Patents

Literature

511results about How to "Low energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting flavonoids from ginkgo biloba leaves with deep eutectic solvent

InactiveCN104887723AReduce lossLow energy consumptionGinkgophyta medical ingredientsChemistryLiquid–liquid extraction

The invention discloses a method for extracting flavonoids from ginkgo biloba leaves with a deep eutectic solvent. The ginkgo biloba leaves are used as raw materials, the choline deep eutectic solvent is used as an extracting agent, water is used as a diluent for decreasing the system viscosity, the flavonoids are extracted under the ultrasonic intensification, the choline deep eutectic solvent is a room-temperature molten salt liquid of ethylene glycol-oxalic acid-choline chloride, and the molar ratio of ethylene glycol to oxalic acid to choline chloride in the room-temperature molten salt liquid is 1:1:1. The method has the advantages as follows: the extraction method has the characteristics that the extracting agent does not explode and volatilize, the loss is low, the energy consumption is low, potential risks are avoided, the operation is convenient, industrialization is easy, the efficiency is high and the like, and the method can be applied to efficient and green large-scale production of the flavonoids and realization of comprehensive utilization of ginkgo biloba leaf resources.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

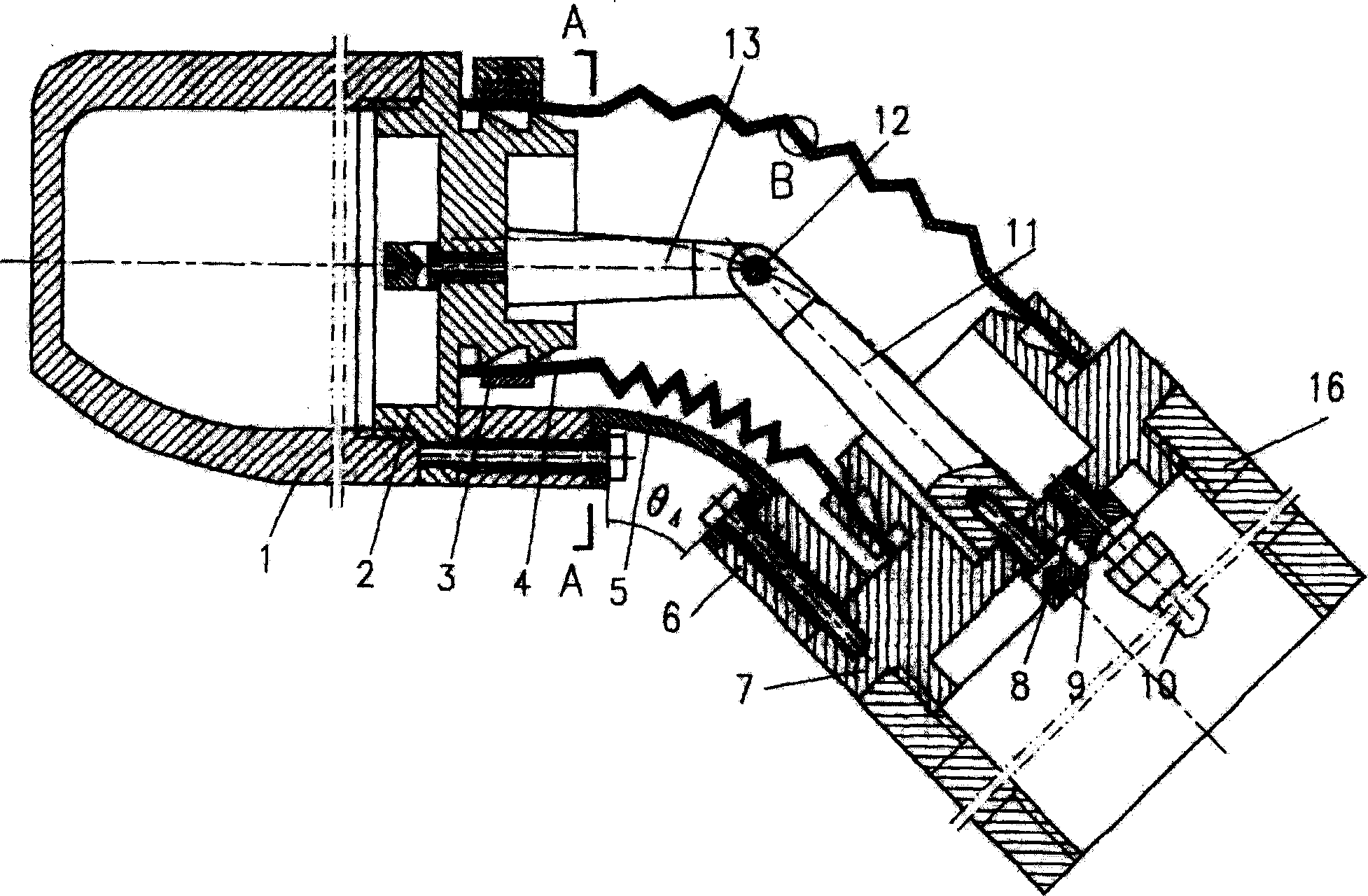

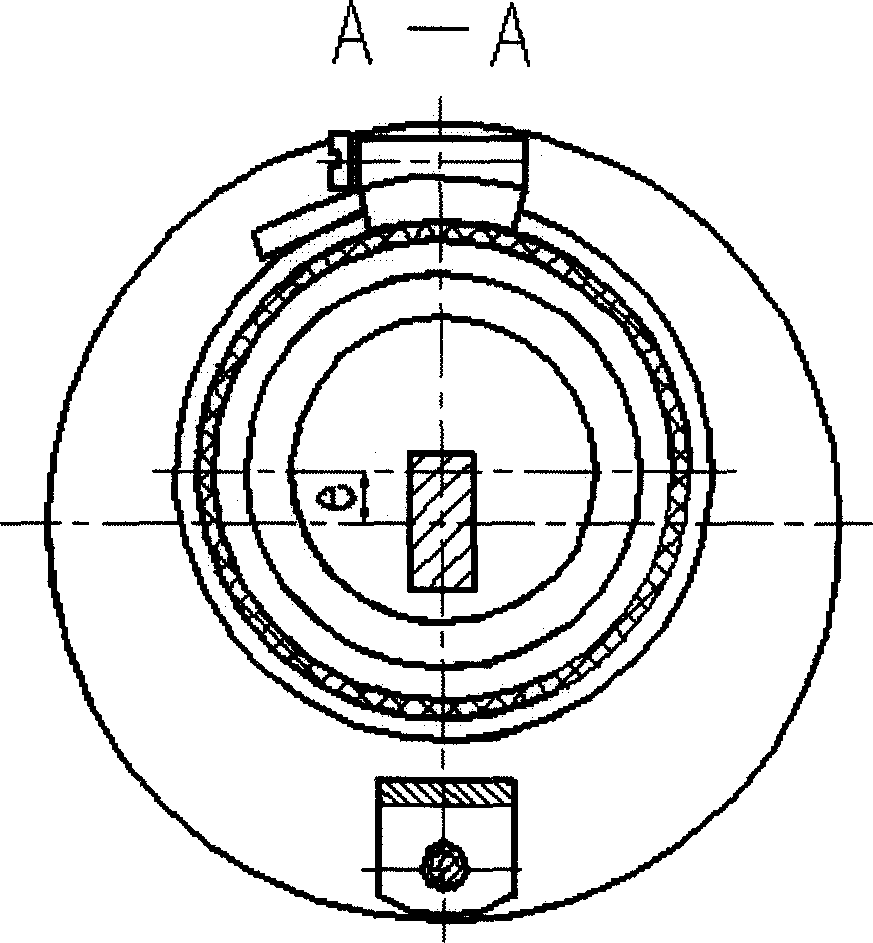

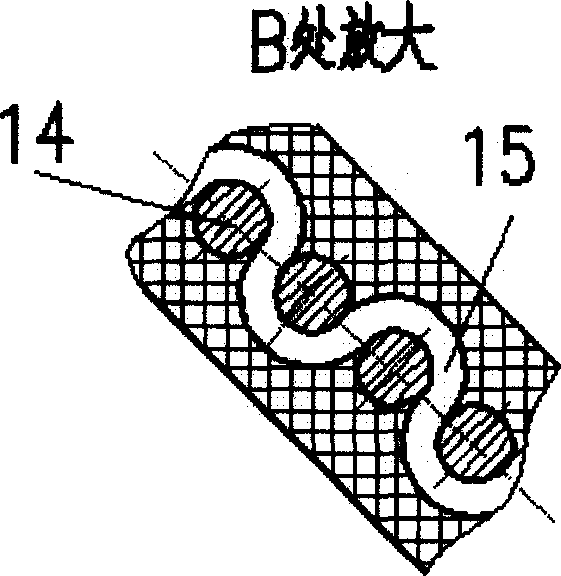

Plate spring skeleton hydrulic pneumatic flexible bending joint

A pneumatic flexible joint for robot or manipulator features that the leaf spring is used as its flexible skeleton and the corrugated shell is pneumatically expanded for providing the muscle power. Under the action of leaf spring, it can be bent but not axially extended. Its advantages are high flexibility and control accuracy, and low energy consumption.

Owner:JIANGNAN UNIV

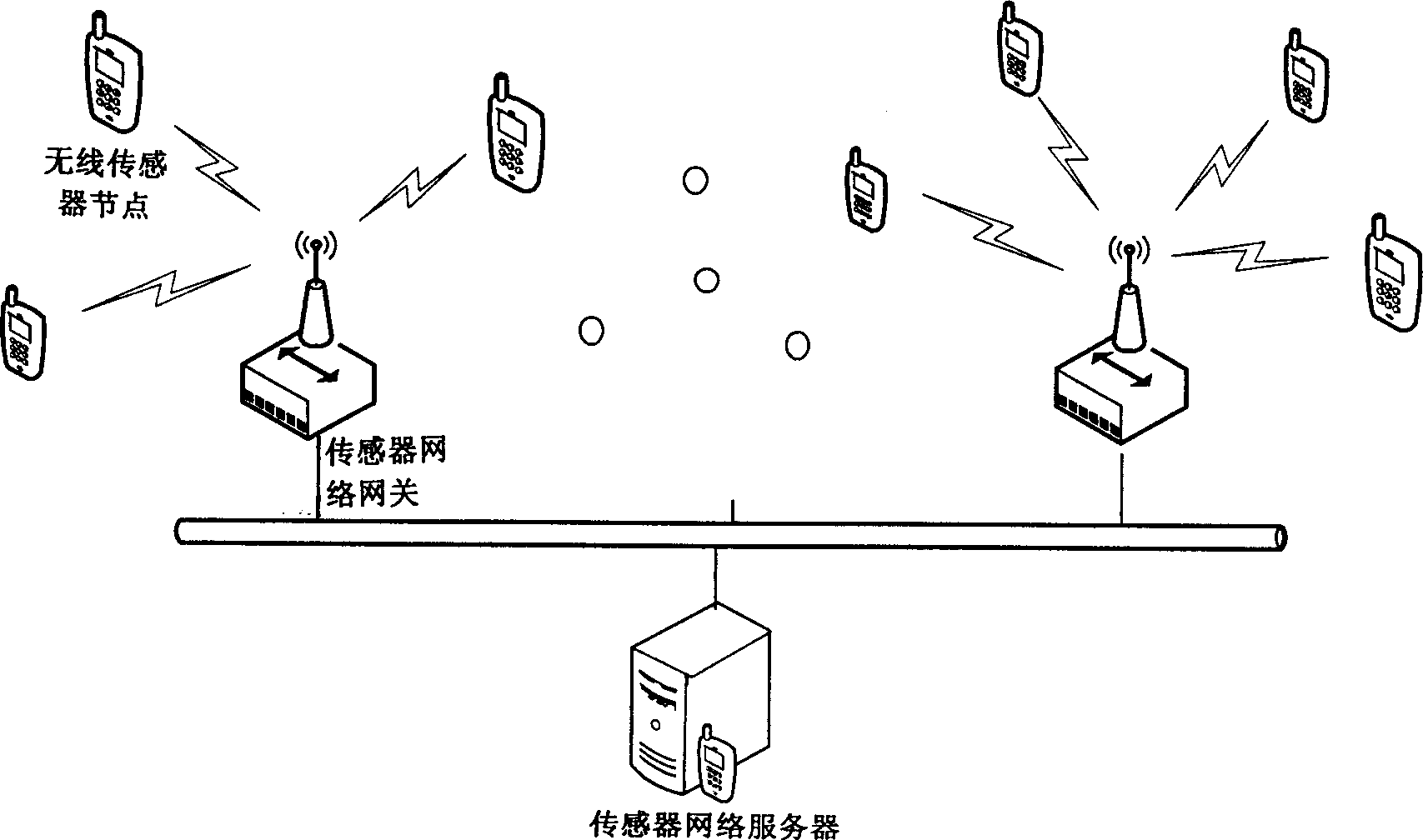

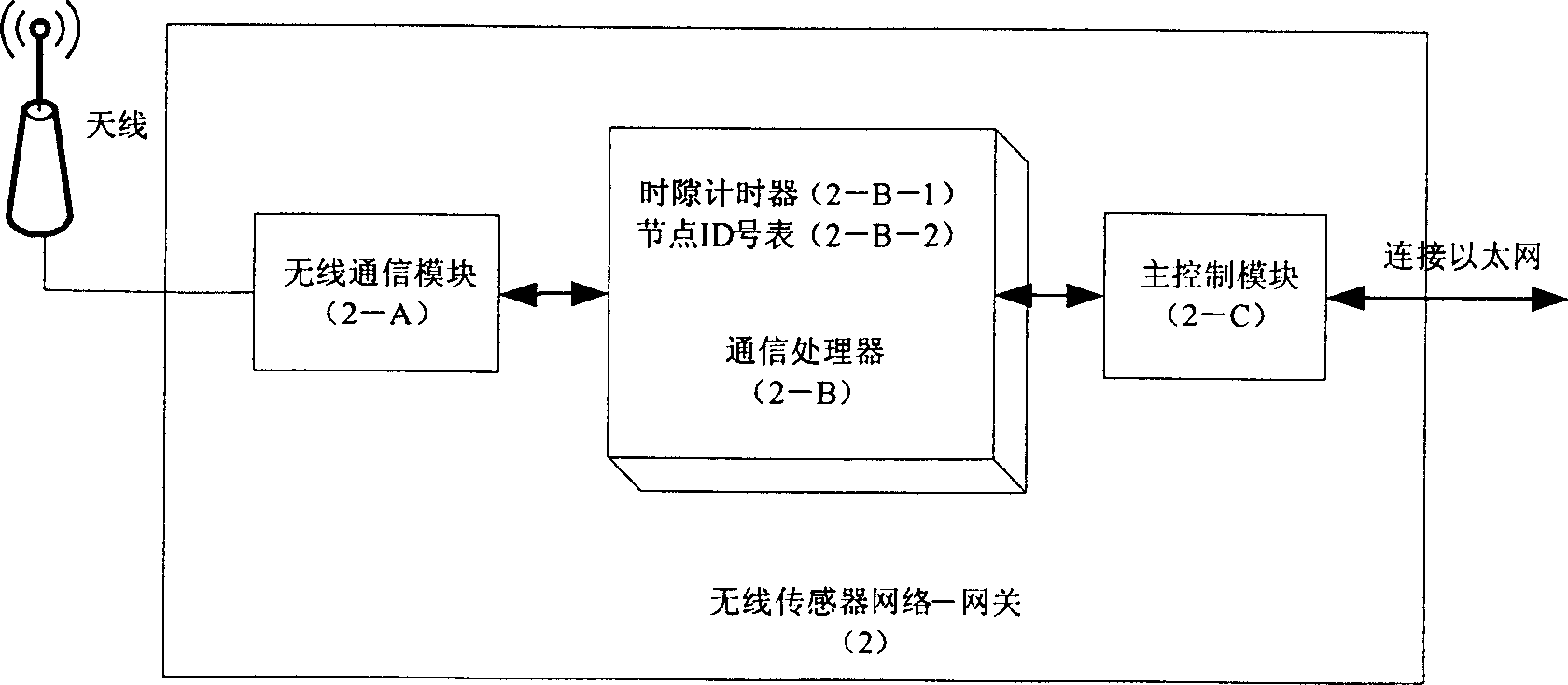

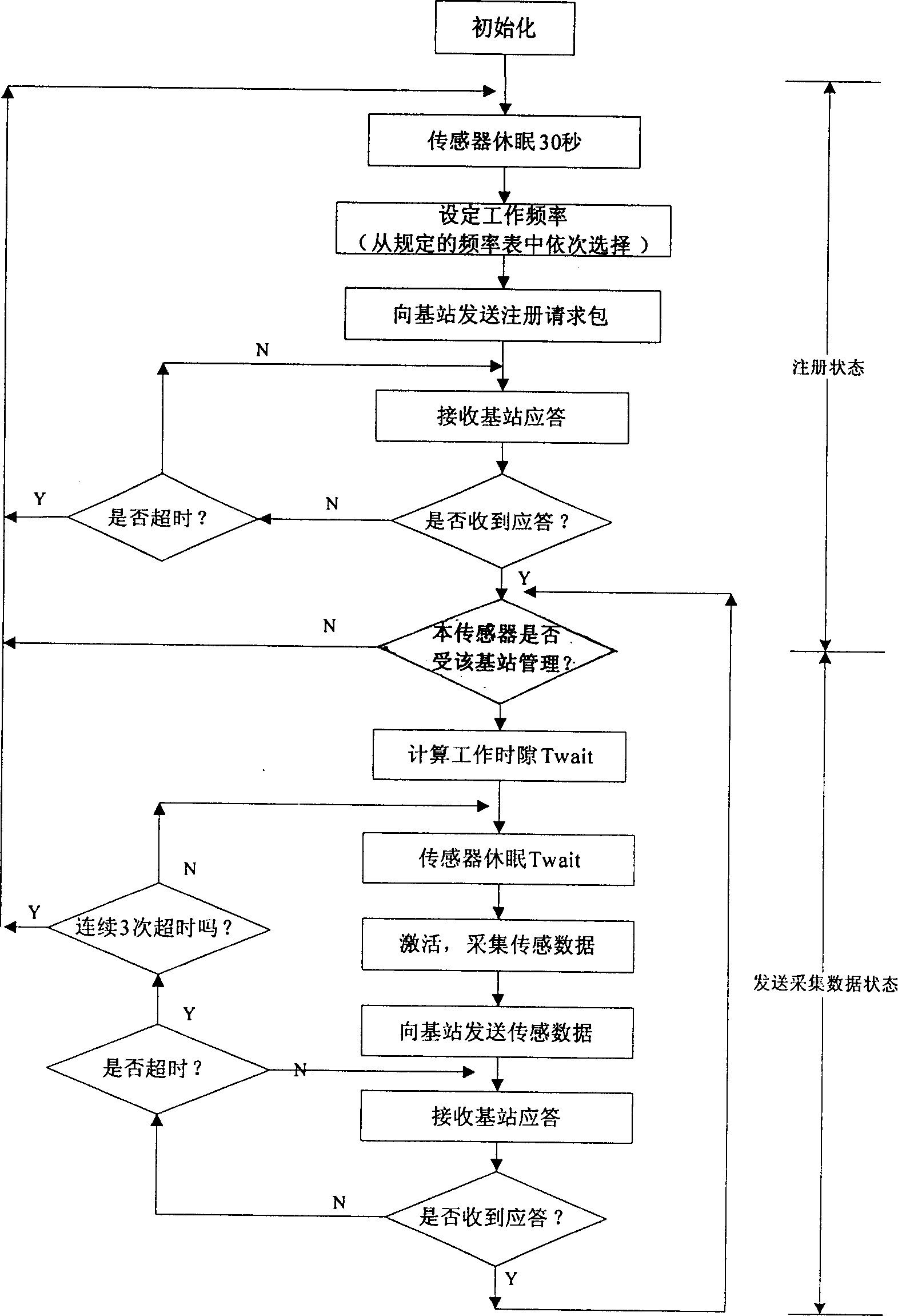

Communication method between wireless sensor network node and gateway

InactiveCN1845520ALow energy consumptionReduce complexityData switching by path configurationTotal factory controlMonitoring dataSensor node

The disclosed new communication method between a wireless sensor node and gateway comprises: with the feature of every node, applying the master (node)-slaver (gateway) way; assigning one wireless channel for every sensor gateway to store all managed ID and corresponding SN; registering the sensor node to build connection with gateway and obtain running parameters; then, gathering and sending monitor data. This invention is simple fit to run on low-performance SCM, and can prolong sensor node lifetime.

