Patents

Literature

1105 results about "Acid production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid Production. The body's metabolism produces acid - which is released into the capillaries and makes the blood slightly more acidic. The blood arrives in the arterioles with a pH of 7.4 (equivalent to [H +] = 40 nMol/L) and leaves the venules with an average pH of 7.36 (equivalent to [H +] = 44 nMol/L).

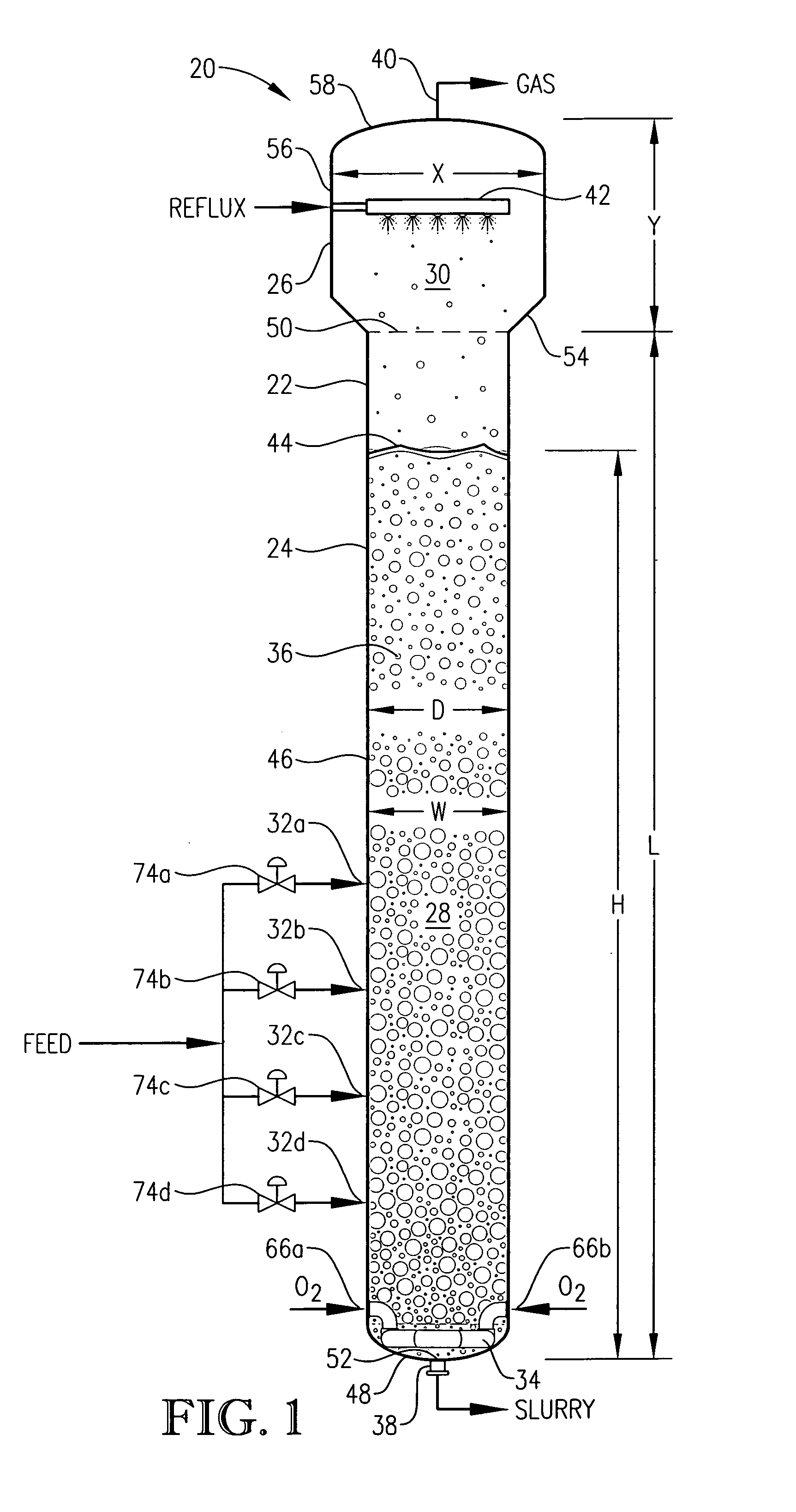

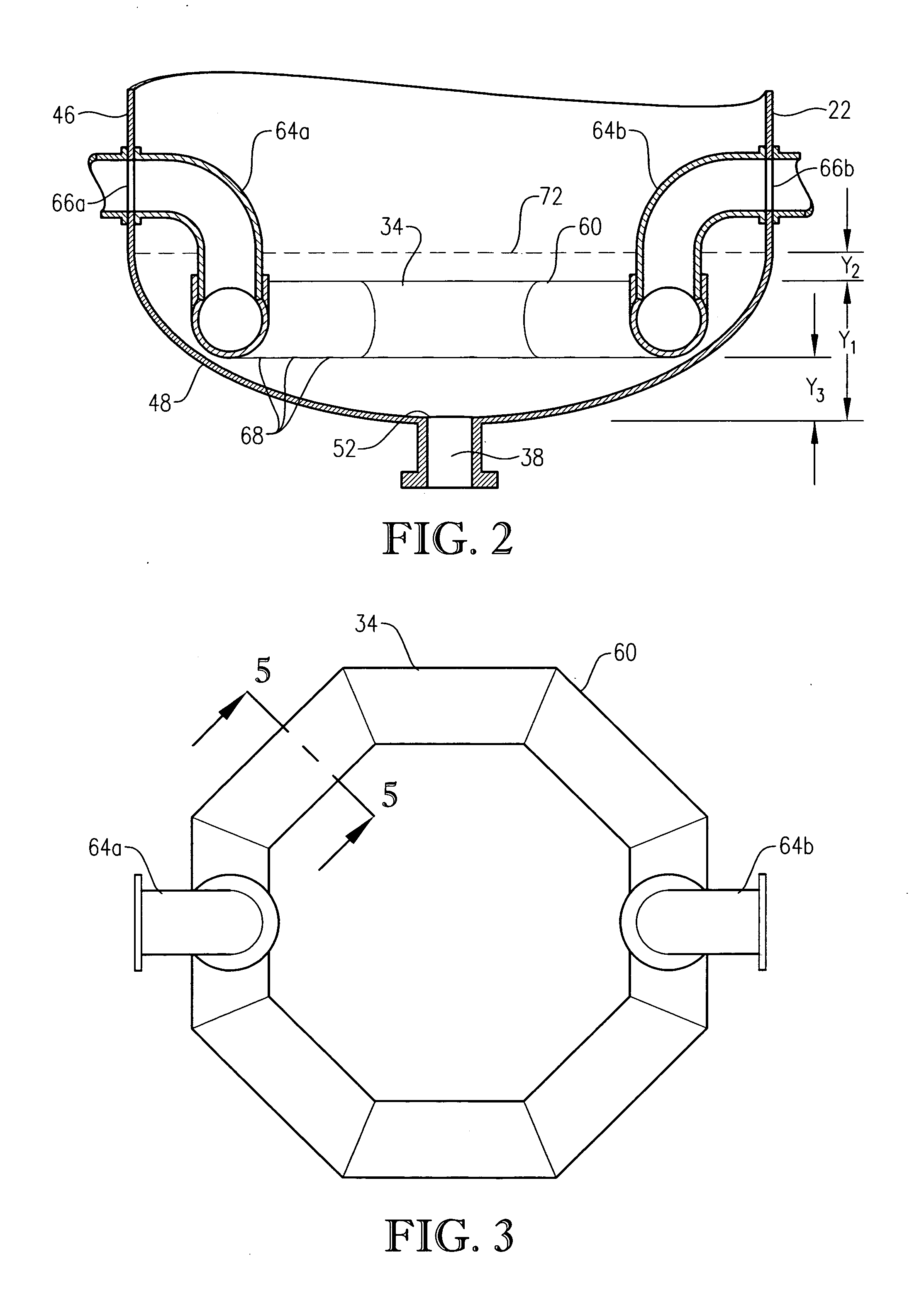

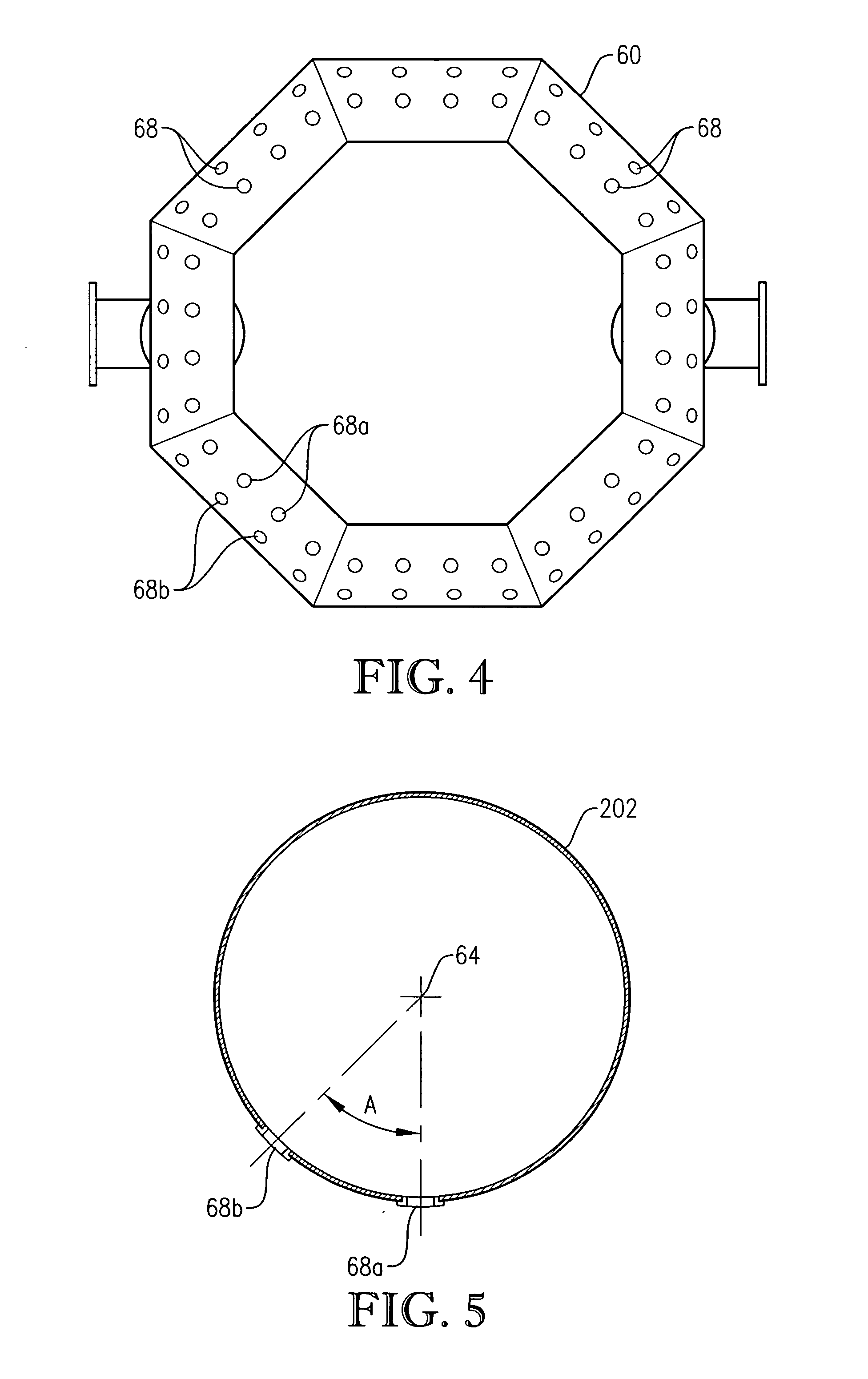

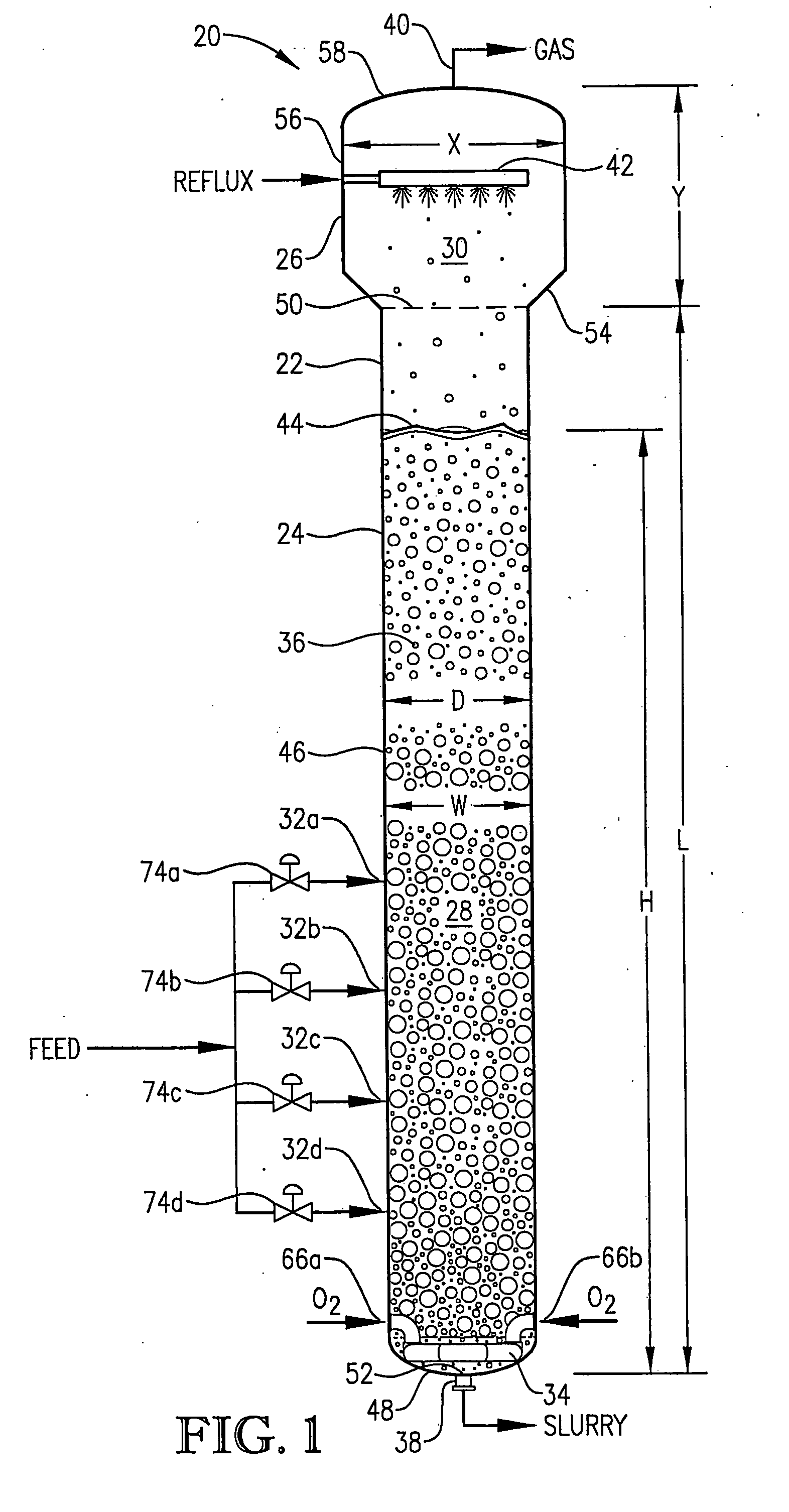

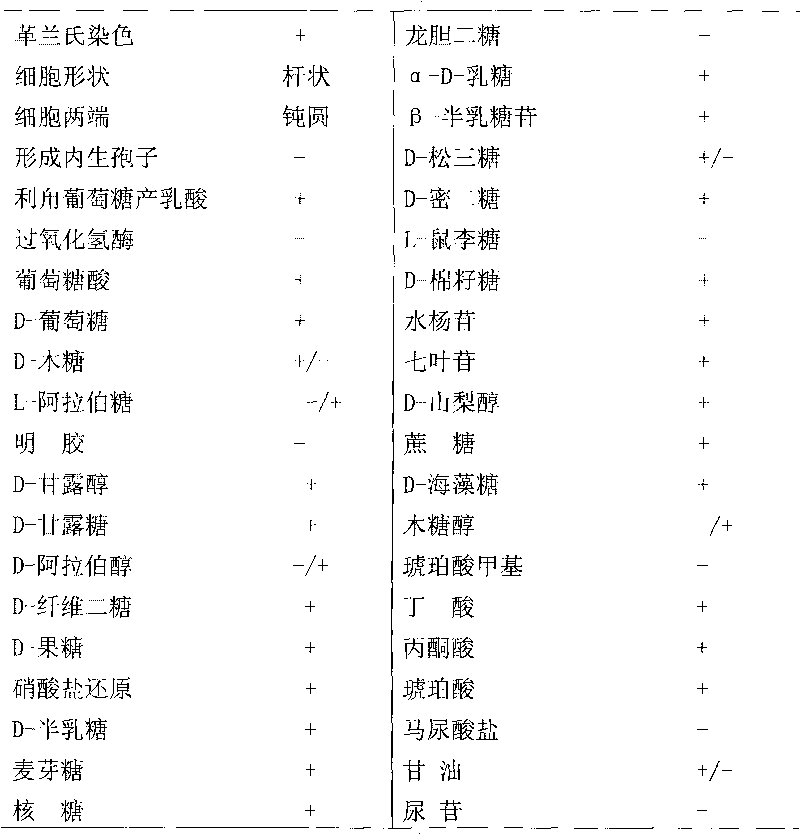

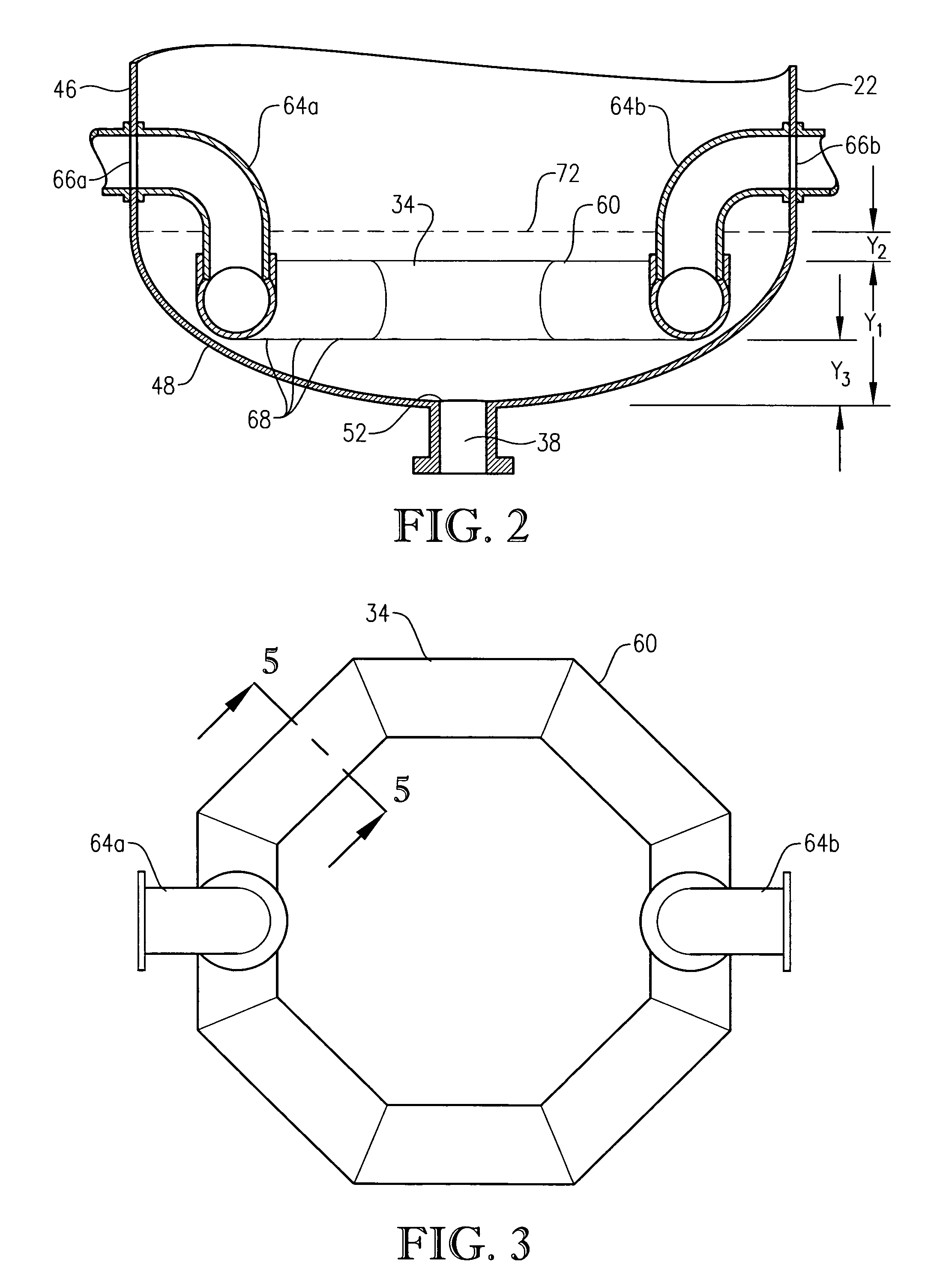

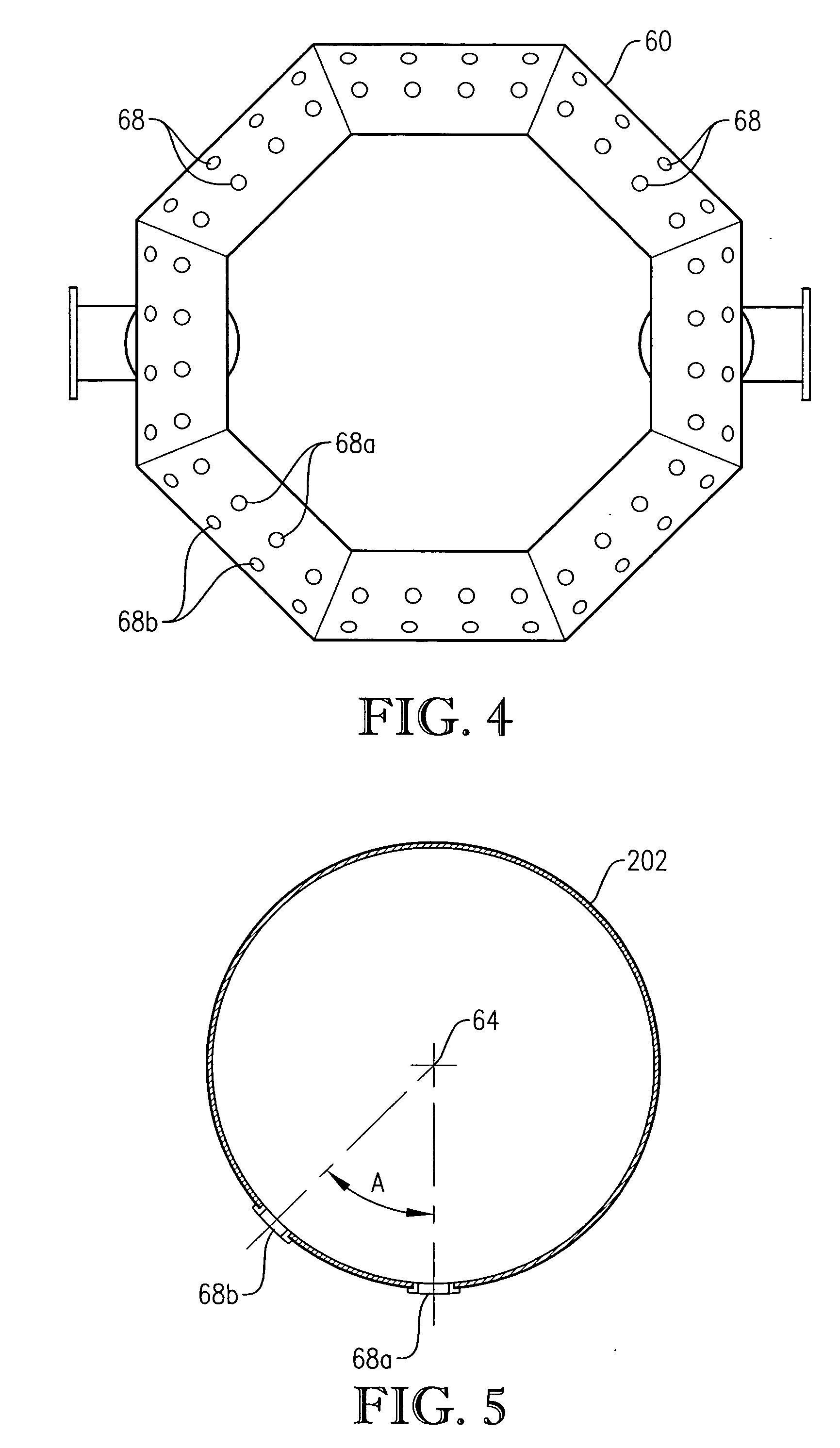

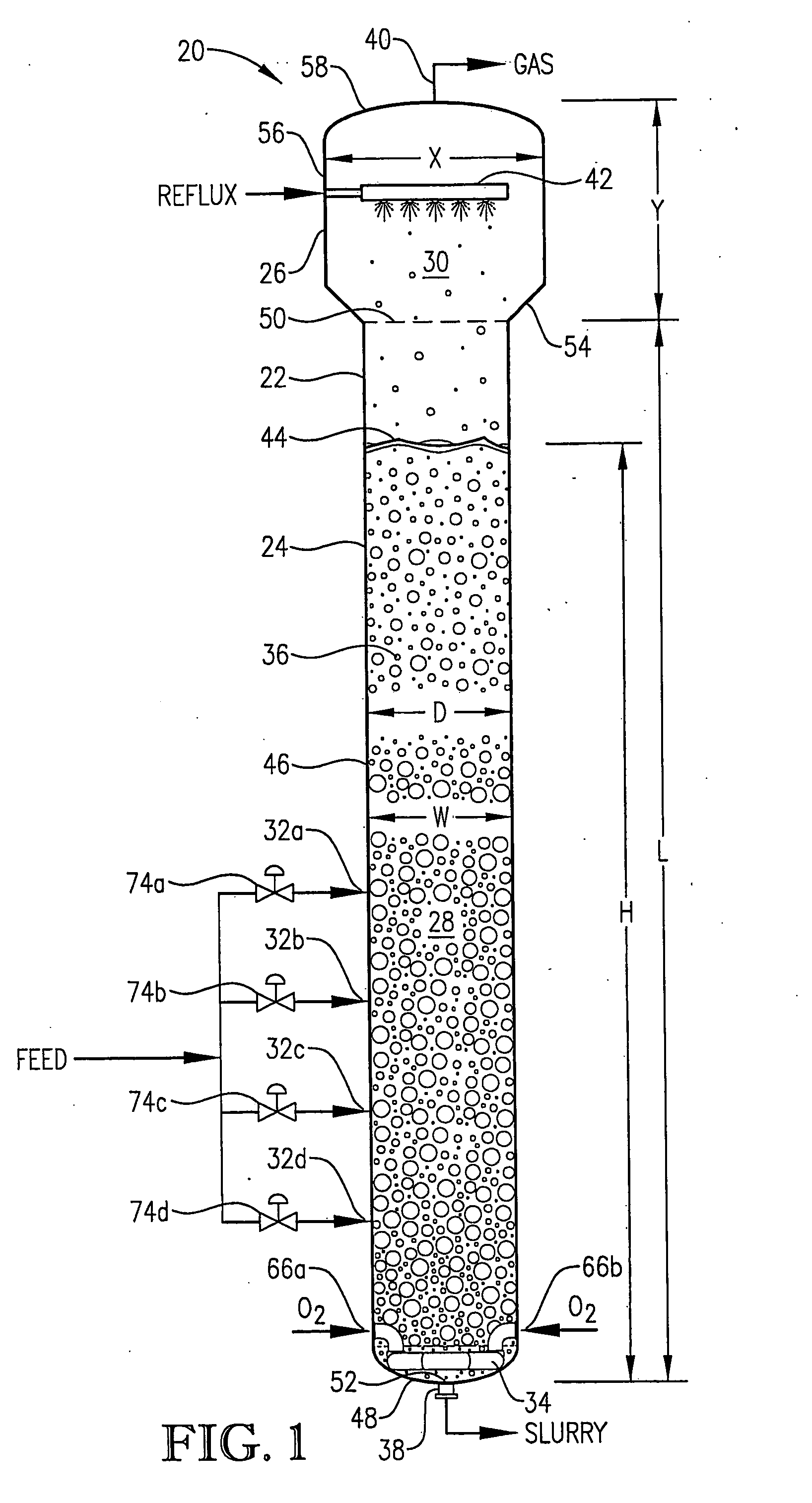

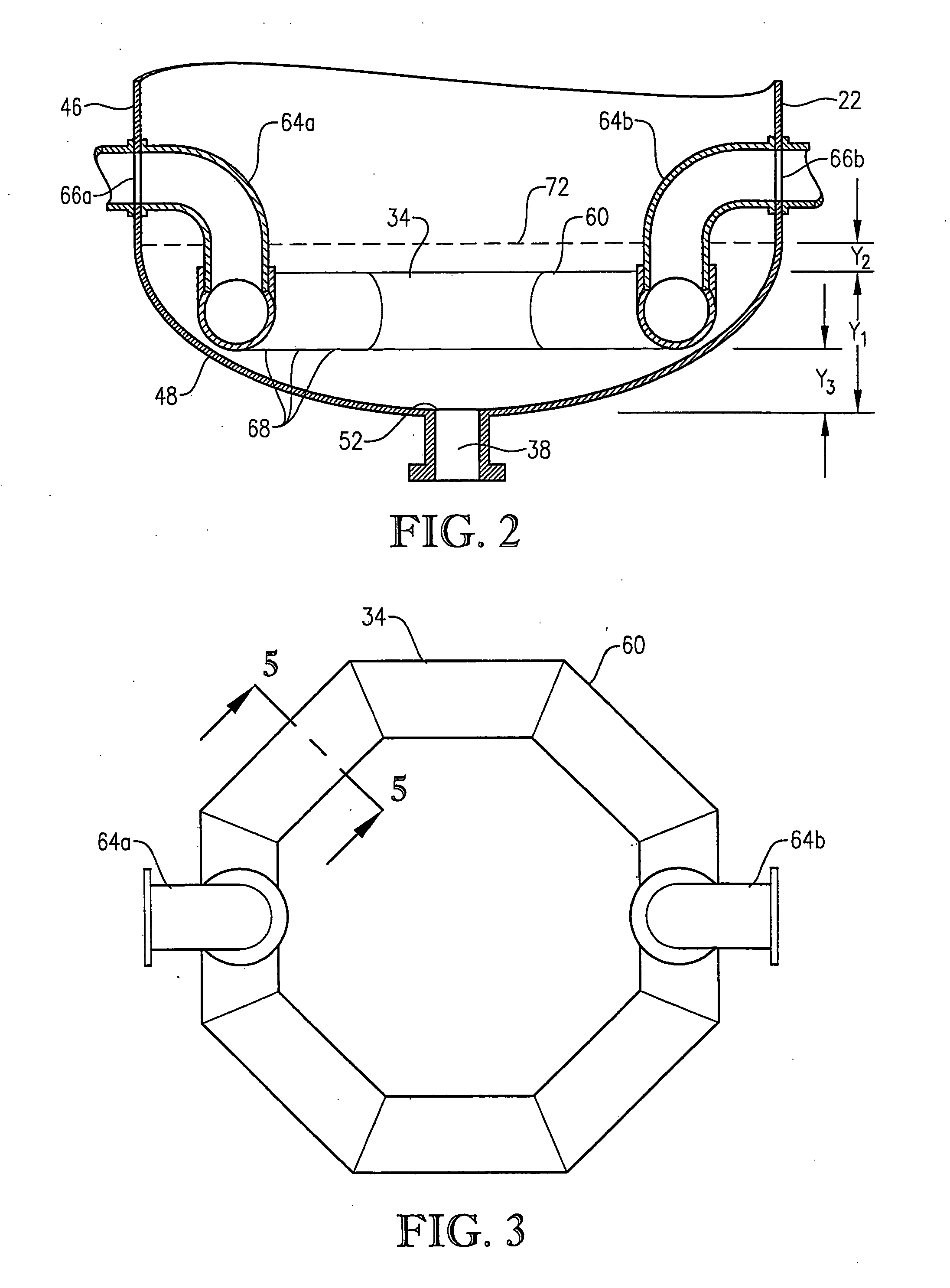

Polycarboxylic acid production system employing oxidative digestion with reduced or eliminated upstream liquor exchange

ActiveUS20070208190A1Reduce formationPromote oxidationOrganic compound preparationCarboxylic preparation by oxidationCarboxylic acidSlurry

Disclosed is an optimized system for more efficiently and economically producing terephthalic acid. The system minimizes or eliminates the need for liquor exchange upstream of oxidative digestion and / or upstream of substantial cooling of the TPA-containing slurry.

Owner:ALPEK POLYESTER SA DE CV

Production method for seaweed bio-composite organic liquid fertilizer

ActiveCN102731176AReduce manufacturing costAvoid high temperatureOrganic fertilisersWater useCompound organic

