Patents

Literature

207 results about "Carbon dioxide removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon dioxide removal (CDR) refers to a group of technologies the objective of which is the large-scale removal of carbon dioxide from the atmosphere. Among such technologies are bio-energy with carbon capture and storage, biochar, ocean fertilization, enhanced weathering, and direct air capture when combined with storage. CDR is a different approach from removing CO2 from the stack emissions of large fossil fuel point sources, such as power stations. The latter reduces emission to the atmosphere but cannot reduce the amount of carbon dioxide already in the atmosphere. As CDR removes carbon dioxide from the atmosphere, it 'creates' negative emissions that offset the emissions from small and dispersed point sources such as domestic heating systems, airplanes and vehicle exhausts. It is regarded by some as a form of climate engineering, while other commentators describe it as a form of carbon capture and storage or extreme mitigation. Whether CDR would satisfy common definitions of "climate engineering" or "geoengineering" usually depends upon the scale at which it would be undertaken.

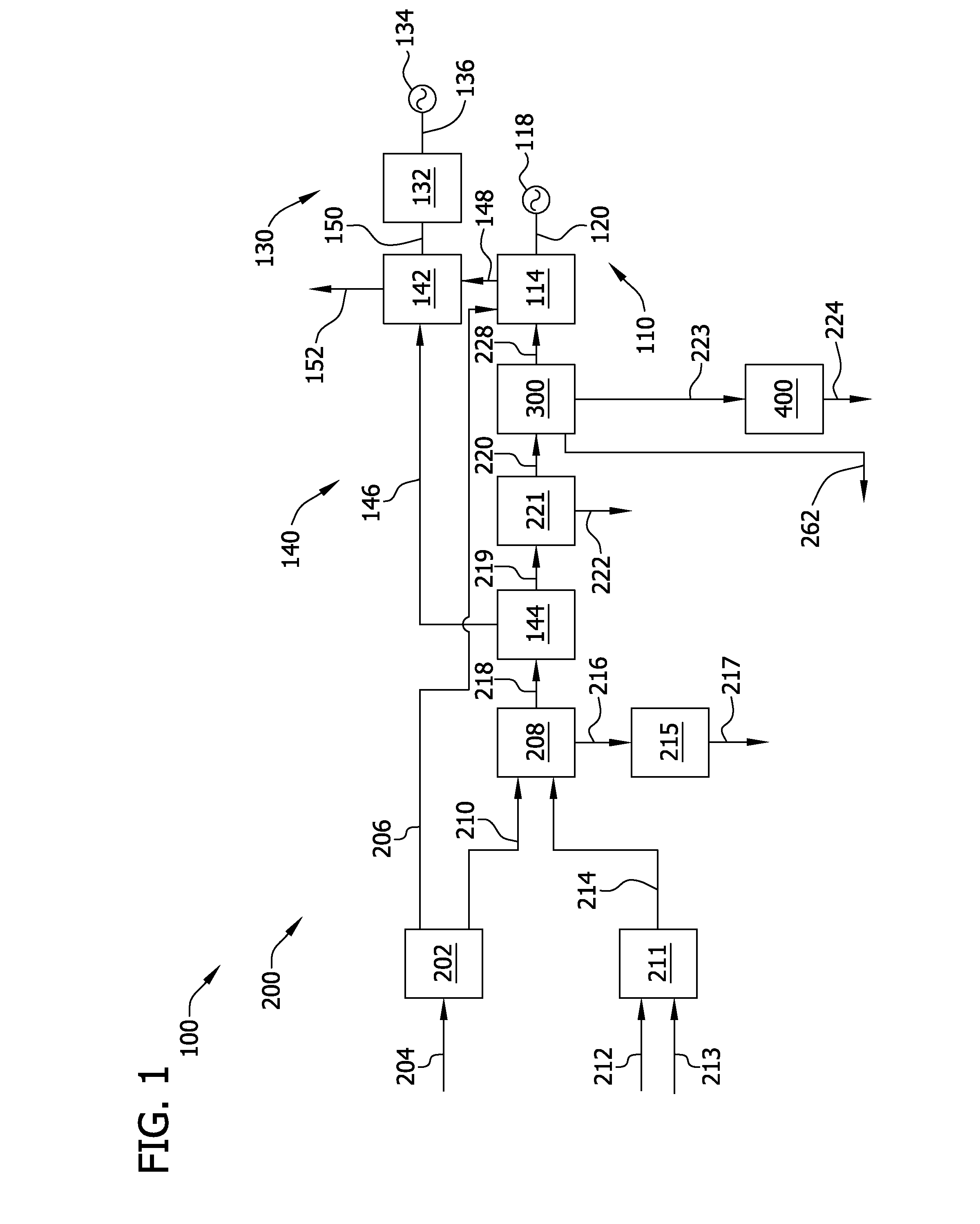

Reforming system for combined cycle plant with partial CO2 capture

A combined cycle system includes, a pre-steam-methane-reformer operating at a temperature of less than about 800 degrees Celsius to reform a mixed fuel stream to generate a first reformate stream, a water-gas-shift reactor to convert carbon monoxide in the first reformate stream to carbon dioxide and form a second reformate stream, a carbon dioxide removal unit for removing carbon dioxide from the second reformate stream and form a carbon dioxide stream and a third reformate stream; wherein less than about 50 percent of the carbon contained in the mixed fuel stream is recovered as carbon dioxide by the removal unit, a gas turbine unit for generating power and an exhaust stream, and a steam generator unit configured to receive the exhaust stream, wherein the heat of the exhaust stream is transferred to a water stream to generate the steam for the mixed fuel stream and for a steam turbine.

Owner:GENERAL ELECTRIC CO

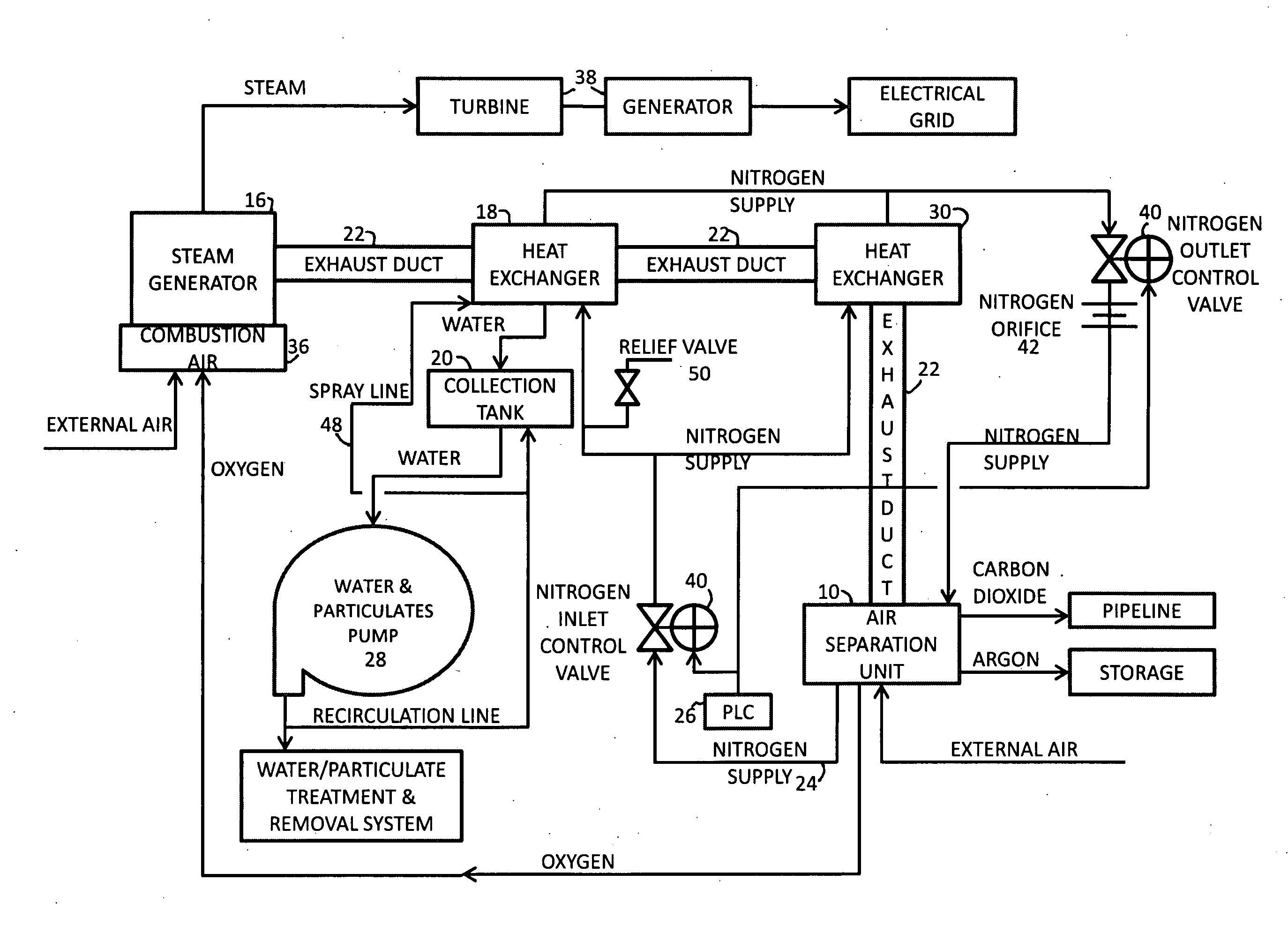

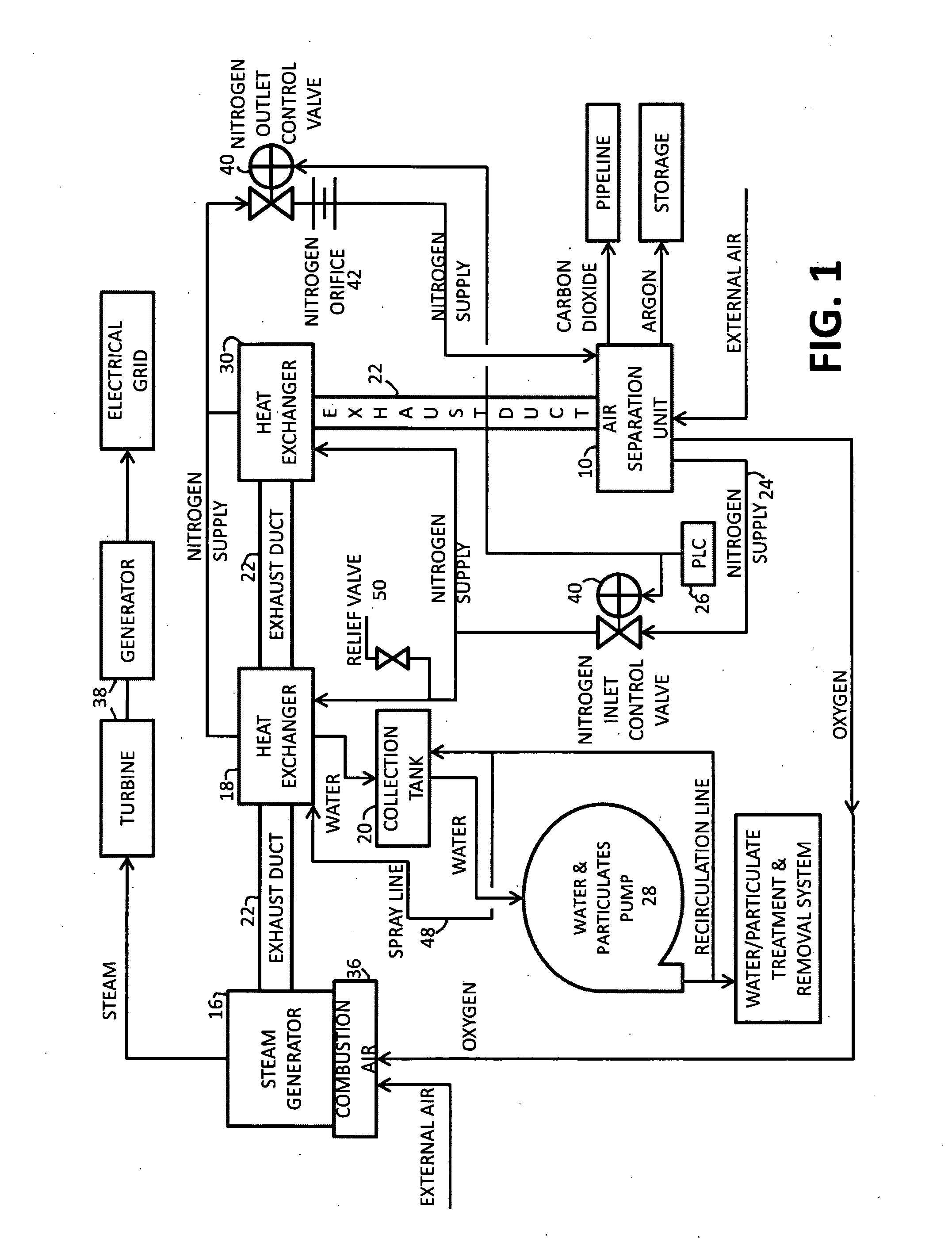

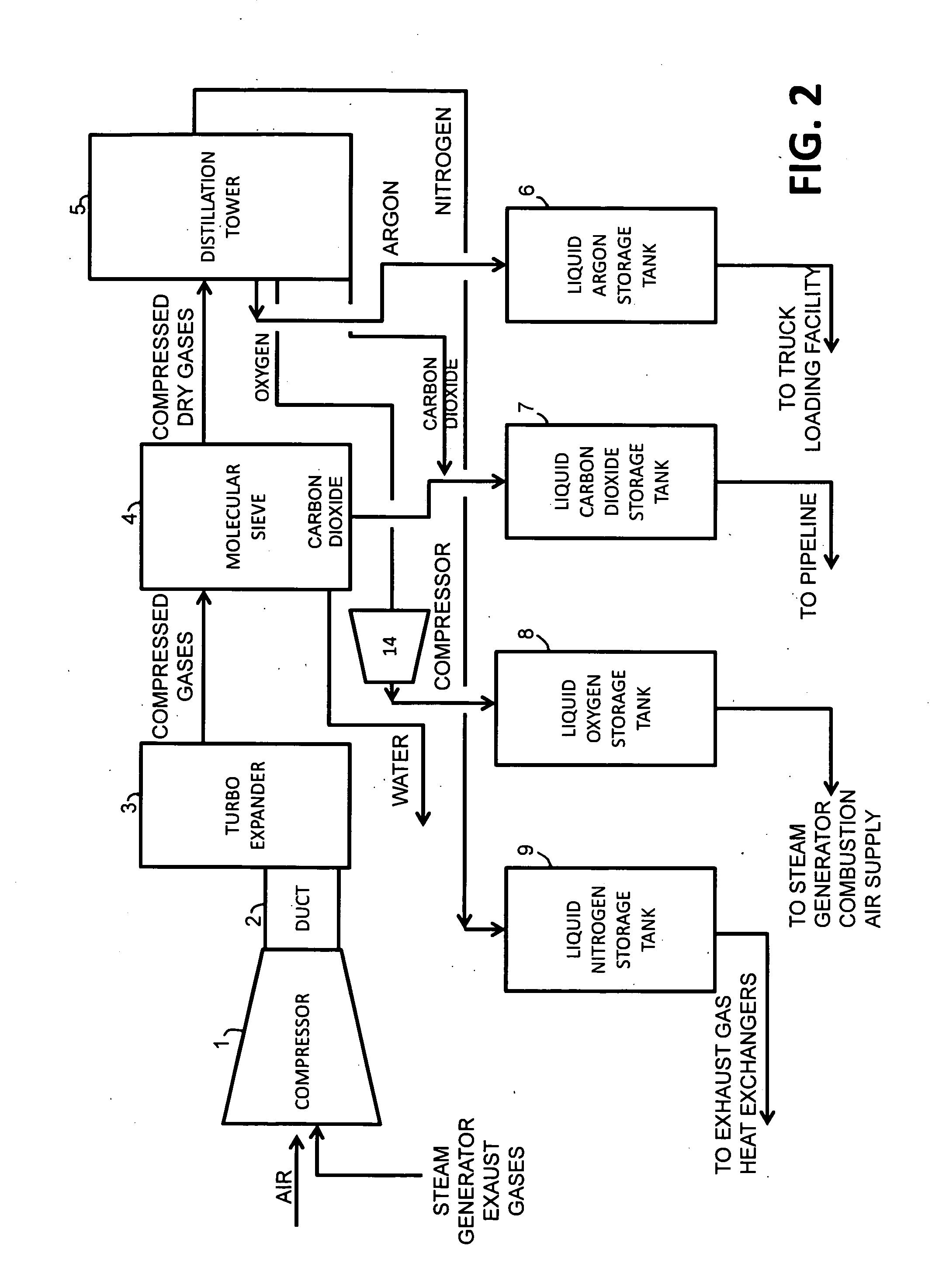

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

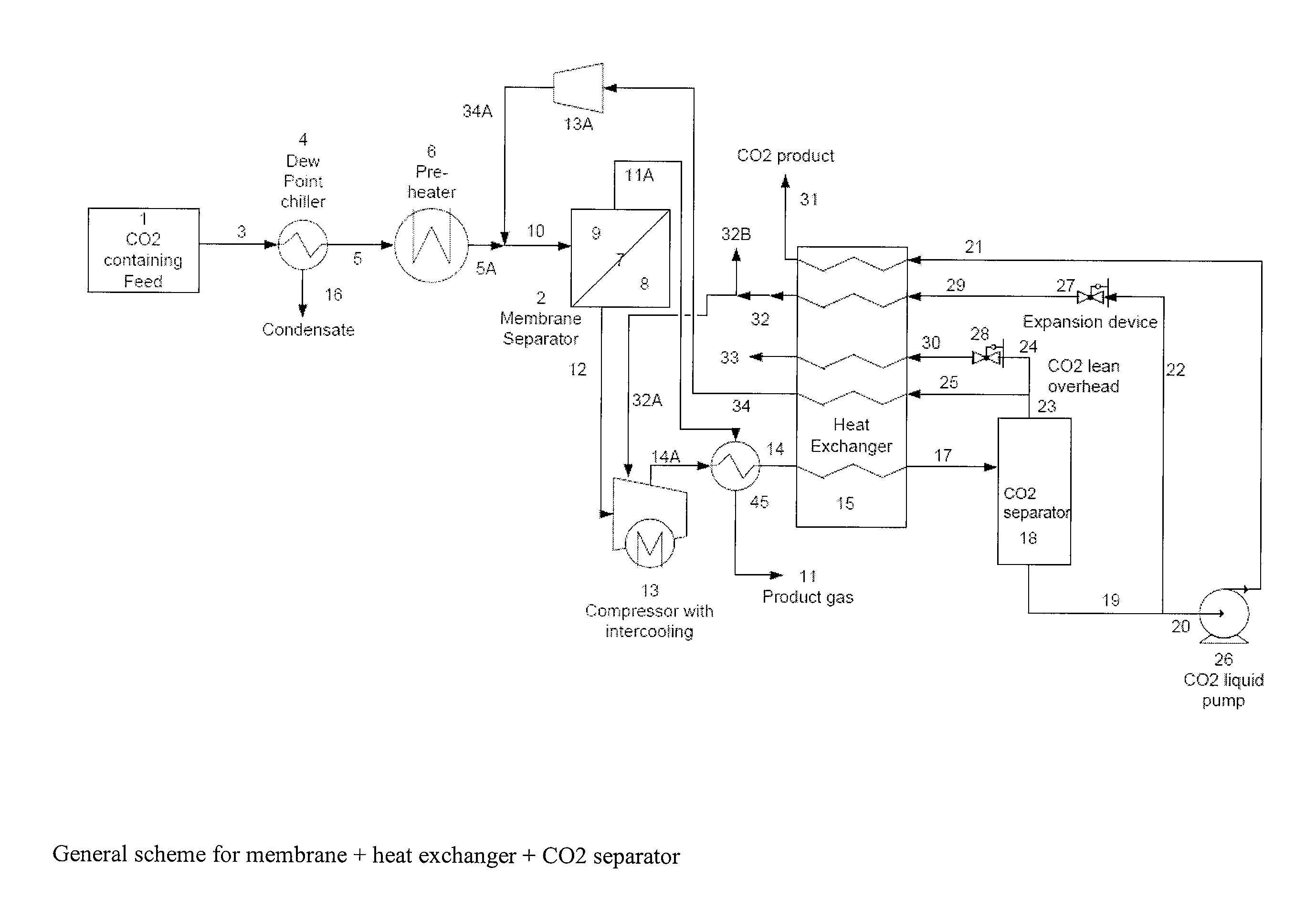

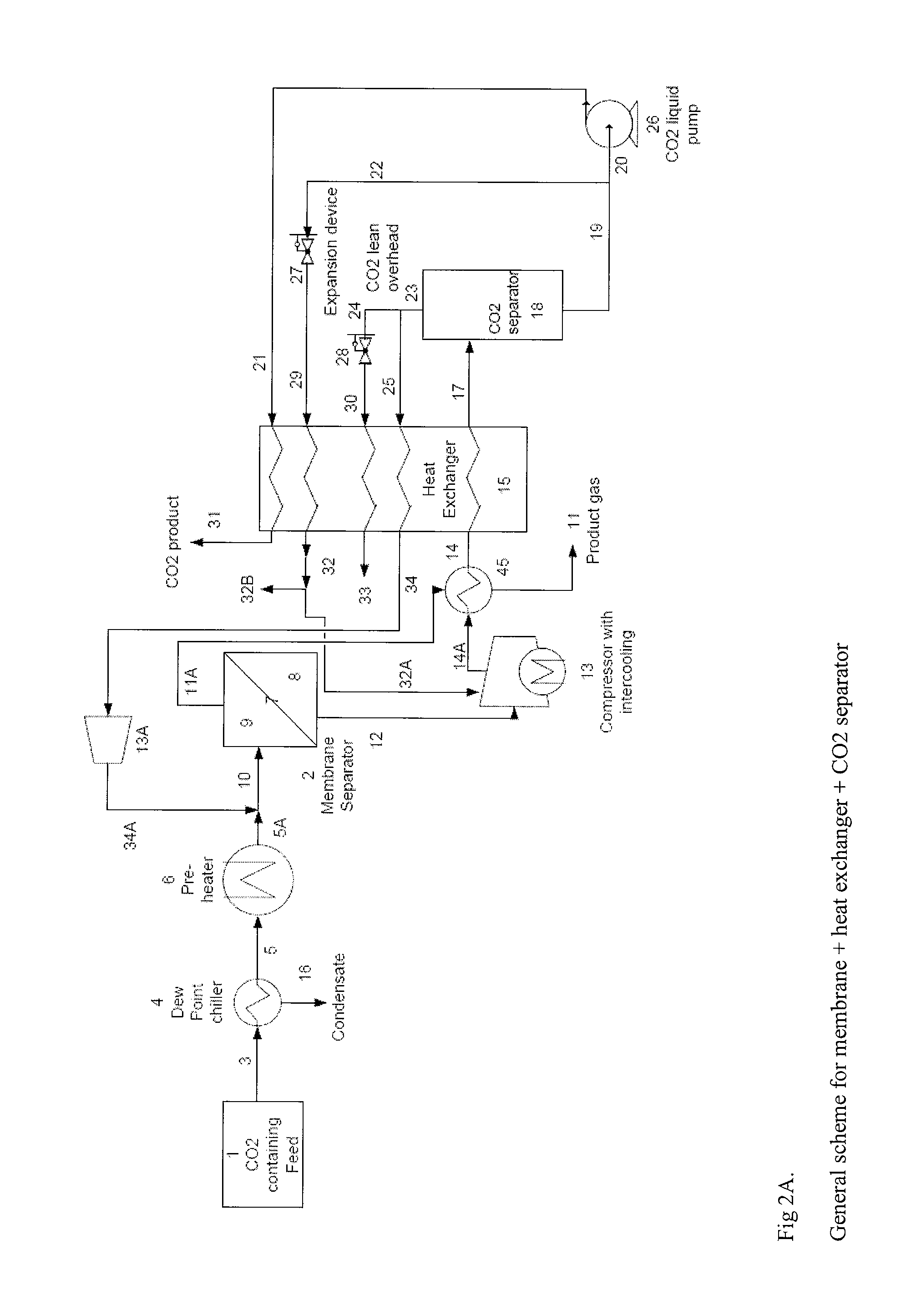

Carbon Dioxide Removal Process

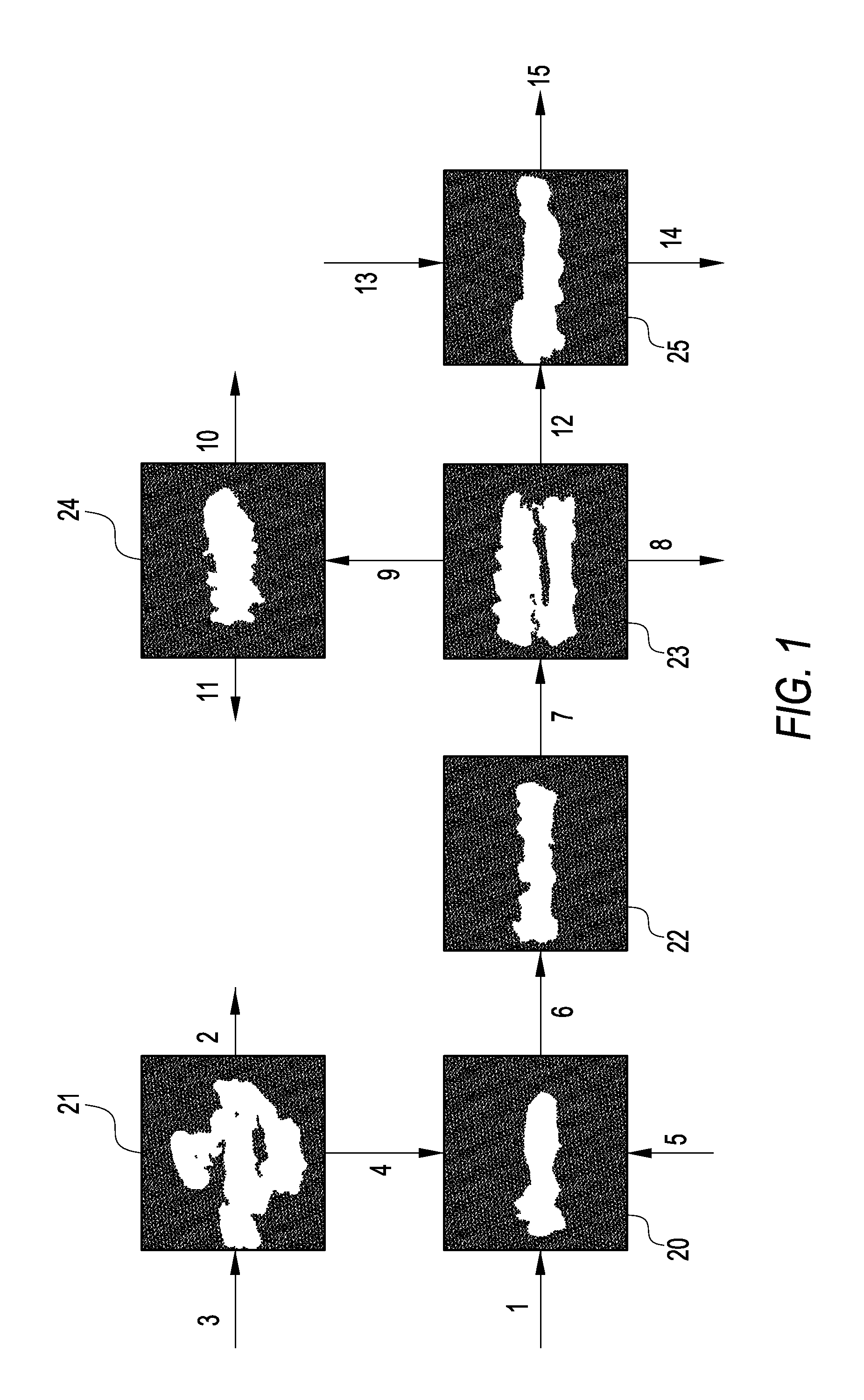

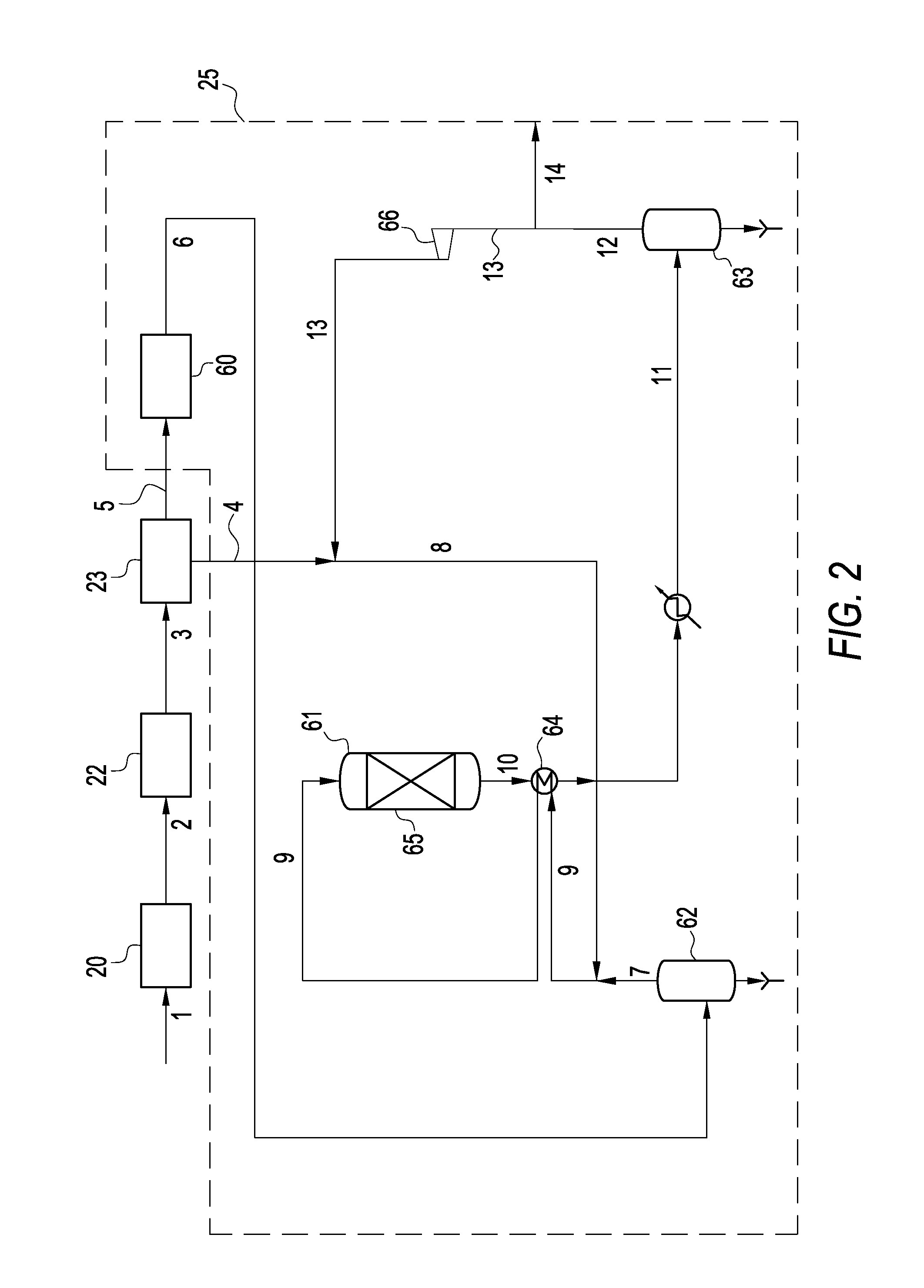

ActiveUS20120111051A1Reduce lossesIncrease pressureSolidificationLiquefactionCooling effectHydrocarbon

A process for efficiently removing carbon dioxide from a hydrocarbon containing feed stream utilizing a membrane separation unit in conjunction with a heat exchanger and a carbon dioxide separation unit wherein the streams obtained in the carbon dioxide separation unit are utilized to provide the cooling effect in the heat exchanger.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Hydrogen storage method and system

A method and system for storing and supplying hydrogen to a hydrogen pipeline in which a compressed hydrogen feed stream is introduced into a salt cavern for storage and a stored hydrogen stream is retrieved from the salt cavern and reintroduced into the hydrogen pipeline. A minimum quantity of stored hydrogen is maintained in the salt cavern to produce a stagnant layer having a carbon dioxide content along the cavern wall and the top of a residual brine layer located within the salt cavern. The compressed hydrogen feed stream is introduced into the salt cavern and the stored hydrogen stream is withdrawn without disturbing the stagnant layer to prevent carbon dioxide contamination from being drawn into the stored hydrogen stream being reintroduced into the hydrogen pipeline. This allows the stored hydrogen stream to be reintroduced into the hydrogen pipeline without carbon dioxide removal.

