Patents

Literature

64results about How to "Improve decarbonization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

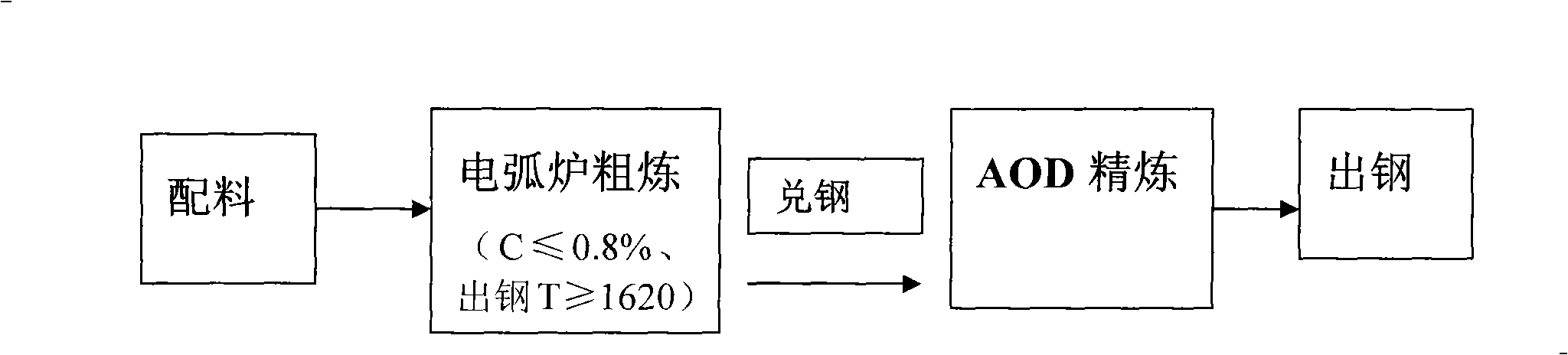

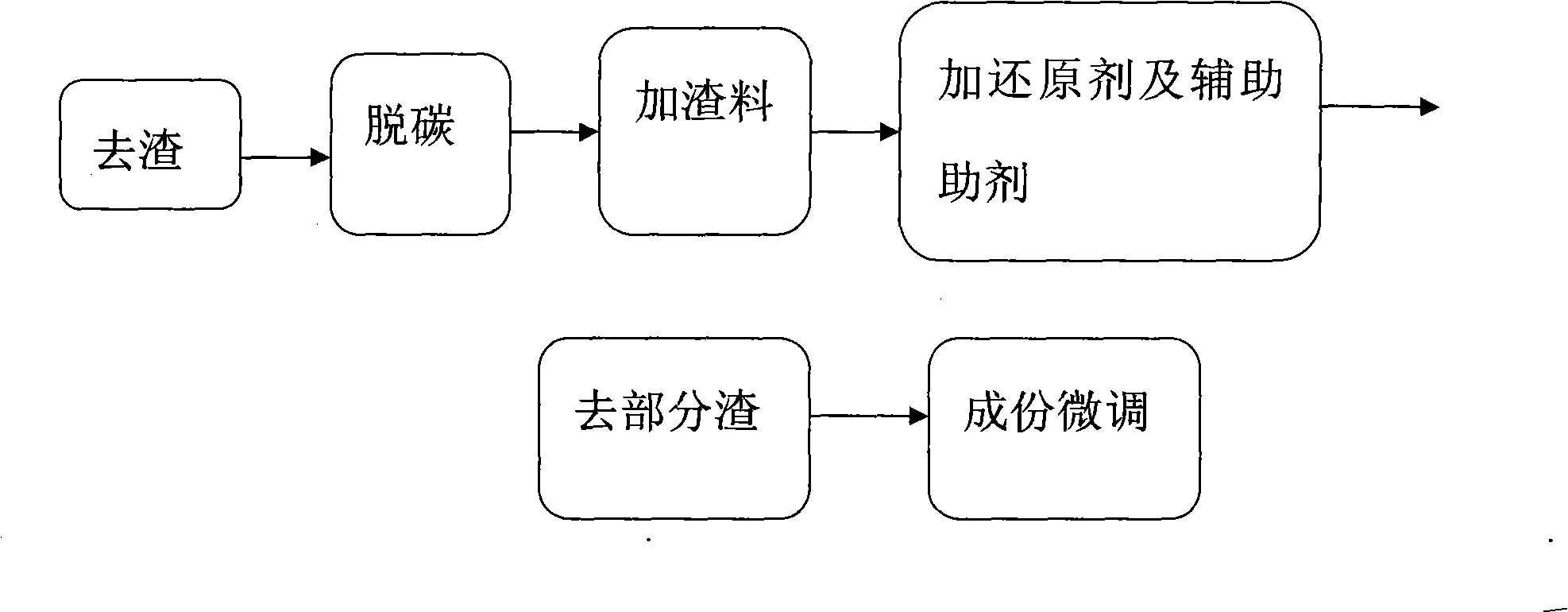

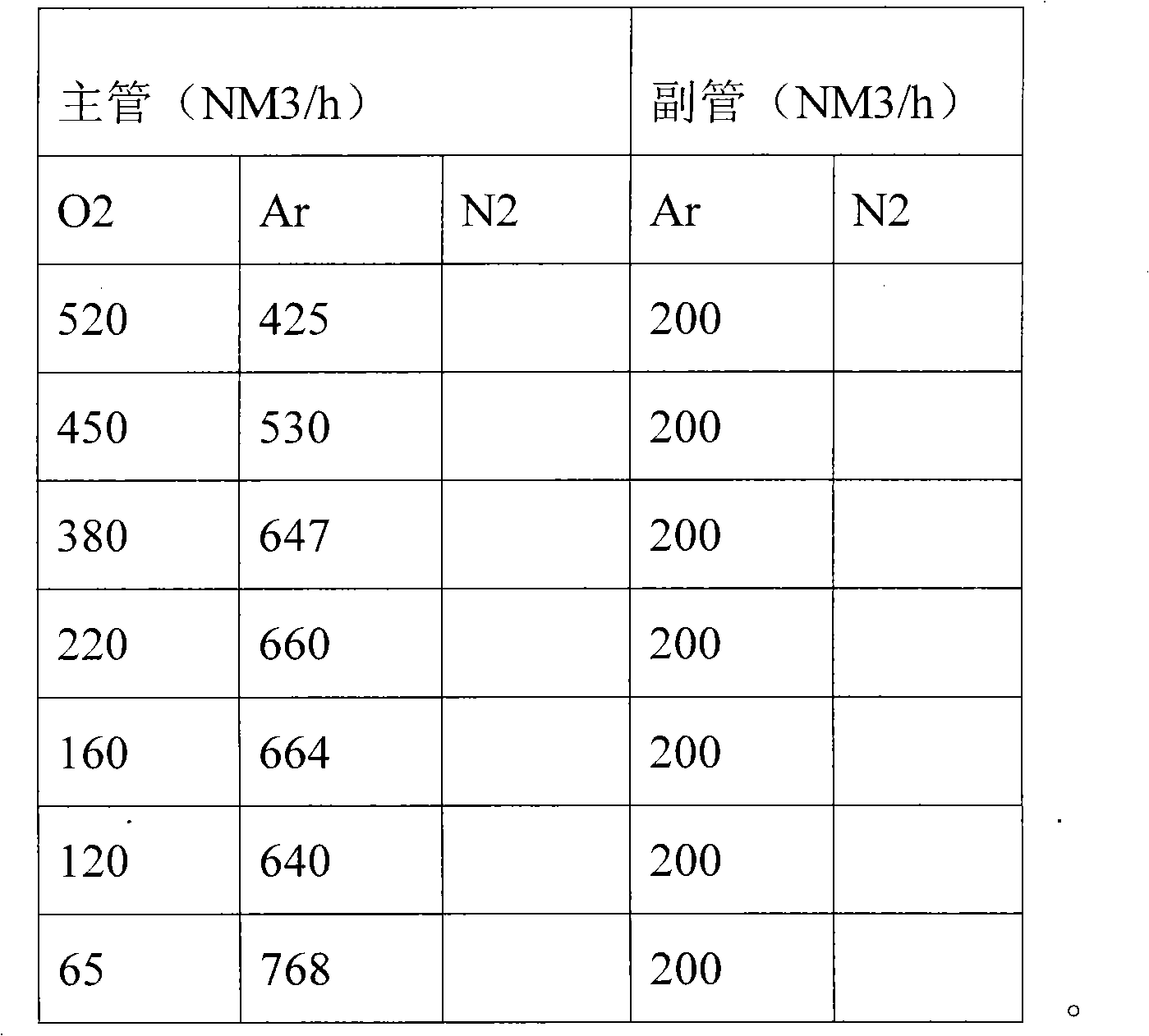

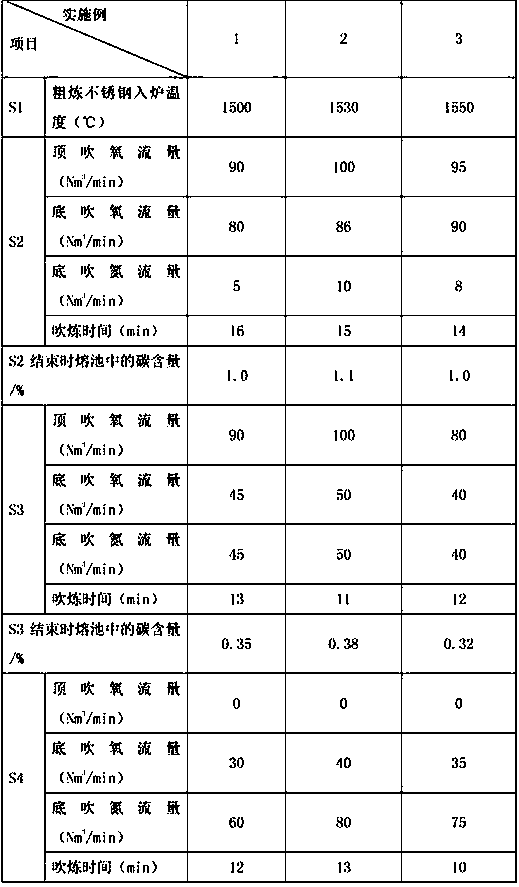

Method for smelting very-low carbon and high silicon stainless steel by AOD

The invention discloses a method for using AOD to smelt extra-low high sillca stainless steel which includes the following technical steps: batching-crude melting by an arc furnace-steel exchange-AOD refining-argon blowing-tapping; wherein, the AOD refining also includes the following steps: removing slag-decarbonizing-adding slag materials-adding a reducer and an auxiliary agent-removing partial slag-fine tuning on the components; the method is characterized in that: a, the argon oxygen blowing in the decarbonizing technique is divided into an initial decarbonizing period and a secondary decarbonizing period; the initial decarbonizing period and the secondary decarbonizing period are blown according to a different argon-oxygen ratio; b, the slag system adopted in the technique of adding the slag materials is a slag system of CaO, Al2O3, MgO and SiO2. The method of the invention leads a steel liquid to finish crude smelting in the arc furnace, namely being capable of stably producing the extra-low stainless steel ( the C is equal to or less than 0.015 percent) in the AOD without a vacuum device, saving the consumption of the reducer, having a low cost, being capable of carrying out industrial batch production, utilizing the existing smelting device to the largest extent as well and saving a plurality of investment.

Owner:YONGXING SPECIAL STAINLESS STEEL

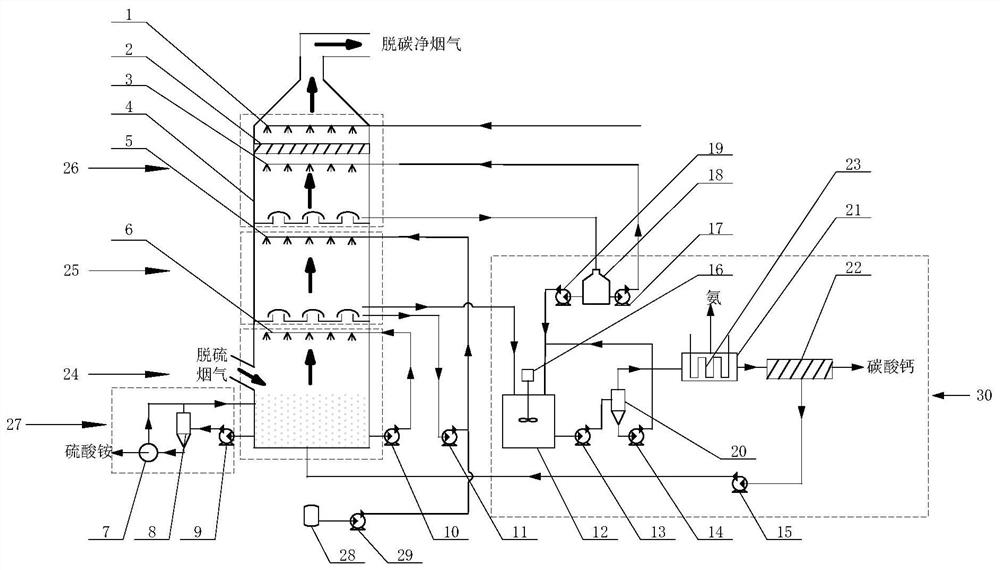

Production process for removing carbon dioxide from smoke and preparing ammonium compound fertilizer and light calcium carbonate

InactiveCN101890283AReduce volumeSmall footprintCalcium/strontium/barium carbonatesProductsCycloneAmmonium compounds

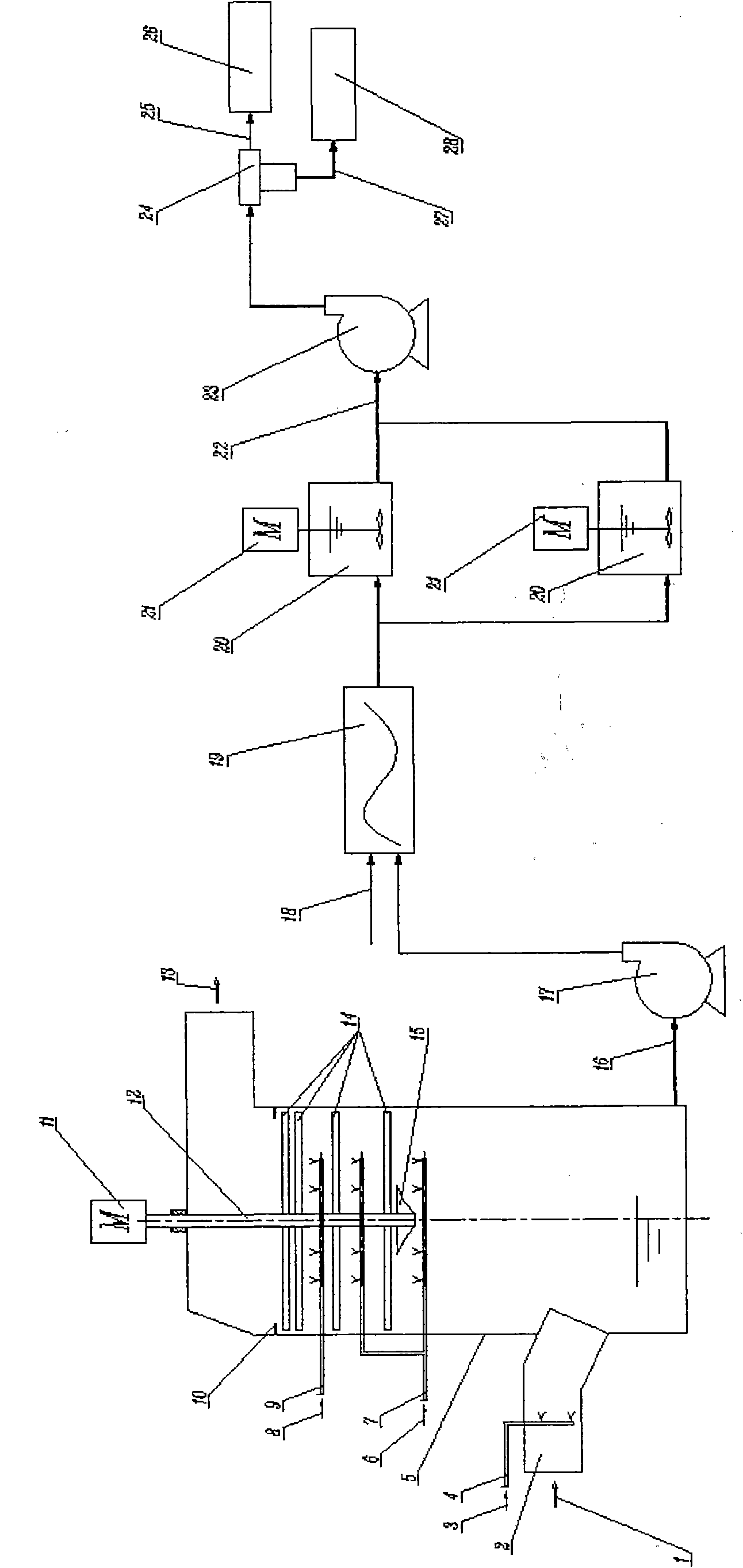

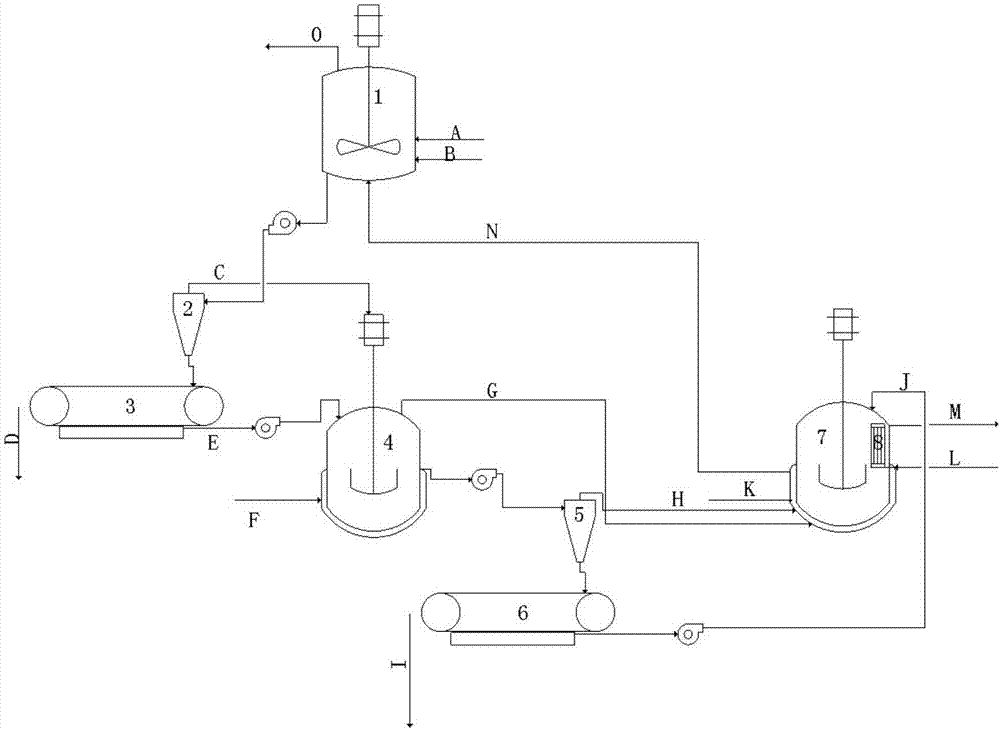

The invention relates to a production process for removing carbon dioxide from smoke and preparing ammonium compound fertilizer and light calcium carbonate. The process comprises the following steps of: performing gas-liquid two-phase high strength mass transfer absorption reaction on the primary smoke through a super-gravity field absorption tower by using dilute aqueous ammonia as an absorbent to remove carbon, discharging the treated smoke through a chimney, and performing further reaction treatment on byproducts of the carbon removal reaction to obtain the ammonium compound fertilizer and the light calcium carbonate with good economic values. The whole set of reaction and separation device for supporting the process comprises the super-gravity field absorption tower, a static mixer 19, a deep reaction tank 20, a cyclone 24, an ammonium compound fertilizer reclaiming system 26, a light calcium carbonate reclaiming system 28, various pumps and the like, wherein the super-gravity field absorption tower is used at a chemical reaction absorption section for removing the carbon dioxide. The brand-new process has the advantages of high efficiency, low investment and low running expense.

