Patents

Literature

440results about How to "High coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of once-fired super-spar ceramic tile and ceramic tile

The invention relates to a production method of once-fired super-spar ceramic tile and the ceramic tile. The production method of the once-fired super-spar ceramic tile comprises the following steps: preparing green body powder; pressing a tile body; cleaning the green body; pouring ground glaze; printing; pouring overglaze; firing a glaze body at a high temperature; polishing; performing surface treatment; performing edge polishing; and packaging to obtain a finished product, wherein the overglaze comprises the following components in parts by weight: 5 to 13 parts of quartz powder, 3 to 20 parts of potassium feldspar, 20 to 28 parts of soda feldspar, 12 to 18 parts of dolomite, 3 to 6 parts of fired talc, 3 to 8 parts of kaolin, 14 to 22 parts of calcined kaolin, 3 to 8 parts of zinc oxide, 7 to 14 parts of barium carbonate and 3 to 6 parts of grammite. According to the invention, the problems that microlite has low wear resistance and is difficult to process in the prior art are solved, and the defect of water ripples caused by the situations that fully-polished glaze absorbs dirt, bottom is easy to expose and the tile surface is uneven is also solved. The super-spar product produced with the method has the advantages that the microlite is transparent, bright and smooth like a mirror and does not absorb dirt completely; and the fully-polished glaze is light, thin and wear-resistant.

