Method for eliminating carbon dioxide in gas through steel slag adsorption

A carbon dioxide, steel slag technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of high cost of activated carbon, adsorption effect is not as good as activated carbon materials, etc., to achieve no pretreatment, fast reaction speed, mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation and beneficial effects of the technical solutions of the present invention will be described in detail below through specific examples, but they cannot be regarded as any limitation to the applicable scope of the present invention.

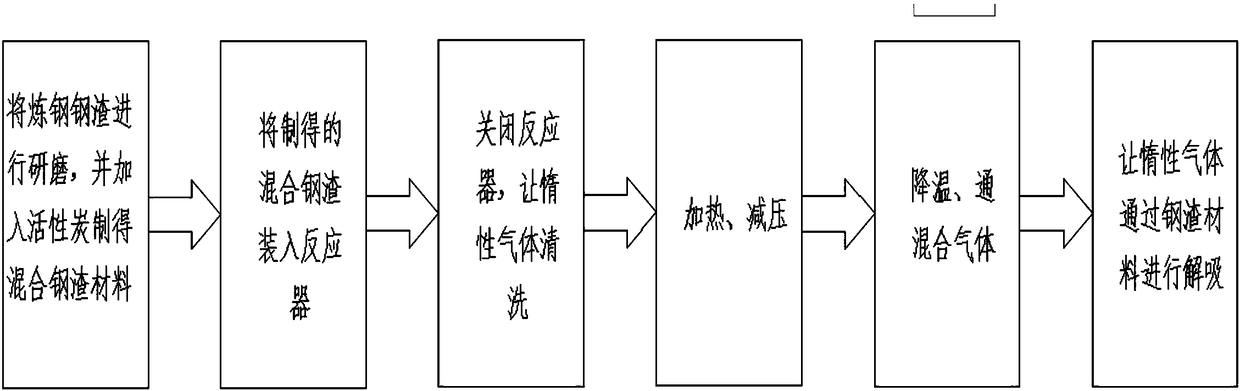

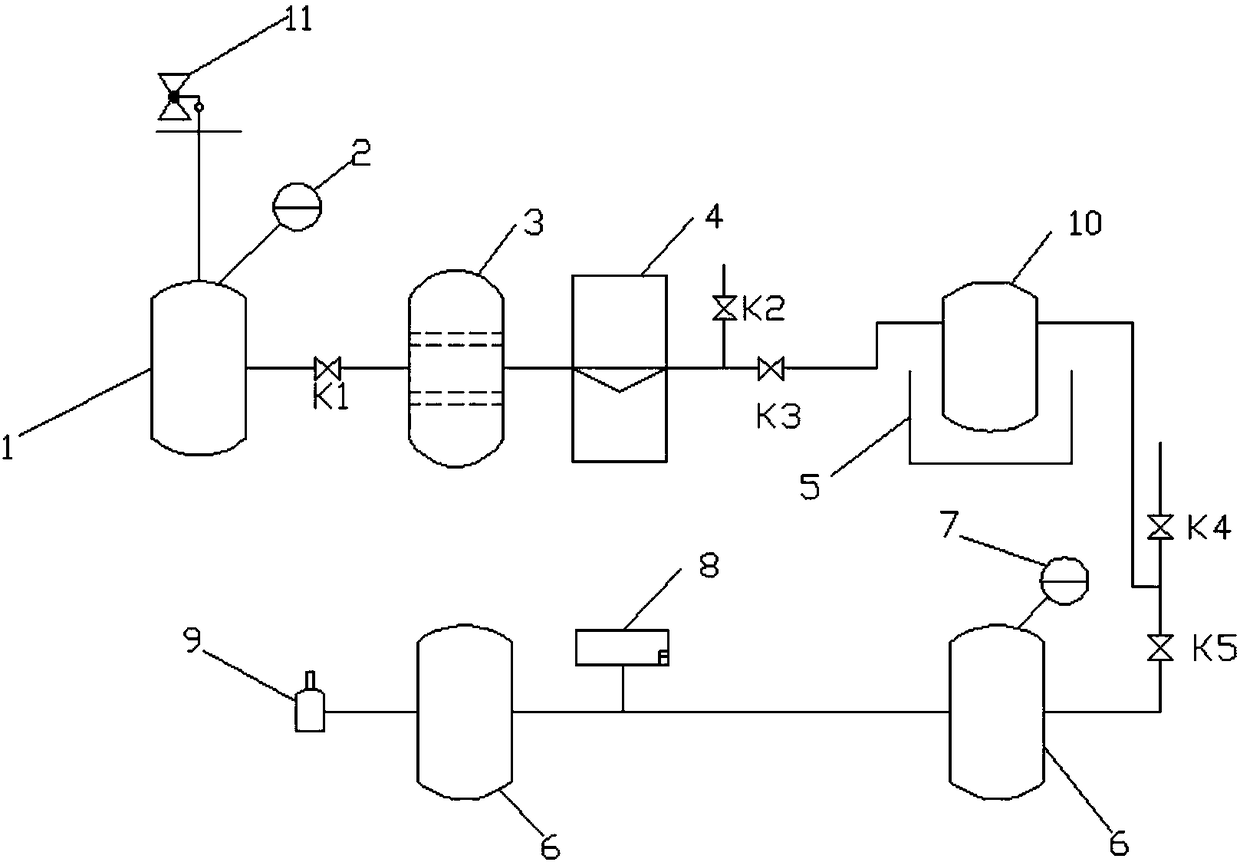

[0028] A method for steel slag adsorption and removal of carbon dioxide in gas, the method is as follows:

[0029] A. Grinding the steelmaking slag.

[0030] B. Add a certain amount of activated carbon material, the steel slag material is composed of more than 80% steel slag material and 20% activated carbon material based on the total weight of the steel slag material, to obtain a steel slag material mixed with activated carbon. Dissolve the steel slag material mixed with activated carbon in ionized water, add 2-8g of steel slag mixture material and 2-15g of pyrrole per 100ml of water, and then add 3-8g of ammonium persulfate, the reaction temperature is 30-90°C, and the reaction time is 6 ~10h, cool down to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com