Patents

Literature

188results about How to "Improve biochemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anaerobic zero-valent iron sewage treatment method

ActiveCN101624250AImprove responseAvoid formingWaste based fuelTreatment with anaerobic digestion processesAnaerobic reactorDyeing wastewater

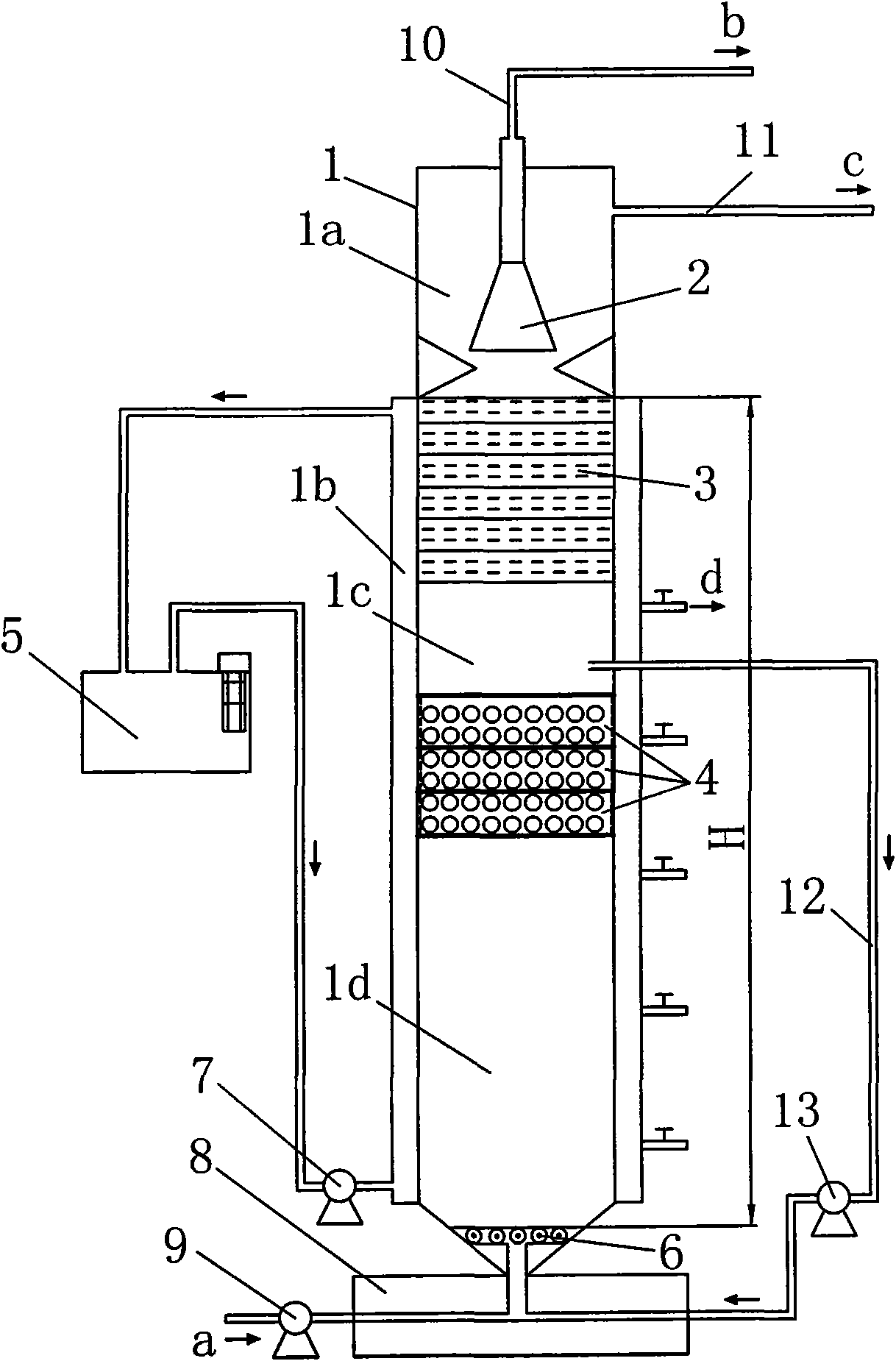

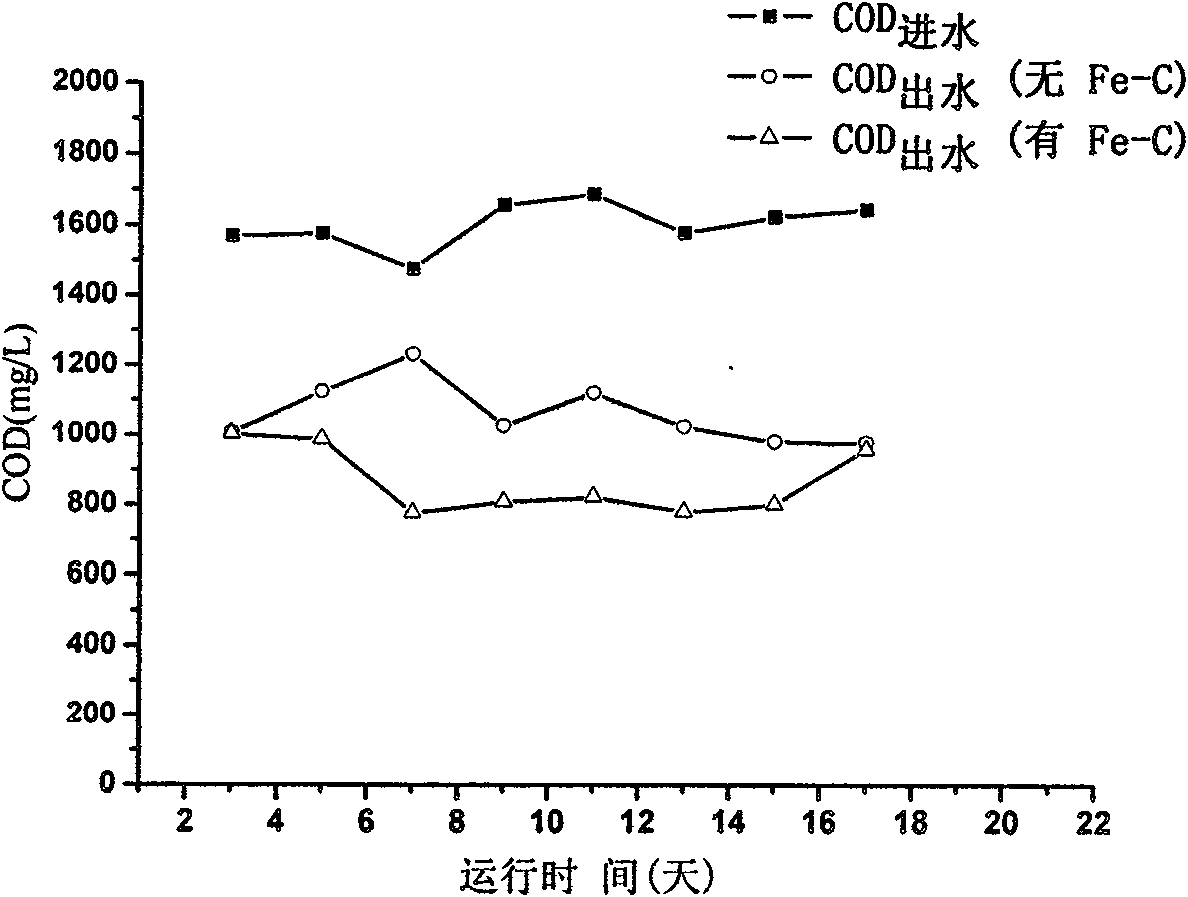

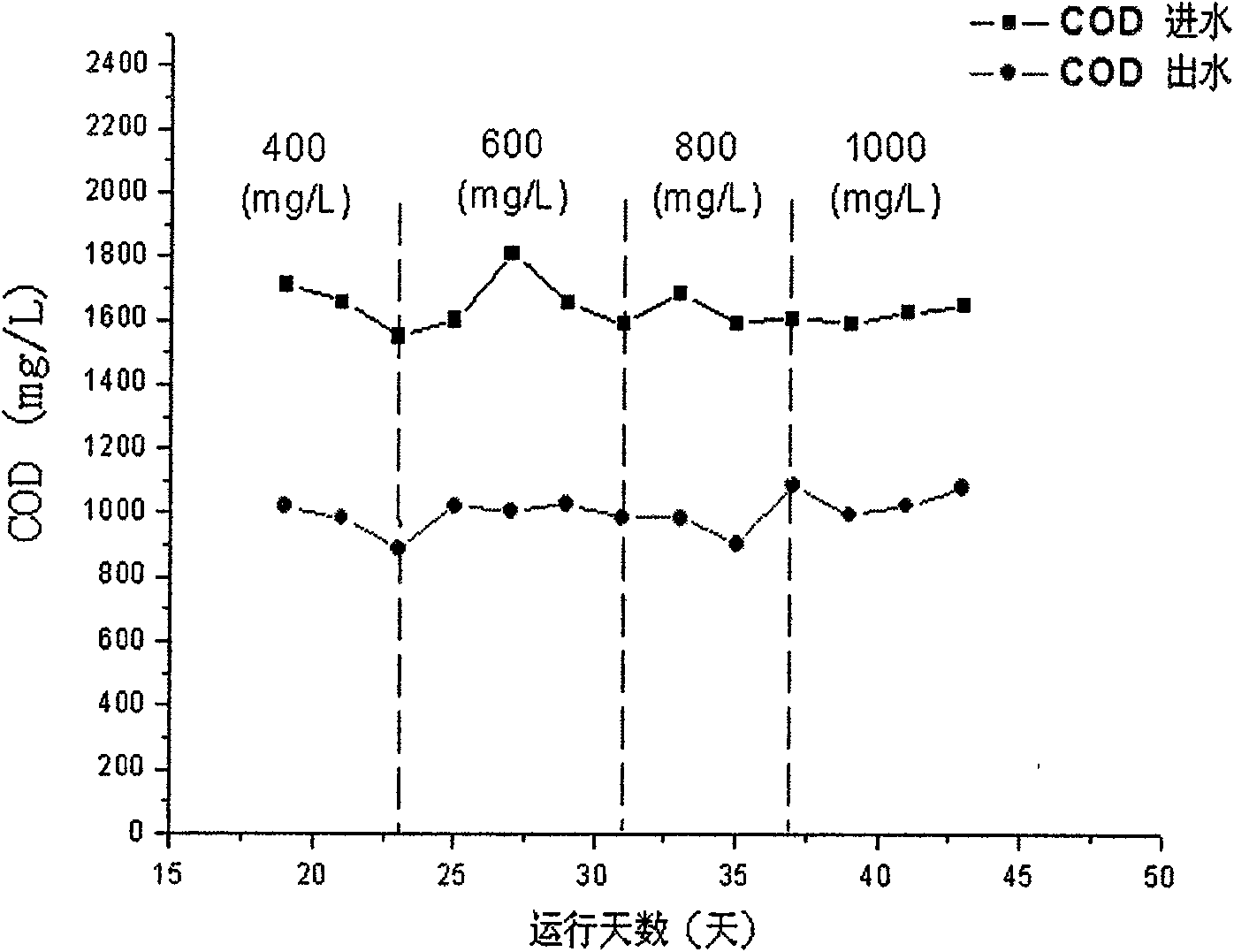

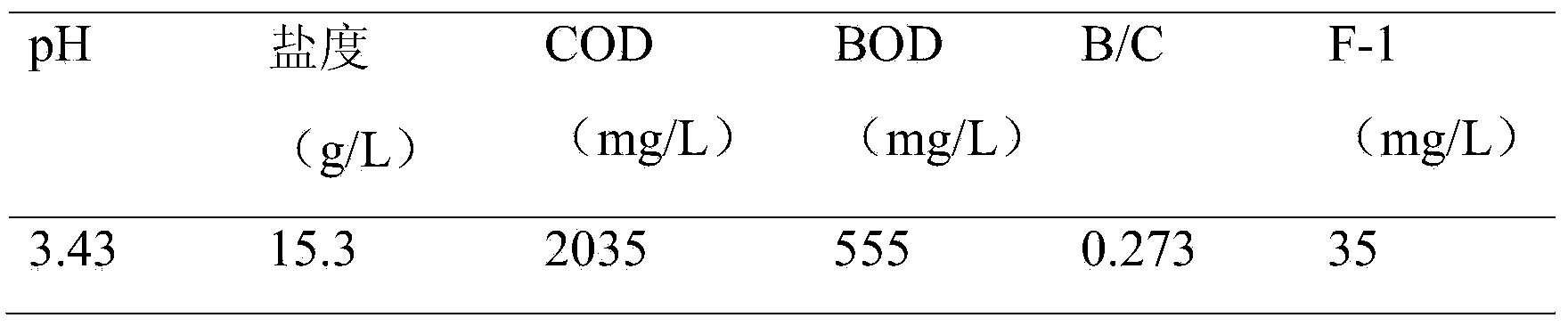

The invention relates to an anaerobic zero-valent iron sewage treatment method, belonging to the sewage treatment technical field. The anaerobic zero-valent iron sewage treatment places zero-valent iron in an anaerobic reactor and utilizes the environmental conditions of the anaerobic isolated air to largely reduce the formation rate of the rust of zero-valent iron and avoid the formation of hardening; meanwhile, the method uses the reducing action of metal iron to increase the anaerobic reductive atmosphere, balance the pH and increase the effect of the anaerobic organism. A circulating pump is adopted for sewage backflow so as to increase the overflow load of an iron / activated carbon layer and the reaction effect of zero-valent iron, improve the fluidization effect of sludge to increase the anaerobic process efficiency. In a sewage treatment system, ferrous iron contained in the discharged sewage is oxidized to Fe(OH)3 with the air and the coagulation generated in the process can further purify the sewage. Long-term experiment research shows that the decolorizing rate of the sewage treatment method for dye wastewater can teach 85%-95%, the COD can be reduced by more than 50% and the biodegradability can be increased to more than 0.3.

Owner:DALIAN UNIV OF TECH

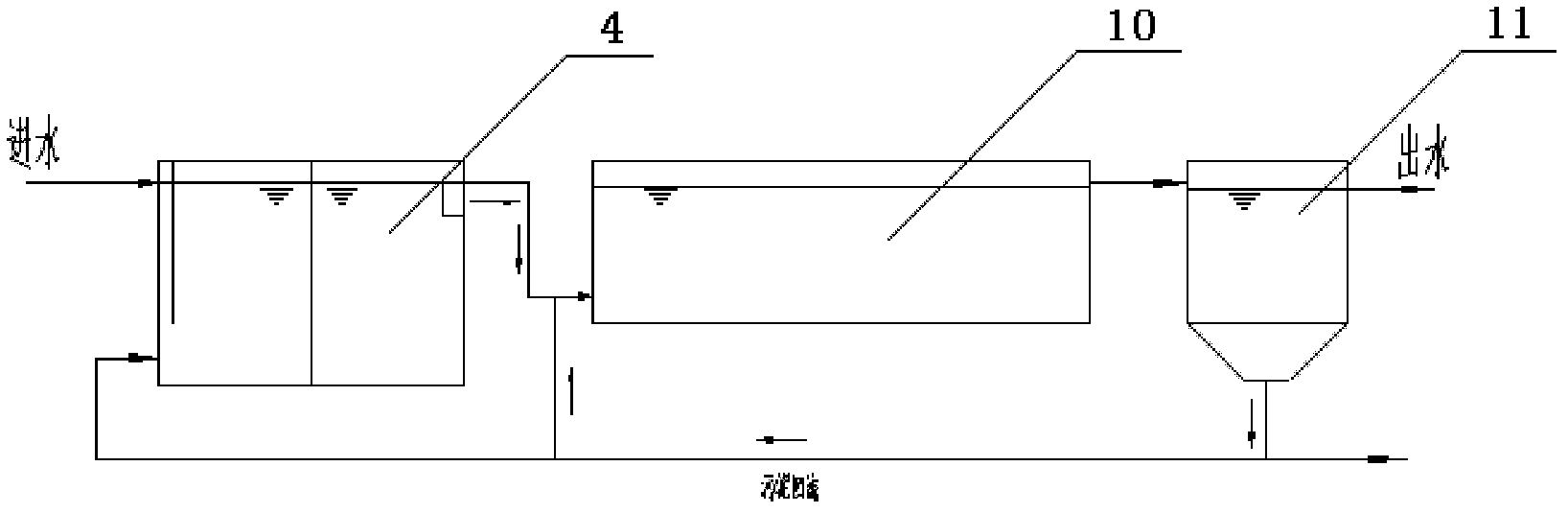

Method and apparatus for treating and recycling carbonized wastewater

ActiveCN101428945ASolve processing problemsImprove biochemical propertiesFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processSludgeTreatment design

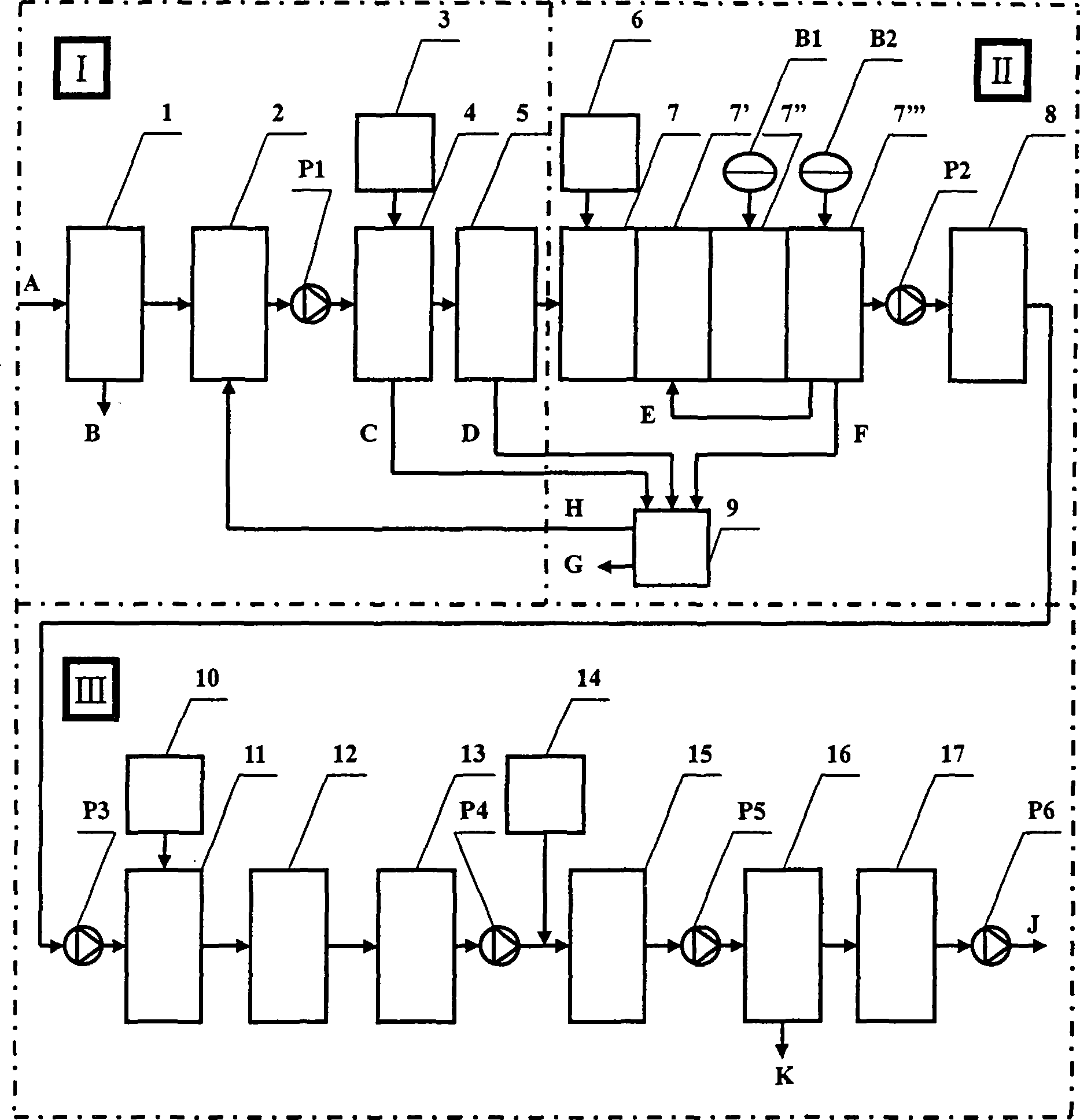

The invention relates to a coking waste water treatment reuse method and a device thereof. The method comprises the following process steps: 1. strengthening pretreatment; 2. biological treatment; and 3. reuse water treatment. The structure of the method is as follows: electrochemical equipment at the strengthening pretreatment step is connected with a water outlet of an air float and a water inlet of biological treatment; and a water outlet pipe of an MBR water outlet tank at the biological and sludge treatment step is connected in serial with an ozone contact tower, an active carbon filter tower and an RO at the reuse water treatment step. The method has the advantages of providing a novel combination process for the coking waste water, effectively combining the technologies of de-oiling, biochemistry, electrochemistry and membrane, improving the biodegradability of difficultly degraded pollutants by utilizing the electrochemical strengthening pretreatment, strengthening the biochemical treatment by MBR, reasonably designing the reuse treatment of ozone-active carbon-RO, solving the problem of the difficult treatment of coking waste water and achieving the aim of the reuse of the coking waste water.