Owner:周予

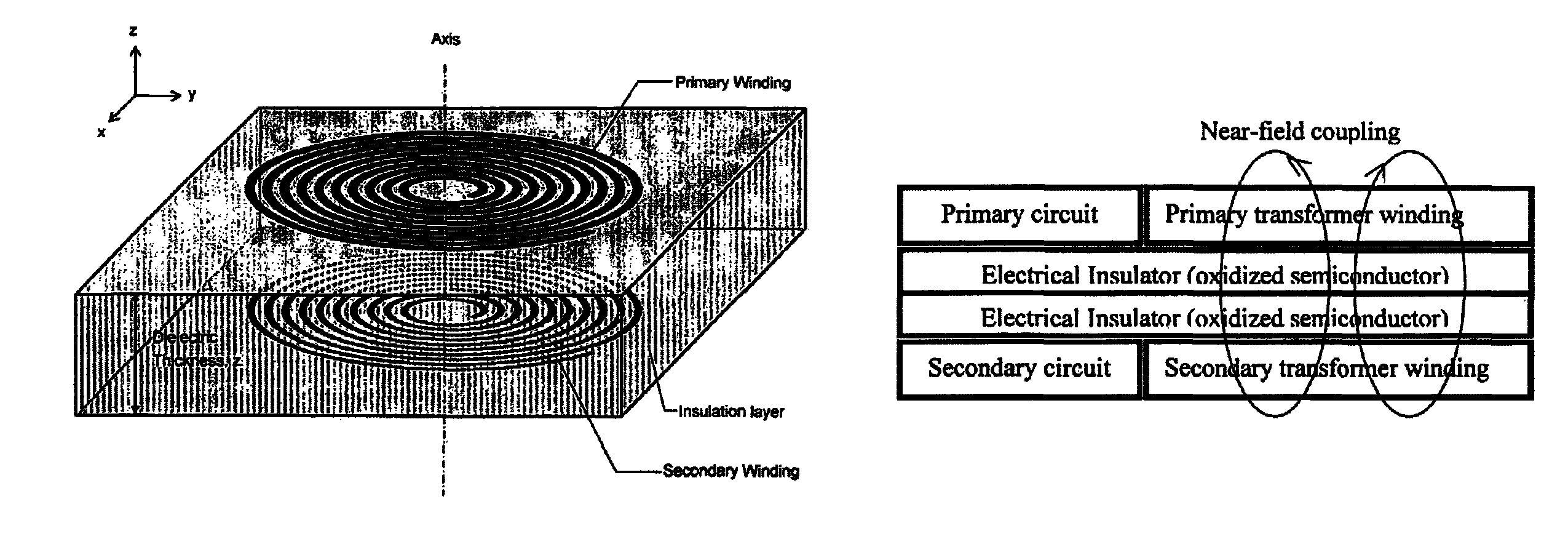

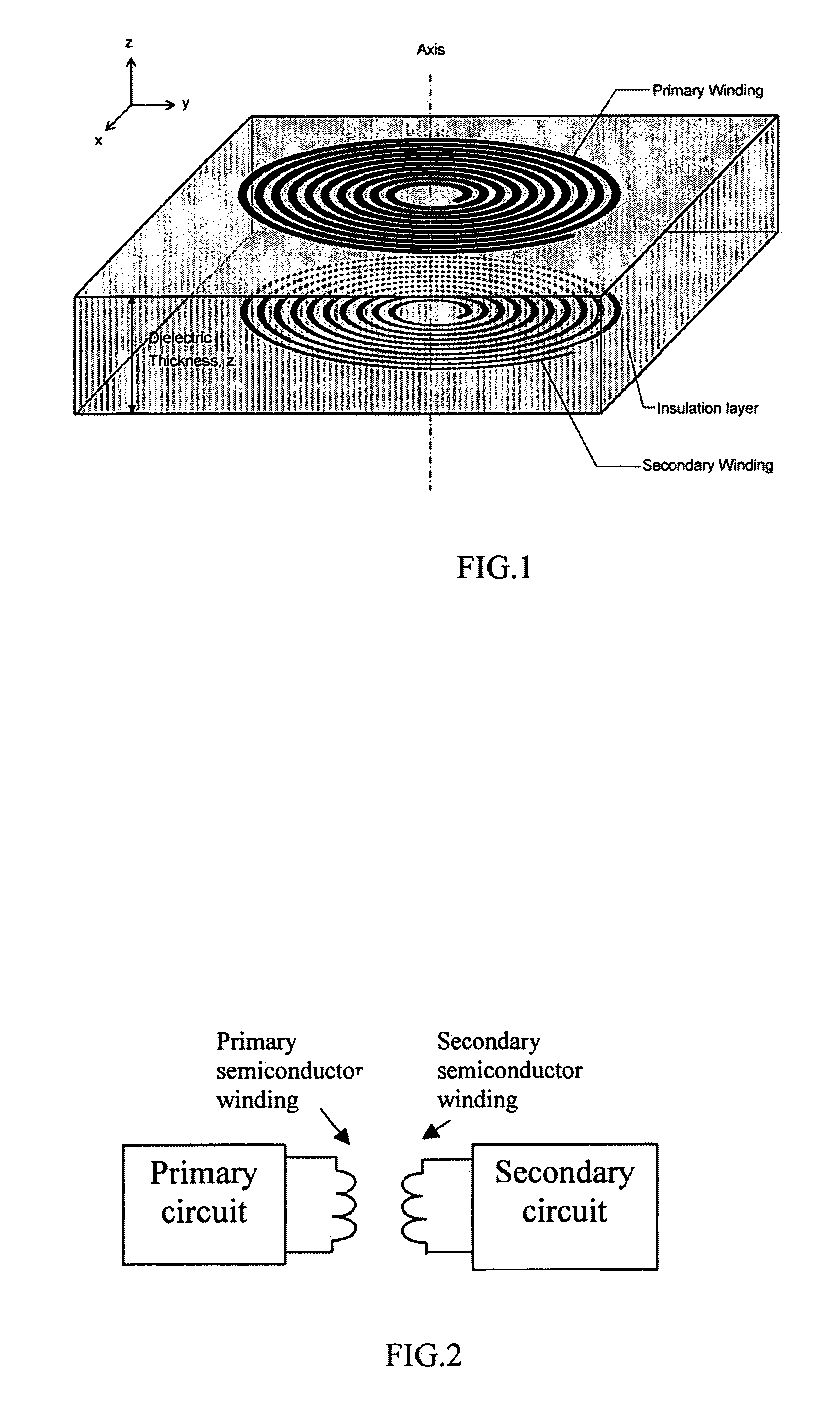

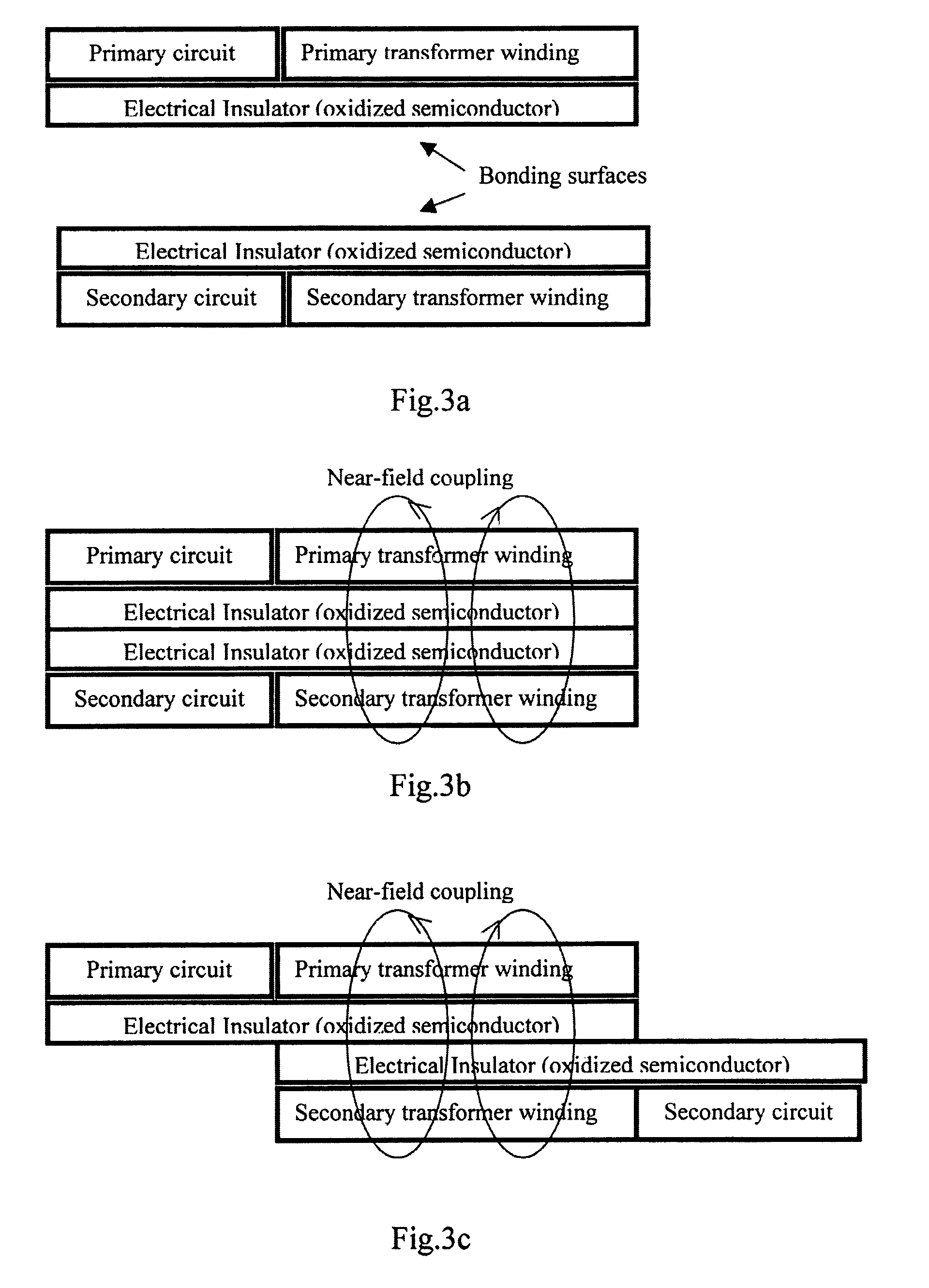

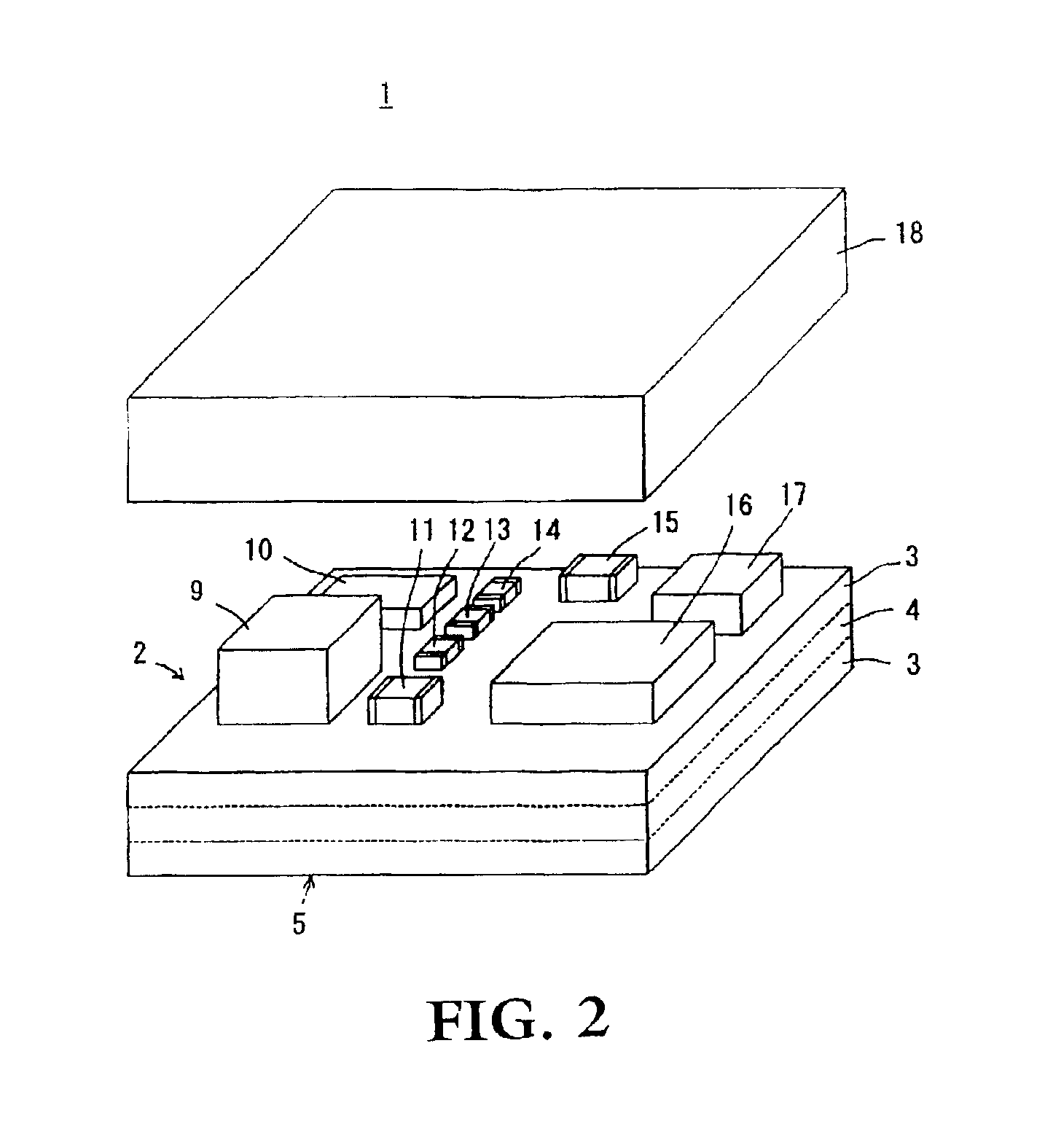

Semiconductor transformers

ActiveUS8049301B2Improve conductivityHigh coefficient of thermal expansionEmergency protective circuit arrangementsSolid-state devicesSalicideElectricity

A planar transformer structure, which can be constructed in an integrated semiconductor circuit without using traditional metallic windings. To avoid large thermal expansion of metallic spiral windings and associated mechanical stress on a metal-semiconductor interface, it is suggested that highly doped semiconductor materials with or without silicides and salicides can be used to form windings or conducting paths because their thermal expansion coefficients are similar to that of semiconductor material. The planar semiconductor transformer may find application for low-power and signal transfer that needs electrical isolation.

Owner:CITY UNIVERSITY OF HONG KONG

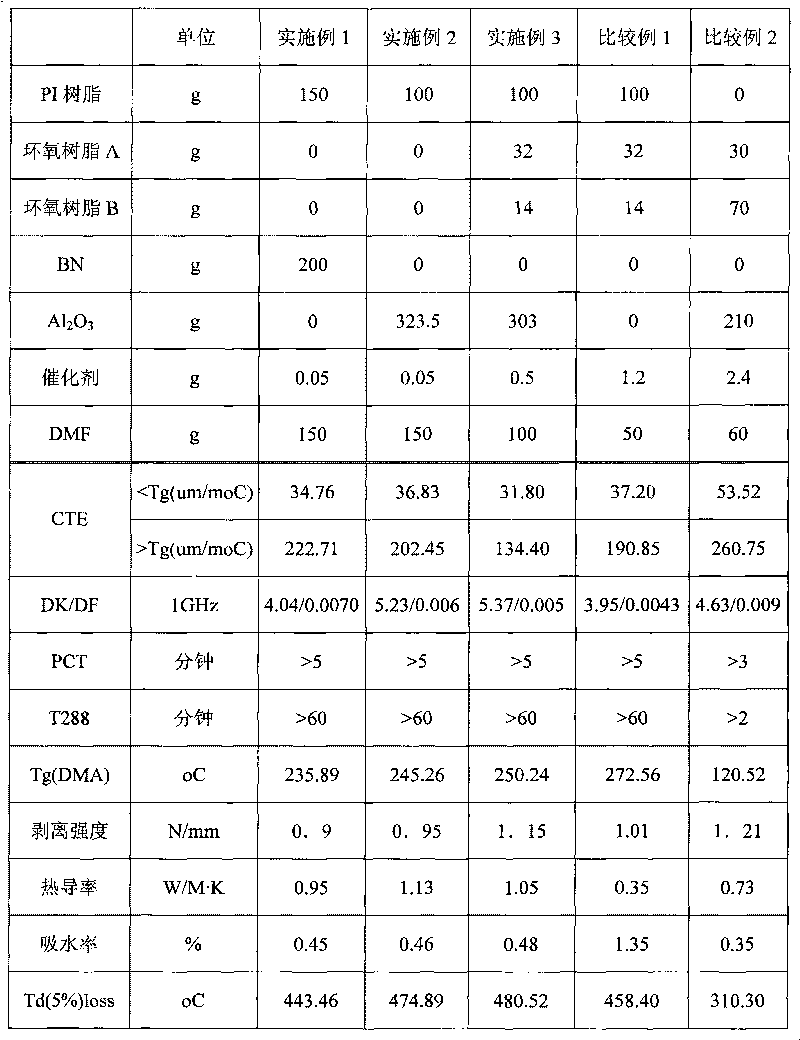

Thermosetting resin composition with high heat conductivity, prepreg manufactured by adopting same and copper-clad laminate

InactiveCN101735611AImprove thermal conductivityHigh glass transition temperatureFibre treatmentPaper coatingPolymer scienceDecomposition

The invention relates to a thermosetting resin composition with high heat conductivity, a prepreg manufactured by adopting the same and a copper-clad laminate. The thermosetting resin composition with high heat conductivity comprises the following components in parts by mass: 5 parts of allyl phenolic compound, 5-40 parts of bismaleimide compound, 0-30 parts of modified resin, 25-85 parts of filler and 1-8 parts of catalyst. The thermosetting resin composition with high heat conductivity, which is provided by the invention, has the superior properties of high heat conductivity, high glass transition temperature, low CTE, high heat decomposition temperature, favorable process deformability and the like; the prepreg is simple to manufacture and has better heat resisting effect and high heat conductivity; and the copper-clad laminate can be applied to the manufacture of a high multi-layer circuit with high-temperature resistance and has simple manufacture process and lower cost.

Owner:GUANGDONG SHENGYI SCI TECH

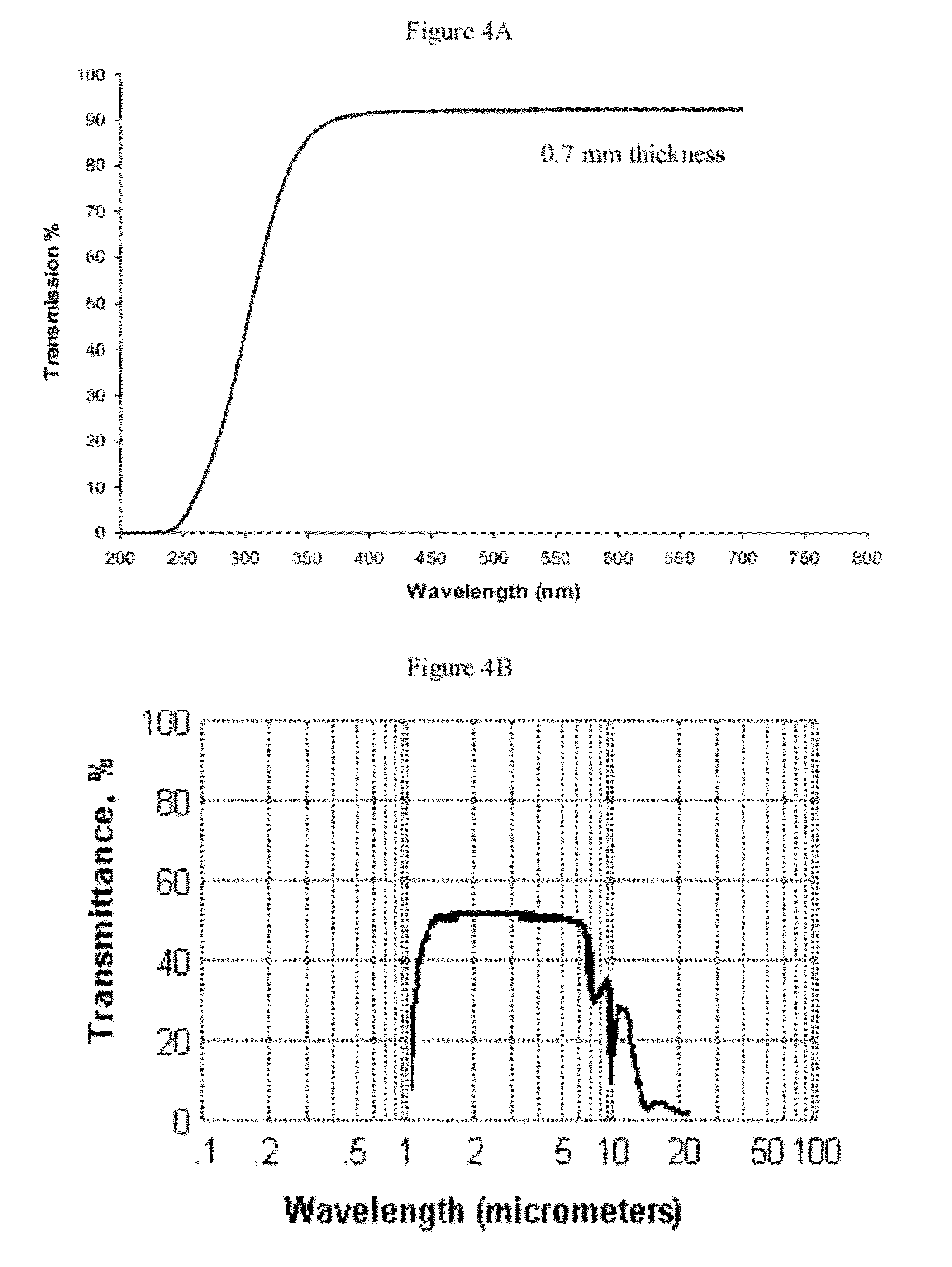

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

Coated ceramic catalyst supports and method

ActiveUS7166555B2Reduce penetrationReduce porosityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyvinyl alcoholMetallurgy

Porous ceramic catalyst supports are pre-coated with a passivation layer prior to applying a catalyst or catalyst support coating, the passivation layer consisting of a coating of a liquid mixture comprising at least one coating material selected from the group of polyvinyl alcohol / vinyl amine copolymer, polyvinyl alcohol / vinyl formamide copolymer, and gelatin.

Owner:CORNING INC

Graphene oxide modified compound type heat conducting silicone rubber and preparation method thereof

ActiveCN103937259AFlexibility does not affectImprove thermal conductivityHeat conductingCoordination complex

The invention discloses graphene oxide modified compound type heat conducting silicone rubber and a preparation method thereof. According to the preparation method, the compound type silicon resin with high heat conduction property and low expansion factor is prepared by using 0.5-1 part of graphene oxide as heat conducting stuffing and an inorganic crosslinking agent, 10-50 parts of nanometer SiO2 as the heat conducting stuffing, 5-30 parts of compound of two MQ silicone resin containing hydroxyl and vinyl and different in viscosity as a special bonding modifying agent, 1-10 parts of organic hydrogen polysiloxane as an organic crosslinking agent, 0.1-2 parts of platinum complex as a catalyst, 0.01-0.001 part of alkynol substance as an inhibitor and 60-100 parts of polysiloxane resin as base rubber and adopting a nanometer compounding method, wherein the graphene oxide is partially modified by a silane coupling agent, and the nanometer SiO2 is prepared by a sol-gel method. The compound type silicon resin can be widely applied to encapsulation of various electronic components and plays a role in shock absorption and heat dissipation.

