Patents

Literature

140results about How to "Easy production organization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

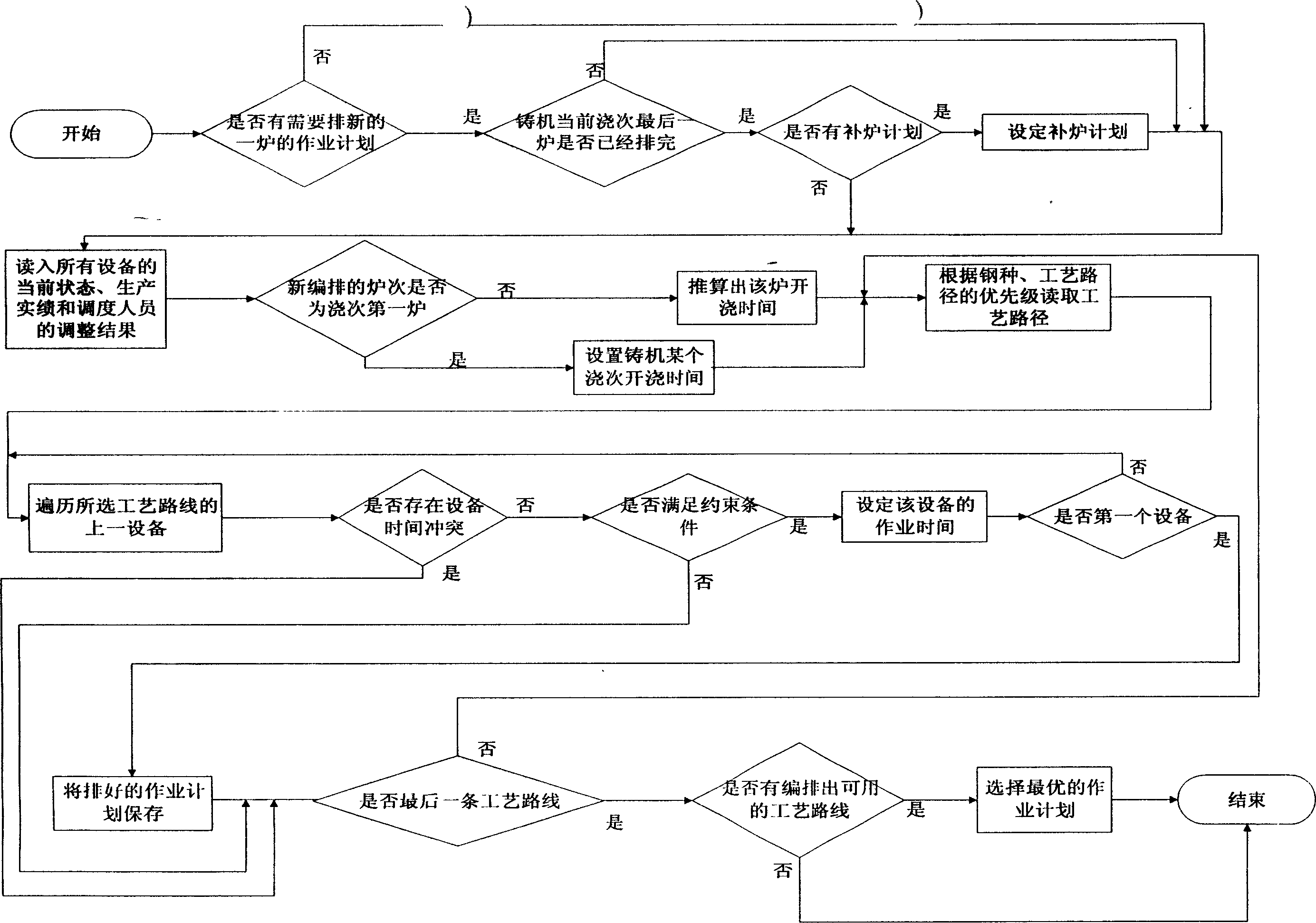

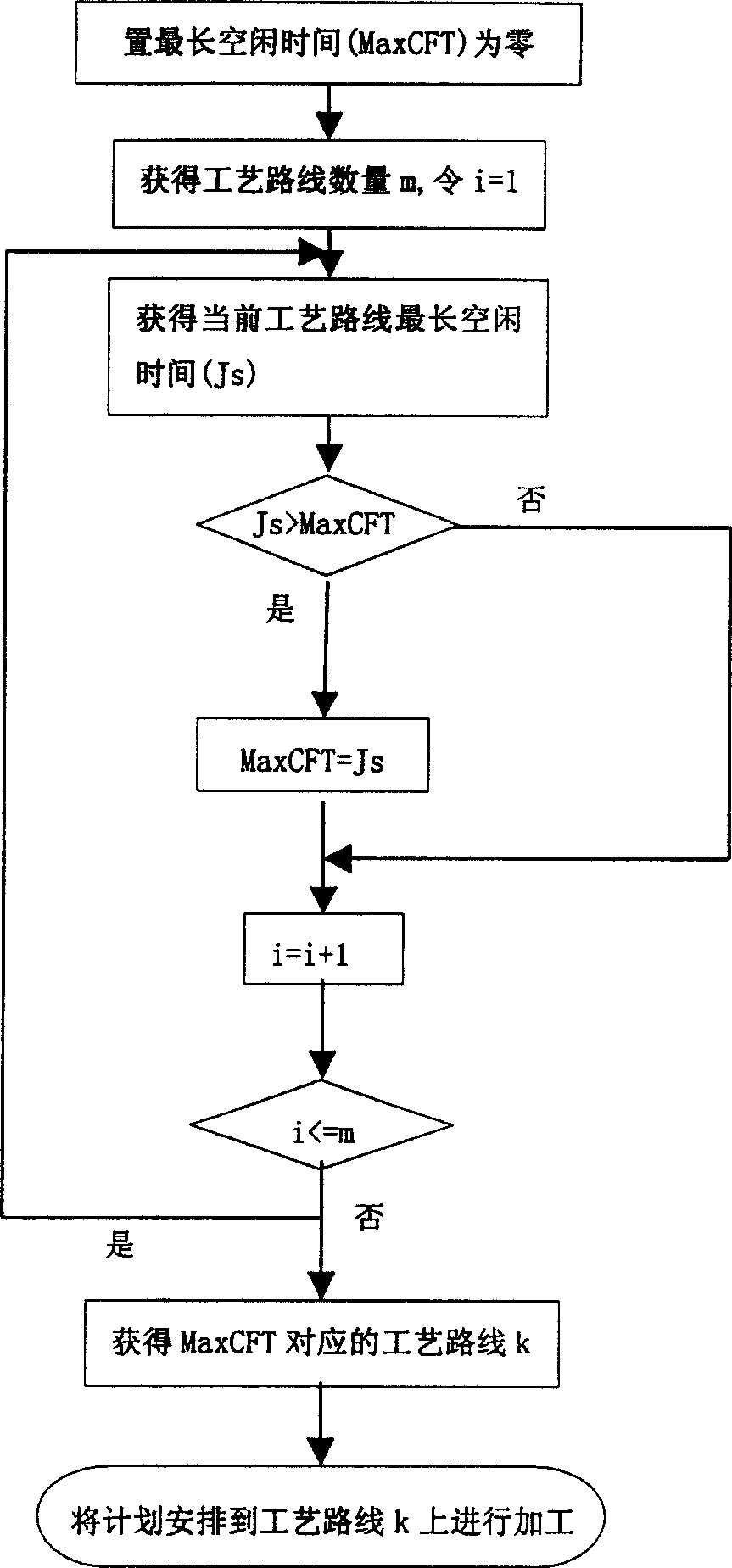

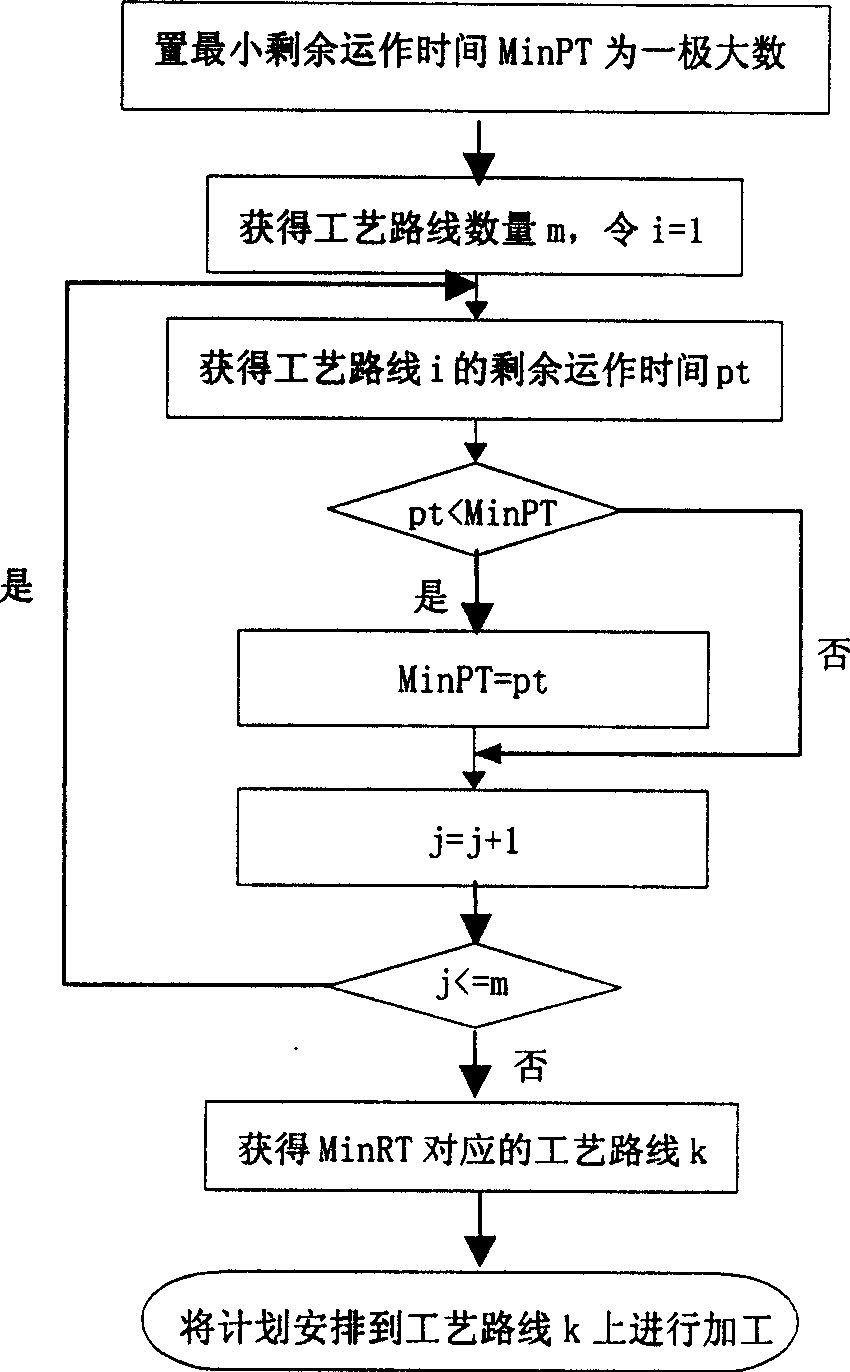

On-line dynamic dispatching method for continuous steel casting production

InactiveCN1614618AReduce cumulative time errorEasy production organizationSpecial data processing applicationsComputerized systemWorkstation

An on-line dynamic dispatching method for continuous production of steel making includes applying distributed computer system; working out a dynamic operation plan suitable for current production state by collecting data from site process and equipment, combining the set of dispatcher and using roll search mode; following the plan to carry out operation by operation station and feeding back regulation request to dispatching room for used as basis of next dispatch.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

Production method of large high chromium steel cold roll blank

InactiveCN1686666AAdvanced technologyStrong maneuverabilityOther manufacturing equipments/toolsChromiumProduction cycle

A production method for the blank of large cold-rolling high-Cr steel roller includes smelting in arc furnace, refining outside the furnace, conveying hot steel ingot, heating in high-temp homogenizing mode, drawing by V-shaped stock, upsetting twice, and post treating. Its advantages are short productive period and low cost.

Owner:SHANGHAI IRON & STEEL CO LTD NO 5 BAOSHAN IRON & STEEL GRP

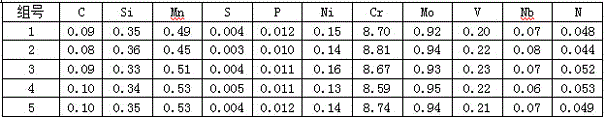

Method for smelting martensitic stainless steel P91 for boiler pipe

ActiveCN106636953AImprove melting efficiencyReduce consumptionElectric arc furnaceMartensitic stainless steel

The invention belongs to the technical field of smelting, and mainly relates to a method for smelting martensitic stainless steel P91 for a boiler pipe. The technological process of an electric arc furnace / medium-frequency induction furnace, an argon-oxygen refining furnace, an LF refining furnace, vacuum degassing, LF and continuous casting is adopted. Components for smelting the martensitic stainless steel for the boiler pipe comprise, by mass percent, 0.08%-0.12% of C, 0.30%-0.50% of Si, 0.30%-0.60% of Mn, not larger than 0.015% of P, not larger than 0.010% of S, not larger than 0.40% of Ni, 8.5%-9.5% of Cr, 0.90%-1.10% of Mo, 0.18%-0.30% of V, not larger than 0.30% of Cu, 0.03%-0.07% of N, 0.05%-0.10% of Nb, not larger than 0.020% of Al, not larger than 0.015% of [As], not larger than 0.010% of [Sn], not larger than 0.010% of [Pb], not larger than 0.010% of [Sb], not larger than 0.010% of [Bi] and the balance Fe and a small quantity of other elements. The method for smelting the martensitic stainless steel P91 for the boiler pipe aims to be low in inclusion content and delta-ferrite content and capable of achieving continuous casting production.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Hot-forming and forging method for large-sized high-temperature alloy turbine disc

ActiveCN1654140ARealize localizationReduce minimum loadWheelsHeating/cooling devicesIngotHot working

The hot forging process of high temperature large alloy turbine disc includes the following steps: 1) conventional upsetting and drawing to form cylindrical alloy blank of 730 mm diameter with electroslag ingot of 900 mm diameter; 2) low temperature heating the blank at 900 deg.c, coating the sides with diathermic cotton, further heating to stipulated temperature and maintaining for prolonged 5 hr; 3) upsetting the blank to intermediate blank of 1700 mm diameter through the first traditional process to machining limit of the press and then local deforming with rectangular upper anvil of width below 400 mm; 4) coating the lower surface of the circular cake blank and heating in furnace for 2 hr; and 5) final rotary forging for local deformation with upper anvil of width of 200 mm and rotating angle of 15 deg to forge the intermediate blank of 1700 mm diameter into finished product of 2000 mm diameter in the reducing amount of 25 mm and deformation amount of 35 %.

