Process for preparing amino G acid

A preparation process, amino technology, applied in sulfonic acid preparation, organic chemistry, etc., can solve the problems of difficult tail gas treatment, high requirements, high production cost, etc., to improve product yield and content, shorten reaction time, and low acidity index Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

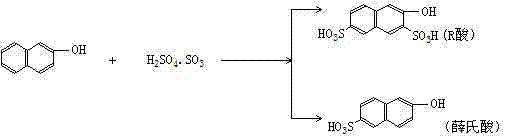

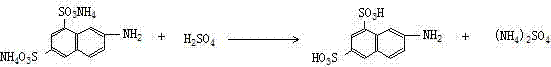

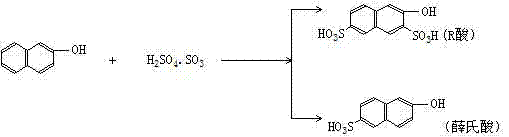

Method used

Image

Examples

Embodiment 1

[0043] Add 100kg of 100% sulfuric acid and 100kg of 105% sulfuric acid into a 1000L enamel reaction kettle, add 150kg of 2-naphthol under stirring and cooling at 20°C, and react at 90°C for 6 hours after adding. After the reaction was completed, the sulfonated material was added to 370L of 20% ammonia solution, stirred for 2 hours, filtered, and centrifugally dehydrated to obtain 400 kg of 82% ammonium 6,8-naphthalene disulfonate. Add 9 kg of sodium chloride to 450 L of dehydration liquid to produce 8.5 kg of R salt. After filtration, the mother liquor is hydrolyzed at a high temperature of 160° C. to recover 0.88 kg of 2-naphthol.

[0044] In a 1000L stainless steel ammoniation reaction kettle, add 400 kg of the above ammonium 6,8-naphthalene disulfonate (G salt), 100L of 20% ammonia water, 300L of 20% ammonium sulfite solution, the detection index is 70.5g / L, and the jacket steam is heated To 140°C, the pressure inside the kettle was 0.6 MPa, and maintained for 8 hours. Aft...

Embodiment 2

[0047] In a 3000L enamel reaction kettle, add 615 kg of 100% sulfuric acid, 615 kg of 105% sulfuric acid, stir and cool at 20°C, add 922.5 kg of 2-naphthol, and react at 90°C for 6 hours after the addition is complete. After the reaction is complete, add the sulfonated material 2250L of 20% ammonia solution, stirred for 2 hours, filtered, and centrifugally dehydrated to obtain 2400 kg of 82% ammonium 6,8-naphthalene disulfonate. Add 110 kilograms of sodium chloride to 5500 L of dehydration liquid to produce 202 kilograms of R salt, and 22 kilograms of 2-naphthol are recovered by high-temperature hydrolysis of mother liquor water after filtration.

[0048] In a 5000L stainless steel ammoniation reaction kettle, add 2400 kg of the above ammonium 6,8-naphthalene disulfonate (G salt), 700L of 20% ammonia water, 1800L of 20% ammonium sulfite solution, the detection index is 70.1 g / L, and the jacket steam is heated to 142°C, the pressure in the kettle was 0.61 MPa, and maintained fo...

Embodiment 3

[0051] In a 3000L enamel reaction kettle, add 600 kg of 100% sulfuric acid, 600 kg of 105% sulfuric acid, stir and cool at 18°C, add 900 kg of 2-naphthol, and react at 90°C for 6 hours after the addition is complete. After the reaction is complete, add the sulfonated material 2190L of 20% ammonia solution, stirred for 2 hours, filtered, and centrifuged to obtain 2320 kg of 82% ammonium 6,8-naphthalene disulfonate. Add 99 kilograms of sodium chloride to 4950 L of dehydration liquid to produce 199 kilograms of R salt, and 22 kilograms of 2-naphthol are recovered by high-temperature hydrolysis of mother liquor water after filtration.

[0052]In a 5000L stainless steel ammoniation reaction kettle, add 2320 kg of the above-mentioned ammonium 6,8-naphthalene disulfonate (G salt), 680L of 20% ammonia water, 1700L of 20% ammonium sulfite solution, the detection index is 70g / L, and the jacket steam is heated to 138°C, the pressure in the kettle is 0.6 MPa, and keep it for 8 hours. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com