Patents

Literature

547 results about "Magnesium matrix composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Conductivity Magnesium Alloy

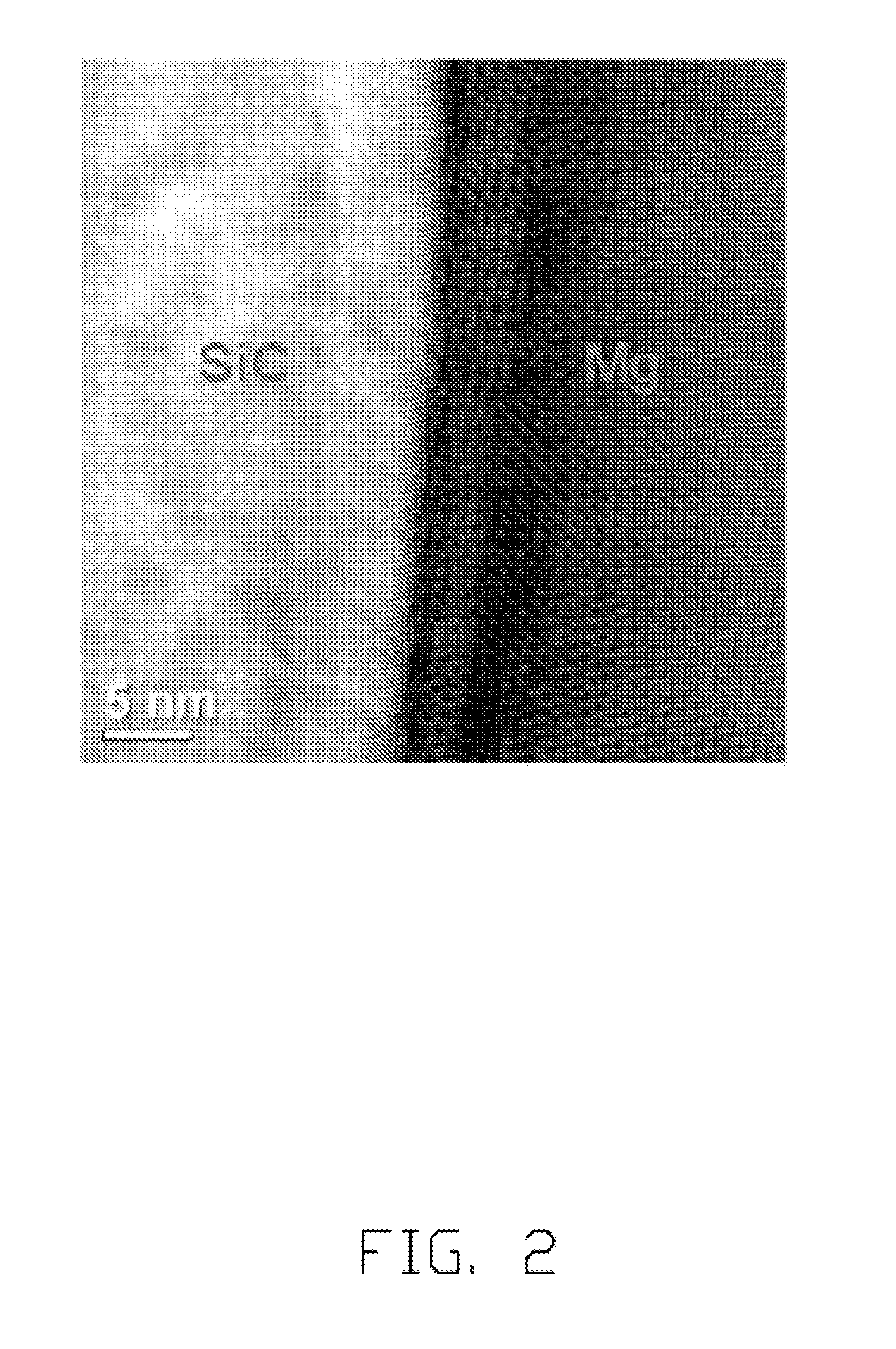

InactiveUS20170268088A1Improved thermalPhysical improvementMaterial nanotechnologyTransportation and packagingMagnesium matrix compositeNanoparticle

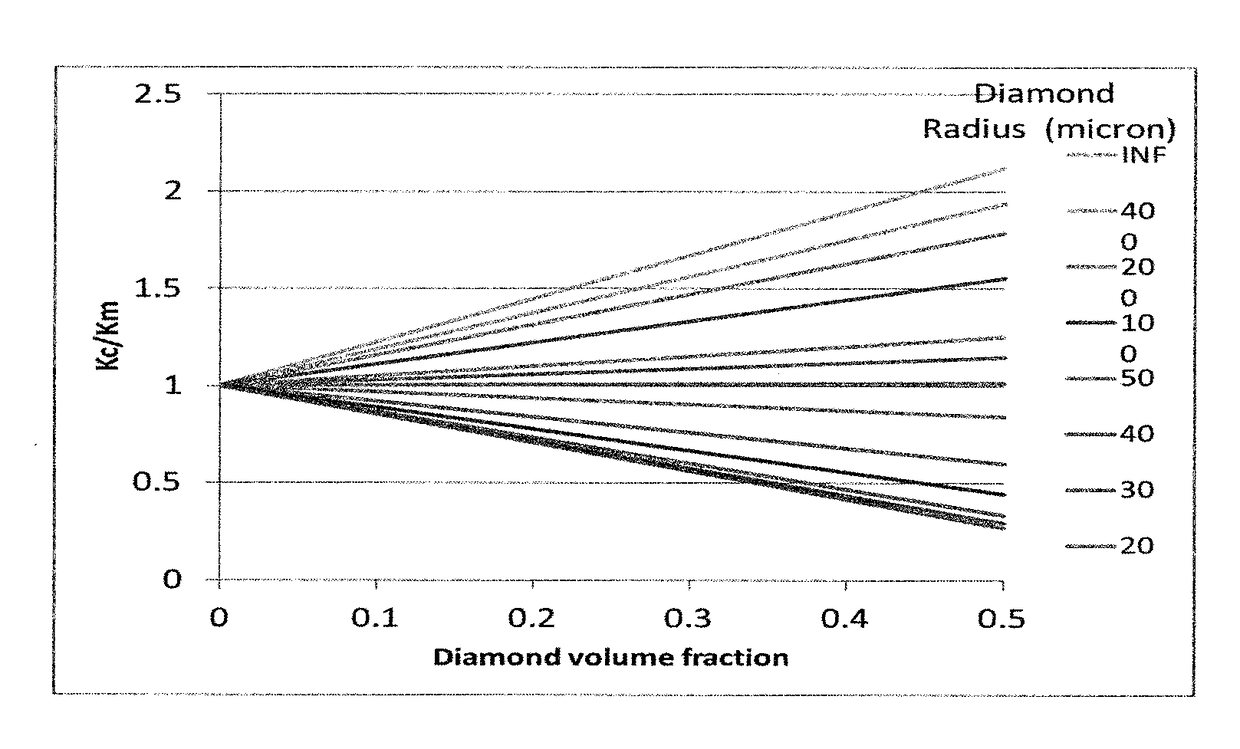

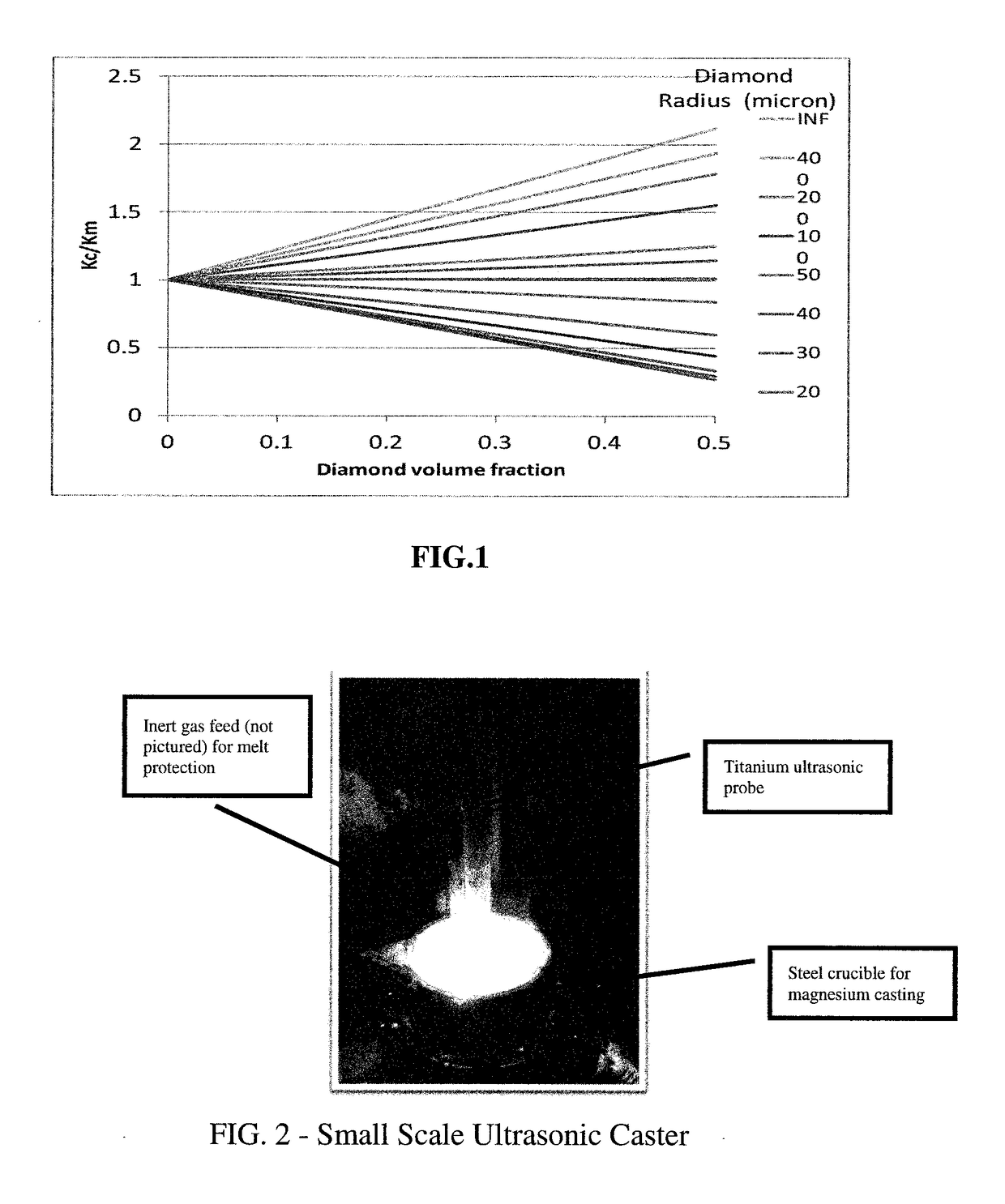

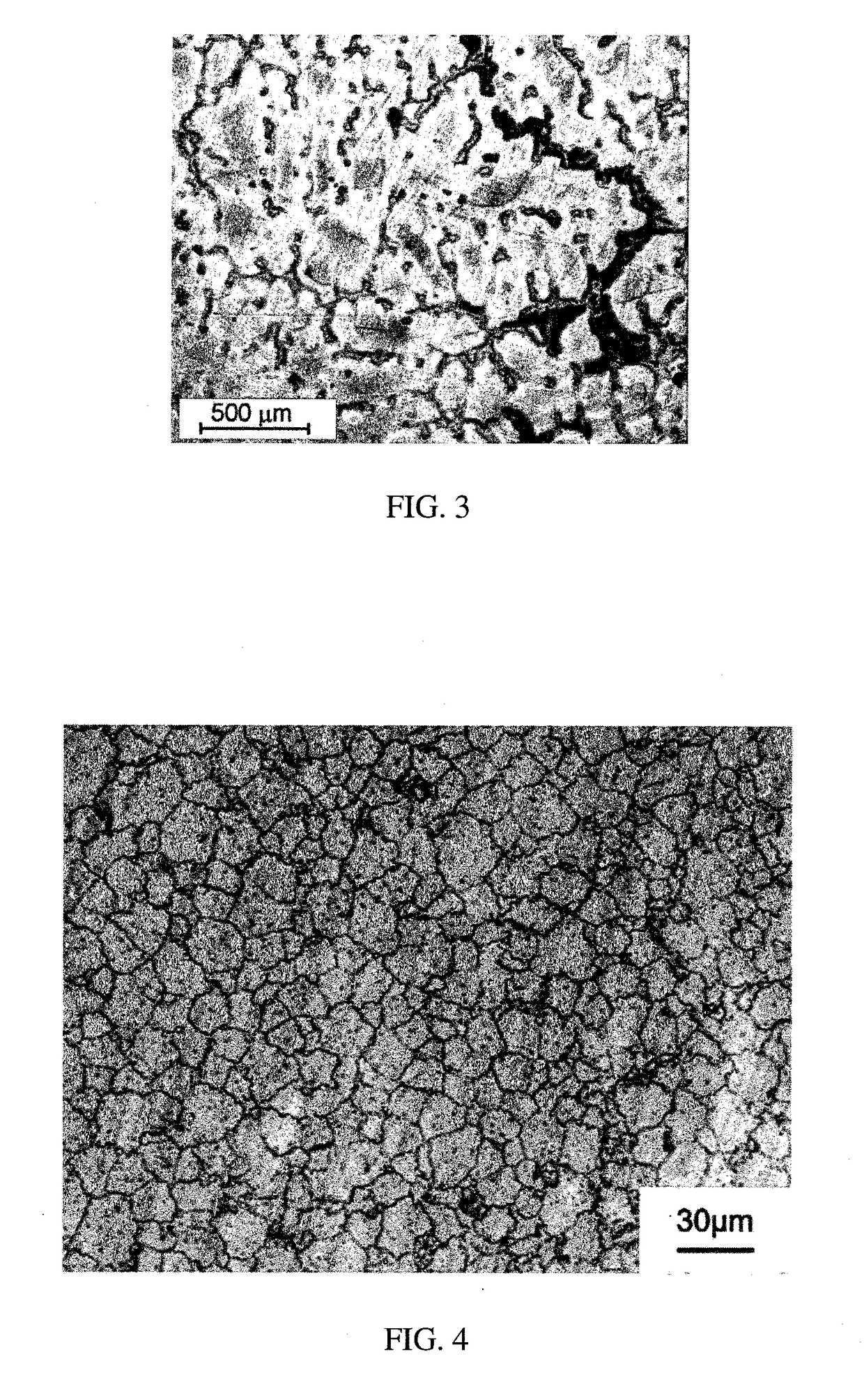

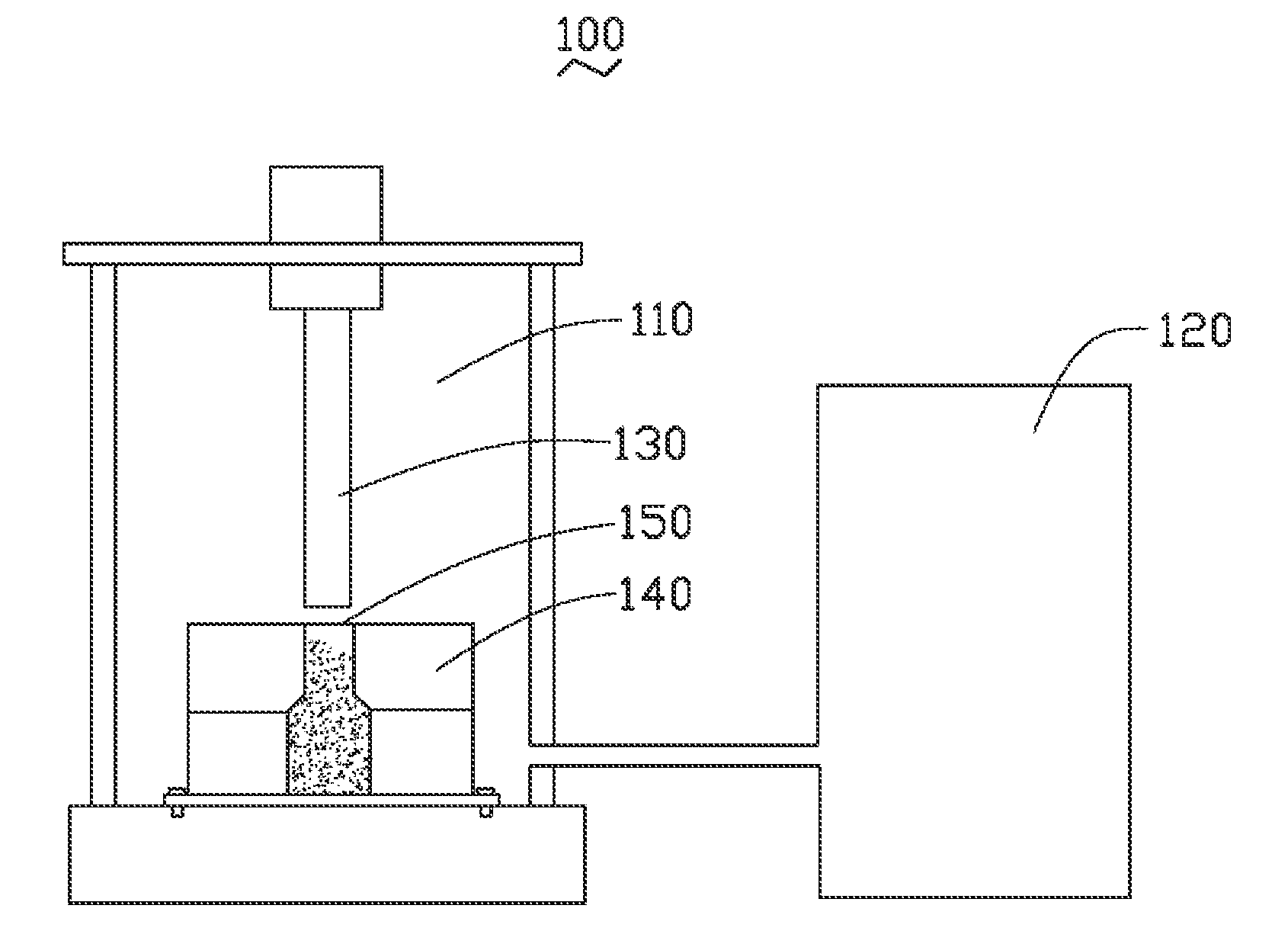

A castable, moldable, or extrudable magnesium-based alloy that includes one or more insoluble additives. The insoluble additives can be used to enhance the mechanical properties of the structure, such as ductility and / or tensile strength. The final structure can be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final structure as compared to the non-enhanced structure. The magnesium-based composite has improved thermal and mechanical properties by the modification of grain boundary properties through the addition of insoluble nanoparticles to the magnesium alloys. The magnesium-based composite can have a thermal conductivity that is greater than 180 W / m−K, and / or ductility exceeding 15-20% elongation to failure.

