Patents

Literature

444 results about "Eddy-current testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Eddy-current testing (also commonly seen as eddy current testing and ECT) is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

Inspection apparatus and method

ActiveUS20100207620A1Current/voltage measurementMagnetic property measurementsCounter-electromotive forceEddy-current testing

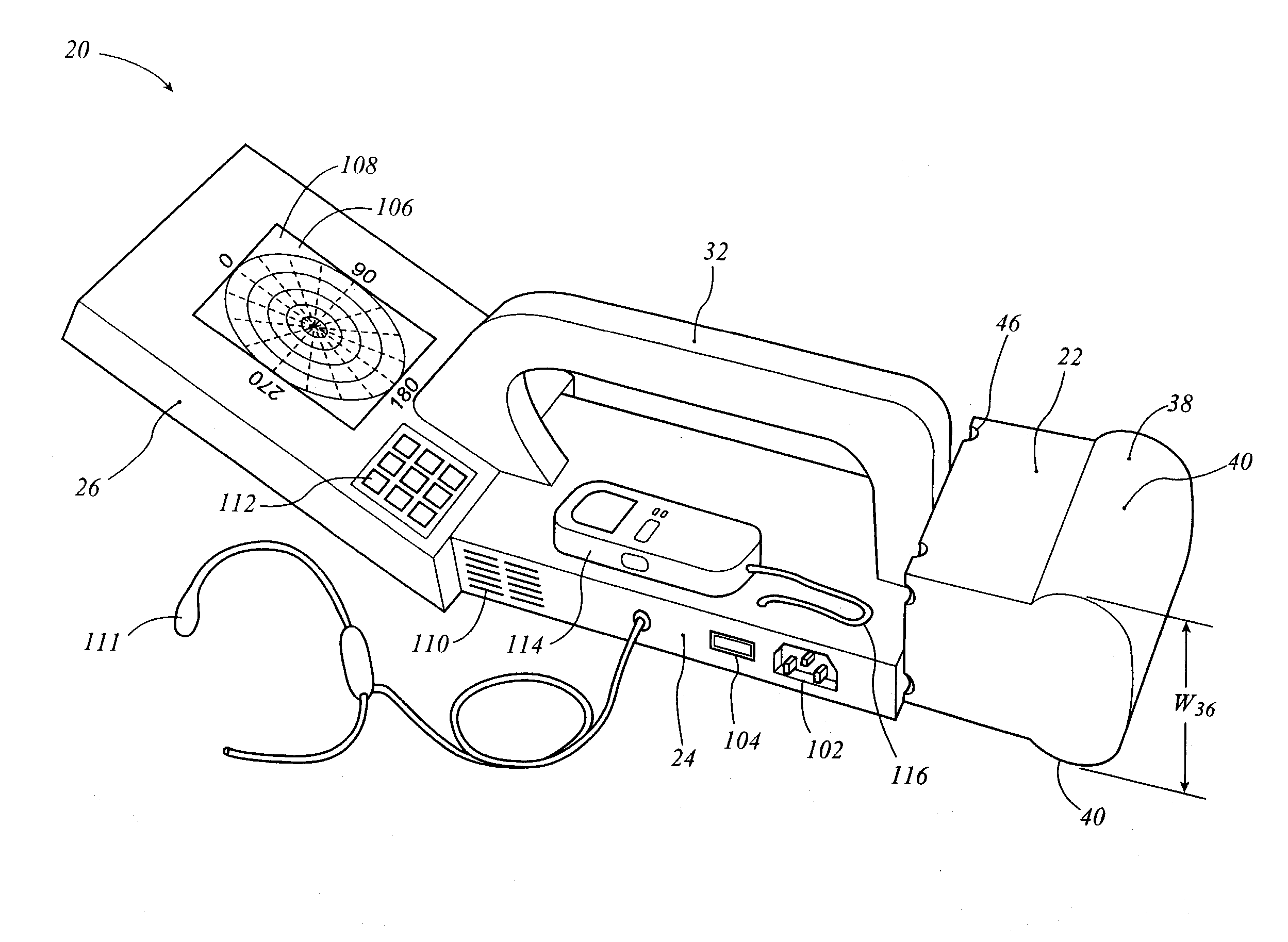

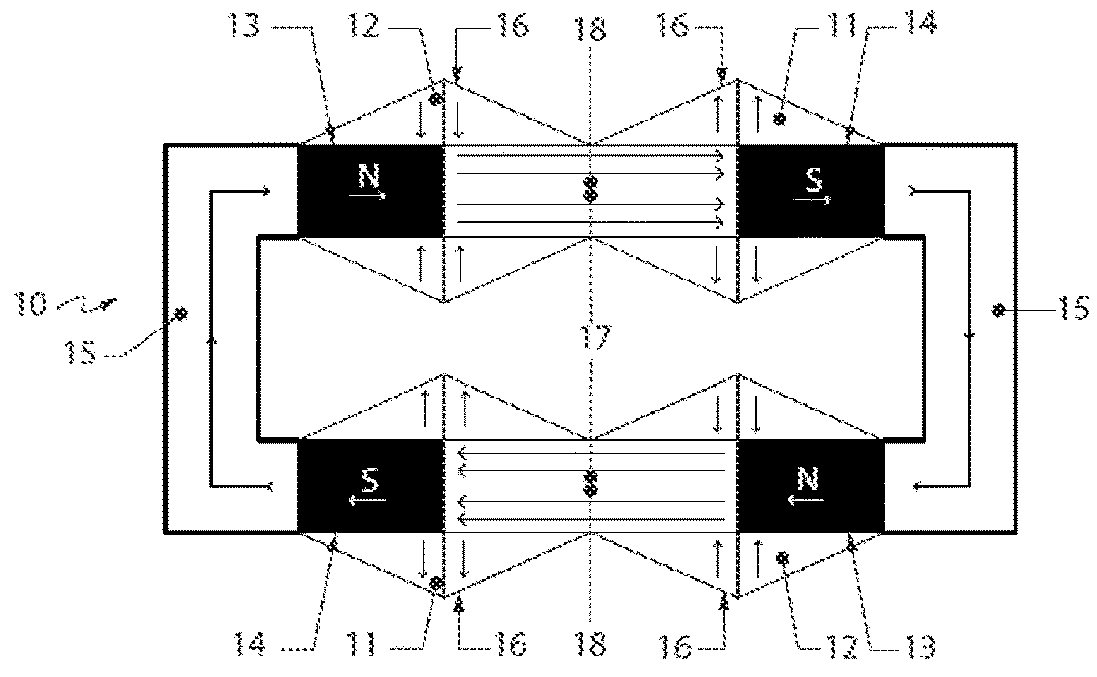

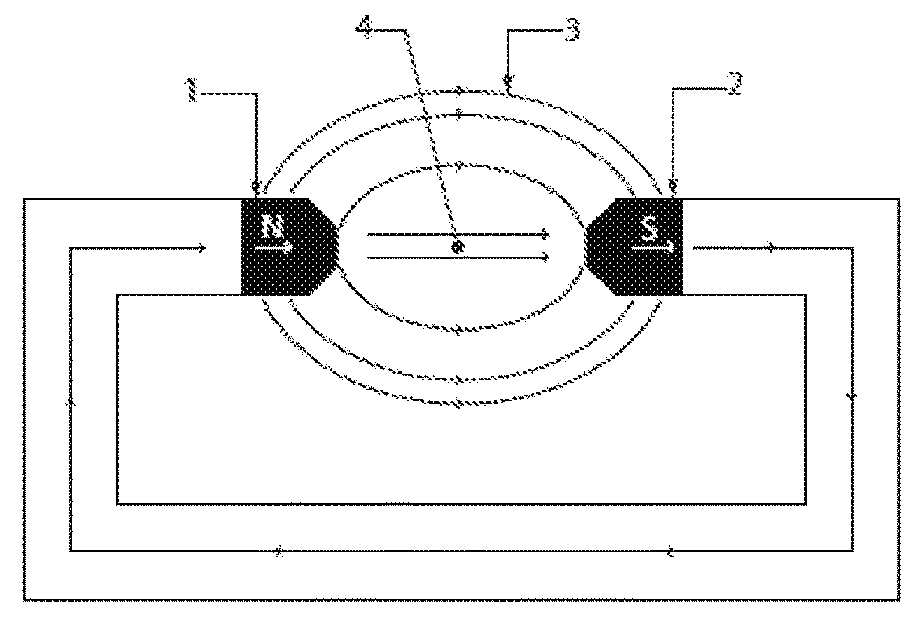

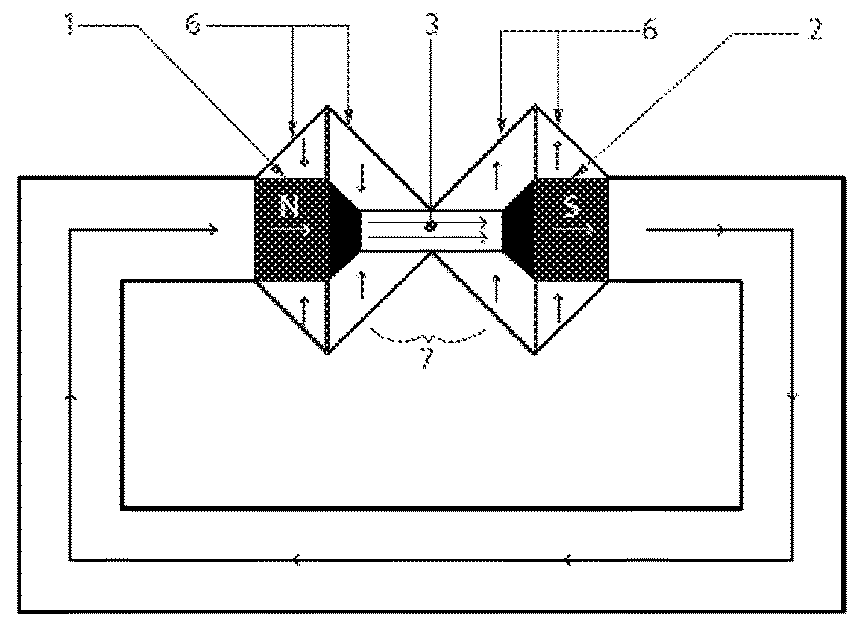

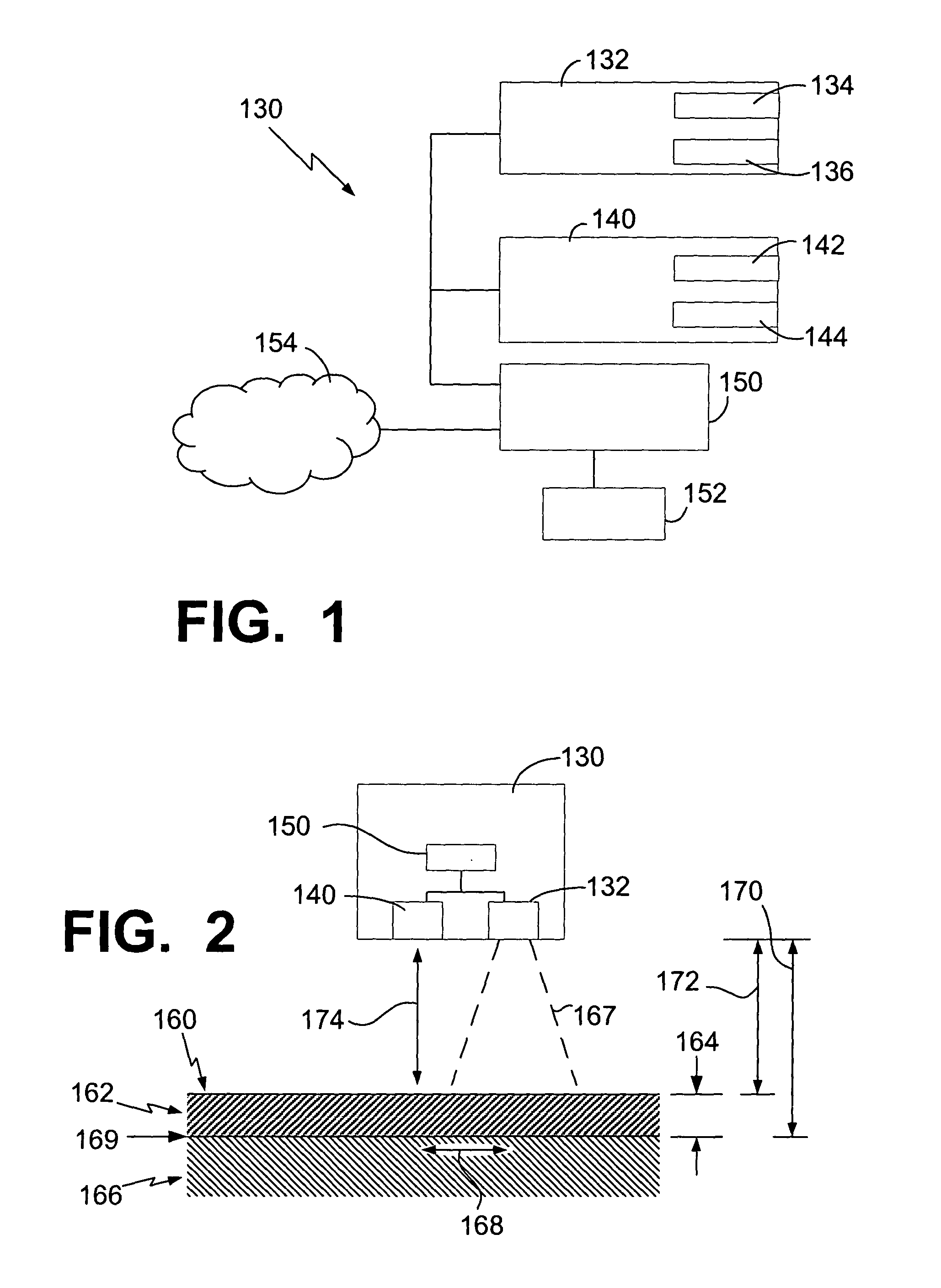

An apparatus and method are disclosed for detecting flaws in electrically conductive materials by observing properties of the back-EMF of the eddy current field generated by driving magnetic flux through the object to be examined. The input signal may include sweeps at several frequencies, and may do so at one time under the principle of wave superposition. The sectorial observations of eddy currents summations may be compared to a known datum for a defect free material, the presence of anomalies in eddy field back EMF divergence tending to provide an indication of an irregularity in the underlying eddy field, and hence in the underlying material itself. The portable unit may have a number of different configurations depending on the nature of the object to be examined, be it a flat or large radius plate, a flange, a rail, or some other structural element.

Owner:ATHENA IND TECH

Eddy current detection

Eddy current detection probes and related methods are disclosed. In some embodiments, the eddy current detection probes are hybrid probes, including a solid state sensor and a detection loop. In some embodiments, the eddy current detection probes include a drive coil and a detection loop, with the detection loop having a sensitive axis that is not parallel to principal axis of the drive coil. In some such embodiments, the sensitive axis of the detection loop is perpendicular to the principal axis of the drive coil.

Owner:RADIATION MONITORING DEVICES

Inspection apparatus and method

ActiveUS8274279B2Current/voltage measurementMagnetic property measurementsCounter-electromotive forceEddy-current testing

Owner:ATHENA IND TECH

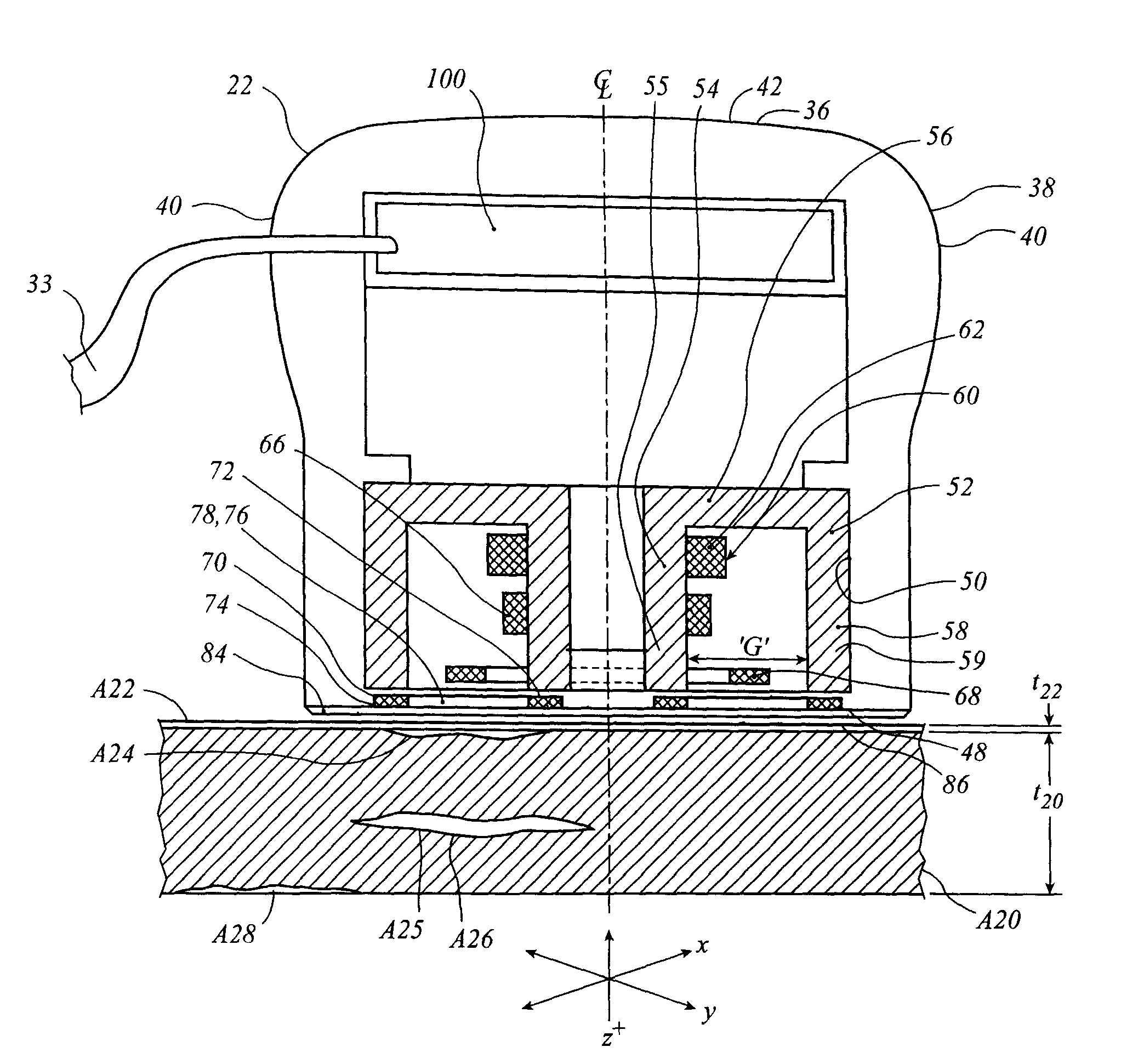

Apparatus and method for determining the position of the end of a threaded connection, and for positioning a power tong relative thereto

InactiveUS20040174163A1Drilling rodsResistance/reactance/impedenceEddy-current testingControl theory