Owner:宝武特种冶金有限公司

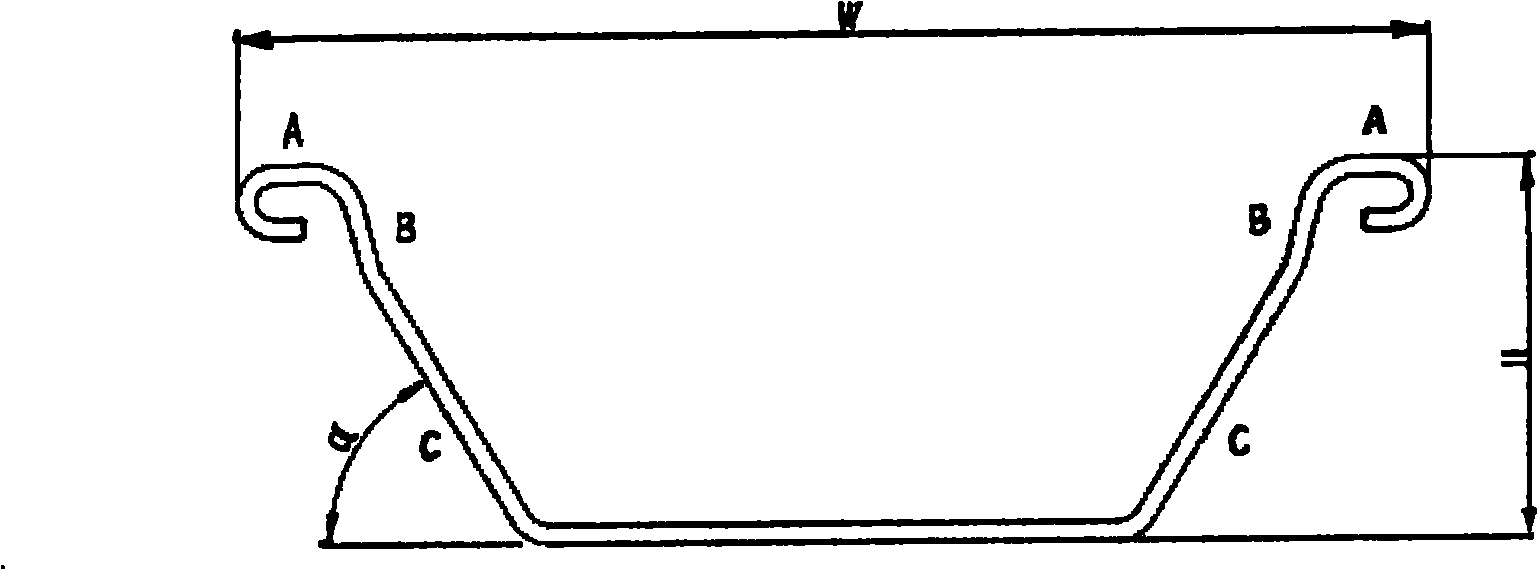

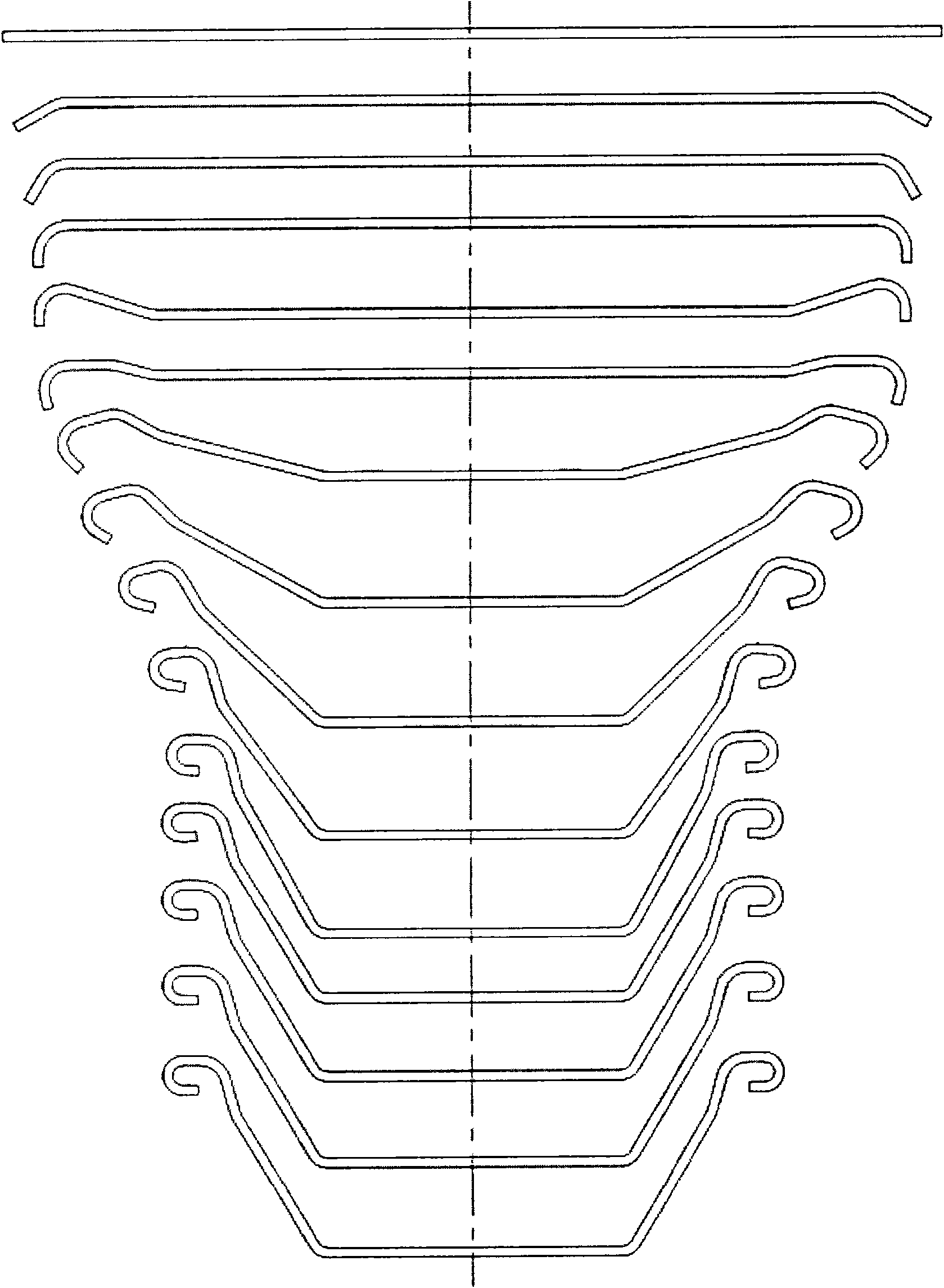

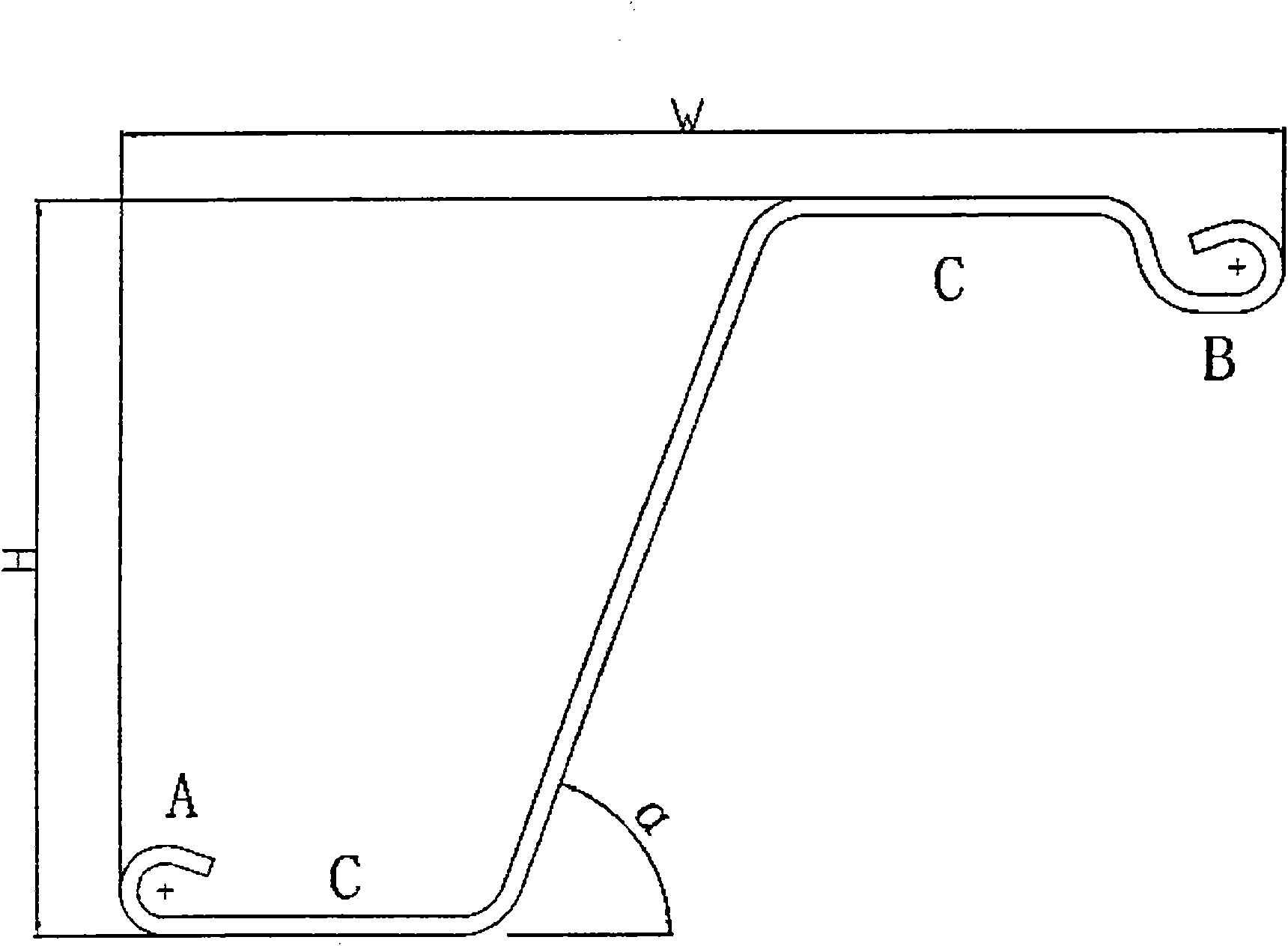

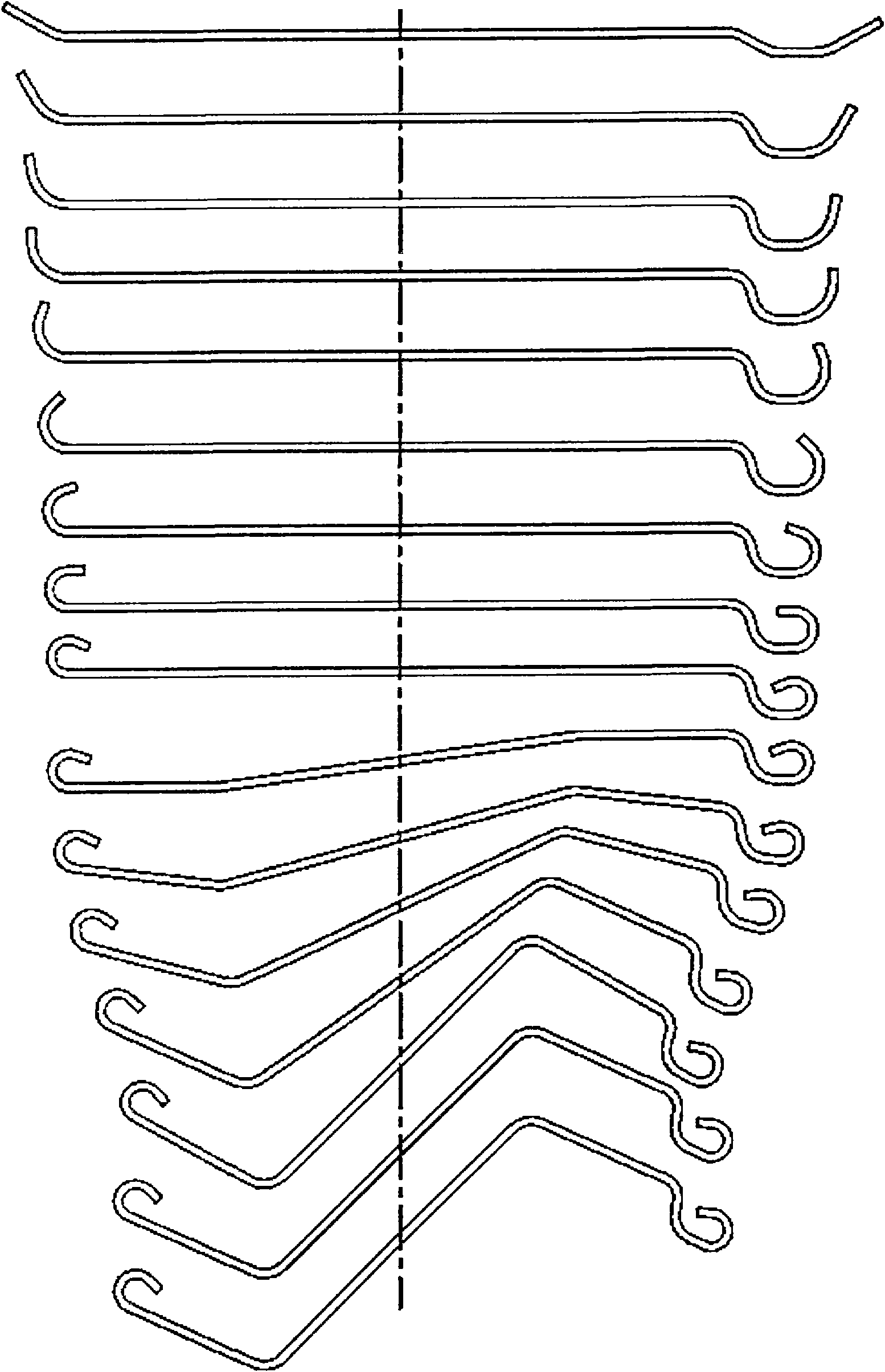

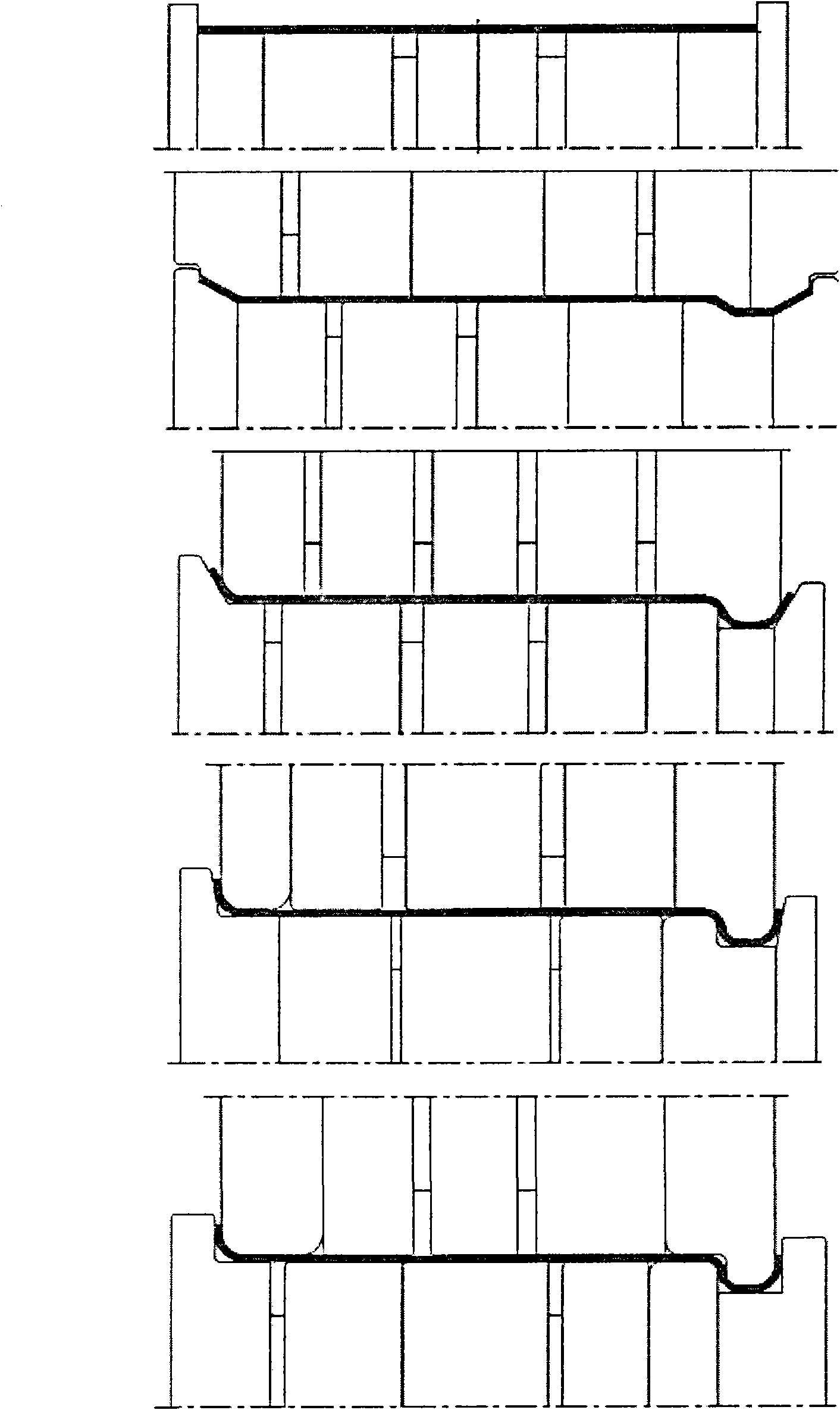

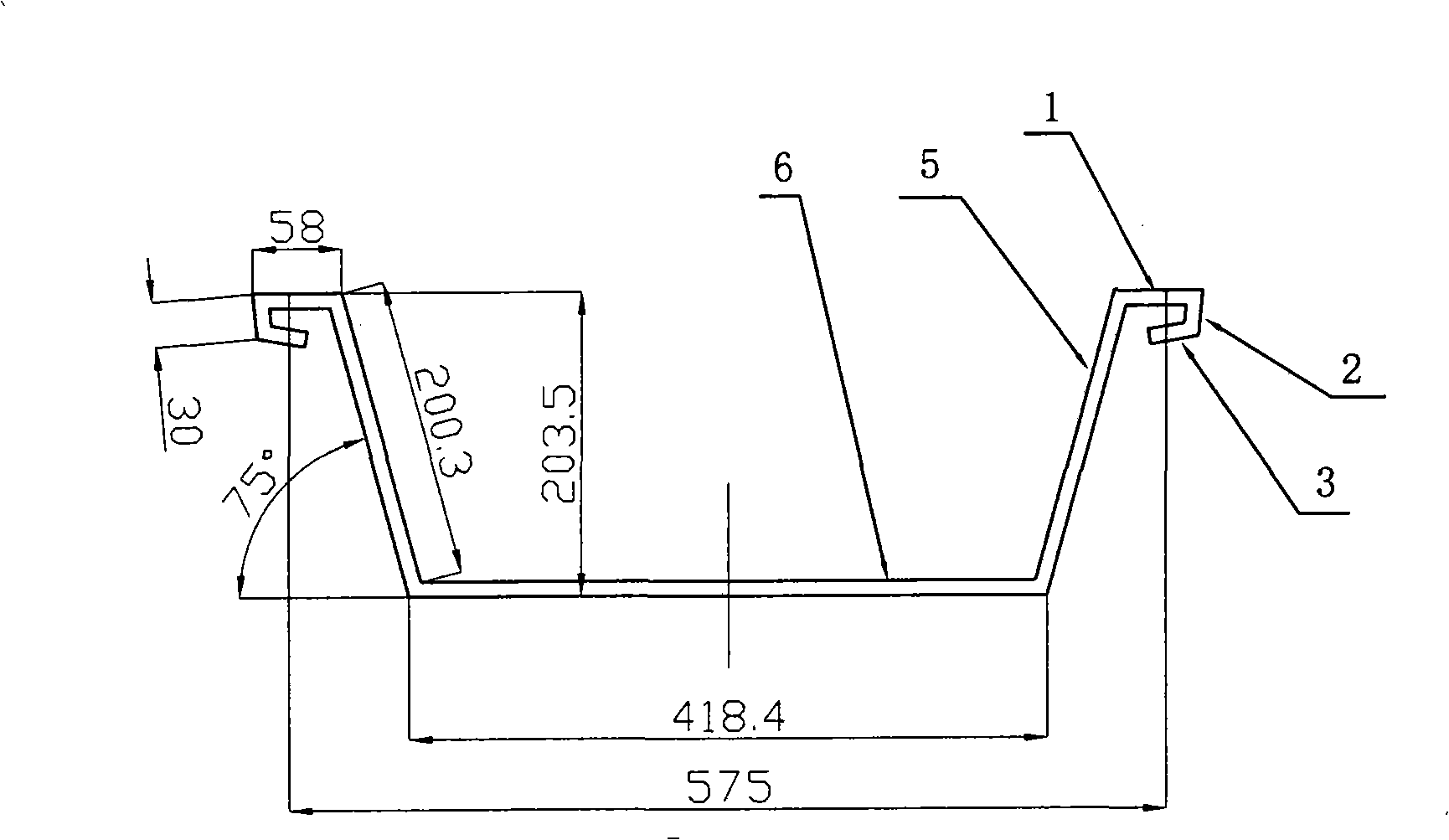

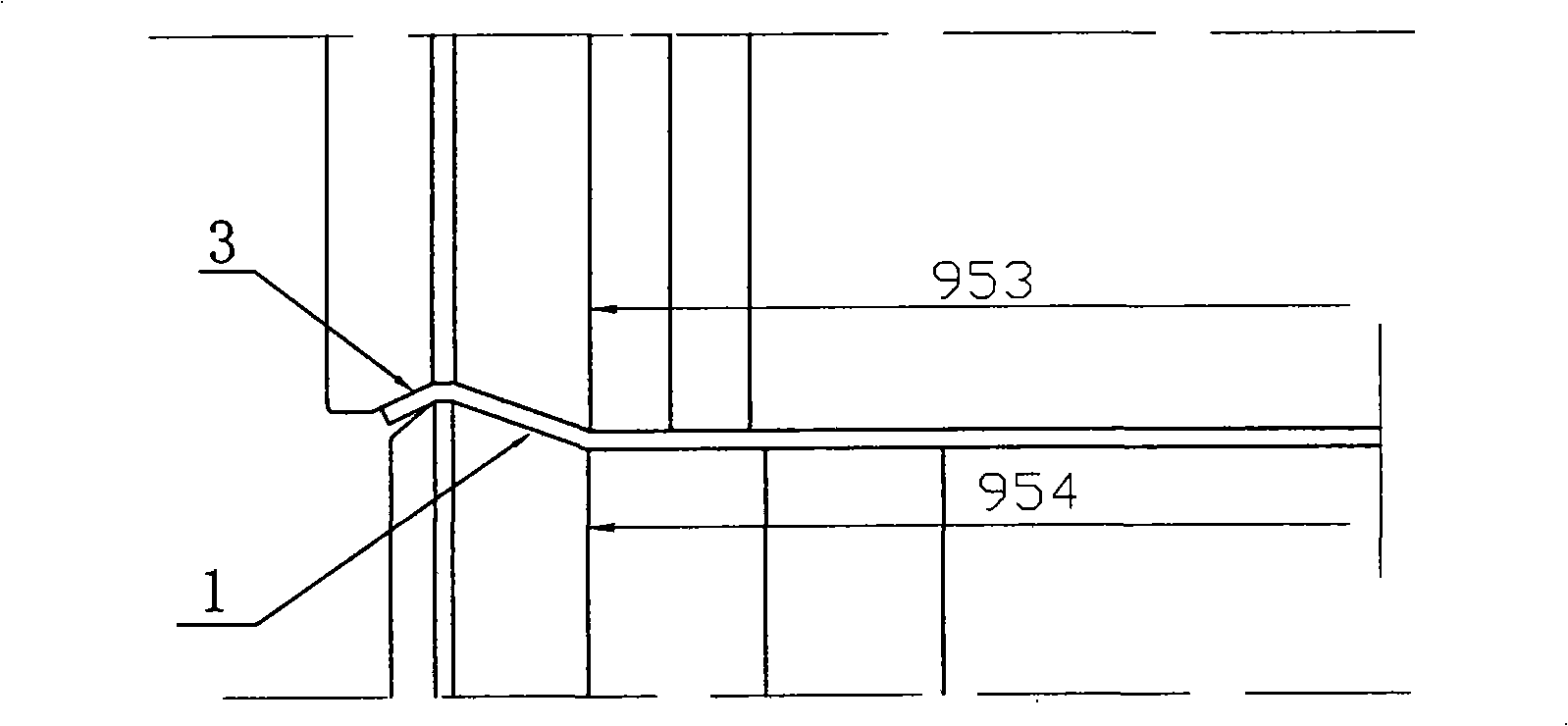

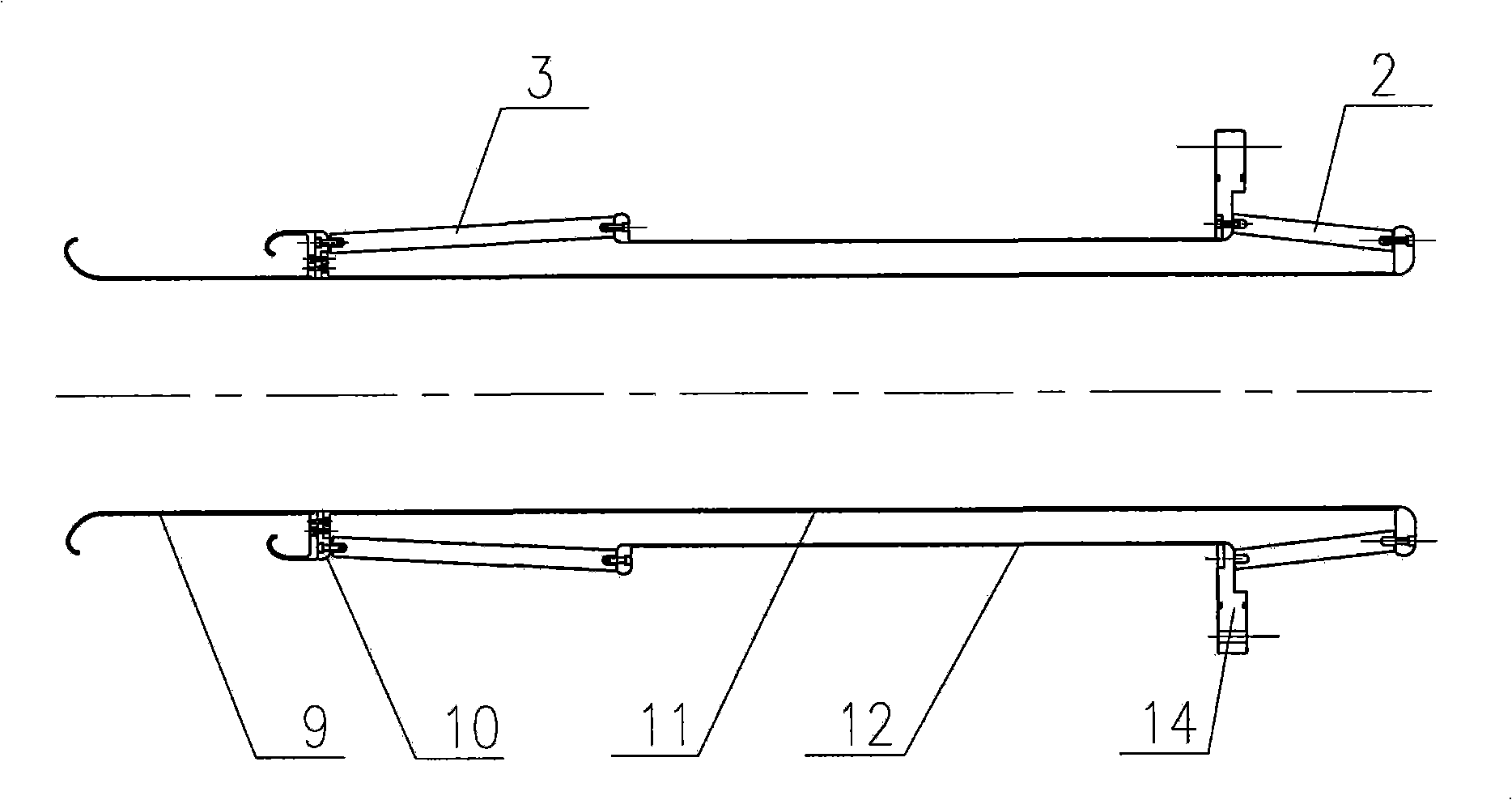

Roll type continuous cold-bending forming fabricating method for U-shaped steel sheet pile

The invention discloses a roll type continuous cold-bending forming fabricating method for a U-shaped steel sheet pile, which comprises the steps of: carrying out continuous rolling and forming by using a cold-bending machine unit and continuously overlapping lateral fore shafts to form a steel structure of sheet pile walls. The process plays an important role in controlling the product quality and improving the mate precision and the connection strength of the fore shafts of the steel sheet pile. The U-shaped steel sheet pile has rich specifications and models, and the most economical and reasonable cross section can be selected according to the actual situation of a project to realize the optimization of engineering design; and compared with a hot rolled steel sheet pile with the same performance, the U-shaped steel sheet pile saves materials of 10% to 15%, which greatly reduces the construction cost.

Owner:NANJING WANHUI STEEL SHEET PILING

Manufacture method of Z-shaped steel sheet pile through continuous cold roll forming

The invention discloses a manufacture method of a Z-shaped steel sheet pile through continuous cold roll forming by continuously rolling and forming with a cold bending unit and distributing preliminary shafts at both sides of a central shaft. Web plates are continuous so as to greatly improve the modulus and the flexible rigidity of a cross section and fully exert the mechanical characteristic of the cross section. The manufacture process takes great effects in aspects, such as controlling the quality of the cold-bent Z-shaped steel sheet pile, improving the matched accuracy and the connection strength of the preliminary shafts of the steel sheet pile, and the like. The invention controls the product size and overcomes the defects generated in the processing process by performing the preliminary shafts of the cold-bent Z-shaped steel sheet pile and wholly forming the Z-shaped steel sheet pile.