Owner:刘海清

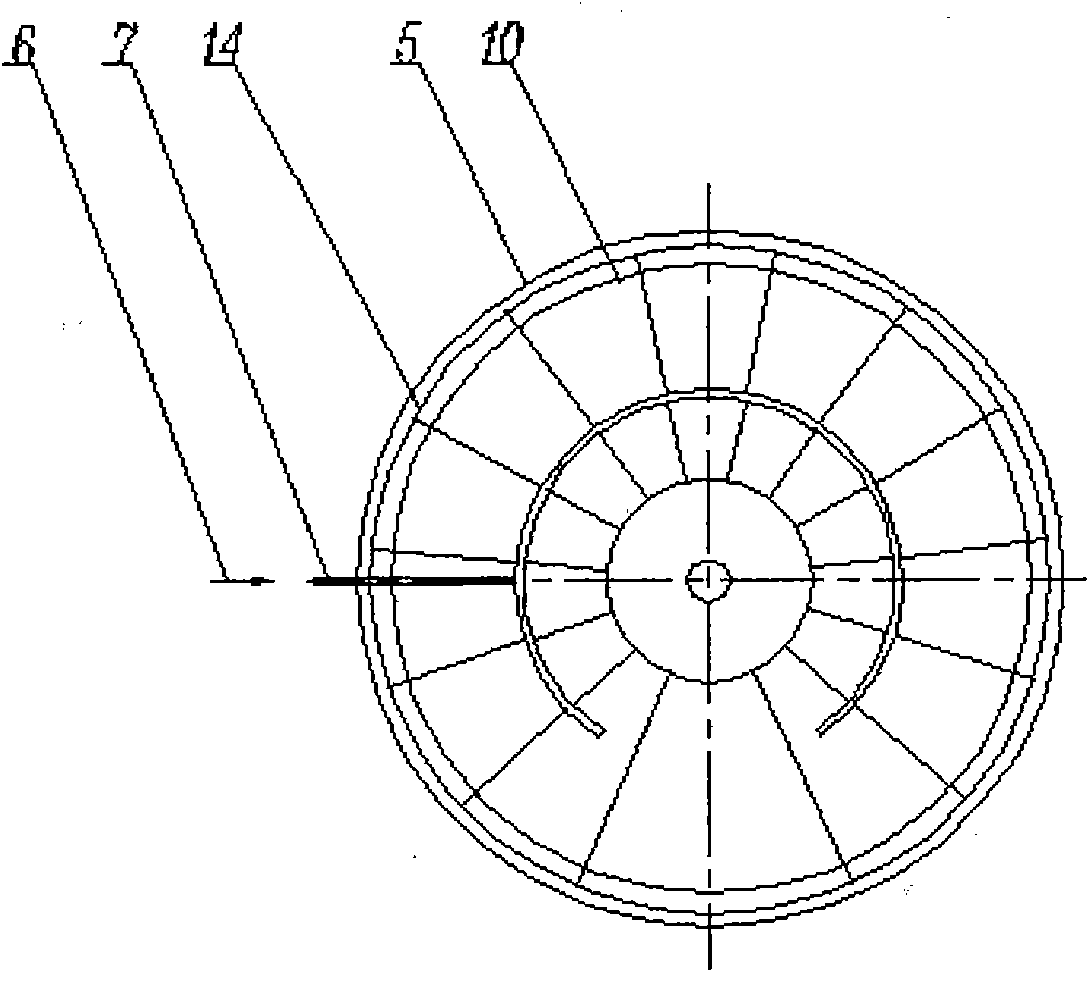

Reverse-blowing tribo-electrostatic separation method and device for fly ash decarburization

InactiveCN105149099AEfficient sortingEasy to operateElectrostatic separationElectrostatic separationForming gas

The invention relates to a reverse-blowing tribo-electrostatic separation method and device for fly ash decarburization. Negative pressure is generated in a nozzle through airflow generated by a negative pressure system, and fly ash particles enter the nozzle through a negative-pressure sucking pipe; fly ash is blown into a gas-solid mixed pipeline under the action of the airflow to form gas-solid two-phase flow, and the fed particles are mixed evenly; the fly ash particles in the gas-solid two-phase flow are subjected to frictional collision when passing a triboelectric charging device so as to carry charges which are opposite in polarity and unequal in electric quantity, the fly ash particles enter a high-voltage static separation chamber and deflect under the action of electric field force, and ash particles and carbon particles in the fly ash are separated; at the same time, reverse-blowing airflow opposite to electrified fly ash particles in moving direction is applied to the electrified fly ash particles in the separation process, particles with large charge mass quickly deflect to achieve rapid separation, particles with small charge mass fall down in a decelerated mode under the action of the reverse-blowing airflow, the staying time of the particles in the high-voltage static separation chamber is increased, and the particles are further separated under the action of electric field force.

Owner:CHINA UNIV OF MINING & TECH

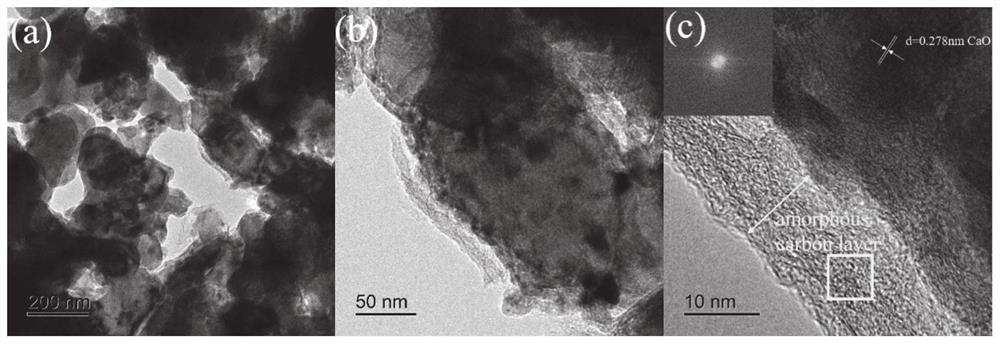

Carbon dioxide solid absorbent capable of effectively inhibiting active components from losing effect

InactiveCN102658023AEasy to getExtended service lifeDispersed particle separationAir quality improvementCo2 absorptionActivated Aluminum Oxide

The invention provides a carbon dioxide solid absorbent capable of effectively inhibiting active components from losing effect. One or more of potassium carbonate, sodium carbonate and alkali metal base carbonates is / are used as the active component, one or more of calcium oxide, magnesium oxide and alkali-earth oxides is / are used as the additive, and active aluminum oxide is used as an absorbent carrier; and a precipitation method, impregnation method, impregnation-precipitation method or impregnation-spray method is used for preparing the carbon dioxide solid absorbent. The absorbent can efficiently and quickly remove carbon dioxide in fume, and can also effectively lower loss of effect of the active component alkali metal base carbonates due to sulfur dioxide and other foreign gases in the fume. The research indicates that the carbon dioxide absorption temperature of the absorbent is 60-80 DEG C, the regeneration temperature is 100-300 DEG C, and calcium oxide, magnesium oxide and other additives react with SO2 in the fume to generate sulfites, thereby effectively lowering the loss of effect of the active components due to SO2 and prolonging the service life of the solid absorbent.

Owner:SOUTHEAST UNIV

Method for preparing low-carbon stainless steel

ActiveCN103255356ANo need to overcome static pressureMeet production requirementsSteelmakingVacuum pressure

The invention relates to a method for preparing low-carbon stainless steel, which sequentially comprises the following steps of 1, pretreatment of molten iron; 2, K-OBM-S converter smelting; 3, primary LF ladle refining; and 4, molten steel circulating vacuum decarburization: a, a common steel hot tank is used in an RH workbench, b, a bottom argon tube blowing tube begins to vacuumize, c, the vacuum pressure is lowered and oxygen blowing is carried out for decarburization, and the decarburization value is 0.025-0.035%, d, when oxygen blowing is over, the vacuum value is lowered to 40mbar, e, the carbon content reaches the target value of 0.025-0.035%, and restoring operation is carried out at the RH workbench, and f, after fine tuning, wherein the molten steel comprises the following components by mass percent: 0.020-0.030 of C, 0.52-0.58 of Si, 2.40-2.80 of Mn, P less than or equal to 0.030, less than or equal to 0.015 of S, 16.00-16.40 of Cr, 6.00-6.20 of Ni, 2.05-2.25 of Cu, and the balance of Fe and inevitable impurities, and then the molten steel is output, and the temperature of the molten steel is 1540-1550 DEG C. The method for preparing low-carbon stainless steel has high decarburization efficiency, and the content of carbon in the finished product can be 0.03% after decarburization.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

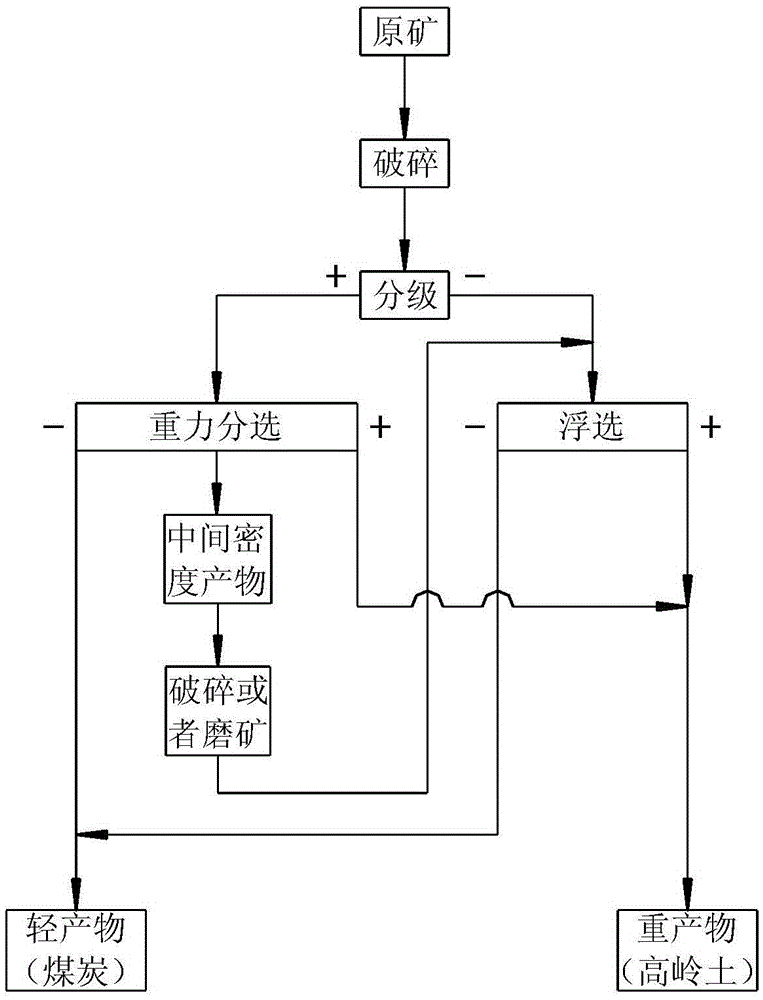

Decarbonization process for coal series kaolin

The invention discloses a decarbonization process for coal series kaolin. The decarbonization process comprises crushing, grading, reselection, reselected medium-density product crushing or ore grinding, and flotation and specifically comprises the steps of crushing coal series kaolin raw ore, and grading crushed products; feeding coarse particle products obtained by grading into reselection equipment for sorting to obtain reselected low-, medium- and high-density products; mixing the reselected medium-density products subjected to crushing or ore grinding with fine particle products obtained by grading and feeding into flotation equipment for sorting to obtain flotated foam products and products in a flotation tank; recycling the reselected low-density products and the flotated foam products which are coal resources, and recycling the reselected high-density products and the products in the flotation tank which are kaolin. According to the process, organic carbon in the coal series kaolin can be efficiently removed, and kaolin products which are higher in purity and more applicable to further deep processing are obtained; furthermore, the decarbonization process can efficiently recycle and use the organic carbon, so that waste of the coal resources is avoided, and the environment is protected.

Owner:CHINA UNIV OF MINING & TECH

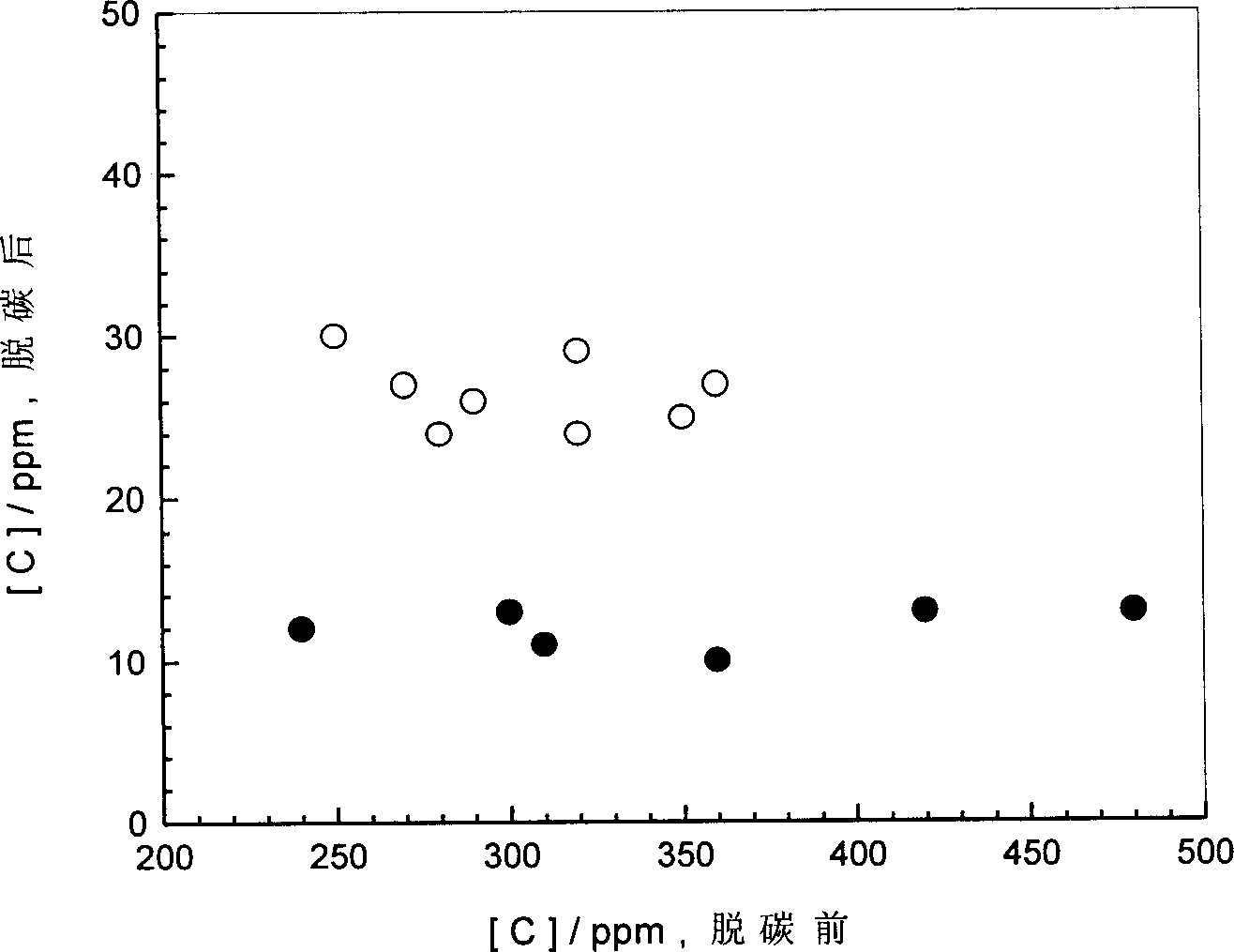

Method of producing super low carbon steel using vacuum degassing

InactiveCN1410559AAvoid damageSolve the problem that the decarburization ability increases with the erosion of the inner diameter of the insertion tubeMetallurgyVacuum level

A process for preparing ultralow-carbon steel by vacuum degassing features that the argon flow and the vacuum level are dependent on the service age of the furnace, that is, for the initial 20 batches, the argon flow is matched with inner diameter of insertion-in tube, and for the following batch whose decarbonizing time is longer than 5 min, the argon flow is increased by more than 20%. Before decarbonizing the molten steel, the vacuum chamber is depressurized in advance. Within 0-10 min after beginning decarbonization, the depressurizing speed is increased.

