Patents

Literature

612 results about "Reinforced concrete slab" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

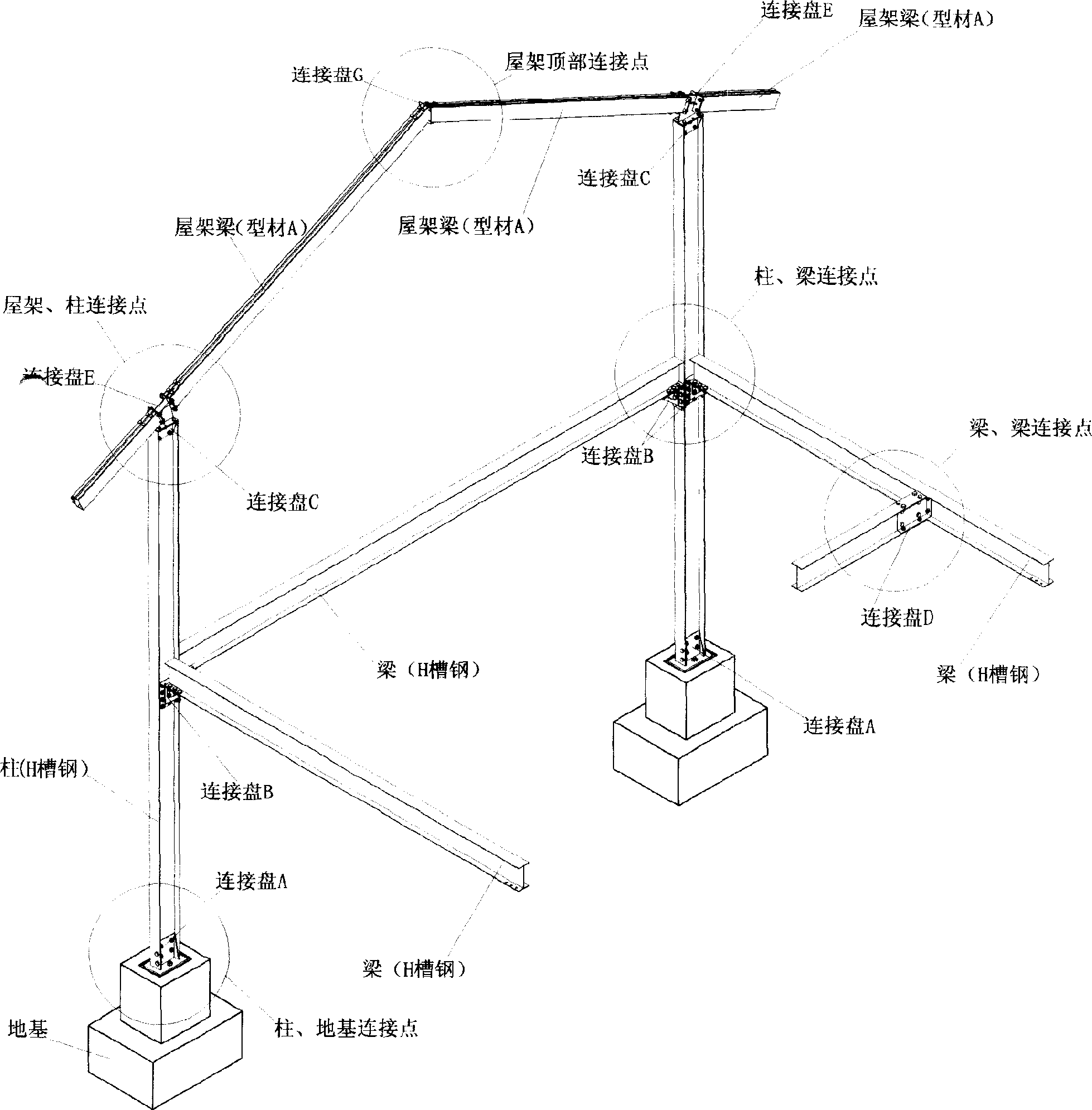

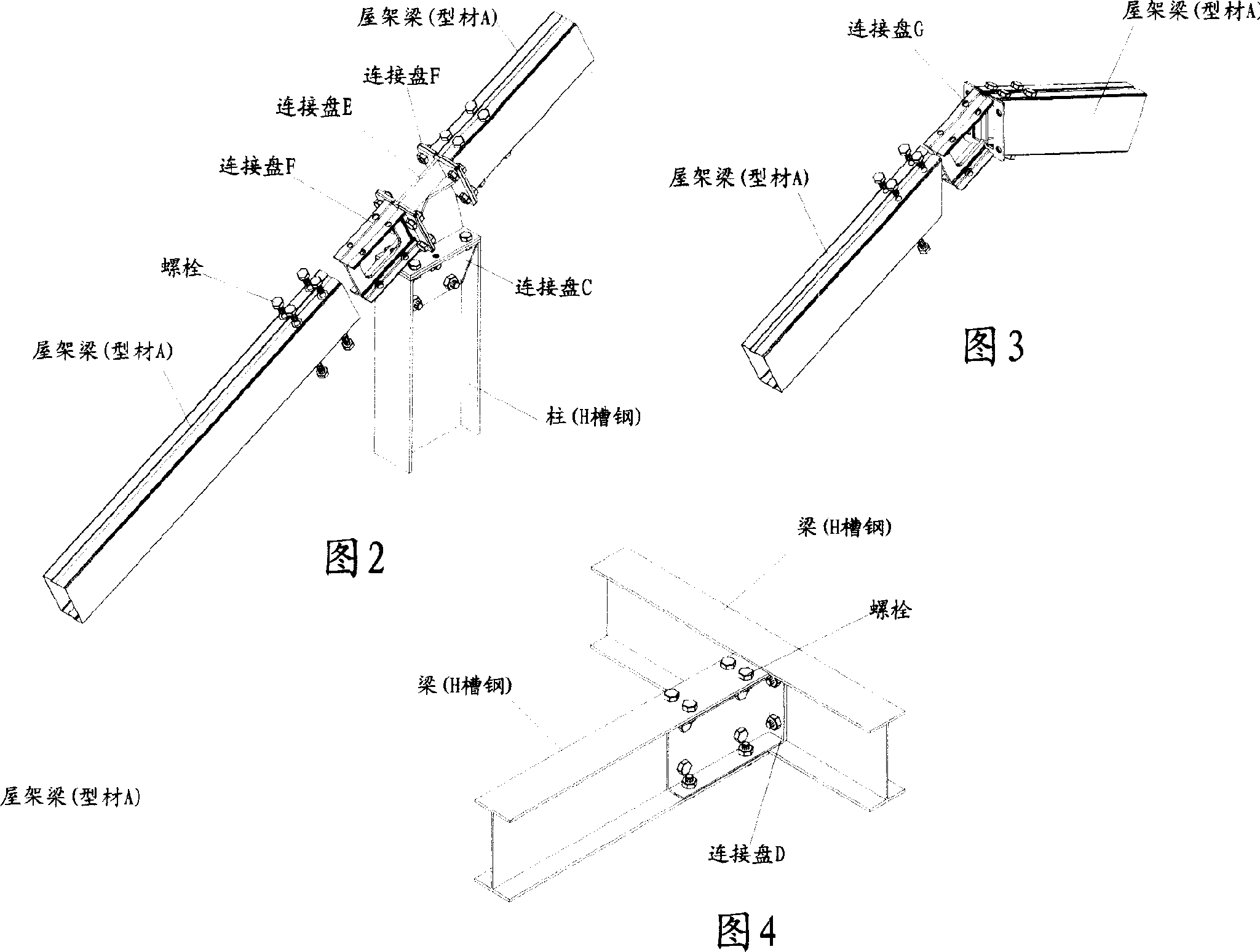

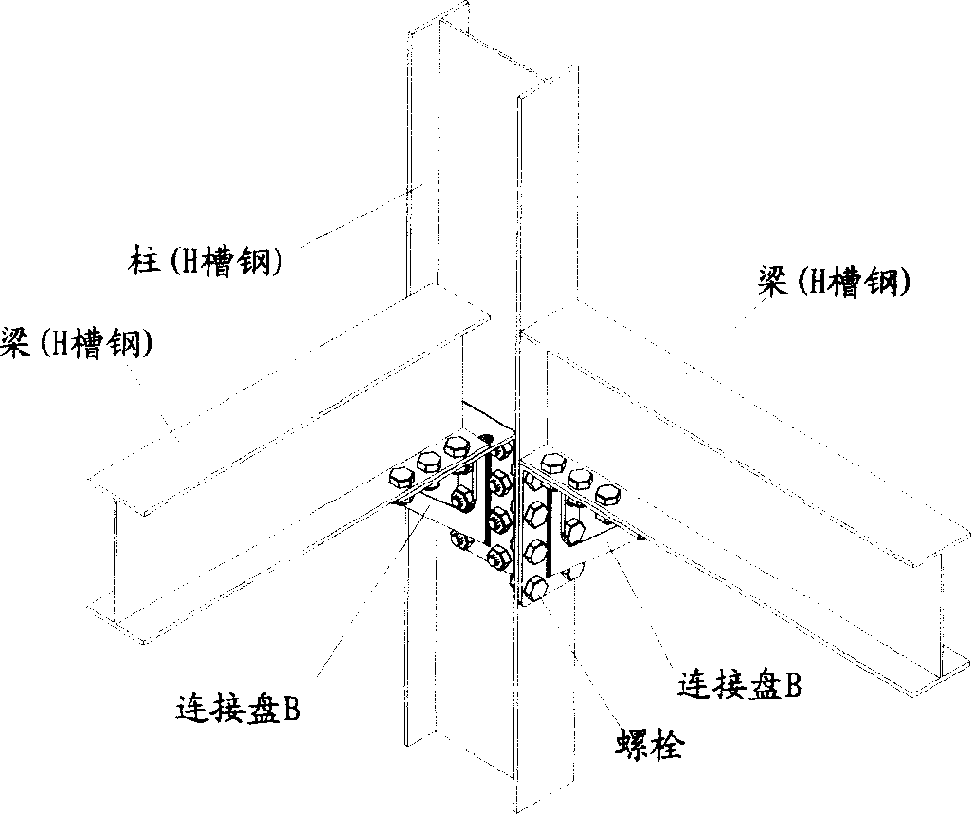

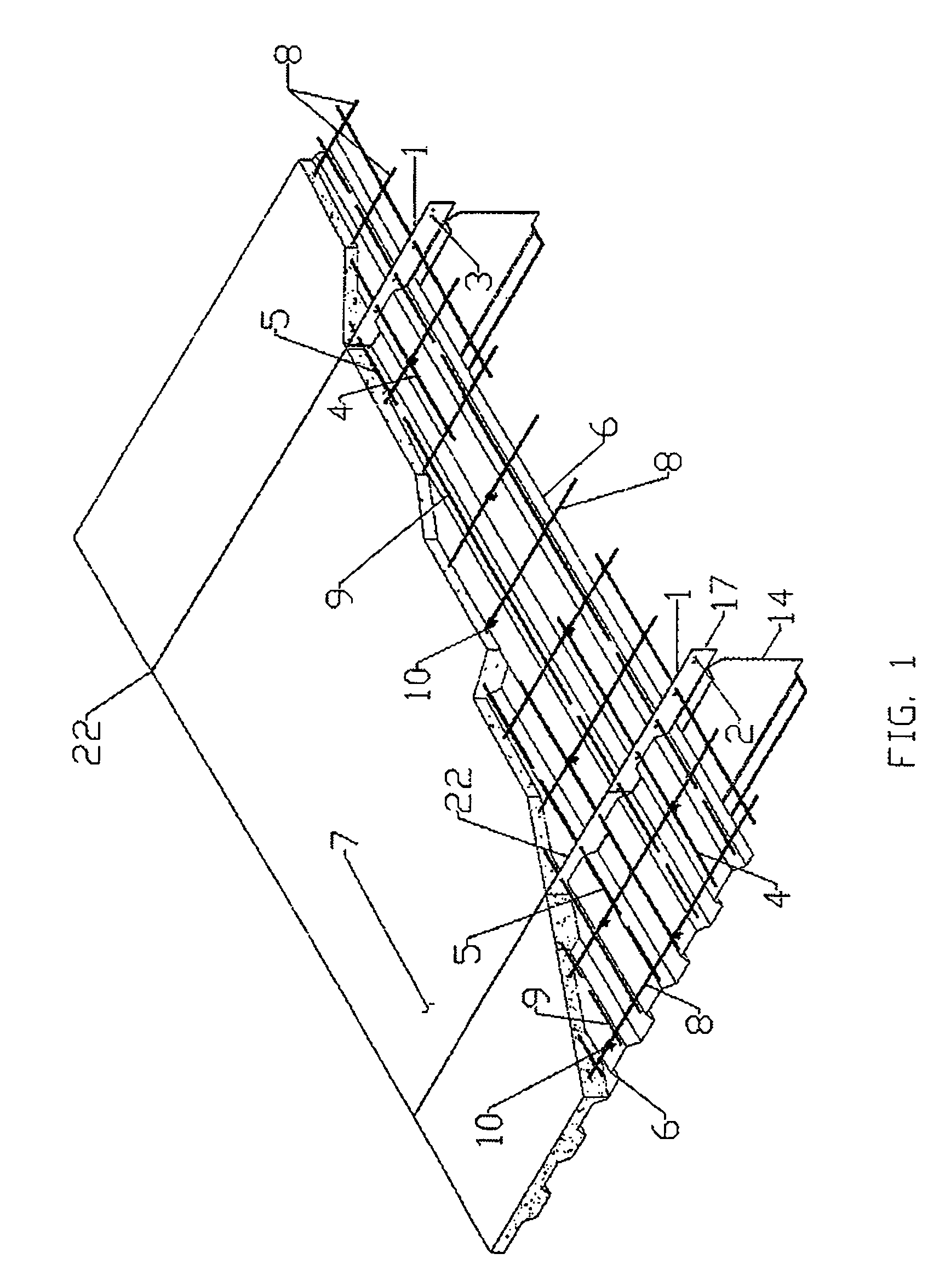

Method for assembling building

The present invention is characterized by using pre-fabricated H-type channel steel, member bar made up by using aluminium alloy section material with special section, specially-made connecting disk, connecting component, metal outer wall plate, reinforced concrete slab and conventional heat-insulating sound-insulating material, wood plate, gypsum board and screw bolt, etc. to assemble the column beam frame, roof truss, roffing, wall and floor of building, and adopting assembling method to implement building work.

Owner:万平华 +2

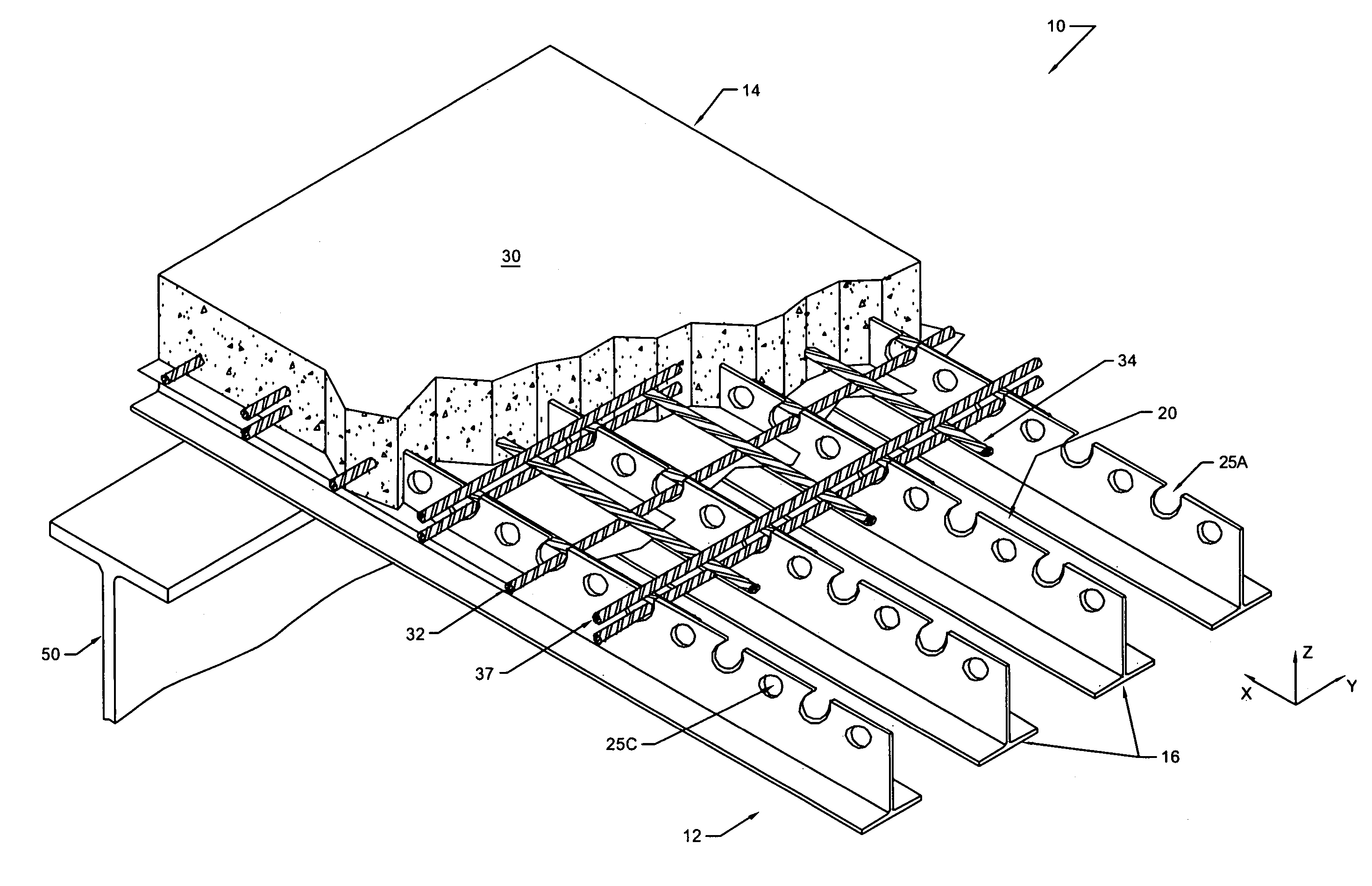

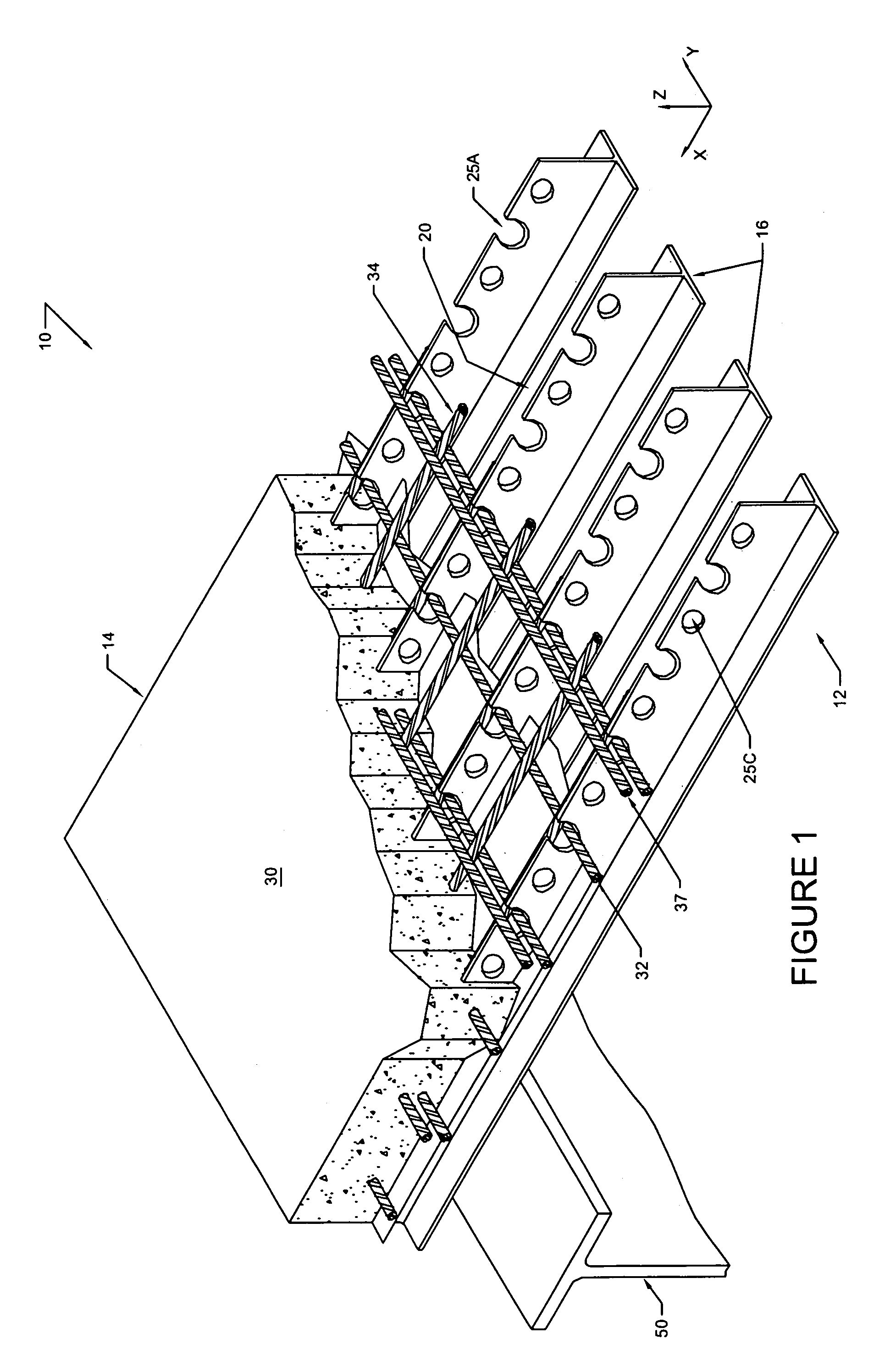

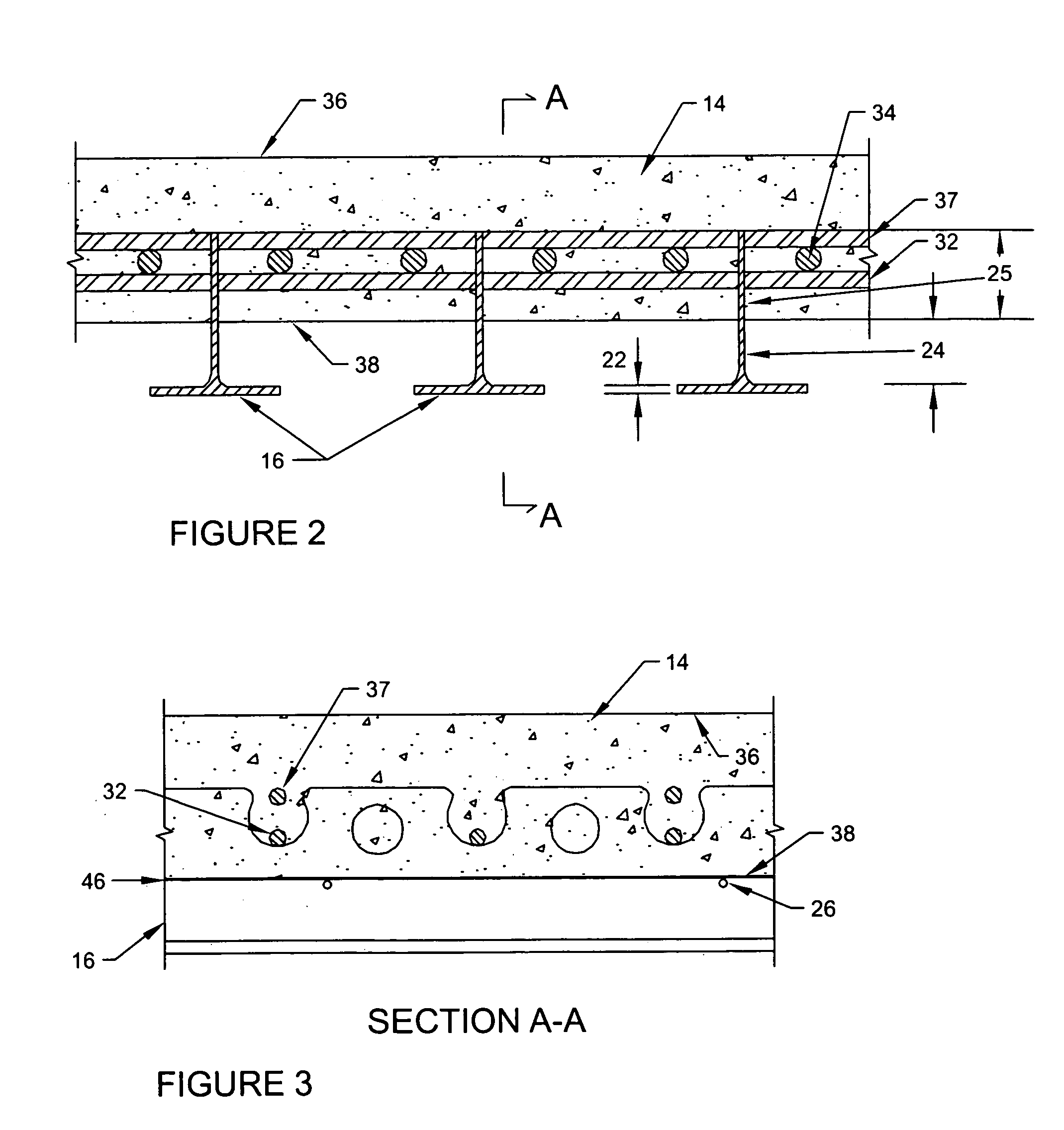

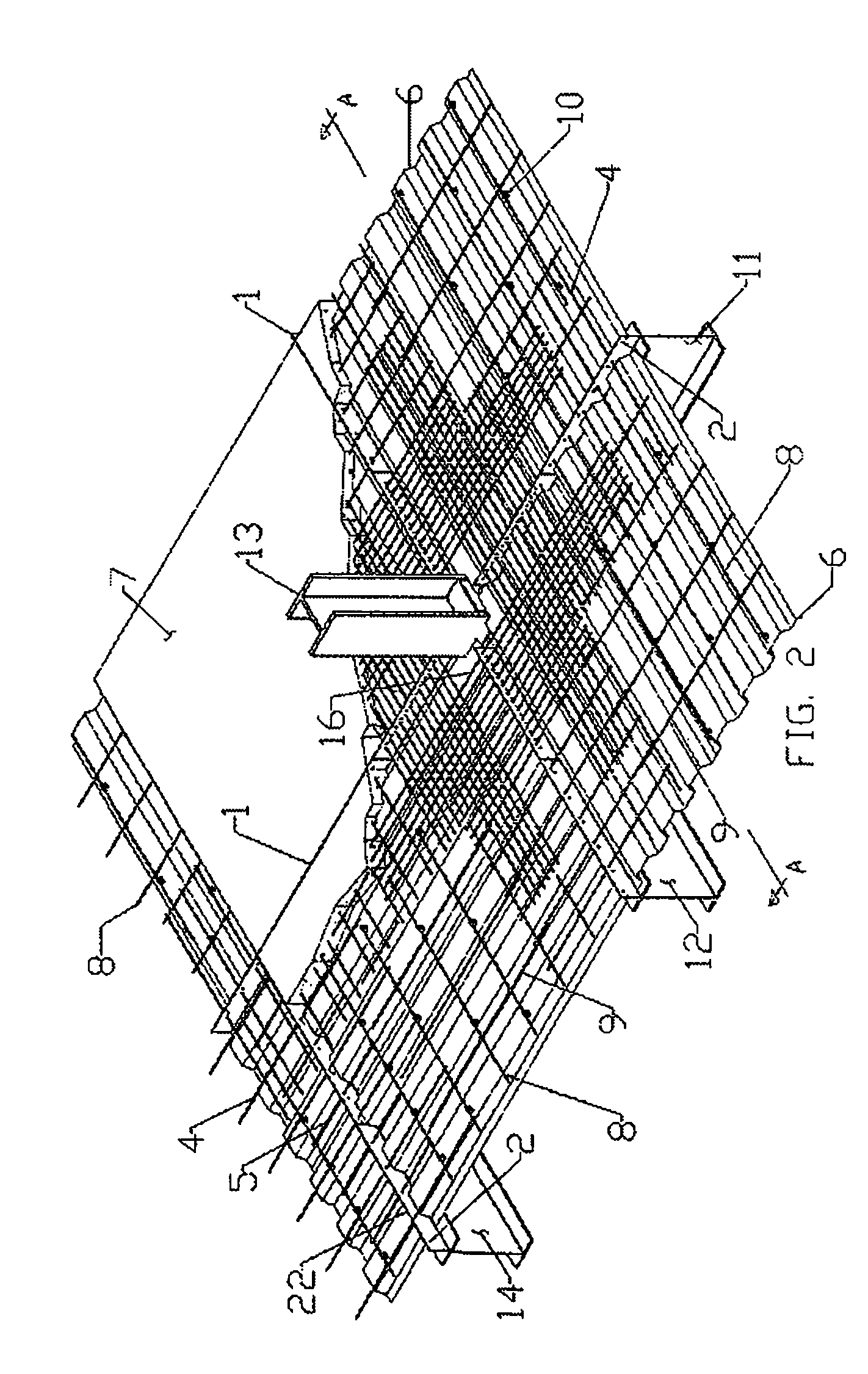

Prestressed or post-tension composite structural system

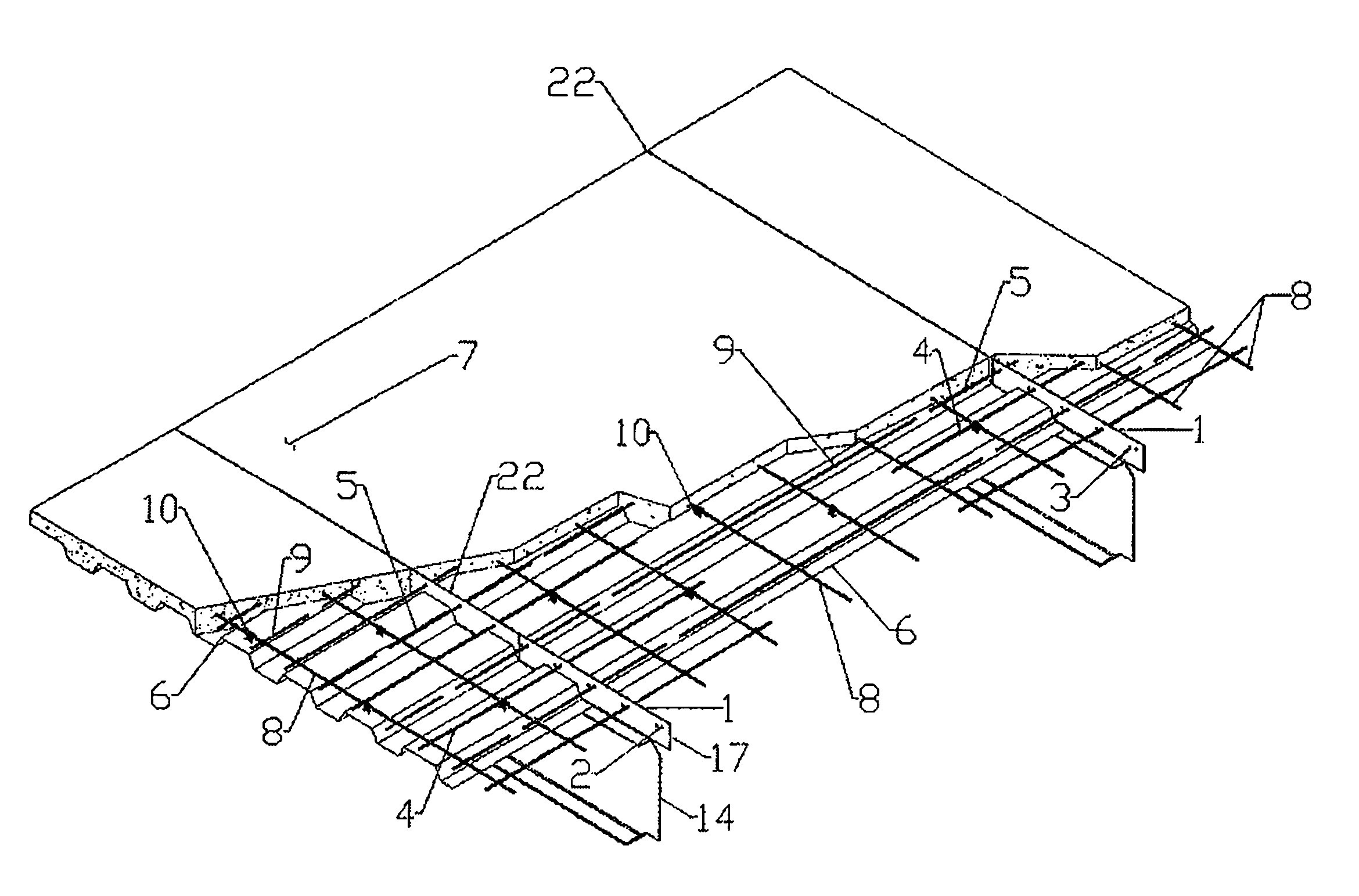

InactiveUS7197854B2Improved shear connectionEliminates some of the punching and all of the weldingFloorsBridge structural detailsGratingFloor slab

A prestressed or post-tensioned composite structural system for bridge floors, road beds, pedestrian walkways, building floors, building walls, or similar structural elements. The structural system comprises a composite structure comprising an unfilled grating as a base component, and a prestressed, post-tensioned reinforced concrete slab as a top component. The base grating component is preferably a plurality of main bearing bars without any distribution bars or tertiary bars. The upper portions of the main bearing bars are embedded in the concrete component permitting horizontal shear transfer and creating a composite deck structure which maximizes the use of tensile strength of steel and the compressive strength of concrete.