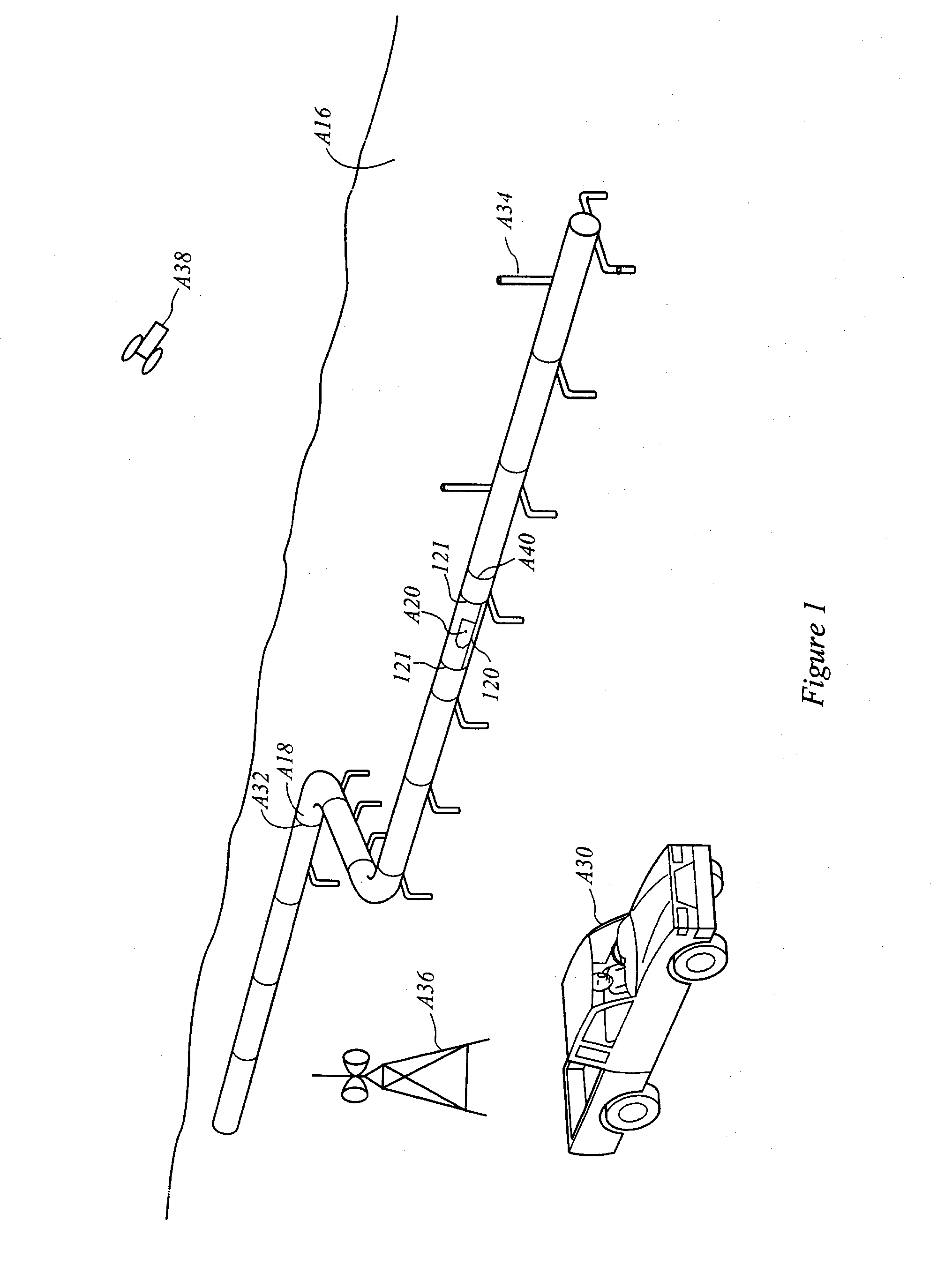

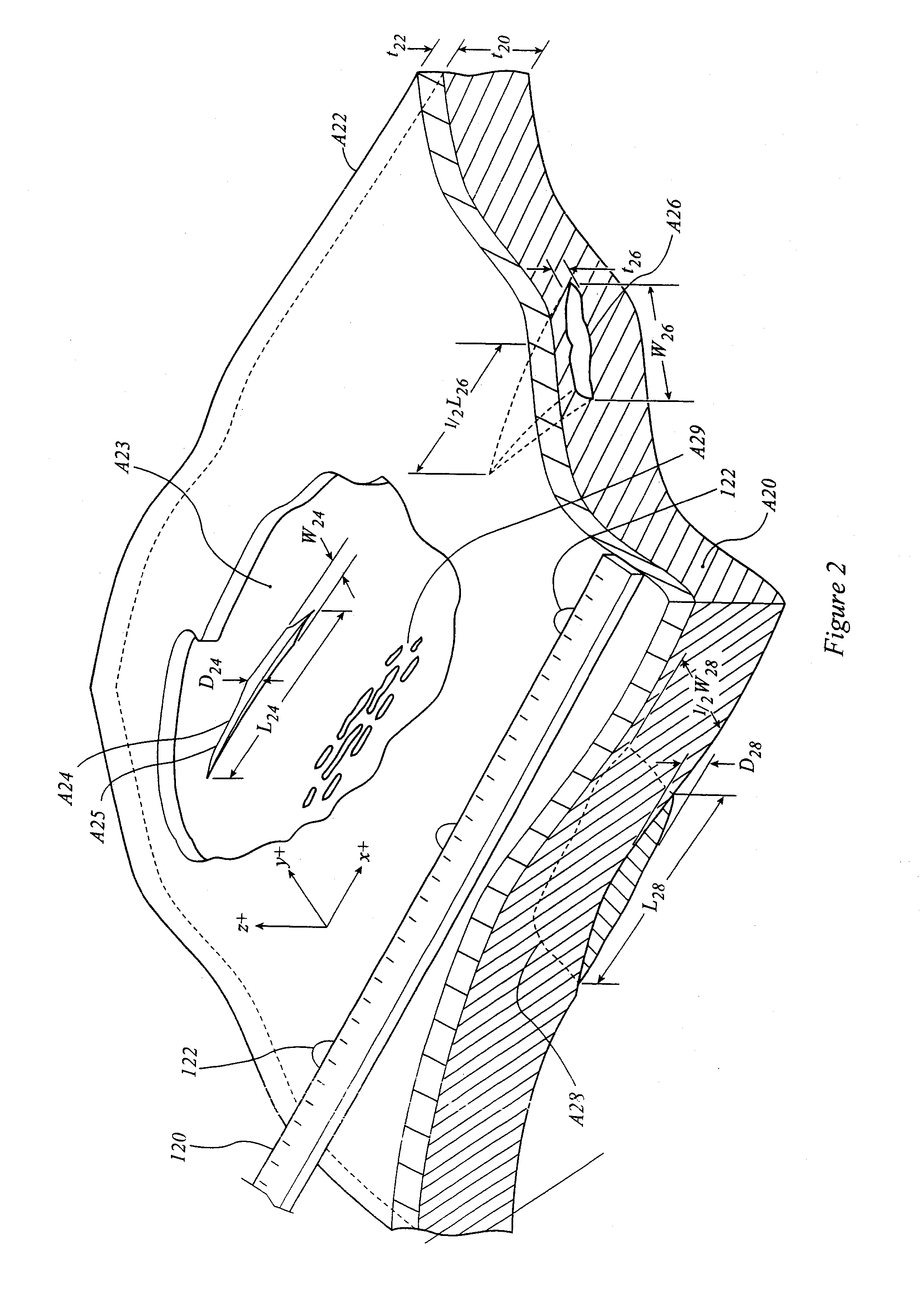

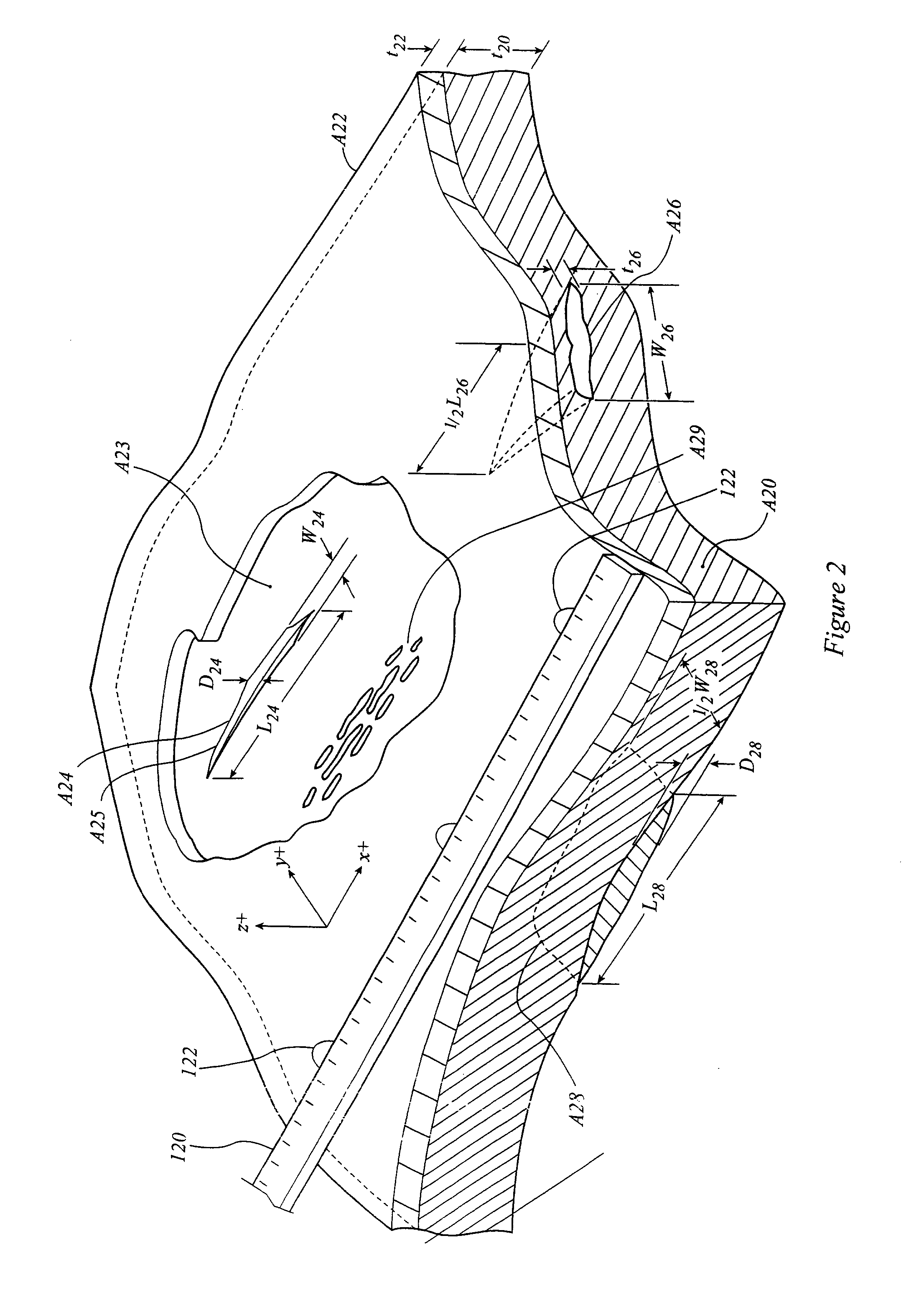

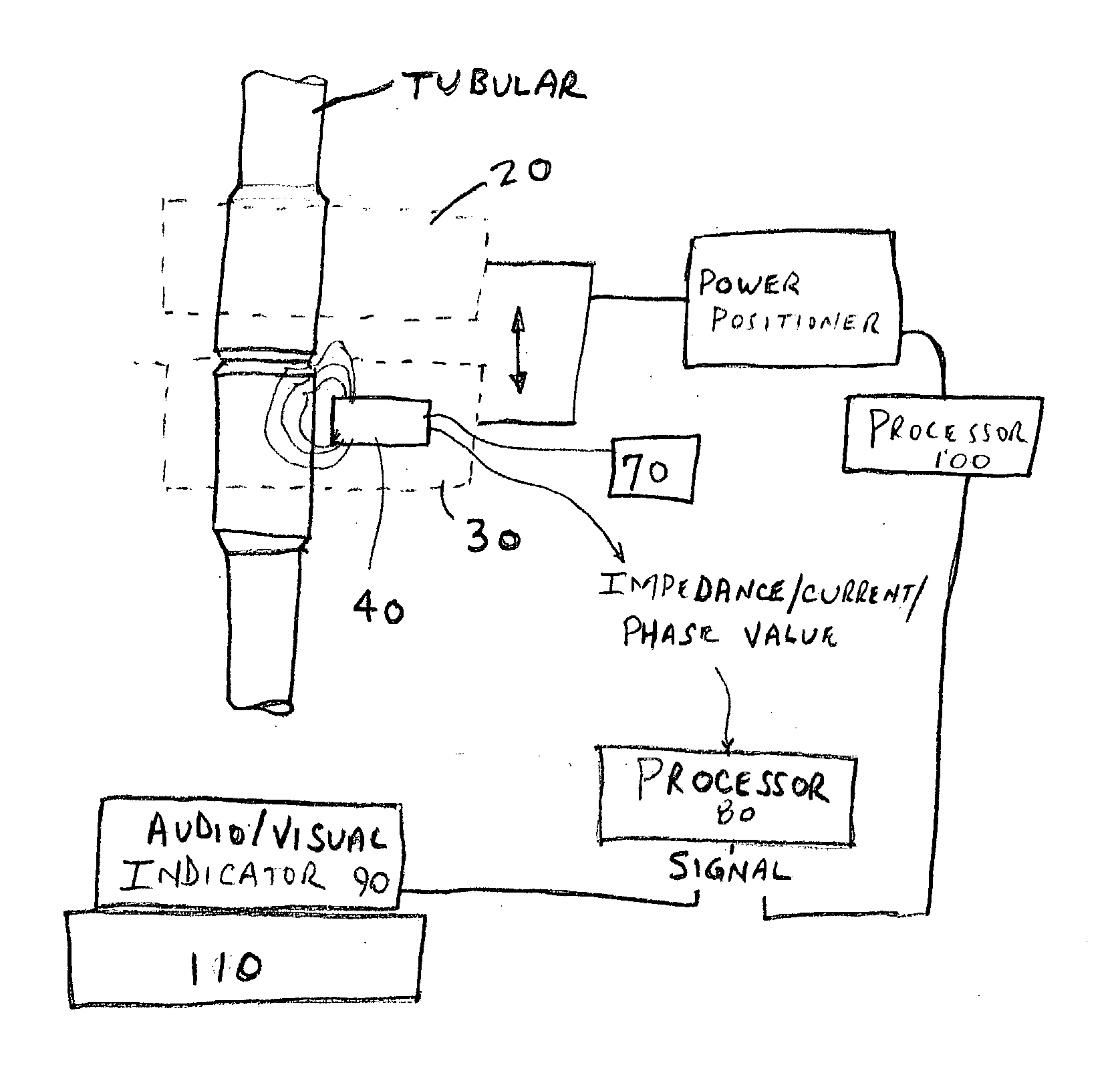

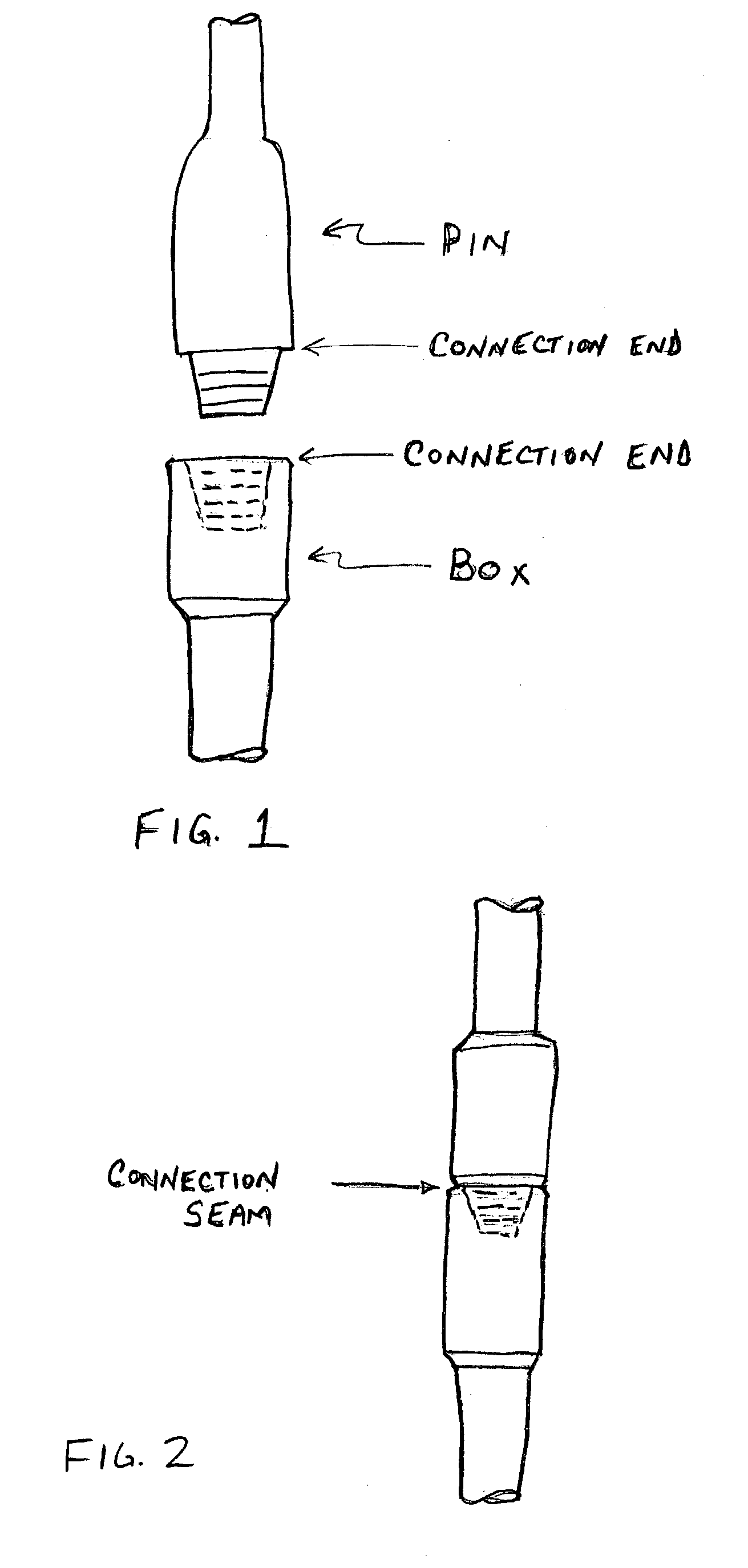

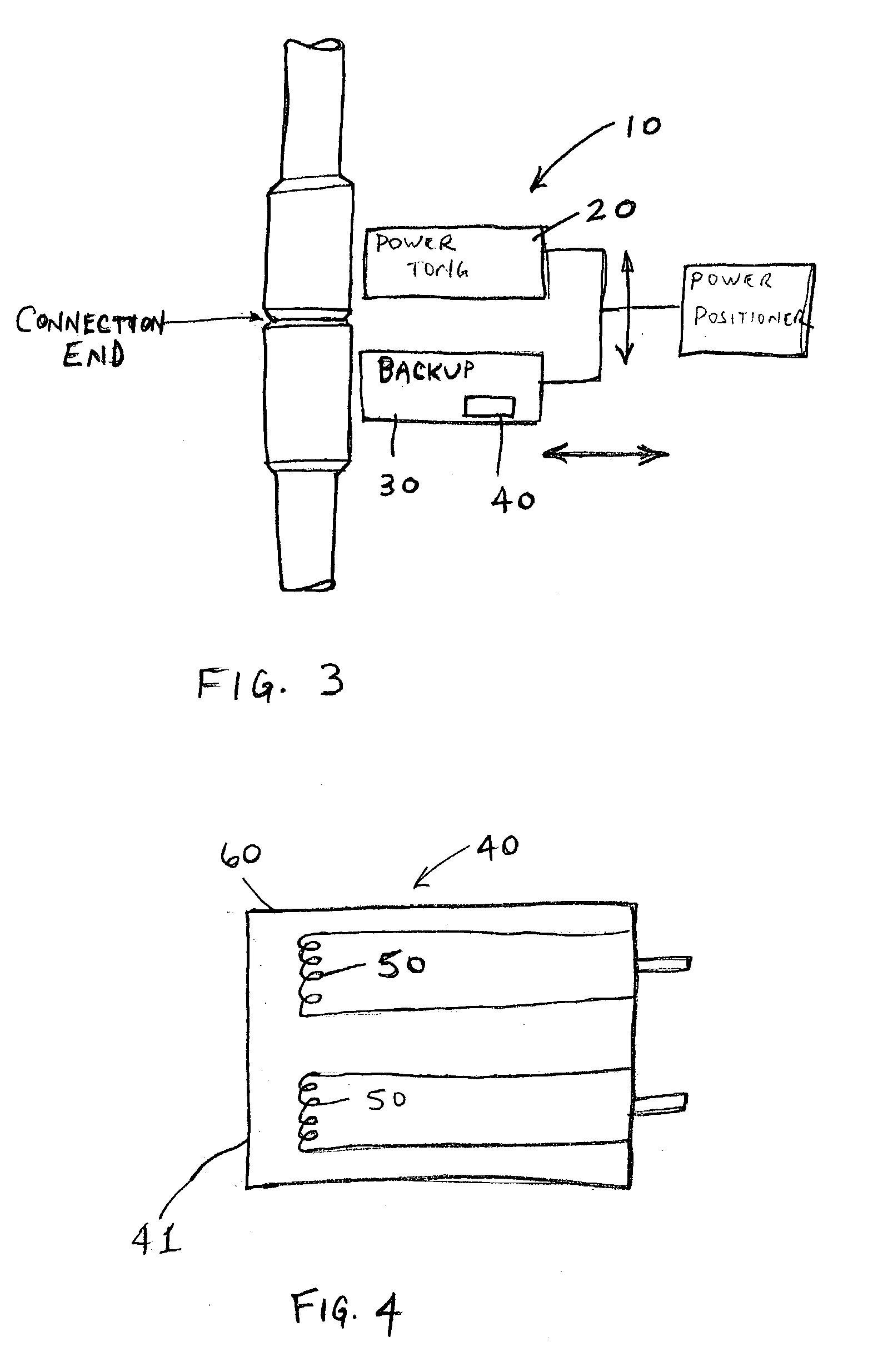

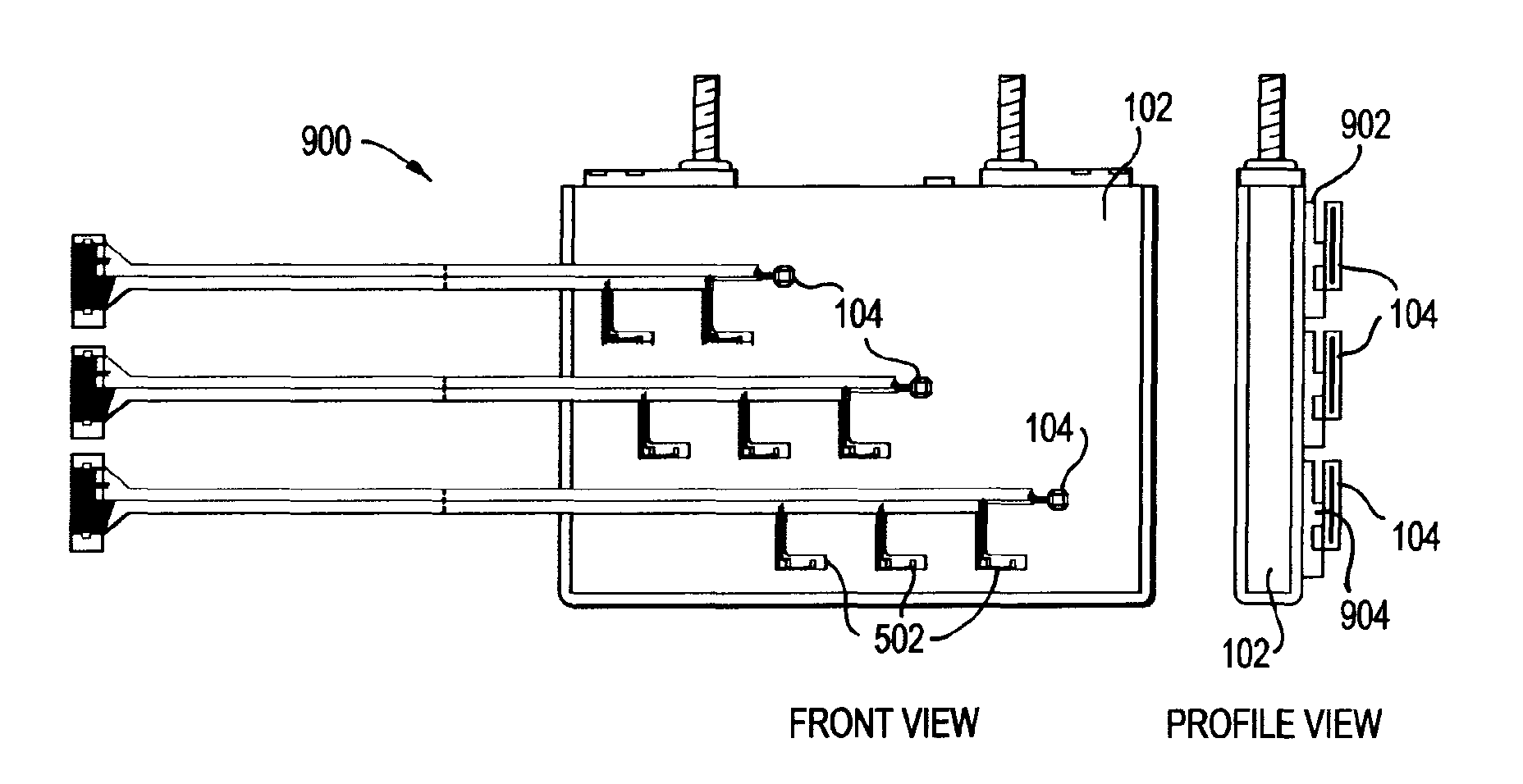

Apparatus and method for positioning a power makeup / breakout device, commonly referred to as a "power tong unit," along the longitudinal axis of a tubular, with respect to the end of a connection. A probe having an electric coil is mounted on the power tong. An alternating electric current is flowed through the coil, creating an electromagnetic field emanating from the coil. Positioning the coil such that the tubular connection is within the magnetic field, then moving the coil such that the connection end moves within the magnetic field, permits the connection end to be seen as a discontinuity, by the principles of eddy current testing. The location of the connection end is used to manually position the tong, or is input to a processor and then to a power positioner, which properly positions the power tong with respect to the connection end.

Owner:ROGERS OIL TOOL SERVICES

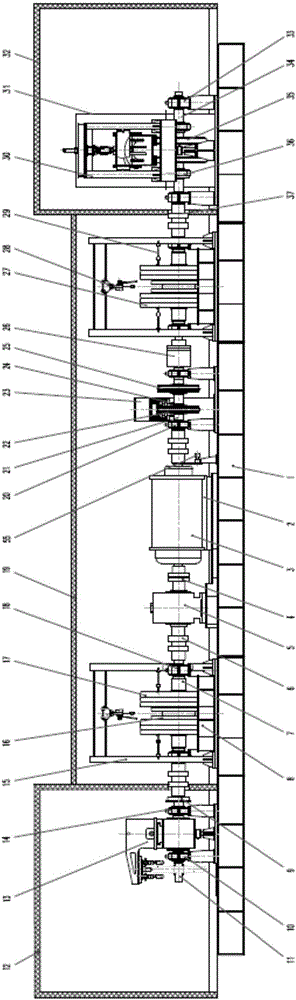

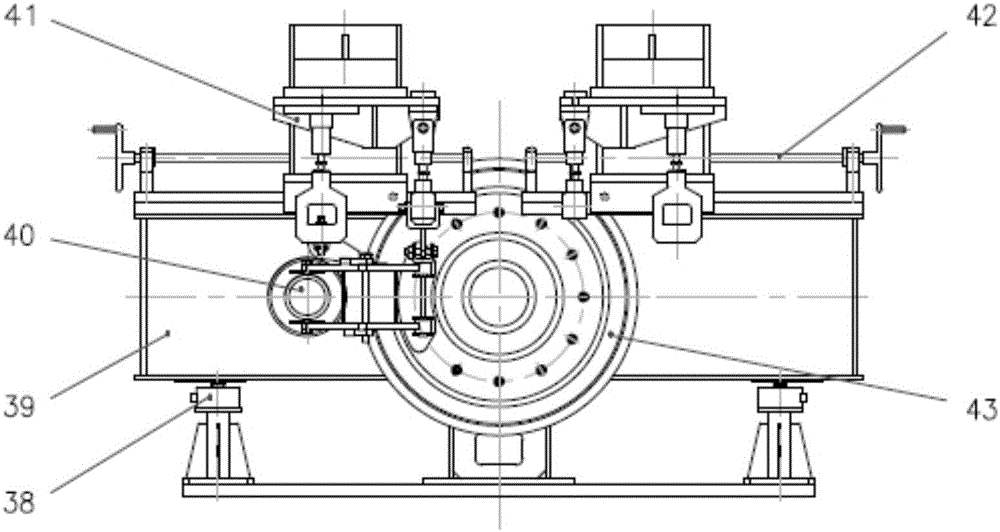

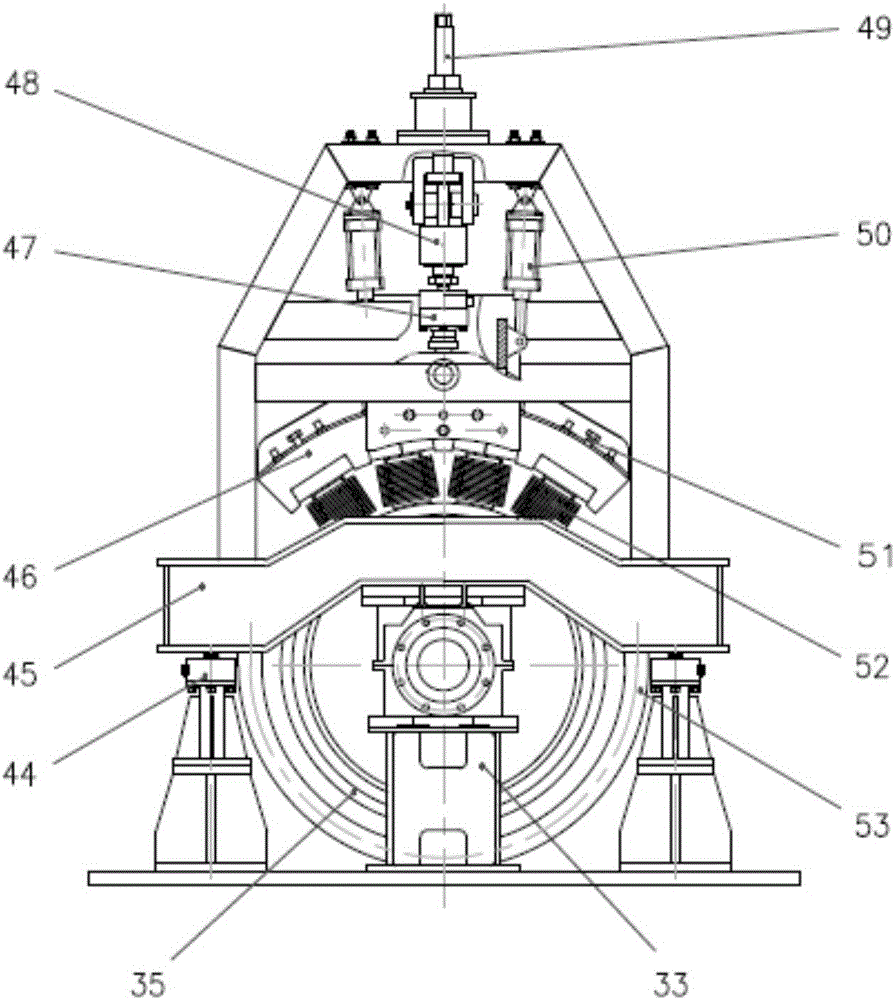

Rail vehicle multifunctional braking power testing platform

InactiveCN105738133AIncrease heating capacityInhibit temperature riseRailway vehicle testingTrack brakePower unit

The invention relates to a multifunctional braking power testing platform which comprises the components of a base; a power and inertia chamber which is arranged on the base and comprises a power unit and a mechanical inertia unit; a first testing chamber which is arranged on the base and is mounted on one end of the power and inertial chamber; and a second testing chamber which is arranged on the base and is mounted on the other end of the power and inertia chamber, wherein a first braking device in the first testing chamber is different from a second braking device of the second testing chamber. The multifunctional braking power testing platform can be used for disc braking, tread braking, eddy current braking or magnetic rail braking tests of high-speed train and other rail vehicles, thereby reproducing a braking energy conversion process in a 1:1 manner and testing braking performance in real time.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

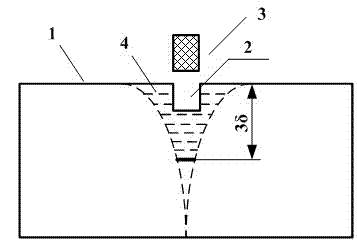

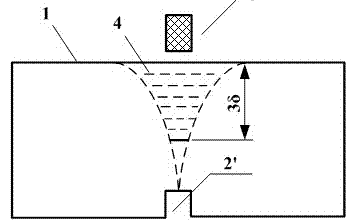

Eddy current testing recognition and evaluation method for defects of inner wall and outer wall of steel pipe under direct current magnetization

InactiveCN102759567ASuppress fluctuations in magnetic permeabilityWalking smoothlyMaterial magnetic variablesPhase differenceMagnetization

The invention discloses an eddy current testing recognition and evaluation method for defects of the inner wall and outer wall of a steel pipe under direct current magnetization. The method comprises the steps of: carrying out non-saturated magnetization on the steel pipe by adopting a traversing direct-current magnetizing coil, picking up electromagnetic disturbance information at the defects by utilizing an eddy current detection coil, and selecting a reasonable direct-current magnetizing range according to phase contrast, thus detecting the defects of the inner wall and the outer wall and recognizing through phase difference, and realizing consistency judgment on the inner and outer wall defects of equivalent damage through respectively setting alarming thresholds of the inner and outer wall defects. A detection device comprises a phase sensitive detection module which aims at eliminating the disturbance of the defects to leakage field. The method is fast in detection speed, easily realizes automation, and can be applicable to defect detection of various ferromagnetism pipelines, thus having wide application prospects.