Owner:PRAXAIR TECH INC

Polyamine/alkali salt blends for carbon dioxide removal from gas streams

InactiveUS20070044658A1Increase chanceReduce absorptionProductsGas treatmentSolventPotassium carbonate

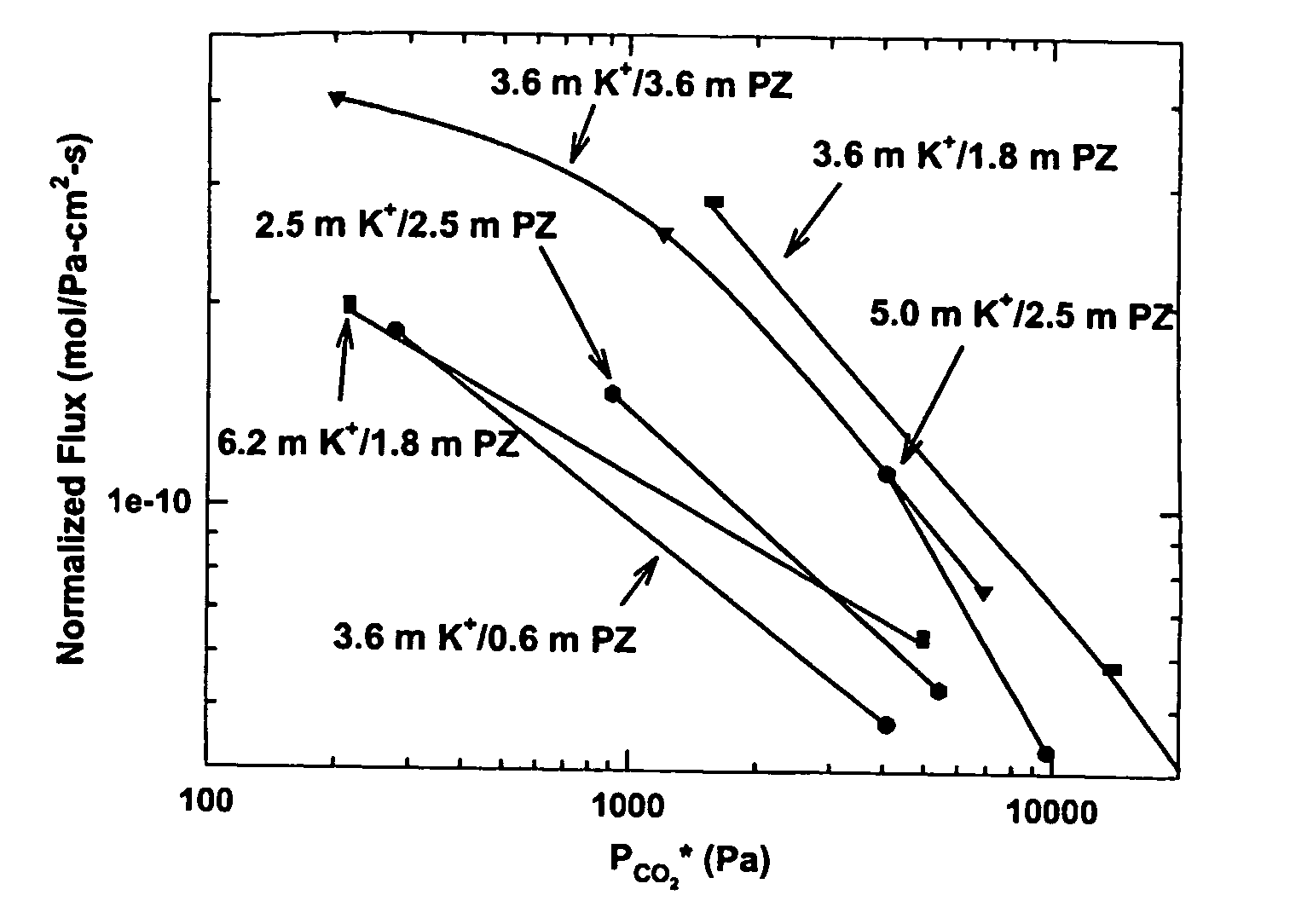

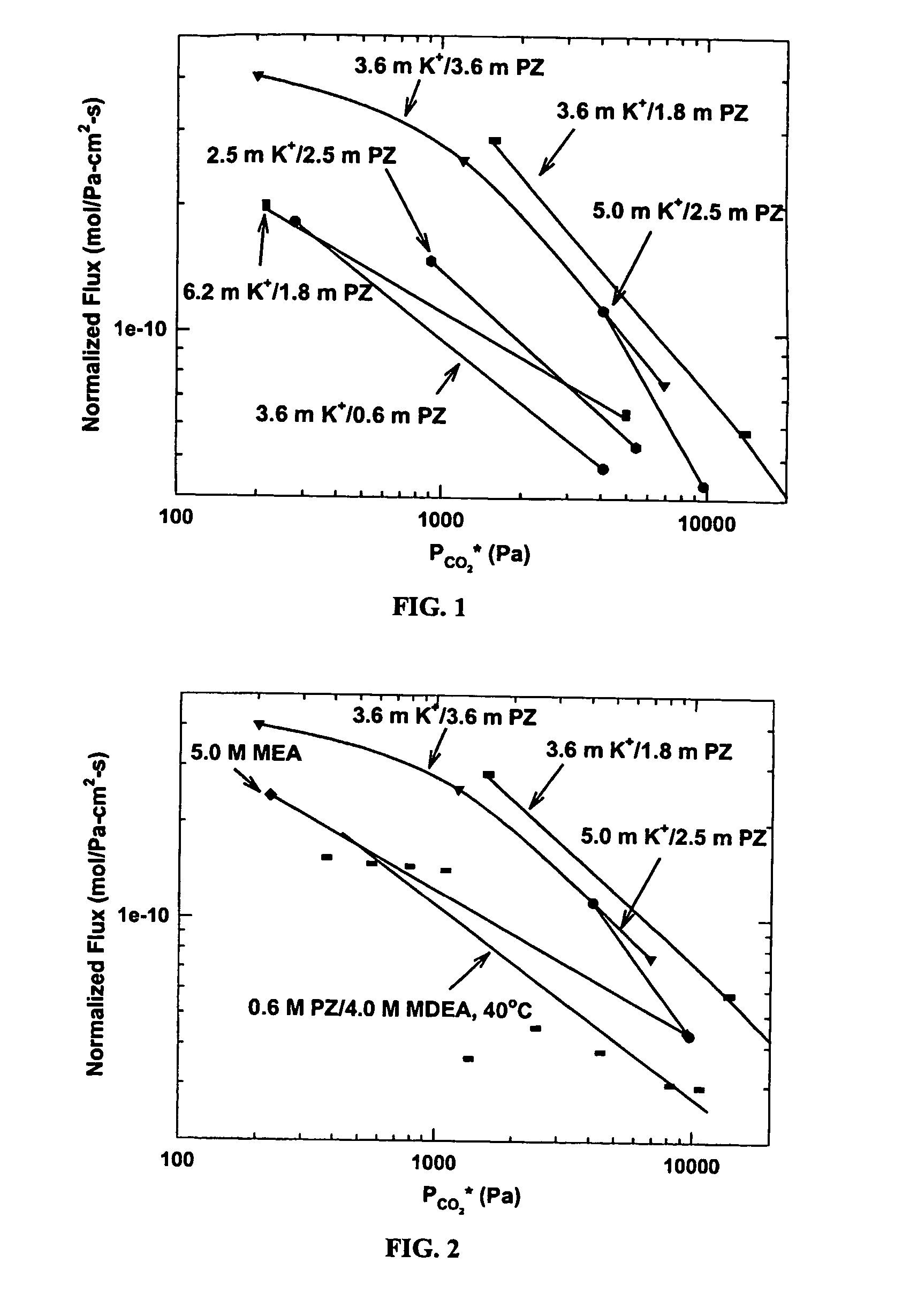

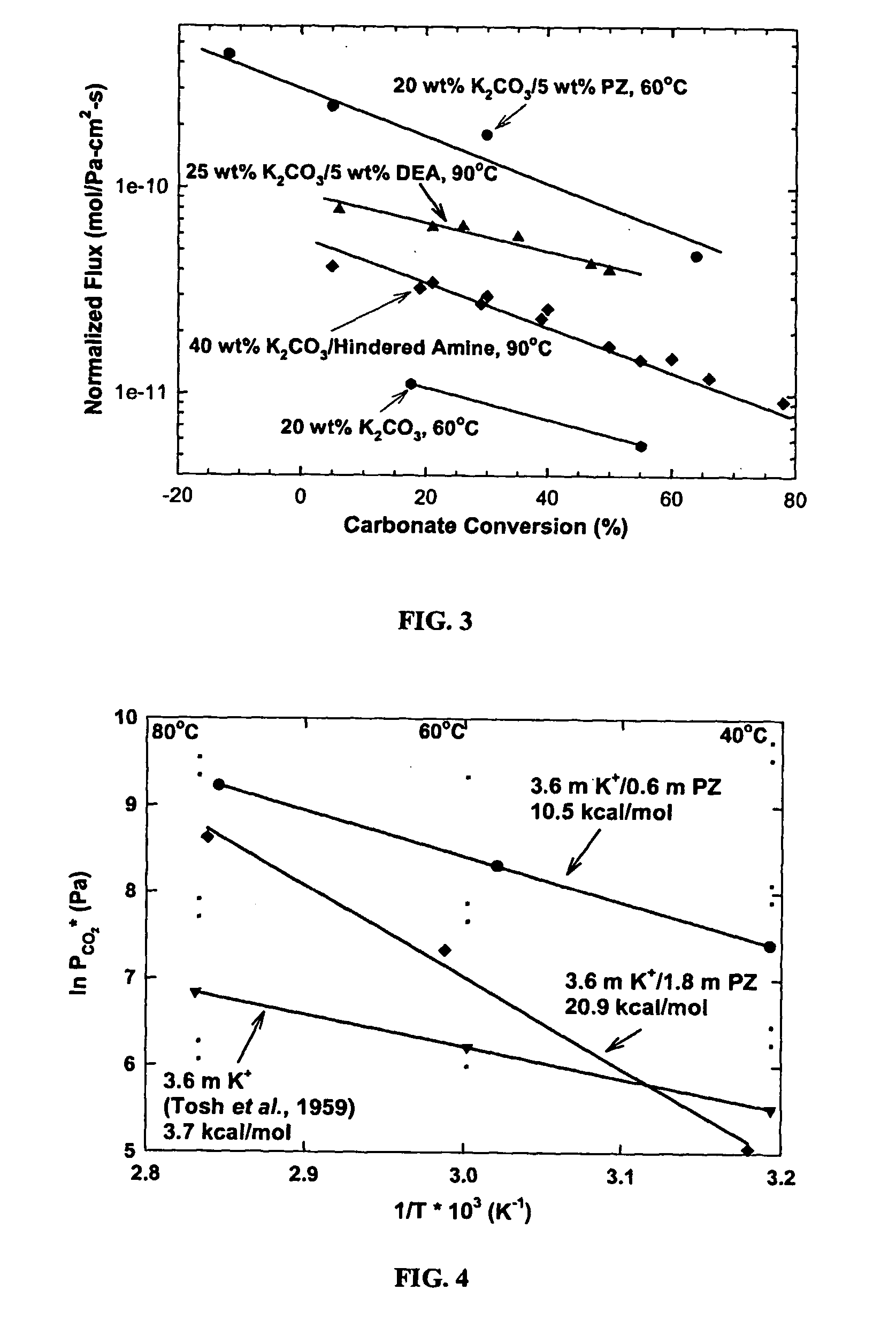

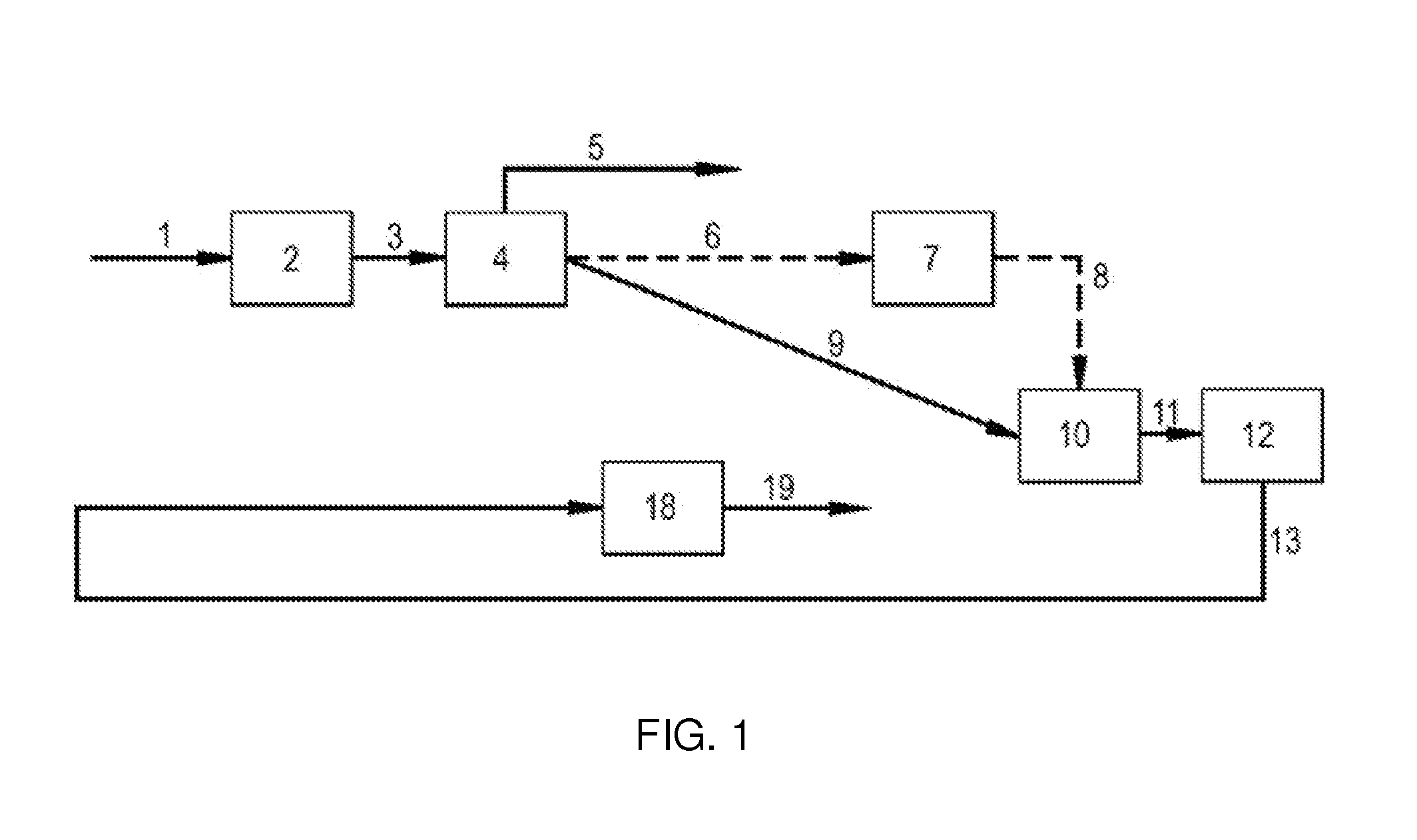

Novel solvents and methods of use for the removal of CO2 from flue gas, natural gas, hydrogen gas, synthesis gas, and other process and waste gas streams are provided. The solvent contains an alkali salt such as potassium carbonate and a polyamine such as piperazine (PZ) where the polyamine concentration is at least 1.5 equivalents / Kg H2O and the alkali salt concentration is at least 0.5 equivalents / Kg H2O. The preferred alkali salt / polyamine ratio is from approximately 1:2 to 2:1, and no additional alcohol is required for solubilizng the PZ. This chemical solvent and method of use provides efficient and effective removal of CO2 from gaseous streams and other sources.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Process for producing hydrocarbons from syngas

The invention pertains to a lean process for the production of hydrocarbons in which a tail gas is subjected to shift conversion, carbon dioxide removal, and then to purification in a PSA to obtain a hydrogen stream comprising more than 99 vol % hydrogen. The Fischer Tropsch process is a single-stage process. The hydrogen stream can be used to upgrade the Fischer-Tropsch hydrocarbons.

Owner:SHELL OIL CO

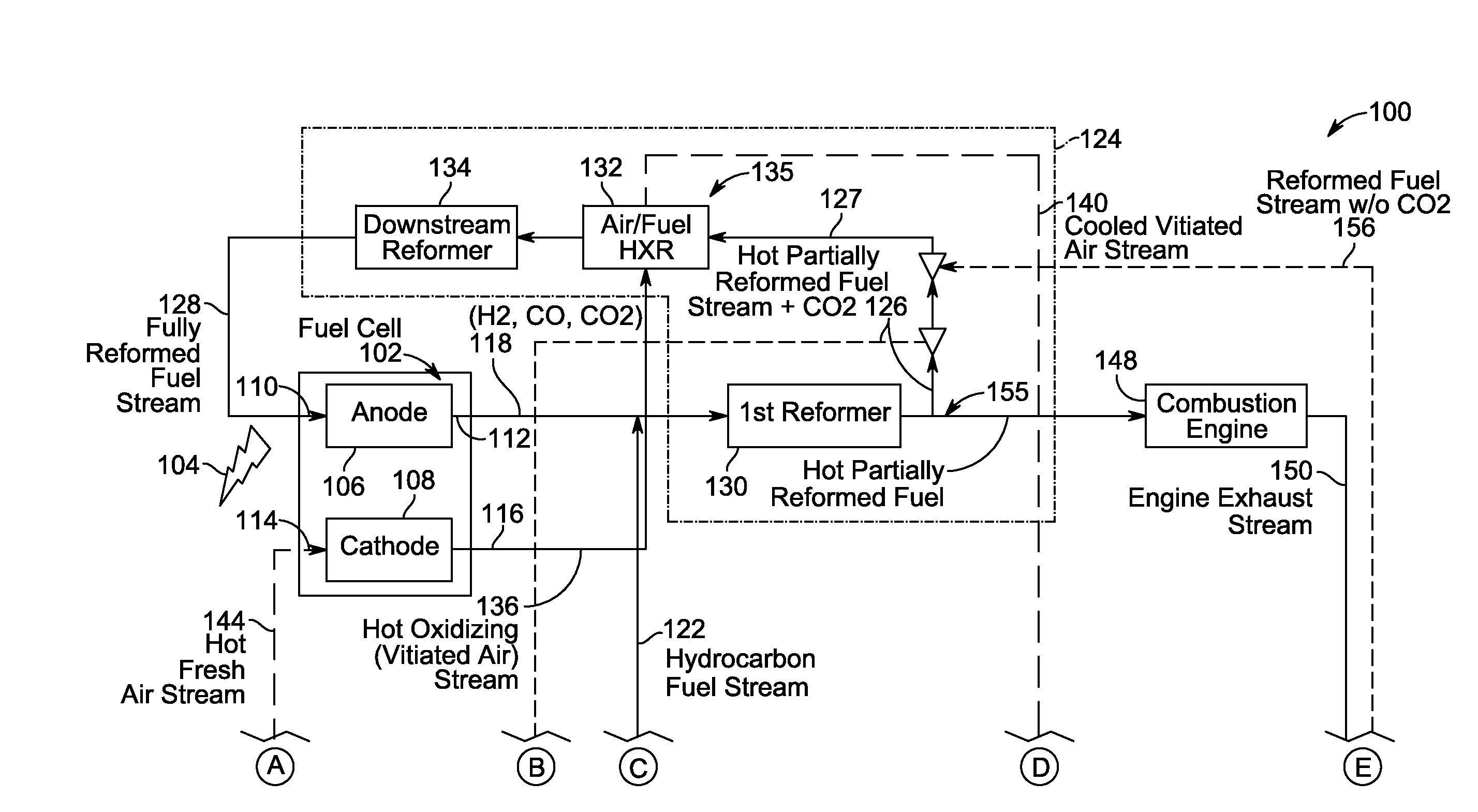

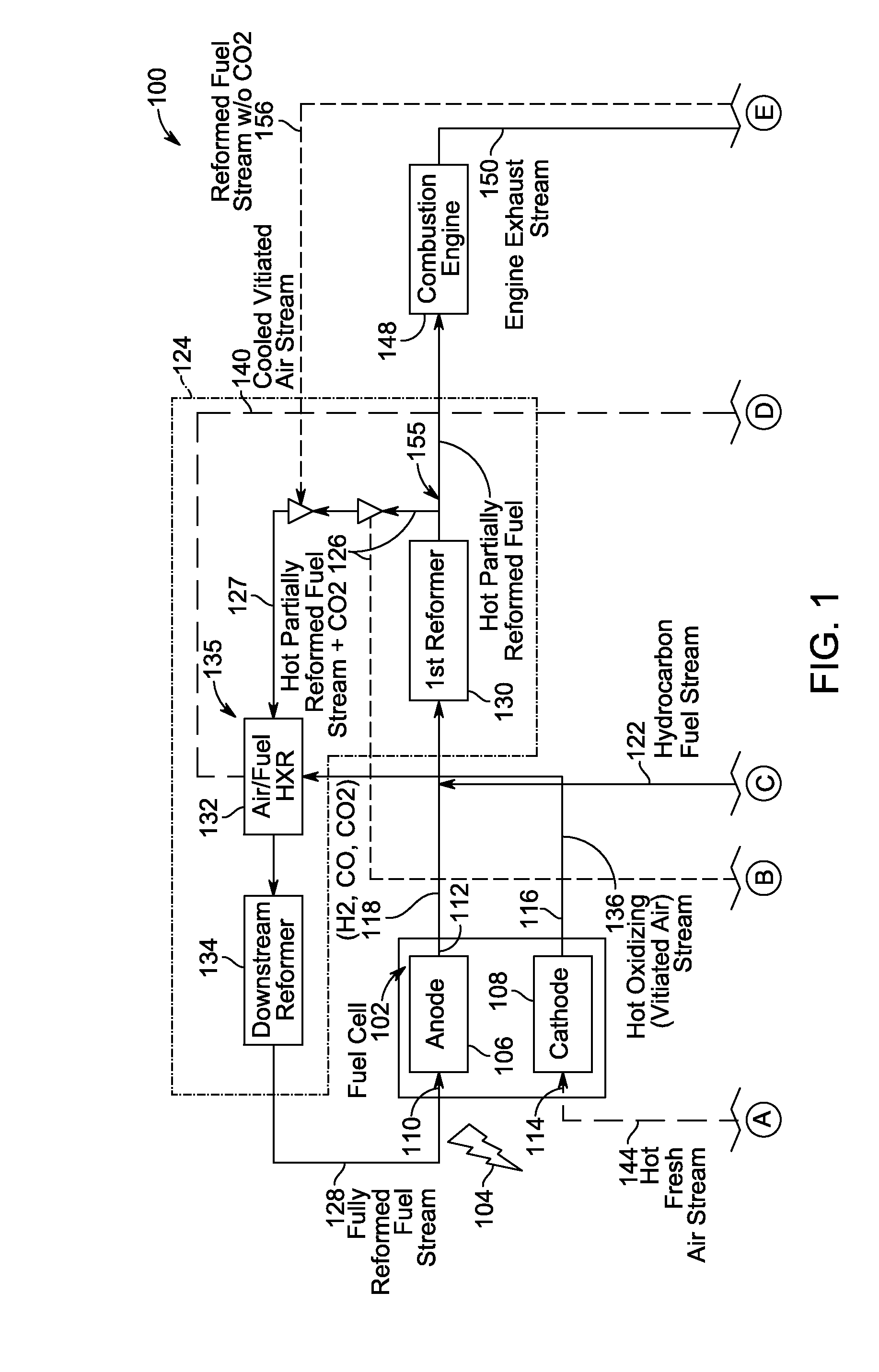

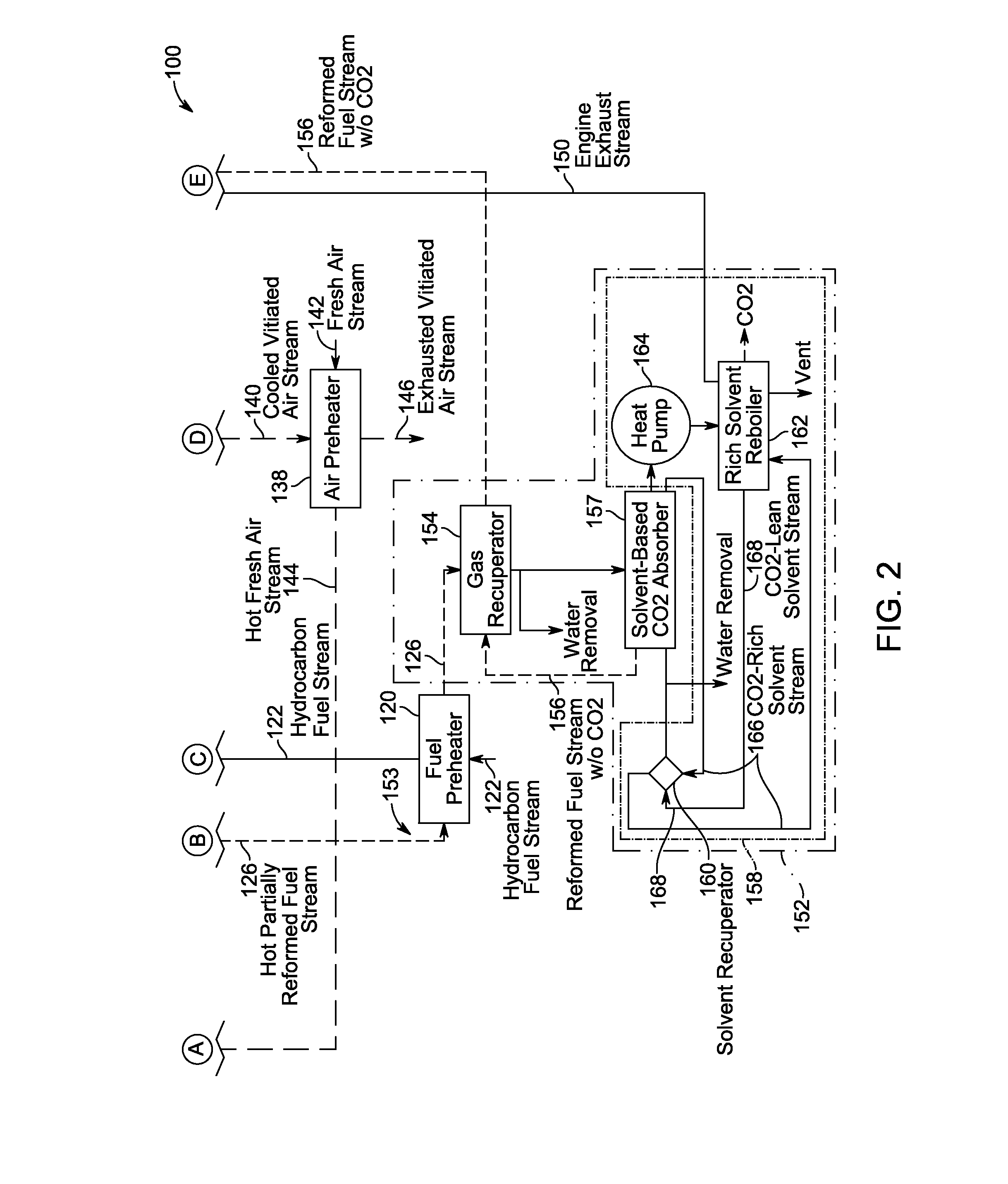

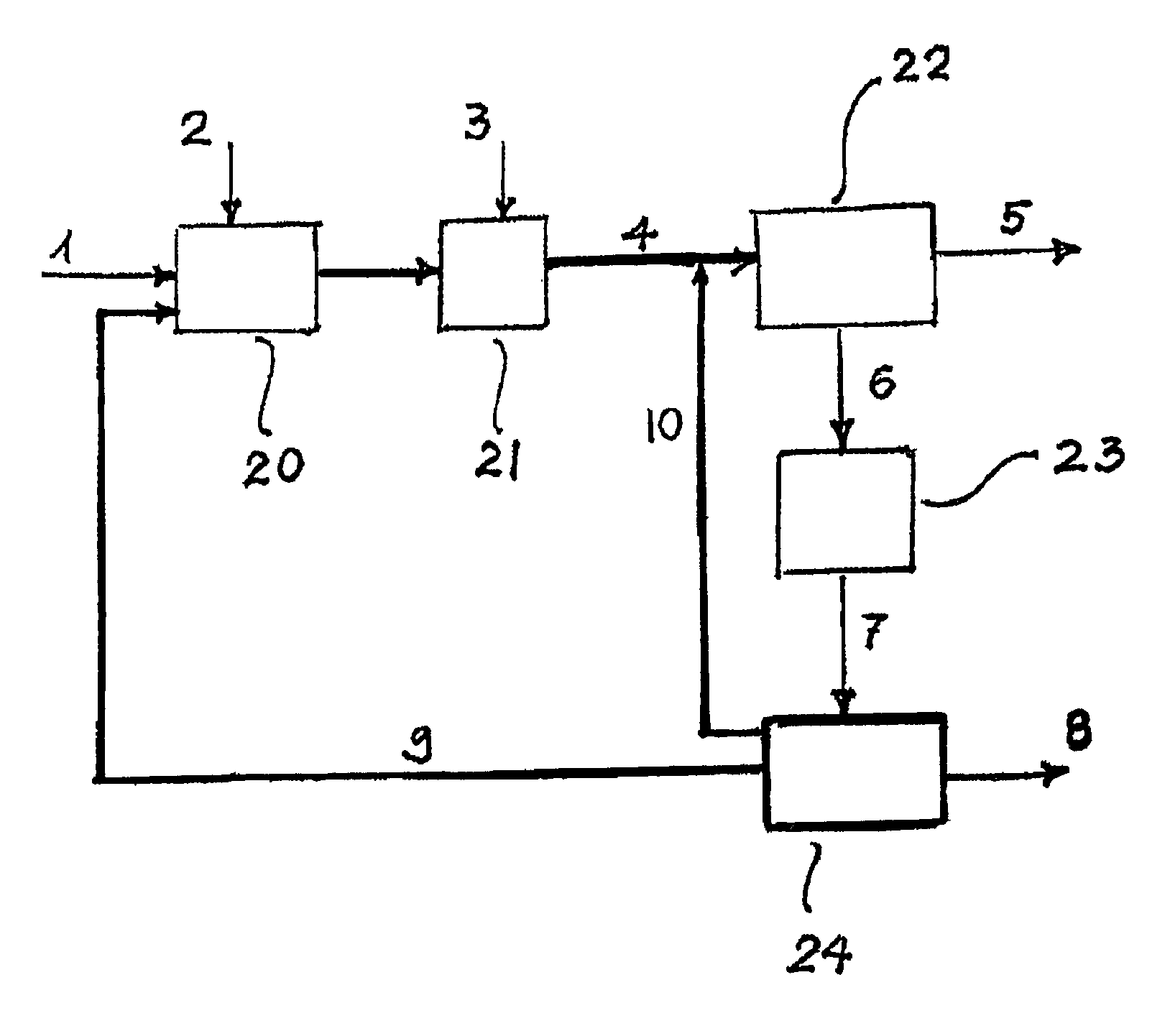

Fuel cell reforming system with carbon dioxide removal

A power generation system includes a fuel cell including an anode that generates a tail gas. The system also includes a hydrocarbon fuel reforming system that mixes a hydrocarbon fuel with the fuel cell tail gas and to convert the hydrocarbon fuel and fuel tail gas into a reformed fuel stream including CO2. The reforming system further splits the reformed fuel stream into a first portion and a second portion. The system further includes a CO2 removal system coupled in flow communication with the reforming system. The system also includes a first reformed fuel path coupled to the reforming system. The first path channels the first portion of the reformed fuel stream to an anode inlet. The system further includes a second reformed fuel path coupled to the reforming system. The second path channels the second portion of the reformed fuel stream to the CO2 removal system.

Owner:CUMMINS ENTERPRISE LLC

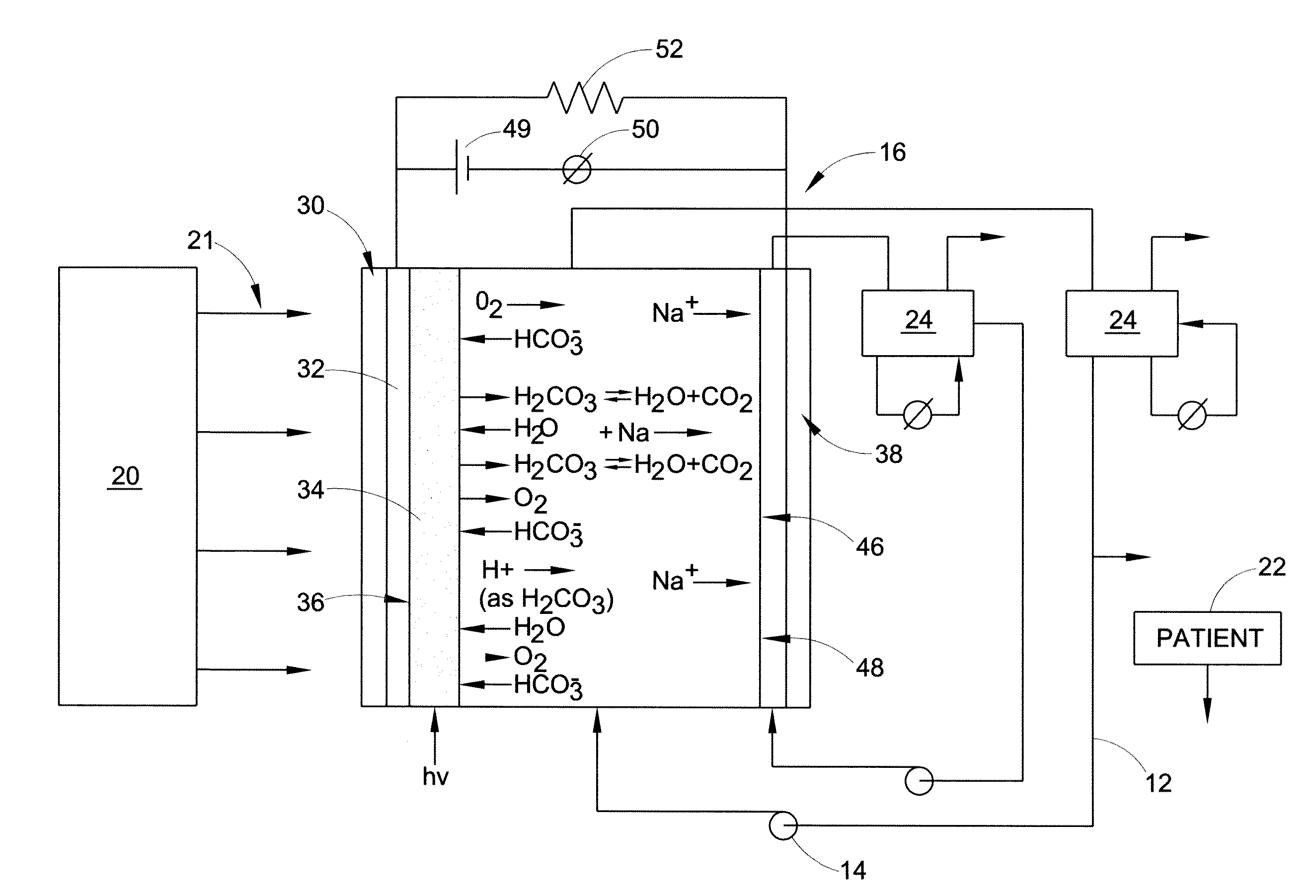

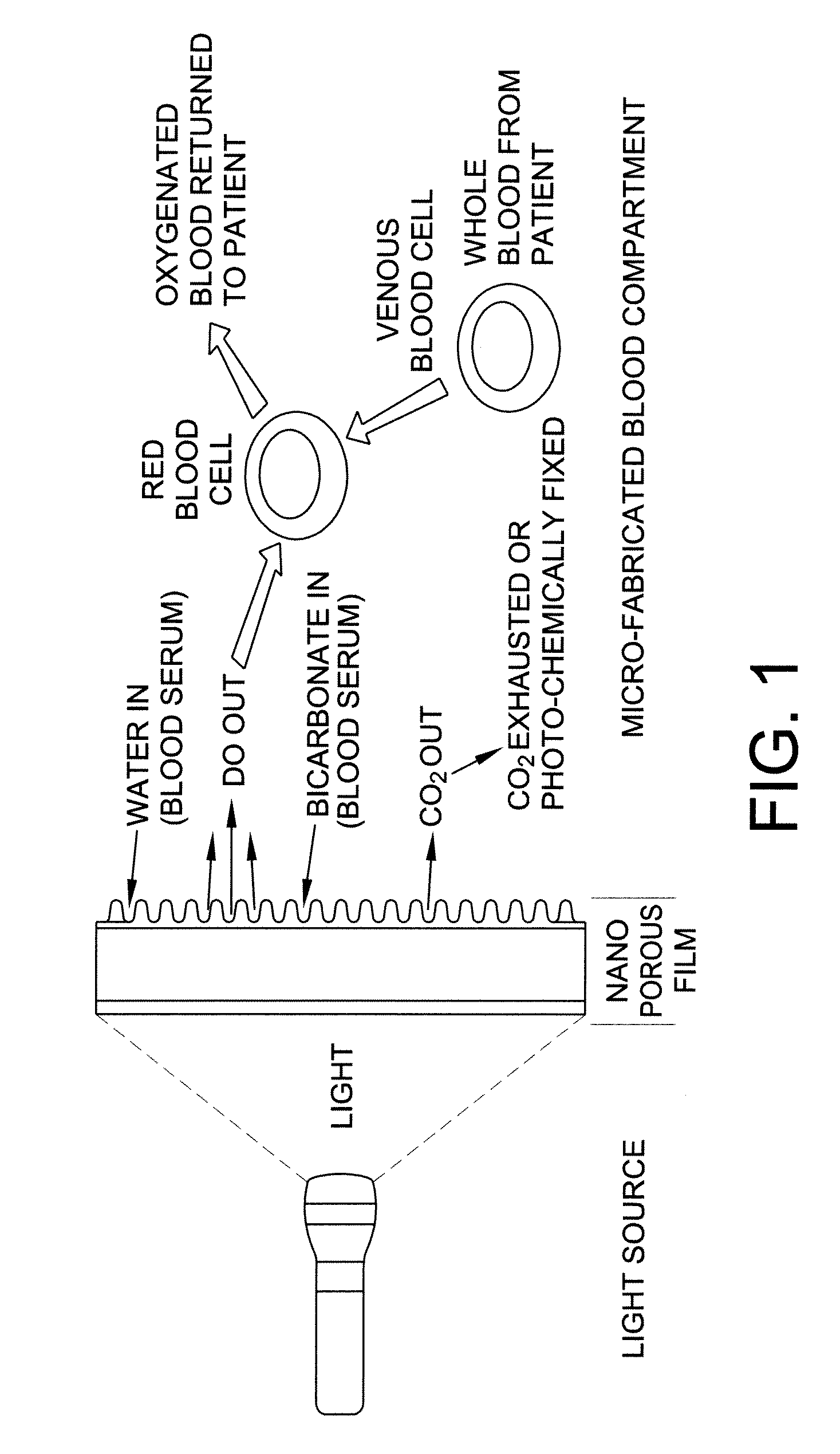

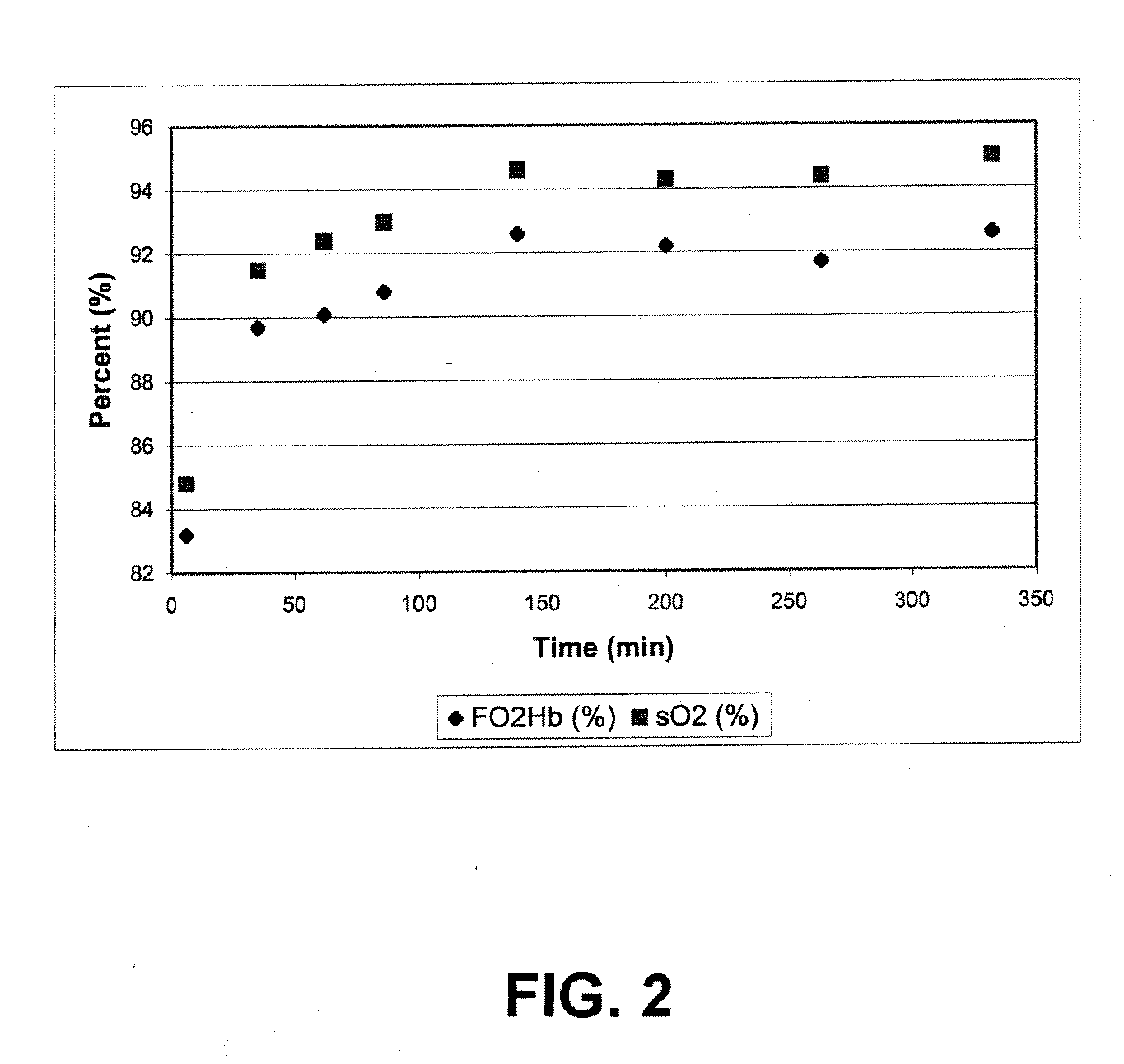

Carbon dioxide removal from whole blood by photolytic activation

Apparatus and methods for removing carbon dioxide from whole blood. Hydrogen ions are generated from water in the blood, resulting in the formation and release of carbon dioxide from the blood.