Owner:TERVES

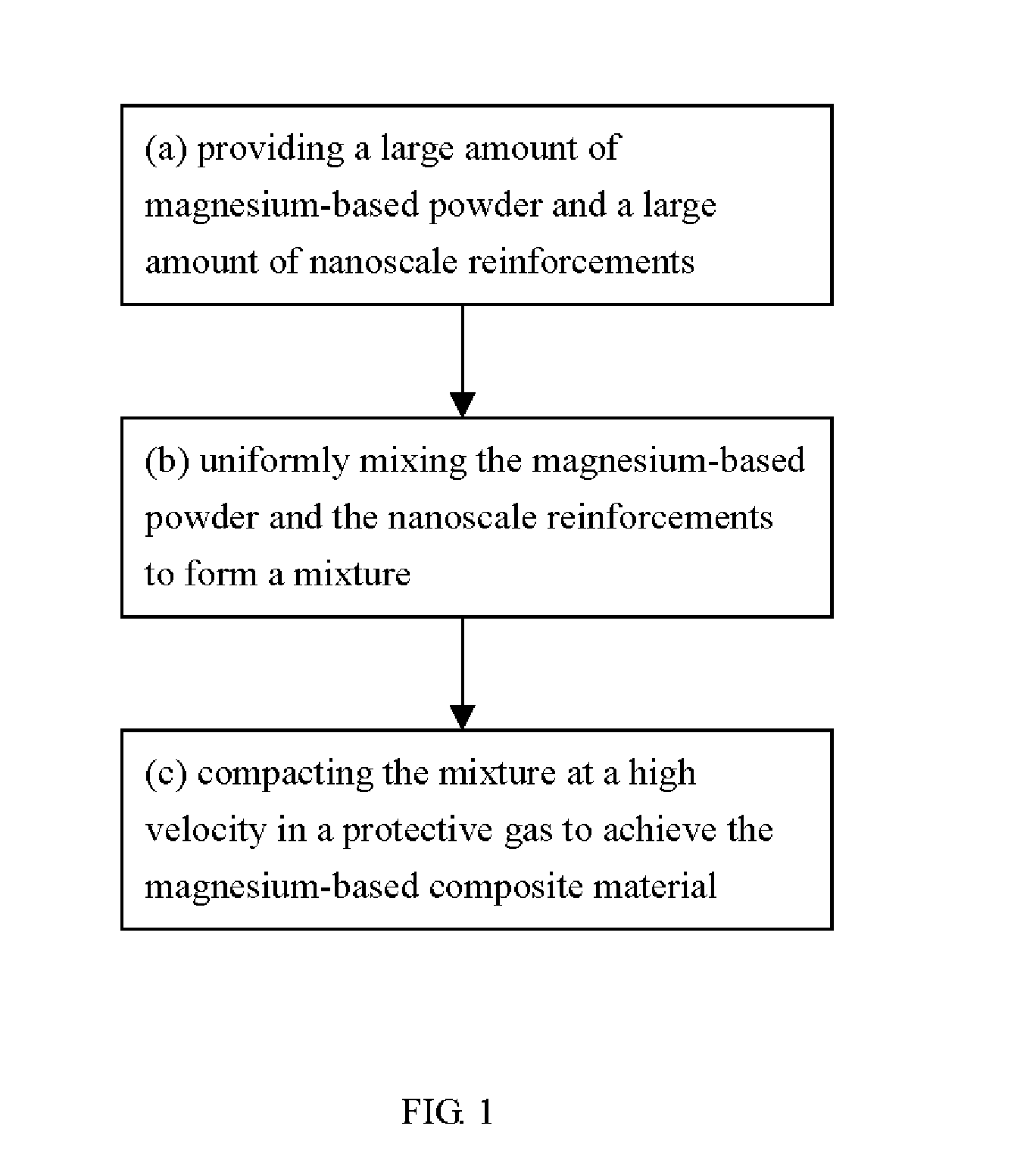

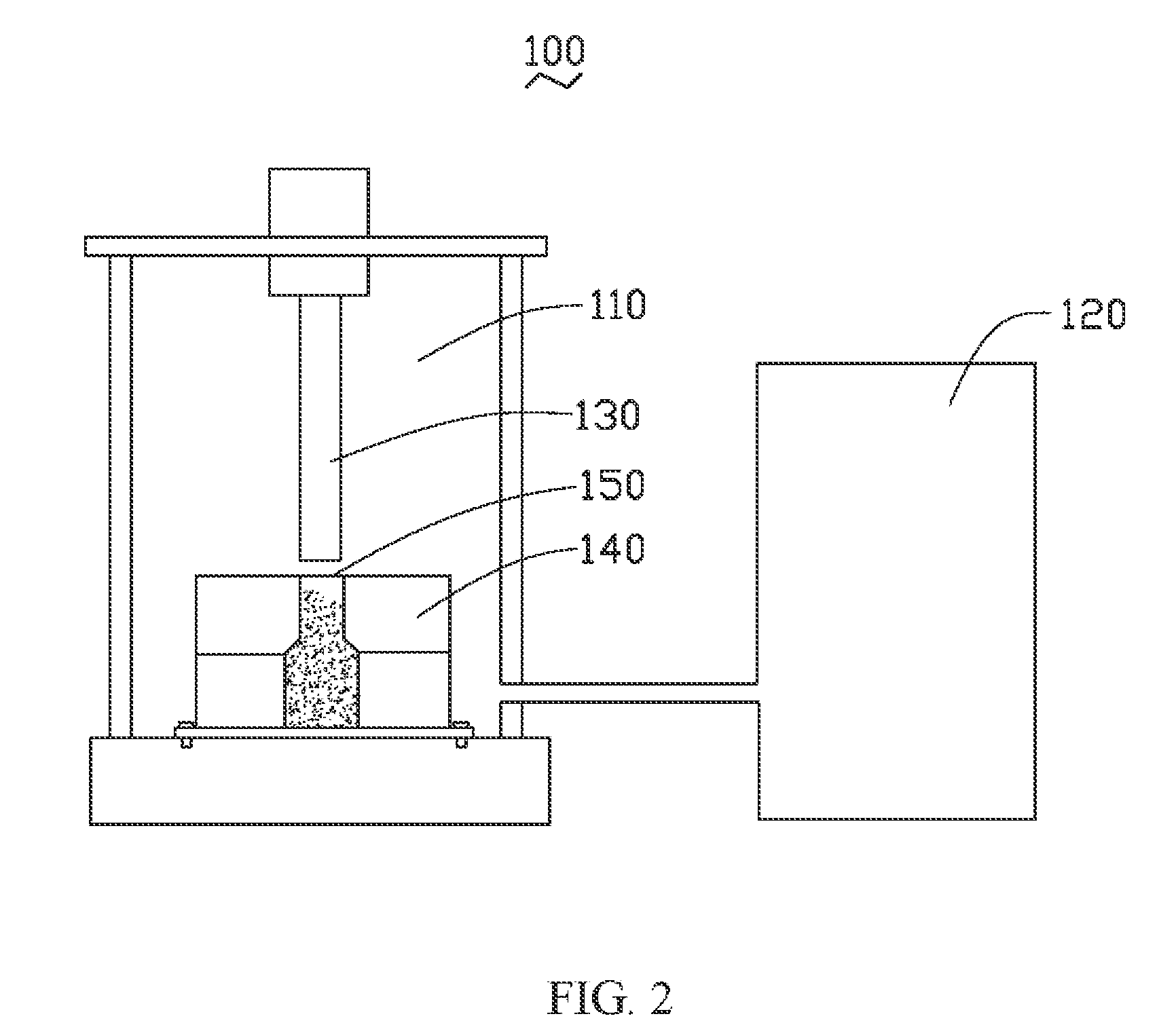

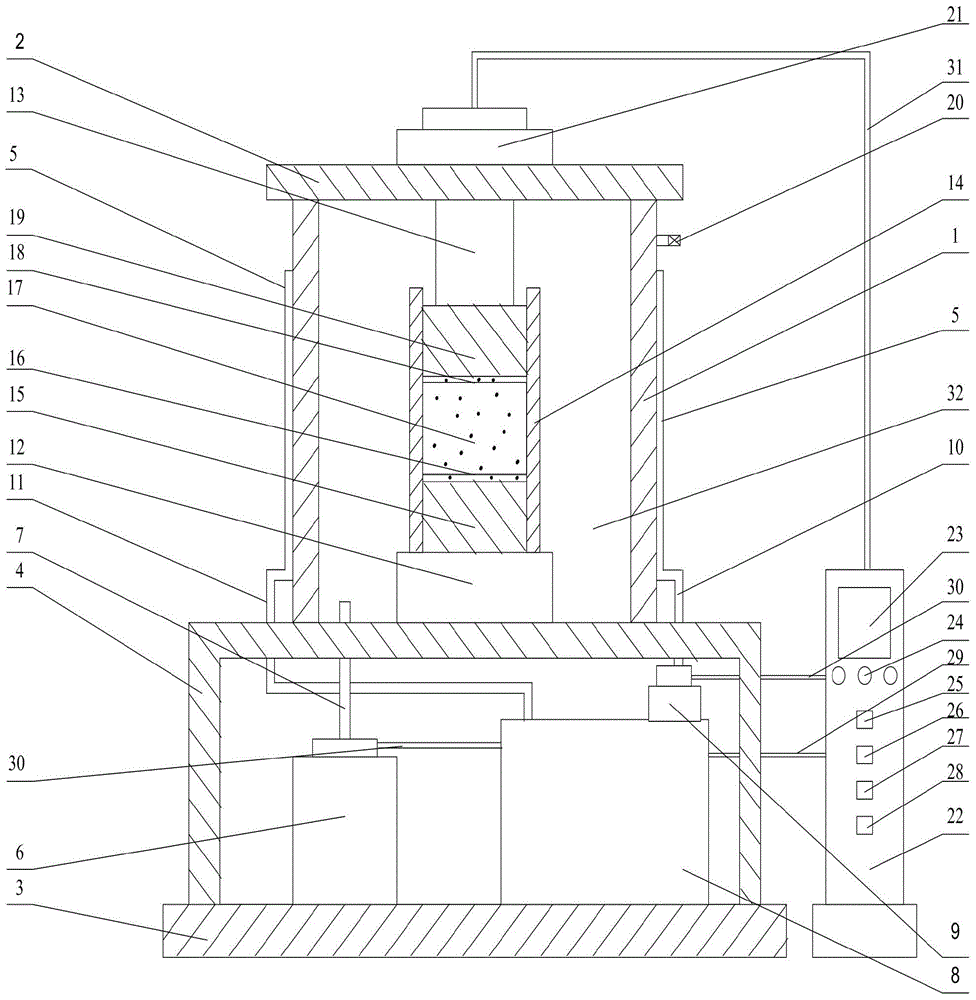

Method for making magnesium-based composite material and equipment for making the same

A method for fabricating a magnesium-based composite material, the method includes the steps of: (a) providing a large amount of magnesium-based powder and a large amount of nanoscale reinforcements; (b) uniformly mixing the magnesium-based powder and the nanoscale reinforcements to form a mixture; and (c) compacting the mixture at a high velocity in a protective gas to achieve the magnesium-based composite material. High velocity compaction equipment for fabricating the magnesium-based composite material includes a sealing chamber, a gas pumping device, a mold, and a hammer. The gas pumping device is connected to the sealing chamber. The mold is disposed in the sealing chamber with an aperture formed on the top thereof. The hammer is disposed in the sealing chamber and above the mold, and moving along longitudinal thereof at a controllable ramming speed.

Owner:TSINGHUA UNIV +1

Method for preparing in-situ particle reinforced magnesium base compound material

ActiveCN101381829AImprove mechanical propertiesGood physical propertiesMagnesium matrix compositeMetal mold

The invention relates to a method for preparing in-situ particle reinforced magnesia-based composite materials, which particularly comprises the following steps: magnesium aluminum alloy raw materials are completely smelt under the protective condition of gas mixture of SF6 and CO2; aluminum-silicon intermediate alloy is pressed into a magnesium aluminum fused mass, and the temperature is raised and maintained, so as to guarantee complete reaction between silicon and magnesium in the magnesium aluminum alloy fused mass, and simultaneously an ultrasonic probe is inserted into the fused mass for treatment; and after the treatment is finished, surface scum is removed and the fused mass is cast into a metal die, and the in-situ Mg2Si particle reinforced magnesia-based composite materials are obtained. The method has the characteristics of good interference compatibility of Mg2Si particles and substrates, controllable particle size of reinforced phases, uniform distribution of the reinforced phase and so on; and the magnesia-based composite materials prepared have good mechanical property.

Owner:JIANGSU UNIV

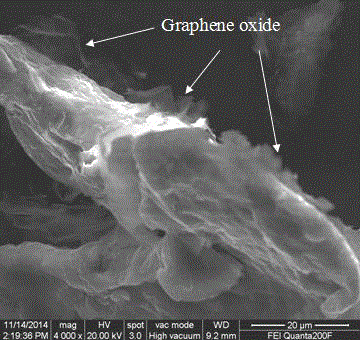

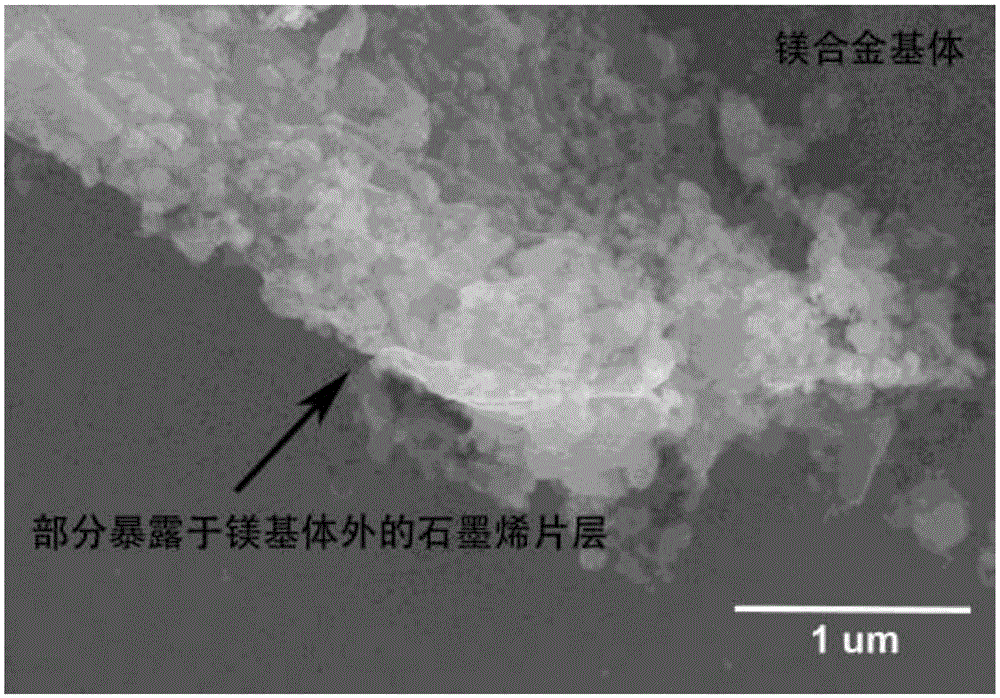

Preparation method of in-situ reduced graphene reinforced magnesium-matrix composite

