Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Good film density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

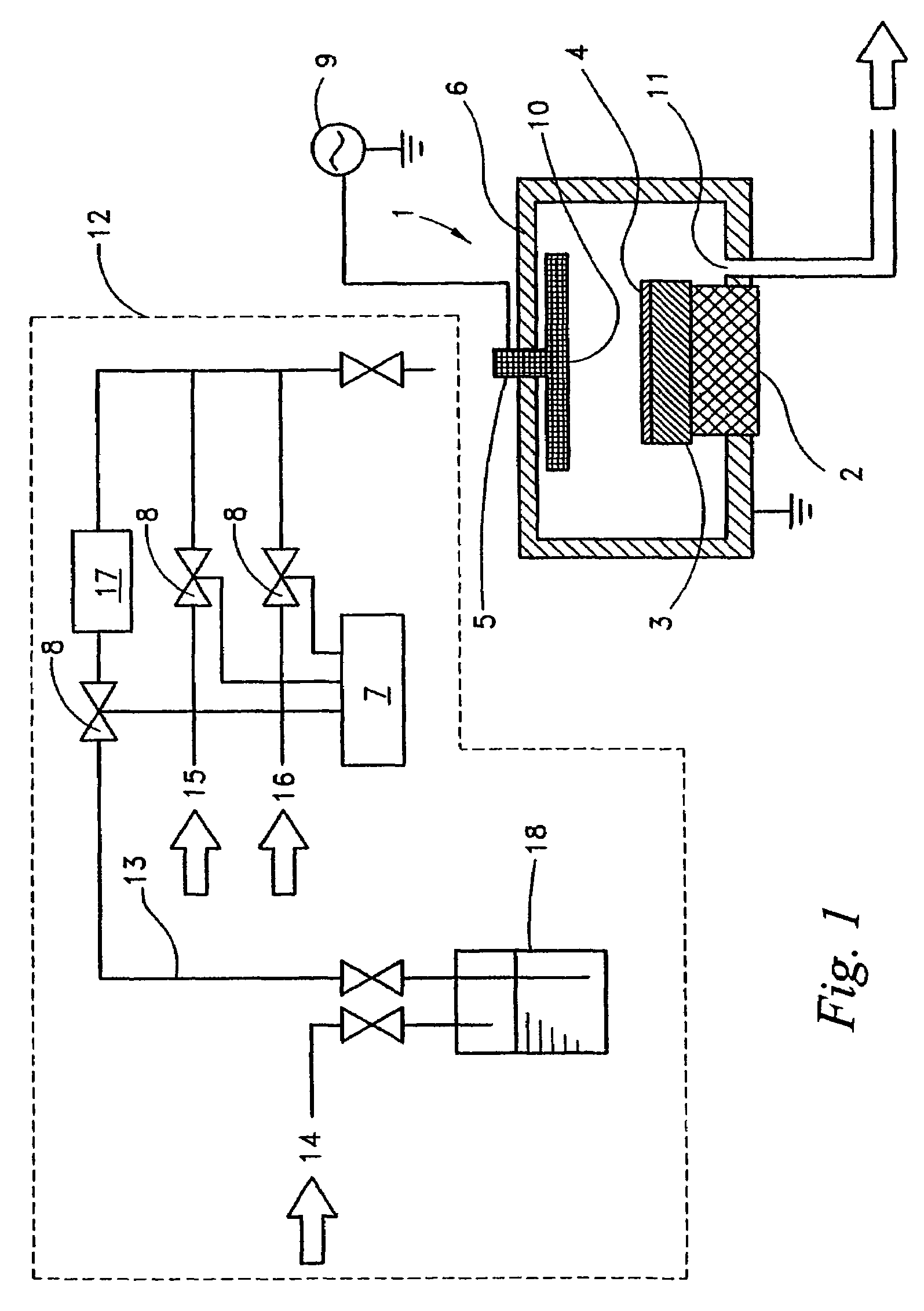

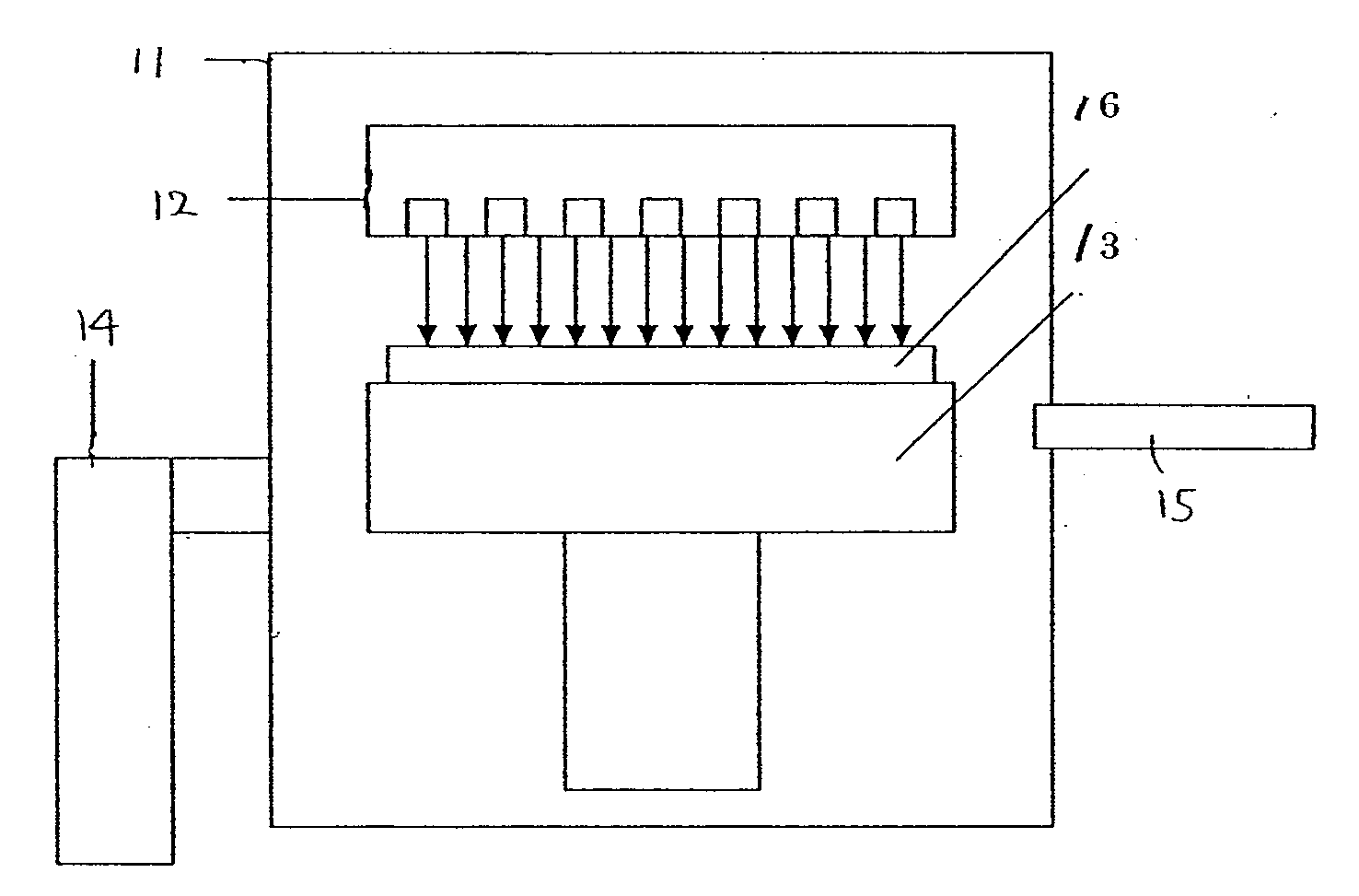

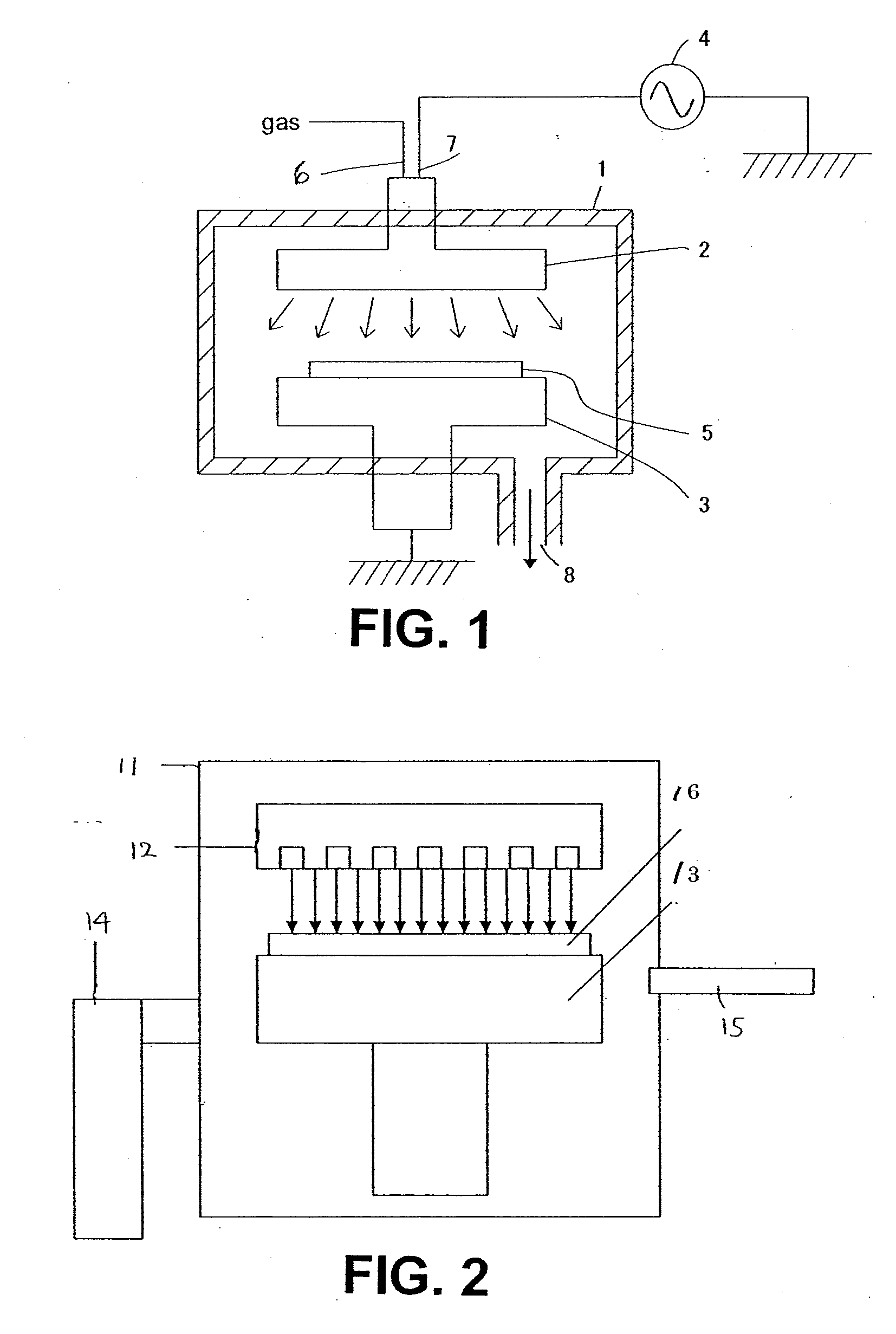

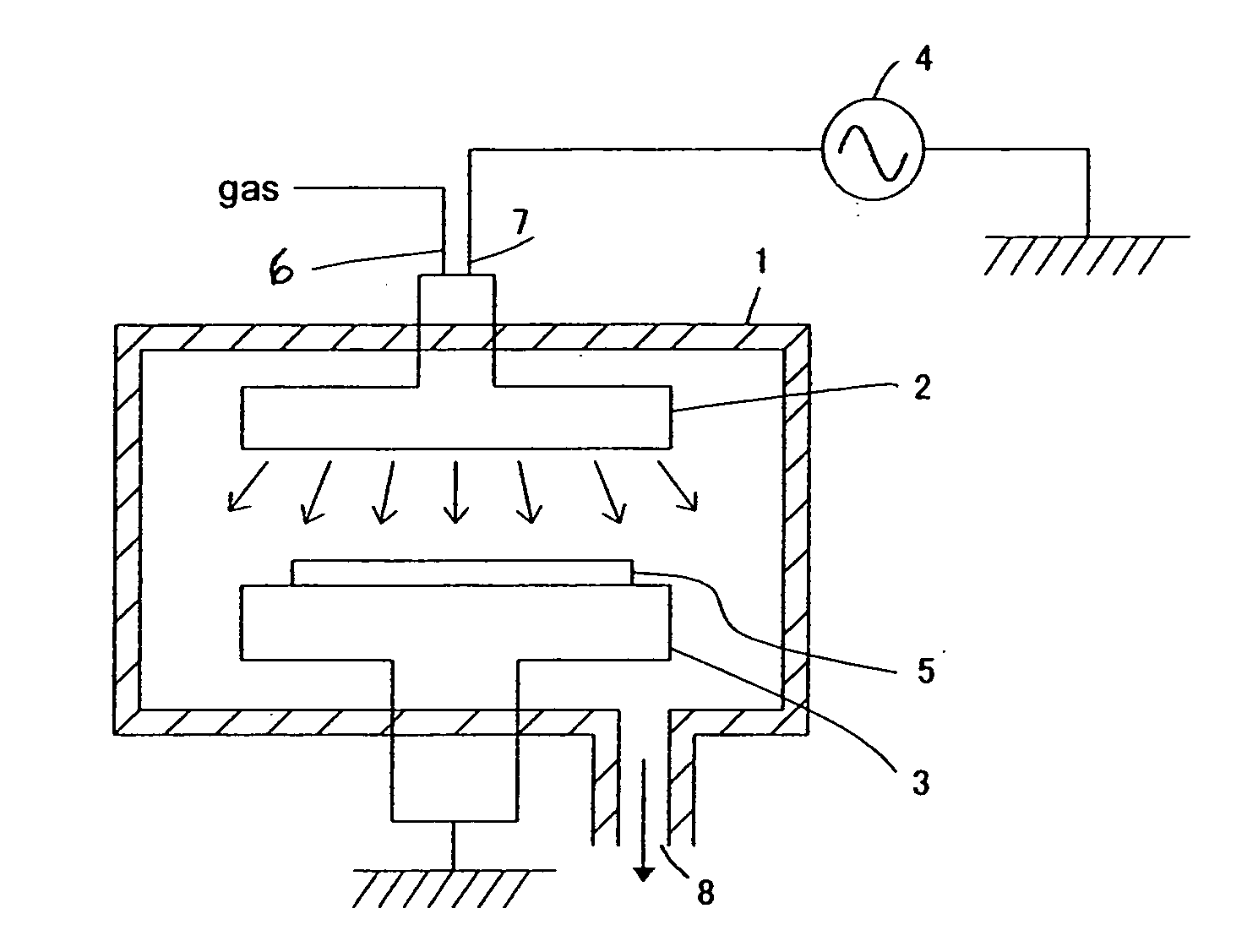

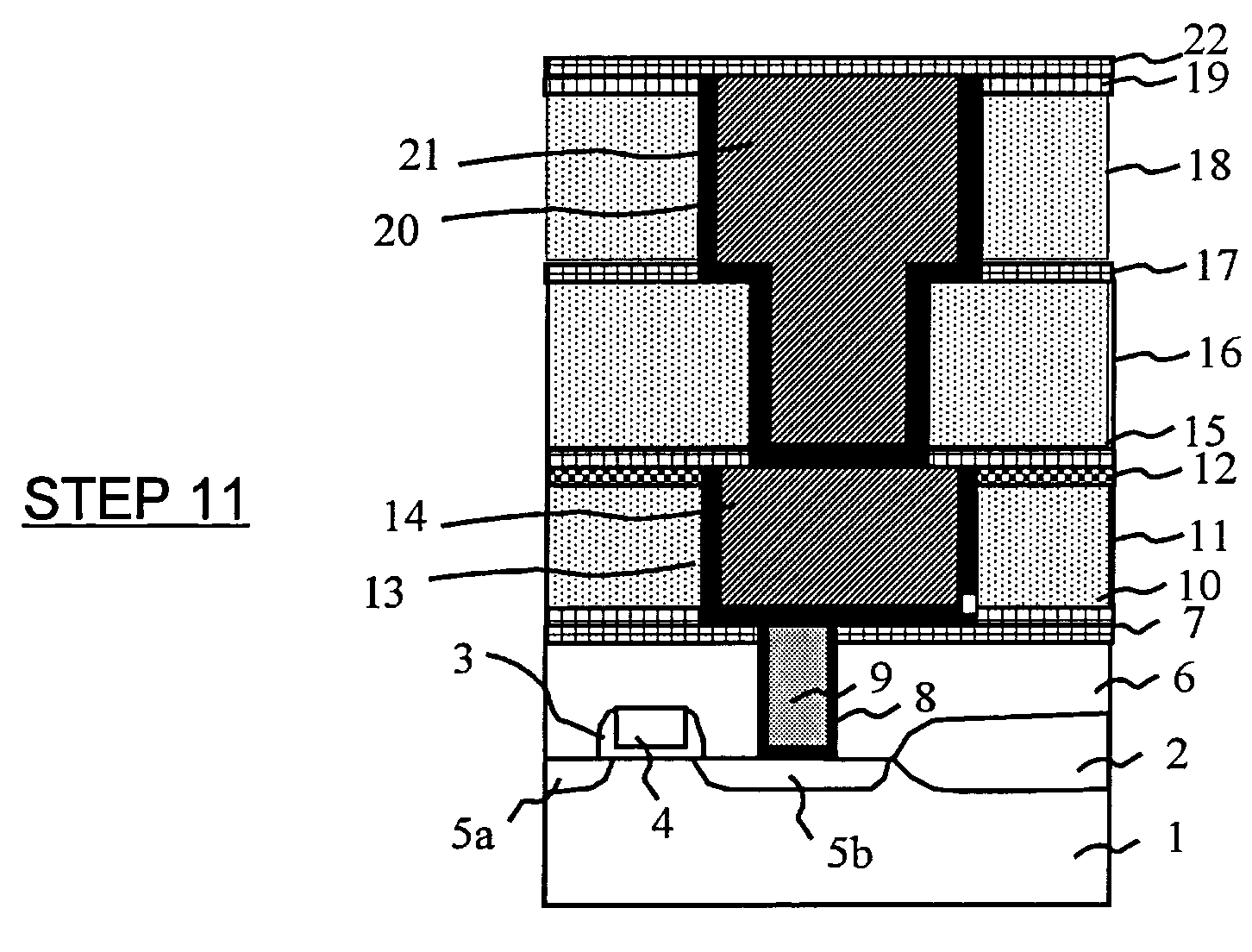

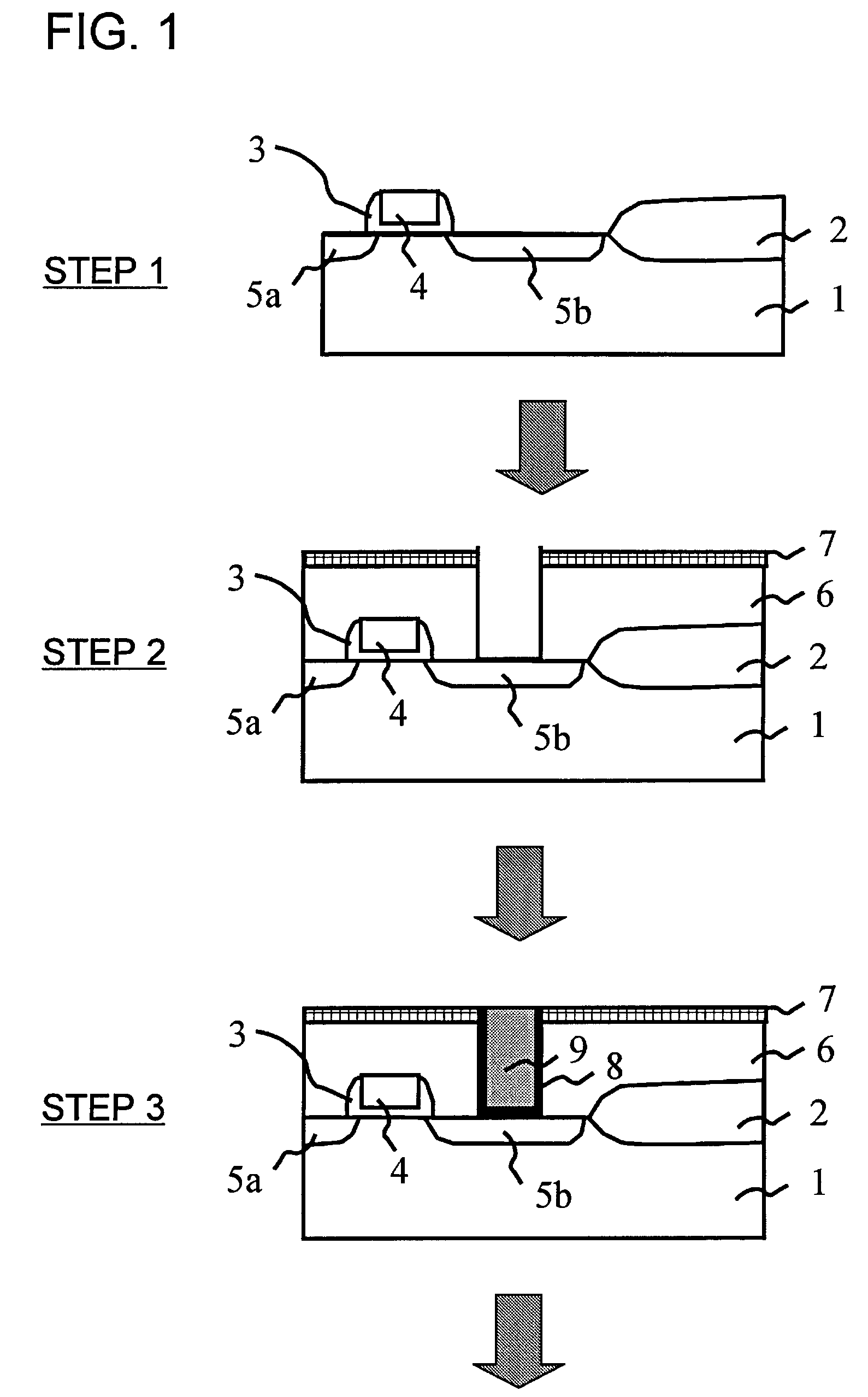

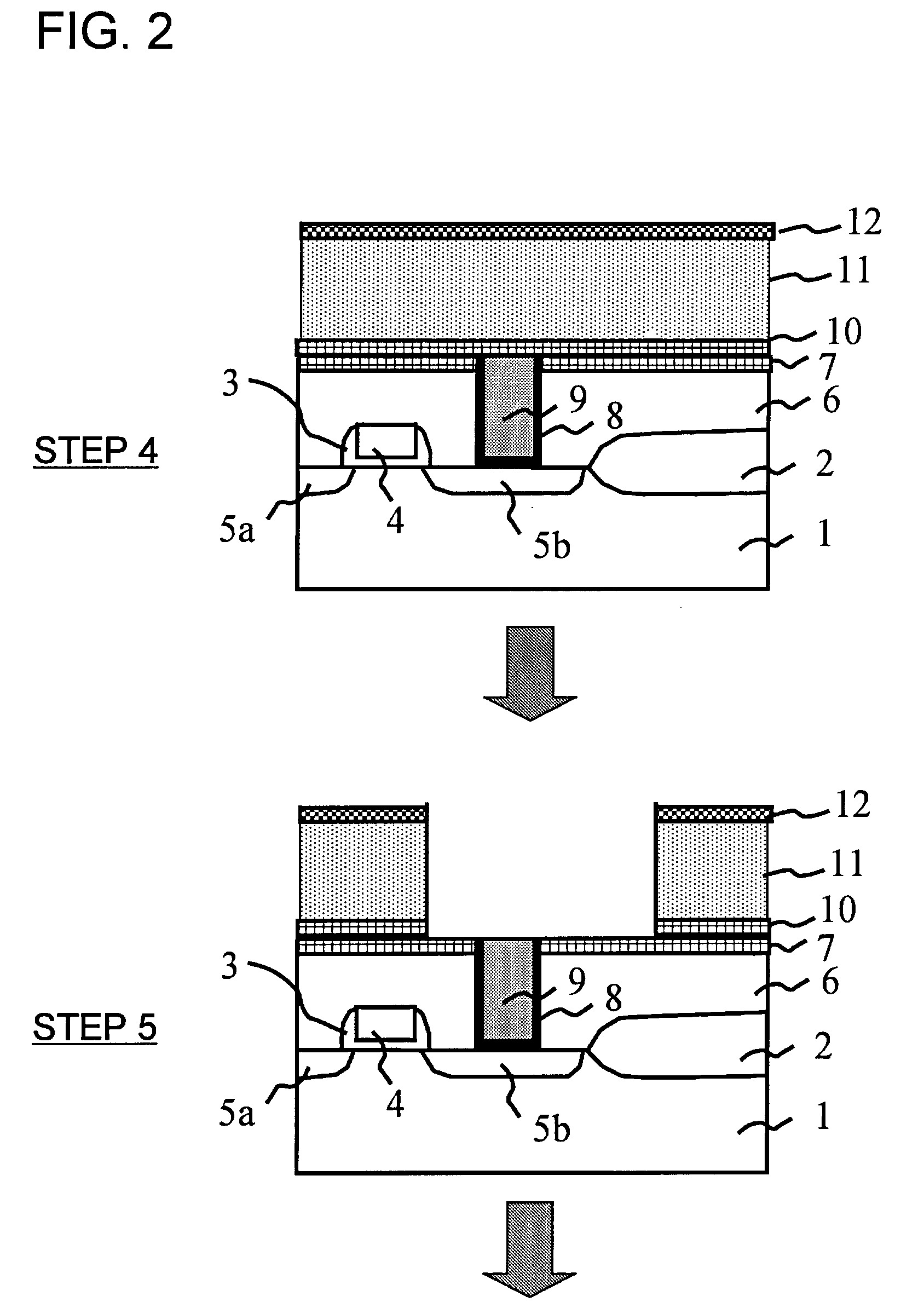

Method for forming insulation film

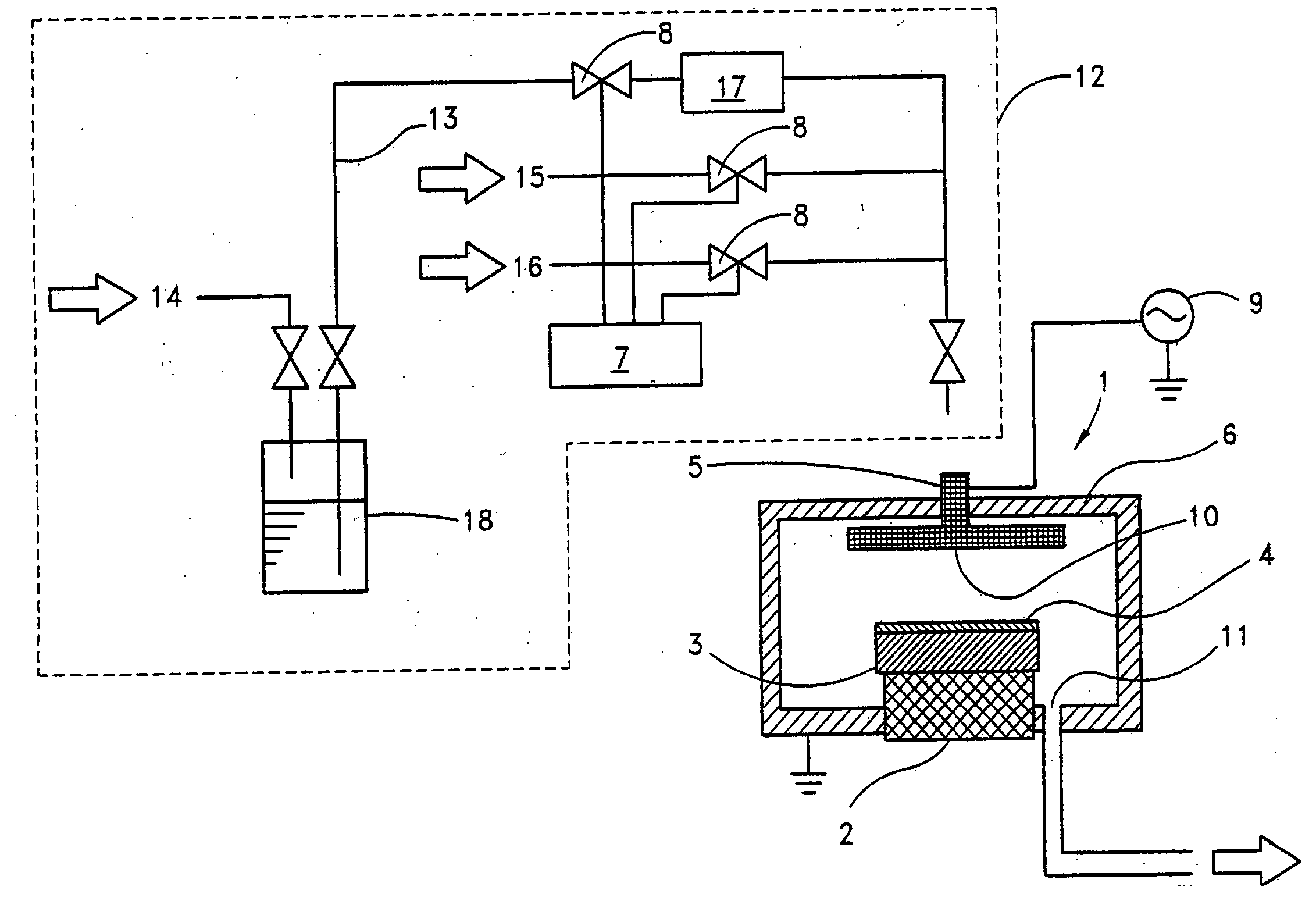

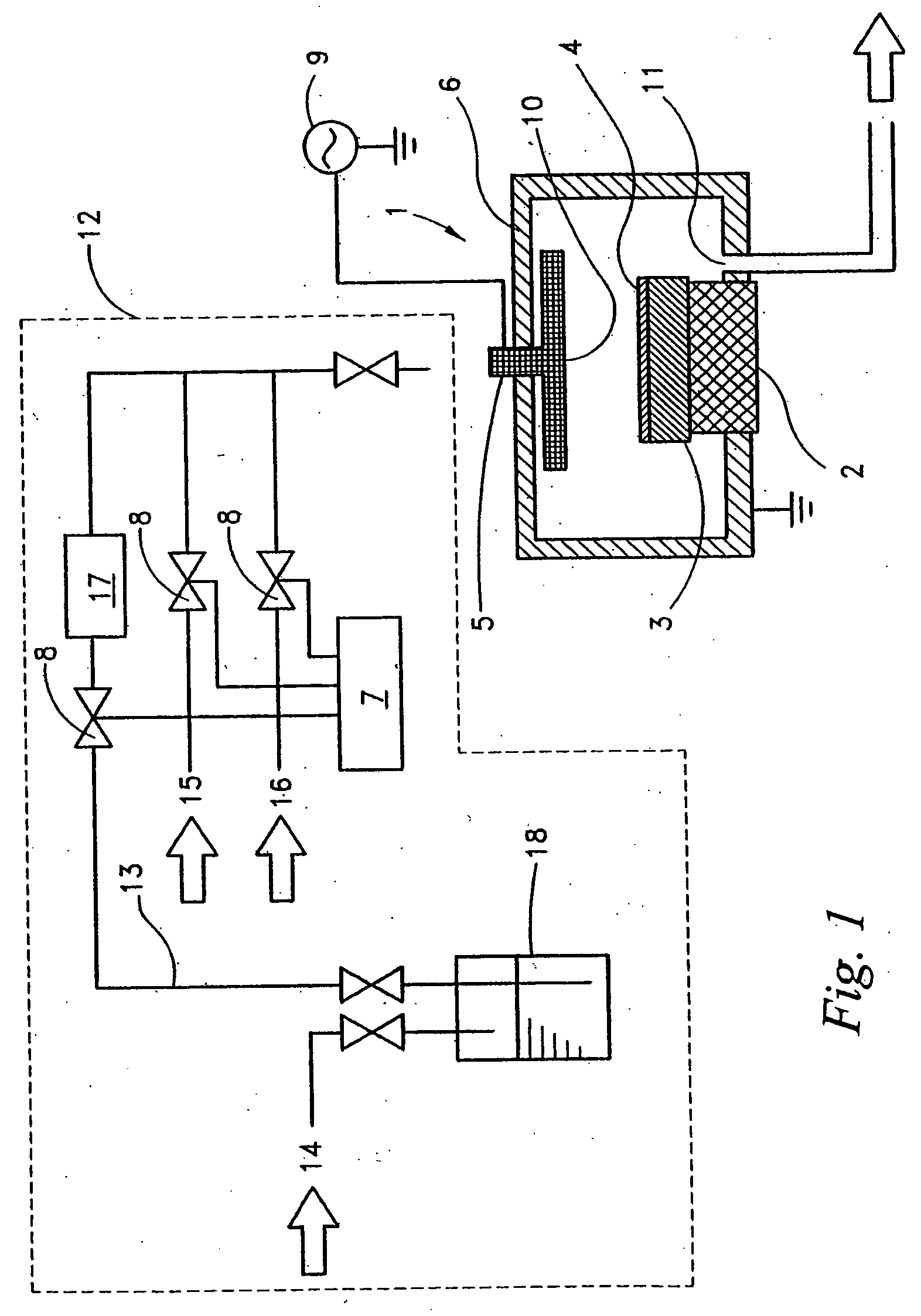

InactiveUS7354873B2Reduce distanceGood film densitySolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