Owner:济南银澳科技有限公司

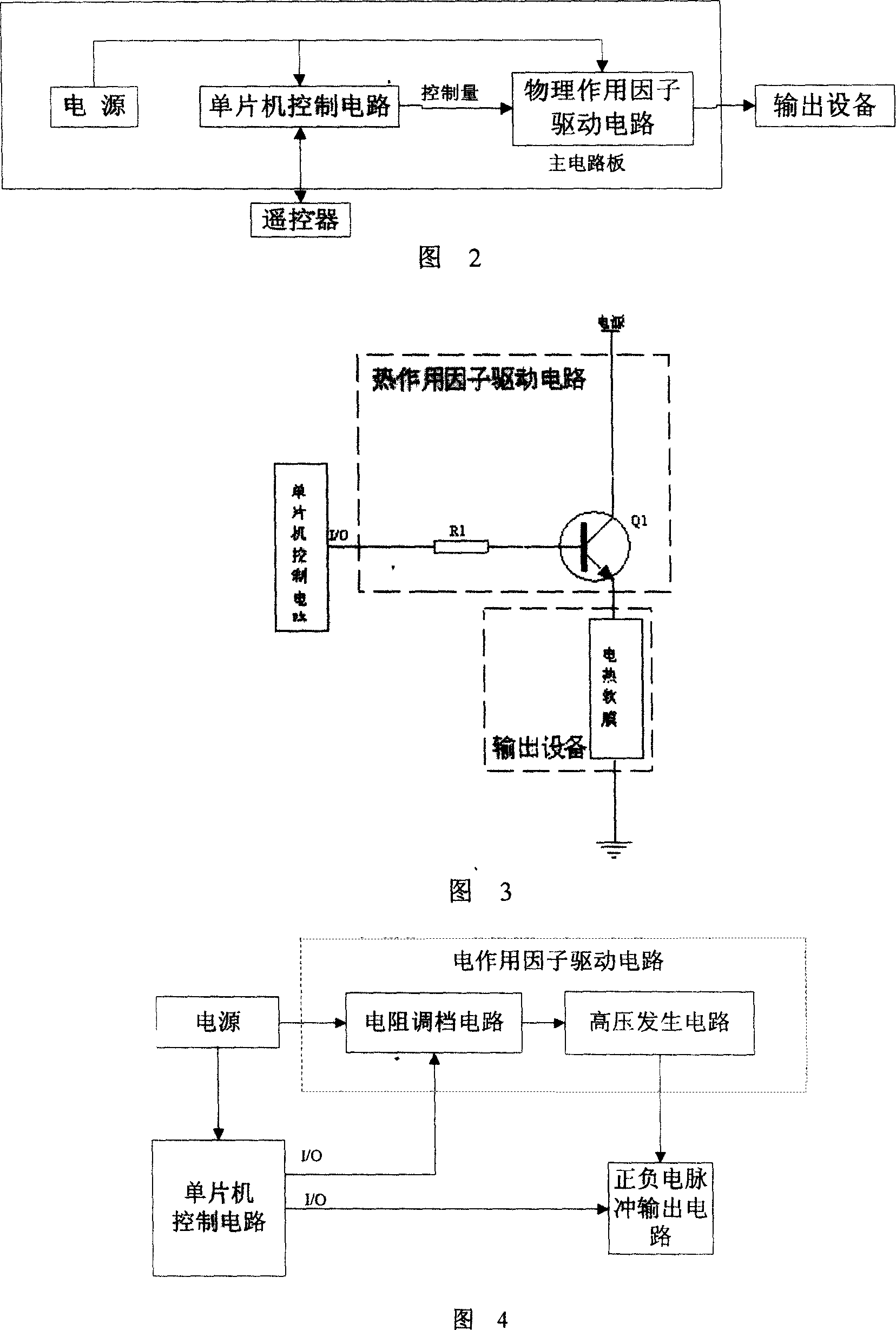

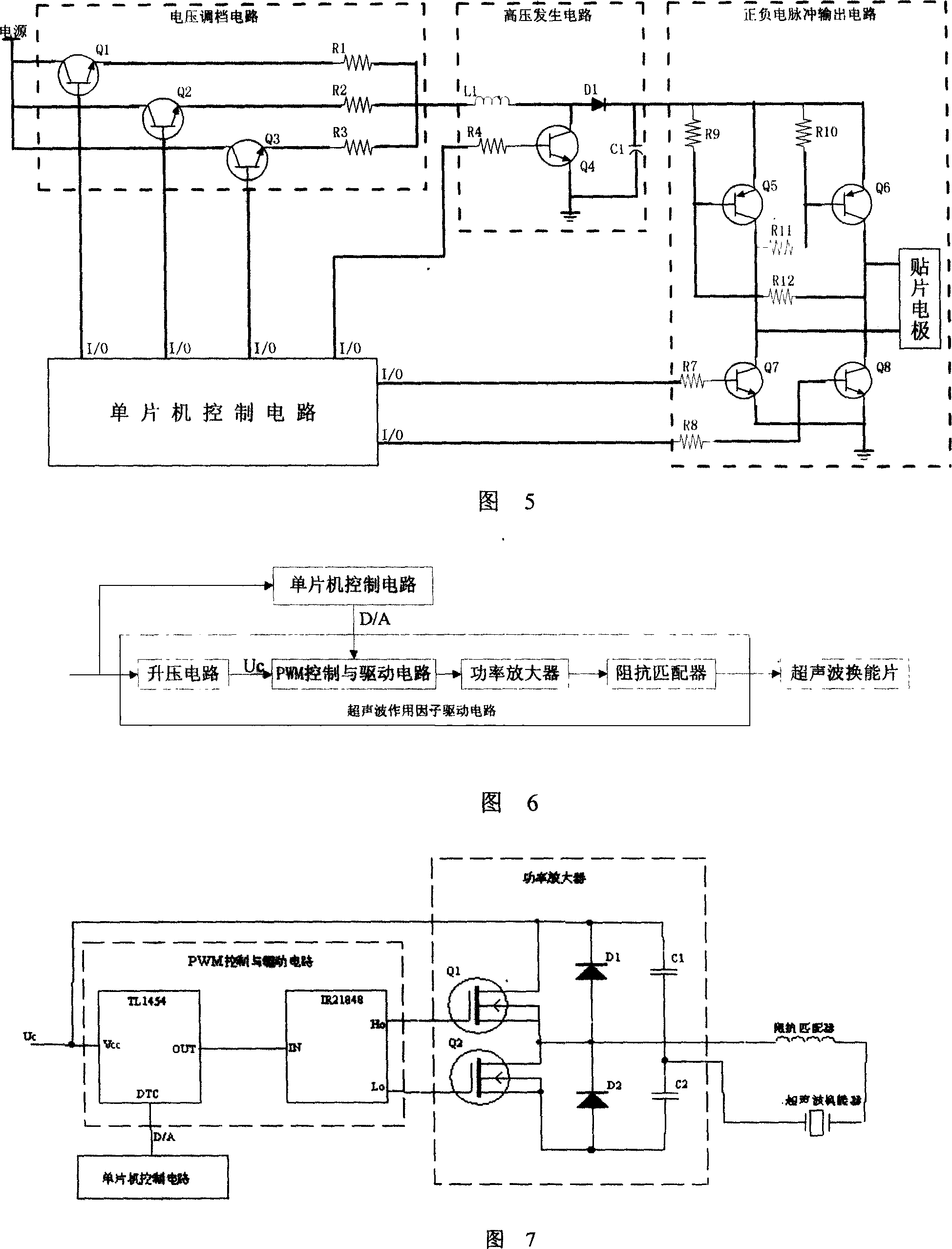

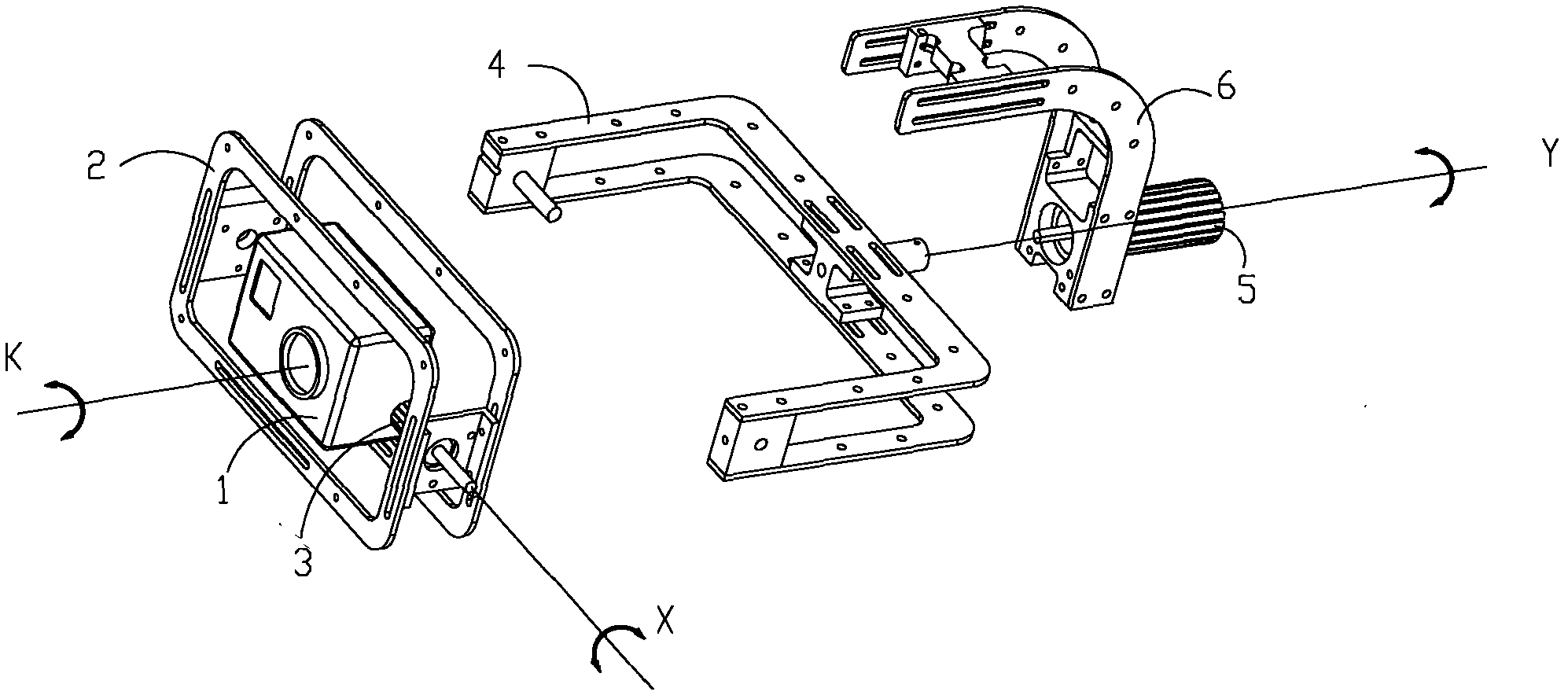

Wearable physiotherapeutic instrument

InactiveCN101015725ALow energy consumptionImprove efficiencyUltrasound therapyElectrotherapyPrinted circuit boardAcupuncture

This invention relates to a wearable physiotherapeutic instruments which comprises a basal body, a main circuit board, and an output unit. The basal body has inside and outside layers. The main circuit board is arranged between the layers and connected with the output unit through cable or wire. The circuit board comprises power supply, singlechip control circuit, and physical factor driving circuit, wherein power supply connects with singlechip control circuit and physical factor driving circuit; control circuit control circuit connects with physical factor driving circuit; and output unit is arranged independently of basal body. The invention has timesaving physical therapy, low energy consumption, high efficiency, thorough effect, high safety, no influence to everyday life and activity, and convenient close regulation.

Owner:FUZHOU UNIVERSITY

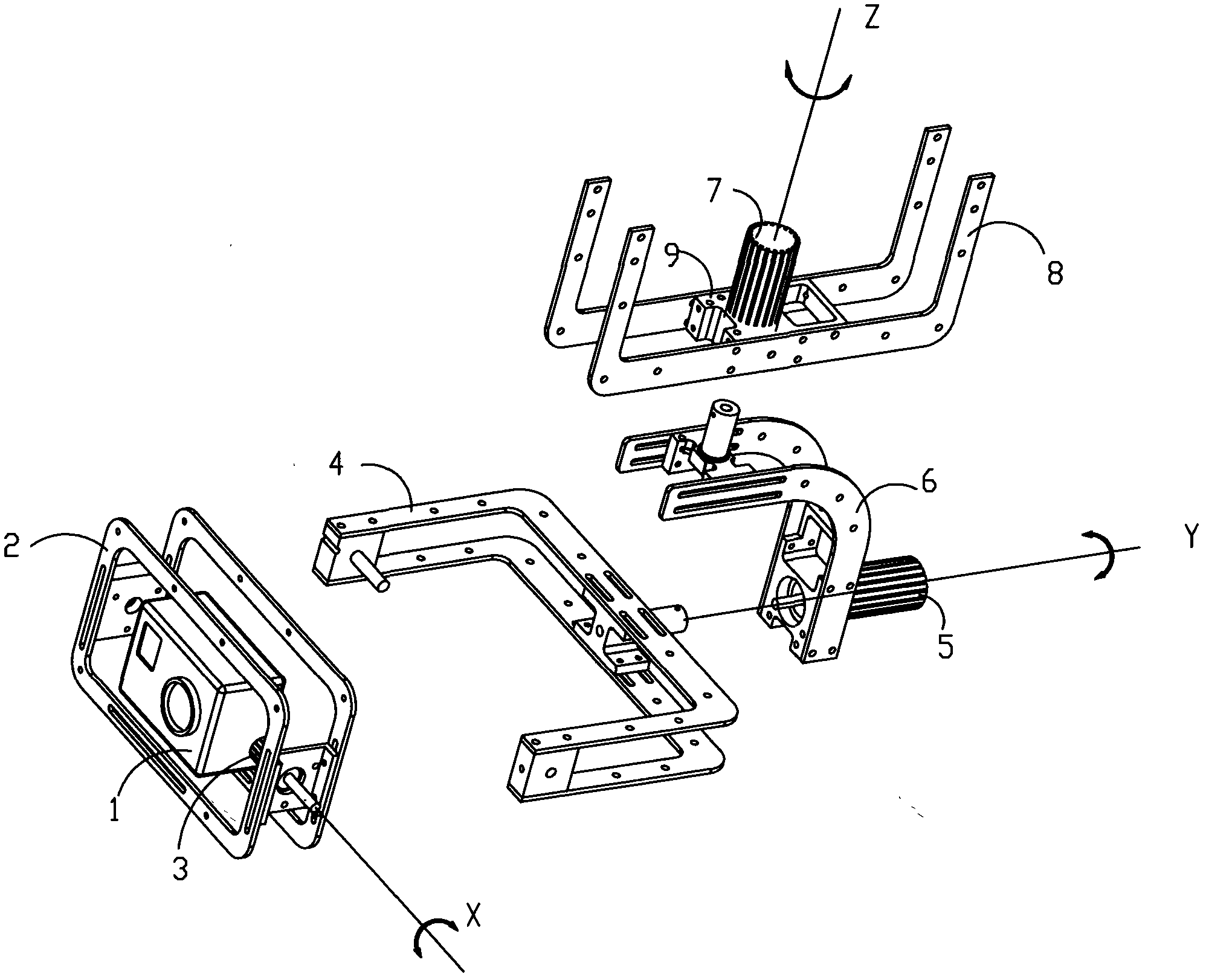

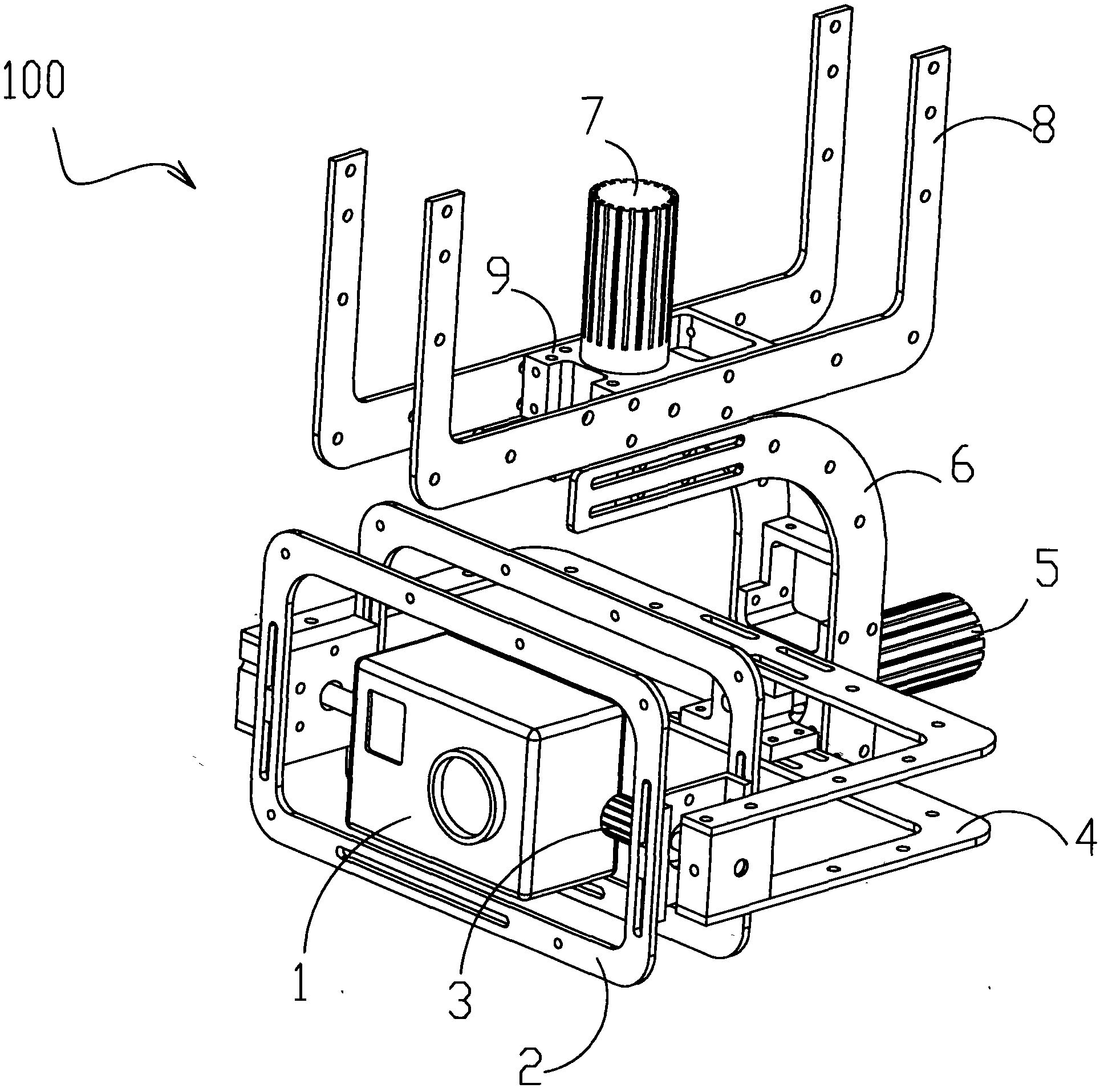

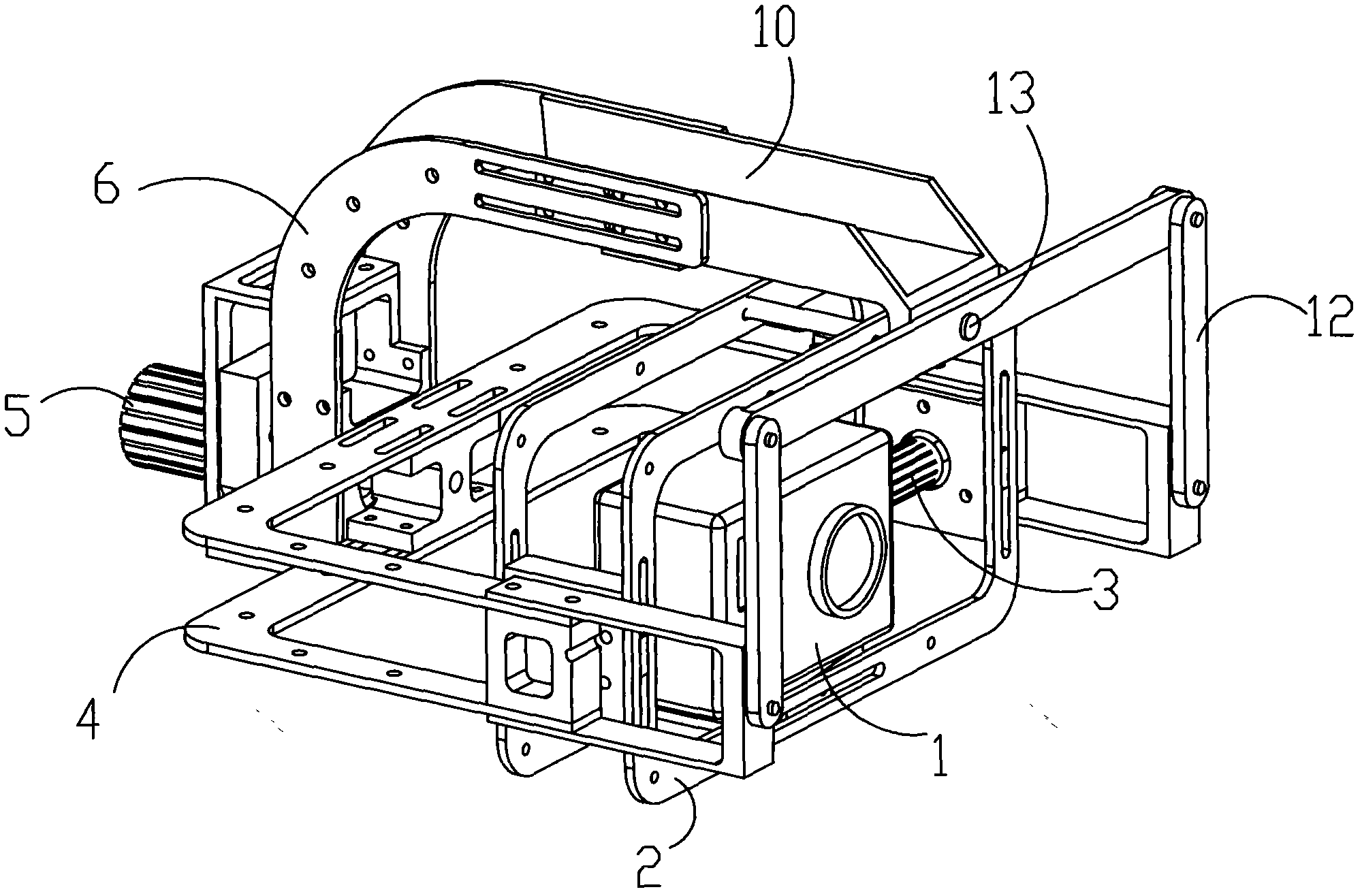

Gyro-type dynamic self-balancing pan-tilt

ActiveCN102996984ALow energy consumptionSave electricityAircraft componentsUnmanned aerial vehiclesElectricityEngineering

The invention discloses a gyro-type dynamic self-balancing pan-tilt which comprises a frame component, a motor component, shooting equipment (1) and a control component; the control component comprises a processor and an inertial sensor; the inertial sensor detects the posture information of the shooting equipment (1); the processor controls the motor component according to the posture information; and the motor component directly drives the frame component to rotate in a manner relative to the shooting equipment so as to adjust the shooting angle of the shooting equipment (1). According to the gyro-type dynamic self-balancing pan-tilt, the motor component is adopted as motive power to directly drive the frame component of the pan-tilt, so that less energy is consumed, and the electricity is saved; and meanwhile, the stepless adjustment can be realized in the driving of the motor, the action response time is short, various postures of a carrier body can be adapted to by quickly starting, stopping or timely adjusting the rotating speed, so that the shooting stability of the shooting equipment (1) is improved.

Owner:SZ DJI OSMO TECH CO LTD

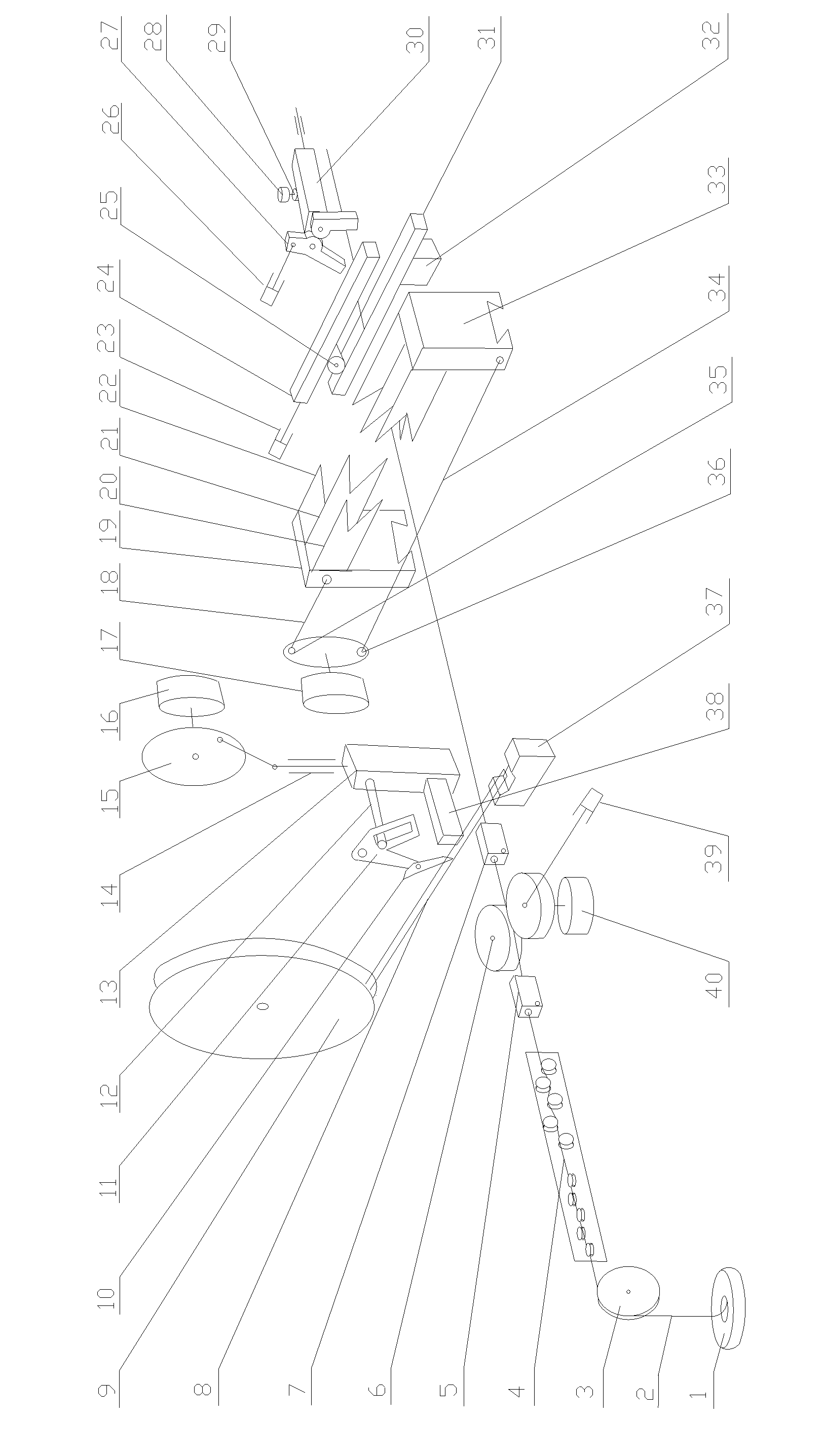

Full-automatic wire harness crimping machine

InactiveCN102074874AIncrease productivityLow energy consumptionConnection formation by deformationBatch productionEngineering

The invention discloses a full-automatic wire harness crimping machine. A feeding device, a connector crimping device, a cutting and stripping device and a wire taking and conveying device are sequentially arranged on a stand according to the wire feeding direction. The full-automatic wire harness crimping machine can finish the integrated operation of automatic feeding at fixed length, automatic cutting, automatic stripping, automatic heat rubbing and automatic crimping of the connector without manual intervention and safely and automatically realize the full-flow streamline production, thus the full-automatic wire harness crimping machine has the advantages of high production efficiency, low energy consumption and high precision and is suitable for batch production of large-scale enterprises; and the quality of the processed products is stable.

Owner:TIANJIN LIGAN TECH

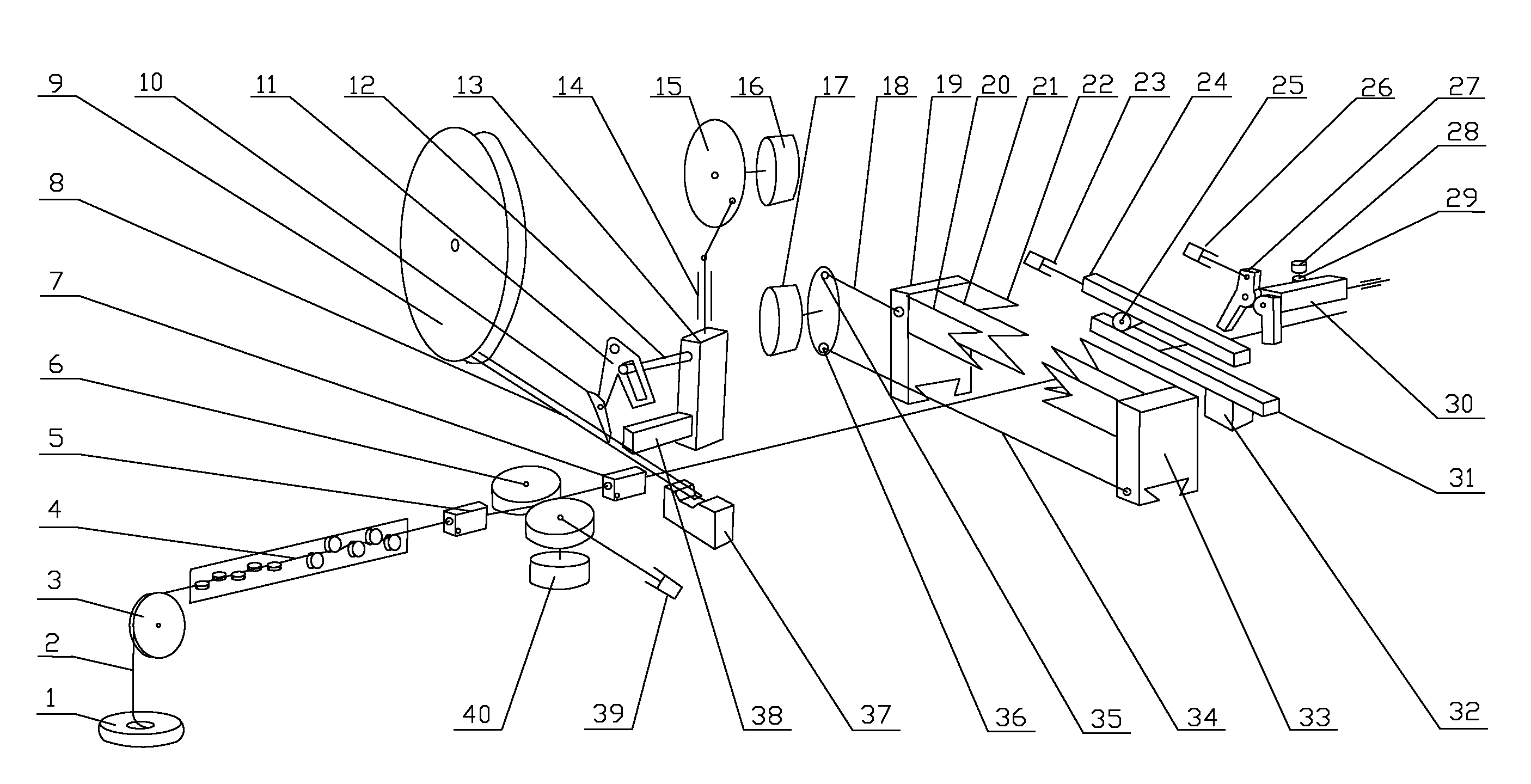

Drying unit of nitrogen-source heat pump

InactiveCN102818434ALow energy consumptionPrevent oxidationDrying gas arrangementsDrying machines with local agitationProcess engineeringDry gas

The invention discloses a drying unit of a nitrogen-source heat pump, comprising a drying box, a control system and an outdoor condenser, wherein the drying box comprises a box body, a heat pump chamber and a drying chamber; and the heat pump chamber and the drying chamber are arranged in the box body. The drying unit forms drying gas adjusting equipment with a nitrogen source, heat-pump equipment and a nitrogen device form a nitrogen heat-pump combining device so as to construct a closed circulation loop which adopts nitrogen as a medium to dry materials and effectively control the content of nitrogen in the drying chamber; and high-viscosity glass cement is used for sealing internal and external gaps of a drying room, a ventilating channel is modified, and a baffle, an arc-shaped air guide plate and an air uniformizing plate are added to enable the gas drying medium to be uniformly distributed in the drying chamber under certain air speed. The drying unit disclosed by the invention has the beneficial effects that the heat pump and a nitrogen combining device are used, the advantages of no pollution and low energy consumption of the heat pump can be fully utilized, the materials are dried under the condition of adopting nitrogen as a drying medium, the oxidation of the materials is prevented, the nutritional ingredients of the materials are retained, and the quality of dried products is improved.

