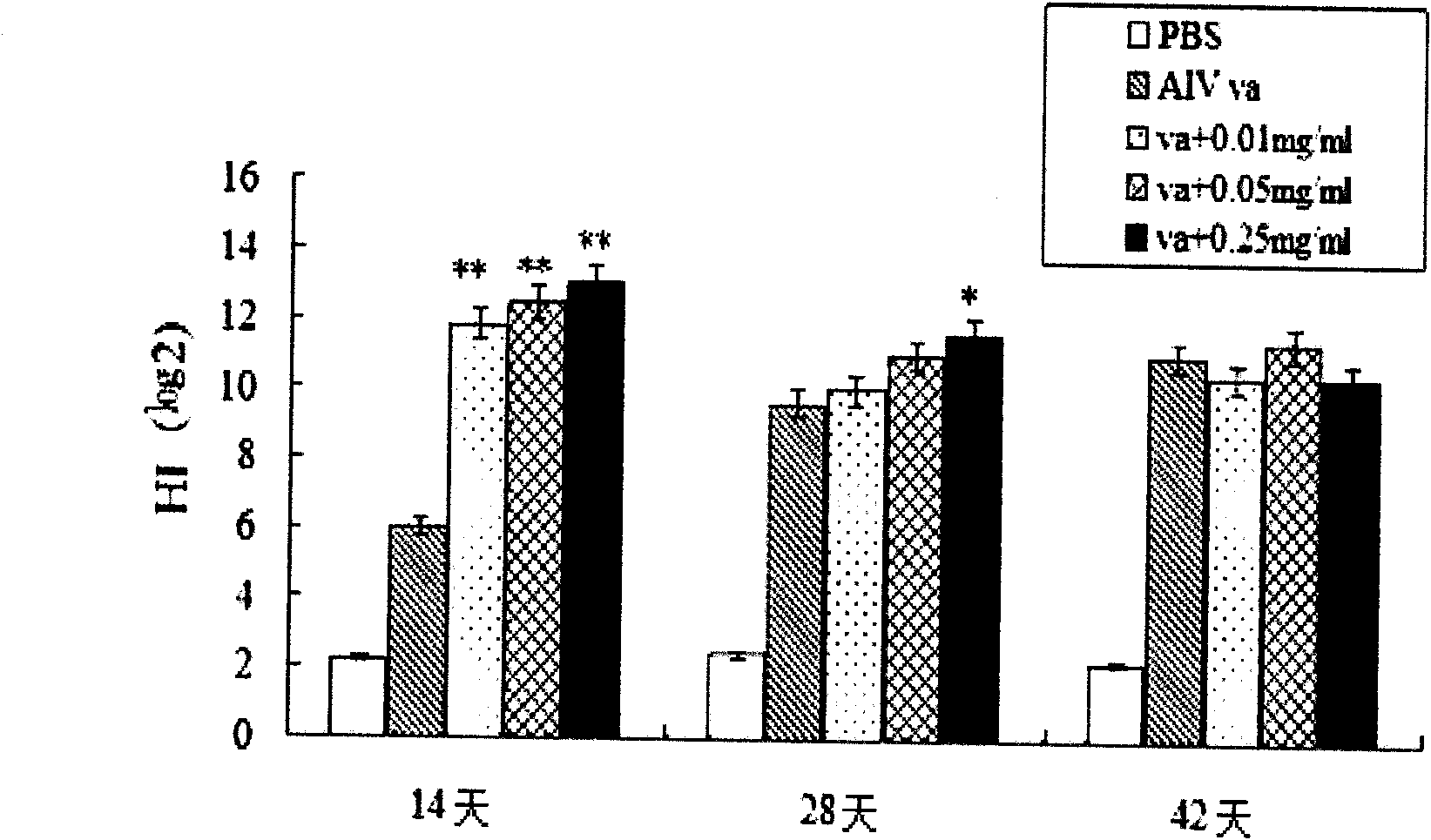

The invention relates to bursa of Fabricius heptapeptide with immune regulation effect and application thereof in immunity (in improving the immune capability of animals, improving the immune effect of vaccines and affecting the activity of tumor cells), and belongs to the field of immunology. The molecular weight of the separated heptapeptide is 722.240, the amino acid sequence is EPASGMM, and the heptapeptide has a simple structure, no toxic or side effect and extremely weak immunogenic property. The heptapeptide can be separated and extracted from bursa of Fabricius, also can be chemically synthesized, has low cost, and can be massively produced. The bursa of Fabricius heptapeptide has induction effect on the production of antibody and subtype thereof, and meanwhile can regulate the production of cell factors, partition of T lymphocytes and proliferation of spleen cells, and promote the immune reaction of the cells. The bursa of Fabricius heptapeptide is an immune regulation factor on functions, has wide application prospect on the aspects of immune regulation, immune therapy and the like, and can be applied in the fields of basic immune research, clinical application research and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

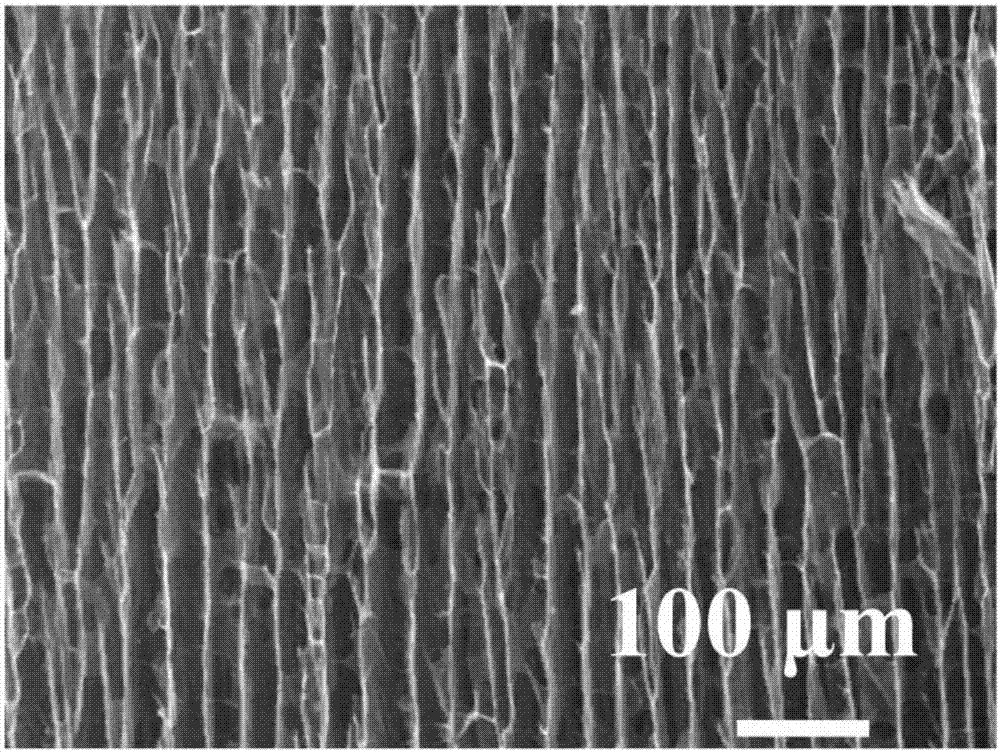

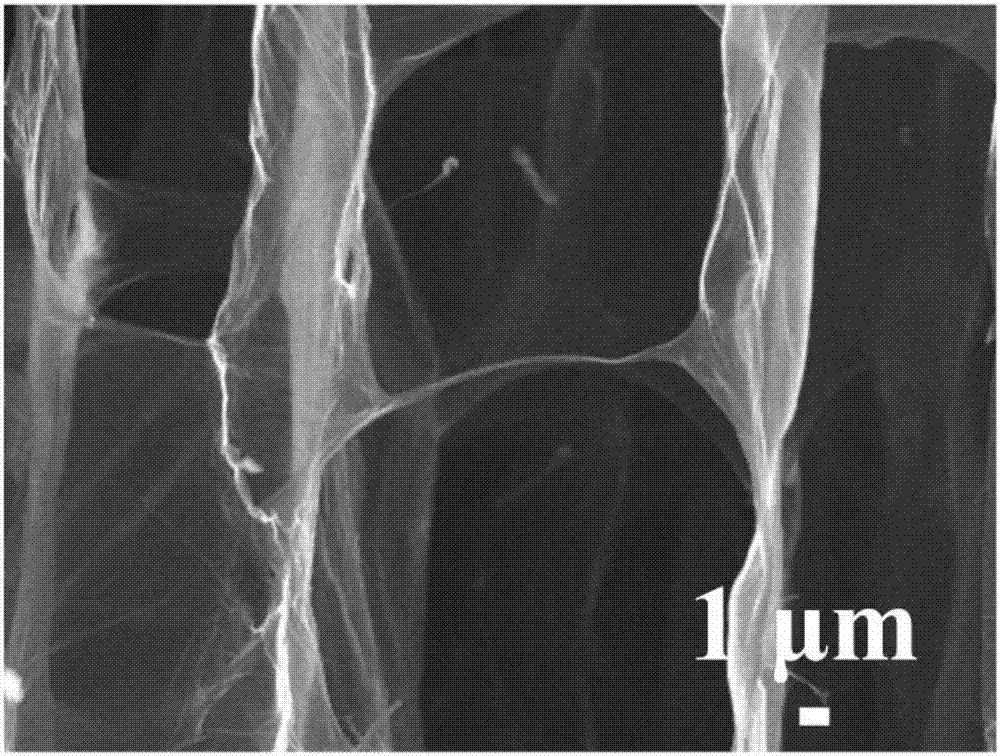

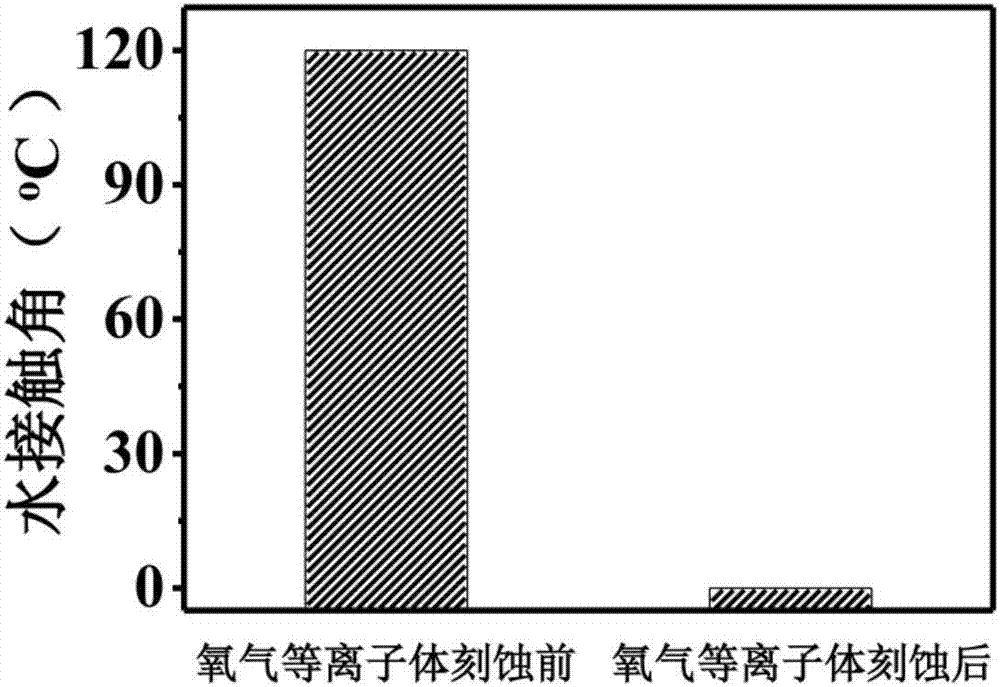

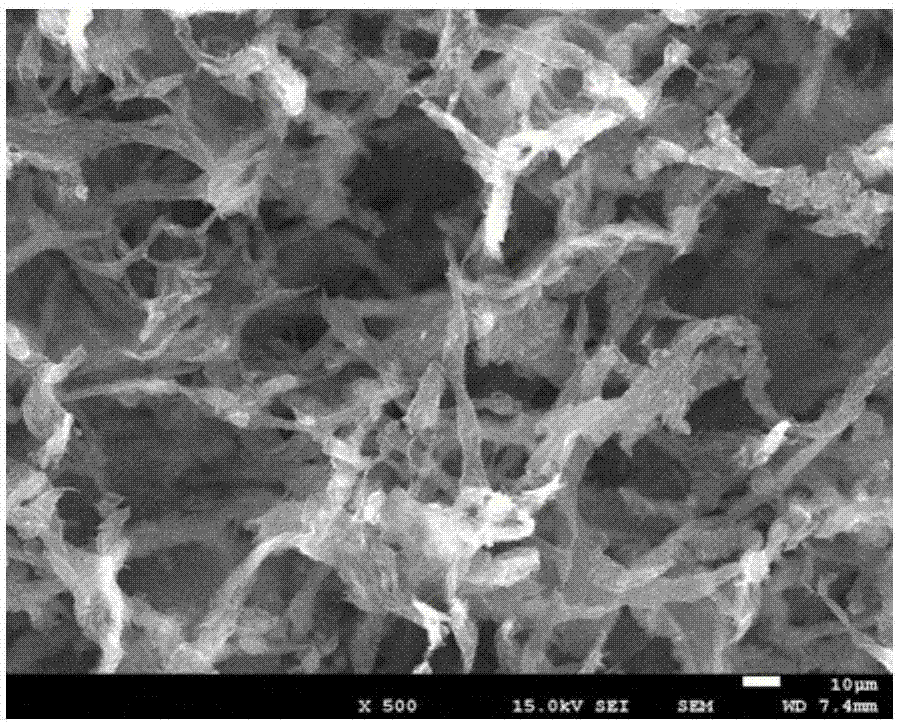

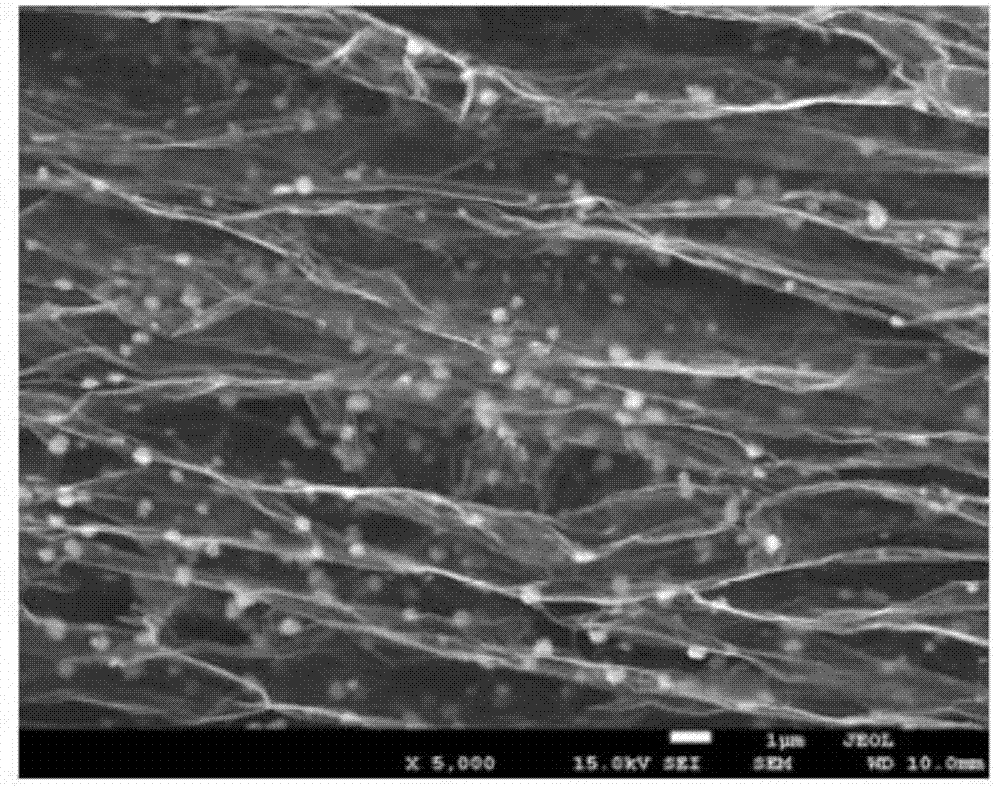

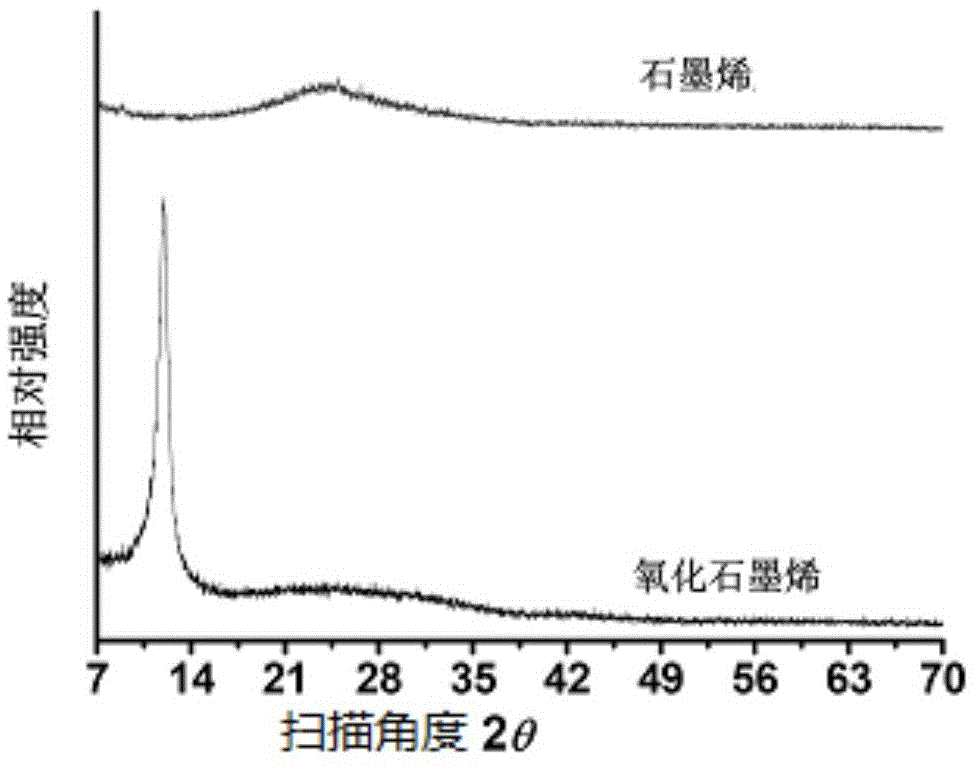

Preparation method and applications of graphene sheet vertically oriented thin film material

ActiveCN106966386ALow costSynthetic technology is matureGeneral water supply conservationSeawater treatmentFreeze-dryingEvaporation

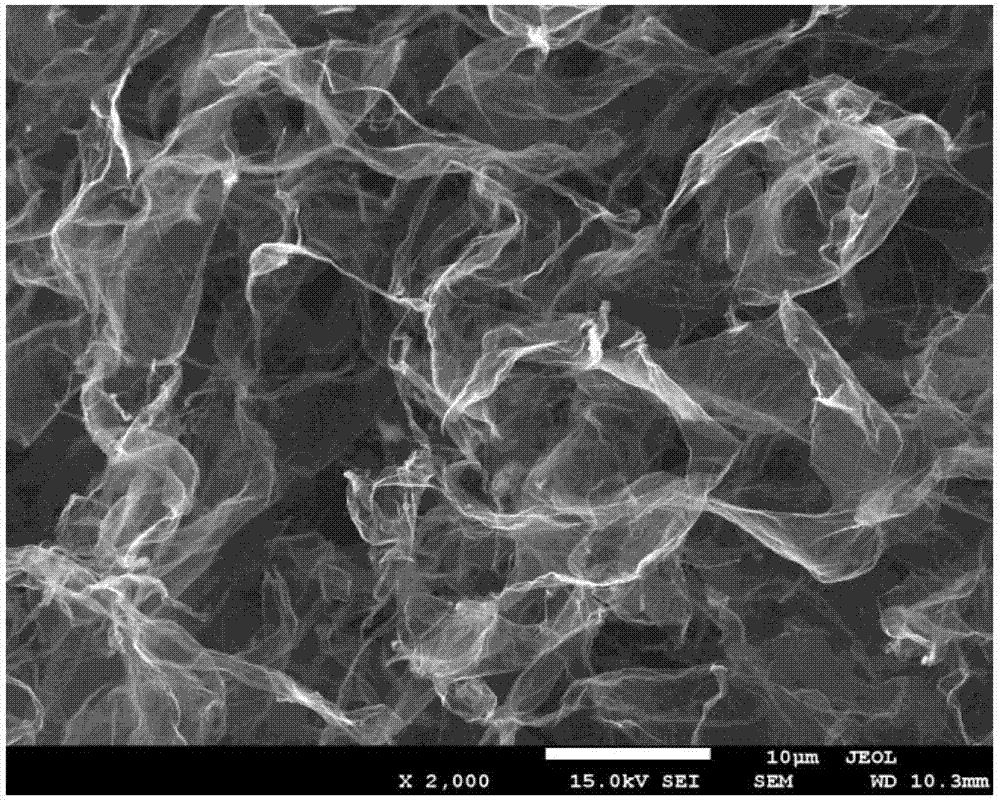

The invention relates to a preparation method and applications of a graphene sheet vertically oriented thin film material, and belongs to the field of functional materials. According to the preparation method, a graphene oxide solution obtained via pre-production is uniformly mixed with an antifreezing agent; an obtained mixture is delivered into a polytetrafluoroethylene container, and then the bottom of the polytetrafluoroethylene container is placed on the surface of liquid nitrogen immediately so as to realize orientation freezing from bottom to top and obtain a hydrogel of the graphene sheet vertically oriented thin film material; the hydrogel is subjected to freeze drying so as to obtain an aerogel of the graphene sheet vertically oriented thin film material; under argon protection, the aerogel is subjected to annealing so as to obtain the graphene sheet vertically oriented thin film material. The preparation method is simple; operation is convenient; the preparation method is suitable for large-scale production; the obtained graphene sheet vertically oriented thin film material possesses highly ordered channels beneficial for water molecule transmission and evaporation; and the graphene sheet vertically oriented thin film material can be used for realizing high efficiency solar energy seawater desalination, and water cleaning of concentrated acid, concentrated alkaline, and heavy metal solution.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

