Patents

Literature

3250 results about "Fluidization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluidization (or fluidisation) is a process similar to liquefaction whereby a granular material is converted from a static solid-like state to a dynamic fluid-like state. This process occurs when a fluid (liquid or gas) is passed up through the granular material.

Drug administration method

InactiveUS7427607B2Reduce weightPrevention of the adhesion of an organBiocidePowder deliveryBiopolymerDrug administration

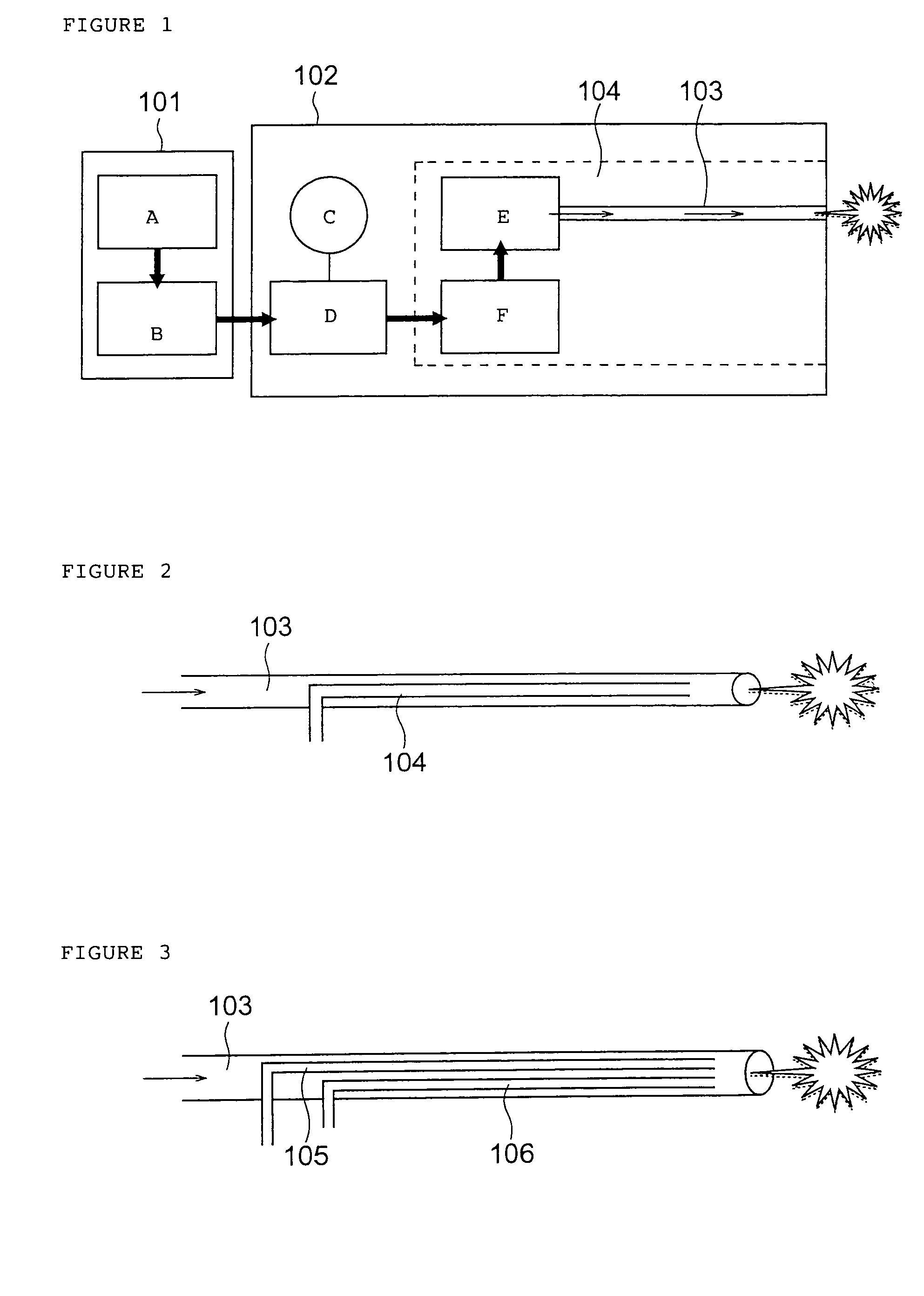

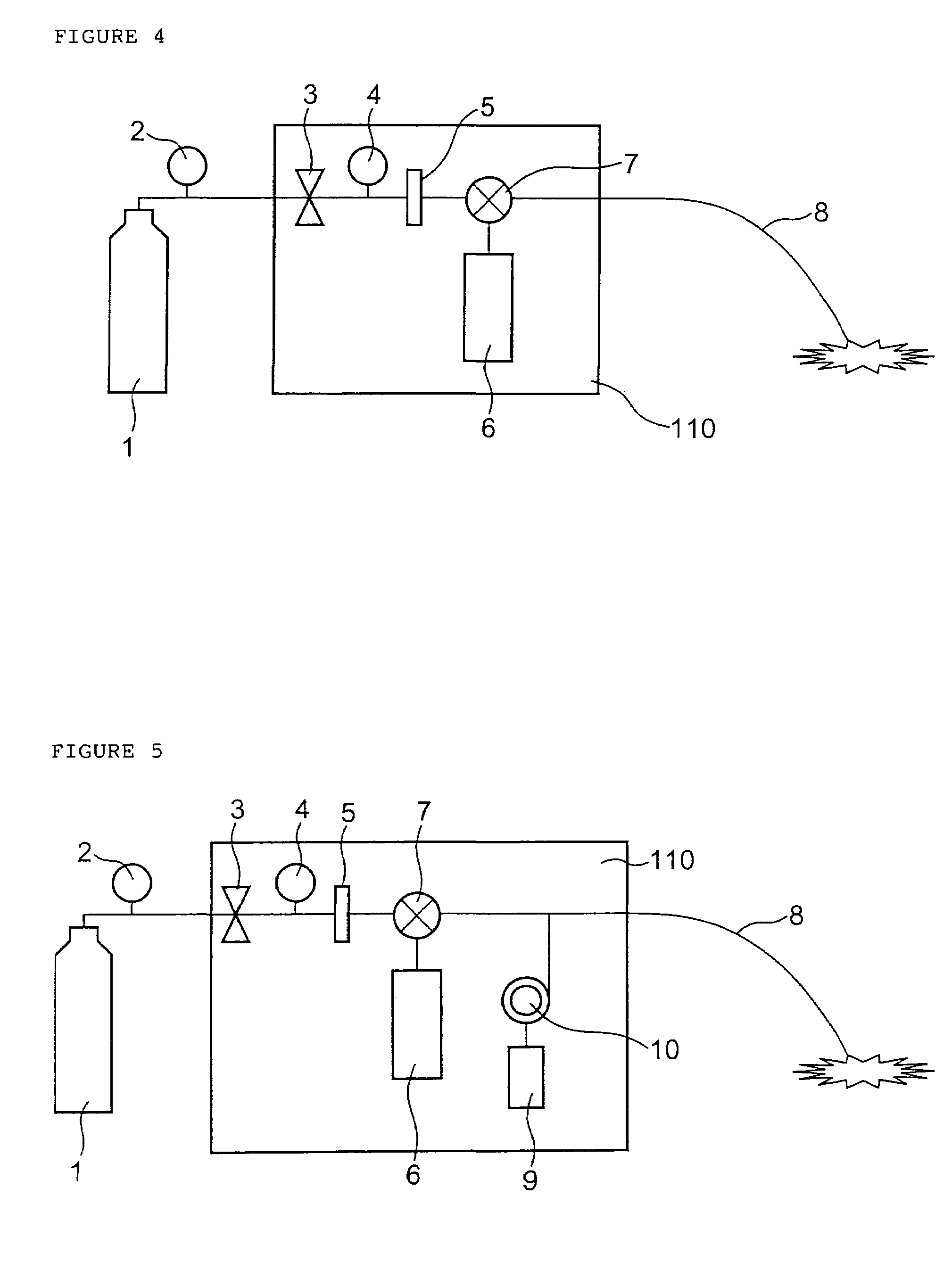

A method of administering a drug whereby a fine drug powder can be accurately administered to a target site (in particular, a target site in the body cavity) via fluidization and spraying with a gas by using a micro tube. Concerning the administration mode, in particular, the drug alone or a biopolymer is administered or the biopolymer is employed as a carrier in the above method. More specifically speaking, a method of administering a fine drug powder which comprises finely milling one or more types fine particles of the drug and / or the biopolymer, blending them each other, fluidizing the blend with a gas, then transporting the fluidized matter in a micro tube by the gas stream and spraying the fine drug powder from the tip of the micro tube toward the target site. Further, an administration method which comprises concentrically providing a capillary tube in the micro tube, supplying an aqueous solution of the drug and / or the biopolymer from the capillary tube into the gas stream and then mixing it with other fine particles of the drug and / or the biopolymer under transportation by the gas.

Owner:NEXT21 KK

Method for gas-solid contacting in a bubbling fluidized bed reactor

InactiveUS6894183B2Eliminate and drastically reduce bypassEffective contactThermal non-catalytic crackingCatalytic crackingForming gasSolid particle

Owner:COUNCIL OF SCI & IND RES

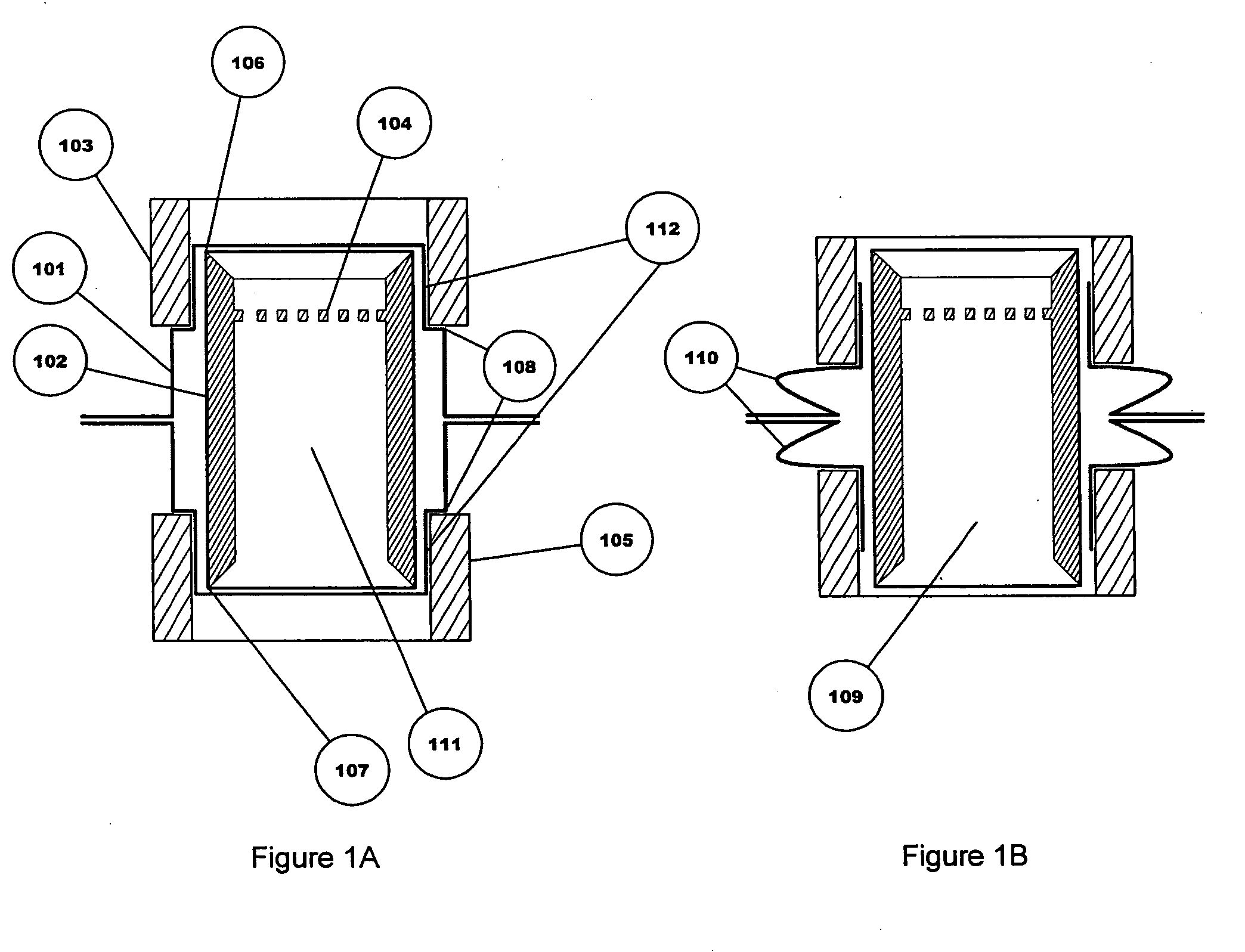

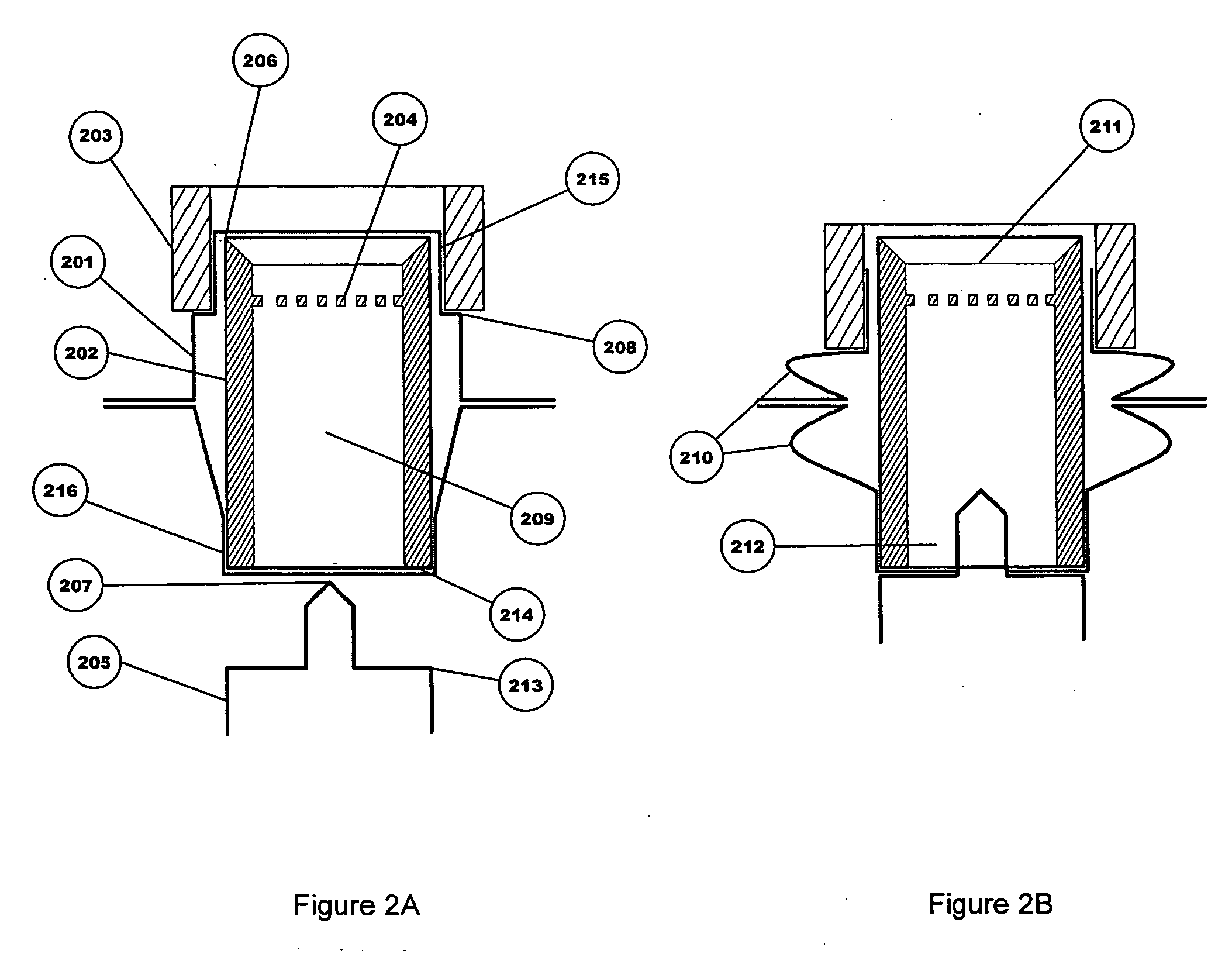

Inhalation device

ActiveUS20070151562A1Inhibit migrationRespiratorsLiquid surface applicatorsInhalation DevicesDelivery system

The present invention provides for the integration of drug dispersion methods into a drug or medicine delivery system. The drug dispersion methods used include shear (e.g., air across a drug, with or without a gas assist), capillary flow or a venturi effect, mechanical means such as spinning, vibration, or impaction, and turbulence (e.g., using mesh screens, or restrictions in the air path). These methods of drug dispersion allow for all of the drug in the system to be released, allowing control of the dosage size. These methods also provide for drug metering, fluidization, entrainment, deaggragation and deagglomeration. The present invention also provides for the integration of a drug sealing system into the device. The drug sealing system provides a way of blocking the migration of drug from one area of the package to another. The drug seal system can also provide a method of tightly containing the drug until the package is opened, of directing airflow through the package and of managing and containing the drug during the package / device manufacturing process.

Owner:MANTA DEVICES

Cracking catalyst

This invention published a fluidization cracking catalyst. The main components of the catalyst are 5~70% (w / w) cracked active component, 5~80%clay and 10~60%agglomerant. Y-type of molecular sieve and 3~20% sialic material which based on catalyst and had been acidized within the cracked active component is the characteristic of the catalyst. The sialic material has a phase structure as thin diaspore. Its formula (calculated by weight of oxidants) is (0-0.3) Na2O . (40-90) Al2O3 . (10-60) SiO2. It has specific area 200~400m2 / g, average aperture 8~20nm, most probable aperture 5~15nm.The acidification treatment mentioned was inorganic acid and sialic material (ratio of the tow: 0.1~0.3) kept contacting for 0.5~3h under room-temperature ~80DEG C.This catalyst has well intensity, high stability of activity, low yield of heavy oil and strong capability of conversion for crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasifier fluidization

InactiveUS20130109765A1Gasifier mechanical detailsCombustible gas catalytic treatmentProduct gasProcess engineering

A method of producing synthesis gas by introducing a feed material to be gasified into a gasification apparatus comprising at least one fluidized component operable as a fluidized bed, wherein the gasification apparatus is configured to convert at least a portion of the feed material into a gasifier product gas comprising synthesis gas; and maintaining fluidization of the at least one fluidized component by introducing a fluidization gas thereto, wherein the fluidization gas comprises at least one component other than steam. A system for producing synthesis gas is also provided.

Owner:RES USA LLC

Methods for coating particles and particles produced thereby

InactiveUS7063748B2Improved pharmacokinetic profileExtended production timeLiquid surface applicatorsElectric discharge heatingParticulatesAtmospheric pressure

Methods of coating core materials by providing target materials and core materials; ablating the target materials to form ablated particulate target materials; and coating the core materials with said ablated particulate target materials; wherein the method is performed at a pressure of about 10 Torr or higher. Methods of coating particles with nanometer to multiple nanometer thick coatings in atmospheric pressure, and using pneumatic fluidization, are also provided.

Owner:NANOTHERAPEUTICS INC

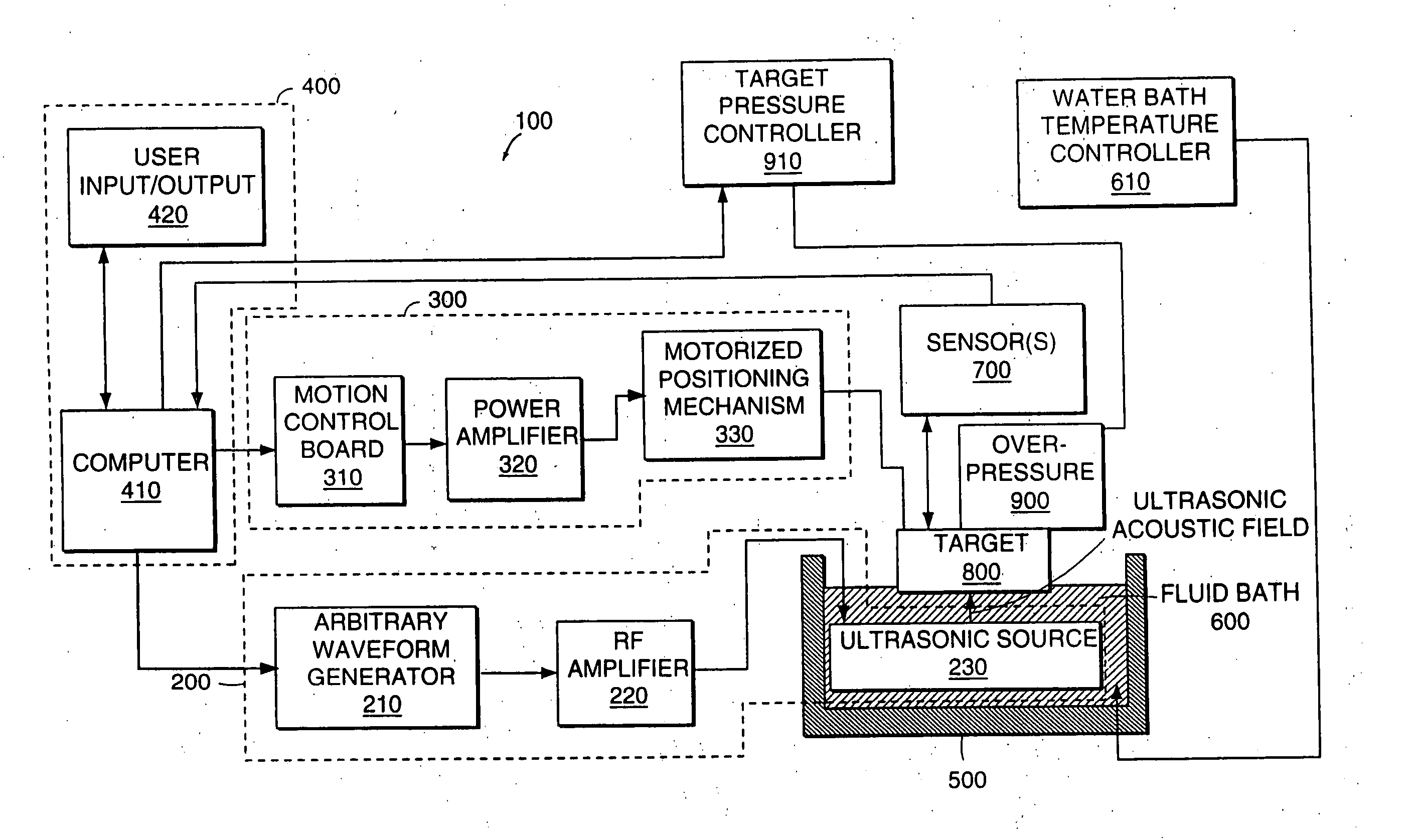

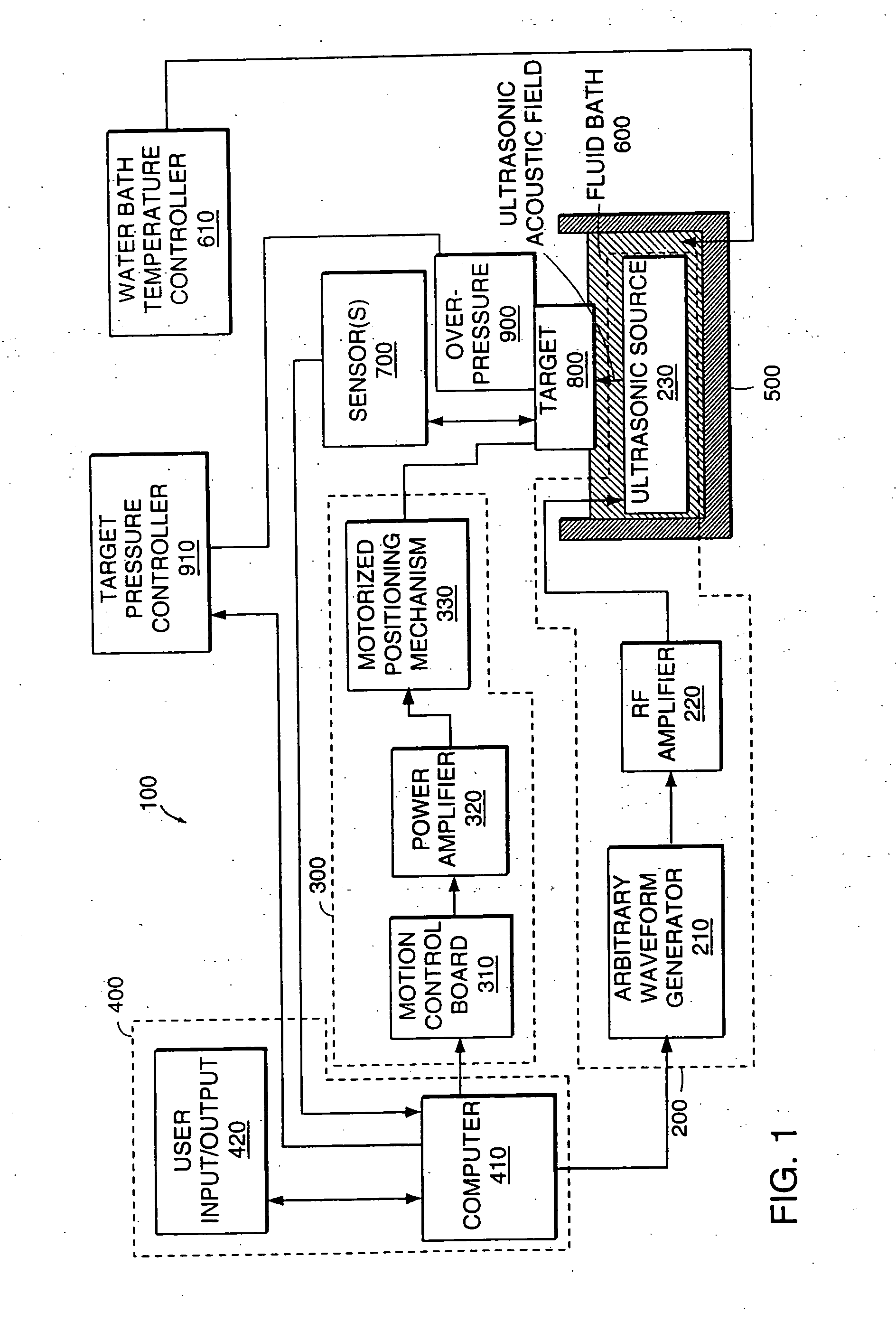

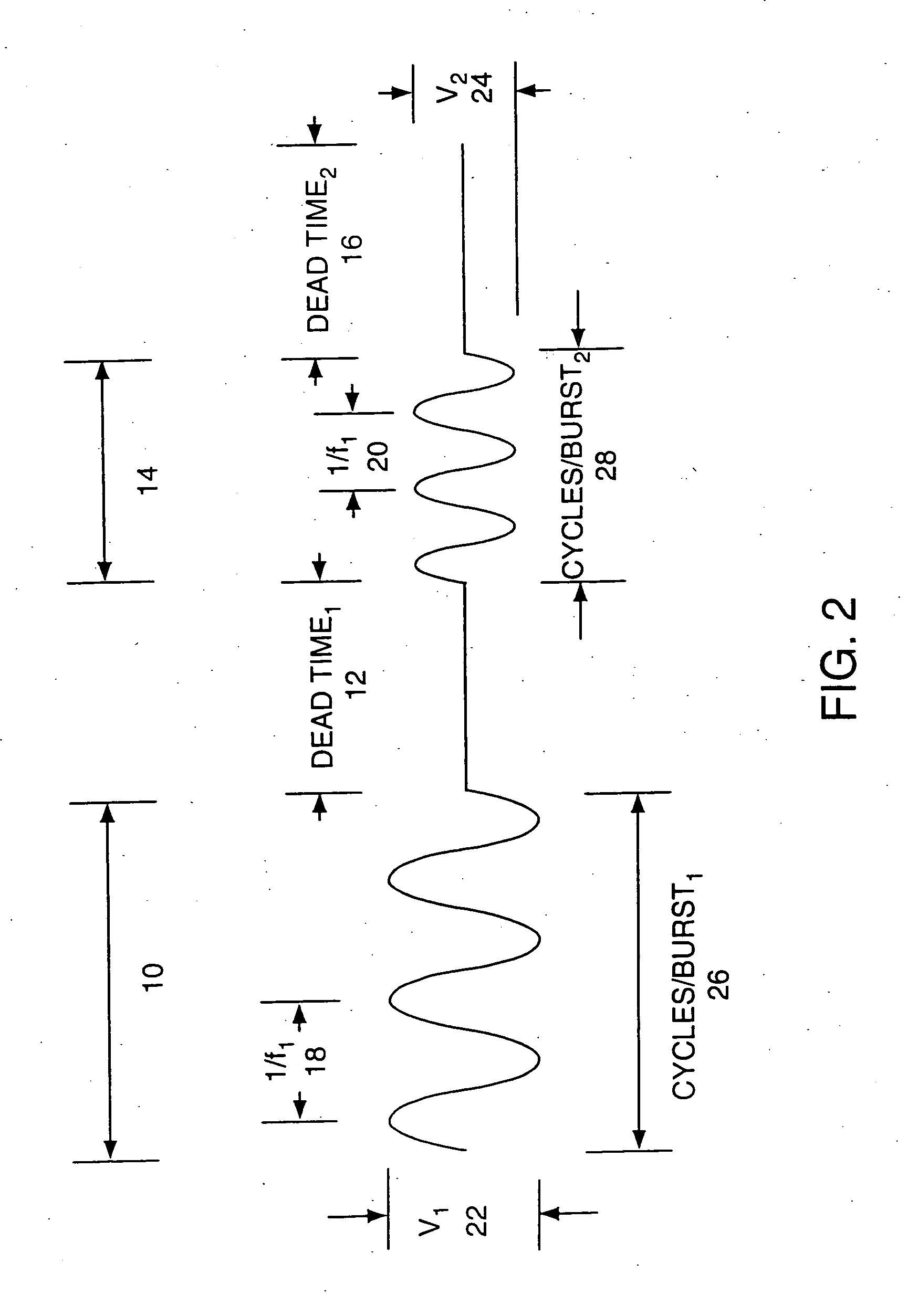

Systems and methods for determining a state of fluidization and/or a state of mixing

InactiveUS20050150830A1Preserve biological activityPreserving viabilityShaking/oscillating/vibrating mixersTransportation and packagingEngineeringFluidization