The present invention relates to a production method for a seaweed bio-composite organic liquid fertilizer. The method comprises the following steps: carrying out crushing grinding on fresh kelps; adding the crushed kelp slurry to a fermentation tank, and adding water; adjusting the pH value to 6.8-8.8, adding a composite enzyme and a microbial fermentation bacteria agent, uniformly stirring, and heating to a temperature of 25-60 DEG C, wherein the thermal insulation fermentation time is at least 85 hours; and filtering, and adding an acid production bacterial agent to obtain the seaweed bio-composite organic liquid fertilizer. According to the present invention, the water used in the method adopting the fresh kelps as the raw material to produce the product is saved by 90% compared with the method adopting the dried kelp raw material to produce the product; the energy is saved by 40% by adopting solar heating and thermal insulation fermentation production, the production cost can be reduced by 25%, and characteristics of energy saving, water saving, low carbon and environmental protection are provided; the seaweed bio-composite organic liquid fertilizer of the present invention has effects of combination of organic fertilizer, inorganic fertilizer, microbial fertilizer, and medium and trace element fertilizer, rapid acting, long lasting time, synergy, fertilizer retention, water retention, cold resistance, insect repelling, disease resistance, soil improving, and the like.

Owner:WEIHAI SHIDAI MARINE BIOTECH

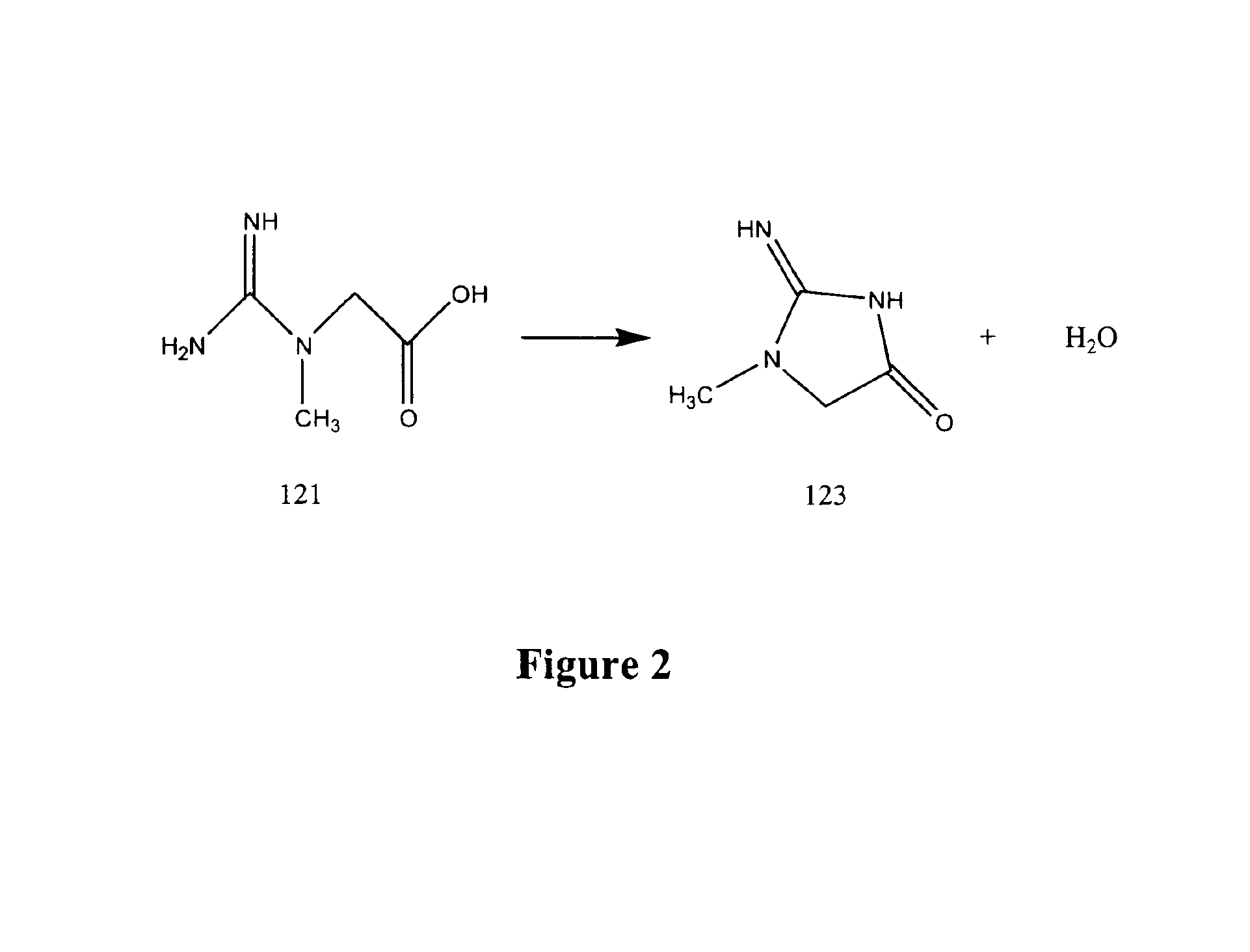

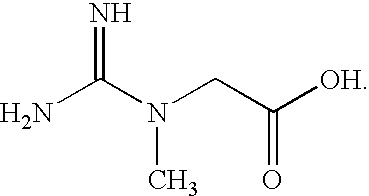

Production of creatine esters using in situ acid production

Methods are provided for the improved production of a creatine ester by in situ production of an acid catalyst.