Owner:HENAN UNIV OF SCI & TECH

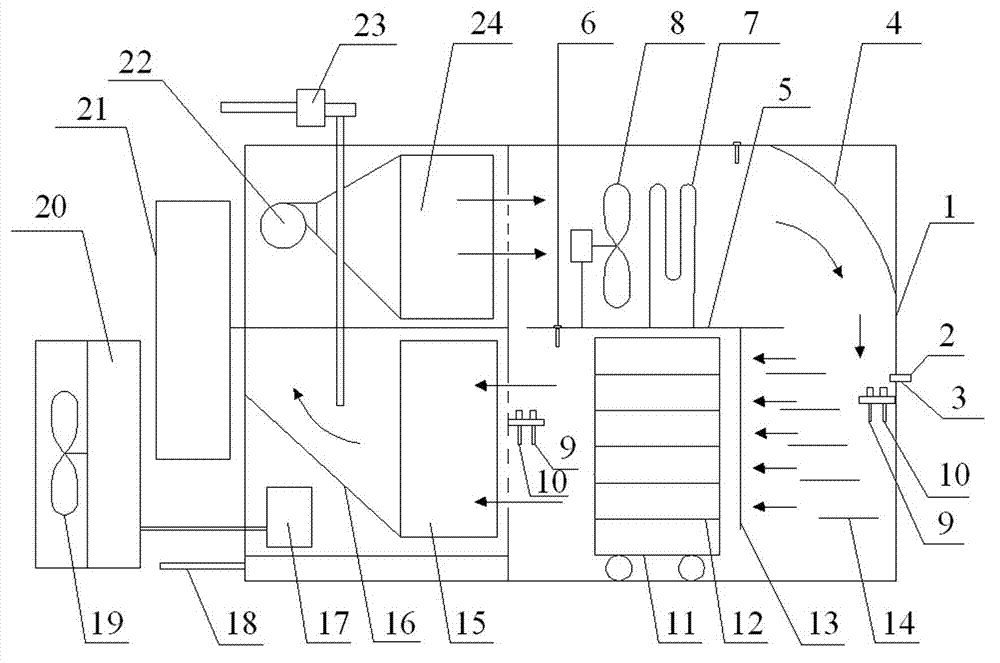

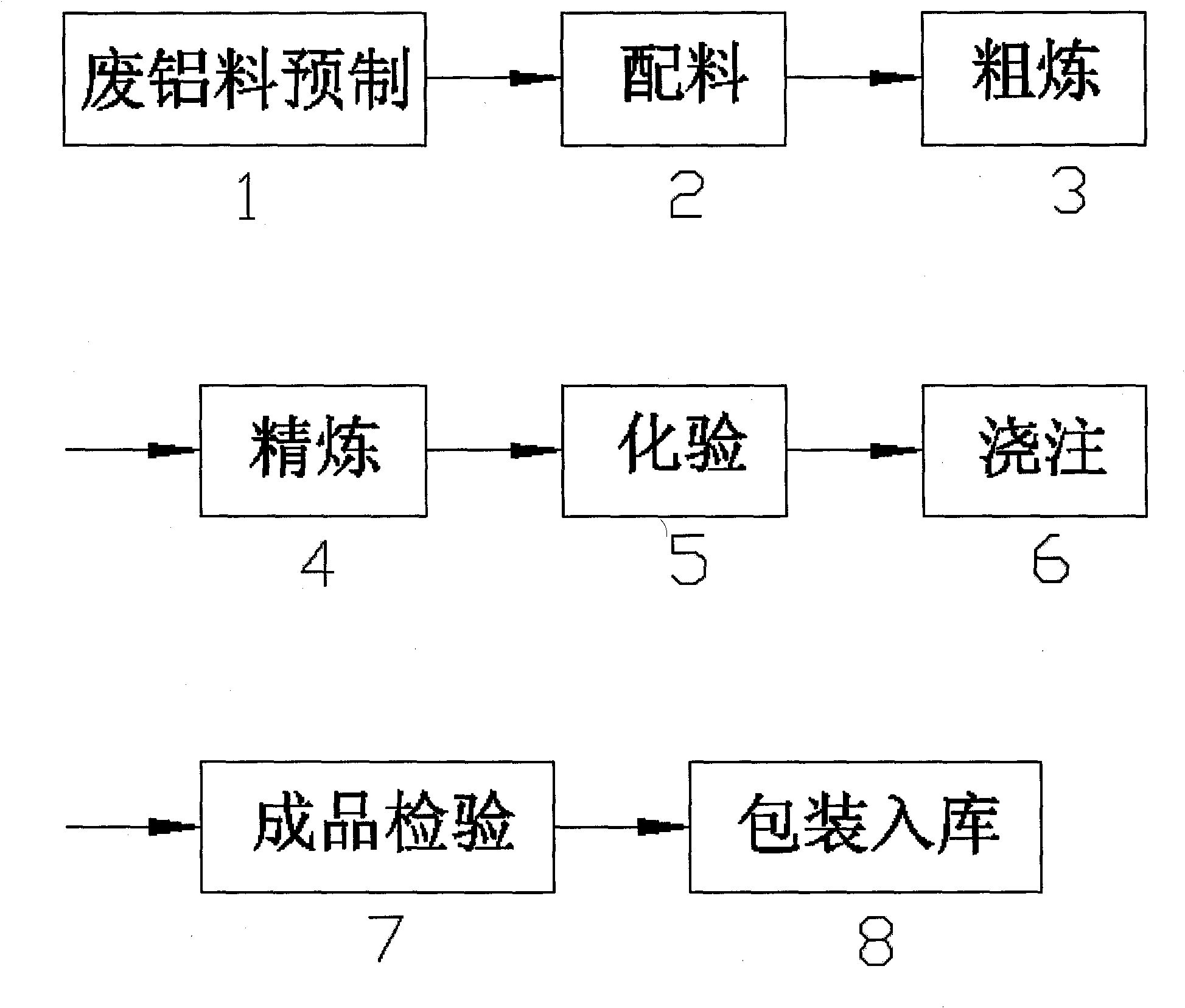

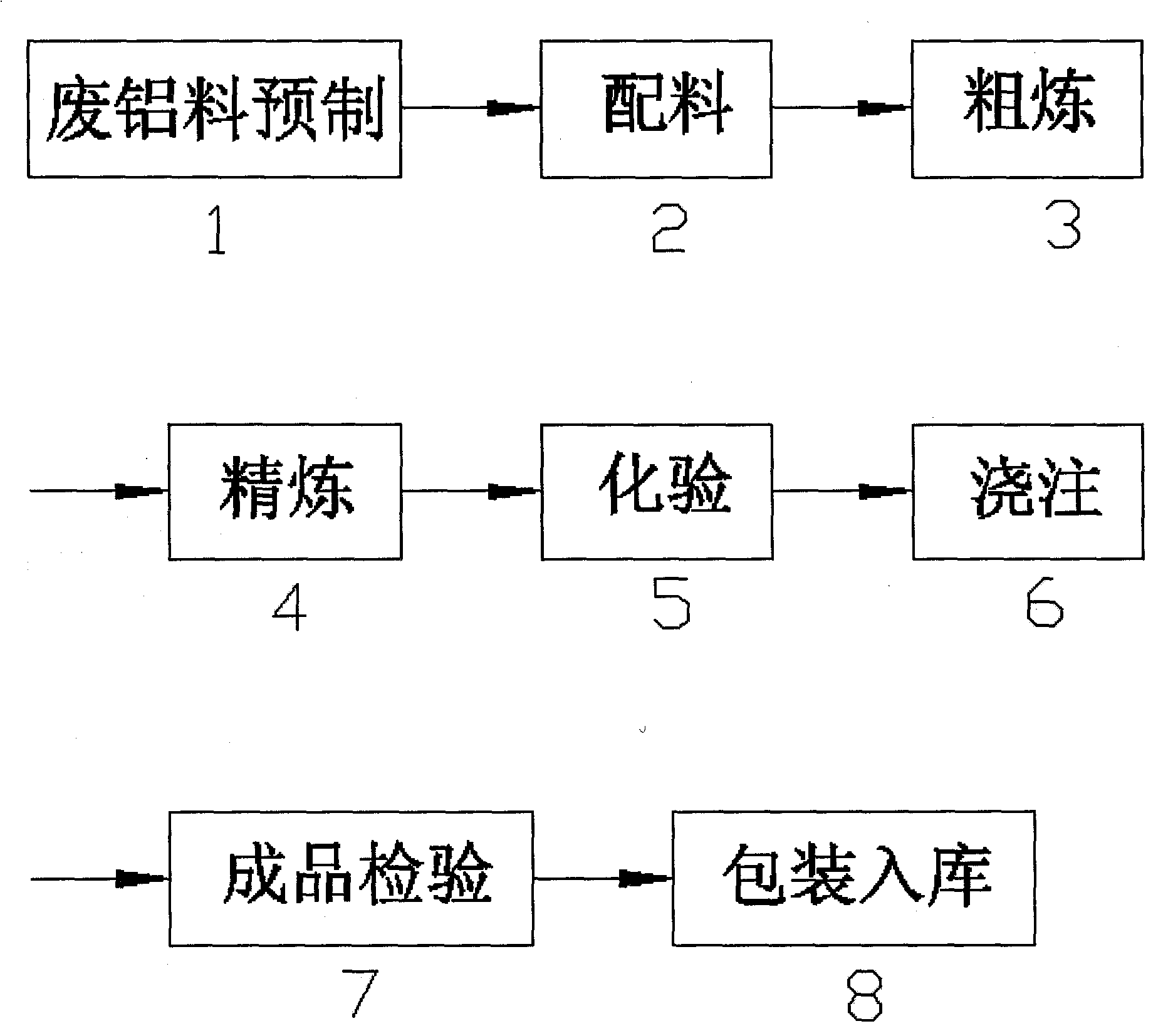

Secondary aluminum production process

InactiveCN102021349ALow energy consumptionReduce displacementProcess efficiency improvementAluminum canPressure casting

The invention relates to a secondary aluminum production process, relating to the waste aluminum smelting process field. The secondary aluminum production process is characterized in that the specific process flows are as follows: prefabricating a waste aluminum material, namely performing primary classification and disassembly on waste aluminum and removing other non-ferrous metal parts; selecting minor ingredients and calculating the dosages of various materials according to demands; smelting, namely sending the prepared waste aluminum material in a smelting furnace to smelt; introducing the smelted aluminum melt in a refining purification furnace to refine; detecting aluminum melt with a spectrograph, analyzing the contents of various chemical elements; using the refined aluminum melt to perform casting moulding; inspecting the finished products to ensure that the chemical element contents of the products all meet the national standard; and bundling up the qualified products, packaging and warehousing. The invention has the following beneficial effects: the secondary aluminum production process has the advantages of low energy consumption, fewer emissions and is resource-saving, and waste aluminum can be used to synthesize aluminum alloy ingots in one step which meet the national standards and are used for pressure casting and casting.

Owner:亳州市正和铝业有限公司

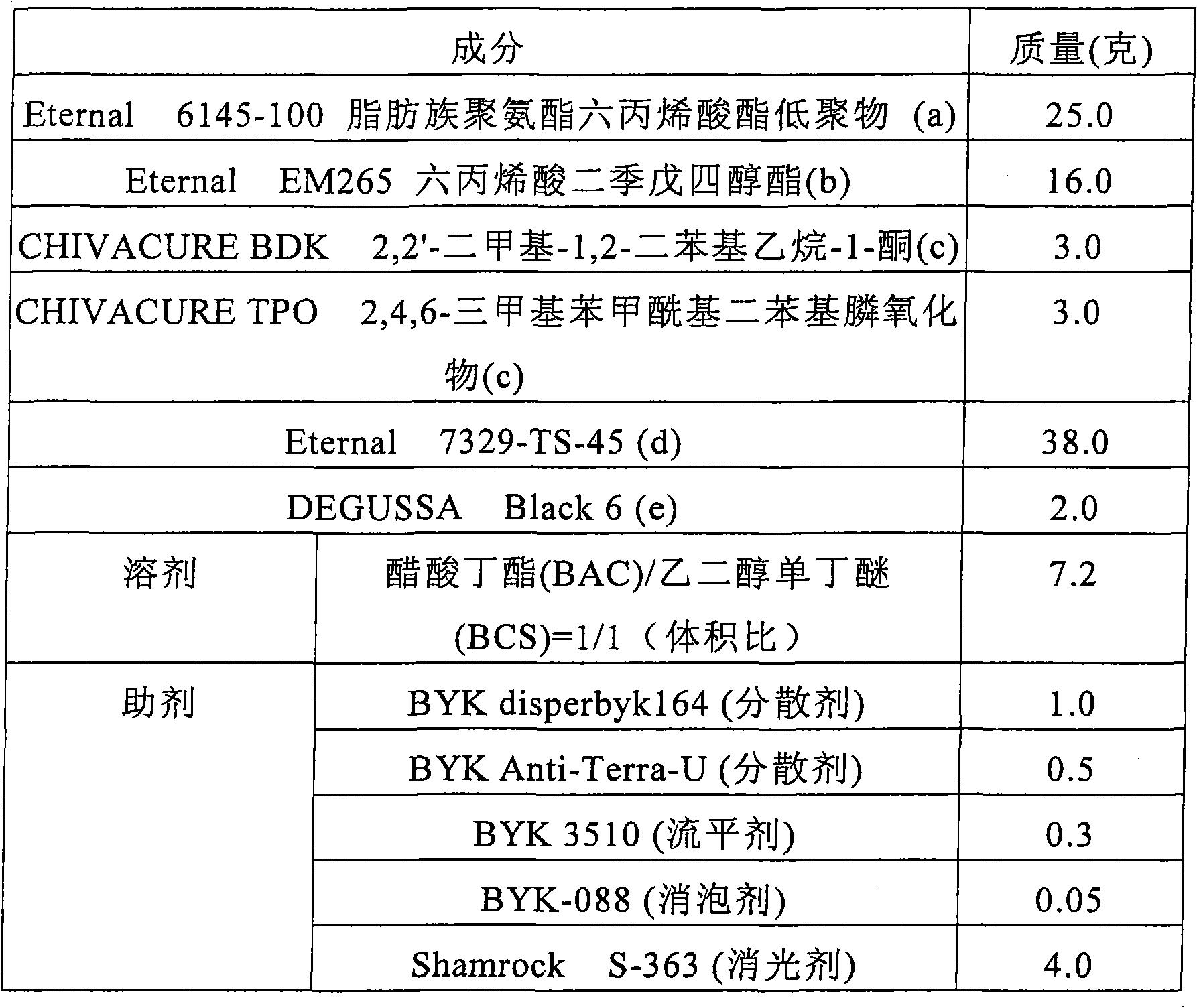

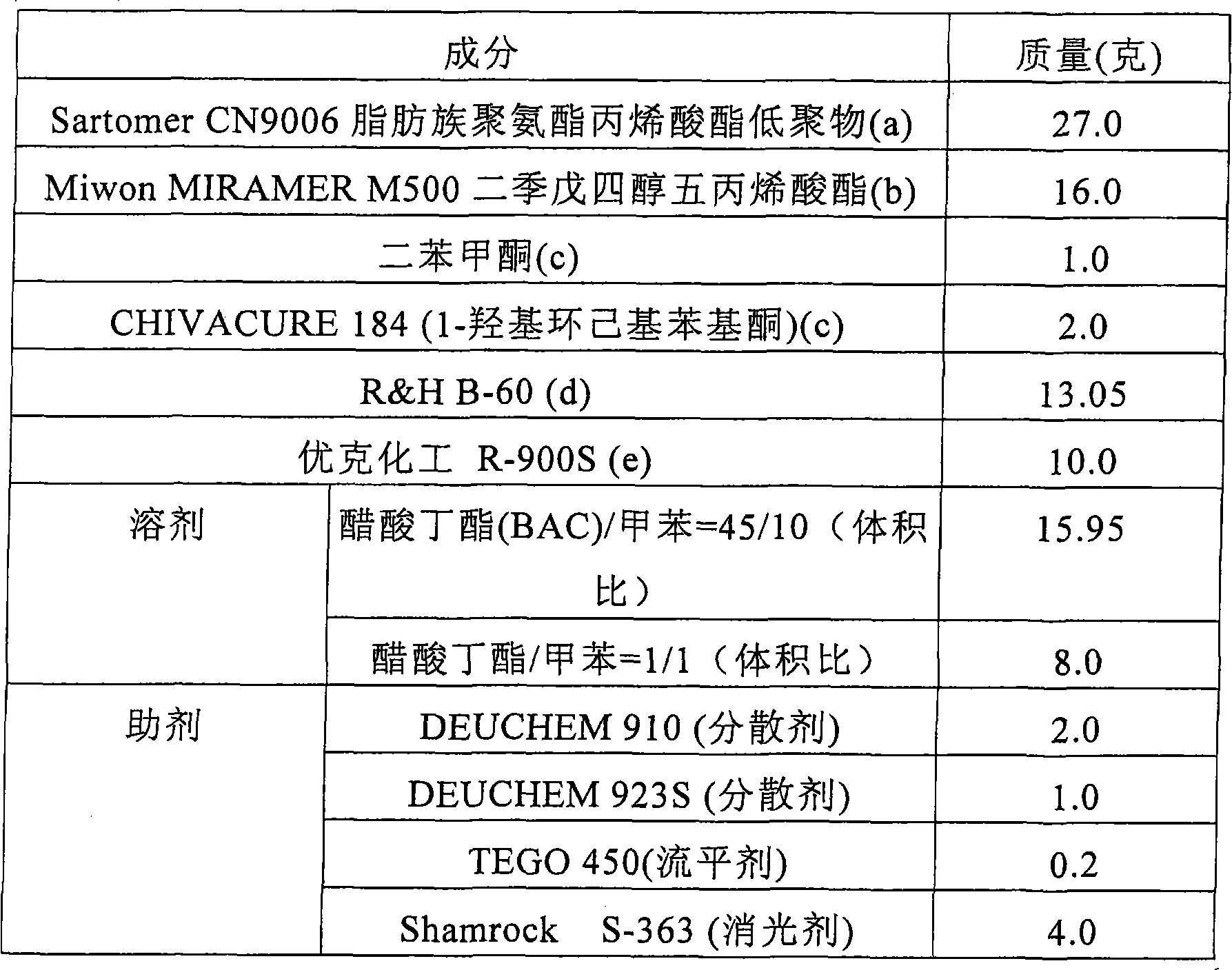

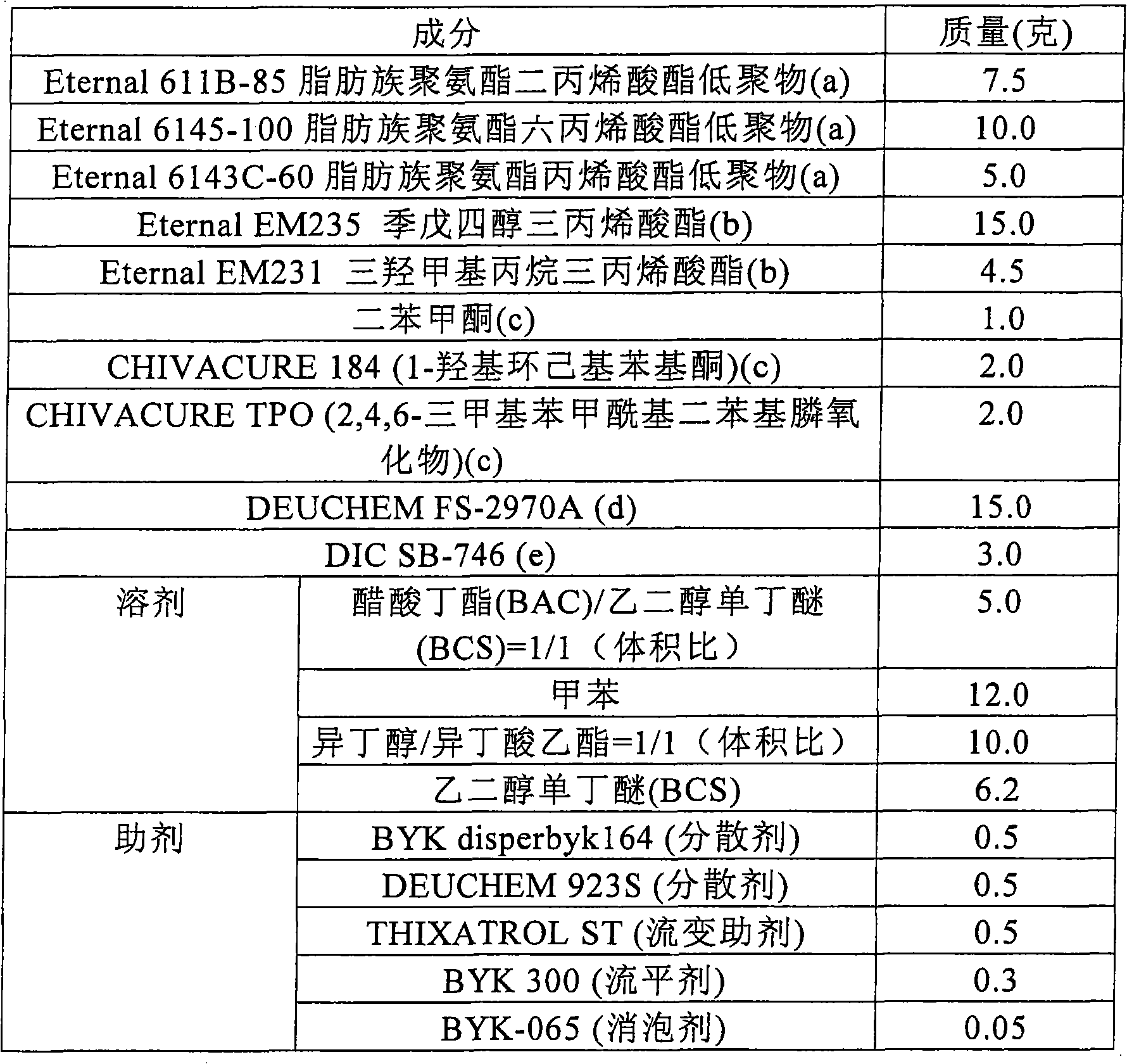

UV-curable colored paint composition

The invention relates to a UV-curable colored paint composition which comprises (a) a low polymer containing at least one unsaturated double bond; (b) a diluted monomer; (c) a light initiator; (d) thermoplastic acrylic resin; and (e) a pigment. The paint composition of the invention can be applied in a one-time construction mode to obtain high-performance coatings with rich colors. Compared with the traditional two-layer or three-layer application mode, the invention can provide high production efficiency, low energy consumption, low manufacturing cost and low possibility of generation of wastes.