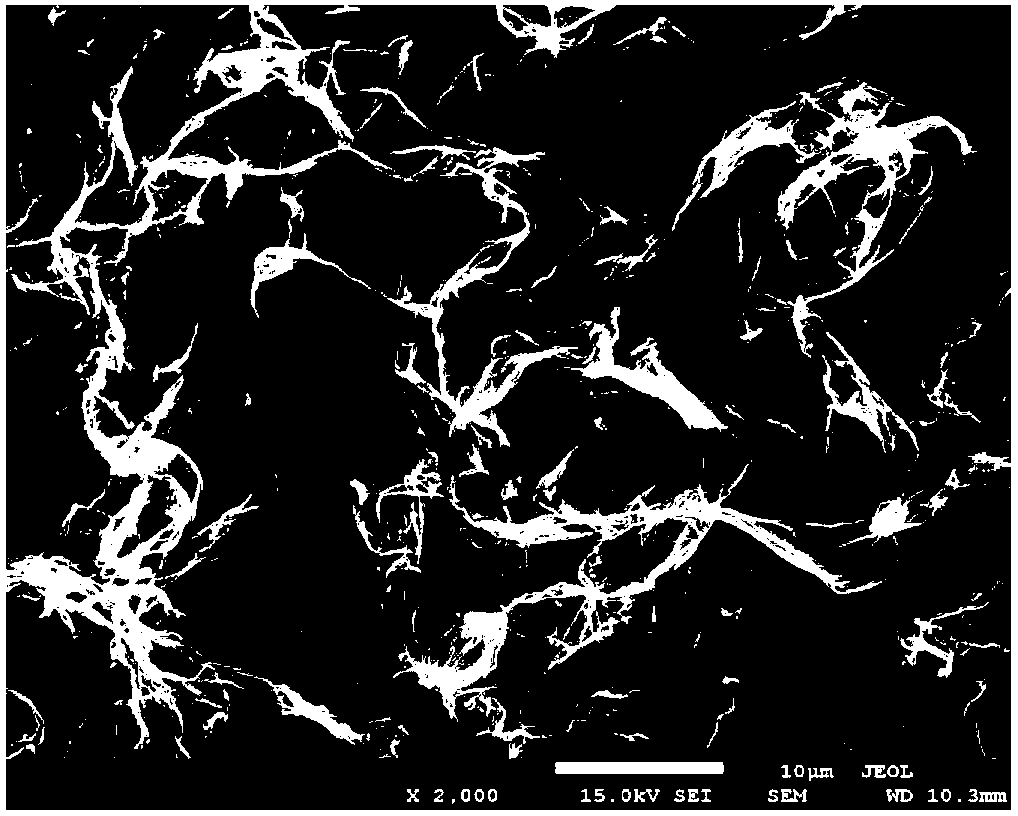

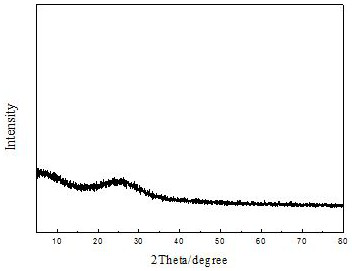

Method for spontaneously depositing three-dimensional graphene on conductive substrate

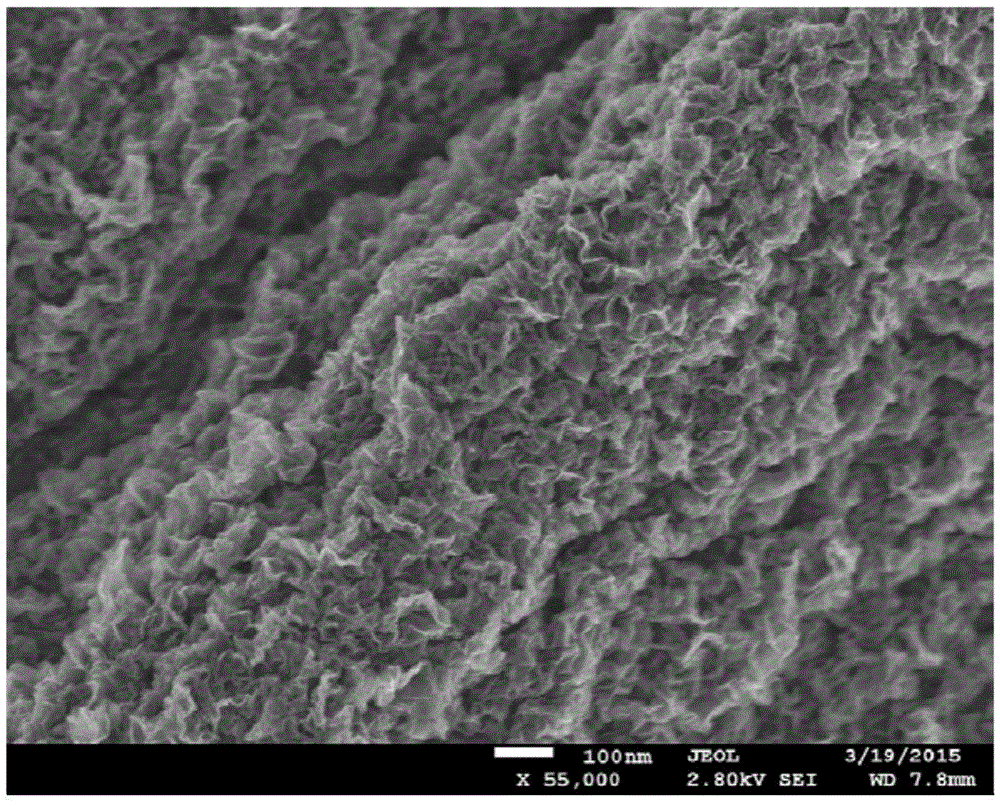

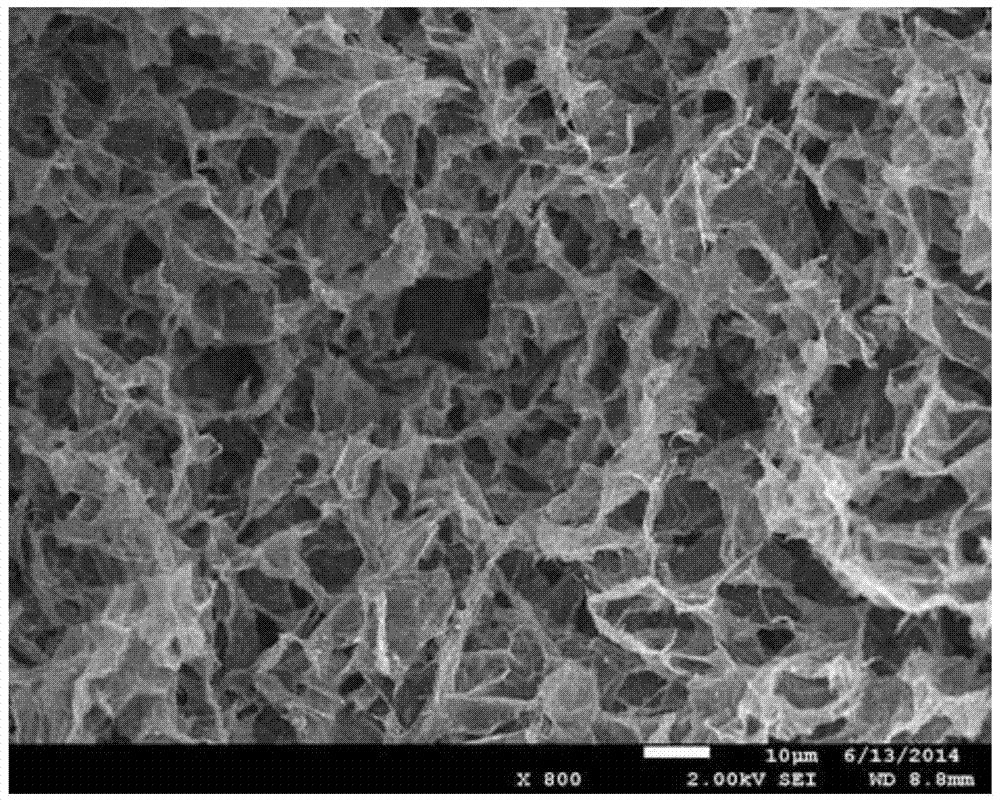

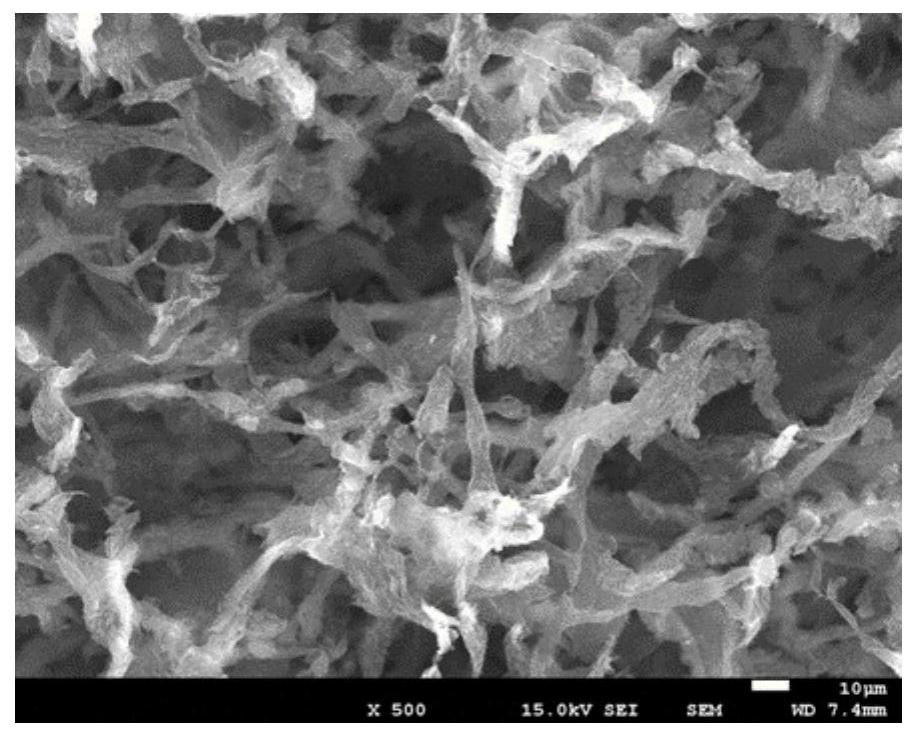

The invention discloses a method for spontaneously depositing three-dimensional graphene on a conductive substrate and belongs to the field of a functional material. The method comprises the following steps of: step one, preparing an 8-20 mg / mL oxidized graphene solution by an oxidizing graphite stripping method; step two, diluting the 8-20 mg / mL oxidized graphene solution so that the concentration of the oxidized graphene solution is changed into 0.5-3 mg / mL; step three, putting the conductive substrate in the oxidized graphene solution for standing, taking out the conductive substrate after reacting for 6-12 hours, thereby obtaining the conductive substrate with three-dimensional graphene deposited on the surface of the conductive substrate; and step four, directly carrying out freeze drying on the three-dimensional graphene obtained in the step three or performing freeze drying after washing, thus obtaining dry porous functionalized three-dimensional graphene or pure dry porous three-dimensional graphene. The method is simple in preparation process and friendly to environment; and the obtained three-dimensional graphene is three-dimensional and porous in structure, and has the characteristics of large specific surface area and good toughness.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

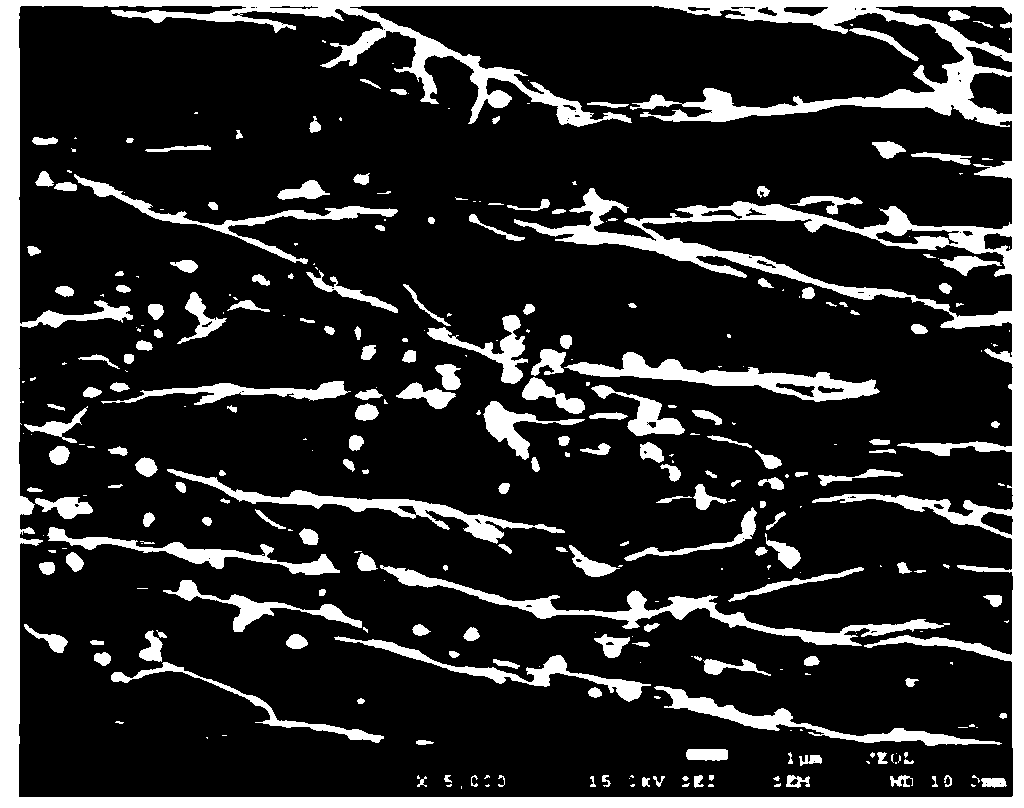

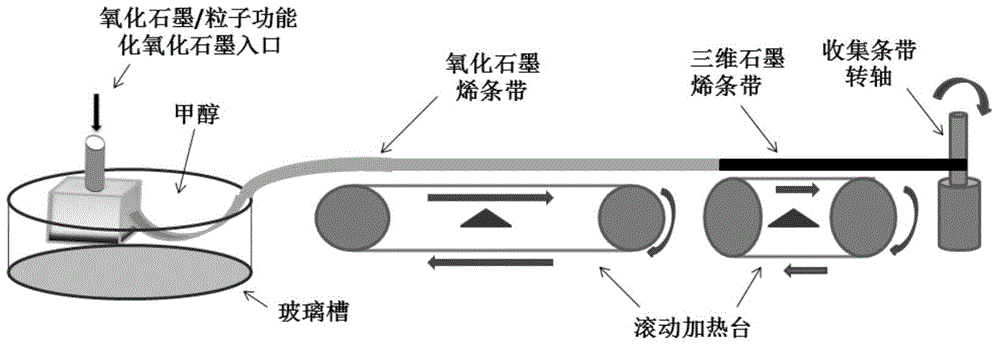

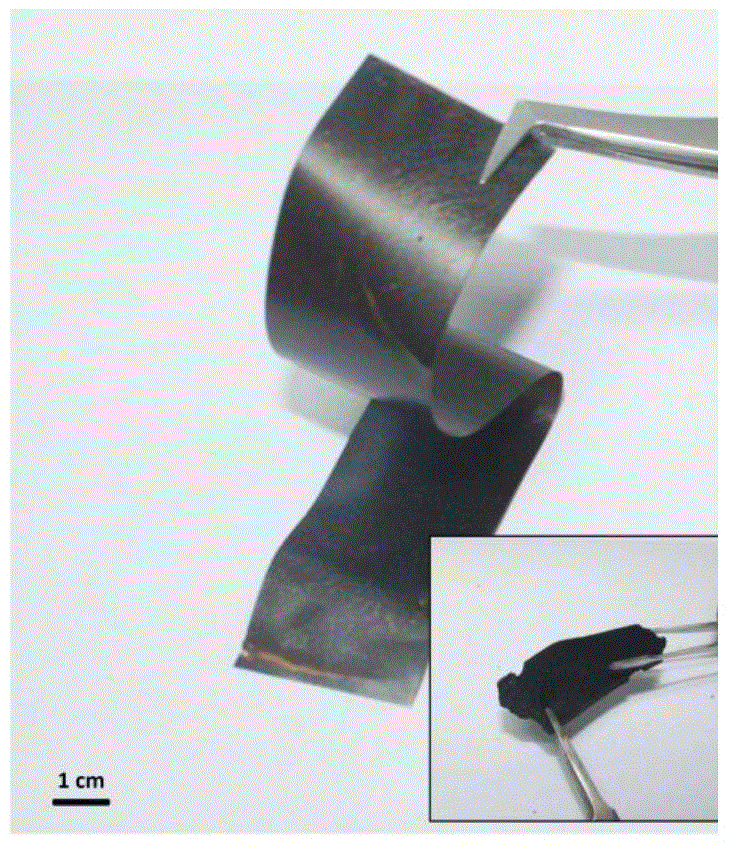

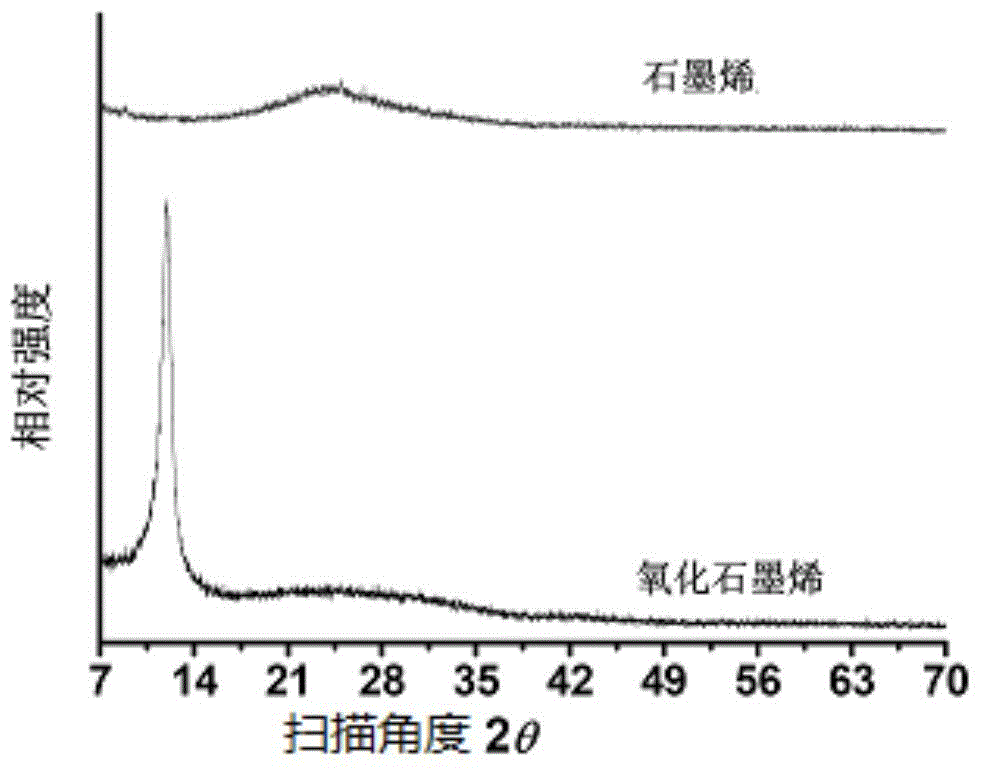

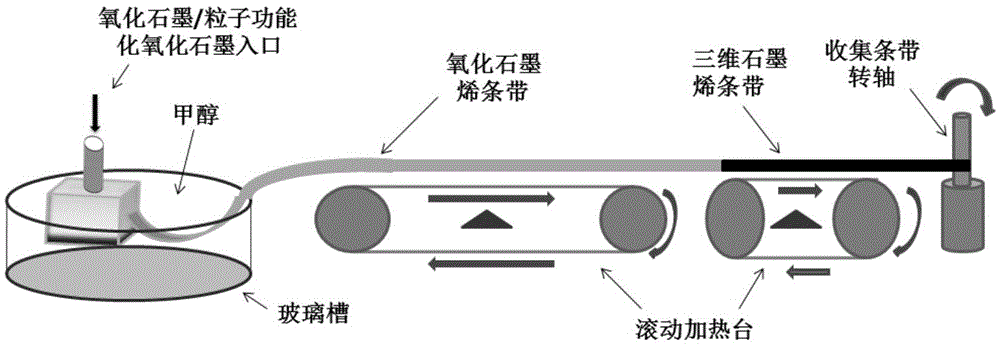

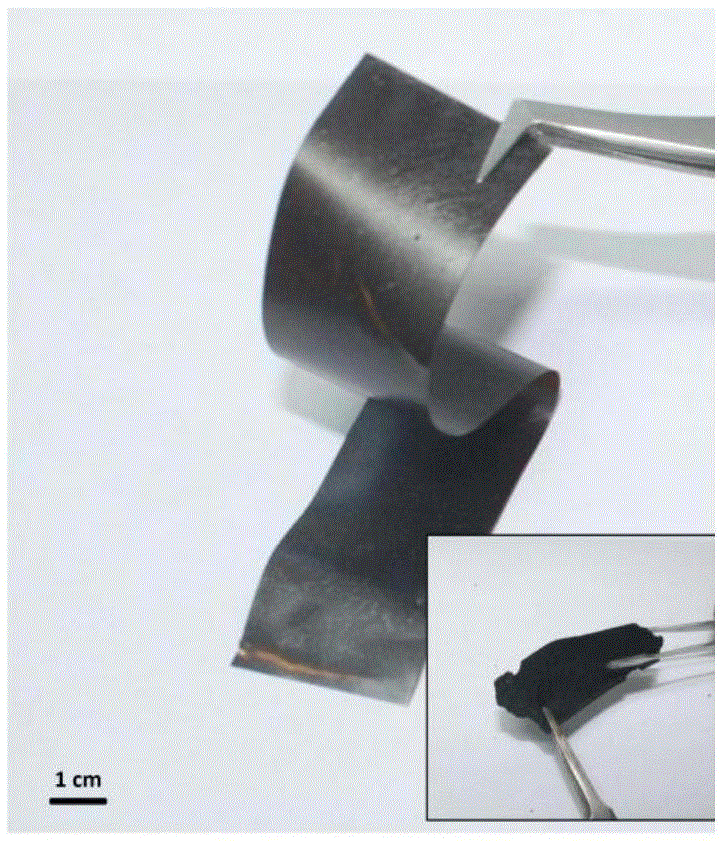

Method for on-scale continuous production of three-dimensional graphene membrane and application