Owner:COVARIS INC

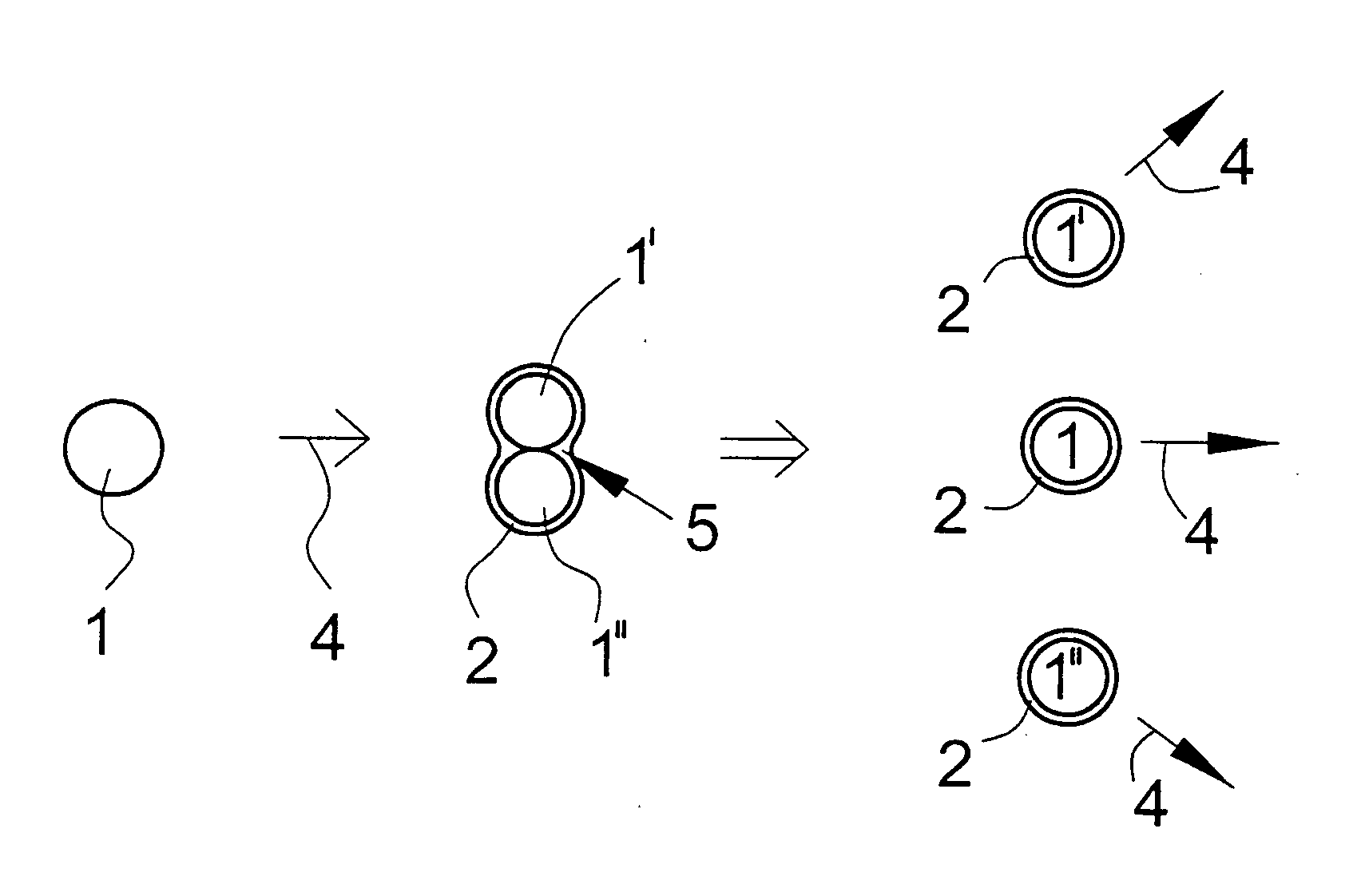

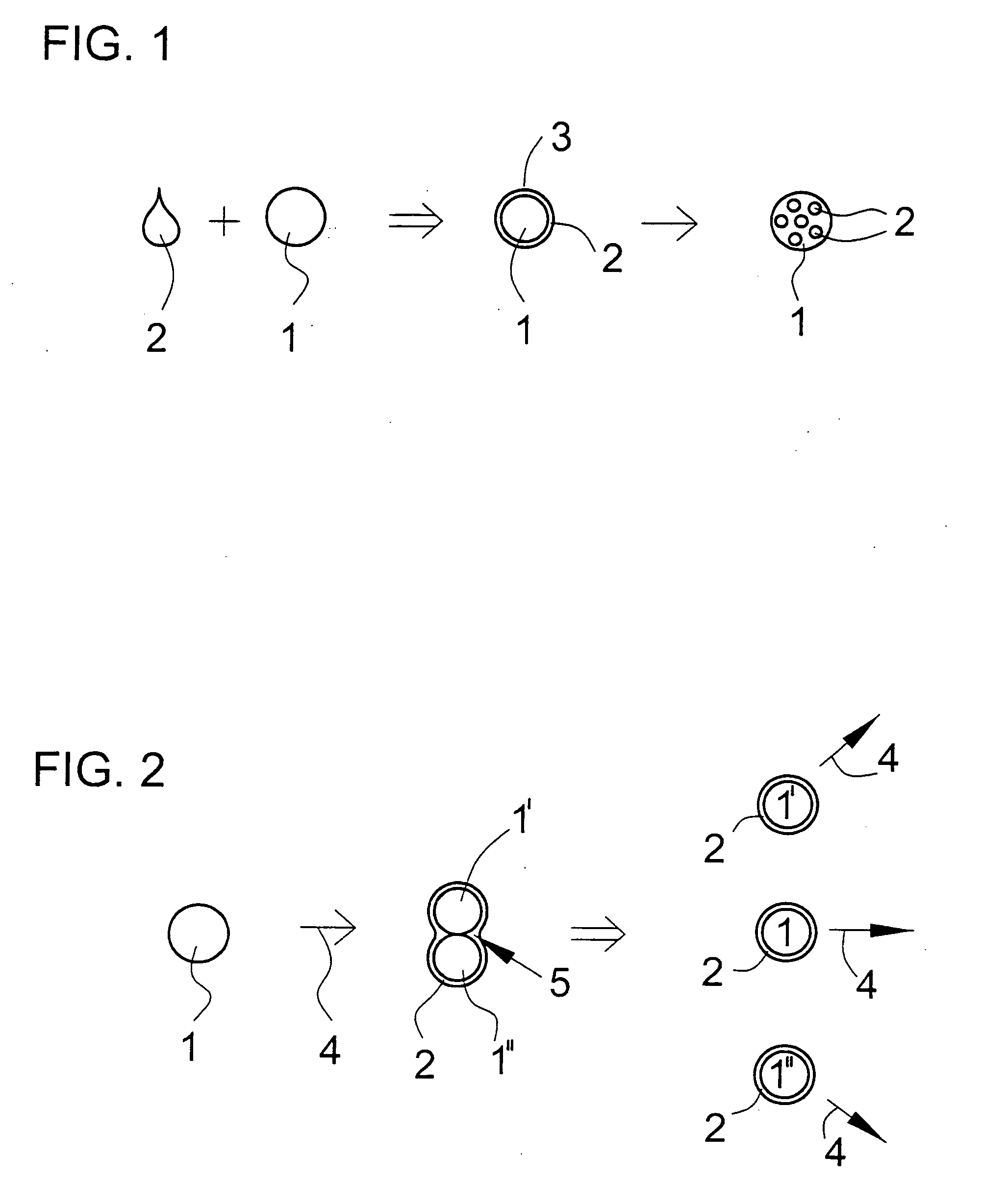

Two-step mixing process for producing an absorbent polymer

A process for producing an absorbent polymer including a first mixing event, in which a plurality of absorbent polymer particles (1) are mixed with a liquid (2) and a second mixing event, in which the liquid (2) is homogenized within the interior of the polymer particles. The polymer particles (1) in the first mixing event are mixed with a speed such that the kinetic energy of the individual polymer particles (1) is on average larger than the adhesion energy of the individual polymer particles (1), and the polymer particles (1) in the second mixing event are stirred at a lower speed than in the first mixing event. The different speeds effect a fluidization of the polymer particles (1), which prevents a clumping of the polymer particles (1) during the mixing event. The absorbent polymers thus produced are distinguished by a particularly rapid swelling behavior.

Owner:EVONIK DEGUSSA GMBH

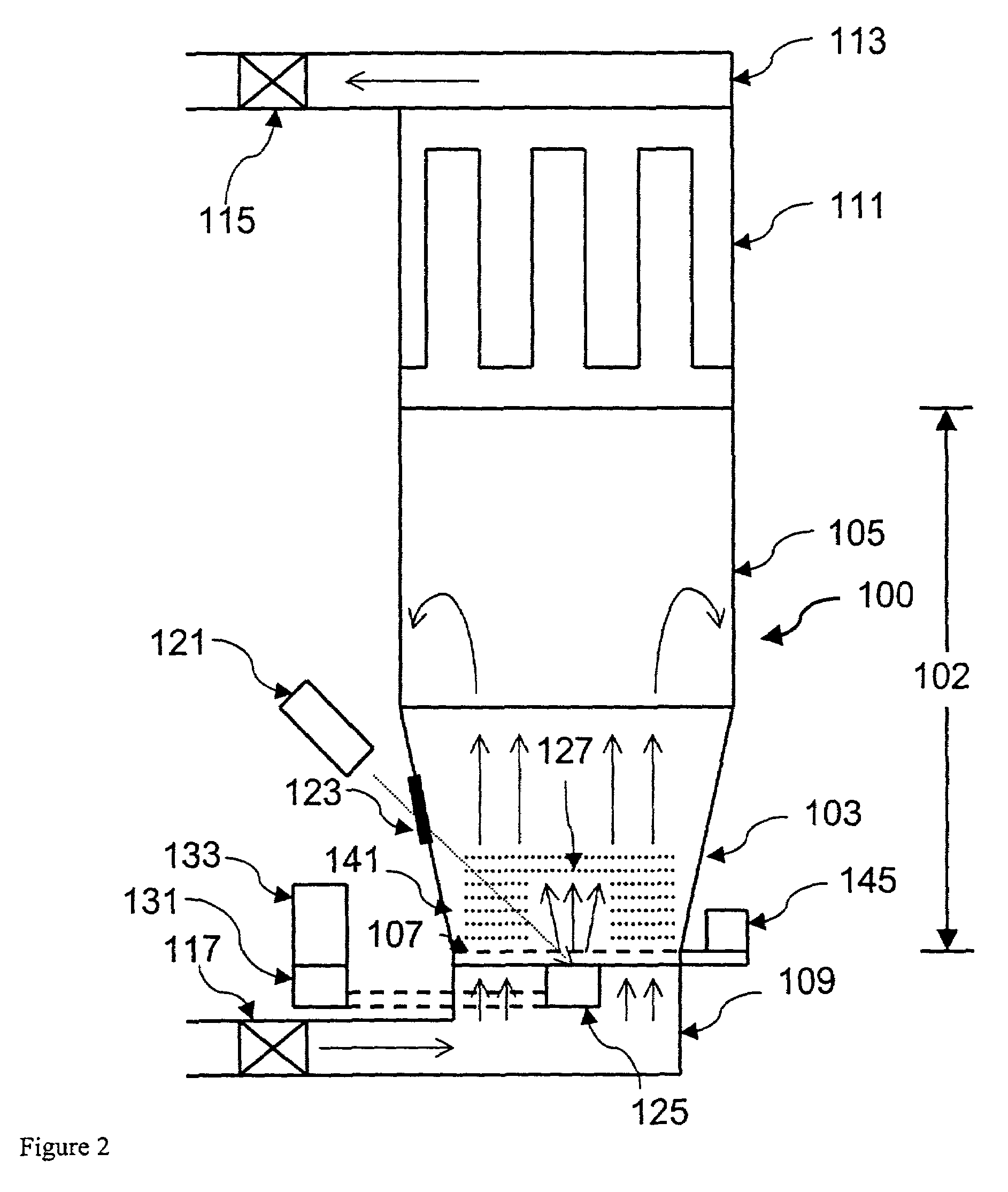

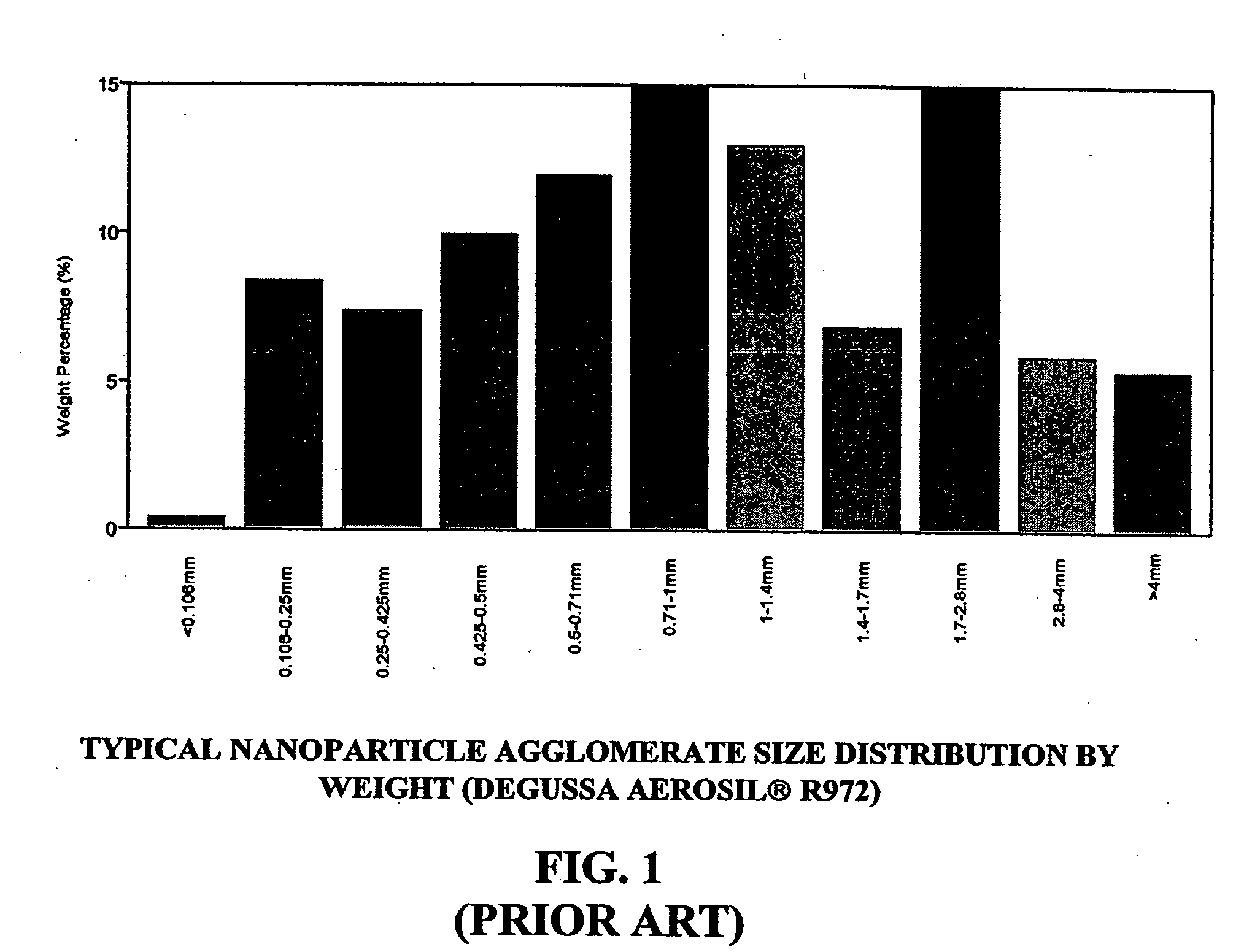

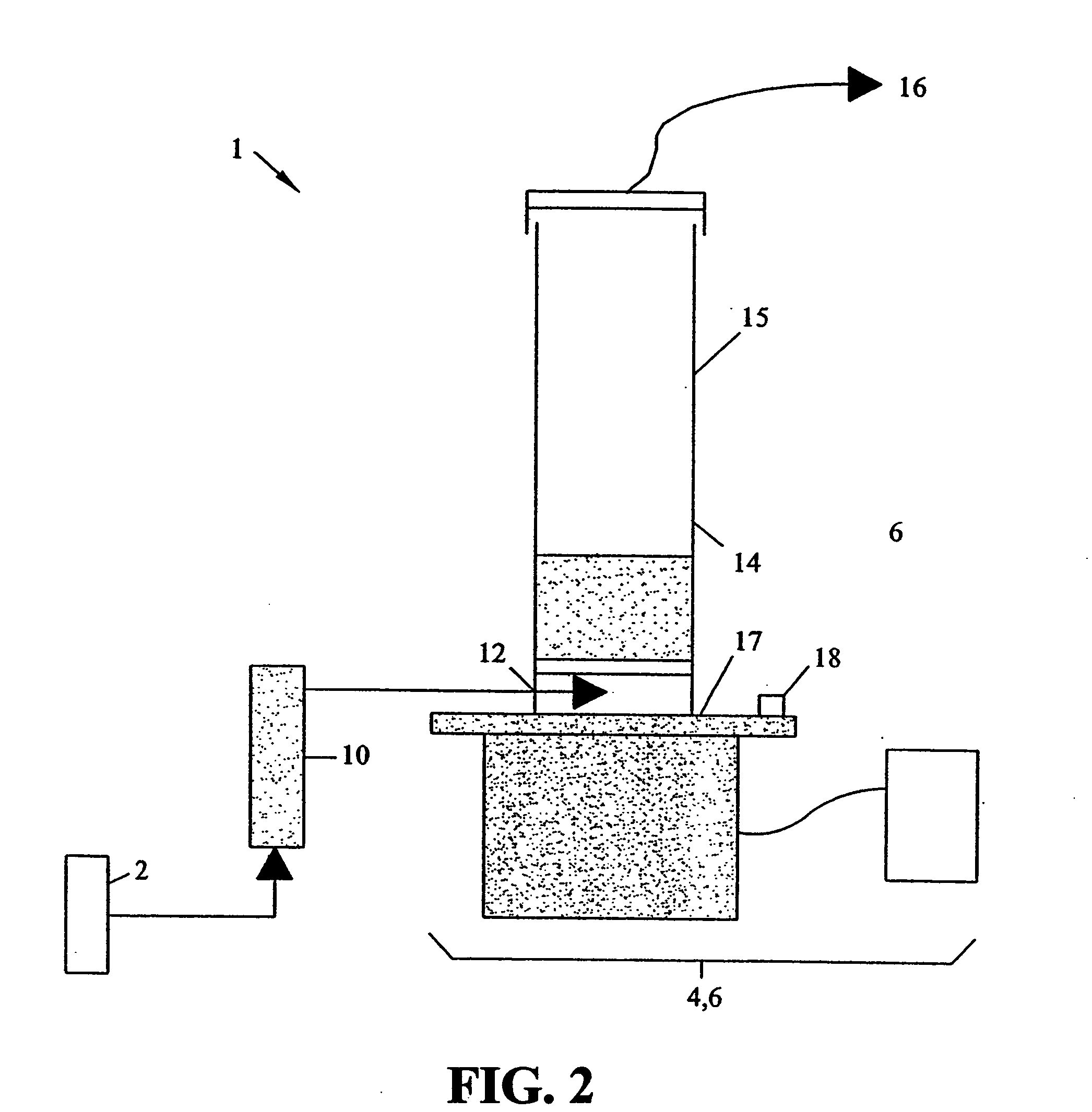

System and method for nanoparticle and nanoagglomerate fluidization

InactiveUS20060086834A1Convenient treatmentEffective dispersionShaking/oscillating/vibrating mixersElectrical apparatusEngineeringElutriation

With the coupling of an external field and aeration (or a flow of another gas), nanoparticles can be smoothly and vigorously fluidized. Multiple external fields and / or pre-treatment may be employed with the fluidizing gas: sieving, magnetic assistance, vibration, acoustic / sound or rotational / centrifugal forces. Any of these forces, either alone or in combination, when coupled with a fluidizing medium, provide excellent means for achieving homogenous nanofluidization. The additional force(s) help to break channels as well as provide enough energy to disrupt the strong interparticle forces, thereby establishing an advantageous agglomerate size distribution. Enhanced fluidization is reflected by at least one of the following performance-related attributes: reduced levels of bubbles within the fluidized system, reduced gas bypass relative to the fluidized bed, smooth fluidization behavior, reduced elutriation, a high level of bed expansion, reduced gas velocity levels to achieve desired fluidization performance, and / or enhanced control of agglomerate size / distribution. The fluidized nanoparticles may be coated, surface-treated and / or surface-modified in the fluidized state. In addition, the fluidized nanoparticles may participate in a reaction, either as a reactant or a catalyst, while in the fluidized state.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

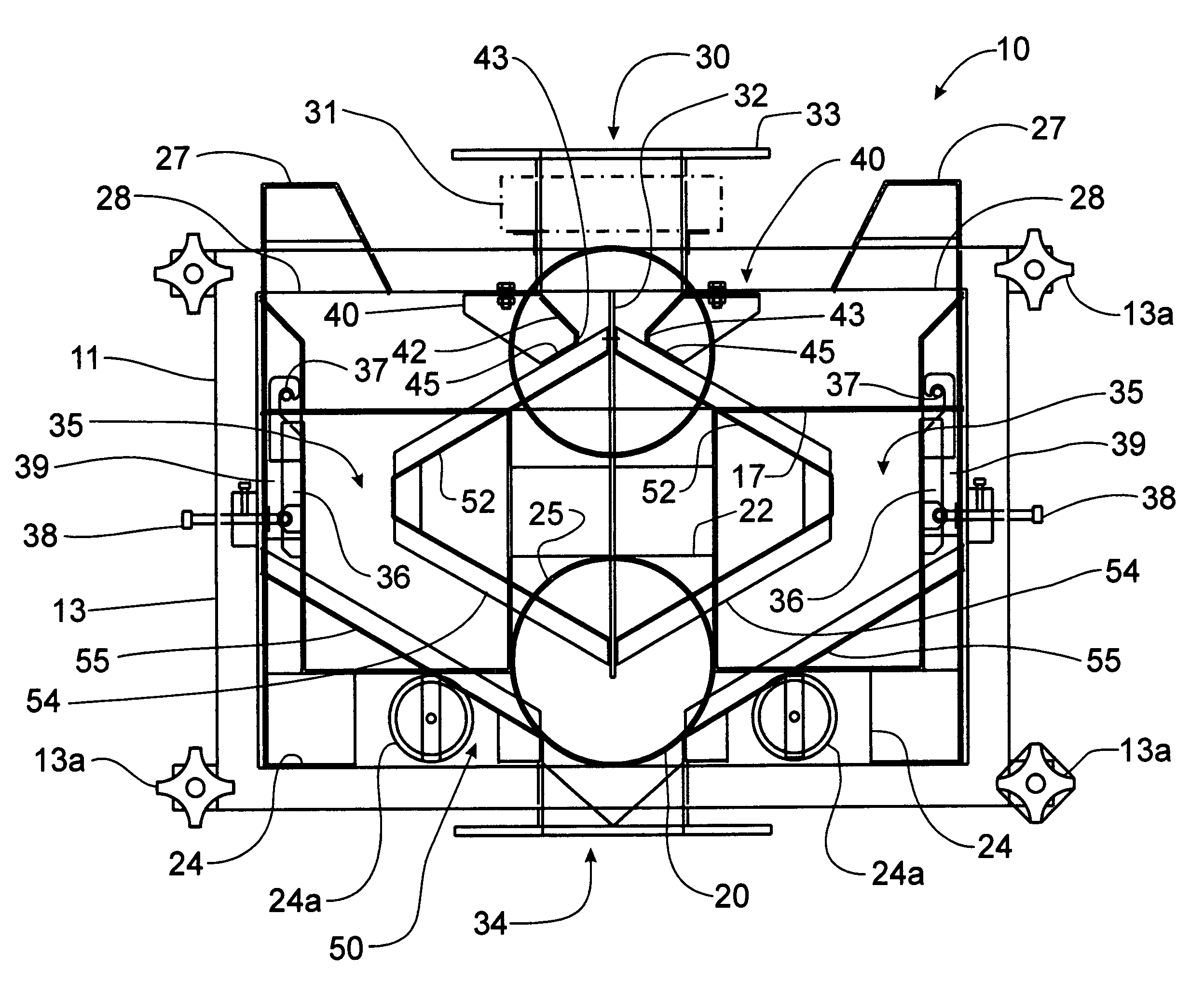

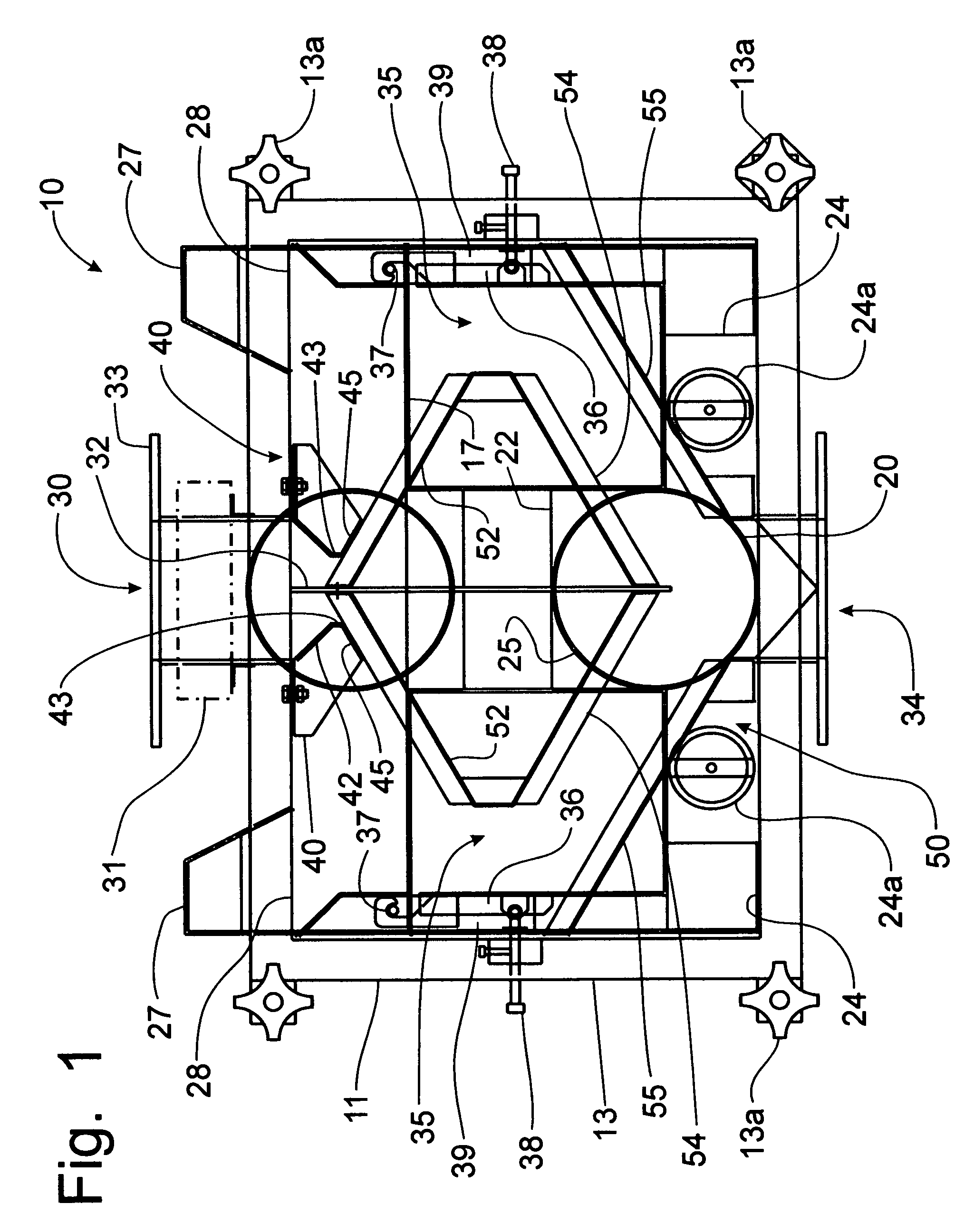

Compact dedusting apparatus

ActiveUS7380670B2Improved airflow characteristicsClean thoroughlyGas current separationMagnetic separationMagnetic fluxDust particles

A compact housing for a dedusting apparatus utilizes a magnetic flux field to disrupt the static charge attracting dust particles to product particles, which along with fluidization and counter current airflow principles that are proven to dislodge dust particles from the product, provides a highly efficient, compact deduster. The housing supports a double wash deck with product flow separated between the back-to-back primary wash decks. A deflector directing the flow of product onto the primary wash decks is provided with an extension that extends parallel to the wash deck to eliminated product bouncing off of the wash deck. The lower air outlets are eliminated, while the upper air outlets are positioned in extensions to the main housing above the product inlet opening. Air flow through the Venturi zone is enhanced by re-directing clean air directly to the backside of the Venturi panels, thereby eliminating the extraneous by-pass boxes.

Owner:PELLETRON CORP

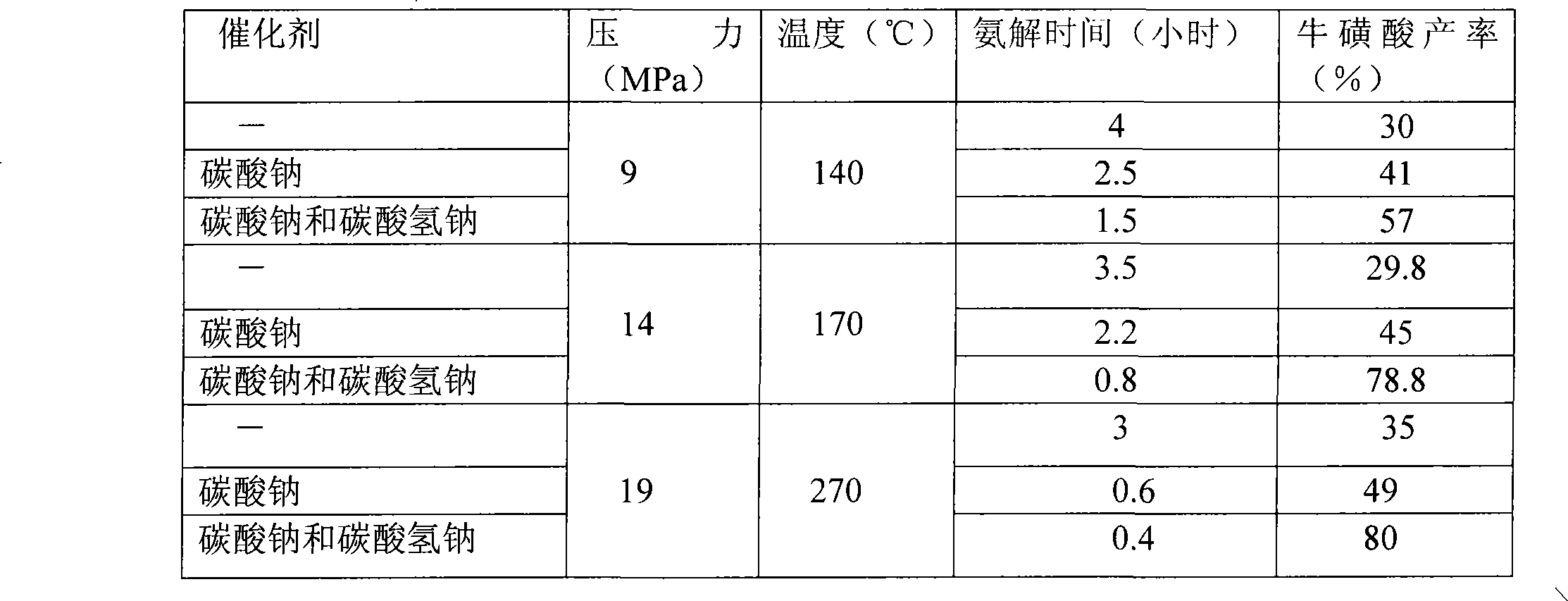

Method for preparing taurine

The invention relates to a method for preparing taurine, comprising the following steps: epoxy ethane and sodium bisulfite are reacted under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction at under 14 to 21MPa and at a temperature between 160 and 280 DEG C to form ammonolysis solution containing sodium taurate; and the ammonolysis solution is evaporated to remove ammonia, neutralized by sulphuric acid, concentrated, crystallized, separated, pre-dried in a boiling drying device or a vibration fluidization drying device, and then added into a microwave drying device to be dried and sterilized to obtain the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production. The water content of a taurine wet product can be reduced to below 0.30 percent through combined application of pre-drying of the boiling drying device or the vibration fluidization drying device and microwave drying, and simultaneously the device has the function of sterilizing.

Owner:王代龙 +1

Methods for coating particles and particles produced thereby

InactiveUS20020106461A1Extended production timeLow production costLiquid surface applicatorsElectric discharge heatingParticulatesAtmospheric pressure

Methods of coating core materials by providing target materials and core materials; ablating the target materials to form ablated particulate target materials; and coating the core materials with said ablated particulate target materials; wherein the method is performed at a pressure of about 10 Torr or higher. Methods of coating particles with nanometer to multiple nanometer thick coatings in atmospheric pressure, and using pneumatic fluidization, are also provided.