Owner:武钢集团有限公司

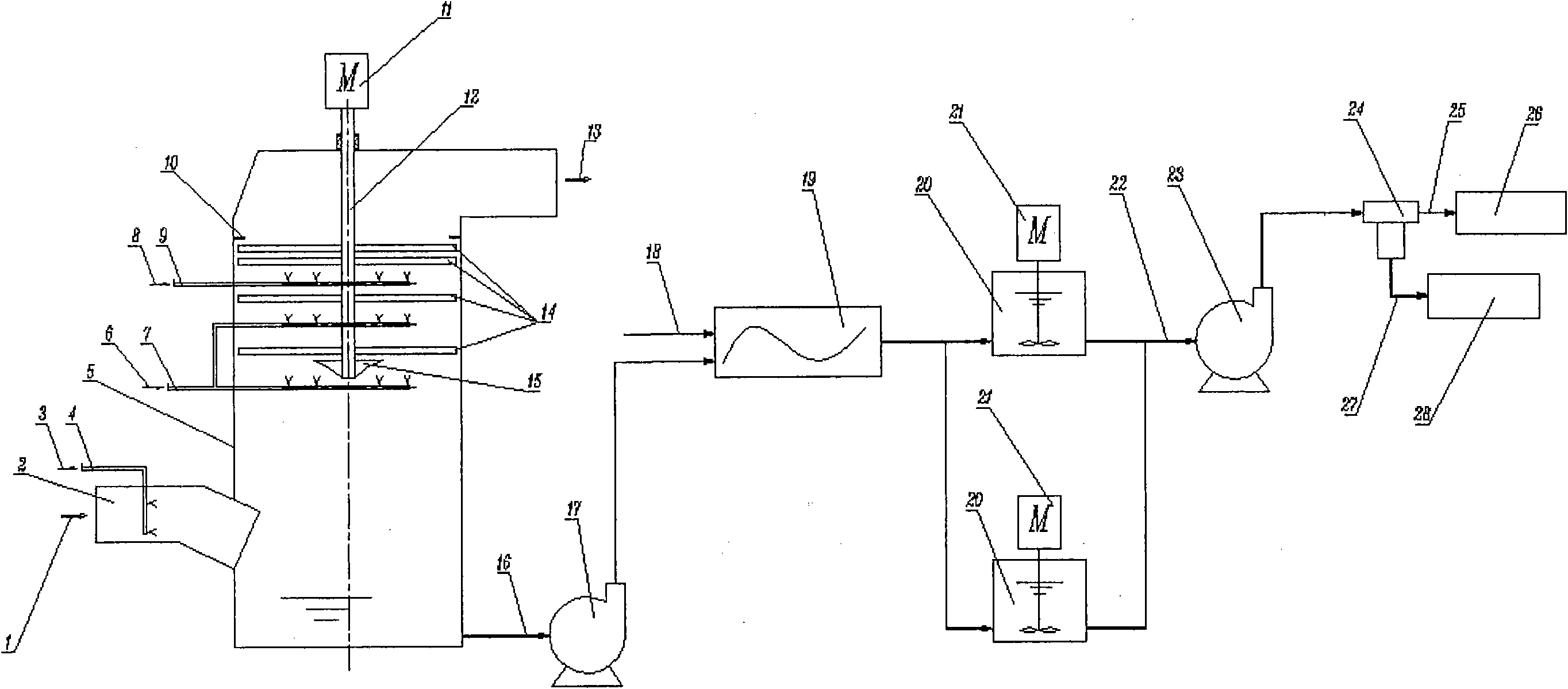

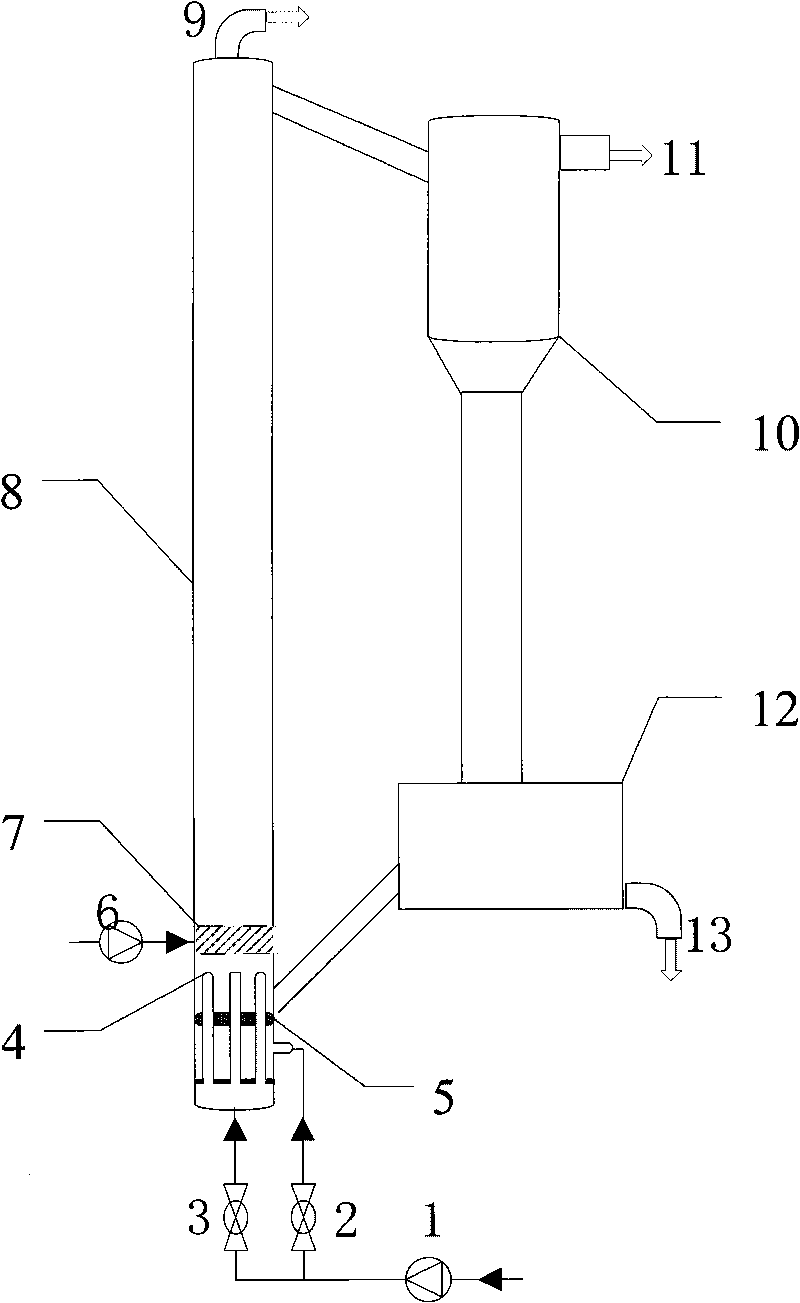

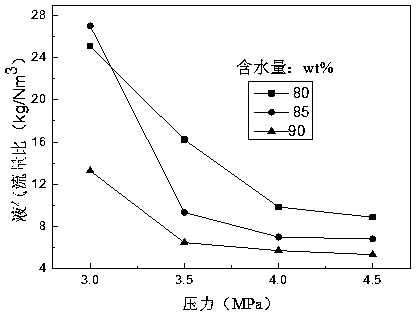

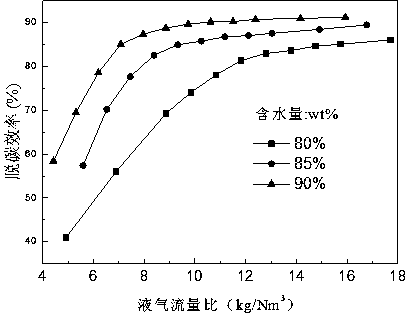

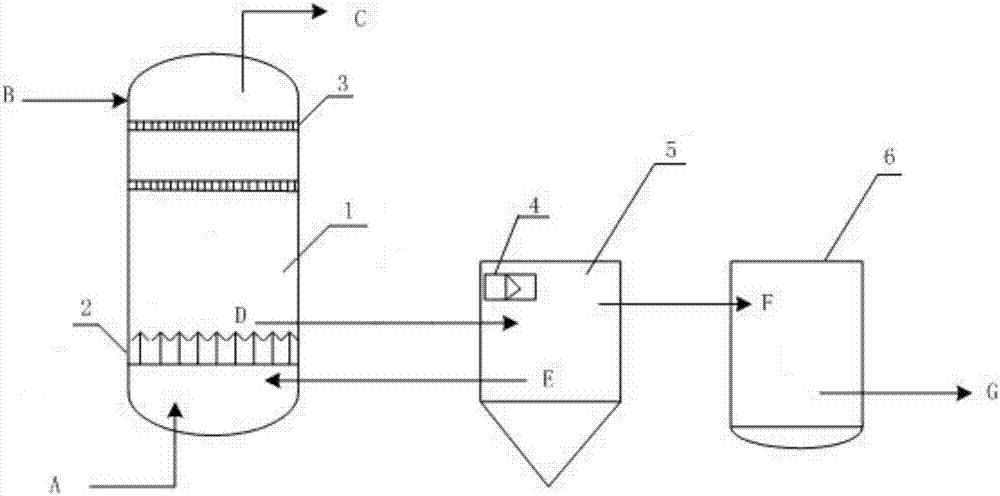

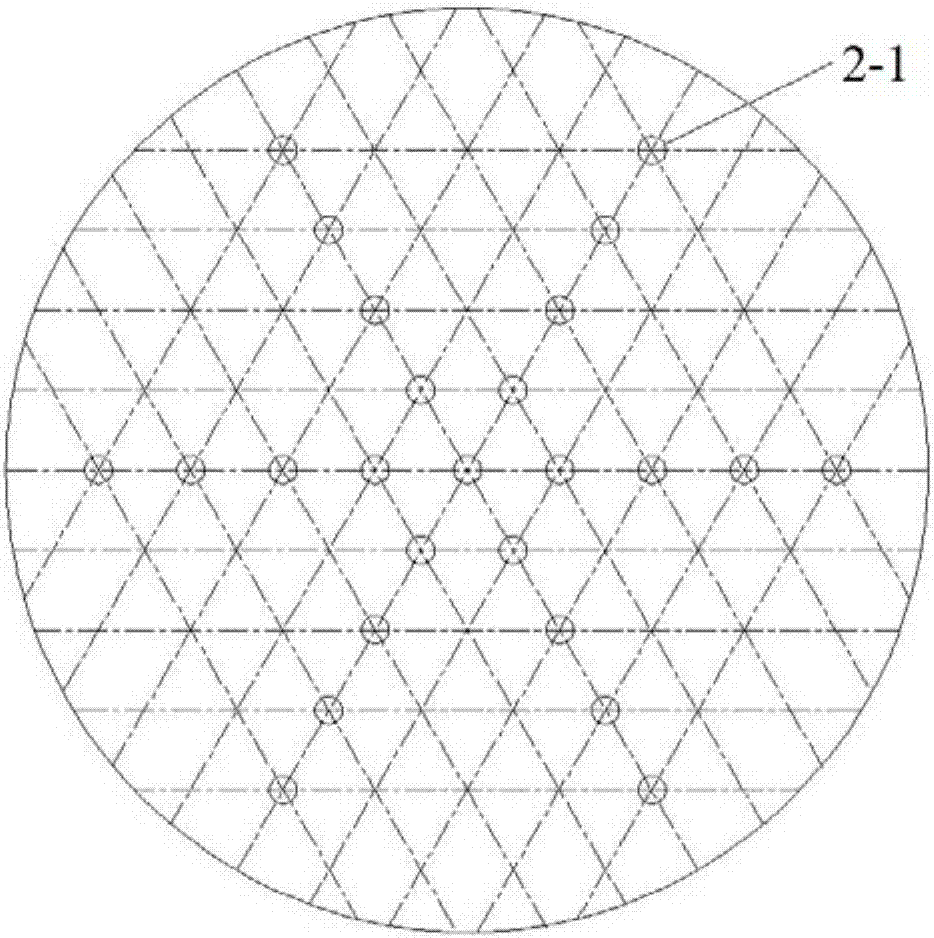

Method and apparatus for capturing CO2 in flue gas by utilizing three-phase circulating fluidized bed and ammonia

ActiveCN101745299AImprove decarbonization efficiencyImprove absorbencyDispersed particle separationBy chemical separationChemistrySmall footprint

The invention relates to a method and an apparatus for capturing CO2 in flue gas by utilizing a three-phase circulating fluidized bed and ammonia, which adopt the ammonia as CO2 absorbent and the three-phase circulating fluidized bed as a reactor. By controlling the flow rates of flue gas and main water flow, gas and liquid in the three-phase circulating fluidized bed can flow in a continuous bubbling state, and chemically react to produce ammonium bicarbonate, and the flying ash in flue gas can promote the crystallization of the ammonium bicarbonate, so that the ammonium bicarbonate can be conveniently recycled; violent gas-liquid mass backmixing transfer is carried out in the three-phase circulating fluidized bed, so the three-phase circulating fluidized bed has high CO2-eliminating efficiency and processing capability; the processing equipment can simply operate, has low requirement on flue gas dedusting, cannot be easily blocked, can be conveniently maintained compared with a packed tower, and occupies a small area, and the investment cost is low.

Owner:TSINGHUA UNIV

Carbon dioxide capturing method

InactiveCN104028079AAbsorptive Capacity LimitationImprove capture efficiencyDispersed particle separationBy absorptionAbsorption capacityLiquid water

The invention discloses a carbon dioxide capturing method. The carbon dioxide capturing method comprises the steps of absorbing CO2 by using an ion liquid water solution containing primary amine as a CO2 capturing working medium and forming a CO2 hydrate. According to the method, two CO2 capturing modes such as an ion liquid method and a hydrate method are integrated, dual-capturing effects on CO2 through the ion liquid water solution and a gas hydrate are achieved, and the CO2 capturing efficiency is greatly improved, so that the decarburization efficiency is improved. The limitation on an existing ion liquid method caused by ion liquid absorption capacity is overcome, and the stress caused by single hydrate decarburization and the limitation on high CO2 content requirement are eliminated; the method is good in industrial application value.

Owner:SUN YAT SEN UNIV

Smelting method of ultra-low carbon steel

The invention relates to the technical field of iron and steel smelting, and particularly discloses a smelting method of ultra-low carbon steel. The smelting method comprises the following process steps that a, desulfurization pretreatment is carried out on molten iron, and then converter smelting is carried out; b, argon blowing stirring is carried out on molten steel tapped from a converter, andLF refining is carried out after argon blowing stirring is finished; and c, the molten steel refined by an LF enters an RH furnace to be refined. According to the method, the LF-RH duplex process isadopted, so that the smelting time of the ultra-low carbon steel is shortened, the tapping temperature of the converter is effectively reduced, the erosion of a furnace lining can be reduced, the operation of an RH oxygen lance can be reduced, the service frequency of the oxygen lance can be reduced, the service life of the oxygen lance can be prolonged, and the production cost can be reduced.

Owner:HEBEI IRON AND STEEL

Argon-oxygen refining method for low-carbon ferrochromium alloy

The invention provides an argon oxygen refining method for refining high-carbon ferrochromium alloy to low-carbon ferrochromium alloy. In the method, the molten ferrochromium alloy is refined at a higher temperature by adjusting the oxygen content of top-blown argon (nitrogen) / oxygen mixed gas, so that decarburization efficiency is improved and the loss of chromium is reduced; the carbon content (wt%) of the refined ferrochromium alloy is less than 0.25%, the loss of the chromium is 6%-8% (wt%), and the invention provides a proposal for the 'spraying-splashing' phenomenon appeared during high-temperature refining of the molten ferrochromium alloy and for decarburization and chromium protection during cooling. By adopting temperature control for refining the ferrochromium alloy, the method is beneficial to realizing on-line automatic control and has the advantages of short refining time, simple production process and easy operation.

Owner:CHANGCHUN UNIV OF TECH +1

Highly-activity sodium-based solid carbon dioxide absorbent

InactiveCN103480273AEasy to getStable traitsDispersed particle separationBy chemical separationCo2 removalDesorption

The invention provides a highly-activity sodium-based solid carbon dioxide absorbent which comprises an active ingredient, a carrier and a catalyst, wherein the active ingredient adopts sodium carbonate and accounts for 20%-40% of the total mass of the solid absorbent; the carrier adopts activated aluminum oxide and accounts for 50%-79% of the total mass of the solid absorbent; and the catalyst adopts one or two of TiO2 and TiO(OH)2 and accounts for 1%-10% of the total mass of the solid absorbent. A preparation method of the absorbent adopts an impregnation method, a precipitation method, an impregnation precipitation or an impregnation spraying method. The solid absorbent belongs to low-temperature absorbents, the CO2 absorbent temperature is 60-80 DEG C, and the CO2 desorption temperature is 120-300 DEG C. Materials of the solid absorbent are cheap and accessible, the preparation process cost is low, the procedure is simple, the absorbent is uneasy to become inactive after multiple times of circulation, a higher CO2 removal rate can be maintained, and the absorbent is an optimization scheme with lower investment and energy consumption for the CO2 emission reduction technology and has a wide application prospect.

