Pre-stress applying device for fiber reinforced polymer (FRP) bars outside reinforced concrete slab

A reinforced concrete slab and applying device technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of FRP bar overtension, etc., and achieve the effect of small prestress loss and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

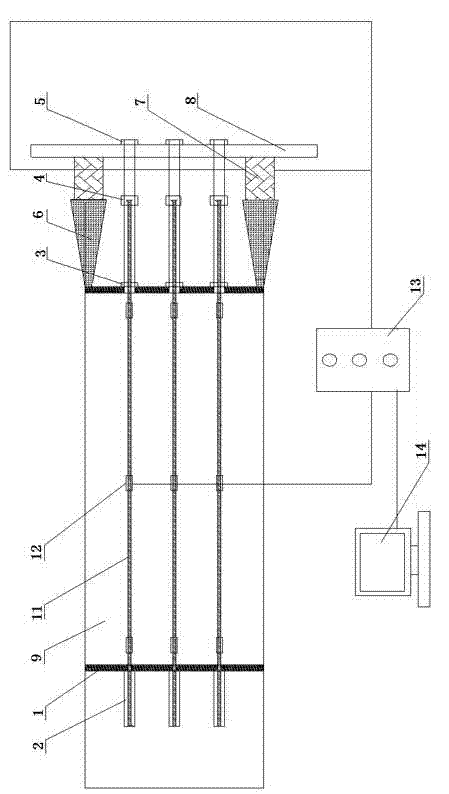

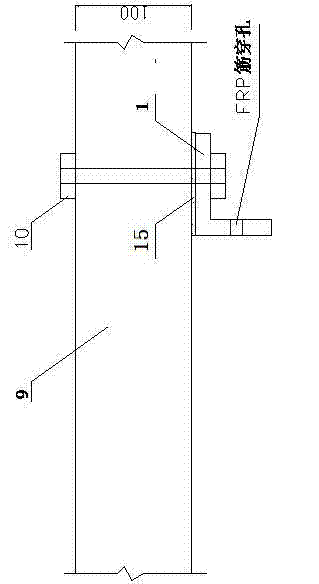

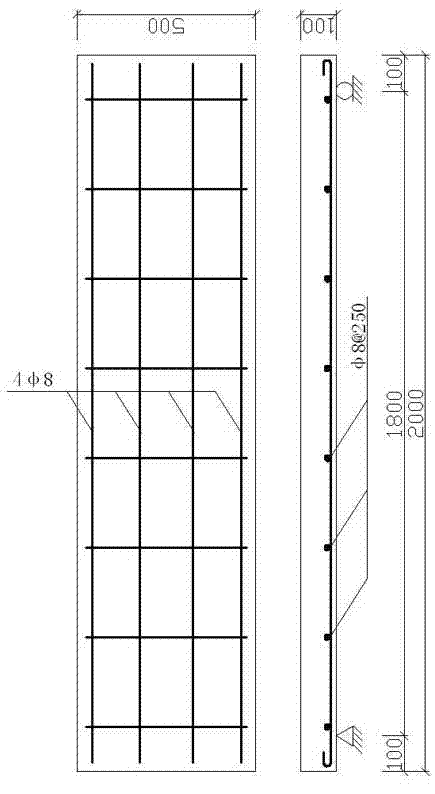

[0028] like figure 1 , figure 2 As shown in the figure, the prestressing device of the FRP tendon outside the reinforced concrete slab body of this example consists of angle steel 1, bottom anchorage 2, anchor nut 3, connecting bolt 4, tension nut 5, jack 6, force sensor 7, Tensile steel plate 8, concrete slab 9, angle steel anchorage 10, FRP tendon 11, strain gauge 12, data acquisition instrument 13, computer 14, cement mortar leveling layer 15 are connected. Due to the poor shear resistance of FRP tendons, tensioning equipment It should be installed strictly along the axis of the FRP tendon, and the centerlines of all anchoring and tensioning equipment should be on the same plane.

[0029] The anchoring system of this embodiment is composed of angle steel 1 , bottom anchor 2 , anchor nut 3 , connecting bolt 4 , concrete slab 9 , angle steel anchor 10 , and FRP bars 11 . Drill holes with impact drills at the set positions at both ends of the reinforced concrete slab 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com