Owner:BATTELLE MEMORIAL INST

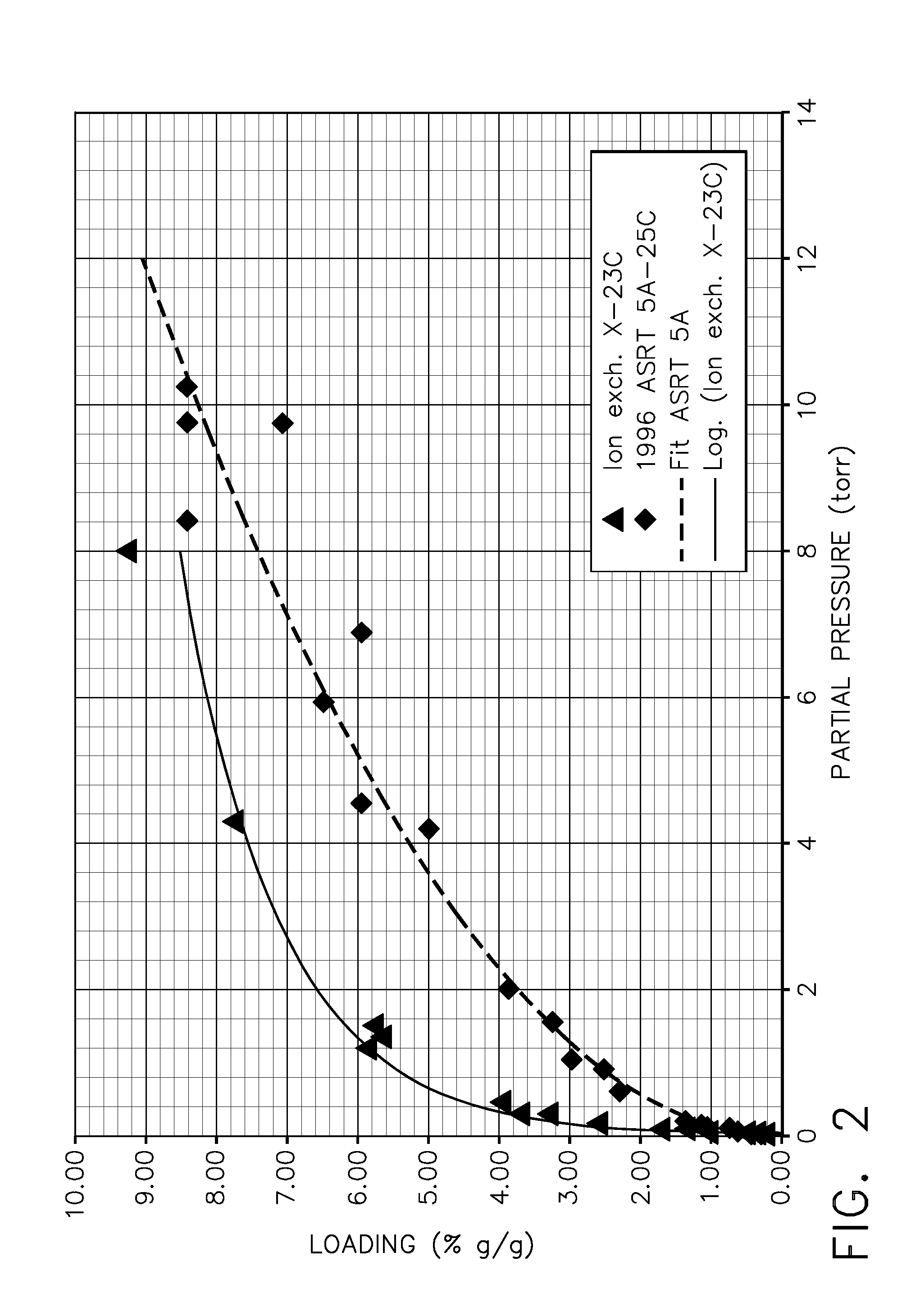

Lithium-exchanged faujasites for carbon dioxide removal

A process for removal of carbon dioxide from air using lithium-exchanged X-zeolites at low carbon dioxide partial pressures is provided. The process is particularly useful in applications where fresh air is not available and exhaled air needs to be recycled. An apparatus for carrying out the process is also provided.

Owner:HONEYWELL INT INC

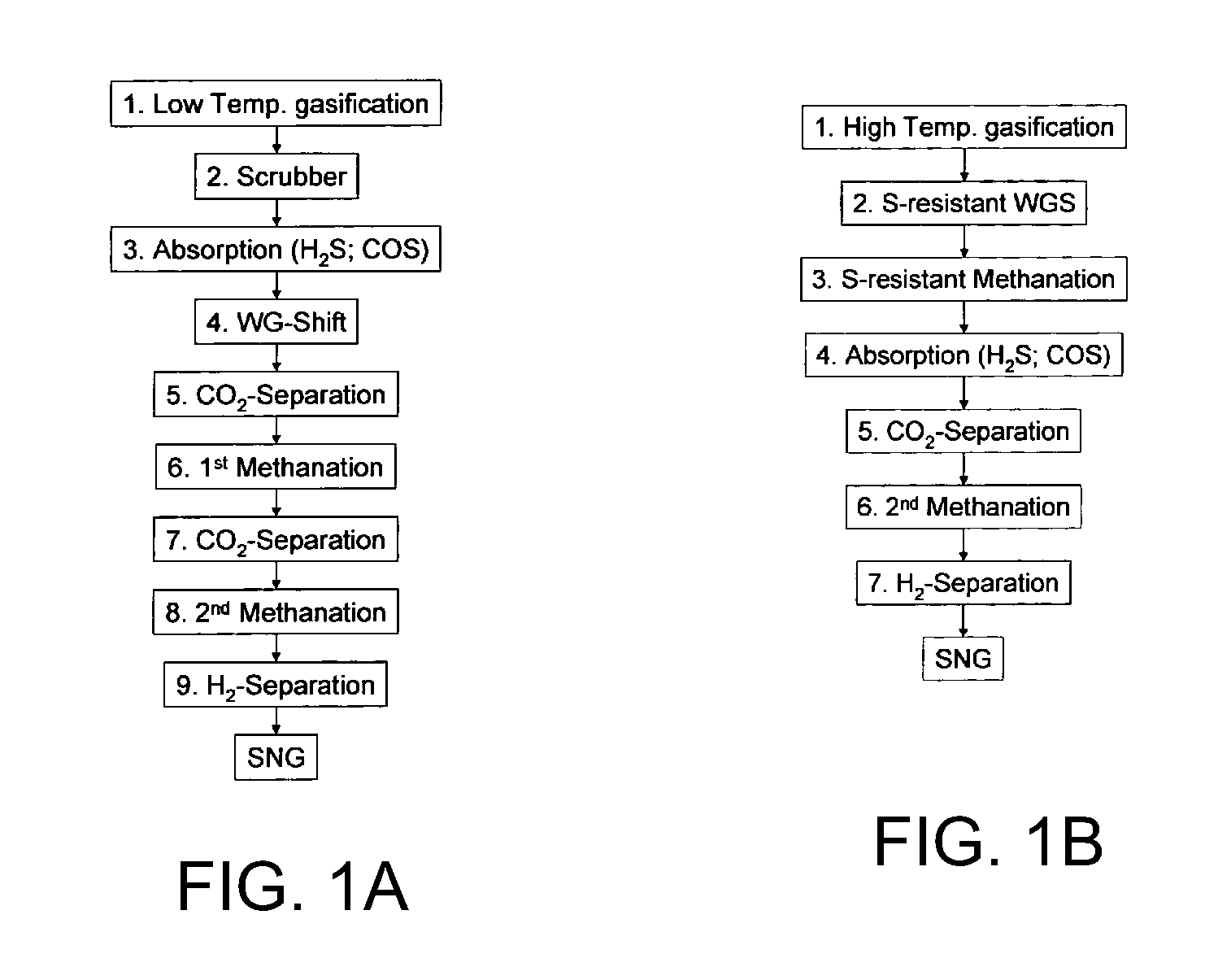

Process for the production of substitute natural gas

InactiveUS20100286292A1Quality improvementHydrocarbon from carbon oxidesOrganic compound preparationMethanationProcess engineering

Process for the production of substitute natural gas (SNG) by the methanation of a synthesis gas derived from the gasification of a carbonaceous material together with water gas shift and carbon dioxide removal thereby producing a synthesis gas with a molar ratio (H2—CO2) / (CO+CO2) greater than 3.00. At the same time, a gas with a molar ratio (H2—CO2) / (CO+CO2) lower than 3.00 is added to the methanation section. The final product (SNG) is of constant high quality without excess of carbon dioxide and hydrogen.

Owner:HALDOR TOPSOE AS

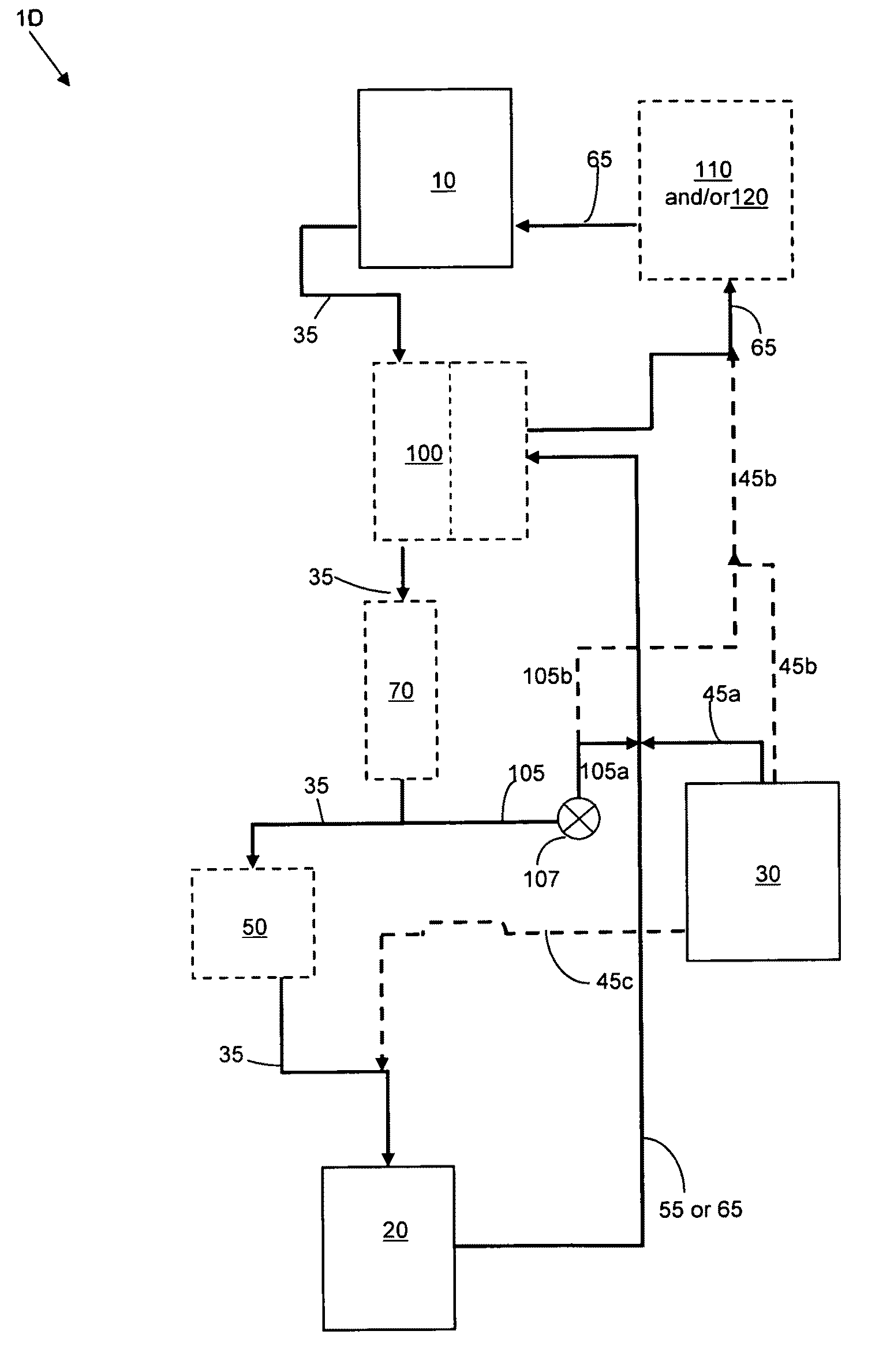

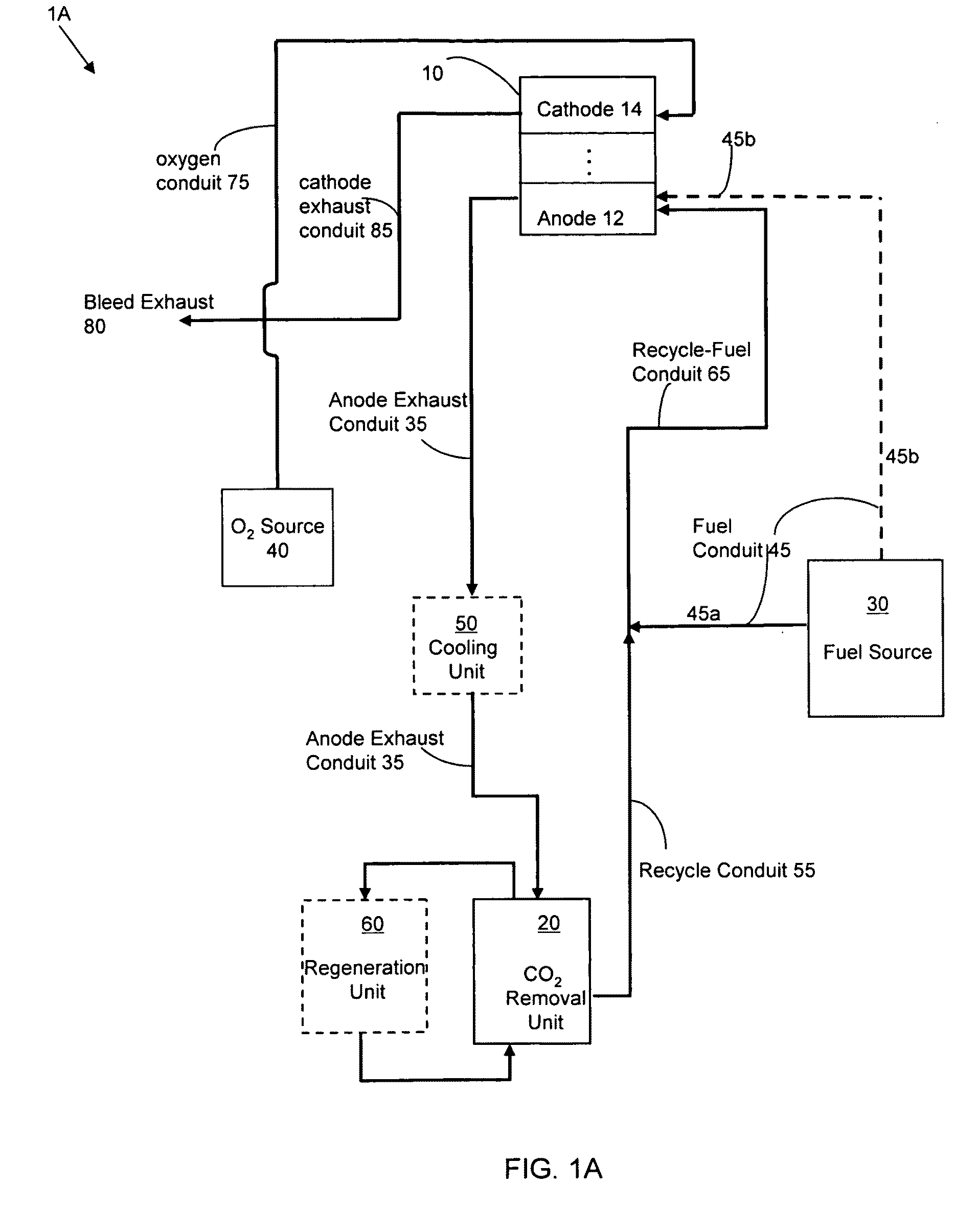

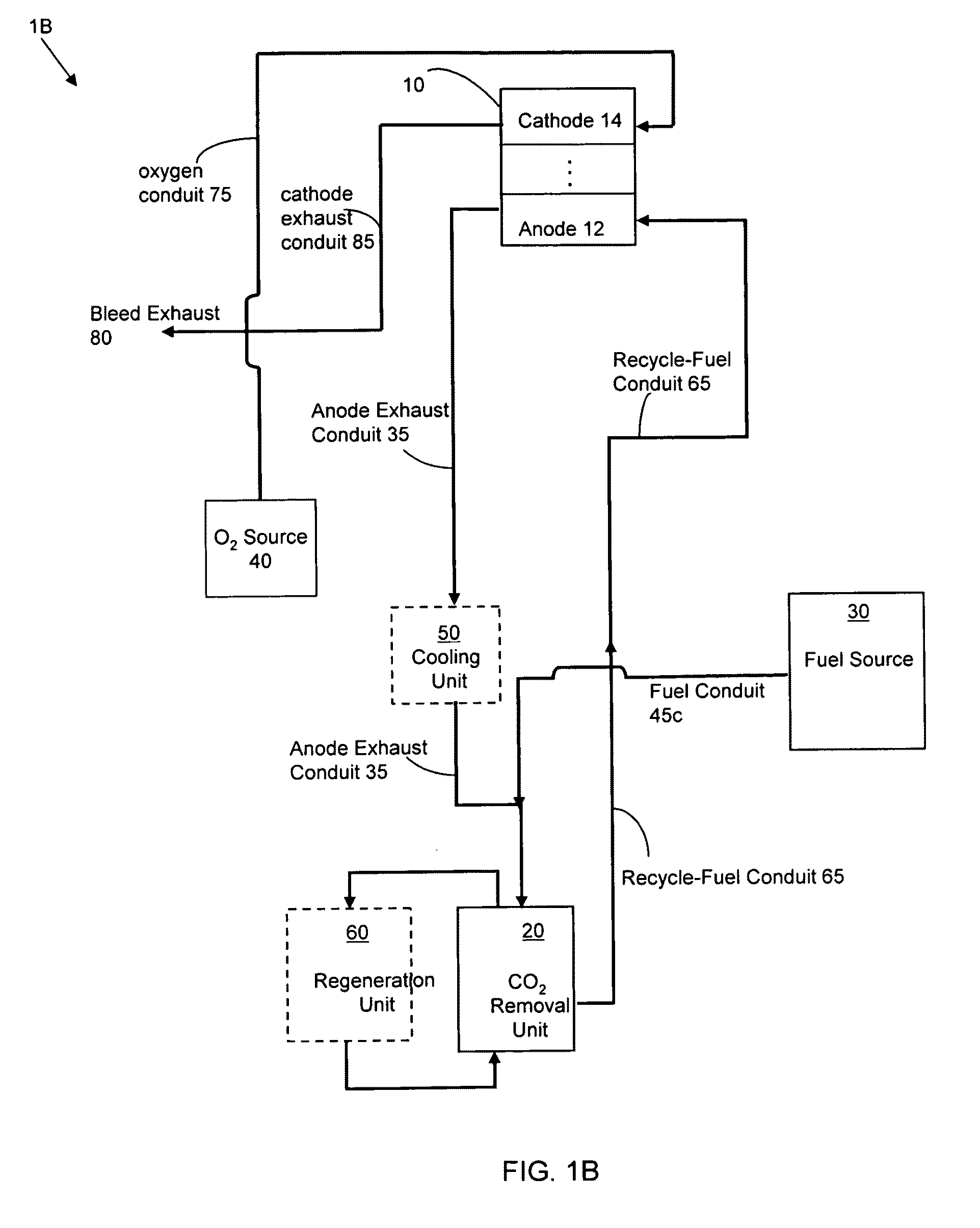

Fuel cell system

InactiveUS20090169931A1Improve system efficiencyHigh fuel concentrationGas treatmentFuel cell heat exchangeFuel cellsGas phase

A fuel cell system comprises a fuel cell assembly, a carbon-dioxide-removal unit, an anode exhaust conduit connecting the fuel cell assembly and the carbon-dioxide-removal unit, a fuel source, an oxygen source, a fuel conduit connecting, at least in part, the fuel source with the fuel cell assembly, and a recycle conduit connecting the carbon-dioxide-removal unit with at least one of the fuel cell assembly, the fuel conduit and the fuel source. The fuel cell assembly includes at least one fuel cell, each fuel cell including an anode and a cathode. The carbon-dioxide-removal unit removes carbon dioxide that is in a gas phase. The carbon-dioxide-removal unit includes a carbon-dioxide-removing material. The fuel source and the oxygen source are each independently in fluid communication with the fuel cell assembly. The fuel conduit and the recycle conduit are optionally merged into a single recycle-fuel conduit that extends to the fuel cell assembly. The recycle conduit and / or the recycle-fuel conduit directs essentially all gaseous fluid from the carbon-dioxide-removal unit to the fuel cell assembly.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

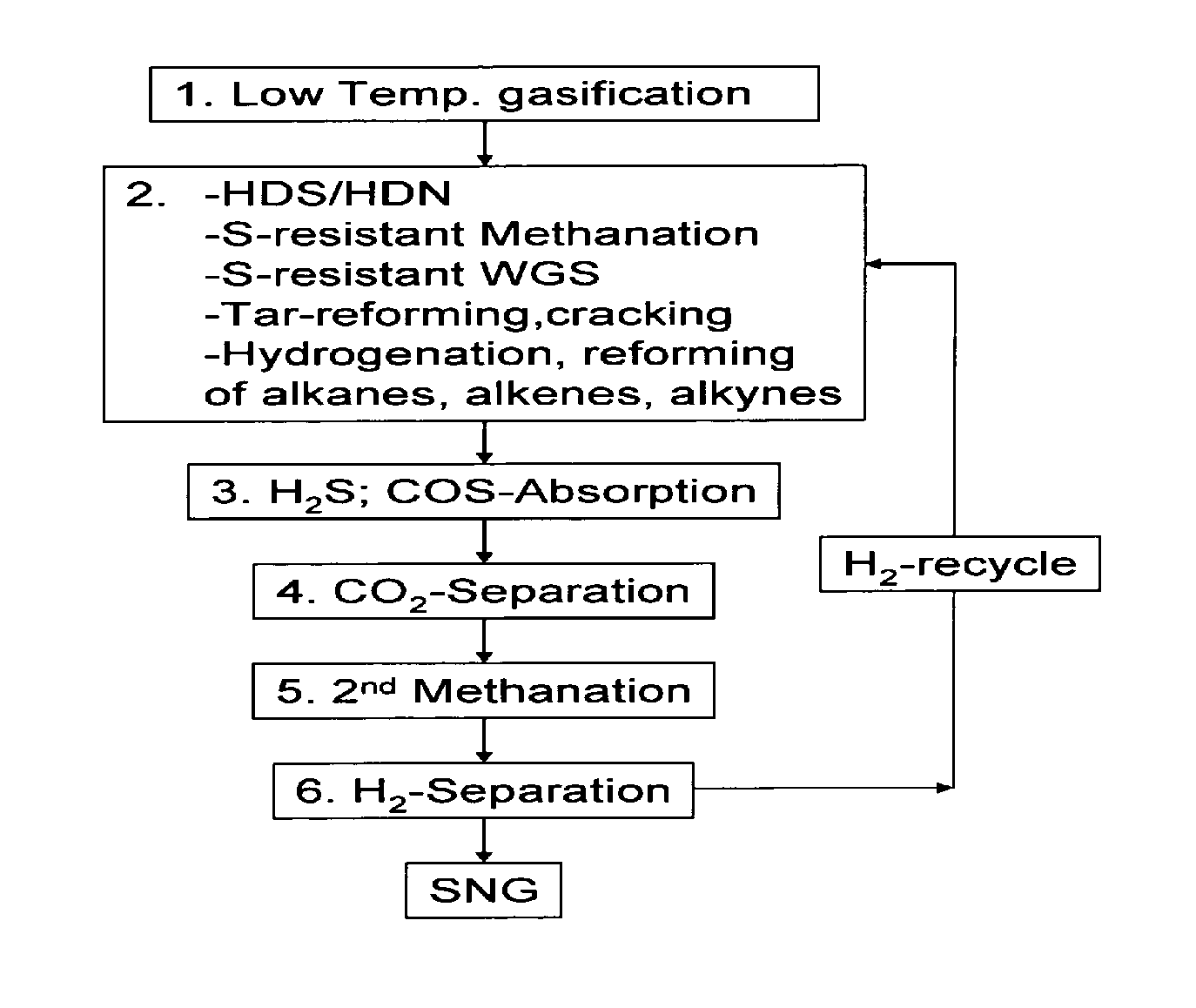

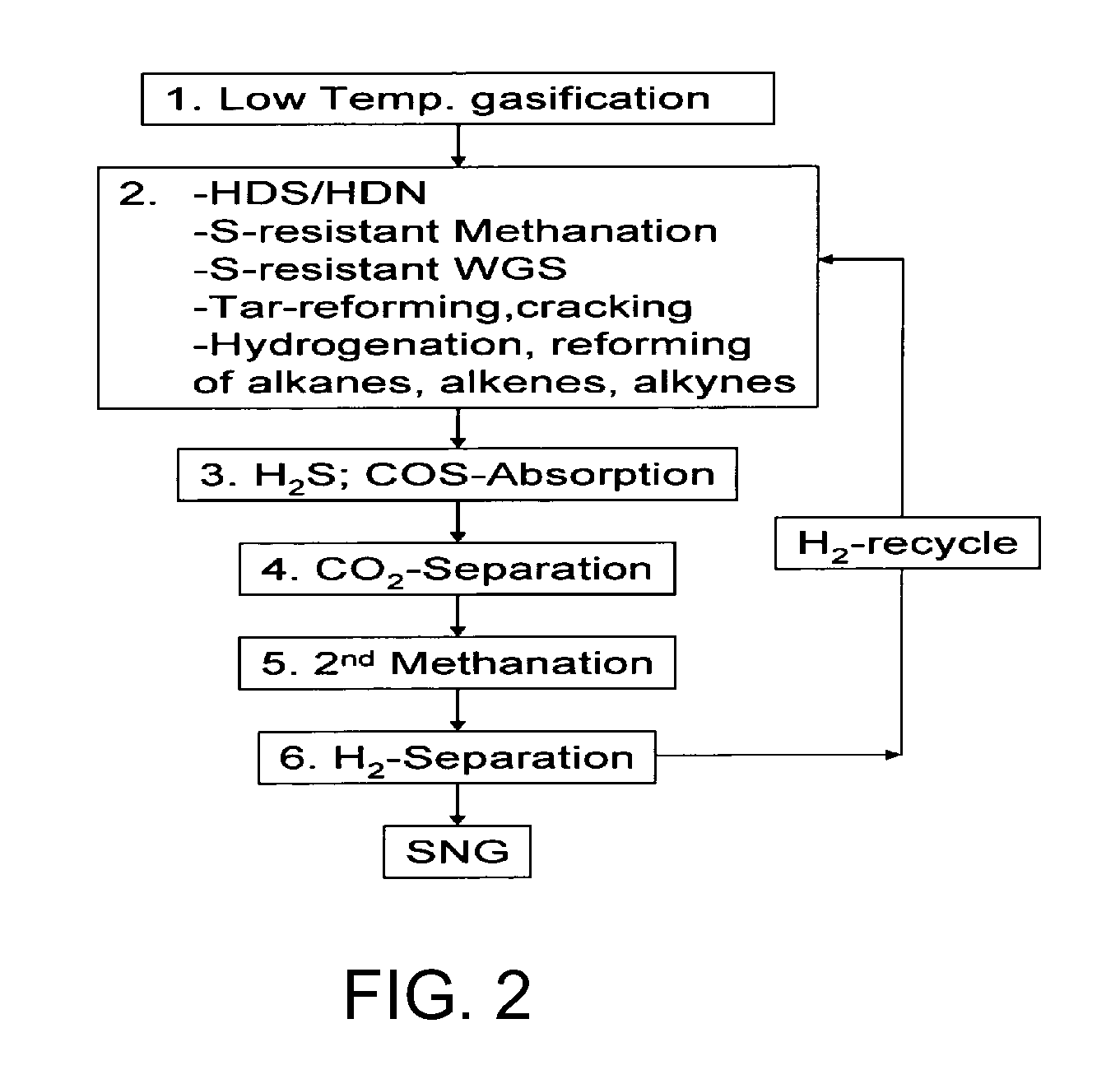

Process to Produce a Methane Rich Gas Mixture From Gasification Derived Sulphur Containing Synthesis Gases

A method for converting a raw gas into a methane-rich and / or hydrogen-rich gas includes the following steps: a) providing the raw gas stemming from a coal and / or biomass gasification process, thereby the raw gas comprising beside a methane and hydrogen content carbon monoxide, carbon dioxide, alkanes, alkenes, alkynes, tar, especially benzole and naphthalene, COS, hydrogen sulfide and organic sulfur compounds, especially thiophenes; thereby the ratio of hydrogen to carbon monoxide ranges from 0.3 to 4; b) bringing this raw gas into contact with a catalyst in a fluidized bed reactor at temperatures above 200° C. and at pressures equal or greater than 1 bar in order to convert the raw gas into a first product gas, thereby simultaneously converting organic sulfur components into hydrogen sulfide, reform tars, generate water / gas shift reaction and generate methane from the hydrogen / carbon monoxide content; c) bringing the first product gas into a sulfur absorption process to generate a second product gas, thereby reducing the content of hydrogen sulfur and COS from 100 to 1000 ppm down to 1000 ppb or less; d) optionally bringing the second product gas into a carbon dioxide removal process to generate a third product gas at least almost free of carbon dioxide; e) bringing the third product gas into a second methanation process to generate a fourth product gas having a methane content above 5 vol %; f) optionally bringing the fourth product gas into a carbon dioxide removal process to generate a fifth product gas at least almost free of carbon dioxide g) bringing the fifth product gas into an hydrogen separation process in order to separate a hydrogen rich gas from a remaining methane-rich gas, called substitute natural gas.