Owner:NANOTHERAPEUTICS INC

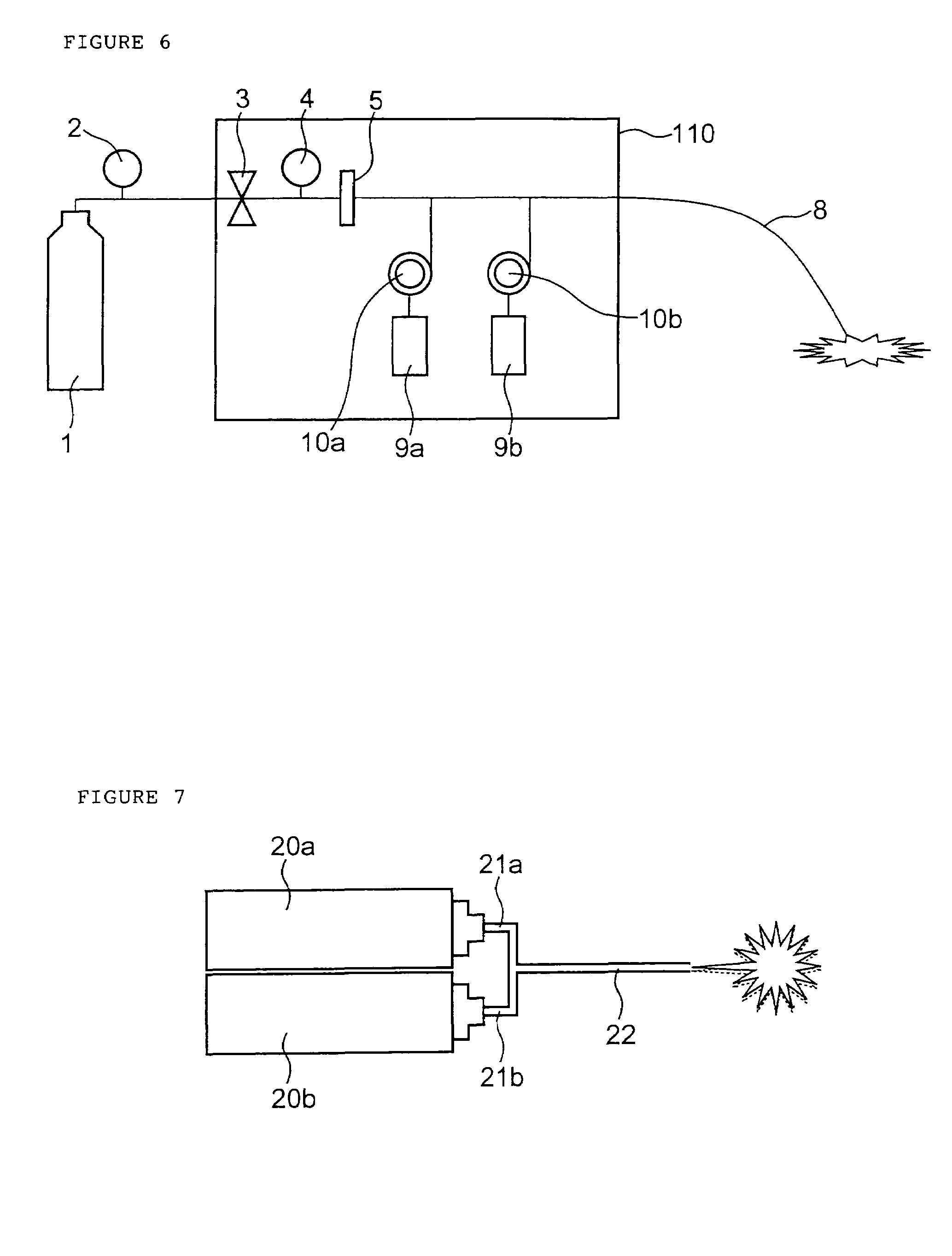

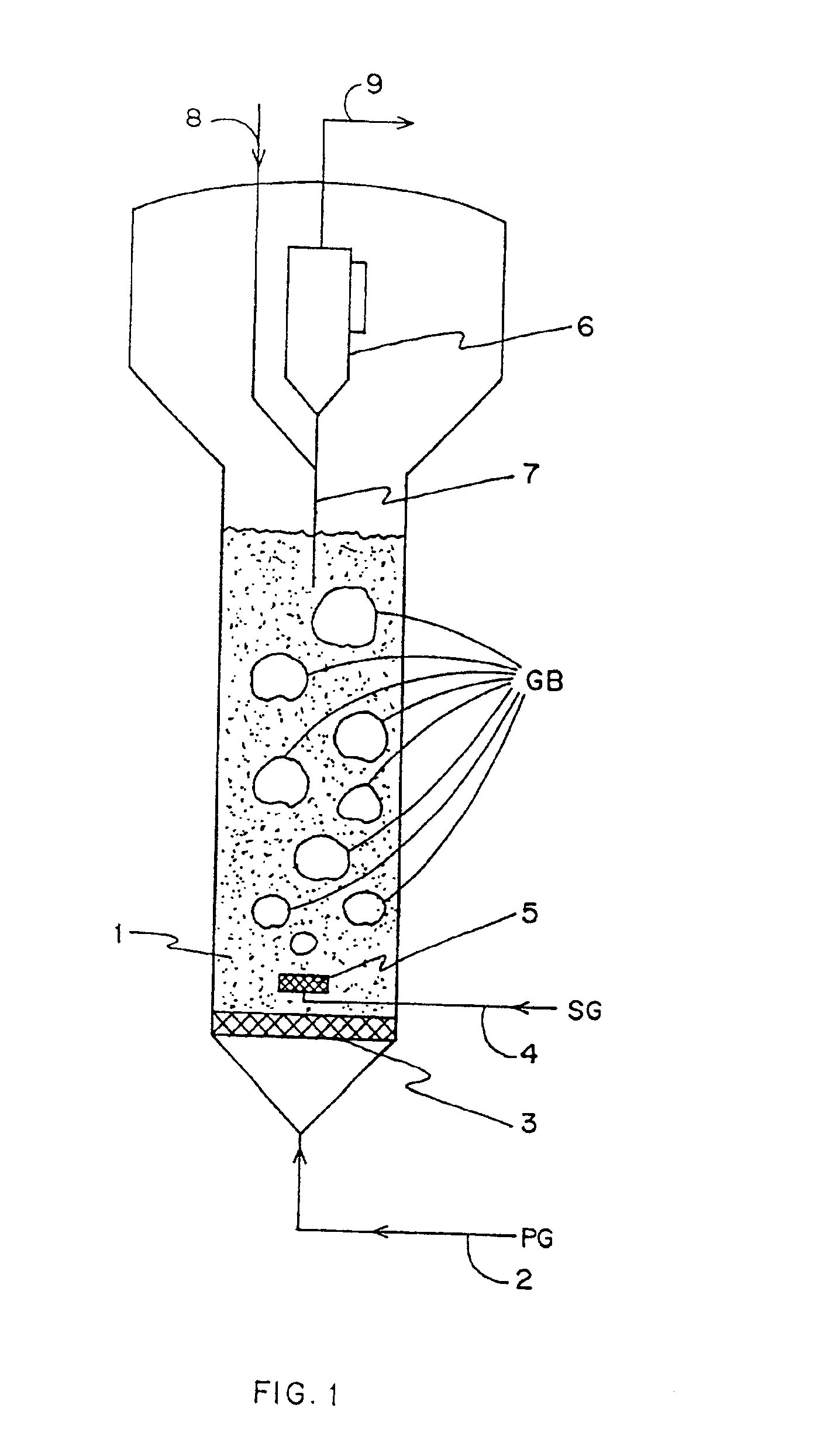

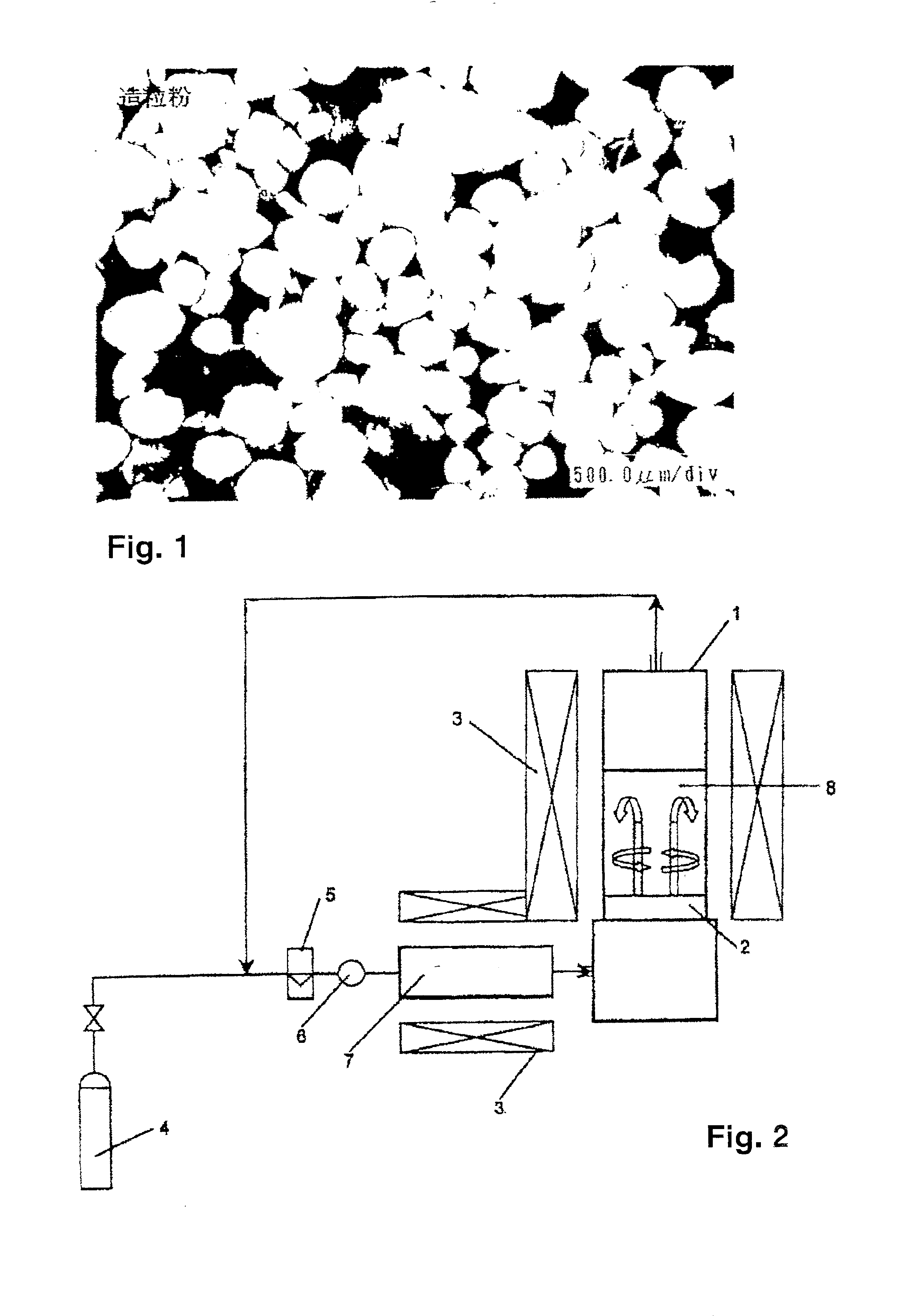

Porous silica granule, method for producing the same, and method for producing synthetic quartz glass powder using the porous silica granule

InactiveUS6849242B1Minimizes pore diameterHigh bulk densitySilicaGlass blowing apparatusMean diameterSlurry

The granule consists of individual granules approximately spherical in shape, having a pore volume of 0.5 cm3, a mean diameter of pores of 50 nm or less, a specific surface area of 100 m2 / g or less, and a bulk density of 0.7 g / cm3 or higher. It is produced by dispersing a fumed silica obtained by hydrolysis of a silicon compound into pure water to obtain a slurry, and drying the slurry. The granule is used for producing high purity synthetic quartz glass powder. The method further comprises: a first heat treatment under an oxygen-containing atmosphere, a second heat treatment in a temperature range of from 600 to 1100° C., and a third heat treatment in a temperature range of from 1100 to 1300° C. under an atmosphere containing hydrogen chloride; and a step of densification comprising calcining the product at a temperature not higher than 1500° C. under vacuum or in an atmosphere of gaseous hydrogen or gaseous helium. To calcine the powder without causing fusion adhesion of the particles, bubbling fluidization of said porous silica granule is conducted by supplying gaseous helium and calcining thereof in a temperature range of from 1000 to 1600° C.

Owner:HERAEUS QUARZGLAS +1

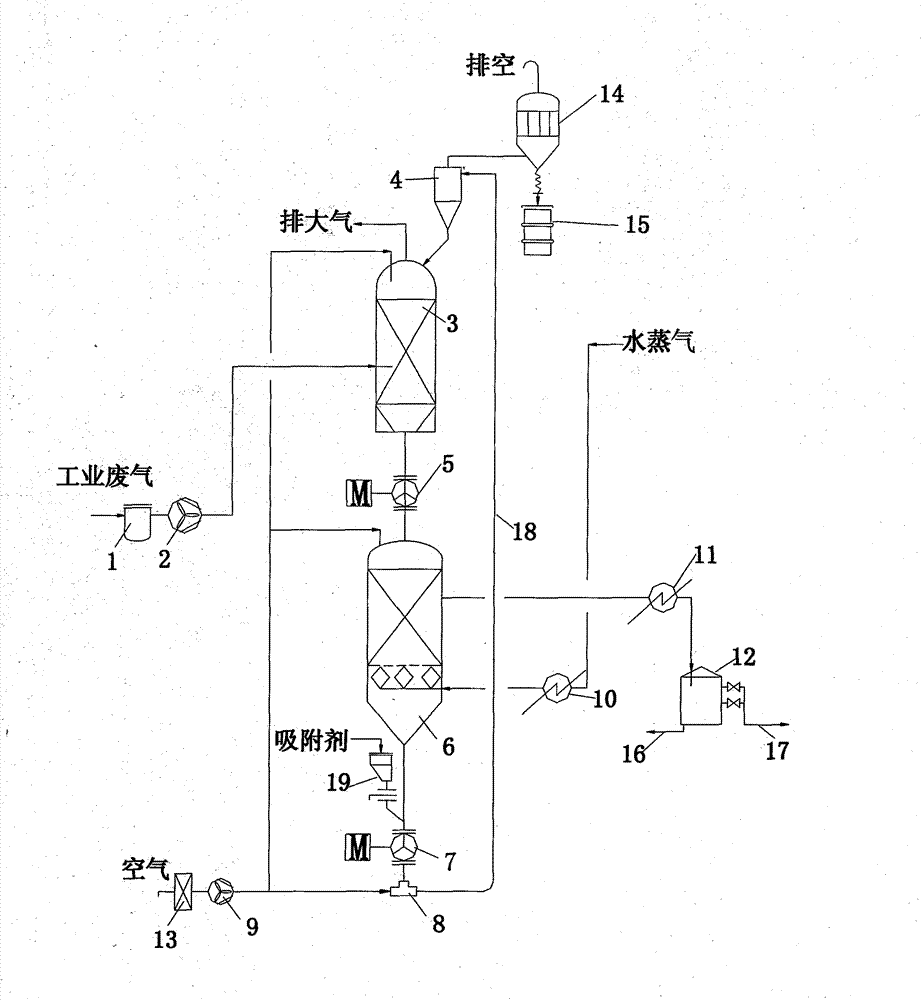

Device for continuously adsorbing and desorbing organic waste gas by using active carbon

ActiveCN102772981AFully furnishedImprove stabilityDispersed particle separationBenzeneActivated carbon

The invention relates to the technical field of industrial waste gas treatment and particularly relates to a treatment technology for continuously adsorbing an organic solvent in the industrial waste gas and continuously desorbing the solvent. The invention provides a device for continuously adsorbing and desorbing organic waste gas by using active carbon. The device comprises an adsorbing tower (3), a desorbing tower (6), an active carbon fluidization system, and an organic solvent recycling system. The organic waste gas, including methylene dichloride, methylbenzene, dimethylbenzene, benzene and the like, is continuously adsorbed by using the active carbon. The device has the outstanding characteristics that the adsorbing process and the desorbing process can be continuously and synchronously carried out. The organic waste gas and the active carbon are in inverse contact; the gas distribution is uniform; and the particle mobility is good. The active carbon is circularly used in a dense phase pneumatic transmission manner. The device provided by the invention has a simple and stable technique; and the labor intensity of staff and the environment pollution caused by the powder active carbon can be greatly reduced.

Owner:甘肃银光聚银化工有限公司 +1

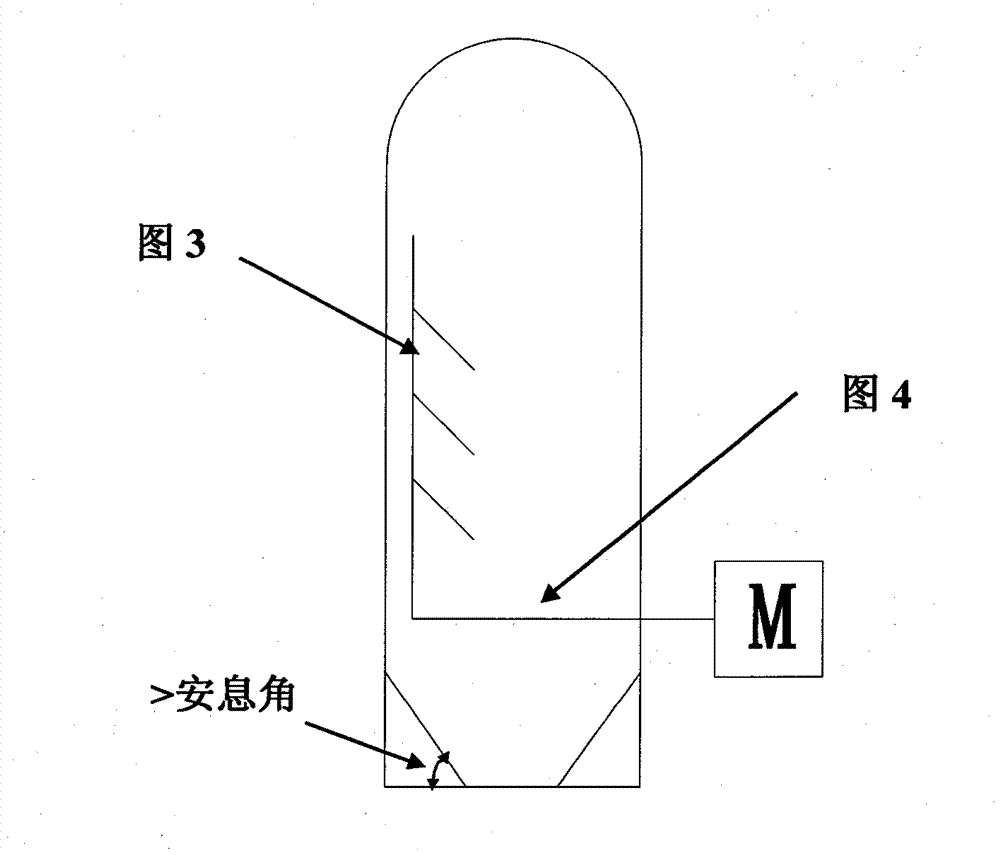

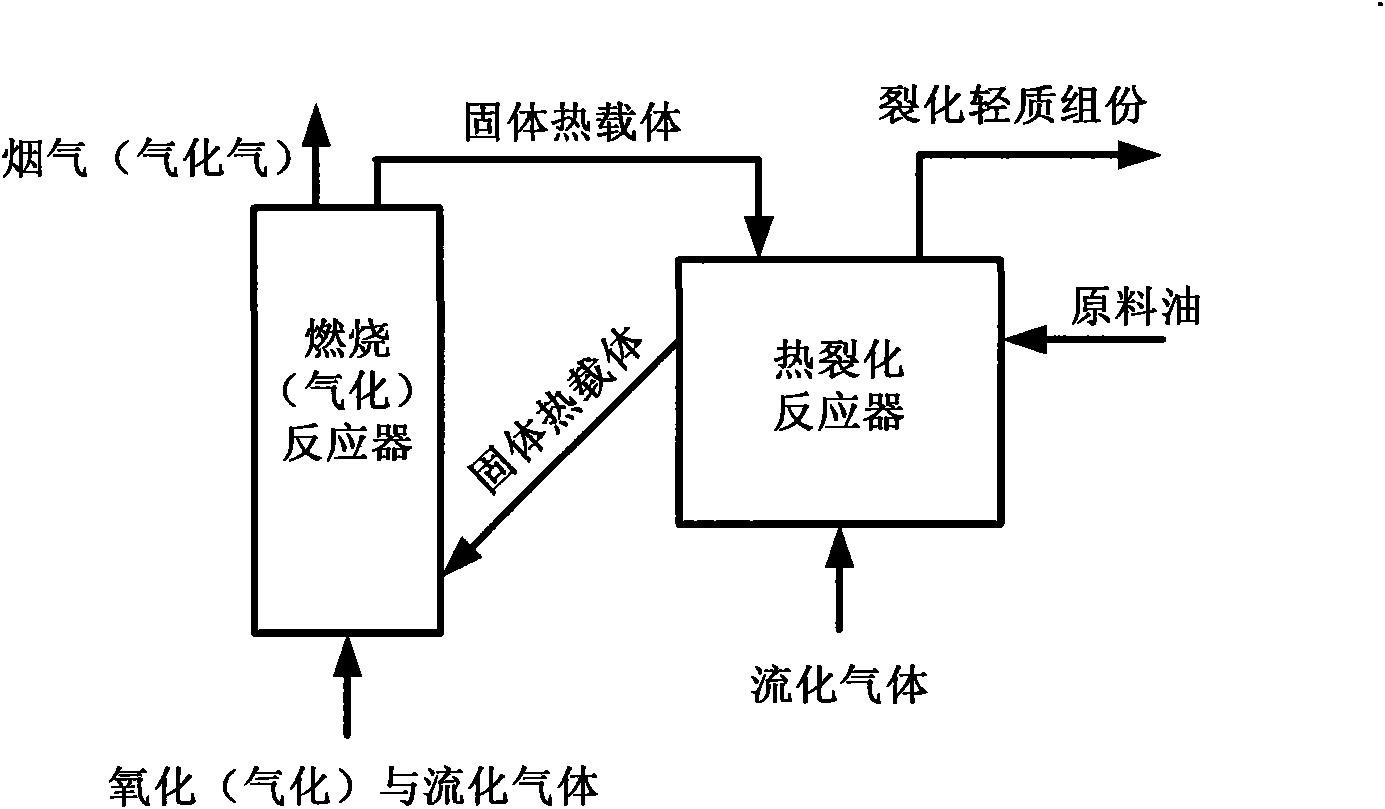

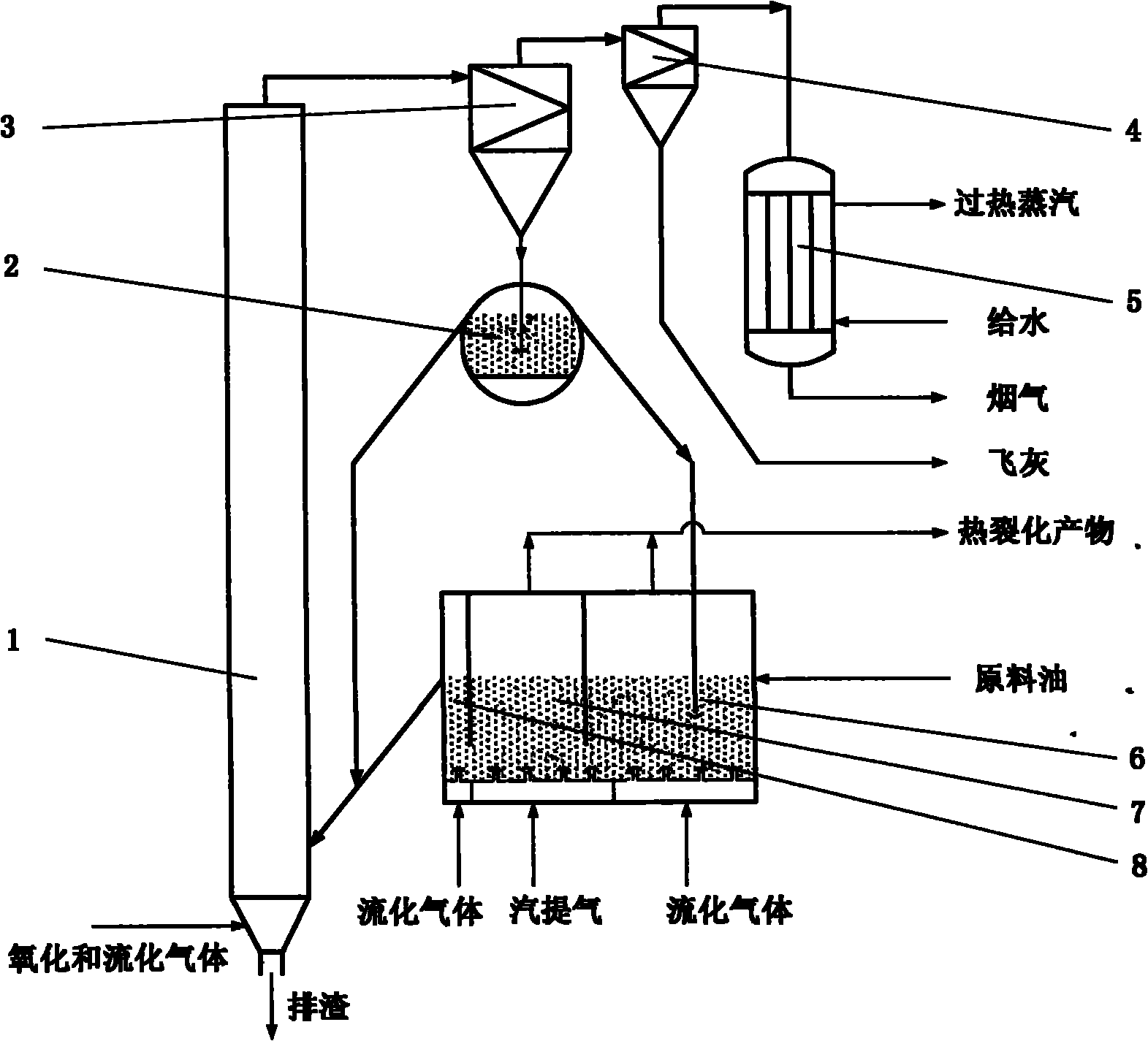

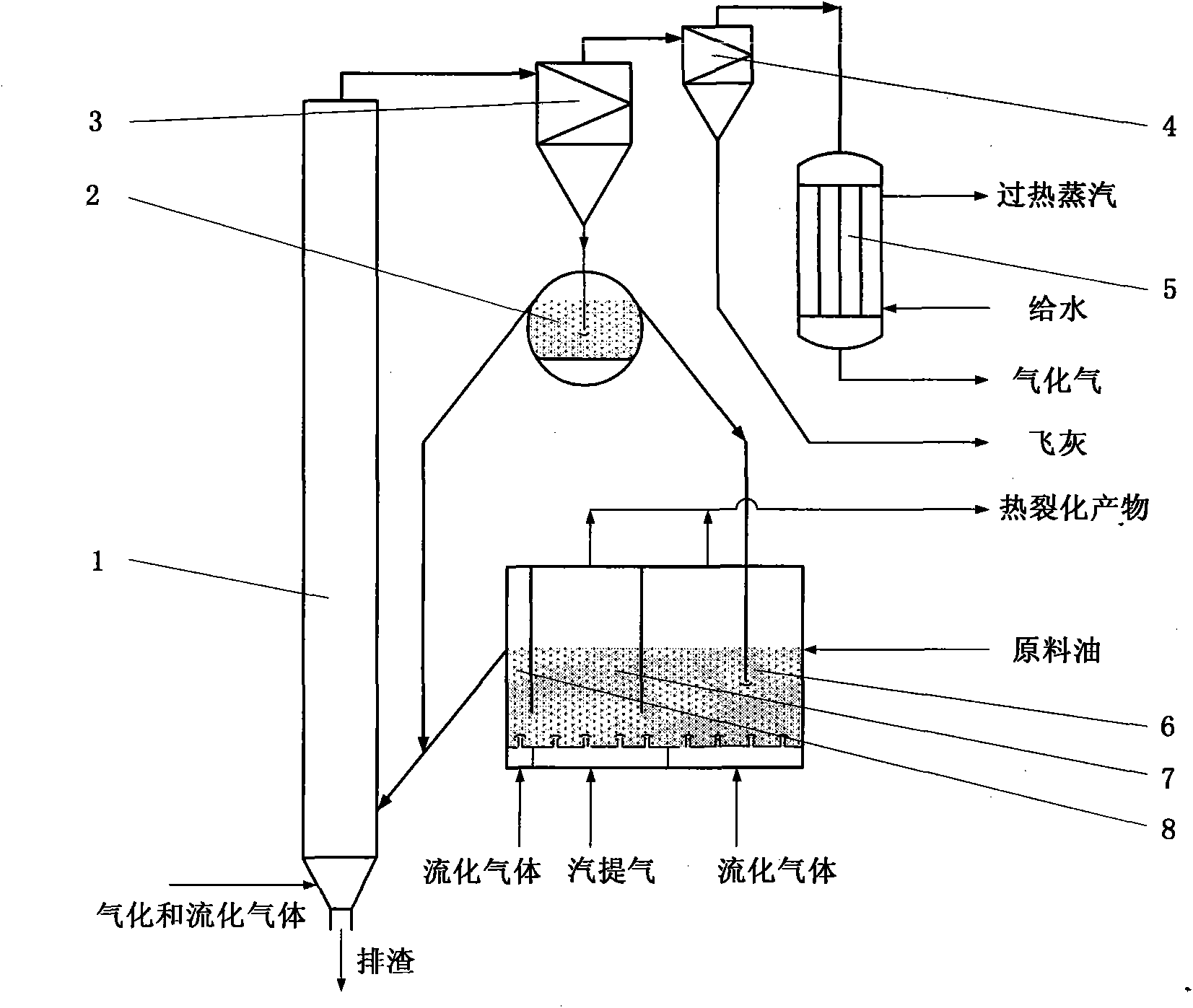

Heavy oil lightening method and device

InactiveCN102115675AAchieve conversionEfficient conversionThermal non-catalytic crackingEnergy inputHeat carrierCombustion

The invention relates to a heavy oil lightening method and technique. The method comprises steps as follows: raw oil is introduced into a thermal cracking reactor through a feed system, and mixed with a high-temperature solid heat carrier from a combustion (gasifying) reactor, so that the raw oil is subjected to fluidizing heat exchange with the solid heat carrier and carries out thermal cracking reaction on the surface of the solid heat carrier; the cracking gas generated by the thermal cracking reaction and a light component product are subjected to steam stripping by fluidizing medium gas and enter a subsequent absorption and stabilization system and a purification and separation system, heavy coke (petroleum coke) is attached to the surface of the solid heat carrier and enters the combustion (gasifying) reactor via a material returning valve, and an oxidizing (gasifying) and fluidizing gas is introduced to realize combustion (gasifying) reaction in the fluidization elevation process of the petroleum coke; and after the reaction product (fume or gasified gas) and the solid heat carrier are separated by a gas-solid separator, the fume (gasified gas) is led into a waste heat recovery system and a gas purification system, the high-temperature solid heat carrier is distributed by a distribution valve and respectively enters the thermal cracking reactor and the combustion (gasifying) reactor for cyclic use, and the collected fly ash can be used after further processing, thereby complete high-value conversion and use of the heavy oil.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

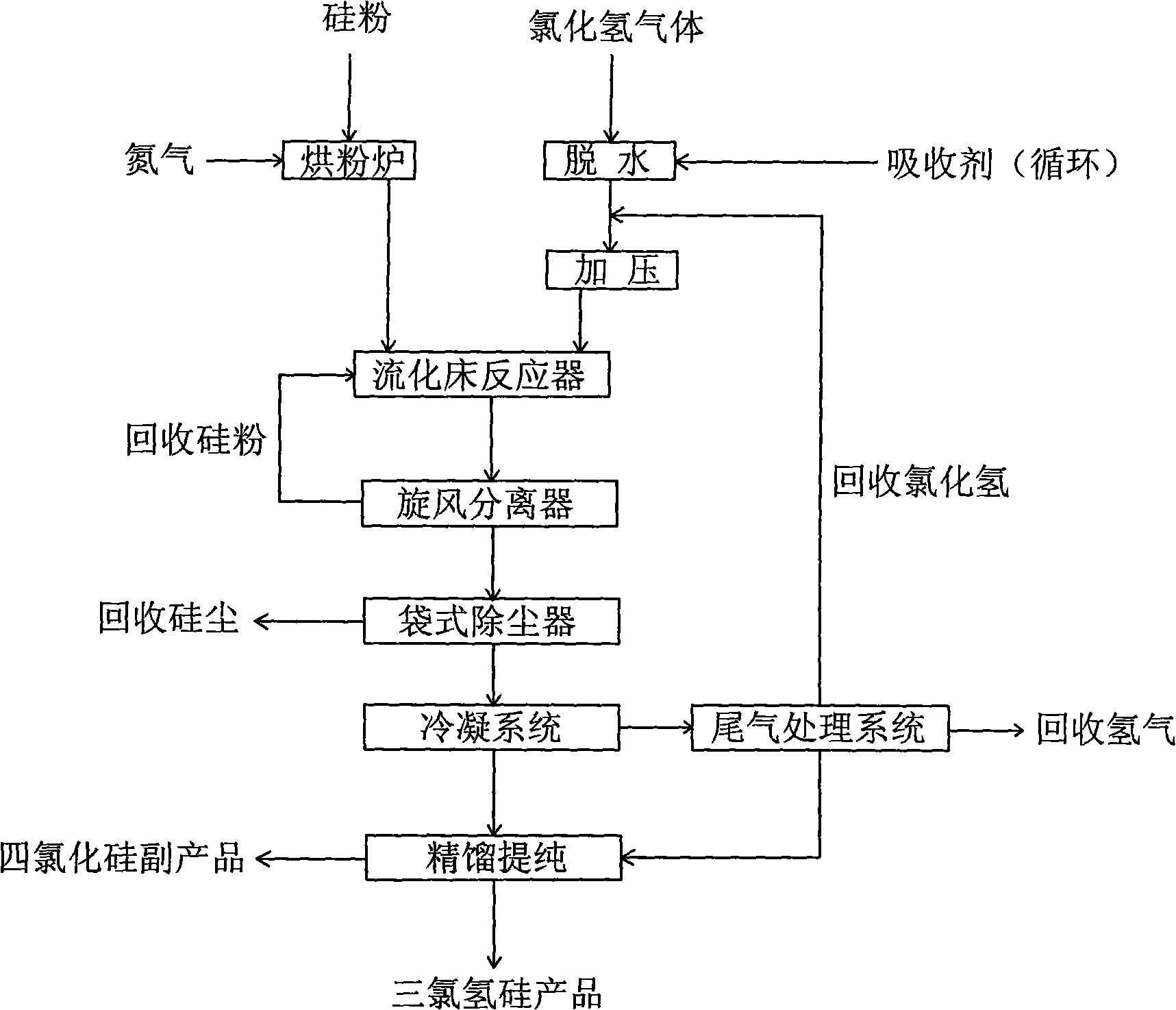

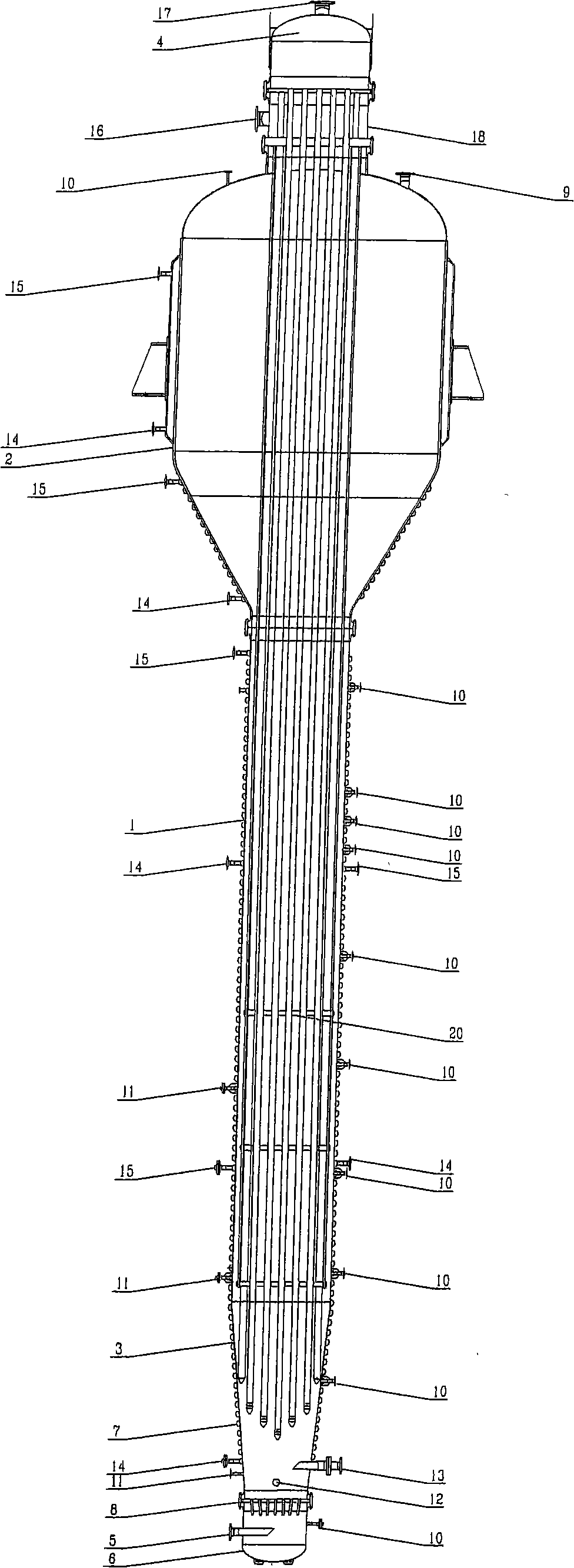

Production method and apparatus for trichlorosilane

InactiveCN101279735AReduce consumptionReduce automatic controlEnergy inputHalogenated silanesReaction temperatureEnergy recovery

