Method for processing surface of Cu electrode of multistage depressed collector through graphene

A technology of electrode surface and multi-layer graphene, which is applied in the manufacture of electrode systems, manufacture of discharge tubes/lamps, collectors of time-of-flight electron tubes, etc., can solve the problems of many reagents, complicated processing, and limited effects. Achieve the effect of large-area uniform growth graphene coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

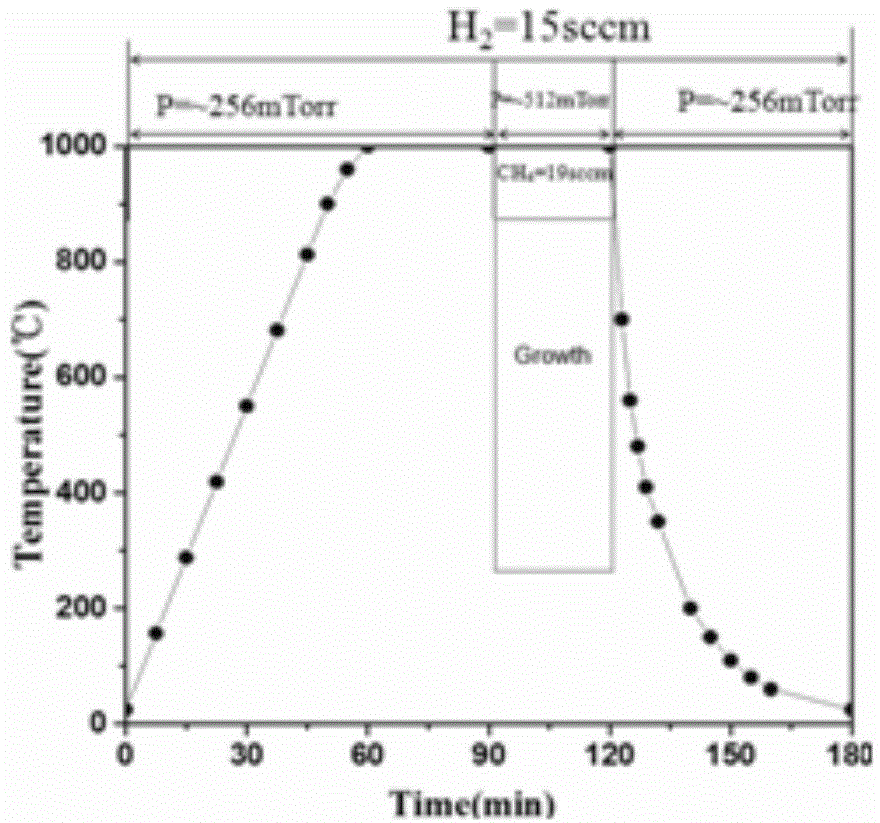

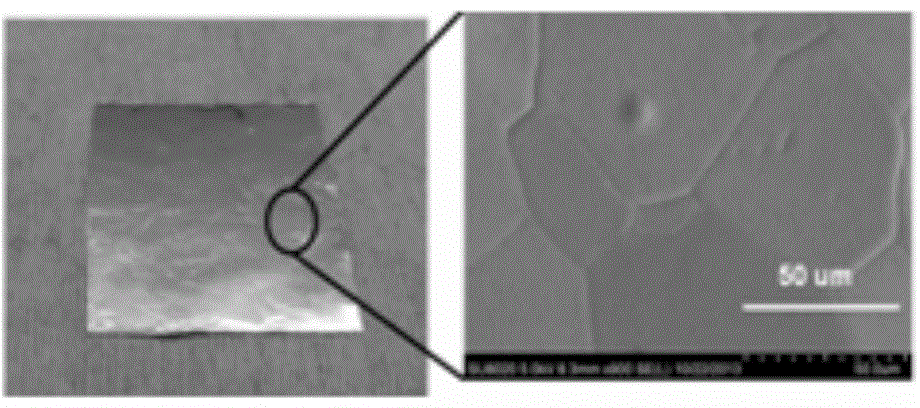

[0031] The invention adopts a vapor deposition method to grow a graphene material coating on the surface of the Cu electrode of the multi-stage depressurized collector, and carries out material modification on the surface of the collector, thereby effectively reducing the secondary electron emission coefficient of the multi-stage depressurized collector electrode.

[0032] Technical process of the present invention:

[0033] 1. Pre-treatment of the electrode: soaking in 10% acetic acid aqueous solution for 30 minutes; acetone ultrasonication for 5 minutes; ethanol ultrasonication for 5 minutes; pure water ultrasonication for 5 minutes; drying the electrode;

[0034] 2. Put the electrode into the sputtering coater and coat with a layer of metal Ni of about 20-50nm;

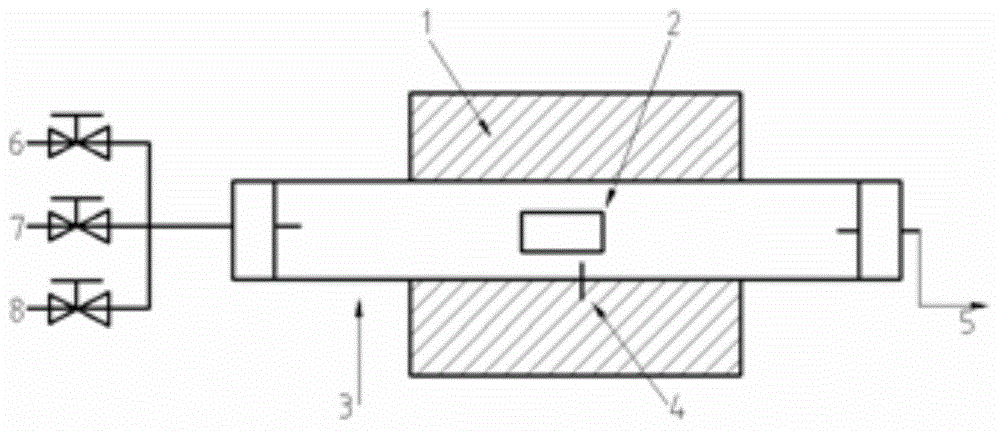

[0035] 3. Coat the coated electrode with nickel skin on the outside and place it in the quartz tube of the graphene production equipment;

[0036] Purge the quartz tube 3 times with nitrogen;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com