High-torque valve torque monitoring system

A monitoring system, high torque technology, applied in the direction of signal transmission system, measuring device, torque measurement, etc., can solve the problems of inability to realize real-time dynamic monitoring of valve torque, limited application range, etc., to improve product quality and design level, operation Safe, stable and reliable, advanced control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

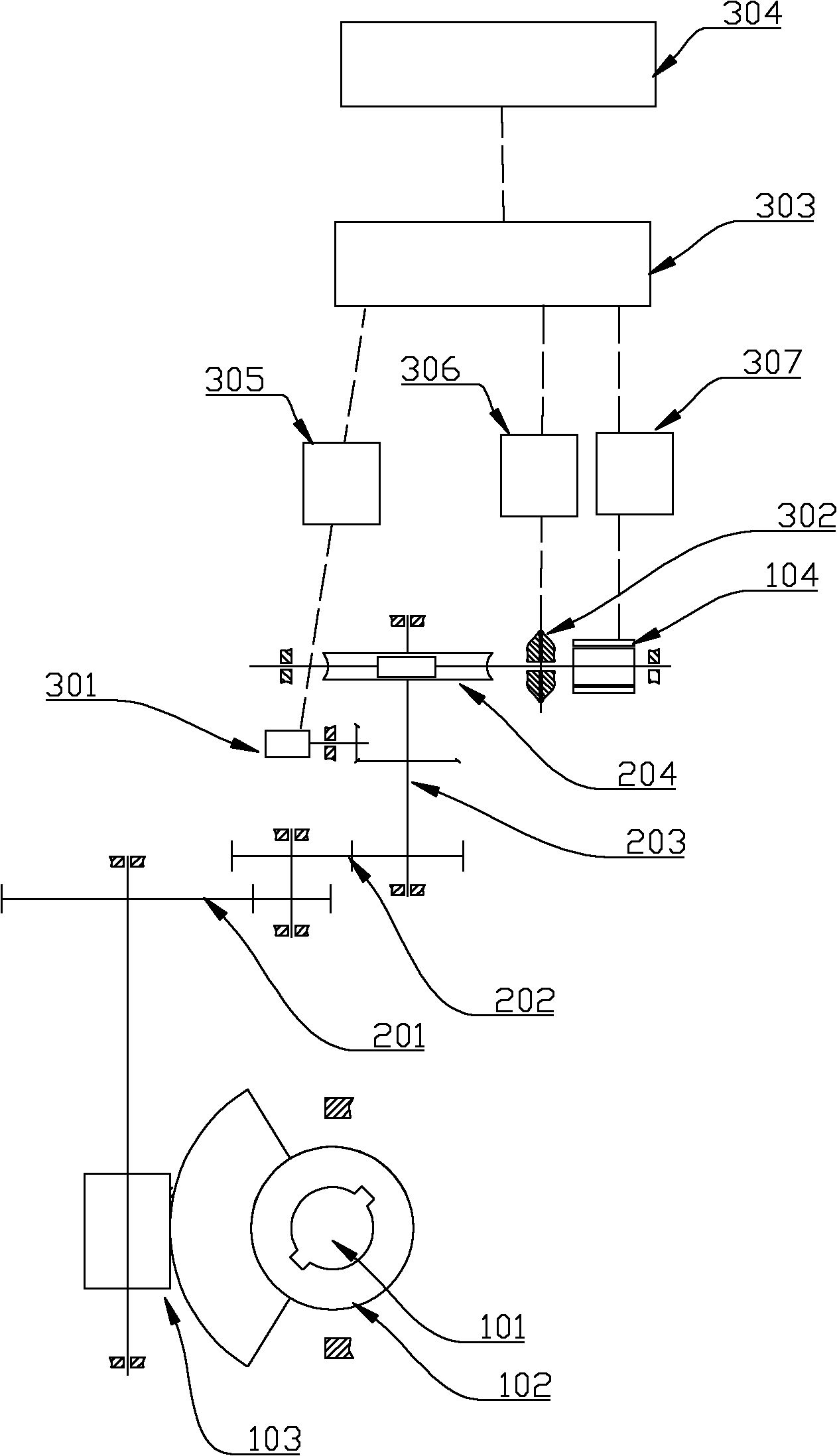