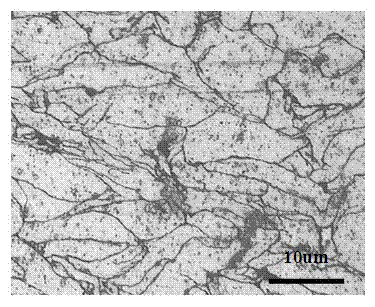

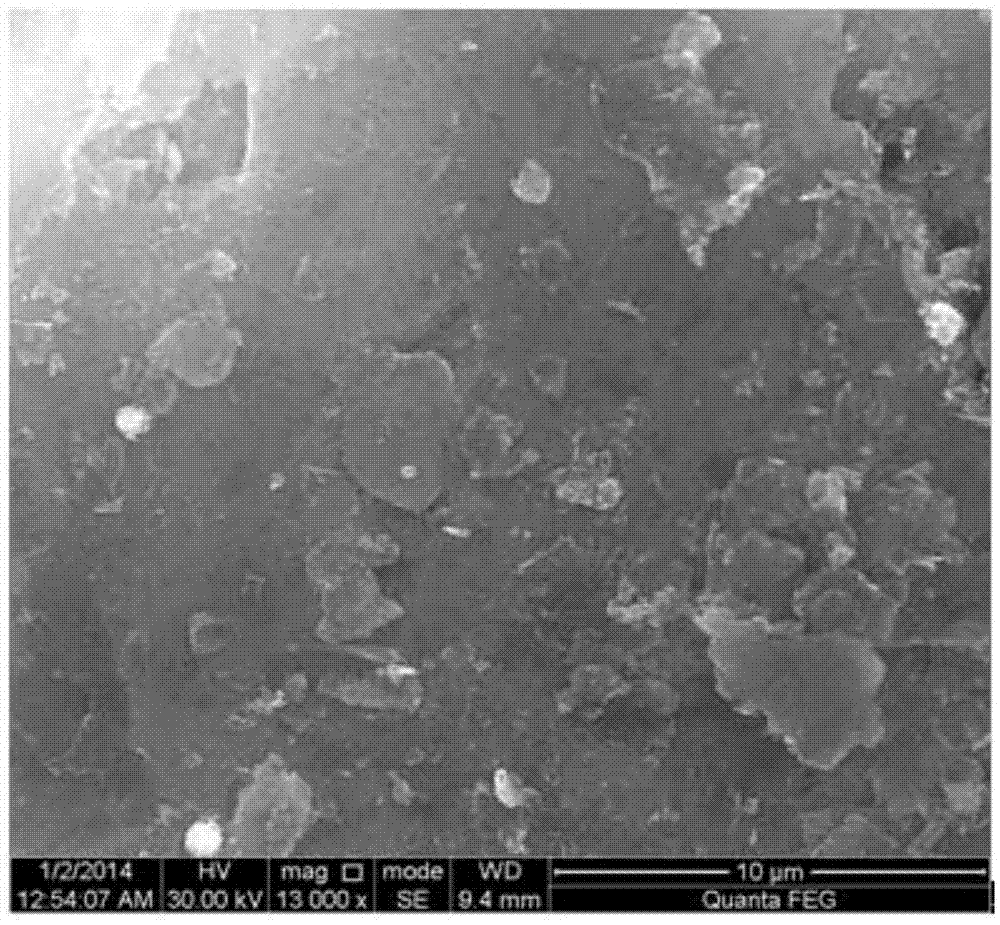

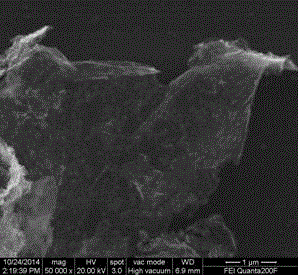

The invention discloses a preparation method of an in-situ reduced graphene reinforced magnesium-matrix composite. The method comprises the following steps: dissolving graphite oxide in an appropriate amount of ethanol solution, and performing ultrasonic treatment for 0.5-2h to obtain a graphene oxide ethanol solution with concentration of less than or equal to 2mg / ml; adding appropriate AZ91 magnesium alloy powder with the particle size of less than or equal to 325 meshes into the mixed solution, and performing ultrasonic treatment and mechanical stirring for 2h to obtain mixed slurry; performing vacuum drying of the mixed slurry, transferring into a mould, and pressing into a composite green under the pressure of 100-600MPa at room temperature; sintering the composite green for 2-4h at 500-600 DEG C in argon protection; and finally performing hot extrusion of the sintered composite at 350-400 DEG C. The preparation method disclosed by the invention is simple in preparation process and safe and reliable; the reduced graphene has good dispersity in magnesium alloy; and the reduction byproduct MgO is good for improving the interface bonding strength so that the reinforcing effect is better and the performance of the composite is excellent. Compared with the method of directly adding graphene into the magnesium matrix, the cost is lower and the dispersity is better; and the preparation method is suitable for industrial preparation of a high-performance graphene reinforced magnesium alloy composite.

Owner:NANCHANG UNIV

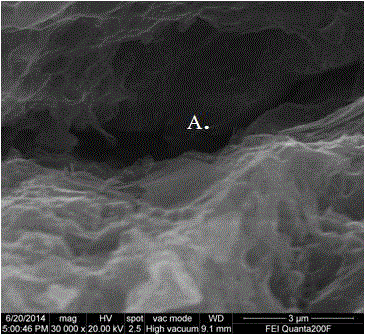

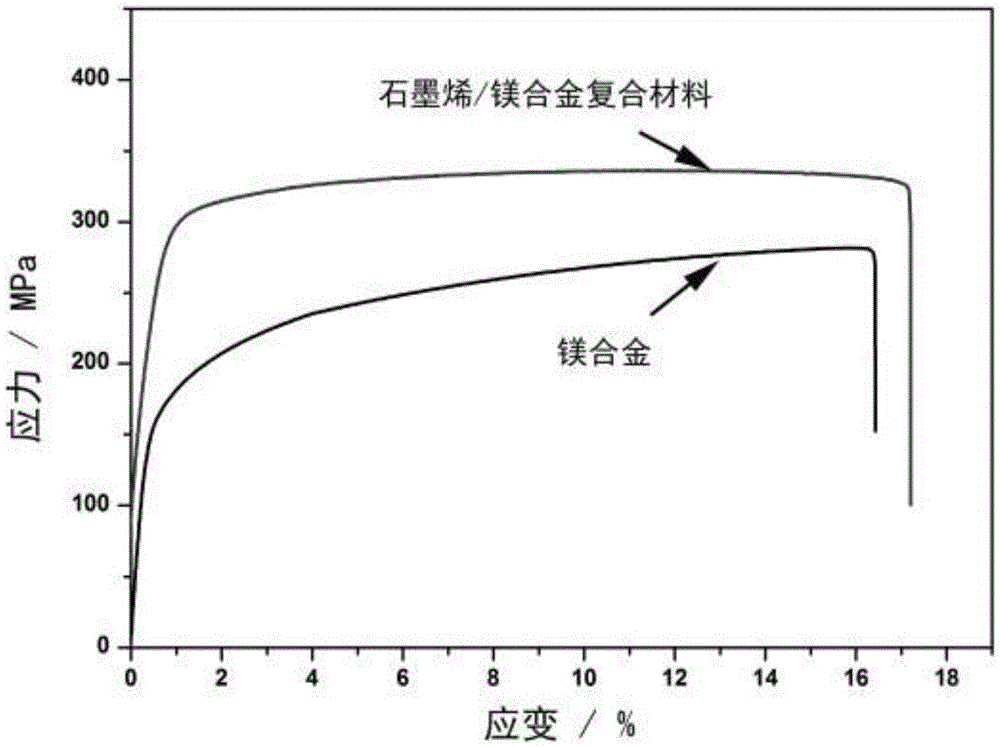

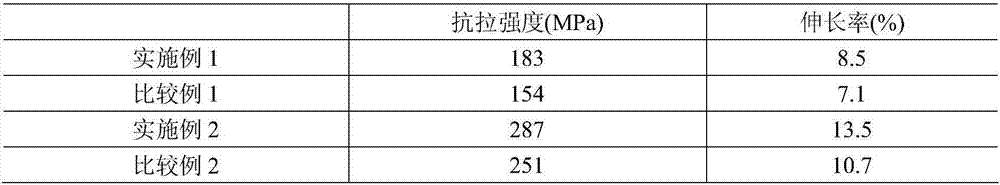

Graphene enhanced magnesium-based composite and preparing method thereof

The invention relates to a graphene enhanced magnesium-based composite and a preparing method thereof, and belongs to the technical field of composites. In the inert atmosphere, graphene with a certain lamella size and pure magnesium particles are subjected to ball-milling treatment, and meanwhile peeling of a graphene lamella and mixing between the graphene lamella and the pure magnesium particles are achieved; an ultrasonic dispersing and mechanical stirring technology is adopted, the peeled graphene lamella is further dispersed in a liquid phase, the pure magnesium particles are inserted in the parts among graphene layers in the stirring process, and the solid phase interval and sufficient mixing between the pure magnesium particles and the graphene layers are achieved; the compactness of graphene / pure magnesium particle composite powder is enhanced through a thermal extrusion technology, a magnesium-based precursor containing graphene is obtained, and the graphene enhanced magnesium-based composite is finally obtained through an alloy component blending and stirring casting method. The method technology is simple and convenient to conduct, environment friendliness is achieved, and sufficient dispersing of graphene in a magnesium base body is achieved. The graphene / magnesium-based composite with the enhanced mechanical performance is obtained, and wide application prospects are achieved in the fields such as aerospace, automobiles and electronics.

Owner:BEIJING UNIV OF TECH

Method for preparing carbon nanotube enhanced magnesium-based composite material

InactiveCN103014567AImprove wettabilityGood for mixing and compoundingMagnesium matrix compositeCarbon nanotube

The invention provides a method for preparing a carbon nanotube enhanced magnesium-based composite material comprises the following steps of: mixing carbon nanotubes and metal powder together in the mass ratio of (1:2)-(1:30), putting the mixture in a ball mill for ball milling for 0.5-24 hours, filtering the milled powder through a 40-100-mesh stainless steel sieve, and then covering the mixture with a metal foil and putting the covered mixture in a die for pressing; after completely melting a magnesium base material, refining, degassing and deslagging the melt, and then pressing the carbon nanotube / metal powder precast block into the melt of the magnesium base material by using a bell jar until the percast block is completely melted into the magnesium or magnesium alloy liquid, stirring for 0.5-10 minutes under the conditions of 700-780 DEG C and 100-1500 r / minute, regulating the melt temperature to the casting temperature, and then performing casting to form the billet of the carbon nanotube enhanced magnesium-based composite material, wherein the content of the carbon nanotubes in the carbon nanotube enhanced magnesium-based composite material is 0.1-5wt%. The method provided by the invention is simple in process, convenient in operation and short in flow; the carbon nanotube particles are evenly distributed in the base body; and the method is excellent in performance and low in production cost, thereby being suitable for industrially preparing a high-performance carbon nanotube enhanced magnesium-based composite material.

Owner:NANCHANG UNIV

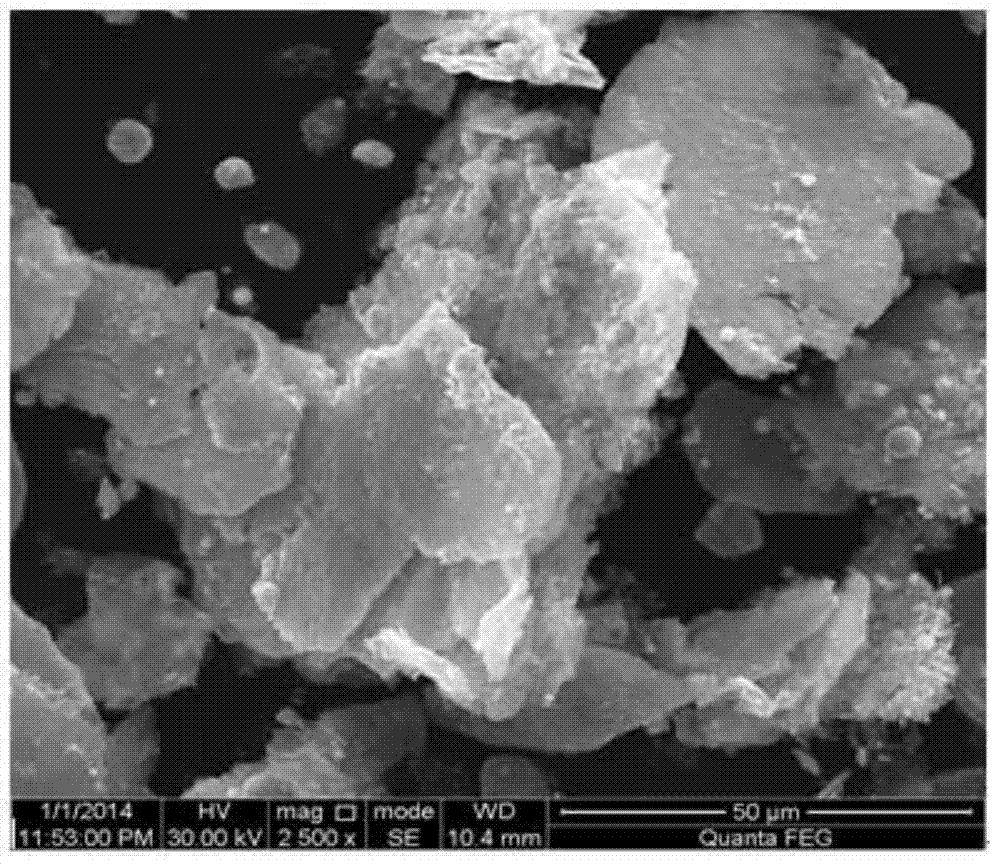

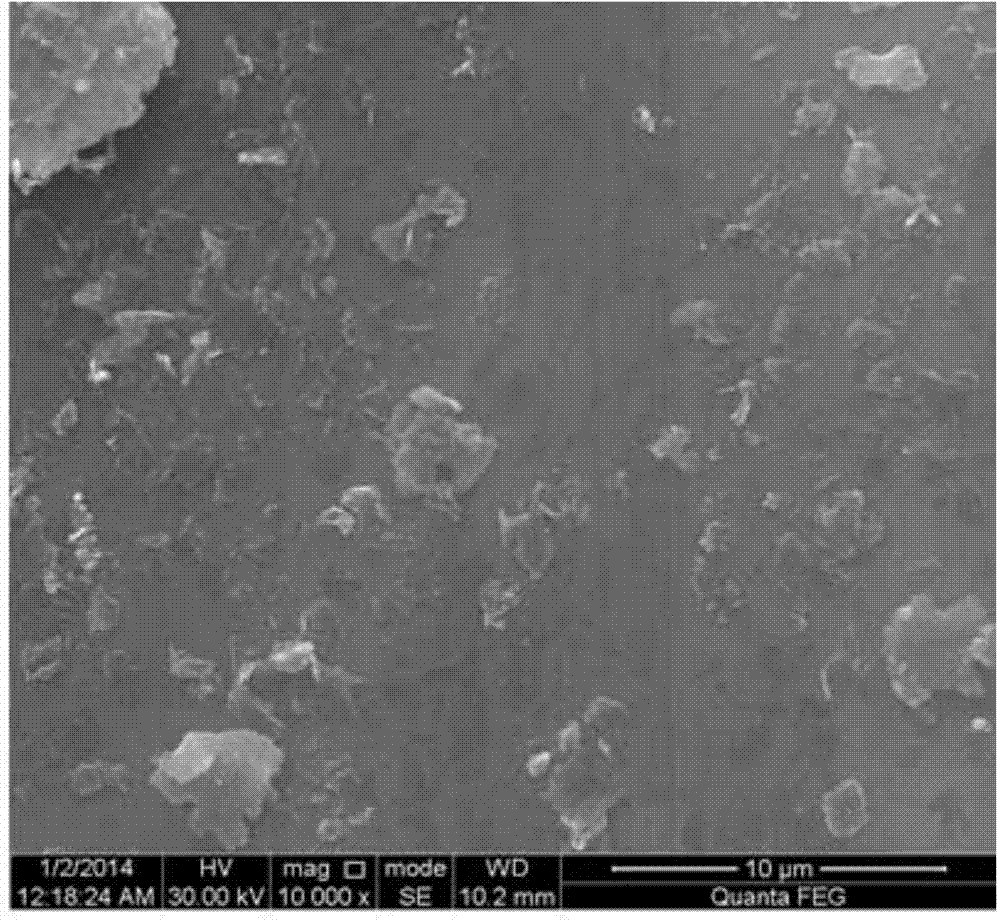

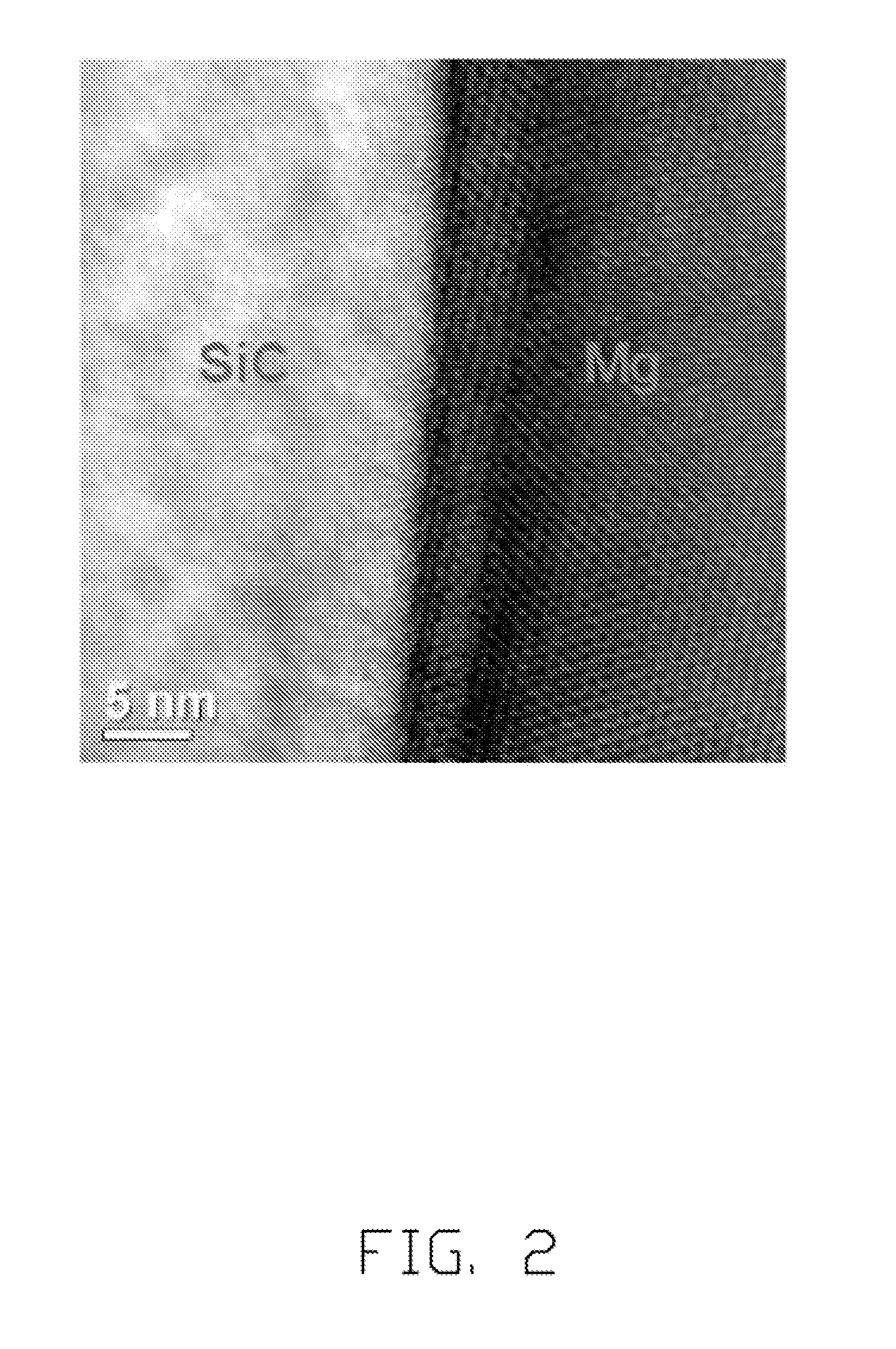

Silicon carbide particle reinforced magnesium-based composite material and preparation method

InactiveCN103031452AImprove mechanical propertiesGood mechanical propertiesAl powderMaterials preparation

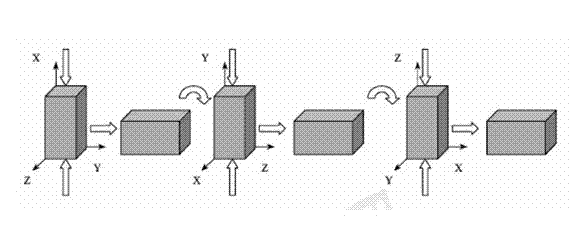

The invention discloses a silicon carbide particle reinforced magnesium-based composite material and a preparation method thereof, and belongs to the field of a metal-based composite material. The silicon carbide particle reinforced magnesium-based composite material is characterized in that the silicon carbide particle reinforced magnesium-based composite material is prepared by taking pure Mg powder, Al powder and SiC particle micro-powder as raw materials through powder metallurgy and a multi-directional forging method. Through two forming methods: powder metallurgy and multi-directional forging method, an excellent wettability and an excellent combining property are guaranteed between a magnesium alloy substrate and the SiC particles, and residual pores in the material in the powder metallurgy forming process are eliminated, so that the prepared magnesium-based composite material is uniform in distribution of the SiC particles and fine in magnesium alloy substrate grains, and the composite material has an excellent mechanical performance. In comparison with other particle-reinforced magnesium-based composite material preparation methods, the preparation method disclosed by the invention, by a solid forming process, is simple in process, low in cost, easy to industrially produce, and is capable of preparing the SiC particle reinforced magnesium-based composite material which is excellent in mechanical performance.