Owner:BOARD OF RGT UNIV OF NEBRASKA

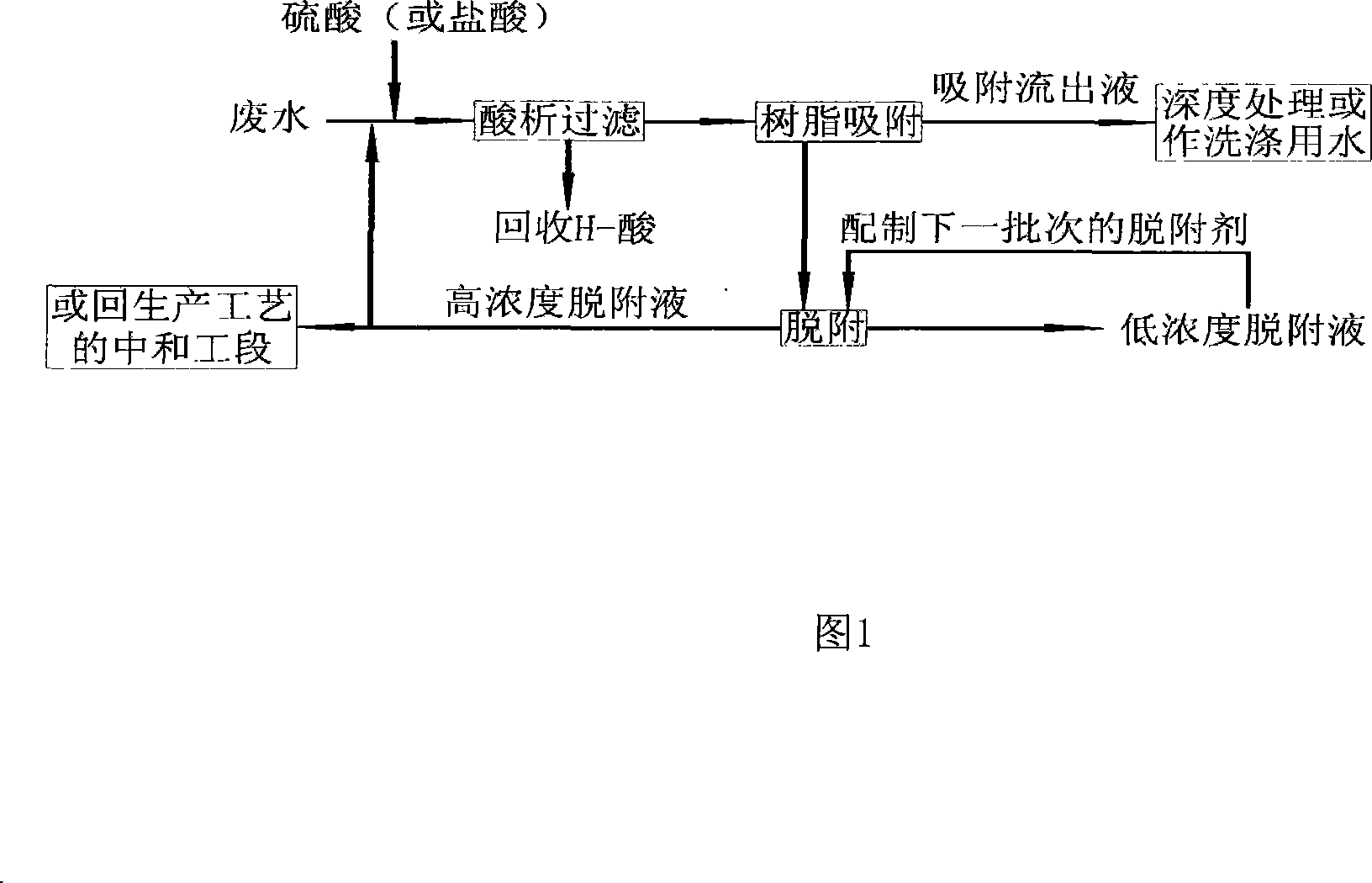

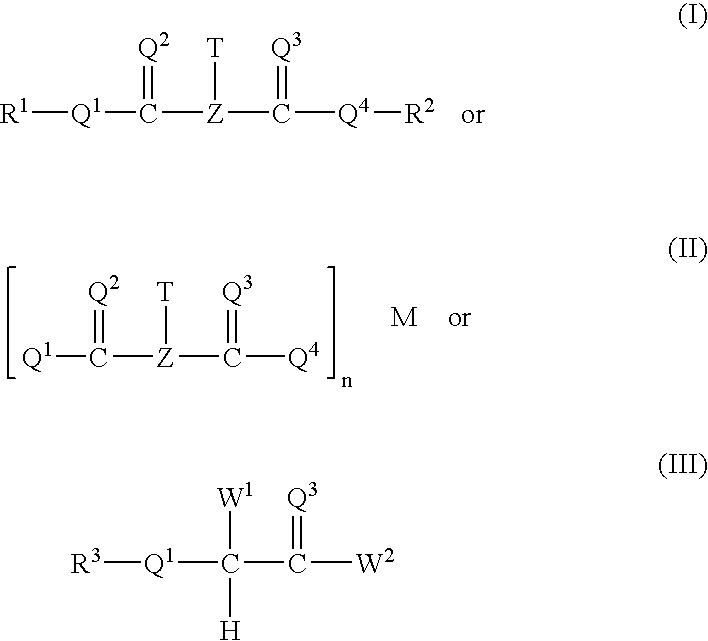

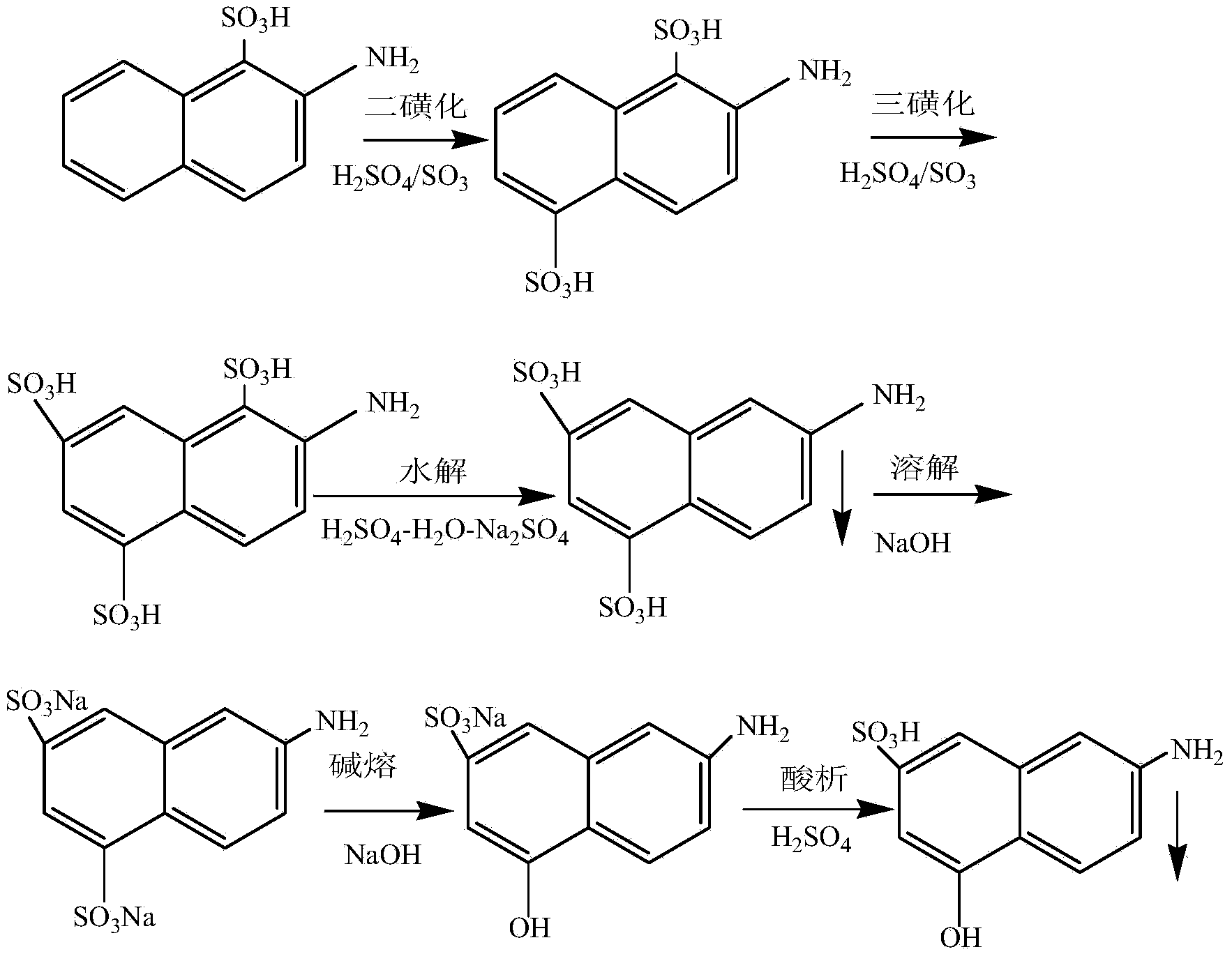

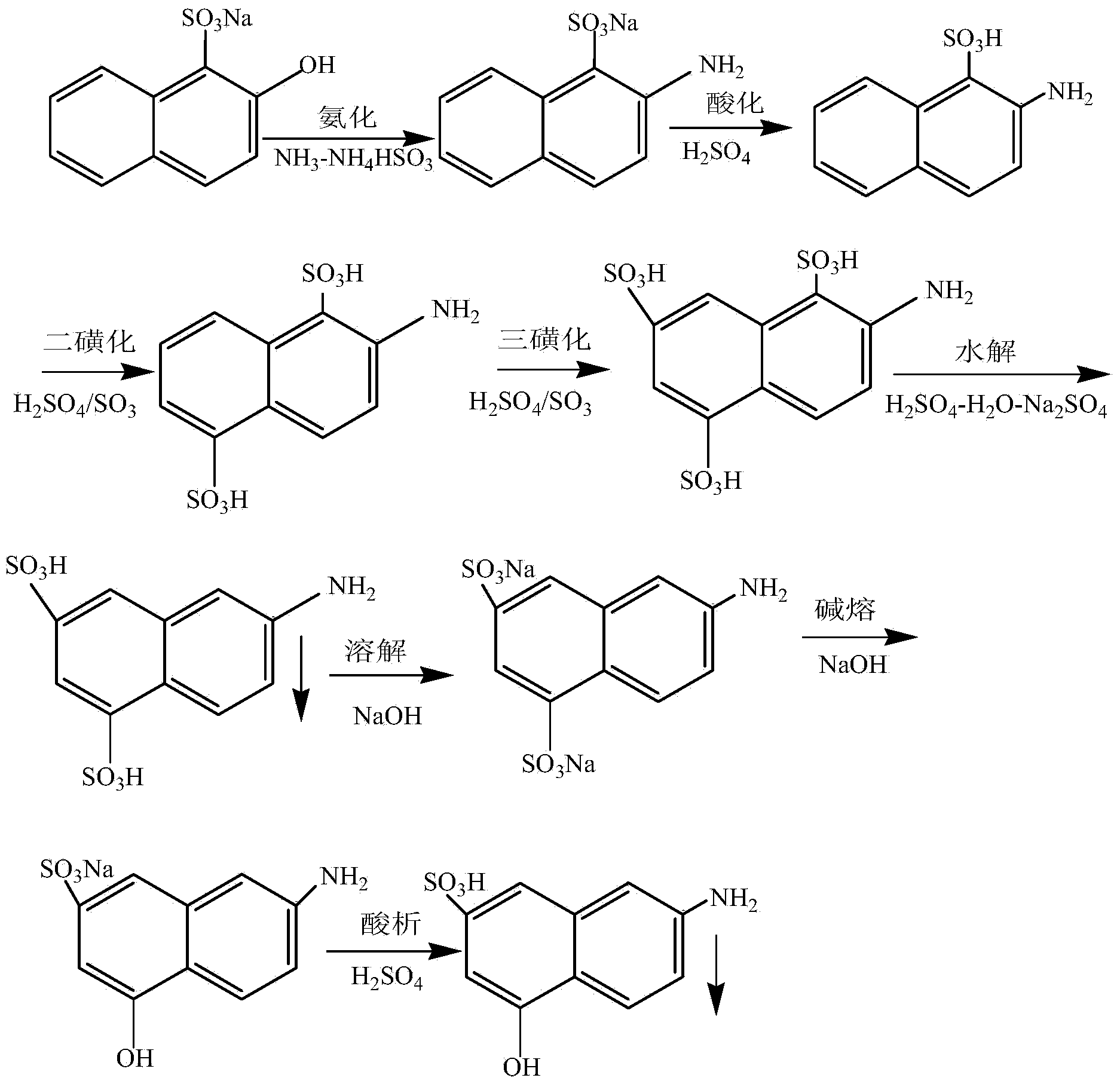

Method for treating waste water of H-acid production

InactiveCN101104533ANot affected by the adsorption effectImprove practicalityOrganic chemistryIon-exchange column/bed processesResource utilizationDesorption

The present invention is a treatment method for naphthalene dye intermediate H-acid production wastewater. After H-acid pretreatment wastewater is preprocessed, organic compounds such as, 1-amido-8- naphthol-3, 6-disulfonic acid (H-acid) and intermediate products, are adsorbed on the resin through alkalescence macroporous adsorption resin; the adsorbed water is added with lye for desorption regeneration and the regenerated liquid will be back into the previous production process for application. The CODcr of the treated wastewater can be effectively reduced to reach the national emission standards; the reclaimed H-acid sodium salt can be used. The resin can be desorbed and regenerated through lye for repeated use. The desorbed liquid is distilled and reclaimed, and the distilled effluent can be used repeatedly. The H-acid sodium salt and the intermediate products reclaimed through the invention can be used as raw materials for the original production process; therefore, the invention not only helps treating wastewater but also realizes waste resource utilization.

Owner:NANKAI UNIV

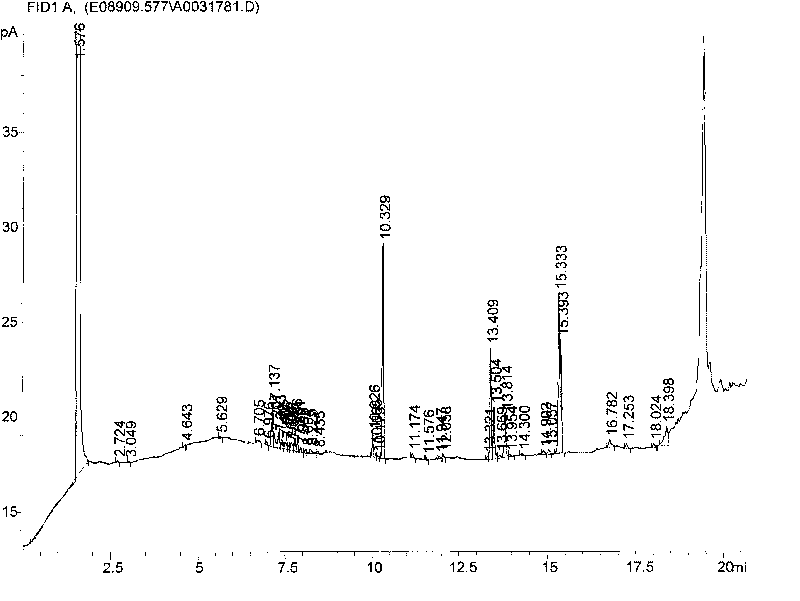

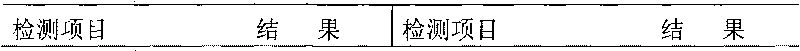

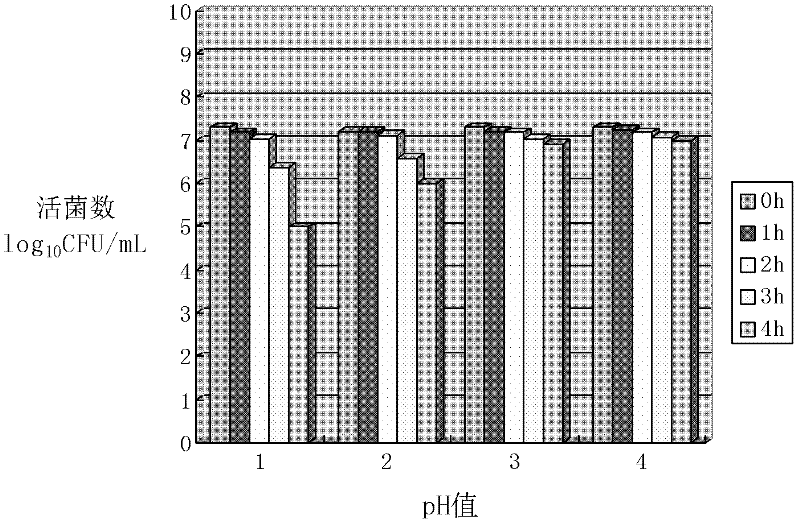

Screening and application of probiotic Enterococcus faecium

ActiveCN102747003AGood antibacterial effectImprove securityAntibacterial agentsBacteriaDiseaseSynechococcus

The invention belongs to the technical field of veterinary microbial additive preparation, and specifically relates to a strain of separated and screened Enterococcus faecium providing significant bacterial inhibition effects for common enteropathogenic bacteria such as staphylococcus aureus, escherichia coli and salmonella in breeding animals, and an application thereof. The probiotic Enterococcus faecium of the present invention is characterized in that: the strain is Enterococcus faecium HDRsEf1, and is preserved in the China General Microbiological Culture Collection Center (CGMCC), and the preservation number is CCTCC NO:M2011031. The probiotic Enterococcus faecium of the present invention has characteristics of fast growth, high acid production capacity, strong stress resistance, safety, disease resistance and growth promotion, and can be used as the microbial feed additive for livestock and poultry feeds.

