Patents

Literature

35results about How to "Improve film adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanent resist composition, cured product thereof, and use thereof

InactiveUS20050260522A1High densityImprove film adhesionNanoinformaticsPhotomechanical apparatusPolymer sciencePhotoacid generator

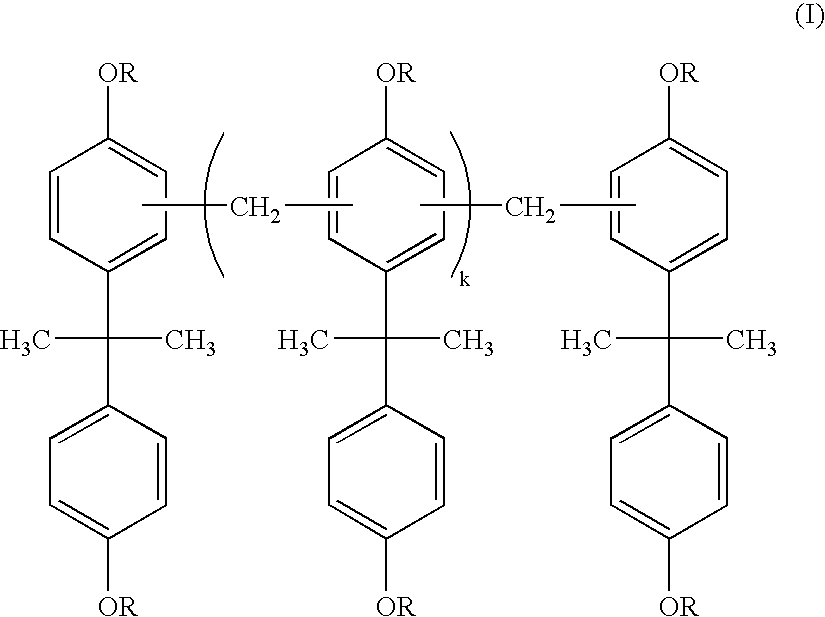

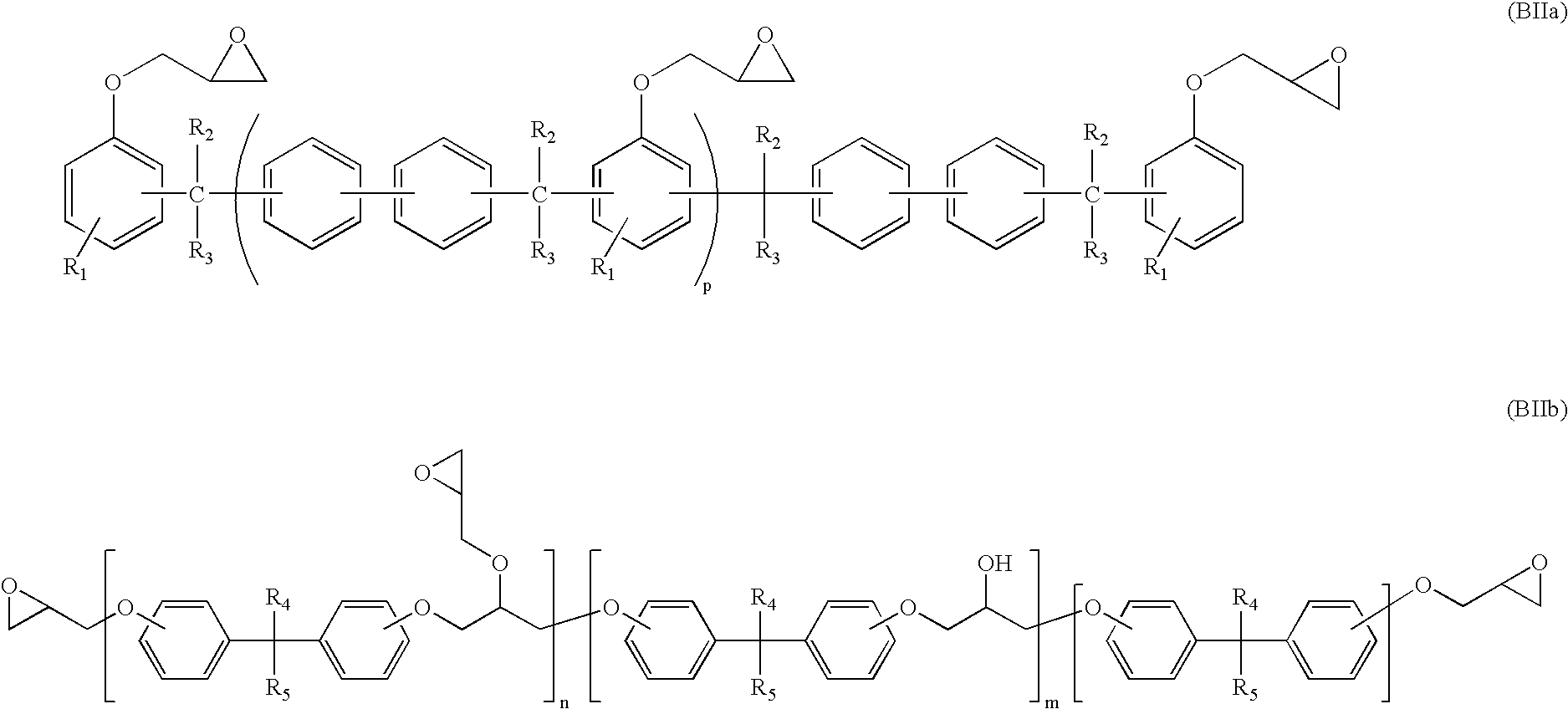

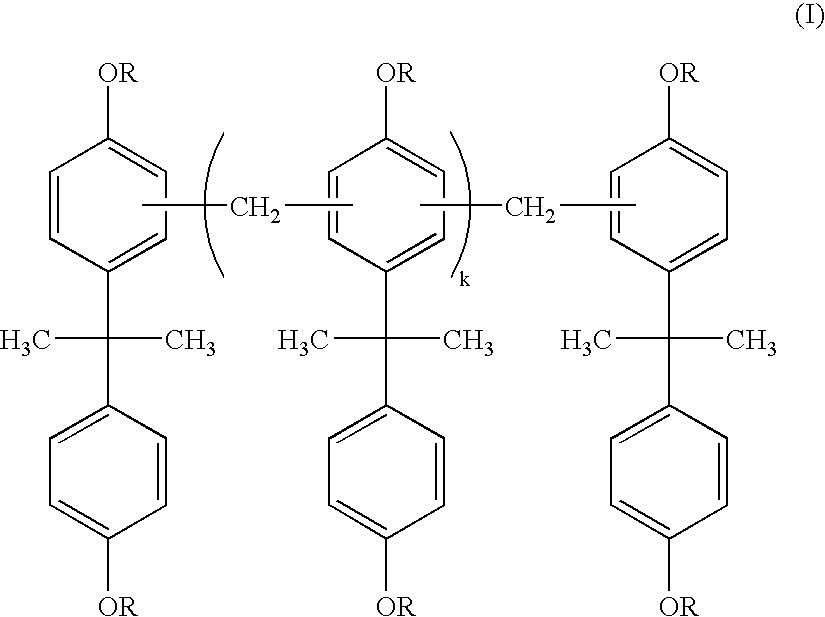

A permanent photoresist composition comprising: (A) one or more bisphenol A-novolac epoxy resins according to Formula I; wherein each group R in Formula I is individually selected from glycidyl or hydrogen and k in Formula I is a real number ranging from 0 to about 30; (B) one or more epoxy resins selected from the group represented by Formulas BIIa and BIIb; wherein each R1, R2 and R3 in Formula BIIa are independently selected from the group consisting of hydrogen or alkyl groups having 1 to 4 carbon atoms and the value of p in Formula BIIa is a real number ranging from 1 to 30; the values of n and m in Formula BIIb are independently real numbers ranging from 1 to 30 and each R4 and R5 in Formula BIIb are independently selected from hydrogen, alkyl groups having 1 to 4 carbon atoms, or trifluoromethyl; (C) one or more cationic photoinitiators (also known as photoacid generators or PAGs); and (D) one or more solvents.

Owner:MICROCHEM CORP +1

Fusion formable sodium free glass

ActiveUS20100300536A1Improve battery efficiencyImprove film adhesionFinal product manufactureSynthetic resin layered productsSilicate glassThermal expansion

A compositional range of fusion-formable, high strain point sodium free, silicate, aluminosilicate and boroaluminosilicate glasses are described herein. The glasses can be used as substrates for photovoltaic devices, for example, thin film photovoltaic devices such as CIGS photovoltaic devices. These glasses can be characterized as having strain points≧540° C., thermal expansion coefficient of from 6.5 to 10.5 ppm / ° C., as well as liquidus viscosities in excess of 50,000 poise. As such they are ideally suited for being formed into sheet by the fusion process.

Owner:CORSAM TECH

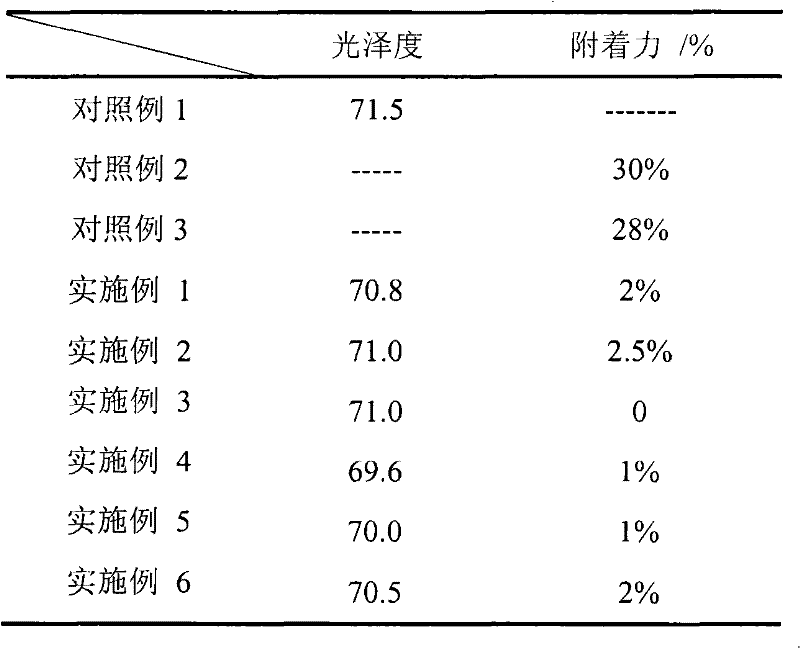

Organic-inorganic hybrid nanometer film coating aluminum powder pigment and preparation method and application thereof

InactiveCN101580653AGood acid and alkali resistance and water resistanceGood metallic lusterCoatingsPigment treatment with organosilicon compoundsDouble bondChemistry

The invention discloses organic-inorganic hybrid nanometer film coating aluminum powder pigment and a preparation method and application thereof. The preparation method comprises the followings steps: by utilizing organic-inorganic hybrid technology and taking aluminum powder pigment as nuclear, firstly performing free radical polymerization on polymerisable carbon-carbon double bond reaction monomers and polymerisable carbon-carbon double bond organosiloxane; and bonding the obtained polymer and ethyl orthosilicate with the surface of the aluminum powder pigment in a hydrolysis mode, and further coating a layer of organic-inorganic hybrid nanometer film on the surface of the aluminum powder. On the basis of maintaining the lustrousness of the aluminum powder, the prepared organic-inorganic hybrid nanometer film coating aluminum powder pigment has excellent compatibility with resin and good acid and alkaline resistance properties, simultaneously well solves the problem of 'powder falling' when the conventional aluminum powder and single-layer or two-layer costing aluminum powder pigment are applied to metallic coatings, and provides a foundation for applying modified aluminum powder pigment and developing high performance metallic coatings.

Owner:SOUTH CHINA UNIV OF TECH

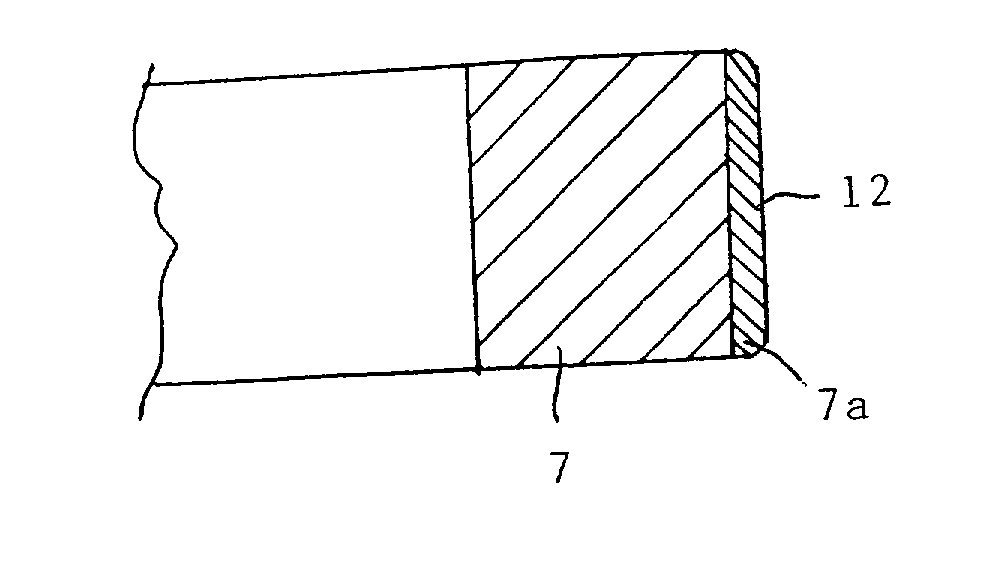

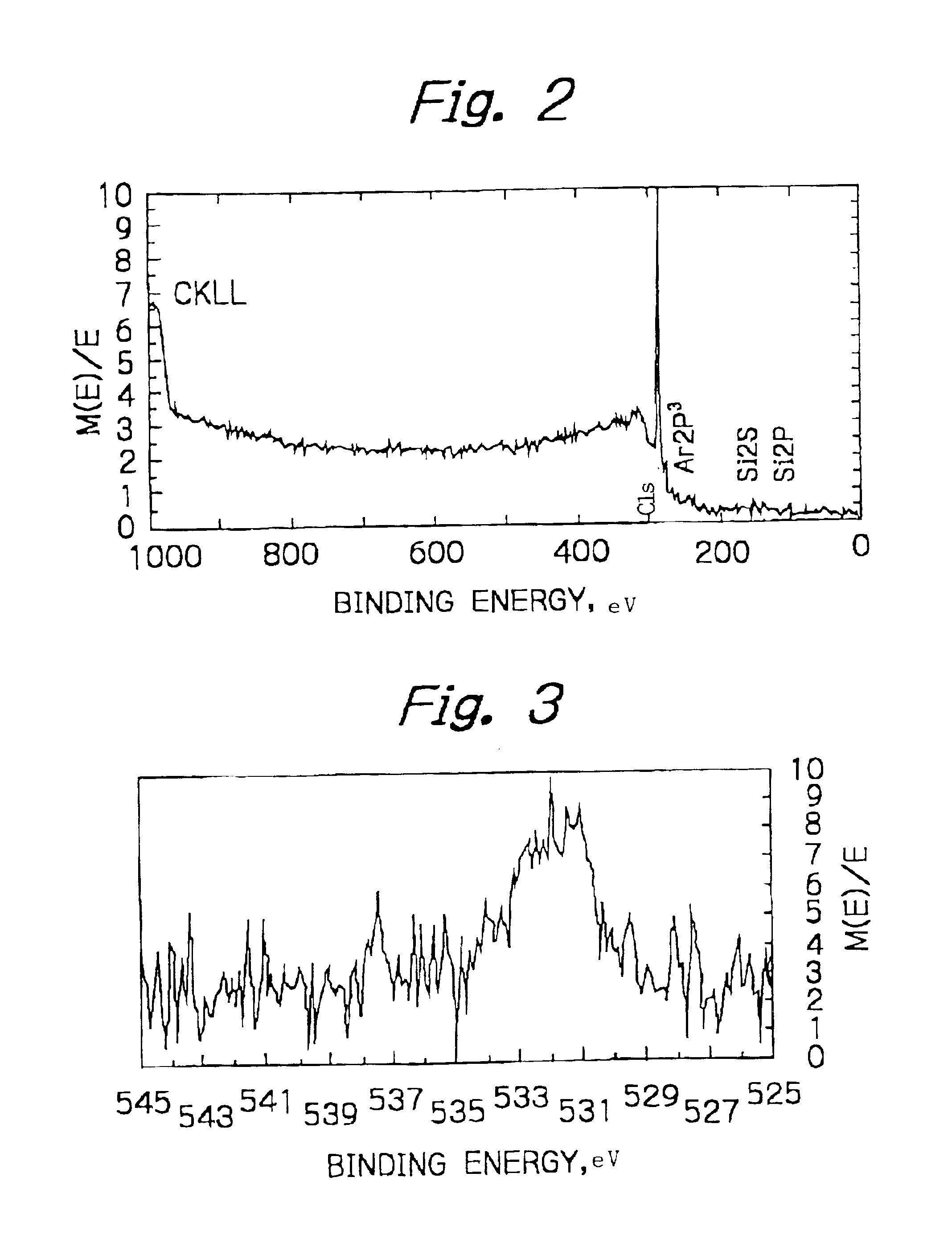

Amorphous hard carbon film, mechanical parts and method for producing amorphous hard carbon film

InactiveUS20020022129A1Reduce coefficient of frictionHigh hardnessLayered productsVacuum evaporation coatingCarbon filmPiston ring

An amorphous hard carbon film has low friction coefficient from the beginning of sliding, when the metal oxide is contained in the film. The adhesion of the film to the substrate is also improved due to the low temperature treatment of RF plasma enhanced CVD method. This film can be applied to many sliding members, e.g., a piston ring, a vane of compressor and a plunger of fuel injection pump, used under severe condition.