Owner:上海缘脉环境科技有限公司

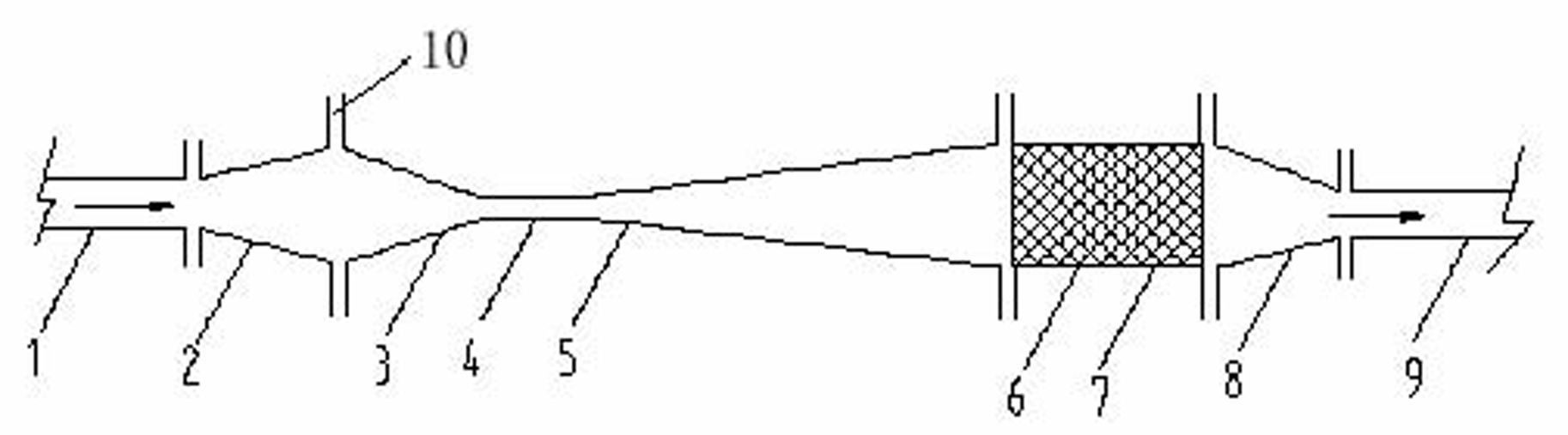

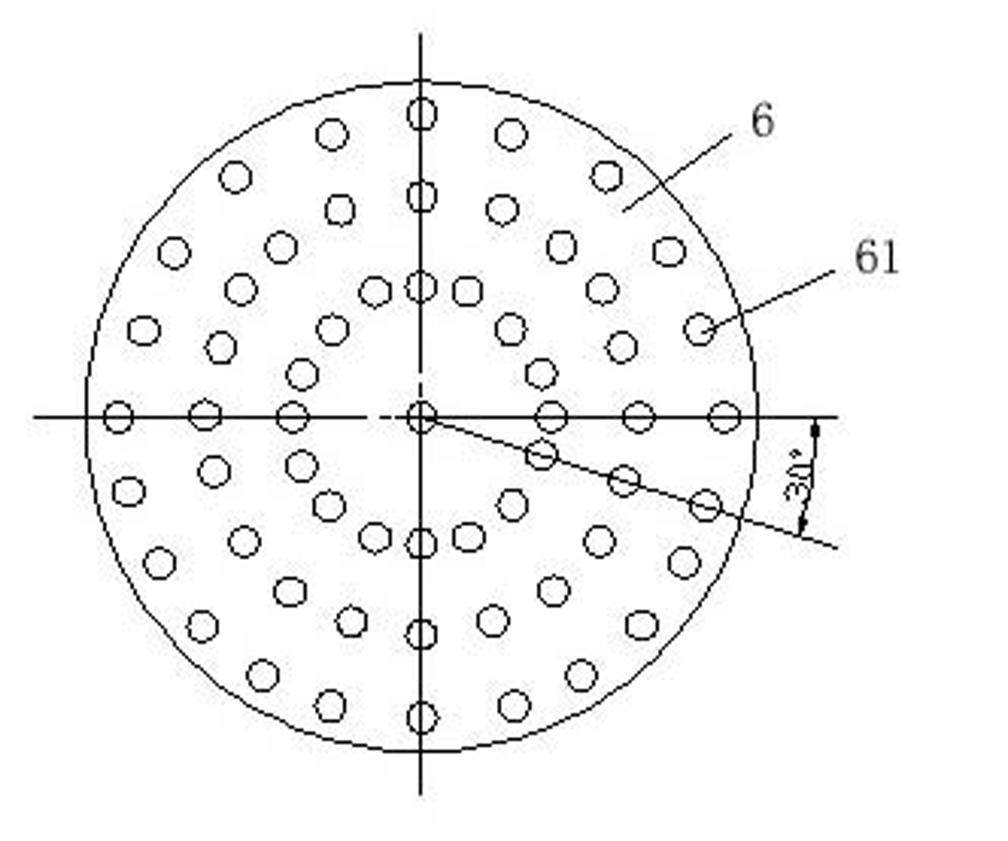

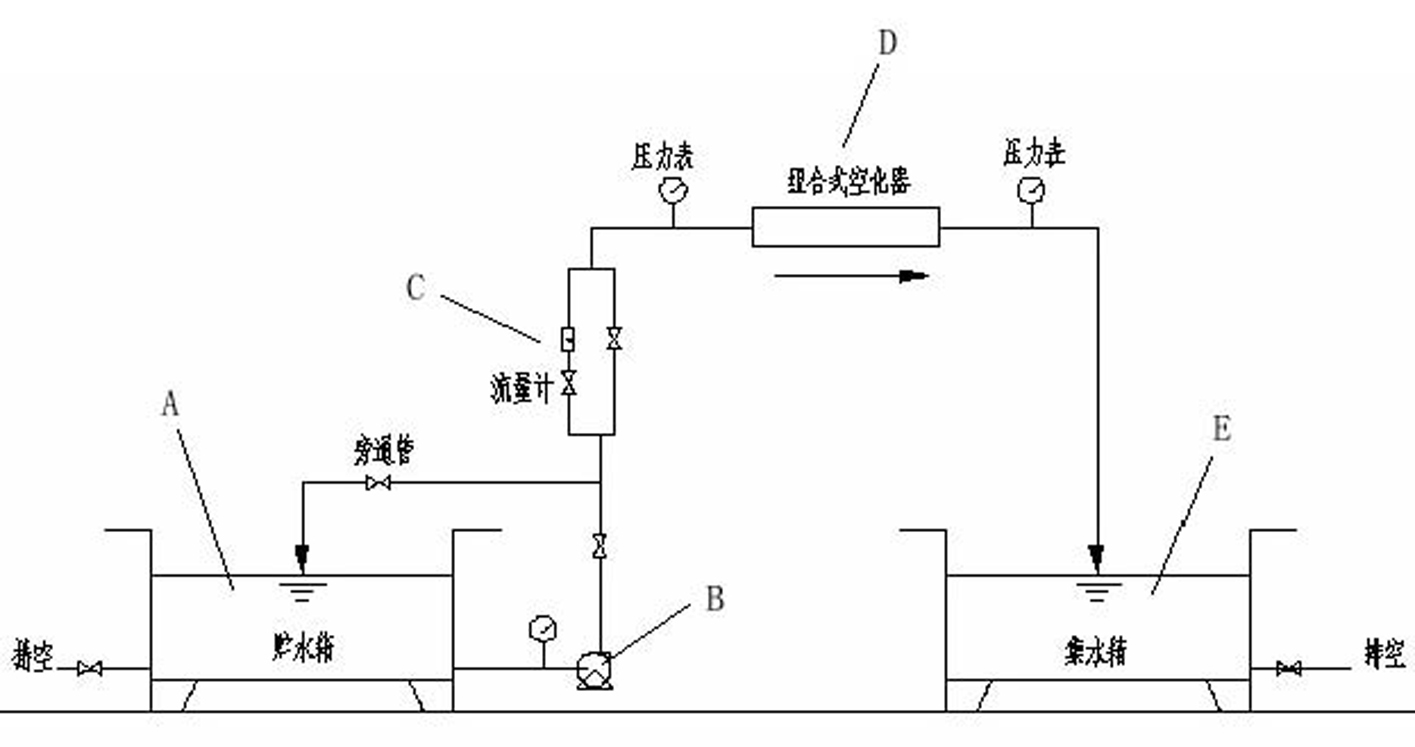

Device for degrading waste water organic matters by combined type hydraulic power cavitation

InactiveCN102531146ABOD/COD improvementImprove subsequent biochemical effectsWater/sewage treatment by oxidationHigh concentrationShock wave

The invention relates to a device for degrading waste water organic matters by combined type hydraulic power cavitation. The device comprises a Venturi tube component and a sieve mesh plate component which are connected in series and communicated with each other, wherein the water inlet end of the Venturi tube component is connected with a high-pressure pump waste water device; and the water outlet end of the sieve mesh plate component is connected with a water outlet pipeline. According to the device, due to the adoption of the structure, ultra-high pressure and high temperature which are similar to the condition of 'wet air oxidation' are generated and accompanied with strong shock waves and jet flows at the moment of collapsing cavitation bubbles after cavitation by utilizing the hydraulic power cavitation principle, so that part of organic matters in waste water are decomposed into CO2, H2O and inorganic oxides to degrade chemical oxygen demands (COD) and biochemical oxygen demands (BOD). The device is suitable for the pretreatment of the high-concentration organic waste water which is insusceptible to biochemical degradation, and the pH value of the waste water is not limited.

Owner:深圳市宇力科技有限公司 +2

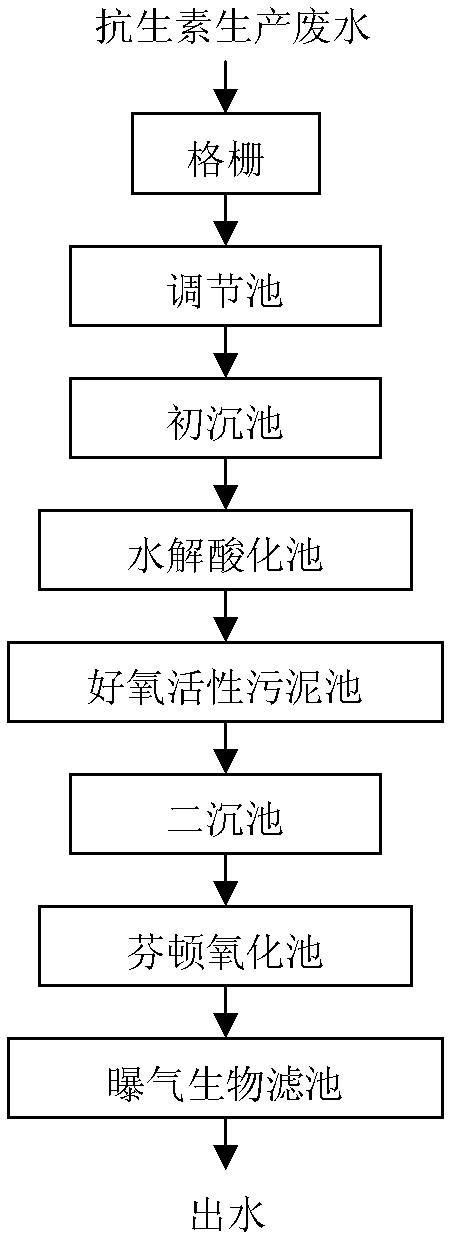

Method for treating antibiotic wastewater

ActiveCN102583903AStrong ability to apply poisonSmall volumeMultistage water/sewage treatmentBioaugmentationChemistry

The invention discloses a method for treating antibiotic wastewater and belongs to the field of wastewater treatment. The treatment method comprises the following steps: pre-treatment, hydrolysis and acidification, bioaugmentation-based first-stage treatment, Fenton oxidation and biological advanced treatment. The method is applied to treat wastewater from antibiotic production, works with high efficiency, ensures that the effluent quality is safe and stable and meets the requirements listed in the water quality standard GB / T18920-2002, and can achieve the purposes of beneficial cycle of water resources and green production in enterprises.

Owner:SHANDONG NEWTIME PHARMA

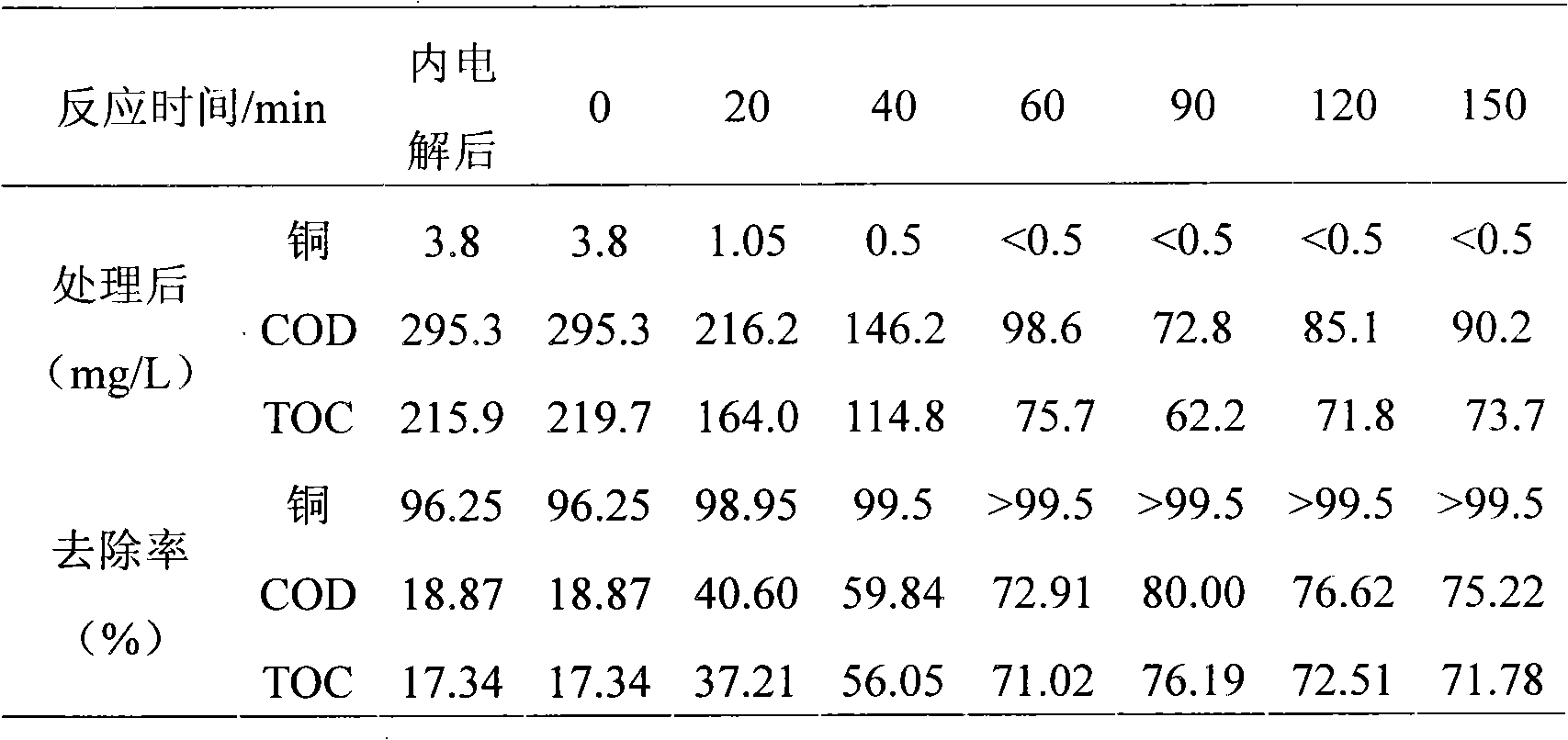

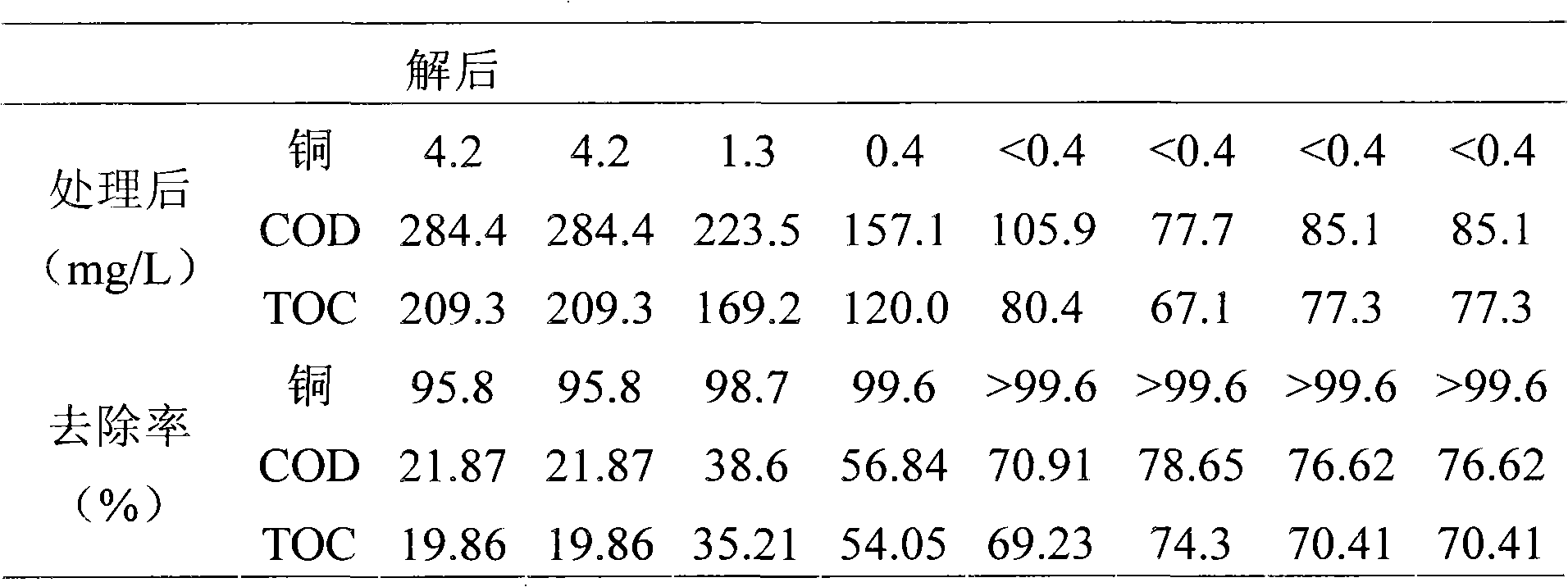

Method for processing heavy-metal complexed wastewater through Fenton reinforced iron-chip internal electrolysis process

InactiveCN102060355AReduce consumptionImprove biochemical propertiesWater/sewage treatmentElectrolysisWastewater

The invention discloses a method for processing heavy-metal complexed wastewater through a Fenton reinforced iron-chip internal electrolysis process. The method comprises the following steps of: filling an internal electrolysis filler into an iron-chip internal electrolysis reactor, then introducing the wastewater into the reactor after regulating the pH value of the wastewater to 1.5-3.5, adding a Na2SO4 solution, controlling dissolved oxygen to be not higher than 3.0mg / L, and controlling the flow speed of the introduced wastewater; then introducing the discharged water of the internal electrolysis reactor into a Fenton reactor, maintaining the ferrous concentration in the water to be 300-750mg / L, adding H2O2 according to the mass concentration ratio of H2O2 to Fe2+ of 2.0-7.0, and sufficiently reacting for 60-120 minutes under the condition of controlling the pH value to be 2.5-5.5; and regulating the pH value of the discharged water to 9.0-10.0, standing and settling, and separating mud from the water. According to the method disclosed by the invention, the operation is simple and convenient, the sewage biodegradability can be markedly improved, the difficulty and the organic load of subsequent processing are greatly reduced, and the cost is saved.