Owner:NANCHANG HANGKONG UNIVERSITY +1

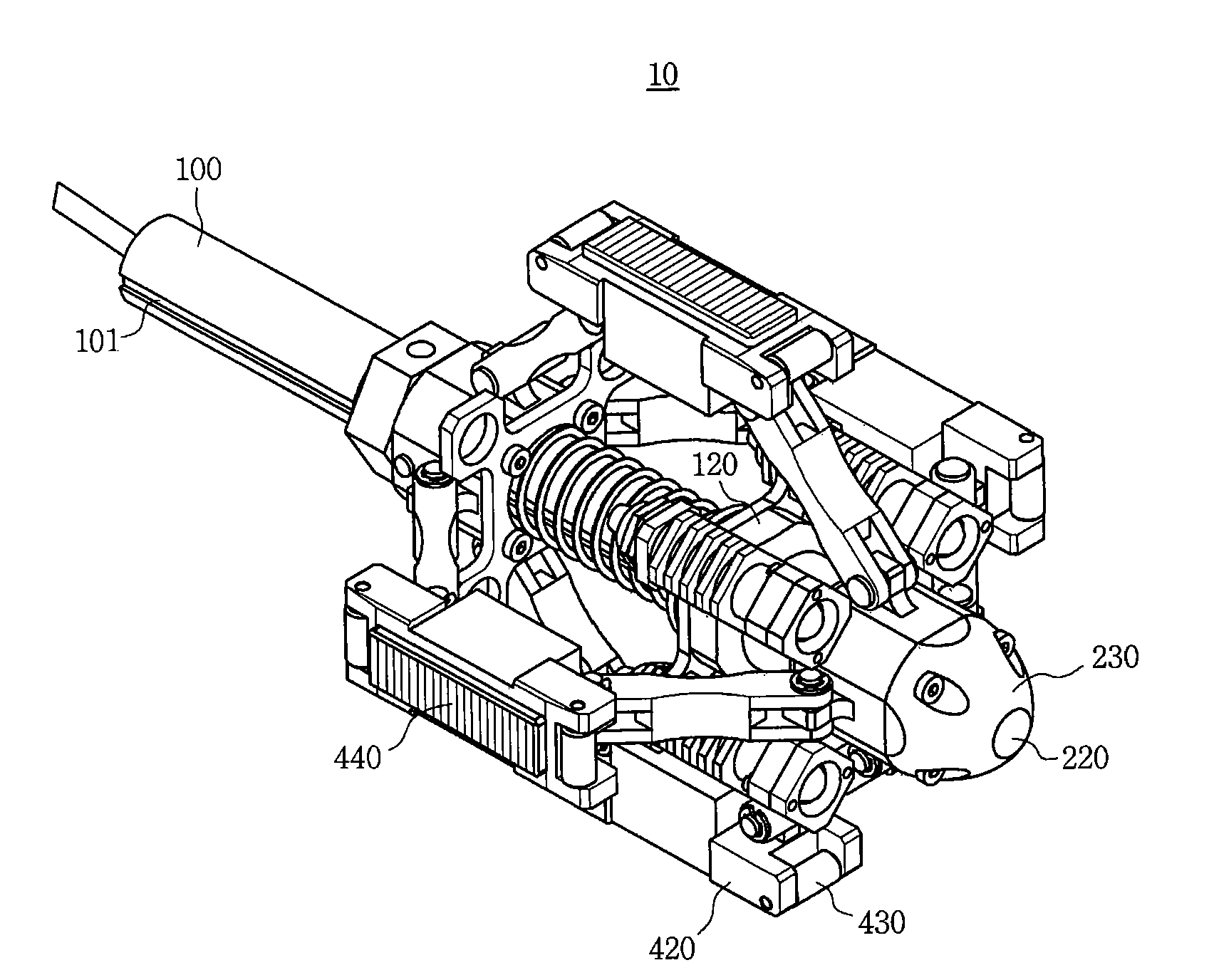

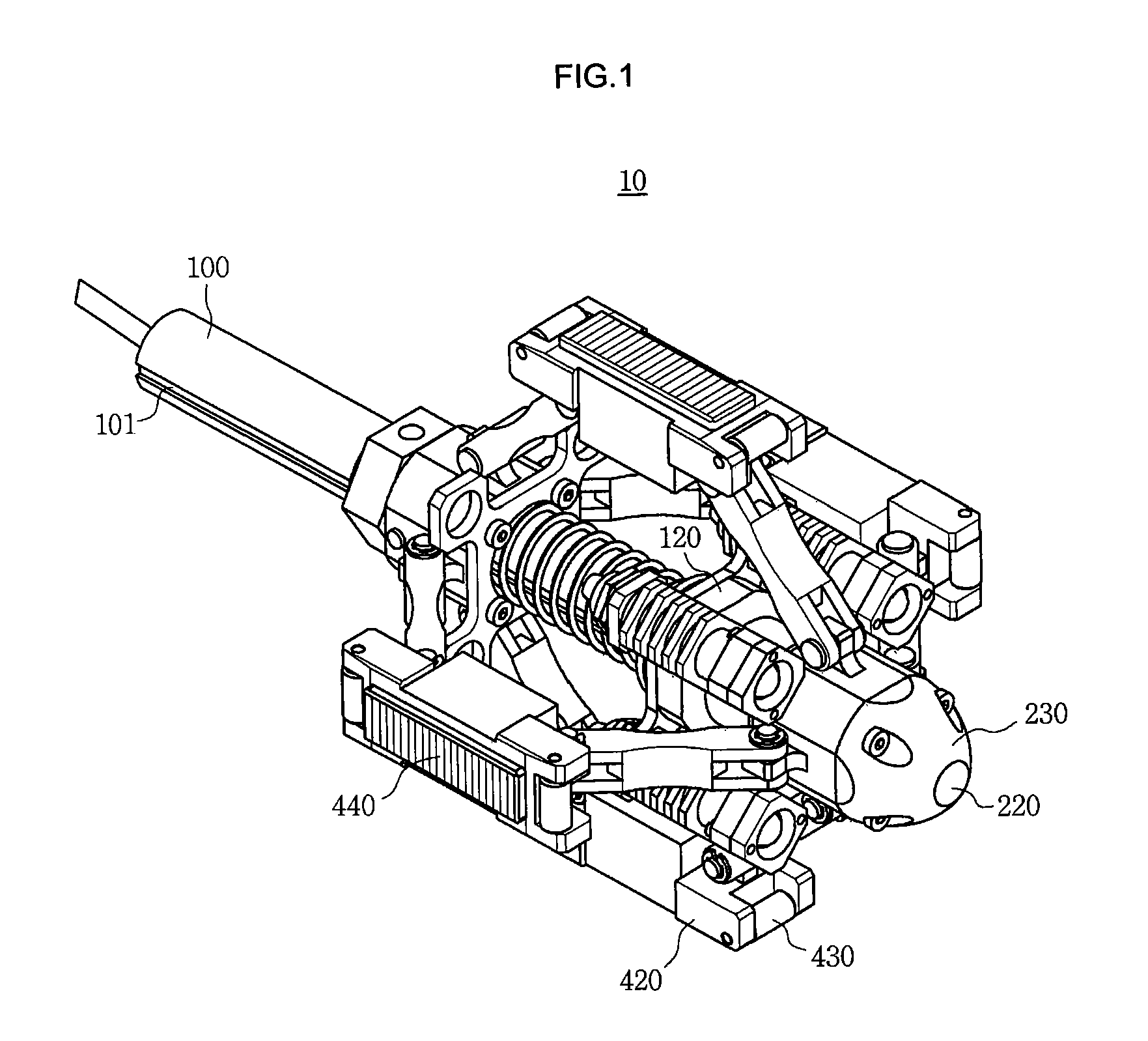

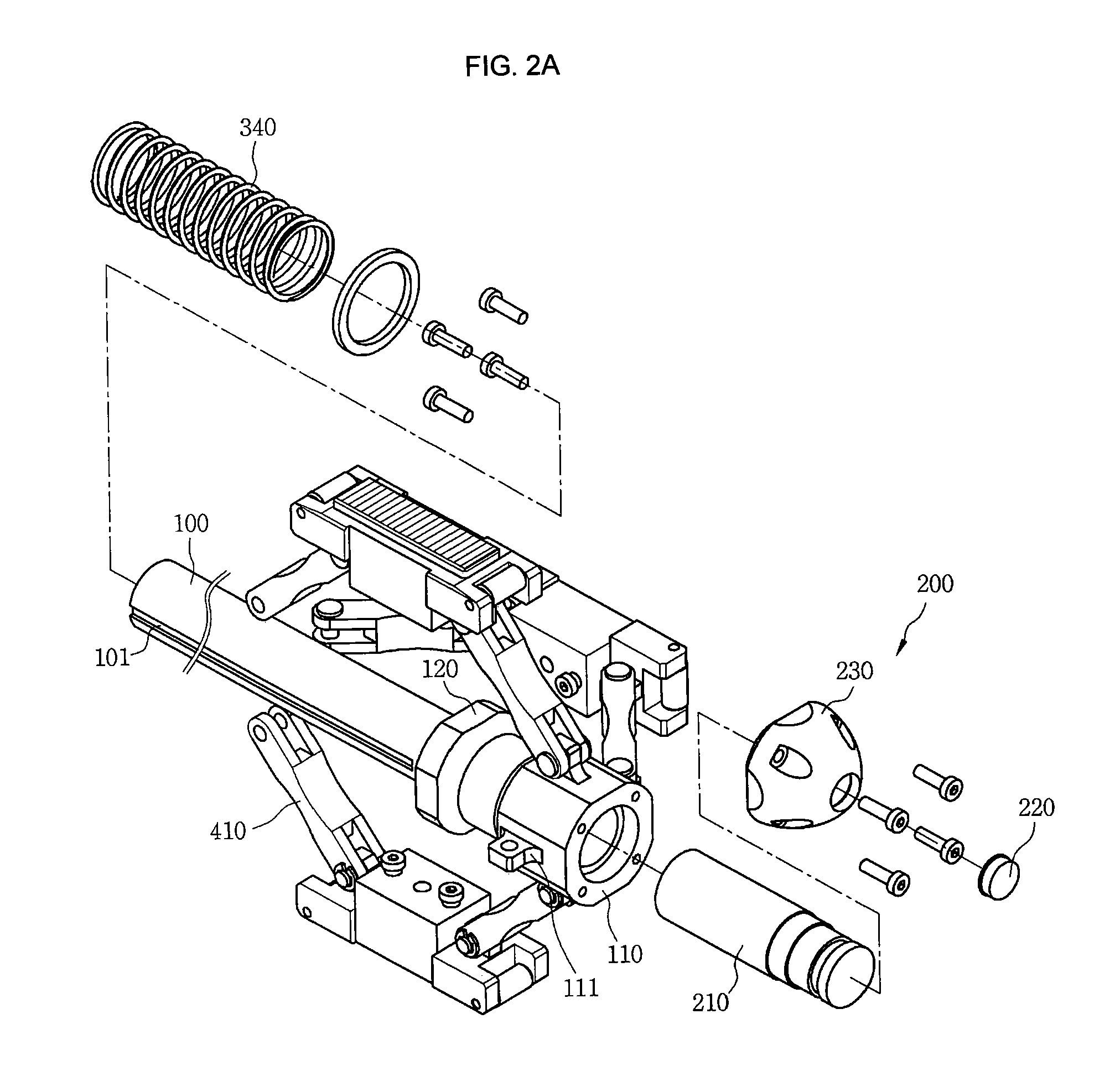

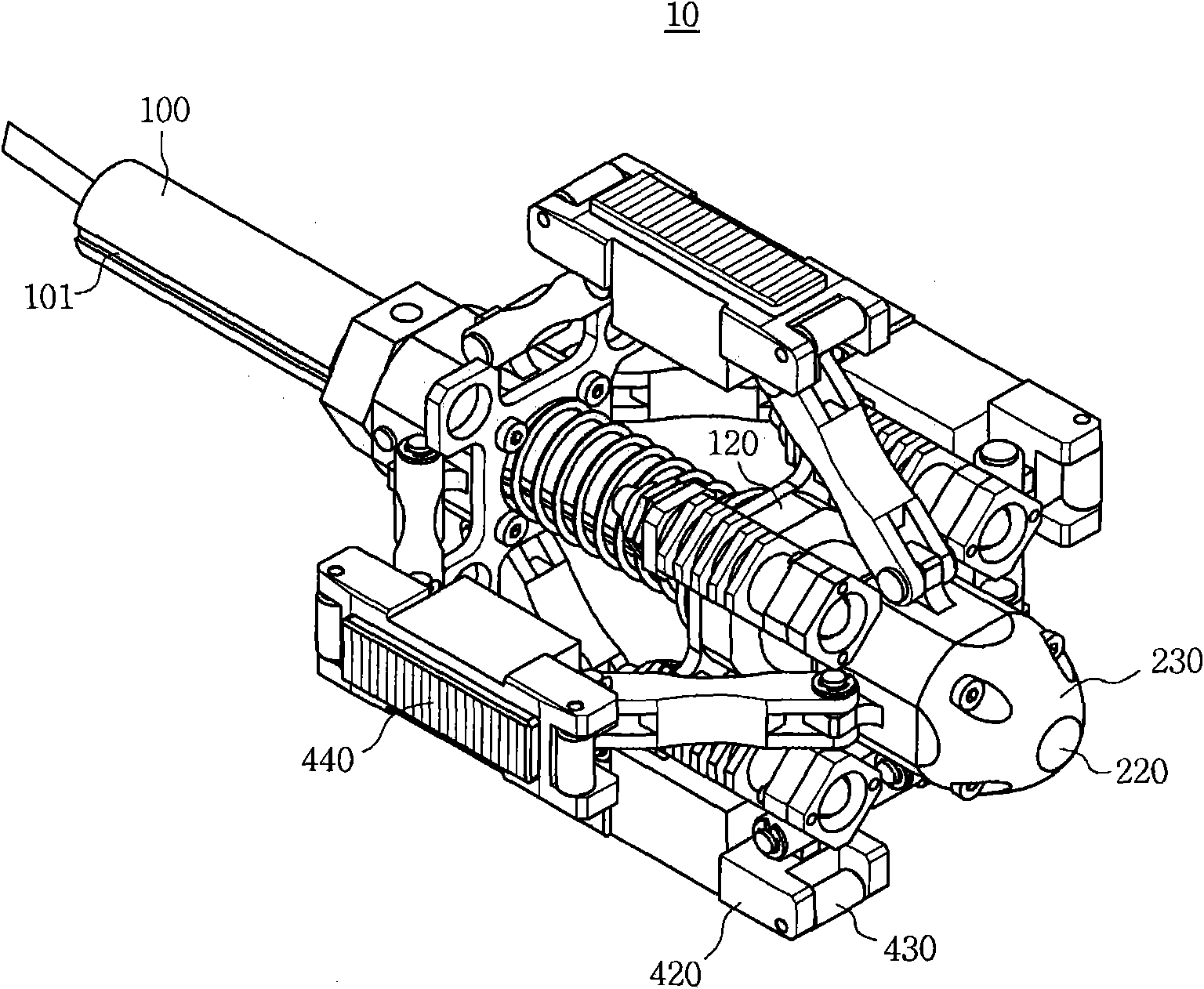

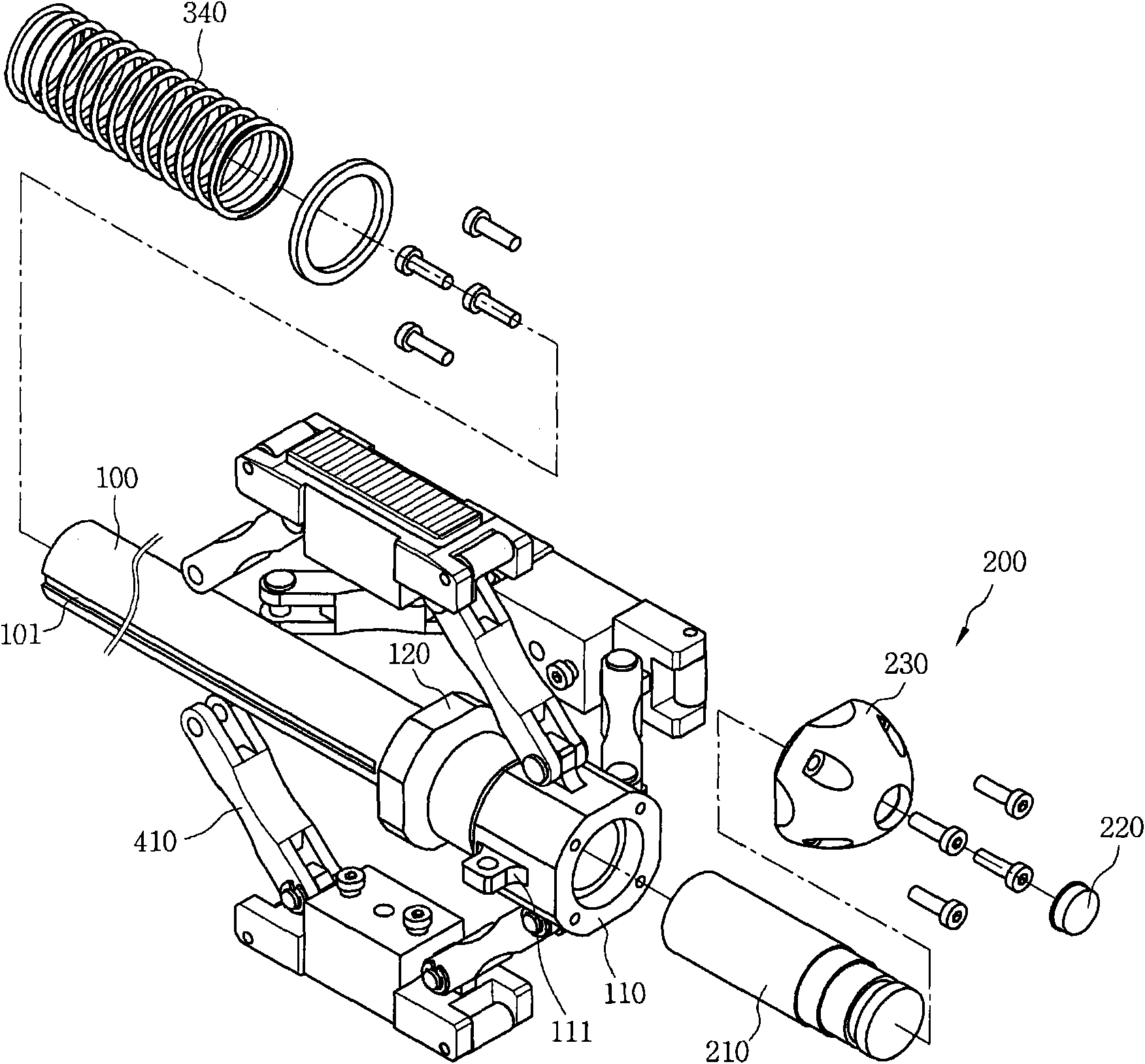

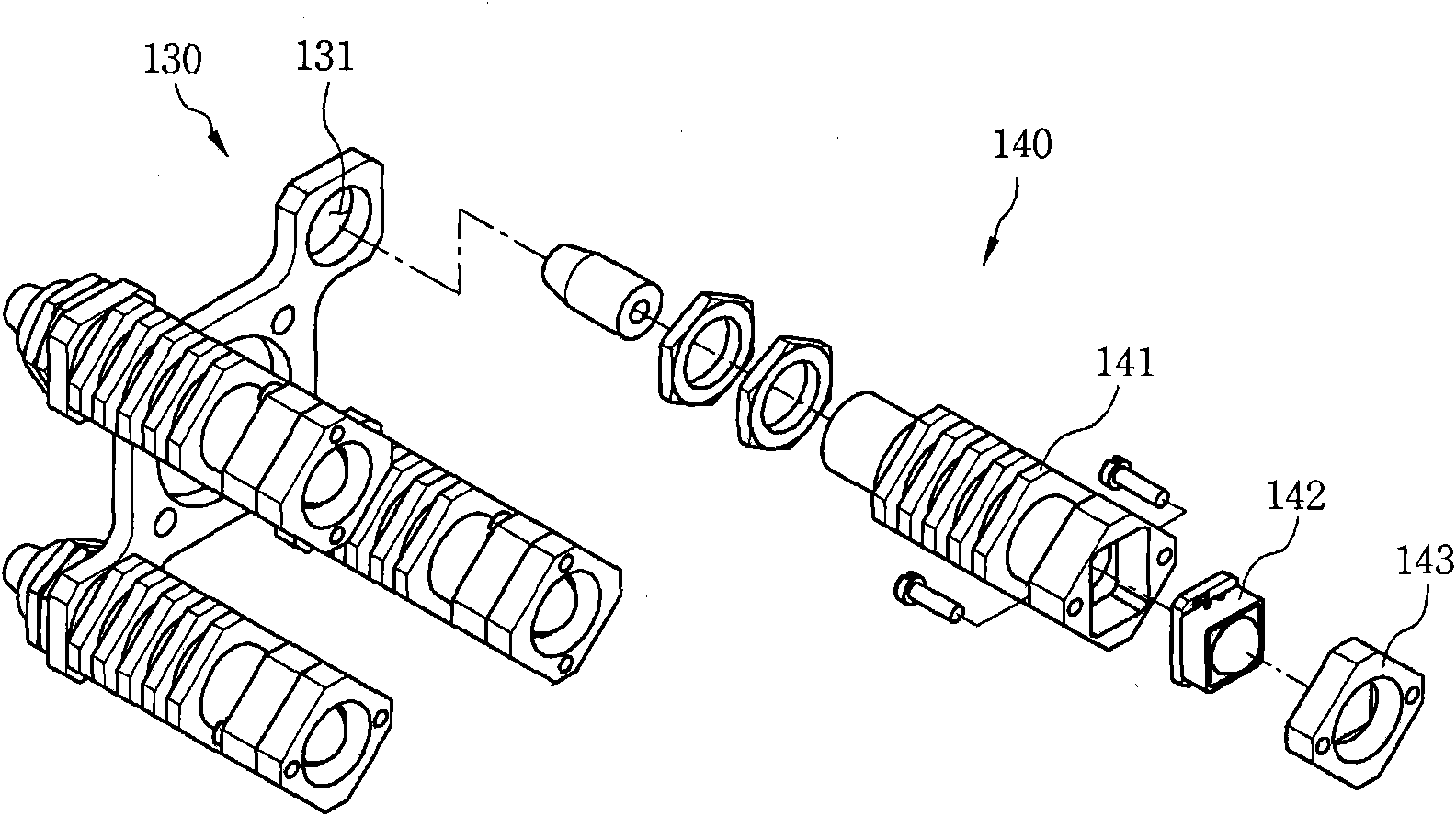

Inspecting device including detachable probe

ActiveUS20110030478A1Analysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationEngineeringEddy-current testing

An inspecting device including a detachable probe has a link structure, and thus a subject having various diameters is tested. In addition, since various probes are changeably used in a scanner housing, ultrasonic wave testing and eddy current testing are simultaneously performed.

Owner:KOREA PLANT SERVICE & ENG CO LTD

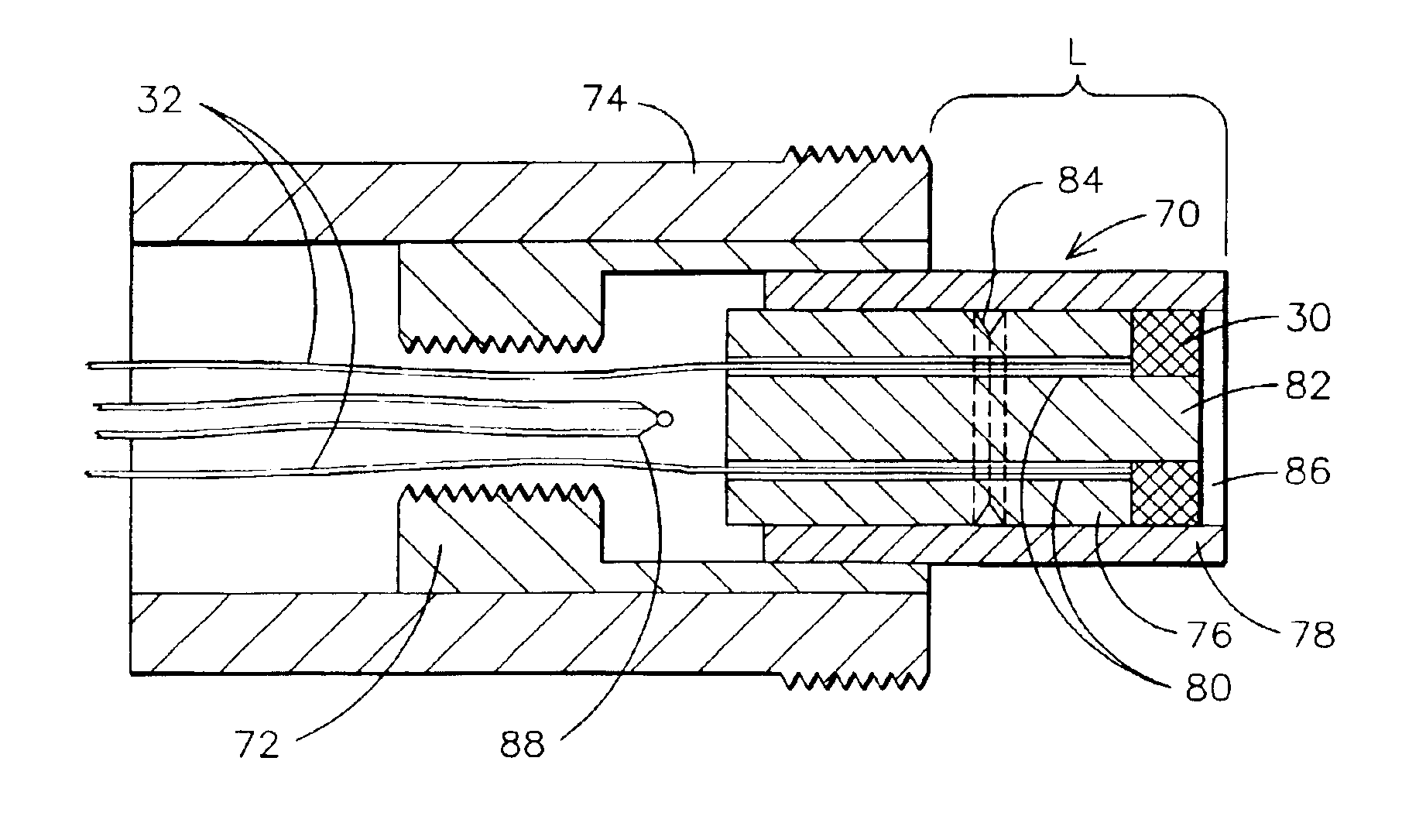

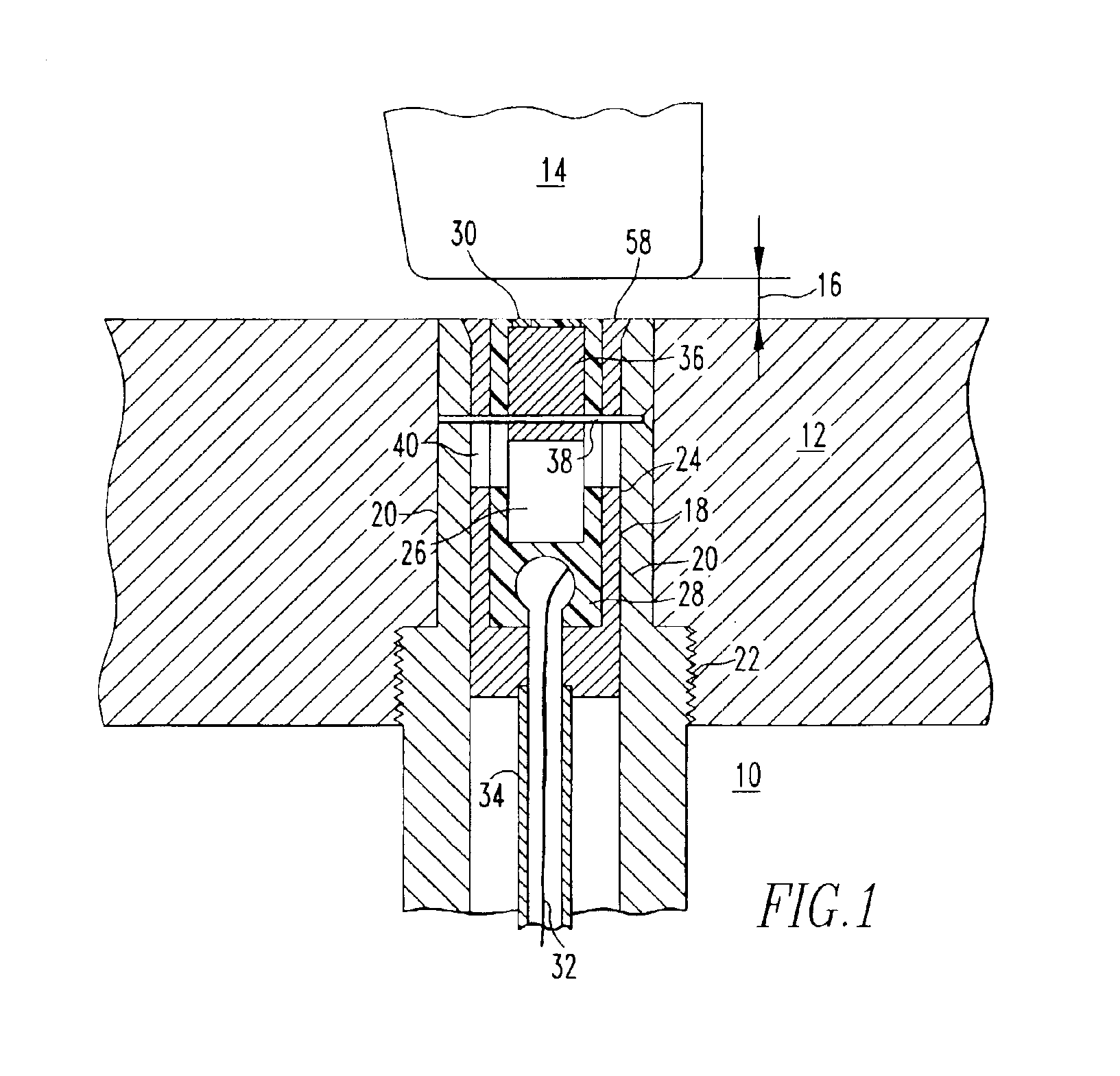

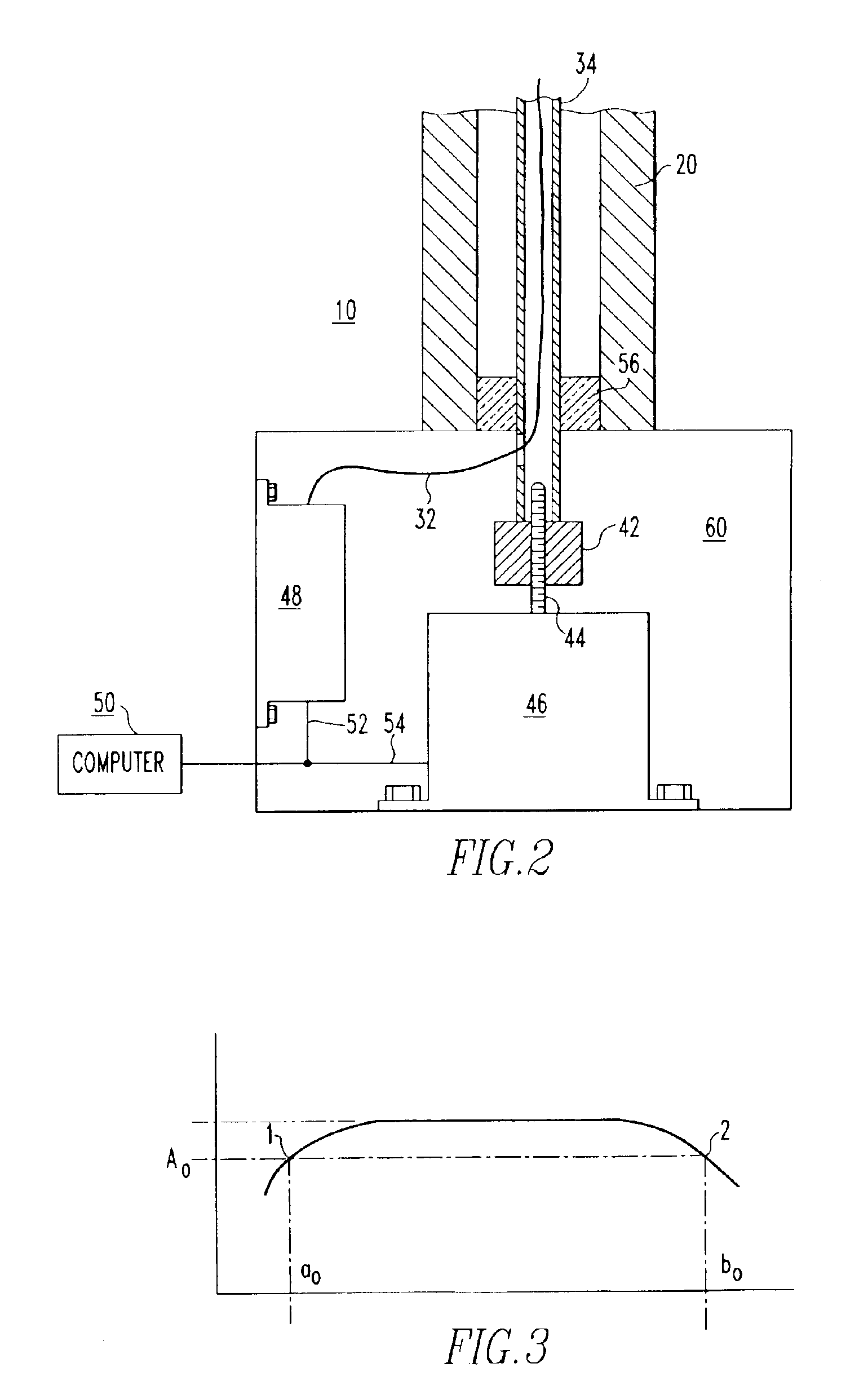

Turbine blade clearance on-line measurement system

InactiveUS6949922B2Accurate clearanceMagnetic property measurementsUsing electrical meansTurbine bladeEngineering

A system (90) for measuring the gap (16) between a rotating blade (14) and a stationary component (12) of a turbo-machine, including an eddy current coil (30) and an eddy current tester (91). The eddy current tester may excite the coil in a pulsed eddy current testing mode. The coil is positioned in a stationary portion (12) of a turbo-machine traversed by a rotating blade and the eddy current tester is coupled to the eddy current coil to provide an indication responsive to a distance between the blade and the stationary portion as the blade traverses the position. The coil may be mounted in a frangible ceramic pill (70) movably disposed in a housing (74). The coil is positioned near the turbine blade, the coil is excited with a voltage step function (120), and the response (122) of the coil to the step function is detected and processed to determine the proximity of the blade.