Owner:NANJING WANHUI STEEL SHEET PILING

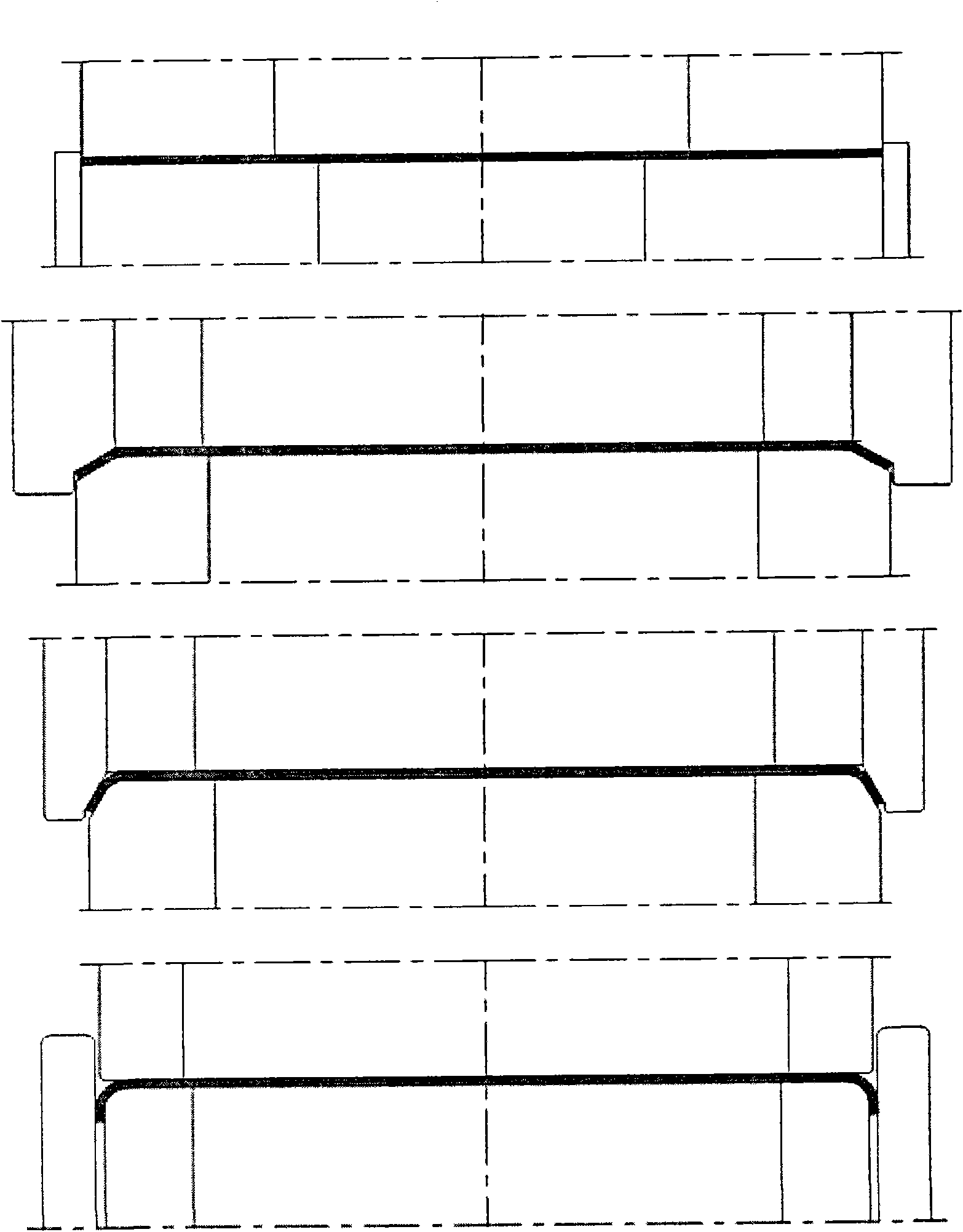

Continuous roller type cold bending shaping method for metal sheet pile

The invention relates to a continuous roll type cold-bending forming method for a steel sheet pile, including scrolling, continuous cold-bending forming and cutting; the method is characterized in that the continuous cold-bending forming refers to that the scrolled steel band is fed into a production line of a multi-pass continuous roll type cold-bending forming machine set for multi-pass continuous roll type cold-bending forming, a frame at each pass is provided with an upper rotation axis and a lower rotation axis which are equipped with inosculated dies, the upper rotation axis and the lower rotation axis rotate oppositely, one rotates along the clockwise direction, while the other rotates along anticlockwise direction; in this way, a scrolled steel plate moves forwards depending on friction force in the roll gap of rotation dies inosculated up and down after being well adjusted and enters the next pass for continue forming, when entering each pass for forming, the steel plate is forced to deform under the action of the inosculated dies, each pass completes setting forming amount, and the forming of the steel sheet pile is finally completed through a plurality of passes, thus rolling the products of the steel sheet pile in line with requirements. The method has the advantages of energy saving, environmental protection, high production efficiency and complete specification, length and size of products.

Owner:江苏顺力冷弯型钢实业有限公司

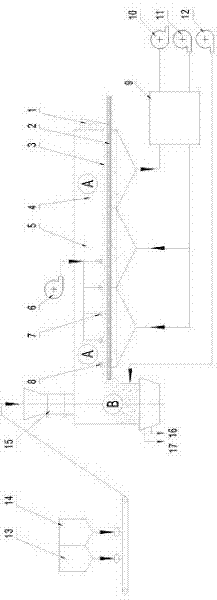

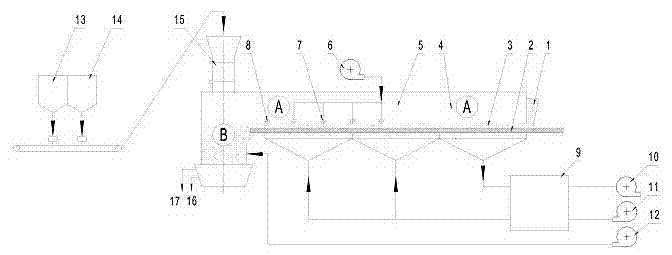

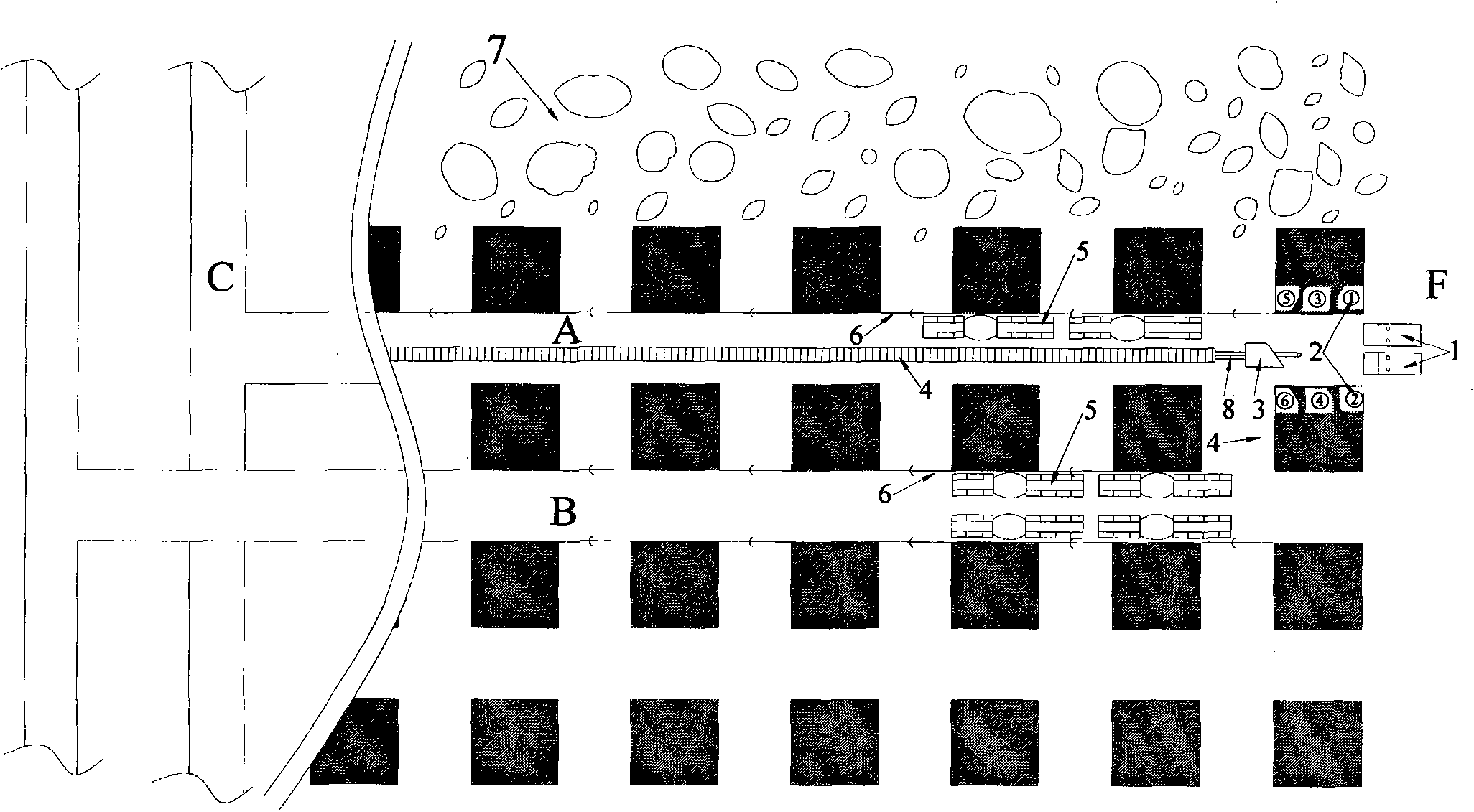

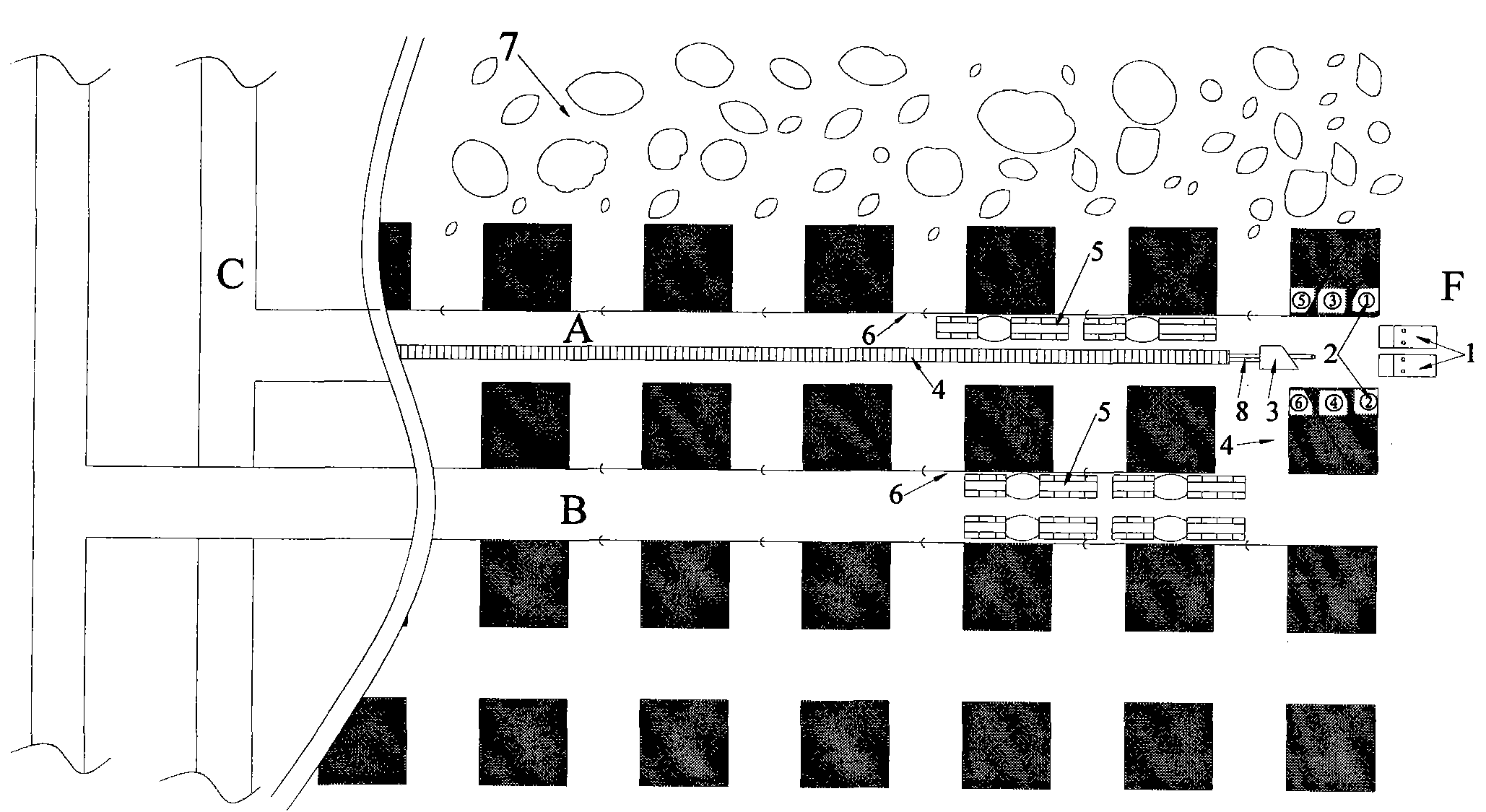

Continued ironmaking device based on melting reduction

The invention relates to a continued ironmaking device based on melting reduction of iron oxide containing carbon iron oxide balling (blocks). In the invention, the device is a continued ironmaking device based on melting reduction and can carry out continual tapping by pre-reducing furnace burden (3) through continually adding the furnace burden (3), extracting air, preheating, blasting and carrying out downstream roasting, and directly conveying the pre-reduced furnace burden (3) into a smelting-separating furnace (B) for continuous smelting-separation; a preheat area (4), a roasting area (5) and the smelting-separation areas behind the preheat area and the roasting area form a connected hearth; a combustion-supporting burner (8) and a secondary tuyere (7) are arranged also; preferably, the high-temperature coat gas generated in the smelting-separation area is subjected to secondary combustion in a pre-reduced furnace (A) for preheating and roasting the furnace burden (3); then the furnace burden (3) is discharged into the smelting-separation area for the further reduction, carburization and melting to separate the slag and iron; in the preheated area (4), the fuse passes through a bed of material to directly heat the furnace burden (3), and then the fuse enters a heat exchanging device (9) and a fuse process system; and a fan blasts the cool air below the bed into a hearth bottom (2) through the heat exchange device (9). The device has the advantages of short flow, reduced energy consumption, low carbon emission, low production cost, simple equipment, less occupied space, less investment and short building period.

Owner:李振洪

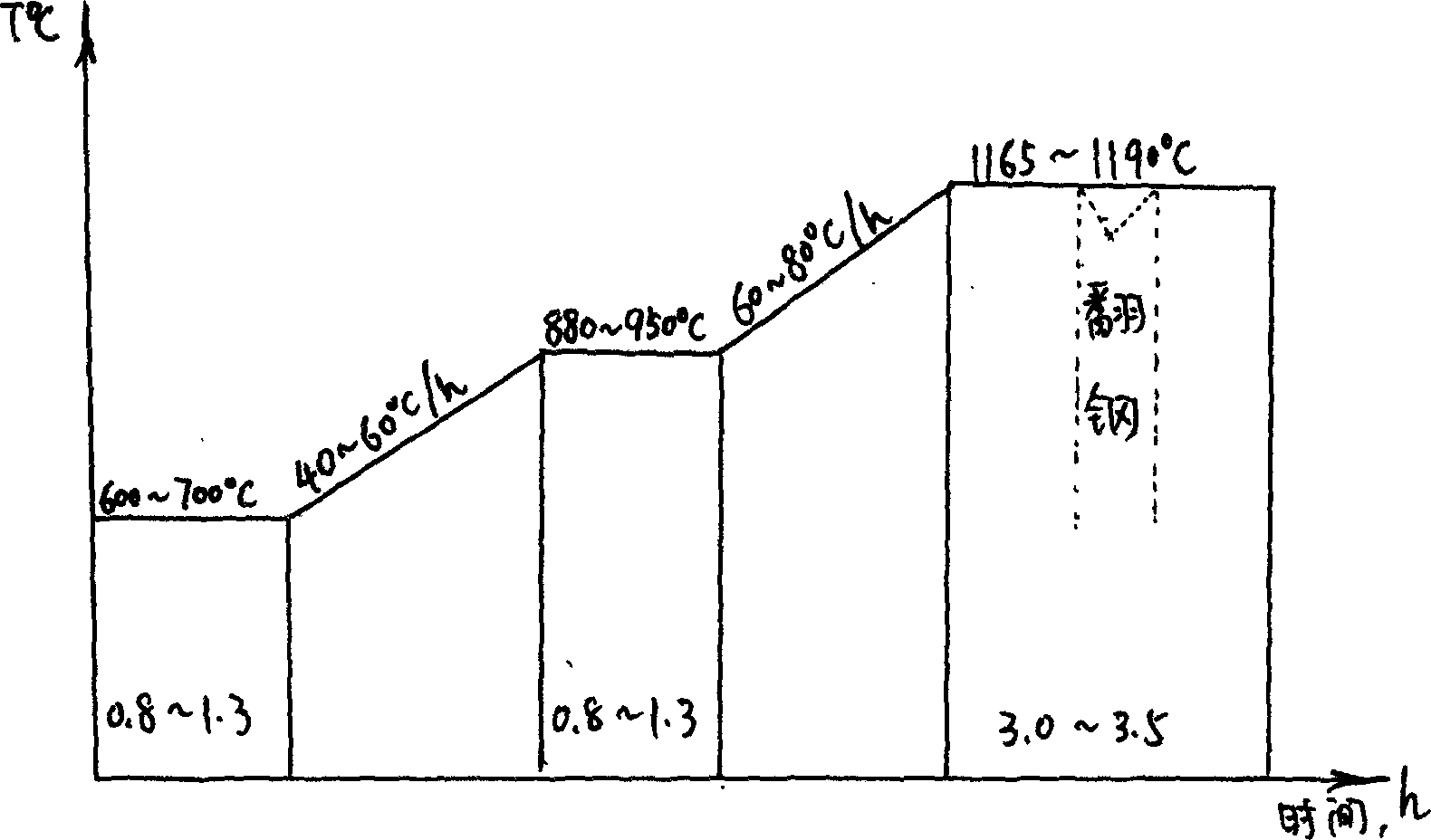

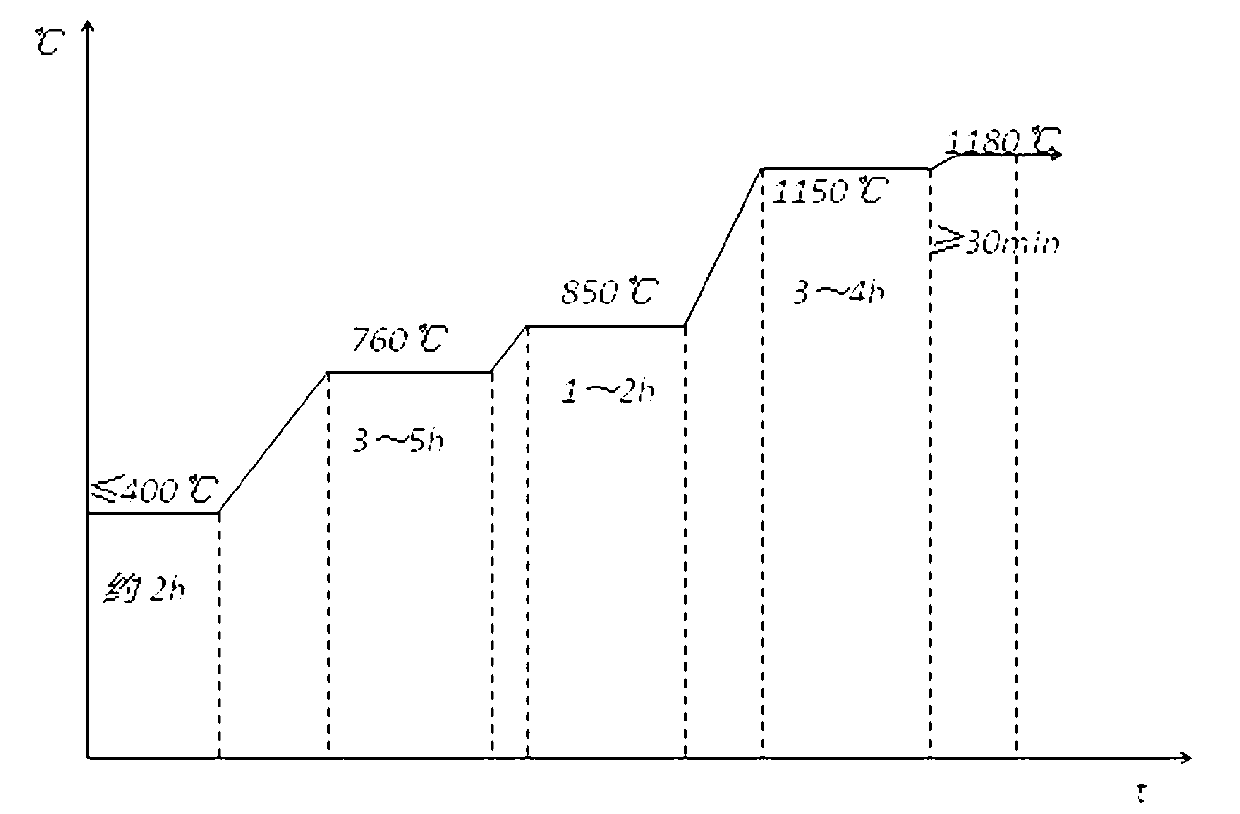

Rolling cogging production method of Cr4Mo4V electroslag steel ingot

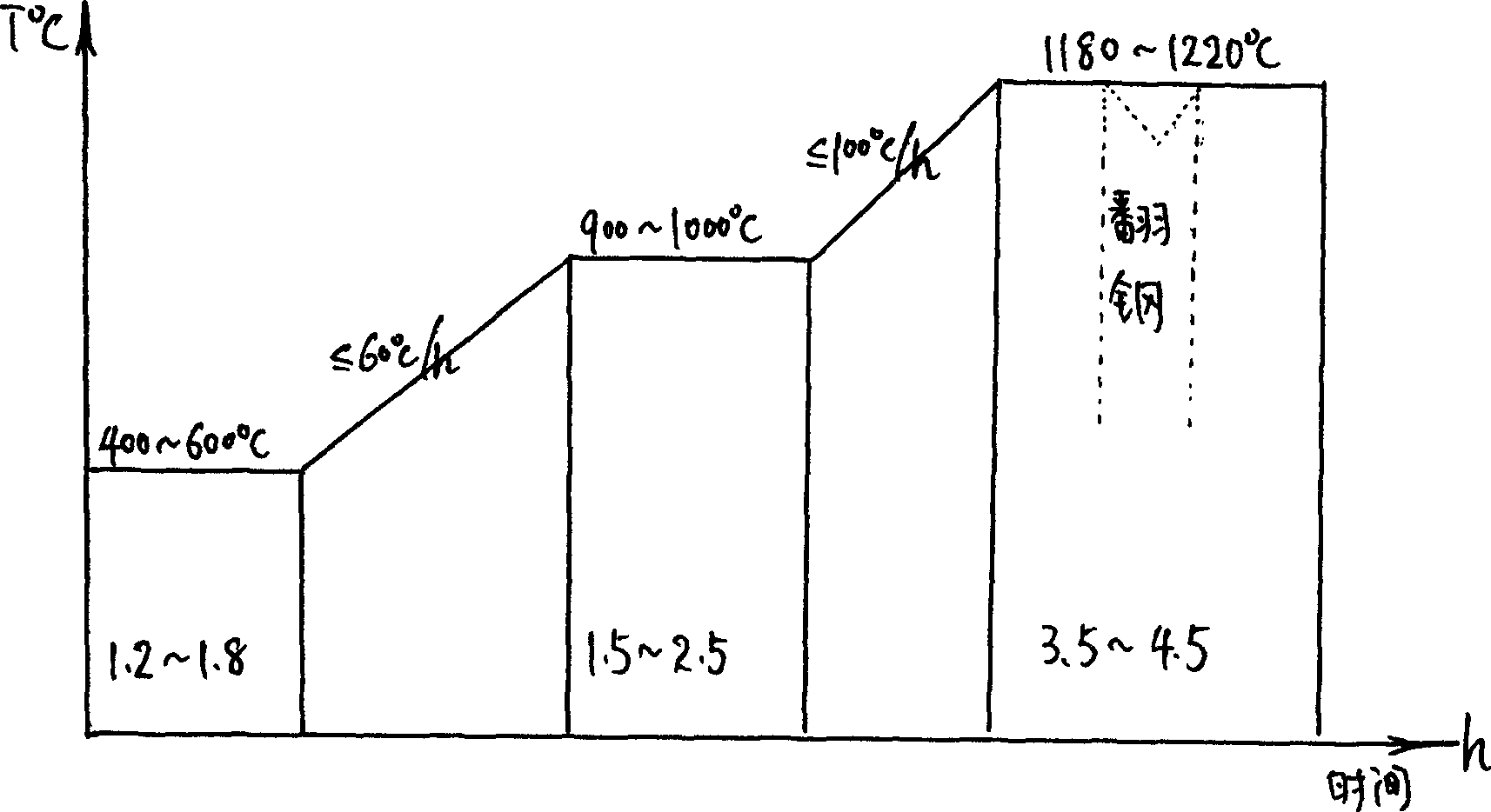

InactiveCN1586749AThe process is reasonable and simpleEasy to operateMetal rolling arrangementsCarbideTemperature difference