Owner:SOUTH CHINA UNIV OF TECH

Process and device for treating tetracycline antibiotic wastewater

ActiveCN104445814AExtended service lifeNot easily oxidizedTreatment by combined electrochemical biological processesMultistage water/sewage treatmentElectrolysisOxygen

The invention discloses a process and a device for treating tetracycline antibiotic wastewater. The process comprises a pretreatment step and an anaerobic / aerobiotic treatment step; the pretreatment step comprises performing electrolytic treatment by taking ferric carbon microelectrolysis ceramsite as a filler; the anaerobic / aerobiotic treatment step comprises orderly performing anaerobic treatment and aerobiotic treatment on the wastewater treated by virtue of the pretreatment step, and fly ash ceramsite is taken as a filler for the anaerobic treatment, and sludge ceramsite is taken as a filler for the aerobiotic treatment. The invention also discloses the device for the process. According to the process and the device for treating the tetracycline antibiotic wastewater, the multi-stage treatment process is simplified, the capital investment is greatly reduced and the capital is saved; and the own characteristics of the wastewater are thoroughly utilized, and the dosage of a chemical agent is reduced, and therefore, secondary pollution is reduced while the cost is saved.

Owner:SHANDONG UNIV

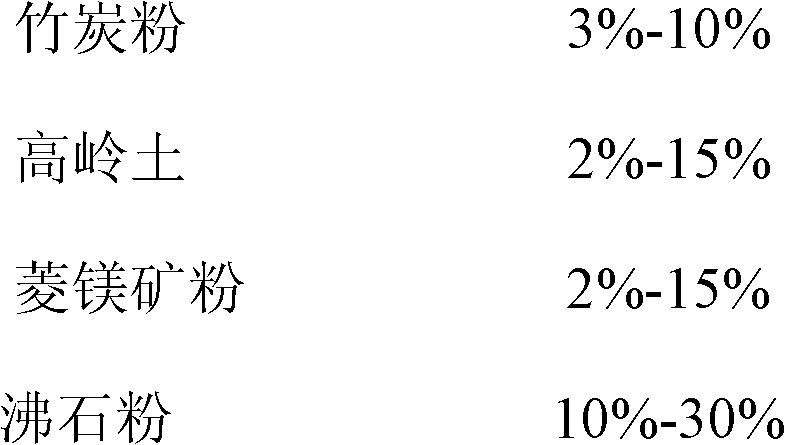

Wastewater treatment filling material and preparation method thereof

ActiveCN102372343AStrong reductionWith electrocatalytic effectWater/sewage treatmentEnergy based wastewater treatmentChemical oxygen demandIron powder

The invention provides a wastewater treatment filling material and a preparation method thereof. The wastewater treatment filling material comprises the following component raw materials by weight percent: 20-70% of iron powder, 2-15% of copper powder, 3-10% of bamboo charcoal powder, 2-15% of kaolin, 2-15% of magnesite powder and 10%-30% of zeolite powder. The preparation method comprises the following steps: respectively smashing and carrying out ball-milling on the component raw materials; then mixing and granulating to form a granular mixture; and finally, preparing a granular filling material by high-temperature sintering or cold pressing. Compared with the prior art, the wastewater treatment filling material prepared by the method provided by the invention has the characteristics that reaction rate is high, wastewater treatment time only needs from several minutes to tens of minutes; treatment amount is large; coagulation effect is good, COD (chemical oxygen demand) removal rateis high, and removal of chroma is better; service life is long, and cost is low; the range of acting on organic pollutants is wide; and operation and management are convenient, and passivation, channeling and wastes are not generated.

Owner:山东晟博环境科技有限公司

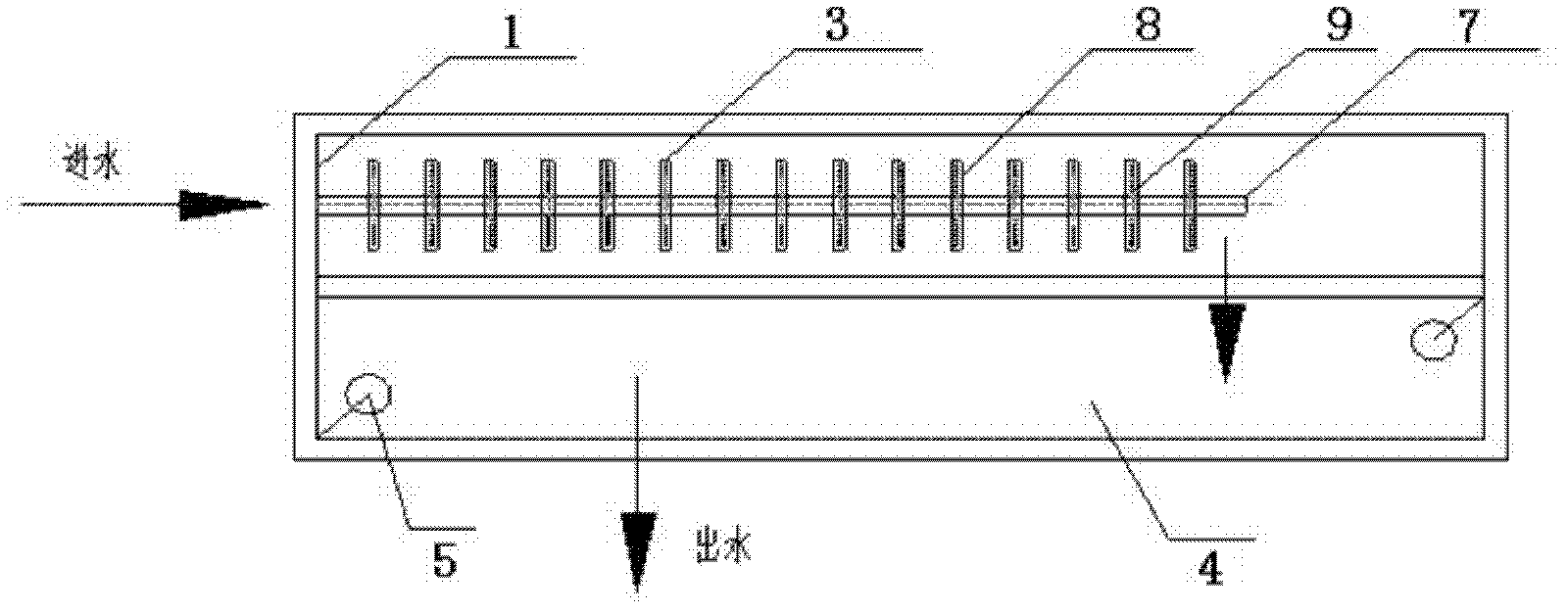

Ceramic membrane aeration and micro-positive pressure ozone membrane regeneration water treatment method and treatment device

PendingCN107337326AHigh porosityUniform pore size distributionWater treatment parameter controlFatty/oily/floating substances removal devicesMicroorganismNanoceramic

The invention discloses a ceramic membrane aeration and micro-positive pressure ozone membrane regeneration water treatment method. Sewage after ozone micropore aeration treatment is conveyed into a membrane tank; when a membrane on a membrane module is blocked by microorganisms or organic matter, compressed air enters the membrane of the membrane module through a water outlet of the membrane module for high-pressure back flushing; contaminants attached to the surface of the membrane are separated from the surface of the membrane; after the back flushing of the compressed air, ozone is supplied to the membrane of the membrane module under critical micro-positive pressure; after a gel layer difficult to degrade on the surface of the membrane is decomposed and dissolved by using an ozone and air space, the compressed air is used for reverse purging of decomposed substances on the membrane to accomplish membrane flushing; a nano ceramic membrane with small pore size distribution, small transmembrane pressure and a very small pore size is used for aeration; the micro-positive pressure aeration is adopted to form many fine and uniform oxygen bubbles to make full use of an oxygen source; oxygen is better dissolved in water; a utilization rate of the oxygen is increased; a biochemical effect is enhanced; and the energy source waste is reduced.

Owner:JIANGXI BOCENT TEC CO LTD

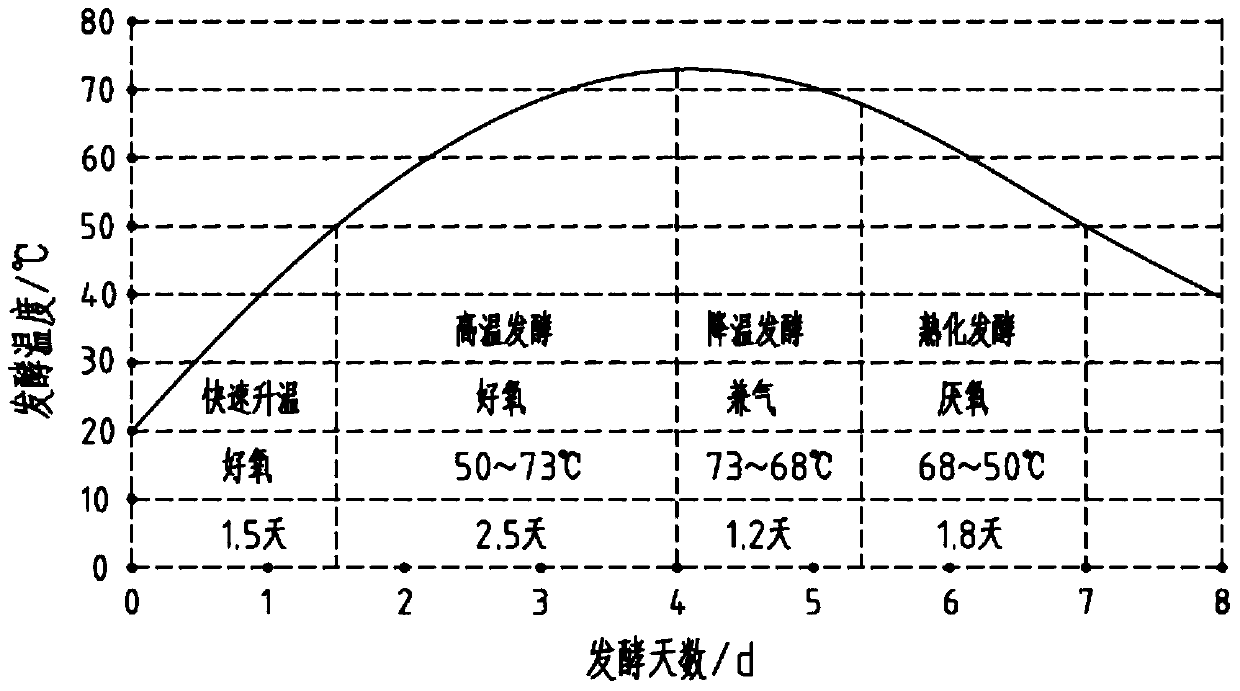

Method for brewing pure grain vinegar

InactiveCN105255701APromote decompositionLow priceVinegar preparationMedicinal herbsIntermediate stage

A method for brewing pure grain vinegar includes the steps that firstly, material mixing is performed, wherein sorghum, bran and rice bran are mixed, and Chinese medicinal herbs are added into the mixture; secondly, material steaming is performed, wherein the materials mixed in the first step are steamed at the temperature of 100-115 DEG C; thirdly, inoculation is performed, wherein the steamed materials are inoculated after being smashed, and the steamed materials and expanding leaven are evenly stirred and inoculated according to the weight ratio of 20:3; fourthly, fermentation is performed, wherein the inoculated materials are placed into a pot, compacted and fermented, the materials are sealed at the early stage of fermentation, the temperature is raised day by day in the middle stage, and the temperature is lowered day by day in the later stage; fifthly, vinegar pouring is performed, wherein the materials are sprayed with vinegar and soaked for 12-13 hours through white vinegar blank fermented in the fourth step, smoked vinegar formed by smoking the vinegar and water according to the weight ratio of 5:2:20, and vinegar liquid drops through a filter screen; sixthly, the vinegar liquid is sterilized; seventhly, the vinegar liquid is filtered; eighthly, the vinegar is stored under low-temperature and dry conditions. The vinegar yield is high, and the finished vinegar is good in taste, color and flavor.

Owner:ZIZHOU COUNTY RUIZHENG BREWING CO LTD

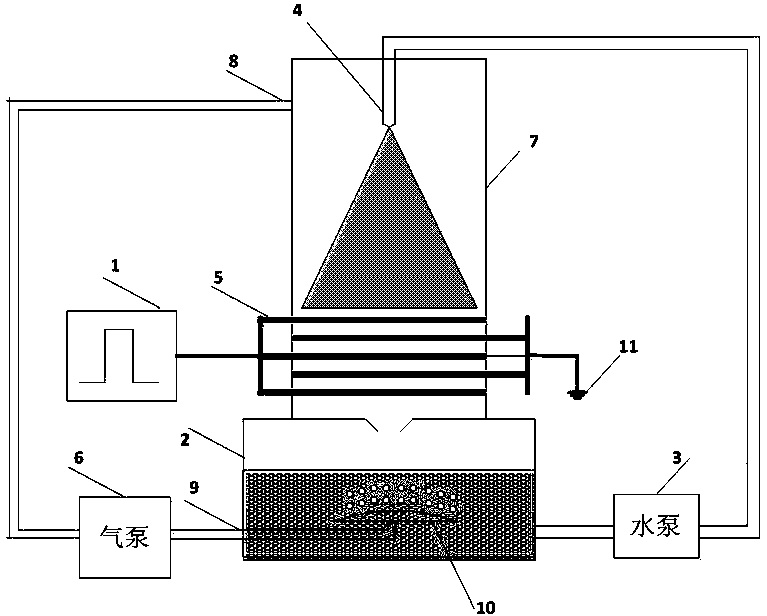

Device for removing toxicity in traditional Chinese medicine wastewater by plasma discharge

InactiveCN103466747AAvoid corrosionLarge amount of processingWater/sewage treatment by irradiationWater/sewage treatment by oxidationBiochemical engineeringWastewater

The invention belongs to the technical field of wastewater treatment, and particularly relates to a device for removing toxicity in traditional Chinese medicine wastewater by plasma discharge. The device is mainly composed of a plasma reactor, a pulse power supply, a sewage receiving tank, am air pump and a water pump. Traditional Chinese medicine wastewater is pumped from a sewage tank to the top of the reactor by the water pump; the middle part is provided with a discharge electrode, and the bottom is provided with the sewage receiving tank. The discharge electrode is connected with the external pulse power supply, and is the core of the whole device. The outer wall of the reactor is connected to the ground, thereby ensuring the electric safety of the whole device. Meanwhile, the air pump connects the upper part of the reactor with the top of the sewage receiving tank, and the gas generated by discharge is recycled and connected to an aeration tank by the air pump and introduced into the sewage receiving tank, thereby further enhancing the treatment efficiency. The device can effectively remove toxic groups in the traditional Chinese medicine sewage, is beneficial to subsequent biochemical degradation of the traditional Chinese medicine sewage to finally achieve the discharge standard, and has the advantages of simple treatment method, low cost and high efficiency.

Owner:FUDAN UNIV +1

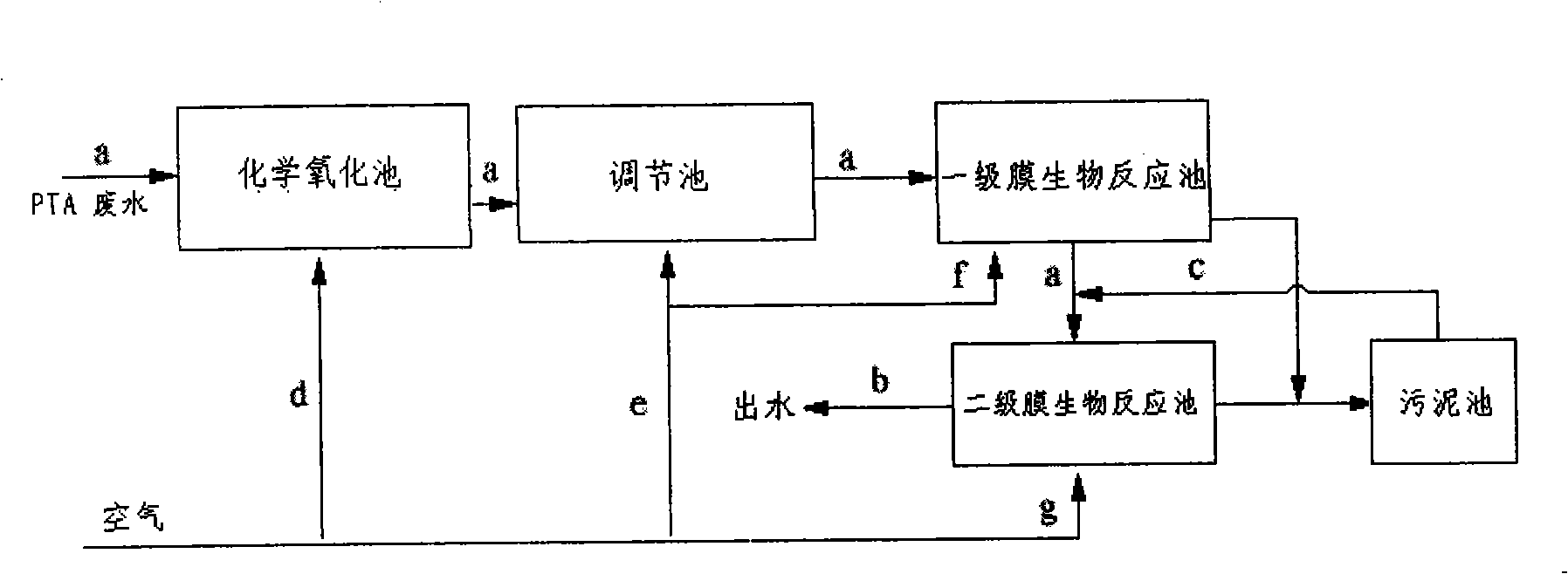

Processing method for waste water in production process of fine terephthalic acid

ActiveCN101333053AReduce CODcrImprove biochemical propertiesMultistage water/sewage treatmentNature of treatment waterActivated carbonChlorine dioxide

The invention discloses a purified terephthalic acid wastewater treatment method, which treats the purified terephthalic acid wastewater through highly efficient catalytic oxidation and dual-membrane bio-reaction tank combined technology to enable the COD of the wastewater to be reduced from 4,000-6,000 mg / L to 100 mg / L below, and enable the terephthalic acid to be reduced from 1,000-2,000 mg / L to 10 mg / L below. The catalytic oxidation takes air and chlorine dioxide as an oxidant, and takes activated carbon as a catalyst; the organic volumetric load of a primary membrane bio-reaction tank reaches 2.85-4.5kg COD / m3.d, while the organic volumetric load of a secondary membrane bio-reaction tank reaches 0.4-0.8kg COD / m3.d.