The invention relates to a method for producing chlorosilane, in particular to a method for producing trichlorosilane and a device thereof and pertains to the chemical field. The method comprises six steps, namely, hydrogenchloride treatment, silica powder drying and pushing material, synthesis reaction, dust removal and condensation, rectification separation and tail gas recovery, and the device relates to a special equipment large fluidized bed reactor. The invention reduces corrosion on the system equipment by hydrogenchloride gas and the fluidization quality of the reactor is high. The tail gas contains chlorosilane and is easy to be condensed, and the consumption of low temperature refrigerant is greatly reduced. The synthesis tail gas is recovered fully, no temperature runaway phenomenon happens at the expansion section of the reactor, reaction heat is removed by heat transfer oil and sent in a waste heat boiler to produce by product steam which is merged into a steam pipe network or directly applied in part heating equipment; the whole technique system is a closed system with self materials cycling and energy recycling. The technique of the invention is advanced and reliable, the reaction temperature can be adjusted accurately and the fluidized bed reactor has long service life and low production cost and is applicable to popularization and application.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Anaerobic zero-valent iron sewage treatment method

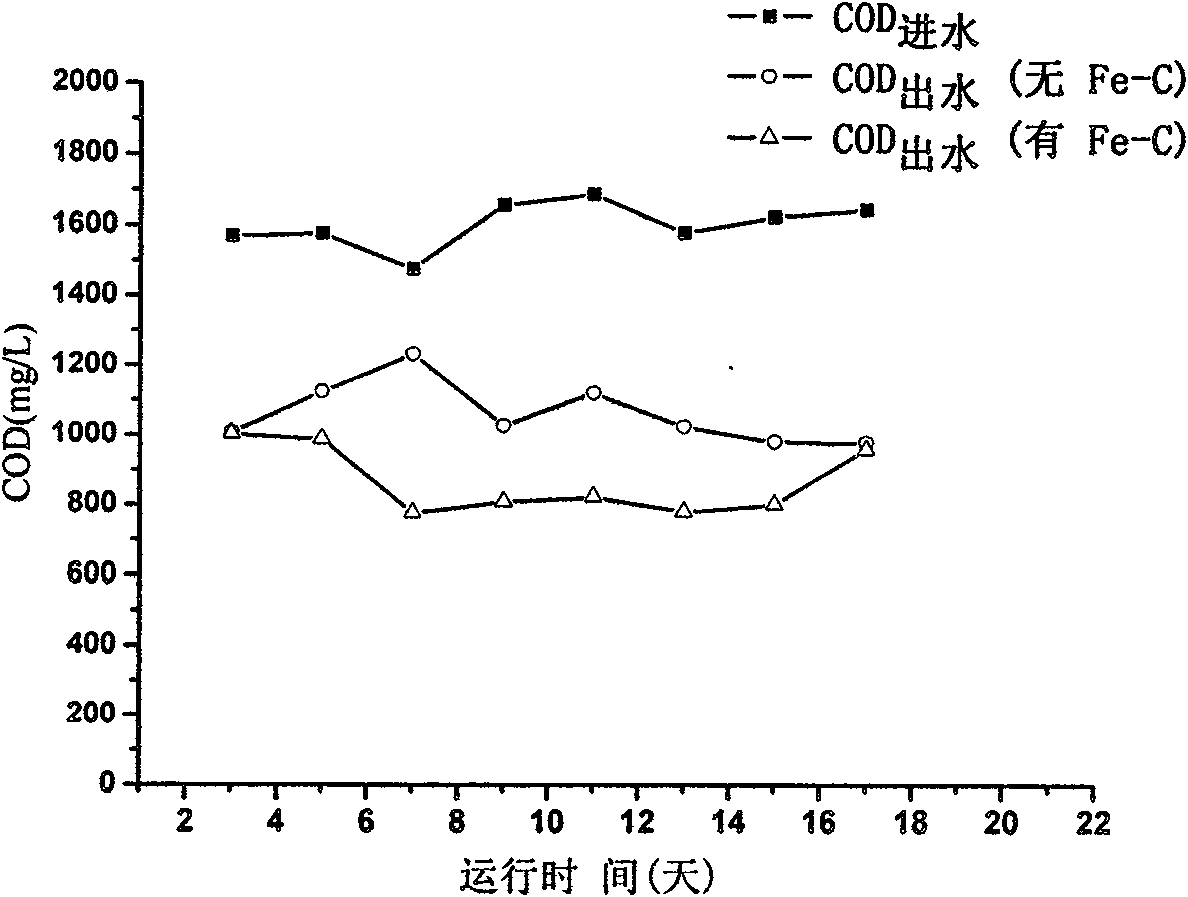

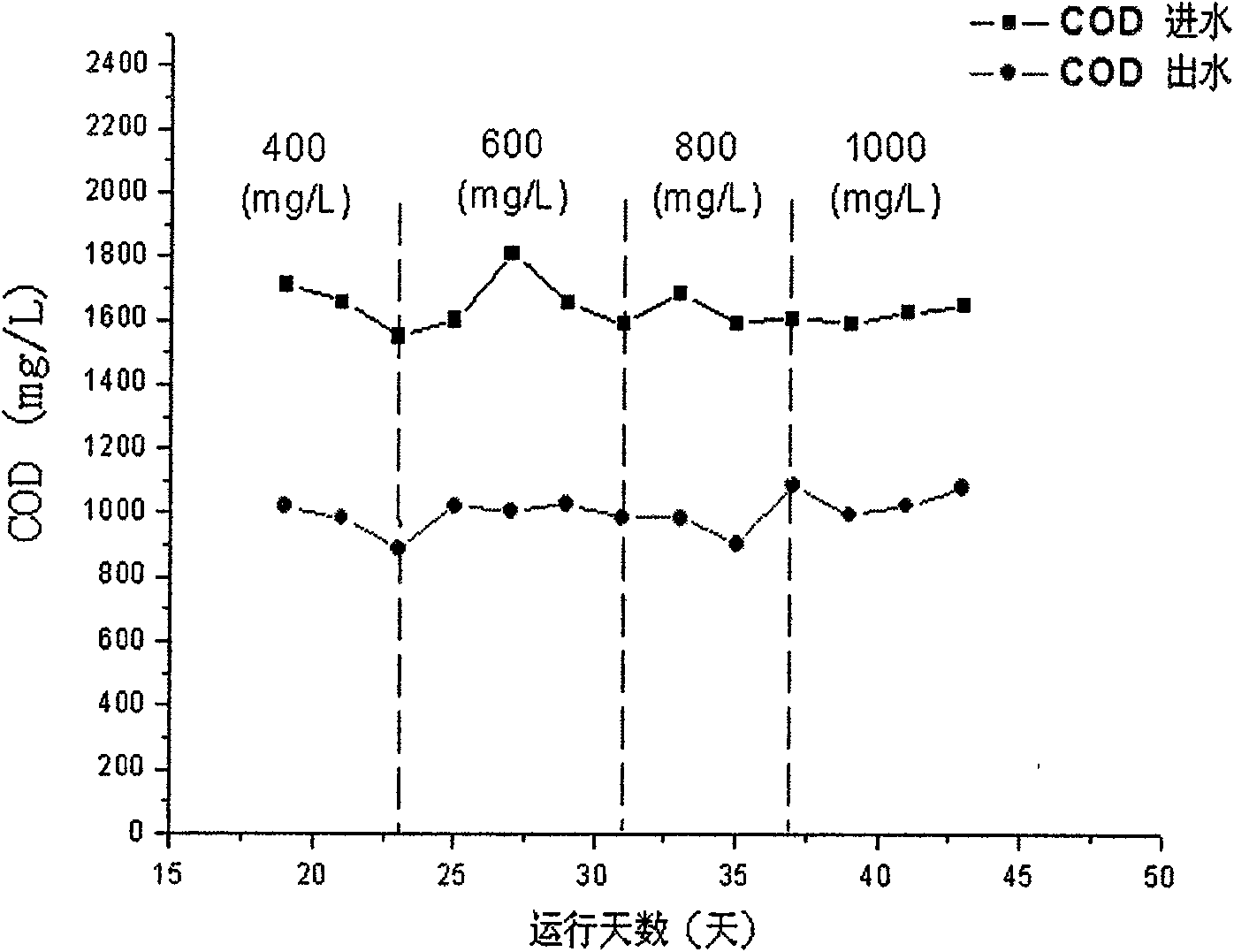

ActiveCN101624250AImprove responseAvoid formingWaste based fuelTreatment with anaerobic digestion processesAnaerobic reactorDyeing wastewater

The invention relates to an anaerobic zero-valent iron sewage treatment method, belonging to the sewage treatment technical field. The anaerobic zero-valent iron sewage treatment places zero-valent iron in an anaerobic reactor and utilizes the environmental conditions of the anaerobic isolated air to largely reduce the formation rate of the rust of zero-valent iron and avoid the formation of hardening; meanwhile, the method uses the reducing action of metal iron to increase the anaerobic reductive atmosphere, balance the pH and increase the effect of the anaerobic organism. A circulating pump is adopted for sewage backflow so as to increase the overflow load of an iron / activated carbon layer and the reaction effect of zero-valent iron, improve the fluidization effect of sludge to increase the anaerobic process efficiency. In a sewage treatment system, ferrous iron contained in the discharged sewage is oxidized to Fe(OH)3 with the air and the coagulation generated in the process can further purify the sewage. Long-term experiment research shows that the decolorizing rate of the sewage treatment method for dye wastewater can teach 85%-95%, the COD can be reduced by more than 50% and the biodegradability can be increased to more than 0.3.