The production process of rolling cogging Cr4Mo4V electroslag steel ingot features the heating in pit heating furnace and cogging in blooming mill to produce 100 mm square bloom. The production process includes heating Cr4Mo4V electroslag steel ingot at 630 deg.c for 90 min, 900 deg.c for 60 min, and 1190 deg.c for 210 min while turning the ingot to make the temperature difference between two opposite sides less than 20 deg.c; and cogging at initial temperature over 1130 deg.c and finishing temperature over 1000 deg.c through 44 gates and final annealing in annealing furnace to eliminate stress. The said production process is simple and has high product quality, raised bloom yield and lowered cost.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

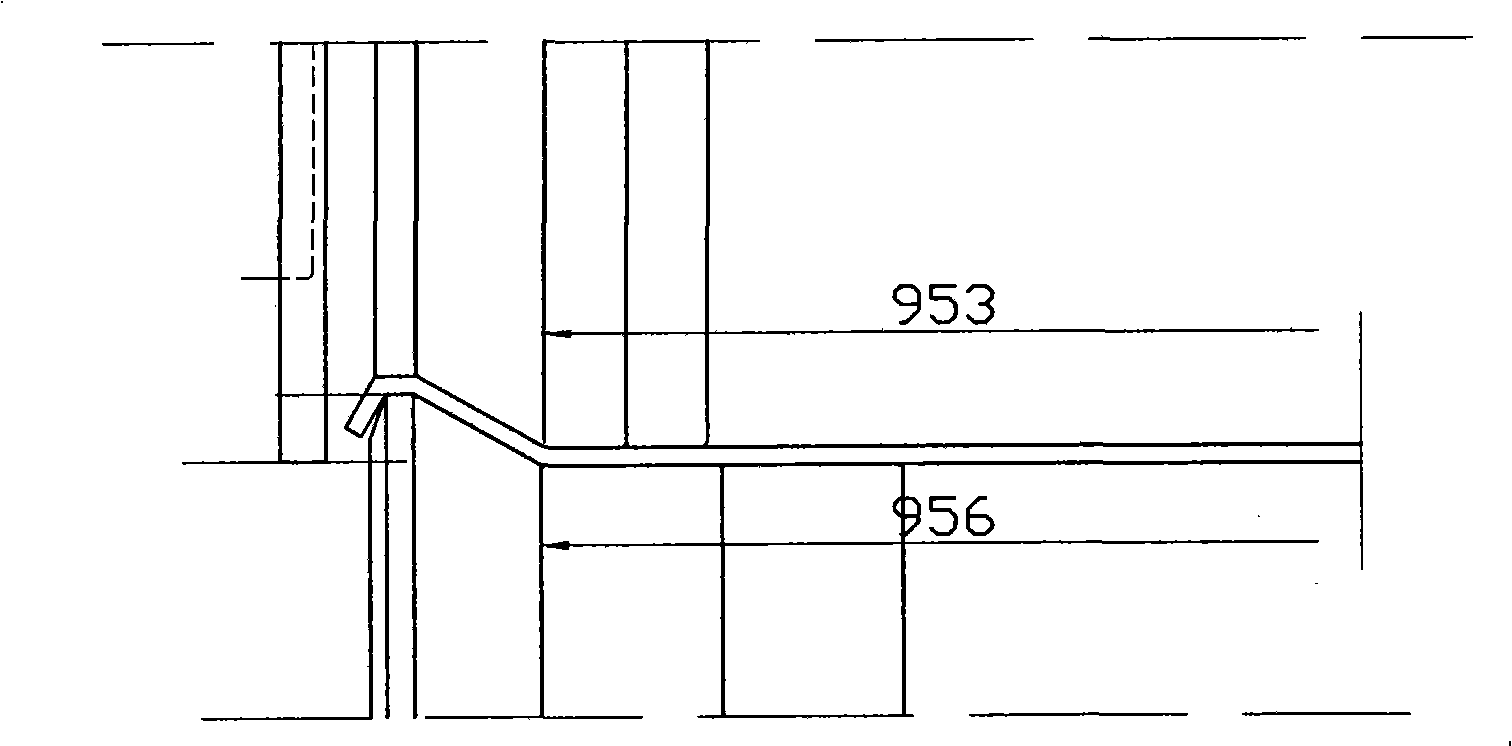

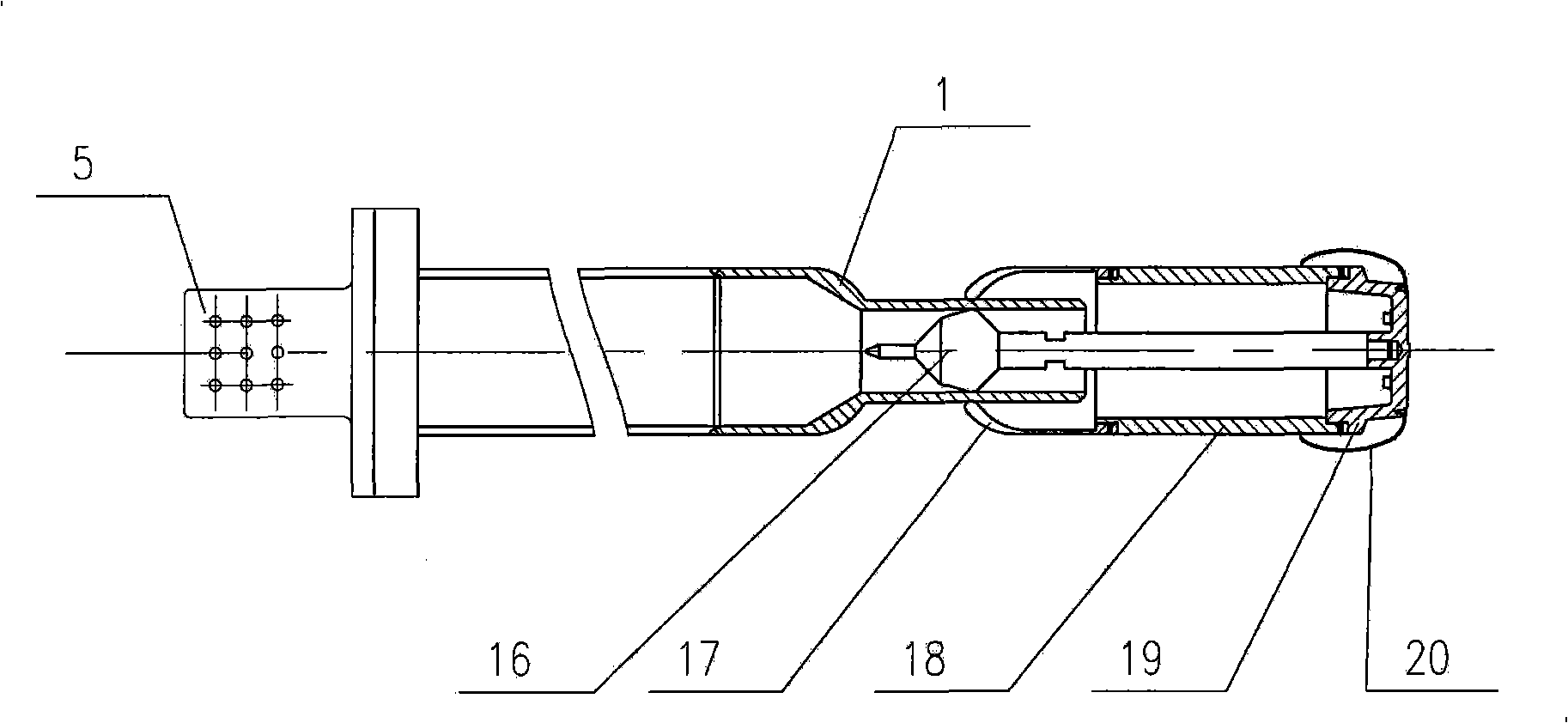

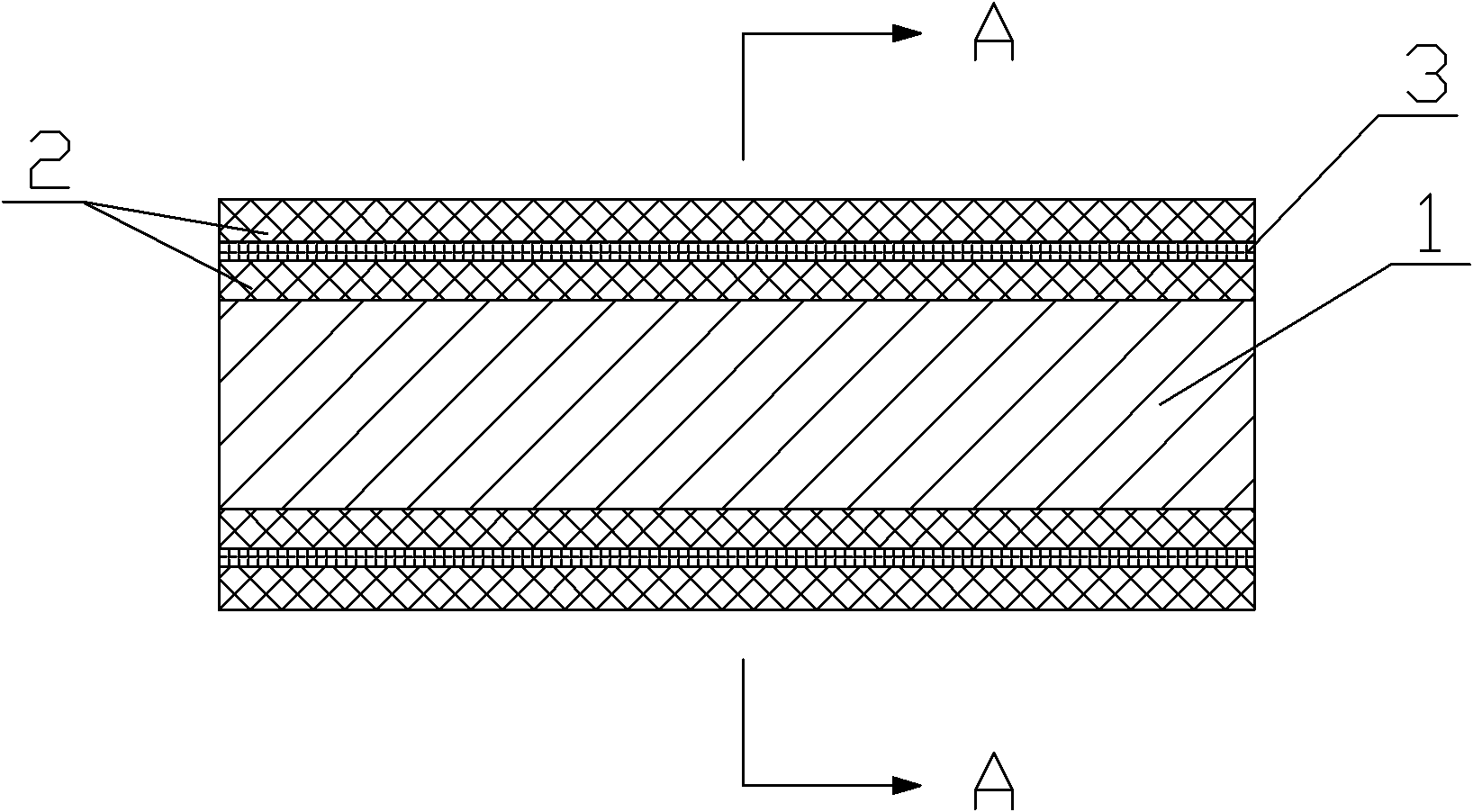

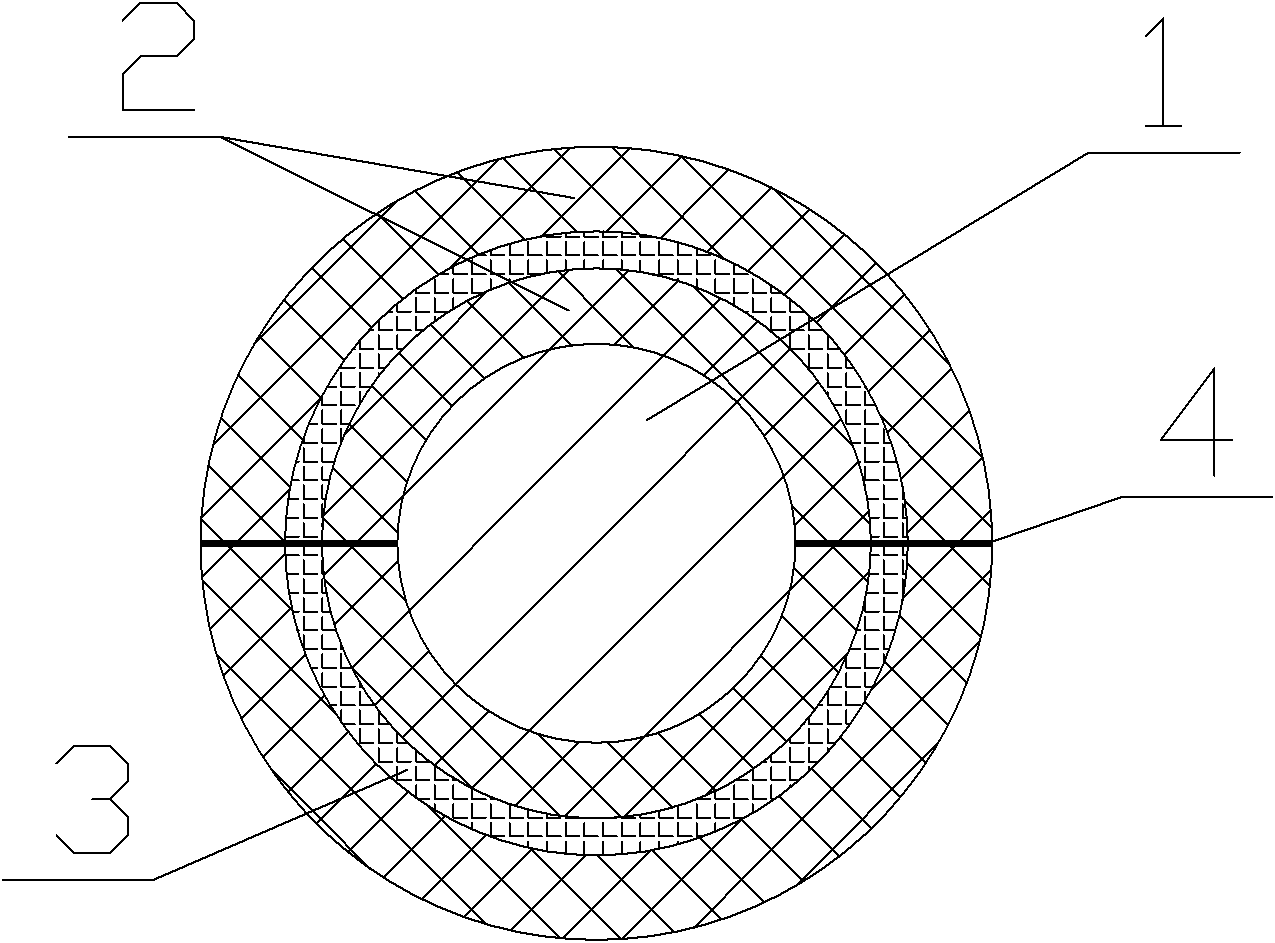

Incoming/outgoing line inflation casing tube for high-voltage switch gear

ActiveCN101404393AEven by forceIncrease stiffnessBus-bar/wiring layoutsSwitchgear arrangementsElectric fieldEngineering

The invention discloses a charging bushing for a standby inlet-outlet wire of a high voltage switch device which comprises an isolating tube penetrated with a central conductor; the upper end of the isolating tube is connected with an outer screen; the lower end of the isolating tube is connected with GIS or the insulating salver of a breaker; the lower end of the central conductor is connected with a contact component on the GIS or the isolating salver of the breaker; the upper end of the central conductor is connected with an external inlet-outlet wire to form a main conductive loop; a coaxial double-layered screening component is arranged between the radical directions of the central conductor and the insulating tube; the invention is characterized in that the double-layered screening component is an integral arc screening structure which is connected with the closed ring of the isolating tube; the contact component connected with the lower end of the central conductor is a self-supported contact device. As the integral arc screening structure is adopted in the invention, the middle screening height is greatly reduced; the rigidity of the screening component is increased and the distribution of an electric field at the tail end of the screen is improved. Simultaneously the self-supported contact device is adopted; the discharge current capability is greatly improved; the structure is very simple; the manufacture cost is reduced.

Owner:CHINA XD ELECTRIC CO LTD +1

Rolling and cogging method for high-temperature alloy GH1015

InactiveCN1584066AInternal material quality is stableImprove production efficiencyMetal rolling arrangementsRolling speedAlloy

A rolling cogging manufacturing method for high temperature alloy GH1015 includes: 1) heating in one heat, electroslag ingot keeping temperature for 1 hr with entering furnace temperature is less than or equal to 700deg.C, keeping temperature for1 hr with is less than or equal to 60deg.C / h up to 900deg.C, keeping temperature for 3.5 hrs with is less than or equal to 80deg.C / h up to 1180deg.C and drawing charge with positive and negative face temperature differential is less than or equal to 20deg.C; 2) cogging in one heat with preheating temperature of roller 120deg.C and beginning temperature is greater than or equal to 1100deg.C, finishing temperature is greater than or equal to 1000deg.C, roller speed is less than or equal to 20 / min, drafts is less than or equal to 30mm and rolling passage is less than or equal to 15; 3) heating in second heat, keeping temperature for 80 mins at 1170deg.C and drawing charge with positive and negative face temperature differential is less than or equal to 20deg.C; 4) cogging in second heat and roller preheating with beginning temperature is greater than or equal to 1100deg.C, finishing temperature is greater than or equal to 1000deg.C, rolling speed is less than or equal to 20 / min, rolling speed of product passage is less than or equal to 10 / min and drafts 30mm. It achieves low cost, simple process and good quality.

Owner:宝钢特钢有限公司

Prehardening treatment method of NAK80 mould steel

ActiveCN1718771AThe pre-hardening treatment process is simple and reasonableEasy to operateFurnace typesHeat treatment furnacesQuenchingForging

A method for prehardening the die steel NAK80 includes such steps as thermal forging with 860-920 deg.C for final temp and 15-20% for final deformation, quenching by directly putting the forged die steel at 900 deg.C in conventional quenching liquid to cool its temp to 200 deg.C, and tempering steps including heating it to 490-560 deg.C at the speed of 80-100 deg.C / h in the tempering furnace, holding the temp for 2-6 hr, and cooling in air. Its advantages are low cost and short period.

Owner:宝武特种冶金有限公司

Manufacturing method for Z210CrW12 ingots by rolling and cogging

InactiveCN1584065AReduce manufacturing costMeet user requirements and market needsMetal rolling arrangementsHeating furnaceHeat treating

A rolling cogging manufacturing method for X210CrW12 steel ingot includes: 1) heating by uniform heating furnace, keeping temperature for 150 mins with entering temperature of steel ingot is less than or equal to 450deg.C, heating to 1170deg.C and keeping temperature for 4.5 hrs with speed is less than or equal to 80deg.C / h, turning over steel ingot and drawing charge with positive and negative face temperature differential is less than or equal to 25deg.C; 2) rolling by rolling mill, closing cooled water of roller before rolling and roller preheating; first rolling with roller speed is less than or equal to 20 / min, beginning temperature is greater than or equal to 1130deg.C, finishing temperature is greater than or equal to 1060deg.C, rolling passage 40 and drafts is less than or equal to 30mm; billet melting down and distressing annealing heat treating. It achieves low cost, simple process and good quality.

Owner:SHANGHAI IRON & STEEL CO LTD NO 5 BAOSHAN IRON & STEEL GRP

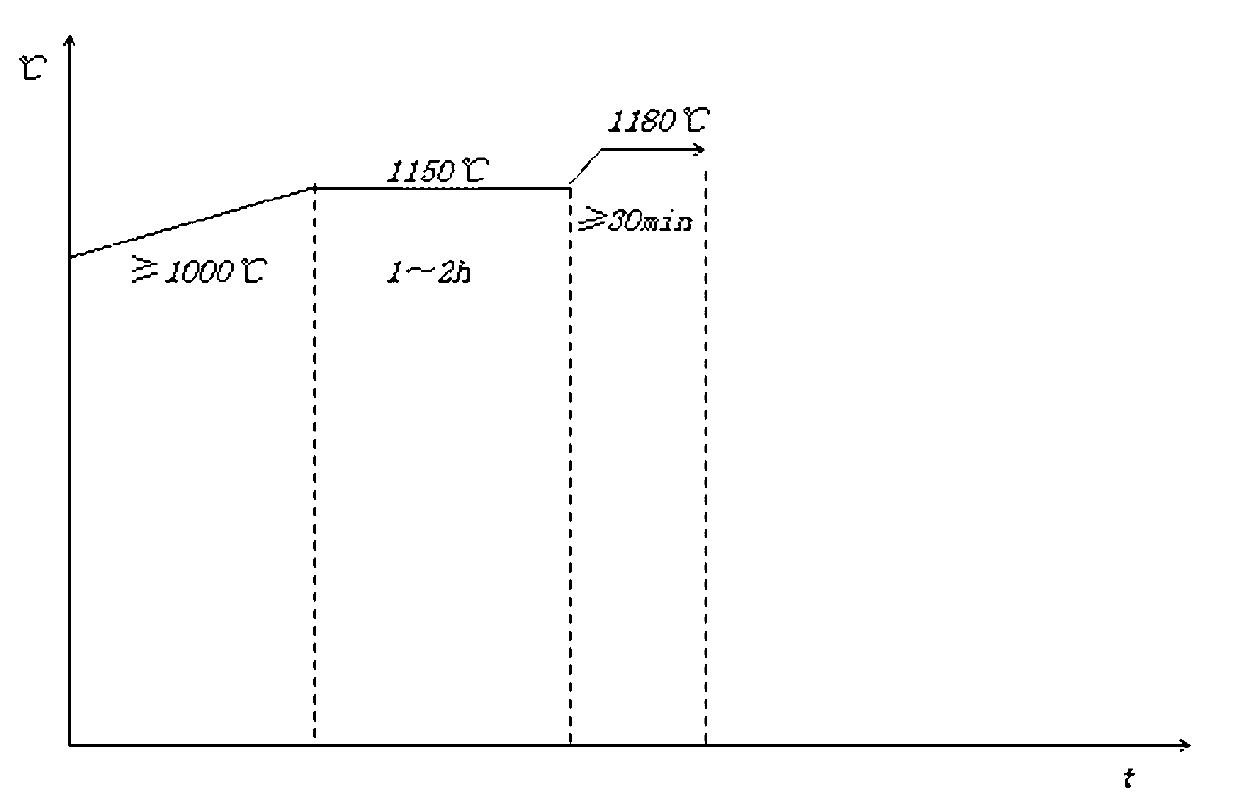

Rolling and cogging method for OCr17Ni4Cu4Nb casting ingots

ActiveCN1584064AMetallurgical manufacturing cost reductionSimple processMetal rolling arrangementsIngot castingRolling speed

A rolling cogging manufacturing method for 0Cr17Ni4Cu4Nb ingot casting includes: 1) heating in one heat, cooling steel ingot and keeping temperature for 1.5 hr when entering furnace temperature is less than or equal to 600deg.C; heating steel ingot, keeping temperature for 1 hr when entering furnace temperature is less than or equal to 690deg.C and keeping temperature for 2 hrs with is less than or equal to 60deg.C / h up to 950deg.C, keeping temperature for 4 hrs with is less than or equal to 80deg.C / h up to 1180deg.C and drawing charge with positive and positive and negative face temperature differential is less than or equal to 30deg.C; 2) cogging in one heat, roller preheating with rolling speed is less than or equal to 10 / min, beginning temperature is greater than or equal to 1150deg.C, finishing temperature is greater than or equal to 1050deg.C, drafts is less than or equal to 40mm and rolling passage is less than or equal to 14; 3) heating in second heat and keeping temperature for 1 hr at 1180deg.C; 4) cogging in second heat with beginning temperature is greater than or equal to 1130deg.C, finishing temperature is greater than or equal to 1000deg.C and drafts is less than or equal to 50mm, rapid shearing billet and hot annealing. It achieves low cost, simple process and good quality.

