Patents

Literature

47results about How to "Improve cleanliness level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

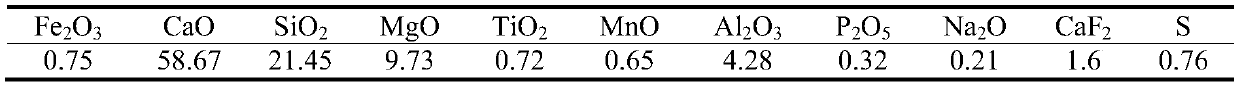

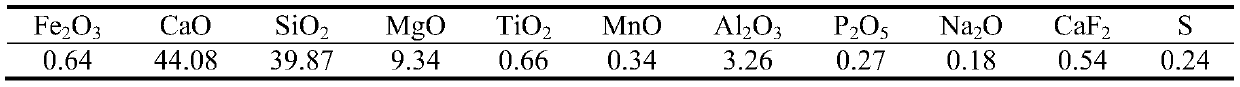

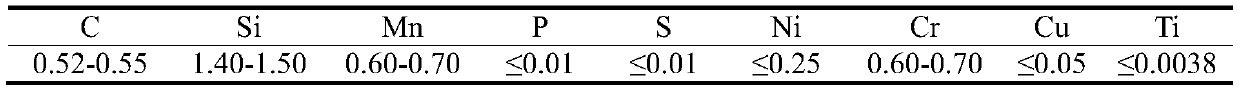

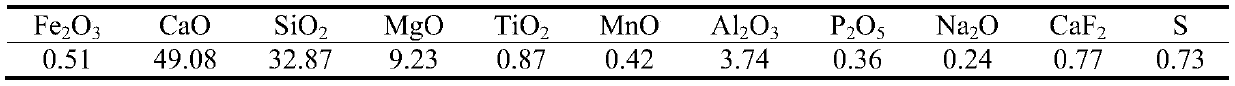

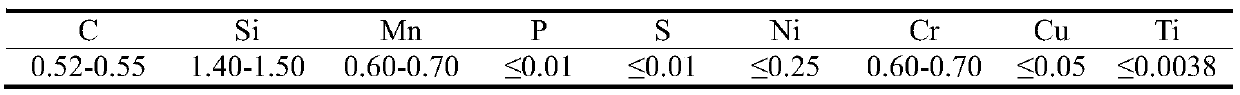

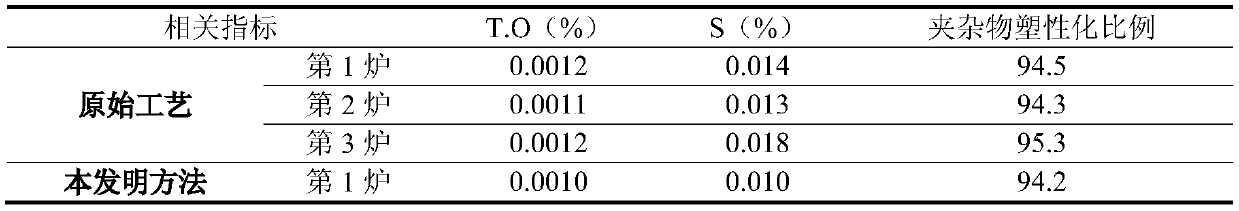

Method for producing silicon deoxygenation low-sulfur high-carbon steel through LF refining double slag method

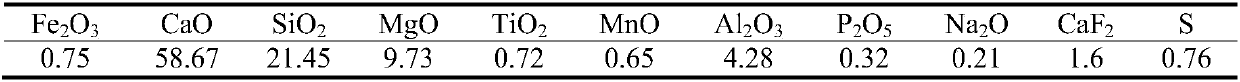

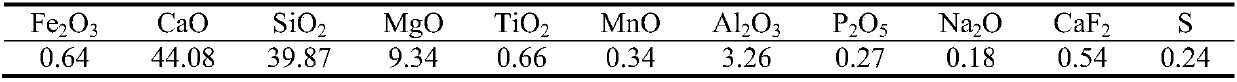

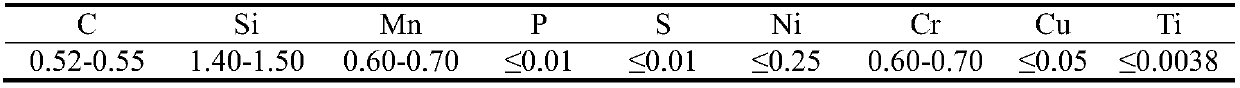

The invention relates to a method for producing silicon deoxygenation low-sulfur high-carbon steel through an LF refining double slag method. An electric furnace-LF-VD continuous casting technology isadopted. The method includes the steps that in the electric furnace tapping process, carbon powder is mixed firstly, then a silicon alloy and a manganese alloy are added for conducting deoxygenationalloying treatment, and lime, calcium carbide and aluminum-free refining slag are added for conducting modification treatment; secondly, after an LF enters a station, lime, calcium carbide, silicon iron and aluminum-free refining slag are added into the furnace for making high-alkalinity reducing refining slag; thirdly, low-alkalinity reducing slag is made, and the content of components in moltensteel is adjusted; and fourthly, the LF withdraws from the station after refining, VD and continuous casting processes are conducted in sequence, and the silicon deoxygenation low-sulfur high-carbon steel is obtained. The method is simple, reliable, high in operability and easy to achieve, the production cost of the whole process is reduced, the sulfur removing efficiency is high, the cleanlinesslevel of molten steel is high, the problem that when a non-molten-steel pretreatment sulfur removing process is adopted for producing high-quality silicon deoxygenation low-sulfur high-carbon steel, sulfur removing is difficult is solved well, and therefore the product quality is improved, and the economic benefits of a steel enterprise are increased.