Owner:D S BROWN

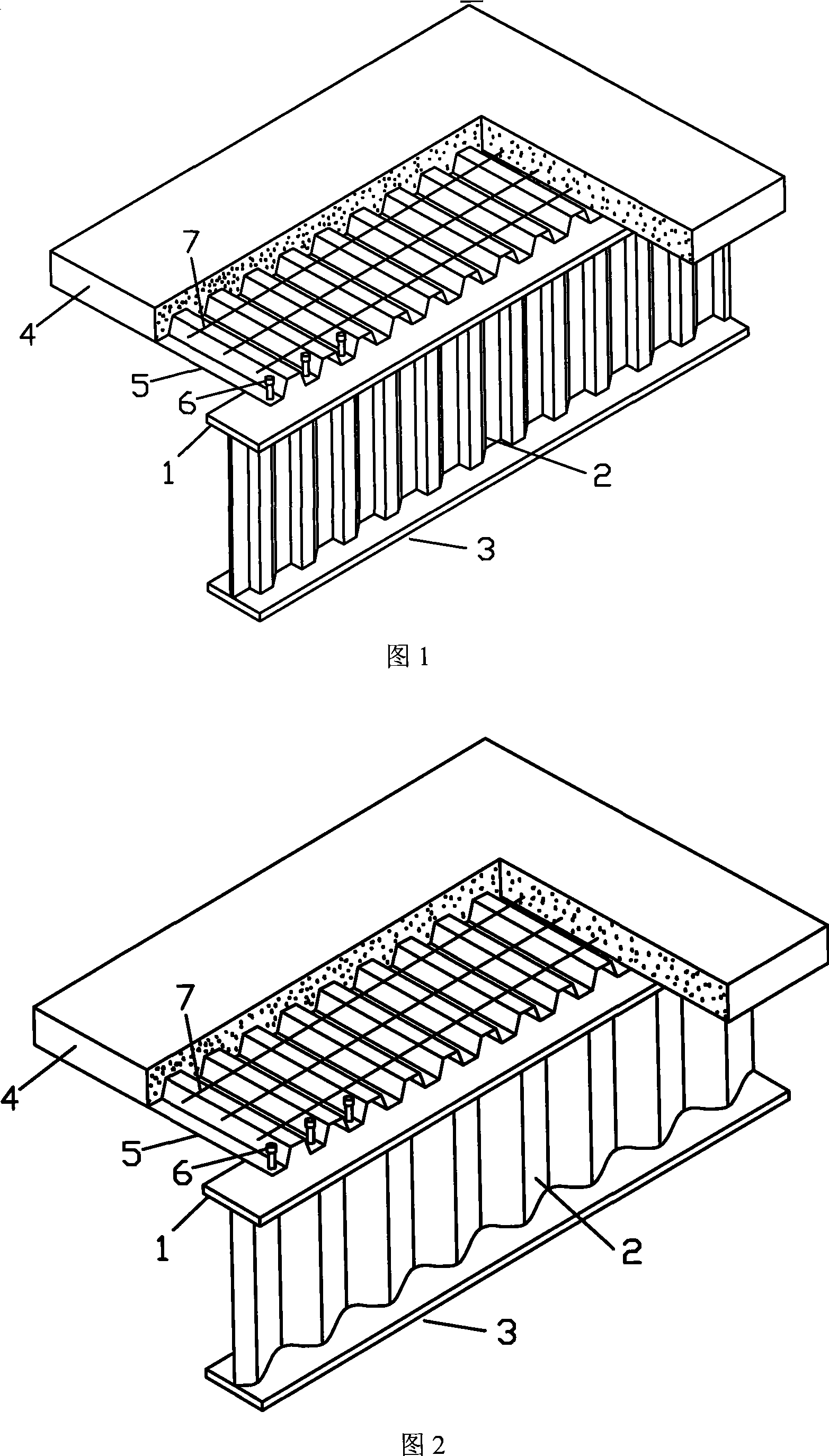

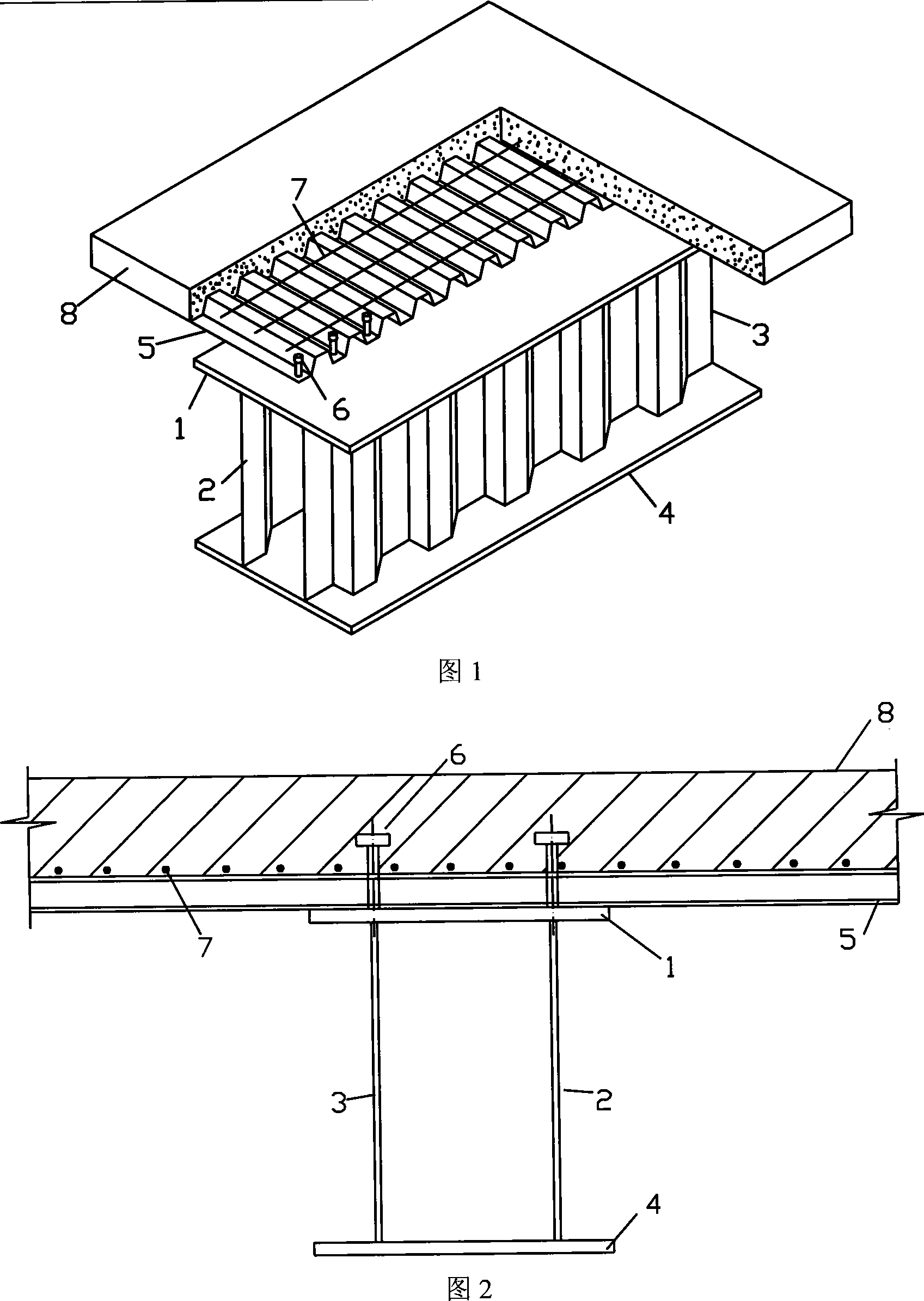

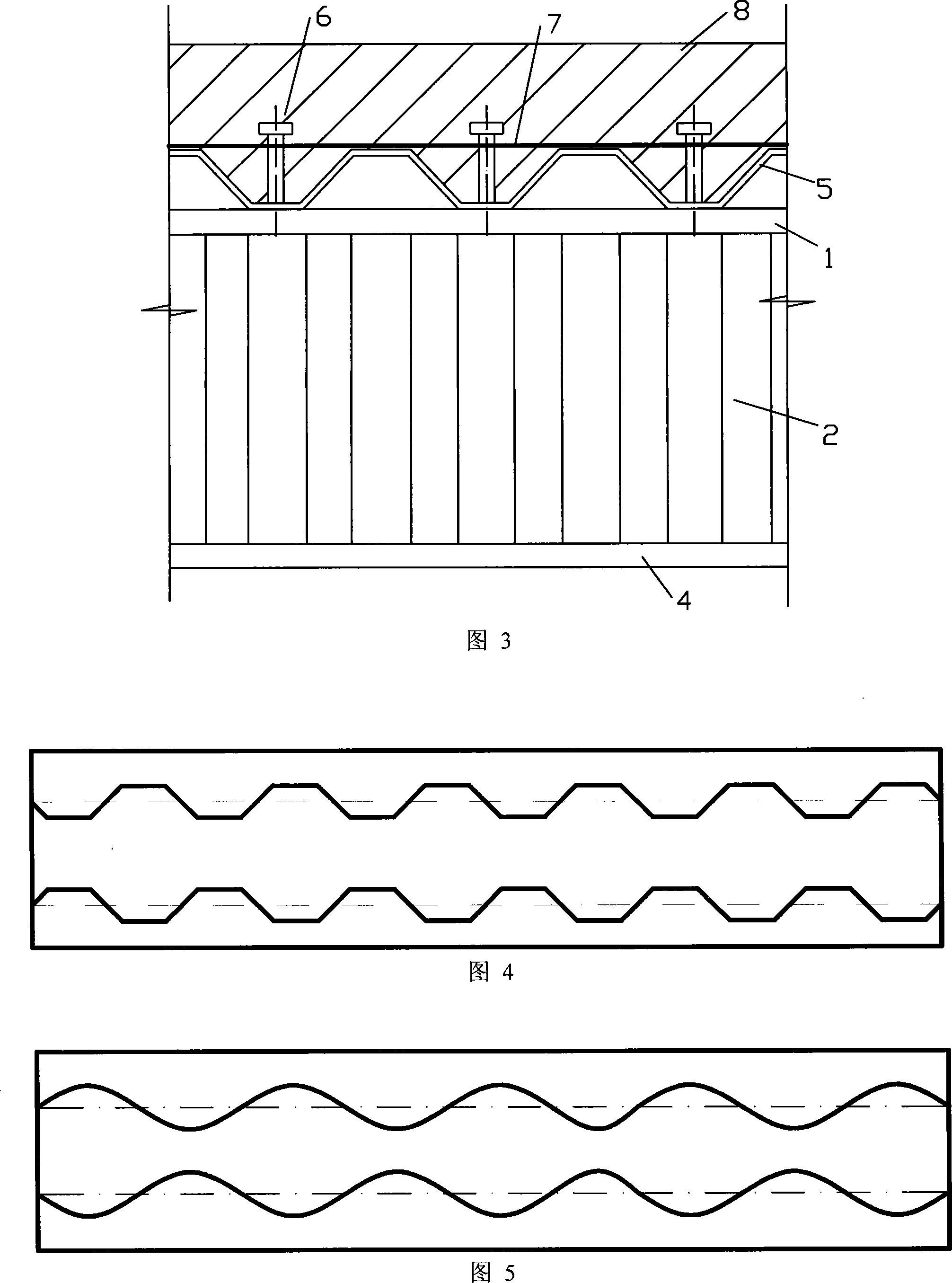

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

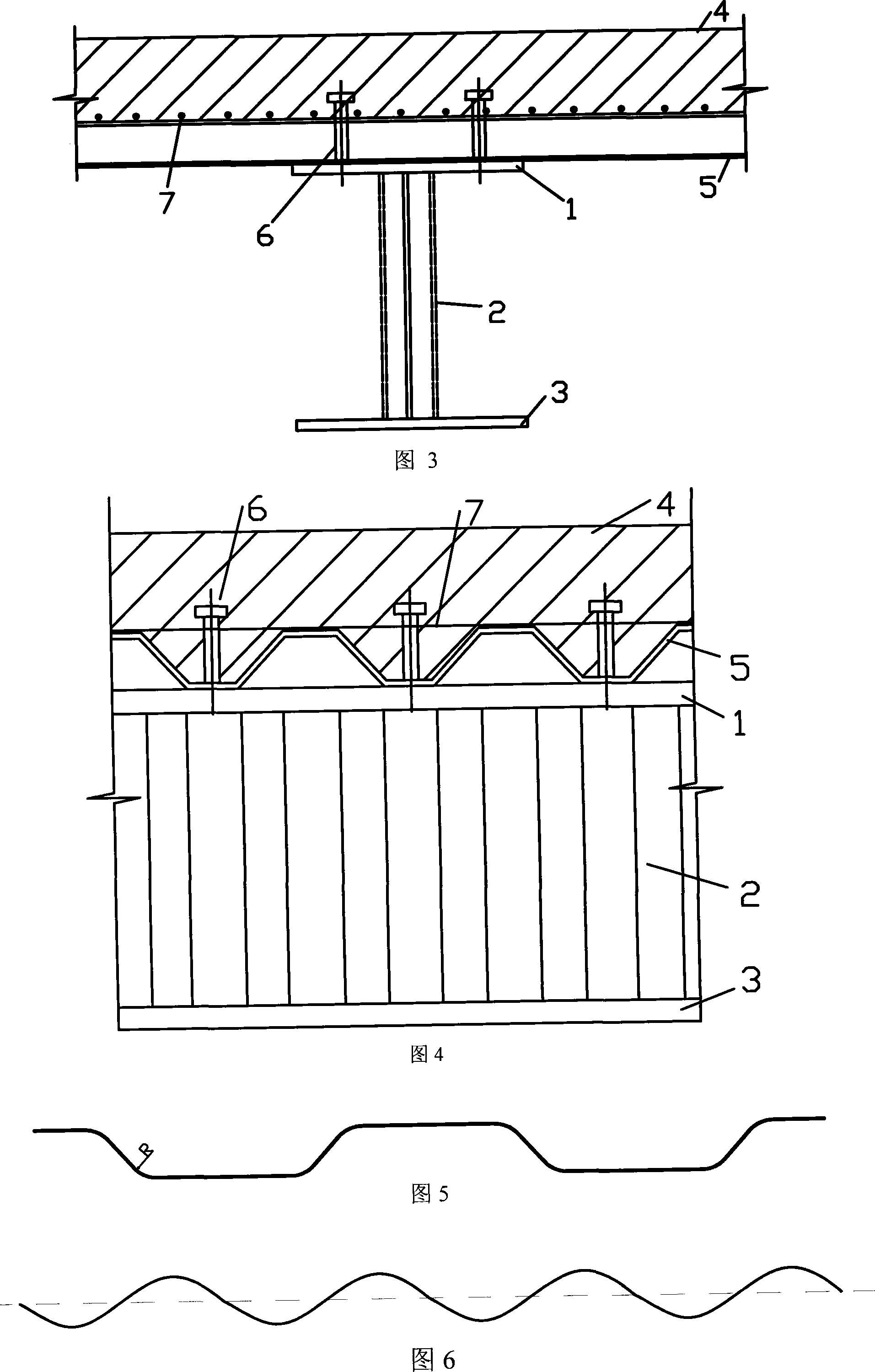

Double-ripple ventral shield steel case built-up beam

InactiveCN101220697APrecise positioningImprove mechanical propertiesFloorsLoad-supporting elementsSteel barSpandrel

The invention belongs to the technical field of architectural profiles and particularly relates to a double corrugated web steel box composite beam. The sectional shape of the invention is composed of two symmetrically arranged corrugated webs, a top flange and a lower flange. The top flange is parallel with the lower flange, the web is vertical to the top flange and the lower flange, the web and the flange are connected by single-side fillet joint, and the web has periodically repetitive trapezoidal wave or sinusoid wave along the length direction. The top of the composite beam is a reinforced concrete wing plate and a profiling steel plate. The top flange, the reinforced concrete slab and the profiling steel plate are connected each other by male pins, and a transverse reinforcement can be additionally used for the connection between the reinforced concrete wing plate and the profiling steel plate. The invention can replace the traditional hot rolled flange beam, H-beam composite beam and welded steel box composite beam; furthermore, the invention has wider application than the flange beam and the H-beam composite beam, and can realize maximization to be used in special fields and special places, including the construction of wide-span industrial and civilian buildings and wide-span bridges, etc.

Owner:TONGJI UNIV

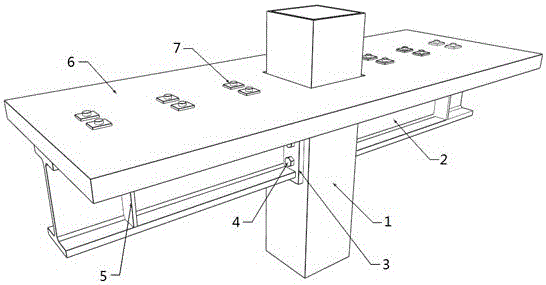

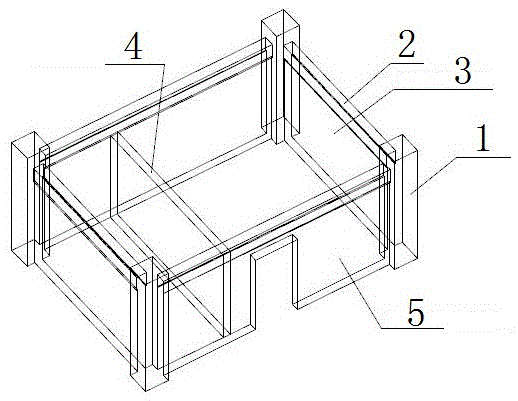

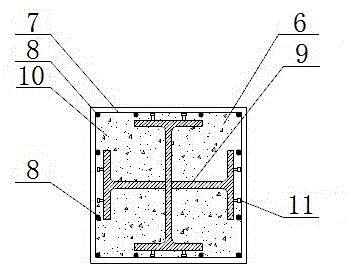

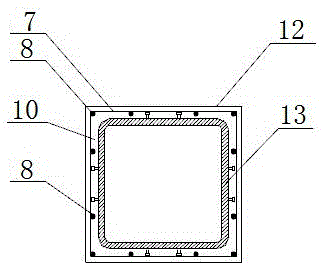

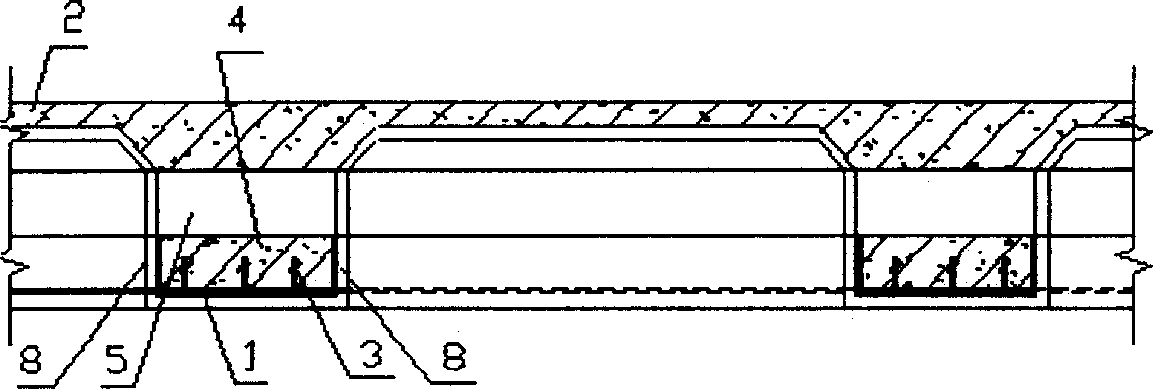

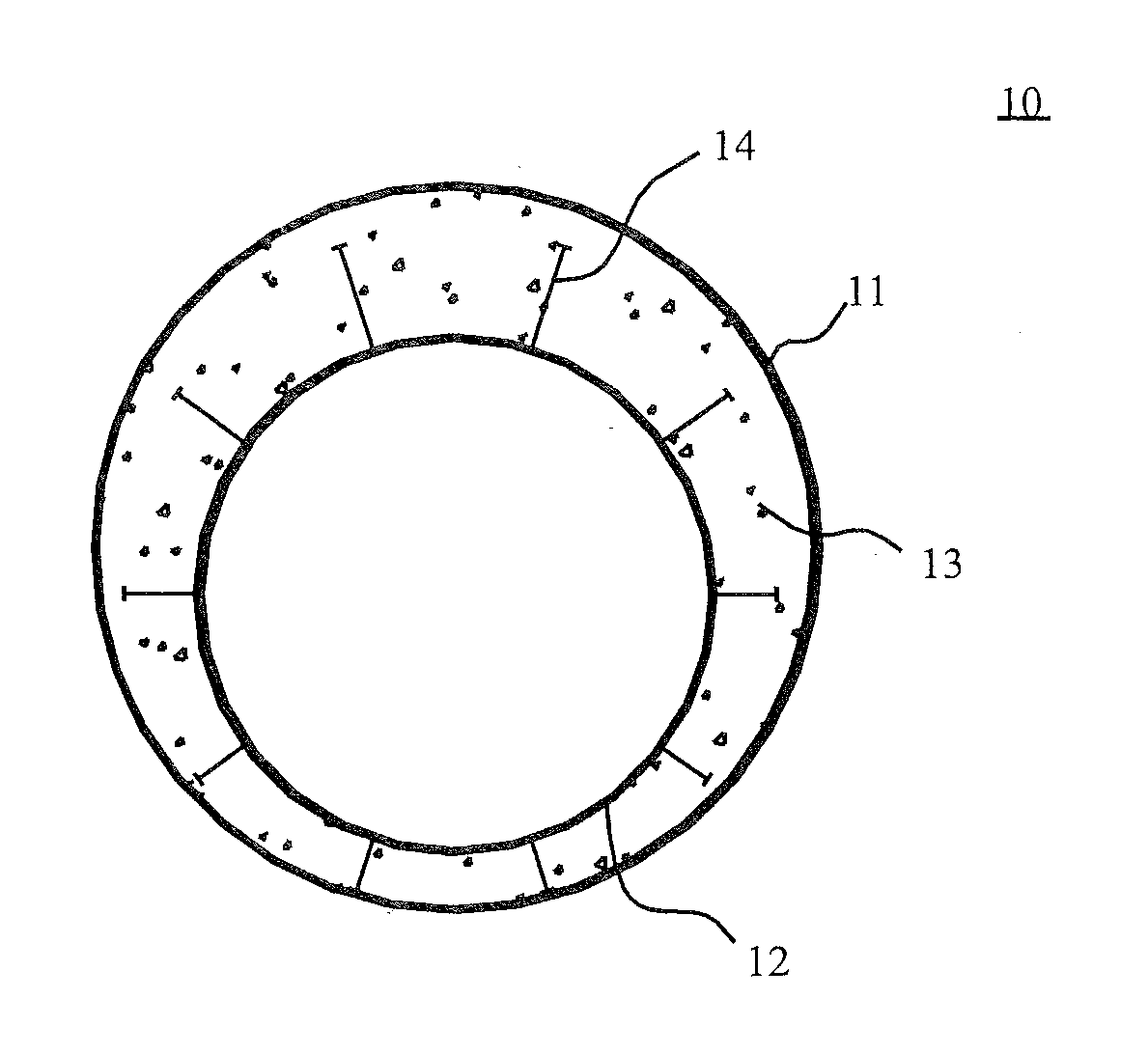

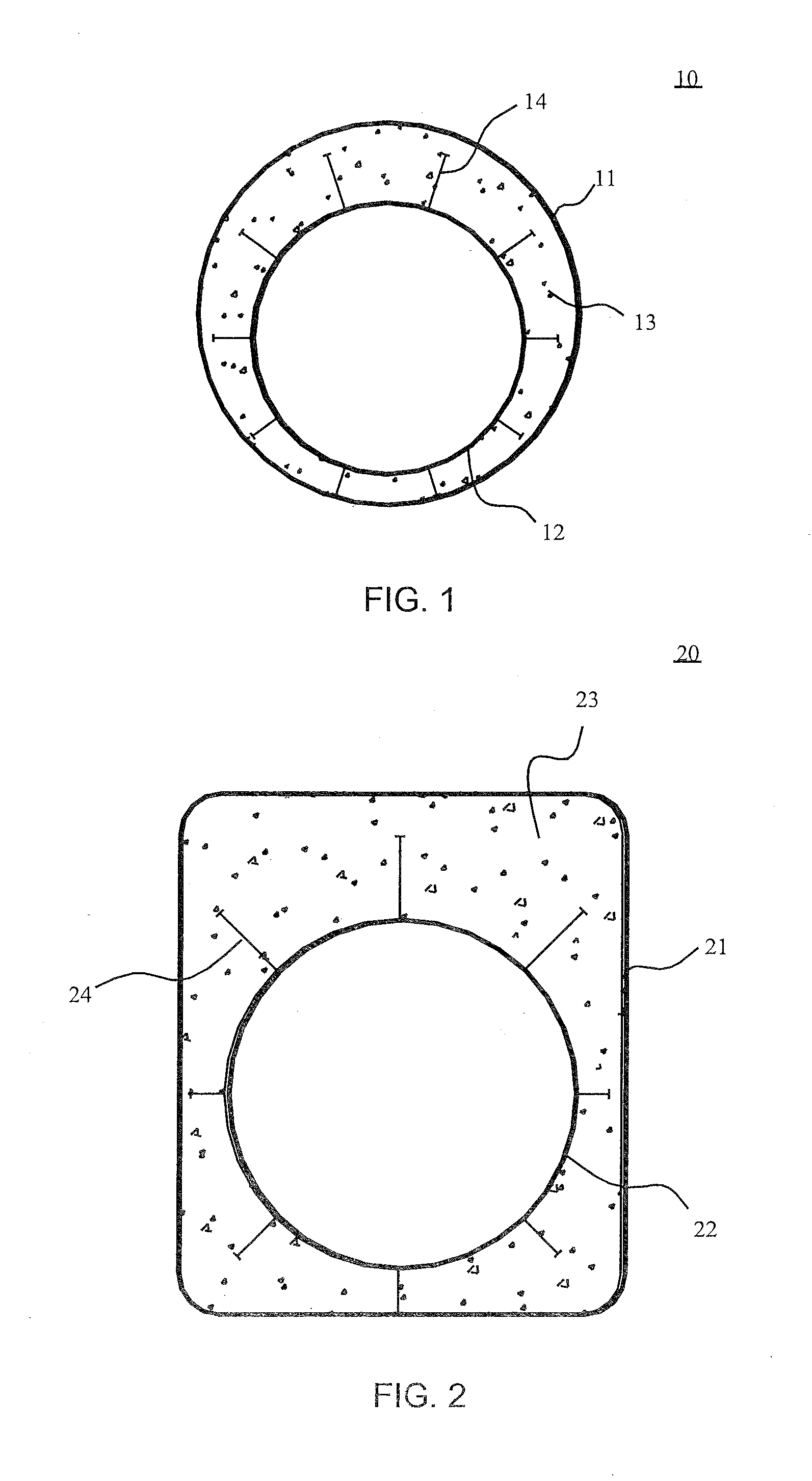

Assembled combining structure and mounting method thereof

InactiveCN105735464AGood compression and bending resistanceReduce weightBuilding material handlingFlangeReinforced concrete slab

The invention relates to an assembled combining structure and a mounting method thereof. The assembled combining structure comprises a steel pipe and concrete combined column which is composed of a steel pipe and concrete filled in the steel pipe, an H-shaped steel frame is arranged on the side wall of the combined column, a reinforced concrete plate is arranged on a steel beam, a through hole allowing the combined column to penetrate is formed in the reinforced concrete plate, and the reinforced concrete plate is fixedly connected on an upper flange through a plurality of bolt shear-resistant connecting members. The assembled combining structure is simple and firm in structure and convenient to mount and transport.

