Design method of anchor bolt support for highway tunnel

A bolt support, road tunnel technology, applied in the installation of bolts, database design/maintenance, calculation, etc., can solve the lack of security of the support structure, waste of materials, difficult to quantitatively analyze joint characteristics and excavation blast disturbance, etc. problems, achieve the effect of shortening the design cycle, improving the rationality, and simplifying the design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

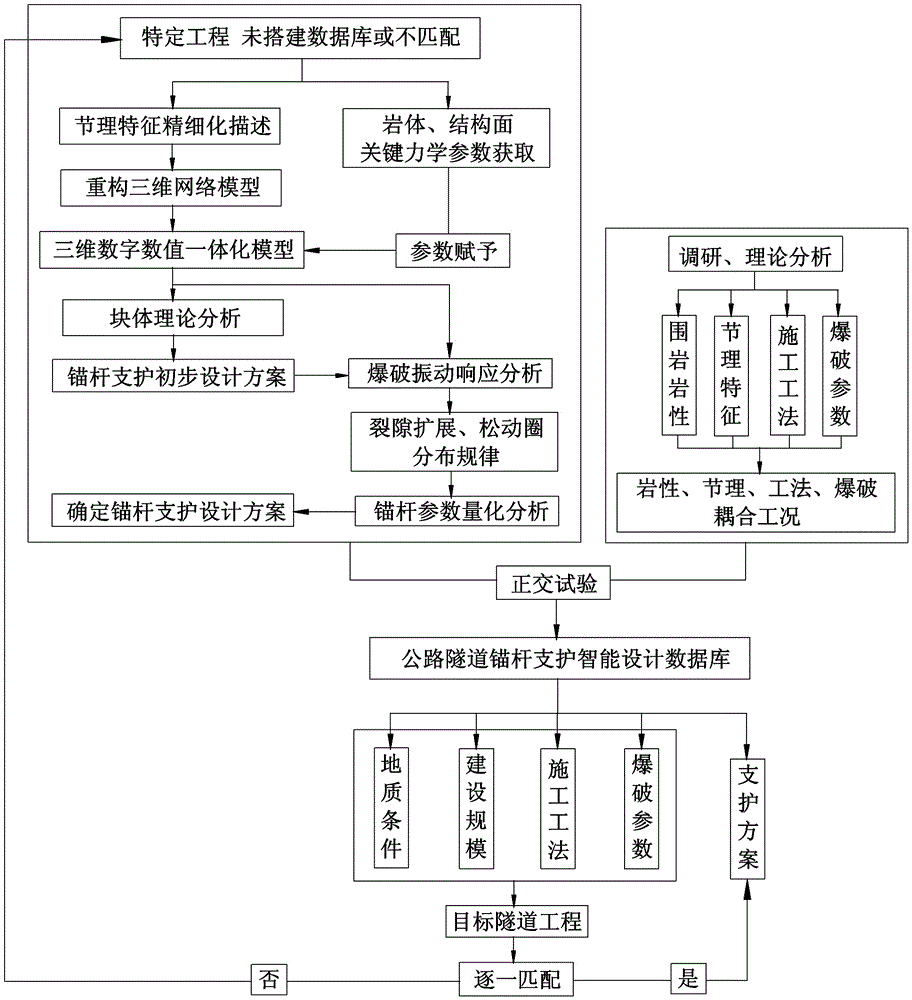

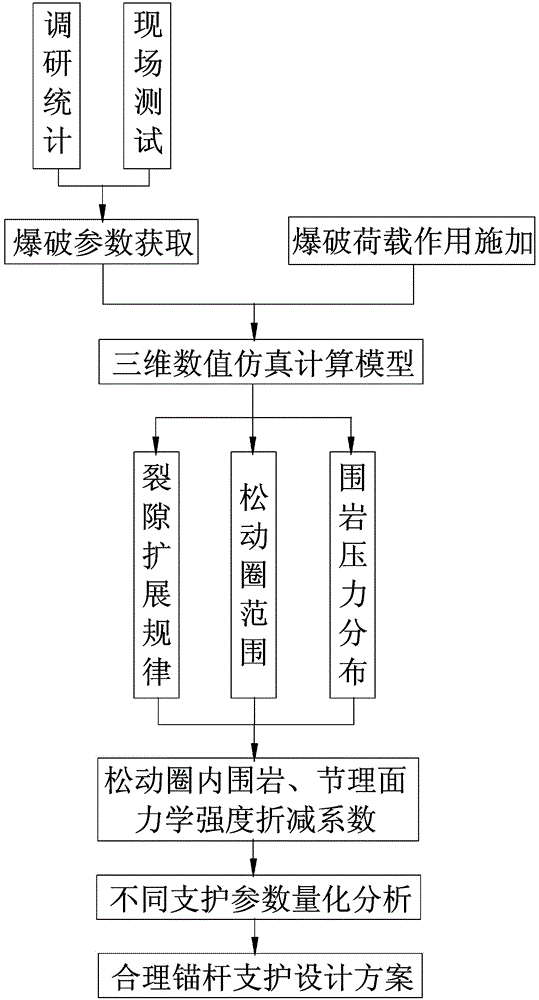

[0034] In the case of a specific tunnel project and the intelligent design database of highway tunnel bolt support has not been established in the early stage, according to the attached Figure 1~4 , the implementation steps of the road tunnel bolt support design method based on rock mass joint characteristics and blasting vibration effects of the present invention are as follows:

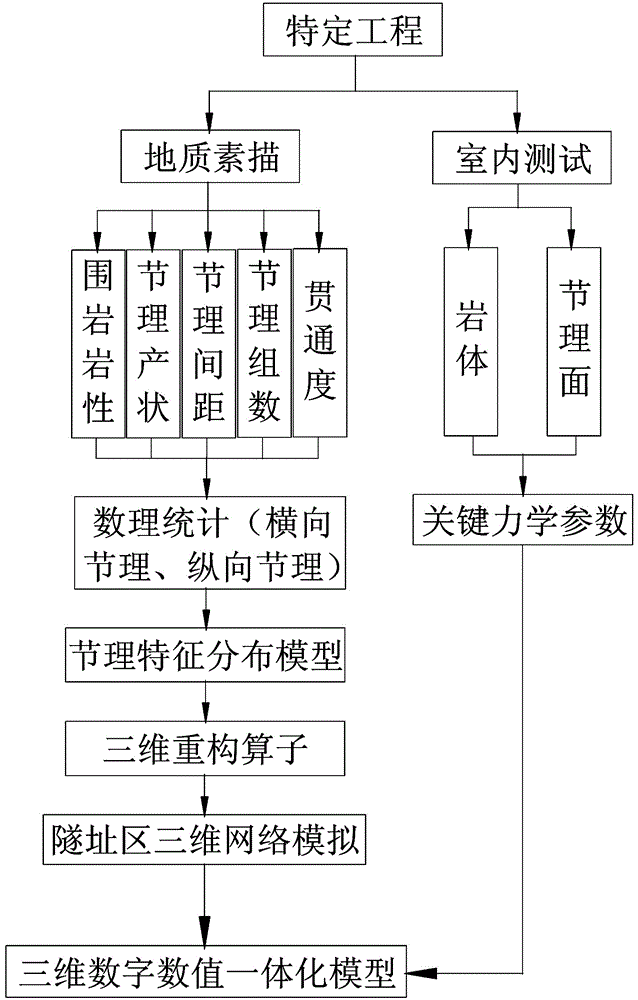

[0035]A. Step (1): Use the on-site geological sketch method to describe the geological conditions of the tunnel face in detail, count the parameters of the tunnel rock formation, joint characteristics and roughness, and quantify the joint characteristics (joint spacing, dip angle, number of groups, etc. ), analyze the dominant joint surface, and give the distribution model and dispersion degree of the above indicators;

[0036] B. Step (2): Use the Monte Carlo method to simulate the spatial distribution characteristics of joints, and construct a three-dimensional network model of the tunnel site ar...

Embodiment 2

[0052] In the case of the intelligent design database of highway tunnel bolt support, according to the attached figure 1 , the implementation steps of the road tunnel bolt support design method based on rock mass joint characteristics and blasting vibration effects of the present invention are as follows:

[0053] A. Step (1): For a given tunnel project, according to geological survey data and design documents, artificially extract the surrounding rock geological conditions, hydrological conditions and construction scale of the tunnel site area, and input the already constructed highway tunnel bolt support Intelligent design database for retrieval;

[0054] B. Step (2): If a matching item is retrieved in the highway tunnel bolting intelligent design database, directly extract the recommended bolting parameter scheme output from the database, form a design document, and guide the construction;

[0055] C. Step (3): If no matching item can be retrieved in the intelligent design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com