Owner:SINOPEC YANGZI PETROCHEM

Specific tea-oil tree compound fertilizer containing tung oil

InactiveCN104045402APromote growthMaintain vigorous growthFertilizer mixturesChemical mixturesCamellia oleifera

The invention discloses a specific tea-oil tree compound fertilizer containing tung oil. The compound fertilizer is prepared from tung oil, tung oil cake, human urine, pig manure, cow dung, chicken manure, cornstalk, urea, diammonium phosphate, potassium chloride and humic acid in a certain weight ratio. The preparation method comprises the following steps: putting tung oil cake and the human urine into tung oil to prepare an oil-urine compound fertilizer, fermenting a humic acid organic fertilizer inside a clay frame, blending urea, diammonium phosphate and potassium chloride into a chemical mixture fertilizer, subsequently uniformly mixing the three fertilizers, and controlling the water content to be less than 14%, thereby obtaining a finished product. The invention aims at customizing a series of specific fertilizers containing tung oil that organic fertilizers and chemical fertilizers are combined, three elements, that is, nitrogen, phosphorus and potassium are combined, secondary elements and microelements are complete, rich activated organic substances are provided and the fertilization period and the fertilizers are determined according to the growth characteristics of tea-oil trees. The compound fertilizer is wide in raw material resource, scientific and reasonable in proportion and process, saved in the labor, lowered in the production cost by more than 30% and applicable to popularization.

Owner:湘西盛泰农业科技有限公司

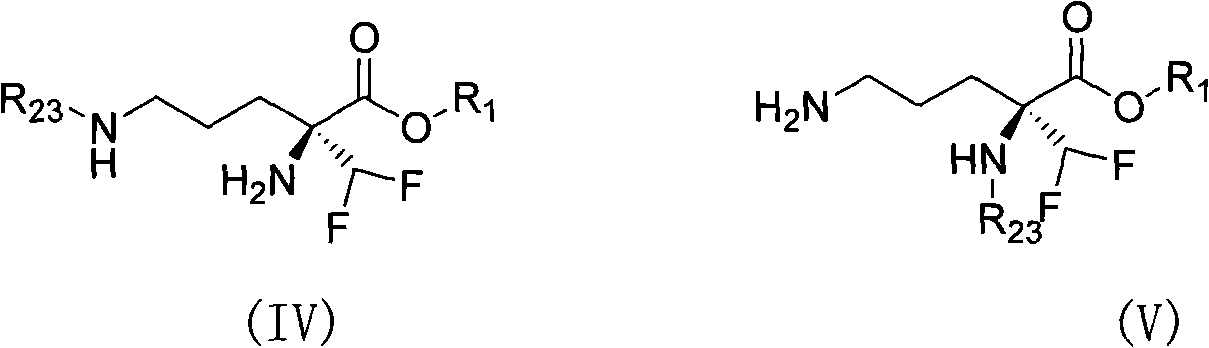

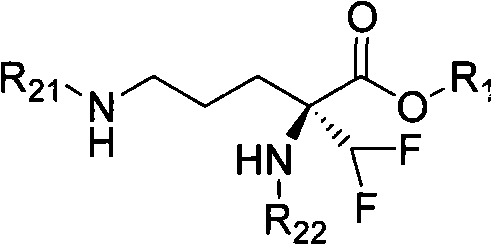

Eflornithine prodrug and conjugate and using method thereof

InactiveCN101898978AImprove biochemical propertiesImprove solubilityOrganic active ingredientsGroup 5/15 element organic compoundsAnti-inflammatory analgesicsChemistry

On one hand, the invention provides a composition of a covalent conjugate of an eflornithine analogue and an anti-inflammatory. On the other hand, the invention provides an eflornithine prodrug composition. In addition, the invention provides a method for treating or preventing cancer by using the conjugate of the eflornithine analogue or the eflornithine prodrug.

Owner:徐锋

Method and device for disinfecting, detoxifying and purifying water by using hydroxyl radicals

InactiveCN103723803ALow costIncrease profitWater/sewage treatment by irradiationWater/sewage treatment using germicide/oligodynamic-processUltravioletTreated water

The invention relates to a method and a device for disinfecting, detoxifying and purifying water by using hydroxyl radicals. The method and the device mainly solve the technical problems that the existing water treatment method and the existing water treatment device cannot remove residual carcinogenic substances in water, and cannot remove overproof heavy metal and organic compounds. The method adopts the technical scheme that the method comprises the following steps that ozone is released to treated water; singlet-state atomic oxygen is generated through radiation of a plurality of mercury lamp ultraviolet lamp modules at UVC (ultraviolet C) 253.7nm or a plurality of LED (light-emitting diode) ultraviolet lamp modules at DUV (deep ultraviolet) LED 280nm; drinking water is continuously disinfected, detoxified and purified, so that the drinking water reaches a sanitary standard for domestic drinking water, and then is discharged; or reclaimed water of waste water is recycled; and zero discharge is reached. The device using the method comprises an ozone generator, an impeller, an aerator, a housing, the ultraviolet lamp modules, an ultrasonic device, a water inlet, a water outlet, an oxygen outlet, a sodium peroxide generation machine, a sodium peroxide collection tank and a sodium peroxide discharge pipe.

Owner:刘传林

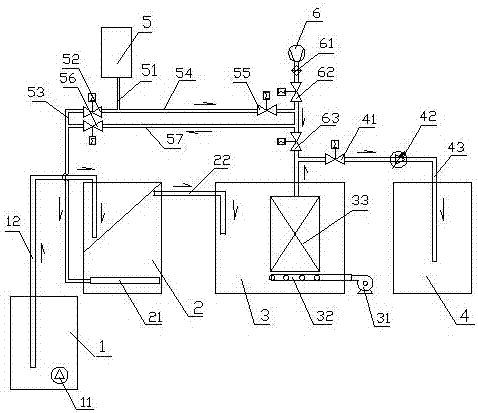

Treatment equipment for recycling car washing waste water and automatic control system

ActiveCN102701516AImprove water qualitySmall water qualityMultistage water/sewage treatmentProgramme control in sequence/logic controllersThird partyOzone generator