Owner:RIKEN CO LTD

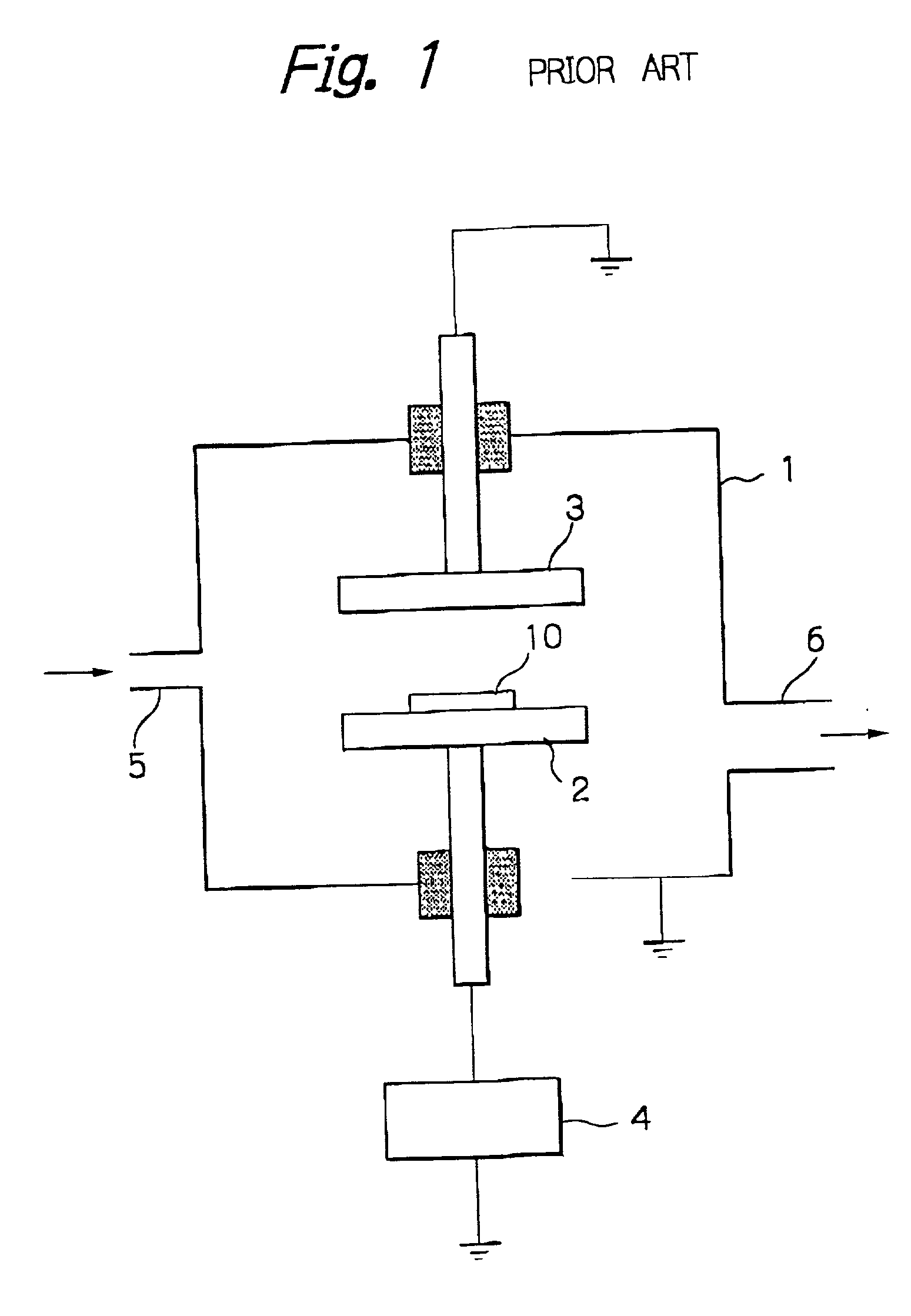

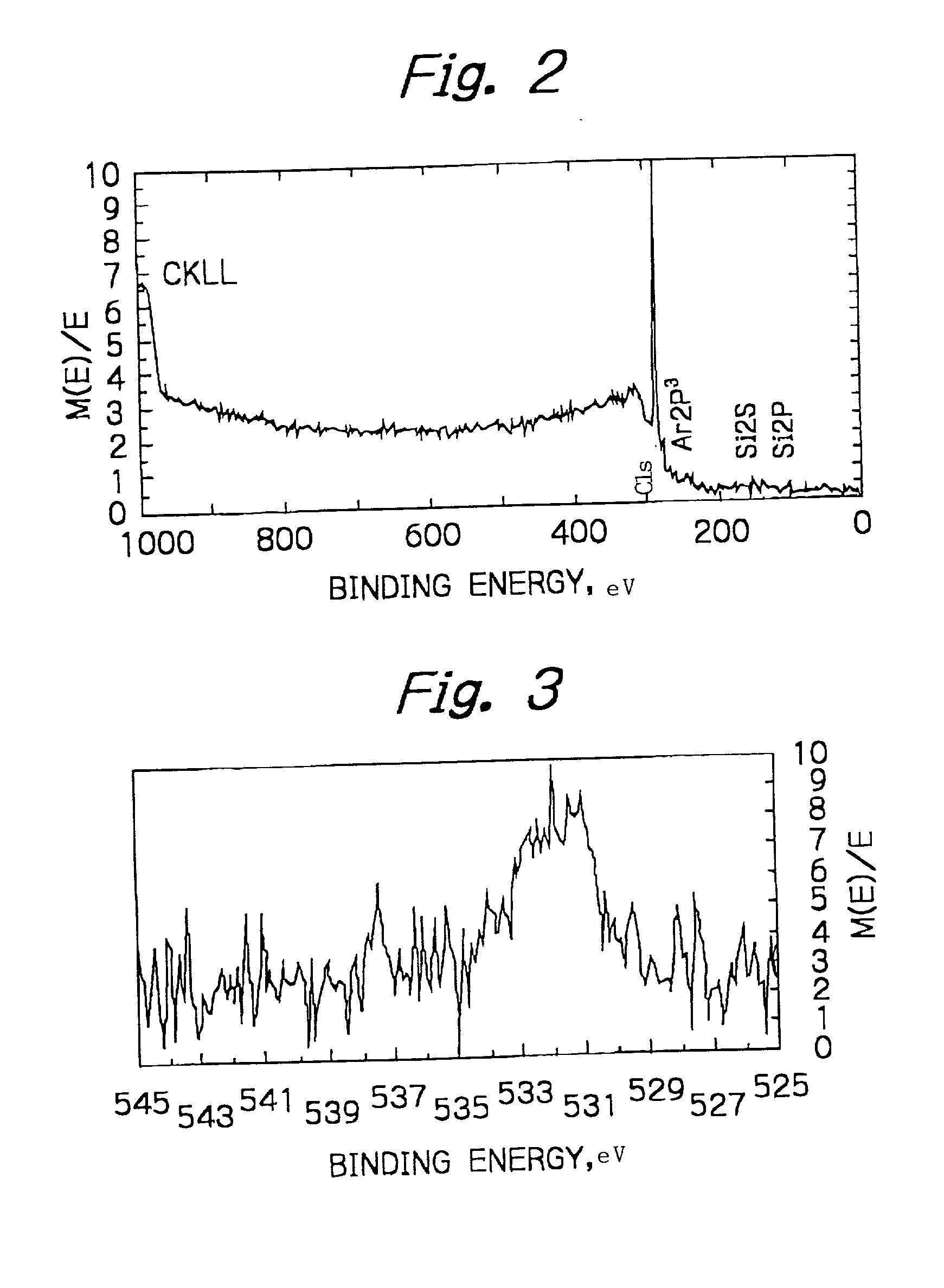

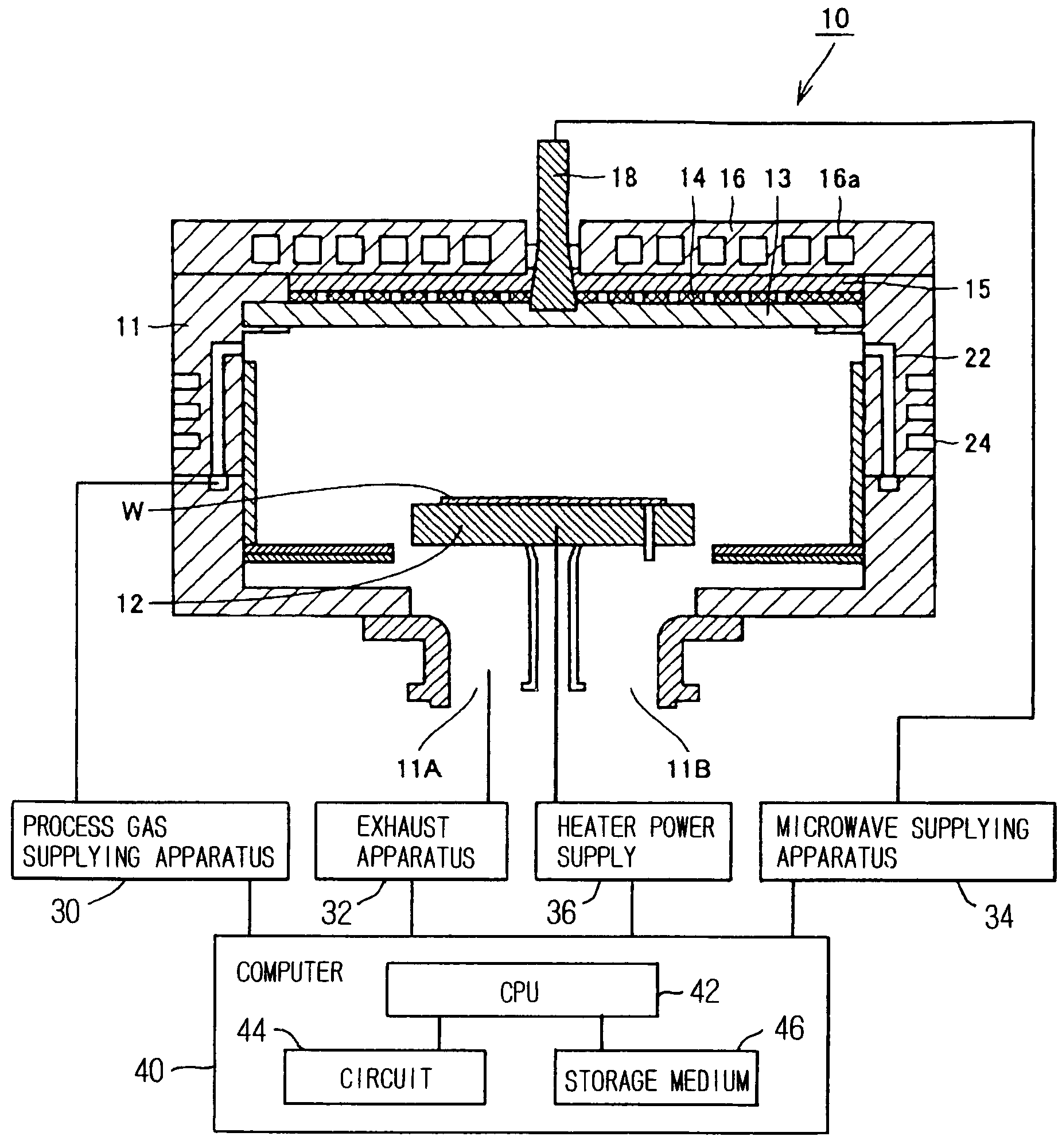

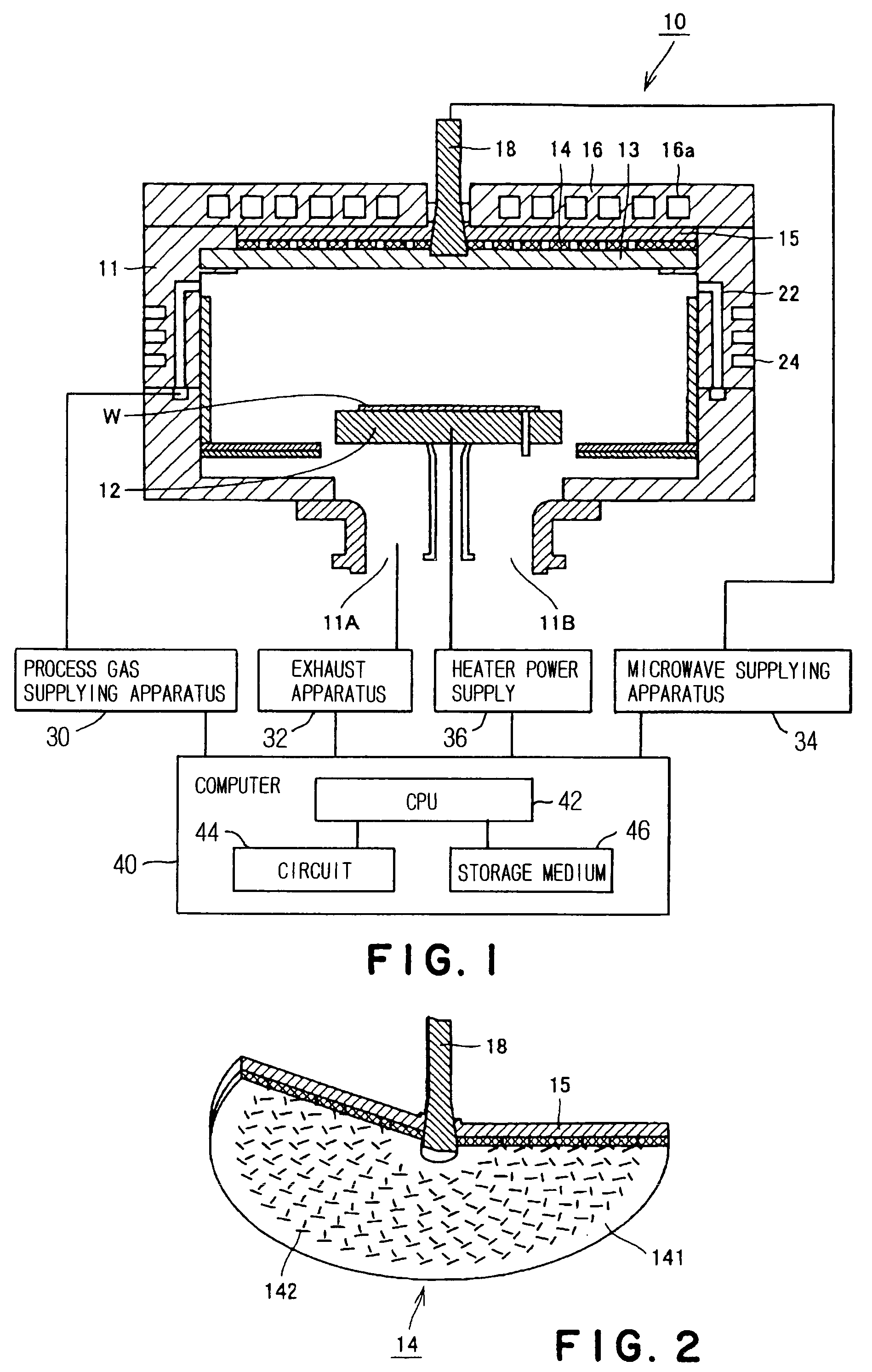

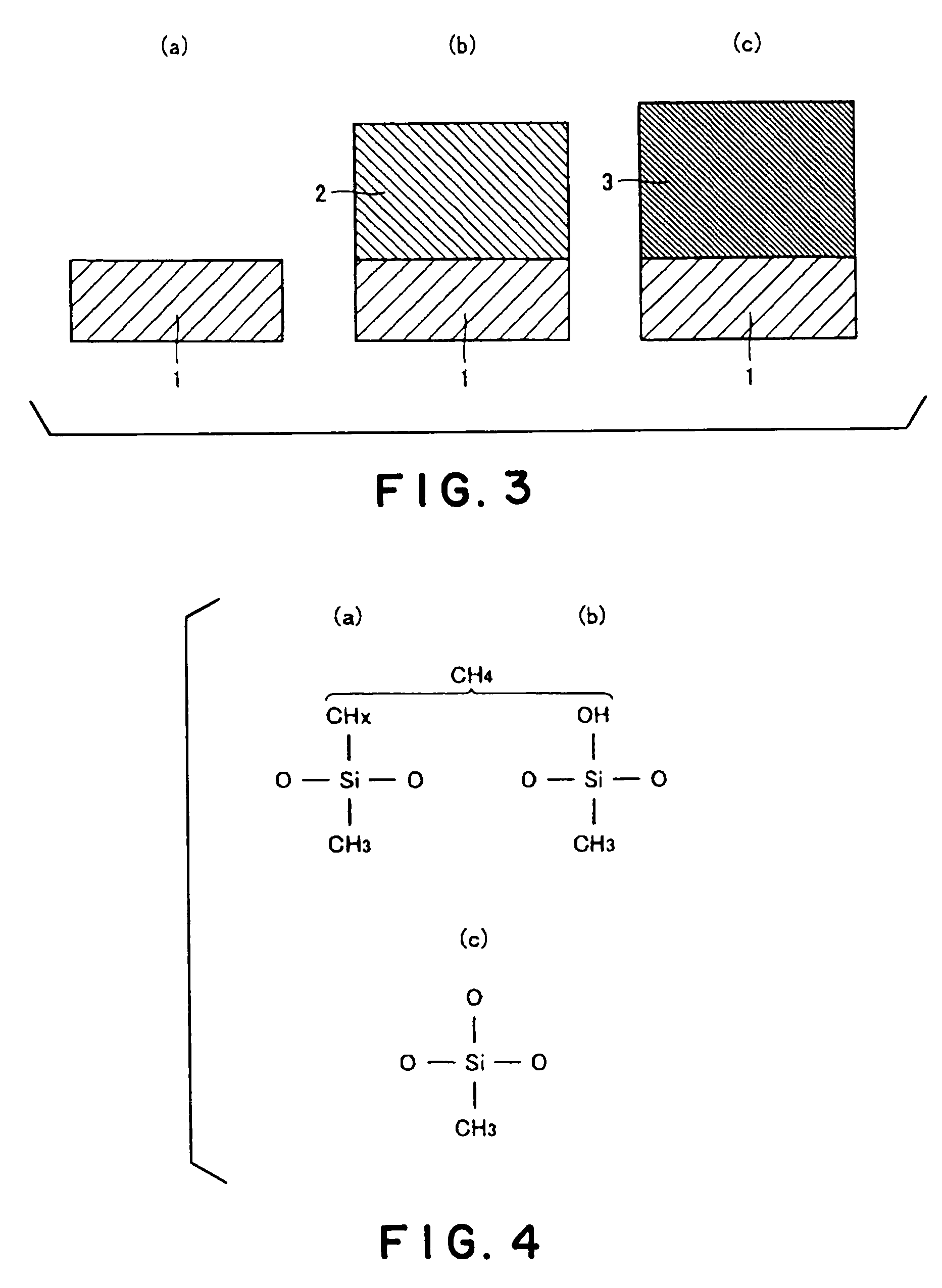

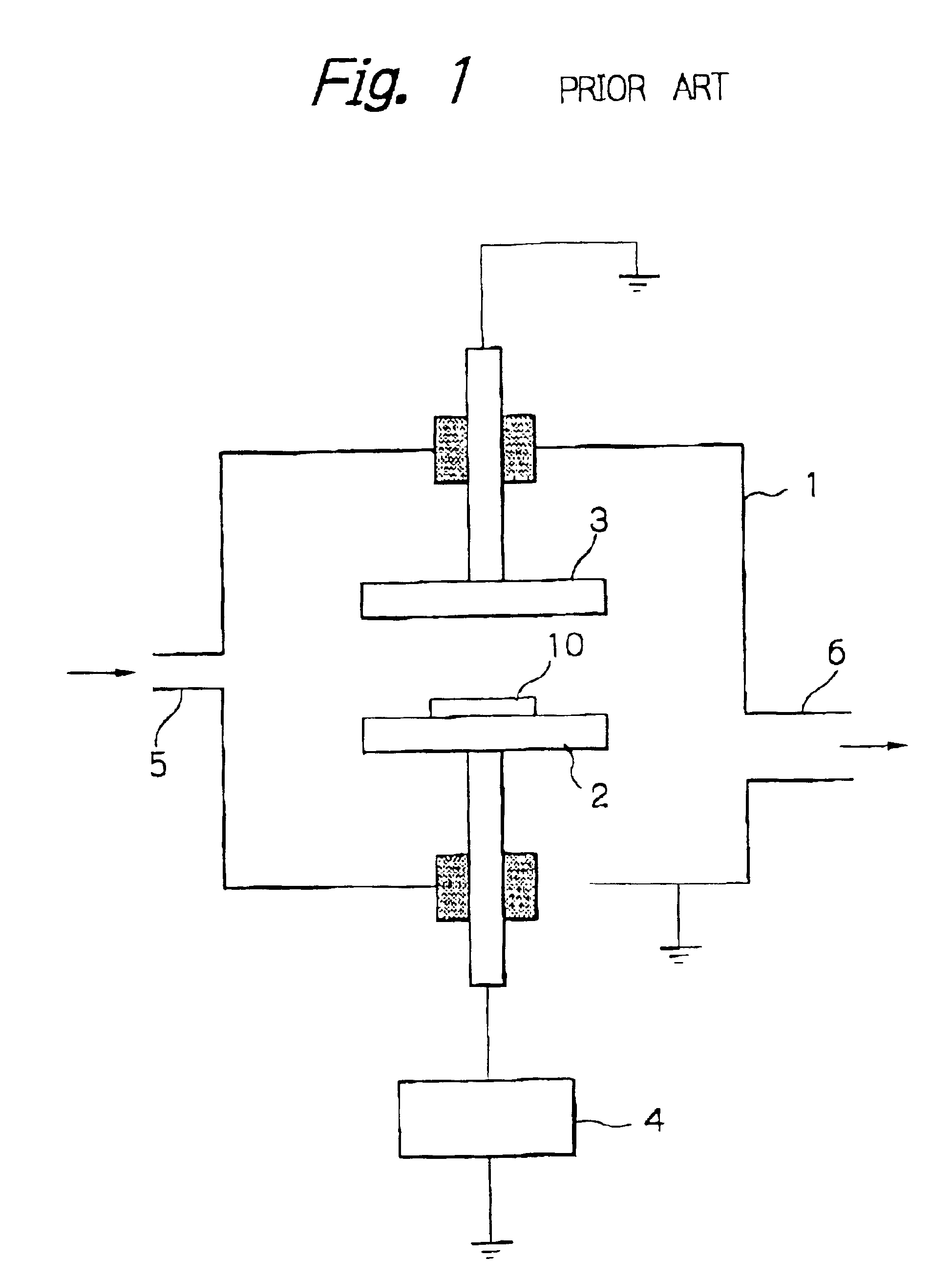

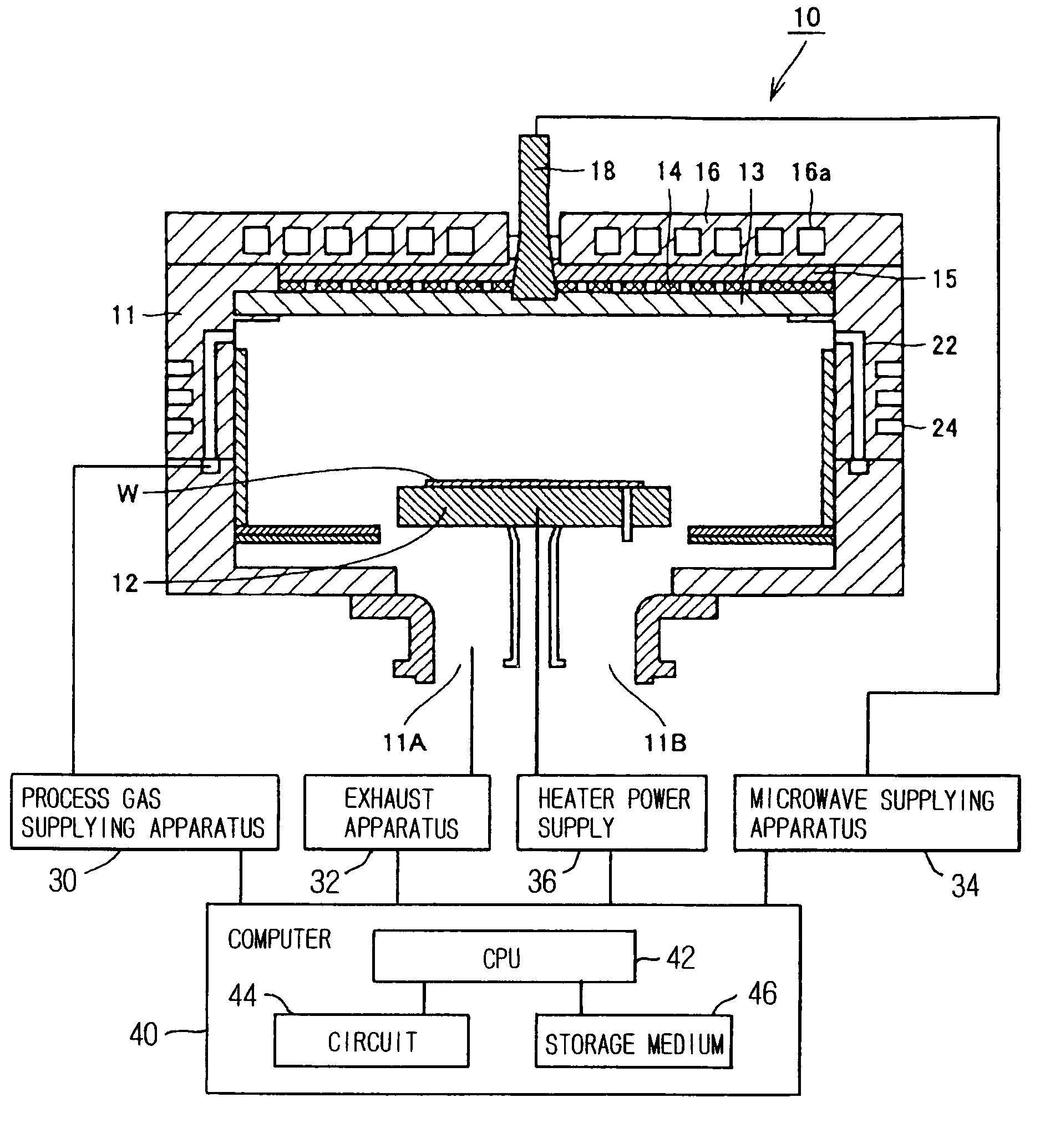

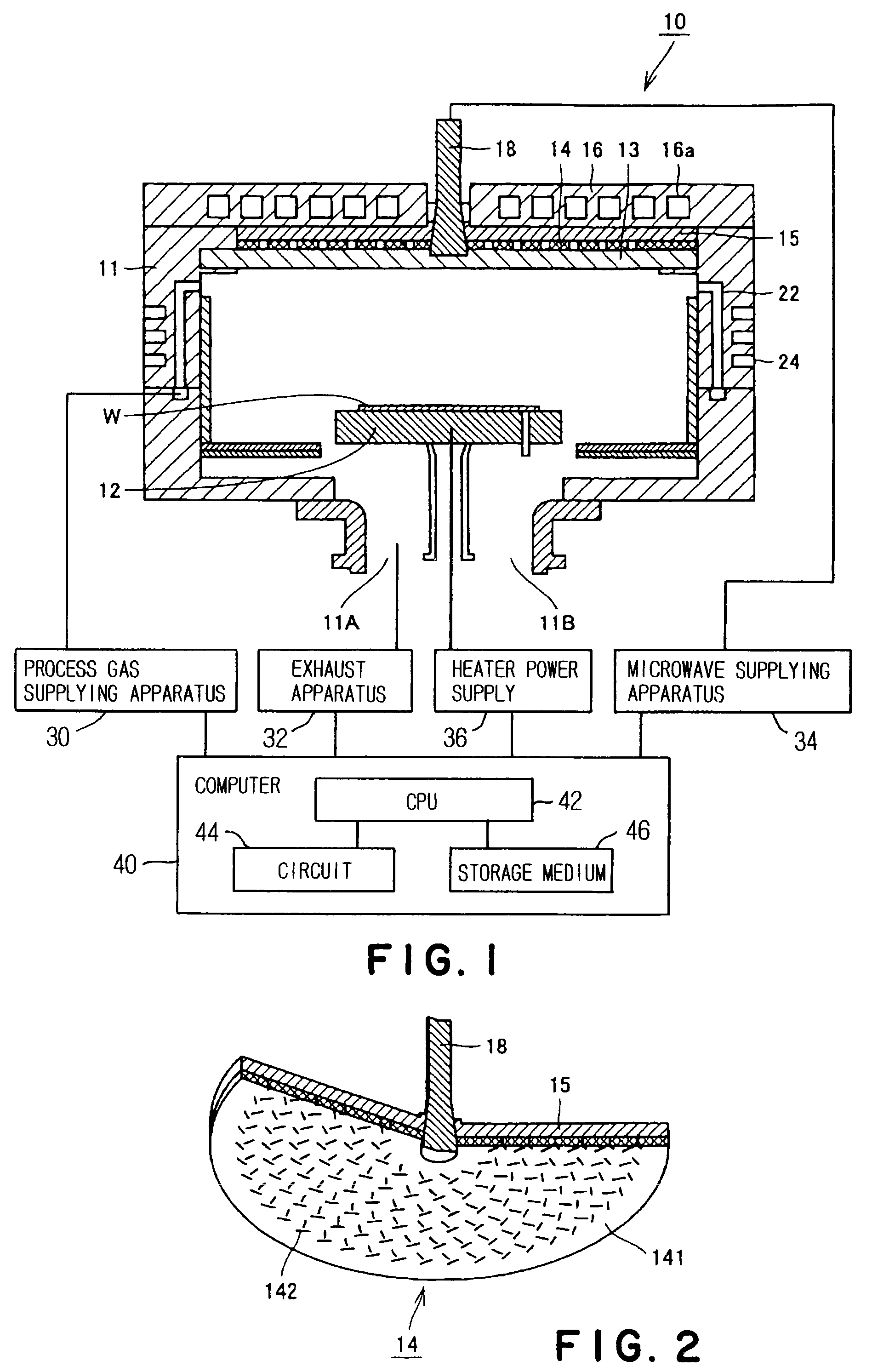

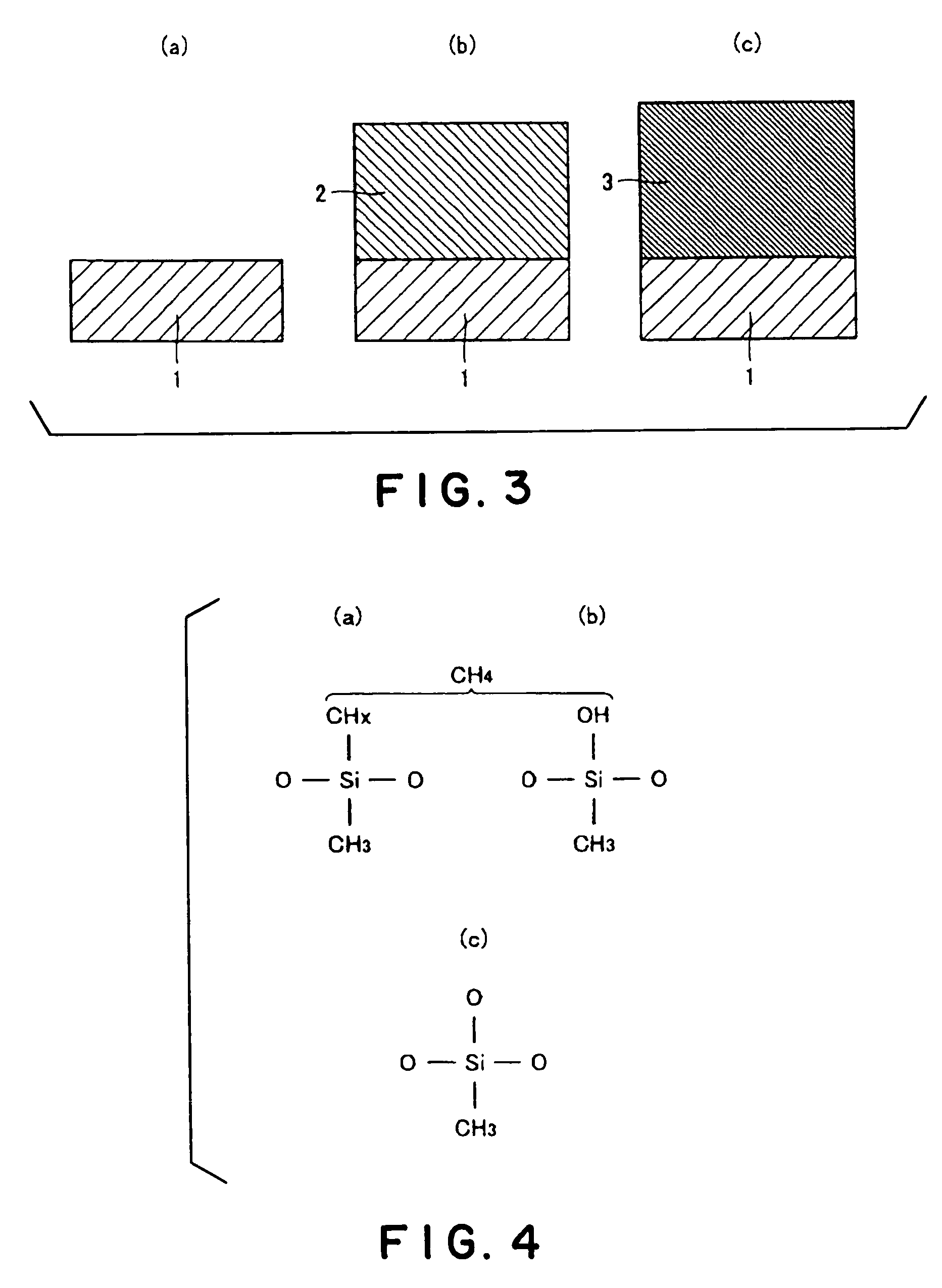

Fabrication of low dielectric constant insulating film

InactiveUS20070098890A1Improve film adhesionLow dielectric constantElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowaveHydrogen atom

The present invention relates to a method of lowering dielectric constant of an insulating film including Si, O and CH formed by a chemical vapor deposition process. A process gas containing hydrogen atoms is supplied into a reaction vessel. A microwave is introduced into the reaction vessel to supply a uniform electromagnetic wave, thereby a plasma containing a hydrogen radical is generated in the reaction vessel. The structure of the insulating film is modified by the hydrogen radical contained in the plasma irradiated to the insulating film, lowering the dielectric constant of the film. The microwave is supplied into the reaction vessel through a radial-slot antenna.

