Graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and preparing method thereof

A technology of nano-magnesium oxide and composite materials, which is applied in the field of graphene-reinforced magnesium-based composite materials and its preparation, can solve the problems of poor graphene dispersion, low interface bonding strength, poor wettability between graphene and magnesium matrix, etc., and achieve improved The effects of interface bonding strength, mechanical properties improvement, and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

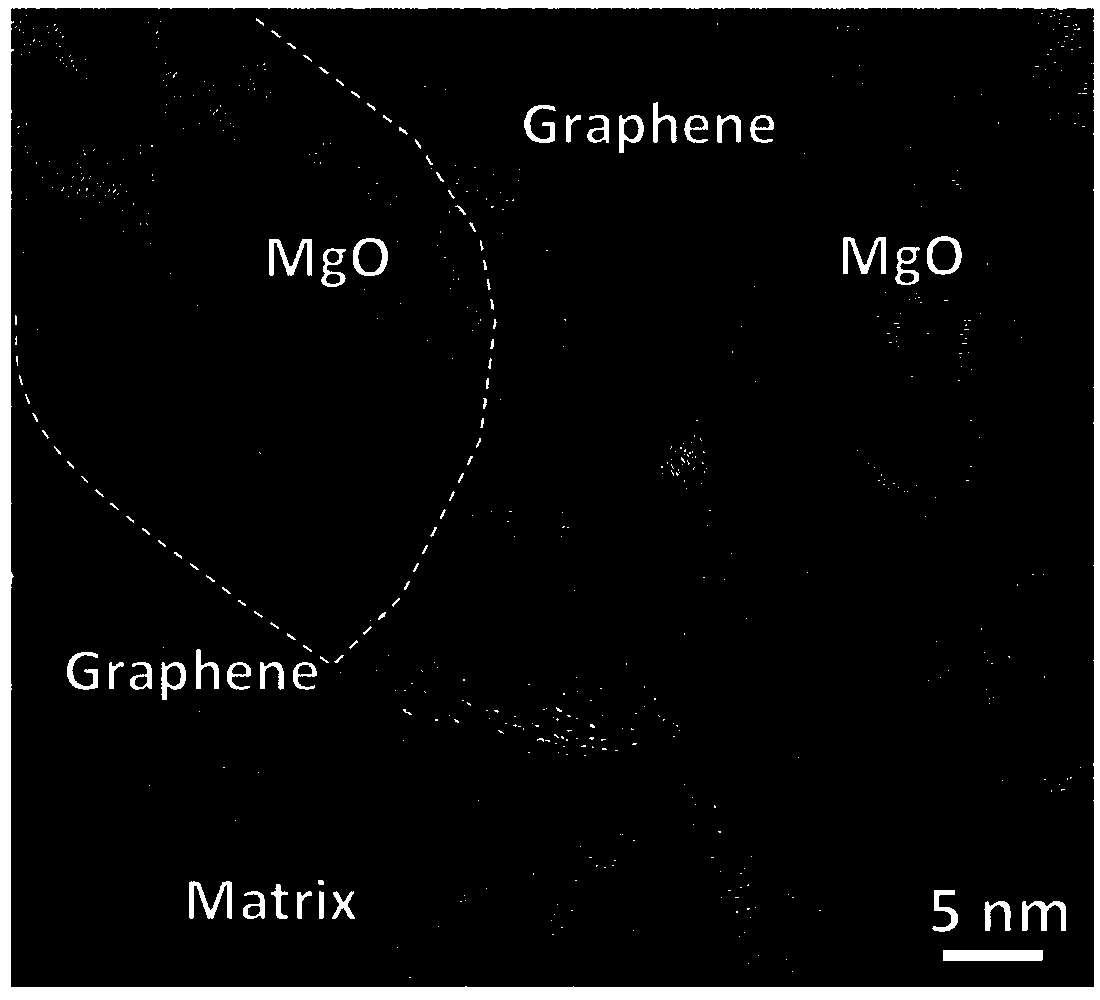

[0038] Specific embodiment one: present embodiment graphene and self-generated nano-magnesium oxide particle composite reinforced magnesium-based composite material are made of three kinds of raw materials of oxide, graphene and magnesium matrix, wherein the mass ratio of oxide and graphene is 1: (1-5), graphene accounts for 0.1%-2.0% of the total mass of the three raw materials, and the rest is magnesium matrix.

[0039] The method in this embodiment has low cost, simple equipment requirements, and is green and pollution-free. In the prepared composite material, the graphene is uniformly dispersed, the bonding strength of the interface between the graphene and the magnesium matrix is high, and the composite material has high strength and high elongation.

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment is different from Embodiment 1 in that: the oxide is zinc oxide, aluminum oxide, silicon oxide, nickel oxide, copper oxide or iron oxide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment is different from Embodiment 1 in that: the magnesium matrix is pure magnesium or a magnesium alloy. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com