Owner:SOUTHEAST UNIV

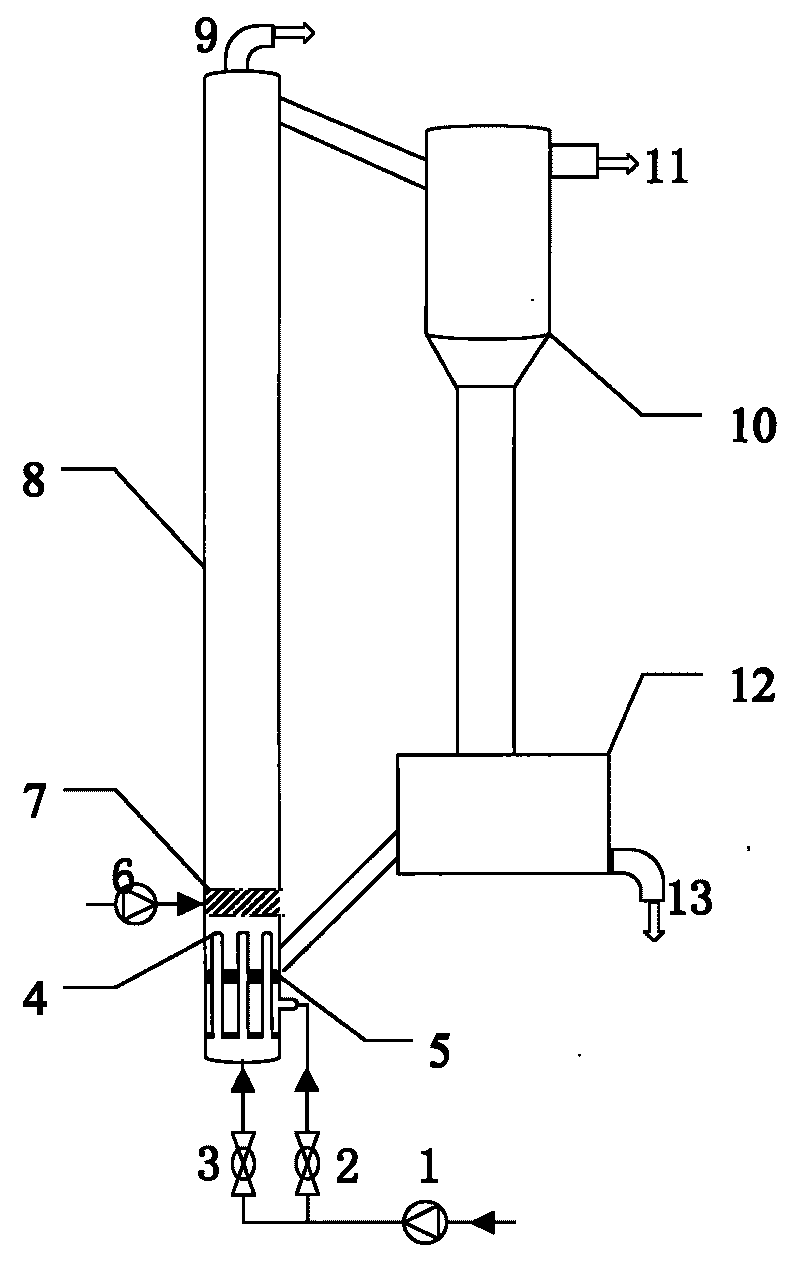

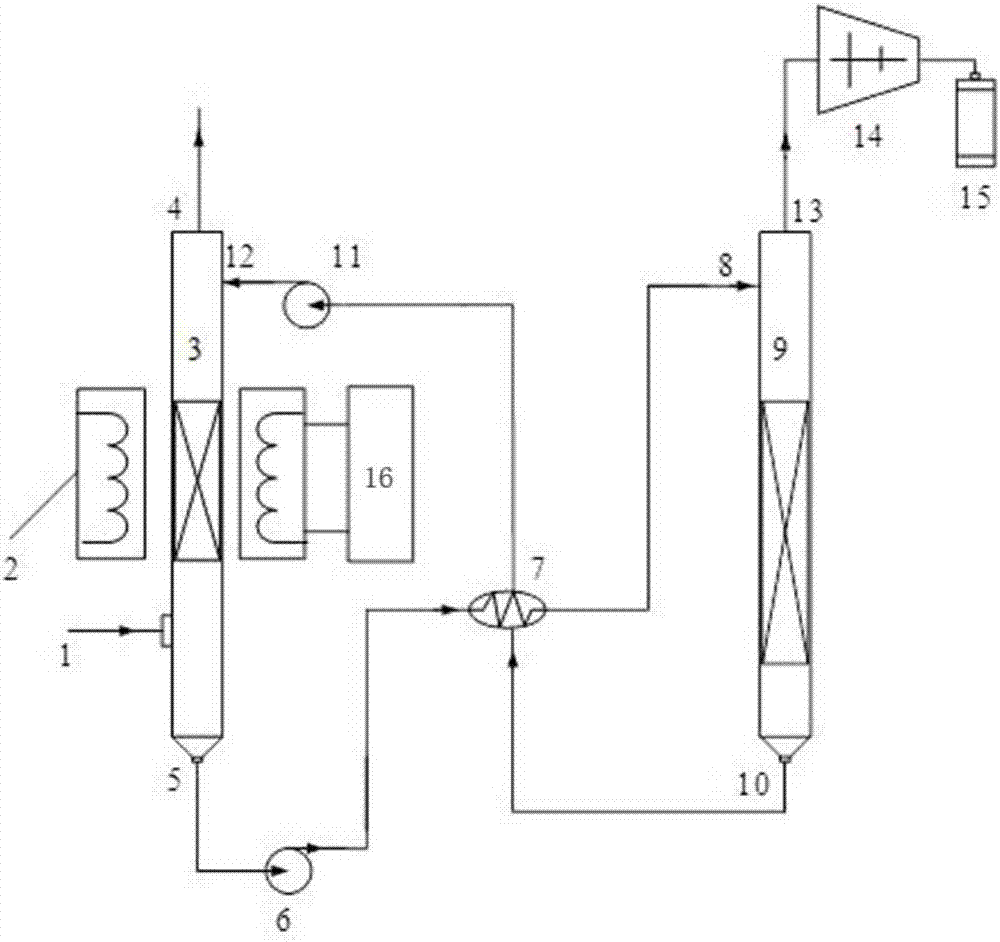

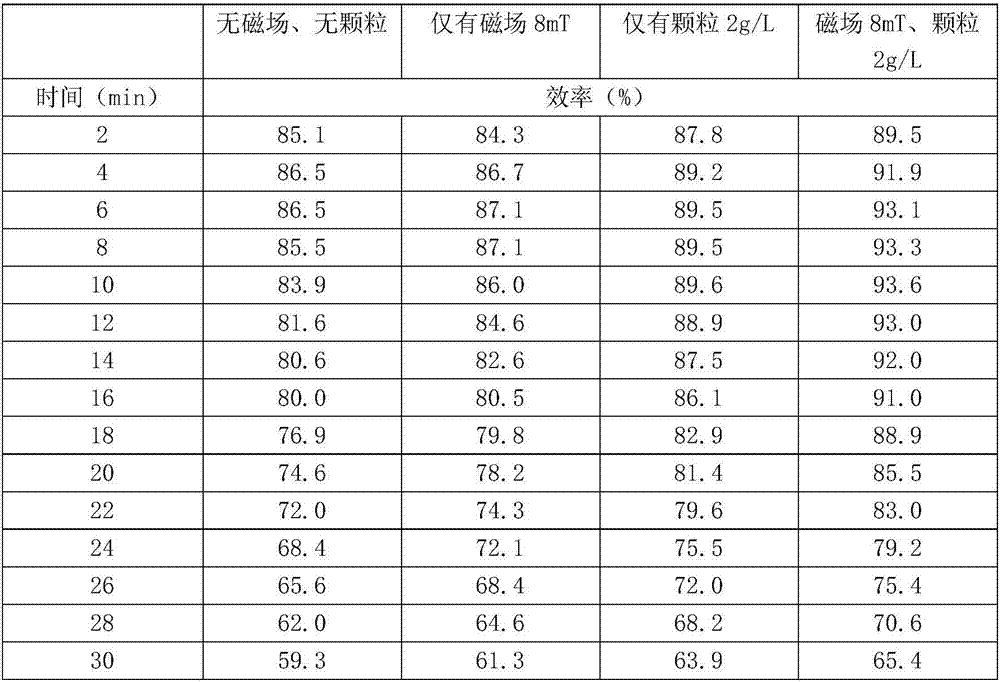

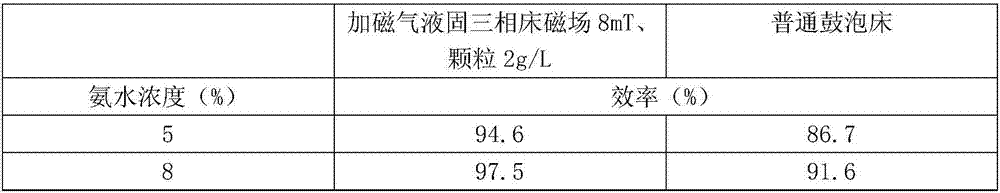

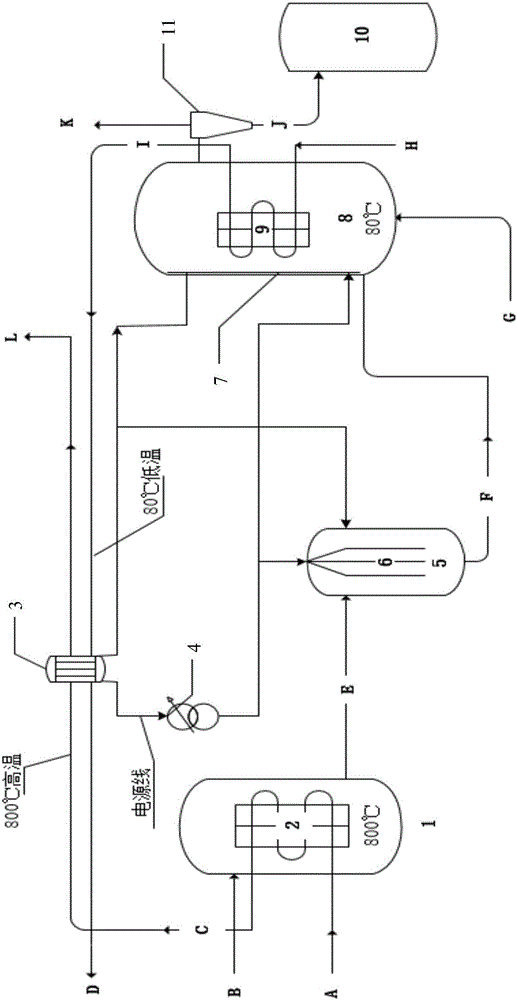

Flue gas decarburization system and method utilizing magnetized gas-liquid-solid three phase bed

InactiveCN106943853ALow regeneration energy consumptionReduced footprint and space volumeGas treatmentDispersed particle separationAtmospheric pollutantsFlue gas

The invention discloses a flue gas decarburization system and method utilizing a magnetized gas-liquid-solid three phase bed, and belongs to the technical field of atmospheric pollutant treatment. The system comprises a magnetized three phase bed absorbing tower, a rich and lean solution heat exchanger, a regeneration tower, and a CO2 storage device. The magnetized three phase bed absorbing tower is connected to the rich and lean solution heat exchanger, the regeneration tower and the CO2 storage device in sequence through pipelines. The regeneration tower is provided with a lean solution outlet, is connected to the rich and lean solution heat exchanger through a pipeline, and is connected to the magnetized three phase bed absorbing tower through a pipeline. CO2 is absorbed by an absorbing agent under the co-effect of magnetic field and magnetic particles. A CO2 rich solution flows through the rich and lean solution heat exchanger and releases CO2 in the regeneration tower, and a CO2 lean solution is obtained at the same time. The lean solution flows through the rich and lean solution heat exchanger, goes back to the three phase bed, and keeps on absorbing CO2. The system utilizes a magnetic field and magnetic particles to increase the CO2 absorption efficiency of an absorbing agent; the rich solution and lean solution both carry with few magnetic particles, which can enhance the heat exchange between rich and lean solutions and the regeneration of absorbing solution and the energy consumption of regeneration is reduced therefore.

Owner:NANJING NORMAL UNIVERSITY

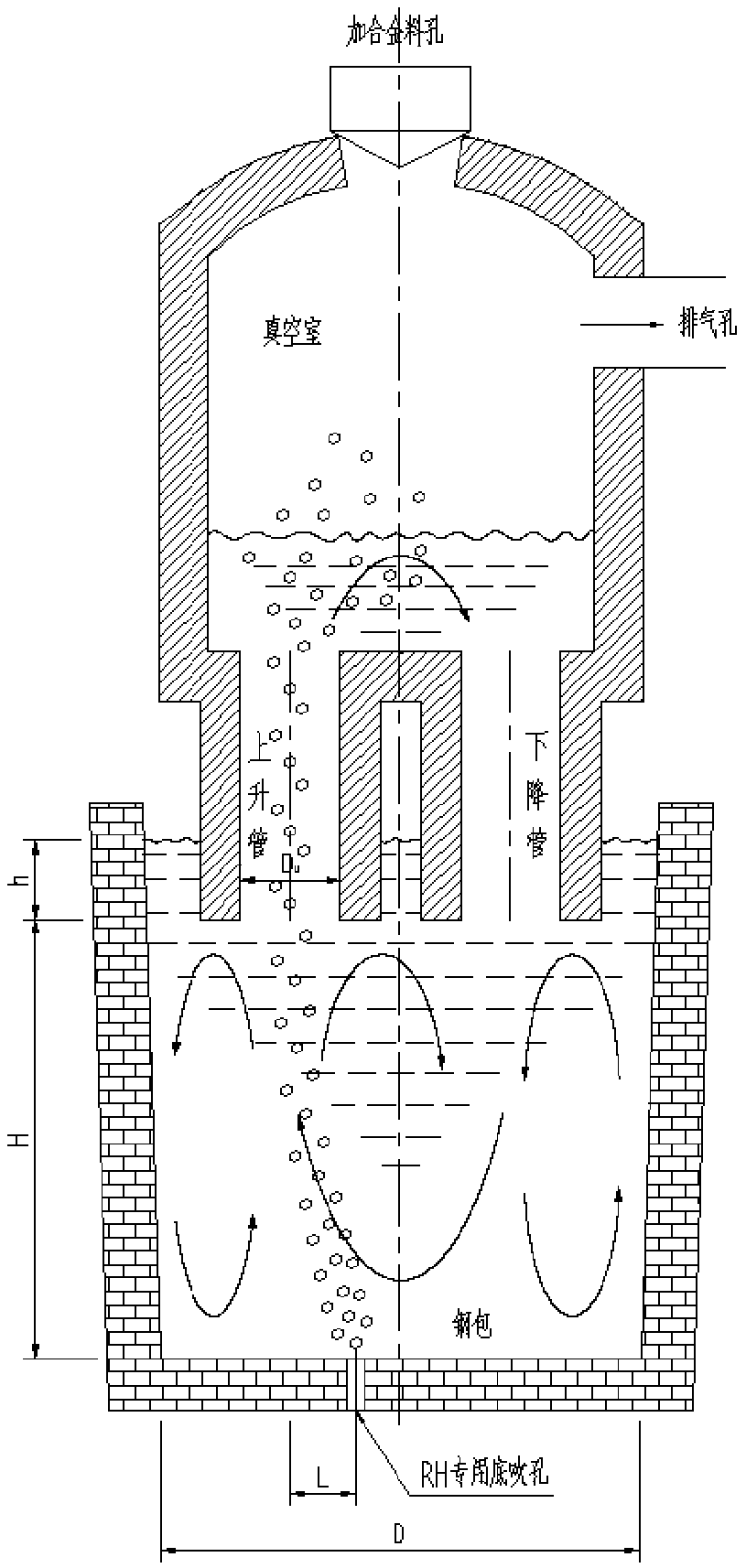

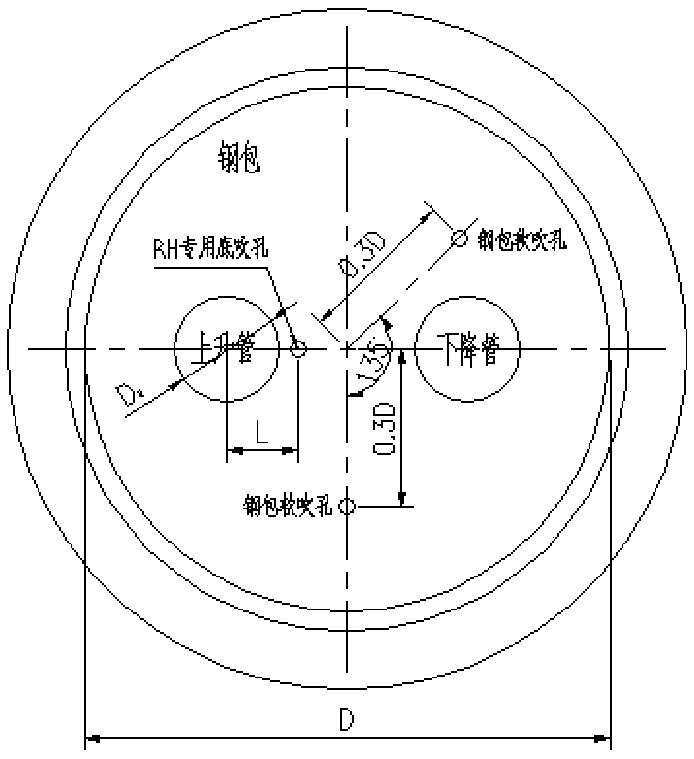

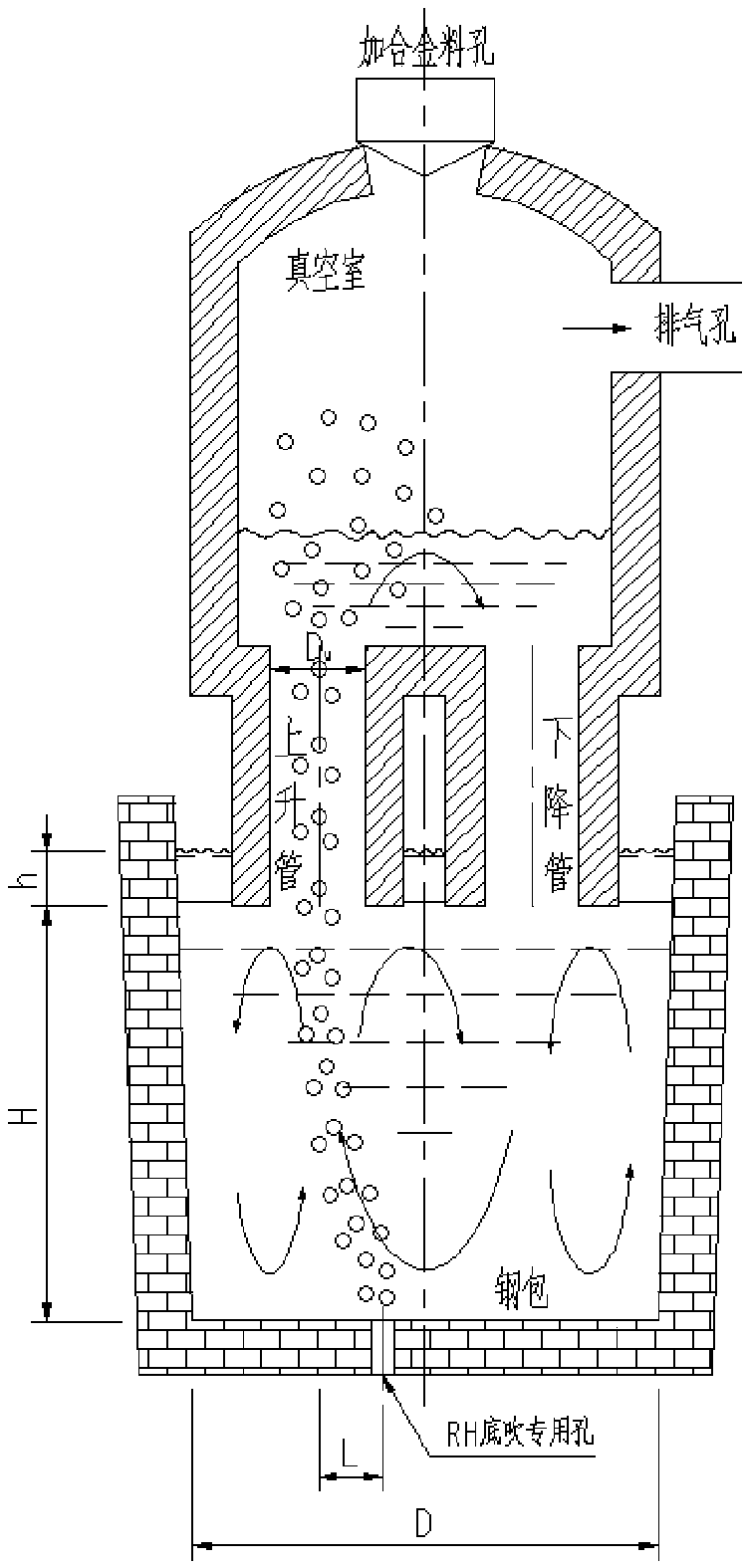

Method for increasing molten steel circulating flow quantity in RH refining process

