Patents

Literature

4220 results about "Anchor bolt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anchor bolts are used to connect structural and non-structural elements to the concrete. The connection is made by an assembling of different components such as: anchor bolts (also named fasteners), steel plates, stiffeners. Anchor bolts transfer different types of load: tension forces and shear forces. A connection between structural elements can be represented by steel column attached to reinforced concrete foundation. Whereas, a common case of non-structural element attached to a structural one is represented by the connection between a facade system and a reinforced concrete wall.

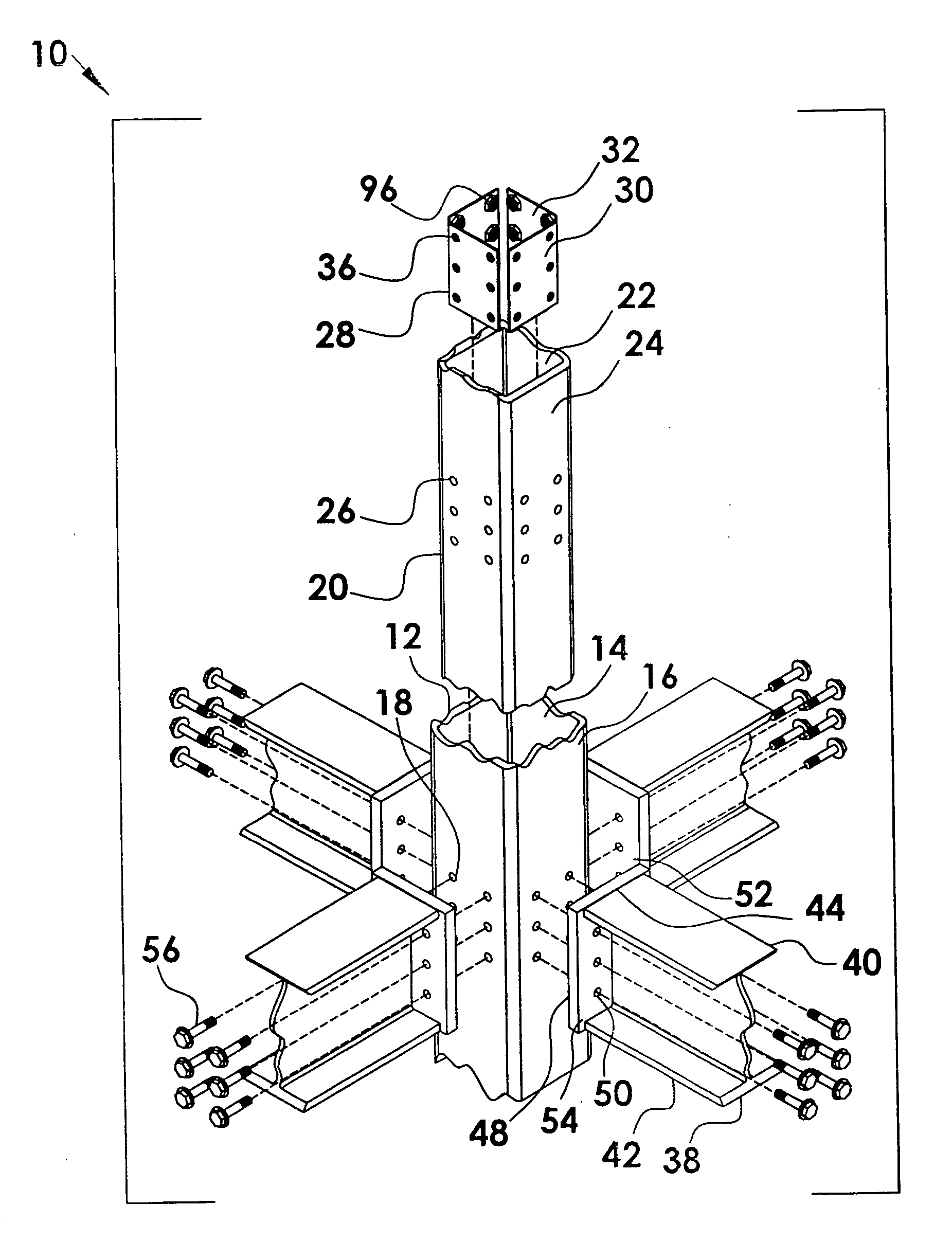

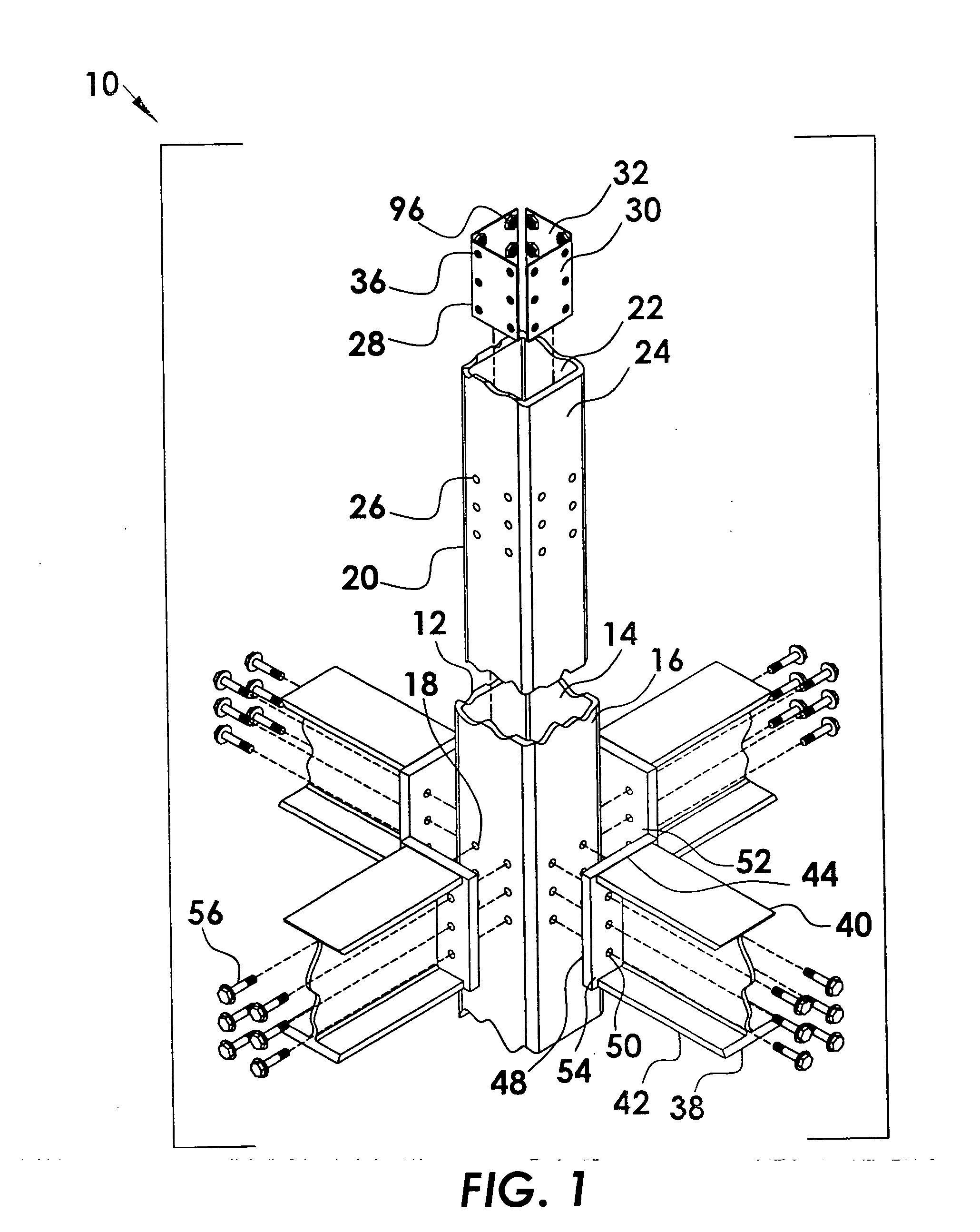

Moment-resistant building column insert system and method

InactiveUS20070209314A1Improves building column strength strengthImprove connection strengthBuilding roofsFloorsArchitectural engineeringVertical load

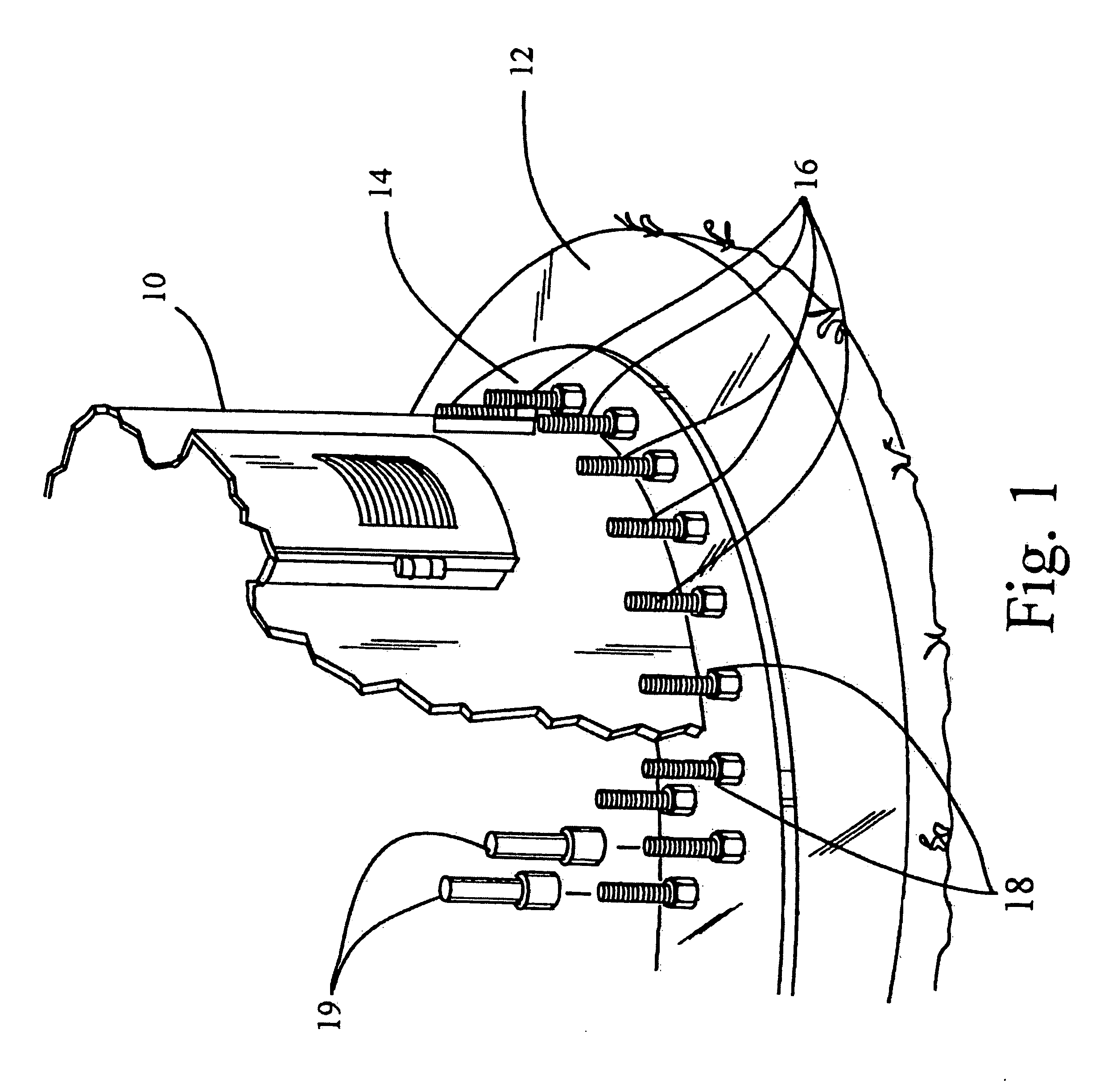

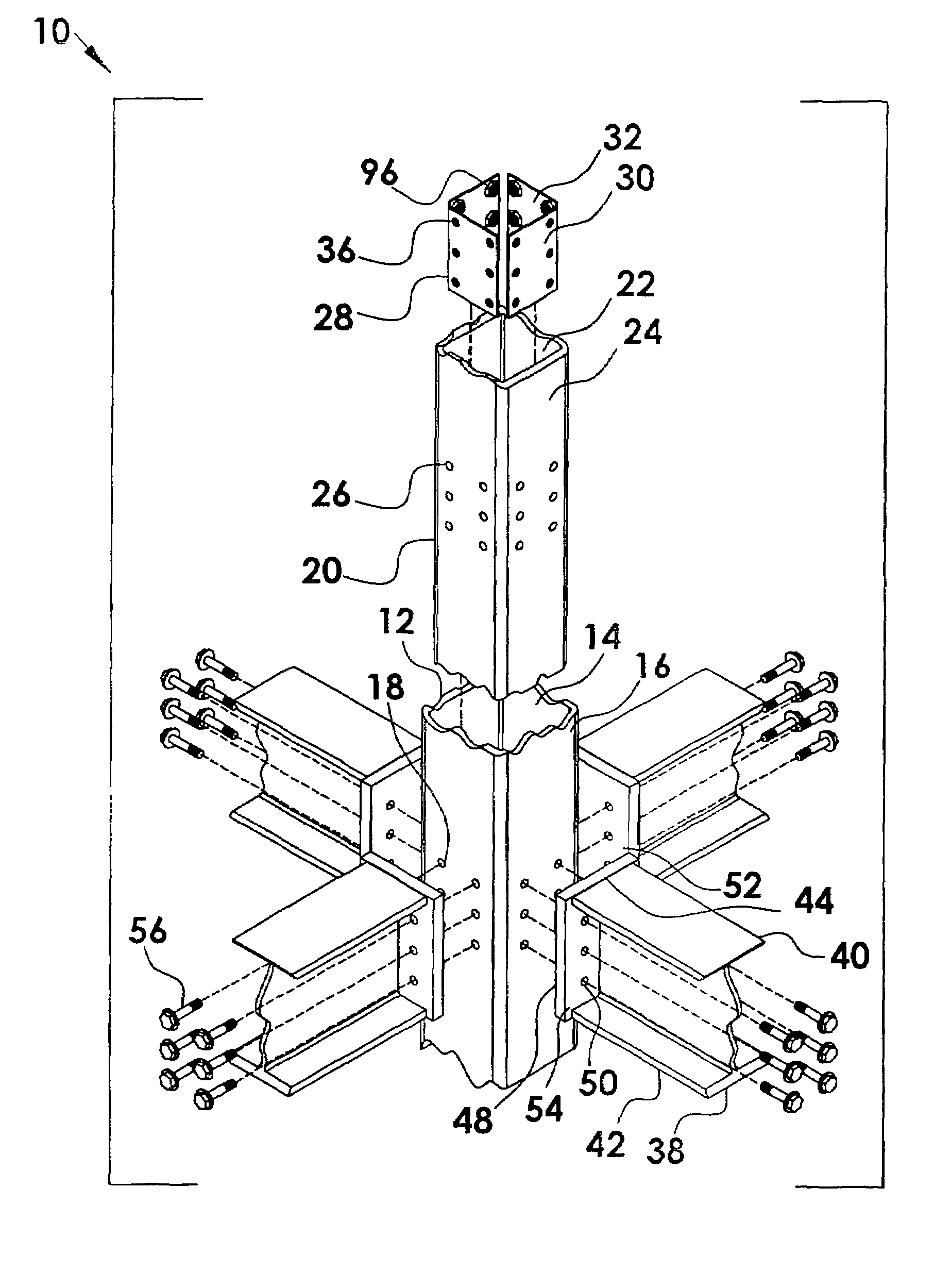

The invention is a novel moment-resistant building column insert system for distributing lateral and vertical loads between the column-beam and column-foundation connections. Loads are distributed between the column and beam using a column insert, nut plates and beam end plates incorporated to beam-ends. The column insert is hollow and similar cross-section shape to the building column for inserting there to. The column, column insert, nut plates and endplates have patterns of mounting holes for receiving mounting bolts tightened to nuts held by nut plates. Loads are distributed between the column and foundation using a base plate, column insert, and insert plates integrated with anchor bolts, nuts and washers in a concrete foundation. The base plate having mounting holes is incorporated to the building column bottom end to receive the plurality of anchor bolts there through for fixedly tightening as an exposed end of the column insert fits in the column.

Owner:VAUGHN WILLAIM B

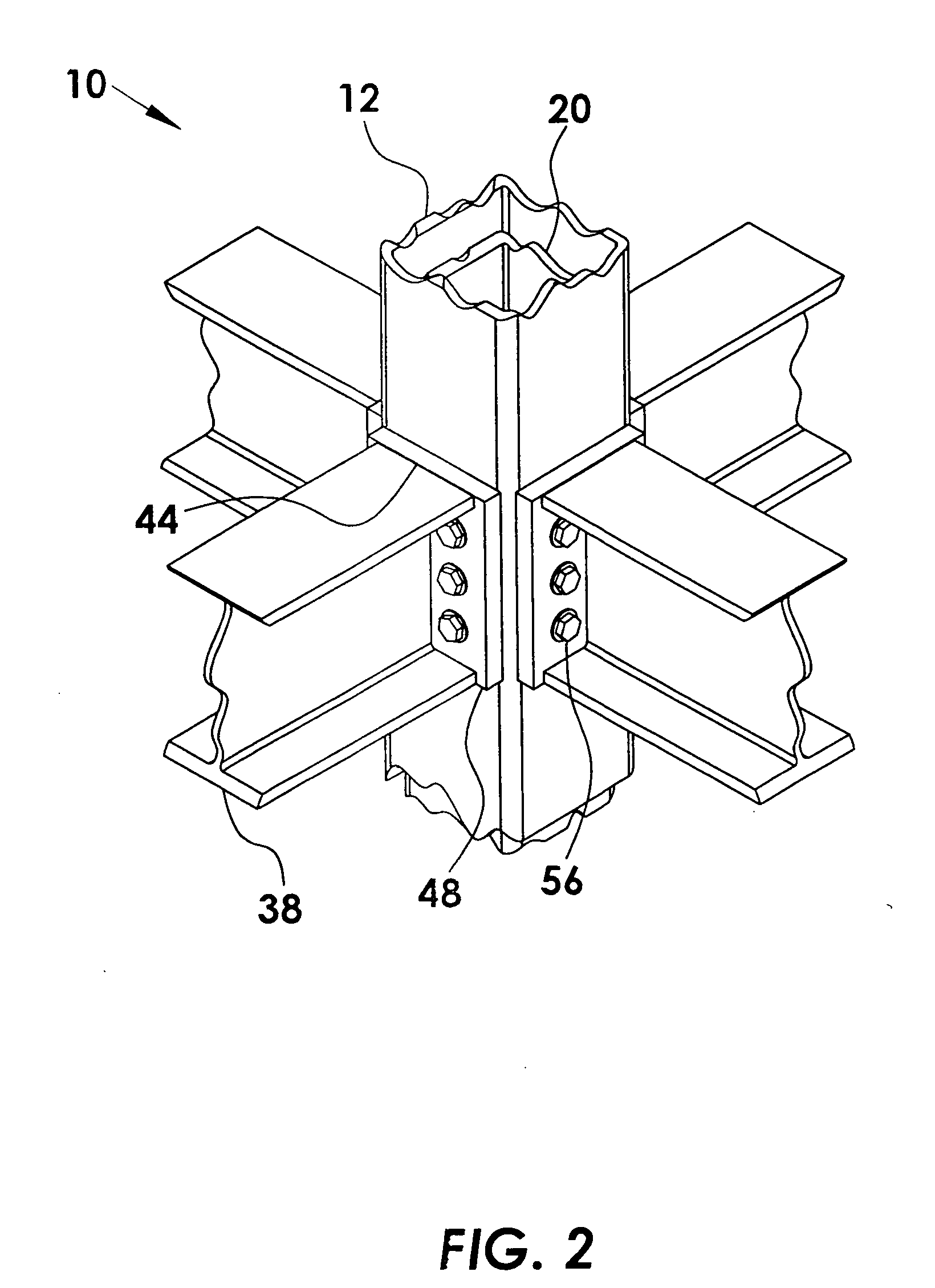

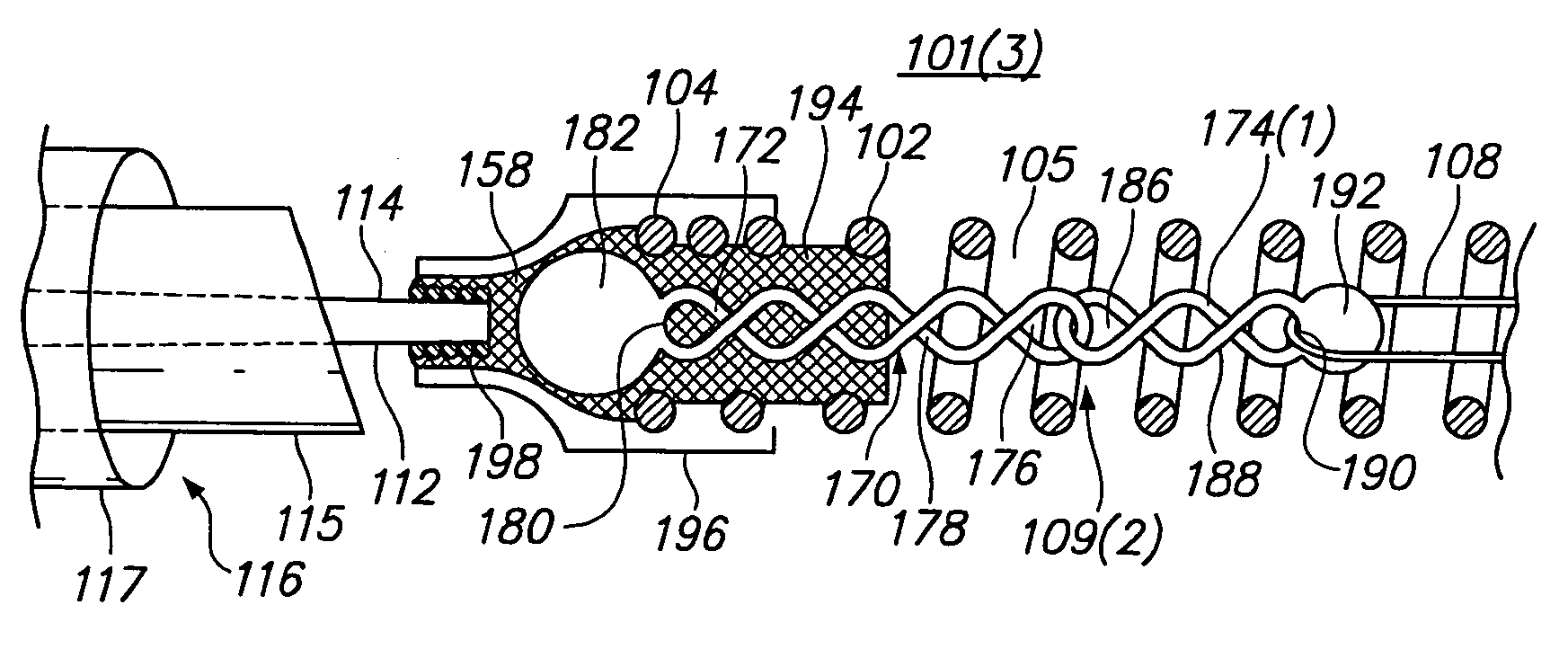

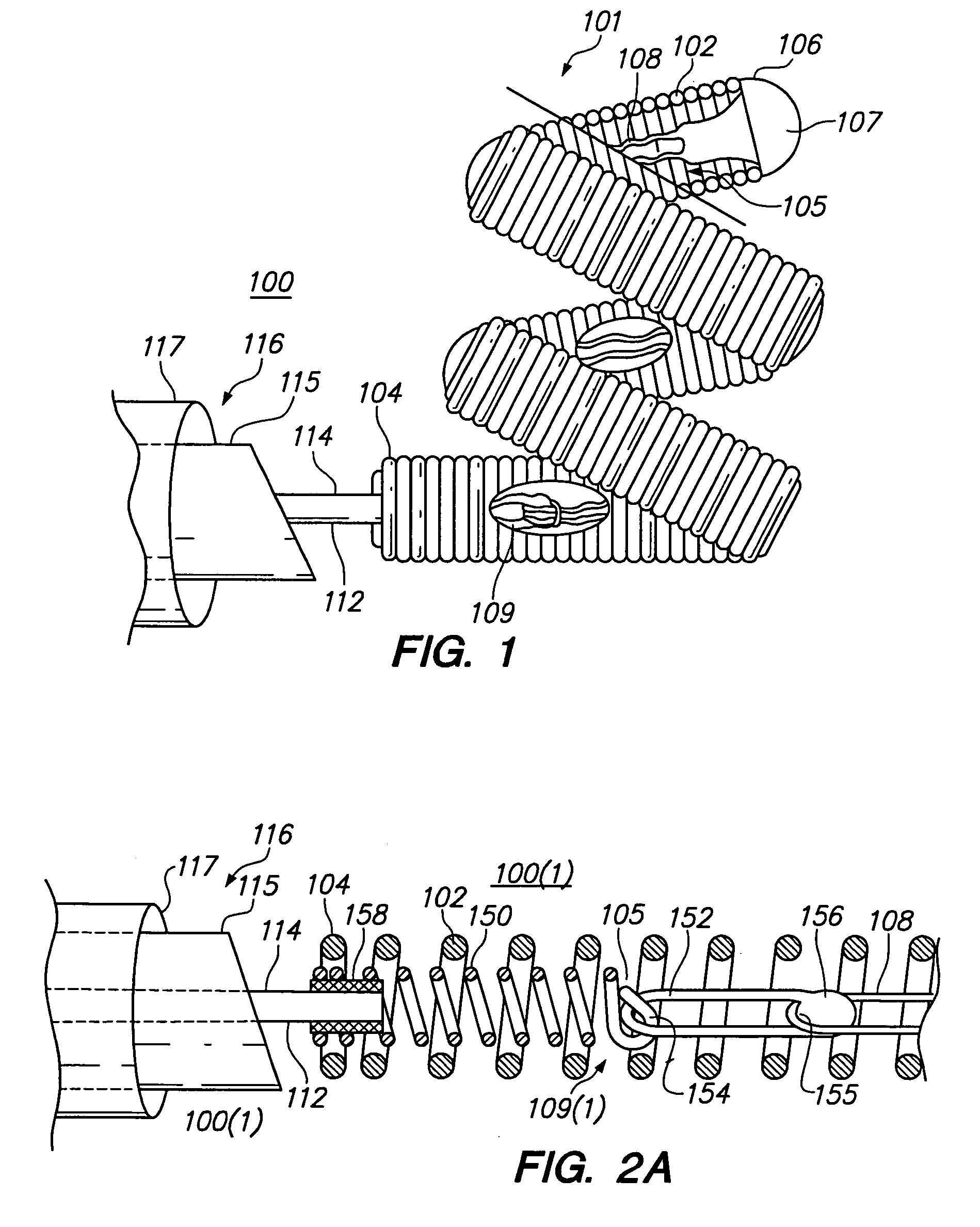

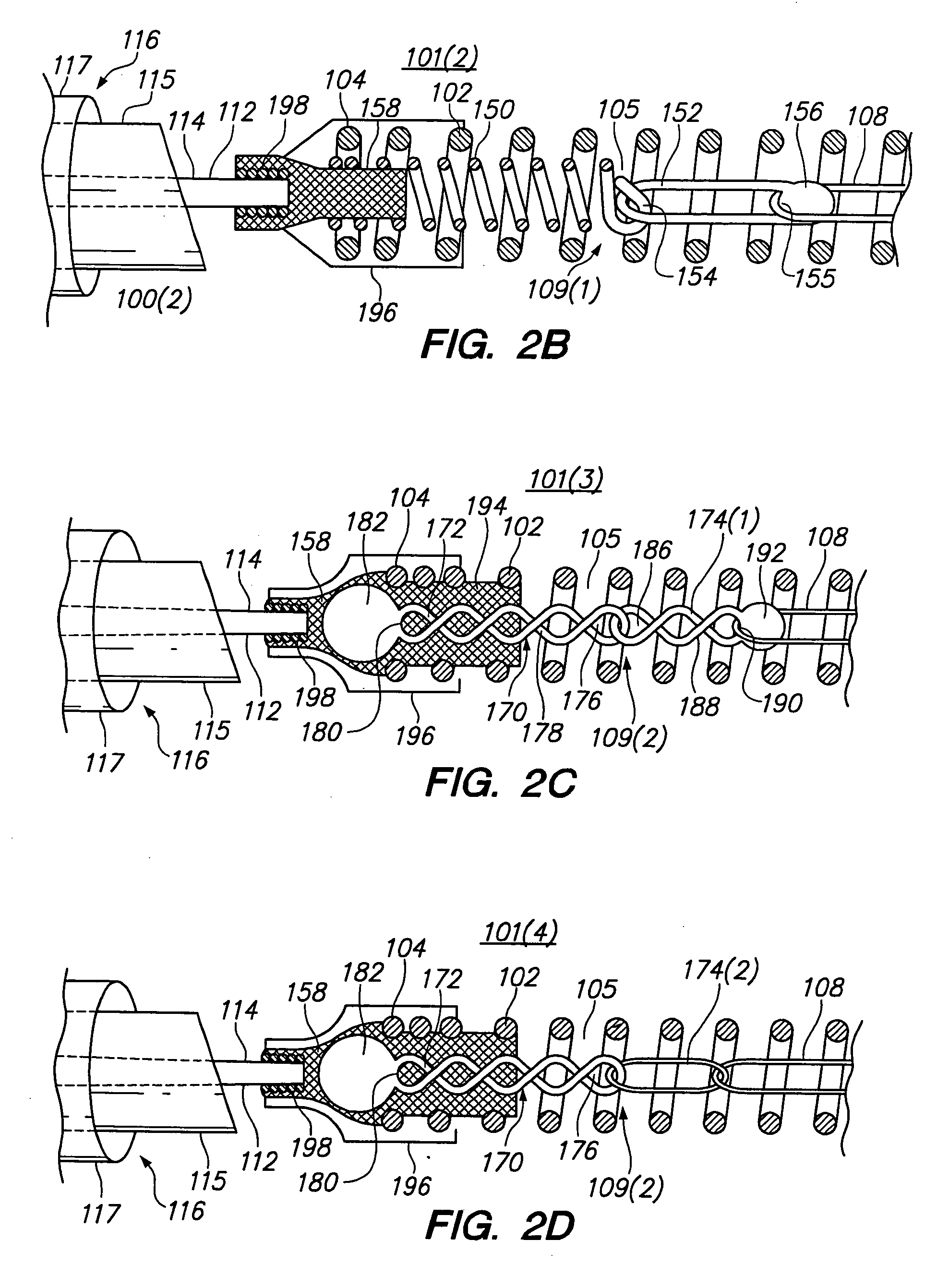

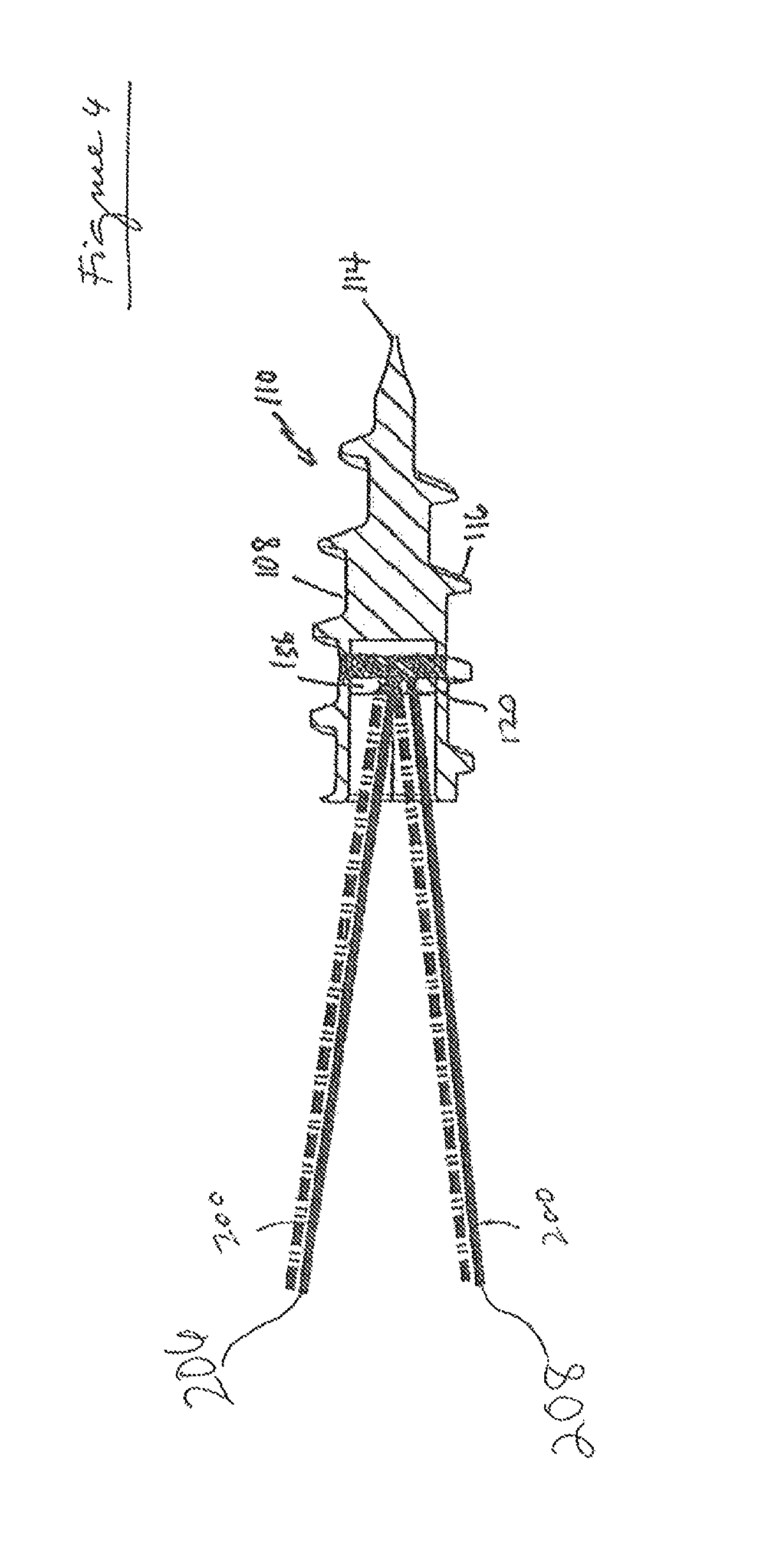

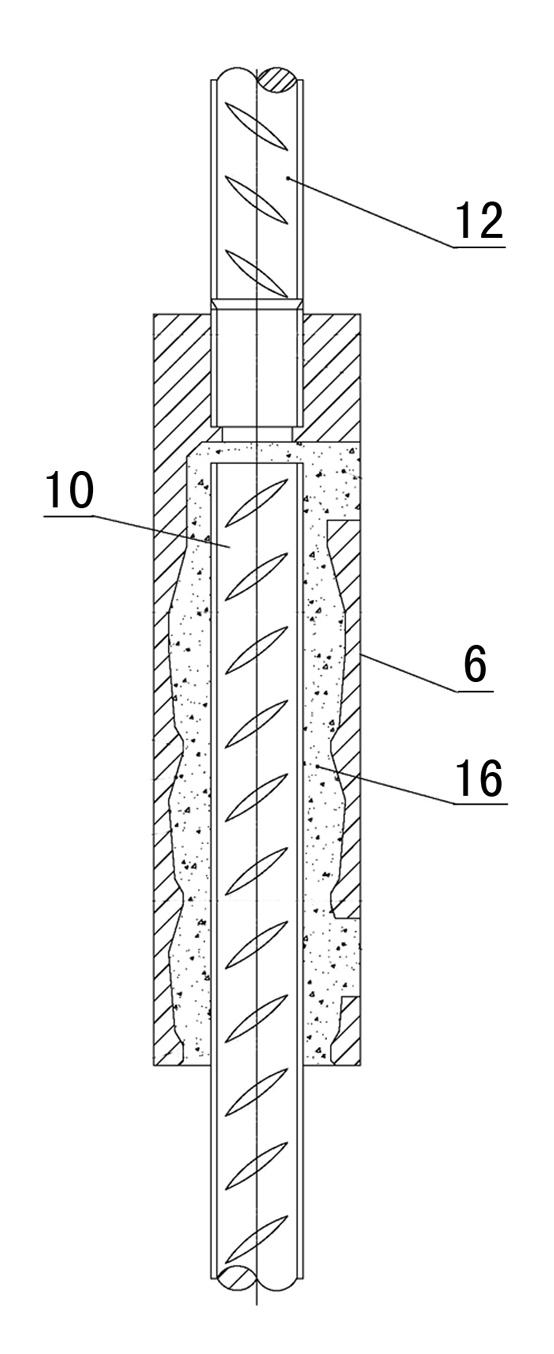

Anchor assemblies in stretch-resistant vaso-occlusive coils

Vaso-occlusive devices are provided for occluding an aneurysm within the human vasculature. The vaso-occlusive device also includes a stretch-resisting member that extends through at least a portion of a lumen of the primary coil and is directly or indirectly attached to the primary coil at two locations axially separated from each other to prevent or minimize axial stretching of the primary coil. At one location, the stretch-resisting member is coupled to the primary coil via a flexible anchor assembly disposed within the lumen. In one embodiment, the anchor assembly may comprise an anchor coil and a link directly or indirectly coupled between the anchor coil and the stretch-resisting member. Alternatively, the anchor assembly may comprise a chain of twisted links.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

