Patents

Literature

306 results about "Low-carbon emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The main components of automobile exhaust are carbon dioxide (CO₂) and water vapour (H₂O). Carbon dioxide is the most important anthropogenic greenhouse gas (GHG) and the most significant Greenhouse Gas emitted in the U.S. (with 82-84% of all U.S. emissions). Increases in carbon dioxide concentration are due primarily to fossil fuel use and land-use change.

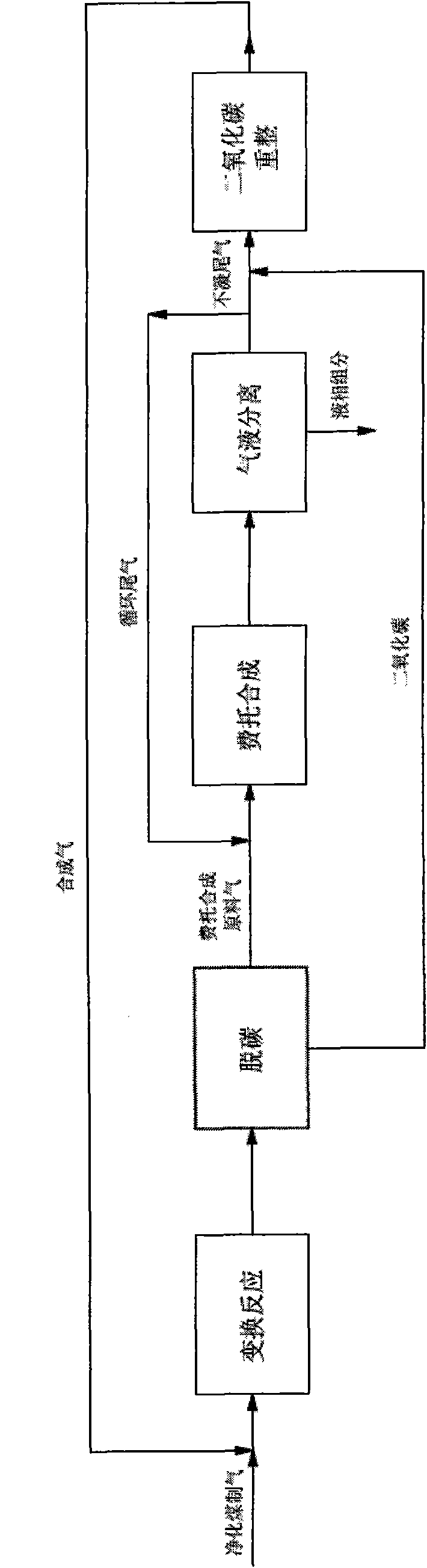

Low-carbon emission Fischer-Tropsch synthesis reaction process

InactiveCN101979468ATake advantage ofAchieve conversionHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionMixed gasLow-carbon emission

The invention discloses a low-carbon emission Fischer-Tropsch synthesis reaction process. The process comprises the following steps of: mediating the ratio of hydrogen to carbon of coal syngas, decarbonizing and separating to obtain a Fischer-Tropsch synthesis raw material gas and carbon dioxide (CO2); after mixing the Fischer-Tropsch synthesis raw material gas and a recycled tail gas, performing a Fischer-Tropsch synthesis reaction in a Fischer-Tropsch synthesis reactor; performing gas-liquid separation on a Fischer-Tropsch synthetic product to obtain a non-condensable tail gas which comprises long-chain hydrocarbons serving as a main liquid component and methane serving as a main component, wherein part of the non-condensable tail gas is used as the recycled tail gas; mixing non-recycled non-condensable tail gas and the CO2 to form a mixed gas; and generating a syngas by performing a reforming reaction on the mixed gas by catalyzing by using a reforming catalyst. The process has the advantages of obtaining the long-chain hydrocarbons, simultaneously greatly reducing the discharge amount of the CO2 in a process, and improving the overall efficiency and the economical efficiency of the process.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

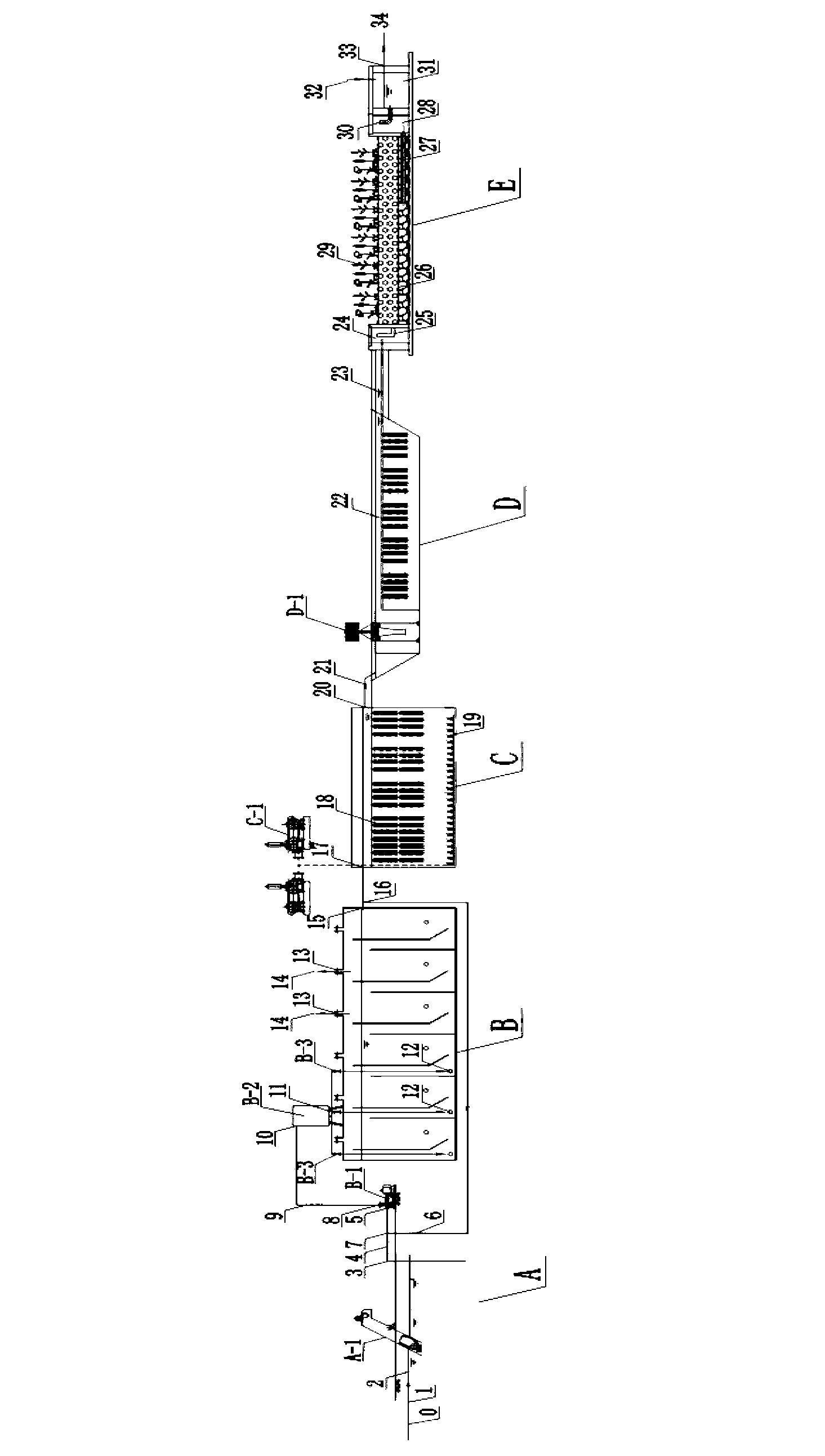

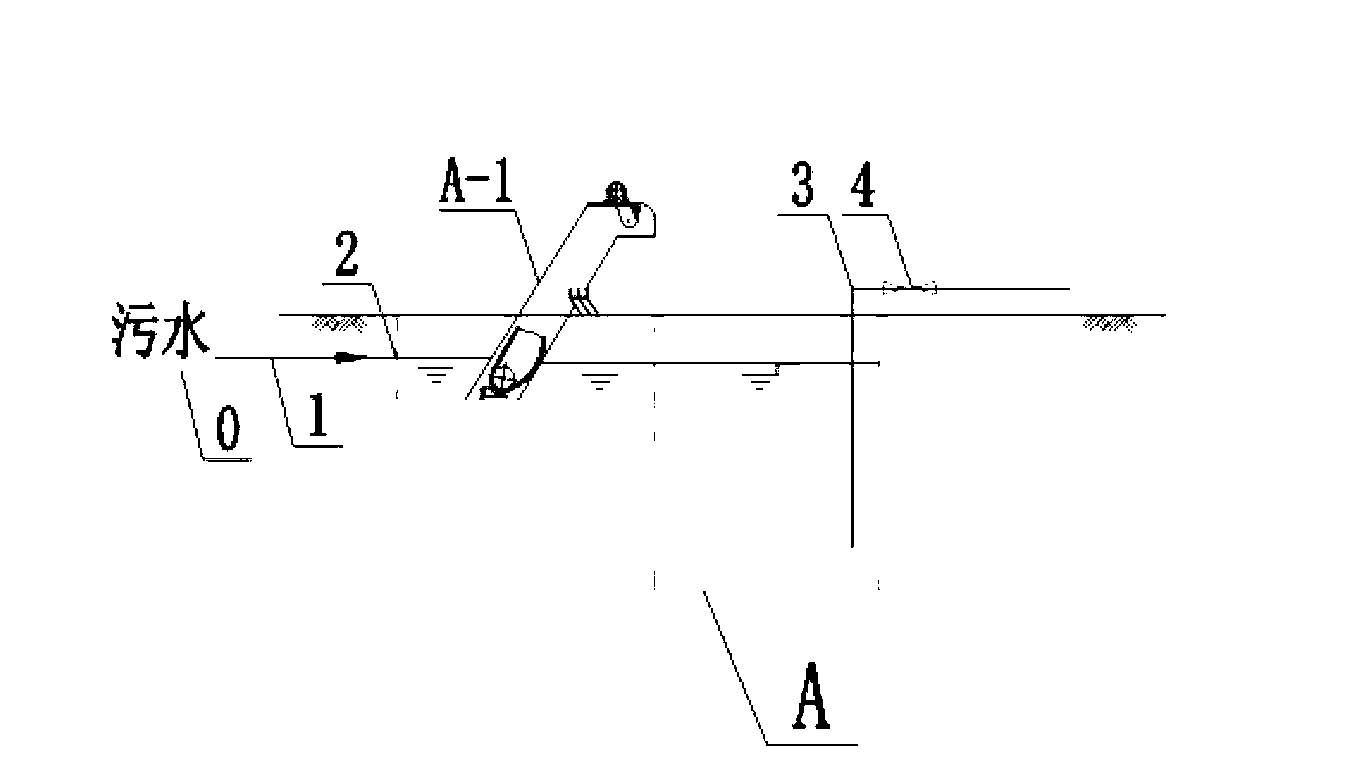

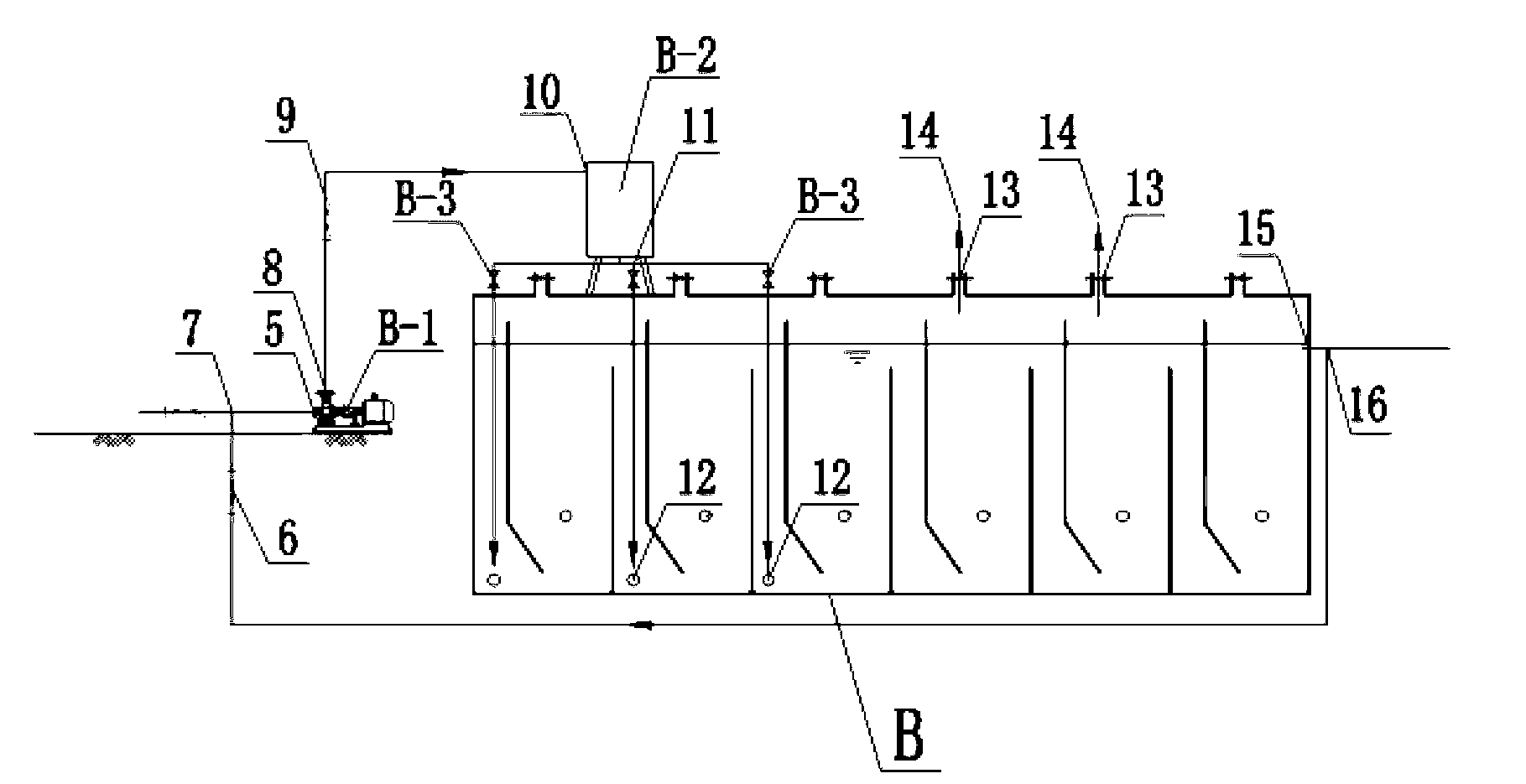

Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

ActiveCN102701521AEasy to handleReduce load ratioEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

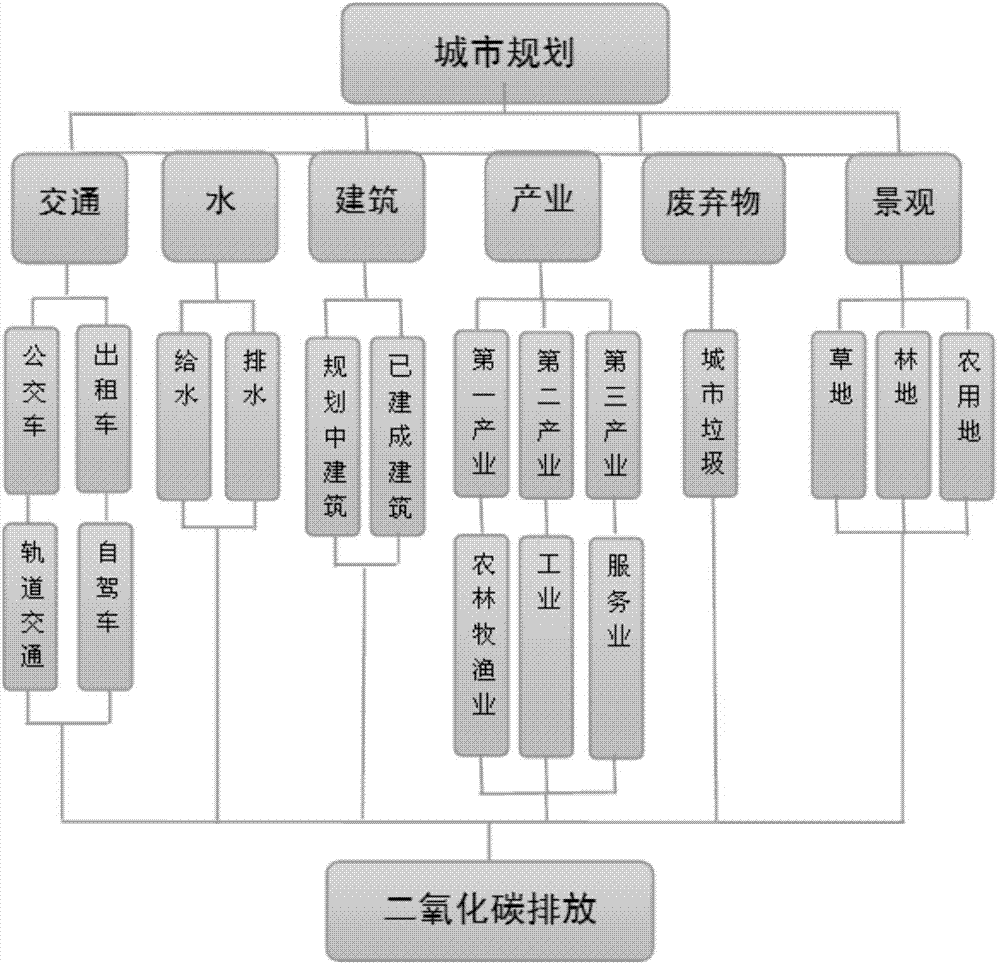

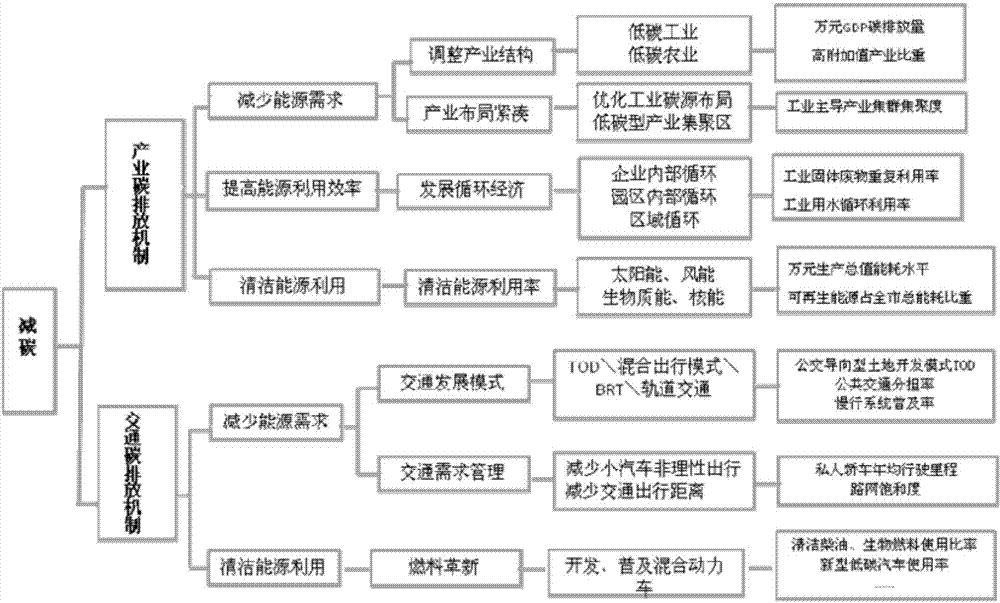

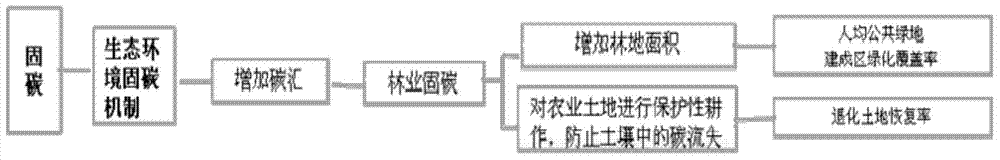

Carbon emission metering method based on city planning

InactiveCN103870678AAchieve quantificationSpecial data processing applicationsCarbon sinkEmission standard

The invention discloses a method and a technique for analyzing and judging the whole carbon emission metering of the city based on city planning. According to the method and the technique, city planning low-carbon emission fields are divided into six aspects, namely traffic, water, buildings, industries, wastes and carbon sink, and the total carbon emission of the whole city is obtained by carbon emission accounting of the specific aspects. According to the method, the energy resource carbon emissions of land are metered and planned by analyzing land usage and gross land characteristics in the city planning, or the traffic carbon emission can be predicted according to traffic road network density and flow and further the total carbon emission of the city at different planning stages is predicted; finally, organic joint of the carbon emission and international and national carbon emission standards is realized while the carbon emission conforms to a city planning system so as to promote low-carbon economic development and low-carbon cause.