Owner:TOKYO ELECTRON LTD

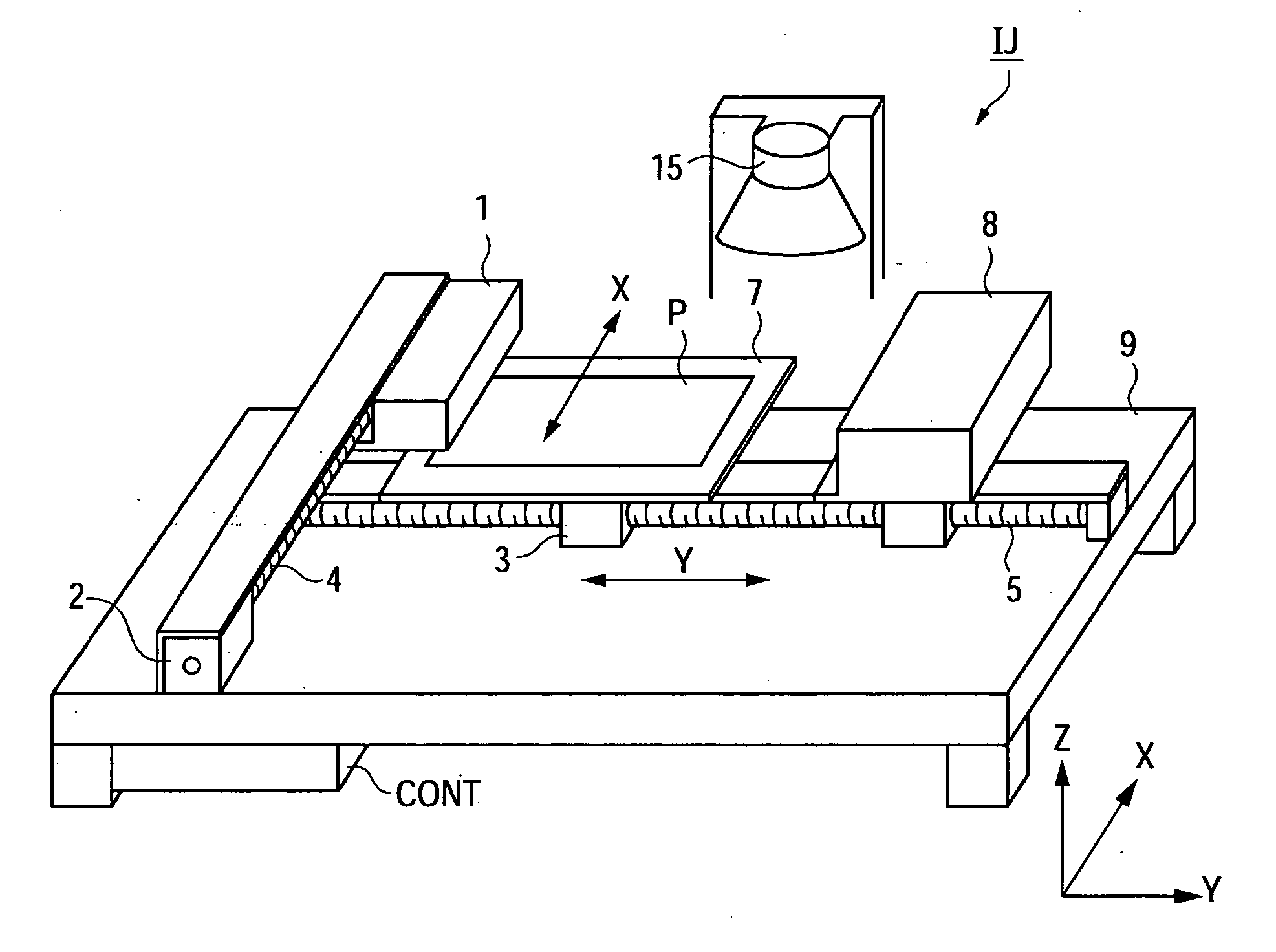

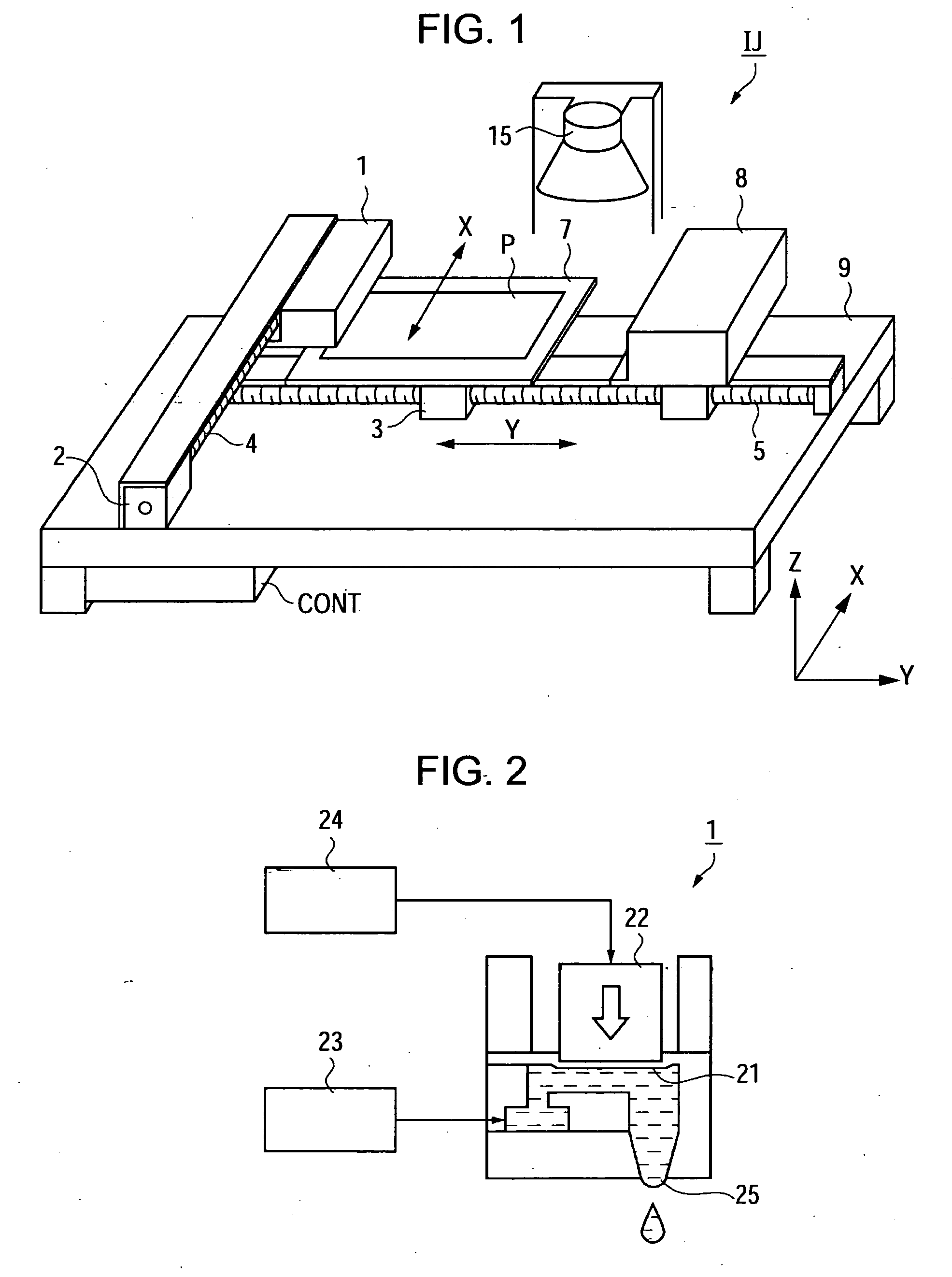

Method of forming film pattern, method of manufacturing device, electro-optical device, and electronic apparatus

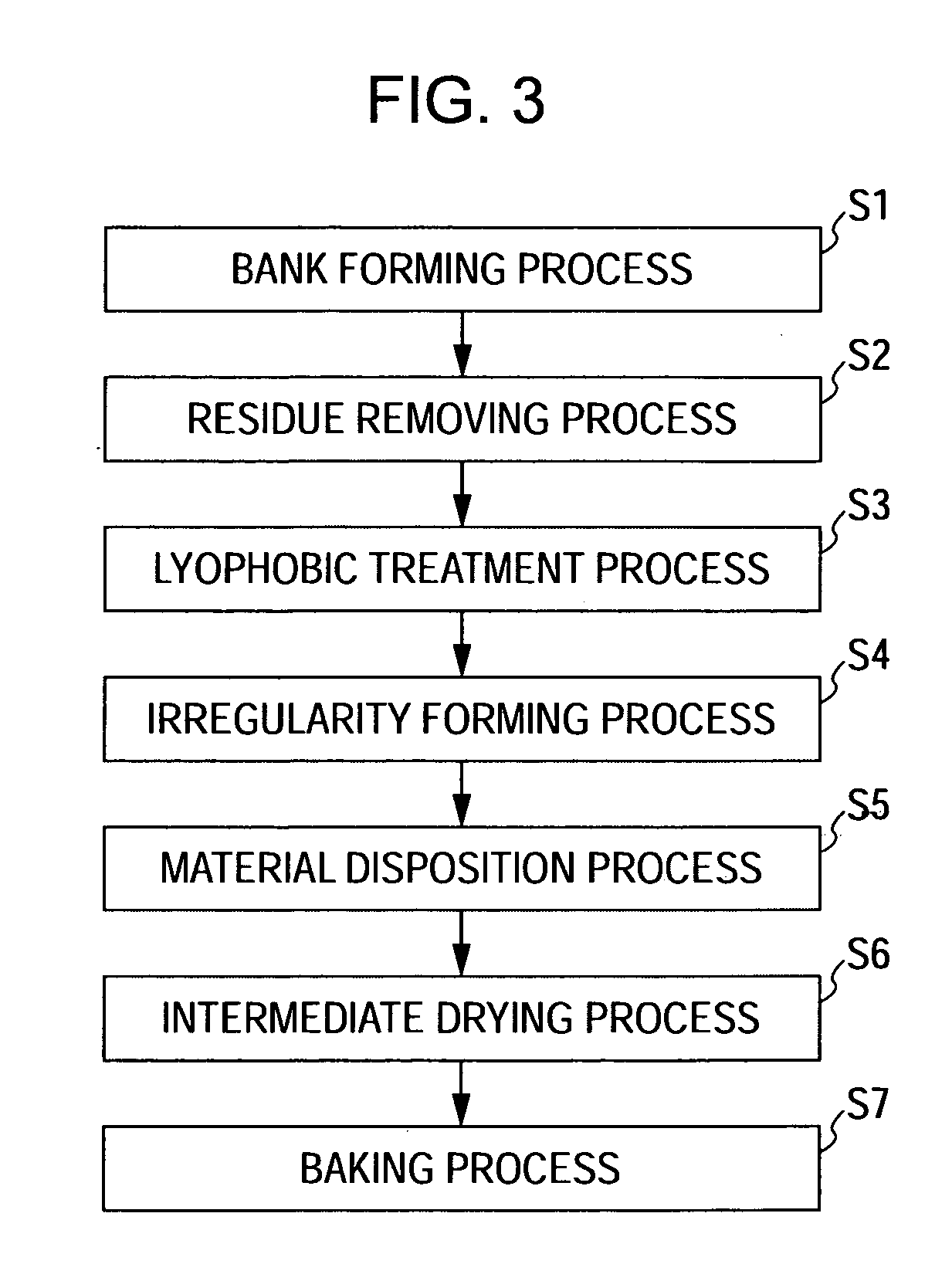

InactiveUS20060183036A1Improve performanceImprove film adhesionPicture framesSolid-state devicesEngineeringElectronic equipment

A method of forming a film pattern by disposing a functional liquid on a substrate includes: forming banks corresponding to the film pattern on the substrate; forming irregularities on bottoms between the banks by using the banks as a mask; and disposing the functional liquid between the banks and on the bottoms formed with the irregularities.

Owner:SEIKO EPSON CORP

Fusion formable silica and sodium containing glasses

ActiveUS8647995B2Improve battery efficiencyImprove film adhesionPV power plantsRadiation controlled devicesSilicate glassThermal expansion

Sodium containing aluminosilicate and boroaluminosilicate glasses are described herein. The glasses can be used as substrates or superstrates for photovoltaic devices, for example, thin film photovoltaic devices such as CIGS photovoltaic devices. These glasses can be characterized as having strain points ≧535° C., for example, ≧570° C., thermal expansion coefficients of from 8 to 9 ppm / ° C., as well as liquidus viscosities in excess of 50,000 poise. As such they are ideally suited for being formed into sheet by the fusion process.