Owner:CENT IRON & STEEL RES INST

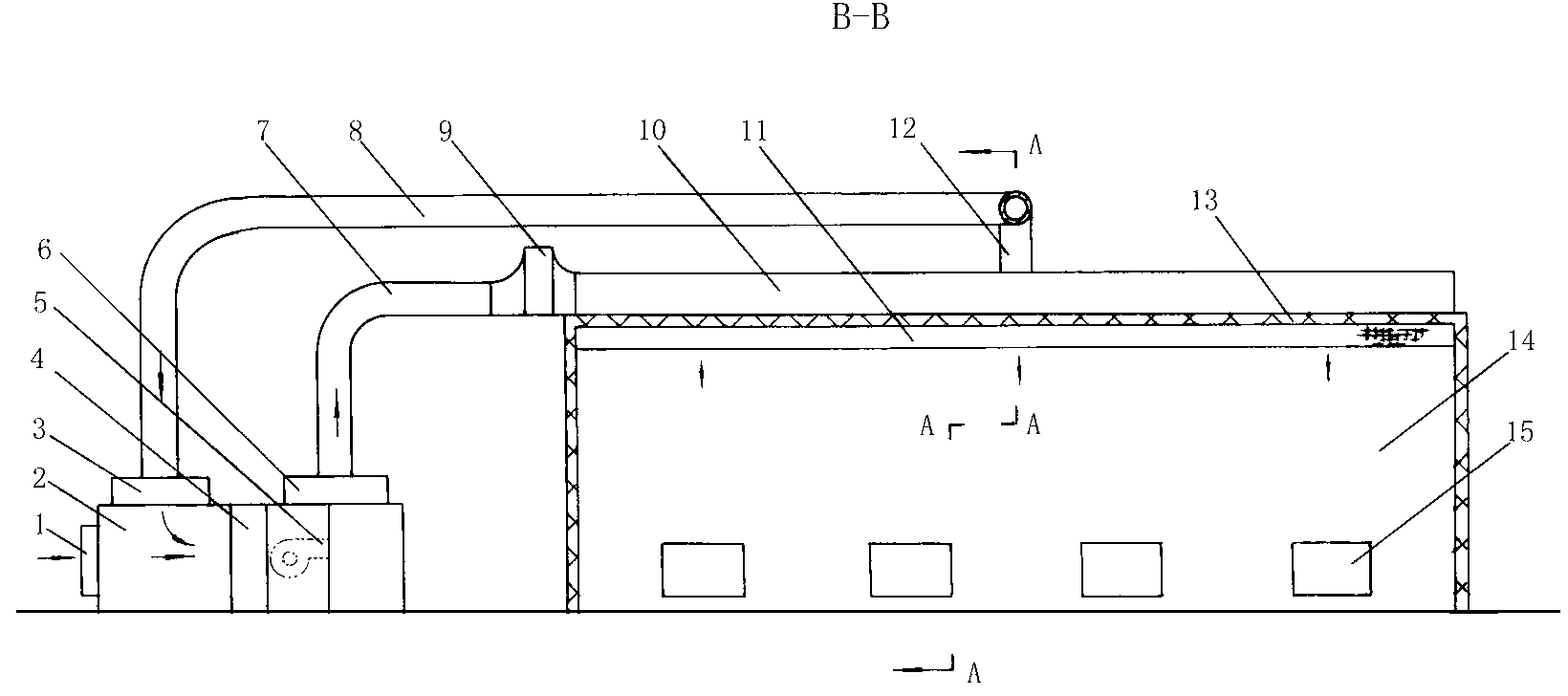

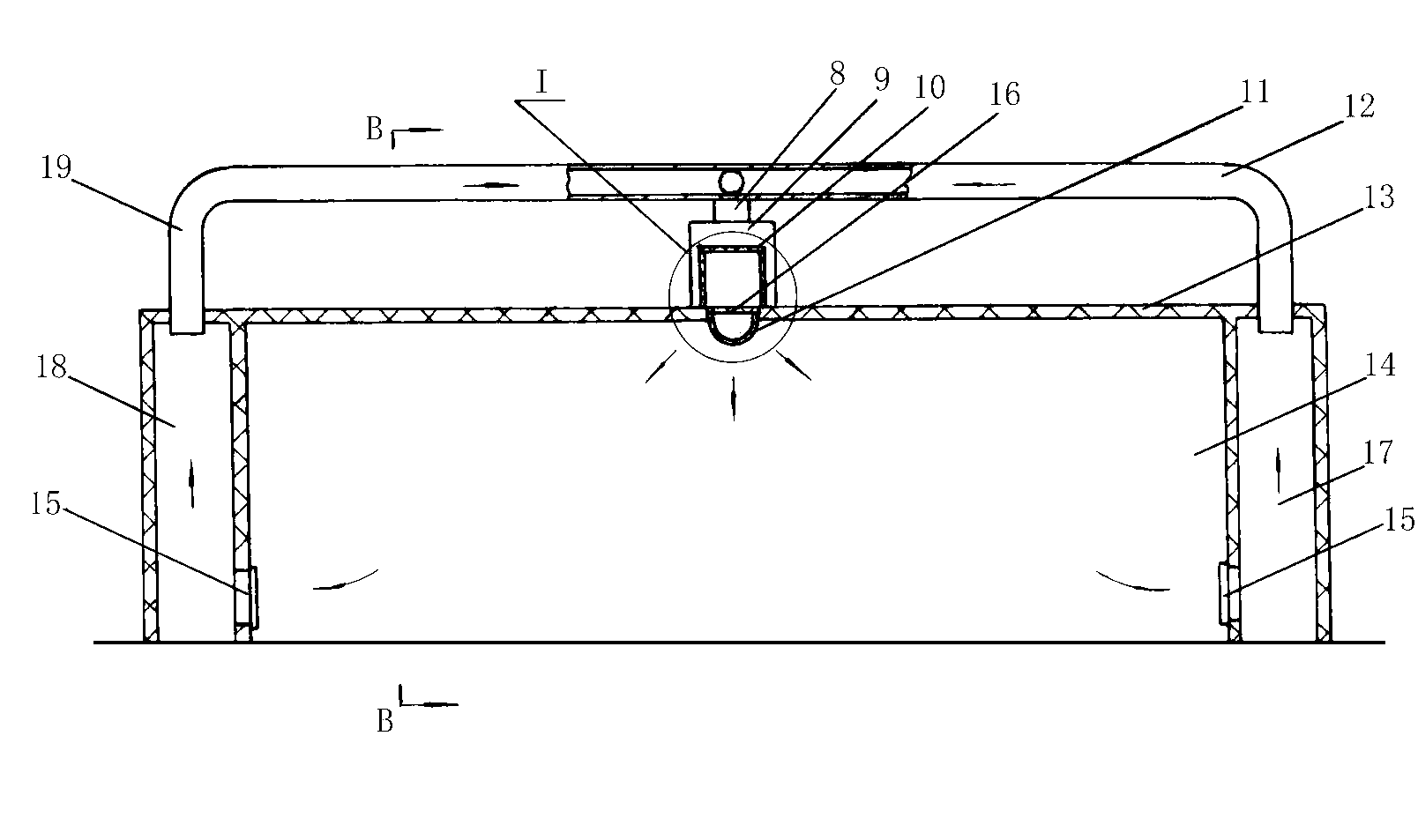

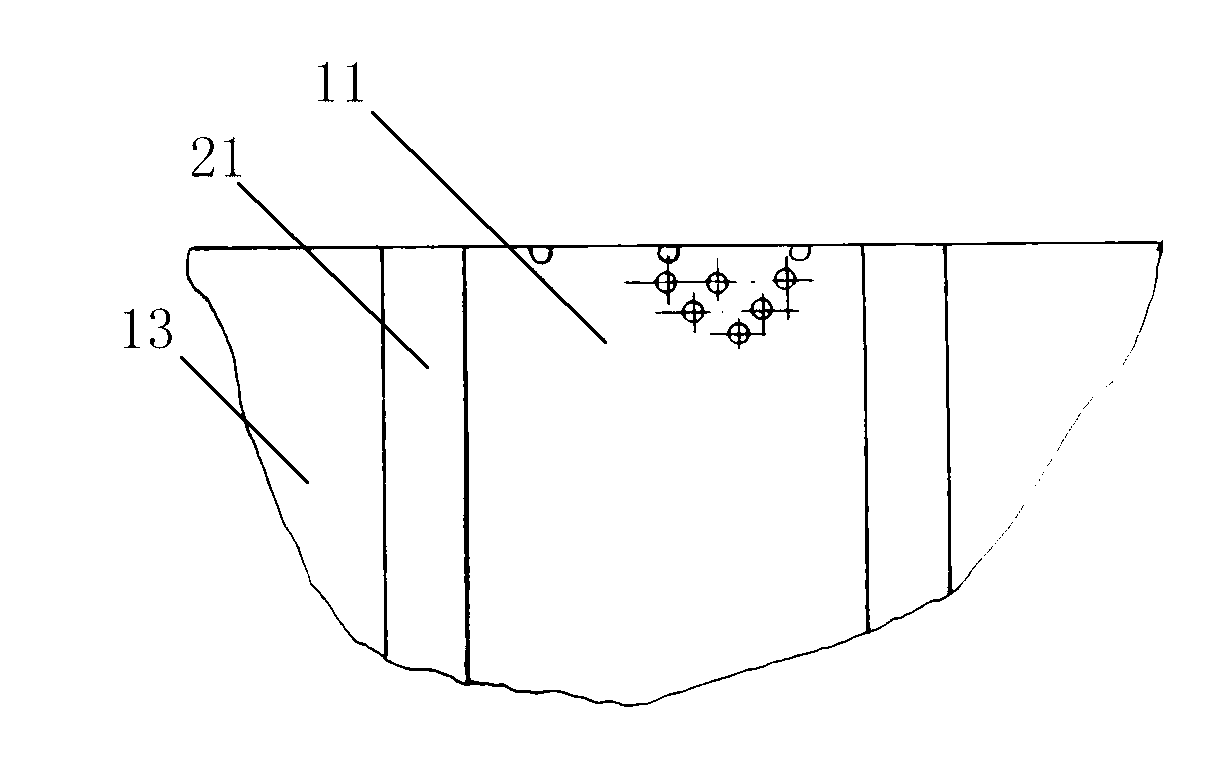

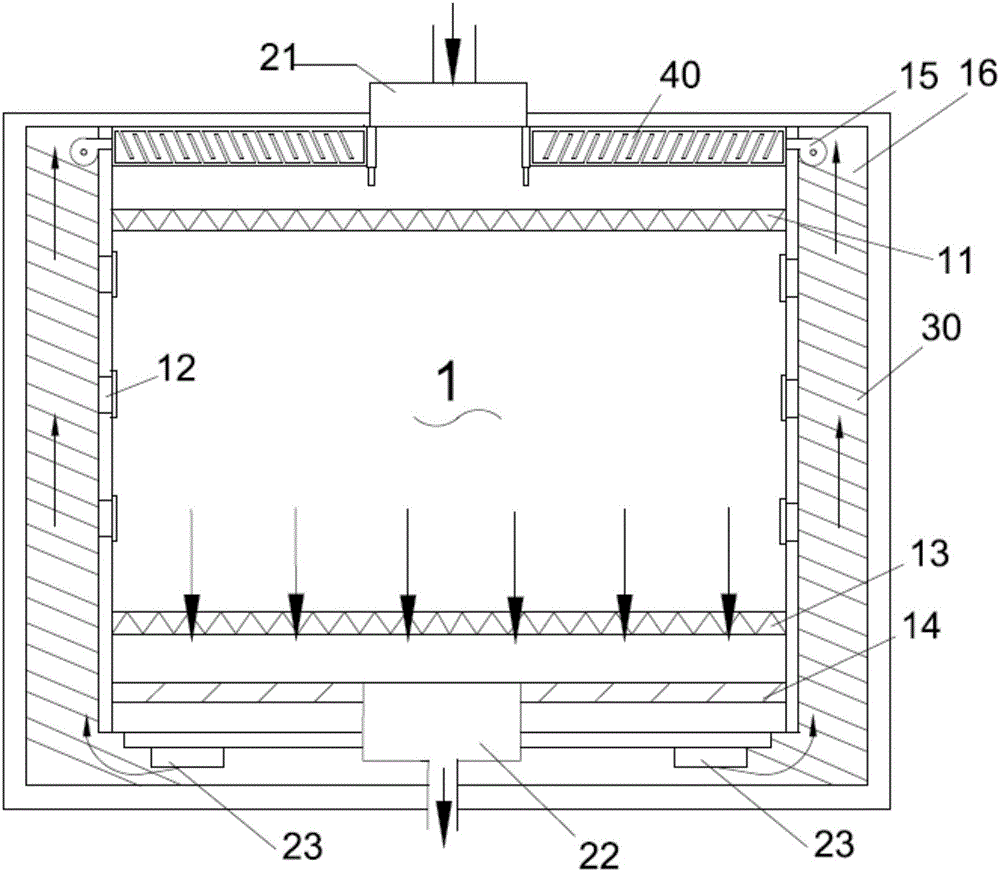

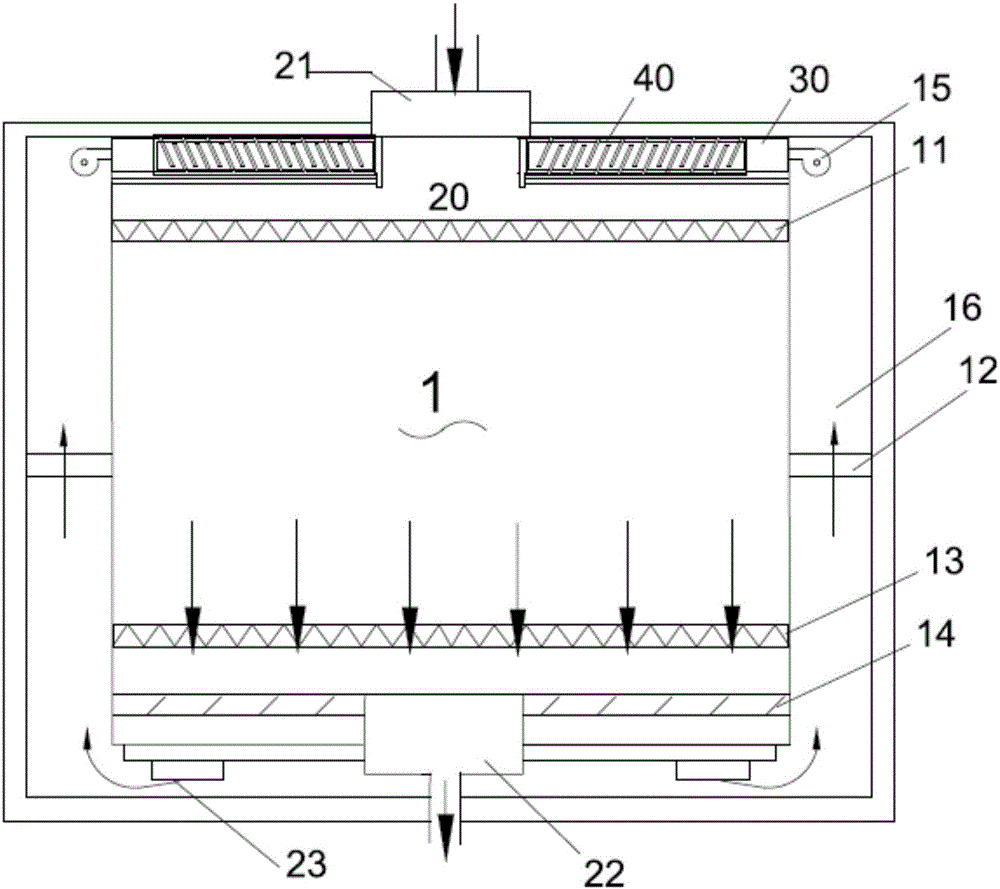

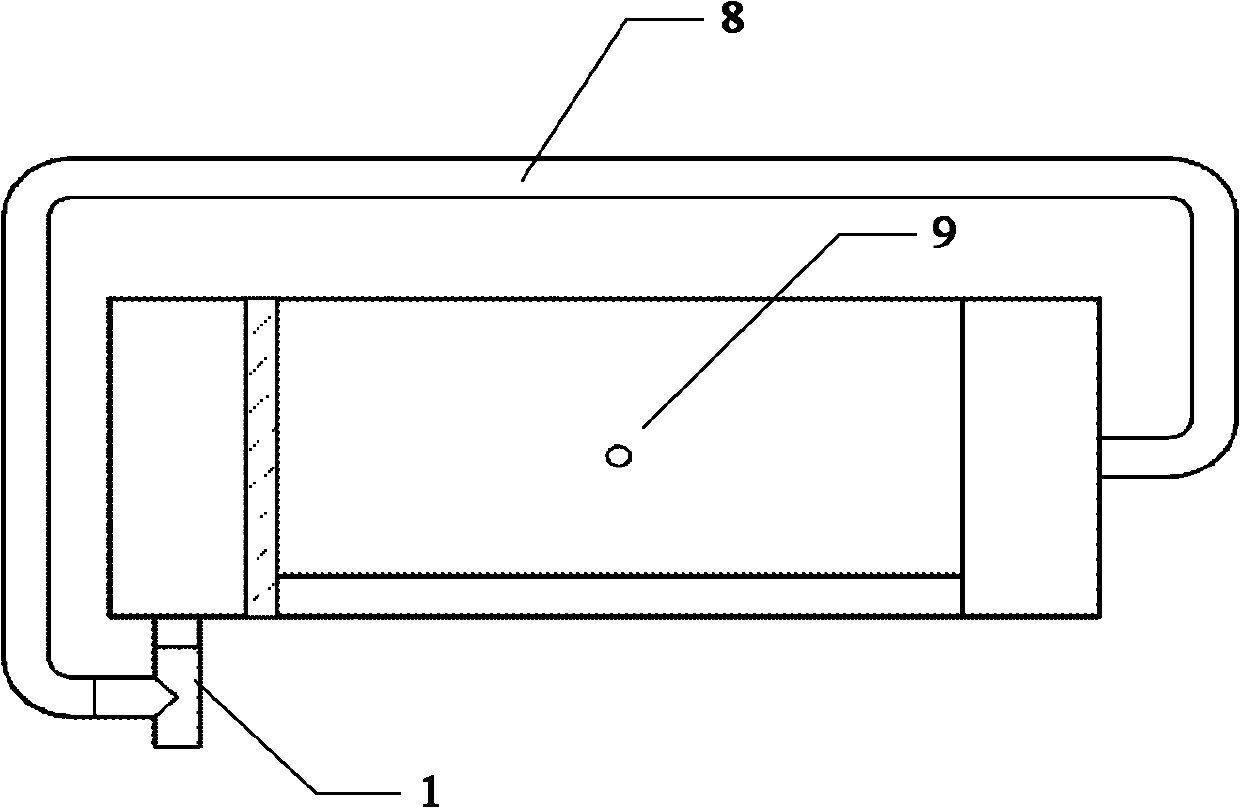

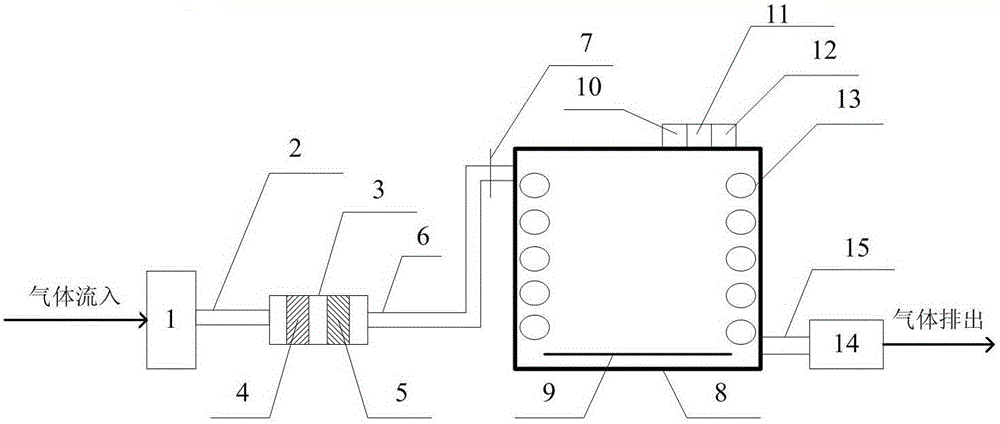

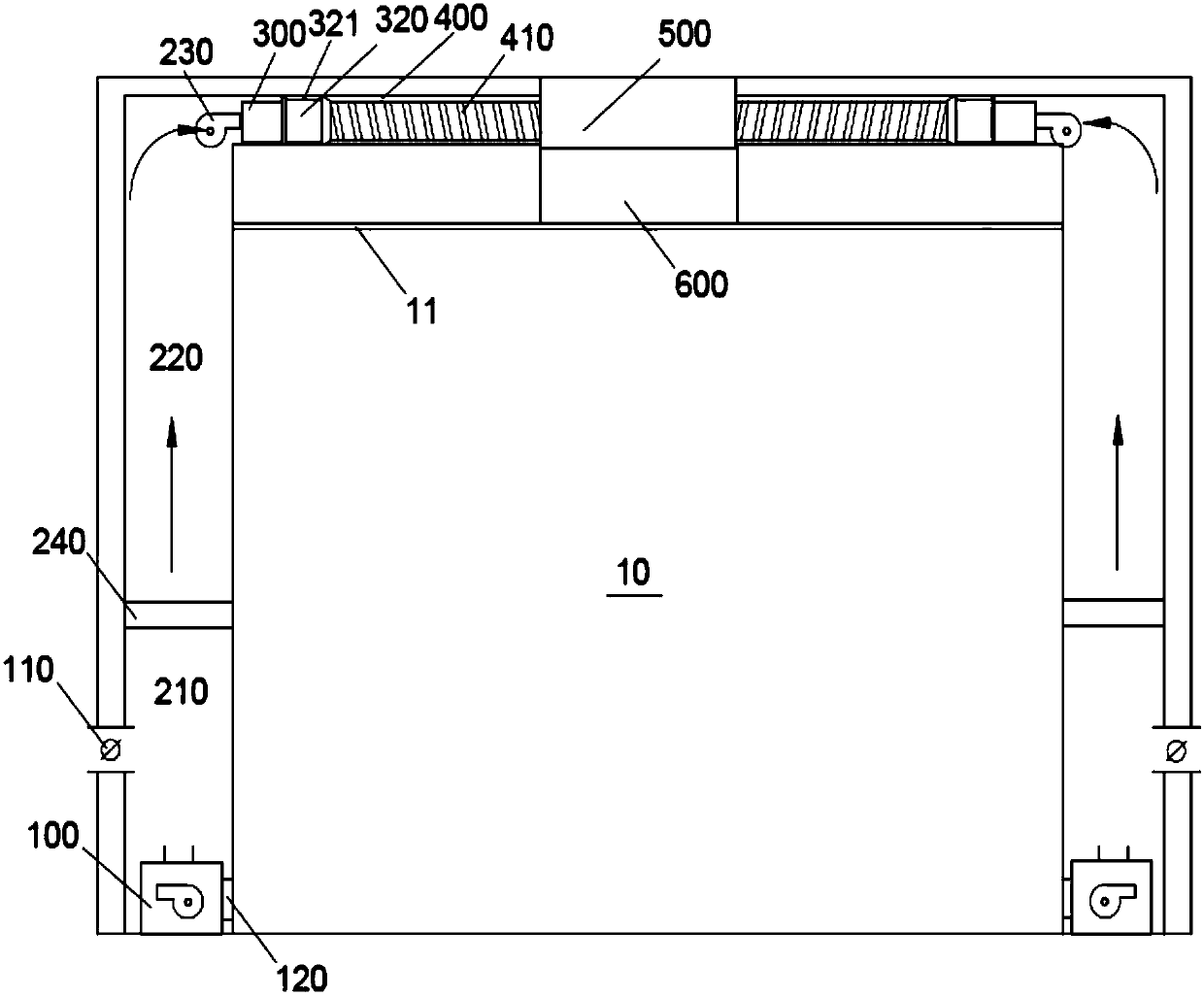

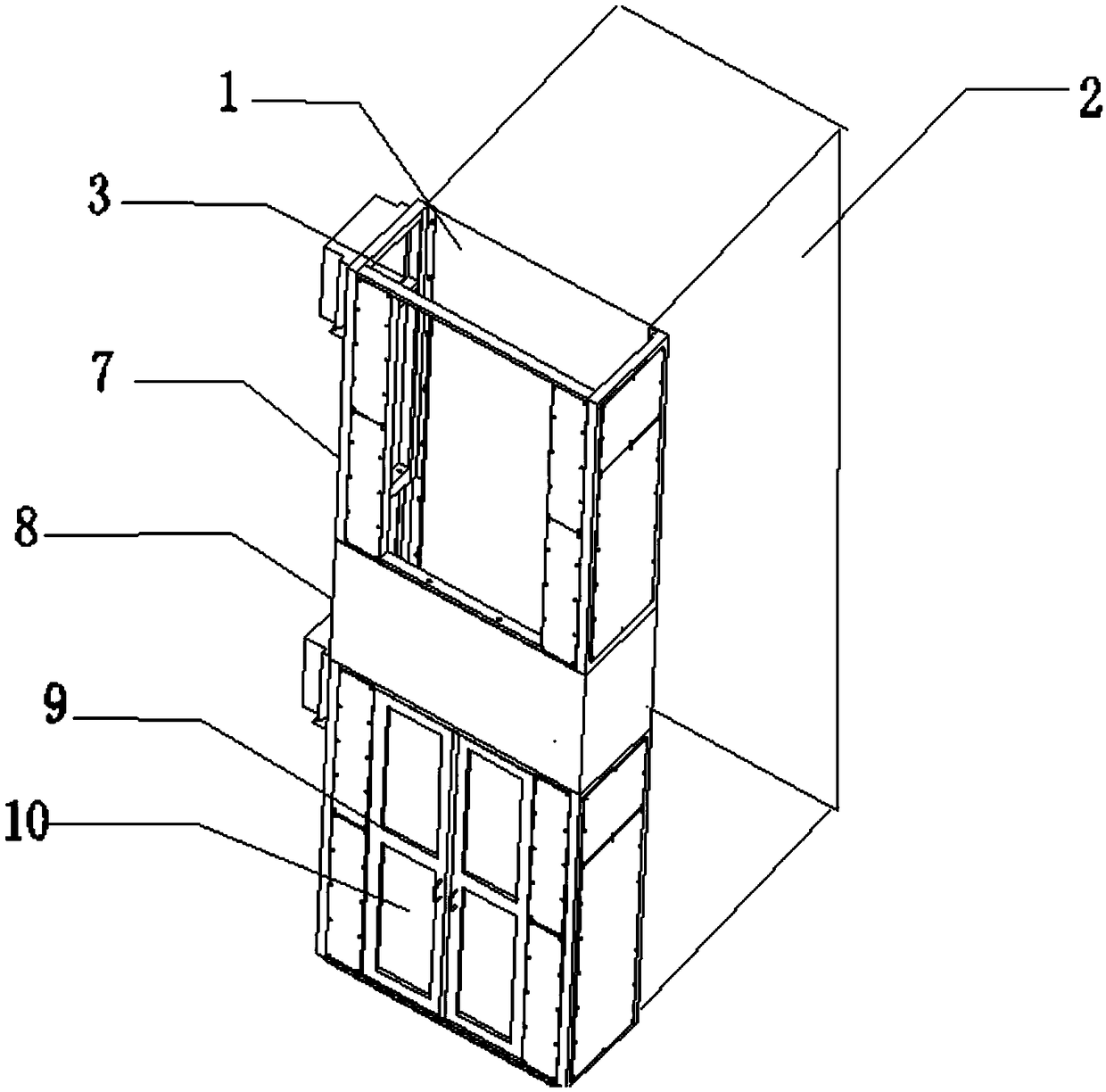

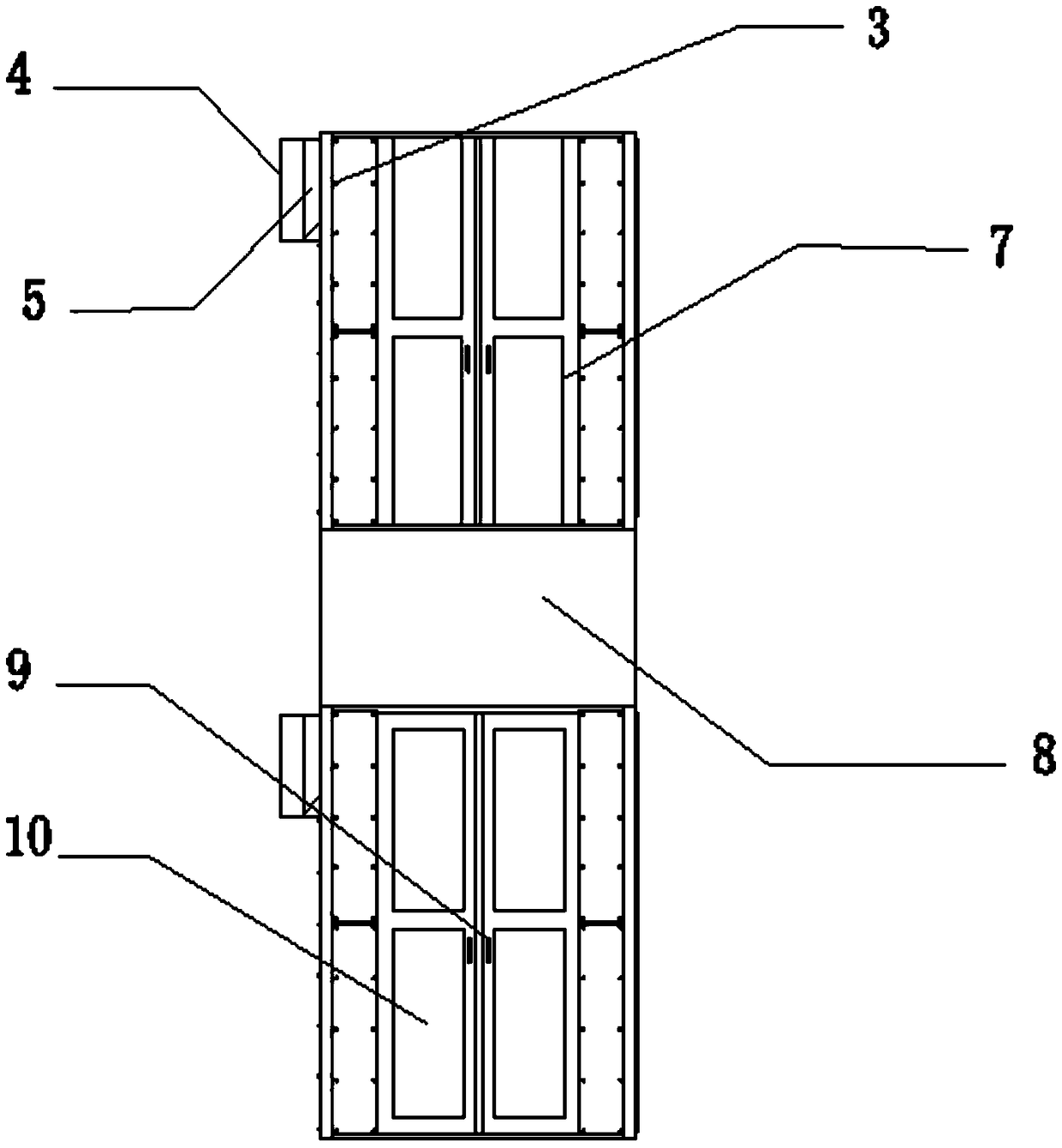

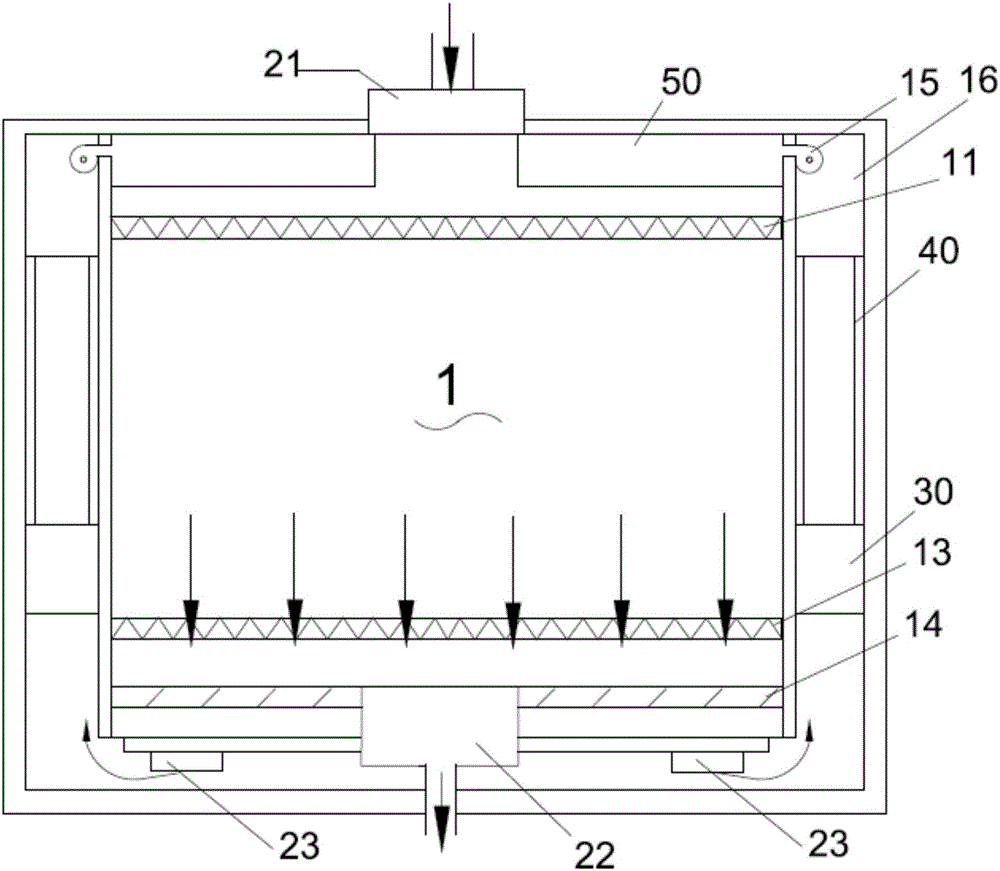

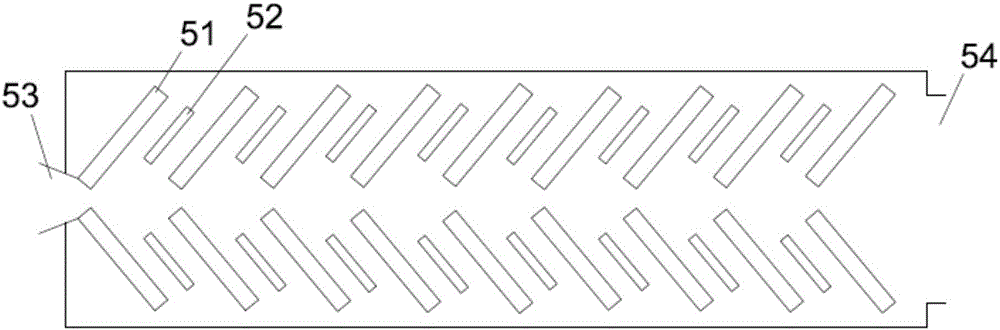

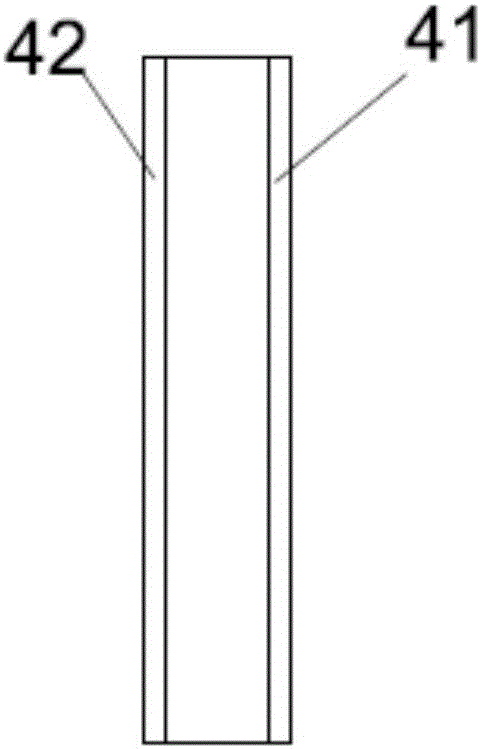

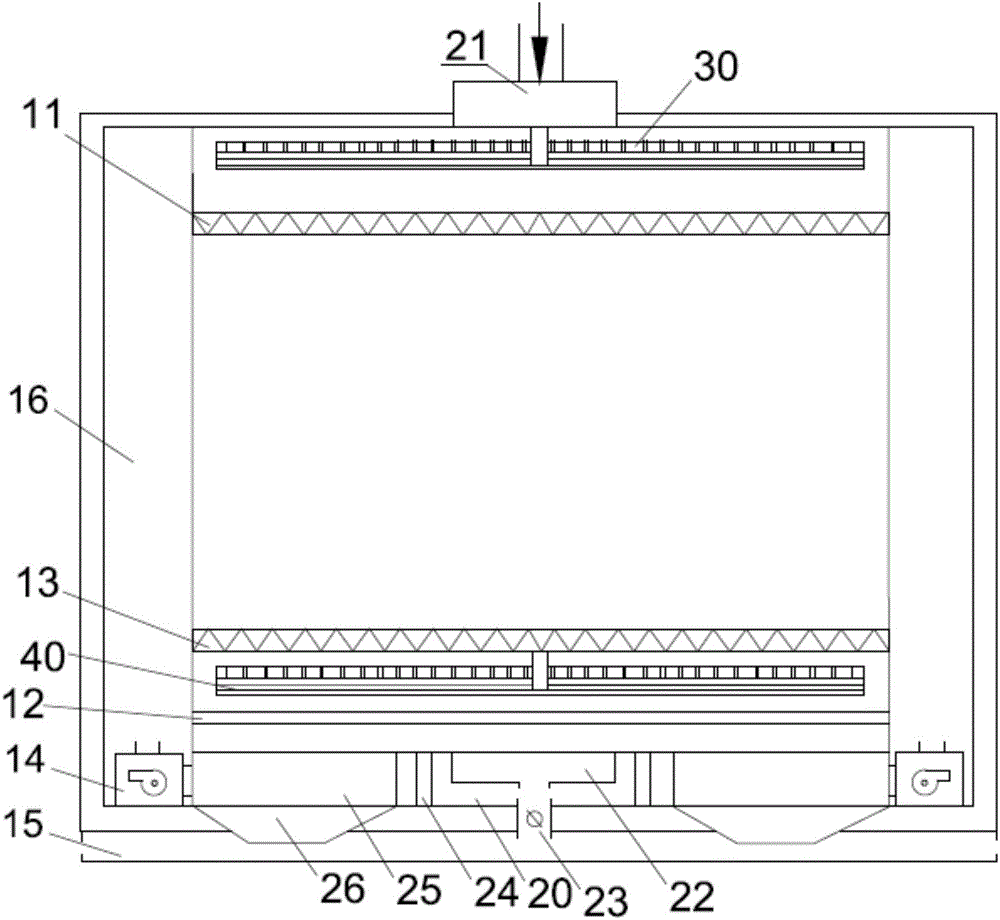

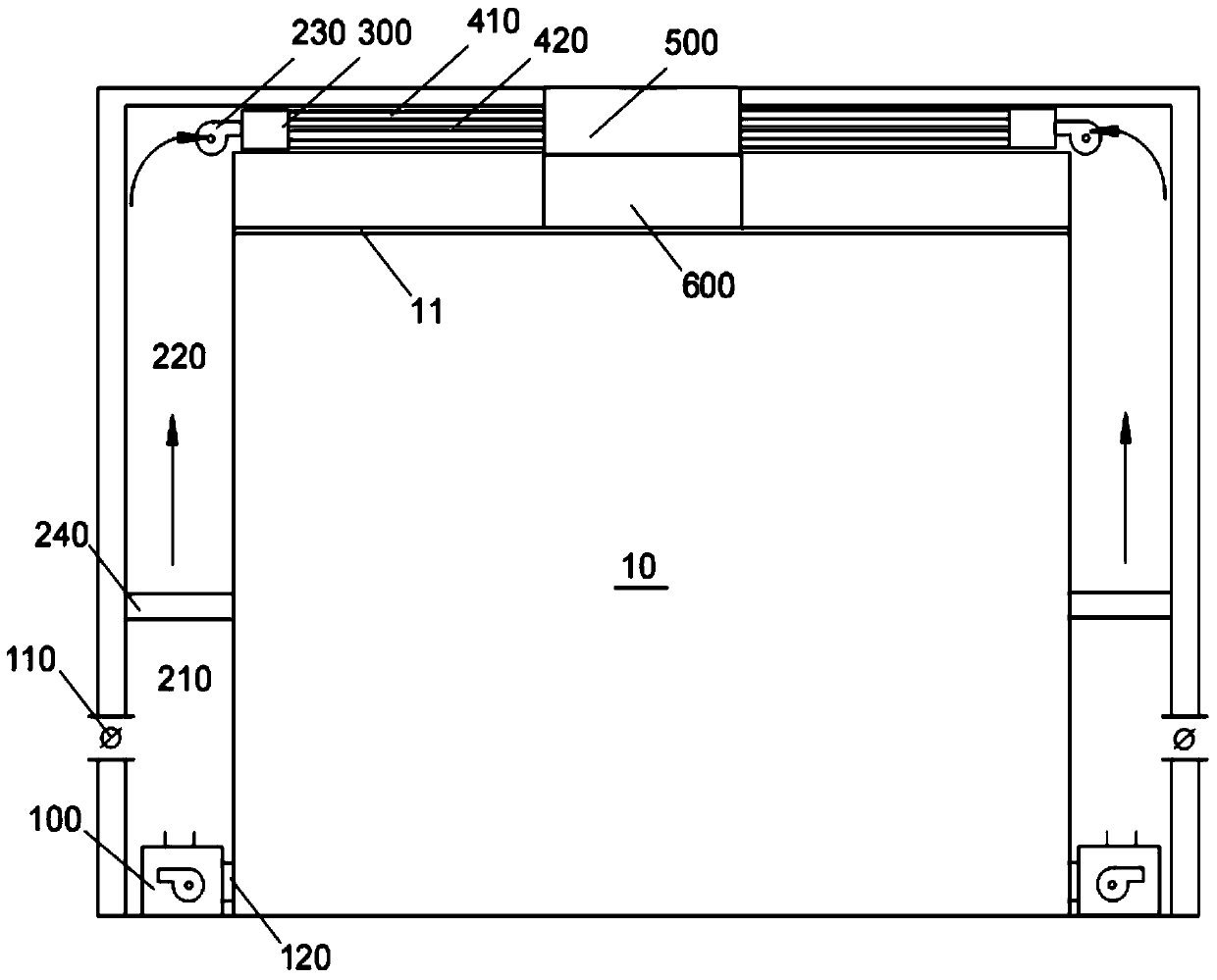

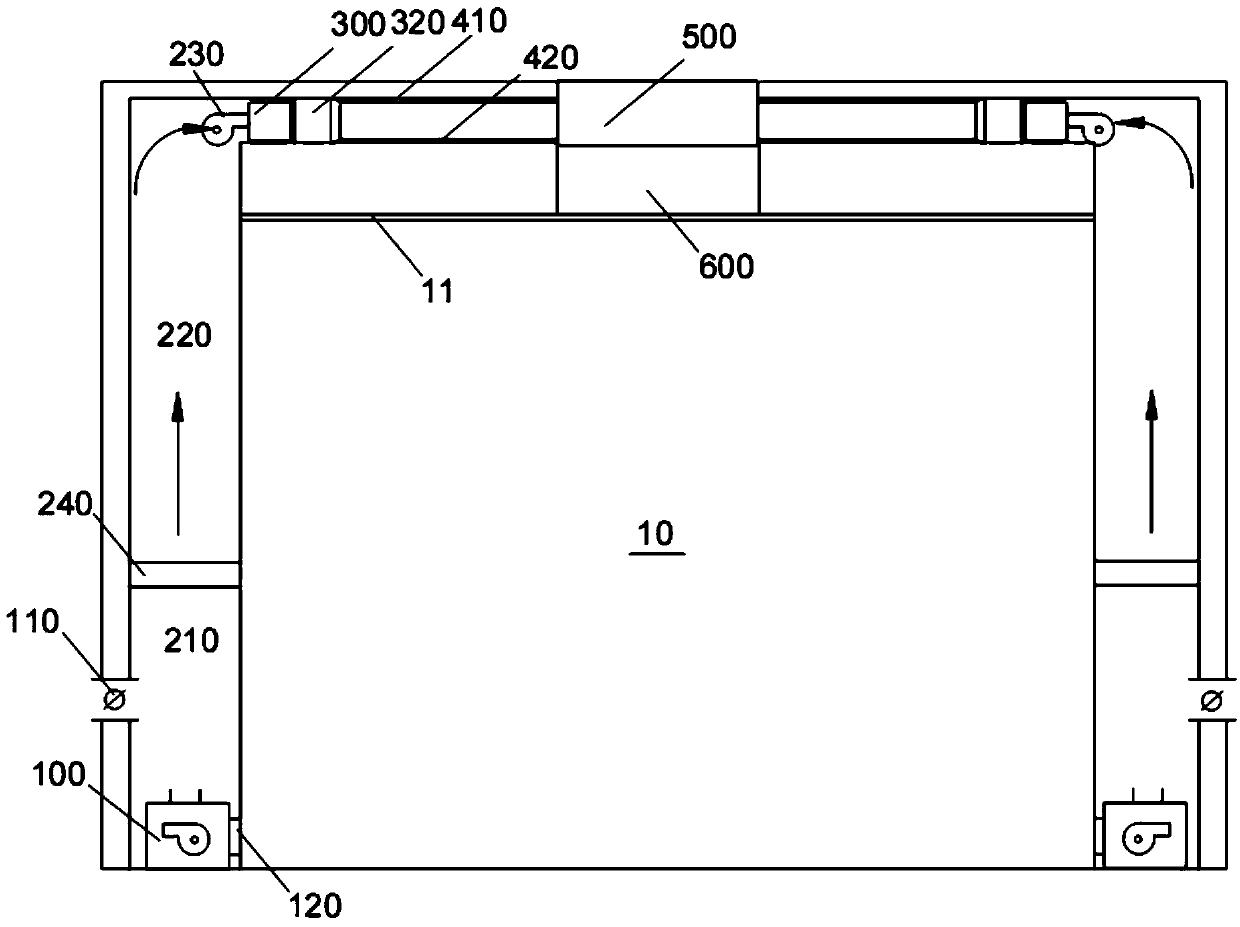

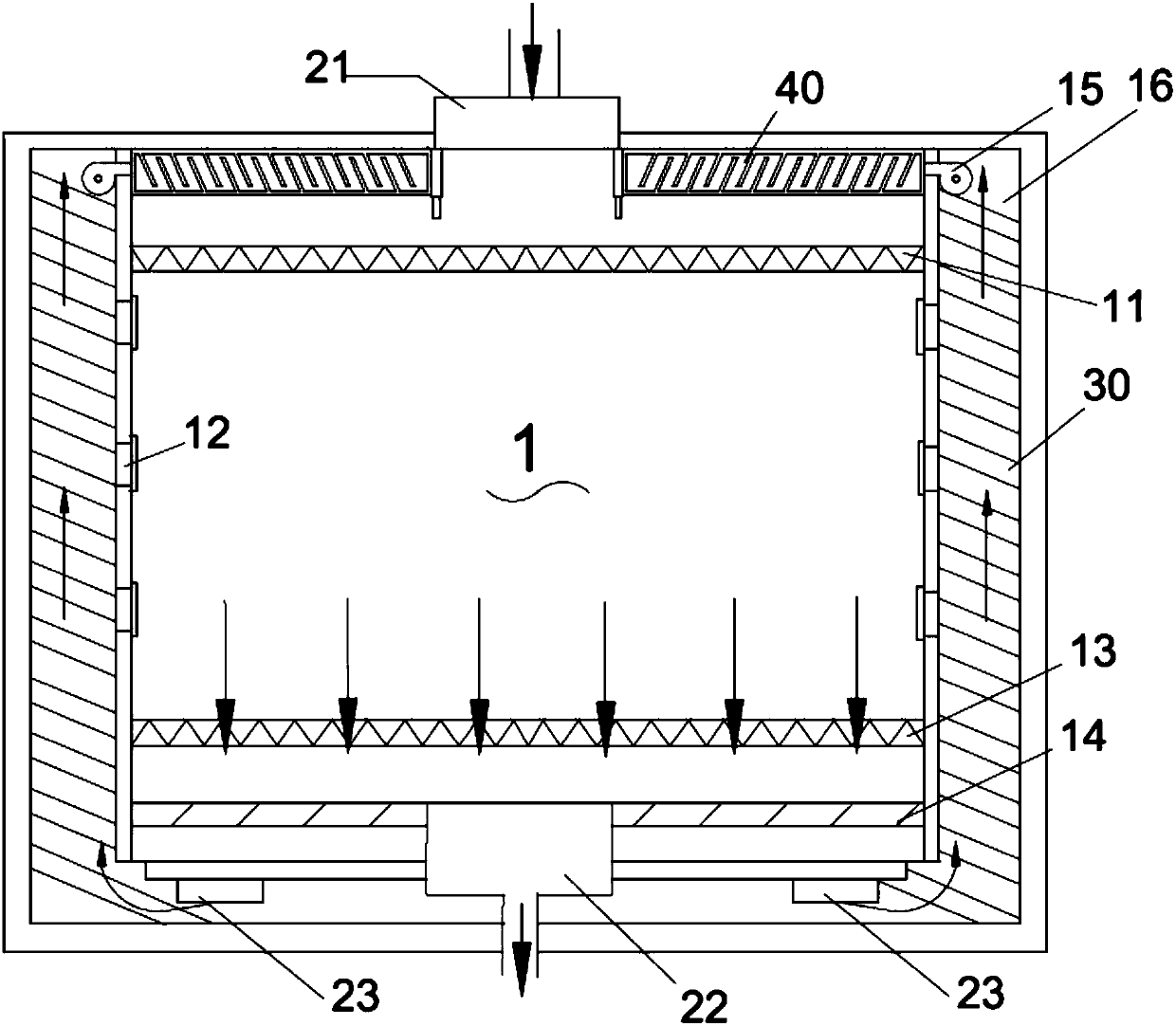

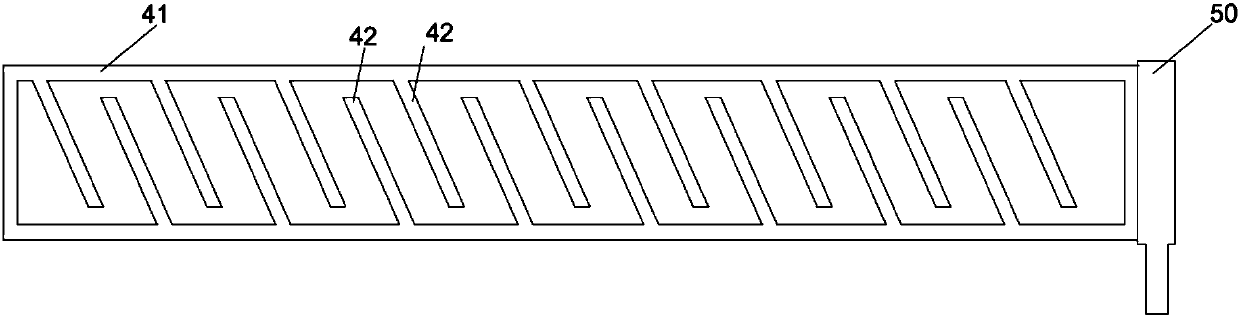

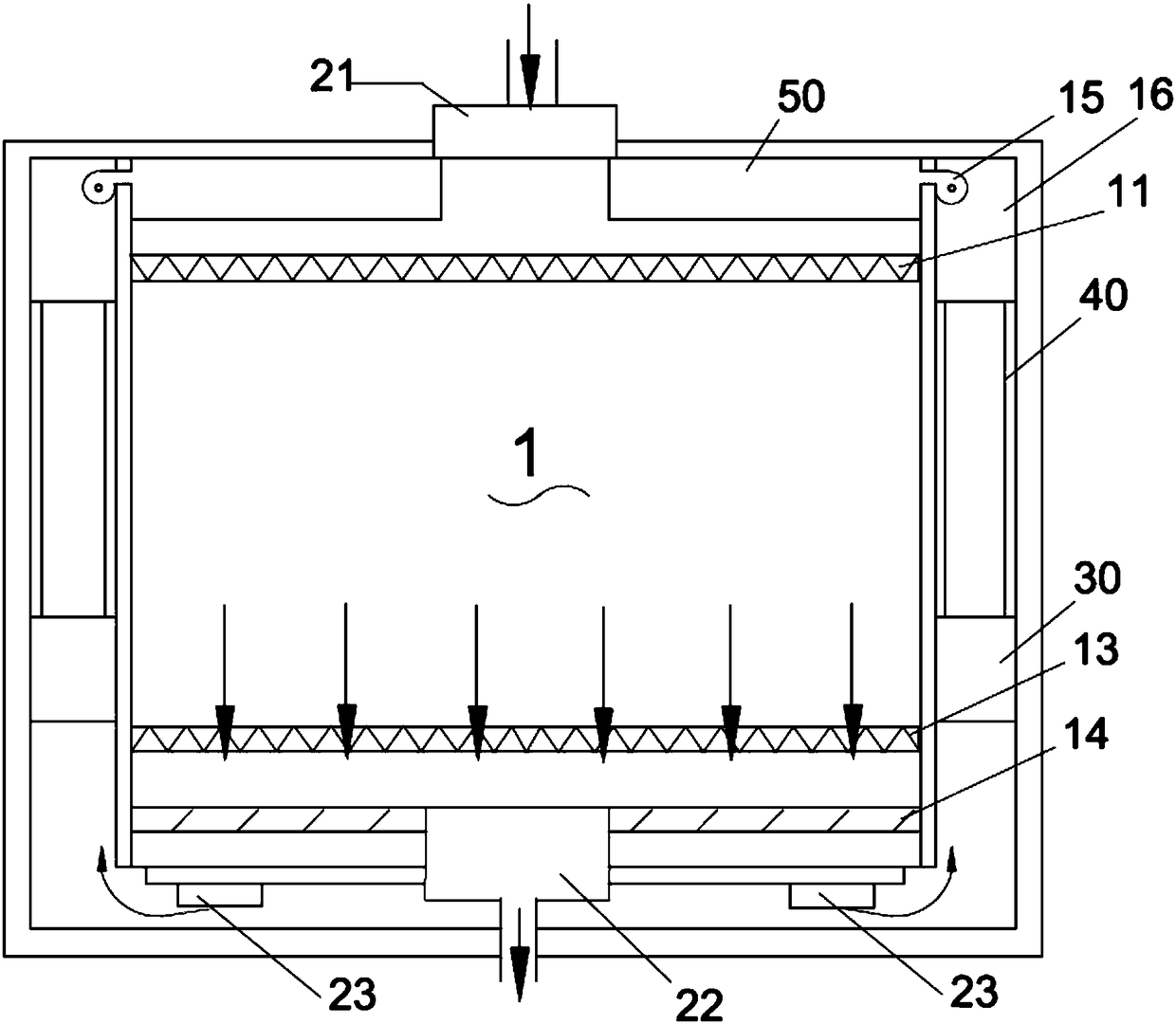

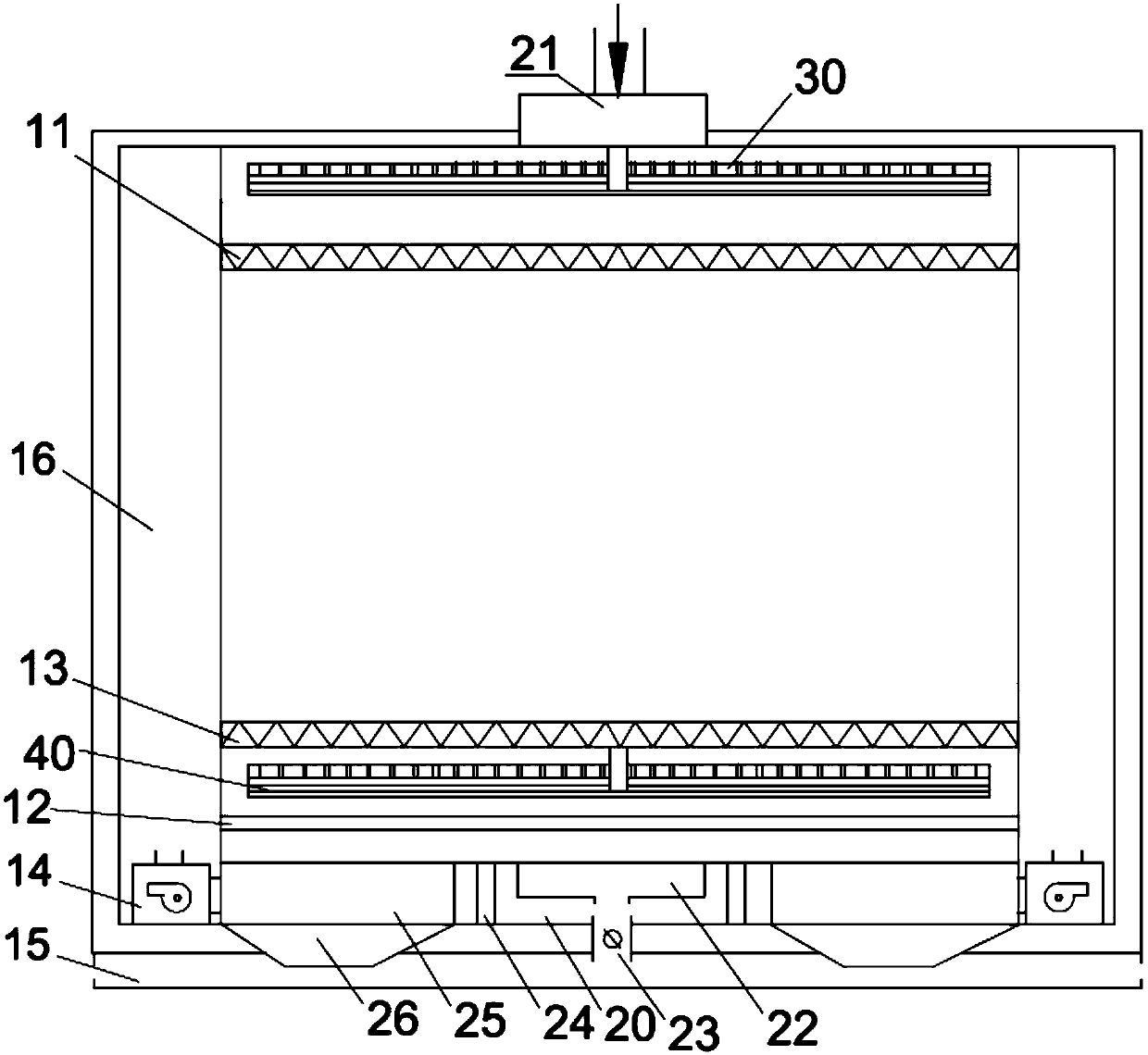

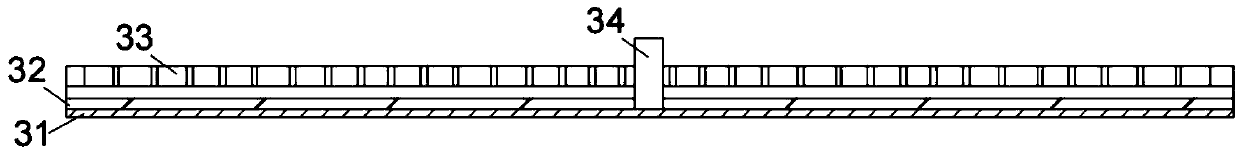

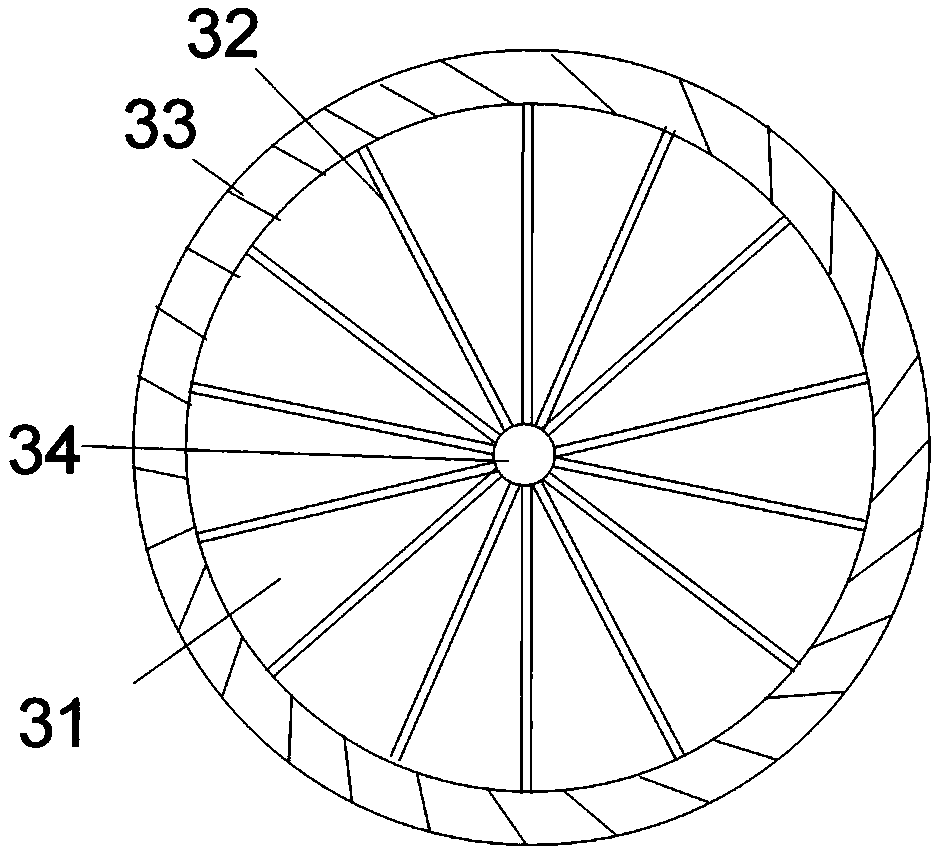

Low steady-speed radial flow clean room air-conditioning air supply and return system

ActiveCN103322657ASmall running resistanceSlow down the spreadDucting arrangementsLighting and heating apparatusSuspended particlesFresh air

The invention relates to a low steady-speed radial flow clean room air-conditioning air supply and return system which comprises a radial flow air supply channel device, a wall-mounted air return channel device, an air-conditioning outlet static pressure box, an air-conditioning air return port static pressure box and an air-conditioning fresh air port filtering device, the radial flow air supply channel device comprises a clean room roof, a static pressure box type air supply channel, a pressure equalizing partition plate, an arc-shaped radial flow cover, a damping layer and a high efficiency filter bank, and the wall-mounted air return channel device comprises a sandwich wall type air return duct and a filtering device mounted at an air return port of the lower end of the sandwich wall type air return duct. The air supply and return system has the advantages that the operation resistance of the air supply and return system is reduced, the diffusion speed of harmful suspended particles in a clean room is the lowest, fewer high efficiency filter banks are used, the clean room is low in construction investment, energy-saving in operation and convenient to maintain, the air cleanliness class of the clean room is improved by more than 30% as compared with that of a mixed airflow clean room, clean time can be shortened by more than 40%, and airflow in the clean room is reasonably distributed.