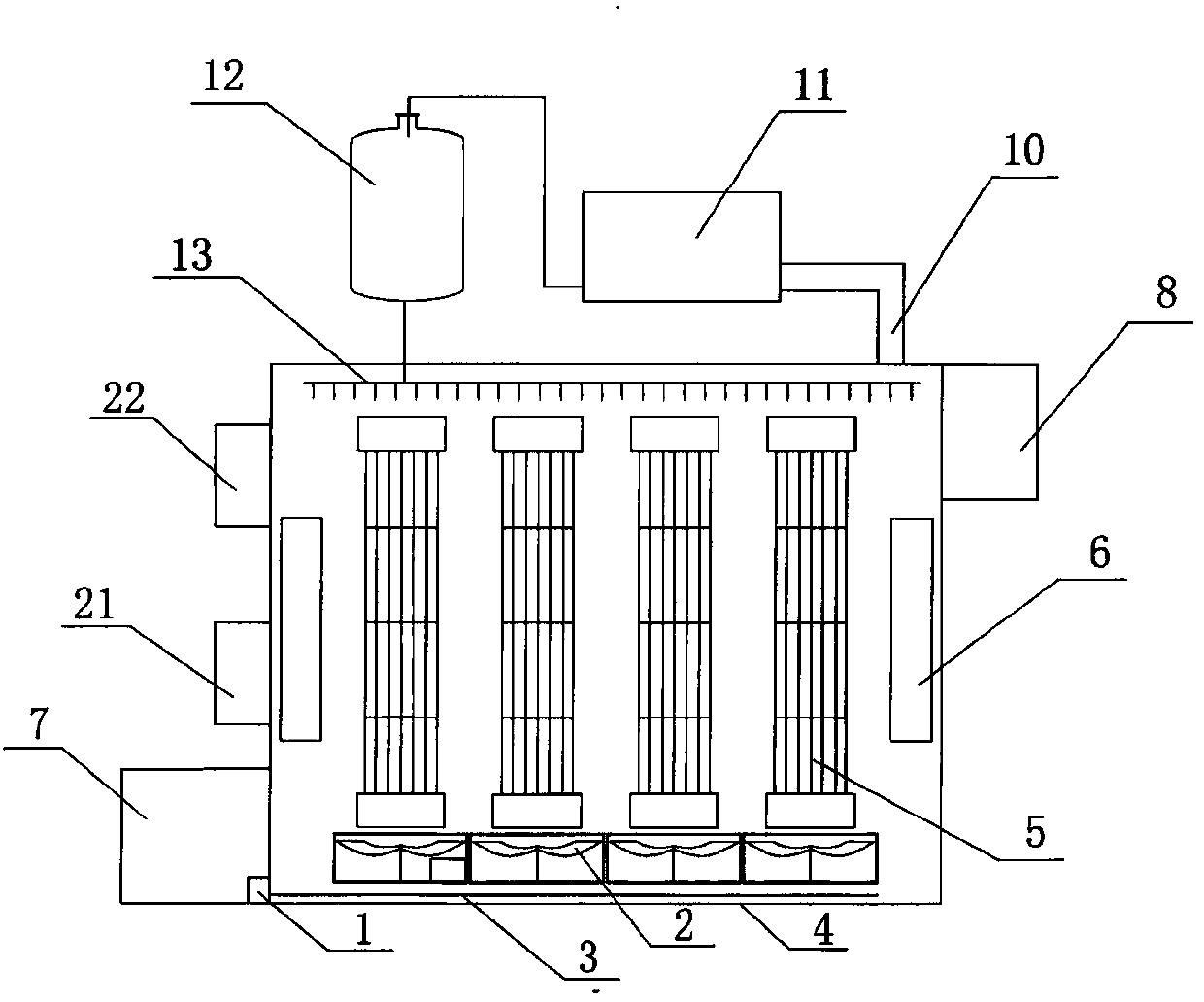

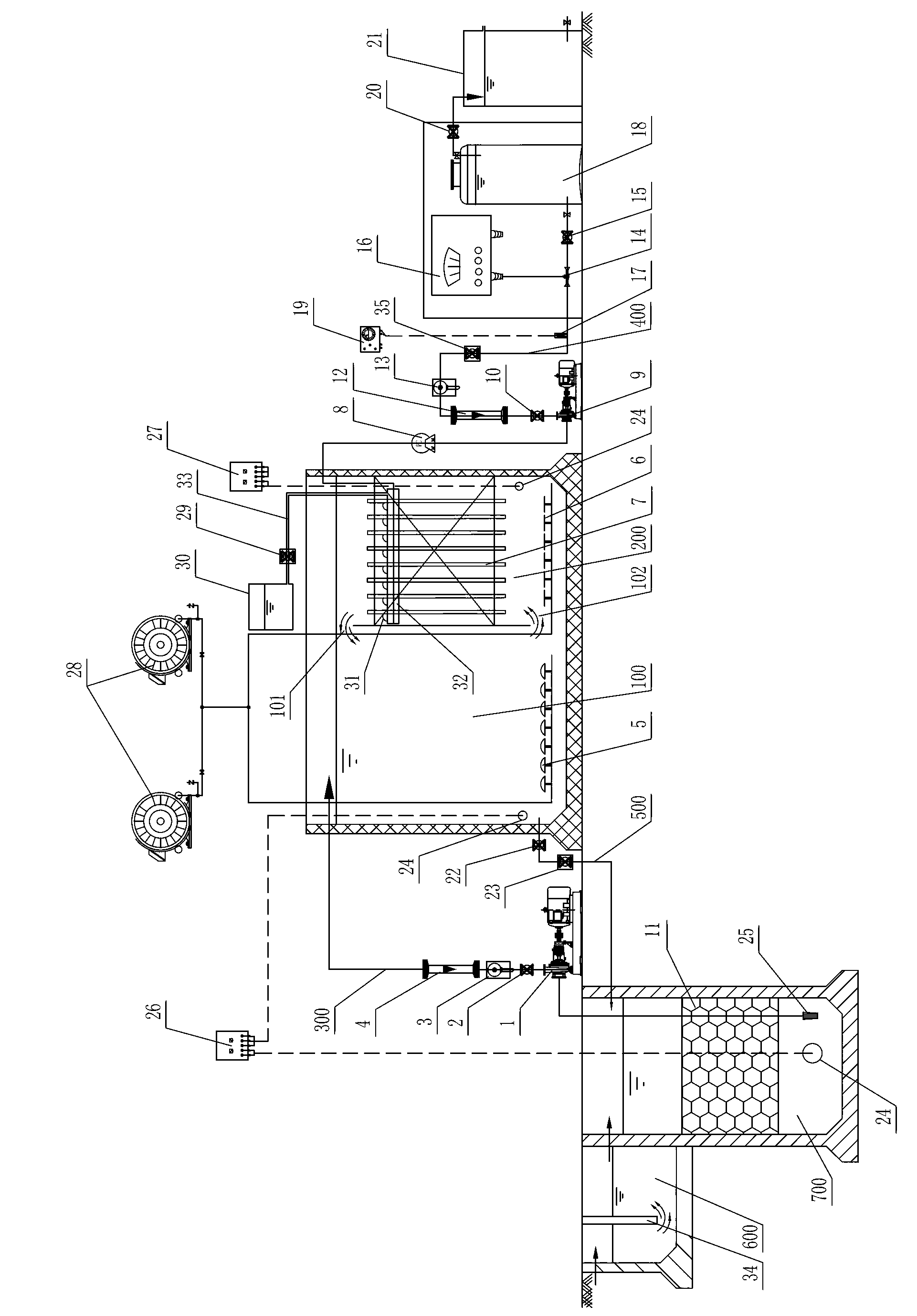

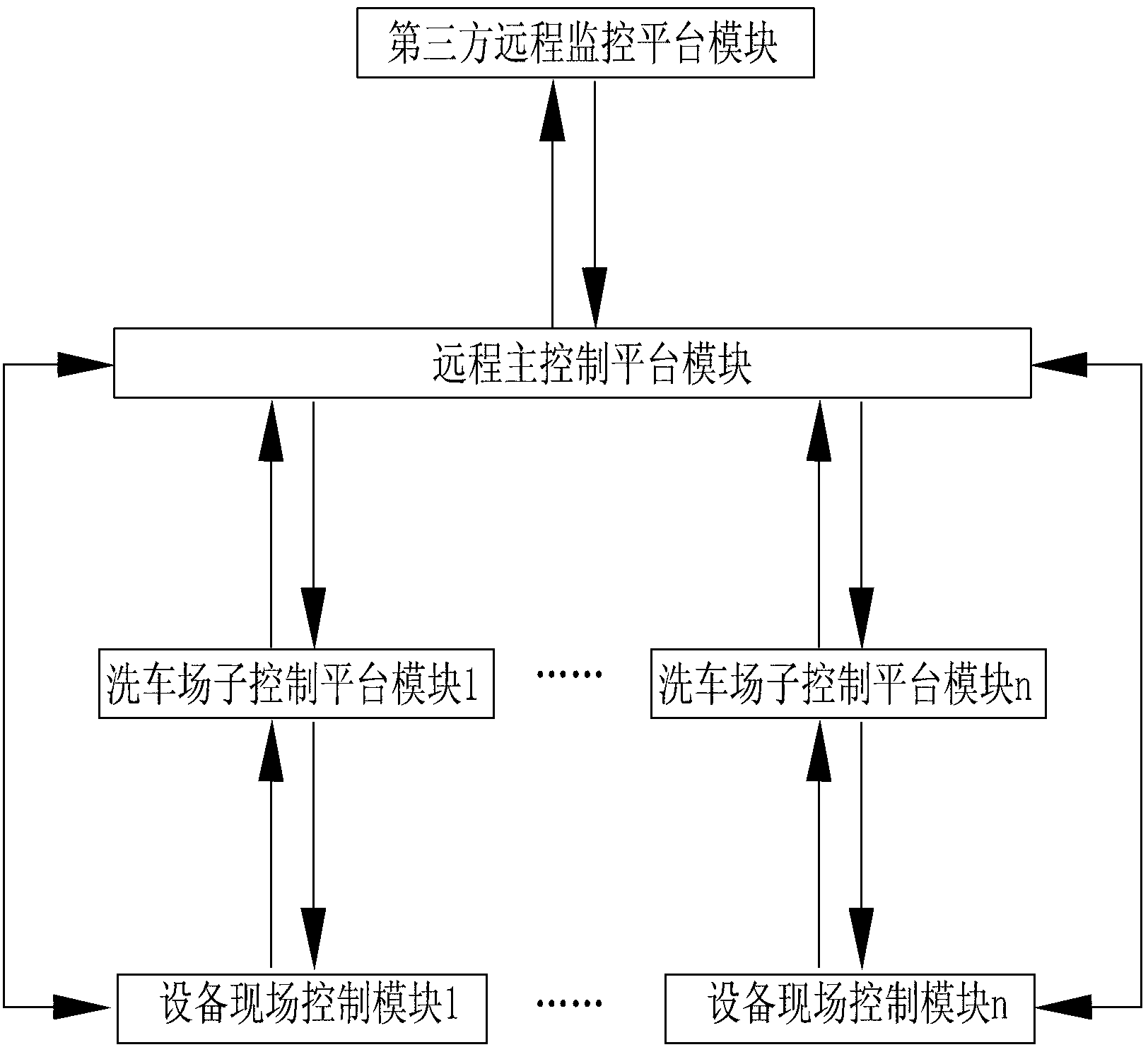

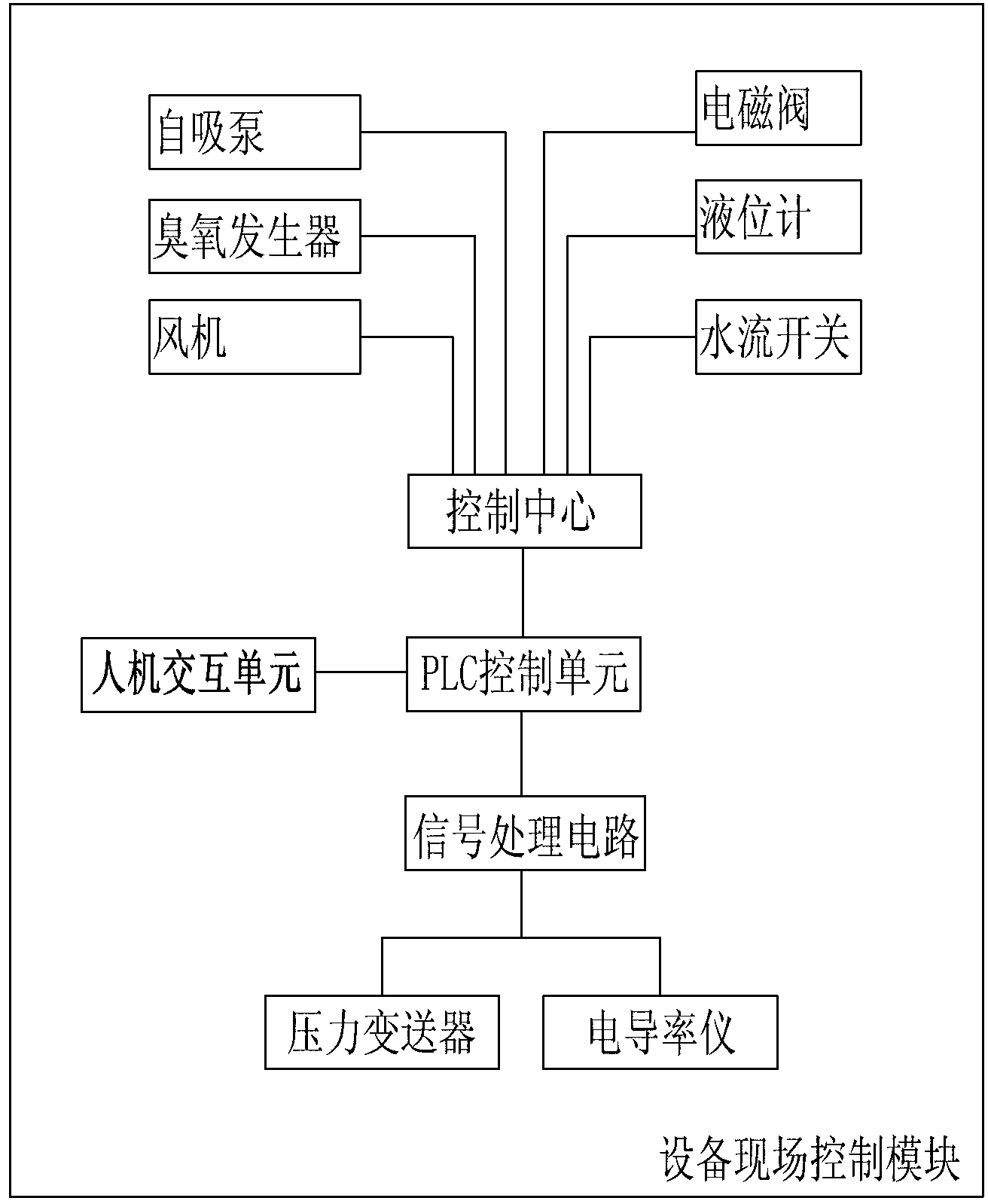

The invention discloses treatment equipment for recycling car washing waste water and an automatic control system. The treatment equipment comprises a combined tank, an ozone generator, an ozone mixed disinfection tank and a recycling water tank, wherein the combined tank consists of an oil-removal grit tank, an anaerobic adjusting tank, a biochemical reaction tank and a flat-panel membrane bioreactor (MRB) tank; an aeration head and an aeration pipe are respectively arranged in the biochemical reaction tank and the flat-panel MRB tank; a flat panel membrane, a suction pipe and a suction hoseare arranged in the flat-panel MRB tank; a membrane cleaning medicine liquid storage tank is connected with the suction pipe; the inlet of a water inlet self-sucking pump is communicated with the anaerobic adjusting tank; the outlet of the water inlet self-sucking pump is connected with the biochemical reaction tank; a inlet of a water outlet self-sucking pump is connected with the suction pipe; the outlet of the water outlet self-sucking pump is connected with the inlet of the ozone mixed disinfection tank through a water outlet pipe; the outlet of the ozone mixed disinfection tank is connected with the recycling water tank; the ozone generator is connected with the water outlet pipe through a jet device; and the biochemical reaction tank is communicated with the anaerobic adjusting tankthrough a discharge pipe. The control system comprises an equipment field control module, a sub-control platform module for a car washing station, a remote main control platform module and a third-party remote monitoring platform module. The treatment equipment and the automatic control system can be applied to the field of recycling of the car washing waste water.

Owner:SHENZHEN HUIQING TECH

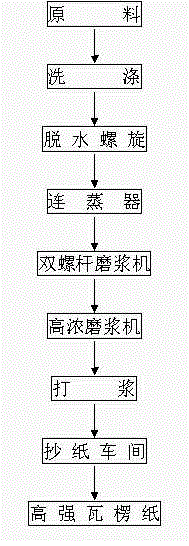

Method for preparing unbleached pulp and producing high-strength corrugated paper from cotton stalk

ActiveCN103215837BIncrease economic incomeIncrease considerable economic incomePulp beating methodsHigh concentrationSURFACTANT BLEND

Owner:石河子市国力源环保制浆有限公司

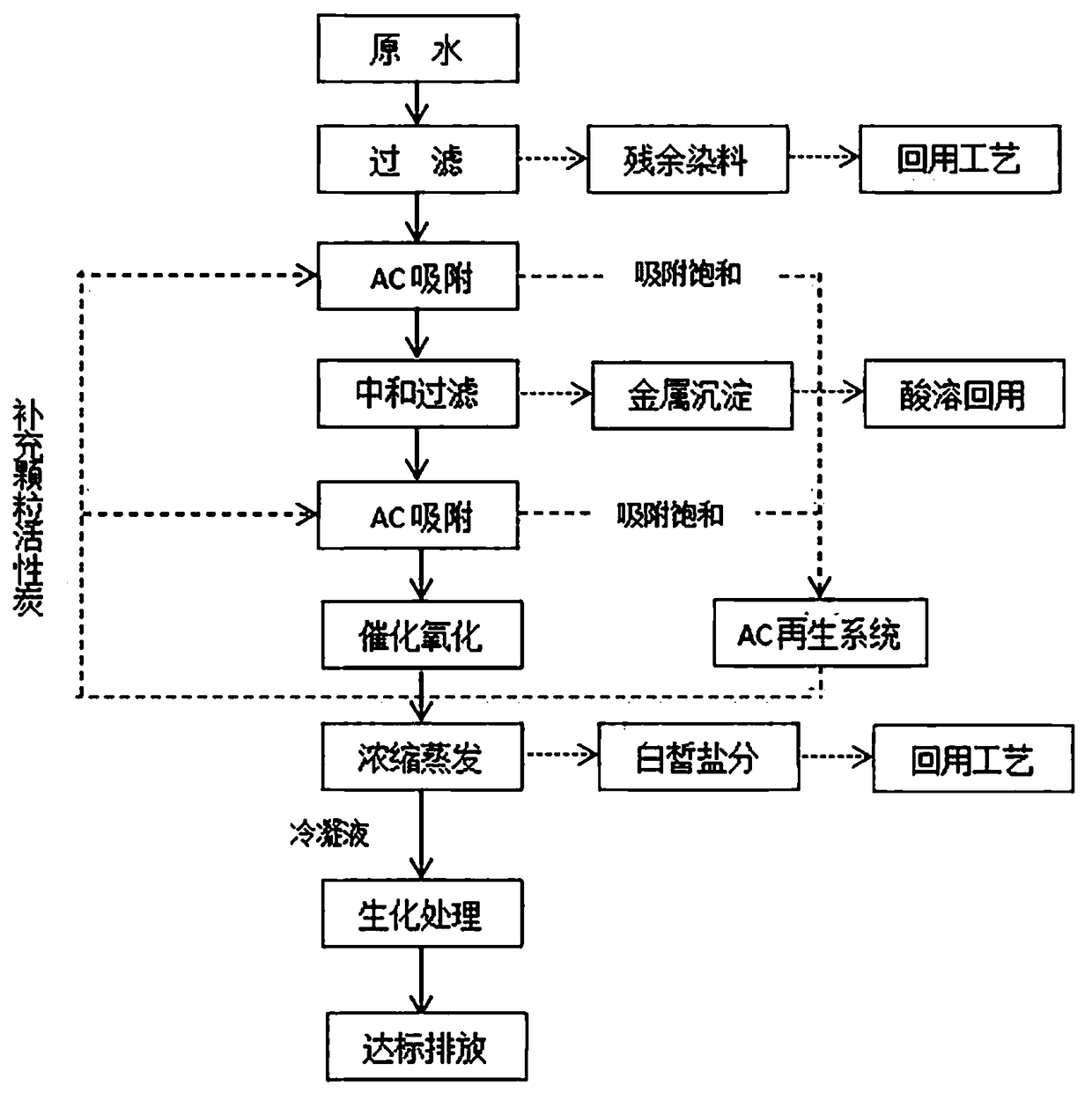

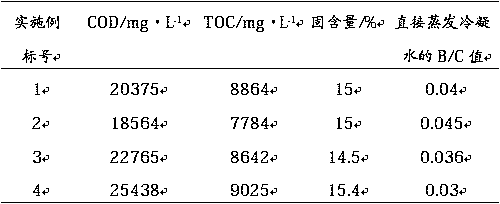

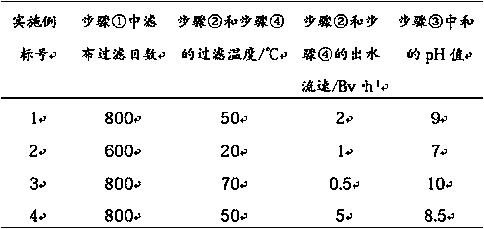

Recycling treatment method of dye wastewater

ActiveCN108328840AHigh degree of automationImprove regeneration efficiencyWater treatment parameter controlSpecific water treatment objectivesTreatment effectEvaporation

The invention discloses a recycling treatment method of dye wastewater and belongs to the technical field of wastewater treatment. The method includes the steps of firstly, filtering; secondly, performing primary adsorption; thirdly, neutralizing; fourthly, performing secondary adsorption; fifthly, performing low-temperature catalytic oxidization; sixthly, performing concentration and evaporation;sixthly, performing biochemical treatment. The recycling treatment method has the advantages that residual dye in the wastewater and catalysts and salt in the wastewater can be recycled, wastewater recycling is achieved, a good wastewater treatment effect is achieved, and stable up-to-standard emission is achieved; meanwhile, the biochemical performance of the wastewater can be increased greatly,the stable operation of a follow-up biochemical system is guaranteed, and solid waste and secondary environment pollution are avoided completely.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