Owner:CORSAM TECH

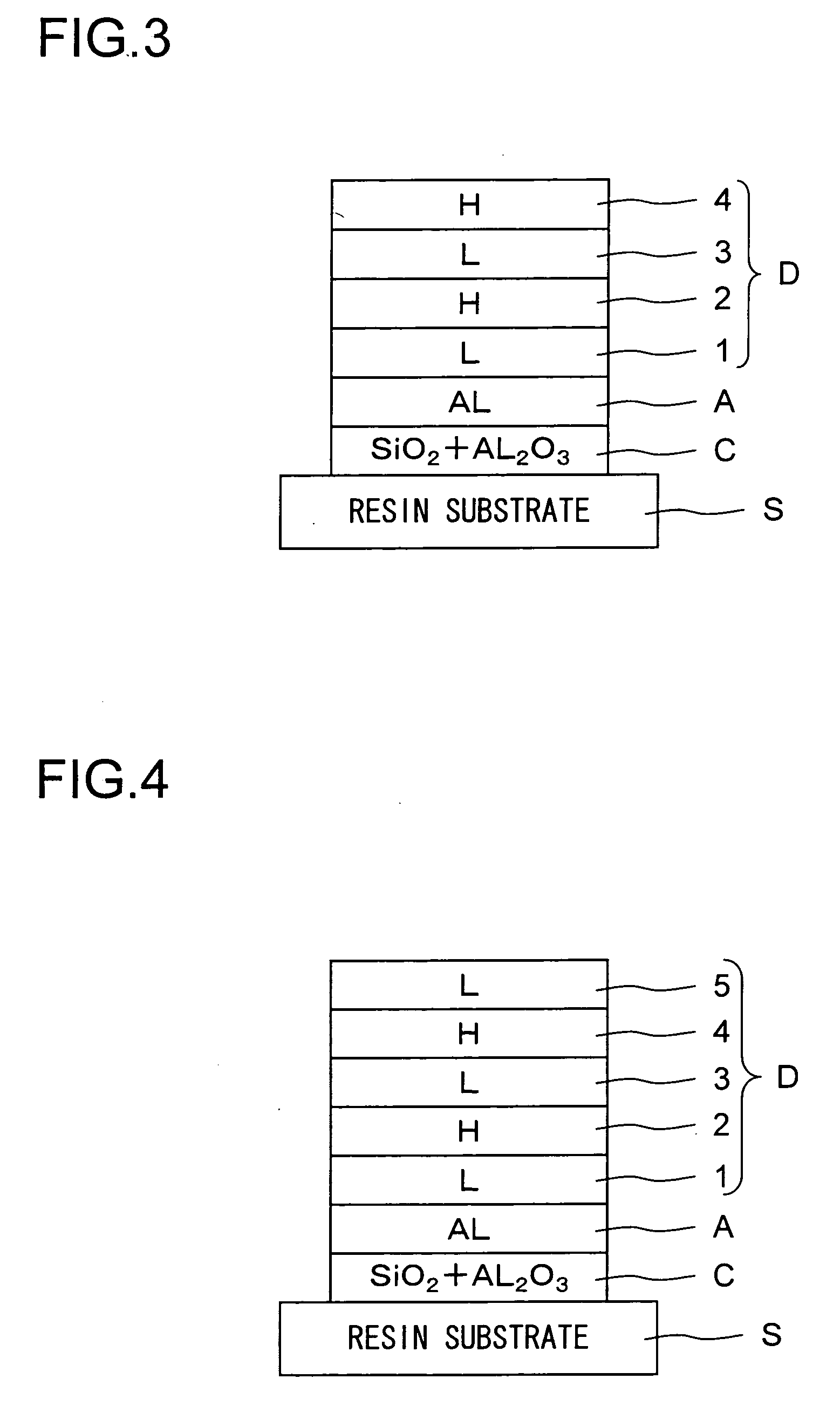

Reflecting Mirror

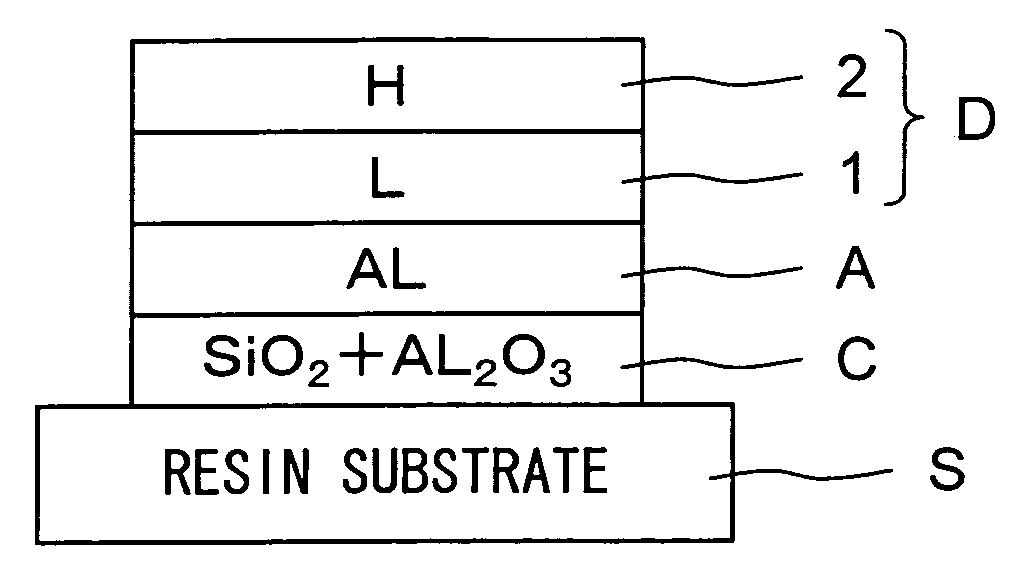

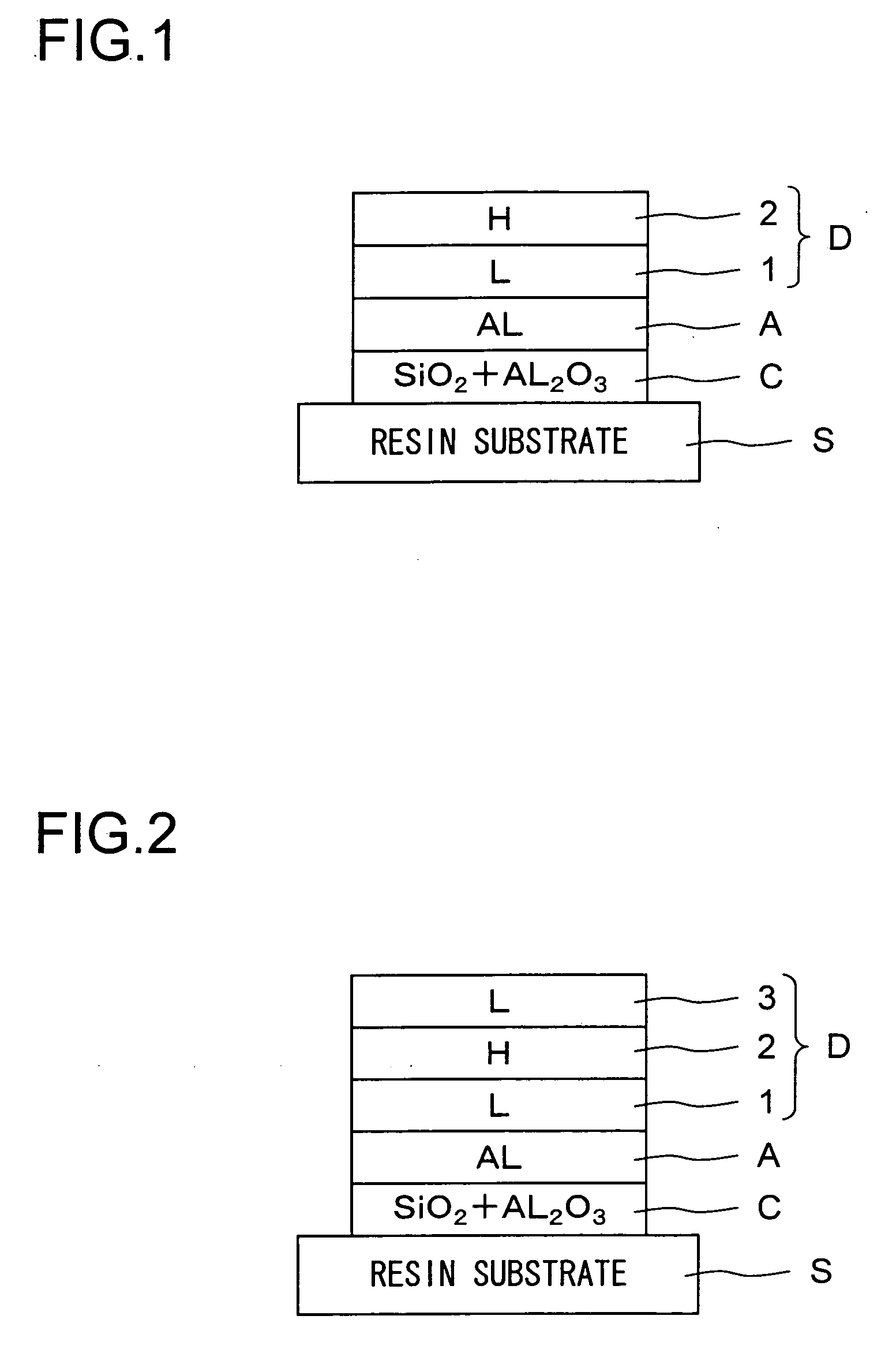

InactiveUS20080158702A1Satisfactory film adhesionSatisfactory mechanical strengthMirrorsReflective layerSilicon dioxide

In a reflecting mirror, an adhesive layer formed of a mixture of silicon dioxide and aluminum oxide is formed between a substrate and an aluminum reflective layer, and, on the aluminum reflective layer, a dielectric layer is formed that has, laid one after another on the aluminum reflective layer, a low-refraction layer containing silicon dioxide and a high-refraction layer formed of a compound of titanium oxide and lanthanum oxide.

Owner:KONICA MINOLTA OPTO

Amorphous hard carbon film, mechanical parts and method for producing amorphous hard carbon film

InactiveUS6821497B2High hardnessImprove adhesionLayered productsRecord information storageCarbon filmPiston ring

An amorphous hard carbon film has low friction coefficient from the beginning of sliding, when the metal oxide is contained in the film. The adhesion of the film to the substrate is also improved due to the low temperature treatment of RF plasma enhanced CVD method. This film can be applied to many sliding members, e.g., a piston ring, a vane of compressor and a plunger of fuel injection pump, used under severe condition.

Owner:RIKEN CO LTD

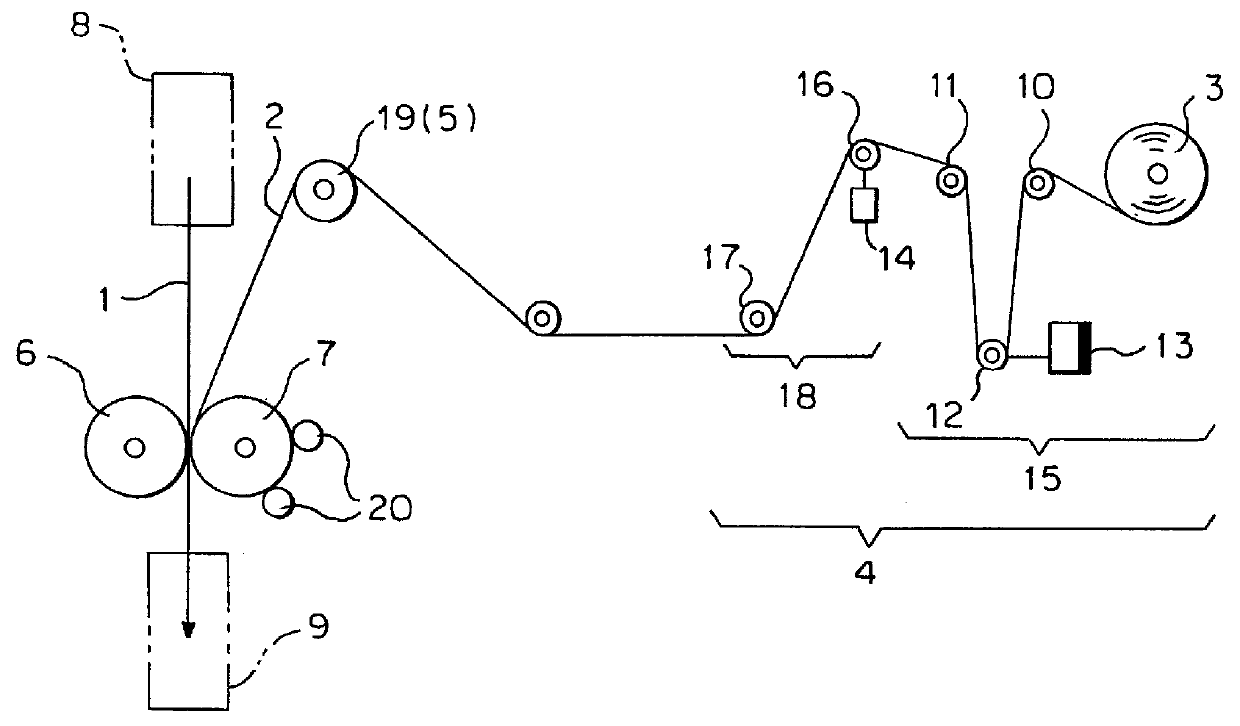

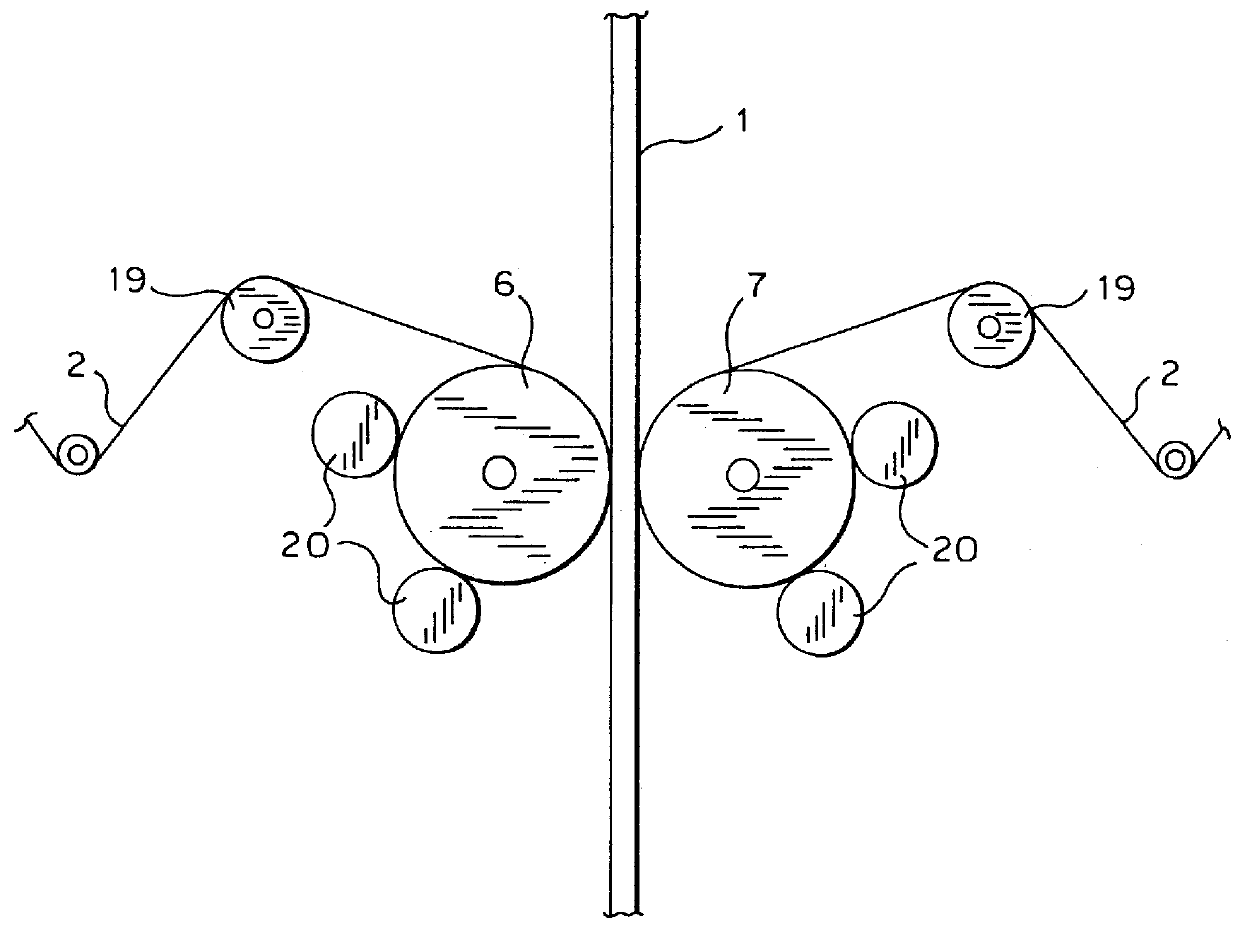

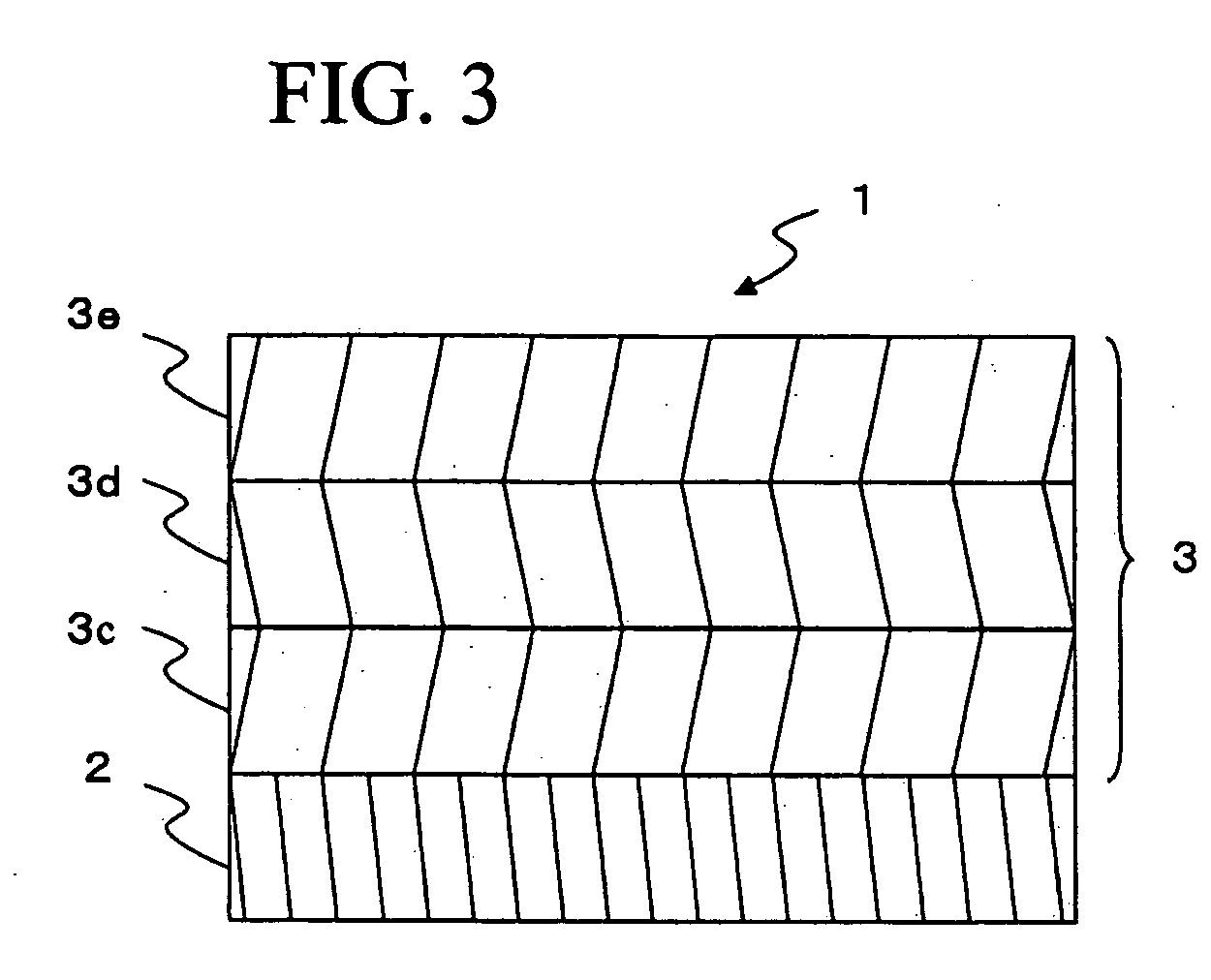

Method and equipment for production of laminated metal sheet

InactiveUS6080260AImprove adhesionSolve easy adhesionAdhesive processesMechanical working/deformationVitrificationThin slab

PCT No. PCT / JP96 / 03218 Sec. 371 Date Apr. 30, 1998 Sec. 102(e) Date Apr. 30, 1998 PCT Filed Nov. 1, 1996 PCT Pub. No. WO97 / 16310 PCT Pub. Date May 9, 1997When producing a laminated metal sheet, the air bubbles taken in when laminating can be lessened so that a laminated metal sheet with low rate of air bubbles can be obtained. For this purpose, in a production method of a laminated metal sheet comprising the steps of laminating of plastic film 2 on at least one side of a metal sheet strip 1, the plastic film is heated to a temperature of between the glass transition temperature of the plastic film and a temperature at which the thermal shrinkage of the film attains 3% when the plastic film is kept for 30 minutes at a constant temperature, and just after the heating, the plastic film is brought into pressure contact with the metal sheet, by which laminated metal sheet in which air bubbles are hard to be taken in when laminating, and the rate of air bubbles is low can be obtained.