The invention provides a method for increasing the molten steel circulating flow quantity in the RH refining process and belongs to the technical field of molten steel refining. According to the method for increasing the molten steel circulating flow quantity in the RH refining process, a process procedure of converter / electric furnace-refining RH-continuous casting is adopted to produce high-quality pure steel, in the RH refining process, by means of utilization of an existing steel ladle argon bottom blowing system, argon is blown into the bottom of a steel ladle, argon bubbles blown in thebottom move along with a molten steel flow field, molten steel is lifted to enter an RH dipping pipe ascending pipe, coordinated control between steel ladle argon bottom blowing and dipping pipe inside gas lifting is realized, so that adverse effects in actual production that the air blowing hole position of an RH dipping pipe cannot be remolded and the lifting gas flow quantity is too large to blow through the molten steel inside the dipping pipe to reduce the lifting driving force instead are overcome, and the purpose of increasing the steel circulating flow quantity in the RH refining process is finally achieved. The method for increasing the molten steel circulating flow quantity in the RH refining process has the advantages of being simple and reliable, high in operability and convenient to realize, the RH circulating flow quantity is increased, the decarbonization efficiency is high, the refining time is obviously shortened, and the molten steel purity is improved.

Owner:CENT IRON & STEEL RES INST

System and method for directly mineralizing carbon dioxide in flue gas by using gypsum

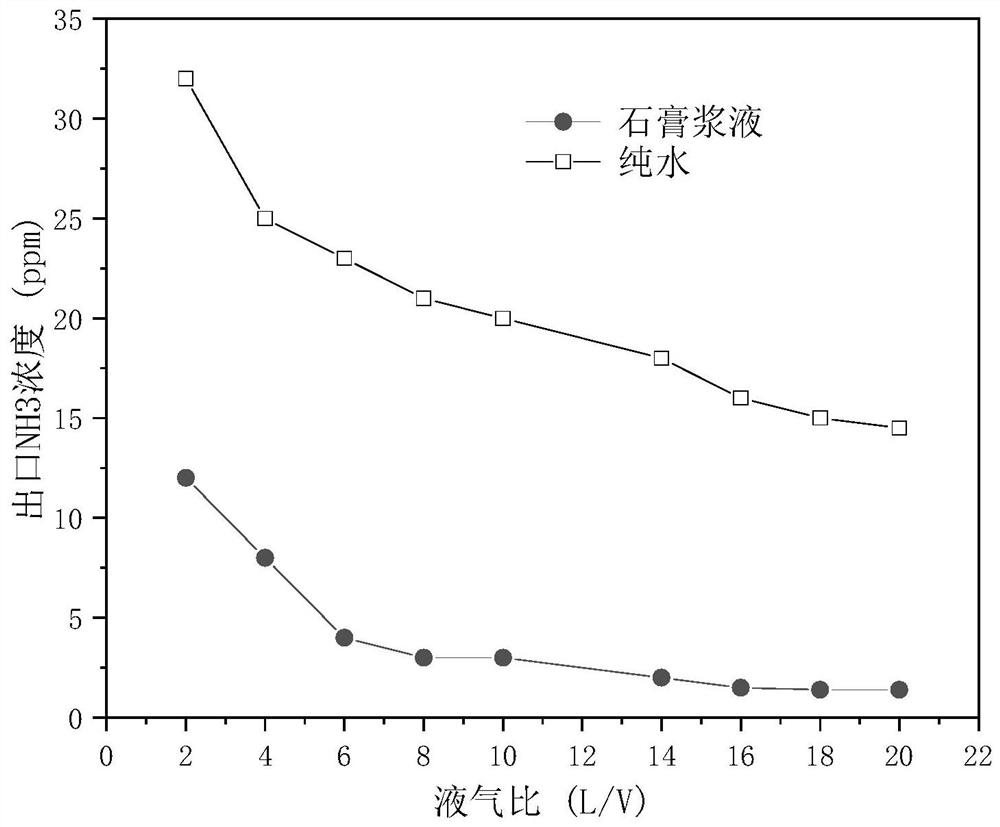

PendingCN113181751AReduce decarbonizationReduce utilization costCalcium/strontium/barium carbonatesGas treatmentPhysical chemistrySlurry

The invention relates to a system and a method for directly mineralizing carbon dioxide in flue gas by using gypsum. An absorption tower can sequentially realize cooling, decarburization and escape ammonia trapping processes of desulfurized flue gas; the bottom of a lower cooling section is provided with a slurry area and is circularly connected with an upper ammonium bicarbonate spraying layer, so that the trapping of the waste heat of the desulfurized flue gas can be realized, and heat is provided for the low-temperature concentration and crystallization of ammonium sulfate slurry; the bottom of a middle decarburization section is provided with an ammonium bicarbonate liquid holding layer, and the ammonium bicarbonate liquid holding layer and the ammonium bicarbonate spraying layer form circulation; ammonia is supplemented through an ammonium bicarbonate spraying layer pipeline, so that continuous decarburization reaction can be carried out on cooled flue gas; and meanwhile, the lower cooling section and the middle decarburization section are separated, and a gypsum spraying layer, a demister, a process water spraying layer, a gypsum liquid holding layer and a gypsum spraying layer which are sequentially arranged on the upper deamination section in the height direction form circulating spraying, and the continuous trapping process of escaping ammonia is achieved. The system is simple in structure, reasonable in design and low in smoke decarburization and utilization cost, and meanwhile, continuous online treatment of a large amount of smoke can be achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

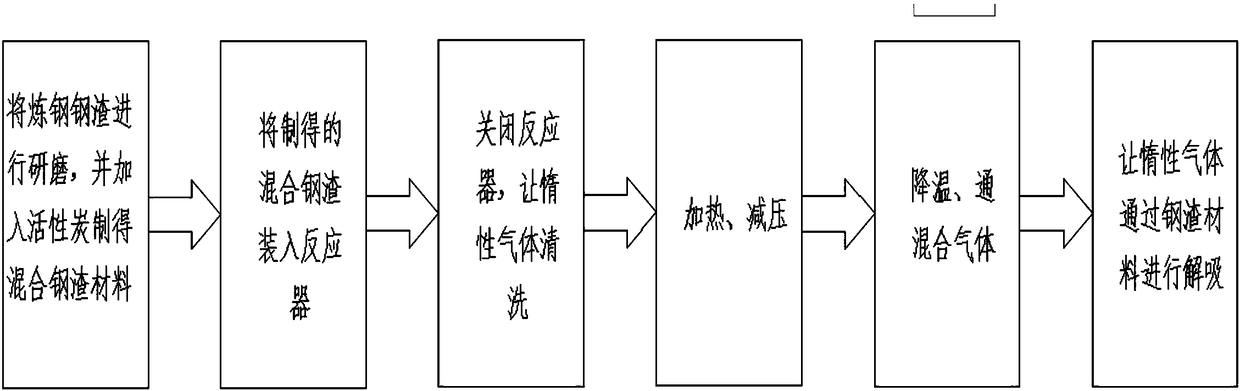

Method for eliminating carbon dioxide in gas through steel slag adsorption

InactiveCN108262016AIncrease surface areaImprove adsorption capacityGas treatmentOther chemical processesSorbentSlag

The invention relates to a method for eliminating carbon dioxide in smoke gas through steel slag adsorption. The method has the advantages of low raw material cost, discharge source approaching, no need of pretreatment, high reaction speed, mild reaction conditions and the like. The steel slag has great surface area and a great number of micro-mesopore structures; the steel slag shows the porous honeycomb-shaped structures in a microscope; a good adsorption effect is realized. The steel slag and the active carbon are proportioned, so that the adsorption effect of carbon dioxide can be improved; the adsorption cost can also be reduced. The method comprises the steps of cleaning the steel slag adsorption agent in a reactor by inert gas; after the heating, removing impurities; performing vacuum pumping; introducing mixed gas containing carbon dioxide into the reactor into the steel slag materials; adsorbing the carbon dioxide; exhausting the smoke gas subjected to carbon dioxide removal;then, lowering the pressure to the normal pressure; then, performing desorption on nitrogen gas through the steel slag material at the room temperature to obtain the removed gas subjected to carbon dioxide.

Owner:NINGBO UNIV

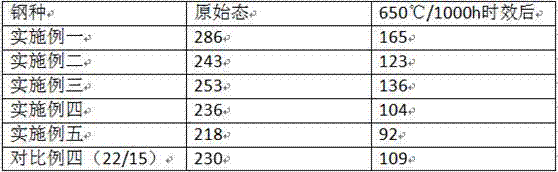

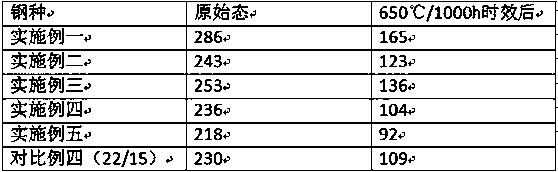

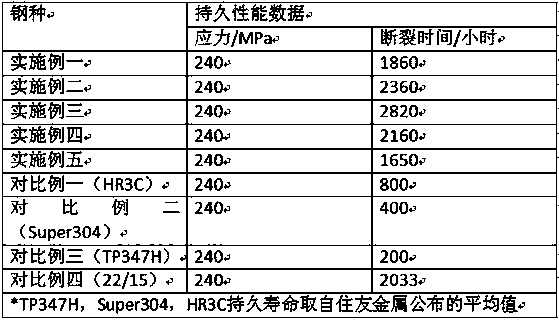

Preparation method of high-endurance-strength steam-corrosion-resistance austenitic heat-resistance steel

ActiveCN107475640APreferential oxidationReduce oxidationProcess efficiency improvementElectric furnaceHeat resistanceOxygen

The invention relates to a preparation method of high-endurance-strength steam-corrosion-resistance austenitic heat-resistance steel, and belongs to the technical field of austenitic heat-resistance steel. The method sequentially comprises the technological steps of ingredient preparation, decarburization by oxygen blowing, reduction, steel tapping, ladle refining, casting, cogging and hot rolling. Compared with 22 / 15 austenitic heat-resistance steel, the SP22 / 15 has the similar nickel content and chrome content, however has the better high temperature endurance strength and high temperature steam corrosion resistance, and therefore the steel has the better market prospect compared with 22 / 15 austenitic heat-resistance steel. The steel can completely replace 22 / 15 austenitic heat-resistance steel, and can adapt to severe conditions to which 22 / 15 austenitic heat-resistance steel cannot adapt, for example, the steel can normally work at the high temperature and high pressure steam environment under 650DEG C and 35 MPa, and keep good impact toughness.

Owner:YONGXING SPECIAL STAINLESS STEEL

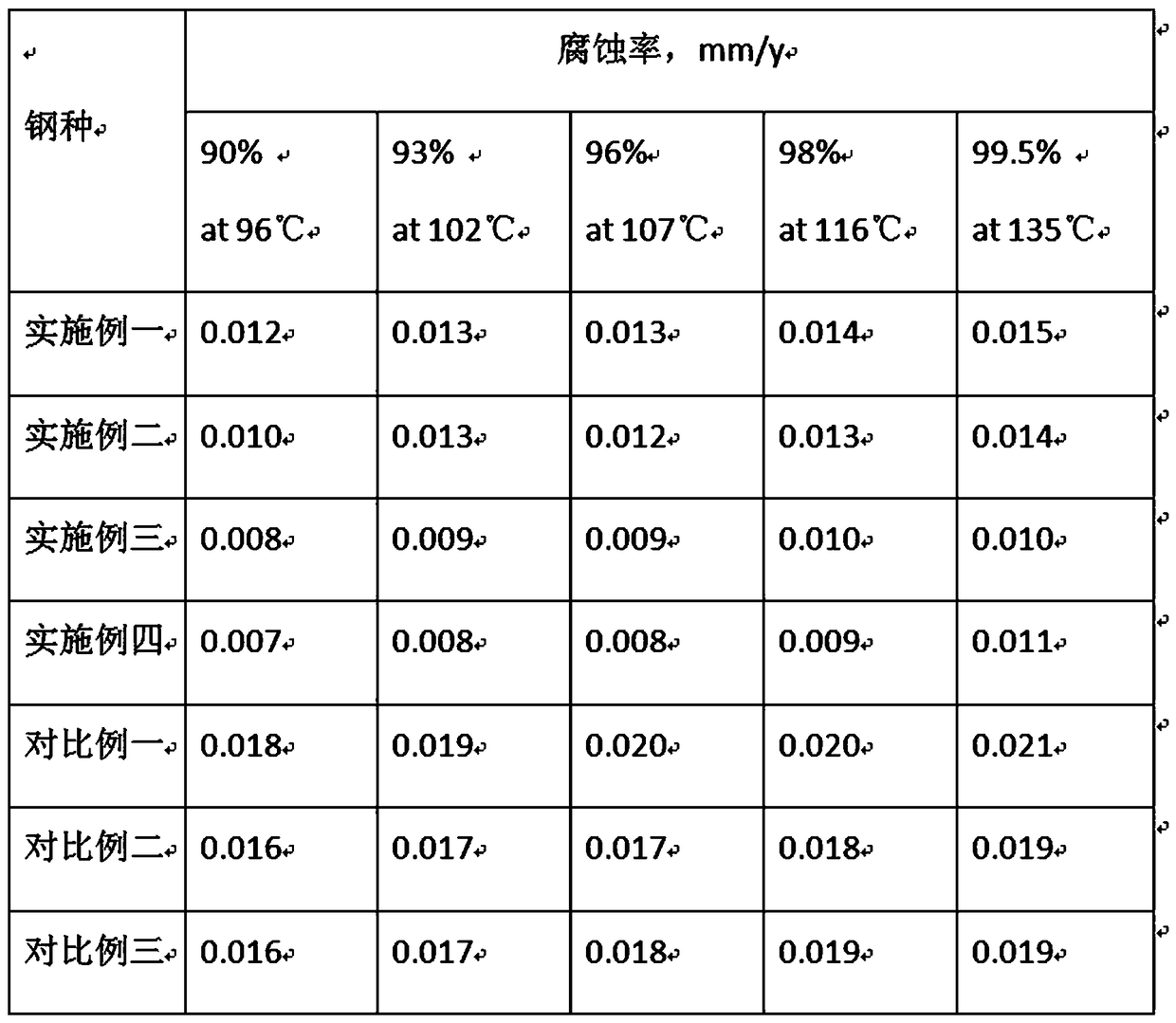

Preparation method of austenitic stainless steel resisting high-temperature and high-concentration sulfuric acid

InactiveCN108118237APreferential oxidationReduce oxidationProcess efficiency improvementMaterials preparationHigh concentration

The invention relates to a preparation method of austenitic stainless steel, in particular to the preparation method of the austenitic stainless steel resisting high-temperature and high-concentrationsulfuric acid and belongs to the technical field of the austenitic stainless steel. The method sequentially comprises the process steps of burdening, oxygen blowing decarburization, reduction, steeltapping, ladle refining, casting, cogging, hot rolling and the like. The invention discloses the austenitic stainless steel resisting the high-temperature and high-concentration sulfuric acid. By query and comparison, steel grades in the prior art, namely Zecor, Saramet35 and sandvik SX developed by foreign companies are similar to a steel grade disclosed by the invention in material design and overall performance; compared with the foreign steel grades, the steel grade disclosed by the invention has more obvious advantages in the aspects of a material preparation process, yield improvement, corrosion resistance and the like.