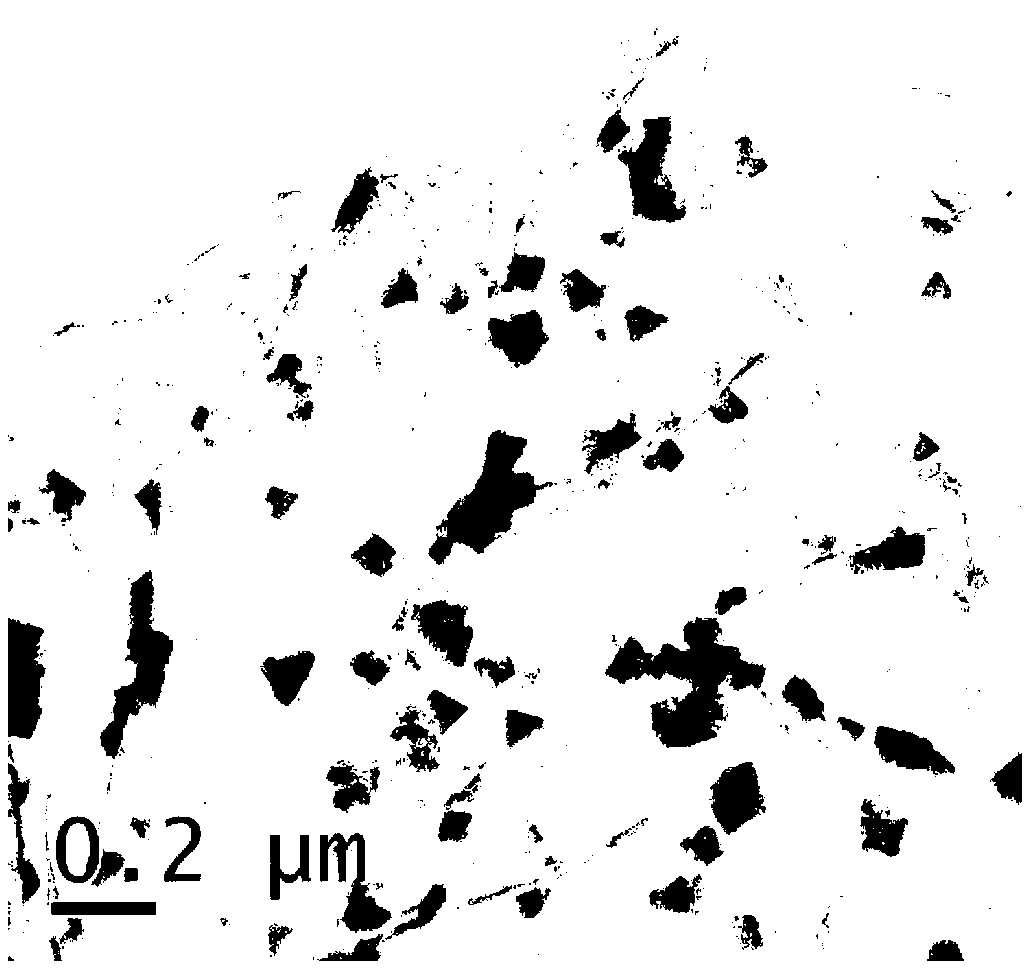

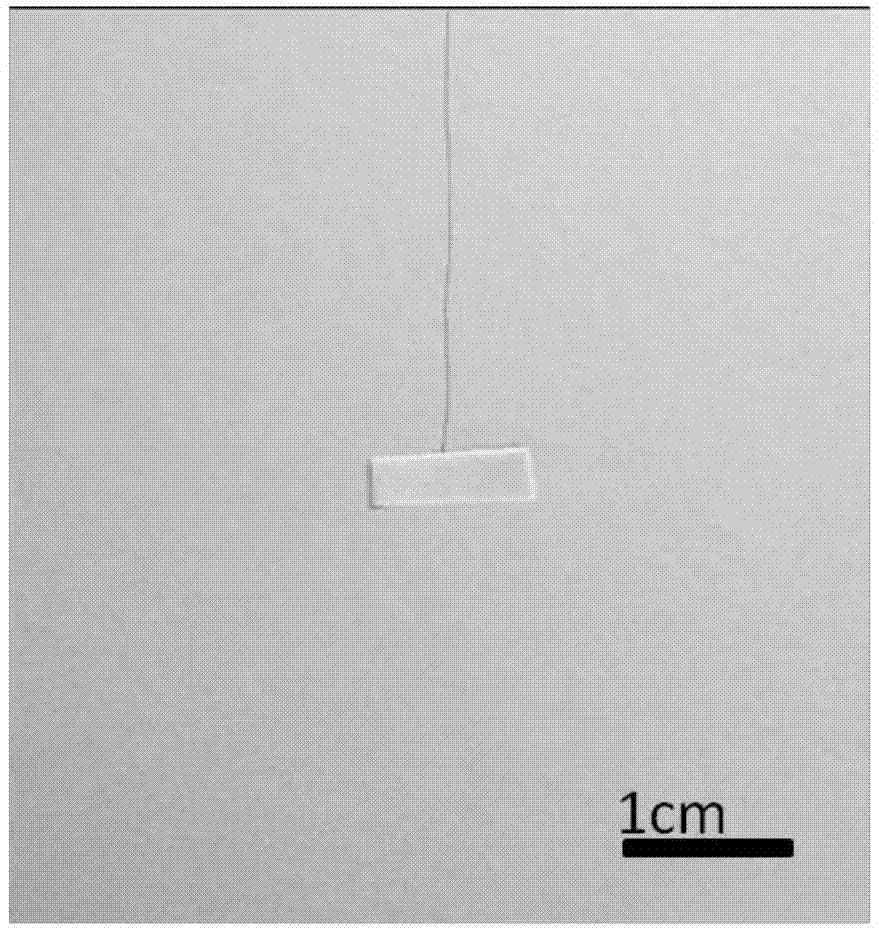

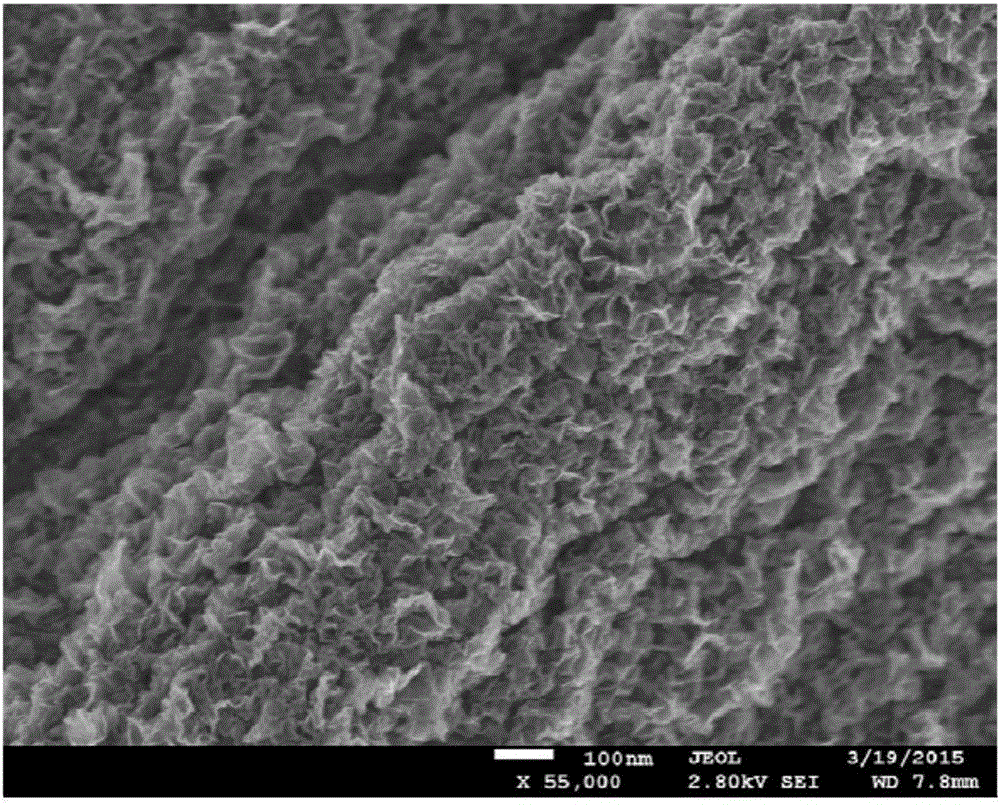

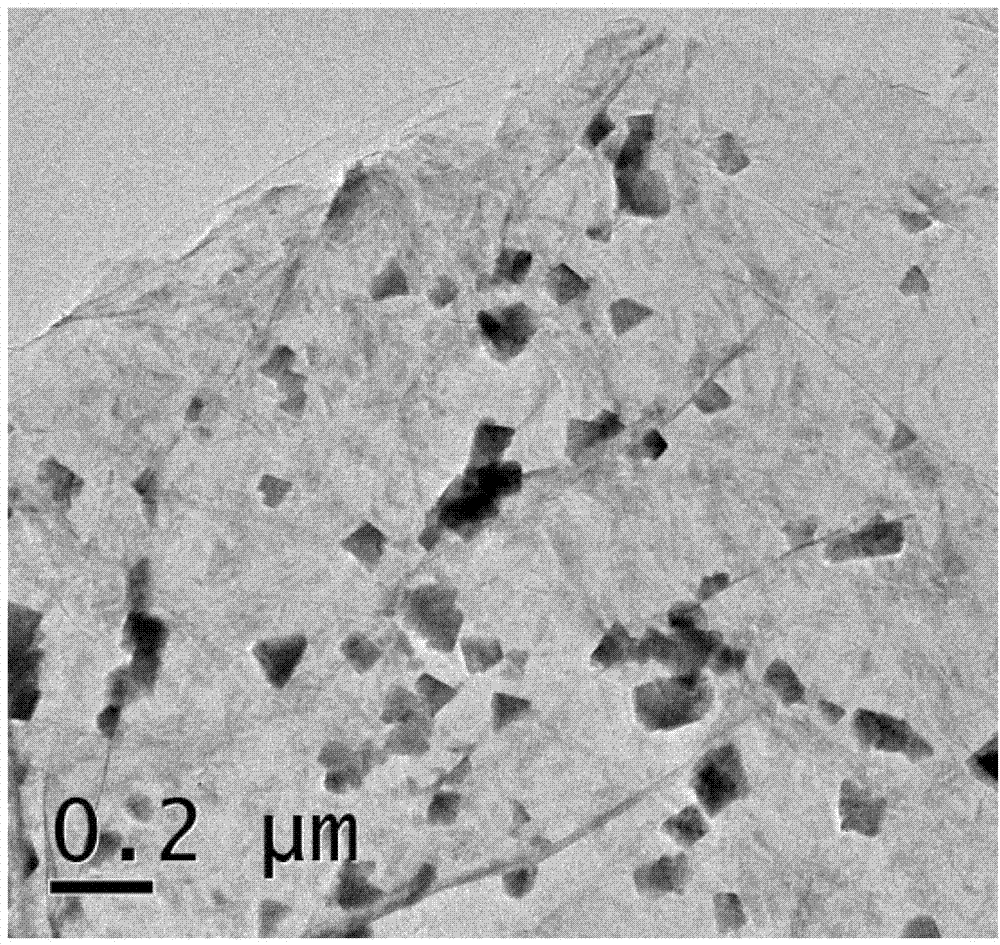

ActiveCN104310381ALow costSynthetic technology is matureMaterial nanotechnologyFerroso-ferric oxidesNanoparticleCvd graphene

The invention discloses a method for on-scale continuous production of a three-dimensional graphene membrane and application, belonging to the field of functional materials. The method comprises the following steps: 1, preparing a graphene oxide solution; 2, stirring and concentrating; 3, soaking a polytetrafluoroethylene bath into methanol; 4, filling the concentrated graphene oxide solution into the polytetrafluoroethylene bath, thereby obtaining graphene oxide strips; 5, leading out the graphene oxide strips from the methanol solution, firstly drying, and further performing reduction expansion, thereby obtaining the three-dimensional graphene membrane; and 6, collecting the three-dimensional graphene membrane, and coiling. The graphene oxide solution and functional nanoparticles are mixed, and the functional three-dimensional graphene membrane can be prepared by performing the above preparation steps. The method is simple in preparation process, environment-friendly, low in cost and applicable to on-scale production, and the three-dimensional graphene membrane prepared by using the method is three-dimensional and porous and has the characteristics of light mass, large specific surface area and good flexibility.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

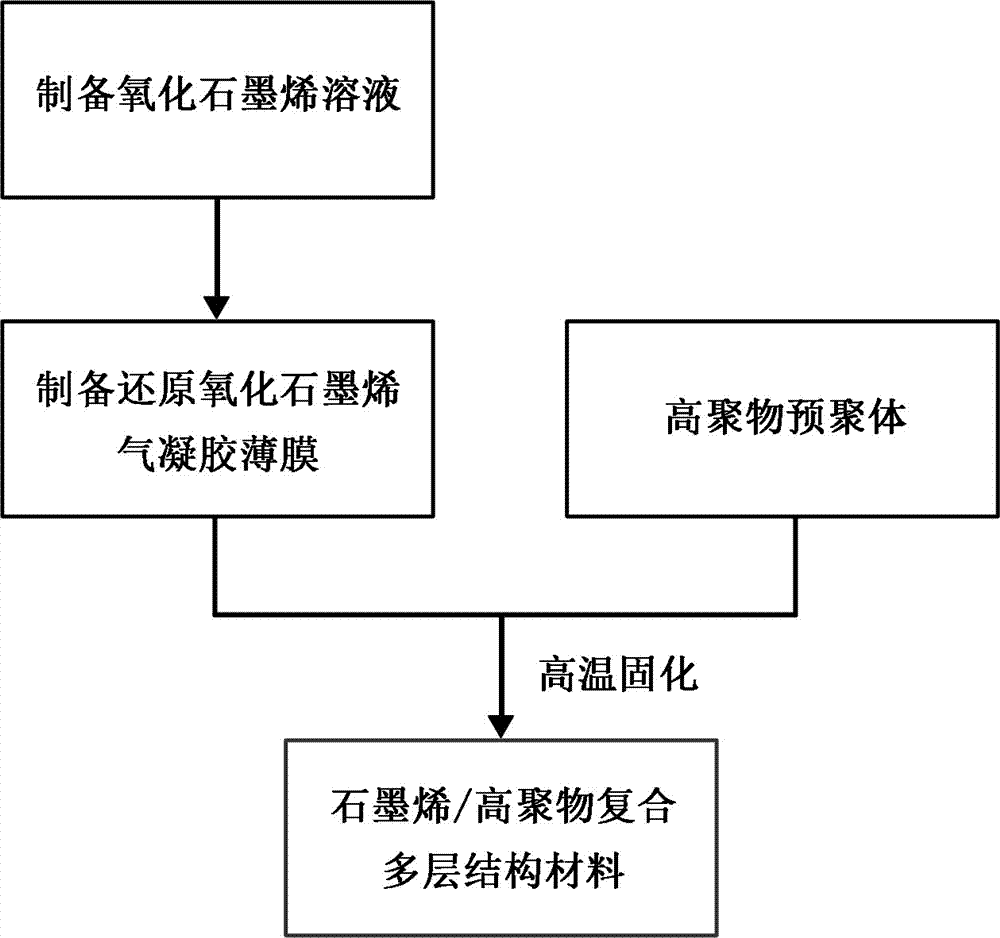

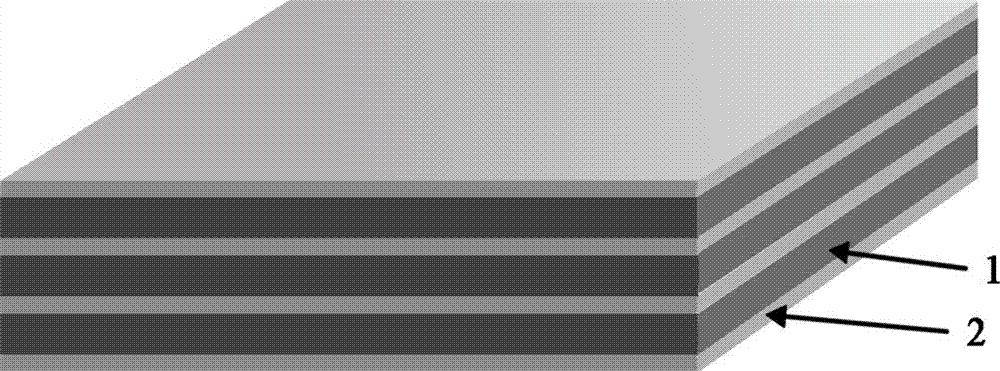

Preparation of graphene/superpolymer multilayer material with high electromagnetic shielding performance

InactiveCN107283949AWide variety of sourcesHigh strengthLamination ancillary operationsSynthetic resin layered productsMetallic foilFreeze-drying

The invention provides a preparation method of a graphene / superpolymer multilayer material with high electromagnetic shielding performance, and belongs to the field of electromagnetic shielding material preparation. The method comprises the following steps: firstly preparing an oxidized graphene solution by adopting a liquid-phase stripping method; then carrying out freeze drying on a graphene thin film reduced by metallic foil under a vacuum condition so as to obtain a graphene aerogel thin film; and finally infiltrating a thin superpolymer layer on the surface of the thin film, laminating thin film layers together to prepare the graphene / superpolymer multilayer material. The method is simple in technological conditions, the flow is easy to control, the source of the raw materials is wide, the cost is low, and the method is convenient for industrial production. Due to the fact that graphene sheets are assembled to form a certain structure before the graphene is mixed with the superpolymer, and agglomeration in the mixing process of the graphene sheets and the superpolymer is avoided, the composite material has the characteristics of high strength, high conductivity, corrosion resistance, high electromagnetic shielding performance and the like, and can be widely applied to civil and military fields such as consumer electronics, communication equipment, information transfer and security.