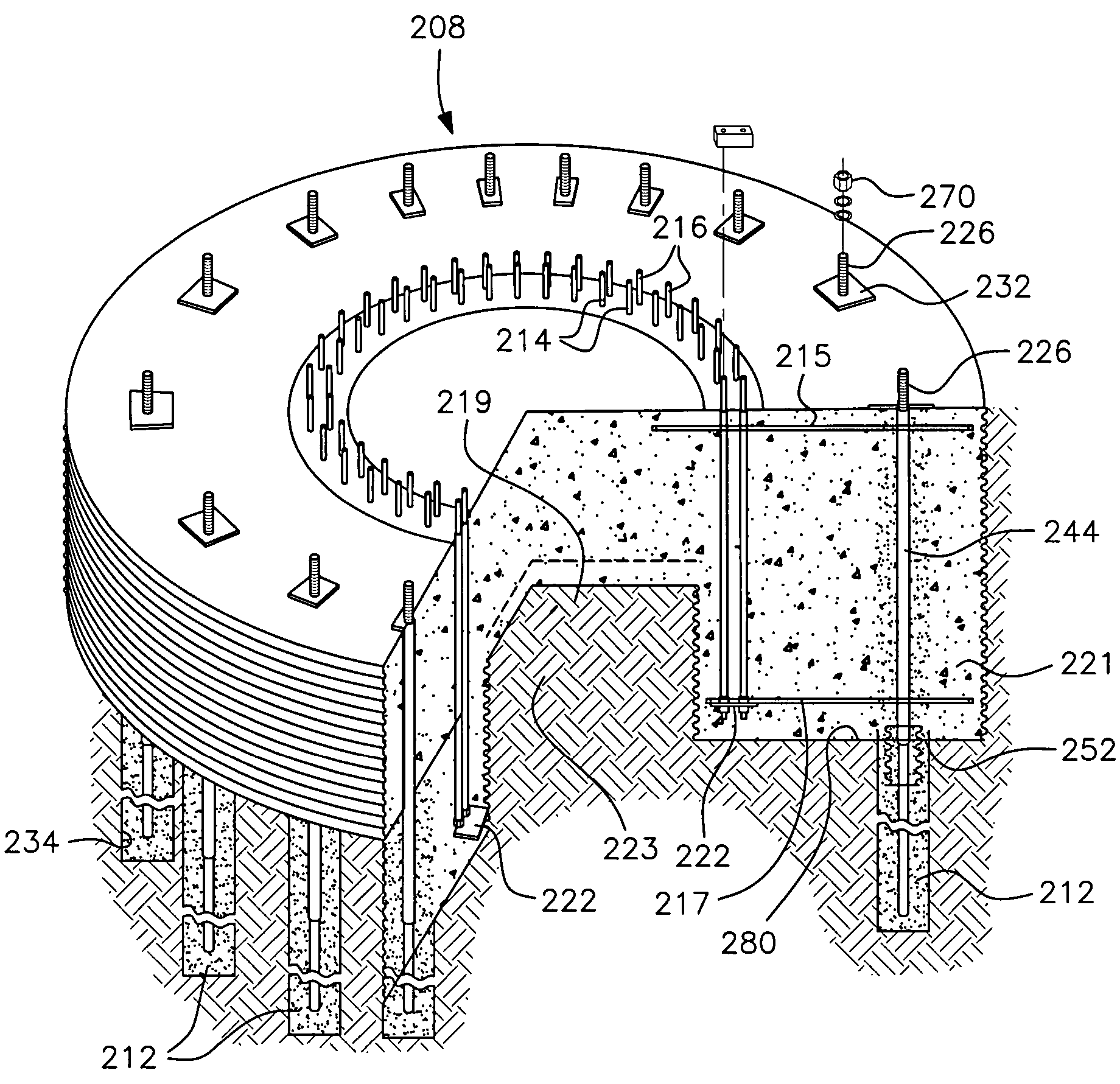

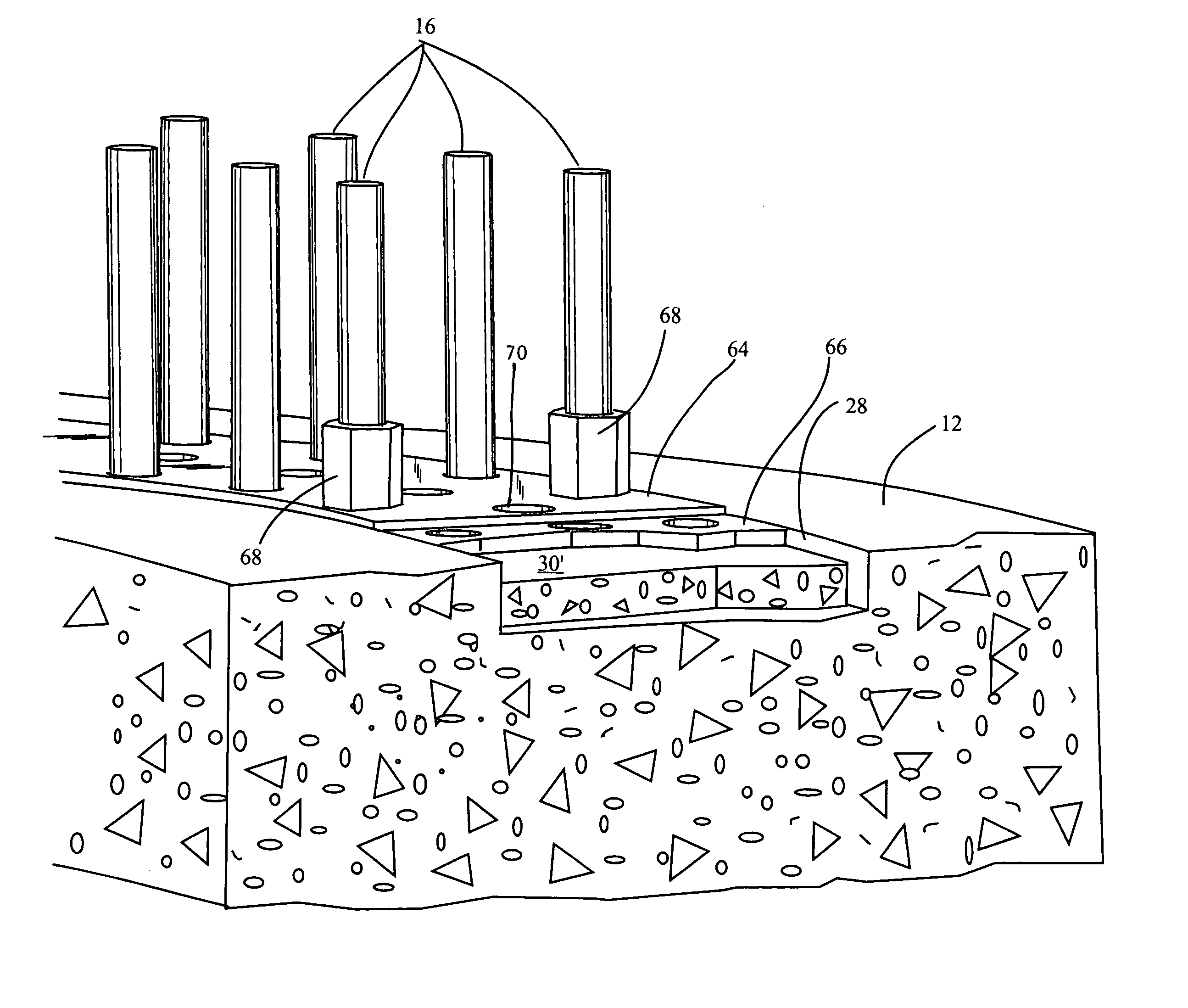

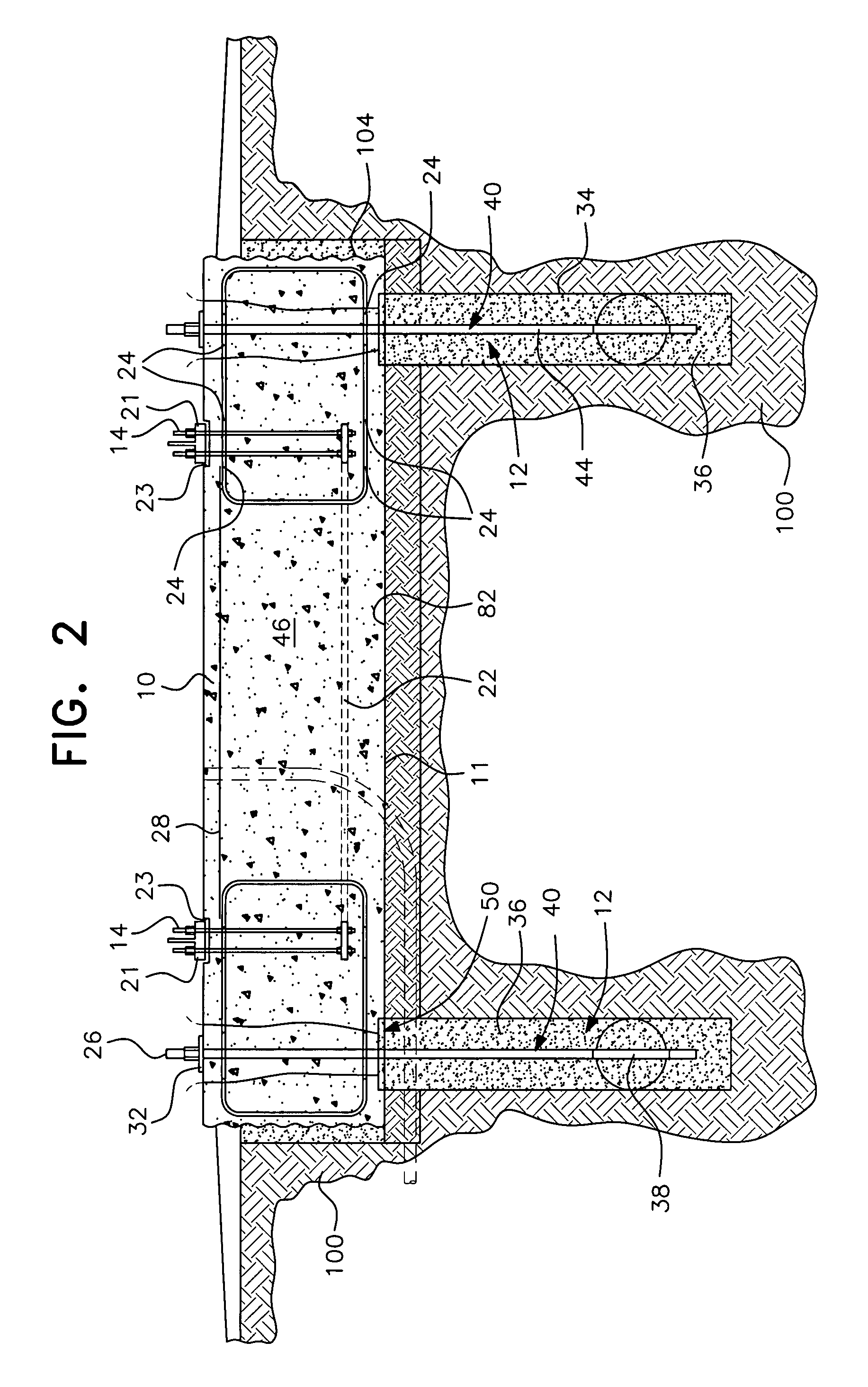

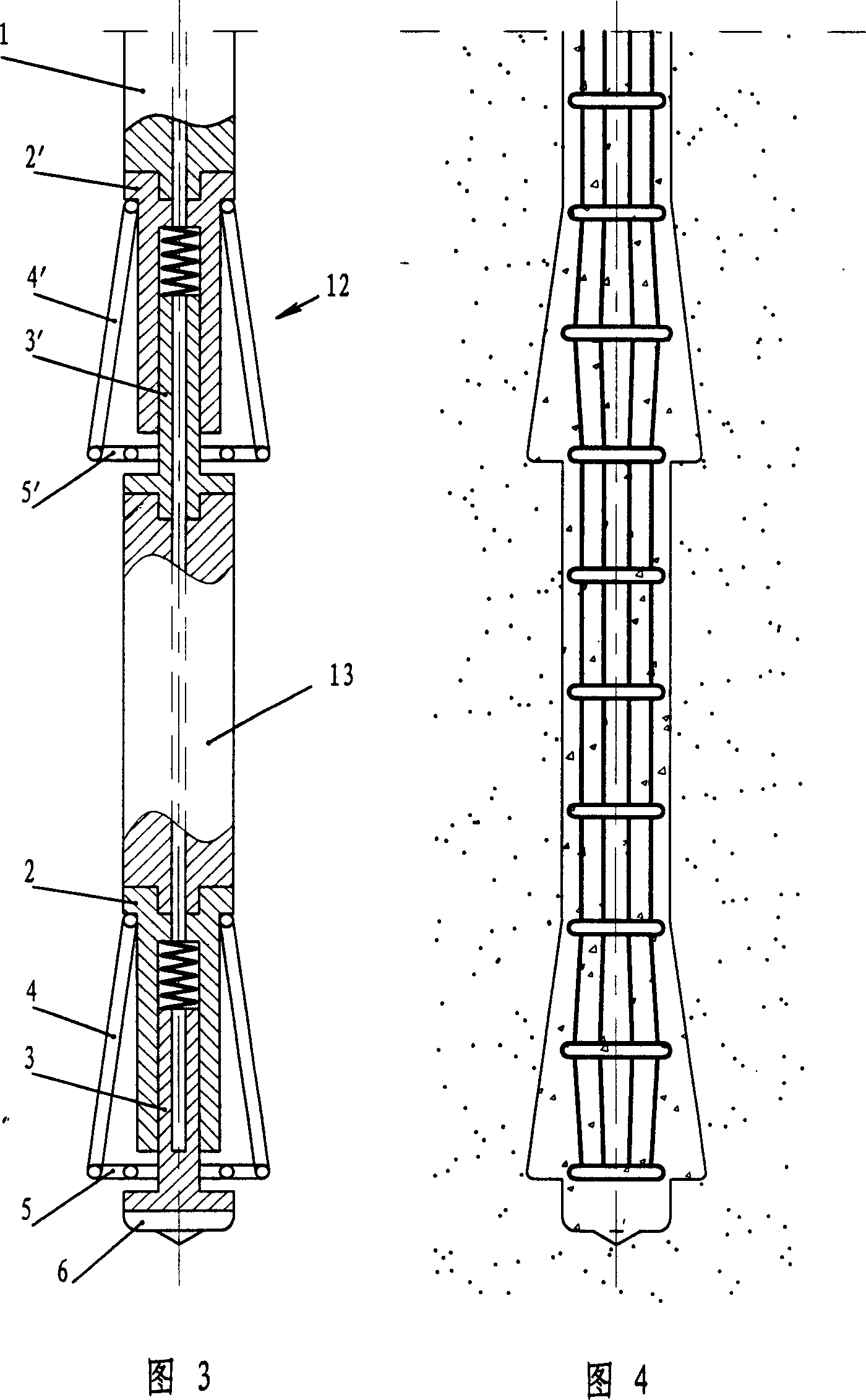

Post-tension pile anchor foundation and method therefor

A post-tensioned pile anchor foundation and method therefor creates a void or highly compressible region between a drilled or driven pile anchor surrounding a post-tensioned anchor bolt or tendon and the bottom of a foundation cap. The void or compressible region can be formed by compressible spacers or void forming elements placed between the top of the pile anchor and the concrete cap. As the anchor bolt or tendon is post-tensioned against the cap, the void forming element is compressed or crushed, allowing the cap to be pulled downwardly and the pile anchor to be pulled upwardly toward the cap against the resistance of the surrounding soil.

Owner:TERRACON CONSULTANTS INC

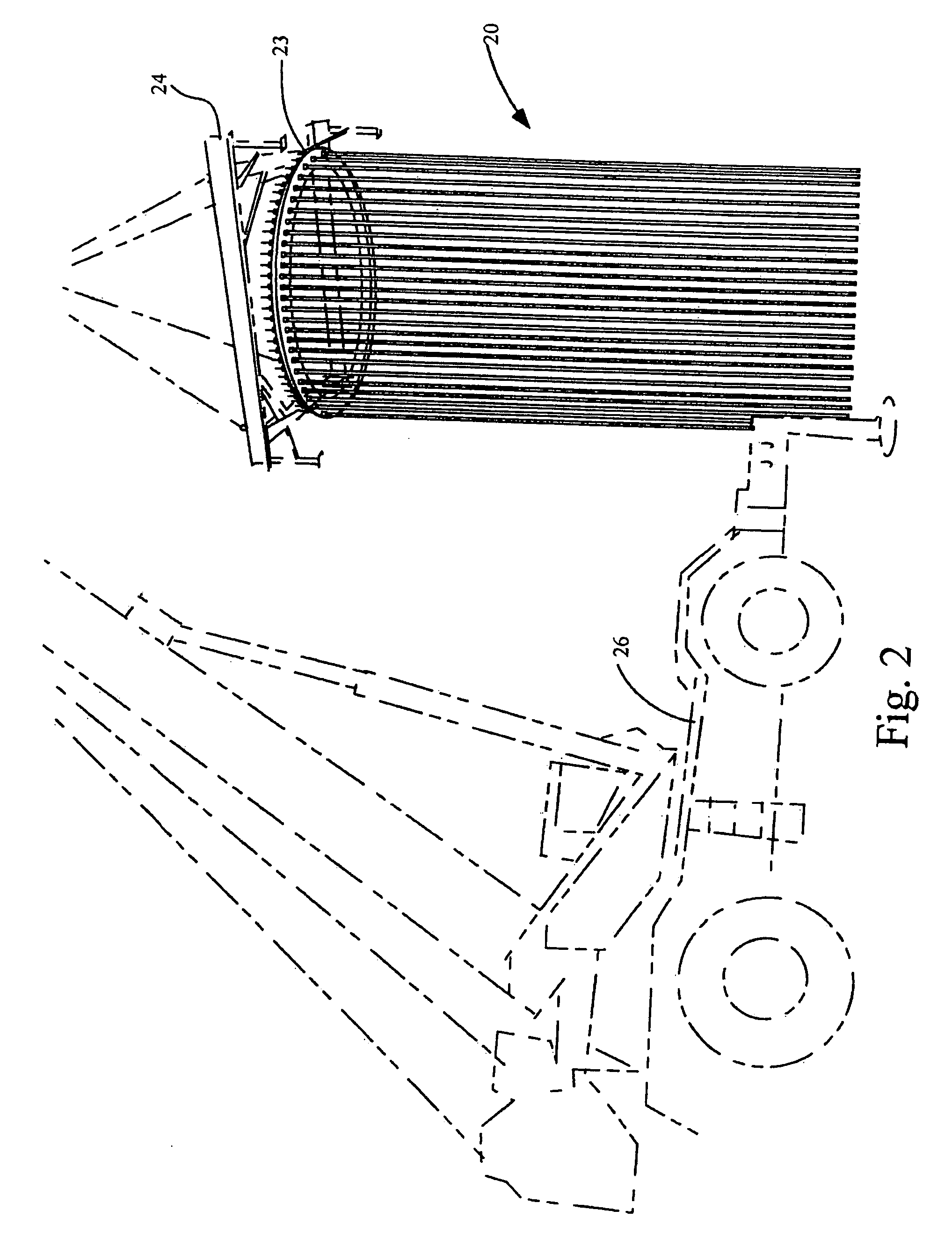

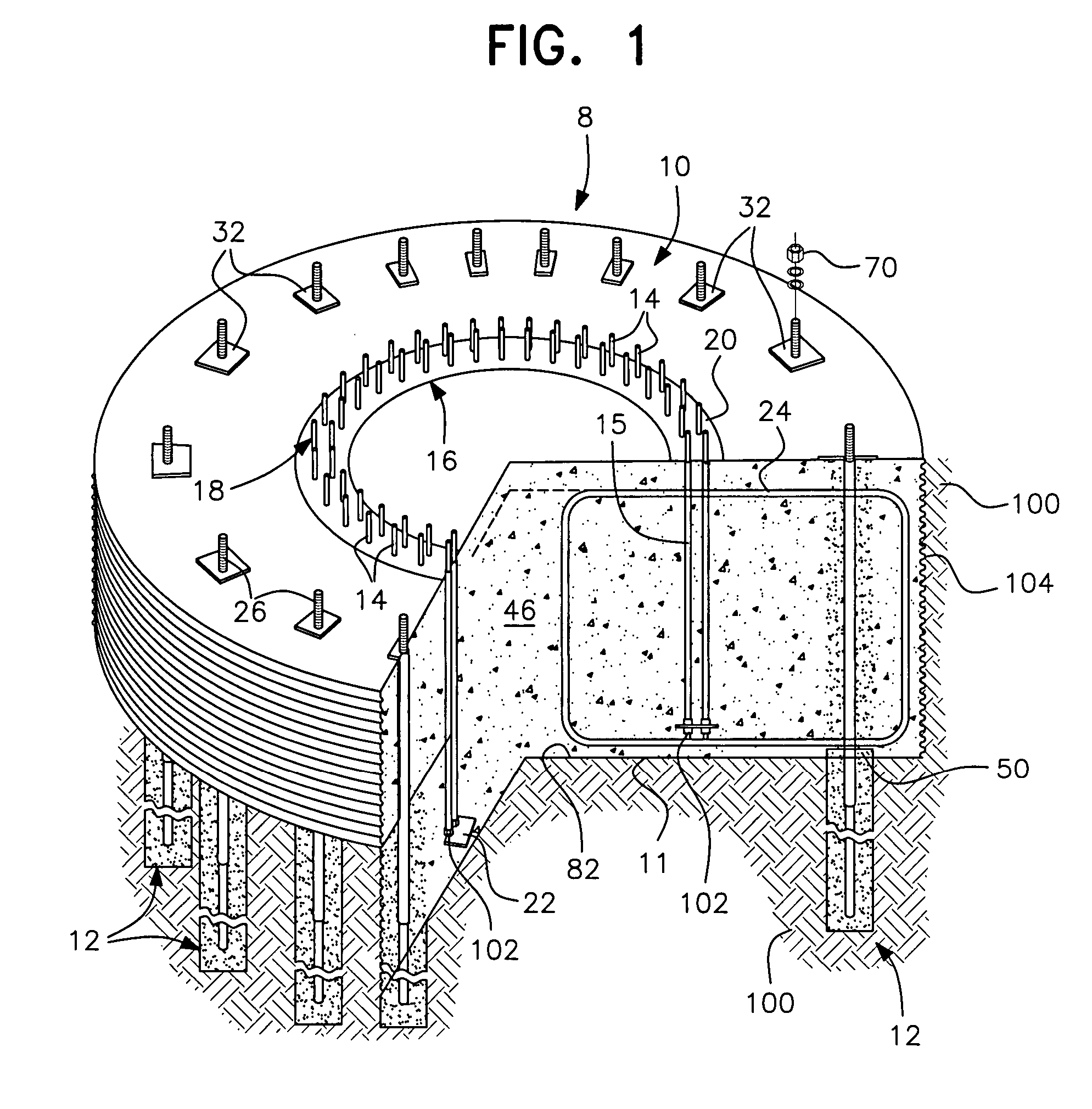

Wind turbine installation comprising an apparatus for protection of anchor bolts and method of installation

InactiveUS20090044482A1Preventing greatly limiting axial migrationAvoid stickingBuilding repairsWind motor supports/mountsEngineeringTower

An apparatus for use in providing a level grout surface for placement of a wind turbine tower flange, the apparatus comprising a template member levelly suspended on the anchor bolts above the grout trough, wherein the template member comprises a surface to which grout will not adhere. The template member can comprise an upper layer and a lower grout engagement layer, wherein the grout engagement layer comprises a surface to which grout will not adhere. The upper layer can comprise a metallic layer, and the lower layer can comprise a plastic layer, wherein the upper layer and the lower layer are bonded together. The lower layer can comprise polypropylene. The means of bonding are selected from the group consisting of mechanical bonding, thermal bonding and chemical bonding. The grout can comprise an epoxy grout. The template member can be suspended through the use of magnetic nuts or the use of a rotating sleeve. The template member can comprise a plurality of sections, and can comprise a circular form.