Owner:宝武特种冶金有限公司

Cold-rolled high-strength steel used for automobile structural member and manufacture method of cold-rolled high-strength steel

The invention discloses a cold-rolled steel plate used for manufacturing automobile structural components and a manufacture method of the steel plate. The steel plate comprises, by weight percentage,0.06-0.08% of C, 0.65-0.95% of Mn, no more than 0.05% of Si, no more than 0.015% of P, no more than 0.015% of S, 0.030-0.055% of Als, 0.025-0.040% of Nb, and 0.010-0.030% of Ti, with the balance beingFe and inevitable impurities. A continuous casting slab containing the chemical components above undergoes hot rolling, acid-pickling cold continuous rolling, continuous annealing, flattening, and tension leveling to obtain a high-strength steel plate having the yield strength of 330-400 MPa, the tensile strength of 410-500 MPa, and the elongation at break no less than 25.0%. The method is low inproduction cost, and the obtained steel plate is stable in mechanical property, excellent in stamping performance, and superior in surface quality.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Production method of large-size titanium alloy intermediate rod material

ActiveCN1657197ASolve technical problems that are prone to cracksAvoid formingMetal-working apparatusSurface cleaningIngot

Owner:宝武特冶钛金科技有限公司

Method for recovering stagnant coal pillars left by breast type coal mining method

The invention provides a method for recovering stagnant coal pillars left by a breast type coal mining method, which is used for a low-gas shallow coal seam with stable top board, smaller mine pressure and coal seam inclination angle, flat baseboard, hard and stable coal quality, no-water pouring top board and hard spontaneous ignition. The coal pillars are recovered with different regions, every three rows of the coal pillars is taken as a distribution unit, and air curtains are arranged between the three rows of the coal pillars and the coal pillars to form into an air inlet passageway and an air retuning passageway; and from the two rows of regular coal pillars beside a goaf, every two rows of regular coal pillars is taken as a recovering unit, the recovering unit is internally provided with a crawler belt walking type hydraulic bracket, a continuous coal mining device and an advanced supporting hydraulic bracket, the stagnant coal pillars are alternately and slantwise cut by means of both wings according to the recovering unit, the recovering unit stopes and withdraws, the stagnant coal pillars and the hydraulic bracket jointly support the top board above a recovering space, and the top board is managed by means of a complete top board falling method. Therefore, by matching with the continuous coal mining device, the scraping board conveying device and the adhesive tape conveying device, the method can recover the regular stagnant coal pillars left by a breast type coal mining method.

Owner:CHINA UNIV OF MINING & TECH

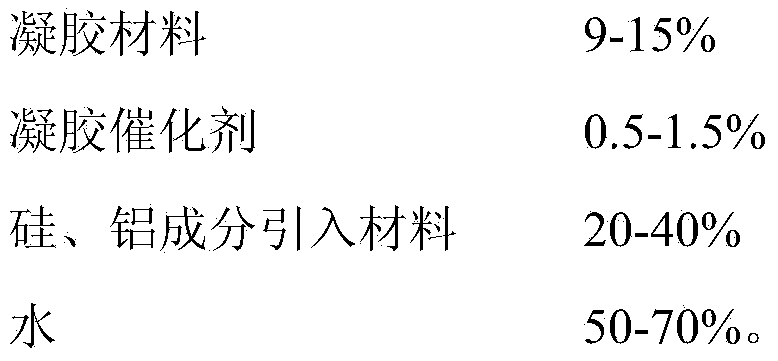

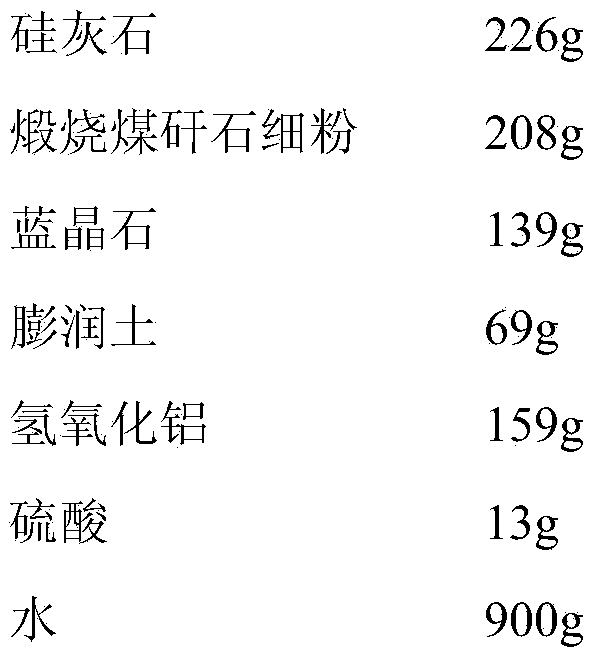

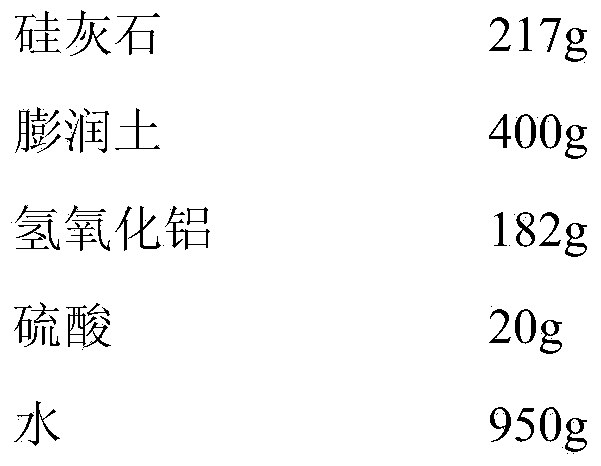

Anorthite light refractory brick and preparation method thereof

The invention belongs to the field of fireproofing materials, and particularly relates to an anorthite light refractory brick and a preparation method thereof. The preparation method comprises steps of dispersing a gel material in water, and adding a gel catalyst for incomplete reaction to form an inorganic gel system; constantly stirring the inorganic gel system so as to disperse the introduced silicon and aluminum components in the gel system to be mixed uniformly to obtain a mixed material; molding the mixed material, then maintaining, curing, drying, calcining, and producing through a manufacture procedure so as to obtain the refractory brick. The preparation method is simple and easy to operate, is environment-friendly, uses the raw materials according to local conditions, is convenient for production organization, has no special requirements on equipment, can produce products with excellent properties, and has remarkable energy conservation effect.

Owner:史新明

Method for quickly casting large precision casting based on 3D printing technology

ActiveCN108907095ASimple processing technologyShort production timeAdditive manufacturing apparatusFoundry mouldsSlagDimensional modeling

The invention relates to the technical field of metal molding and casting, in particular to a method for quickly casting a large precision casting based on a 3D printing technology; through combination of a 3D printing and molding technology and a lost foam casting technology, by using special shell type coatings, a casting without the defects of recarburization, pores, slag inclusion or wrinkledskin can be cast, and the requirements of a high grade and complex structure and the precision casting can be met; and the method has the advantage of green, environmental protection and no pollution.The method comprises the steps of three-dimensional modeling, making of a fusible model and a special shell mold, boxing of the shell mold, negative pressure pouring and the like. The method has theadvantages of simple processing technology, no need of developing a mould, short production time, easy regulation and modification, low production cost, green, environmental protection and no pollution, and the molding process can be finished in real time; the requirements of individualization and customization cam be met; high quality products can be made, and massive casting and precision casting are both taken into consideration.

Owner:河南圣得威机械科技有限公司

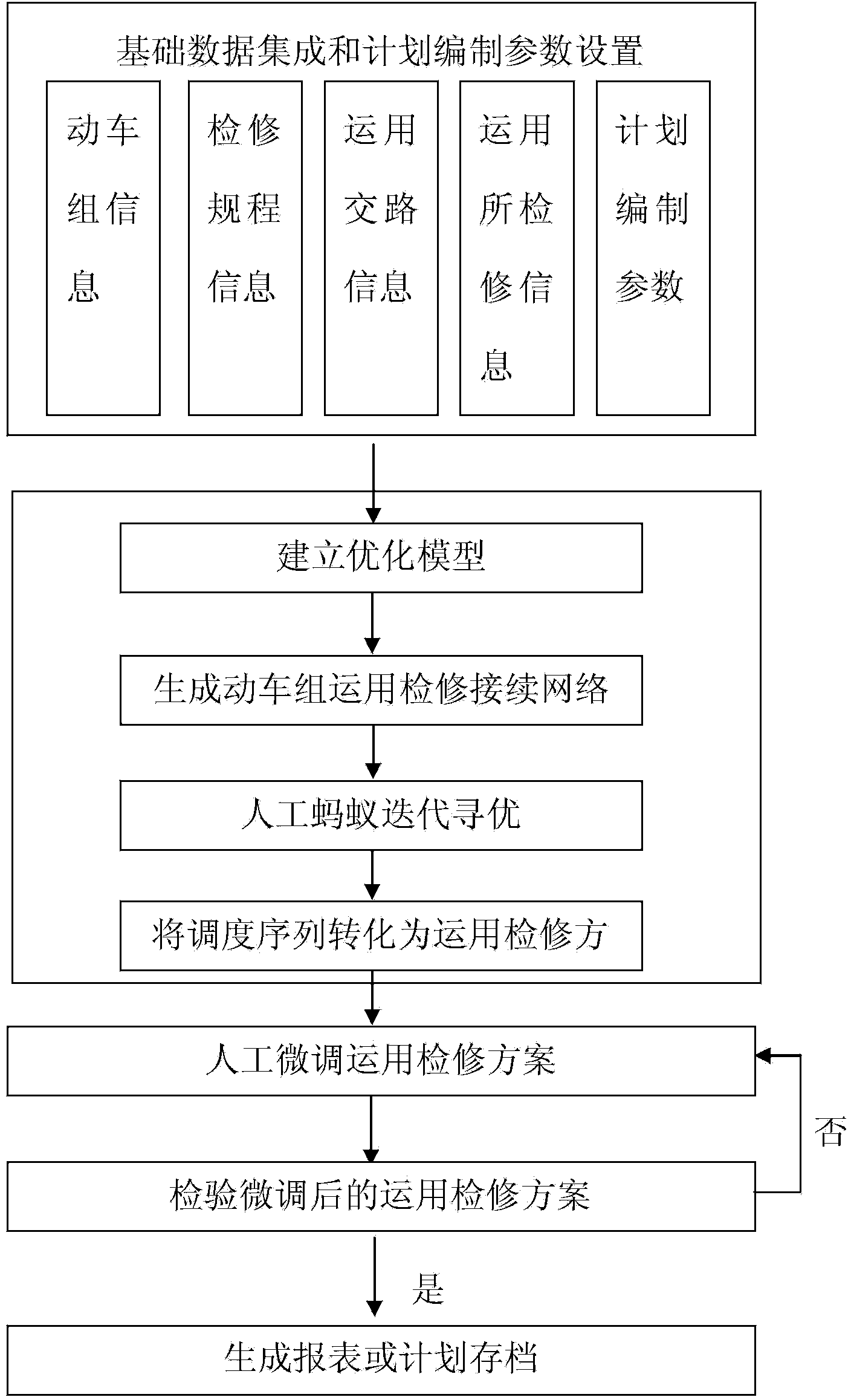

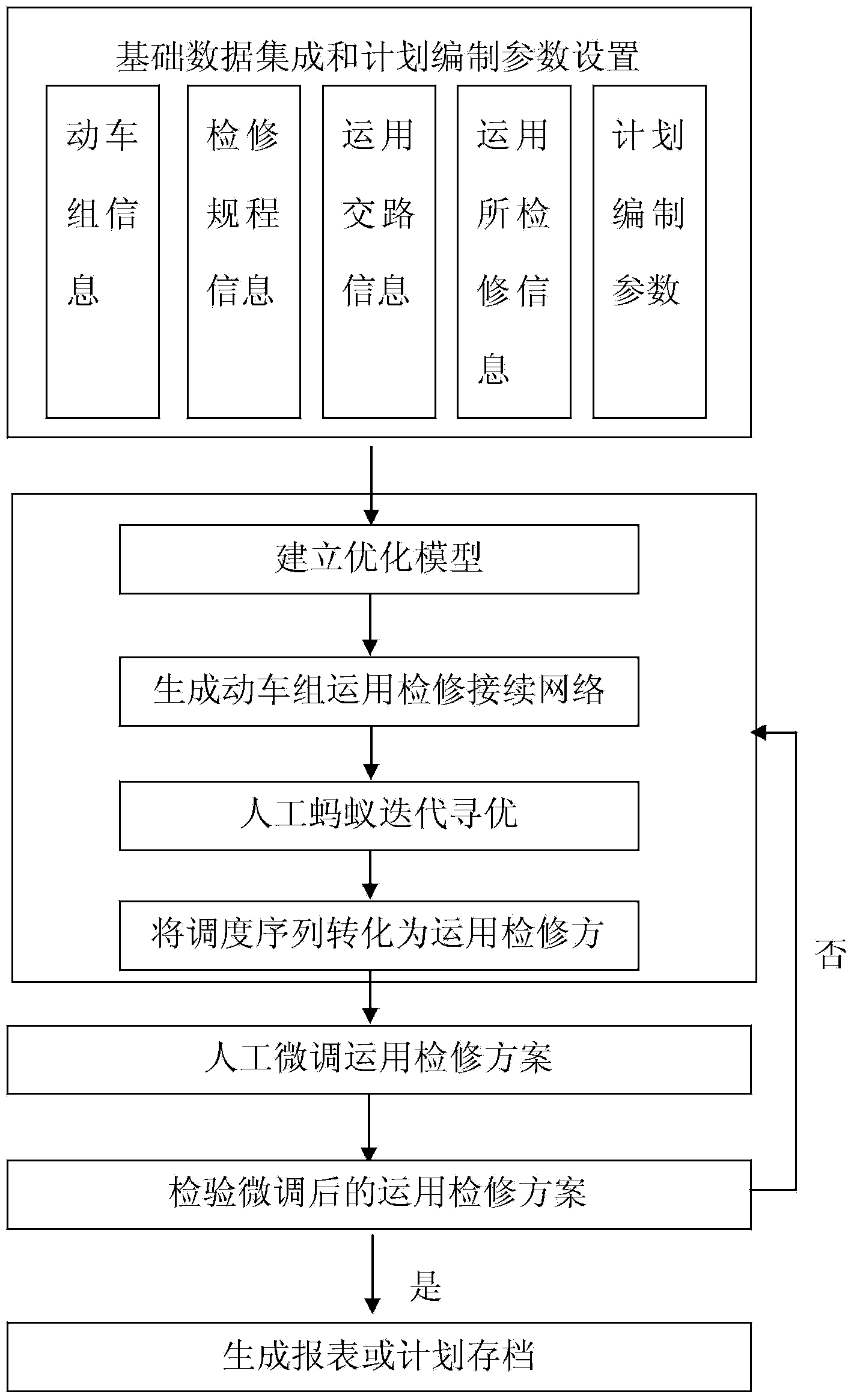

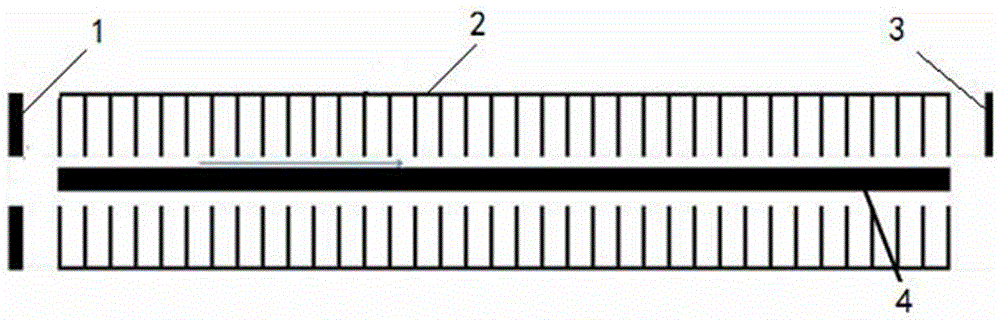

Rapid intelligent optimization method and system for motor train unit application and maintenance scheme

The invention provides a rapid intelligent optimization method for a motor train unit application and overhaul scheme. The method comprises the steps that basic data are integrated, and planning parameters are set; a preliminary motor train unit application and maintenance scheme is obtained through a rapid intelligent optimization algorithm; manual fine tuning is conducted; constraint checking is conducted, and then a reasonable application and maintenance scheme is obtained. The invention further provides a rapid intelligent optimization system capable of implementing the rapid intelligent optimization method. According to the rapid intelligent optimization method and system, it is ensured that motor train unit maintenance projects are not omitted and do not exceed the time limit, the application and maintenance of the motor train unit are reasonably balanced, the using number of motor train units is reduced to the greatest extent, the motor train unit utilization ratio is improved, pre-maintenance quantity is reduced, the maintenance cost is reduced, the motor train application workloads are reasonably balanced, key maintenance resources for the motor train application are efficiently utilized, maintenance handling capacity is improved, automatic planning is achieved, and heavy planning tasks of scheduling personnel are relieved.

Owner:INST OF COMPUTING TECH CHINA ACAD OF RAILWAY SCI +1

Method for avoiding steel plate surface hot sending direct loading cracks

A method for avoiding steel plate surface hot sending direct loading cracks is characterized in that an on-line continuous casting sheet billet is cut in a fixed-length mode; burrs on cutting end faces of the continuous casting sheet billet are removed through deburring devices, and then the continuous casting sheet billet is sent to a specially-designed high-strength and high-density rapid cooling device area; the continuous casting sheet billet is subjected to high-strength and high-density impact jet flow cooling for 120-150 seconds through continuous casting secondary cooling water with the water pressure of 1.0-1.2 MPa; the ratio of the lower surface spraying time to the upper surface spraying time is equal to 1.3-1.5; and the temperature of the upper surface of the casting billet is rapidly reduced below 550 DEG C. Then the continuous casting sheet billet is sent into a heating boiler directly through a continuous casting sheet billet rollgang, heated to the required temperature and then rolled. According to the method, the continuous casting sheet billet is prevented from the hot sending direct loading cracks of the rolled steel plate surface caused by the process of hot sending direct loading.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