Owner:武汉华大瑞尔科技有限公司 +1

Polycarboxylic acid production system employing cooled mother liquor from oxidative digestion as feed to impurity purge system

ActiveUS20070208193A1High purityReduce formationOrganic compound preparationCarboxylic preparation by oxidationSlurrySolvent

Disclosed is an optimized system for more efficiently and economically producing terephthalic acid. A solvent purification system is employed to remove of at least one aromatic impurity present in a solvent purification feed. At least about 20 weight percent of the solvent purification feed originates from a cooled, post-digestion, TPA-containing slurry.

Owner:ALPEK POLYESTER SA DE CV

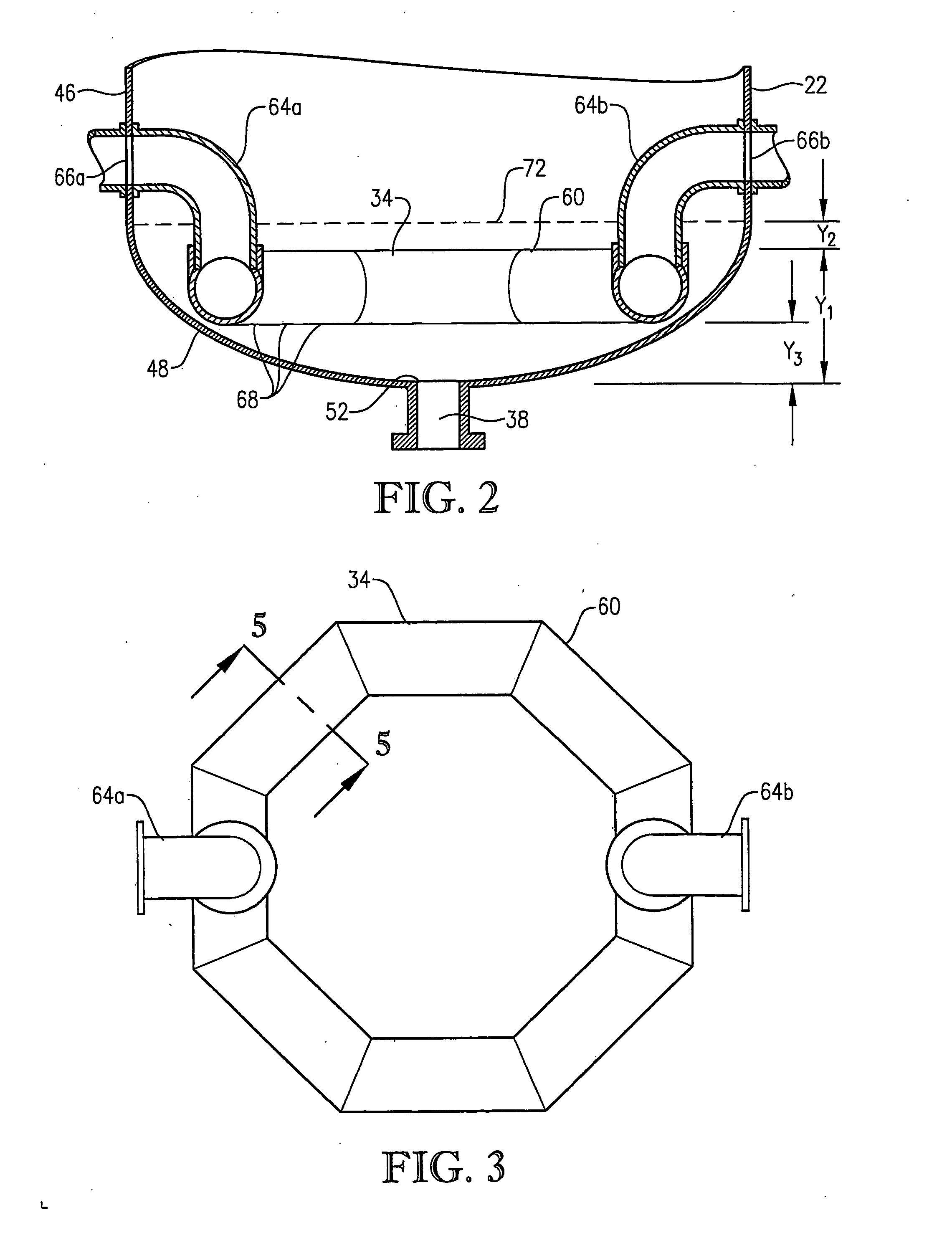

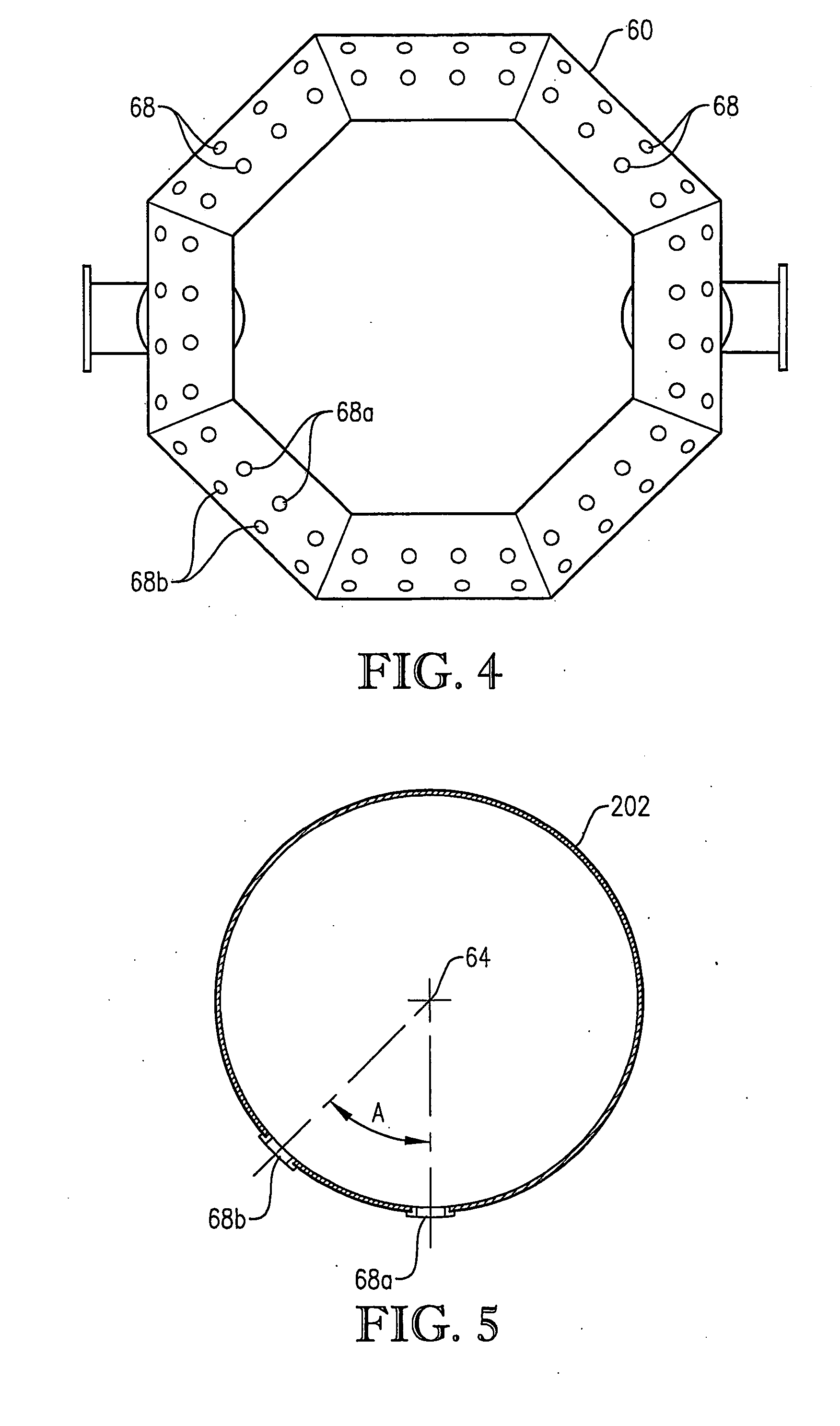

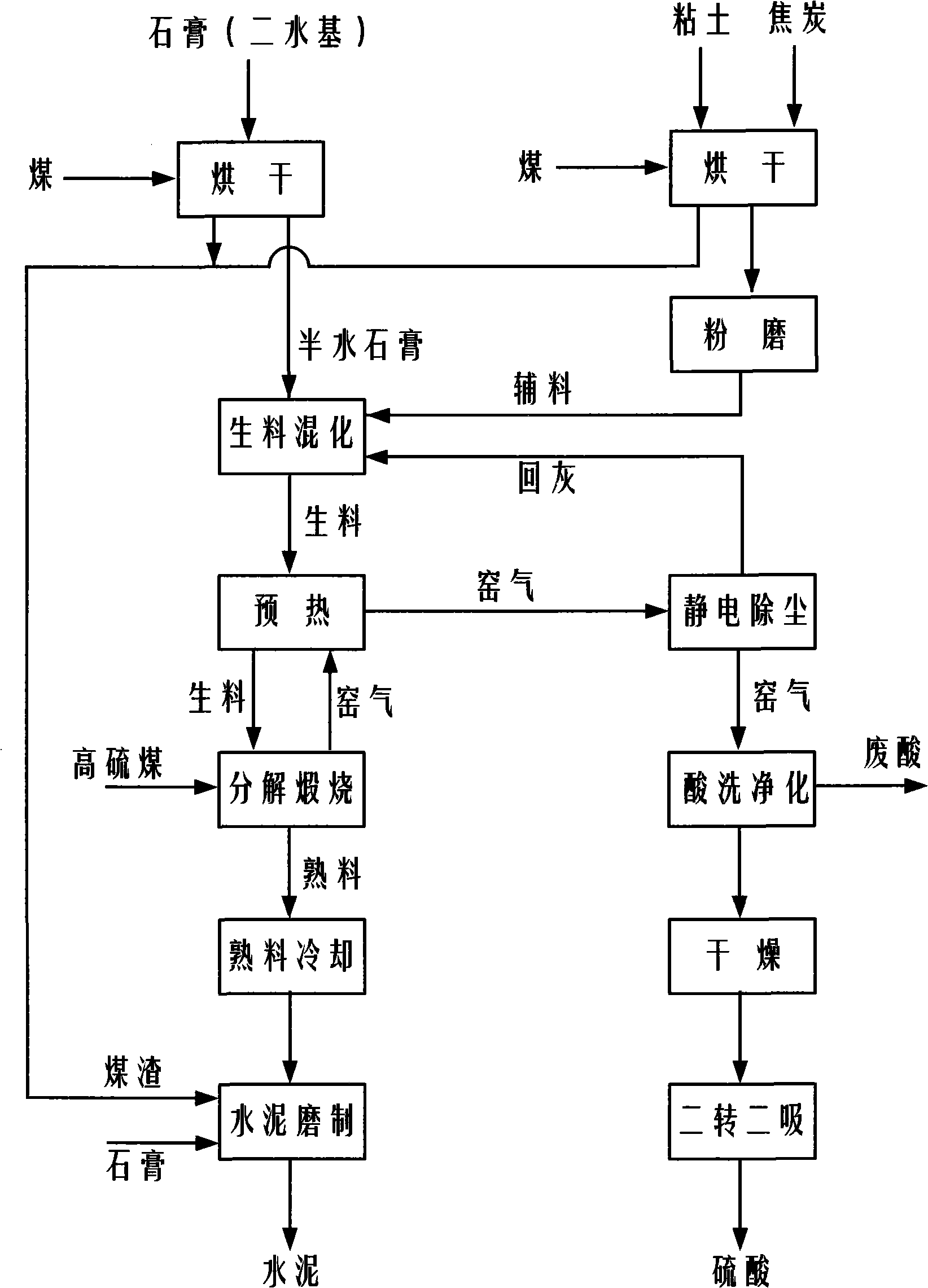

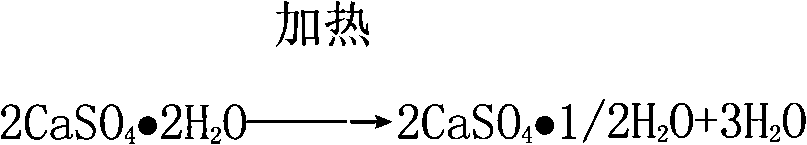

Improved preparation technique for preparing sulphuric acid and cement with gypsum

ActiveCN101343047AEliminate pollutionAlleviate supply shortagesCement productionSulfur-trioxide/sulfuric-acidSource materialAcid washing

The invention provides an improved production process of utilizing gypsum to produce sulfuric acid and cement, which relates to the sulfuric acid and cement industry production technology, and the resource comprehensive utilization and environmental protection governing field of the industrial byproduct gypsum. The improved production process is characterized in that natural gypsum with the CaSO4*2H2O as the main composition or the industrial byproduct gypsum is adopted as the main source material; clay, coke and fly ash clinker are used as supplementary materials; the half-water drying gypsum flow, the single stage powder grinding, raw material mixing melting, suspension preheater kiln decomposing calcination, closing diluted acid washing and purification, two-turning and two-suction processes are adopted; the sulfuric acid and cement products are prepared through six steps of source material homogenizing, drying and dehydration, raw material preparation, clinker burning, kiln gas acid production and cement grinding; the improved production process has the advantages of wide range source material, solving the land occupation and environmental pollution problems of the gypsum waste residue, realizing the circulation utilization of sulfur resource, adopting a plurality of new processes and devices, realizing the large scale production easily, advanced technology, mature process, easy operation in production control, low energy consumption, high benefit, no waste water and waste residues exhaust.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