Owner:FUZHOU UNIV

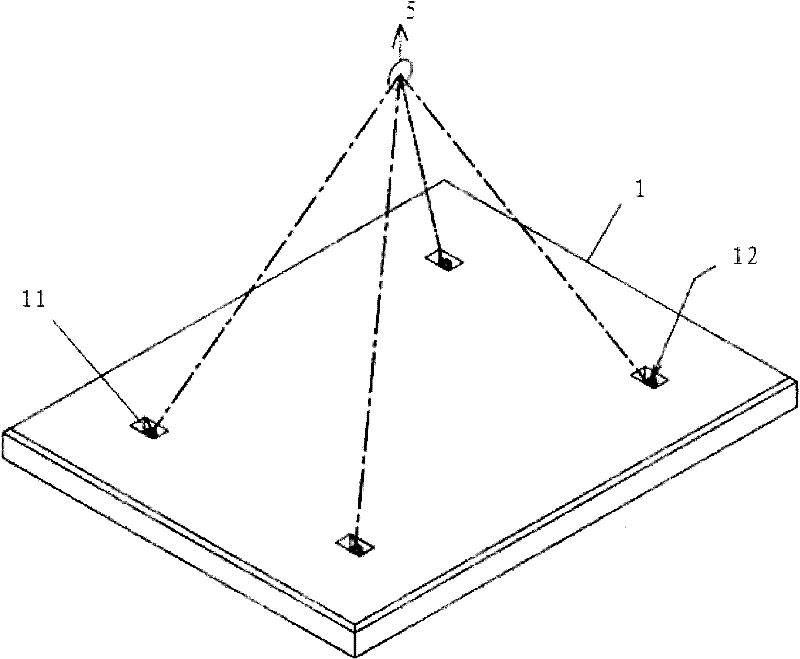

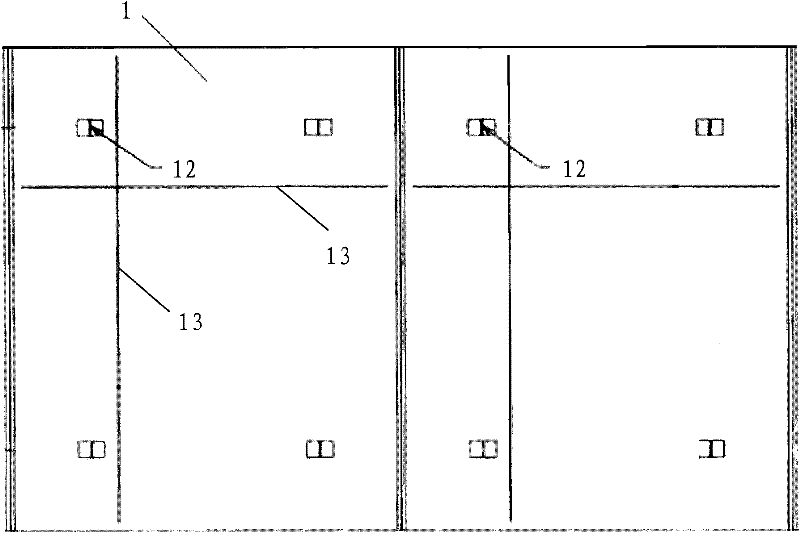

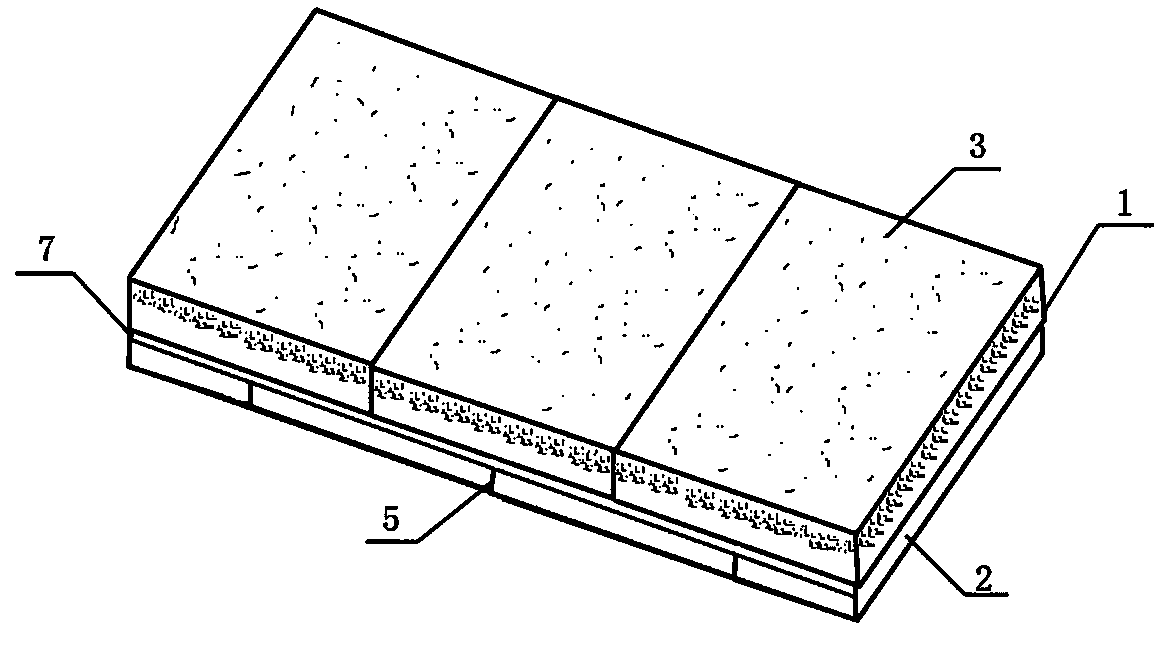

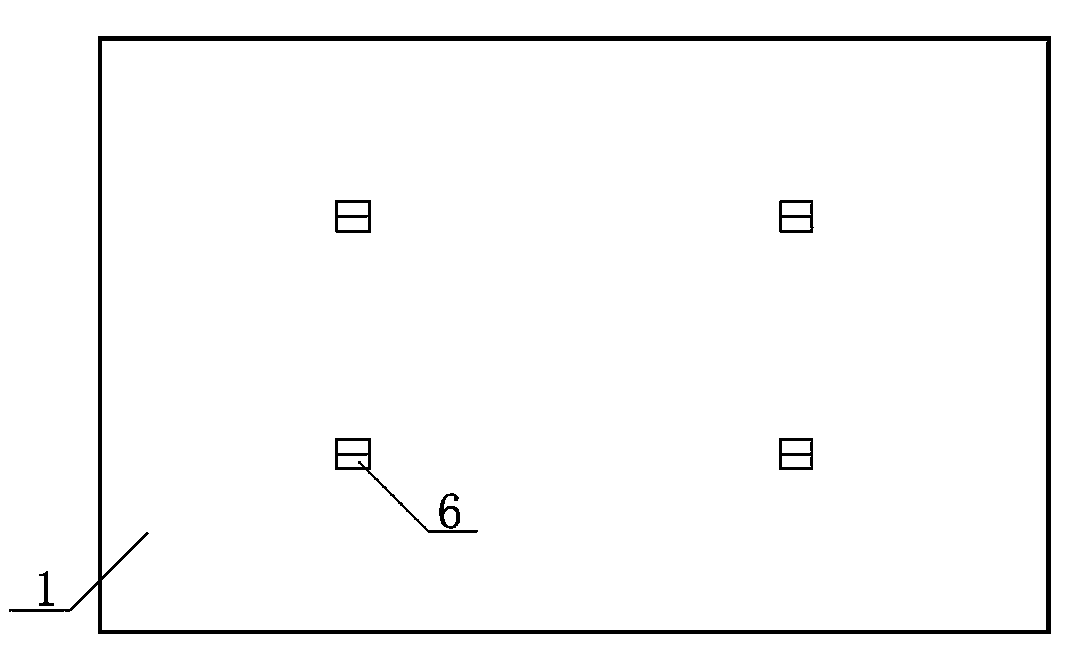

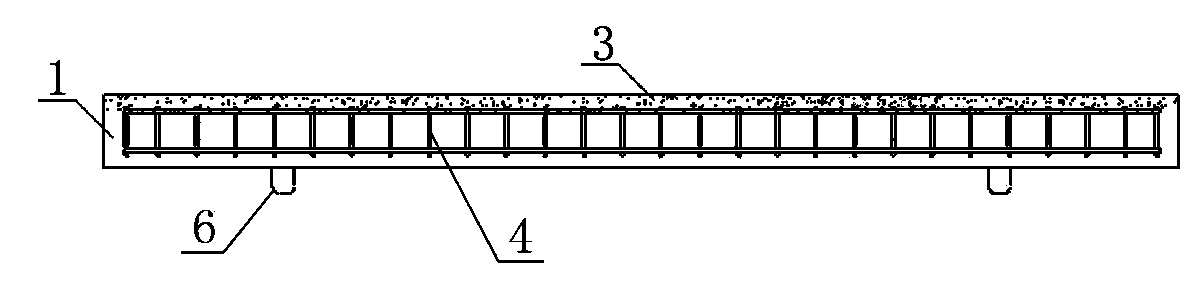

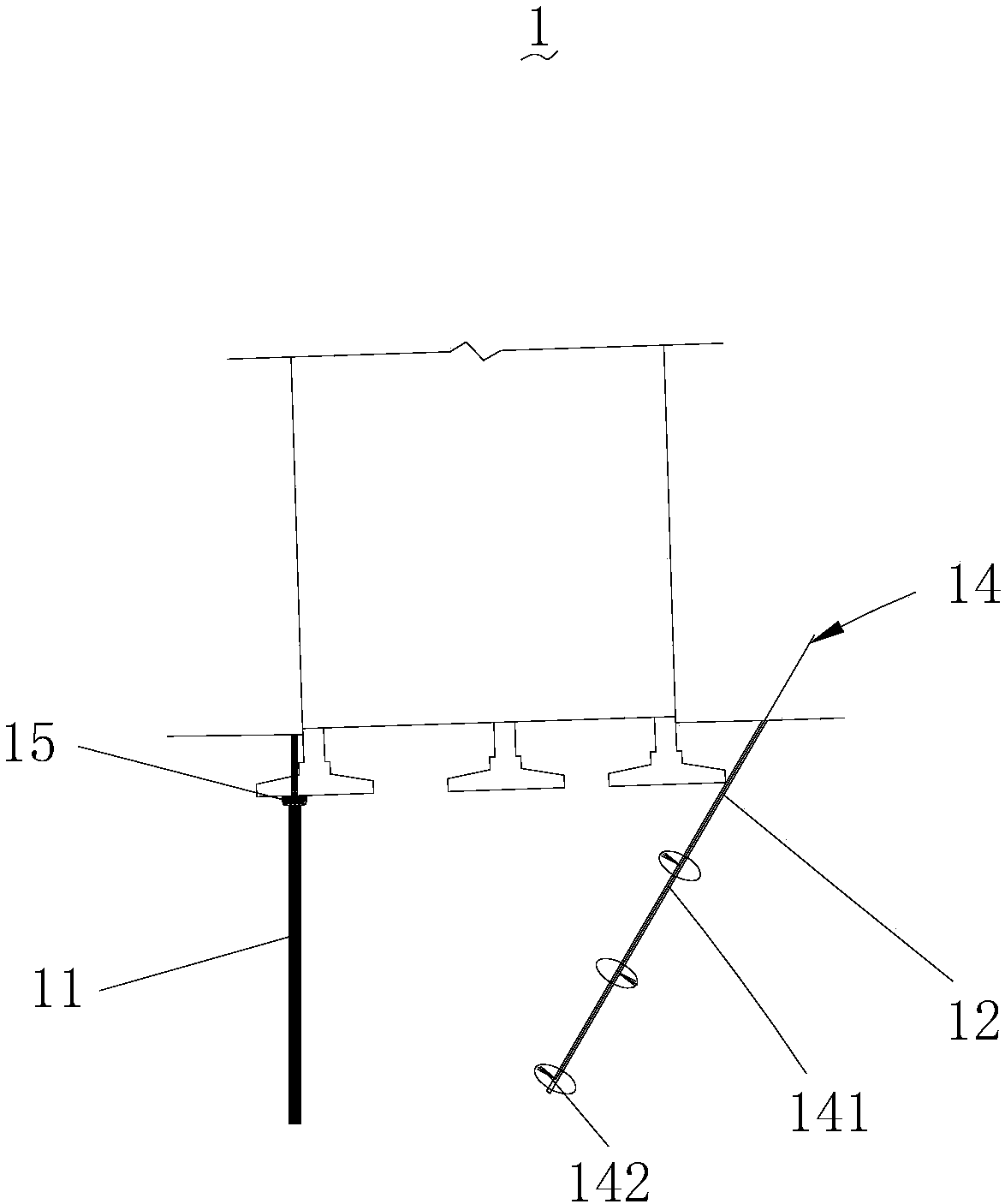

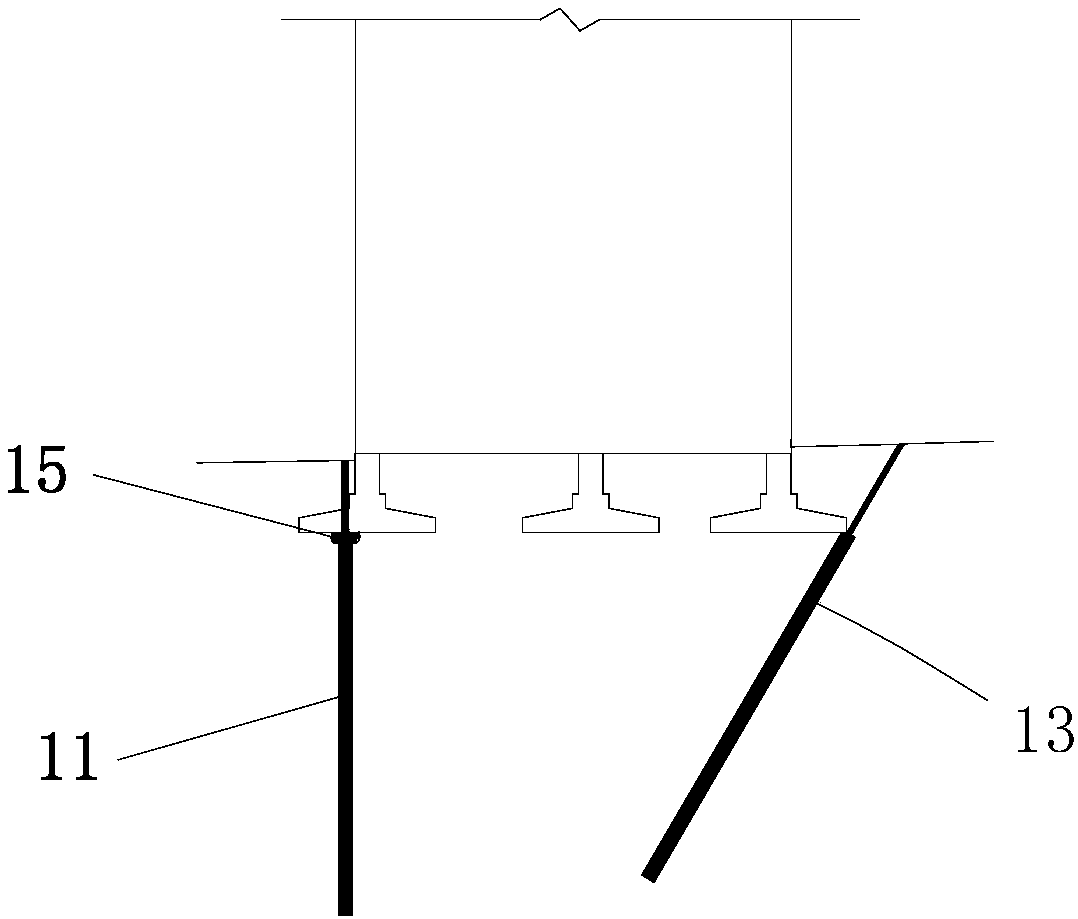

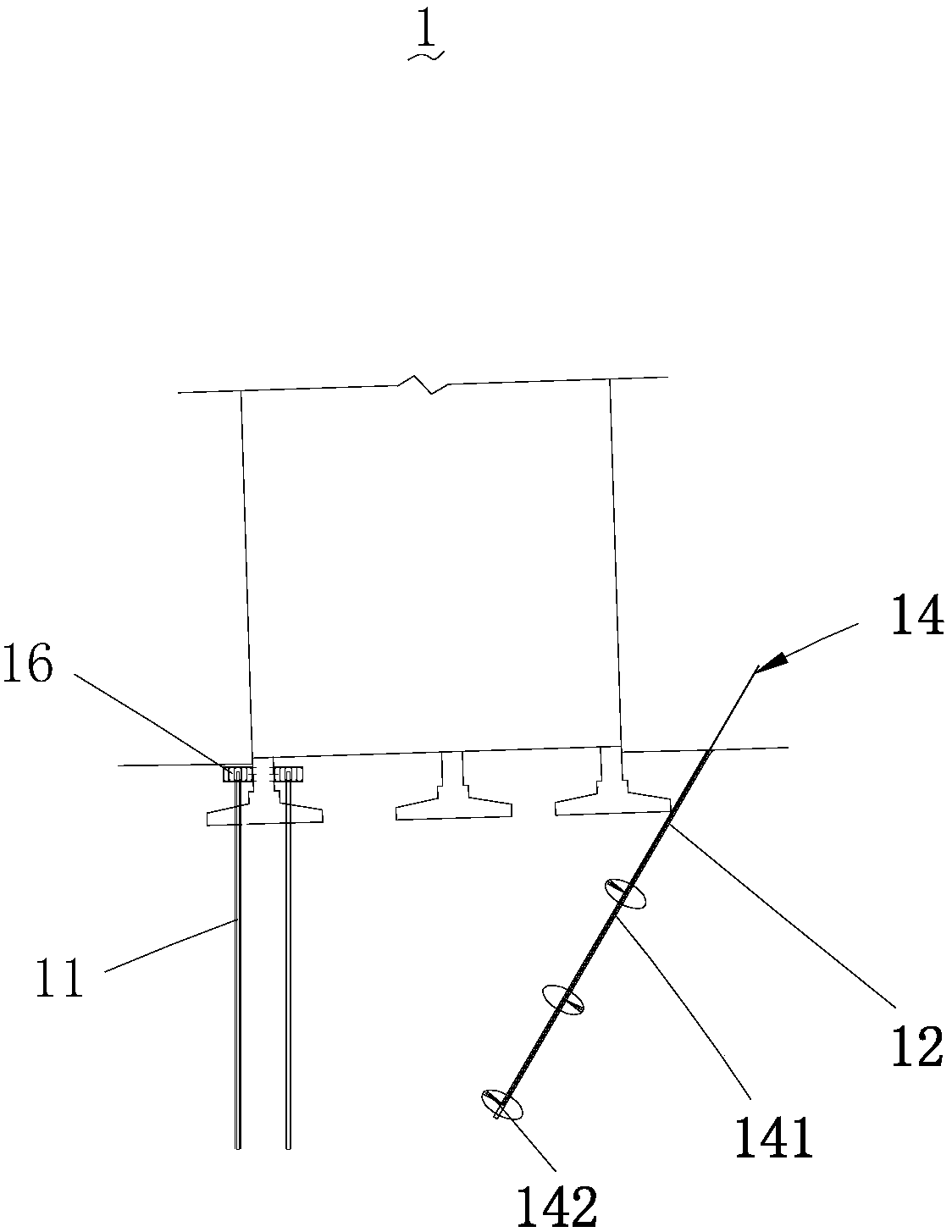

Cyclically used temporary pavement platen, and method for paving temporary pavement therewith

InactiveCN102242537AQuick entryNo pollution in the processSingle unit pavingsTemporary pavingsRoad surfaceRebar

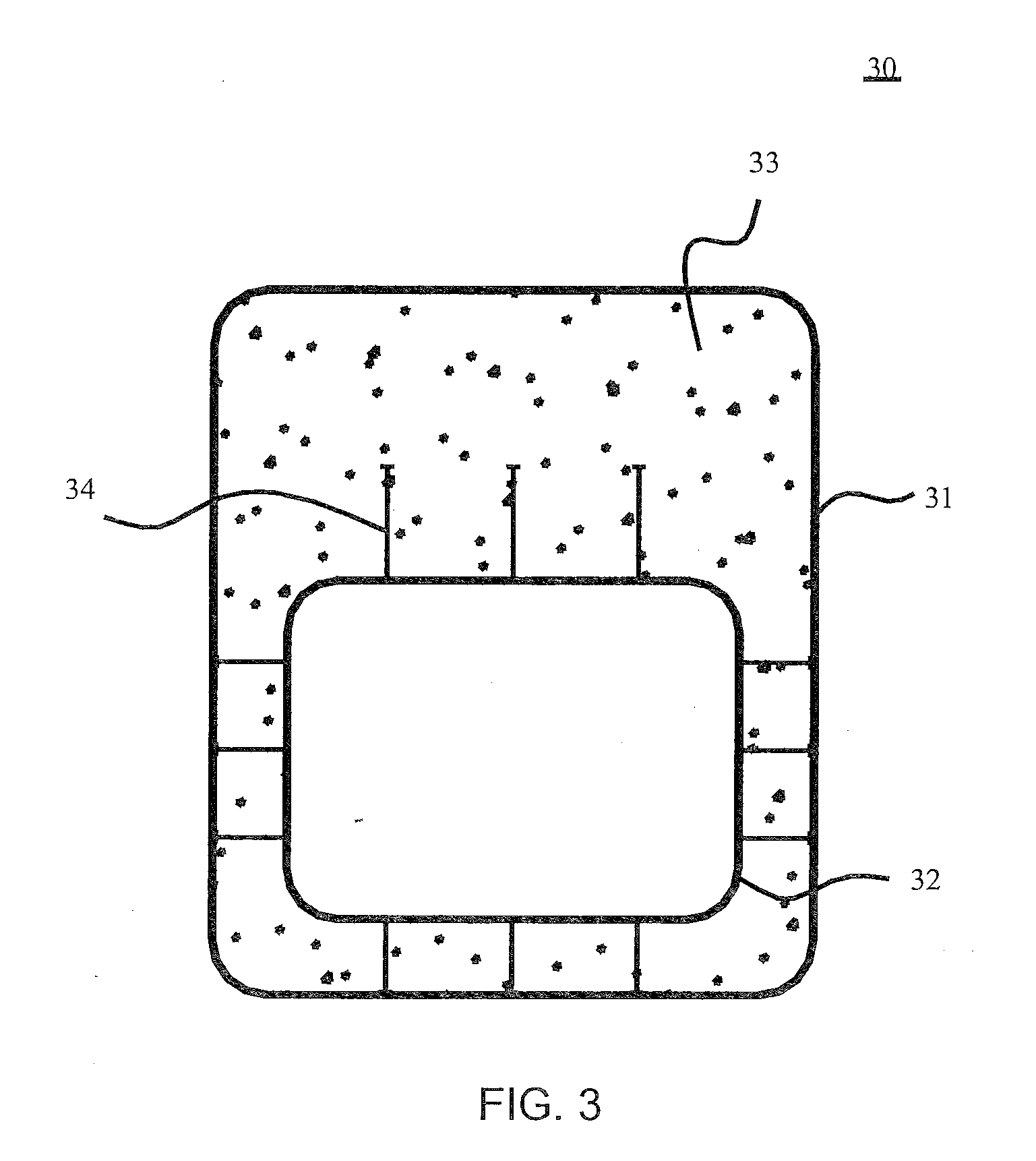

The invention discloses a cyclically used temporary pavement platen, and a method for paving a temporary pavement therewith. The cyclically used temporary pavement platen is characterized in that: the platen comprises a modularized rectangular reinforced concrete slab (1); reinforcement mats (13) which are composed of a plurality of steel bars vertically extending and steel bars transversely intersecting are arranged in the reinforced concrete flat (1); the reinforced concrete slab (1) is provided with a plurality of uniformly-distributed grooves (11) that are close to the edges of the slab(1) and suspension hooks (12) hiding in the grooves (11), the suspension hooks (12) are anchored with the reinforcement mats, and tops of the suspension hooks (12) are slightly lower than the upper surface of the reinforced concrete flat (1). The size and the shape of the cyclically used platen match with those of standard roads, and the platen which is provided with suspension hooks therein and has the characteristics of convenience of lifting and simplicity of construction when the temporary road is paved allows cyclic utilization, and safety and environmental protection to be realized.