Owner:PAUL SCHERRER INSTITUT

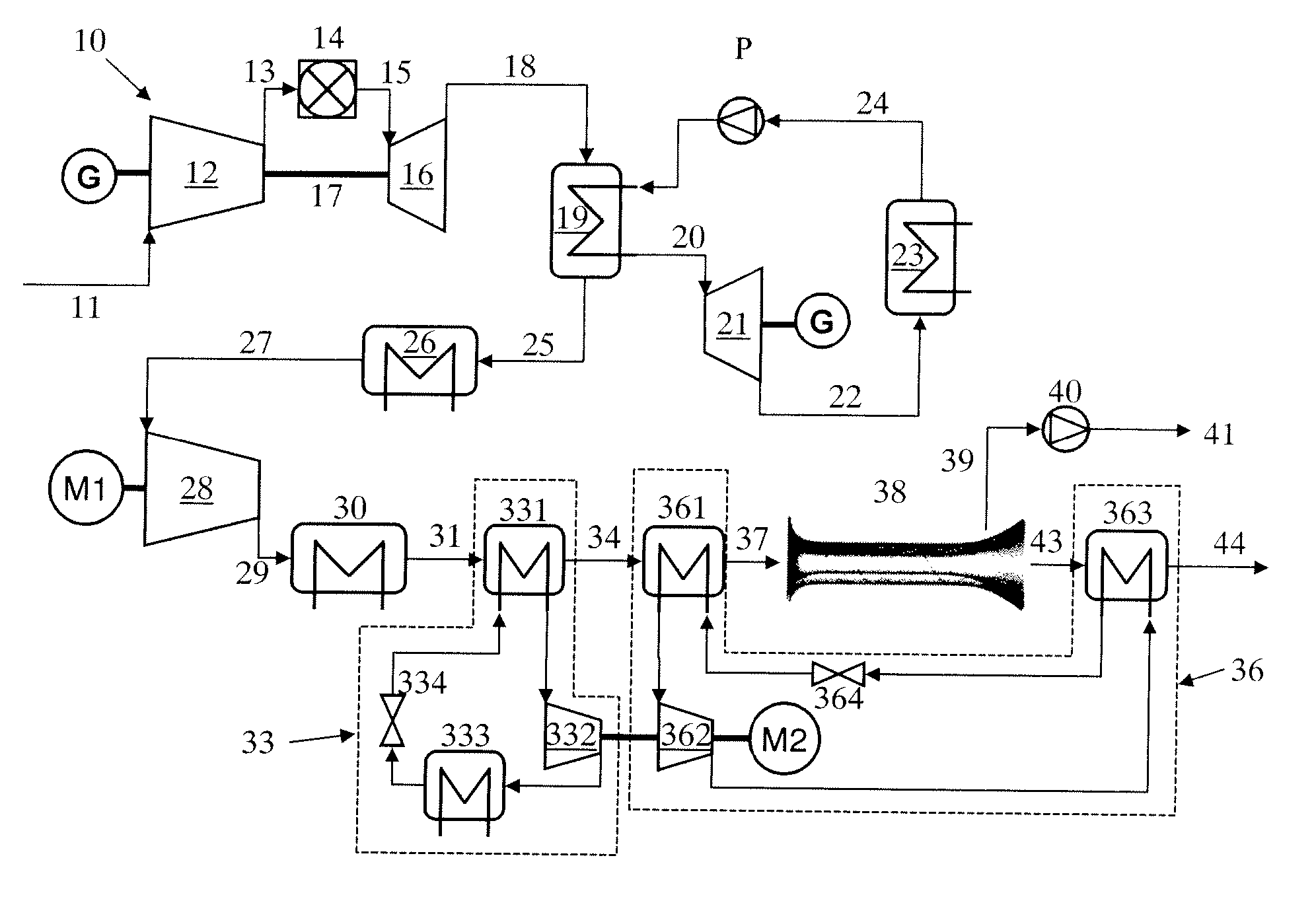

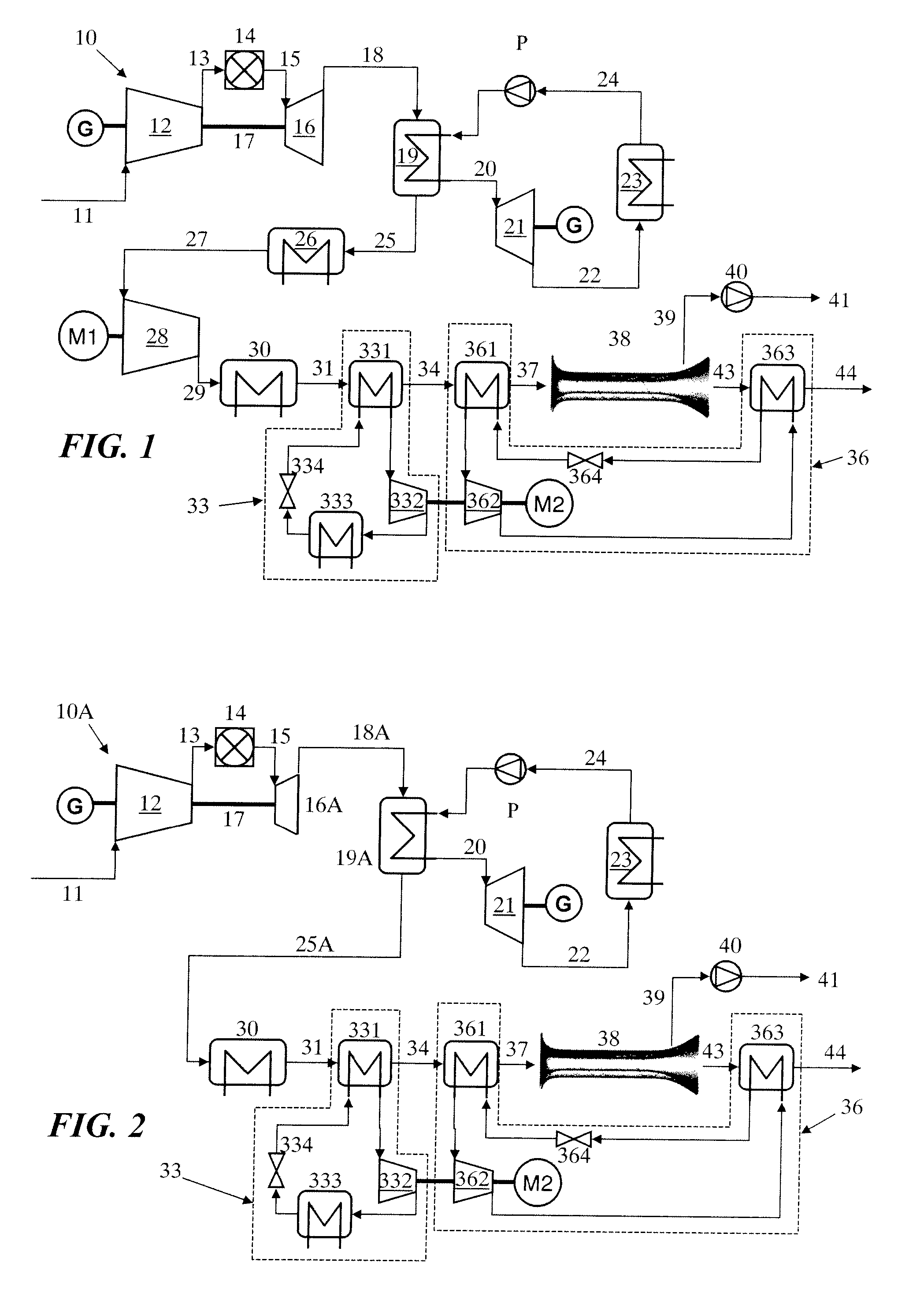

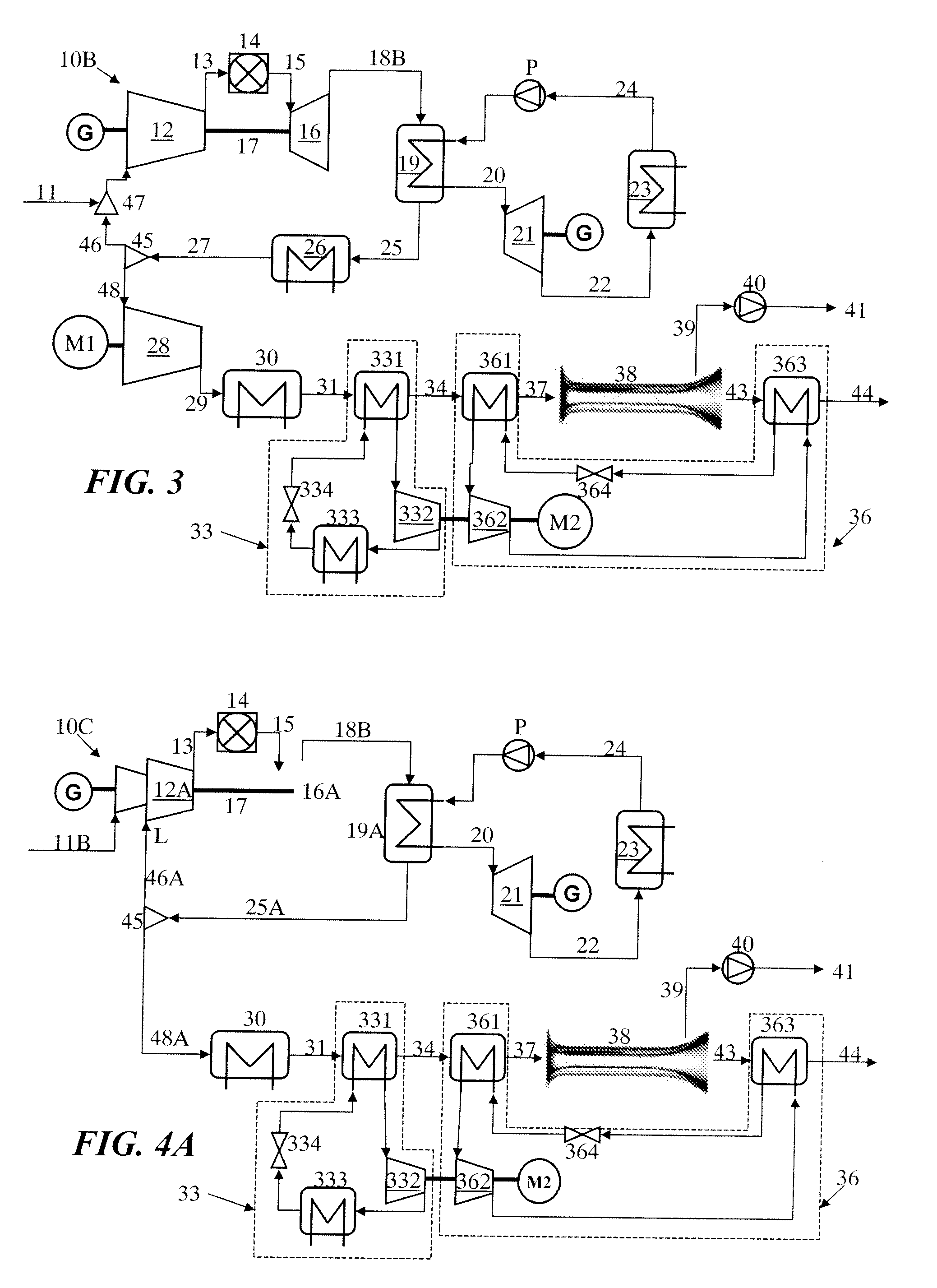

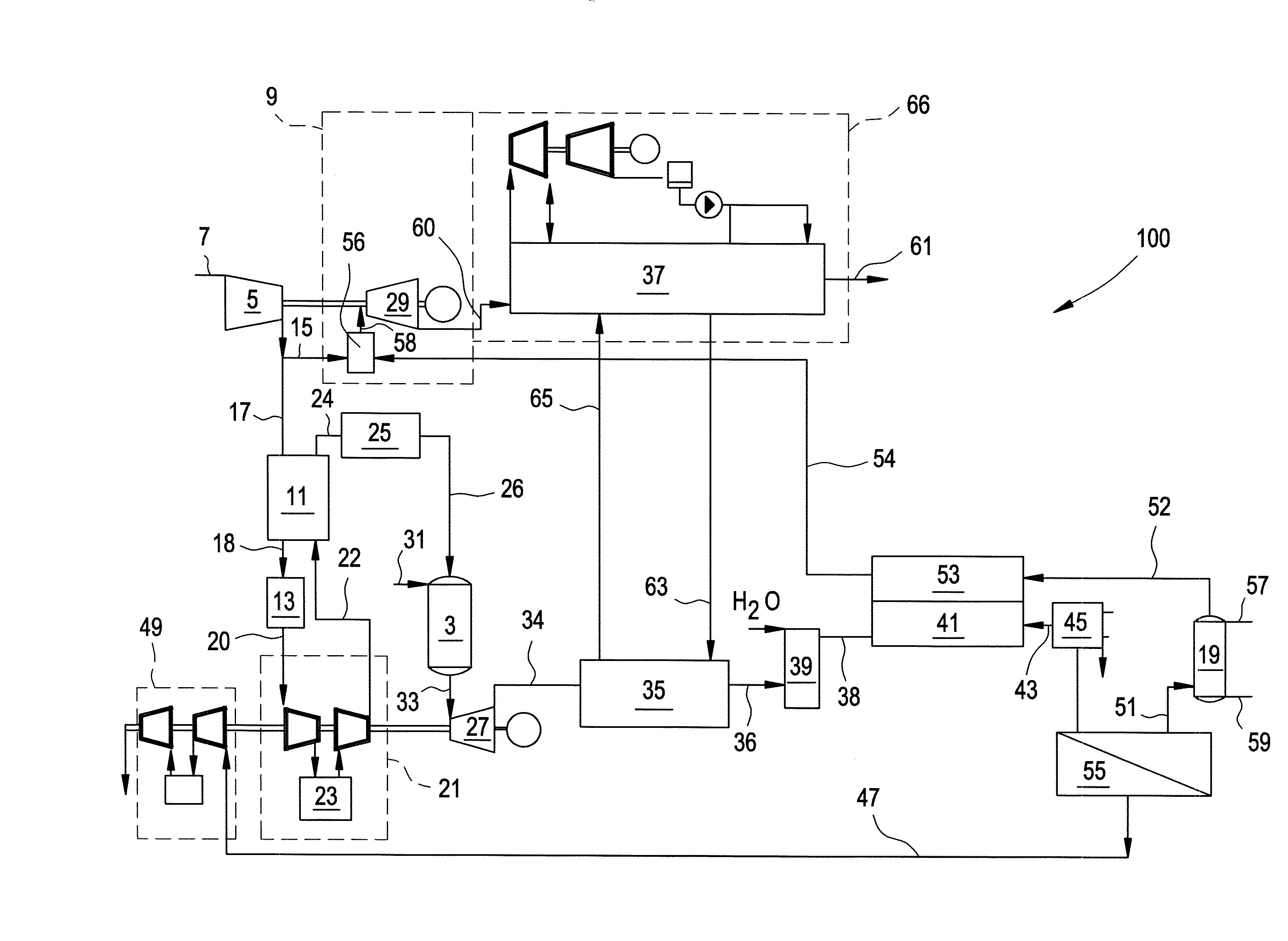

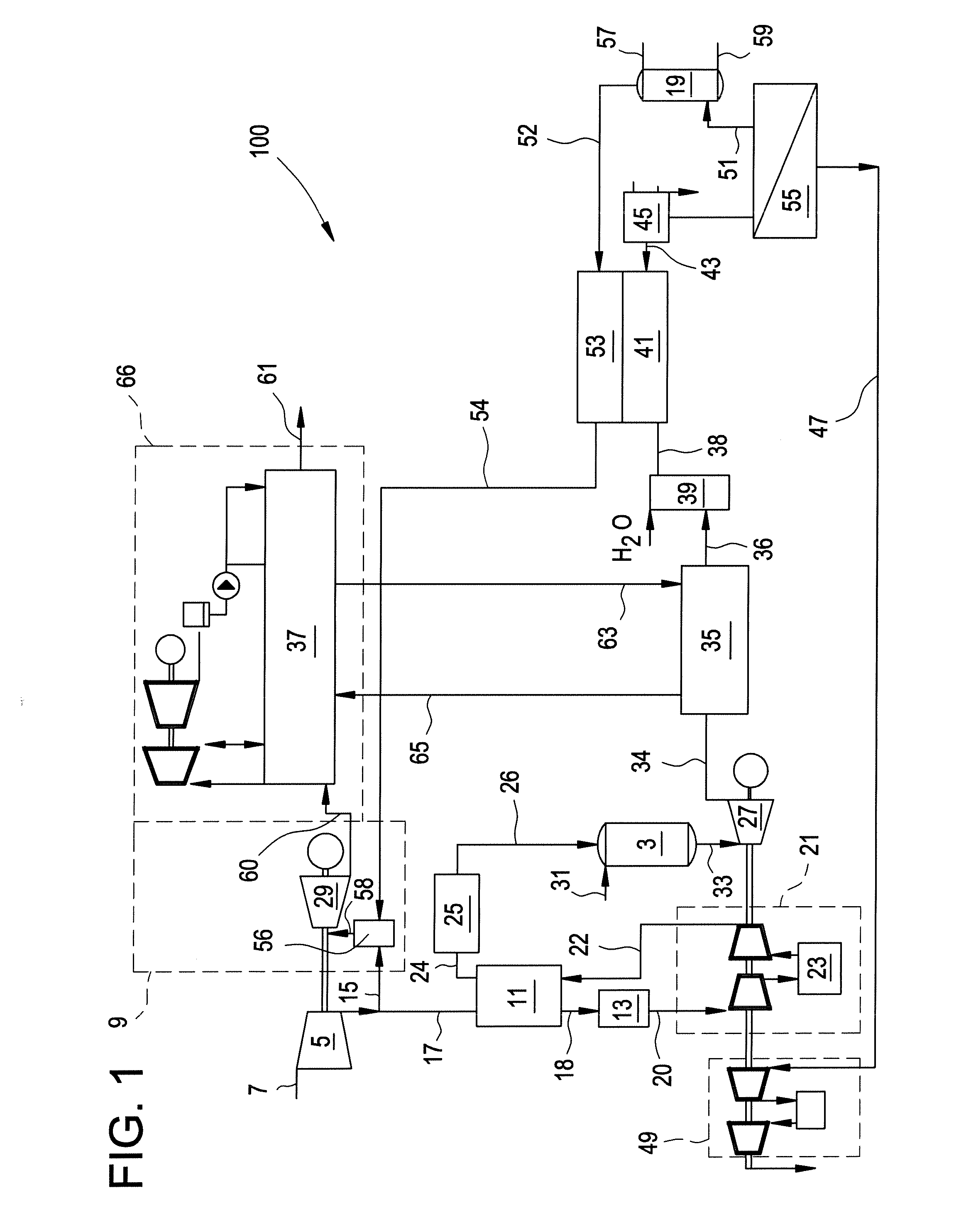

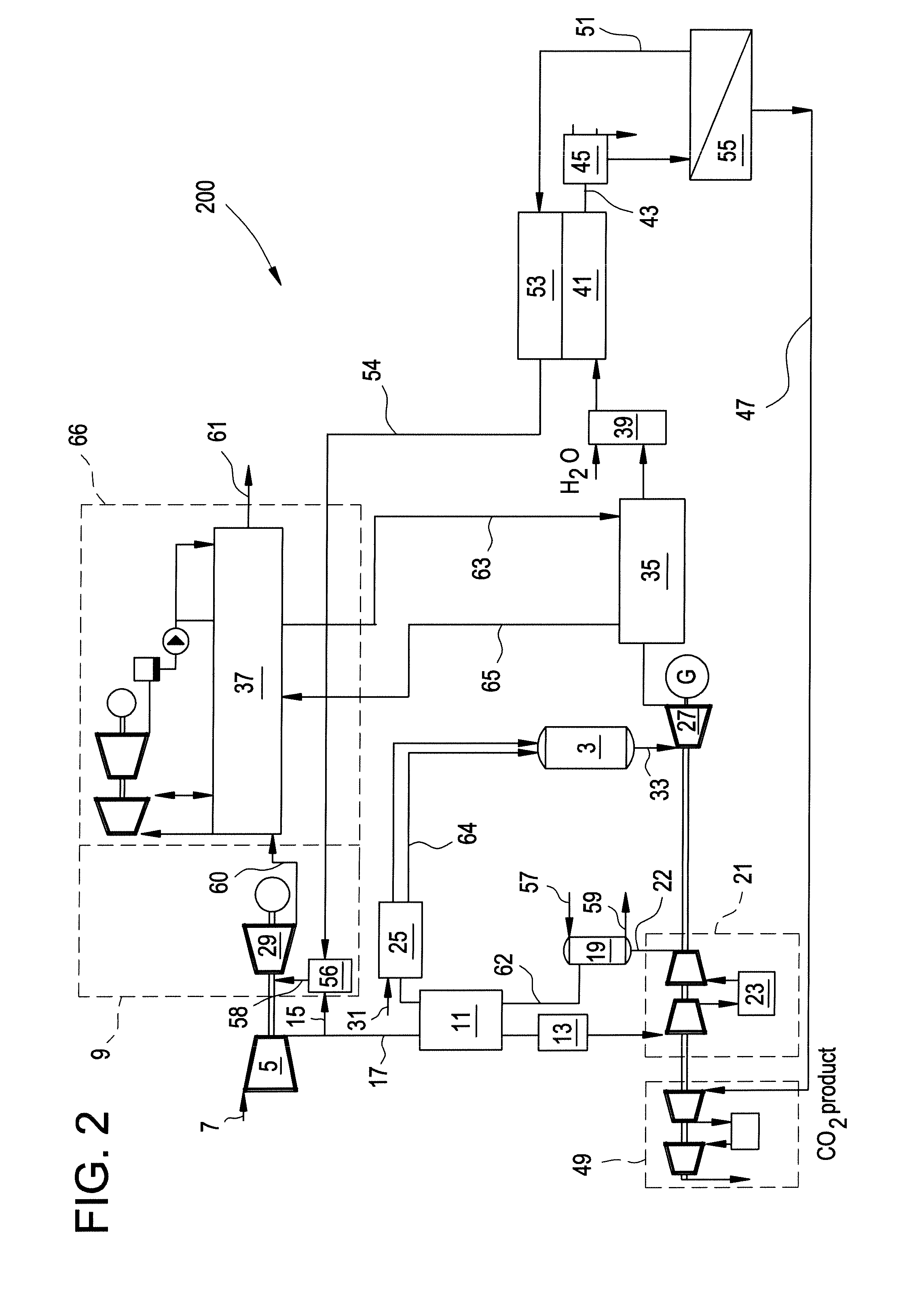

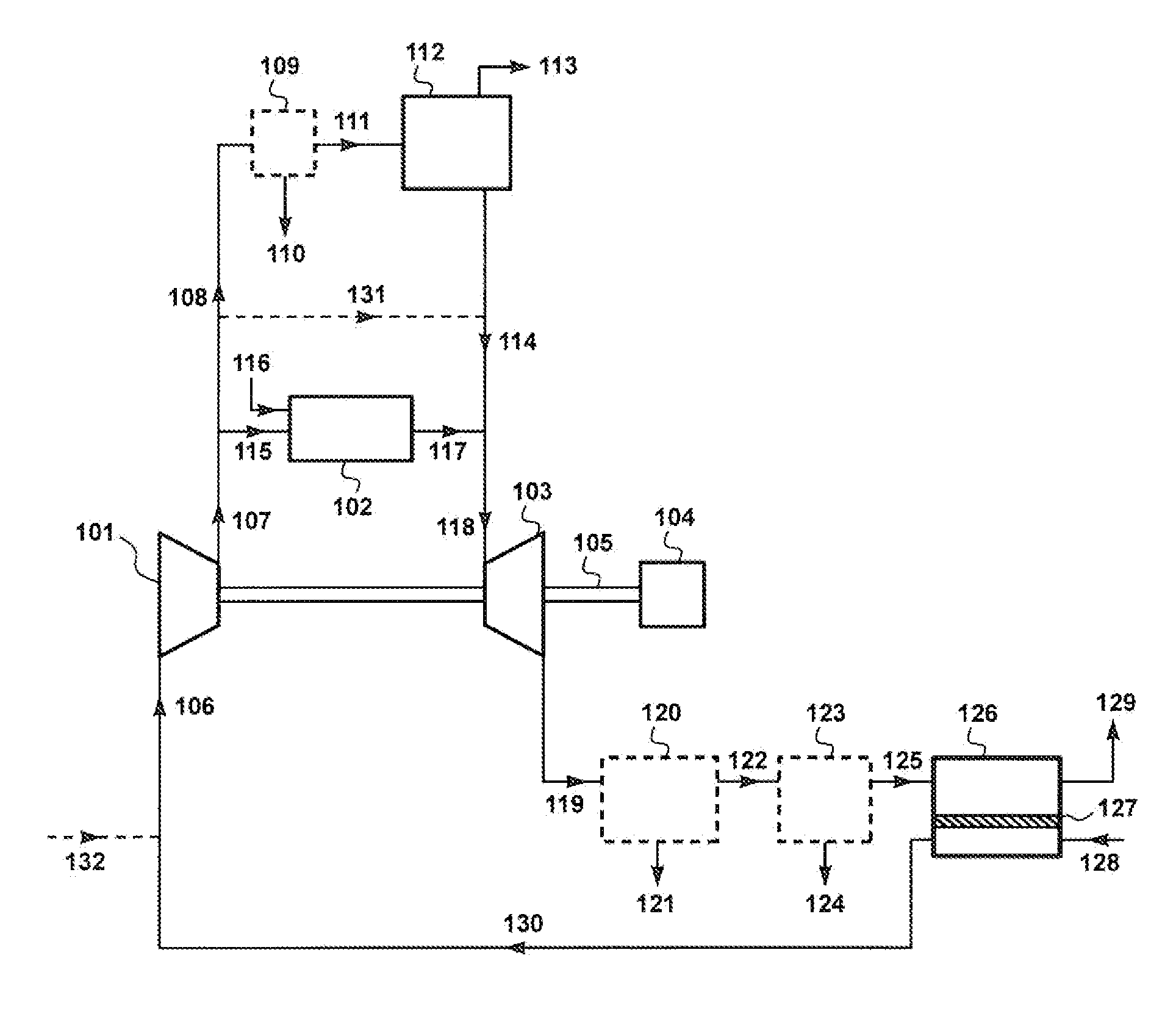

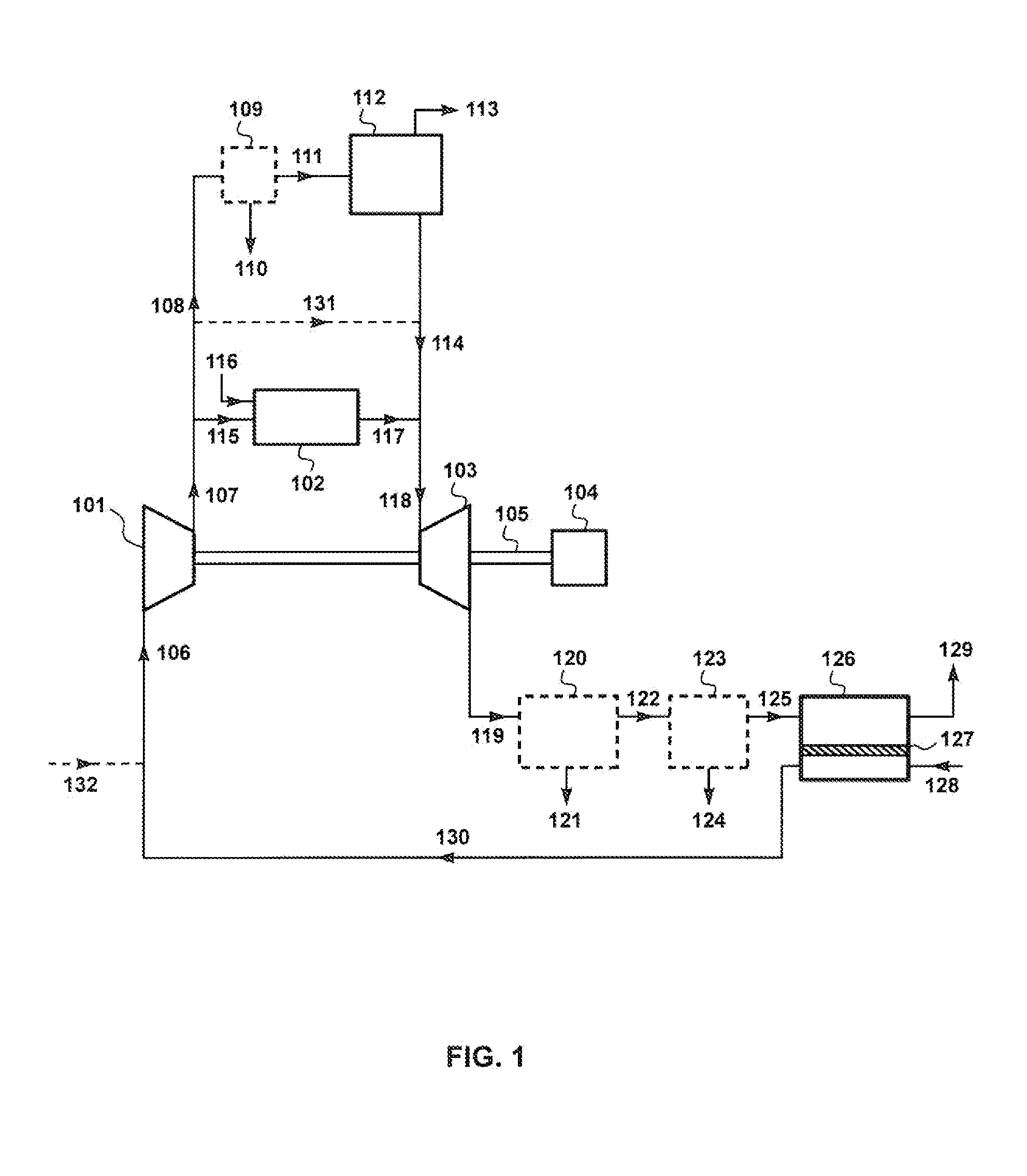

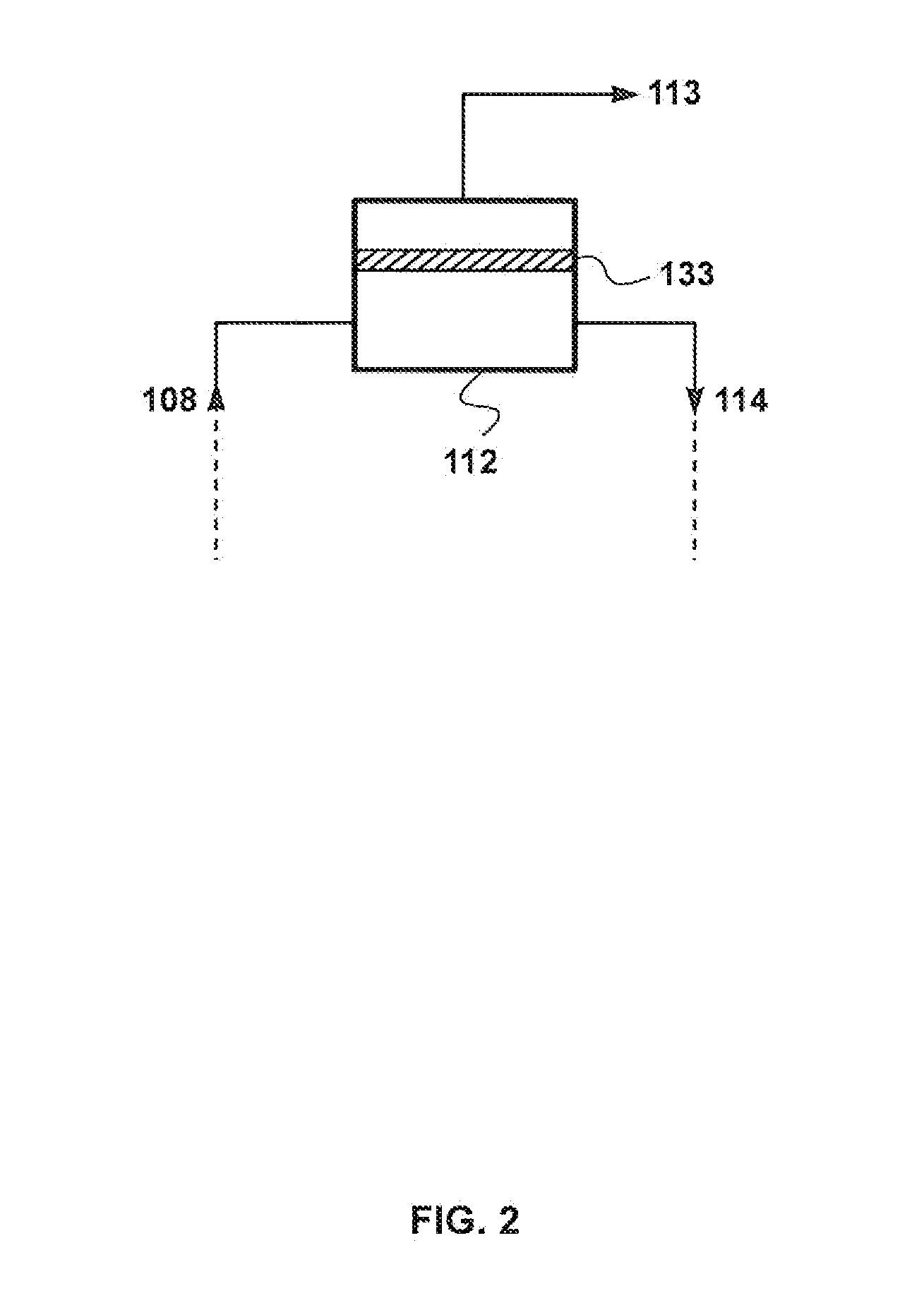

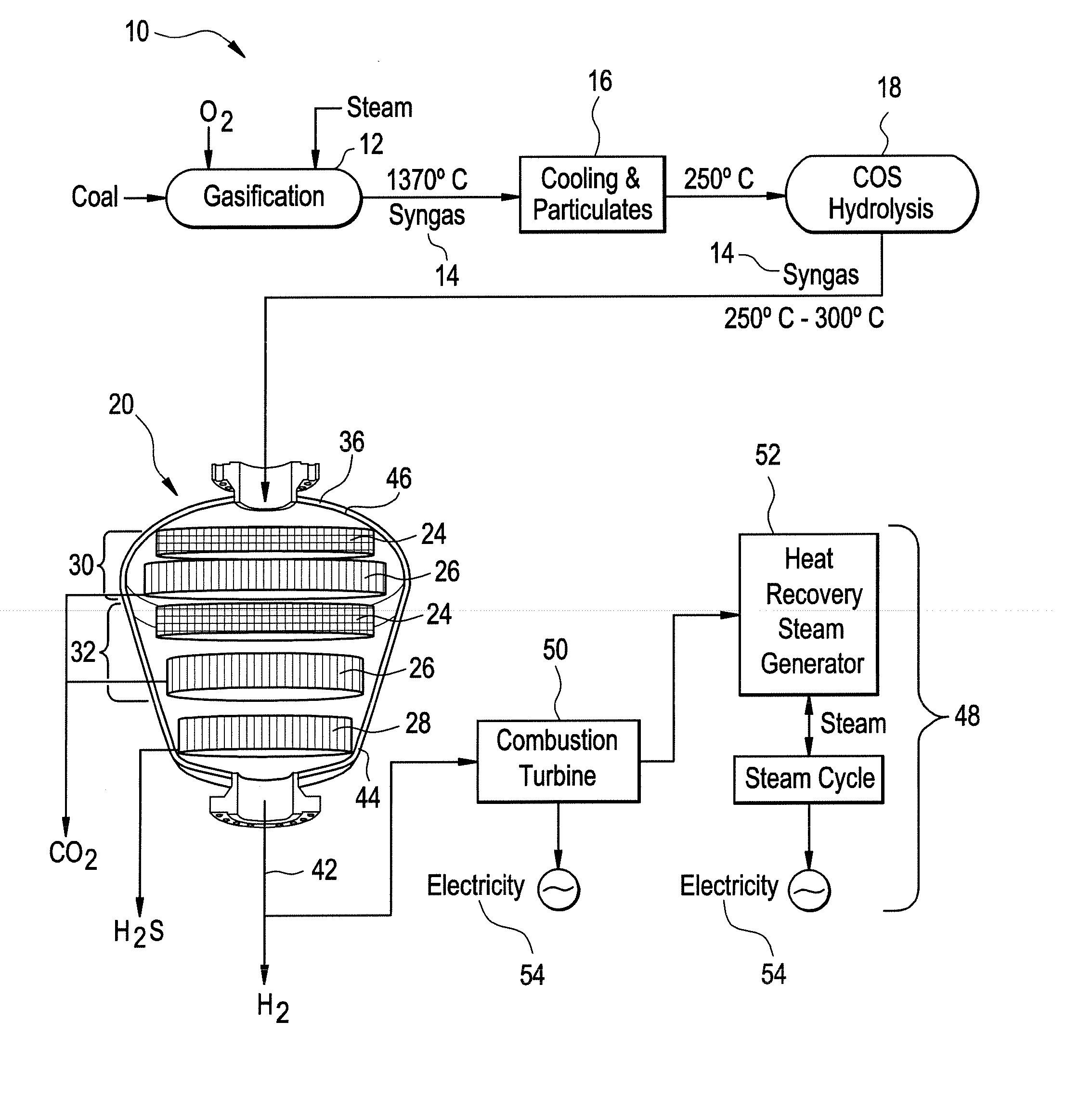

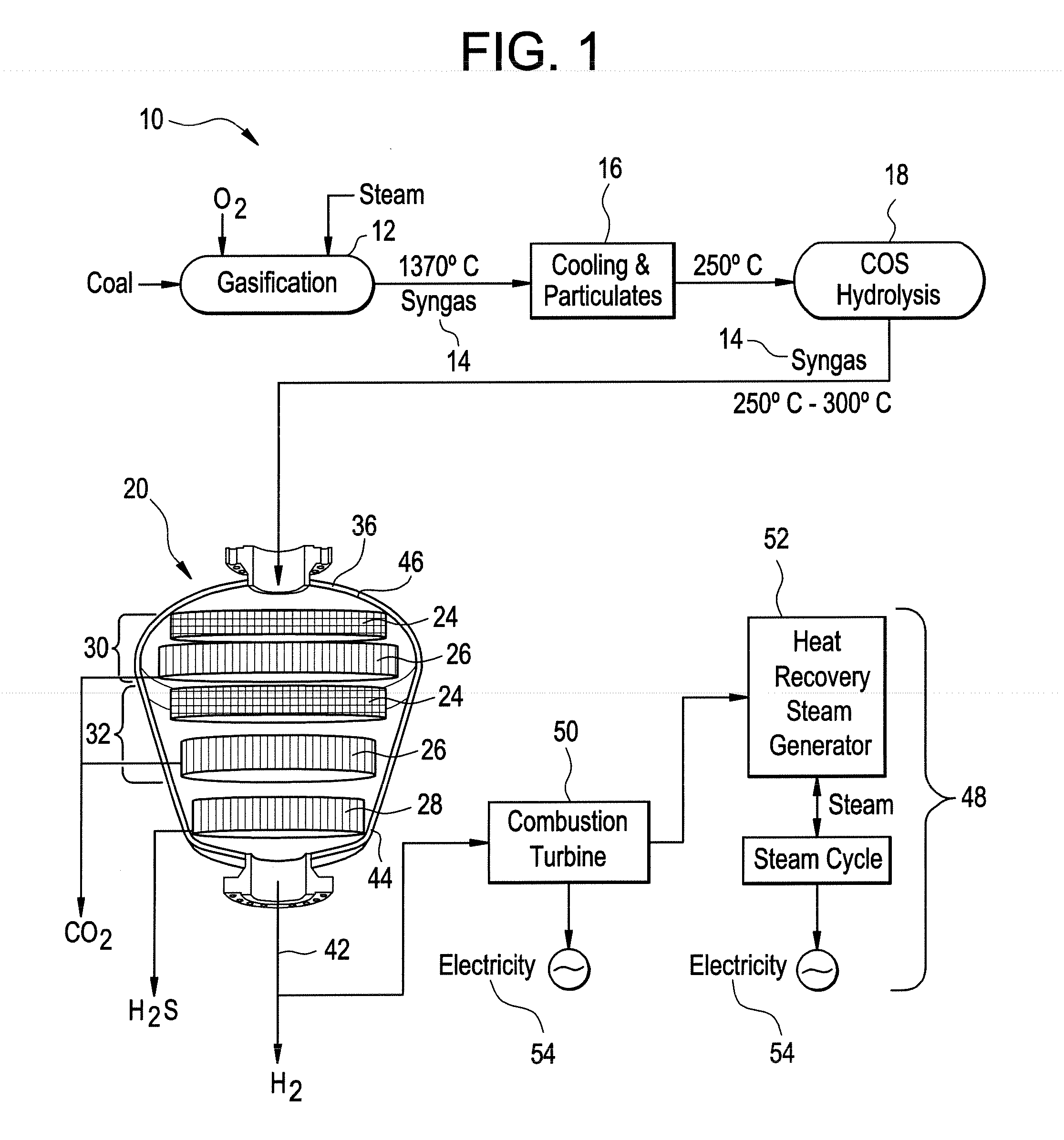

Low carbon emissions combined cycle power plant and process

InactiveUS20100319354A1Increase percentageMinimize mixing lossGas treatmentGas turbine plantsLow-carbon emissionGas cooling

A low carbon emissions, combined cycle power plant utilizes vortex nozzles (38) operative at cryogenic temperatures to separate out carbon dioxide (39) from the flue gases. Complexity of the plant is minimized by operating a gas turbine engine component (10) of the plant at a turbine exhaust pressure of at least 2 bar, so that downstream components of the plant, including a heat recovery steam generator (19A), a gas cooling system (30, 33, 36), and the inlets of the vortex nozzles, all operate at the same pressure of at least two bar. To increase carbon dioxide concentration in the flue gases (37) that pass through the vortex nozzles (38), and thereby increase efficiency of carbon dioxide removal from the flue gases, up to 50% of the flue gases that exit the heat recovery steam generator (19A) may be recirculated to a location (L, FIG. 4)) in the compressor of the gas turbine engine where the pressure of the compressor air matches the flue gas pressure.