Owner:SHIJIAZHUANG AOXIANG MEDICAL ENG

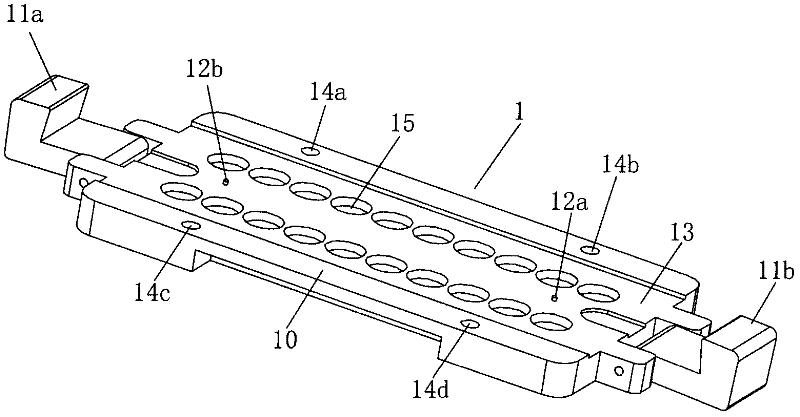

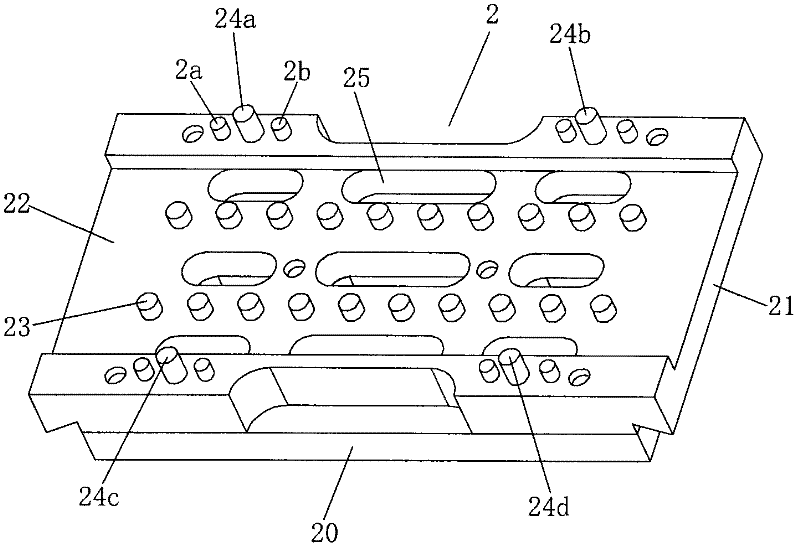

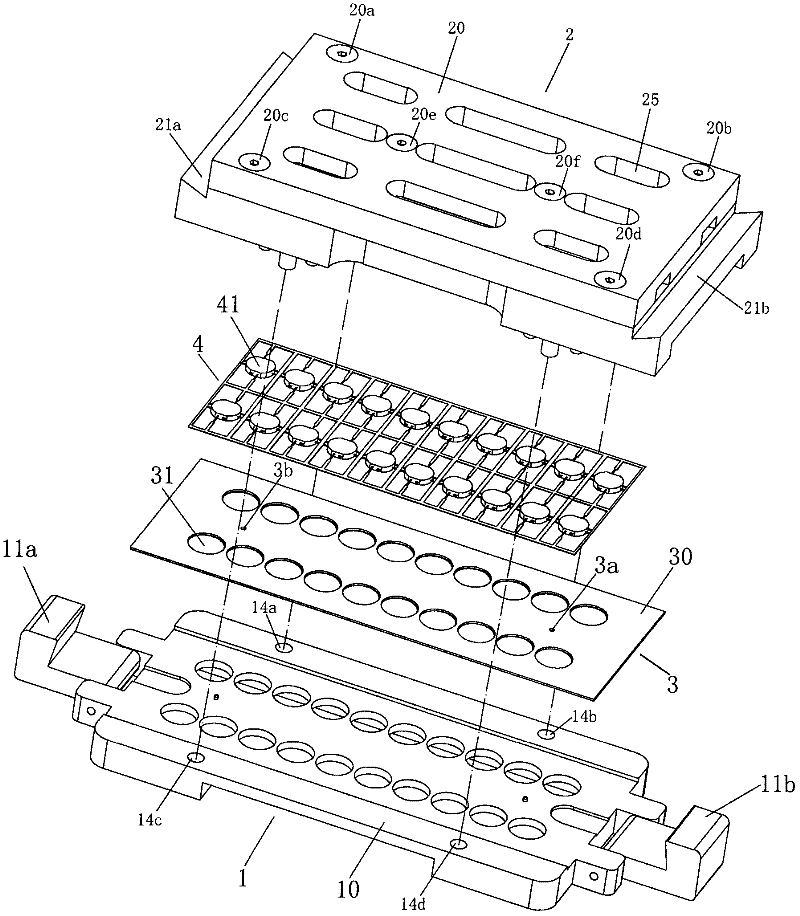

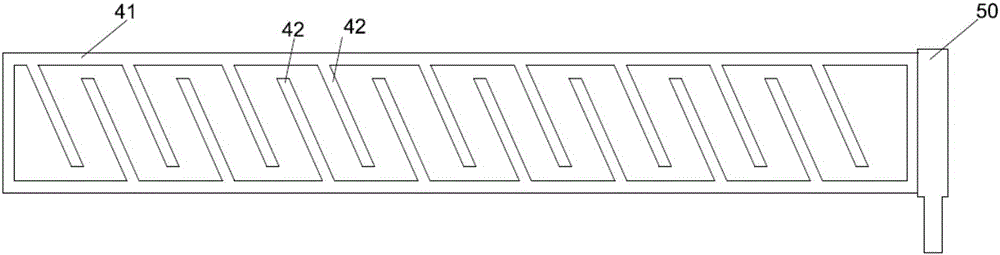

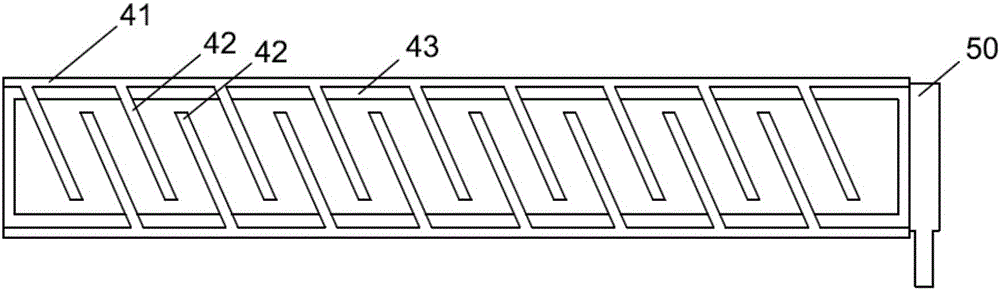

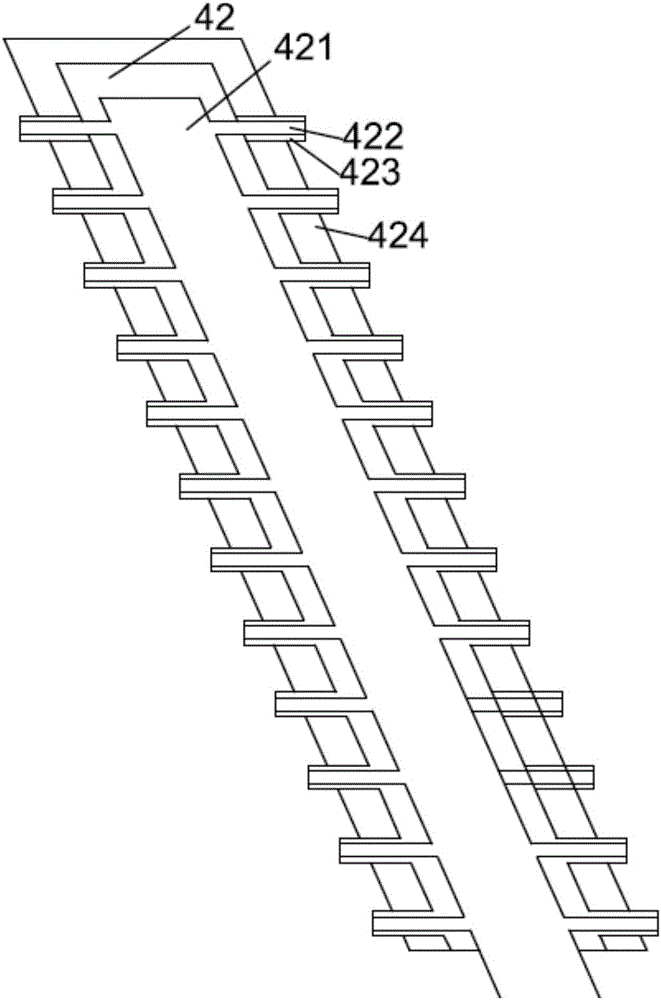

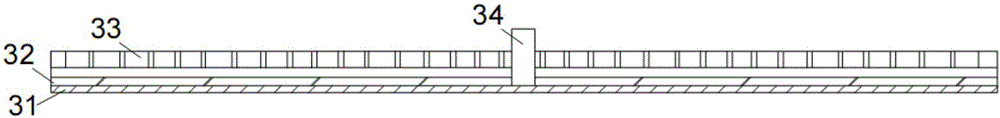

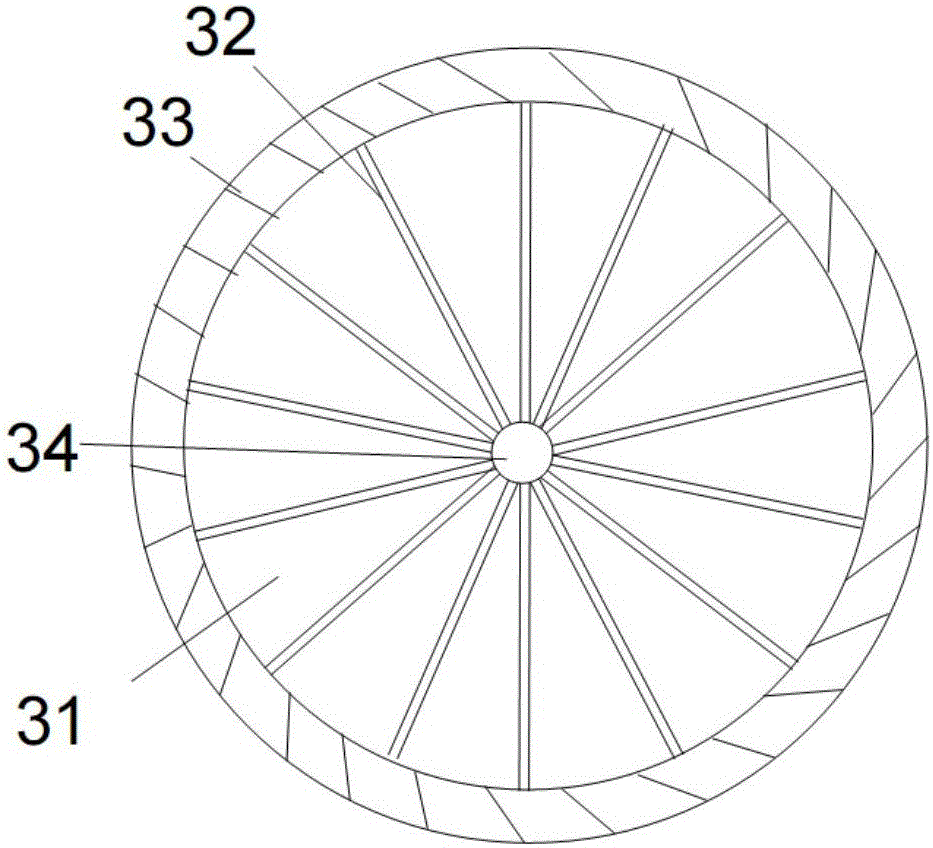

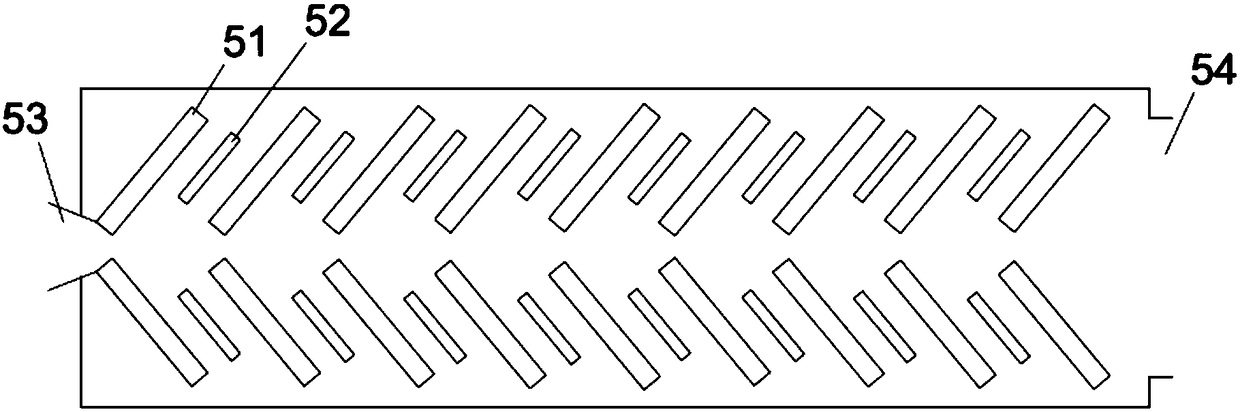

A jig for making led silicone lens

InactiveCN102299217ANot easy to damageImprove cleanliness levelSemiconductor devicesEngineeringSilica gel

The invention discloses a clamp for manufacturing a light emitting diode (LED) silica-gel lens, which comprises an upper pressure plate and a lower press plate, wherein the upper press plate and the lower press plate are in mutually independent two-piece type split structures, a mold strip and a support frame strip are sequentially placed between the upper press plate and the lower press plate from bottom to top, the upper press plate is positioned on the lower press plate through a positioning post and a positioning hole , both sides of the upper press plate are respectively hinged with fixed clamp buckles, the back side of the upper press plate is provided with fixed grooves matched with the fixed clamp buckles, and the upper press plate and the lower press plate are tightly clamped in the fixed grooves through the fixed clamp buckles so that the upper press plate and the lower press plate are tightly locked. In the technical scheme of the clamp, the completely independent two-piecetype structure is adopted, the elastic clamping is realized through the fixed clamp buckles arranged on the lower press plate and the fixed grooves arranged on the upper press plate, no dust is generated in the whole manufacture process, in addition, the clamping and the dismounting are convenient, the time consumption is short, accessories are not easy to damage, the dustless degrade of an LED encapsulation workshop can be obviously improved, the production efficiency is improved, and the production cost is reduced.