Owner:DALIAN UNIV OF TECH

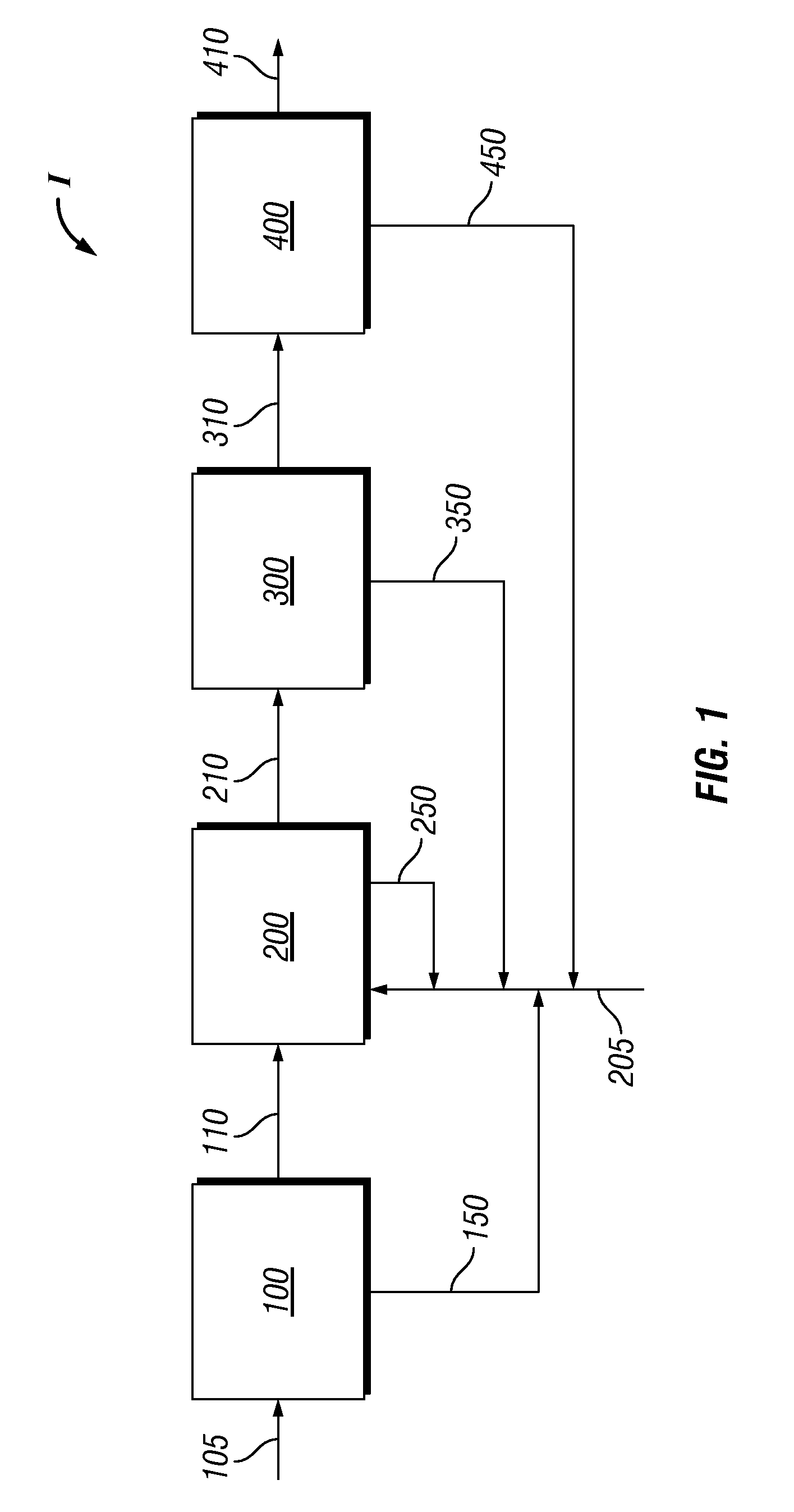

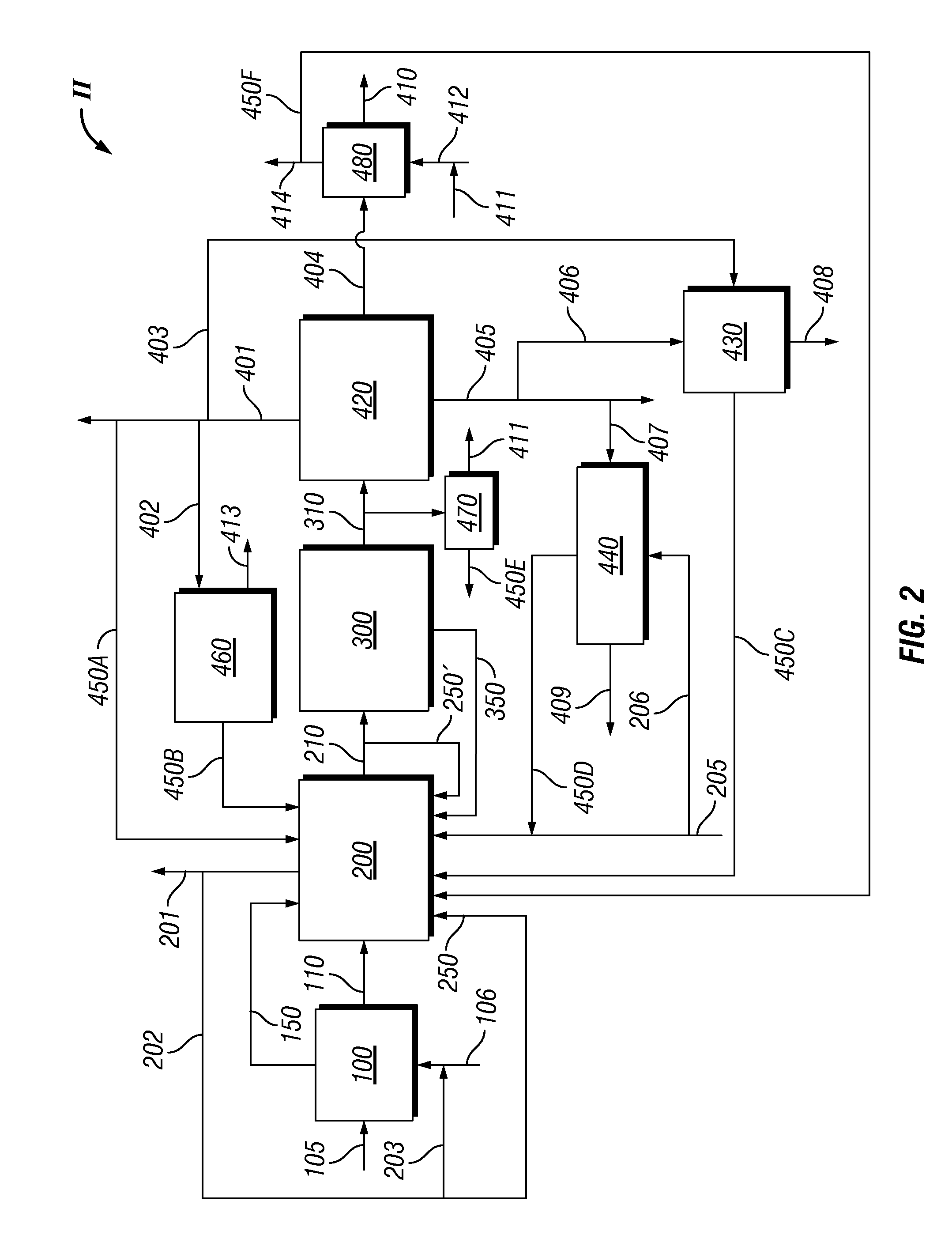

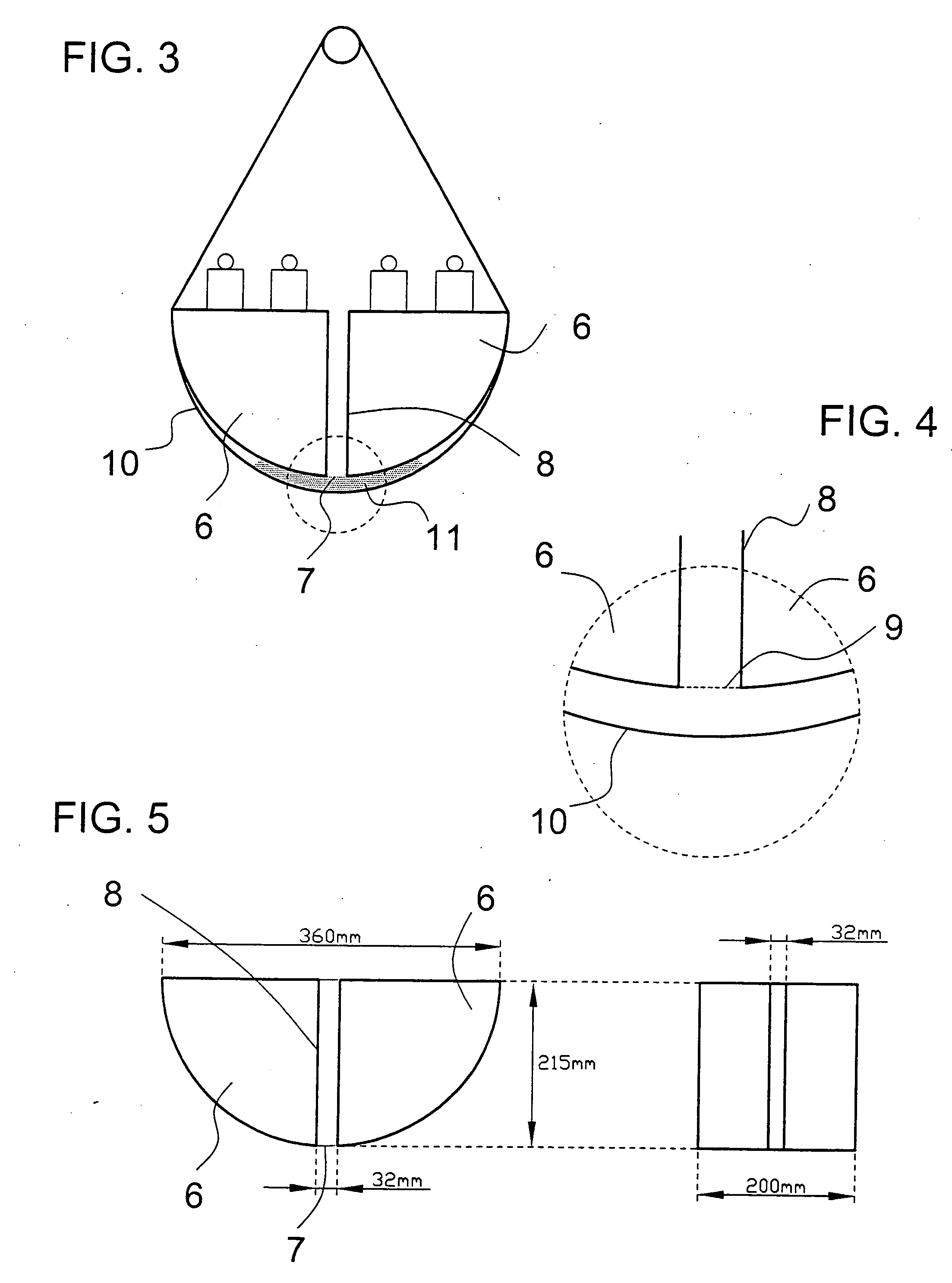

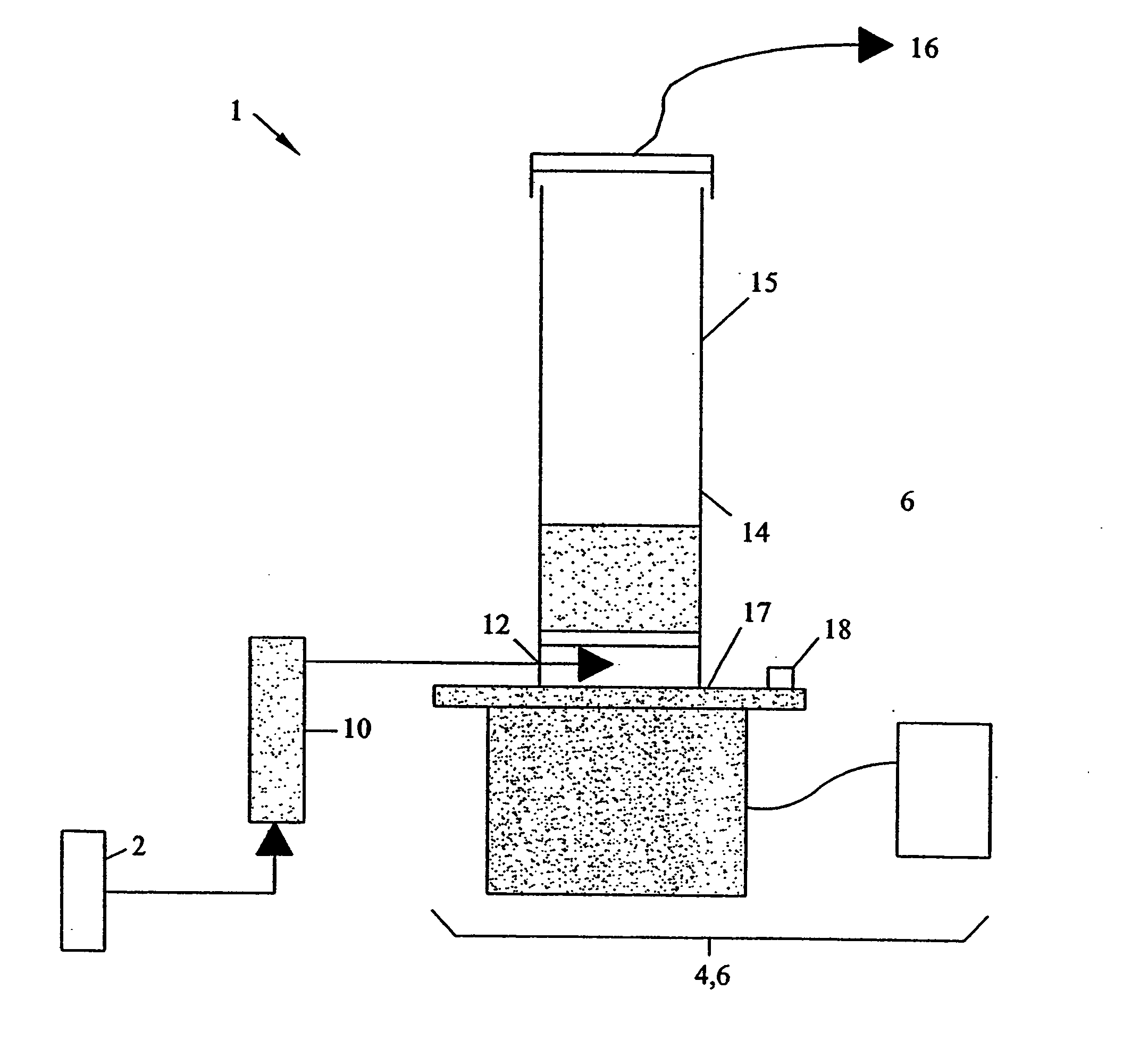

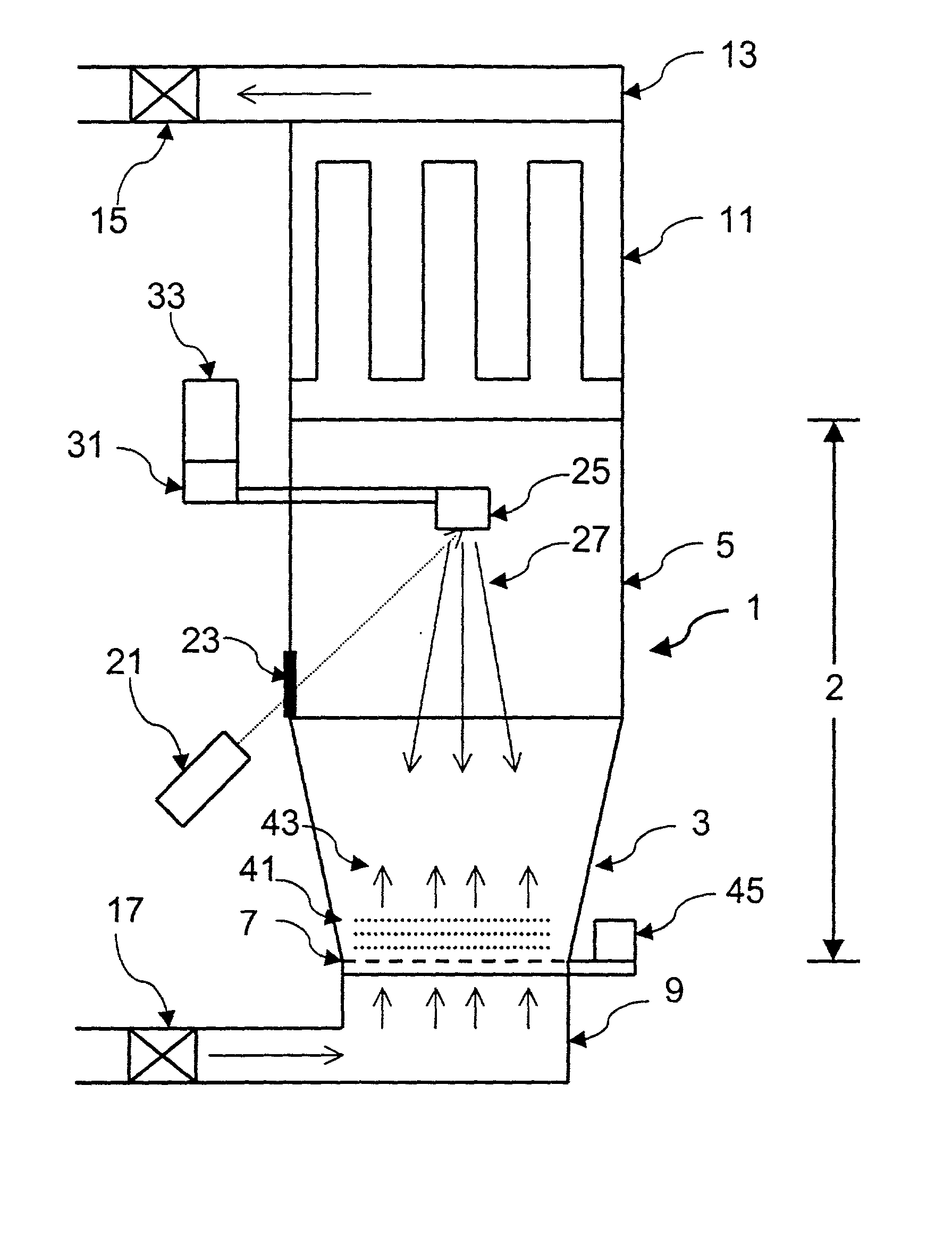

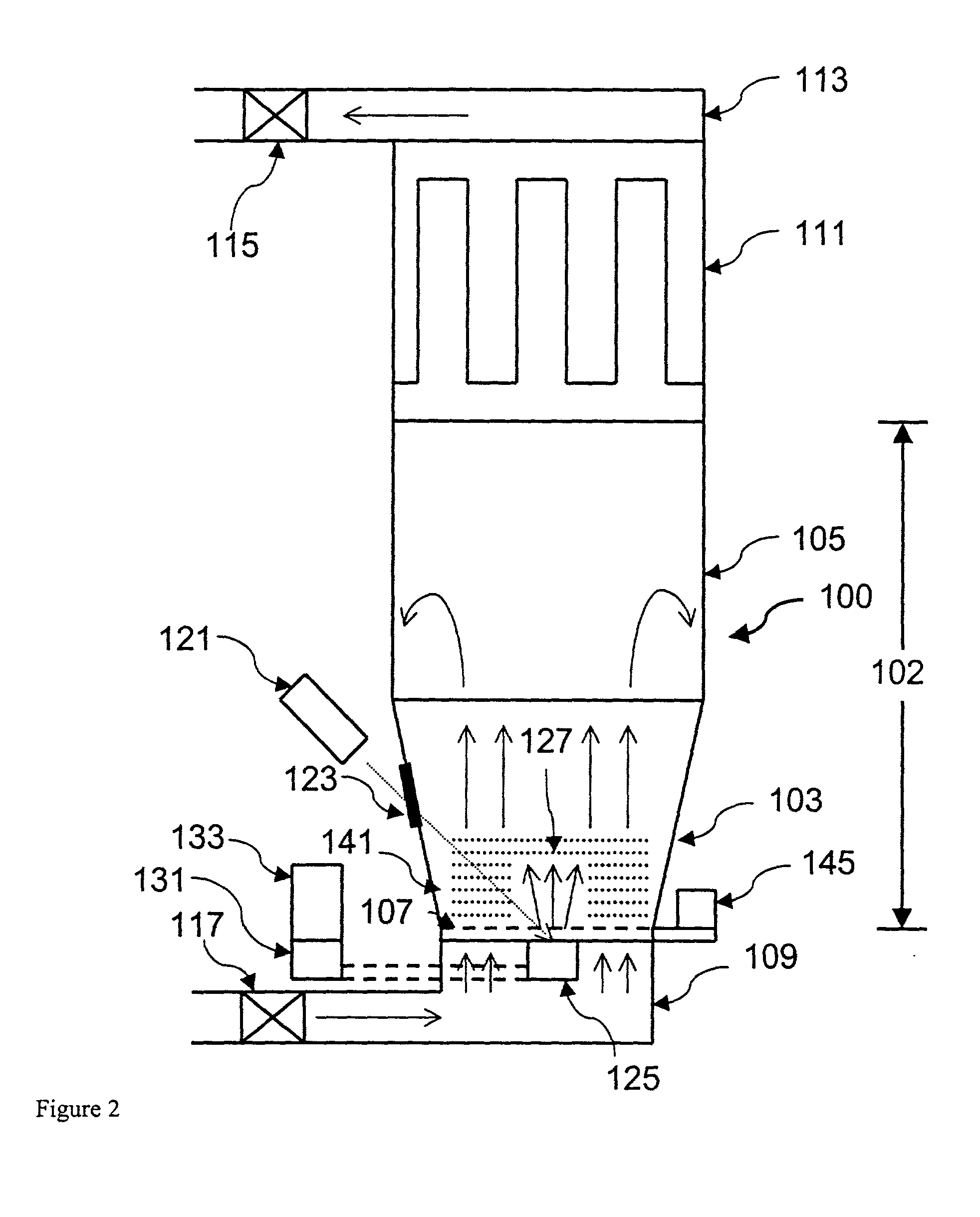

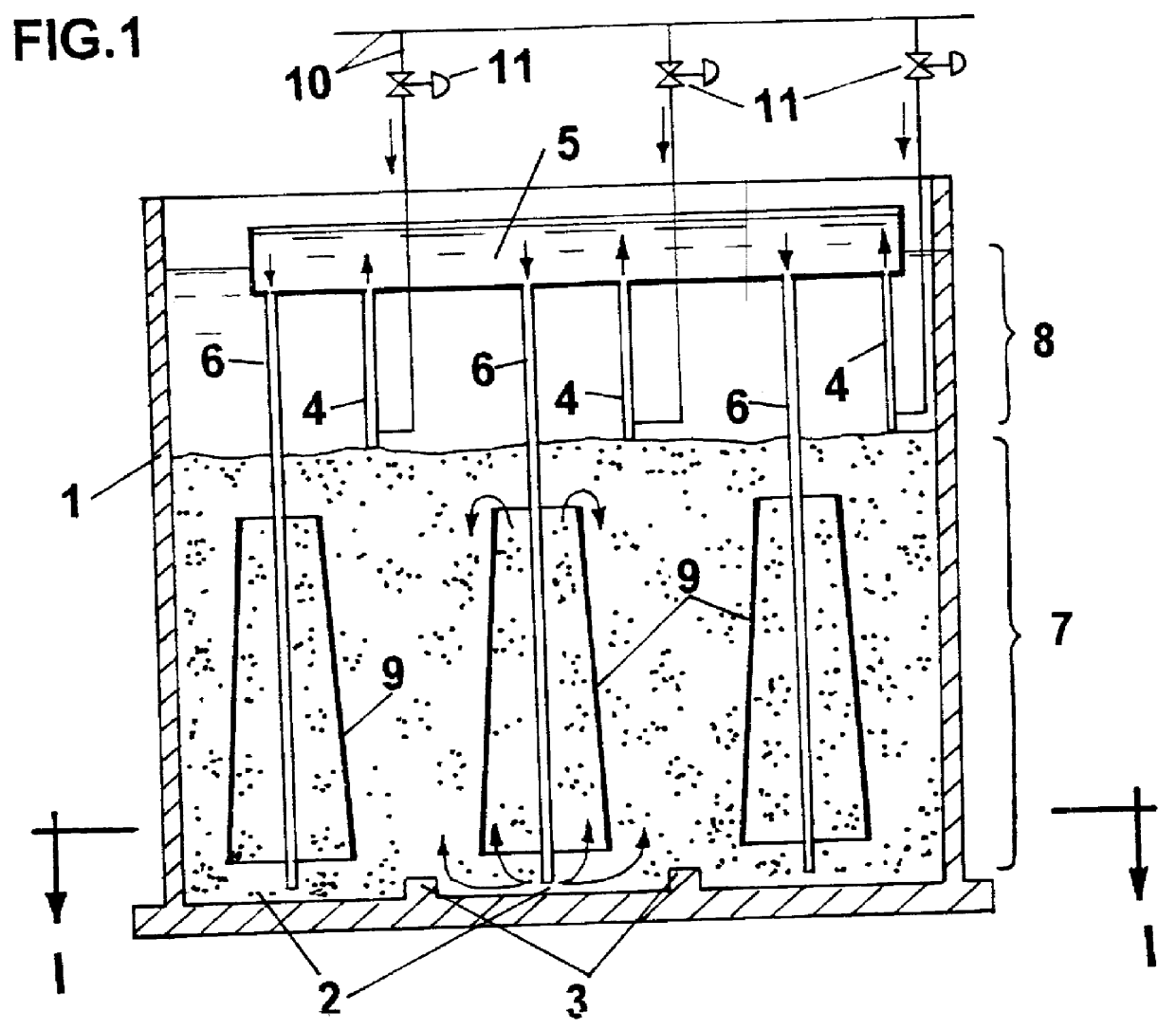

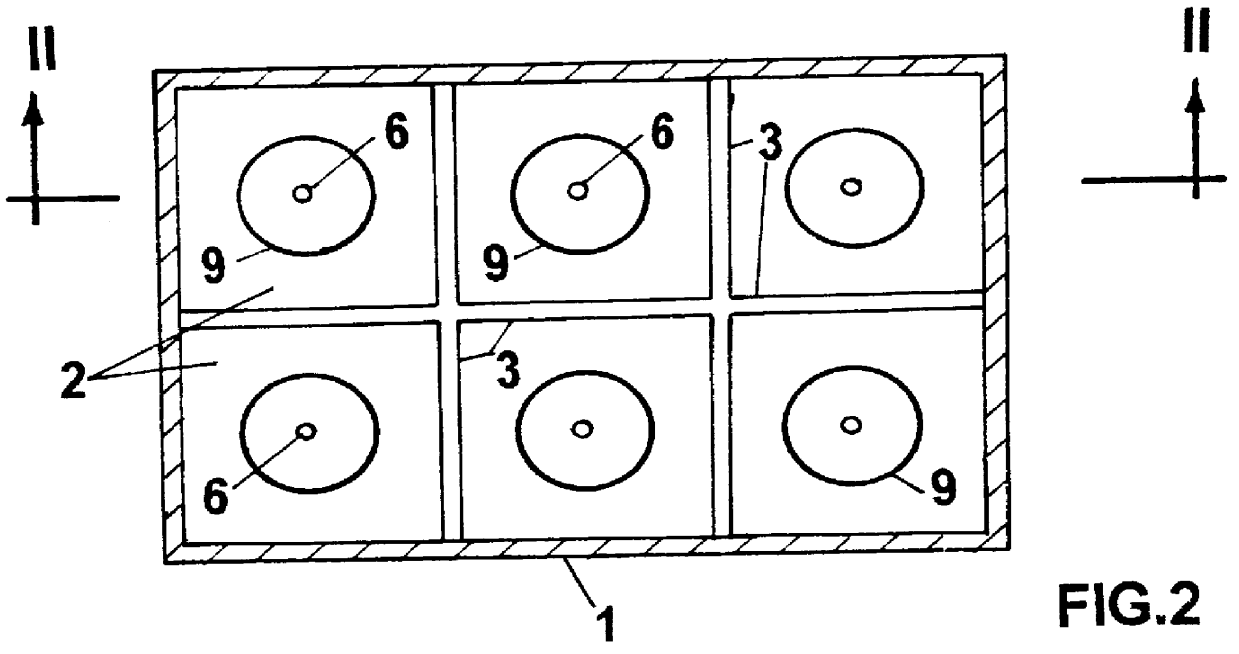

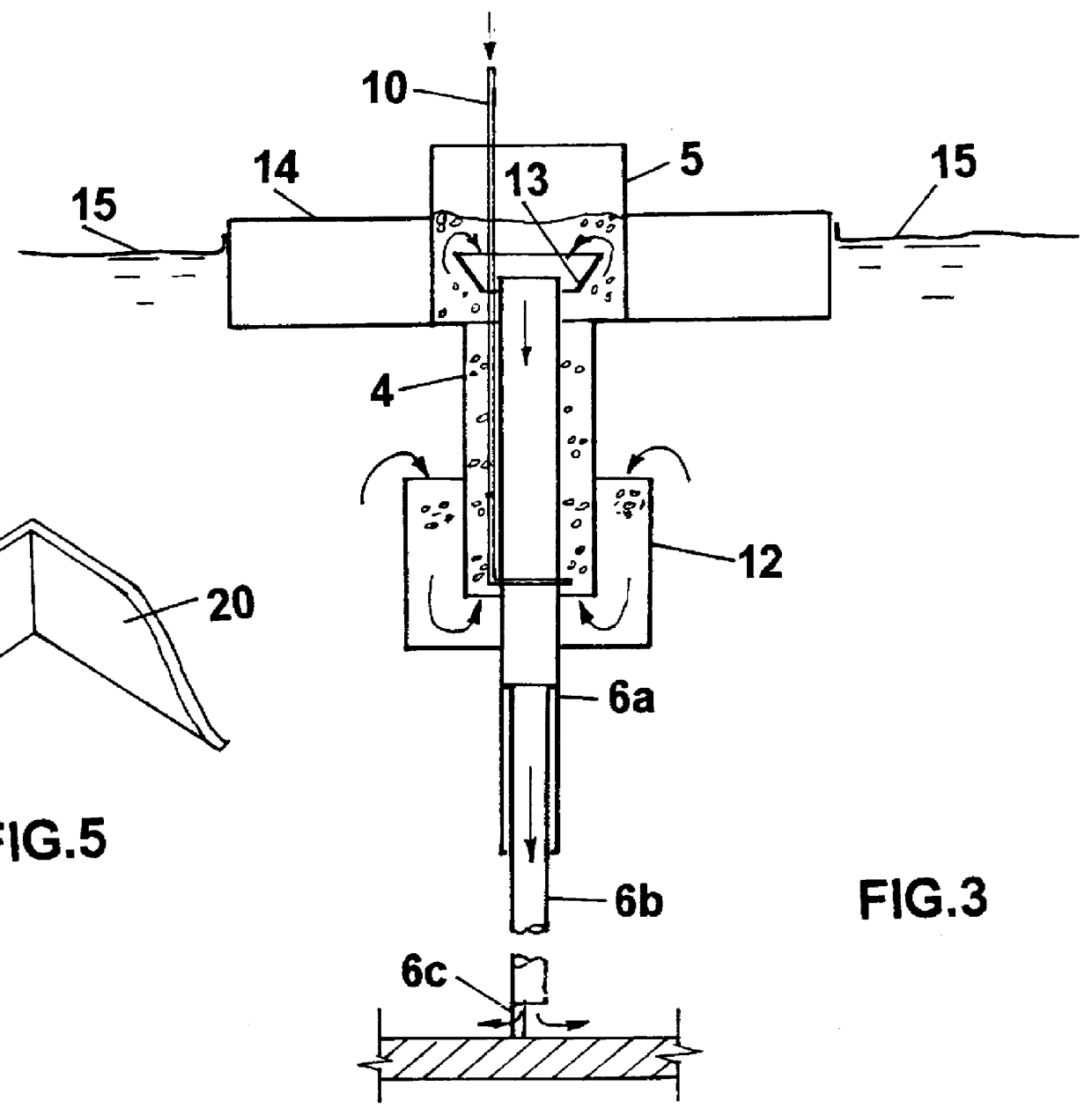

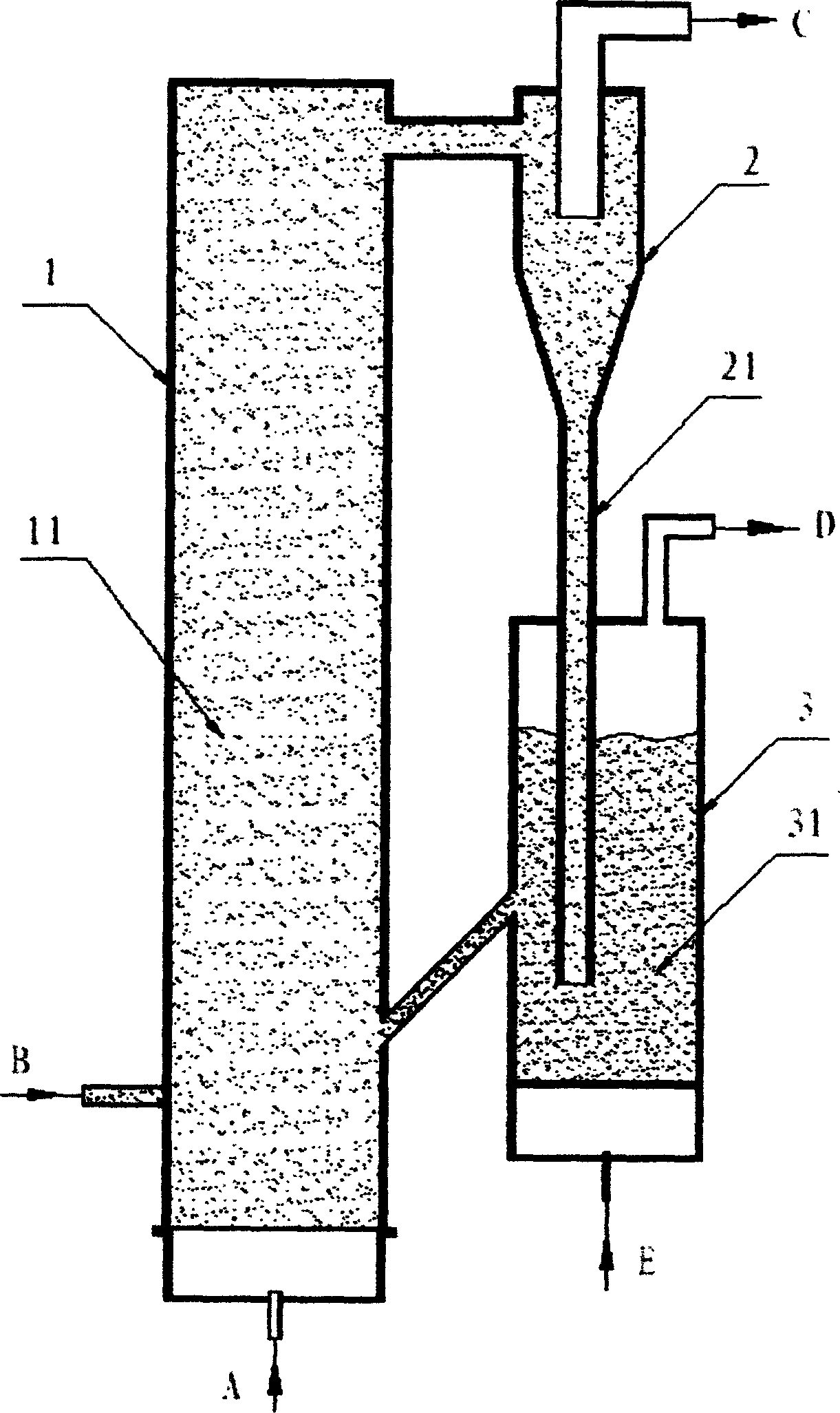

Method and apparatus for fluidization of particulate bed materials

InactiveUS6048459ATreatment using aerobic processesSolid sorbent liquid separationParticulatesOrganismal Process

A method for fluidization of a particulate bed material in a fluidized bed reactor with an upflow of fliud being treated, wherein a step of recycling said treated fluid is provided and further comprising the steps of (a) uniformly collecting at least a portion of the fluid above the fluidized bed and lifting this fluid by at least one gaslift having an intake above the bed, and (b) recycling the lifted fluid under the bed via at least one downcomer positioned within the bed. An generic apparatus for conducting the method steps in a variety of applications is also provided. The fluidized bed reactor can be used for chemical, physical chemical, biological processes, and combinations thereof in the chemical processing, food, environmental and other industries.