Owner:GENERAL ELECTRIC TECH GMBH

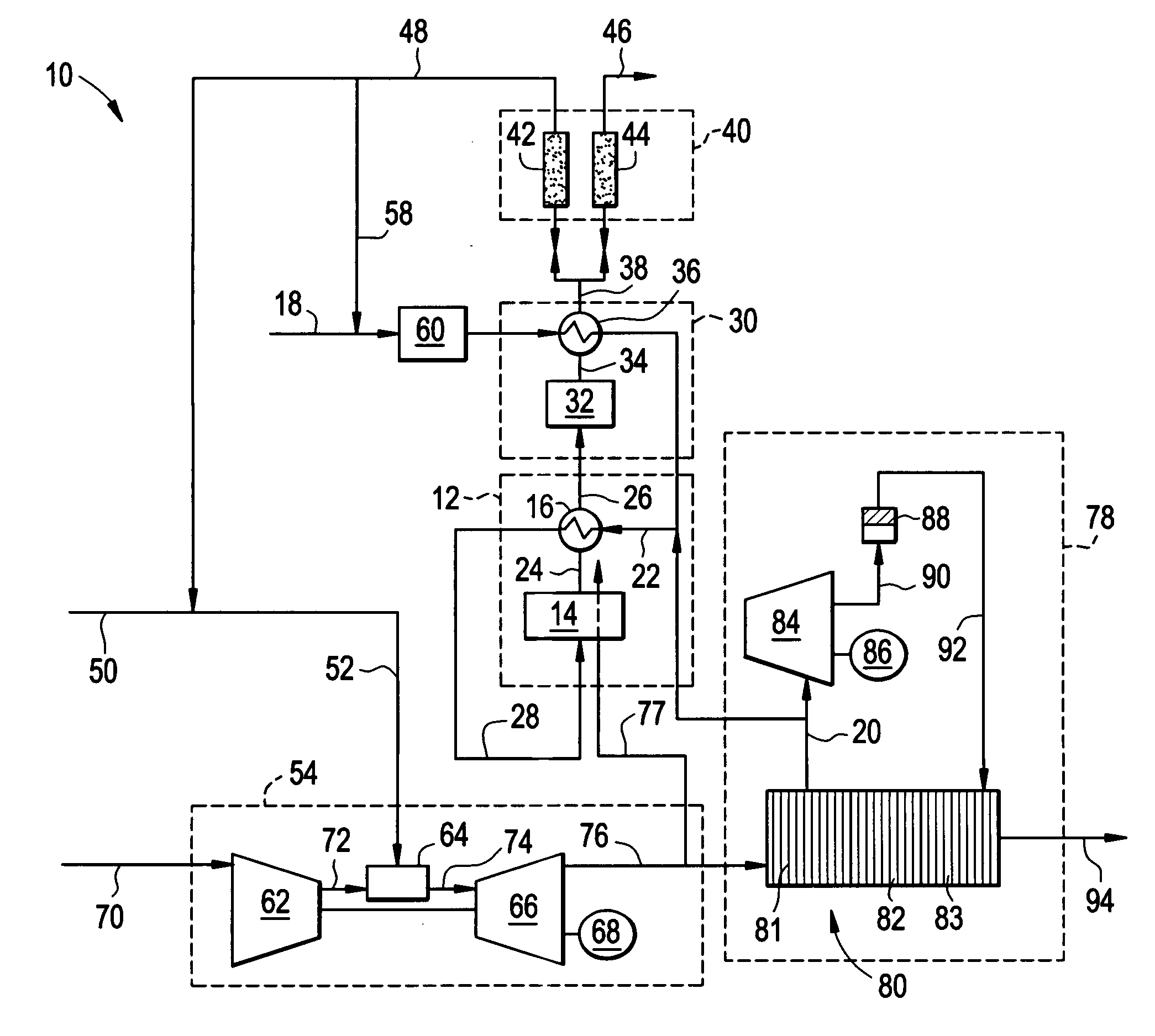

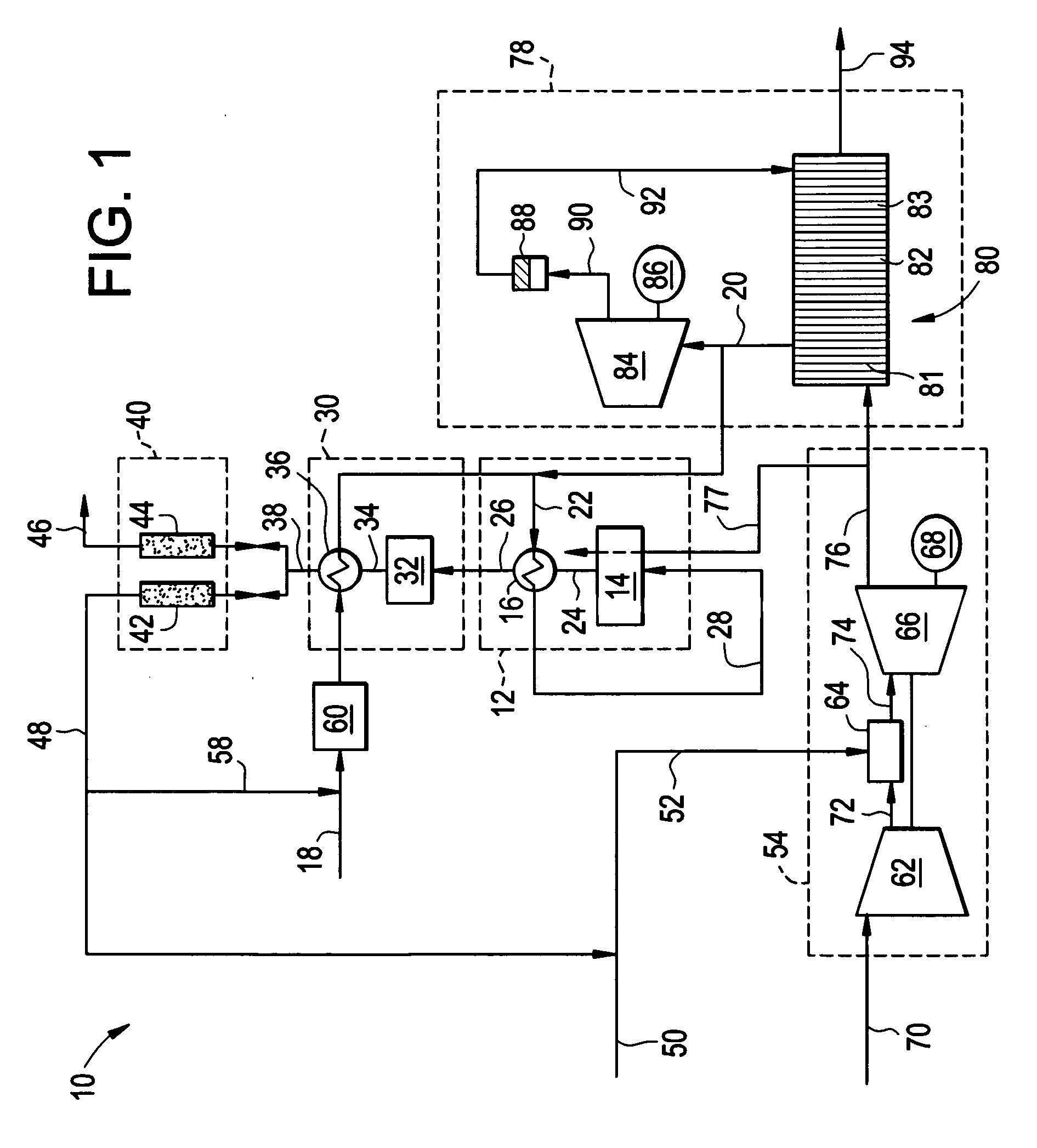

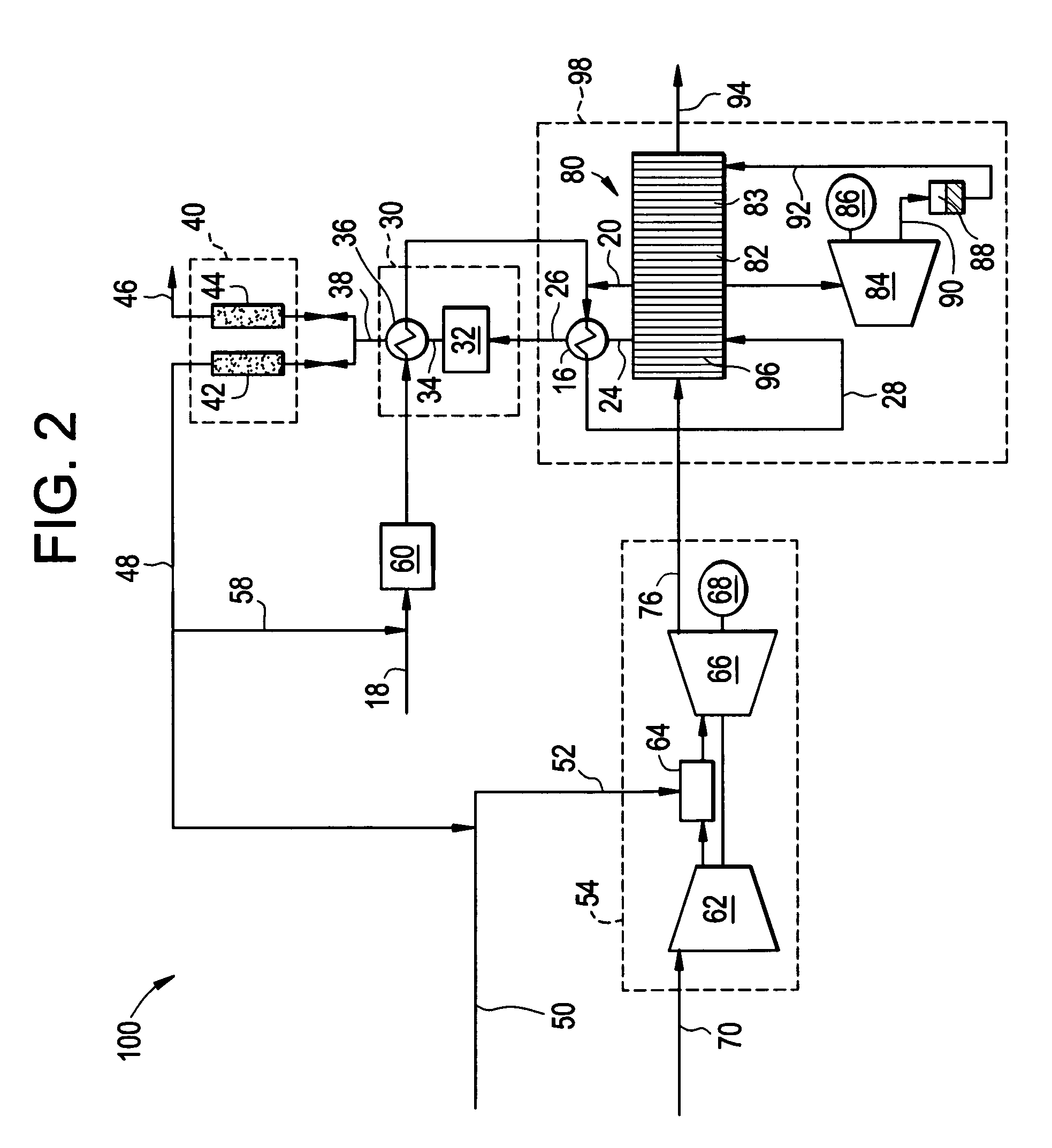

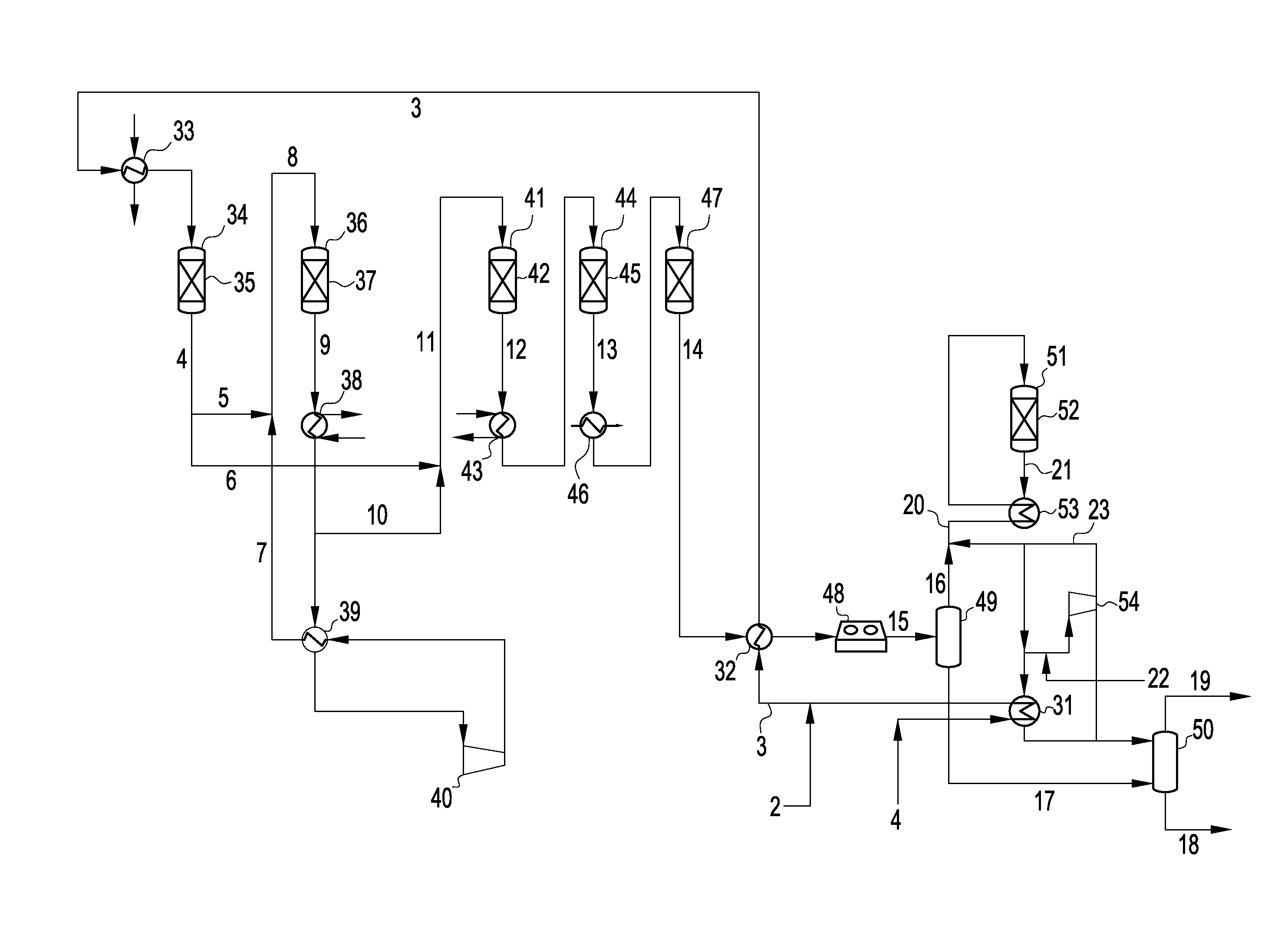

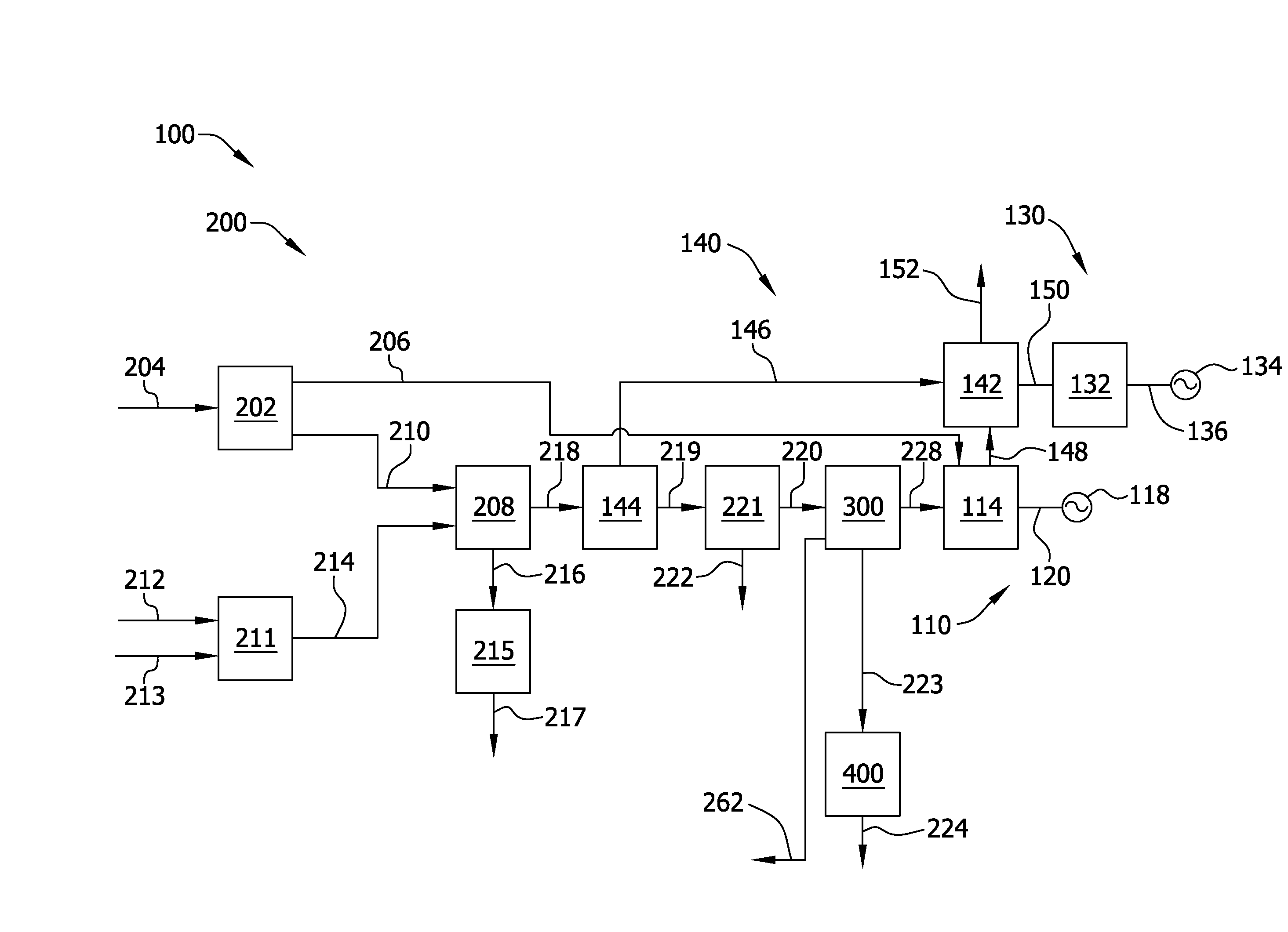

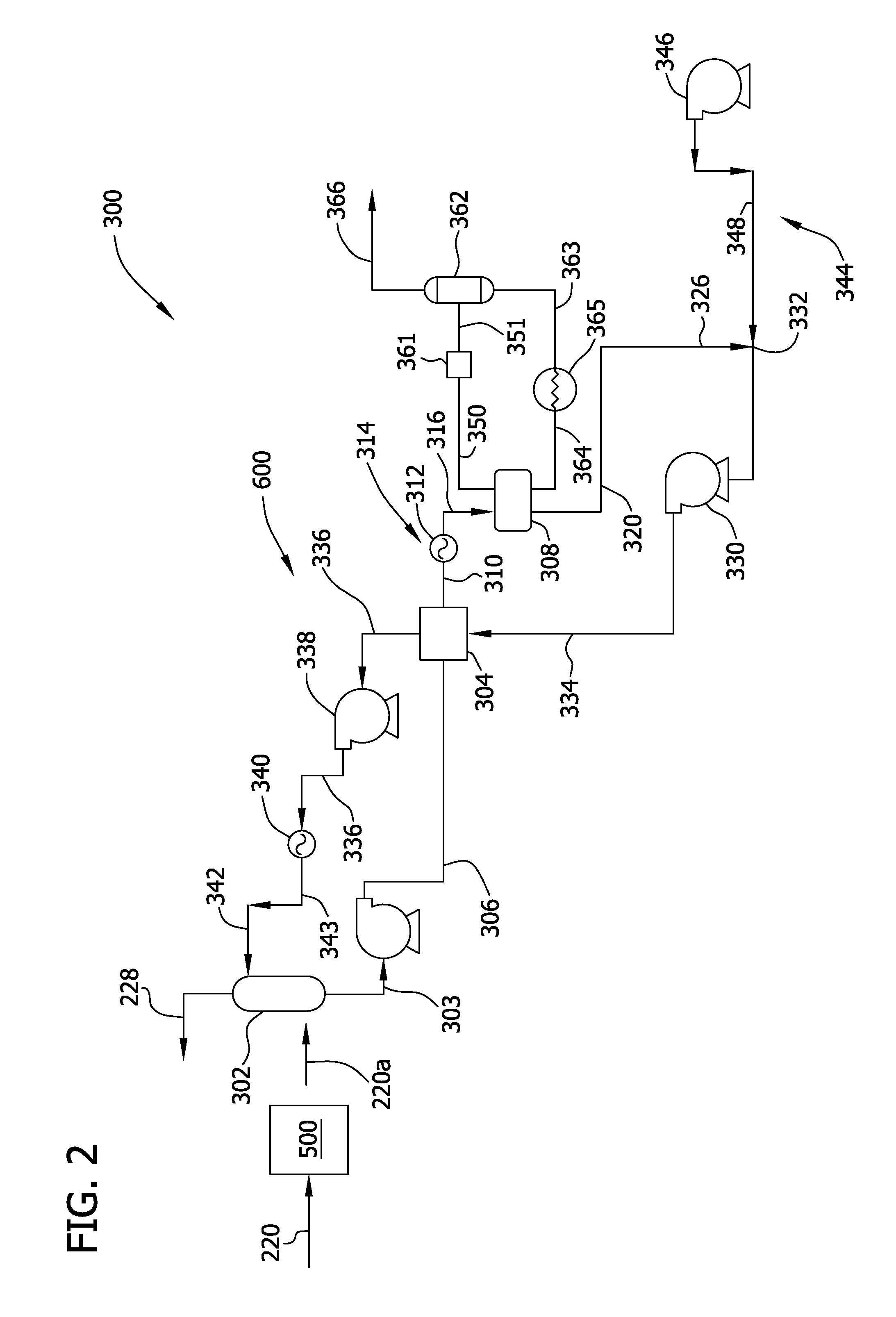

Syngas Power Systems and Method for Use Thereof

In one embodiment, a power system comprises: a first compressor unit, a syngas generator in fluid communication with a fuel stream and the first compressor unit, a syngas expander unit configured to directly receive the first syngas stream from the syngas generator, a first steam generator, a water gas shift reactor, and a carbon dioxide removal unit. The first compressor unit is configured to compress an air stream and form a first pressurized stream, while the syngas generator is configured to generate a first syngas stream. The syngas expander is configured to reduce the pressure of the first syngas stream. The first steam generator is configured to cool the second syngas stream. The carbon dioxide removal unit configured to remove carbon dioxide from the converted syngas stream.

Owner:AIR PROD & CHEM INC

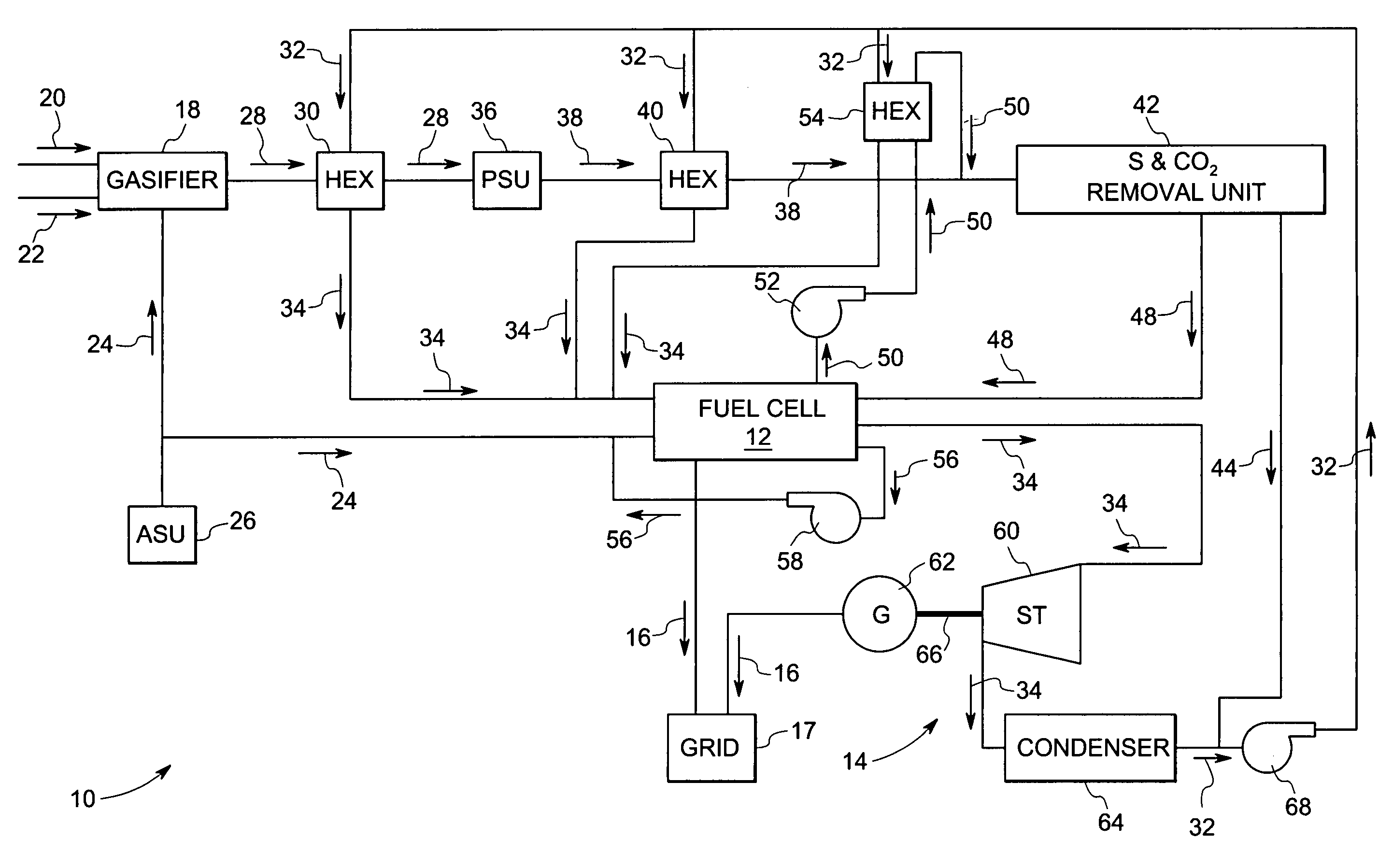

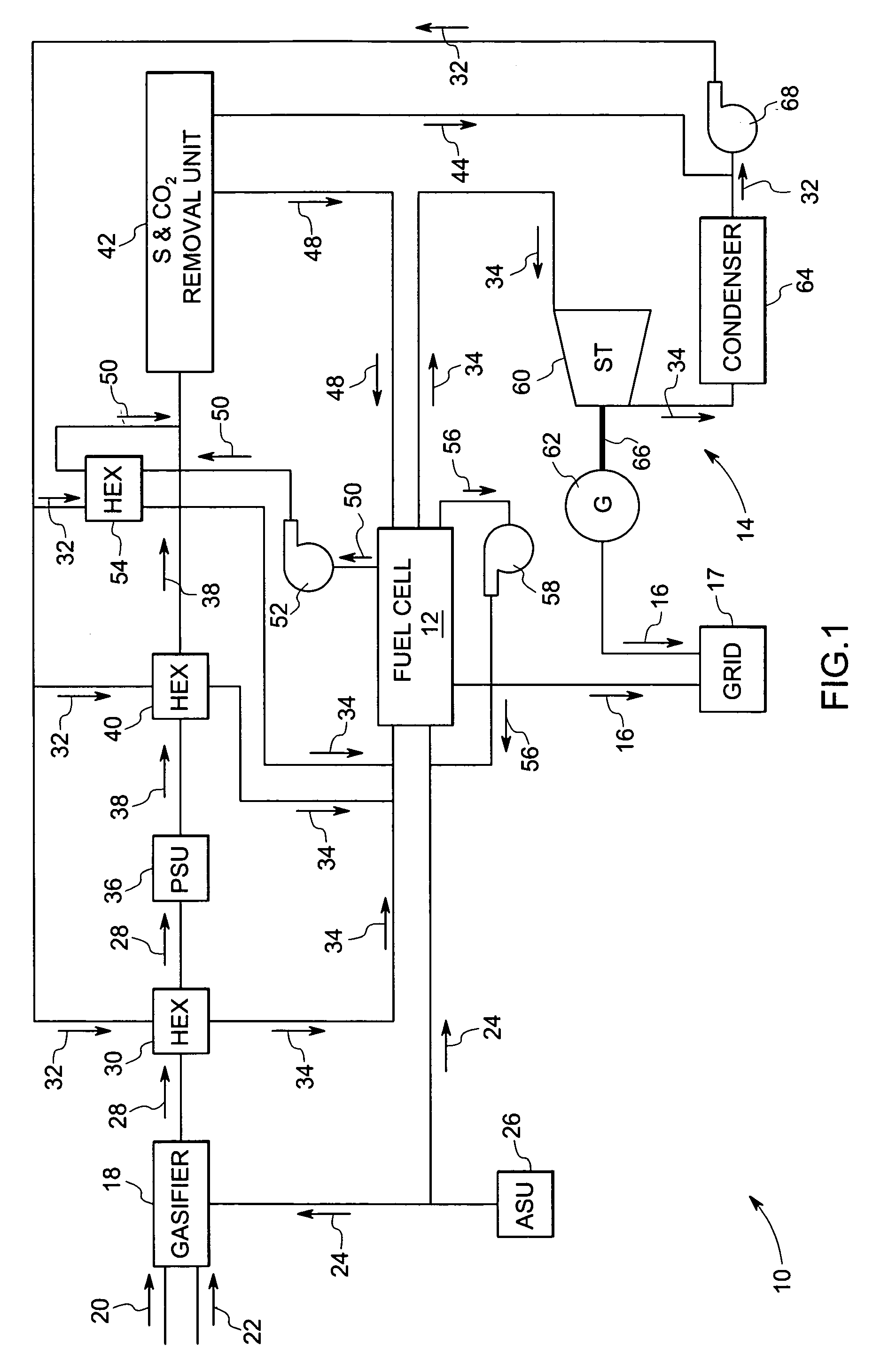

Integrated power plant and system and method incorporating the same

A system and method for producing electricity is described. The system comprises a fuel cell assembly. The system may comprise a steam turbine and a generator. The fuel cell assembly may be used to provide heat to produce the steam used to power the steam turbine. The system may comprise a gasifier that is operable to produce a fuel for use in the fuel cell assembly. The system may comprise an air separation unit that is operable to supply oxygen to the gasifier and to the fuel cell assembly for reaction with the fuel. The oxygen that is not reacted in the fuel cell assembly may be recirculated through the fuel cell assembly. Spent fuel from the fuel cell assembly may be recirculated through the fuel cell assembly. A carbon dioxide removal system may be used to remove carbon dioxide from the fuel upstream of the fuel cell.