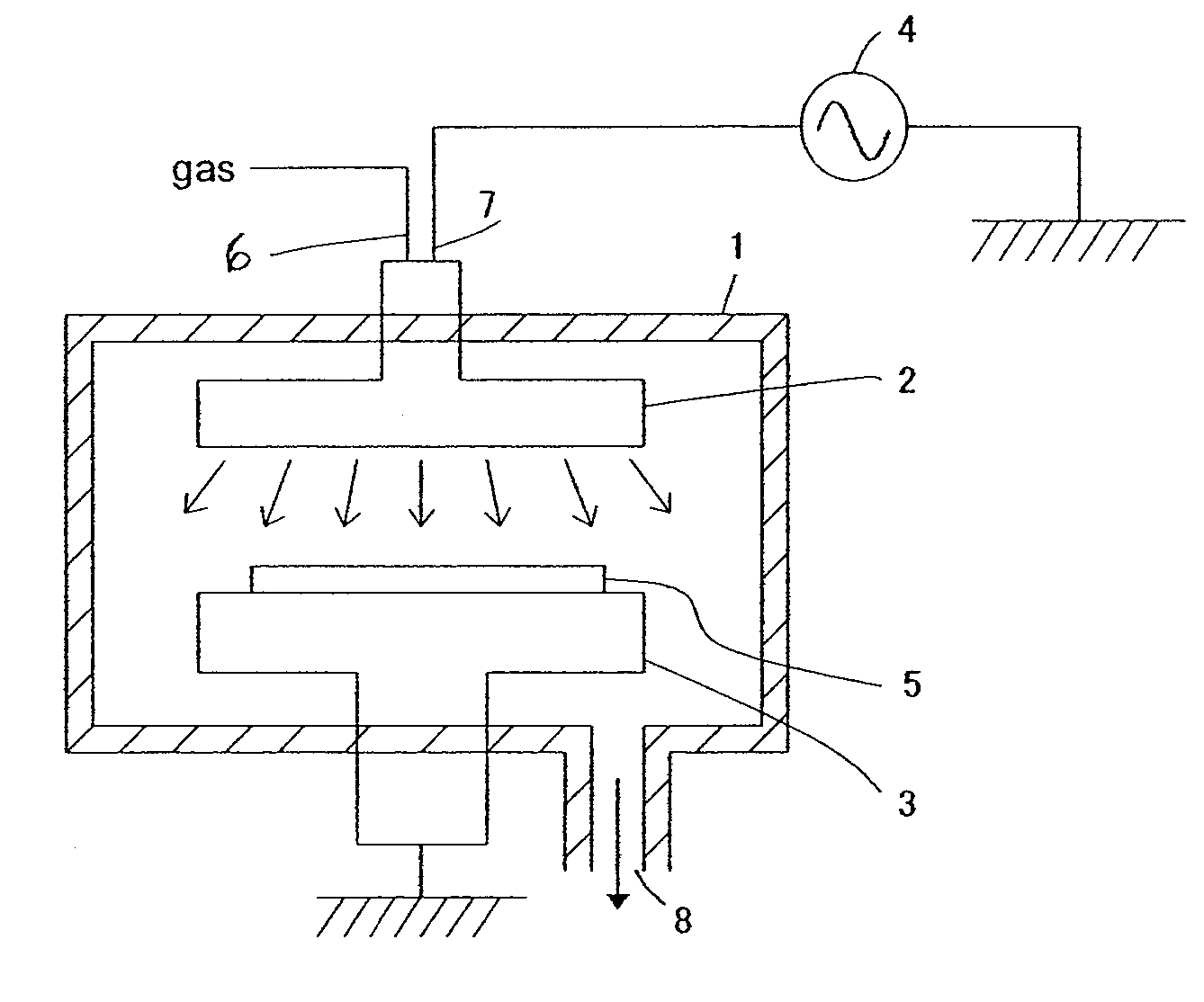

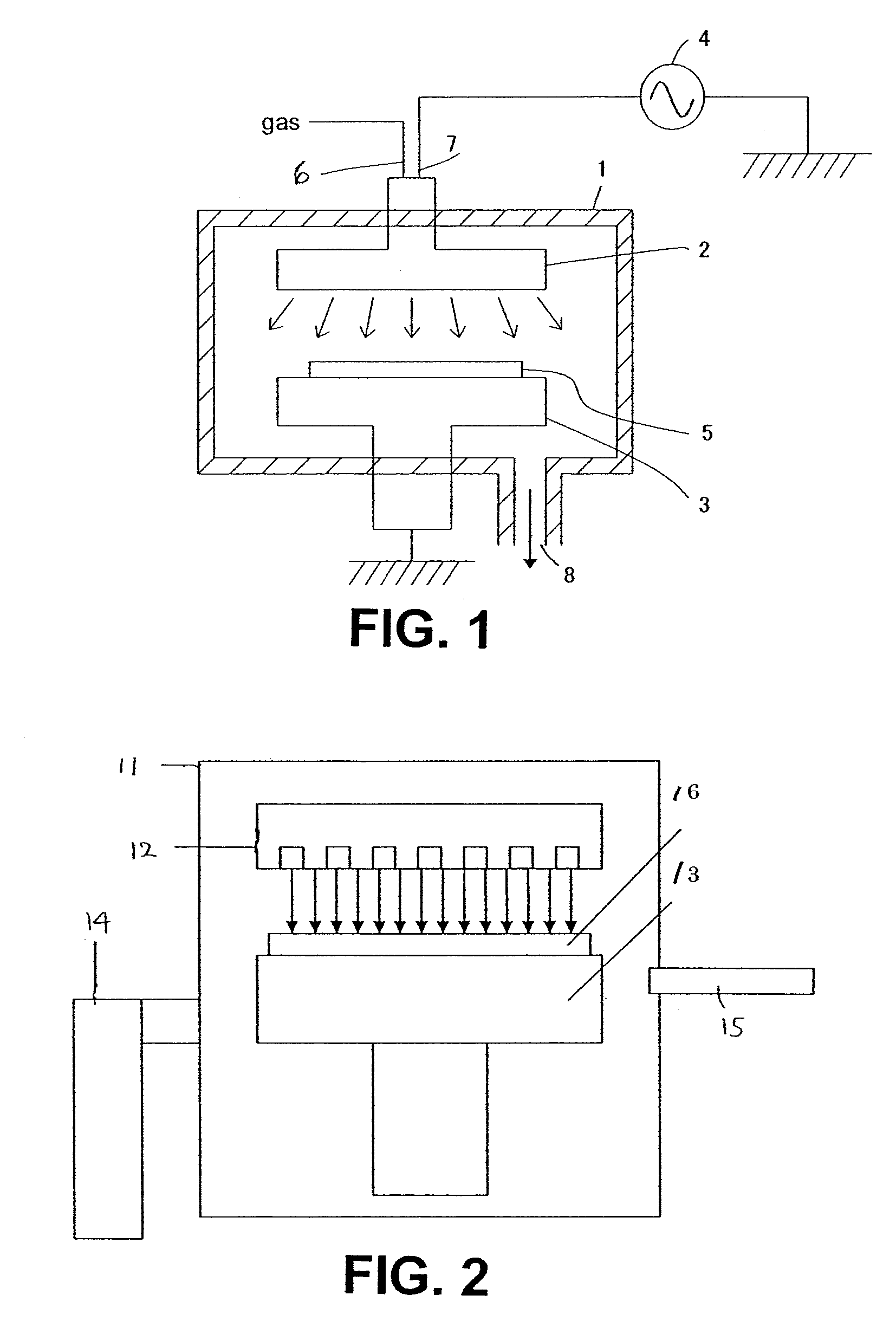

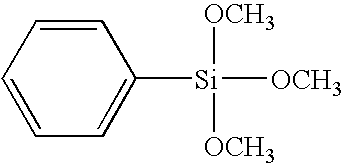

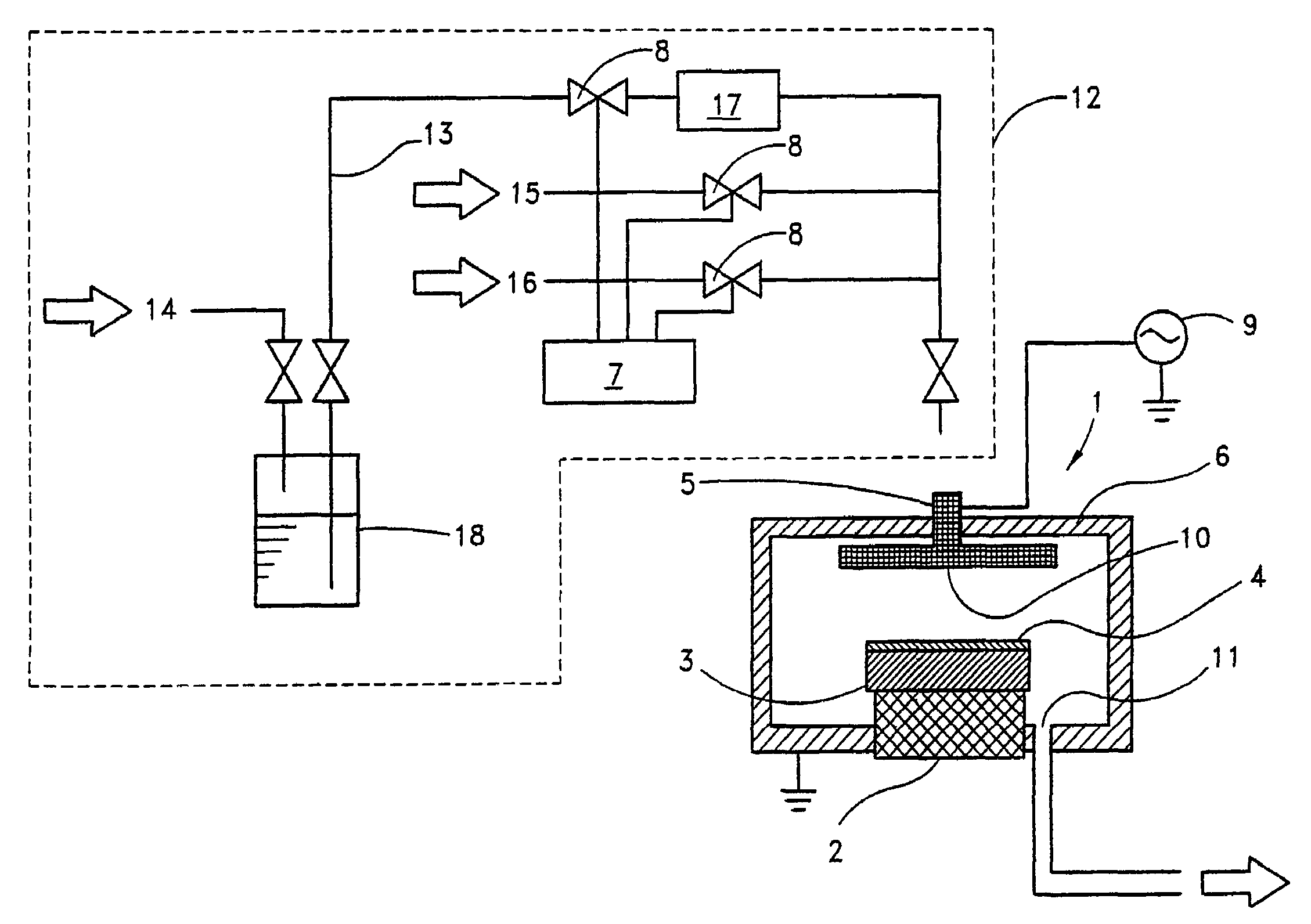

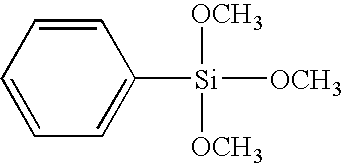

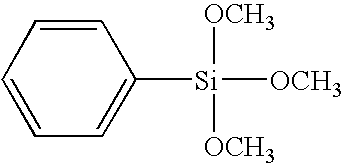

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Method for forming insulation film

InactiveUS7582575B2Reduce trafficReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

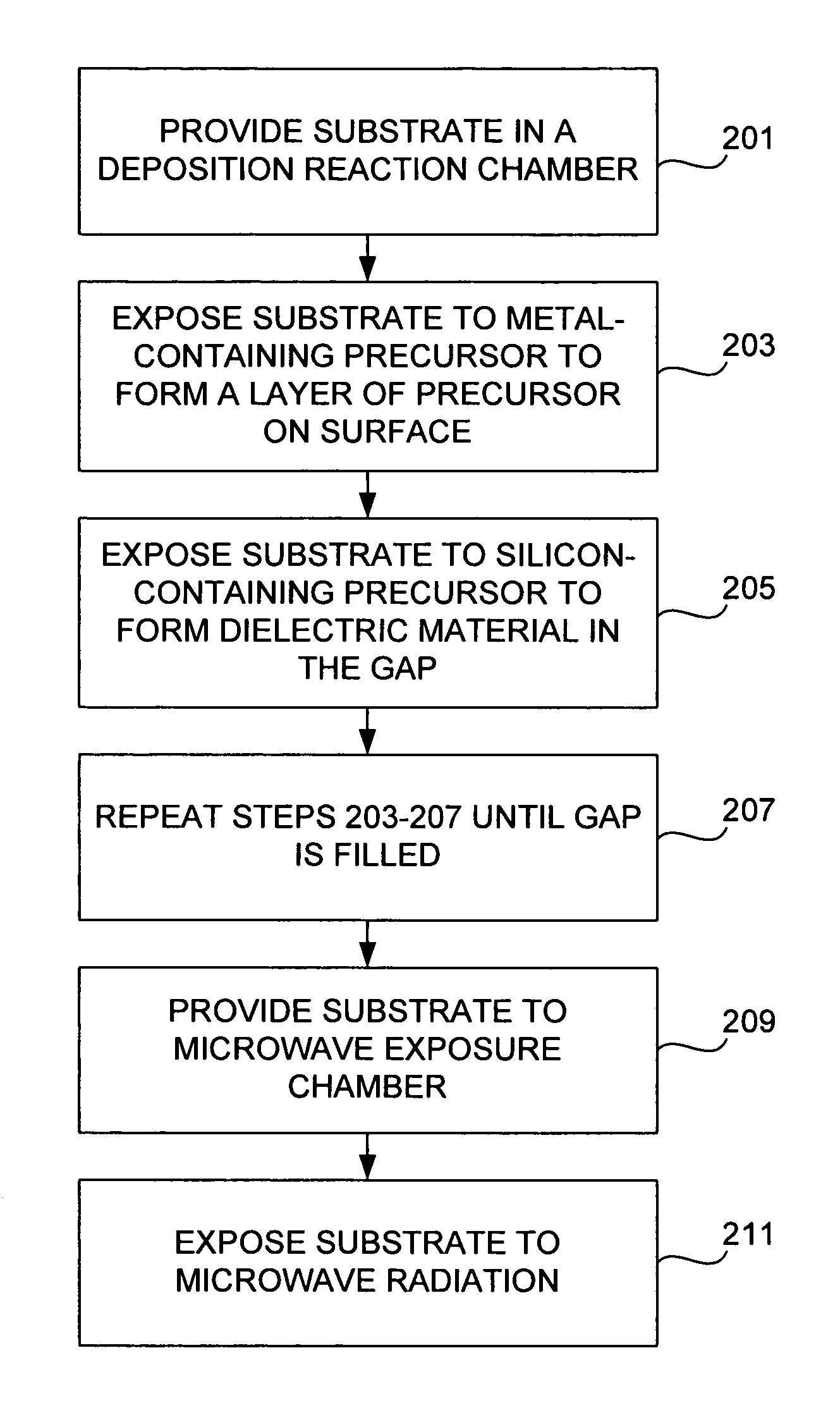

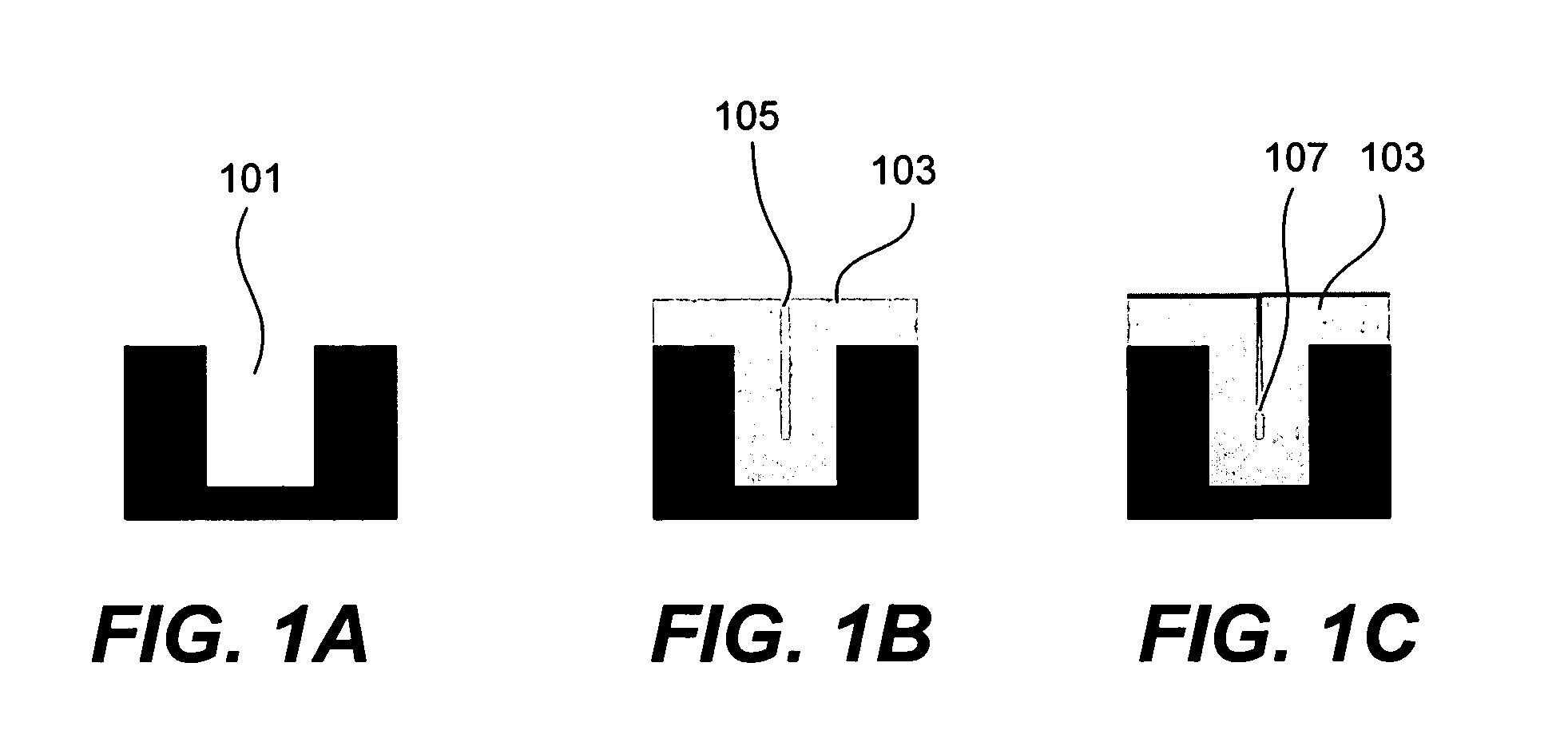

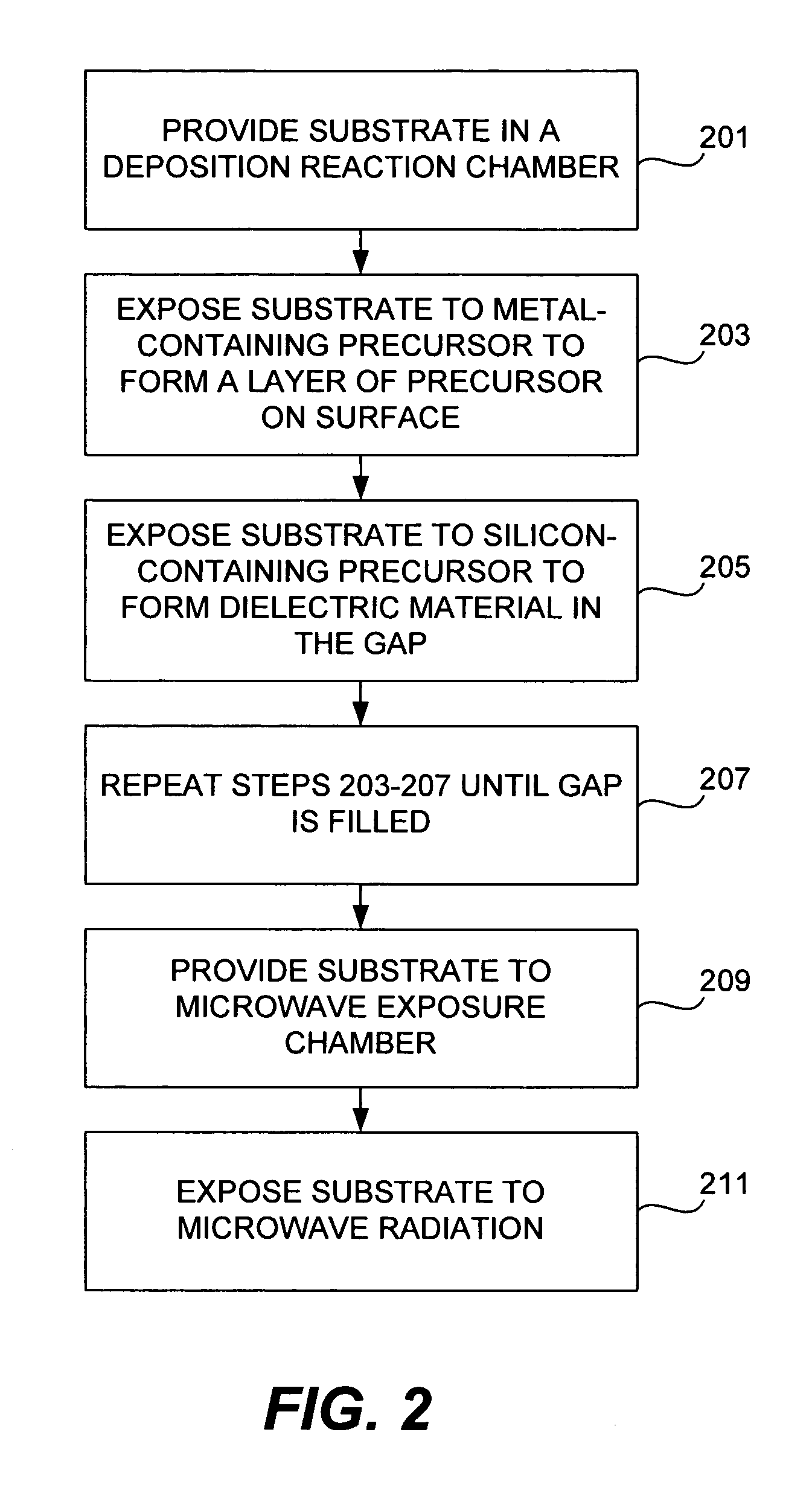

Hydroxyl bond removal and film densification method for oxide films using microwave post treatment

ActiveUS7589028B1High densityImprove film propertiesRadiation applicationsSemiconductor/solid-state device manufacturingDielectricMicrowave

Methods of forming dielectric films with increased density and improved film properties are provided. The methods involve exposing dielectric films to microwave radiation. According to various embodiments, the methods may be used to remove hydroxyl bonds, increase film density, reduce or eliminate seams and voids, and optimize film properties such as dielectric constant, refractive index and stress for particular applications. In certain embodiments, the methods are used to form conformal films deposited by a technique such as PDL. The methods may be used in applications requiring low thermal budgets.

Owner:NOVELLUS SYSTEMS

Method for forming insulation film

InactiveUS20070004204A1Reduce trafficDecrease in flow volumeSolid-state devicesSemiconductor/solid-state device manufacturingProduct gasPlasma reaction

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Method for forming insulation film

InactiveUS20060110931A1Reduce distanceIncrease film densitySolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryRadio frequency

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Permanent resist composition, cured product thereof, and use thereof

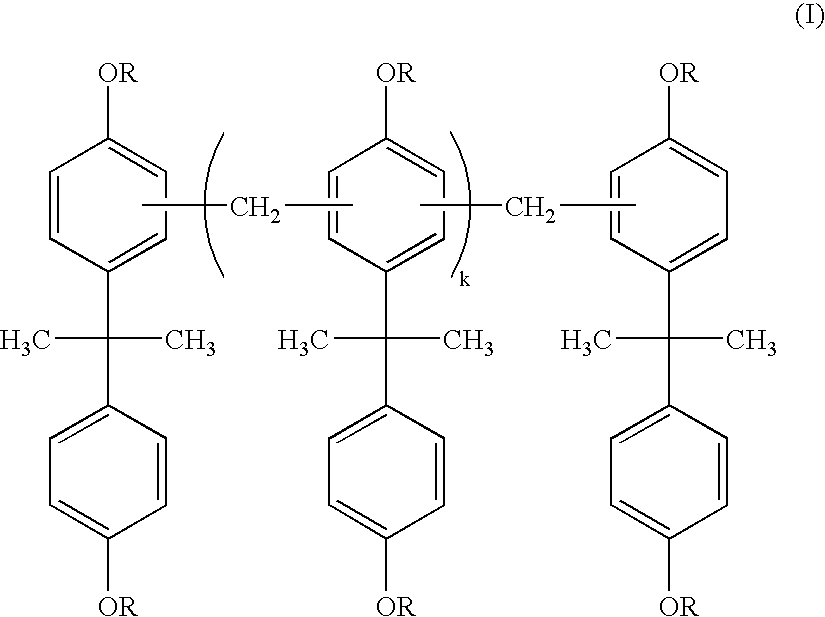

InactiveUS20050260522A1High densityImprove film adhesionNanoinformaticsPhotomechanical apparatusPolymer sciencePhotoacid generator

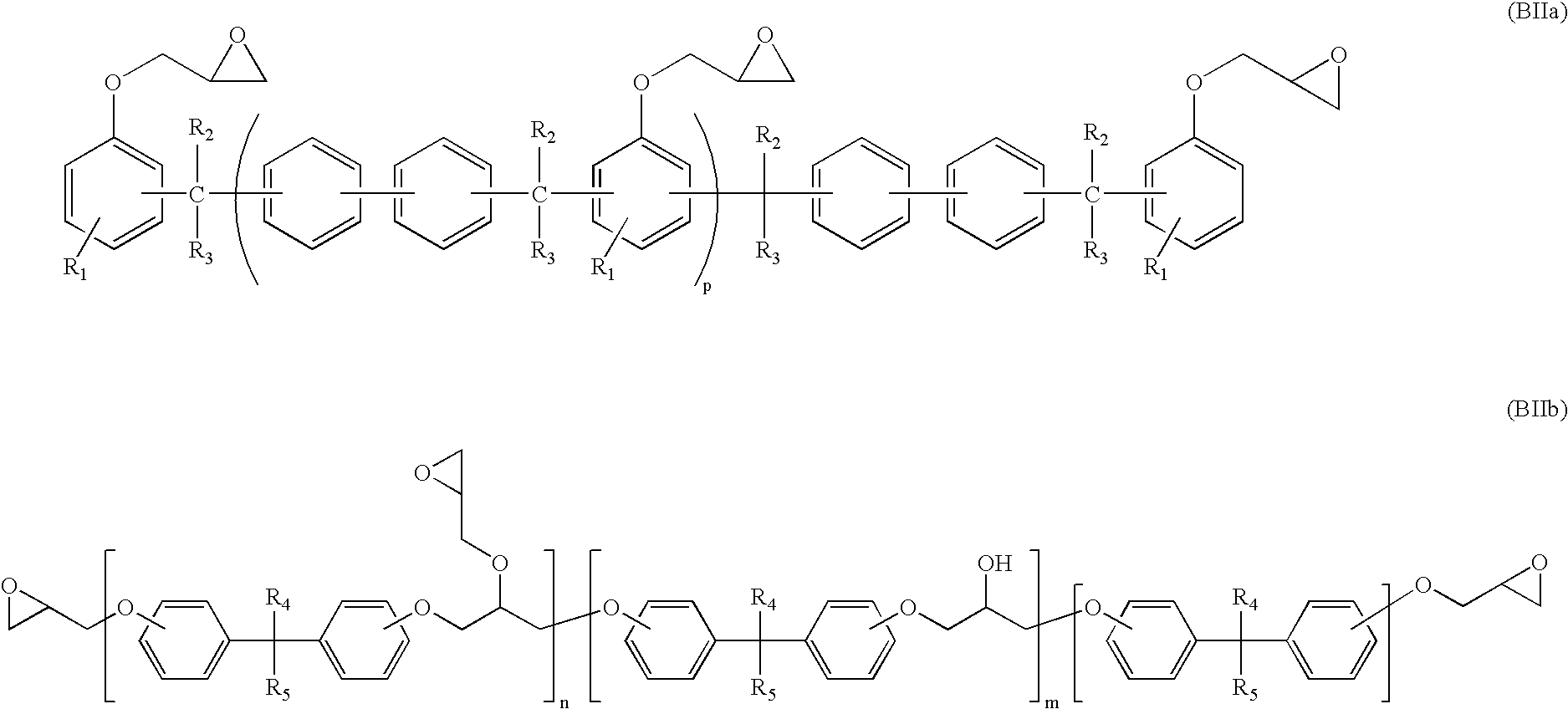

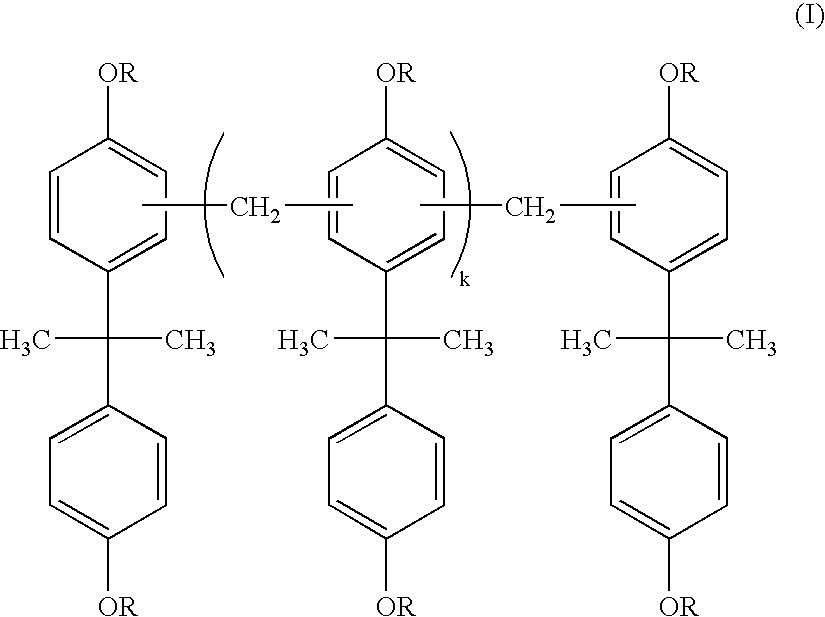

A permanent photoresist composition comprising: (A) one or more bisphenol A-novolac epoxy resins according to Formula I; wherein each group R in Formula I is individually selected from glycidyl or hydrogen and k in Formula I is a real number ranging from 0 to about 30; (B) one or more epoxy resins selected from the group represented by Formulas BIIa and BIIb; wherein each R1, R2 and R3 in Formula BIIa are independently selected from the group consisting of hydrogen or alkyl groups having 1 to 4 carbon atoms and the value of p in Formula BIIa is a real number ranging from 1 to 30; the values of n and m in Formula BIIb are independently real numbers ranging from 1 to 30 and each R4 and R5 in Formula BIIb are independently selected from hydrogen, alkyl groups having 1 to 4 carbon atoms, or trifluoromethyl; (C) one or more cationic photoinitiators (also known as photoacid generators or PAGs); and (D) one or more solvents.