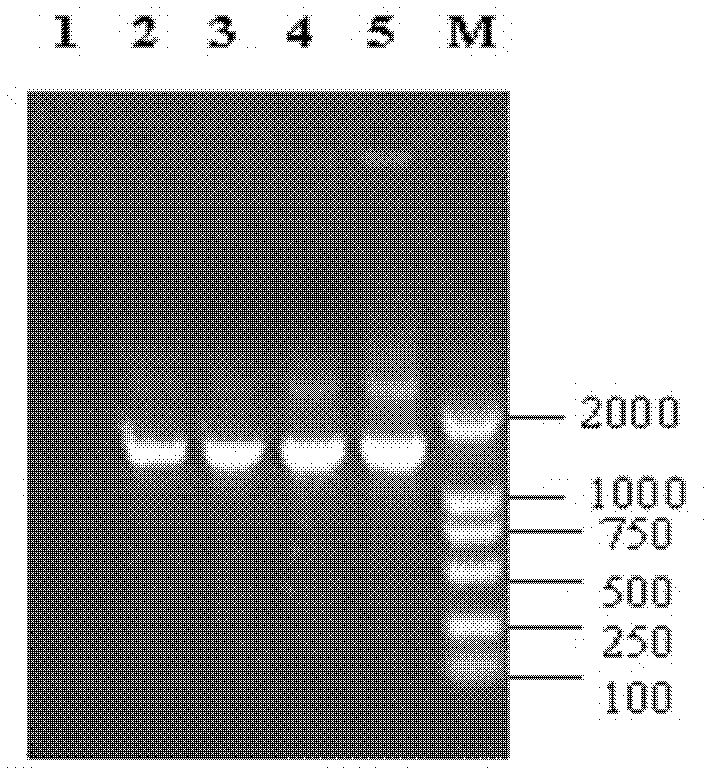

Bifidobacterium longum and applications thereof

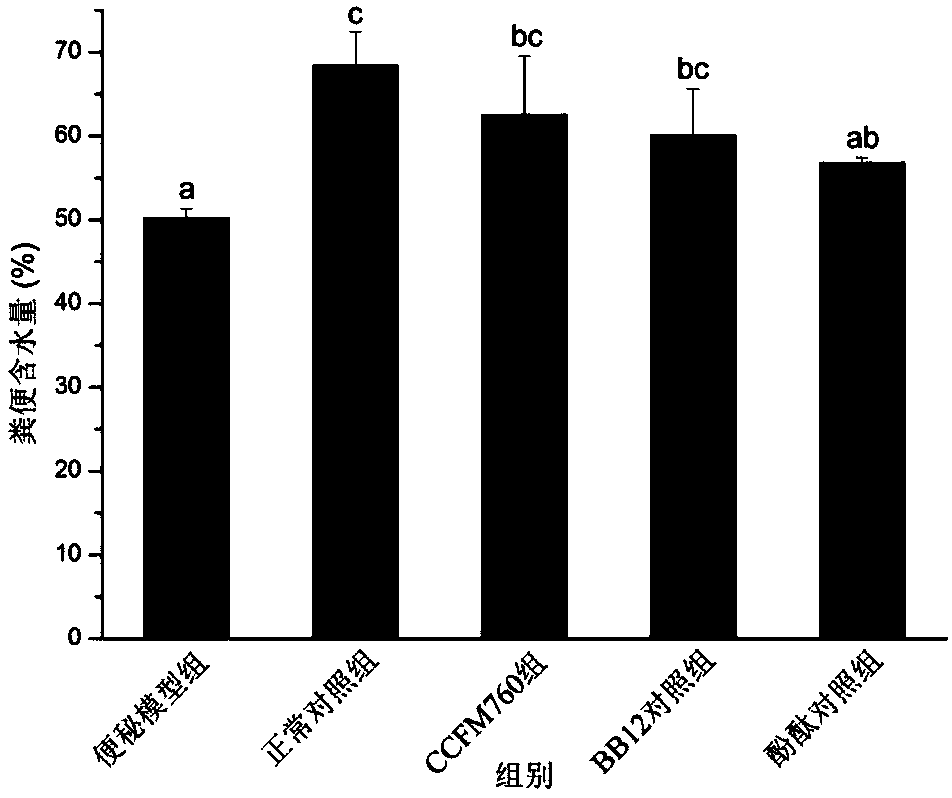

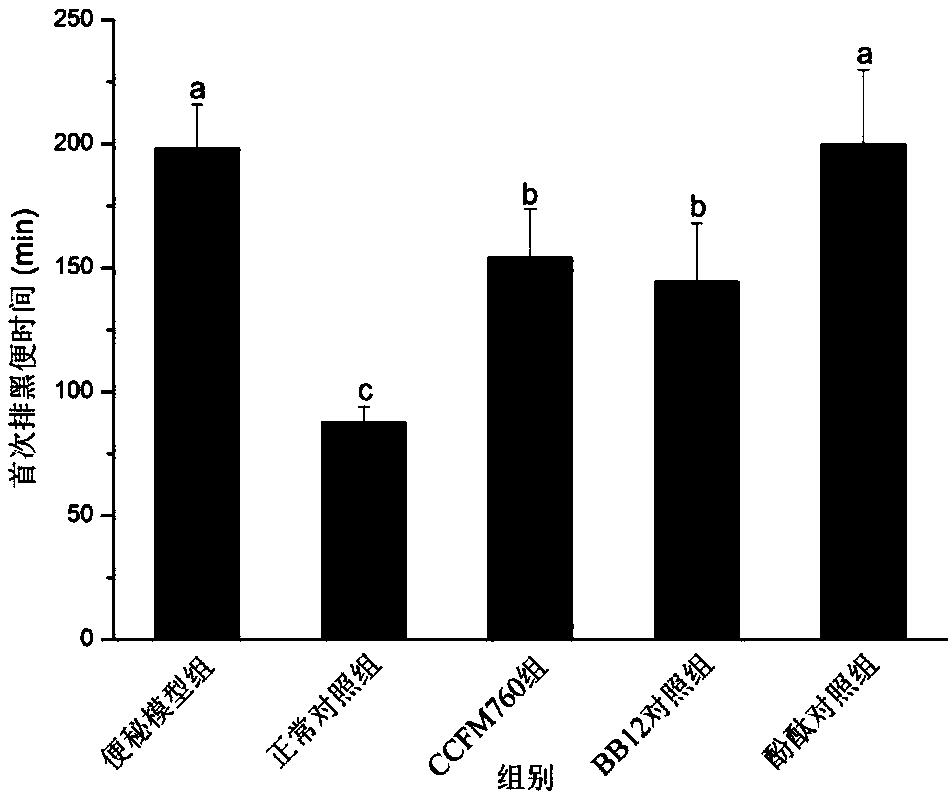

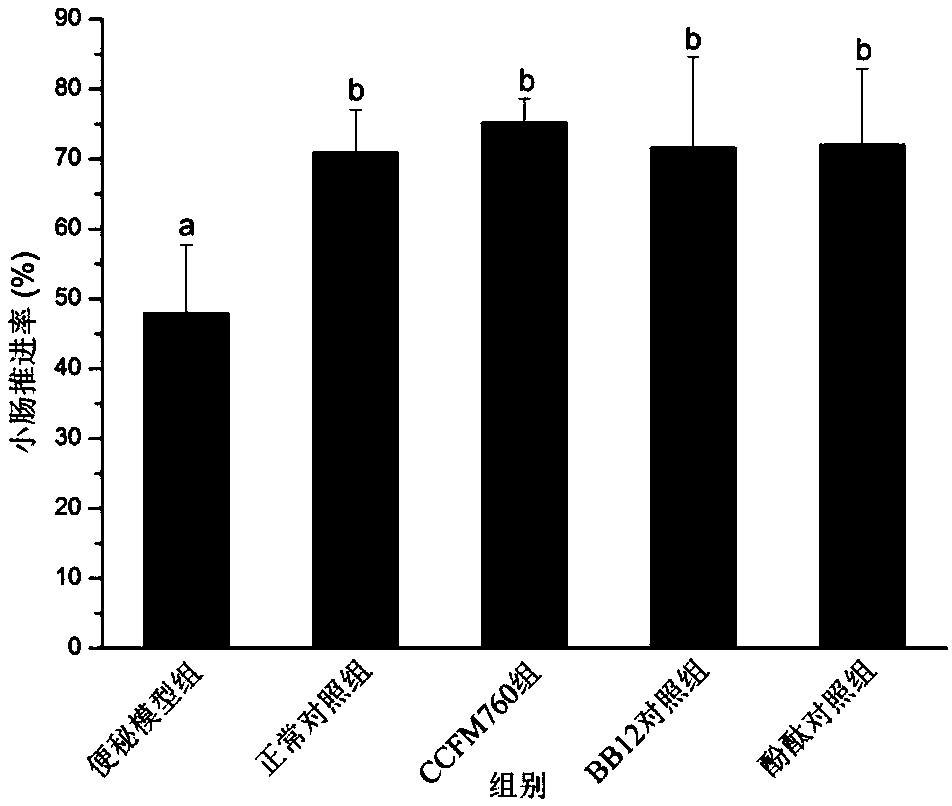

ActiveCN107893044AImprove toleranceGood growth and acid productionBacteriaDigestive systemPhenolphthaleinFeces

The invention discloses bifidobacterium longum and applications thereof, and belongs to the technical field of microorganisms. The bifidobacterium longum is deposited in the China General Microbiological Culture Collection Center in Institute of Microbiology, Chinese Academy of Sciences at number 3, No.1 yard, Beichenxi road, Chaoyang district, Beijing on December 7, 2017, and the accession numberis CGMCC NO.15032. The bifidobacterium longum has good growth, acid production, and acid resistant properties, and high adhesive capacity, can significantly increase the water content of faeces and the pushing rate of small intestine of mice with constipation, shortens the first black stool evacuation time, relieves inflammation of colonic mucosas, and regulates contents of gastrointestinal peptides related to constipation in serum. A constipation relieving effect of the bifidobacterium longum is equivalent to that of bifidobacterium animalis BB12, but an effect of the bifidobacterium longumon the pushing rate of small intestine is superior to those of bifidobacterium animalis BB12 and phenolphthalein. Accordingly, the bifidobacterium longum strain CCFM760 can be widely applied in various foods or medicine matrixes.

Owner:上海华朴生命健康科技有限公司

Lactobacillus leavening agent, preparation method thereof and special bacterial strain

InactiveCN101748082AIncrease productionHigh content of live bacteriaMilk preparationBacteriaAdditive ingredientBacterial strain

The invention discloses a lactobacillus leavening agent, a preparation method thereof and a special bacterial strain. The preservation serial number of lactobacillus is CCTCC M208151. An active constituent of the lactobacillus leavening agent is the lactobacillus. The invention also discloses a method for preparing the lactobacillus leavening agent, which comprises the following steps: firstly, leavening and culturing lactobacillus plantarum SC79 CCTCC M208151 in SC79 optimal culture medium; and secondly, collecting thallus in the step 1 and then adding a protective agent to the thallus to obtain the leavening agent. The lactobacillus leavening agent has small dosage, quick acid production speed through mixing the lactobacillus leavening agent and a harvestless exopolysacchatide yoghourt bacterial strain to prepare yoghourt, better relative viscosity, elasticity, denseness and adhesiveness than that of the conventional yogurt and small syneresis sensibility of formed sticky yogurt colloids, larger water holding capacity than that the conventional yogurt and hard whey separation.

Owner:JILIN ACAD OF AGRI SCI

Production method of fermented beef jerky

The invention discloses a production method of fermented beef jerky. The production method is characterized by comprising the steps of: cutting fresh beef into 3-4cm strips, soaking the strips by a mixing solution of CaCl2, composite phosphate and ginger juice for a whole night, adding glucose and a fermenting agent in the mixture, fermenting for 8 hours and roasting for 12 hours, boiling in boiling water and roasting for 1 hour, and implementing vacuum packaging and high-pressure sterilization to obtain the fermented beef jerky. The production method makes use of the acid production capacity of acid kumiss from natural fermentation and lactobacillus which is excellent in growth property, and is easy to control a fermentation process and short in fermentation cycle; the production method changes conventional processes of boiling twice, frying and the like, so that the deterioration of a later product due to over oxidation in the frying process is avoided and the shelf life is prolonged; and by adding a tendering pickling process and the fermentation process, the fermented beef jerky is unique in flavor, and has soft lactic acid taste and good color, reflects the fermentation property of lactobacillus, is soft and tender in texture, and is applicable to people of all ages.

Owner:贺银凤 +1

Fermenting type apple vinegar beverage and preparation method thereof

ActiveCN102771864ARetain nutrientsPreserve the flavorVinegar preparationFood preparationFood flavorCulture fungus

The invention discloses a fermenting type apple vinegar beverage and a preparation method thereof. The fermenting type apple vinegar beverage is characterized by being prepared by preparing, filtering, sterilizing and filling the following raw materials by weight proportion: 50-70 parts of apple vinegar, 80-120 parts of concentrated apple juice, 2-8 parts of honey, 1-3 parts of aspartame and 799-867 parts of water. The fermenting type apple vinegar beverage has the advantages of well retaining the original nutrient substances and flavor of apple, having high acid production rate, being obviously shortened in fermenting time, further being capable of separating cured acetic bacteria cells and products easily and being used repeatedly, enabling strains to be efficient, greatly improving production efficiency, saving production cost and reducing pollution discharging.

Owner:YANTAI QIWEI WINE IND

Polycarboxylic acid production system with enhanced residence time distribution for oxidative digestion

ActiveUS20070219393A1Reduce formationPromote oxidationOrganic compound preparationExhaust apparatusDigestionOrganic chemistry

Disclosed is an optimized system for more efficiently and economically producing terephthalic acid. The system includes an oxidative digestion reactor / zone configured to provide optimized residence time distribution for the solid and liquid phases of the reaction medium processed therein.

Owner:ALPEK POLYESTER SA DE CV

Polycarboxylic acid production system employing enhanced multistage oxidative digestion

ActiveUS20070208191A1Reduce formationPromote oxidationOrganic compound preparationCarboxylic preparation by oxidationCarboxylic acidSlurry

Disclosed is an optimized system for more efficiently and economically producing terephthalic acid. The system includes a multi-stage oxidative digestion system for processing an improved initial slurry from primary oxidation. The multi-stage digestion system is capable of adequately purifying the improved initial slurry without requiring significant liquor exchange between primary oxidation and oxidative digestion.

Owner:ALPEK POLYESTER SA DE CV

Clostridium butyricum having diarrhea treating effect and application of clostridium butyricum as substitute of sodium butyrate

ActiveCN102559550AIncrease acidityRepair mucous membraneBacteriaAnimal feeding stuffChronic diarrheaActive component

The invention discloses a clostridium butyricum having a diarrhea treating effect. The strain is named as clostridium butyricum Cb-2 which is conserved in China Center for Type Culture Collection with the conservation number of CCTCC M2011384, in November 9th, 2011. A test proves that the clostridium butyricum disclosed by the invention has strong acid producing capability especially butyric acidproducing capability; and the clostridium butyricum has obvious effects on diseases, such as intestinal tract flora infection, acute and chronic diarrhea, irritable bowel syndrome and non-ulcer dyspepsia, caused by various reasons, and has no toxicity and harm. Thus, the clostridium butyricum or clostridium butyricum powder disclosed by the invention is used as a raw material for preparing a micro-ecological preparation and used for replacing sodium butyrate to be applied; and when a specific application is carried out, a clostridium butyricum preparation can be singly used as an active component to be prepared into the micro-ecological preparation together with corn starch, or, the clostridium butyricum preparation is mixed with at least one of other bacterial preparations and the corn starch to prepare a composite micro-ecological preparation.

Owner:山东宝来利来生物工程股份有限公司

Process of treating and reusing effluent from 1-amino-8-naphthol-3, 6-disulfonic acid production

InactiveCN101066824ARealize recycling of resourcesNot affected by the adsorption effectOrganic chemistryTreatment using aerobic processesResource recoveryOrganic matter

The present invention is process of treating effluent from the production of dye intermediate 1-amino-8-naphthol-3, 6-disulfonic acid and recovering resource. The process includes: distilling pre-treatment of the effluent; adsorbing 1-amino-8-naphthol-3, 6-disulfonic acid, intermediate product and other organic matter from the effluent with macroporous weak alkaline resin ND900 in serially connected three column; neutralizing the adsorbed columns treated water with alkali and decompression distilling; and final aerobic biochemical treatment for the water to reach exhaust standard. The process can reduce CODcr in the effluent from 16,700 mg / l to below 100 mg / l. The used resin may be desorbed with NaOH+H2O desorbing agent for reuse, and the desorbed liquid may be distilled for recovery.

Owner:NANKAI UNIV

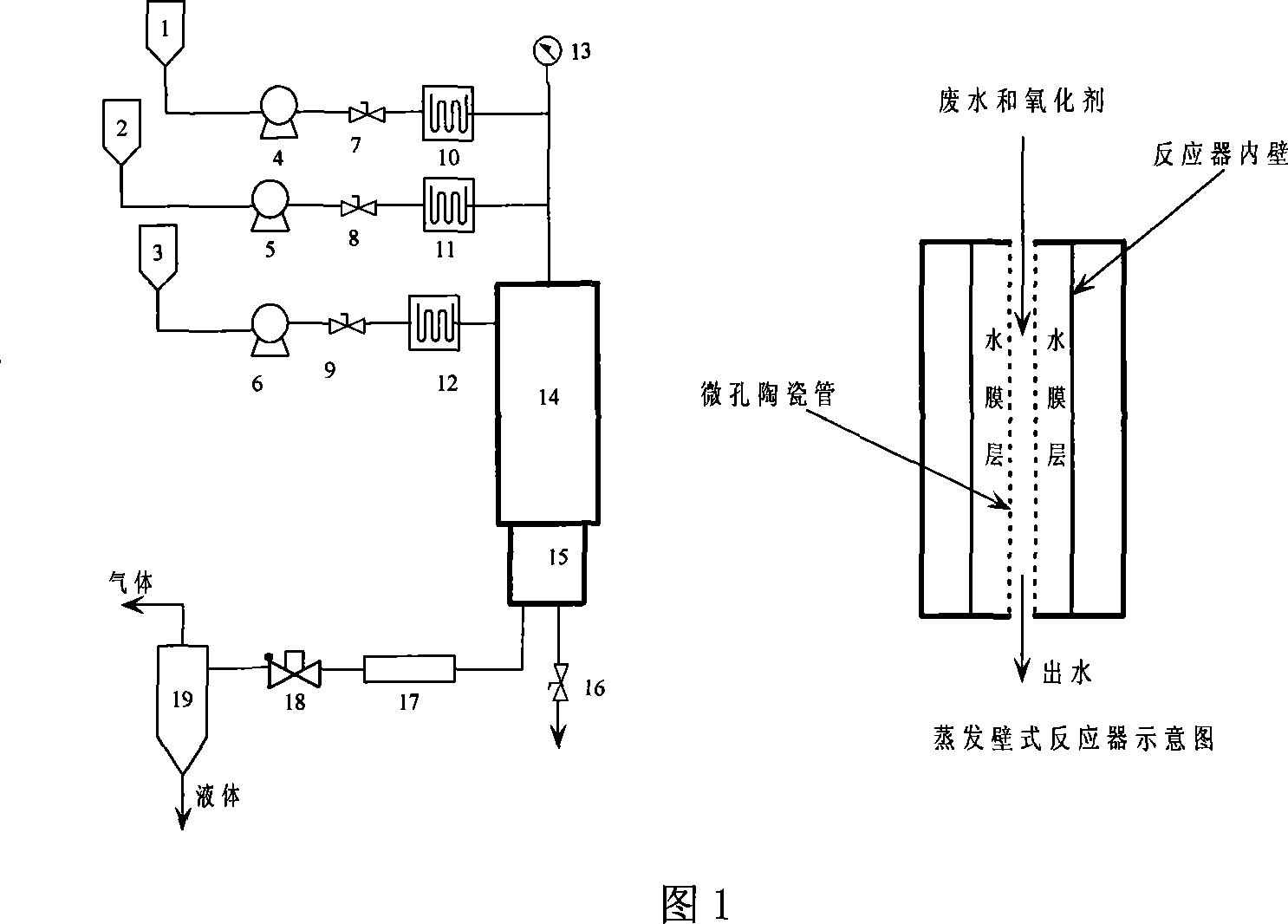

Method for treating high-concentration organic waste water in acroleic acid production

InactiveCN101182065ASolve corrosiveSolve the problem of pipeline blockageNature of treatment waterWater/sewage treatment by oxidationHigh concentrationHigh pressure

The invention relates to a high concentrated organic compound wastewater treating method in the acrylic acid production, including that firstly oxidant and deionized water are mixed for preparing oxidant solution and is put in an oxidant tank. Secondly, wastewater and clear water for the acrylic acid production are respectively arranged in a wastewater tank and a clear water tank and catalysts are added in the wastewater. Thirdly, a pre-heater is heated to be at the temperature of 300-400 degree Celsius and a reactor is heated to be at the temperature of 400-600 degree Celsius. Fourthly, a high pressure plunger pump is opened, in which a sampler is put. The wastewater and the oxidant solution enter a microporous ceramic tube of the reactor after being preheated and pressurized respectively. The supercritical water oxidation under the pressure of 22-28MPa and the temperature of 374-600 degree Celsius is implemented. The clear water infiltrates into the microporous ceramic tube through an exine of a ceramic film. Fifthly, the treated effluent is qualified to be discharged through the cooling and the gas-liquid separation. The invention solves problems of the reactor inner wall corrosion and the tube blockage of a traditional supercritical water oxidation technology. The organic removal rate reaches to 99.99 percent above. And no secondary pollution can be made. The invention is friendly to the environment.