Owner:东莞九天量子科技有限公司

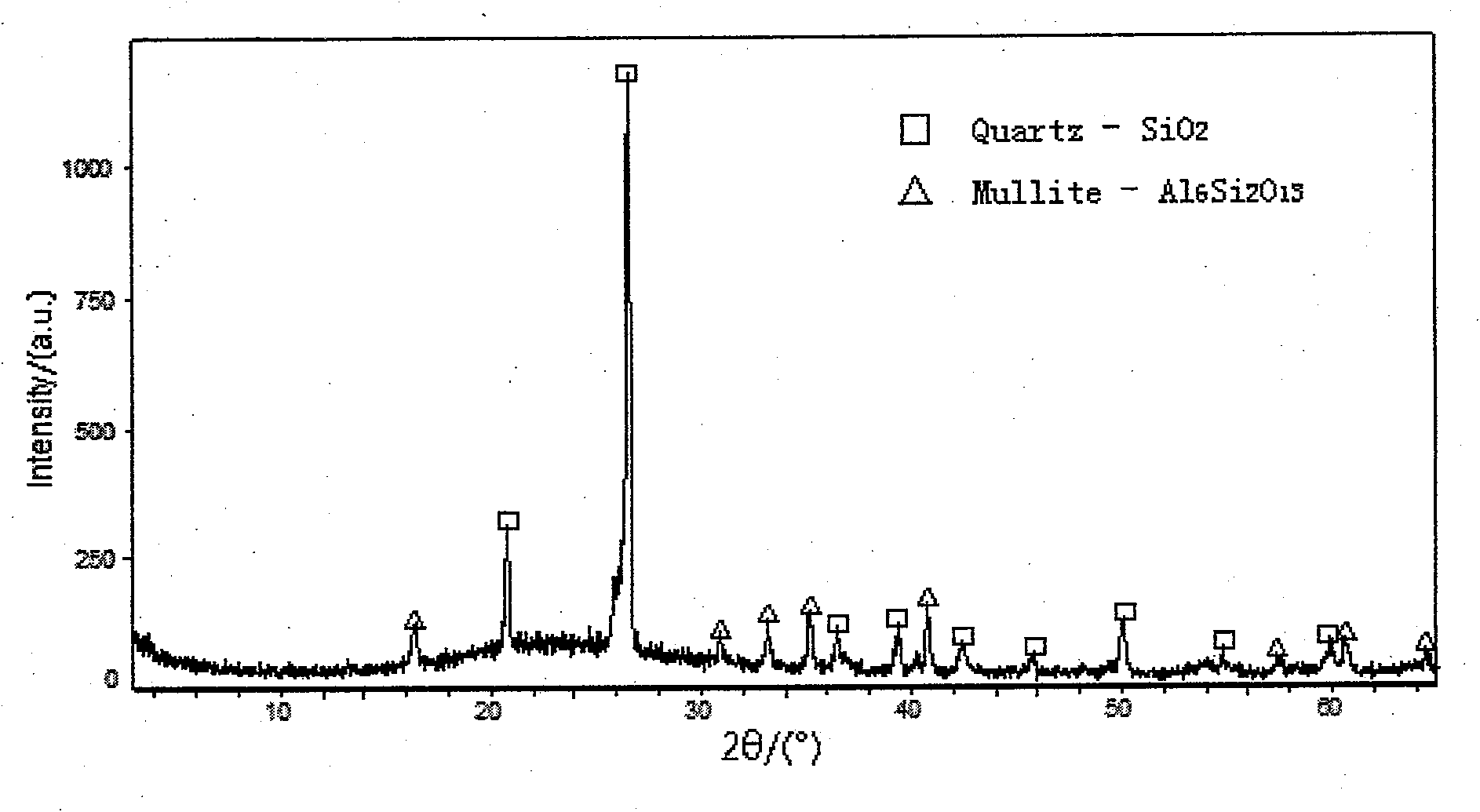

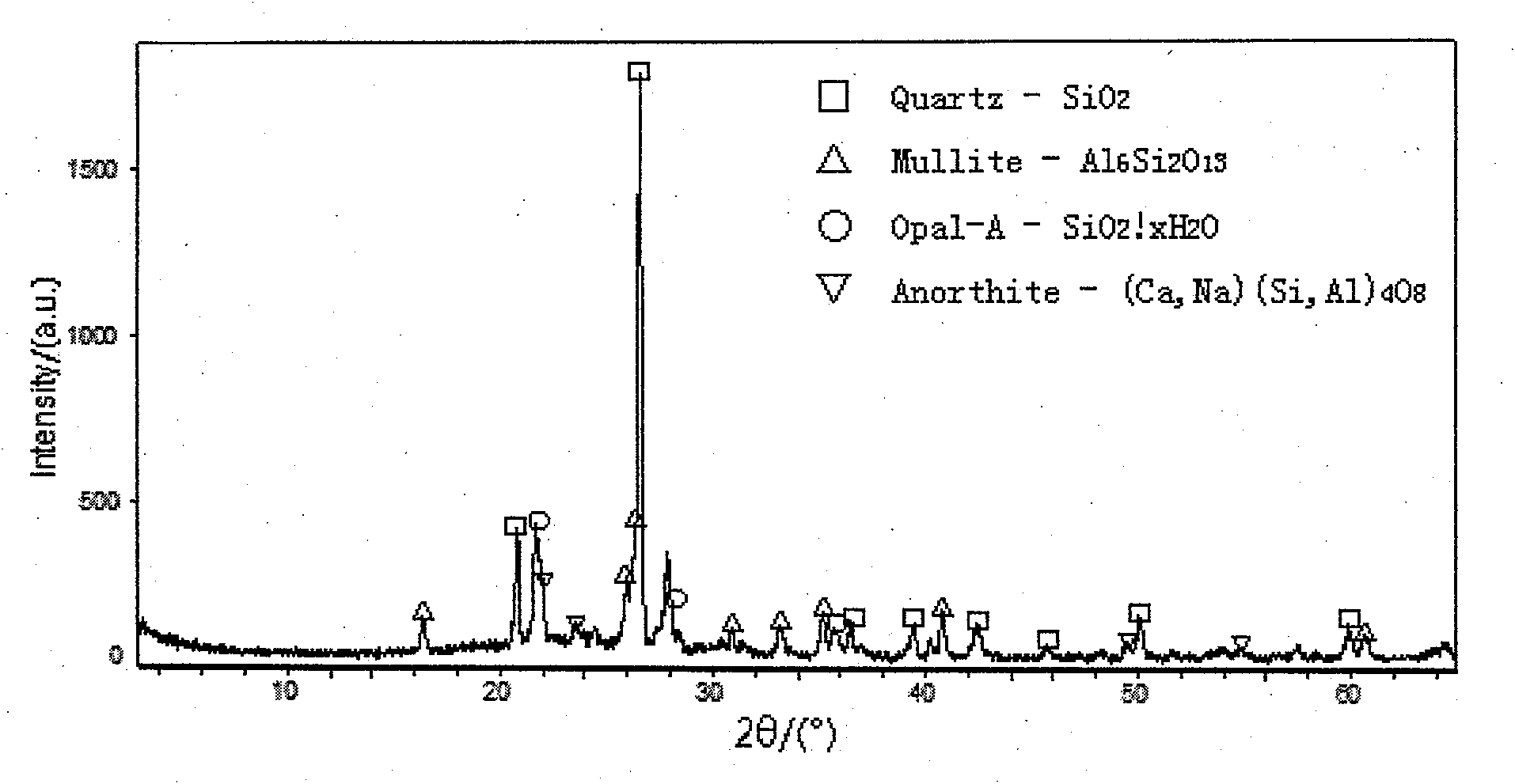

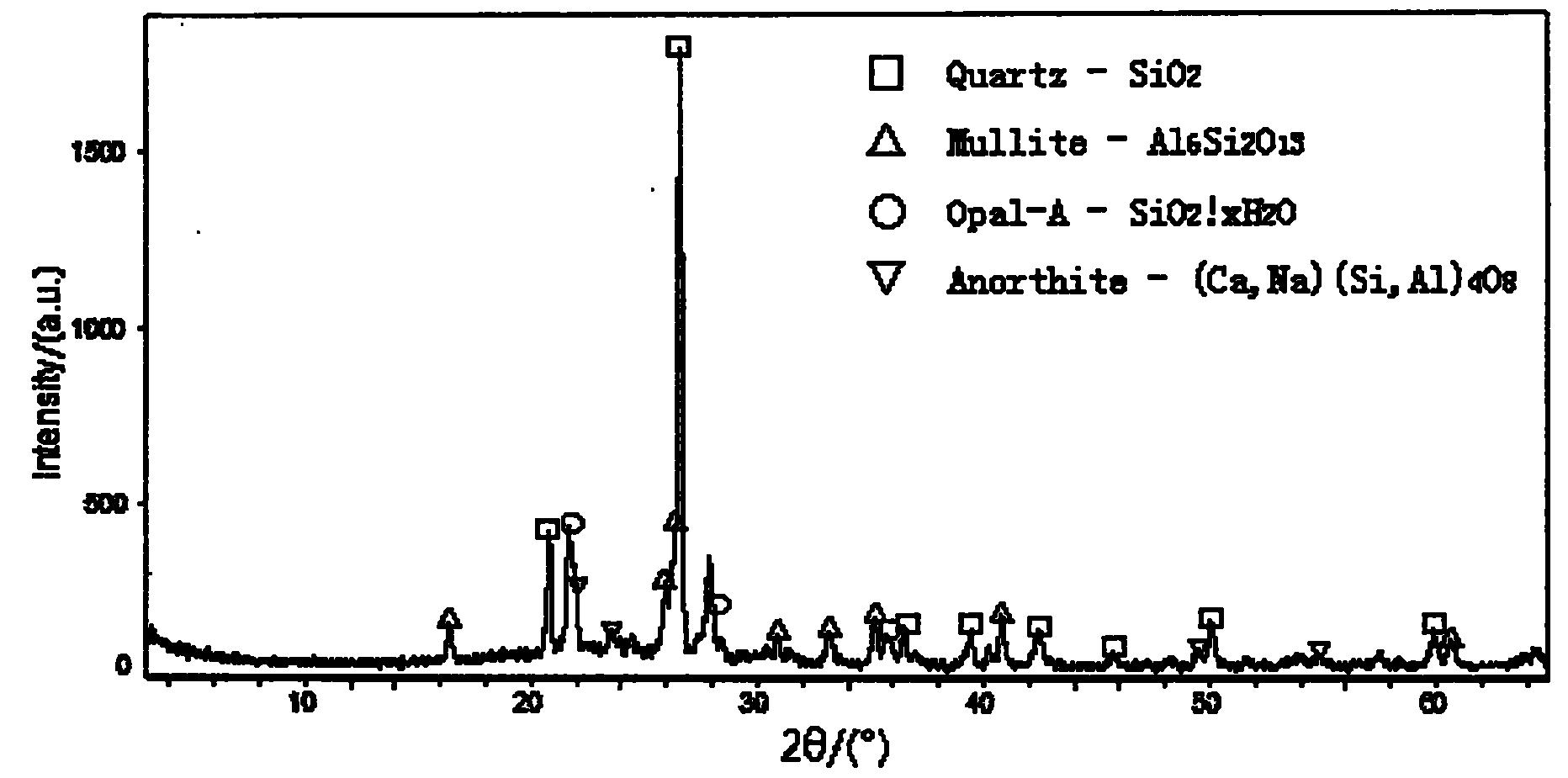

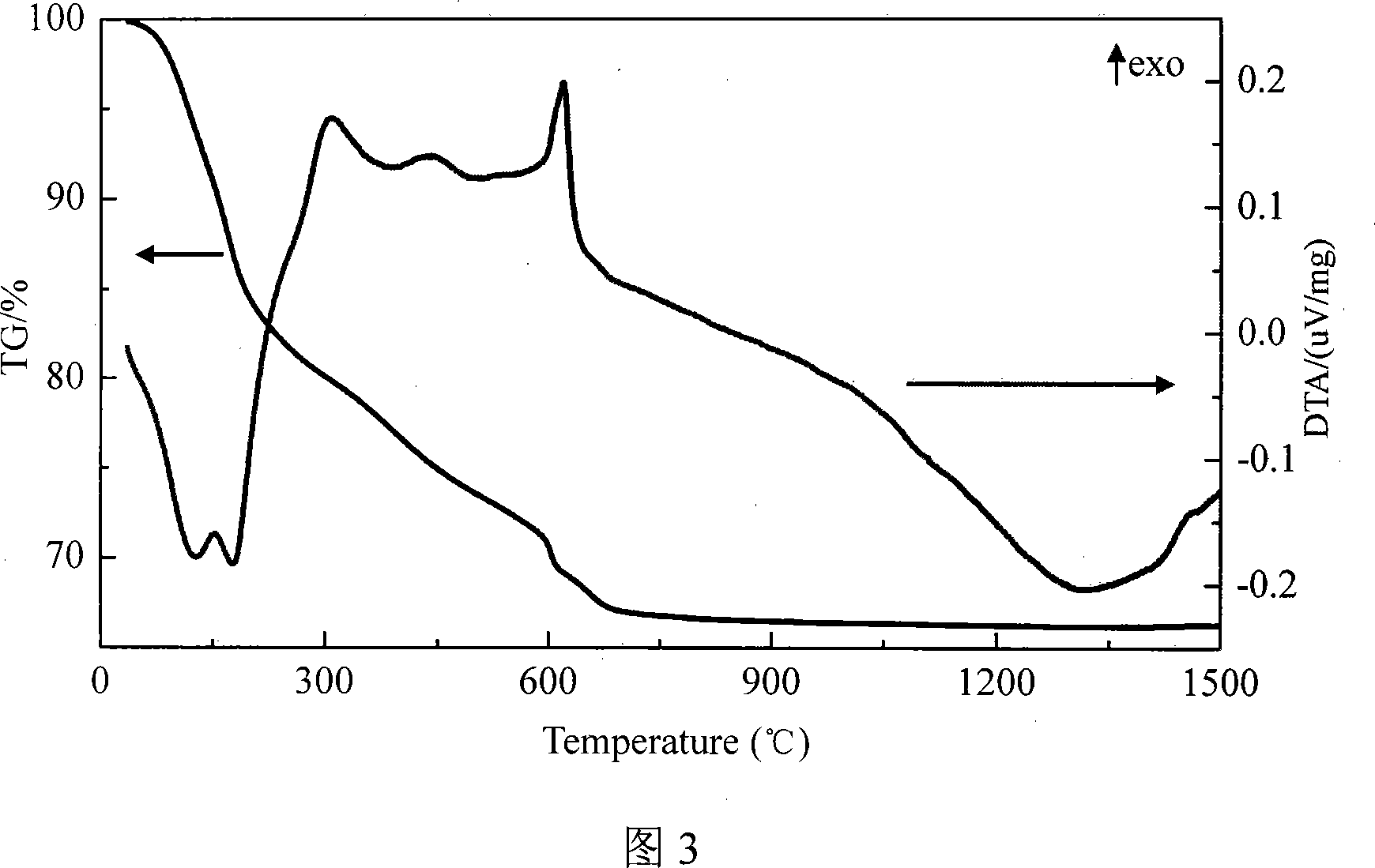

Fine-pottery sanitary ceramic body and manufacturing method thereof

ActiveCN101811858AReduce hygroscopic swellingHigh coefficient of thermal expansionClaywaresGranularityMullite