Owner:MICROCHEM CORP +1

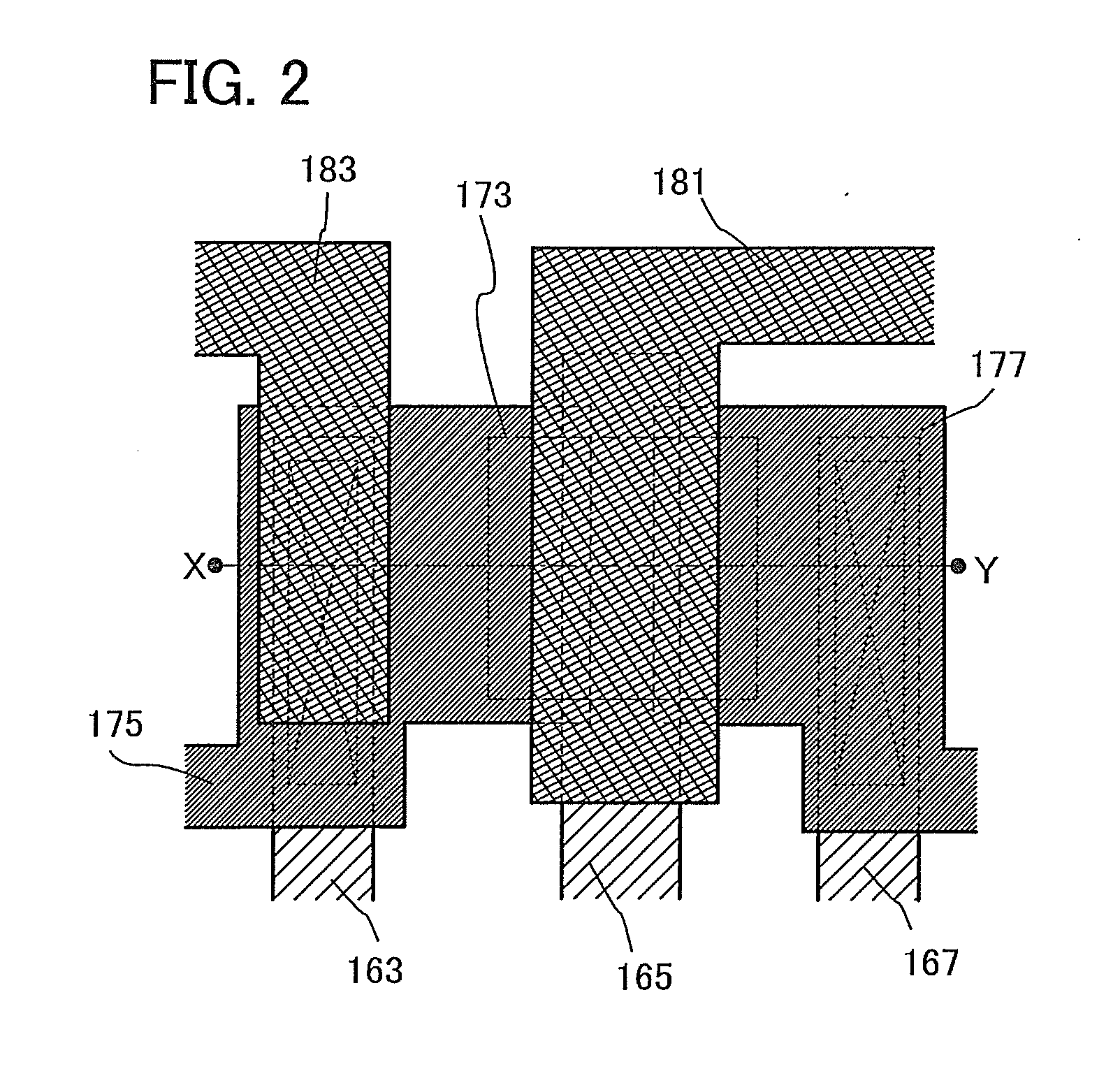

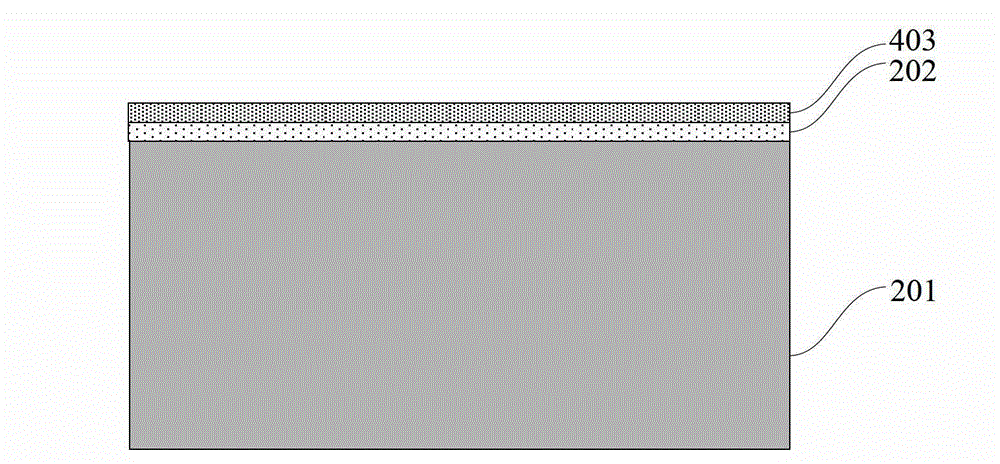

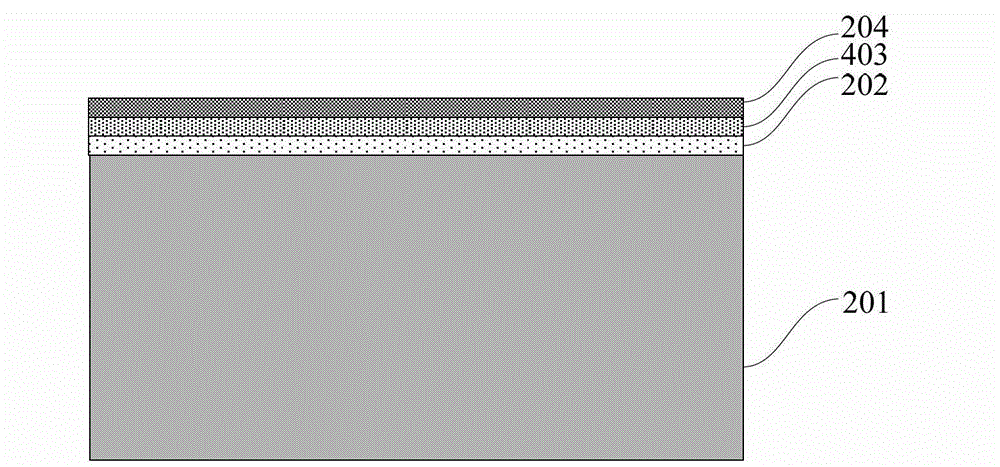

Semiconductor device

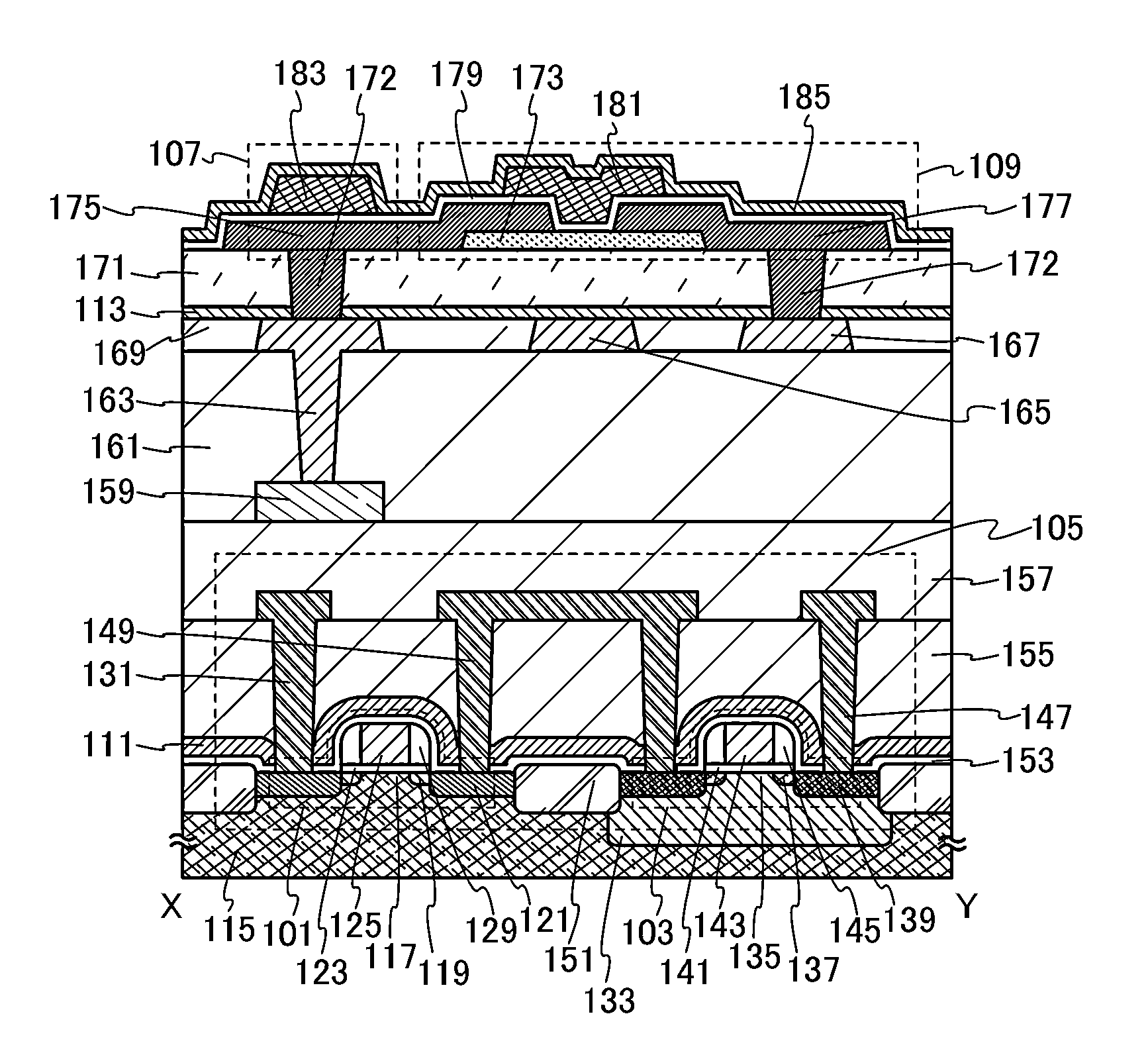

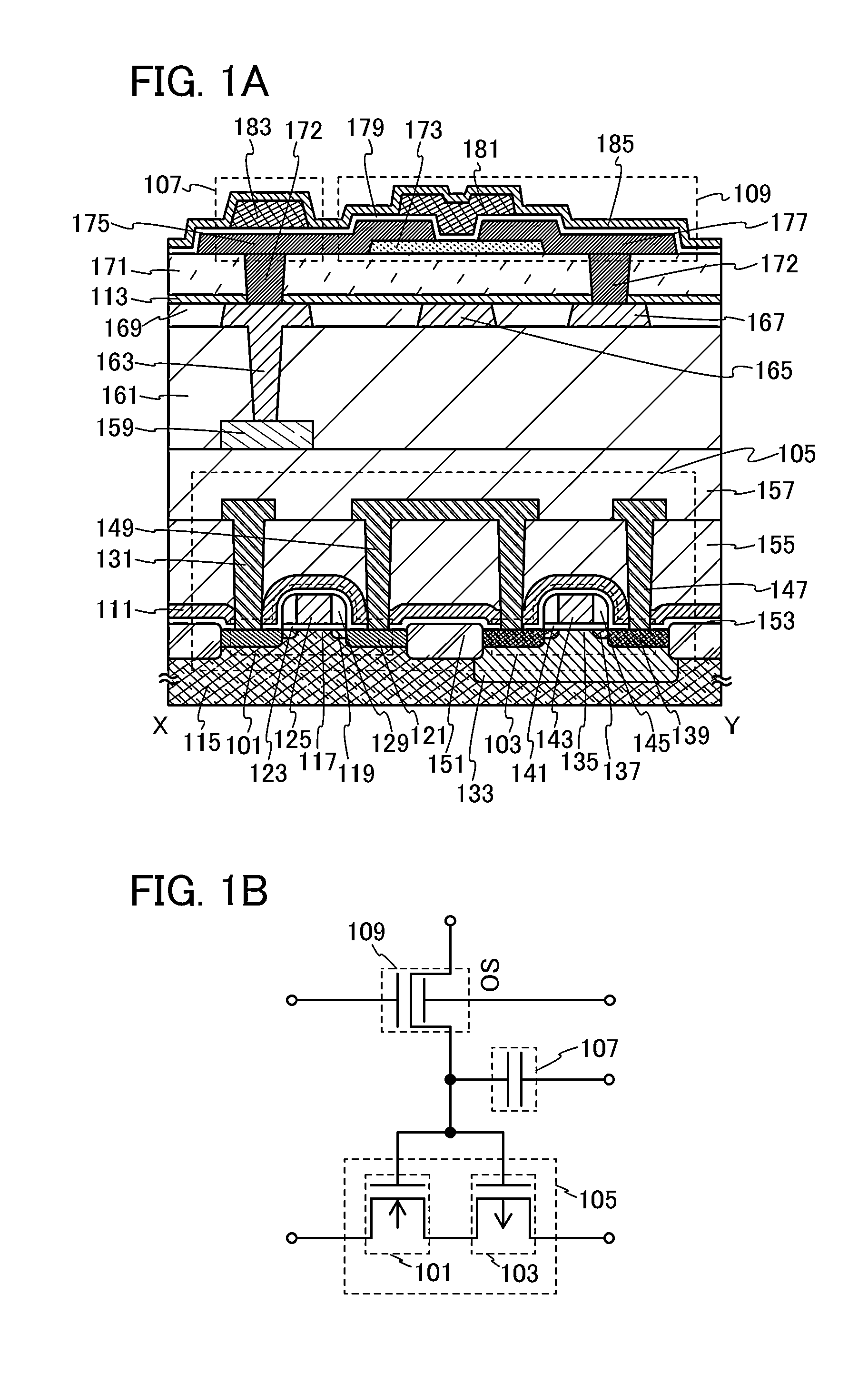

ActiveUS20140027764A1High refractive indexReduce etch rateTransistorSolid-state devicesPower semiconductor deviceHydrogen content

A nitride insulating film which prevents diffusion of hydrogen into an oxide semiconductor film in a transistor including an oxide semiconductor is provided. Further, a semiconductor device which has favorable electrical characteristics by using a transistor including a silicon semiconductor and a transistor including an oxide semiconductor is provided. Two nitride insulating films having different functions are provided between the transistor including a silicon semiconductor and the transistor including an oxide semiconductor. Specifically, a first nitride insulating film which contains hydrogen is provided over the transistor including a silicon semiconductor, and a second nitride insulating film which has a lower hydrogen content than the first nitride insulating film and functions as a barrier film against hydrogen is provided between the first nitride insulating film and the transistor including an oxide semiconductor.

Owner:SEMICON ENERGY LAB CO LTD

Method for forming insulation film

InactiveUS20060258176A1Reduce flowReduce flow volumeLiquid surface applicatorsSemiconductor/solid-state device detailsChemistryResidence time

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

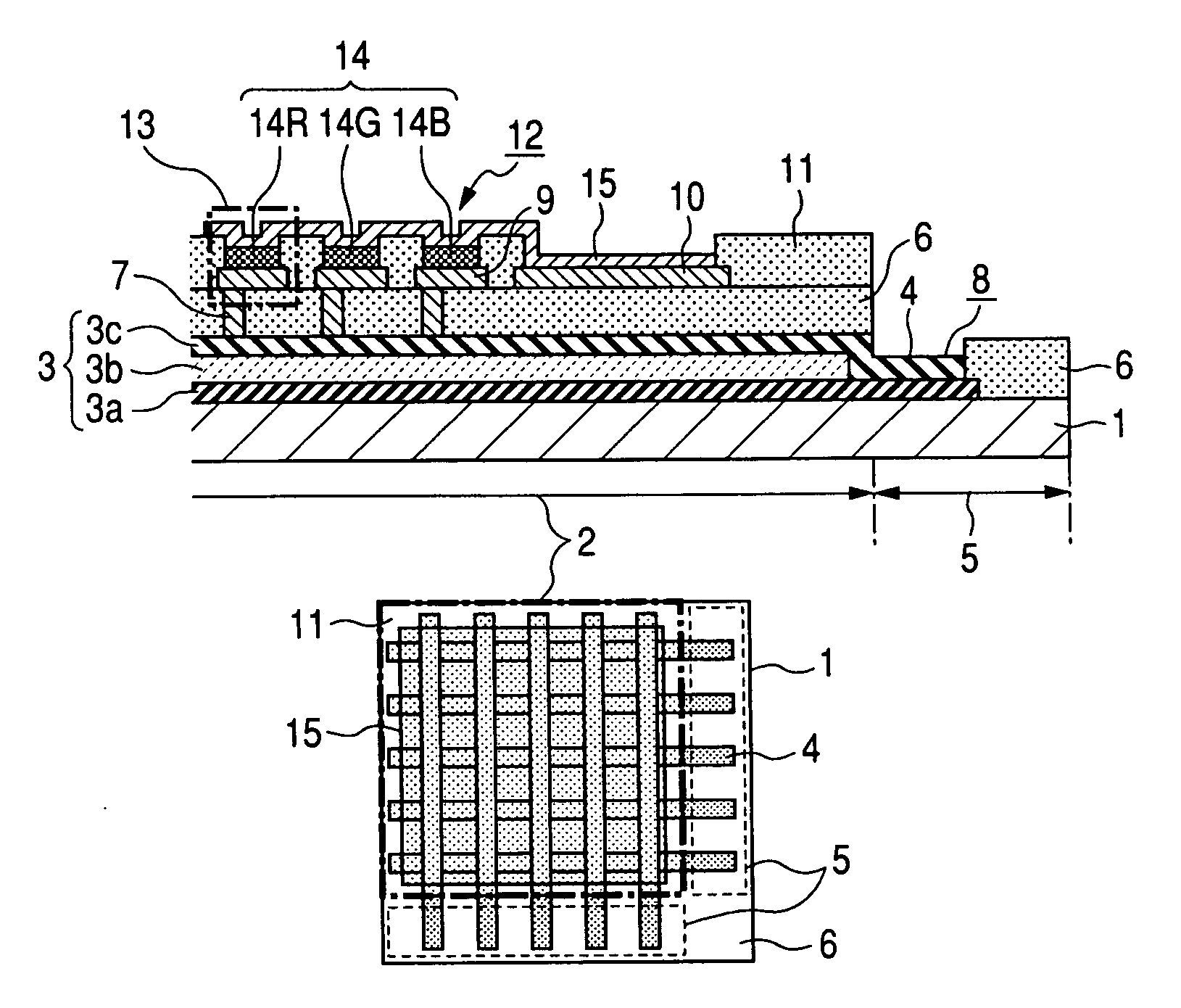

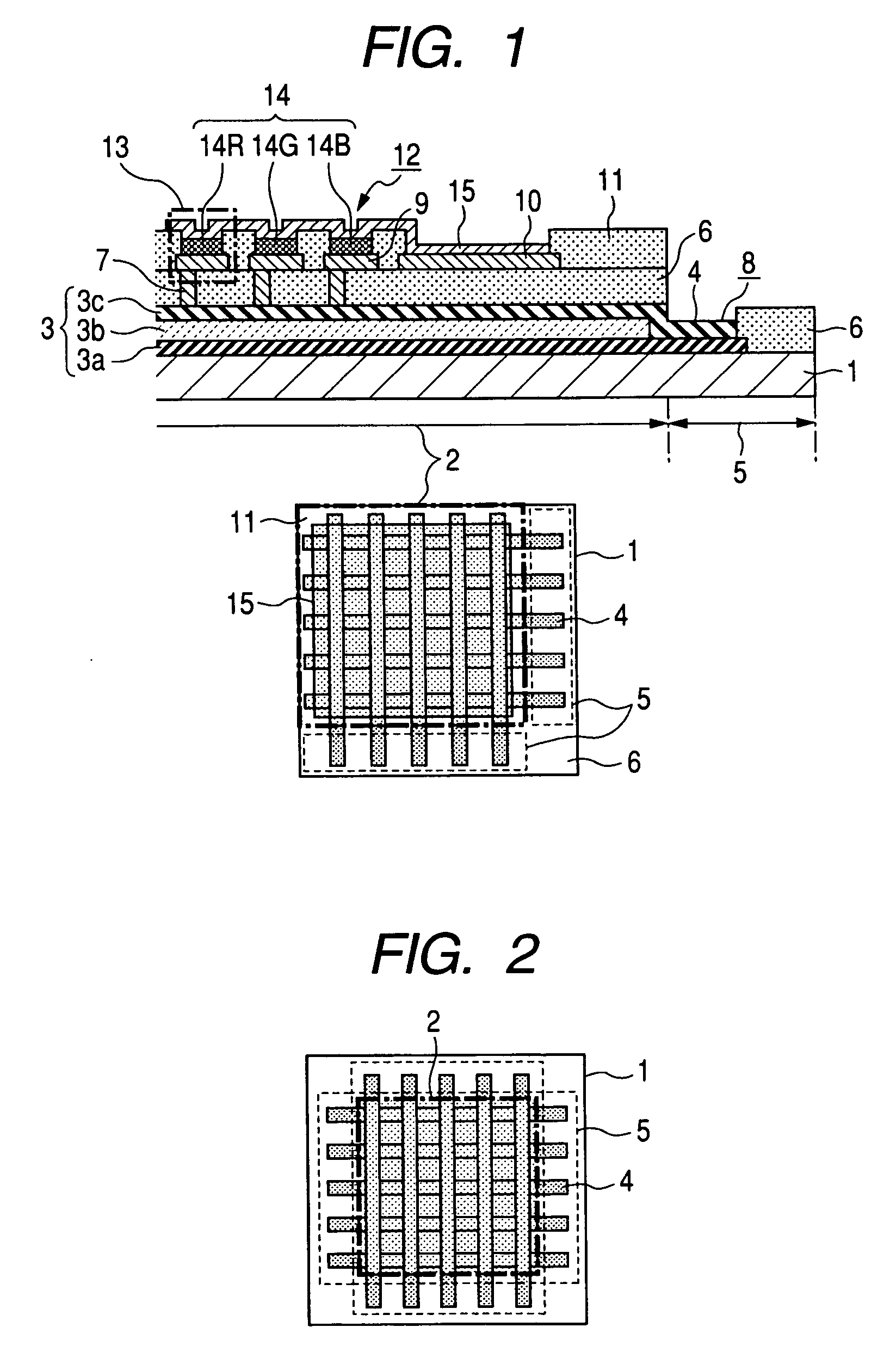

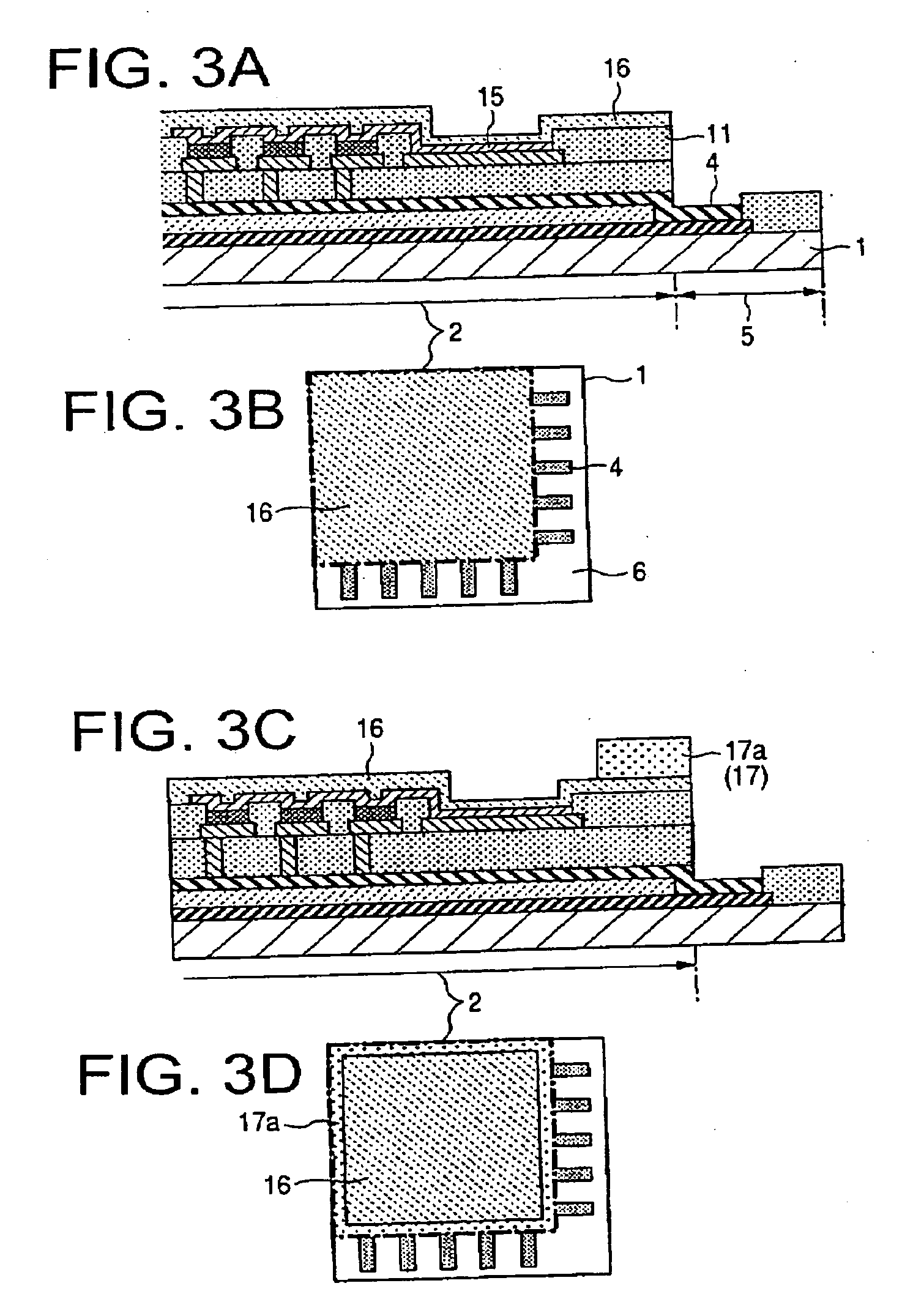

Method of fabricating display device and display device

ActiveUS20070105255A1InhibitionComplicates fabrication sequenceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOrganic layer

A method of fabricating a display device having a TFT substrate and an array of plural light-emitting devices arranged on the substrate, each of the light-emitting devices having a lower electrode, an upper electrode, and organic layers sandwiched between the lower and upper electrodes, includes the steps of: arraying the light-emitting devices on a display region of the TFT substrate; bringing out external connector terminals from the light-emitting devices; placing the external connector terminals outside the display region on the TFT substrate while exposing surfaces of the external connector terminals; and selectively forming a protective film on the display region of the TFT substrate by a method of application such that at least the light-emitting devices are covered.

Owner:JOLED INC

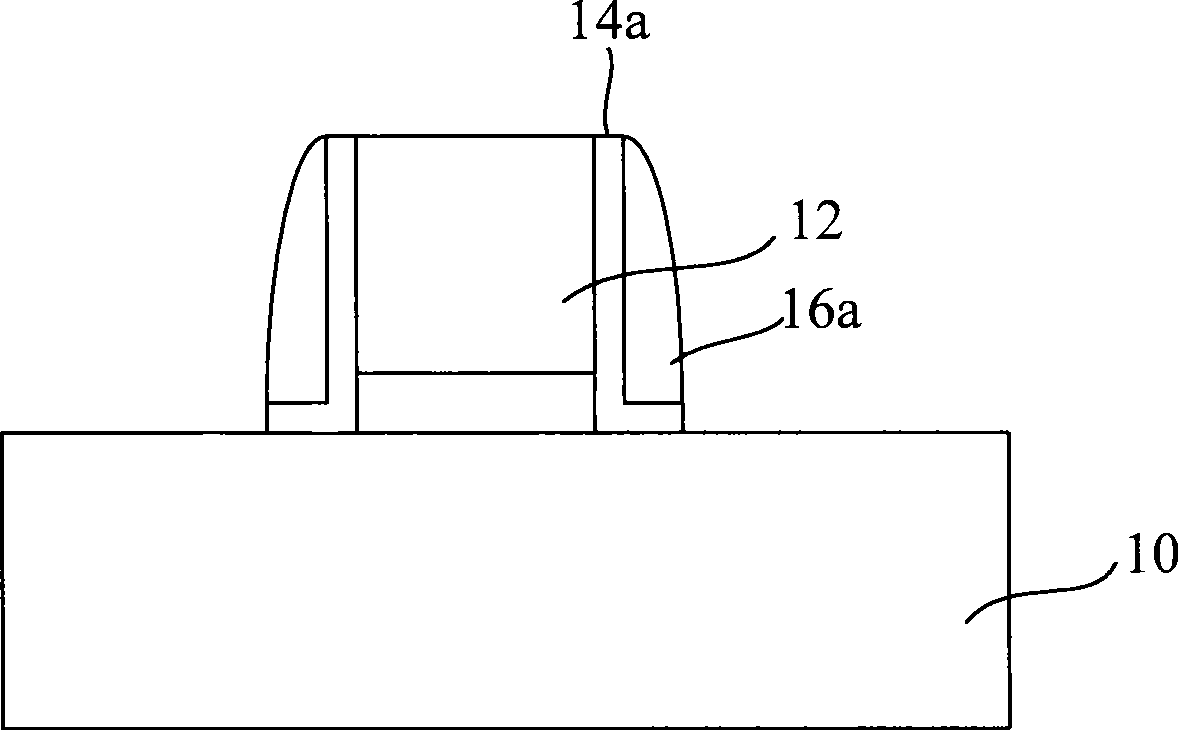

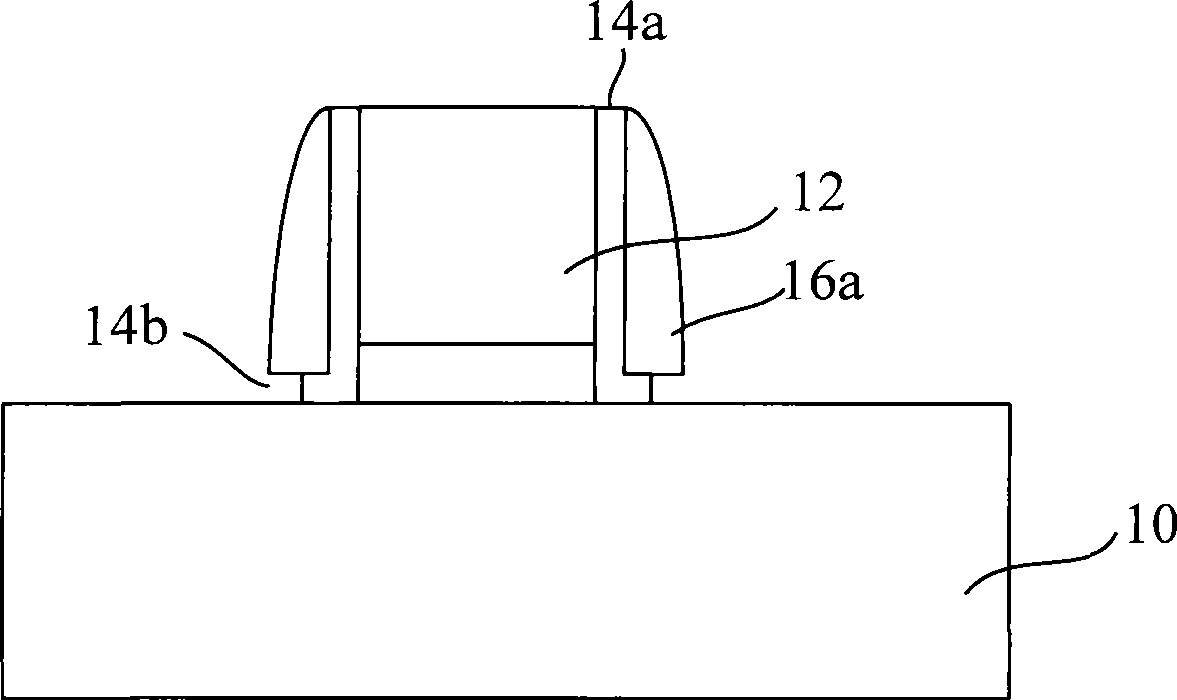

Manufacturing method for gate lateral wall layer and semi-conductor device

InactiveCN101393862AReduce the number of handlingThe process steps are simpleSemiconductor/solid-state device manufacturingSemiconductor devicesSilanesSemiconductor

A method for forming a side wall layer on a grid electrode comprises the following steps: a semi-conductor substrate provided with the grid electrode is provided; a first silica layer is formed on the surfaces of the semi-conductor substrate and the grid electrode; with hexa-chloro silane as a precursor, a first silicon nitride layer is formed on top of the first silica layer; and parts of the first silica layer and the first silicon nitride layer are removed in a selective manner so as to preserve the first silica layer and the first silicon nitride layer already formed on the side wall of the grid electrode. The invention further provides a method for manufacturing a semiconductor device. The invention can solve the problem that the bottom part of the side wall layer on the grid electrode is susceptible to depression.

