Processing method for waste water in production process of fine terephthalic acid

A technology for producing purified terephthalic acid and waste water, which is applied in biological water/sewage treatment, natural water treatment, sustainable biological treatment, etc., and can solve problems such as failure to meet direct discharge requirements, secondary pollution, and complex operation , to achieve the effects of reducing the amount of excess sludge produced, improving the impact of operating load, and improving the efficiency of biochemical degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

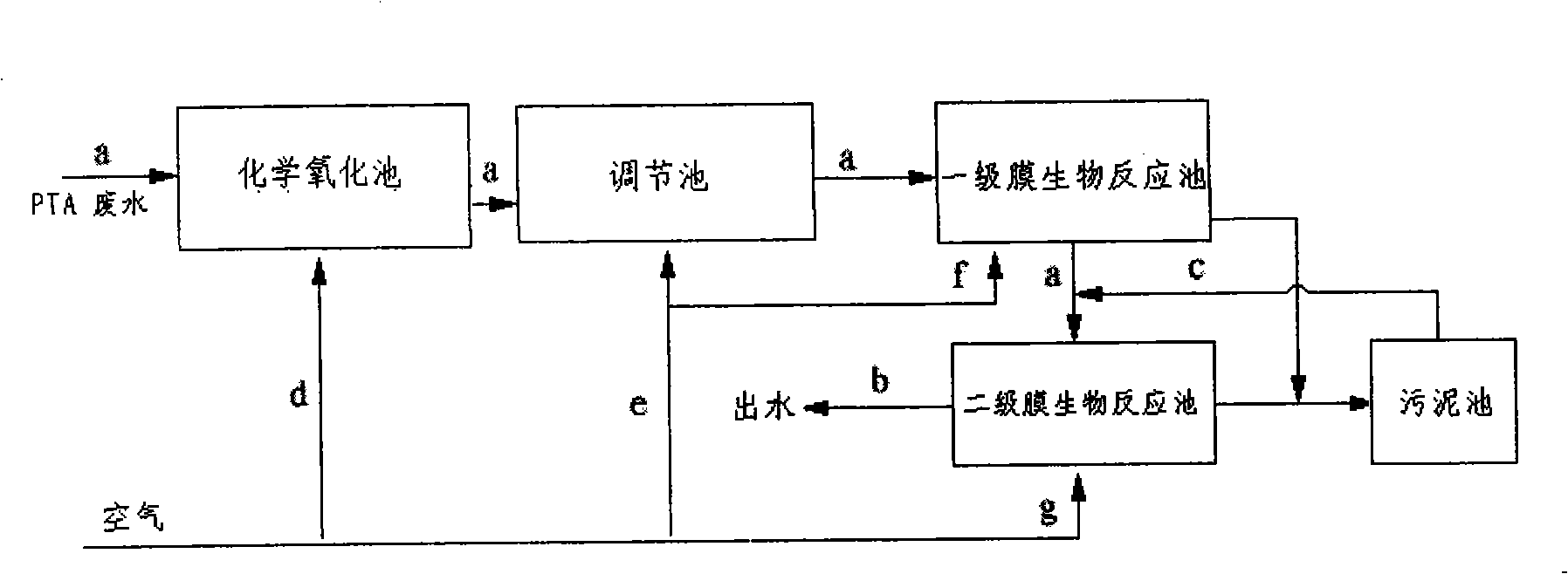

[0022] process such as figure 1 shown.

[0023] Pump purified terephthalic acid production wastewater (COD 4000mg / L, terephthalic acid concentration 1200mg / L) into catalytic oxidation reaction tank 1, catalytic oxidation reaction tank 1 is a vertical cuboid structure, length × width × height = 2 ×2×3m, the interior of the reaction tank is parallel to the length direction, and two rectangular deflectors are installed vertically and symmetrically to the bottom of the tank. 0.25m from the width side, 0.25m from the bottom of the pool, and 0.25m from the upper edge. Perforated aeration PVC pipes were installed at the bottom of the pool, φ15mm×5, and 2% (mass fraction) of total water was added to the pool with granular activated carbon (20-50 mesh). The air is passed into the catalytic oxidation reaction tank 1 through the perforated aeration pipe at the bottom, and the air velocity is 50m 3 / h, oxidation reaction for 1 hour, the wastewater after the oxidation reaction enters th...

Embodiment 2

[0029] Processing method is as embodiment 1. The COD of purified terephthalic acid production wastewater is 4500mg / L, the concentration of terephthalic acid is 1400mg / L, the sludge concentration of the primary membrane bioreactor tank is 7.3g / L, and the efficient terephthalic acid degradation strain is YPC-TA2, which controls the dissolution Oxygen is 1.0mg / L, the sludge concentration in the secondary membrane bioreaction tank is 3.2g / L, the terephthalic acid degradation strain is YPC-TA2, the dissolved oxygen is controlled at 2.0mg / L, and the biochemical reaction temperature is 32°C. The specific operating indicators are as follows:

[0030] The effluent COD of the catalytic oxidation reaction pool is 3460mg / L, and the concentration of terephthalic acid is 1092mg / L.

[0031] The effluent COD of the primary membrane bioreactor tank is 212mg / L, the concentration of terephthalic acid is 15mg / L, and the organic volume load reaches 3.2kgCOD / m 3 .d.

[0032] The effluent COD of ...

Embodiment 3

[0034] Processing method is as embodiment 1. The COD of purified terephthalic acid production wastewater is 5000mg / L, and the concentration of terephthalic acid is 1700mg / L. The sludge concentration in the first-stage membrane bioreaction tank is 7.6g / L, the highly efficient terephthalic acid degradation strain is YPC-TA3, and the dissolved oxygen is controlled at 1.0mg / L. The sludge concentration in the second-stage membrane bioreaction tank is 3.6g / L. The high-efficiency dicarboxylic acid degradation strain is YPC-TA3, the dissolved oxygen is controlled at 2.0mg / L, and the biochemical reaction temperature is 32°C. The specific operating indicators are as follows:

[0035] The effluent COD of the catalytic oxidation reaction tank is 3970mg / L, and the concentration of terephthalic acid is 1292mg / L.

[0036] The effluent COD of the primary membrane bioreactor tank is 236mg / L, the concentration of terephthalic acid is 18mg / L, and the organic volume load reaches 3.8kgCOD / m 3 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com