Method for spontaneously depositing three-dimensional graphene on conductive substrate

A conductive substrate, spontaneous deposition technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of insufficient graphene reduction, cumbersome preparation process, difficult to ensure assembly, etc., to achieve good photoelectric response, process Simple, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Prepare a 20 mg / mL graphene oxide solution using the oxidized exfoliated graphite method (Hummers method);

[0039] 2. Dilute the 20mg / mL graphene oxide solution with distilled water so that the concentration of the graphene oxide solution is 3mg / mL;

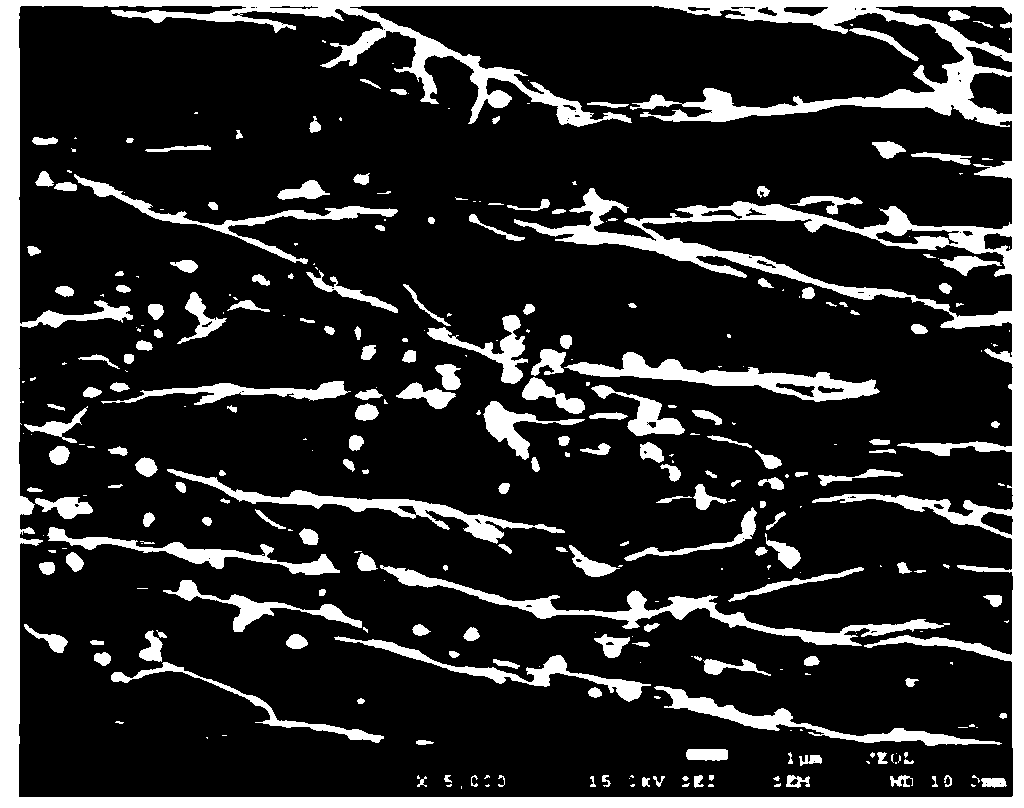

[0040] 3. Put the Zn conductive substrate in the graphene oxide solution prepared in the second step and let it stand at room temperature, take out the conductive substrate after reacting for 6 hours, the graphene oxide is reduced to obtain graphene, and deposit on the surface of the conductive substrate;

[0041] 4. First immerse the graphene obtained in the previous step into liquid nitrogen to freeze, and then put it into a freeze dryer at -50°C to freeze-dry to obtain the product. The product is tested, and the ZnO can be seen from the X-ray powder diffraction test chart. The characteristic peaks (32°, 34°, 36°, 48°, 57°, 63°, 66°, 68° and 69°), and the characteristic peak of graphene oxide (10°) disappeared, and t...