Owner:TAIYUAN UNIV OF TECH

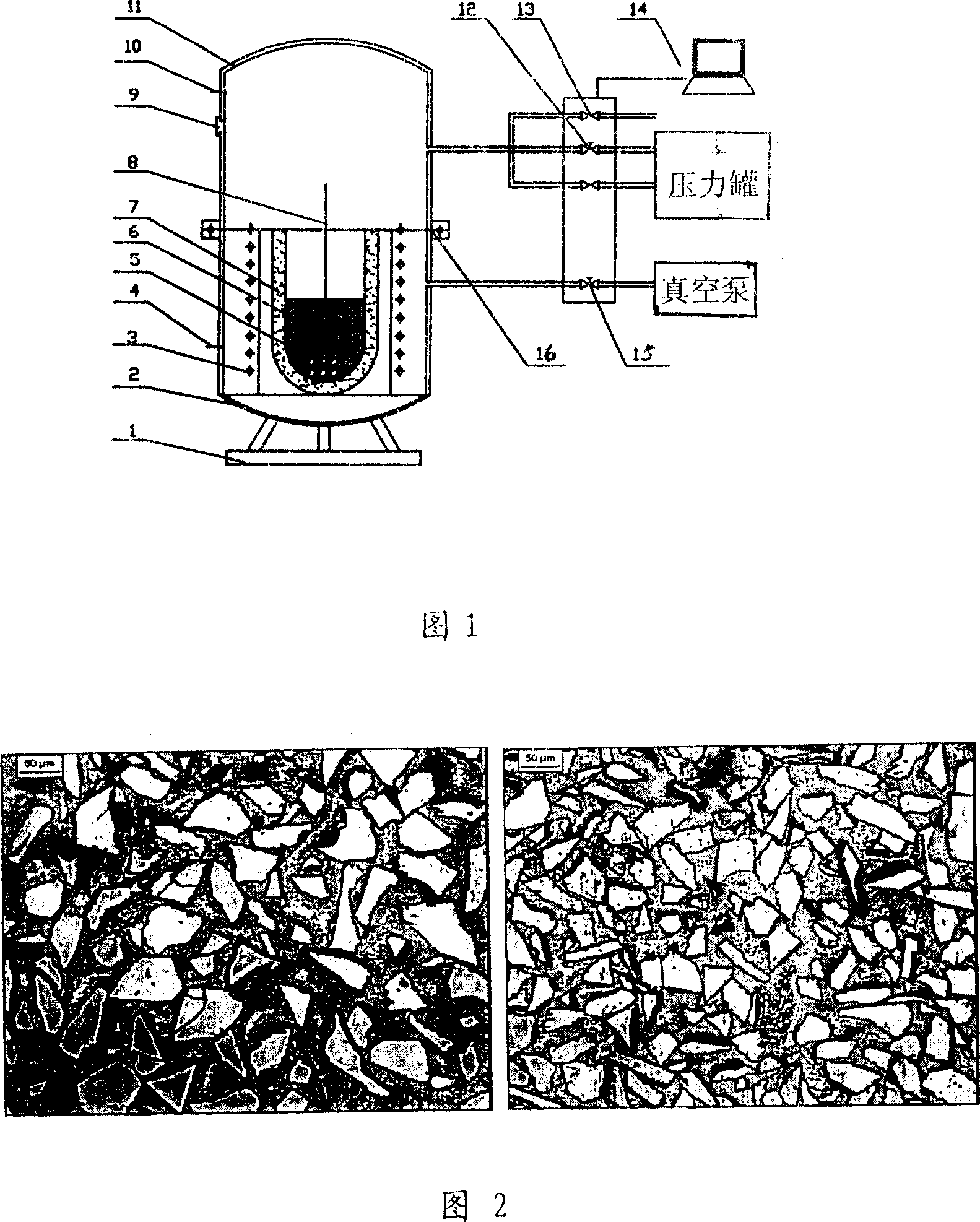

Process for preparing particle-reinforced magnesium-base composite material by vacuum pressure impregnation

InactiveCN1936047AUniform volume fractionReduce volume fractionVacuum pressureMagnesium matrix composite

The invention discloses a technology to make particle enhanced magnesium radical composite material through vacuum pressing infiltration. It covers a protection film on magnesium melt surface and uses air as pressure resource. It has good physical and mechanical properties. Thermal couple, pressure sensor and observation window are set on vacuum pressing infiltration device that would ensure safety. It also has excellent repeatability and stable technology.

Owner:NANCHANG AERONAUTICAL ENG INST

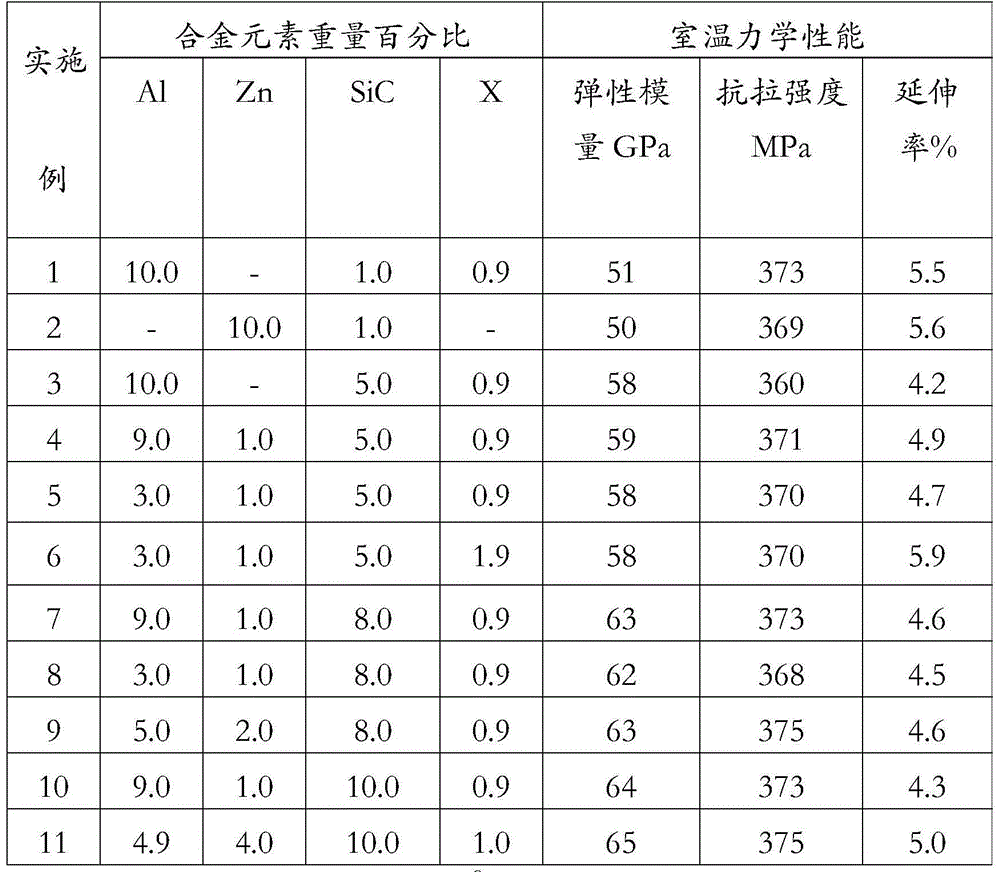

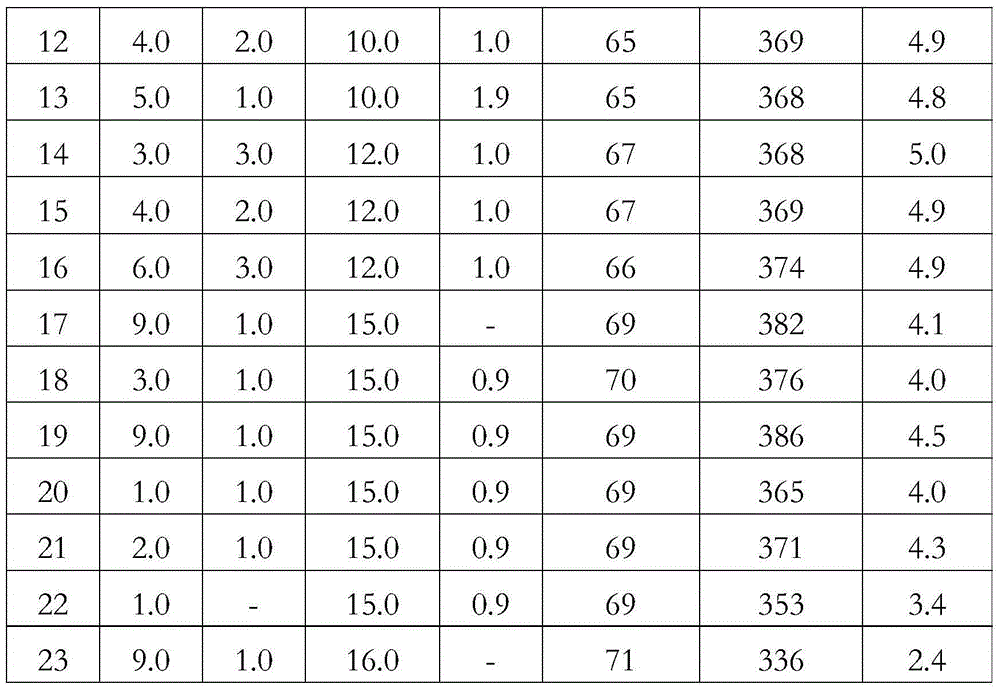

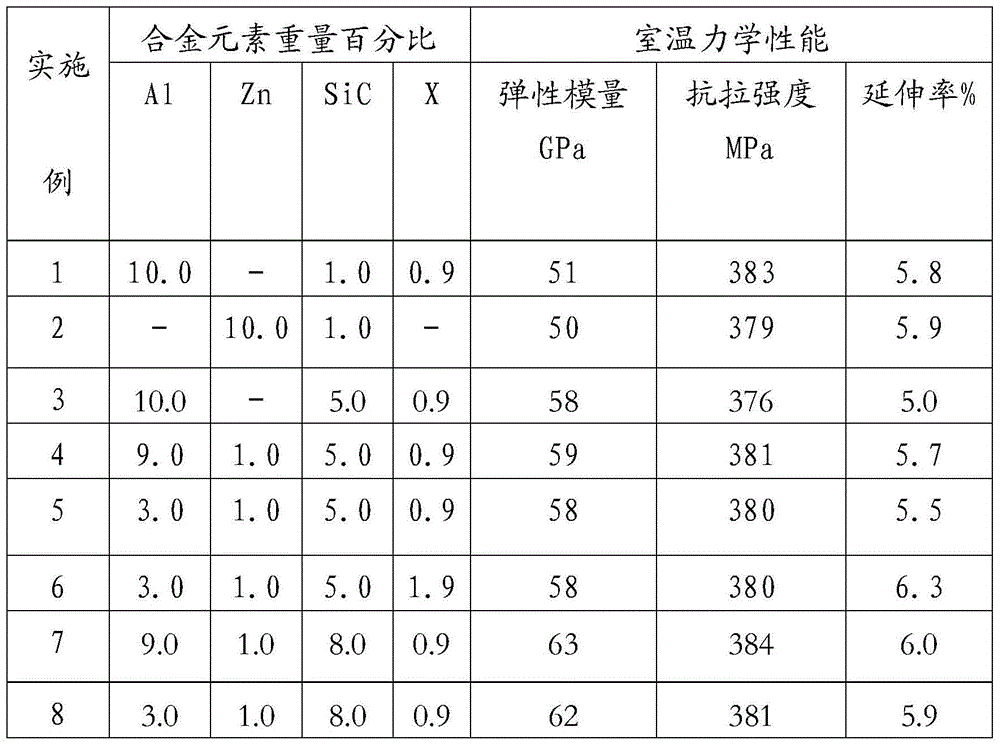

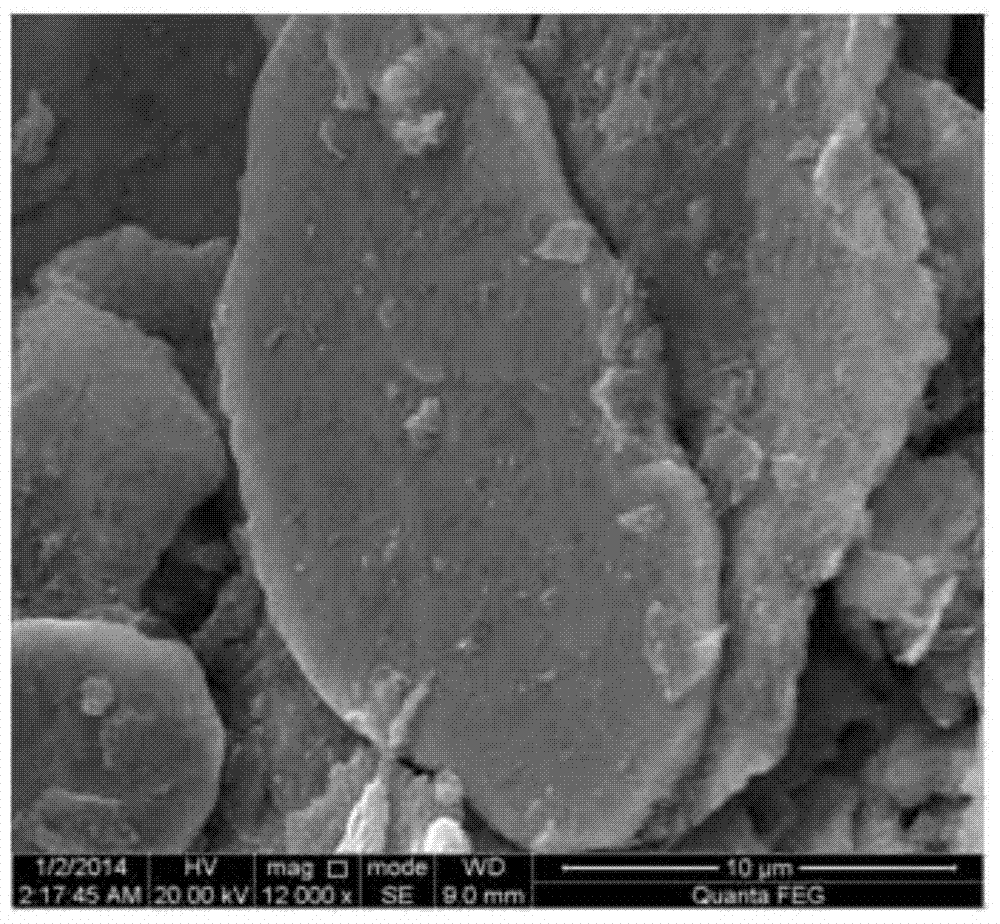

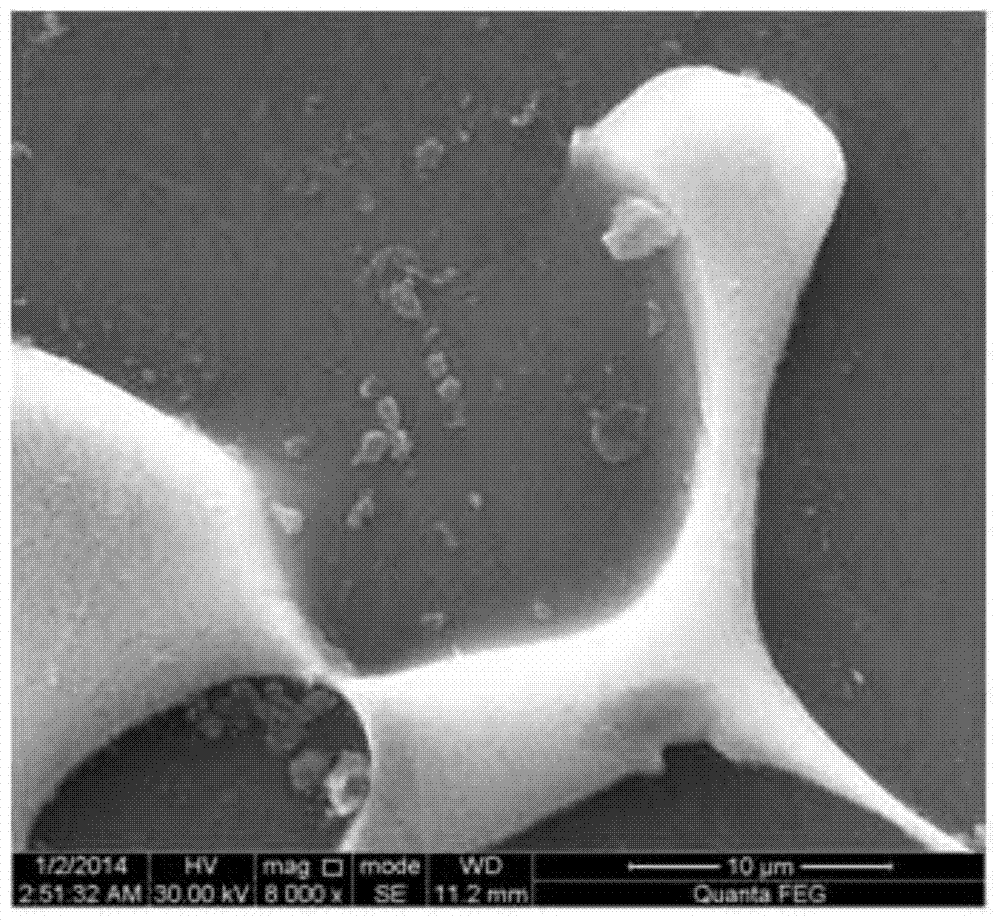

SiC particle-containing magnesium alloy high in elastic modulus and preparation method of magnesium alloy