Owner:TOYO KOHAN CO LTD

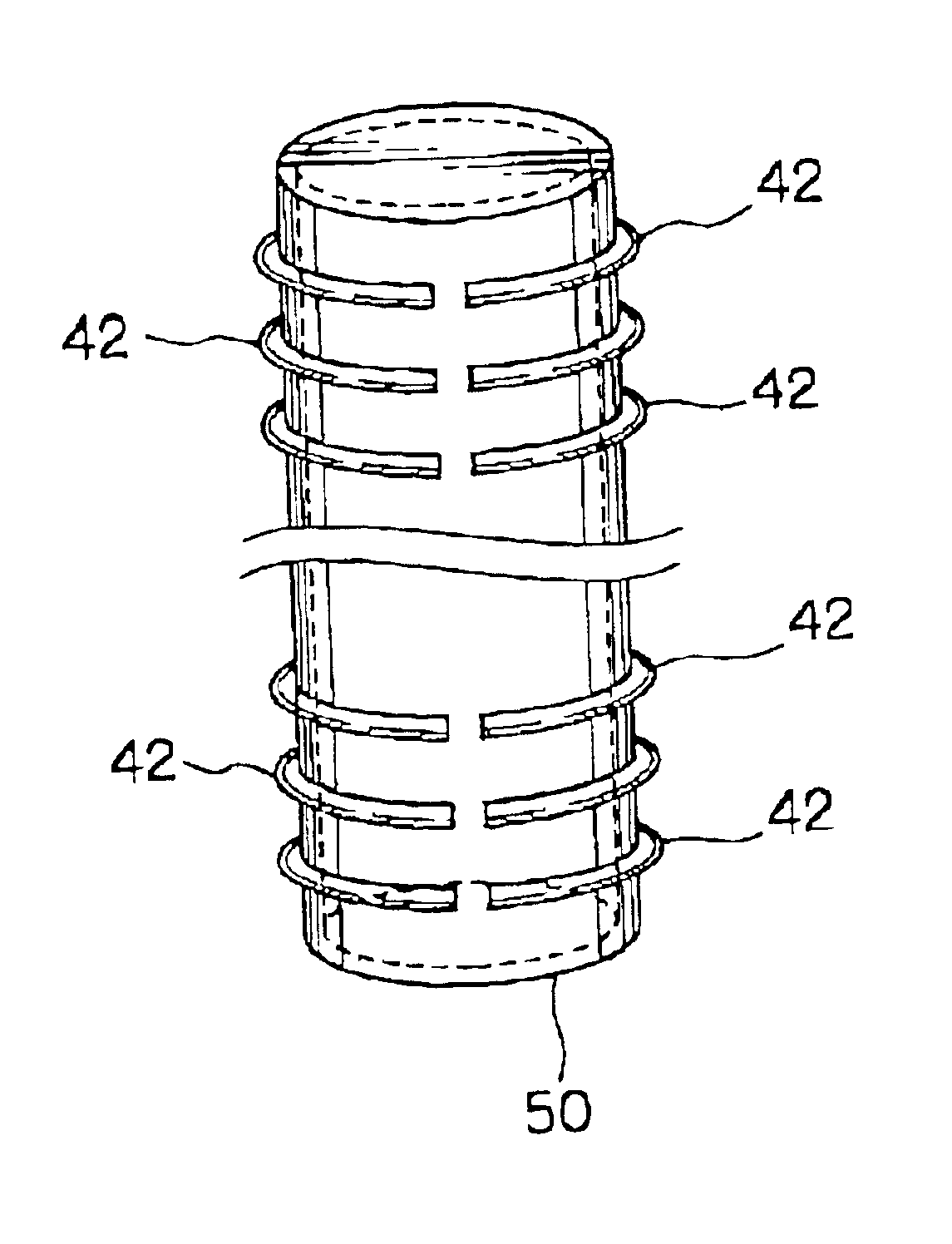

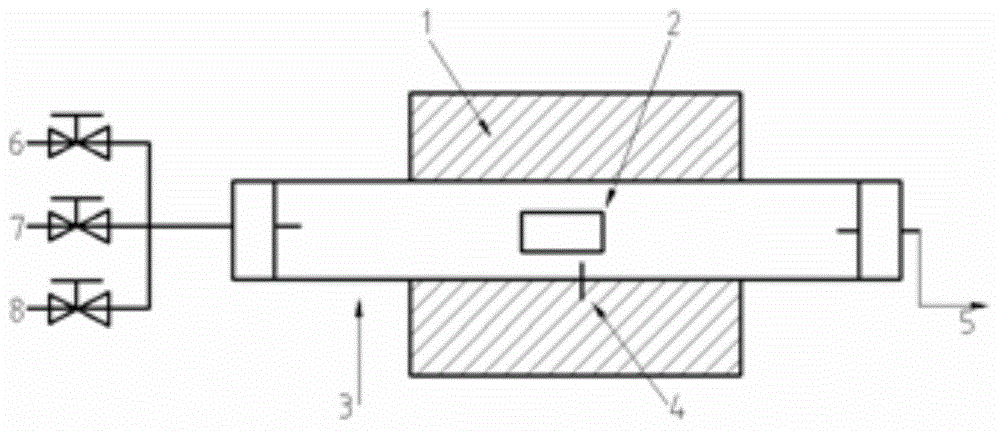

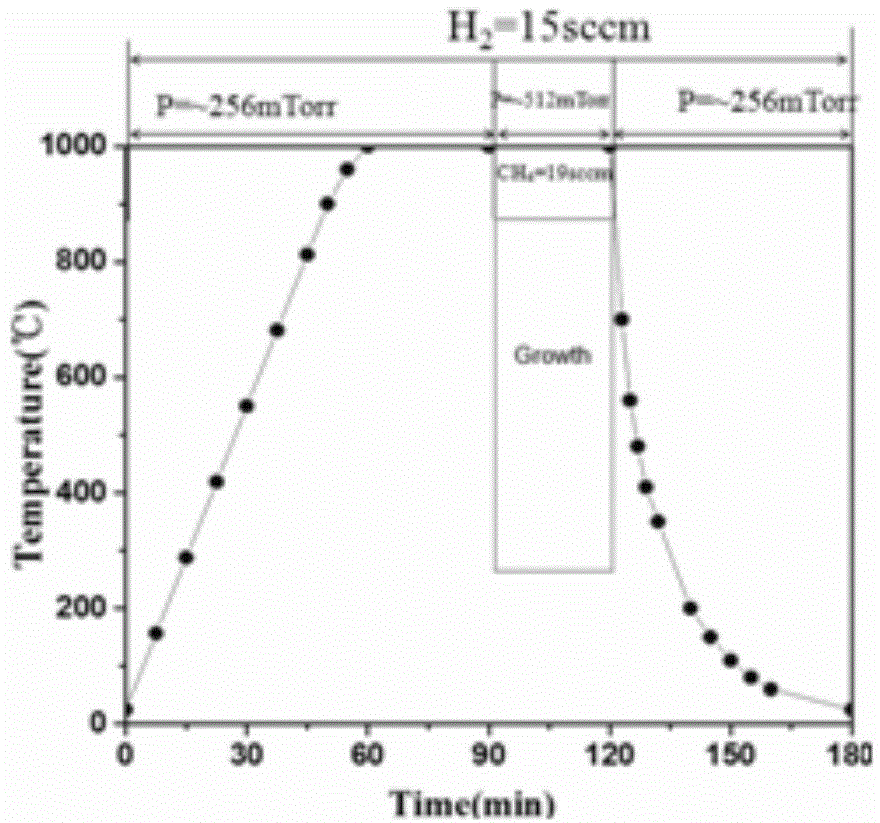

Method for processing surface of Cu electrode of multistage depressed collector through graphene

ActiveCN104465267ASolve the challenges of successful preparationOvercome the three-dimensional structureTransit-tube collectorsCold cathode manufactureSecondary electronsVacuum electronics

The invention discloses a method for processing the surface of a Cu electrode of a multistage depressed collector through graphene, relates to the technology of vacuum electronics, and provides a novel collector processing technology applicable to a high-efficiency travelling-wave tube. According to the method, a grapheme coating is adopted and can be directly used for processing the oxygen-free copper electrode, secondary electron emission is restrained, the recovery efficiency of the multistage depressed collector is improved, and the overall efficiency of the travelling-wave tube is improved. The method is simple in process, controllable in technology and low in cost, and the processed multistage depressed collector can achieve the same secondary electron emission restraining effect as a collector made of graphite. The processed multistage depressed collector has the advantages of a traditional graphite collector, has higher mechanical performance, electric conduction performance and heat conduction performance, and solves the problems that the structure is loose, strength is low and the graphite collector is prone to generating graphite dust under a long-term bombardment of electron beams, thereby effectively improving the efficiency and reliability of the travelling-wave tube.

Owner:HEFEI UNIV OF TECH

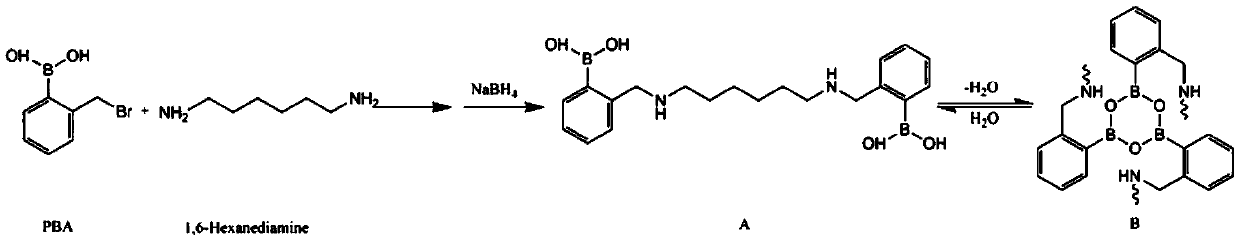

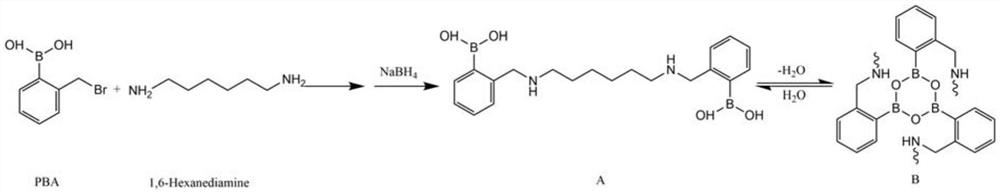

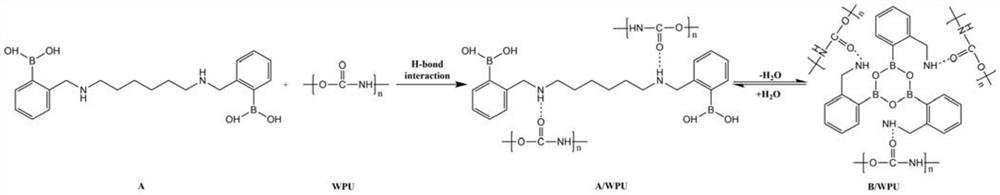

Self-repairing water-based polymer composite coating agent, and preparation method and application thereof

ActiveCN111548714AStrong self-healing efficiencyLow costGroup 3/13 element organic compoundsPolyurea/polyurethane coatingsPhenylboronic acidBoronic acid

The invention discloses a self-repairing water-based polymer composite coating, and a preparation method and application thereof, and belongs to the technical field of coating agent production. The preparation method comprises the following steps of: (1) reacting phenylboronic acid, a primary amine compound and NaBH4 to obtain a compound containing a boric acid bond, and performing dehydration, trimerizing and crosslinking to obtain a nitrogen coordination-containing boric acid ester bond compound; and (2) blending and compounding the nitrogen coordination-containing boric acid ester bond compound and a water-based polymer to obtain the self-repairing water-based polymer composite finishing agent. The preparation method disclosed by the invention has the advantages of simple and easily-controlled process, low cost, wide application range and the like, and is suitable for industrial production. The self-repairing water-based polymer composite coating agent prepared by the preparation method has a boron-oxygen six-membered ring and hydrogen bond dual self-repairing structure, can be quickly and efficiently self-repaired in an aqueous medium at room temperature, has the characteristics of good stability, excellent mechanical properties, obvious repairing effect and the like, and can be applied to various room-temperature self-repairing coatings.

Owner:SHAANXI UNIV OF SCI & TECH

Coated stainless steel member

InactiveUS20130327435A1Improve corrosion resistanceSimple and economical processCorrosion preventionElectrophoretic coatingsMaterials scienceMetallic Nickel

Owner:HONDA MOTOR CO LTD

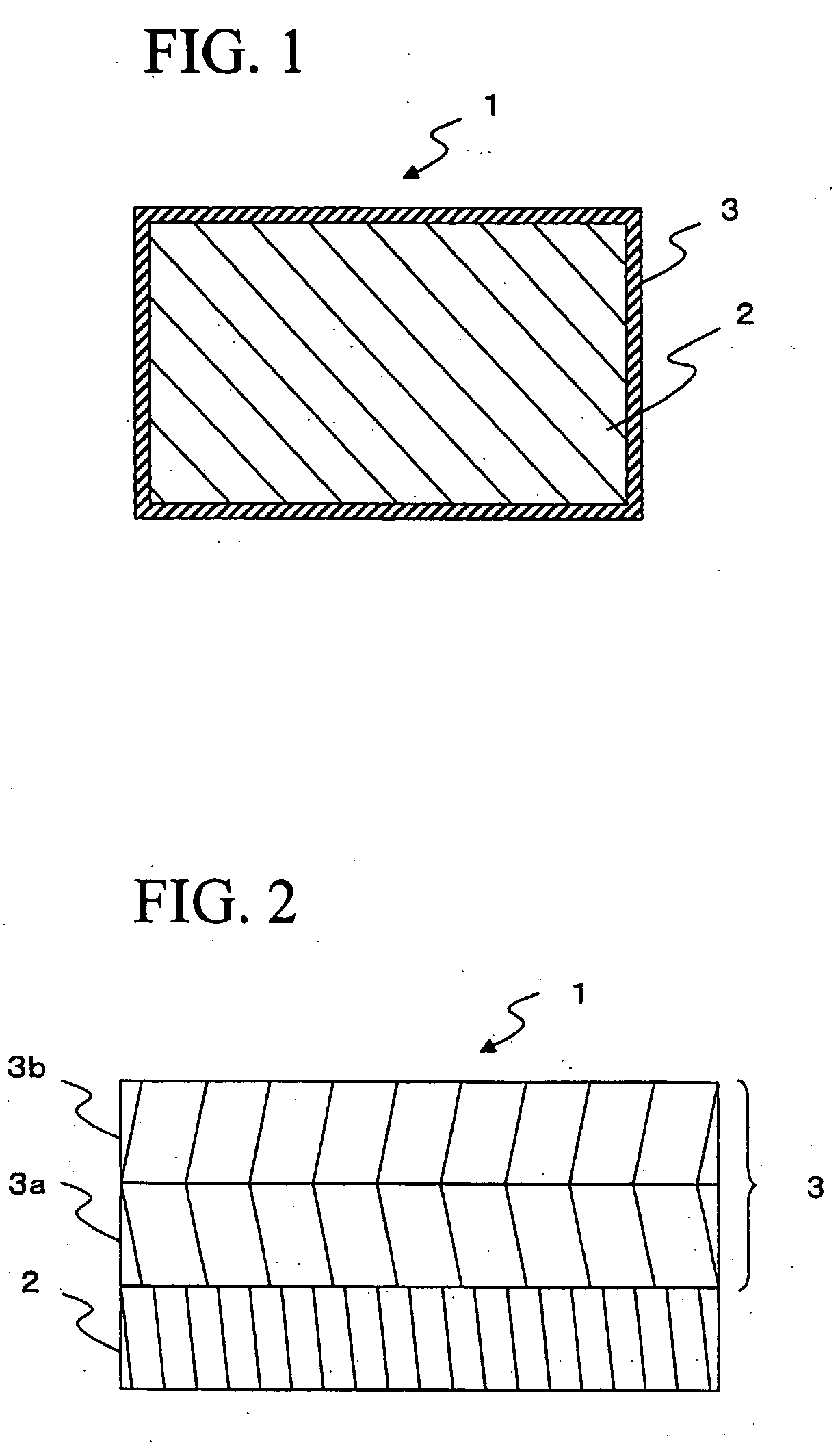

R-T-B system permanent magnet and plating film

InactiveUS20060141281A1High hardnessEasy to controlLiquid/solution decomposition chemical coatingMagnetic materialsHardnessGrain boundary

It is an object of the present invention to provide an R—T—B system permanent magnet which is easy to apply in the production of an actual R—T—B system permanent magnet, and which contains a plating film that is also effective in securing hardness. The present invention achieves this object by providing an R—T—B system permanent magnet 1 which contains a magnet base body 2 constituted from a sintered body which contains at least main phase grains containing an R2T14B compound, and a grain boundary phase which contains a larger amount of R than the main phase grains, and a plating film 3 which covers the magnet base body 2 surface and which contains, when C content is defined as Cc (wt. %), 0.005<Cc≦0.2 wt. %.

Owner:TDK CORPARATION

Two-component solventless adhesive compositions

ActiveUS20200140729A1Keep for a long timeSlow curingAdhesive articlesPolyureas/polyurethane adhesivesPhosphoric Acid EstersPolymer science

Two-component solventless polyurethane adhesive compositions comprising an isocyanate component and an isocyanate-reactive are disclosed, the compositions comprising an isocyanate component comprising an isocyanate-terminated prepolymer and an isocyanate-reactive component comprising a hydroxy-terminated polyurethane resin, a polyether polyol, a phosphate ester adhesion promoter, and, optionally, a bio-based polyol. Methods for forming laminate structures are also disclosed, the methods comprising forming an adhesive composition by mixing an isocyanate adhesive component comprising an isocyanate-terminated prepolymer and an isocyanate-reactive adhesive component comprising a hydroxy-terminated polyurethane resin, a polyether polyol, a phosphate ester adhesion promoter, and optionally, a bio-based polyol, applying the adhesive composition to a surface of a first substrate, and bringing a surface of a second substrate into contact with the adhesive composition on the surface of the first substrate, thereby forming the laminate structure. Laminate structures are also disclosed.