Owner:CUMMINS ENTERPRISE LLC

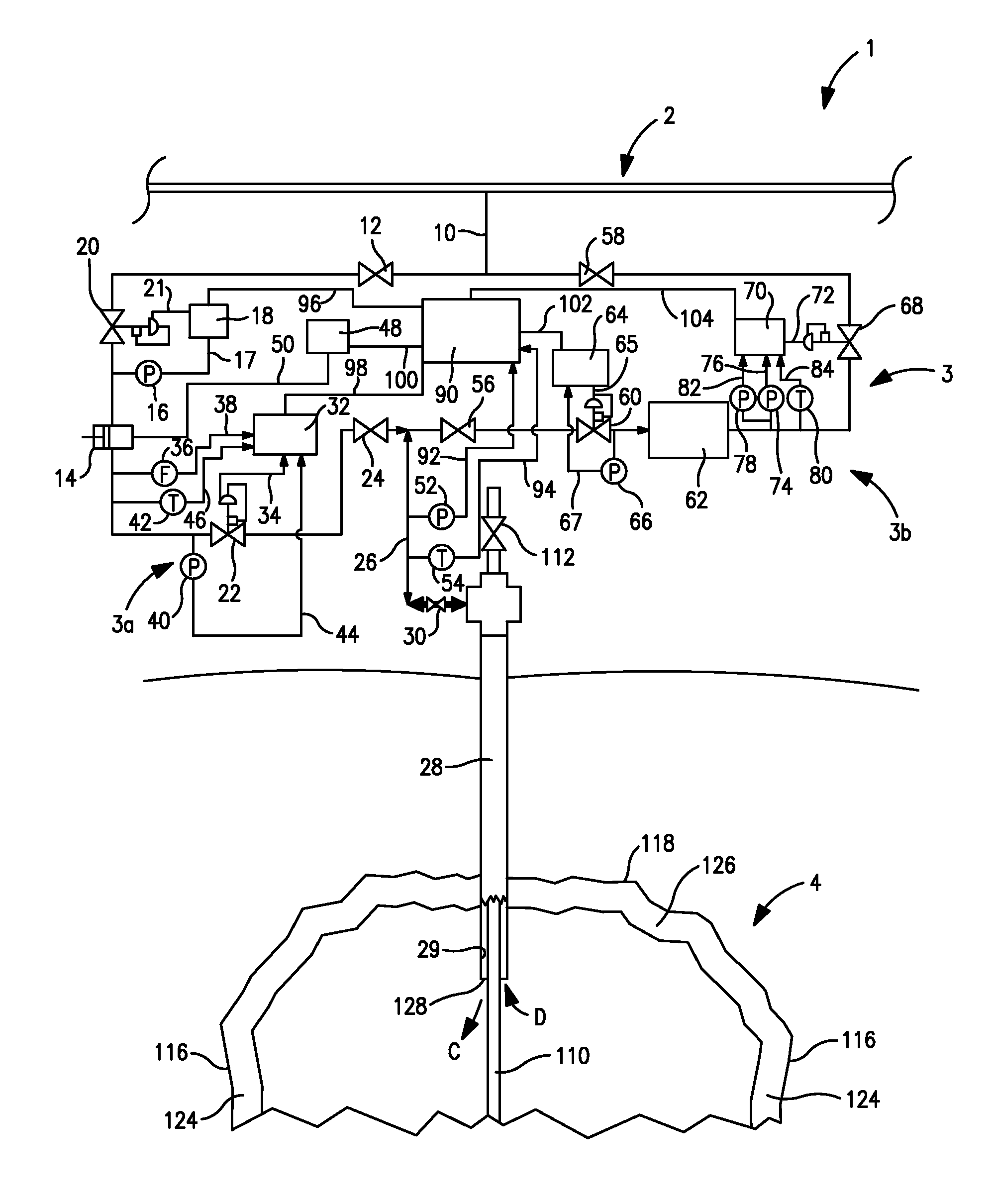

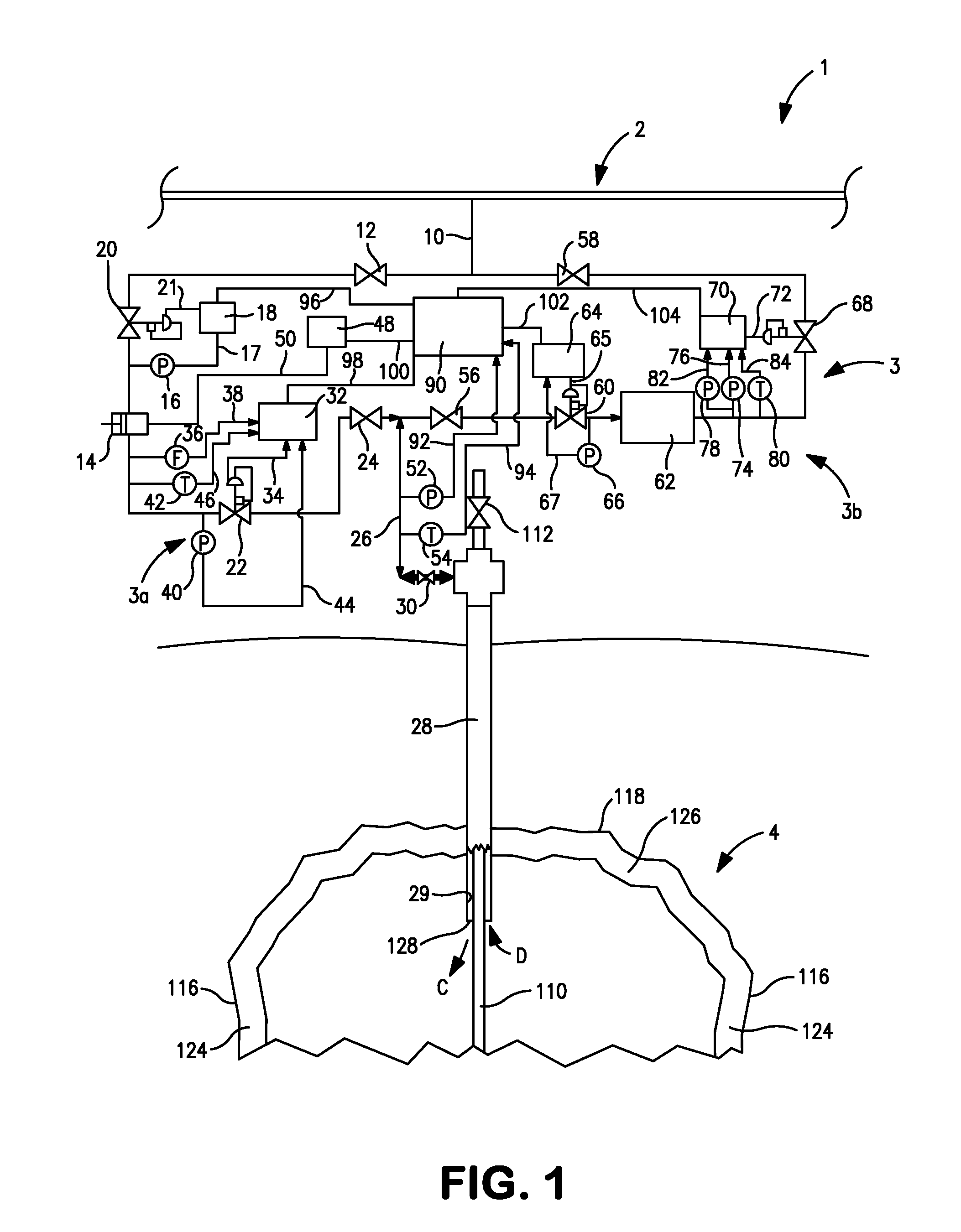

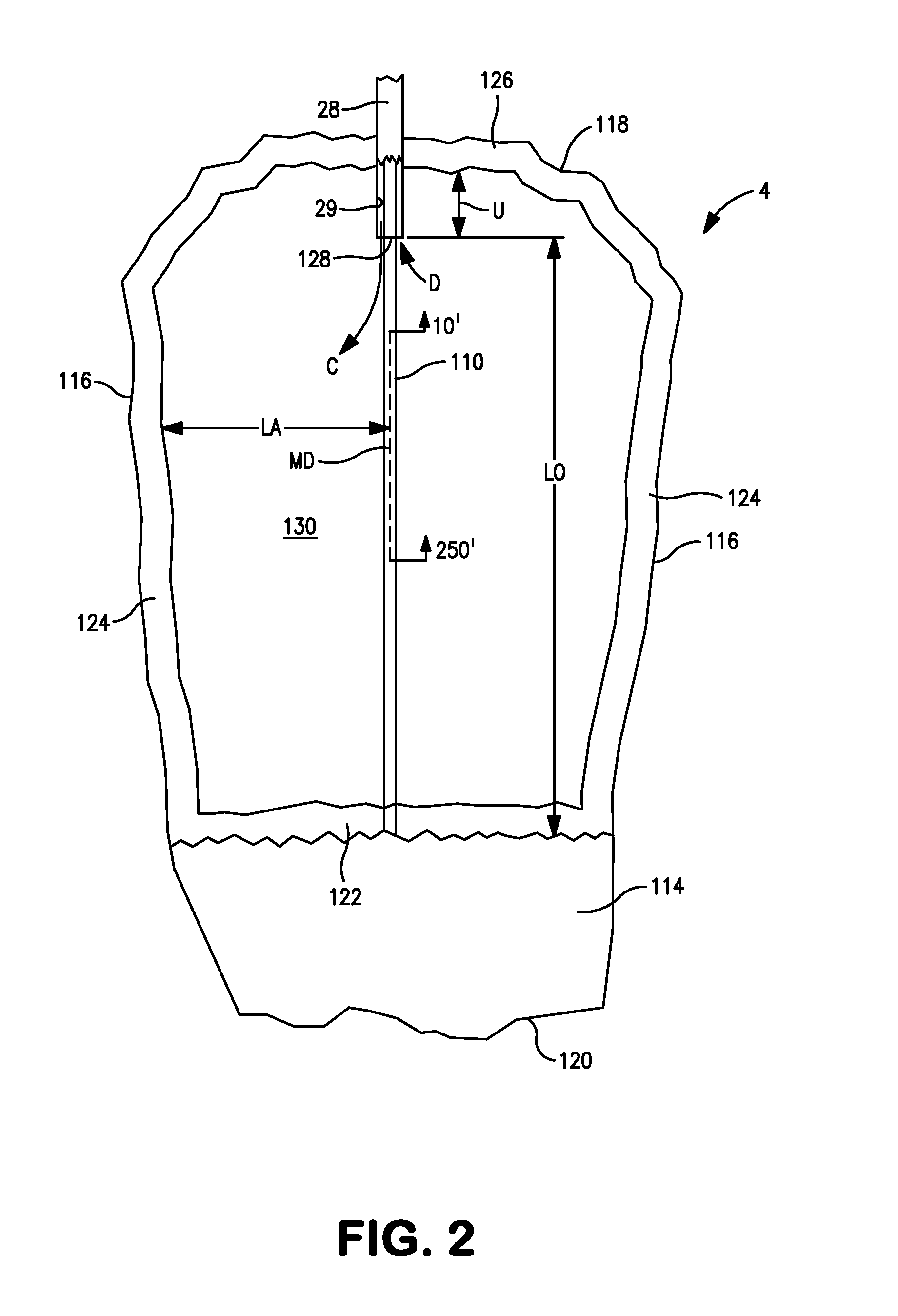

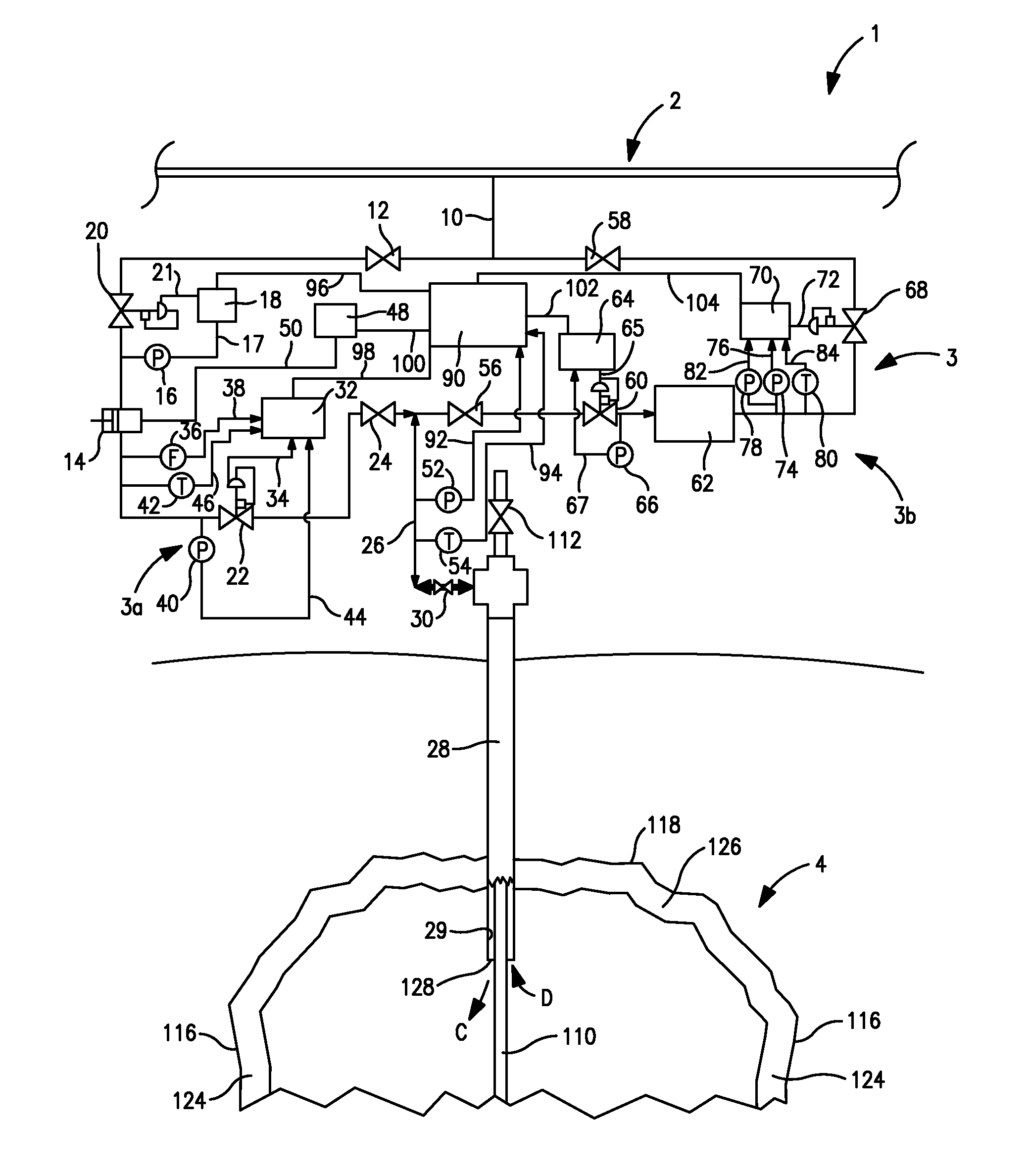

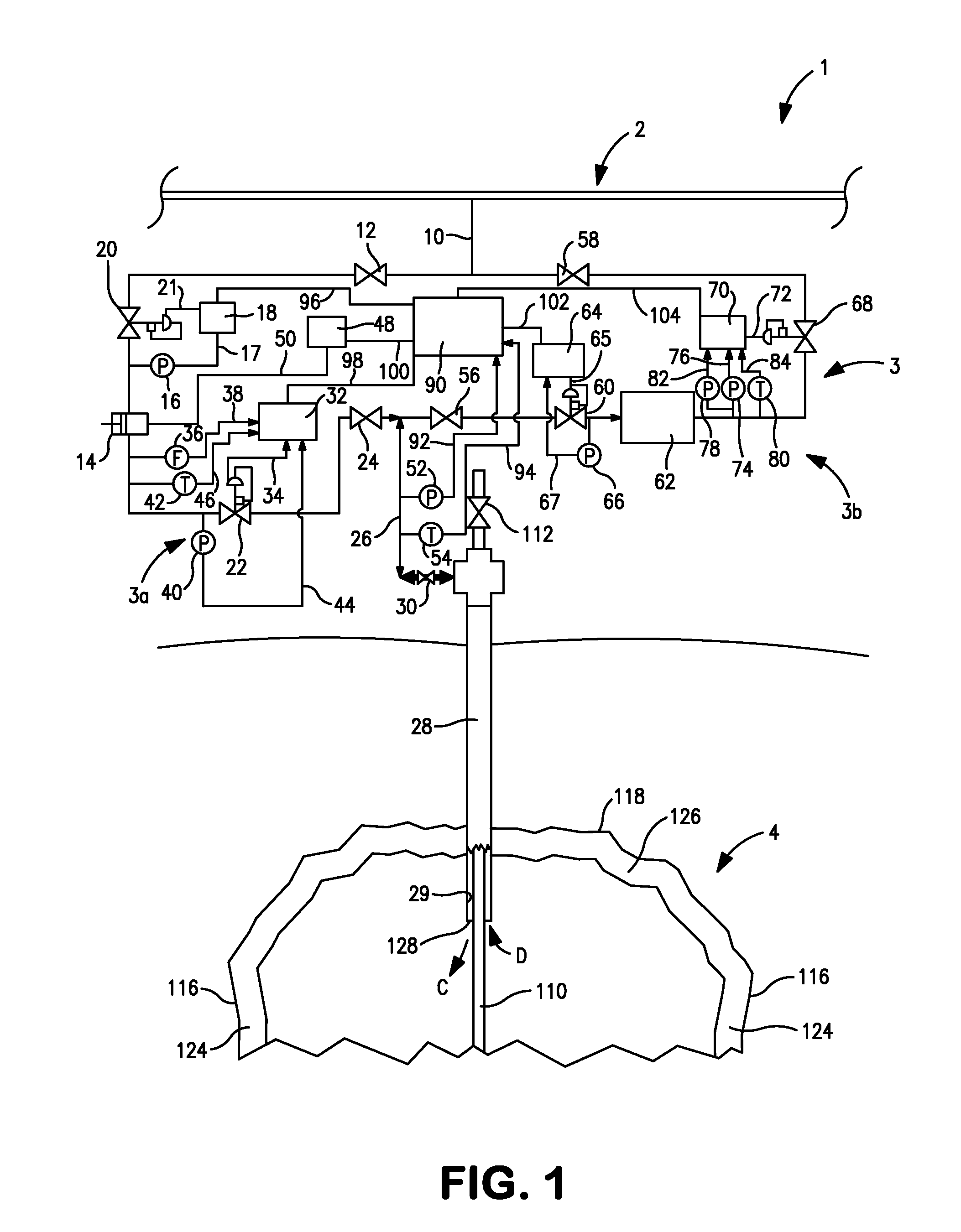

Hydrogen storage method and system

A method and system for storing and supplying hydrogen to a hydrogen pipeline in which a compressed hydrogen feed stream is introduced into a salt cavern for storage and a stored hydrogen stream is retrieved from the salt cavern and reintroduced into the hydrogen pipeline. A minimum quantity of stored hydrogen is maintained in the salt cavern to produce a stagnant layer having a carbon dioxide content along the cavern wall and the top of a residual brine layer located within the salt cavern. The compressed hydrogen feed stream is introduced into the salt cavern and the stored hydrogen stream is withdrawn without disturbing the stagnant layer to prevent carbon dioxide contamination from being drawn into the stored hydrogen stream being reintroduced into the hydrogen pipeline. This allows the stored hydrogen stream to be reintroduced into the hydrogen pipeline without carbon dioxide removal.

Owner:PRAXAIR TECH INC

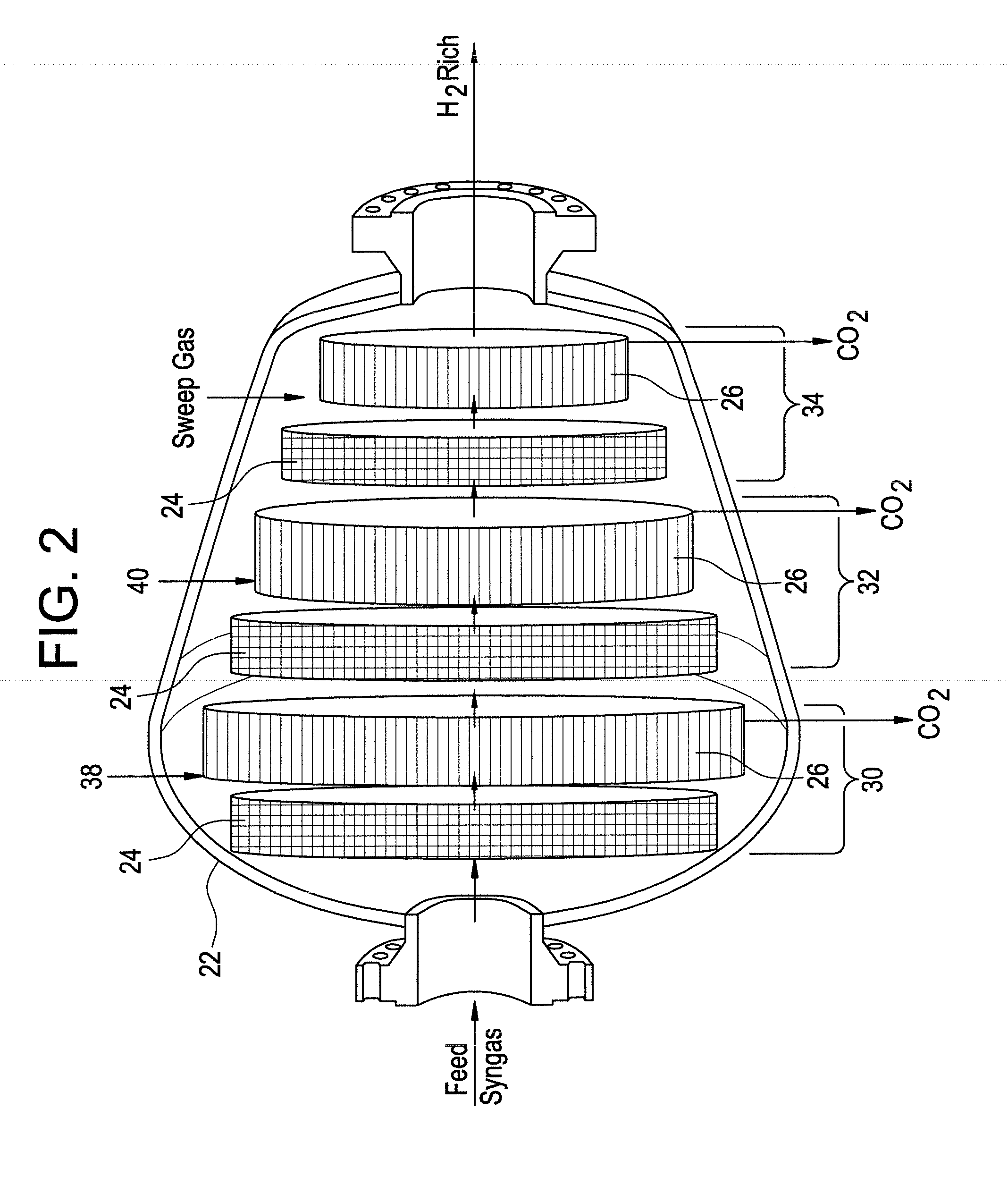

Sweep-Based Membrane Gas Separation Integrated With Gas-Fired Power Production And CO2 Recovery

ActiveUS20130200625A1Reduce environmental impactEasy to handleGas turbine plantsDirect carbon-dioxide mitigationPower stationMembrane gas separation

A process involving membrane-based gas separation and power generation, specifically for controlling carbon dioxide emissions from gas-fired power plants. The process includes a compression step, a combustion step, and an expansion / electricity generation step, as in traditional power plants. The process also includes a sweep-driven membrane separation step and a carbon dioxide removal or capture step. The carbon dioxide removal step is carried out on a portion of gas from the compression step.

Owner:MEMBRANE TECH & RES

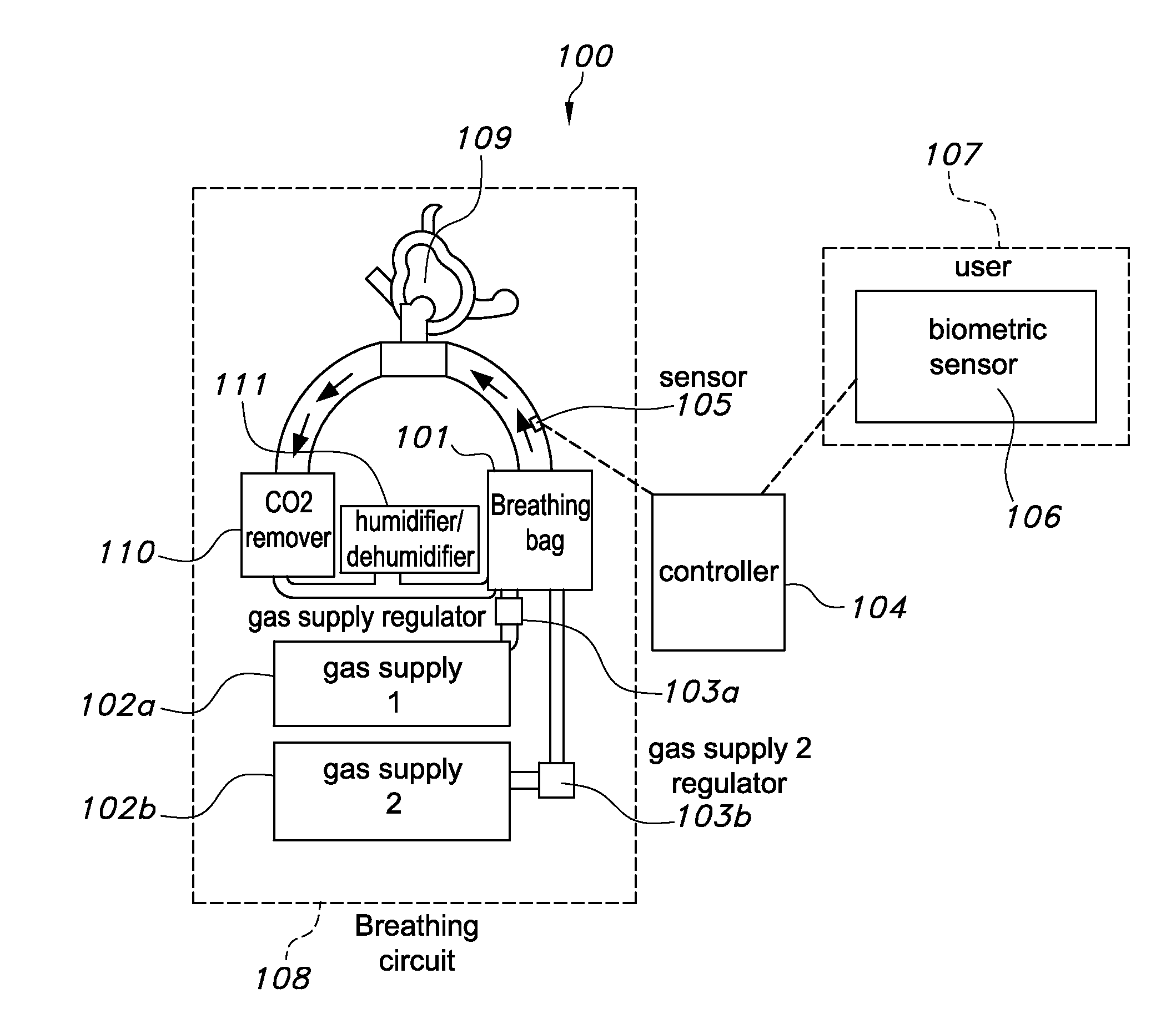

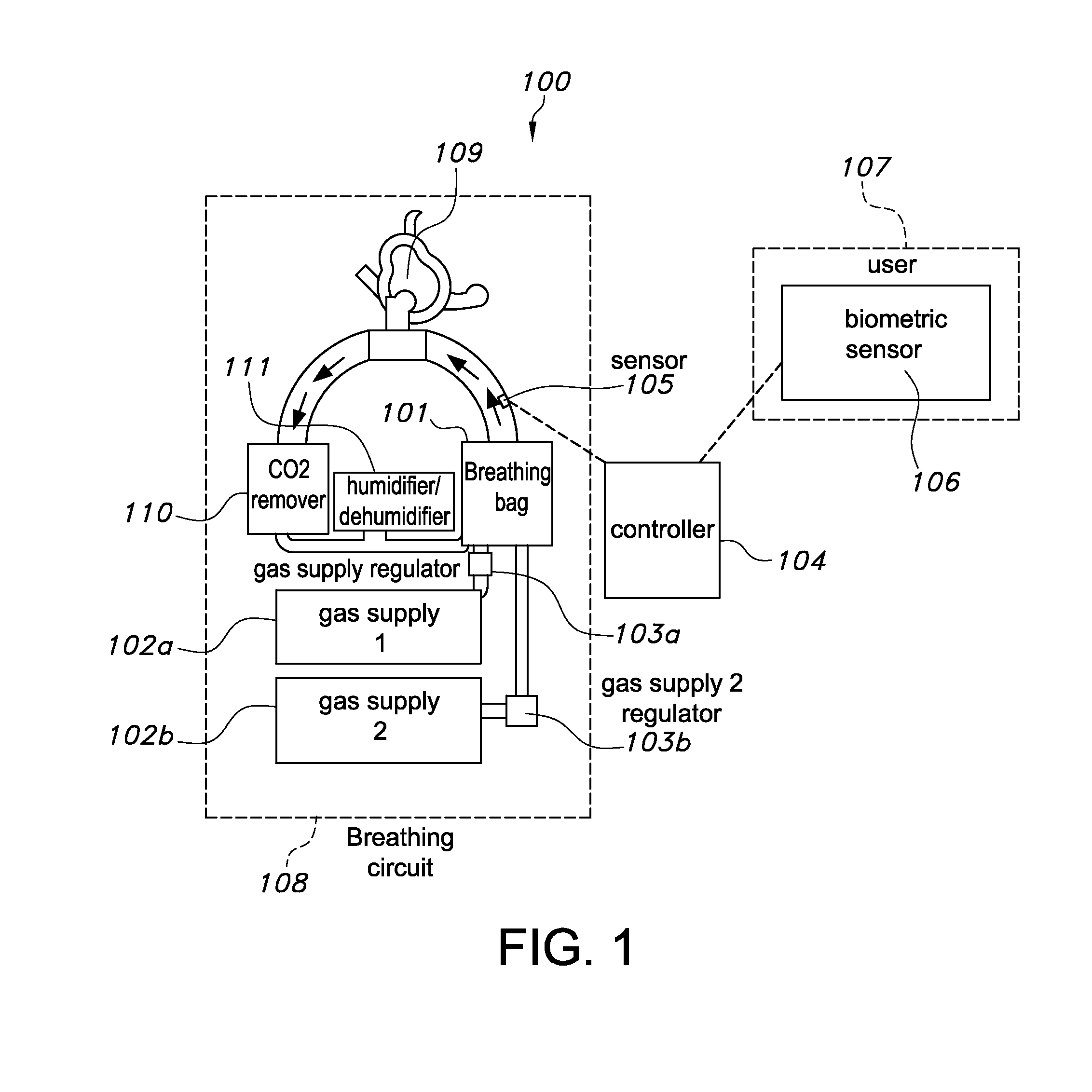

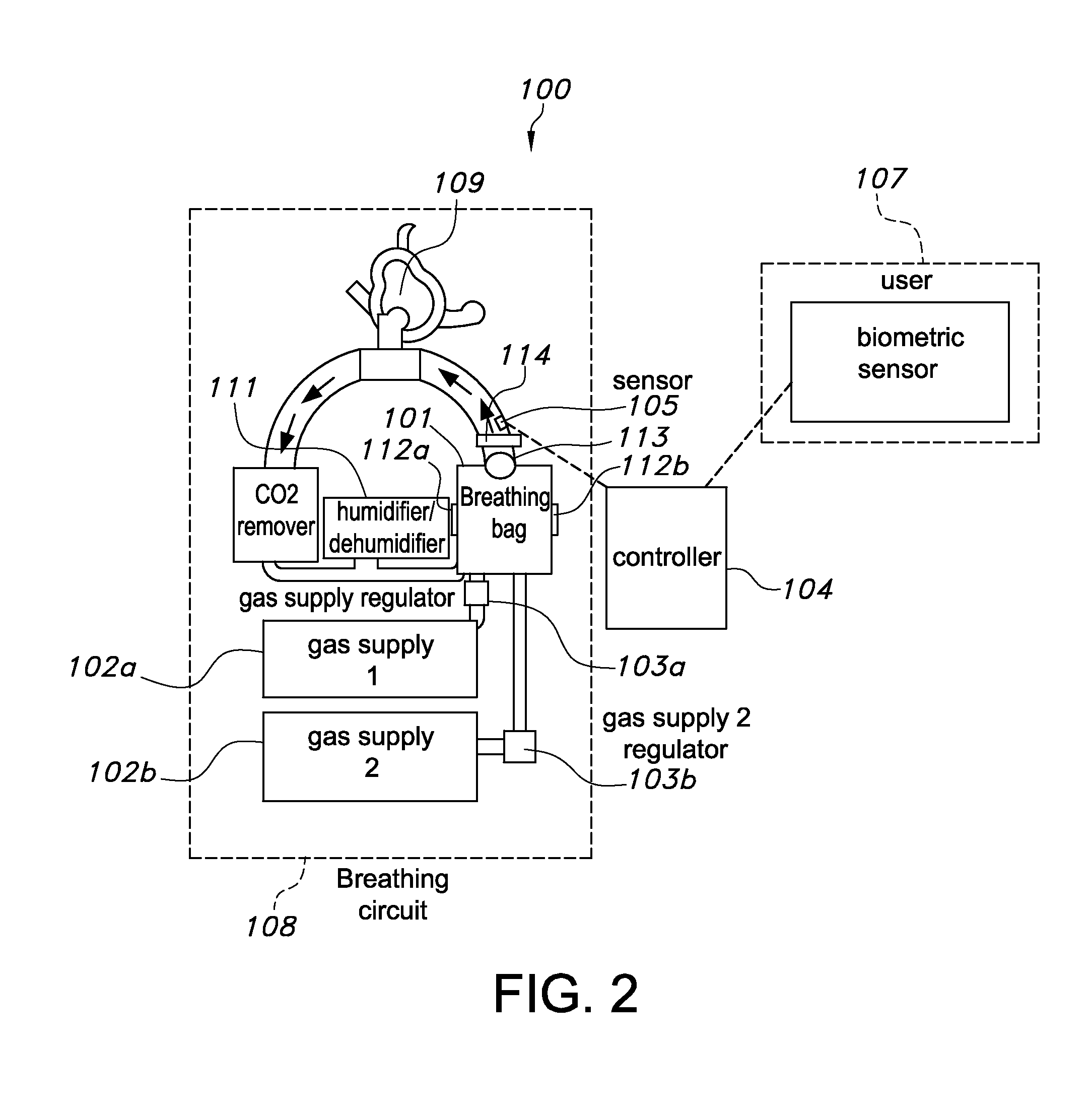

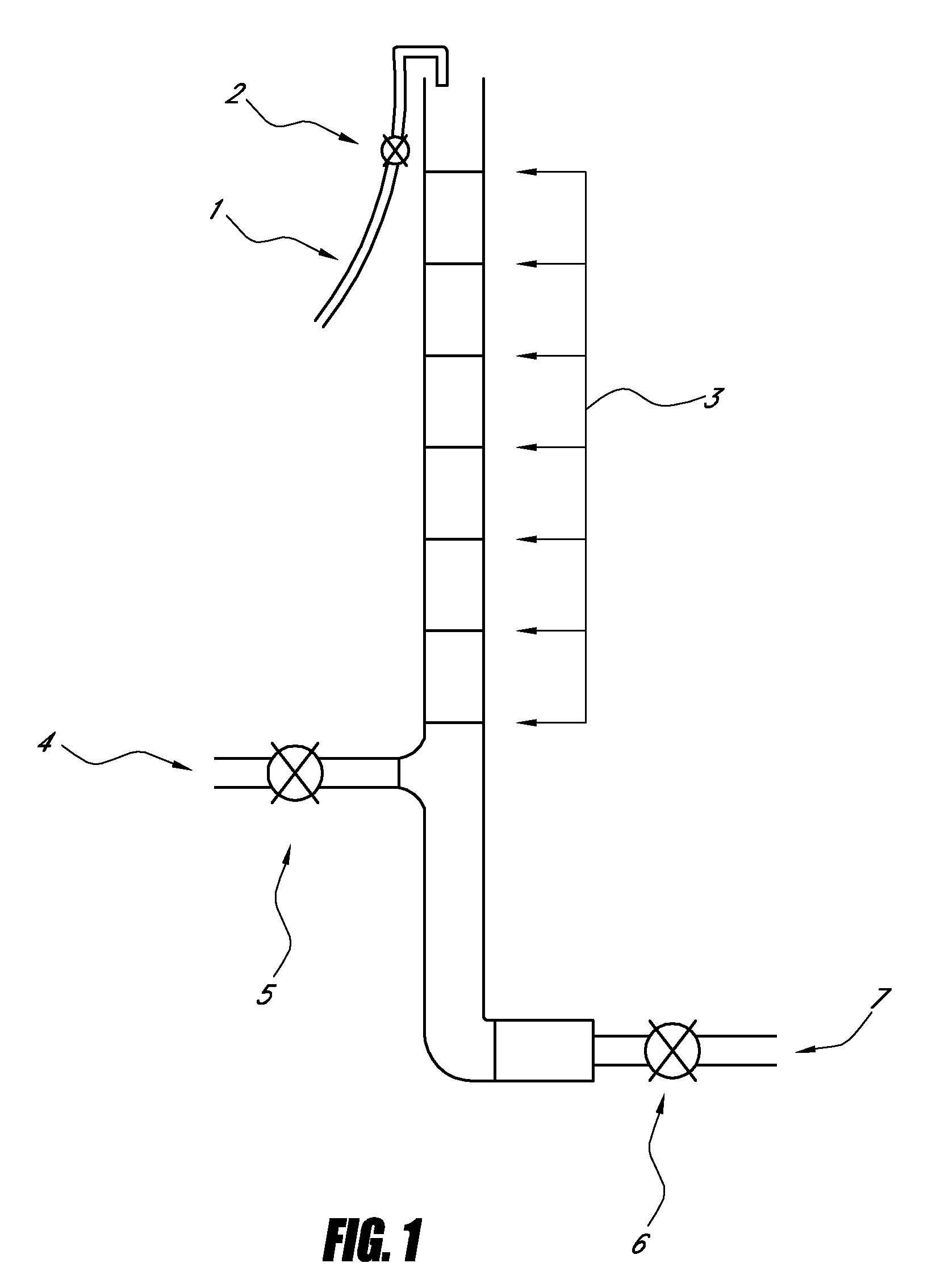

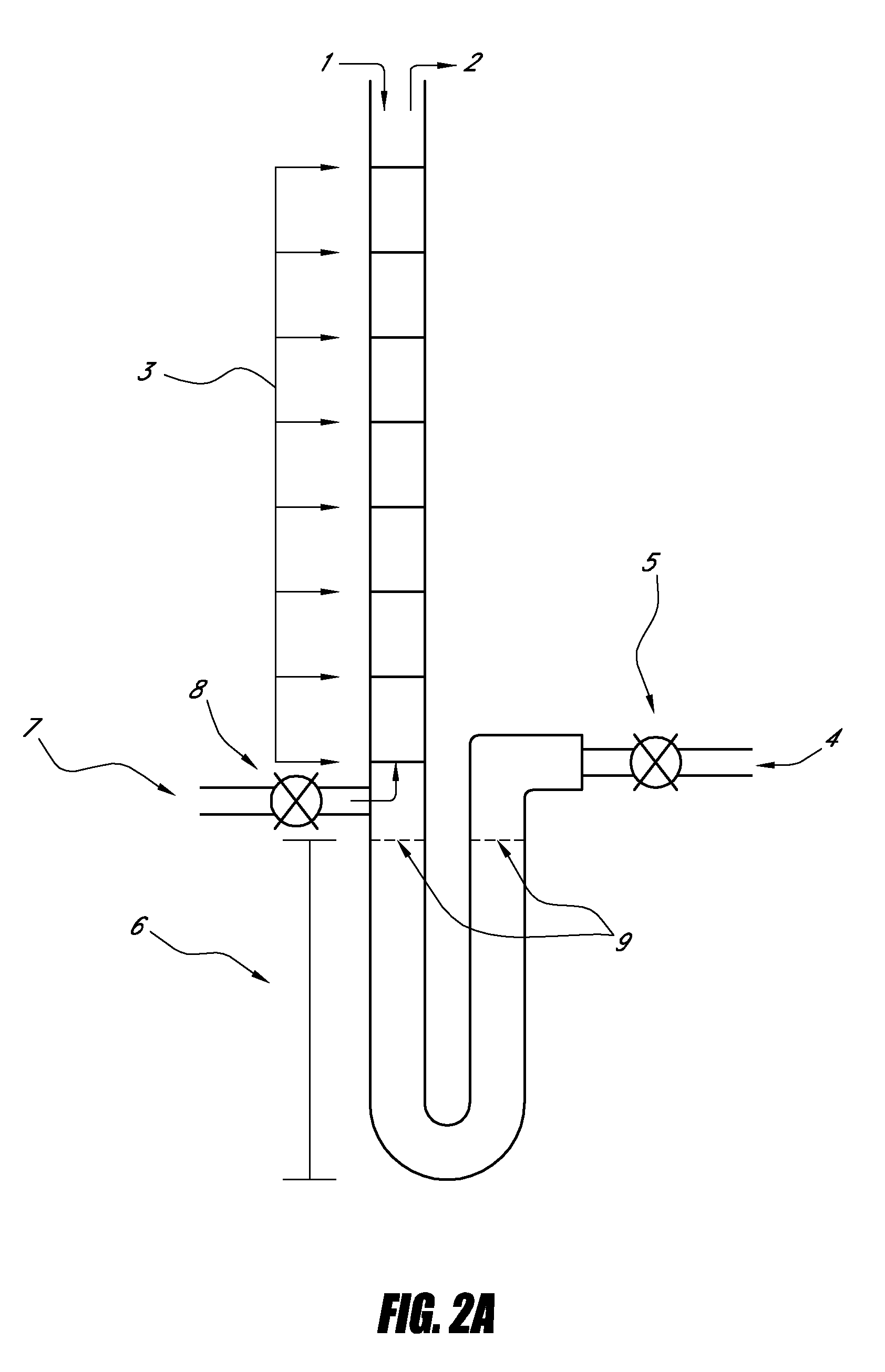

A home-based heliox system with carbon dioxide removal

ActiveUS20160213879A1Simple for individual operationSufficiently compactRespiratorsElectrocardiographyHelioxHome based

A closed-circuit heliox delivery system and methods for alleviating symptoms of COPD and related disorders are provided. The system is self-monitoring and can be used outside of a hospital environment. The system contains a gas supply fluidly connected to a breathing circuit. The breathing circuit contains an upper airway device, such as a mask. The system contains a sensor(s) and controller. The sensors measure parameters in the system, the ambient environment, or related to the physiological state of the user. The controller can adjust the system to maintain parameters within the device, i.e. pressure, temperature, humidity, within predetermined ranges. The controller can adjust the system to maintain a target physiological state of the user, i.e. target blood oxygen levels or Work of Breathing (WOB).

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

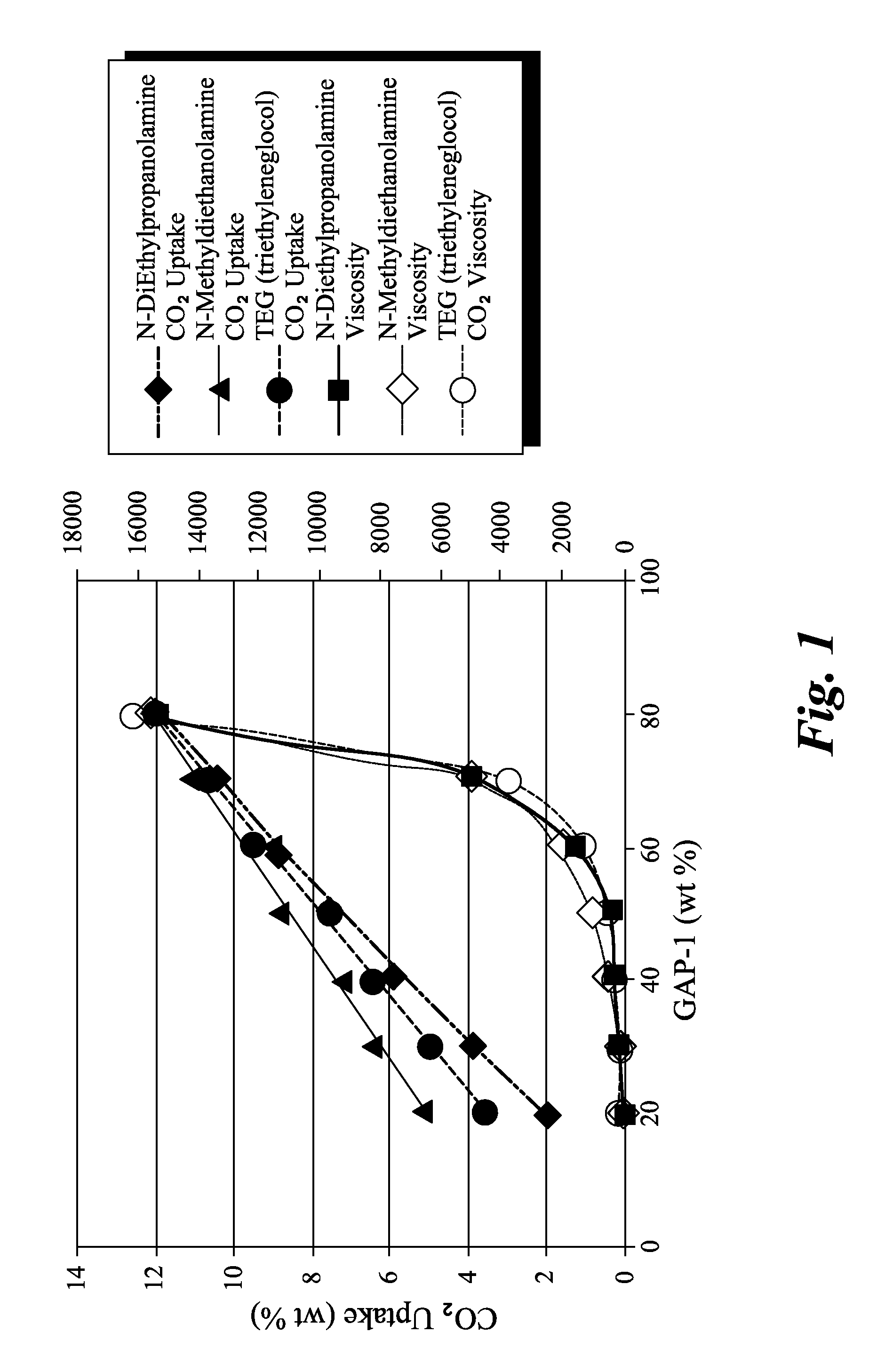

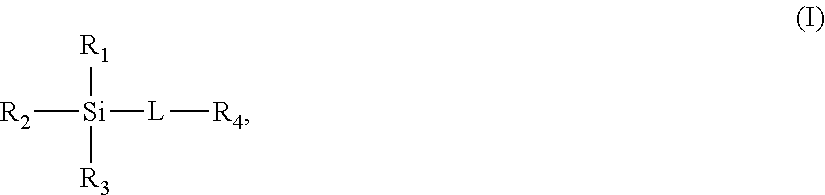

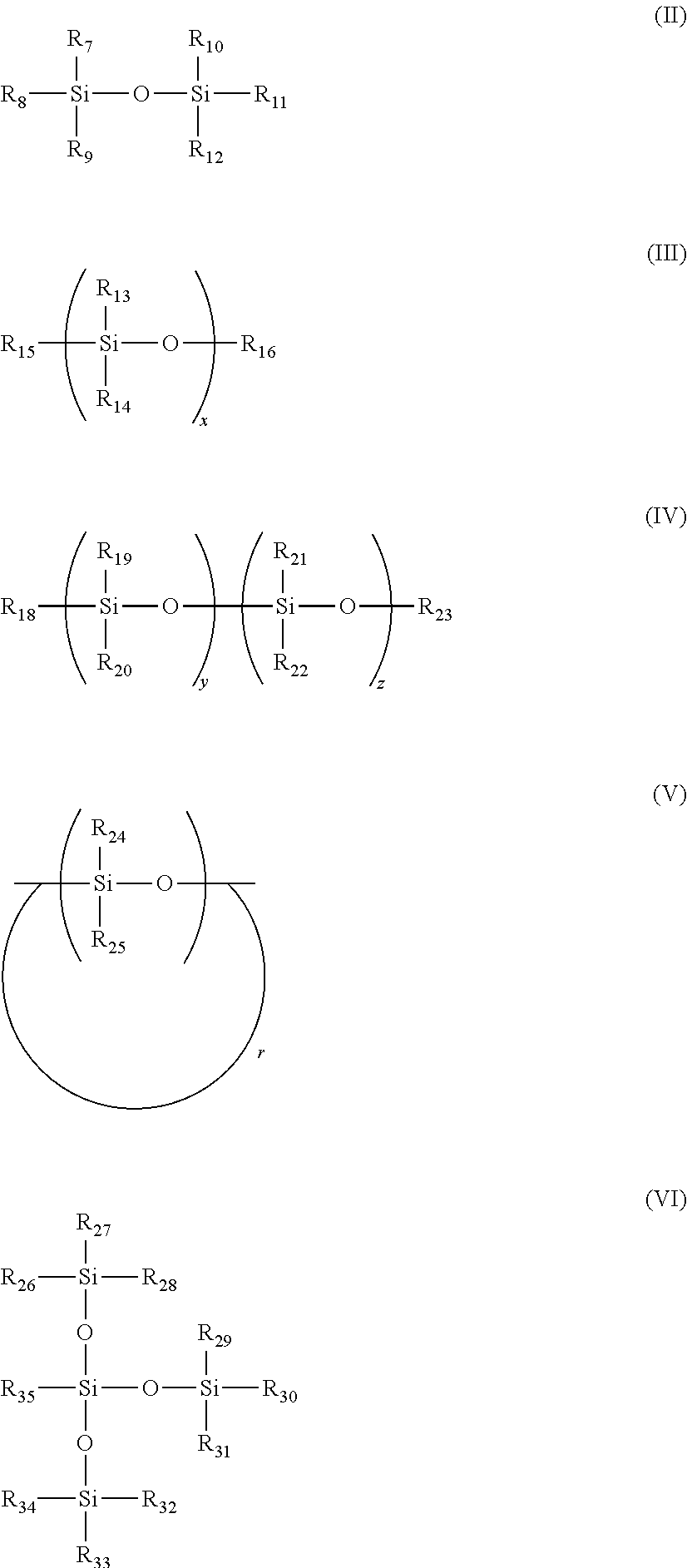

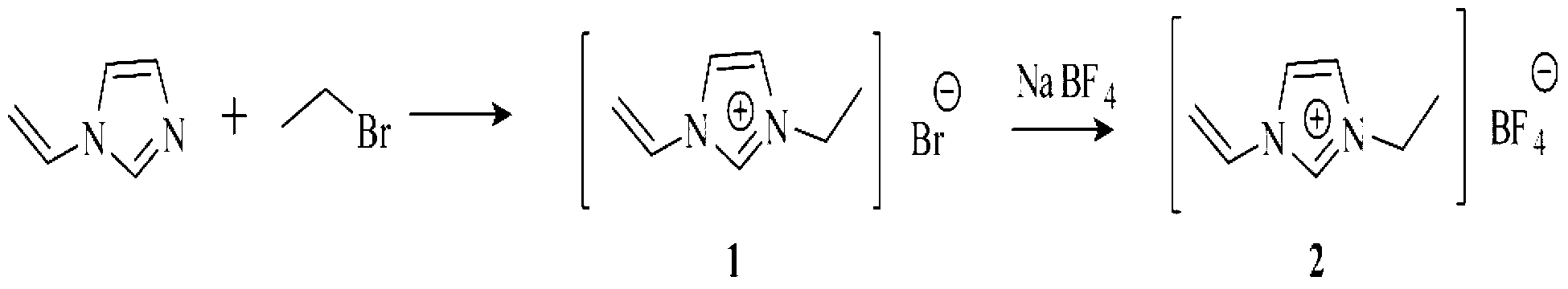

Compositions for absorbing carbon dioxide, and related processes and systems

InactiveUS20130052109A1Reduce carbon dioxide emissionsGas treatmentOther chemical processesAlcoholPower station

A carbon dioxide absorbent is disclosed. The absorbent compostion contains a liquid, non-aqueous, silicon-based material, functionalized with one or more groups that reversibly react with CO2 and / or have a high-affinity for CO2; and at least one amino alcohol compound. A method for reducing the amount of carbon dioxide in a process stream is also described. The method includes the step of contacting the stream with the carbon dioxide absorbent composition. A power plant that includes a carbon dioxide removal unit based on the carbon dioxide absorbent is also described.