Owner:PEKING UNIV +1

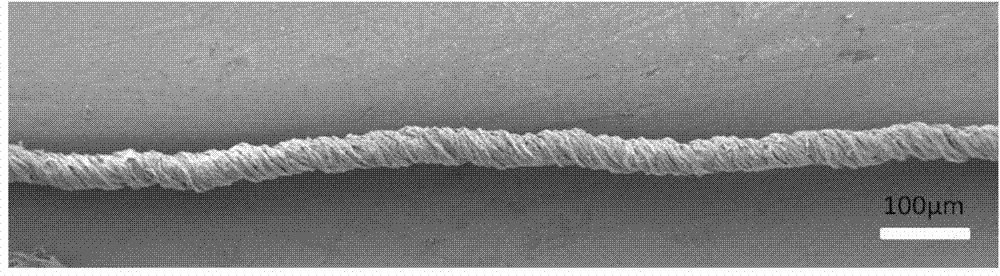

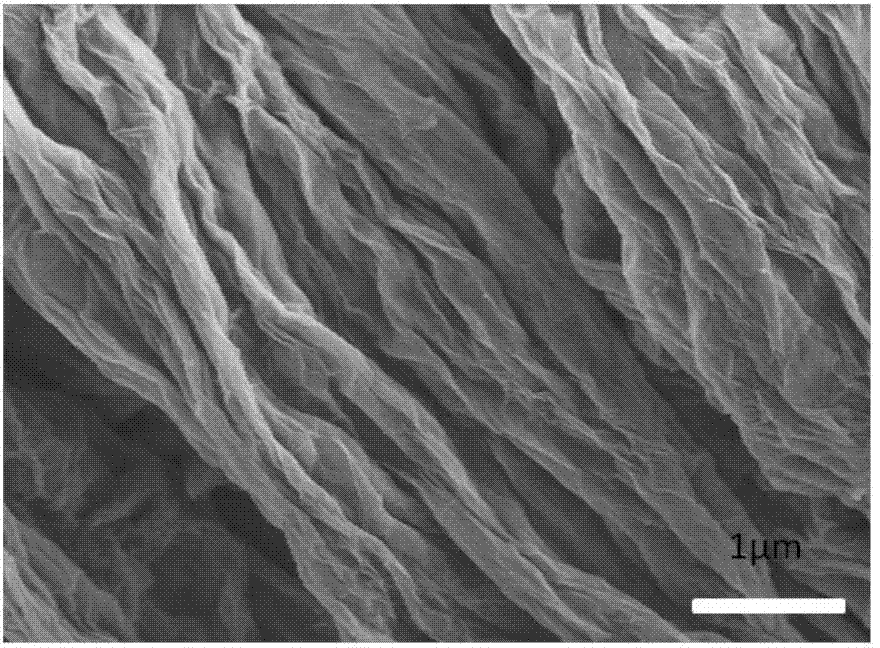

Graphene oxide fiber and preparation method and application thereof

ActiveCN103806128AQuality improvementSmooth rotationFibre chemical featuresMechanical energy handlingFiberEvaporation

The invention relates to a graphene oxide fiber and a preparation method and application thereof, belonging to the field of functional materials. The preparation method comprises the steps of preparing a graphene oxide solution by adopting a Hummers method, then performing water evaporation and concentration, injecting the concentrated graphene oxide solution into saturated potassium chloride methanol solution to obtain wet graphene oxide hydrogel fiber by using a syringe, rotating and processing and then naturally airing, thus obtaining the graphene oxide fiber. Under the ambient environment humidity change condition, the fiber is applied in a power generator, energy generated due to humidity change in the environment is converted into electric energy, the open circuit voltage of the power generator is 0.5-1mV, and the short-circuit current is 20-40muA. The fiber is high in quality, stable in properties, and excellent in rotating performance, and the method is low in cost and can be massively produced; the fiber is applied in the power generator, and the energy source is green and environment-friendly, and pollution-free.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

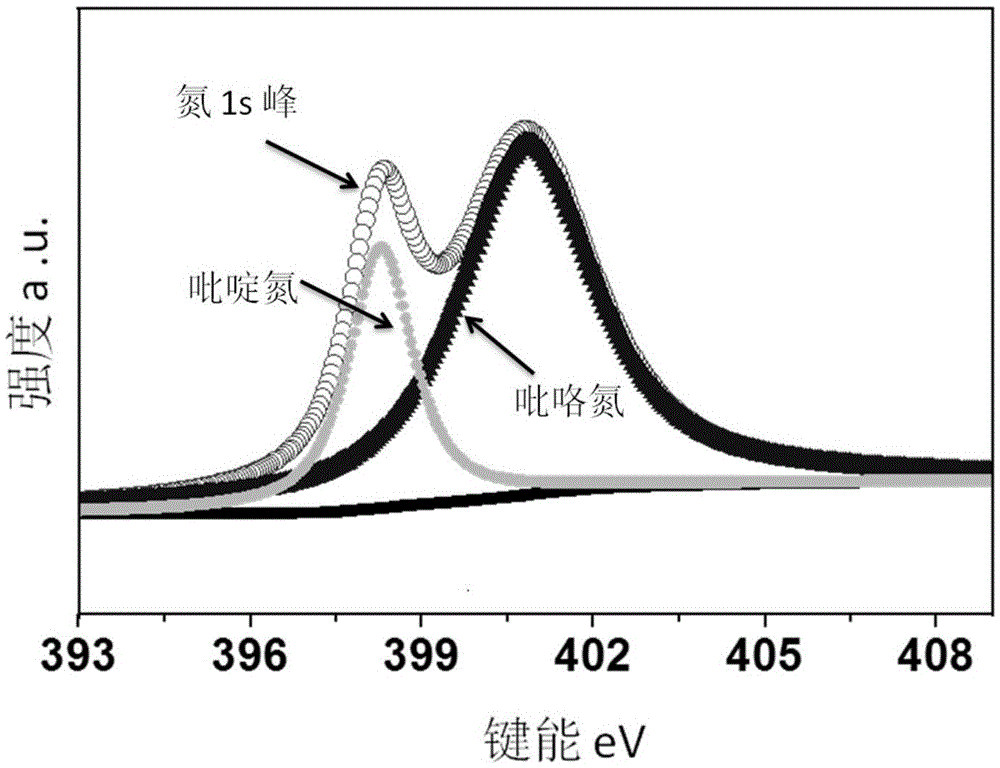

High-density nitrogen doped graphene as well as preparation method and application thereof

The invention relates to the field of functional materials and discloses high-density nitrogen doped graphene as well as a preparation method and an application thereof. The preparation method comprises the following steps: (1) allowing a nitrogen source and graphene oxide to contact in the presence of a solvent; (2) drying the product obtained in the step (1); and (3) reducing the product dried in the step (2). The high-density nitrogen doped graphene provided by the invention has high specific discharge capacity and specific volumetric capacity, and the method for preparing the high-density nitrogen doped graphene provided by the invention is simple and is suitable for large-scale industrial production.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

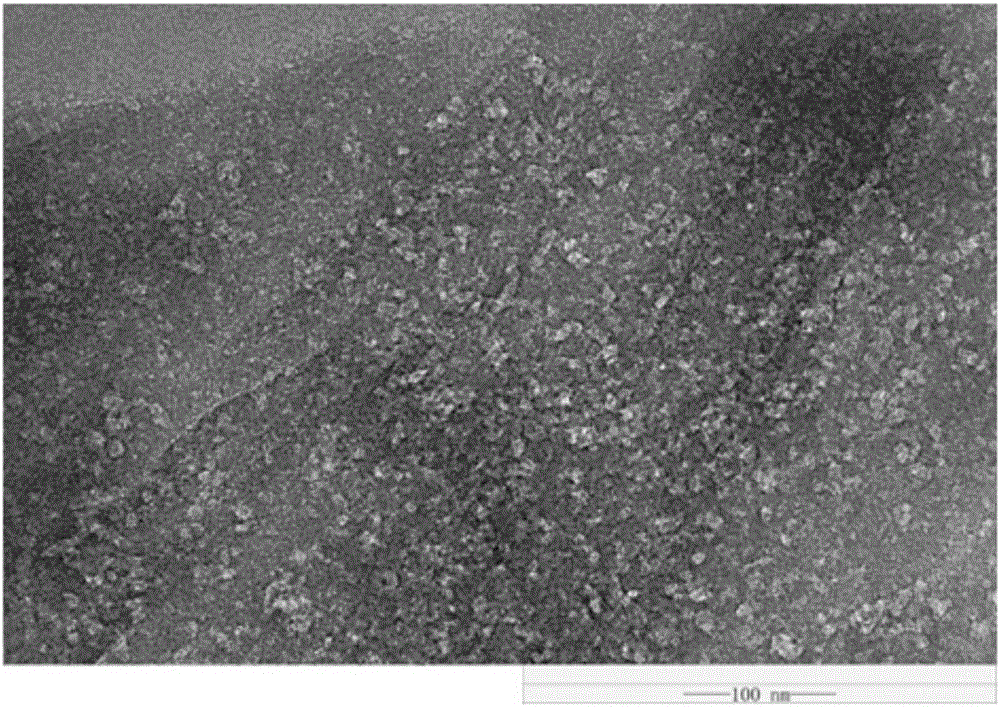

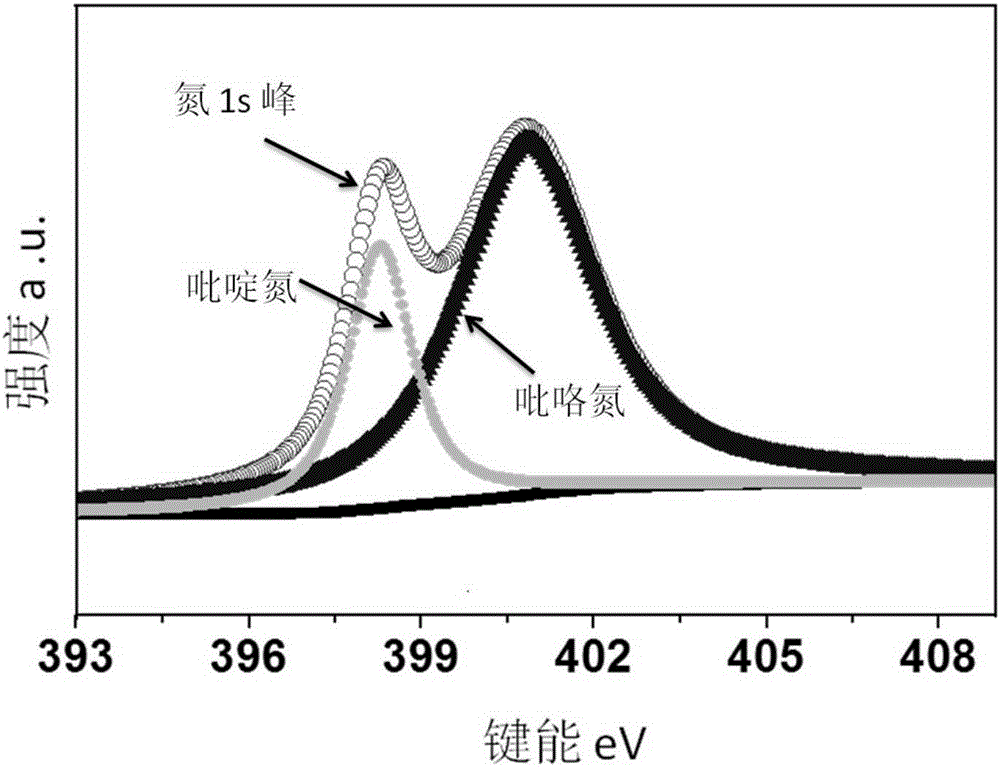

High density nitrogen doped graphene, preparation method and applications thereof

InactiveCN105565306ASynthetic technology is matureQuality improvementGrapheneDoped grapheneHigh density

The invention relates to the field of functional materials, and discloses a high density nitrogen doped graphene, a preparation method and applications thereof. The preparation method comprises the following steps: (1) in the presence of a solvent, contacting a nitrogen source with oxidized graphene; (2) drying the product obtained in the step (1); (3) reducing the product, which has been dried in the step (2). The provided high density nitrogen doped graphene has the advantages of high mass specific capacity and volume specific capacity. Moreover, the preparation method is simple and is suitable for industrial massive production.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

Method for preparing graphene composite structural material

ActiveCN108178151AExcellent light-to-heat conversion performanceSimple manufacturing methodEnergy inputGrapheneHeat energySolar irradiance

The invention relates to a method for preparing a graphene composite structural material, which belongs to the technical field of preparation of a functional material. The method combines with a vapour deposition technology, a freeze drying technology, and a laser processing technology, construction of a composite structure in a graphene block material is realized, the graphene assembly is composited with two structures, the prepared composite structural material has a two-layer structure, wherein an upper layer is a porous gel structure having good photothermal conversion capability, a lowerlayer is a film structure having good electrothermal conversion capability, and compositing of two structures and properties in the graphene material is realized. The preparation method has the advantages of easy operation, matured synthesis technology, and large-batch production. The porous gel structure at the upper layer of the prepared graphene composite structural material can convey the solar irradiance to self heat energy, the structure at the lower layer can convey electric energy to heat energy, and under synergism of light, heat and electricity, the graphene composite structural material is in favor of application in the fields of solar energy cleaning water and anti-freeze equipment.

Owner:TSINGHUA UNIV

Graphene solar energy water cleaning foam as well as preparation method and application thereof

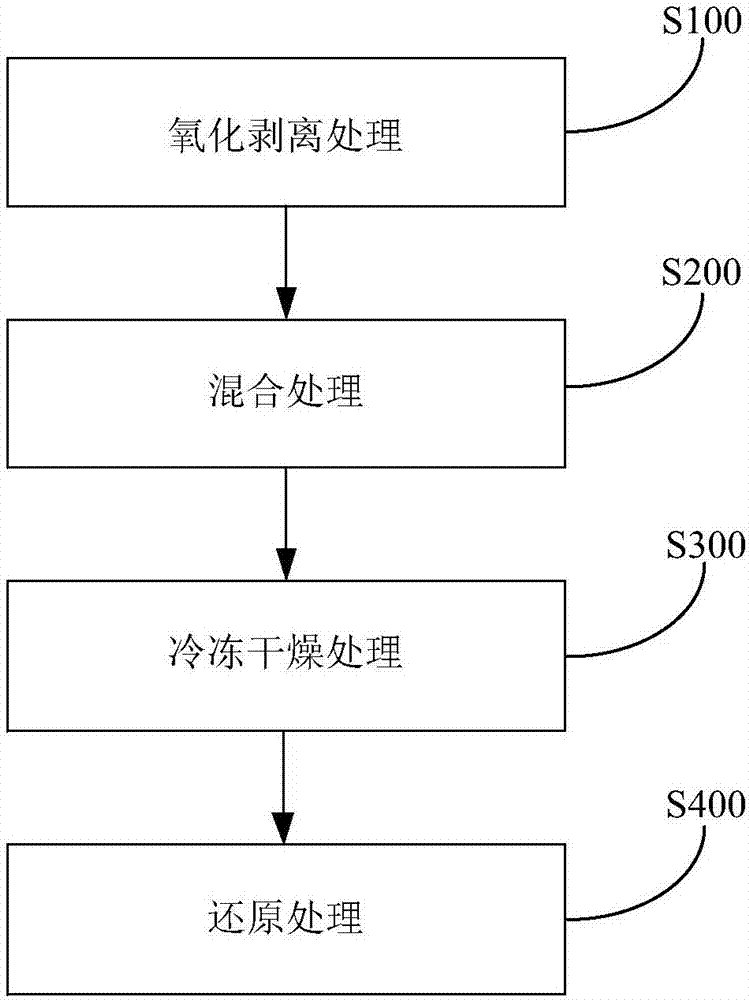

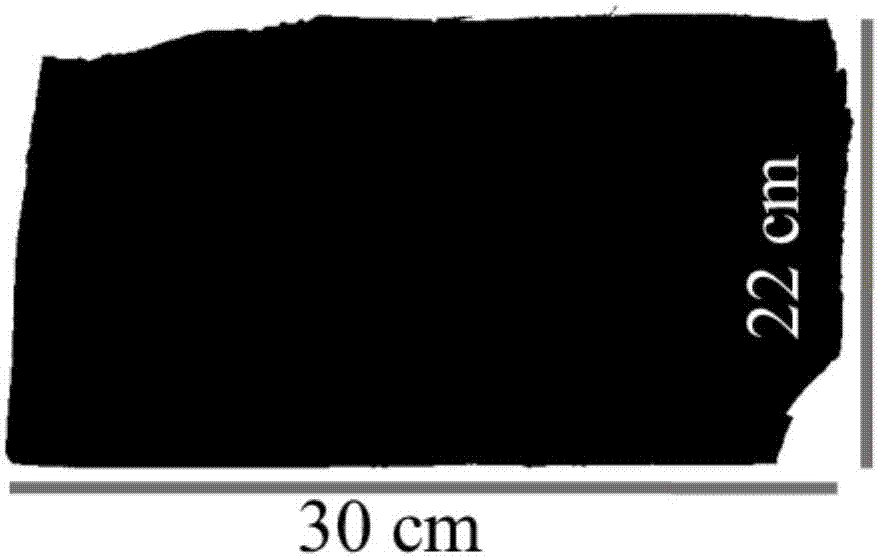

ActiveCN108002366AImprove light-to-heat conversion efficiencySimple manufacturing methodGeneral water supply conservationGrapheneReduction treatmentFreeze-drying

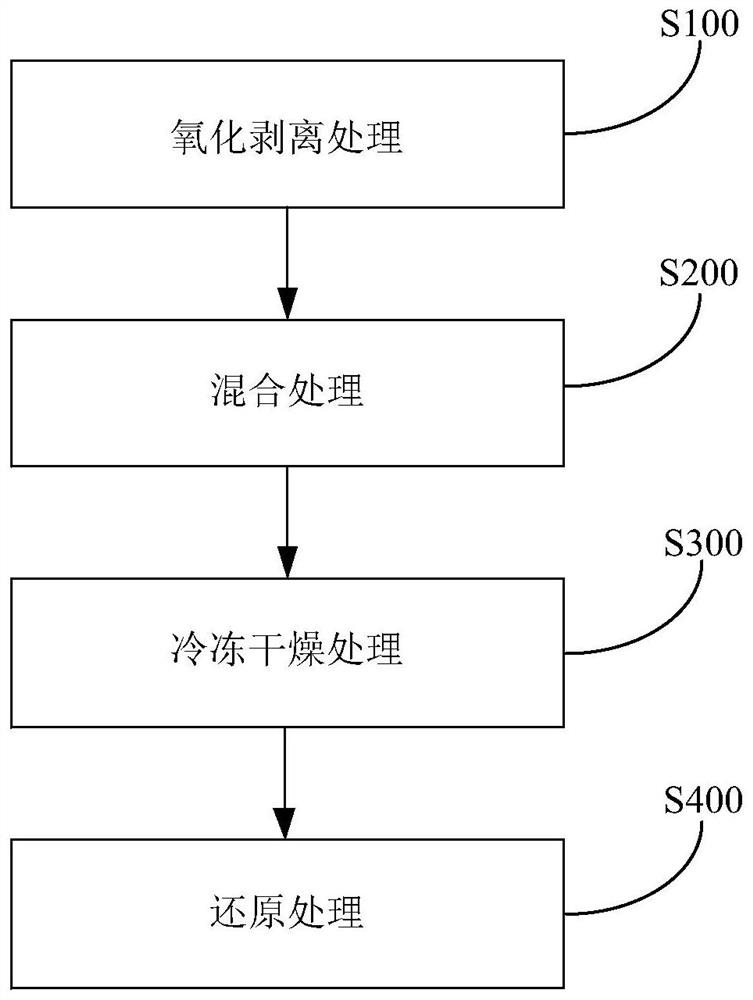

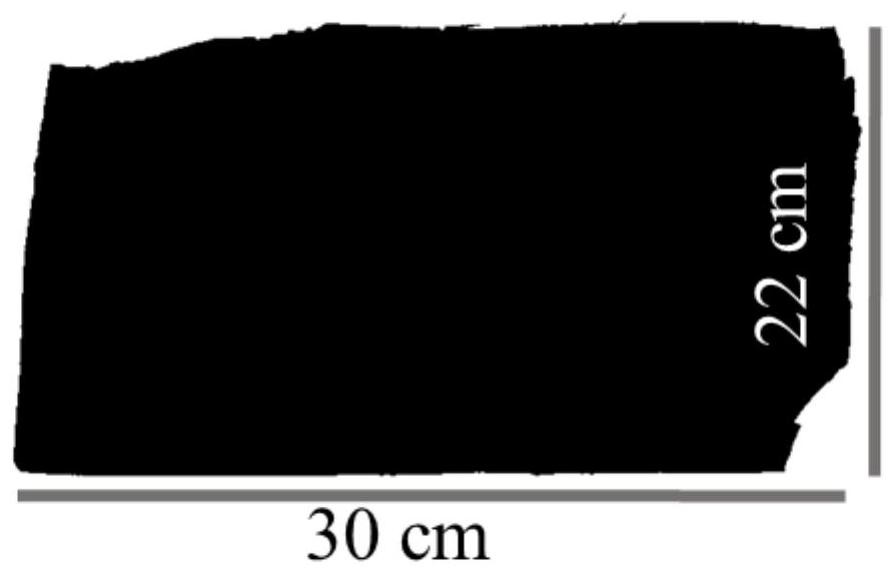

The invention discloses graphene solar energy water cleaning foam as well as a preparation method and application thereof. The preparation method of the graphene solar energy water cleaning foam includes the following steps: (1) performing oxidation stripping treatment on graphite powder to obtain a graphene oxide aqueous solution; (2) mixing the graphene oxide aqueous solution and a low-freezing-point solvent to obtain a mixed solution; (3) performing freeze-drying treatment on the mixed solution to obtain large-scale graphene oxide foam; and (4) performing reduction treatment on the grapheneoxide foam to obtain the graphene solar energy water cleaning foam. The preparation method of the graphene solar energy water cleaning foam provided by the invention is simple, the graphene solar energy water cleaning foam can evaporate moisture in sewage by utilizing solar radiation, and the prepared water meets the drinking water standard, wherein the ion removing rate is not lower than 99.5%,and the bacterium removing rate is not lower than 99.9%.