Owner:ROHM & HAAS CO +1

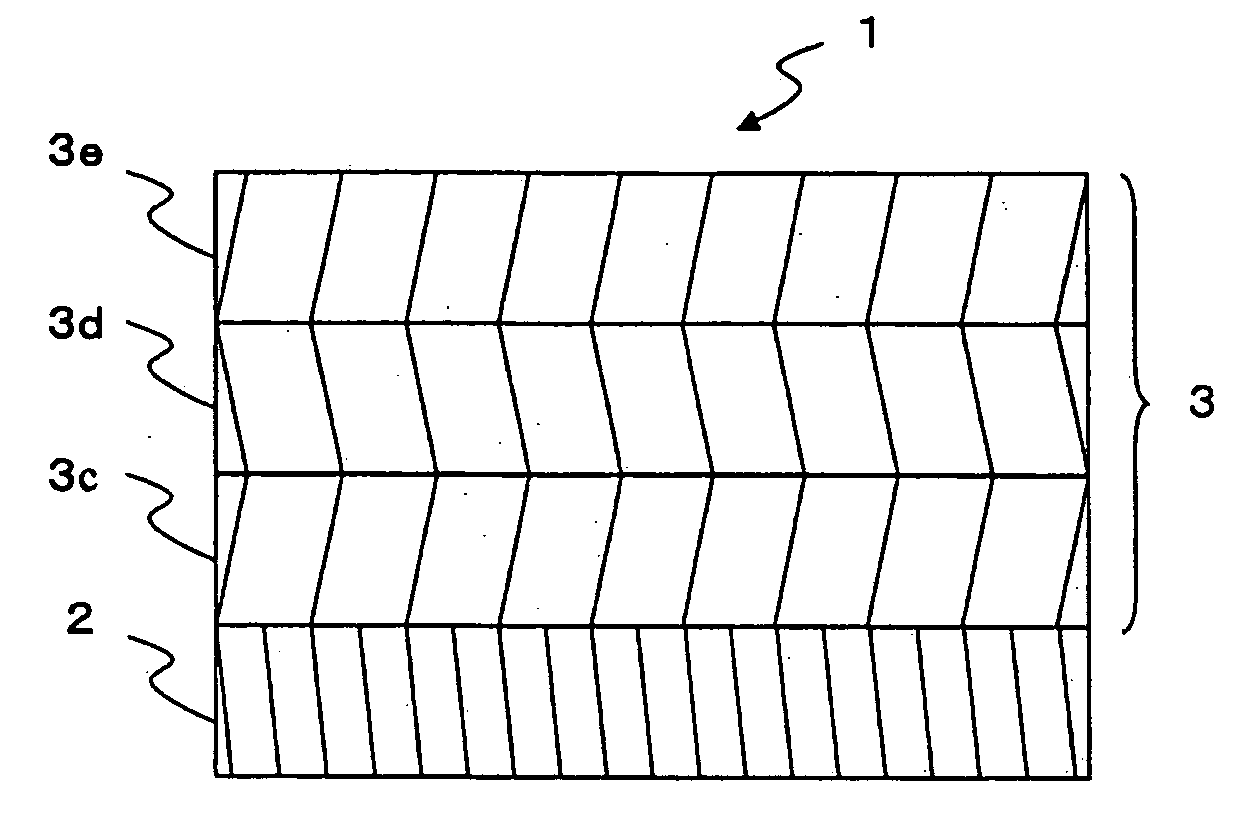

Multilayer Film, Laminate Using the Same, and Method for Producing the Laminate

InactiveUS20080138613A1Improve adhesionAdvantageously producedFilm/foil adhesivesSynthetic resin layered productsThermal expansionInorganic materials

Disclosed is a multilayer film for a strain-free laminate that is used for flexible TFT substrates or the like. Also disclosed are a laminate obtained by arranging such a multilayer film on a substrate made of an inorganic material, and a method for producing such a laminate. Specifically disclosed is a multilayer film wherein an adhesive resin layer that can be adhered to inorganic materials is arranged on a base film made of a resin. This multilayer film has a first average thermal expansion coefficient at temperatures from 60° C. to 80° C. measured during a first raise of the temperature of the multilayer film from 30° C. to 130° C. by heating the multilayer film, which first average thermal expansion coefficient is larger by 30 to 400 ppm / ° C. than a second average thermal expansion coefficient measured at temperatures from 60 to 80° C. during a second raise of the temperature from 30° C. to 130° C. after cooling the multilayer film from 130° C. to 30° C. subsequent to the first raise. Also specifically disclosed is a laminate obtained by sticking such a multilayer film onto at least one surface of a substrate made of an inorganic material. Further specifically disclosed is a method for producing such a laminate wherein the multilayer film is stuck to the substrate of an inorganic material at a temperature of not less than 40° C. and not more than the glass temperature of the resin of the adhesive resin layer.

Owner:ZEON CORP

Method for preparing ceramic membrane on surface of PE membrane by employing vacuum magnetron sputtering technology

InactiveCN106169552AImprove film adhesionImprove wettabilityVacuum evaporation coatingSecondary cellsIntermediate frequencyIon source

The invention discloses a method for preparing ceramic membrane on a surface of PE membrane by employing a vacuum magnetron sputtering technology. The method comprises the steps of cutting to-be-processed PE membrane into a required size in a purification room, and mounting the PE membrane on an unwinding roller of a device; starting the roll-roll vacuum magnetron sputtering coating device, and adjusting the device to a technological condition capable of coating; starting an ion source to bombard the PE membrane, and opening hydrocarbon accumulation macromolecule bonds; moreover, starting an intermediate frequency sputtering cathode, sputtering an Si target by utilization of intermediate frequency sputtering cathode reaction, thereby forming an SixNy-ceramic material, embedding the material into the locations of the opened hydrocarbon accumulation molecule bonds, thereby forming the ceramic membrane; carrying out annealing in a vacuum state, thereby eliminating the stress of the ceramic membrane; carrying out winding-unwinding continuous sputtering; finishing whole roll coating; breaking vacuum; taking a winding roller down; carrying out sampling and performance detection; and packaging the product and putting the product in storage. According to the method, a layer of ceramic membrane is deposited on the surface of the PE membrane for a lithium battery by employing the vacuum magnetron sputtering coating technology, the wettability of the PE membrane for electrolyte is improved, and the thermostability of the PE membrane is improved.

Owner:SHENZHEN XIGU ENERGY CO LTD

Coating composition for lubrication film

InactiveUS20160115421A1Improve adhesionCrack can be avoided and reducedPretreated surfacesBearing componentsChemical compoundHigh energy

A coating composition for lubrication film comprises: (A) a (meth)acrylic acid compound, the (meth)acrylate equivalent weight of which is less than or equal to 100; (B) a (meth)acrylic acid compound, the (meth)acrylate equivalent weight of which is in the range of 120 to 300; (C) a thermosetting resin and / or high energy beam-curable resin; and (D) at least one type of solid lubricant. The coating composition is capable of forming a resin film having high adhesion to the surfaces of various types of substrates by heating and / or high energy beam irradiation.

Owner:DOW CORNING TORAY CO LTD

Two-component solventless adhesive compositions

PendingUS20200157393A1Keep for a long timeSlow curingPolyureas/polyurethane adhesivesAdhesive articlesPhosphoric Acid EstersPolymer science

Two-component solventless polyurethane adhesive compositions comprising an isocyanate component and an isocyanate-reactive component are disclosed, the compositions comprising an isocyanate component comprising an isocyanate-terminated prepolymer, and an isocyanate-reactive component comprising a polyether polyol, a phosphate ester adhesion promoter, and, a bio-based polyol. Methods for forming laminate structures are also disclosed, the methods comprising forming an adhesive composition by mixing an isocyanate adhesive component comprising an isocyanate-terminated prepolymer and an isocyanate-reactive adhesive component comprising a polyether polyol, a phosphate ester adhesion promoter, and a bio-based polyol, applying the adhesive composition to a surface of a first substrate, and bringing a surface of a second substrate into contact with the adhesive composition on the surface of the first substrate, thereby forming the laminate structure. Laminate structures are also disclosed.

Owner:ROHM & HAAS CO +1

Fusion formable sodium containing glass

ActiveUS9637408B2Improve battery efficiencyImprove film adhesionSynthetic resin layered productsPhotovoltaic energy generationChemistryLiquidus

Sodium-containing aluminosilicate and boroaluminosilicate glasses are described herein. The glasses can be used as substrates for photovoltaic devices, for example, thin film photovoltaic devices such as CIGS photovoltaic devices. These glasses can be characterized as having strain points ≧540° C., thermal expansion coefficient of from 6.5 to 9.5 ppm / ° C., as well as liquidus viscosities in excess of 50,000 poise. As such they are ideally suited for being formed into sheet by the fusion process.

Owner:CORSAM TECH

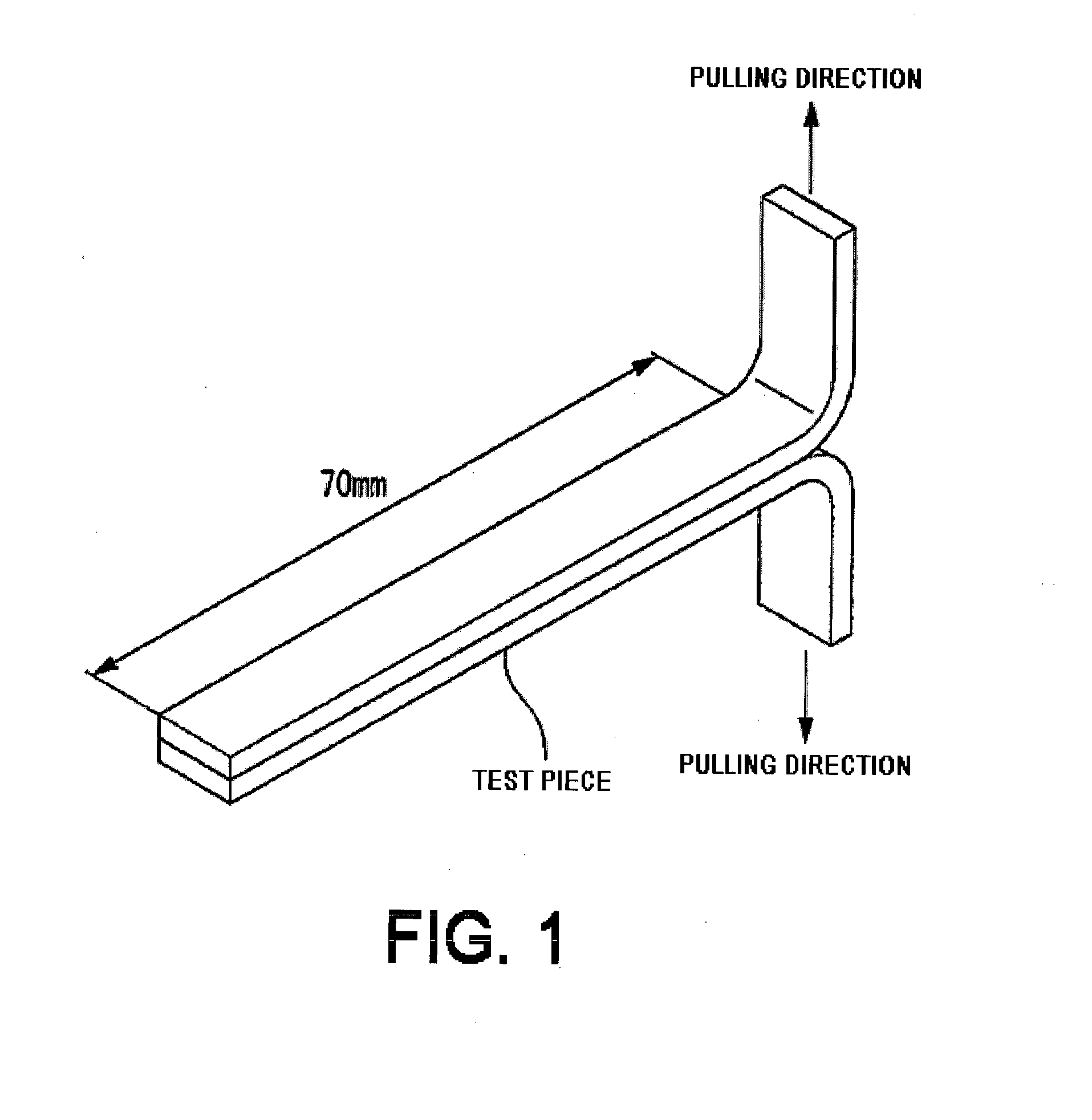

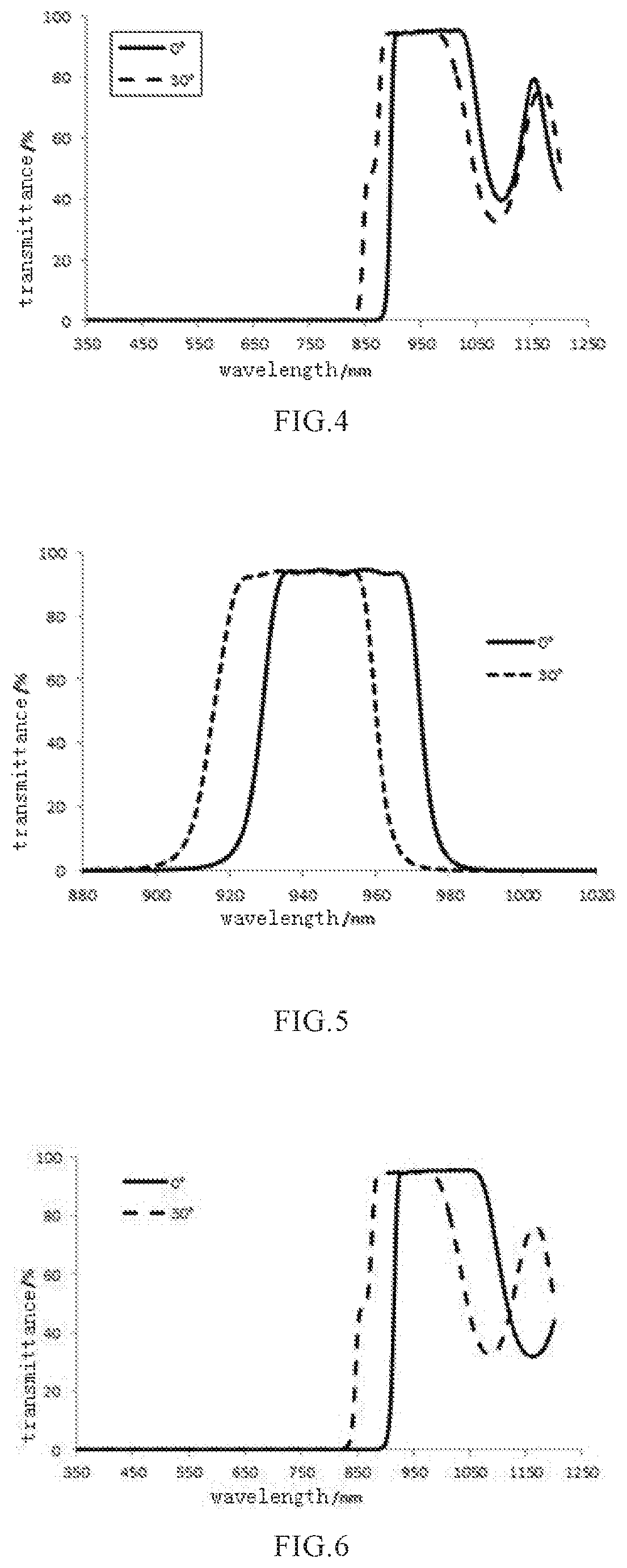

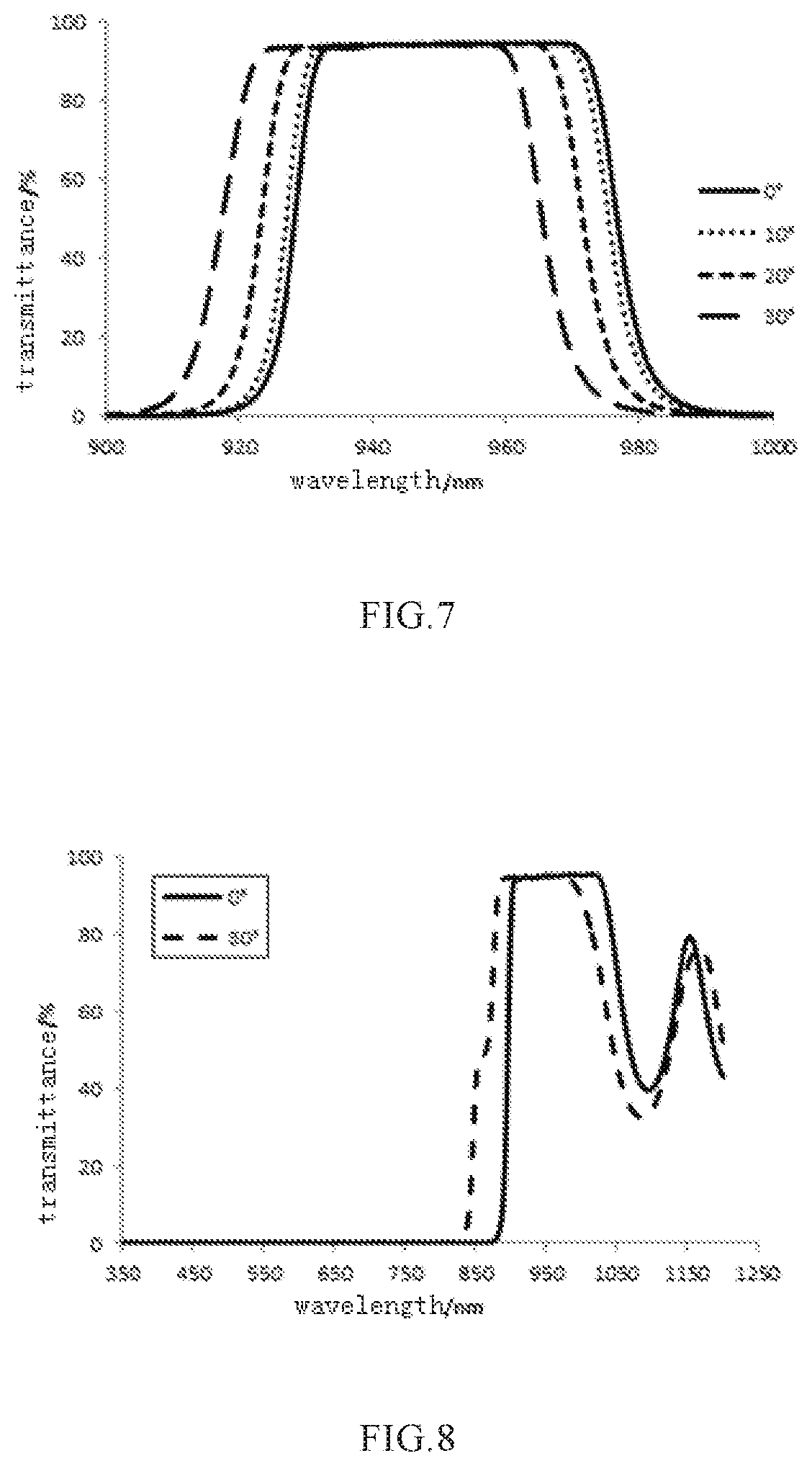

Optical filter and Infrared Image Sensing System Including the Same

PendingUS20200393601A1Eliminate the effects ofPoor adhesionTelevision system detailsOptical filtersRefractive indexLight filter

The present disclosure relates to an optical filter and an infrared image sensing system including the optical filter. The optical filter includes a glass substrate, and an IR film layer and an AR film layer plated on two opposite surfaces of the glass substrate; the IR film layer includes a first refractive-index-material layer, a second refractive-index-material layer, and a third refractive-index-material layer; the refractive index of the third refractive-index-material layer is greater than the refractive index of the first refractive-index-material layer, and the refractive index of the second refractive-index-material layer is greater than the refractive index of the third refractive-index-material layer. The optical filter of the present disclosure has a good anti-reflection effect on near-infrared light so that a high accuracy of face recognition and gesture recognition is ensured.