Owner:MOCKBA CORP

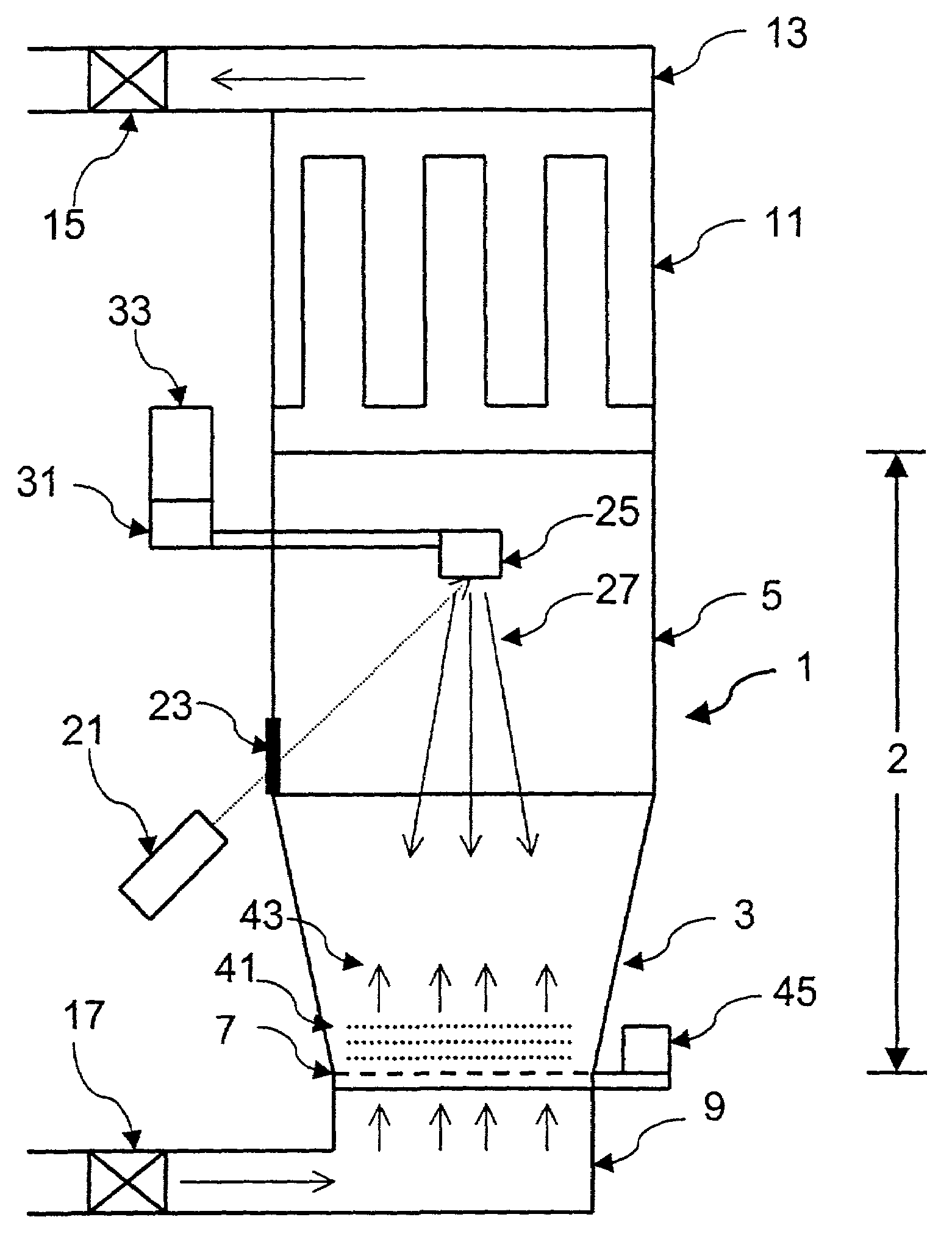

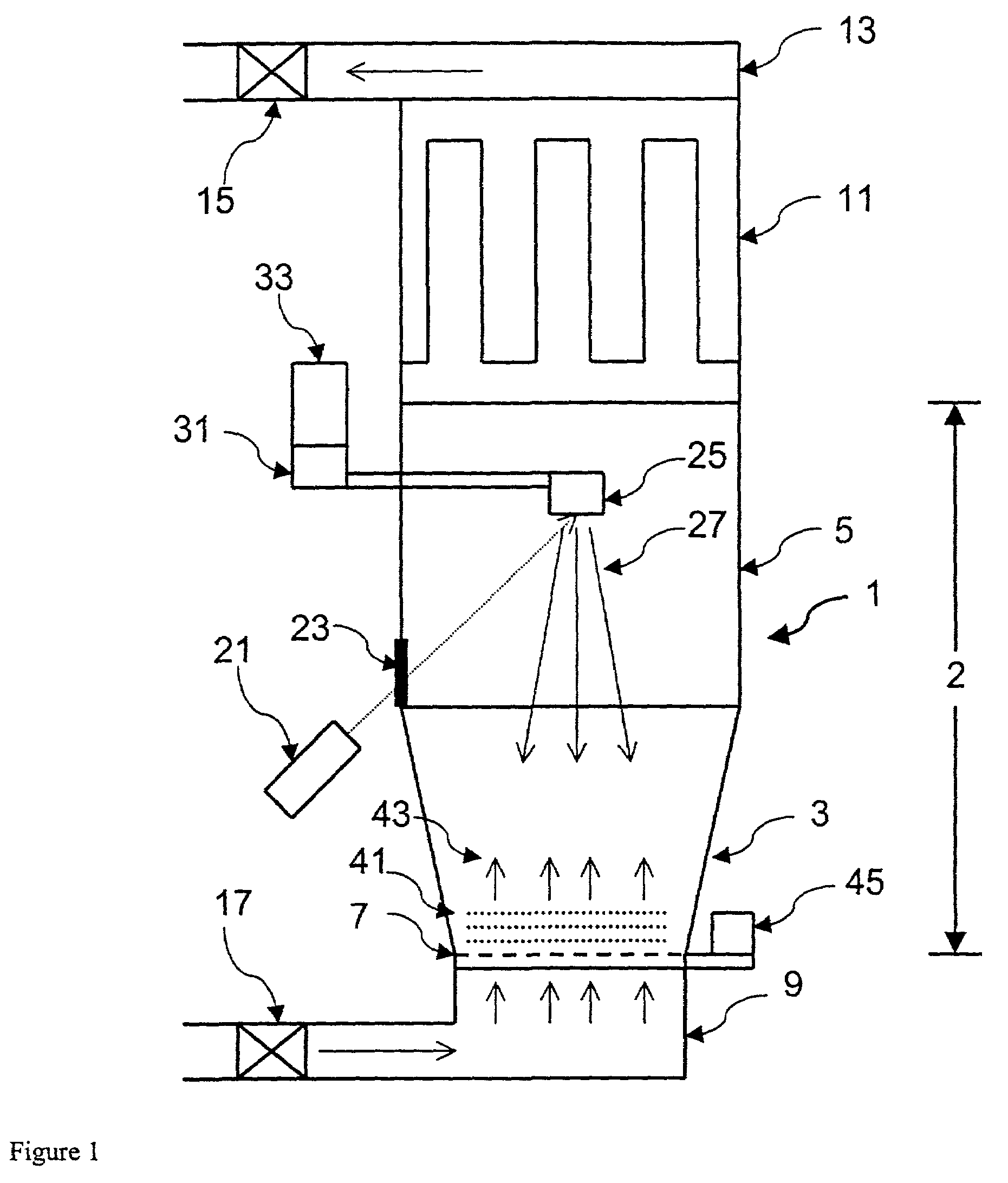

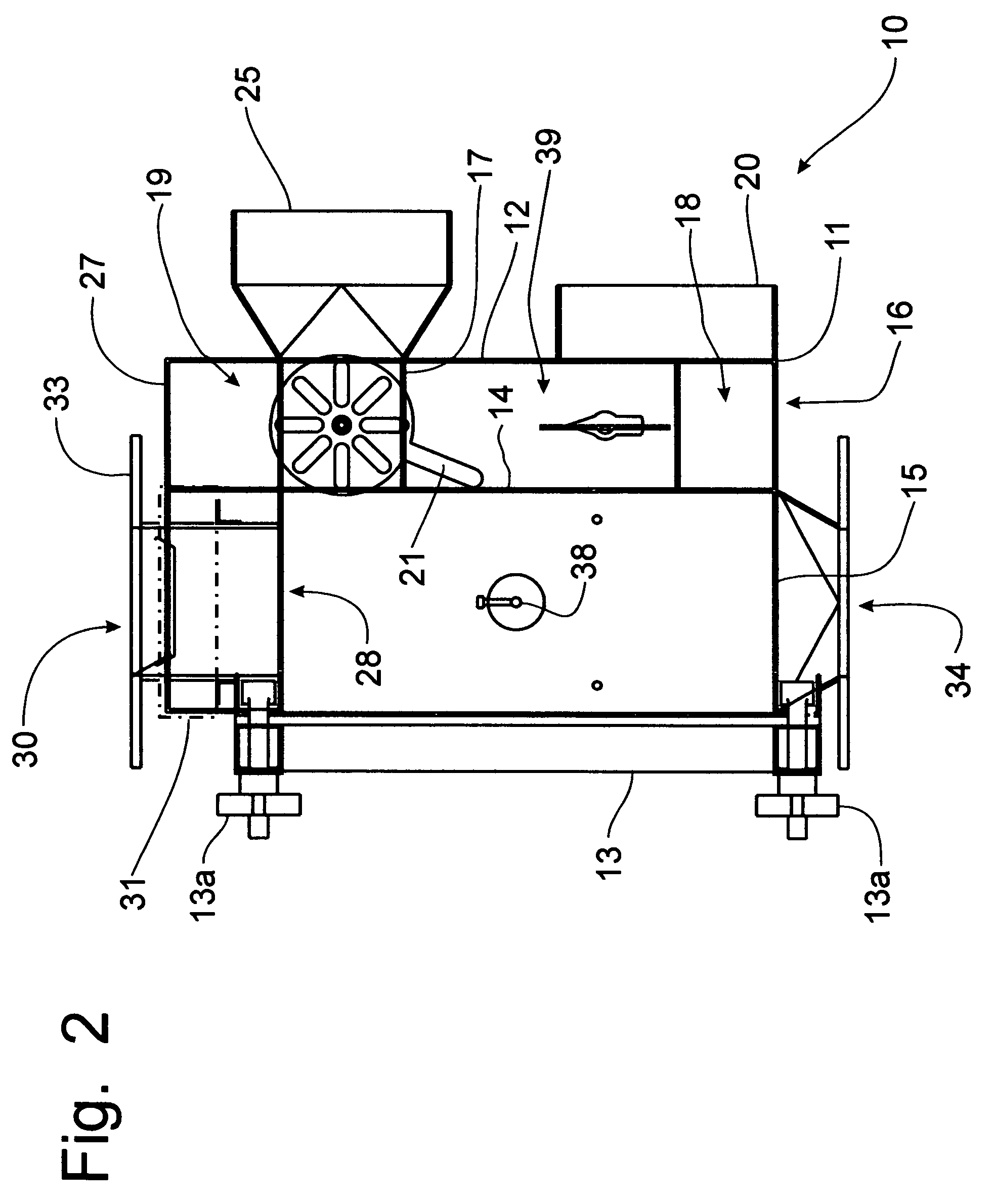

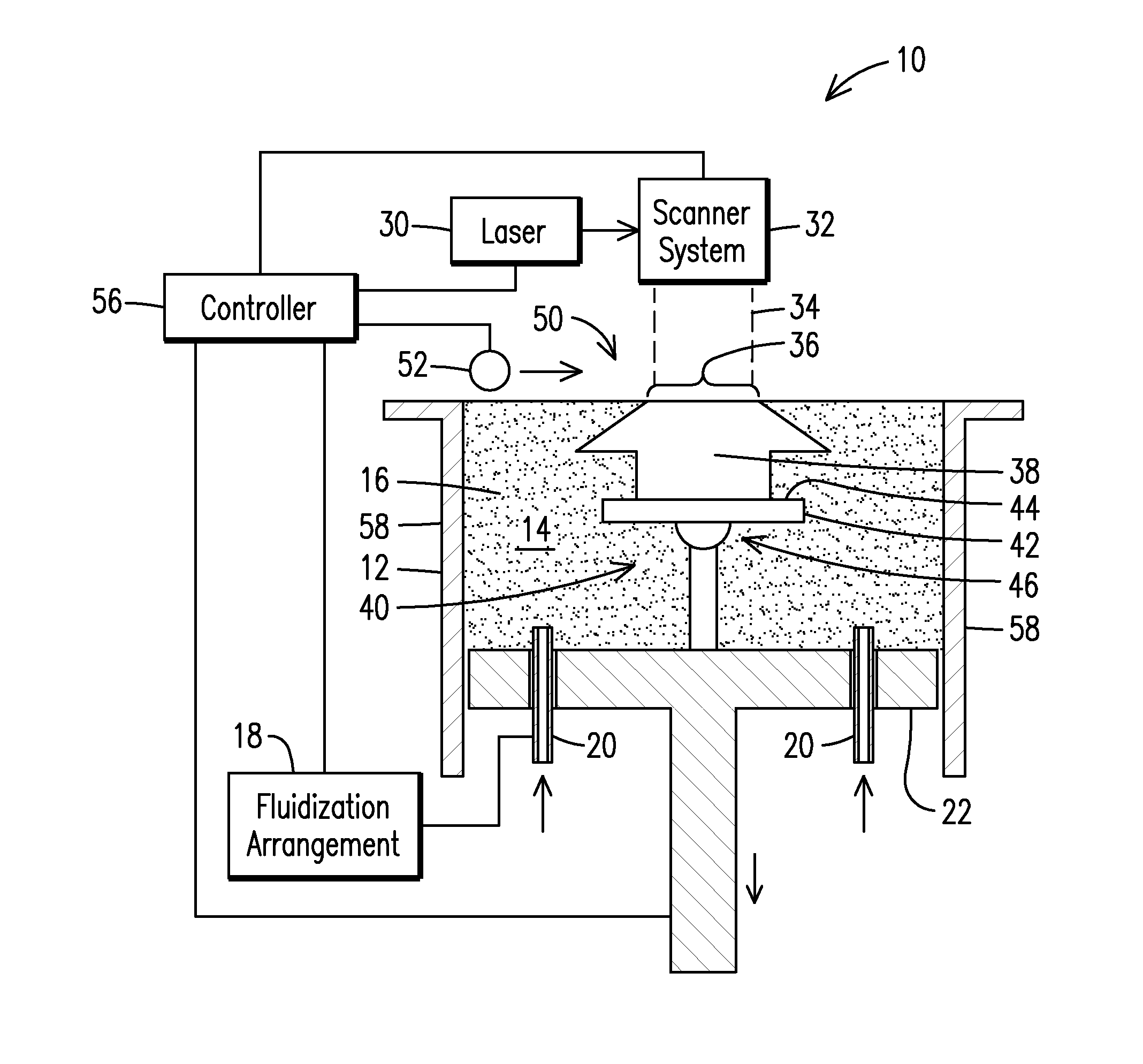

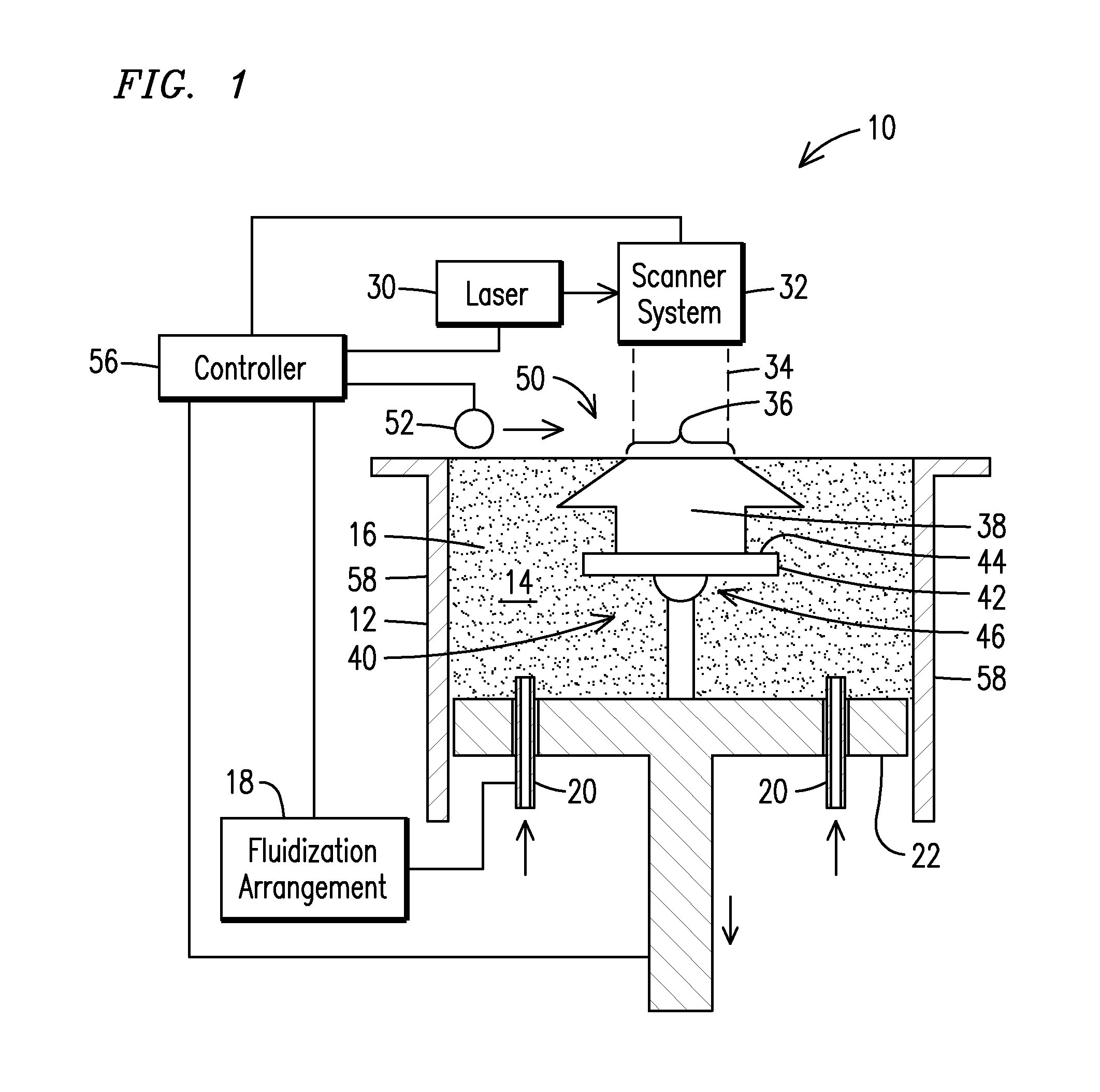

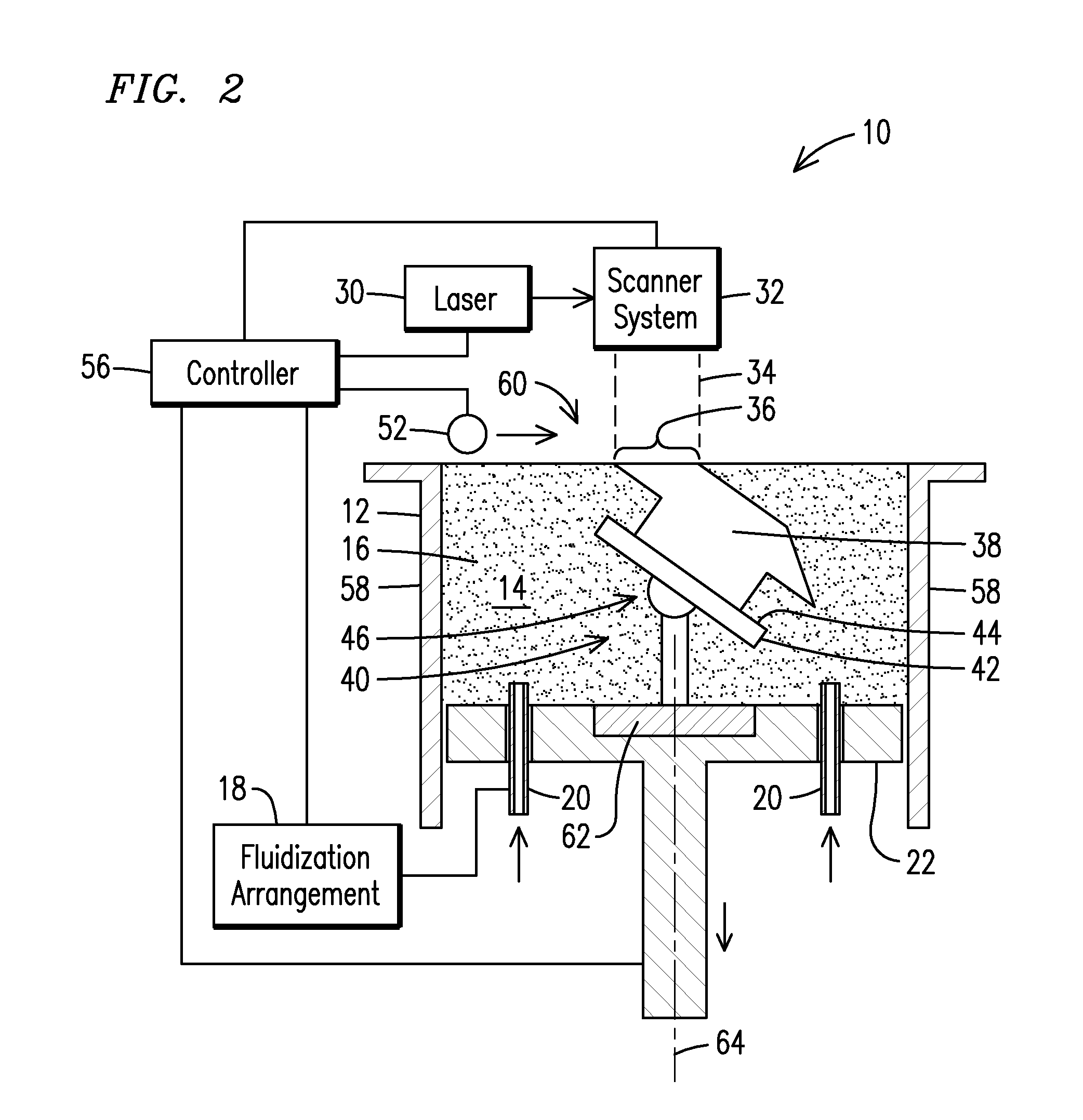

Articulating build platform for laser additive manufacturing

ActiveUS20160067923A1Additive manufacturing apparatusAuxillary shaping apparatusMarine engineeringMetallic materials

An additive manufacturing apparatus (10) including: a container (12) configured to bound a bed of powdered metal material; a fluidization arrangement (18) configured to fluidize the bed of powered material; an articulation mechanism (40) disposed within the container and configured to support and to rotate a component (38) about at least one horizontal axis; and an energy beam (34) configured to selectively scan portions (36) of a surface of the bed of powdered metal material to melt or sinter the selectively scanned portions onto the component.

Owner:SIEMENS ENERGY INC

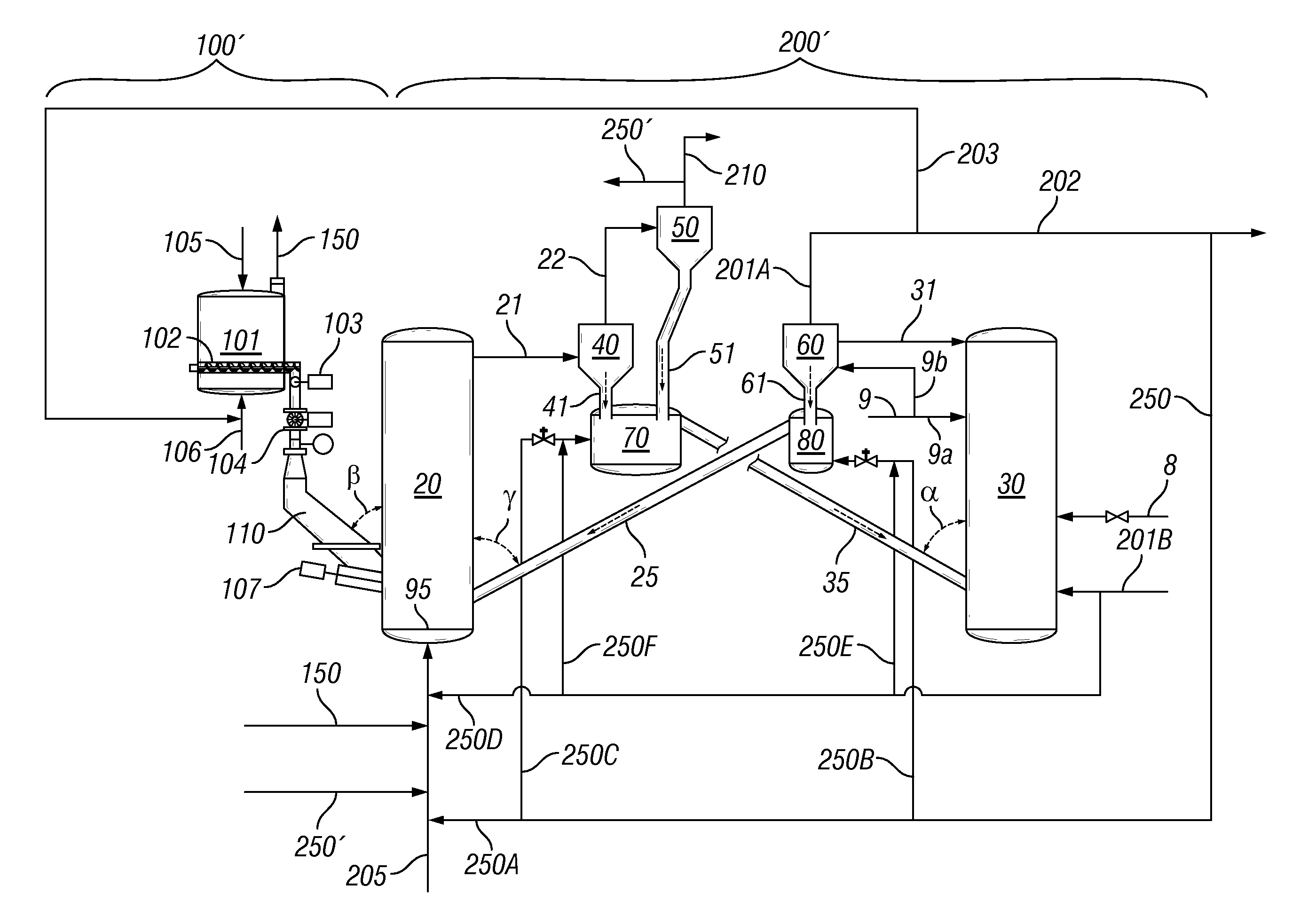

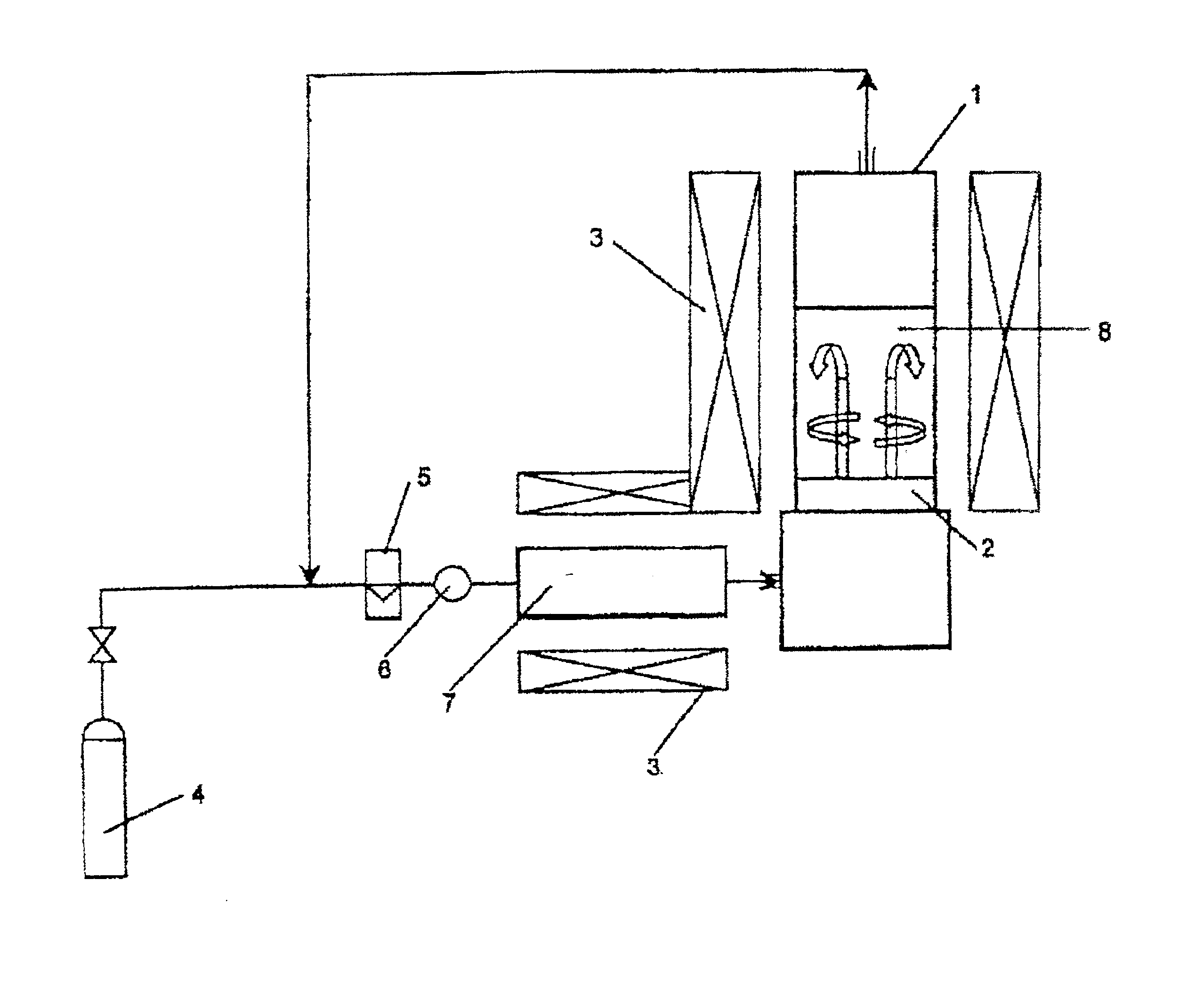

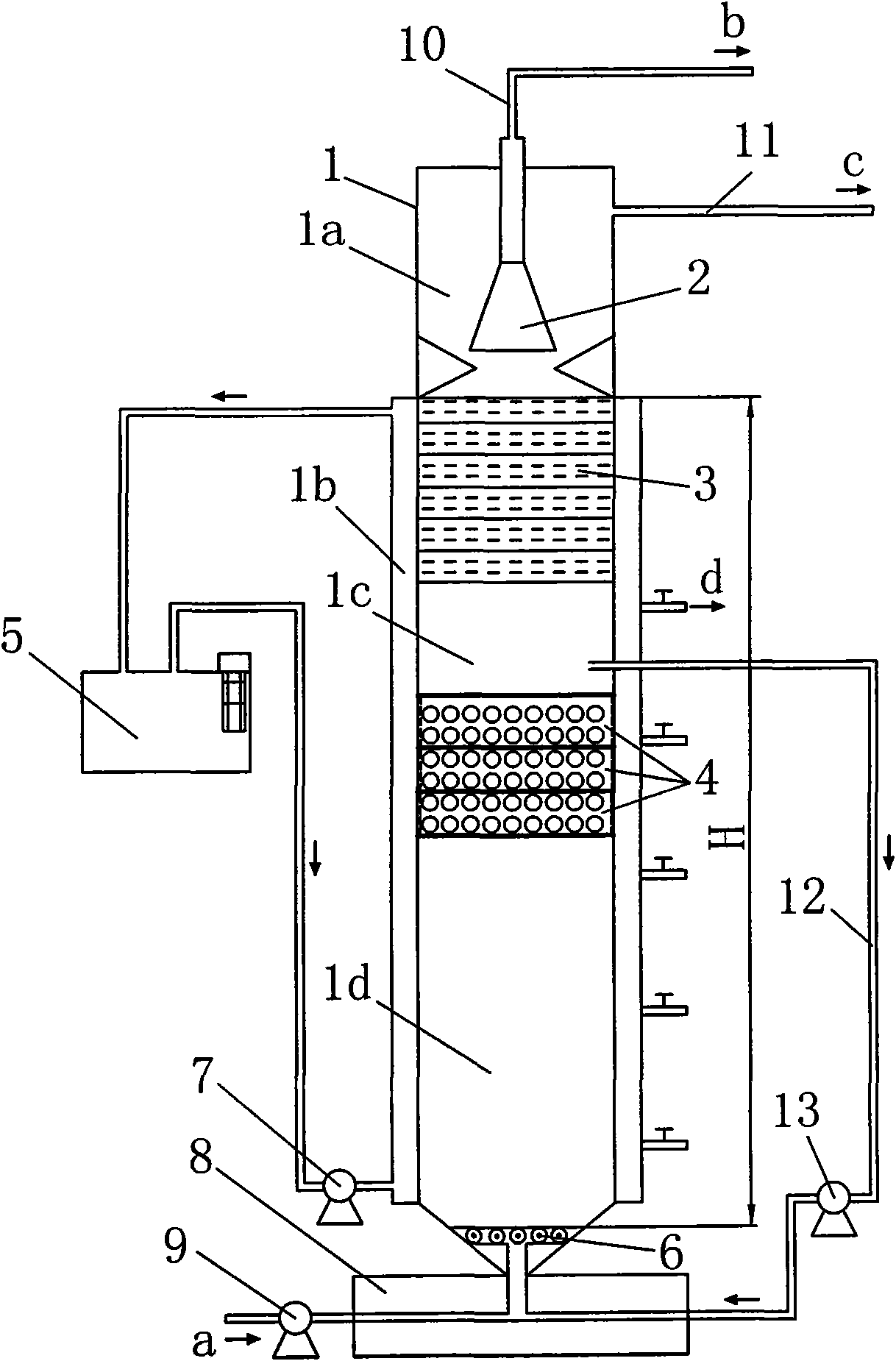

Biomass-gasifying hydrogen generating serial fluid bed apparatus and method

InactiveCN1608972AEfficient hydrogen productionSimple structureHydrogen productionGranular/pulverulent flues gasificationHydrogenDecomposition

The present invention is one method of generating hydrogen via catalytic thermolysis and gasification of biomass. The hydrogen generating apparatus consists of circulating fluidizing bed, cyclonic separator and bubbling fluidizing bed connected serially. The hydrogen generating process the fluidization of biomass with steam in circulating fluidizing bed with catalyst CaO / MgO grains; the catalytic thermolysis and gasification of biomass to produce hydrogen; the fixation reaction of CO2 in gas product with catalyst CaO / MgO grains to form CaCO3 / MgCO3; the separation of CaCO3 / MgCO3 grains and coke grains in cyclonic separator; burning of coke grains to promote the decomposition of CaCO3 / MgCO3 to release CO2 and high temperature CaO / MgO grains; and returning the high temperature CaO / MgO grains to the circulating fluidizing bed as catalyst and heat source.