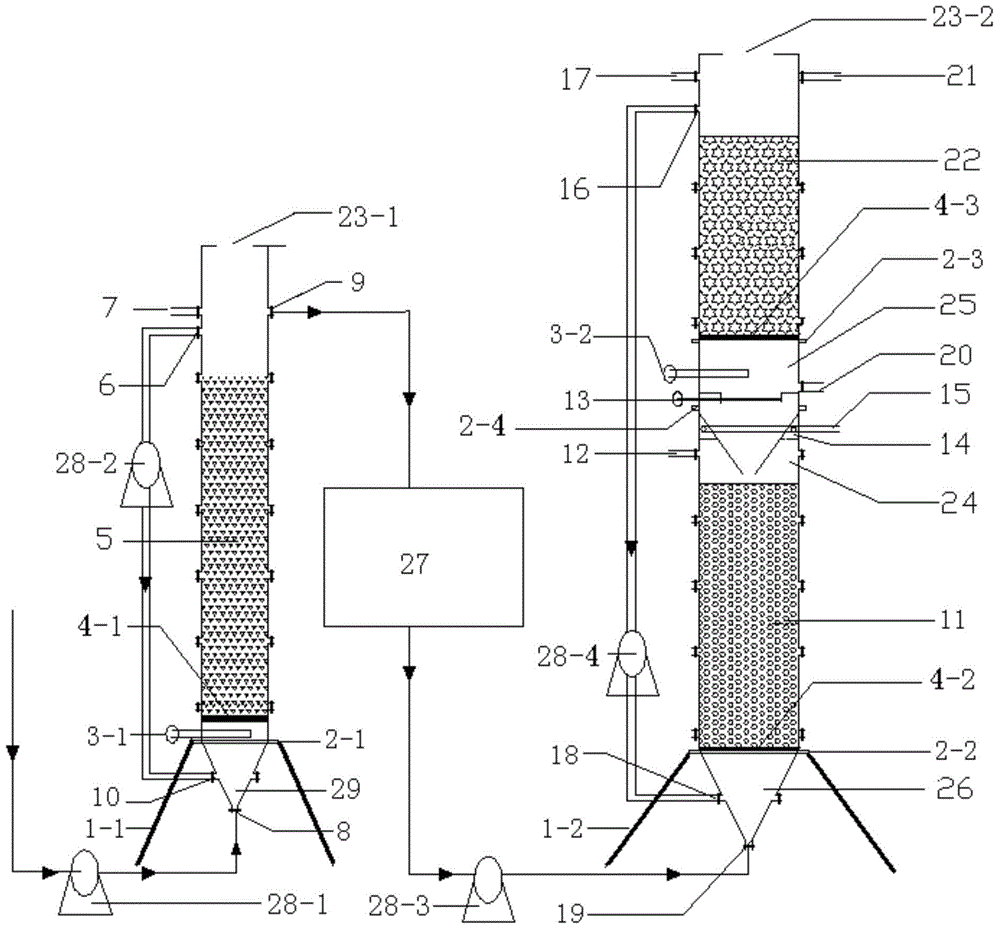

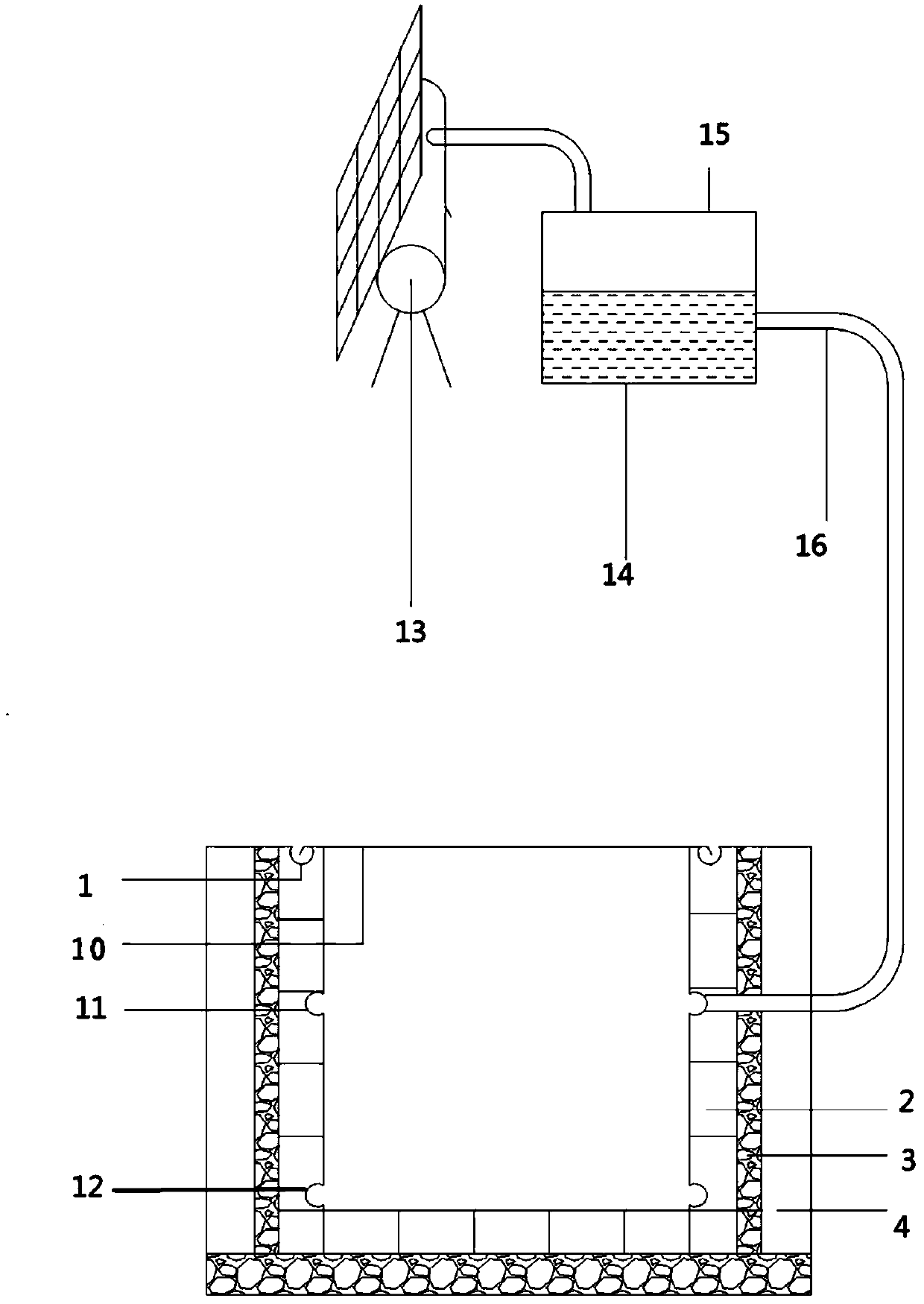

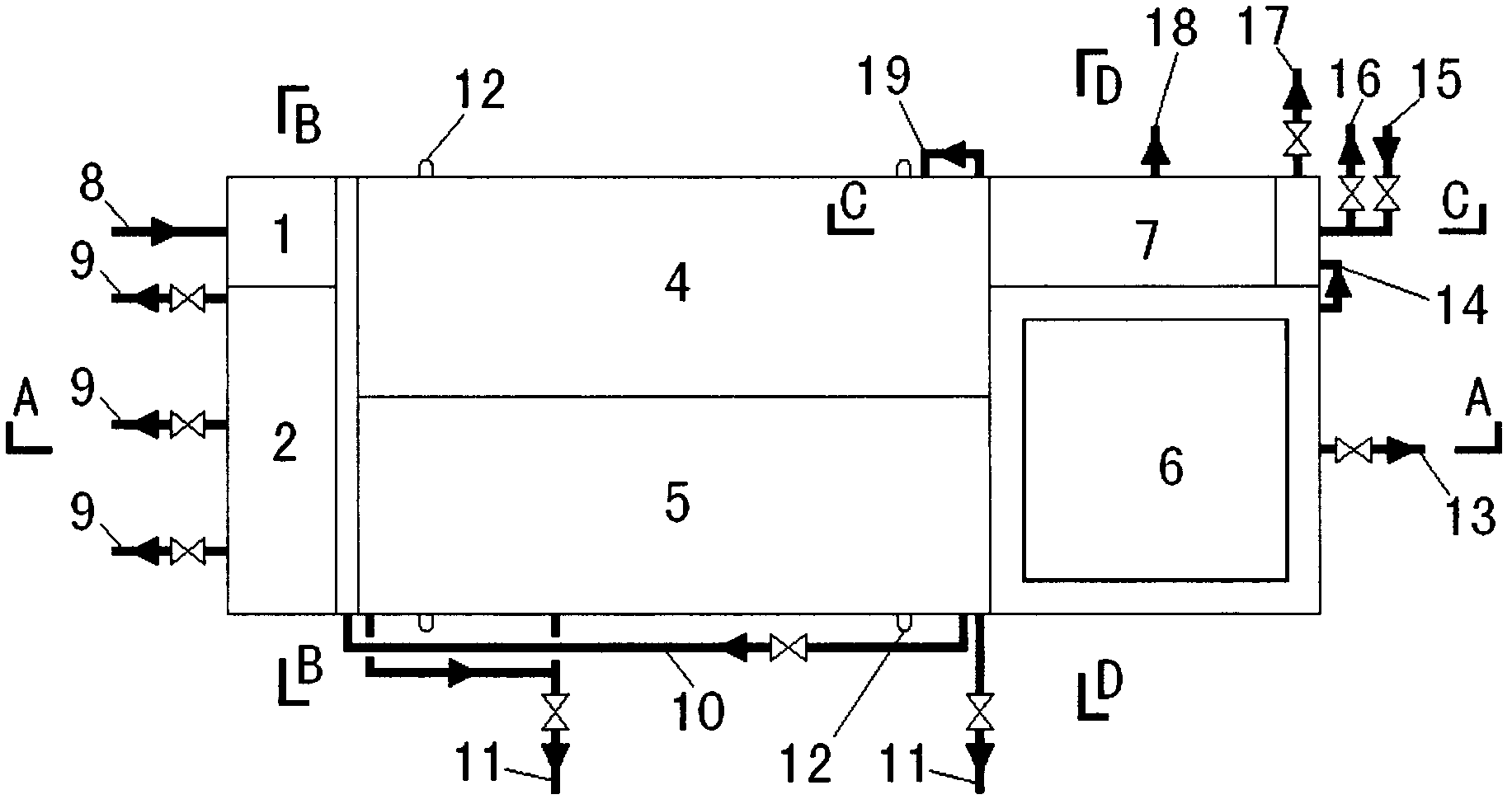

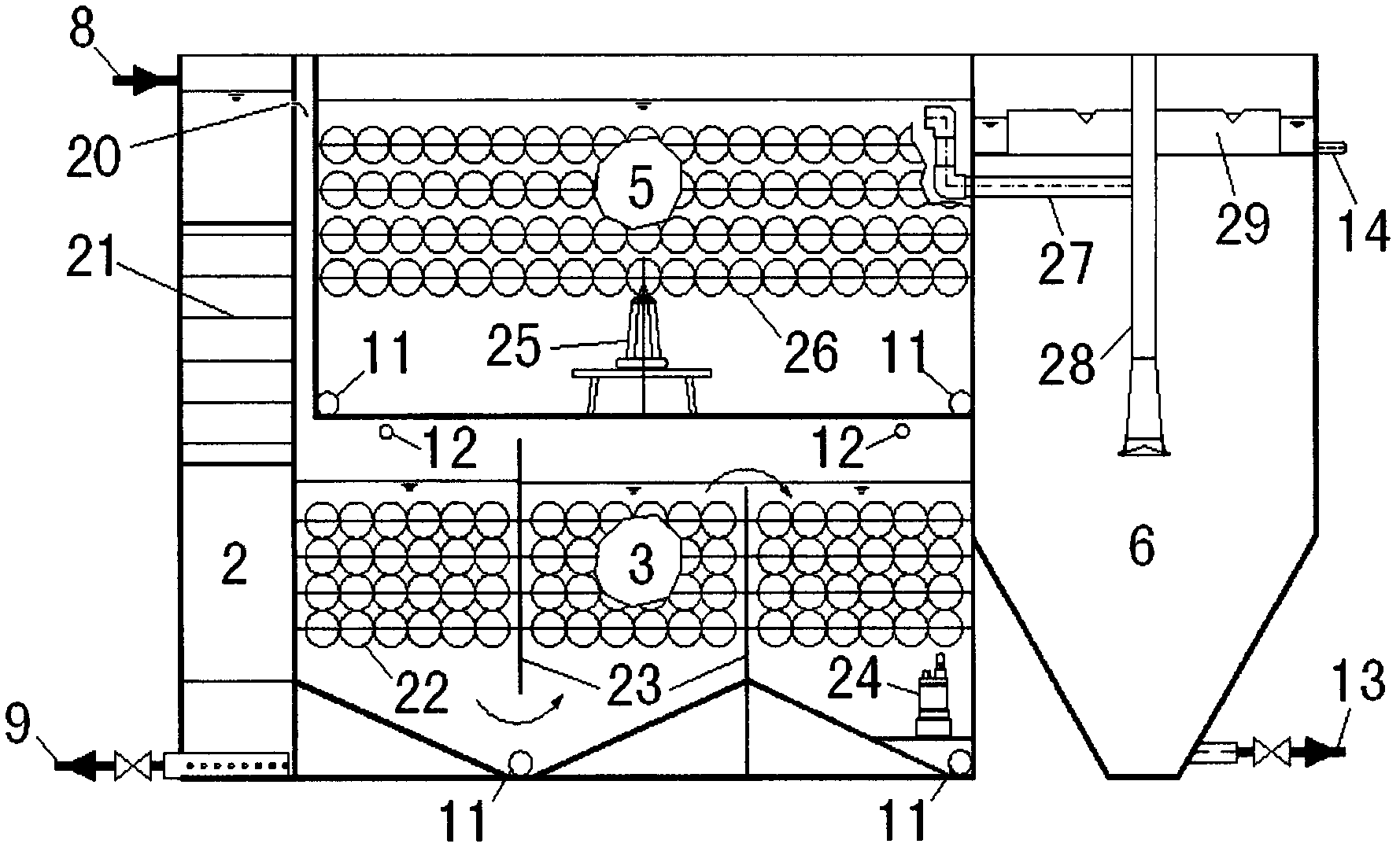

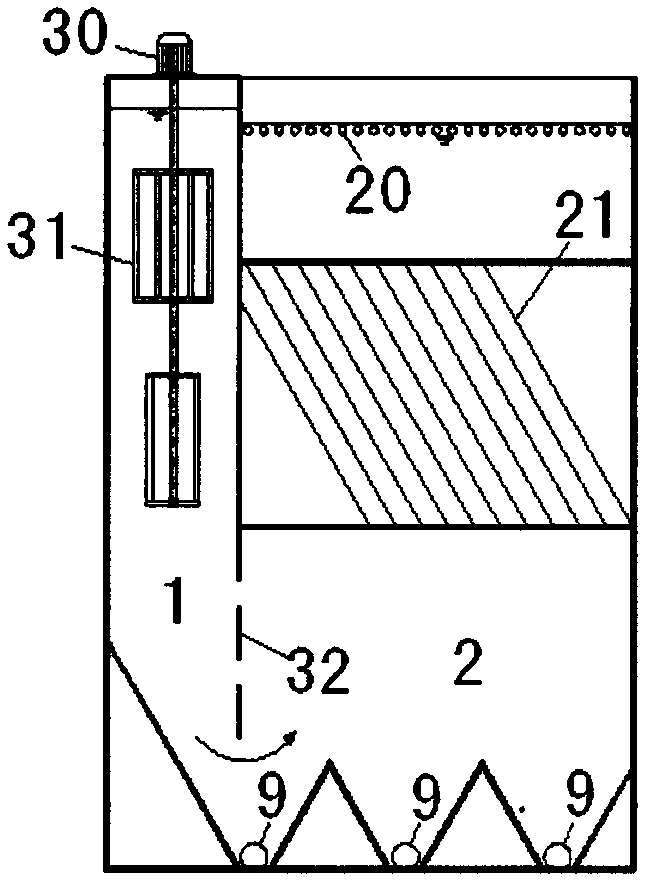

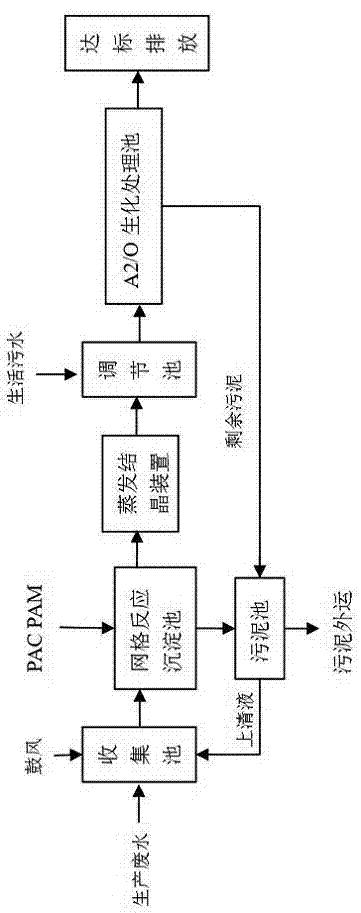

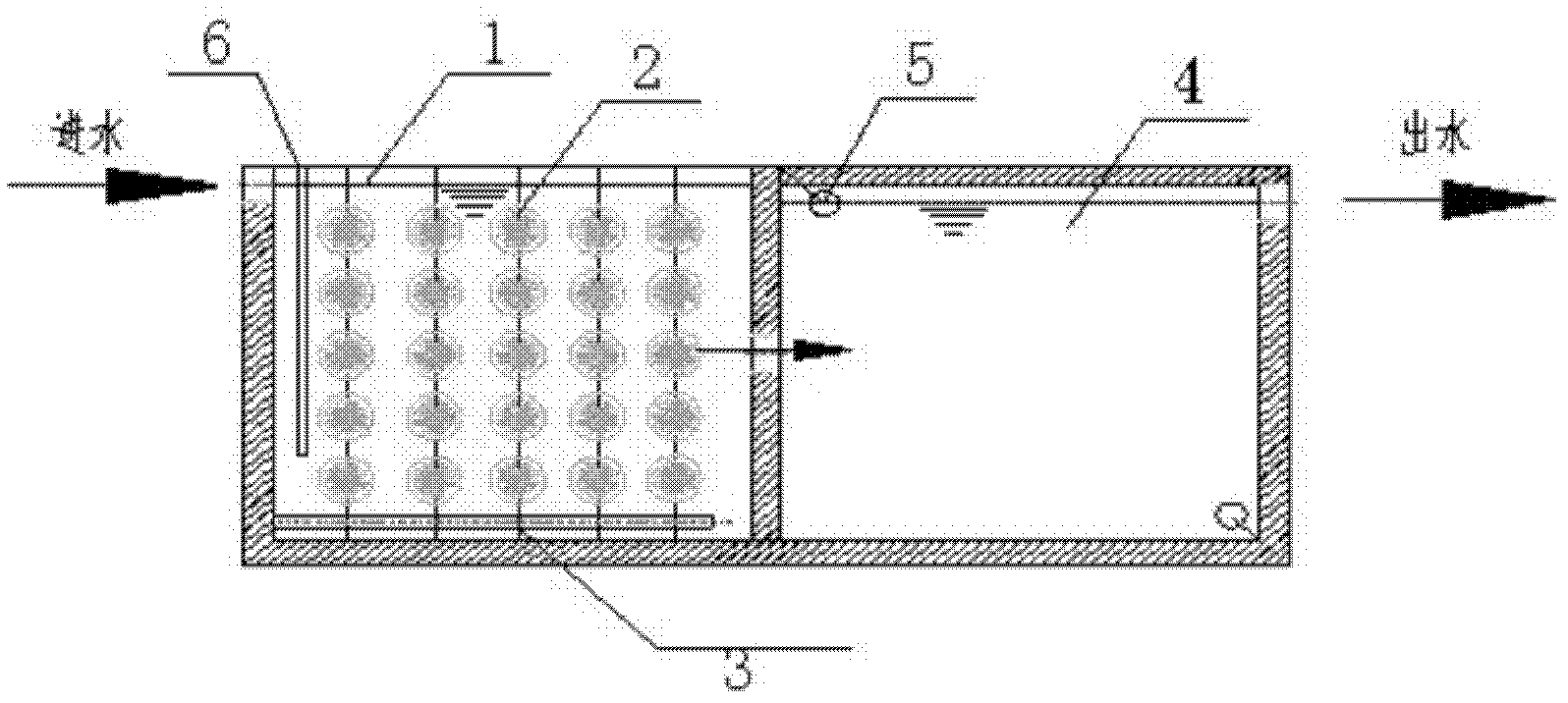

Integrated white wine production waste water treatment device

ActiveCN102659285AImprove biochemical propertiesLow running costMultistage water/sewage treatmentWaste water treatment from food industryFlocculationTreatment effect

The invention relates to waste water treatment, in particular relates to an integrated white wine production waste water treatment device which is convenient to transport, easy and convenient to operate and manage, low in running cost and good in treatment effect. The integrated white wine production waste water treatment device comprises a flocculation stirring region, an inclined plate sedimentation region, a hydrolysis acidifying region, an air floating region, a biological contact oxidization region, a vertical flow sedimentation region and a sand filter region. The waste water treatment method comprises the following steps of: adding lime into the original waste water; adjusting the pH of the waste water until the waste water to be neutral; adding flocculating agent for flocculation and sedimentation; removing granular alumen ustum to improve the biochemical property of the waste water; performing anaerobic hydrolysis, and degrading large-molecule organics in the waste water into small-molecule organics to improve the biochemical property of the waste water again; performing coagulation and air floating treatment on the waste water subjected to anaerobic hydrolysis; performing aerobic biological treatment on effluent; and finally performing vertical flow sedimentation and sand filtering treatment, and discharging the effluent. The integrated white wine production waste water treatment device has a compact structure and is convenient to convey and manage, safe to operate, low in running cost, high in waste water treatment capacity and suitable for waste water treatment matched with white wine production; and the organics elimination rate is high.

Owner:CHONGQING CHENMING WATER TREATMENT EQUIP

Method for improving COD (Chemical Oxygen Demand) degradation efficiency and biochemical property of wastewater

InactiveCN106242018AEasy to handleImprove biochemical propertiesWater treatment compoundsMultistage water/sewage treatmentElectricityCombined method

The invention discloses a method for improving COD (Chemical Oxygen Demand) degradation efficiency and a biochemical property of wastewater. The method adopts a fenton oxidization-ozone oxidization-electrocatalytic oxidation combined method, and comprises the following steps: (1) firstly, carrying out oxidization on the wastewater by adopting a fenton oxidization method; (2) secondly, oxidizing the wastewater through ozone; (3) finally, carrying out electrocatalytic oxidation on the wastewater. The method disclosed by the invention can be used for oxidizing the wastewater for a plurality of times and the limitation of a single method is made up, so that treatment range and capability are improved.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

Method for processing degradation-resistant organic wastewater and multi-element catalyst adopted by method

ActiveCN104743652AAchieve strong oxidative degradationImprove conversion abilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by reductionHigh concentrationSludge

The invention discloses a method for processing degradation-resistant organic wastewater through a Fenton-like multi-element catalytic oxidation technology. The method comprises the following steps: adding an oxidant into to-be-treated degradation-resistant organic wastewater and sufficiently mixing to obtain a mixture; introducing the mixture into a reactor to perform oxidization and reduction reaction; filling the reactor with a multi-element catalyst; processing the wastewater until the COD Cr removal rate is 25-35%. The invention further relates to a multi-element catalyst used for processing degradation-resistant organic wastewater. The method is used for degradation-resistant organic wastewater, a multi-element Fenton-like reagent comprising a catalytic oxidant is coppered with catalytic oxidization action to generate a series of free radical reactions, so that output of high-concentration high-strength hydroxyl free radical is realized, the transfer ability of hydrogen peroxide is greatly improved, and the strong-oxidization degradation of degradation-resistant organic substances in the wastewater by the hydroxyl free radical is realized. According to the method disclosed by the invention, the reaction conditions are gentle, much acid or alkaline is not required to regulate the pH value, sludge is not generated in the processing process, and the method can be used for pretreatment and posttreatment of the degradation-resistant organic substances, so that the up-to-standard emission is guaranteed, and the application prospect is wide.

Owner:武汉森泰环保股份有限公司

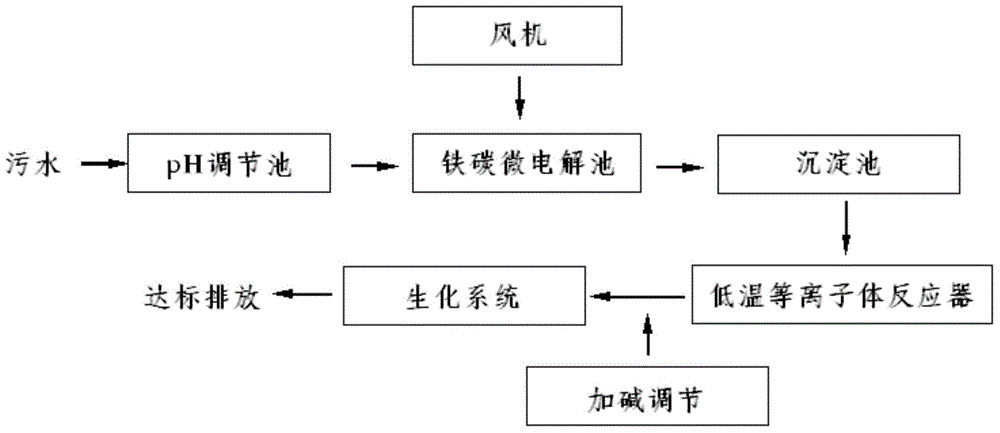

Low-temperature plasma and microelectrolysis combined treatment method for nitrotoluene production sewage

ActiveCN103601332AEfficient conversionReduce CODWater/sewage treatmentMultistage water/sewage treatmentChemical oxygen demandSludge

The invention discloses a low-temperature plasma and microelectrolysis combined treatment method for nitrotoluene production sewage. The low-temperature plasma and microelectrolysis combined treatment method comprises the following steps of regulating the pH value of the sewage, and then, enabling the sewage to enter a micro-electrolytic cell; settling the effluent, and then, removing sludge; enabling the effluent to enter a low-temperature plasma reactor, and treating the effluent by using plasmas, wherein the plasmas are generated through high-pressure gas-liquid mixed discharging; regulating the low-temperature plasma treated wastewater by adding alkaline, then, enabling the regulated low-temperature plasma treated wastewater to enter a biochemical system, and discharging the sewage after carrying out biochemical treatment. By using the low-temperature plasma and microelectrolysis combined treatment method, the COD (Chemical Oxygen Demand) of the nitrotoluene production sewage can be reduced to below 1500, and the B / C can be increased to over 0.3; in addition, the chemical structures of aromatic compounds with toxic and side effects in the sewage can be changed, so that the biochemical property of the sewage is greatly improved; after the sewage is biochemically treated, all main indexes of the effluent can be up to the first-grade discharging standard. The pollution caused by the discharge of the nitrotoluene production sewage is avoided, the environment is favorably protected, and the energy resources are recycled.

Owner:NANJING UNIV

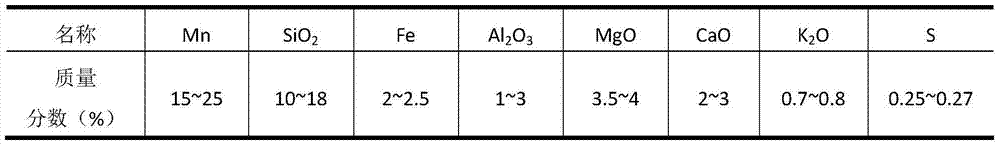

Manganese charcoal catalytic internal electrolysis filler as well as preparation method and application thereof

InactiveCN104261518ARealize the recycling of solid wasteTo achieve the purpose of recyclingWater treatment parameter controlWater contaminantsHigh concentrationActivated carbon

The invention relates to manganese charcoal catalytic internal electrolysis filler as well as a preparation method and an application thereof. The internal electrolysis filler is prepared from manganese ore wastes, activated charcoal, an adhesive and a pore-foaming agent, wherein the mass percent of the manganese ore wastes is 40-65%, the mass percent of the activated charcoal is 35-60% and the sum of mass percents of the manganese ore wastes and the activated charcoal is 100%. The method comprises the following steps: grinding the manganese ore wastes; adding the activated charcoal, the adhesive and the pore-foaming agent; putting into a muffle furnace after balling to be roasted for 2-3 hours at 1100 DEG C; and preparing a final product. Meanwhile, the application comprises the following steps: using the final product in high concentration organic wastewater; aerating for 2 hours; and removing organic matters. The filler provided by the invention has the beneficial effects that a novel catalytic internal electrolysis filler is prepared by applying the manganese ore waste, so that the method is convenient to operate, treats wastes by wastes, and is energy-saving, good in removal effect of organic matters, strong in practicality and wide in prospect.

