Pulsed eddy-current-based metal plate thickness information detection method

A technology of information detection and pulsed eddy current, applied in the direction of electric/magnetic thickness measurement, electromagnetic measurement device, etc., can solve the problem of not being able to achieve good results, and achieve the effect of optimizing the barrier of dependence, improving the timeliness, and simplifying the experimental method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

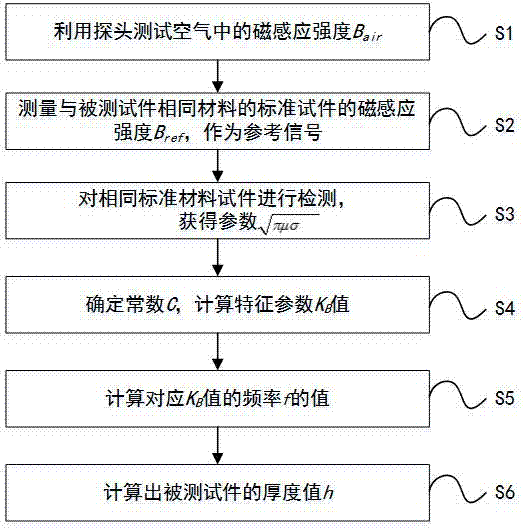

[0042] Further describe the technical scheme of the present invention in detail below in conjunction with accompanying drawing:

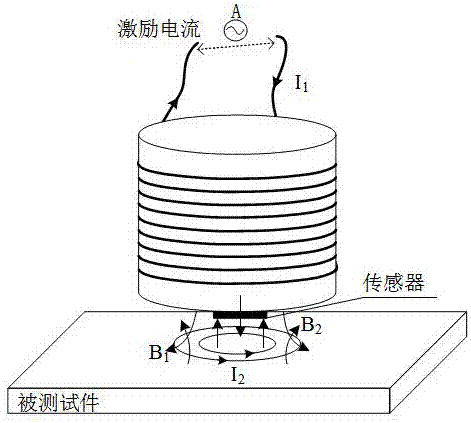

[0043] The theoretical technology of pulsed eddy current testing technology (PECT) in this embodiment is electromagnetic field theory and eddy current effect. The main process is: a square wave (equivalent to a pulse) excitation current signal is generated by the excitation coil, thereby generating a pulsed magnetic field signal (time-varying signal) in space; due to the excitation of the pulsed magnetic field, a pulsed eddy current signal is formed in the material , the eddy current signal also generates an induced magnetic field in space; the combined magnetic field signal of the two magnetic fields is detected by the HALL sensor in the probe as a detection signal; this signal, as a carrier carrying information on the thickness (defect depth) of the test piece, will be used as a data Source to analyze, so as to solve the specific size of the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com