Owner:SHANGHAI ZED CONSTR SCI & TECH +1

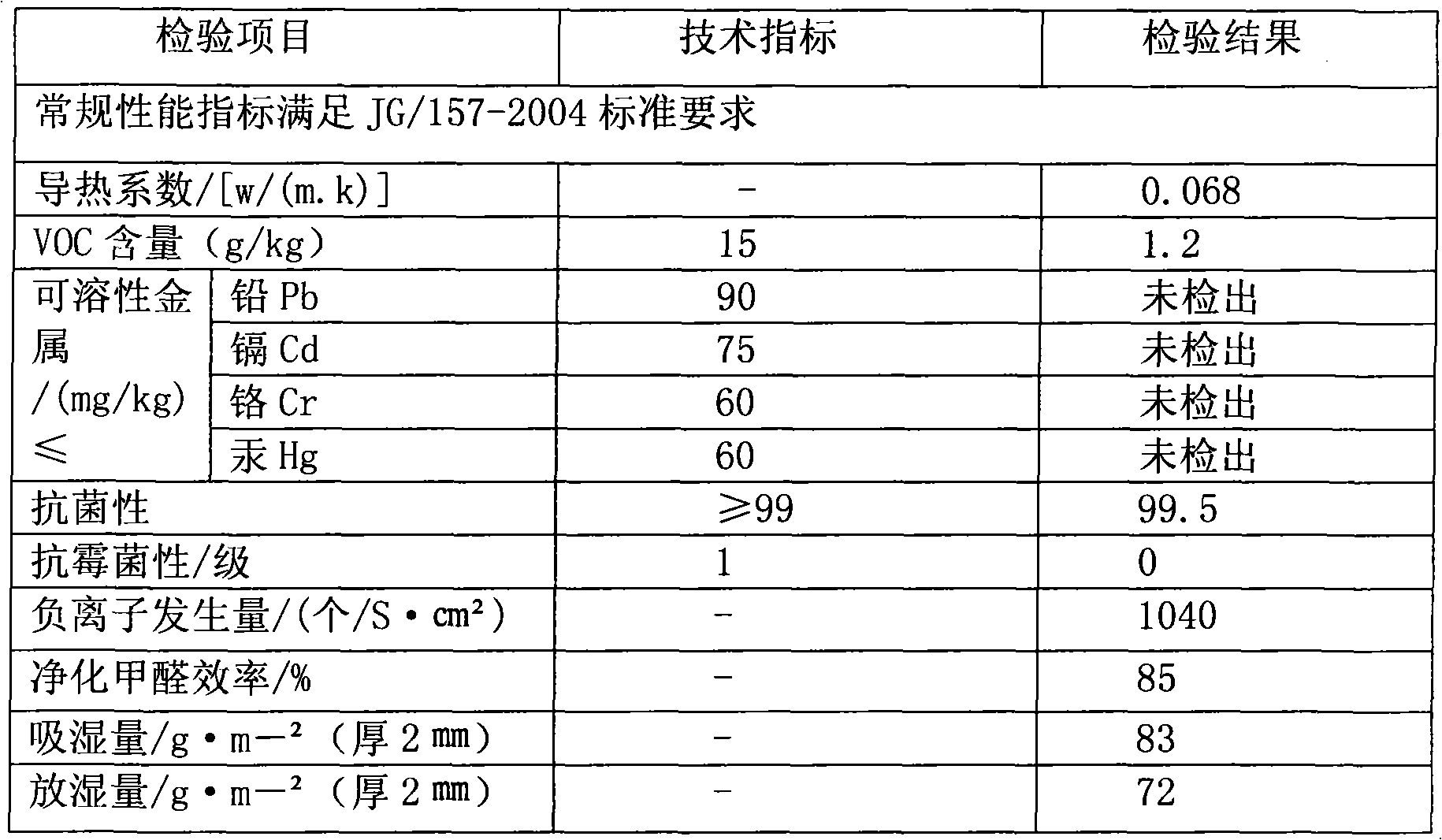

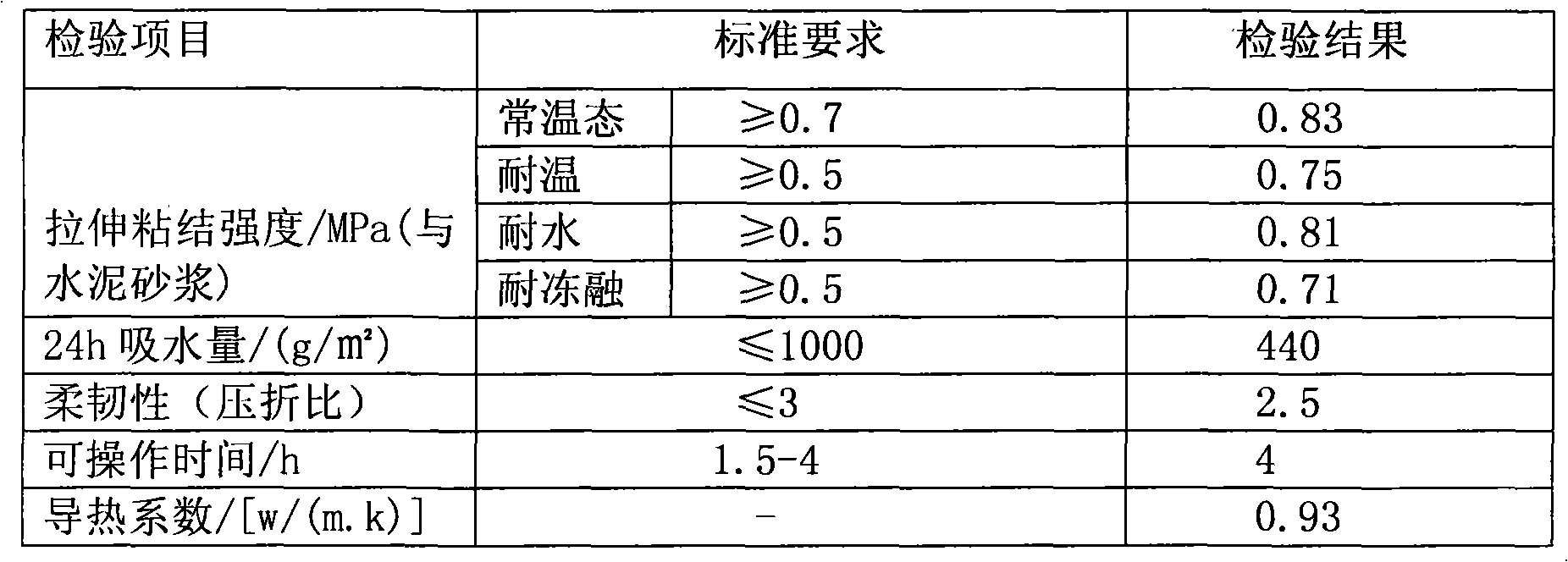

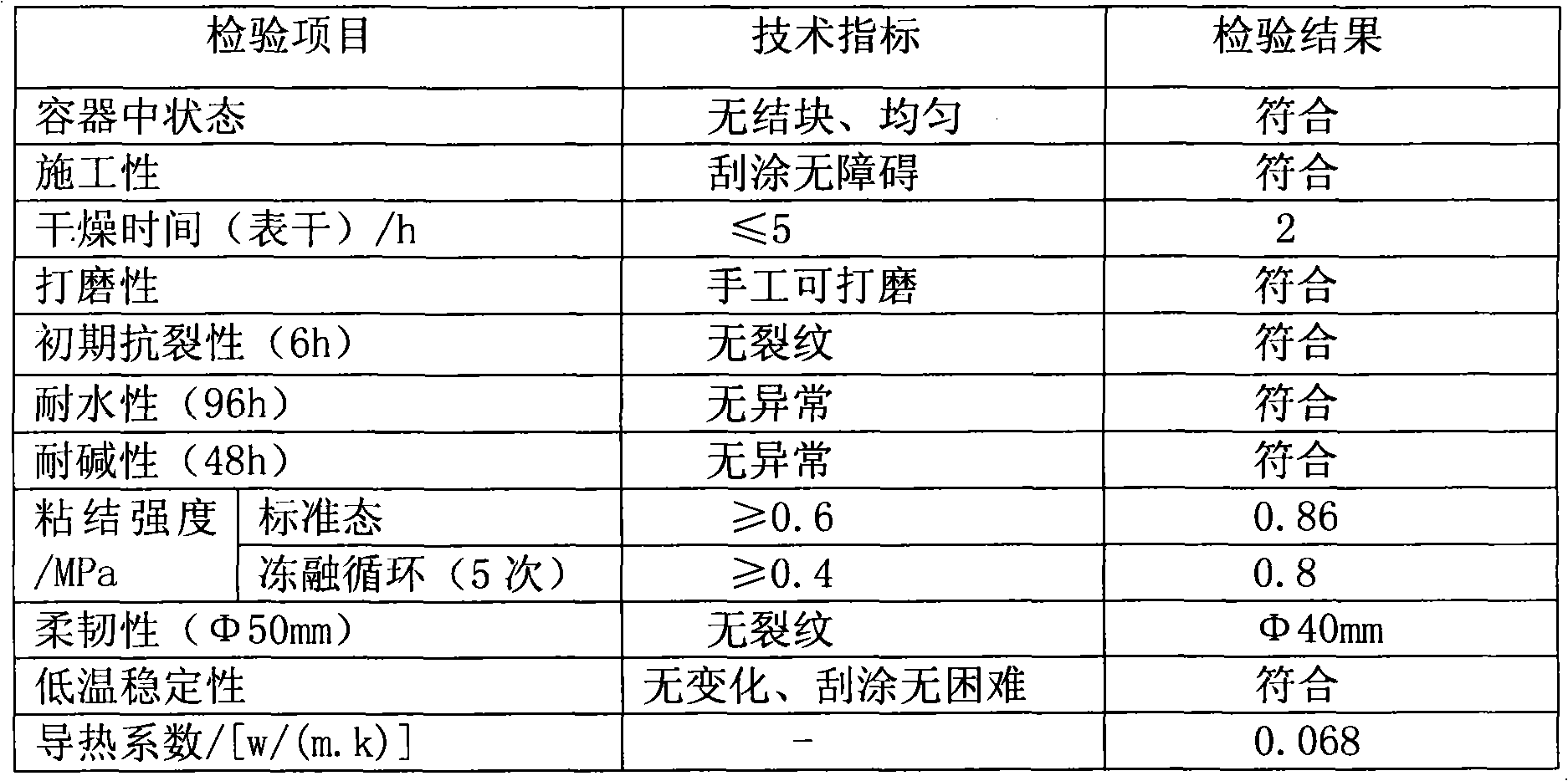

Construction method for heat-insulating wall body of building

InactiveCN102518220AReduce pollutionSave energyClimate change adaptationHeat proofingStructural engineeringMoisture absorption

The invention discloses a construction method for the heat-insulating wall body of a building. The method adopts the combined system of an inner wall heat-insulating decorative material and an outer wall heat-insulating decorative material for the wall body of the building, and comprises the following steps: plastering phase-change energy-storage inorganic / organic heat-insulating mortar, plastering phase-change energy-storage rendering mortar and mesh fabric, puttying phase-change energy-storage flexible water-fast putty, coating permeating-type elastic priming paint through rolling, and coating solar reflection heat-proof exterior wall coating through rolling on the outer wall of the wall body; plastering phase-change energy-storage desulphurized gypsum heat-insulating mortar, puttying temperature-regulating humidifying anti-bacterial flexible putty, and puttying temperature-regulating humidifying anti-bacterial interior wall coating on the inner wall of the wall body; and the like. Through the adoption of the construction method, the wall body has the functions of heat insulation, energy conservation, air purification, solar phase-change temperature adjustment, moisture absorption, moisture discharging, sound absorption, noise reduction, bacterium resistance, mold prevention, water prevention, and ventilation. Therefore, the method has the advantage that the functions of low carbon emission, pollution reduction, energy conservation, beautiful decoration and environment protection of the wall body are realized; and the method is convenient to popularize and apply.

Owner:北京国泰瑞华精藻硅特种材料有限公司

Titanium-containing cold heading steel wire rod for 12.9-grade fastener and production method for titanium-containing cold heading steel wire rod

InactiveCN102321846AEmission reductionReduce pollutionProcess efficiency improvementWire rodTitanium

The invention discloses a titanium-containing cold heading steel wire rod for a 12.9-grade fastener and a production method for the titanium-containing cold heading steel wire rod. The wire rod comprises the following components in percentage by weight: 0.34 to 0.38 percent of C, 0.15 to 0.30 percent of Si, 0.60 to 0.90 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.020 percent of S, 0.90 to 1.10 percent of Cr, 0.17 to 0.24 percent of Mo, 0.005 to 0.05 percent of Ti, 0.01 to 0.04 percent of Al and 40 to 110ppm of N, which are basic components, more than one of 5 to 30ppm of B, 5 to 20ppm of Ca and 0.05 to 0.20 percent of Cu, which is optional components, and the balance of iron and impurities. The preparation method sequentially comprises the following steps of: smelting in an electric furnace; refining outside the furnace; continuously casting small square billets; polishing the square billets; and performing high-speed wire controlled rolling; cooling large-roll coiled wires in piles or Stelmor wire controlled cooling, and the preparation method also can comprise a step of performing vacuum treatment after the step of refining outside the furnace. The titanium-containing cold heading steel wire rod completely meets the production and use requirements of the 12.9-grade fastener, has the advantages of simple production process, low cost, low energy consumption, low carbon emission and light environmental pollution and meets the long-term requirements of low-carbon economy and sustainable development.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

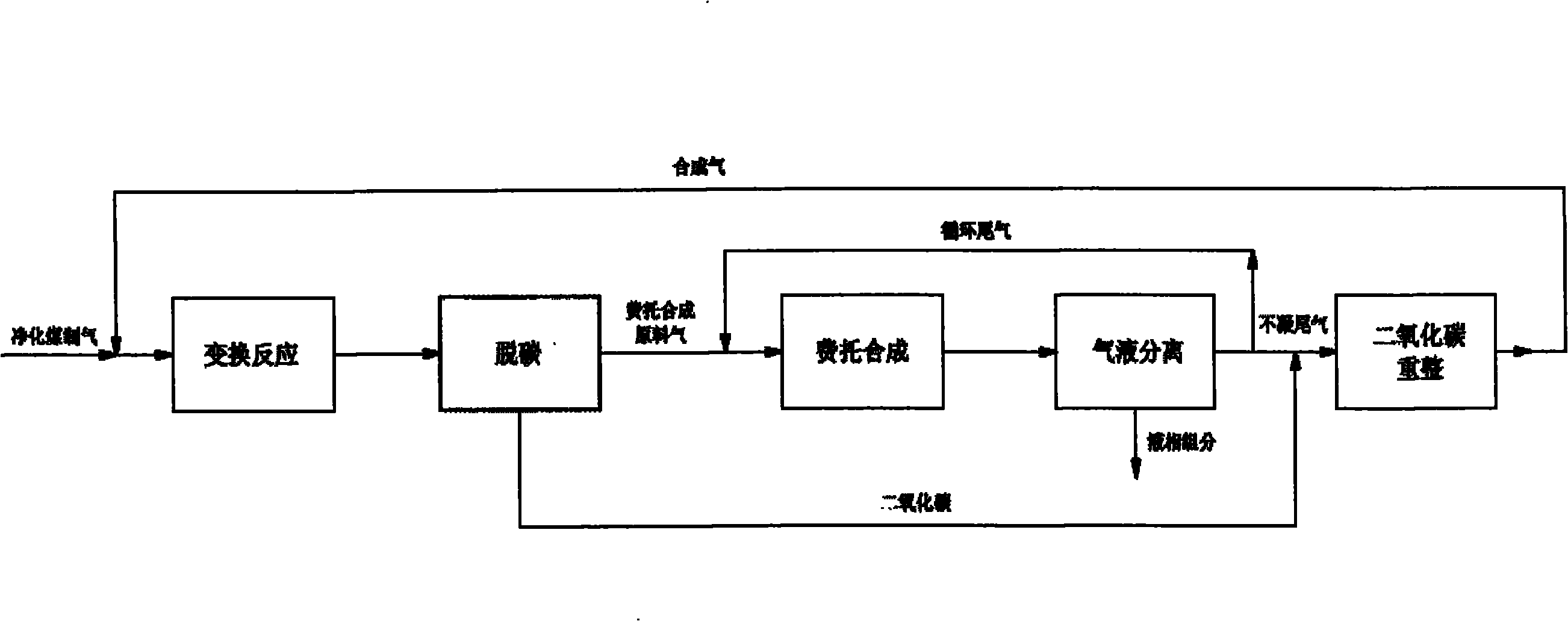

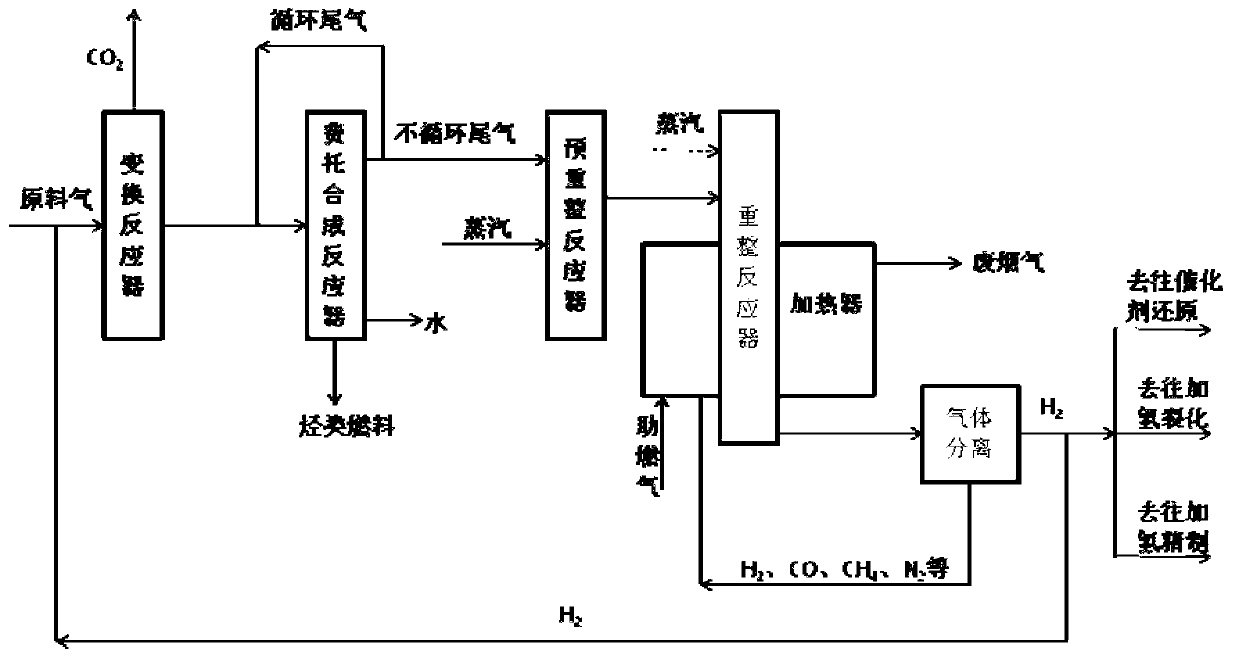

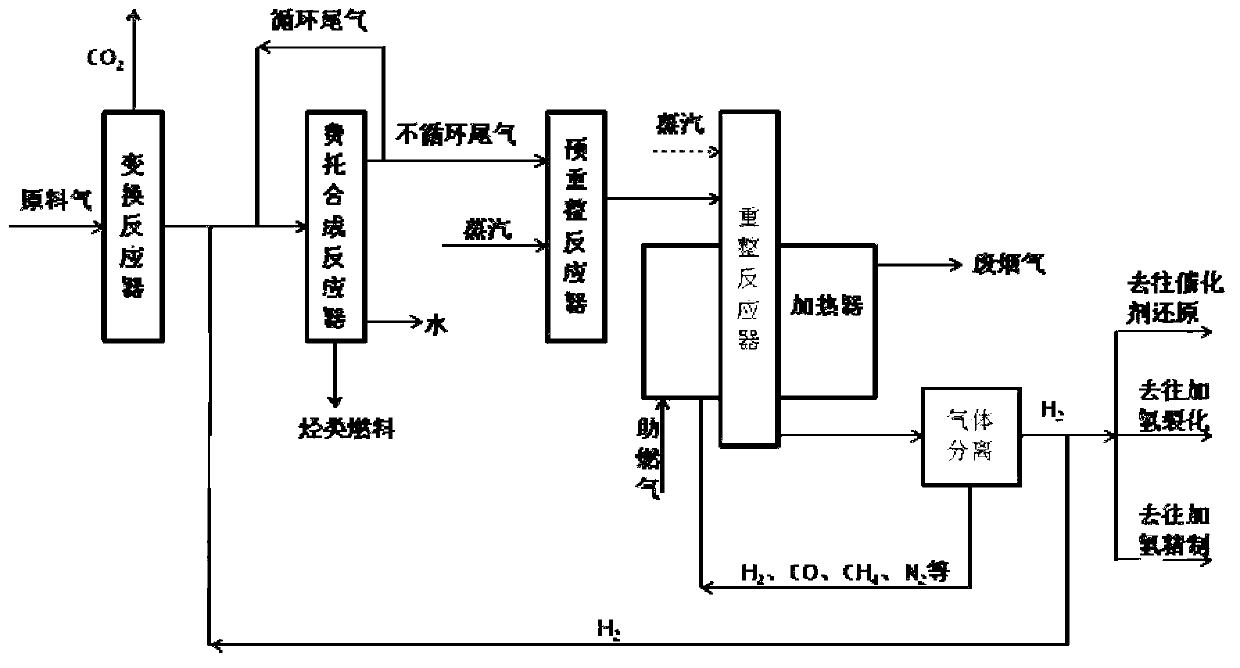

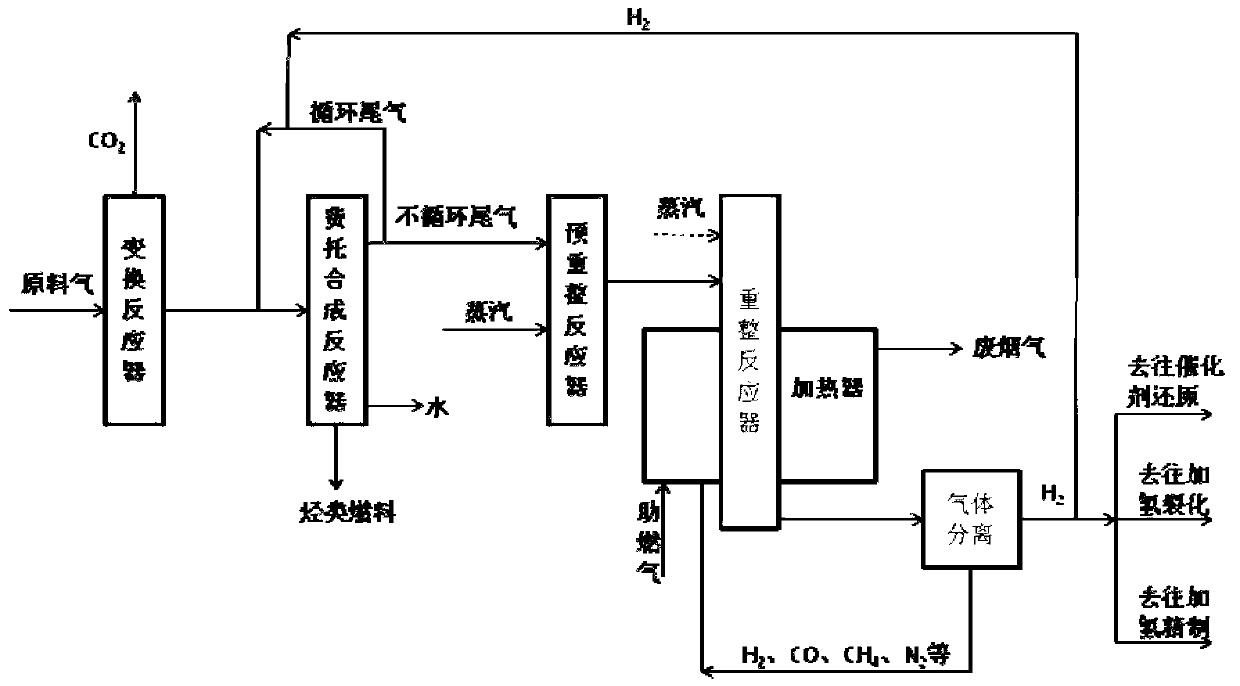

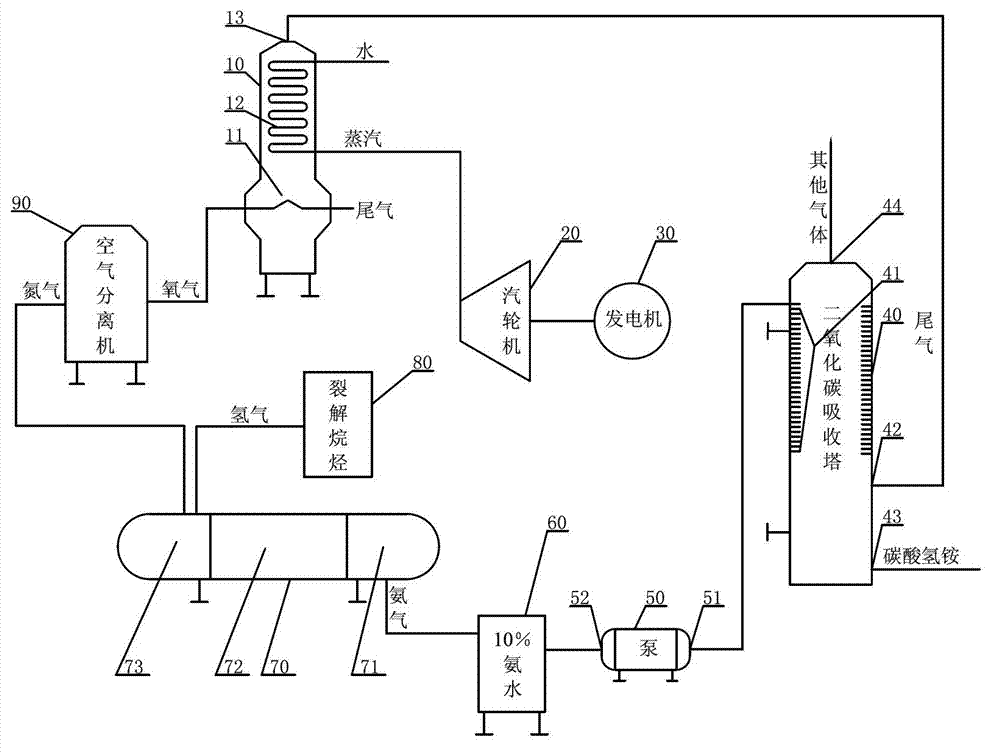

Comprehensive utilization process for low-carbon-emission Fischer-Tropsch synthesis tail gas

ActiveCN102730637AEfficient use ofImprove utilization efficiencyHydrogenChemical industryHydrogenWater vapor

The invention discloses a comprehensive utilization process for a low-carbon-emission Fischer-Tropsch synthesis tail gas. The process is used for converting the non-circular tail gas generated after the Fischer-Tropsch synthesis reaction into synthesis gas containing hydrogen through water vapor reforming, and then separating and extracting high-purity hydrogen from the synthesis gas containing hydrogen for use. The comprehensive utilization process comprises the following steps: 1) obtaining converted gas through a water vapor conversion reaction, 2) obtaining a hydrocarbon fuel through a Fischer-Tropsch synthesis reaction, 3) converting a hydrocarbon compound containing two or more than two carbon atoms into methane after a pre-reforming reaction, 4), converting methane and water vapor into hydrogen and carbon monoxide through a reforming reaction, 5) separating gases respectively containing hydrogen and carbon monoxide, 6) and providing heat for a reforming reactor. The process disclosed by the invention can be used for effectively utilizing the Fischer-Tropsch synthesis tail gas, especially the tail gas containing a large amount of inert components, and converting the tail gas into the hydrogen for use. Meanwhile, the comprehensive utilization process disclosed by the invention can be used for effectively utilizing residual combustible components after the hydrogen in the reforming gas is separated, thereby enhancing the utilization efficiency of the energy.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Garbage microwave pyrolysis comprehensive treatment system and method and equipment used by same

InactiveCN101797578AReduce oxygen contentLower operating temperatureSolid waste disposalHydrocarbon distillationLiquid productFuel oil

The invention discloses a garbage microwave pyrolysis comprehensive treatment system and a method and equipment used by the same, aiming to solve the problems of microwave pyrolysis treatment, and the method and equipment used by the system. The comprehensive treatment system comprises a municipal solid waste (MSW) preprocessing system A, a vertical garbage continuous microwave heating low temperature cracking furnace B, a solid product activated carbon production system C, a pyrolysis gas preparation fuel gas system D, a liquid product distilled extraction light oil and fuel oil system F and a matched sewage treatment system G, wherein the MSW preprocessing system A, the solid product activated carbon production system C and the pyrolysis gas preparation fuel gas system D are respectively connected with the vertical garbage continuous microwave heating low temperature cracking furnace B; and the liquid product distilled extraction light oil and fuel oil system F is connected with the oil recovery pipeline of the pyrolysis gas preparation fuel gas system D. The invention has the advantage that: low carbon emission is realized in the treatment process under the reducing atmosphere, fixed carbon in the garbage is emitted without violent toxicity like dioxin and heavy metal solid powder, the treated wastewater can be recycled and max garbage resource recycling is realized.