Owner:GENERAL ELECTRIC CO

Method for purifying natural gas

The invention provides a method for purifying natural gas. The method comprises the following steps of firstly, desulfuration of the natural gas; secondly, carbon dioxide removal from the desulfurated natural gas; and thirdly, dehydration of the natural gas with carbon dioxide removed so as to obtain the purified natural gas. According to the method, the production cost can be remarkably reduced, the desulfurization and purification efficiency can be improved, and no contamination is caused to the environment.

Owner:东莞新盈能源利用有限公司

Carbon dioxide removal from synthesis gas at elevated pressure

A method for removing CO2 from a pressurized gas stream with the effluent CO2 remaining at system pressure or higher is disclosed. Specifically, the removal method provides near isothermal absorption of CO2 from a gas stream in a suitable solvent at an elevated pressure and relatively low temperature. The solvent is then removed from contact with the gas stream, and the temperature is increased to such an extent that the CO2 will flash from the solvent.

Owner:GENERAL ELECTRIC CO

Methods and Apparatus for Carbon Dioxide Removal from a Fluid Stream

An apparatus for producing hydrogen gas wherein the apparatus includes a reactor. In one embodiment, the reactor includes at least two conversion-removal portions. Each conversion-removal portion comprises a catalyst section configured to convert CO in the stream to CO2 and a membrane section located downstream of and in flow communication with the catalyst section. The membrane section is configured to selectively remove the CO2 from the stream and to be in flow communication with a sweep gas.

Owner:GENERAL ELECTRIC CO

Co-production of methanol and ammonia

ActiveUS8303923B2Minimum release of carbon dioxide to the atmosphereSimple and inexpensiveHydrogenOrganic compound preparationAir separationAmmonia

Process for the co-production of methanol and ammonia from a hydrocarbon feed without venting to the atmosphere carbon dioxide captured from the methanol or ammonia synthesis gas and without using expensive air separation units, water gas shift and carbon dioxide removal steps.

Owner:TOPSOE AS

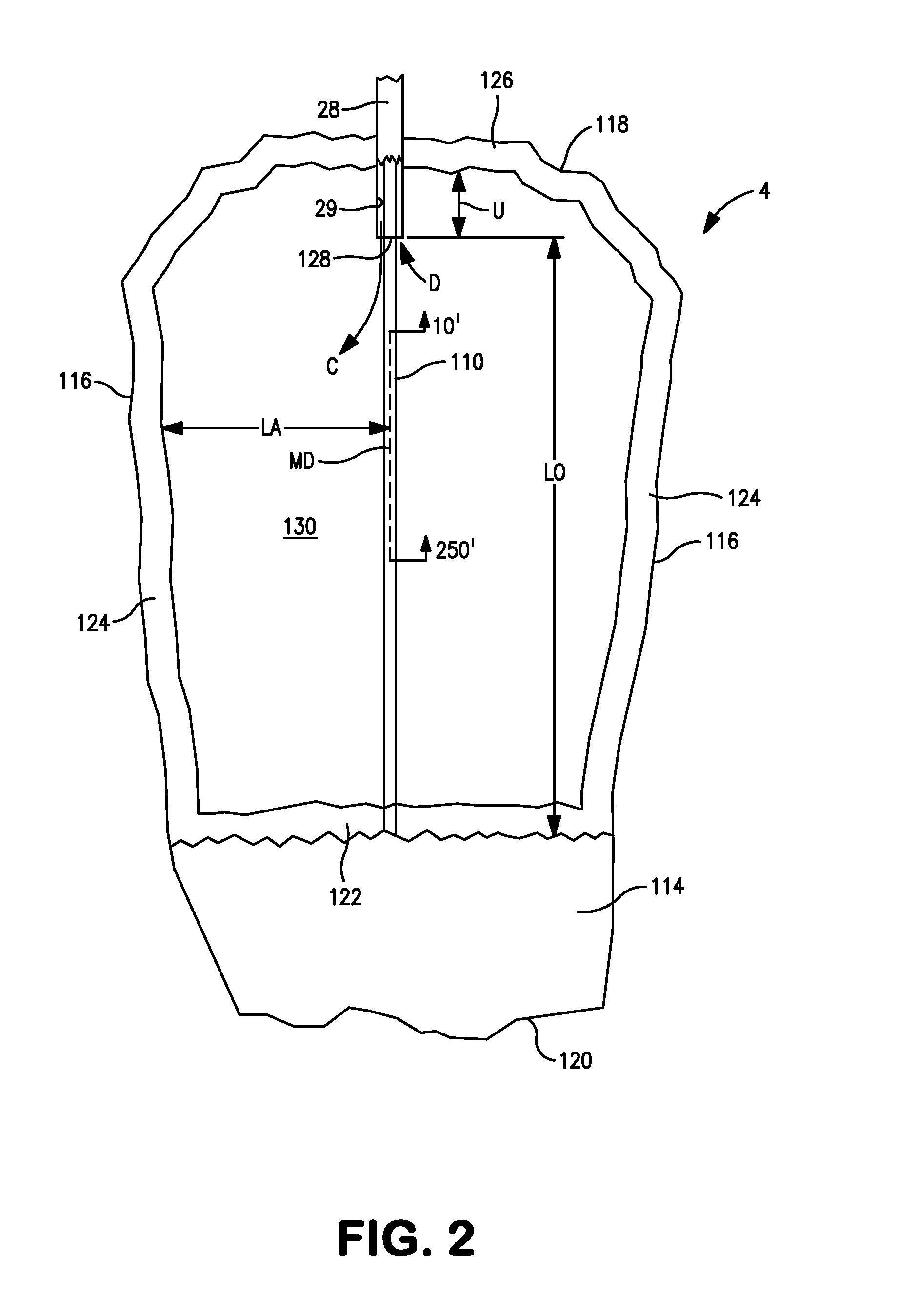

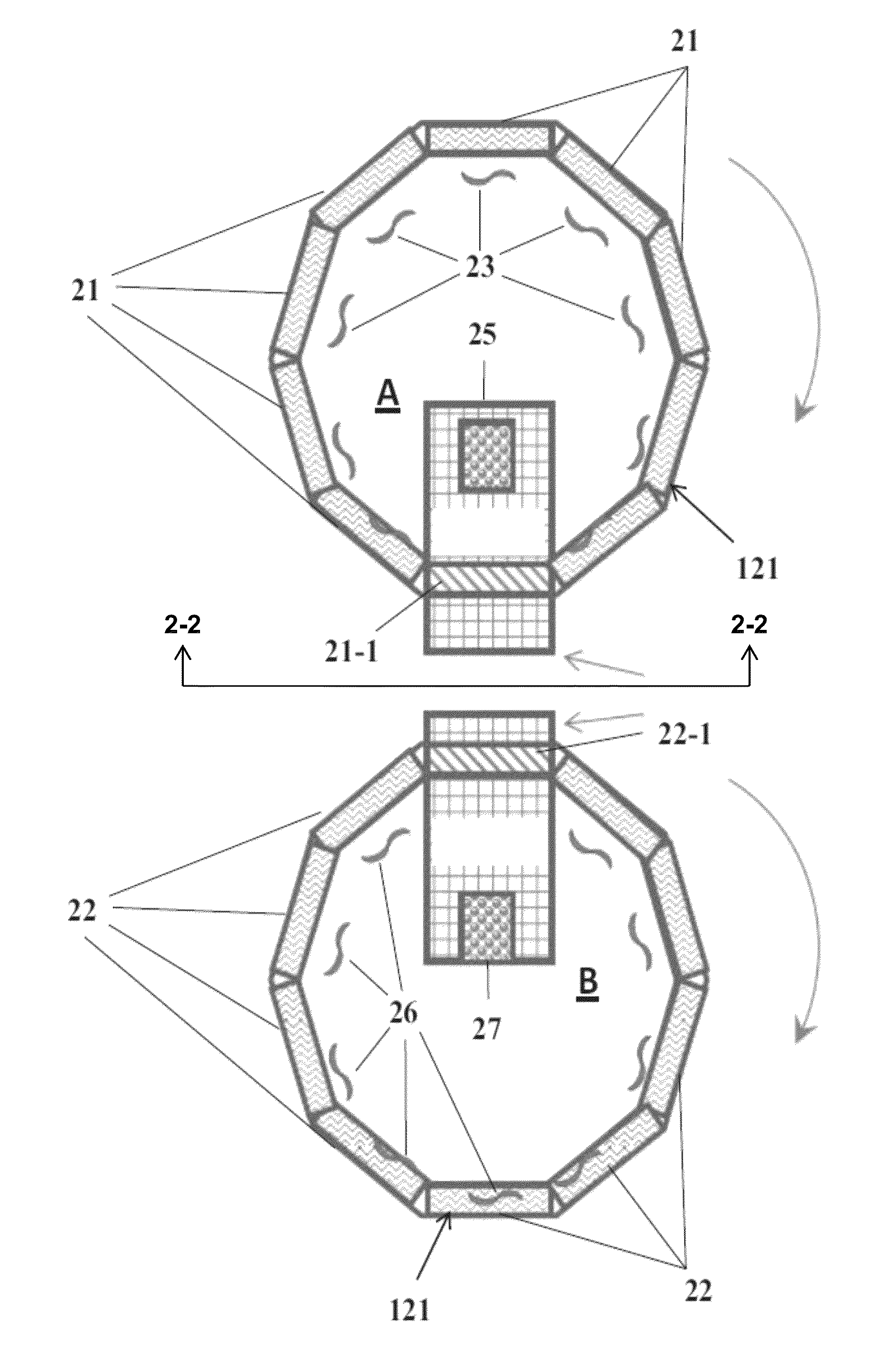

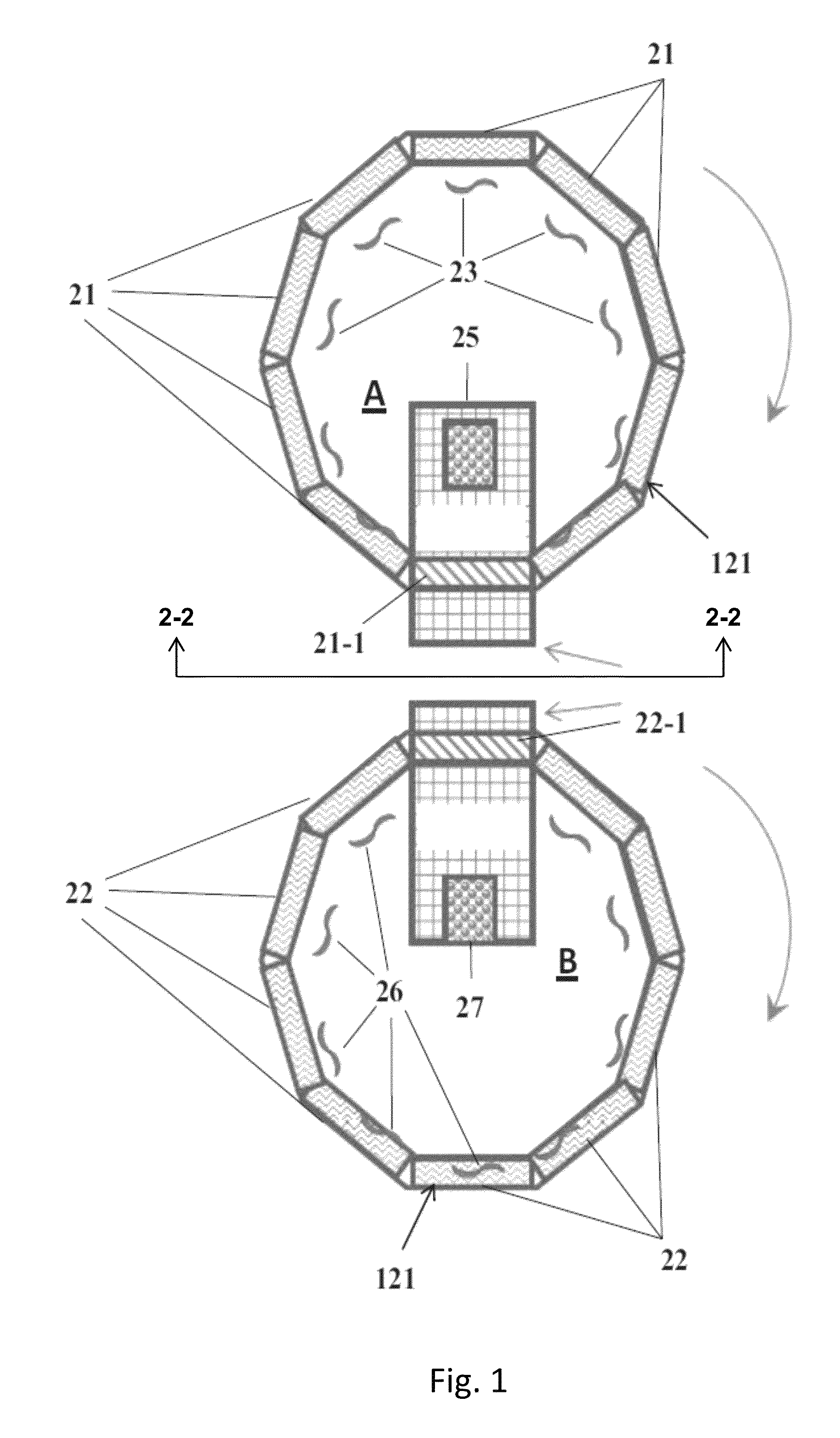

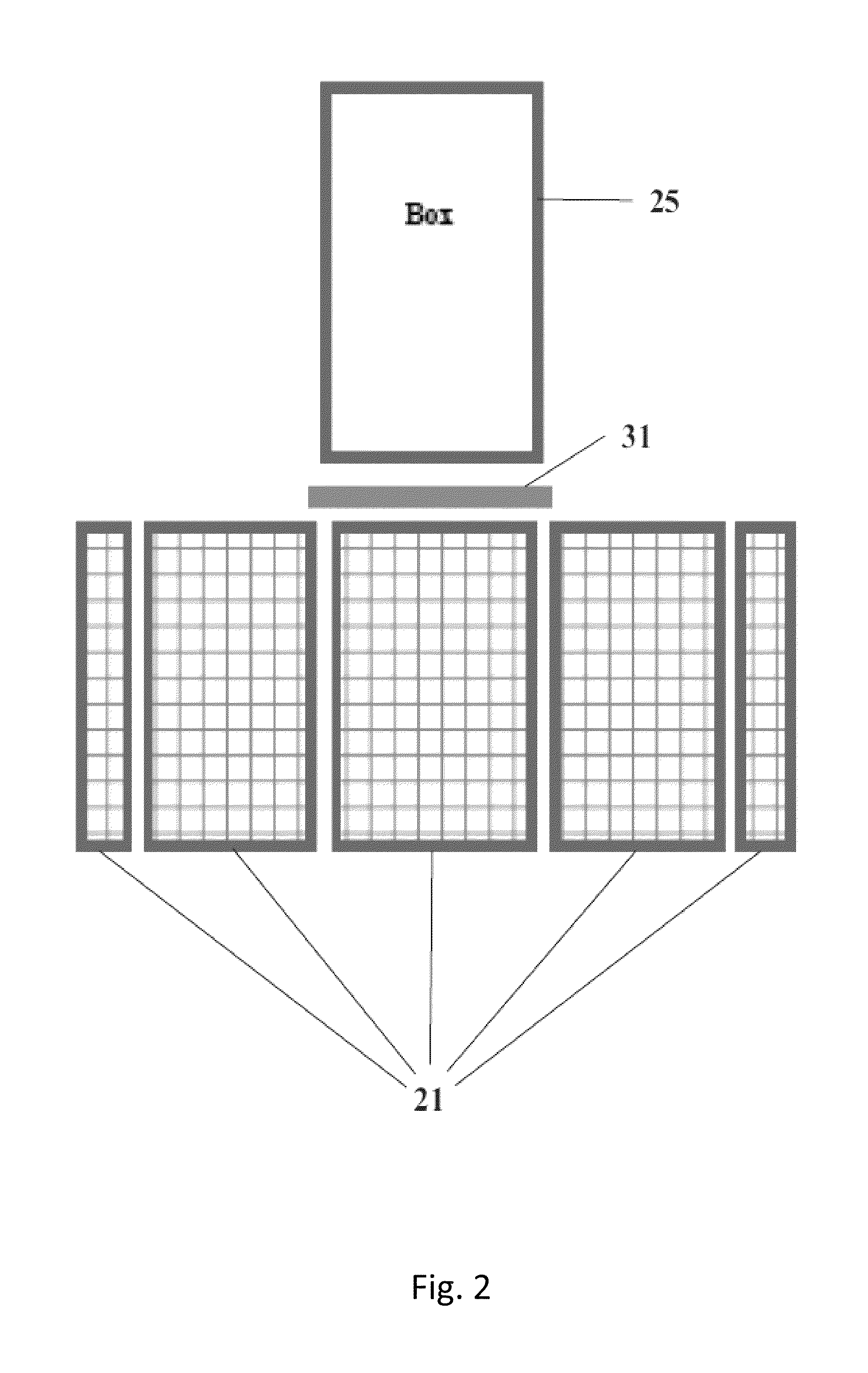

Rotating multi-monolith bed movement system for removing co2 from the atmosphere

ActiveUS20150273385A1Improve efficiencyLow costGas treatmentIsotope separationPorous substrateSorbent

A system for removing carbon dioxide from a carbon dioxide laden gas mixture, the system comprising two groups of carbon dioxide removal structures, each removal structure within each group comprising a porous solid mass substrate supported on the structure and a sorbent that is capable of adsorbing or binding to carbon dioxide, to remove carbon dioxide from a gas mixture, the sorbent being supported upon the surfaces of the porous mass substrate solid; an endless loop support for each of the groups of the removal structures, the endless loop support being so arranged as to move the support structures of each group along a closed curve while being exposed to a stream of the gas mixture; and a sealable regeneration box at one location along each of the endless loop supports, in which, when a porous solid mass substrate is sealed in place therein, carbon dioxide adsorbed upon the sorbent is stripped from the sorbent and the sorbent regenerated; each removal structural supporting a porous substrate in a position to be exposed to a flow of carbon dioxide laden gas mixture so as to allow for the removal of CO2 from the gas mixture; the number of removal structures to the number of regeneration boxes being directly determined by the ratio of the time to adsorb CO2, from a base level to desired level on the sorbent, to the time to strip the CO2 from the desired level back to the base level.

Owner:GLOBAL THERMOSTAT OPERATIONS LLC

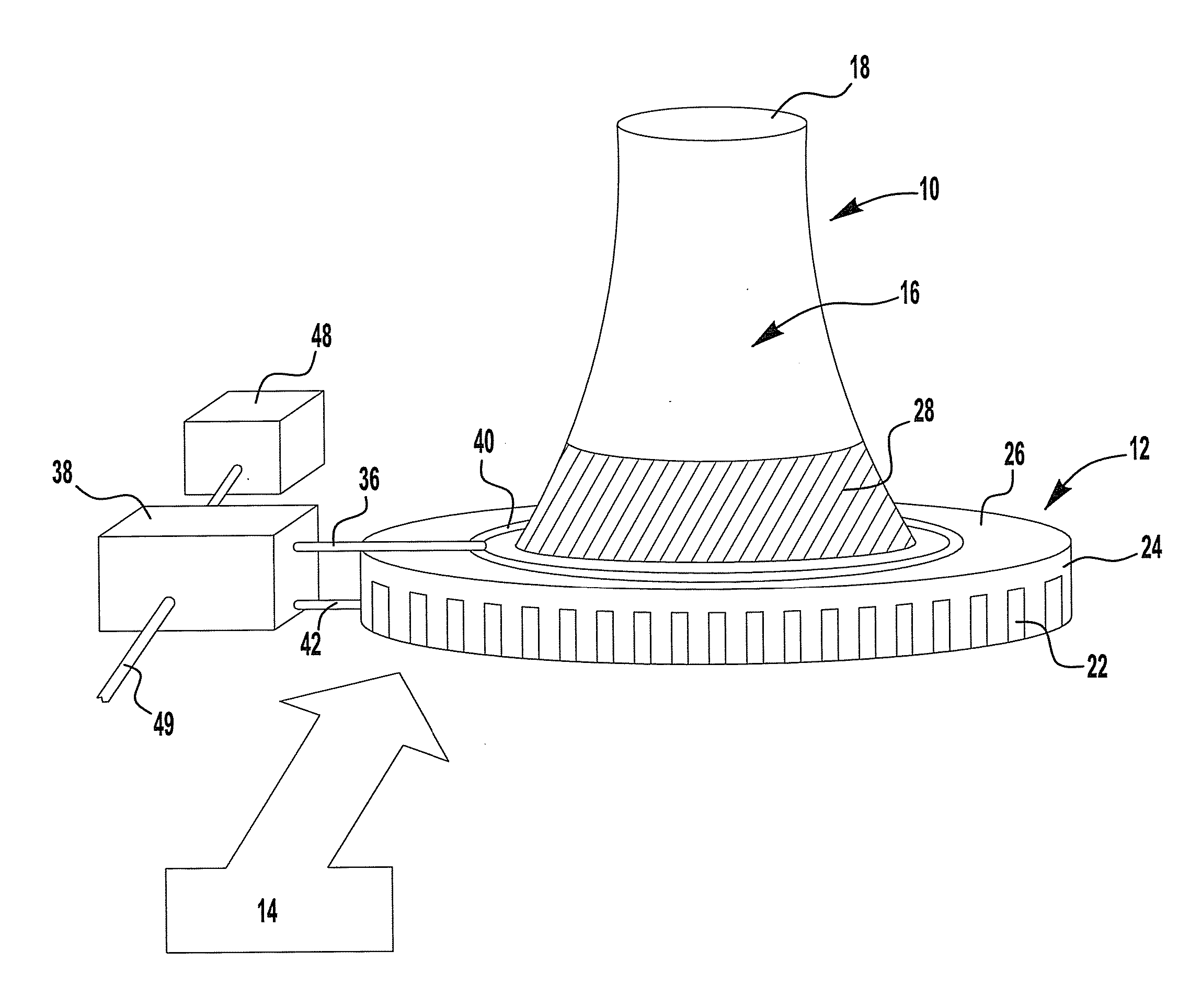

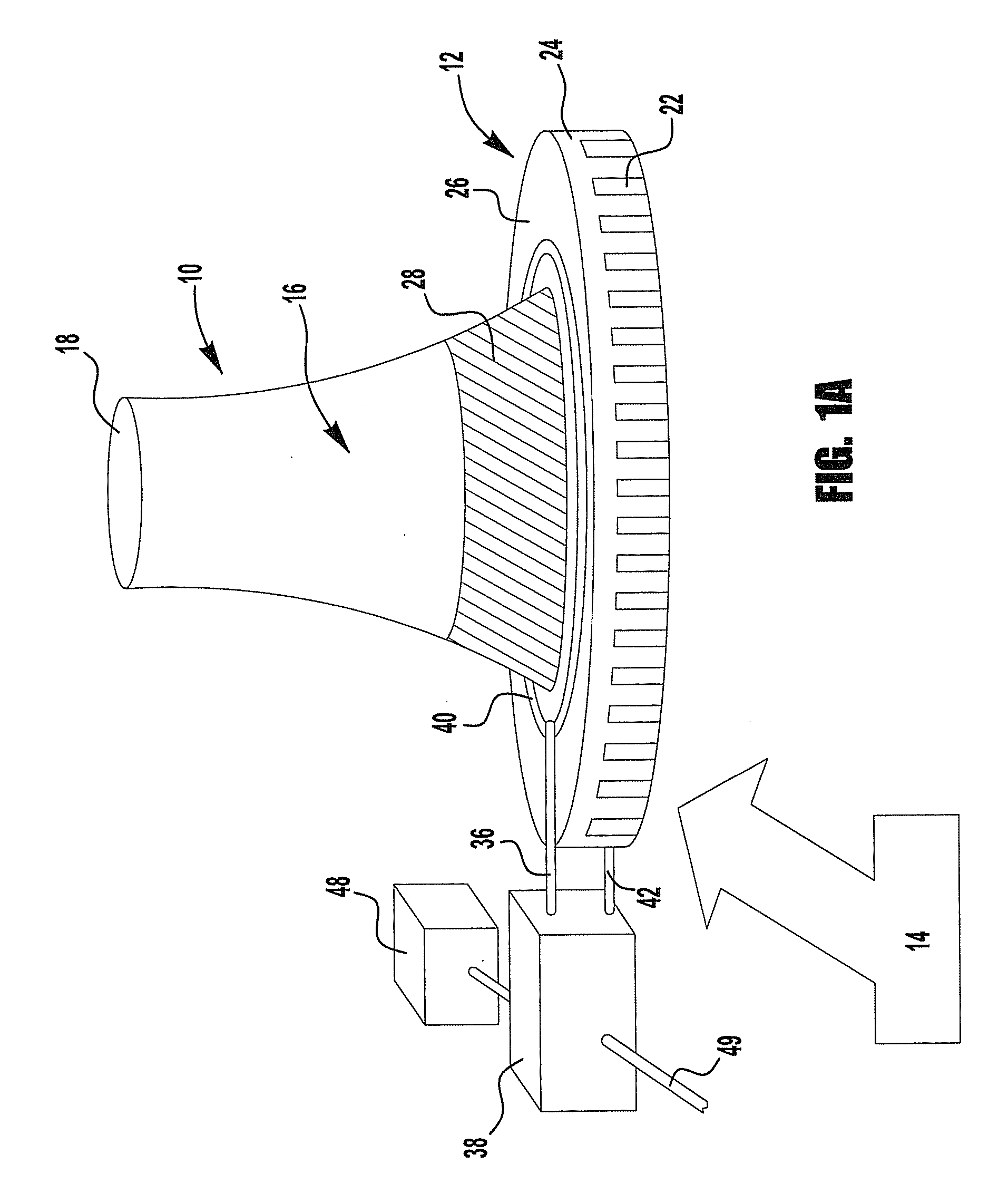

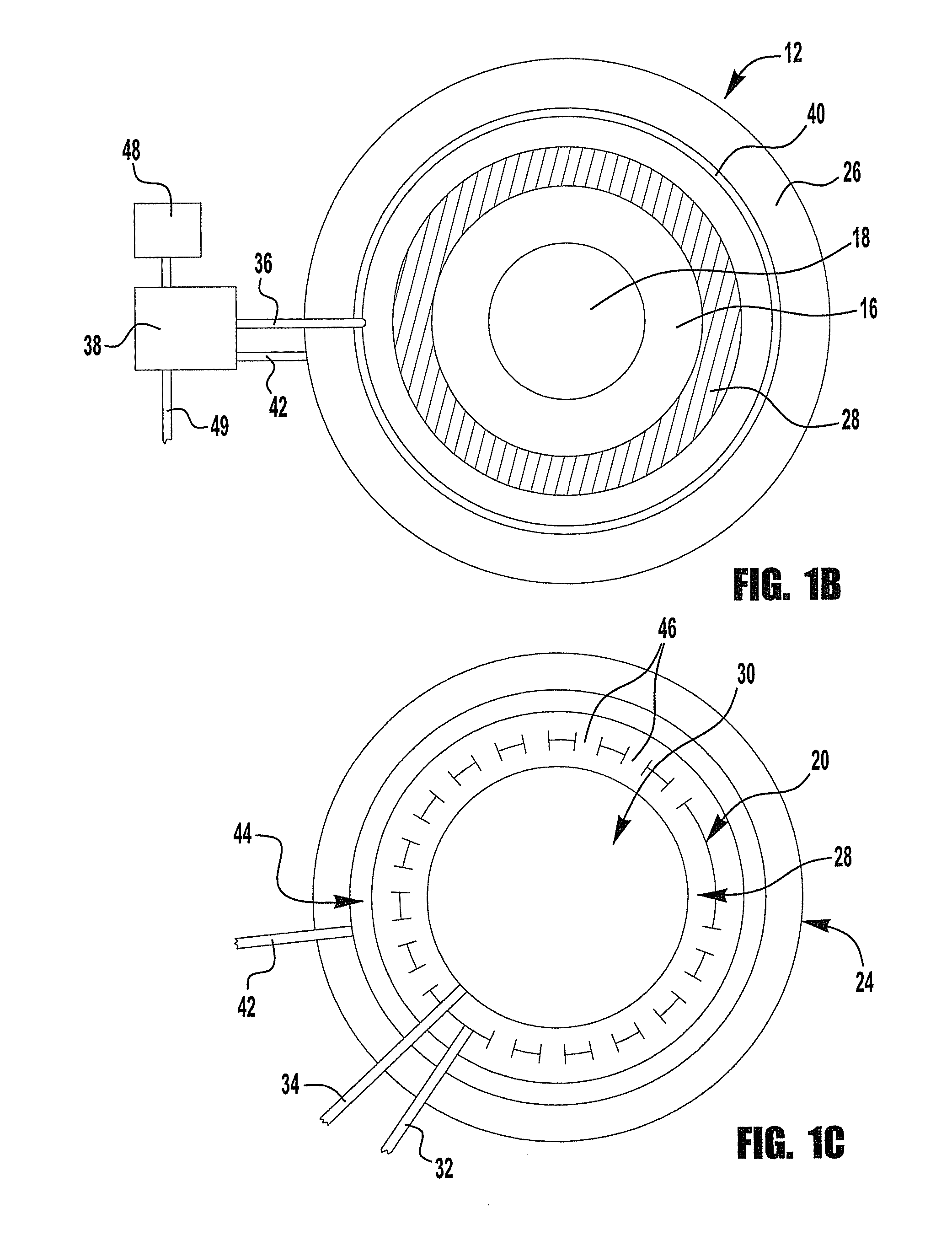

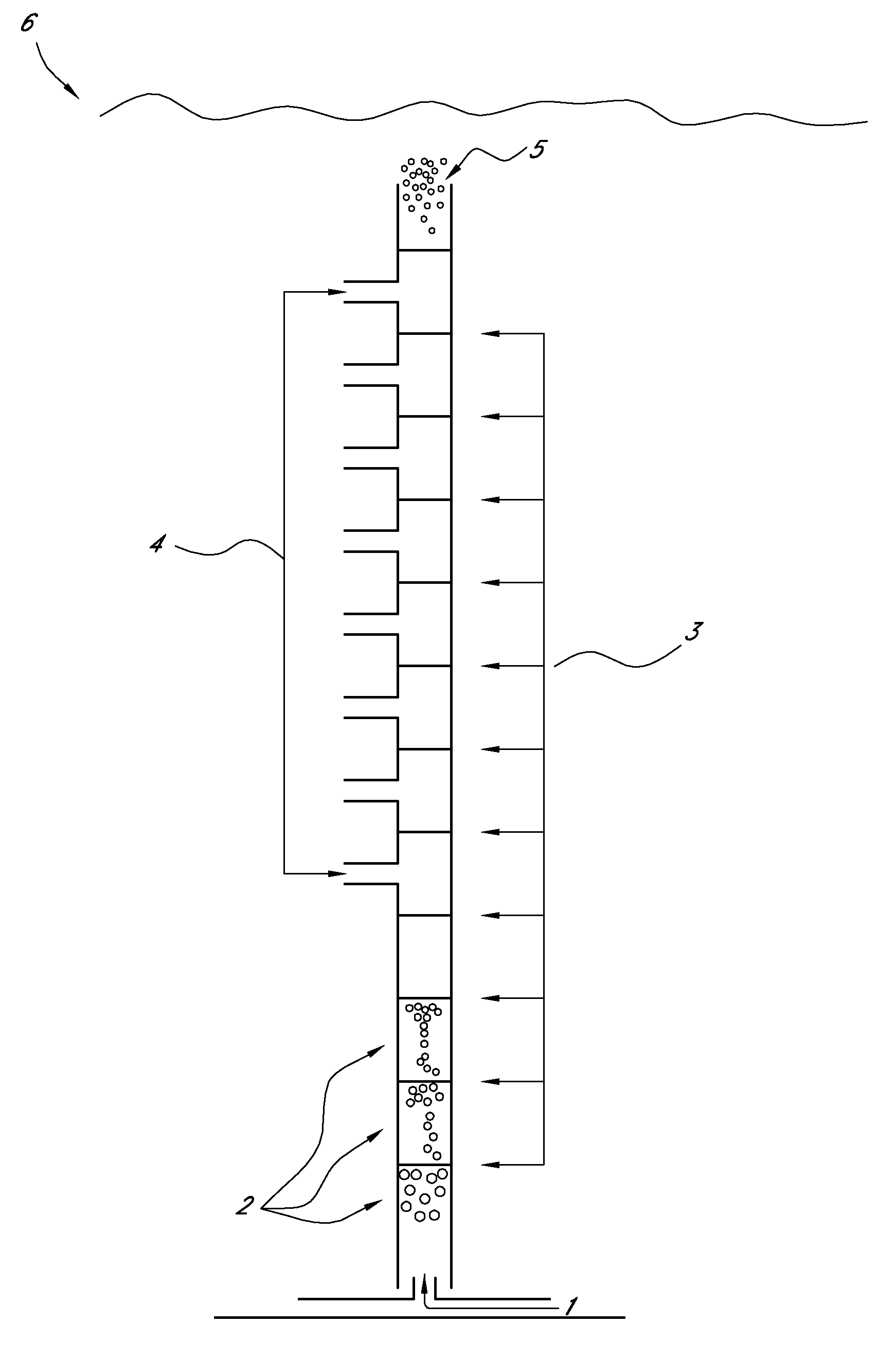

Carbon dioxide removal systems

A system for removing CO2 from air such as atmospheric air is described that uses a cooling tower, a pseudo-cooling tower, or a wind capture device to provide a large volume of atmospheric air. A CO2 capture apparatus is positioned to contact atmospheric air moving towards or within the cooling tower, pseudo-tower, or wind capture device, and includes wherein the CO2 capture apparatus includes a CO2 binding agent that binds to CO2 in atmospheric air. An associated reprocessing apparatus releases C02 from the binding agent, directs the released CO2 to a CO2 storage chamber, and returns the binding agent to the CO2 capture apparatus. A system for removing CO2 from flue gas is also described.