Owner:YONGXING SPECIAL STAINLESS STEEL

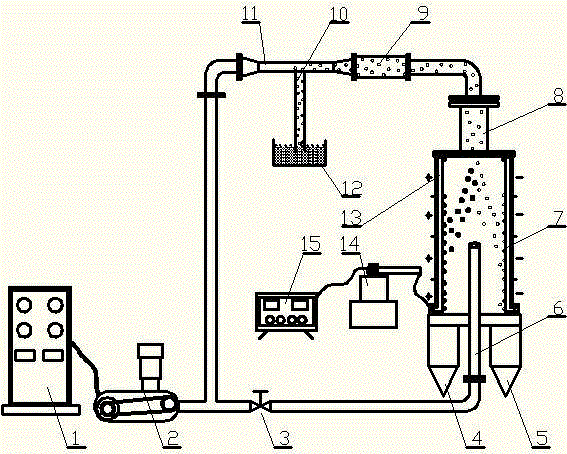

Device and method for removing CO2 from flue gas in power plant by using fly ash

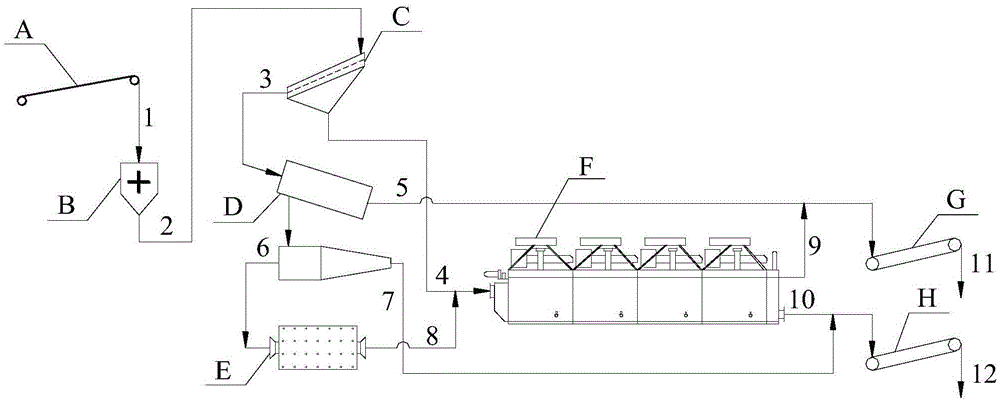

ActiveCN106474912ARealize resource utilizationLow costGas treatmentDispersed particle separationCold airFluidized bed

The invention discloses a device for removing CO2 from flue gas in a power plant by using fly ash. The device comprises an activation reactor, a charging device, a fluidized bed, a cyclone separator and a waste material bin, wherein the output end of the activation reactor is connected with the charging device; the output end of the charging device is connected with the fluidized bed; the output end of the fluidized bed is connected with the cyclone separator; and the output end of the cyclone separator is connected with the waste material bin. The invention also discloses a method for removing the CO2 from the flue gas in the power plant by using the fly ash. The method comprises the following steps: conveying the fly ash into the activation reactor and carrying out activation treatment, then carrying out conveying into the charging device and carrying out charging treatment, then carrying out conveying into the fluidized bed so as to remove the CO2 in the flue gas, and finally carrying out conveying into the waste material bin. According to the invention, the device organically combines with a coal-fired power generating system; the flue gas and cold air in the coal-fired power plant can be utilized to provide a heat source and a cold source for the device; meanwhile, needed electric energy is provided for the device through a thermoelectric power generation technology; thus, an optimization scheme capable of reducing cost and energy consumption is realized.

Owner:NANJING NORMAL UNIVERSITY

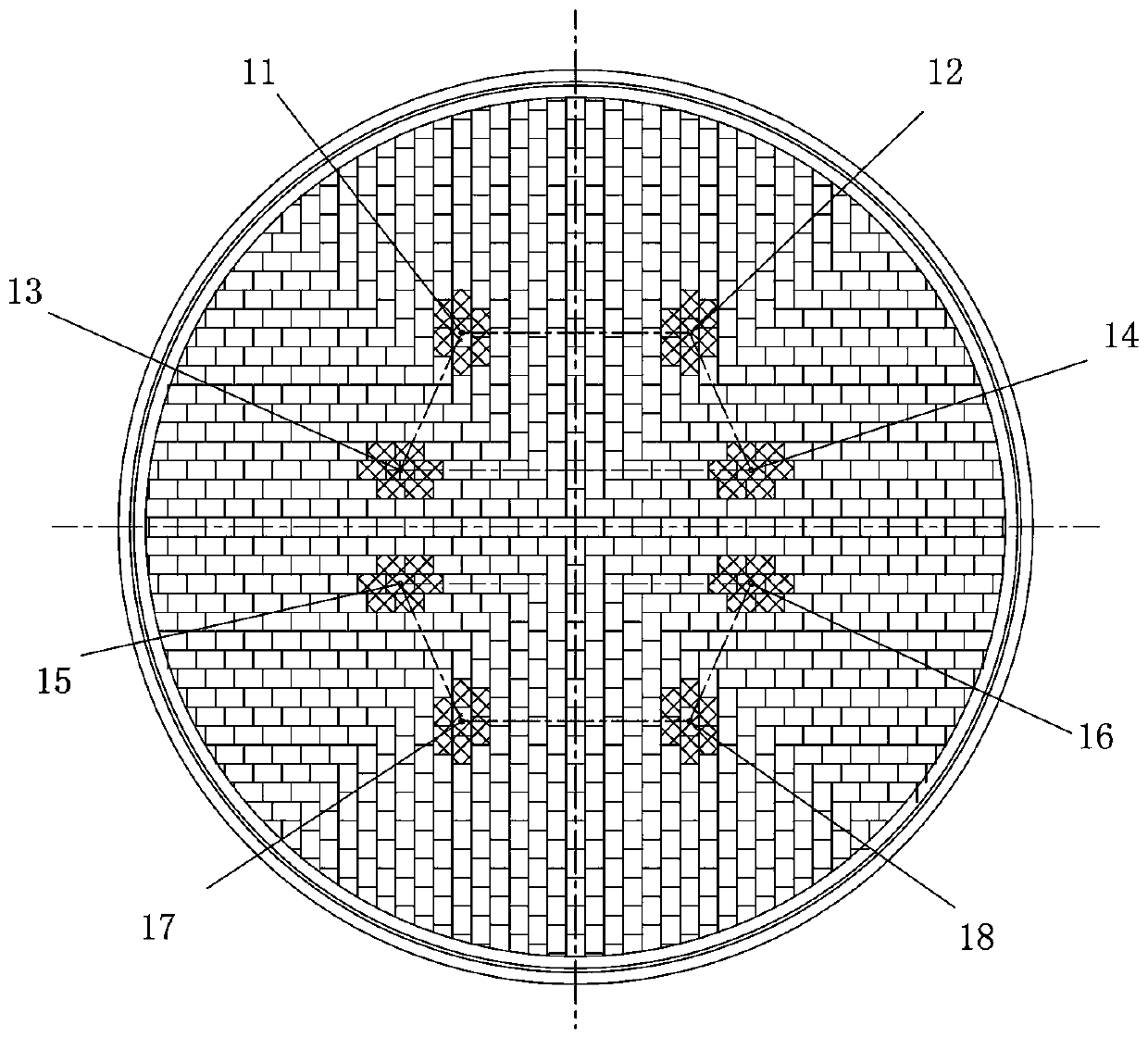

Method for smelting low-carbon stainless steel by utilizing GOR converter

ActiveCN110923389AIncrease oxygen intensityImprove mixing efficiencyManufacturing convertersSlagSS - Stainless steel

The invention discloses a method for smelting low-carbon stainless steel by utilizing a GOR converter. The method is characterized in that eight bottom guns are used in the GOR converter, the eight bottom guns are symmetrically distributed on the bottom of the GOR converter in a shape like a Chinese character 'jing' and basically coincide with an impact area for blowing oxygen by top guns, so thatthe bottom blowing flow is increased, the mixing efficiency of a molten pool is improved, meanwhile, the impact of the oxygen blown by the top guns is utilized to suppress the problem that the bottomblowing flow is too large to cause air flow to break through the molten pool, and strong decarburization capability is realized; then, through reasonable oxygen, argon / nitrogen ratio and flow distribution in the decarburization stage, a certain proportion of mixed oxygen and nitrogen (or argon) are blown in the dynamic decarburization stage through bottom blowing, so that the partial pressure ofCO in the molten pool is controlled, C in the molten pool is oxidized prior to Cr, decarburization efficiency is improved, Cr oxidation is reduced, and C can reach about 0.010% at the GOR end point and even lower, and the Cr2O3 content in reduced slag is controlled within 2%, so that the GOR converter can economically and stably produce medium-high chromium stainless steel with the C content lowerthan 0.030%.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