Owner:深圳市兖能环保科技有限公司

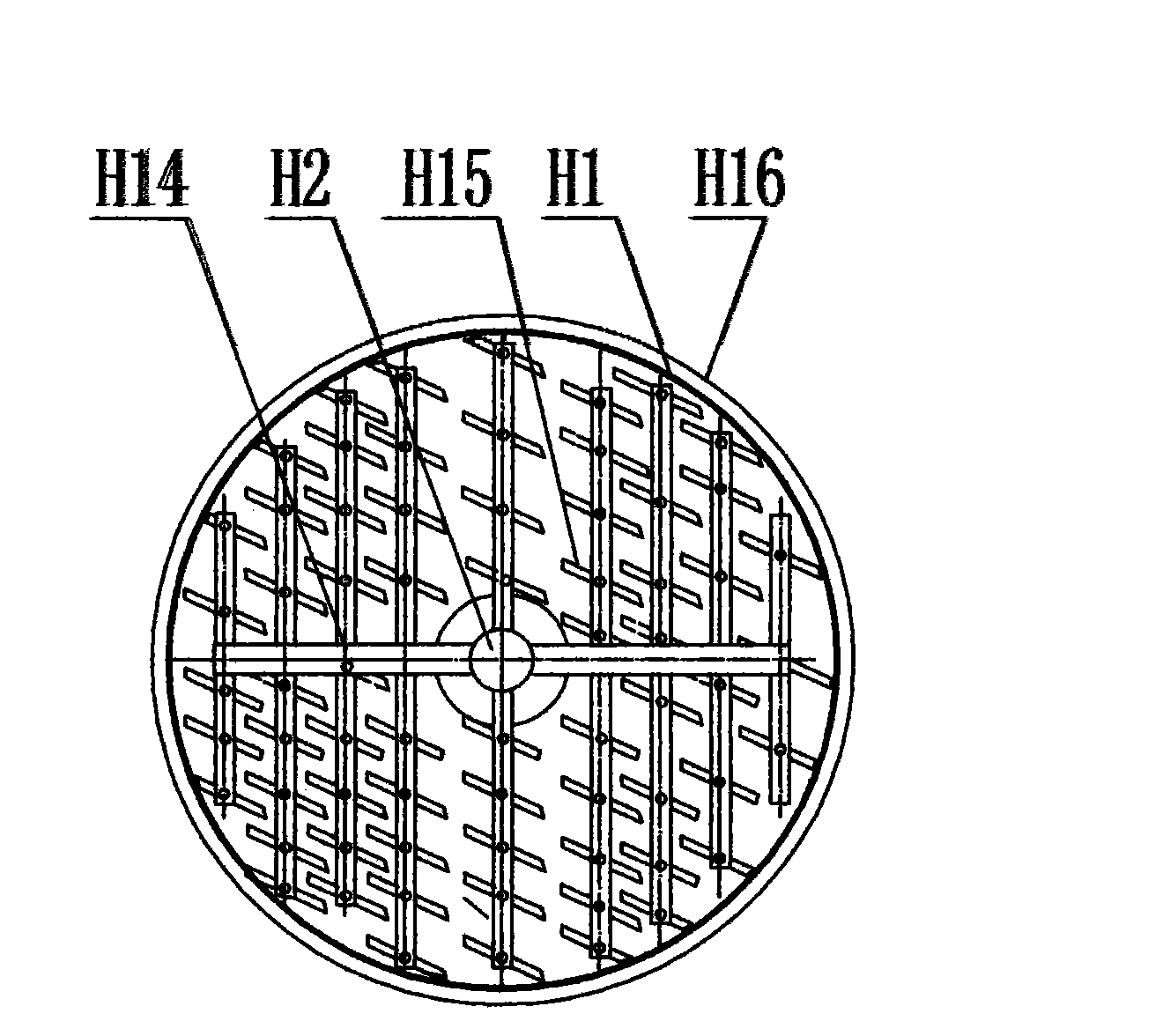

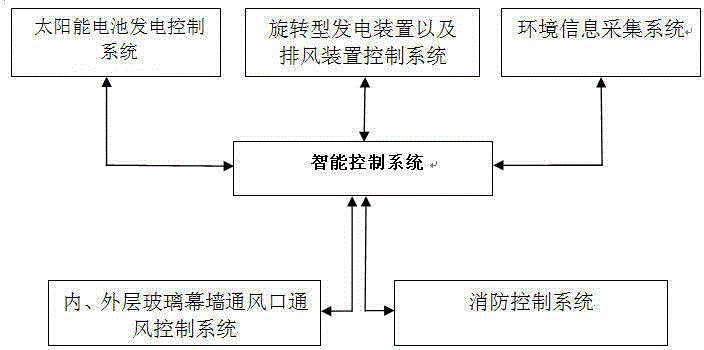

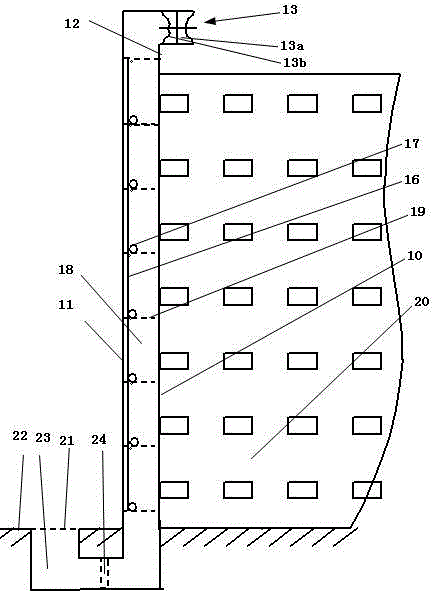

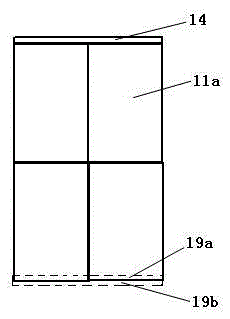

Double-layer glass curtain wall structure and intelligent control method

ActiveCN105649242AReduce consumptionEmission reductionPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringSolar cell

The invention provides a double-layer glass curtain wall structure and an intelligent control method and belongs to the field of construction. An intelligent control system with a plurality of control modes is arranged on a double-layer glass curtain wall. Electric opening degree adjusting devices are arranged at a ventilation opening in an inner glass curtain wall body and at a ventilation opening in an outer glass curtain wall body. Ventilating grill sealing devices are arranged on ventilating grills. A temperature and humidity sensor and smoke probes are arranged in a ventilating channel and in a building correspondingly. Flexible sunshade fabric blinds capable of being rolled are arranged on the inner side of the outer glass curtain wall body. The double-layer glass curtain wall structure is provided with a power generation device. According to the double-layer glass curtain wall structure, indoor temperature adjustment can be conducted automatically through the intelligent control system, natural wind is sufficiently utilized for driving the rotary power generation device to generate power, and flexible solar cells are utilized for generating power, so that green energy resources are generated, carbon emission can be reduced, the greenhouse effect is avoided, and green ecology of the building is achieved.

Owner:宿迁芊森窗业有限公司

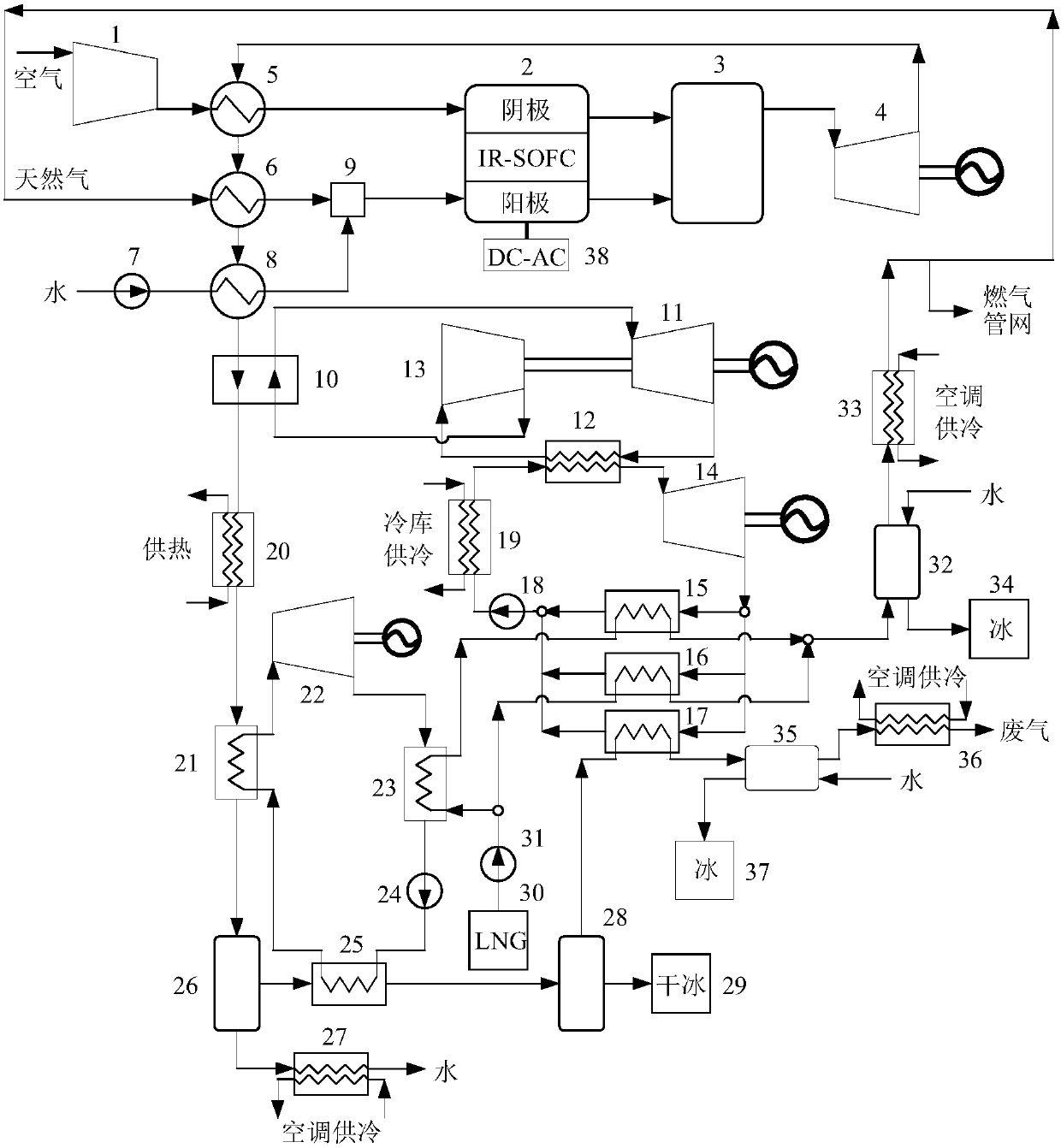

Combined cooling, heating and power supply system

The invention discloses a combined cooling, heating and power supply system. The combined cooling, heating and power supply system is characterized by being formed through treating a SOFC / GT hybrid power generation system as a reference system and introducing CO2 circulation, ORC circulation and a LNG cold energy utilization system. According to the combined cooling, heating and power supply system, a SOFC / GT serves as a prime mover, high-temperature waste heat, medium-temperature waste heat and low-temperature waste heat of a recovery system of the CO2 circulation and the ORC circulation areutilized correspondingly, and an LNG is used as a cold source for the CO2 circulation and the ORC circulation, and therefore, external cooling (air conditioning and refrigeration), external heating, external power supply, external natural gas supply and external supply of ice and dry ice can be achieved; and the low-carbon emission of the system is realized by condensing and separating CO2 in a flue gas, the available energy loss of the combined supply system can be effectively reduced, gradient and efficient utilization of energy is achieved, and the good energy-saving and emission-reducing effects are achieved.

Owner:SHANDONG UNIV

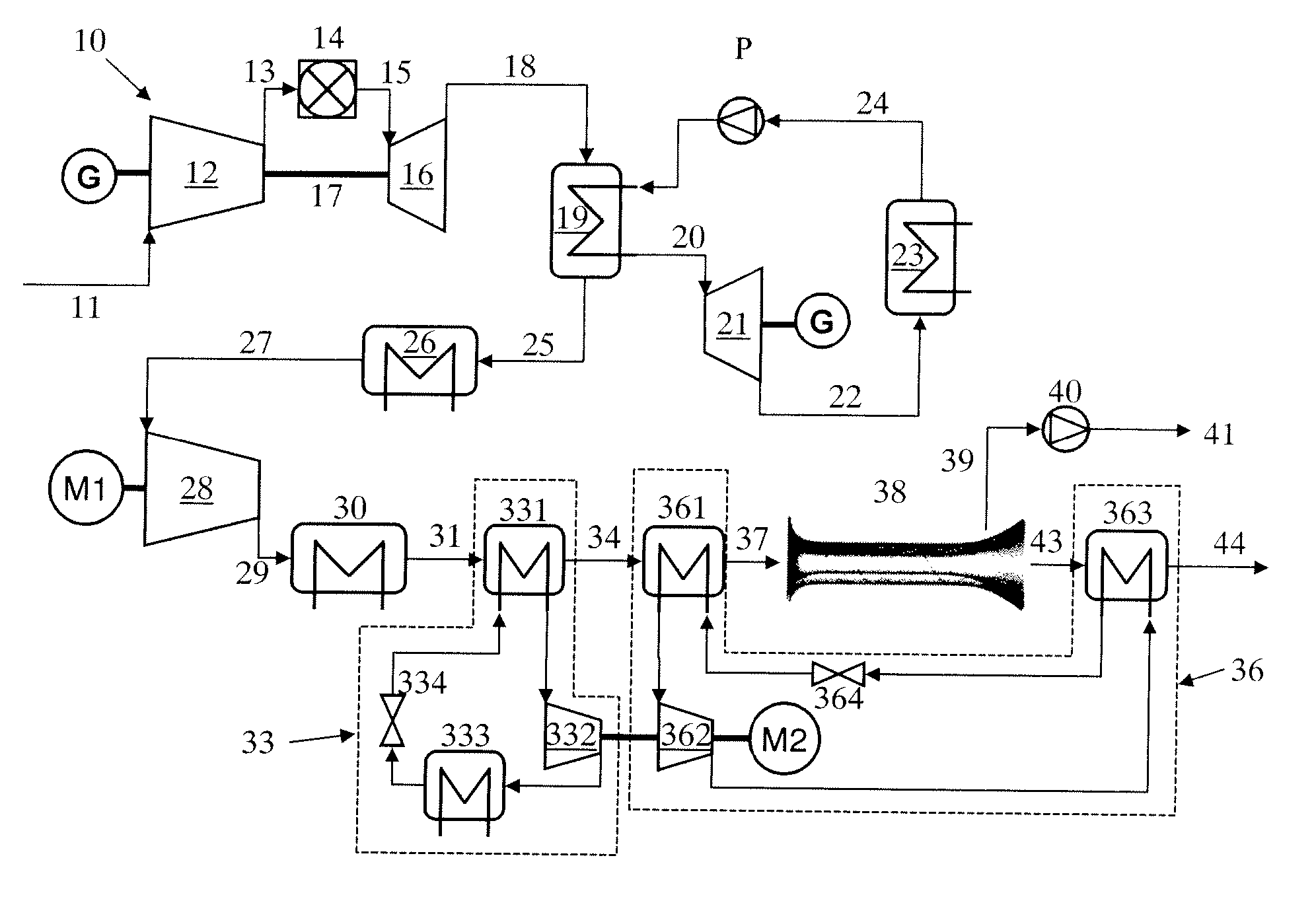

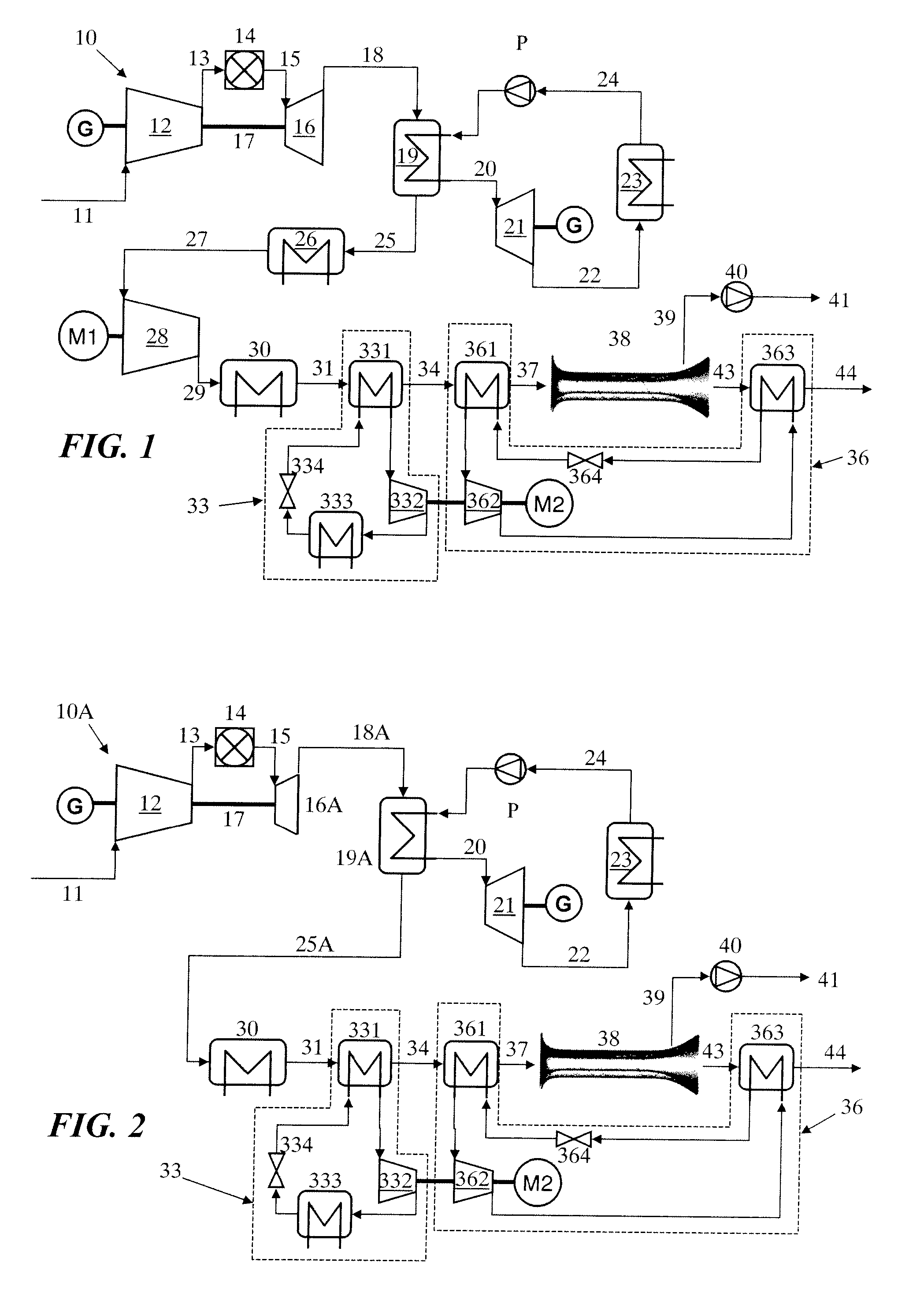

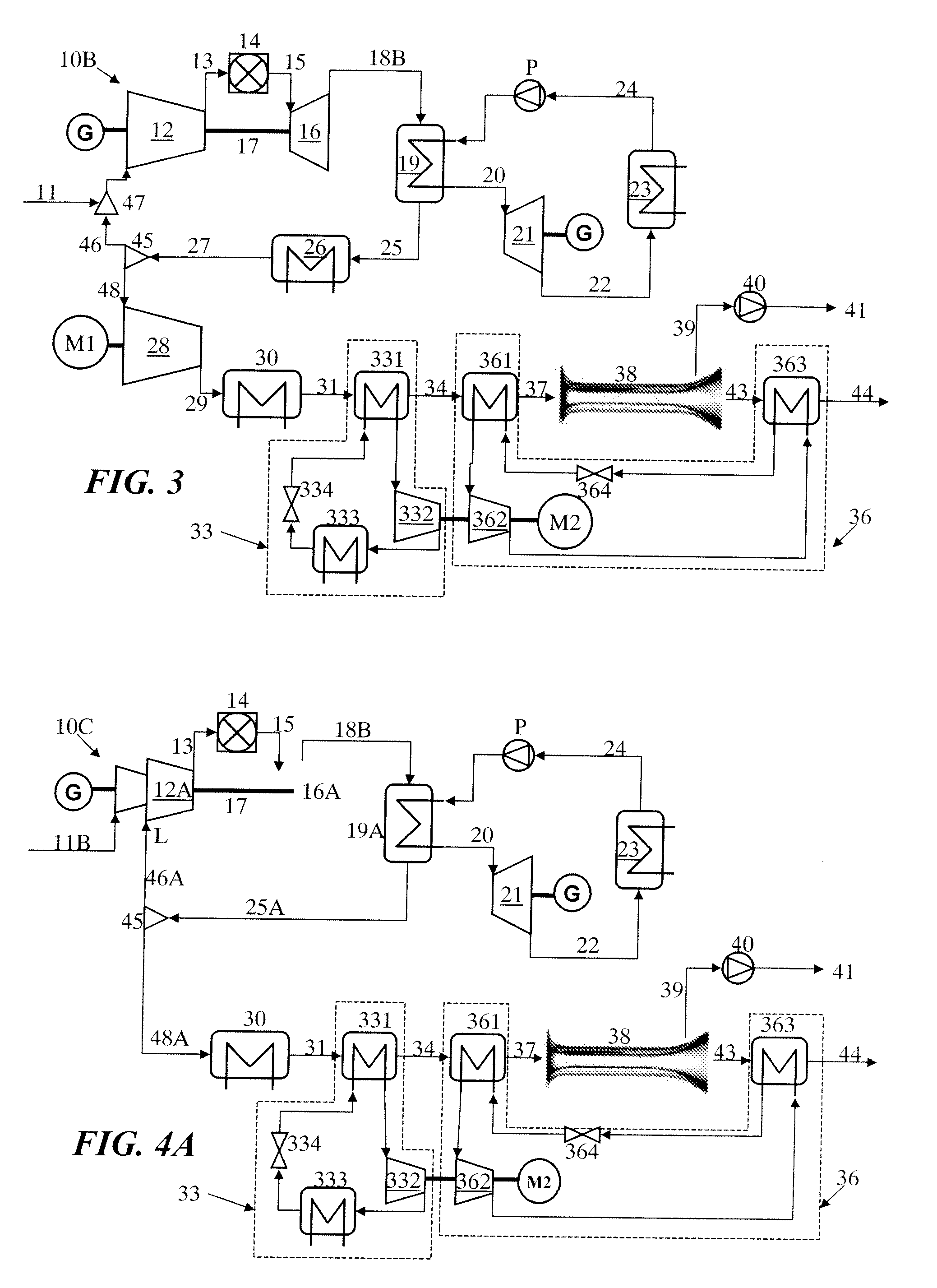

Low carbon emissions combined cycle power plant and process

InactiveUS20100319354A1Increase percentageMinimize mixing lossGas treatmentGas turbine plantsLow-carbon emissionGas cooling

A low carbon emissions, combined cycle power plant utilizes vortex nozzles (38) operative at cryogenic temperatures to separate out carbon dioxide (39) from the flue gases. Complexity of the plant is minimized by operating a gas turbine engine component (10) of the plant at a turbine exhaust pressure of at least 2 bar, so that downstream components of the plant, including a heat recovery steam generator (19A), a gas cooling system (30, 33, 36), and the inlets of the vortex nozzles, all operate at the same pressure of at least two bar. To increase carbon dioxide concentration in the flue gases (37) that pass through the vortex nozzles (38), and thereby increase efficiency of carbon dioxide removal from the flue gases, up to 50% of the flue gases that exit the heat recovery steam generator (19A) may be recirculated to a location (L, FIG. 4)) in the compressor of the gas turbine engine where the pressure of the compressor air matches the flue gas pressure.

Owner:GENERAL ELECTRIC TECH GMBH

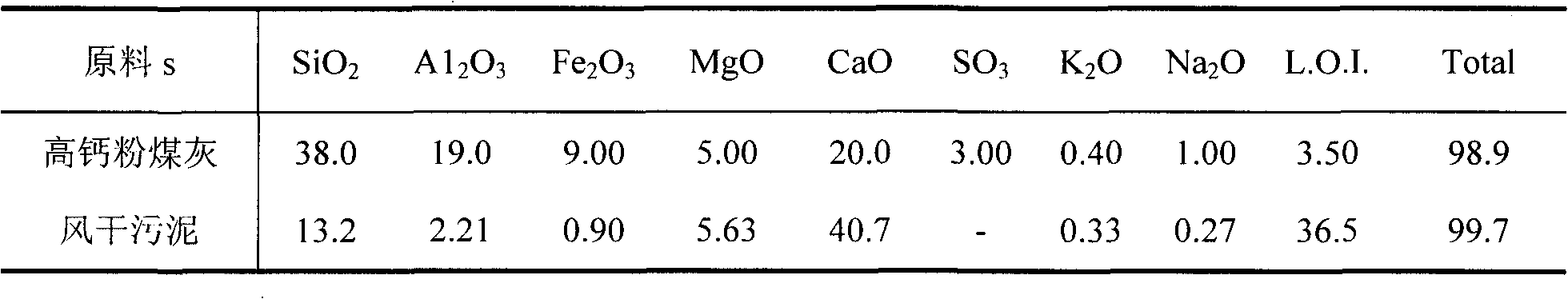

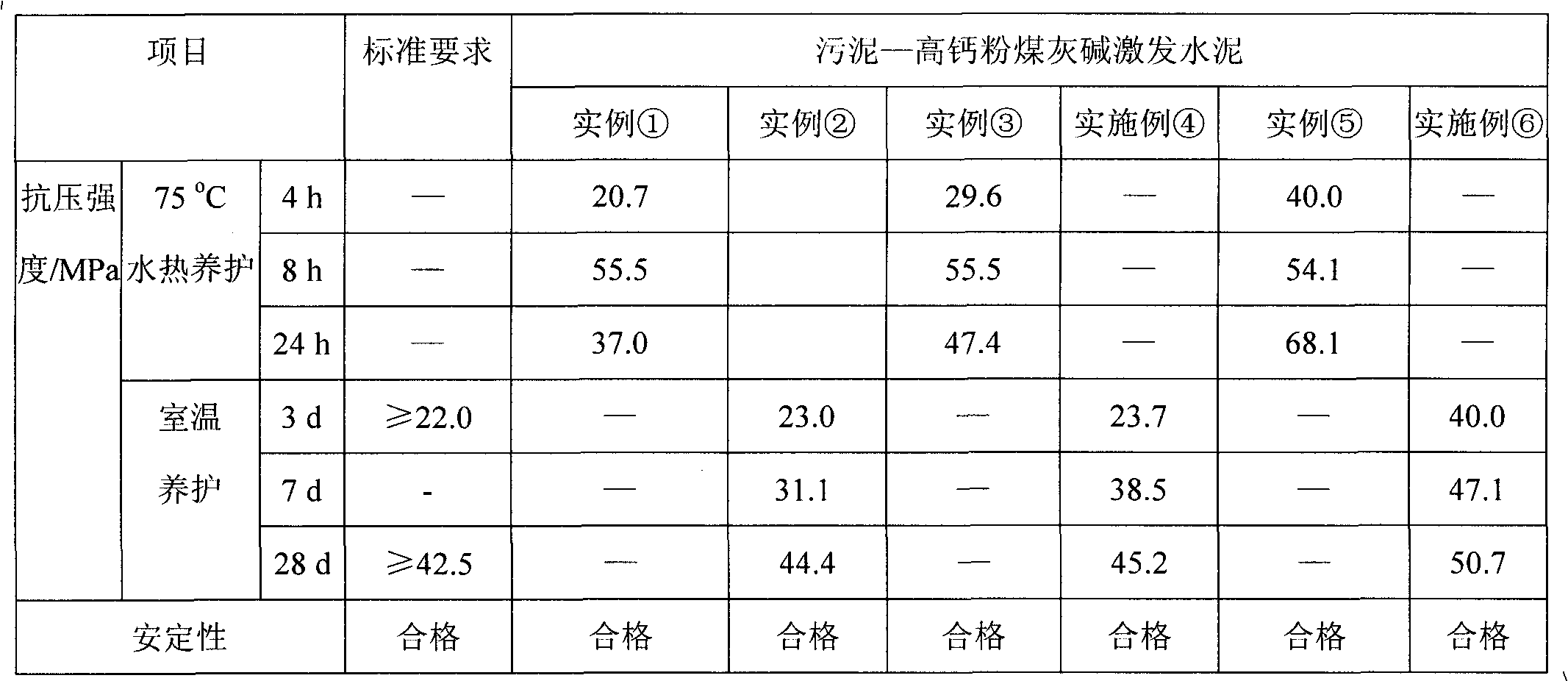

Sludge-high calcium fly ash alkali-excited cement and preparation method thereof

InactiveCN101830653AImprove performanceReduce the burden onCement productionActivated sludgeChemical admixture

The invention discloses sludge-high calcium fly ash alkali-excited cement and a preparation method thereof. The alkali-excited cement uses high calcium fly ash as a main raw material, thermally activated sludge as a mineral additive and solution prepared from sodium hydroxide and liquid sodium silicate as a composite chemical additive and makes the system have good performance in a certain curing environment. The method alleviates the environmental burden, and reduces the cost and resource consumption by using industrial waste such as high calcium fly ash and sludge; and the novel alkali-excited cement only has little emission of greenhouse gas, is a low-carbon emission, green and environment-friendly gel material, meets the trend of current social development, and has good economic and social benefits.