Owner:弘润清源(北京)科技有限责任公司

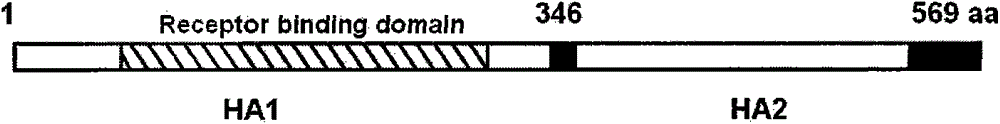

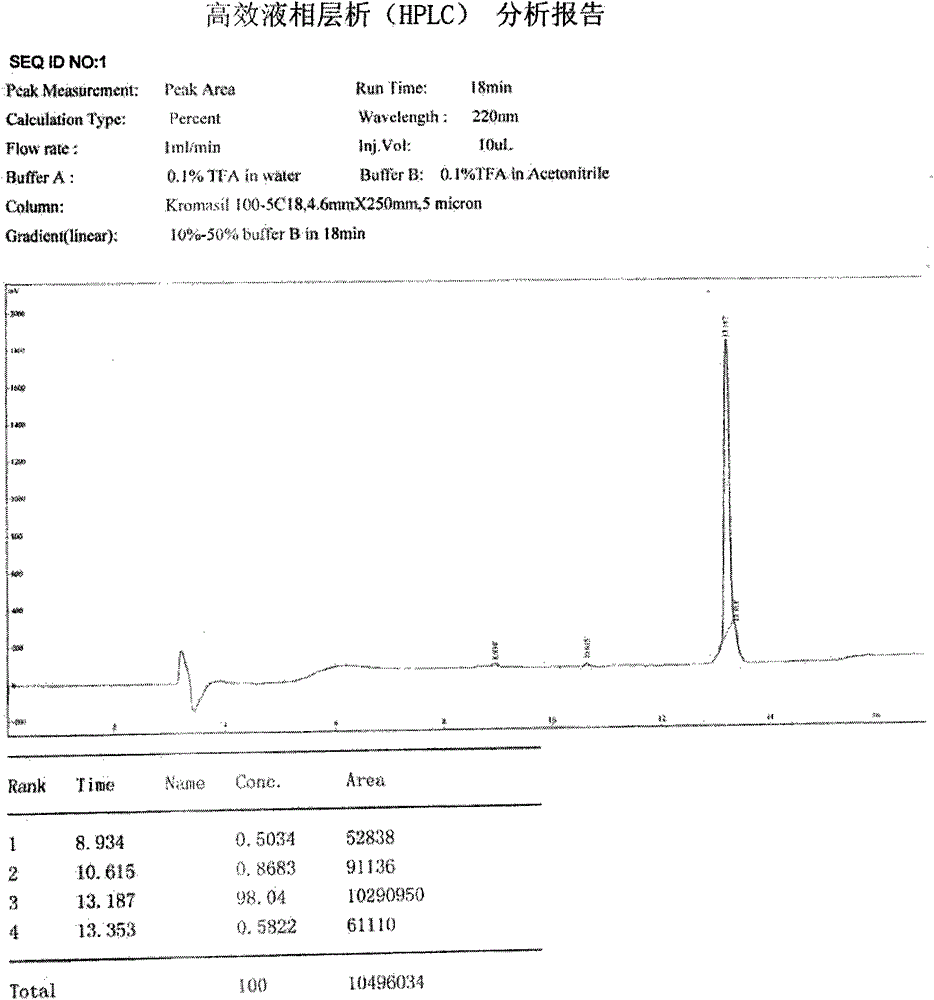

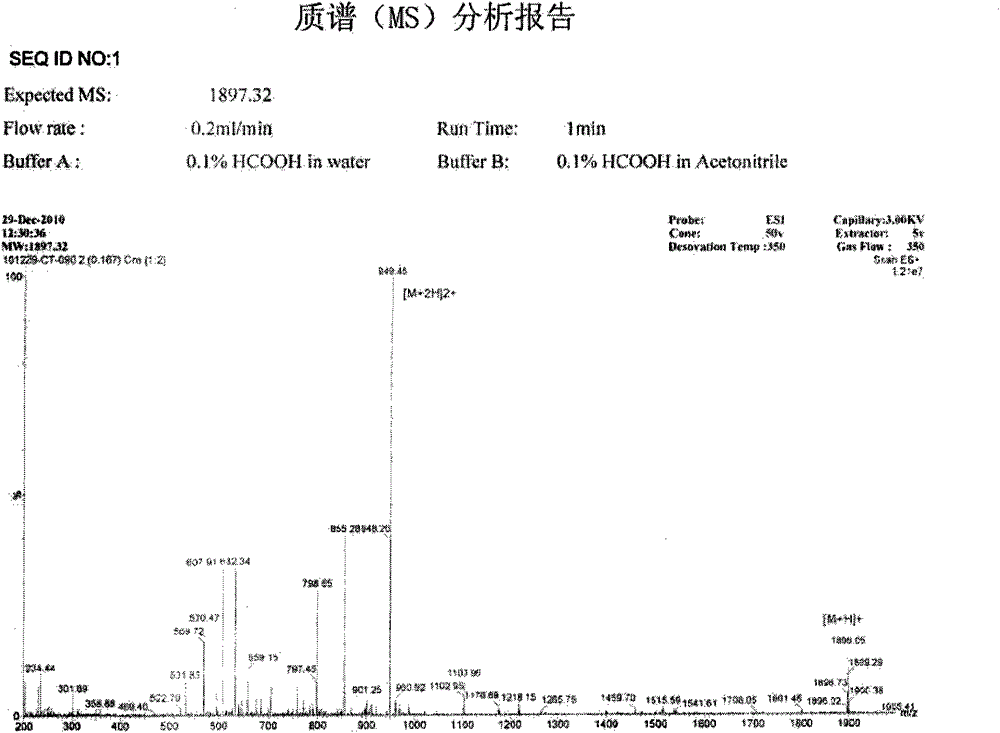

Polypeptide or derivative thereof and application of polypeptide or derivative in influenza virus infection

ActiveCN104151403AGood anti-influenza activityShort peptide chain lengthSsRNA viruses negative-senseGenetic material ingredientsHemagglutininInfluenza virus A hemagglutinin

The invention relates to polypeptide, protein or peptide-like medicine from influenza virus hemagglutinin, and a method of the polypeptide, belongs to the technical field of biological medicines, and in particular relates to eight influenza virus hemagglutinin fragment peptides which can block influenza virus infection and have the serial numbers SEQ ID NO.1 to SEQ ID NO.8. The fragment peptides can inhibit and block infection of different species and influenza viruses of different subtypes to a host, including multiple influenza virus strains such as highly pathogenic avian influenza virus, seasonal human influenza virus and the like. The invention provides the peptide sequence (including amino acid sequences of peptides and polynucleotide sequences of encoded peptides), derivative peptides (including amino acid sequences of peptides and polynucleotide sequences of encoded peptides), peptide compositions and independent or united applications of peptides in preventing or treating influenza virus, such as medicine combination of peptides provided by the invention and other anti-influenza medicines.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

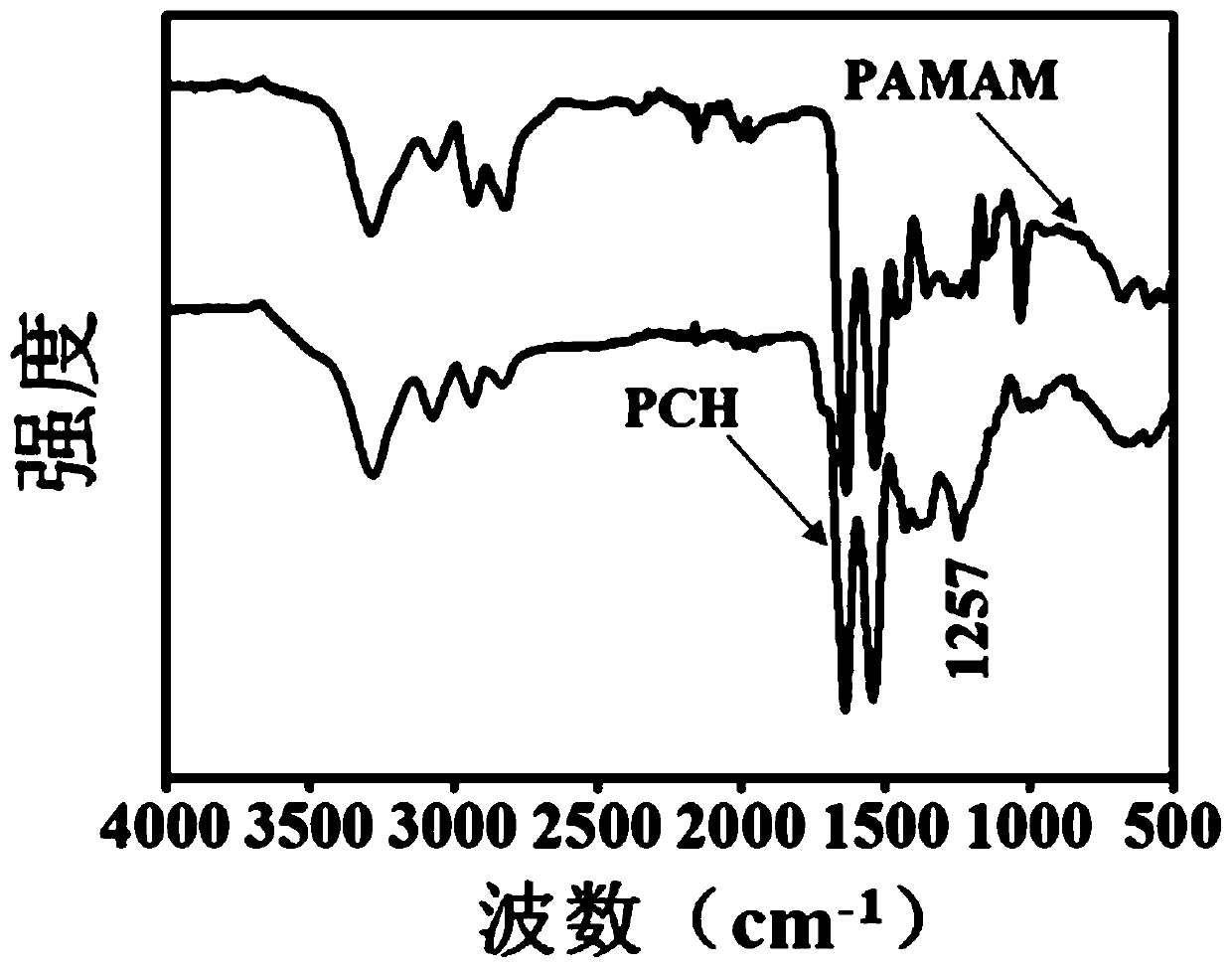

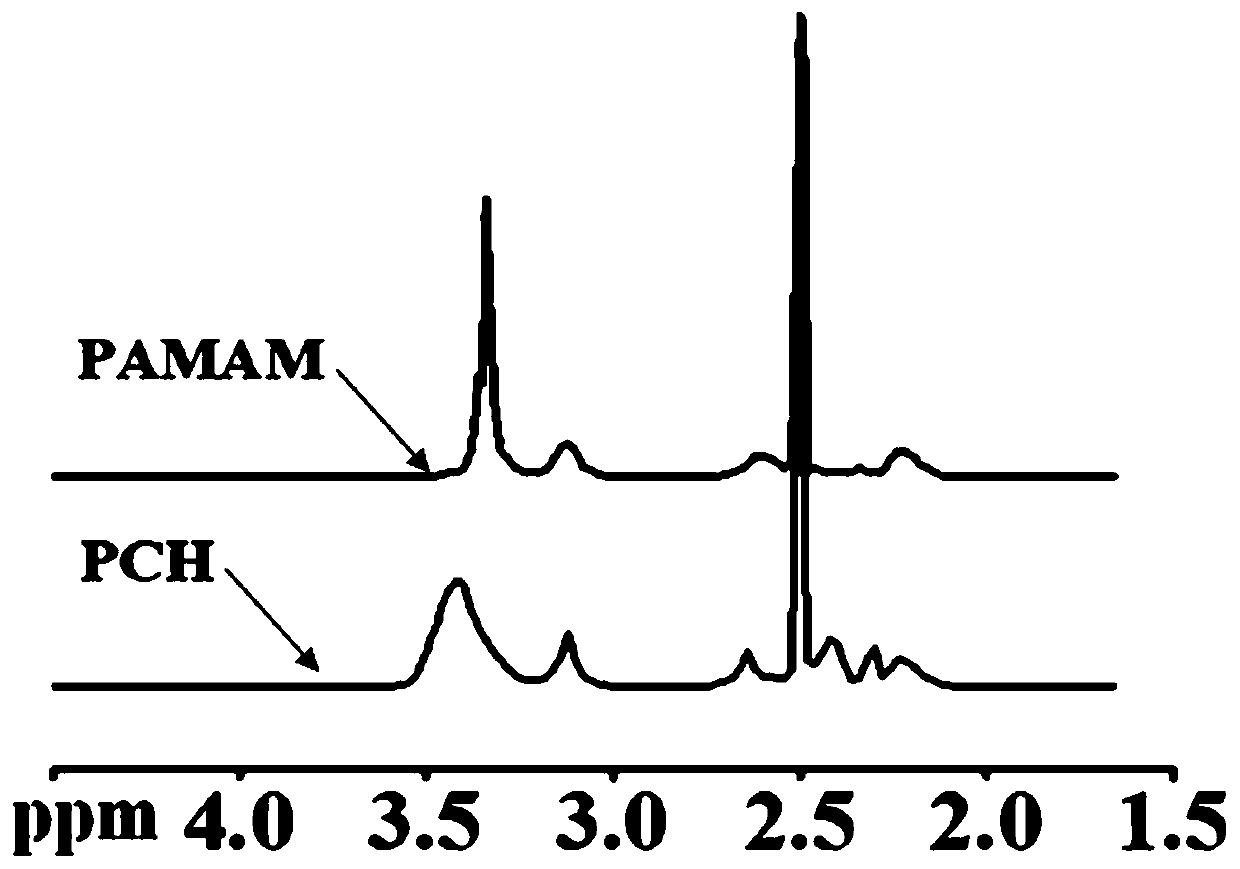

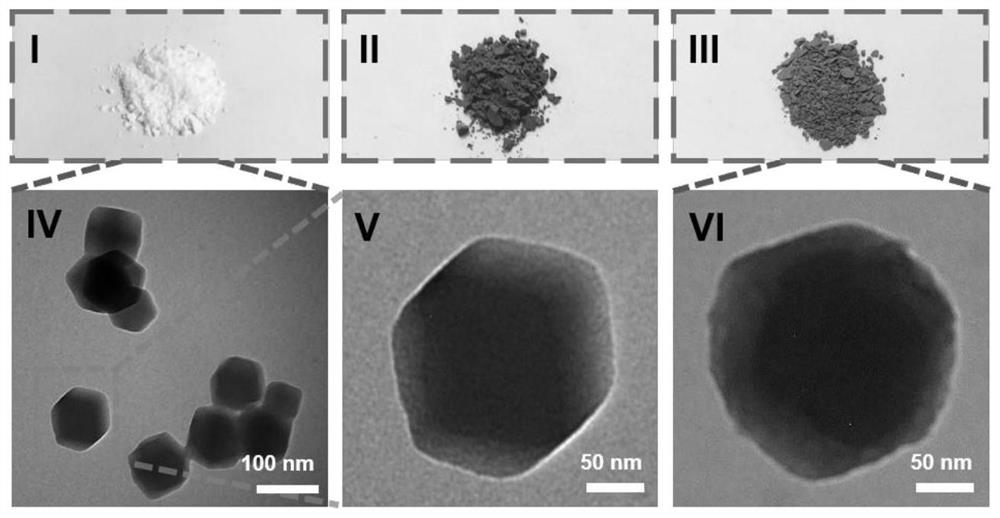

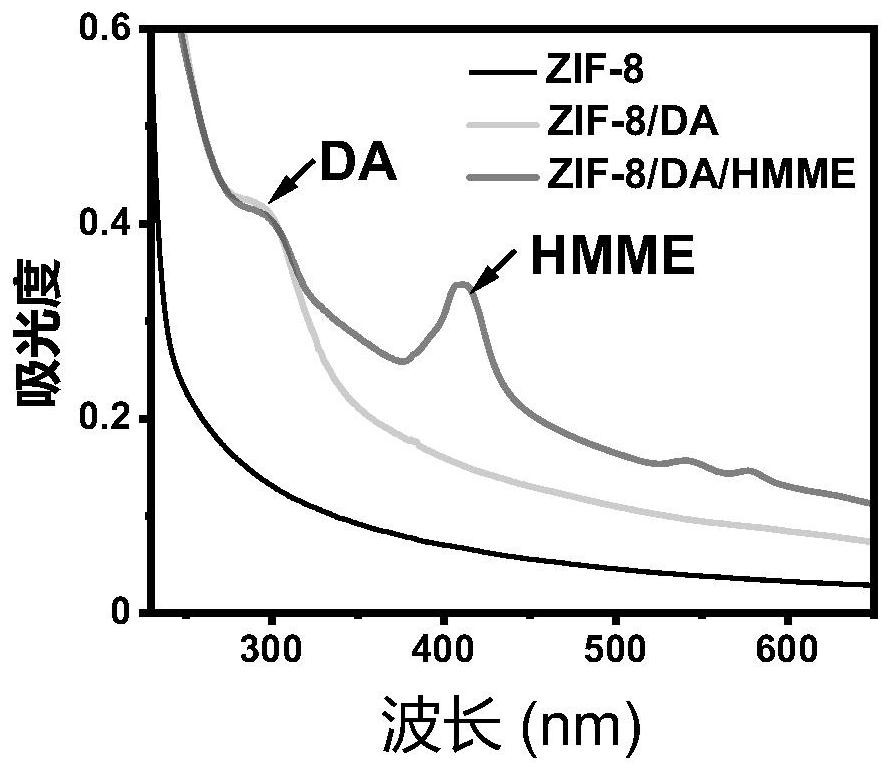

Tumor-targeted nanometer compound, preparing method and application of compound to acoustic-power-mediated precise tumor treatment

ActiveCN109999197AGood biocompatibilitySmall particle sizeOrganic active ingredientsPharmaceutical non-active ingredientsTumor targetDendrimer

The invention discloses a tumor-targeted nanometer compound, a preparing method and application of the compound to acoustic-power-mediated precise tumor treatment. The nanometer compound comprises compound nanoparticles wrapped by hyaluronic acid. A preparing method of the compound nanoparticles includes the steps of converting part of amino groups on the surface of a dendrimer PAMAM into carboxylgroups through succinic anhydride, and compounding the dendrimer PAMAM with a sensitizer (indocyanine green), an anti-tumor medicine (doxorubicin) and hyaluronic acid. The nanometer compound has a good acoustic power anti-tumor effect, the sensitizer and the anti-tumor medicine have a good synergistic effect in treatment, and the nanometer compound is suitable for noninvasive / minimally invasive tumor treatment.