Owner:SEMICON MFG INT (SHANGHAI) CORP

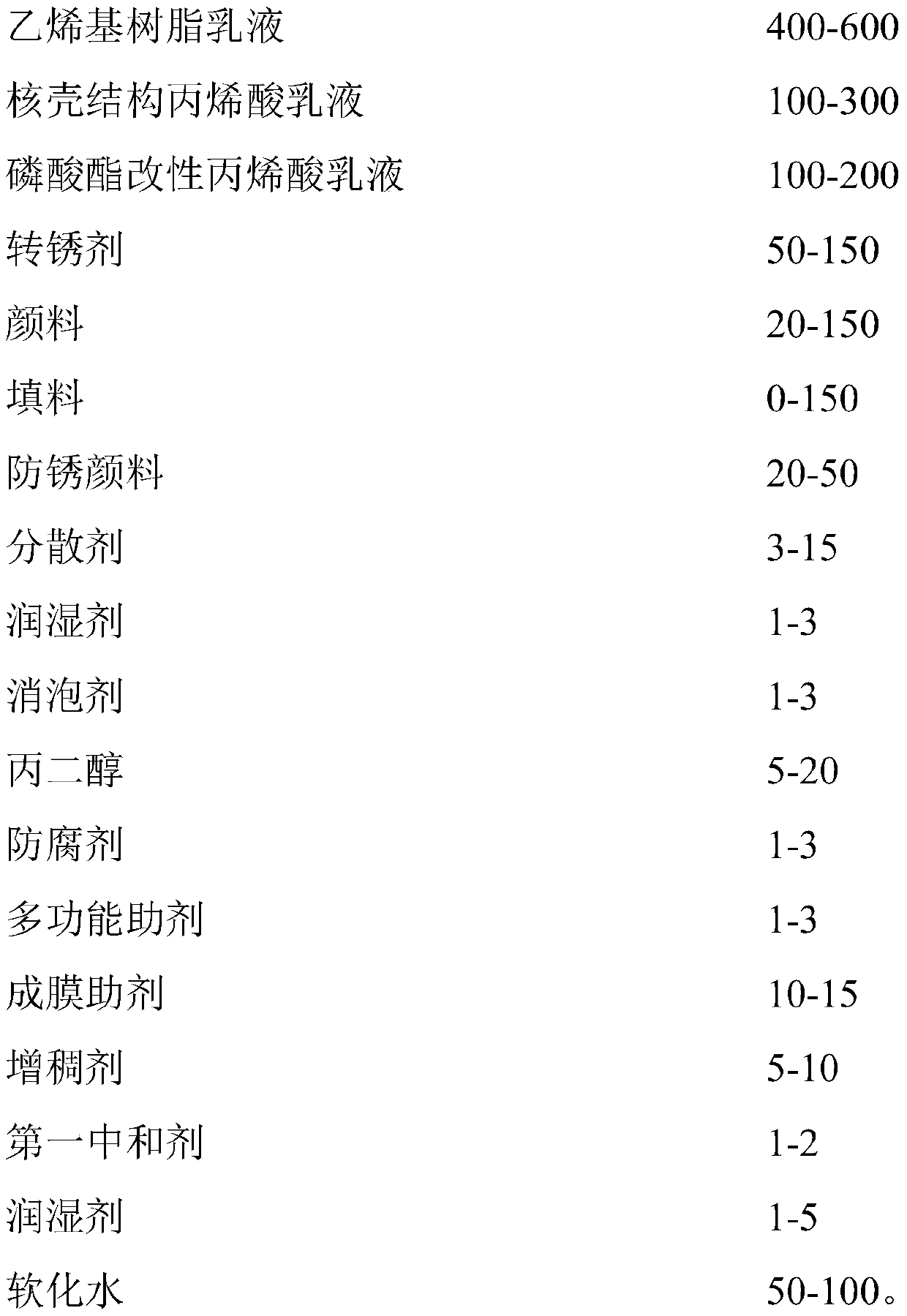

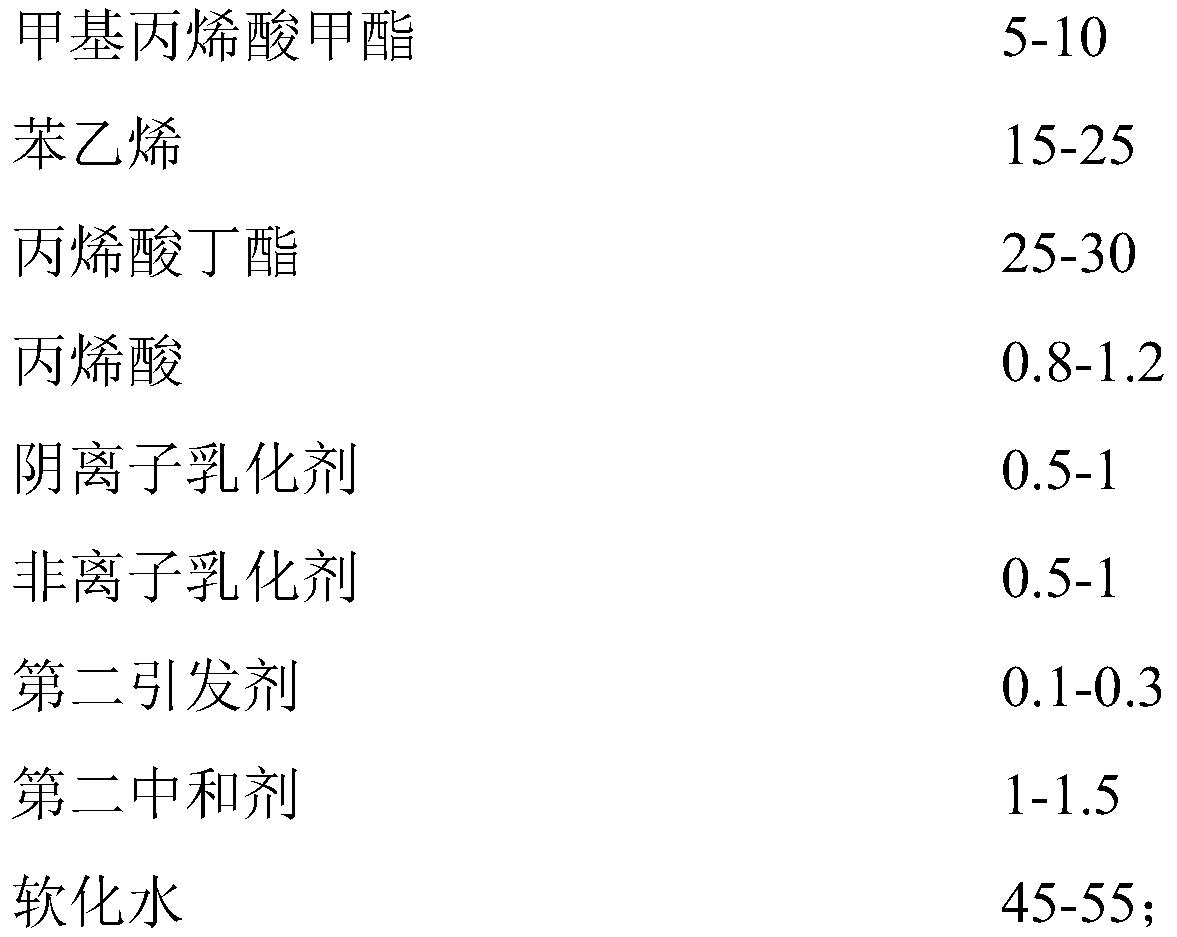

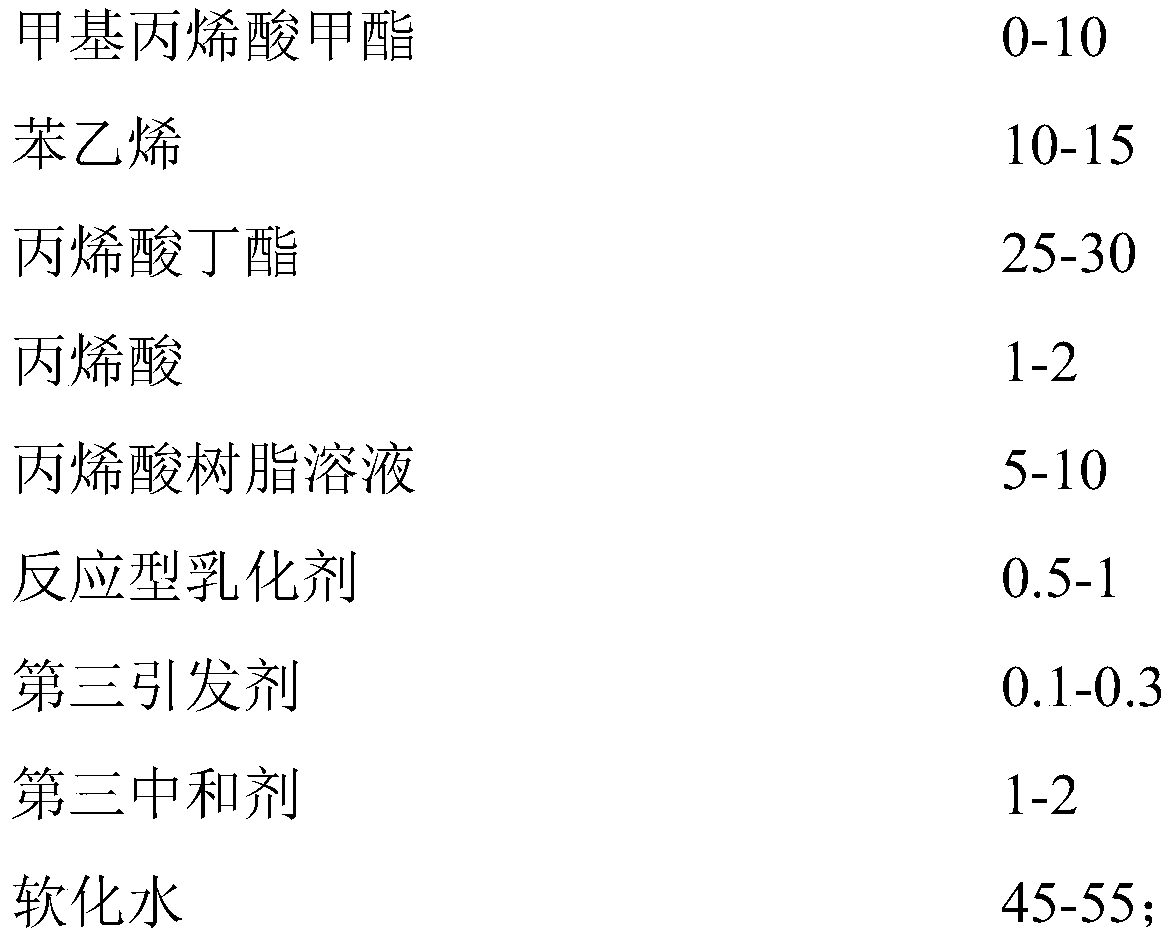

Water-based rust-proof primer with rust and preparation method thereof

The invention relates to the field of chemical anti-corrosion coatings, particularly to a water-based rust-proof primer with rust and a preparation method thereof. The water-based rust-proof primer with rust uses a vinyl emulsion, a core-shell-structured acrylic emulsion and a phosphate-modified acrylic acid emulsion as base materials. The preparation method comprises the following steps: firstly,selecting the main base material, i.e., the vinyl emulsion; then synthesizing the auxiliary base materials, i.e., the core-shell-structured acrylic resin emulsion and the phosphate-modified acrylic emulsion; and then with the above three emulsions as the base materials, mixing the base materials with a rust conversion agent, an antifreezing agent, a wetting agent, an antifoaming agents and otheradditives to prepare the water-based rust-proof primer with rust. The obtained water-based rust-proof primer with rust is low in VOC content, safe and environment-friendly, convenient to construct, good in compatibility with common anti-corrosion topcoats, good in rust conversion effect, strong in adhesion and long in an antirust period, and has wide application prospects.

Owner:深圳安盾海洋新材料有限公司

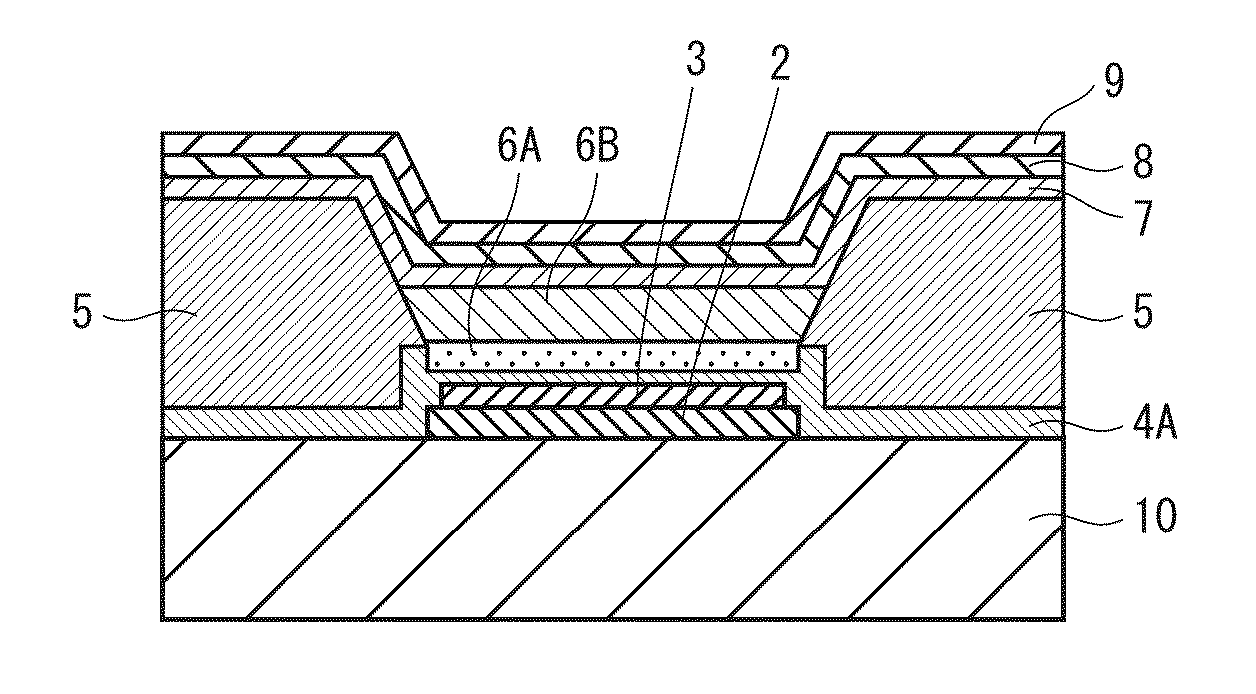

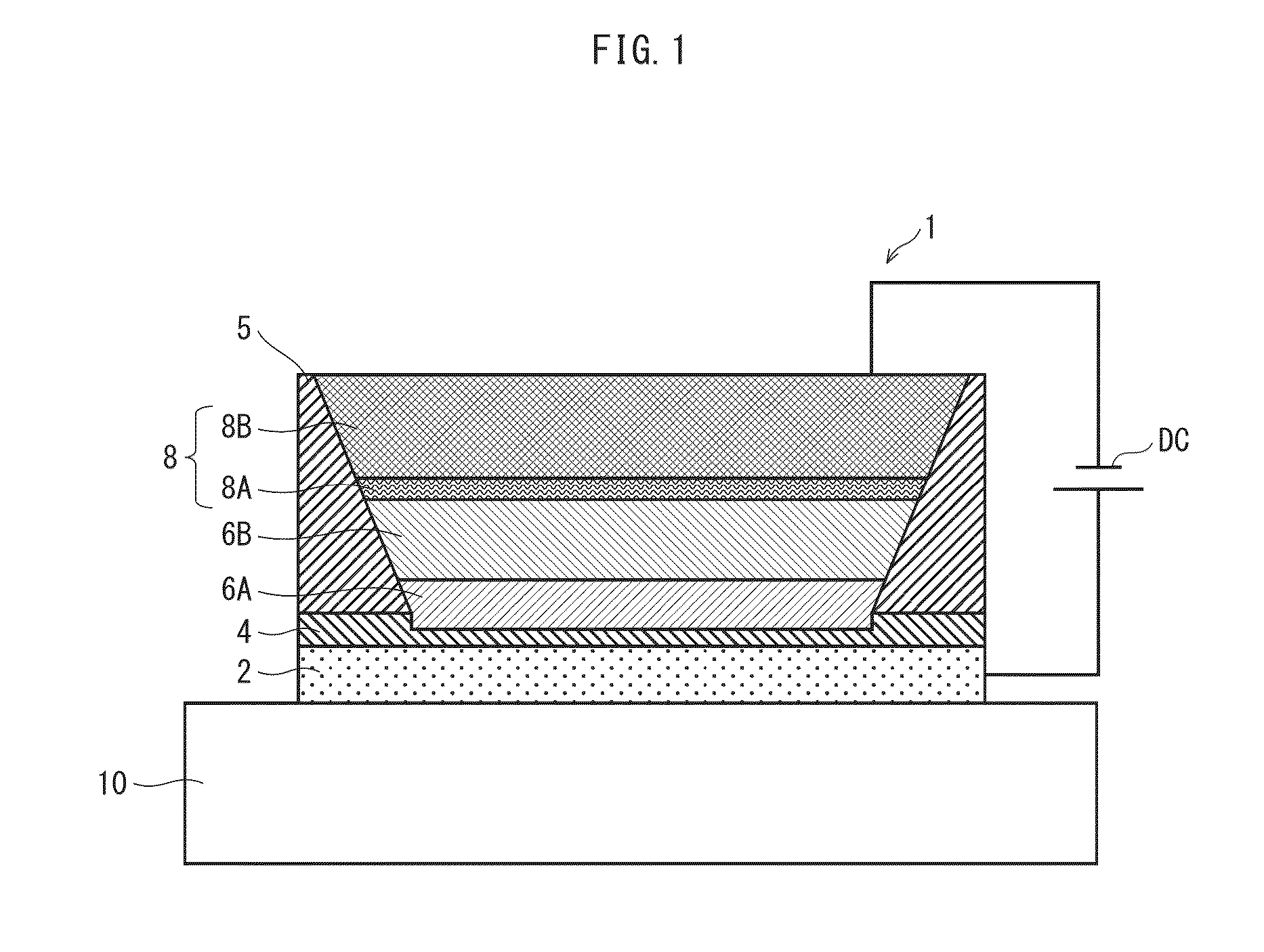

Method for producing organic light-emitting element

ActiveUS20140127846A1Improved hole injection characteristicReduce the amount requiredSolid-state devicesSemiconductor/solid-state device manufacturingBinding energyValence band

Method for manufacturing organic EL element including anode, hole injection layer, buffer layer, light-emitting layer, and cathode, layered on substrate in the stated order, and banks defining a light-emission region, and having excellent light-emission characteristics, due to the hole injection layer having excellent hole injection efficiency, being a tungsten oxide layer including an oxygen vacancy structure, formed under predetermined conditions to have an occupied energy level within a binding energy range from 1.8 eV to 3.6 eV lower than a lowest binding energy of a valence band, and after formation, subjected to atmospheric firing at a temperature within 200° C.-230° C. inclusive for a processing time of 15-45 minutes inclusive to have increased film density and improved dissolution resistance against an etching solution, a cleaning liquid, etc., used in a bank forming process.

Owner:JOLED INC

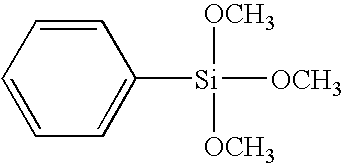

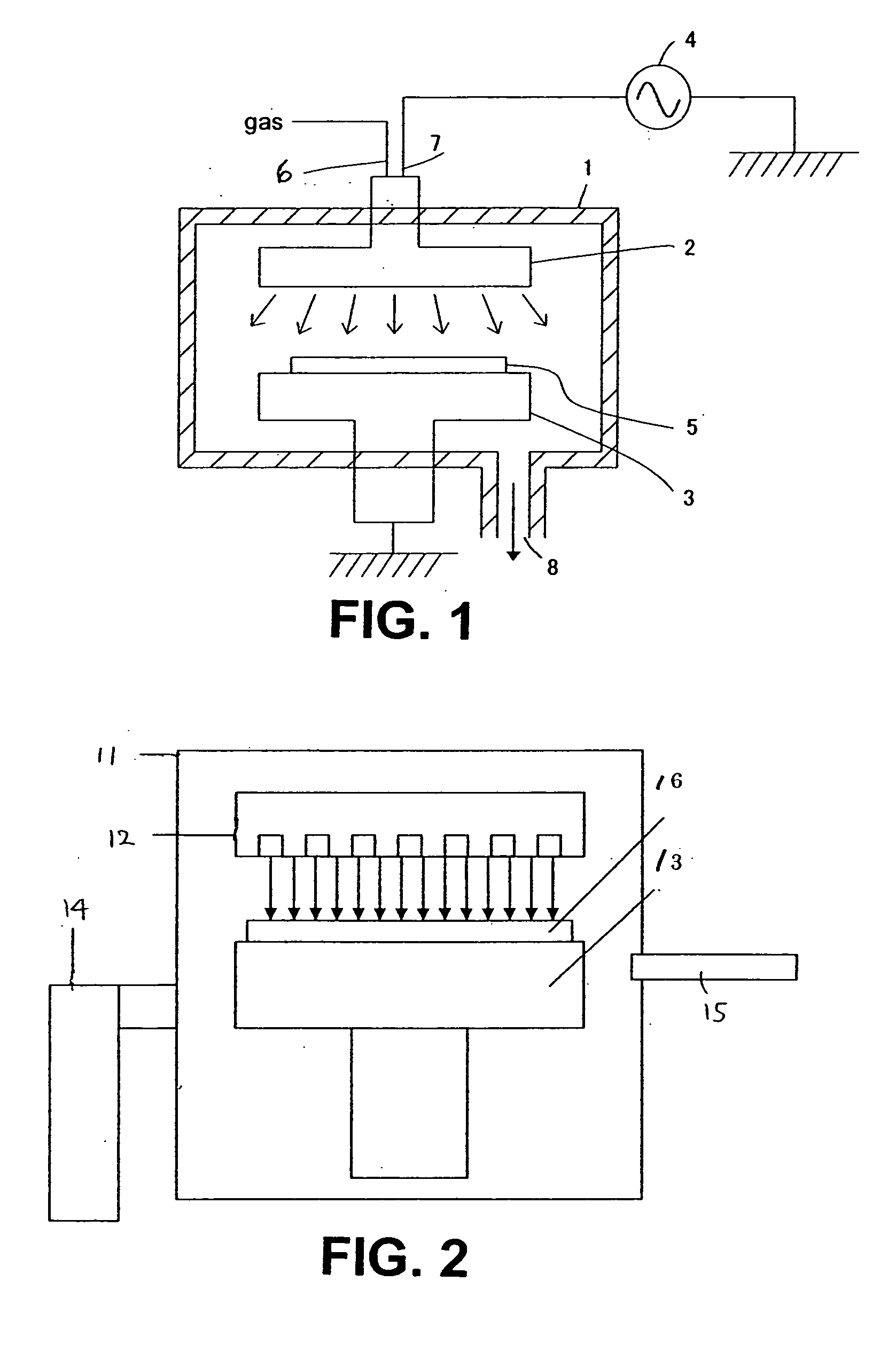

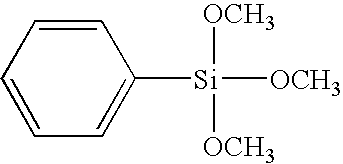

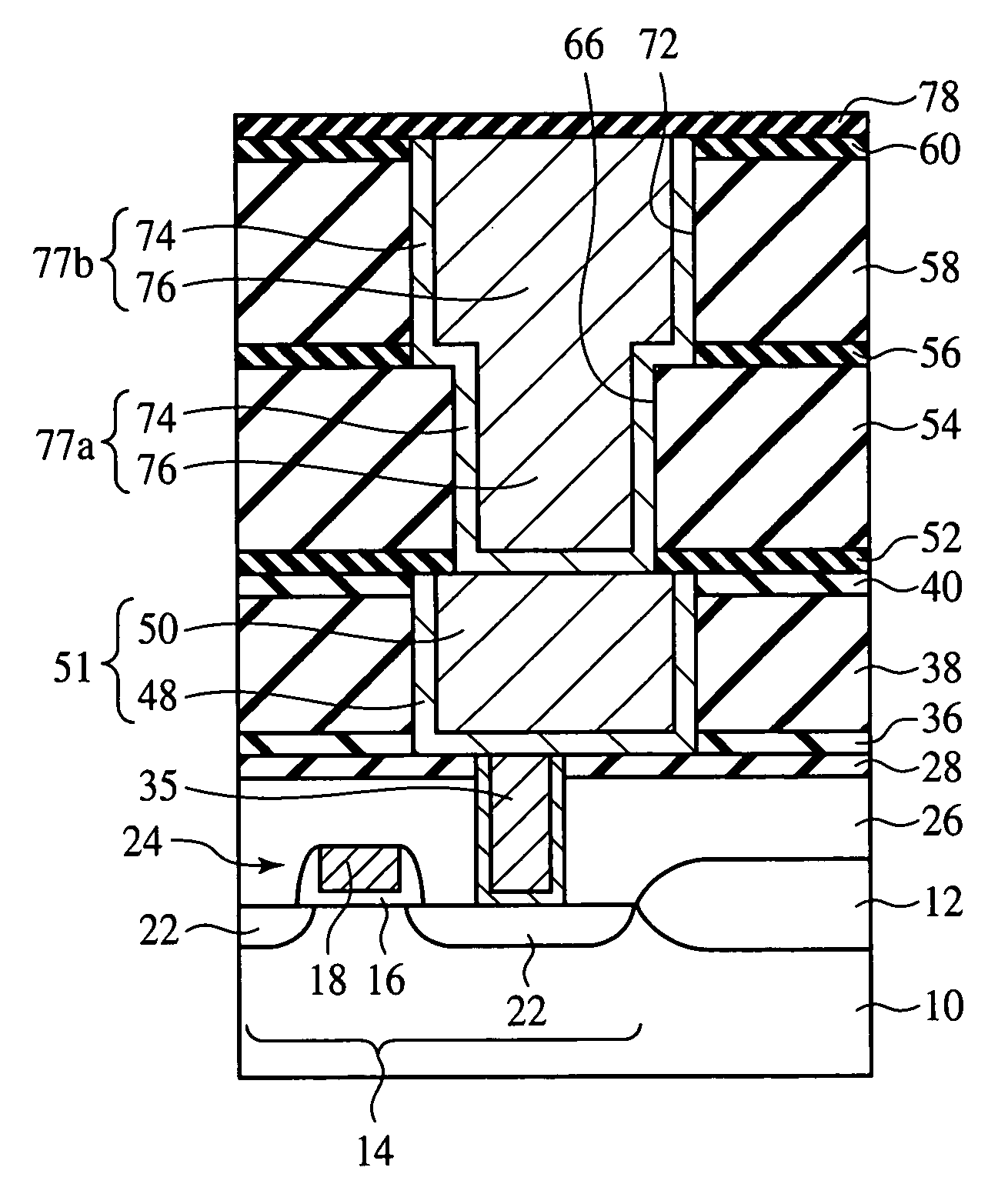

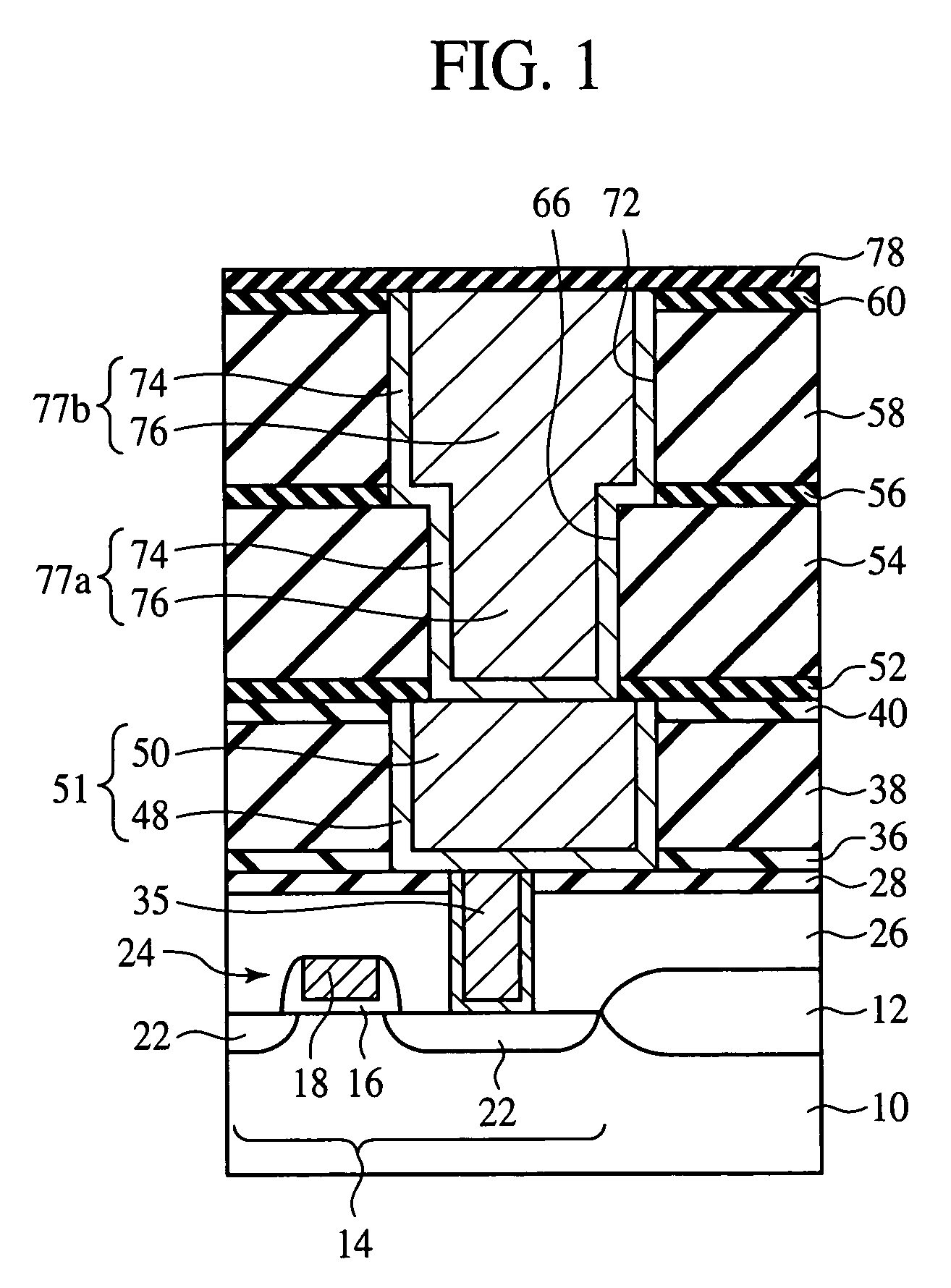

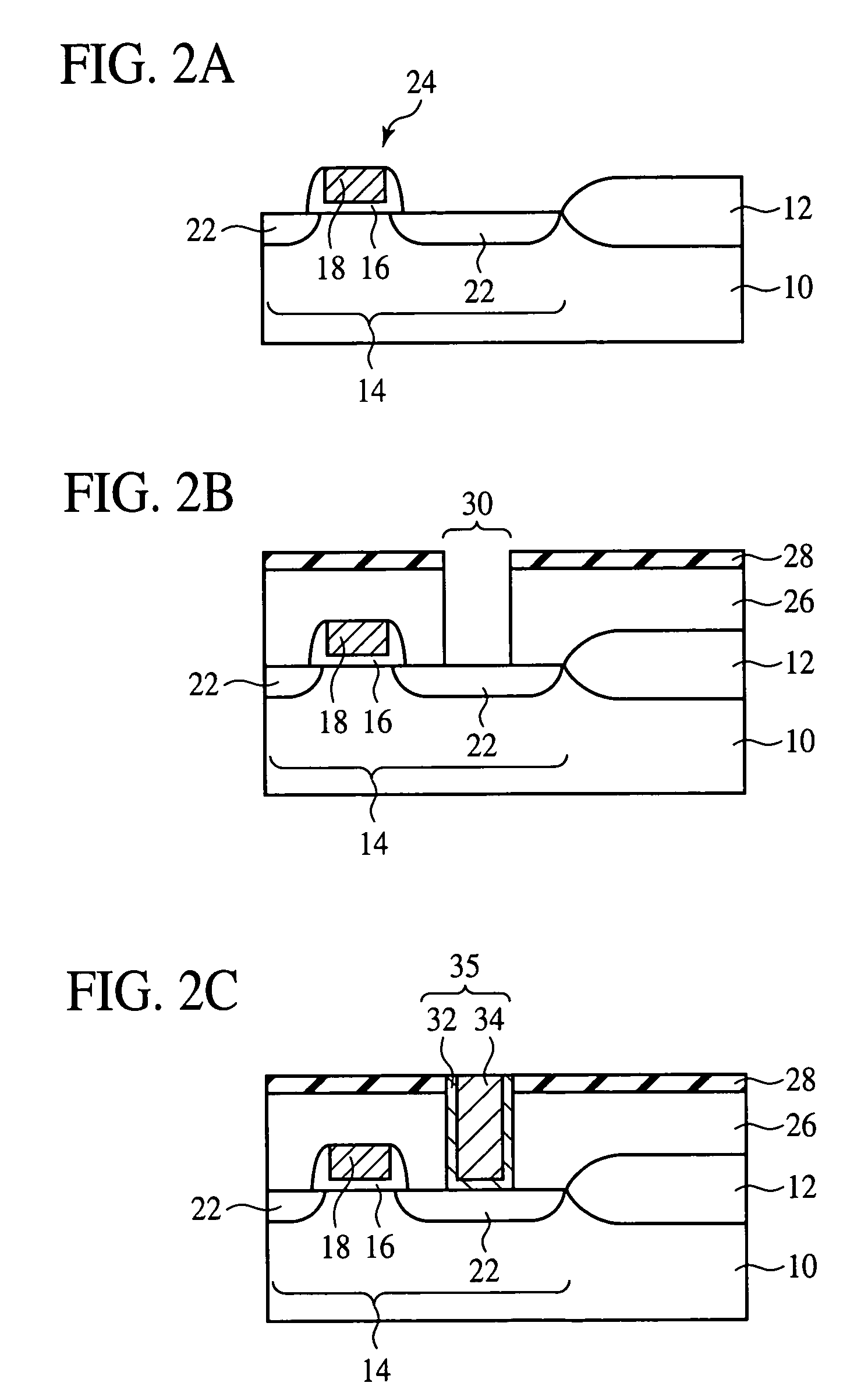

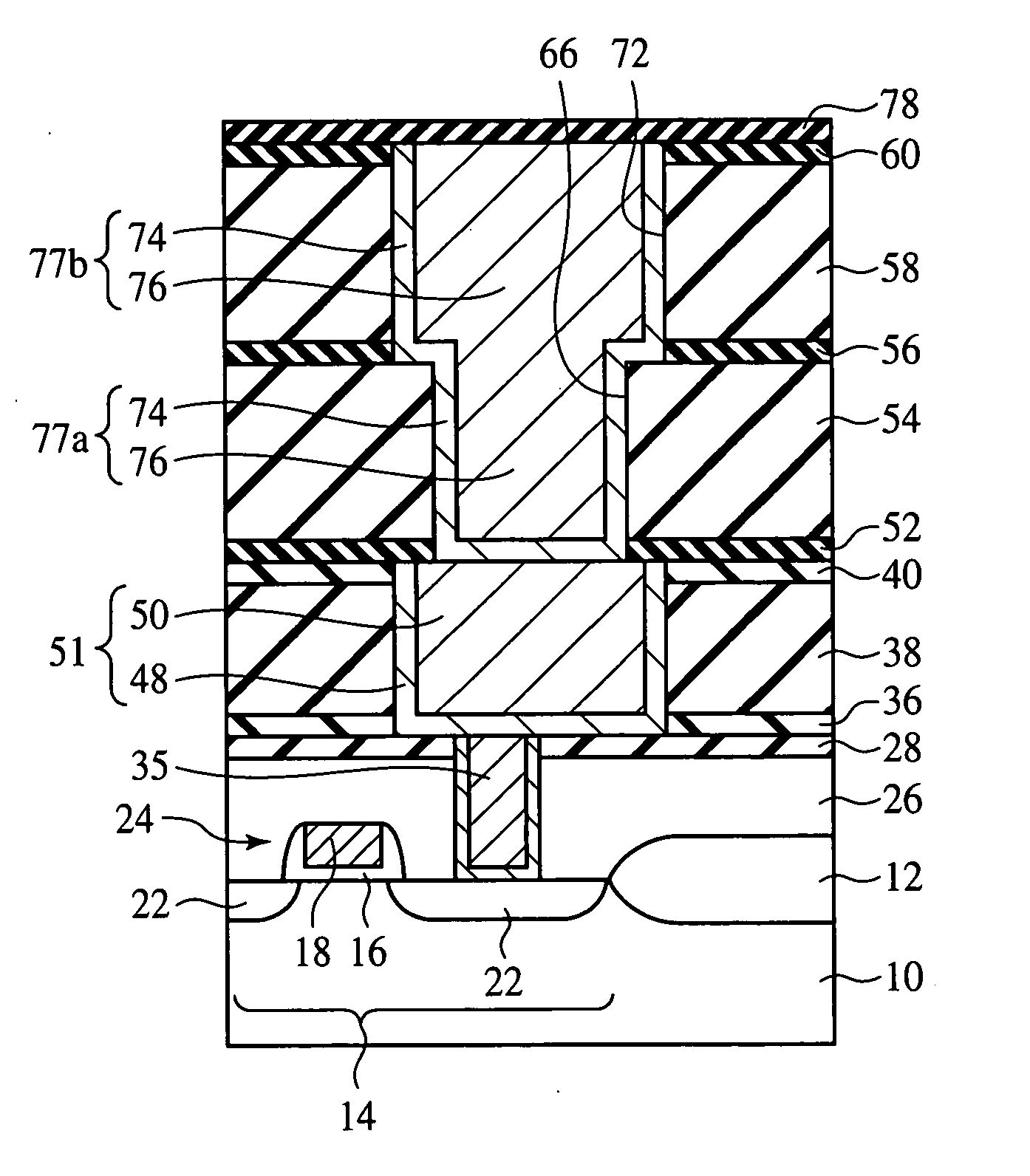

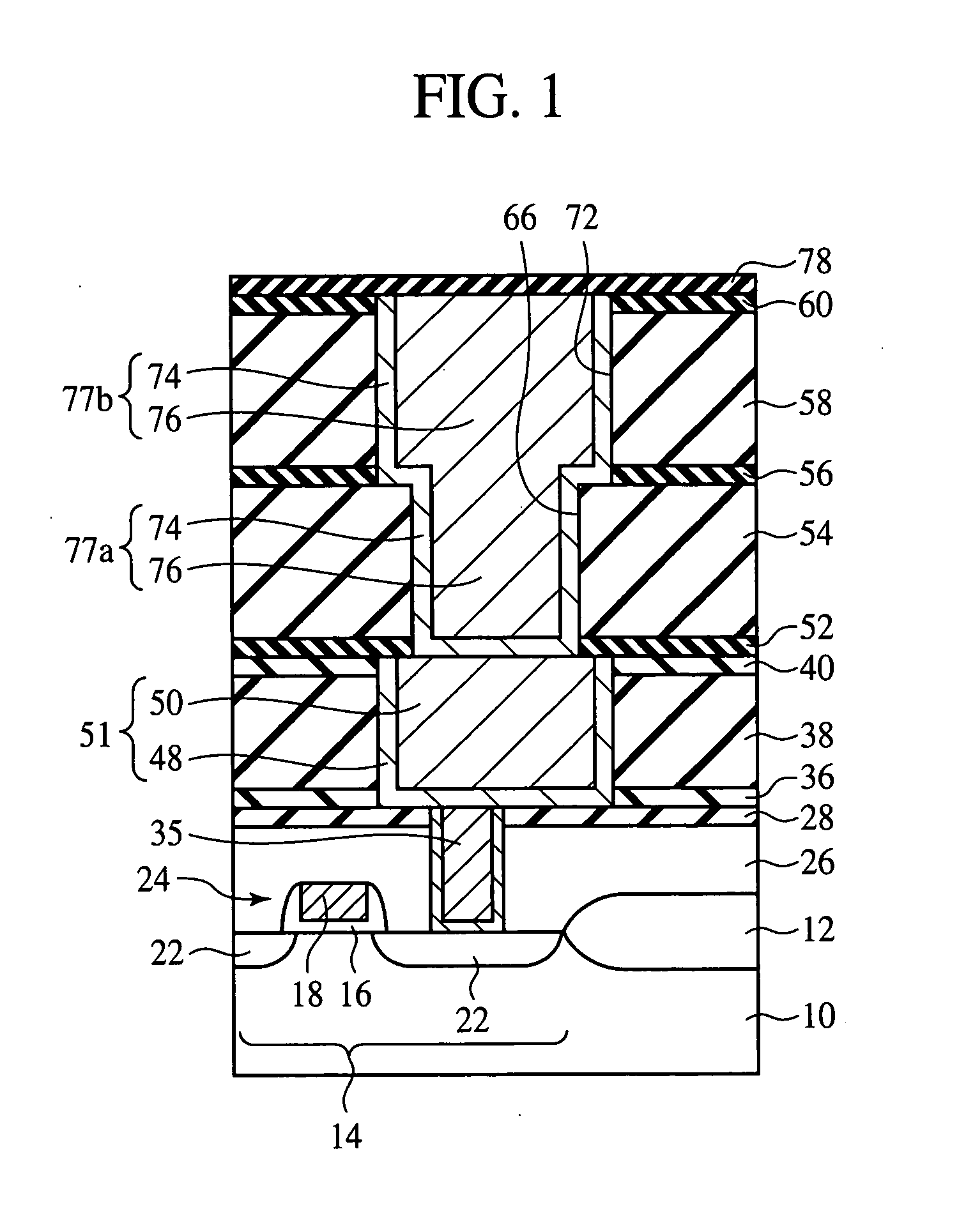

Composition for forming insulating film and method for fabricating semiconductor device

ActiveUS7476970B2Improve reliabilityReduce adhesionSemiconductor/solid-state device detailsSolid-state devicesHigh intensityLength wave

A method for fabricating a semiconductor device utilizing the step of forming a first insulating film of a porous material over a substrate; the step of forming on the first insulating film a second insulating film containing a silicon compound containing Si—CH3 bonds by 30-90%, and the step of irradiating UV radiation with the second insulating film formed on the first insulating film to cure the first insulating film. Thus, UV radiation having the wavelength which eliminates CH3 groups is sufficiently absorbed by the second insulating film, whereby the first insulating film is highly strengthened with priority by the UV cure, and the first insulating film can have the film density increased without having the dielectric constant increased.