Owner:TONGJI UNIV

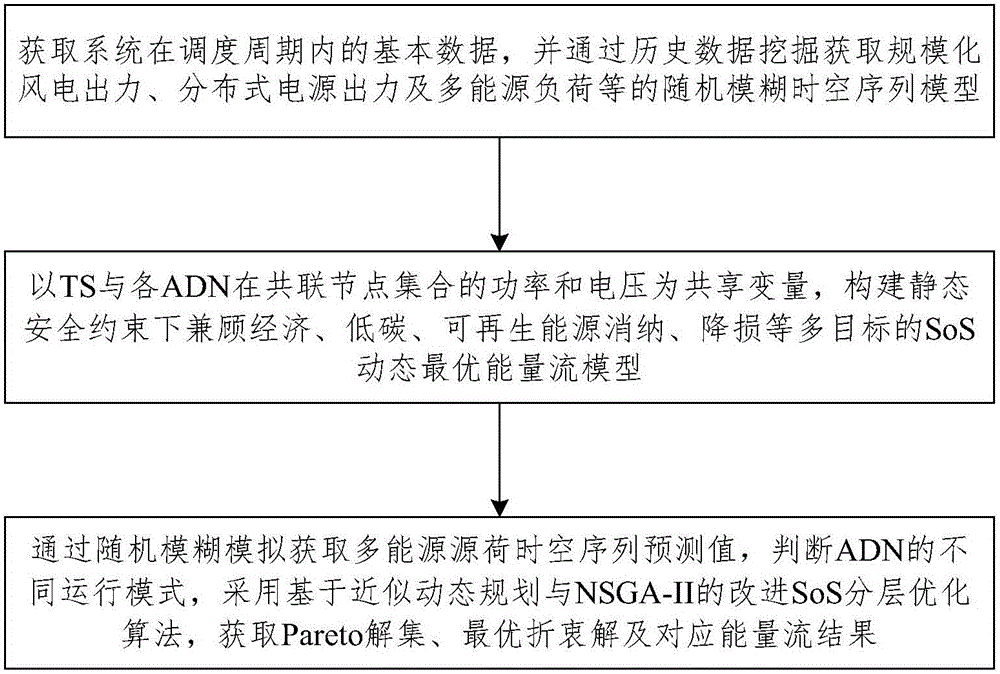

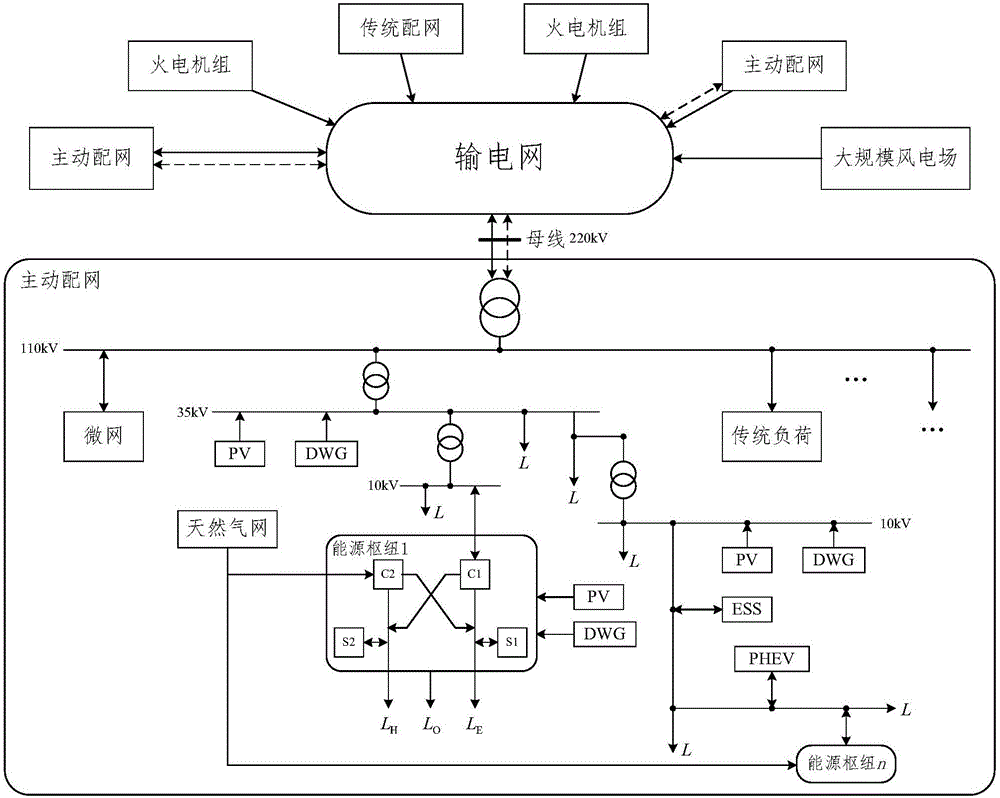

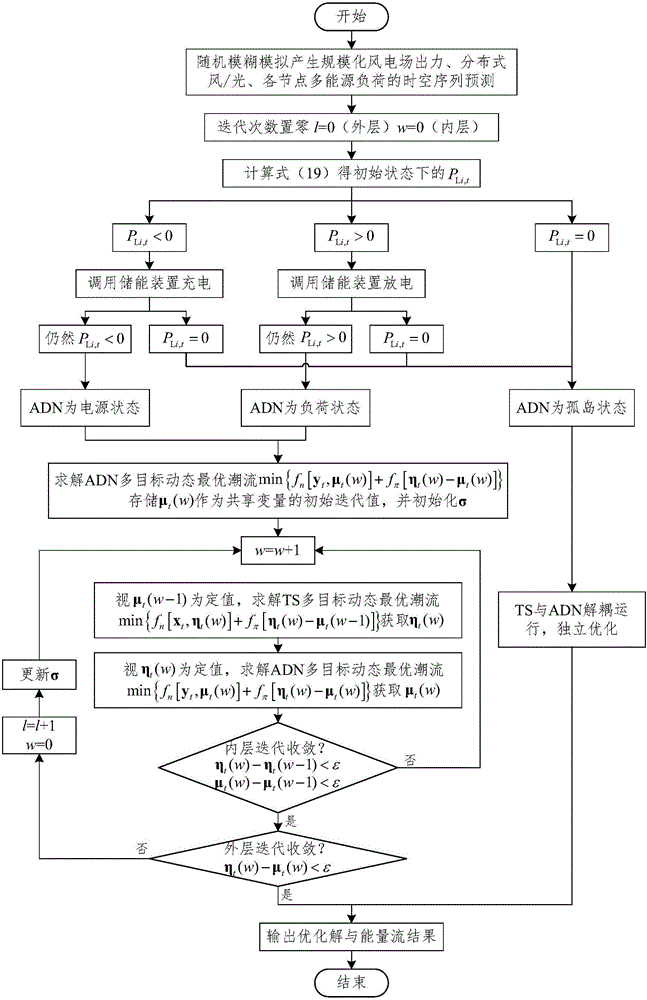

Multi-target random fuzzy dynamic optimal energy flow modeling and solving method for multi-energy coupling transmission and distribution network

ActiveCN105703369ARealize comprehensive coordination and optimization of schedulingAc networks with different sources same frequencyElectric power systemEnergy coupling

Owner:马瑞

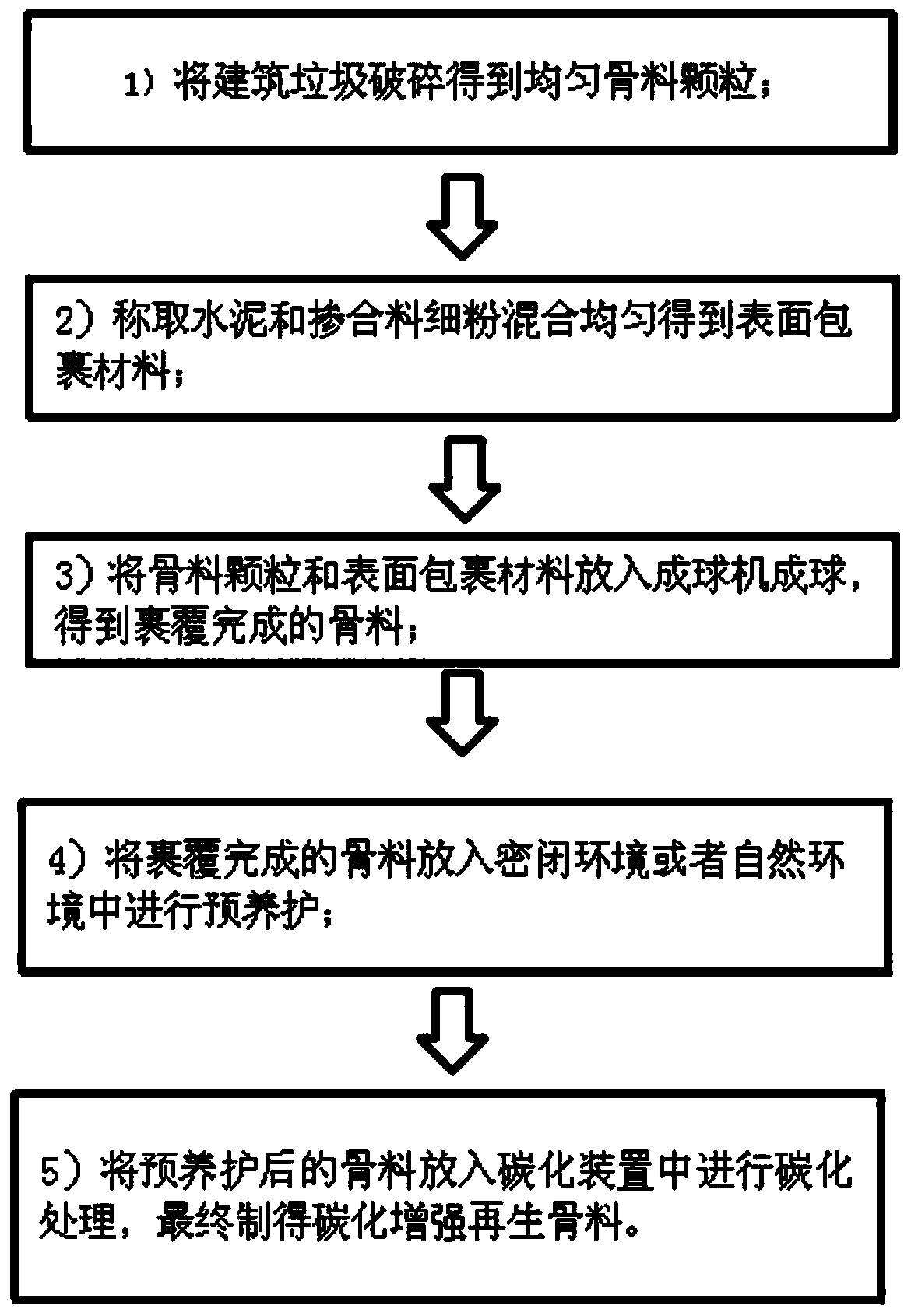

Carbonization reinforced regenerated aggregate, and preparation method and applications thereof

InactiveCN110357473ARealize resource utilizationPermanent storageSolid waste managementResource utilizationCarbonization

The invention discloses a carbonization reinforced regenerated aggregate, and a preparation method and applications thereof, and belongs to the technical field of building material. The preparation method comprises following steps: building garbage is crushed so as to obtain uniform aggregate particles; cement and admixture fine powder are weighted for uniform mixing so as to obtain a surface coated material; the prepared aggregate particles and the surface coated material are mixed, and are introduced into a granulator, water is sprayed uniformly for granulation so as to obtain a coated aggregate; the coated aggregate is introduced into a sealed environment or the natural environment for pre-curing; an aggregate obtained through pre-curing is introduced into a carbonization device for carbonization treatment so as to obtain the carbonization reinforced regenerated aggregate. The preparation method is adopted to prepare the light aggregate, so that aggregate light weight and high strength are achieved, aggregate cylinder compressive strength can be as high as 13.0MPa, and is higher than the using standard cylinder compressive strength 6.5MPa of common light aggregate. The production technology is simple; resource utilization of solid waste is realized; adsorption immobilization of carbon dioxide is realized; sintering is not needed; and low carbon emission and environment protection are realized.

Owner:NANJING UNIV OF TECH

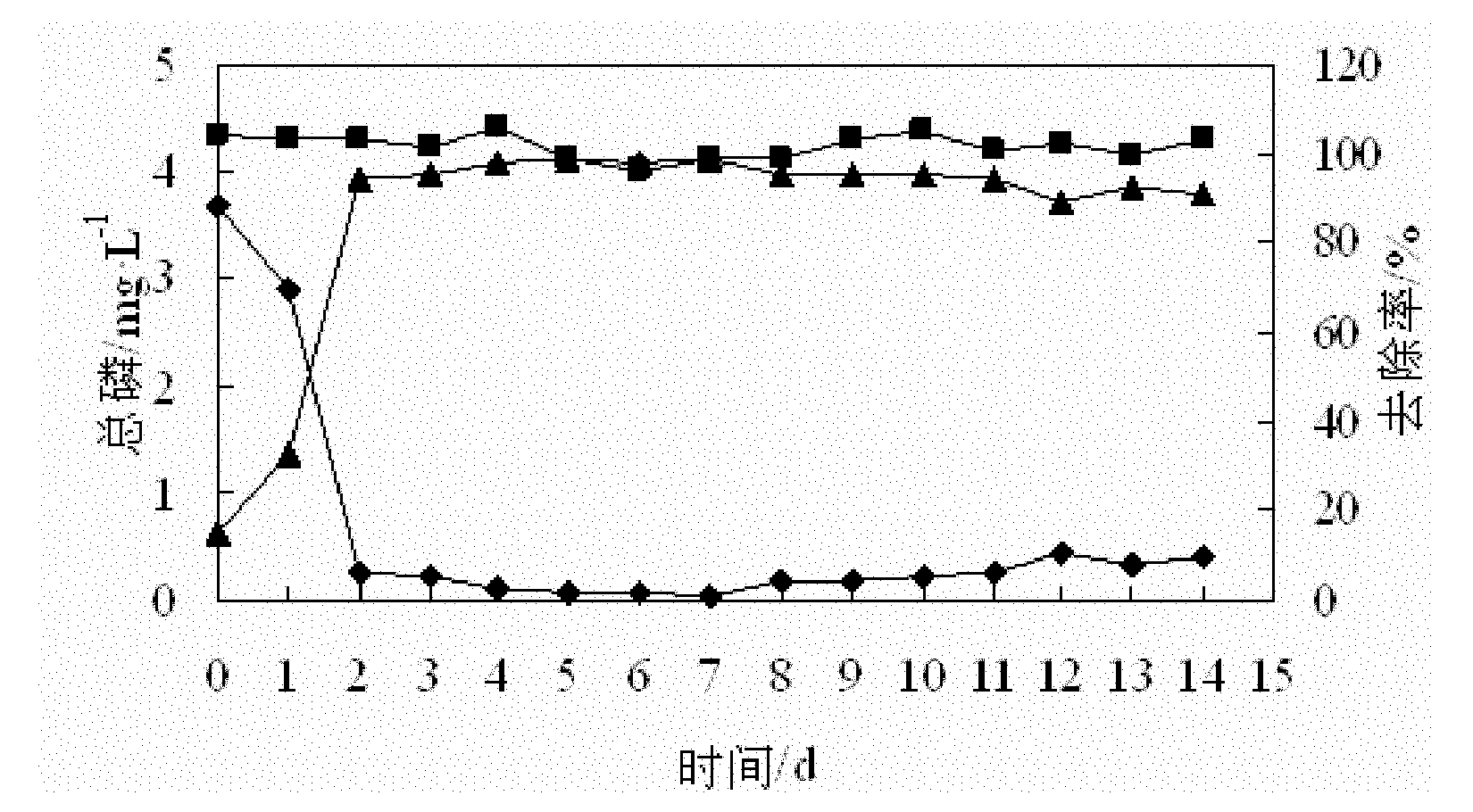

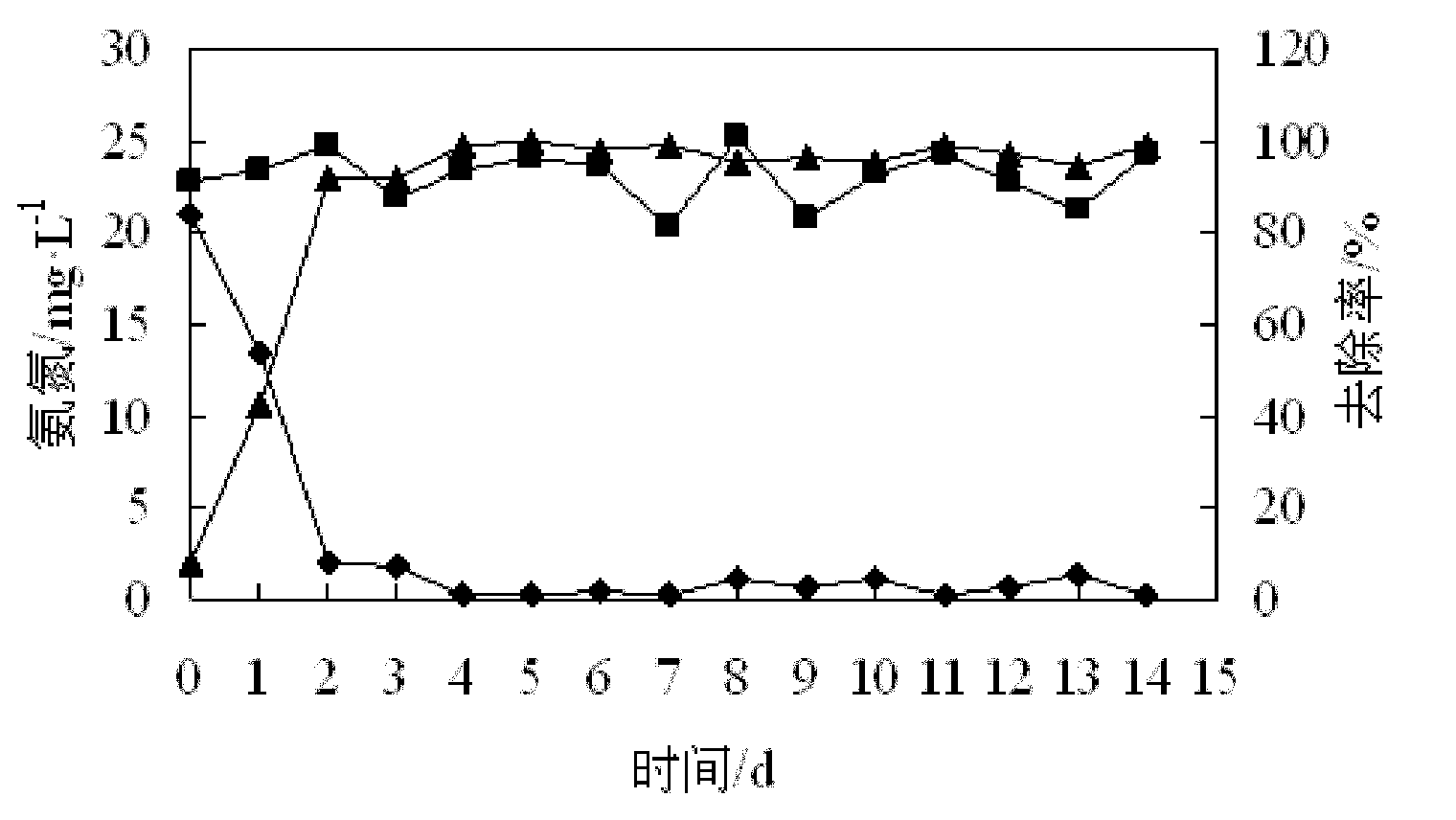

Production method of microalgae grease based on low-carbon emission recycling of domestic sewage

InactiveCN101955846AReduce manufacturing costReduce pollutionUnicellular algaeBiofuelsOil and greaseBiodiesel

The invention relates to a production method of microalgae grease based on low-carbon emission recycling of domestic sewage, belonging to the field of grease production and solving the problems of low carbon recovery rate and high domestic sewage cost in the domestic sewage treatment process. The method of the invention comprises the following steps of: sterilizing primarily treated wastewater and guiding into a photobioreactor; and then, inoculating microalgae in the photobioreactor, culturing by using CO2 as an aeration air source, collecting the microalgae in effluent and dewatering to extract the grease to obtain microalgae grease. The method of the invention has the advantages of high carbon recovery rate and low grease production cost and is applied to the biodiesel field.

Owner:HARBIN INST OF TECH

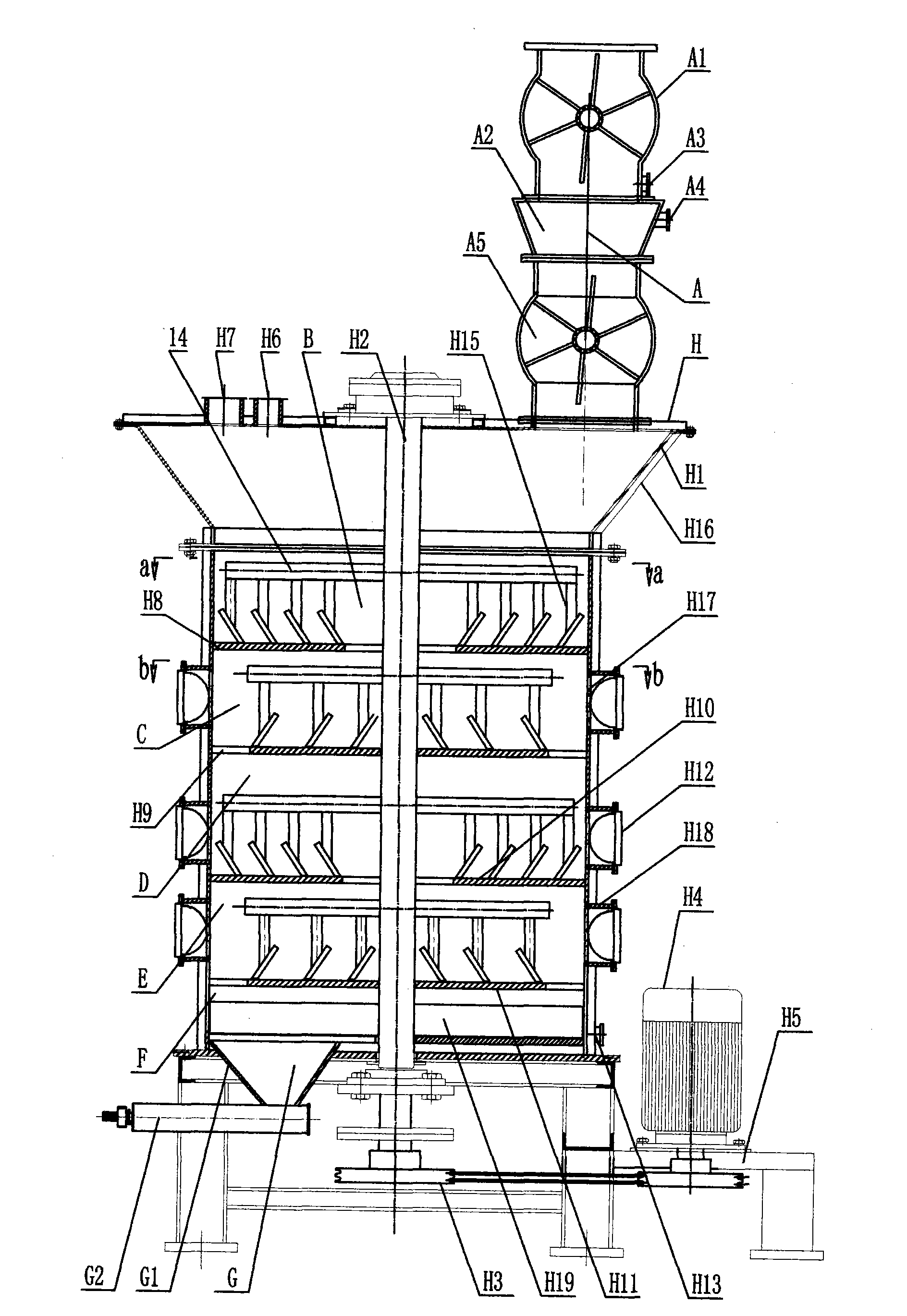

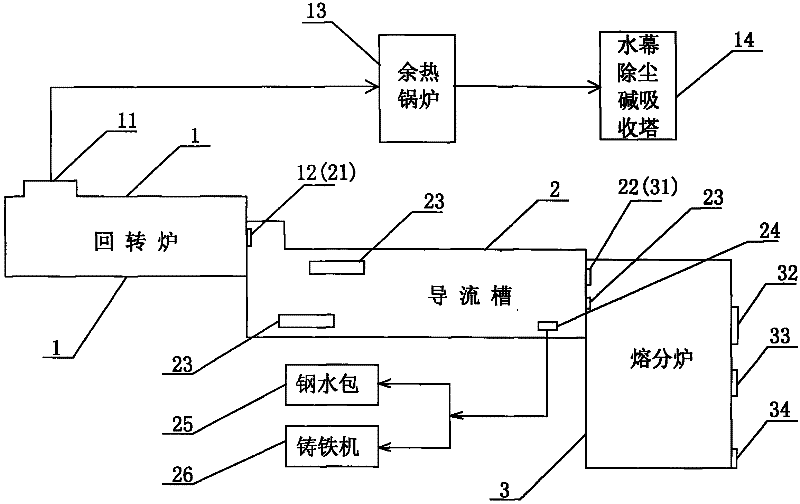

Continued ironmaking device based on melting reduction

The invention relates to a continued ironmaking device based on melting reduction of iron oxide containing carbon iron oxide balling (blocks). In the invention, the device is a continued ironmaking device based on melting reduction and can carry out continual tapping by pre-reducing furnace burden (3) through continually adding the furnace burden (3), extracting air, preheating, blasting and carrying out downstream roasting, and directly conveying the pre-reduced furnace burden (3) into a smelting-separating furnace (B) for continuous smelting-separation; a preheat area (4), a roasting area (5) and the smelting-separation areas behind the preheat area and the roasting area form a connected hearth; a combustion-supporting burner (8) and a secondary tuyere (7) are arranged also; preferably, the high-temperature coat gas generated in the smelting-separation area is subjected to secondary combustion in a pre-reduced furnace (A) for preheating and roasting the furnace burden (3); then the furnace burden (3) is discharged into the smelting-separation area for the further reduction, carburization and melting to separate the slag and iron; in the preheated area (4), the fuse passes through a bed of material to directly heat the furnace burden (3), and then the fuse enters a heat exchanging device (9) and a fuse process system; and a fan blasts the cool air below the bed into a hearth bottom (2) through the heat exchange device (9). The device has the advantages of short flow, reduced energy consumption, low carbon emission, low production cost, simple equipment, less occupied space, less investment and short building period.