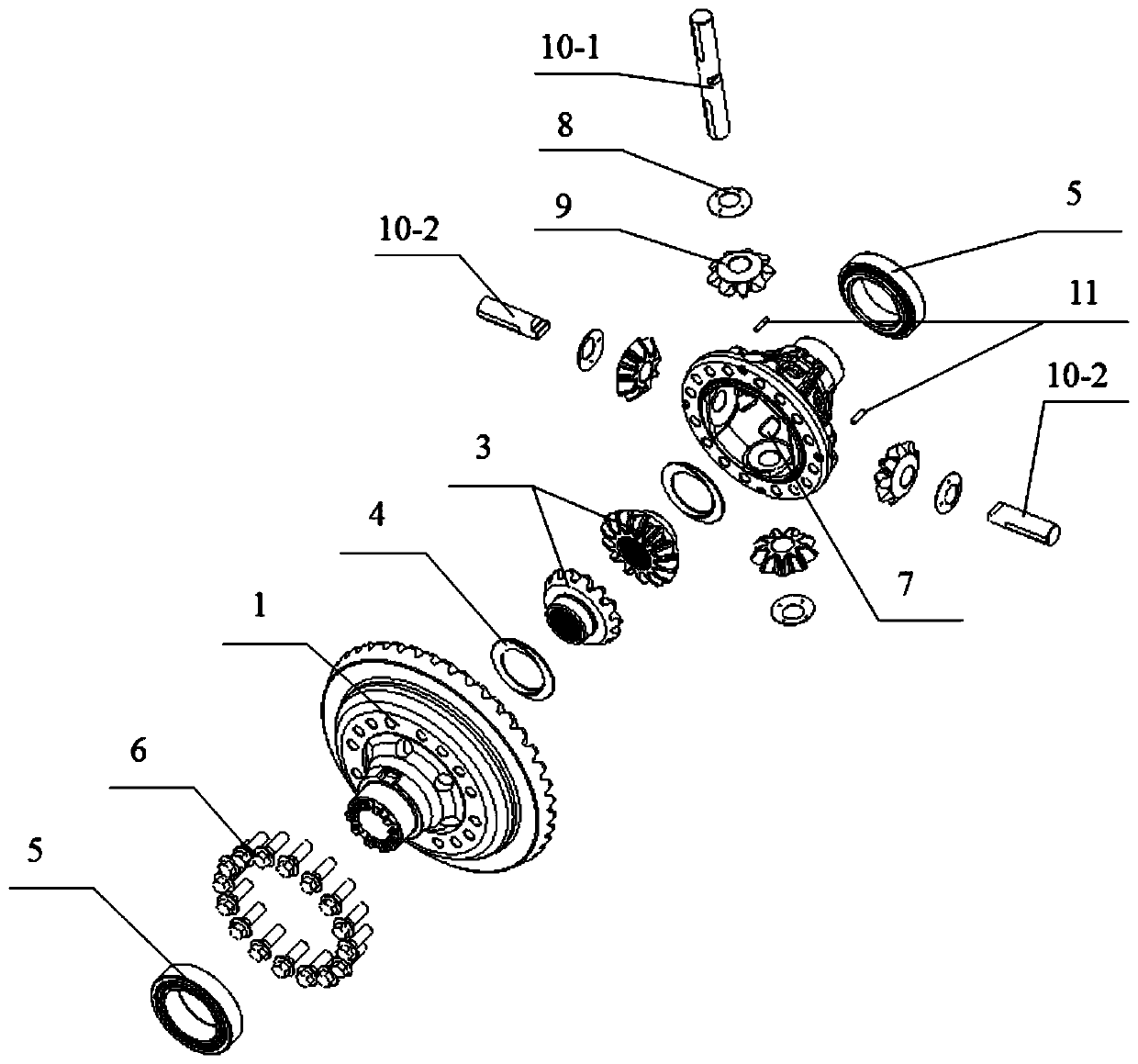

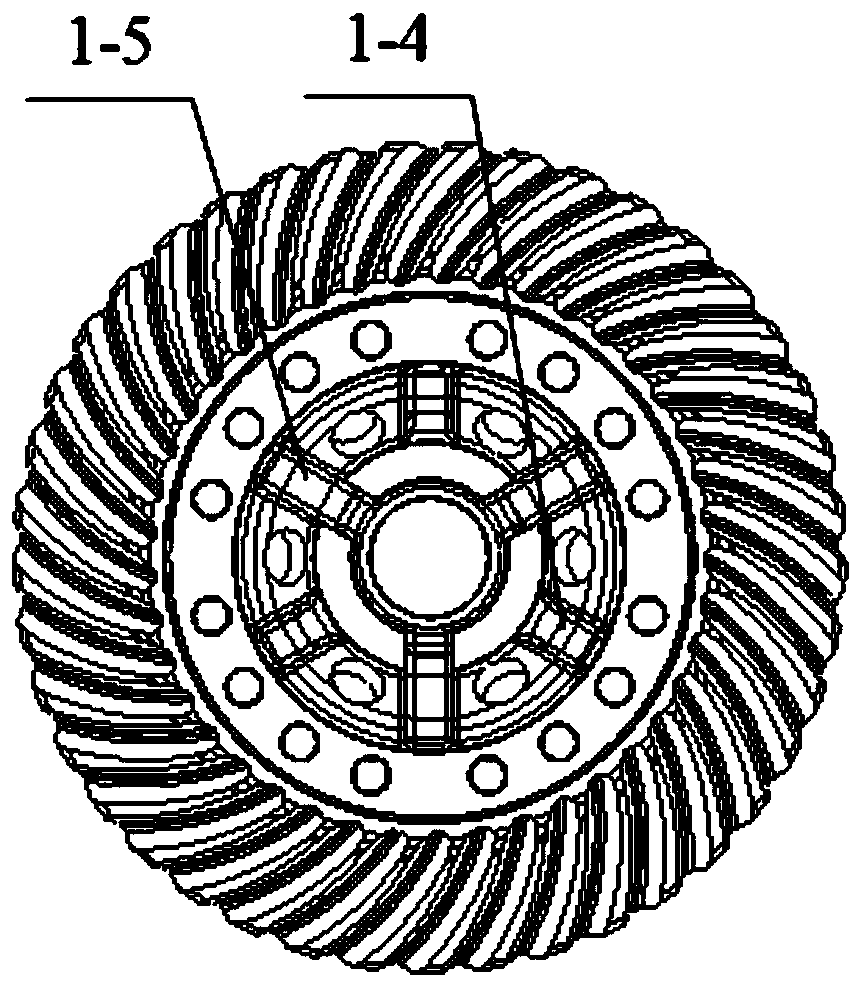

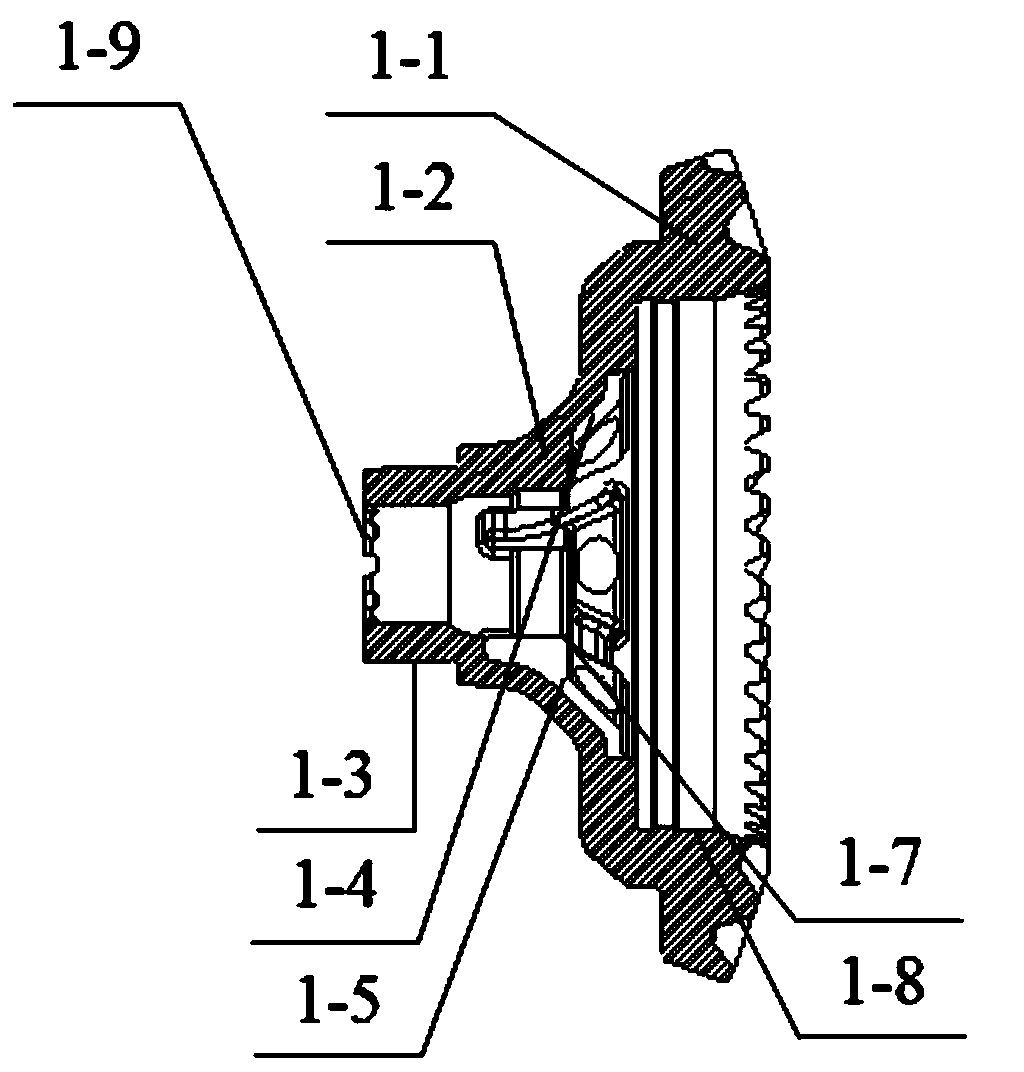

Novel commercial automobile wheel differential mechanism assembly and assembling method

PendingCN109973611AGuaranteed to workImprove organizational efficiencyDifferential gearingsCar manufacturingEngineering

The invention discloses a novel commercial automobile wheel differential mechanism assembly and an assembling method, and belongs to the technical field of automobile manufacturing. According to the wheel differential mechanism assembly and the assembling method, an integrated structure of a driven bevel gear and a left shell of the differential mechanism is adopted, an anti-rotation cross shaft assembly is integrated on a right shell of the differential mechanism, and a good lubricating system is arranged, so that the phenomena that the driven bevel gear is broken during connecting bolts, a driving bevel gear and the driven bevel gear are in collision with each other, and a spherical surface of a planetary gear of the differential mechanism is seriously worn can be eliminated; connectingparts are also reduced, processing and assembly processes are convenient, the production takt is improved, and the transmission efficiency and the reliability of the product are improved; compared with an original structure, the weight is reduced by 7.9%, and the cost is reduced by about 6%; and compared with an wheel differential mechanism assembly with different speed ratios, the right shell ofthe differential mechanism can be commonly used and interchanged, so that the organization production is facilitated, the interchangeability of the product and the organization efficiency of spare parts are also improved, and therefore the purposes of light weight, economy and refined production are achieved.

Owner:FAW JIEFANG AUTOMOTIVE CO

Method for preparing multi-component niobium alloy ingot

The invention discloses a method for preparing a multi-component niobium alloy ingot, which comprises the following steps of: 1, proportioning raw materials according to components of the multi-component niobium alloy ingot to be prepared; 2, preparing an alloy package; 3, placing the alloy package into a spongy base metal and pressing into a semicircular electrode; 4, welding the two sections of electrodes into a complete electrode; and 5, smelting the electrode to obtain a multi-component niobium alloy ingot. The method has the advantages of simple process, low cost and convenience of production organization, can greatly improve production efficiency of the niobium alloy ingot industry, and is applicable to preparation of all kinds of binary system and polynary system niobium alloy ingots containing low-melting low-intensity components.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

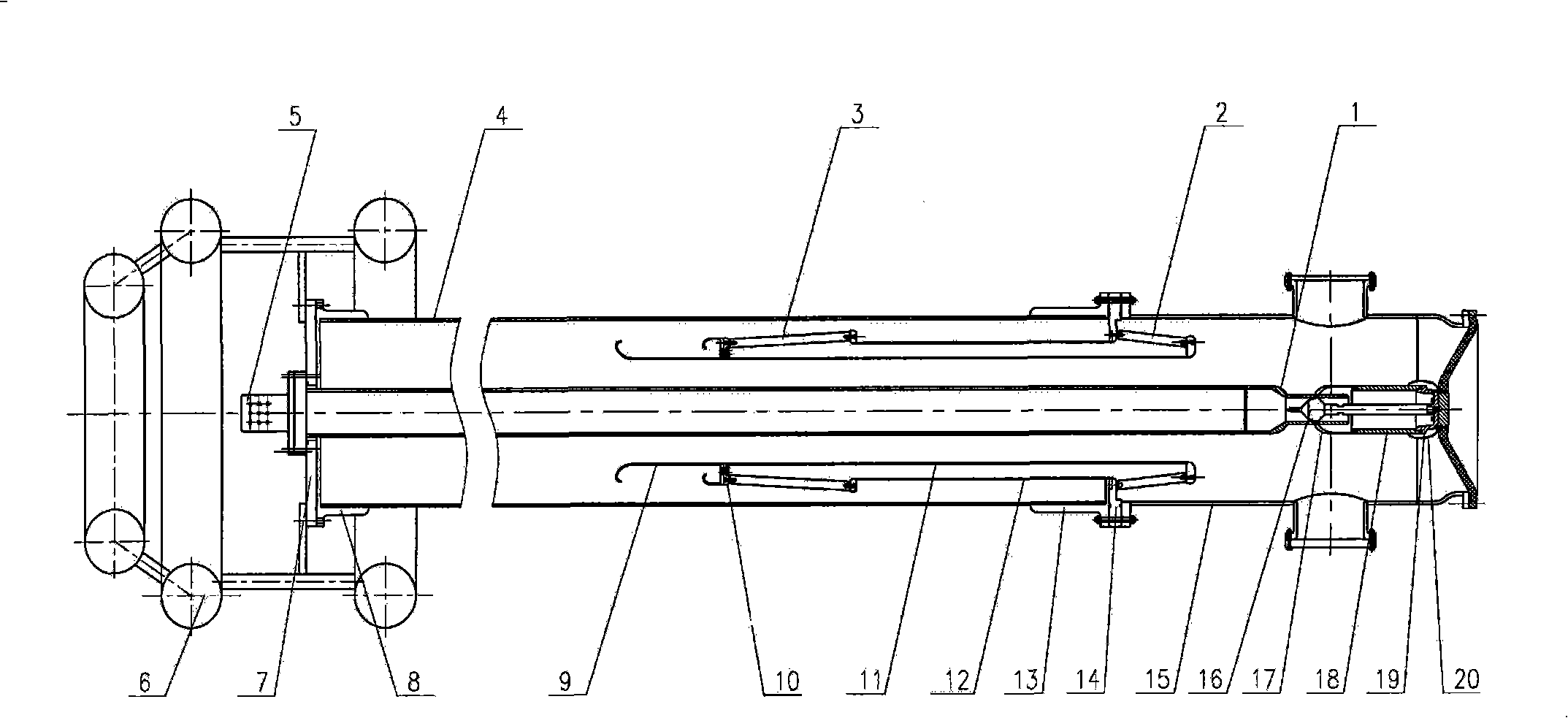

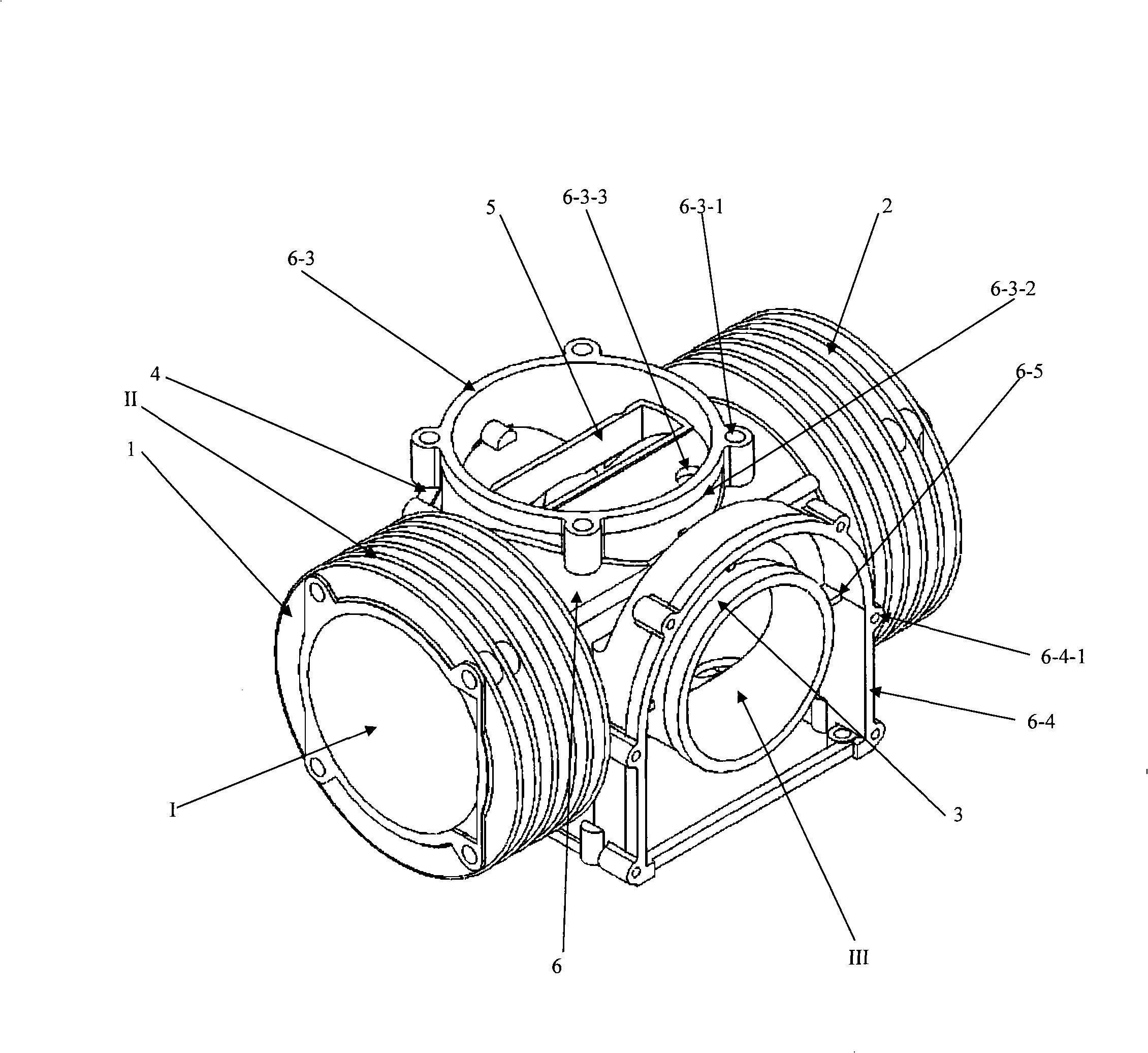

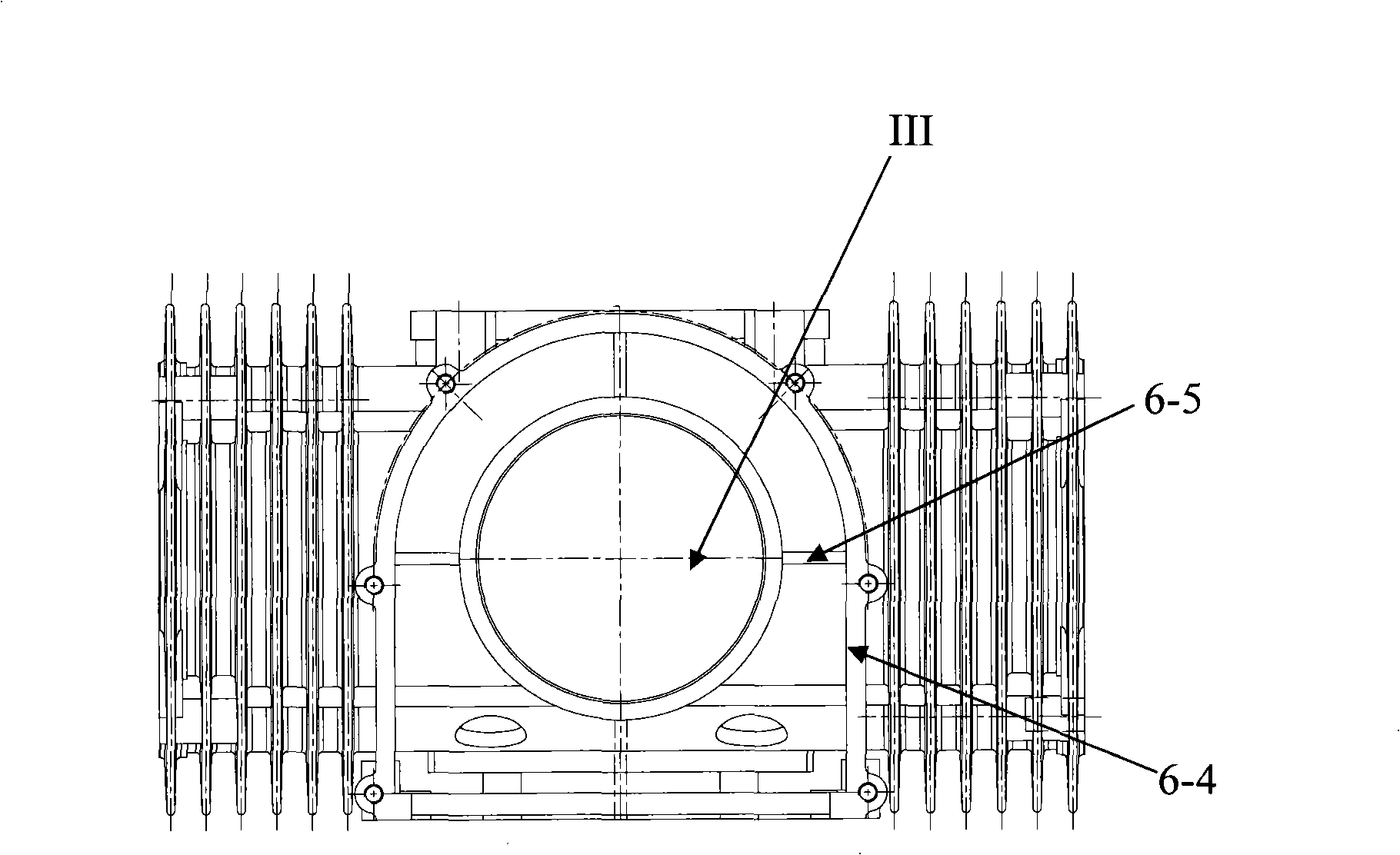

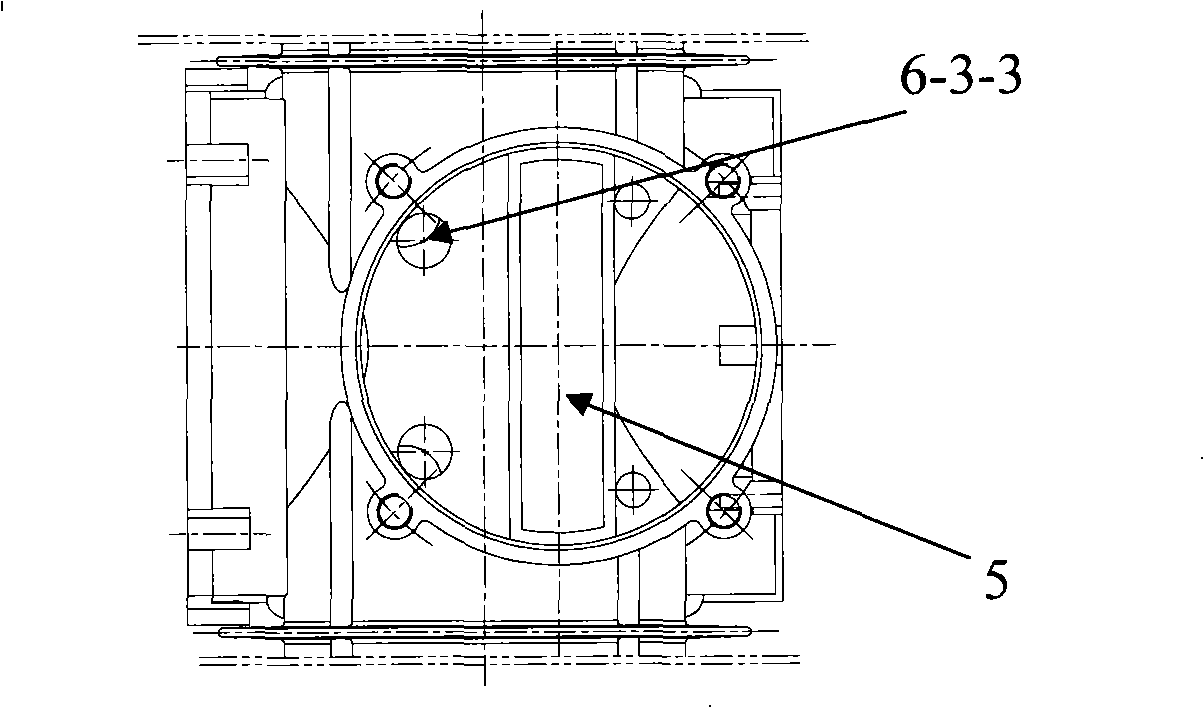

Reciprocating-piston compressor body

ActiveCN101338743ASimple processingLow costPositive displacement pump componentsPositive-displacement liquid enginesCentral planeMain bearing