Owner:SHENZHEN GLORY SKY OPTOELECTRONICS CO LTD

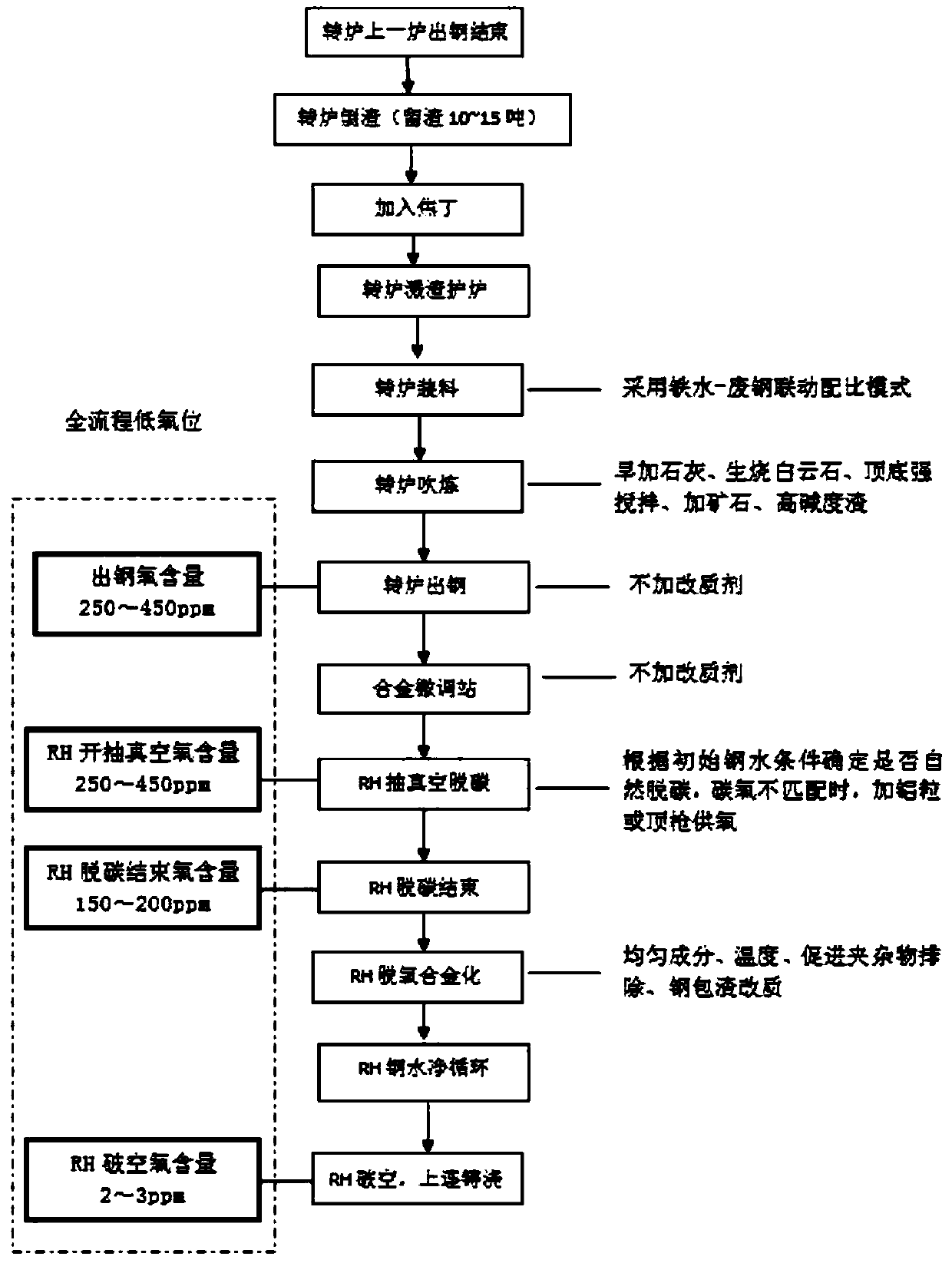

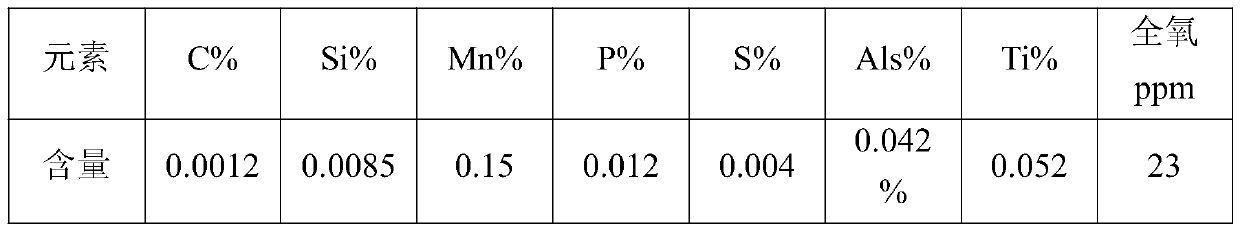

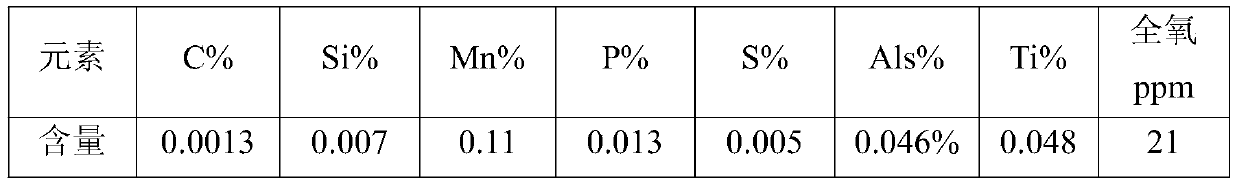

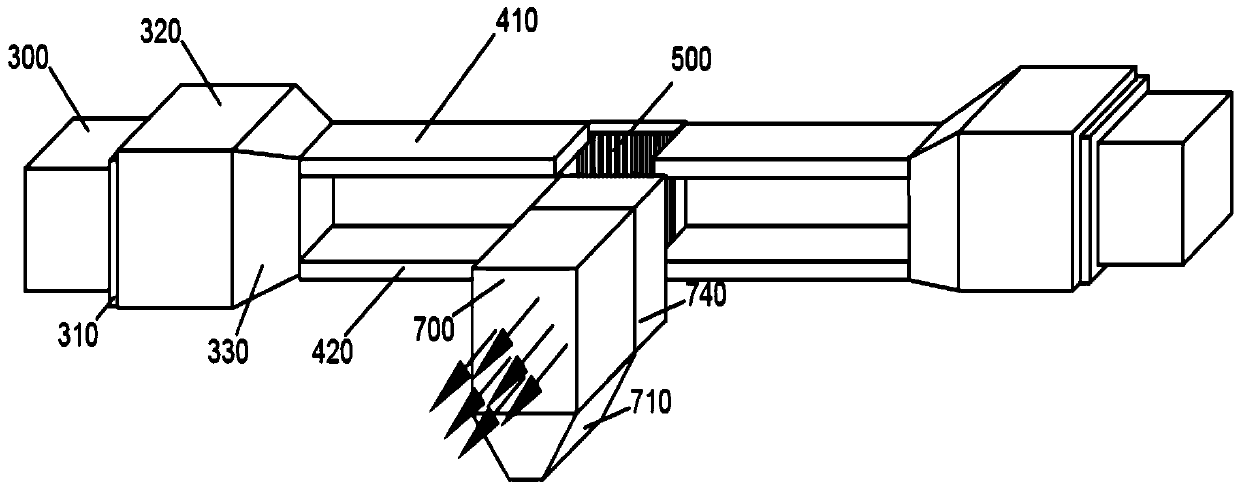

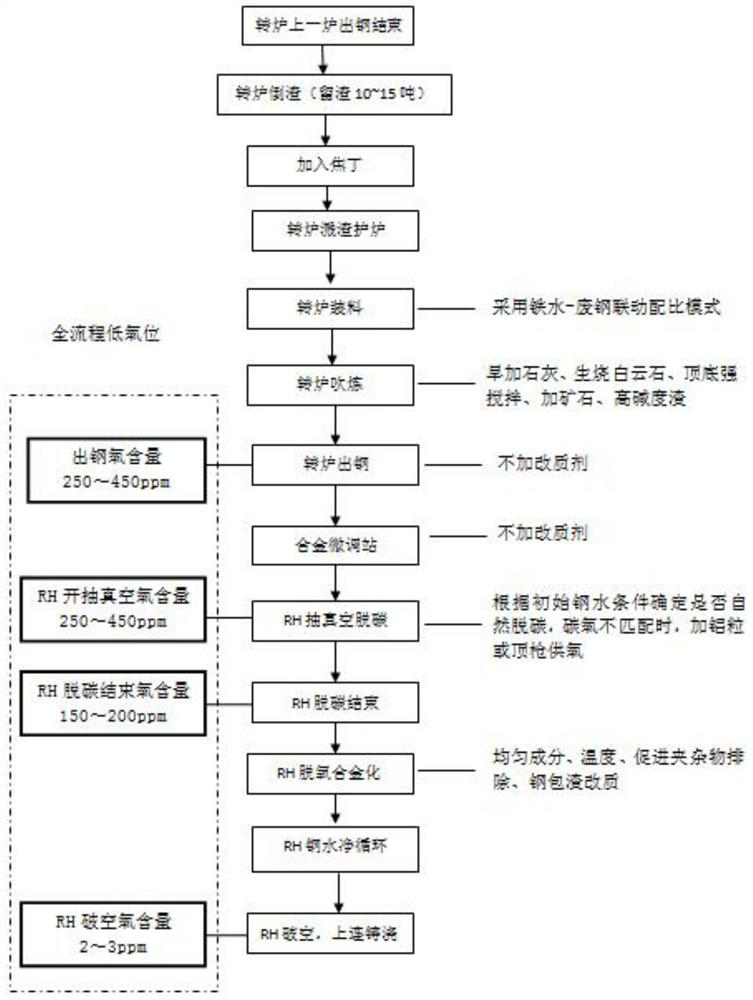

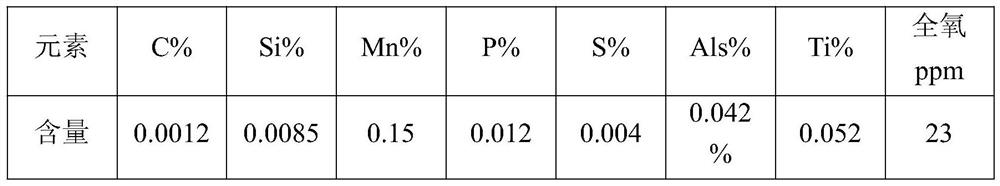

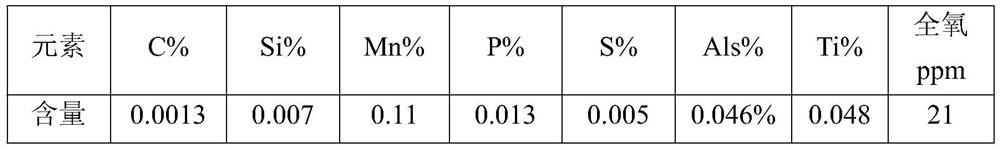

Smelting method for complete-flow low-oxygen-level producing of IF steel

ActiveCN110205436AReduce peroxidationReduce oxidationManufacturing convertersProcess efficiency improvementVacuum pumpingSlag

The invention discloses a smelting method for complete-flow low-oxygen-level producing of IF steel, and belongs to the technical field of steel smelting. The method comprises the steps that firstly, after converter steel smelting is finished, deslagging is carried out, 10 to 15 tons of slag is left in a converter, 50 to 100 kg of coke powder is added for removing oxygen in the slag, and the slag-splashing furnace protection operation is carried out; secondly, converter charging is carried out; thirdly, converter main blowing is carried out; fourthly, after converter main blowing is finished, through an auxiliary gun, the molten steel temperature and the carton content are measured, and according to the measuring value, auxiliary oxygen blowing amount is controlled; fifthly, after auxiliaryblowing is finished, before tapping, strong bottom blowing is carried out for 30 seconds; sixthly, converter tapping is carried out; seventhly, molten steel enters in the RH procedure; and eighthly,after a steel ladle is jacked, a vacuum pump is started for vacuum pumping decarburization. The converter tapping molten steel peroxidation degree is reduced, the steel ladle slag oxidation is reduced, the generation amount of deoxidation type inclusions Al2O3 can be reduced, the molten steel cleanliness level is improved, the cost is reduced, and the obvious economic benefits are achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

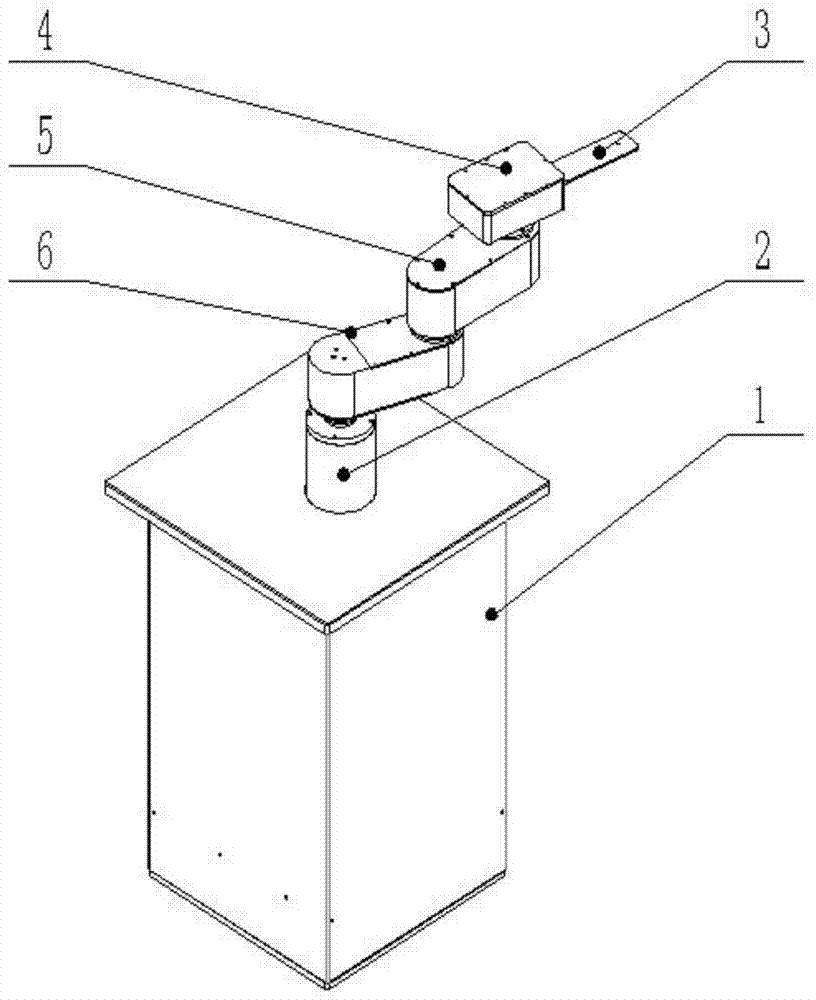

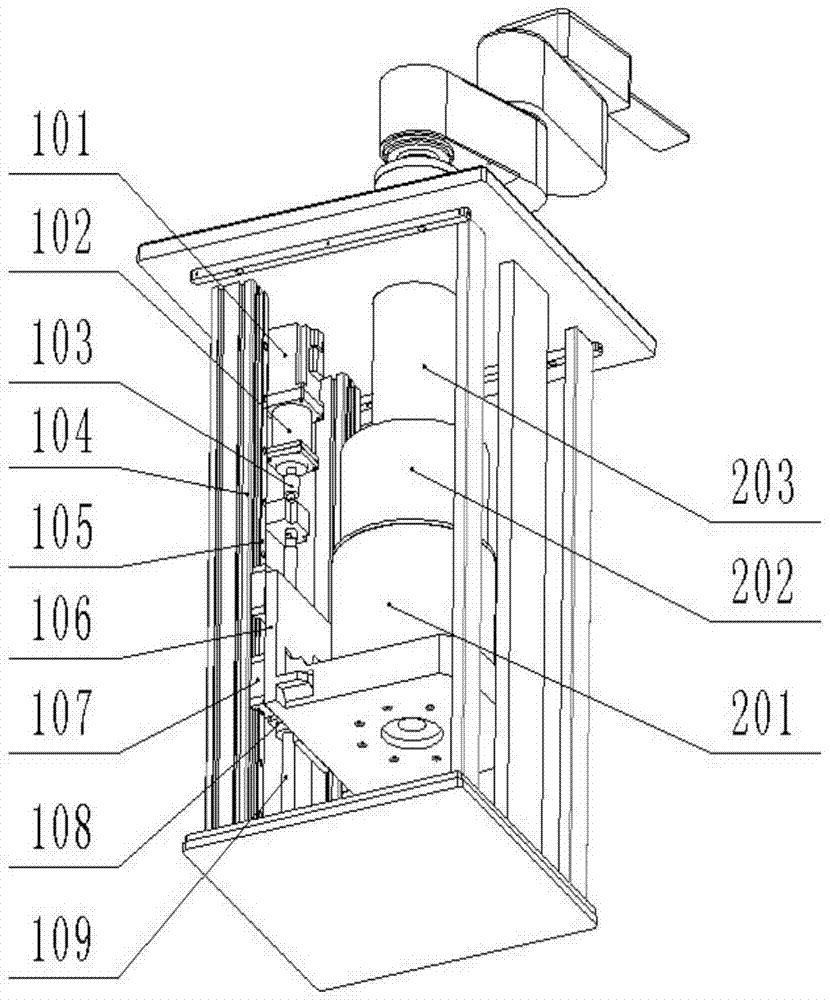

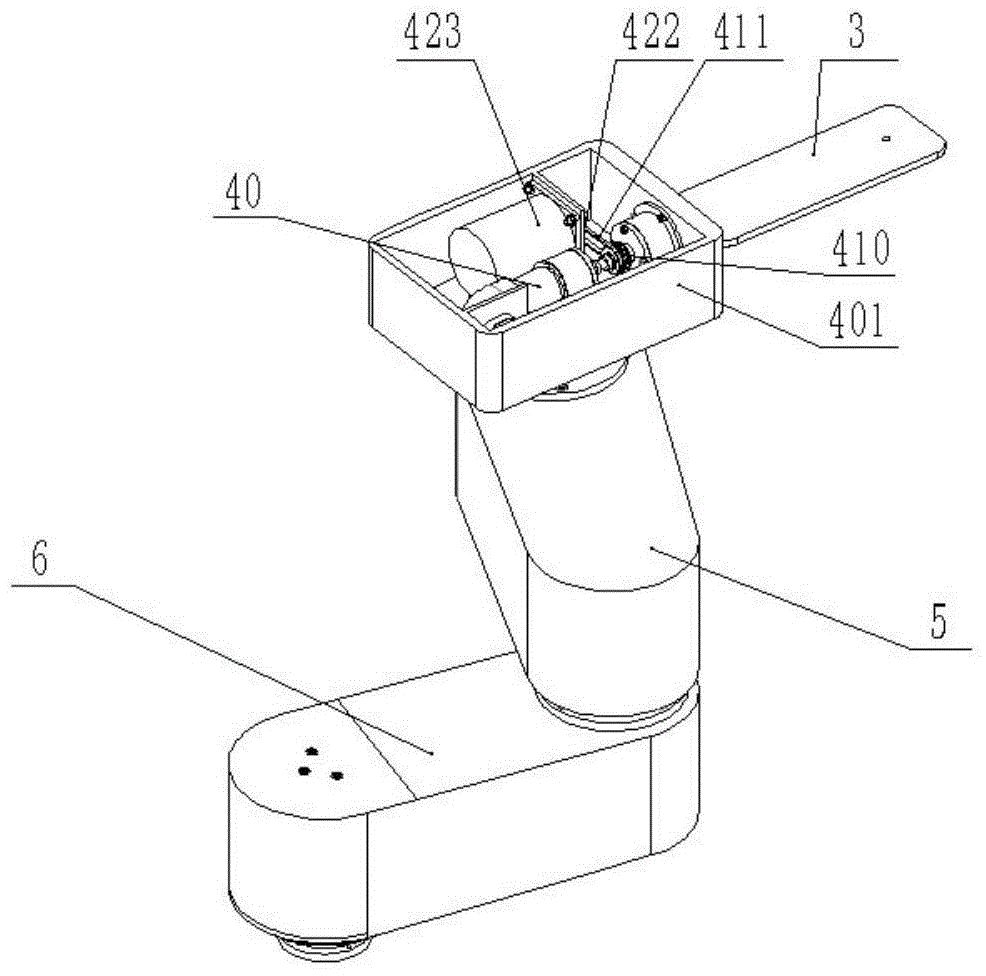

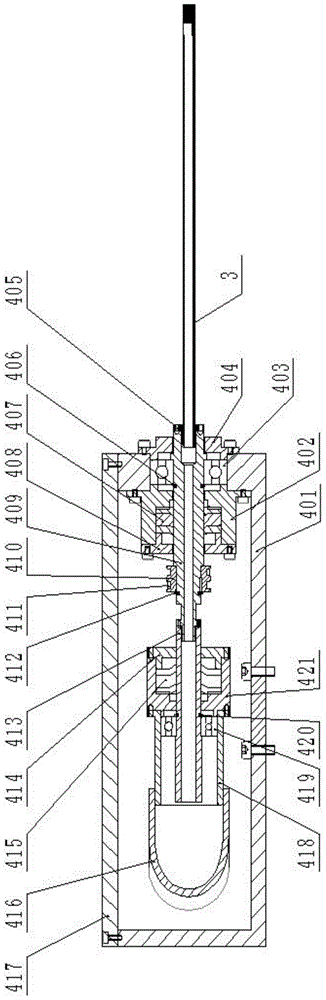

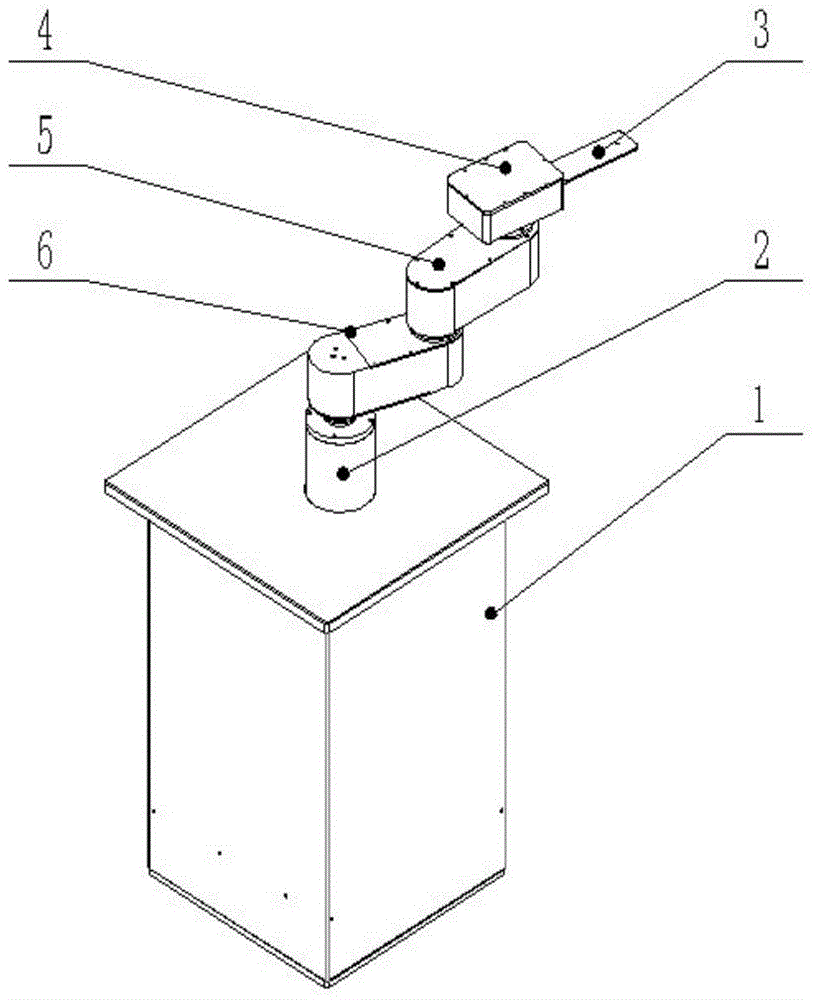

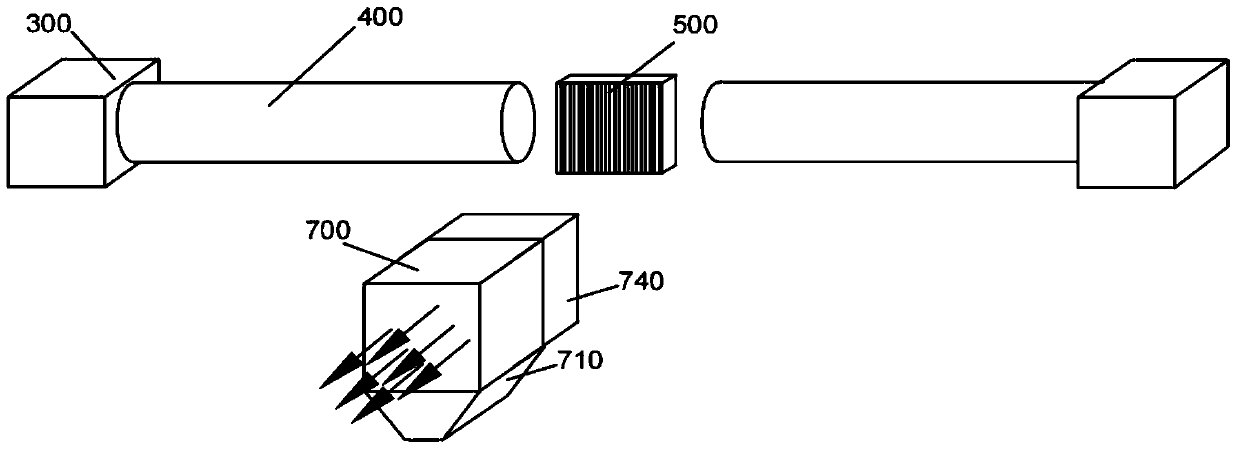

Direct drive type reversible wafer transmission robot

ActiveCN104723332AHigh transmission precisionImprove transmission efficiencyProgramme-controlled manipulatorConveyor partsDegrees of freedomEngineering

The invention discloses a direct drive type reversible wafer transmission robot. A lifting and dropping and swing mechanism is installed on the inner portion of a base seat, the lifting and dropping and swing mechanism is connected with one end of a big arm, the other end of the big arm is connected with one end of a small arm, the other end of the small arm is connected with one end of a reverse wrist, and the other end of the reverse wrist is connected with a vacuum adsorption tail end. When the wafer transmission robot moves, a three-connection rod which composed of the big arm, the small arm and the reverse wrist fixes a specific speed movement, and a straight line expansion movement in the radial direction is achieved; a motor is used for driving the vacuum adsorption tail end, so that a reverse movement of the reverse wrist is achieved; by the adoption of the direct drive motor to drive directly, an interior structure of the robot is simplified, the number of intermediate links is reduced, and the rotating precision and the rotating efficiency of the robot are improved. Due to fewer part mechanisms, the robot is convenient to assemble and produce. A steel belt is used rotatably, so that the rotating precision is provided, the reliability of the robot is enhanced, the production of contaminant particles is lowered, and the level of cleanliness of the robot is improved. The degree of freedom of reversing of the robot is increased by the reverse wrist, and the range of application of the robot is enlarged.