Owner:YOULIHUA BUILDING MATERIALS HUIZHOU

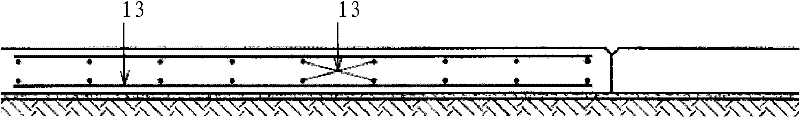

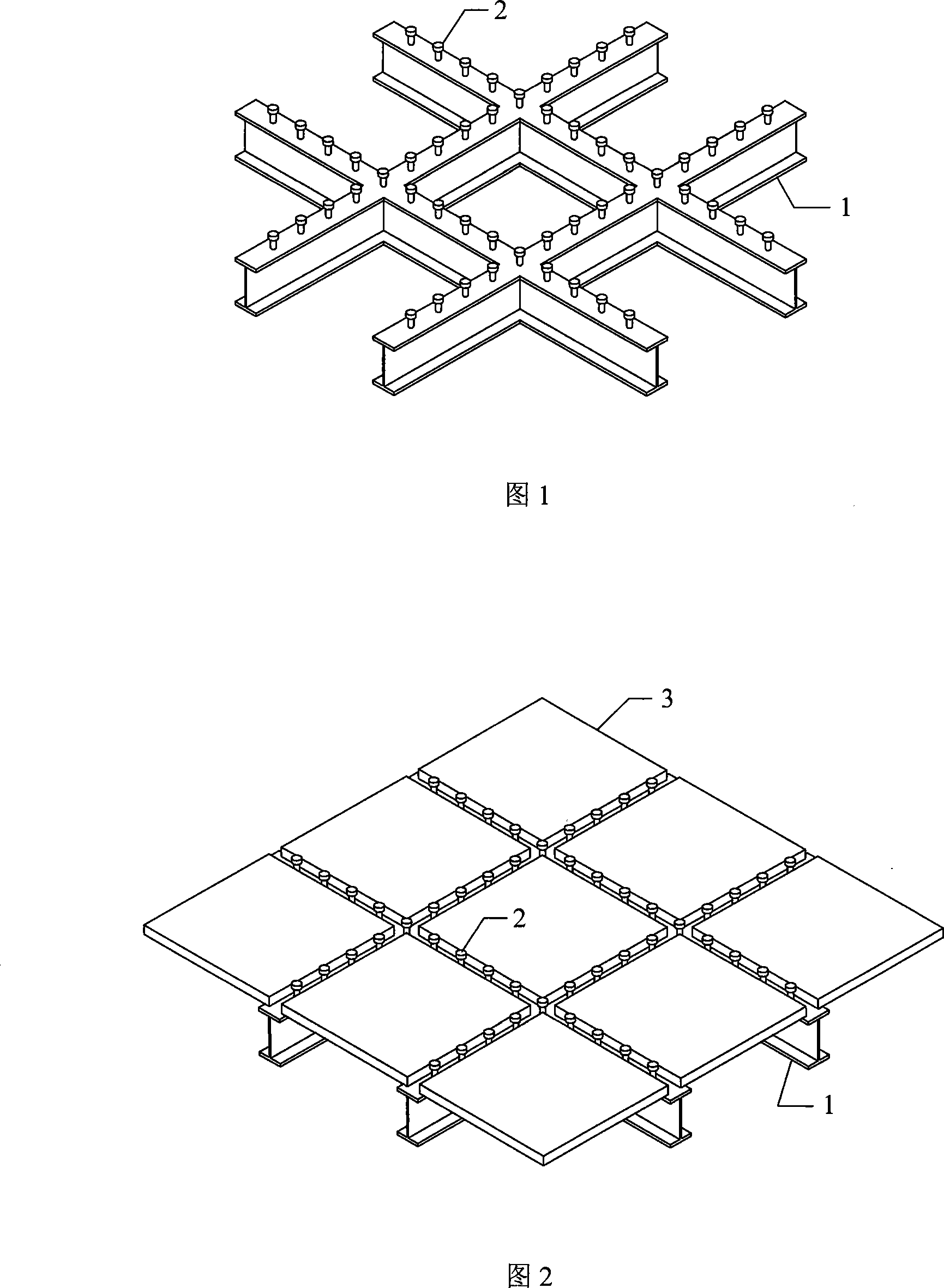

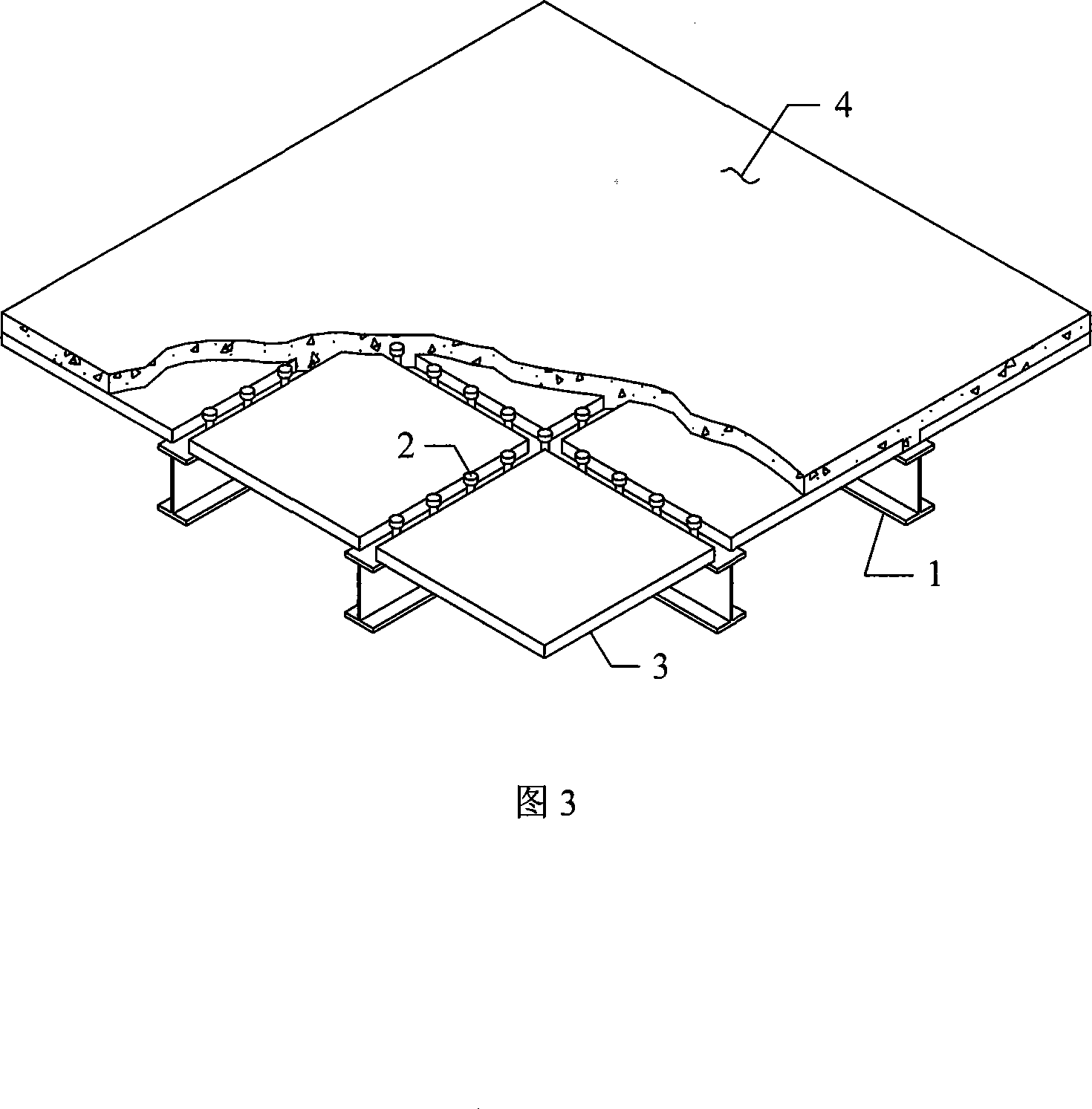

Bidirectional steel-stacked plate concrete composite building roof

The invention relates to a dual-way steel-laminated slab concrete composite floor, belonging to a new large span floor structure, comprising a cross steel beam, a prefabricated slab and a later pouring concrete layer, wherein the cross steel beam is an I shaped cross section or box section steel beam; the prefabricated slab, a common reinforced concrete slab or a prestressed concrete slab, is held on the cross steel beam and covered on the grids between the steel beams; the later pouring concrete layer is concrete poured on the prefabricated slab and the steel beam. The invention has the advantages of low structure height, high bearing capacity, stiffness, bilateral support effect, saved forming procedure and formwork, reduced the wet work amounts of site concrete, favorableness to the three-dimensional construction, and shortened construction period.

Owner:TSINGHUA UNIV

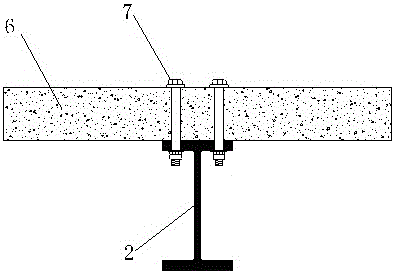

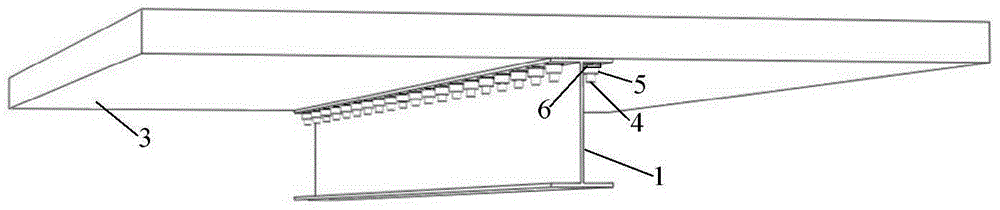

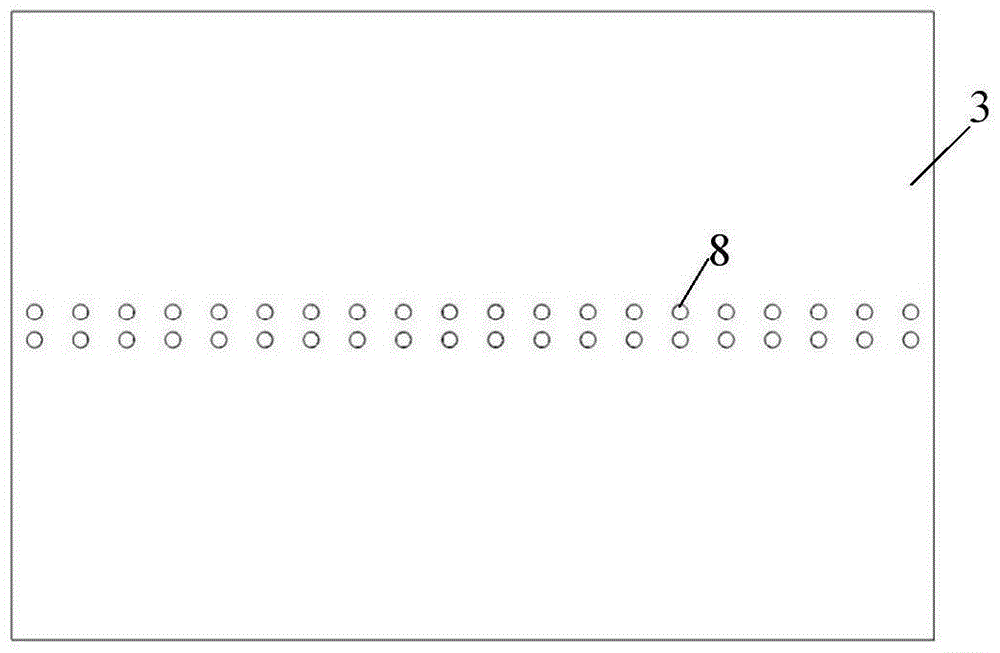

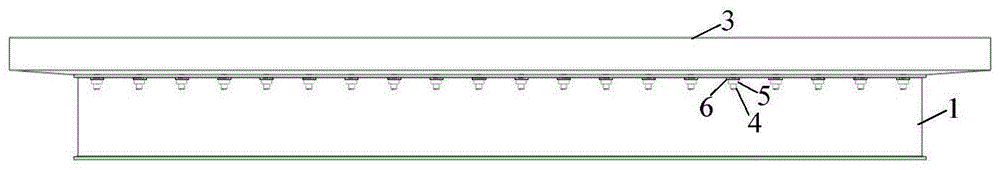

Prefabricated assembled steel-concrete composite beam connected by adopting high-strength bolt

InactiveCN105239720AImprove assembly efficiencyWork lessLoad-supporting elementsBridgesRebarPrecast concrete

The invention discloses a prefabricated assembled steel-concrete composite beam connected by adopting a high-strength bolt. The composite beam main comprises a steel beam, a prefabricated reinforced concrete slab and a shearing resistant bolt connection pair, wherein reasonable structural measures are reserved on the steel beam and the prefabricated concrete slab, and the shearing resistant bolt connection pair is adopted to connect the steel beam with the prefabricated concrete slab, so that compared with a situation that the beam-slab connection part is in rigid connection and the shear capacity is not substantially reduced, strong ductility and deformability can be obtained. When a prefabricated slab needs to be replaced, by detaching the nut of the shearing resistant bolt, the prefabricated slab is separated from the steel beam, so as to realize detaching and replacement of the prefabricated slab. All components adopted in the invention are assembled and connected on site, so that field welding work and template engineering can be reduced, the industrial assembly efficiency of buildings is improved, the function of detaching, separating and replacement of the beam-slab main body structure of the assembled composite structure can be achieved, and the novel architectural concept of capability of detachment and energy conservation and environment protection of building components can be embodied.

Owner:HUNAN UNIV

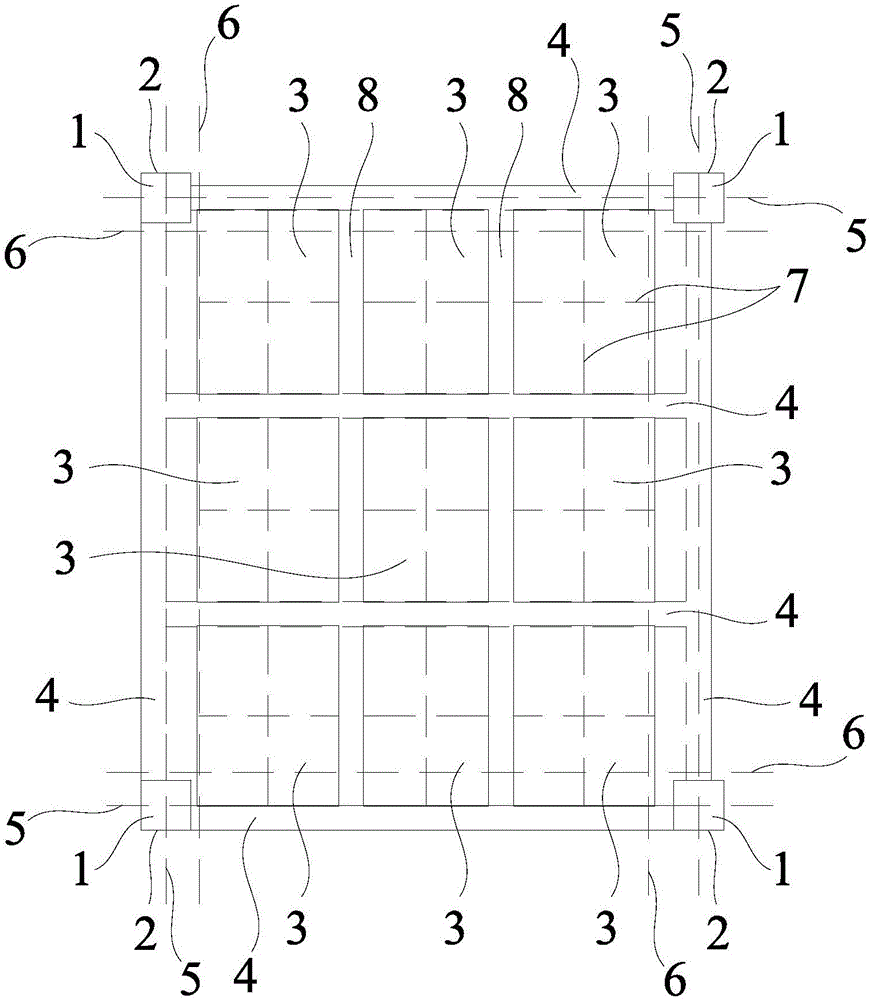

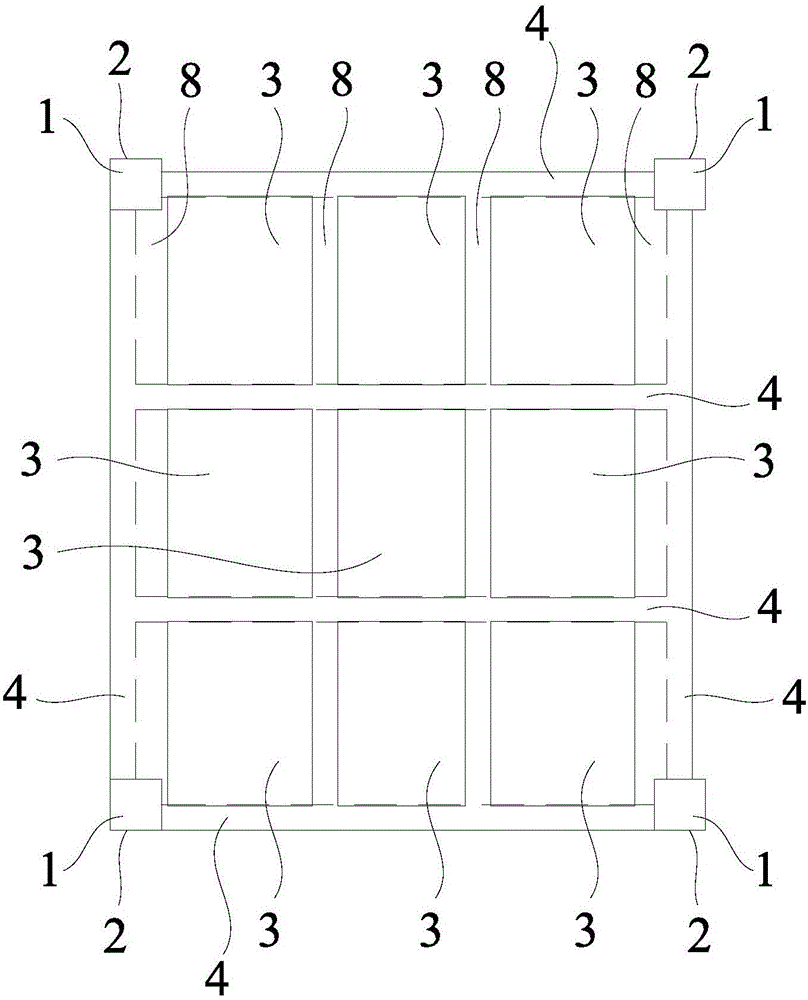

Integral assembling type building system and installing method

InactiveCN105649360AImprove quality controlEasy to installBuilding material handlingDwelling buildingTime of usePrecast concrete

The invention belongs to the technical field of building engineering and particularly relates to an integral assembling type building system and an installing method. The integral assembling type building system is characterized by comprising prefabricated steel reinforced concrete combination columns, prefabricated steel reinforced concrete combination beams, prefabricated reinforced concrete slabs, a prefabricated light integral inner wall and a prefabricated concrete heat preservation outer wall which are assembled together. The building system has the beneficial effects that all the members are prefabricated in a factory, quality is controlled conveniently, and the construction difficulty caused by outdoor weather changes can be reduced. Moreover, splicing is carried out on site, and installing is safe, fast and convenient. The recycle rate of formworks is high, work for the formworks and frame pipes on site is avoided, the number of times of use and consumption of the formworks and frame pipes are reduced, on-site labor is saved, the on-site dust raise phenomenon is improved substantially, the influence on the environment is small, and environmental pollution is reduced.

Owner:SHANDONG YUANBO BUILDING TECH CO LTD

Combined hollow floor slab comprising steel, concrete and hung fireproof ardealite plate and its production process

The present invention discloses large hollow steel-concrete floor slab and its production process. The floor slab has formwork of U-shaped cross section thin steel sheet connected into lattice and reinforced concrete deposited into the formwork to constitute integral lower rib lattice slab of the large hollow floor slab; in-situ deposited dense rib reinforced concrete slab with ardealite formwork as the upper rib lattice slab; reinforced concrete shear key to connect the lower rib lattice slab and the upper rib lattice slab integrally; and fireproof ardealite board fixed to the outside of the U-shaped cross section thin steel sheet. The present invention has the advantages of low steel consumption, low construction cost, high rigidity, high strength, convenient construction, etc.

Owner:GUIZHOU UNIV

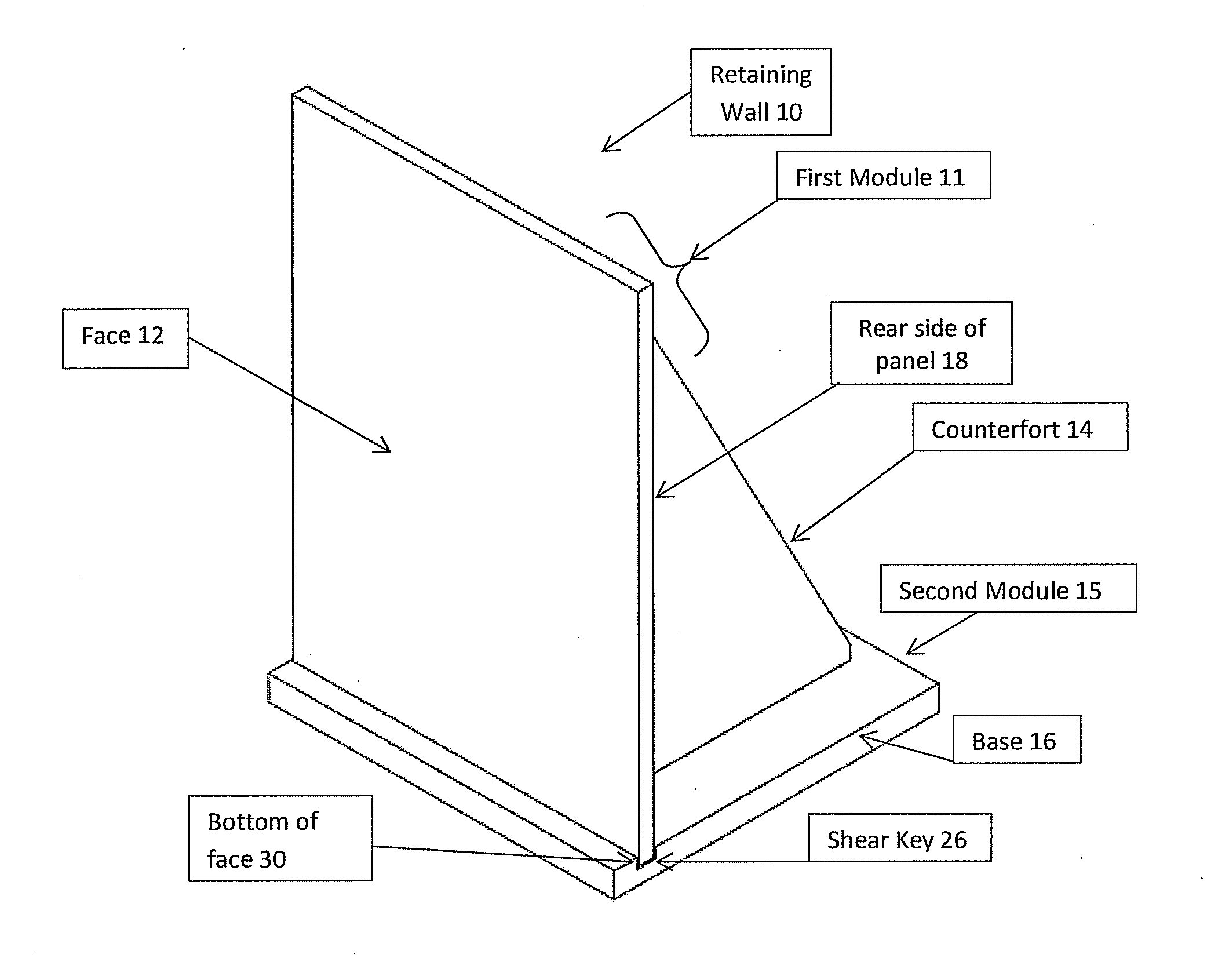

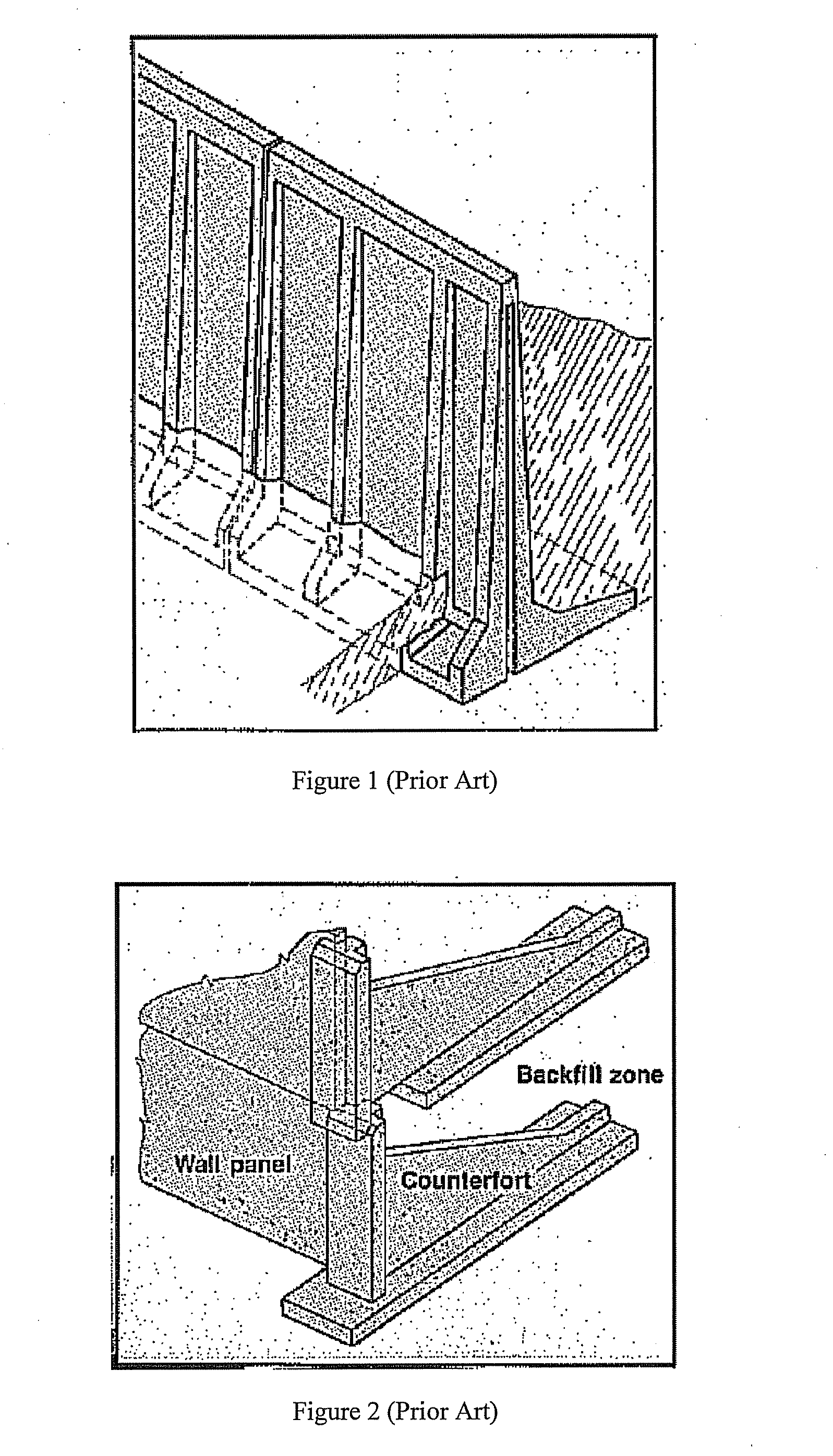

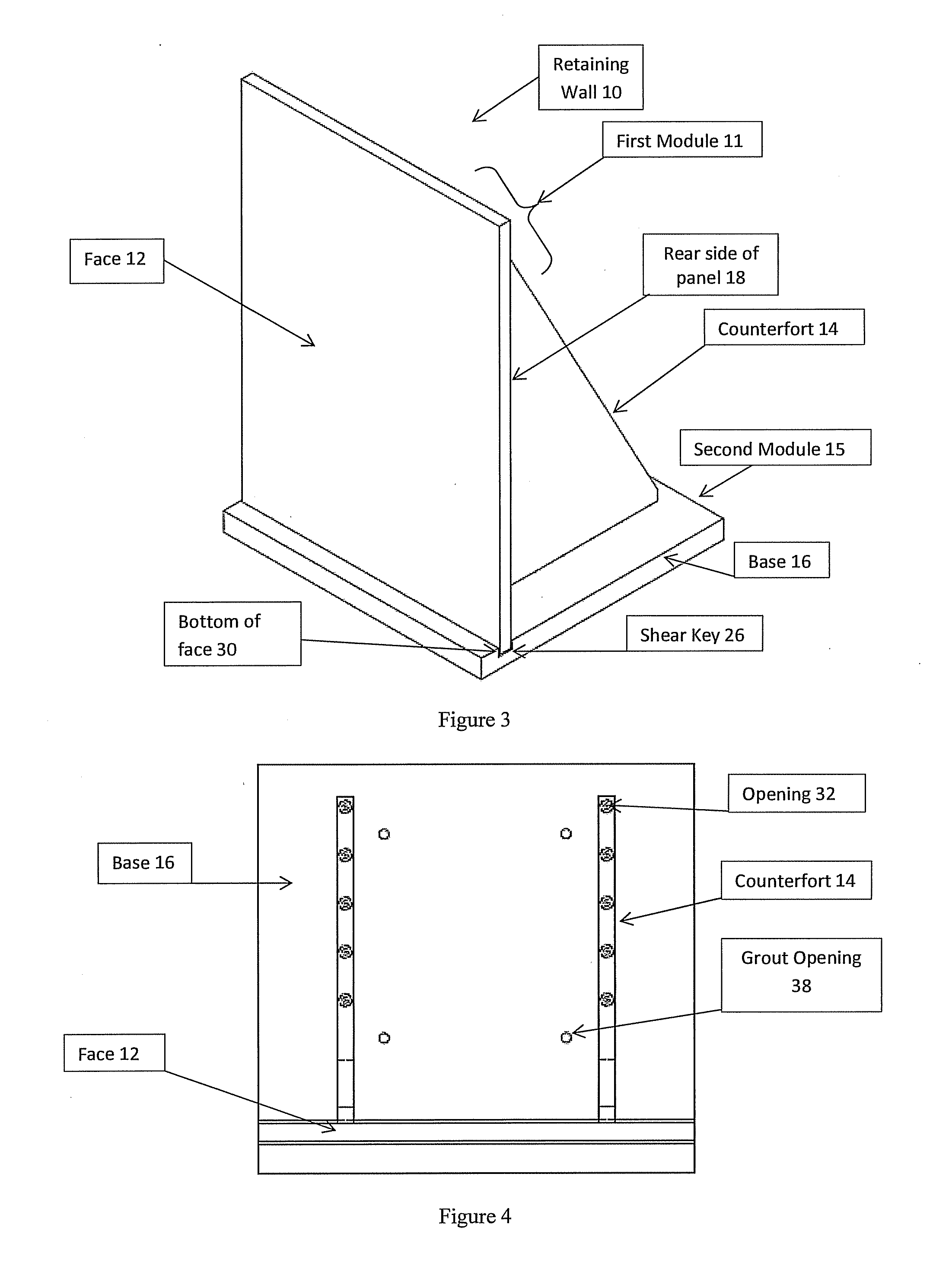

Precast concrete retaining wall

InactiveUS20140270990A1Reduce installation costsLow transportation costArtificial islandsExcavationsRebarPrecast concrete

A retaining wall comprises a precast concrete face panel with integral counterfort connected to the rear of the facing and a precast concrete base supporting the facing and the counterfort. The counterfort comprises a reinforced concrete slab having a substantially vertical front portion at a substantially right angle to a base portion, and a rear portion running from substantially the top of the counterfort to the rear of the base portion thereof. The face and counterfort module is connected to the base module through the use of rebar and openings which are fixedly attached together using a high strength group.