Owner:TOOMAN NORMAN L

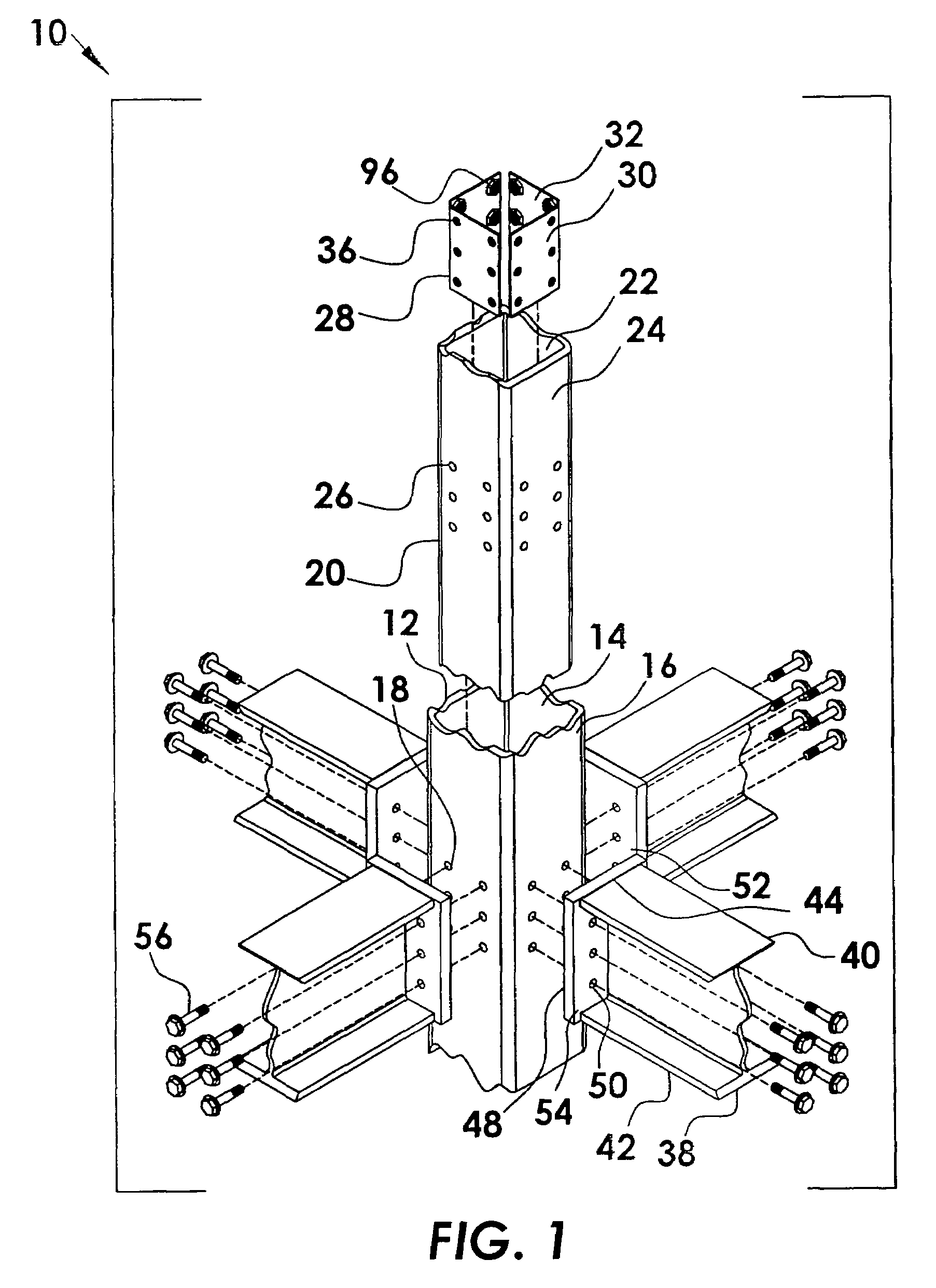

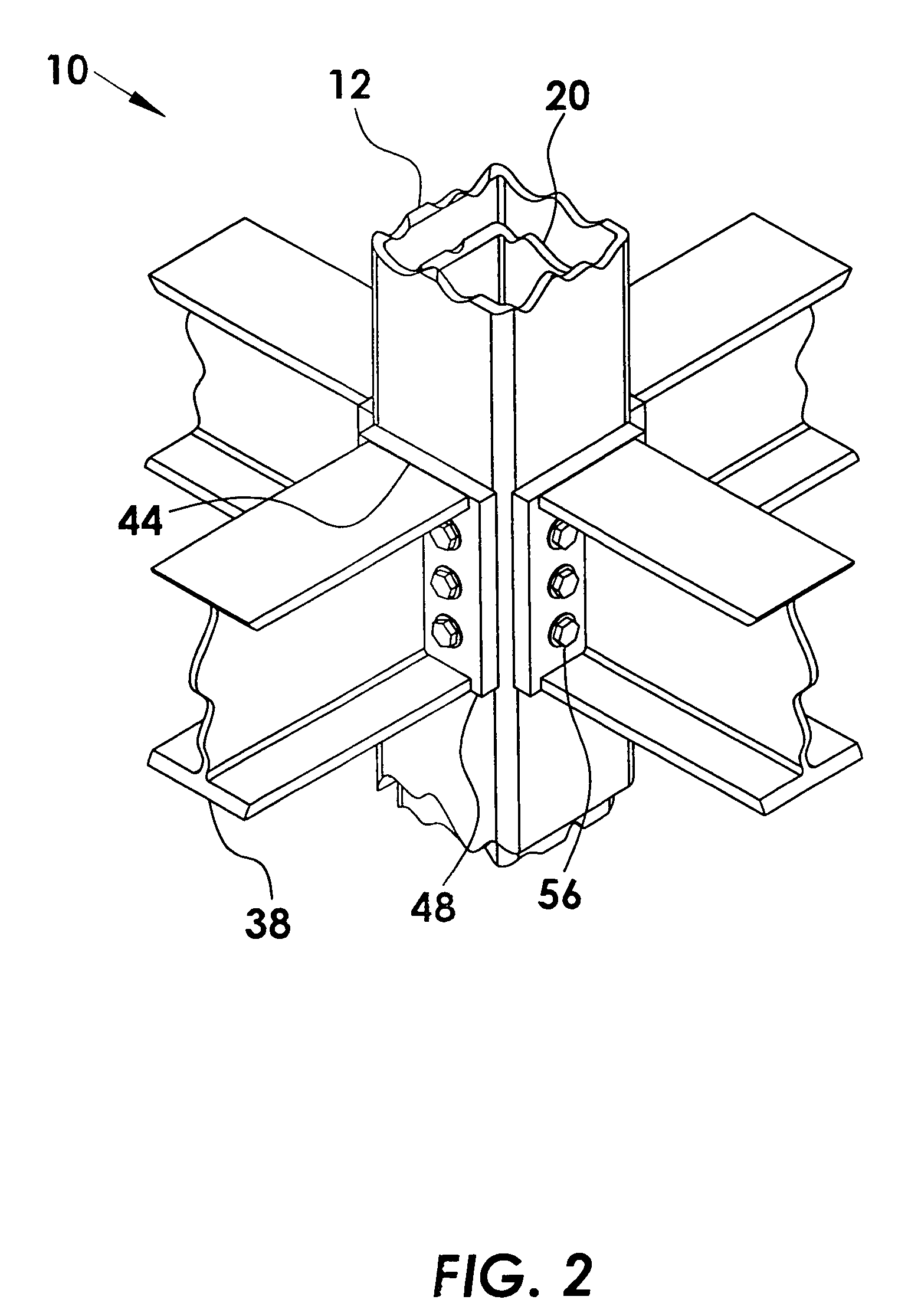

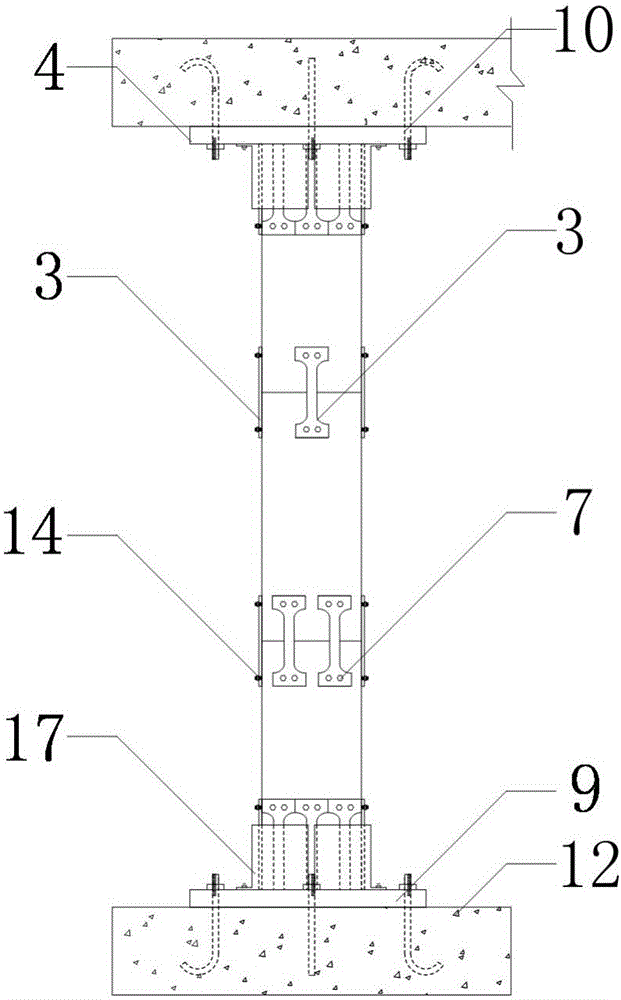

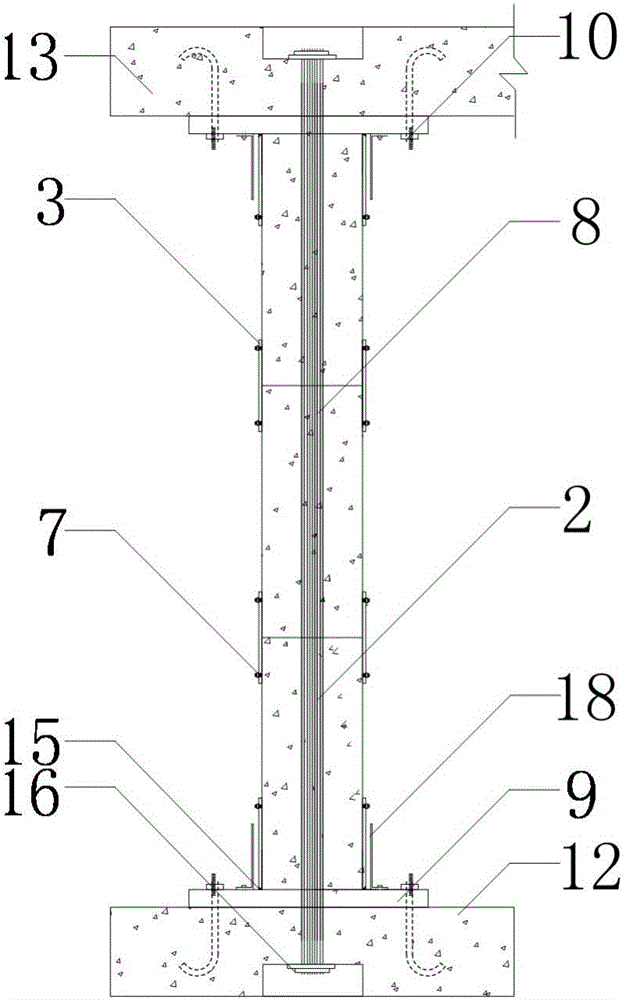

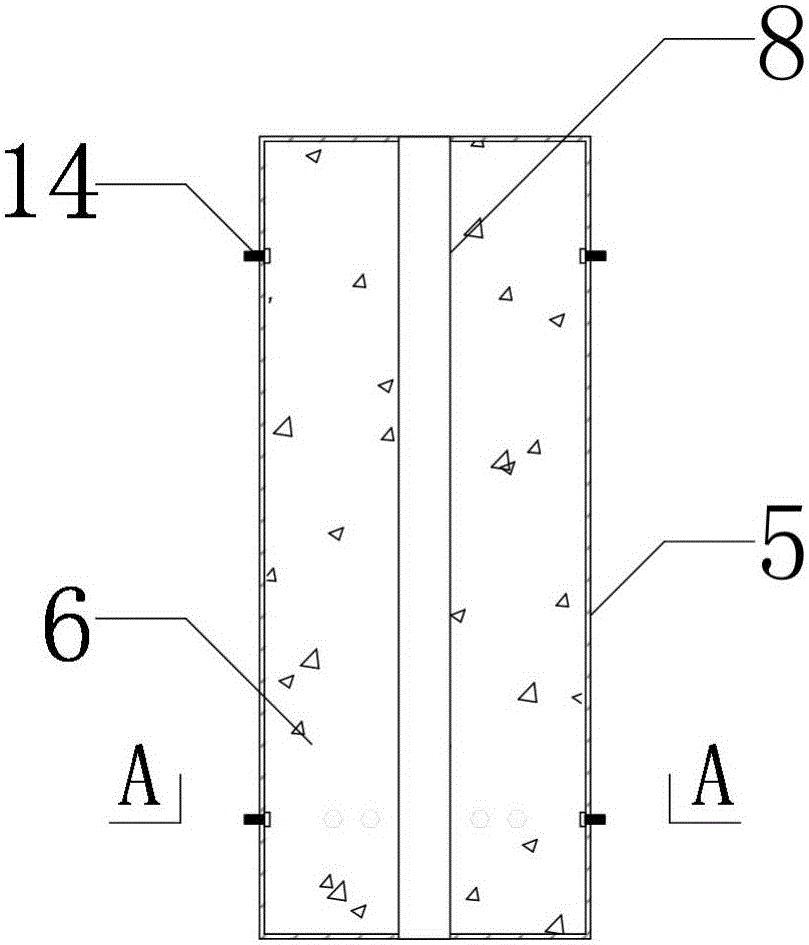

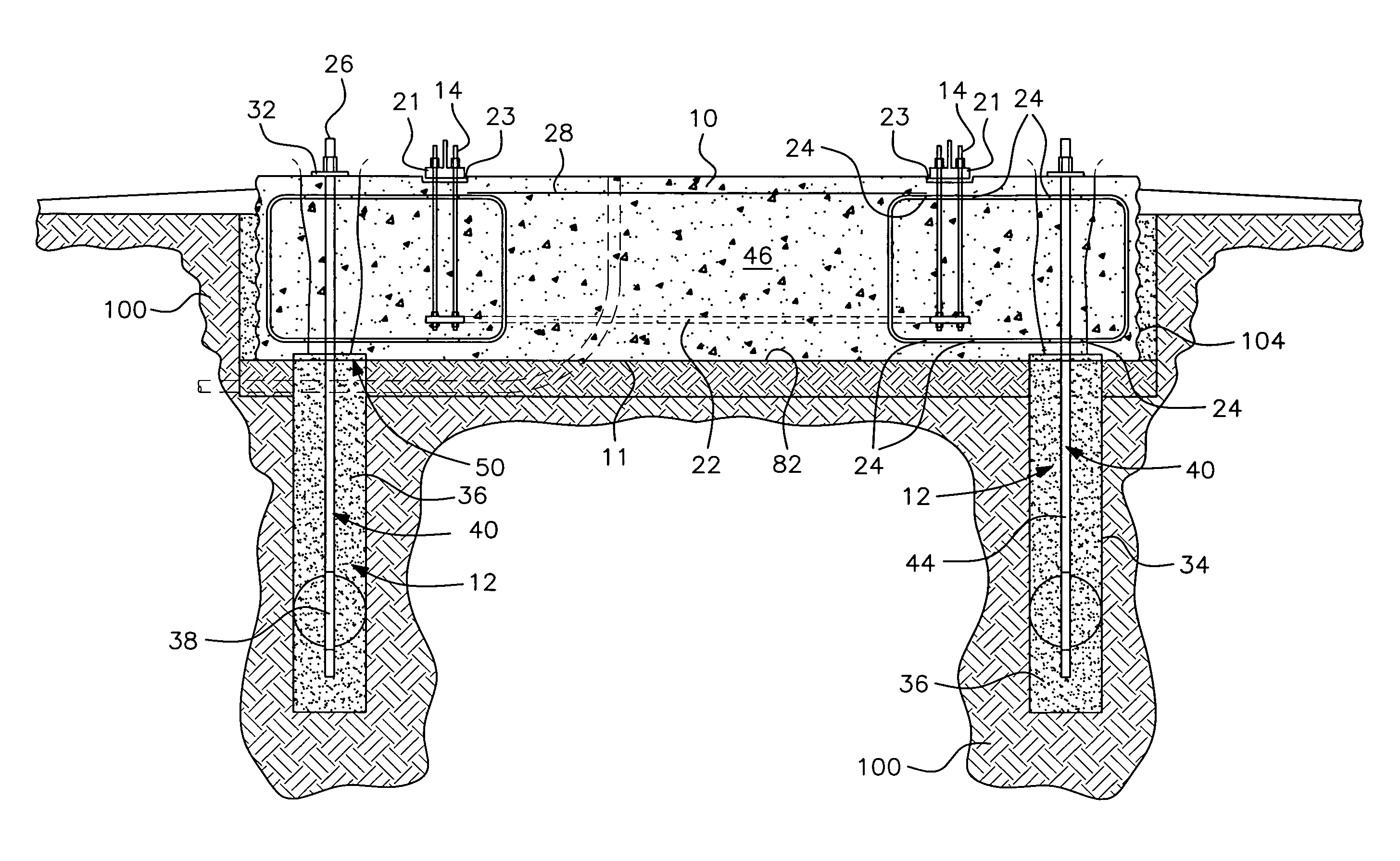

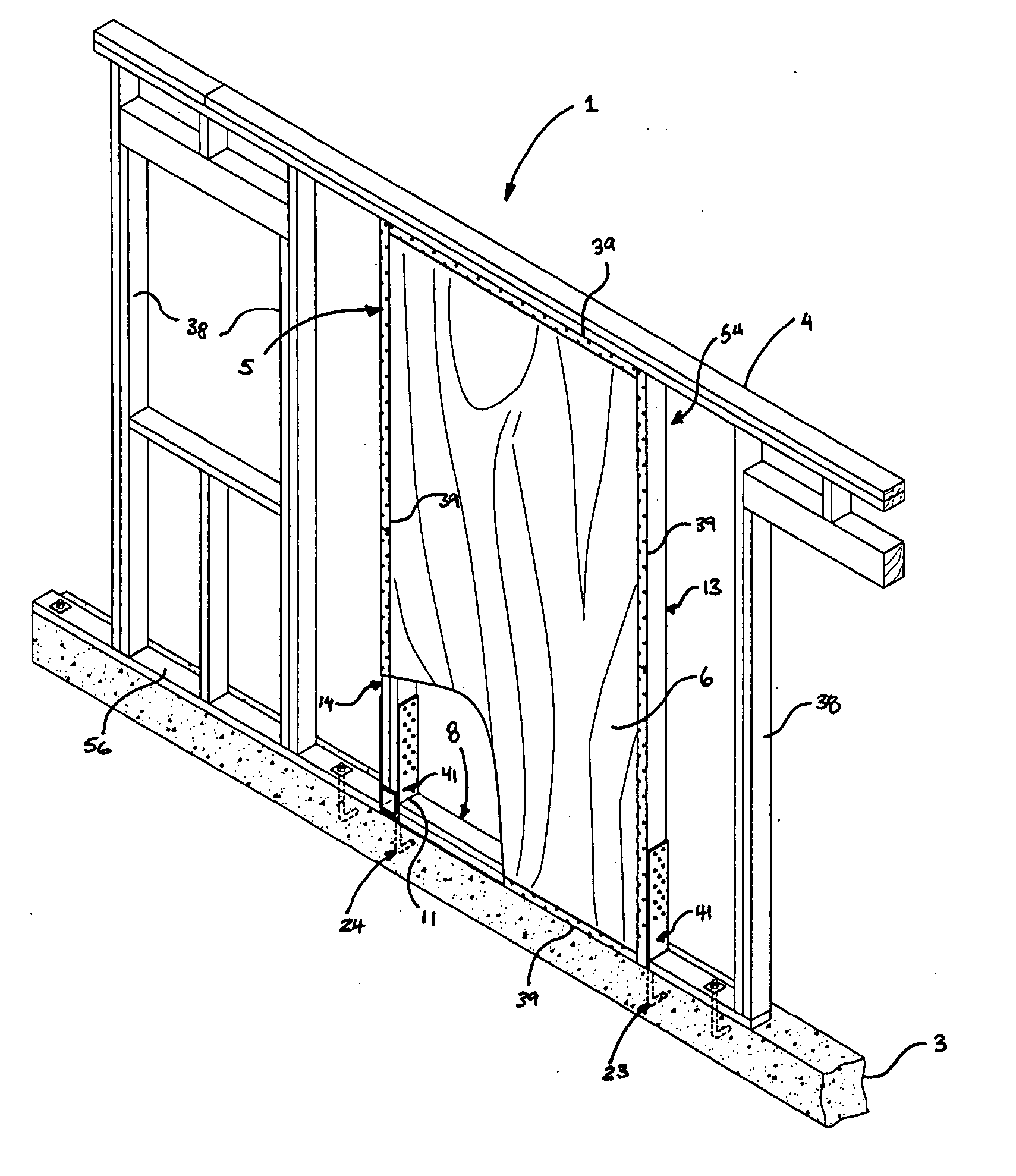

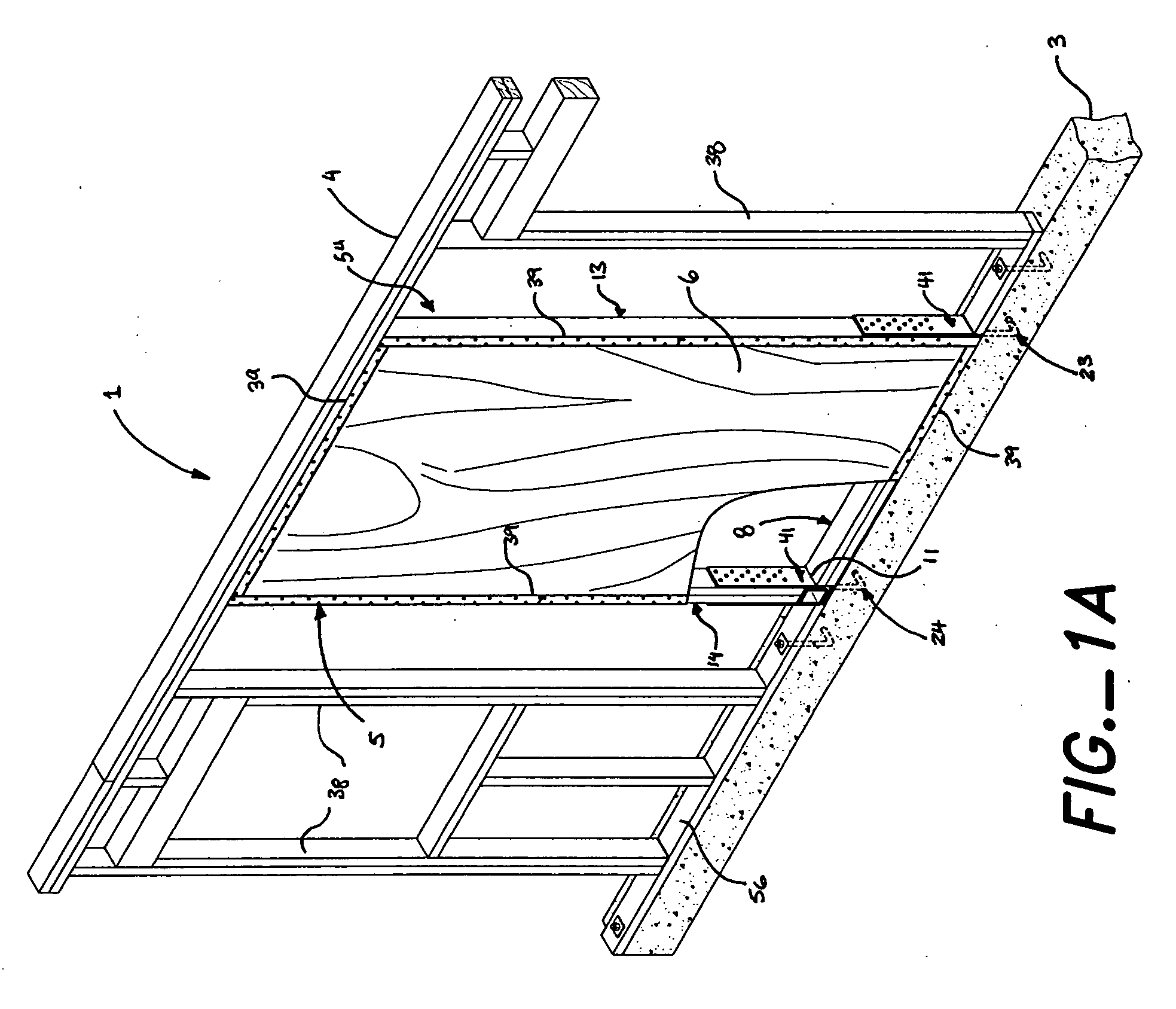

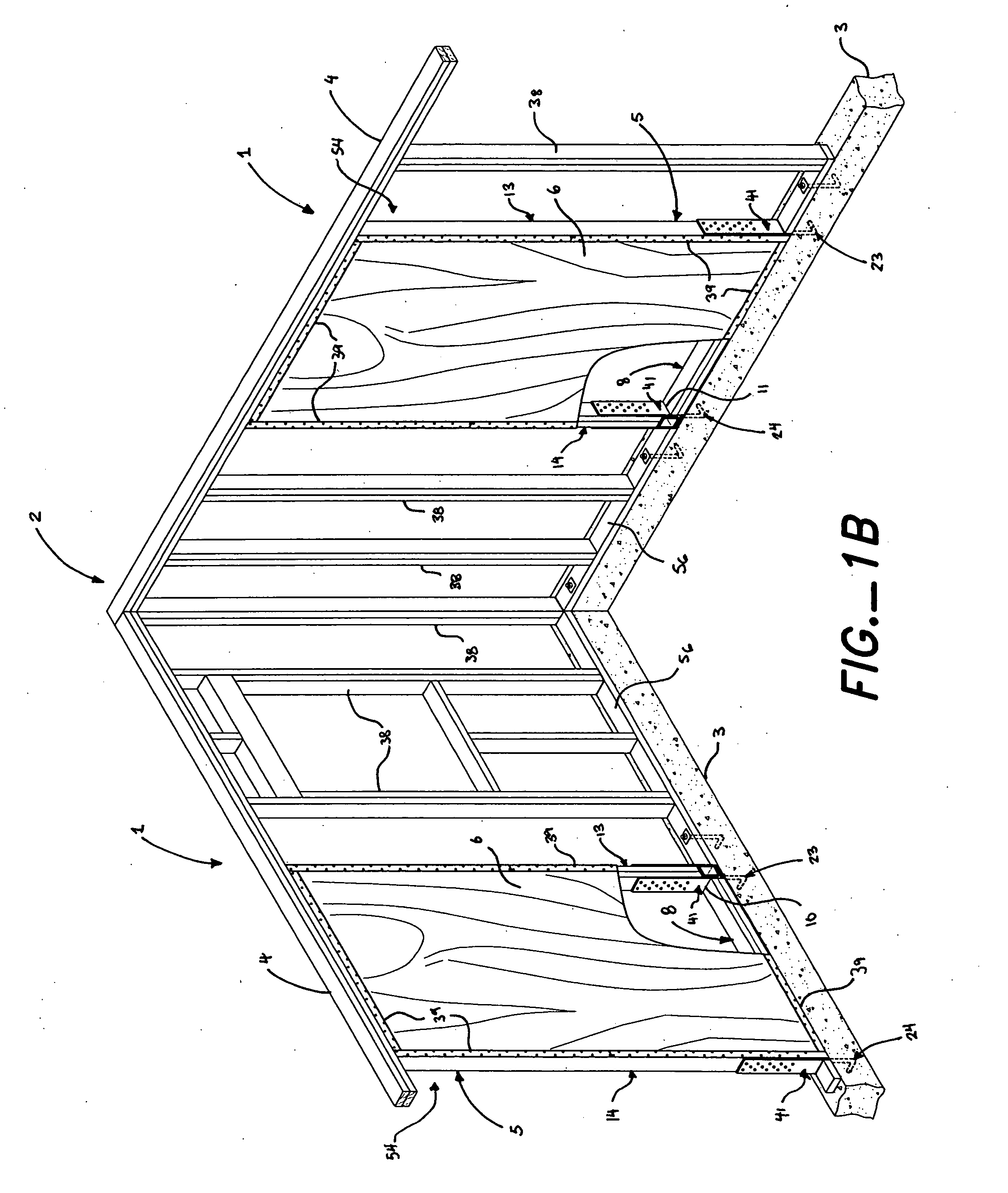

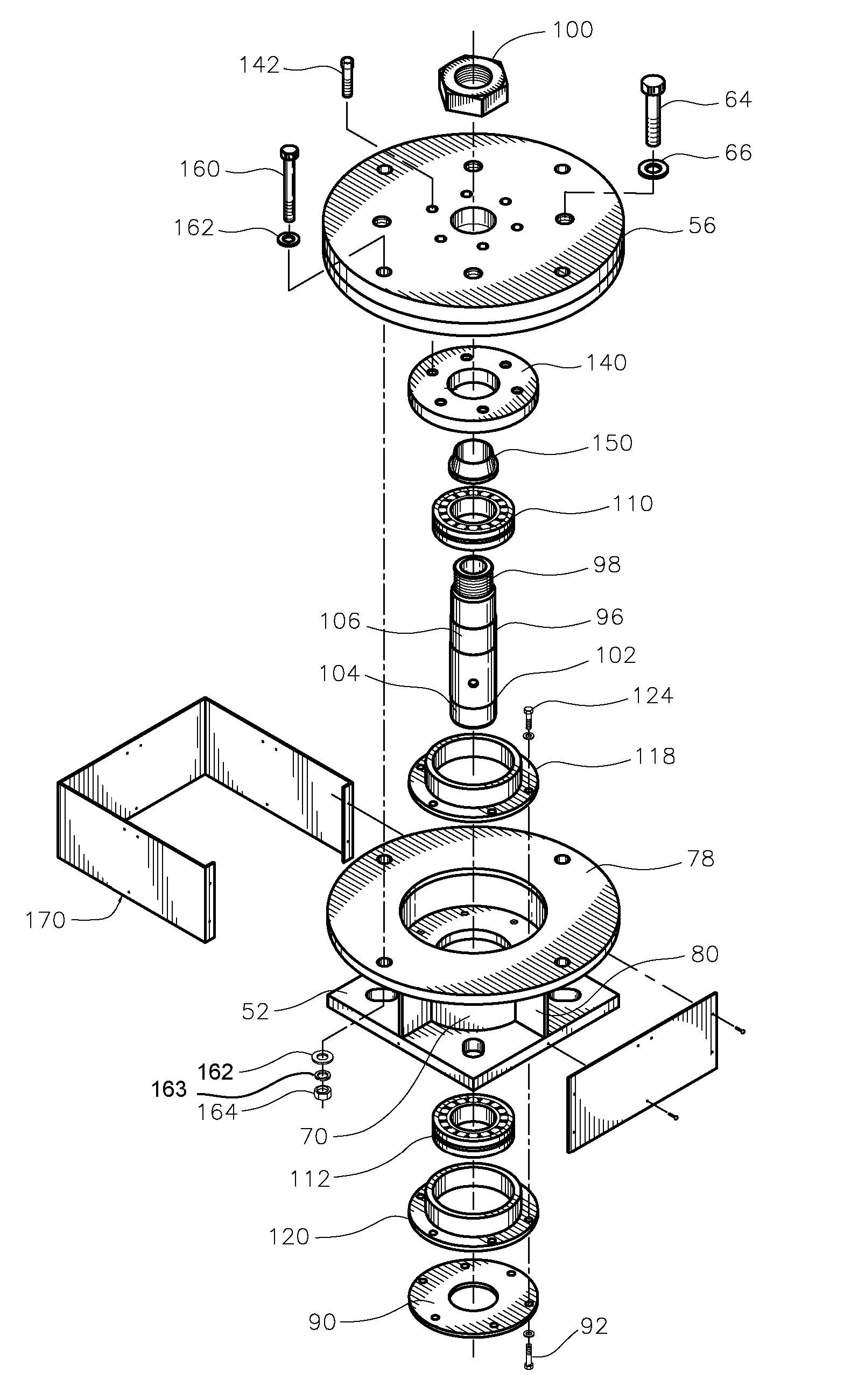

Moment-resistant building column insert system and method

InactiveUS7637076B2Firmly connectedHigh strengthBuilding roofsFloorsArchitectural engineeringVertical load

The invention is a novel moment-resistant building column insert system for distributing lateral and vertical loads between the column-beam and column-foundation connections. Loads are distributed between the column and beam using a column insert, nut plates and beam end plates incorporated to beam-ends. The column insert is hollow and similar cross-section shape to the building column for inserting there to. The column, column insert, nut plates and endplates have patterns of mounting holes for receiving mounting bolts tightened to nuts held by nut plates. Loads are distributed between the column and foundation using a base plate, column insert, and insert plates integrated with anchor bolts, nuts and washers in a concrete foundation. The base plate having mounting holes is incorporated to the building column bottom end to receive the plurality of anchor bolts there through for fixedly tightening as an exposed end of the column insert fits in the column.