Owner:JIANGSU KUANGSHUN PHOTOSENSITIVITY NEW MATERIAL

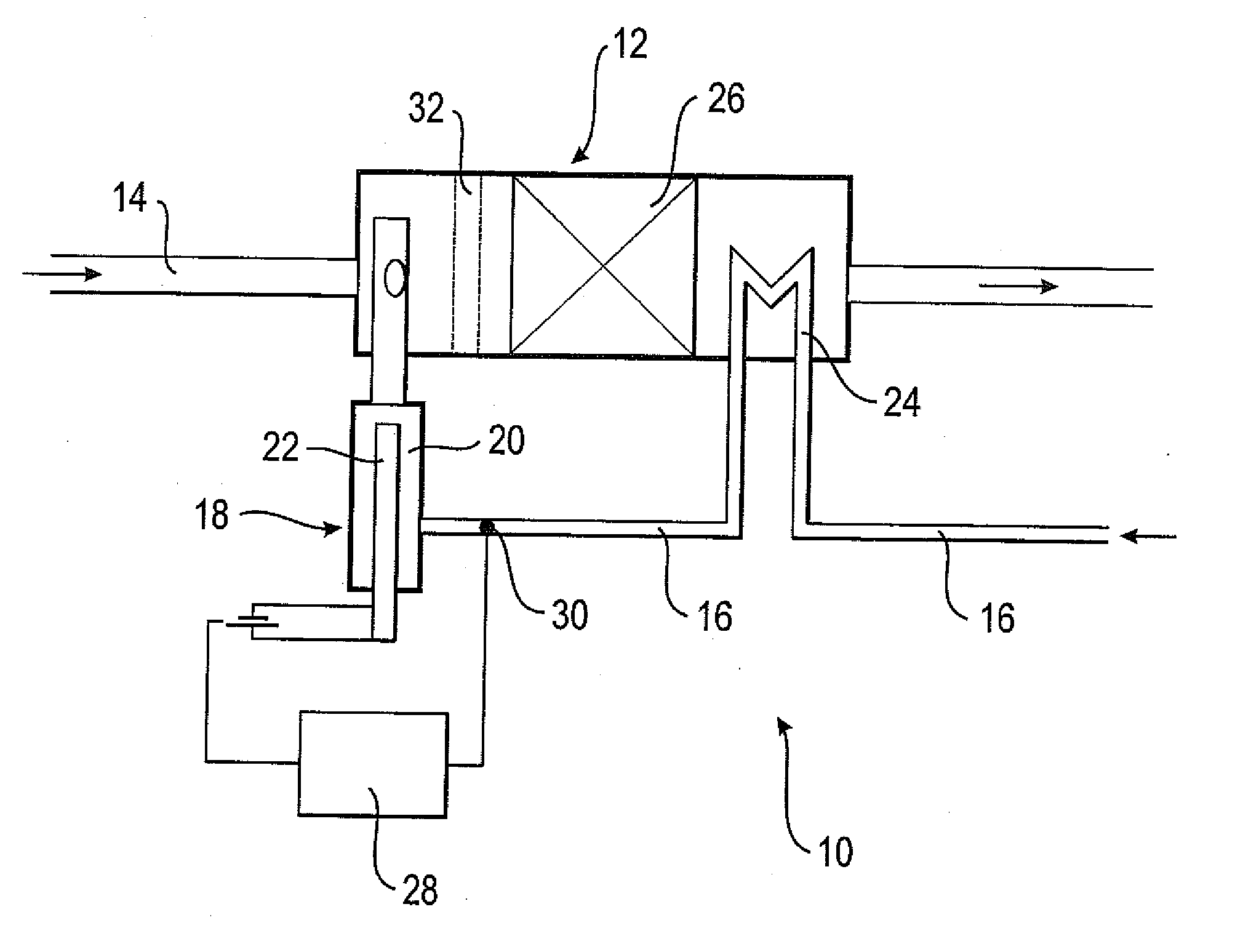

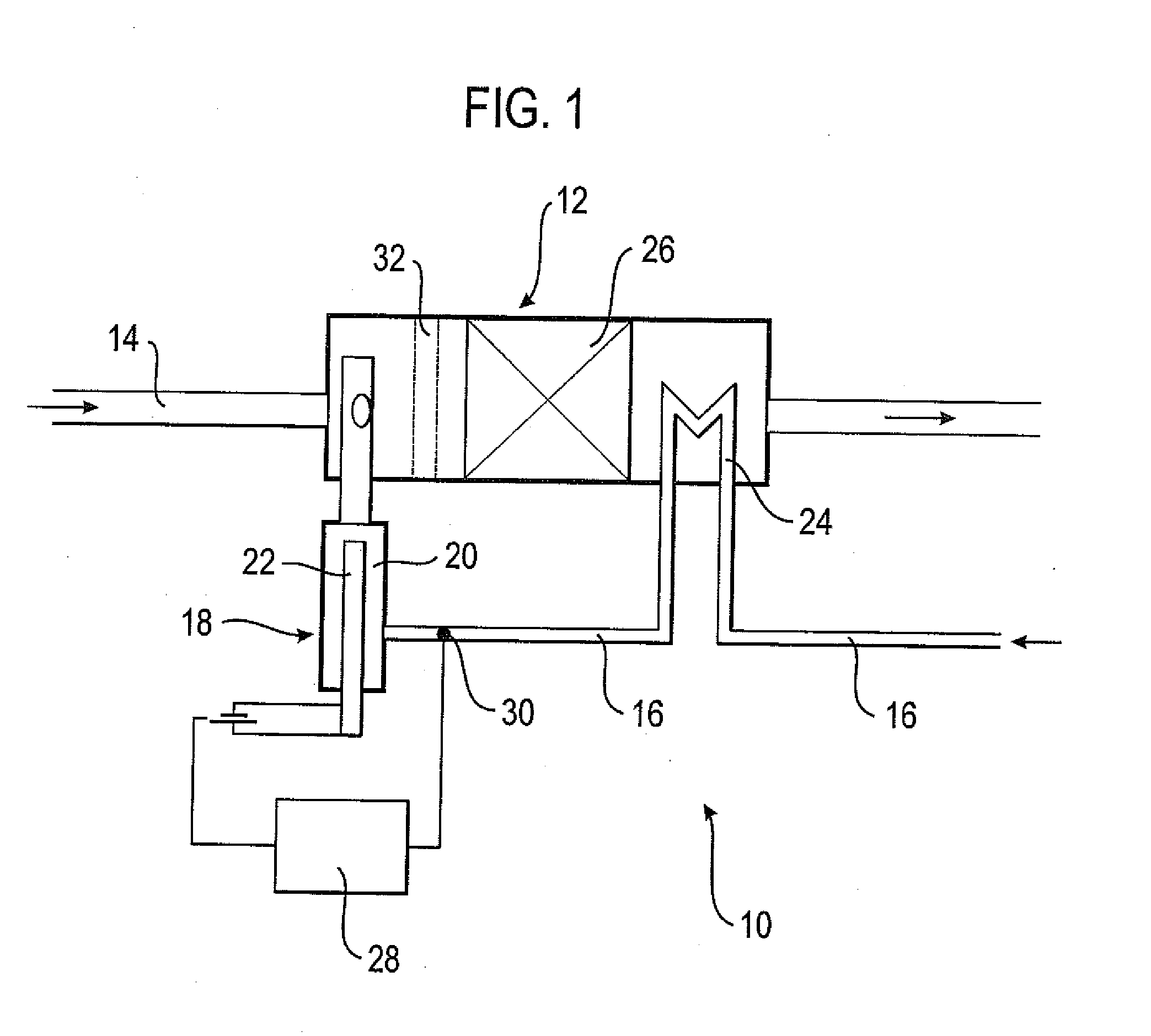

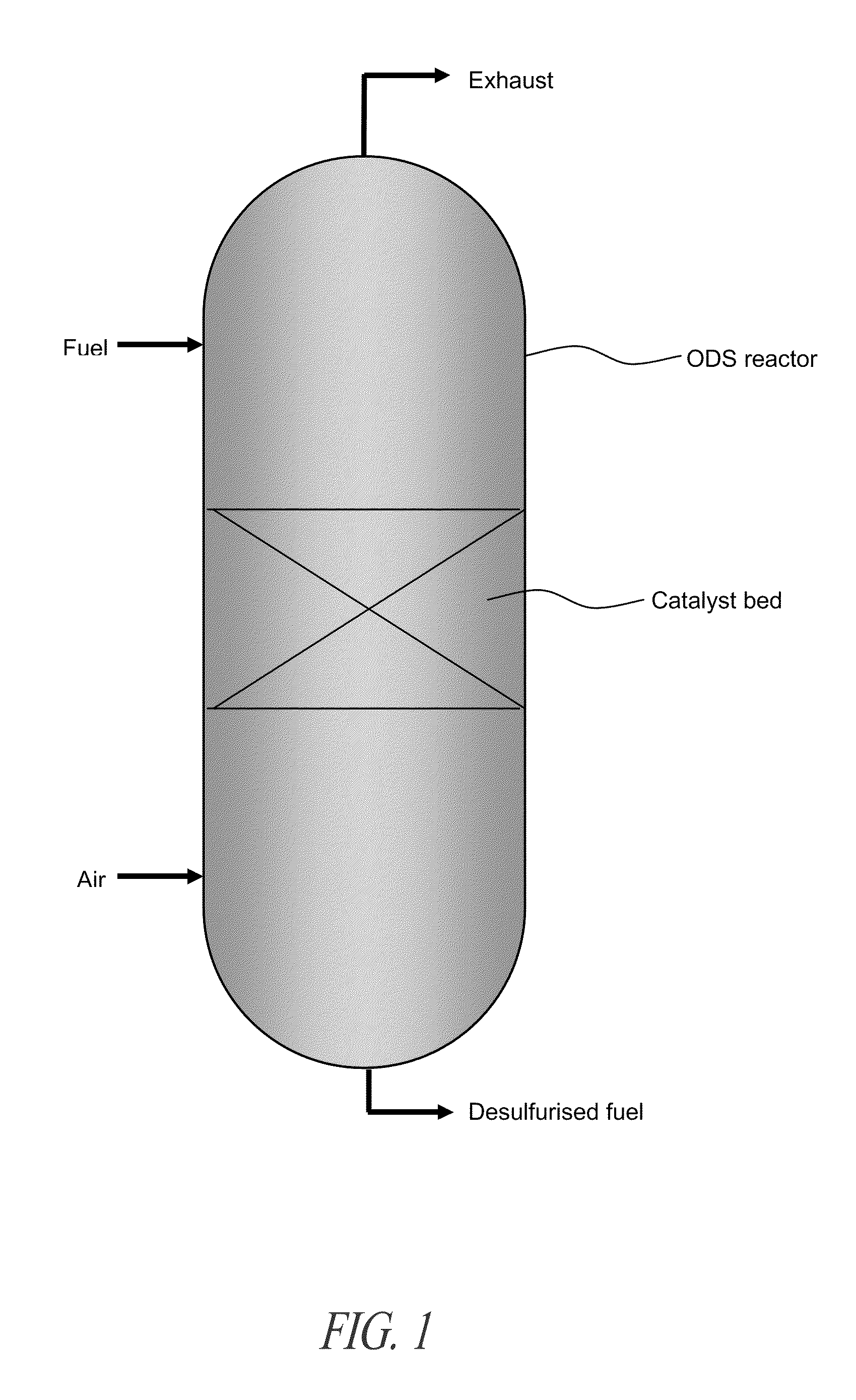

Assembly for producing a hydrogenous gas

InactiveUS20100015479A1Low energy consumptionReduce energy consumptionHydrogenRegenerative fuel cellsFuel supplyProcess engineering

An assembly for producing a hydrogenous gas has a reformation device with a fuel supply, a gas supply, and a catalytic converter. A vaporization unit is arranged upstream of the catalytic converter of the reformation device with respect to the gas flow and has a heating element arranged in a chamber for vaporizing a fuel. The vapor is guided into the gas flow and a preheating device for the fuel is arranged upstream of the chamber and configured as a heat exchanger.

Owner:EMCON TECHNOLOGIES GERMANY (AUGSBURG) GMBH

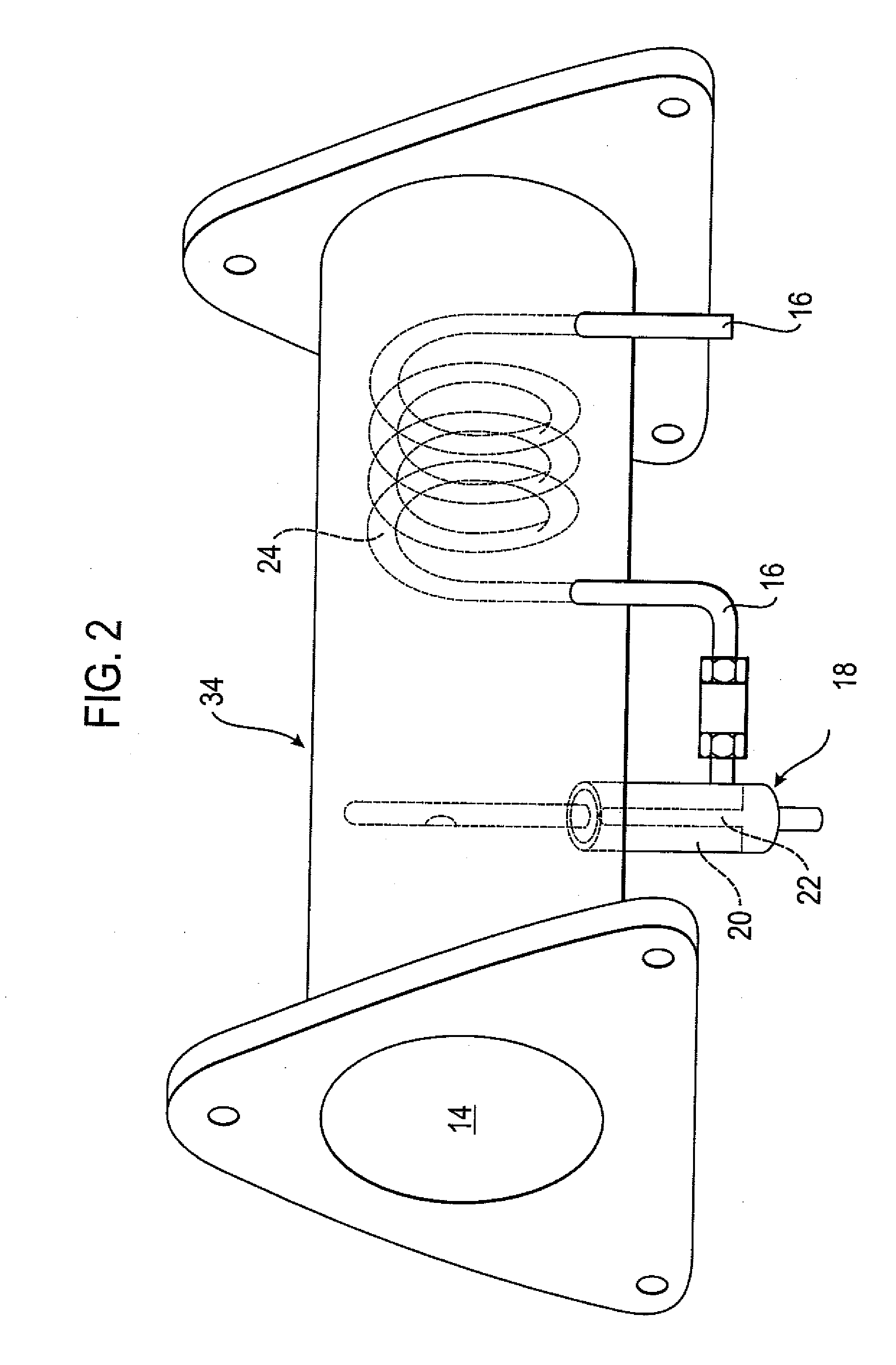

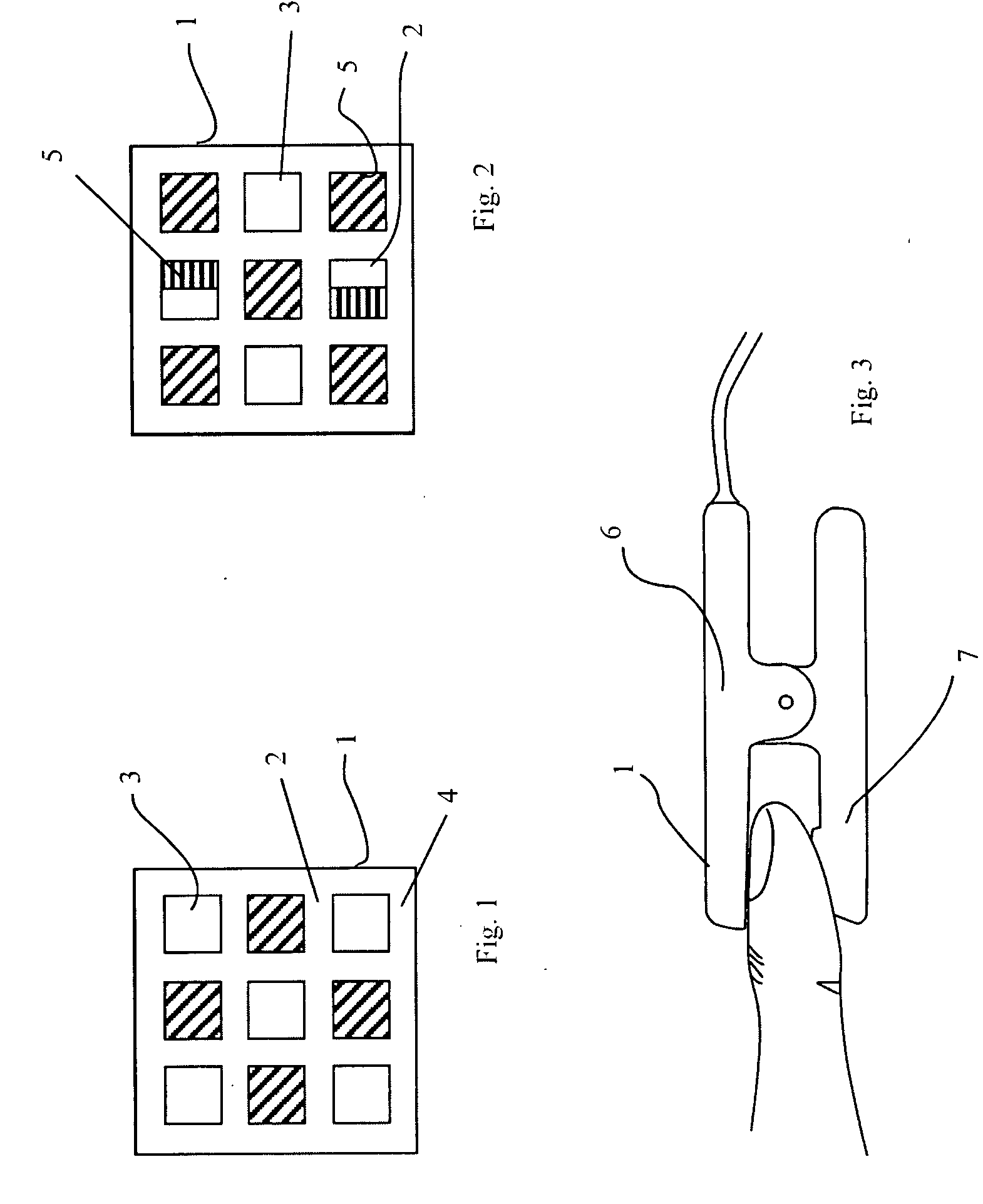

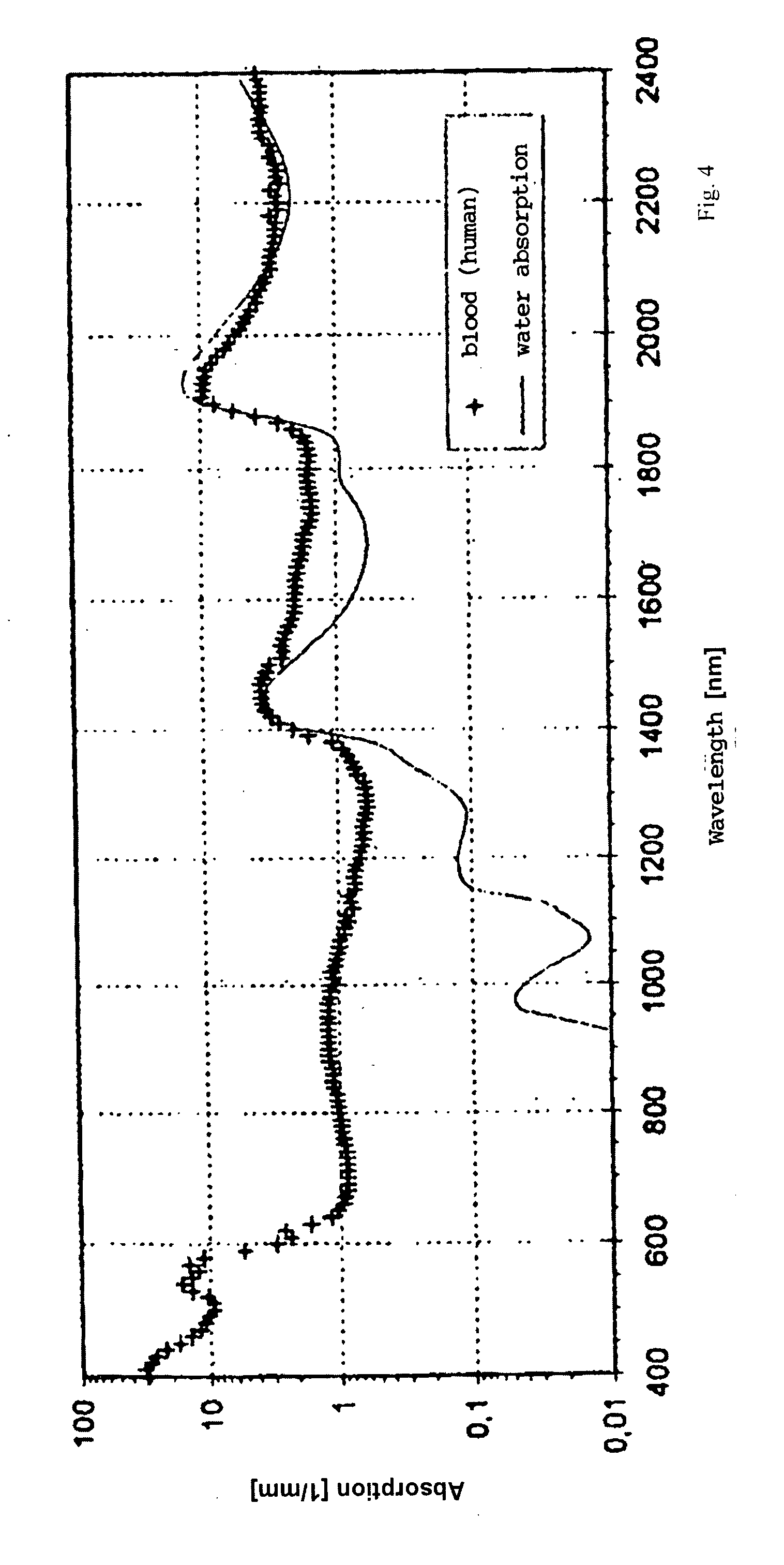

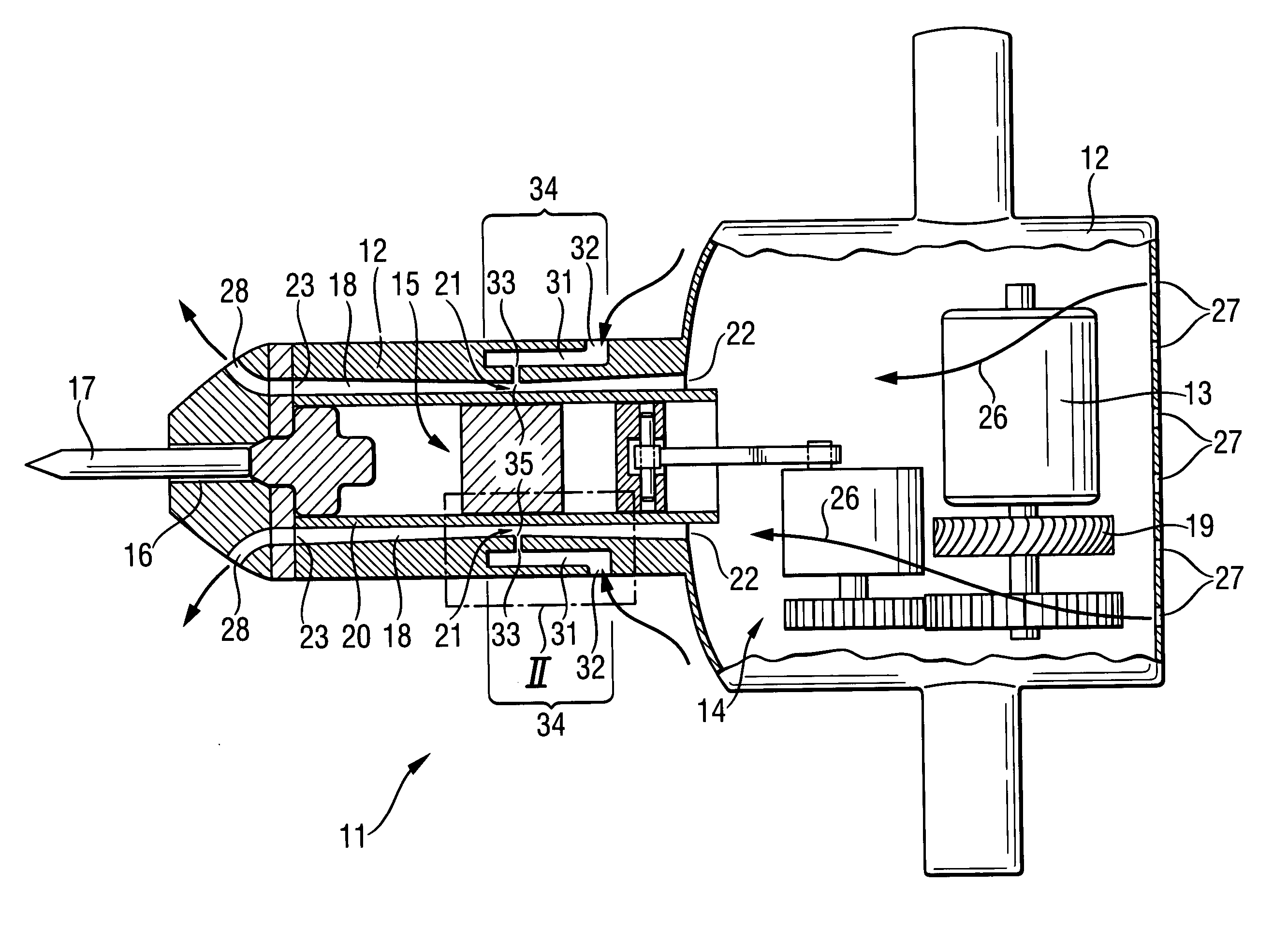

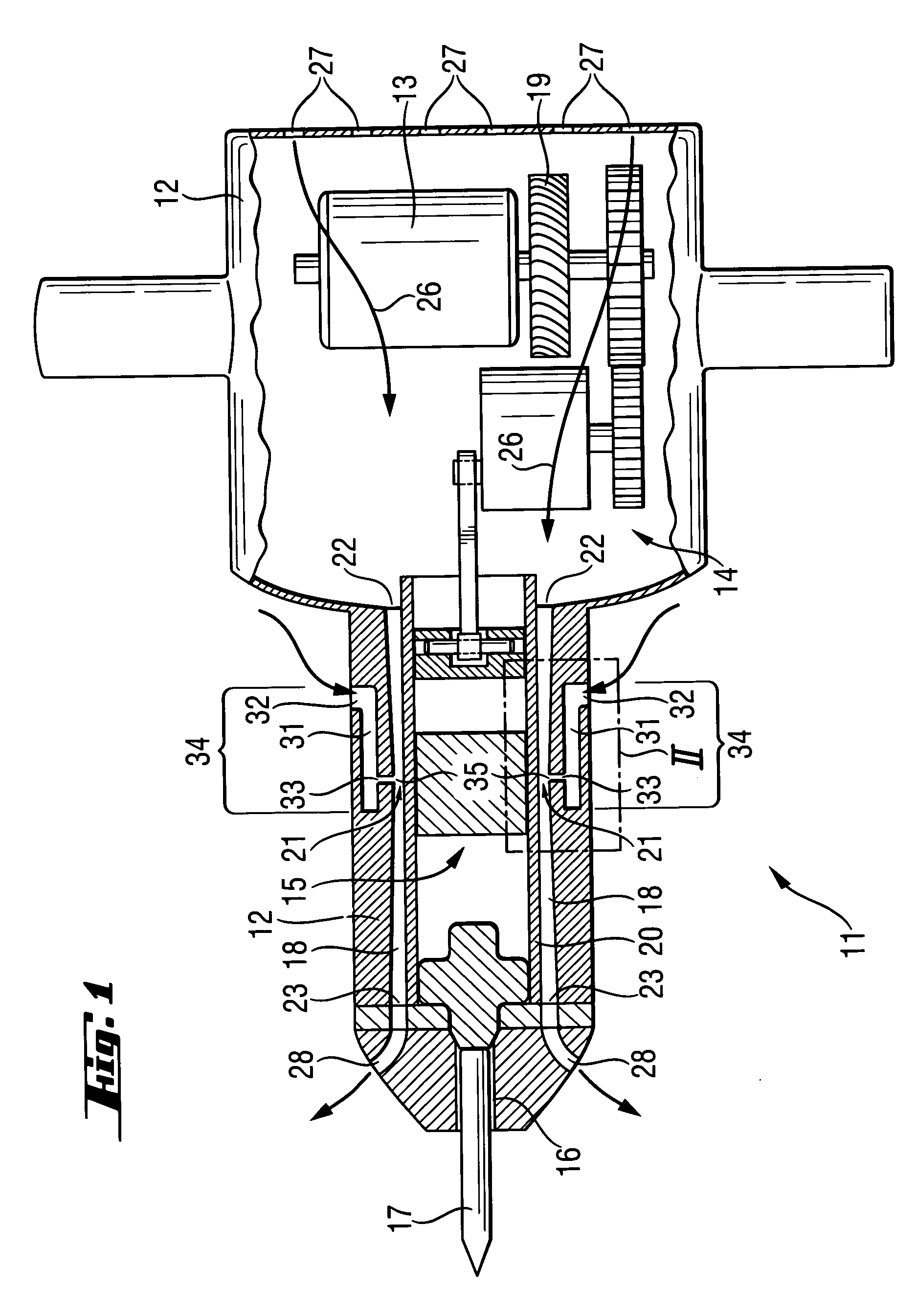

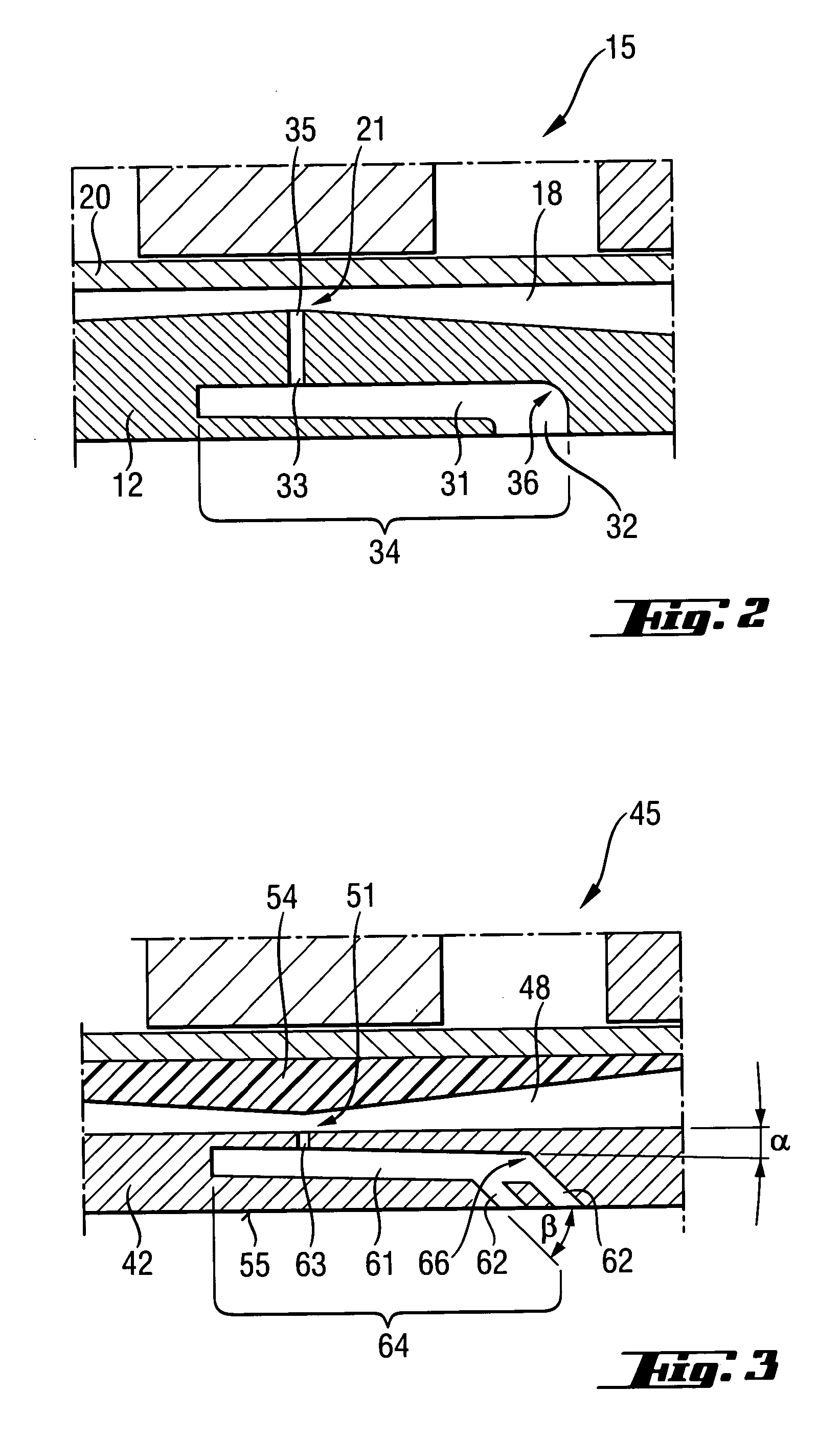

Method and device for the identification of at least two substances of content of a body fluid

InactiveUS20070282183A1Low energy consumptionLong life spanMaterial analysis by optical meansDiagnostic recording/measuringPhysicsA hemoglobin

A method and a device for the identification of at least two substances of content of a body fluid, wherein adjacent to a body tissue containing the body fluid, are arranged at least one radiation source and a photo receiver. The radiation source generates radiation of two different wavelengths. The radiation is directed onto the body tissue and the photo receiver receives radiation reflected by the body tissue and / or reduced through the body tissue. At least at times the radiation of a third wavelength is directed onto the body tissue for the identification of a hemoglobin derivate.