Owner:XINYANG SUNNY OPTICAL CO LTD

Organic-inorganic hybrid nanometer film coating aluminum powder pigment and preparation method and application thereof

InactiveCN101580653BIsolated contactGood acid and alkali resistanceCoatingsPigment treatment with organosilicon compoundsAluminium powderDouble bond

The invention discloses organic-inorganic hybrid nanometer film coating aluminum powder pigment and a preparation method and application thereof. The preparation method comprises the followings steps:by utilizing organic-inorganic hybrid technology and taking aluminum powder pigment as nuclear, firstly performing free radical polymerization on polymerisable carbon-carbon double bond reaction monomers and polymerisable carbon-carbon double bond organosiloxane; and bonding the obtained polymer and ethyl orthosilicate with the surface of the aluminum powder pigment in a hydrolysis mode, and further coating a layer of organic-inorganic hybrid nanometer film on the surface of the aluminum powder. On the basis of maintaining the lustrousness of the aluminum powder, the prepared organic-inorganic hybrid nanometer film coating aluminum powder pigment has excellent compatibility with resin and good acid and alkaline resistance properties, simultaneously well solves the problem of 'powder falling' when the conventional aluminum powder and single-layer or two-layer costing aluminum powder pigment are applied to metallic coatings, and provides a foundation for applying modified aluminum powder pigment and developing high performance metallic coatings.

Owner:SOUTH CHINA UNIV OF TECH

Edible film compositions for processing of meat products

ActiveUS20050238792A1Improve adhesionImproved shine appearanceProtein composition from fishFood ingredientsGelatinPolymer

Novel film compositions are described for use in the processing of meat products, particularly as sausage casings and wrappers for hams and other cured meat products. By combining gelatin and other hydrocolloid film forming polymer materials, edible film compositions are achieved by solution casting which exhibit superior and desirable properties for adhering to the meat product and presenting a shining, appealing surface.

Owner:LIVING CELL RES

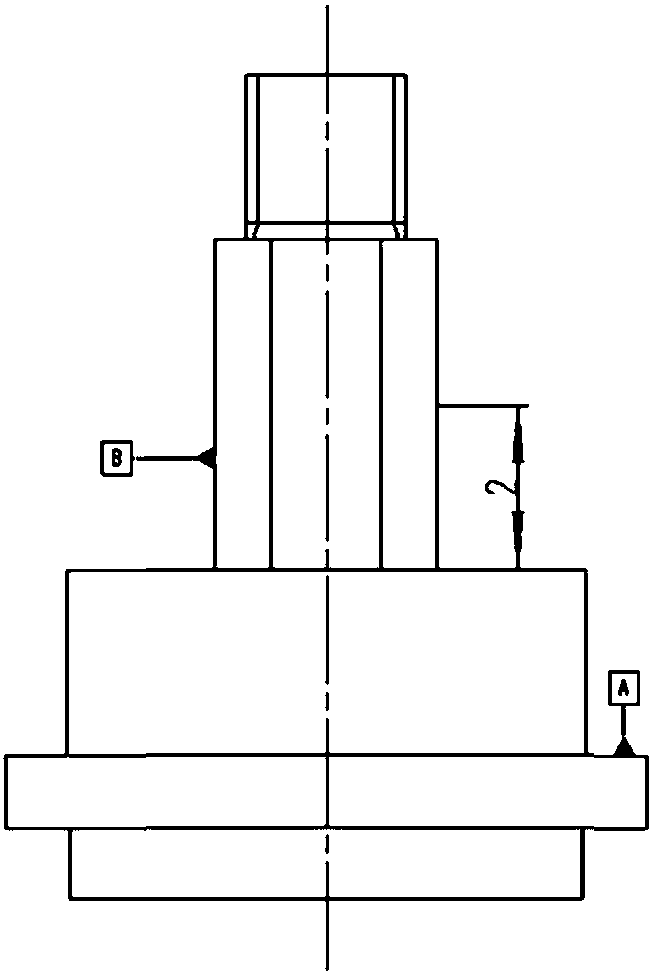

Preparation method of insulated isolation coating suitable for high-temperature piezoelectric sensor

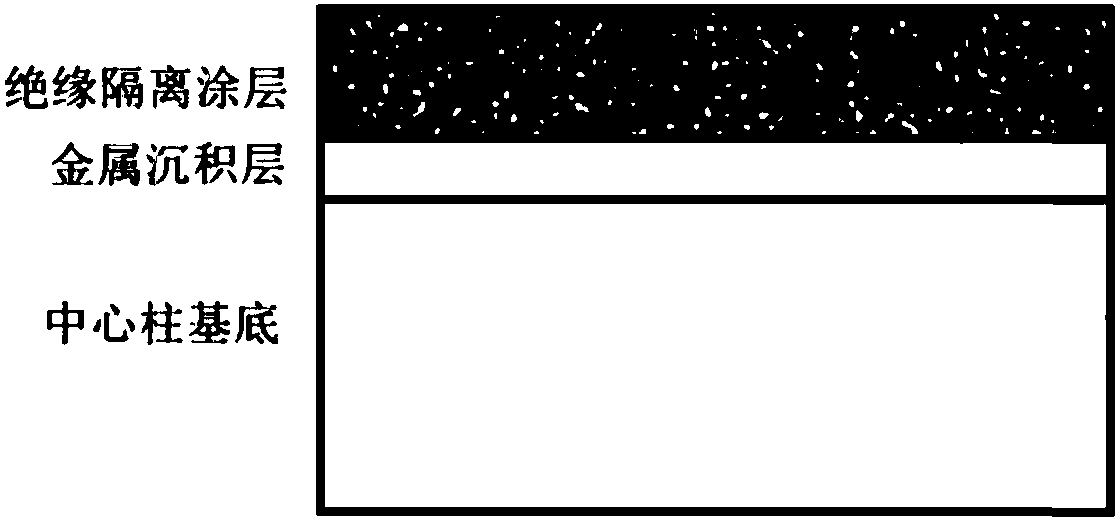

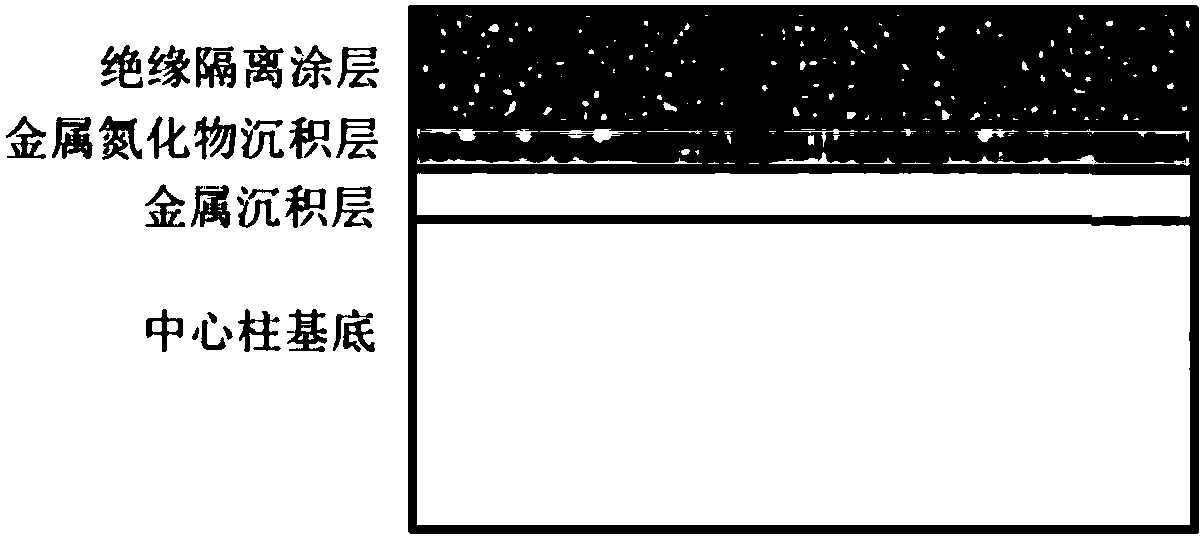

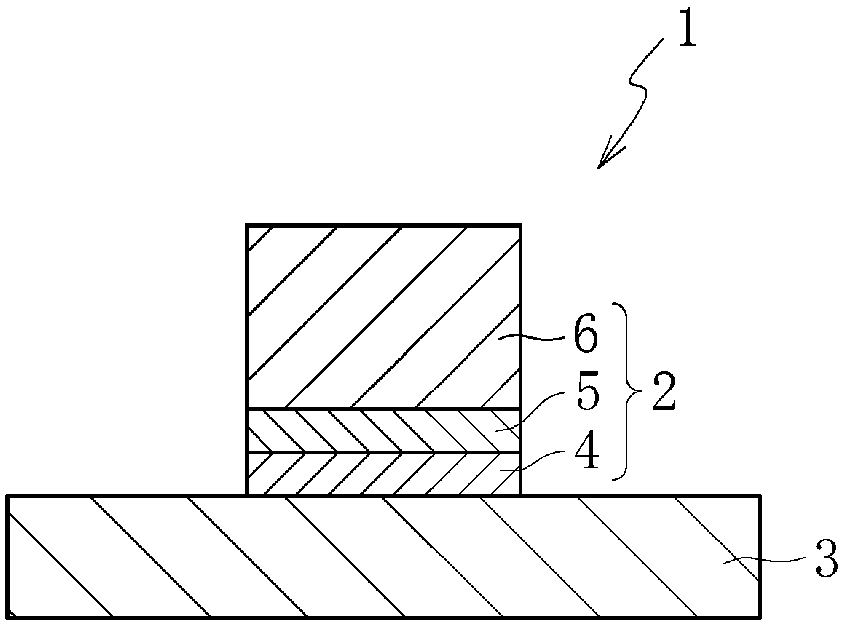

InactiveCN110016648AImprove insulation performanceImprove film adhesionVacuum evaporation coatingSputtering coatingSputter cleaningDecomposition

The invention belongs to the technical field of electron device preparation, and particularly relates to a preparation method of an insulated isolation coating suitable for a high-temperature piezoelectric sensor. The preparation method of insulated isolation coating suitable for the high-temperature piezoelectric sensor comprises the steps of installing and fixing after pretreating a center column, then placing into a vacuum chamber, heating, baking, degassing, sputter cleaning, and then carrying out transition layer deposition and insulated isolation coating deposition. Micron-order ceramicmetallic oxide or metallic oxide is deposited on a center support structure so as to be used as the insulated isolation coating, so that the insulated isolation of positive and negative lead structures is realized; and the coating has a stable insulation performance and a high film layer binding force, can solve the problems such as linear expansion and decomposition of a traditional insulated sleeve pipe under severe environment conditions such as high temperature and high impact, and realizes component integrity, so that the stability and the accuracy of electron devices are improved, and the product quality is stable.

Owner:SOUTHWESTERN INST OF PHYSICS +1

Method For Producing Glass Plate Having Film

InactiveCN107709262AImprove film adhesionLiquid/solution decomposition chemical coatingElectroless platingPrecious metal

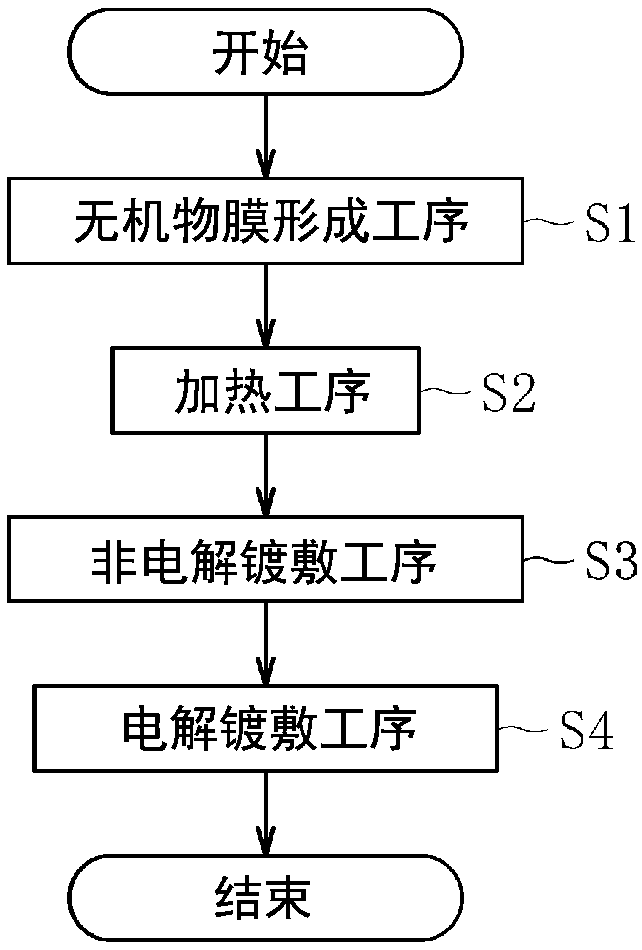

Provided is a method for producing a glass plate having a film, in which a laminated film that is black when viewed from the glass-plate side and that is obtained by laminating a plurality of films isformed on the glass plate, wherein a step for forming the laminated film is provided with an inorganic film formation step S1 for forming an inorganic film that includes at least a precious metal onthe glass plate, a heating step S2 for heating the inorganic film, an electroless plating step S3 for forming an electroless-plated metal film on the inorganic film, and an electroplating step S4 forforming an electroplated metal film on the electroless plated metal film. A pyrophosphoric acid inorganic bath is used in the electroplating step S4.

Owner:NIPPON ELECTRIC GLASS CO LTD

Fabrication of low dielectric constant insulating film

InactiveUS7645481B2Improve film adhesionLow dielectric constantPolycrystalline material growthElectric discharge tubesHydrogen atomMicrowave

Owner:TOKYO ELECTRON LTD

Multilayer film, laminate using the same, and method for producing the laminate

InactiveUS7527857B2Improve adhesionAdvantageously producedCovering/liningsGlass/slag layered productsThermal expansionInorganic materials

Disclosed is a multilayer film for a strain-free laminate that is used for flexible TFT substrates or the like. Also disclosed are a laminate obtained by arranging such a multilayer film on a substrate made of an inorganic material, and a method for producing such a laminate. Specifically disclosed is a multilayer film wherein an adhesive resin layer that can be adhered to inorganic materials is arranged on a base film made of a resin. This multilayer film has a first average thermal expansion coefficient at temperatures from 60° C. to 80° C. measured during a first raise of the temperature of the multilayer film from 30° C. to 130° C. by heating the multilayer film, which first average thermal expansion coefficient is larger by 30 to 400 ppm / ° C. than a second average thermal expansion coefficient measured at temperatures from 60 to 80° C. during a second raise of the temperature from 30° C. to 130° C. after cooling the multilayer film from 130° C. to 30° C. subsequent to the first raise. Also specifically disclosed is a laminate obtained by sticking such a multilayer film onto at least one surface of a substrate made of an inorganic material. Further specifically disclosed is a method for producing such a laminate wherein the multilayer film is stuck to the substrate of an inorganic material at a temperature of not less than 40° C. and not more than the glass temperature of the resin of the adhesive resin layer.

Owner:ZEON CORP

A kind of self-healing water-based polymer composite finishing agent and preparation method and application thereof

ActiveCN111548714BStrong self-healing efficiencyLow costGroup 3/13 element organic compoundsPolyurea/polyurethane coatingsPhenylboronic acidPolymer science

The invention discloses a self-repairing water-based polymer composite finishing agent, a preparation method and application thereof, and belongs to the technical field of finishing agent production. The preparation method comprises: (1) passing through phenylboronic acid, primary amine compounds and NaBH 4 reaction to obtain a compound containing a boronic acid bond, which is then dehydrated and trimerized and cross-linked to form a nitrogen-containing coordination boronate bond compound; (2) the nitrogen-containing coordination boronate bond compound is blended and compounded with an aqueous polymer to obtain Self-healing water-based polymer composite finishing agent. The preparation method of the invention has the advantages of simple and easy-to-control process, low cost, wide application range and the like, and is suitable for industrial production. The self-healing water-based polymer composite coating agent prepared by the preparation method has a double self-repairing structure of boron-oxygen six-membered ring and hydrogen bond, can self-repair quickly and efficiently in an aqueous medium at room temperature, and has good stability, mechanical properties and mechanical properties. It has the characteristics of excellent performance and obvious repair effect, and can be applied to various room temperature self-healing coatings.

Owner:SHAANXI UNIV OF SCI & TECH

Edible film compositions for processing of meat products

ActiveUS8728561B2Improve film adhesionIncrease contentProtein composition from fishFood ingredientsGelatinPolymer

Novel film compositions are described for use in the processing of meat products, particularly as sausage casings and wrappers for hams and other cured meat products. By combining gelatin and other hydrocolloid film forming polymer materials, edible film compositions are achieved by solution casting which exhibit superior and desirable properties for adhering to the meat product and presenting a shining, appealing surface.

Owner:LIVING CELL RES

Method for improving adhesive force of metal film circuit on silicon wafer

ActiveCN112234023AImprove film adhesionShorten process timeSemiconductor/solid-state device manufacturingWaveguide type devicesPhysicsThin membrane

The invention discloses a method for improving adhesive force of a metal film circuit on a silicon wafer, which belongs to the technical field of microwave integrated circuit micromachining. The method comprises the following steps of: growing a metal film on the silicon wafer by adopting normal-temperature direct-current magnetron sputtering, completing the patterning of the metal film circuit, then putting the silicon wafer into a high-temperature and high-pressure atmosphere furnace, carrying out heat preservation and pressure maintaining treatment for a certain period of time, and then cooling and taking out the silicon wafer. Compared with the prior art, the method provided by the invention has the advantages that the adhesive force of a metal film circuit film layer is remarkably improved, the overall process time is shortened by more than a half by a normal-temperature magnetron sputtering process, and the requirements of silicon-based cavity circulator device production on device reliability and production efficiency are met.

Owner:中国电子科技集团公司第九研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com