Owner:VAUGHN WILLAIM B

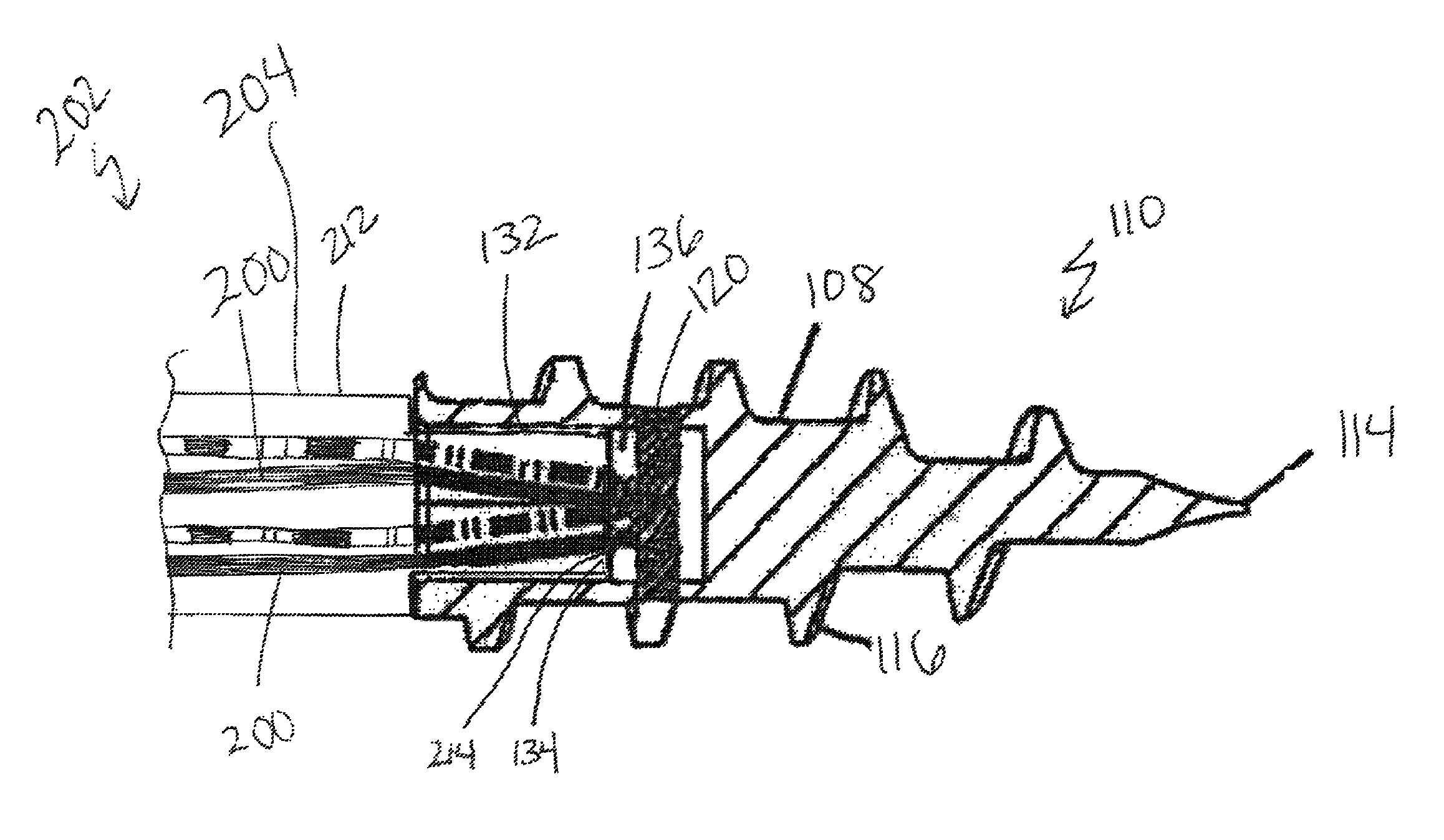

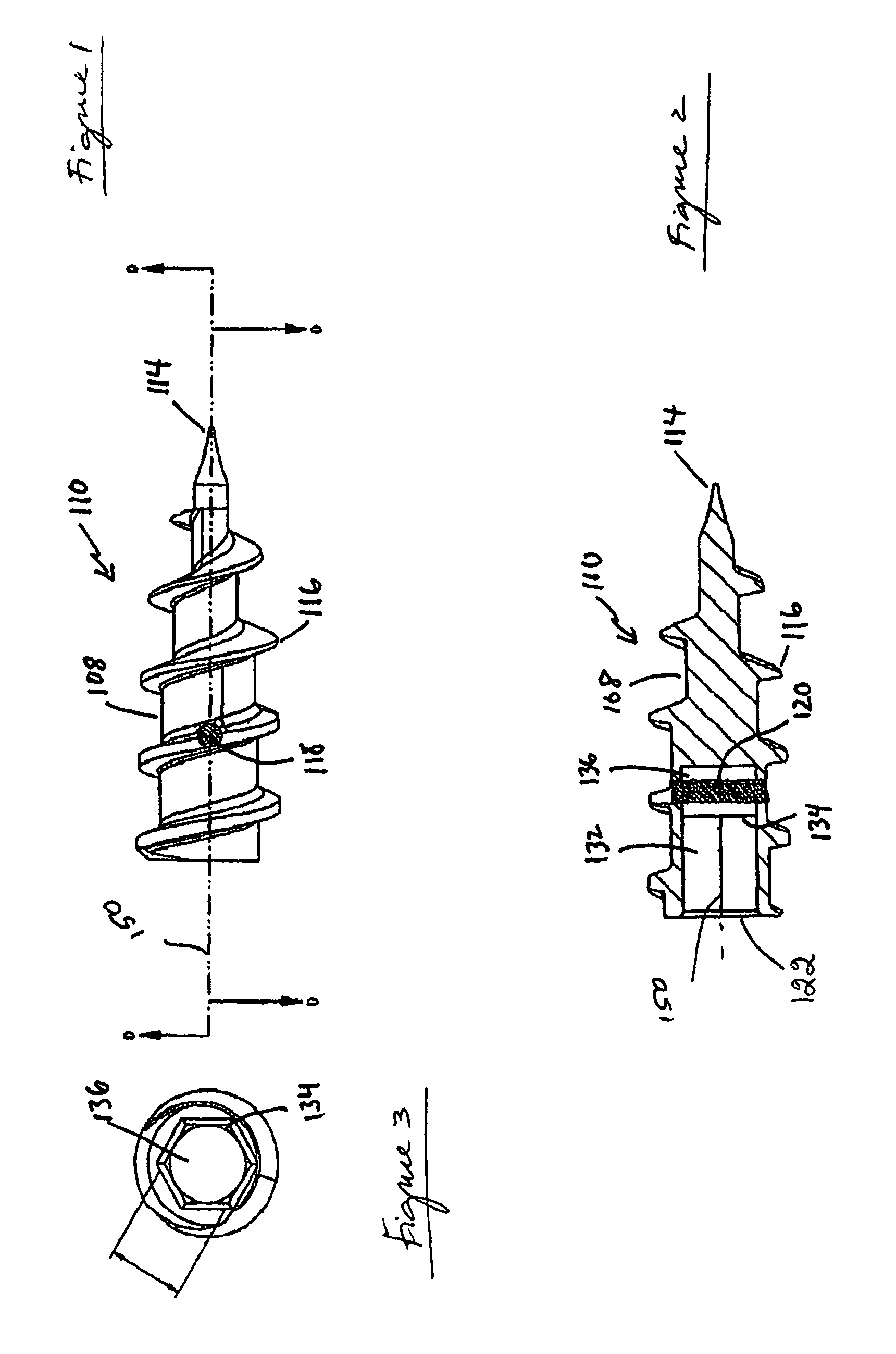

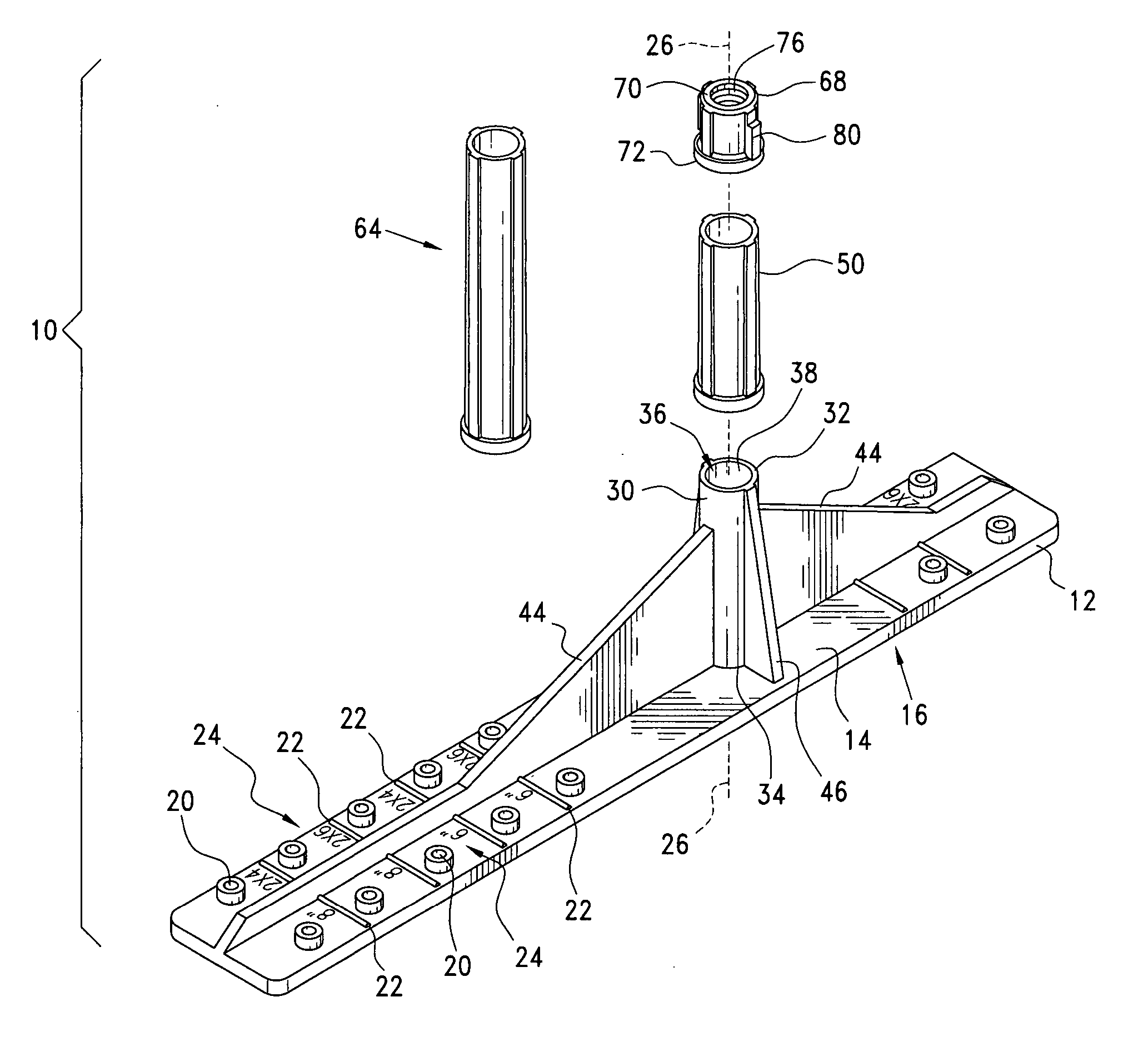

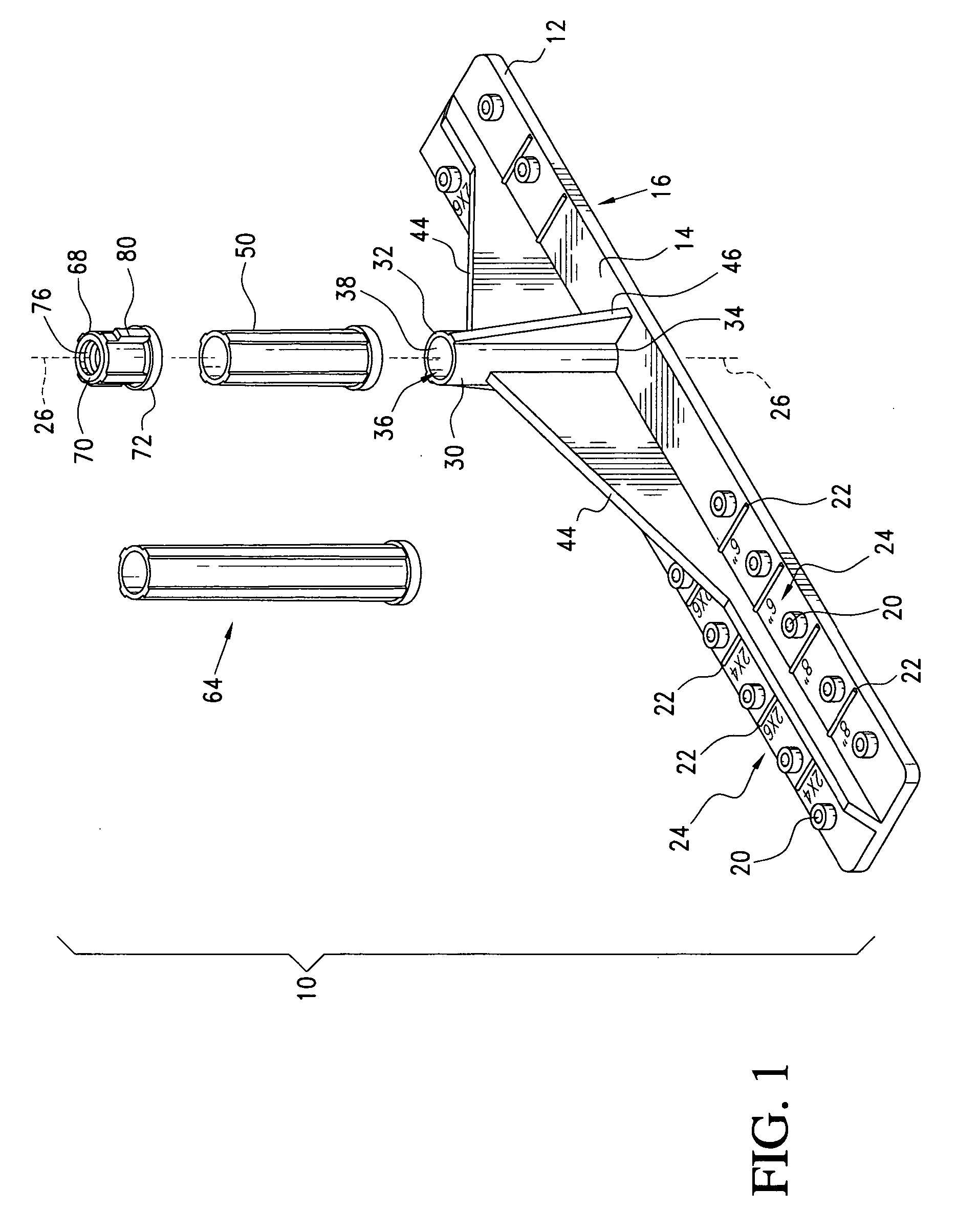

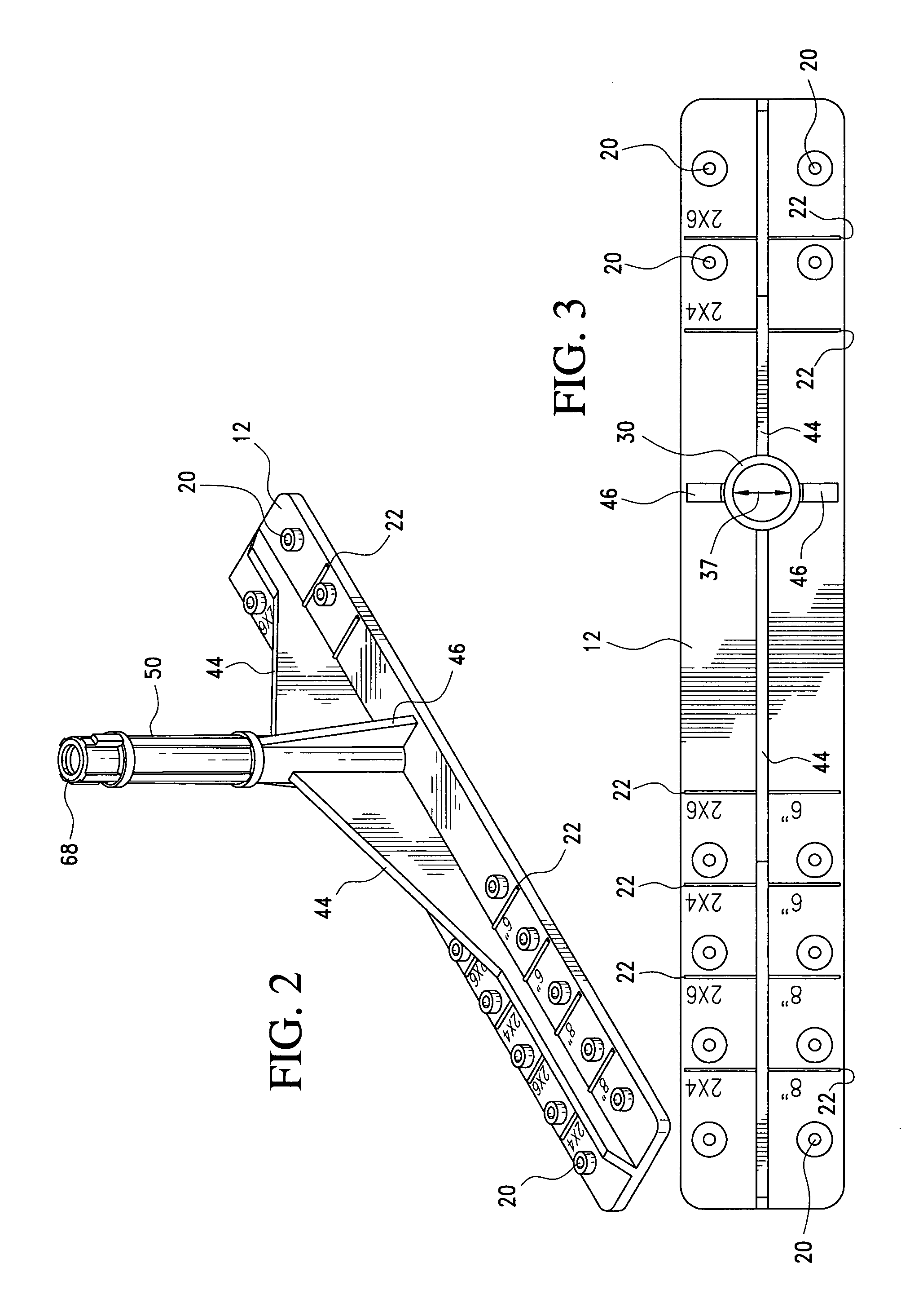

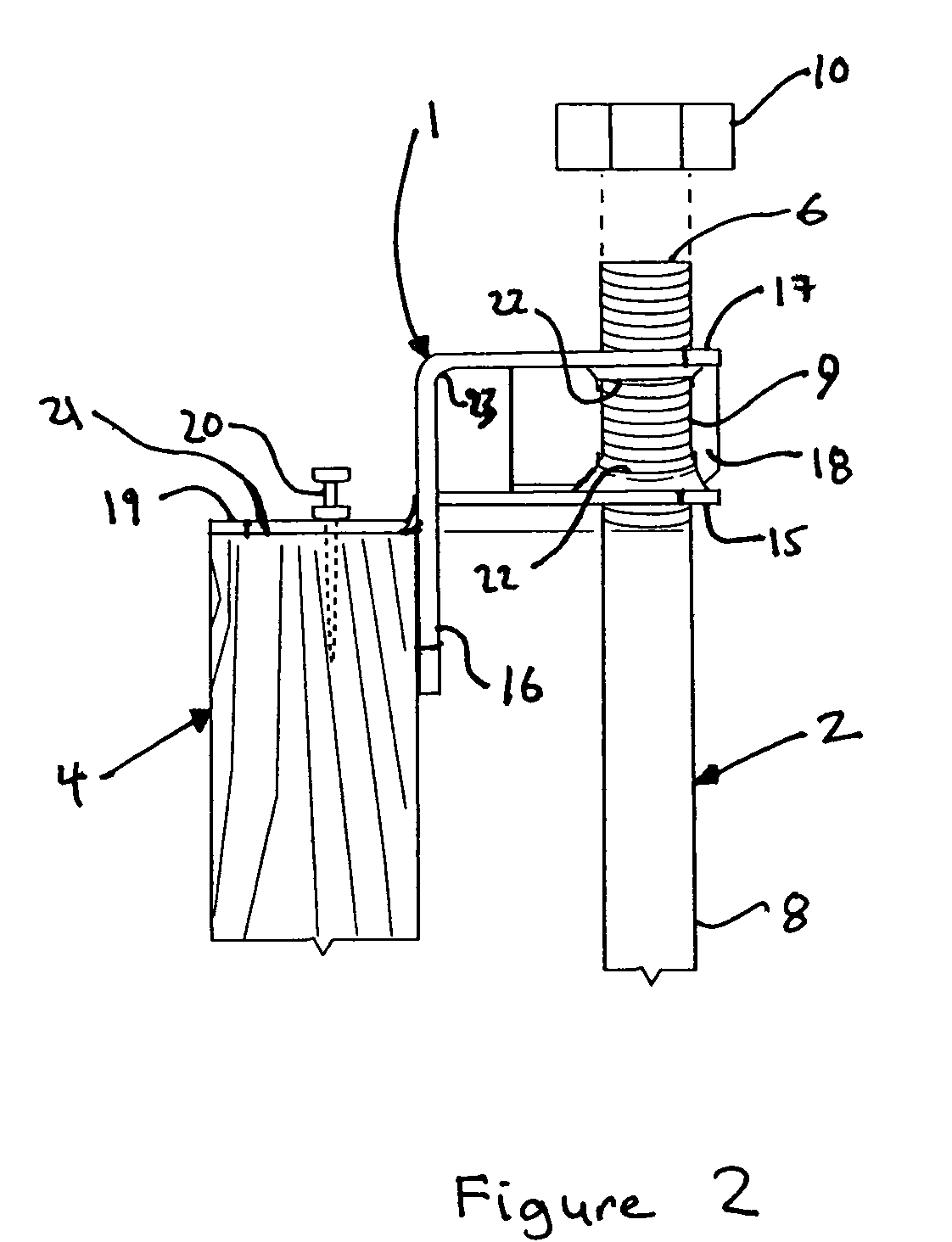

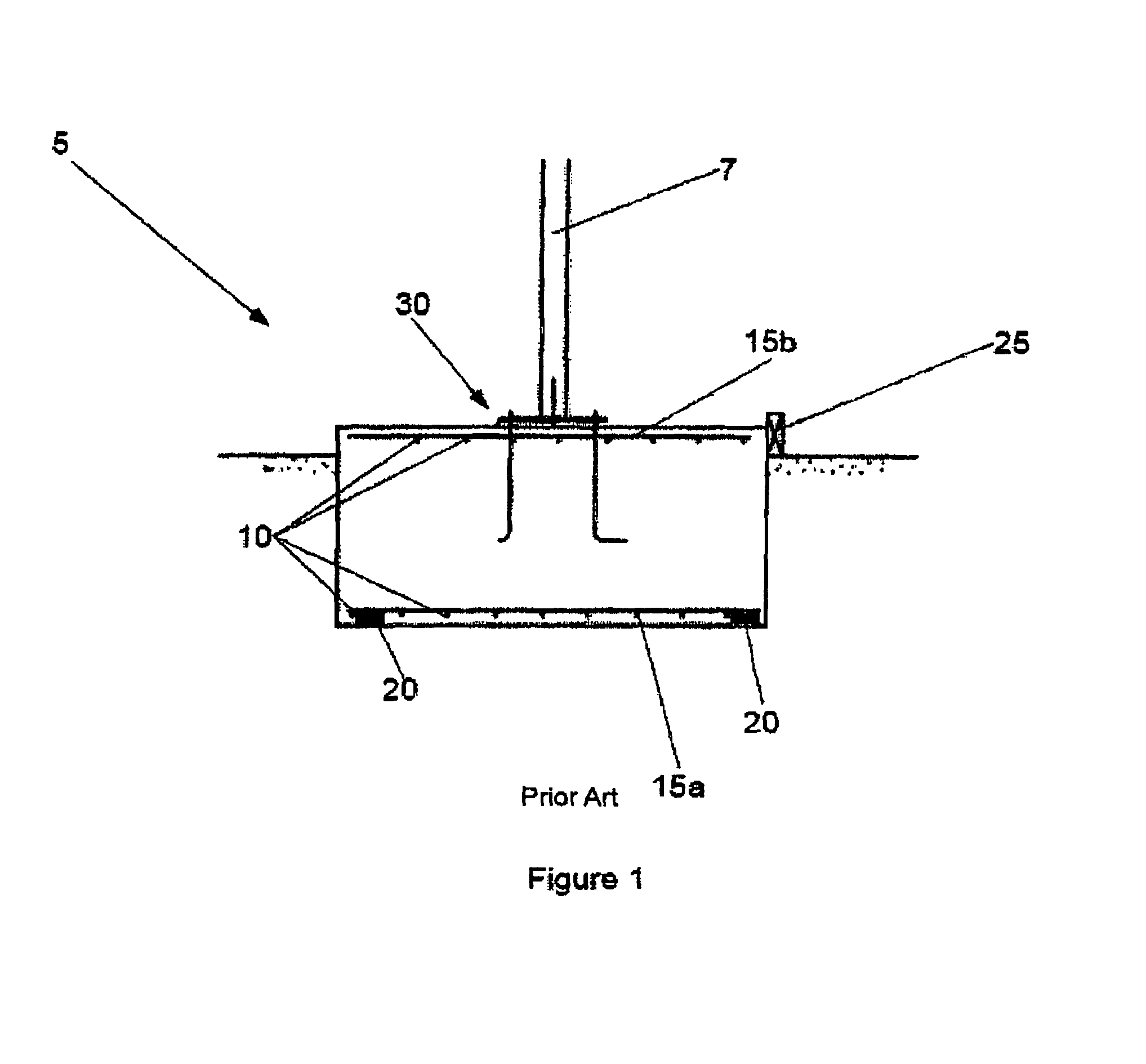

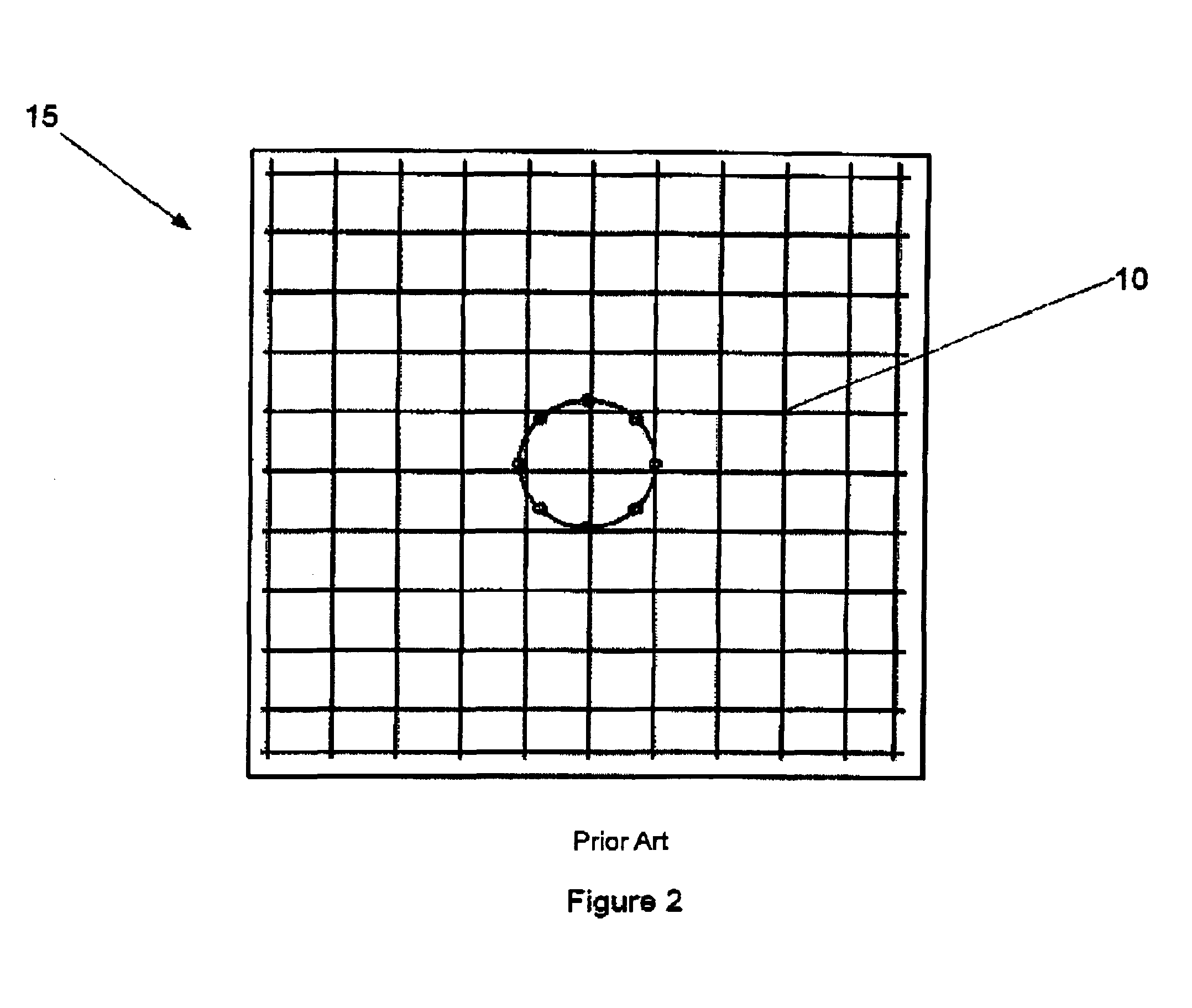

Anchor bolt placement protection assembly and method for aligning structural elements in a form when pouring concrete

InactiveUS20060016140A1Precise positioningAccurate spacingFoundation engineeringEngineeringScrew thread

An anchor bolt placement and protection assembly for positioning or setting a threaded anchor bolt in a concrete stem foundation or concrete slab in relation to spaced form boards for controlling the depth of the anchor bolt in the concrete and the protected length of the anchor bolt projecting above the concrete foundation or slab. The assembly includes a base plate carrying a fixed, elongated tubular member having a lumen with an inner diameter dimensioned to receive the selected anchor bolt. The tubular member is sized to abut a detached tubular having an inside diameter that is substantially equal to the fixed tubular member's inside diameter. The assembly also includes a fastener with an anchor bolt thread engaging lumen with an inside diameter that is substantially equal to said fixed tubular member's inside diameter.

Owner:SMITH JAMES R

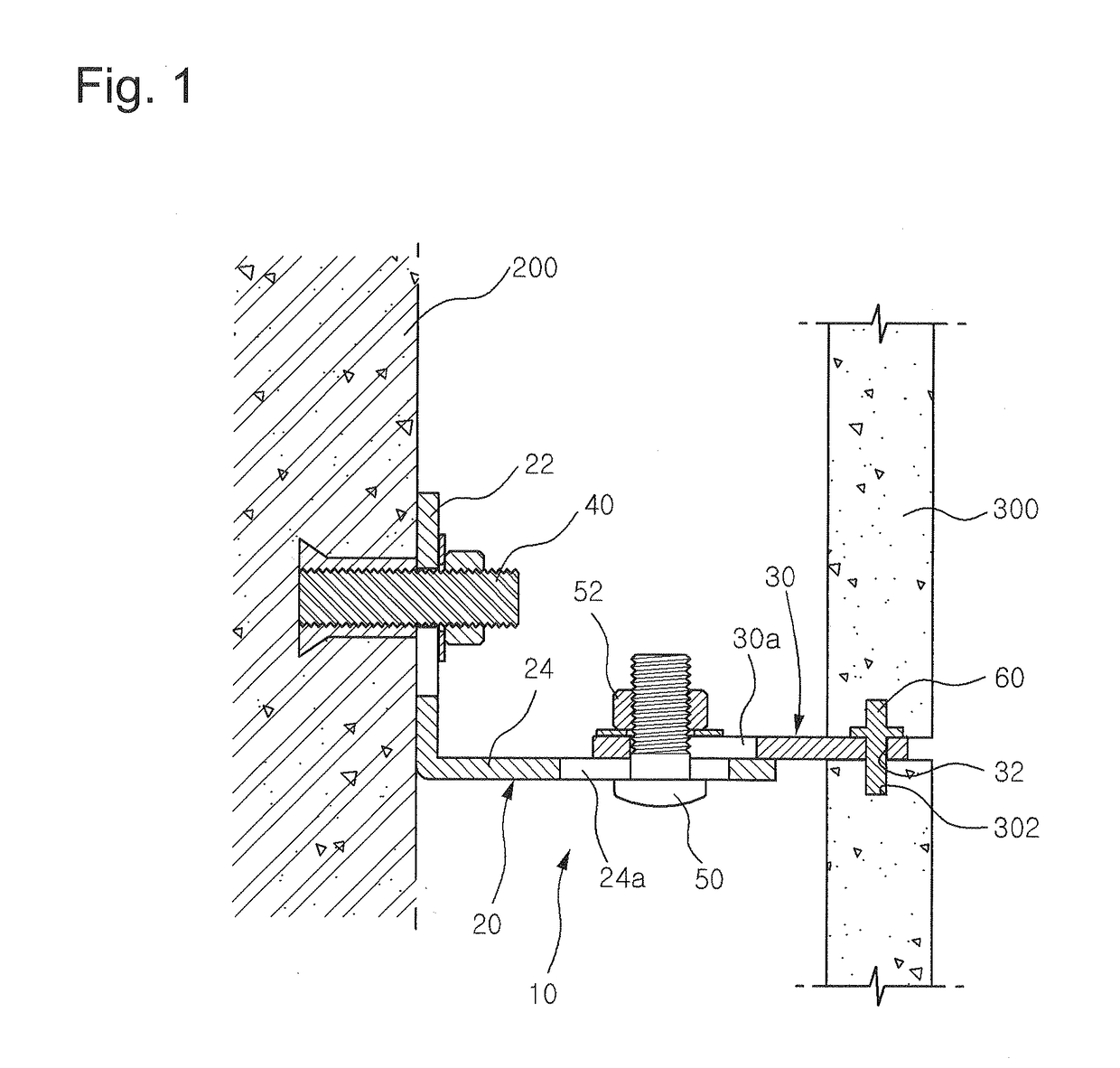

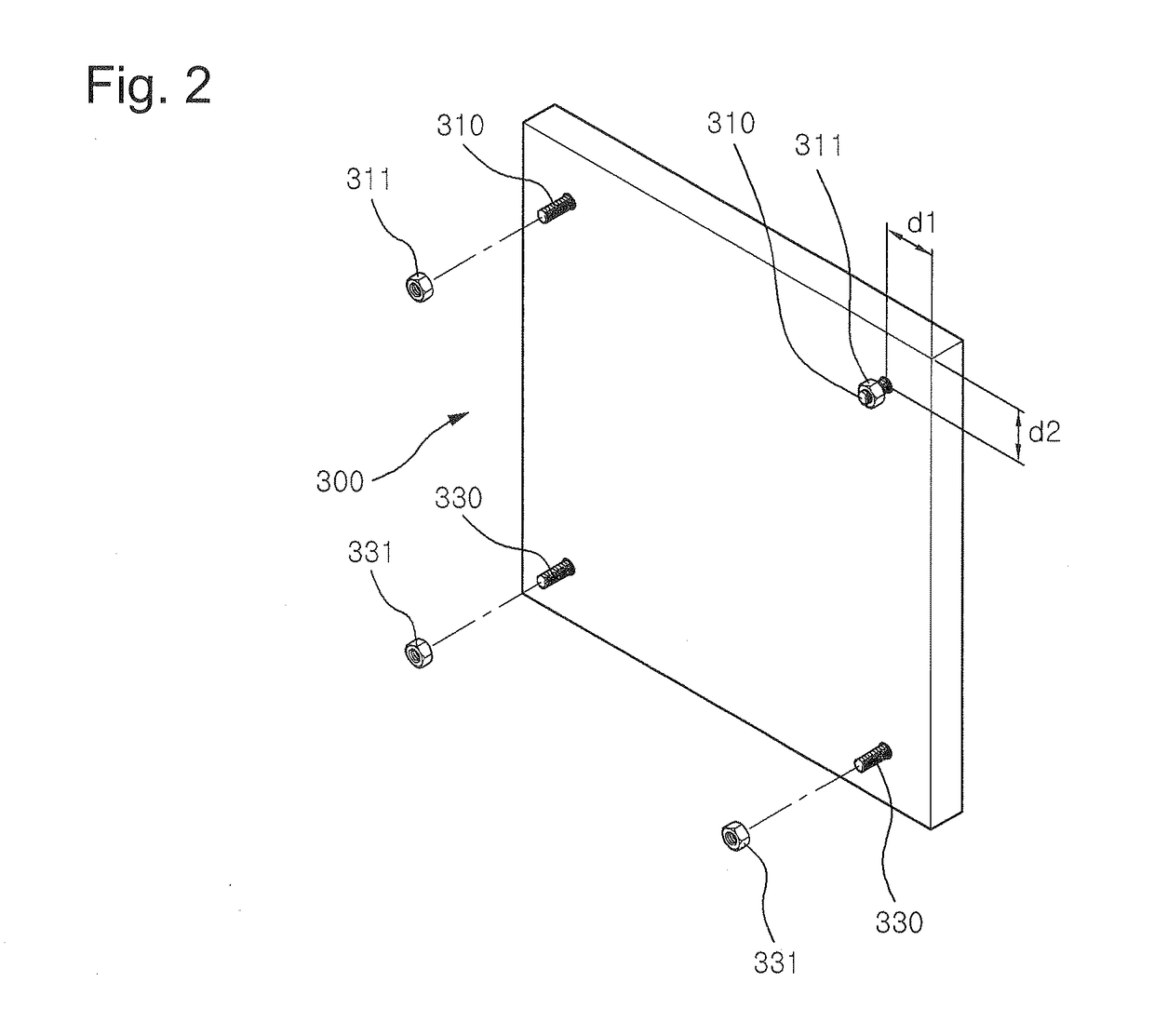

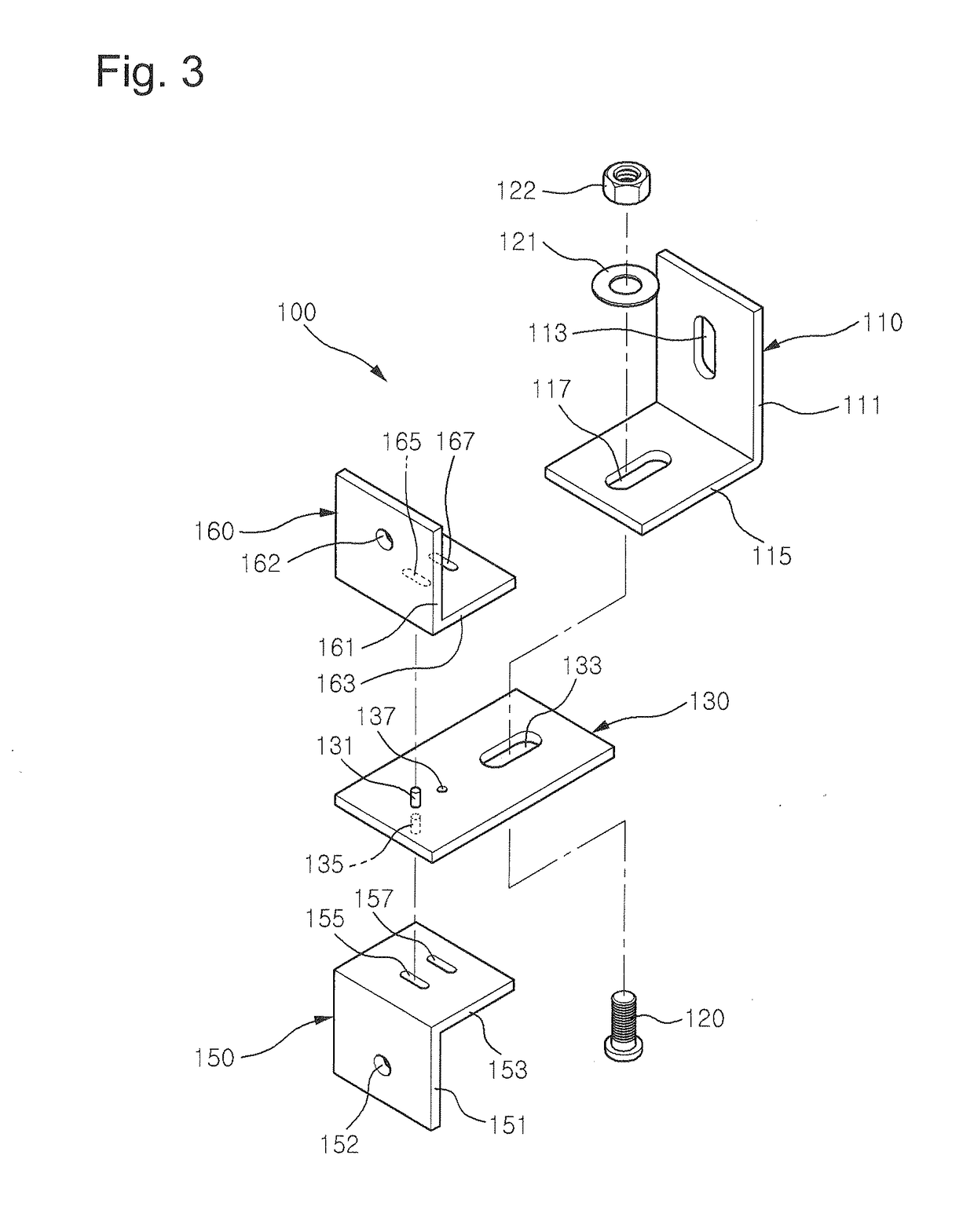

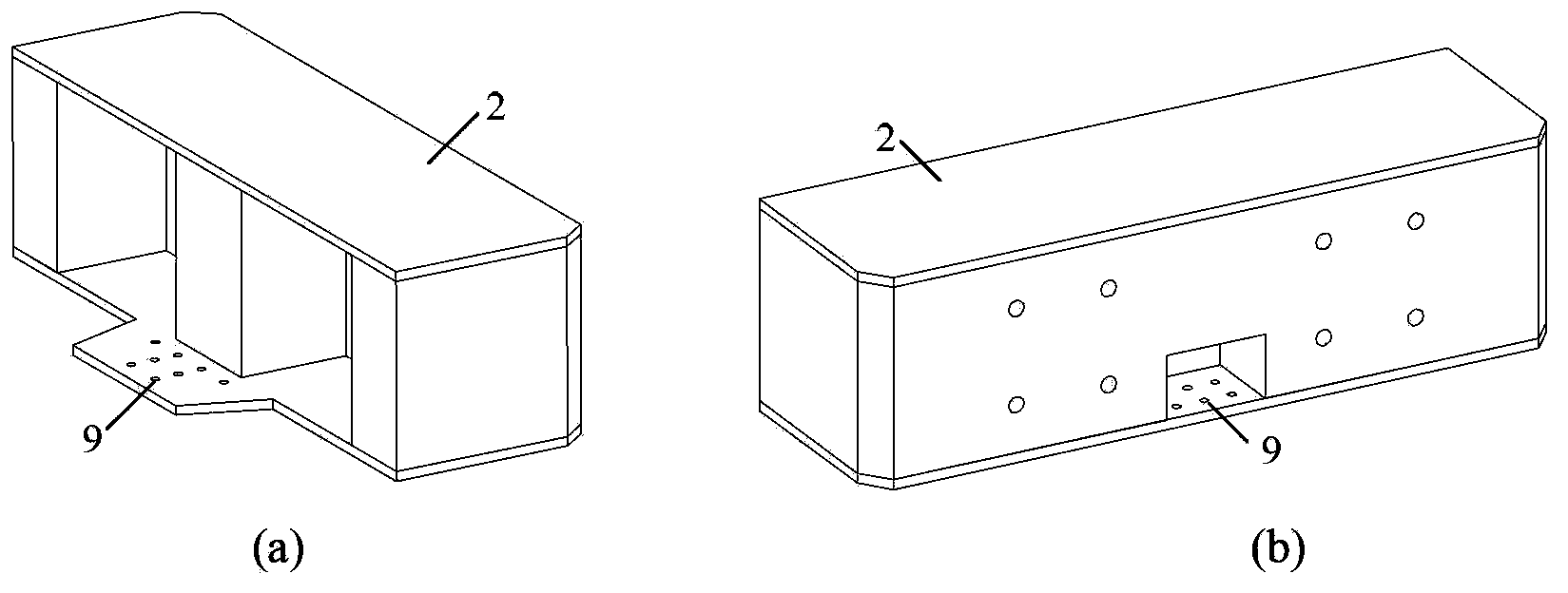

Panel fixing device

InactiveUS8468765B1Rapidly and easilyShorten the overall cycleCeilingsConstruction materialEngineeringSecond ancillary