Owner:SIEMENS ENERGY INC

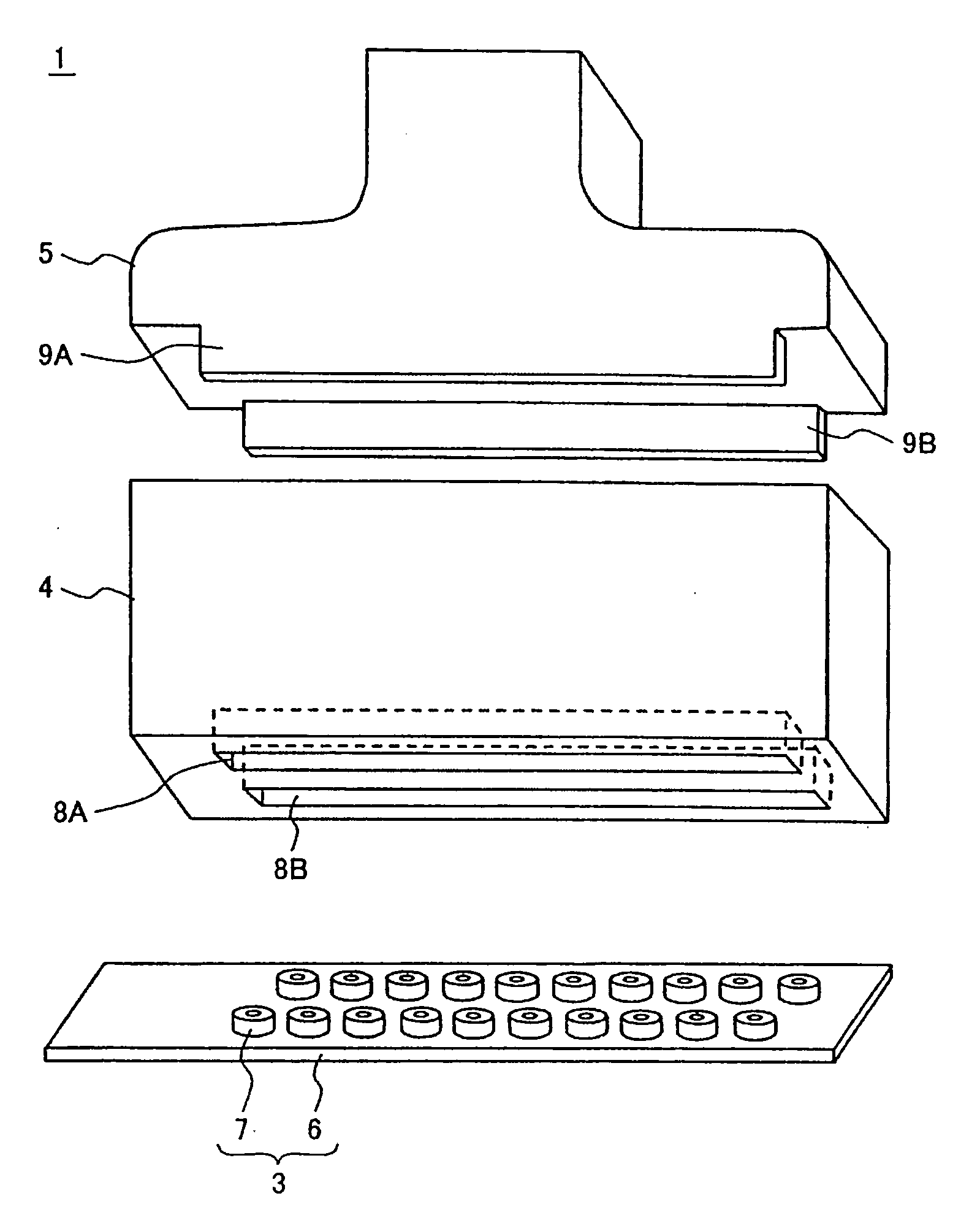

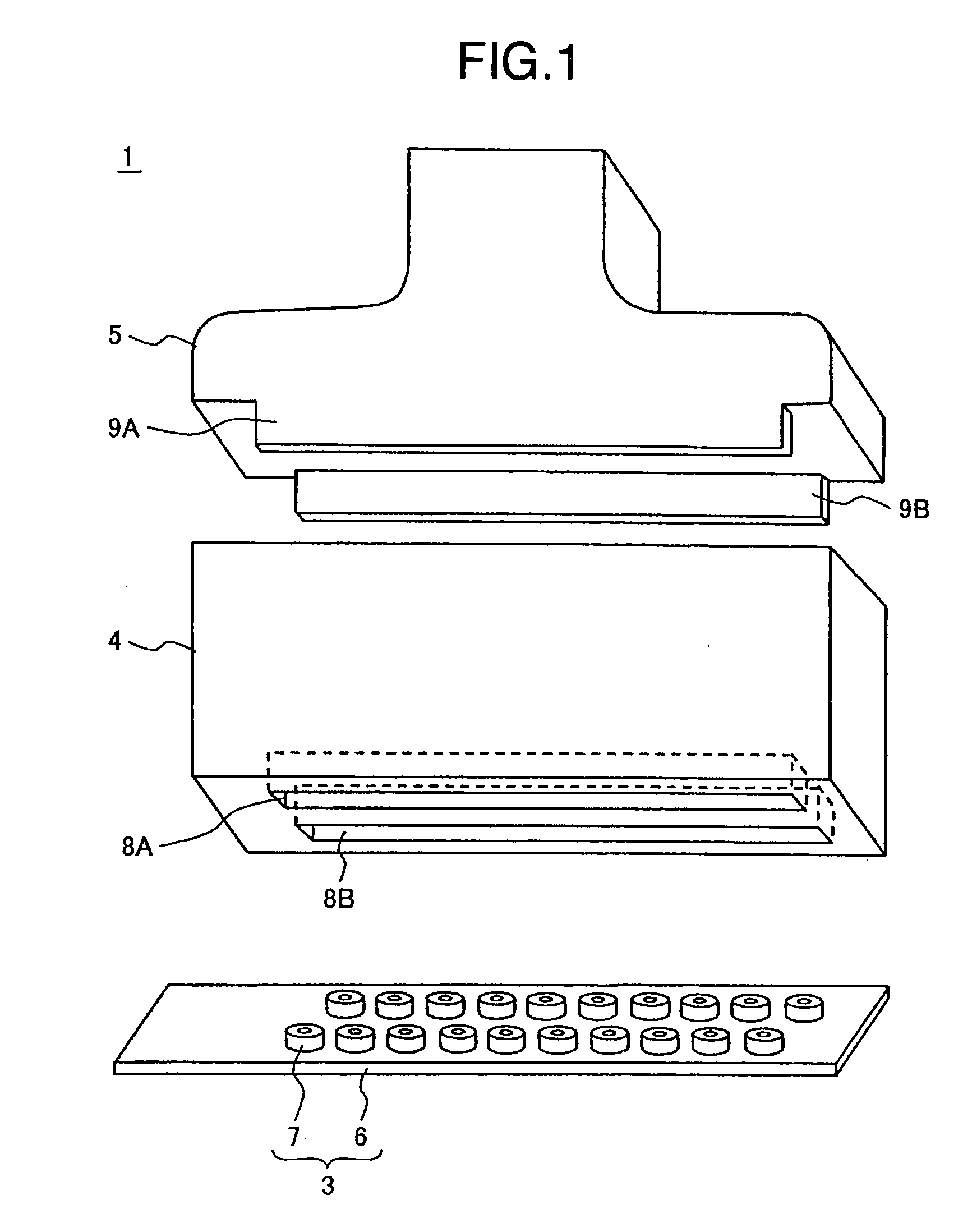

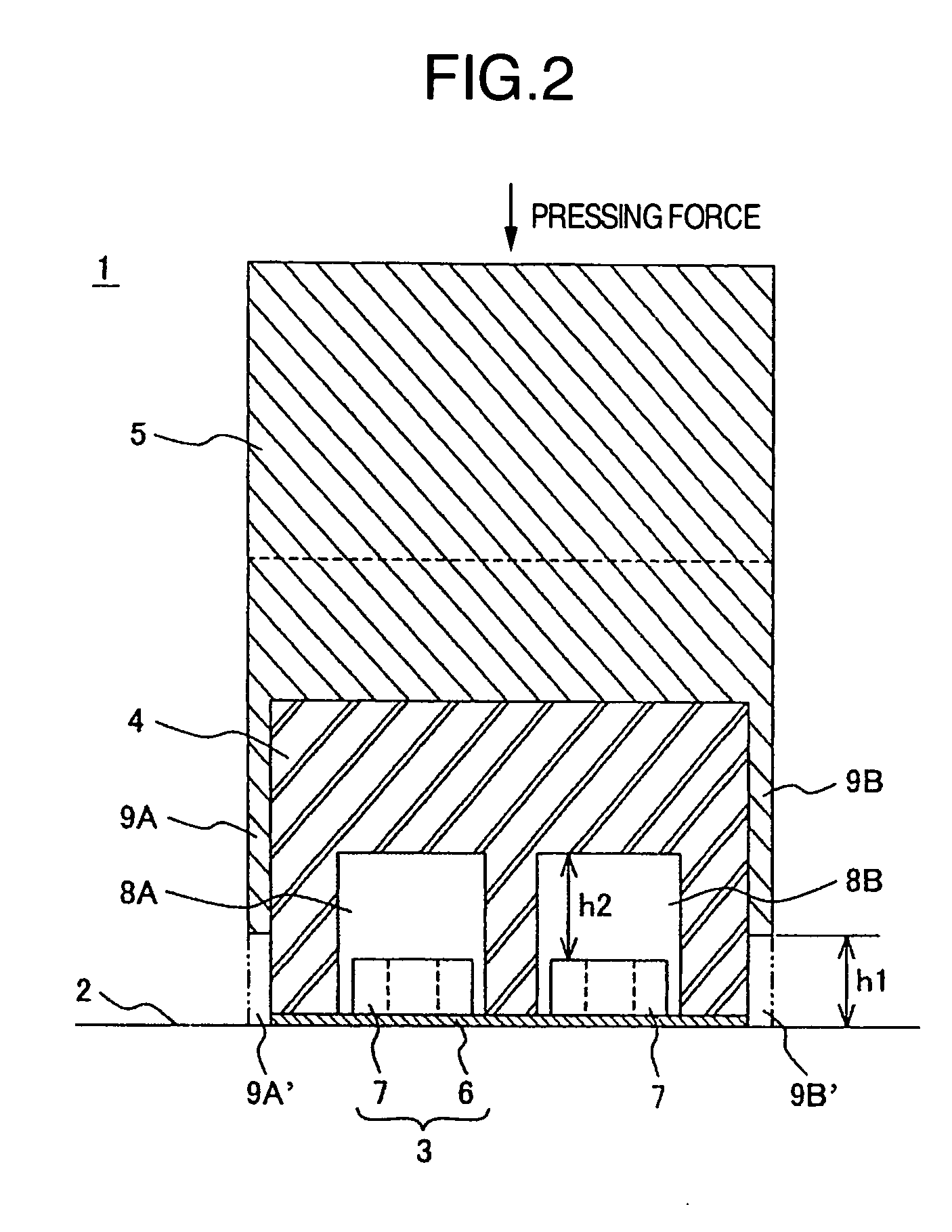

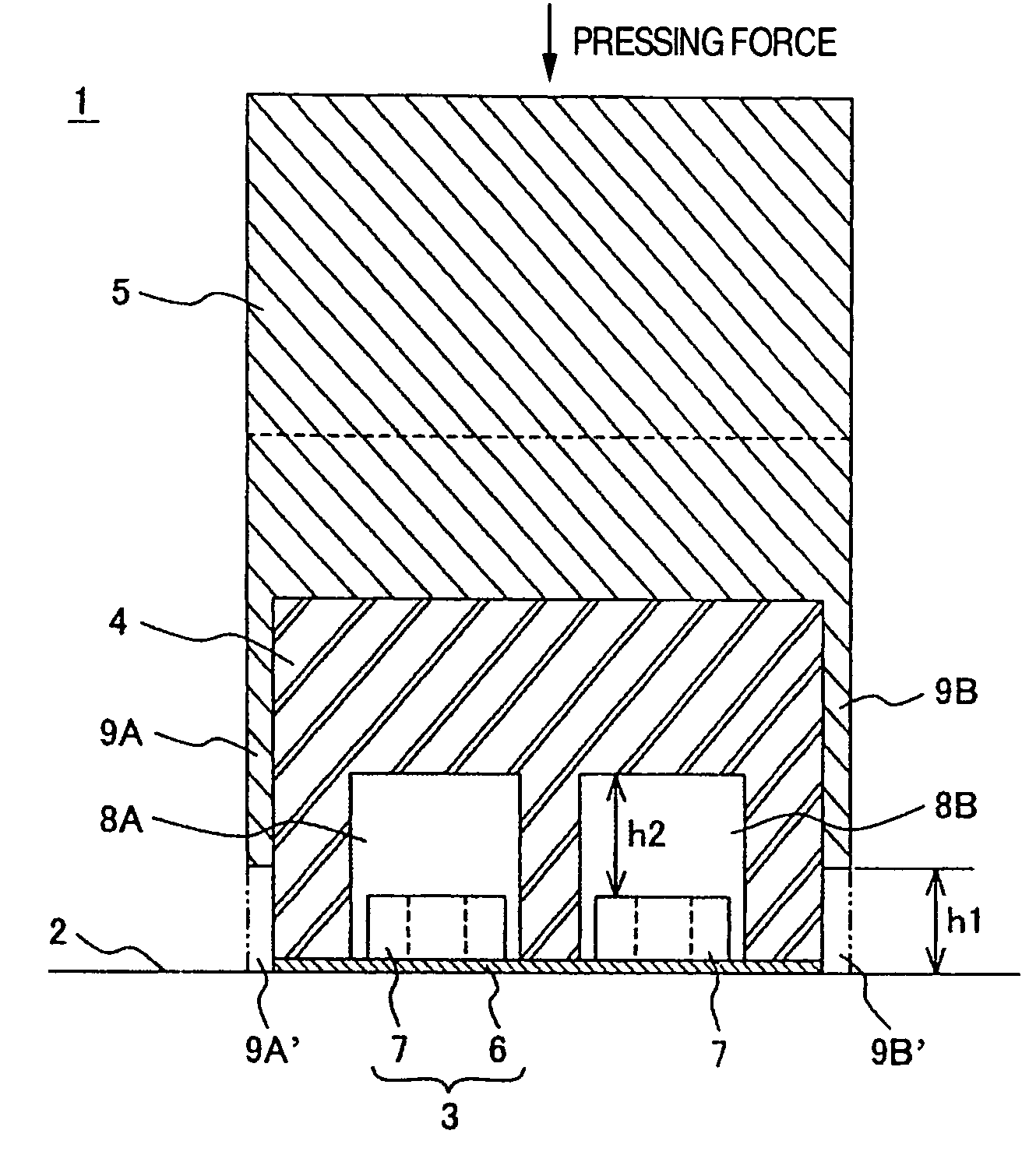

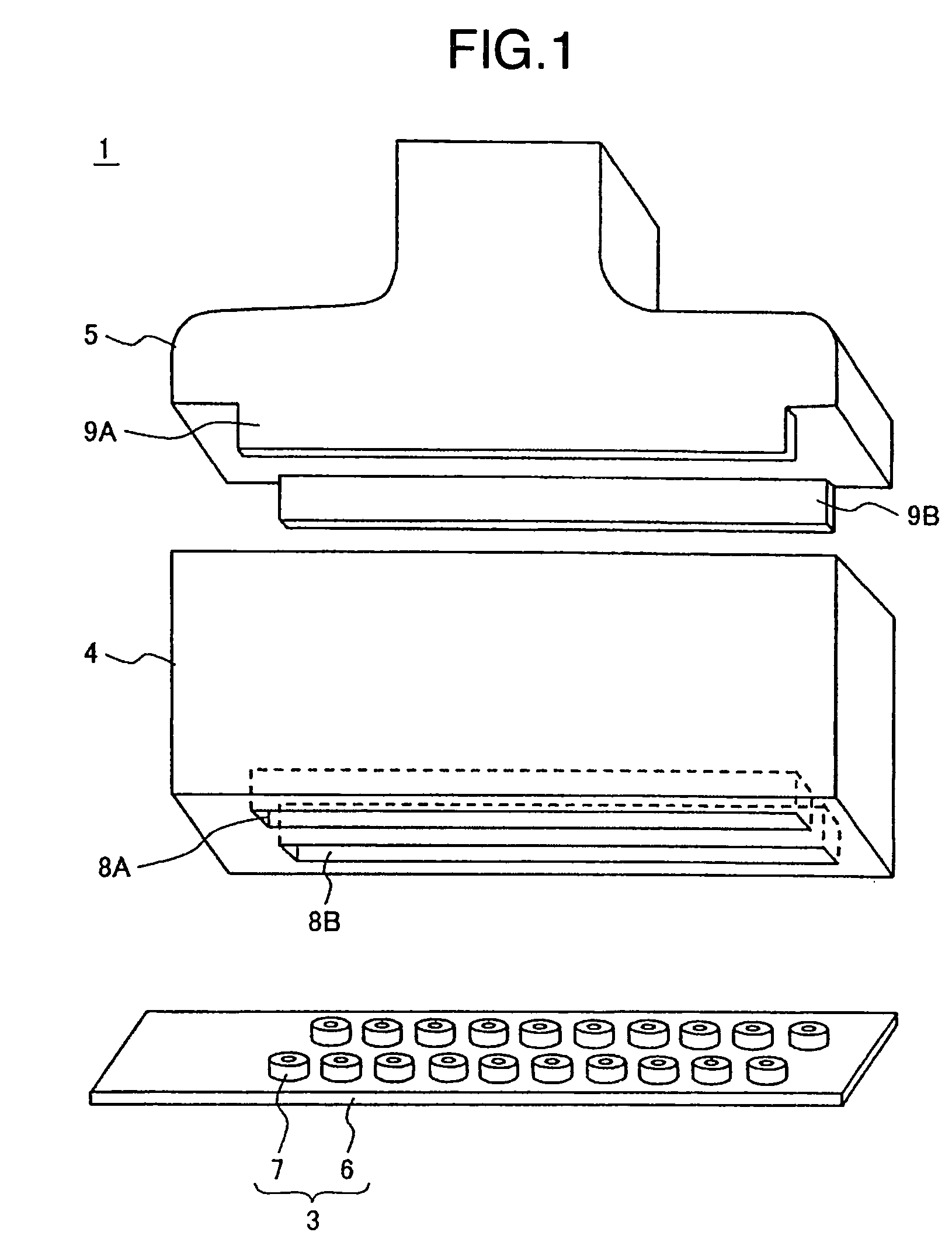

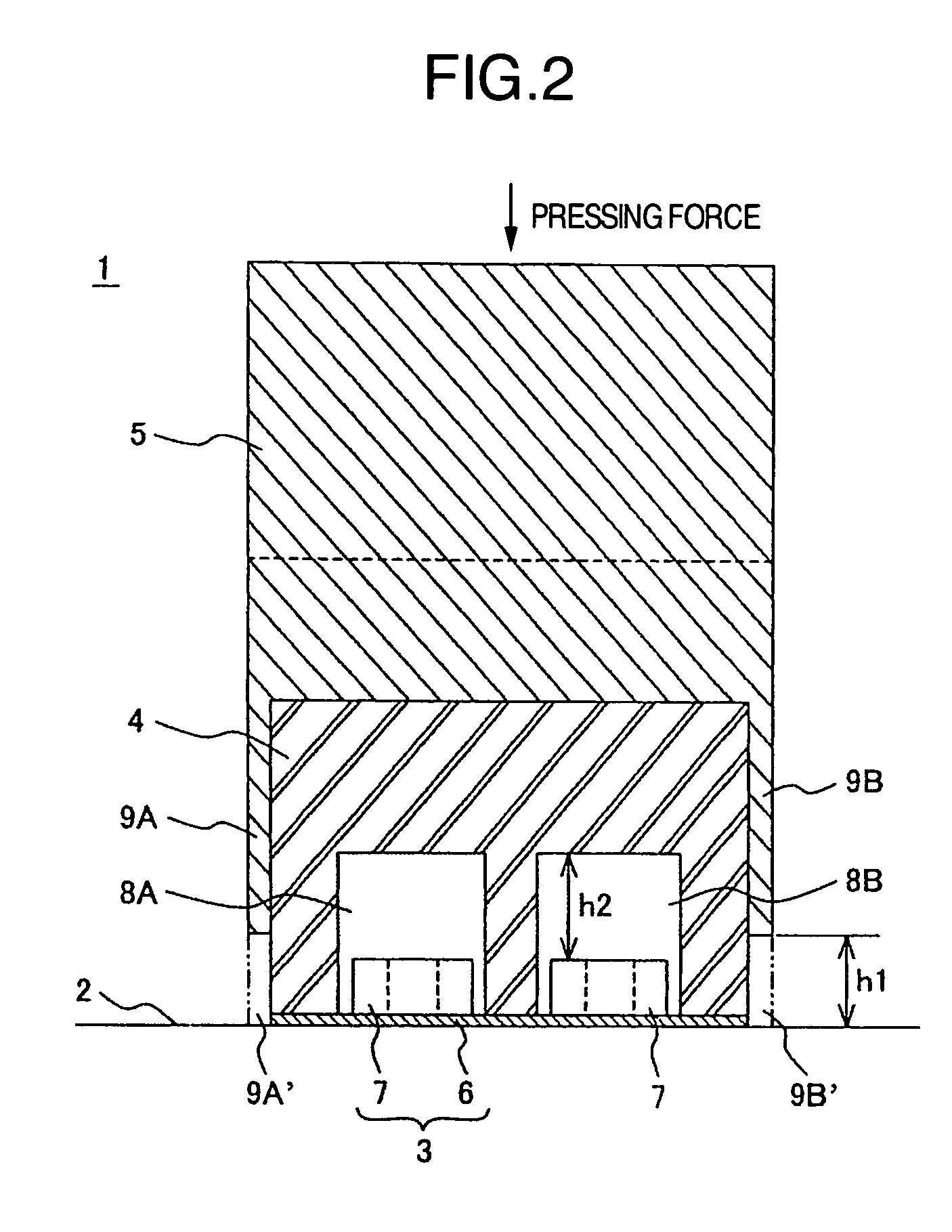

Eddy current testing probe and eddy current testing apparatus

ActiveUS20060170420A1Avoid deformationEnsure correct executionMagnetic property measurementsMaterial magnetic variablesTest articleElastic component

An eddy current testing probe has a flexible substrate adapted to face to a surface of a test article, a plurality of coils which are fixed to the flexible substrate and energized one of which is capable of being changed sequentially, a pressing member for pressing the substrate toward the test article, an elastic member arranged between the substrate and the pressing member, and a movement limiting member for limiting a movement of the pressing member toward the test article.

Owner:HITACHI LTD

Cold drawing welded tube manufacture process for high-accuracy hydraulic oil cylinder

InactiveCN102527767AReduce processing difficultyImprove deburring speedEngineeringEddy-current testing

The invention discloses a cold drawing welded tube manufacture process for a high-accuracy hydraulic oil cylinder, which sequentially comprises the following steps of longitudinal shearing, roll bending molding, high frequency welding, welding joint treatment, online eddy current testing, sizing cutting, normalization, pinching, surface treatment, cold drawing, annealing, straightening, defect detection and cutting for measurement. The method is quick in processing molding, high in production volume, free of damage on surfaces in cold drawing and high in manufacture accuracy. After cold drawing, bearing capacity of a welded tube is improved by about 60%, and the welded tube is high in tensile strength and good in elongation rate. Follow-up gold processing amount is reduced, utilization rate of steel materials is improved, and manufacture cost is reduced. The cold drawing welded tube can be directly applied to manufacture of high-accuracy hydraulic oil cylinders.

Owner:MARCEGAGLIA CHINA

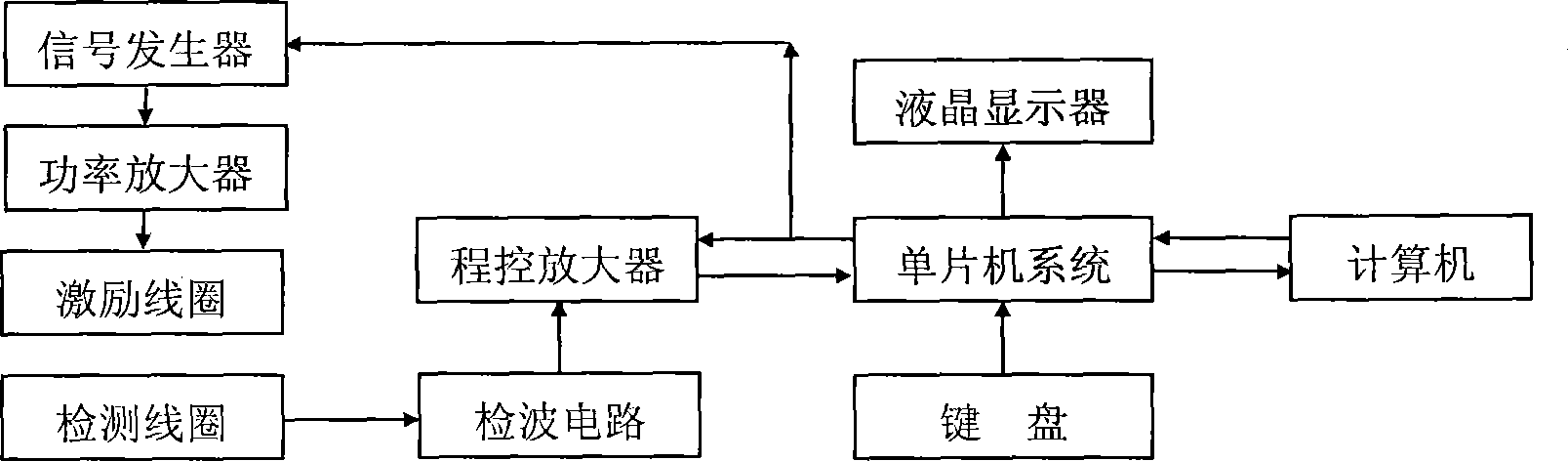

Nondestructive thickness measuring method for nickel coat on Fe substrate

InactiveCN101131314ALow costEasy to carryElectrical/magnetic thickness measurementsCoated surfaceNon destructive

The invention discloses a non-destructive thickness measuring method of nickel coating on iron base metal; the method is to setting samples of known thickness of nickel coating on iron base metal, by detecting the nickel coated surface of samples through eddy current sensor installed with exciting coils and magnetic test coils, the exciting coils send out pumping signals, obtain eddy current testing data corresponding to the thickness of nickel coating on iron base metal after managing the eddy current induction signal the magnetic test coils obtained, so as to establish a thickness model of nickel coating on iron base metal, in the actual measurement, with the help of this model, the thickness of nickel coating on iron base metal can be tested using the same method. The method is nondestructive, suitable for testing the thickness of all nickel coating on iron base metal, has the advantages of low cost, easy to carry with testing equipment, simple to operate, intuitive and detect fast, can immediate get the testing results at the scene with accurate results.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD +1

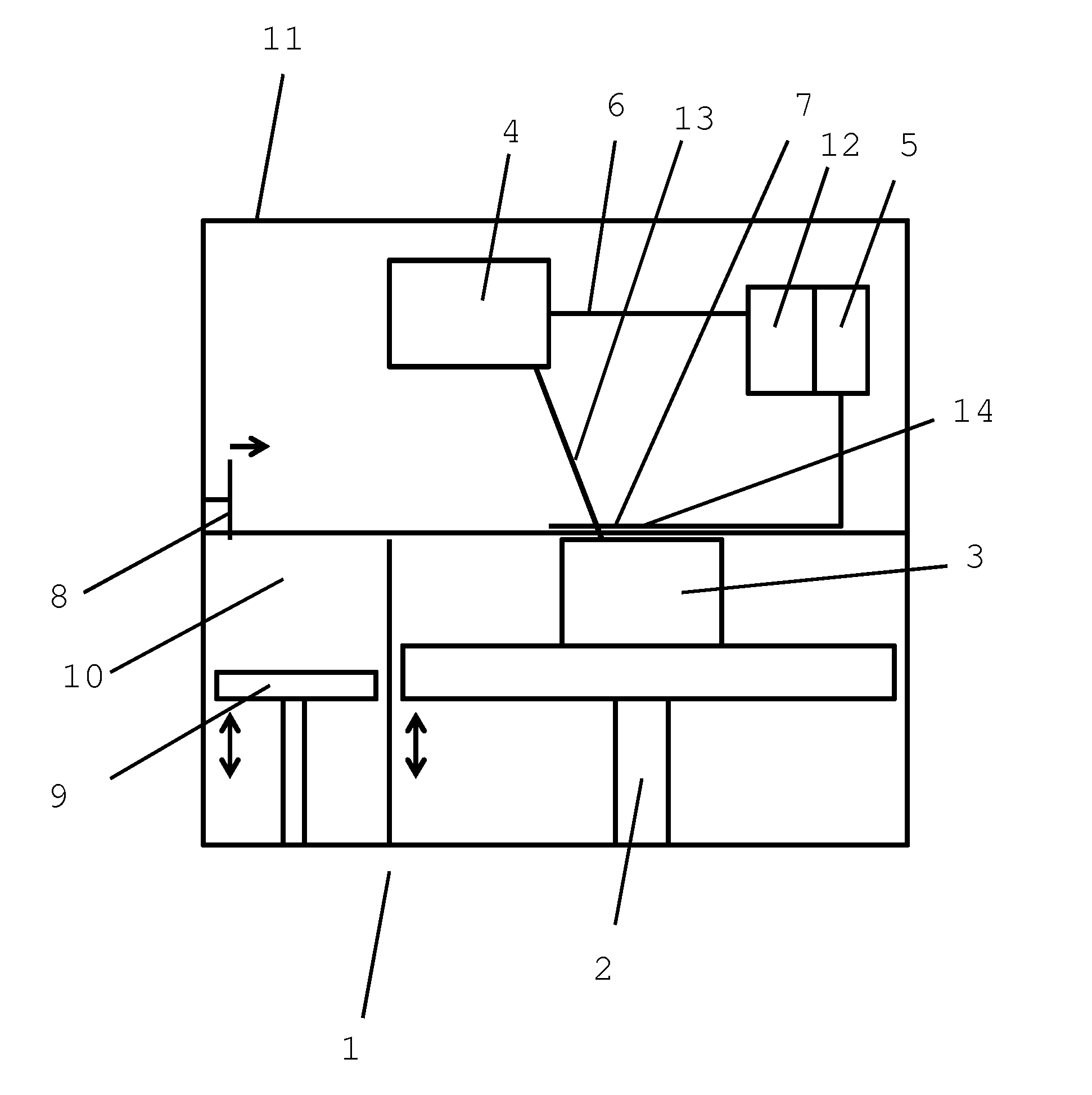

Control in generative production

ActiveUS20150017054A1Improve signal-to-noise ratioAdditive manufacturing apparatusArc welding apparatusMetallurgyEddy-current testing

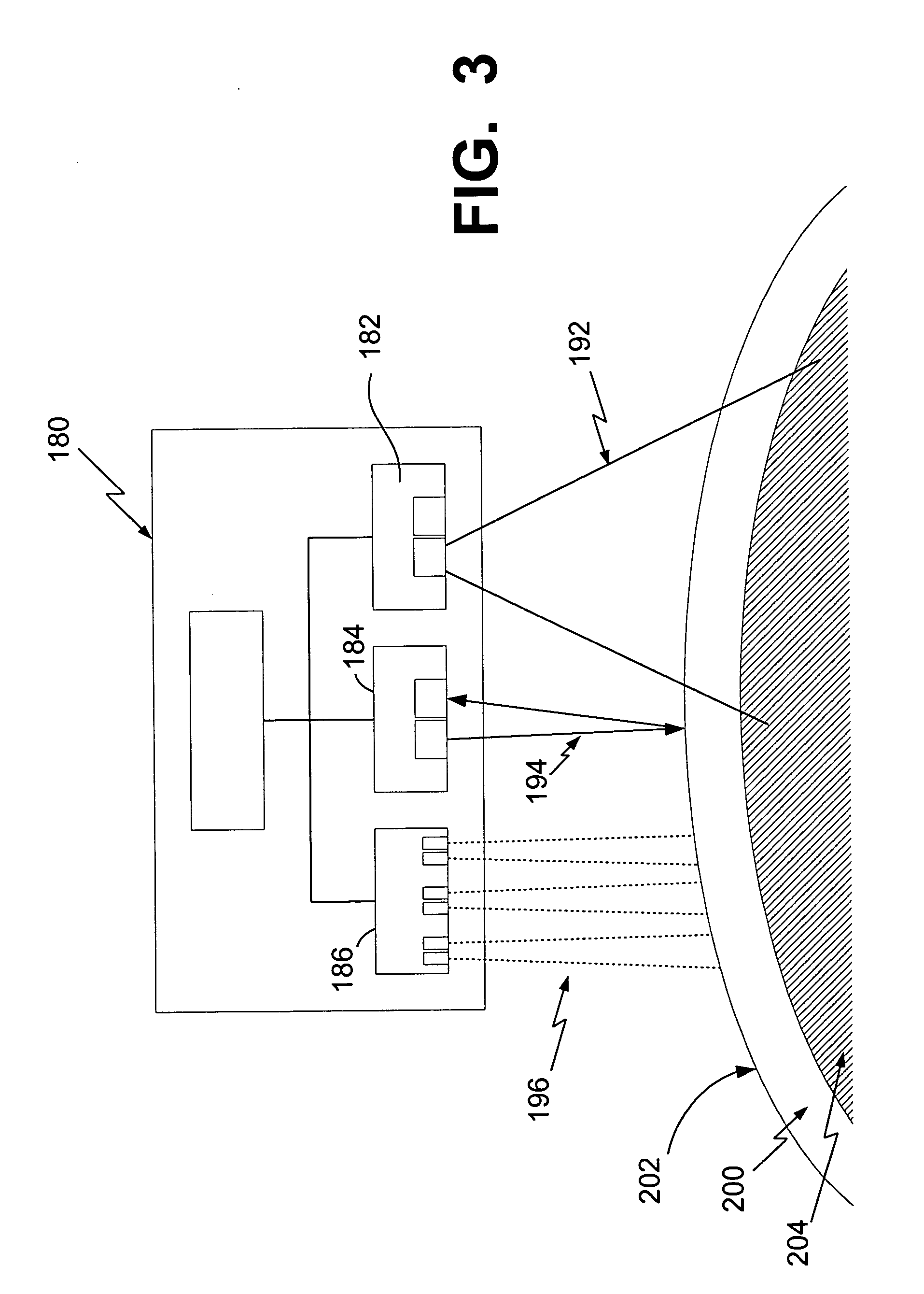

Disclosed is a method for generatively producing components by layer-by-layer building from a powder material by selective material bonding of powder particles by a high-energy beam. An eddy current testing is carried out concurrently with the material bonding. Also disclosed is an apparatus which is suitable for carrying out the method.