Owner:XI AN JIAOTONG UNIV

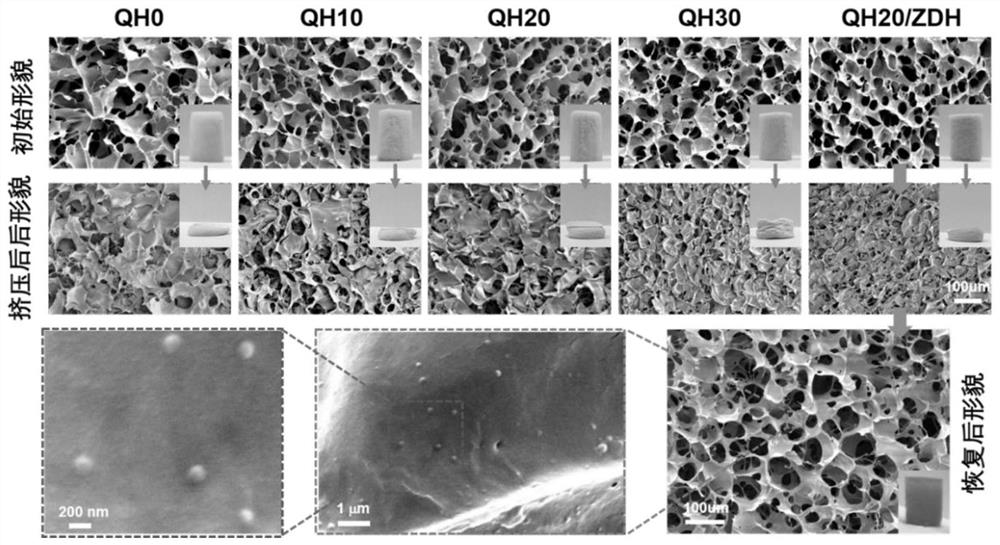

Cryogel for stopping bleeding and carrying anti-cancer drug and preparation method thereof

ActiveCN112933286AGood hemostatic effectGood tissue adhesionSurgical adhesivesNanocapsulesDouble bondPolyphenol

The invention discloses a cryogel for stopping bleeding and bearing an anti-cancer drug and a preparation method thereof, the preparation method comprises the following steps: a double bond is modified to a biomacromolecule, a polyphenolic compound is grafted onto the biomacromolecule, and the dopamine molecule and the Zn 2 + ion are coordinated to prepare dopamine-modified ZIF -8; and all the components are respectively prepared into aqueous solutions or dispersion solutions, and then under the action of an initiator, through double-bond polymerization, the multifunctional water / blood triggered shape memory cryogel l is formed at low temperature. According to the preparation method, polysaccharide and other biomacromolecules with good biocompatibility and degradation performance are taken as the basis, the process of chemical grafting of double-bond or polyphenol compounds also has the characteristics of low toxicity and no pollution, the used double-bond functionalized biomacromolecules are simple to prepare, the synthesis technology is mature, and the prepared product has good universality.

Owner:XI AN JIAOTONG UNIV

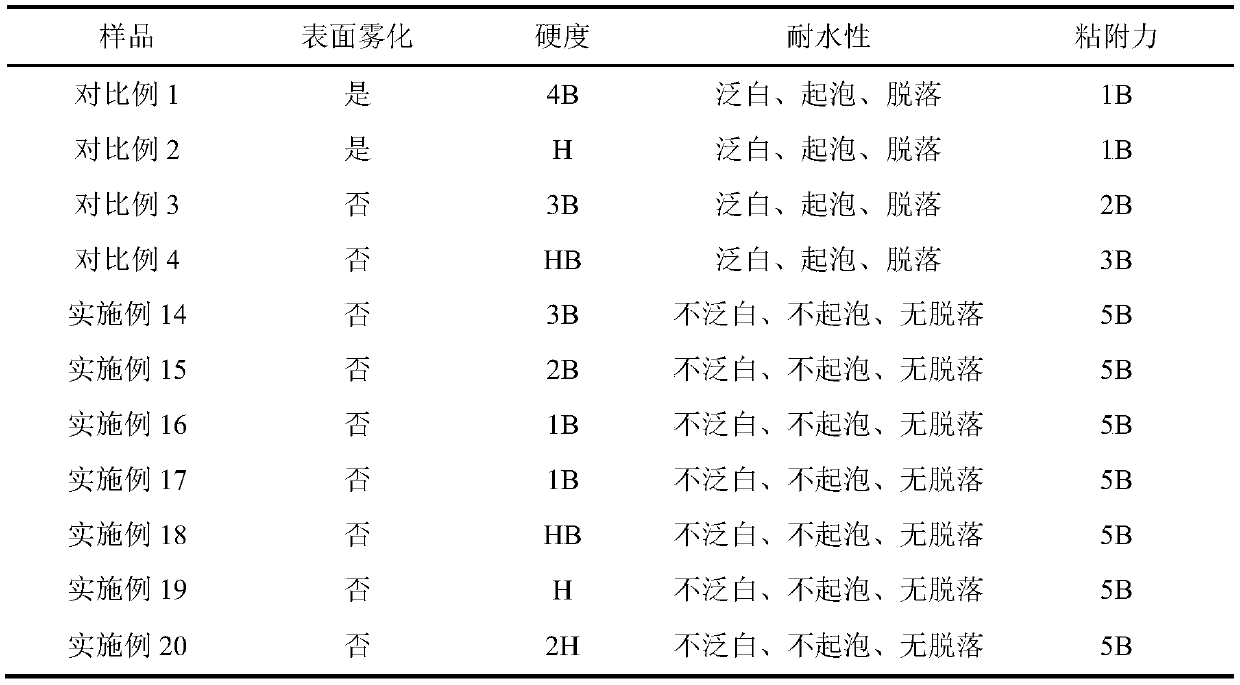

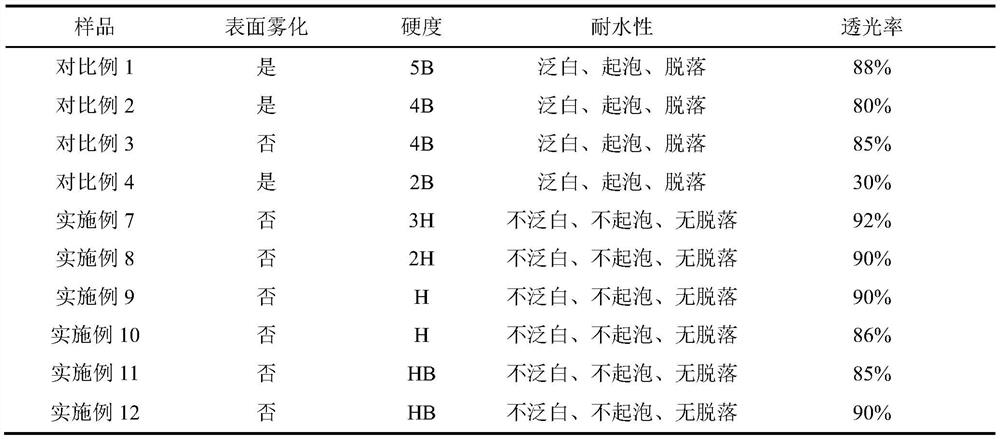

Photo-cured polyurethane anti-fog film with controllable soft/hard structure and preparation method thereof

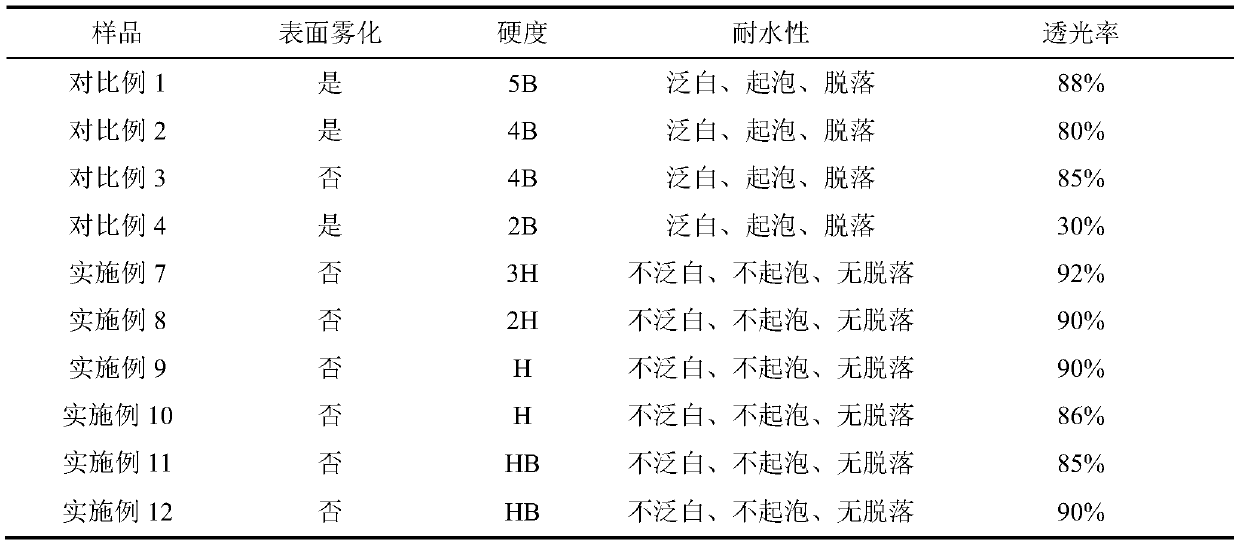

The invention provides a photo-cured polyurethane anti-fog film with a controllable soft / hard structure and a preparation method thereof, and belongs to the technical field of polymer materials. The anti-fog film comprises a polyurethane prepolymer with a soft structure, a polyurethane prepolymer with a hard structure, and a crosslinking agent containing a carbon-carbon double bond according to aweight ratio of 100:(5-100):(0.5-5). The provided anti-fog film has a long lasting anti-fog effect, the surface is scratch resistant, the waterproof performance is excellent, the basic material adhesion force is high, the performance and structure can be controlled and adjusted, the cost is low, the technique is matured, and the preparation method is suitable for production.

Owner:JIANGNAN UNIV +1

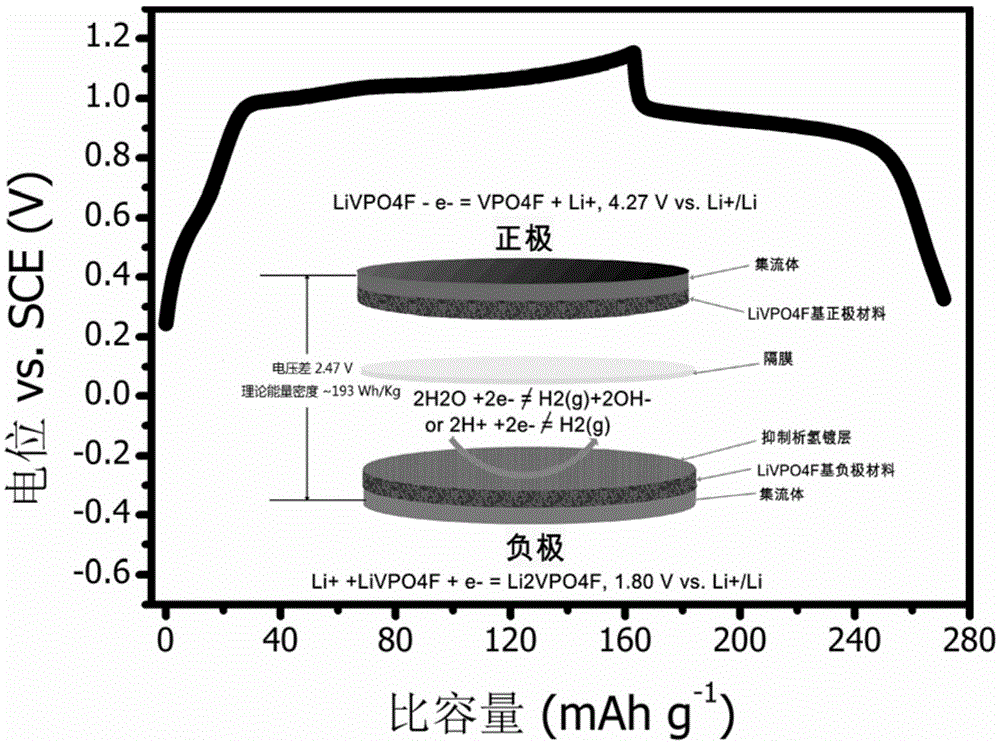

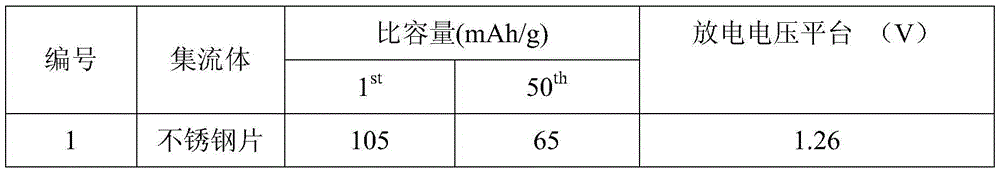

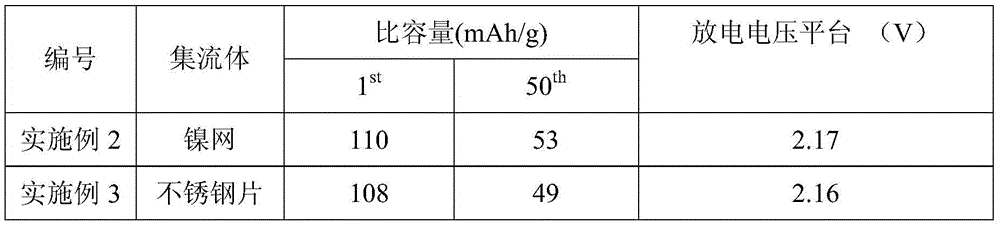

A symmetrical aqueous solution lithium-ion battery

ActiveCN103928681BIncrease energy densityImprove power densityElectrode carriers/collectorsSecondary cellsElectrical batteryLithium-ion battery

The invention discloses a symmetric aqueous solution lithium ion battery and a modification method. Fluorine lithium vanadium phosphate is simultaneously used as a positive electrode and a negative electrode, and an aqueous solution containing lithium ions serves as electrolyte. An electrode surface serving as the negative electrode is covered with a protection film which is 5-1,000nm thick and has high hydrogen evolution overpotential so as to suppress hydrogen evolution of the negative electrode. According to the symmetric aqueous solution lithium ion battery, the fluorine lithium vanadium phosphate is simultaneously applied to the positive electrode and the negative electrode of water system lithium ions, so that the manufacturing cost of an electrode piece material is reduced. The symmetric aqueous solution lithium ion battery modified by the modification method disclosed by the invention effectively suppresses hydrogen evolution reaction and has the characteristics of long service life, high power, high safety, no environment pollution and the like.

Owner:湖南豪曼新能源科技有限公司

A method for preparing graphene and composite materials by sunlight and laser reduction

ActiveCN104609404BSimple processLow priceMaterial nanotechnologyIron oxides/hydroxidesSolar lightFreeze-drying

The invention relates to a method for preparing graphene and composite materials through sunlight and laser reduction, and belongs to the field of functional materials. The method is as follows: the graphene oxide solution is obtained by oxidizing and exfoliating graphite, mixed evenly with the material to be composited to obtain a mixed substance, and the graphene oxide solution or the mixed substance is freeze-dried to obtain block graphene oxide or graphene oxide composite material , focused irradiation with laser light or sunlight, and reduced to bulk graphene or bulk graphene composites. The method is a general method for preparing graphene and its composite materials; the obtained graphene and its composite materials are foamy, and the internal structure is three-dimensional, porous, and has a large specific surface; the raw materials of the method have a wide range of sources, and the price is low. Inexpensive and environmentally friendly, the process is simple and mature, and suitable for large-scale production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Thermosetting abrasion-resistant polyurethane type anti-fog film and preparation method thereof

The invention provides a thermosetting abrasion-resistant polyurethane type anti-fog film and a preparation method thereof and belongs to the technical field of high polymer materials. The anti-fog film comprises silicon dioxide microspheres with isocyanate terminated macromolecular chains and a multifunctional curing agent, wherein the weight ratio is 100 to (5-50), the silicon dioxide microspheres with the isocyanato-terminated macromolecular chains mainly comprise isocyanate or isocyanate polymer, polyoxyethylene ether and silicon dioxide microspheres, wherein the weight ratio is 100 to (10-80) to (5-50). The anti-fog film has a lasting anti-fog effect, high surface hardness, abrasion resistance, scratch resistance, excellent water resistance, adjustable performance and structure, low cost and mature technology and is suitable for production.

Owner:JIANGNAN UNIV

Method for synthesizing suspensible and deformable polyacrylamide

This invention relates to a method for synthesizing suspension-deformable polyacrylamide that can be used to adjust the stratum injection profile to increase crude oil productivity after second and third oil production. The method comprises: mixing acrylamide 20-30%, 3,5-diacryloyloxyethyl-benzenesulfonic acid 2-8%, and desalted water as balance, adding catalysts potassium persulfate 5-10 ppm and sodium bisulfate 5-10 ppm, and polymerizing at 0-15 deg.C to obtain polyacrylamide. Polyacrylamide thus synthesized has high salt resistance, which is not limited by the mineralization degree of speed are adjustable according to the spot conditions. The colloid particles have certain solubility and viscosity in aqueous solution, thus can be uniformly suspended in the solution without any volume change when contacting oil. When absorbing water, the colloid particles expand and turn soft. Under the action of outside force, the colloid particles can deform, and the deformation is reversible. The polyacrylamide can change the underground pressure field and flow field driven by water flow, thus can adjust the stratum injection profile. The polyacrylamide is suitable for bulk polymerization in kettle.