The invention relates to a fine-pottery sanitary ceramic body and a manufacturing method thereof and belongs to the technical field of ceramic products, which is used for reducing the deformation of a sanitary ceramic product and improving the quality of glaze. The fine-pottery sanitary ceramic body is characterized in that a body raw material comprises the following components in part by mass: 10 to 30 parts of ball clay, 30 to 60 parts of kaoline, 5 to 15 parts of porcelain clay, 5 to 15 parts of quartz and 5 to 15 parts of wollastonite, wherein the kaoline comprises 10 to 25 calcined kaoline. In the manufacturing method, the raw materials and the adding proportion of the fine-pottery body are preferably selected, the crystal phase content of mullite, quartz and the like is controlled, and the glass phase content and the high-temperature plastic deformation are reduced so as to fulfill the aim of reducing the deformation of fine-pottery sanitary ceramics; while reducing the hygroscopic expansion of the body, the manufacturing method improve thermal expansion coefficient of the body at the temperature of 200 DEG C to make the glaze bear high compressive stress, thereby improving the anti-cracking performance of products and ensuring enough long service life. Through the refinement of slurry granularity, the method remarkably reduces the occurrence of disadvantage of glaze pinholes, does not need to reduce the pinholes by using engobe, simplifies a production process, and improves the production efficiency and the qualification rate of the products.

Owner:HUIDA SANITARY WARE

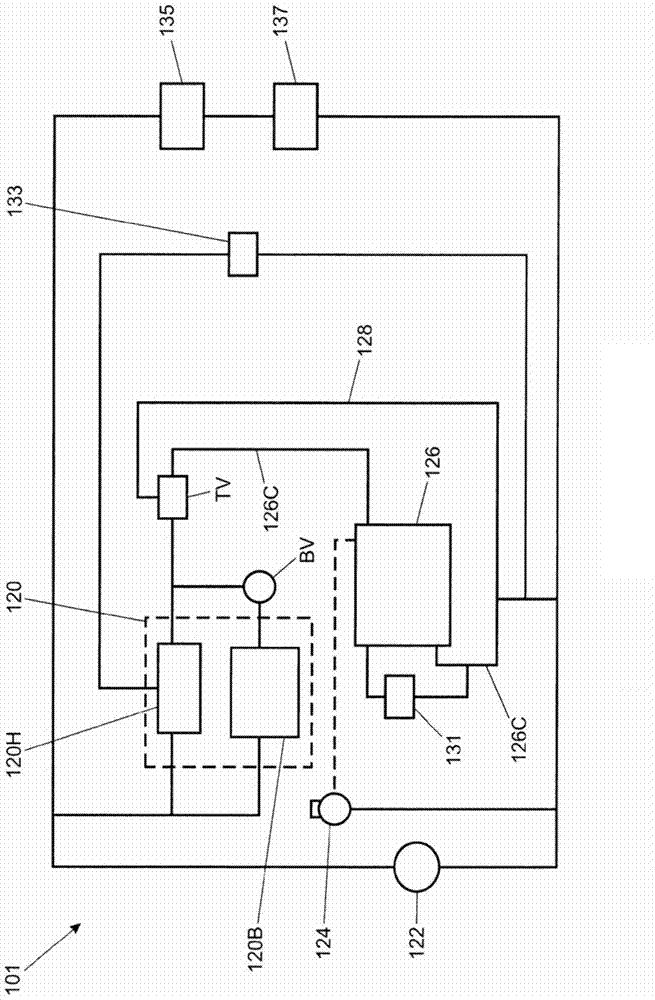

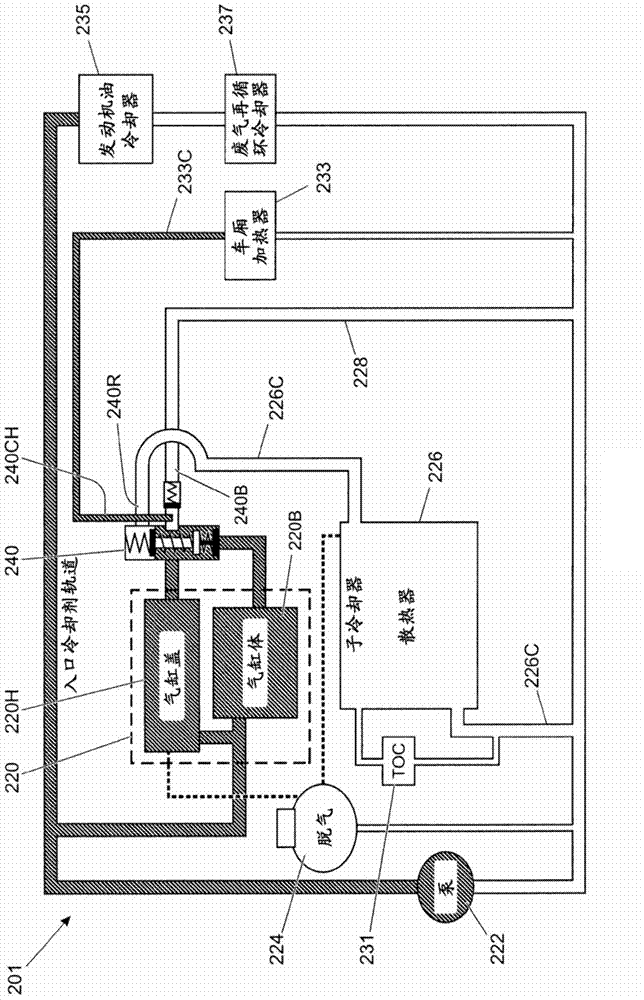

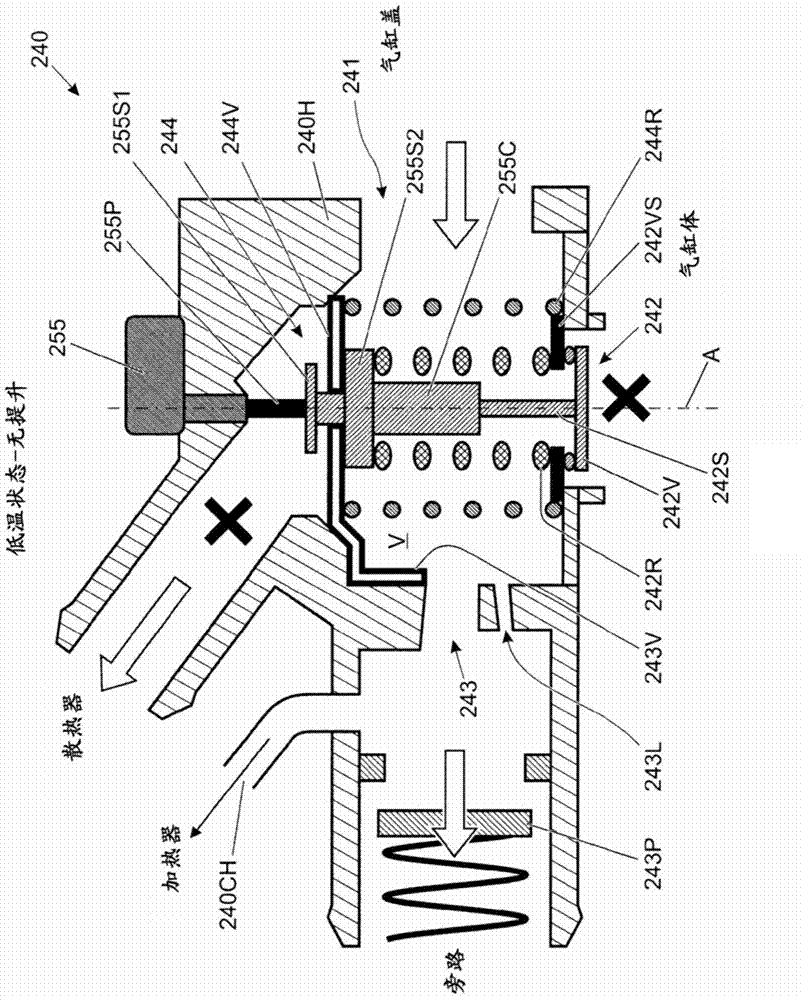

Motor vehicle engine cooling system and method

InactiveCN104508274ATemperature determinationGood thermal controlLiquid coolingCoolant flow controlHigh rateCylinder block

The device has a valve including a closure member 344V that opens and closes in response to a temperature of coolant flowing through the device. When moving from a closed position to an open position, the member moves in a direction downstream of the direction of coolant flow through the device. A vehicle engine cooling system comprising the device is also claimed. When claimed as part of the vehicle engine cooling system, the device additionally comprises a first inlet 341 connected to a cylinder head of the engine, a second inlet 342 connected to a cylinder block of the engine, a first outlet 343 connected to a radiator bypass conduit and a second outlet 344 connected to a radiator, whereby the valve is associated with the second outlet. The closure member may automatically open when a pressure differential across the valve exceeds a predetermined value. The system may include a variable speed coolant pump controlled based upon at least one vehicle operating parameter, such as the temperature of coolant, engine / transmission oil, or engine speed, that pumps coolant in the system at two different non-zero rates, the higher rate causing opening of the valve. A method is also claimed.

Owner:JAGUAR LAND ROVER LTD

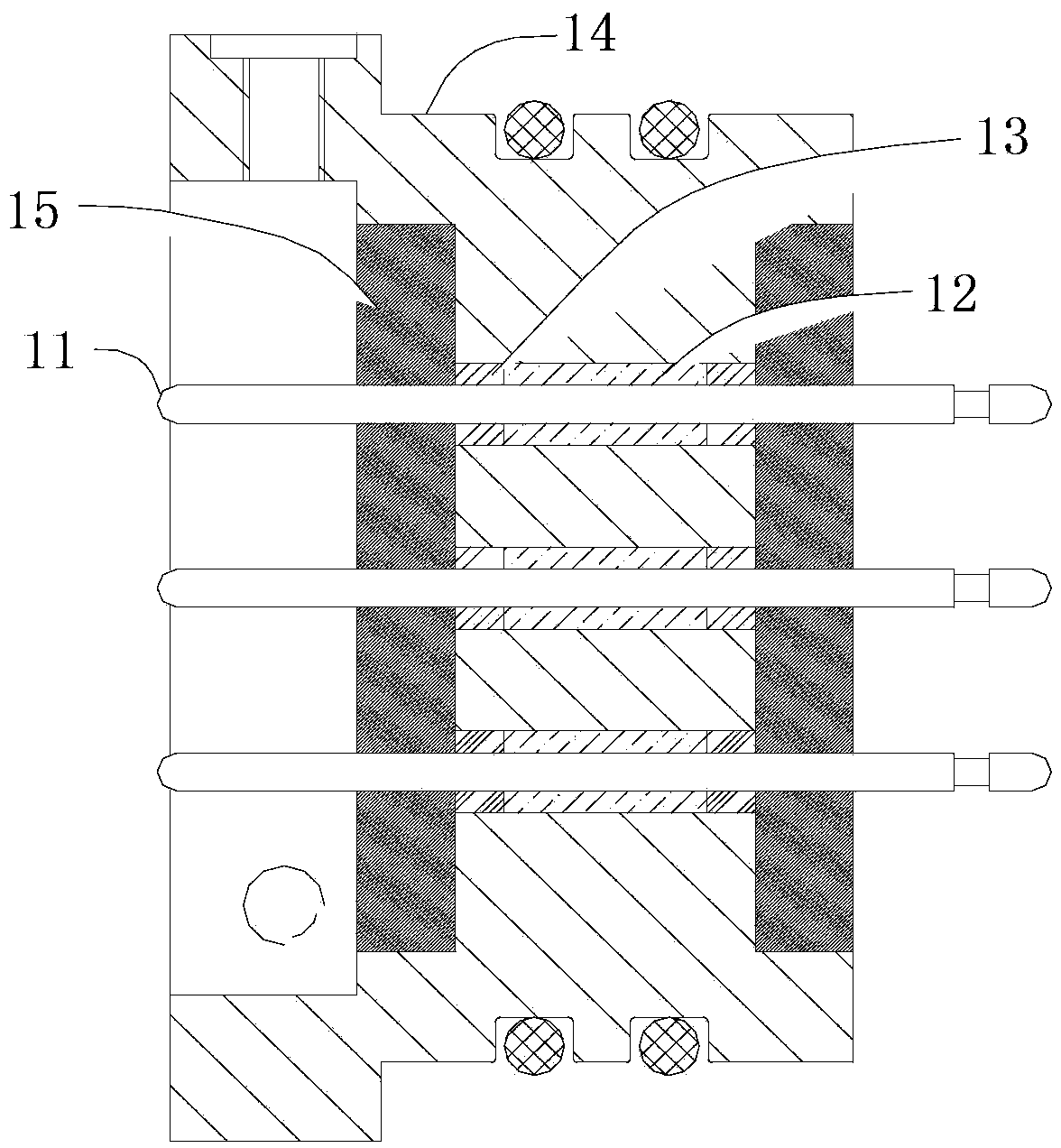

Glass sintered high temperature and high pressure sealing electric connector

ActiveCN103474831AHigh temperature resistanceProne to compressive stressSecuring/insulating coupling contact membersCoupling contact membersElectrical conductorUltra high pressure