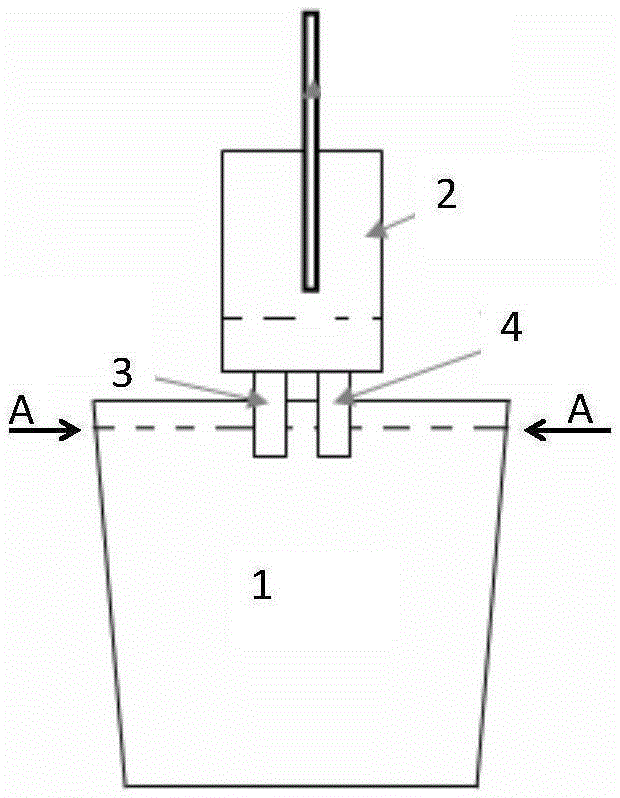

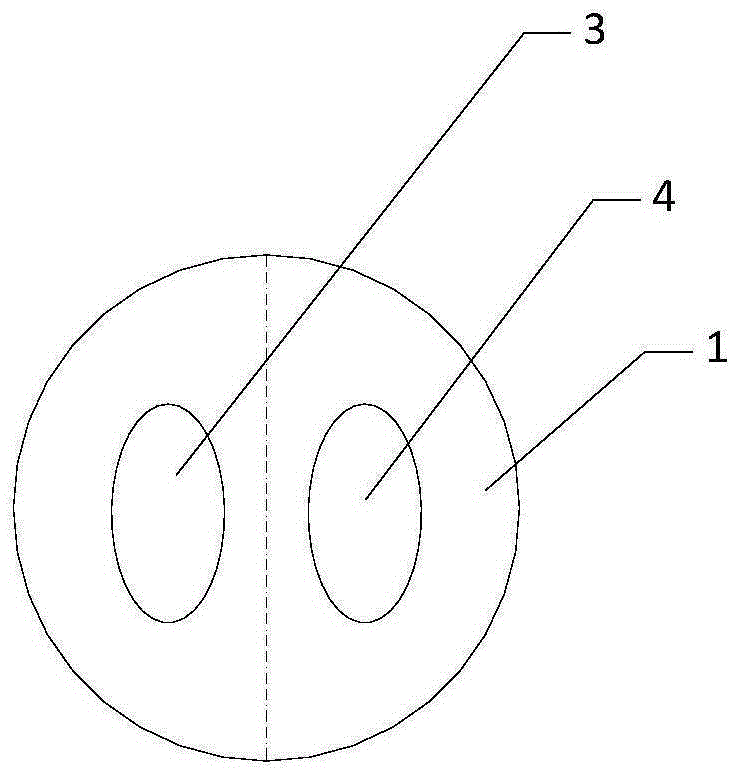

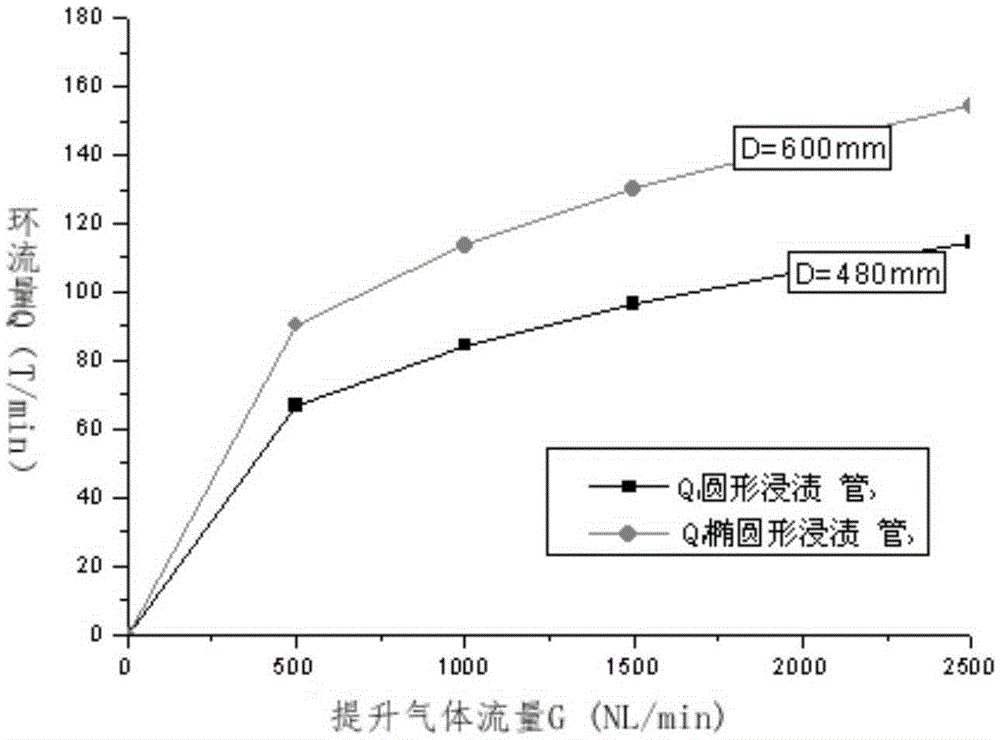

RH refining device

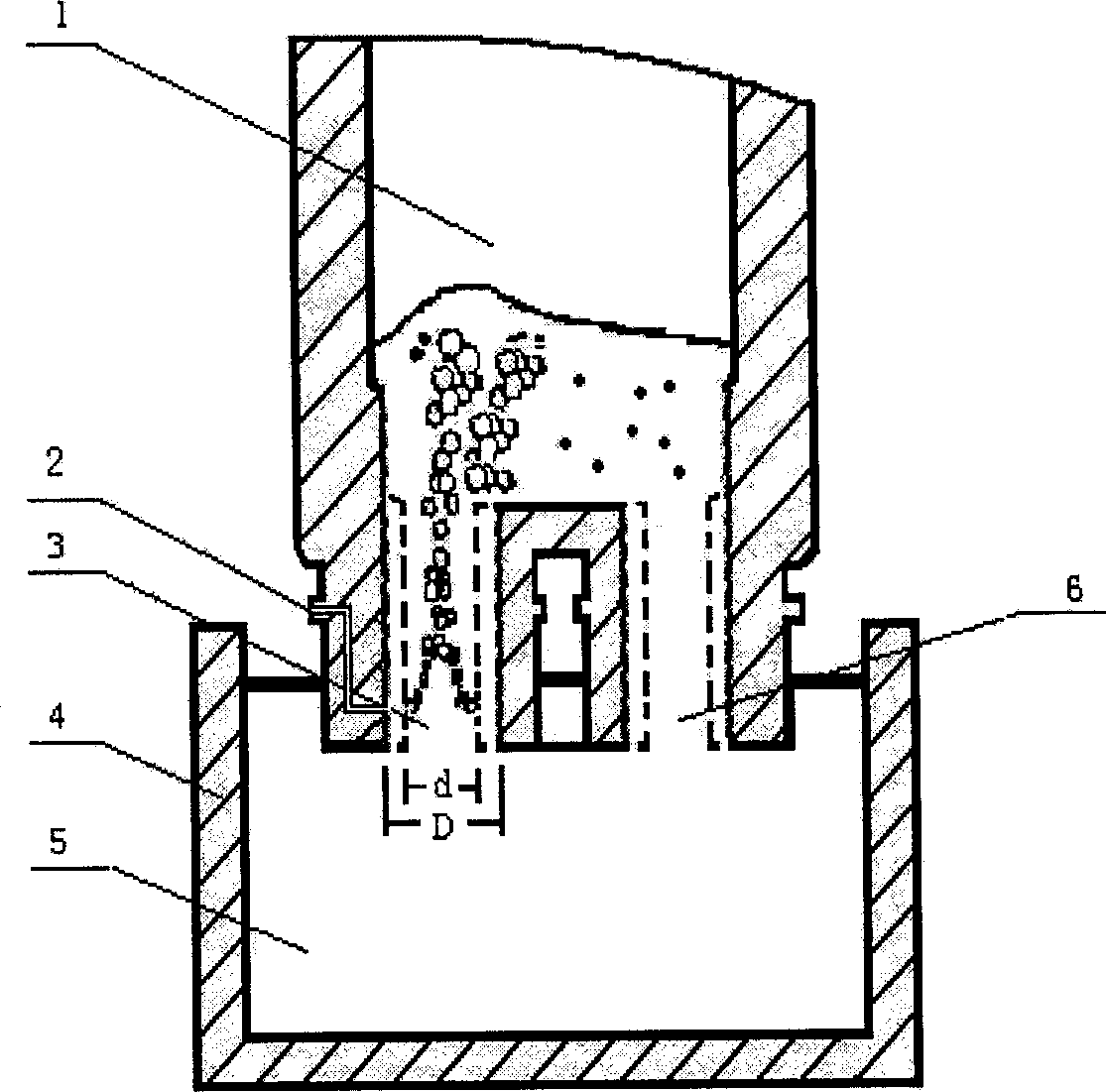

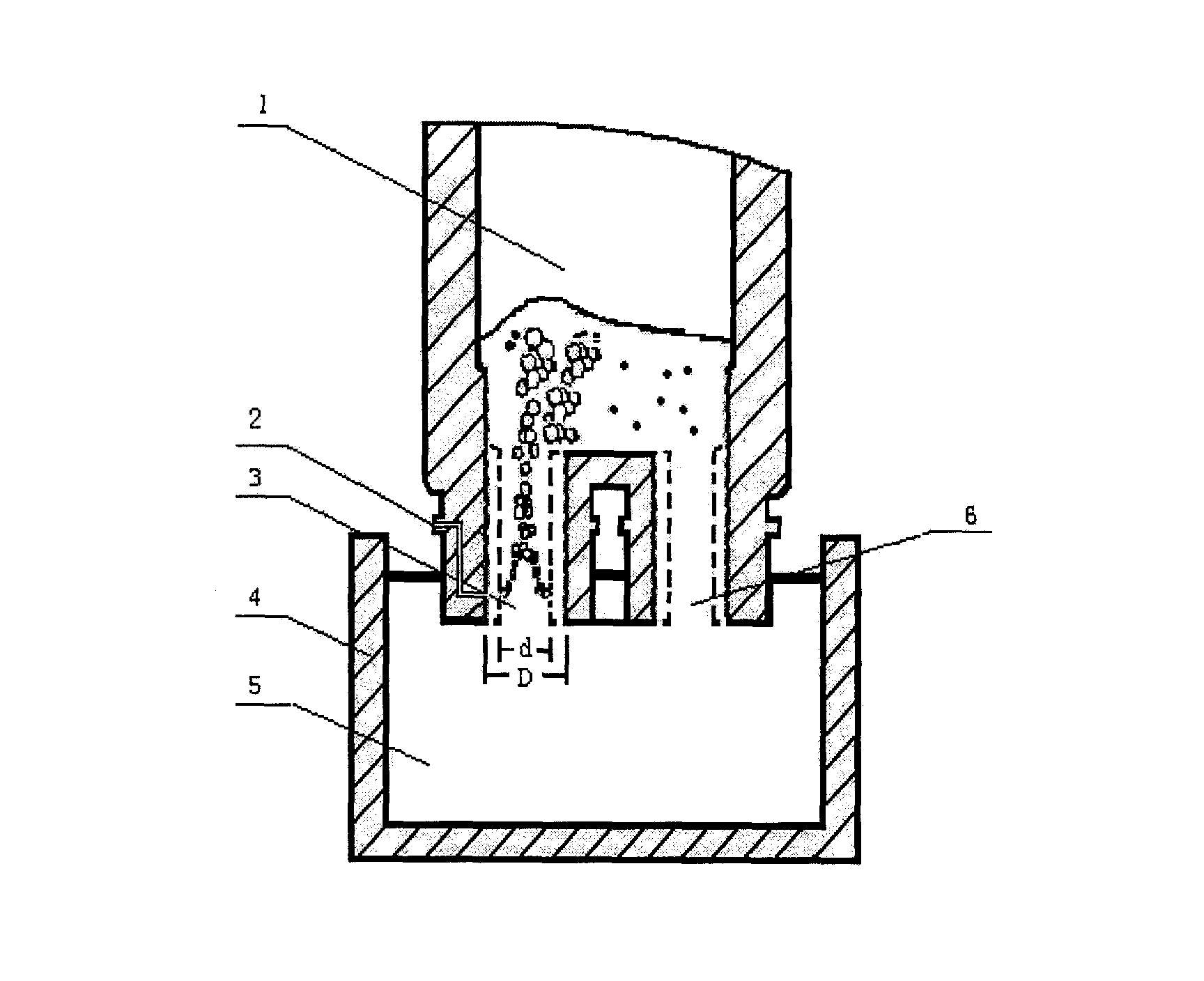

InactiveCN105256106AIncrease circulation flowImprove decarbonization efficiencyMaterials scienceMolten steel

The invention discloses a RH refining device which comprises a steel ladle (1) and a vacuum slot (2), wherein the steel ladle (1) and the vacuum slot (2) communicate through an ascending impregnation tube (3) and a descending impregnation tube (4) which are parallel; and cross sections of the ascending impregnation tube (3) and the descending impregnation tube (4) are oval. According to the device, by changing the shapes of the sections of the impregnation tubes, equivalent diameters of the RH impregnation tubes are increased, so that the problem that loop flow of molten steel is difficult to increase is radically solved.

Owner:SHANDONG IRON & STEEL CO LTD

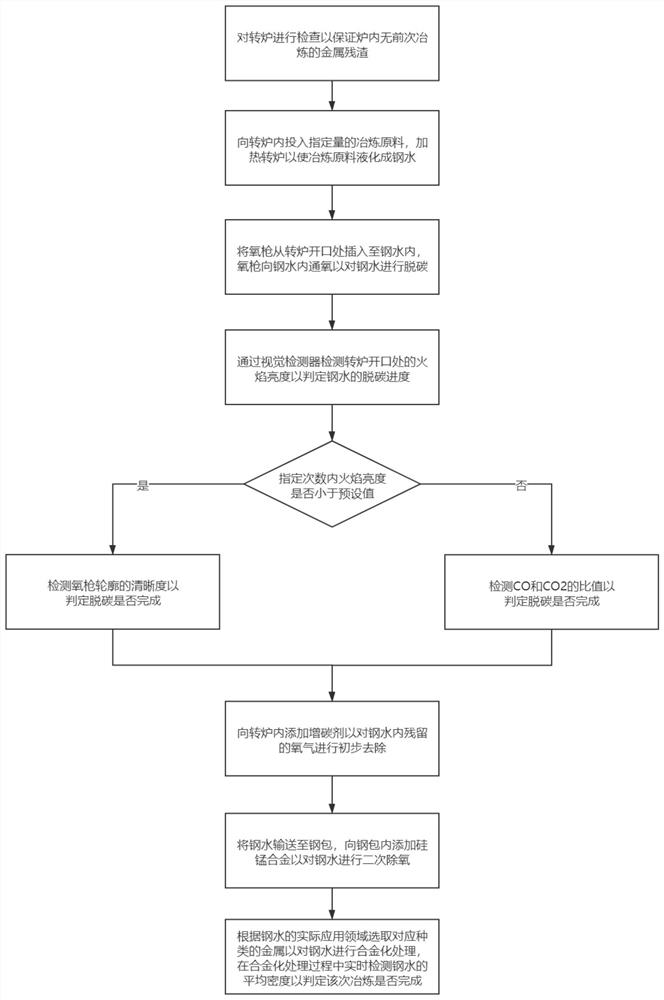

Converter smelting process of HRB400cE corrosion-resistant steel

ActiveCN112522469AGuaranteed decarbonizationImprove decarbonization efficiencySteel manufacturing process aspectsIncreasing energy efficiencyDeoxygenationCorrosion resistant

The invention relates to a converter smelting process for HRB400cE corrosion-resistant steel. The converter smelting process comprises the following steps that a converter is checked; smelting raw materials are fed into the converter, and heating is carried out to liquefy the smelting raw materials in the converter into molten steel; an oxygen lance is inserted into the converter and introduces oxygen above the molten steel to decarburize the molten steel; the molten steel decarburization progress is judged according to the flame brightness and whether decarburization is completed or not is judged according to the oxygen lance outline definition; a carburant is added into the converter to primarily remove oxygen in the molten steel; the molten steel is conveyed to a steel ladle, and silicon-manganese alloy is added to conduct secondary deoxygenation on the molten steel; and corresponding types of metal are selected to perform alloying treatment on the molten steel. A preset matrix is established by using a central control processor, the oxygen introduction duration of the oxygen lance is determined according to the carbon content in the molten steel, so that the oxygen introduced by the oxygen lance just reacts with the carbon element in the molten steel, so that the molten steel is decarburized by using the specified amount of oxygen, the decarburization efficiency of the process for the molten steel is effectively improved, and therefore, the smelting efficiency of the process is improved.

Owner:福建三宝钢铁有限公司

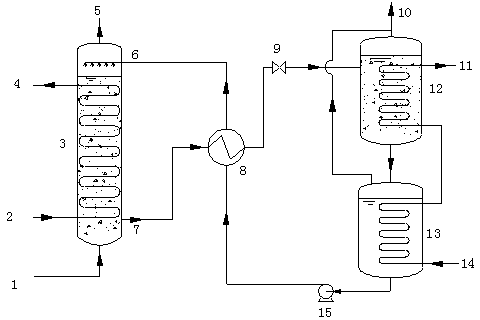

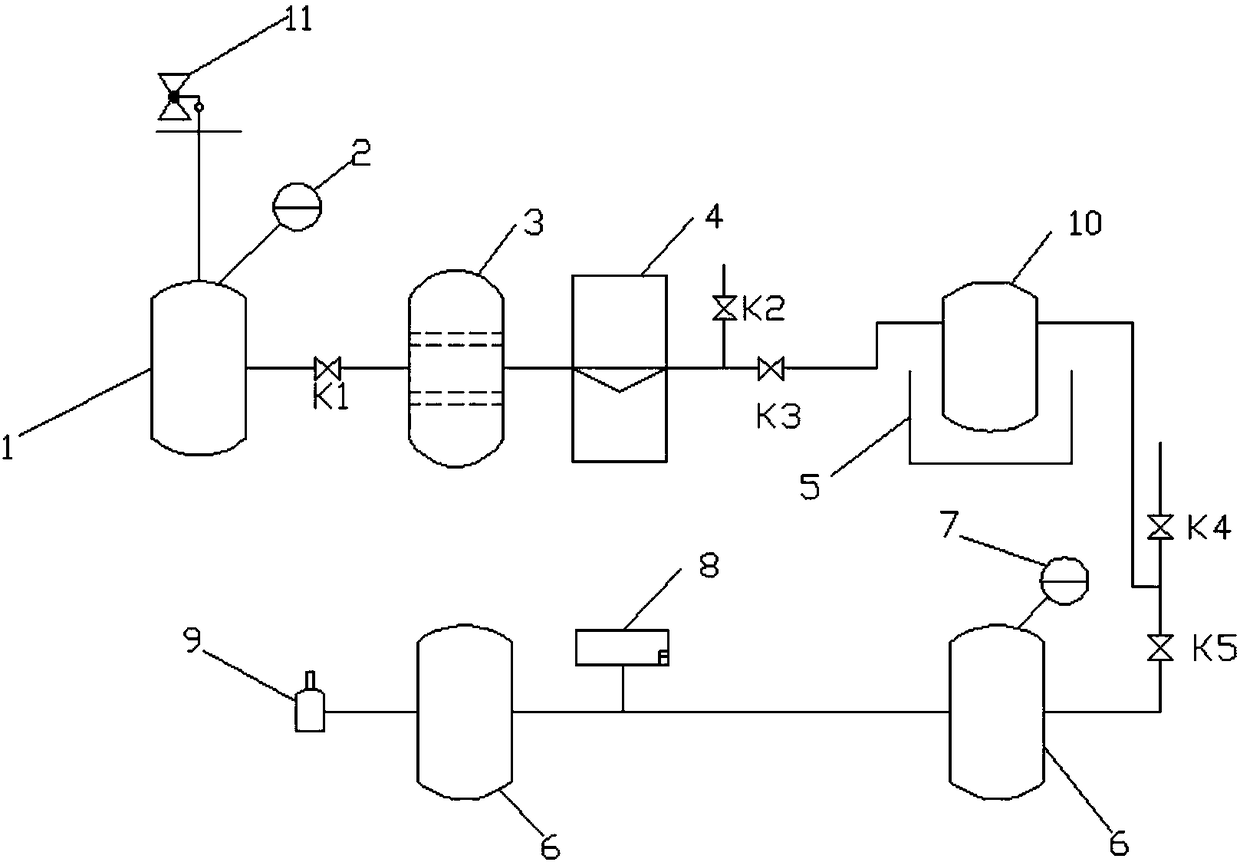

Device and method for removing CO2 from power plant flue gas by utilizing non-dehydrated flue gas desulfurization gypsum

InactiveCN106925118ARealize resource utilizationLow costGas treatmentDispersed particle separationWaste productSlurry

The invention provides a device and a method for removing CO2 from a power plant flue gas by utilizing non-dehydrated flue gas desulfurization gypsum. The device comprises a super-gravity rotary packed bed, a first reaction kettle and a second reaction kettle, wherein flue gas desulfurization gypsum, ammonium hydroxide and CO2-containing power plant exhaust gas are fed from an input end of the super-gravity rotary packed bed; the first reaction kettle is connected with an output end of the super-gravity rotary packed bed; slurry for preparing a desulfurizing agent is fed from the input end of the first reaction kettle; the output end of the first reaction kettle is connected with the second reaction kettle; the input end of the second reaction kettle is connected with an ammonia station of the power plant; and the output end of the second reaction kettle is connected with the super-gravity rotary packed bed. According to the method provided by the invention, the waste product (non-dehydrated flue gas desulfurization gypsum) generated from a wet desulphurization process is utilized to effectively collect CO2 in the exhaust gas, the available resources of the coal-fired power plant are fully utilized so that the reaction materials and conditions required by the running of the system can be supplied, the use efficiency of the system energy can be effectively increased, the cost can be saved and the energy consumption can be reduced.

Owner:NANJING NORMAL UNIVERSITY

Preparation method of austenitic heat-resistant steel with high durable strength and steam corrosion resistance

ActiveCN107475640BPreferential oxidationReduce oxidationElectric furnaceProcess efficiency improvementHeat resistanceHigh pressure

The invention relates to a preparation method of high-endurance-strength steam-corrosion-resistance austenitic heat-resistance steel, and belongs to the technical field of austenitic heat-resistance steel. The method sequentially comprises the technological steps of ingredient preparation, decarburization by oxygen blowing, reduction, steel tapping, ladle refining, casting, cogging and hot rolling. Compared with 22 / 15 austenitic heat-resistance steel, the SP22 / 15 has the similar nickel content and chrome content, however has the better high temperature endurance strength and high temperature steam corrosion resistance, and therefore the steel has the better market prospect compared with 22 / 15 austenitic heat-resistance steel. The steel can completely replace 22 / 15 austenitic heat-resistance steel, and can adapt to severe conditions to which 22 / 15 austenitic heat-resistance steel cannot adapt, for example, the steel can normally work at the high temperature and high pressure steam environment under 650DEG C and 35 MPa, and keep good impact toughness.

Owner:YONGXING SPECIAL STAINLESS STEEL

Chromium-containing low-nickel molten iron pretreatment process and application for 200-series stainless steel production

ActiveCN110819880ALarge smelting loadImprove decarbonization efficiencyManufacturing convertersSS - Stainless steelNitrogen gas

The invention aims at providing a chromium-containing low-nickel molten iron pretreatment process and application for 200-series stainless steel production. The process comprises the following steps that chromium-containing low-nickel molten iron is added into a top-bottom compound blowing primary smelting furnace, and blowing smelting is conducted in the primary smelting furnace under the conditions of top lance oxygen blowing and bottom lance no oxygen blowing; when the carbon in a melting pool in the primary smelting furnace is reduced to 0.60%-1.50%, the silicon is reduced to less than 0.10%, and the endpoint temperature is controlled to range from 1620 DEG C to 1680 DEG C, oxygen blowing of a top lance of the primary smelting furnace is stopped, and then solid high-carbon ferrochromeand molten high-carbon ferrochrome are added into the primary smelting furnace; and a bottom lance of the primary smelting furnace is used for blowing nitrogen or inert gas into the melting pool, theblowing intensity of the bottom lance is controlled to range from 0.18 Nm<3> / t.min to 0.30 Nm<3> / t.min for stirring, slag is blocked for steel discharging, and then coarse smelting molten iron for 200-series stainless steel production is obtained, wherein the slag basicity is controlled to range from 1.3 to 1.6. According to the chromium-containing low-nickel molten iron pretreatment process, thewear resistance of furnace-bottom refractory materials of the primary smelting furnace can be reduced, the furnace age of the primary smelting furnace is proloned, and the equipment cost is reduced.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