Owner:KIM JONG SUNG

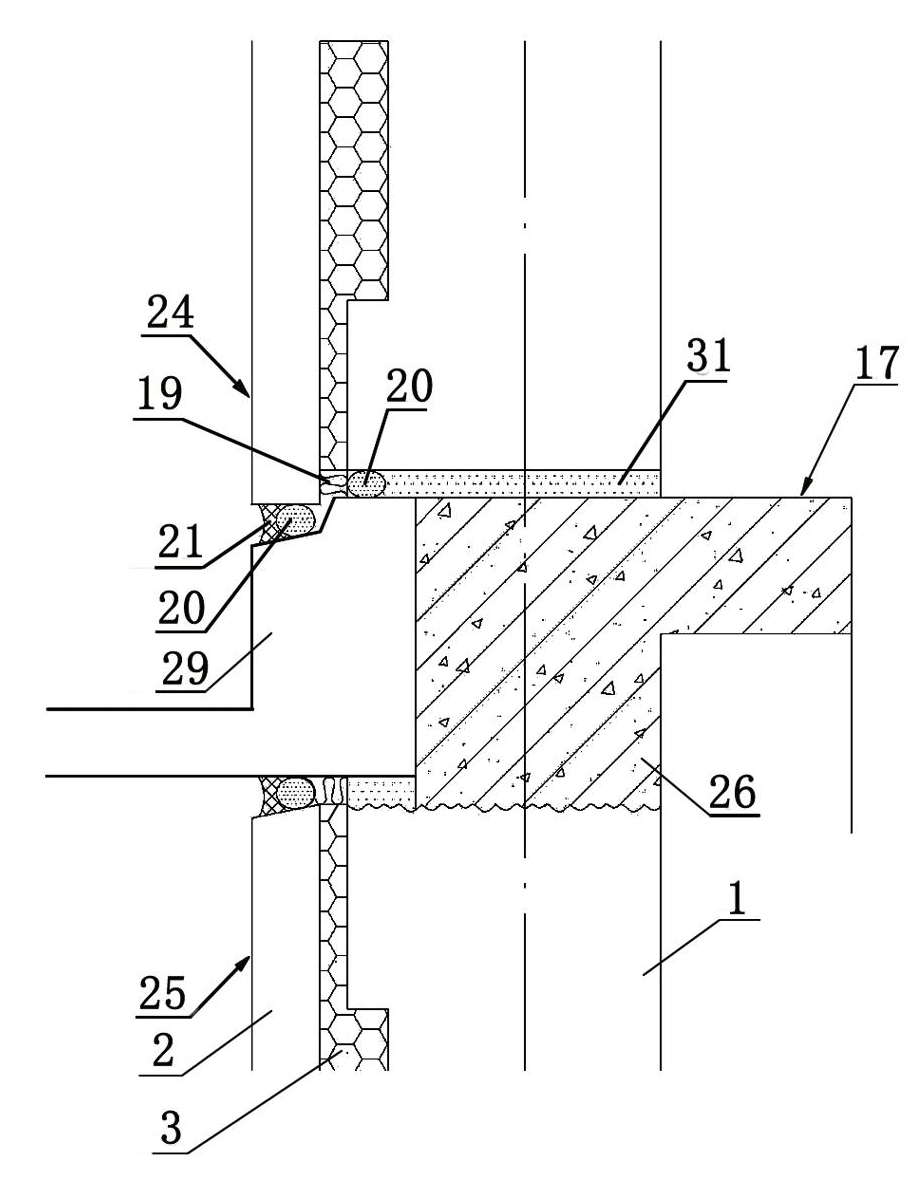

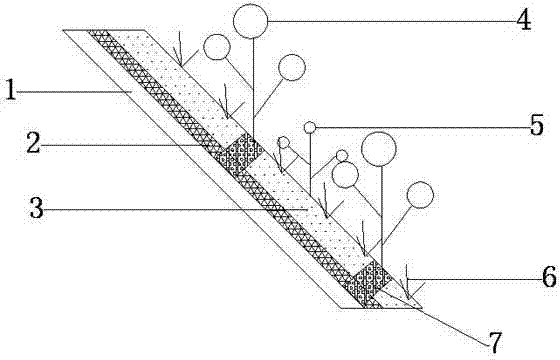

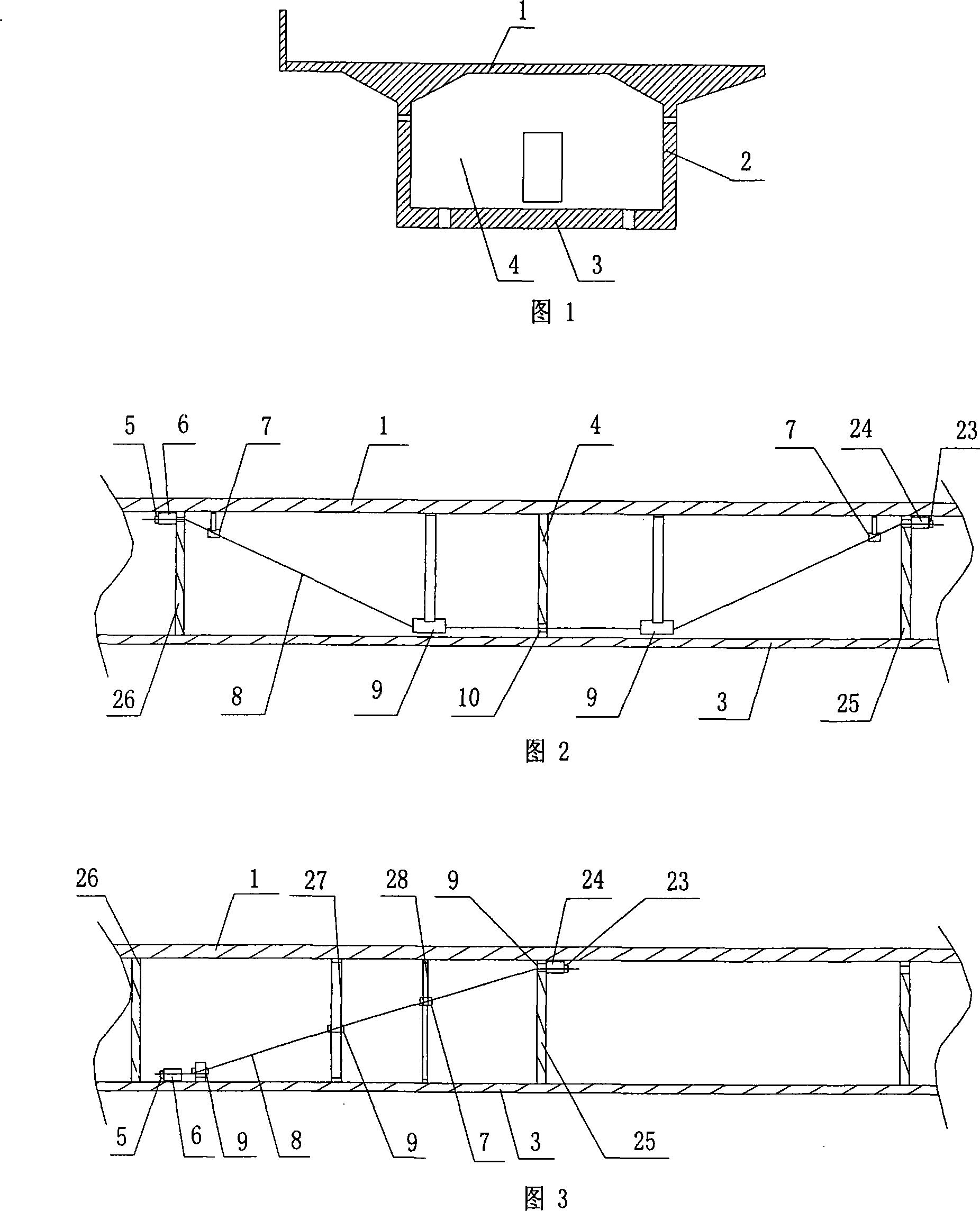

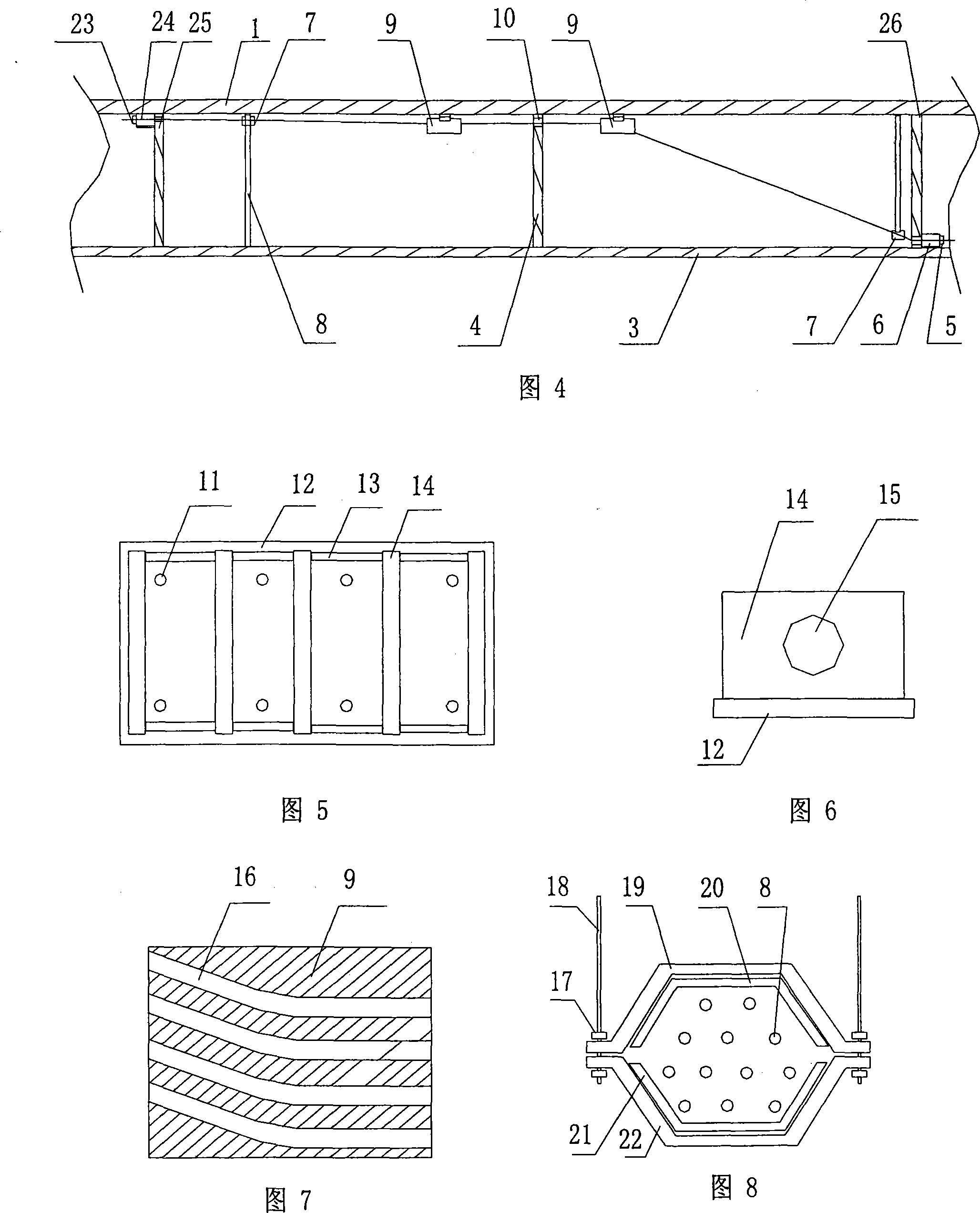

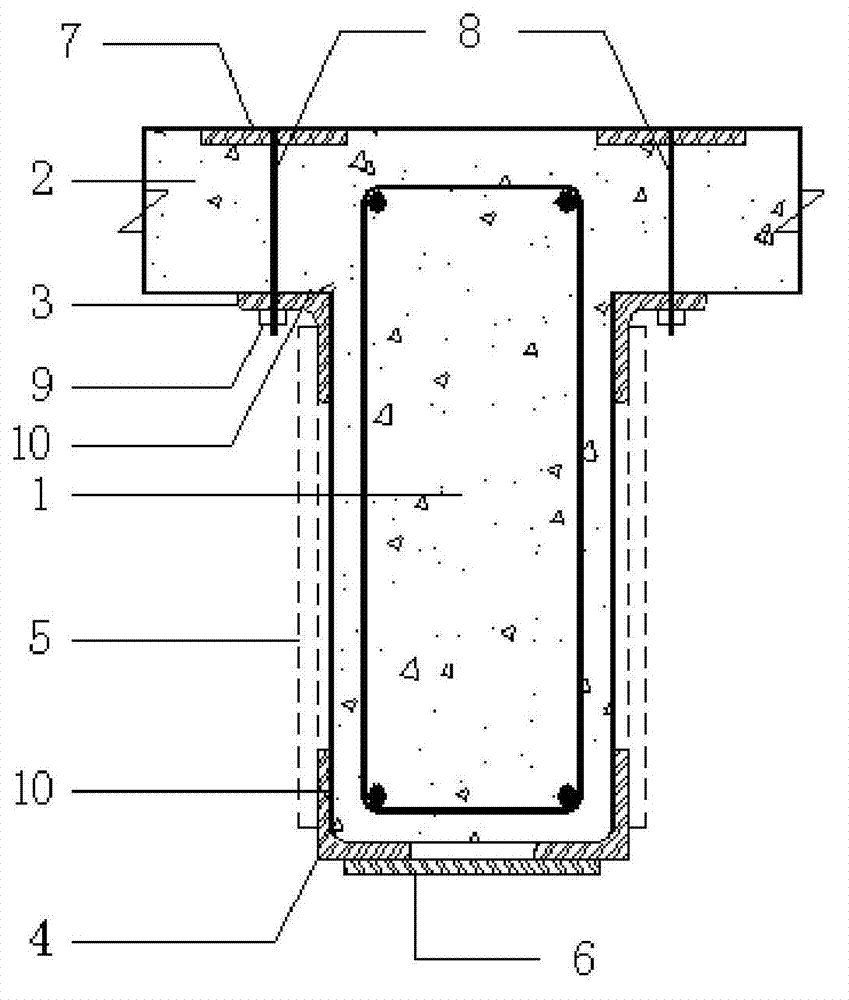

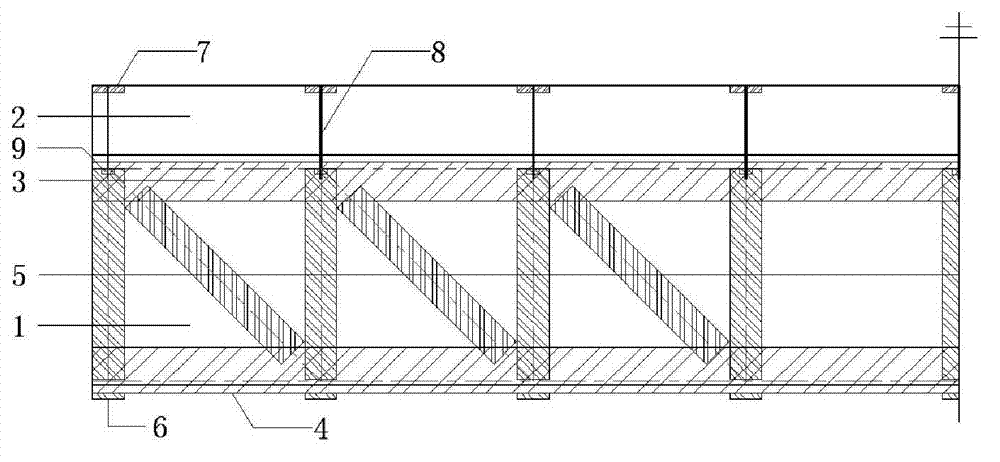

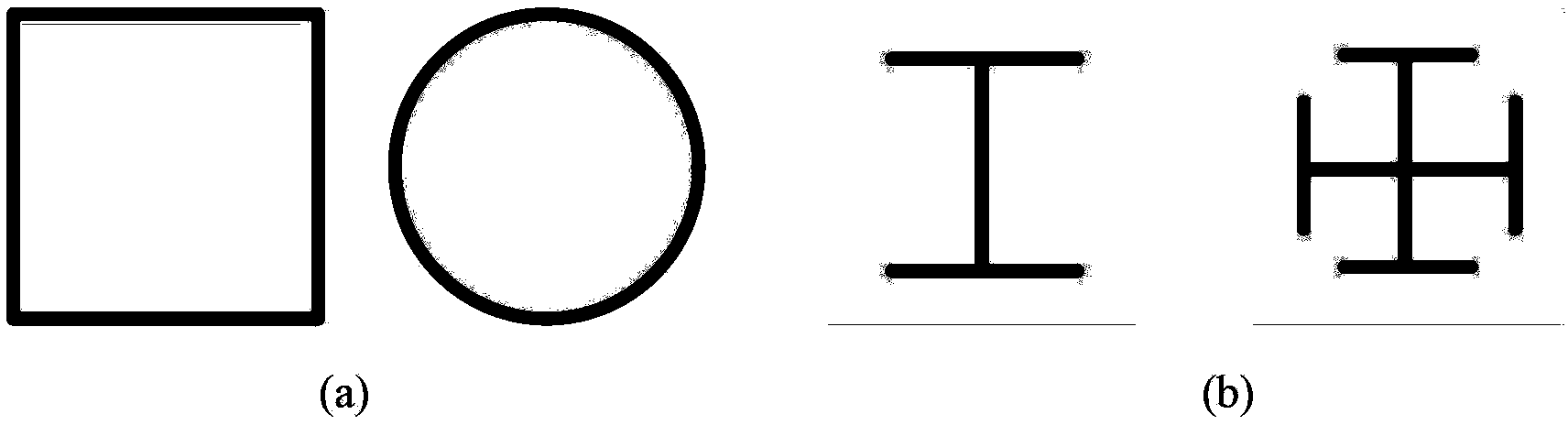

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

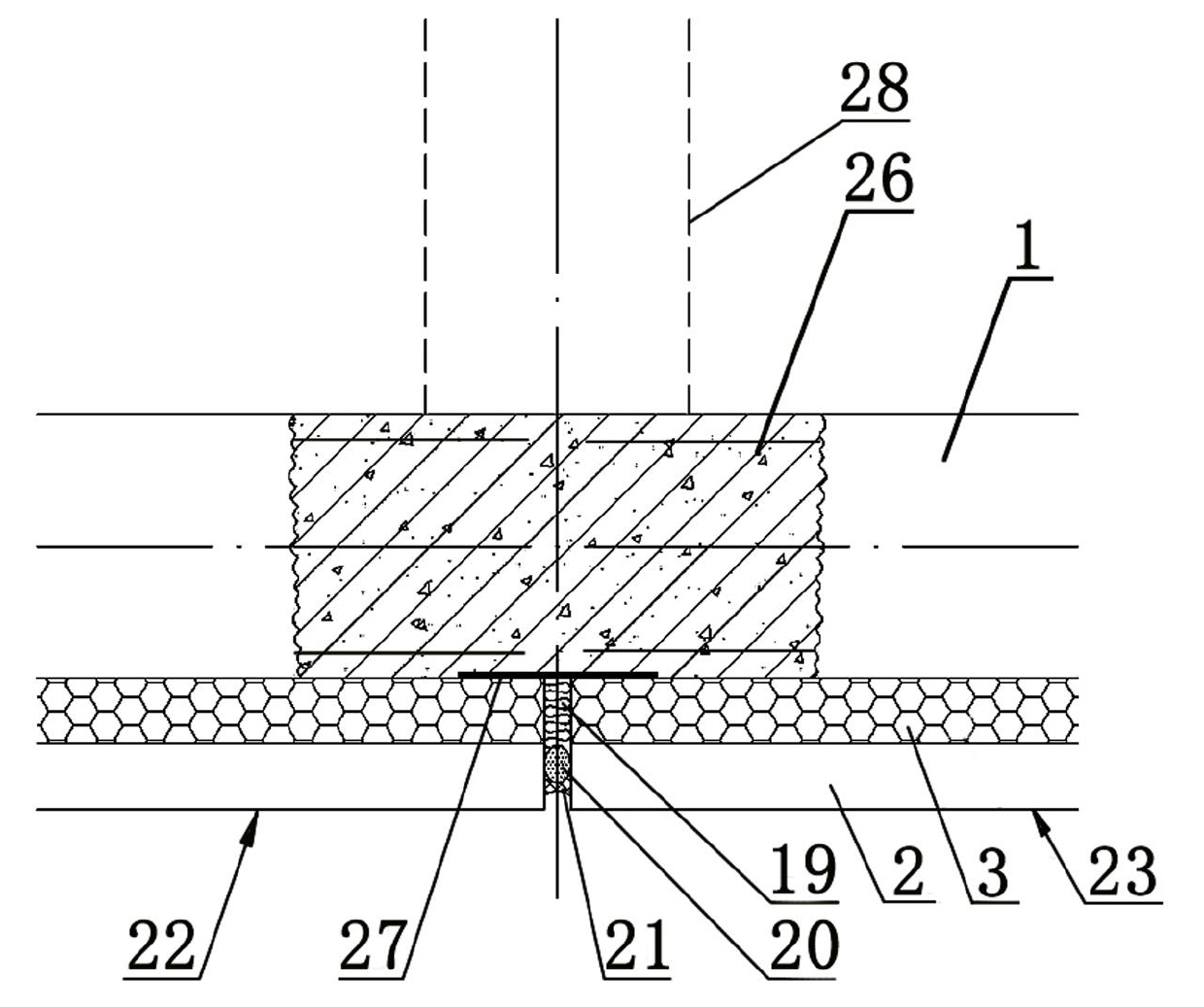

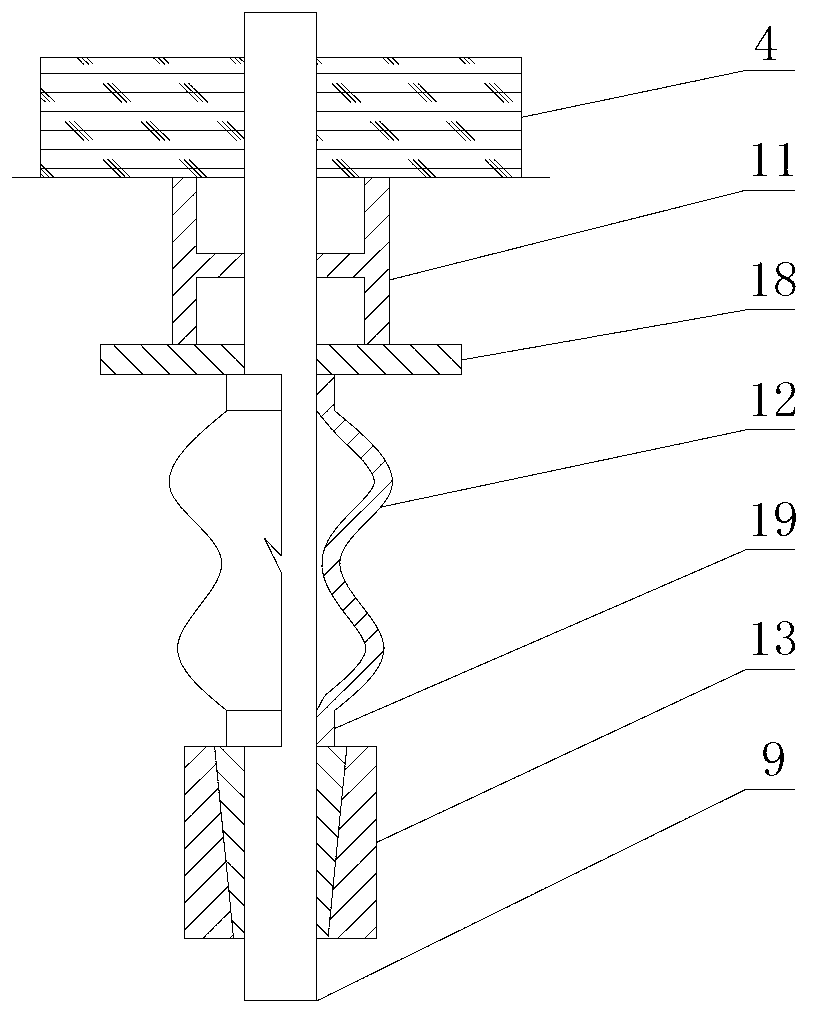

Damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and manufacturing method thereof

ActiveCN105908621ASmall residual displacement after earthquakeImprove bearing capacityBridge structural detailsBridge erection/assemblyBridge engineeringHigh energy

The invention discloses a damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and a manufacturing method thereof, and belongs to the field of bridge engineering. An exposed node connecting piece consists of a foot plate, anchor bolts, end connecting plates and buckling restraining sleeves. A connecting plate is mounted between prefabricated steel pipe concrete sections through high-strength bolts; the exposed node connecting piece is connected with each of a cover beam and a bearing platform by utilizing the anchor bolts, and is connected with a prefabricated steel pipe concrete section through the high-strength bolts relying on the end connecting plates. A pre-stressed tendon penetrates through a section prefabricated steel pipe concrete pier; the two ends of the pre-stressed tendon are respectively anchored to the interiors of the bearing platform and the cover beam by using anchorage devices. The energy consumption-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier disclosed by the invention has the characteristics of small post-seismic residual displacement, high energy consumption capacity, controllable energy consumption, high assembling degree, convenience and quickness in construction process, greenness, high efficiency, energy conservation, environment friendliness, easiness in factory production, convenience and quickness in construction, and the like; the construction period of the pier can be remarkably shortened.

Owner:BEIJING UNIV OF TECH

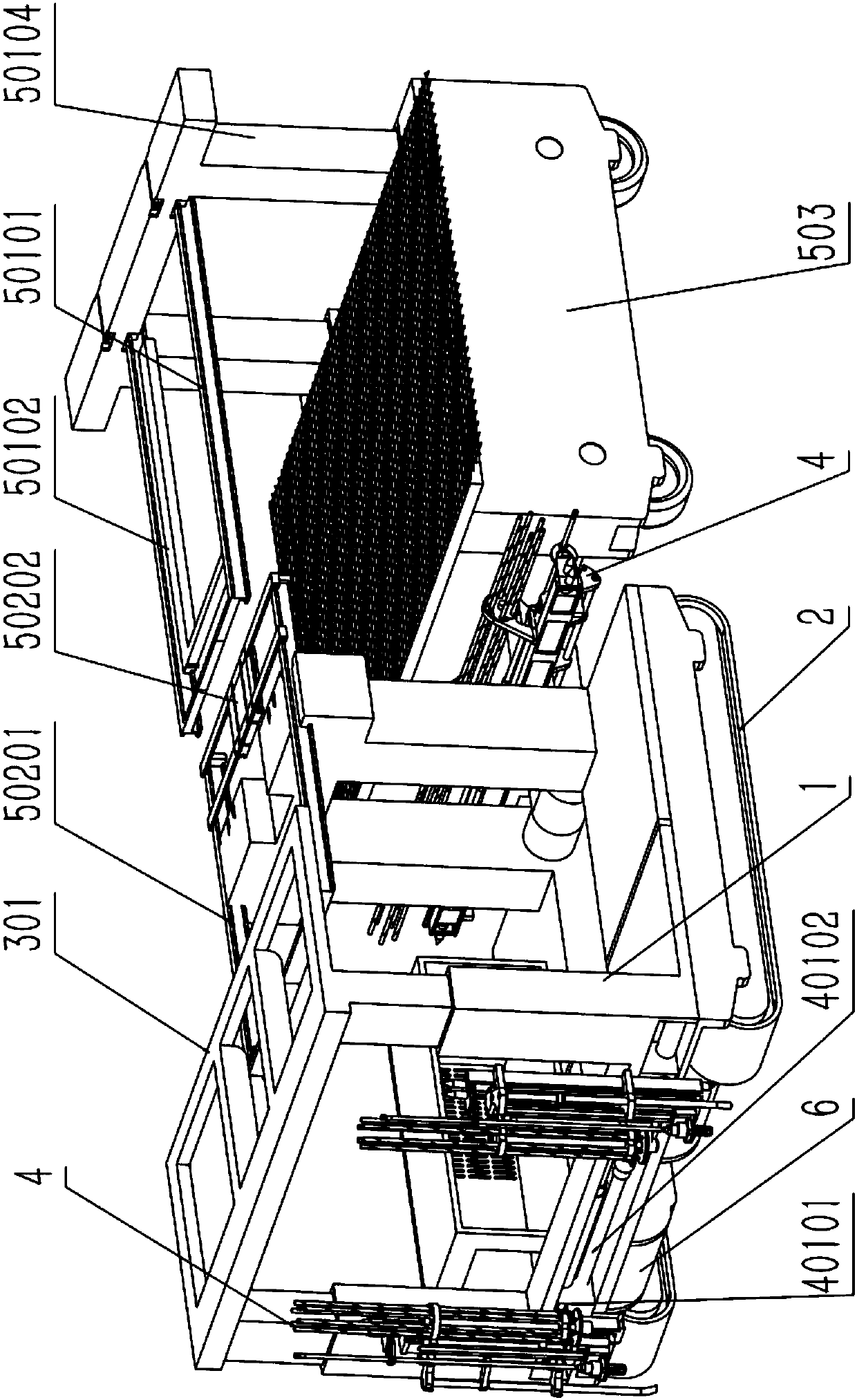

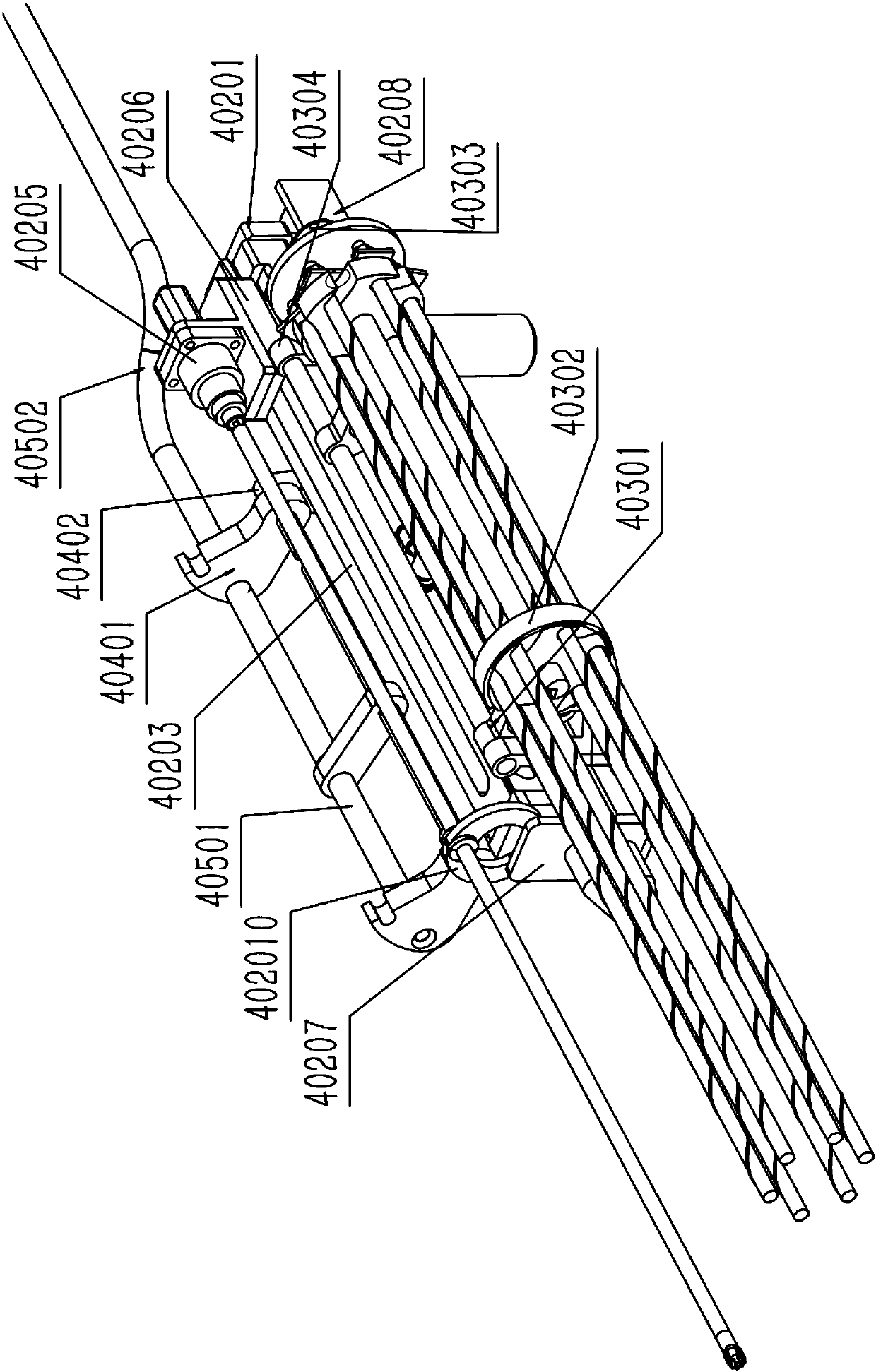

Fully automatic drilling anchor work vehicle

ActiveCN108104853AReduce volumeLess interferenceDrilling rodsConstructionsHydraulic cylinderEngineering

The invention discloses a fully automatic drilling anchor work vehicle integrating processes of anchor net paving, anchor hole drilling, anchoring agent injecting and installing of anchor bolt, and relates to the field of coal mine downhole tunnel support. The fully automatic drilling anchor work vehicle solves the existing problem of misalignment of digging and supporting caused by complicated process and low efficiency of tunnel support operation. The fully automatic drilling anchor work vehicle is characterized by comprising a vehicle body, a self-walking mechanism, a temporary support mechanism, an anchor drilling automation device, and an anchor net storing and a conveying mechanism. The anchor net is grabbed and conveyed to a temporary support frame by the anchor net conveying mechanism from an anchor net storage vehicle, and is supported by the temporary support frame to complete the anchor net laying work; and the anchor drilling automation device realizes the left-right and up-down displacement by the double-acting hydraulic cylinder in a car body sliding slot, and the rotation of the anchor drilling automation device is realized by a swing motor. According to the fully automatic drilling anchor work vehicle, the automatic laying of a back anchor net can be completed, mechanized support and automatic support of a top anchor rod and a side anchor rod can be realized, and the fully automatic drilling anchor work vehicle is matched with tunneling equipment to realize the parallel operation of digging and supporting anchor.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

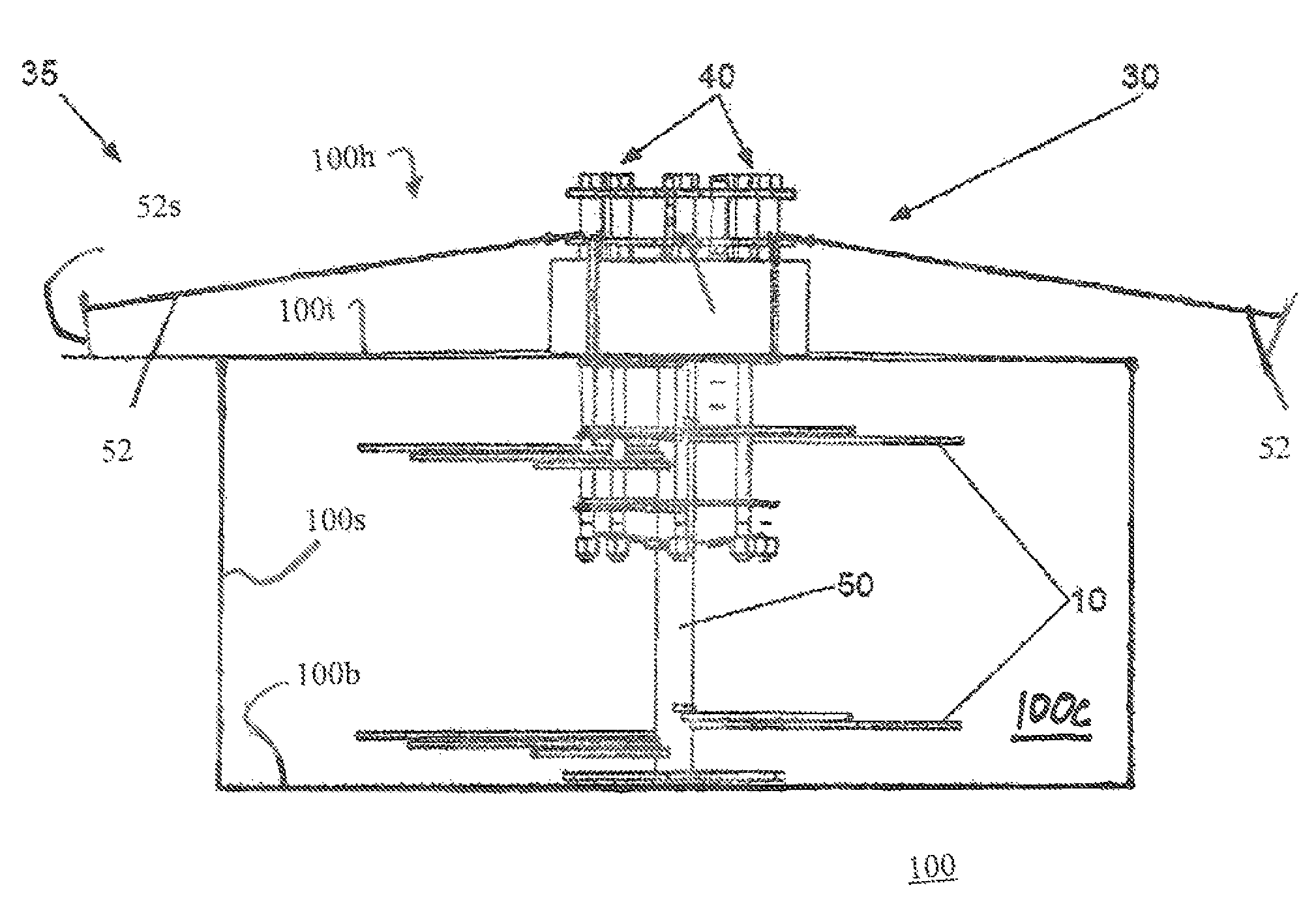

Post-tension pile anchor foundation and method therefor

A post-tensioned pile anchor foundation and method therefor creates a void or highly compressible space between a drilled or driven pile anchor surrounding a post-tensioned anchor bolt or tendon and the bottom of a foundation cap. The void or space can be formed by compressible spacers or void forming elements placed between the top of the pile anchor and the concrete cap. As the anchor bolt or tendon is post-tensioned against the cap, the void forming element is compressed or crushed, allowing the pile anchor to be pulled upwardly toward the cap, developing pull out resistance, and the cap to be pulled downwardly against the surrounding soil to provide a secure foundation for a tower or other structure to be supported thereon.

Owner:TERRACON CONSULTANTS INC

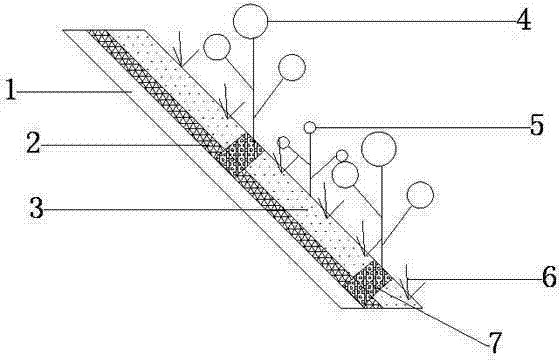

Revegetation method for mine slopes

The invention discloses a revegetation method for mine slopes, which includes steps: firstly, clearing a slope to remove impurities on the slope; secondly, configuring planting material, namely selecting planting soil, peat soil, turf fibers, slow release fertilizer, fast release fertilizer, super absorbent polymers and adhesive prior to well mixing, and using the mixture as the reserve material; thirdly, constructing a planting-bag cofferdam planter, namely using planting bags filled with the planting material to construct the bird's nest shaped planter on a local concave lot of the slope; fourthly, performing material spraying, namely fastening anchor bolts on a non-planter portion of the slope, hanging a metal net on the anchor bolts, spraying the planting material to the metal net, mixing plant seeds with surface soil on the surrounding mountain land to obtain mixture, and using a sprayer to spray the mixture to the planting material; fifthly, planting a seedling in the planter; and sixthly, replanting material-type containerized seedlings. The revegetation method is low in cost, great economic benefits are obtained by using the method, and a composite revegetation process based on arbors and shrubs and combination of arbors, shrubs and grasses is built.