Owner:深圳武汉理工大研究院有限公司

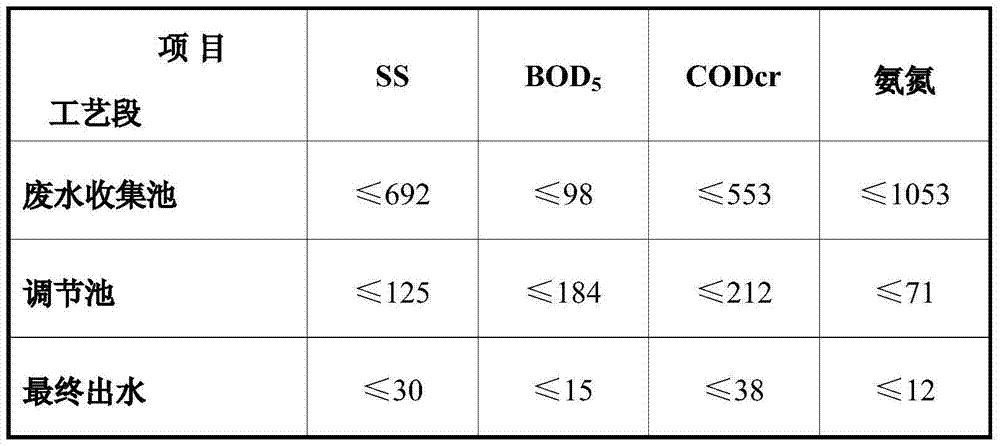

Method for treating high-ammonia-nitrogen industrial wastewater of denitration catalyst

InactiveCN103482825AReduce ammonia nitrogen contentImprove biochemical propertiesMultistage water/sewage treatmentAluminium chlorideTherapeutic effect

The invention relates to the field of wastewater treatment, in particular to a method for treating high-ammonia-nitrogen industrial wastewater of a denitration catalyst, and aims to solve the technical problems that when BOD 5 value in wastewater is relatively small, the biochemical performance of the wastewater is poor, so that a biochemical treatment effect can not be ensured well, when a sulphuric acid solution is used as an absorbent of an ammonia washing tower, the content of salt (ammonium sulfate) in the wastewater is relatively high, so that the biochemical treatment effect is affected. The method comprises the following steps: using air to perform aeration adjustment on the wastewater so as to enable the air and the wastewater to be mixed uniformly, and performing pre-oxidation on parts of substances; sequentially adding poly aluminium chloride and polyacrylamide in a grid flocculation reaction precipitation tank, and adopting a triangular weir manner for water outflow; performing desalinization pretreatment to remove ammonia nitrogen and salinity, and enabling condensate outlet water subjected to evaporative crystallization to be mixed with domestic sewage and to flow to an adjusting tank automatically; allowing the mixed liquid to sequentially pass anaerobic, facultative, aerobiotic and the like biochemical treatment sections, and utilizing biological florae to treat organic materials and the ammonia nitrogen in the wastewater so as to enable the outlet water to meet discharge standards finally.

Owner:ZHEJIANG DONGFA ENVIRONMENTAL PROTECTION ENG

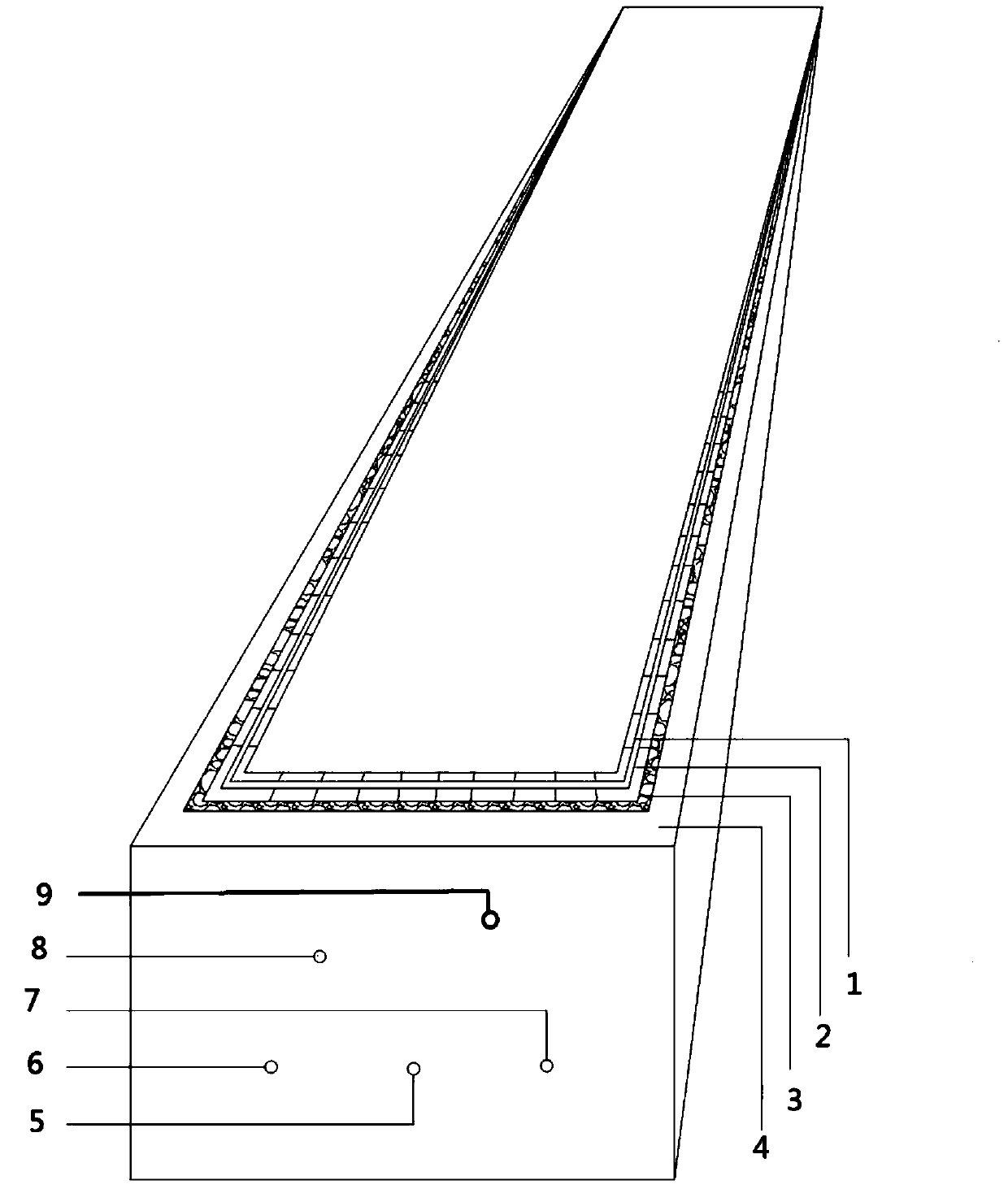

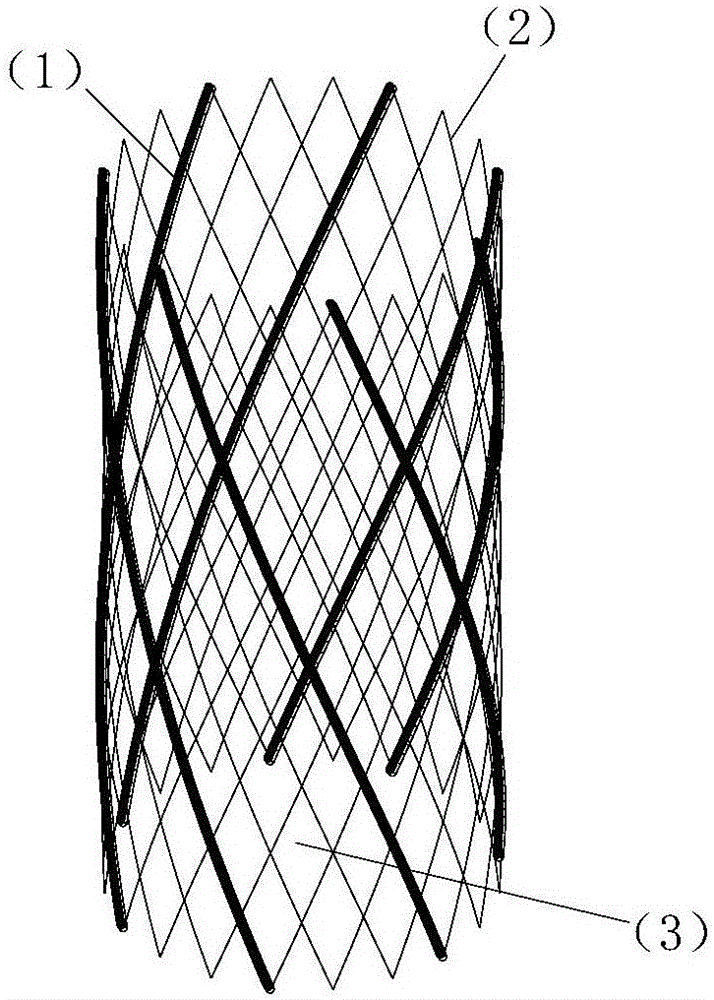

Micropore biofilm carrier filler based on mesh structure

ActiveCN105906035AIncrease load capacityImprove stabilityBiological treatment apparatusSustainable biological treatmentBiofilmPolymer science

The invention discloses a micropore biofilm carrier filler based on a mesh structure and belongs to the field of sewage and wastewater treatment. A polyethylene or polypropylene high-molecular polymer serves as the main carrier material, auxiliary materials polyvinyl alcohol and limestone powder are added, the adding amount of polyvinyl alcohol is 10% of the total weight of the main material and the auxiliary materials, limestone powder is 150-200-mesh powder, and the adding amount of limestone powder is 15-20% of the total weight of the main material and the auxiliary materials. The whole structure is a web cylinder, an elevated fin is arranged every other several netting wires outside the web cylinder in the direction of the netting wires, the elevated fins are integrated with the web cylinder, and the elevated fin and the web cylinder are made of the same material. A biofilm carrier is provided with two-grade gaps, the first-grade microbubble gaps are formed through foaming, and the second-grade fine gaps are formed through acid dissolution of small limestone granules. The filler has high bacteria adhesiveness property, high biological film load performance and excellent biological film stability after biofilm formation, and therefore excellent biochemical performance is realized.

Owner:BEIJING UNIV OF TECH

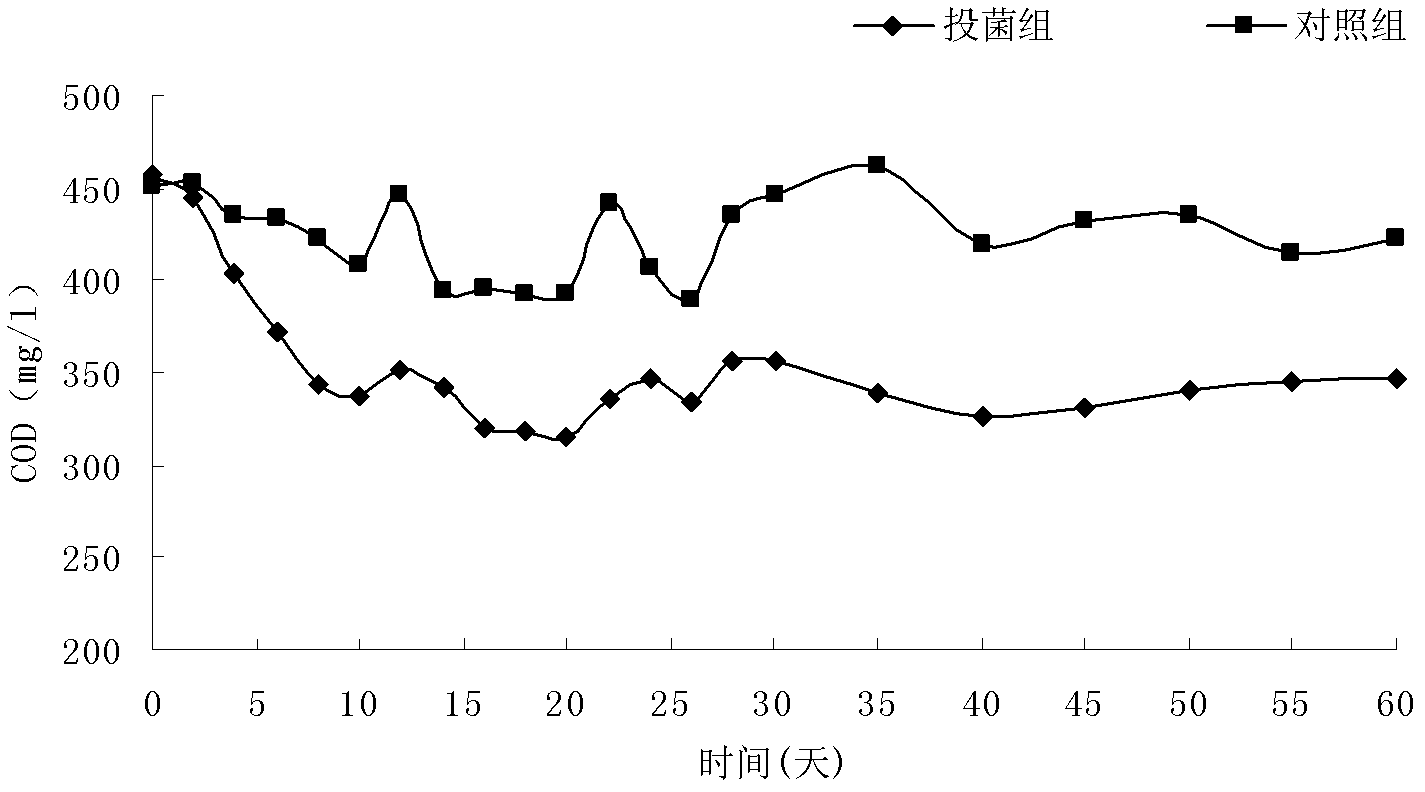

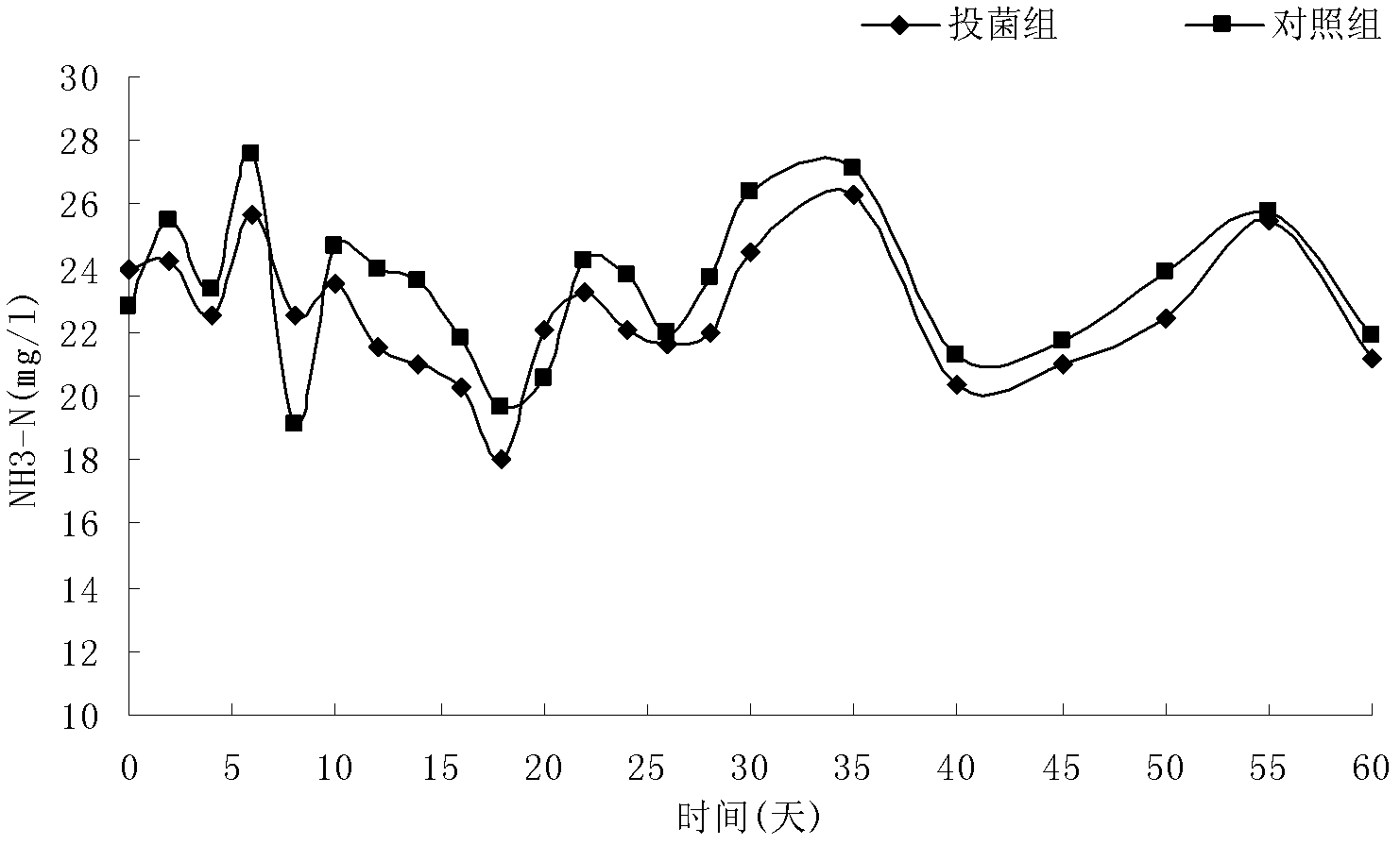

Method for treating and printing and dyeing wastewater by using hydrolysis tank

ActiveCN102329043AEasy to hang filmPromote metabolism and renewalMultistage water/sewage treatmentSustainable biological treatmentPre treatmentOxidation ditch

The invention discloses a method for treating and printing and dyeing wastewater by using a hydrolysis tank. The hydrolysis tank comprises a front half tank and a rear half tank, wherein the front half tank of the hydrolysis tank is provided with a water inlet; the rear half tank of the hydrolysis tank is provided with a water outlet; the rear half tank is connected with an oxidation ditch and a secondary sedimentation tank in series; the front half tank is an opened tank of which the upper part is opened; the rear half tank is a closed tank of which the upper part is closed; the printing anddyeing wastewater is treated and then is mixed with sludge in the secondary sedimentation tank at the water inlet; the mixture enters the inside of the front half tank of the hydrolysis tank from thelower part of a baffle plate; when DO value of the printing and dyeing wastewater reaches 0.2-0.3mg / L, the wastewater enters the interior of the rear half tank of the hydrolysis tank; and when the DOvalue of the printing and dyeing wastewater reaches 0.3-0.5mg / L, the wastewater is discharged after reaching the standard. According to the method disclosed by the invention, the biochemical quality of the hydrolysis tank is greatly improved; the ammonifying effect of organisms which are difficult to degrade, such as organic nitrogen, is remarkably improved; and the removal rates of subsequent COD (Chemical Oxygen Demand) and NH3-N are greatly improved.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

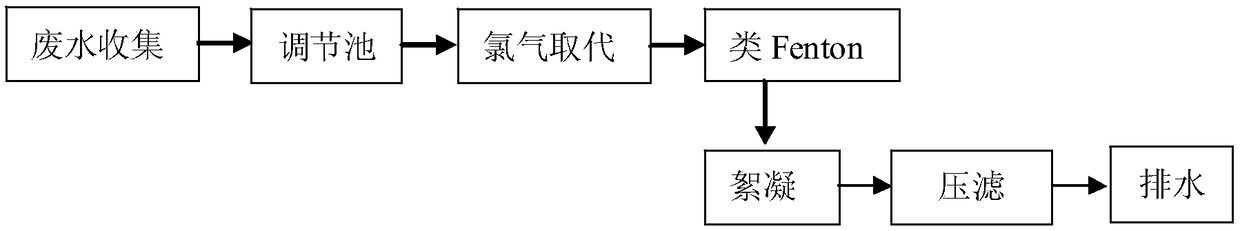

Method for treating chloropyridine wastewater

ActiveCN108706761AImprove hydrophobicityLower pHWater/sewage treatment by irradiationWater contaminantsHigh concentrationFlocculation

