Anaerobic zero-valent iron sewage treatment method

A sewage treatment method and zero-valent iron technology, applied in water/sewage treatment, anaerobic digestion treatment, reduced water/sewage treatment, etc., can solve problems such as affecting the efficiency of sewage treatment, blocking the passage of water, and short-circuiting local channels. To achieve the effect of increasing the fluidization effect, increasing the water load and slowing down the rate of rust formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

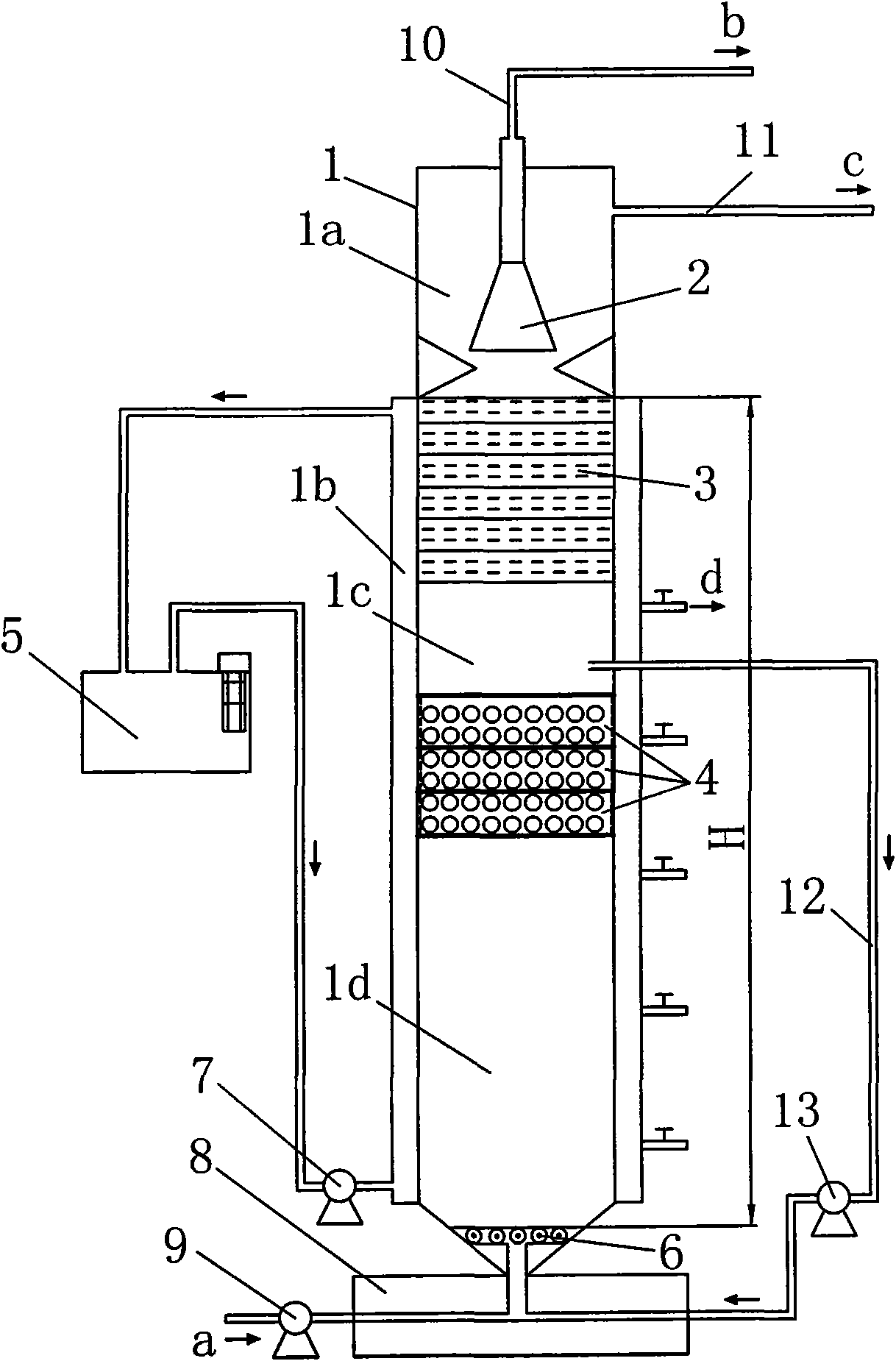

[0036] figure 1 A working principle diagram of an anaerobic reactor is shown. The anaerobic reactor mainly includes a cylindrical reactor shell 1, in which a water distributor 6, three zero-valent iron filling layers 4, and a biological filter layer are sequentially arranged in the reactor shell 1 from bottom to top. 3 and a three-phase separator 2, which divide the inner cavity of the reactor shell 1 into a gas-liquid solid separation zone 1a located above the biological filter material layer 3, and a gas-liquid solid separation zone 1a located between the biological filter material layer 3 and the zero-valent iron filling layer 4 There is a suspended sludge zone 1c between them and a sludge bulking zone 1d between the zero-valent iron filling layer 4 and the water distributor 6 . The reactor shell 1 is made of plexiglass or FRP, with an inner diameter of 90cm, a height of 120cm, and an effective volume of 6.36L. The height of the biological filter material layer 3 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com