Owner:WEINMANN GERATE FUR MEDIZIN

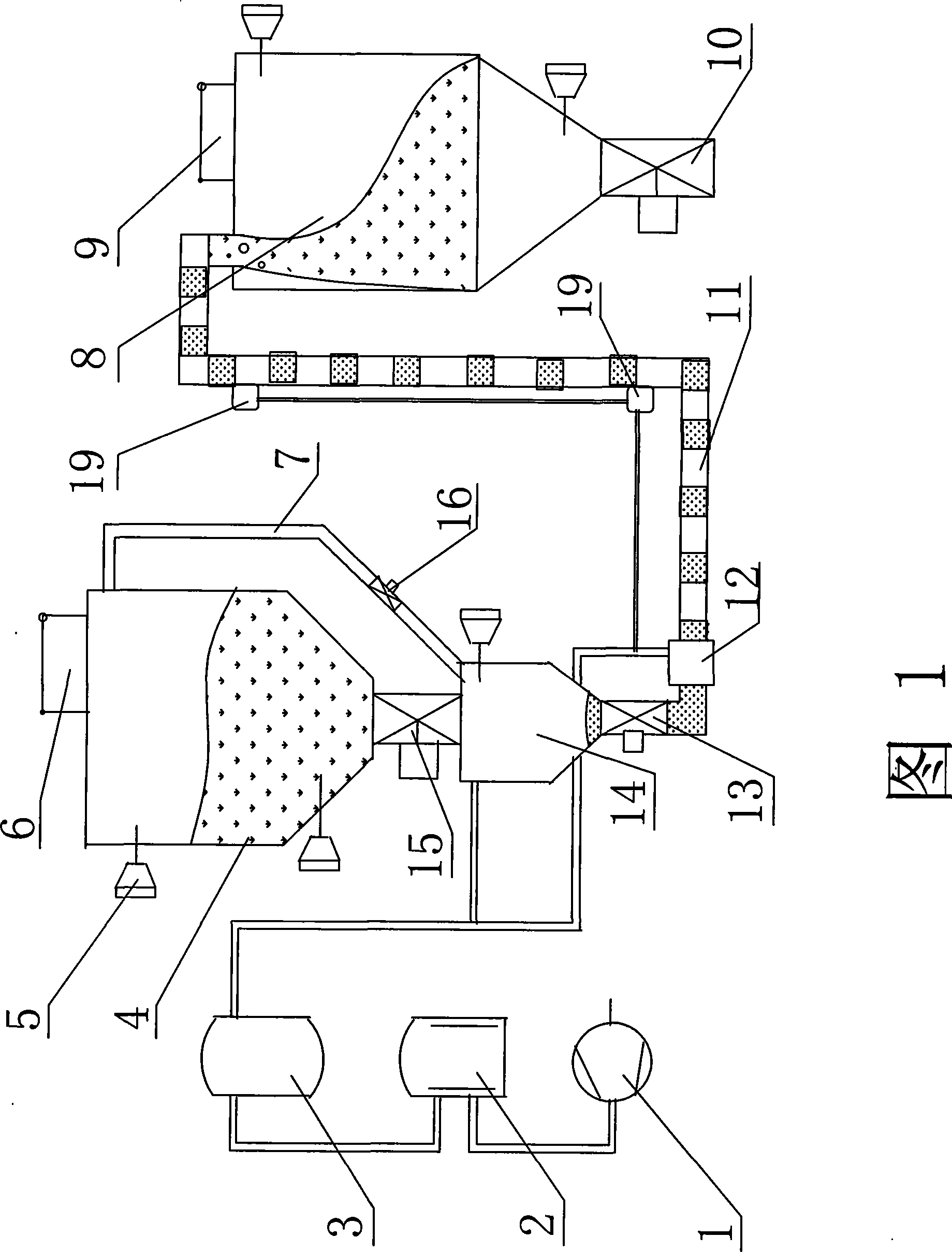

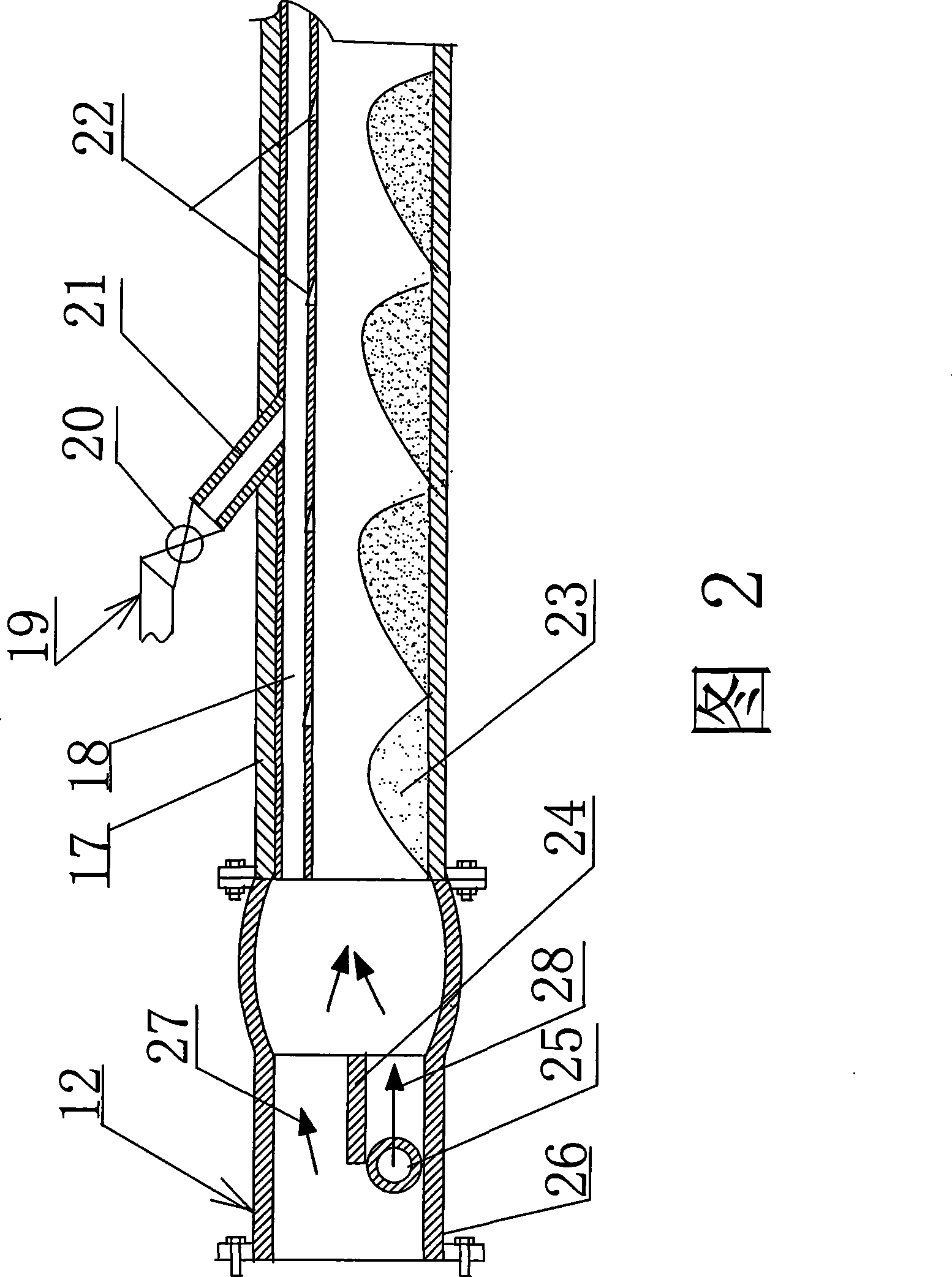

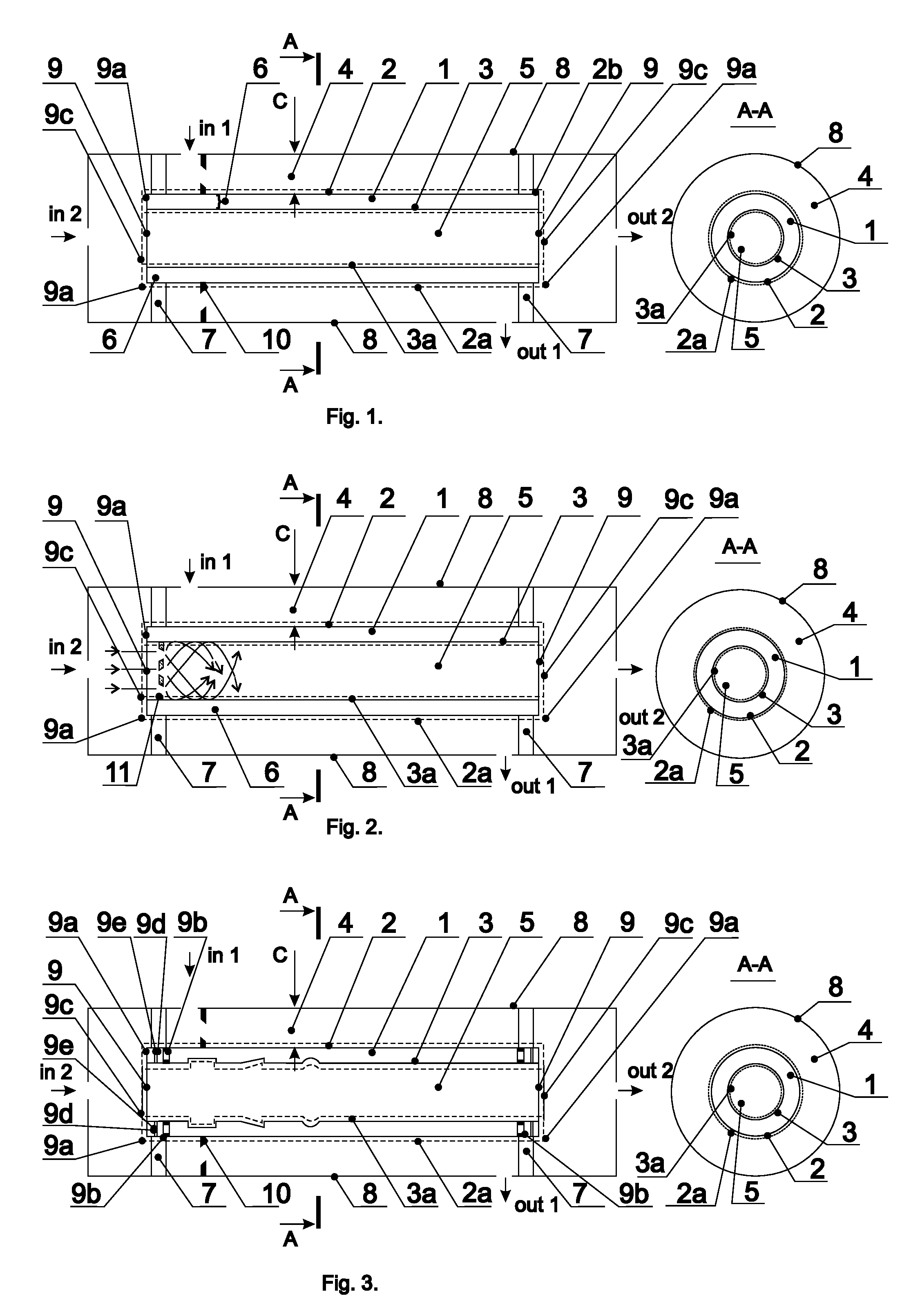

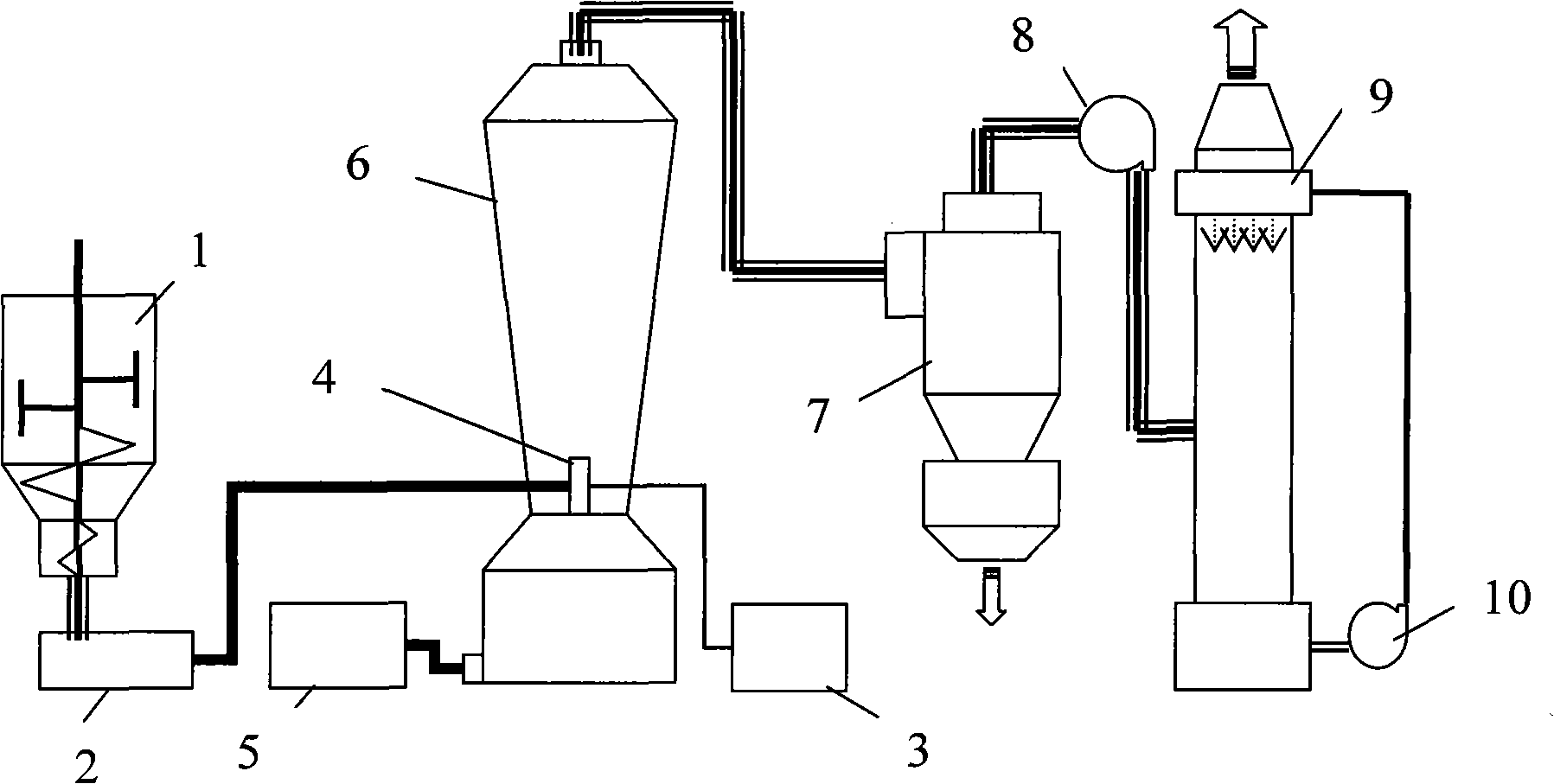

Long distance concentrated phase conveying system and method with auxiliary blowing apparatus

InactiveCN101391709ARealize automatic operationPrecise positioningBulk conveyorsProcess engineeringAir compressor

The invention relates to a long-distance dense-phase conveying system provided with an assistant blowing device and a method thereof. The conveying system comprises an air control apparatus formed by an air compressor, an air storage tank and a system control apparatus; a material storage bin and an on-line sub-bin which are formed by a material tank, a bin controller and a solid-air separator; a sending tank; a fluidization conveyor formed by a streamline casing, a guiding clapboard and an air inlet; a tube liner provided with air inlets arranged by an outer conveying pipe according to subsections and a dense-phase conveying pipeline formed by the assistant blowing device . The tube liner is fixedly connected with the inner upper wall of the outer conveying pipe; the assistant blowing device is fixedly connected and communicated with the outer pipe and tube liner. The dense-phase conveying method comprising the following steps: materials enters the sending tank from the material storage bin and then enters the dense-phase conveying pipeline through the fluidization conveyor and under the effect of compressed air to form a series of material plugs flowing in the conveying pipeline and finally the material reaches the sub-bin for processing and manufacturing. The invention has the advantages that the energy cost is low; the damage to material during the conveying process is less; the wearing to pipeline can be reduced; and the service life is long.

Owner:XIUYAN SHUNDA PNEUMATIC TRANSMISSION EQUIP MANUFACTORY

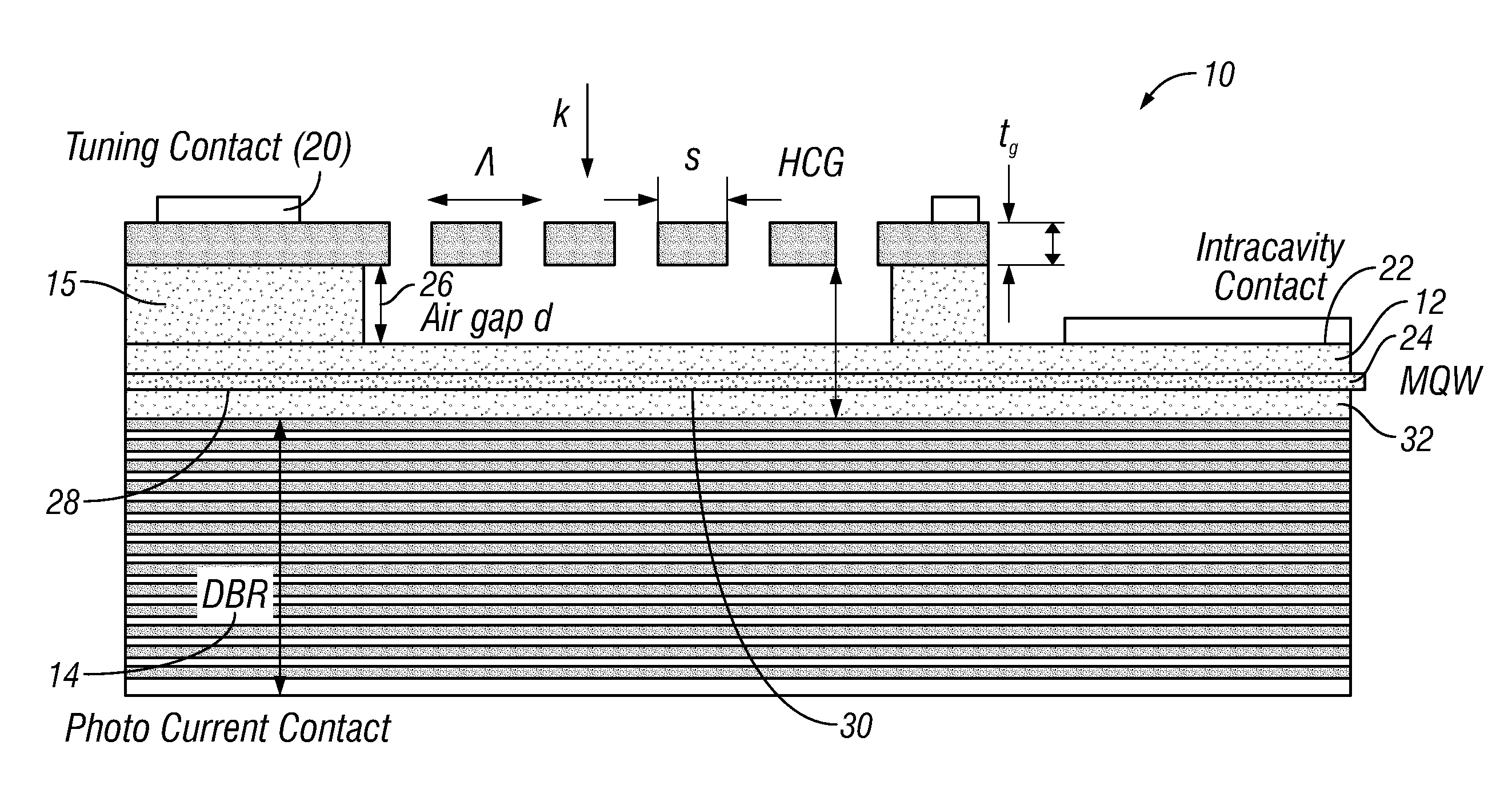

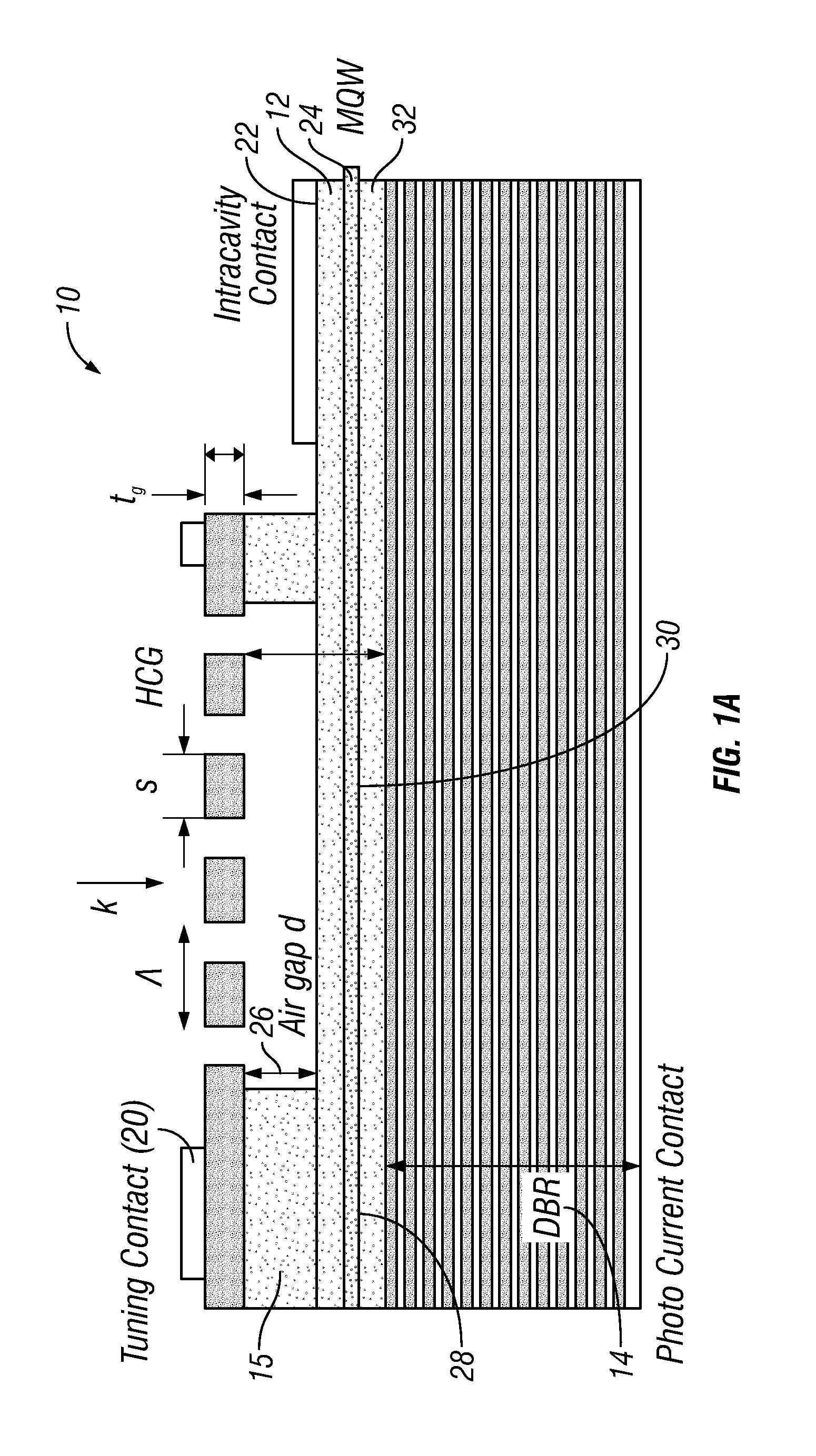

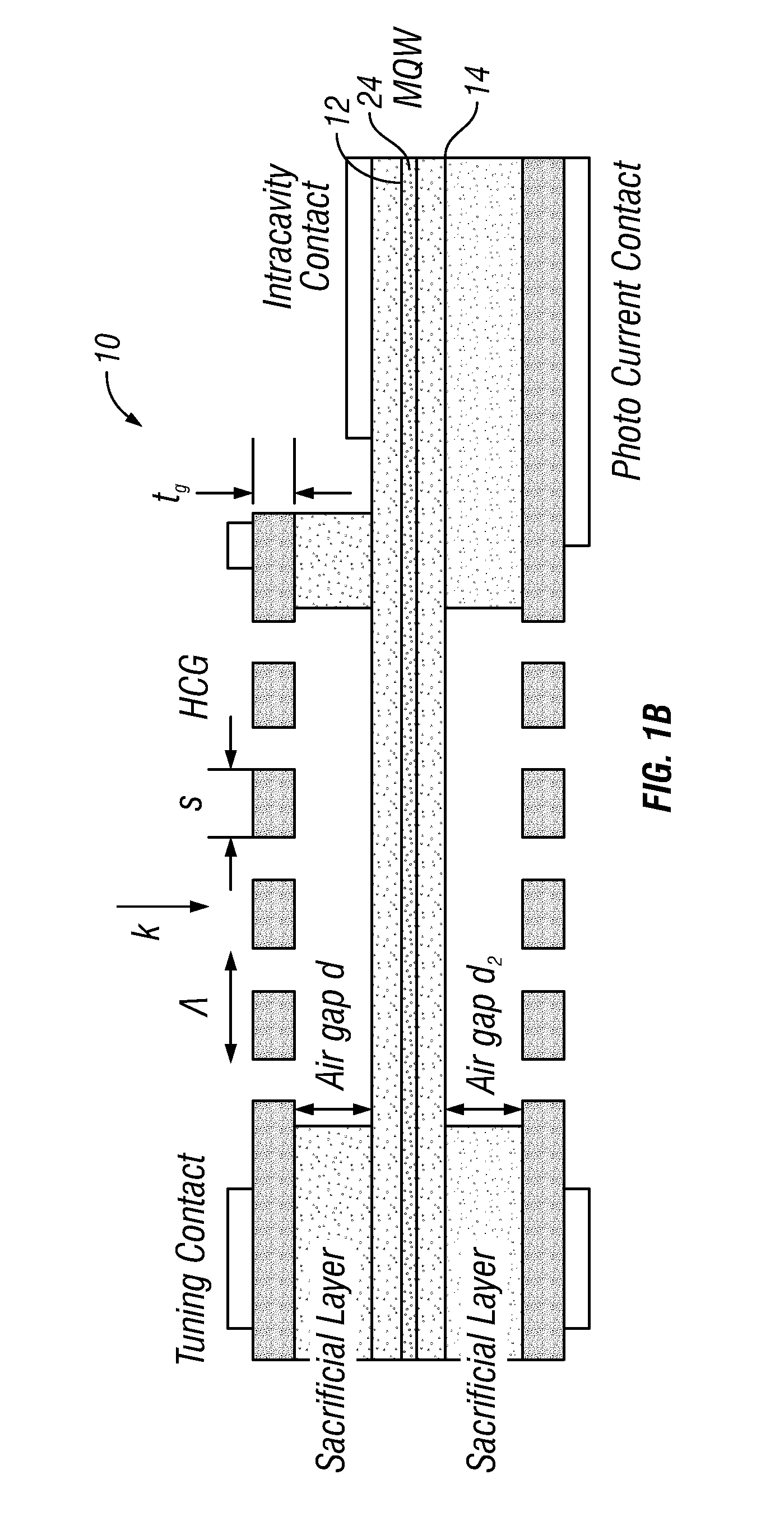

Polarization independent dual usage hcg vcsel-detector with high contrast grating and two dimensional period structure