Embodiment 2

[0043] 1. Prepare 8 mg / mL graphene oxide solution by using the oxidized exfoliated graphite method (Hummers method);

[0044] 2. Dilute the 8mg / mL graphene oxide solution with distilled water so that the concentration of the graphene oxide solution is 0.5mg / mL;

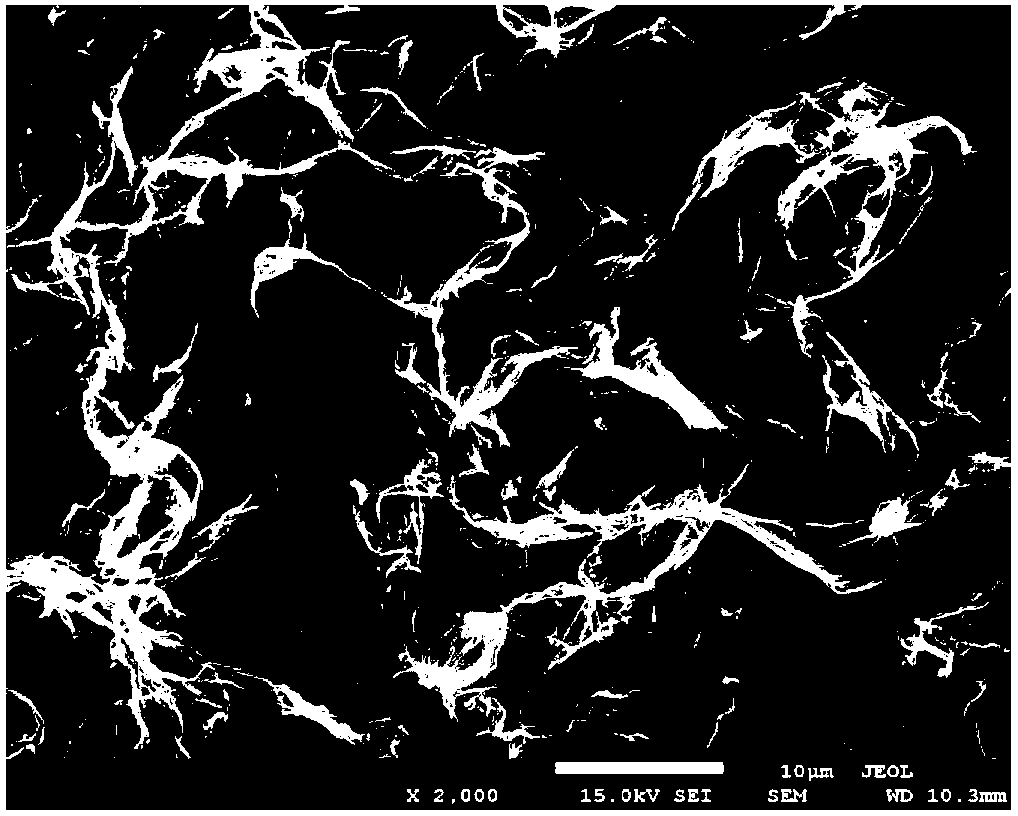

[0045] 3. Put the Fe conductive substrate in the graphene oxide solution prepared in the second step and let it stand at room temperature, take out the conductive substrate after reacting for 6 hours, graphene oxide is reduced to obtain graphene, and deposited on the surface of the conductive substrate;

[0046] 4. After the graphene obtained in the previous step is washed with 100 mL of 2mol / L hydrochloric acid solution, the graphene is first immersed in liquid nitrogen to freeze, and then freeze-dried in a freeze-dryer at -50°C to obtain the product. The product is detected, and the characteristic peak (10°) of graphene oxide disappears through the X-ray powder diffraction test chart, and the characteristic peak (23...