A glass sintered high temperature and high pressure sealing electric connector comprises conductor pins (11) used for transmitting currents, wherein a glass insulator (12) and a ceramic insulator (13) wrap each conductor pin (11), a metal outer shell (14) is arranged on the peripheries of the glass insulators (12) and on the peripheries of the ceramic insulators (13), the conductor pins (11), the glass insulators (12), the ceramic insulators (13) and the metal outer shell (14) are combined into a whole through the glass sintering process. The conductor pins (11) are made of expansion alloy, the glass insulators (12) are made of electronic seal glass, and the metal outer shell (14) is made of nickel-based superalloy. According to the electric sealing connector, pressure can be more easily produced between glass and a substrate, the micro combination degree of sealing between glass and metal is improved, and accordingly the probability that air leakage occurs in the sintering process or in the use process is greatly lowered.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

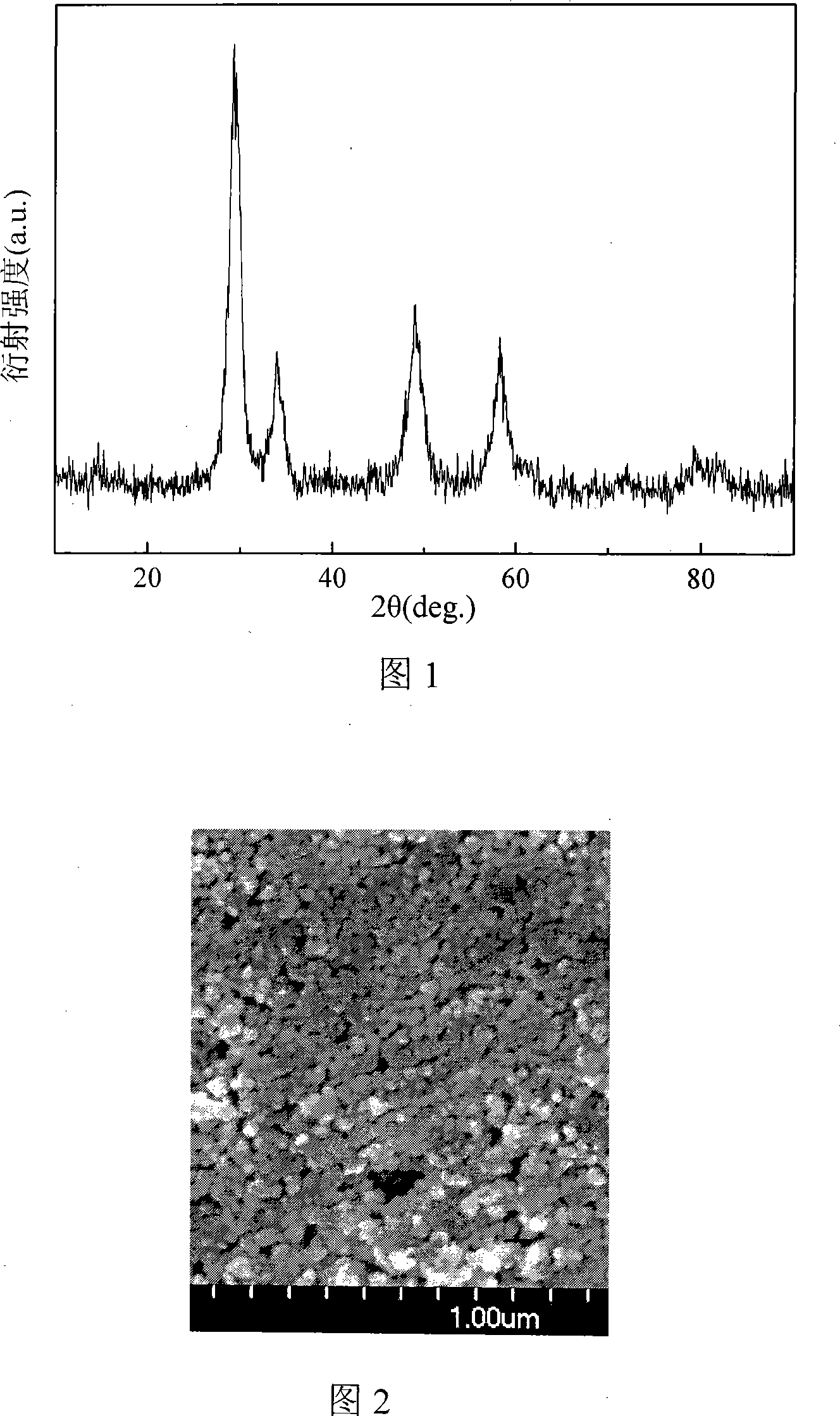

Nano rare earth zirconate ceramic powder material for high temperature heat barrier coat and preparation method thereof

InactiveCN101104557ASmall particle diameterHigh coefficient of thermal expansionRare-earth elementZirconate

Disclosed are a nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings, and the preparation method, relating to a nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings, and the preparation method. The invention solves the problems that the existing ceramic materials for high-temperature thermal barrier coatings are of phase change failure, serious sintering, and too high thermal conductivity and mismatch with the matrix thermal expansion. The chemical formula of the nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings is Ln2Zr2O7, wherein, Ln is the combination of one or more rare earth elements among Gd, Sm, Nd or Yb. The preparation method is that rare earth oxide or soluble salt and zirconium salt containing rare earth oxides are used to respectively prepare the solution containing Ln3 + and the solution containing Zr4 +; the two solutions are mixed and added with surfactant under the ongoing mixing conditions; the mixed solution is dropped into precipitator to get sediment; after repeated washing, the sediment is dried, grinded and calcined. The invention can effectively protect high temperature alloy.

Owner:HARBIN INST OF TECH

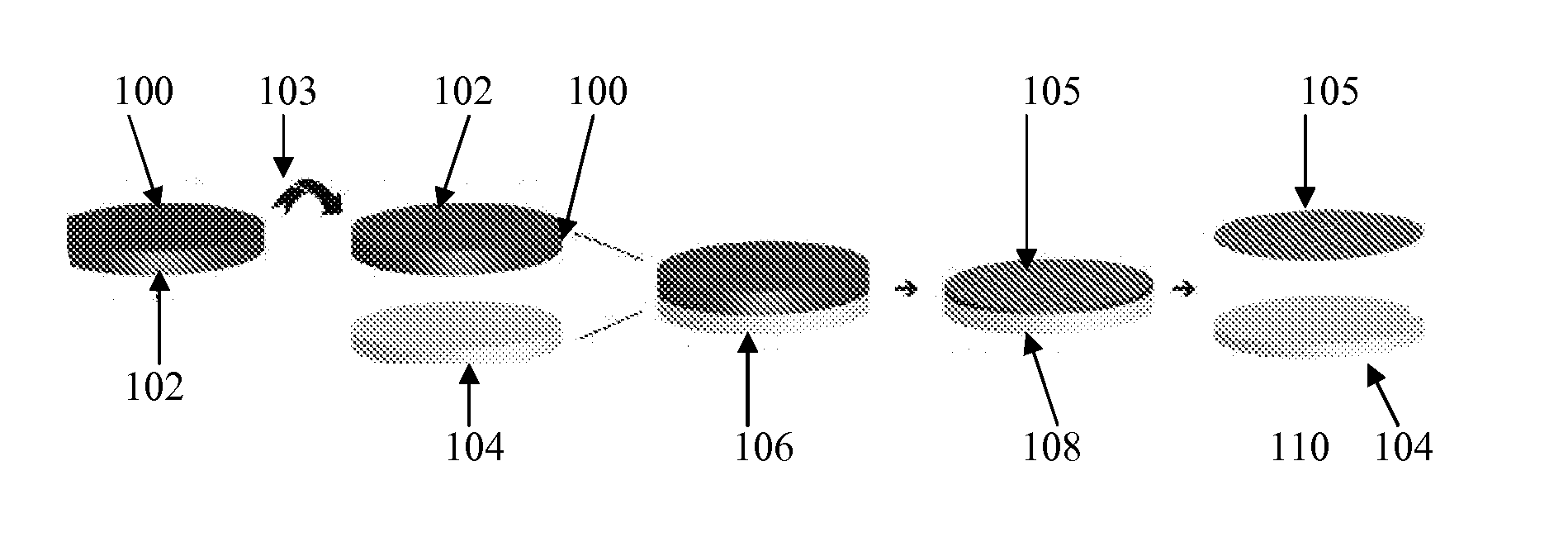

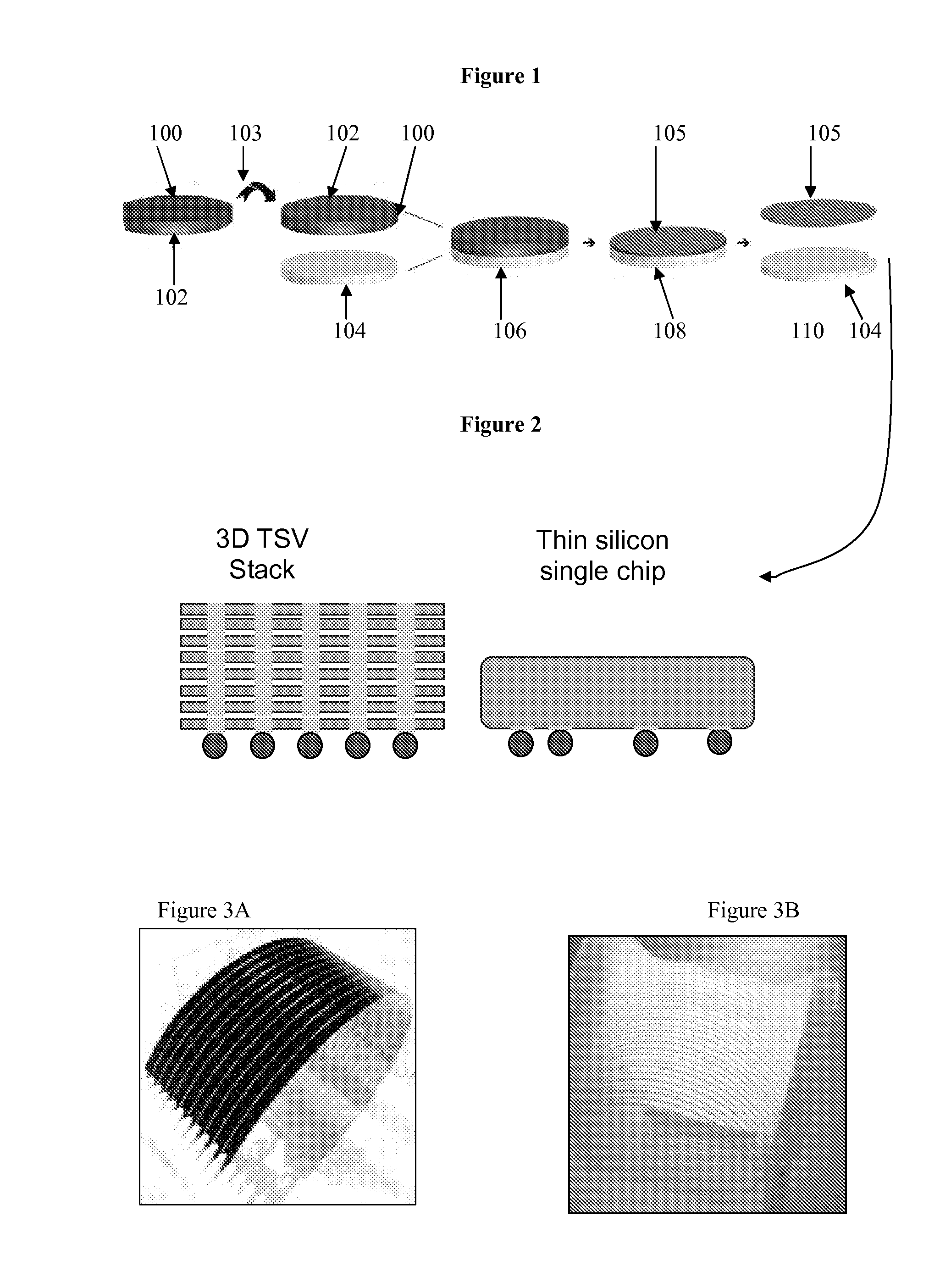

Glass Wafers for Semiconductor Fabrication Processes and Methods of Making Same

ActiveUS20120276689A1High coefficient of thermal expansionFunction increaseSemiconductor/solid-state device detailsSolid-state devicesInterposerThermal expansion

The present disclosure is directed to the use of glass wafers as carriers, interposers, or in other selected applications in which electronic circuitry or operative elements, such as transistors, are formed in the creation of electronic devices. The glass wafers generally include a glass having a coefficient of thermal expansion equal to or substantially equal to a coefficient of thermal expansion of semiconductor silicon, an indexing feature, and a coating on at least a portion of one face of the glass.