InactiveUS20140353530A1Small footprintLow energy consumptionPhotometryMaterial analysis by optical meansPhotodetectorHigh contrast

A dual usage HCG VCSEL detector is provided with a high contrast grating (HCG) reflector first reflector that has a two dimensional periodic structure. The two dimensional structure is a periodic structure that is a symmetric structure with periodic repeating. The symmetrical structure provides that polarization modes of light are undistinguishable. A second reflector is in an opposing relationship to the first reflector. A tunable optical cavity is between the first and second reflectors. An active region is positioned in the cavity between the first and second reflectors. The photodetector is polarization independent. An MQW light absorber is included converts light to electrons. A dual usage HCG VCSEL-detector includes a high contrast grating (HCG) reflector first reflector, and a second reflector in an opposing relationship to the first reflector. A tunable optical cavity is between the first and second reflectors. An active region is positioned in the cavity between the first and second reflectors. The dual usage HCG VCSEL-detector that operates as a dual usage HCG VCSEL and as a tunable photodetector.

Owner:BANDWIDTH10 +1

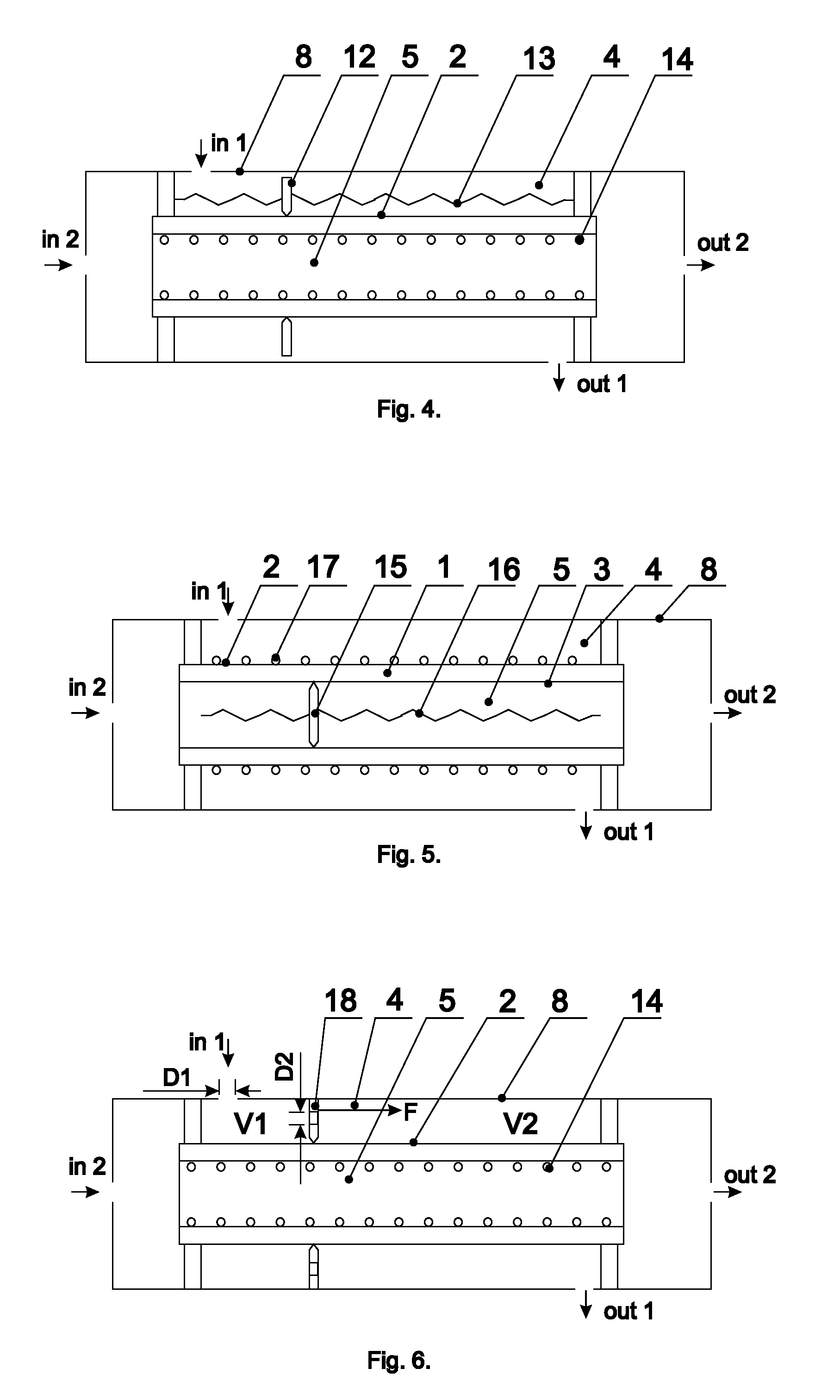

System and method for liquid treatment

InactiveUS8475725B1Low energy consumptionReduce energy consumptionSemi-permeable membranesWater/sewage treatment by irradiationChemistryPollutant

A method and energy-efficient apparatus for the treatment of liquids through the joint use of a gas mixture-oxidizing agent and UV radiation. This method uses an excimer UV lamp performing two actions affecting the liquid and changing its properties with UV radiation and the generation of a gas mixture containing strong oxidizing agents for influence on the liquid, disinfection and purification of the liquid being treated from contaminants. The apparatus incorporates energy efficient design features to reduce energy consumption and operational costs, as well as an excimer lamp design that improves performance parameters to surpass and outlast existing devices. Unique electrode designs, cleaning systems, and materials combine to create a state-of-the-art liquid treatment apparatus that exceeds existing industrial analogs and norms.

Owner:EAST COAST DISTRIBUTION

Method for preparing high-performance conductive fiber

InactiveCN101215693AReduce pollutionLow energy consumptionLiquid/solution decomposition chemical coatingWoven fabricCopper plating

The invention relates to a method for preparing a high performance conductive fiber, which comprises the following steps: V1ing, pretreatment and washing. V2ing, fiber is socked by coarsening agent to improve the surface structure of the fiber. V3ing, the fiber is socked by stannous chloride or cadmium chloride solution, and a layer of tin ions or cadmium ions are adsorbed on the surface of the fiber. V4ing, the fiber is socked by palladium chloride solution, and the tin ions or cadmium ions which are replaced by palladium colloid are adsorbed on the surface of the fiber. V5ing, electroless copper plating. V6ing, after being socked by oxalic acid solution, the fiber is dried. V7ing, the fiber which is plated with copper is socked and treated by tin dichloride solution. V8ing, the copper-plating fiber is socked by palladium chloride solution, and the tin ions or cadmium ions which are replaced by palladium colloid are adsorbed on the surface of the fiber. V9ing, chemical nickel plating. V10ing, after being socked by deionized water, the fiber is dried, and a product is obtained. The invention has small pollution to environment and less energy dissipation, and is easy to industrially produce. The conductive fiber which is prepared using the invention has excellent conductivity, the resistance of the specific surface area is 1-10 ohm, the original characteristics of the fiber is preserved, and the high performance conductive fiber is capable of being used for various non-woven fabrics.

Owner:江苏奈特纳米科技有限公司

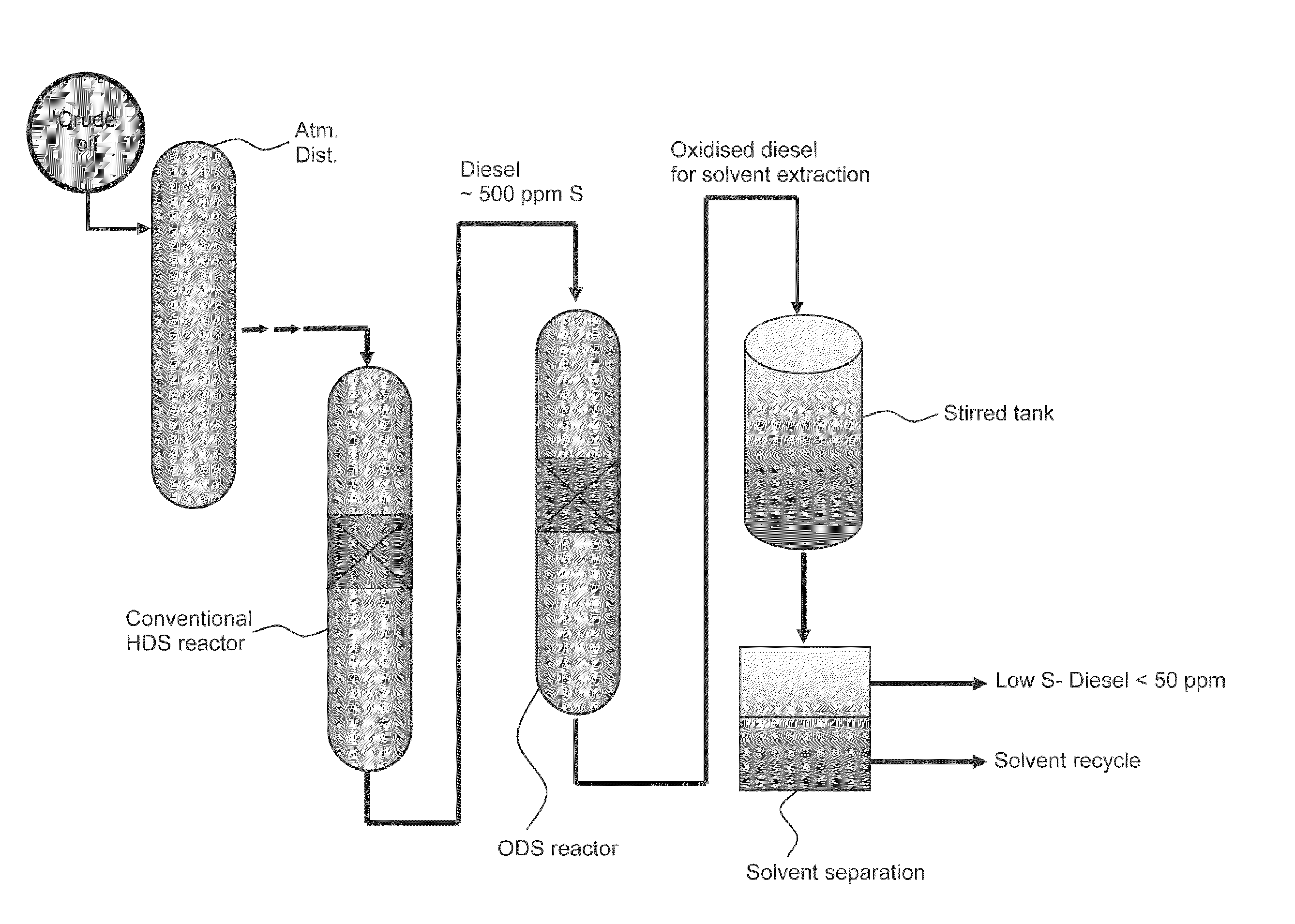

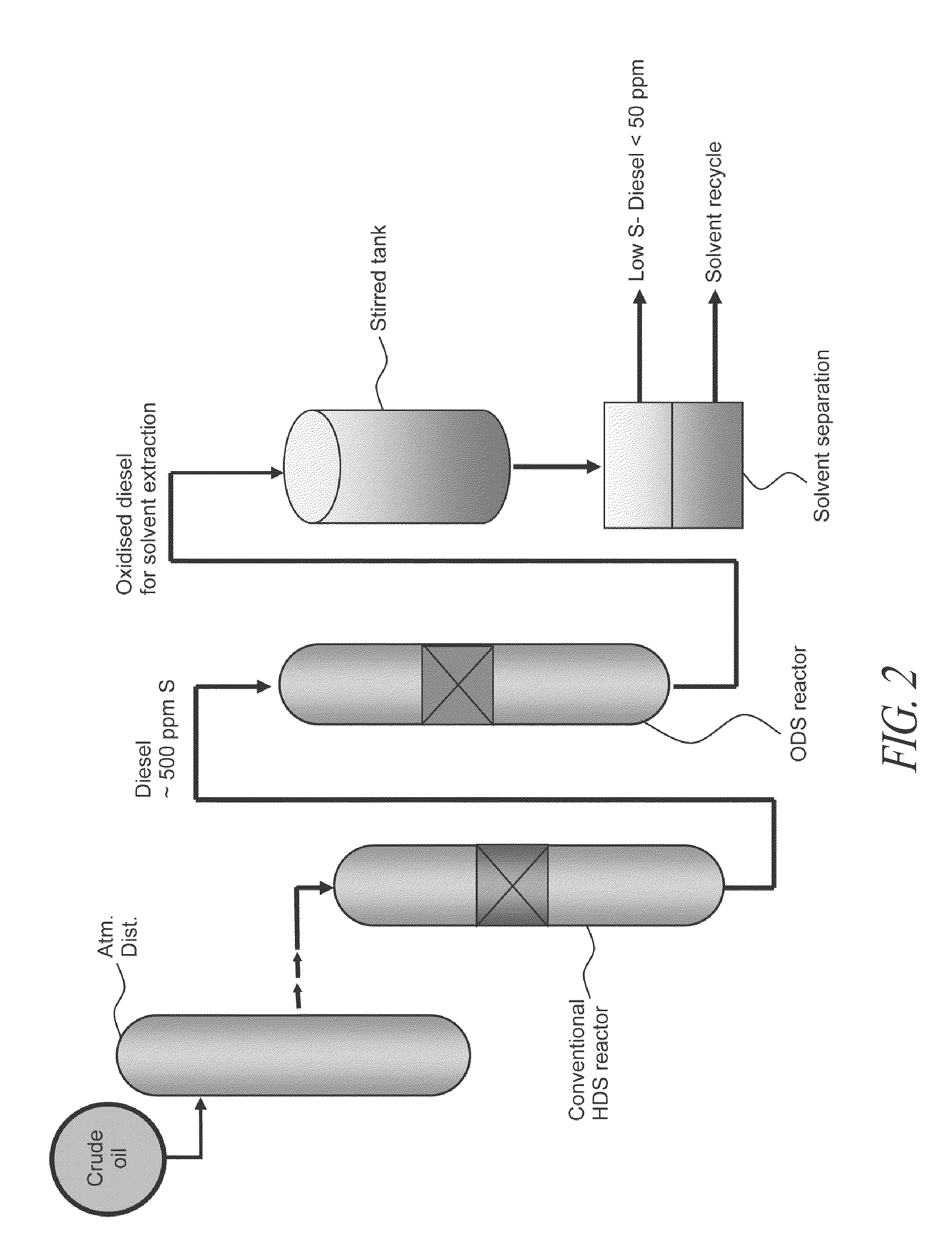

Novel process for removing sulfur from fuels

InactiveUS20100025301A1Carry out economicallyLow energy consumptionRefining with oxygen compoundsTreatment with plural serial refining stagesManganese oxideOxide

A process for removing sulfur-containing compounds from fuel, said process comprising contacting the fuel in liquid phase with air to oxidize the sulfur-containing compounds, said contacting being carried out in the presence of at least one transition metal oxide catalyst, wherein the catalyst is supported on a porous support and wherein the porous support comprises a support material selected from the group consisting of a titanium oxide, a manganese oxide and a nanostructured material of the aforementioned support materials.

Owner:AGENCY FOR SCI TECH & RES

Clutch facing piece for automobile and production method thereof

InactiveCN101655128AHigh strengthHigh modulusMixing operation control apparatusCeramic shaping apparatusConductor CoilAntimony trisulfide

The invention discloses a clutch facing piece for an automobile and a production method thereof. The production method comprises the following steps: stirring 10-20% of water soluble phenolic resin, 0.5-1.5% of alumina, 4-8% of crystalline flake graphite, 0.6-1.2% of antimony trisulfide, 6-10% of ground calcium carbonate, 8-12% of chalcopyrite powder, 6-10% of magnetite powder, 3-8% of vermiculitepowder, 12-18% of barium sulfate, 6-15% of powder nitrile-butadiene rubber and water according to parts by weight of each component, preparing suspension, then dipping 15-25% of basalt fibre and obtaining a product by drying, winding, pressing, heat treatment and mechanical processing. By using the invention, the temperature resistance and the wear resistance of the clutch facing piece for the automobile are enhanced, a phenomenon of dust raising in the production and use process is reduced, and the product is more affinitive to the environment.

Owner:十堰法雷诺动力科技有限公司

Method for disposing straws by sulfur trioxide gas

InactiveCN101538597ASimple equipmentLow energy consumptionFermentationPaper material treatmentChemistryButyric acid

A method for disposing straws by sulfur trioxide gas is characterized in that the method comprises the following steps of firstly pumping the sulfur trioxide gas in the straws to carry out a reaction; subsequently, soaking the reacted straws in a diluted aqueous alkaline solution or disposing the reacted straws by an ammonia to obtain a lignocellulose; finally putting the lignocellulose into a buffer solution with cellulase to carry out saccharification, thus obtaining saccharification liquid. The method adopts the sulfur trioxide gas to dispose and obtain the plant cellulose easy to be saccharified and fermented by the cooperation function together with the suitable diluted lye, has simple pre-disposal process, low consumption of raw materials and auxiliary materials, hardly produces wastewater and the produced cellulose is easy to be saccharified. The prepared saccharification liquid has no inhibition to the subsequent fermentation and can be used for producing chemical products such as ethanol, butanol, butyric acid, lactic acid, and the like, by fermentation.

Owner:安徽安生生物化工科技有限责任公司

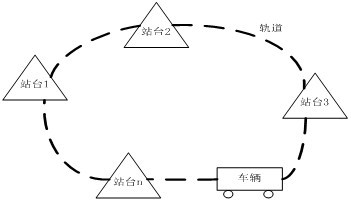

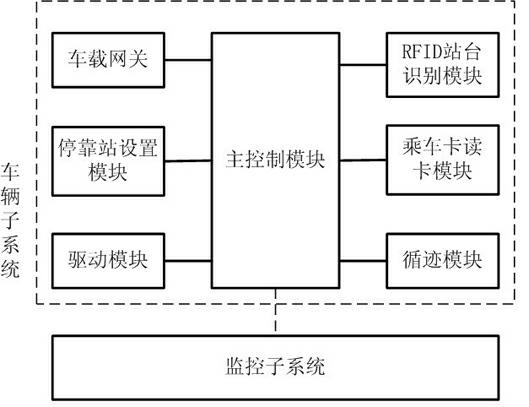

Unmanned vehicle running controlling method based on Zigbee and radio frequency identification (RFID)

InactiveCN102566575ALow costLow energy consumptionPosition/course control in two dimensionsTelecommunicationsRadio-frequency identification

The invention discloses an unmanned vehicle running controlling method based on Zigbee and radio frequency identification (RFID). The method comprises the following steps of: (1) standby; (2) station calling in a standby state: when a certain station sends a request signal, receiving and processing station request information by a vehicle-mounted gateway, and starting a vehicle; (3) automatic tracking; (4) station calling in a running process: if other stations send request signals in the running process of the vehicle, receiving and processing station request information by the vehicle-mounted gateway, and acquiring information of the stations sequentially required to stop; and (5) arrival of a destination station: after an RFID station identification module identifies arrival of the destination station, stopping the vehicle, reading cards and selecting the stations to arrive after passengers get on the vehicle, starting the vehicle to run to the next required destination station, repeating the (4) till the destination station does not have a request, and returning to the (1). By the method, unmanned driving becomes possible under the condition of low cost and high efficiency.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

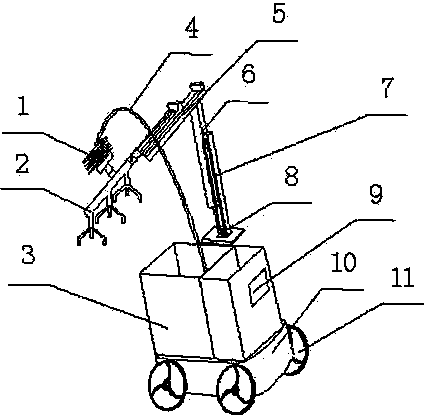

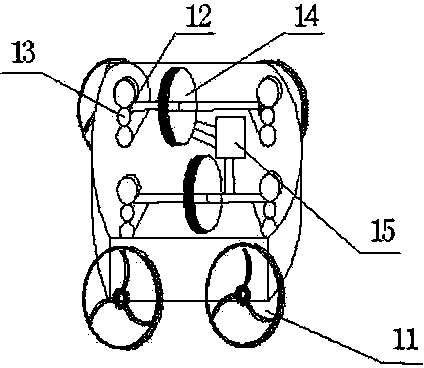

Full-automatic watering vehicle

InactiveCN105248256ALow energy consumptionReduce labor intensityWatering devicesCultivating equipmentsElectric machineryPiping

The invention discloses a full-automatic watering vehicle. The full-automatic watering vehicle is characterized in that a water storing tank and a storage cabinet are arranged over a lower vehicle body; a vertical telescopic assembly is arranged beside the water storage tank; a telescopic rod of the vertical telescopic assembly is provided with a chain; the chain is driven by a motor; a horizontal driving slide block of a horizontal telescopic assembly is engaged with a horizontal driving screw rod; the end part of the horizontal driving screw rod is provided with a pressing device; the pressing device is installed over a supporting water pipe; a water spraying head is installed under the supporting water pipe; the lower vehicle body is provided with a worm gear rod and a damping wheels; the worm gear rod is engaged with a turning gear via a driving motor; the turning gear is engaged with a wheel driving shaft; and the worm gear rod and the turning gear transmit power to damping wheels, so the damping wheels can rotate and drive the lower vehicle body to move forward, backward and steer. Watering load can be reduced for workers, so less labor and time can be achieved for flower planting workers; and the full-automatic watering vehicle benefits people.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