Owner:李振洪

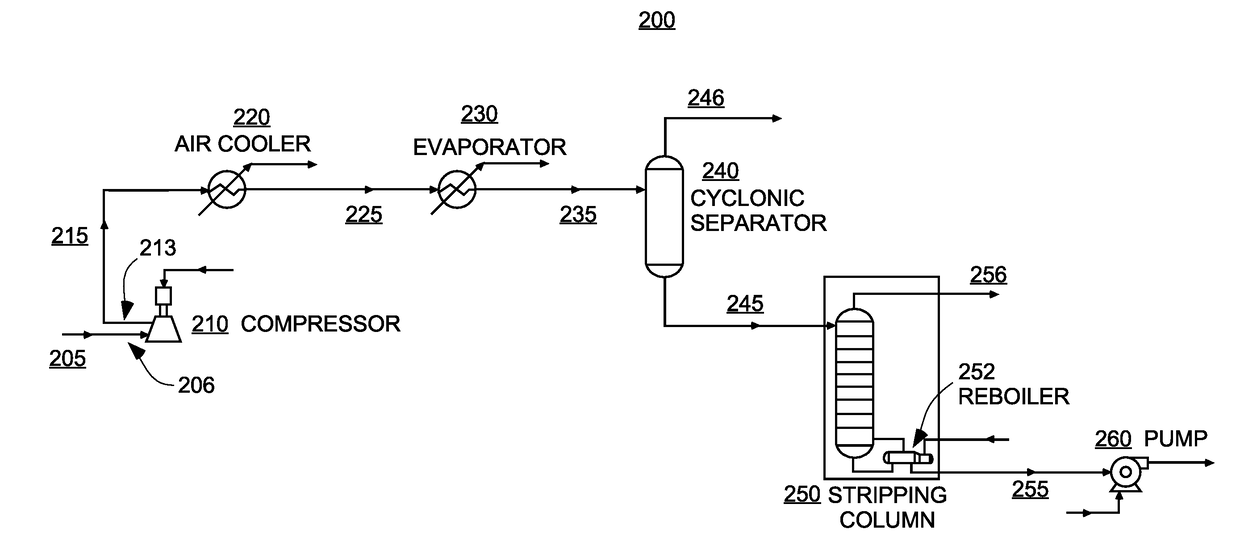

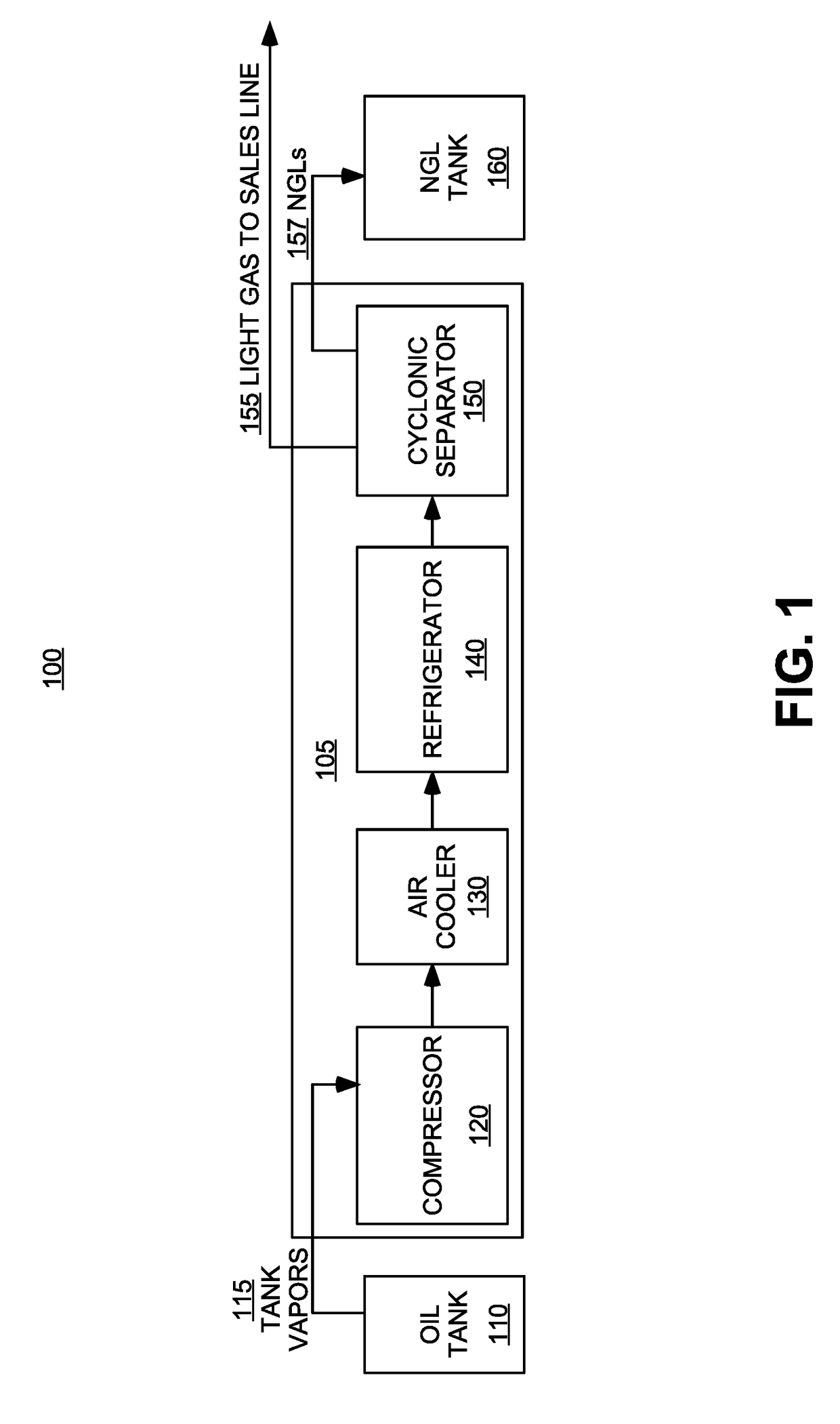

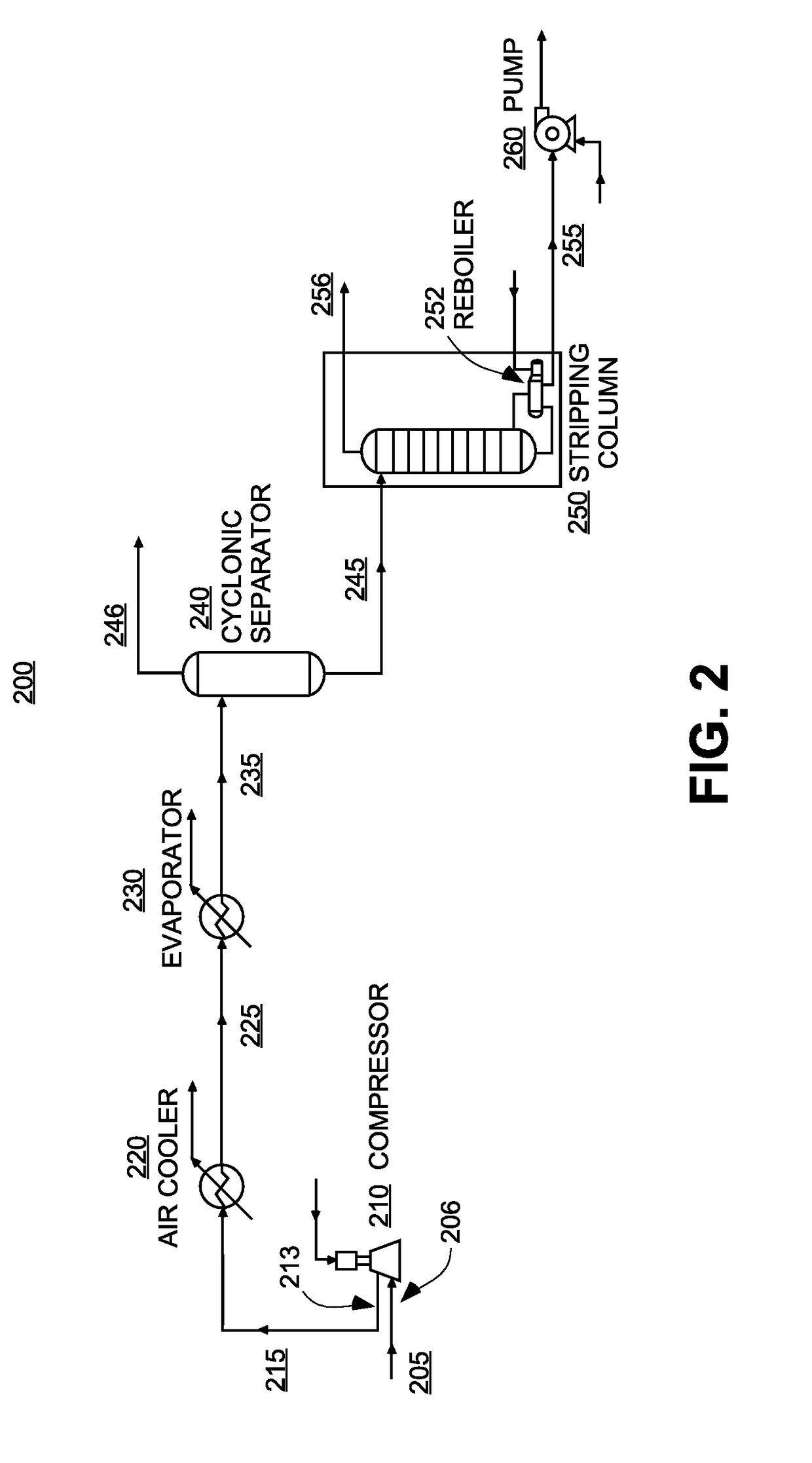

Systems and methods for capturing natural gas liquids from oil tank vapors

A hydrocarbon vapor capture and processing system is disclosed to reduce both carbon emissions and conventional pollution, while producing financial returns by turning waste vapors into high quality NGLs. In one embodiment, the hydrocarbon vapor is sent to a compressor for compression. Compressed vapor is then cooled via an air cooler, before being condensed by a refrigerator to form a liquid. The resulting two-phase flow is then separated into a dry gas stream and a liquid stream using a cyclonic separator. The dry gas stream may be transmitted as a light gas to sales line. The resulting liquid stream is passed to a stripping column to produce NGLs. The system offers great benefits to the environment and public health, by providing a technology that drastically cuts carbon emissions and noxious pollution, while incentivizing drillers to implement such measures through its ability to produce revenue.

Owner:PIONEER ENERGY

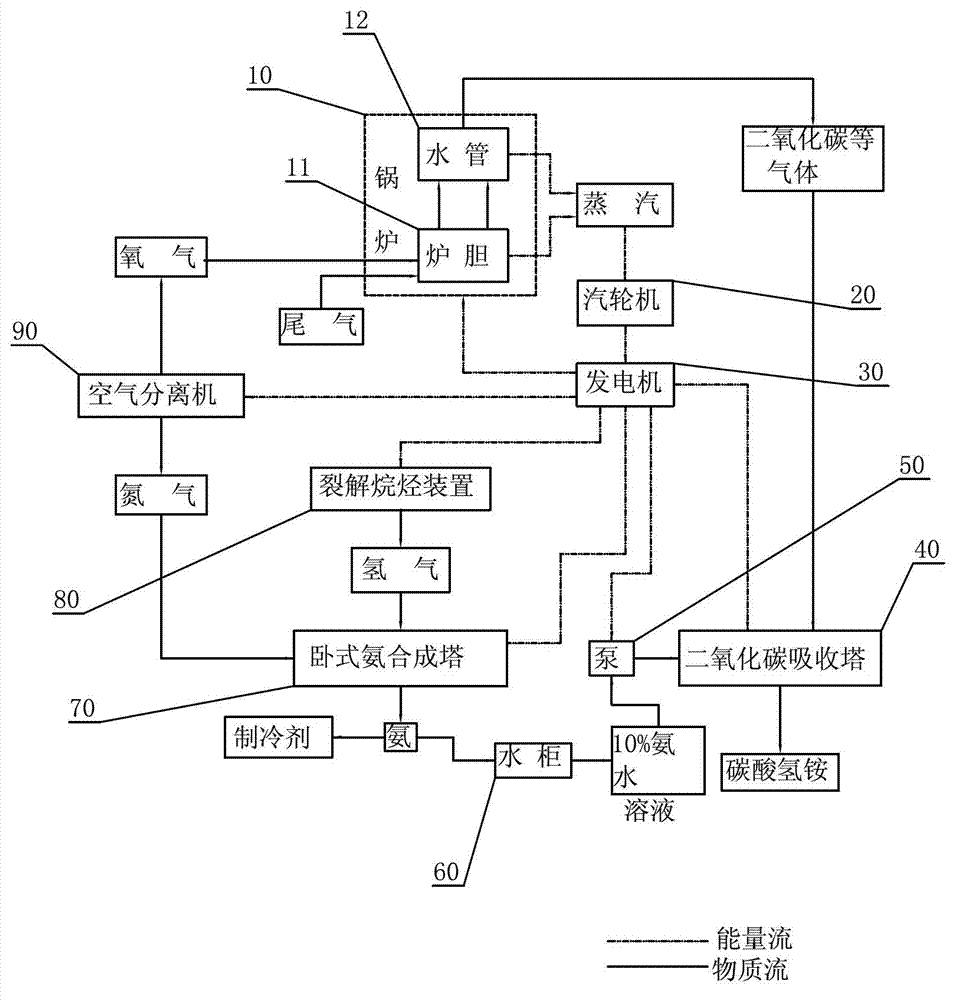

System and method for waste heat recovery and tail gas treatment of marine main engine

InactiveCN103111172AEmission reductionImprove fuel efficiencyDispersed particle separationIndirect carbon-dioxide mitigationAlkaneCo2 absorption

The invention discloses a system and a method for waste heat recovery and tail gas treatment of a marine main engine. The system comprises a waste gas boiler, a steam turbine, an electric generator, a carbon dioxide absorption tower, a water pump, a water tank, a horizontal ammonia converter, an alkane cracker and an air separator, wherein the waste gas boiler is connected with the steam turbine; the waste gas boiler is further connected with the carbon dioxide absorption tower; a stainless steel shower nozzle is arranged inside the carbon dioxide absorption tower; the waste gas boiler is connected with the air separator and the horizontal ammonia converter in sequence; the horizontal ammonia converter is connected with the alkane cracker through a carbon steel pipeline; and the horizontal ammonia converter is further connected with the water tank, the water pump and the carbon dioxide absorption tower in sequence. The system for waste heat recovery and tail gas treatment of the marine main engine based on oxygen-enriched combustion and carbon dioxide capture technology takes material flow and energy flow into account simultaneously, the waste heat of the marine main engine is efficiently utilized, the utilization efficiency of energy is improved, the carbon dioxide in the tail gas is absorbed based on carbon capture technology, and the carbon emission is reduced.

Owner:DALIAN MARITIME UNIVERSITY

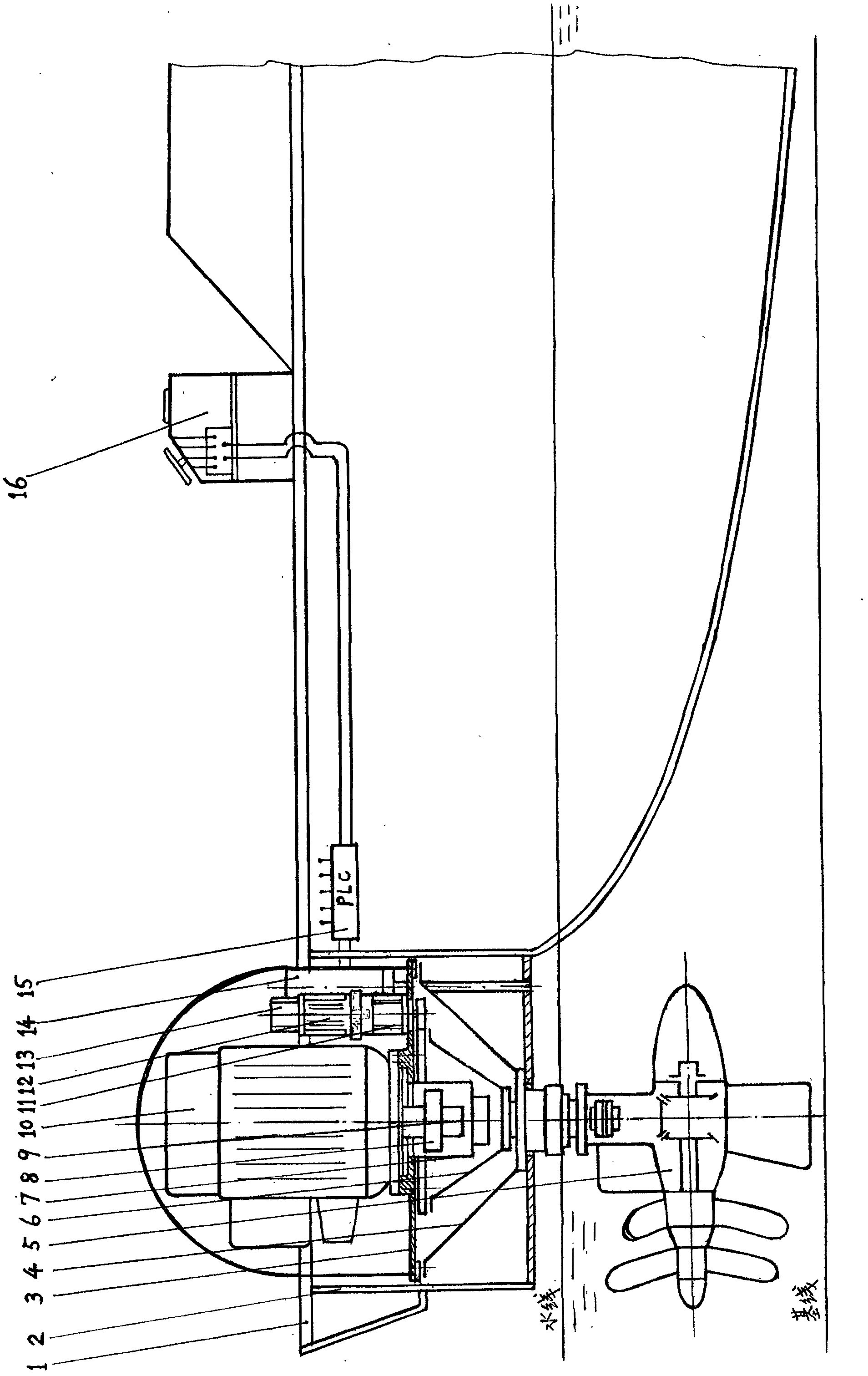

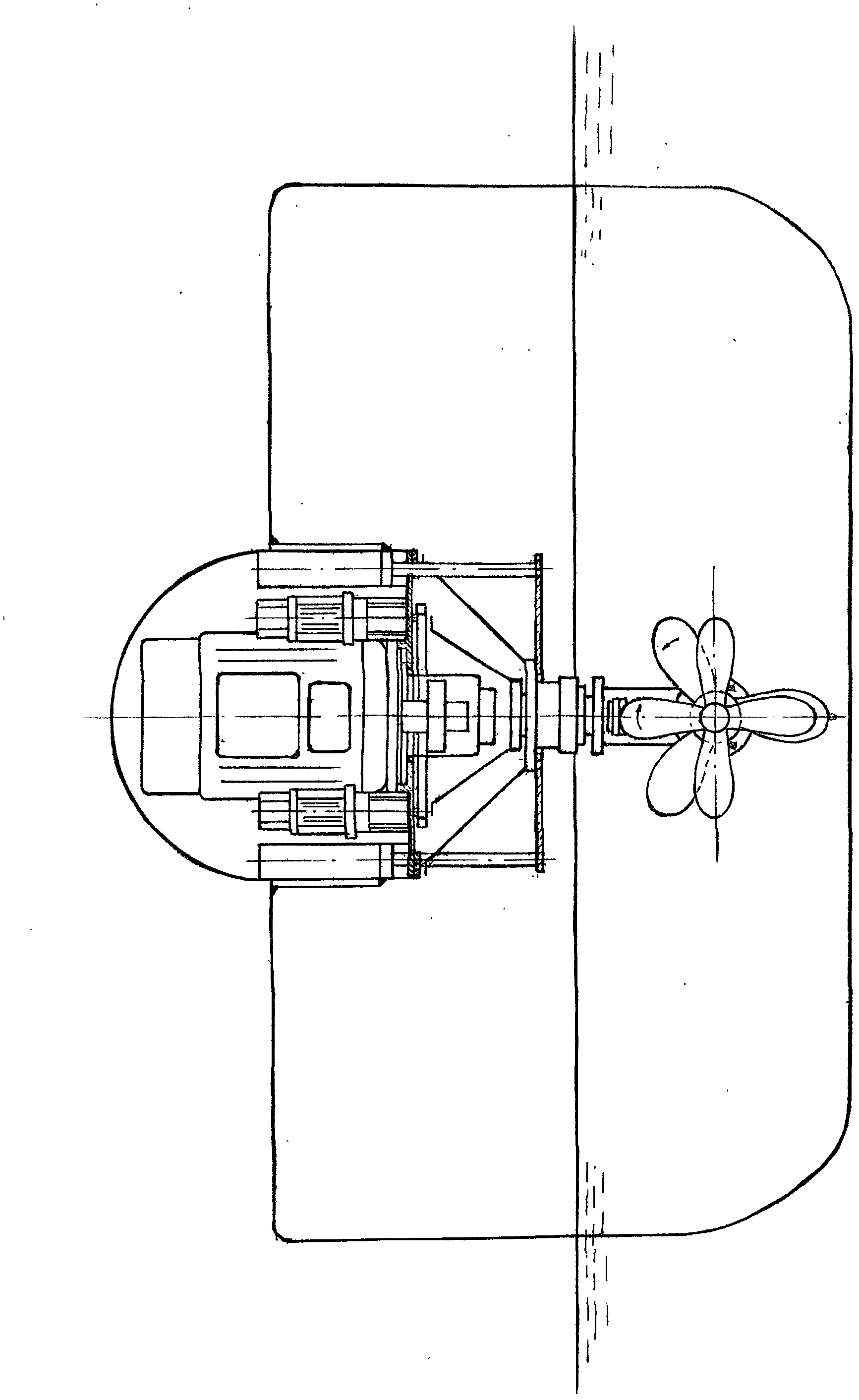

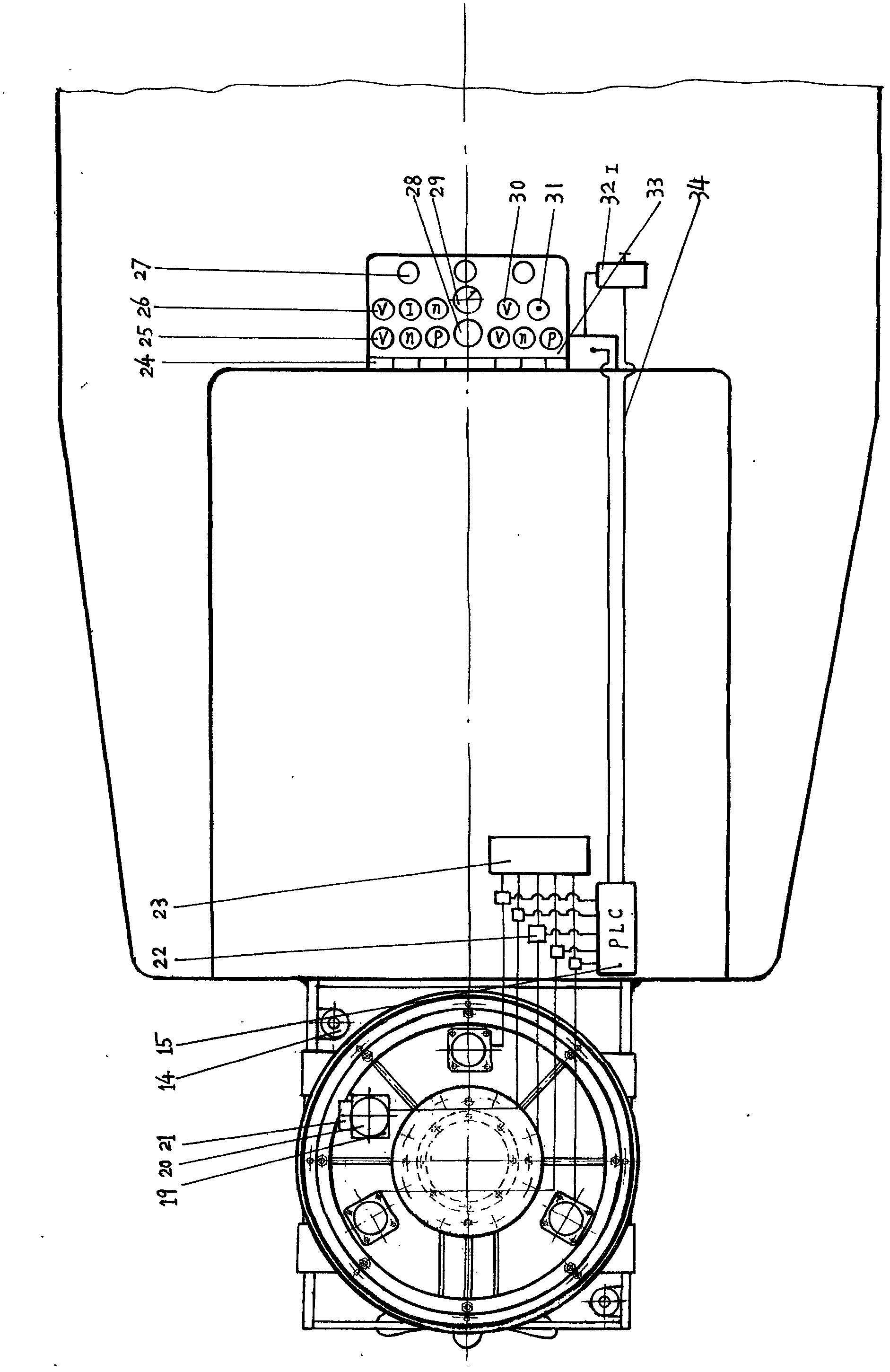

Electric full-circle rotation inboard and outboard (double-motor) contra-rotating propeller propulsion unit

ActiveCN102501958AFlexible U-turnLarge thrustPropulsion power plantsOutboard propulsion unitsAlternating currentLow-carbon emission

An electric full-circle rotation inboard and outboard (double-motor) contra-rotating propeller propulsion unit is applicable to various small and medium-sized ships and boats, an energy conservation value is increased by 10% to 12%, and navigational speed and propulsion efficiency are improved by about 10%. The electric full-circle rotation inboard and outboard (double-motor) contra-rotating propeller propulsion unit comprises encoders, servo motors, speed reducers and large and small cylindrical gears, a rotary support and a sleeve are connected with a lower box to realize full-circle rotation, a ship can turn around flexibly, the reversing speed of the ship is increased by 1.6 times, and the ship runs safely. Optimal three-dimensional movement efficiency of contra-rotating propellers is realized by the aid of a hydraulic lifting mode or an electric lifting mode. A propulsion unit support is connected with a hull, propulsion force, vibration and impact force are absorbed, and the unit is protected. The front and the back of the lower box are streamline-shaped, the upper section of the lower box is wing-shaped, accordingly resistance is reduced, and the lower box is novel and compact in structure, small in dimension and light in weight. In addition, alternating-current frequency converters or direct-current drivers, a PLC (programmable logic controller) single cable connected with a driving cab liquid crystal display, double-motor double-propeller controllers, full-circle steering wheels and direction indicators are adopted, and double-motor full-circle synchronous electronic omnidistance operation is realized. The electric full-circle rotation inboard and outboard (double-motor) contra-rotating propeller propulsion unit is powered by batteries and emergency generator sets or in a hybrid mode, and zero or low-carbon emission is realized.