Owner:FUJITSU LTD

Method for preparing titanium-stibium-tellurium (Ti-Sb-Te) phase change material and method for preparing phase change storage unit

ActiveCN102978588APrecise and controllable thicknessGood film densityElectrical apparatusChemical vapor deposition coatingHigh density storageComposite material

The invention provides a method for preparing a titanium-stibium-tellurium (Ti-Sb-Te) phase change material and a method for preparing a phase change storage unit. The method for preparing the Ti-Sb-Te phase change material comprises the following steps: 1) introducing a precursor SbCl3 pulse of Sb to a substrate, washing away unabsorbed SbCl3, then introducing a precursor (R3Si)2Te pulse of Te and washing away the unabsorbed (R3Si)2Te and by-products of reaction; 2) introducing a TiCl4 pulse of Ti to the substrate, washing away the residual TiCl4, then introducing the precursor (R3Si)2Te pulse of Te and washing away the residual (R3Si)2Te and by-products of reaction; and 3) introducing a precursor SbCl3 pulse of Sb to the substrate, washing away the residual SbCl3, then introducing a (R3Si)3Sb of Sb and washing away the unabsorbed (R3Si)3Sb and by-products of reaction. The Ti-Sb-Te phase change material prepared by using the method has the characteristics of accurately controllable thickness, good film compactness and strong pore-filling capability. A phase change film prepared by using the method can realize high-density storage when applied to a memorizer, and meanwhile a low power-cost device can be obtained.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

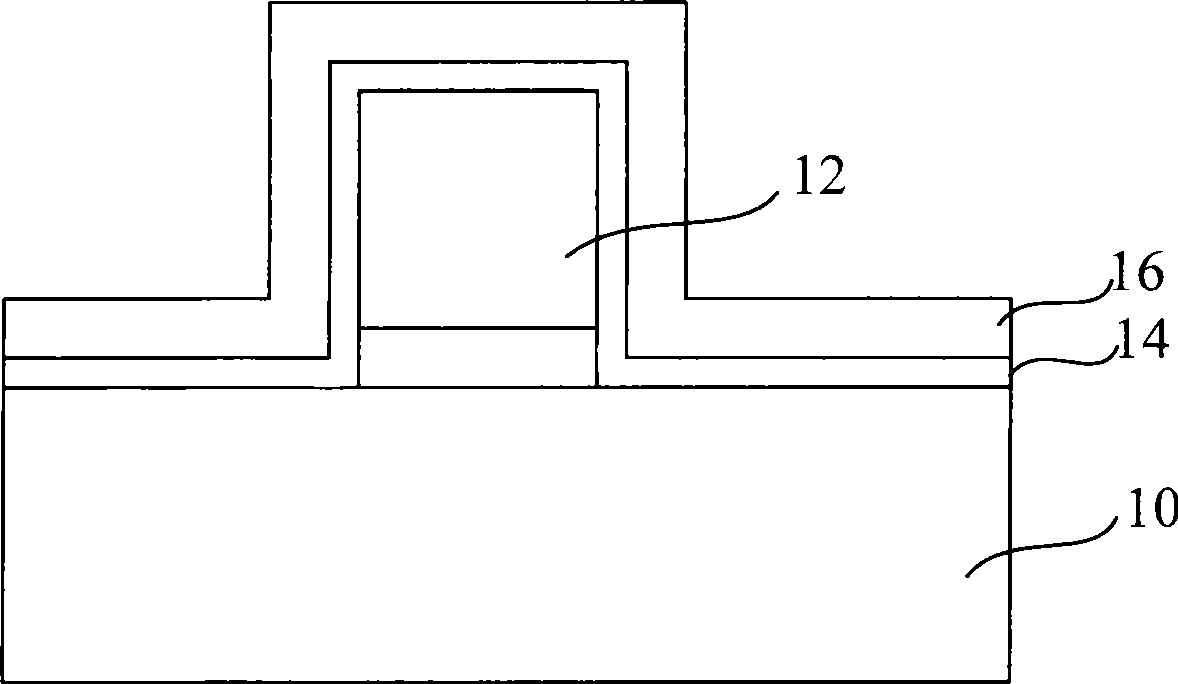

Composition for forming insulating film and method for fabricating semiconductor device

ActiveUS20070232058A1Improve reliabilityIncrease film densitySemiconductor/solid-state device detailsSolid-state devicesDevice materialUltraviolet

The method for fabricating a semiconductor device comprises the step of forming a first insulating film 38 of a porous material over a substrate 10; the step of forming on the first insulating film 38 a second insulating film 40 containing a silicon compound containing Si—CH3 bonds by 30-90%, and the step of irradiating UV radiation with the second insulating film 40 formed on the first insulating film 38 to cure the first insulating film 38. Thus, UV radiation having the wavelength which eliminates CH3 groups is sufficiently absorbed by the second insulating film, whereby the first insulating film is highly strengthened with priority by the UV cure, and the first insulating film can have the film density increased without having the dielectric constant increased.

Owner:FUJITSU LTD

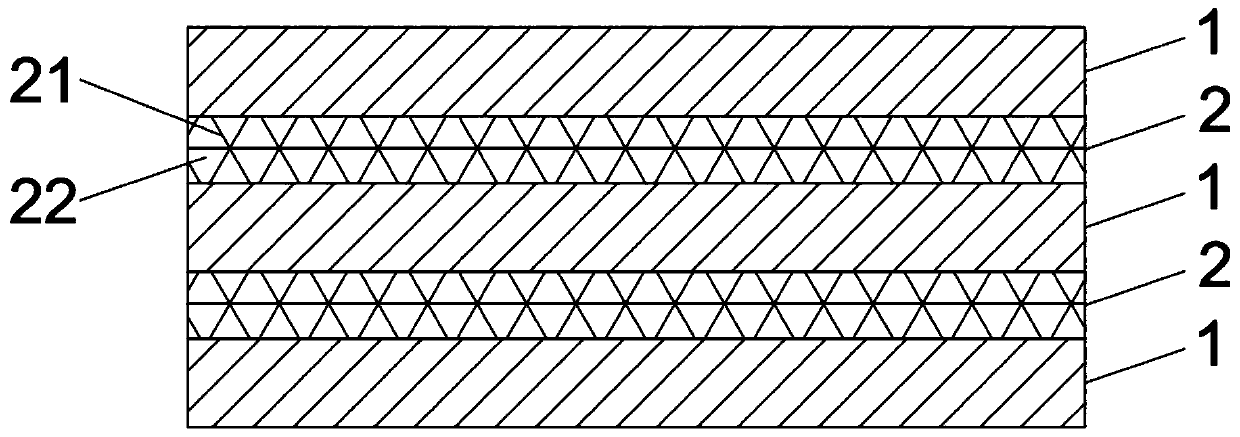

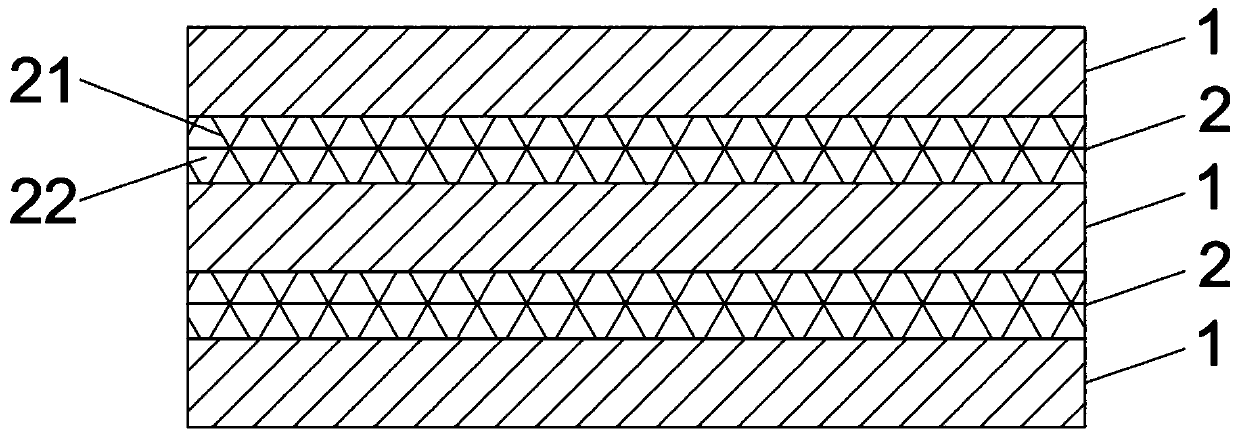

High-barrier high-thermal-conductivity packaging structure for flexible OLED display and preparation method thereof

ActiveCN109920934AIncrease heat transfer rateReduce the temperatureSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialOrganic layer

The invention belongs to the technical field of display, and particularly relates to a high-barrier high-thermal-conductivity packaging structure for flexible OLED display and a preparation method thereof. The packaging structure provided by the invention comprises an inorganic passivation layer and a composite buffer layer which are alternately stacked, wherein the composite buffer layer comprises a heat conduction silk screen layer and an organic layer embedded in the heat conduction silk screen layer; and the heat conduction silk screen layer is exposed on the surface of the organic layer and is attached to the inorganic passivation layer. All layers in the packaging structure of the structure are alternately stacked, so that the structure is excellent in barrier property for water andoxygen; the heat conduction silk screen layer improves the heat conduction rate of the packaging structure, the heat dissipation of the OLED device is facilitated, the increasing of the degradation rate of the OLED device material is avoided, and the service life of the OLED device is prolonged. According to the preparation method provided by the invention, the composite buffer layers with different layers are prepared at different temperatures, and the thickness of the composite buffer layer is larger than that of the inorganic passivation layer, so that various functional materials of the OLED display layer are protected, and the compactness of the inorganic passivation layer is also improved.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

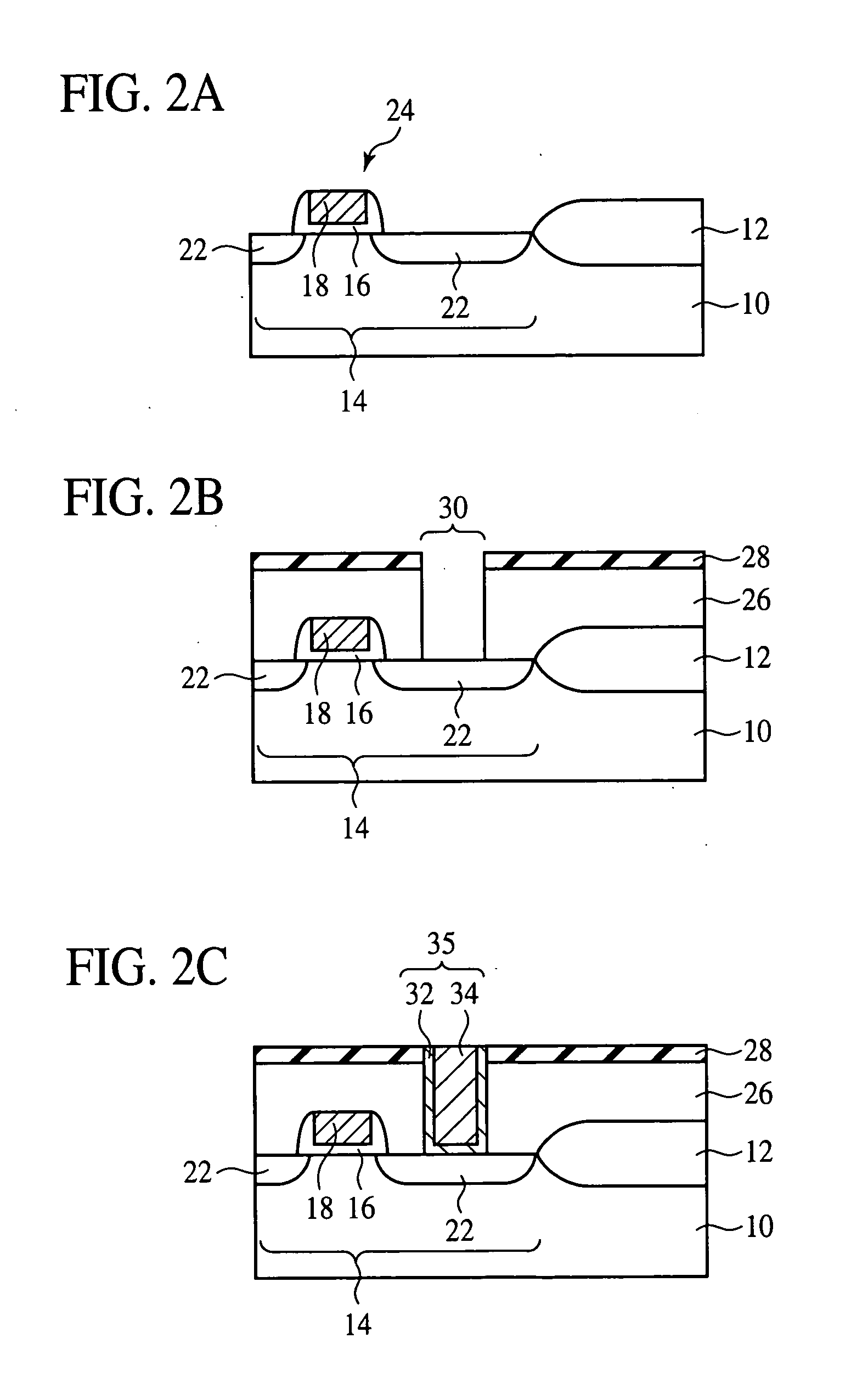

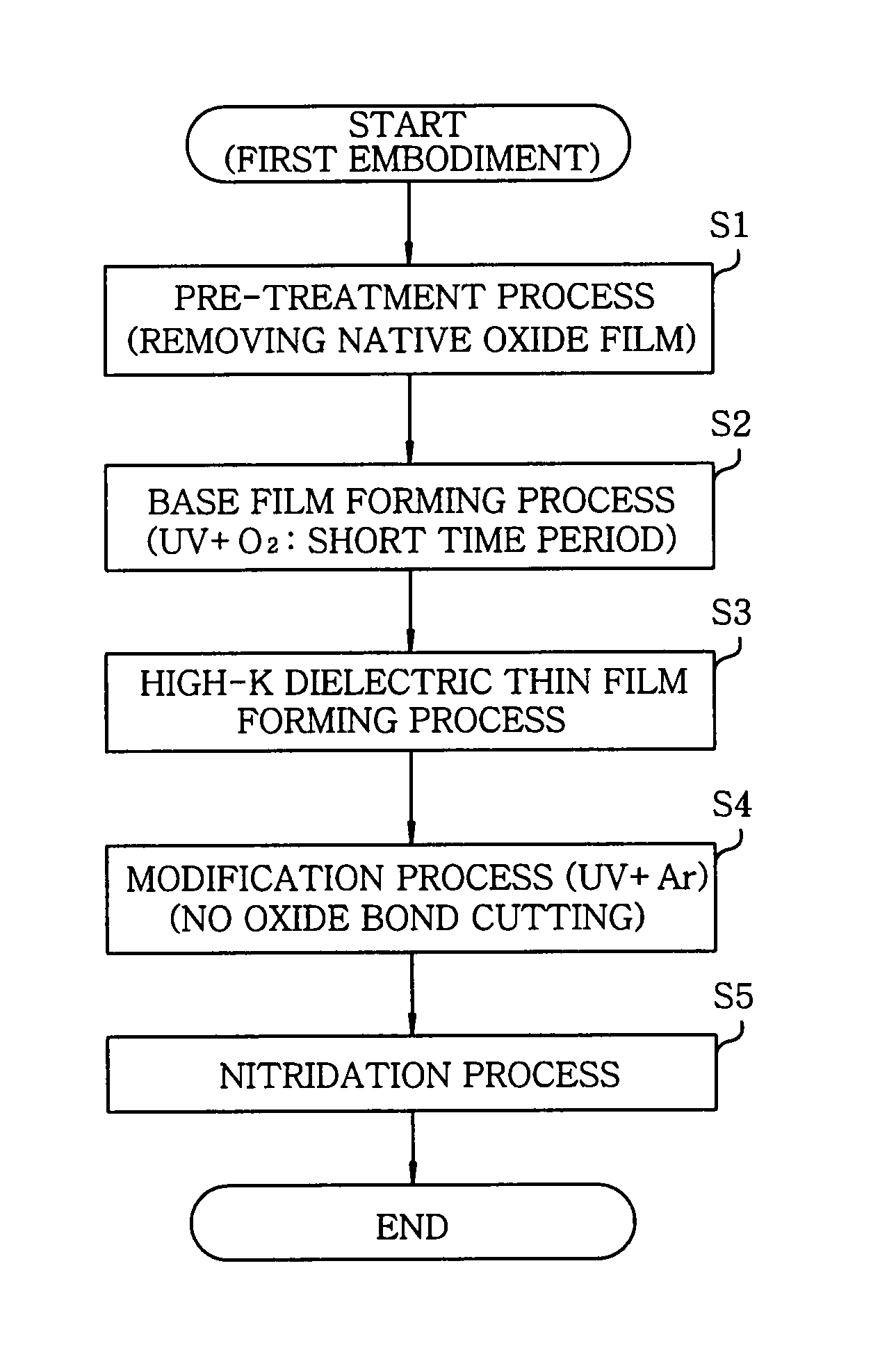

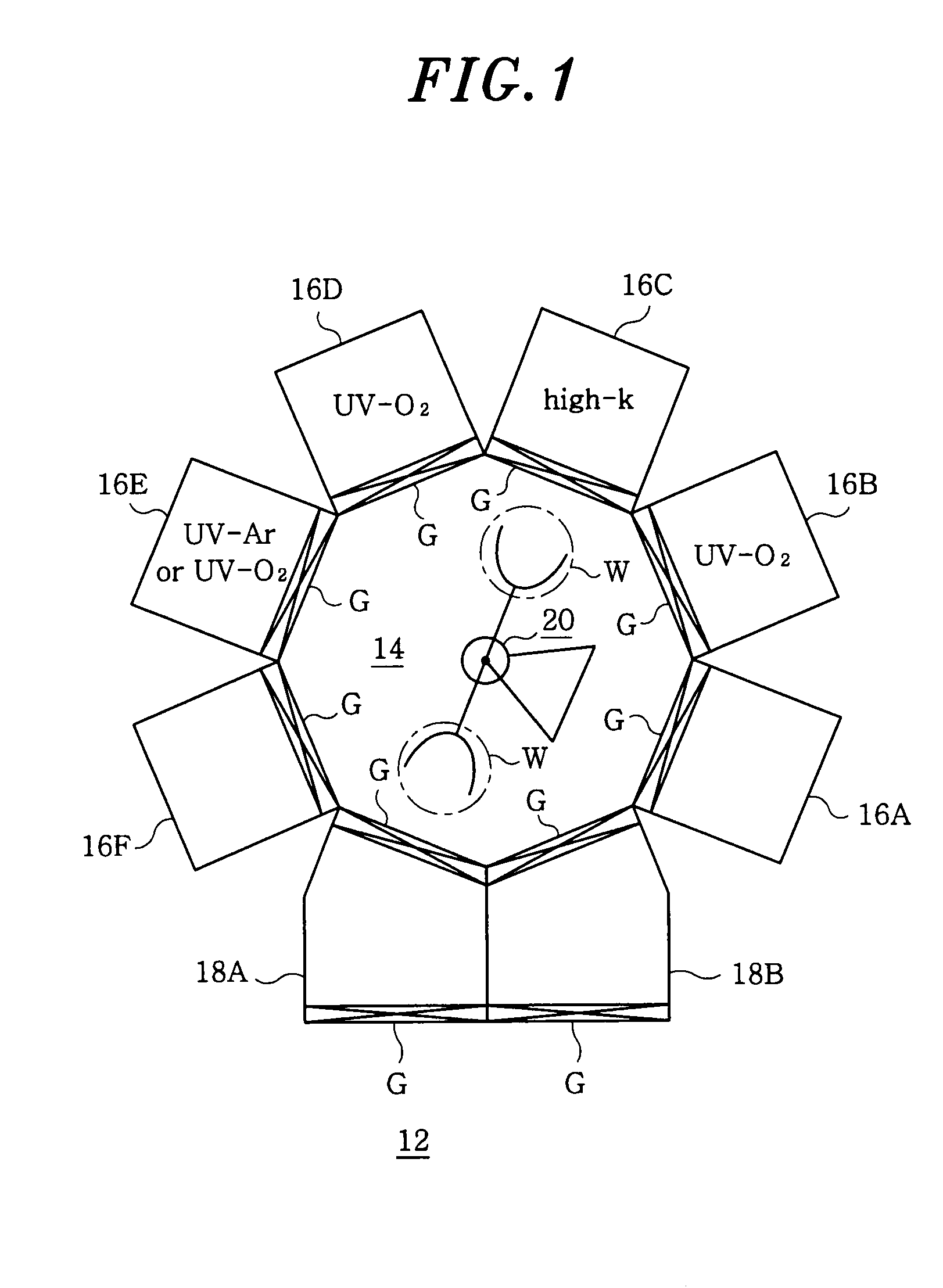

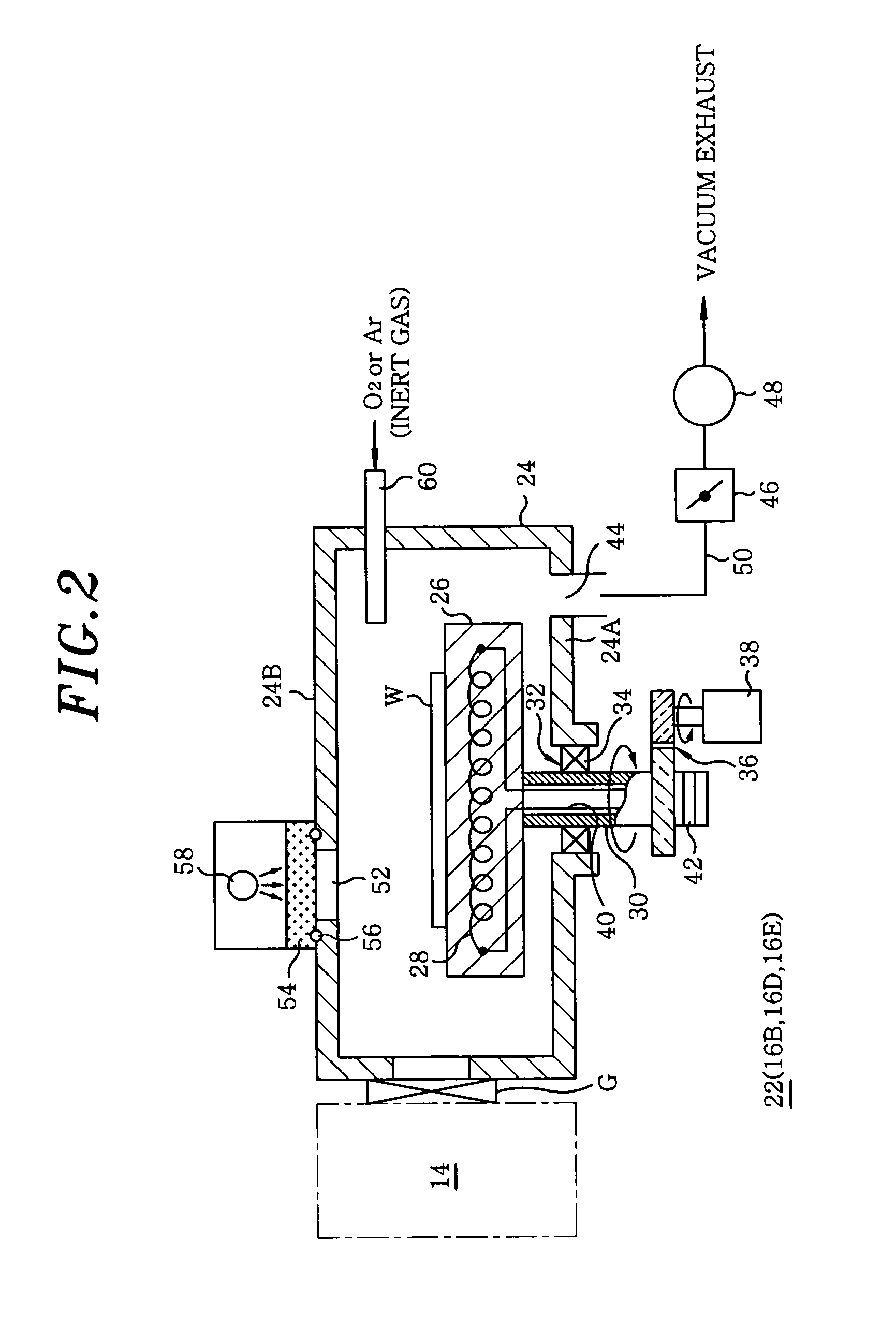

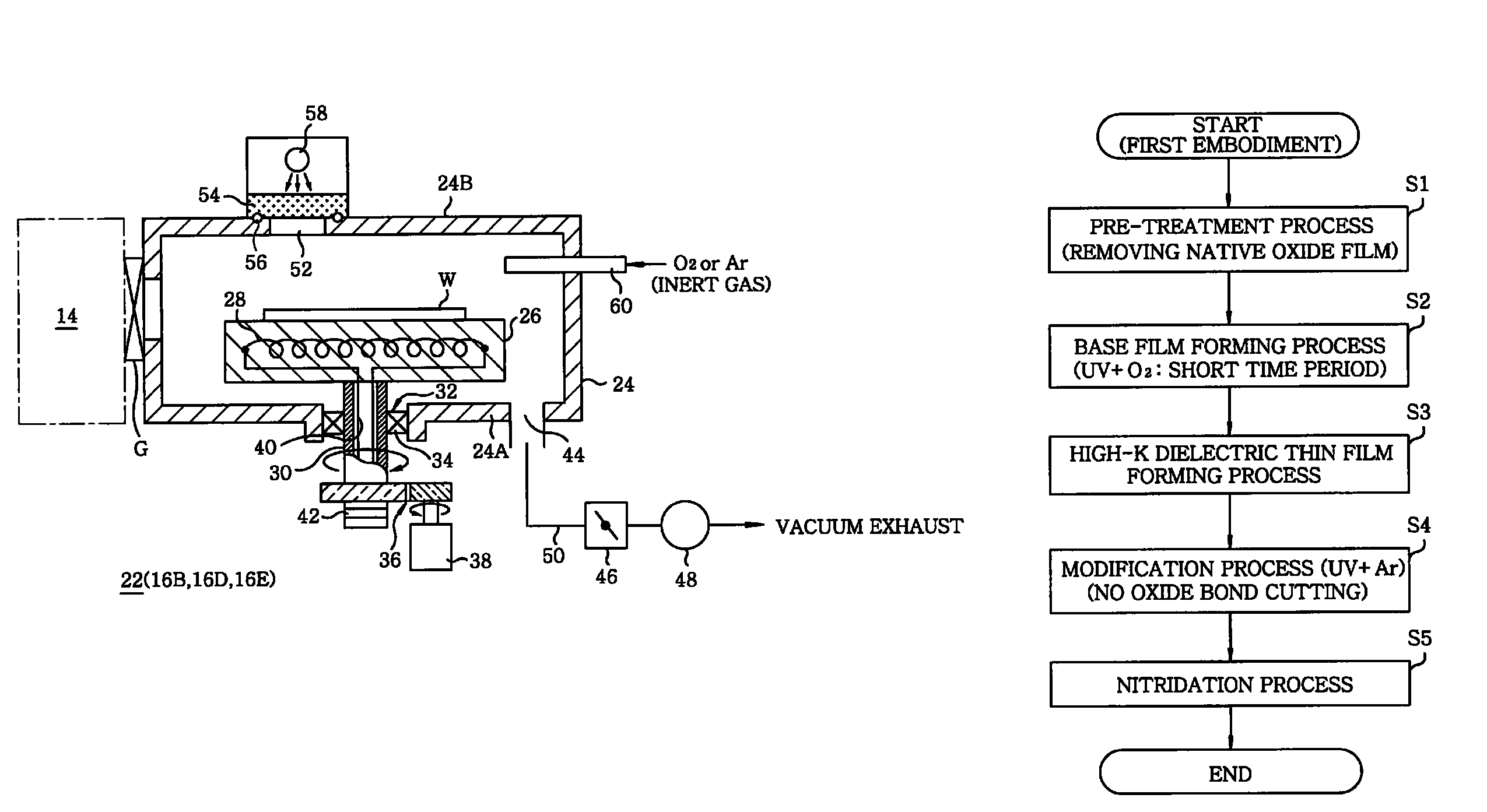

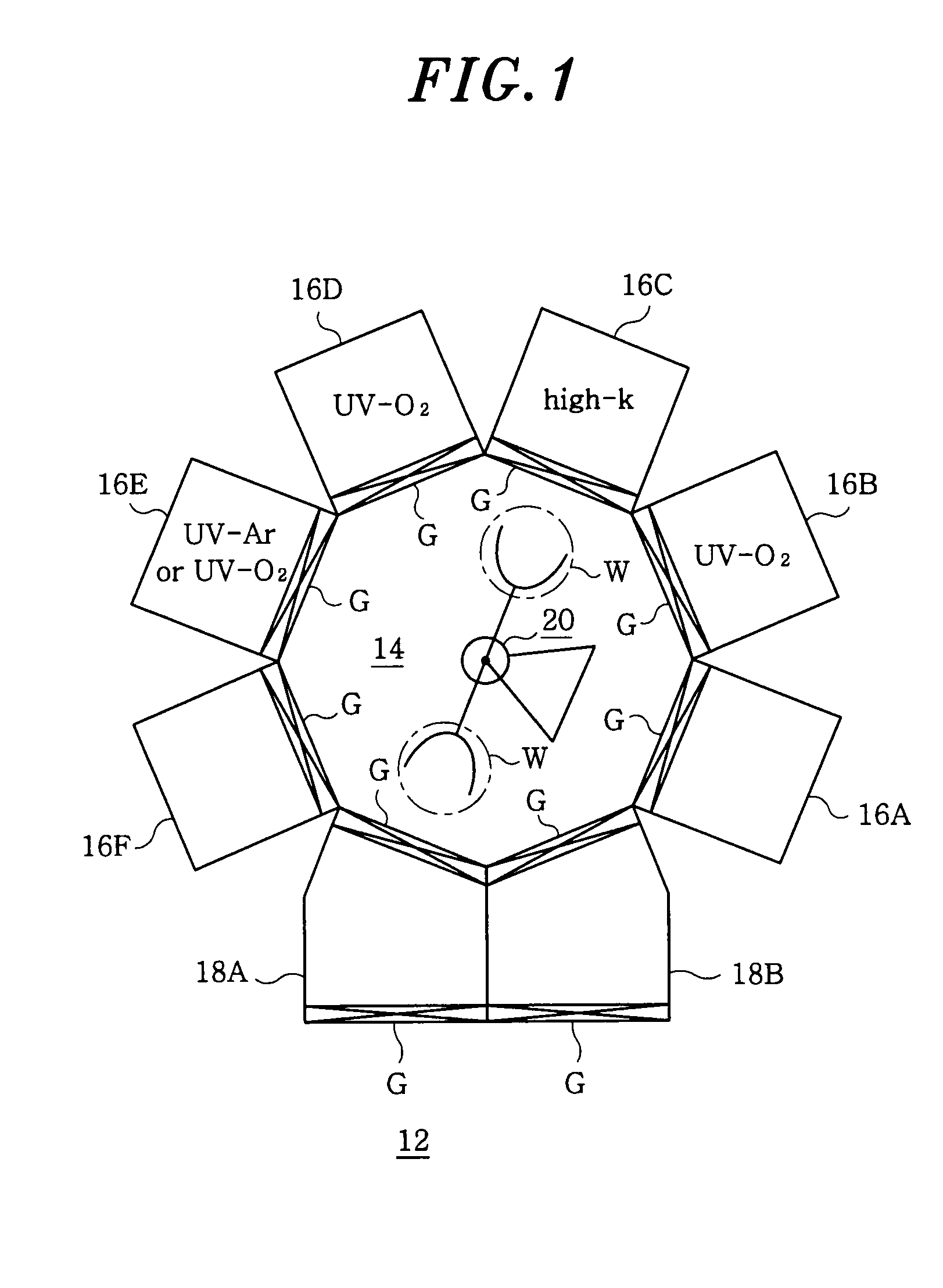

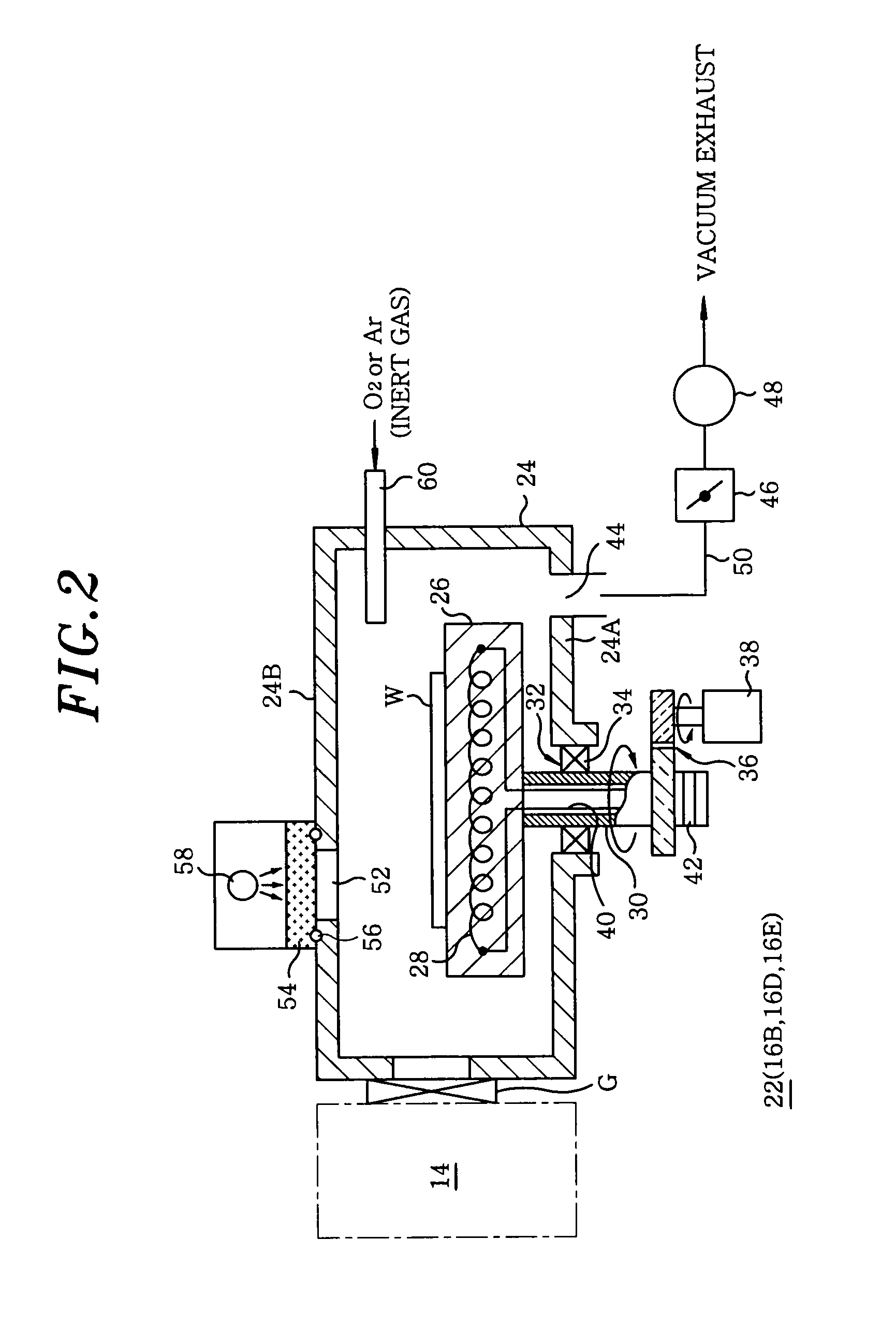

Method for modifying high-k dielectric thin film and semiconductor device

InactiveUS20090302433A1High dielectric constantImprove featuresSemiconductor/solid-state device detailsSolid-state devicesUltravioletPermittivity

There is provided a method for modifying a high-k dielectric thin film provided on the surface of an object using a metal organic compound material. The method includes a preparation process for providing the object with the high-k dielectric thin film formed on the surface thereof, and a modification process for applying UV rays to the highly dielectric thin film in an inert gas atmosphere while maintaining the object at a predetermined temperature to modify the high-k dielectric thin film. According to the above constitution, the carbon component can be eliminated from the high-k dielectric thin film, and the whole material can be thermally shrunk to improve the density, whereby the occurrence of defects can be prevented and the film density can be improved to enhance the specific permittivity and thus to provide a high level of electric properties.