Owner:BEIJING SINOCEP ENGINE TECH

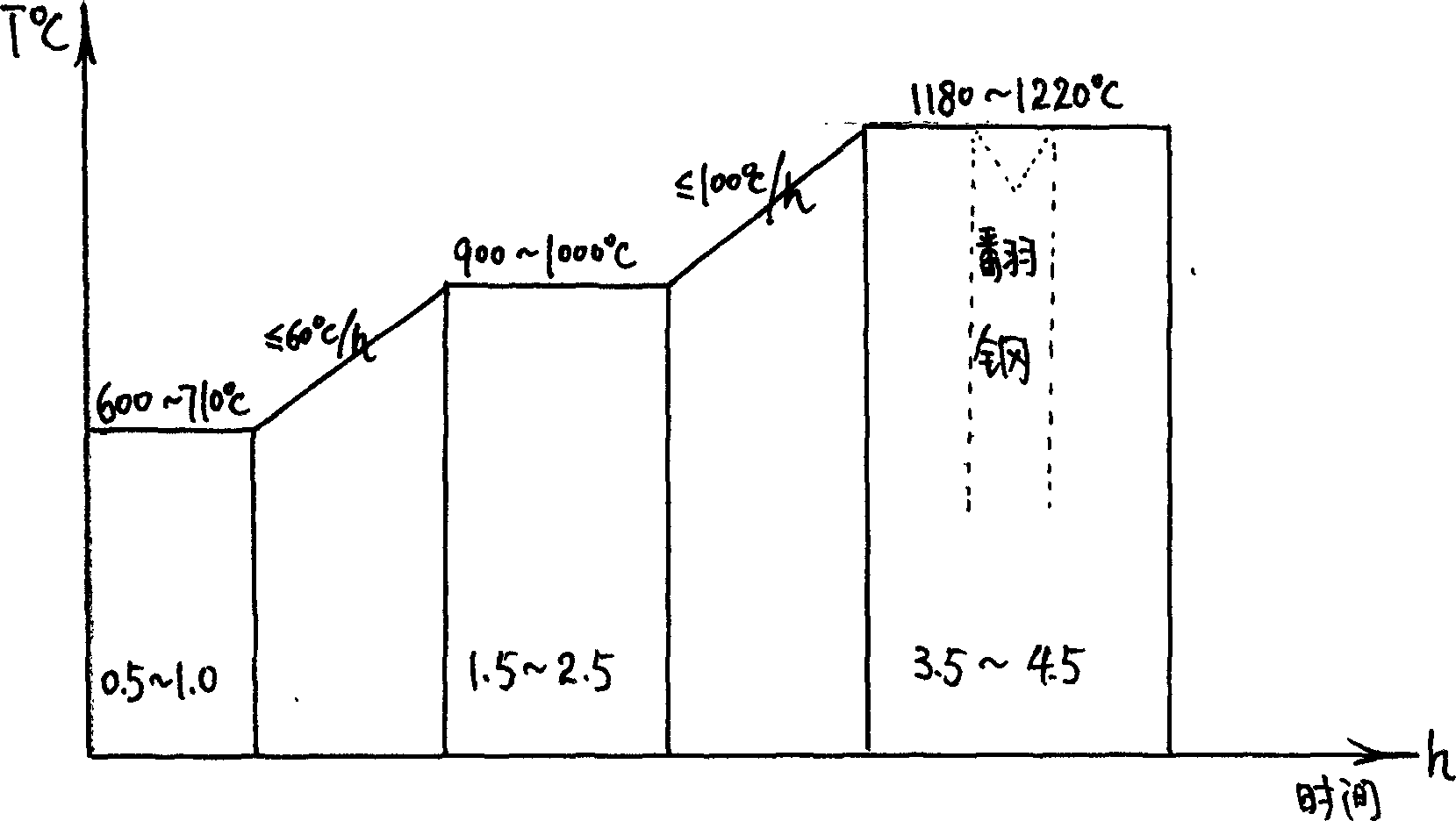

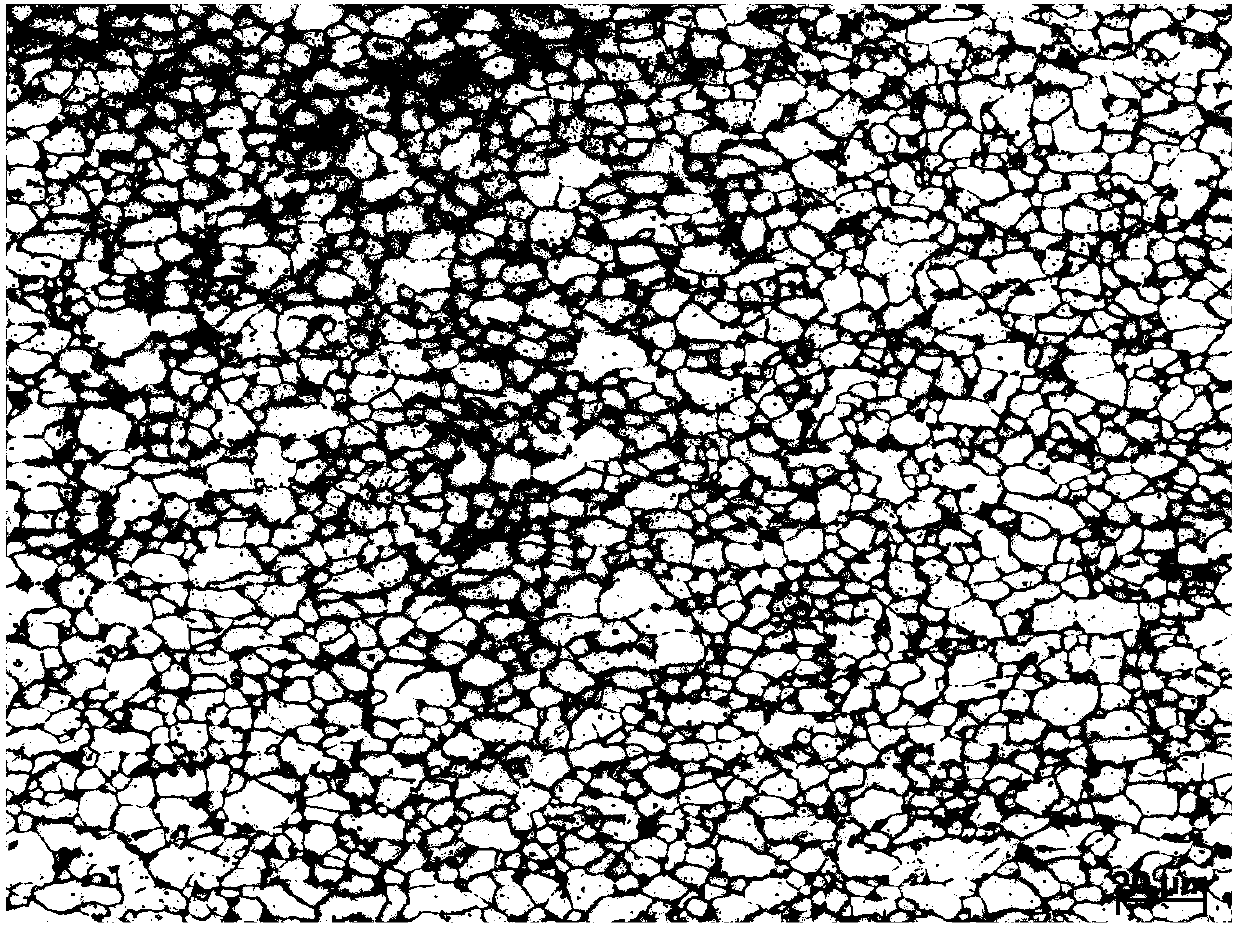

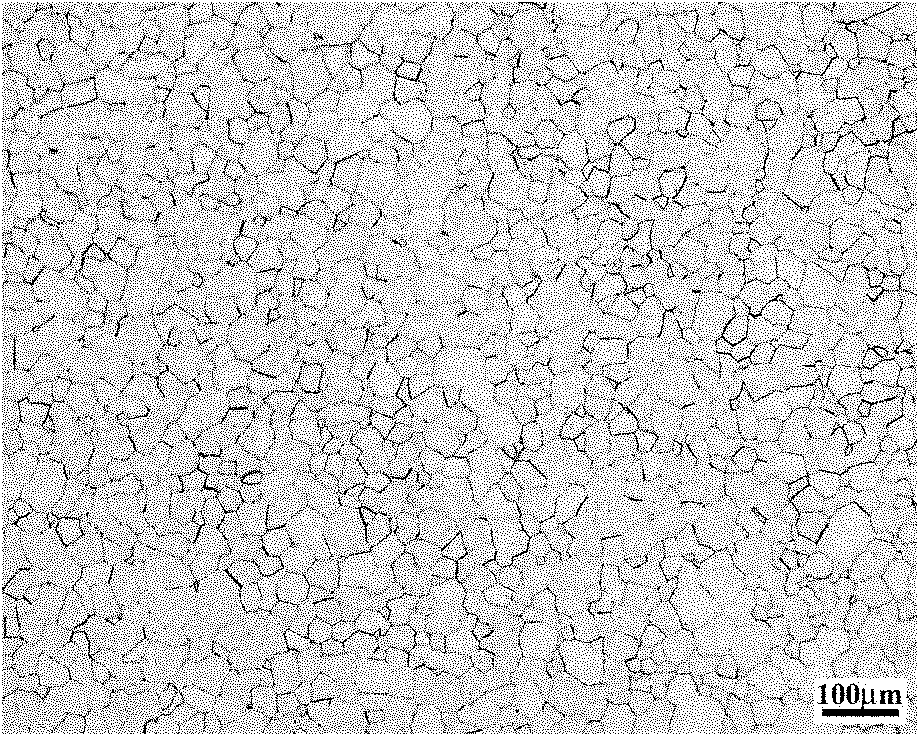

Super duplex stainless steel ingot hot working cogging method

ActiveCN103121034AReduce manufacturing costFulfil requirementsTemperature control deviceMetal rolling arrangementsIngotSS - Stainless steel

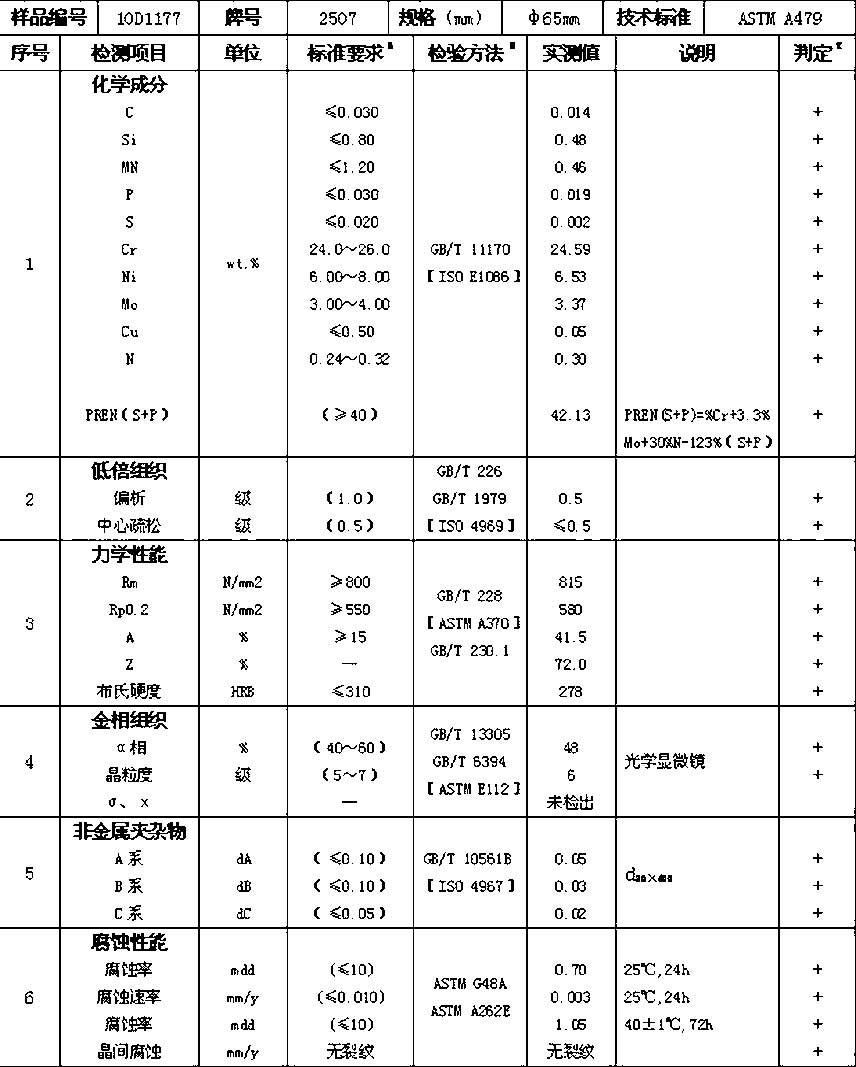

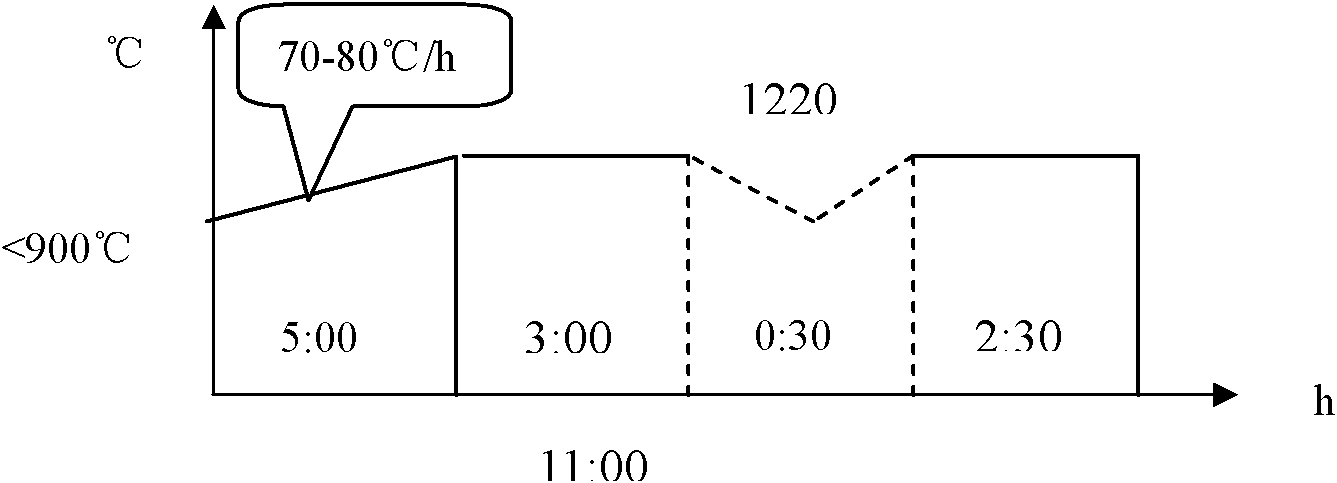

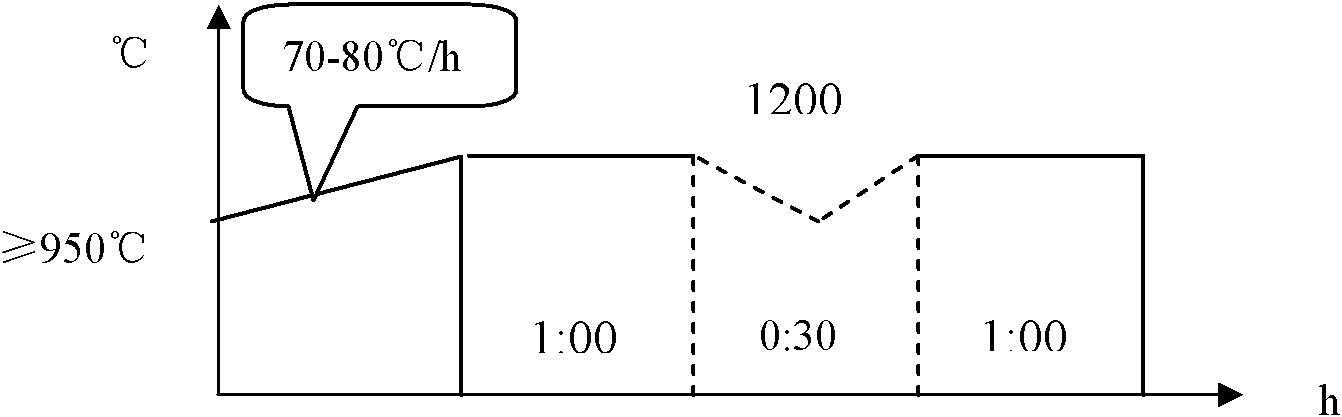

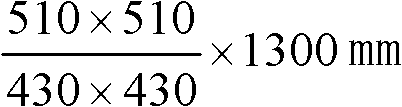

The invention belongs to the metallurgical industry, and particularly relates to a super duplex stainless steel ingot hot working cogging method. The methods comprises hot working cogging first fire rolling and hot working cogging second fire rolling. The method comprises the steps of heating a steel ingot with a soaking pit, hot working cogging with a blooming mill, heating a rolled piece with the soaking pit, and hot working second fire cogging with the blooming mill. According to the super duplex stainless steel ingot hot working cogging method, a forging press is replaced by the blooming mill for hot working cogging, a qualified 2507 billet is rolled for being further rolled into a seamless tube circular tube billet, the problems of long production period and low metal cogging yield are solved, production cost of metallurgy manufacturing is greatly reduced, and user requirements and market demands are met.

Owner:浙江青山钢铁有限公司

Rolling and cogging production method for large austenite stainless and heat-resistant gas valve steel 21-4N ingot

InactiveCN102836870ASimple processEasy to operateTemperature control deviceMetal rolling arrangementsWire rodIngot casting

A rolling and cogging production method for a large austenite stainless and heat-resistant gas valve steel 21-4N (5Cr21Mn9Ni4N) ingot comprises the steps as follows: 1, the austenite stainless and heat-resistant gas valve steel ingot is subjected to hot charging; 2, the ingot is heated by a first fire of a soaking furnace, and rolled piece returns to the furnace and is heated by a second fire; in the heating process of the ingot by the first fire, (A) the ingot enters the furnace at 500-900 DEG C; (B) the temperature rises to 1150-1250 DEG C; (C) the temperature is kept at 1150-1250 DEG C for 2-6 hours; (D) the temperature difference between male and female faces of the ingot is less than or equal to 20 DEG C; in the returning and heating process of the rolled piece by the second fire, (A) the temperature rises to 1150-1250 DEG C and kept for 2-3 hours; (B) the temperature difference between the male and female faces of the rolled piece is less than or equal to 20 DEG C; and 3, after the two heating procedures, the ingot and the rolled piece are subjected to rolling; (A) a roll is preheated to 100-300 DEG C; (B) the rolling temperature is 1150-1250 DEG C, and the finished rolling temperature is greater than 900 DEG C; and (C) the bite speed of the roll is 10-40 rpm. The rolling and cogging production method is simple in technology; the ingot case is enlarged; the production cycle is shortened greatly; the energy consumption is reduced greatly; the cogging yield is increased; manufactured steel billet wires are used for producing a wire coil; and the piece weight of the coil is increased greatly.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

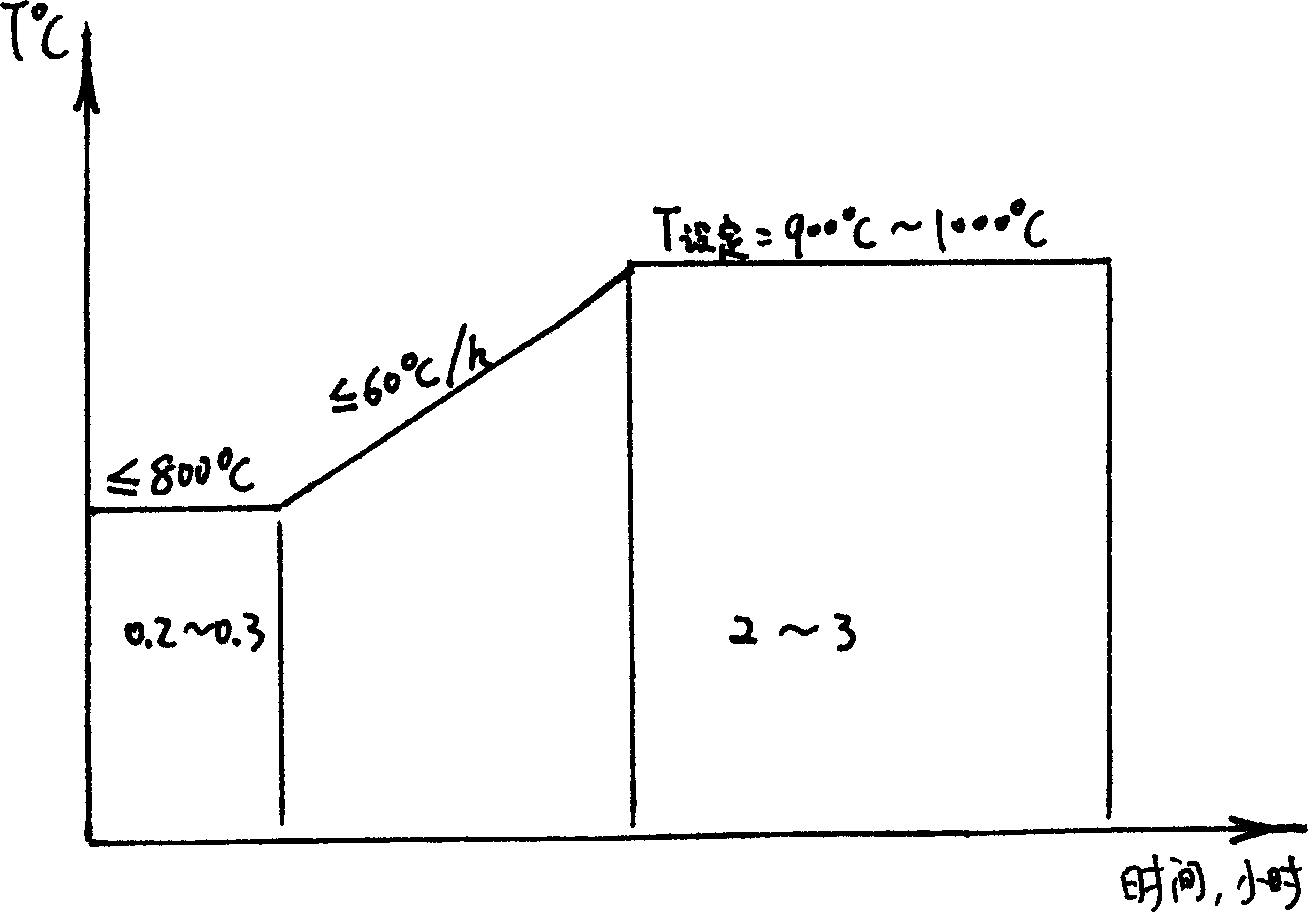

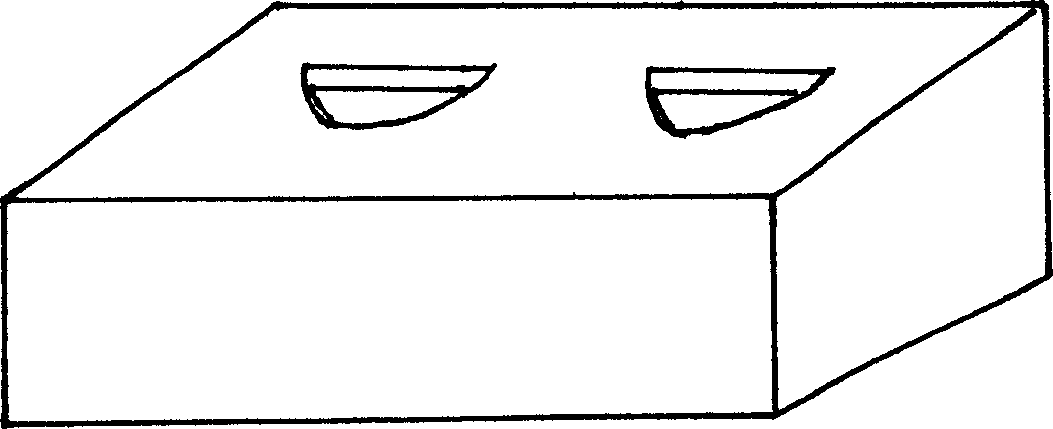

Method for heating titanium and titanium alloy ingot

ActiveCN1609240AEnsure heating uniformitySolve efficiency problemsFurnace typesHeat treatment furnacesTitaniumIngot

The titanium and titanium alloy ingot heating method for cogging of titanium and titanium alloy ingot features the heating of cast ingot in soaking furnace. The heating process includes the steps of: setting isolating block with pits in the surface horizontally on the bottom of soaking furnace; leaning the cast ingot on the furnace wall with one end in the pit while maintaining some interval between adjacent ingots; and heating the ingot through maintaining in the furnace at 800 deg.c for 15 min, heating to set temperature of 900-1000 deg.c in the temperature raising speed of not higher than 60 deg.c / hr and maintaining in the temperature for 2.5 hr before discharging. The present invention has the advantages of low cost, simple technological process, etc.