ActiveCN104087800AThe group ratio is reasonableEasy to processMagnesium matrix compositeRoom temperature

The invention provides a SiC particle-containing magnesium-based composite material high in elastic modulus. The SiC particle-containing magnesium-based composite material comprises the following components in percentage by weight: 1.0-10.0% of aluminum and / or zinc, 1.0-15.0% of SiC and the balance of magnesium, wherein the sum of percentages by weight of the components is 100%; the alloy element comprises aluminum and / or zinc. A preparation method of the SiC particle-containing magnesium-based composite material comprises the following steps: punching holes in a pure magnesium ingot, adding SiC particles subjected to surface modification and drying into the holes, heating and melting pure magnesium under the protective atmosphere, stirring and then quickly raising the temperature again, adding intermediate alloys of the other components and stirring, controlling the time for fully melting the intermediate alloys till the casting time is shorter than or equal to 3 minutes, refining and slagging, casting to obtain a cast ingot. The SiC particle-containing magnesium-based composite material is reasonable in ratio of components, easy to process and manufacture and low in cost; the prepared magnesium-based composite material is high in room temperature strength and elastic modulus and good in plasticity; the comprehensive performance of the magnesium-based composite material is apparently higher than that of the existing ordinary magnesium alloy; the magnesium-based composite material is suitable for industrialized production.

Owner:BAIC MOTOR CORP LTD

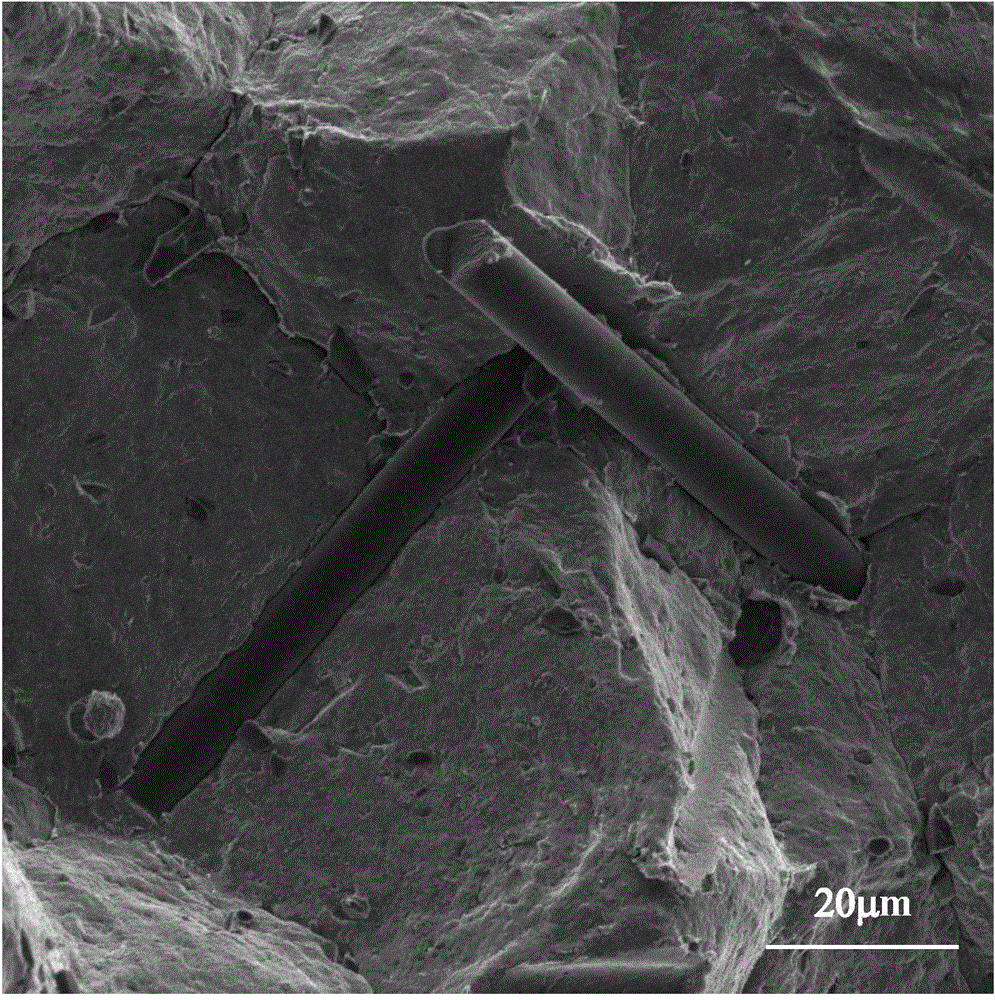

Method for preparing short carbon fiber reinforced magnesium-base composite material with good damping characteristic

The invention relates to a method for preparing a carbon fiber reinforced magnesium-base composite material with a good damping characteristic, which comprises the following steps: (1) removing organic rubber layers on the surfaces of short carbon fibers; (2) depositing metallic nickel coating layers through chemical plating, and obtaining the coating layers with required thicknesses by controlling the deposition time under an alkaline condition; and (3) after preparing the short carbon fibers of which the surfaces are plated with the metallic nickel coating layers, preparing the carbon fiber reinforced magnesium-base composite material with the good damping characteristic by adopting a powder metallurgic method. In the method, 3 to 20 percent (volume percentage) of chemical nickel plating short carbon fibers are added into a magnesium base, so a matrix is improved, and the matrix is endowed with a better damping characteristic; the material has a lower density compared with that the conventional damping alloy material and the better damping characteristic compared with that of pure magnesium, and the damping performance of the material can reach a high damping range of 0.015.

Owner:CHONGQING UNIV

Preparation method of graphene enhanced magnesium-based composite material

The invention relates to a preparation method of a graphene enhanced magnesium-based composite material, and relates to a preparation method of a nanometer composite material. The invention aims at solving the technical problem of nonuniform dispersion of the traditional graphene in a matrix metal. The preparation method comprises the following steps of 1, mixing graphene with an alcohol dispersant in absolute ethyl alcohol, chemically dispersing under an ultrasonic condition to obtain chemically dispersed graphene; 2, mixing the chemically dispersed graphene with Zn powder for ball milling to obtain Gra@Zn composite powder; 3, adding Gra@Zn composite powder to a semi-solid state Mg-Zn alloy fusant for mechanical stirring, then increasing temperature till liquid state, and stretching an ultrasonic rod below an alloy liquid level for ultrasonic dispersion treatment to obtain an alloy fusant; 4, pouring the alloy fusant into a preheated mould, and then solidifying so as to prepare the graphene enhanced magnesium-based composite material. The preparation method disclosed by the invention is applied to the field of preparation of the nanometer composite material.

Owner:严格集团股份有限公司

Method for in-situ preparation of TiBO2 reinforced magnesium-based composite material

The invention relates to a method of in-situ preparing TiB2 granule strengthening Mg-based composite material in the composite material technical field. The steps are that: powder of K2TiF6, KBF4 and Na3AlF6 are mixed uniformly and then put into a kiln for drying, thus obtaining waterless powder. Aluminum ingot is melted in a resistance furnace with heat preservation and uniformity; the waterless powder after dried is added to the melting Al melt liquid by batch and then is stirred with a graphite disc, and scum on the surface of the melt liquid is removed after stirred and stewed, thus obtaining TiB2-Al intermediate alloy; magnesium alloy is smelted with the protection of SF6 and CO2 mixing gas, and flame retardant element beryllium is added; the TiB2-Al intermediate alloy is added into the magnesium alloy melting solution slowly, stirred, stewed and cast. The technology of the invention is comparatively simple, has low cost, and the density of TiB2 / Mg composite material is between 1.8-2.0g / cm<3> and tensile strength thereof is increased by more than 60 percent than base alloy.

Owner:SHANGHAI JIAO TONG UNIV

Reaction and ball grinding process to prepare in-situ reinforced Mg-based composite material

The present invention belongs to the field of material technology. The technological process includes determining alloy element components; selecting reinforcing phase based on the lubricating property between the substrate and the reinforcing phase, controlling the reinforcing phase particle content in 2-15%, ball grinding compounded prefabricated body in high-energy ball mill to synthesize the prefabricated body containing the reinforcing phase for magnesium-base composite material and pressing the ball ground synthesized prefabricated body powder into block; smelting magnesium substrate material; stoving the prefabricated body at 150-250 deg.c for hr, fluxing treatment, adding the prefabricated body into magnesium melt at selected temperature, temperature maintenance and stirring; and casting with the melt after being letting stand.

Owner:SHANGHAI JIAO TONG UNIV

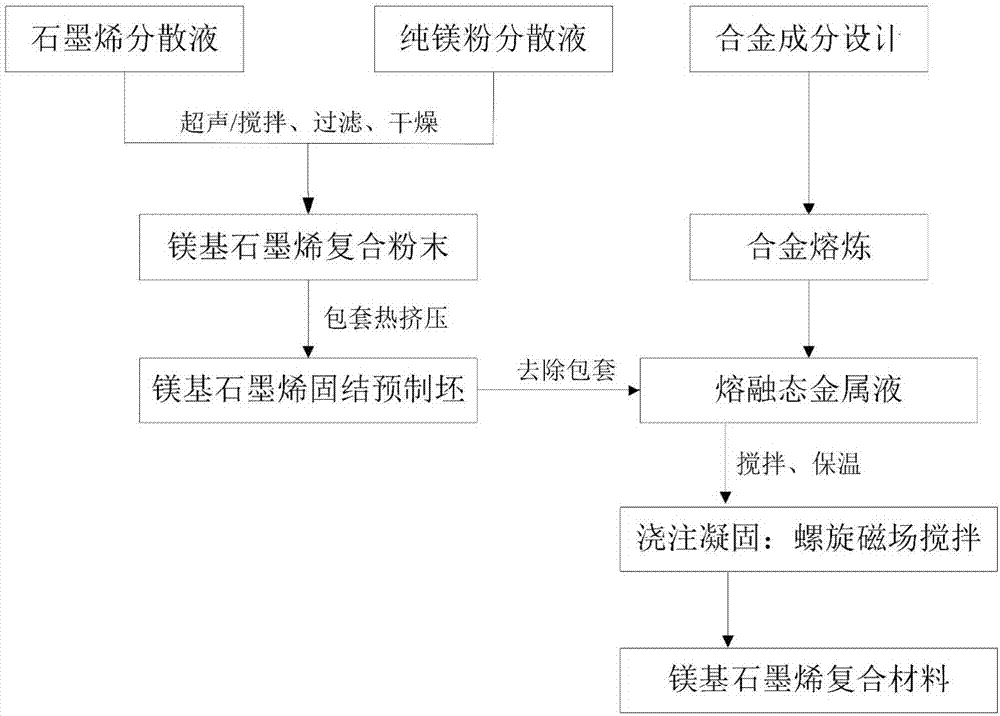

Preparation method of magnesium base graphene composite material

ActiveCN107058786AEvenly dispersedEffective dispersionMaterials preparationMagnesium matrix composite

The invention discloses a preparation method of a magnesium base graphene composite material, and belongs to the technical field of magnesium base composite materials. Firstly, graphene powder is dissolved in a proper amount of anhydrous ethanol solution to prepare graphene ultrasonic dispersion liquid; metal magnesium powder is dissolved in anhydrous ethanol for ultrasonic treatment and mechanical mixing to obtain graphene / magnesium powder mixed liquid; magnesium base graphene composite powder is prepared through vacuum drying after filtration; the composite powder is coated and thermally extruded to prepare a magnesium base graphene consolidation prefabricated blank; and the consolidation prefabricated blank is added in molten metal liquid after the coat is removed, and is stirred through a spiral magnetic field for casting solidification to finally prepare the magnesium base graphene composite material. The preparation method adopts a simple preparation process liable to realize, is low in production cost, wide in material preparation range, safe and environment-friendly, is wide in application and popularization prospect, and is suitable for preparing novel high-performance magnesium base graphene composite material.

