Acoustical method and device for detecting low-concentration sulfur hexafluoride gas

A technology of sulfur hexafluoride gas and acoustic devices, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the difficulty in reconciling the detection accuracy of the sound velocity method or propagation delay method and detection range to achieve the effect of easy miniaturization, low power consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

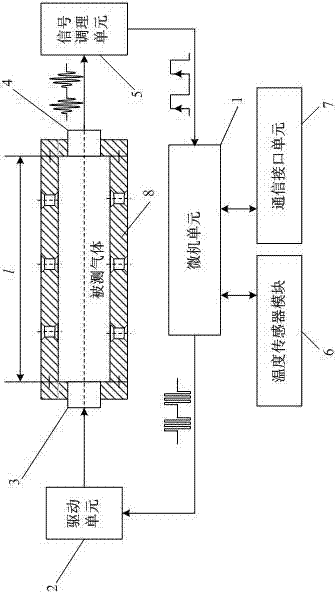

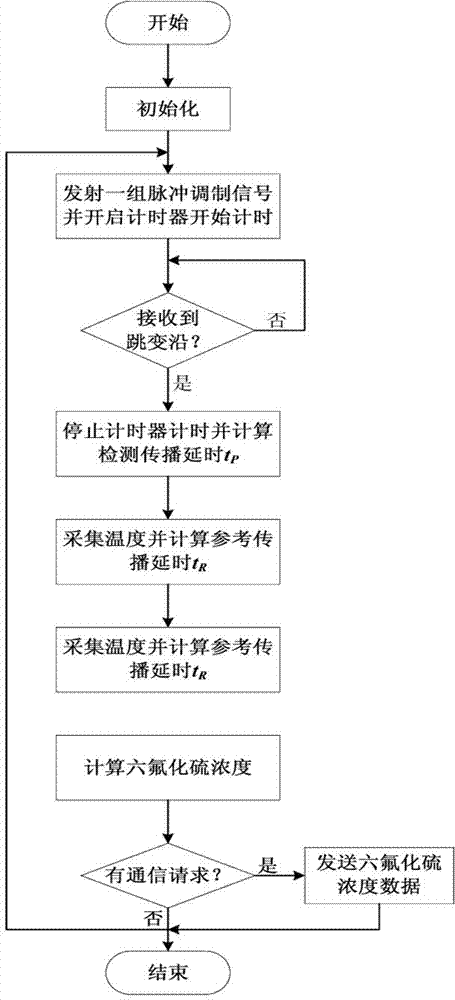

[0030] Such as figure 1 , 2, Shown in 4, a kind of acoustic method of low-concentration sulfur hexafluoride gas detection, the step of described detection is:

[0031] Step a, the pulse modulation wave is sent by the microcomputer unit 1, and the timer starts counting;

[0032] Step b, after the pulse modulation wave is amplified by the power of the driving unit 2, it drives the transmitting end of the acoustic wave transmitting transducer 3 and emits sound waves, and the acoustic wave transmitting transducer 3 is mounted on a length of One end of the detection channel 8;

[0033] Step c, the sound wave that the sound wave emitting transducer 3 sends passes through a length of After the detection channel 8, it is received by the sound wave receiving transducer 4 installed at the other end of the detection channel 8, and the sound wave receiving transducer 4 converts the received sound wave into an electrical signal;

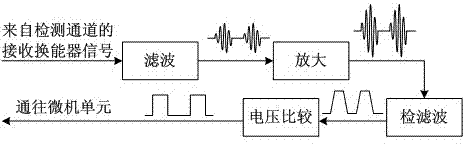

[0034] Step d, after the electrical signal output by ...

Embodiment 2

[0047] Such as figure 1 , 2 , 3, an acoustic device for detecting low-concentration sulfur hexafluoride gas, including a microcomputer unit 1 with a built-in timer, a drive unit 2, an acoustic wave transducer, a signal conditioning unit 5, a temperature sensor module 6, and a communication interface The unit 7 and the detection channel 8 containing the detection gas mixed with sulfur hexafluoride; the acoustic wave transducer includes an acoustic wave transmitting transducer 3 and an acoustic wave receiving transducer 4, and the acoustic wave transmitting transducer 3 and the acoustic wave receiving transducer The transducers 4 are installed at both ends of the detection channel 8 respectively; the output end of the microcomputer unit 1 is electrically connected with the acoustic wave transmitting transducer 3 installed at one end of the detection channel 8 through the drive unit 2, and is installed at the other end of the detection channel 8 The acoustic wave receiving trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com