Owner:CORNING INC

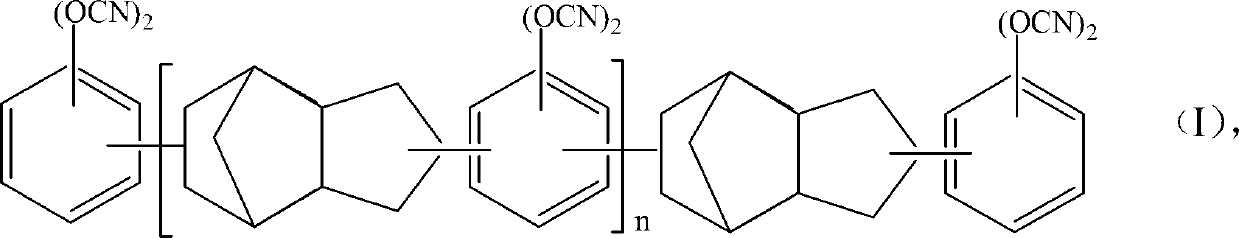

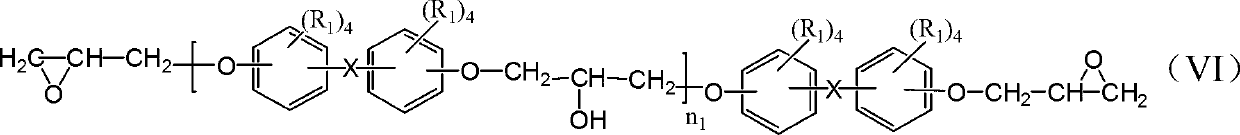

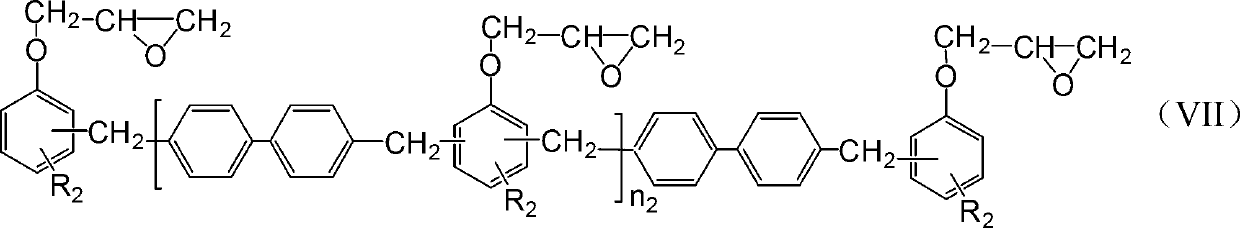

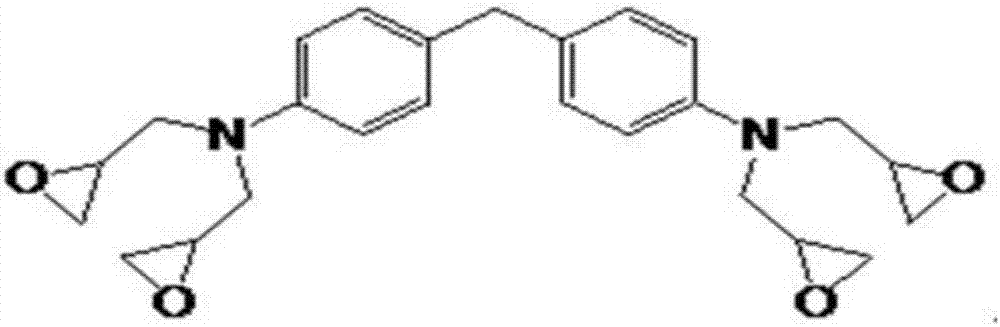

Thermosetting cyanate resin composition and application of thermosetting cyanate resin composition

ActiveCN102942684AOvercome the disadvantage of high water absorptionImprove heat resistanceSynthetic resin layered productsEpoxyCopper coating

The invention relates to a thermosetting cyanate resin composition, which comprises the following components: polyfunctional cyanate, epoxy resin, flame retardant agent and inorganic filler. The thermosetting cyanate resin composition is used for preparing resin substrates, resin compound metal copper foils, prepregs, laminating plates, copper-coating plate laminating plates, printed circuit boards and the like. The thermosetting cyanate resin composition has good heat resistant property, humidity resistant property and flame retardant property and low heat expansion coefficient.

Owner:GUANGDONG SHENGYI SCI TECH

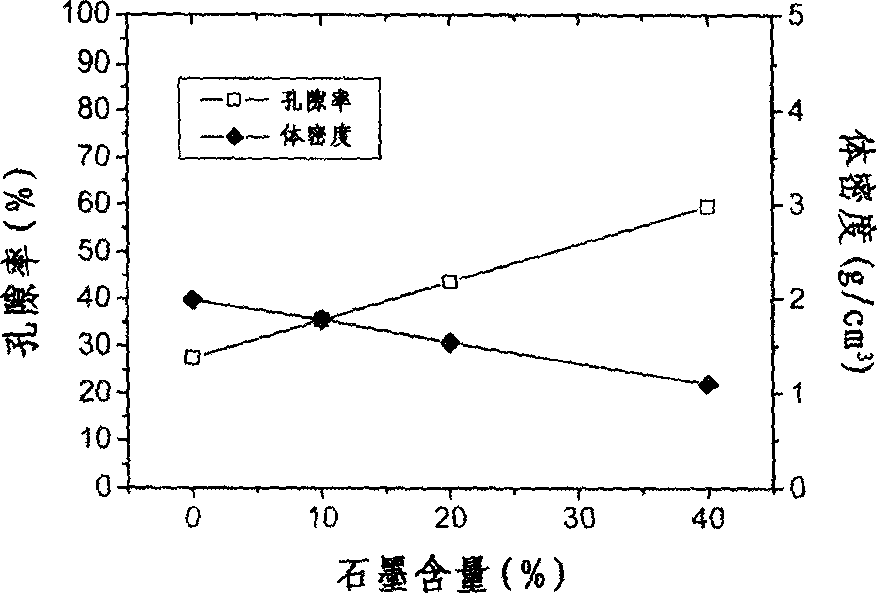

Silicon carbide-cordierite composite porous ceramic and its preparation method

InactiveCN1800097AImprove purification effectLower firing temperatureFiltration separationCeramicwareCordieriteThermal expansion

The invention provides a composite porous ceramic of silicon carbide-cordierite, its preparing method and application; during the production of said composite porous ceramic, we take silicon carbide particles as the first phase, and cordierite as the second phase. The cordierite phase is made by clay, talcum and aluminum oxide, etc, through burning at the temperature of about 1400 Deg C; during the formation of cordierite phase, silicon carbide particles are connected together through cordierite phase and form porous ceramic with certain strength; in order to enhance the factor of porosity of said porous ceramic, we need to add some black lead particles as pore-creating agent; the porous ceramic produced in this way is made up of 10-90wt% cordierite and 90-10wt% silicon carbide, whose factor of porosity is 24~65%, pore size distribution is double quotidian mode, and bending strength is 4~55MPa, coefficient of thermal expansion is 1.71~6.26*10-6K-1 (20~800 Deg C), thermal-shock resista nce at the temperature of 1000 Deg C could reach more than 5 times; The porous ceramic provided in said invention could be used to produce wall-flowing mode honeycomb ceramic and enhance the purification capacity to end gas and waste gas.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

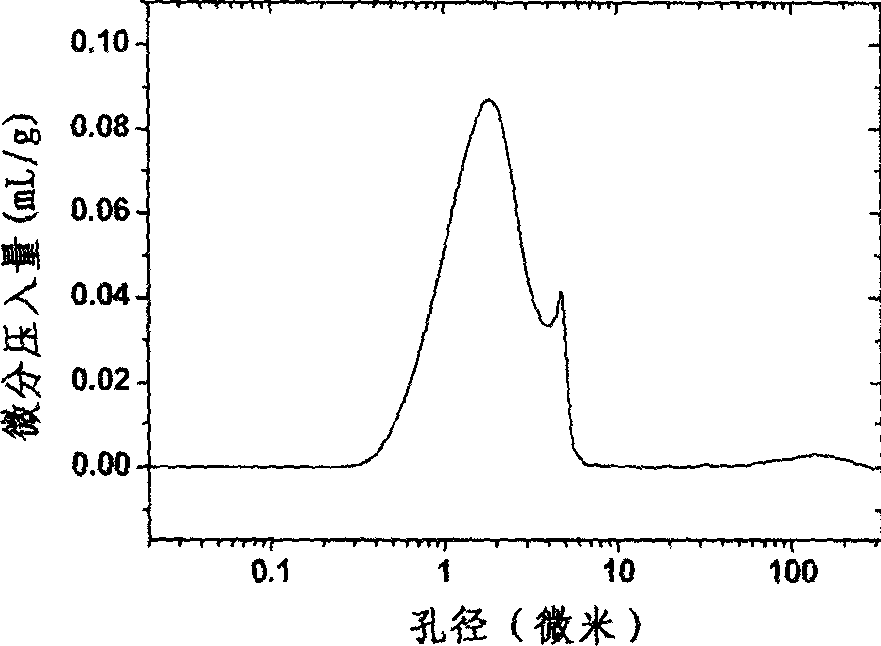

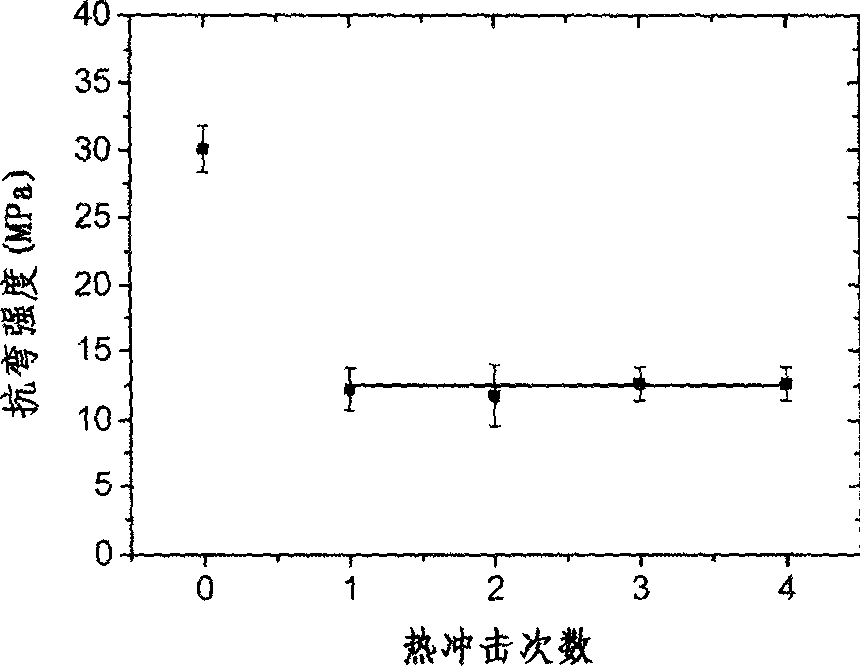

ActiveCN102295474AMitigate Thermal MismatchHigh coefficient of thermal expansionSurface layerHigh density

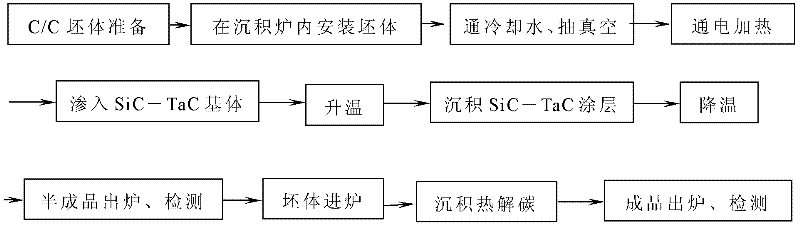

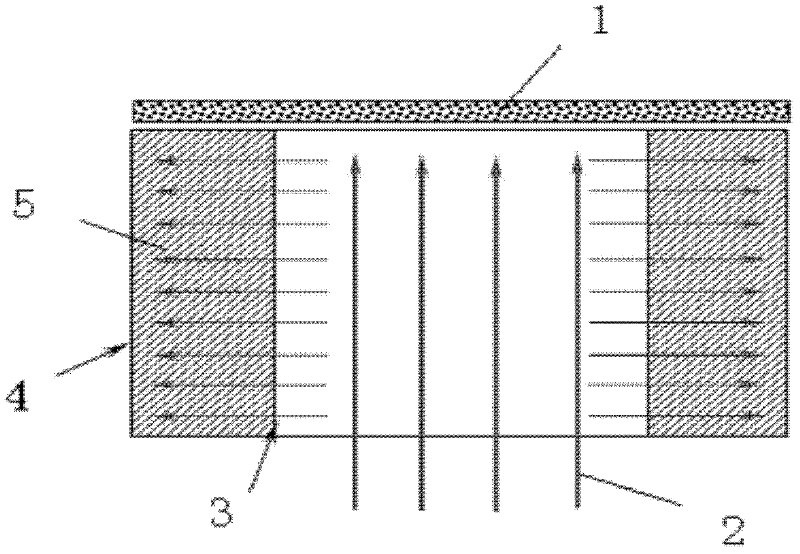

The invention discloses a SiC-TaC coating / matrix collaborative modified C / C composite material and its preparation method. The composite material provided by the invention comprises two parts. The portion below the surface of the C / C composite material is the matrix modified portion with the thickness being 0.1-10mm. In addition, carbide in the C / C composite material emerges in gradient distribution. The portion which is deposited on the surface of a carbon material is a coating portion with the thickness being 10-300 microns. The preparation method of the composite material comprises the following steps of: cutting a C / C green body at the density of 0.80g / cm<3>-1.60g / cm<3> into an annular shape or a plate shape, followed by ultrasonic cleaning and drying, placing into a multifunctional CVD furnace, depositing carbide on the surface layer and surface of the C / C green body by controlling deposition parameters, further densifying the green body by the use of pyrolytic carbon so as to obtain the high-density coating / matrix collaborative modified C / C composite material. The main advantages of the invention are as follows: by the penetration of carbide through the surface layer of the C / C composite material, the thermal expansion coefficient of the matrix is raised, the interfacial bonding state is improved, a continuous transition of carbide is formed between the coating and the matrix, and the metallurgical bonding is accomplished between the coating and the matrix.