Owner:DONGHUA UNIV

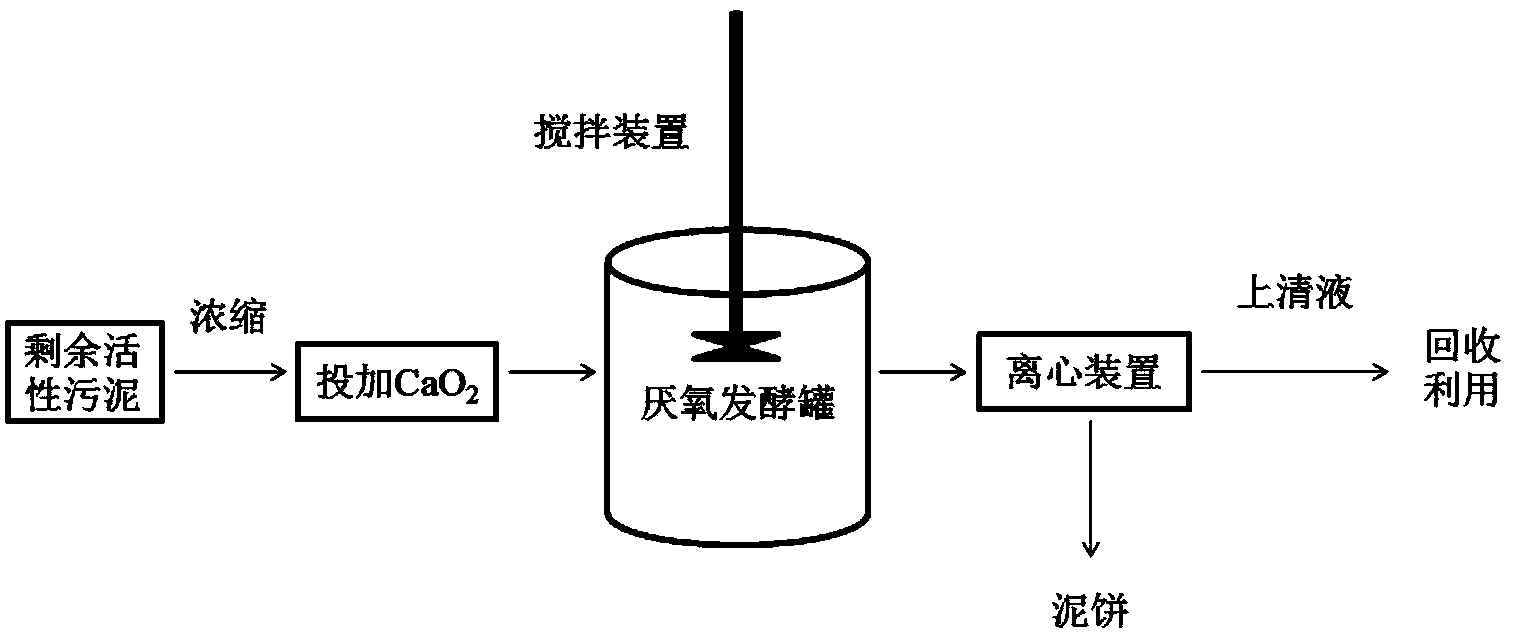

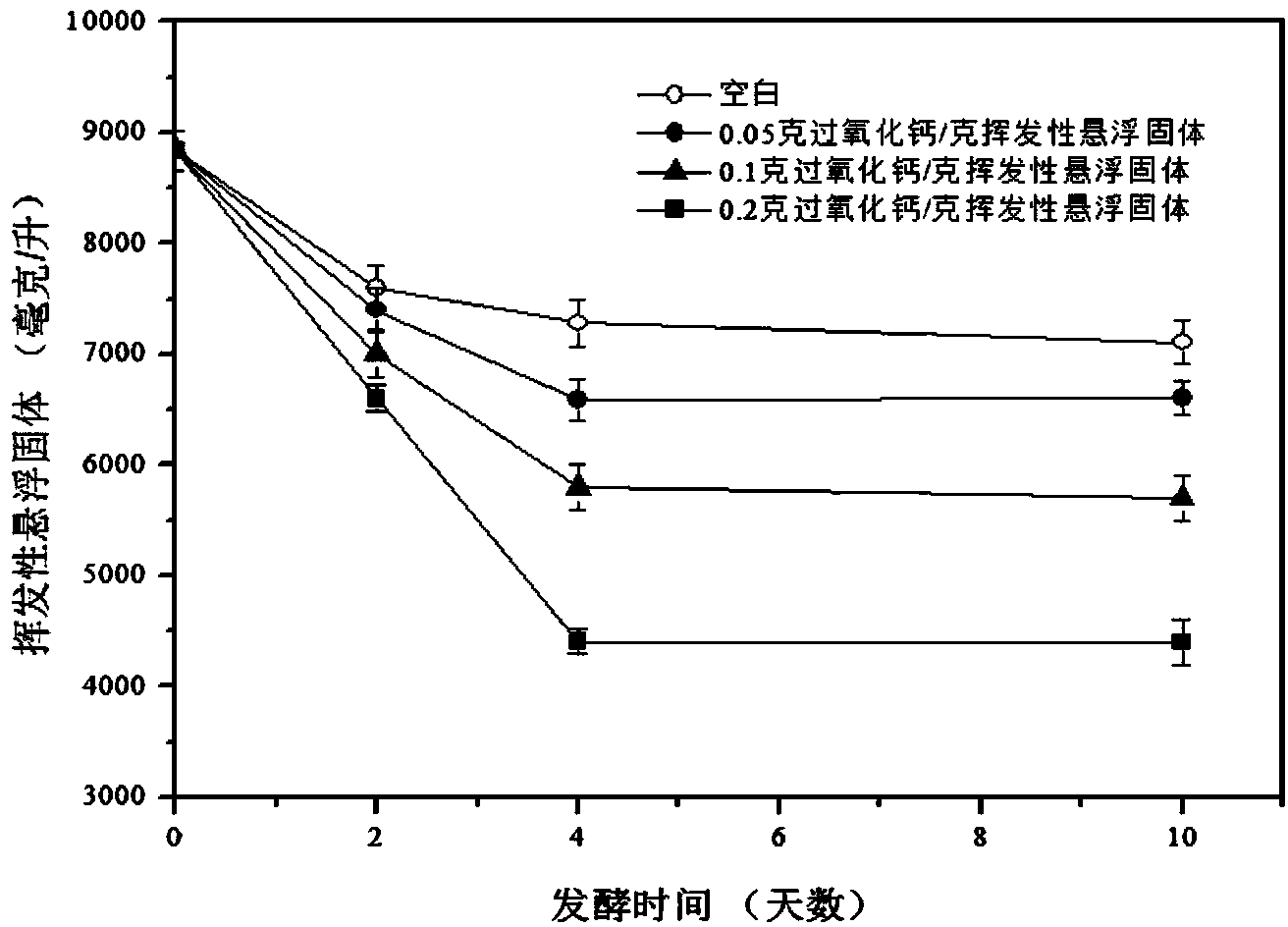

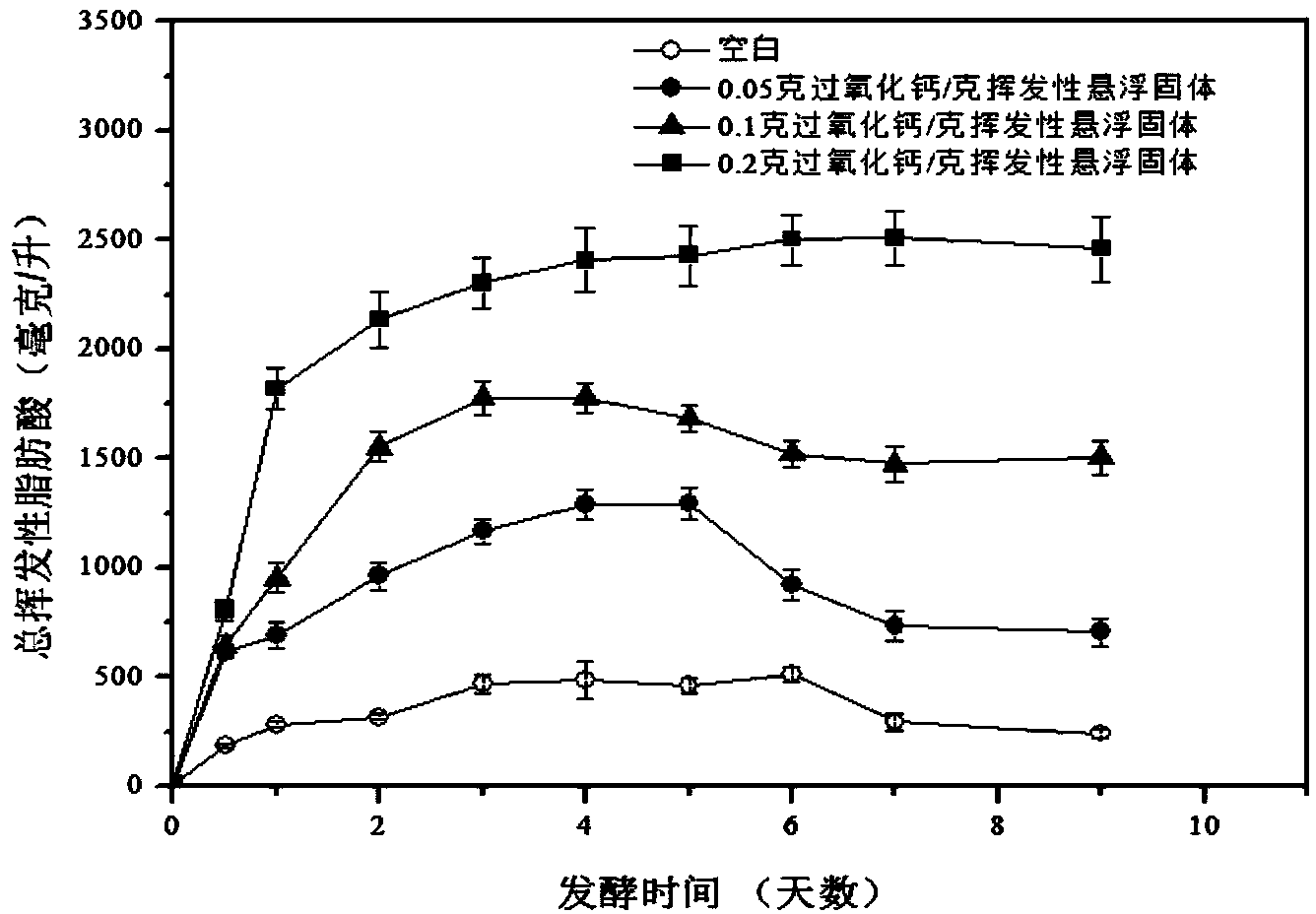

Method for improving acid production quality and acetic acid proportion in anaerobic fermentation of residue active sludge

InactiveCN104031949AImprove solubilityImprove acidificationFermentationBiological sludge treatmentSolubilityParticulates

The invention relates to a method for improving acid production quality and acetic acid proportion in anaerobic fermentation of residue active sludge. The method comprises the following steps of firstly, adding calcium peroxide into concentrated residual sludge in a wastewater treatment plant, wherein adding amount of the calcium peroxide is 5%-20% of the weight of the volatile suspended solid in the residual active sludge; then, sealing at 30-40 DEG C, carrying out anaerobic digestion in an anaerobic digestion tank with stirring speed of 100-200rpm, wherein the anaerobic digestion time is 5-10 days. The result indicates that calcium peroxide can promote dissolution of particulate organic substances, can improve acidification degree of deliquescent organic substances and can inhibit a methane production process, so that accumulation of volatile short-chain fatty acid is facilitated and transformation of other acids to acetic acid is promoted; meanwhile, a plurality of harmful organic substances in the sludge are effectively removed, so that the acid production quality in anaerobic fermentation of the residue active sludge is improved. The method disclosed by the invention is simple to operate and gentle in reaction condition, is used for recycling and carrying out harmless disposal on the concentrated residual sludge of the sewage treatment plant, and has very good economic and social benefits.

Owner:TONGJI UNIV

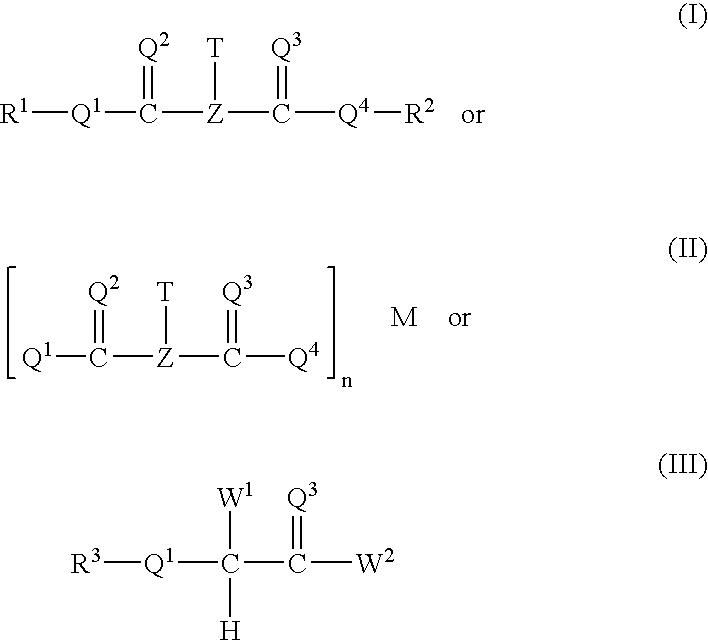

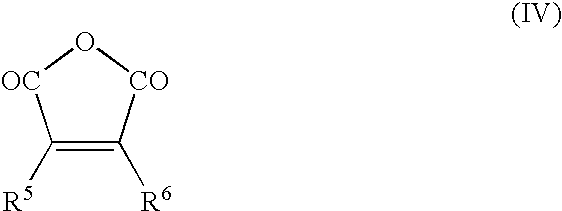

Functionalized polymer composition for grease

A grease composition containing: (a) the reaction product of: (i) a calcium containing overbased organic acid; and (ii) at least one acid producing compound or derivatives thereof selected from the group consisting of: (1) a non-polymeric hydrocarbyl substituted dicarbonyl derivative selected from the group consisting of an acid, an ester, a salt, an anhydride, ester-acid, acid-salt and mixtures thereof; (2) a copolymer derived from monomers containing (1) an olefin; and (2) an unsaturated dicarboxylic acid anhydride or derivatives thereof; and (3) an inorganic acid containing about 2 or more acidic hydrogens; and (b) an oil of lubricating viscosity, wherein the overbased calcium sulphonate contains colloidally dispersed calcium carbonate is selected from the group consisting of calcite, vaterite and mixtures thereof. The invention further relates to the process to make the composition and its use in greases to increase water resistance.

Owner:THE LUBRIZOL CORP

Preparation method of J acid and J acid waste water comprehensive treatment and recycling method

ActiveCN103896438ALow costDoes not affect productivityMultistage water/sewage treatmentSulfonic acid preparationWastewaterHydrolysis

The invention relates to a preparation method of J acid and a J acid waste water comprehensive treatment and recycling method. The J acid waste water comprehensive treatment and recycling method is as follows: the following treatment is carried out on hydrolysis waste water: (1) 30-40% of the total quantity of the hydrolysis waste water is used in an acidification reaction for preparing 2-naphthylamine-1-sulphonic acid by utilizing sodium 2-naphthylamine-1-sulphonate; (2) extraction and reextraction are carried out on the residual hydrolysis waste water, so that Na2SO4 and extraction waste liquor are obtained, the extraction waste liquor is used in a hydrolysis working procedure in a J acid production process, an extraction agent adopted during extraction is composed of 10-30wt% of complex agent, 30-70wt% of diluent and 5-20wt% of tributyl phosphate, and the complex agent is trioctylamine, or trialkyl tertiary amine or combination of trioctylamine and trialkyl tertiary amine. By adopting the preparation method of the J acid, the cost of water for the J acid and waste water treatment cost can be greatly reduced, and environmental pollution can be reduced.

Owner:XIANGSHUI HENRYDA TECH CHEM

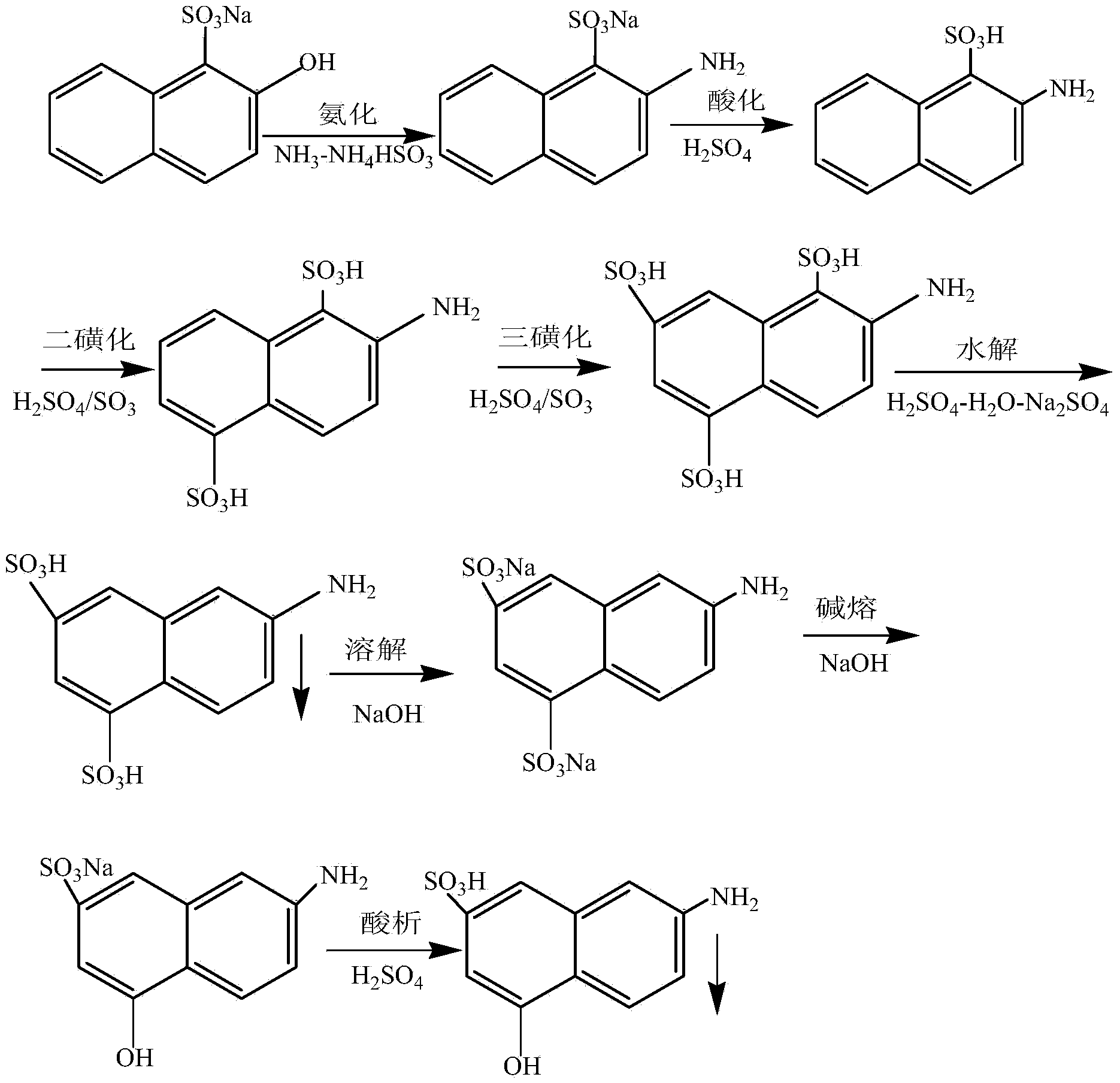

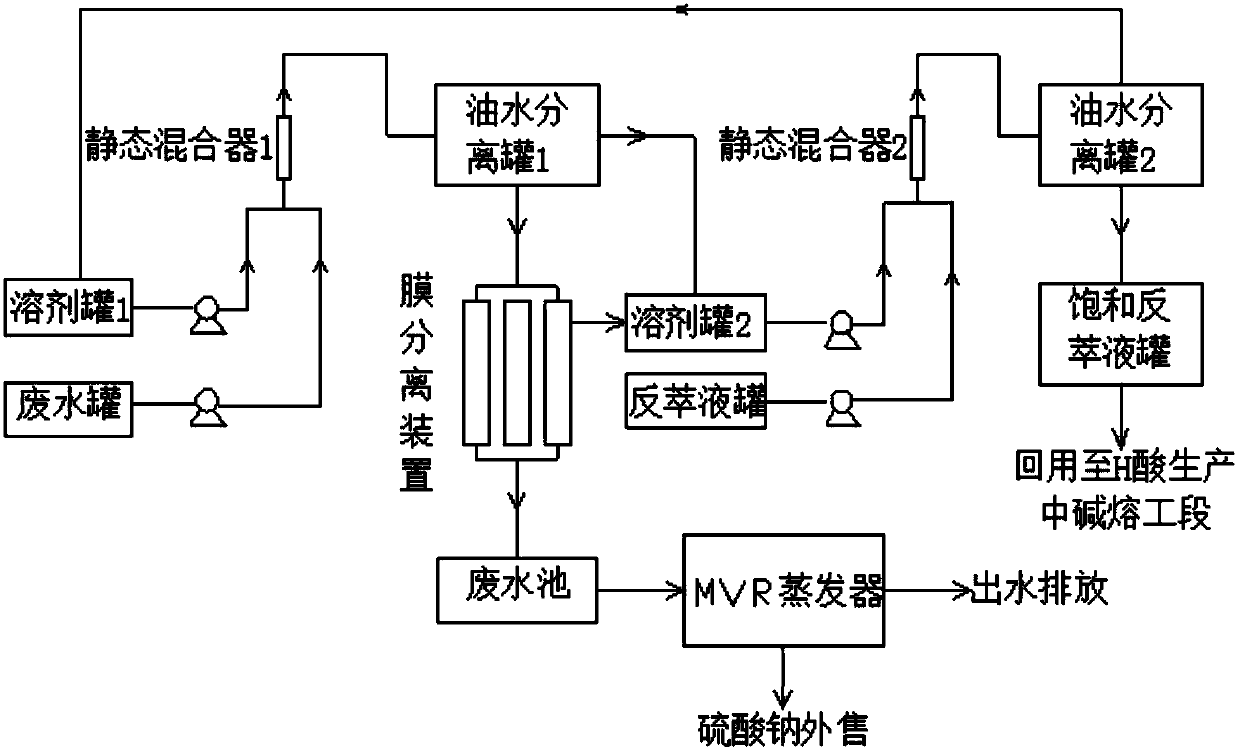

Comprehensive treatment method of H acid production wastewater

ActiveCN104326614AImprove extraction efficiencyHigh partition coefficientTransportation and packagingMixingLeather industryResource utilization