Owner:BEIJING UNIV OF TECH

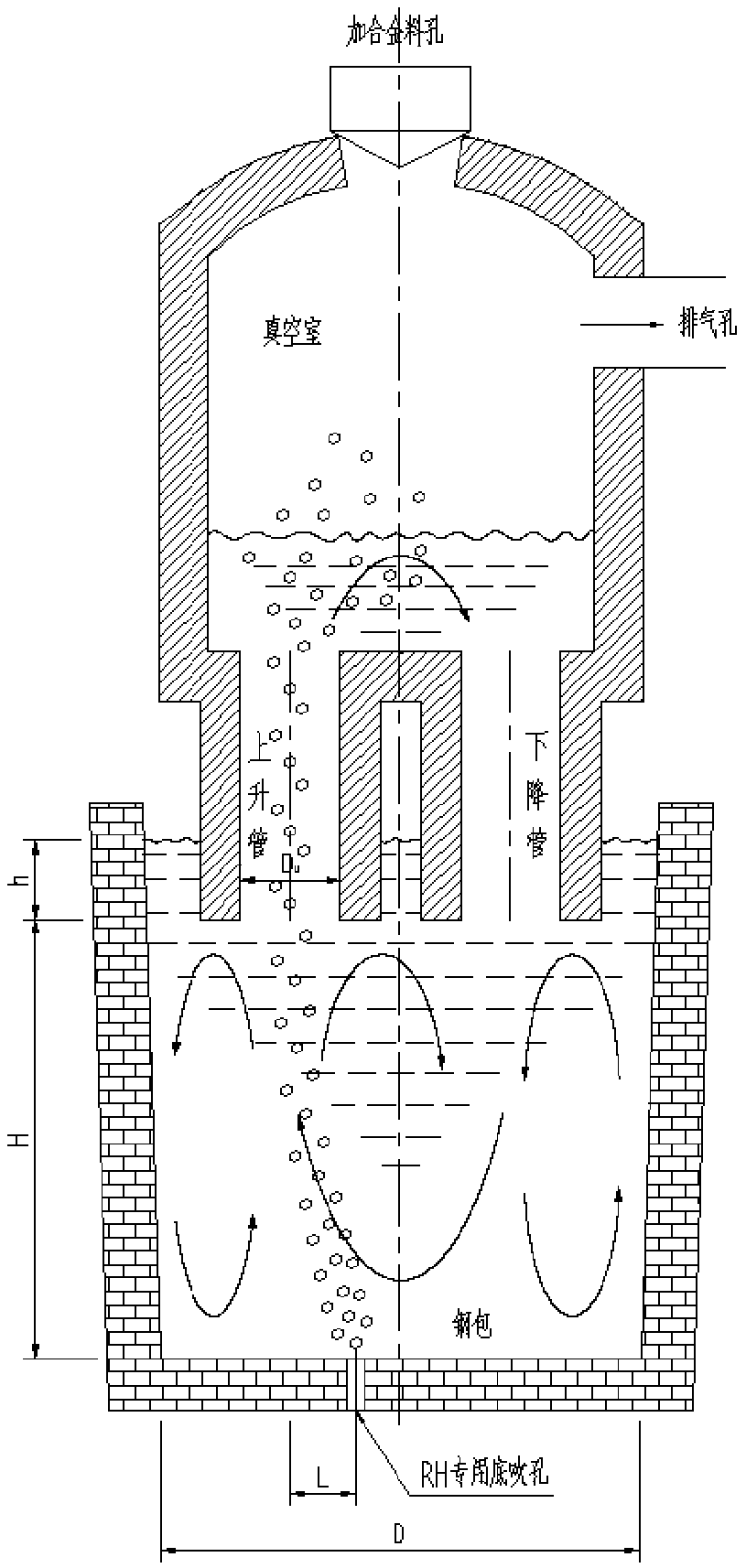

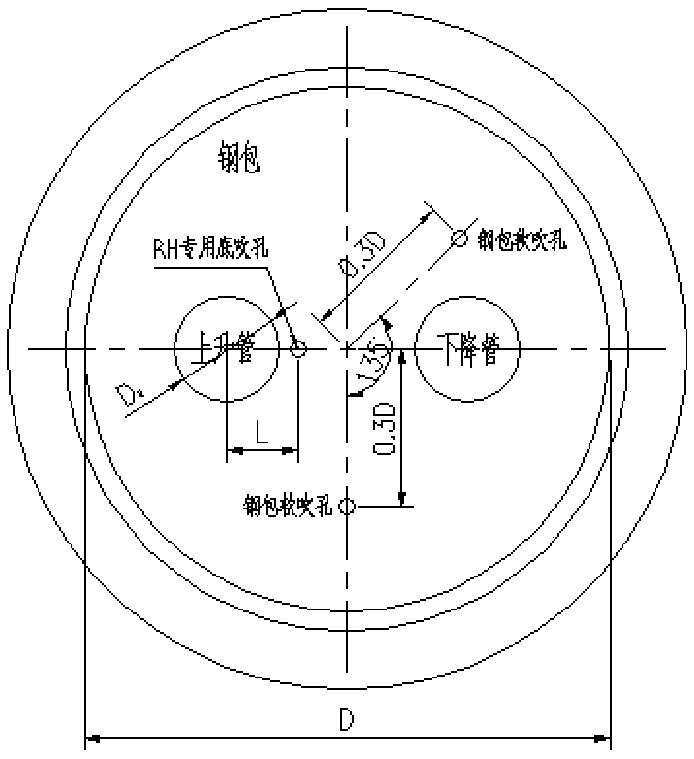

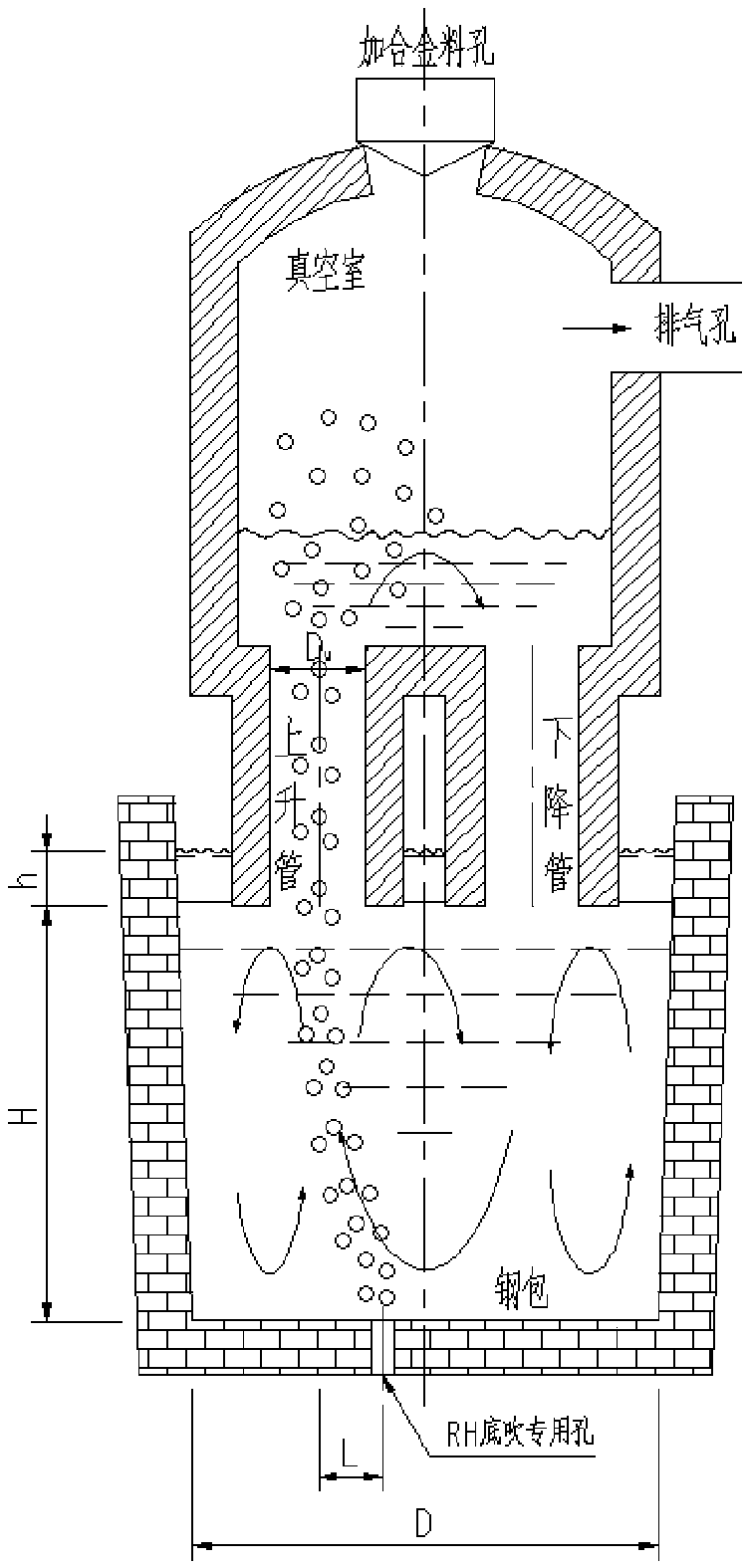

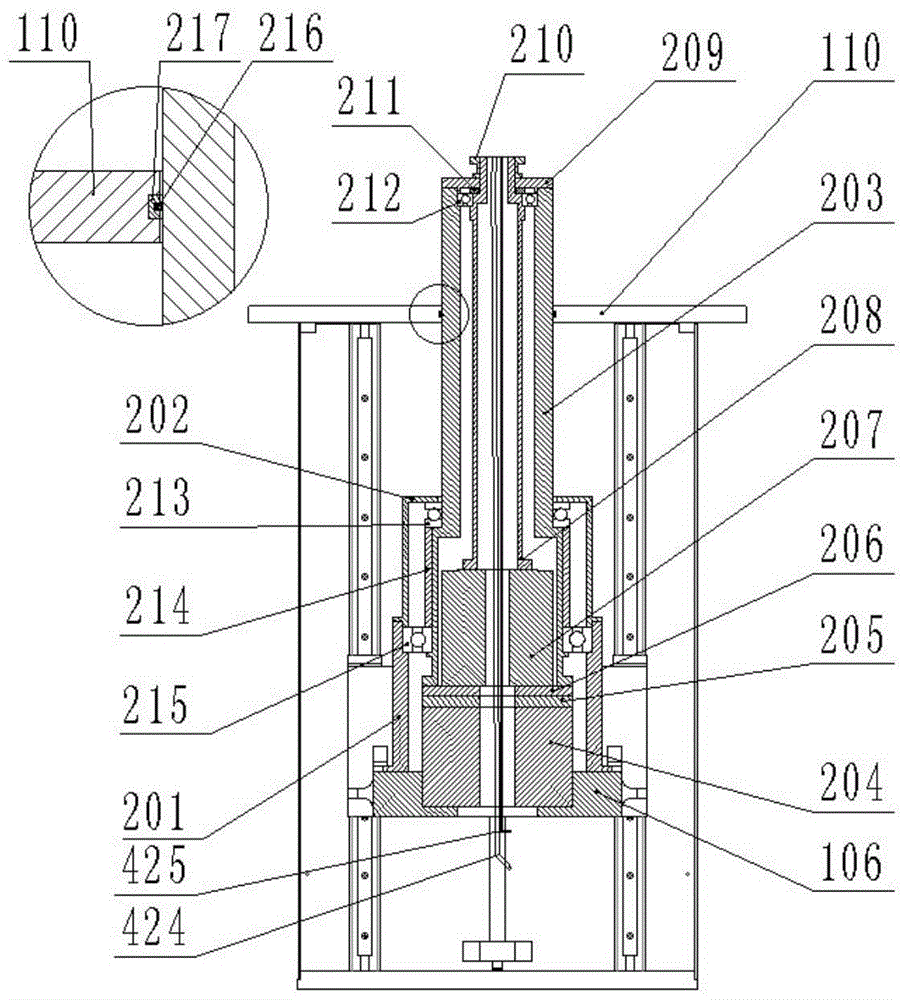

Method for increasing molten steel circulating flow quantity in RH refining process

The invention provides a method for increasing the molten steel circulating flow quantity in the RH refining process and belongs to the technical field of molten steel refining. According to the method for increasing the molten steel circulating flow quantity in the RH refining process, a process procedure of converter / electric furnace-refining RH-continuous casting is adopted to produce high-quality pure steel, in the RH refining process, by means of utilization of an existing steel ladle argon bottom blowing system, argon is blown into the bottom of a steel ladle, argon bubbles blown in thebottom move along with a molten steel flow field, molten steel is lifted to enter an RH dipping pipe ascending pipe, coordinated control between steel ladle argon bottom blowing and dipping pipe inside gas lifting is realized, so that adverse effects in actual production that the air blowing hole position of an RH dipping pipe cannot be remolded and the lifting gas flow quantity is too large to blow through the molten steel inside the dipping pipe to reduce the lifting driving force instead are overcome, and the purpose of increasing the steel circulating flow quantity in the RH refining process is finally achieved. The method for increasing the molten steel circulating flow quantity in the RH refining process has the advantages of being simple and reliable, high in operability and convenient to realize, the RH circulating flow quantity is increased, the decarbonization efficiency is high, the refining time is obviously shortened, and the molten steel purity is improved.

Owner:CENT IRON & STEEL RES INST

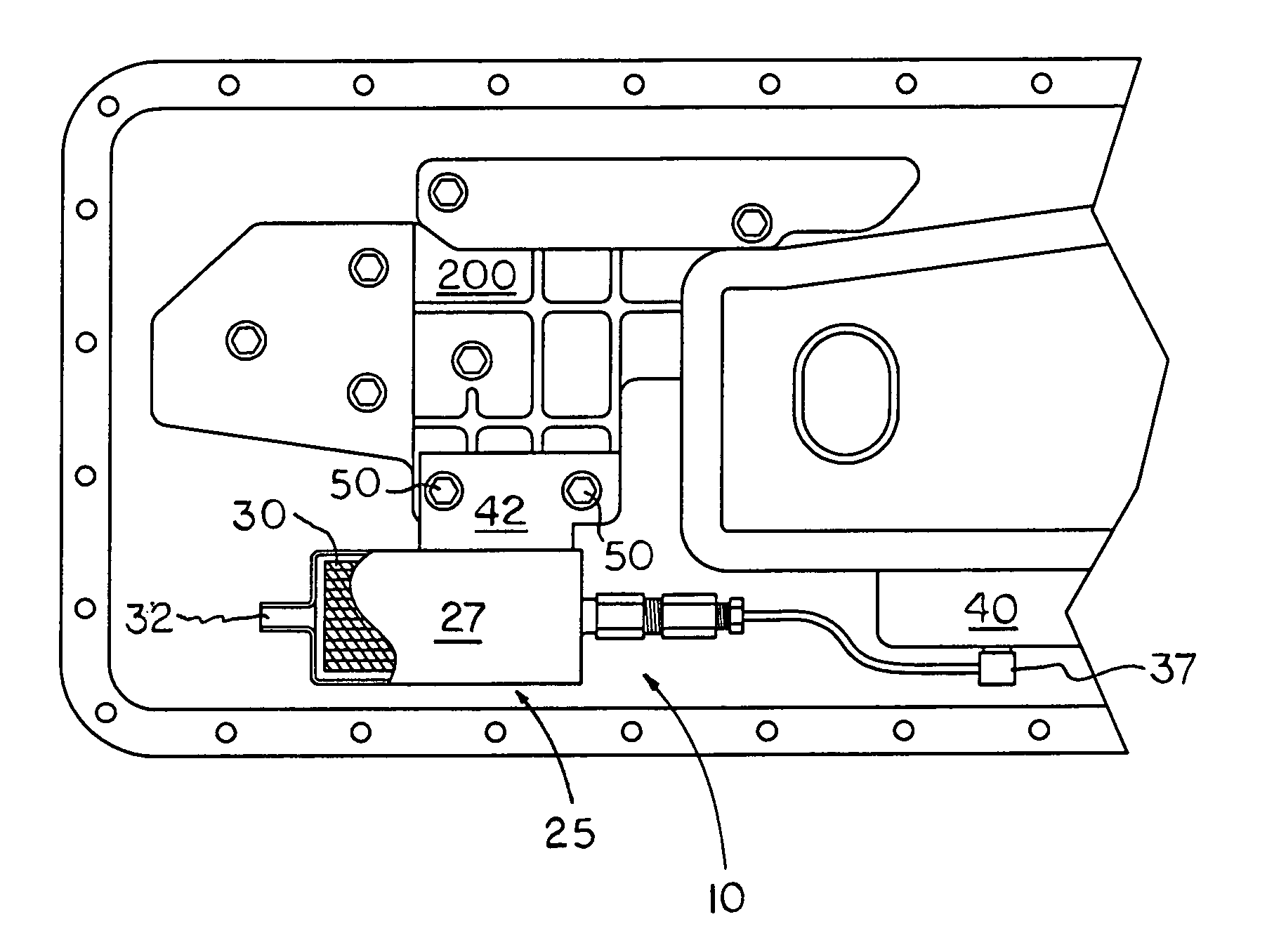

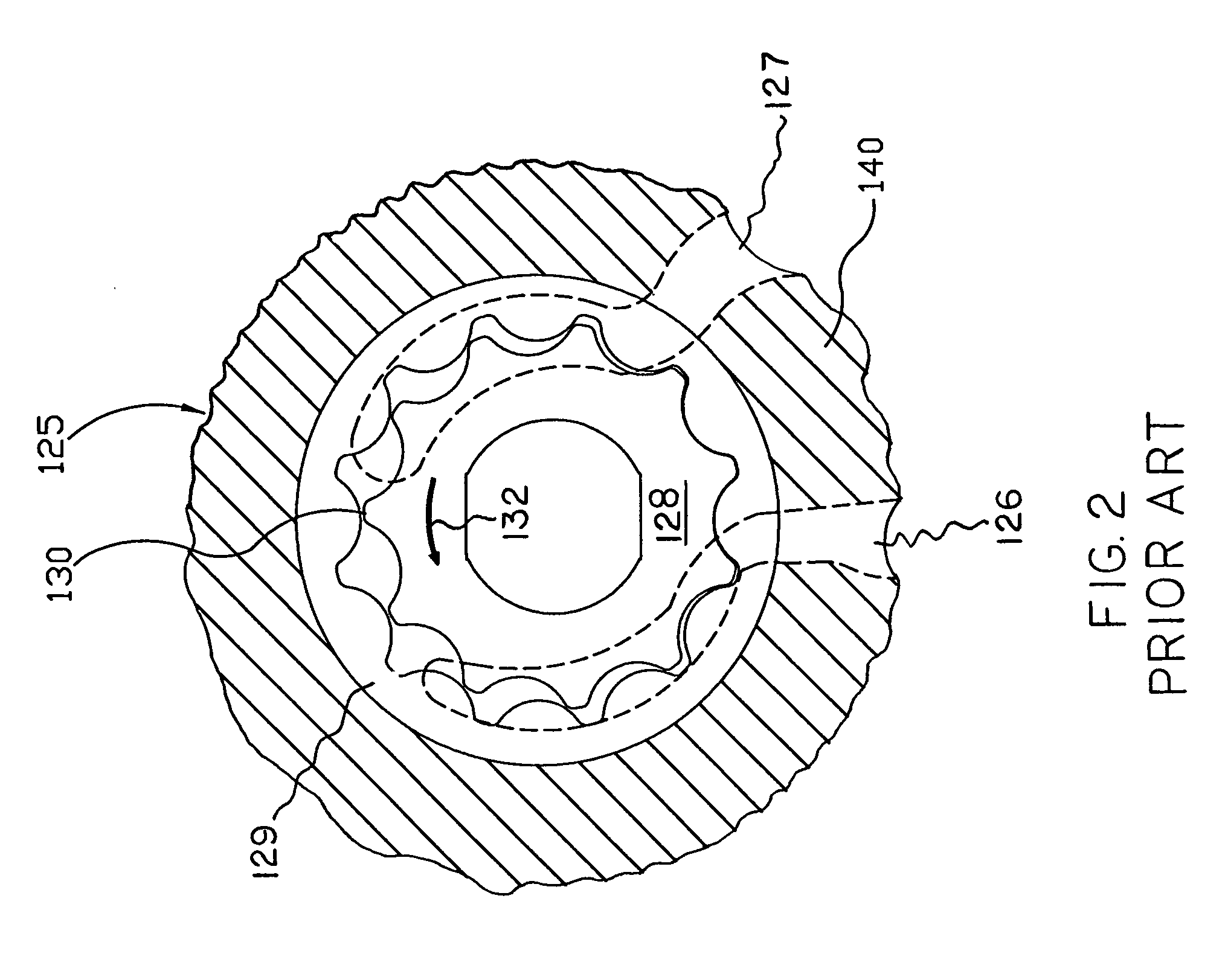

Internal bypass filtration circuit

InactiveUS8486277B1Improve cleanliness levelImprove filtrationLiquid separation auxillary apparatusWater/sewage treatmentDepth filterEngineering

An internal bypass filtration circuit including a microfine depth filtration cartridge, which operates in combination with the sump filter of an automatic transmission is disclosed. The present depth filtration cartridge functions to remove particulate matter as small as five microns to improve fluid cleanliness level without restricting fluid flow to the pump ensuring its volumetric efficiency. In one embodiment transmission fluid passes through a calibrated orifice in the bypass circuit to regulate flow to the depth filtration cartridge. In an alternate embodiment the depth filter media itself regulates filtration below a predetermined fluid pressure. The internal bypass circuit is installed by accessing a pressurized fluid circuit in the transmission valve body. A hydraulic bypass line interconnects such pressurized fluid circuit with the depth filtration cartridge, which is mounted internally of the transmission housing. The outlet of the depth filtration cartridge exhausts directly into the sump bypassing all other functional circuits.

Owner:SONNAX TRANSMISSION CO

Tracking analysis method for large size inclusions in steel

InactiveCN109014096AImprove cleanliness levelImprove product qualityMelt-holding vesselsManufacturing convertersRare-earth elementPotassium

The invention discloses a tracking analysis method for large size inclusions in steel. The method includes the steps that (1) in a tundish preparation phase, a rare earth compound is added to a coating or a ramming material of a tundish working lining; a rare earth compound is added into a tundish covering agent; and in the LD tapping process, a rare earth compound is added to a steel ladle, rareearth elements in the three rare earth compounds are different, and mold powder contains potassium oxide or sodium oxide; (2) a sample is taken and analyzed by a sample-electrolysing method to determine content of the inclusions in the steel; and (3) the inclusions selected by the sample-electrolysing method are fixed on a metal block, the morphology and composition of the inclusions are observedunder a scanning electron microscope, and sources and distribution of the inclusions in the steel are analyzed according to the contents of the rare earth elements and potassium or sodium. According to the tracking analysis method for the large size inclusions in the steel, sources and distribution of the inclusions in the steel can be thoroughly found out, targeted improvement measures are put forward for improving the cleanliness level of continuous casting slab, the production process is optimized, and the product quality is improved.