Owner:UTILITY CONCRETE PROD

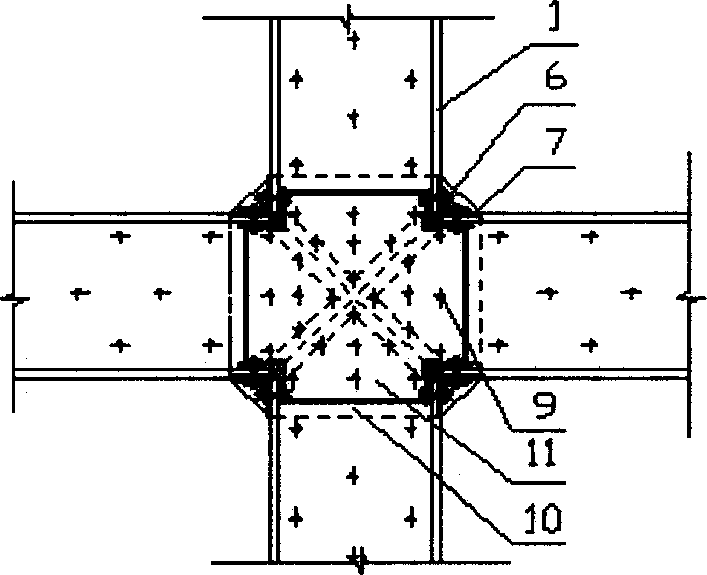

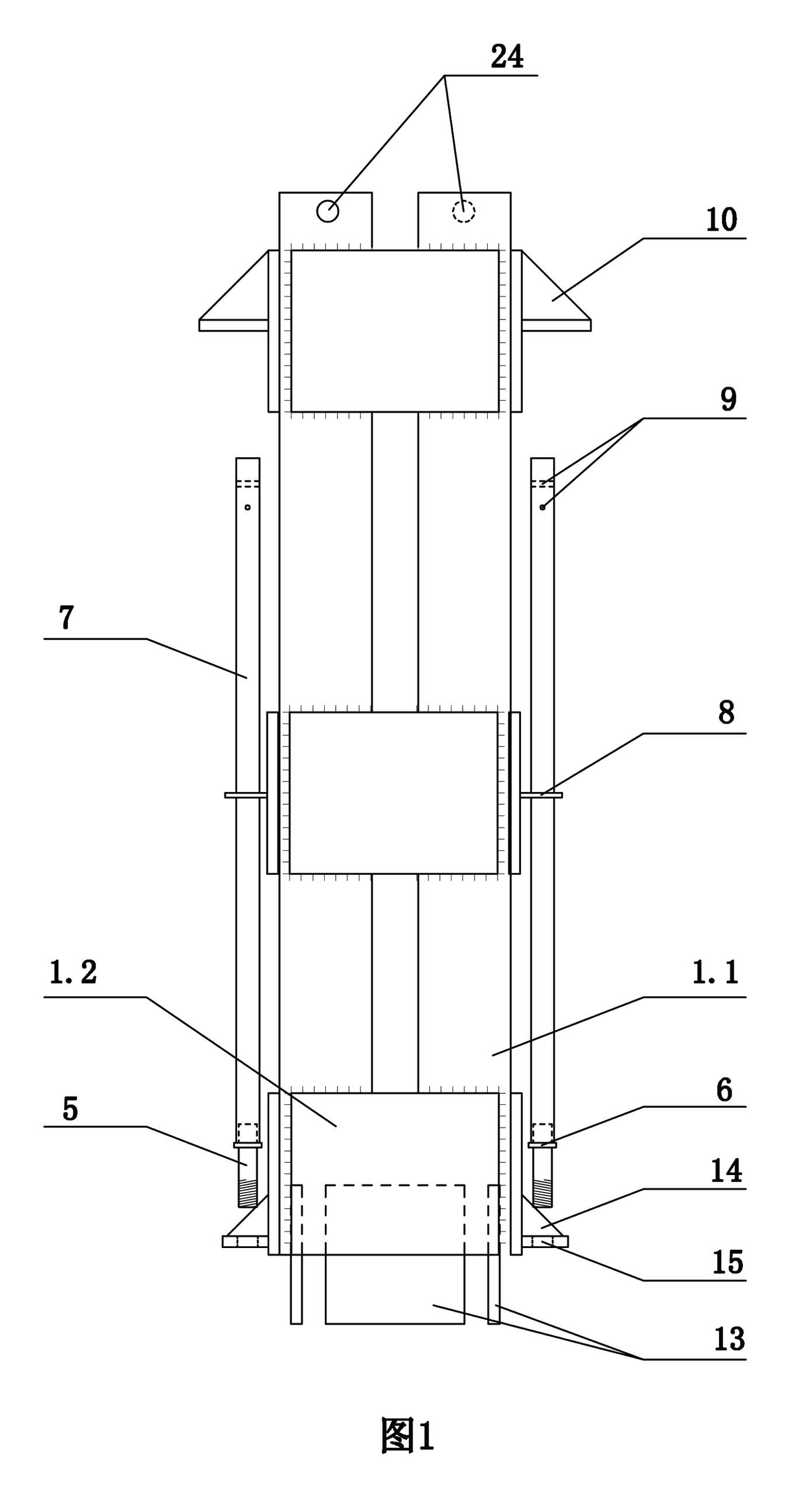

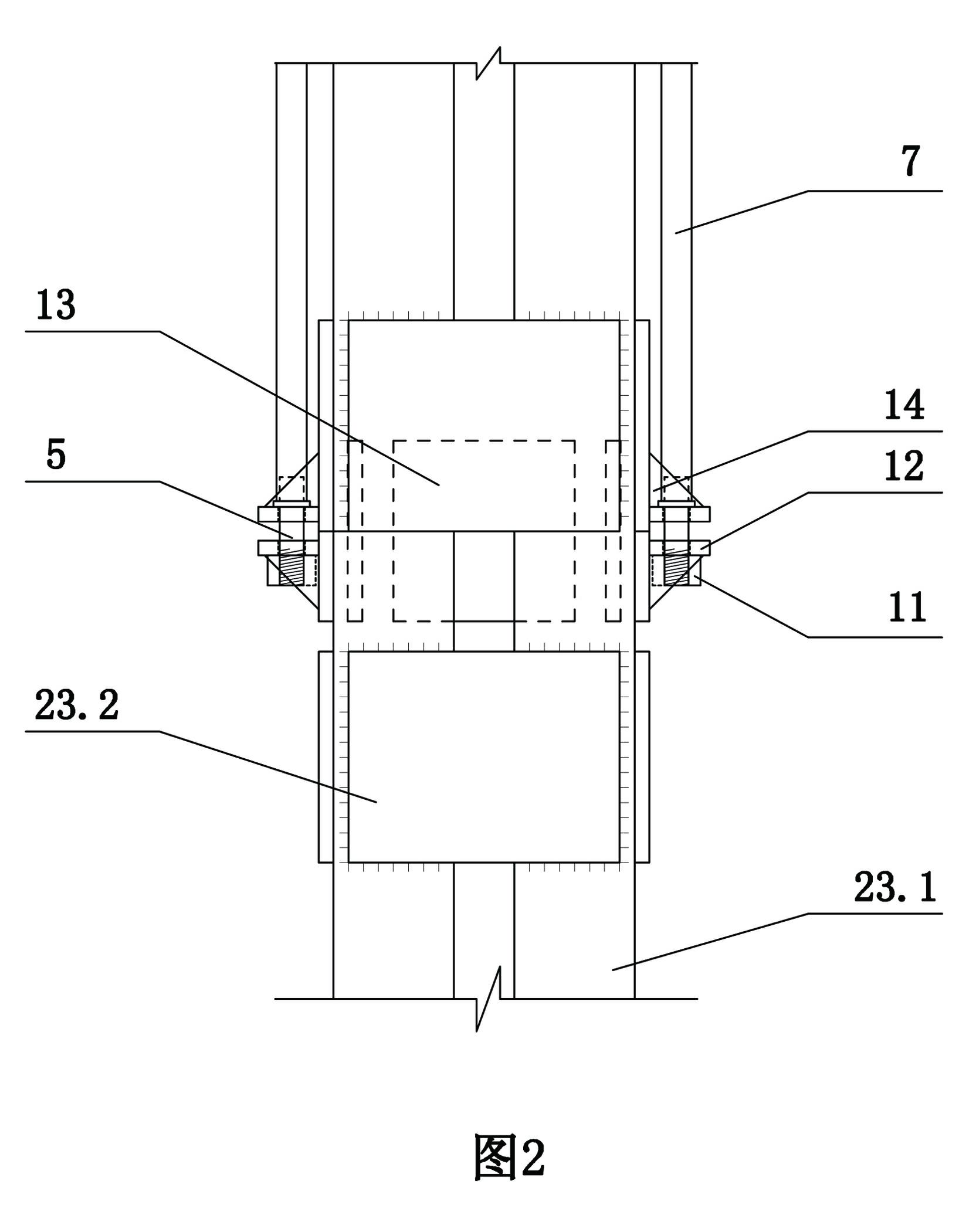

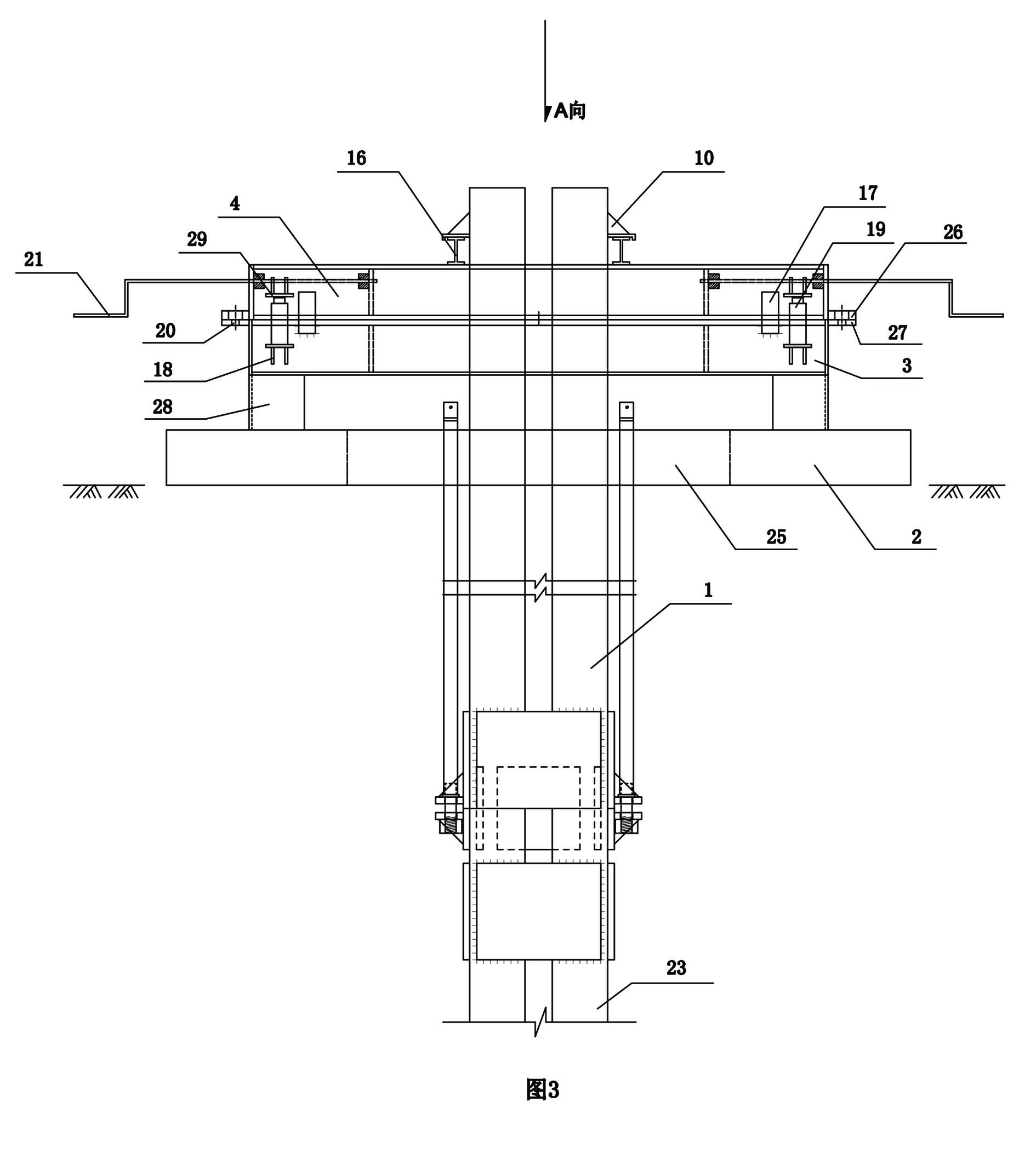

Abutting joint device of steel lattice column, and construction method of same

ActiveCN102493554AAdjust the positioning accuratelyMeet the design requirementsBuilding constructionsExcavationsSheet steelSteel columns

The invention discloses an abutting joint device of a steel lattice column, which comprises the steel lattice column, wherein the steel lattice column is composed of four angle steel arm members and batten plates which are surrounded and welded around the four angle steel arm members at intervals; the upper end of the steel lattice column is connected with a movable joint; the upper end of the movable joint is connected with a locator; the movable joint is connected as a rigid main body by four section steel columns and steel surrounding members which are welded around the four section steel columns at intervals; the left side surface and the right side surface of the rigid main body are symmetrical structures; the movable joint is connected with the steel lattice column through an abutting joint screw rod; the locator is composed of a base plate, an adjusting frame support and an adjusting frame; the base plate is a cast-in-place reinforced concrete plate with middle holes; the adjusting frame support is a square-shaped hollow frame with four support legs; the hollow frame is internally filled with concretes; the adjusting frame is a square-shaped hollow frame obtained by welding steel plates and is arranged on the adjusting frame support; and the size of the adjusting frame is the same as that of the adjusting frame support. The abutting joint device of the steel lattice column, and the construction method of the same disclosed by the invention solve the problems in material waste and control of location and construction qualities if the steel lattice column is lengthened directly.

Owner:北京城建中南土木工程集团有限公司

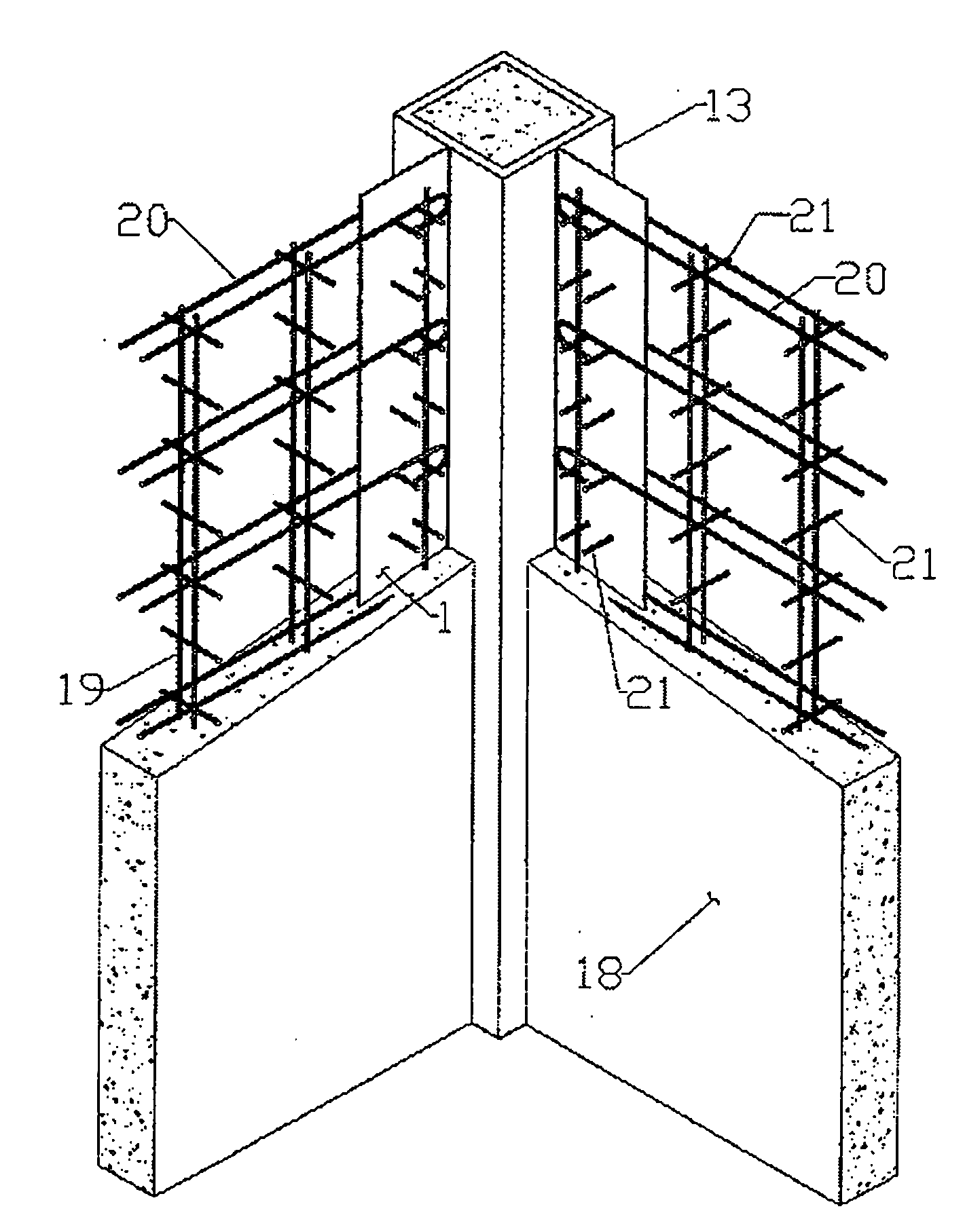

Integral composite-structure construction system

Composite structural system for floors or roofs comprising steel beams and reinforced concrete slab or shear walls comprising steel columns and reinforced concrete diaphragms. In both cases a steel plate with holes crossed with rebars is welded to the steel beam or to the steel column which performs the integral combination of the concrete, the structural element and the rebars.

Owner:OSPINA PEDRO

Hybrid frp-concrete-steel double-skin tubular beams and hybrid dstb/slab units using the beams

InactiveUS20120124937A1Improve corrosion resistanceFirmly connectedStrutsFloorsCost effectivenessSteel tube

This invention relates to a novel hybrid FRP-concrete-steel double-skin tubular beam and a hybrid beam / slab unit which employs the hybrid tubular beam. The hybrid double-skin tubular beam consists of an outer FRP tube, an inner steel tube, and concrete filled between the outer FRP tube and the inner steel tube, and the inner steel tube is provided with a plurality of shear connectors on its side engaged with concrete. The inner steel tube is located eccentrically relative to the outer FRP tube towards the side of the hybrid tubular beam to be tensed. The inventive hybrid beam / slab unit is a slab-on-girder system which is comprised of the hybrid double-skin tubular beam and the lightweight slab of good corrosion resistance (such as a FRP slab or an aluminum slab) that is provided thereon, or a deck or floor system which is comprised of the hybrid double-skin tubular beam and a FRP-rib reinforced concrete slab and in which the upper portion of the hybrid double-skin tubular beam is engaged with the bottom of the FRP-rib reinforced concrete slab thereinside so as to form an integrated body. The inventive hybrid tubular beam features an excellent resistance against corrosion, a good ductility and cost-effectiveness. and is lightweight, while at the same time allows for easy construction and connection with other members.

Owner:THE HONG KONG POLYTECHNIC UNIV

Integral composite-structure construction system

Composite structural system for floors or roofs comprising steel beams and reinforced concrete slab or shear walls comprising steel columns and reinforced concrete diaphragms. In both cases a steel plate with holes crossed with rebars is welded to the steel beam or to the steel column which performs the integral combination of the concrete, the structural element and the rebars.

Owner:OSPINA PEDRO

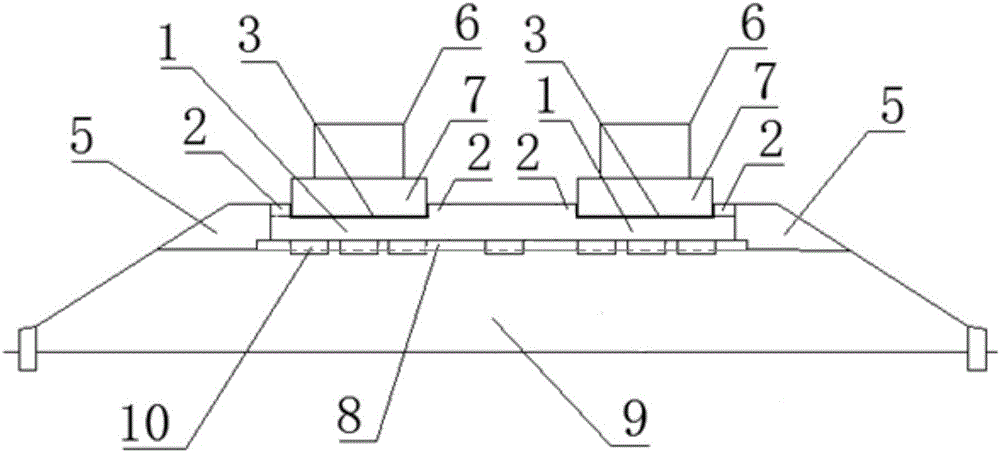

Novel fabricated vehicle bearing pavement and construction method thereof

InactiveCN103866670AImprove structural strengthEasy to transportSingle unit pavingsTemporary pavingsFiberWear resistant

The invention discloses a novel fabricated vehicle bearing pavement and a construction method thereof. The novel fabricated vehicle bearing pavement is formed by superposing, assembling and laying fabricated reinforced concrete plate members in double layers, wherein double-layer bidirectional steel reinforcement frameworks are uniformly distributed inside upper pavement slabs and lower pavement slabs; lifting rings are embedded on lower parts of the frameworks in advance; rubber films are laid between the upper pavement slabs and the lower pavement slabs; a wear-resistant steel fiber concrete layer is arranged on the upper parts of the upper pavement slabs. The construction method comprises the following steps: 1. fabricating reinforced concrete pavement members; 2. lifting and transporting the prefabricated pavement members; 3. flattening the roadbed, laying the lower pavement slabs, rubber films and upper pavement slabs sequentially, laying the pavement slabs in a manner of staggering from each other according to seams, namely the seams between the slabs are not communicated with one another. The construction quality is easily guaranteed, the prefabricated pavement member is light in structure, high in strength, and convenient to transport and construct, can be repeatedly used and is particularly suitable for laying temporary vehicle bearing roads on the construction site, the rubber films can achieve a buffer effect, the friction force between the pavement slabs can be increased, and the pavement slabs are prevented from slipping.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Low implantation line double-wire section terminal spine type bearing rail beam limiting structure in medium and low speed magnetic levitation transportation engineering

InactiveCN105887586AAvoid the problem of uneven track surfaceIncrease lateral frictionBallastwayLow speedRebar

The invention discloses a low implantation line double-wire section terminal spine type bearing rail beam limiting structure in medium and low speed magnetic levitation transportation engineering. The limiting structure comprises bearing rail beam lower subgrade filling, a bearing rail beam underlayer, two adjacent sections of bearing rail beams, vertical slab staggering prevention lapping plates, horizontal slab staggering prevention bosses and a bearing rail beam backfill material, wherein the vertical slab staggering prevention lapping plates are fixedly arranged on the bearing rail beam lower subgrade filling, and the lower ends of the vertical slab staggering prevention lapping plates stretch into the bearing rail beam lower subgrade filling. According to the invention, slab staggering prevention reinforced concrete lapping plates are arranged at bearing rail beam section positions, the bearing rail beam is arranged on the same reinforced concrete slab staggering prevention plate with a certain rigidity, and the problem that the rail surface is unsmooth due to differential settlement of the bearing rail beam lower subgrade is effectively solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

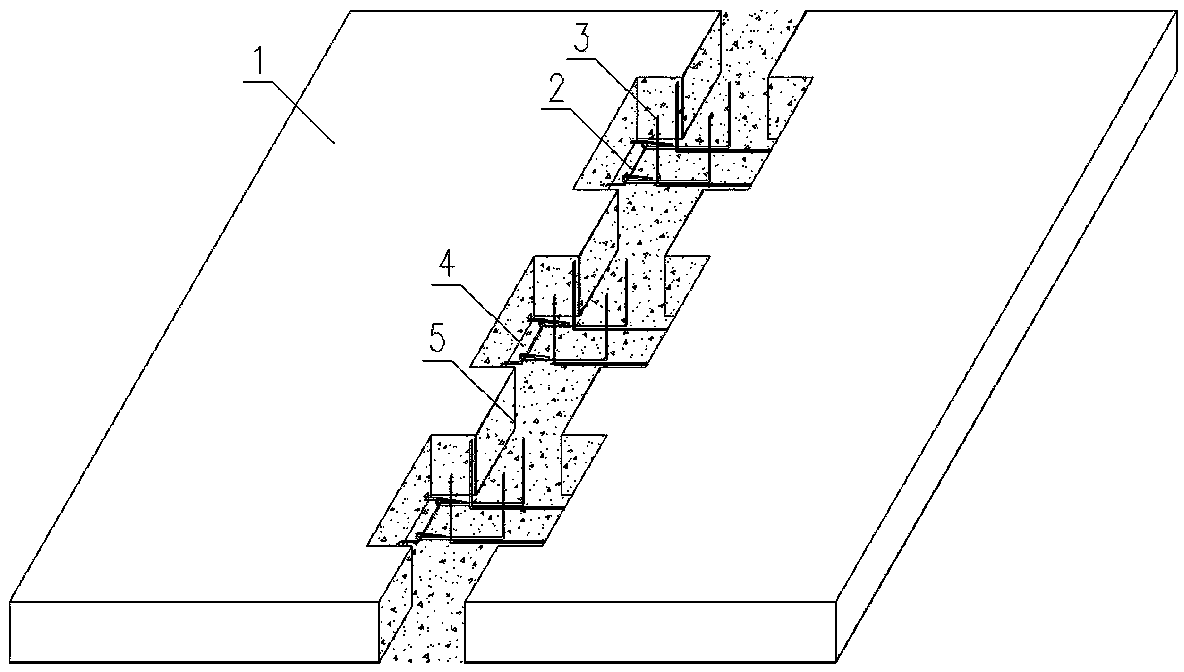

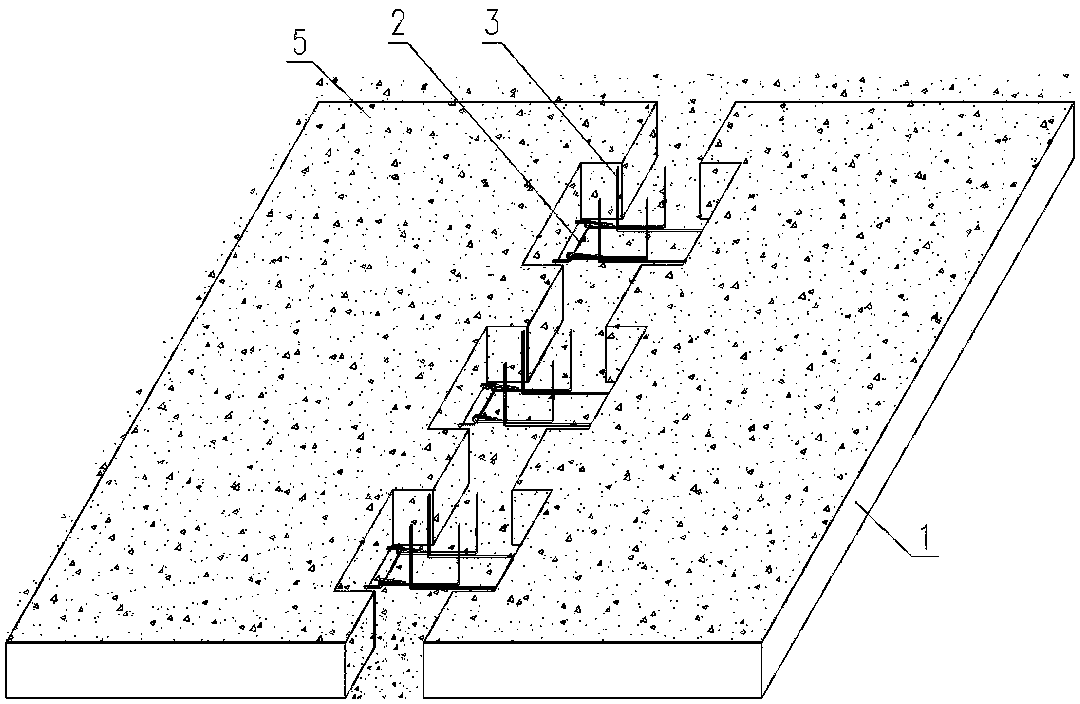

Connection method of precast reinforced concrete slabs

The invention discloses a connection method of precast reinforced concrete slabs, and belongs to the technical field of building structures. The connection method is characterized in that reinforcing steel bars which are fully anchored and of which exposed parts are in a shape of a half ring are embedded on lateral sides of the precast reinforced concrete slabs, transverse reinforcing steel bars are hung on the reinforcing steel bars in the shape of the half ring, and lapped in a reserved gap among the precast reinforced concrete slabs; a template is arranged at the lower part of the reserved gap, the precast reinforced concrete slabs are connected as a whole by pouring concrete in the reserved gap; or the template is arranged at the lower part of the reserved gap, and the concrete is poured in the reserved gap and at the upper parts of the precast reinforced concrete slabs to form a precast concrete composite slab. The connection method disclosed by the invention can improve the integrity of an assembled monolithic concrete structure and promote the development of building industrialization.

