Frame-shear wall structure building of dismantling-free prefabricated reinforced concrete formwork and construction method thereof

A reinforced concrete and shear wall technology, which is applied in the cast-in-place reinforced concrete frame-shear wall structure system and its construction field, can solve problems such as poor earthquake resistance, reduce workload, facilitate long-distance transportation, and ensure integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

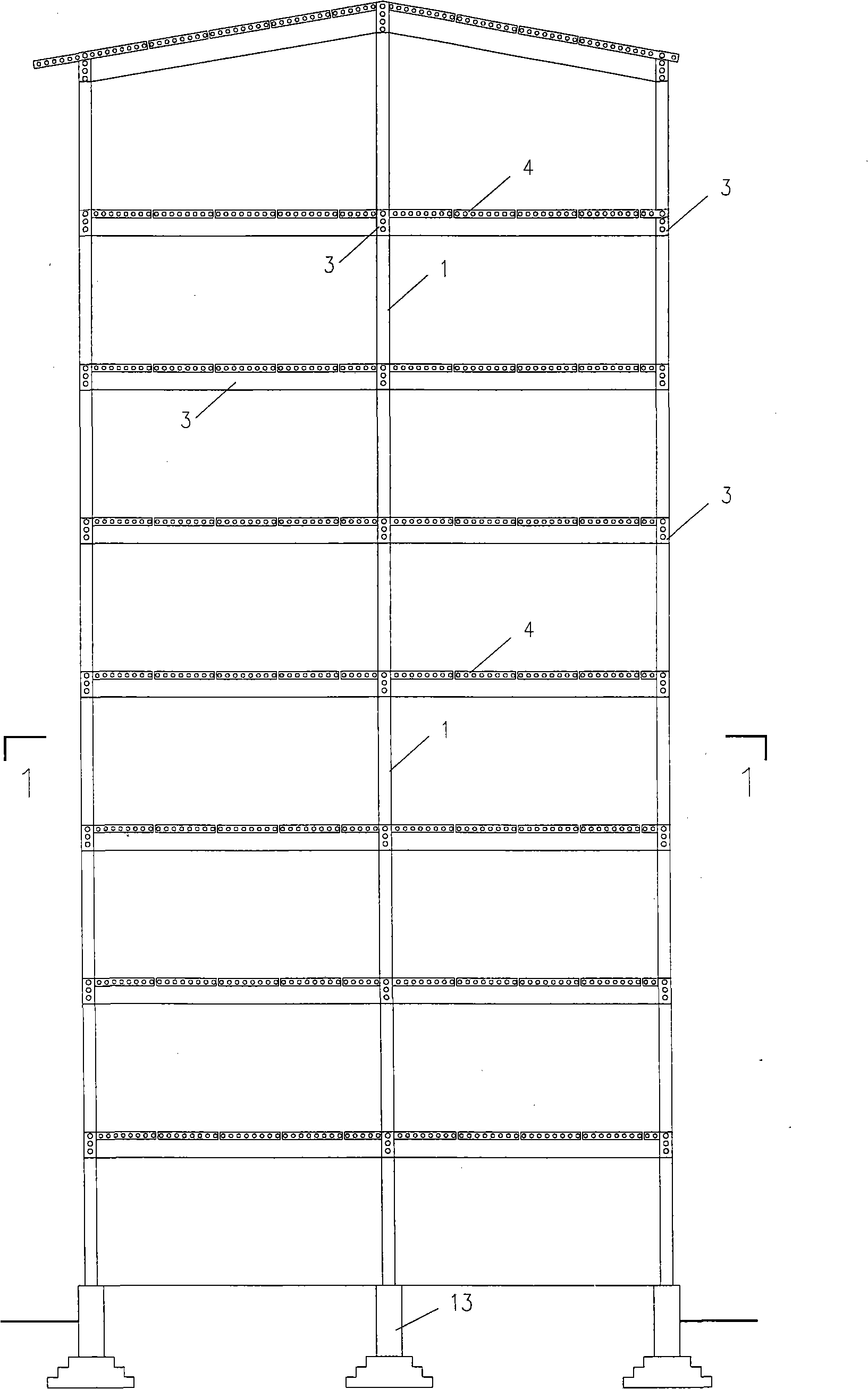

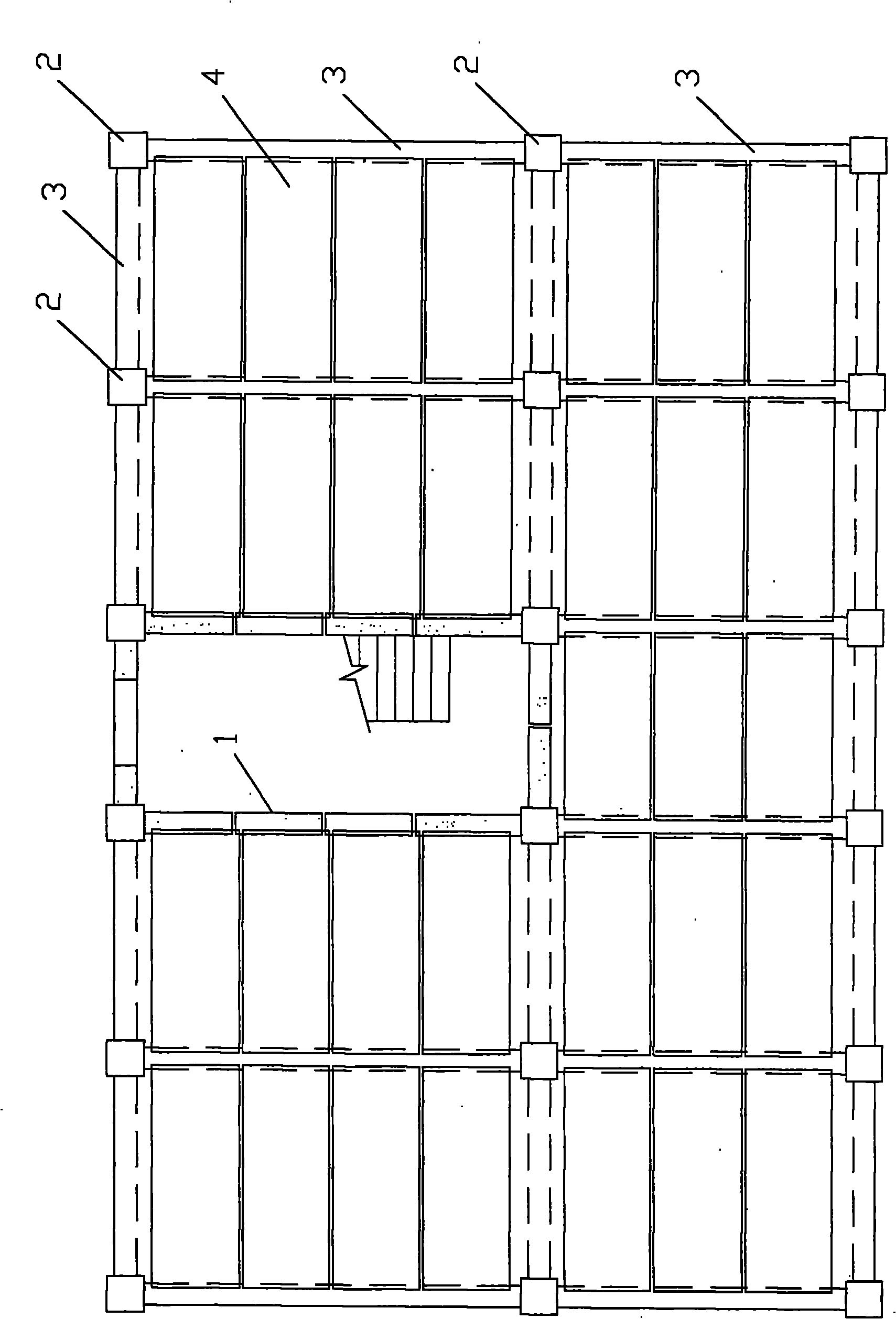

[0037] The frame-shear wall structure building and construction method of the frame-shear wall structure proposed by the present invention are described in detail in conjunction with accompanying drawings and embodiments as follows:

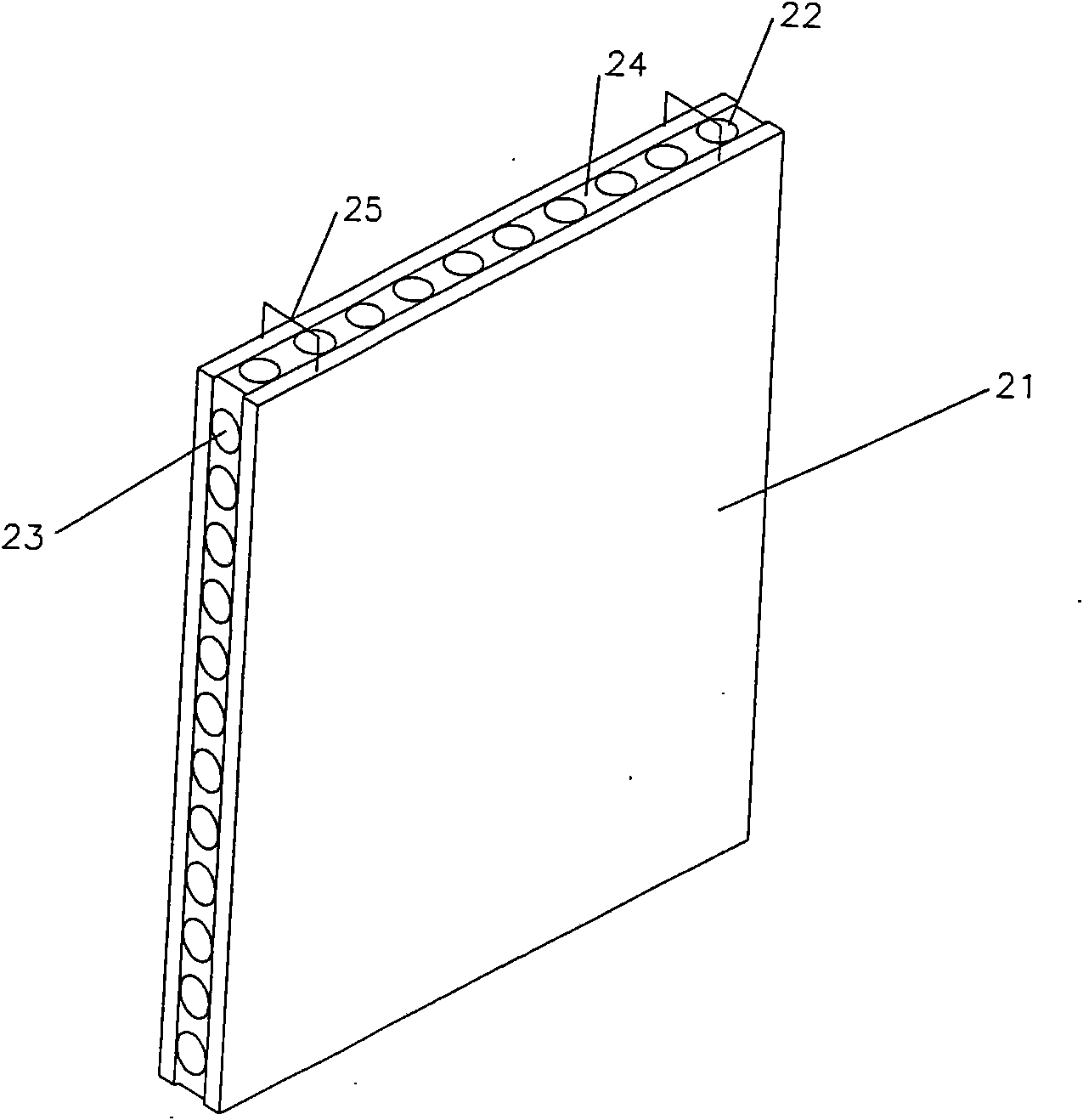

[0038] The overall structure of the embodiment of the present invention is shown in Fig. 1 and Fig. 2. This embodiment is an 8-storey building with a frame-shear wall structure using a prefabricated reinforced concrete formwork without demolition. The building includes: a wall formwork 1, a column formwork 2, a beam formwork 3, a building (roof) cover formwork 4 and concrete (not shown in the figure). Wall formwork, column formwork, beam formwork and building (roof) cover formwork are lapped together to form a column, beam and slab space formwork system. Each formwork is a prefabricated reinforced concrete slab with cross holes. The vertically penetrating holes parallel to the surface, and the transversely penetrating holes (the size and spacing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com