Owner:HANDAN IRON & STEEL GROUP +1

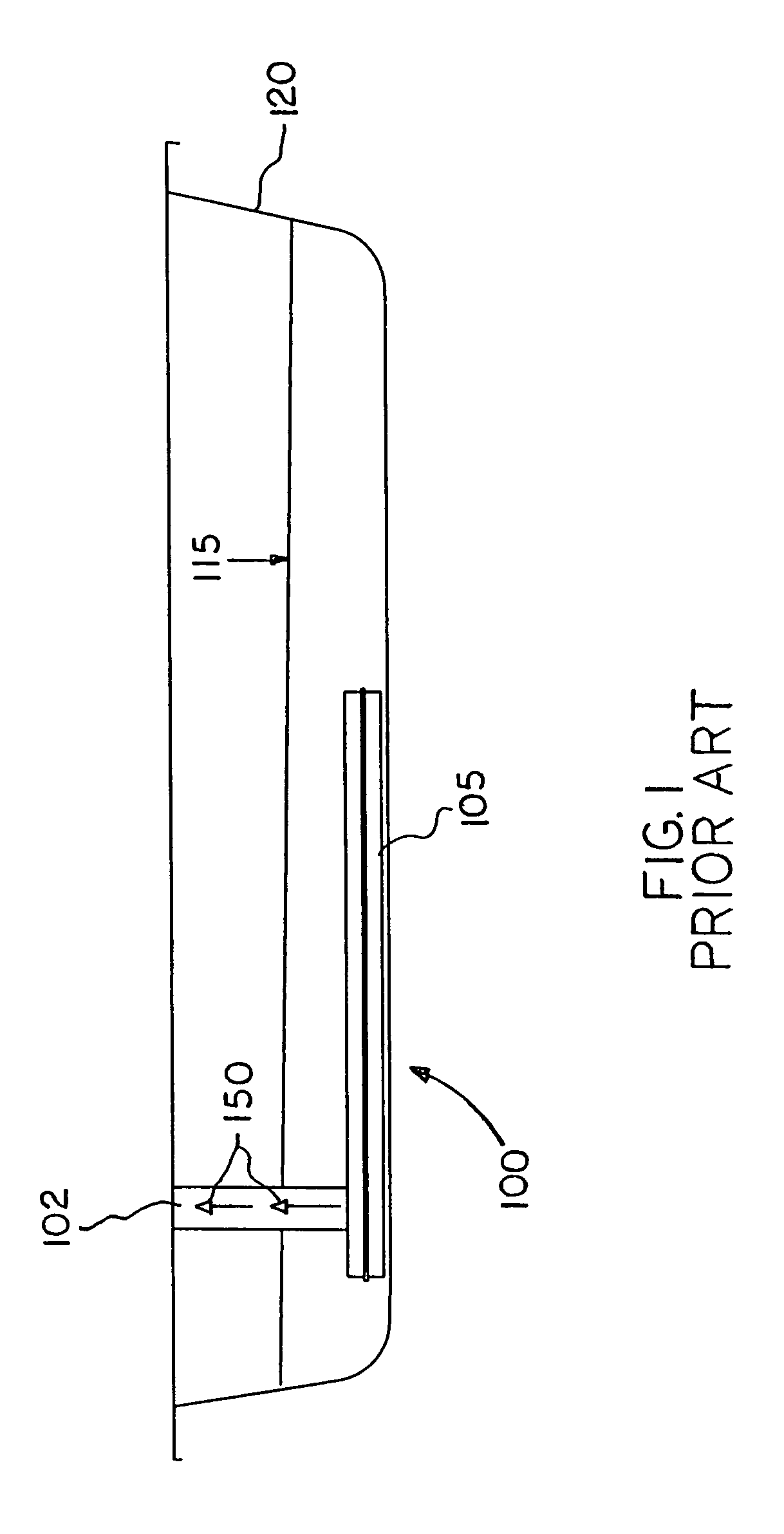

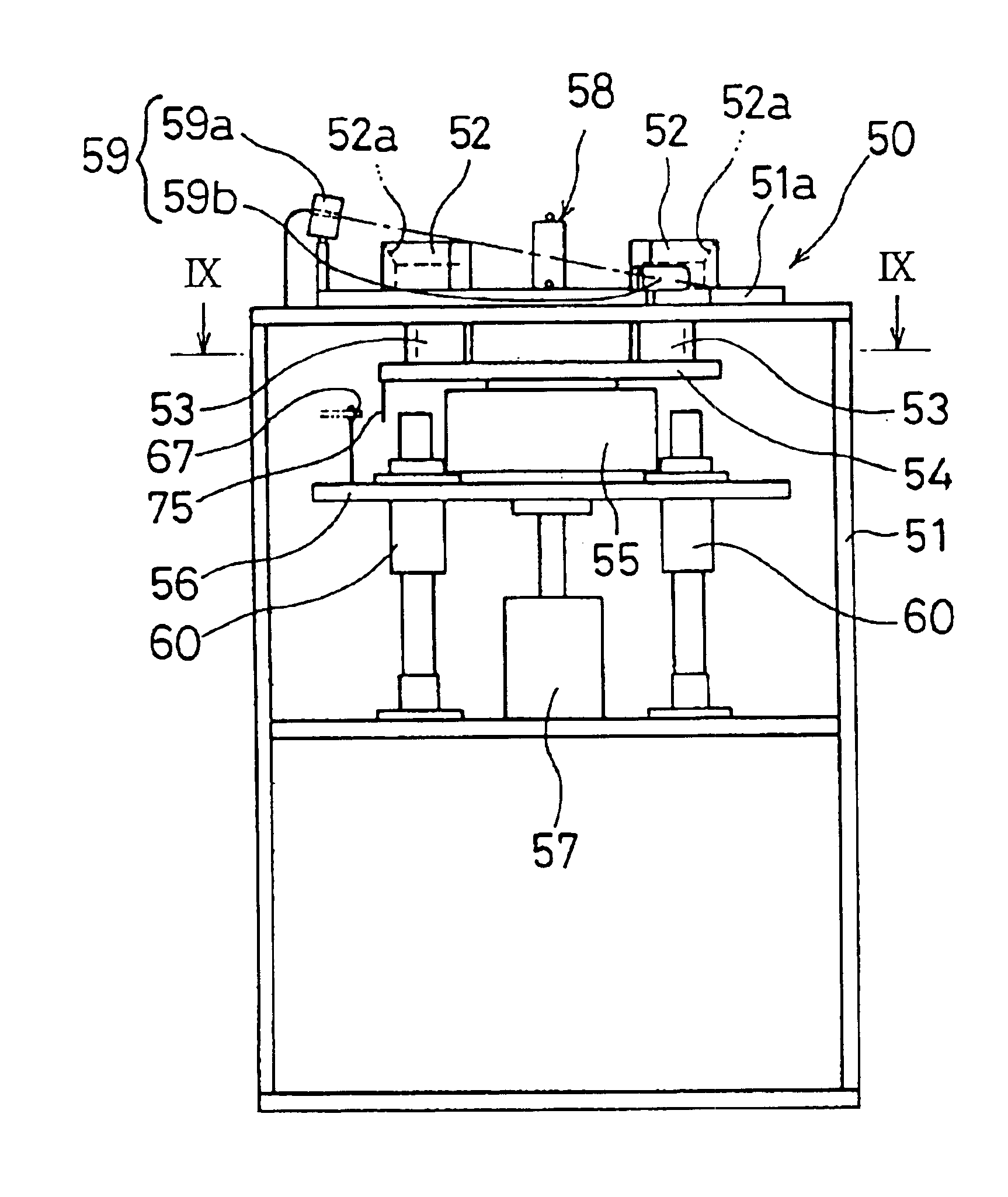

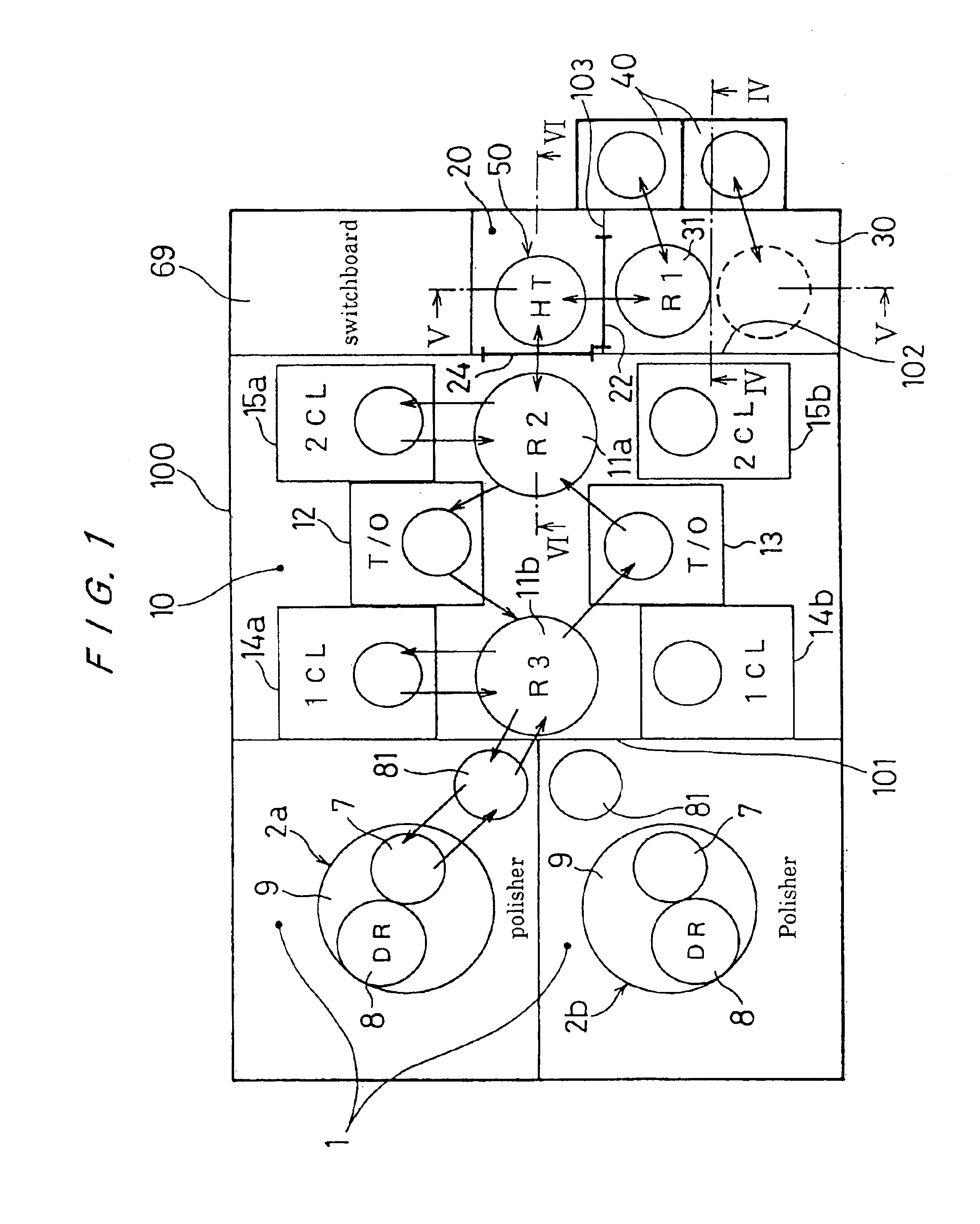

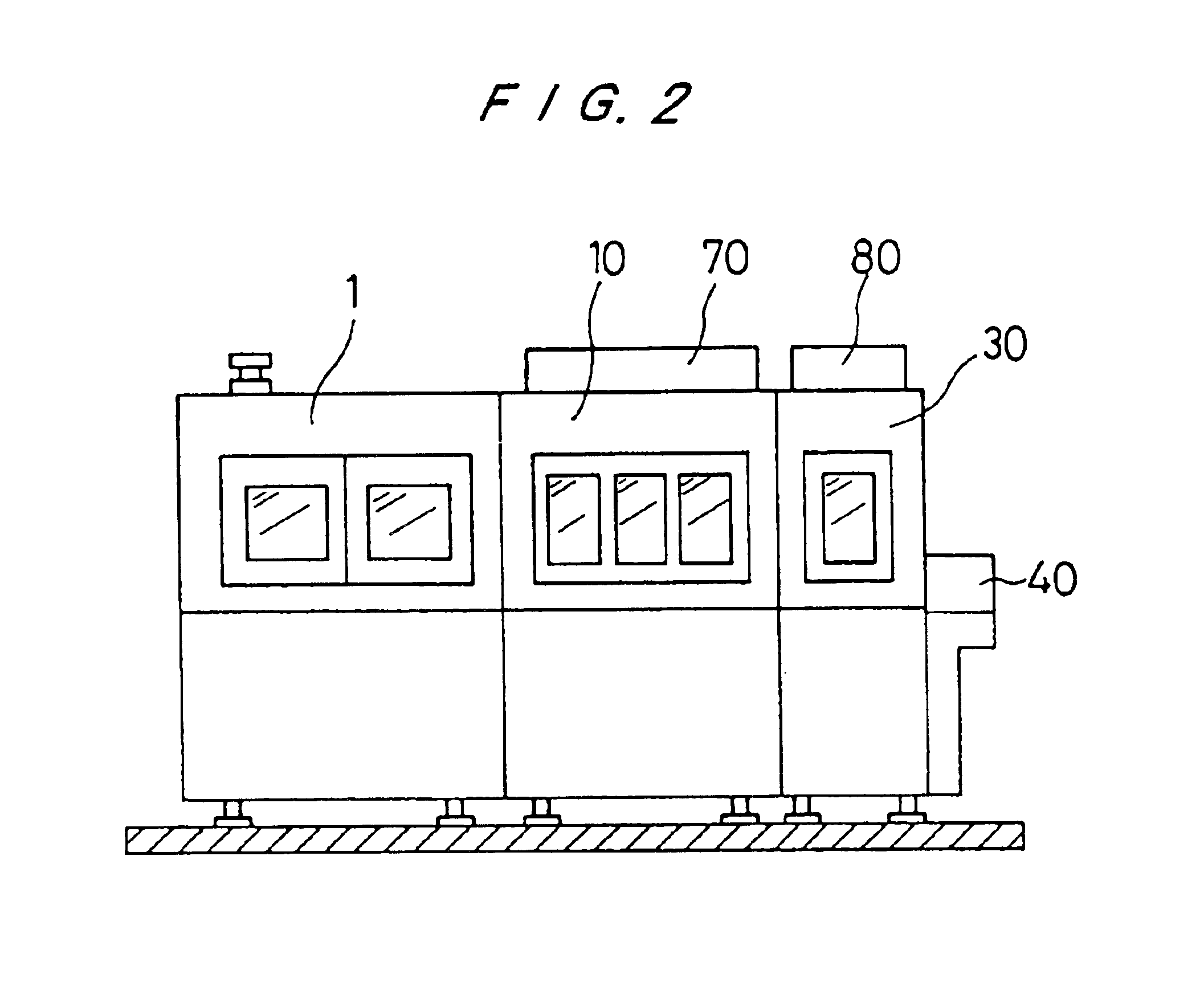

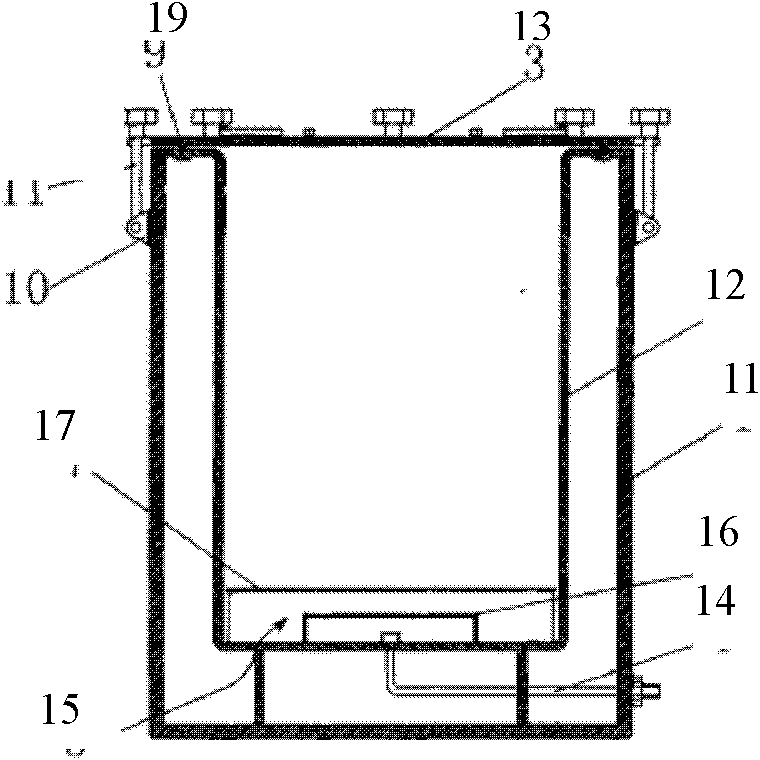

Polishing apparatus

InactiveUS6929529B2Improve cleanlinessAvoid pollutionEdge grinding machinesSemiconductor/solid-state device manufacturingSemiconductorWafering

The present invention relates to a polishing apparatus for polishing a workpiece such as a semiconductor wafer. The polishing apparatus has a processing section including a polishing section (1) for polishing a semiconductor wafer (6) and a cleaning section (10) for cleaning a polished semiconductor wafer, a receiving section (40) for supplying a semiconductor wafer (6) to be polished to the processing section and receiving a polished semiconductor wafer (6), and a cleaning chamber (20) disposed between the processing section and the receiving section and defined by partitions (102, 103) with shutters (22, 24) which separate the processing section and the receiving section from each other.