Owner:宝武特冶钛金科技有限公司

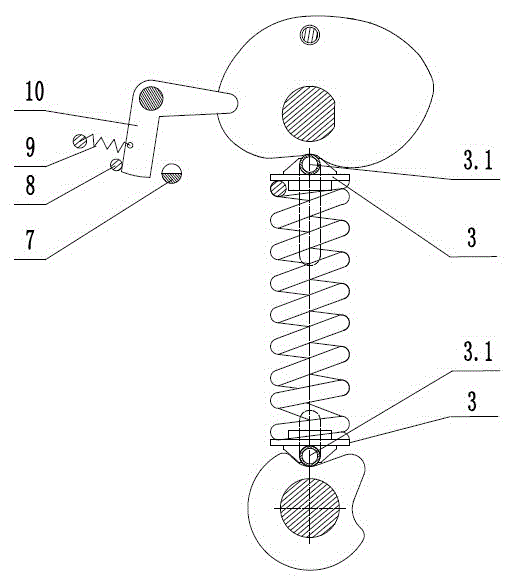

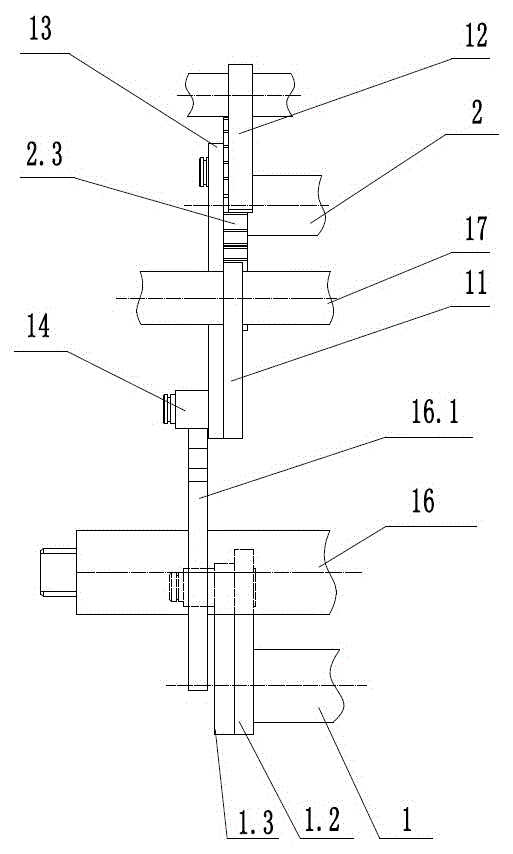

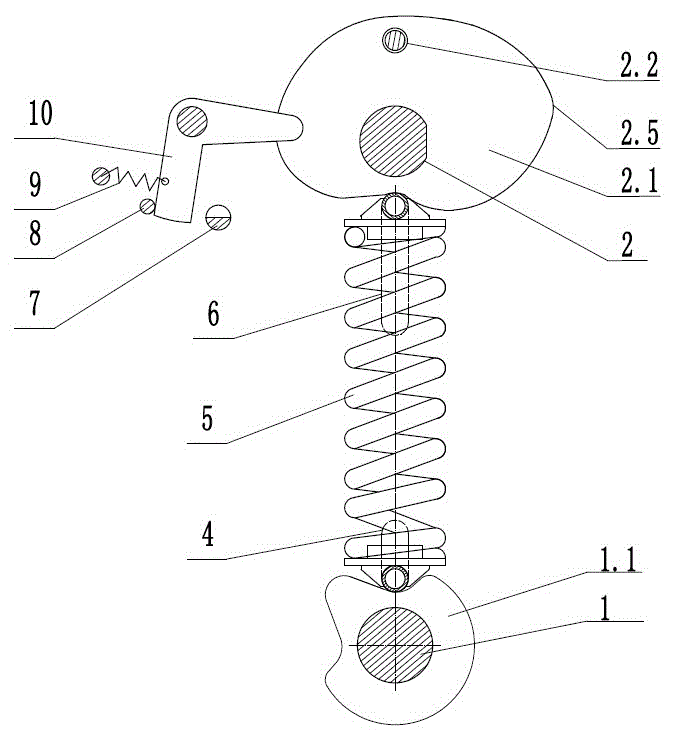

Spring drive device for three-position switching operating mechanism

InactiveCN106571253AReduce the swing of the included angleMiniaturizationSwitch power arrangementsDrive shaftMiniaturization

The invention relates to the technical field of power switch equipment, especially a spring drive device for a three-position switching operating mechanism. Aiming at a problem that a space is needed for the swinging amplitude of a spring and the telescoping motion of the spring because a spring device of a conventional three-position switching operating mechanism is disposed on a connecting lever of an operating shaft and a drive shaft and the spring passes through the connecting lever to form inclined angles with the drive shaft and the operating shaft, and a problem of miniaturization difficulty caused by that the size of the connecting lever cannot be too small because of the limiting of a drive moment, the device employs a mode that the spring drives a cam to move. The axis of a switching-on spring, the axis of a grounding operating shaft, the axis of a switching operating shaft, the axis of a spring seat roller and the axis of a guide groove are enabled to be collinear, thereby enabling the spring to just move up and down and not to swing, solving a problem that the space occupied by the spring is too big, remarkably reducing the size of an operating mechanism, and enabling the device to be simpler and more practical.

Owner:BEIHAI GALAXY SWITCH DEVICES

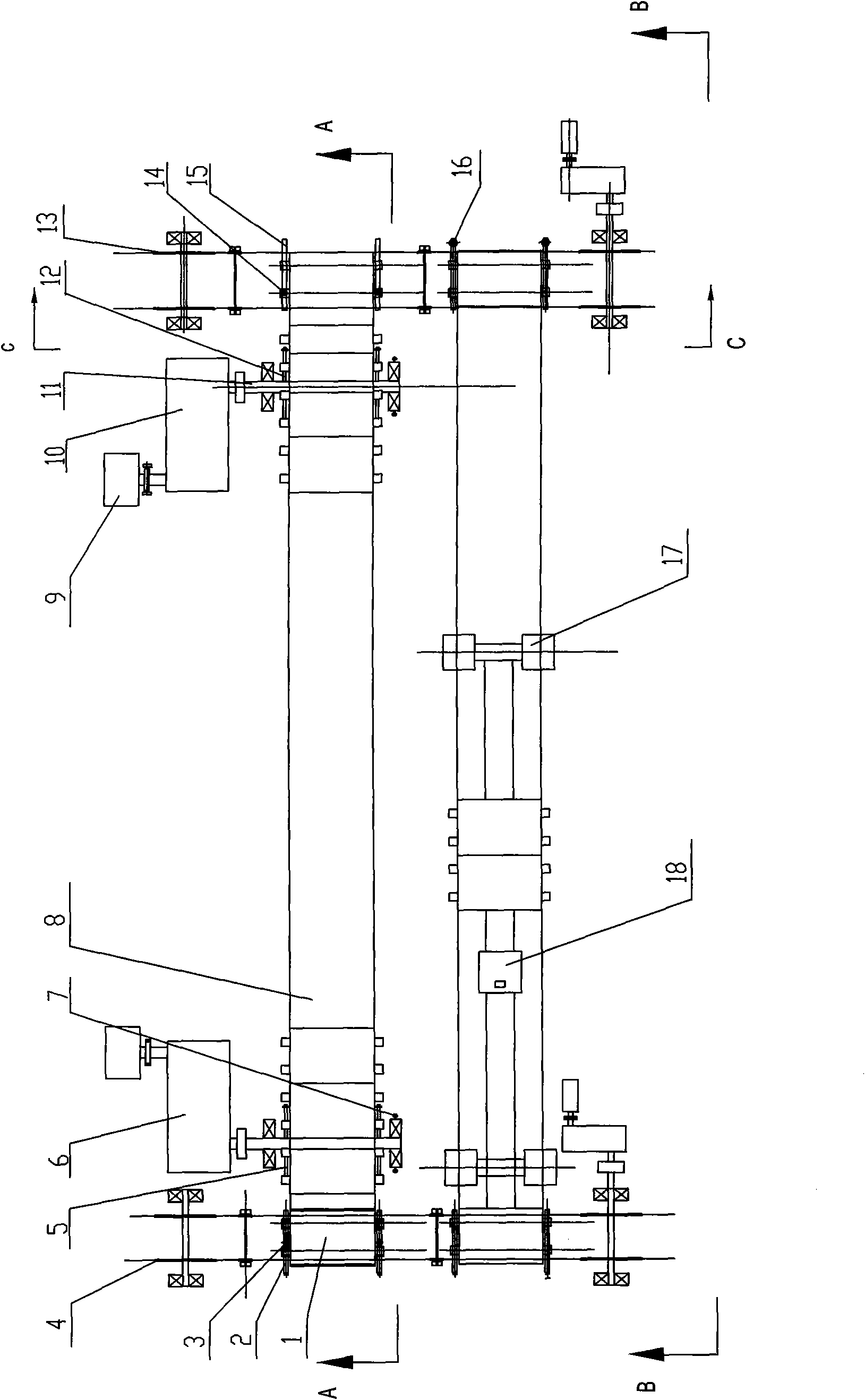

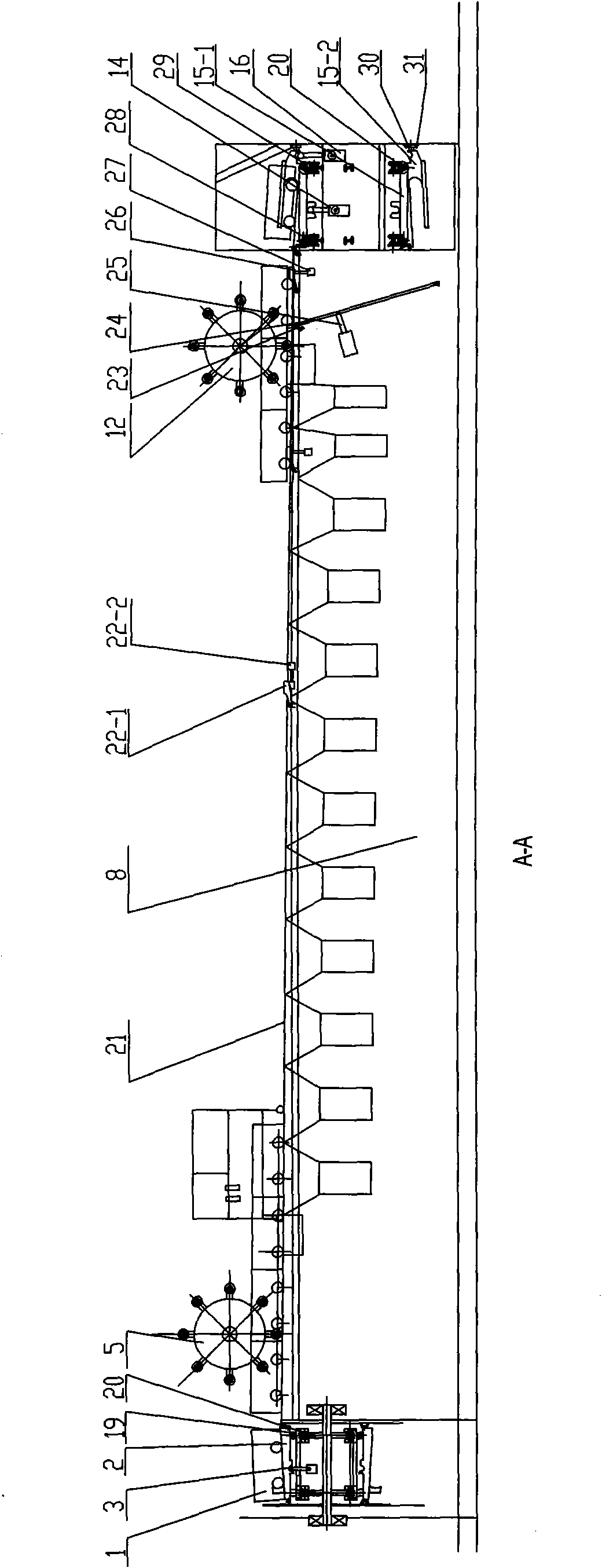

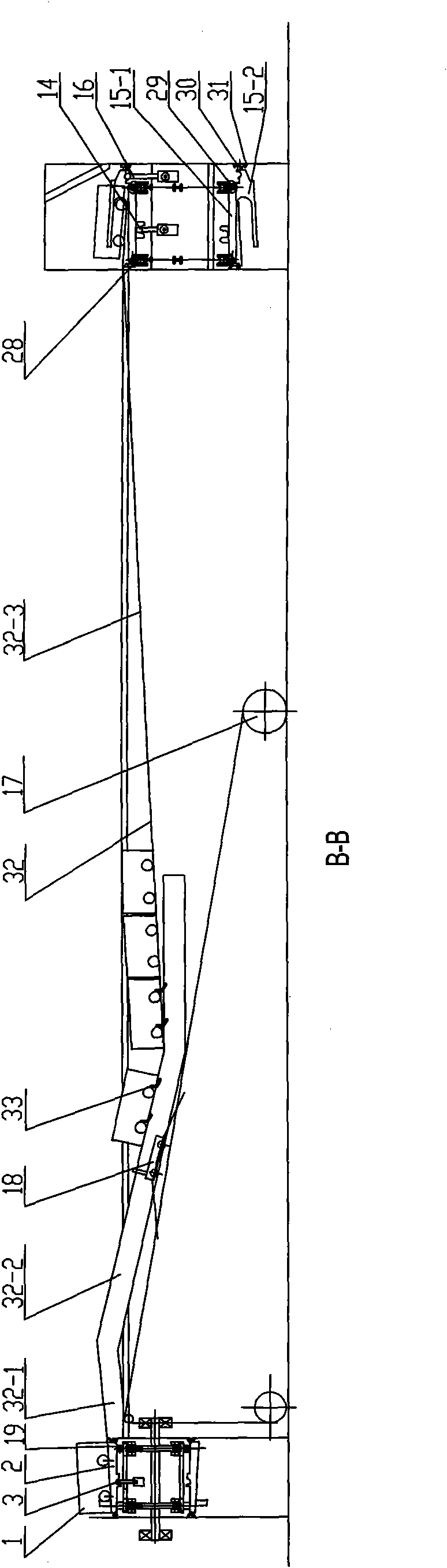

Energy-saving continuous operation inclined plane sintering machine

The invention relates to an energy-saving continuous operation inclined plane sintering machine, which is characterized in that: a trolley track is obliquely arranged in a mode of a high feed end and a low discharge end; a tail of a sintering machine main body is provided with a damping mechanism and a rapid feeding mechanism; a trolley limiting mechanism is arranged between a head and the tail of the trolley track and on the tail of the trolley track; supports below two chain wheel groups of a head chain conveying device and a tail chain conveying device are provided with guide grooves respectively, a head board turning mechanism is transversely arranged discontinuously between left and right chains of the head chain conveying device, and a tail board turning mechanism is transversely arranged discontinuously between left and right chains of the tail chain conveying device; the trolley return track consists of a low-front high-back trolley rolling section, a high-front low-back climbing section and a low-front high-back conveying section; and a winding gear is arranged below the climbing section of the trolley return track, and the supports below the climbing section are uniformly provided with backward stoppers. The energy-saving continuous operation inclined plane sintering machine has the advantages of good energy-saving effect, low air leakage ratio of a device and easy implementation of the large-scale device.

Owner:张健

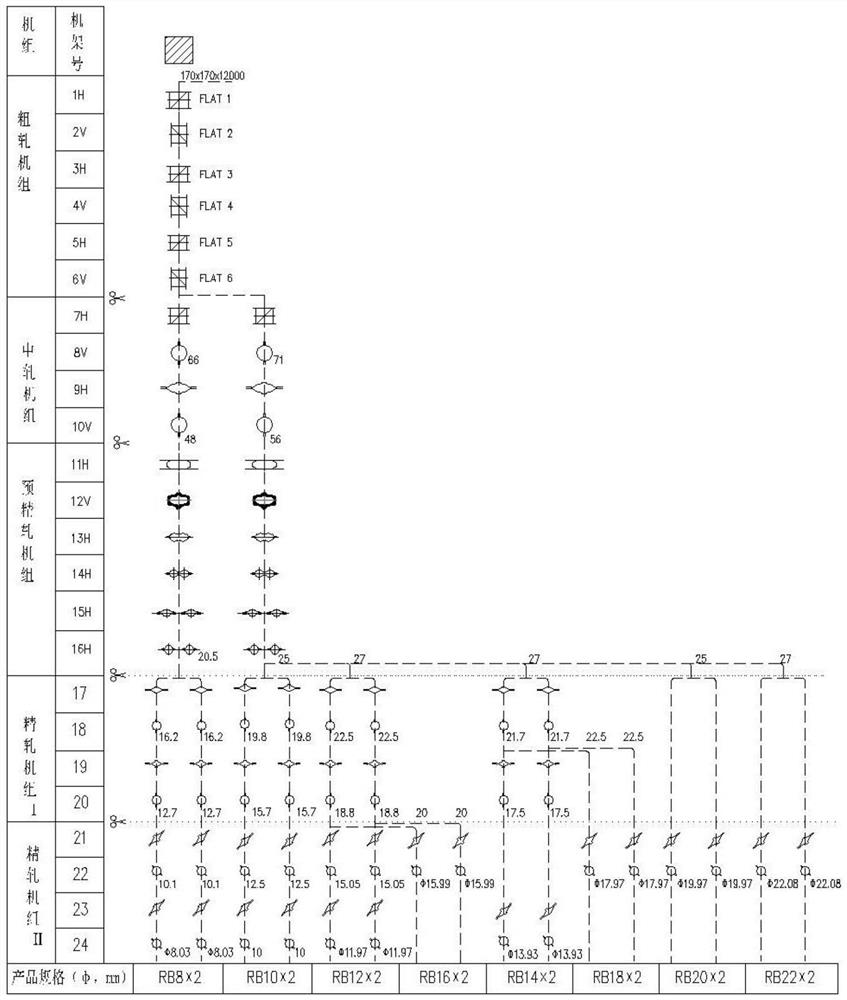

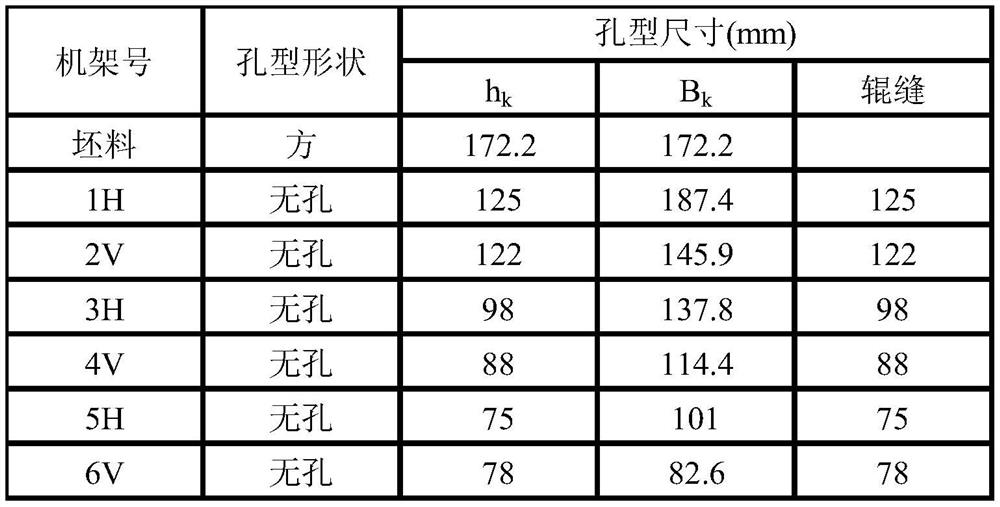

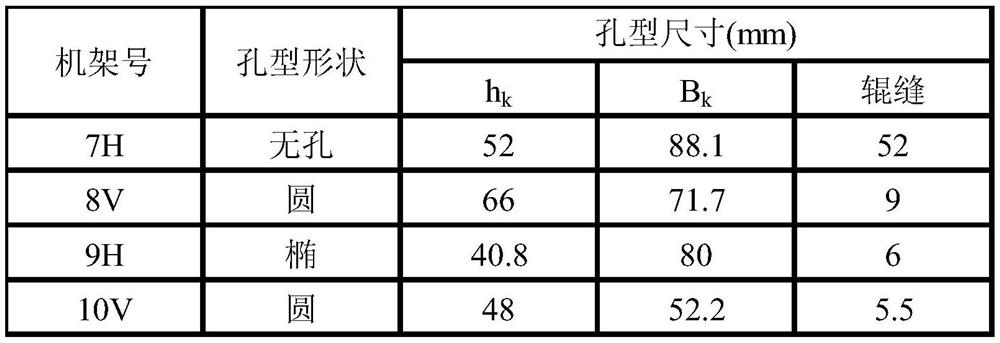

Double-high-bar rolling system suitable for multi-specification and multi-size production

PendingCN111618091AReduce reservesReduce occupancyMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

The invention provides a double-high-bar hole pattern rolling system suitable for multi-specification and multi-size production. The double-high-bar hole pattern rolling system is used for solving theproblem that in the prior art, multiple hole pattern systems are needed for production of double high bars of different specifications. The double-high-bar hole pattern rolling system sequentially comprises a roughing mill unit, an intermediate rolling unit, a pre-finishing mill unit and a finishing mill unit in the rolling direction; the roughing mill unit is of a flat-roller hole-free pattern rolling structure; the intermediate rolling unit comprises a hole-free pattern rolling structure and a hole pattern rolling structure, and the bar is sequentially subjected to hole-free pattern rollingand hole pattern rolling in the intermediate rolling unit; the pre-finishing mill unit adopts the same hole pattern rolling structure; and the finishing mill unit adopts the same hole pattern rollingstructure, more than one rack is arranged in the finishing mill unit, and the roll gap of each rack in the finishing mill unit is adjustable. The double-high-bar hole pattern rolling system can adaptto a wider size rolling range, the spare amount of dies such as rollers, roll collars and guides can be greatly reduced, and the capital occupation of enterprises is reduced.

Owner:CHONGQING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com