Owner:DAQIAN ECOLOGY & LANDSCAPE

Shear transfer plate

InactiveUS20060037256A1Large deformationImprove ductilityHuman health protectionWallsLateral shearEngineering

A wall either wholly or partially made from a shear-resisting assembly that has a shear transfer device, or plate, disposed between the bottom strut and the underlying foundation. The shear transfer device joins the two anchor bolts, eliminating intermediate foundation bolts by transferring lateral shear loads to the anchor bolts in combination with the bottom strut

Owner:SIMPSON STRONG TIE

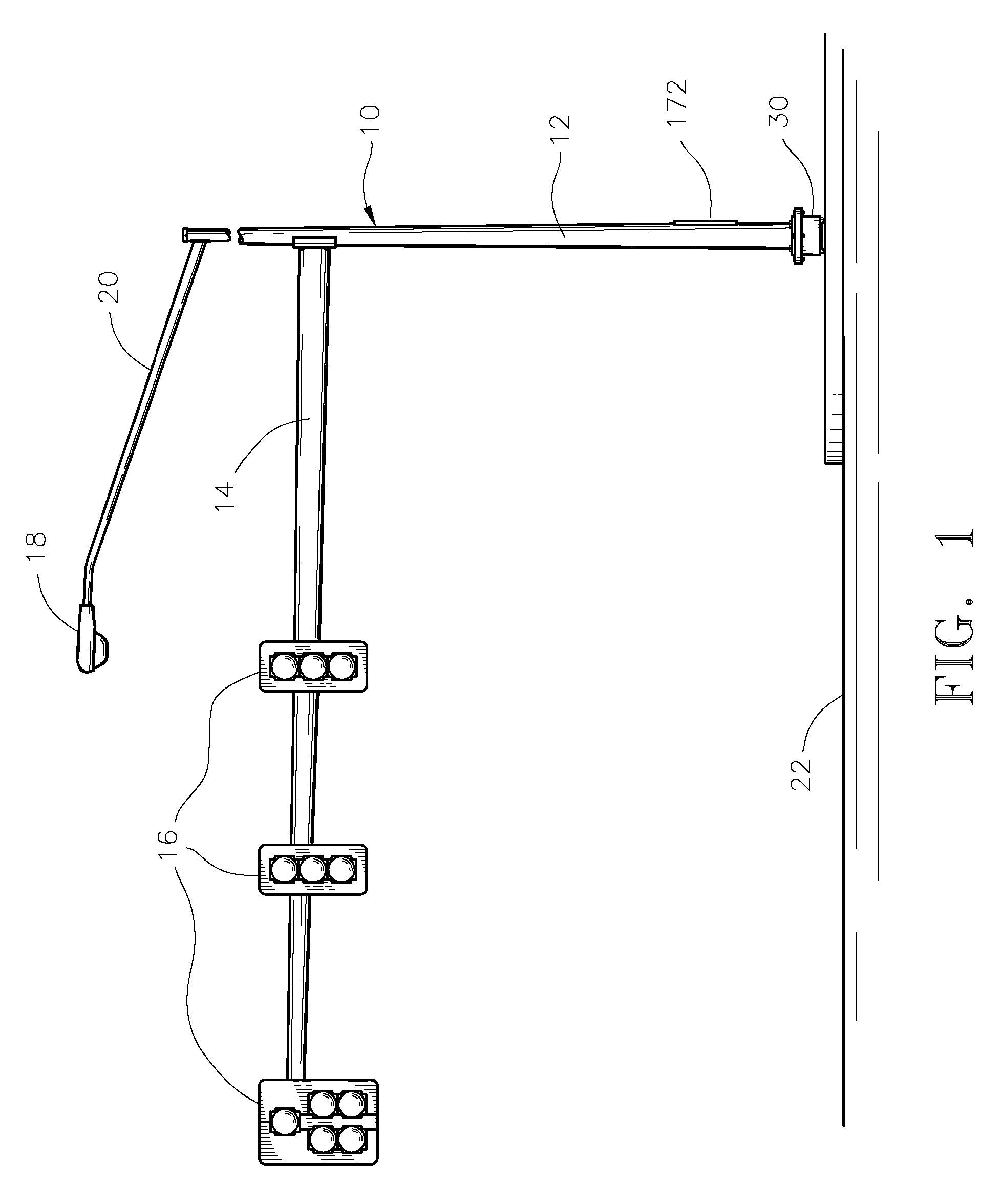

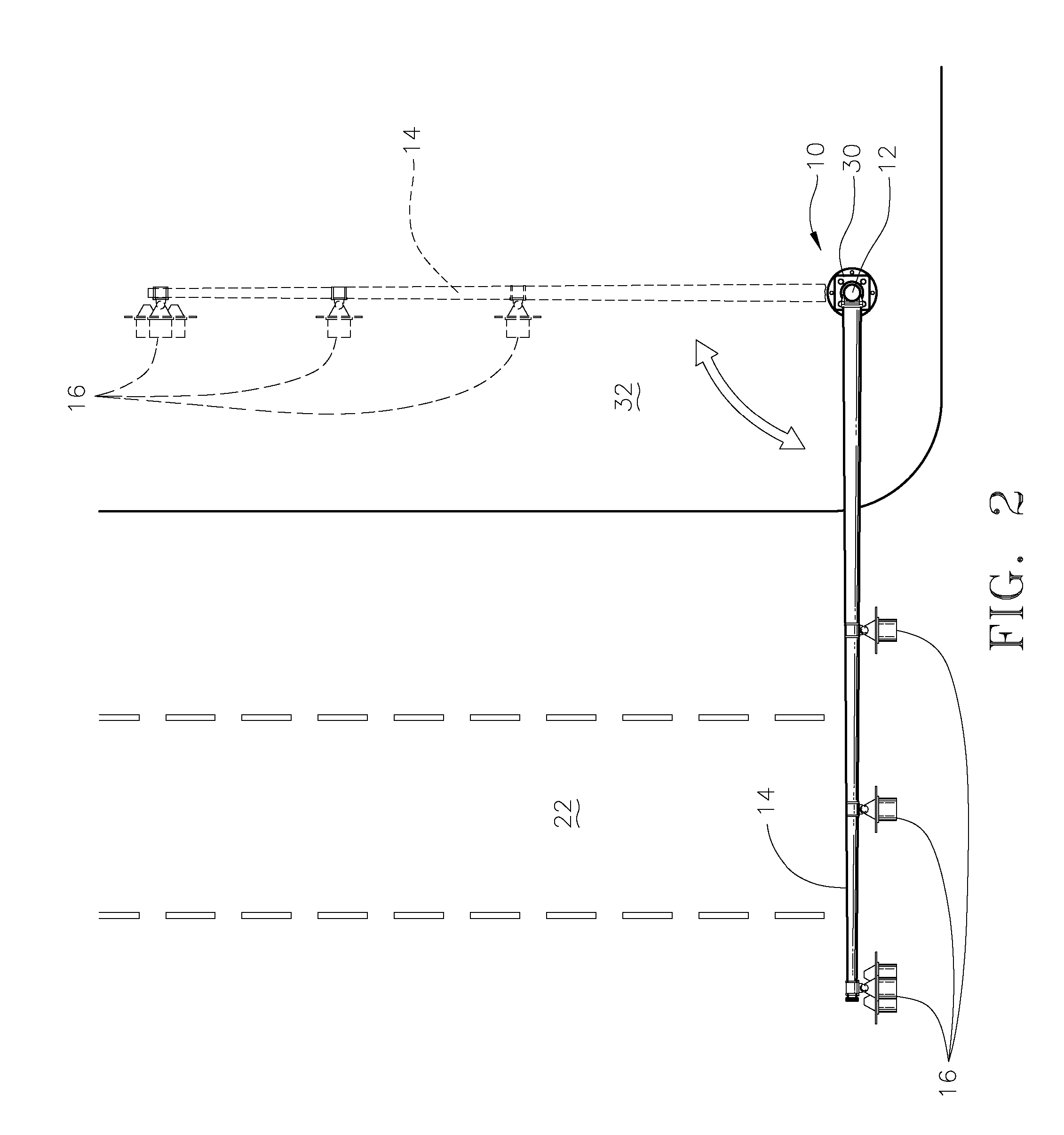

Pivot base assembly for traffic pole

A pivot assembly that can be retrofitted to existing traffic poles. The pivot assembly comprises a bearing assembly disposed between a top plate and a bottom plate. The bottom plate connects to the existing pole foundation with the standard anchor bolt arrangement. Similarly, the top plate connects to the base plate of the traffic pole using additional bolts. Bearings in the pivot assembly allow the pole to rotate relative to the foundation. Preferably, roller bearings are utilized, as these can be contained substantially within the pivot assembly without extending down into the foundation or up into the pole. This means the pivot assembly can be installed in existing, standard traffic poles and foundations without modifying either. The pivot assembly does not interfere with existing wiring or access openings.

Owner:PELCO PRODS

Construction method for chamber type bridge maintaining external pre-stress

InactiveCN101173505AEasy constructionFlexible constructionBridge erection/assemblyBridge strengtheningPre stressPre stressing

The invention discloses an external prestressing construction method for box bridge maintenance, which is characterized in that: 1). The position of an anchor block, a redirector and a shock absorber are decided according to external cable arranging mode for external prestressing; 2). The installation of the anchor block: 2.1). concrete base surface processing; 2.2). hole drilling, hole cleaning and reinforcing bar planting; 2.3). the installation of steel-bonded steel plate: the anchor block comprises a steel-bonded steel plate, a connecting plate and a stiffening plate; all anchor bolts are penetrated through a corresponding fixing hole on the steel-bonded steel plate; 2.4). the installation of other steel plates for the anchor block; the connecting plate is welded with the steel-bonded steel plate, the stiffening plate is welded with the steel-bonded steel plate and is provided with a through hole for external cable; 2.5). glue pouring for the steel-bonded steel plate: glue pouring is made between the steel-bonded steel plate and the concrete base surface for the anchor block; 3). Horizontal partition wall perforation; 4). The installation of a redirecting support and a damping support; 5). The installation of the redirector; 6). Penetrating and tension of prestressing steel strand; 7). The installation of the shock absorber. The invention has the advantages of convenient construction, flexibility and stronger reliability.

Owner:CHINA FIRST METALLURGICAL GROUP

Shear wall template

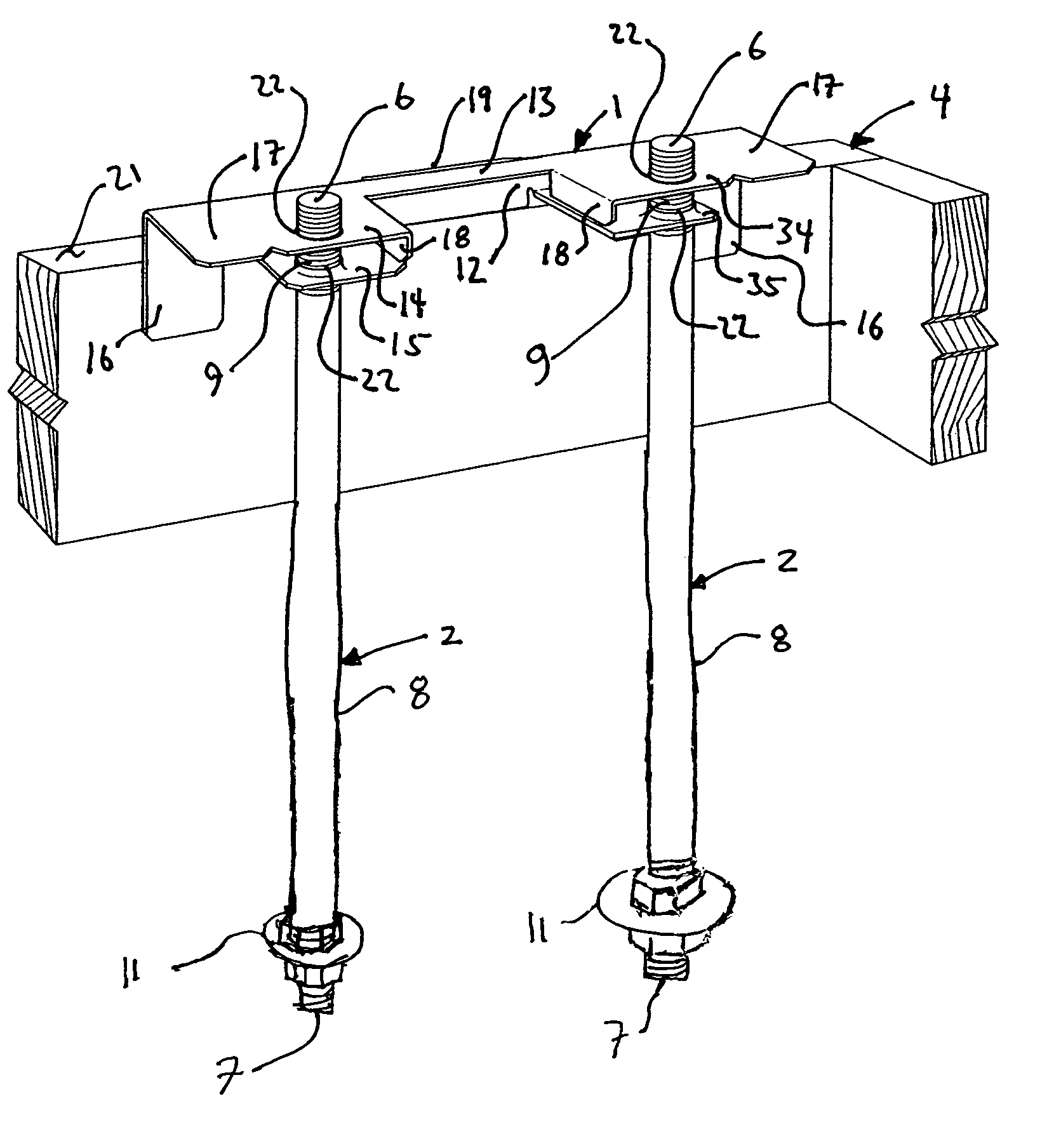

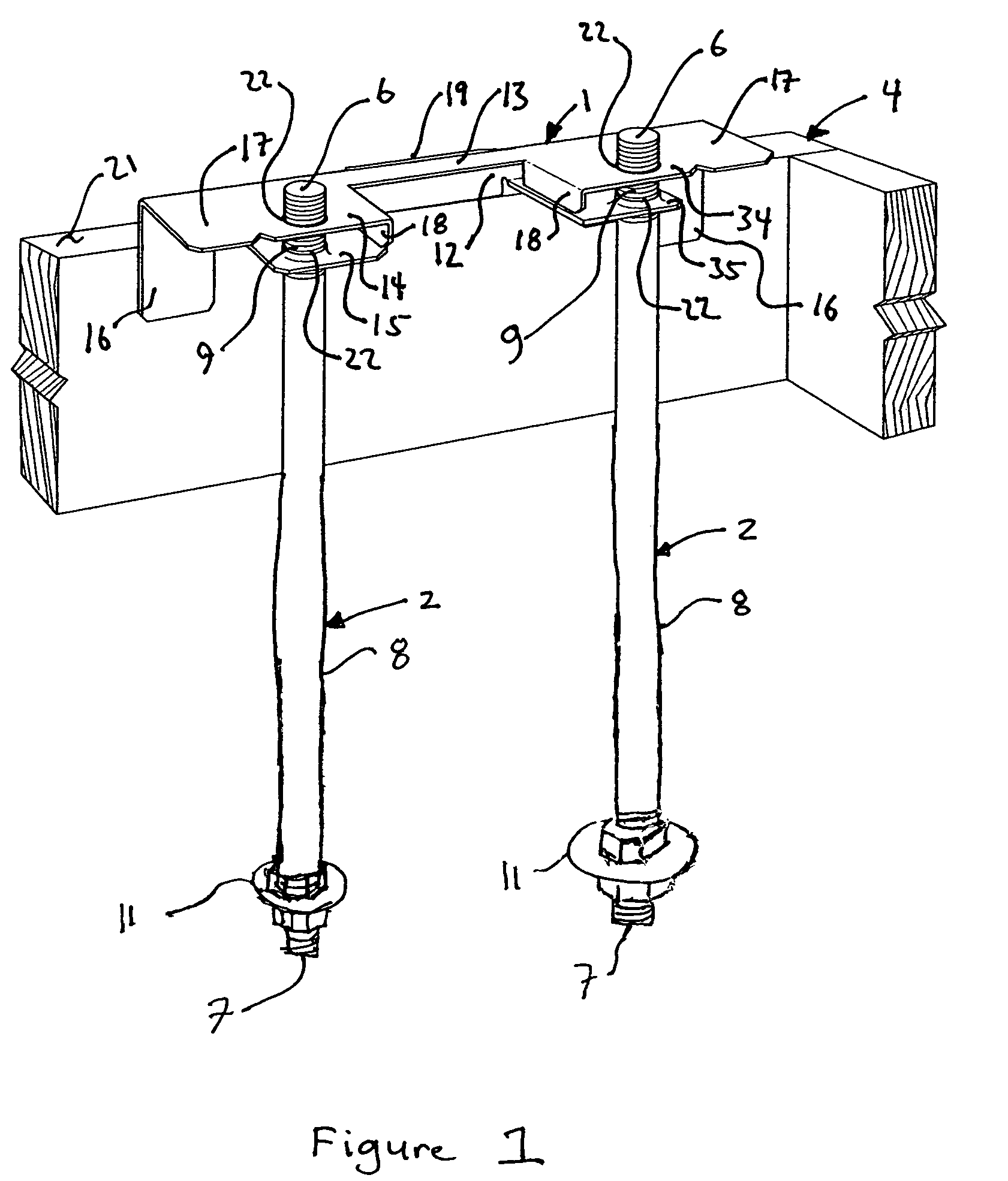

ActiveUS7445192B2Precise positioningPig casting plantsAuxillary members of forms/shuttering/falseworksEngineeringFastener

A connection is provided between a holder and a plurality of anchor bolts by means of a template. The holder is typically a form board for a cementious member such as a foundation. The template is releasably attached to the form board. The template is formed with a central elongated support, and a plurality of pairs of primary and secondary anchor bolt receiving platforms connected to the central elongated support. The pairs of primary and second anchor bolt receiving platforms are spaced along the central elongated support from each other. Each of the primary and secondary anchor bolt receiving platforms has an opening therein for receiving one of the anchor bolts there through, the openings in each pair of primary and secondary anchor bolt receiving platforms being in alignment so as to receive the same one of the anchor bolts. A plurality of fasteners are releasably connected to the plurality of anchor bolts and are supported by the template to releasably attach the anchor bolts to the template, suspending them in the form where wet cement can surround and envelope the lower portions of the anchor bolts.

Owner:SIMSON STRONG TIE COMPANY

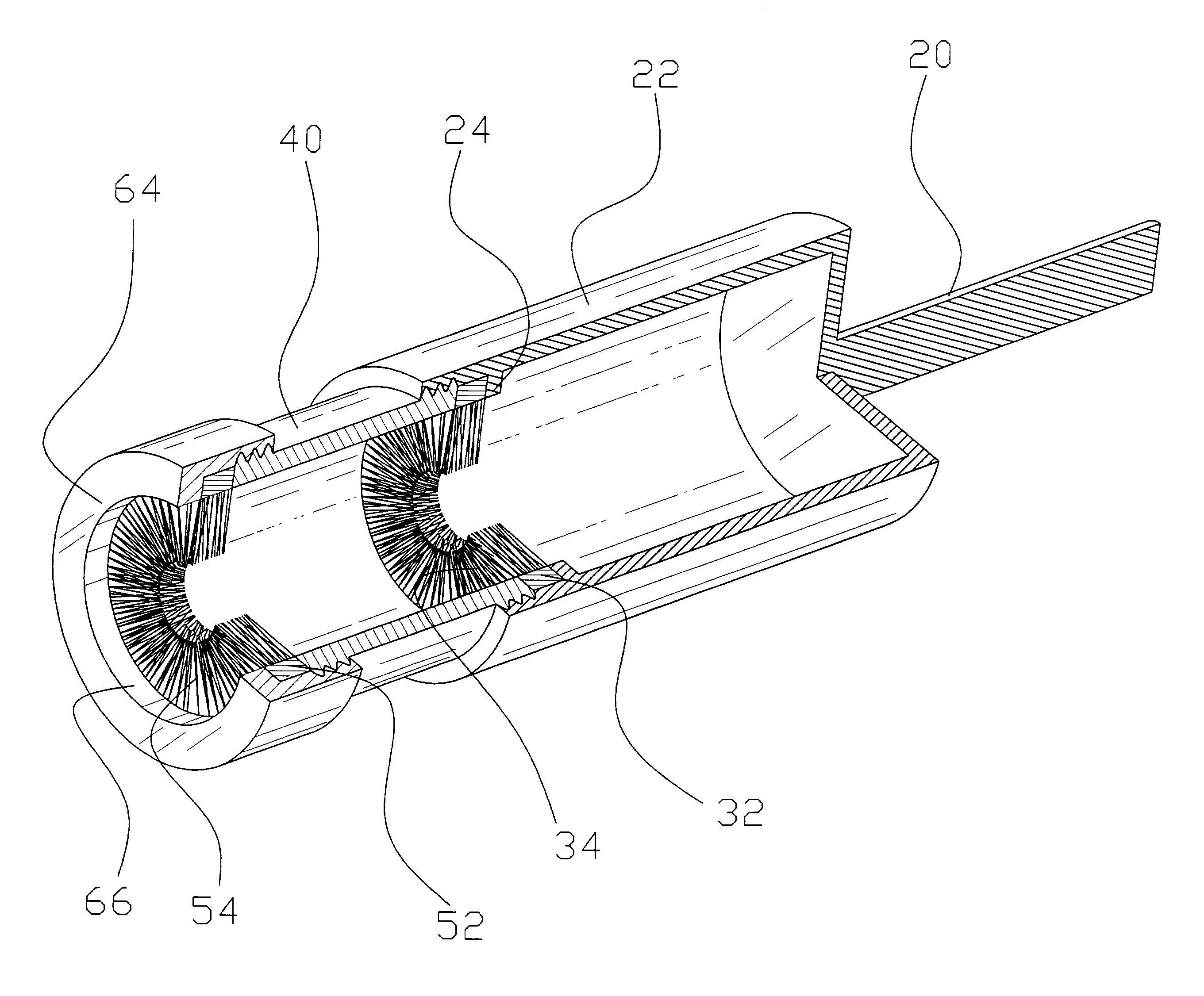

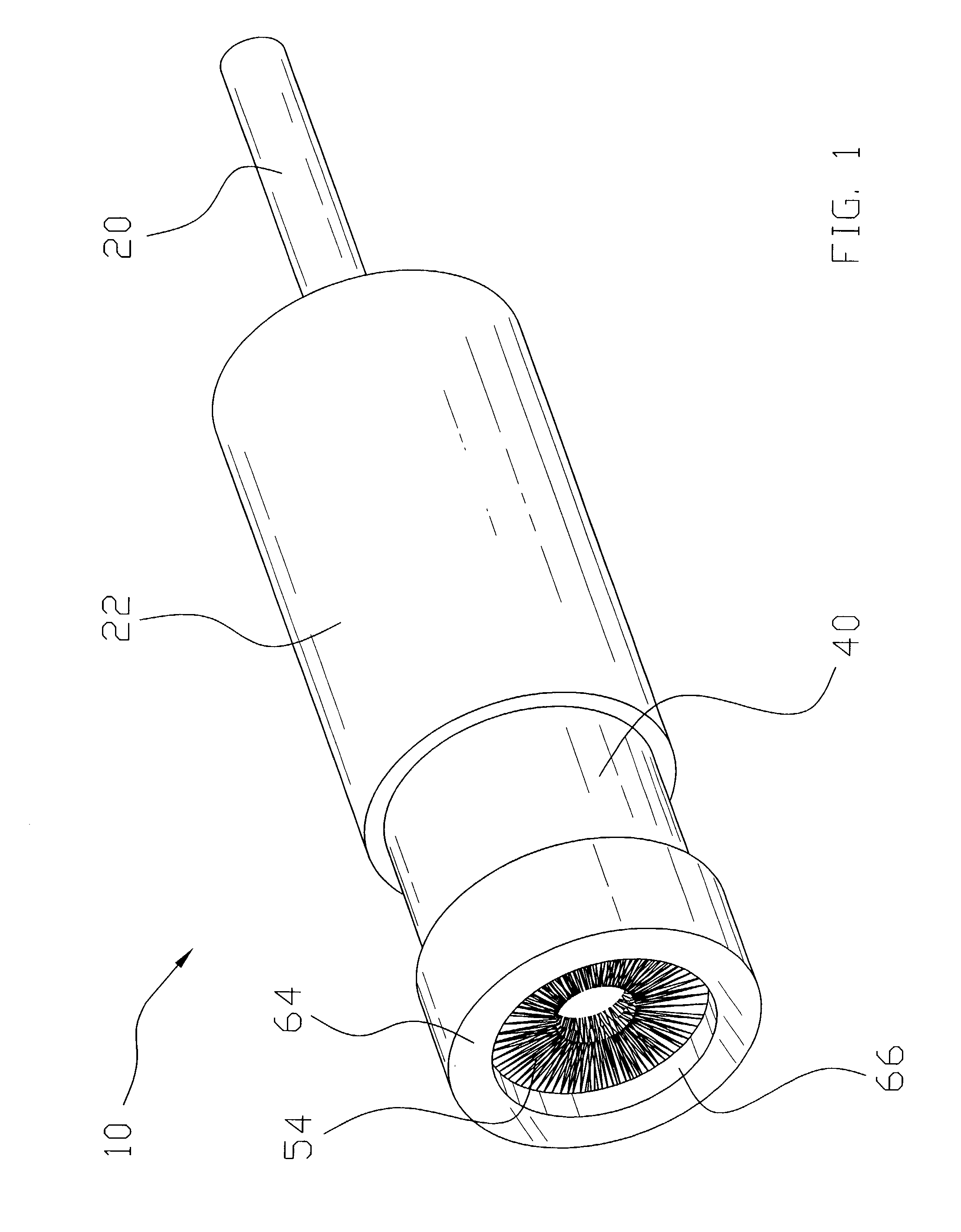

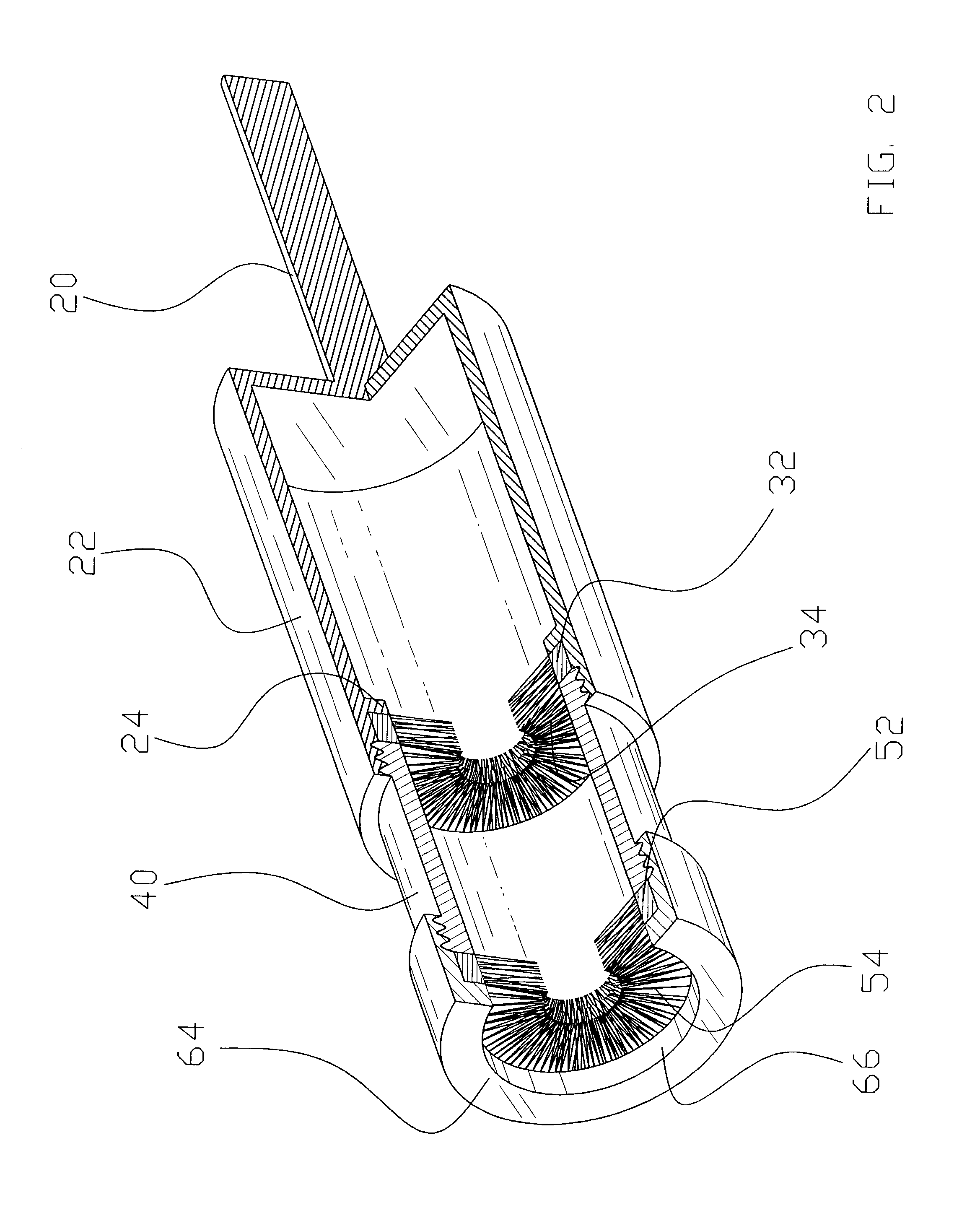

Bolt cleaning system

InactiveUS6983508B2Efficient removalEasy to cleanBowling gamesCarpet cleanersScrew threadAnchor bolt

A bolt cleaning system for removing debris from the threaded portions of anchor bolts. The bolt cleaning system includes a shaft member, an inner member attached to the shaft member having an annular member, a first cleaning unit removably positionable within the inner member, a connector member connectable to the inner member, an outer member connectable to the connector member, and a second cleaning unit removably positioned between the connector member and the outer member.

Owner:SAURER JAMES M

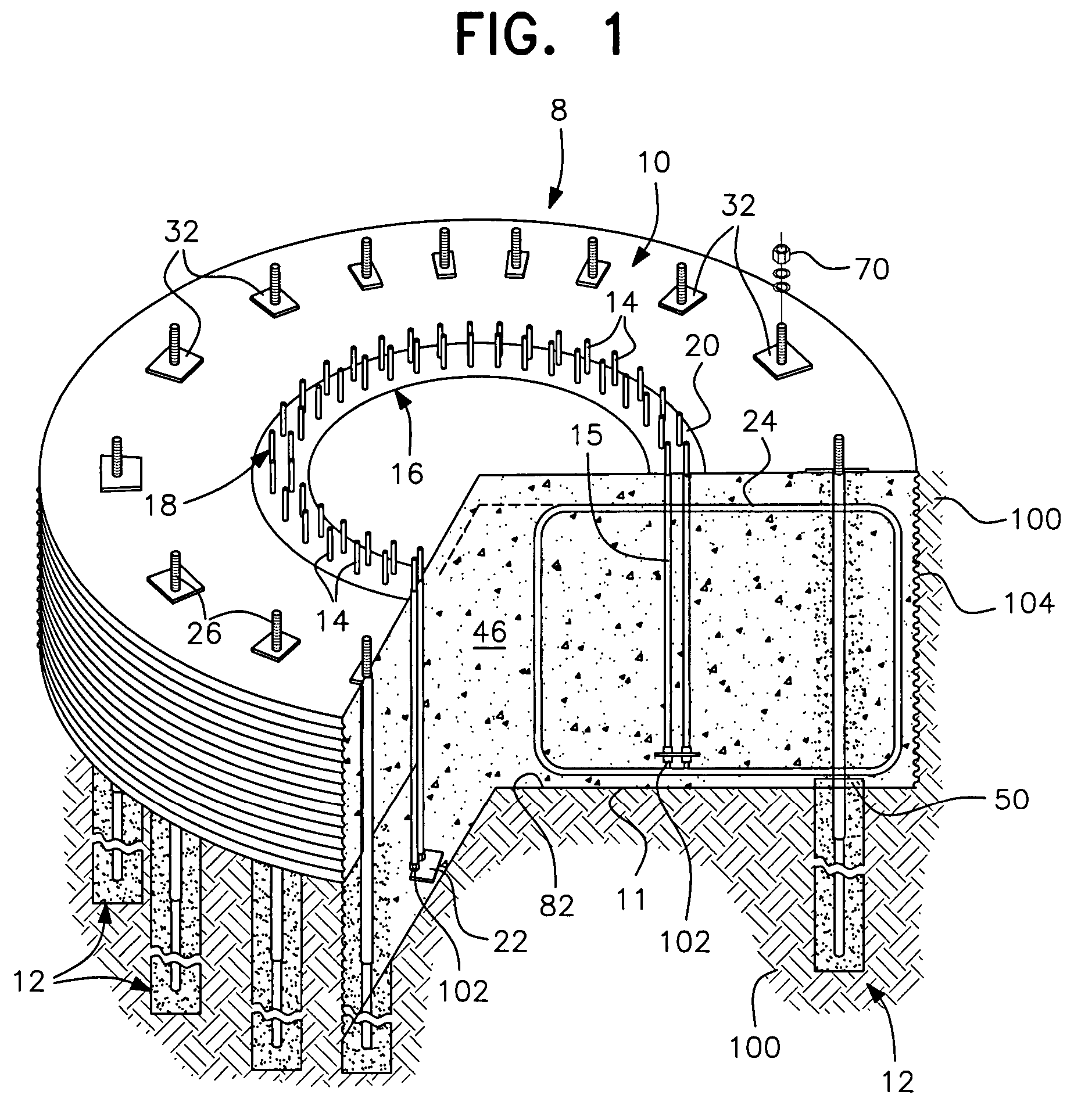

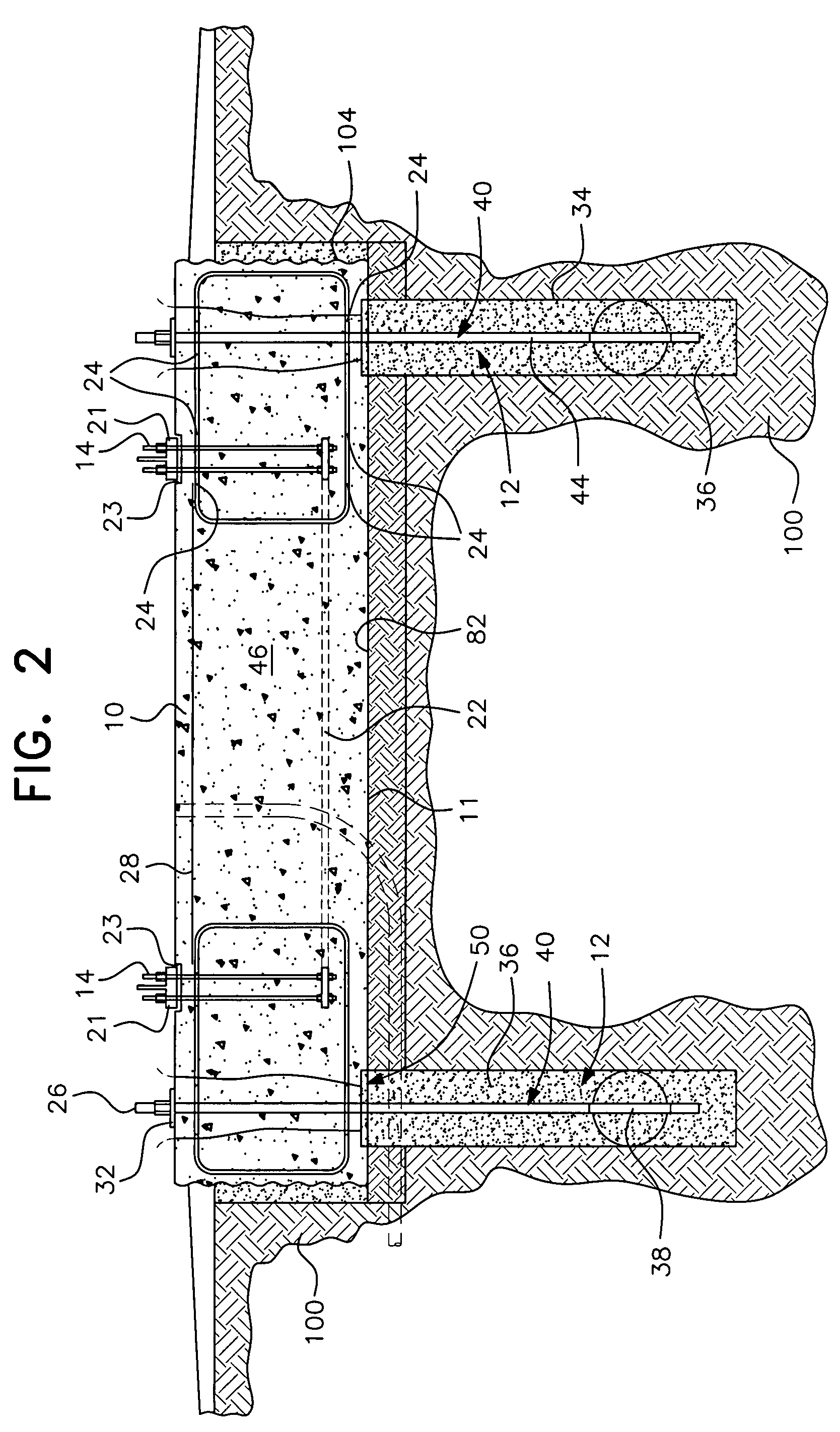

Foundation for monopole wind turbine tower

ActiveUS8161698B2Easy to useReduce laborWind motor supports/mountsFoundation engineeringEngineeringTower

An innovation is disclosed which relates to a wind turbine foundation. A circular foundation using fiber reinforced concrete has optional circular reinforcement rods. The foundation includes a vertical stanchion that rests in the bottom of an excavated hole and supports anchor bolts and reinforcement bars in a predetermined configuration while concrete is poured into the hole. All the necessary foundation materials can be combined in a simple and compact kit which can be shipped to a customer.