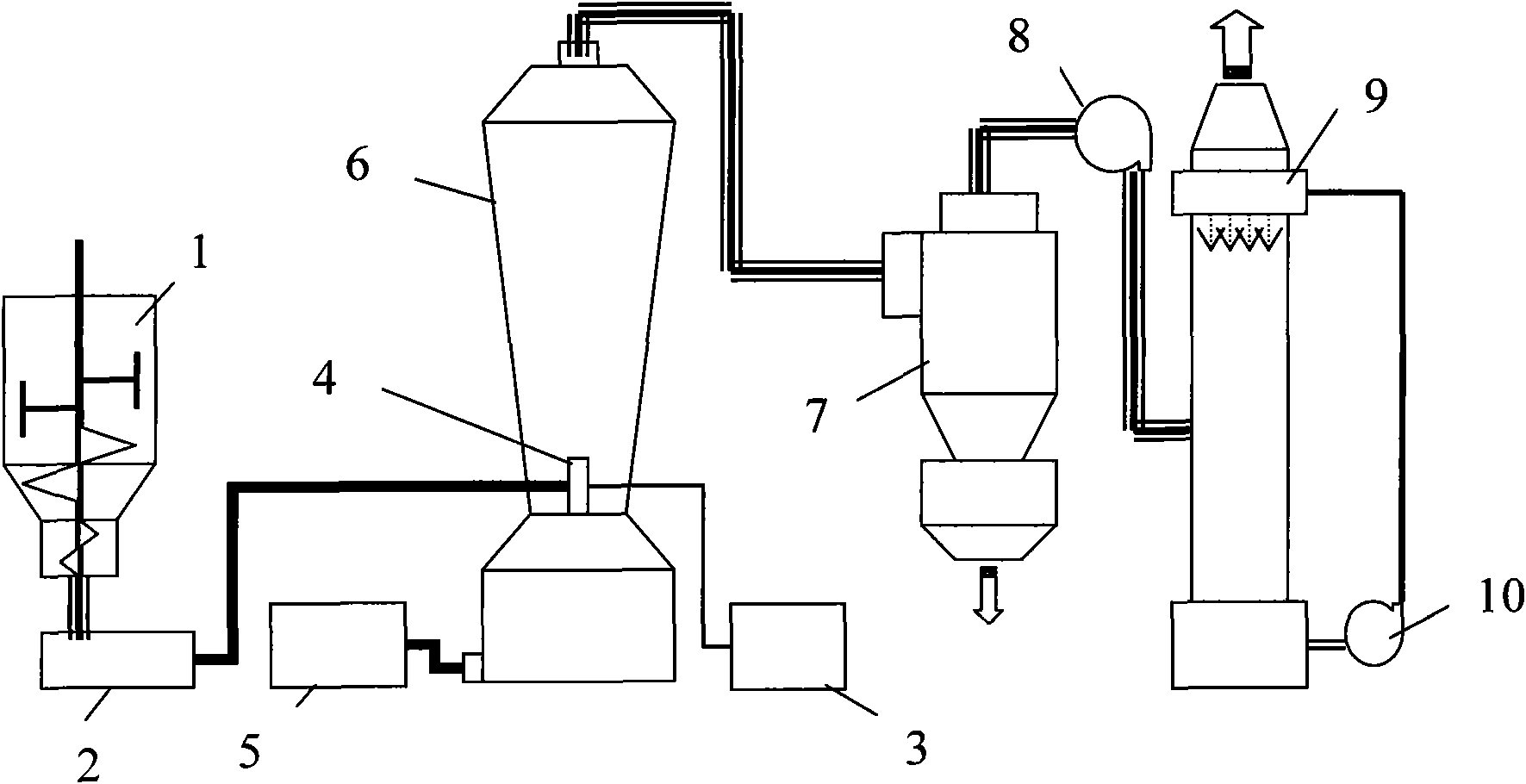

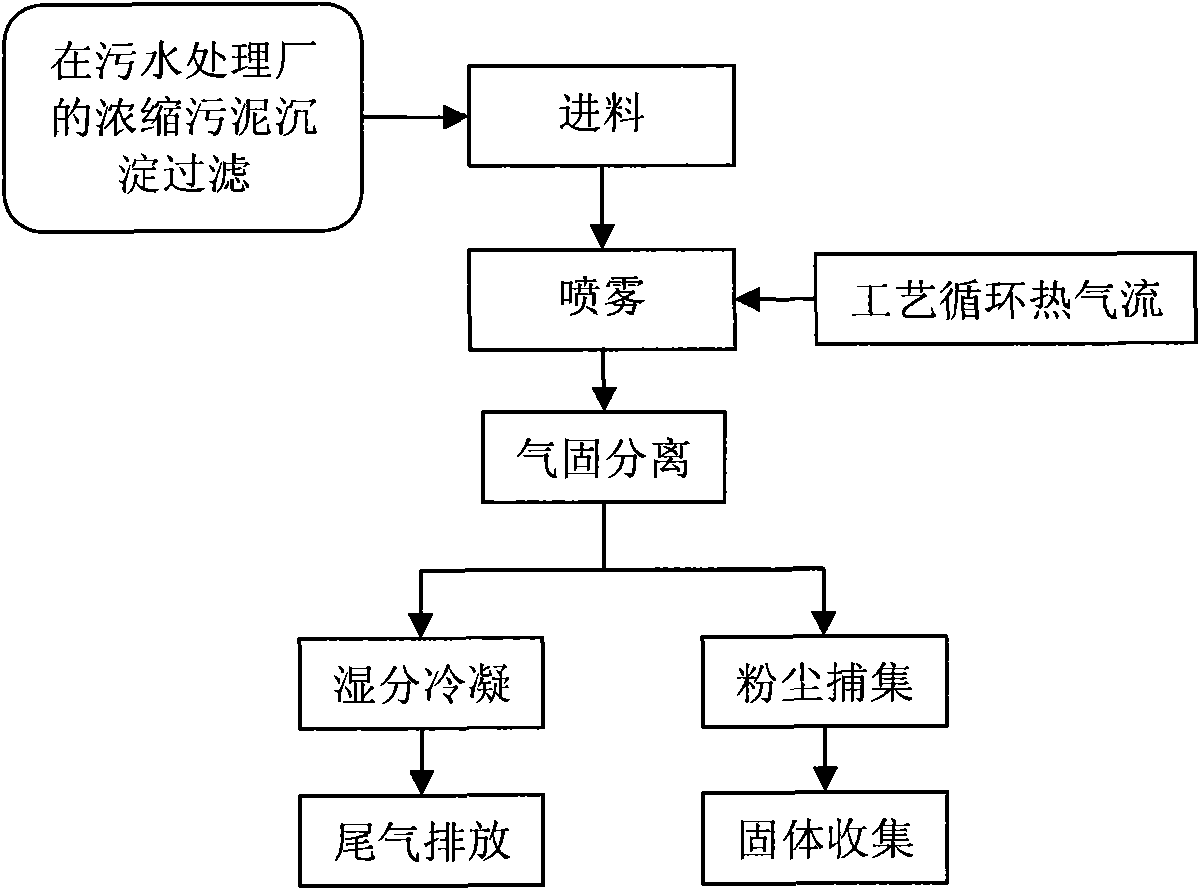

System device for directly and effectively spray-drying high-solid-content sludge and method thereof

InactiveCN101781078ASmall particlesLow and small sludge particles after atomizationSludge treatment by de-watering/drying/thickeningPorositySludge

The invention provides a system device for directly and effectively spray-drying high-solid-content sludge, which comprises a hopper, wherein the hopper is connected with a feed pump and used for feed agitation, the feed pump is connected with one end of a nozzle in a spray drying tower through a pipeline, and the other end of the nozzle is connected with an air compressor; an air inlet at the lower part of the spray drying tower is connected with a hot blast furnace through the pipeline, the top of the spray drying tower is connected with a dust remover through the pipeline, the dust remover is connected with a smoke gas wet recovery tower through the pipeline provided with an exhaust fan, and the recovery tower is communicated with a pool arranged at the bottom of the recovery tower and a nozzle at the top through the pipeline provided with a water pump. The invention also provides a method adopting the system device for directly and effectively spray-drying the high-solid-content sludge. The invention has the effects that the energy consumption is low by using the method, and the atomized sludge has small grains, uniform diameter, good drying effect, high loosening degree and high porosity and is markedly superior to other drying forms. The produced drying sludge is adaptable to the paths of combustion heating, cement manufacture, greening, landfill and the like.

Owner:星河航天科技(天津)有限公司

Gasoline of high proportion methanol directly used for vehicle

The invention discloses gasoline of high proportion methanol directly used for a vehicle. The methanol mass fraction is not less than 70%. The methanol gasoline comprises: 70-90% of methanol, 7-29% of component oil and 1 to 3% of additive, wherein, the component oil comprises C5-C7 saturated alkane, solvent oil, 90 # gasoline and toluene, the additive comprises C3-C8 monobasic alcohol, petroleum ether with distillation range of 30-60 degrees C., EGME, N, N'-2 salicylidene -1,2- propylene diamine and other raw materials which can be added or not. The provided gasoline of high proportion methanol directly used for the vehicle in the invention overcomes the existing technical problem of the gasoline of high proportion methanol under the circumstances that the existing engine is not required to be modified, and leads the gasoline of high proportion methanol to be well applied to the vehicle.

Owner:山西华顿实业有限公司

Electric power tool

ActiveUS20060131042A1Simple to manufactureLow energy consumptionDrilling rodsConstructionsPower toolElectric machinery

Owner:HILTI AG

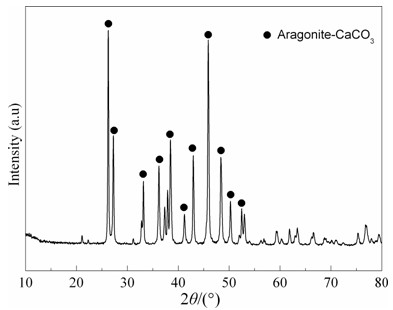

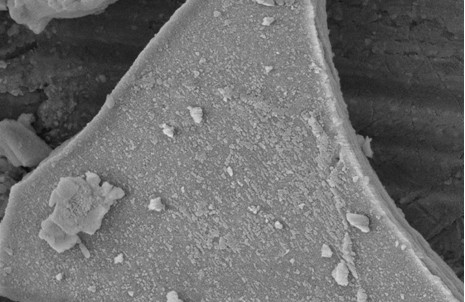

Preparation method of flake-shaped aragonite calcium carbonate

InactiveCN102583482AWide variety of sourcesImprove surface activityCalcium/strontium/barium carbonatesCuticlePapermaking

The invention discloses a preparation method of flake-shaped aragonite calcium carbonate. The preparation method comprises the following steps: (1) performing dry method coarse grinding to a shell raw material, soaking the shell raw material in lotion for 4-48h at normal temperature, utilizing roller watering to remove a cuticle layer and a prismatic layer, and obtaining nacreous layer calcium carbonate by washing; (2) adding water to the nacreous layer calcium carbonate, performing high-speed agitation to prepare slurry with the concentration to be 30-80wt%, adding a grinding aid with the weight being 0.5-5% that of the nacreous layer calcium carbonate, and using a stripping machine to perform wet grinding for 60-180min with zirconia ball, alumina balls or ceramic balls serving as grinding mediums; and (3) performing filter pressing and drying grinding to obtain the flake-shaped aragonite calcium carbonate. The preparation method of the flake-shaped aragonite calcium carbonate is simple in process and does not use a poisonous harmful reagent, the operation conditions are mild, the surface activity of the prepared flake-shaped aragonite calcium carbonate is good, and the flake-shaped aragonite calcium carbonate can be widely applied to industries such as plastics, papermaking, rubber, ink, coating, building materials, medicines and food.

Owner:ZHEJIANG UNIV

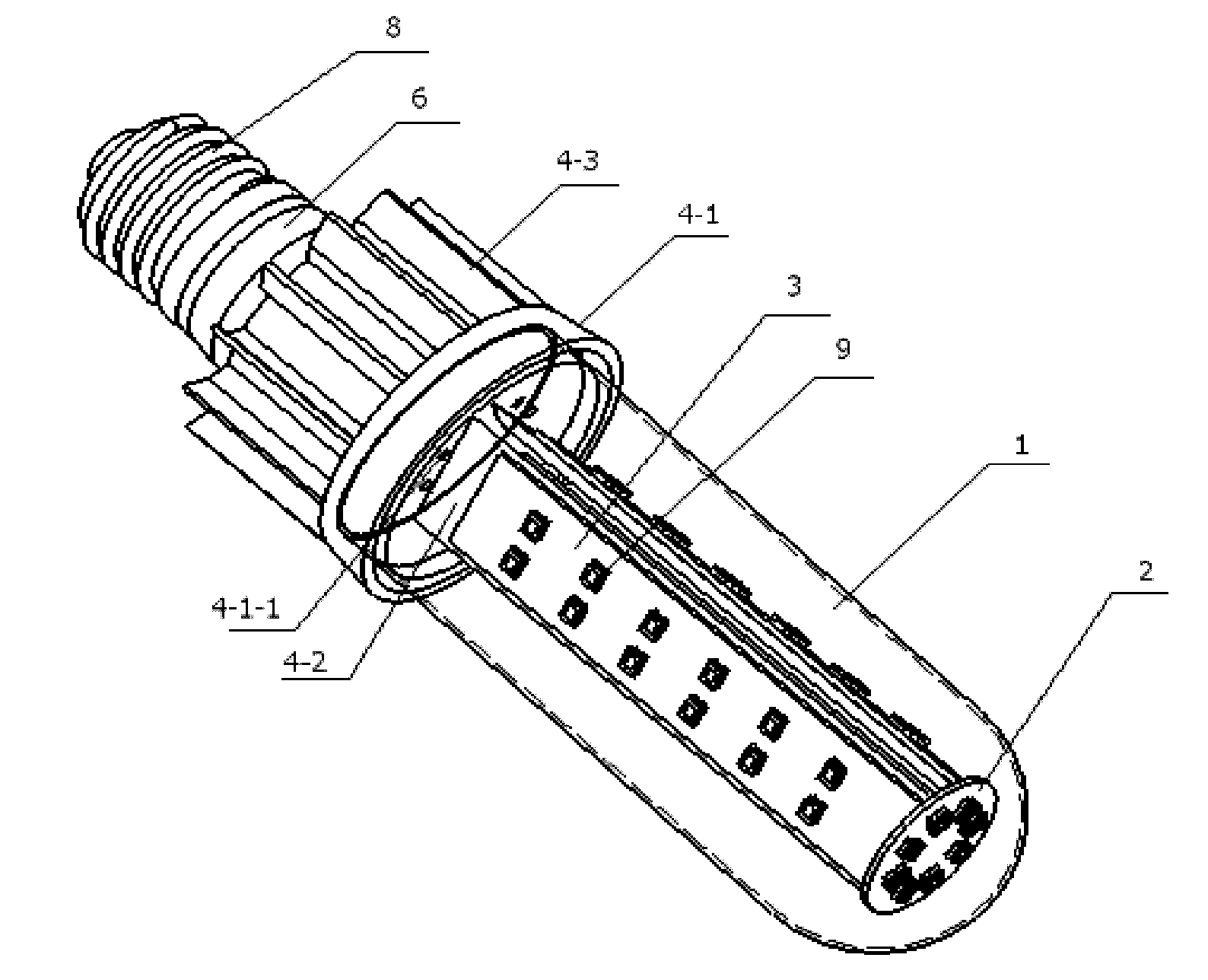

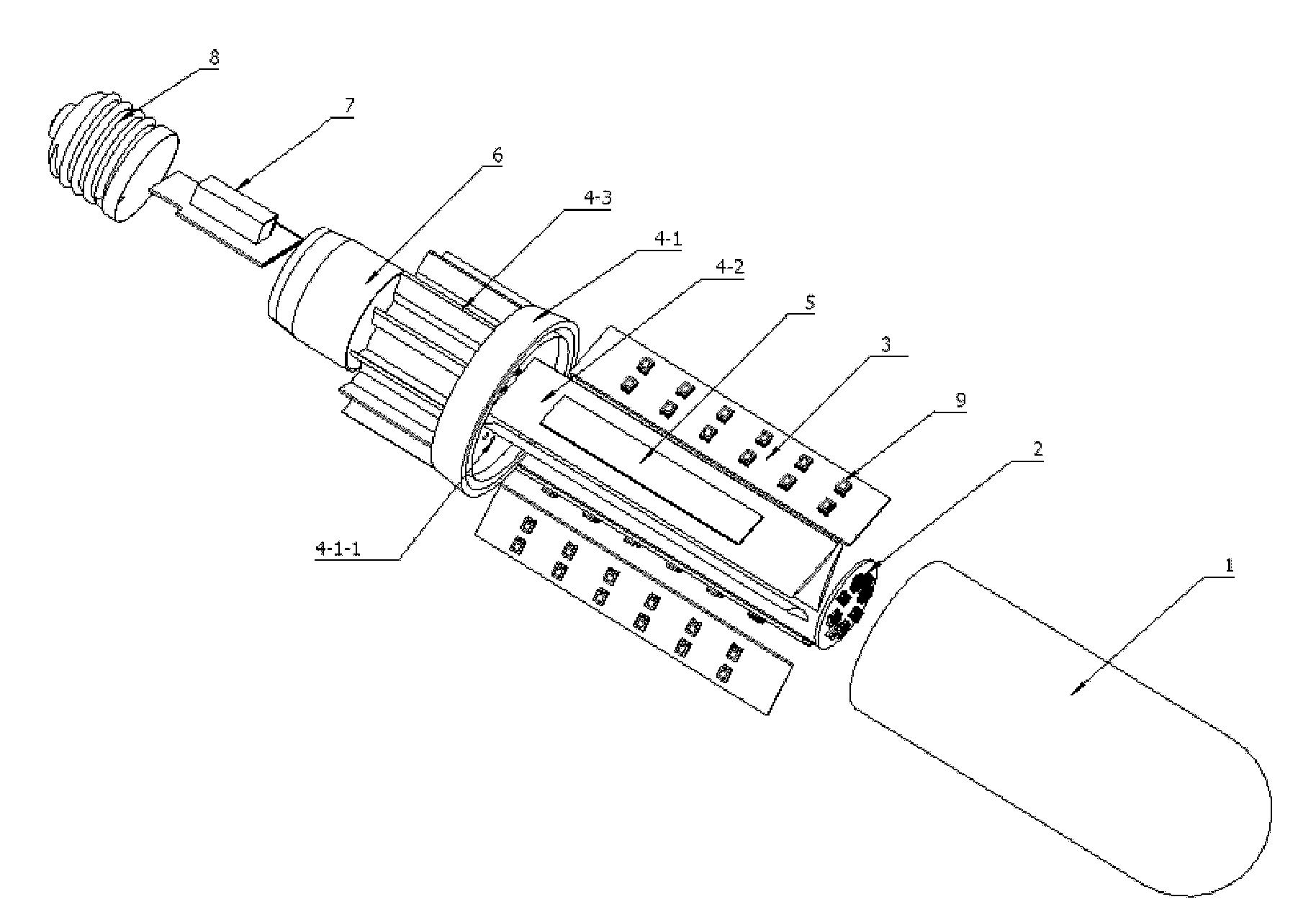

LED lamp capable of replacing compact fluorescent lamp

InactiveCN102147068AReduce volumeLow energy consumptionPoint-like light sourceElectric circuit arrangementsHeat sinkEngineering

The invention discloses an LED lamp capable of replacing a compact fluorescent lamp, which comprises a lamp shade (1) and a lamp holder (8), and also comprises a lamp carrier body, wherein the middle part of the lamp carrier body is provided with a base (4-1) with an air hole (4-1-1), the lower part of the lamp carrier body is provided with at least three base plates (4-2), the upper part of the lamp carrier body is provided with a heat radiating sheet (4-3); the lamp shade (1) is arranged on the base (4-1), the lamp holder (8) is arranged at the end part of the heat radiating sheet (4-3); LED lamp panels are arranged on the end parts and the outer surfaces of the base plates (4-2), LED lamp wicks (9) are fixed on the LED lamp panels; and the lamp holder (8) is internally provided with a drive circuit board (7) electrically connected with the LED lamp panels. The invention has the advantages of small volume, less energy consumption, good stability, no mercury, long service life, and the like.

Owner:SOUTHEAST UNIV

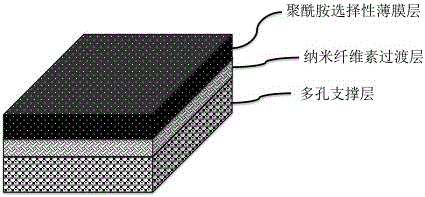

Composite thin membrane with multilayer composite structure and preparation method thereof

InactiveCN106739363ALow energy consumptionPromote formationSemi-permeable membranesLamination ancillary operationsElectrolysisFiltration membrane

The invention belongs to the technical field of semi-permeable membrane separation processes, and relates to a composite thin membrane with a multilayer composite structure and a preparation method thereof. The composite thin membrane is formed by coating nano-cellulose and a transition layer which is formed from a polyelectrolyte by a layer-by-layer assembling method on a porous supporting layer substrate in sequence, and then coating a polyamide selective membrane layer which is formed through a common interface polymerization reaction method. A composite thin membrane structure can be applied to preparation of a nano-filtration membrane, a reverse osmosis membrane and a forward osmosis membrane. The application of the composite thin membrane with the multilayer composite structure comprises tap water purification, municipal water supply, sewage purification, brackish water desalination, seawater desalination, drink juice concentration process, dairy industry, blood dialysis medicine industry and semiconductor industry.

Owner:林小锋

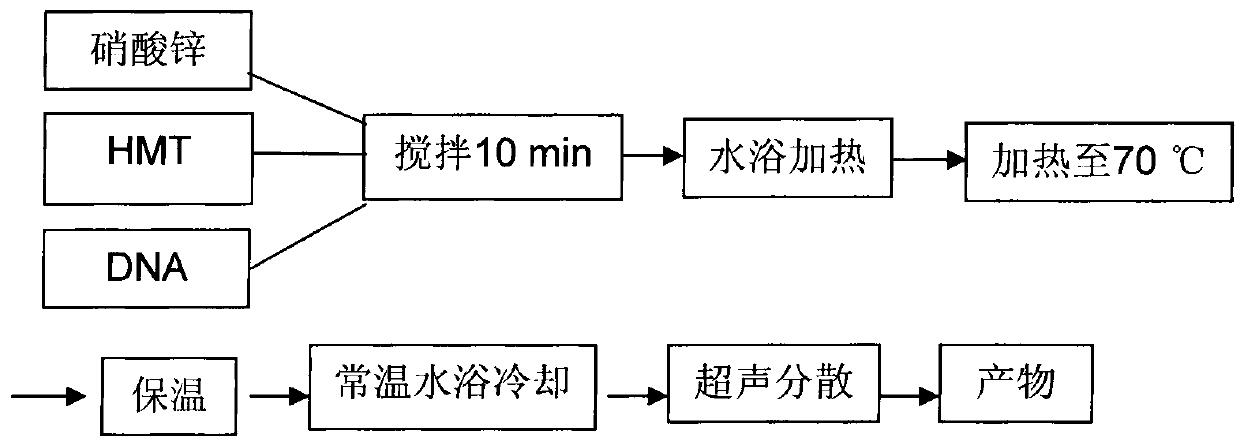

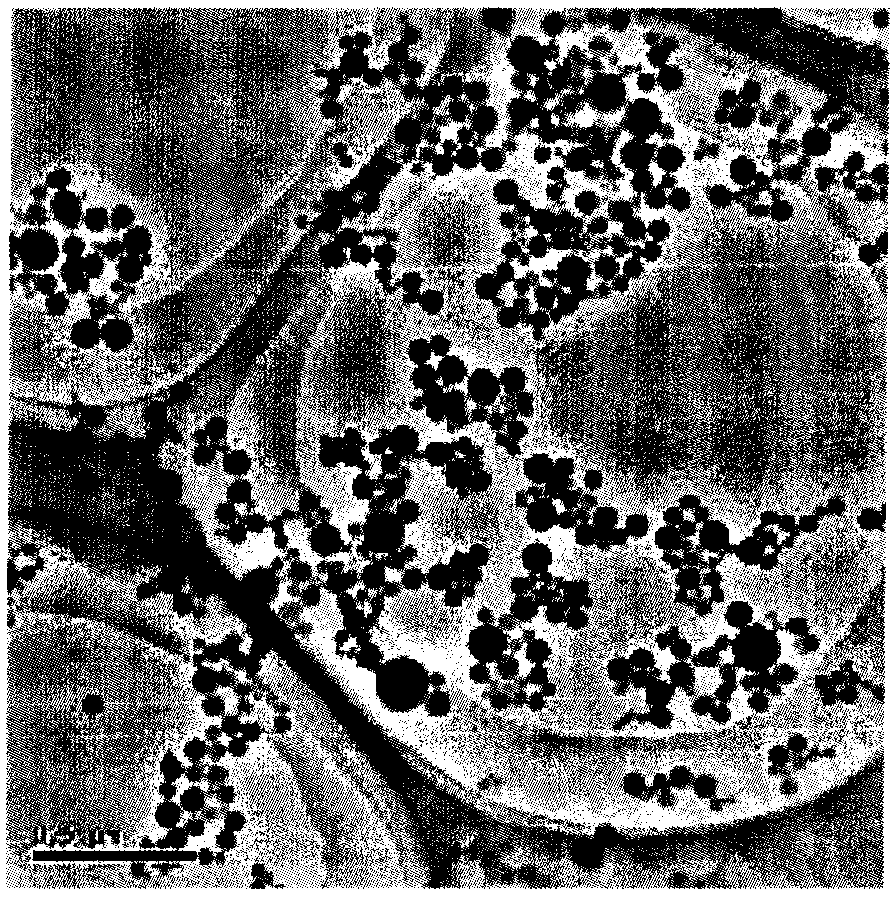

Method for assembling zinc oxide nano-chain by using DNA as template

InactiveCN101717112ASimple ingredientsLow energy consumptionNanostructure manufactureZinc oxides/hydroxidesBiological macromoleculeBatch production

The invention discloses a method for assembling a zinc oxide nano-chain by using DNA as a template, comprising the following steps of: (1) mixing and stirring an aqueous solution of DNA, an aqueous solution of zinc nitrate and an aqueous solution of hexamethylenetetramine; (2) heating to 60 DEG C-80 DEG C and keeping the temperature for 0.5-4h; and (3) reducing the temperature to room temperature of 20 DEG C-25 DEG C and carrying out ultrasound treatment in an ultrasound wave dispersion instrument for 10-20 minutes and sampling to obtain the zinc oxide nano-chain by using the DNA as the template. The method is simple, easily obtains raw materials, consumes less energy and reduces the pollution to the environment; the equipment is less and the cost is low, so the method is suitable for batch production; the reaction time is short, the yield is high and no toxicity and harm exist, so that the method provides the possibility for preparing the zinc oxide nano-chain on a large scale; and zinc oxide nano-chains with different shapes can be constructed by operating the space structure of biological macromolecule DNA. The invention can simultaneously solve the problems of the control of the size and the shape of nanometer materials and the dispersion stability.