Owner:MTU AERO ENGINES GMBH

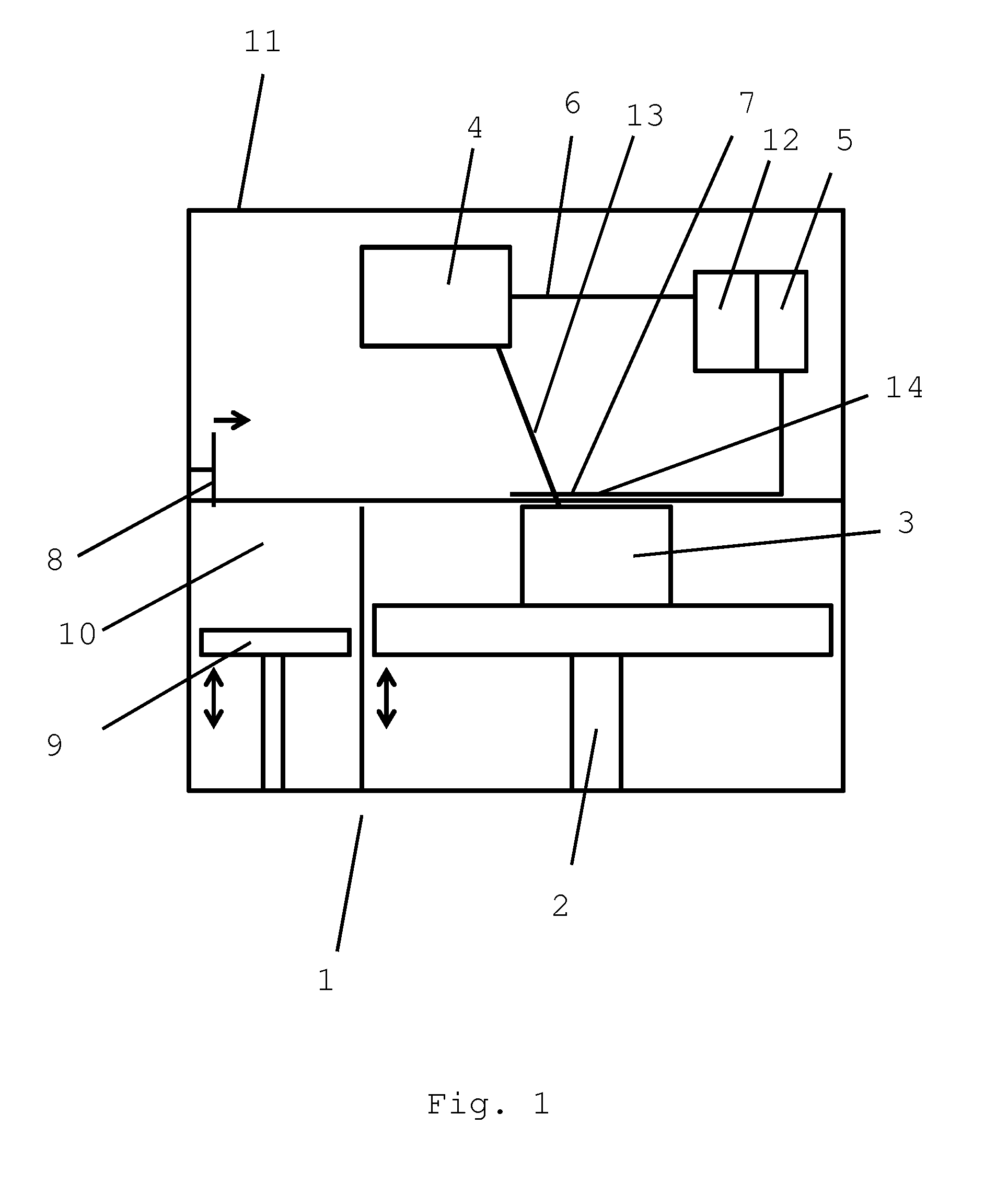

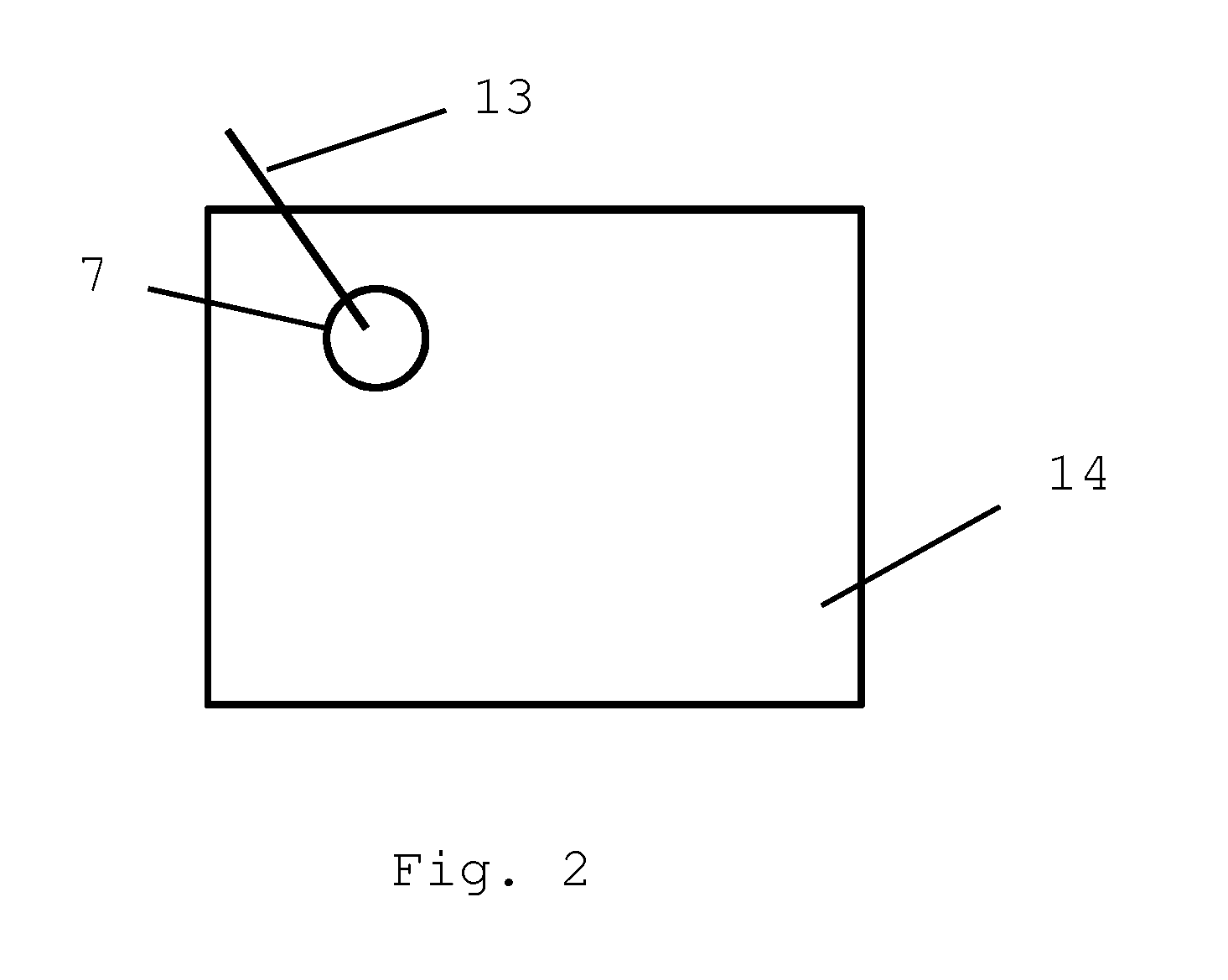

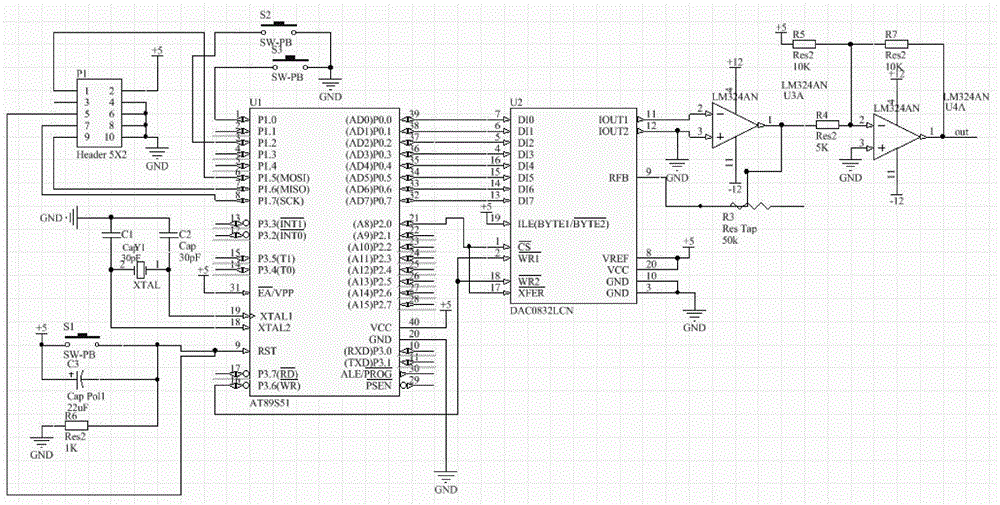

Multi-layered thickness eddy current testing device based on giant magnetoresistance sensor and intelligent algorithm

InactiveCN101532816ASizeReduce volumeBiological neural network modelsElectrical/magnetic thickness measurementsMicrocontrollerBack calculation

The invention discloses a multi-layered thickness eddy current testing device based on a giant magnetoresistance sensor and an intelligent algorithm. The device generates actuating signals via a signal generator, and provides the actuating signals for built-in GMR and drive coil of magnetic steel after the signals are amplified by a power amplifier. The device detects the magnitude of the eddy current signals based on the built-in GMR and the drive coil of the magnetic steel, and the signals are sent to an amplifying circuit for being amplified after being tested by a detection circuit. The output of the amplifying circuit is collected to a computer by a data acquisition circuit based on a single chip microcomputer to be processed. The signal has a close relation with the thickness of the detected multi-layered conducting materials, carries out back calculation after adopting an improved BP network and can obtain the thickness of the conducting materials of each layer. The device is applicable to the thickness testing of multi-layered conducting structure in fields of machine, printed circuit board, aerospace, national defense and the like.

Owner:ZHEJIANG UNIV

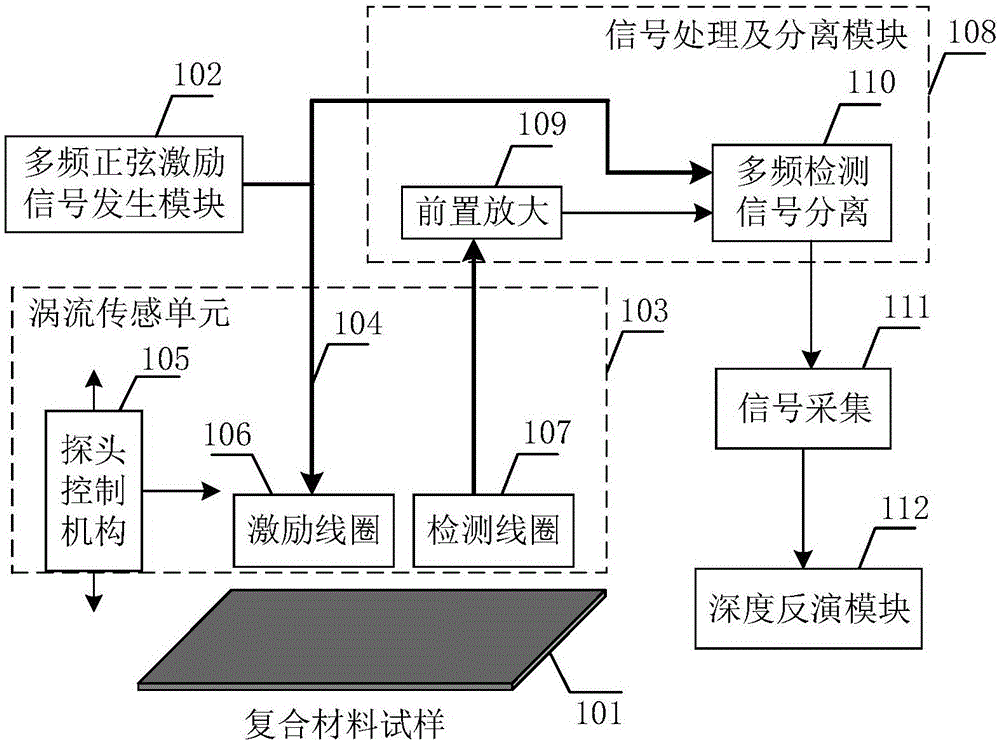

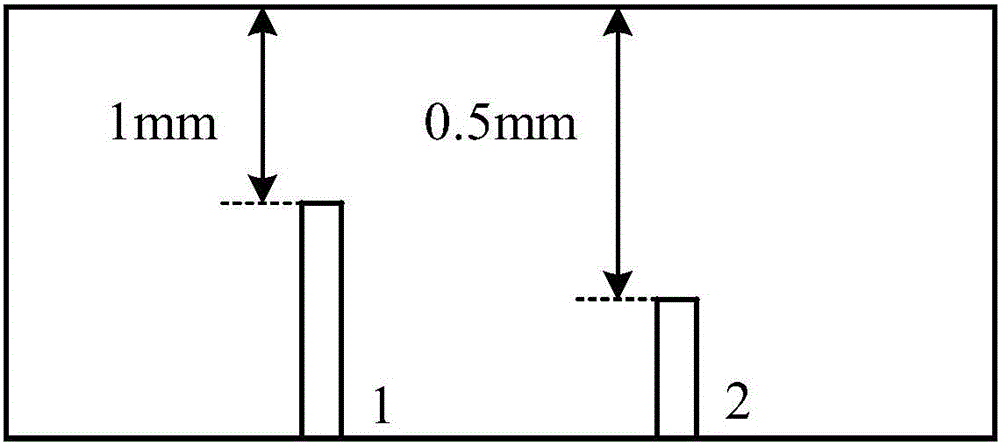

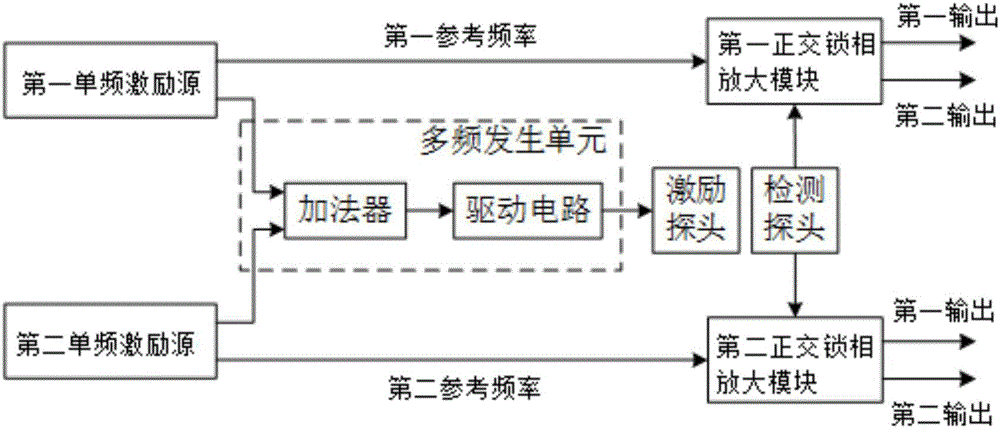

Multi-frequency eddy current testing system and method for evaluating carbon fiber plate defect depth

InactiveCN106645391AReduce noise disturbanceReduce transmission lossMaterial magnetic variablesFiberEngineering

The invention discloses a multi-frequency eddy current testing system and method for evaluating carbon fiber plate defect depth. The system comprises a composite-material to-be-tested part, a multi-frequency sine excitation signal generating module, an eddy current sensing unit, a signal processing and separating module, a signal collecting module and a depth inversion module, wherein the eddy current sensing unit comprises a transmission cable, a probe control mechanism, an eddy current excitation coil and an eddy current detecting coil; the signal processing and separating module comprises a pre-amplifier and a multi-frequency detecting signal separating module. The multi-frequency eddy current testing system and method for evaluating the carbon fiber plate defect depth has the advantage that defect size information is obtained by measuring the peak sensing voltage and peak frequency of different-depth defects, and accordingly the defect depth of composite plates can be evaluated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

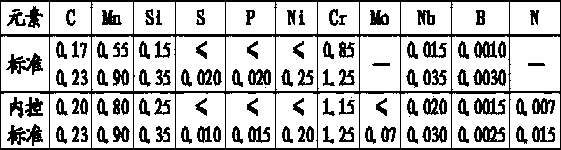

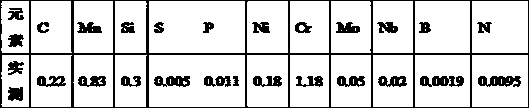

Method for manufacturing high-quality SCr420 HB automobile gear steel

ActiveCN103350202AImprove cleanliness levelGuaranteed surface qualityProcess efficiency improvementElectric furnaceSteelmakingChemical element

The invention discloses a method for manufacturing high-quality SCr420 HB automobile gear steel. The method aims at reducing the oxygen content and occluded foreign substances in the steel, guaranteeing the stability of the quenching degree and guaranteeing the high quality of the surface of the steel. The method includes the process routes of using an ultra high power electric furnace, conducting LF, conducting VD, conducting continuous casting, continuously heating through the ultra high power electric furnace, conducting rolling through a continuous rolling mill, conducting finishing, conducting straightening and chamfering, conducting surface eddy current testing and packaging. The continuous casting in the steelmaking process adopts long nozzle protection, casting powder and argon shielding pouring, internal control compositions are appropriately designed, the N element content in the steel is controlled, and the form of the B element in the steel is controlled. The superheat degree and the casting speed in the continuous casting are controlled. The method has the advantages of reducing the oxygen content and the occluded foreign substances in the steel, enabling the gas oxygen content in the steel to be less than 15ppm, and enabling the non-metallic inclusion completely to meet the Korea modern standards, controlling the close limit of the chemical element, guaranteeing the quenching degree, guaranteeing the high quality of the surface of the steel, and meeting the precision forging requirement.

Owner:FUSHUN SPECIAL STEEL SHARES

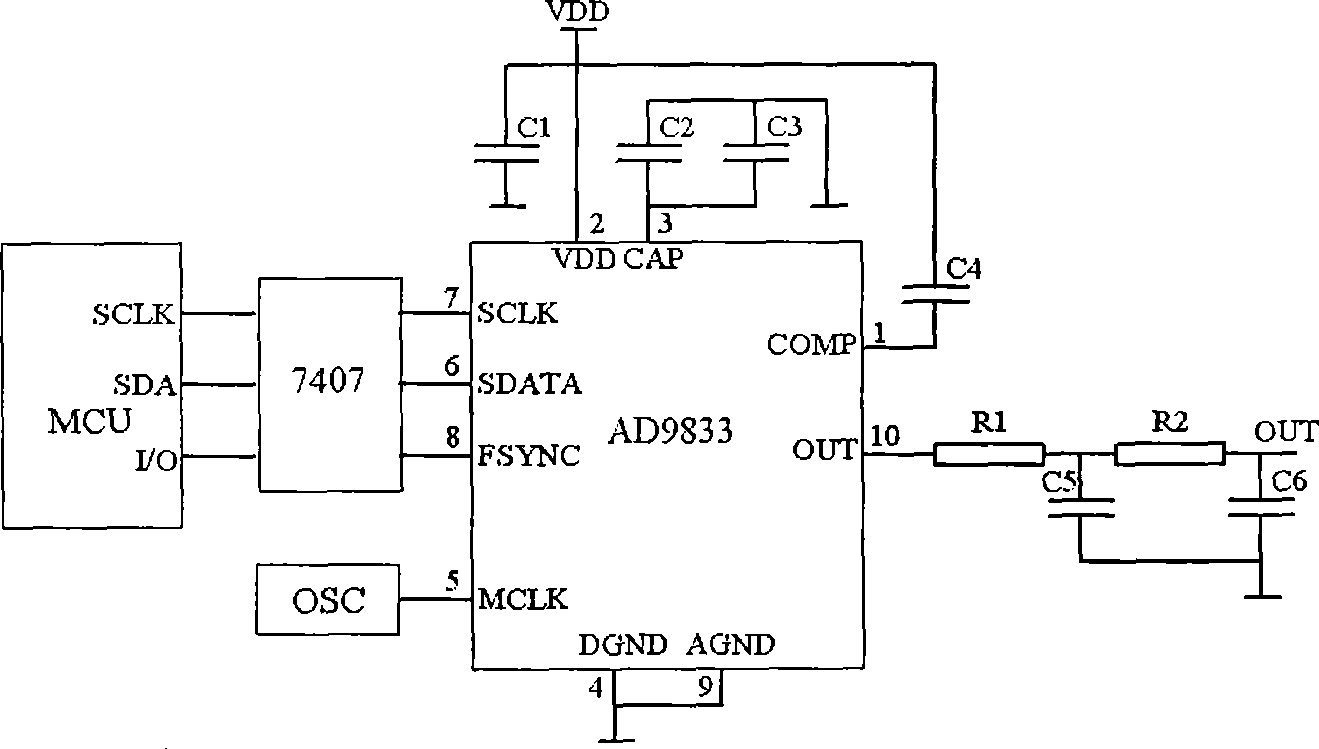

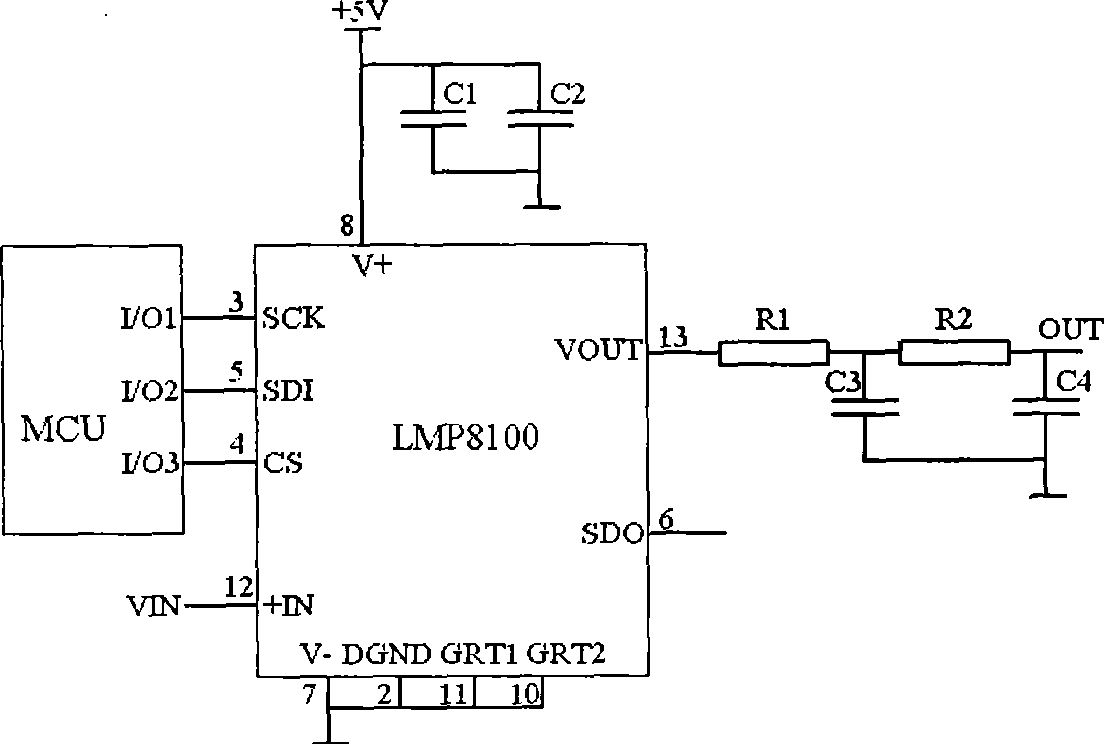

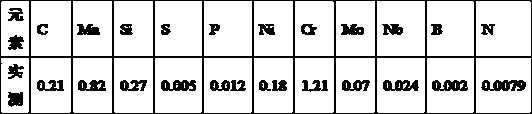

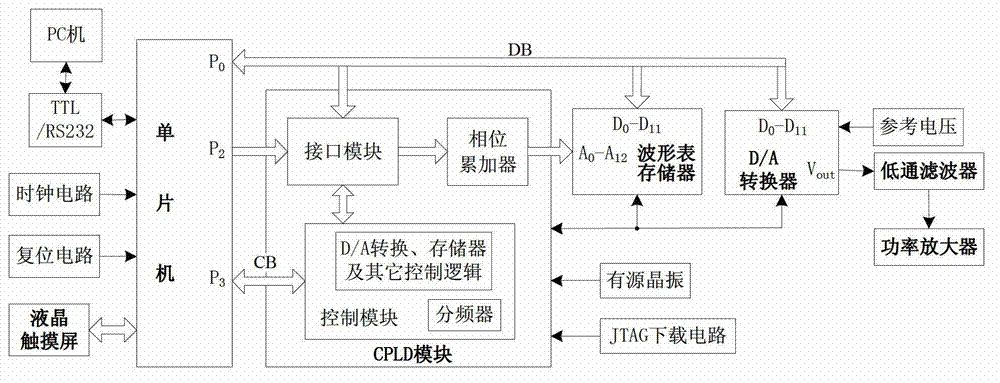

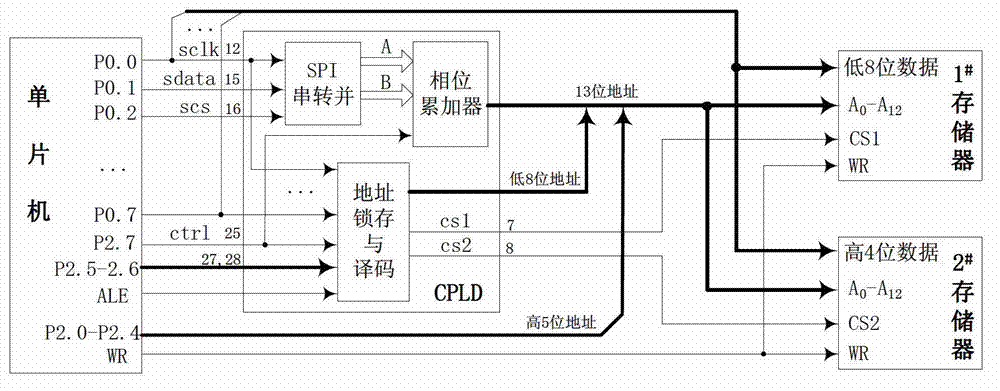

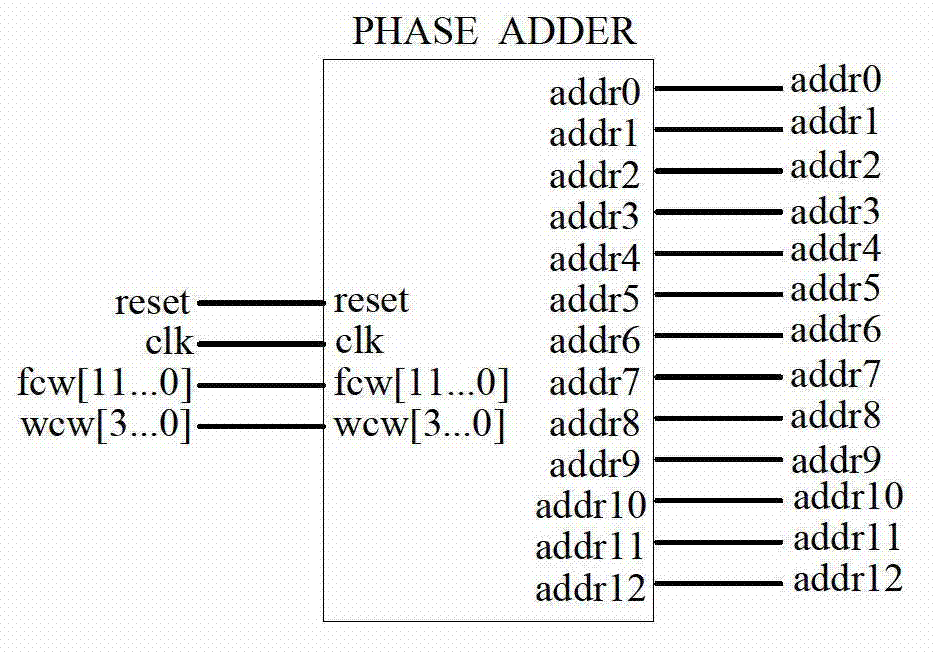

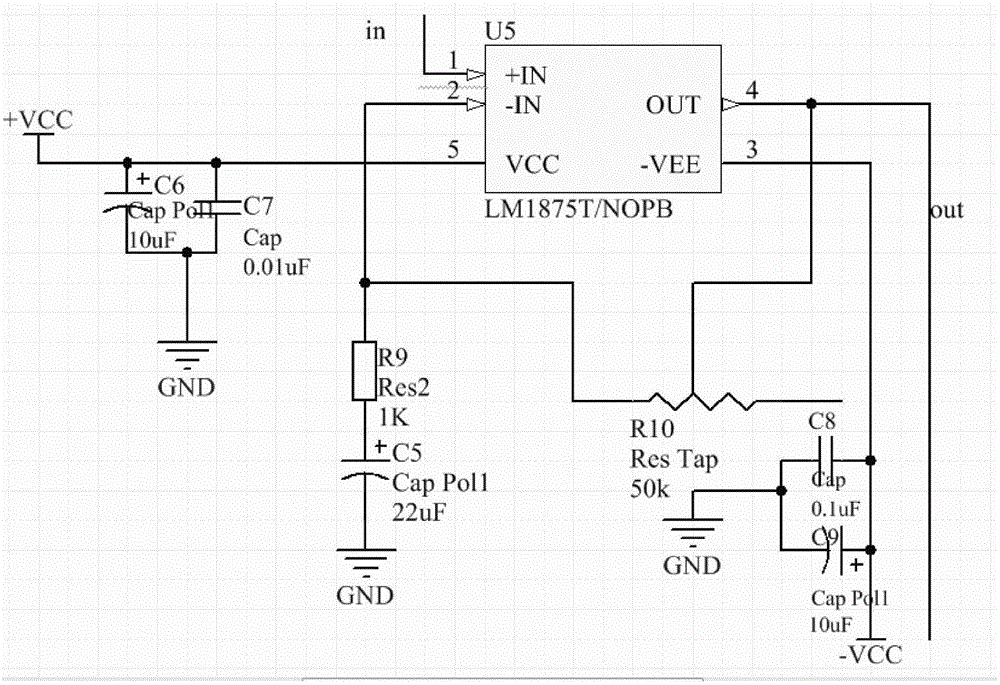

Eddy current testing excitation signal source based on DDS (Direct Digital Synthesis) technology

InactiveCN102967651AInteractive friendlyGood value for moneyMaterial magnetic variablesMicrocontrollerLow-pass filter

The invention discloses an eddy current testing excitation signal source based on a DDS (Direct Digital Synthesis) technology, and the eddy current testing excitation signal source comprises a singlechip, a CPLD (Complex Programmable Logic Device) module, a waveform memory, a D / A (Digital-to-Analogue) converter, a low-pass filter, a power amplification circuit, a liquid crystal touch screen and an upper PC (Personal Computer) machine, wherein the liquid crystal touch screen is connected with the singlechip; the upper PC machine is connected and in series communicated with the singlechip; the CPLD module is connected with the singlechip; the waveform memory is connected with the singlechip and the CPLD module; the D / A converter is connected with the singlechip and the CPLD module, and the D / A converter is connected with the low-pass filter; and the low-pass filter is connected with a power amplifier. The eddy current testing excitation signal source disclosed by the invention can generate standard excitation signals, namely sine waves, pulse waves, and the like with parameters easily adjusted, and excitation signals with any waveforms for eddy current testing.