Owner:ANEMERGONICS

Friction energy consumption type node connection device for self-centering pier column structure

InactiveCN101936043AImprovement of local pressure problemsImprove performanceShock proofingPile capResidual deformation

The invention relates to a friction energy consumption type node connection device for a self-centering pier column structure, which is a device used for connecting a bridge pier or a frame column with a pile cap (a foundation), so as to improve the energy consumption of the pier column structure under the action of earthquake and eliminate or reduce the residual deformation and the injuries of the structure. The device comprises a pier column strengthening steel plate, a foundation pre-embedded steel plate, an angle steel, a friction bolt, a friction plate, unbonded prestressed tendons, an anchor bolt and the like. The device can connect a concrete pier column and the foundation into a whole through the unbonded prestressed tendons which are vertically arranged. When the earthquake strength achieves a certain degree, the pier column-foundation contact surface is open, and the pier column can produce a certain rotation relative to the foundation. A friction device can dissipate earthquake energy through friction at this time, and the prestress provided by the prestressed tendons can recover the structure to the initial position after the earthquake. A pre-embedded part at the end part of the pier column is used for improving the local bearing pressure of the concrete when the pier column rotates relatively.

Owner:SOUTHEAST UNIV

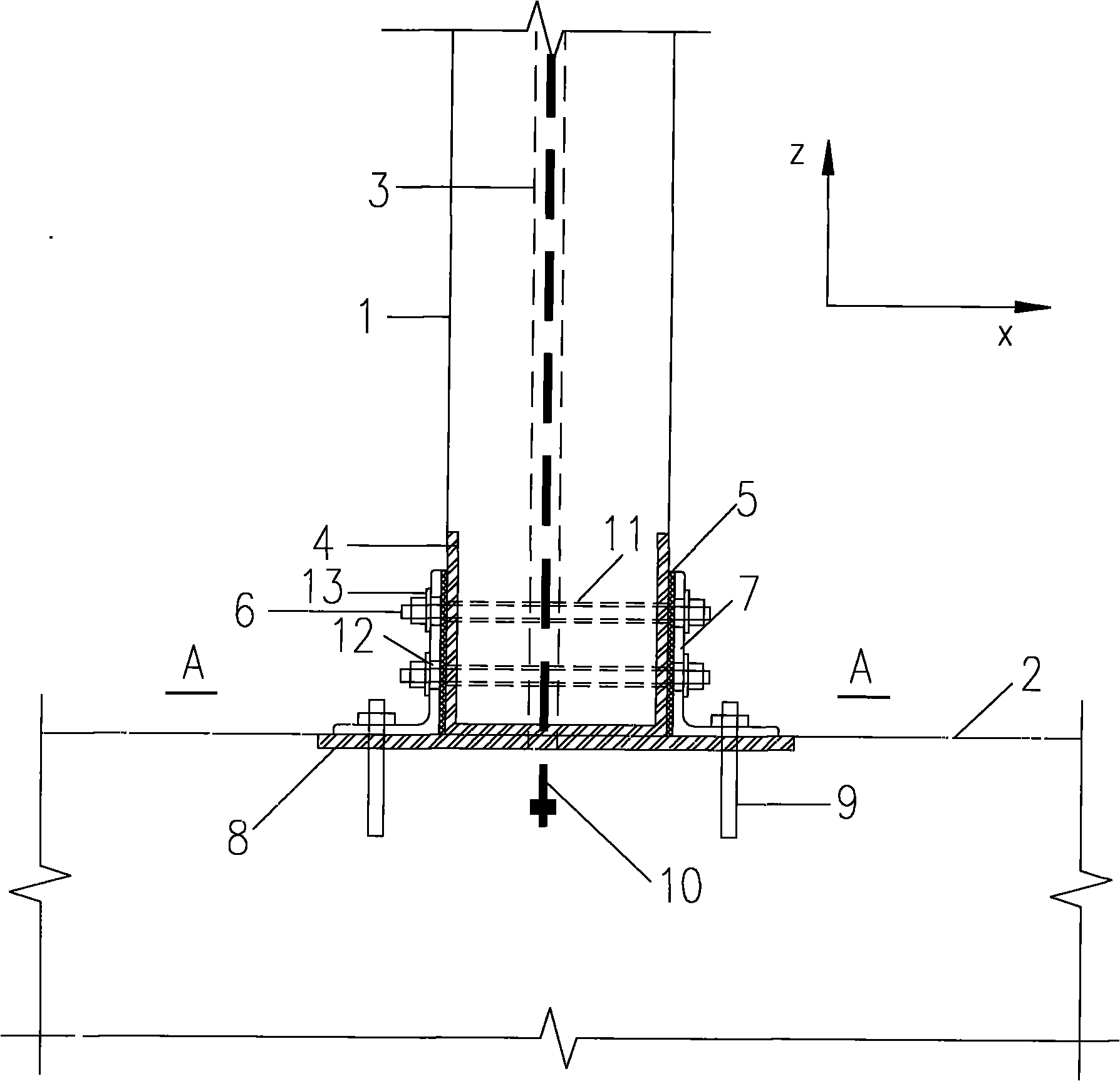

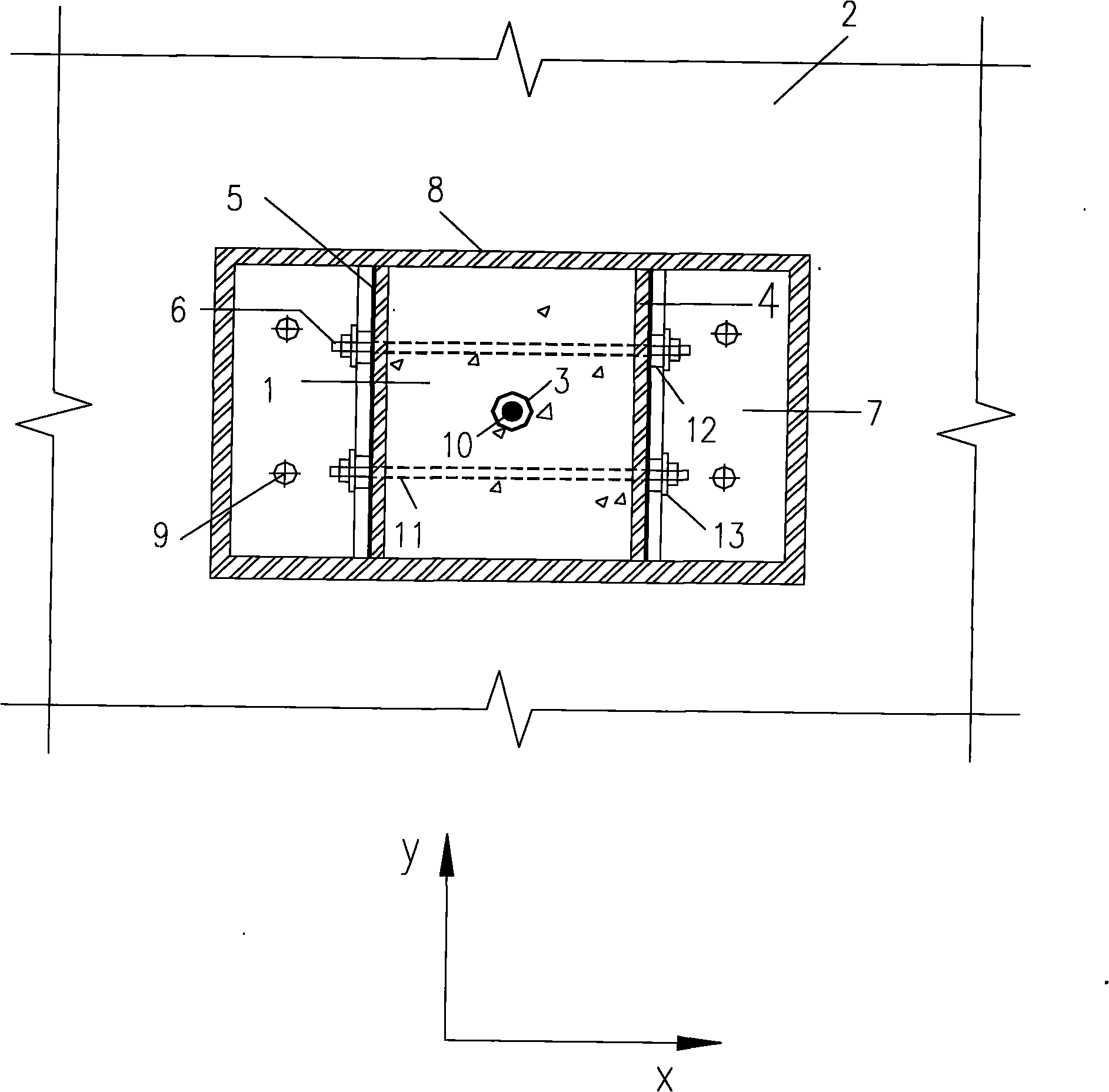

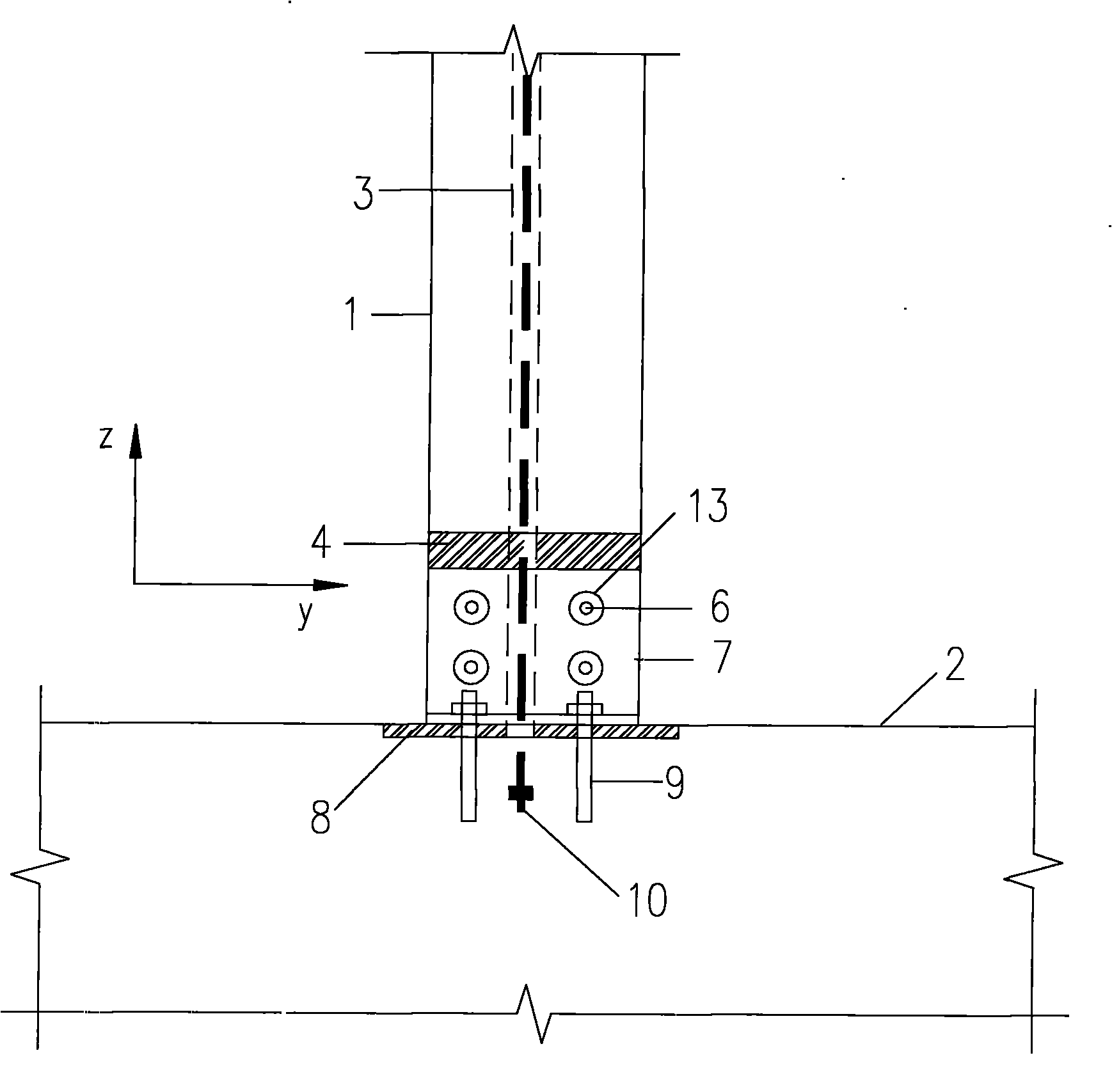

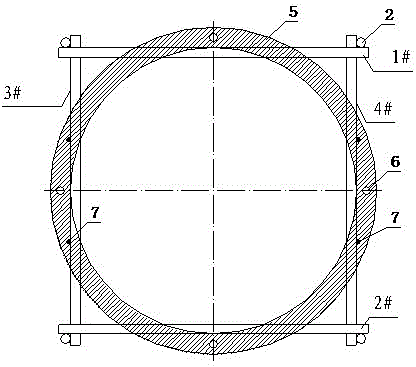

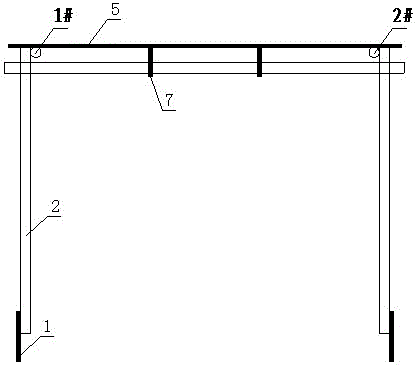

Integral built-in process for groups of anchor bolts

ActiveCN101338566AAdjustable deviationTimely correctionRail fastenersFoundation engineeringEngineeringWrench

The invention discloses an integral embedded method for a group of anchor bolts. The method comprises the following steps: after assembled lower positioning plates are fixed on a steel bracket in a foundation trench, the lower ends of the embedded bolts are fixedly connected with the lower positioning plates, and upper positioning plates are correspondingly installed on the embedded anchor bolts; steel pipe cat anchors are arranged on the periphery of the foundation trench to adjust the axial line positions of the embedded bolts, concrete is poured into the foundation trench, and after the concrete pouring is accomplished, the axial line positions of the embedded anchor bolts are adjusted. By adopting the method, the bracket and the ring-shaped positioning steel plate can be processed in a plant in advance, few construction site and little operational sequence time are occupied, the on-site splicing can be accomplished by only a spanner tool, the operational sequence is simple, the conventional on-site splicing time is saved, not only the construction speed is greatly accelerated, simultaneously the installation precision is enhanced, the engineering embedded bolt detection indicates that the permissible accuracy error for the embedded bolt installation is above the requirement of the national regulation, and the qualification rate of the engineering large-scale embedded anchor bolt can be up to 100 percent.

Owner:河北省第四建筑工程有限公司

Bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock

The invention specifically discloses a bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock, and the method comprises the following steps of: (1) after the roadway is excavated, immediately shotting concrete to close the surrounding rock, employing a high-pretightening force overstrength anchor bolt for supporting in the first disintegration zone, and arranging a steel bar net on the inner wall of the roadway surrounding rock and shotting concrete again; (2) applying a pretightening force anchor cable on the top plate of the roadway surrounding rock such that the anchoring end of the anchor cable is located in the deep intact rock mass, arranging a steel I-beam closely to the surrounding rock, passing the anchor cable through the shotcrete, the steel I-beam and a yielding ring and fixing the anchor cable on the inner wall of the roadway surrounding rock by using an anchor cable lock, thereby realizing coupling and supporting of the anchor bolt and the anchor cable; and (3) according to the monitoring result of the zonal disintegration of the surrounding rock, performing the delayed anchor bolt support for about 20-30 days, and performing grouting reinforcement on each disintegration zone by virtue of long and short combined injection pipes or a hollow sectional spiral grouting anchor bolt. The bolting-grouting integrated support method is capable of effectively performing bolting-grouting integrated reinforcement on the disintegrated surrounding rock of the deep roadway and thereby obviously enhancing the stability of the roadway.

Owner:SHANDONG UNIV

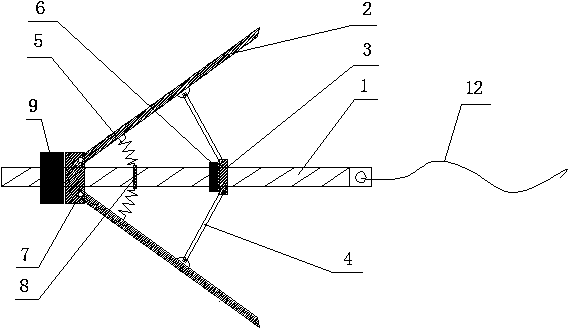

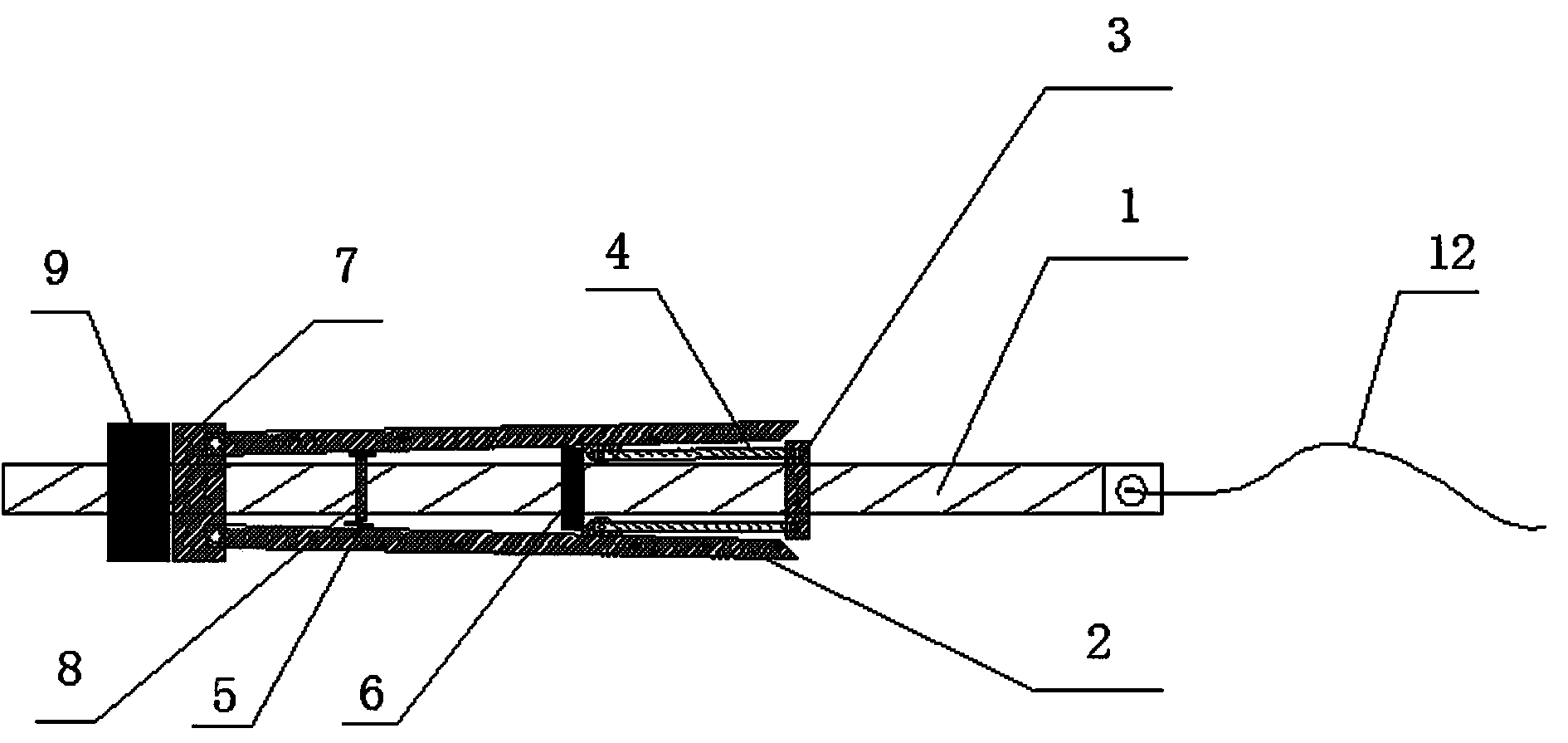

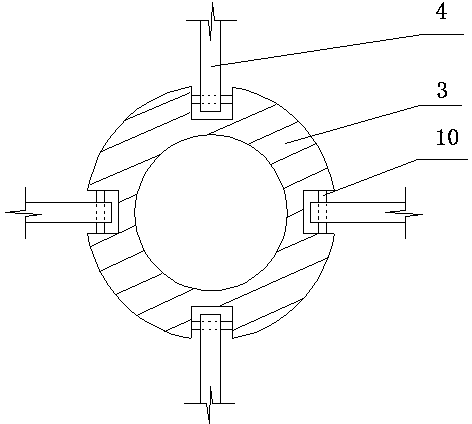

Flexible umbrella supporting anchor bolt and method for supporting soil slope thereby

ActiveCN104179178AIncrease anchoring forceConstruction quality is easy to ensureExcavationsBulkheads/pilesGeogridRock bolt

The invention relates to a flexible umbrella supporting anchor bolt and a method for supporting a soil slope thereby. An end ring and an end circular connector are fixedly disposed at one end of a round anchor bolt. A spring circular connector and a middle ring are fixedly disposed in the middle of the round anchor bolt. A lower circular connector adjacent to the right side of the middle ring movably sleeves the round anchor bolt. A drag umbrella surrounding the round anchor bolt comprises reacting plates evenly arranged, pull rods and compression springs. One end of a flexible pull rope is fixed to a round hole arranged in the other end of the round anchor bolt. More than one flexible umbrella supporting anchor bolt is connected with a soil high slope protective structure, composed of a geogrid mesh, a vegetation protective layer and a retaining wall, through the flexible pull ropes, and a whole for firmly and reliably anchoring and protecting the soil high slope is formed. The umbrella reacting plates are connected with the protective structural mesh through the flexible pull rope, anchoring force is greatly higher than that of a traditional anchor bolt, anchoring effect is more reliable, and engineering cost can be decreased by 50-60%.

Owner:NANCHANG INST OF TECH

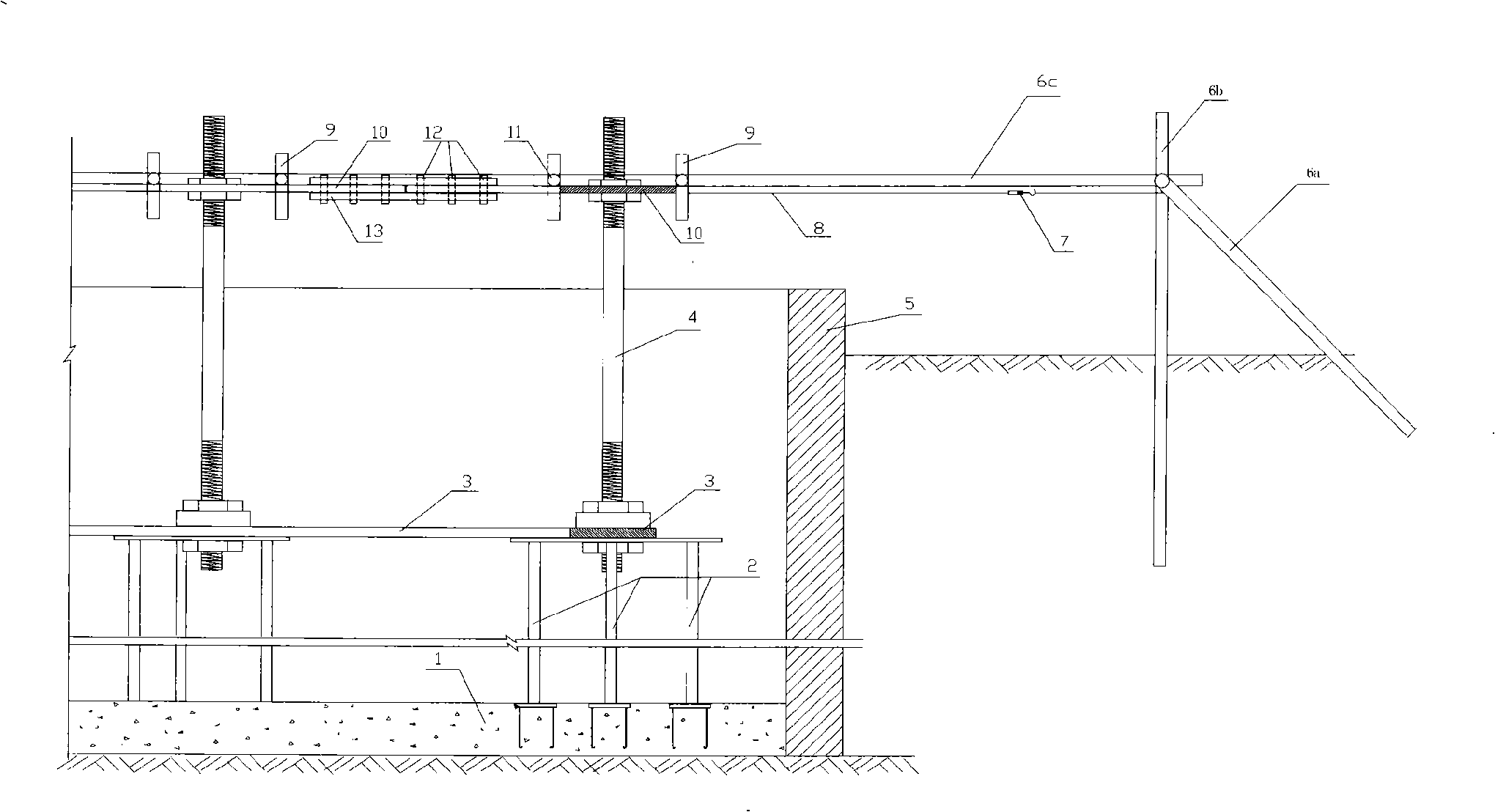

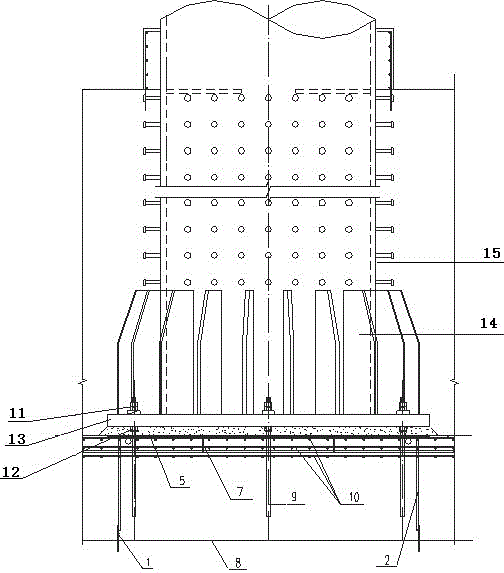

Installation and construction method of column base of large-diameter steel pipe column

ActiveCN104141318AImprove construction qualityQuality assuranceStrutsFoundation engineeringEngineeringSteel tube

The invention discloses an installation and construction method of a column base of a large-diameter steel pipe column. The method comprises the following steps: a, pouring a foundation pit cushion layer into a foundation pit; b, binding a bottom steel net and a lateral wall steel net above the foundation pit cushion layer; c, installing four anchor bolts. The installation and construction method is characterized in that the anchor bolts are M36 anchor bolts; the anchor bolts are positioned by adopting embedded positioning ring plates during installation, and the positioning ring plates are positioned and installed by adopting upright tube bracket supports with the steel pipe structure before being embedded. The installation and construction method has the advantages of being more convenient to operate, more accurate and faster to install, and higher in construction quality, and is especially suitable for installation and construction of the column base of the large-diameter steel pipe column, and the construction quality of the column base is ensured, so as to ensure the quality of the steel pipe column.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