Owner:CENT SOUTH UNIV

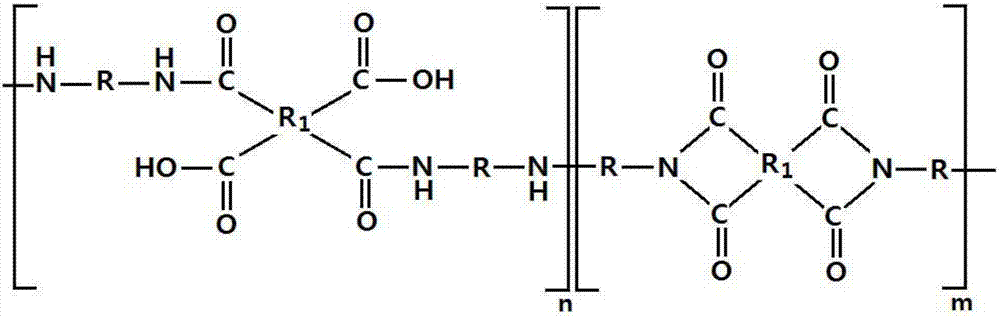

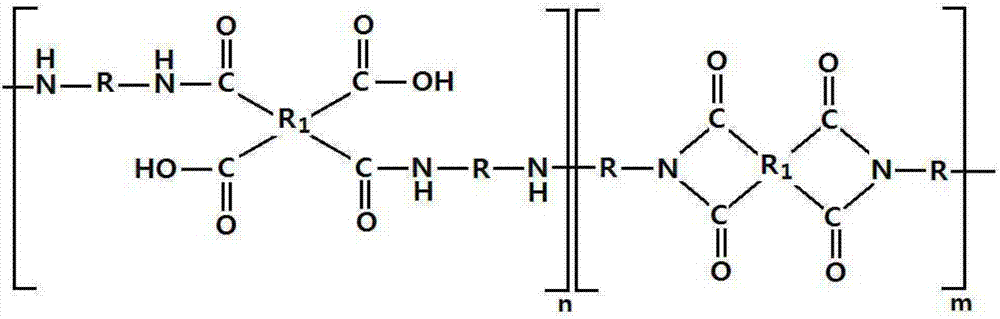

Polyimide polymer composition, method for producing the same, and polyimide film

ActiveCN106928707AHigh coefficient of thermal expansionImprove transmittanceThermal expansionPolyamic acid

Provided are a polyimide polymer composition, a method for producing the same, and a polyimide film using the same. The polyimide polymer composition comprises a dimethyl propionamide and a polyamic acid-polyimide copolymer of Chemical Formula 1, thereby providing a thermal expansion coefficient (CTE) as compared with a conventional polar solvent and the like.(wherein R1 is a fluorine group or an aromatic anhydride monomer, R is a diamine monomer Body, n is a constant from 1 to 1,000, and m is a constant from 1 to 1,000.

Owner:DONGJIN SEMICHEM CO LTD

Welding deformation control aid of large-size stainless steel cylinder and welding deformation control method

ActiveCN101797671AAvoid mechanical propertiesAvoid thermal shaping processWelding/cutting auxillary devicesAuxillary welding devicesDirect observationFree state

The invention relates to a welding deformation control aid of a large-size stainless steel cylinder, comprising an inner arc flat panel, an outer arc flat panel and jack screws, wherein the inner arc flat panel and the outer arc flat panel are flat panels one side of which is an arc side, and the arc radiuses of the arc sides are the same as that of the cylinder; the jack screws are fixedly connected to both sides of points of the plat panels opposite to a longitudinal welding line of the cylinder; and the top ends of the jack screws face towards the arc sides of the plat panels. When in use, the assembly datum lines of the inner circumference and the outer circumference of the cylinder are drawn out on a welding platform, and the arc segment of the cylinder is hung on the platform and takes the places according to the datum lines; the lengths and the angles of a non-line length segment at both sides of the longitudinal line under a free state are measured, and the aid is selected according to the non-line lengths and the angles; the aid is spot welded on the cylinder, and the longitudinal line of the cylinder is alternately welded; and the welding order and the jack screws on the aid are adjusted according to the deformation condition of the longitudinal line. The invention has the advantages that the working procedures of mechanical shape correction and the hot shape correction after welding of the cylinder are avoided; the deformation in a welding process can be directly observed and regulated by taking technical measures; and the aid has simple structure and use method.