Owner:EBARA CORP

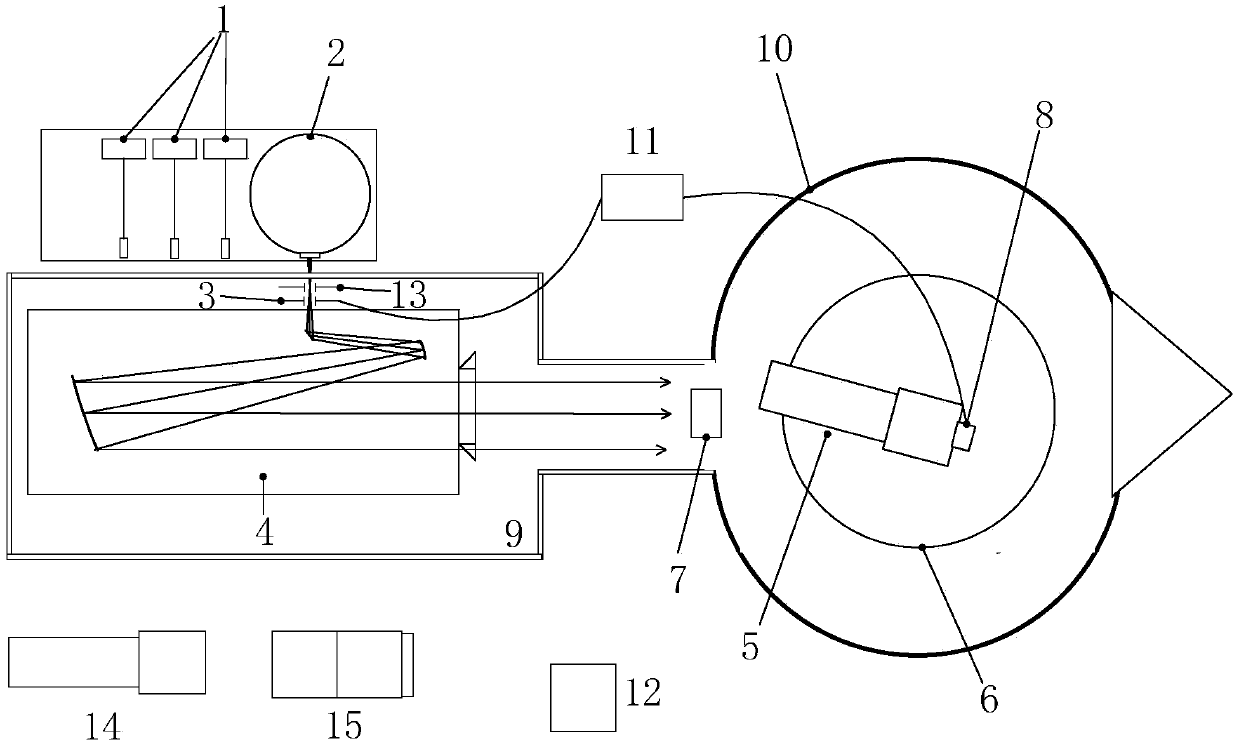

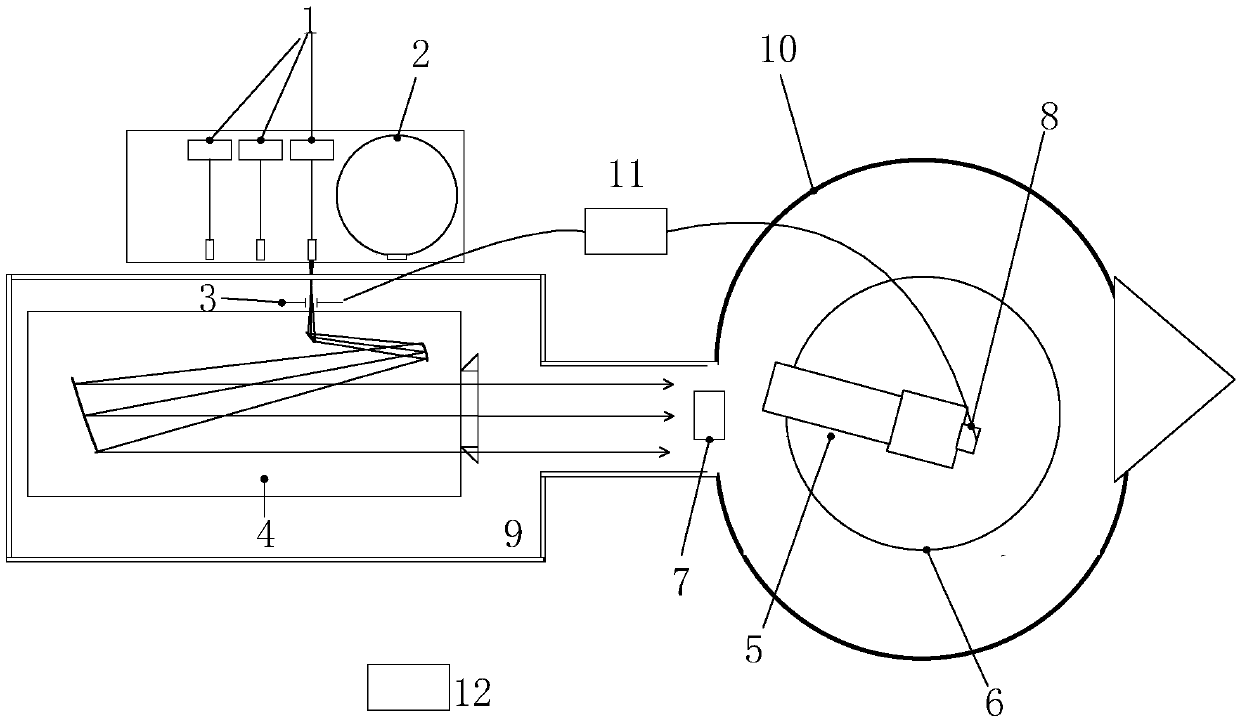

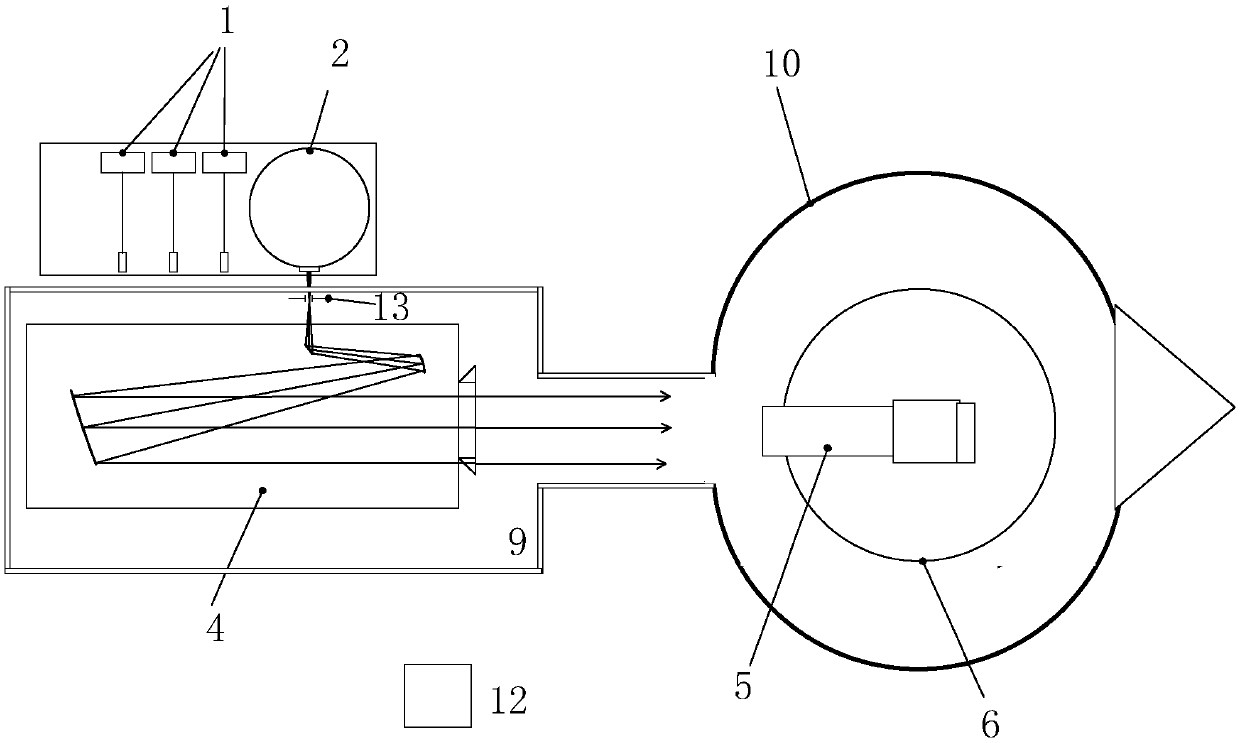

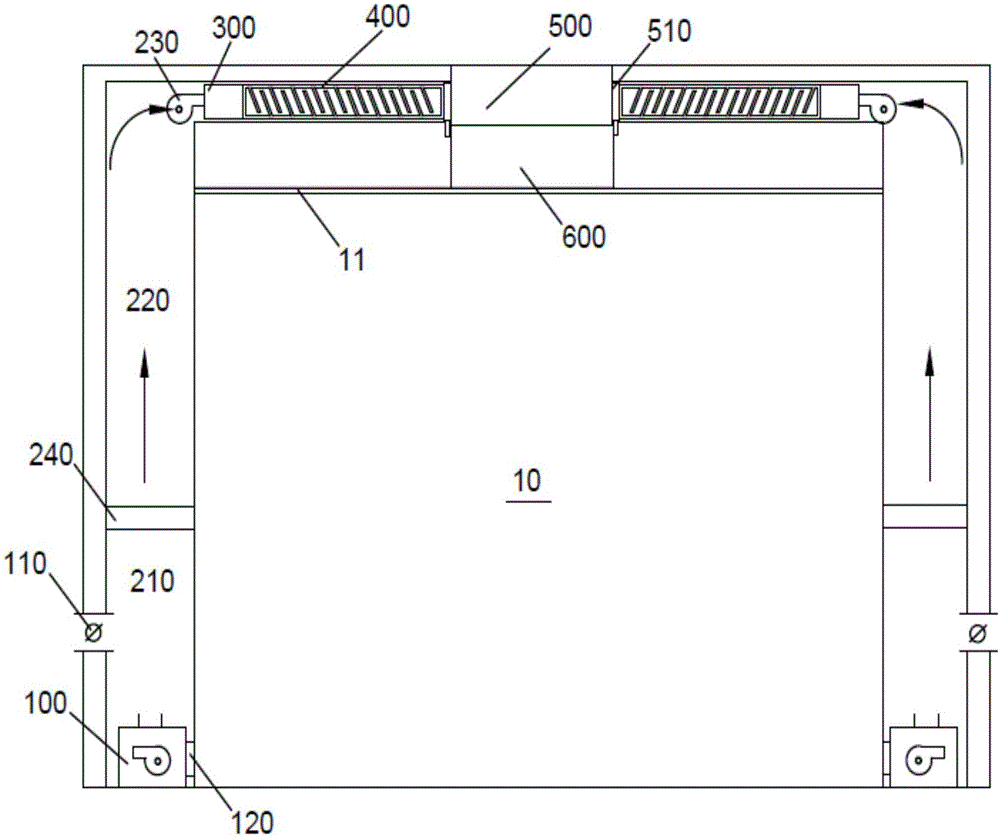

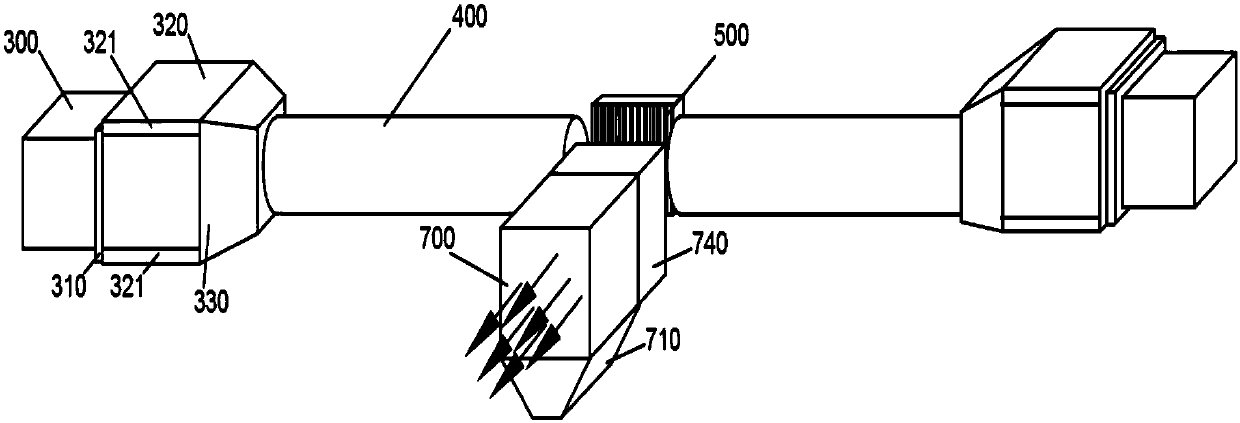

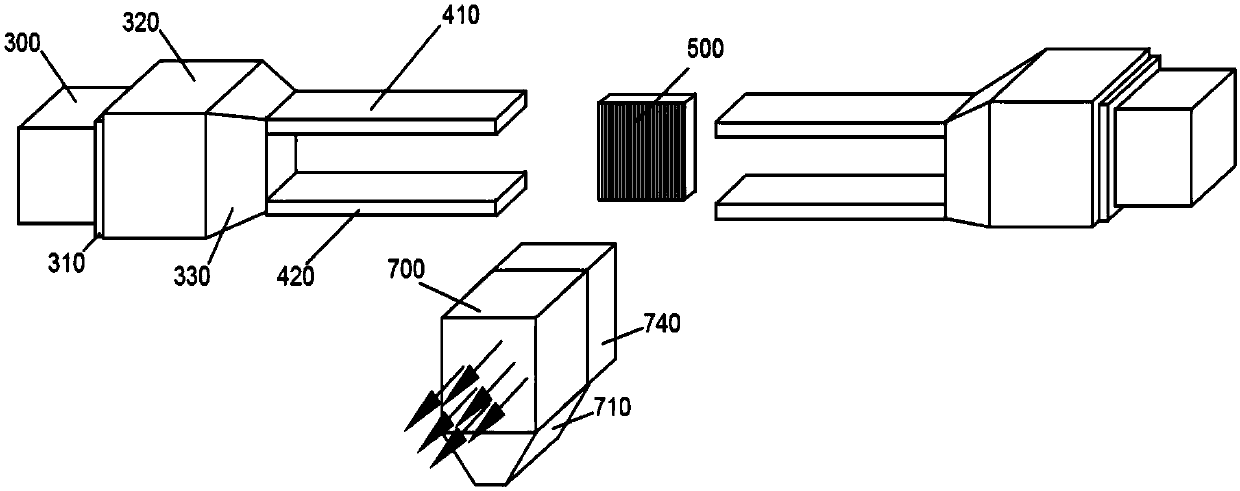

PST test, extremely low object simulation system, and test method of PST and detection capability

PendingCN108680188AImprove interoperabilityLower acquisition costsTesting optical propertiesLower limitControl system

The invention relates to PST (point source transmittance) test, an extremely low object simulation system, and a test method of PST and detection capability. The system mainly comprises a point sourcetransmittance test system, the extremely low object simulation system, and a master control system; the point source transmittance test system and the extremely low object simulation system are combined, so that the universality of the main assemblies is achieved, and construction of a low pressure environment is adopted, so that the vacuum degree of the point source transmittance test system andthe extremely low object simulation system is reduced to 50Pa, the point source transmittance test lower limit reaches 10 to 15, and the extremely low object simulation lower limit reaches +18Mv; andinfluences of the environment on the two systems are avoided at a high degree.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Air purifying system with loop-current cyclone dust removal

ActiveCN105920966ARealize circulation utilizationDoes not take up external spaceCombination devicesCycloneAir filter

The invention discloses an air purifying system with loop-current cyclone dust removal. The air purifying system comprises an inlet air filter set, a cyclone mixing device, a gas washing device, a first return air filter and a second return air filter, wherein the lower end of the inlet air filter set is provided with a top channel; the cyclone mixing device is arranged in a sandwich layer of an indoor side wall; the inlet end of the cyclone mixing device communicates with the upper end of the top channel; the outlet end of the cyclone mixing device communicates with the top channel; indoor return air treated by the cyclone mixing device is transmitted into the gas washing device; the first return air filter is arranged on the center of the indoor bottom; the first return air filter communicates with the air inlet of an air regulating system; the second return air filter is arranged at the two sides of the indoor bottom; the second return air filter is used for treating indoor air and directly transmitting the treated indoor air into the cyclone mixing device. The air purifying system solves the technical problem of great space usage and low treatment efficiency of the air purifying system.

Owner:苏州艾尔新净化科技有限公司

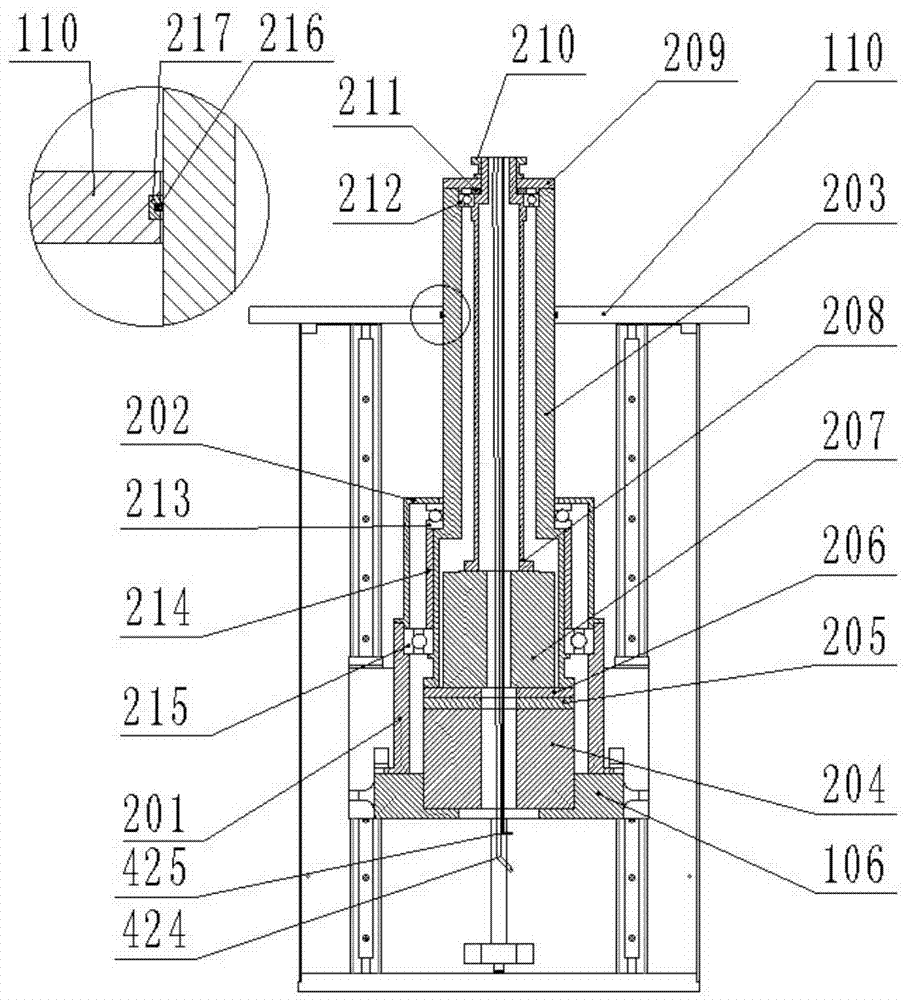

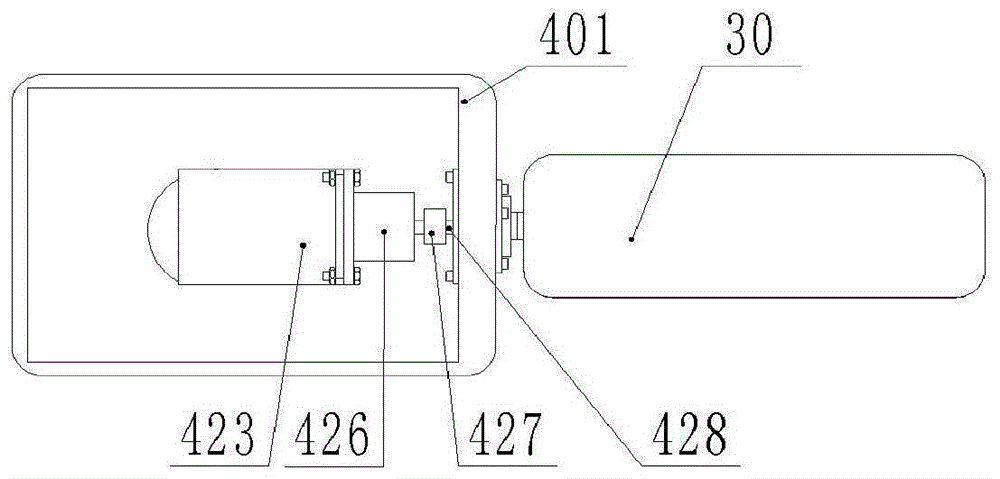

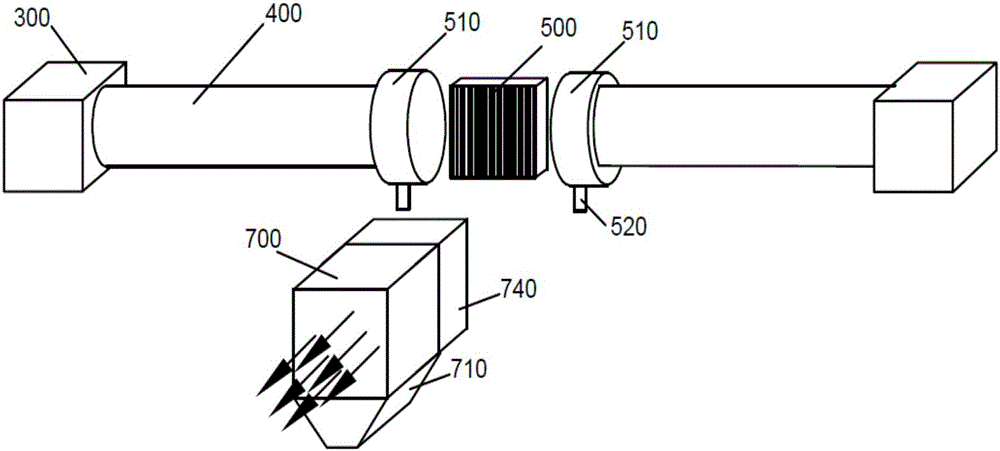

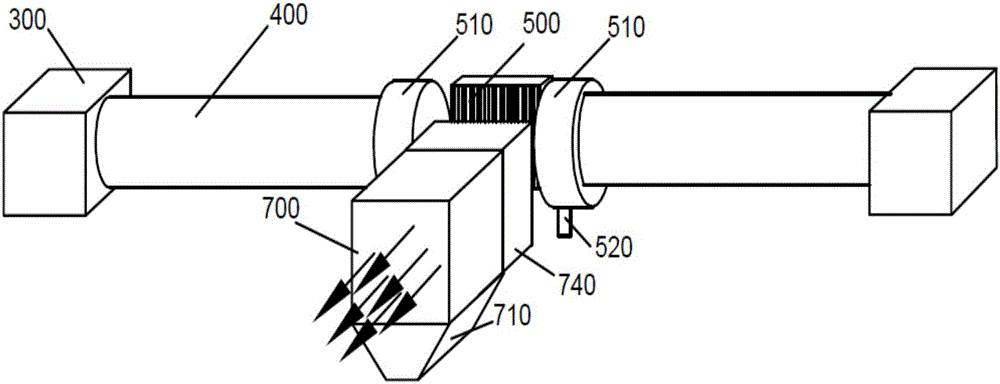

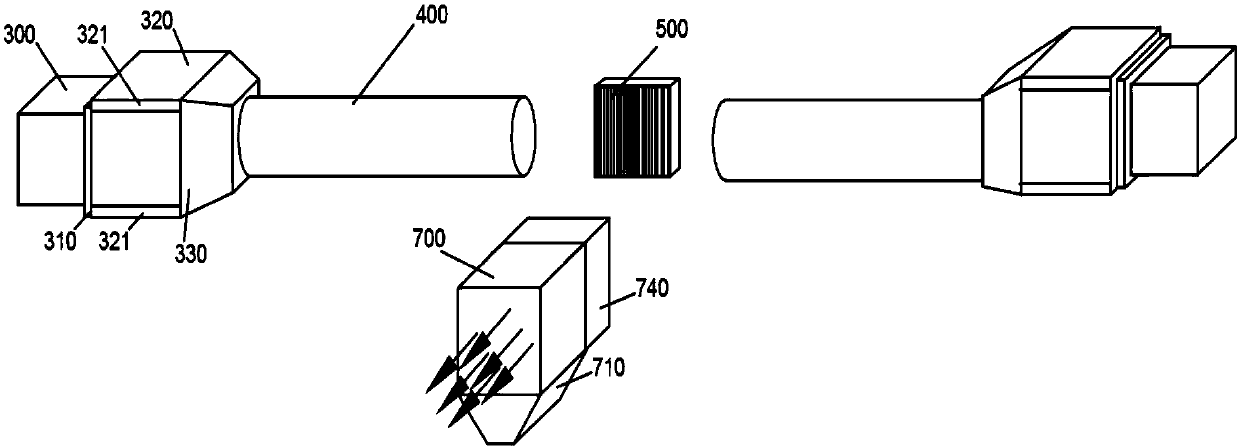

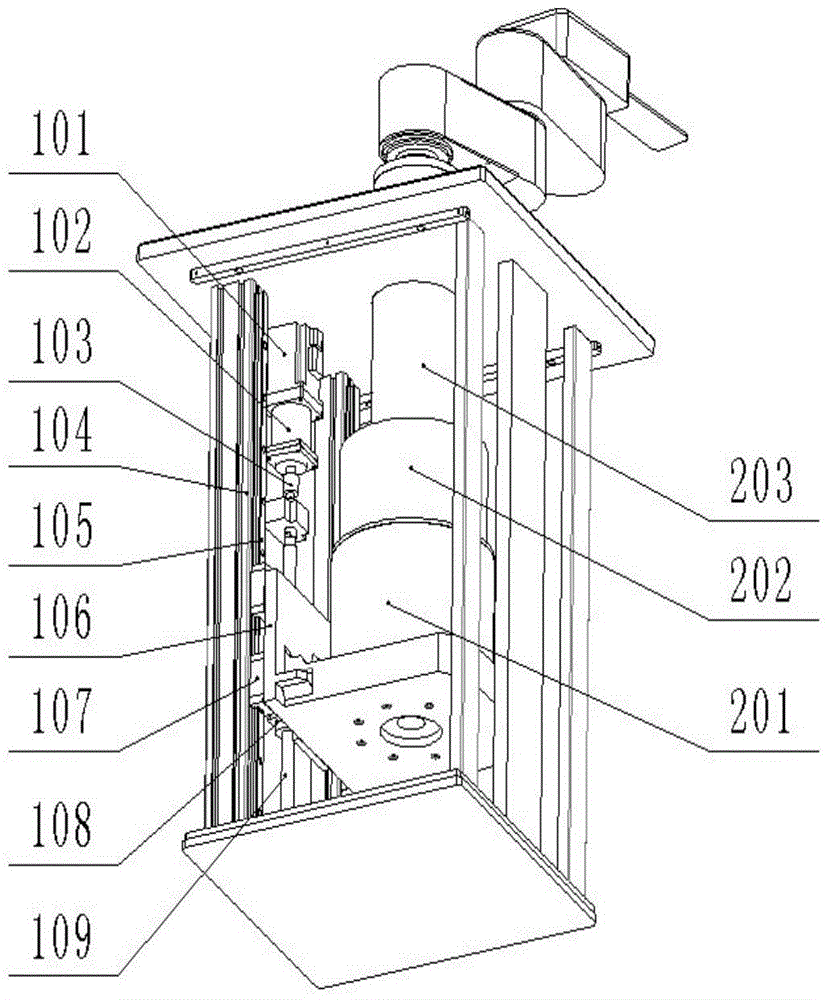

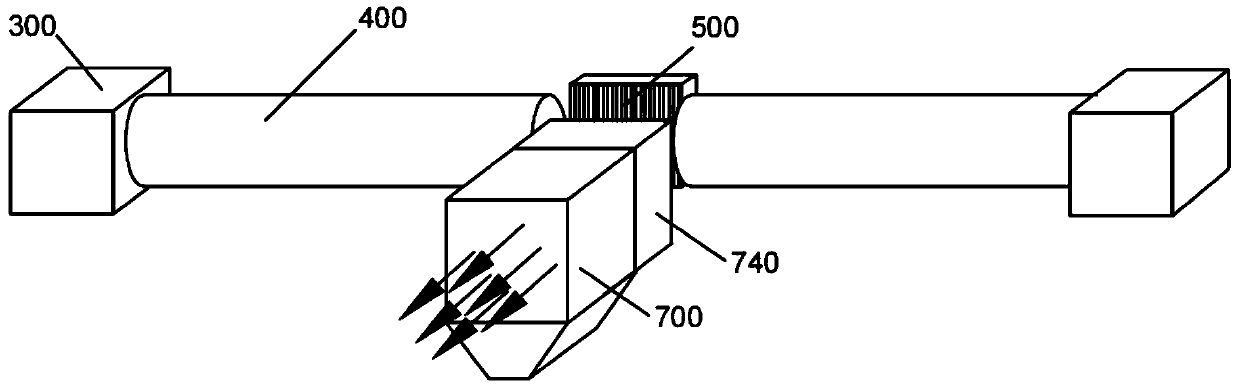

A reversible end assembly applied to a wafer transfer robot

ActiveCN104723345BImprove reliabilityImprove cleanliness levelJointsGripping headsInternal pressureVacuum pressure

Provided is a reversible tail end assembly applied to a wafer conveying robot. A wrist shell of the robot is connected with one end of a small arm, a servo motor is installed in the wrist shell, a motor belt wheel is installed on an output shaft of the servo motor, a steel strip is connected between the motor belt wheel and a swing mechanism belt wheel, the swing mechanism belt wheel is fixed on a swing mechanism, one end of the swing mechanism is fixed in the wrist shell, the other end of the swing mechanism is connected with a vacuum adsorption tail end, and the left end of the swing mechanism is connected with a vacuum air tube joint. In other embodiments, the servo motor can also be replaced with other motors. When a wafer is adsorbed, vacuums are firstly generated in a fixed bent tube and a fixed outer tube, a vacuum can also be generated in a rotating inner tube while the rotating inner tube rotates, vacuum pressure is generated in a hollow duct of the vacuum adsorption tail end and an inner duct of a vacuum tail end connecting shaft, the wafer is adsorbed by means of a difference between internal pressure and external pressure, and vacuum pressure is generated in an inner duct of the swing mechanism while the swing mechanism rotates. Line winding is prevented, and coaxial design of a reversal action and a vacuum generation action is achieved.

Owner:BEIJING UNIV OF TECH

Air purification system adopting water mist charged dust removal

ActiveCN106152275AReduce dust contentImprove cleanliness levelMechanical apparatusLighting and heating apparatusIndoor airElectricity

The invention discloses an air purification system adopting water mist charged dust removal. The air purification system comprises an air inlet filter unit, an electric induction device, a water mist charged device, a first air return filter and second air return filters, wherein a top channel is formed in the lower end of the air inlet filter unit; the electric induction device is arranged on one side of the top channel, indoor return air is conveyed to the electric induction device, and a high-voltage negative power supply is arranged in the electric induction device; the inlet end of the water mist charged device communicates with the outlet end of the electric induction device, and the outlet end of the water mist charged device communicates with the outlet end of the air inlet filter unit; the first air return filter is arranged in the middle of the indoor bottom, and the first air return filter communicates with an air inlet of an air conditioning system; and the second air return filters are arranged on both sides of the indoor bottom, and indoor air is processed by the second air return filters and then is directly conveyed to the electric induction device. According to the air purification system, the technical problems of low purification efficiency of the air purification system and difficulty in complete purification of the indoor air are solved.

Owner:苏州艾尔新净化科技有限公司

Pollution testing device and method

ActiveCN103293271AFunction increaseSimple structureIndividual particle analysisEngineeringTest material

The invention provides a pollution testing device and method. The pollution testing device comprises an air inlet pipe, a static pressure cavity, a filter, an operating cavity, a fixed porous plate, an air return porous plate, an air return cavity and an air return pipe, wherein one end of the air inlet pipe is connected with an external air source, and the other end of the air inlet pipe is connected with the static pressure cavity; the filter is arranged between the static pressure cavity and the operating cavity; an opening is formed in the back surface of the operating cavity; the fixed porous plate is arranged at the bottom of the operating cavity; the air return porous plate is arranged between the operating cavity and the air return cavity; and one end of the air return pipe is connected with the air return cavity, and the other end of the air return pipe is connected with the air inlet pipe. According to the pollution testing device and method, multiple pollution tests can be realized, the characteristics that the material and the motion part release particles and molecular pollutants can be tested simultaneously, and the device is diversified in functions and simple in structure.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Air purifying system with washing function

ActiveCN106123157AReduce dust contentEasy capture condensationMechanical apparatusLighting and heating apparatusElectricityAir filter

The invention discloses an air purifying system with a washing function. The air purifying system comprises air return channels, electric induction devices, washing devices, dehumidifying devices, an inlet air filtering unit and an electrostatic dust removing device. The electric induction devices are arranged on the top of the interior of a room. The inlet end of each electric induction device communicates with the corresponding air return channel. Each of the electric induction devices is internally provided with a high-voltage negative power source. The inlet end of each washing device communicates with the outlet end of the corresponding electric induction device. A water solution with positive ions is arranged in each washing device. Each dehumidifying device is arranged at the outlet end of the corresponding washing device. The outlet end of the inlet air filtering unit is arranged on one sides of the outlet ends of the dehumidifying devices. The inlet end of the inlet air filtering unit communicates with an air supply opening of an air conditioning system. The inlet end of the electrostatic dust removing device is arranged on the other sides of the outlet ends of the dehumidifying devices. The outlet end of the electrostatic dust removing device communicates with the top space in the room. According to the air purifying system, the technical problems that an air purifying system is high in consumed cost and poor in dust removing effect are solved.