Owner:HARBIN UNIV OF SCI & TECH

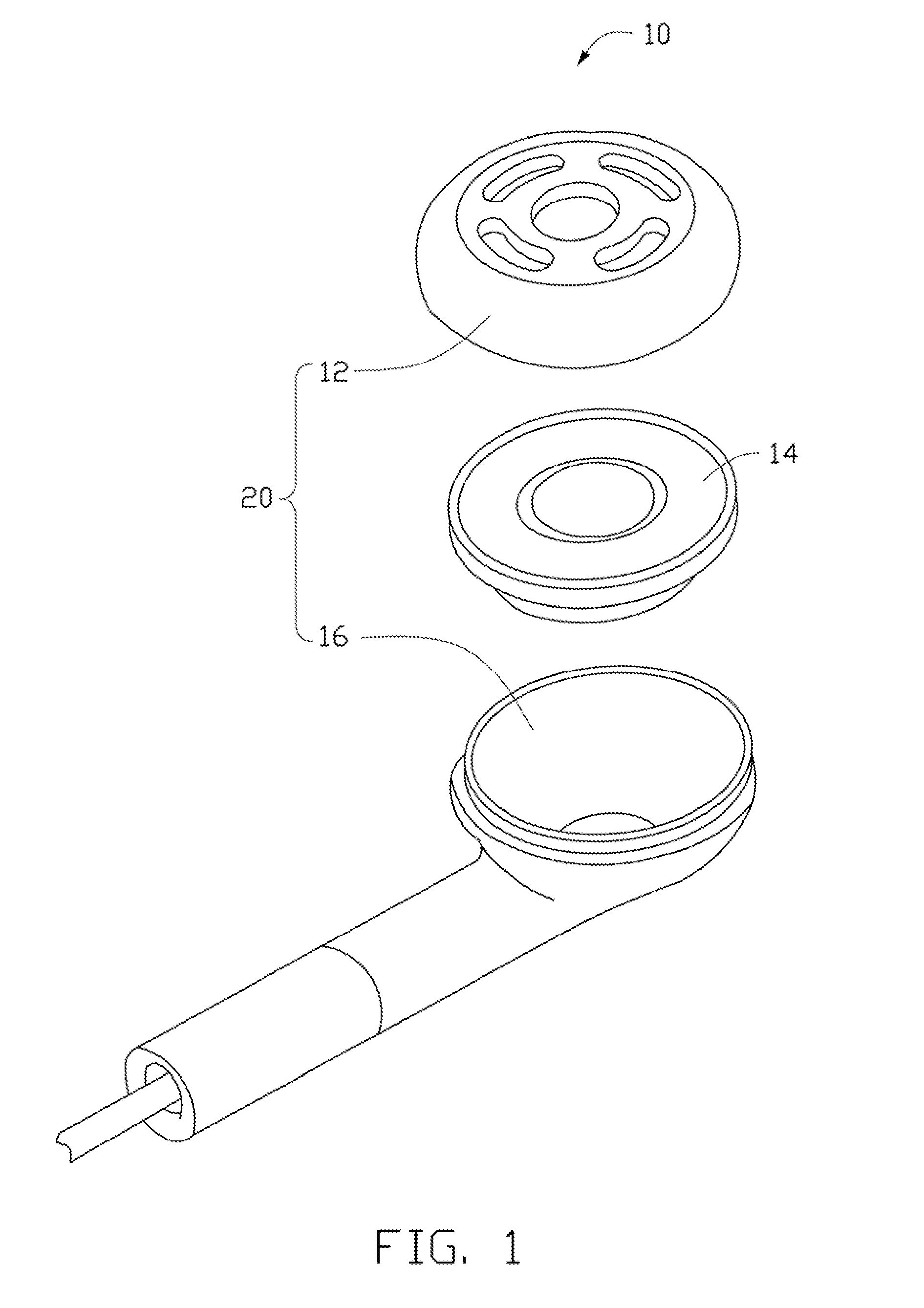

Magnesium based composite material and method for making the same

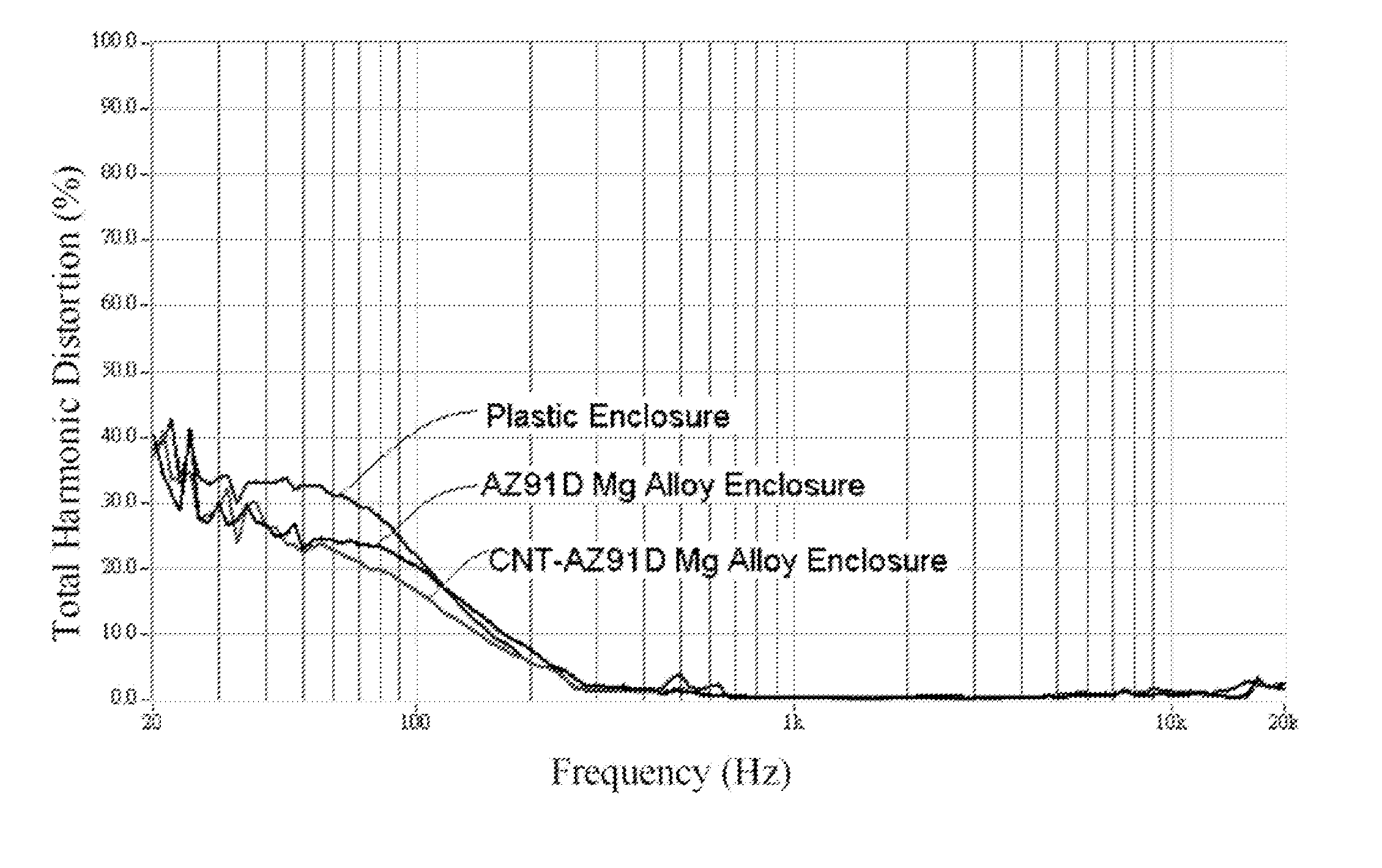

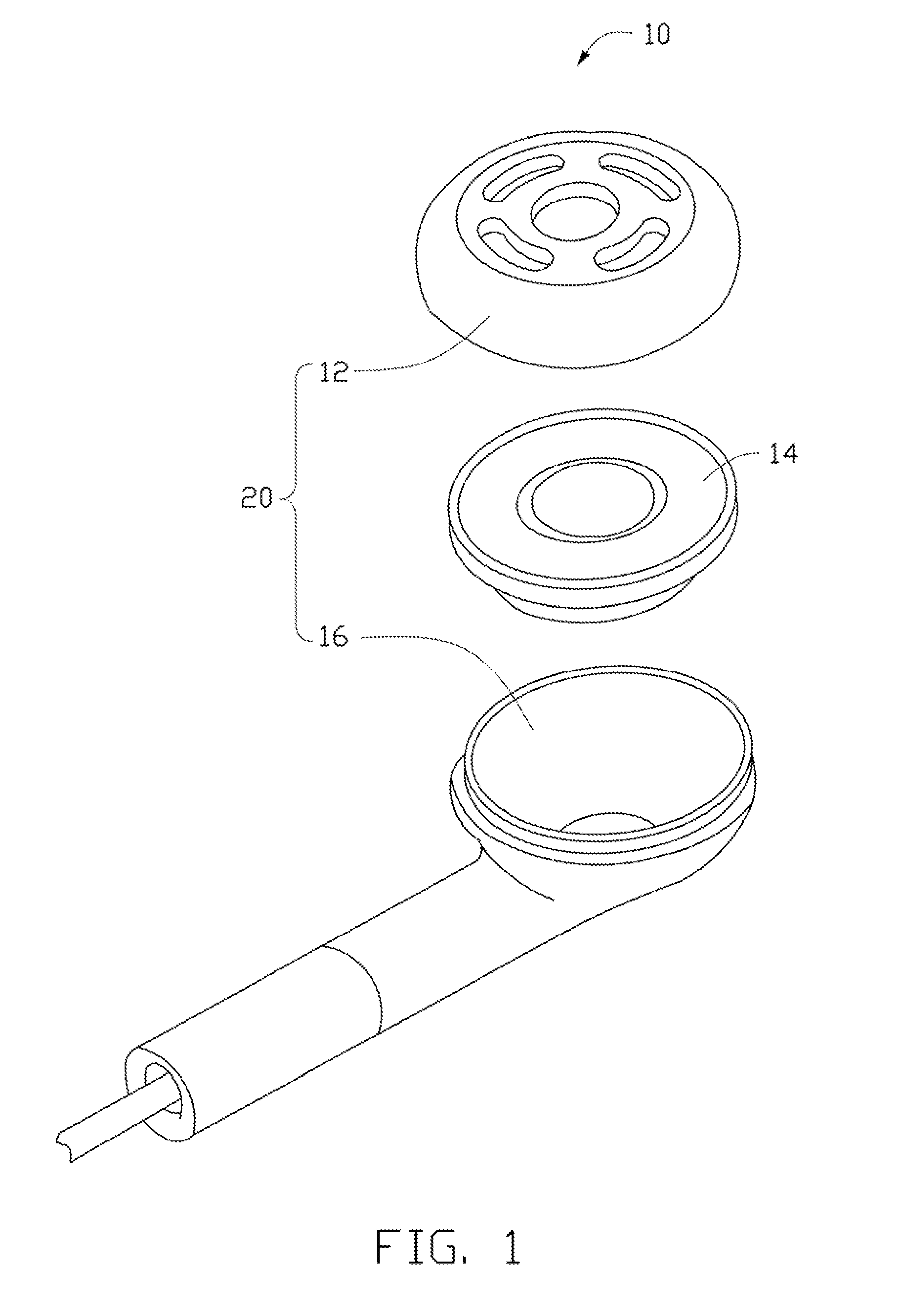

ActiveUS20110303866A1Improve sound qualityMaterial nanotechnologyBuilding constructionsMagnesium matrix compositeNanoparticle

The present disclosure relates to a magnesium based composite material. The magnesium based composite material includes a magnesium based metal matrix and nanoparticles dispersed in the magnesium based metal matrix in a weight percentage of a range from about 0.01% to about 2%. The present disclosure also relates to a method for making the magnesium based composite material. In the method, the nanoparticles are added to the magnesium based metal at a temperature of about 460° C. to about 580° C. to form a mixture. The mixture is ultrasonically vibrated at a temperature of about 620° C. to about 650° C. The mixture is casted at a temperature of about 650° C. to about 680° C., to form an ingot.

Owner:TSINGHUA UNIV +1

Prepn process of particle-reinforced Mg-base composite mateiral

InactiveCN1441075AImprove mechanical propertiesGood physical propertiesMagnesium matrix compositeMaterials science

The preparation process of Mg-base composite material includes the following steps: determining the alloy element components and reinforcing phase of the composite material, controlling the reinforcing phase content in 2-15 wt%, mixing and ball milling; pressing the mixed powder into prefabricated block and sintering under inert gas protection to synthesize the reinforcing phase for the Mg-base composite material; smelting magnesium substrate material; stoving and melting the prefabricated block and adding it into magnesium melt at proper temperature while stirring and maintaining the temperature; and casting the melt after being let stand to form. The reinforcing phase is fine, homogeneously distributed and excellent in interface binding, and the Mg-base composite material has excellent material and physical performance and may be used widely.

Owner:SHANGHAI JIAO TONG UNIV

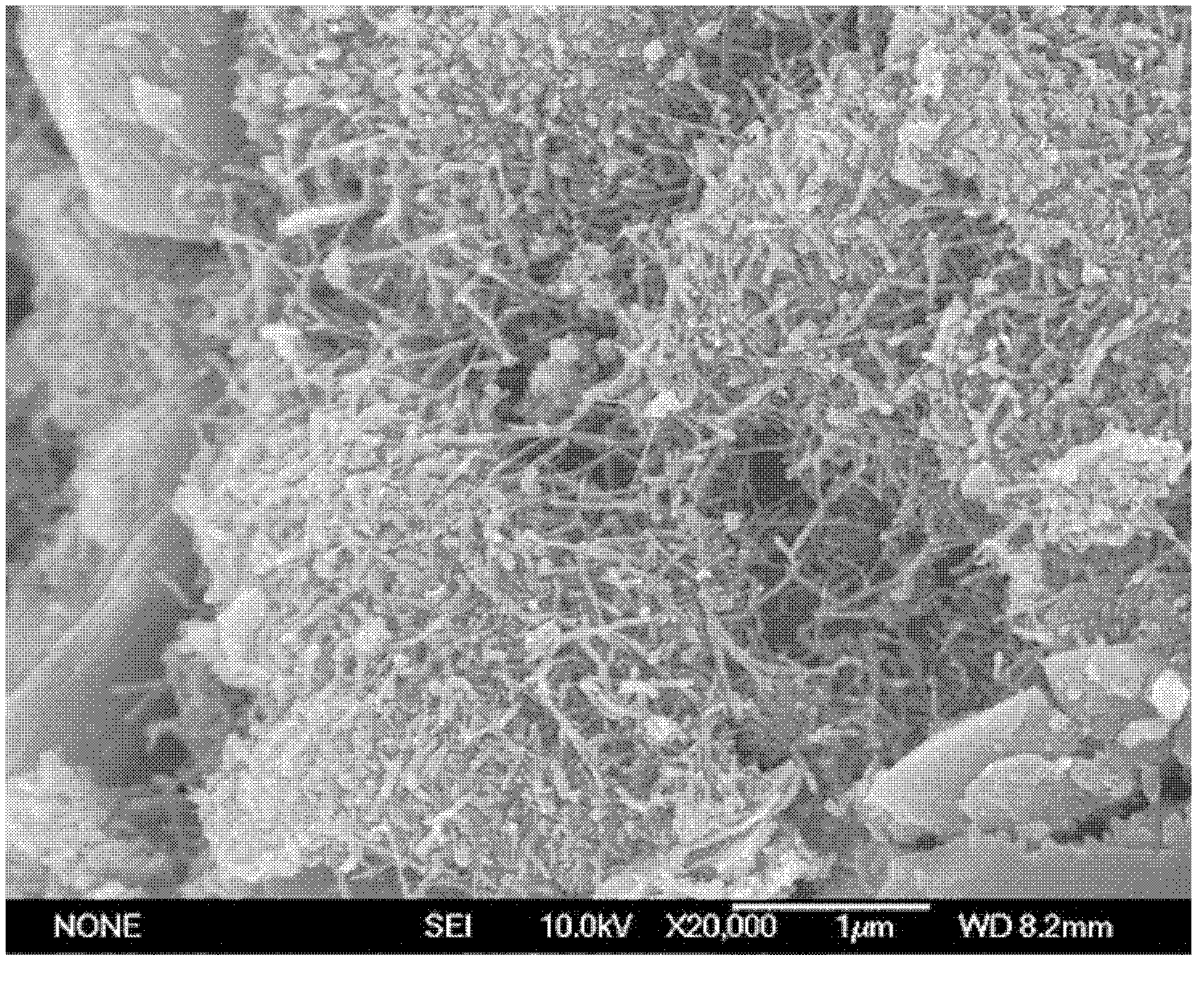

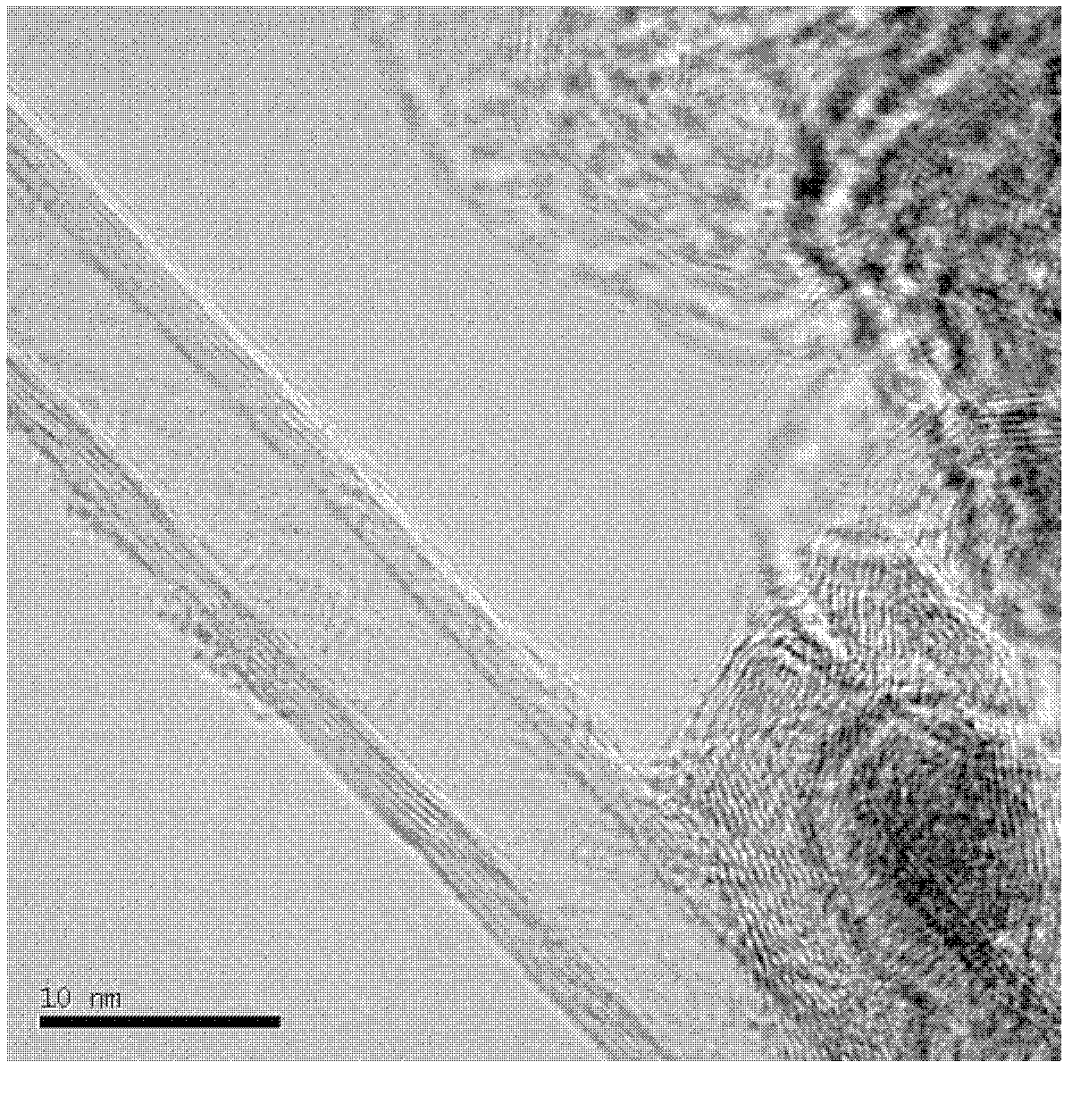

Preparation method of high-performance graphene nanosheet reinforced magnesium matrix composite

InactiveCN103773980AEffective dispersionSolve difficulties that are not easy to disperseMagnesium matrix compositeGraphene

The invention discloses a preparation method of a high-performance graphene nanosheet reinforced magnesium matrix composite, relates to a preparation method of a graphene nanosheet reinforced magnesium matrix composite, and aims at solving the problems that a graphene nanosheet has relatively low wettability and is not uniformly dispersed in a matrix metal. The method comprises the following steps: (I) mixing and ball-milling the graphene nanosheet and Zn powder; (II) adding the composite powder into an Mg-Zn alloy melt; (III) performing ultrasonic treatment; (IV) pouring and solidifying. According to the method disclosed by the invention, the preparation process of the composite is simple and feasible, the mechanical properties of the prepared composite are remarkably improved, and the graphene nanosheet has good wettability and is uniformly dispersed in the matrix metal. The method disclosed by the invention is applied to preparation of a high-performance graphene nanosheet reinforced magnesium matrix composite.