Owner:SOUTHEAST UNIV

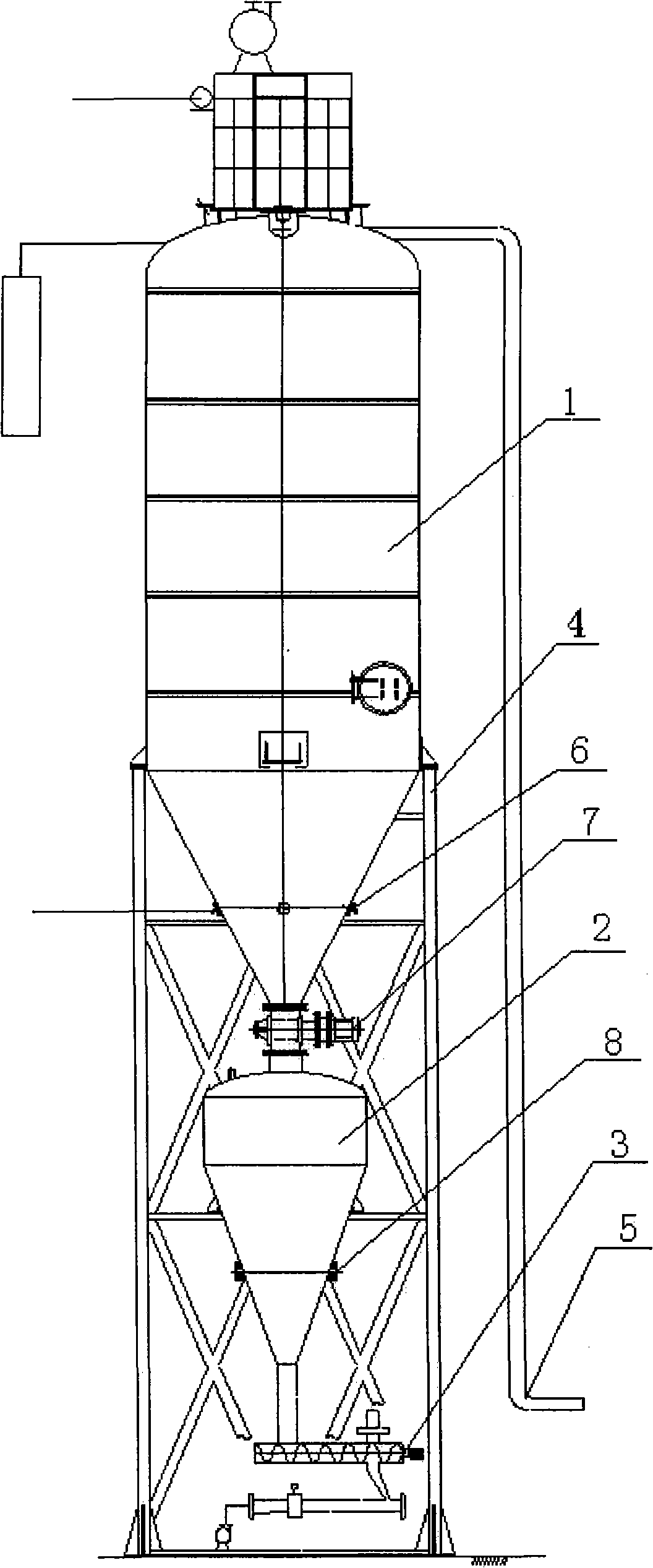

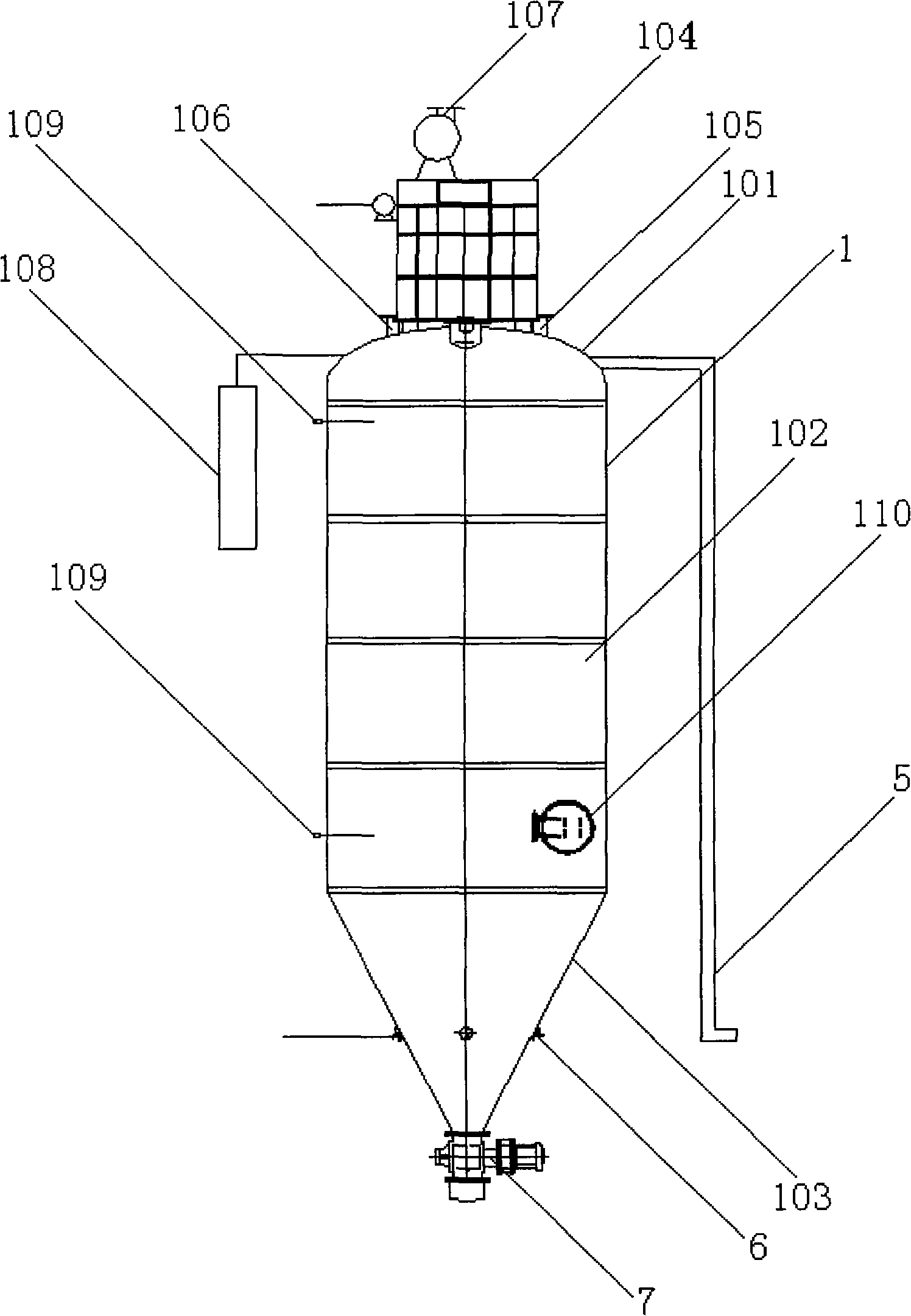

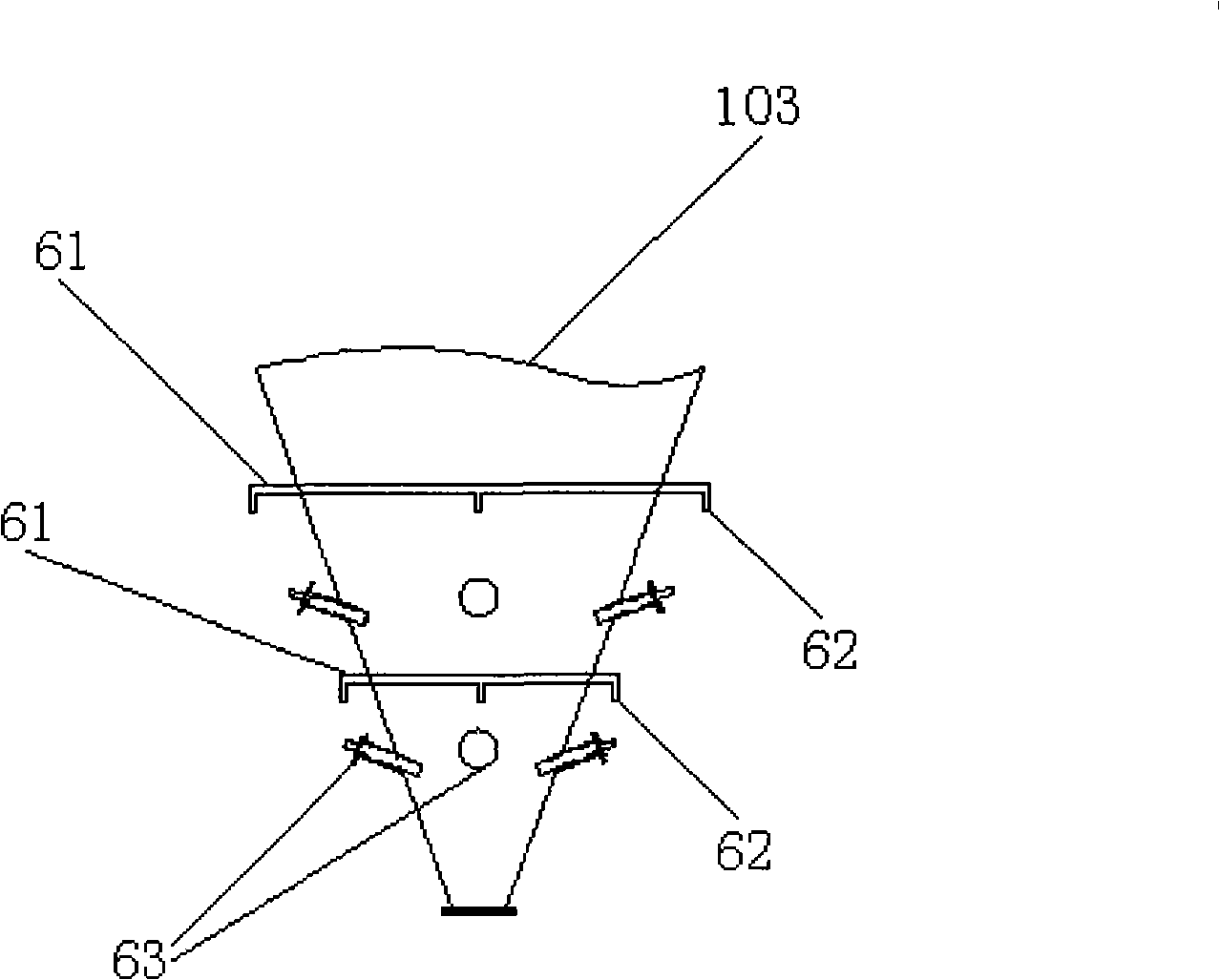

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

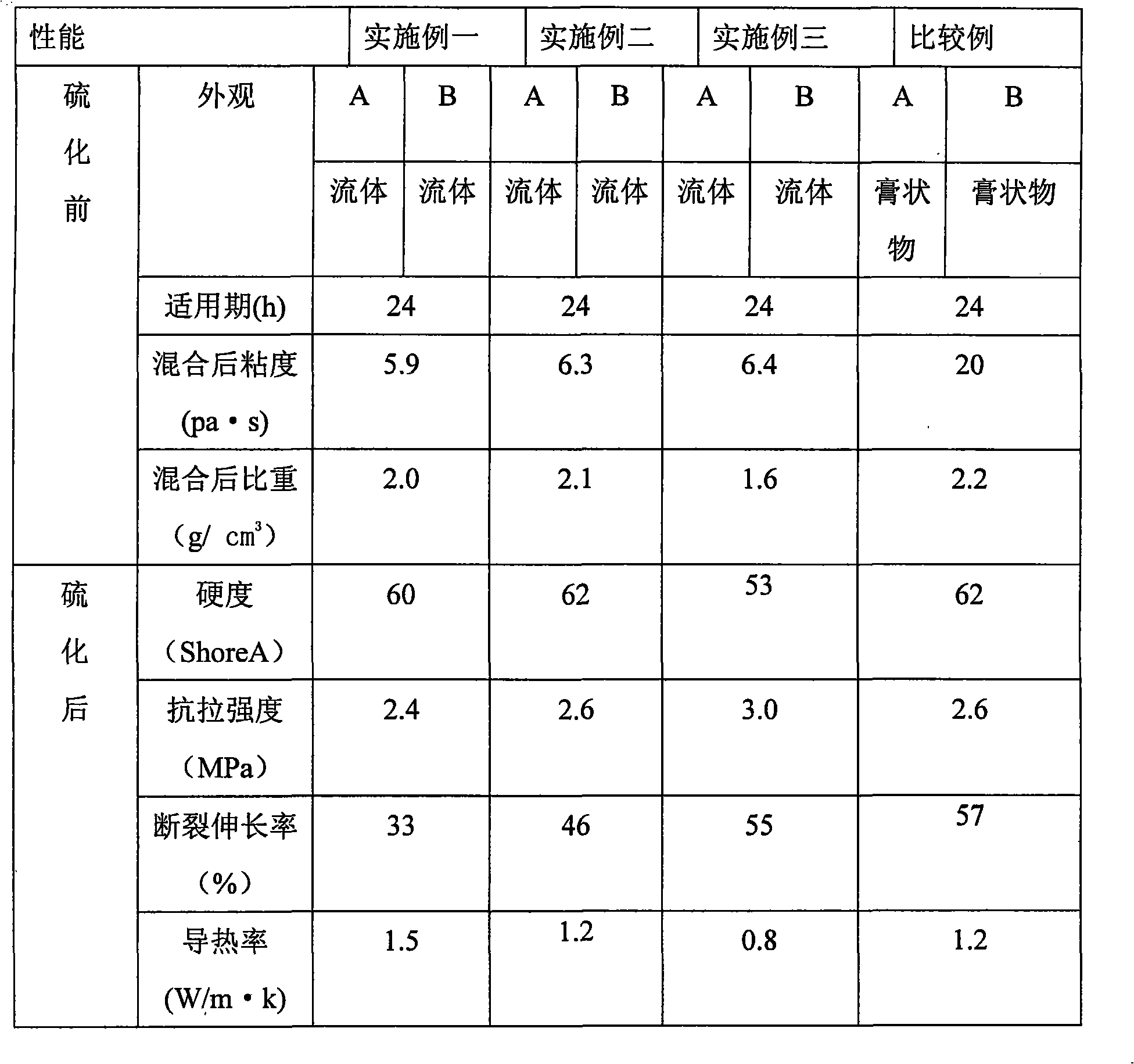

Addition type heat conducting silicon rubber and manufacturing method thereof

Owner:CHENGDU GUIBAO SCI & TECH

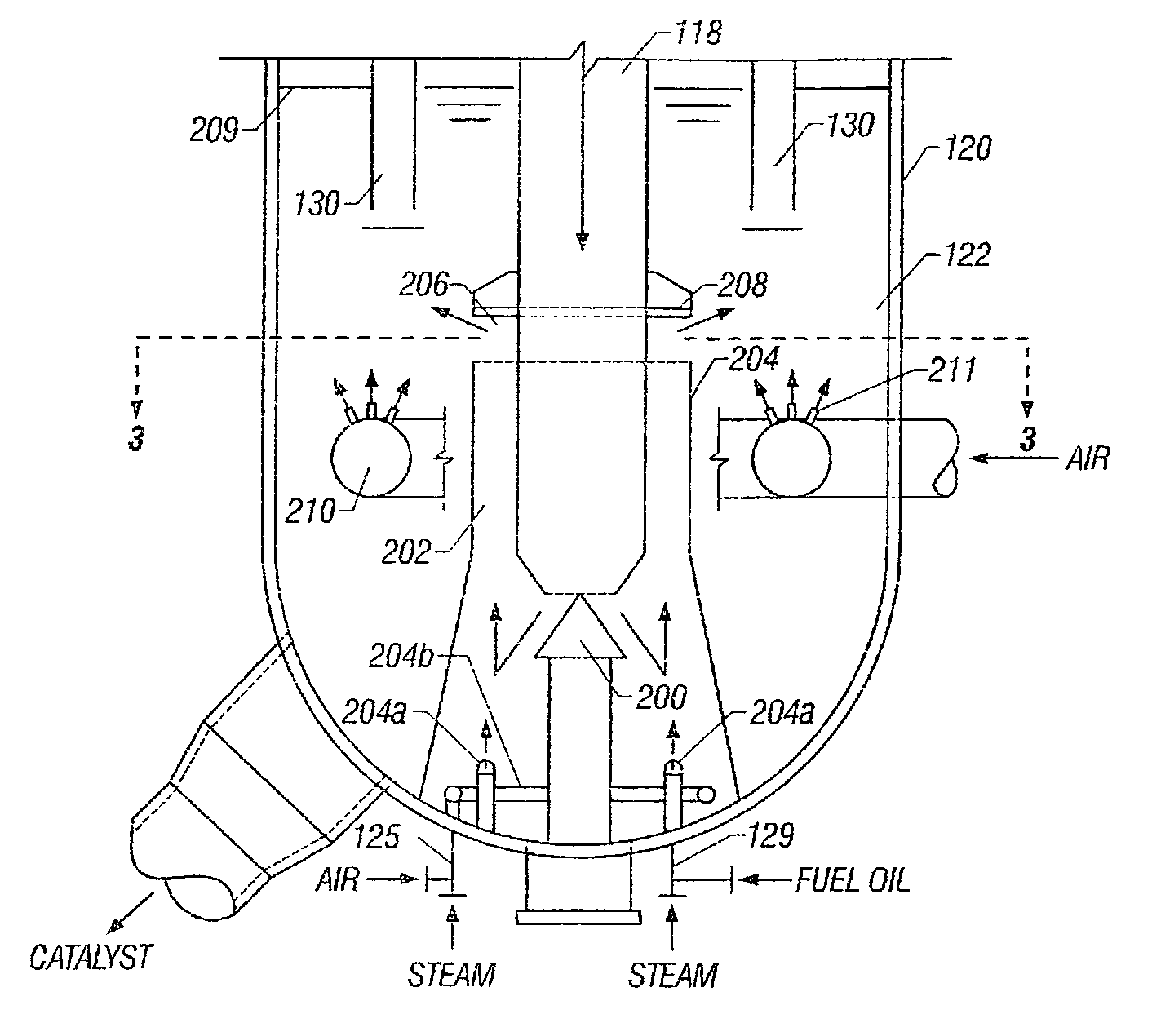

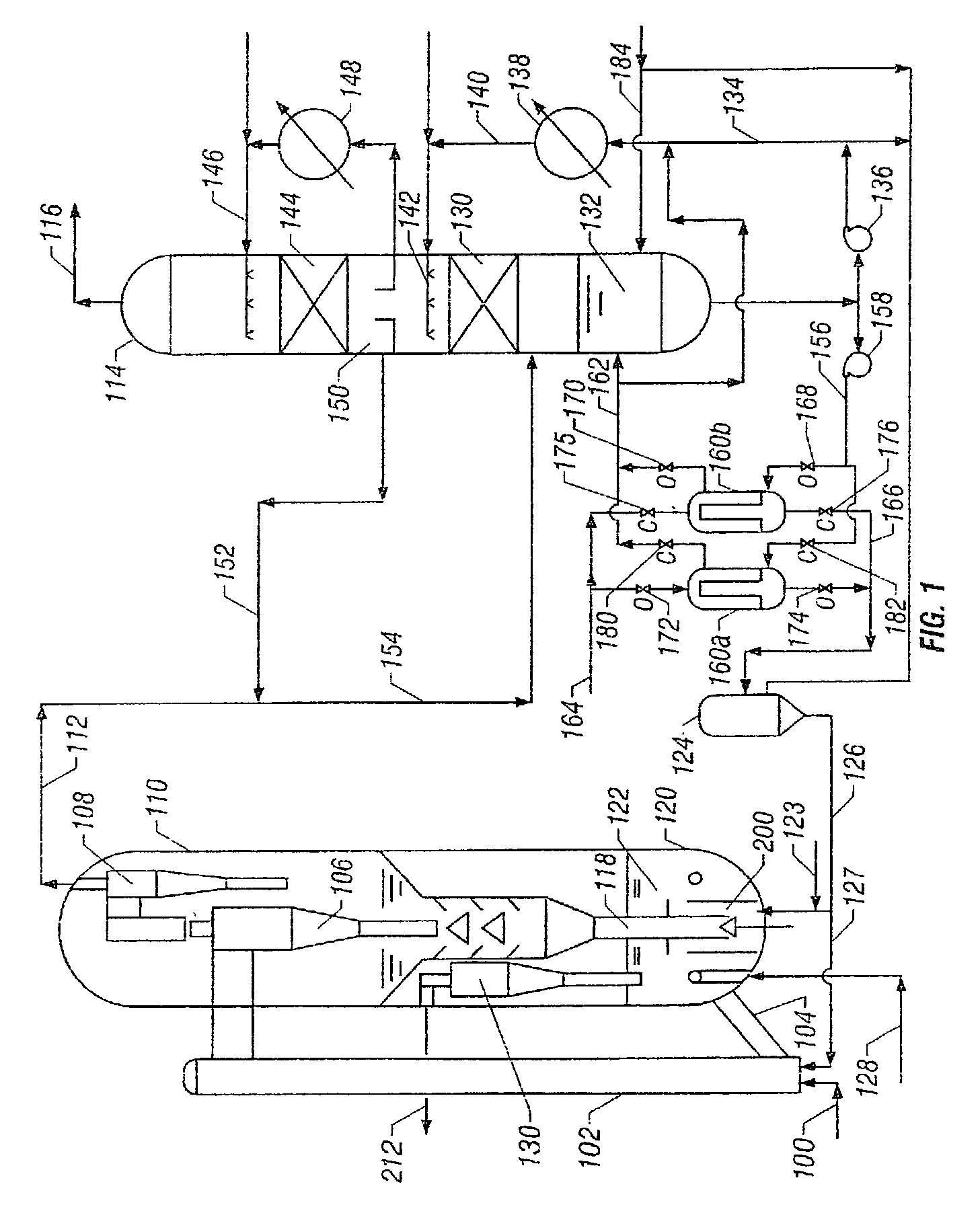

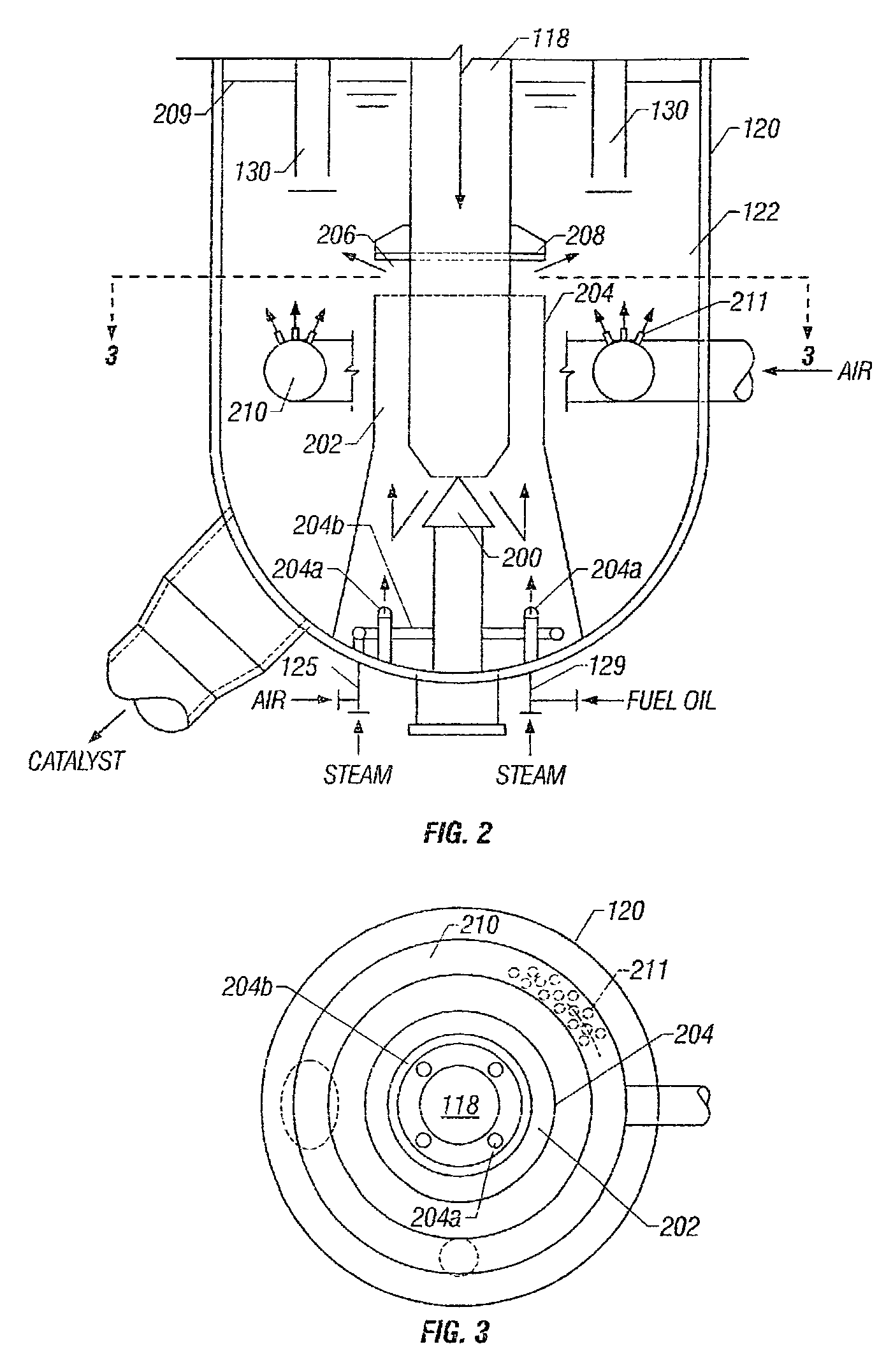

Catalyst regenerator with a centerwell

ActiveUS7153479B2Eliminate catalyst lossThermal non-catalytic crackingCatalytic crackingCombustionProcess engineering

A catalyst regenerator for regenerating spent light FCC catalyst and heating the catalyst to supply heat to an FCC reactor. The regenerator has discharge outlets for catalyst and off gas and a valve for introducing spent catalyst through a central stand pipe portion. The regenerator houses a dense phase catalyst bed. A centerwell receives a lower end of the standpipe portion and defines an annulus therebetween. The spent catalyst is introduced through the standpipe portion into the annulus. A fuel distributor introduces fuel into the centerwell for mixing with the catalyst in the annulus. A fluidization distributor introduces fluidization gas into the centerwell for fluidizing the catalyst in the annulus. A radial slot in the centerwell introduces the catalyst and fuel mixture from the annulus below the upper surface of the dense phase bed. An air distributor located below the radial slot introduces combustion air into the dense phase bed.

Owner:KELLOGG BROWN & ROOT LLC

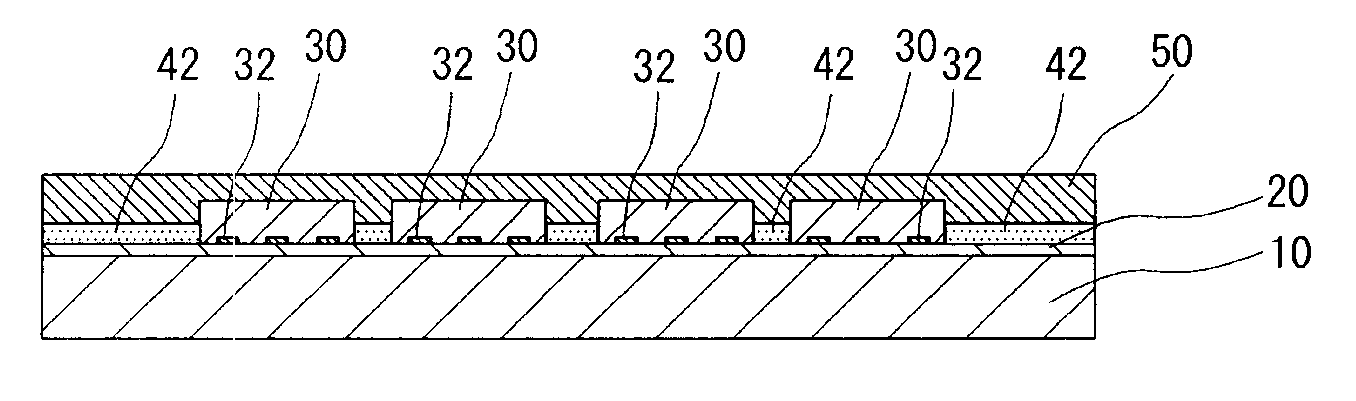

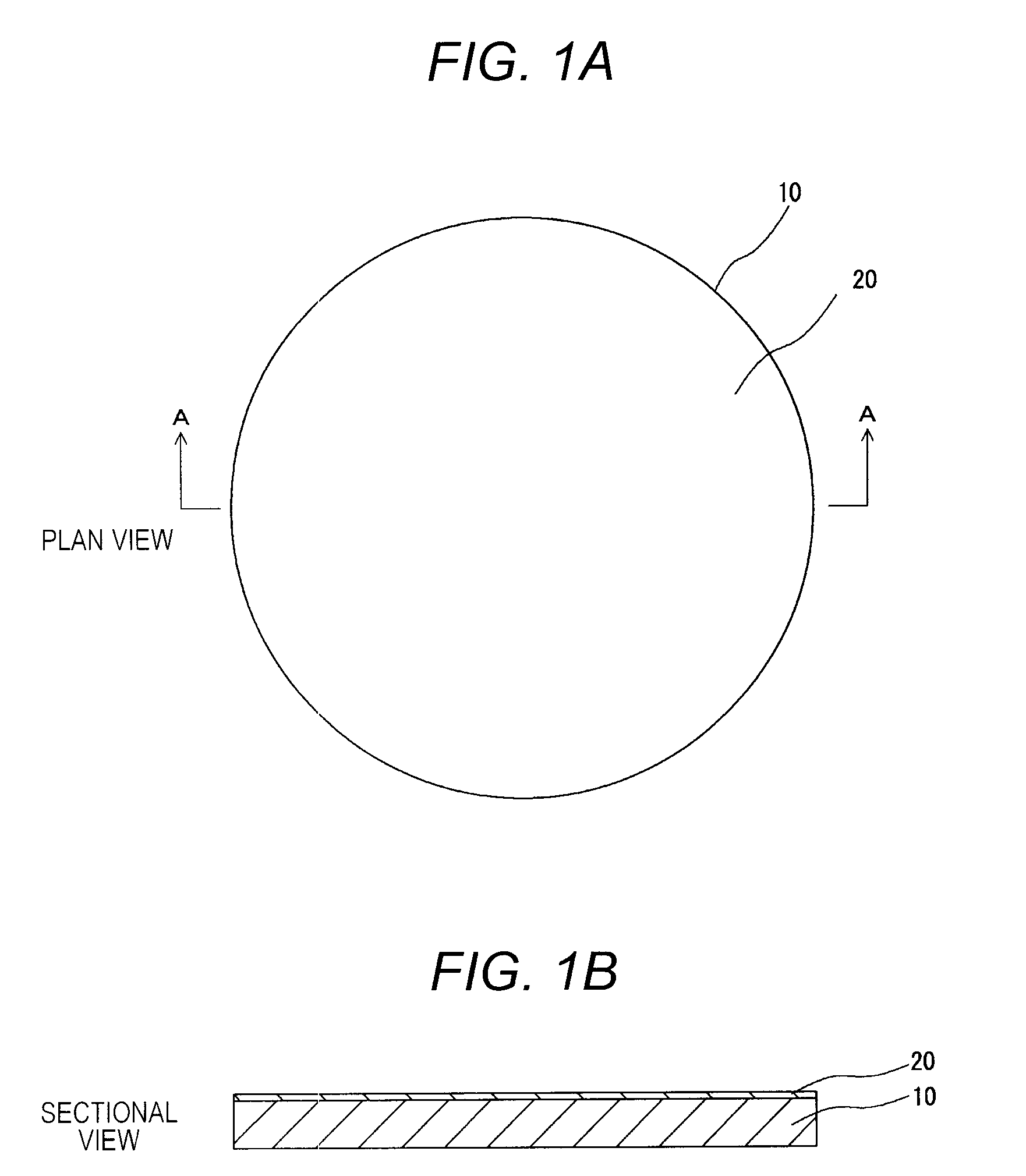

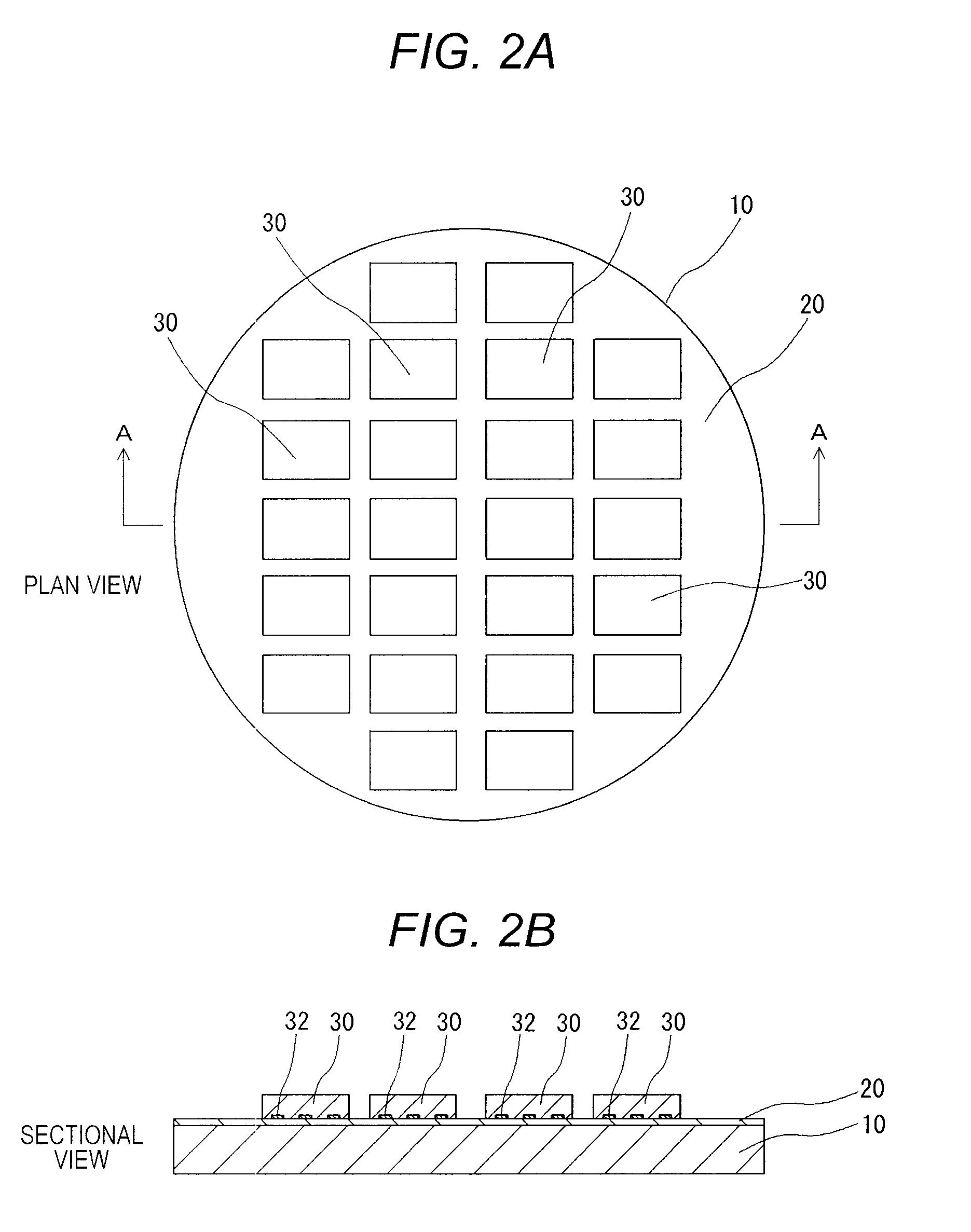

Resin sealing method of semiconductor device

ActiveUS20100184256A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

A resin sealing method of a semiconductor device includes: positioning semiconductor devices at predetermined positions of an adhesive layer formed on a support body and adhering the semiconductor devices thereto, sealing a part of each of the semiconductor devices with resin by curing a first seal resin in a fluidization state so as to fix the semiconductor devices adhered to the predetermined positions of the adhesive layer formed on the support body, setting the semiconductor devices fixed to the predetermined positions of the adhesive layer formed on the support body in a mold and sealing the exposure parts of the semiconductor devices exposed from the first seal resin with a second seal resin, and removing the support body and the adhesive layer from the semiconductor devices sealed with the resin.

Owner:SHINKO ELECTRIC IND CO LTD

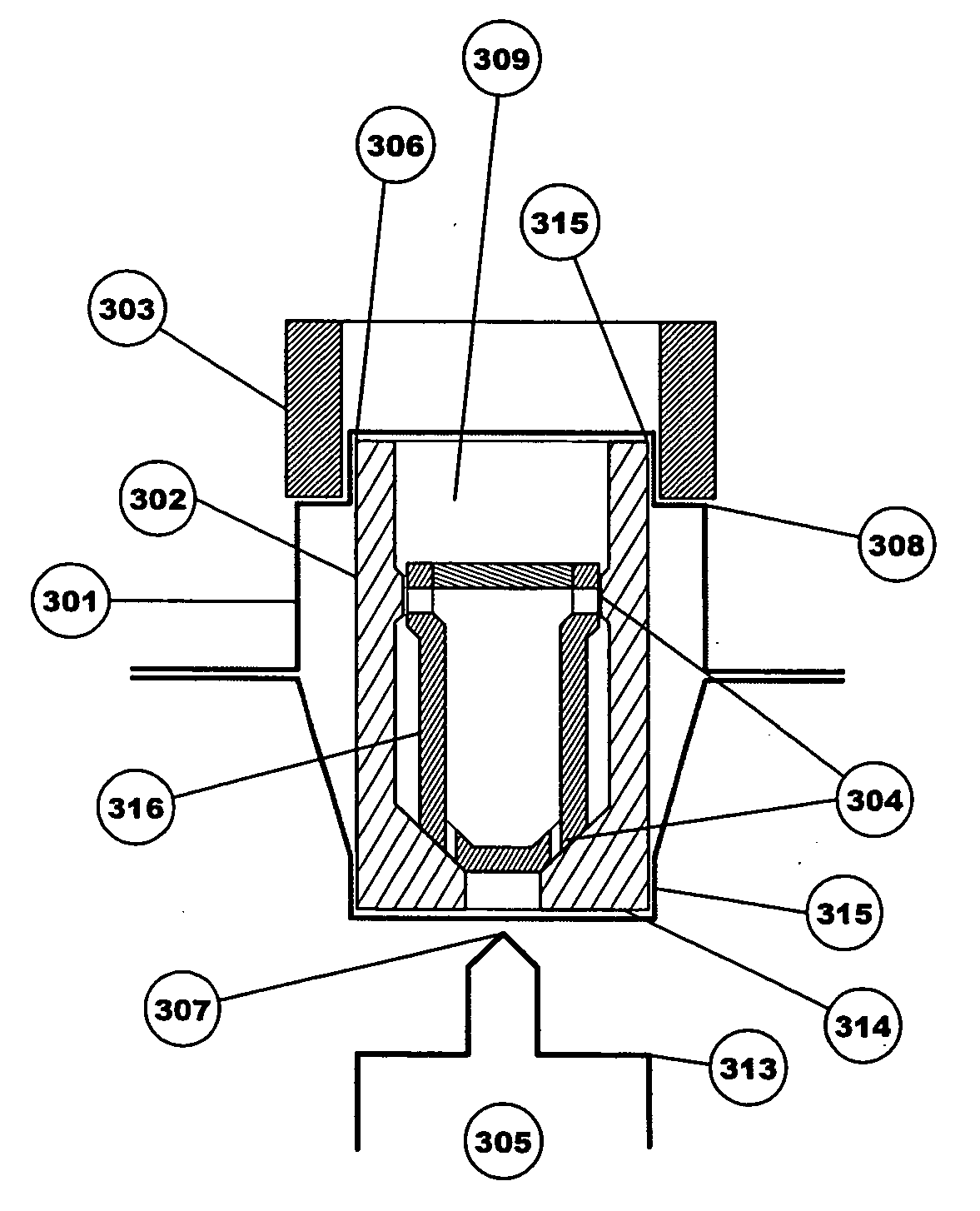

Standpipe distributor for short time contact of hydrocarbon compounds with particles

InactiveUS6143253ACompact and convenientSmall and convenientCatalytic crackingFluidised-bed furnacesParticle flowJet flow

An arrangement for the controlled production of an essentially linear array of hydrocarbon feed injection jets reduces required clearances and elevation while facilitating modification of the contacting locating a feed distributor containing a linear array of jets at a standpipe junction point to provide choke point for particle flow control. The flow properties of the extended particle layer are controlled by adjusting the density of the particles above the choke point created by the upper part of the standpipe inside diameter and the top of the distributor. Steam or another fluidization medium may be added to the particles directly above the distributor for this purpose. This invention can also modify the particle or feed injection characteristics by changing the projection of the distributor into the standpipe to adjust the flow area over the choke point and by the use of bottom slides or baffles to change the flow area size and configuration. Location of the distributor at a standpipe junction will also typically allow the placement of the distributor at a lower location in the process which eliminates the need to add vessel height for supplying pressure drop for the particle discharge point. The distributor arrangement also fits compactly into most common standpipe junctions. Thus, the arrangement of this invention solves the problem of inserting an extended array of feed injection points into a fluidized particle contacting process without providing a large amount of clearance or additional vessel height.

Owner:UOP LLC

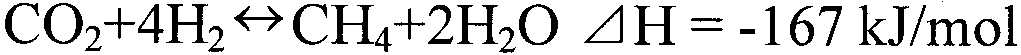

Catalyst for full methanation of carbon dioxide and preparation method thereof

ActiveCN101884927AImprove fluidization qualityHigh strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationThermal stability

The invention discloses a catalyst for full methanation of carbon dioxide, which belongs to the technical field of methanation of carbon dioxide. In the catalyst, spherical gamma-Al2O3 is used as a carrier, Ni and Fe are used as active ingredients, and MgO, La2O3 or CeO2 is used as an auxiliary agent. The catalyst is prepared by adopting an ordered soaking method through drying, roasting and reduction. The catalyst comprises the following components in percentage by mass: 60 to 80 percent of gamma-Al2O3, 10 to 20 percent of NiO, 5 to 15 percent of Fe2O3, 1 to 10 percent of MgO, and 1 to 10 percent of La2O3 or CeO2. Under the reaction conditions that the pressure is between 3.0 and 5.0MPa, the volume airspeed of the raw material gas is 5,000 to 10,000 per hour and the ratio of H2 to CO2 is 4.1, both the CO2 conversion rate and the CH4 selectivity can be close to 100 percent. The catalyst has the characteristics of high strength, good thermal stability, carbon deposition resistance, easy fluidization and the like.