Owner:TIANJIN UNIV

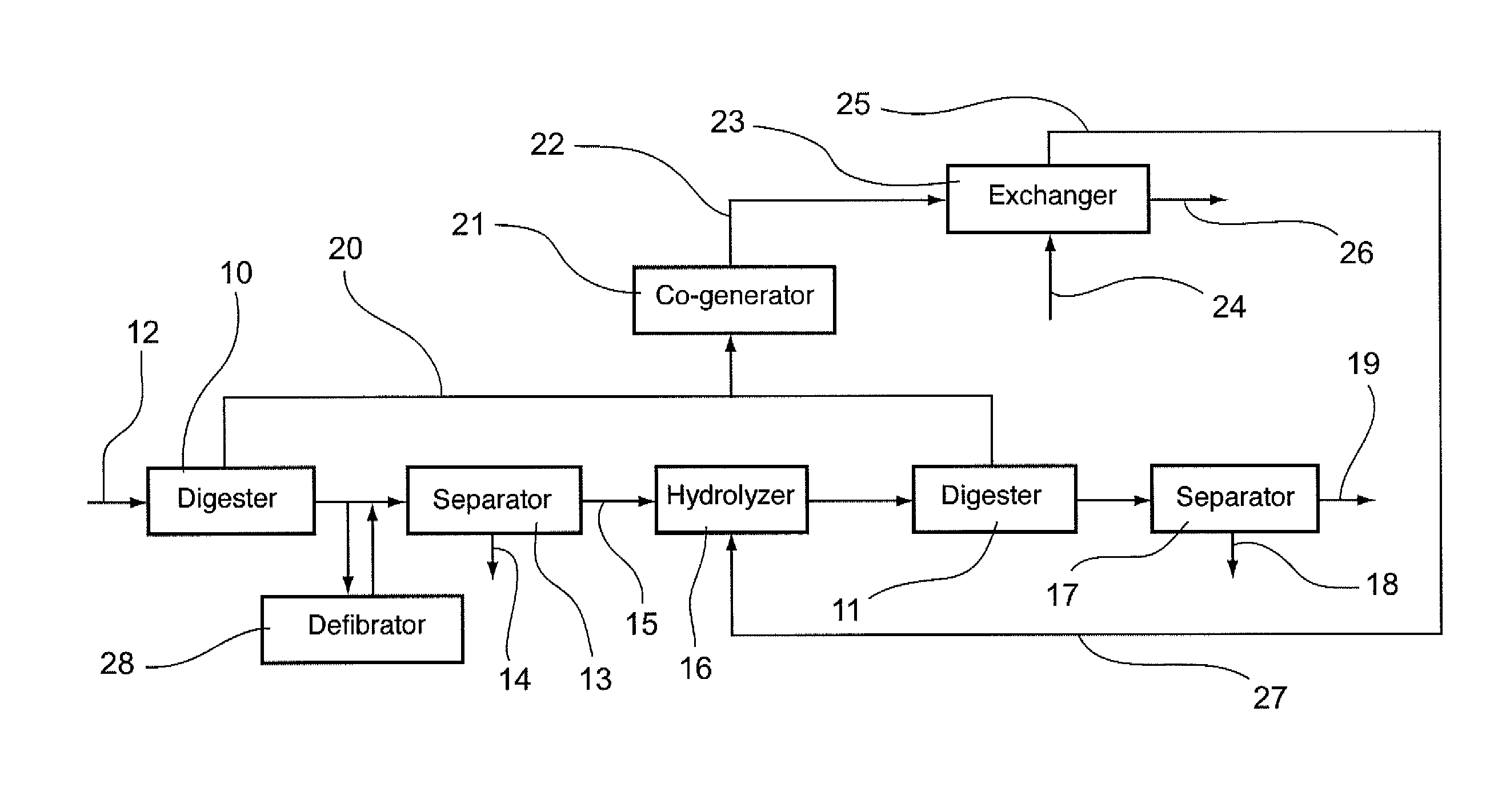

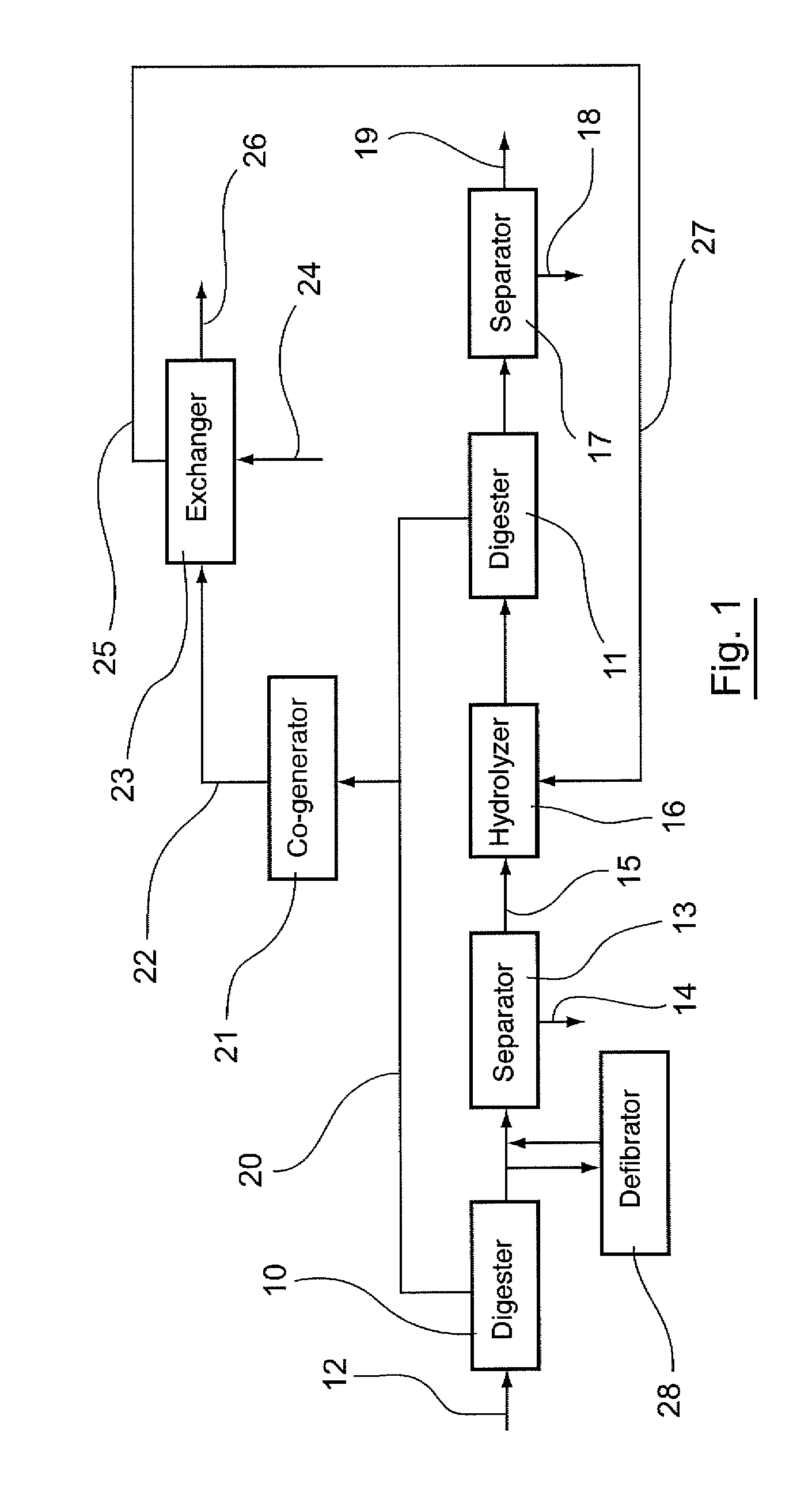

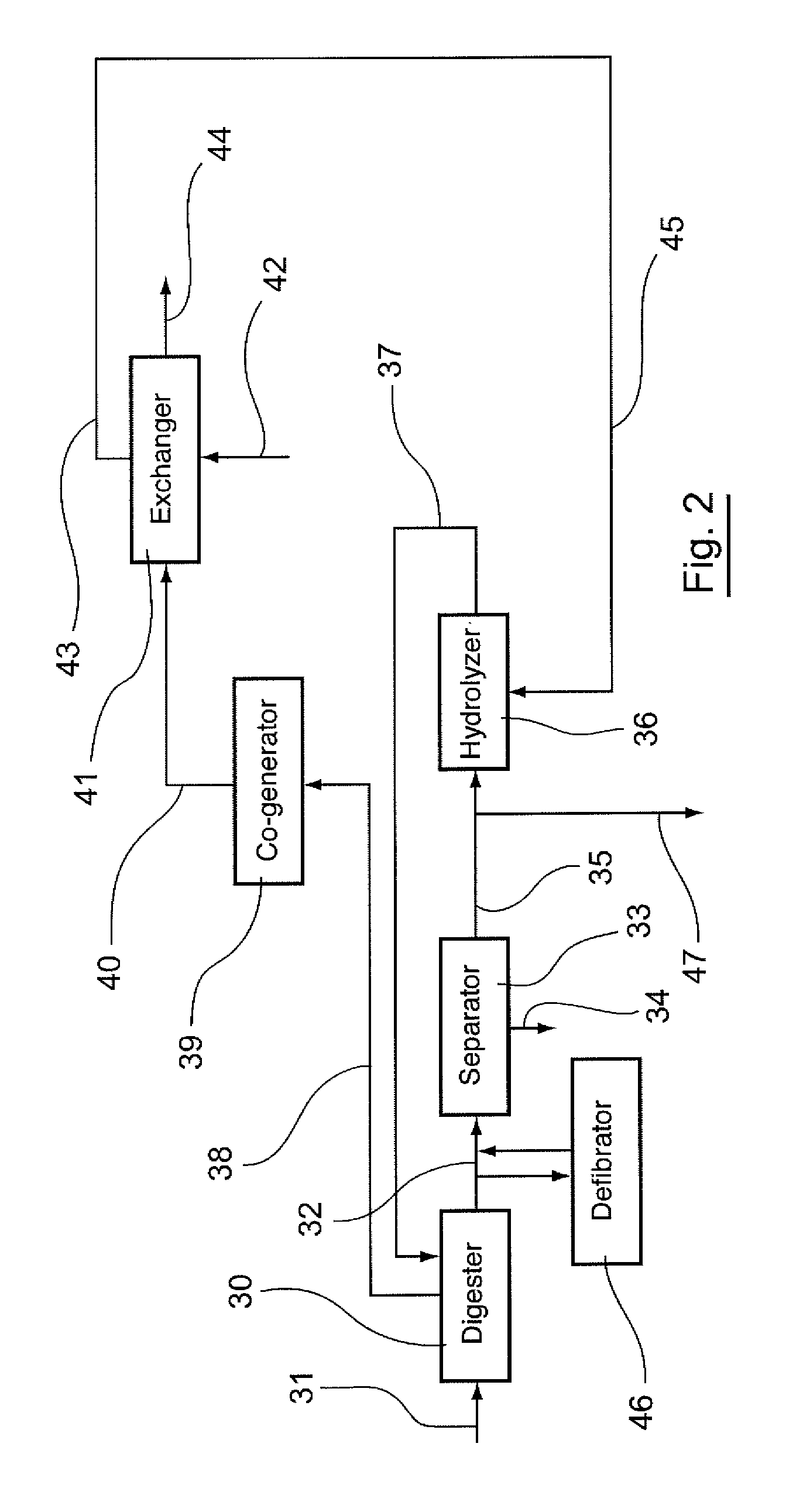

Method for Producing Non-Putrescible Sludge and Energy and Corresponding Plant

InactiveUS20120094363A1Low energy consumptionReduce in quantityBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasChemistry

The invention relates to a method for producing non-putrescible sludge and energy, wherein said method includes the following steps: (i) producing digested sludge by means of primary sludge digestion; (ii) producing a first aqueous effluent and digested sludge, which are at least partially dehydrated by a first liquid-solid separation of the digested sludge produced in step (i); (iii) producing digested sludge at least partially dehydrated and hydrolysed by thermal hydrolysis of the at least partially dehydrated digested sludge produced in step (ii); (iv) digesting the at least partially dehydrated and hydrolysed digested sludge produced in step (iii); wherein said method further includes a step of recovering the biogases formed during said digestion and said primary digestion, and a step of producing energy from said biogas, including a first sub-step of producing the energy required for implementing said thermal hydrolysis and a sub-step of producing excess energy, the entirety of the biogas being used for producing electricity.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

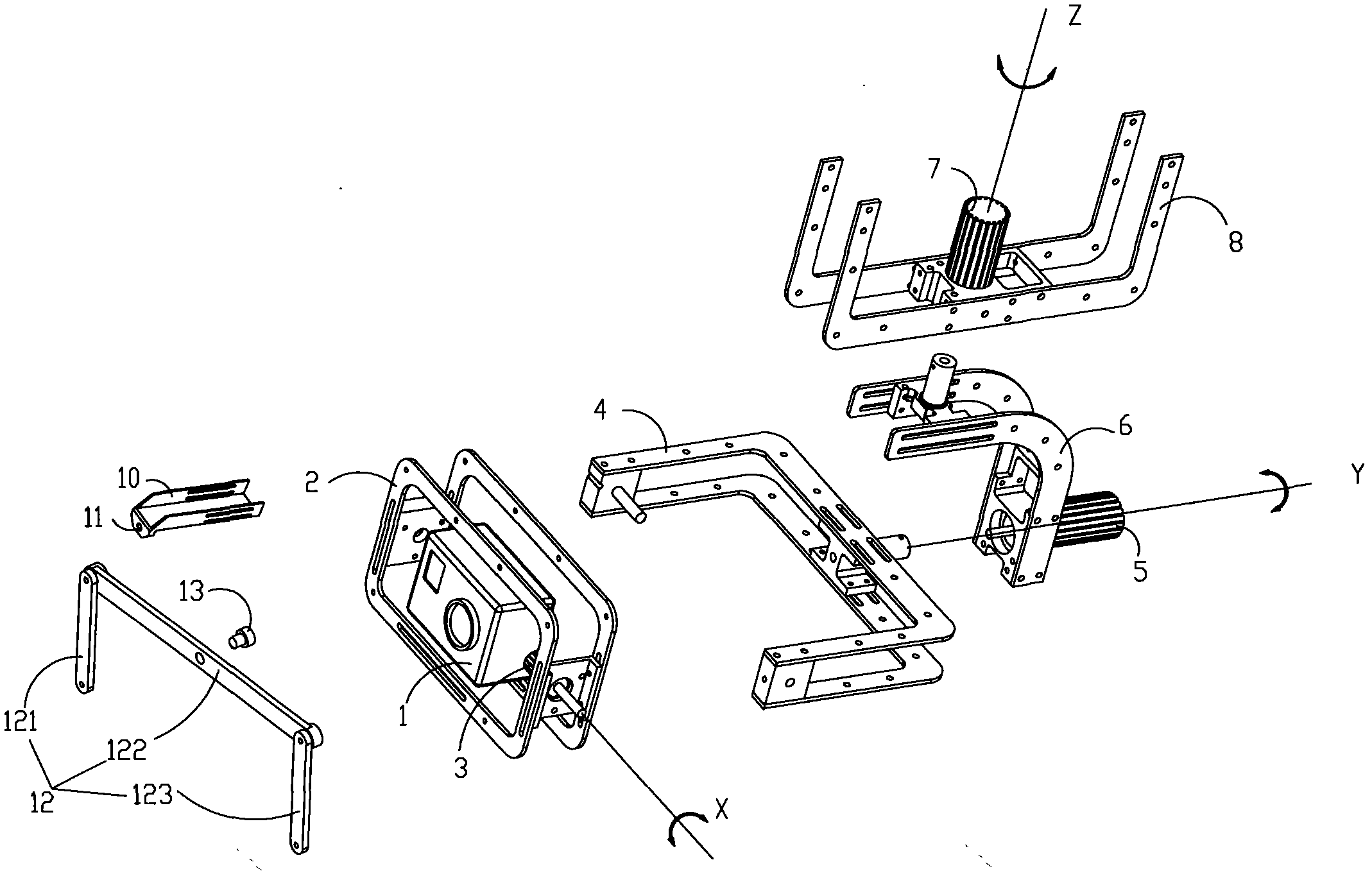

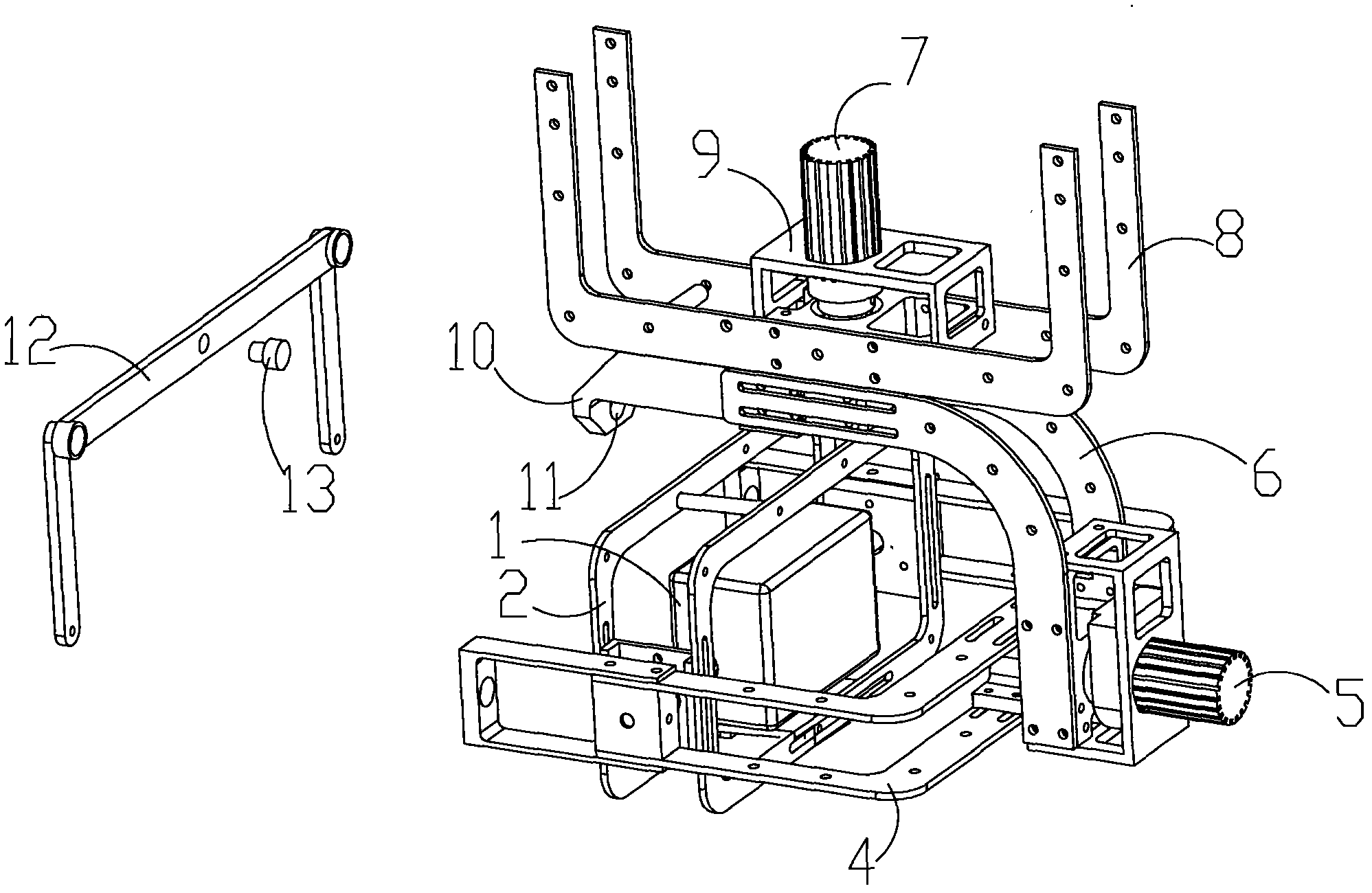

Gyro-type dynamic self-balancing pan-tilt

ActiveCN102996983ALow energy consumptionSave electricityAircraft componentsUnmanned aerial vehiclesElectricitySelf weight

The invention discloses a gyro-type dynamic self-balancing pan-tilt which comprises a frame component, a motor component, shooting equipment and a control component; the control component comprises a processor and an inertial sensor; the inertial sensor detects the posture information of the shooting equipment; the processor controls the motor component according to the posture information; the motor component directly drives the frame component to rotate in a manner relative to the shooting equipment so as to adjust the shooting angle of the shooting equipment; a connecting rod component for assisting the frame component is also arranged; and the connecting rod component rotates along with the frame component and supports the frame component. According to the gyro-type dynamic self-balancing pan-tilt, the motor component is adopted as the motive power to directly drive the frame component of the pan-tilt, so that less energy is consumed, and the electricity is saved; the connecting rod component and the frame component form a four-link component; the connecting rod component provides effective support for the frame component in a vertical direction, so that the load and the rigidity of the frame component are increased; when the load of the frame component is larger, the deformation of the frame component is effectively reduced; and meanwhile, the self-weight of the frame component is reduced, and the diameter of a motor is reduced.

Owner:SZ DJI TECH CO LTD

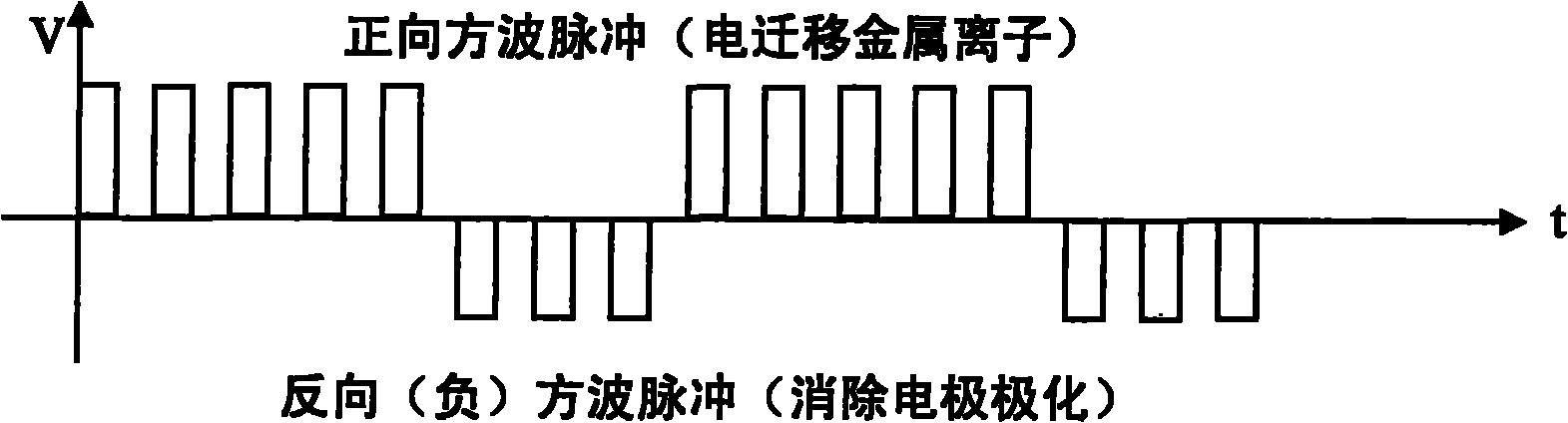

Method for removing soluble heavy metal ions in situ

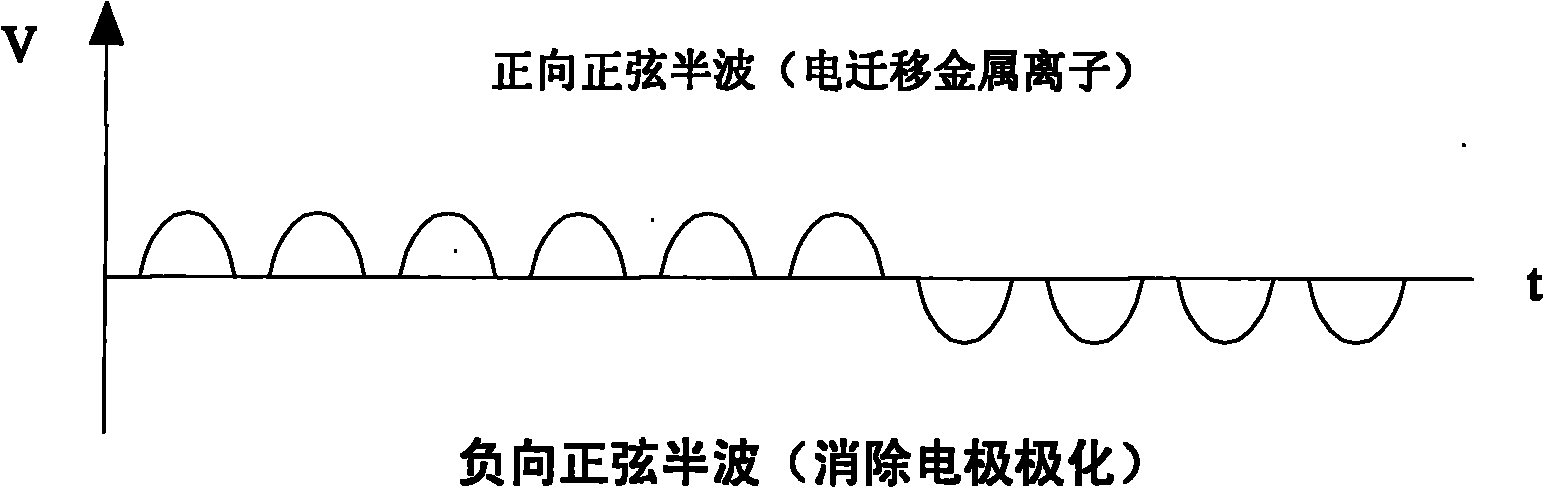

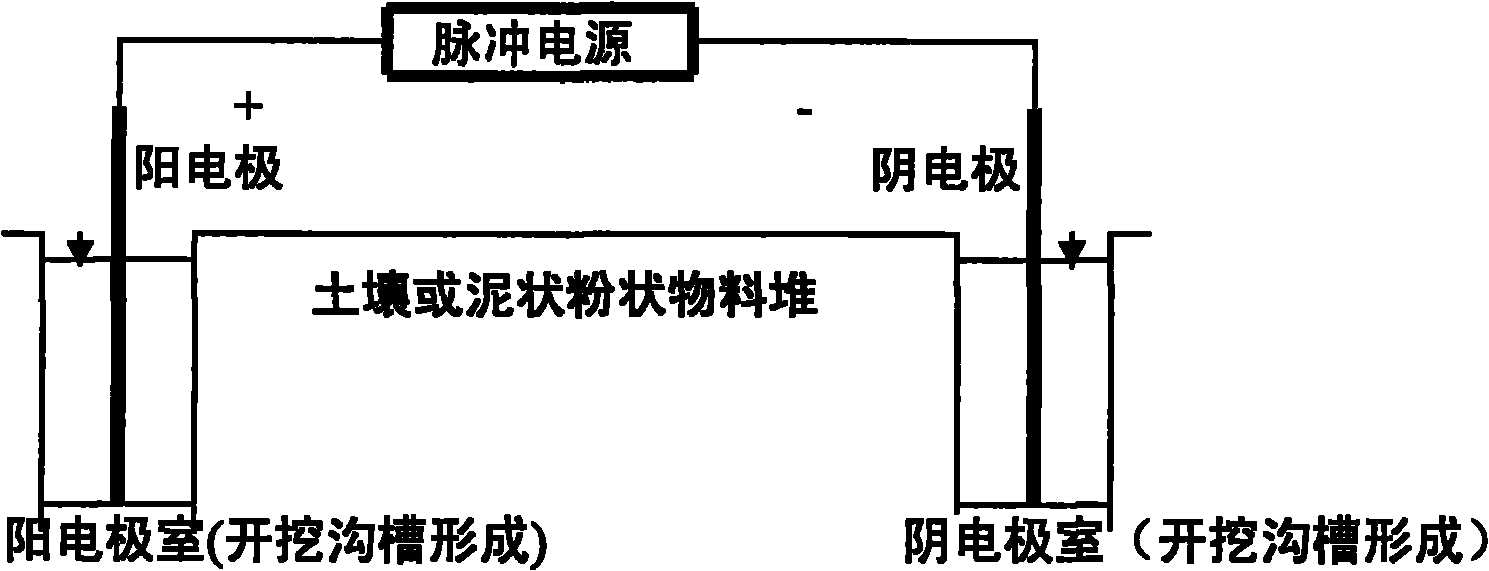

InactiveCN101838740AWell formedAvoid breakingContaminated soil reclamationProcess efficiency improvementPolarization phenomenonPulse voltage

The invention relates to a method for removing soluble heavy metal ions in situ from soil or mud / powdery deposits. In the method, a negative electrode and a positive electrode are directly inserted into the soil or a material deposit containing the soluble heavy metal ions, the driving power source of the negative electrode and the positive electrode is a pulse power source, and the positive of the pulse voltage output by the pulse power source is connected with the positive electrode, while the negative is connected with the negative electrode. The method provides the pulse power source capable of generating high-impact electric field force, eliminates three electrode polarization phenomena which cannot be overcome by the conventional DC kinetics method, has no secondary pollution on environment, and greatly improves the efficiency of removing the heavy metal ions from the soil or mud / powdery waste materials through in-situ migration by adopting the conventional DC kinetics method.

Owner:中钢集团武汉安全环保研究院有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com