The invention discloses a comprehensive treatment method of H acid production wastewater. The method comprises the following steps: regulating the pH value of the H acid production wastewater, afterwards complexing and extracting a naphthalene sulfonic acid type substance in the wastewater, back-extracting an extract phase by using alkaline liquor, recycling an extracting agent after the extracting agent is regenerated, evaporating and concentrating back-extraction liquid to synthesize a liquid dispersant product; transferring a raffinate phase into an evaporation system, evaporating and separating to obtain a sodium sulfate byproduct, and discharging the desalted evaporation and condensation water after the water reaches the standards by means of biochemical or oxidization flocculation treatment. According to the method disclosed by the invention, the naphthalene sulfonic acid type substance in the wastewater is recycled by utilizing a complexation-extraction method, and the sodium sulfate salt product is recycled by utilizing an evaporation method. The liquid dispersant product (degree of polymerization is 1-3) synthesized by utilizing the recycled naphthalene sulfonate solution is used as a dispersing agent in textile dyeing and leather industries. The method disclosed by the invention is reasonable in process design and can be used for effectively realizing comprehensive treatment and resource utilization of the H acid production wastewater.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Method for fermentation-membrane separation combined production of long-chain dicarboxylic acid

ActiveCN104862348AHigh substrate conversion rateReduce inhibitionMicroorganism based processesFermentationAlkaneCandida viswanathii

The invention discloses a method for fermentation-membrane separation combined production of long-chain dicarboxylic acid and especially relates to a method for high yield production of dodecanedioic acid (DC12). The method comprises introducing a Candida viswanathii culture seed liquid into a liquid fermentation medium mixed solution which contains 5-40% (v / v) of C10-C18 n-alkane and 95-60% (v / v) of saccharic multielement substrate as a growth carbon source and has pH of 5.0-8.5, carrying out culture on the mixed solution under conditions of a temperature of 24-40 DEG C and ventilatory capacity of 0.1-3.0vvm for 42-194h, starting a fermentation-membrane separation combined device, returning the cells separated by the combined device into a fermentation cylinder, feeding the permeate liquid separated by the combined device into an extraction unit, preparing long-chain dicarboxylic acid, simultaneously, supplying a medium into the fermentation cylinder and carrying out fermentation. In n-dodecane transformation production of DC12, the method has an acid yield of 250g / L and an acid production rate of more than 1.6g / h.L, improves microbial density in fermentation, shortens a fermentation period, improves dicarboxylic acid production intensity and returns the unused n-dodecane into the fermentation unit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

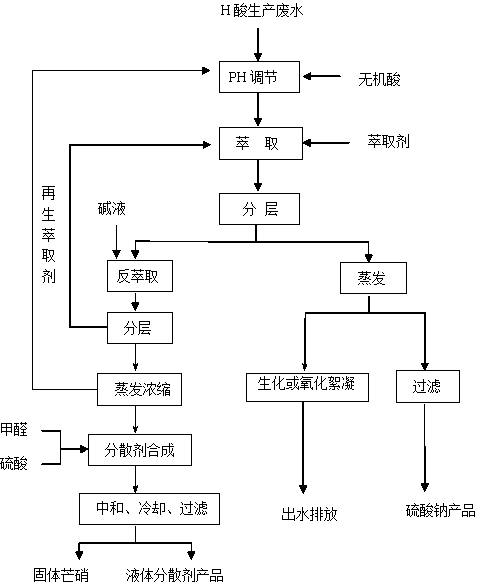

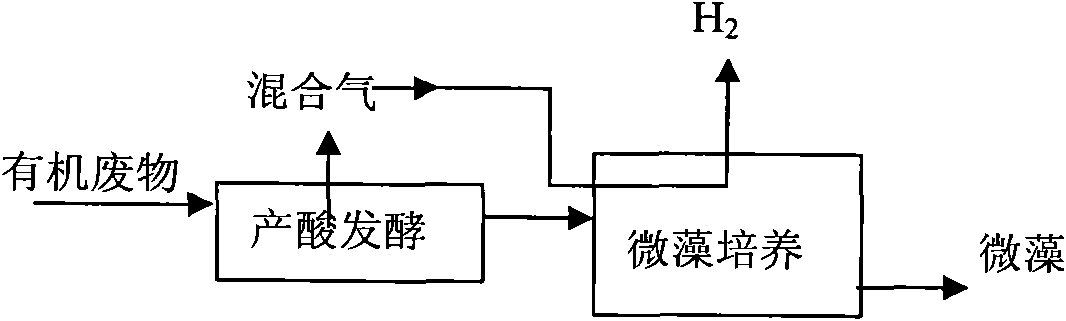

Method for culturing microalgae

InactiveCN101921811AShort cycleIncrease growth rateUnicellular algaeMicroorganism based processesPhotobioreactorAcid production

The invention relates to a method for culturing microalgae, which is characterized by comprising the following steps of: (1) fermenting to produce acid, enabling the supernatant which is acid liquor obtained after fermentation to flow to a culture device, and collecting the produced gas mixture in a gas storage tank; (2) inoculating the cultured microalgae to the acid liquor contained in the culture device for heterotrophic culture; and (3) circularly introducing the gas mixture in the gas storage tank to a photobioreactor for aerobic autotrophic culture. In the invention, the acid production stage through methane fermentation and the microalgae culturing process are coupled, and heterotrophy and autotrophy are combined; thus, oil-rich microalgae with high biomass is cultured, and meanwhile, a hydrogen-rich gas with high concentration can be obtained. The method is mainly used for culturing the oil-rich microalgae.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Method for increasing acid production rate and extracting rate of glutamic acid

ActiveCN109504719AReduce generationHigh transparencyBacteriaOrganic compound preparationProduction rateCeramic membrane

The invention belongs to the technical field of amino acids and discloses a method for increasing an acid production rate and an extracting rate of glutamic acid. The method for increasing the acid production rate and the extracting rate of the glutamic acid comprises the following steps: putting a brevibacterium flavum seed solution for producing the glutamic acid into a fermentation tank filledwith fermentation medium to carry out fermentation cultivation; when the brevibacterium flavum seed solution is fermented for 24 hours, separating out a fermentation solution in the fermentation tankvia a ceramic membrane; draining a filter liquor; putting concentrated thalli back into the fermentation tank; and meanwhile, supplementing a fermentation medium B to the fermentation tank; and continuing to carry out fermentation for 16 h to finish fermentation. The method for increasing the acid production rate and the extracting rate of the glutamic acid, disclosed by the invention, has the advantages that the glutamic acid fermentation process is more stable and easy to control by optimizing a culture medium; and moreover, the yield and glucose conversion rate of the glutamic acid are increased, the quality of the fermentation solution is improved, the glutamic acid extracting cost is reduced, and the comprehensive benefits are increased.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD +2

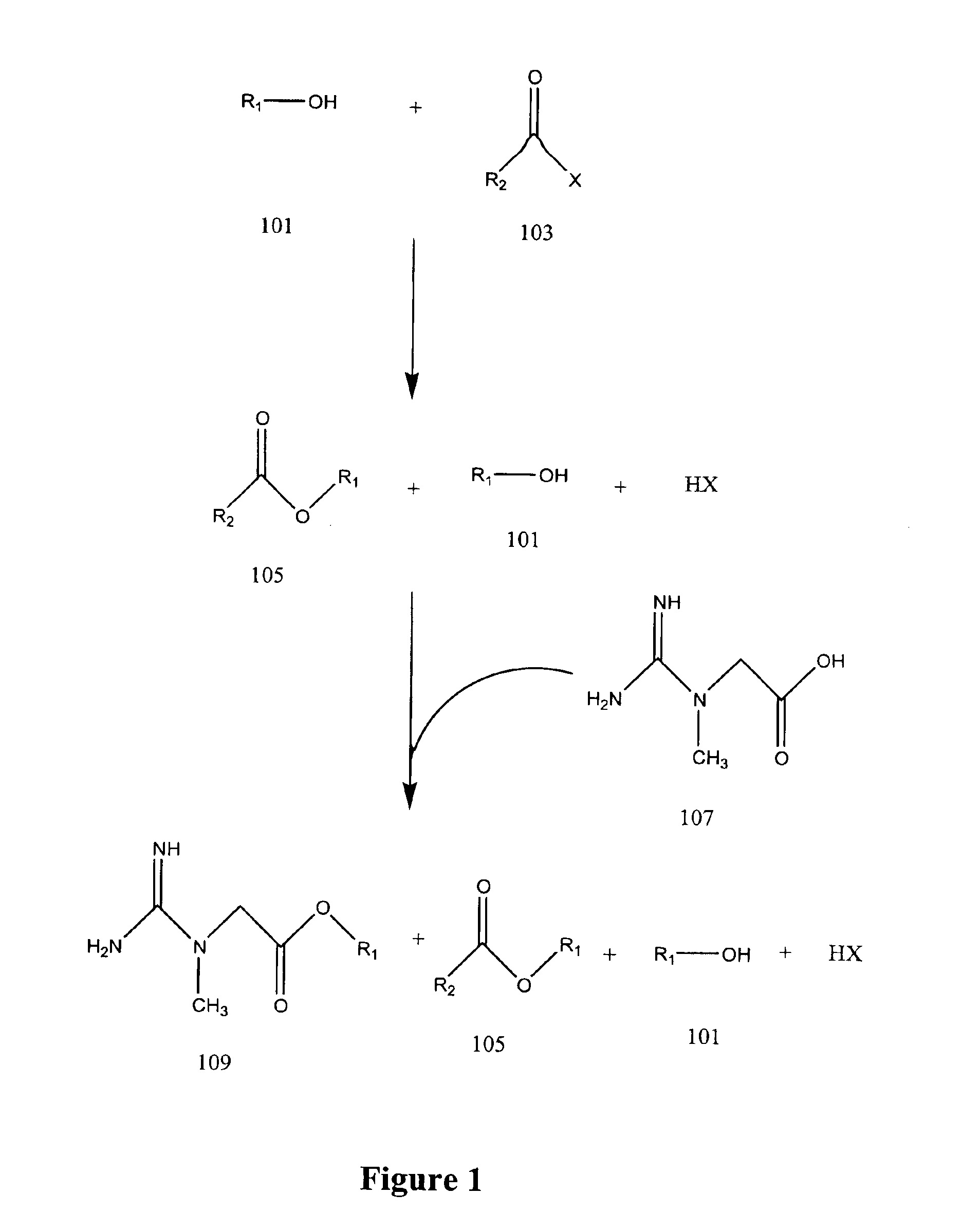

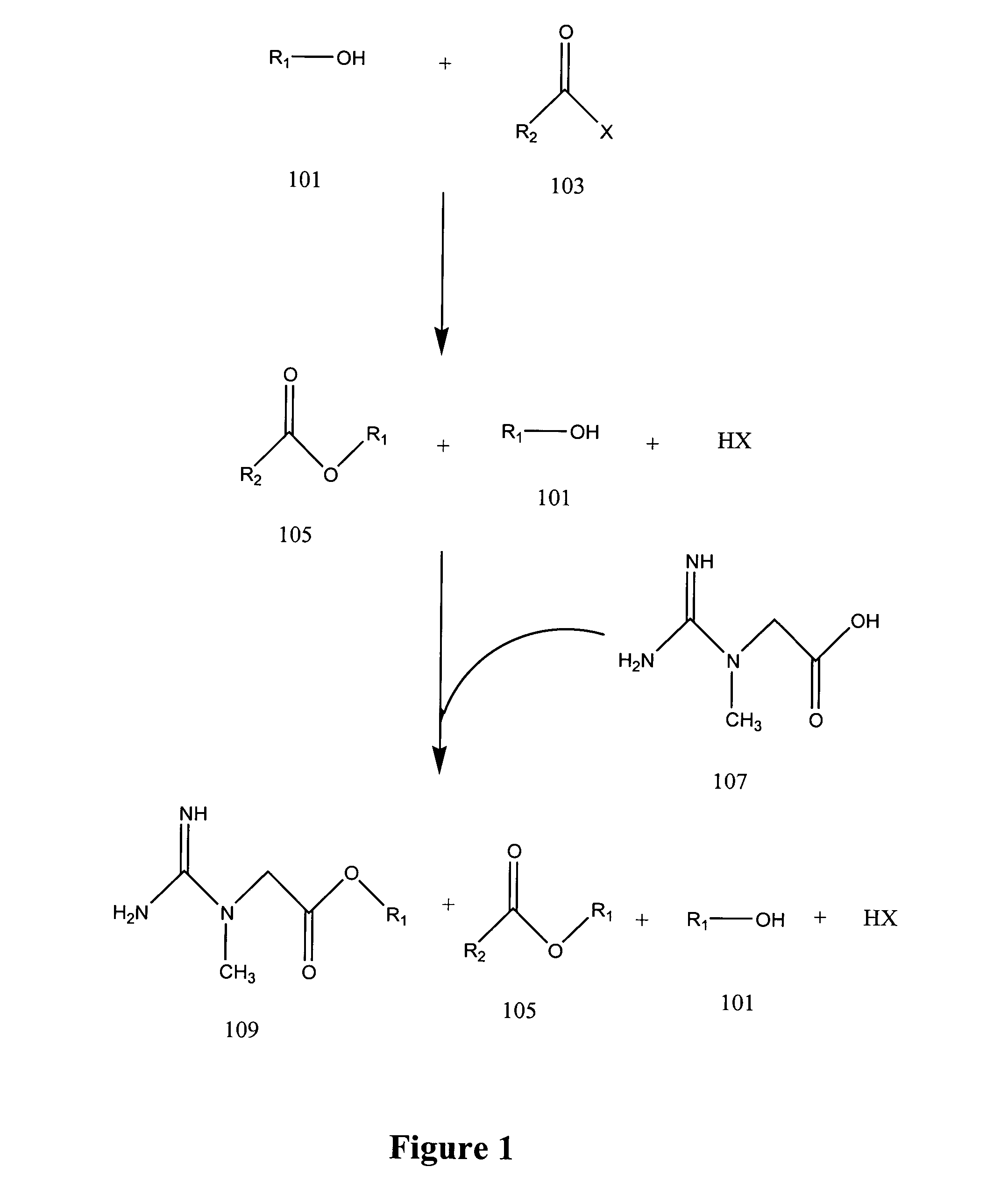

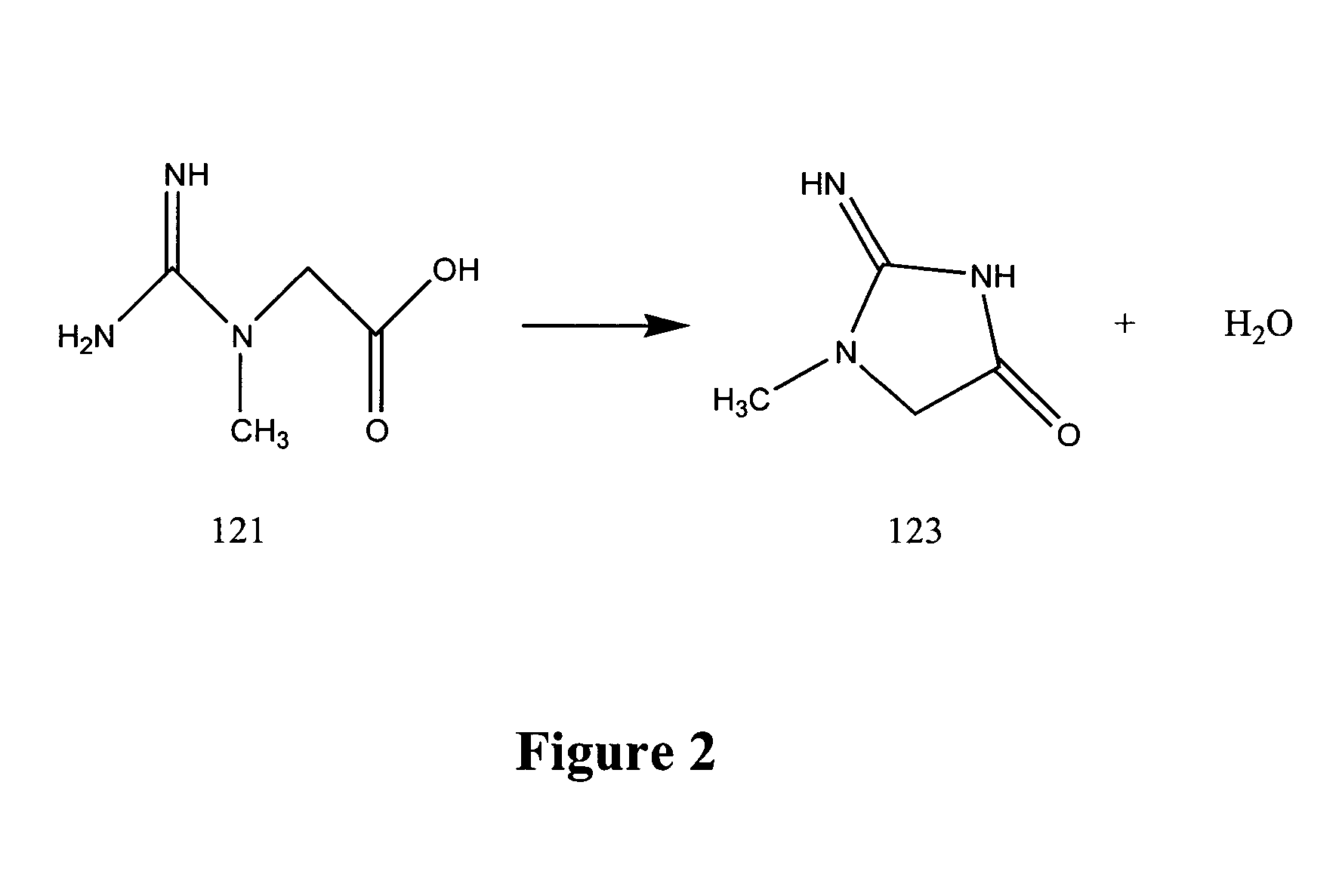

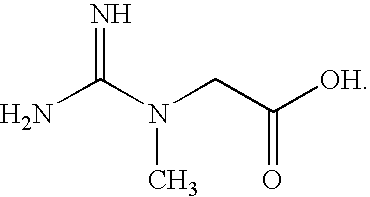

Production of creatine esters using in situ acid production

InactiveUS20050049428A1Increase productionOrganic chemistryOrganic compound preparationOrganic chemistryCreatine

Methods are provided for the improved production of a creatine ester by in situ production of an acid catalyst.