Embodiment 3

[0048] 1. Prepare a 14 mg / mL graphene oxide solution using the oxidized exfoliated graphite method (Hummers method);

[0049]2. Dilute the 14mg / mL graphene oxide solution with distilled water so that the concentration of the graphene oxide solution is 1.7mg / mL;

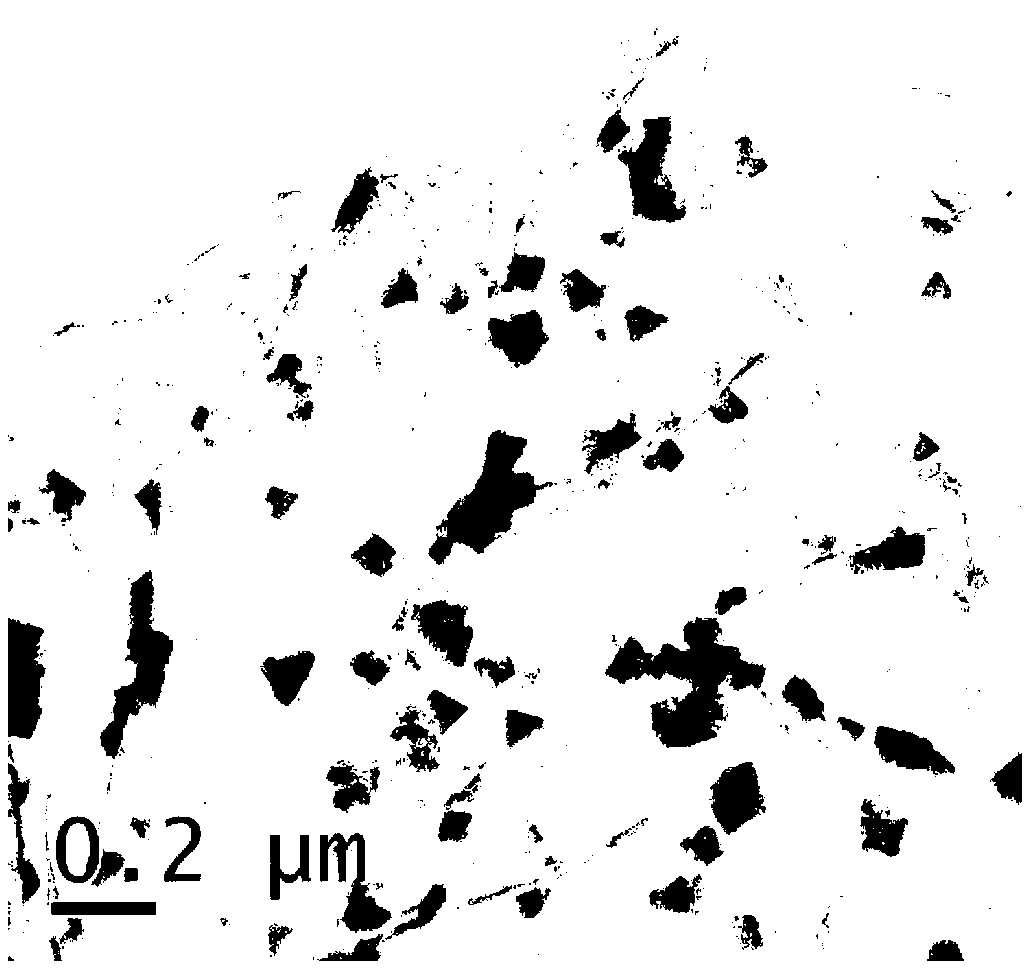

[0050] 3. Put the Cu conductive substrate in the graphene oxide solution prepared in the second step and let it stand at 30°C. After reacting for 10 hours, take out the conductive substrate, and the graphene oxide is reduced to obtain graphene, which is deposited on the surface of the conductive substrate;

[0051] 4. First immerse the graphene obtained in the previous step into liquid nitrogen to freeze, and then put it into a freeze dryer at -50°C to freeze-dry to obtain the product. The product is tested, and Cu can be seen from the X-ray powder diffraction test chart. 2 The characteristic peaks of O (40°, 47°, 68°, 82° and 86°), and the characteristic peak of graphene oxide (10°) disappeared, and the characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com