Owner:初明进

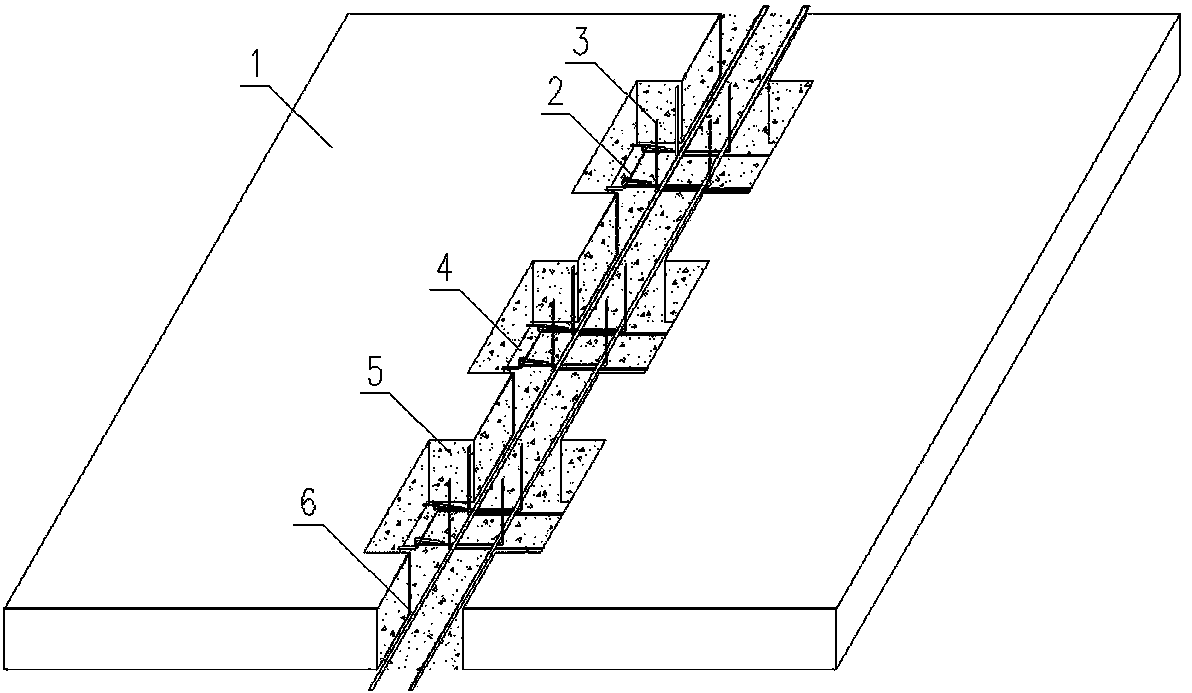

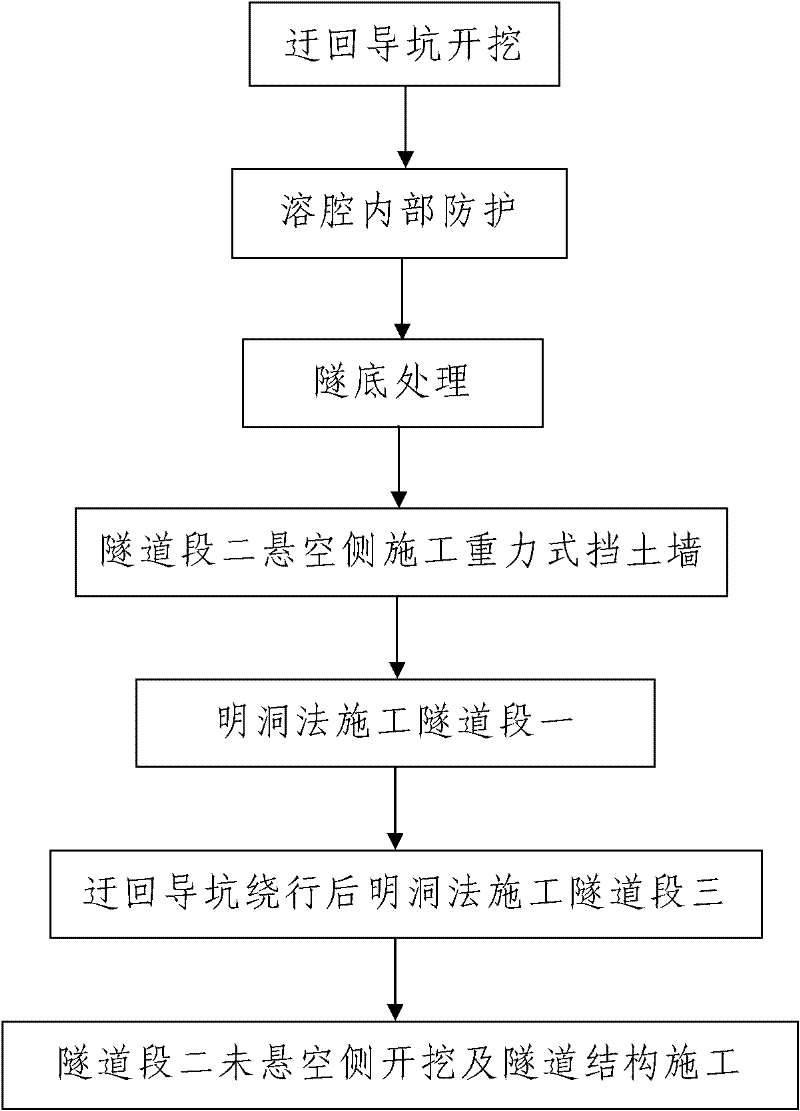

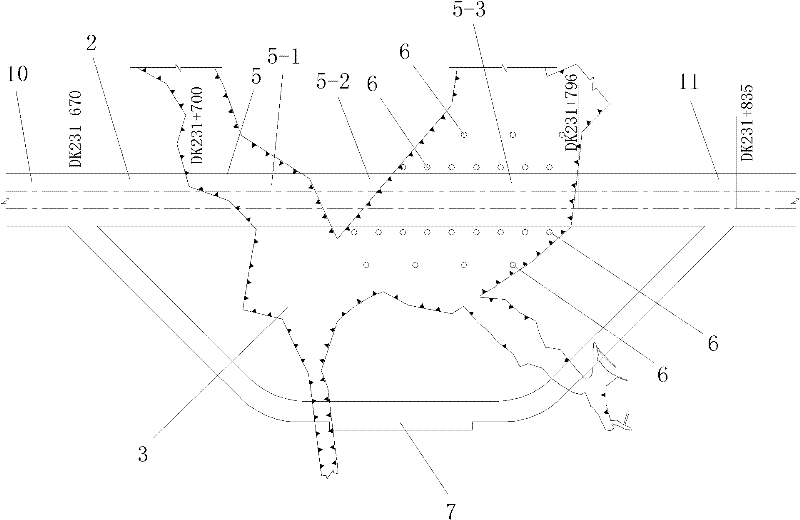

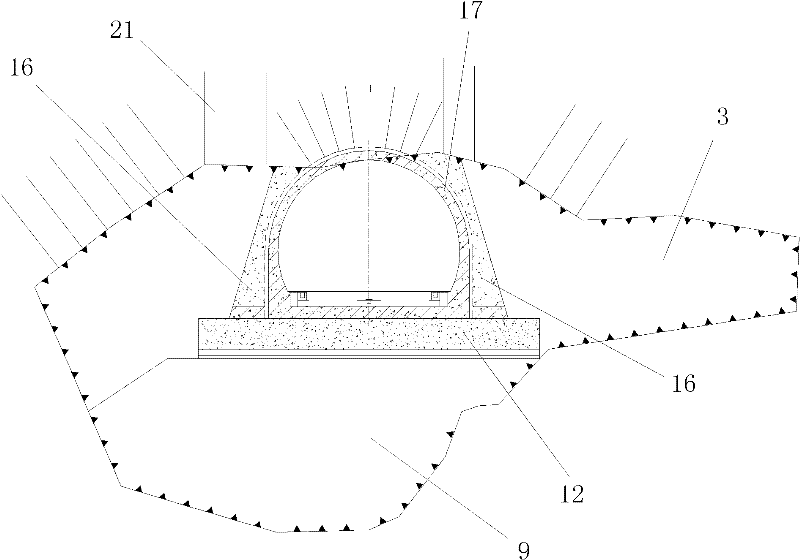

A large-scale solution cavity treatment method for karst tunnels

ActiveCN102296961AReasonable designSimplify construction stepsUnderground chambersTunnel liningLarge distanceKarst tunnel

The invention discloses a karst tunnel large-scale cavern processing method. A cavern traversing tunnel section penetrating through a cavern comprises a tunnel section I, a tunnel section II and a tunnel section III according to the distribution positions, wherein two sides of the tunnel section I are suspended in midair and the top of the tunnel section I is at a smaller distance away from a cavern top plate, one side of the tunnel section II is suspended in midair, and two sides of the tunnel section III are suspended in midair and the top of the tunnel section III is at a larger distance away from the cavern top plate. The processing method comprises the steps of: 1, excavating a bypass pilot tunnel; 2, protecting inside of the cavern; 3, processing the bottom of the tunnel: filling the cavern below the tunnel section I with rock residues and grouting for reinforcing, and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section III with concrete and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section II with hard fillers; 4, constructing a gravity retaining wall at the suspending side of the tunnel section II; 5, constructing the tunnel section I with an open cut tunnel process; 6, constructing the tunnel section III with the open cut tunnel process after the bypass pilot tunnel bypasses; and 7, constructing the tunnel section II. The karst tunnel large-scale cavern processing method has the advantages of reasonable design, convenience for construction, safe and reliable construction process and short construction period, good processing effect on the large-scale cavern.

Owner:CHINA RAILWAY 20 BUREAU GRP

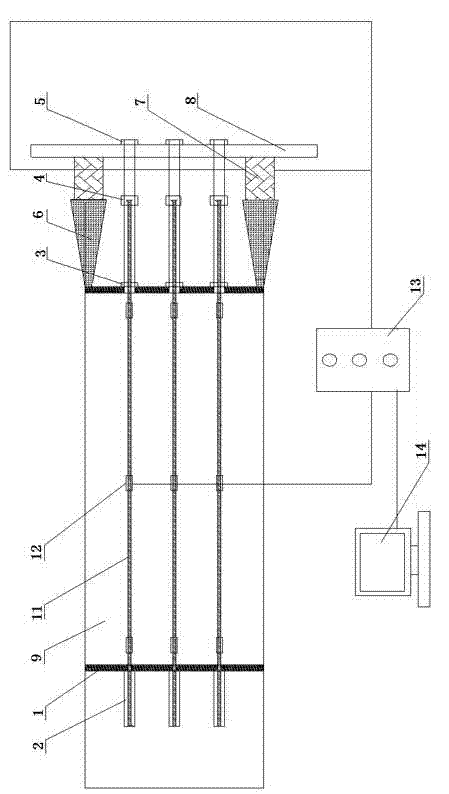

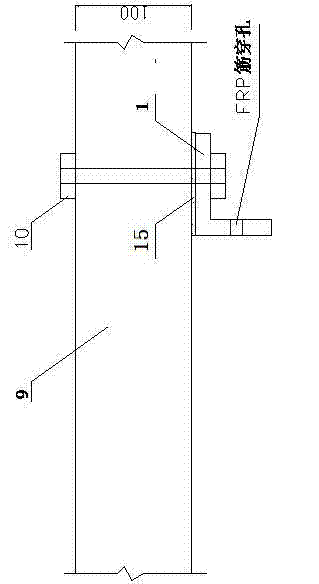

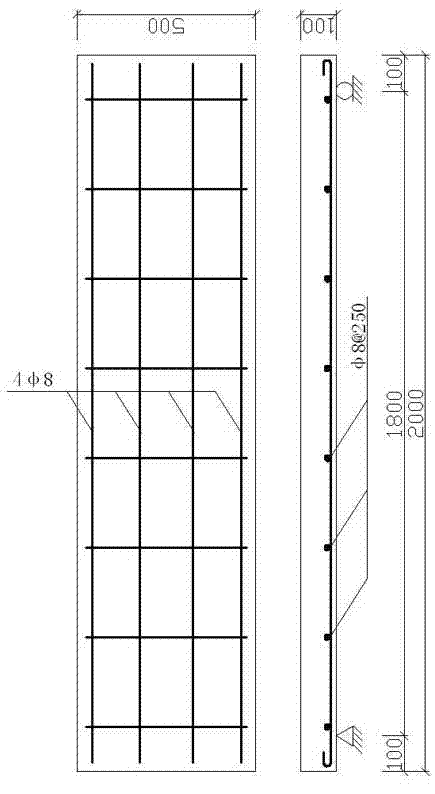

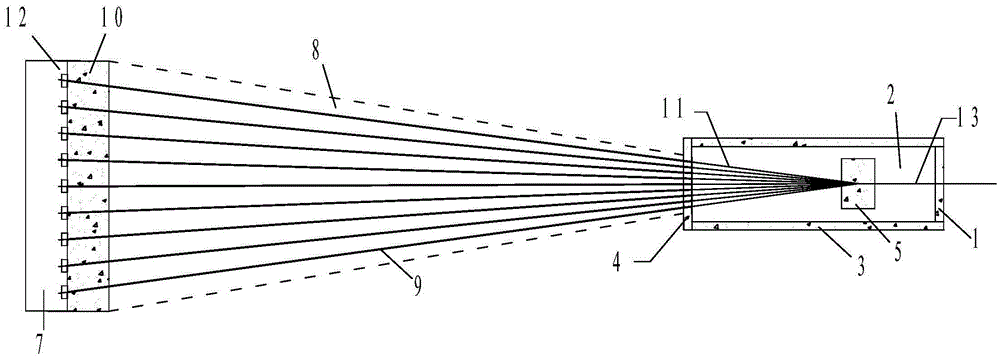

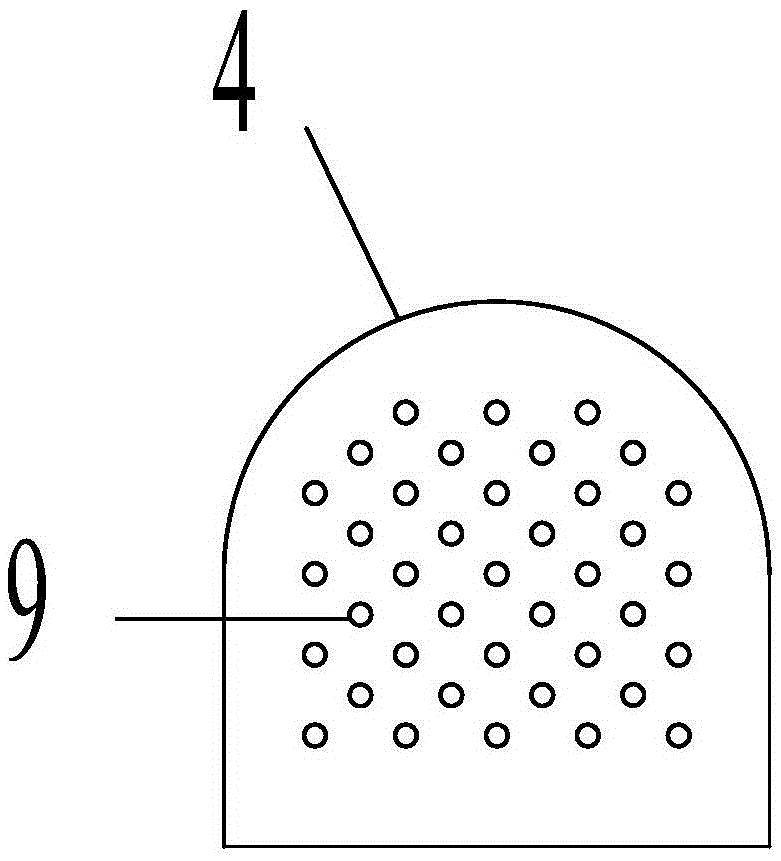

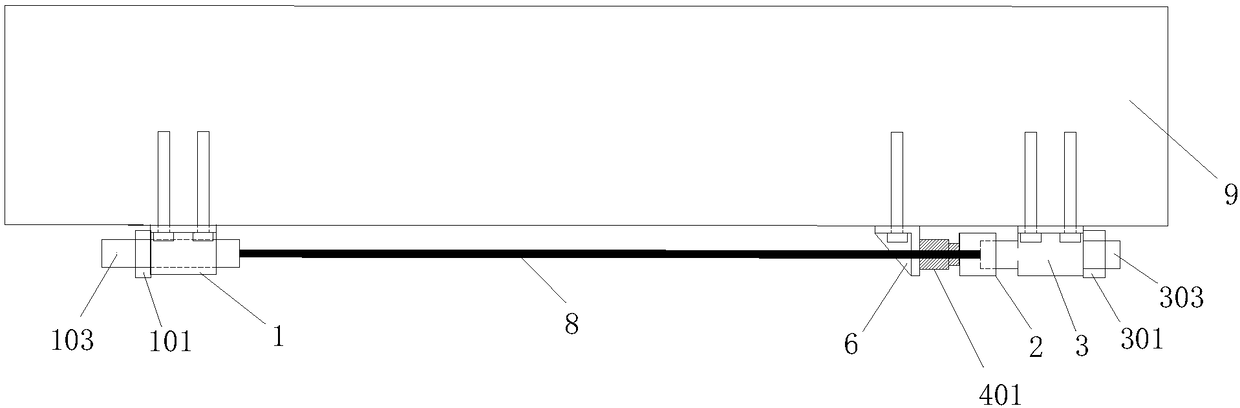

Pre-stress applying device for fiber reinforced polymer (FRP) bars outside reinforced concrete slab

The invention discloses a pre-stress applying device for fiber reinforced polymer (FRP) bars outside a reinforced concrete slab; the device comprises an anchoring system, a loading device which is connected with the anchoring system, and a data acquisition and processing system which is connected with the anchoring system and the loading device; angle steel on both sides is arranged with the holes being in alignment; the FRP bars can be accurately installed at preset positions, so that the deployment directions of the FRP bars are in parallel with the reinforced concrete slab; and anchor devices on the bottom ends of the FRP bars are connected with a tension steel sheet by connecting bolts. Firstly, tensioning force can be enabled to be applied along the centerlines of the FRP bars, so that the shear force which is produced when the FRP bars are eccentrically pulled affects the display of the tensile strength; secondly, the pre-stress is applied to the FRP bars totally, selectively or one by one conveniently by tightening or unscrewing the connecting bolts; and an anchoring bolt is adopted to fasten the FRP bars on the tension end after tensioning, so that the operation is convenient, and the loss of the pre-stress is small.

Owner:ZHENGZHOU UNIV

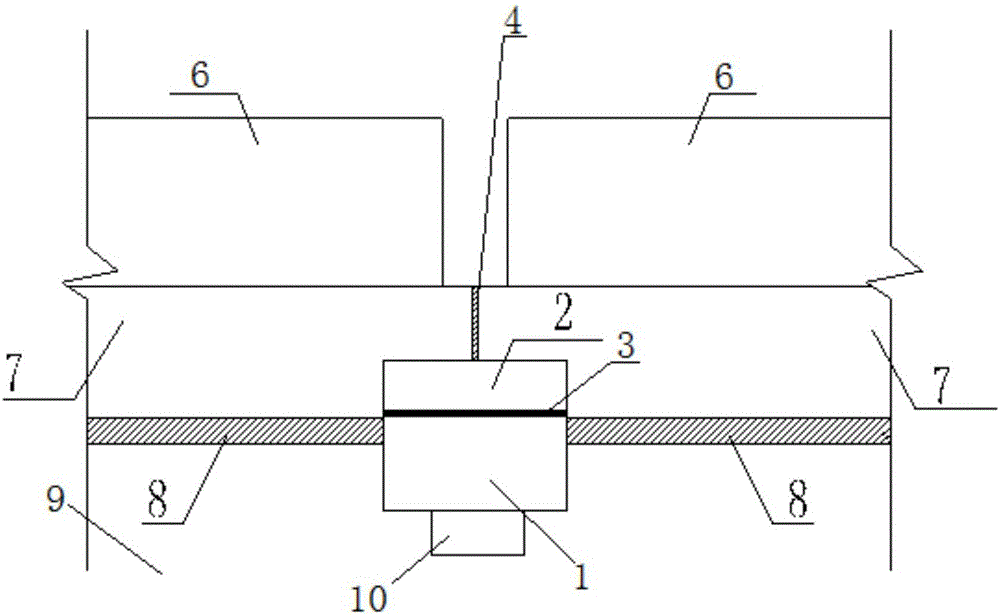

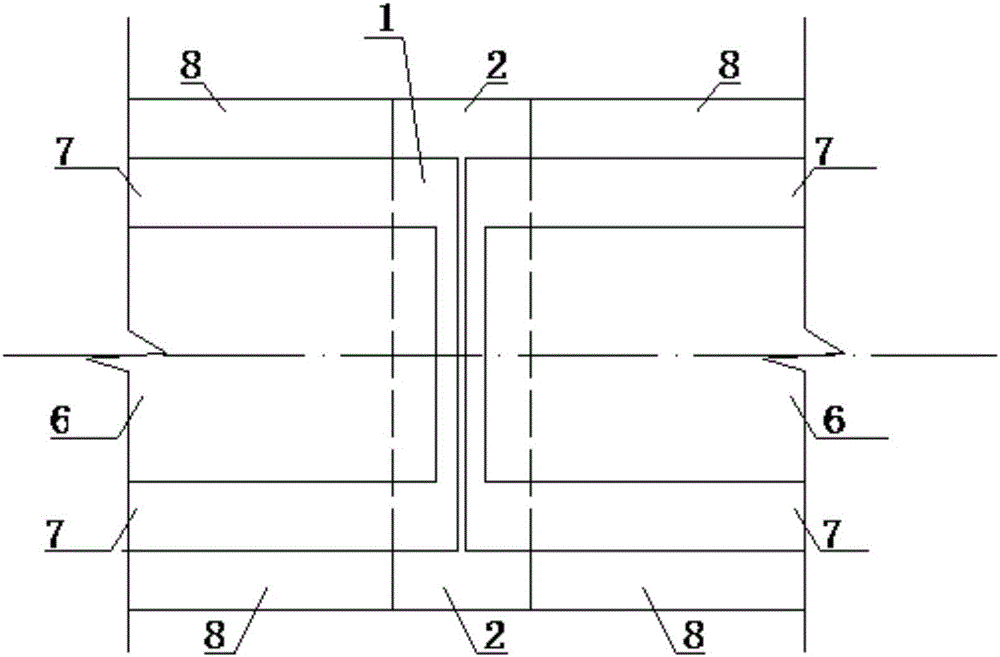

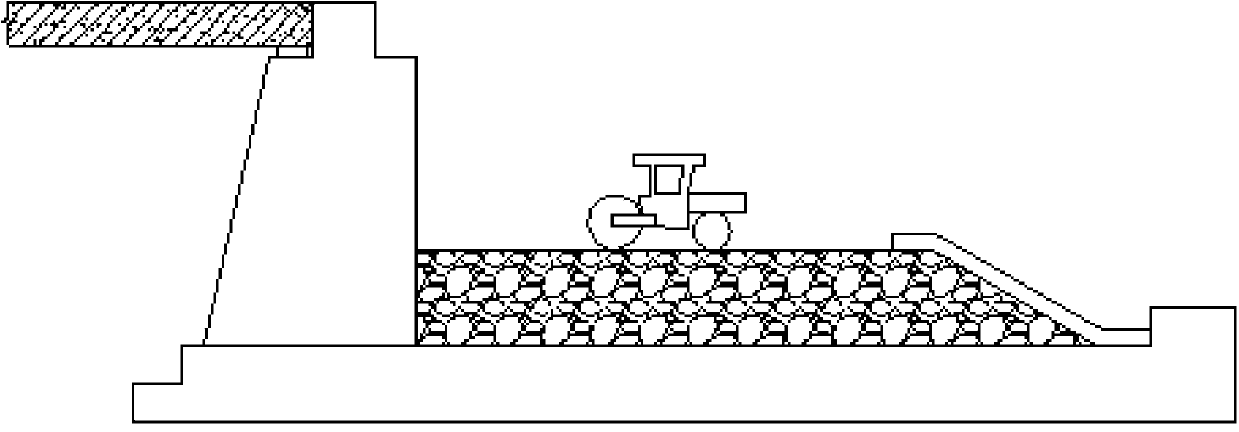

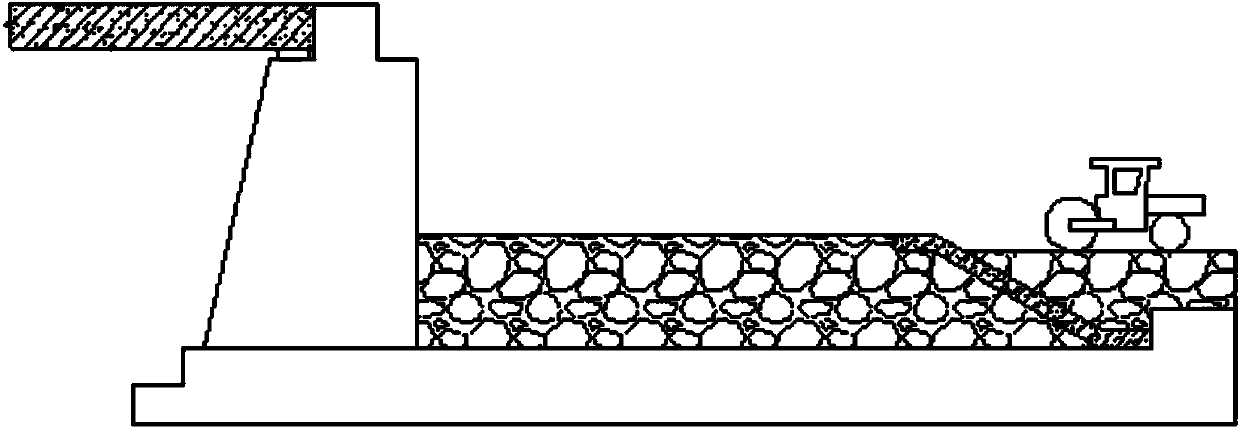

Stepped reinforced concrete slab capable of preventing abutment vehicle skips and construction method

ActiveCN103614961AGuaranteed reliabilityComplete combinationBridge structural detailsBridge erection/assemblyArchitectural engineeringLap joint

The invention discloses a stepped reinforced concrete slab capable of preventing abutment vehicle skips and a construction method of the stepped reinforced concrete slab. A transition section is arranged between an abutment and an embankment so that the abutment vehicle skips can be prevented. According to the transition section, the stepped reinforced concrete slabs are mainly adopted, the mode of layered backfill and layered roller compaction is adopted, after roller compaction is carried out on each step layer of backfill, each stepped reinforced concrete slab is arranged on the backfill, each slab surface is made to be a slope, the wheel rolling portion of a rolling machine can fully roll the backfill and the slab surface of each stepped reinforced concrete slab, the problem that due to the facts that the surface of a traditional abutment is perpendicular, and roller compaction of the backfill is limited by the wheel track, the backfill cannot be rolled compactly is solved, the situation that a roadbed or the road surface sinks due to backfill sedimentation caused by roller compaction is prevented, and the probability of the abutment vehicle skips is effectively reduced. A secondary vehicle skip can happen at the position of lap joint between the other end of a traditional bridge abutment butt strap and the backfill, and the problem of secondary abutment vehicle skips can be solved through the stepped reinforced concrete slab capable of preventing the abutment vehicle skips and the construction method of the stepped reinforced concrete slab.