Owner:JIANGSU UNIV OF SCI & TECH

Method for measuring non-uniform conductive material surface coating thickness according to eddy currents

ActiveCN103344174AAvoid measurement effectsHigh precisionElectrical/magnetic thickness measurementsConductive materialsEddy-current testing

The invention discloses a method for measuring non-uniform conductive material surface coating thickness according to eddy currents. Based on the frequency sweep eddy current testing technology, continuous frequency within a certain range is used for stimulating one test point of a tested non-uniform conductive material provided with a coating and a substrate standard test block without the coating; the optimal measuring frequency at the test point is found, therefore, the effect of the nonuniformity of the conductivity of a substrate on the measurement of the surface coating thickness can be effectively avoided, and the accuracy of the measurement of the surface coating thickness is effectively improved.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

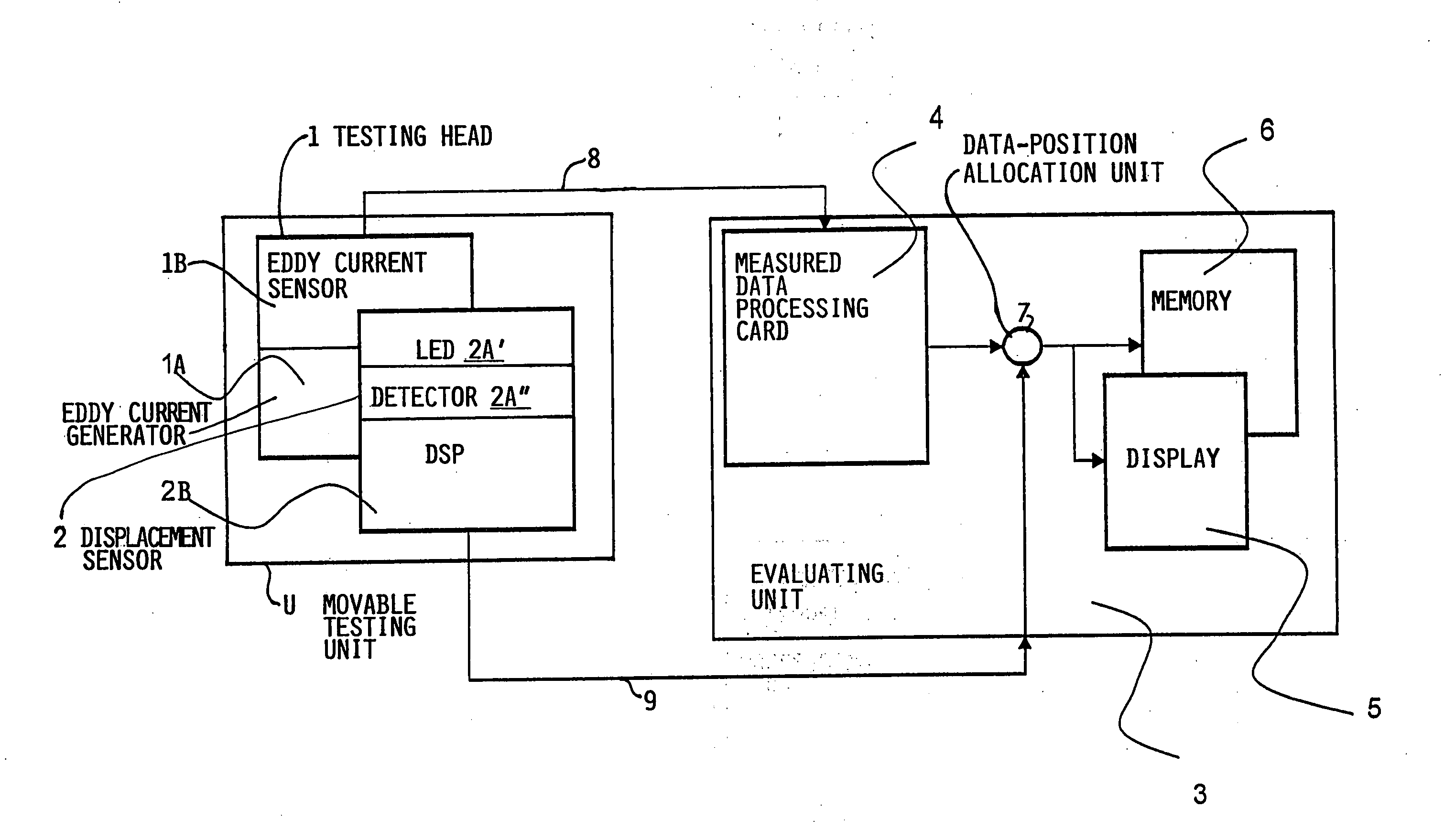

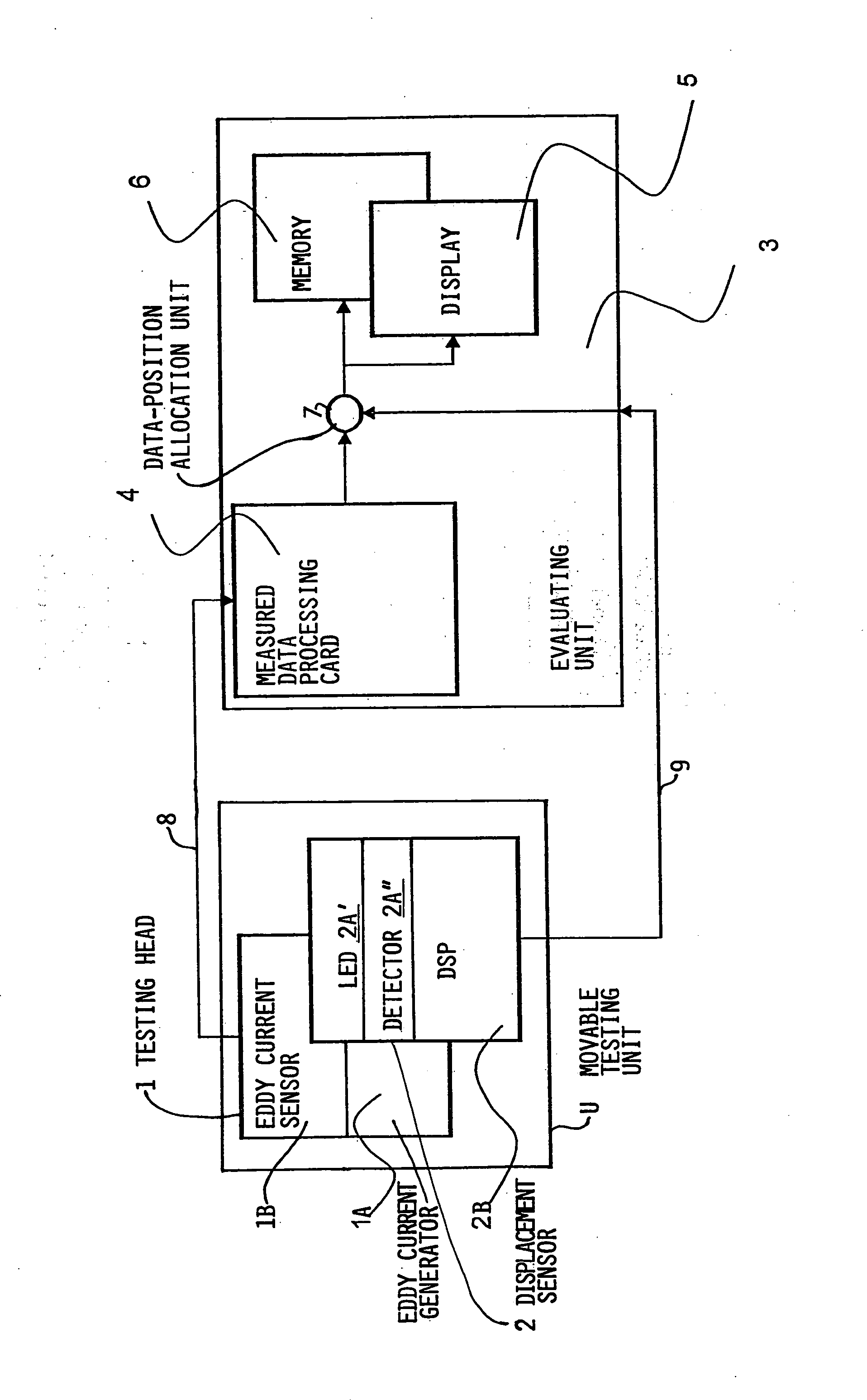

Eddy current testing apparatus with integrated position sensor

InactiveUS20050015209A1Reduce effortReduce expensesSpecial data processing applicationsMechanical roughness/irregularity measurementsCMOS sensorEddy-current testing

An apparatus for eddy current testing of a test specimen includes a movable testing unit and a separate evaluating unit. Incorporated therein, the movable testing unit includes an optical position sensor as well as a testing head that has an eddy current generator and an eddy current sensor. The testing head generates and measures an eddy current in the test specimen, while the optical position sensor optically senses the position of the testing head on the test specimen. The optical position sensor includes a camera unit and a signal processor that determines the displacement direction and distance of the testing head based on differences among successive images of the specimen surface sensed by the camera unit. The camera unit includes a light emitting diode and an optical detector such as a CMOS sensor. The evaluating unit evaluates the measured data and allocates it to the associated position data.

Owner:WUEBKER STEFAN

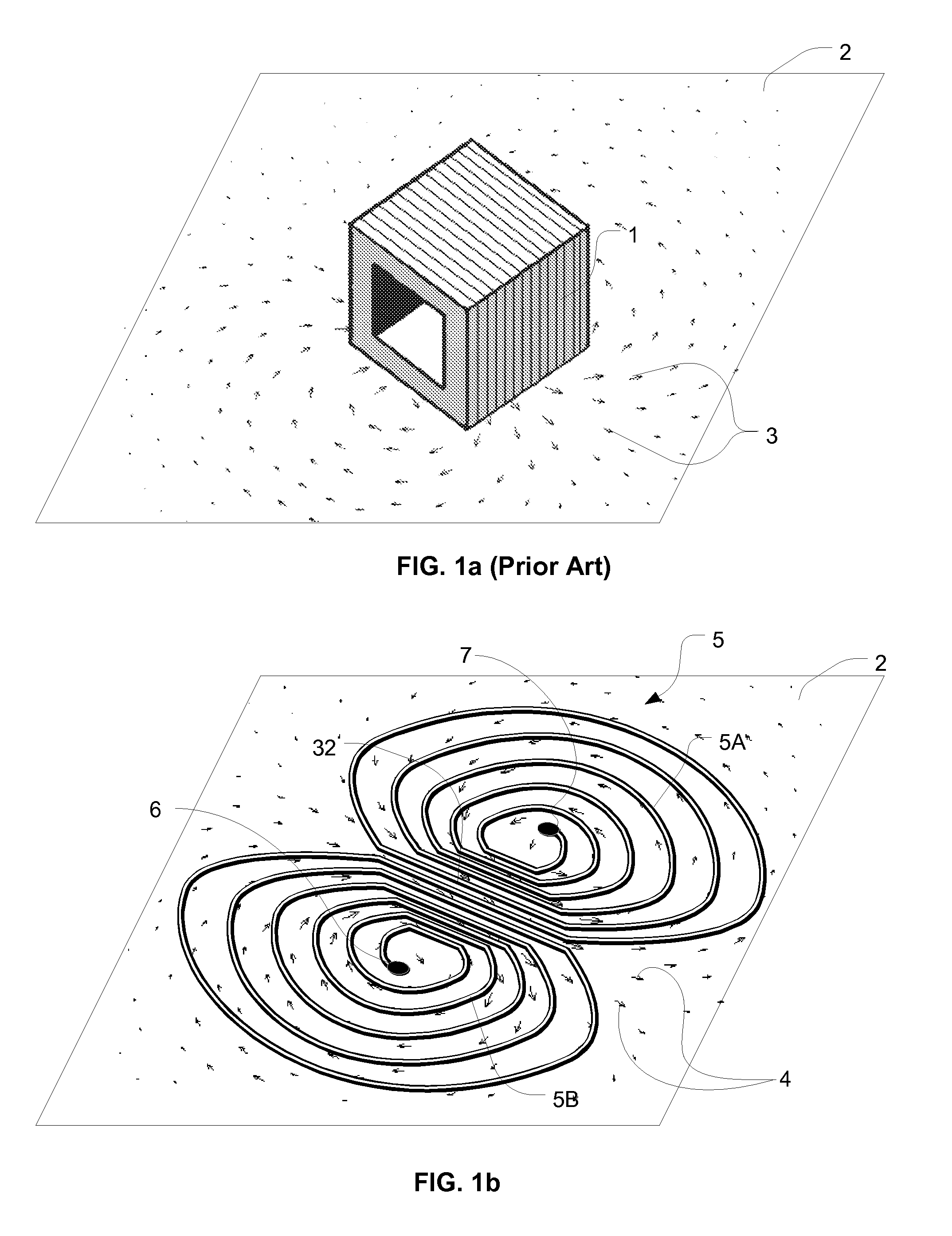

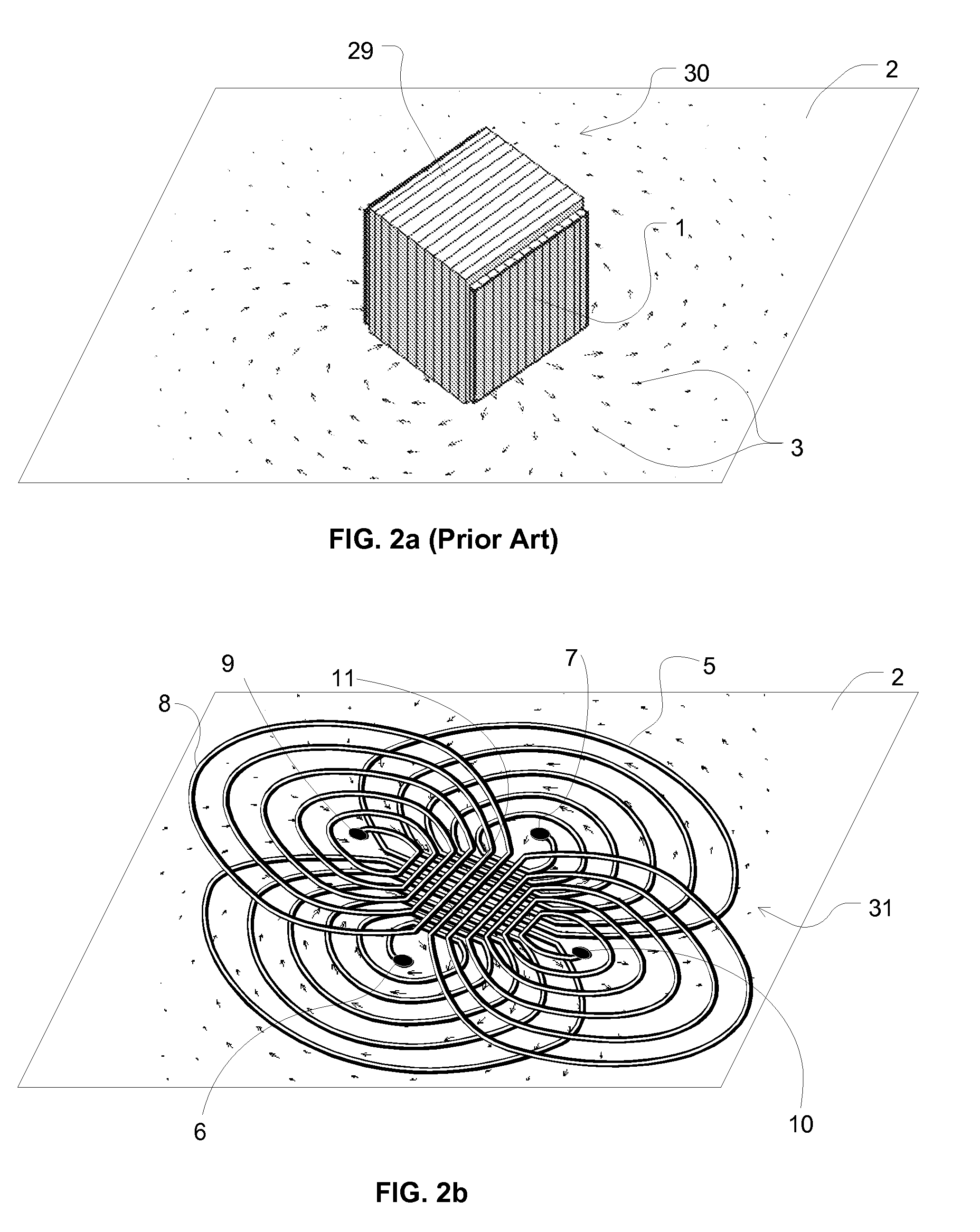

Methods of altering eddy current interactions

Described herein are braking mechanisms and related methods of use using eddy current interactions to resist relative movement between members, the magnetic flux about an eddy current region being modified beyond an inherent drag effect resulting from a simple magnetic pole arrangement.

Owner:EDDY CURRENT PARTNERSHIP

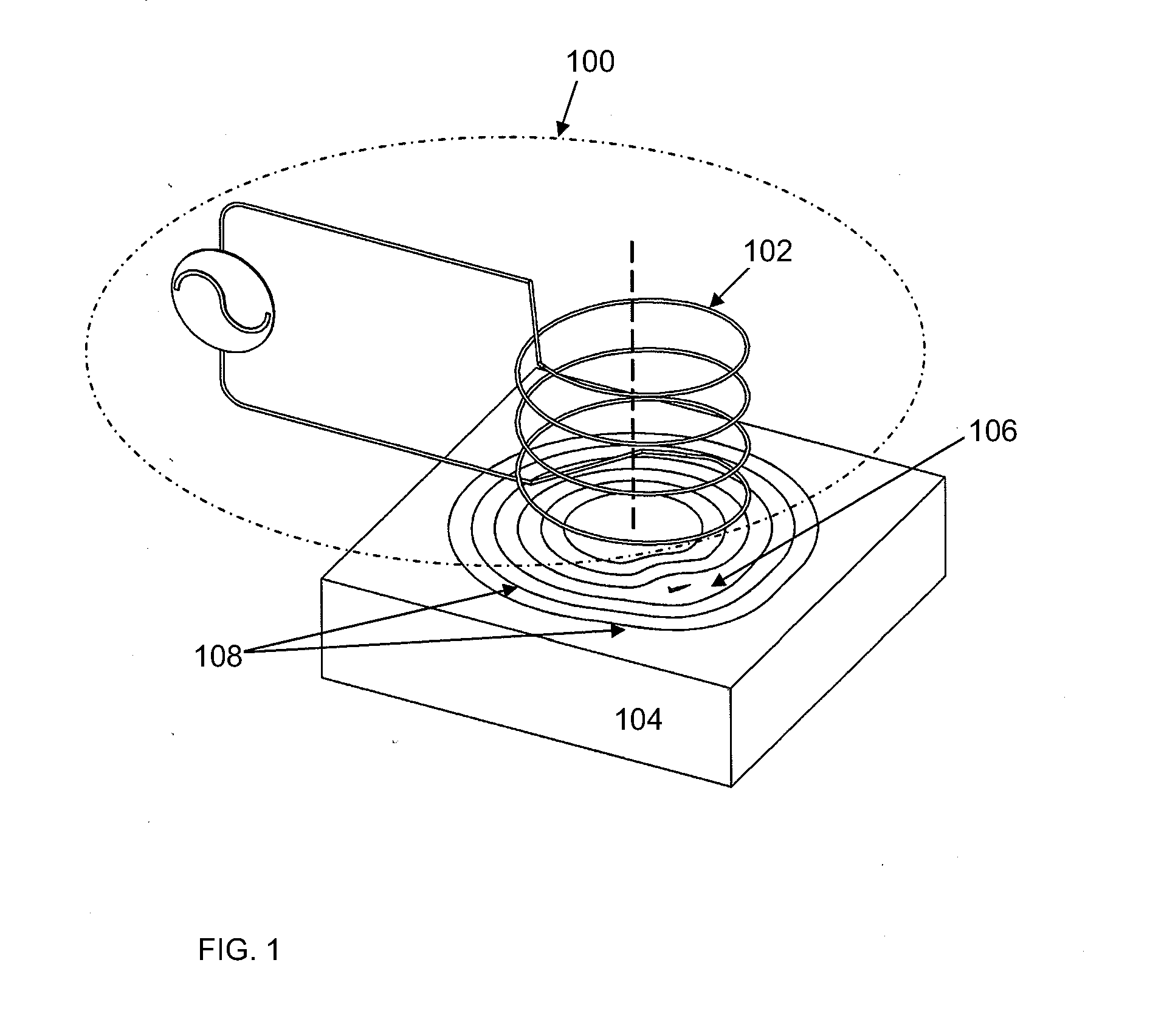

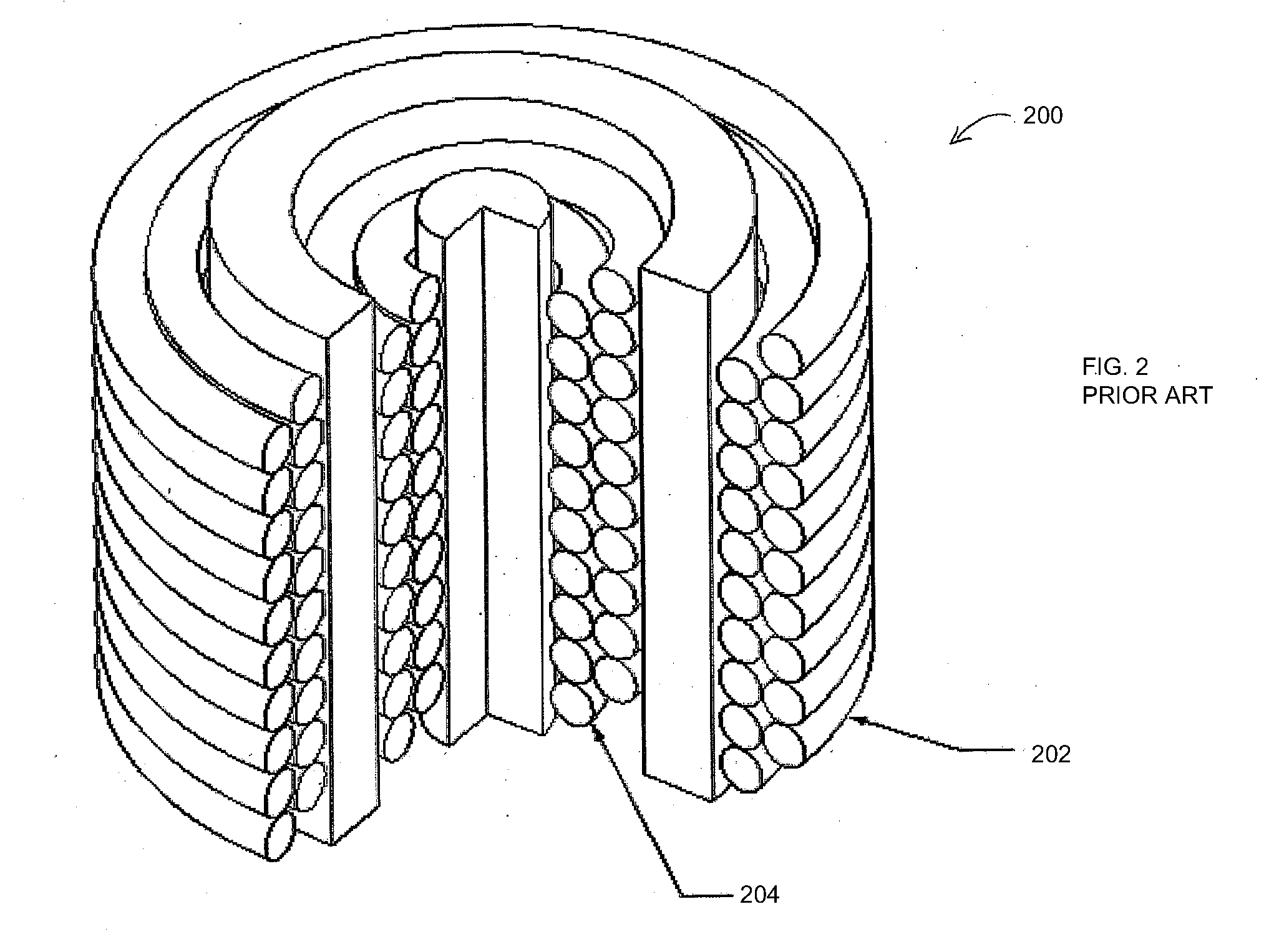

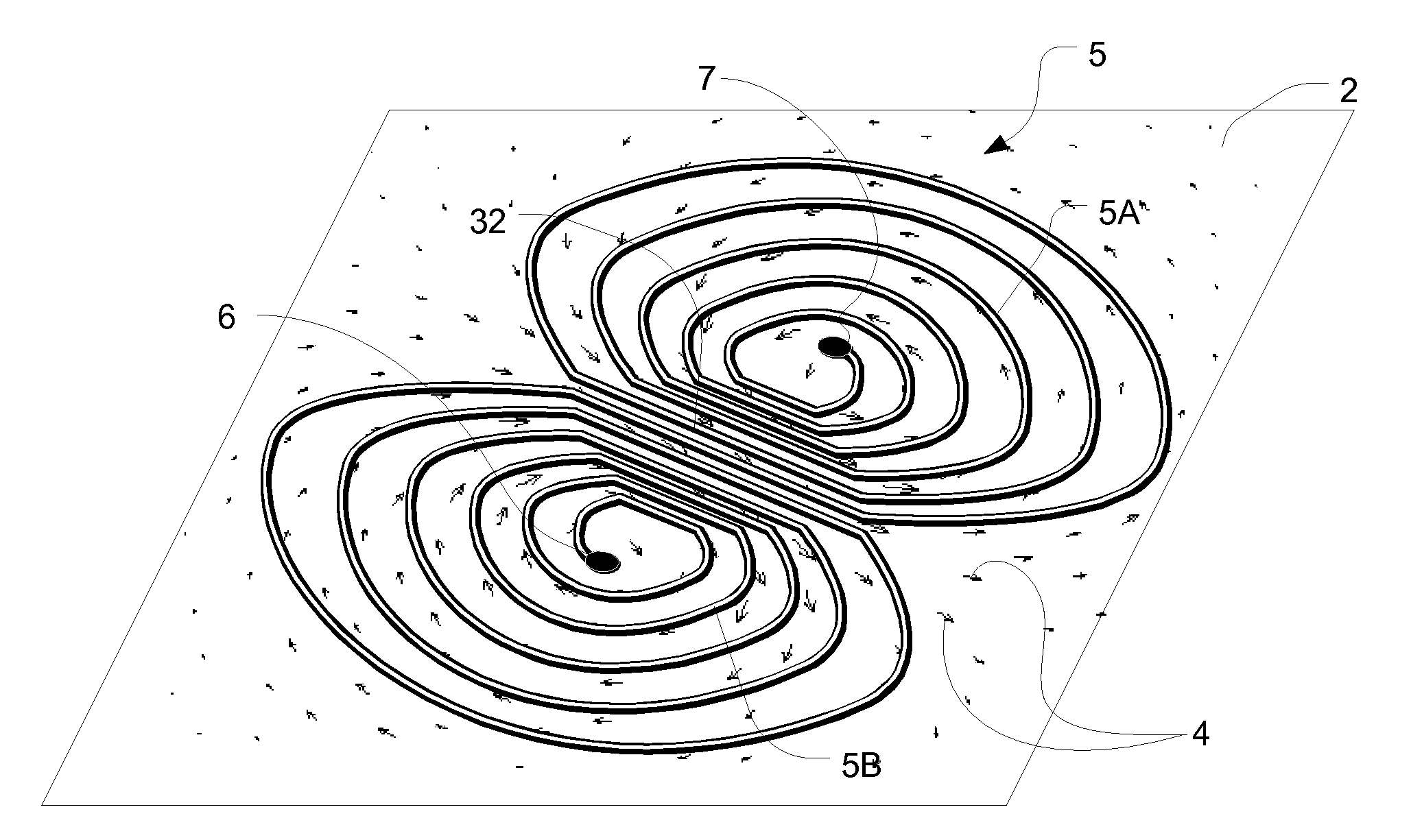

2d coil and a method of obtaining ec response of 3D coils using the 2d coil configuration

ActiveUS20120007595A1Low costEasy to useMagnetic property measurementsMaterial magnetic variablesEngineeringEddy-current testing

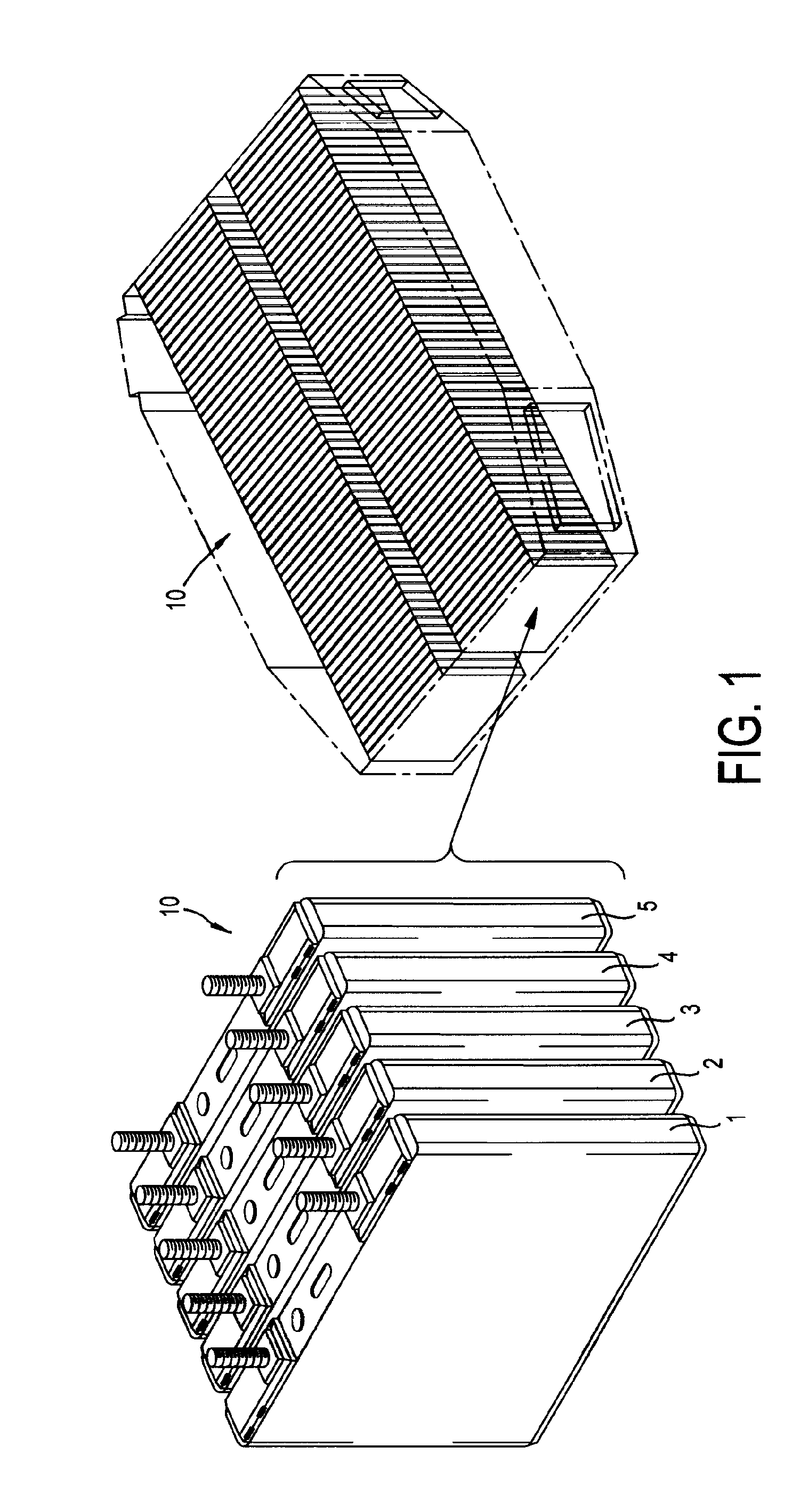

The invention herein disclosed provides a 2D coil and a method of using the 2D wound EC sensor for reproducing the Eddy Current Testing (ECT) response of a prior art 3D orthogonal sensor. The 3D orthogonal sensor is conventionally wound onto a 3D core, with at least some of the surfaces being un-parallel to the surface be inspected. Using the herein disclosed 2D configuration allows the use of printed circuit board technologies for the manufacturing of these EC sensors. The herein disclosed method and the associated 2D EC sensors are particularly useful for reproducing the EC effect of conventional orthogonal probe arrays.

Owner:OLYMPUS NDT

Inspecting device including detachable probe

ActiveCN101988902AMaterial analysis using sonic/ultrasonic/infrasonic wavesNuclear energy generationEddy-current testingBiomedical engineering

An inspecting device including a detachable probe has a link structure, and thus a subject having various diameters is tested. In addition, since various probes are changeably used in a scanner housing, ultrasonic wave testing and eddy current testing are simultaneously performed.