Owner:TSINGHUA UNIV

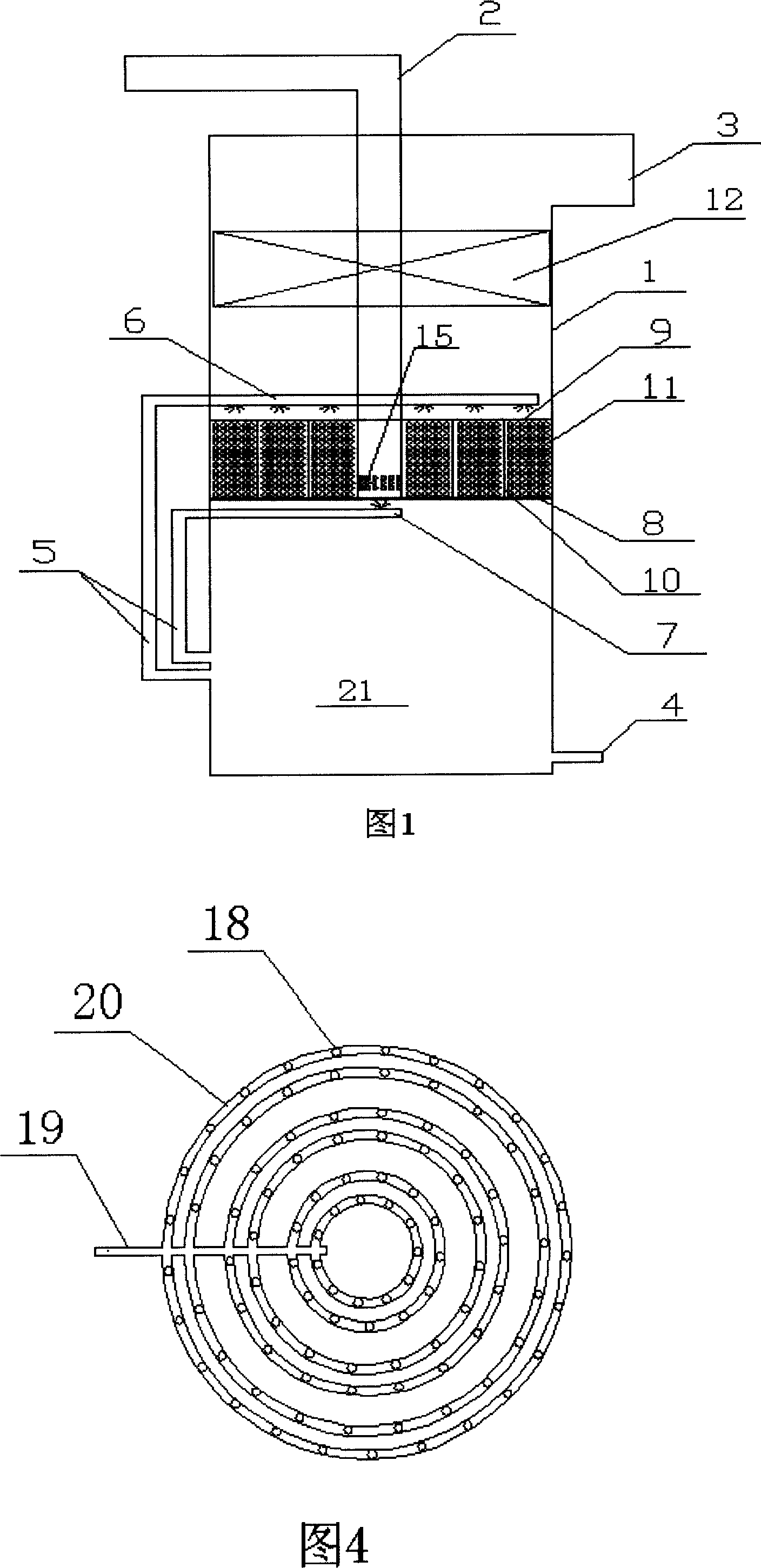

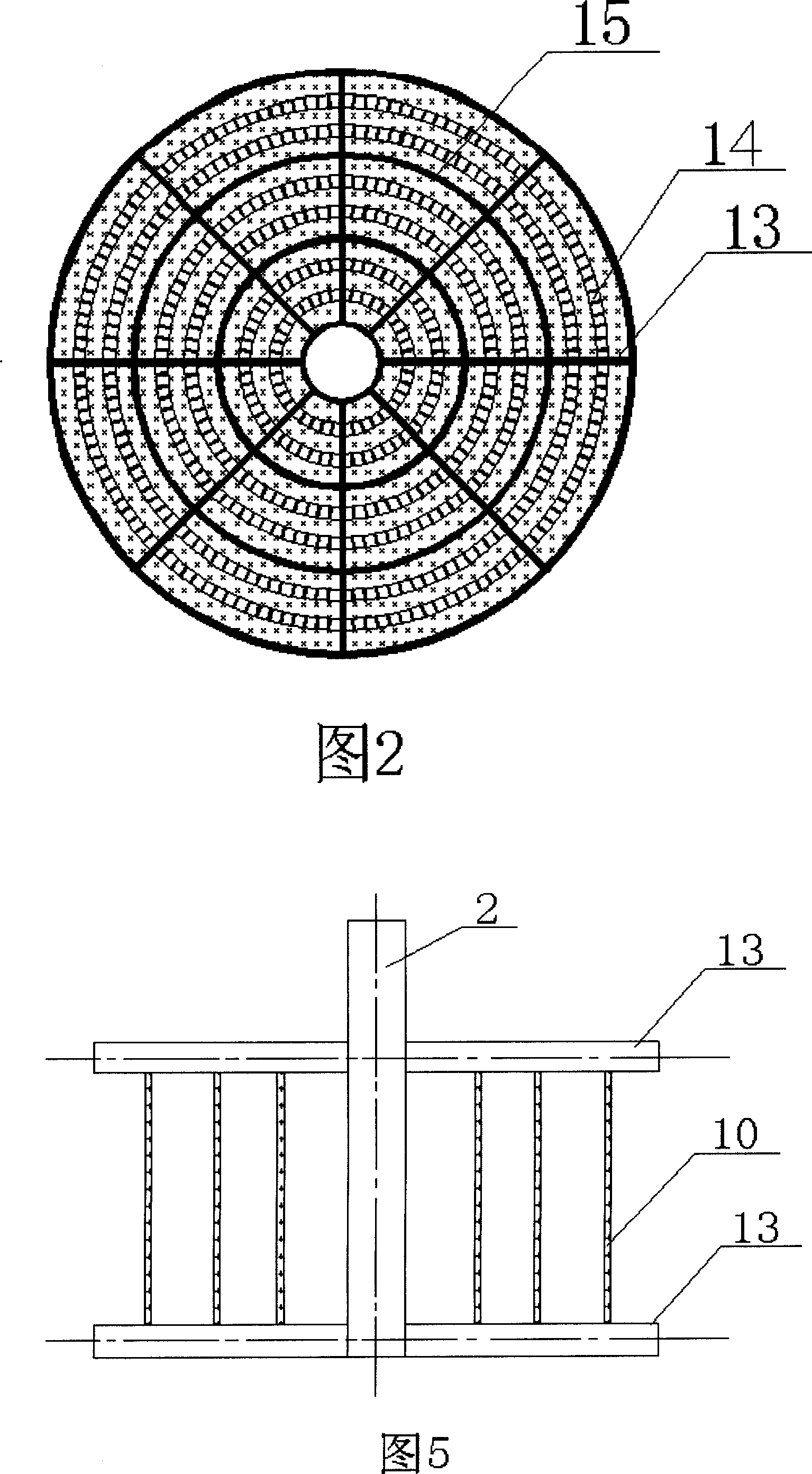

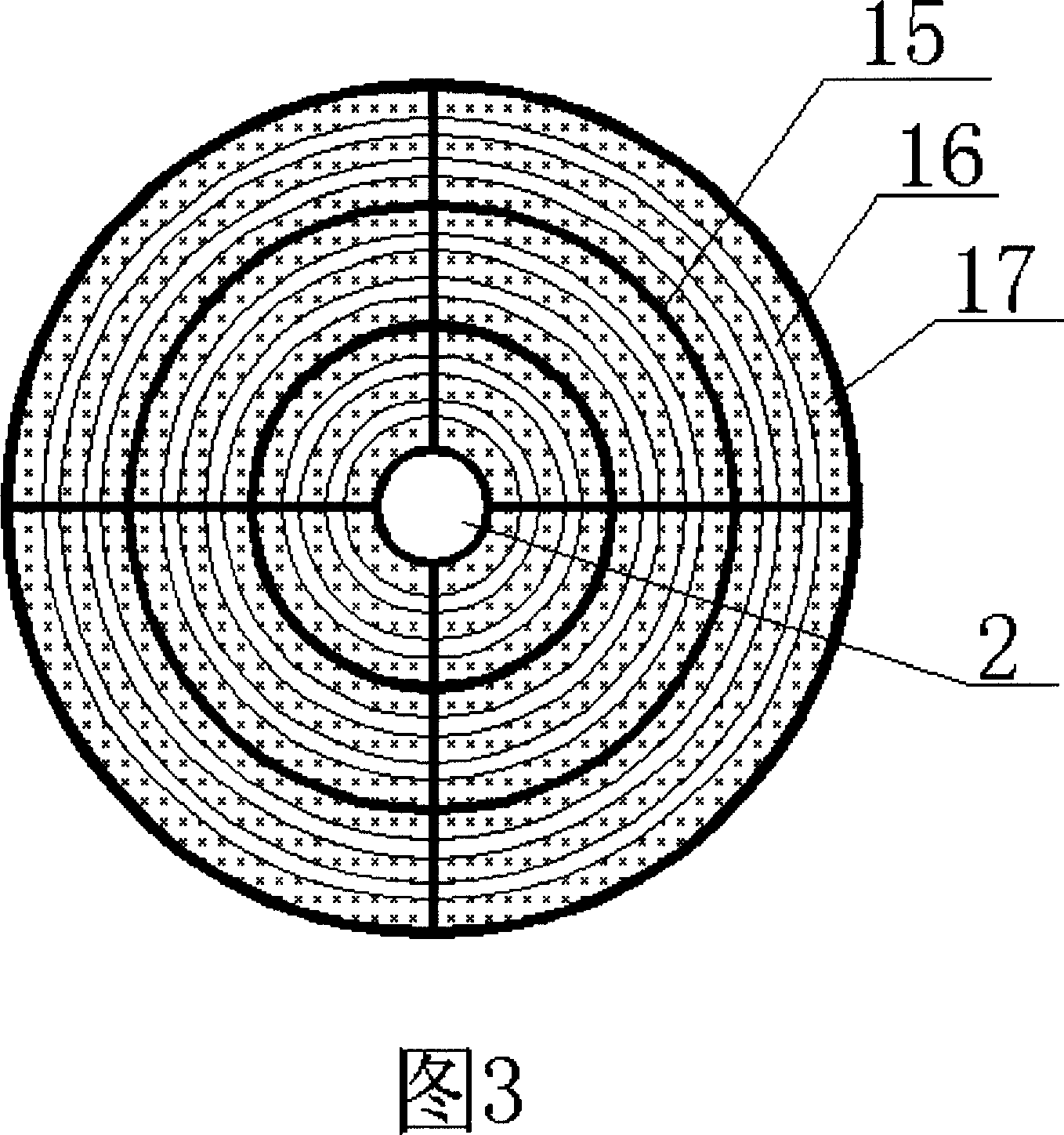

Novel barrier type air-actuated three-phase fluidization synthetized absorbing tower

InactiveCN101081348ANot easy to cause blockageTo achieve the purpose of purification and absorptionDispersed particle separationInlet channelGrating

The grating type pneumatic triphase fluidizing comprehensive absorption tower includes one housing, one gas inlet channel and gas outlet channel in the top of the tower, one rotary defogging and dewatering unit, one stuffing assembly comprising support boards, hold-down boards and stuffing, one coaxial tubular grating member, one liquid distributor with ring sprinkler pipe, one large caliber reverse sprayer inside the gas inlet channel, and one absorbing slurry pond in the bottom of the tower. It features the special grating structure, the regularly arranged stuffing for cyclic fluidizing, the combined foam absorption and stuffing absorption, etc, and has high absorption efficiency, great gas treating amount and other advantages.

Owner:BEIJING HUAYU RONGTONG POWER TECH DEV

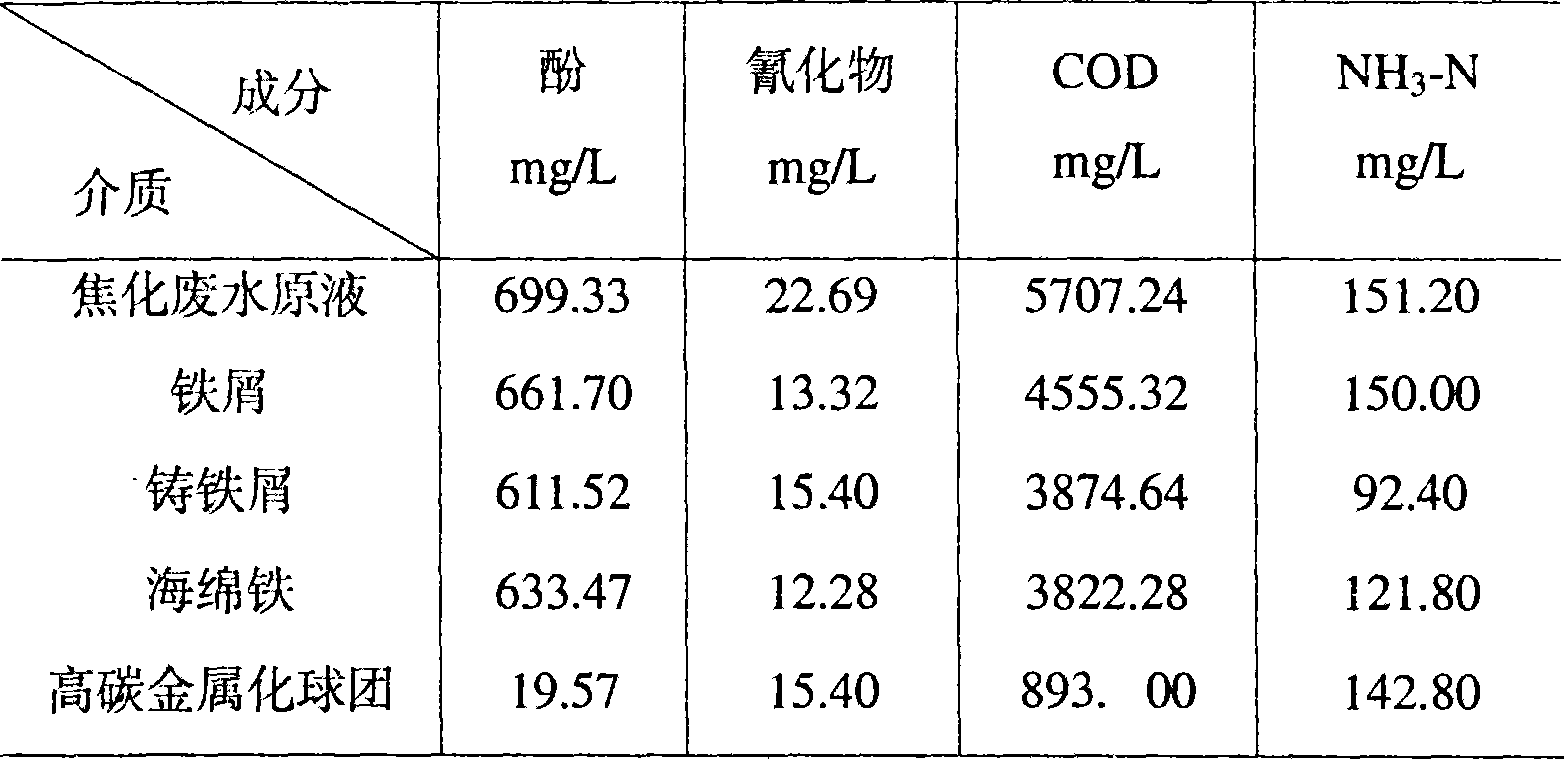

High-carbonaceous metallized pellet for treating waste water and preparation method

ActiveCN101200320AImprove adsorption capacitySmall bulk densityWater/sewage treatment by electrochemical methodsWater/sewage treatment by flocculation/precipitationElectrolysisHigh carbon

The invention relates to a preparation method of high carbon metalized pellet for waste water treatment, belonging to a technical field of metallurgical products, which is used to solve the problem that the surface passivation is easy to be generated in the material filtering in iron carbon by the method of electrolysis so as to affect waste water treatment effect. The invention is characterized in that: the high carbon metalized pellet contains single iron, activated carbon and few impurities, wherein the particle diameter of the single iron is less than 0.2mm, the activated carbon is a pore structure, the specific surface area reaches 500-800 square meter per gram. The method of the invention is composed of raw material preparation, pellet building, drying, reduction and other steps. Experiments evidence: the product in the invention has rich pore structures and huge specific surface, and has strong capability of absorbing contaminations in waste water, moreover the product has higher reaction activities, good osmosis, easy fluidization and no agglomeration. Compared with the conventional electrolysis process, the COD removal ratio of the used filling is improved by above 50 percent under equal time, the waste water with large variable concentration and wide PH value range can be treated.

Owner:唐山助纲炉料有限公司

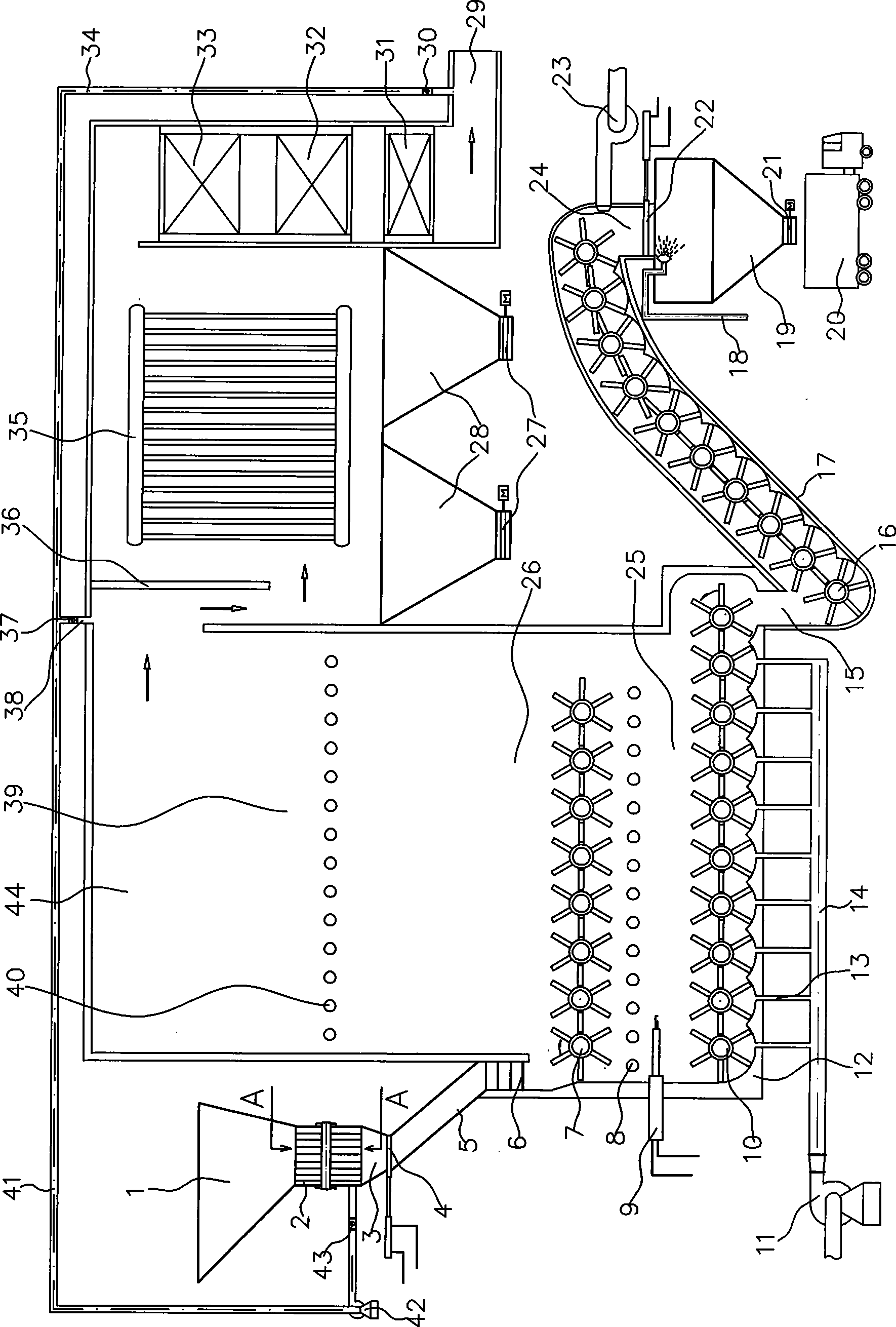

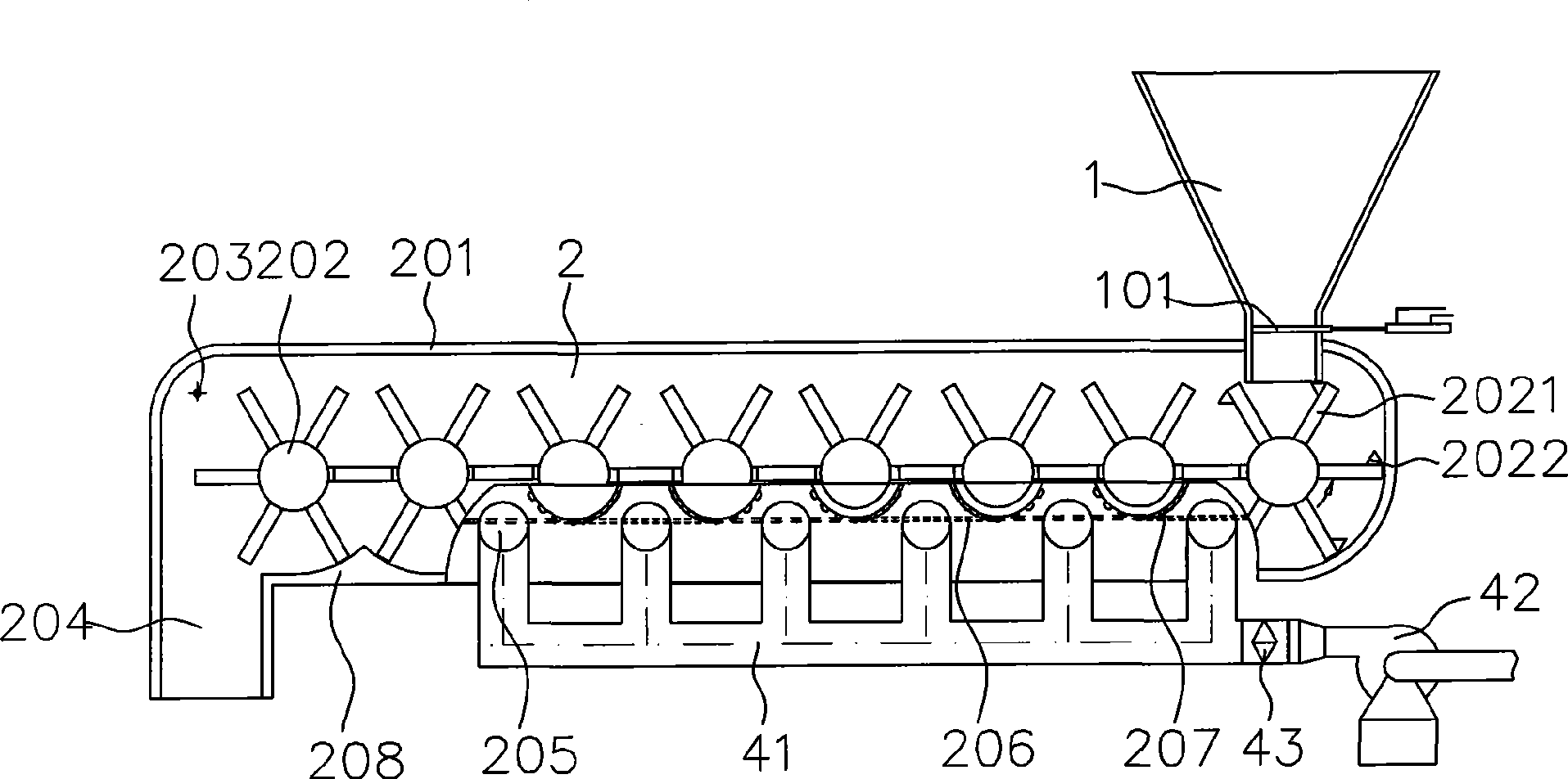

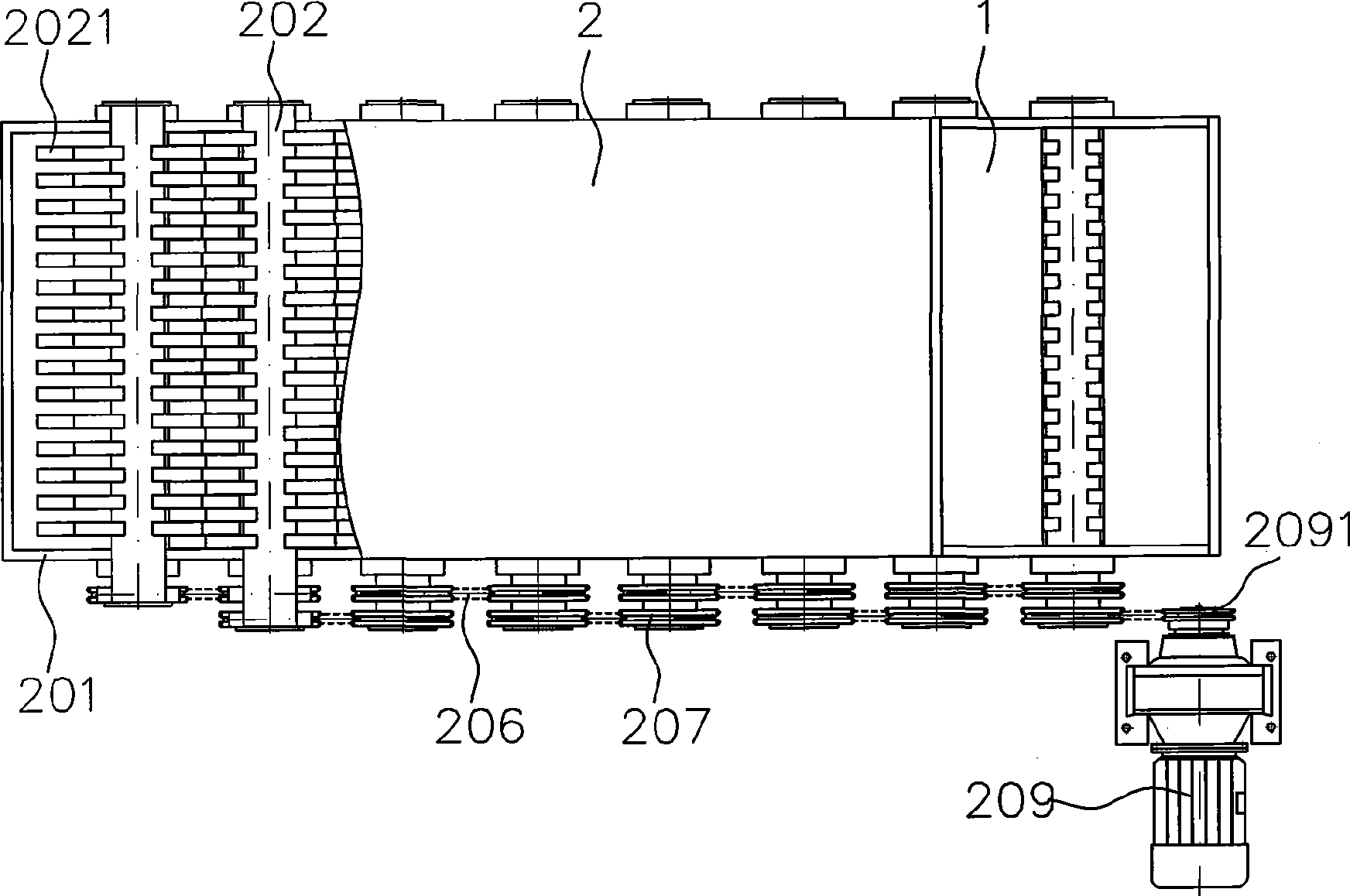

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

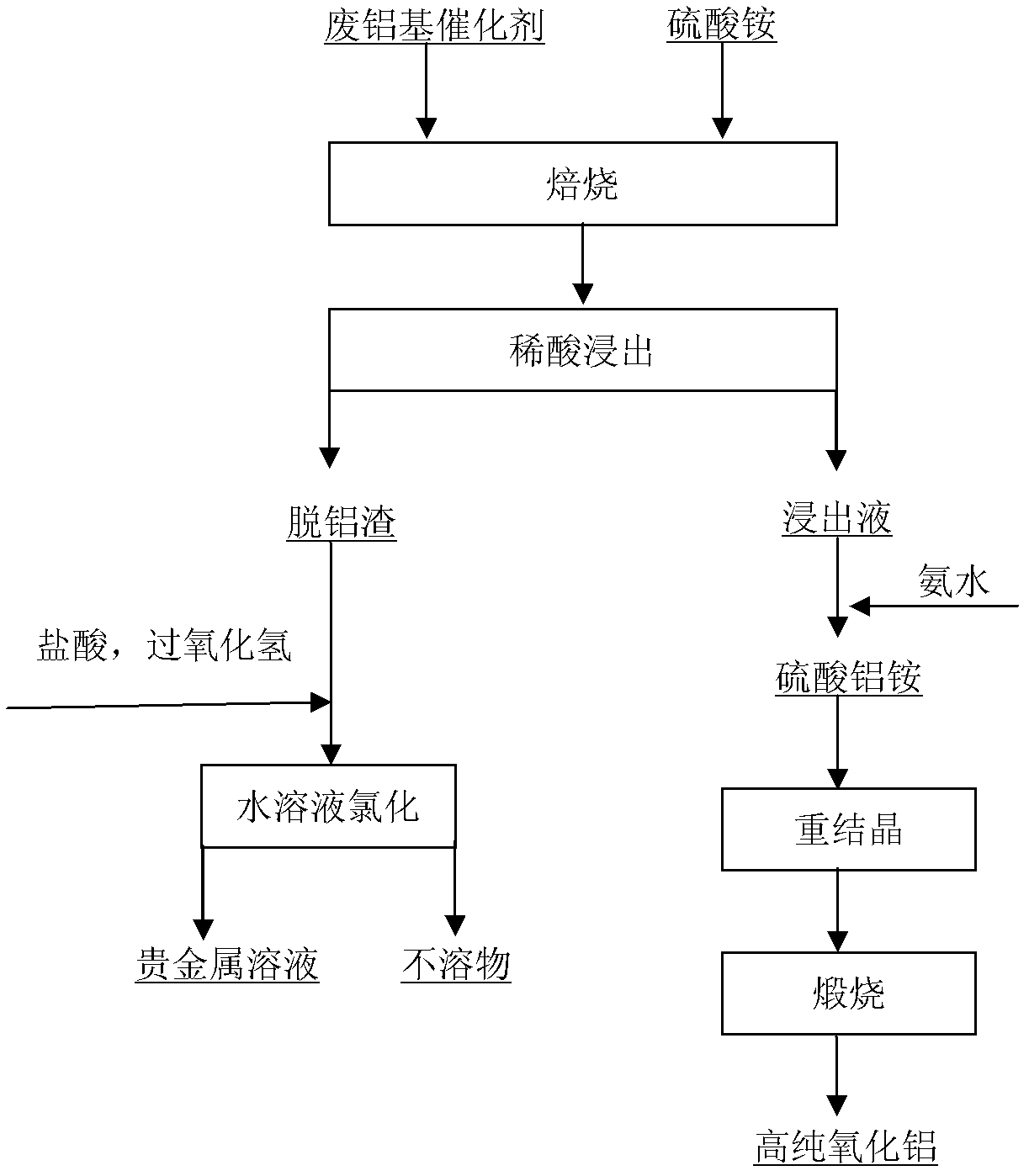

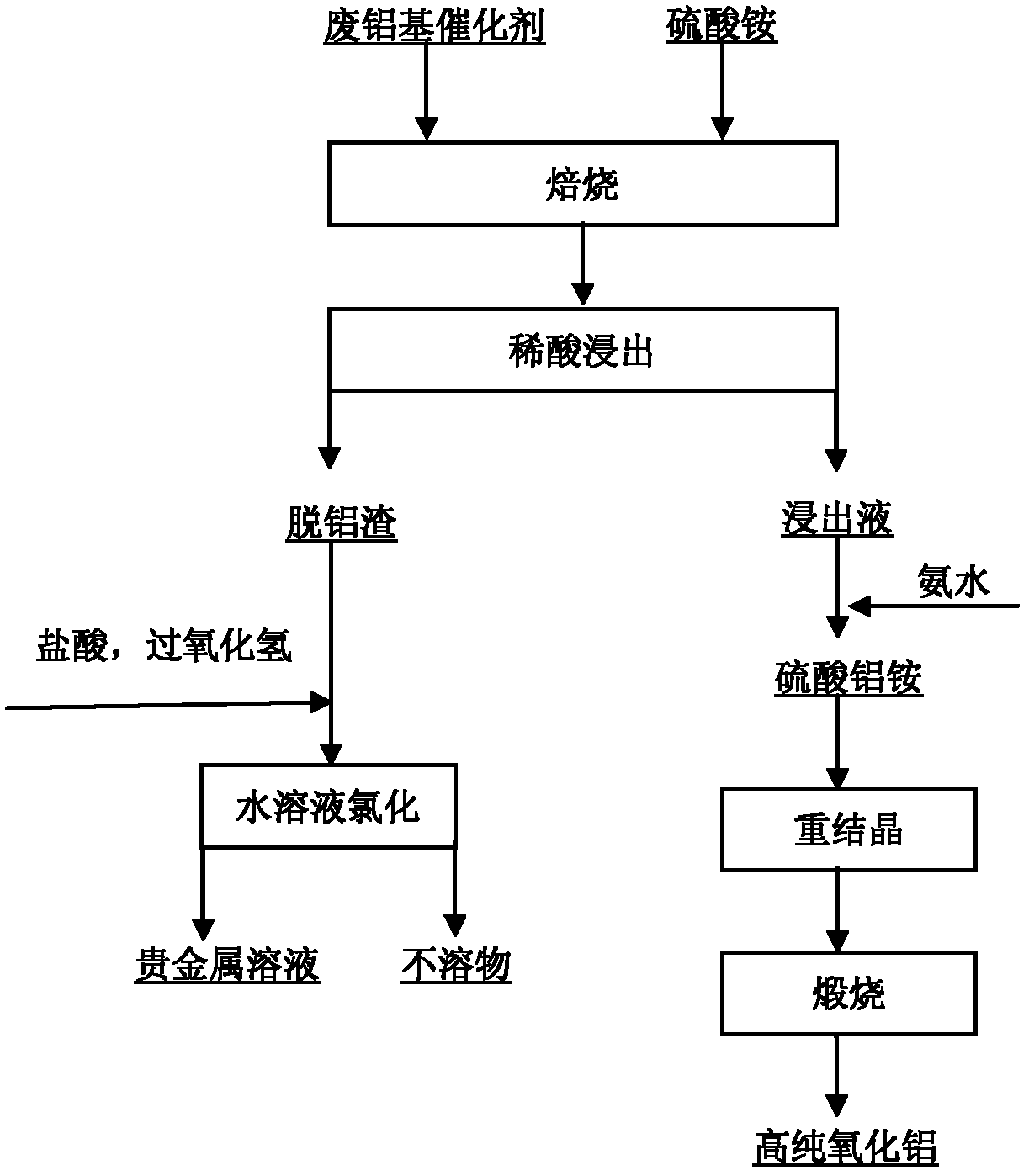

Method for recovering precious metal from waste aluminum-based catalyst and preparing high-purity alumina

InactiveCN102560129AAchieve recyclingReasonable processProcess efficiency improvementSlagAmmonium aluminium sulfate

The invention discloses a method for recovering precious metal from a waste aluminum-based catalyst and preparing high-purity alumina. The method mainly comprises the processes of: roasting, leaching to remove aluminum by using dilute sulfuric acid, recovering the precious metal from slag from which the aluminum is removed by an aqueous solution chlorination method, adding ammonia water into leachate to precipitate an ammonium aluminum sulfate coarse crystal, recrystallizing, and calcining and decomposing to prepare the high-purity alumina. The method specifically comprises the following steps of: mixing the finely ground waste aluminum-based catalyst (40mu m) and ammonium sulfate in a weight ratio of 1:(1.3-1.5), roasting at the temperature of between 300 and 500 DEG C for 2 to 4 hours, performing fluidization leaching on a roasting product by using 1mol / L dilute sulfuric acid for 2 hours, performing solid-liquid separation, and recovering the precious metal from the slag from which the aluminum is removed by the traditional aqueous solution chlorination method, wherein the recovery rate of the precious metal is over 99 percent; and adding the ammonia water into the leachate to regulate the pH value and precipitate the ammonium aluminum sulfate coarse crystal, recrystallizing, and calcining and decomposing to prepare the high-purity alumina, wherein the purity is over 99.99 percent, and the recovery rate is over 95 percent. The invention has the advantages that: the process is reasonable, the method is easy to operate, the added value of a product is high, pollution is light, mass production is convenient to implement, and the like.

Owner:KUNMING INST OF PRECIOUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com