Owner:苏州艾尔新净化科技有限公司

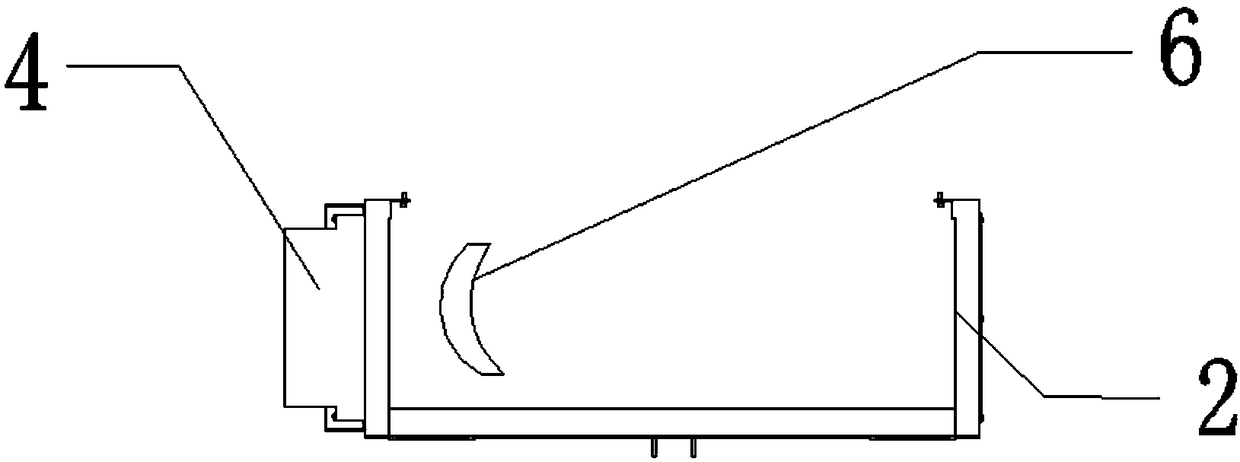

Baking device used for removing trace of organic pollutants on surface of light machine element

InactiveCN105234131AImprove cleanliness levelGood removal effectCleaning processes and apparatusAviationVacuum pressure

The invention provides a baking device used for removing a trace of organic pollutants on the surface of a light machine element. According to the baking device, the organic pollutants on the surface or the sub-surface of the metal or fused quartz light machine element are baked out through an infrared baking lamp in a low-vacuum baking manner, and the organic pollutants are taken out of a vacuum box through a trace of circulating air. An air filter and an AMC filter are used for the baking device, and secondary pollution of particles and organic matter in air to the surface of the light machine element is avoided. According to the baking device, by regulating vacuum pressure and baking temperature, it can be guaranteed that the organic pollutants on the surface or the sub-surface of the light machine element are removed under the condition that the performance of the light machine element is not changed, and meanwhile a high cleanliness level is achieved. The baking device has the beneficial effects that the organic pollutant removing effect is good, the structure is simple, no secondary pollution is caused, and use is easy; and the baking device can be expanded to be applicable to the fields, such as aviation and aerospace, with high requirements for cleanliness.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Cyclone charged dedusting air purification system

ActiveCN106196278AImprove the adsorption effectImprove cleanliness levelDucting arrangementsMechanical apparatusActivated carbonElectrostatic precipitator

The invention discloses a cyclone charged dedusting air purification system. The cyclone charged dedusting air purification system comprises an air return channel, electric induction devices, cyclone devices, an intake air filter bank and an electrostatic dedusting device, wherein the electric induction devices are arranged on the top of the inside of a room, the inlet ends of the electric induction devices communicate with the air return channel, the electric induction devices are connected with a high-voltage negative power supply, the inlet ends of the cyclone devices communicate with the outlet ends of the electric induction devices, a plurality of dust collection chambers are arranged on the cyclone devices in an outward protrusion manner, activated carbon fiber layers used for purifying air are arranged on the upper sides of the outlet ends of the cyclone devices, the outlet end of the intake air filter bank is arranged on one side of the outlet ends of the cyclone devices, the inlet end of the intake air filter bank communicates with the air supply port of an air conditioning system, the inlet end of the electrostatic dedusting device is arranged on the other side of the outlet ends of the cyclone devices, and the outlet end of the electrostatic dedusting device communicates with the top space of the inside of the room. With the cyclone charged dedusting air purification system, the technical problem that the indoor cleanliness cannot be upgraded is solved.

Owner:苏州艾尔新净化科技有限公司

Optical fiber wiredrawing purification device

The invention discloses an optical fiber wiredrawing purification device. The optical fiber wiredrawing purification device comprises a purifying cover, wherein the purifying cover is fixedly mountedon one side of the optical fiber wiredrawing of an optical fiber wiredrawing tower, and forms purifying space with the optical fiber wiredrawing tower; an air inlet externally communicating with the purifying space is arranged on the purifying cover; an air inlet fan and a purifying device are arranged at the air inlet; gas enters from the air inlet fan, and flows out from an optical fiber runningchannel on the optical fiber wiredrawing tower, so that positive pressure is formed inside the purifying cover. According to the invention, optical fiber exposed between a furnace mouth of a heatingfurnace and a UV furnace in the optical fiber wiredrawing tower is in independent purification space by arranging the purifying cover outside the optical fiber wiredrawing tower, and the flow direction of airflow can be ensured through the arrangement of the air inlet fan, so that the positive pressure is formed in the purifying space, external dust can be prevented from entering into the opticalfiber running channel, the cleanliness level of the optical fiber drawing channel can be effectively improved, the cleanliness of the optical fiber wiredrawing can be ensured, the screening strength value of the optical fiber can be increased, and the fiber breaking rate during wiredrawing can be reduced.

Owner:江苏亨芯石英科技有限公司

Air purification system with high blast capacity

ActiveCN105999960AImprove processing timeIncrease air volumeCombination devicesElectricityAir volume

The invention discloses an air purification system with high blast capacity. The system comprises an air inlet filter tank provided with a top channel at the lower end, an electric induction device arranged on the bottom of an air return channel in a transverse covering mode, an electrical charge dust collection device arranged in the air return channel at the upper end of the electric induction device, an electrostatic dust removal device transversely arranged at one end of the top channel, a first returned air filter and a second returned air filter, wherein the outlet end of the electrical charge dust collection device is communicated with the inlet end of the electrostatic dust removal device, and the outlet end of the electrostatic dust removal device is communicated with the outlet end of the air inlet filter tank. The technical problem of poor purified air blast capacity is solved.

Owner:苏州艾尔新净化科技有限公司

Low-energy air purification system

ActiveCN106051920AImprove replacement efficiencyImprove cleanliness levelMechanical apparatusLighting and heating apparatusEqualizationReturn channel

The invention discloses a low-energy air purification system. The low-energy air purification system comprises an intake filtering unit, an air return channel, a first blade wheel, an air return filtering unit and electrostatic dust collection devices, wherein a first flow equalization device is transversely arranged at the lower end of the intake filtering unit; the air return channel is arranged in the indoor side wall; the first blade wheel is transversely arranged between the intake filtering unit and the first flow equalization device, a center rotary shaft of the first blade wheel penetrates an indoor ceiling upwards and is connected with a drive mechanism, and a bottom channel is transversely arranged at the indoor bottom; an intake opening of the air return filtering unit communicates with the indoor bottom space, and an air outlet of the air return filtering unit communicates with the bottom channel; and the electrostatic dust collection devices are arranged in the portion, on the two sides of the air return filtering unit, of the bottom channel, an inlet of each electrostatic dust collection device communicates with the bottom channel, and an outlet of each electrostatic dust collection device communicates with the bottom of the air return channel. The low-energy air purification system solves the technical problem that energy consumption is too high by means of an existing air purification system.

Owner:苏州艾尔新净化科技有限公司

A Direct Drive Reversible Wafer Transfer Robot

ActiveCN104723332BHigh transmission precisionImprove transmission efficiencyProgramme-controlled manipulatorConveyor partsDegrees of freedomDrive motor

Owner:BEIJING UNIV OF TECH

Wet dust removal air purification system

ActiveCN106152276BImprove adsorption capacityCongeal and easyMechanical apparatusLighting and heating apparatusElectricityIndoor air quality

The invention discloses an air purification system adopting wet dust removal. The air purification system comprises an air return channel, an electric induction device, a spray device, an air inlet filter unit and an electrostatic dust removal device, wherein the electric induction device is arranged on the indoor top, the inlet end of the electric induction device communicates with the air return channel, and a high-voltage negative power supply is arranged in the electric induction device; the inlet end of the spray device communicates with the outlet end of the electric induction device, and an air cleaning agent is arranged in the spray device; the outlet end of the air inlet filter unit is arranged on one side of the outlet end of the spray device, and the inlet end of the air inlet filter unit communicates with an air inlet of an air conditioning system; and the inlet end of the electrostatic dust removal device is arranged on the other side of the outlet end of the spray device, and the outlet end of the electrostatic dust removal device communicates with the indoor top space. According to the air purification system, the technical problems of poor dust removal effect of the air purification system and difficulty in increasing the quality of indoor air are solved.

Owner:苏州艾尔新净化科技有限公司

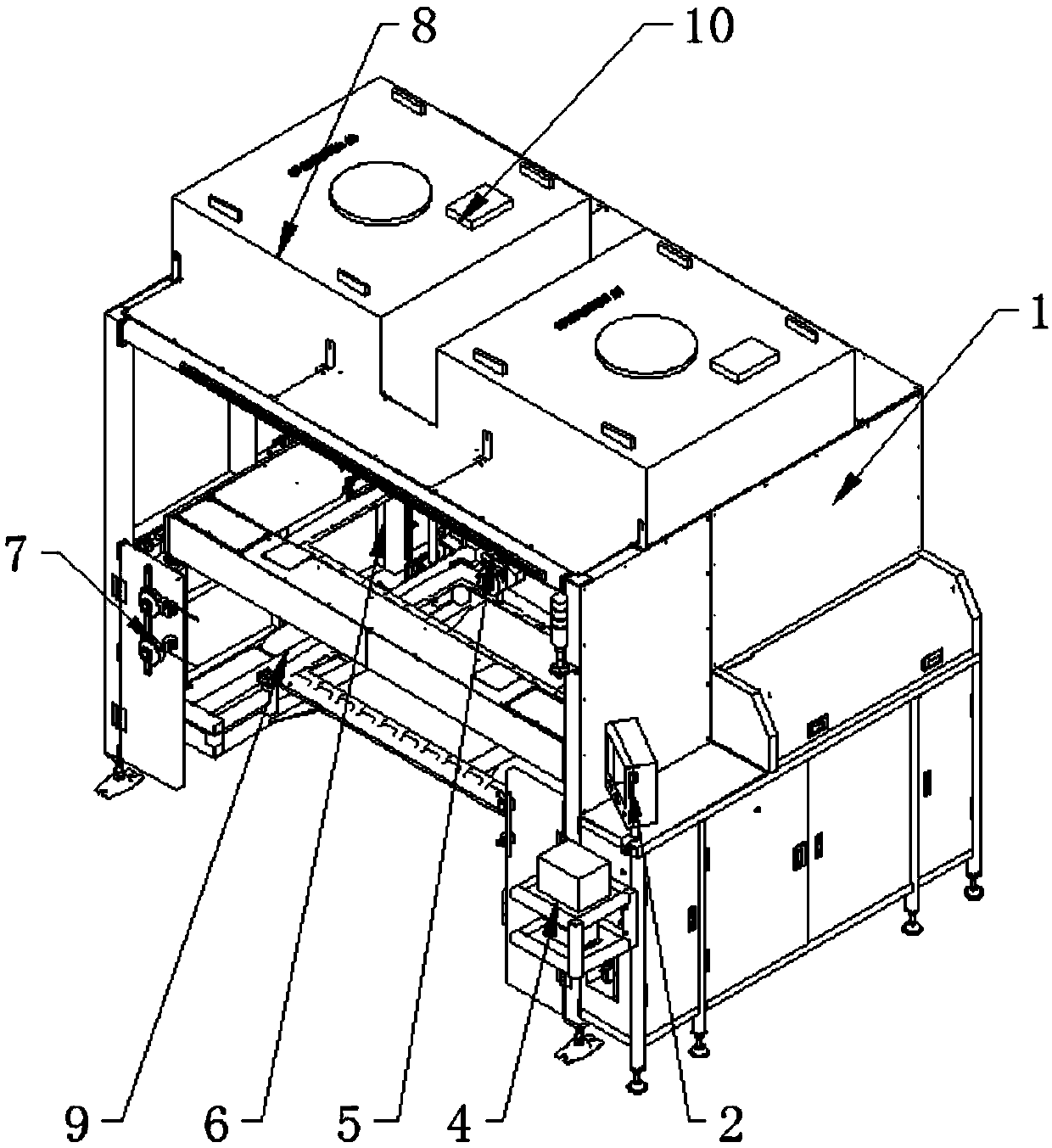

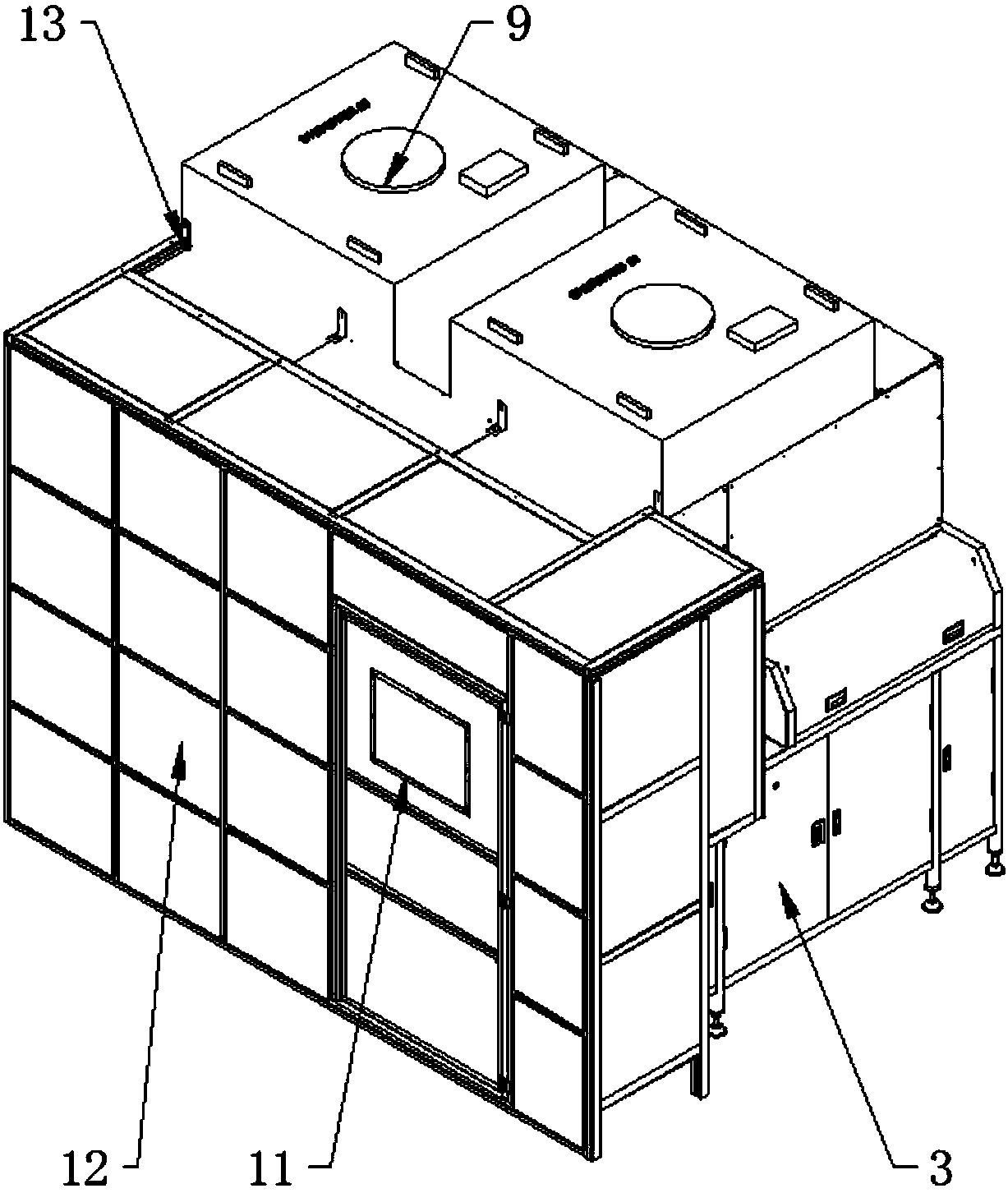

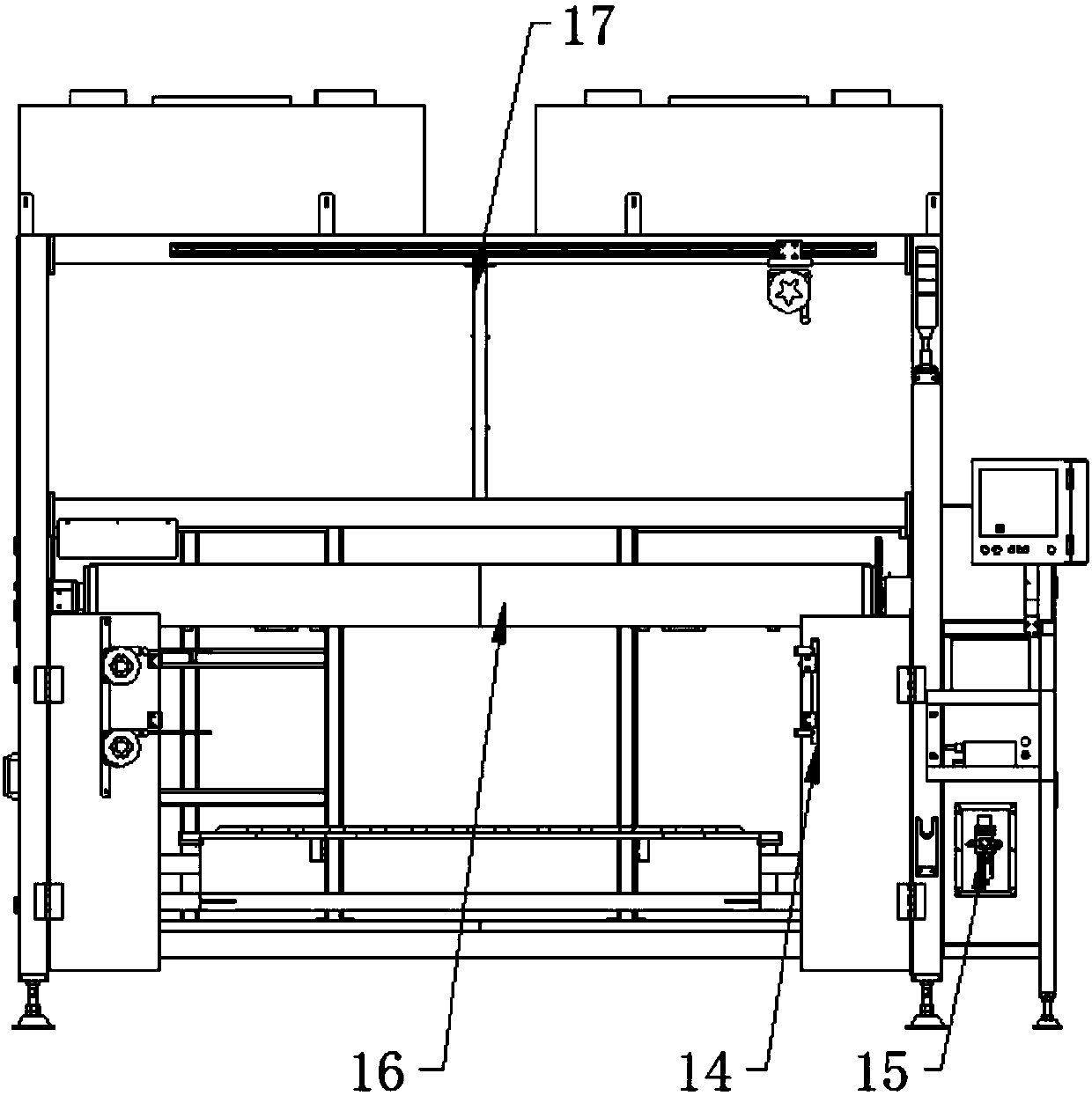

Automatic photomask multifunctional overturn inspection machine

The present invention discloses an automatic photomask multifunctional overturn inspection machine. The machine comprises an inspection machine main body and a duplex piece, symmetrical FFU air filters are arranged at the upper end of the inspection machine main body, the FFU air filters are tightly fixed with the inspection machine main body, FFU controllers are arranged at the top portions of the FFU air filters, and the bottom portions of the FFU controllers are in contact with the surfaces of the FFU air filters. Through combination of an air source processing mode of a traditional duplexpiece and the inspection machine main body, the automatic photomask multifunctional overturn inspection machine can detect work of an object such as device operation states, processing conditions, defects, shapes and sizes and also can utilize an overturn bench to perform 360-degree overturning of workpieces so that a cleanliness grade of a detection area is improved and an operation safety is improved; and moreover, when safe drawing rope ensures device operation, personnel cannot enter the device, and once the drawing rope is moved by people to cause sudden stopping of the device so that operators' safety is ensured.

Owner:SUZHOU HUIQIAO AUTOMATION EQUIP CO LTD

Secondary charge dust removal air purification system

ActiveCN106091118BImprove adsorption capacityCongeal and easyDucting arrangementsMechanical apparatusElectricityAir filter

The invention discloses a secondary charged dust removing air purification system. The secondary charged dust removing air purification system comprises a return air channel, an electric induction device, a charged dust collection device, an inlet air filter unit and an electrostatic dust removing device, wherein the electric induction device is arranged at the top of the interior of a room; the inlet end of the electric induction device communicates with the return air channel; the electric induction device is internally provided with a high-voltage negative power source; the inlet end of the charged dust collection device communicates with the outlet end of the electric induction device; direct current high voltages are connected to the upper side and the lower side of the charged dust collection device; the outlet end of the inlet air filter unit is arranged on one side of the outlet end of the charged dust collection device; the inlet end of the inlet air filter unit communicates with an air supply outlet of an air conditioning system; the inlet end of the electrostatic dust removing device is arranged on the other side of the outlet end of the charged dust collection device; and the outlet end of the electrostatic dust removing device communicates with a space at the top of the interior of the room. According to the secondary charged dust removing air purification system, the technical problem that fine dust in air cannot be effectively filtered is solved.

Owner:苏州艾尔新净化科技有限公司

A smelting method for producing IF steel with low oxygen level in the whole process

ActiveCN110205436BImprove cleanliness levelIncrease insertion depthManufacturing convertersProcess efficiency improvementSlagCoke

The invention discloses a smelting method for producing IF steel with low oxygen level in the whole process, and belongs to the technical field of iron and steel smelting. The steps of the present invention are as follows: step 1: slag dumping at the end of converter steel smelting, leaving 10-15 tons of slag in the converter, adding 50-100 kg of coke powder to remove oxygen in the slag, and then performing slag splashing to protect the furnace; step 2: charging the converter ;Step 3: Converter main blowing; Step 4: After the converter main blowing, measure the molten steel temperature and carbon content through the sub-lance, and control the auxiliary blowing oxygen amount according to the measured value; Step 5: After the auxiliary blowing, before tapping Bottom blowing for 30 seconds; Step 6: Converter tapping; Step 7: Molten steel enters the RH process; Step 8: After the ladle is lifted, turn on the vacuum pump to vacuum and decarburize. The invention can reduce the degree of peroxidation of molten steel in converter tapping, reduce the oxidizability of ladle top slag, and reduce deoxidized inclusions Al 2 o 3 The amount of production is increased, the cleanliness level of molten steel is improved, and the cost is reduced, which has significant economic benefits.

Owner:MAANSHAN IRON & STEEL CO LTD

Air Purification System for Circulation Cyclone Dust Removal

ActiveCN105920966BRealize circulation utilizationDoes not take up external spaceCombination devicesCycloneEngineering

Owner:苏州艾尔新净化科技有限公司

Air purification system with high air volume

ActiveCN105999960BImprove processing timeIncrease air volumeCombination devicesElectricityAir volume

The invention discloses an air purification system with high blast capacity. The system comprises an air inlet filter tank provided with a top channel at the lower end, an electric induction device arranged on the bottom of an air return channel in a transverse covering mode, an electrical charge dust collection device arranged in the air return channel at the upper end of the electric induction device, an electrostatic dust removal device transversely arranged at one end of the top channel, a first returned air filter and a second returned air filter, wherein the outlet end of the electrical charge dust collection device is communicated with the inlet end of the electrostatic dust removal device, and the outlet end of the electrostatic dust removal device is communicated with the outlet end of the air inlet filter tank. The technical problem of poor purified air blast capacity is solved.

Owner:苏州艾尔新净化科技有限公司

A method of producing silicon-deoxidized low-sulfur high-carbon steel using lf refining double-slag method

The invention relates to a method for producing silicon deoxygenation low-sulfur high-carbon steel through an LF refining double slag method. An electric furnace-LF-VD continuous casting technology isadopted. The method includes the steps that in the electric furnace tapping process, carbon powder is mixed firstly, then a silicon alloy and a manganese alloy are added for conducting deoxygenationalloying treatment, and lime, calcium carbide and aluminum-free refining slag are added for conducting modification treatment; secondly, after an LF enters a station, lime, calcium carbide, silicon iron and aluminum-free refining slag are added into the furnace for making high-alkalinity reducing refining slag; thirdly, low-alkalinity reducing slag is made, and the content of components in moltensteel is adjusted; and fourthly, the LF withdraws from the station after refining, VD and continuous casting processes are conducted in sequence, and the silicon deoxygenation low-sulfur high-carbon steel is obtained. The method is simple, reliable, high in operability and easy to achieve, the production cost of the whole process is reduced, the sulfur removing efficiency is high, the cleanlinesslevel of molten steel is high, the problem that when a non-molten-steel pretreatment sulfur removing process is adopted for producing high-quality silicon deoxygenation low-sulfur high-carbon steel, sulfur removing is difficult is solved well, and therefore the product quality is improved, and the economic benefits of a steel enterprise are increased.

Owner:CENT IRON & STEEL RES INST

Low energy consumption air purification system

ActiveCN106051920BImprove replacement efficiencyImprove cleanliness levelMechanical apparatusLighting and heating apparatusEqualizationReturn channel

The invention discloses a low-energy air purification system. The low-energy air purification system comprises an intake filtering unit, an air return channel, a first blade wheel, an air return filtering unit and electrostatic dust collection devices, wherein a first flow equalization device is transversely arranged at the lower end of the intake filtering unit; the air return channel is arranged in the indoor side wall; the first blade wheel is transversely arranged between the intake filtering unit and the first flow equalization device, a center rotary shaft of the first blade wheel penetrates an indoor ceiling upwards and is connected with a drive mechanism, and a bottom channel is transversely arranged at the indoor bottom; an intake opening of the air return filtering unit communicates with the indoor bottom space, and an air outlet of the air return filtering unit communicates with the bottom channel; and the electrostatic dust collection devices are arranged in the portion, on the two sides of the air return filtering unit, of the bottom channel, an inlet of each electrostatic dust collection device communicates with the bottom channel, and an outlet of each electrostatic dust collection device communicates with the bottom of the air return channel. The low-energy air purification system solves the technical problem that energy consumption is too high by means of an existing air purification system.

Owner:苏州艾尔新净化科技有限公司

A kind of production method of silicon deoxidized low-sulfur high-carbon steel

The invention relates to a production method for silicon deoxidation low-sulfur high-carbon steel. An electric furnace-LF-VD-continuous casting process is adopted. The production method comprises thesteps that 1, in the steel tapping process of an electric furnace, carbon powder is added firstly, then a silicon alloy and a manganese alloy are added for deoxidation alloying treatment, and then lime, calcium carbide, aluminum-free refining slag are added to conduct modification treatment on slag; 2, after an LF enters a station, reductive refining slag is made; 3, after it is determined that the sulfur content in molten steel is controlled to be under a target value, the content of all components in the molten steel is adjusted to be within the required high-carbon steel component range; and 4, the LF leaves the station after refining, VD and continuous casting processes are sequentially conducted, and the silicon deoxidation low-sulfur high-carbon steel is obtained. The production method is provided under the overall background of the molten-iron-free pretreatment desulfurization process in traditional smelting production of the silicon deoxidation low-sulfur high-carbon steel, thelimit of production of the silicon deoxidation low-sulfur high-carbon steel through the molten-iron-free pretreatment desulfurization process on equipment is overcome, in the LF refining process, therefining slag with the specific components and properties is smelted, and the dual purposes of efficient desulfurization of the molten steel and plastification control over inclusions are realized.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com