Owner:KEPCO KPS CO LTD

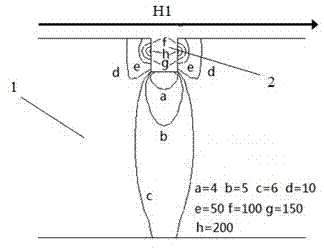

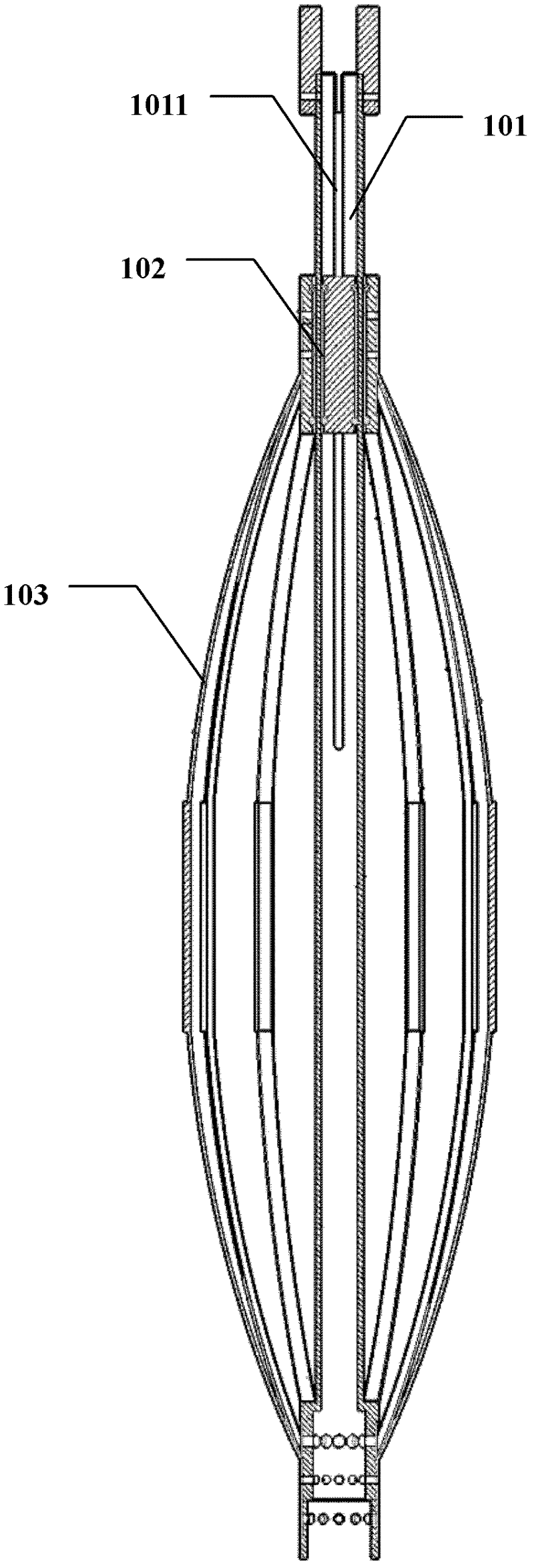

Detection apparatus for defects of inner and outer walls of pipeline based on remote field eddy current testing

ActiveCN102313777AImplement defect detectionMaterial magnetic variablesPhase differenceComputer module

The invention discloses a detection apparatus for defects of inner and outer walls of a pipeline based on remote field eddy current testing. According to the invention, at the part of a mechanical structure, spring leaves are controlled to stretch and fold so as to make a horizontal part at the top of the spring leaves abut the inner wall of the pipeline; the horizontal part at the top of each spring leaf is provided with a magnetoresistor member for receiving remote field eddy current signals which indicate defects of the inner and outer walls of the pipeline in a remote field; a data processing module outputs electric signals to the magnetoresistor members and calculates phase difference with excitation signals provided by an excitation module as reference signals so as to obtain a plurality of sets of data which indicate defects of the inner and outer walls of the pipeline and enable detection of the inner and outer walls of the pipeline to be completed. According to the invention,arc spring leaves are uniformly circumferentially distributed along a main axis, each magnetoresistor member abuts the inner wall of the pipeline, and the circumference of the pipeline are totally occupied by the magnetoresistor members; therefore, detection of circumferential position and minimal defects of a defective pipeline can be realized, defect detection of overall inner and outer walls of a pipeline is achieved, and parameters of the shape and dimension of a defect is obtained.

Owner:四川庆达实业集团有限公司

Eddy current testing probe and eddy current testing apparatus

ActiveUS7235967B2Accurate detectionAvoid deformationMagnetic property measurementsMaterial magnetic variablesTest articleEngineering

Owner:HITACHI LTD

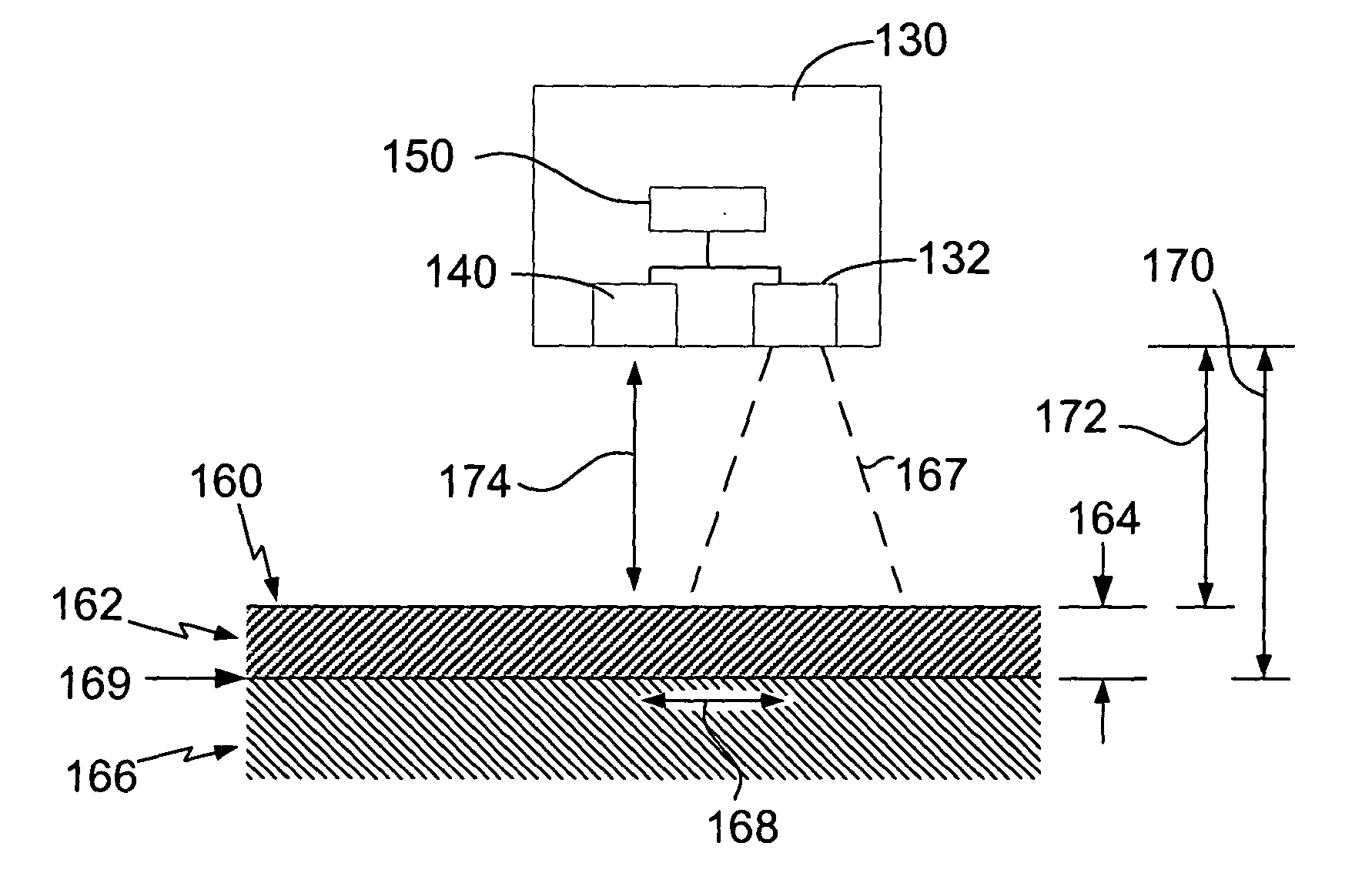

Method and apparatus for non-contact thickness measurement

ActiveUS20050046874A1Caliper-like sensorsMaterial analysis by optical meansLight beamLayer thickness

The present invention provides a method and apparatus for use in measuring a thickness of a layer and / or variations in layer thickness for layers that are flat, curved or have curves. The apparatus comprises a light source to generate a light beam, a light beam detector to detect at least a portion of the light beam reflected, an eddy current field generator that induces an eddy current, an eddy current detector to detect the induced eddy current and a processor coupled with the light source, light detector, eddy current field generator and eddy current detector, wherein the processor controls the light detector, eddy current field generator and eddy current detector. A radial characteristic of a region of the surface can be determined, a scaling factor can be determined based on the radial characteristic and a measured distance can be scaled based on the scaling factor in determining a thickness.

Owner:THE BOEING CO

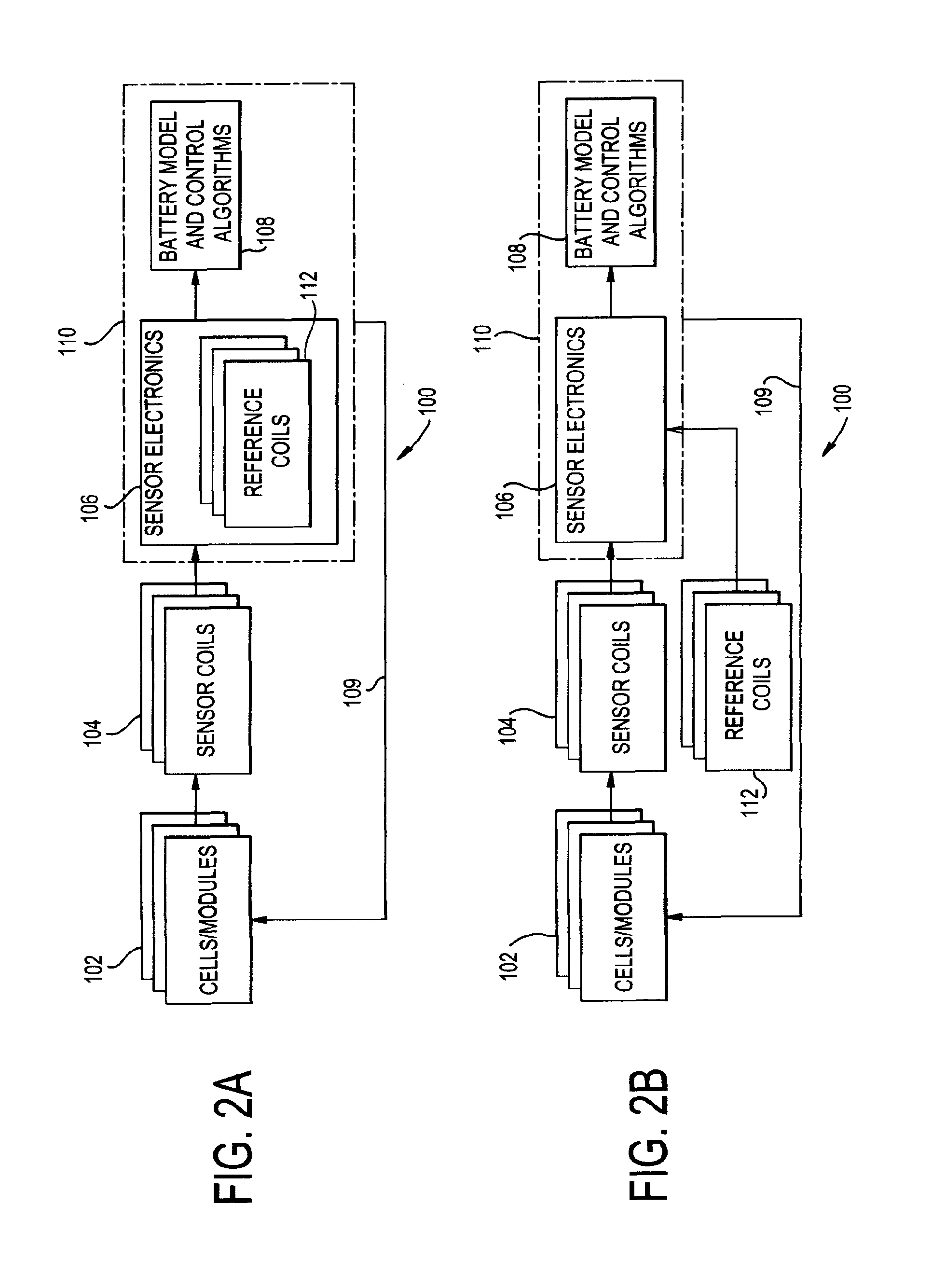

Battery cell health monitoring using eddy current sensing

InactiveUS20150340744A1Batteries circuit arrangementsMaterial analysis by electric/magnetic meansMicrocontrollerElectrical battery

The invention provides a battery sensing system comprising a battery module comprising a plurality of battery cells, at least one sensor coil coupled to or placed adjacent to one of more of the plurality of battery cells to determine cell expansion during cell operation, and a battery management system comprising one or more processors and / or microcontrollers that control operation of the plurality of battery cells.

Owner:AMPHENOL THERMOMETRICS

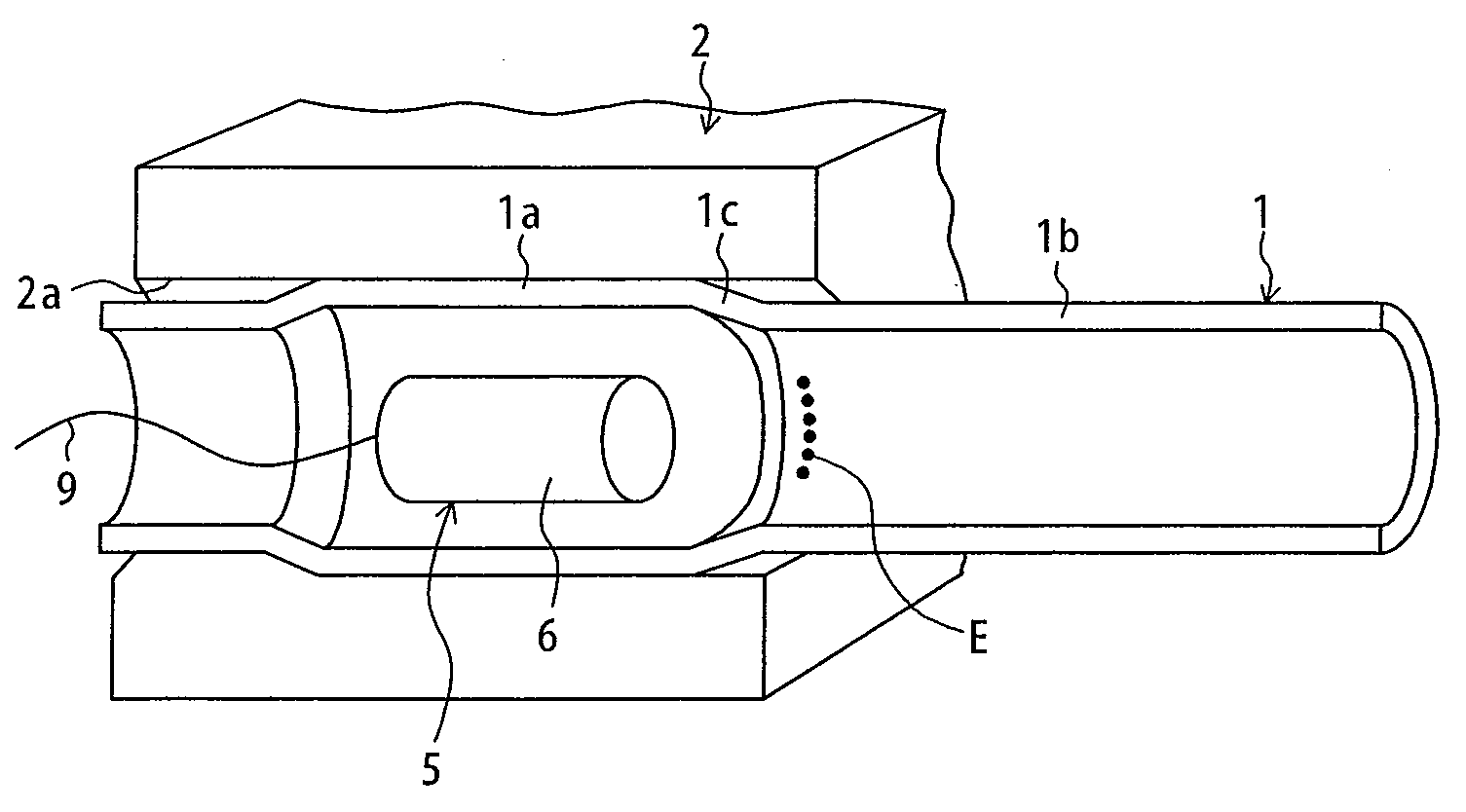

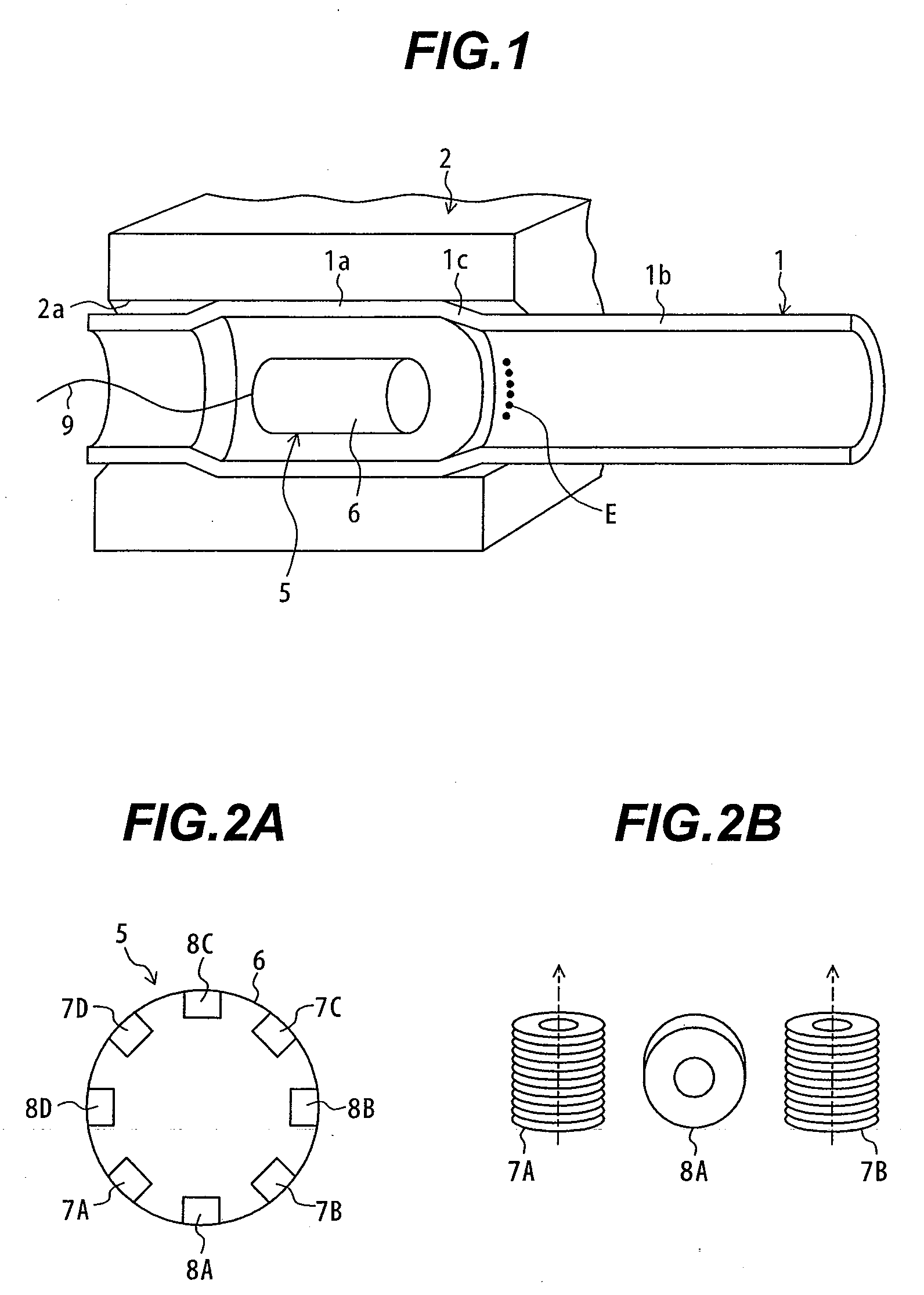

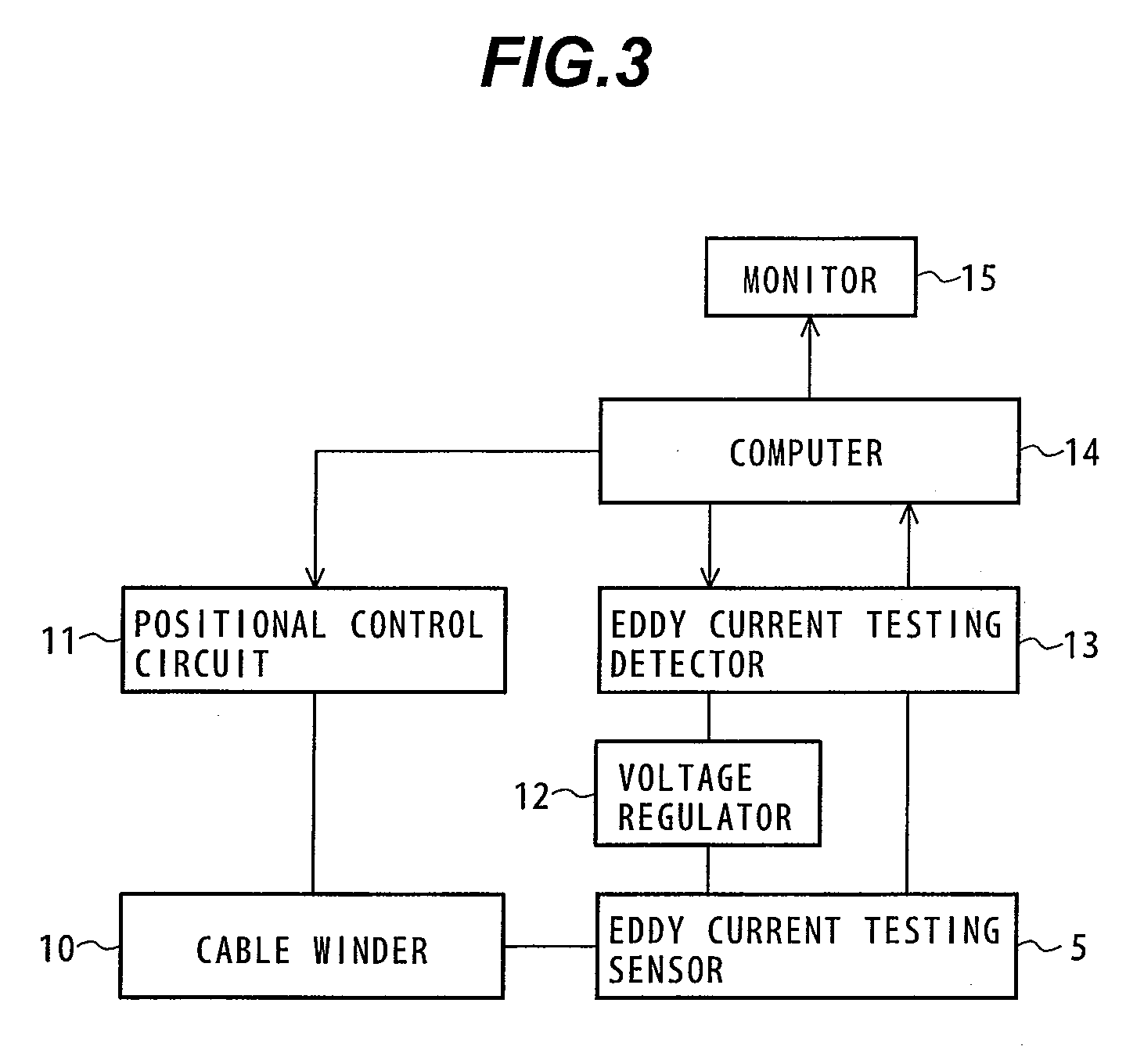

Eddy current testing method and eddy current testing apparatus

InactiveUS20090102473A1Small amountHigh positioning accuracyMaterial magnetic variablesVoltage regulationEngineering

The present invention provides an eddy current testing method and an eddy current testing apparatus that can reduce detection noise to increase the SN ratio thus improving the defect detection accuracy.An eddy current testing sensor includes a pair of excitation coils and a detection coil disposed therebetween. For example, a voltage regulator applies voltages having different amplitudes to the pair of excitation coils so as to reduce detection noise caused by a deformed portion of a heat exchanger tube and a tube plate in a detection signal of the detection coil. Alternatively, for example, an eddy current testing detector applies a first excitation frequency f1, at which tube material noise is reduced to negligible an amplitude, and a second excitation frequency f2, which is higher than the first excitation frequency f1, to the eddy current testing sensor. The phase and gain of a measurement waveform with the second excitation frequency f2 are adjusted and then a differential waveform of the first and second excitation frequencies f1 and f2 is obtained based on an induction voltage detected by the detection coil so as to cancel out tube expansion noise.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

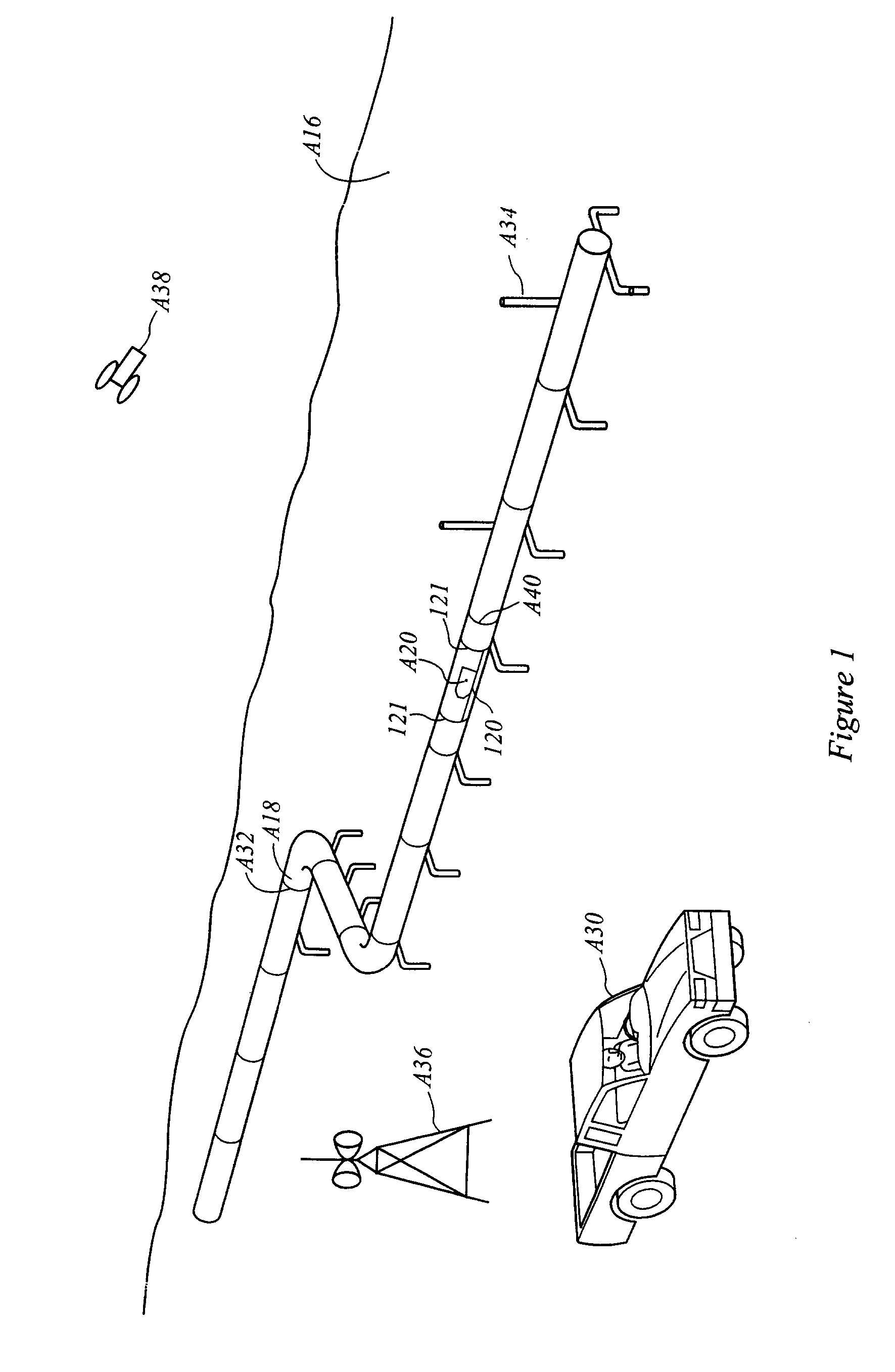

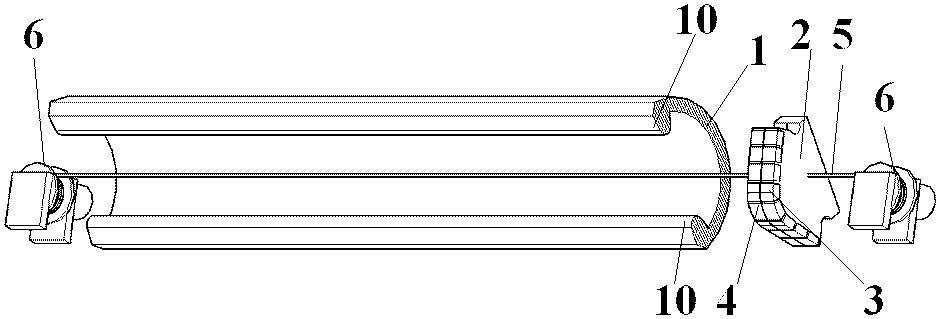

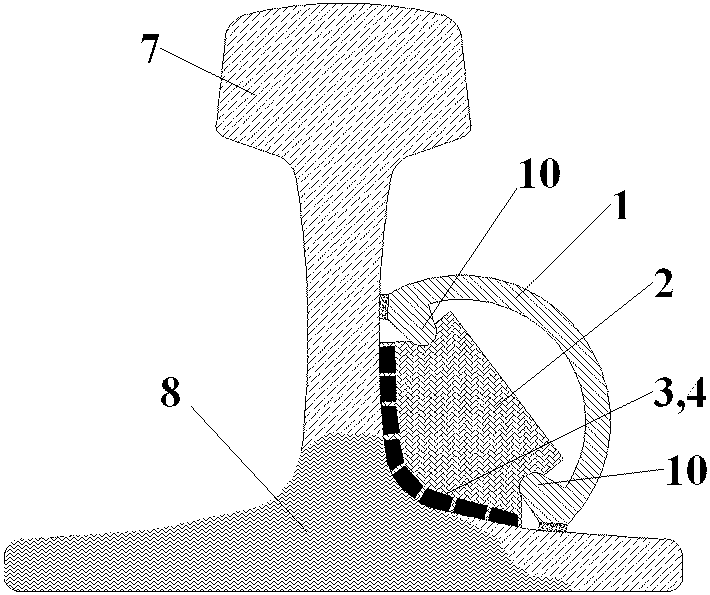

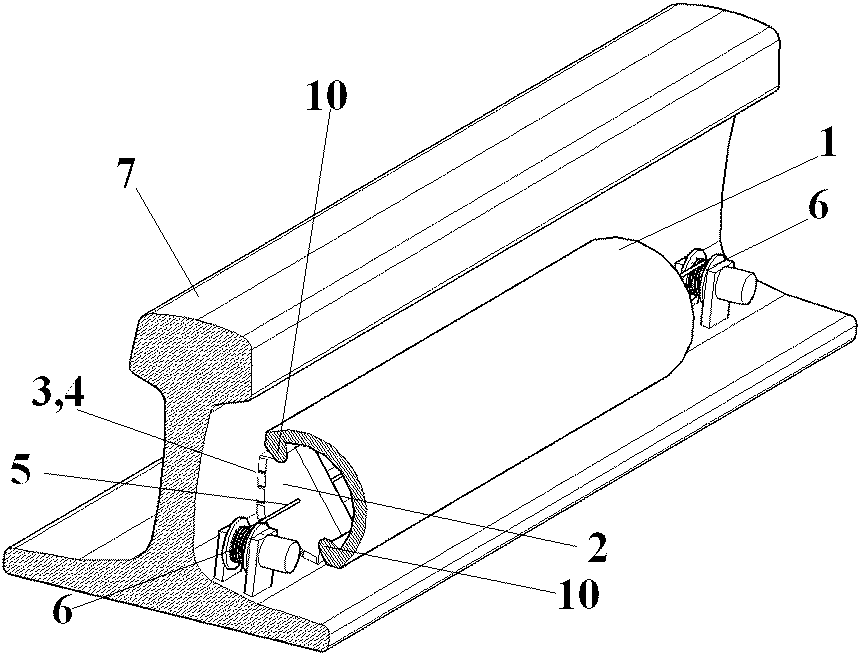

Automatic electromagnetic nondestructive testing method and device for in-use steel rail