Owner:肖鑫生

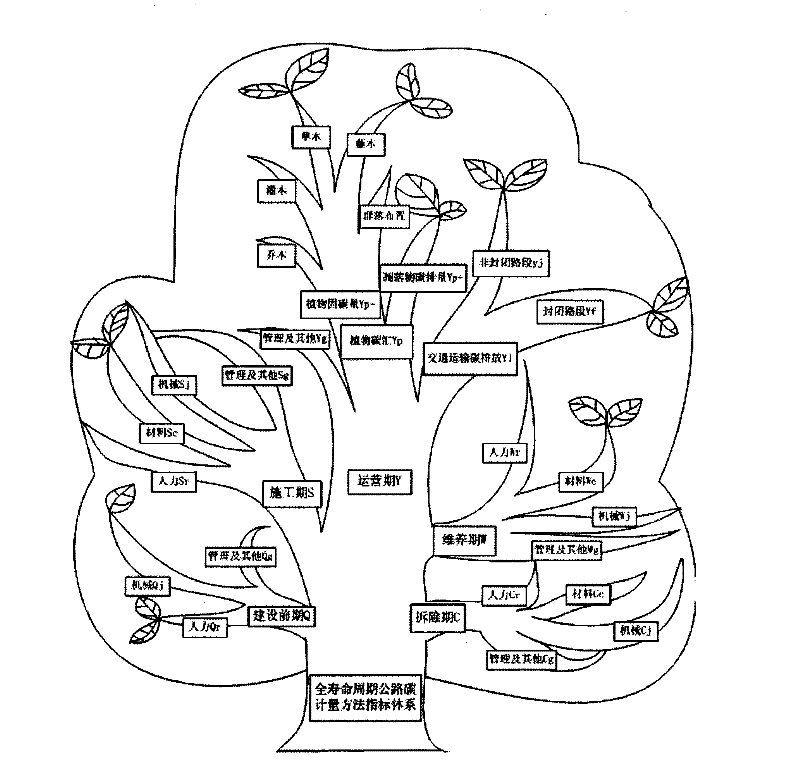

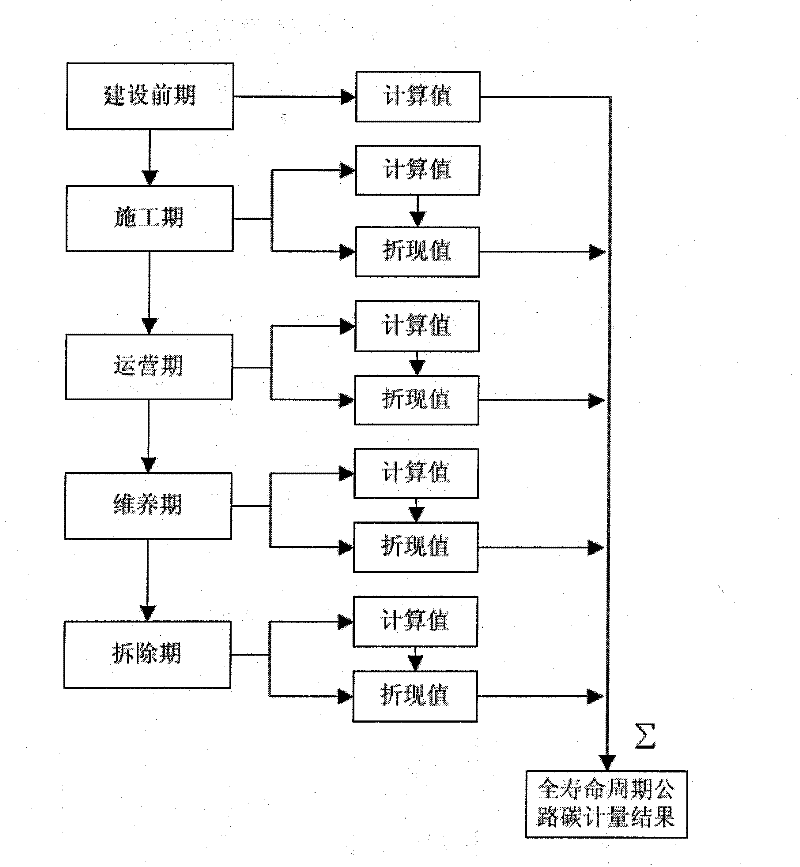

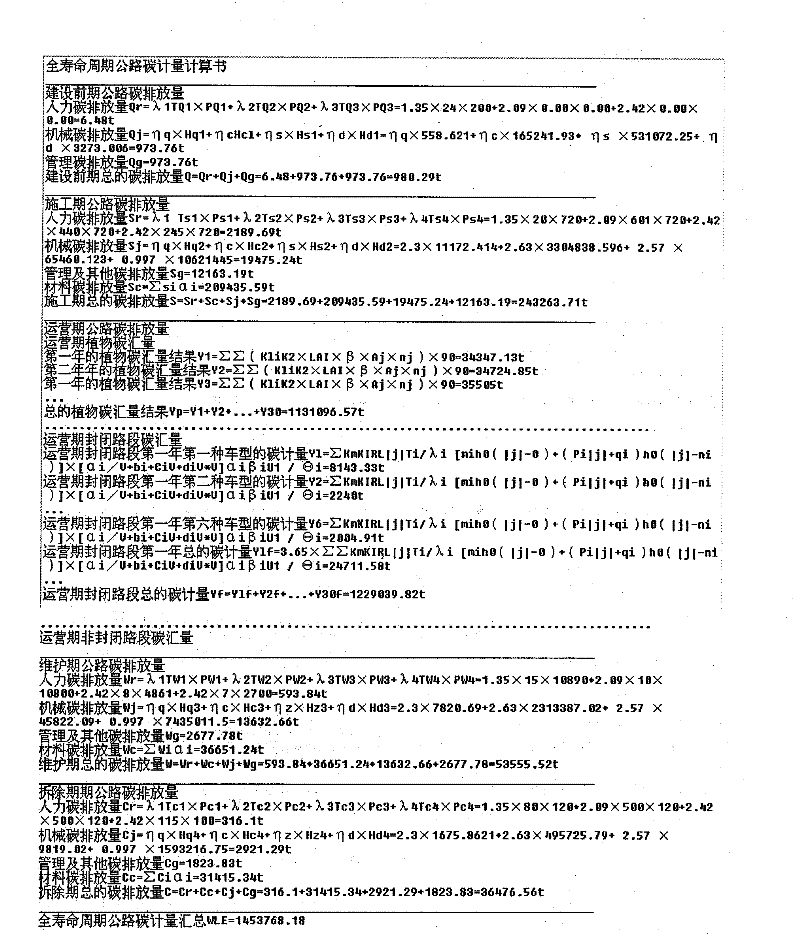

Method for metering carbon emission of roads in whole life cycle and application thereof

The invention discloses a method for metering carbon emission of roads in the whole life cycle. The carbon emission of the roads in the whole life cycle relates to carbon emission directly related to construction and use of road engineering in the whole life cycle in the carbon emission caused by social activities, and the whole life cycle includes the early building stage, the construction stage, the operation stage, the maintenance stage and the dismantling stage. The results of multiple embodiments of the method indicate that carbon emission of the roads is effectively evaluated, and the method for building of load-carbon model roads provides reference for further construction of low-carbon roads. In view of realizing low-carbon emission, a basis system of carbon metering and evaluating for the roads is established, research and construction progress of the low-carbon roads is boosted greatly, deterioration of the environment due to carbon emission of the social activities is alleviated, and the method has great contribution for realizing low-carbon emission and emission reduction.