Owner:PETROCHINA CO LTD

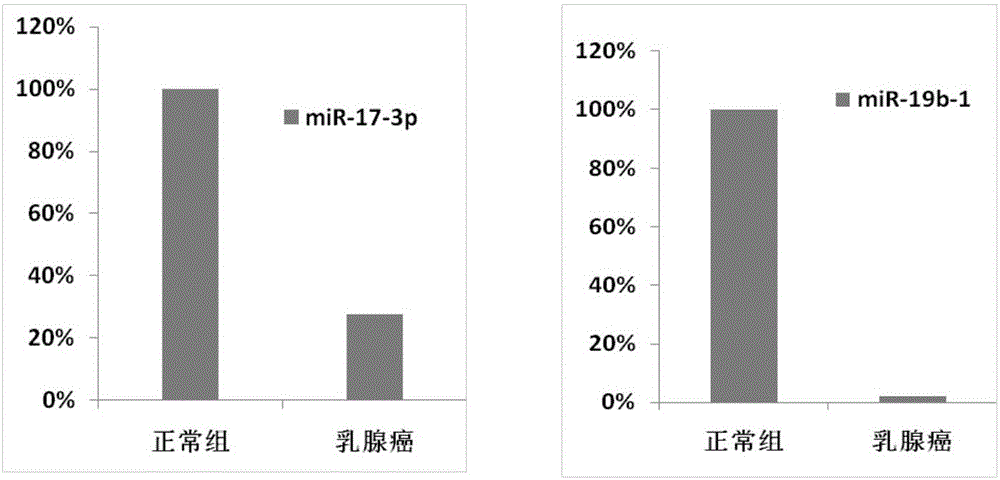

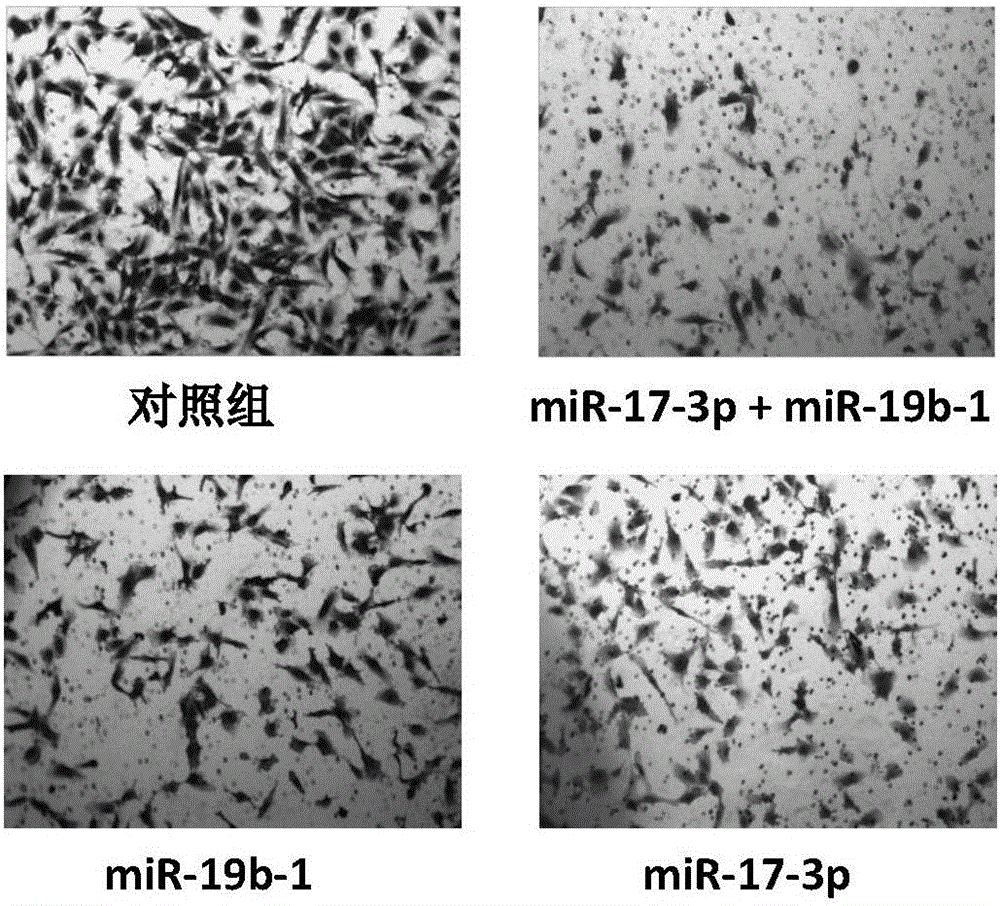

MiRNA-17-3p and miRNA-19b-1 combination and application thereof

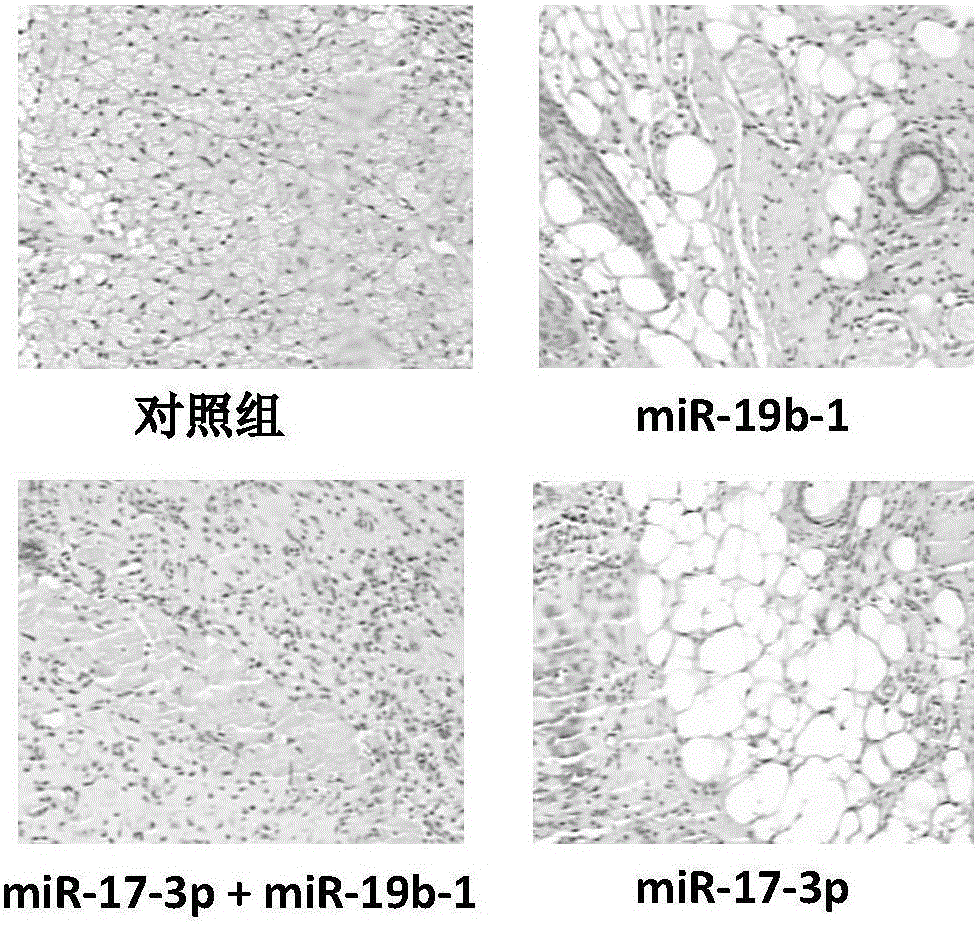

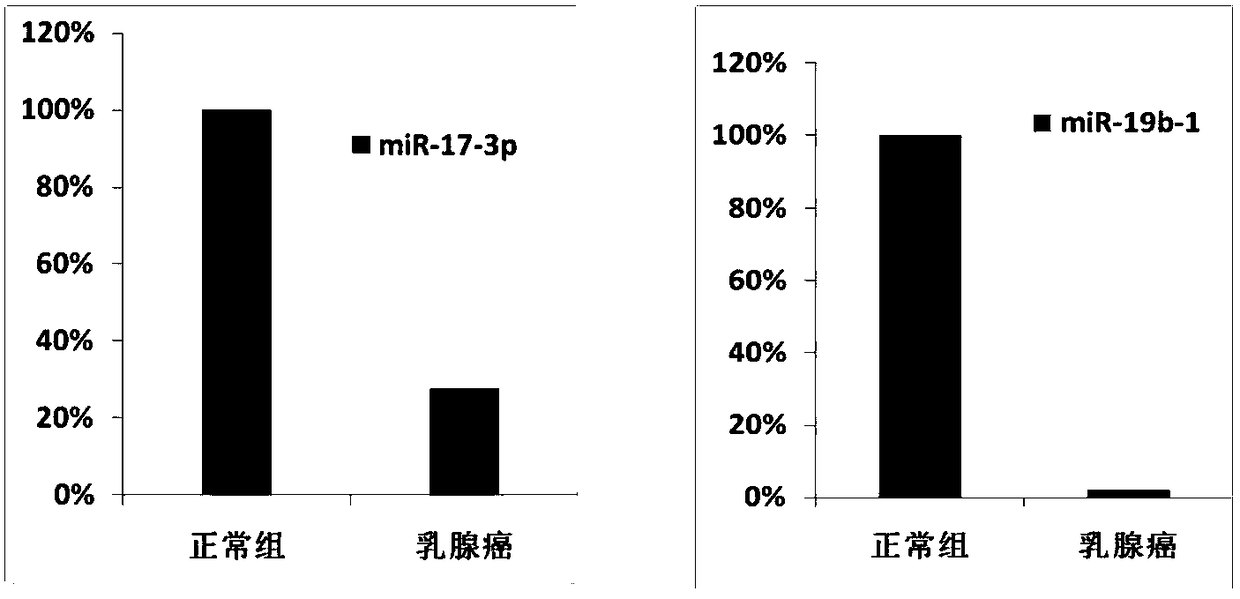

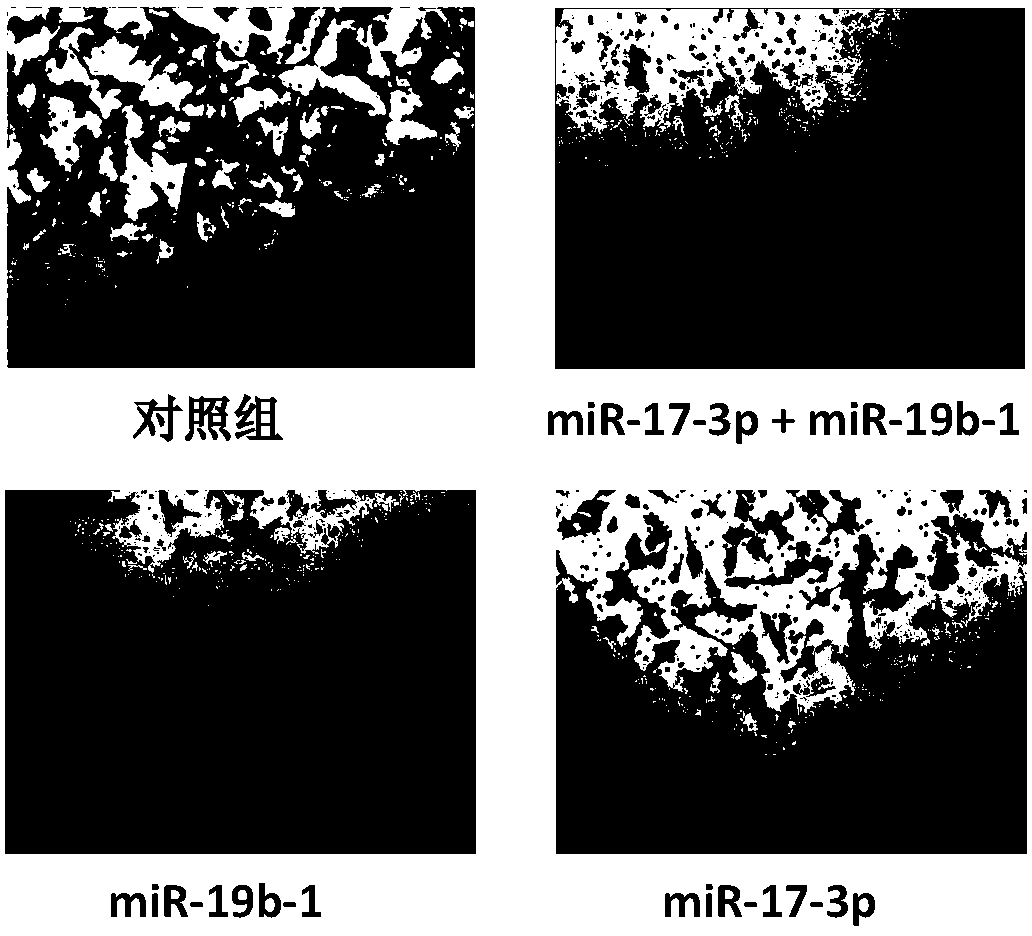

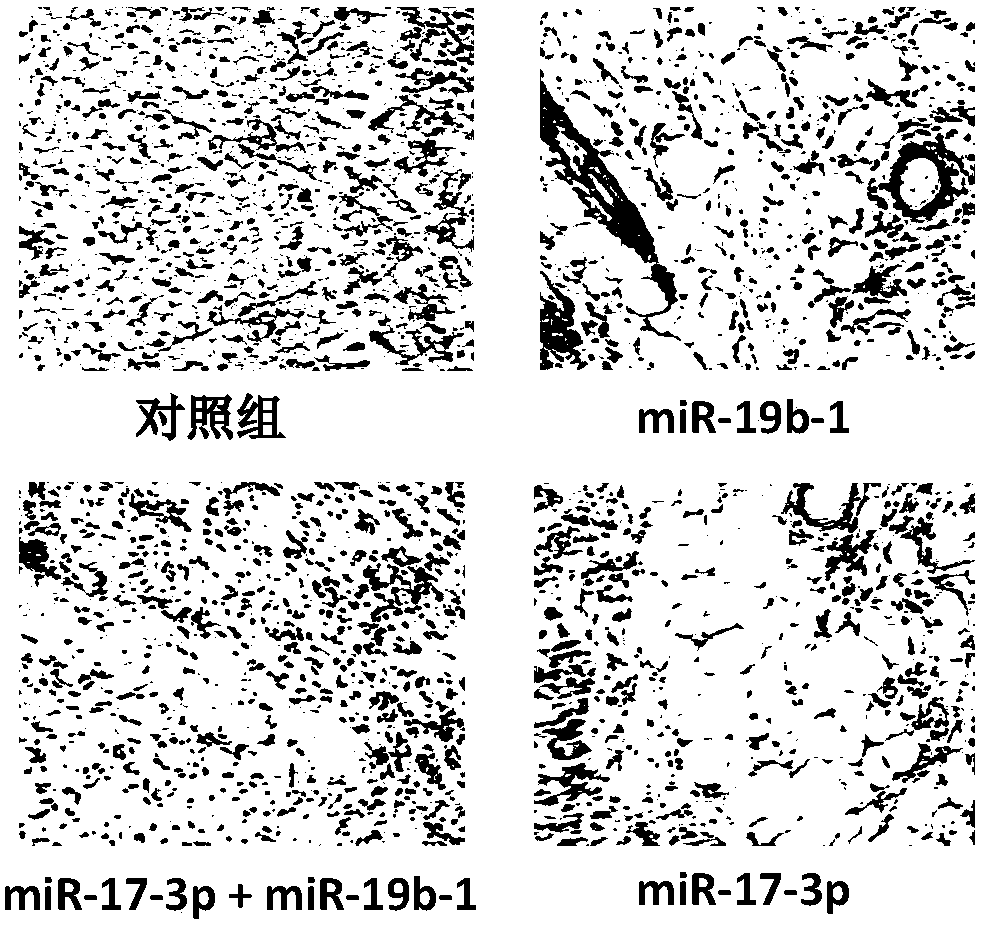

ActiveCN105726559ABlocking nutrient supplyBlock transfer channelOrganic active ingredientsGenetic material ingredientsCancer cellTumor vessel

The invention belongs to the field of biotechnology and medical science and particularly relates to a miRNA-17-3p and miRNA-19b-1 combination and application thereof. The invention provides application of miRNA-17-3P, or a combination of its precursor and mimR-19b-1, or a combination of its precursor in the preparation of drugs for preventing or treating tumors. The invention discloses for the first time that miR-17-3p and miR-19b-1 can specifically inhibit the generation of tumor vessels and have significantly lower expression than normal tissues in breast cancer; in addition, the miR-17-3p and miR-19b-1 combination can inhibit the growth of cancer cells both in vitro and in vivo. The miR-17-3p and miR-19b-1 combination is useful in the preparation of drugs for preventing or treating solid tumors, particularly in the preparation of drugs for preventing or treating breast cancer.

Owner:NANTONG UNIVERSITY

Method for detecting ascorbic acid based on gold cluster and TMB colorimetric fluorescence double signals

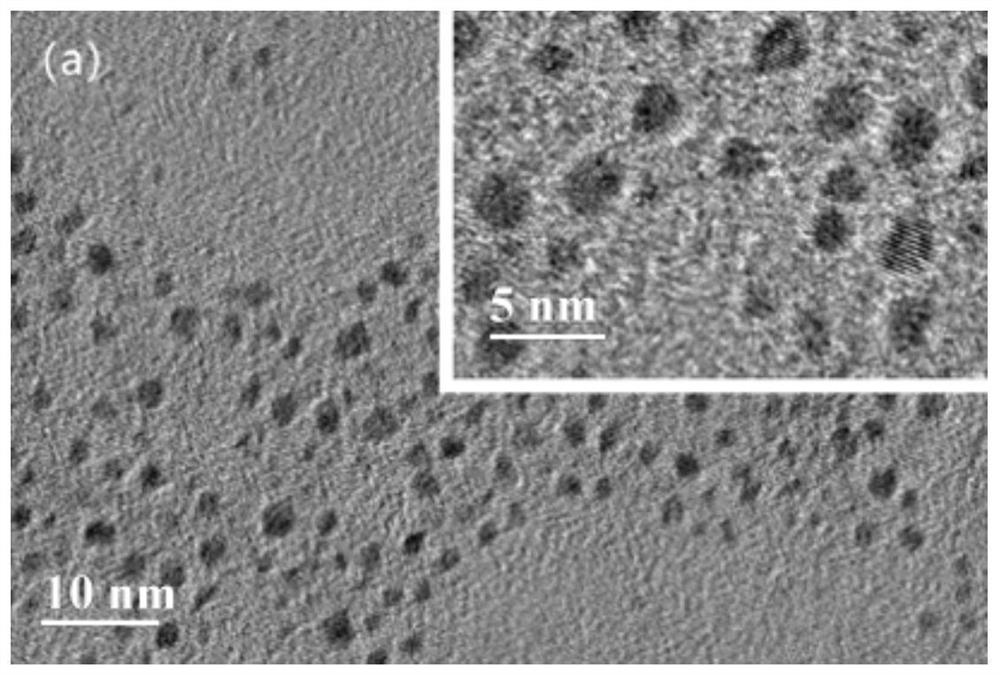

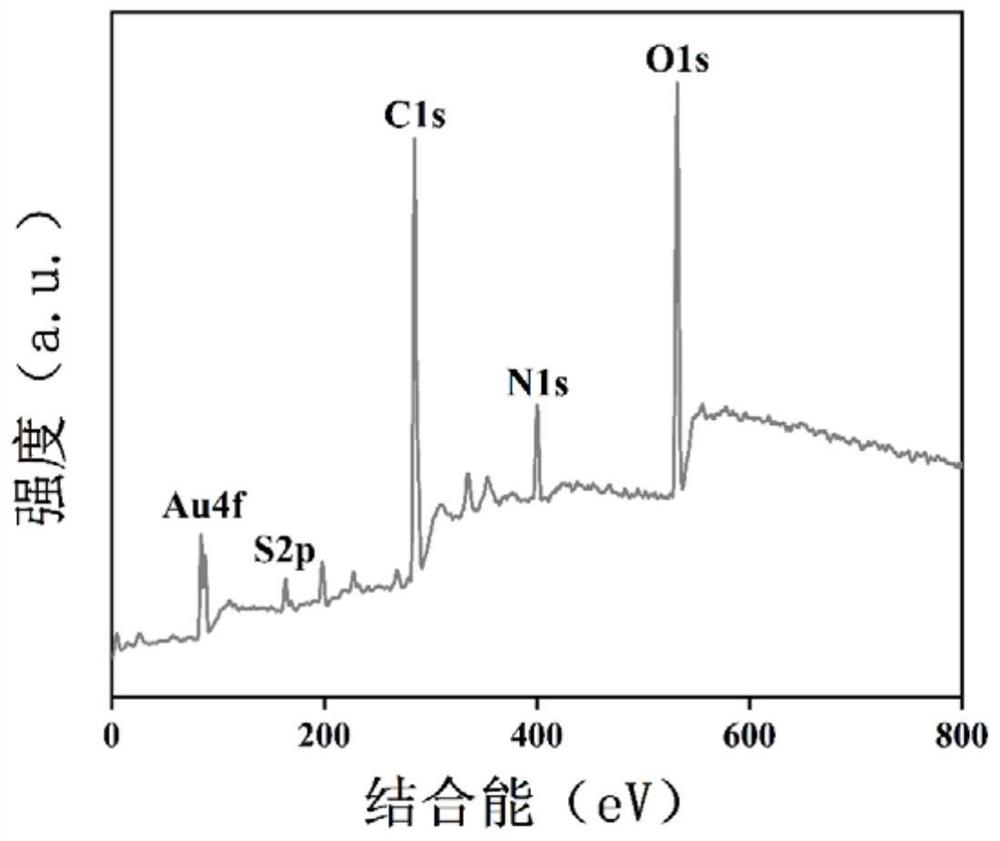

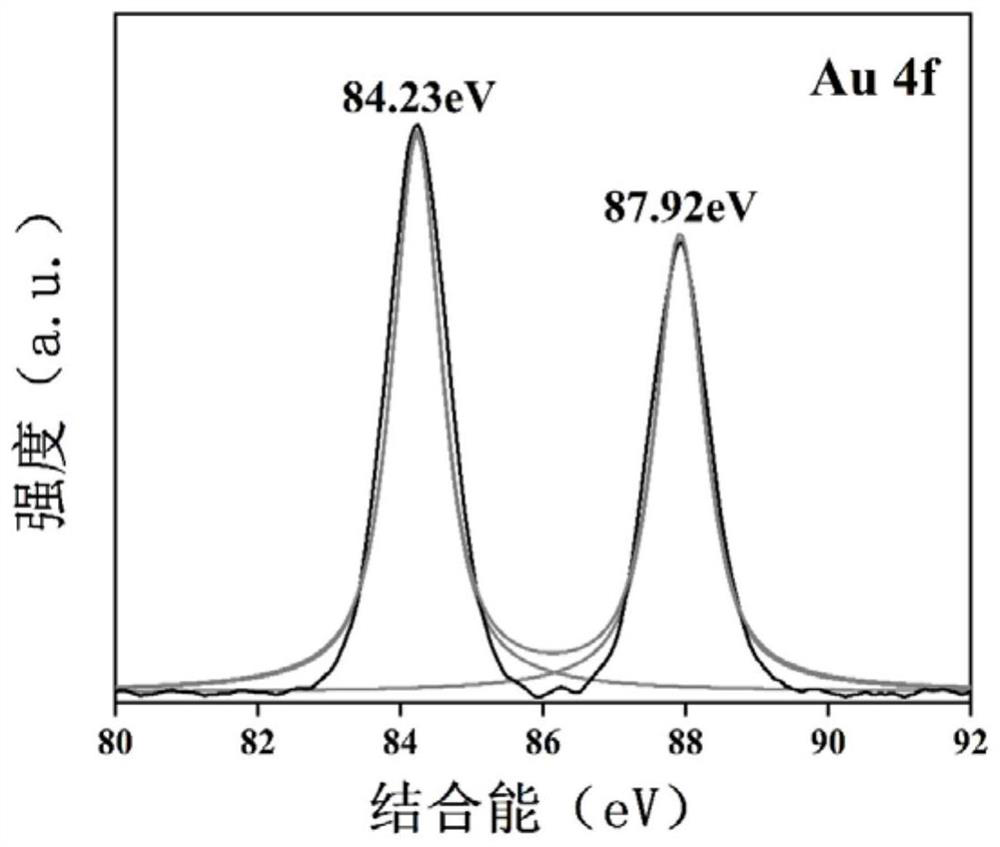

InactiveCN113324962ASynthetic technology is matureLow detection limitMaterial analysis by observing effect on chemical indicatorNanoparticle analysisUv absorbanceGold cluster

The invention discloses a method for detecting ascorbic acid based on fluorescence and colorimetric double signals, and belongs to the technical field of fluorescence analysis and detection. In the prior art, single fluorescence or colorimetric detection of ascorbic acid is adopted, which has the problems of large background signal interference and large environmental fluctuation. The detection method comprises the following steps: mixing a TMB solution and nano MnO2, carrying out oxidation incubation, filtering to remove the nano MnO2 after incubation to obtain a blue oxTMB solution, mixing the oxTMB solution, an AuNCs solution and an AA-containing to-be-detected solution for reaction, and detecting AA by measuring relative fluorescence intensity and ultraviolet absorption intensity based on a fluorescence inner filtration effect. According to the invention, detection can be carried out without operation of expensive instruments and professional training personnel, and the method has the advantages of time and labor saving, low detection limit, good accuracy and simple and rapid detection.