Owner:TOKYO ELECTRON LTD

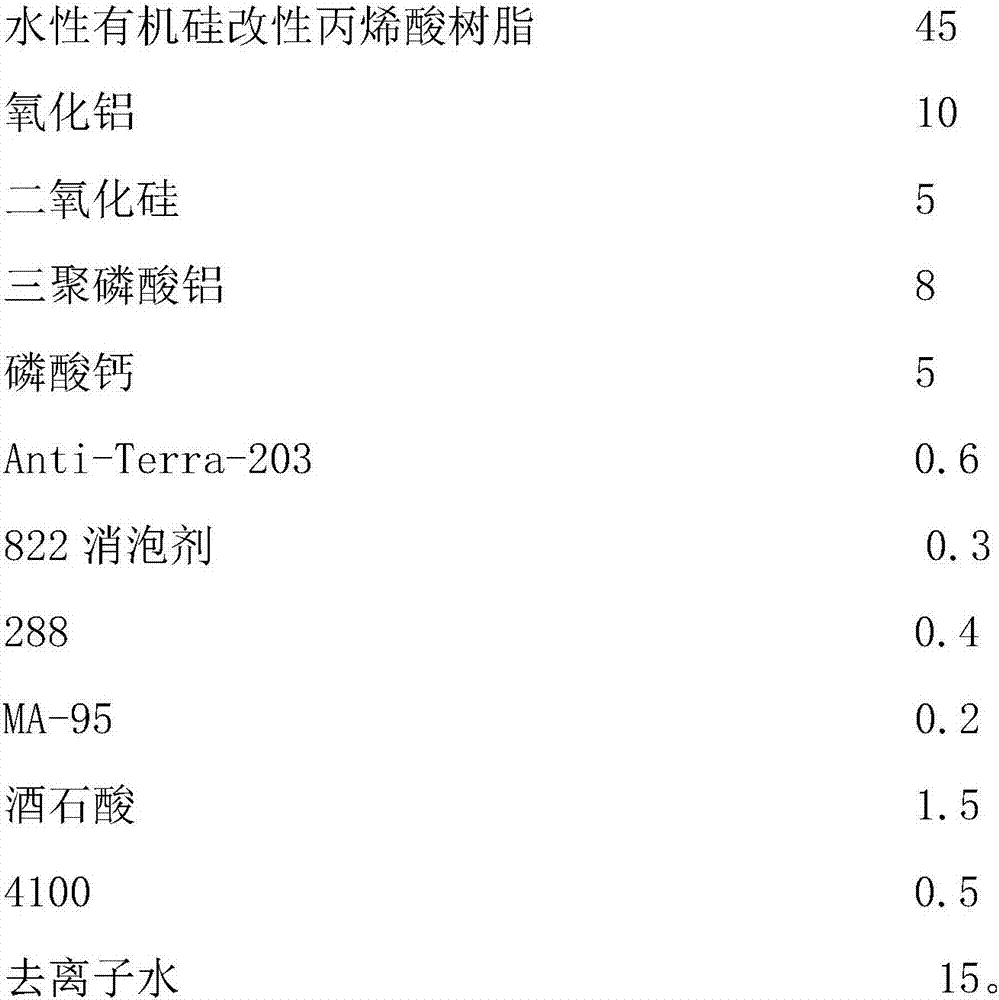

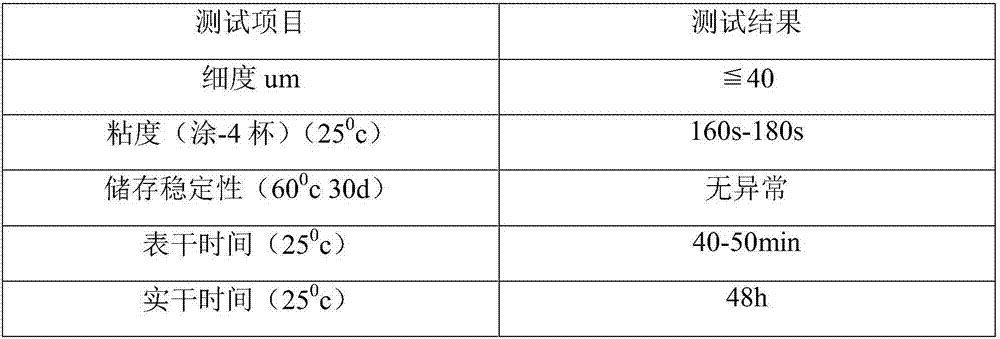

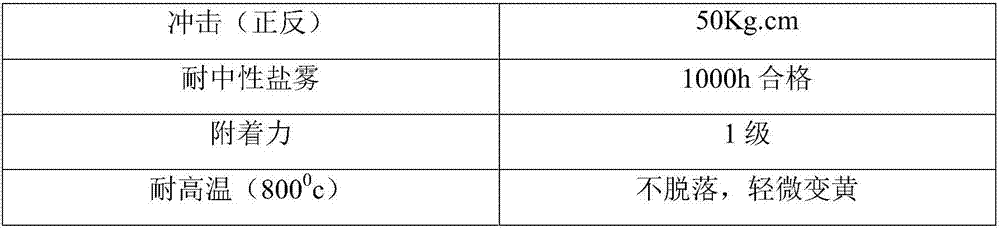

Water-based high-temperature-resistant anti-rust multifunctional coating and preparation method thereof

InactiveCN107880670ASimple and convenient constructionStrong adhesionFireproof paintsAnti-corrosive paintsWater basedAcrylic resin

The invention discloses a water-based high-temperature-resistant anti-rust multifunctional coating. The coating is prepared from the following raw materials in parts by weight: 30-50 parts of siliconemodified acrylic resin, 10-20 parts of high-temperature-resistant pigments, 6-10 parts of aids, 15-30 parts of anti-rust pigments and 15-25 parts of deionized water. Meanwhile, the invention furtherprovides a preparation method of the water-based high-temperature-resistant anti-rust multifunctional coating. The film-forming compactness of the coating during spraying is improved, and the adhesiveforce and toughness are improved to different degrees.

Owner:HUNAN UNIV OF ARTS & SCI

Lithium-titanium complex oxide, and battery electrode and lithium ion secondary battery using same

ActiveUS20130260251A1Easy to handleIncrease film densityAlkali titanatesNon-aqueous electrolyte accumulator electrodesLithiumPhysical chemistry

A lithium-titanium complex oxide containing Li4Ti5O12 is characterized in that, based on SEM observation, the number-based percentage of particles whose size is less than 0.1 μm is 5 to 15% or 40 to 65%, the number-based percentage of particles whose size is 0.3 to 1.5 μm is 15 to 30%, the specific surface area measured by the BET method is 5.8 to 10.1 m2 / g, and the average particle size D50 according to the particle size distribution measured by laser diffraction measurement is preferably 0.6 to 1.5 μm.

Owner:TAIYO YUDEN KK

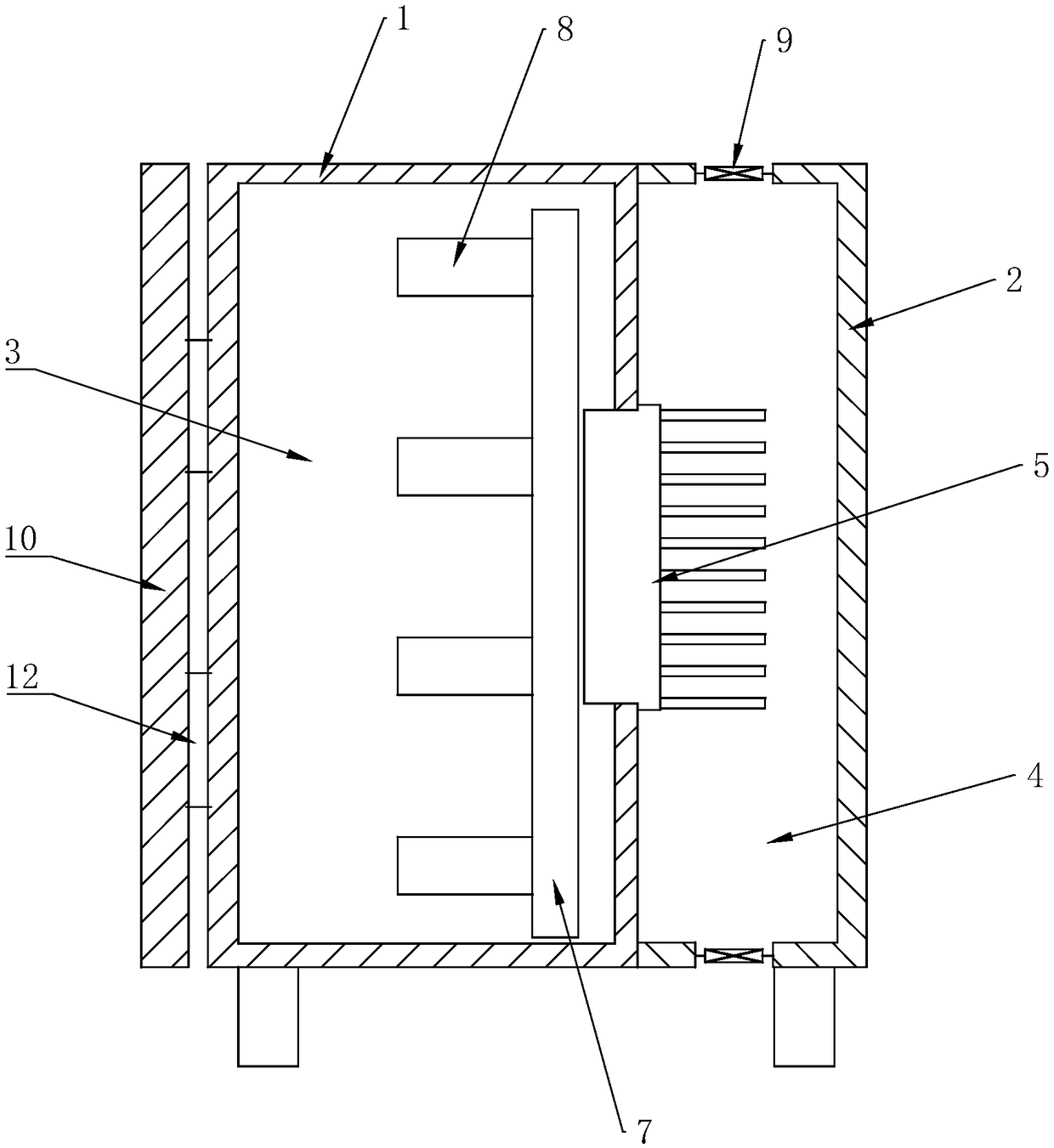

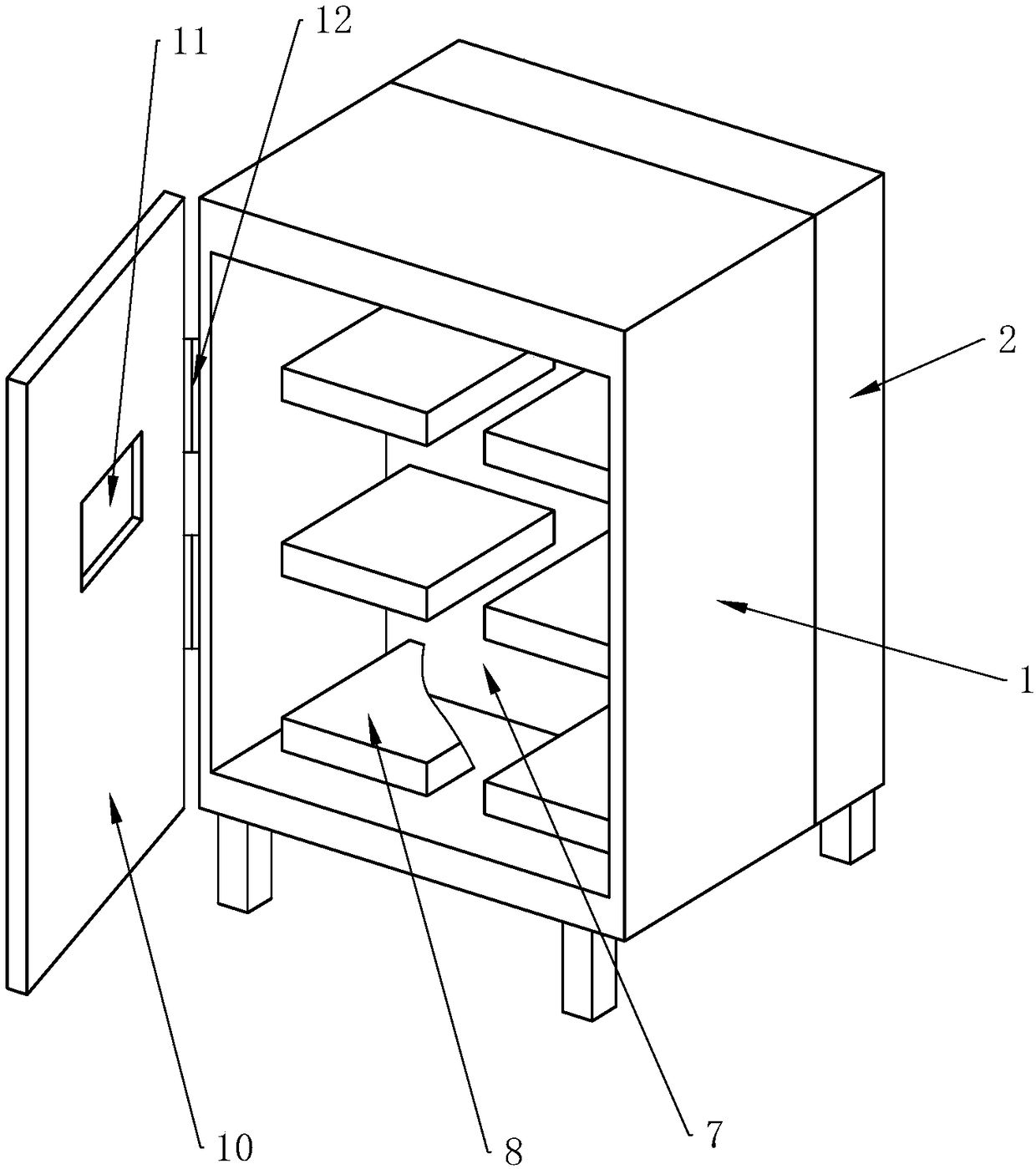

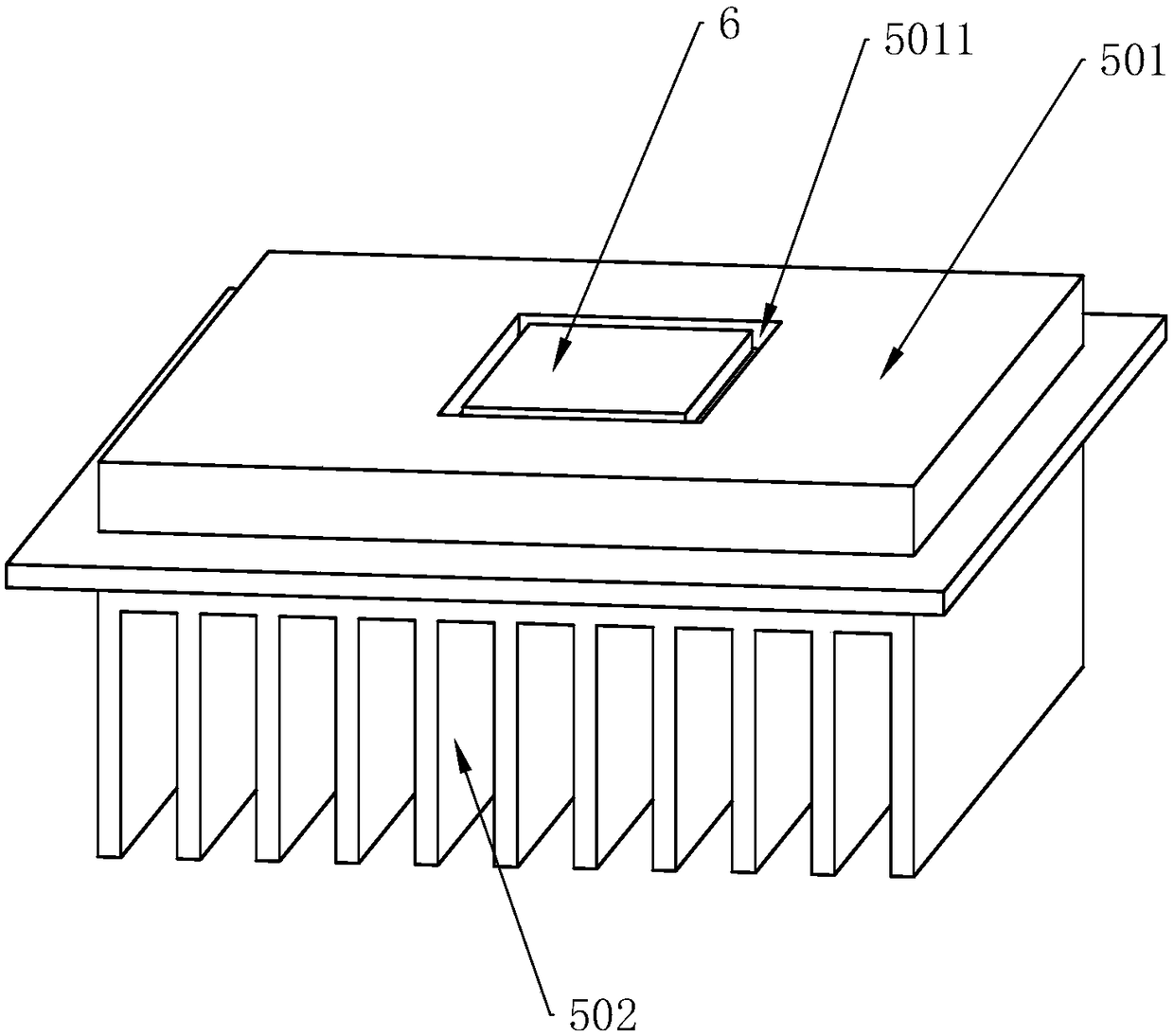

Electric control cabinet and assembly method thereof

InactiveCN108565725AEvenly dispersedGood film densitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEnvironmentally friendlyEngineering

The invention discloses an electric control cabinet and an assembly method thereof. The cabinet body of the electric control cabinet comprises an explosion-proof housing and a ventilation housing andis characterized in that the explosion-proof housing is a rectangular parallelepiped housing and defines an explosion-proof cavity; the ventilating housing is located at one side of the explosion-proof housing and forms a ventilation cavity with the explosion-proof housing; the explosion-proof housing is provided with a mounting hole at a side close to the ventilation housing; the explosion-proofcavity is in communication with the ventilation cavity by the mounting hole; a heat dissipation device is mounted on the mounting hole; the inner walls of the explosion-proof housing and the ventilation housing are first sprayed with zinc-rich primer, and then the surface of the zinc-rich primer is coated with an anticorrosive material layer. The cooling and heat dissipation function of the electric control cabinet is efficient, and the content of VOC in the discharged hot air is significantly reduced so as to be more environmentally friendly.

Owner:SHOUGUANG JUNENG ELECTRIC

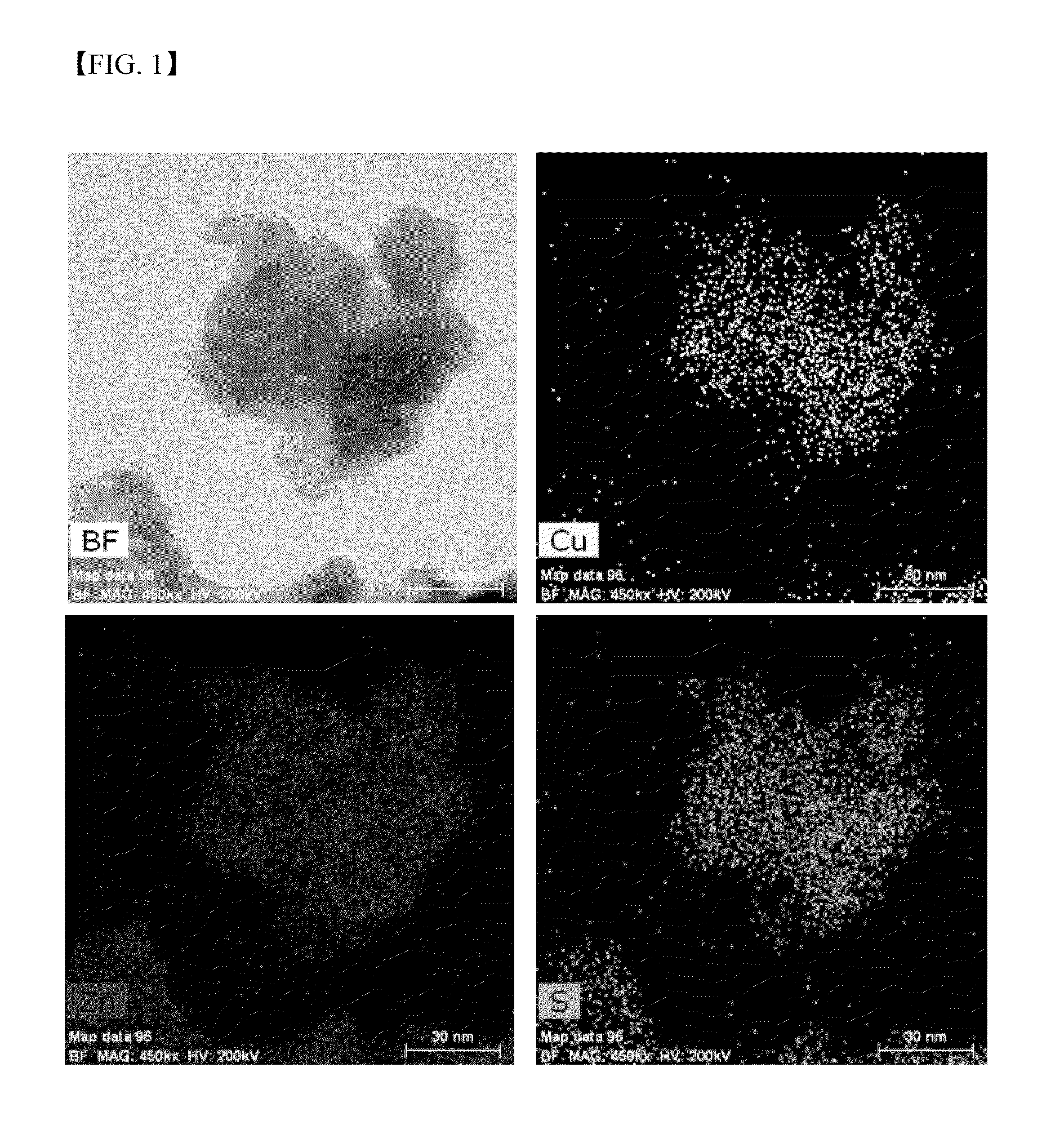

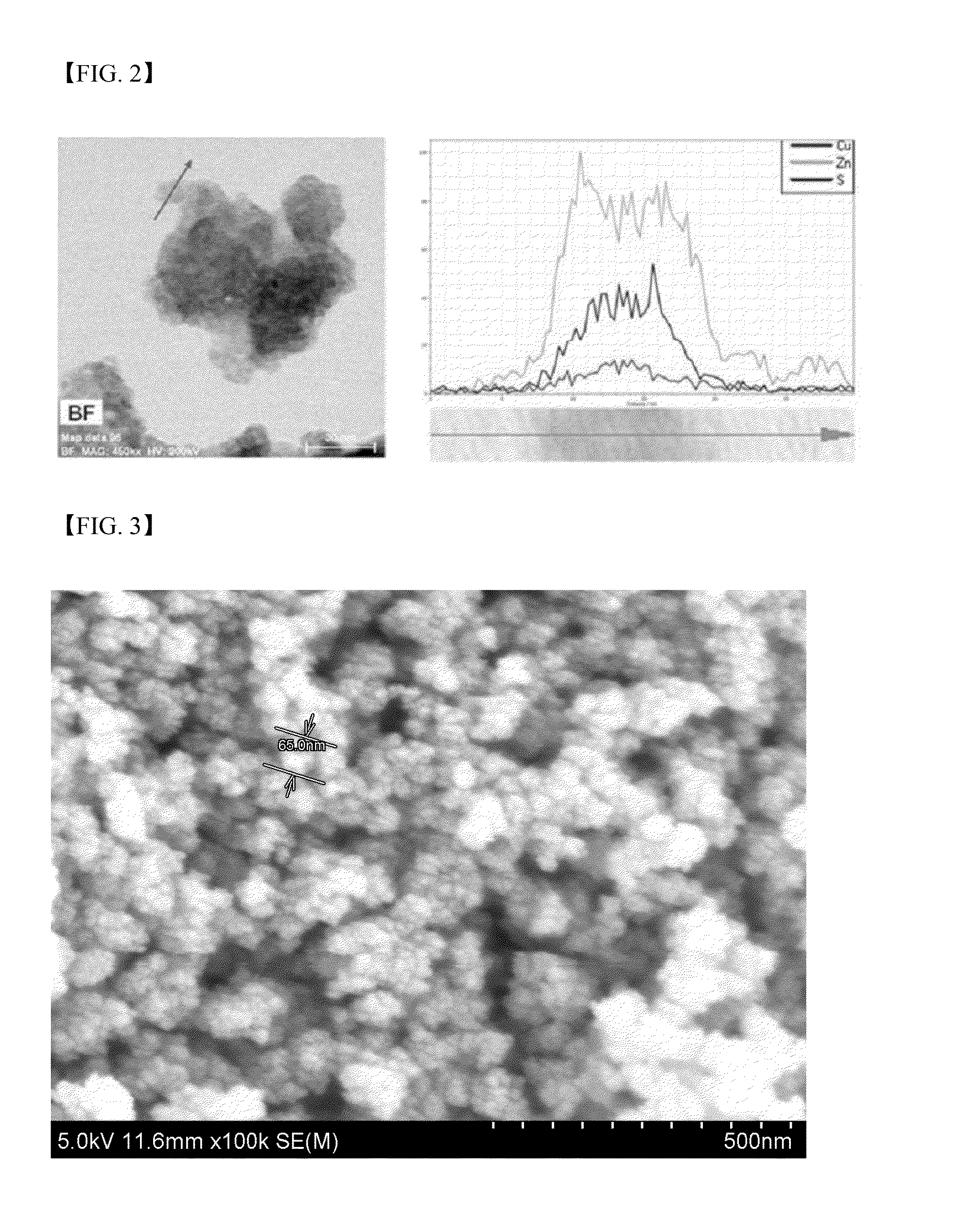

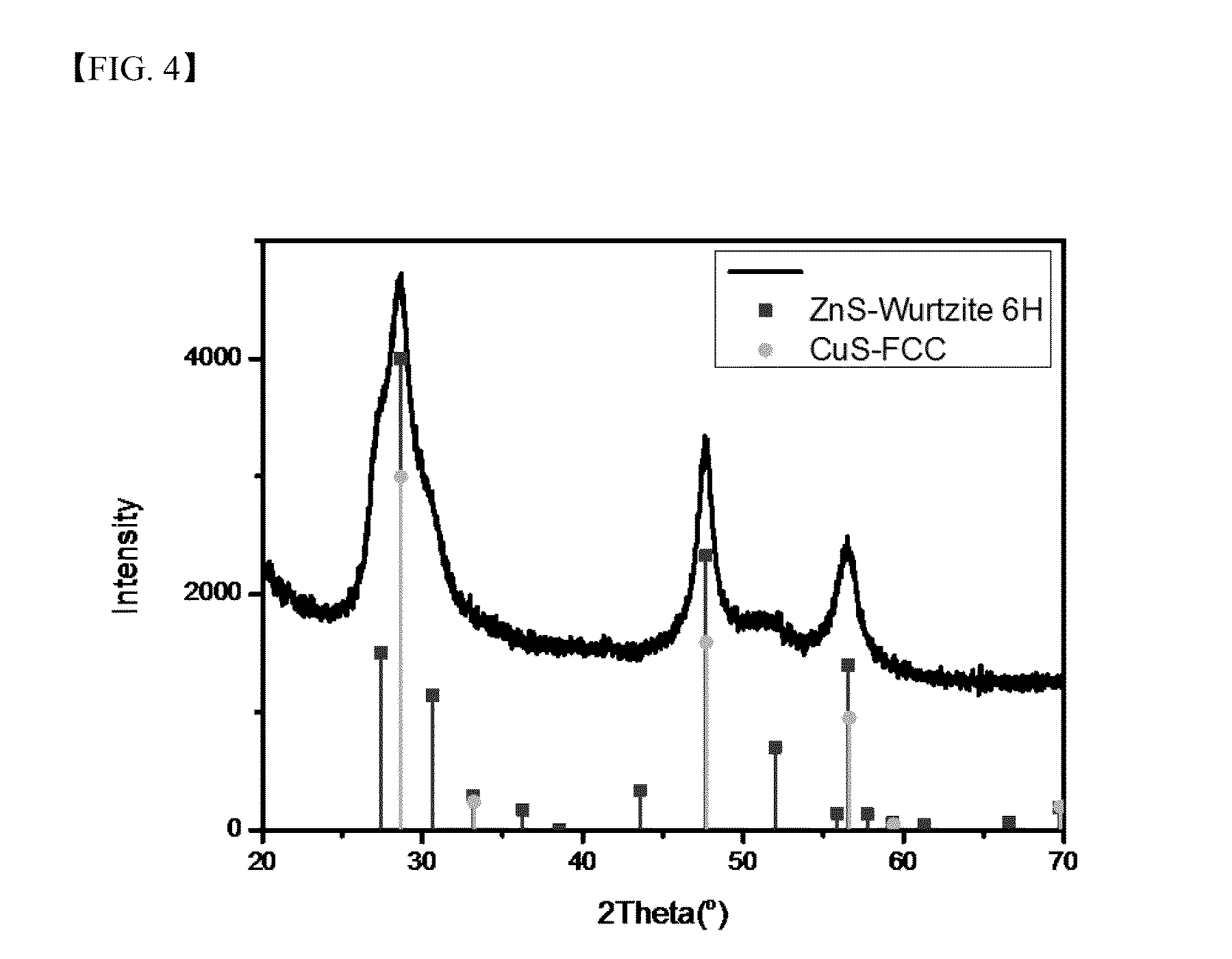

Metal chalcogenide nanoparticles for manufacturing solar cell light absorption layers and method of manufacturing the same

InactiveUS20160149061A1Oxidation stabilityQuality improvementFinal product manufactureConductive materialThird phaseChalcogenide

Disclosed are metal chalcogenide nanoparticles forming light absorption lavers of solar cells including two or more phases selected from a first phase including zinc (Zn)-containing chalcogenide, a second phase including tin (Sn)-containing chalcogenide and a third phase including copper (Cu)-containing chalcogenide, and a method of manufacturing the same.