Owner:HARBIN INST OF TECH

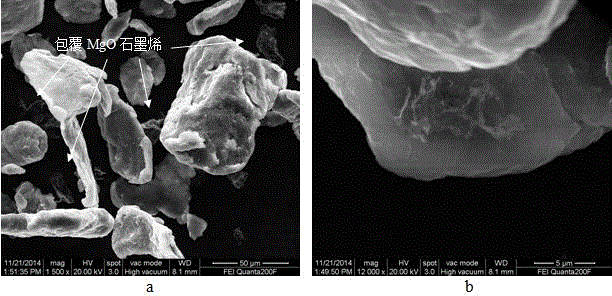

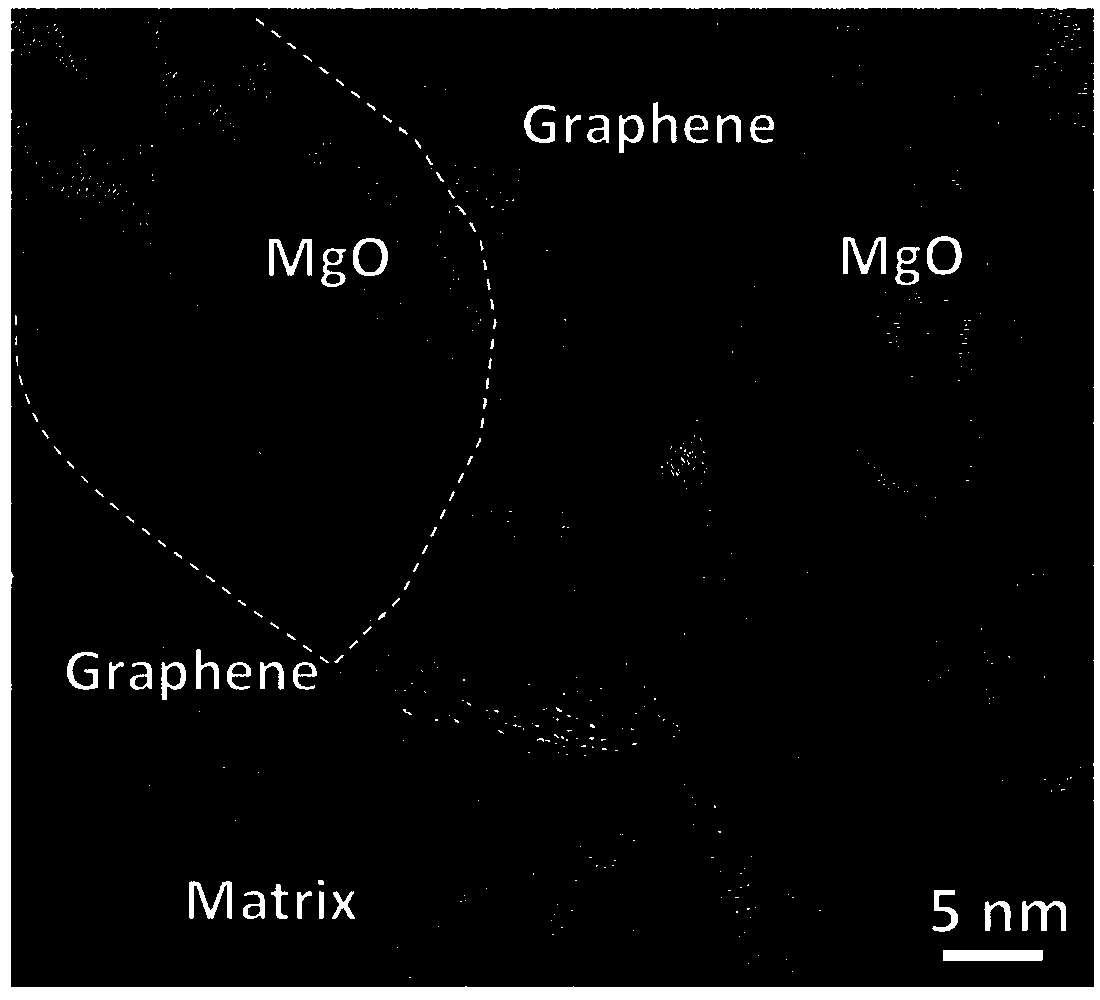

Method for reinforcing magnesium matrix composite by using magnesium oxide-coated graphene

The invention provides a method for reinforcing a magnesium matrix composite by using magnesium oxide-coated graphene. The method comprises the following steps: mixing 0.1 to 5 g of magnesium oxide-coated graphene with no less than 250 ml of an ethanol solution and carrying out ultrasonic treatment for 1 to 2 h so as to obtain a magnesium oxide-coated graphene ethanol mixed liquor; adding magnesium alloy powder with mass of no less than 95 g and granularity of no more than 325 meshes into the mixed liquor and carrying out ultrasonic treatment and mechanical stirring for 1 to 3 h so as to obtain mixed slurry; carrying out filtering and vacuum drying on the mixed slurry, then transferring the obtained substance to a die and carrying out cold pressing at room temperature under a pressure of 100 to 600 MPa; sintering a cold-pressed composite at 500 to 600 DEG C under the protection of argon for 2 to 4 h; carrying out hot extrusion on the sintered composite at 350 to 400 DEG C; and subjecting the extruded composite to T6 heat treatment. The method has the advantages of low process cost, safety, reliability and simple operation; the magnesium oxide-coated graphene is uniformly distributed in magnesium alloy and has high bonding strength with a matrix interface, obvious grain refinement effect is obtained, and the composite has excellent performance; and the method can realize industrial preparation of the high-performance graphene-reinforced magnesium alloy composite.

Owner:NANCHANG UNIV

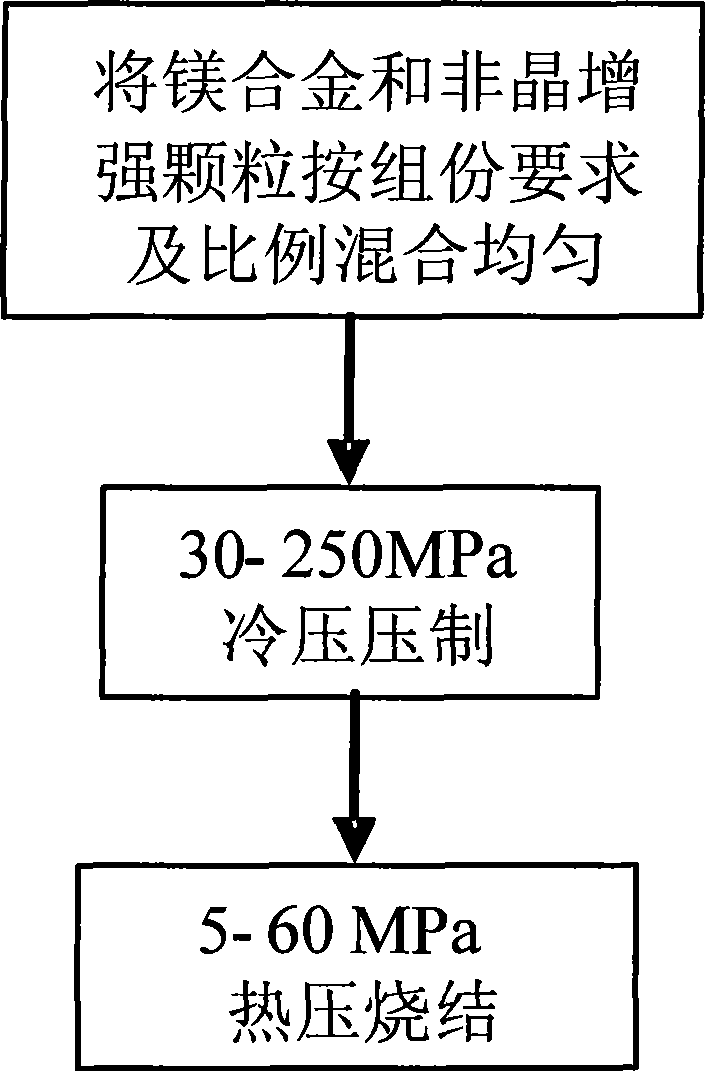

Amorphous particle reinforced magnesium-base composite material and manufacture process

InactiveCN101368242ASimple manufacturing processImprove reliabilityMagnesium matrix compositeAmorphous metal

The invention discloses an amorphous reinforced magnesium-based compound material and a preparation technique thereof. The material includes an amorphous grain NixMyTz and a magnesium-based alloy MgaAlbQcRd; wherein, x is equal to or more than 30 or equal to or less than 70; y is equal to or more than 3 or equal to or less than 50; z is equal to or more than 0, or equal to or less than 35; a is equal to or more than 80, or equal to or less than 100; b is equal to or more than 0, or equal to or less than 18; c is or is equal to or more than 0, or equal to or less than and d is equal to or more than 0, or equal to or less than 3. Simultaneously, the invention also provides the preparation technique of the amorphous reinforced magnesium-based compound material: the grains of a magnesium alloy and the grains of an amorphous alloy are uniformly mixed and pressed in a cold pressing way with a cold pressing pressure of 30 to 250MPa; then the grains of the magnesium alloy and the grains of the amorphous alloy are sintered in a hot pressing sinter boiler with a hot pressing pressure of 5 to 60MPa; the sintering temperature is arranged between 500 and 700 DEG C; the sintering time lasts 30 to 180 minutes. An amorphous metal reinforcement adopted by the amorphous reinforced magnesium-based compound material has typical metal characteristics and can be better combined with the interface between magnesium and a magnesium alloy matrix, thereby better facilitating to improving the reliability of the material during the using process; simultaneously the preparation technique of the amorphous reinforced magnesium-based compound material is more simplified, thus being suitable for industrial production.

Owner:上海市机械制造工艺研究所有限公司

Preparation method of titanium particle reinforced magnesium base composite material

InactiveCN1718792AEvenly distributedChange the ratioMagnesium matrix compositeElectromagnetic shielding

A process for preparing the Ti particle reinforced Mg-base composition includes such steps as proportionally mixing Ti particles with Mg or Mg-alloy powder, proportionally adding agate pellets, ball grinding, die pressing to become blocks, vacuum sintering, hot squeezing and cold machining to obtain parts with light weight, high specific strength and specific rigidity, and electromagnetic shielding function.

Owner:SHANGHAI JIAO TONG UNIV

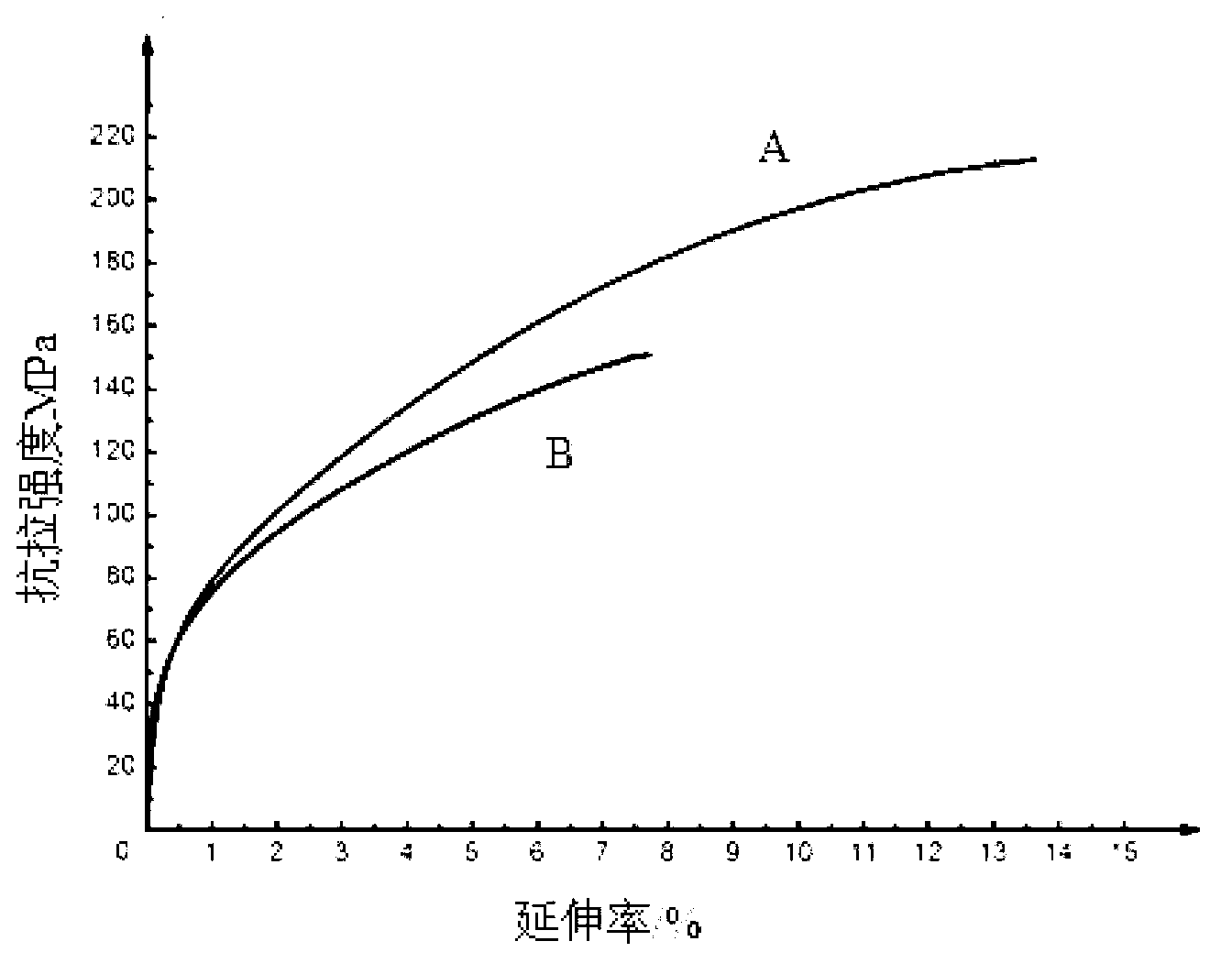

Preparation method of enhanced magnesium-based composite material of carbon nanotubes

The invention relates to a preparation method of an enhanced magnesium-based composite material of carbon nanotubes, relates to a preparation method of a nanometer composite material, and mainly solves the technical problems that the carbon nanotubes are difficultly scattered uniformly in a magnesium alloy matrix and the tensile strength of the enhanced magnesium-based composite material is low. The preparation method comprises the following steps of: firstly, carrying out mixing and ball milling on Zn powder and the carbon nanotubes to obtain composite powder; secondly, pressing the composite powder and magnesium powder into precast blocks after uniformly mixing the composite powder and the magnesium powder; and finally, adding the precast blocks into the molten magnesium powder, heating until obtaining metal solution, and transferring the metal solution into a die to be pressed, thus obtaining the enhanced magnesium-based composite material of the carbon nanotubes, wherein the tensile strength of the enhanced magnesium-based composite material is 195-210 MPa, and the elongation rate of the enhanced magnesium-based composite material is 13-15%. According to the preparation method of the enhanced magnesium-based composite material of the carbon nanotubes, the tensile strength is high, the dispersity is good, and the enhanced magnesium-based composite material of the carbon nanotubes can be applied to the fields of aerospace, automobiles and sports equipments.

Owner:HARBIN INST OF TECH

Electromagnetic/ultrasonic preparation method of in-situ particle reinforced magnesium-based composite material

InactiveCN101608277AImprove bindingEnhancement effect is goodSelf-propagating high-temperature synthesisMagnesium matrix composite

An electromagnetic / ultrasonic preparation method of an in-situ particle reinforced magnesium-based composite material belongs to the technical field of metallurgy. The invention discloses a method for preparing the magnesium-based composite material with an electromagnetic continuous casting method, which is characterized by comprising the following steps of: melting a magnesium-based melt added with micro-alloying elements of Ca, rare earth Y, rare earth Ce; selecting an Al-Ti-C or Al-Ti-B reinforced system, adopting a self-propagating high-temperature synthesis method to synthesize a magnesium-based composite material melt containing reinforced particles in situ, and implementing electromagnetic / ultrasonic combined stirring to the magnesium-based composite material melt; and finally adopting a continuous casting process to form the magnesium-based composite material by continuous casting, and applying an electromagnetic field and an ultrasonic field within the range of a crystallizer so as to obtain a multi-phase reinforced magnesium-based composite material continuous-casting billet. The electromagnetic / ultrasonic preparation method has the effects and advantages of organically combining the self-propagating reaction method with the electromagnetic continuous casting technology and the ultrasonic technology, obtaining the magnesium-based composite material continuous-casting billet with smooth surface, uniform distribution of particle reinforcement phases in the basal body and good combination of the reinforced bodies and the basal body, and having simple preparation process.

Owner:DALIAN UNIV OF TECH

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

InactiveCN102206793AHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

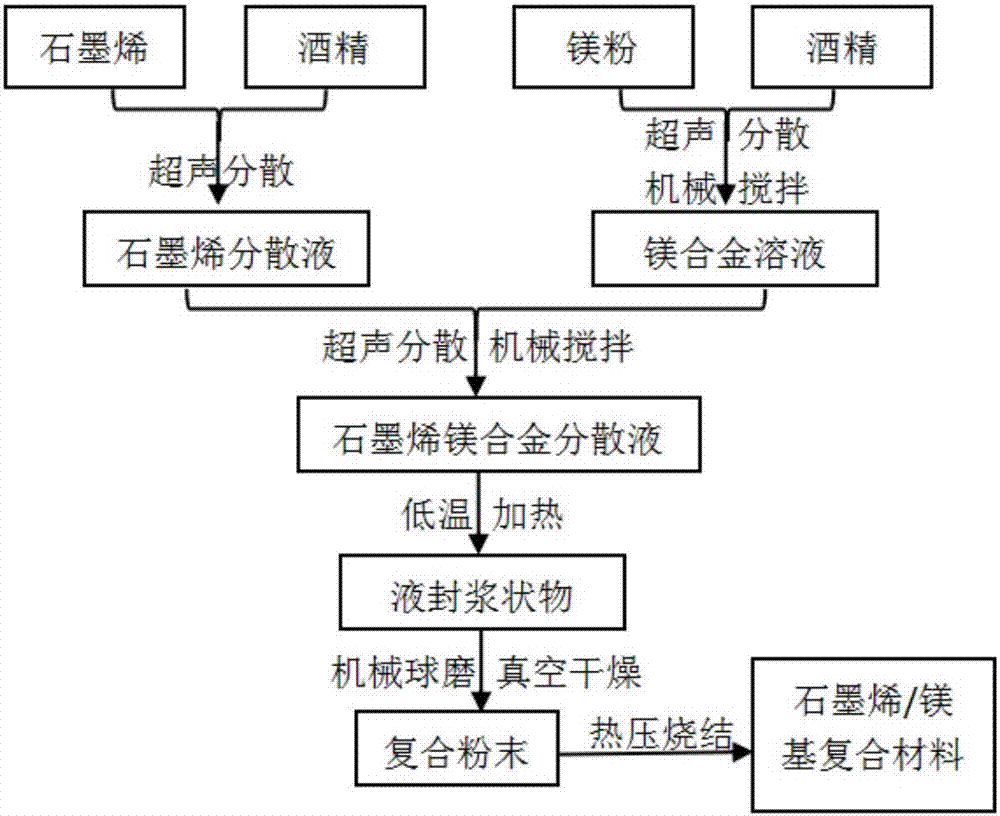

Preparation method for graphene reinforced magnesium matrix composite material

The invention discloses a preparation method for a graphene reinforced magnesium matrix composite material. The preparation method comprises the following steps that magnesium powder is dissolved in ethanol, mechanical stirring and ultrasonic dispersion are conducted, and a magnesium alloy solution is obtained; graphene is added into the ethanol, ultrasonic mixing is conducted, and a graphene dispersion solution is obtained; the graphene dispersion solution is added into the magnesium alloy solution drop by drop, ultrasonic dispersion and mechanical stirring are conducted, and a graphene magnesium alloy dispersion solution is obtained; the graphene magnesium alloy dispersion solution is placed in a low-temperature water bath kettle to be heated; after the solution evaporates to be liquid seal pulp, heating is stopped, the pulp is taken out to be subjected to vacuum ball milling, vacuum pumping is conducted after standing, then high-purity argon is pumped in, and ball milling is conducted; a ball-milled mixture is taken out, subjected to vacuum drying and put into a vacuum glove box to be subjected to manual dispersion grinding; and composite powder is put into a sintering furnace to be sintered. The technological process is simple, practicability is wide, and the graphene reinforced magnesium matrix composite material has wide military and aviation application prospects.