Owner:四川中科微纳科技有限公司 +1

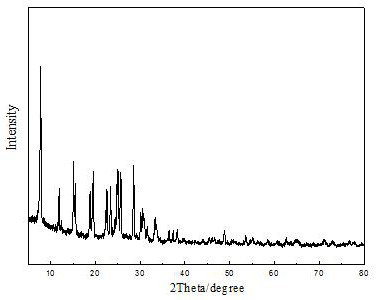

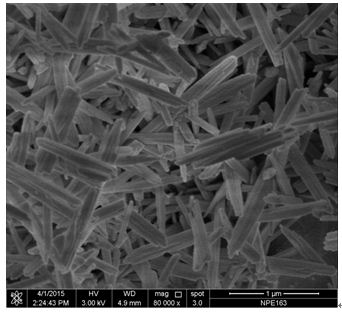

Preparation method of SUZ-4 molecular sieve

ActiveCN112723369ASynthetic technology is matureReduce procurement costsMolecular-sieve silicatesCrystalline aluminosilicate zeolitesMolecular sievePhysical chemistry

The invention discloses a preparation method of an SUZ-4 type molecular sieve, which comprises the following steps: mixing an aluminum source, a silicon source, an alkali source, deionized water and an HZSM-5 type molecular sieve, and performing crystallization, filtration and drying to obtain the SUZ-4 type molecular sieve. The method does not need a template agent, is low in preparation cost and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for spontaneously depositing three-dimensional graphene on conductive substrate

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

A kind of thermosetting wear-resistant polyurethane anti-fog film and preparation method thereof

The invention provides a thermosetting abrasion-resistant polyurethane type anti-fog film and a preparation method thereof and belongs to the technical field of high polymer materials. The anti-fog film comprises silicon dioxide microspheres with isocyanate terminated macromolecular chains and a multifunctional curing agent, wherein the weight ratio is 100 to (5-50), the silicon dioxide microspheres with the isocyanato-terminated macromolecular chains mainly comprise isocyanate or isocyanate polymer, polyoxyethylene ether and silicon dioxide microspheres, wherein the weight ratio is 100 to (10-80) to (5-50). The anti-fog film has a lasting anti-fog effect, high surface hardness, abrasion resistance, scratch resistance, excellent water resistance, adjustable performance and structure, low cost and mature technology and is suitable for production.

Owner:JIANGNAN UNIV

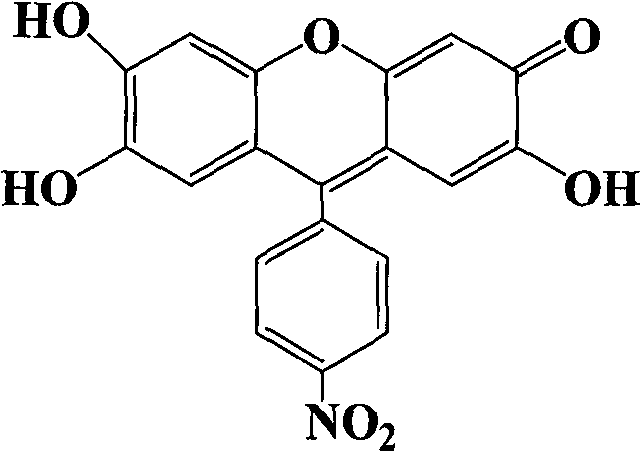

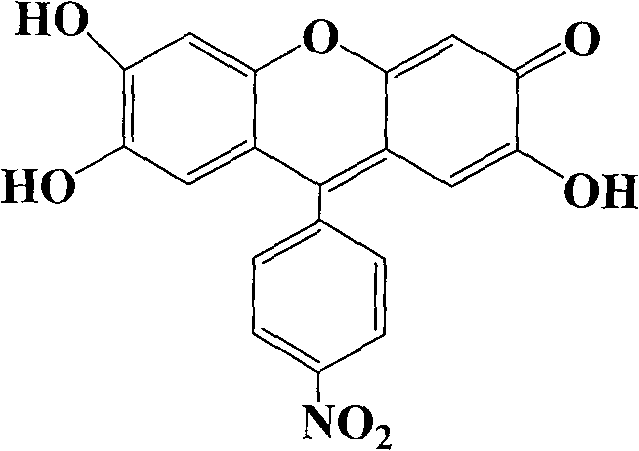

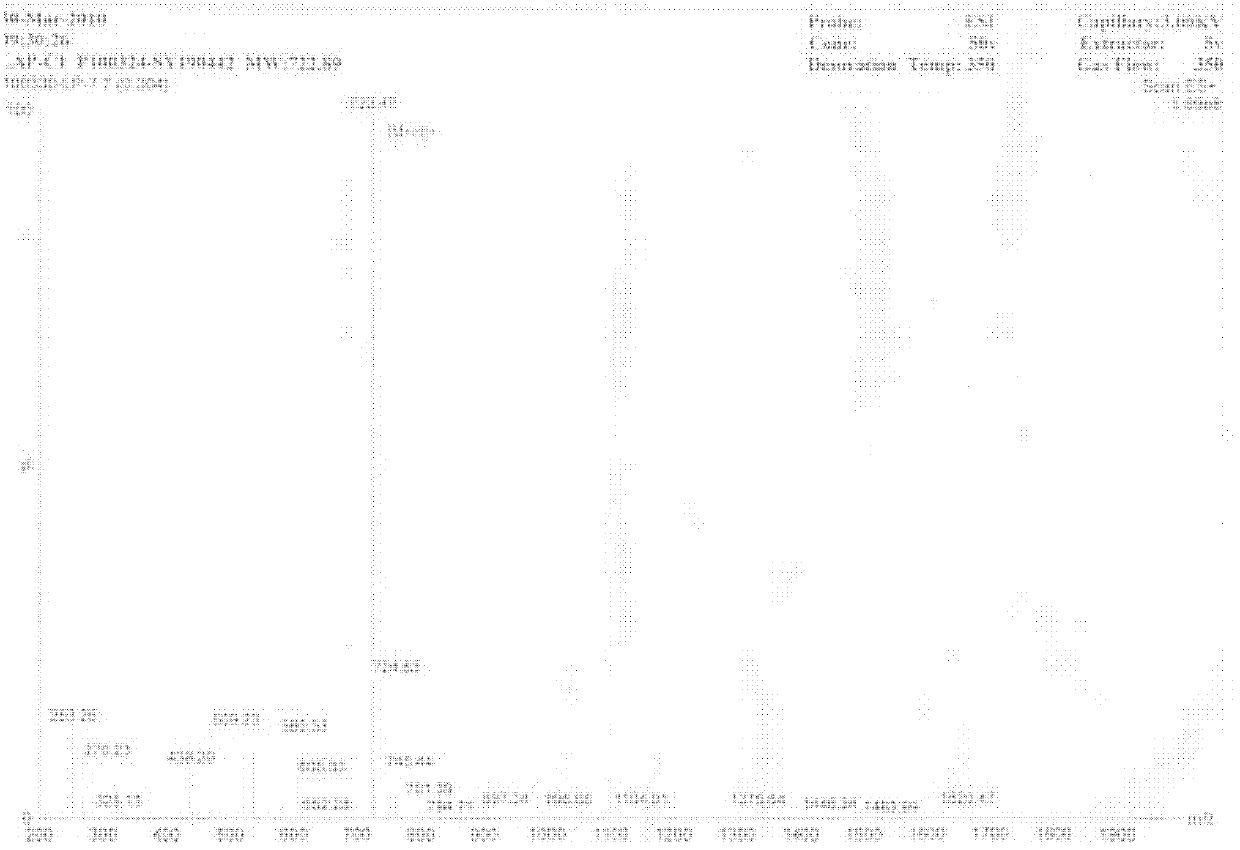

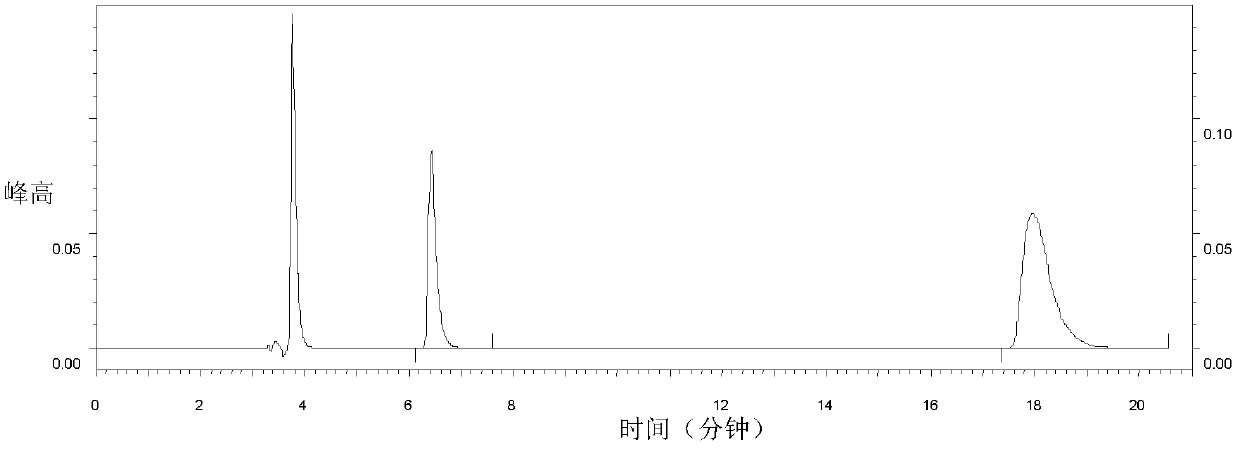

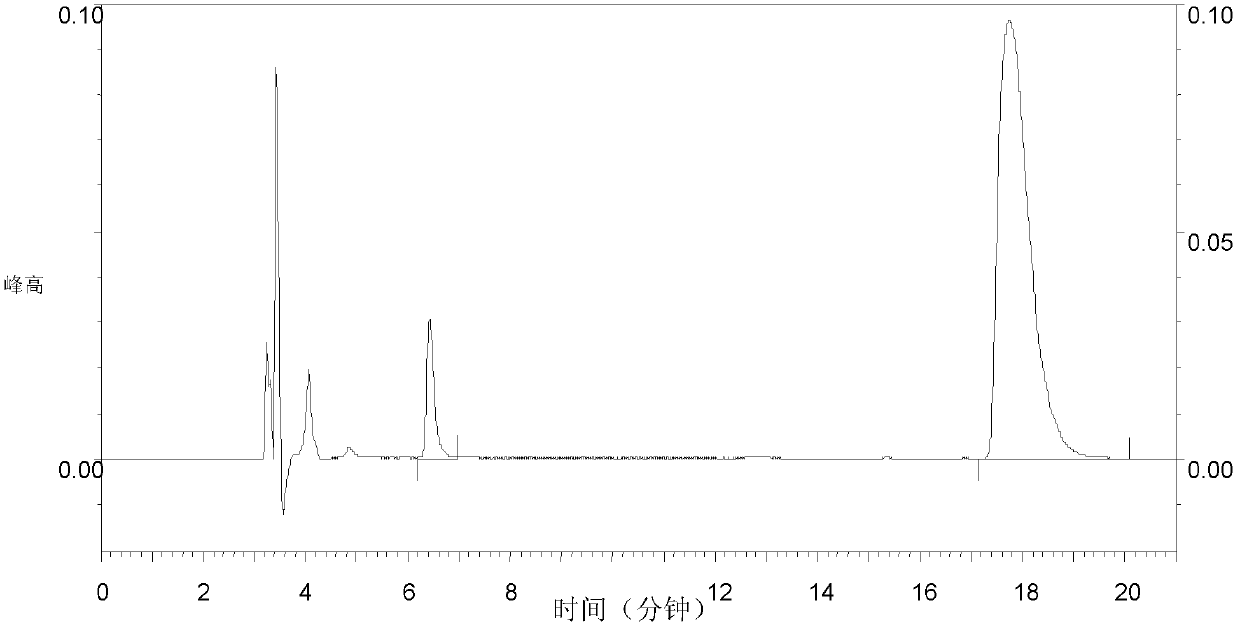

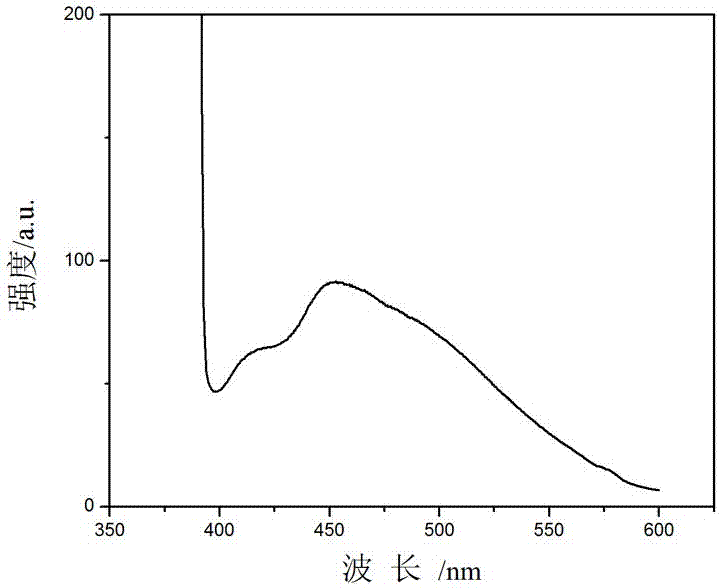

Novel finger print developing reagent and developing method thereof

InactiveCN101082565BHigh sensitivityGood choiceMaterial analysis by optical meansReagentPara-nitrophenyl

Owner:湖北景深安全技术有限公司

Angiotensin converting enzyme inhibitory peptide milky white peptide C1 and application thereof

InactiveCN102336810BGood antihypertensive effectExtended half-lifePeptidesAngiotensin-converting enzymeHalf-life

The invention belongs to the technical field of pharmacology and particularly discloses an angiotensin converting enzyme inhibitory peptide milky white peptide C1 with pressure lowering effect and an application thereof. The amino acid sequence of the angiotensin converting enzyme inhibitory peptide LAP-C1 is Leu-Arg-Pro-Val-Ala-Ala-Pro, the activity IC for inhibiting angiotensin converting enzymes in vitro is 50-18.06 muM, and the inhibitory peptide has an effect of lowering pressure and can be used as a medicament for treating and preventing hypertension. The angiotensin converting enzyme inhibitory peptide LAP-C1 has stronger effect of lowering pressure and long half-life period. The administration times of a patient can be reduced, the obedience of the patient is improved, and medical fees are saved.

Owner:TONGJI UNIV

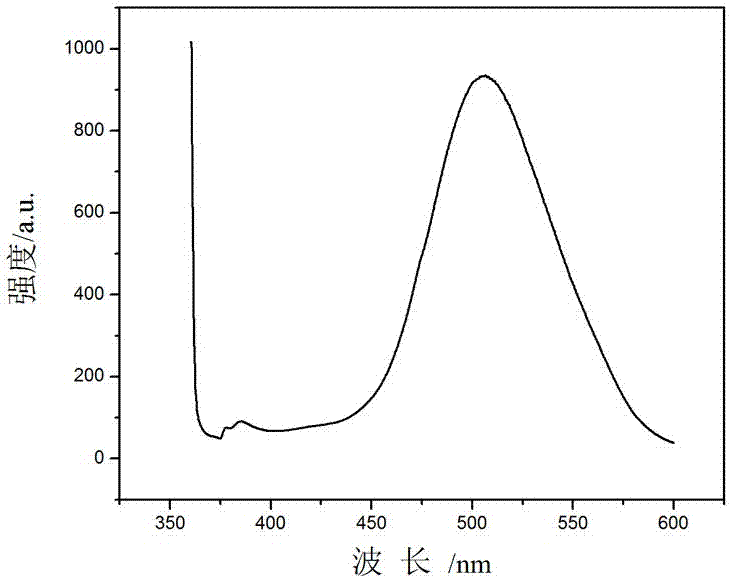

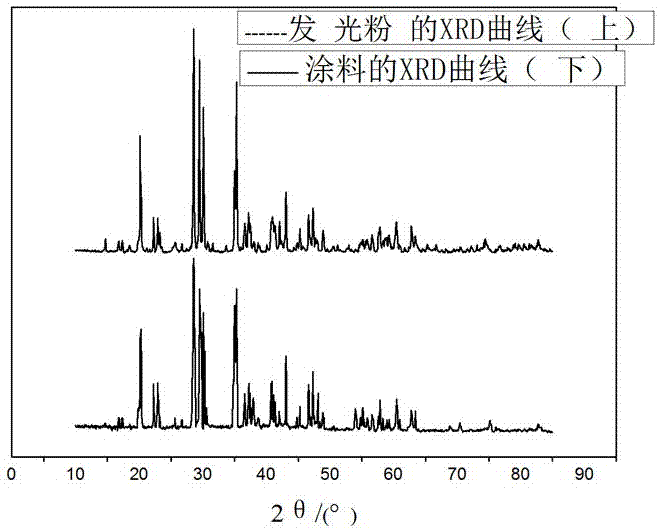

Preparation method of long afterglow waterborne alkyd resin coating

InactiveCN105001769BReduce dosageSynthetic technology is matureLuminescent paintsPolyester coatingsXylyleneLithium hydroxide

The invention discloses a preparation method of a long-lasting water-based alkyd resin paint, which introduces a long-lasting luminous powder into a water-based alkyd resin system, and first uses soybean oil, tung oil, glycerin and other biomass oils to undergo alcoholysis with lithium hydroxide. , through xylene, phthalic anhydride, maleic anhydride esterification, and then through neutralization and dilution to obtain water-based alkyd resin, and then fully react with titanium dioxide, talc powder and long-lasting luminous powder mixture, through three Adjust pH=8.0-8.5 with ethylamine and keep warm to obtain an environment-friendly long-lasting water-based alkyd resin coating with fluorescent properties. The long-lasting luminous coating product prepared by the method for preparing the long-lasting water-based alkyd resin coating has the advantages of good water resistance and dryness, low production cost, excellent product performance and environmental protection.

Owner:LONGYAN UNIV

Graphene solar water cleaning foam and its preparation method and use

ActiveCN108002366BImprove light-to-heat conversion efficiencySimple manufacturing methodGeneral water supply conservationEnergy inputFreeze-dryingSolar water

Disclosed are a graphene solar energy water-cleaning foam, a preparation method therefor and the use thereof. The method for preparing the graphene solar energy water-cleaning foam comprises: (1) subjecting a graphite powder to an oxidative stripping treatment so as to obtain a graphene oxide aqueous solution; (2) mixing the graphene oxide aqueous solution with a low-freezing-point solvent so as to obtain a mixed solution; (3) subjecting the mixed solution to a freeze-drying treatment so as to obtain a large-scale graphene oxide foam; and (4) subjecting the graphene oxide foam to a reduction treatment so as to obtain the graphene solar energy water-cleaning foam.

Owner:弘润清源(北京)科技有限责任公司

Compositions of mirna-17-3p and mirna-19b-1 and applications thereof

ActiveCN105726559BSuppress generationHigh activityOrganic active ingredientsGenetic material ingredientsCancer cellTumor vessel

The invention belongs to the field of biotechnology and medical science and particularly relates to a miRNA-17-3p and miRNA-19b-1 combination and application thereof. The invention provides application of miRNA-17-3P, or a combination of its precursor and mimR-19b-1, or a combination of its precursor in the preparation of drugs for preventing or treating tumors. The invention discloses for the first time that miR-17-3p and miR-19b-1 can specifically inhibit the generation of tumor vessels and have significantly lower expression than normal tissues in breast cancer; in addition, the miR-17-3p and miR-19b-1 combination can inhibit the growth of cancer cells both in vitro and in vivo. The miR-17-3p and miR-19b-1 combination is useful in the preparation of drugs for preventing or treating solid tumors, particularly in the preparation of drugs for preventing or treating breast cancer.

Owner:NANTONG UNIVERSITY

Method for synthesizing suspensible and deformable polyacrylamide

The invention relates to a method for synthesizing suspension deformation polyacrylamide, which comprises 20-30% of acrylamide, 2-8% of 3,5-diacryloyloxyethyl-benzenesulfonic acid, and the rest is desalted water, the total amount is 100%. , adding 5-10ppm of catalyst potassium persulfate and 5-10ppm of sodium bisulfite, the initial reaction temperature is 0-15°C, and polymerized. It has good salt resistance and is not limited by the salinity of prepared water and formation water. Particle strength, particle size, expansion multiple, and expansion speed can be controlled through ground production according to site conditions. It has certain solubility and viscosity in aqueous solution, so that colloidal particles can be evenly suspended in the solution, and the volume of the oil does not change, and the water-absorbing body expands. It becomes soft and can be deformed under the action of external force, and the deformation is reversible. The surface is cross-linked and combined, which avoids the problem of underground non-gelling, and can change the pressure field and streamline field formed by long-term water flooding in the deep formation, achieving the effect of regulating and flooding. .

Owner:PETROCHINA CO LTD

A method and application of large-scale continuous production of three-dimensional graphene film

ActiveCN104310381BLow costSynthetic technology is matureMaterial nanotechnologyFerroso-ferric oxidesTetrafluoroethyleneNanoparticle

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com