Owner:BOARD OF RGT UNIV OF NEBRASKA

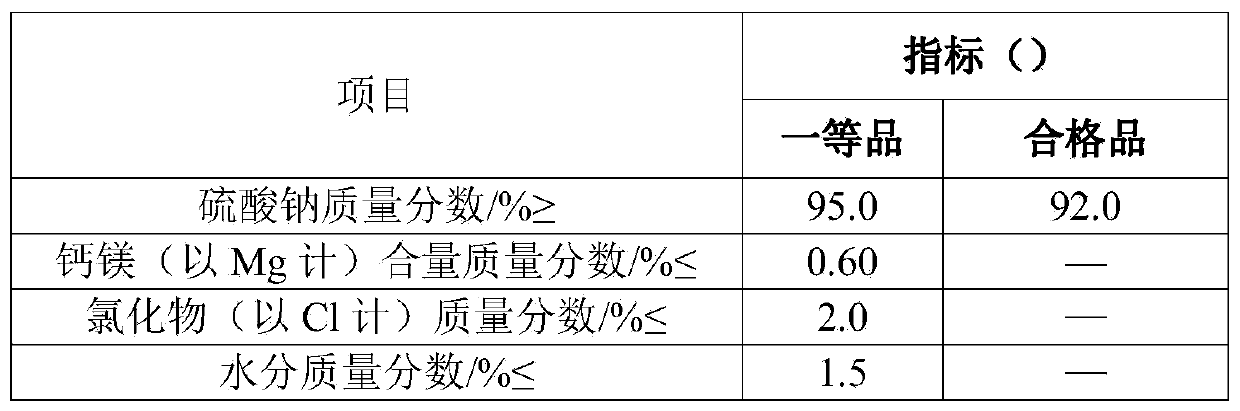

Comprehensive recovery treatment method for H acid industrial waste water

ActiveCN103803753AAchieve phase transferAchieve transfer enrichmentWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical oxygen demandIndustrial waste water

The invention discloses a comprehensive recovery treatment method for H acid industrial waste water, belonging to the field of an industrial waste water recovery treatment method. The comprehensive recovery treatment method comprises the steps of (1) after the pH value of H acid industrial waste water is regulated to 10-1.5, extracting by adopting a complexation extraction method so as to separate organic matters from waste water, filtering extraction water through a membrane so as to reduce the loss of an extractant, carrying out back extraction on the extractant by utilizing a 13% sodium hydroxide solution, wherein the ratio of the back-extraction oil to base is 4:1, and the recycling of the extractant and the enrichment of organic matters in the waste water can be realized; (2) after the back-extraction base liquid is saturated, directly recycling the back-extraction liquid into alkali fusion workshop section in H acid production, and further carrying out H acid production; (3) regulating the pH value of the extraction water to 6-9, concentrating and evaporating the extraction water by using MVR (Mechanical Vapor Recompression) technology, and recycling to obtain sodium sulfate. By combination use of extraction technology, membrane separation technology and MVR technology, the running cost can be saved, and the COD (Chemical Oxygen Demand) value of the evaporation water can achieve the administration standard of a sewage treatment plant in a chemical industrial park.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Fruit juice health care vinegar production method

InactiveCN101654647AIncrease profitUnique flavorMicroorganism based processesVinegar preparationFruit juiceDiluent

A fruit juice health care vinegar production method comprises following steps: producing the fruit adaptive to popular fruit vinegar taste into a concentrated fruit juice according to routine technology; adding water for dilution or producing into fruit juice according to routine technology; adjusting total sugar degree; heating the above diluent and cooling; adopting the segmentation vinegar taking fermentation and filtering to get the fruit juice with pure taste. The fruit juice health care vinegar has no nutrient additive, has special flavor, fast acid production, high alcohol-acid conversion rate up to 96%, high raw material utilization rate and improved fermentation period of only 8-24 hours, accords with national consumption custom, maintenances the raw fruit flavor, enriches the edible vinegar variety and can be blended into the fruit vinegar beverages with various tastes.

Owner:许朝辉

Preparation and use methods of nitrogen-vanadium co-doped modified titanium dioxide catalyst

InactiveCN101972662AHigh visible light activityImprove dust removal efficiencyPhysical/chemical process catalystsSulfur compoundsEngineering industryMixed crystal

The invention discloses preparation and use methods of a nitrogen -vanadium co-doped modified titanium dioxide catalyst, belonging to the technical field of preparation and use of catalysts. The preparation method comprises the following steps of: adding a nitrogen source and a vanadium source in a process of preparing titanium dioxide by using a sol-gel method; hydrolyzing the mixture to obtain gelatin and standing, aging and drying to form particles; then grinding and carbonizing and heating to 600 to 800 DEG C for roasting to obtain a mixed crystal type titanium dioxide catalyst with different doping amounts. The compounding of electron-hole pair is influenced by doping metal ions to improve utilization ratios of visible light.With simple operation and easy control, the prepared nitrogen -vanadium co-doped modified titanium dioxide catalyst can achieve greatly improved visible light activity and can be applied to sulphuric acid production in the chemical engineering industry, SO2 tail gas treatment in the smelting industry, sulfur dioxide control of coal-fired and fuel boilers, acid rain prevention and control, smoke gas adjustment of coal-fired power plants, improvement on the dust removal efficiency of an electric precipitator, and other fields.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

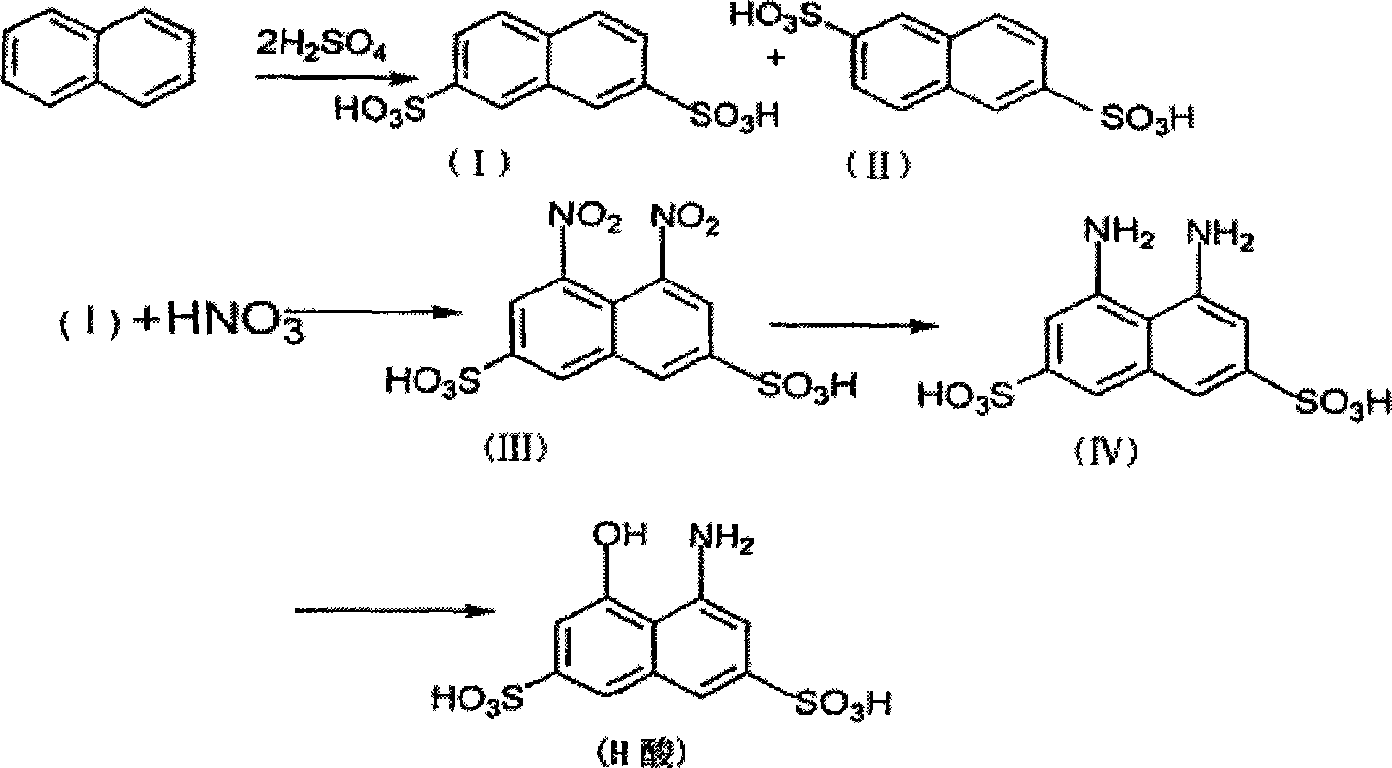

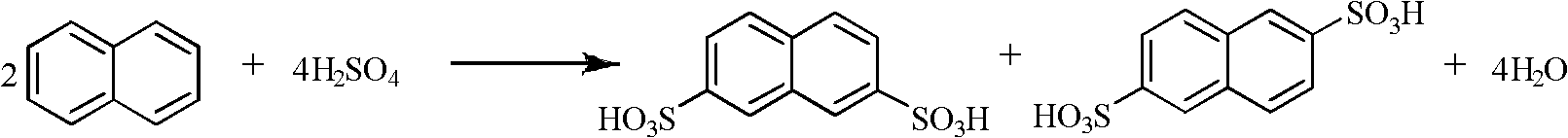

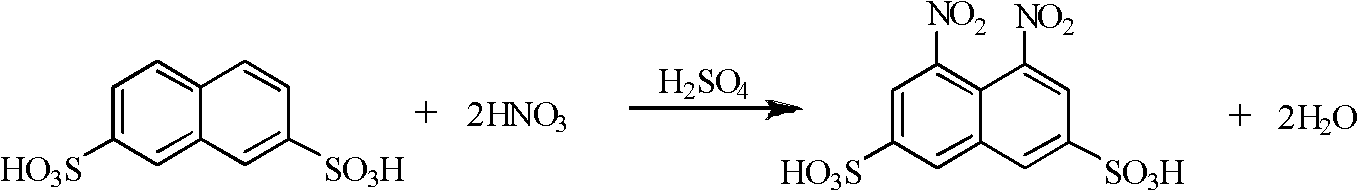

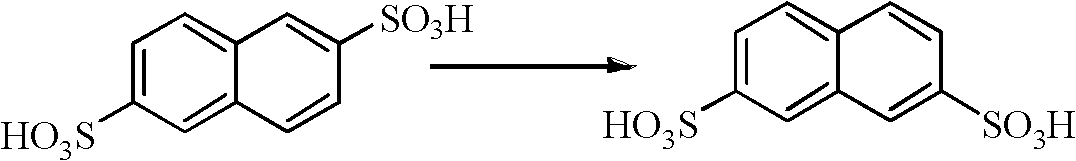

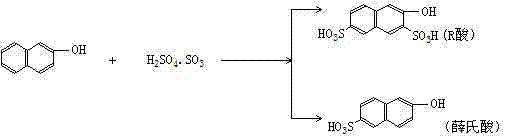

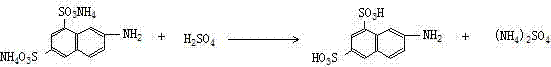

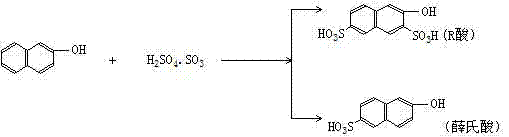

Method for clean preparation H acid

The invention discloses a method for clean preparation H acid. The method includes: adopting refined naphthalene as the raw material, using concentrated sulfuric acid to conduct sulfonation so as to prepare 2, 7-naphthalene disulfonic acid, separating the byproduct 2, 6-naphthalene disulfonic acid therein, and subjecting the 2, 7-naphthalene disulfonic acid to a nitration reaction in a sulfonation mother liquor directly to prepare 1, 8-dinitro-3, 6-naphthalene disulfonic acid; reusing the nitration mother liquor in a naphthalene sulfonation reaction step; and conducting hydrogenation reduction to prepare 1, 8-diamino-3, 6-naphthalene disulfonic acid, which is then subjected to acidic hydrolysis to prepare H acid. The nitration mother liquor and the hydrolysis mother liquor in the reaction can be recycled. An extraction process is employed to treat the repeatedly recycled mother liquors to remove the accumulated impurities therein. The method provided in the invention greatly reduces the wastewater generated in the H acid production process, by over 80% compared with the prior art, and at the same time can improve the product quality and yield.

Owner:中国中化股份有限公司 +1

Process for preparing amino G acid

The invention relates to a process for preparing amino G acid, which belongs to the technical field of amino K acid production process. The process comprises the steps of sulfonating, salting out by ammoniacal liquor, treating G salt mother liquor, ammoniating G salt ammonium base sulfite, treating dehydrated liquid and the like, ammonium base sulfite is employed as a catalyst for replacing ammonium bisulfite, so that the pressure generated during ammonification process can be effectively reduced, the reaction time can be shortened, and the product yield and content can be increased. The method is characterized in that two streams of waste water are respectively treated, 2-naphthol is hydrolyzed and recovered by G salt mother liquor, neutralized for reaching the standard, and then exhausted; ammonium sulfate-rich effluent is used for producing fertilizer, and the zero discharge is realized. The unit consumption of the raw material 2-naphthol is decreased from 0.75 ton / ton in a traditional process to less than 0.64 ton / ton when the problem of waste water treatment is solved, so that the production cost is reduced, the production safety coefficient is high and no harmful gas is discharged. The process of the invention solves the problems that two streams of waste water are generated during the present production process, the difficulty of waste water treatment is large, the production cost is high and the large harm on environment is caused.

Owner:湖北鑫慧化工有限公司

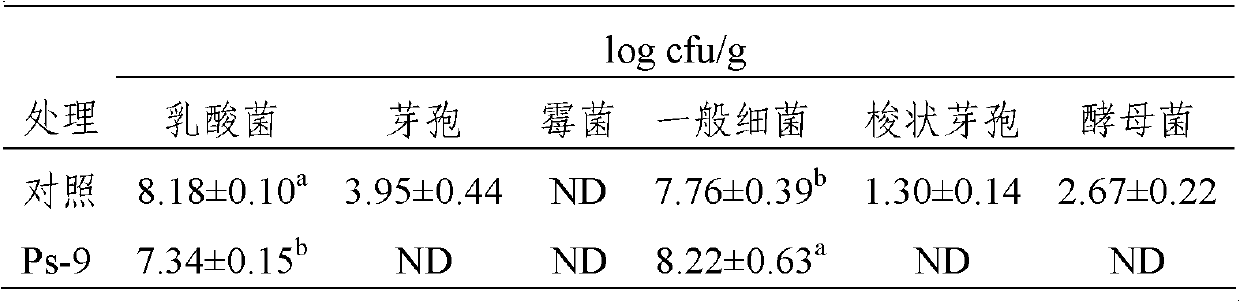

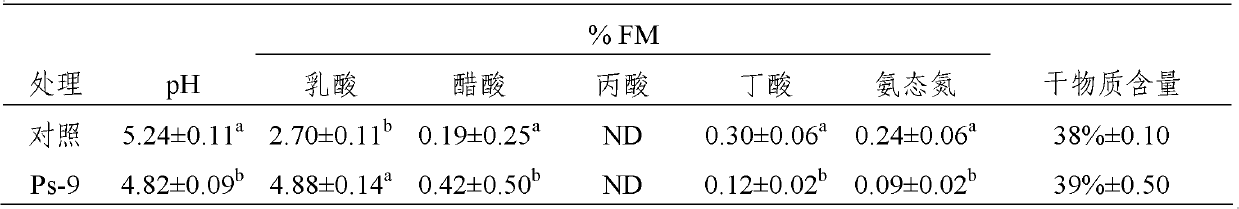

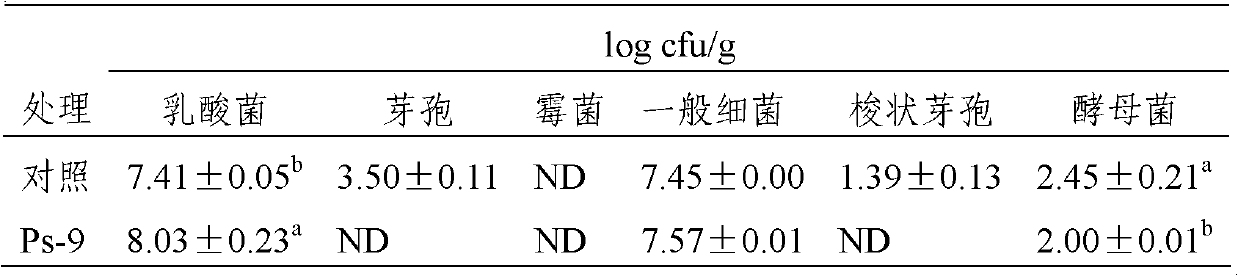

Lactobacillus plantarum used for silage alfalfa and use method thereof

ActiveCN102864095AImprove qualityAromaBacteriaMicroorganism based processesBacterial strainMicrobiological culture

The invention discloses a lactobacillus plantarum used for the silage alfalfa, which can improve the quality of the alfalfa silage feed. The lactobacillus plantarum used for the silage alfalfa has the technical scheme that the lactobacillus plantarum (L. plantarum Ps-9) is lactic acid bacteria which is screened from 100 plants of lactobacillus plantarum and has the advantages of favorable acid resistance, strong growth capability and high acid production speed. The bacterial strain of the bacteria is collected in the China general microbiological culture collection center with the collection number of CGMCC (China general microbiological culture collection center) No. 5489, and the collection data is 23rd, Nov., 2011. The invention also discloses a use method for the lactobacillus plantarum.

Owner:BEIJING SCITOP BIO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com