Owner:OCEAN UNIV OF CHINA

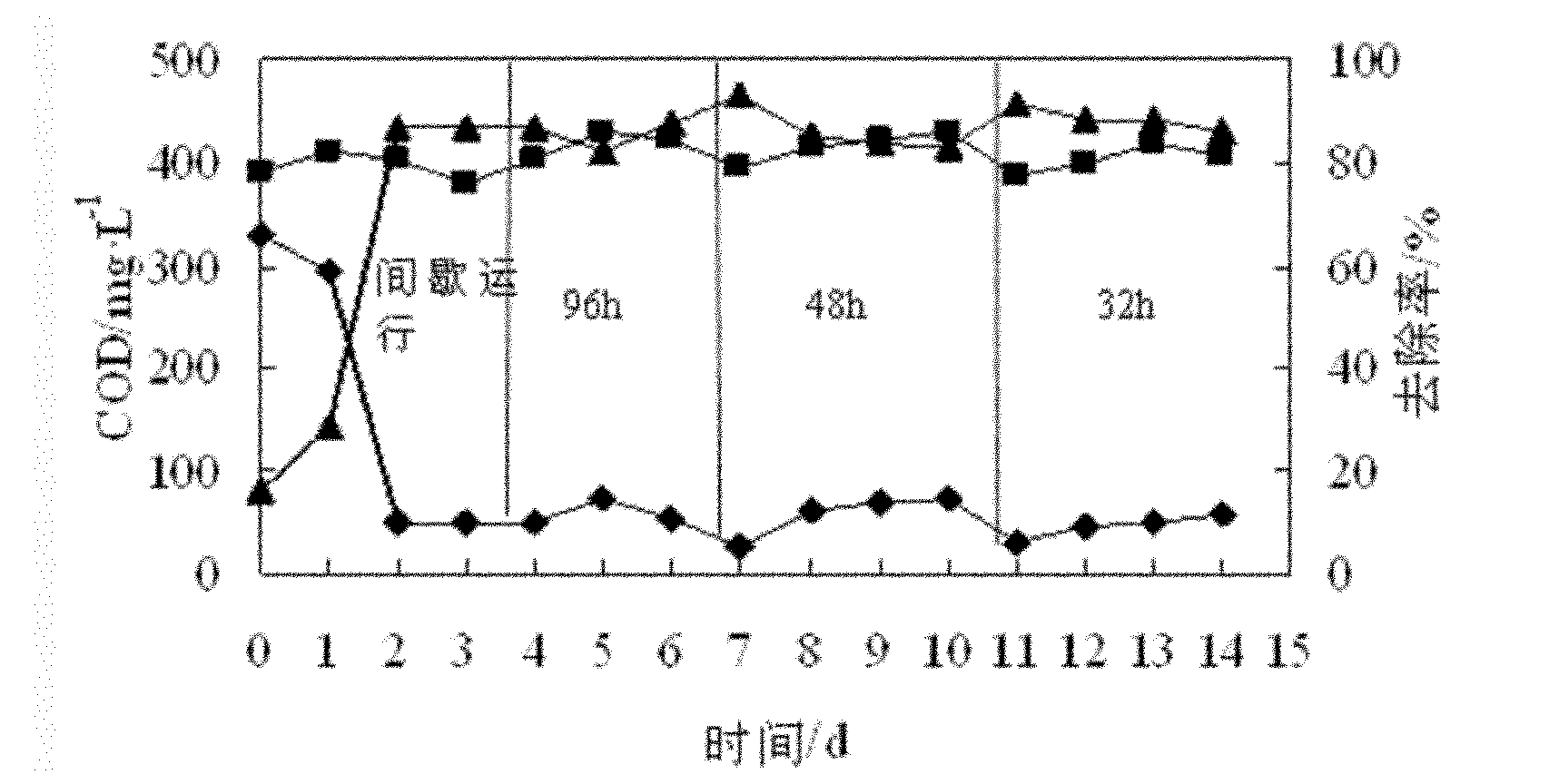

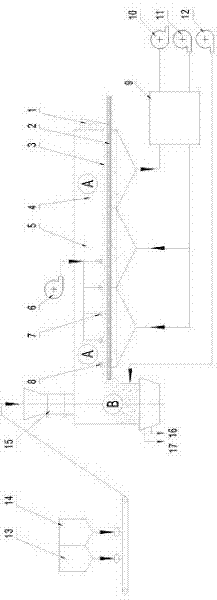

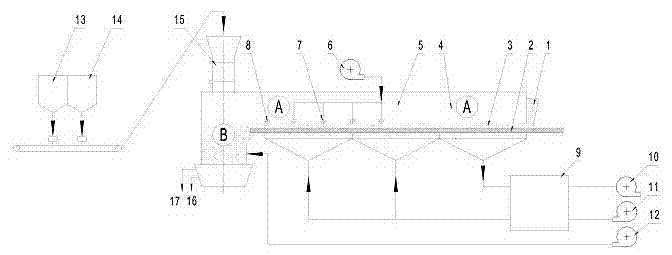

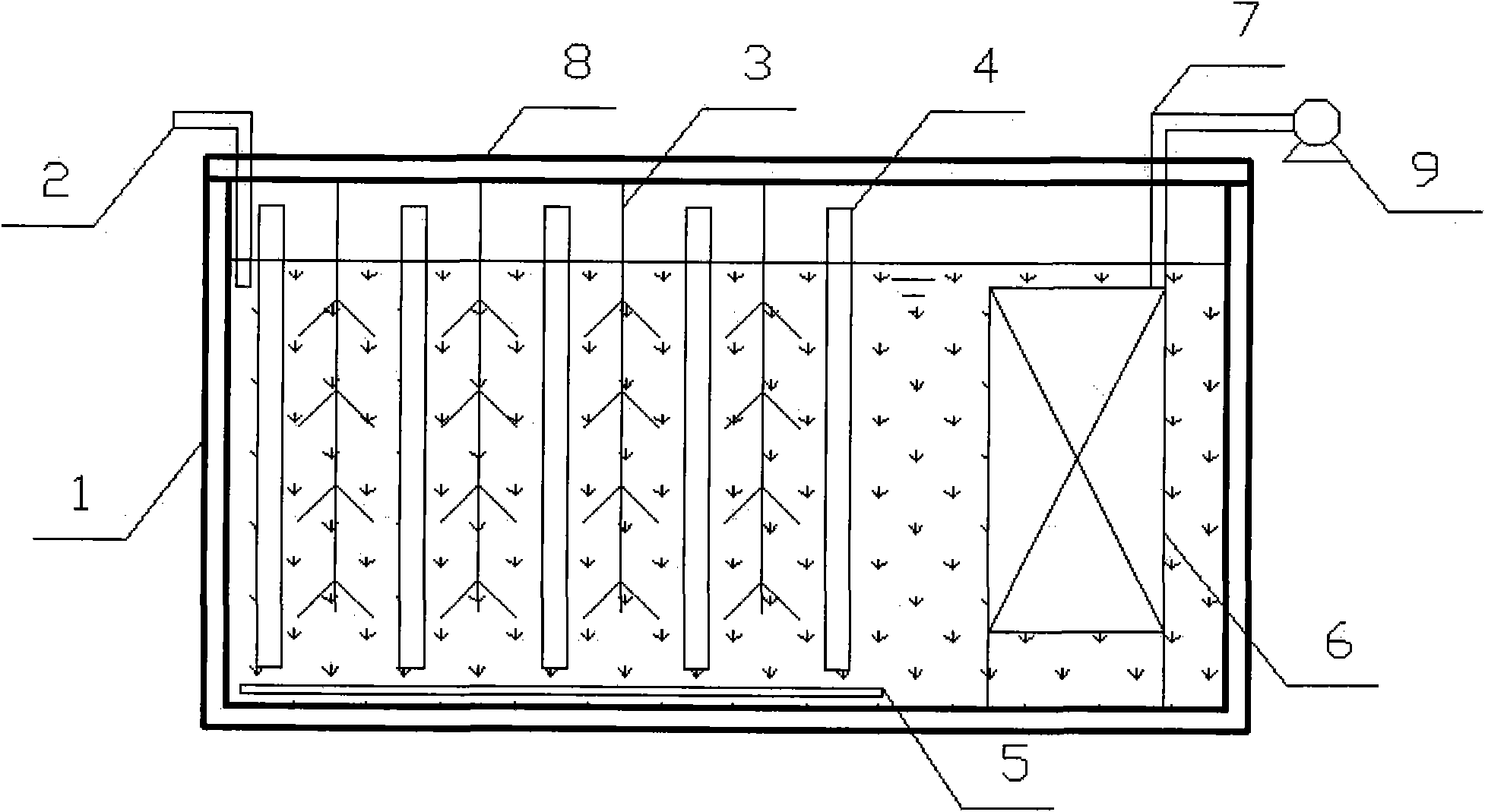

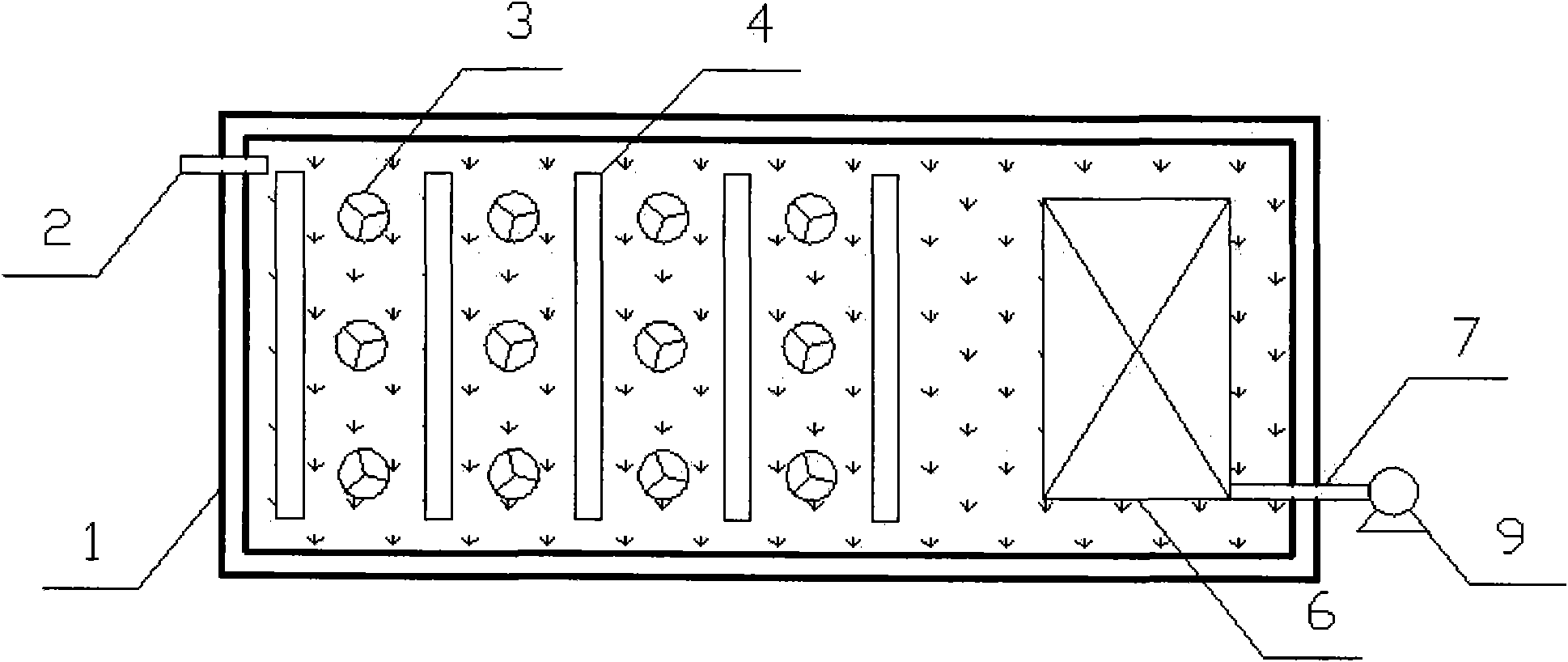

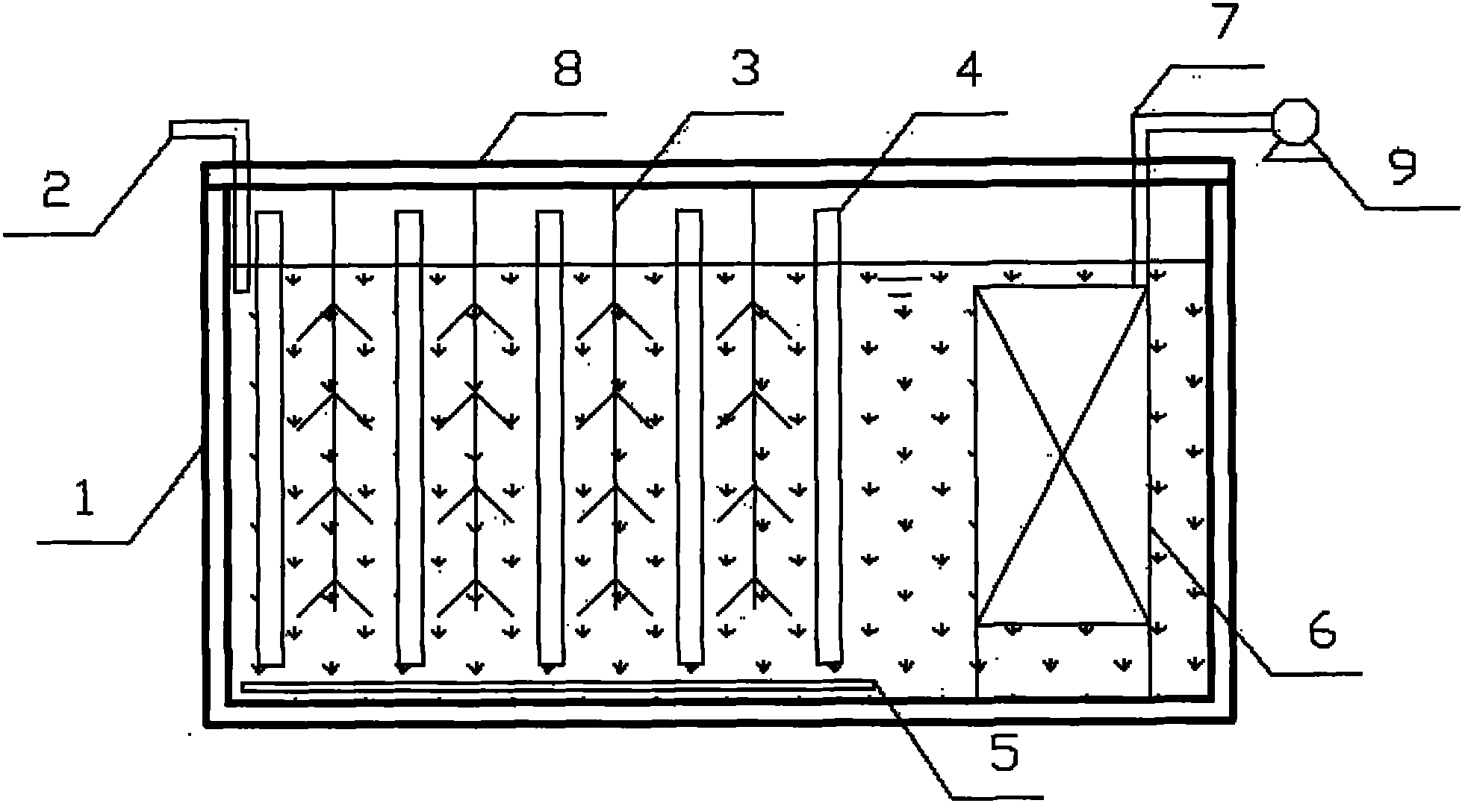

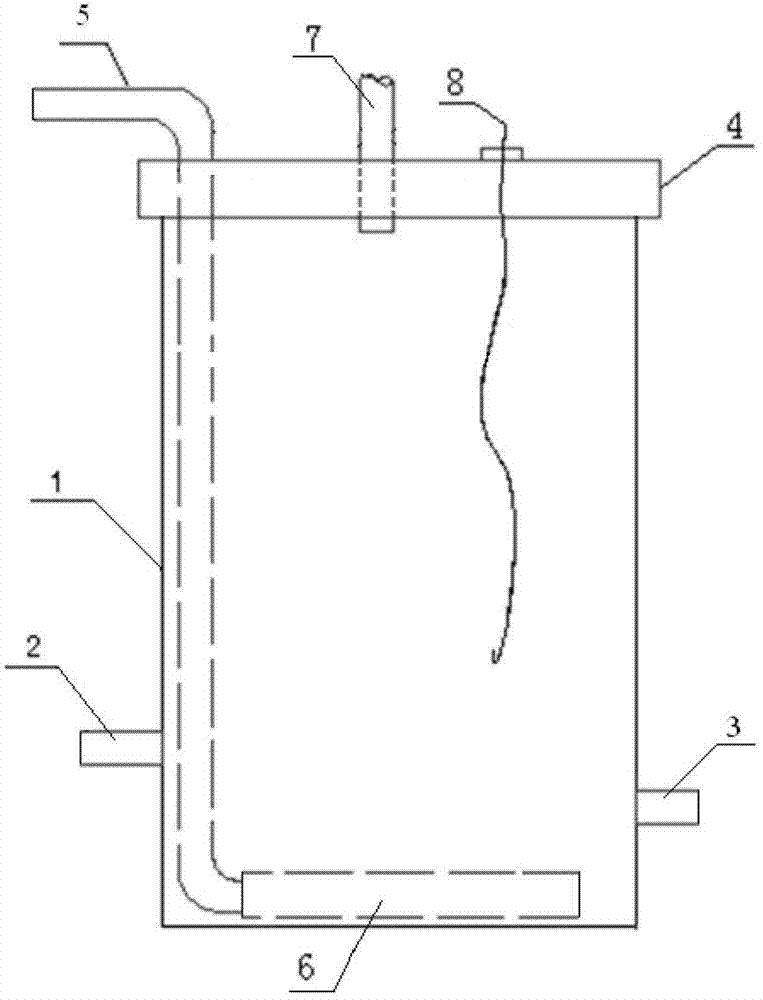

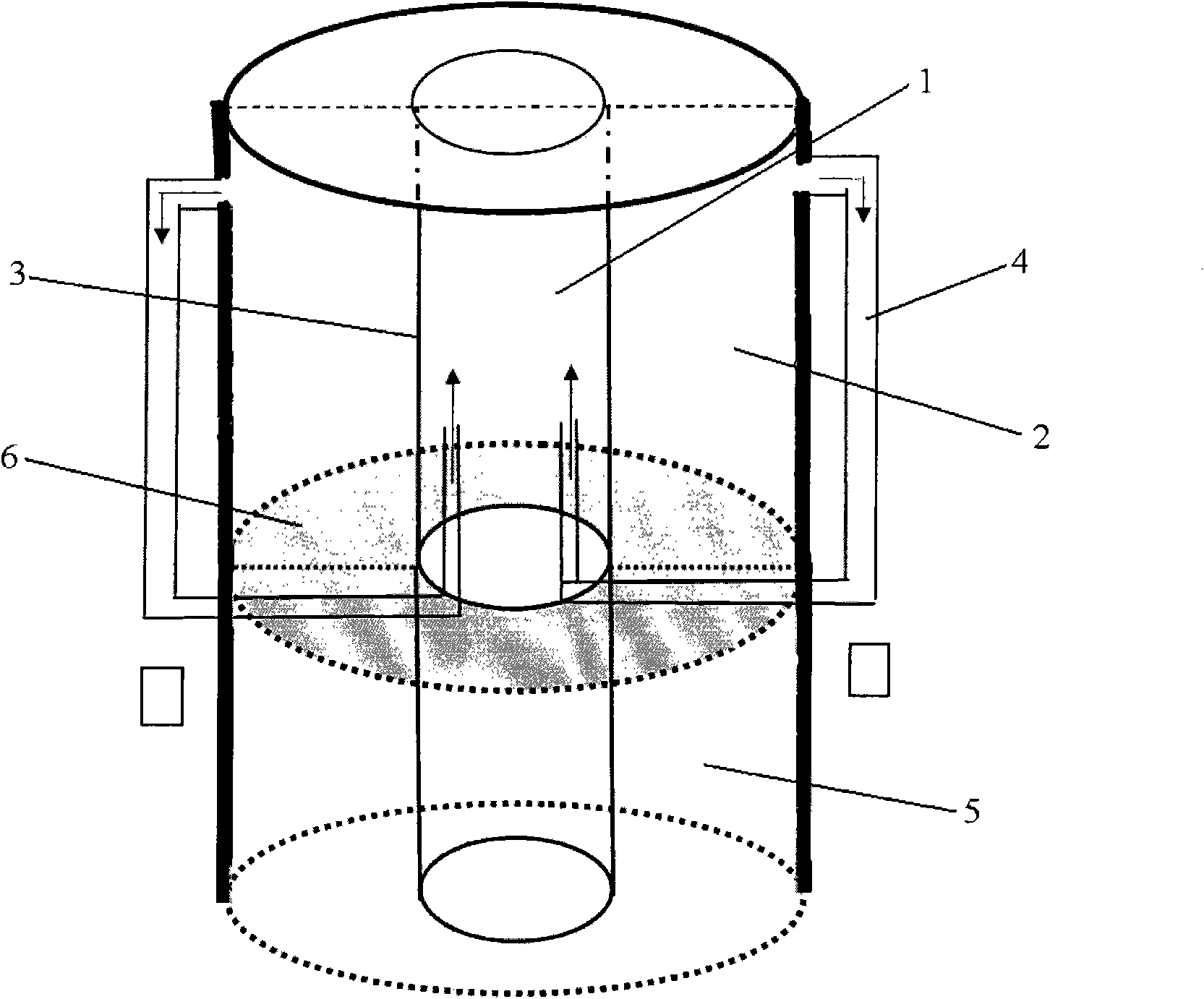

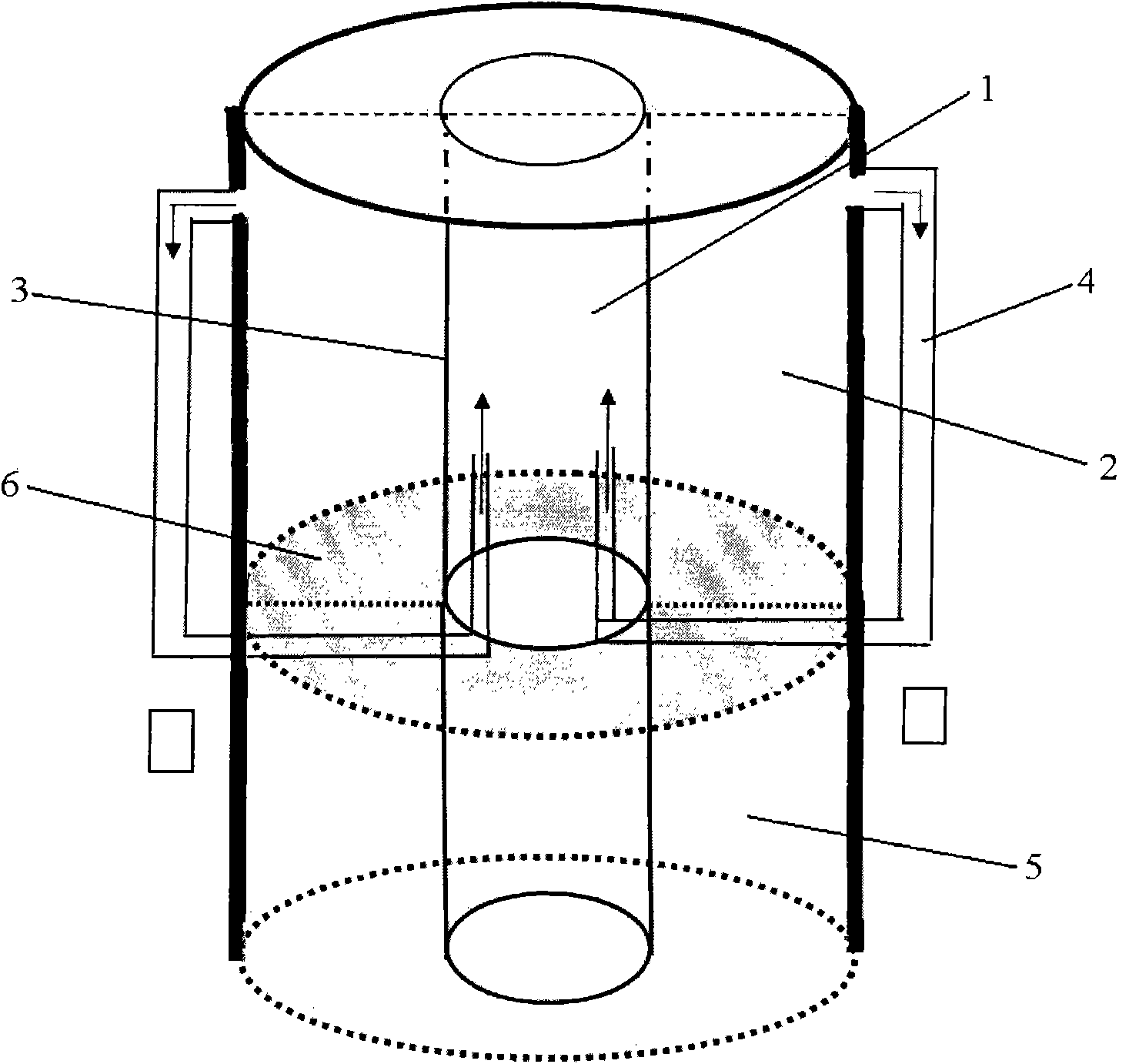

Bacteria-algae synergism low-carbon membrane bio-reaction system

InactiveCN101885534AEmission reductionReduce consumptionTreatment using aerobic processesSustainable biological treatmentWater treatment systemGreenhouse

The invention belongs to the technical field of environmental protection, and more particularly relates to a bacteria-algae synergism membrane biological photosynthetic reaction system, aiming at realizing low-carbon emission. The system comprises a pond body, a water inlet pipe, filler, illumination devices, an aerating apparatus, a membrane module, a water outlet pipe and a suction pump, and ischaracterized in that the pond body is internally provided with the filler; the illumination devices are evenly distributed at the two sides of the filler; the aerating apparatus is positioned at thebottom of the pond body; the membrane module is arranged inside the pond body and is close to the water outlet pipe; the water outlet pipe is connected with the suction pump; and the water inlet pipeis positioned at one side of the pond body, and the water outlet pipe is arranged at the other side of the pond body. By utilizing the physical and chemical properties of bacteria and algae, and carrying out synergistic effect according to metabolic coupling of substrate and product, the bacteria-algae synergism membrane biological photosynthetic reaction system can reach system metabolic flux balance, thus reducing the aeration consumption of a sewage disposal system and the emission of greenhouse gases such as carbon dioxide and the like. Meanwhile, by utilizing the technology of membrane separation, the system realizes separation between bacteria, algae and water, and ensures the quality of outlet water to be stable.

Owner:TONGJI UNIV

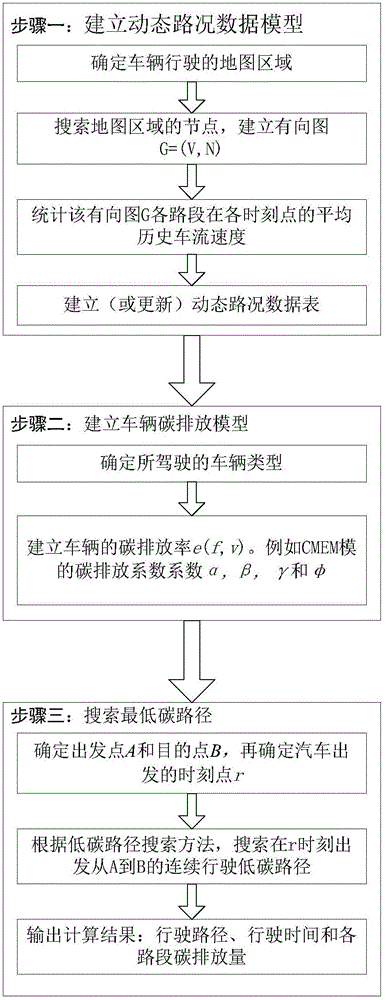

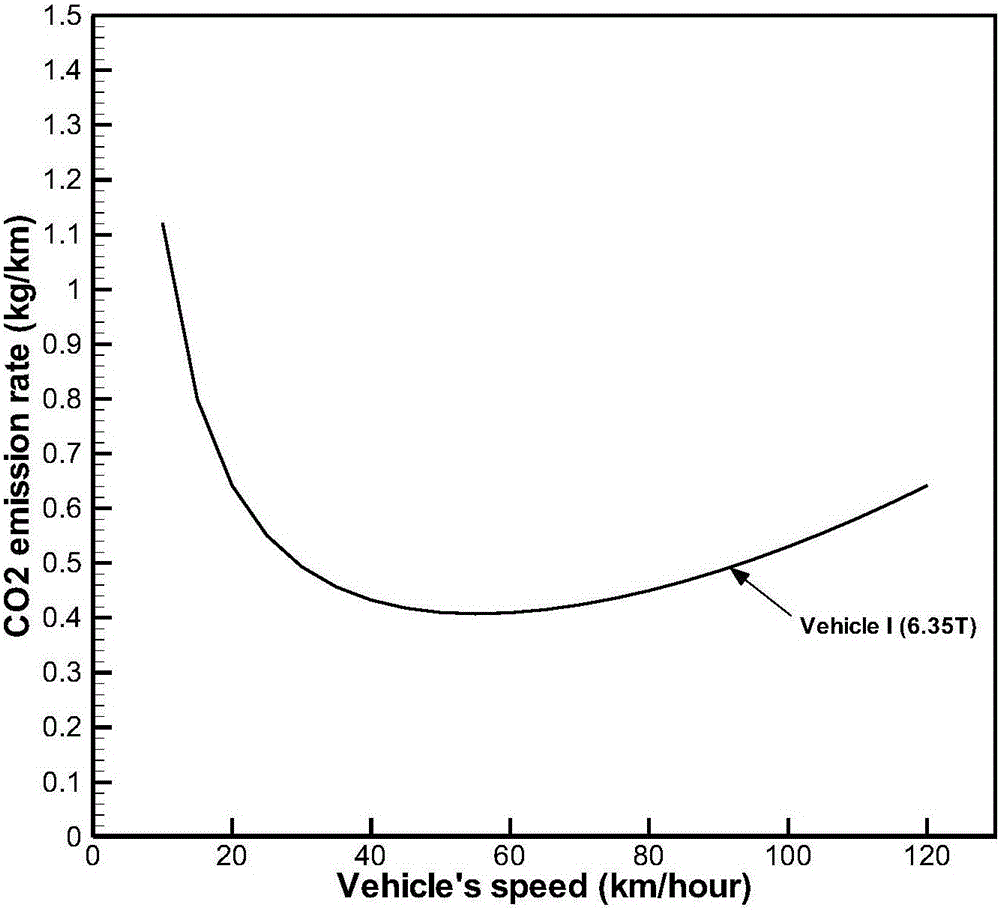

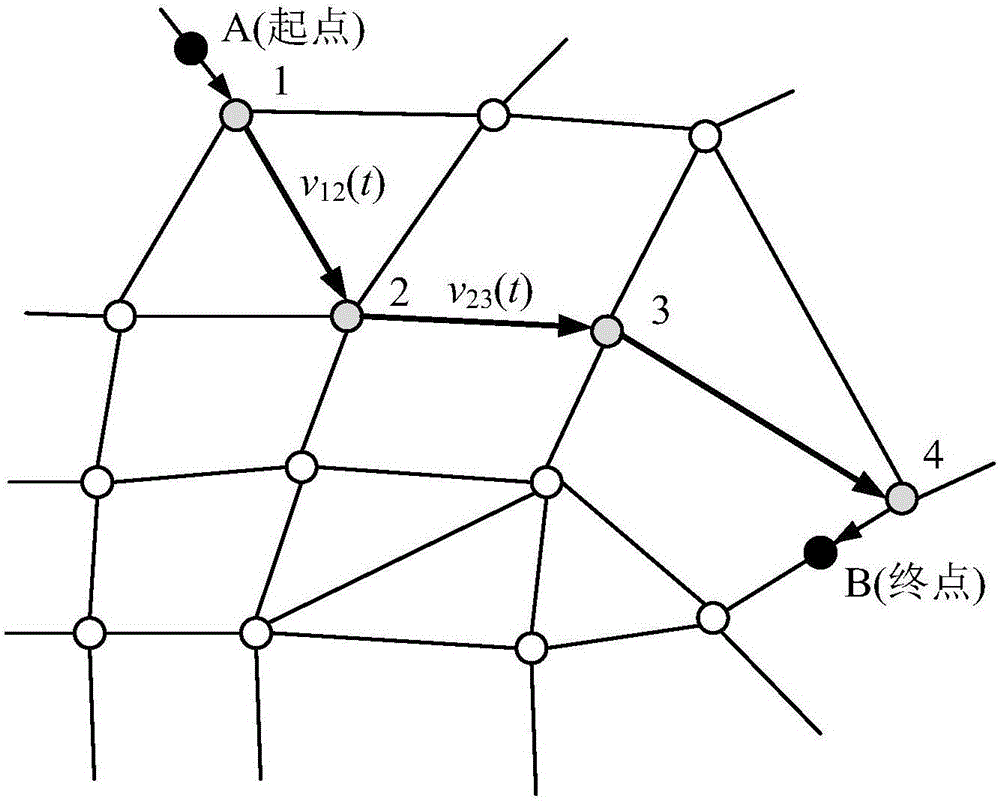

Method for searching lowest carbon path of automobile under dynamic traffic environment

ActiveCN105865476AImprove computing efficiencyInstruments for road network navigationSimulationFuel oil

The invention relates to a method for searching the lowest carbon path of an automobile under a dynamic traffic environment. The method comprises the following steps: 1) establishing a dynamic traffic data model of a road traffic network; 2) establishing a CO2 (carbon dioxide) emission model of the automobile; 3) searching for the lowest carbon path between a given start point and a destination point. According to the above steps, a driving path with the lowest carbon emission can be searched from the dynamic traffic network, so as to cause the total emitted CO2 volume be the lowest when a vehicle starts from A point at r moment and continuously drives to B point; the method is fit for the lowest carbon path searching service for the general passenger vehicles as well as the lowest carbon path searching service for the larger load trucks; according to the method, the problem of optimal design for the driving path of the fuel oil type vehicle (gasoline, diesel oil, and the like) under the instant changing condition of the traffic condition can be effectively solved so as to achieve the purposes of saving fuel and reducing emission.

Owner:BEIHANG UNIV

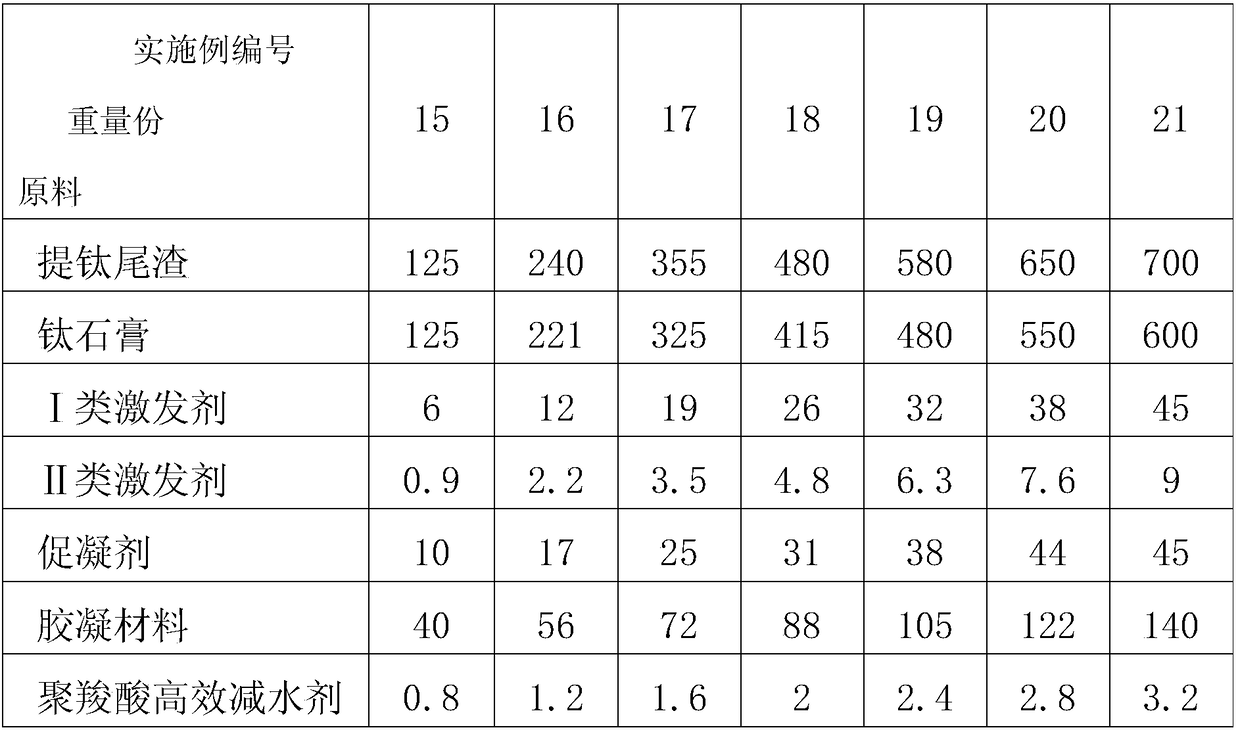

Titanium extracting tailing-titanium gypsum based foam concrete and preparation method thereof

InactiveCN108358578ALow thermal conductivityShorten the setting timeCeramicwareFoam concreteInsulation layer

The invention discloses titanium extracting tailing-titanium gypsum based foam concrete and a preparation method thereof. The titanium extracting tailing-titanium gypsum based foam concrete is prepared from the following components in parts by weight: 120 to 840 parts of titanium extracting tailings, 120 to 840 parts of titanium gypsum, 4 to 84 parts of type I exciting agent, 0.67 to 17.87 parts of type II exciting agent, 0.8 to 120 parts of coagulant, 20 to 178.7 parts of gel material, 0.4 to 5.9 parts of polycarboxylic acid efficient water reducing agent, 10.7 to 32 parts of physical foamingfoam and 266 to 600 parts of water. The preparation method comprises the following steps: weighing the raw materials according to the weight part ratio; grinding the titanium extracting tailings andthe titanium gypsum; mixing and stirring the raw materials and adding the foam; molding and curing to prepare the titanium extracting tailing-titanium gypsum based foam concrete. The titanium extracting tailing-titanium gypsum based foam concrete disclosed by the invention is a light-weight building material with low carbon emission and is suitable for being used as a heat-preservation and heat-insulation layer of a wall body and a heat-preservation layer of a floor heating system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

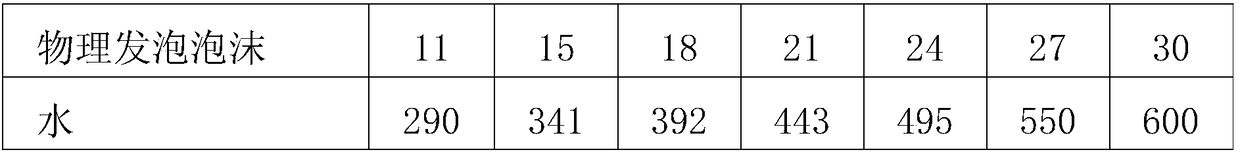

Process for preparing hot molten iron and byproducts by utilizing red mud

InactiveCN102344982ASolve the problem that "spitting dregs" cannotSolve the problem of land occupationRotary drum furnacesProcess efficiency improvementRed mudSlag

The invention provides a process for preparing hot molten iron and byproducts by utilizing red mud. The process comprises the following steps of: a) mixing the red mud, lime and coal; b) adding a mixture obtained in the step a) in a rotary kiln for drying and pre-reduction; c) introducing a reduced material into a diversion trench for air injection and combustion supporting, carrying out melting and slag-iron separation, discharging the slag on the upper layer from a slag outlet, and flowing the hot molten iron on the lower layer out of an hot molten iron outlet; d) preparing cement clinker and silicon-titanium-aluminum alloy from the slag in a melt separation furnace; e) preparing microlite powder from the slag in the melt separation furnace; and f) recovering superheated steam, and preparing a mixed liquid. The process has the advantages that a large amount of calcium compounds are not necessarily doped, and coke is also not necessarily used, thereby solving the problem that slag spitting is not carried out by using a blast furnace process, and greatly reducing cost; toxic red mud is recycled so as to obtain the elementary substance iron, thereby solving the problems that the red mud occupies land and pollutes environment; and the byproducts such as silicon-titanium-aluminum alloy, superheated steam, sodium salt, microlite powder and the like can also be obtained, the zero emission of solid pollutants is achieved, gas reaches the standard to be discharged and low-carbon discharge is achieved. Thus, the process provided by the invention is environmentally friendly.