Owner:COAWAY

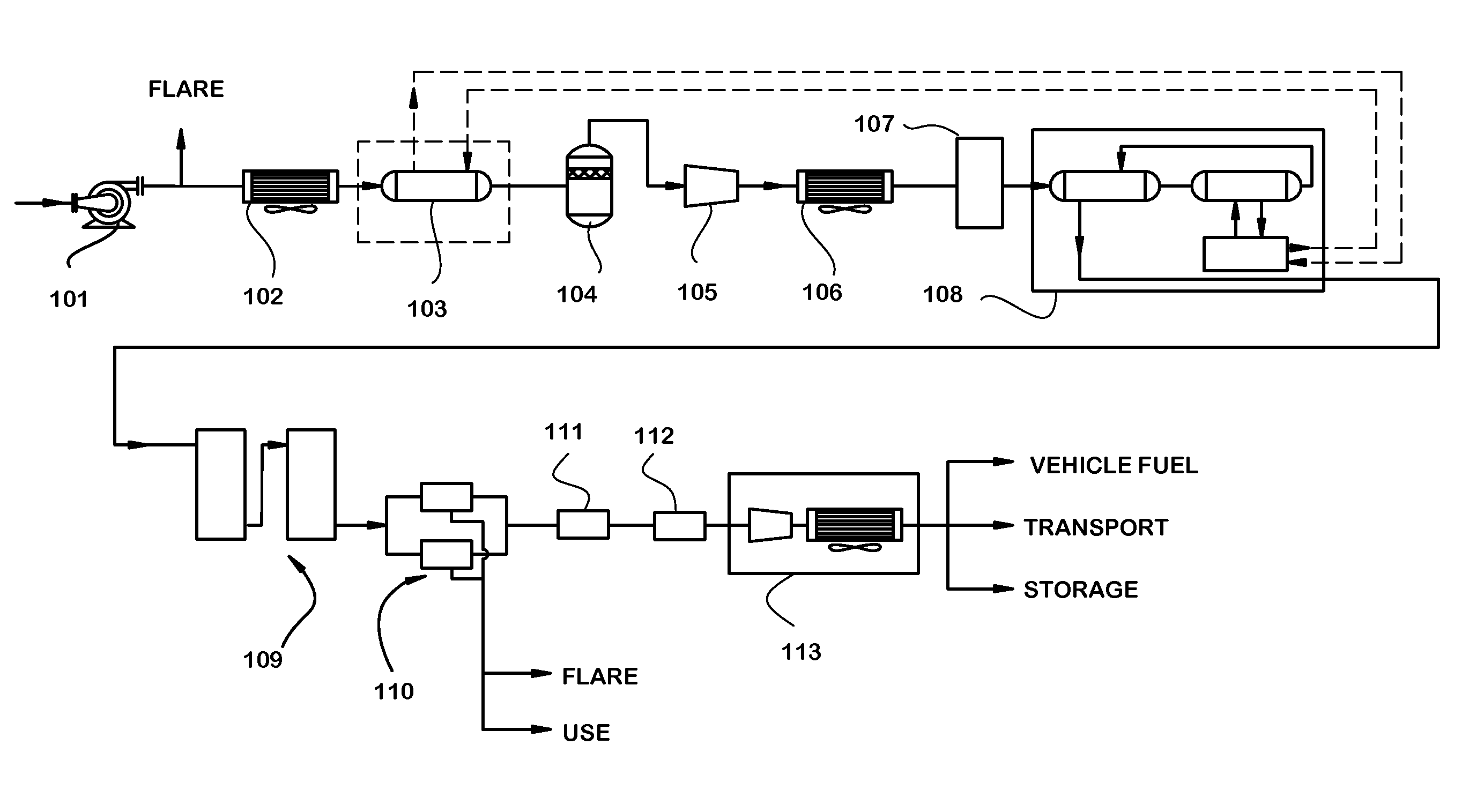

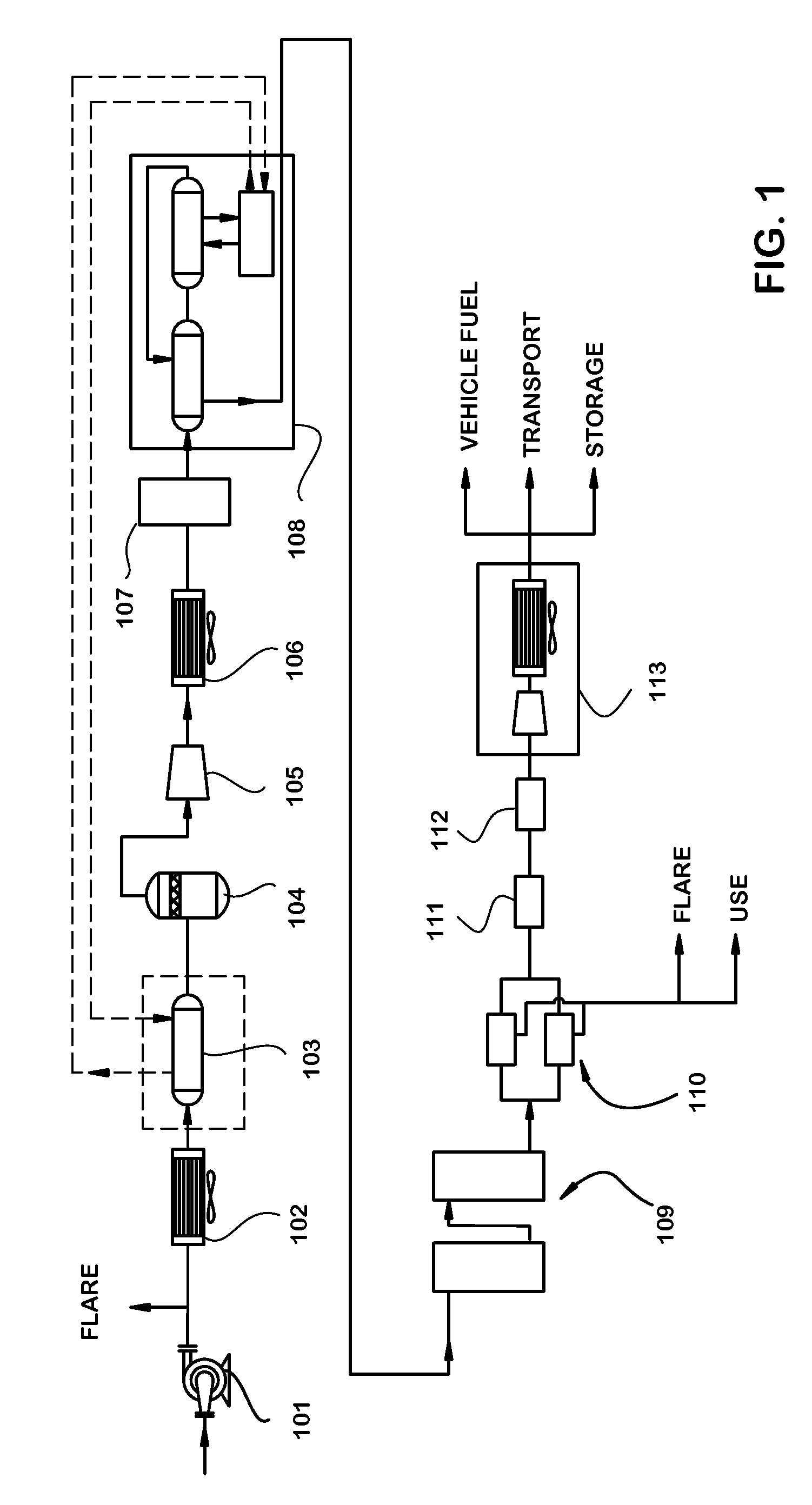

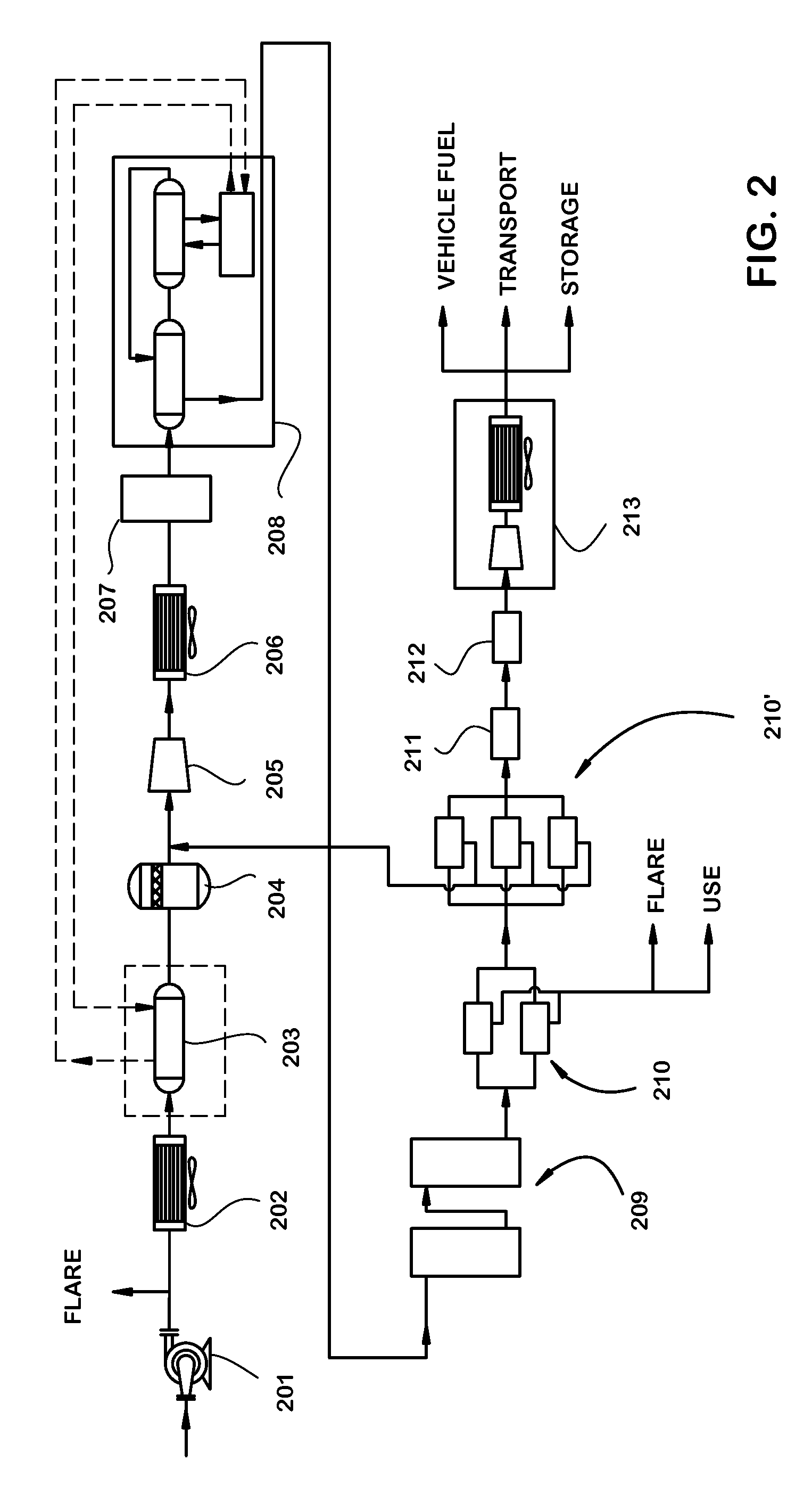

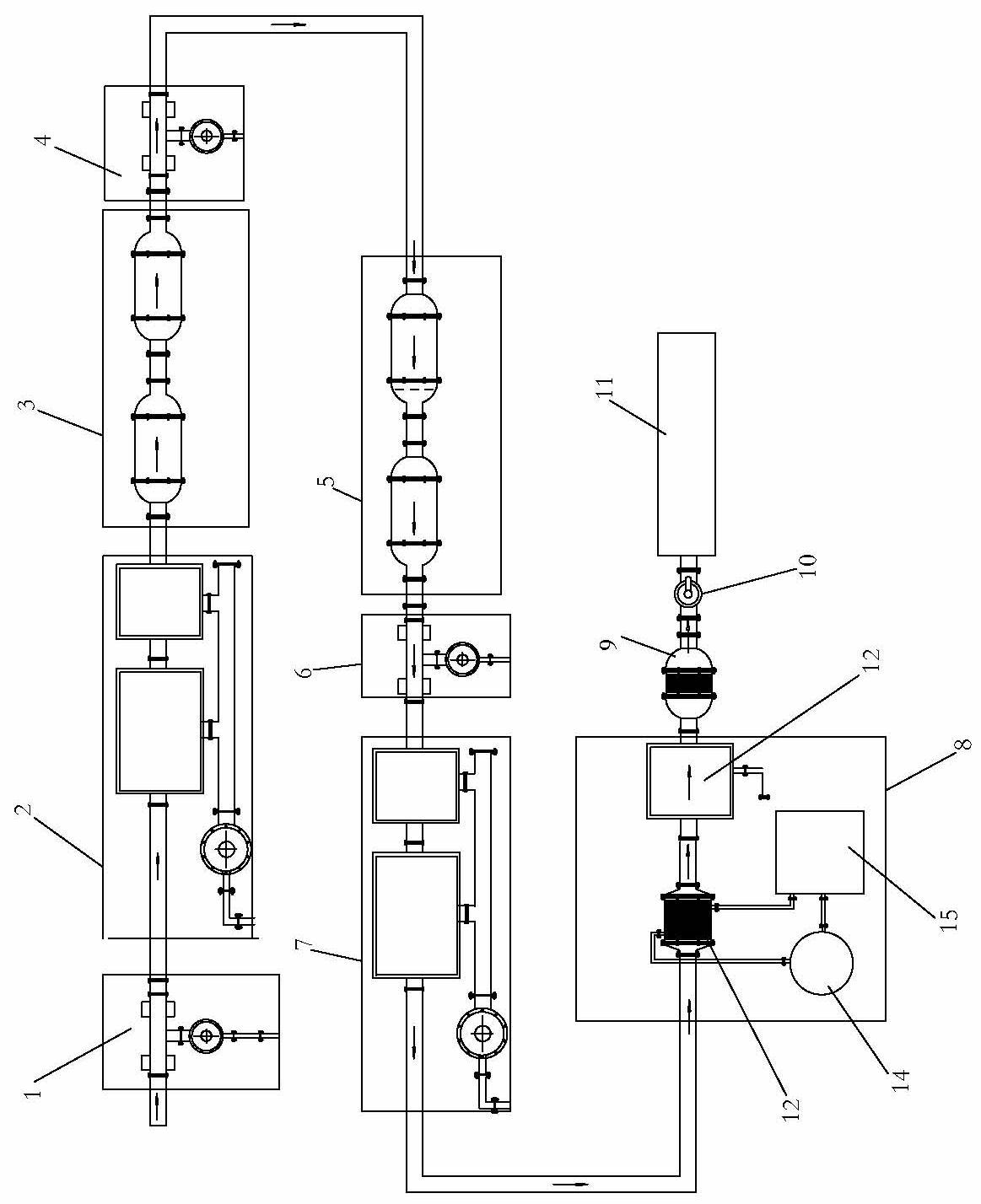

Method for production of a compressed natural gas equivalent from landfill gas and other biogases

ActiveUS8999036B2Reduce maintenanceLess powerBioreactor/fermenter combinationsSolidificationActivated carbonCompressed natural gas

Biogas is converted to a vehicle fuel equivalent to compressed natural gas high in methane in a simple, low cost process involving steps of refrigeration, non-regenerative activated carbon purification and carbon dioxide removal using low-pressure membrane technology.

Owner:STEARNS CONRAD SCHMIDT CONSULTING ENGINEERS

Diesel exhaust gas scrubbing method for carbon dioxide removal

InactiveUS20090162922A1Minimize impactReducing carbon dioxideCombination devicesGas treatmentExhaust fumesDiesel exhaust

Systems and methods for removing carbon dioxide from gas, e.g., diesel exhaust gas, are provided. The systems involve uptake of carbon dioxide by algae in water to which the gas is exposed.

Owner:CARBON CAPTURE CORP

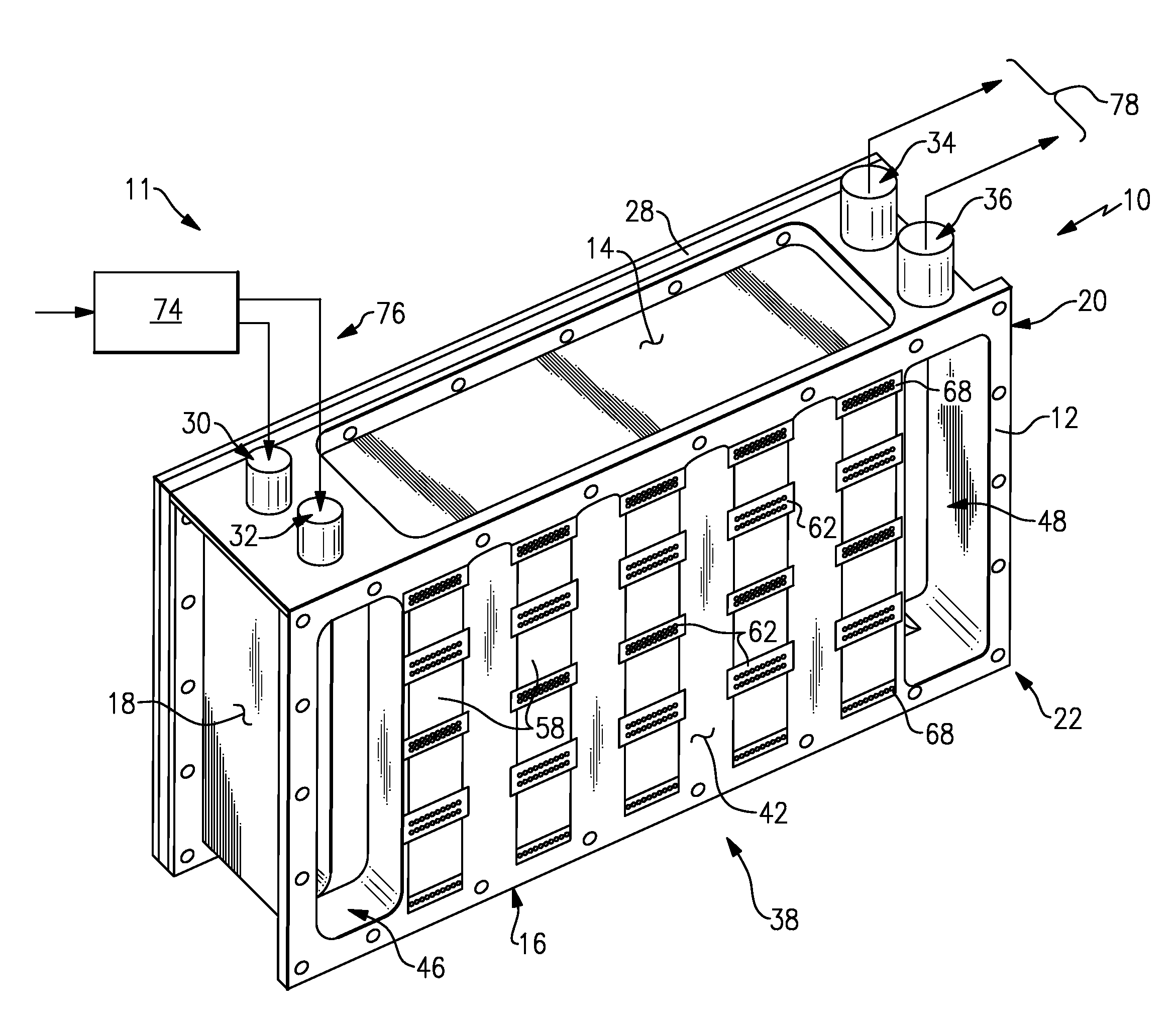

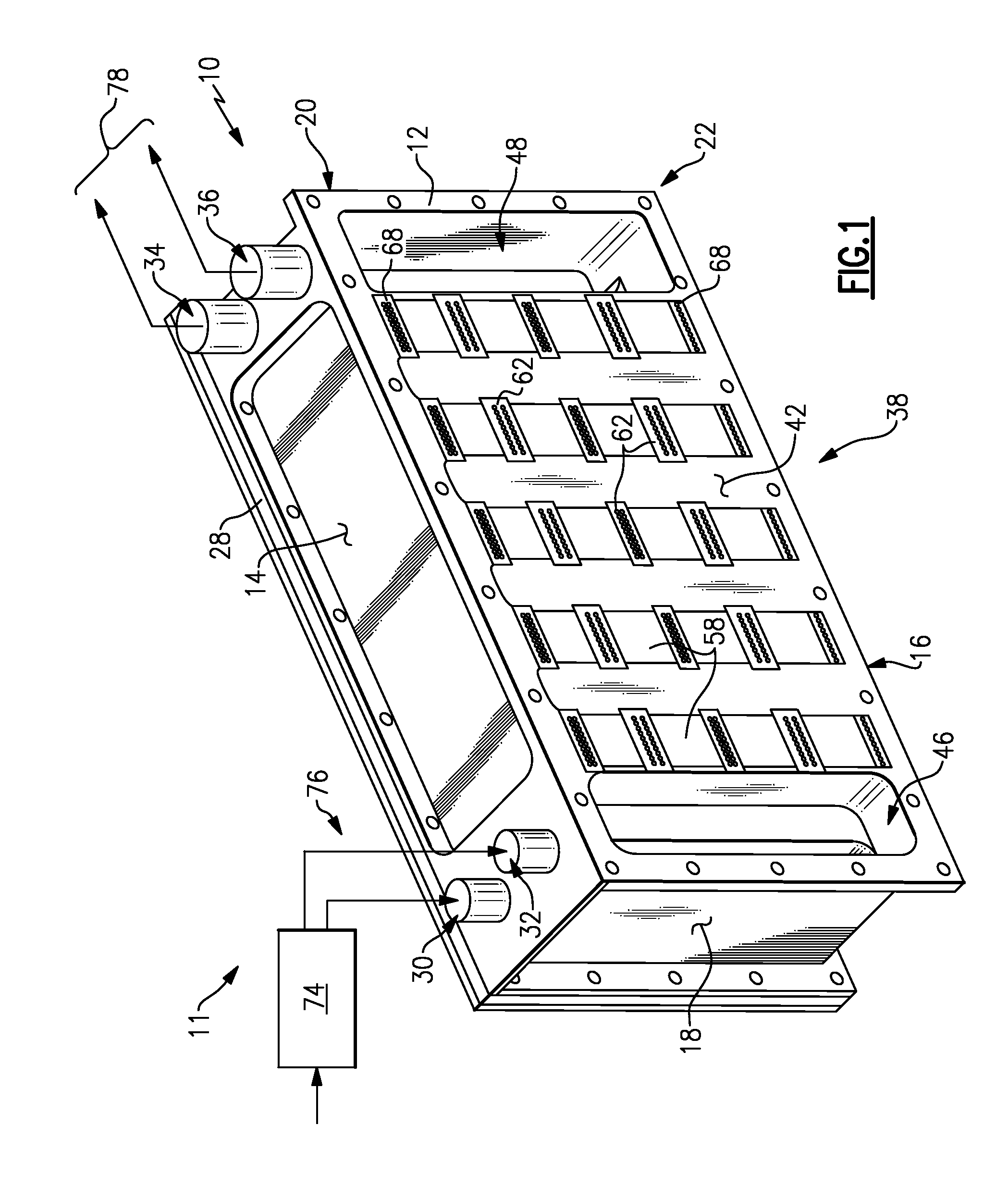

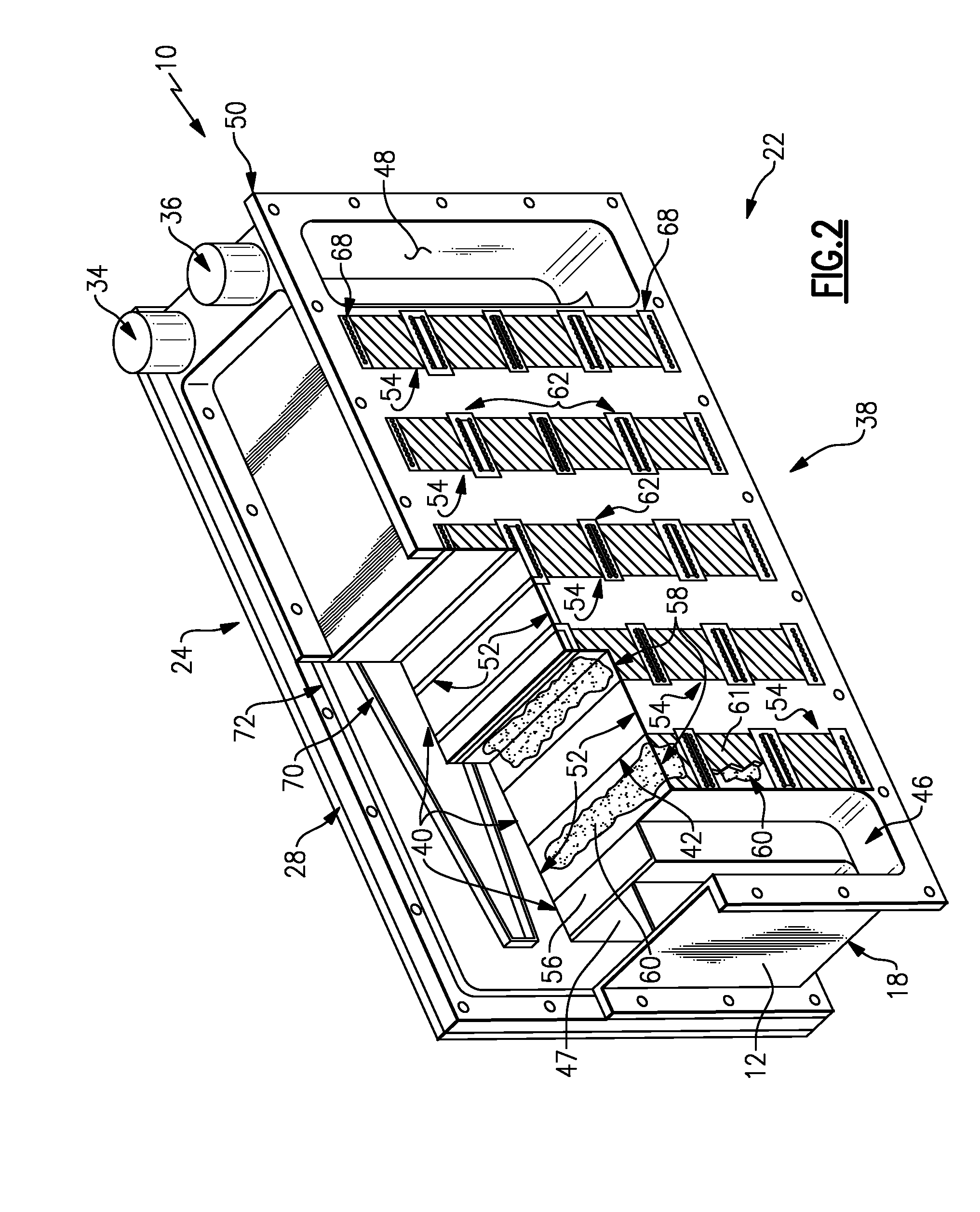

Swing bed canister with heat transfer features

ActiveUS20080233019A1Efficient use ofEasy to assembleCombination devicesGas treatmentDesorptionEngineering

A swing bed canister assembly for a regenerative carbon dioxide removal system includes a housing that includes an integrally formed central wall that divides an adsorbing amine bed from a desorbing amine bed. The central wall defines spaces for each of the amine beds so that each portion of the desorbing amine bed is disposed in thermal communication with an adsorbing amine bed to facilitate desorption.

Owner:HAMILTON SUNDSTRAND CORP

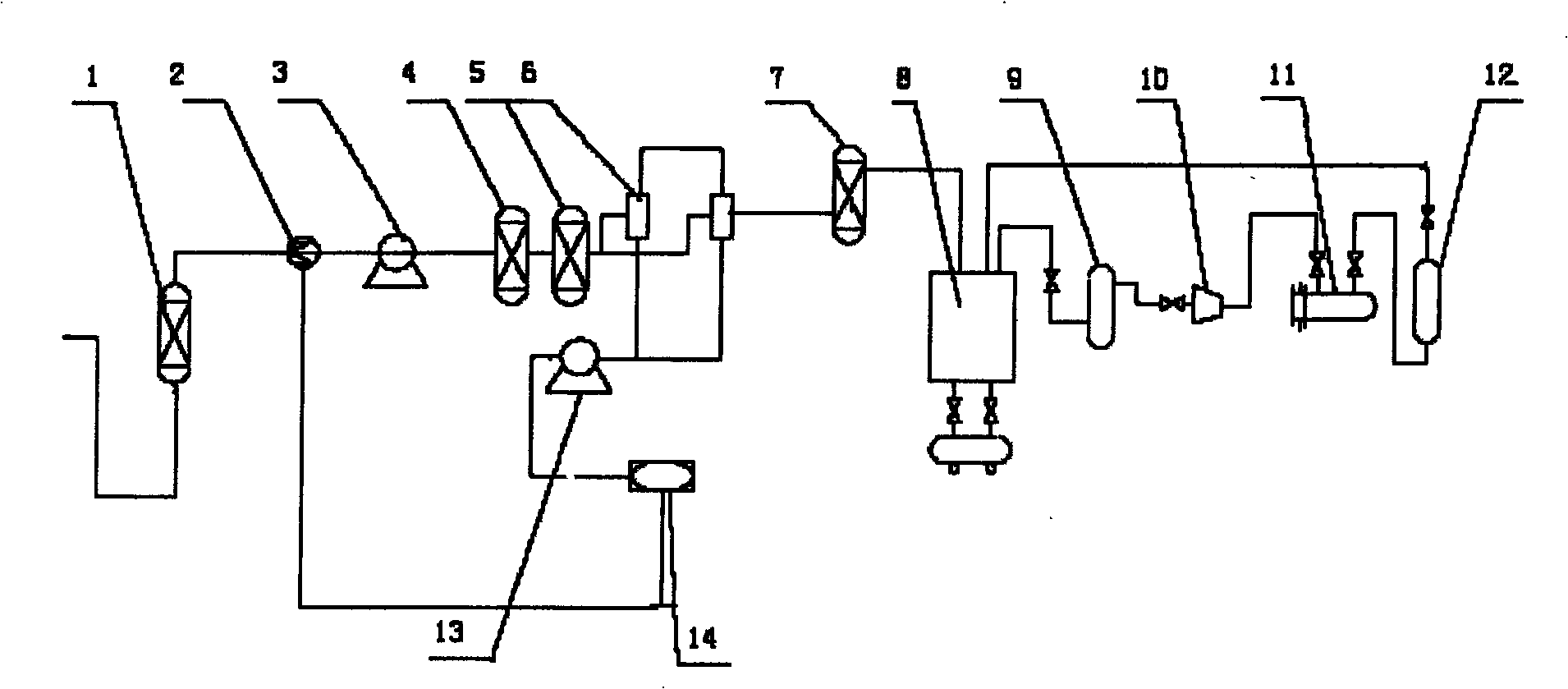

Well head accompanying gas on site recovery purification method

The invention relates to a field recovery and purification method for associated gas at a well head, which is used for the field purification and recovery of the associated gas at the well head. The invention solves the problem of difficult recovery of the associated gas at well heads of remote and dispersed oil field, makes full use of energy and reduces environmental pollution. The technical proposal comprises the following steps: inputting the associated gas into a separator to remove tiny solid particles and heavy hydrocarbon emulsion in the associated gas and reclaim condensed oil; then inputting the gas into a gas preheater for heating and reaching the required purification temperature, inputting the gas into a compressor for reaching certain pressure, and inputting the gas into a devulcanizer for removing hydrogen sulfide gas; inputting the devulcanized associated gas into a decarburization tank for removing carbon dioxide; sending the gas into a purification assembly and a deep drain sump for carrying out deep dehydration and carbon dioxide removal through a molecular film; and finally sending the gas into a cold box for decompression and cooling, and preparing the associated gas into liquefied gas which is inputted into a storage tank. The method applicable to oil fields can realize the aims of energy conservation and emission reduction; the method facilitates the skid migration with simple structure and convenient use; and the recovery operation is free of field limitations.

Owner:SOUTHWEST PETROLEUM UNIV

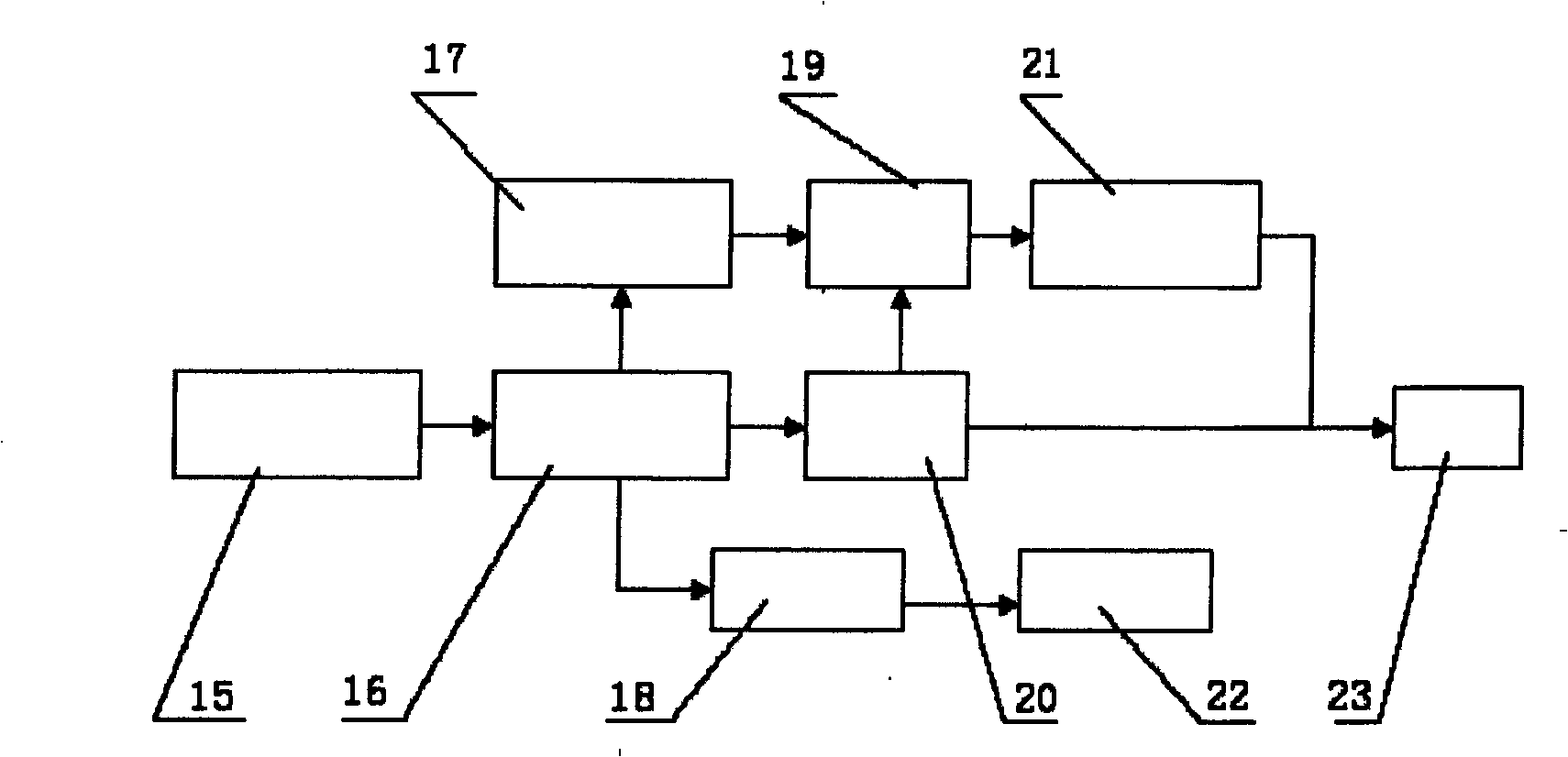

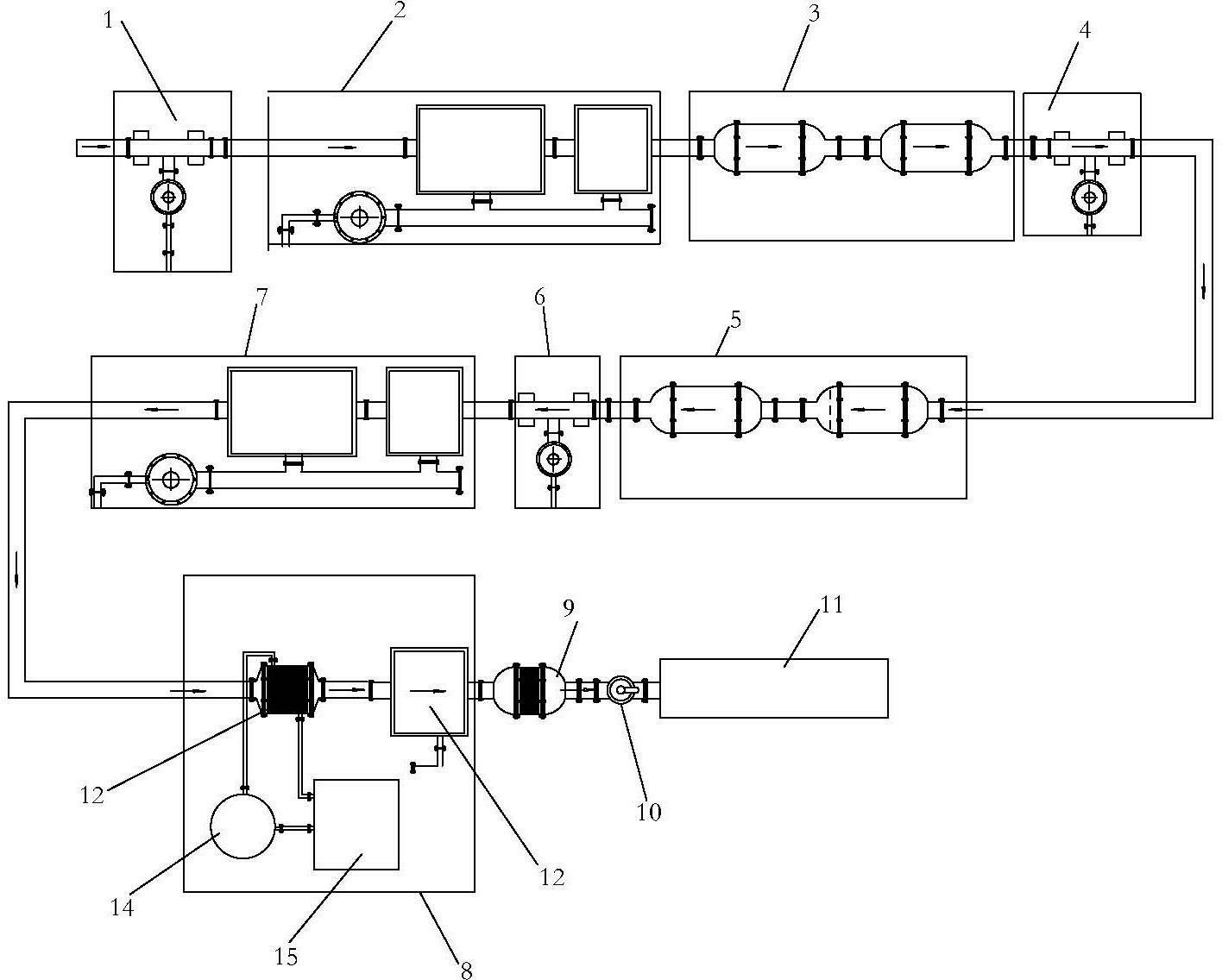

Low-concentration gas power generation treatment method

InactiveCN102424767AReduce pollutionThe effect is safe and reliableGaseous fuelsEngineeringPollution

The invention relates to a low-concentration gas power generation treatment method, which can effectively realize the effects of preventing environment pollution and saving energy sources when low-concentration gas is utilized for power generation. The method is characterized in that firstly, the low-concentration gas is conveyed into a water settling type bleeding valve by a pumping pump stationfor pressure regulation, then, large-particle impurities of the gas are filtered by a first water sealing type bleeding flame arrestor, next, the gas enters a pipeline gas cooling displacer for carbon dioxide removal and enters a water settling type waterproof valve, dissociative liquid in the gas is removed, next, the gas enters the gas pipeline gas cooling displacer for further carbon dioxide removal and dissociative liquid removal, the gas is subjected to water sealing isolation by the water sealing type bleeding flame arrestor and passes through a condensing dehydration system, the impurities in the gas are subjected to temperature reduction and cooling, the dehydration is carried out, and finally, the gas enters a cylinder through a dry type flame arrestor and an explosion-proof electromagnetic valve to be combusted for work application and power generation. The treatment method has the advantages that safety and reliability are realized, the treated gas can be effectively utilized for power generation, and the environment pollution is reduced.

Owner:ZHENGZHOU TONGMING ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com