Owner:HARBIN UNIV OF SCI & TECH

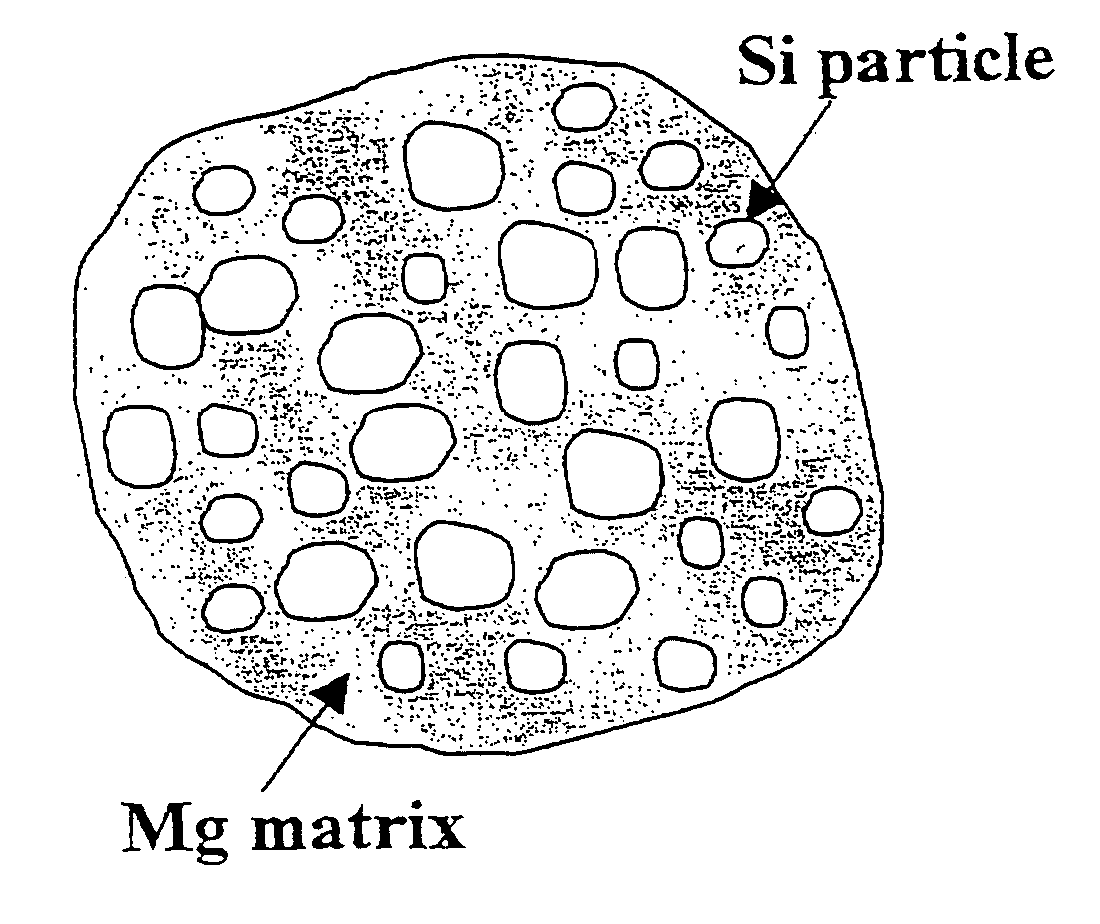

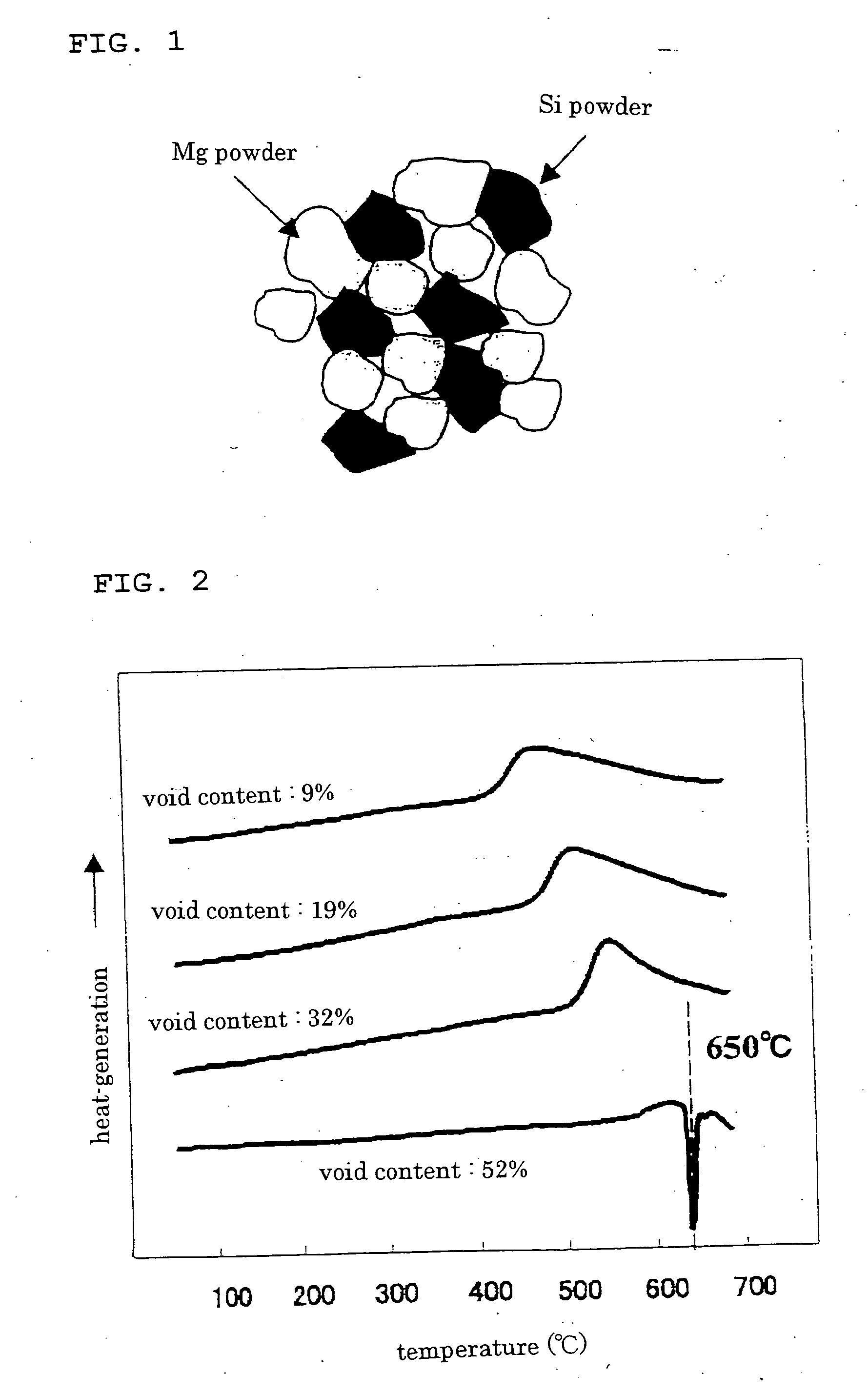

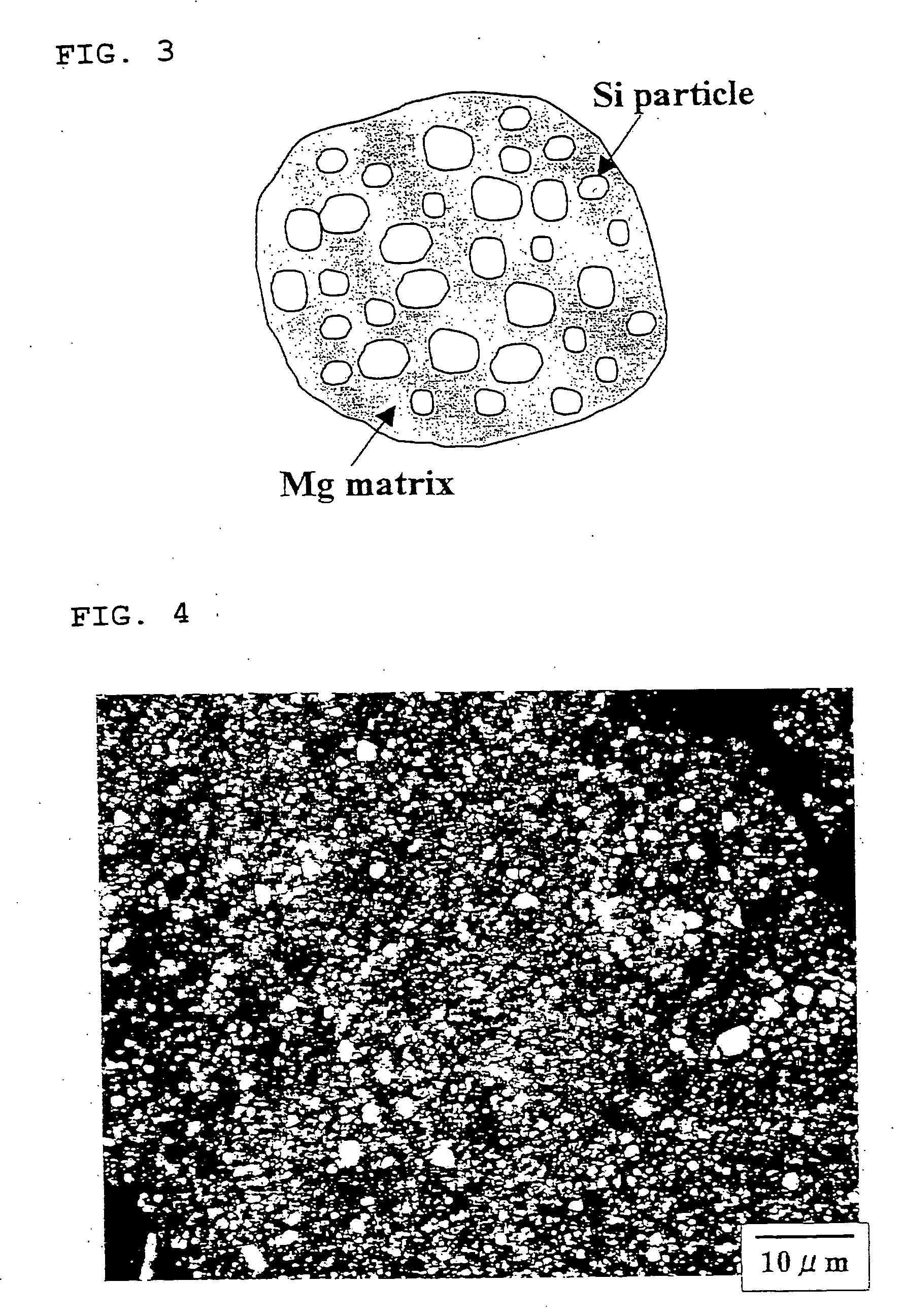

Magnesium base composite material

InactiveUS20050016638A1Improve mechanical propertiesReactionMetal silicidesMagnesium matrix compositeHardness

The present invention provides a magnesium-base composite material capable of suppressing coarse growth of a crystal particle size of a magnesium matrix and Mg2Si particles, thereby providing excellent mechanical properties such as strength and hardness, and a manufacturing method thereof. The manufacturing method includes the steps of: blending matrix powder containing Mg and Si powder to obtain a blended matter; applying a plasticization treatment to the resulting blended matter to form a solid body; heating the solid body to allow Mg and Si to react with each other to form a heat solid body containing Mg2Si; and applying a warm plasticization treatment to the heat solid body. Thus, it is possible to provide a magnesium-base composite material having a tensile strength from not less than 100 MPa to not more than 500 MPa.

Owner:TOUDAITLO LTD

Method of improving damping performance of fiber reinforced magnesium base composite material

A process for improving the damping performance of fibres reinforced Mg-base composition includes such steps as removing the colloidal layer from the surface of carbon (or graphite) fibre, thermodecomposing the high-C alkane gas to generate carbon, depositing it on the surface of said fibres by CVD to form a plated carbon layer, and pressure immersing of said fibres in the liquid magnesium or Mg-alloy. Its damping coefficient can reach 0.01.

Owner:NINGBO SUNLIGHT MOTOR PARTS

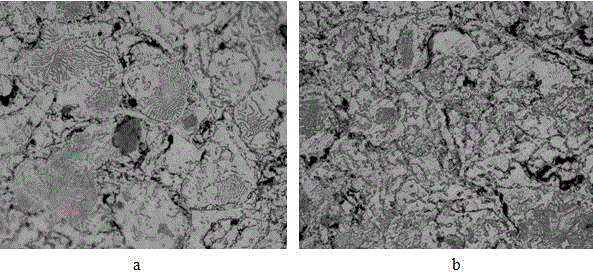

Graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and preparing method thereof

ActiveCN108754264AHigh densityImprove the bonding strength of the interfaceMagnesium matrix compositeCvd graphene

The invention discloses a graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and a preparing method thereof, relates to a graphene enhanced magnesium-based composite material and a preparing method thereof, and aims at solving the problems that in existing composite materials, graphene and magnesium matrix wettability is poor, graphenedispersibility is poor, and the interface bonding strength is low. The composite material is prepared through three raw materials including oxide, graphene and a magnesium matrix. The method comprises the steps that firstly, stirring casting or powder metallurgy is conducted; and secondly, heat deformation is conducted, and a cast-state composite material or a sintered-state composite material issubjected to hot extrusion or rolling deformation. The interface position of the composite material prepared through the method is free of holes and impure phases, graphene and matrix wettability isgood, and the interface interaction between graphene and a matrix is high. The graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and thepreparing method thereof are used in the magnesium-based composite material field.

Owner:HARBIN INST OF TECH

Preparation method of carbon fiber reinforced magnesium matrix composite

The invention relates to a preparation method of a carbon fiber reinforced magnesium matrix composite, which is implemented by taking magnesium and carbon fibers as raw materials through carrying out surface galvanization, ball-milled powder mixing, die-filling, vacuum discharge and plasma sintering, and rolling on carbon fibers so as to obtain the carbon fiber reinforced magnesium matrix composite. The preparation method is advanced in process and detailed and accurate in data, a galvanization layer on the surface of the carbon fiber can effectively improve the wettability of the carbon fiber and a magnesium matrix, the interface bonding is good, the micro-hardness of the prepared carbon fiber reinforced magnesium matrix composite is 58 HV, the bending strength is 206 MPa, and the tensile strength is 172 MPa, therefore, the method is an extremely ideal preparation method of carbon fiber reinforced magnesium matrix composites.

Owner:TAIYUAN UNIV OF TECH

Preparation method of carbon-nanotube-enhanced magnesium-based composite material

ActiveCN102747240AImprove performanceAvoid melting temperatureMagnesium matrix compositeModified carbon

The invention relates to a preparation method of a carbon-nanotube-enhanced magnesium-based composite material. The method comprises the steps that: carbon nanotubes are subjected to surface modification, such that a uniform and compact Ni-P alloy layer is formed on the surface of the carbon nanotubes; the modified carbon nanotubes are mixed with powders of elements such as magnesium, aluminum, and zinc, such that a mixed raw material is obtained; the mixed raw material is mixed with ceramic balls, such that mixed powder is obtained; the mixed powder is placed in a mold, and is subjected to bidirectional cold-pressing under room temperature; the composite material obtained by cold-pressing is subjected to vacuum sintering with the mold; and the composite material obtained by vacuum sintering is subjected to hot extrusion. With the method provided by the invention, the carbon-nanotube-enhanced magnesium-based composite material with high performance, light weight, and high strength can be prepared. The combination of the enhancing phase and the substrate is good. The material is advantaged in relatively high specific strength, high specific rigidity, high thermal conductivity, excellent machining performance, and the like. The composite material has good application prospect in industrial fields such as aeronautics and astronautics, automotives, 3C industries, sports and entertainments, and the like.

Owner:NORTHEASTERN UNIV

Magnesium based composite material and method for making the same

The present disclosure relates to a magnesium based composite material. The magnesium based composite material includes a magnesium based metal matrix and nanoparticles dispersed in the magnesium based metal matrix in a weight percentage of a range from about 0.01% to about 2%. The present disclosure also relates to a method for making the magnesium based composite material. In the method, the nanoparticles are added to the magnesium based metal at a temperature of about 460° C. to about 580° C. to form a mixture. The mixture is ultrasonically vibrated at a temperature of about 620° C. to about 650° C. The mixture is casted at a temperature of about 650° C. to about 680° C., to form an ingot.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com