Owner:LG CHEM LTD

Waterborne epoxy emulsion,

ActiveCN108912947AHigh resistance to salt sprayHigh activityAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention provides a waterborne epoxy emulsion. The waterborne epoxy emulsion comprises, by weight, 50 to 130 parts of epoxy resin, 0.05 to 15 parts of phosphoric acid, 1 to 25 parts of polyether,and 0.005 to 7 parts of a catalyst. The waterborne epoxy emulsion is high in film forming compactness; epoxy groups with relatively high activity are maintained, and room temperature solidification is realized under cooperation effect with a curing agent; introduction of phosphoric acid is capable of increasing the clunging force between the waterborne epoxy emulsion and a base material, and improving the salt spray resistance of the waterborne epoxy emulsion.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

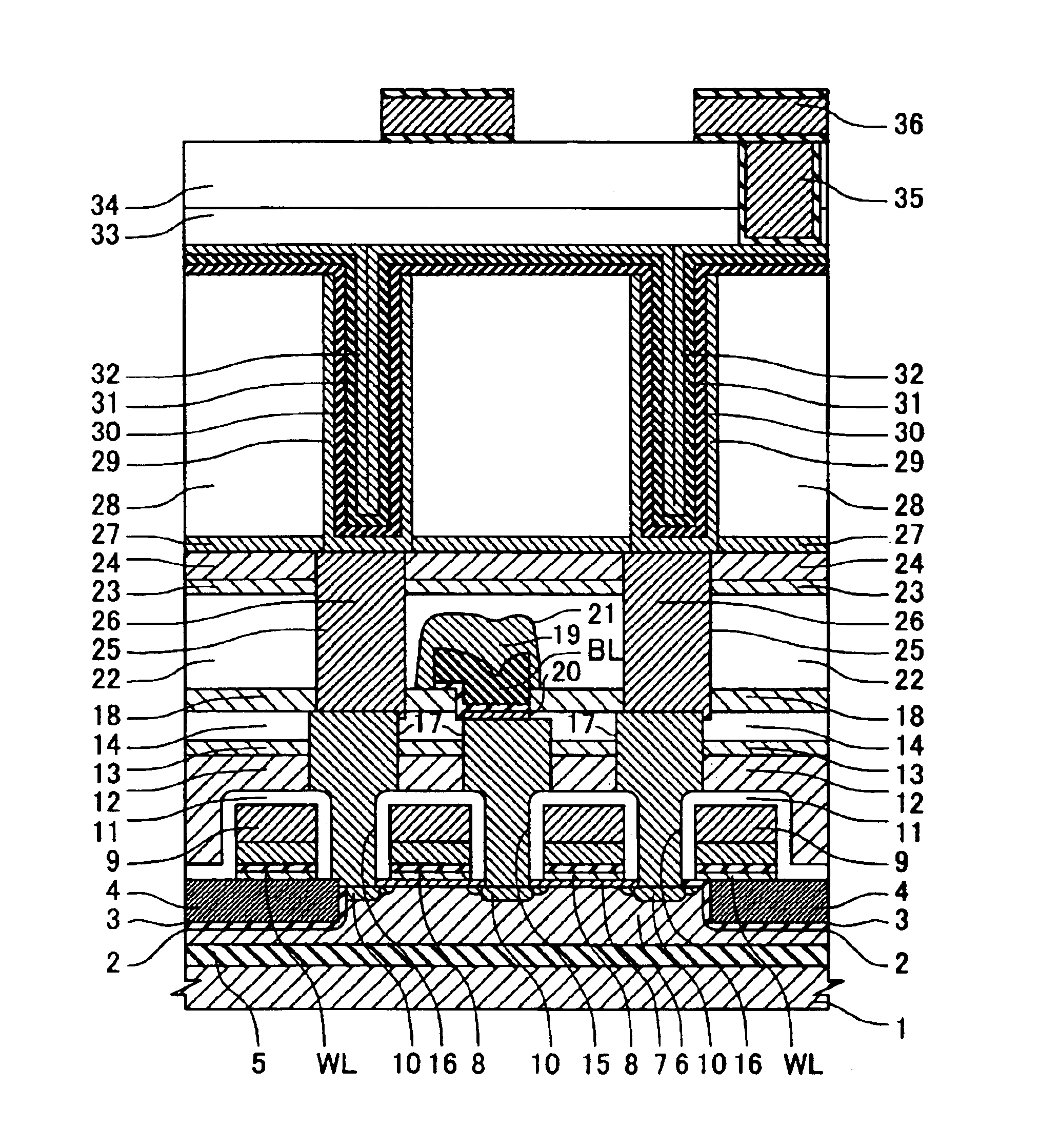

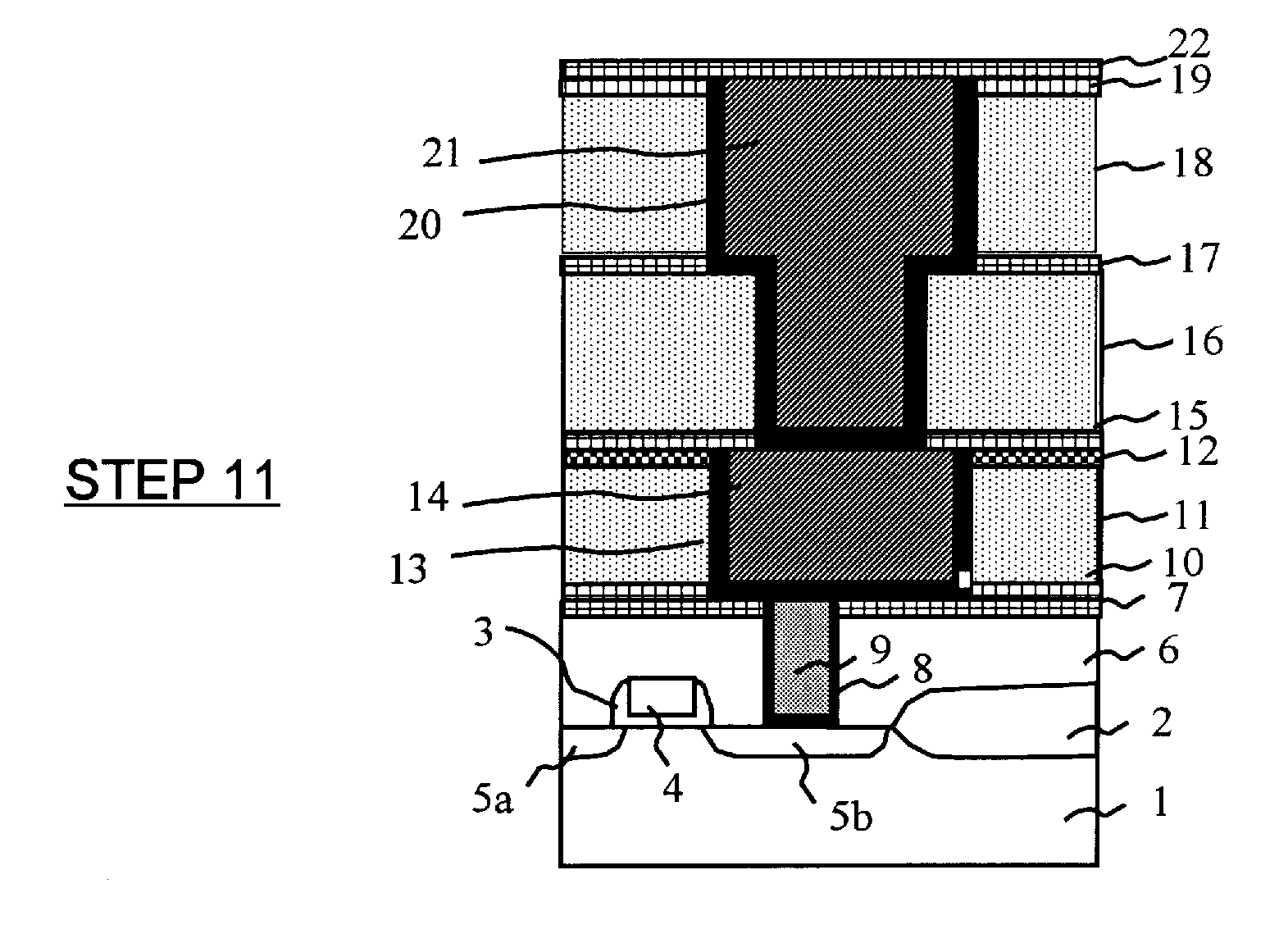

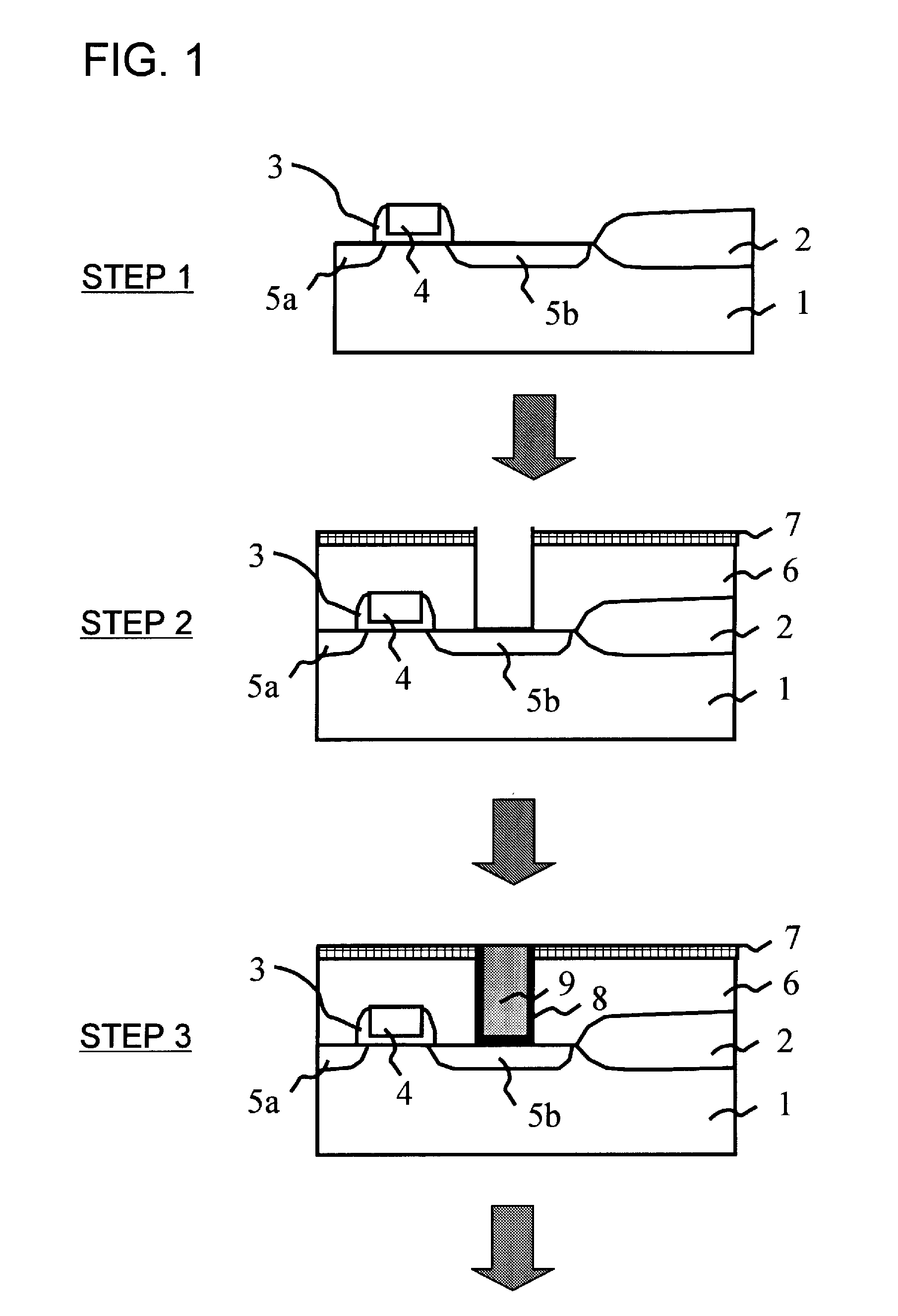

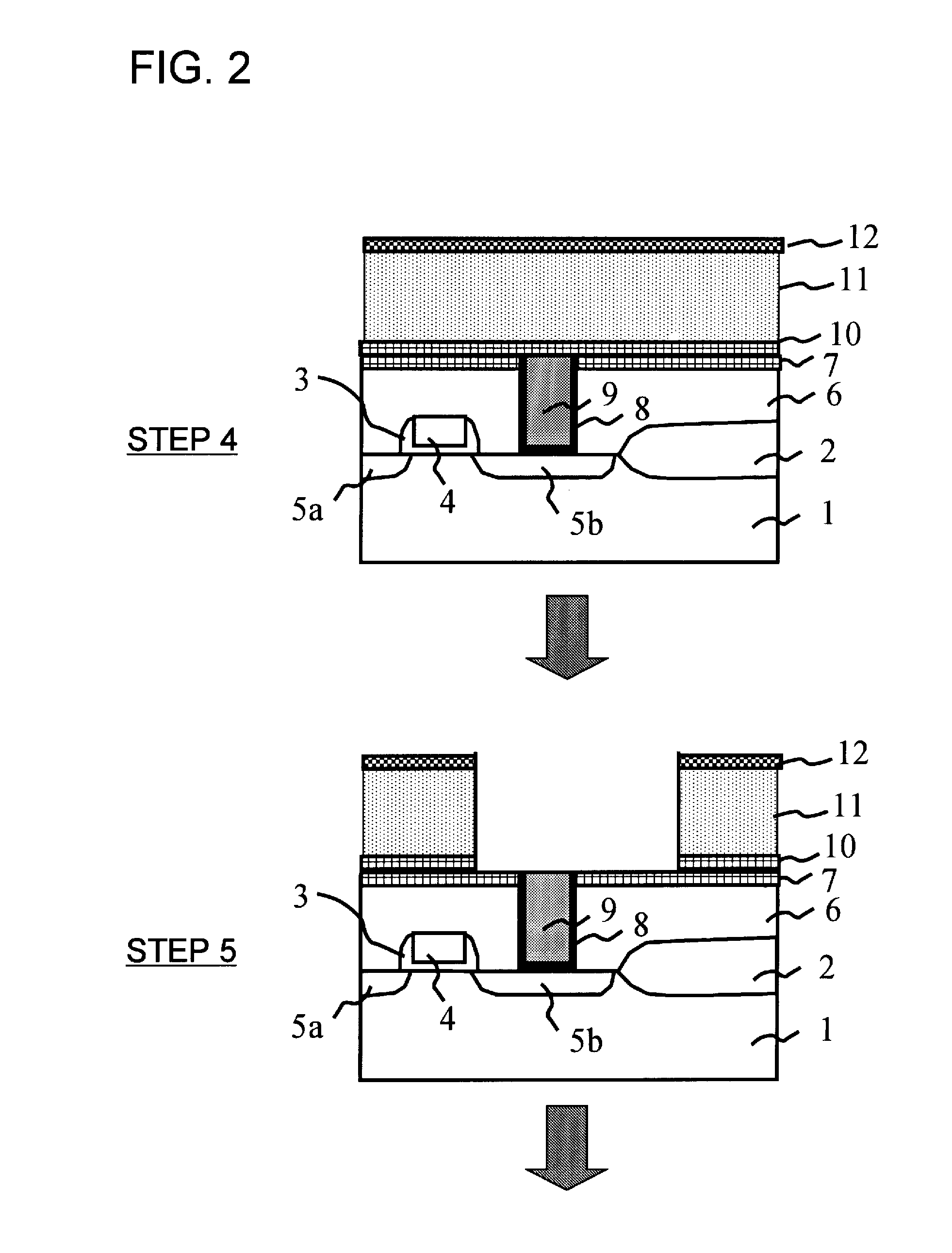

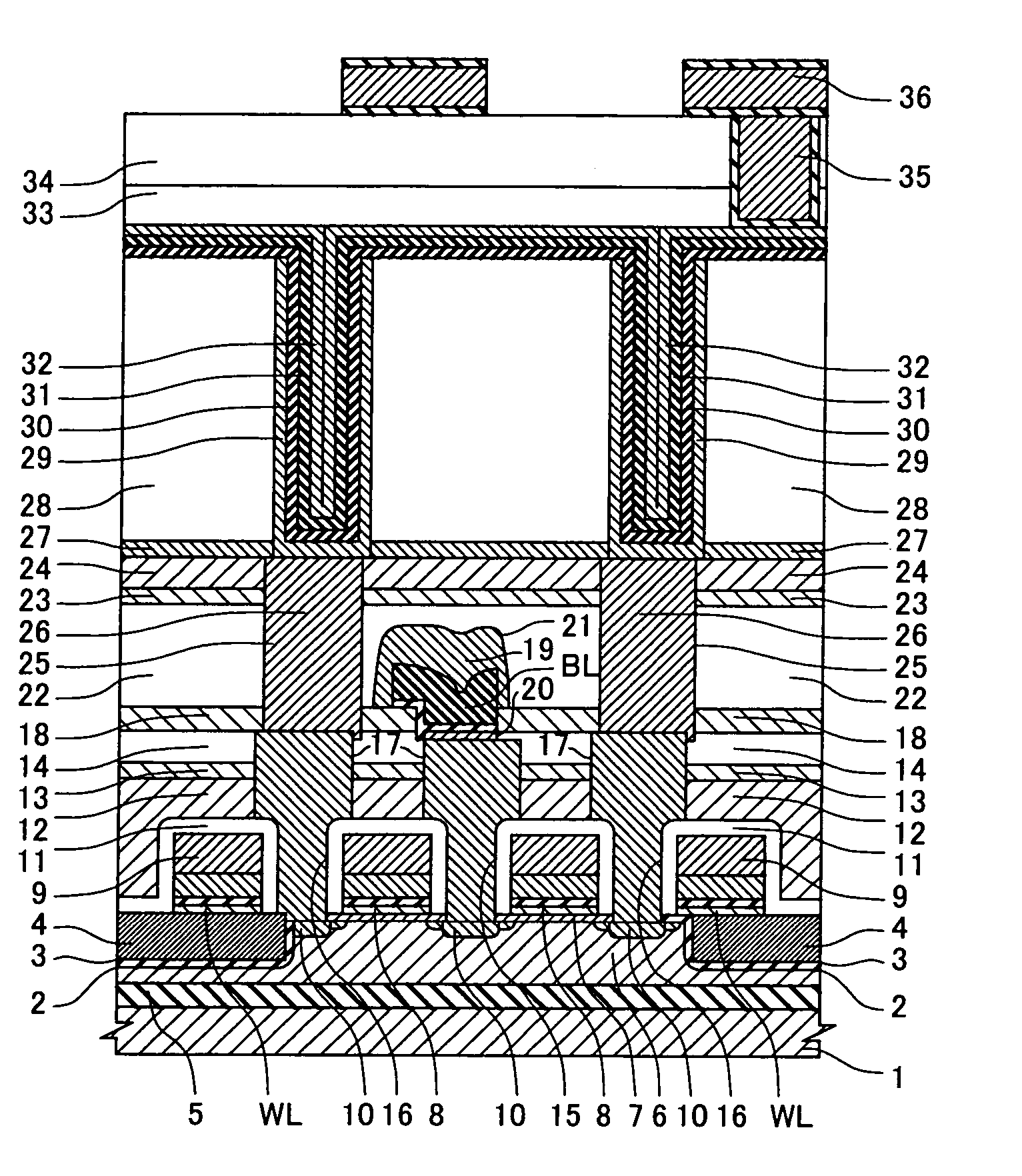

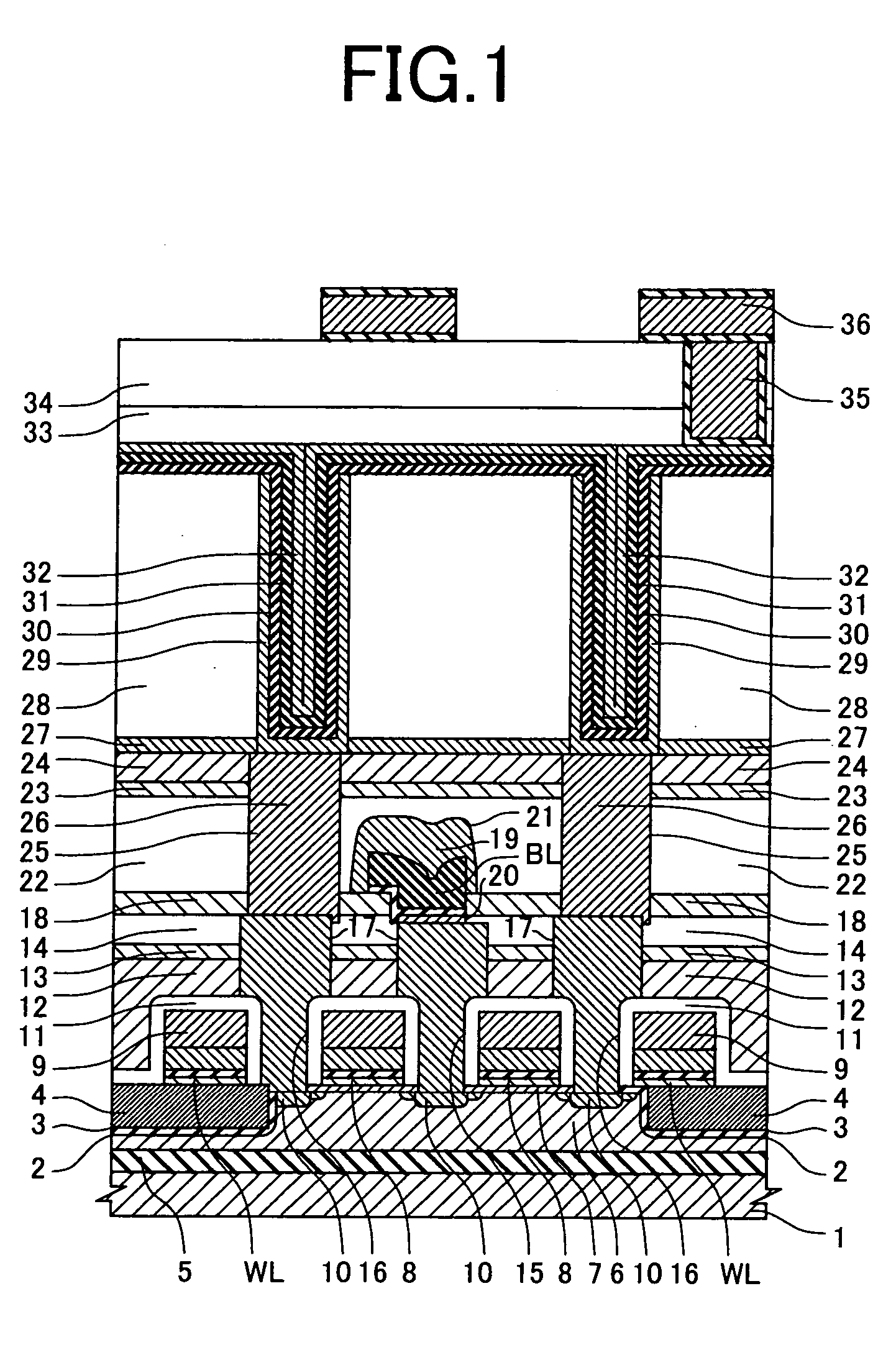

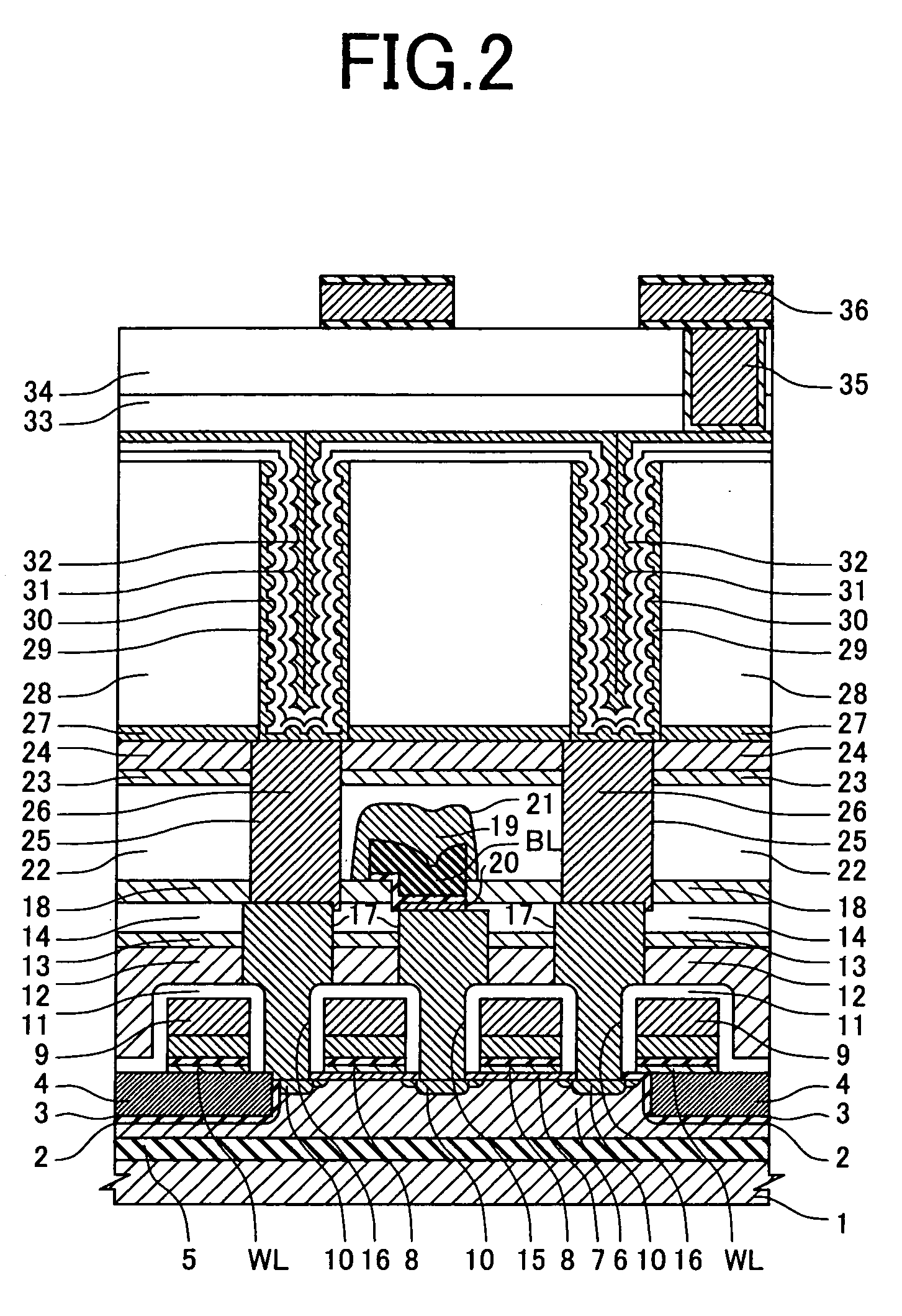

Method of making a memory structure having a multilayered contact and a storage capacitor with a composite dielectric layer of crystalized niobium pentoxide and tantalum pentoxide films

InactiveUS6955959B2Lower crystallization temperatureReduce leakage currentTransistorSolid-state devicesCrystallization temperatureLeakage current reduction

The present invention relates to a structure of a capacitor, in particular using niobium pentoxide, of a semiconductor capacitor memory device. Since niobium pentoxide has a low crystallization temperature of 600° C. or less, niobium pentoxide can suppress the oxidation of a bottom electrode and a barrier metal by heat treatment. However, according to heat treatment at low temperature, carbon incorporated from CVD sources into the film is not easily oxidized or removed. Therefore, a problem that leakage current increases arises. As an insulator film of a capacitor, a layered film composed of a niobium pentoxide film and a tantalum pentoxide film, or a layered film composed of niobium pentoxide films is used. By the use of the niobium pentoxide film, the dielectric constant of the capacitor can be made high and the crystallization temperature can be made low. By multiple-stage formation of the dielectric film, leakage current can be decreased.

Owner:RENESAS ELECTRONICS CORP

Method for modifying high-k dielectric thin film and semiconductor device

InactiveUS7867920B2High dielectric constantImprove featuresSemiconductor/solid-state device manufacturingUltravioletPermittivity

There is provided a method for modifying a high-k dielectric thin film provided on the surface of an object using a metal organic compound material. The method includes a preparation process for providing the object with the high-k dielectric thin film formed on the surface thereof, and a modification process for applying UV rays to the highly dielectric thin film in an inert gas atmosphere while maintaining the object at a predetermined temperature to modify the high-k dielectric thin film. According to the above constitution, the carbon component can be eliminated from the high-k dielectric thin film, and the whole material can be thermally shrunk to improve the density, whereby the occurrence of defects can be prevented and the film density can be improved to enhance the specific permittivity and thus to provide a high level of electric properties.

Owner:TOKYO ELECTRON LTD

Preparation method of waterborne epoxy emulsion

ActiveCN108912948AGood film densityImprove adhesionAnti-corrosive paintsEpoxy resin coatingsThermal insulationPhosphoric acid

The invention provides a preparation method of a waterborne epoxy emulsion. The preparation method comprises following steps: 1, an appropriate amount of epoxy resin is introduced into a reaction container, polyether and a catalyst are introduced into the reaction container, an obtained mixture is stirred to be uniform, is heated to 30 to 150 DEG C, and is subjected to thermal insulation for 1 to7h; 2, the left epoxy resin is introduced into the reaction container, an obtained mixed material is stirred to be uniform, at 30 to 150 DEG C, phosphoric acid is added, uniform stirring is carried out, and thermal insulation is carried out for 0.5 to 6h; and 3, an obtained product is cooled to 25 to 100 DEG C, water is added for emulsification so as to obtain the waterborne epoxy emulsion. The waterborne epoxy emulsion is high in film forming compactness; epoxy groups with relatively high activity are maintained, and room temperature solidification is realized under cooperation effect with acuring agent; introduction of phosphoric acid is capable of increasing the clunging force between the waterborne epoxy emulsion and a base material, and improving the salt spray resistance of the waterborne epoxy emulsion.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