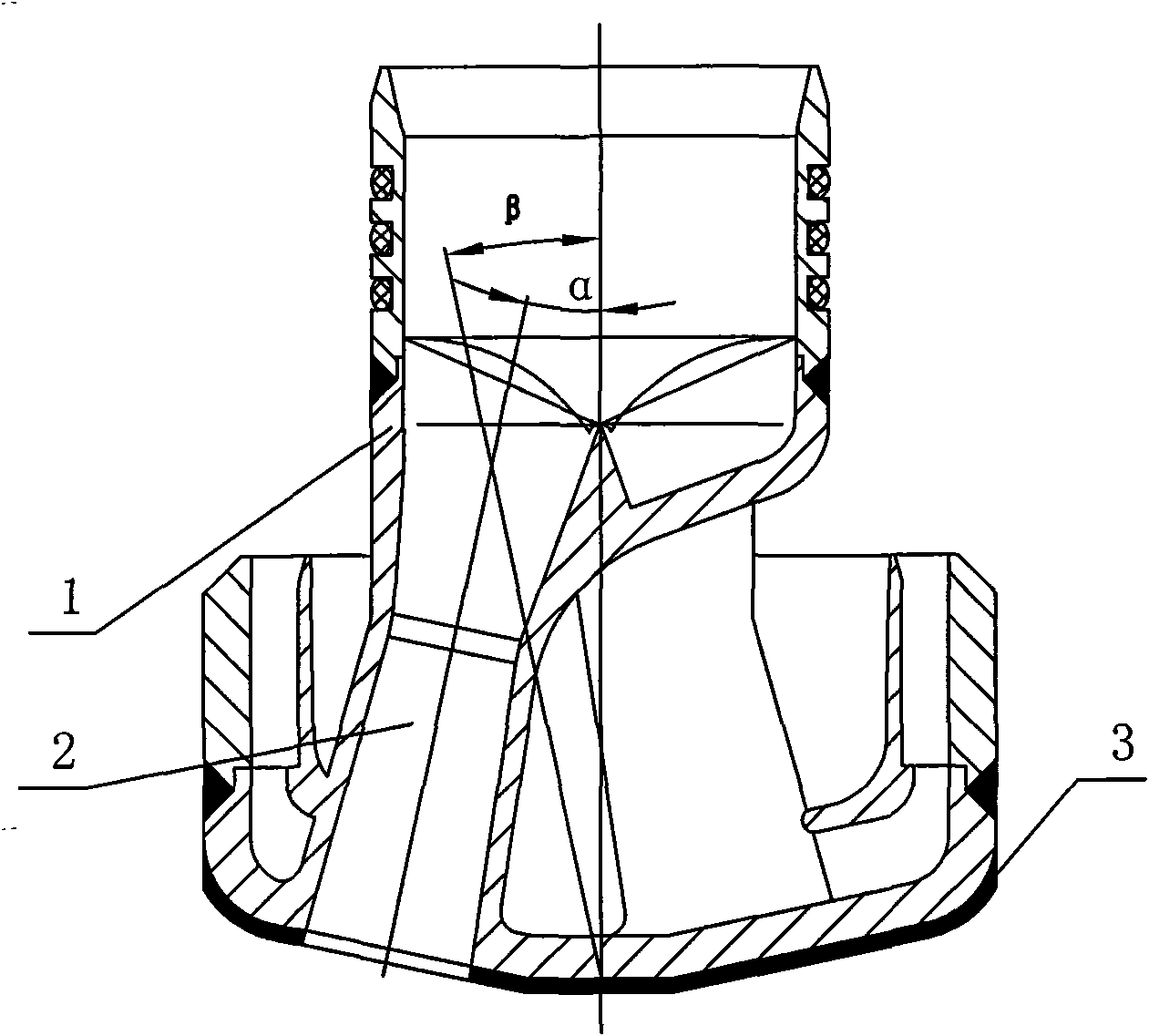

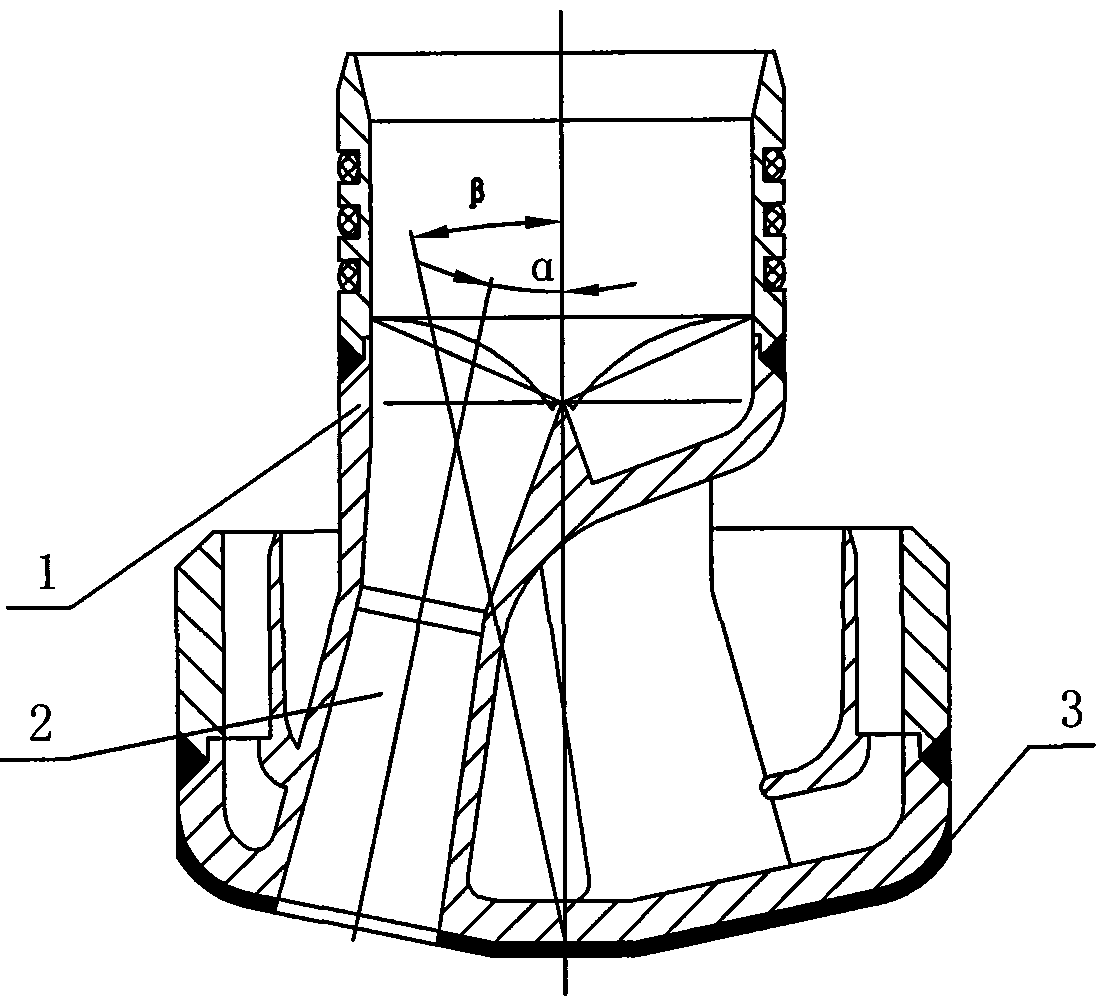

Oxygen lance nozzle

InactiveCN101929801AExtended service lifeStir wellCharge manipulationManufacturing convertersMelting tankJet flow

The invention discloses an oxygen lance nozzle, which relates to accessories used in steel smelting. The lower end of the oxygen lance nozzle is arranged in a molten pool; and the oxygen lance nozzle comprises a nozzle body, wherein a plurality of spray holes are formed on the periphery of the nozzle body, and the lower end face of the nozzle is coated with a nickel and chromium alloy layer. In the invention, the lower end face of the nozzle body is coated with nickel and chromium alloy layer, so that the lower end face of the nozzle body can be well protected due to the high-strength and anti-corrosion performance of the nickel and chromium alloy; the included angle between the axis of the nozzle and the axes of the spray holes and the included angle between the axial plane of the spray holes and the axial plane of the nozzle body make tangential component energy generated when oxygen jet flow is jetted into the molten pool, so the stirring between furnace slag and molten steel is improved; meanwhile, the splashing is avoided, the steel making smelting is improved, the decarburization efficiency is improved, and the service life of the nozzle is improved.

Owner:JIANGSU BOJI HEATING TECH

Device and method for removing CO2 in power plant exhaust gas by means of ash slurry

InactiveCN107185383ARealize resource utilizationLower decarbonization costsGas treatmentDispersed particle separationAtmospheric airResource utilization

The invention discloses a device and method for removing CO2 in power plant exhaust gas by means of ash slurry. The device comprises a reaction kettle, a settling pond and a clarification pond, wherein ash slurry is fed into the upper input end of the reaction kettle, exhaust gas obtained after power plant desulfuration is fed into the lower input end, the upper output end is led into the atmosphere, and the lower output end is connected with the settling pond; the output end of the settling pond is connected with the clarification pond. The alkali ash slurry is sufficiently utilized for removing acid CO2 gas in the exhaust gas to generate neutral salt, the pH value of the waste ash slurry can be effectively adjusted, and the discharge limitation standard is reached; on one hand, waste resource utilization can be achieved, and the problem that environment pollution caused by direct discharge of the waste alkali slurry is solved; on the other hand, the system decarburization cost and energy consumption can be effectively lowered. The device is combined with power plant ash slurry, treatment of wastes with processes of wastes against one another can be achieved, and the optimum scheme with the low cost and energy consumption is obtained.

Owner:NANJING NORMAL UNIVERSITY

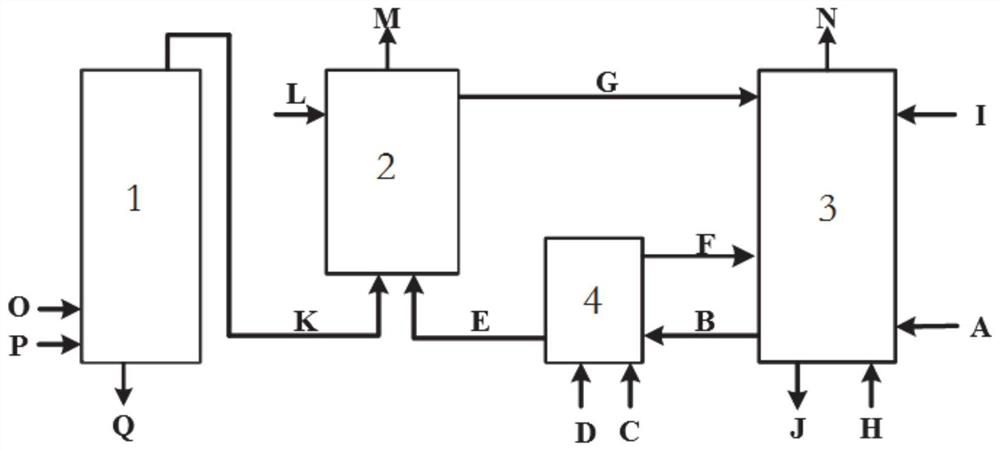

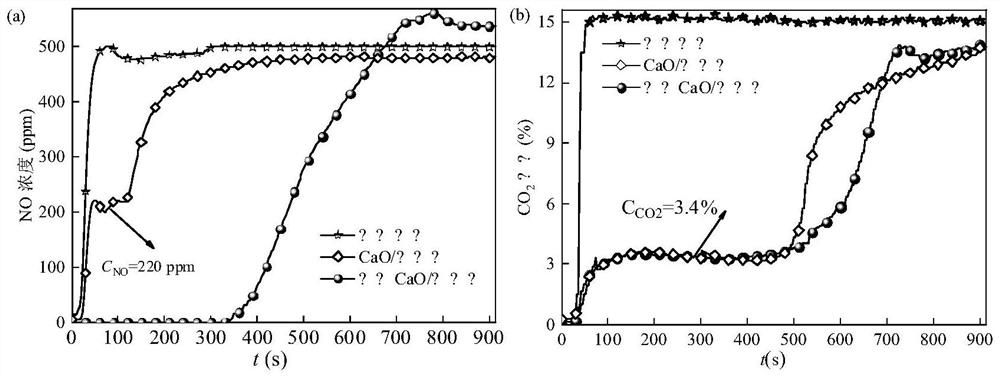

System for simultaneously removing carbon dioxide and nitric oxide and method thereof

PendingCN111790266AEfficient removalNo intractableGas treatmentDispersed particle separationPtru catalystNitric oxide

The invention discloses a system for simultaneously removing carbon dioxide and nitrogen oxide and a method. The system comprises a decarburization and denitrification furnace, a calcining furnace anda pyrolysis carbon deposition furnace; a gas inlet of the decarburization and denitrification furnace is connected with a flue gas exhaust port of a coal-fired boiler; the calcining furnace is provided with a calcium carbonate supply port, and a calcium oxide discharge port of the calcining furnace is connected with the pyrolysis carbon deposition furnace; and the pyrolysis carbon deposition furnace is provided with a biomass supply port, and a solid discharge port of the pyrolysis carbon deposition furnace is connected with the decarburization and denitrification furnace. In the system for circularly capturing CO2 by calcium, a pyrolysis carbon deposition furnace is added between the calcining furnace and a carbonating furnace, biomass is pyrolyzed by using high-temperature calcium oxideflowing between the carbonating furnace and the calcining furnace as a heat source, and carbon deposition calcium oxide / biomass coke is generated in the biomass pyrolysis process. In the decarburization and denitrification furnace, calcium oxide serves as a denitrification catalyst and a carbon dioxide absorbent, deposited carbon and biomass coke serve as denitrification reducing agents, and efficient removal of carbon dioxide and nitric oxide can be achieved at the same time.

Owner:SHANDONG UNIV

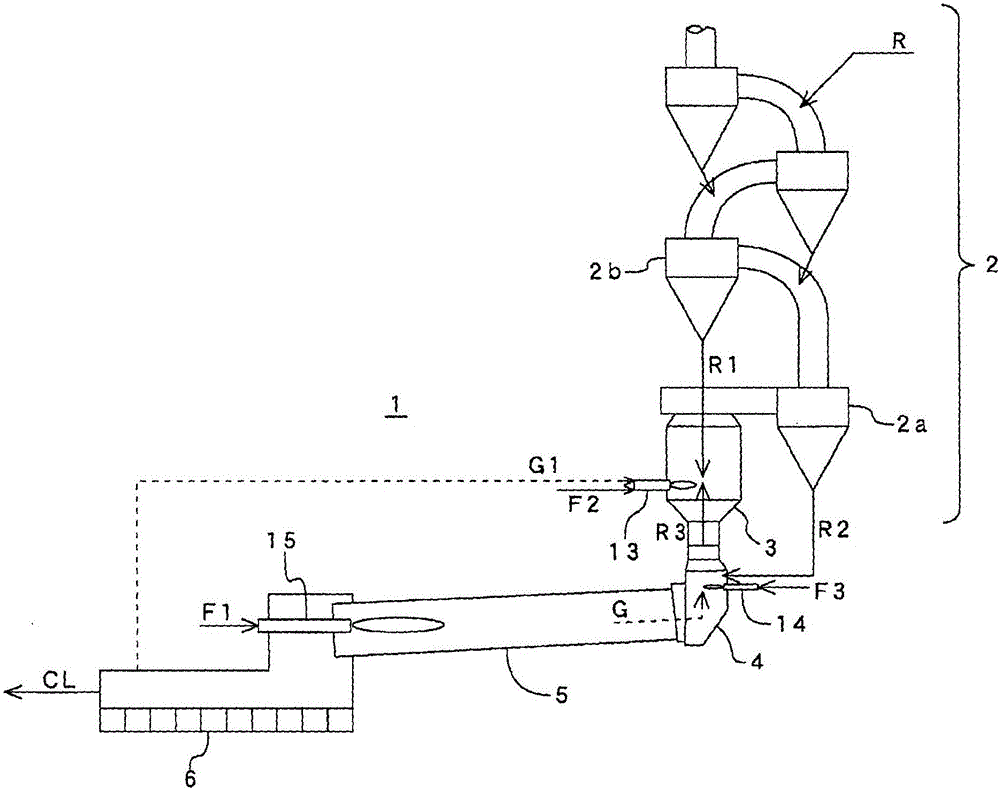

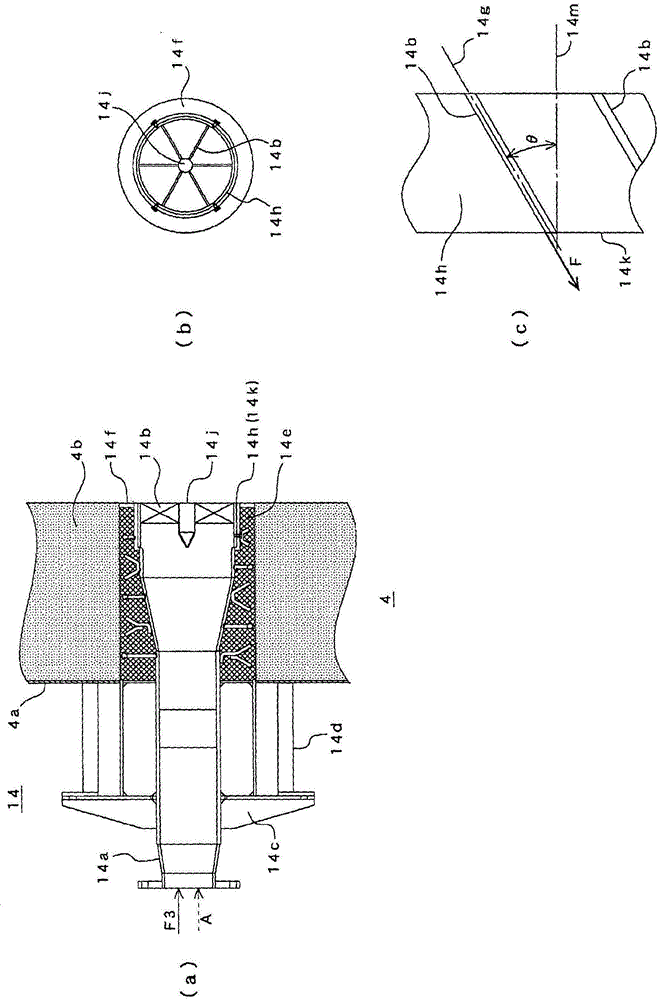

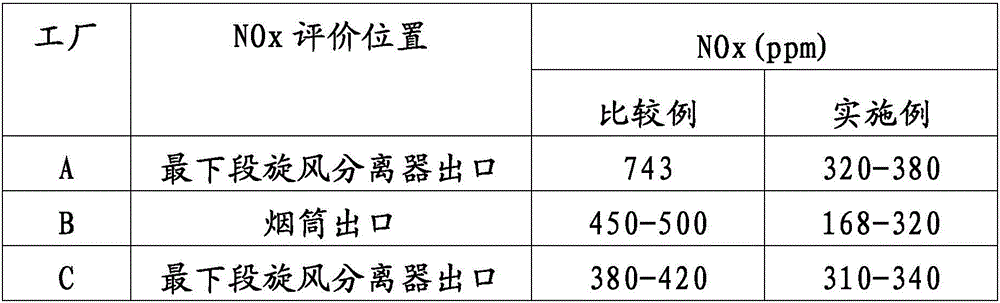

Cement burning apparatus, and method for denitrating exhaust gas from cement kiln

InactiveCN106029599AImprove decarbonization efficiencyReduce NOx concentrationFurnace componentsDispersed particle separationExhaust gasCoal

[Problem] To efficiently reduce the concentration of NOx in an exhaust gas from a cement kiln while keeping the burned state at a good level regardless of the type of a calcining furnace to be used. [Solution] A cement burning apparatus (1) equipped with a burner (14) for blowing a fuel (F3) and combustion air into a kiln tail part (4) of a cement kiln (5) to burn the fuel. It becomes possible to reduce NOx, which is contained in an exhaust gas from the cement kiln, in a low-oxygen zone in the kiln tail part, and it also becomes possible to improve the decarbocxylation efficiency of a cement raw material due to the burning of the fuel. The burner may be equipped with a swirl vane (a swirl means) (14b) for swirling a mixed flow of the fuel and the combustion air. It is preferred that the amount of the fuel to be supplied into the kiln tail part of the cement kiln is 20% or more and less than 50% of the amount of the fuel to be supplied into a calcining furnace (3) that is provided in the cement kiln. The fuel to be supplied into the kiln tail part of the cement kiln may comprise at least one of pulverized coal, a heavy oil and a burnable waste material.

Owner:TAIHEIYO ENG

Method for smelting medium-low carbon ferromanganese

ActiveCN114574641AAvoid formingAvoid severe erosionBlast furnace detailsManufacturing convertersSmelting processBlast furnace

The invention relates to a method for smelting medium-low carbon ferromanganese, which is characterized in that the smelting cost of the medium-low carbon ferromanganese is further reduced by setting a blast furnace-converter process, and the smelting cost of the medium-low carbon ferromanganese is further reduced by mixing and blowing carbon dioxide and oxygen in different proportions in multiple directions in the converter process. The corrosion to equipment in the converter smelting process is reduced to the minimum, meanwhile, the volatilization loss of manganese is reduced, and the quality of a final product is guaranteed.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com