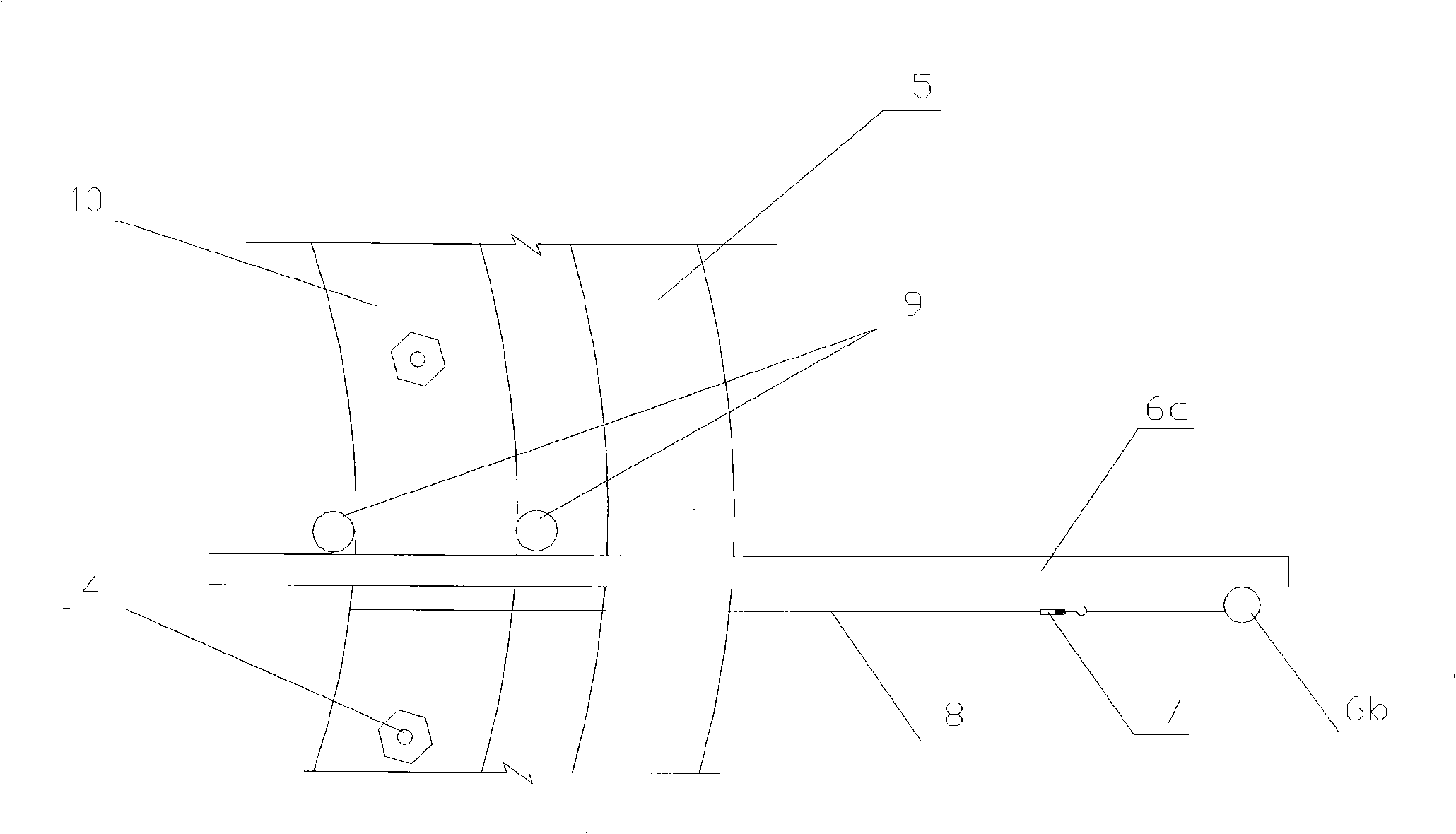

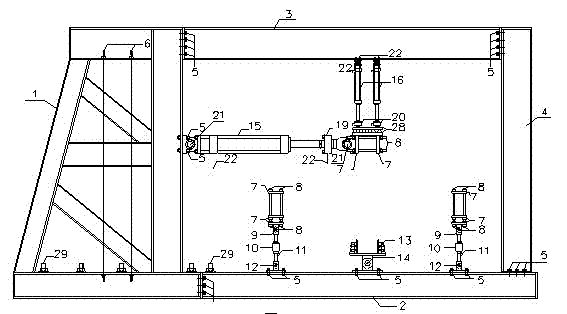

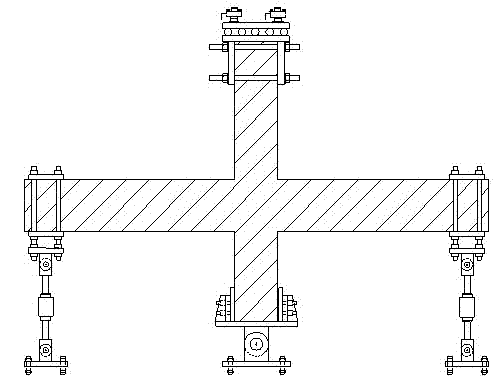

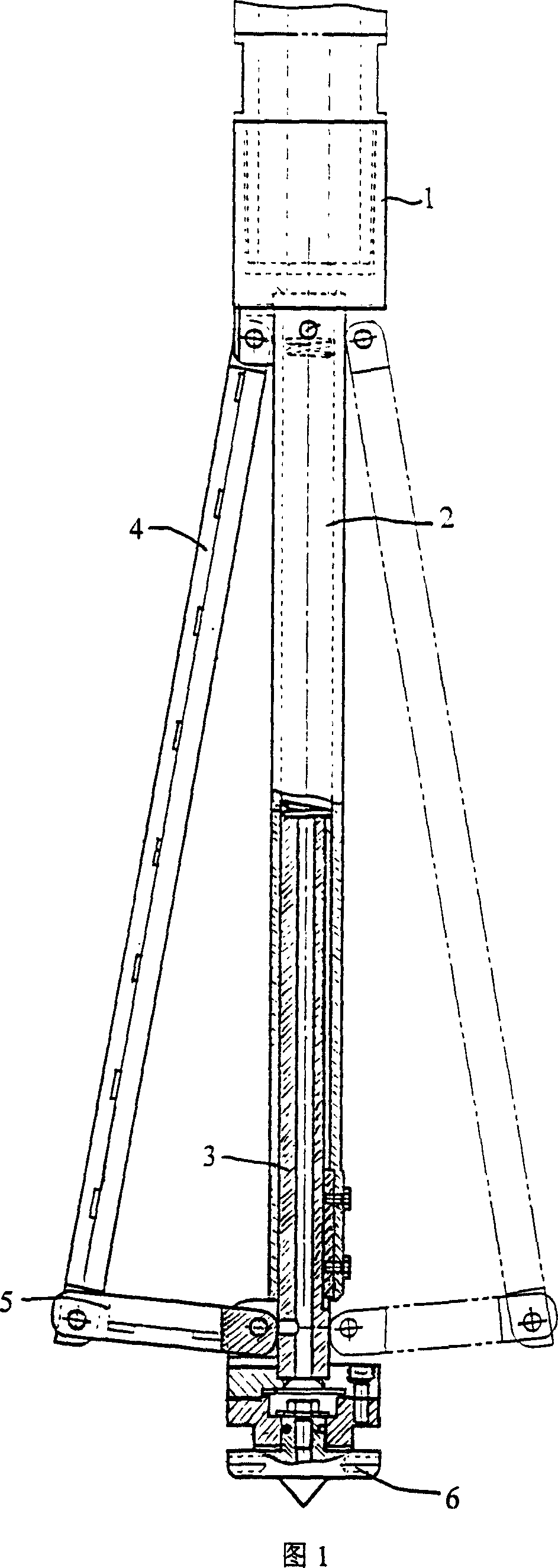

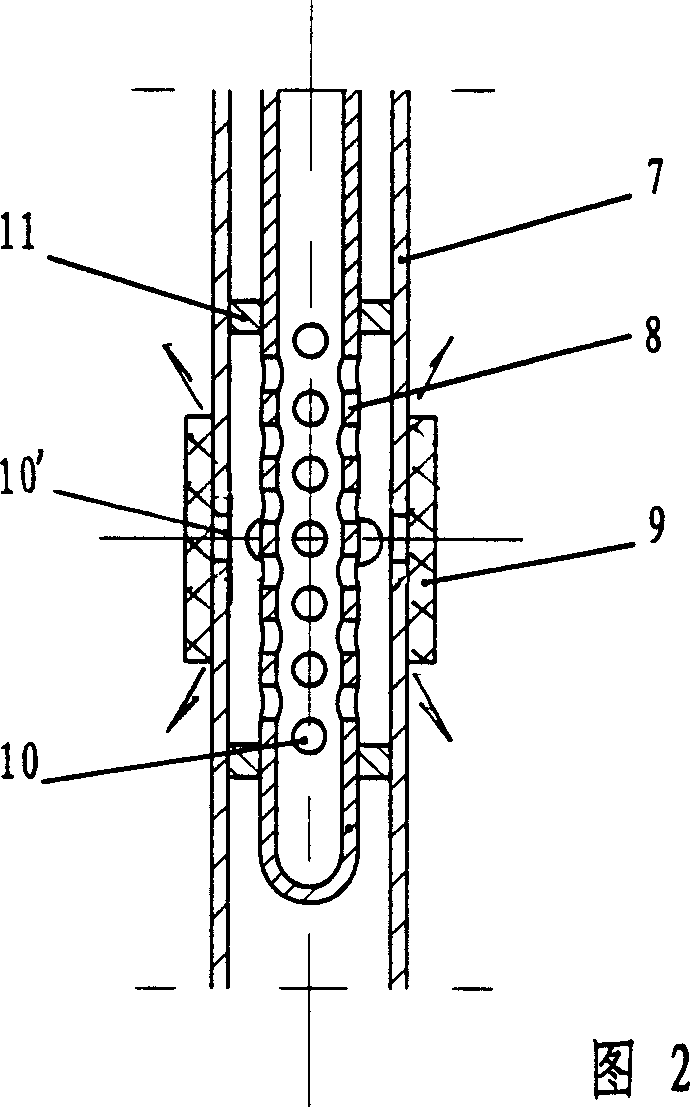

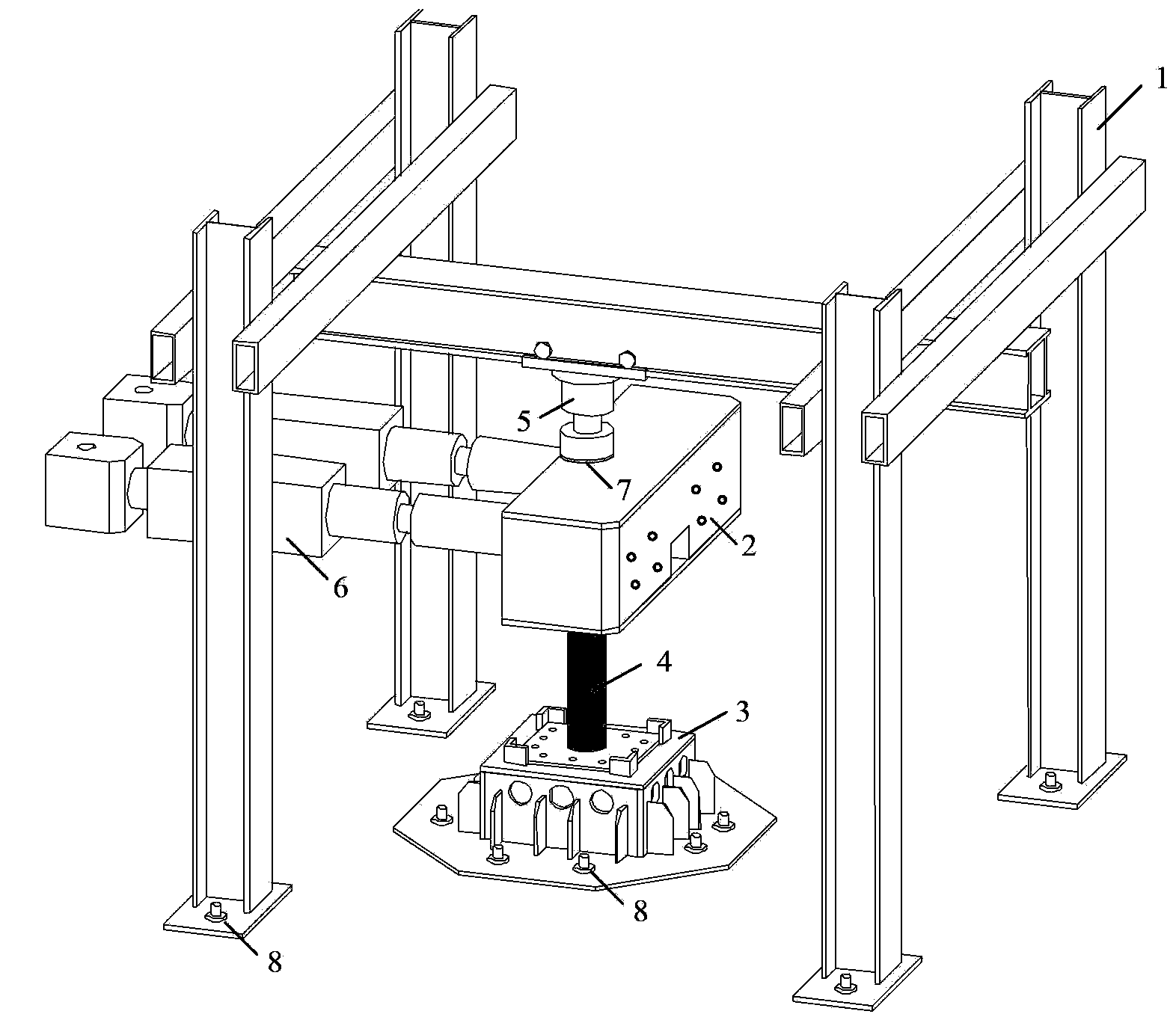

Portable performance test device for automatic control of combined action of bidirectional load of beam-column joint and determination method

InactiveCN103076192AFlexible stroke adjustmentPrevent movementStructural/machines measurementShaped beamAutomatic control

The invention discloses a portable performance test device for automatic control of a combined action of a bidirectional load of a beam-column joint and a determination method. The test device comprises an outer frame fixing device, a test piece fixing device, a test piece loading device and a data acquisition system, wherein the outer frame fixing device comprises a trapezoidal horizontal counter-force frame, an I-shaped girder bearing platform, an I-shaped beam, an I-shaped upright and a prestress wire rope; the test piece loading device comprises a horizontal actuator, two vertical actuators, a hydraulic oil source, a horizontal load sensor and a vertical load sensor; the test piece fixing device comprises two steel splints, an anchor bolt rod, a column fixing base and a column bottom hinge support; and the data acquisition system comprises a controller, a multi-channel strain collector and a computer. The device, provided by the invention, has the advantages of simple structure, convenience for assembly and disassembly, and few required materials, and is suitable for testing hysteretic behavior of a node test piece at scientific research and construction sites.

Owner:HOHAI UNIV +1

Construction method for mechanical hole reaming of anchor rod

InactiveCN1963043AShorten the lengthImprove carrying capacityBulkheads/pilesDrilling machines and methodsCarrying capacityPre stress

The invention involves an anchorage method to reinforcing and maintaining the layer of rock and soil, namely the construction method of producing the prestress anchor bolt using the mechanical reaming reamer. It includes drilling, reaming, washing and slip casting, the slurries are wrapped with the prestress dabber together and are solidified to forming the anchor bolt. The second slip casting is needed after the first slip casting according the design requirements; the second slip casting adopts high pressure splitting casting pipe or many pipes. The construction method of the invention applies to ground layers with different soil strata, it can work in the direction of horizontal angle is 0~90degree, it is equipped with cylinderin volumes and conical reaming volumes along the length of the anchor bar; it can ream only once, and can ream many times or for many volumes, and they are connected with each other for a whole to increasing the contact area between the anchor bolt and the rock or soil. Because of the combination of the effect of anchor bolt end bearing and the effect of friction, it doubles the carrying capacity of anchor bolt and correspondingly shortens the length of the anchor bolt, so it has significant economic benefits.

Owner:CHINA JINGYE ENG

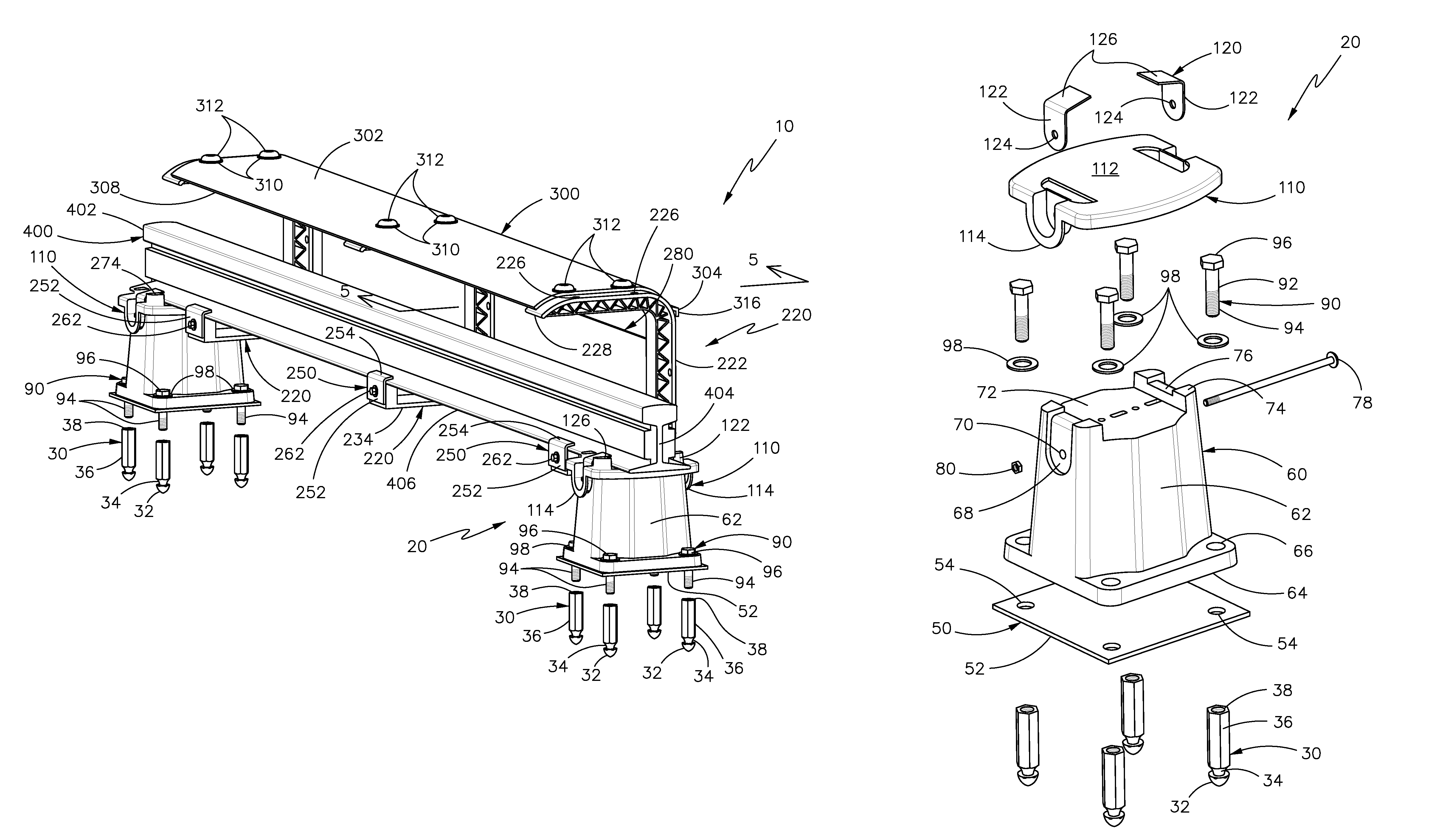

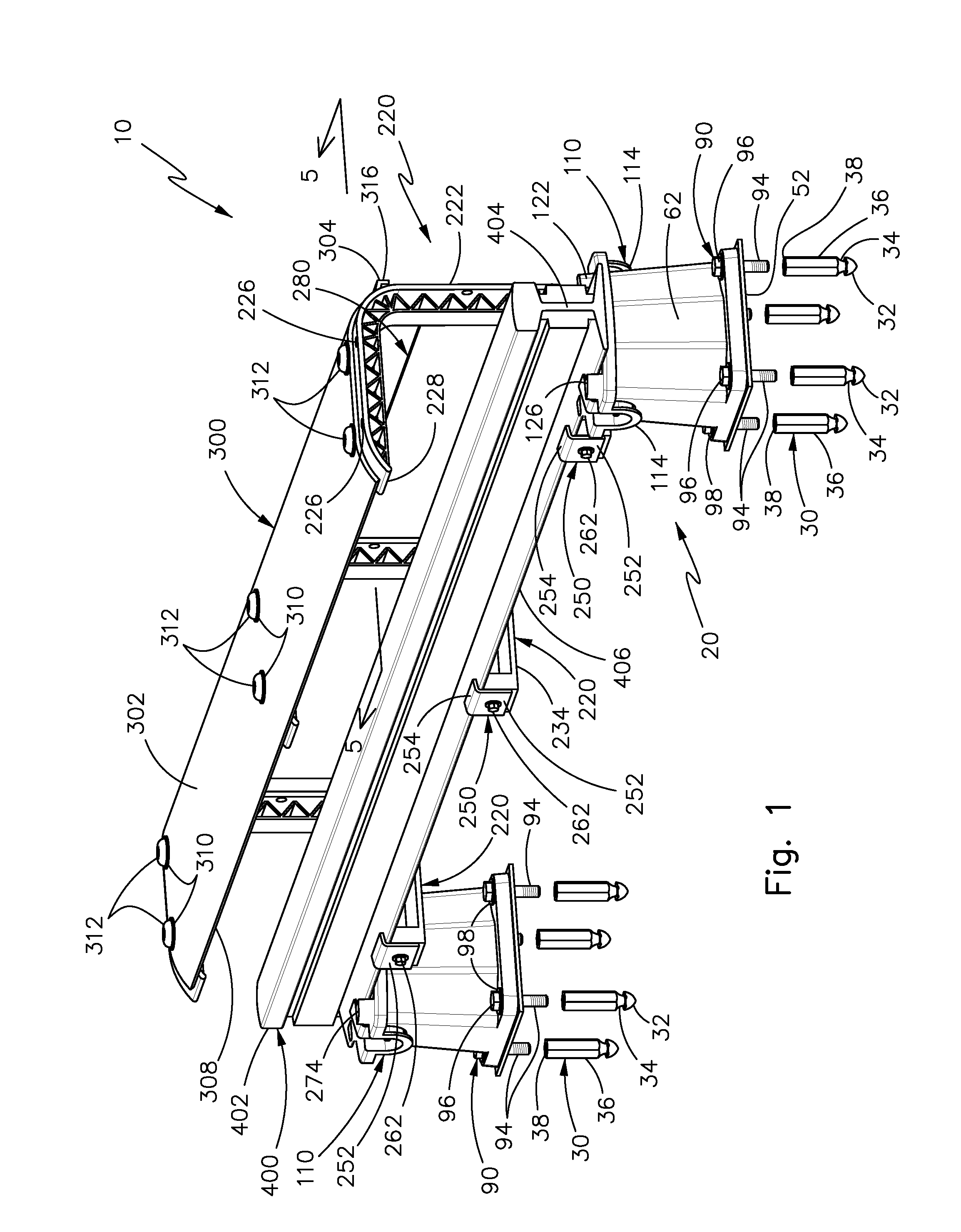

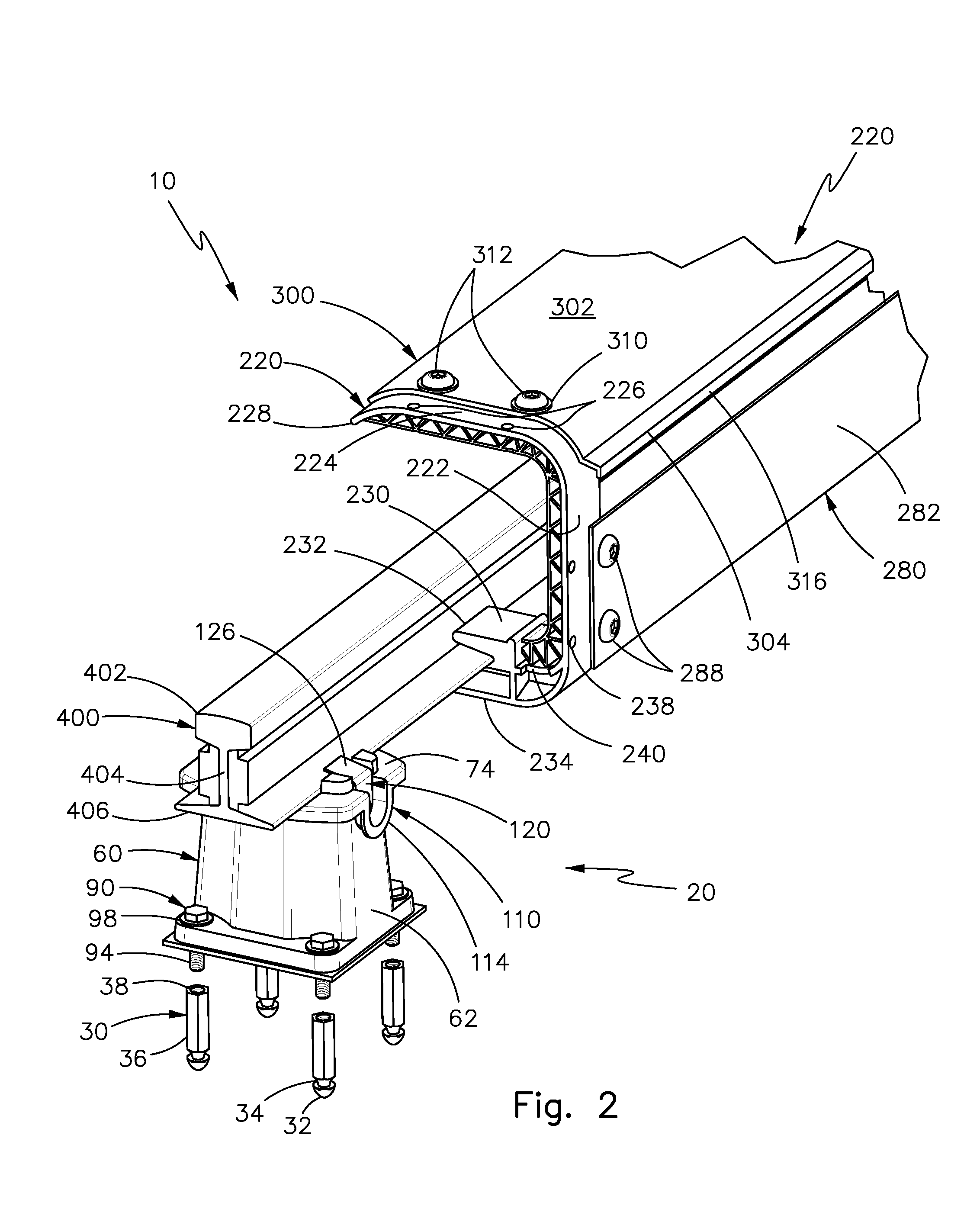

Third rail power insulating system

ActiveUS7926634B1Cheap manufacturingInexpensive to maintainPower railsPower supply line detailsEngineeringElectric power

A third rail power insulating system, comprising an insulator assembly and a cover board assembly. The insulator assembly comprises pedestal supporting insulators that are mounted onto a contact rail assembly. The insulator assembly further comprises an insulator anchor bolt assembly, a base shim plate, a bolt assembly, a lubricating shim, and retaining clips. The cover board assembly is also mounted onto the contact rail assembly and it comprises a support bracket assembly, retaining clips, a side cover board, and a top cover board. The support bracket assembly has a general C-shape and comprises a lateral wall, a top wall, a base wall, and a protrusion. The side cover board comprises an elongated plate having at least one hole, and the top cover board comprises an elongated plate having sufficient curvature to contour the support bracket assembly.

Owner:MORALES MIGUEL ANGEL

Steel bar concrete beam reinforcing structure with partially restrained steel truss

The invention discloses a steel bar concrete beam reinforcing structure with a partially restrained steel truss, comprising upper angle steel, lower angle steels, a web batten plate, a bottom steel plate, an anchored steel plate, a shear resistant anchor bolt and a bolt, wherein the upper angle steel, the lower angle steels, the web batten plate and the bottom steel plate are spliced to form an opened steel truss for tightly hooping a beam to be reinforced, the lower angle steels are respectively arranged at two lower corners of the beam to be reinforced and are connected with each other by the bottom steel plate, the upper angle steel is mounted between the beam to be reinforced and a slab, and is connected with the lower angle steels by the web batten plate, the anchored steel plate is arranged in the slab and is connected with the shear resistant anchor bolt arranged in the slab, and the shear resistant anchor bolt is connected with the upper angle steel by the bolt in a pre-fastening mode. The steel truss and the steel bar concrete beam form two load bearing protection lines, so the bearing capacity of the steel bar concrete beam meets the reinforcing design requirement, and the safety of a member and a structure can be ensured.

Owner:NANJING UNIV OF TECH

Steel-concrete composite column anti-seismic anti-torsion test loading device and manufacturing method thereof

InactiveCN103398908AGuaranteed to twist freelyFor quick replacementMaterial strength using steady bending forcesServo actuatorTorsion test

The invention relates to a steel-concrete composite column anti-seismic anti-torsion test loading device and a manufacturing method thereof, and belongs to the technical field of structure engineering. The steel-concrete composite column anti-seismic anti-torsion test loading device comprises a loading frame, a top beam, a base, an antifriction plate, a thrust jack, and two electro-hydraulic servo actuators. The loading frame is obtained by welding steel plates. All column bases of the loading frame are provided with bolt holes and are fixedly connected to the ground by ground anchor bolts. The top beam is obtained by welding steel plates. The bottom of the top beam is provided with bolt holes and is fixedly connected to a top steel plate of a test piece by bolts. The base is obtained by welding steel plates. The top of the base is provided with bolt holes and is connected to a bottom steel plate of the test piece by bolts. An upper end of the thrust jack is connected to the loading frame by a rolling bearing. The antifriction plate is horizontally arranged in the center of the top of the top beam. The electro-hydraulic servo actuators are arranged horizontally and are fixedly connected to the top beam. The steel-concrete composite column anti-seismic anti-torsion test loading device solves the problem of the prior art, has a simple structure, is convenient for use, has strong universality, can be used for anti-seismic anti-torsion tests on various steel-concrete composite columns, and has wide application prospects.

Owner:TSINGHUA UNIV

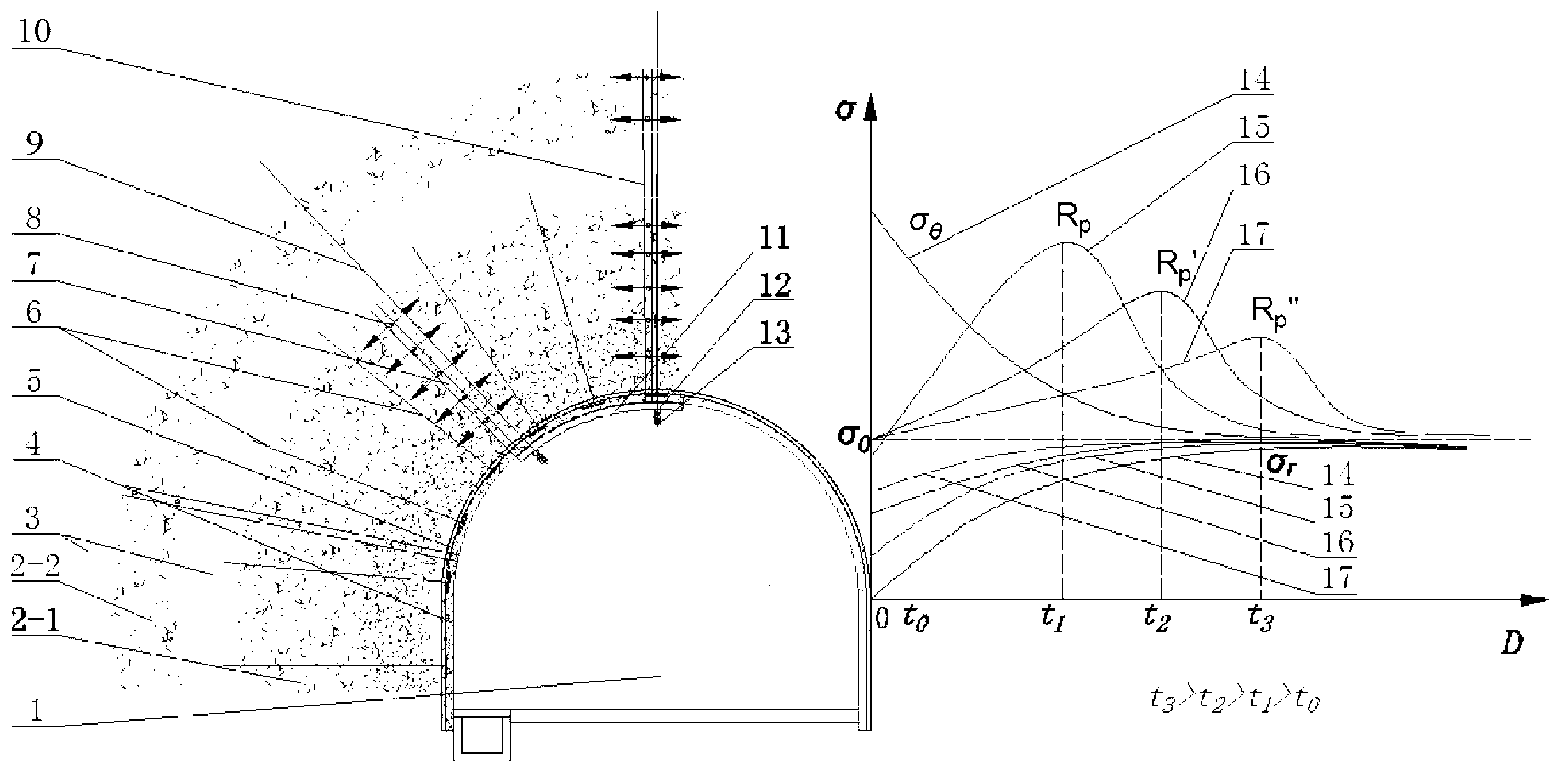

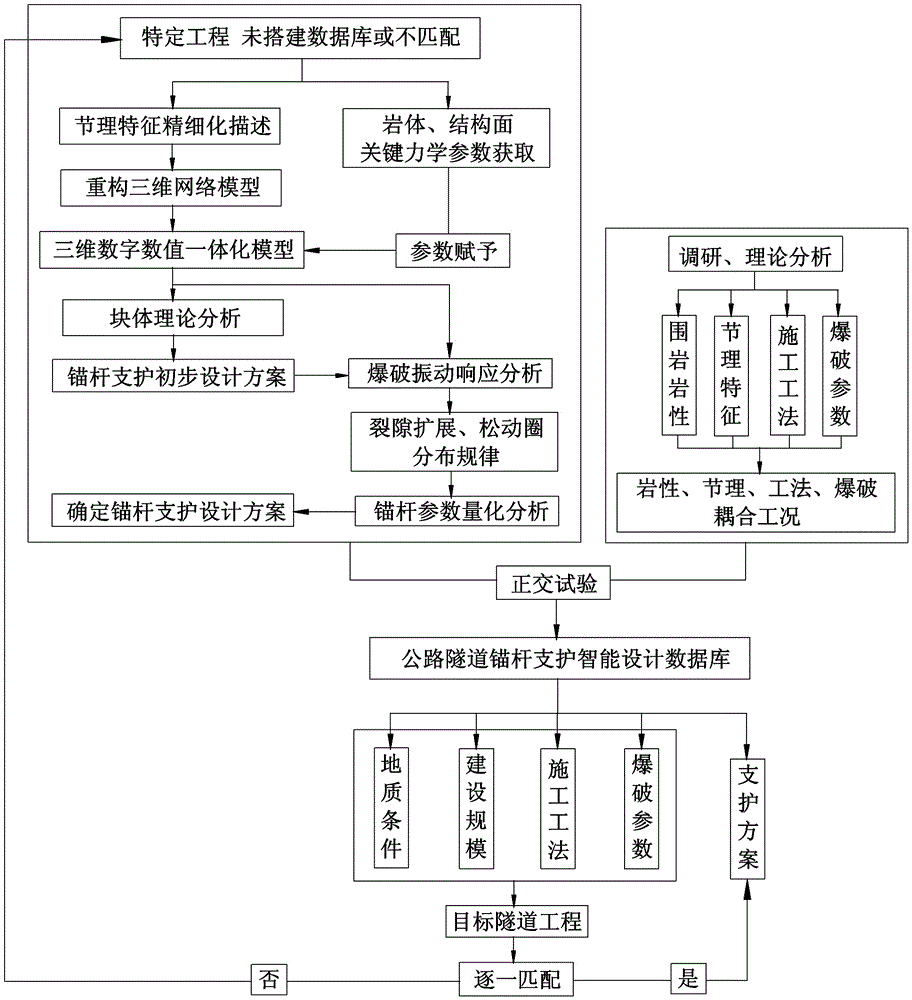

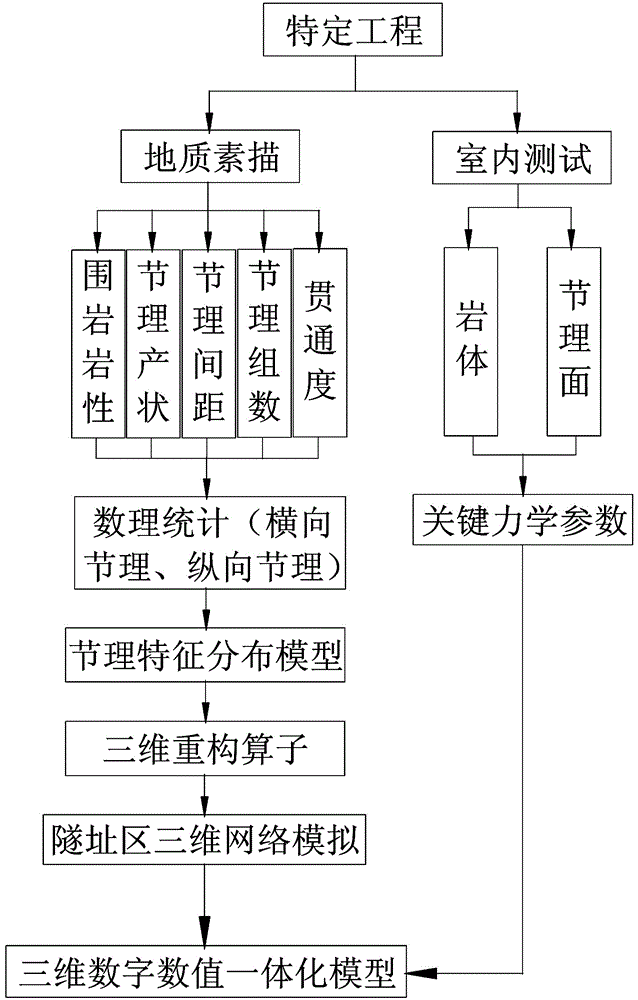

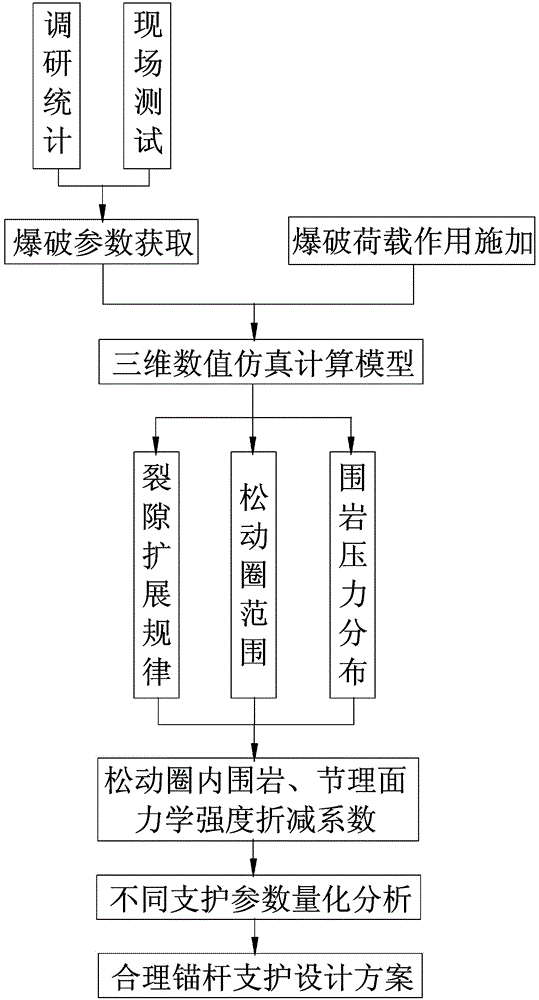

Design method of anchor bolt support for highway tunnel

ActiveCN105787206AResolution cycleSolve operational problemsGeometric CADSpecial data processing applicationsBlasting vibrationDesign methods

The invention discloses a design method of an anchor bolt support for a highway tunnel. The method is characterized in that the design method of the anchor bolt support for the highway tunnel is designed on the basis of rock mass joint characteristics and blast vibration effects. The design method of the anchor bolt support for the highway tunnel comprises implementing steps as follows: step (1) establishing a three-dimensional digital and numerical value integrated model; step (2) proposing a preliminary scheme of the anchor bolt support; step (3) dynamically determining an anchor bolt support scheme and parameters which are suitable for an engineering; step (4) establishing an intelligent design database of the anchor bolt support for the highway tunnel; step (5) gradually improving the engineering applicability of the design scheme and the established database.

Owner:TONGJI UNIV +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com