Owner:GUANGXI SHENGTIAN CEMENT PROD CO LTD

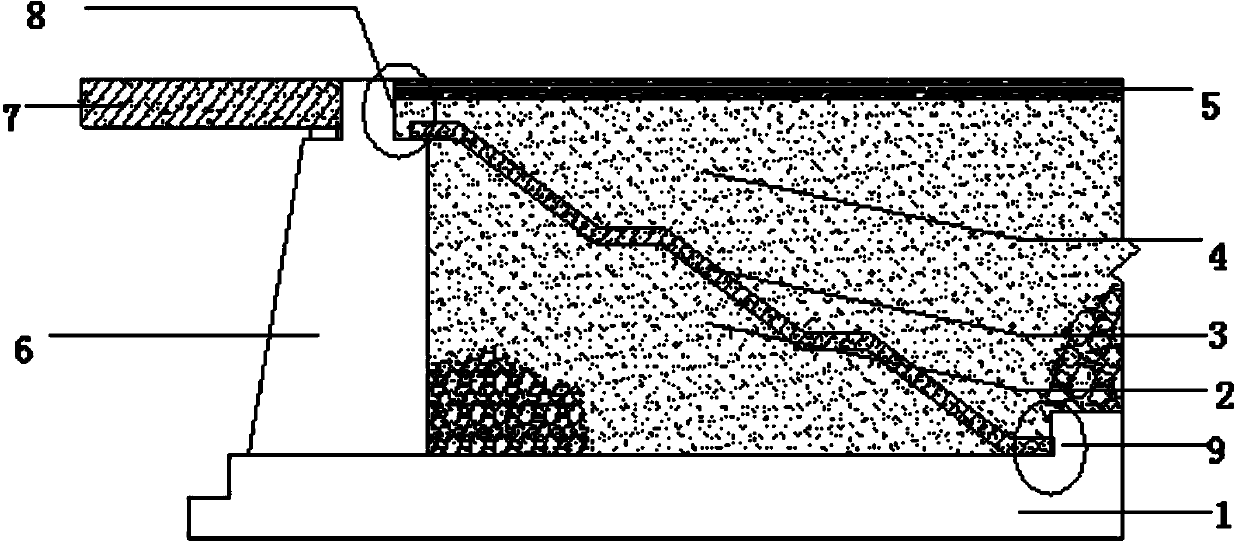

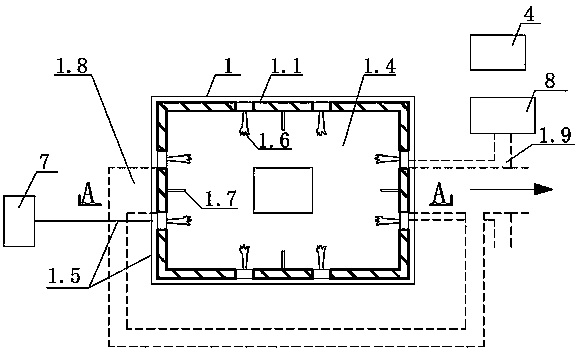

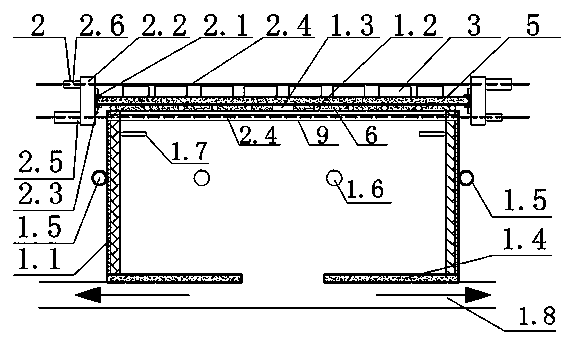

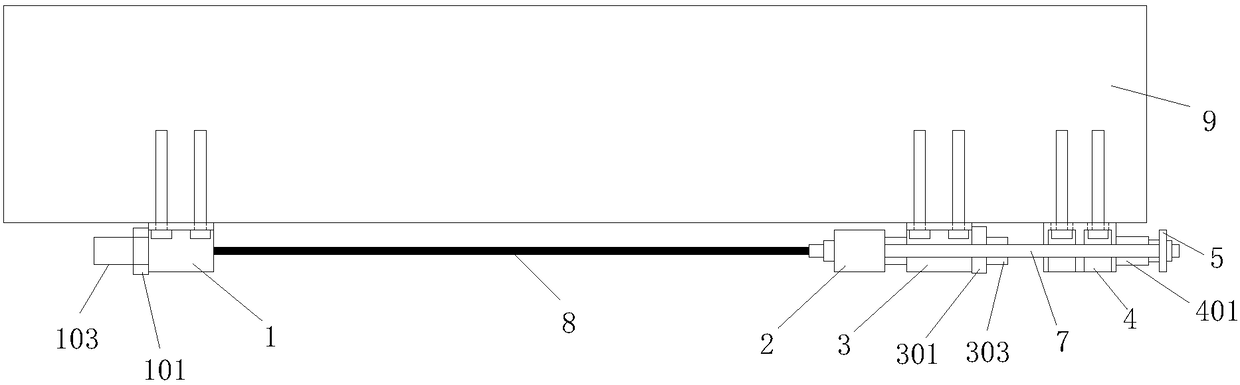

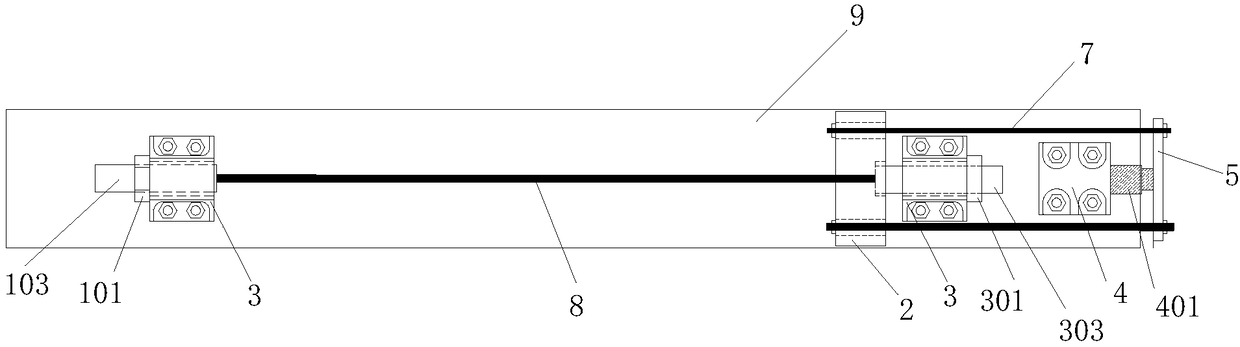

System for testing fire resistance of reinforced concrete plate under effect of boundary restriction by utilizing jack

ActiveCN104215653AEasy to installEasy to disassembleMaterial thermal analysisFloor slabData acquisition

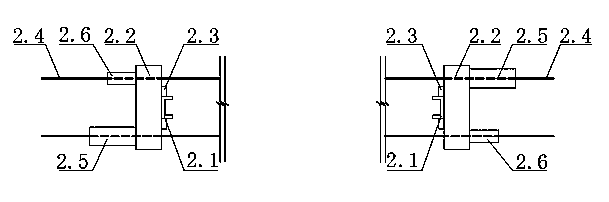

The invention discloses a system for testing fire resistance of a reinforced concrete plate under effect of boundary restriction by utilizing a jack. The system comprises a test furnace device (1), a boundary restriction device (2), a loading article (3) and a control and data acquisition device (4), wherein a steel ball (1.2) and a steel rolling shaft (1.3) are arranged between the top surface of a furnace body (1.1) and a reinforced concrete test floor slab (5); the boundary restriction device comprises a grooved support (2.1), a steel support (2.2), a steel strand (2.4), a jack (2.5) and a steel strand clamp (2.6); the control and data acquisition device comprises a central processor, a flame control loop, a temperature acquisition loop, a displacement acquisition loop, a strain acquisition loop and a jack control loop. According to the system for testing the fire resistance, the interaction between two adjacent components of the structure in the fire is approximately considered by a way of applying restriction to the boundary of the component, so that the influence law of different boundary restriction action on the fire resistance of the reinforced concrete plate can be researched conveniently.

Owner:CHINA UNIV OF MINING & TECH +1

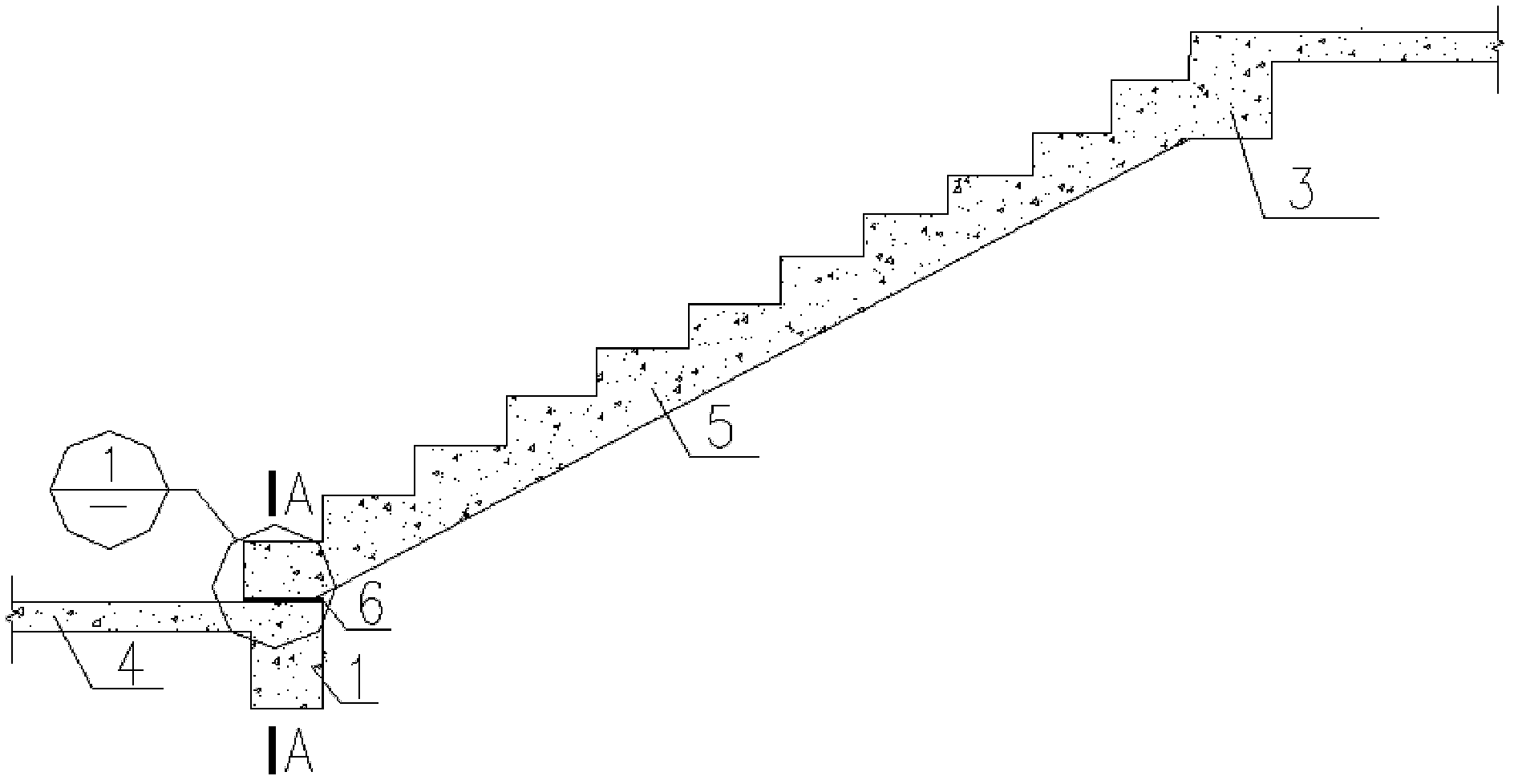

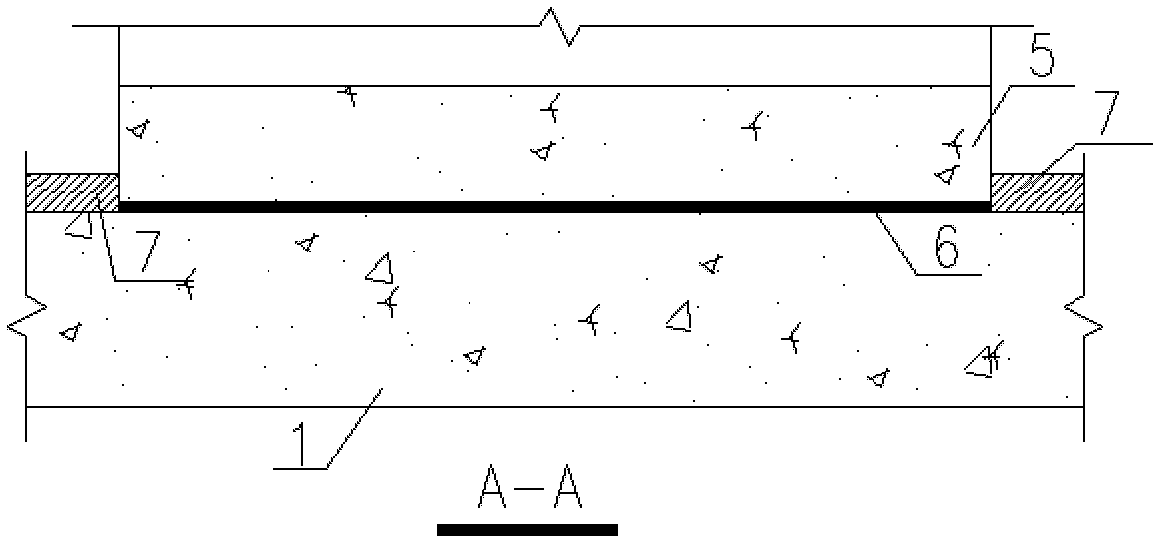

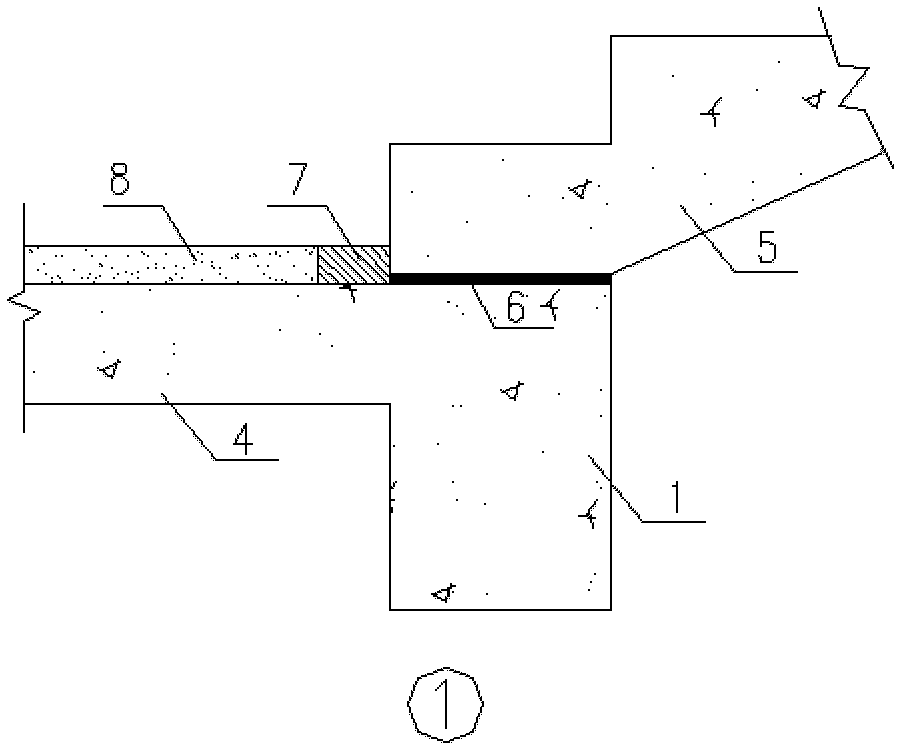

Reinforced concrete platy stair with simple sliding support and construction method

InactiveCN102605909APrevent premature destructionAvoid stiffnessStairwaysShock proofingSurface layerEngineering

The invention relates to a reinforced concrete platy stair with a simple sliding support and a construction method, which belong to the field of civil engineering and are mainly used for building engineering. The reinforced concrete platy stair is a cast-in-place concrete platy stair, the upper end of a stair section plate and an upper-end supporting component connected to a main body structure are in integral casting, and the simple sliding support is arranged at the lower end of the stair section plate. The method includes that the stair section plate and a lower-end supporting component or a stair beam bridging piece are separately provided with bars and are in pouring separately, the lower end of the stair section plate is shelved on the lower-end supporting component, the upper surface of the lower-end supporting component is a smooth and flat horizontal plane, a plastic film isolating layer is fully laid on the horizontal plane, so that the lower-end supporting component is isolated from the lower end of the stair section plate, the sliding support is formed and is used as a pouring bottom formwork at the lower end of the stair section plate during construction, and the lower end of the stair section plate is also isolated from a building surface layer of the supporting component. The problem that the stair is broken in advance during earthquake and adverse influences to the main body structure are avoided due to the sliding support, earthquake damage is relieved, and the reinforced concrete platy stair is simple, economical and durable, and can be widely used for multiple high-rise building structures and particularly concrete structures.

Owner:BEIJING UNIV OF TECH

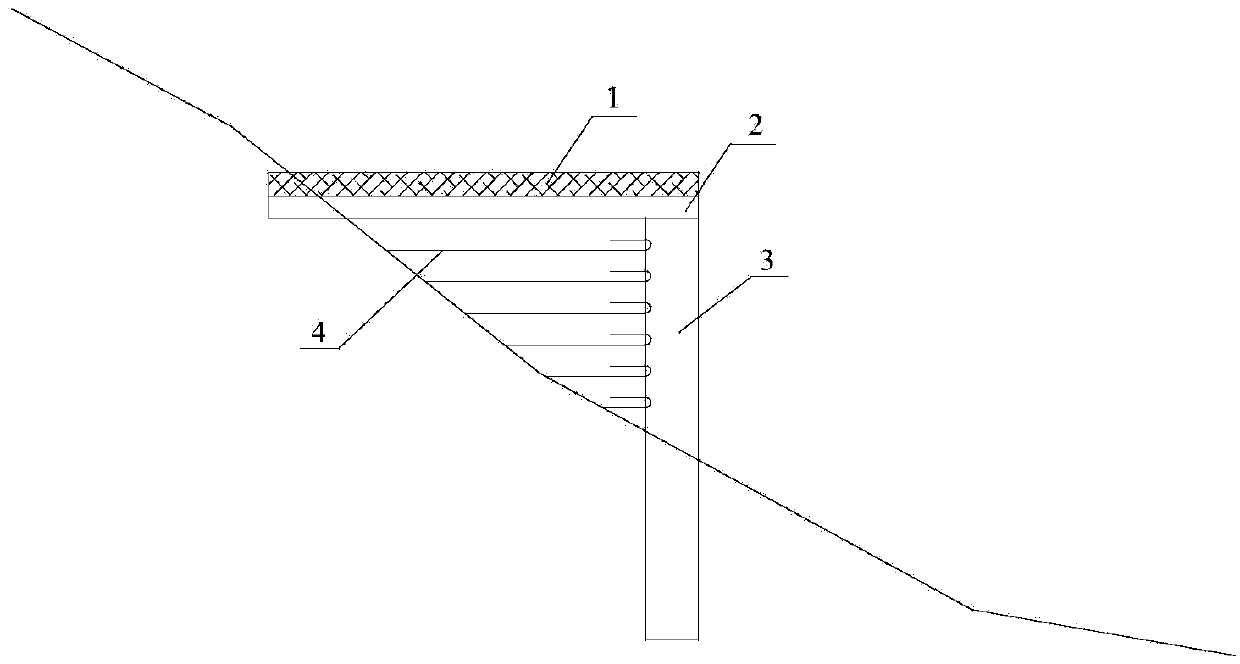

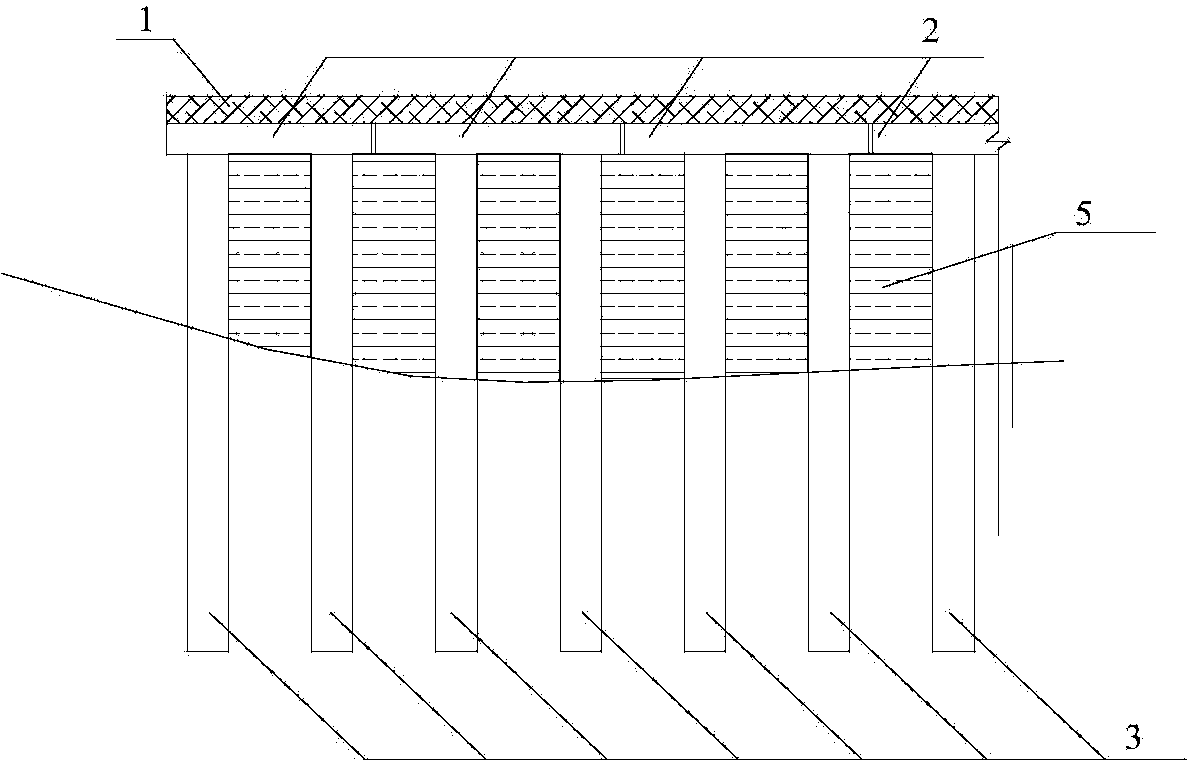

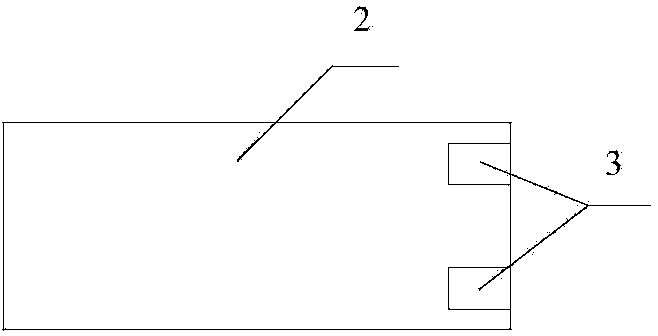

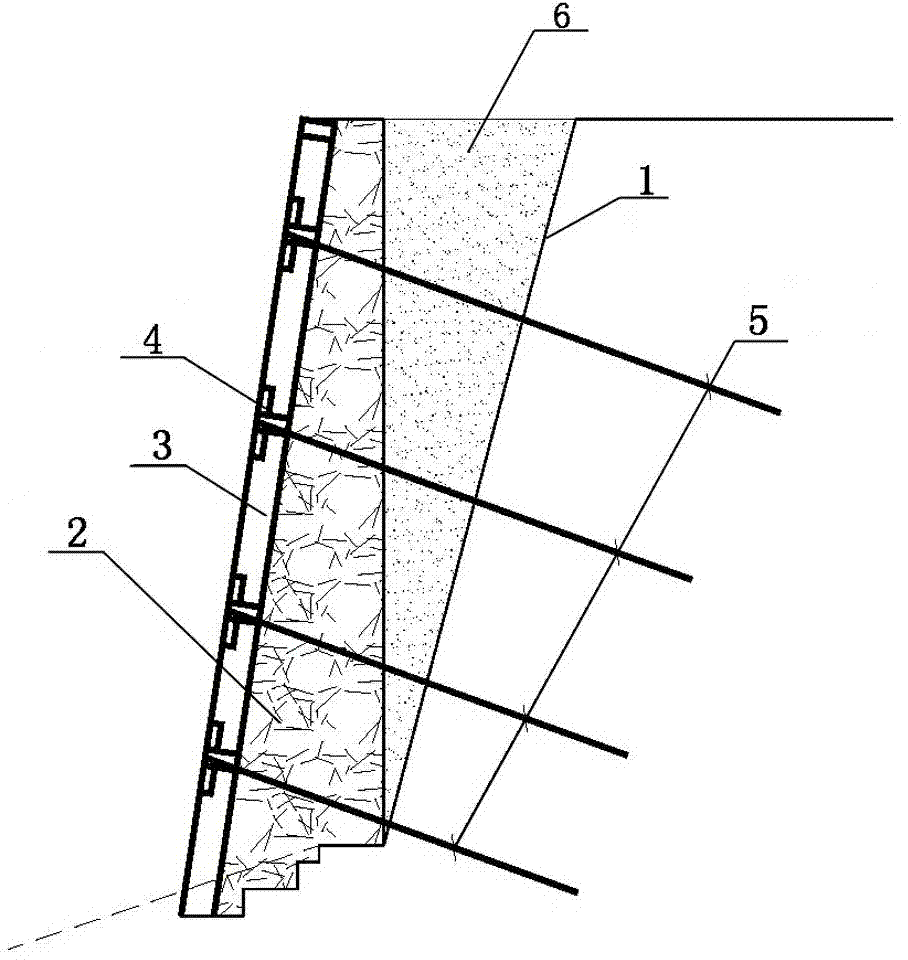

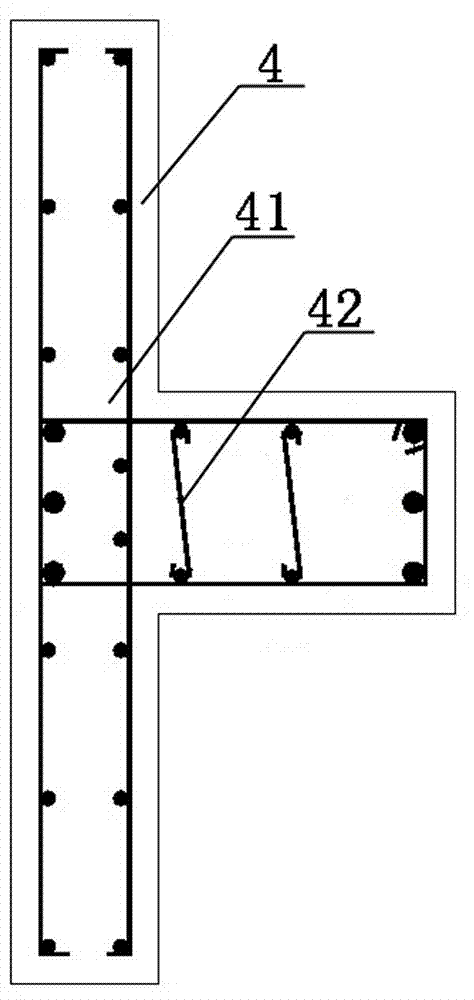

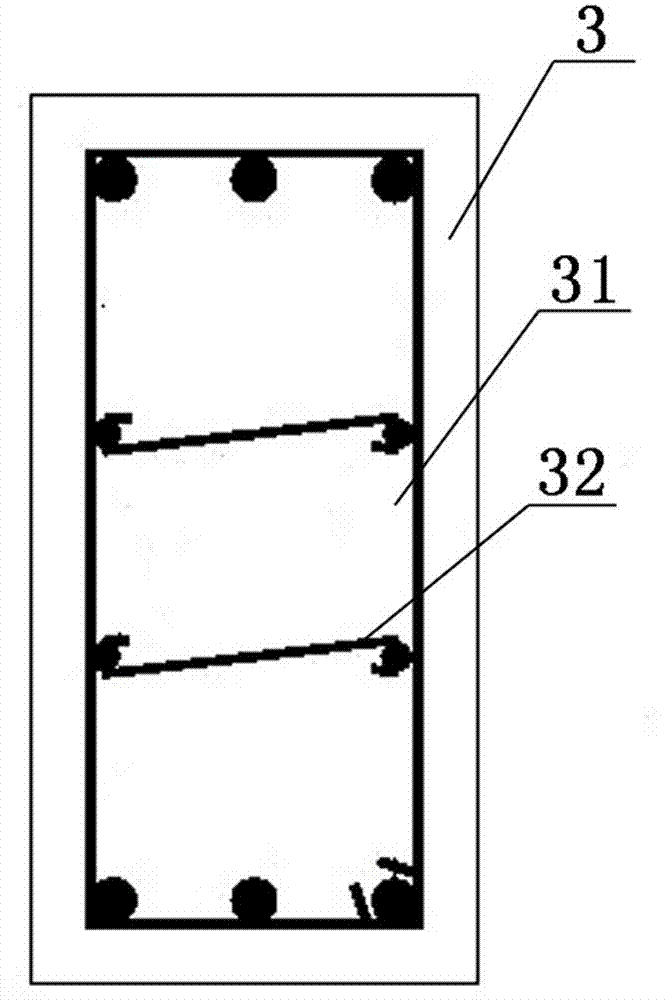

Lateral pile-plank structure suitable for rocky abrupt-slope embankment

ActiveCN103806347AAvoid differences in lateral stiffnessAvoid uneven settlementRoadwaysRailway tracksMountainous terrainEngineering

The invention discloses a lateral pile-plank structure suitable for a rocky abrupt-slope embankment. According to the lateral pile-plank structure, reliable retaining is provided for an abrupt-slope road in a mountain area, the transverse stiffness coordination of the road bed is effectively controlled, non-uniform settlement is avoided, the operation comfortableness of an expressway or high-speed railway is improved and safety accidents are avoided. The lateral pile-plank structure comprises cantilever piles (3), reinforced concrete slabs (2) and fills, wherein the cantilever piles (3) are arranged on the lower side of the abrupt-slope embankment, in the extending direction of the embankment, at intervals; the lower parts of the cantilever piles (3) are anchored in a rock body; the reinforced concrete slabs (2) are laid below a pavement structural layer (1); the outer ends of the reinforced concrete slabs (2) are fixedly connected with the tops of the cantilever piles (3); the fills are placed at the rear parts of the cantilever piles (3); geogrids (4) are vertically laid in the fills in a layering manner.