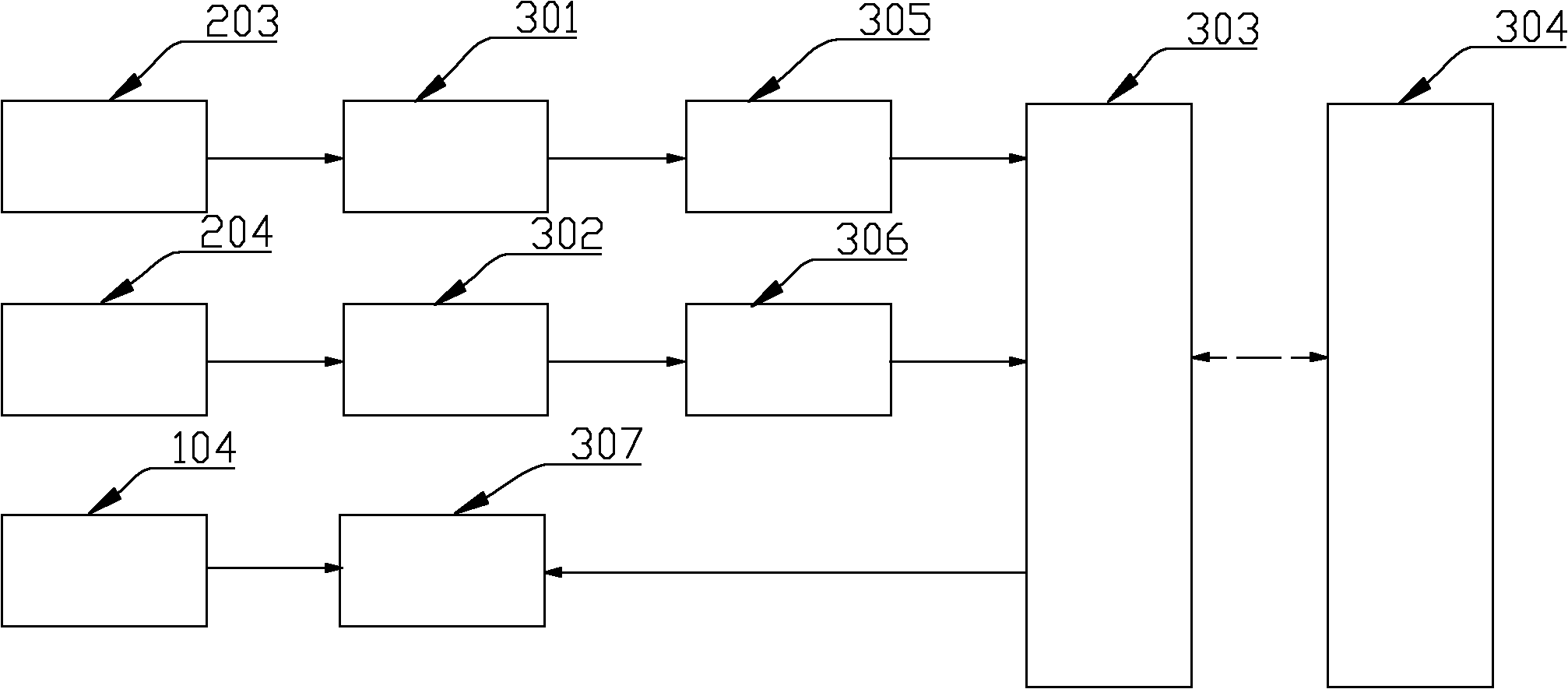

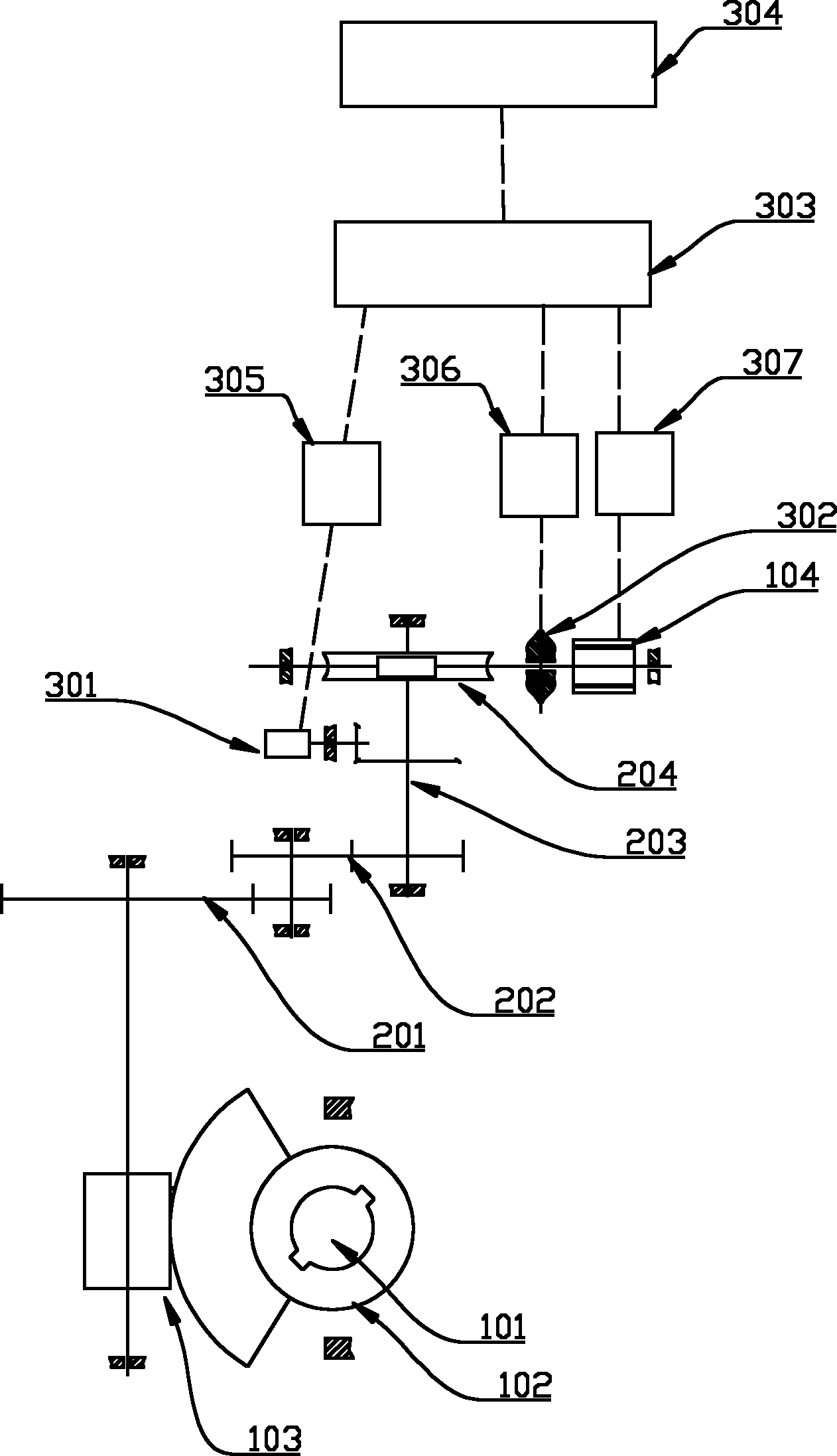

[0027] Such as figure 1 with figure 2 As shown, the data acquisition and monitoring device 303 drives the motor 104 through the motor drive module 307, and the motor 104 drives a set of small torque worm gear pair 204 to drive the small output shaft 203, and the small output shaft 203 is connected to a set of small spur gears 202. The gear set 202 drives a set of large spur gear set 201, and the large spur gear set 201 drives the high-torque worm gear pair 103, and finally drives the tested valve 101 to rotate through the large output shaft 102; A small torque worm gear pair 204 and a torque amplification mechanism are sequentially added between them, that is, the large torque change of the measured valve is reflected on the axial movement of the small worm gear pair 204 by speeding up and reducing torque, and by detecting the small worm gear pair The disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com