Owner:胡长春 +1

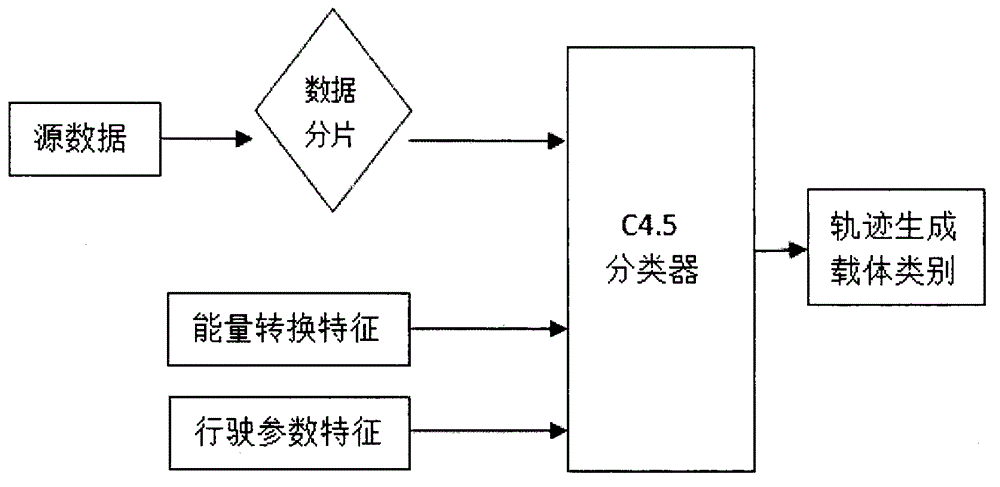

Mode recognition technique for different travel modes

InactiveCN105989224AImprove relationshipImprove reliabilitySpecial data processing applicationsTravel modeData segment

The invention discloses a mode recognition technique for different travel modes. The mode recognition technique takes green travel of an electric vehicle as background, three types of data, namely energy consumption, travelling carrier state and motion characteristics which are provided by an input terminal in motion and are monitored in real time, are preprocessed, then for a large amount of time, longitude, latitude, voltage, current, course and three-dimensional acceleration information, data segments of continuous data are cut into a track list according to the motion characteristic, extraction of power and travelling characteristics and vector calculation are carried out on the track list, results are input into a C4.5 classifier formed after the actual measurement to be calculated, and class of a track generating carrier is output. The mode recognition technique disclosed by the invention aims at screening out a green travel part in track unit and providing a data source for measurement and calculation of low carbon emission reduction green travel and the like.

Owner:南京乐行天下智能科技有限公司

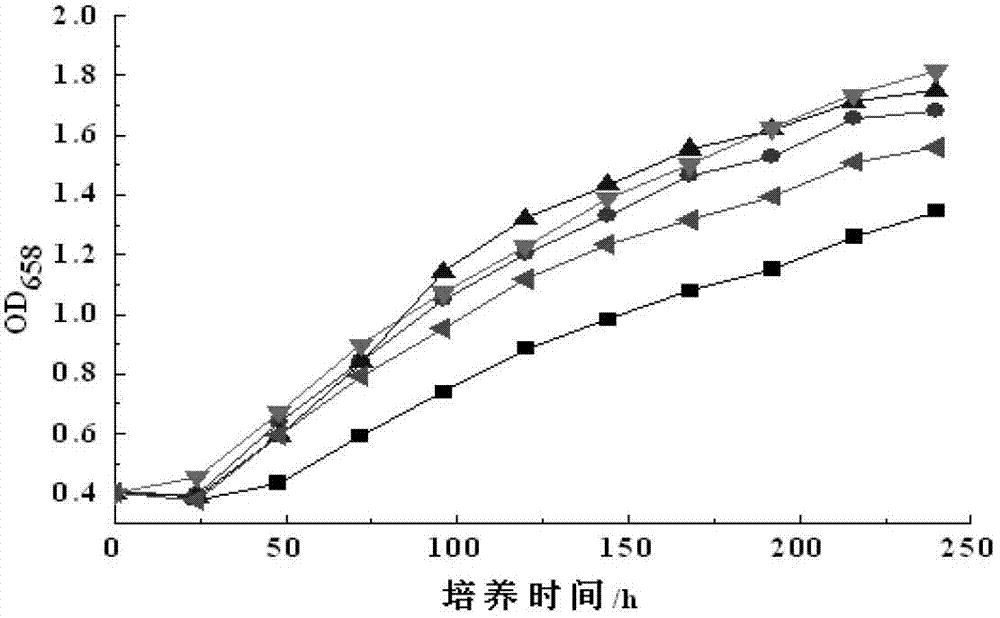

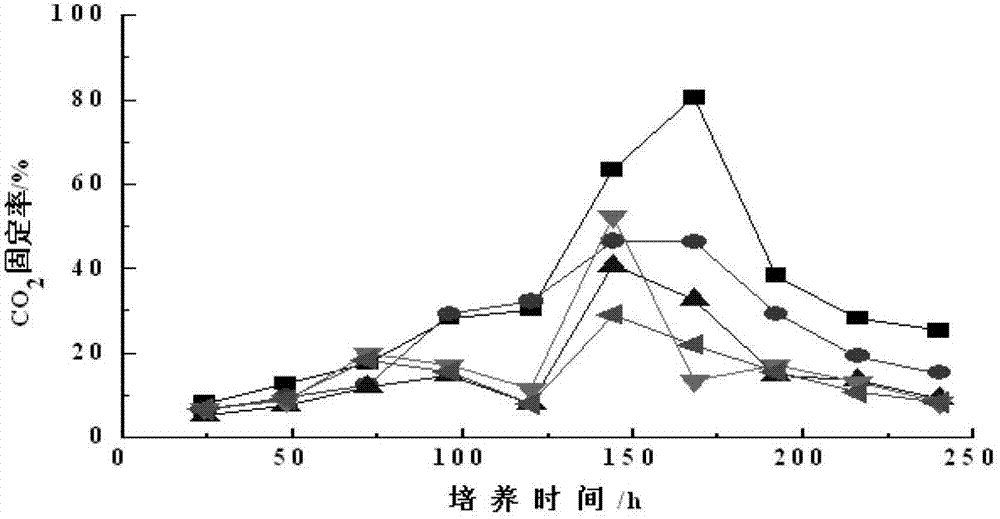

Method and device for low-carbon emission energy regeneration by coupling waste gas and waste water

InactiveCN102815839APromote growthRealize resourcesBioreactor/fermenter combinationsBiological substance pretreatmentsOil and greaseEnergy regeneration

The invention relates to a method and a device for energy regeneration, in particular to a method and a device for low-carbon emission energy regeneration by coupling waste gas and waste water, aiming at solving the problems of low carbon recovery rate, low CO2 fixing rate and high microalgae lipid cost in the waste water treatment process. The method comprises the steps of: (1) carrying out high-pressure steam sterilization pretreatment on the waste water treated by primary treatment, then introducing the treated waste water into a reactor, and inoculating microalgae nutrient solution; (2) filling the waste gas into the reactor, and culturing microalgae; and (3) collecting the cultured microalgae, dehydrating the microalgae until constant weight, extracting the lipid of the microalgae, and completing the low-carbon emission energy regeneration by coupling the waste gas and the waste water. The device for the low-carbon emission energy regeneration by coupling the waste gas and the waste water comprises a main body, a liquid inlet pipe, a liquid outlet pipe, a cover, an air inlet pipe, an air distribution device, an air outlet pipe and a heat sensor. The invention is applied to the field of low-carbon emission energy regeneration by coupling the waste gas and the waste water.

Owner:HARBIN INST OF TECH

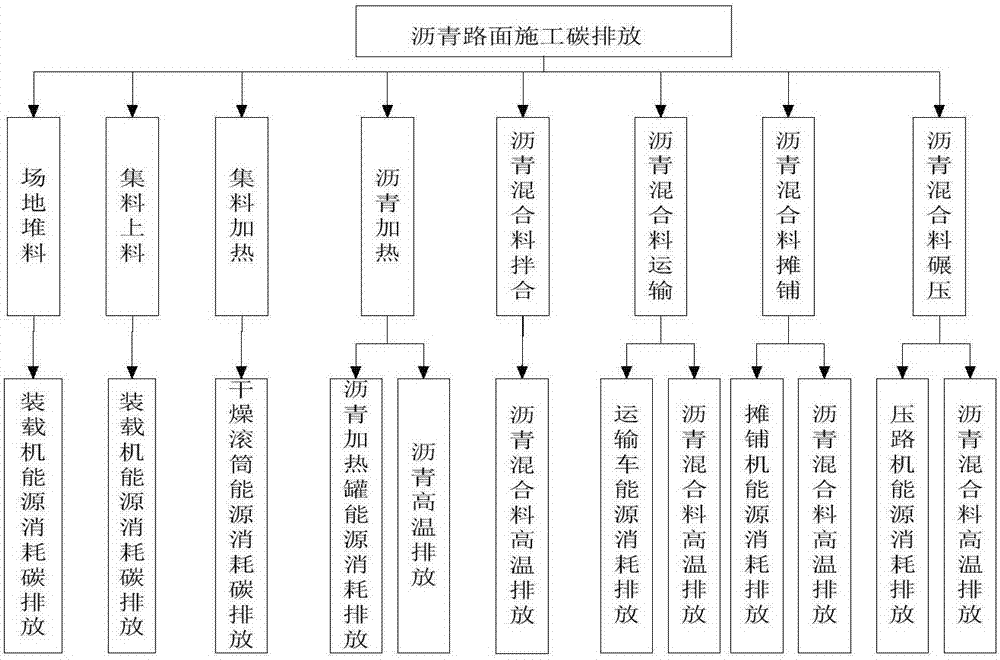

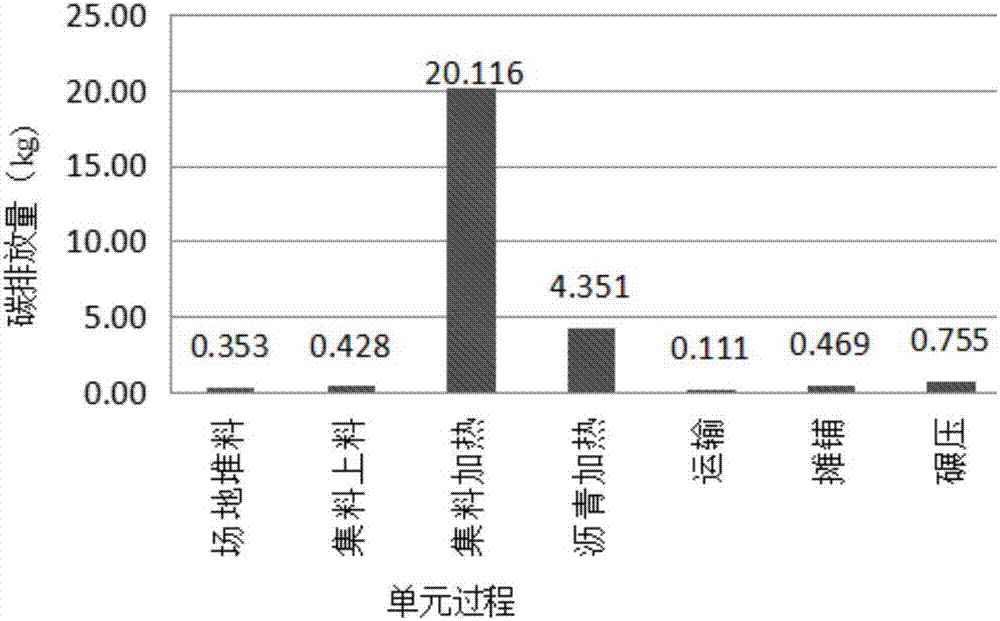

Method for evaluating carbon emission in asphalt surface course construction

ActiveCN107122591AThe evaluation content is comprehensiveIntuitively reflect the emission situationTechnology managementInformaticsHigh carbonMechanical equipment

The invention discloses a method for evaluating carbon emission in asphalt surface course construction. According to the method, the carbon emission in the asphalt surface course construction is divided into 8 units of site stockpiling, aggregate loading, aggregate heating, asphalt heating, asphalt mixture mixing, transportation, paving and grinding according to different unit processes of the asphalt surface course construction, and a carbon emission source is defined into energy consumption carbon emission generated by using of mechanical equipment and a transport cart, and carbon emission of asphalt and asphalt mixtures under a high-temperature state. According to the method, corresponding asphalt surface course construction carbon emission calculation formulas are established according to different construction units and carbon sources under the historical background of energy conservation and emission reduction as well as low carbon and environment protection, the carbon emission loads are graded, and an asphalt surface course carbon emission evaluation method is established on above basis, so that a research direction is indicated for the change, from a high carbon emission mode to a low carbon emission mode, of the later asphalt surface course construction process, and great significance is brought to remit the greenhouse effect and propel the research process of low-carbon type roads.

Owner:CHANGAN UNIV

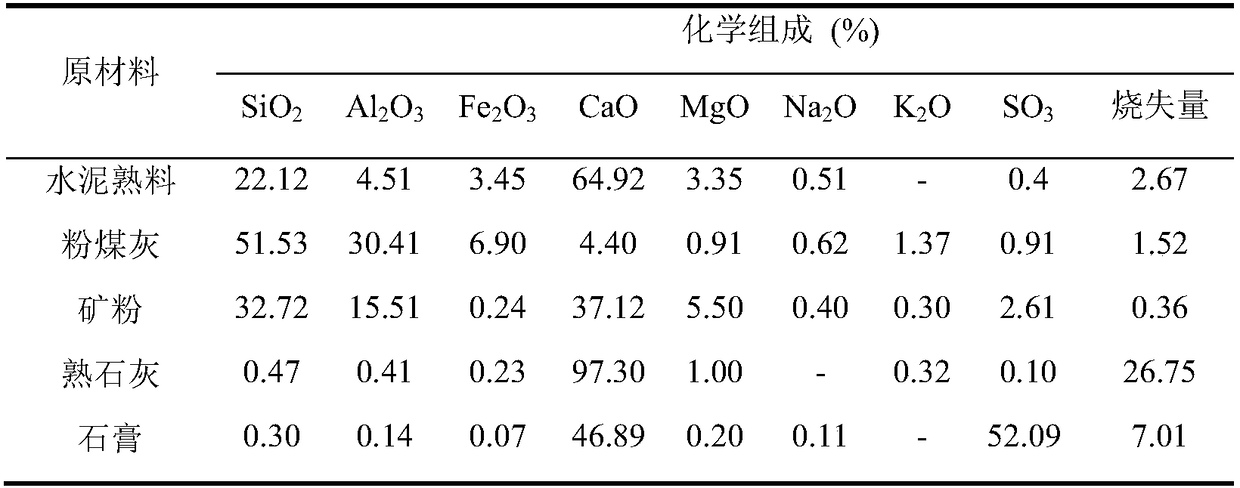

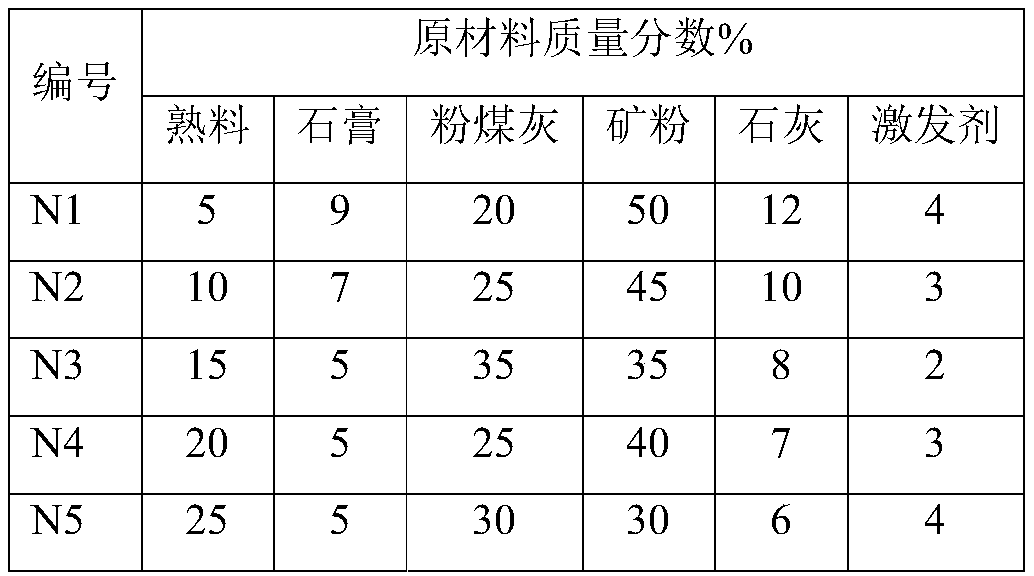

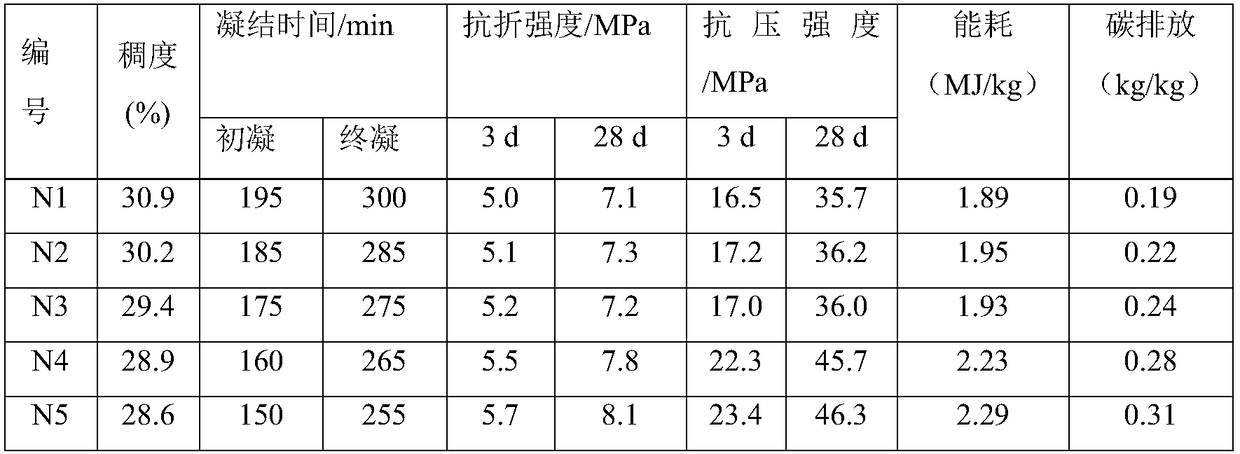

High-volume low carbon cement doped with large amount of industrial waste residue and preparation method thereof

InactiveCN108623196ALow gel calcium contentHigh compressive strengthCement productionUltimate tensile strengthFly ash

The invention discloses high-volume low carbon cement doped with a large amount of industrial waste high-volume and a preparation method thereof. The low carbon cement is characterized by comprising the following components in parts by weight: 10 to 40 parts of cement clinker, 1 to 35 parts of fly ash, 20 to 45 parts of ore powder. 3 to 10 parts of lime, 3 to 7 parts of gypsum, and 1 to 4 parts ofactivator. The cement clinker and gypsum are mixed and co-powdered in proportion, and after the fineness requirement is met, the mixture is mixed and homogenized with fly ash, high-volume, lime and the activator. The composite portland cement prepared by the method has the advantages of less cement clinker consumption, low carbon emission and energy consumption in the production process, high early strength and large strength enhancement rate in the later stage.

Owner:SOUTHEAST UNIV

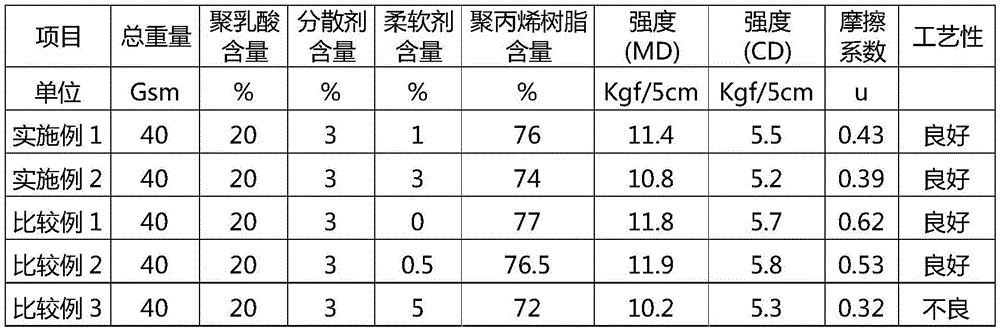

Polylactic acid blended non-woven fabric having improved flexibility and method for preparing same

ActiveCN105556014AReduce coefficient of frictionWell mixedNon-woven fabricsPolymer scienceNonwoven fabric

The present invention relates to a polylactic acid blended non-woven fabric having improved flexibility, and a method for preparing same. The polylactic acid blended non-woven fabric having improved flexibility of the present invention is characterized in that: the non-woven fabric prepared by weaving polylactic acid and a polypropylene blend includes 10 to 80 wt% of polylactic acid, 10 to 89 wt% of polypropylene, 1 to 7 wt% of a dispersing agent, and 1 to 3 wt% of a softening agent with respect to the total weight of a polymer mixture for the blending; and in that the total weight of the non-woven fabric is 10 to 100 gsm. In the polylactic acid blended non-woven fabric having improved flexibility, and the method for preparing same as configured above according to the present invention, in addition to the low carbon emission properties of a conventional polypropylene / polylactic acid non-woven fabric, a disadvantage thereof in having low flexibility due to the distinctive stiffness of polylactic acid is resolved by adding a particular softening agent in a certain ratio in order to reduce the surface friction coefficient of the non-woven fabric and thereby improve flexibility. Also, the typical disadvantage described above is resolved particularly by controlling the conditions in a preparation process of mixing and weaving through the use of a dispersing agent to homogeneously mix polylactic acid and polypropylene for weaving and fabricating into the non-woven fabric, thereby improving productivity.

Owner:TORAY ADVANCED MATERIALS KOREA

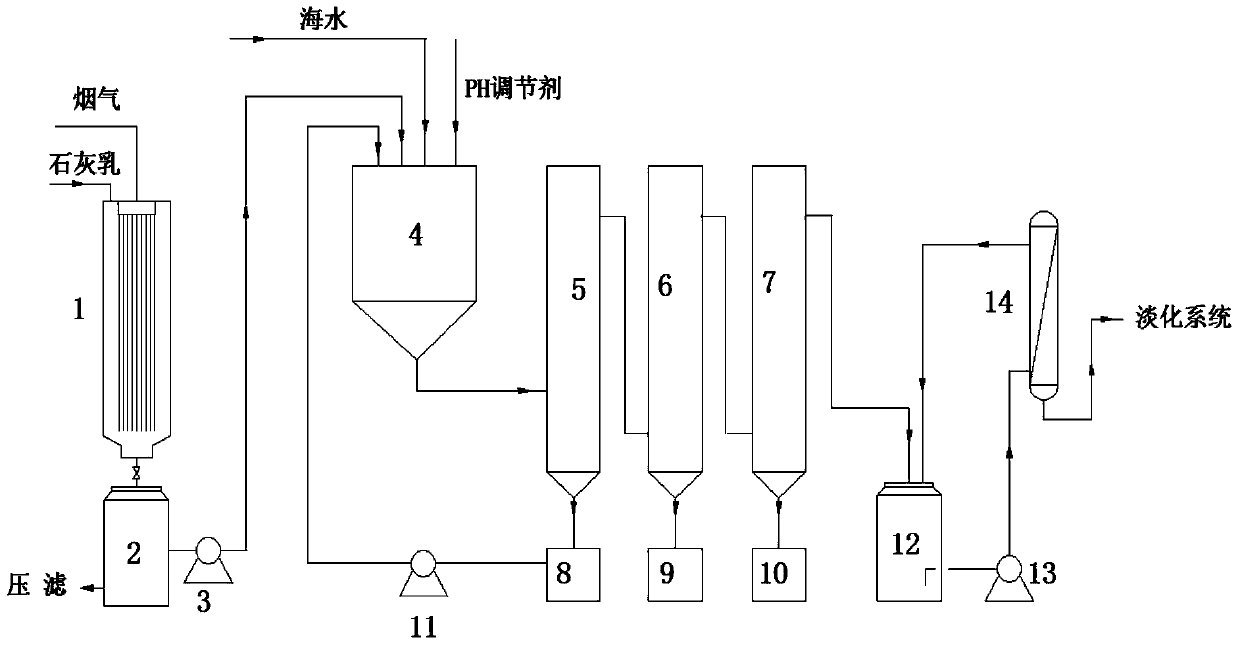

Method for reducing emission of thermal power generation smoke CO2 and subsidiarily producing superfine nanometer CaCO3 from thermal power generation smoke CO2

ActiveCN103990370ARemove calcium ionsRealize low carbon emissionsCalcium/strontium/barium carbonatesMaterial nanotechnologyWater desalinationEngineering

The invention provides a method for reducing the emission of thermal power generation smoke CO2 and subsidiarily producing superfine nanometer CaCO3 from the thermal power generation smoke CO2. A device for realizing the method comprises a decarburization tower, a settling tank, a water inlet pump I, a reaction tank, a first-level settling tank, a second-level settling tank, a third-level settling tank, an intermediate tank, a water inlet pump II and a ceramic membrane filter which are successively connected through a pipeline, wherein the settling tanks are all connected with a calcium carbonate storing groove. The method provided by the invention has the advantages that smoke discharged from thermal power generation is purified and decarburized, the low carbon emission of the smoke of a power plant is realized, the environment stress of the power plant is relieved, and the green power generation is realized; the temperature of the smoke is reduced through the contact heat transfer of seawater and the smoke, waste heat is fully utilized, and the heat pollution caused by high temperature smoke emission is reduced; the CO2 in the smoke is converted into a CaCO3 product after being absorbed, the waste is turned to wealth, the smoke decarburization and the seawater decarburization are combined, the treating cost spent on the seawater decarburization is reduced, and an equipment scaling problem in the later sea water desalination process is prevented.

Owner:天津海桓科技有限公司

Self-combustion biomass char production furnace

InactiveCN101967386AReduce total usageEmission reductionCoke quenchingCombustible gas coke oven heatingCombustible gasCarbonization

The invention relates to equipment for producing biomass char, in particular to a self-combustion biomass char production furnace. The production furnace is cylindrical; an inner wall which is concentric with the production furnace is arranged in the production furnace; a part inside the inner wall is a combustion hearth; a drawing plate is arranged in the middle of an annular region between a combustion hearth wall and the outer wall of the production furnace to divide the annular region into an upper carbonization hearth and a lower cooling hearth; a plurality of combustible gas reflux pipelines are arranged; and one end of each combustible gas reflux pipeline is connected to the side wall of the upper part of the carbonization hearth, while the other end is communicated to the combustion hearth from the lower side of the drawing plate. In the production furnace, biomass energy is utilized, so that the utilization of fossil energy is avoided and low carbon emission is achieved; combustible gas is recycled and heat utilization ratio is high, so that pollution on the atmospheric environment is reduced; due to a carbonization and cooling integrated design, safety and high efficiency are achieved; and the production furnace has a simple design, low cost and high comprehensive energy utilization ratio and is movable.

Owner:CHINA AGRI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com