Owner:四川省交通勘察设计研究院有限公司

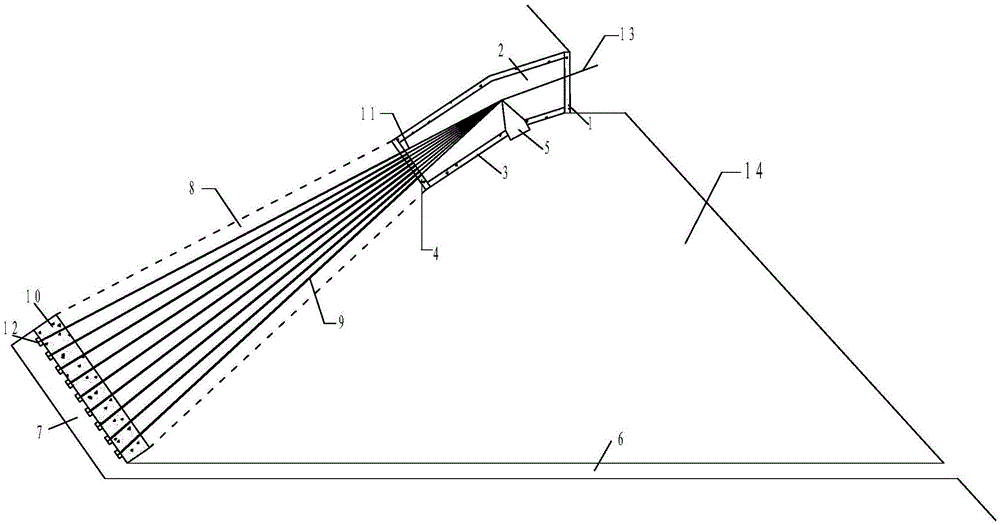

Suspension bridge rock mass and reinforced concrete plate composited type anchorage and construction method thereof

ActiveCN105648921AReduce the amount of constructionAvoid excavationBridge erection/assemblyEcological environmentEconomic benefits

The invention provides a suspension bridge rock mass and reinforced concrete plate composited type anchorage and a construction method thereof. The construction method comprises the steps that 1, the composited type anchorage is located on one side or the two sides of a suspension bridge, a front anchor chamber is excavated on the side slope side of a mountain, a worker enters the mountain through a construction hole with a small cross section to excavate a back anchor chamber, and rock masses between the front anchor chamber and the back anchor chamber are reserved to replace a reinforced concrete anchor plug; 2, hole sites are quincuncially arranged in the front anchor surface and the back anchor surface, and anchor cable holes are drilled from the front anchor surface to the back anchor chamber; 3, a reinforced concrete anchor plate is poured in the back anchor chamber, and anchor holes are reserved; 4, anchor cables penetrate through the reserved rock masses and the reinforced concrete anchor plate to the back anchor chamber through the anchor cable holes from the front anchor chamber and are anchored; and 5, a main cable is connected with the anchor cables through a cable splaying saddle. According to the suspension bridge rock mass and reinforced concrete plate composited type anchorage and the construction method thereof, the resistance of the rock masses is made full use of, excavation of large-size earth rock is avoided, construction of large-size concrete is reduced, the influence on the bridge area ecological environment is small, the construction cost of the composited type anchorage is significantly reduced compared with a tunnel type anchorage, and economic benefits are great.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Carbon fiber bar reinforcement device and method for reinforced concrete beam and slab

The invention discloses a carbon fiber bar reinforcement device and method for a reinforced concrete beam and a reinforced concrete slab. The carbon fiber bar reinforcement method comprises the following steps: first, assembling a carbon fiber bar and anchorage devices, opening holes in a beam, fixing the anchorage devices to the beam by using chemical anchors, mounting a tensioning device and thecarbon fiber bar onto brackets, tensioning the carbon fiber bar by using a jack, and detaching the mounting brackets after tensioning is completed. The carbon fiber bar is used for reinforcing the reinforced concrete beam, so that the reinforced concrete beam has a smaller area than a carbon fiber plate, the carbon fiber bar reinforcement device and the carbon fiber bar reinforcement method are suitable for beam and slab reinforcement in civil buildings, and during anchorage, less holes need to be opened in an original structure, so that less damage is caused to the structure; the circular carbon fiber bar is directly fixed to supports through nuts, and no connection screw rod is required, so that the length of the anchoring end is short, the prestress loss is less, and the reinforced concrete beam and the reinforced concrete slab can be effectively reinforced; when walls exist at the two ends of the bottom of the beam required to be reinforced, the beam can be reinforced from two sides of the beam; the carbon fiber bar reinforcement device is simple in structure; the reinforcement method is easy to implement; the carbon fiber bar reinforcement device and the carbon fiber bar reinforcement method can be popularized and applied to a variety of occasions where reinforced concrete reinforcement is required.

Owner:NANNING UNIV

Anchor rod gravity retaining wall for high slope support and manufacturing method

The invention discloses an anchor rod gravity retaining wall for high slope support and a manufacturing method. A high slope comprises a rock surface which forms a steep terrain. The anchor rod gravity retaining wall comprises a stone-built retaining wall close to the rock surface, and a reinforced concrete plate strip layer with reinforced concrete rib columns is manufactured on the outer lateral surface of the stone-built retaining wall; the reinforced concrete plate strip is connected with a plurality of connecting anchor rods which obliquely pass through the stone-built retaining wall towards the inside and are straightly inserted in the rock surface. The manufacturing method includes steps that a) constructing the stone-built retaining wall, reinforced concrete plate strip and rib columns; b) drilling anchor rod holes in the rock surface and grouting; c) connecting steel anchor rods. The anchor rod gravity retaining wall for the high slope support combines the advantages of the gravity retaining wall and anchor rod retaining wall and reasonably uses rocks at the back of the retaining wall, one part of the pressure on the retaining wall is transmitted into the rocks, and the anchor rod gravity retaining wall for the high slope support is reasonable in structure, clear in stress, convenient to construct and suitable for the high slope support and the like of the mountainous area.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

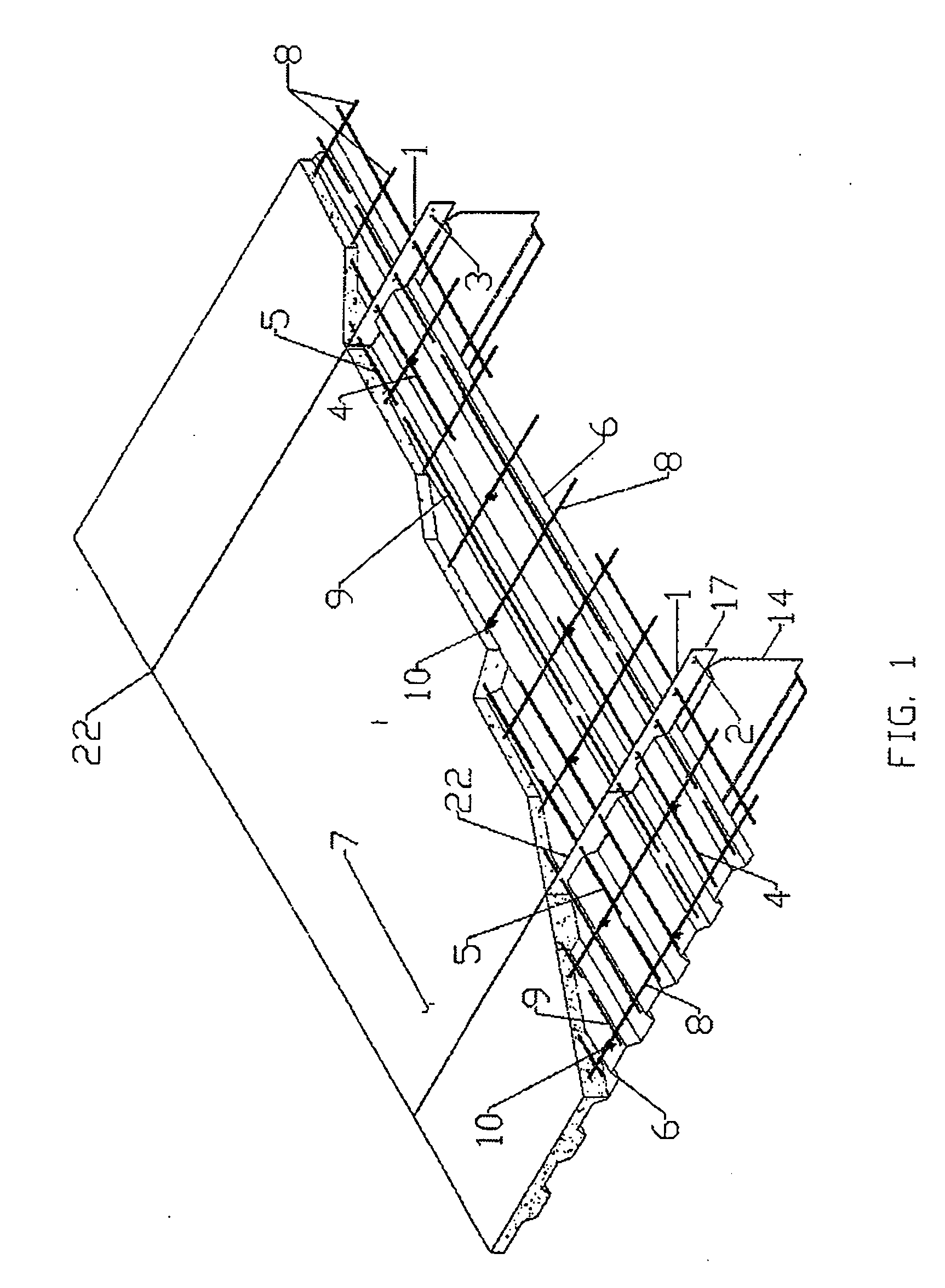

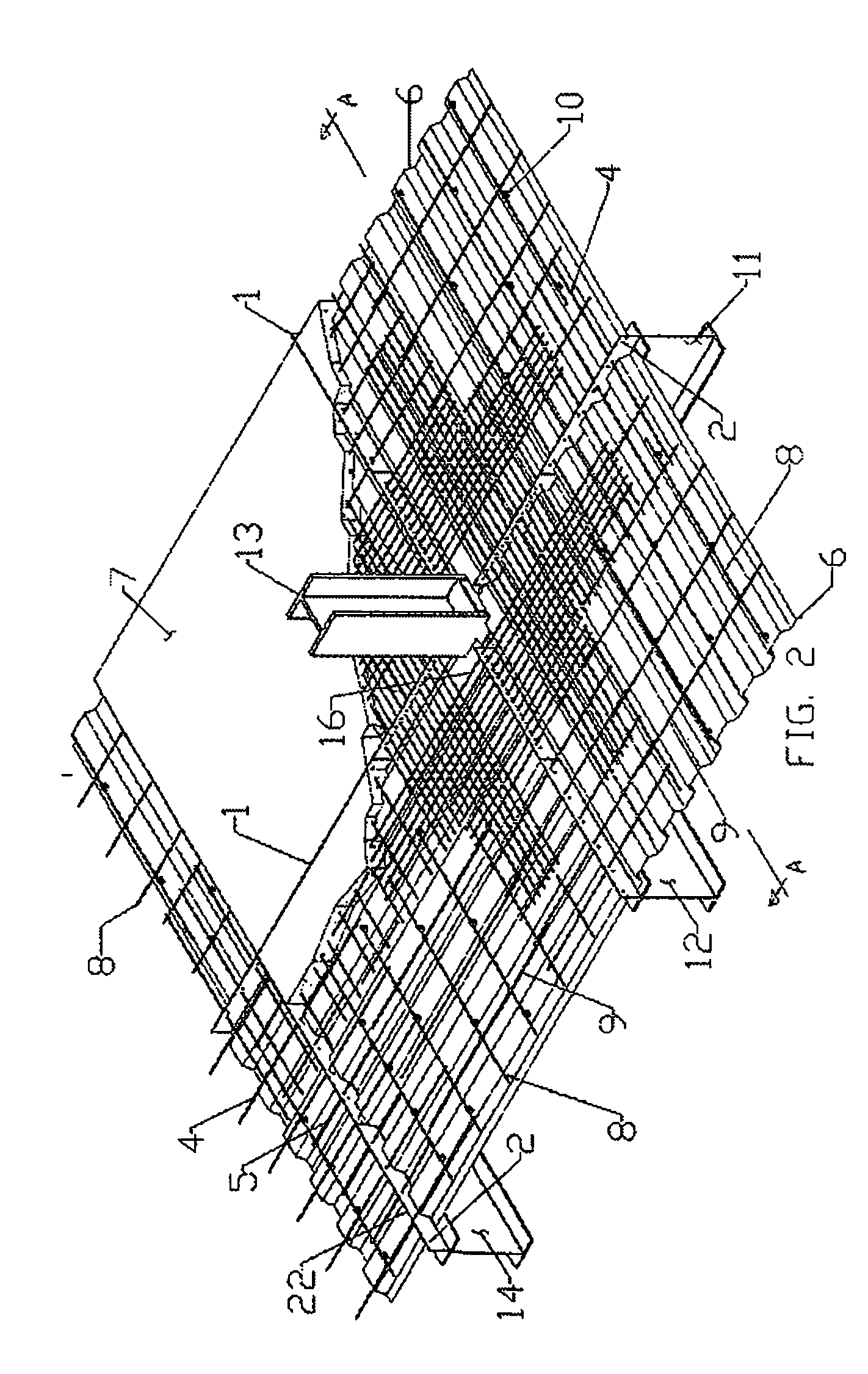

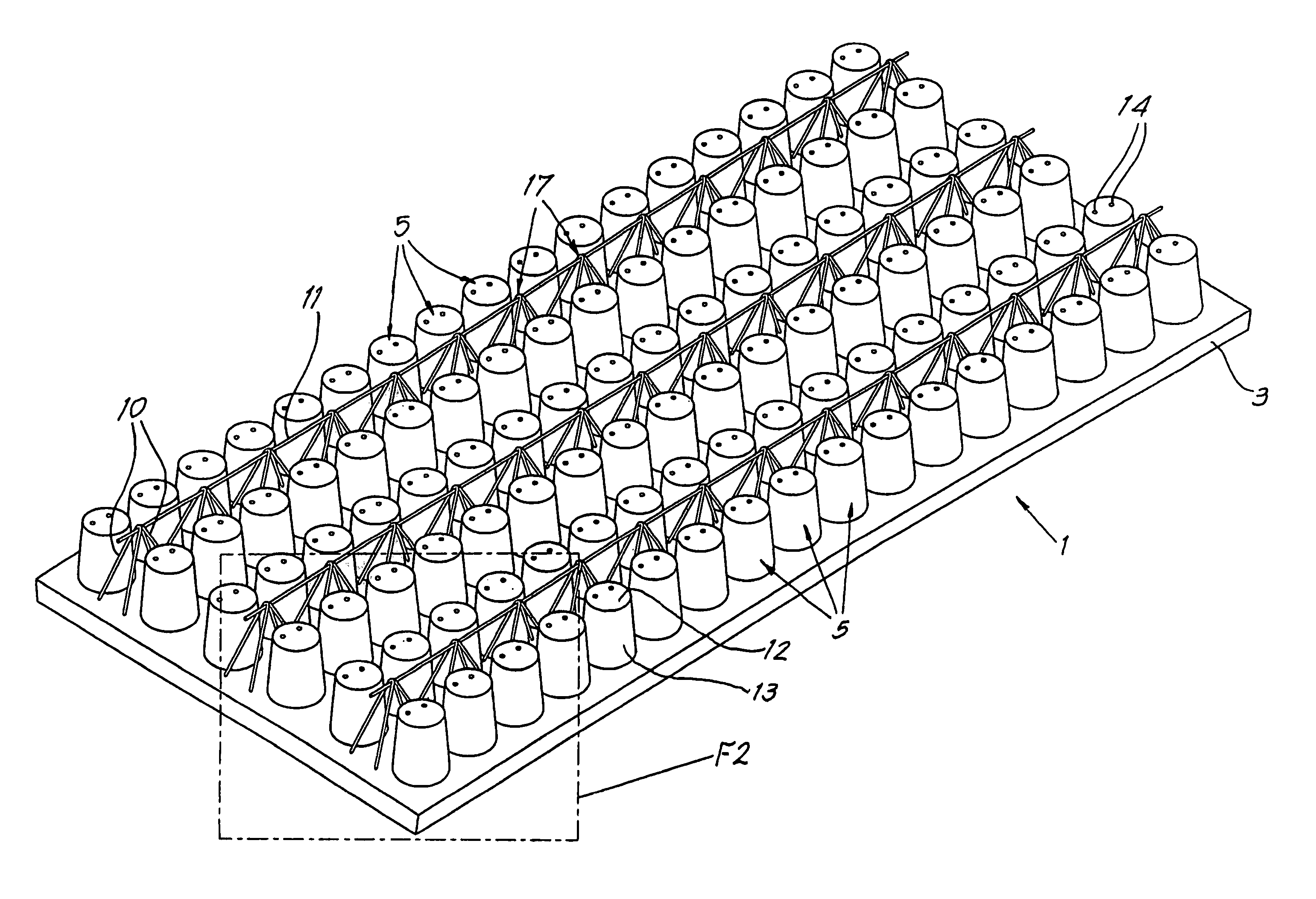

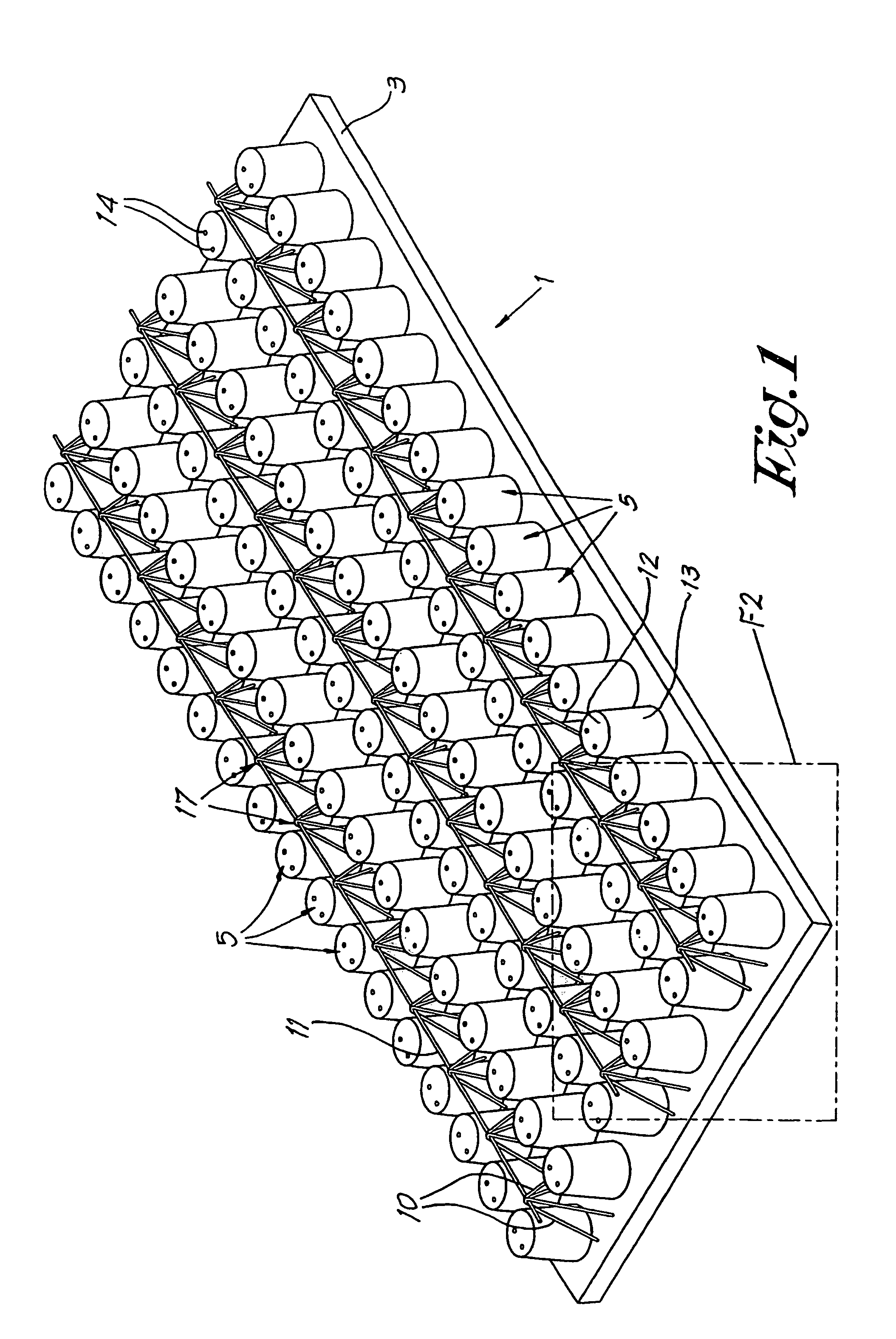

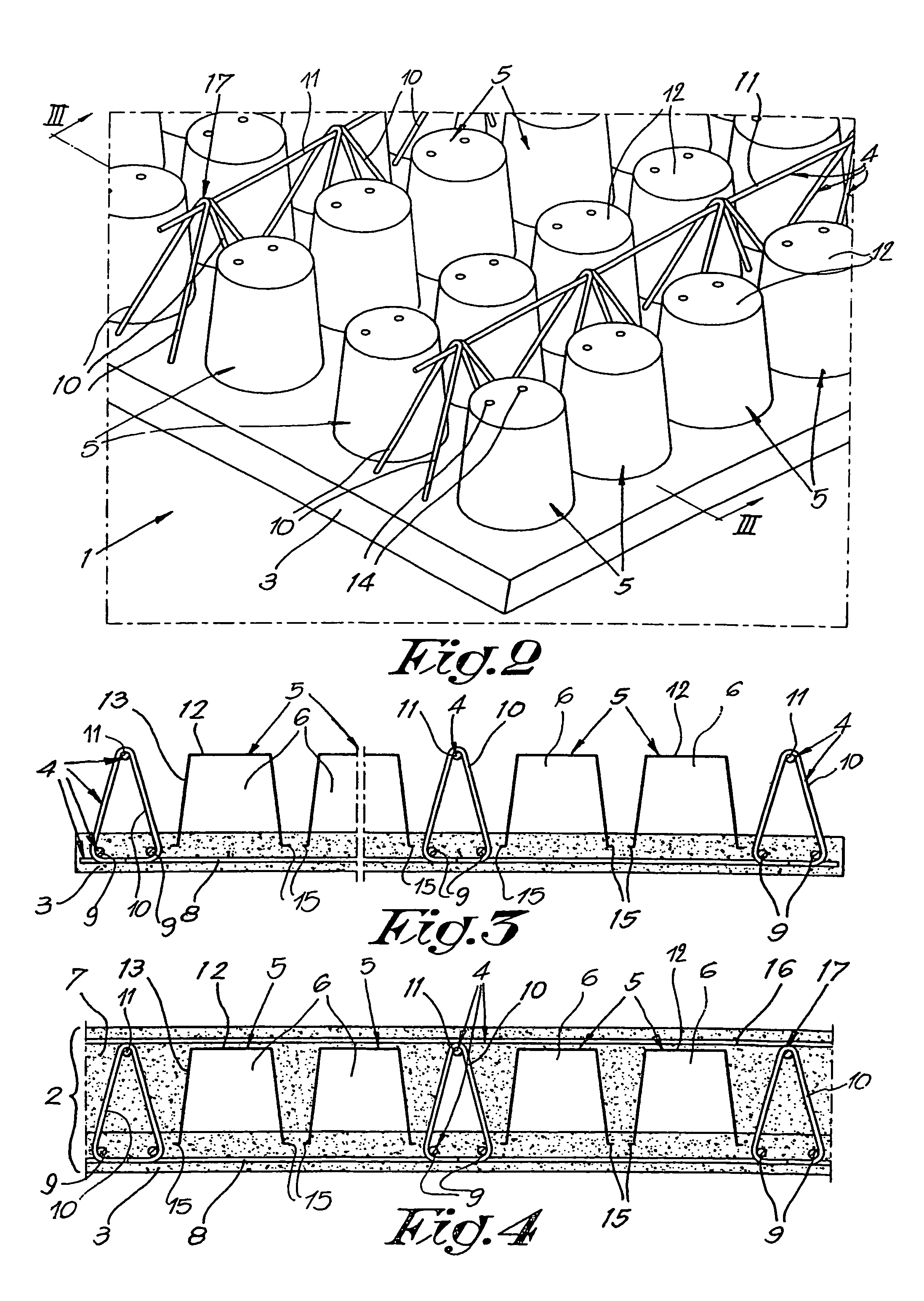

Construction element and method for manufacturing it

Construction element for forming a reinforced concrete slab (2), consisting of the combination of at least a hardened concrete layer (3), at least a number of reinforcement elements (4) and elements (5) extending at least partially from the concrete layer (3) and defining cavities (6), whereby these elements (5) are designed to be covered with concrete (7) at a later stage characterised in that the above-mentioned elements (5) defining the cavities (6) consist of elements (5) which can be mutually nested as such.

Owner:AIRDECK BUILDING CONCEPTS NV

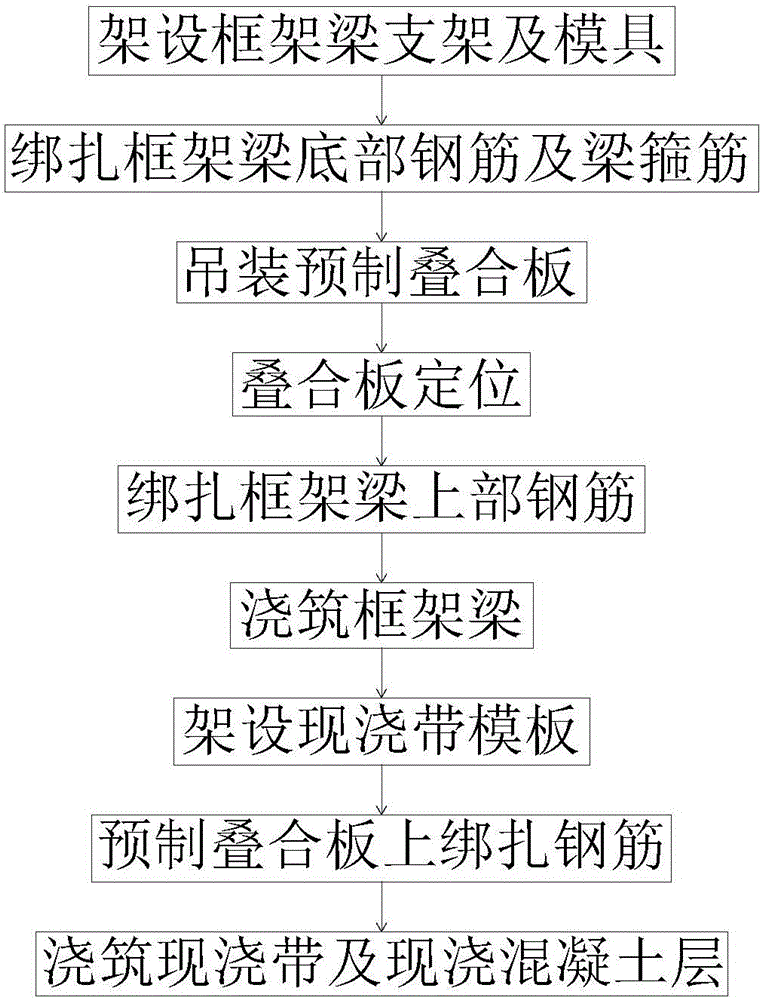

Assembly type laminated slab installing and locating method

The invention discloses an assembly type laminated slab installing and locating method. The assembly type laminated slab installing and locating method comprises the following steps that A, a frame beam support and a mold are erected; B, bottom rebars and beam stirrups of a frame beam are bound; C, all prefabricated laminated slabs are lifted; D, all the prefabricated laminated slabs are located; E, upper rebars of the frame beam are bound; F, the frame beam is subjected to pouring; G, a cast-in-place belt template is erected; H, rebars are bound on all the prefabricated laminated slabs; and I, cast-in-place belts and cast-in-place concrete layers are subjected to pouring. Through the assembly type laminated slab installing method, many prefabricated laminated slabs are installed on the designed and set frame beam and are located, and then the cast-in-place concrete layers are formed on the prefabricated laminated slabs so as to form the complete laminated slabs. The laminated slabs installed through the installing method have the integrality of cast-in-place reinforced concrete slabs and have the advantages that the rigidity is high, the crack resistance is good, rebar consumption is not increased, templates are saved, and the construction period of the whole project is shortened, and the safety is high.

Owner:CHENGDU NO 4 CONSTR ENG

Rectification and reinforcement structure for inclined building and construction method thereof

ActiveCN108343260ADoes not affect structural safetyReduce labor intensityBuilding repairsFoundation engineeringCement slurryHigh pressure

The invention relates to a rectification and reinforcement structure for an inclined building and a construction method thereof. The rectification and reinforcement structure for the inclined buildingcomprises a plurality of reinforcing piles which penetrate through a reinforced concrete slab of a foundation of a building on the inclined side of the building along the outline of the building andone or more rows of rectification holes formed in the opposite side of the inclined side of the building along the outline of the building. The rectification holes are formed by means of being inclined to the inner side of the foundation of the building. The direction of the rectification holes are corrected by a high-pressure jet machine in the rectification holes. The rectification holes are reinforced by high-pressure jet of cement slurry after high-pressure jet of high-pressure air-water on the foundation of the building and the elevation range below the foundation of the building. According to the rectification and reinforcement structure for the inclined building and the construction method thereof, the reinforcing piles are used for reinforcing the inclined side of the building, therectification holes are formed in the opposite side of the inclined side of the building, high-pressure air-water forced landing rectification technology is used for enabling the building to be subjected to rotating rectification by using the inclined side as the axis, and according to the monitoring data, the speed, rotating speed and air-water pressure of high-pressure jet machine are adjusteddynamically and informationally to punch and cut soil with any depth; and the construction is simple, efficient and easy to operate, the cycle is short, the structural safety of the building is not affected.

Owner:湖南化工地质工程勘察院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com