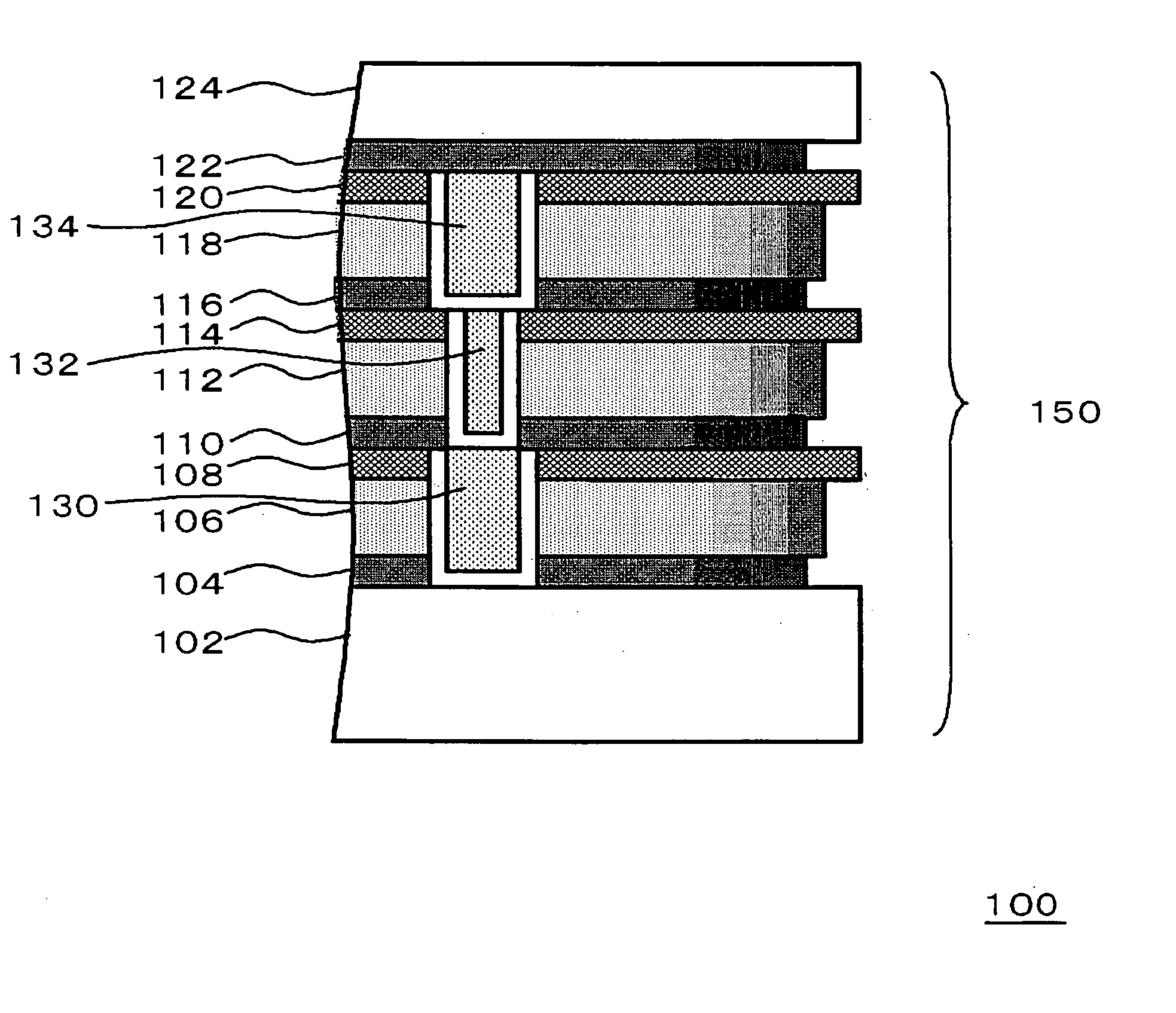

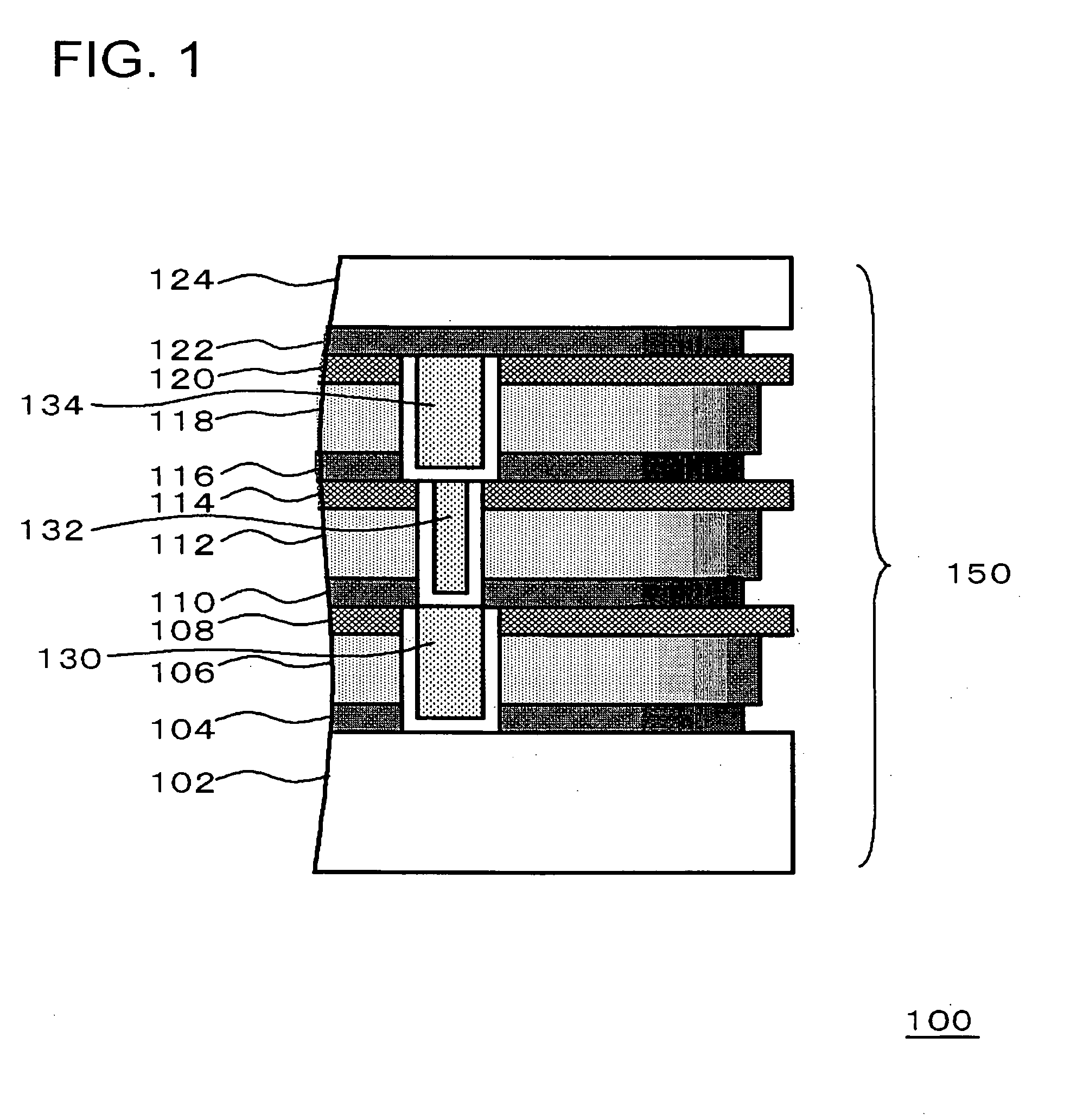

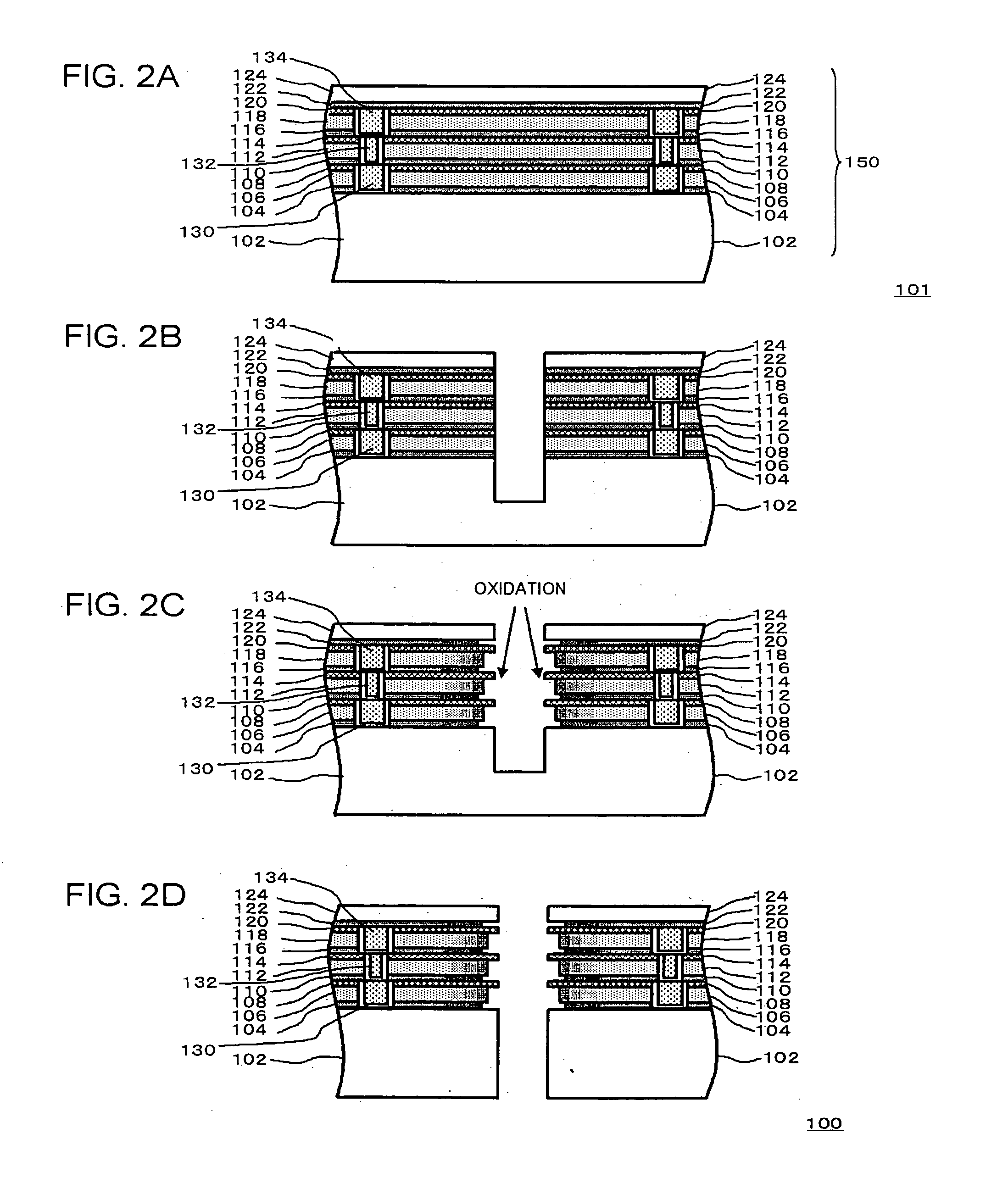

Semiconductor chip

InactiveUS20060208361A1Improve adhesionSimple procedureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor chip 100 includes a semiconductor substrate (not shown), and a stacked film 150 formed over the semiconductor substrate, which includes carbon-containing insulating films such as a first interlayer insulating film 106, and carbon-free insulating films such as an underlying layer 102 and a top cover film 124. The end faces of the carbon-free insulating films herein are located on the outer side of the end faces of the carbon-containing insulating films. The carbon composition of the carbon-containing insulating films is lowered in the end portions thereof than in the inner portions. The film density of the carbon-containing insulating films is raised in the end portions thereof than in the inner portions.

Owner:RENESAS ELECTRONICS CORP

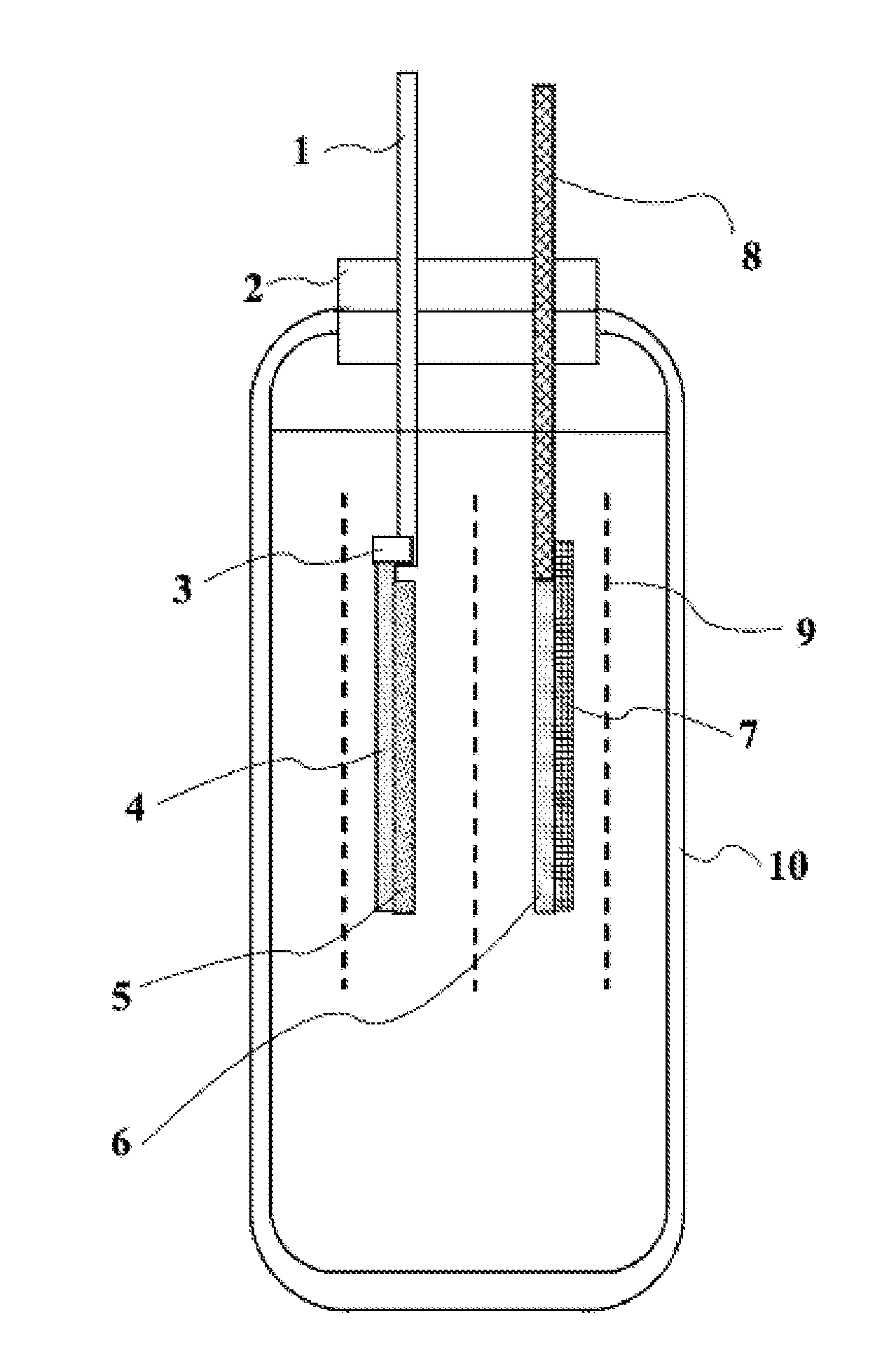

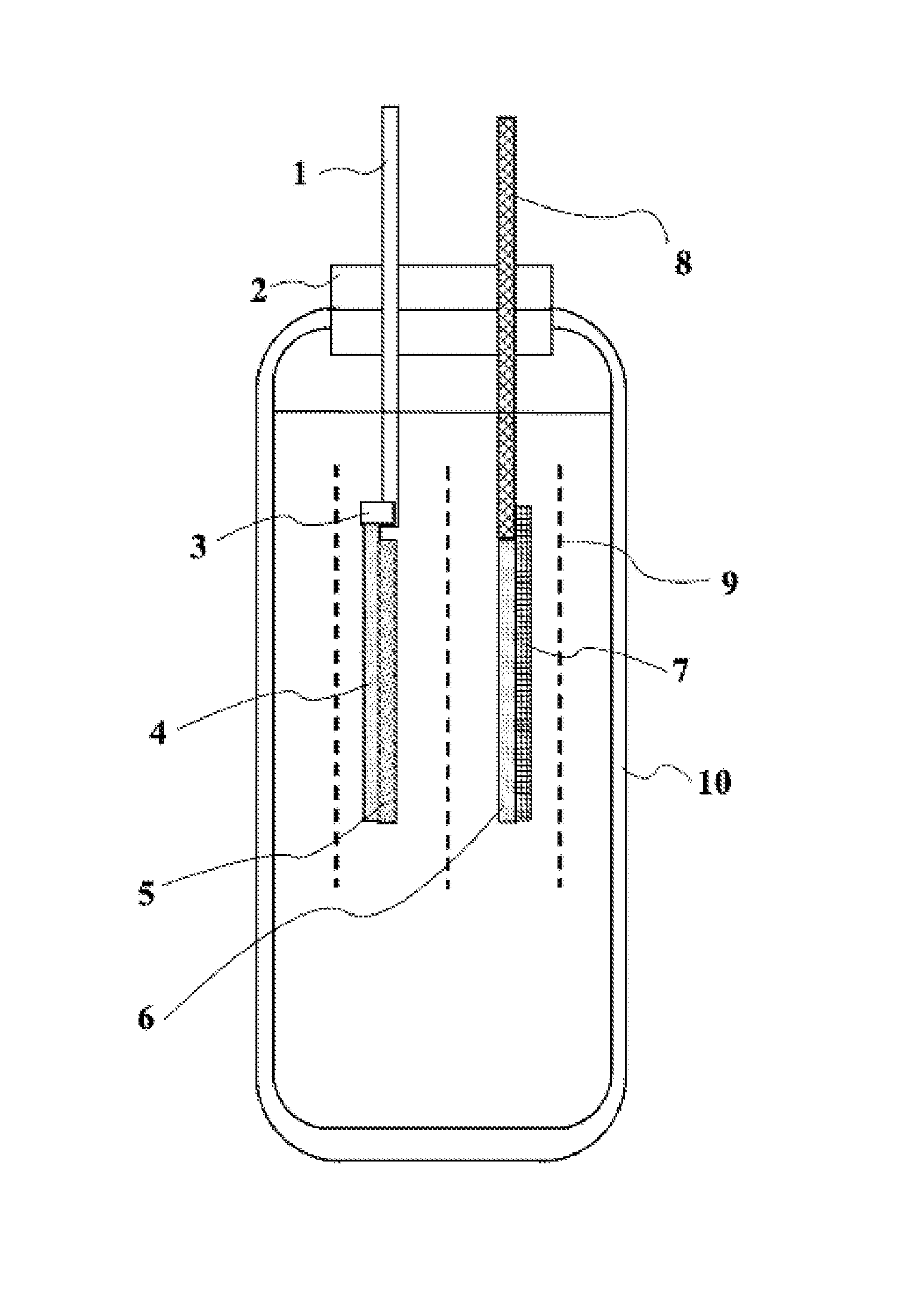

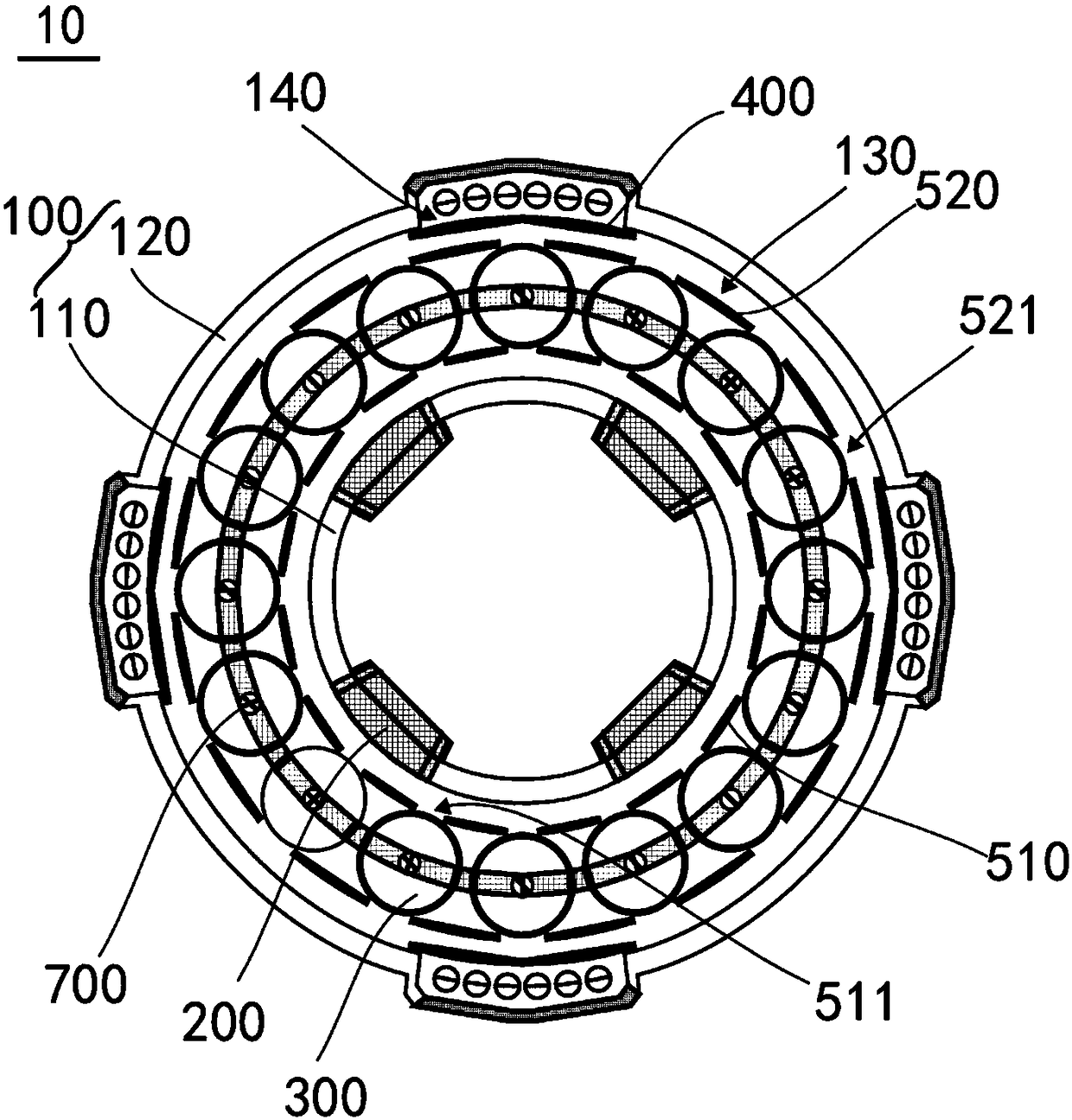

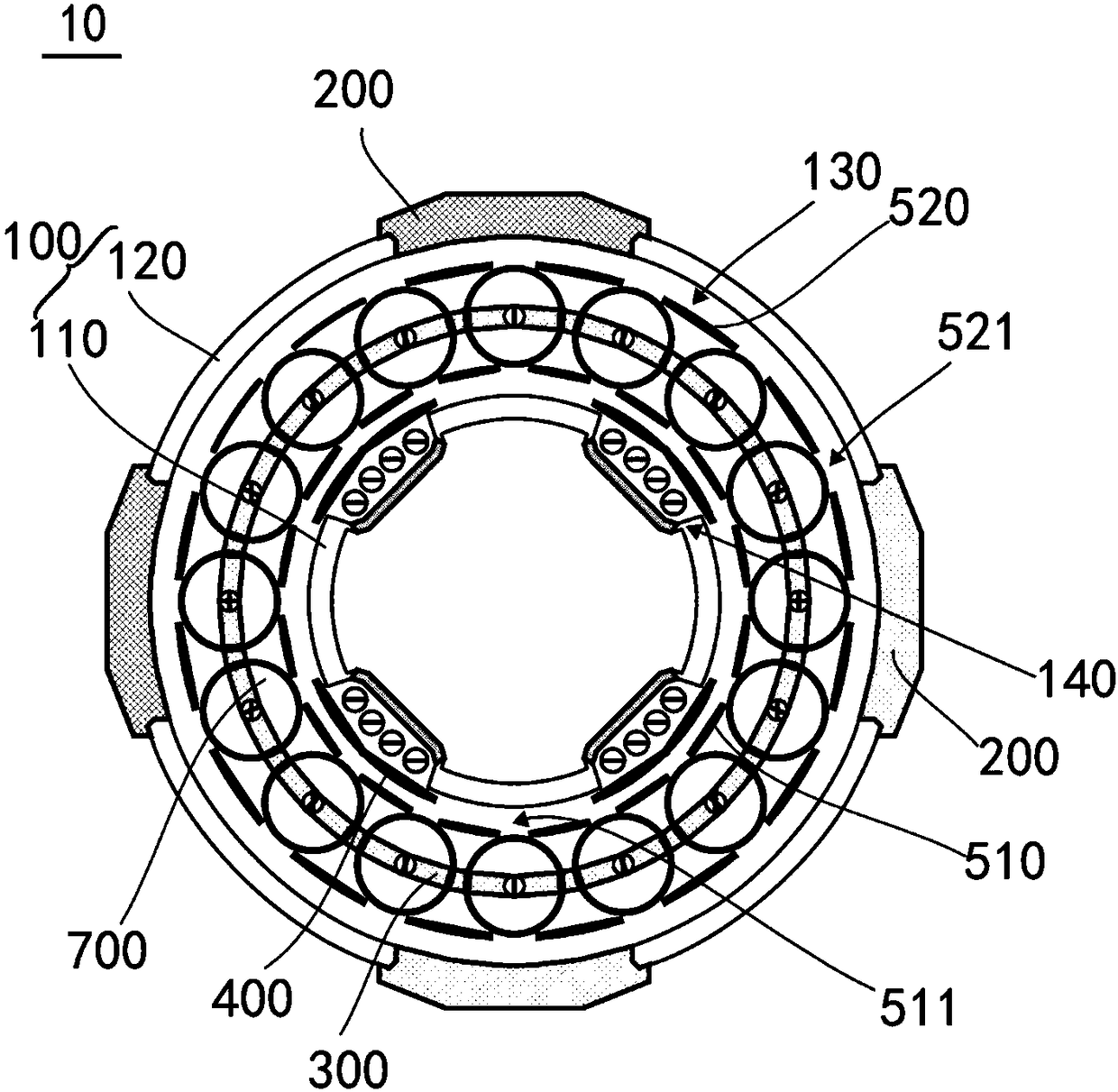

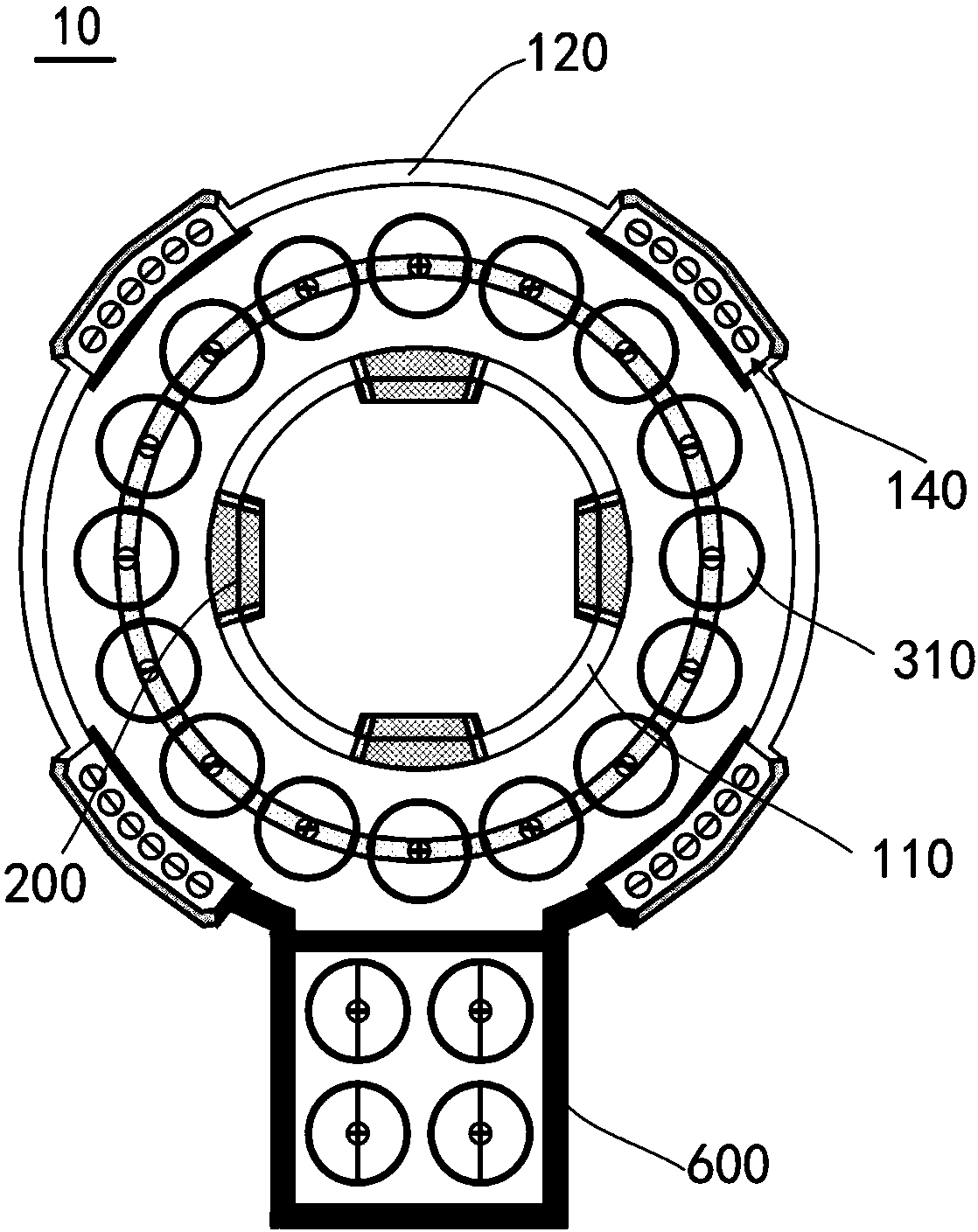

Tunnel-type sputtering film-plating machine

PendingCN108425093ASmall duty cycleLarge amountVacuum evaporation coatingSputtering coatingRadio frequencyEngineering

The invention discloses a tunnel-type sputtering film-plating machine. The tunnel-type sputtering film-plating machine comprises a film plating cylinder, a radio-frequency ion source, a film plating hanger, and a hanger driving device; the film plating cylinder comprises an inner cylinder and an outer cylinder; a film plating chamber is formed between the inner cylinder and the outer cylinder; thetwo ends of the inner cylinder and the two ends of the outer cylinder are correspondingly connected in a sealed manner, so that the film plating chamber is sealed; the internal wall of the outer cylinder facing the film plating chamber, or the external wall of the inner cylinder facing the film plating chamber are provided with a plurality of film plating target grooves; the radio-frequency ion source is connected with the internal wall of the outer cylinder facing the film plating chamber, or the external wall of the inner cylinder facing the film plating chamber; the film plating hanger isdesigned to be annular, and is arranged in the film plating chamber; the inner cylinder is sleeved with the film plating hanger; the film plating hanger is connected with a plurality of hanging rods;the hanging rods are arranged in an annular manner in parallel; and the hanger driving device is connected with the film plating hanger, and is used for driving the film plating hanger to rotate. Thetunnel-type sputtering film-plating machine is capable of increasing production power and efficiency effectively.

Owner:VITALNK IND SHENZHEN +1

Process for producing silicic coating, silicic coating and semiconductor device

InactiveUS8431464B2Increase the number ofHigh densitySemiconductor/solid-state device detailsSolid-state devicesSilane compoundsHigh density

Owner:FUJITSU LTD

Process for producing silicic coating, silicic coating and semiconductor device

InactiveUS20100133692A1Easy to produceFast chemical reactionSemiconductor/solid-state device detailsSolid-state devicesSilane compoundsHigh density

A silicic coating of 2.4 g / cm3 or higher density, obtained by forming a silicic coating precursor with the use of at least one type of silane compound having a photosensitive functional group and thereafter irradiating the silicic coating precursor with at least one type of light. This silicic coating can be used as a novel barrier film or stopper film for semiconductor device.

Owner:FUJITSU LTD

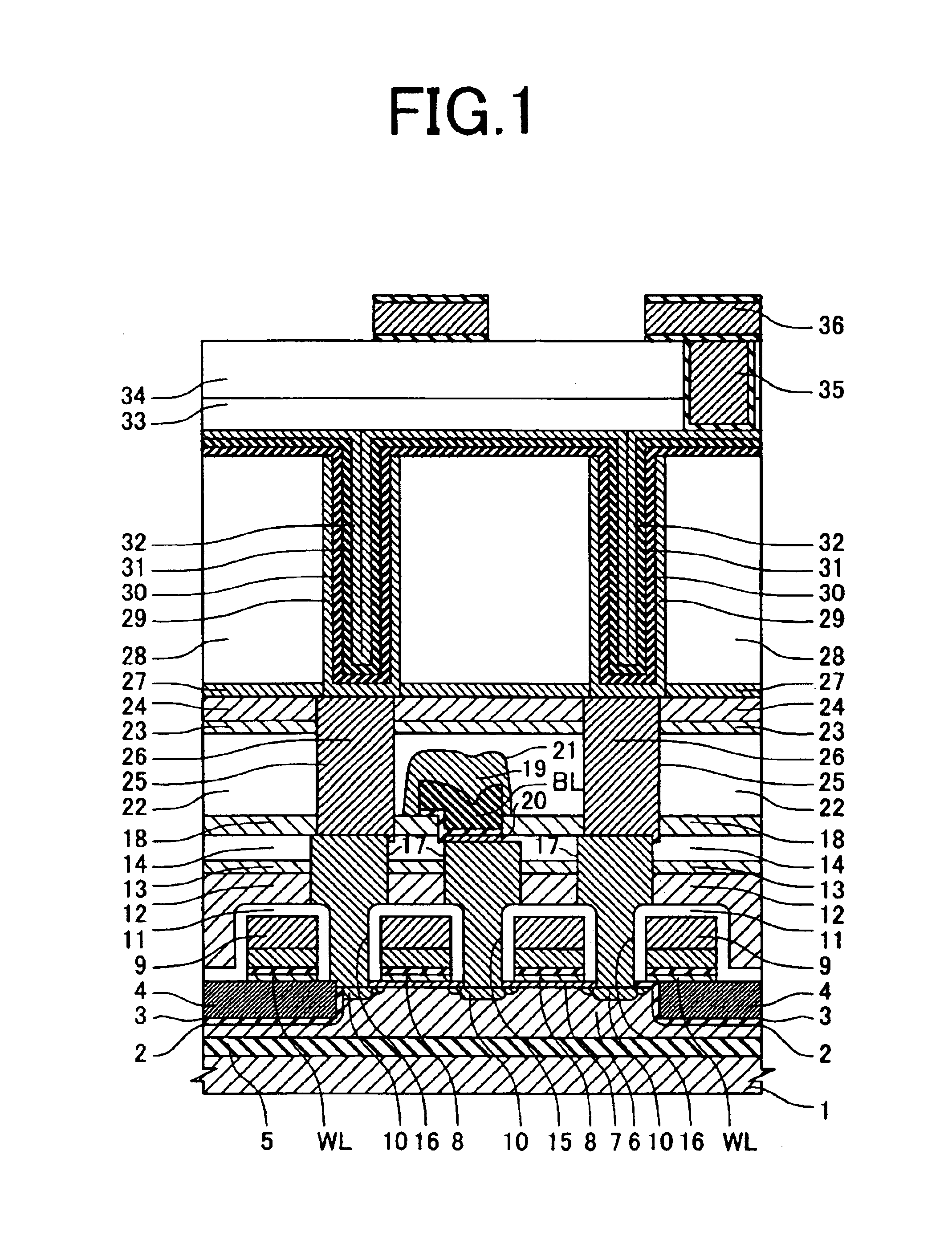

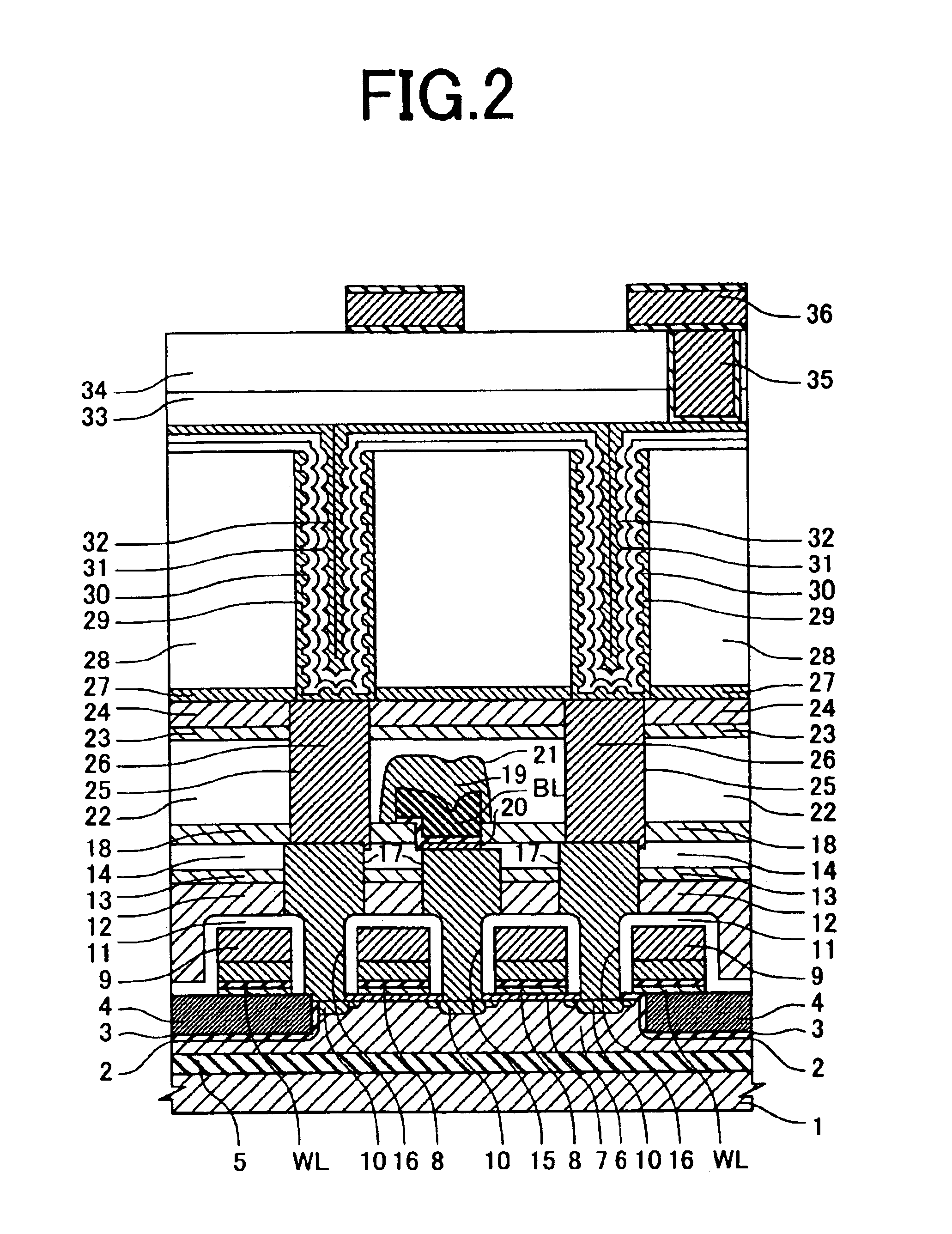

Capacitive electrode having semiconductor layers with an interface of separated grain boundaries

InactiveUS20060027851A1Lower crystallization temperatureLarge currentTransistorSolid-state devicesCapacitanceGrain boundary

The present invention relates to a structure of a capacitor, in particular using niobium pentoxide, of a semiconductor capacitor memory device. Since niobium pentoxide has a low crystallization temperature of 600° C. or less, niobium pentoxide can suppress the oxidation of a bottom electrode and a barrier metal by heat treatment. However, according to heat treatment at low temperature, carbon incorporated from CVD sources into the film is not easily oxidized or removed. Therefore, a problem that leakage current increases arises. As an insulator film of a capacitor, a layered film composed of a niobium pentoxide film and a tantalum pentoxide film, or a layered film composed of niobium pentoxide films is used. By the use of the niobium pentoxide film, the dielectric constant of the capacitor can be made high and the crystallization temperature can be made low. By multiple-stage formation of the dielectric film, leakage current can be decreased.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com