ActiveCN103018324AEliminate chatterEliminate distractionsMaterial magnetic variablesAutomatic controlMagnetic memory

The invention discloses an automatic electromagnetic nondestructive testing method and device for an in-use steel rail. The device comprises a semi-circular tubular rail frame, a slide block, arrayed eddy current probes, arrayed metal magnetic memory probes, electronically-controlled wire take-up and pay-off racks and a steel wire rope. According to the method and the device, based on the principle of electromagnetic nondestructive testing, a rail slide testing method is adopted, the slide block is fixed outside a testing face of the steel rail, a probing face of the slide block is matched with the testing face of the steel rail to be tested, arrayed electromagnetic detection probes and arrayed metal magnetic memory detection probes are fixed on the probing face of the slide block, and the slide block is electromechanically and automatically controlled to slide along the testing face of the steel rail to be tested so as to carry out testing; various defects of the surface of the steel rail to be tested can be tested by adopting differential eddy current scanning rules and absolute eddy current scanning rules in an array eddy current testing method, and meanwhile, the interference and influence caused by vibration and lift-off are eliminated; the situations of early fatigue and stress concentration of the steel rail can be evaluated by an array metal magnetic memory testing method; and the device is high in testing efficiency and testing accuracy, facilities and equipment are not required for being in operation suspension, and the in-use testing can be carried out.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

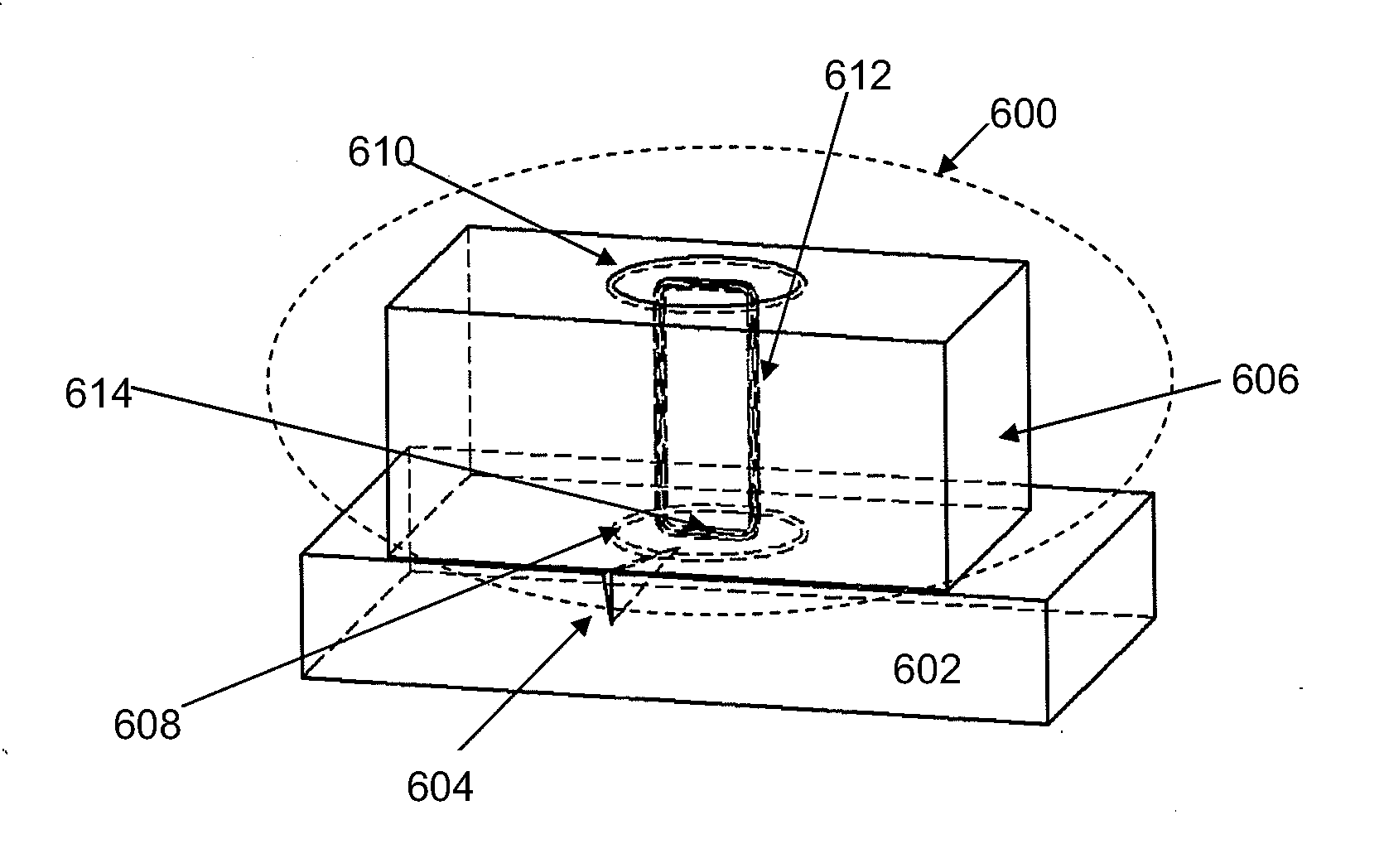

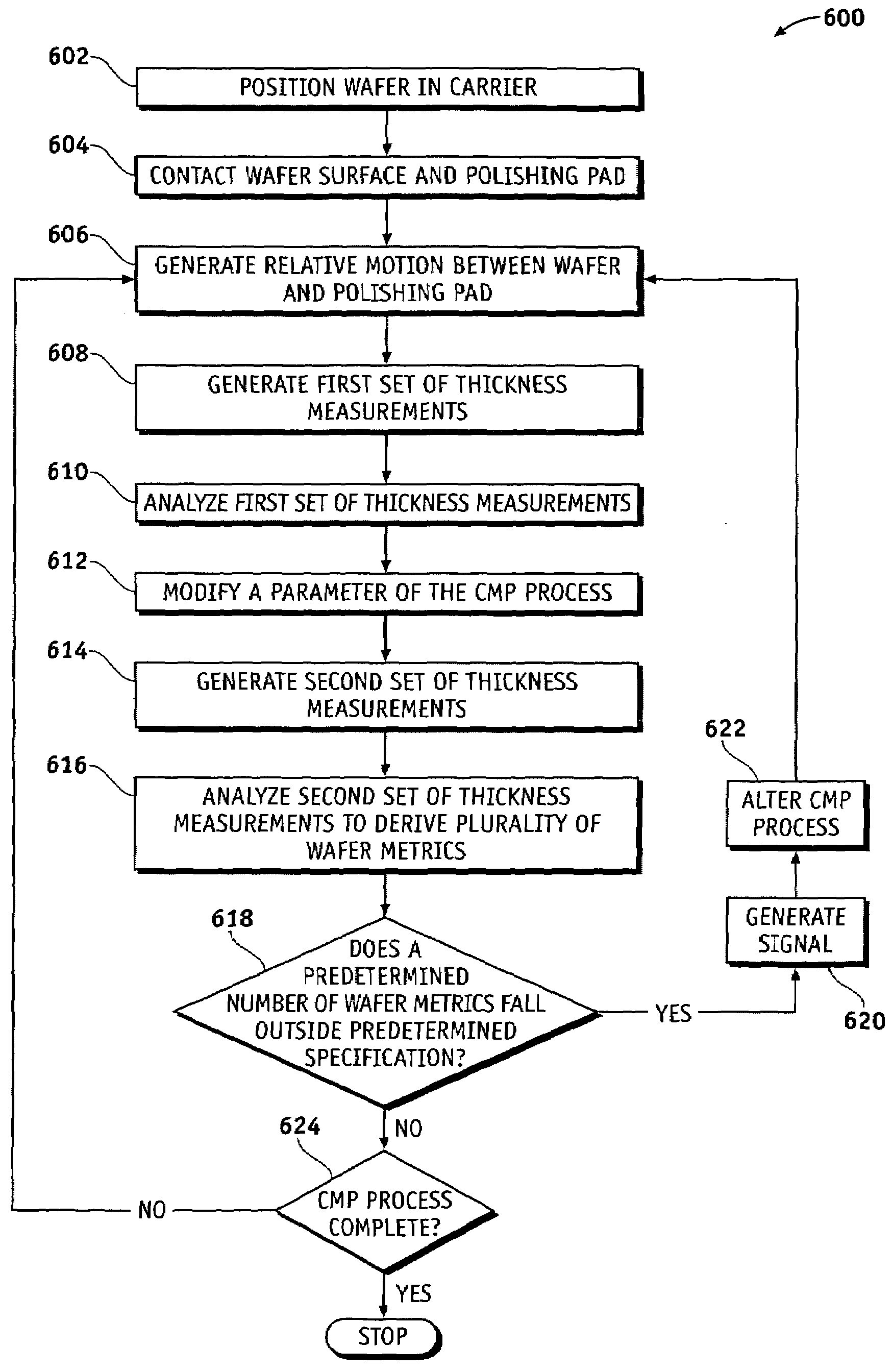

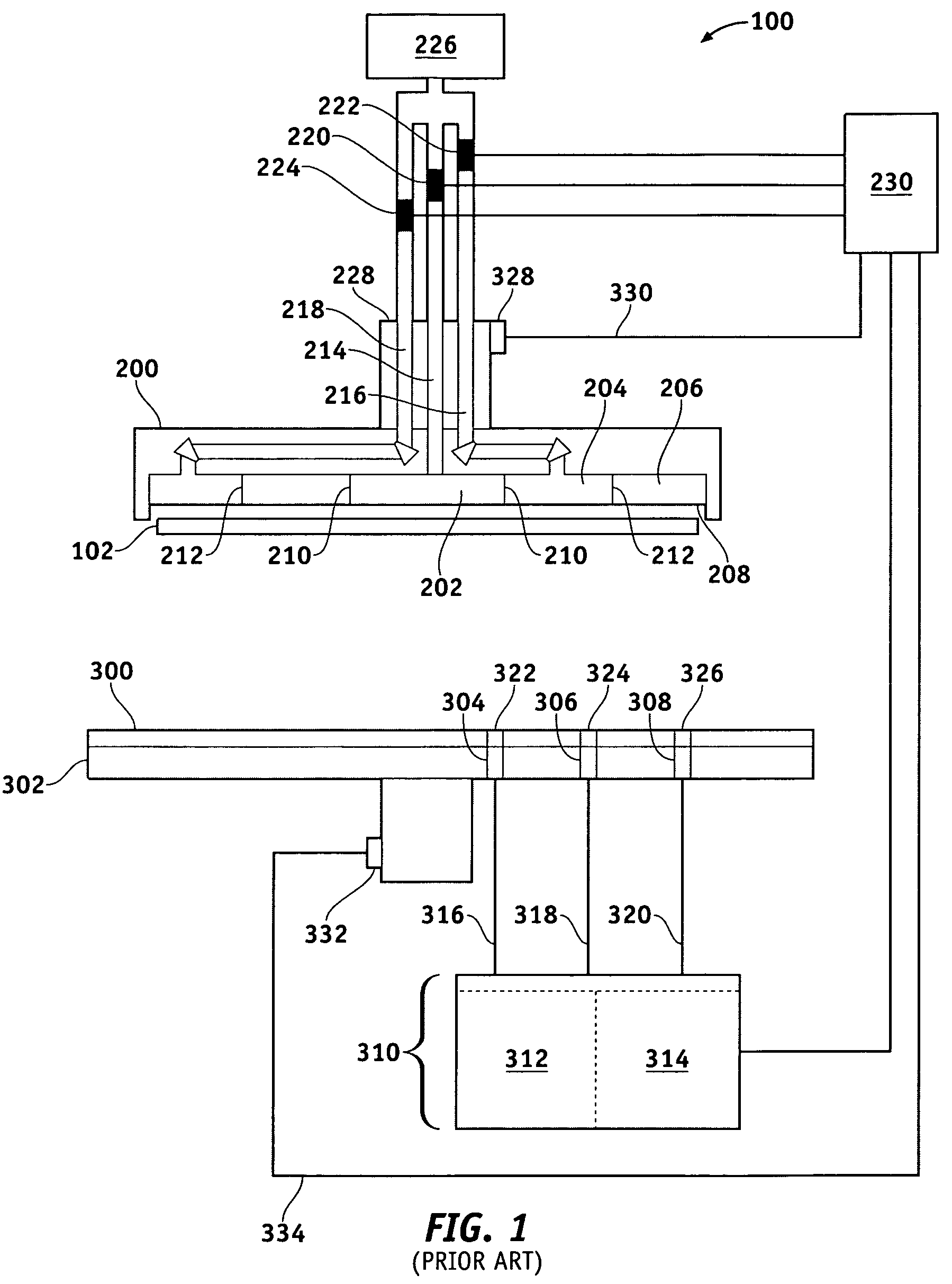

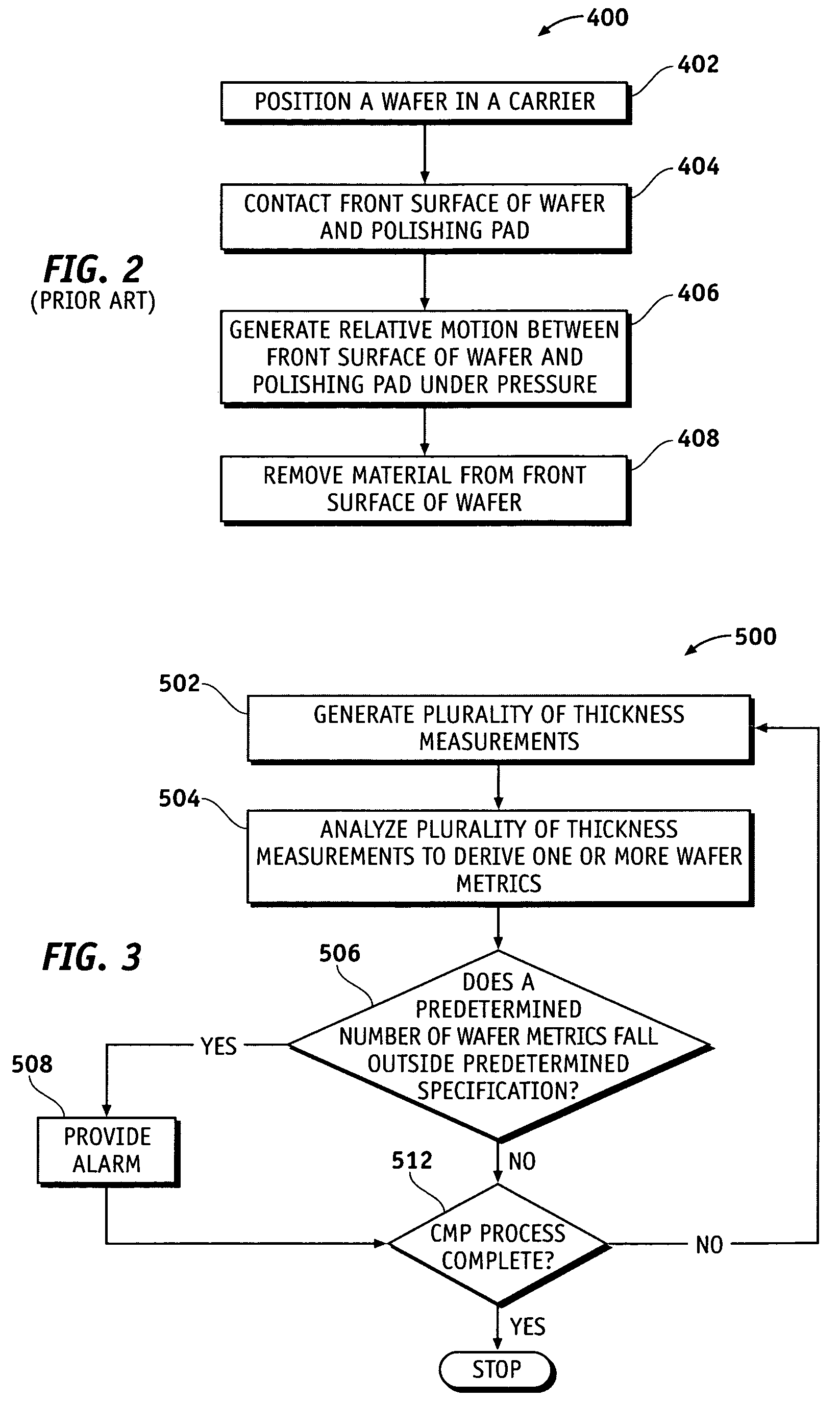

Methods for monitoring a chemical mechanical planarization process of a metal layer using an in-situ eddy current measuring system

InactiveUS7264537B1Lapping machinesGrinding feed controlChemical-mechanical planarizationEddy-current testing

Methods are provided for monitoring a CMP process. An exemplary method comprises generating a plurality of thickness measurements of a metal layer using an in-situ eddy current measuring system. The thickness measurements are analyzed to derive a plurality of work piece metrics and the work piece metrics are assessed to determine if a predetermined number is within a predetermined specification. A signal is generated if the predetermined number of the work piece metrics is outside the predetermined specification.

Owner:NOVELLUS SYSTEMS

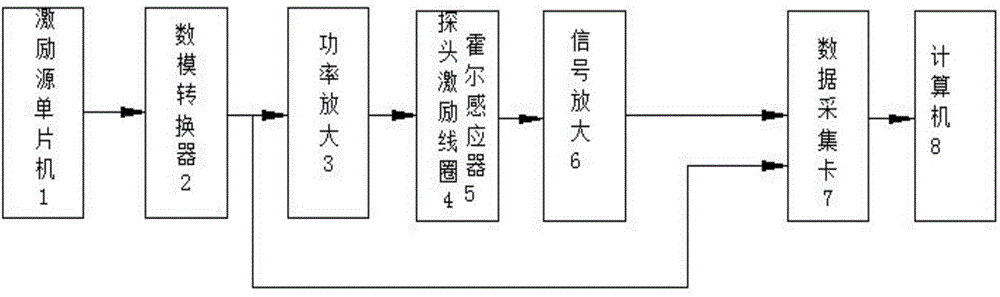

Defect and stress non-destructive testing system and non-destructive testing method based on pulsed eddy current and Barkhausen

ActiveCN104977352AMixed Signal Simple and EffectiveReliable detection methodMaterial magnetic variablesData acquisitionFerromagnetism

The present invention provides a defect and stress non-destructive testing system and non-destructive testing method based on pulsed eddy current and Barkhausen, and belongs to the field of non-destructive testing. According to the present invention, the system comprises an excitation signal generator, a digital-to-analog converter, a power amplifier, an excitation coil, a Hall sensor, a signal amplification circuit, a data acquisition card and a computer; on the basis of eddy current testing, based on the ferromagnetic material, the mixed wave of the rectangular wave and the triangular wave is adopted as the excitation signal, the rectangular wave band at the first half section in the mixed signal produces the pulsed eddy current phenomenon, the triangular wave band at the later half section in the mixed wave produces the barkhausen effect, the sectional treatment is performed on the signal by using a signal time domain average method to achieve the separation of the eddy current signal and the Barkhausen noise signal, and the signal is respectively subjected to feature extraction and data processing so as to concurrently achieve online detection of the surface defect, the stress and the microstructure state of the ferromagnetic material and achieve the discrimination of the ferromagnetic material recessive defect, the prediction of the defect being not yet formed, and the prediction of the service life; and the method has characteristics of long-term and reliable work, high sensitivity, simpleness, intuitive display, high efficiency, feasibility, and the like.

Owner:江苏高特高金属科技有限公司

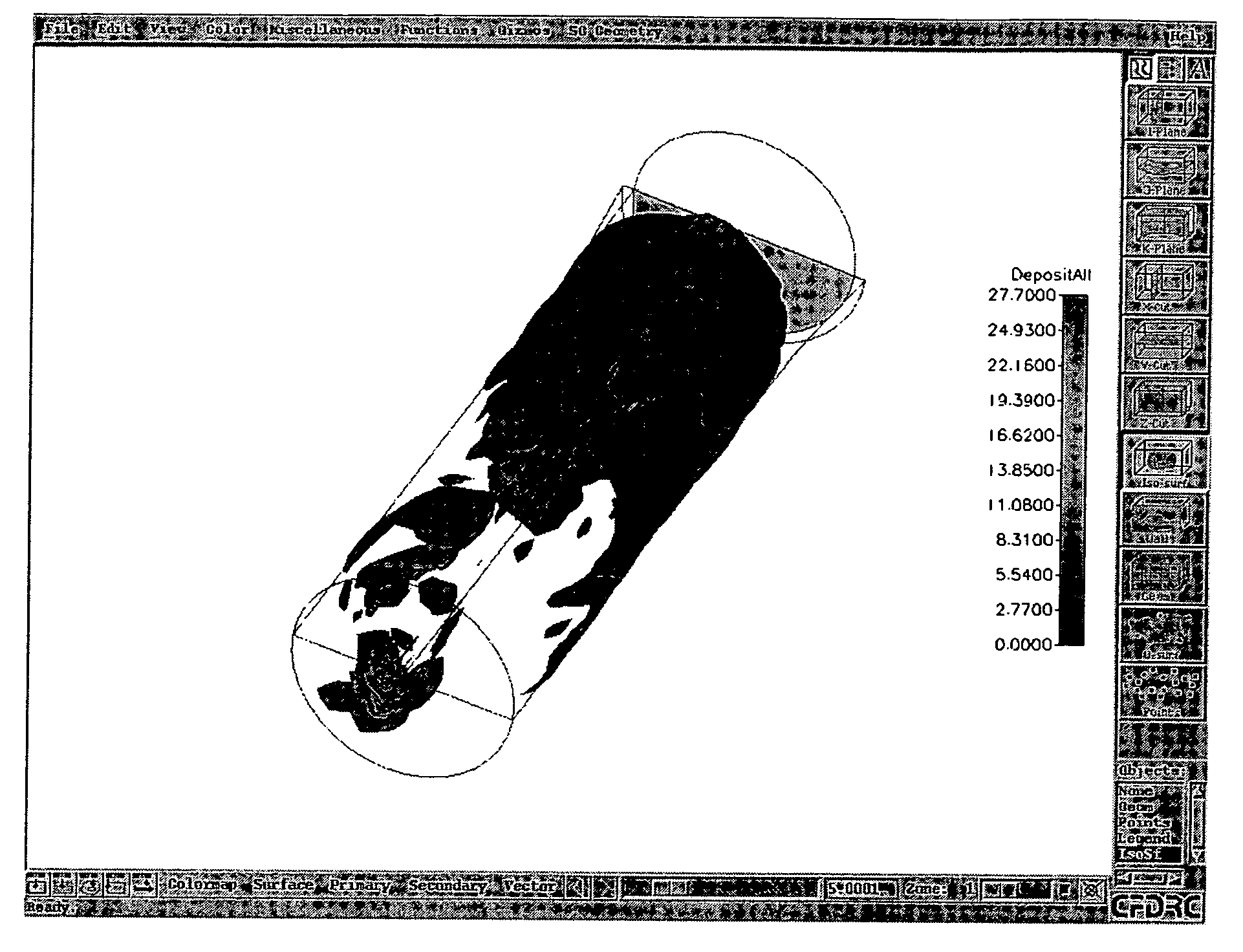

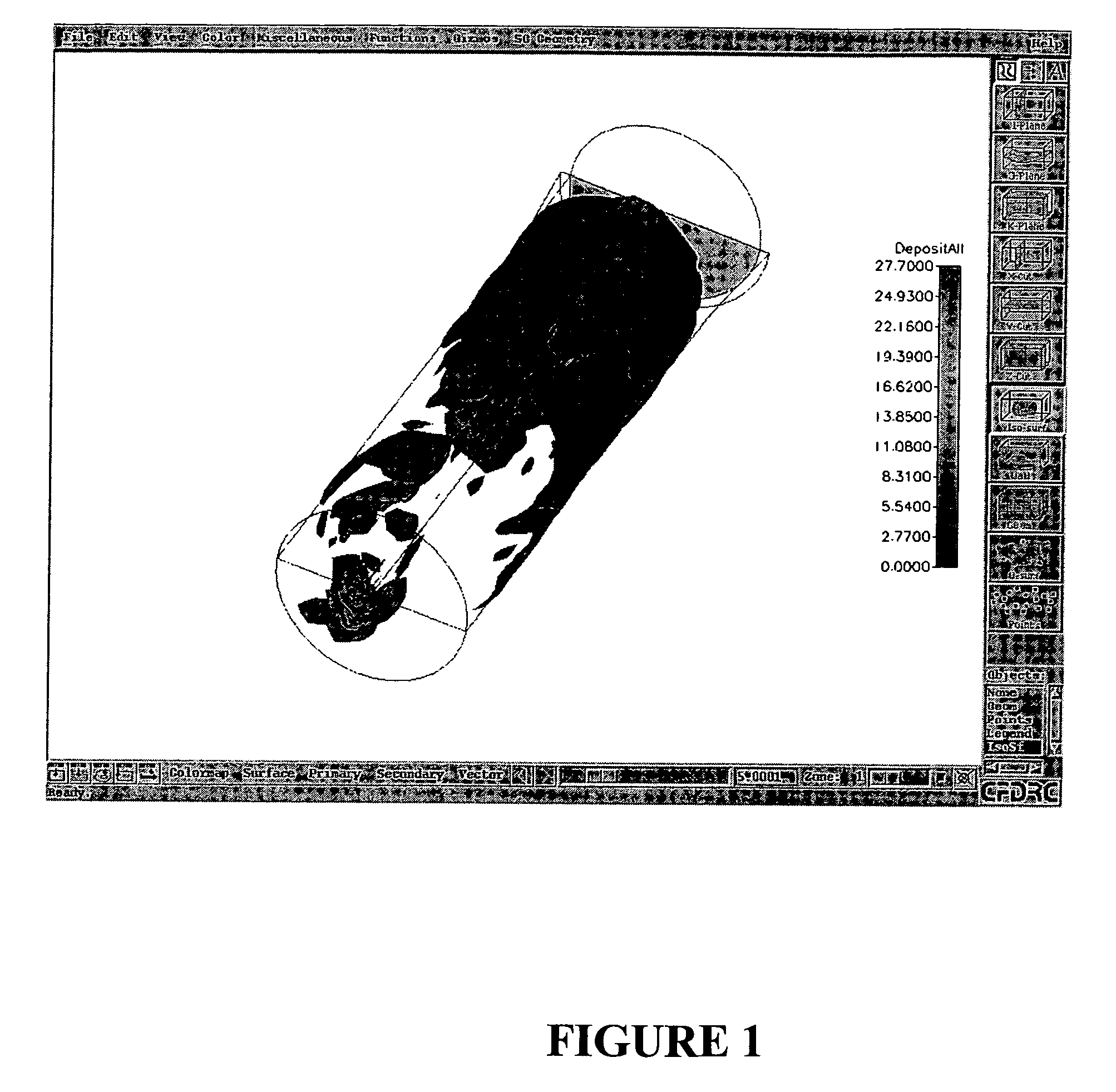

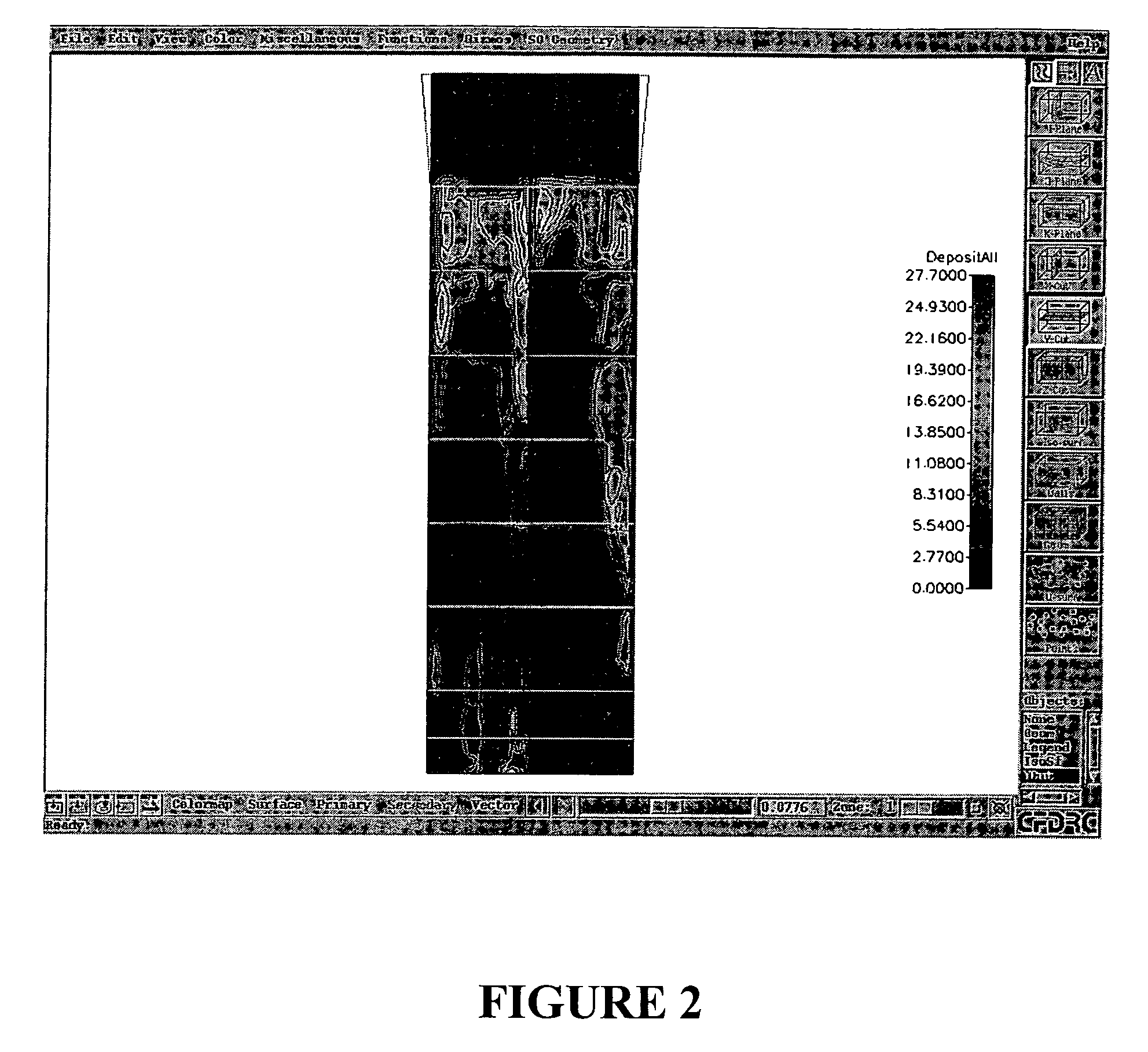

Steam generator mapping with reflections of eddy current signal

ActiveUS7405558B2Minimization requirementsWeather/light/corrosion resistanceNuclear energy generationEddy-current testingEngineering

A method to determine deposits in a steam generator having the steps of creating a calibration standard having at least two rings of deposit material, subjecting the calibration standard to an eddy current signal, wherein an amplitude of the signal reflected from the calibration standard is used to obtain a polynomial equation fit of the reflected eddy current signals to actual thickness of the rings, obtaining a steam generator with tubes, initiating an eddy current signal into the tubes of the steam generator, detecting and recording reflections of the eddy current signal initiated into the tubes of the steam generator, and determining a thickness of the deposits in the steam generator from the recorded reflections of the eddy current signal and the polynomial equation.

Owner:AREVA NP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com