The invention discloses a method for treating chloropyridine wastewater. The method comprises the following steps that 1, the pH value of the chloropyridine wastewater is adjusted to be 8-10, chlorineis introduced into a polymerization free radical initiator under ultraviolet light till the pH of the wastewater is reduced to 2-4, filtering is carried out, and filtrate I is obtained; 2, a catalystand an oxidizing agent are added into the filtrate I, and a reaction is carried out for 60-180 min at the temperature of 100-150 DEG C and at the pressure of 0.5-2 MPa; 3, the pH of the outflow waterobtained after the oxidization reaction is adjusted to be 8-10, and flocculation and filtration are carried out. The treatment method can be used for carrying out deep treatment on the high-concentration chloropyridine wastewater, and is easy to operate and good in treatment effect.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

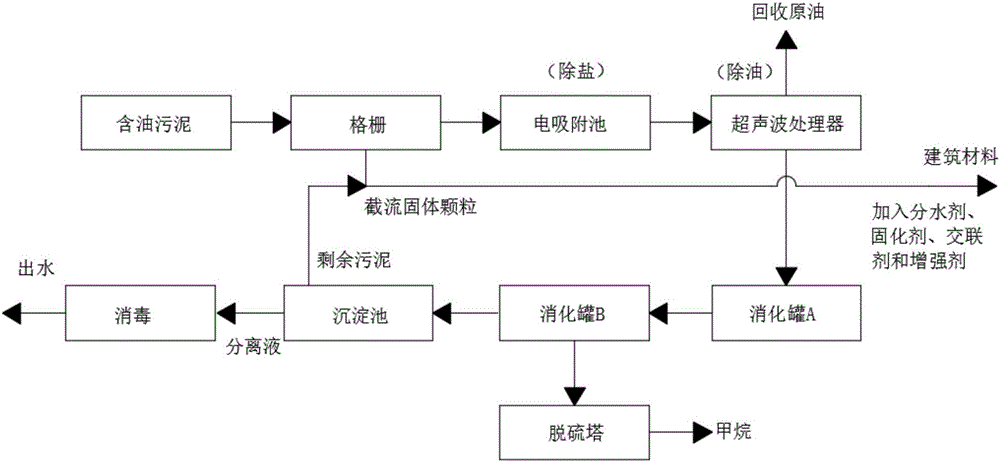

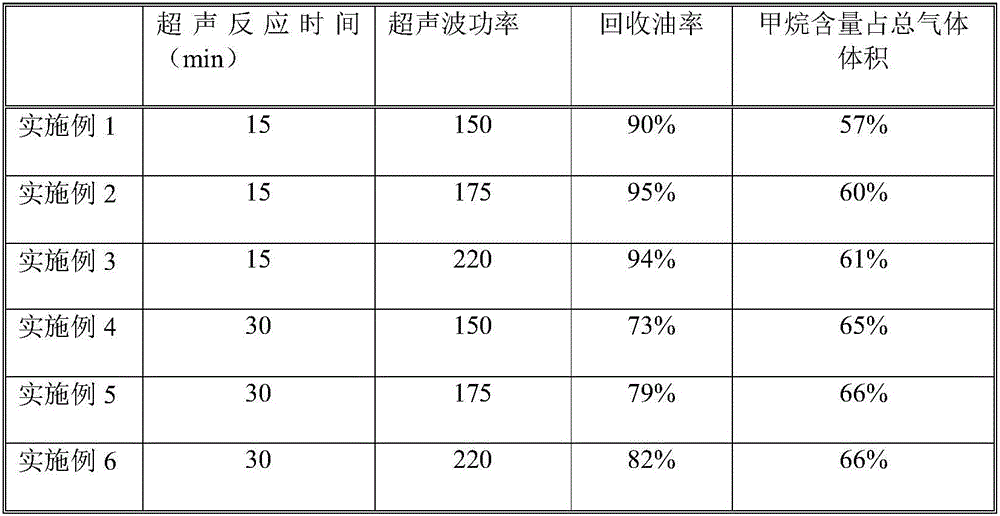

Oil field drilling sludge treatment and comprehensive utilization method

InactiveCN105731745AImprove biochemical propertiesIncrease productionWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningEcological environmentResource development

The invention relates to the technical field of resource development, in particular to an oil field drilling sludge treatment and comprehensive utilization method.The method sequentially comprises the steps of solid impurity removal, heavy metallic salt removal through electro-adsorption, ultrasonic demulsification and anaerobic fermentation.Gas obtained after anaerobic fermentation is subjected to desulfuration so that methane can be obtained.An obtained solid-liquid mixture is treated in a settling pond, upper-layer digestive liquid is sterilized and then discharged after meeting the discharge standard, and lower-layer sludge is thickened and then mixed with an additive to generate cement raw materials.Compared with the prior art, the method has the advantages that a complete method is provided for oil field drilling sludge treatment, oily sludge is treated in a reducing and harmless mode, maximum resource utilization of oily sludge is achieved, and the method has great significance in ecological environmental protection and sustainable development of the petroleum industry.

Owner:WUHAN UNIV OF TECH

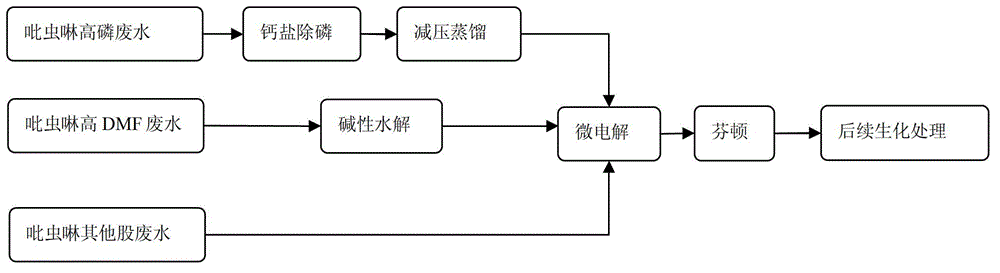

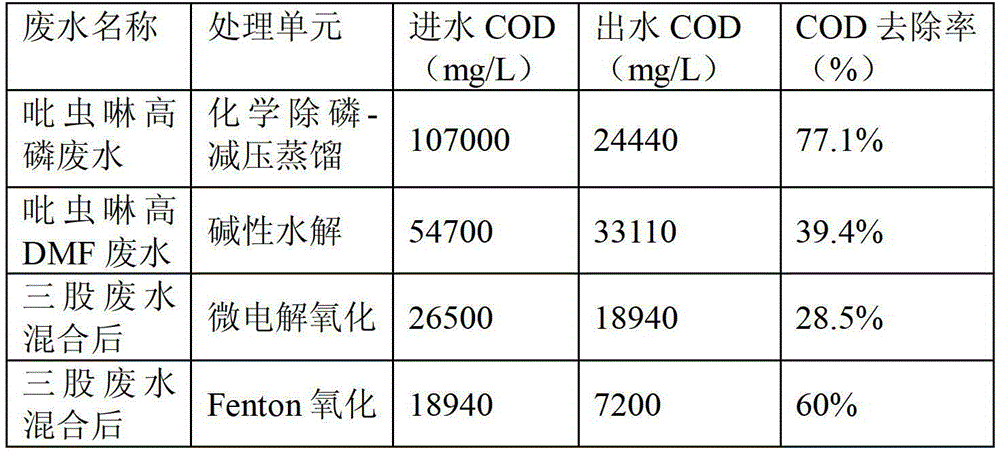

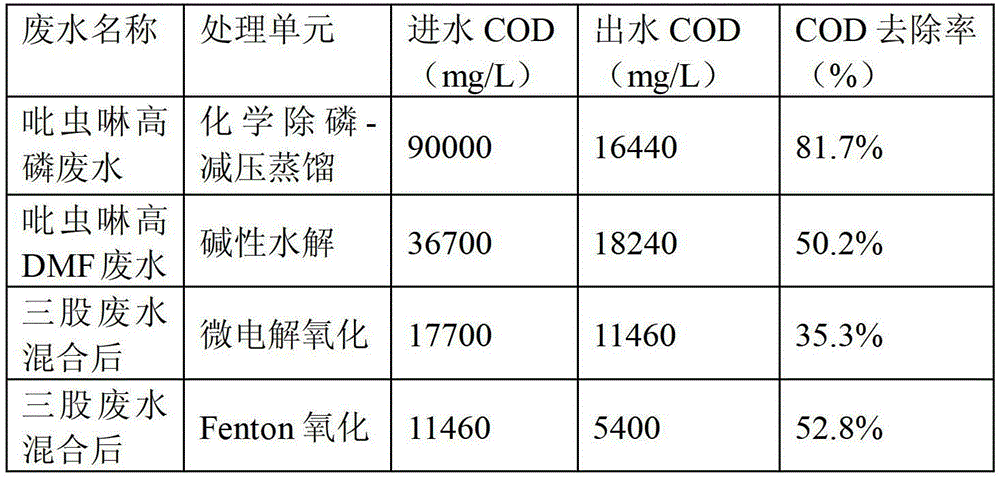

Pre-treatment process of imidacloprid wastewater

InactiveCN103145302AReduce CODLow biological toxicityMultistage water/sewage treatmentPretreatment methodWater quality

The invention relates to a pre-treatment process of imidacloprid wastewater. The pre-treatment process is characterized by being used for collecting wastewater generated in the production process of the imidacloprid pesticide by classifying, and comprising the following steps of: firstly treating according to quality and then mixing the wastewater to carry out oxidation treatment on account of the characteristics of blasts of wastewater. Due to the pre-treatment process of imidacloprid wastewater, the classified collection of the imidacloprid wastewater, quality-distinguishing efficient pre-treatment, strong pertinence and good treatment effect can be realized, the concentration of degradation-resistant organic matters is greatly reduced, the biodegradability of the wastewater is improved and the economical efficiency is improved; the pre-treatment process has the advantages of being wild in reaction condition, simple to operate, good in treatment effect and low in operation cost; and the pre-treatment process of imidacloprid wastewater disclosed by the invention can be used for overcoming the defects of high reaction condition requirement, unstable water quality and the need of great amount of water for diluting after pre-treating of the existing pre-treatment method of the imidacloprid wastewater.

Owner:NANJING UNIV OF TECH

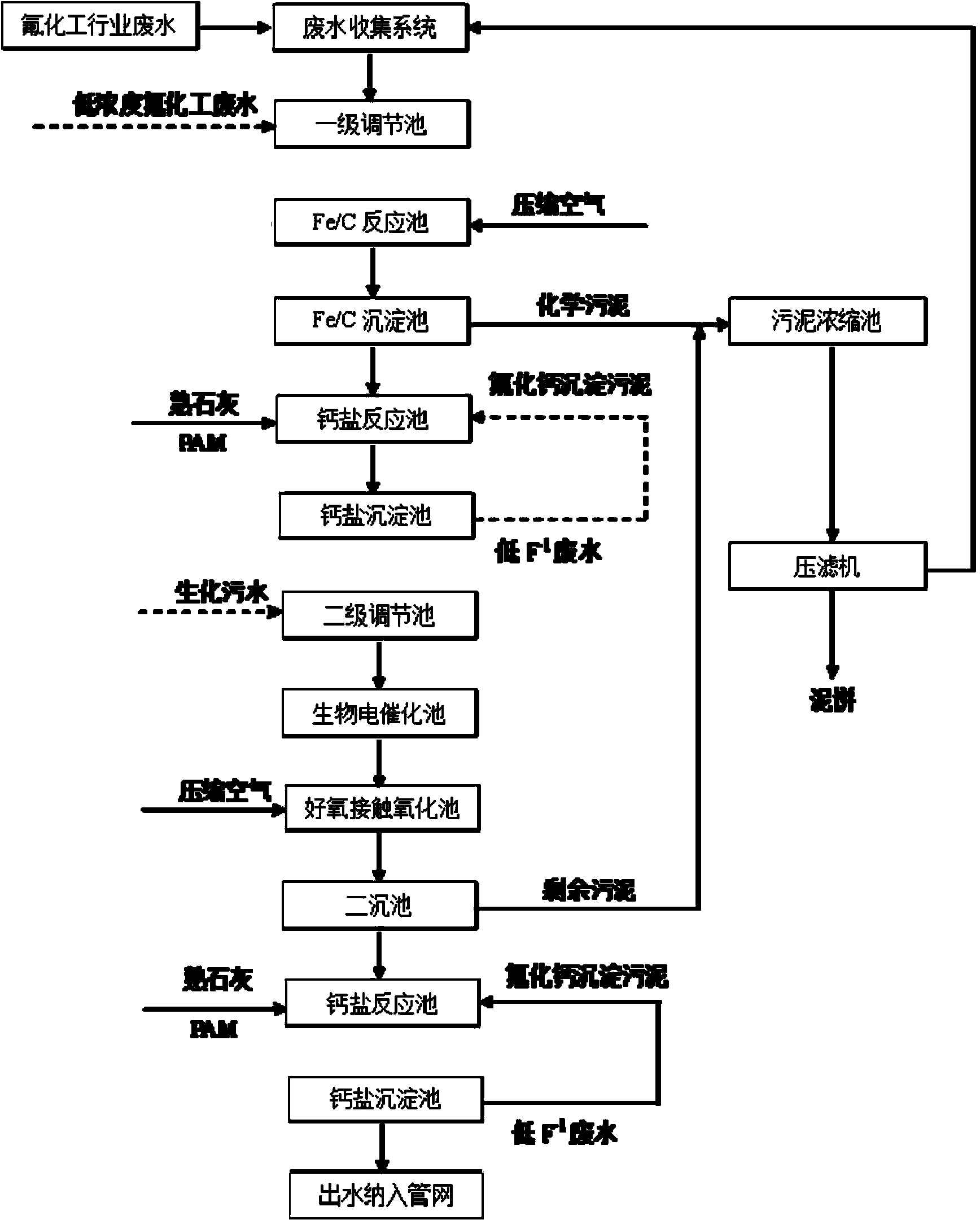

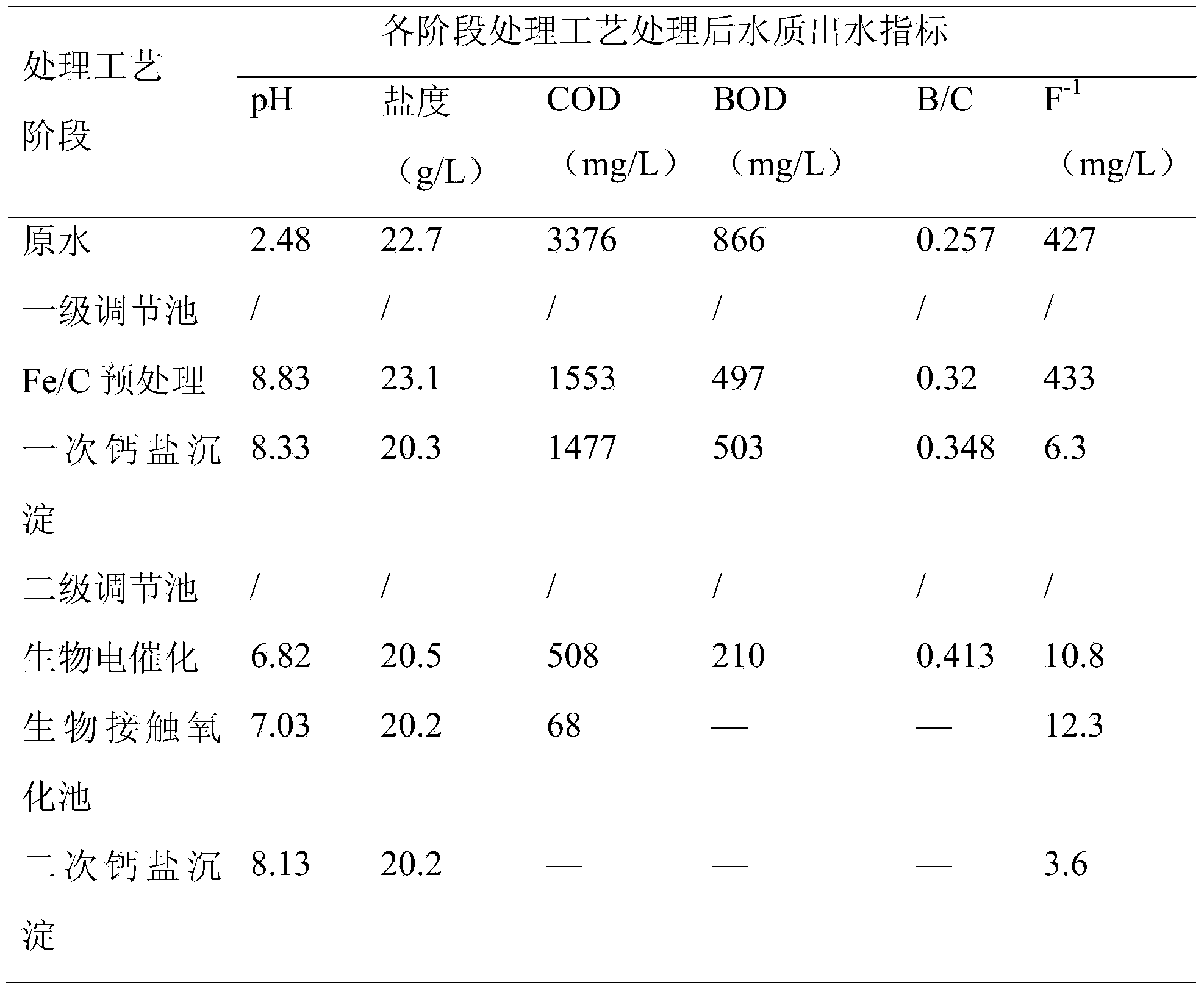

Treatment process for fluorine chemical wastewater

ActiveCN103708679AReduced settling timeEasy to handleWater contaminantsMultistage water/sewage treatmentSewagePre treatment

The invention discloses a treatment process for fluorine chemical wastewater. The process comprises the following steps: sequentially carrying out one-time regulating, carrying out iron-carbon reaction pre-treatment, carrying out iron-carbon precipitation, carrying out one-time calcium salt reaction, carrying out one-time calcium salt precipitation, adjusting for the second time, carrying out bioelectrocatalysis, carrying out an aerobic contact oxidation, carrying out second-time calcium salt reaction, second-time precipitation and discharging water. The process provided by the invention is used for treating the fluorine chemical wastewater; the wastewater treated by the process can achieve primary standards of Integrated Wastewater Discharge Standard (GB8978-1996) and the operation cost of wastewater treatment is low.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Ion exchange waste water denitrification material and preparation method thereof

InactiveCN101992132AReduce stress changesHigh breaking strengthWater contaminantsWater/sewage treatment by ion-exchangePolyolefinIon exchange

The invention relates to an ion exchange waste water denitrification material and a preparation method thereof. A segmented copolymer containing a polyolefin acetal chain segment and a polyolefin sodium carboxylate chain segment is prepared from polyolefin alcohol and polyolefin sodium carboxylate which have low polymerization degree, as well as aldehydes, kieselguhr, kaolin, imvite and the like under the action of an initiator. The copolymer has sodium carboxylate groups, can be used as cation exchange resin, and performs the exchange with NH4<+> in waste water;and the roughness of the material can be increased by adding inorganic nanometer powder soil, and the specific surface area is increased to improve the hydrophily and affiliation capacity of microbes. The preparation method comprises the following steps of: dissolving the polyolefin alcohol and the polyolefin sodium carboxylate by using NaSCN solution, adding the initiator for polymerizing, adding a terminator and inorganic nanometer powder, stirring and mixing uniformly to prepare spinning solution, coagulating the spinning solution with inorganic salt solution in coagulating bath to form nascent fibers, performing post processing processes such as drawing, heat setting, acetalation, washing, drying and the like, and weaving to form a specific shape to obtain the required product. The material has the good mechanical strength, hydrophily, microbe affinity and ion exchange performance.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com