Owner:CHINA FIRST HEAVY IND +1

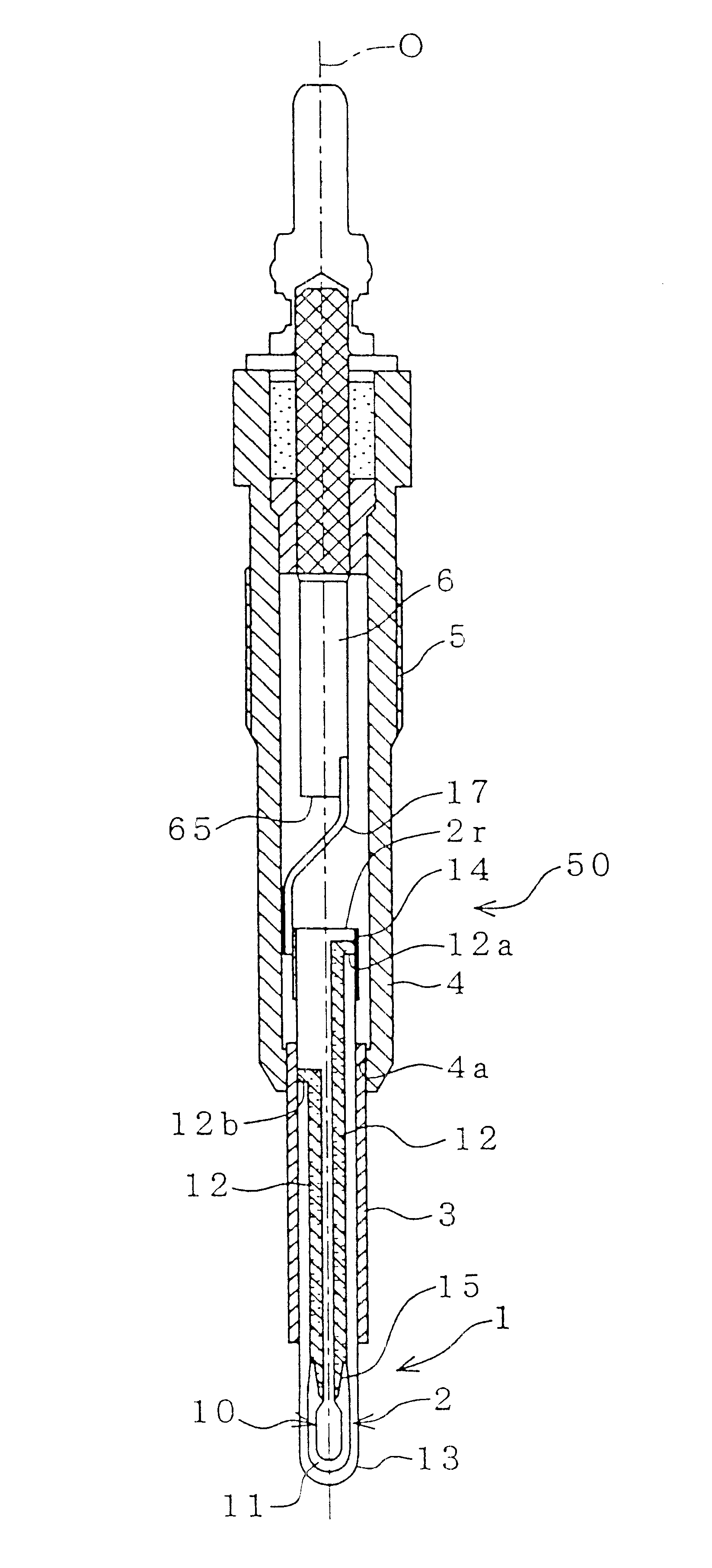

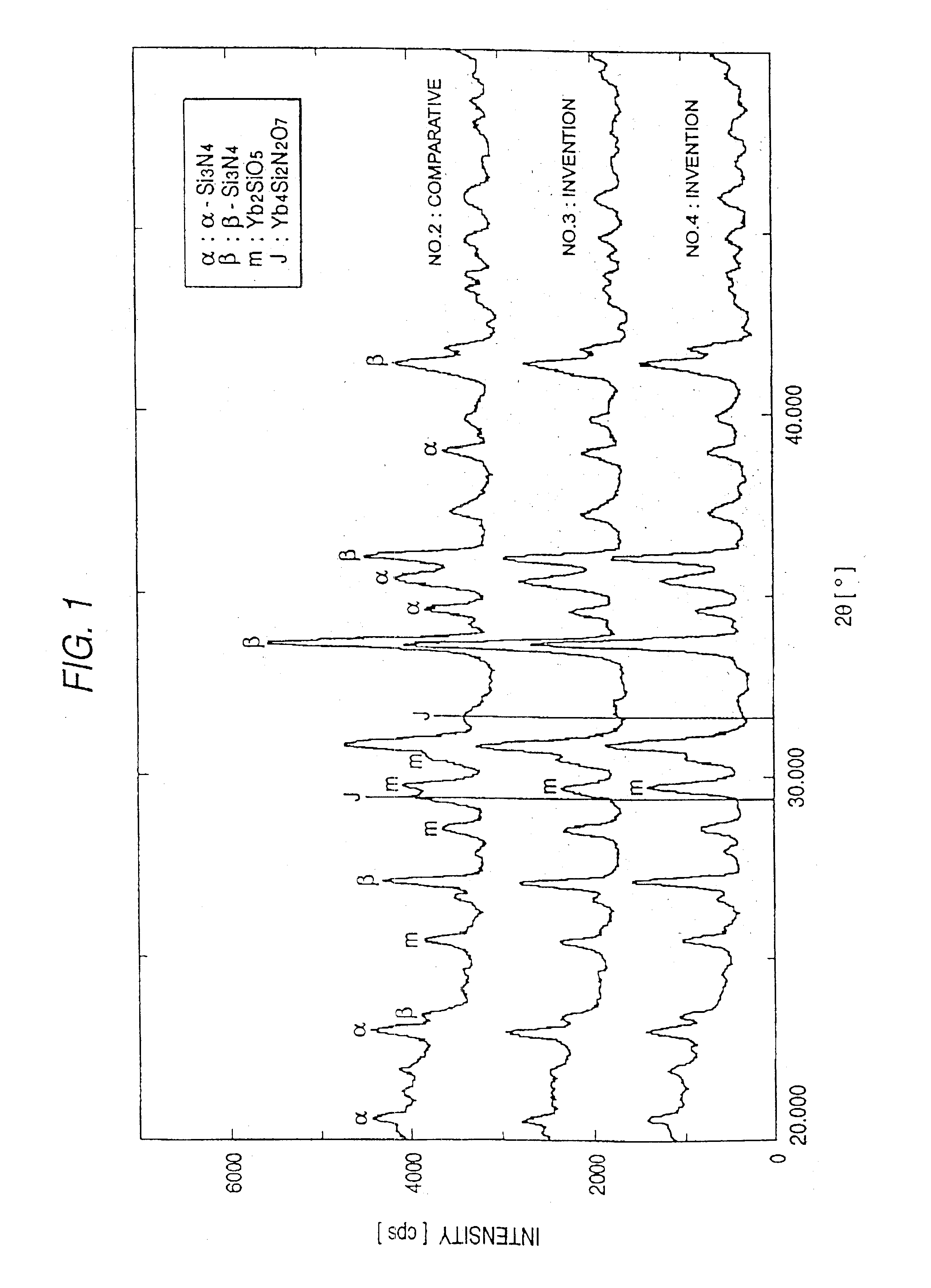

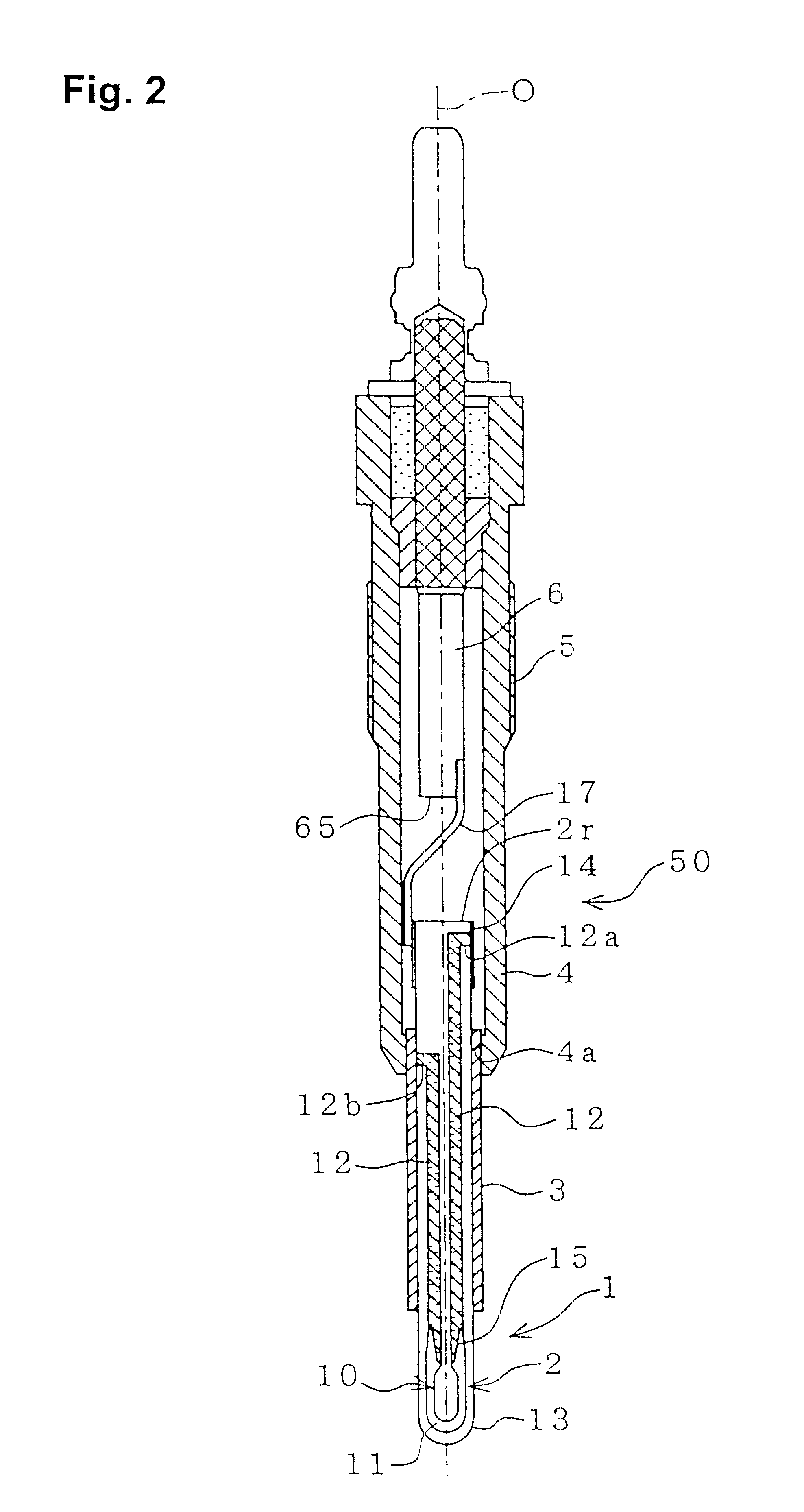

Silicon nitride sintered material and production process thereof

InactiveUS6657166B2High coefficient of thermal expansionImprove anti-corrosion performanceIncandescent ignitionMachines/enginesRare-earth elementSilicon oxygen

A silicon nitride sintered material containing silicon nitride, a Group 4a through 6a element, a rare earth element, and silicon carbide, characterized in that the amount of the rare earth element as reduced to a certain oxide thereof is 5.7-10.3 mol %; the ratio by mol of subtraction remainder oxygen amount calculated in relation to the oxygen contained in the sintered material, the remainder oxygen amount being expressed in terms of silicon dioxide, to the amount of oxygen contained in the sintered material is at least 0.50 and less than 0.70; a four-component crystalline phase of rare earth element-silicon-oxygen-nitrogen is not present; and the thermal expansion coefficient is at least 3.7 ppm / ° C. between room temperature and 1,000° C.

Owner:NGK SPARK PLUG CO LTD

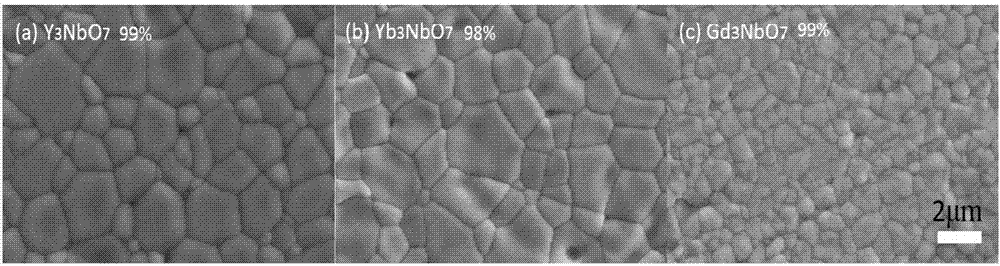

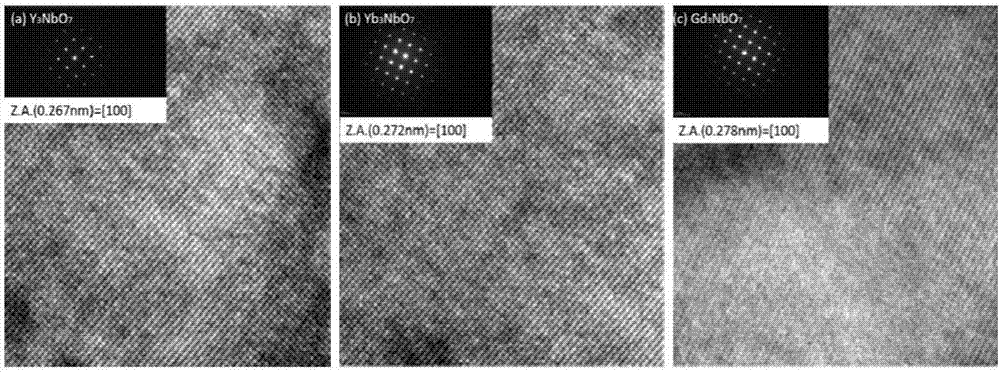

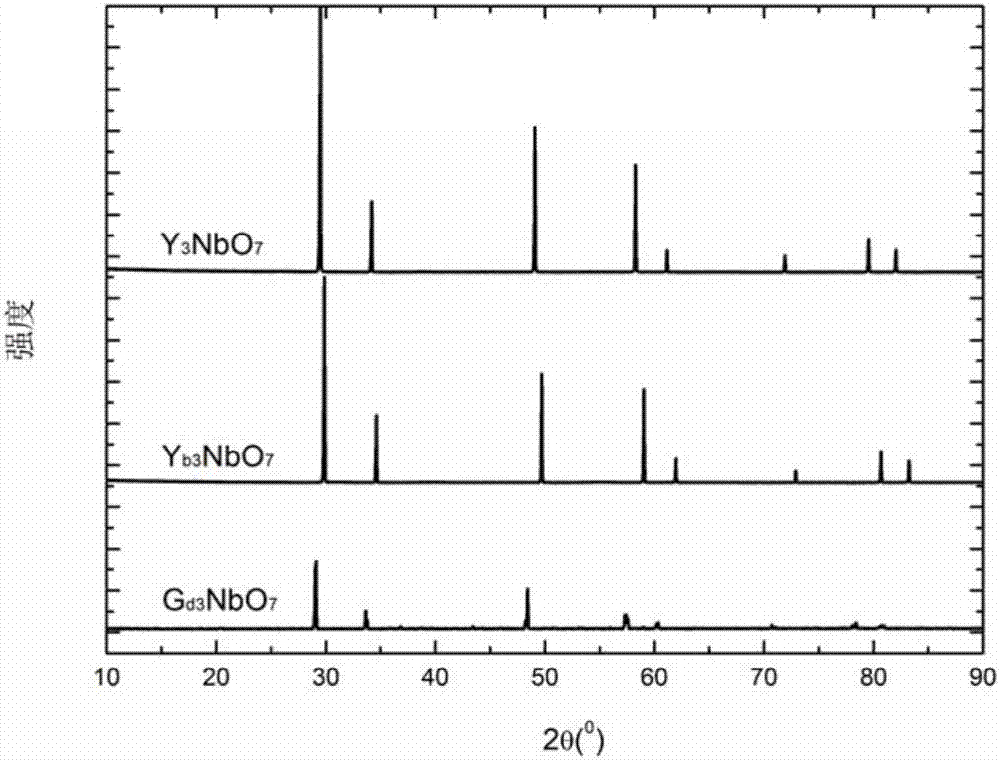

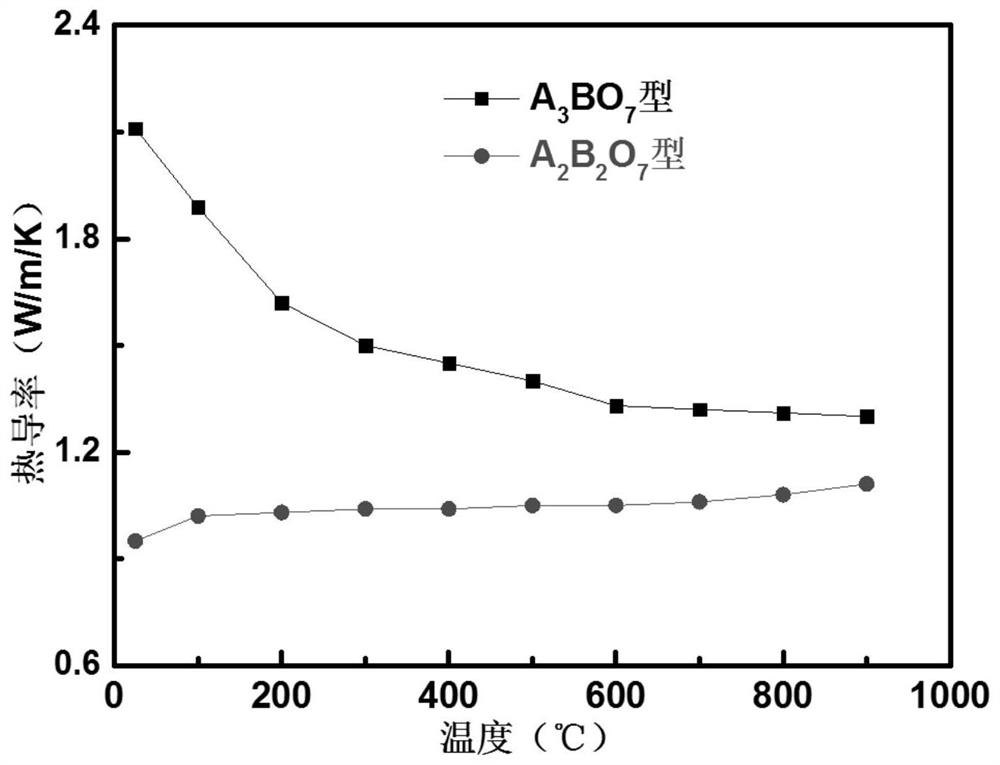

High-temperature thermal barrier coating material

InactiveCN106884132AIncrease scatteringLow thermal conductivityMolten spray coatingVacuum evaporation coatingRare-earth elementYttria-stabilized zirconia

The invention relates to a high-temperature thermal barrier coating material. The high-temperature thermal barrier coating material is rare earth niobate and a solid solution thereof. The chemical constitution of the rare earth niobate is Ln3NbO7, and Ln comprises the rare earth elements of La, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y and Sc. The chemical constitution of the solid solution is Ln3(Nb1-xTax)O7 (x is larger than or equal to 0 and smaller than 1). Ln is a combination of one or more than one of the rare earth elements. The high-temperature thermal barrier coating material is characterized in that the heat conductivity of the material is low, when the temperature is 1000 DEG C, the intrinsic thermal conductivity of a compact block body is 1.1-1.4 W / m.k, compared with a commercial yttria-stabilized zirconia (YSZ) material (the thermal conductivity is about 2.5 W / m.k) with the weight percentage being 7%-8%, the thermal conductivity of the material is reduced by a large margin, and the material keeps phase stability and excellent oxygen-resistance capacity from the indoor temperature to the temperature of 1600 DEG C. The material can be applied to protection of high-temperature metal hot end parts of gas turbines or aero-engines.

Owner:TSINGHUA UNIV

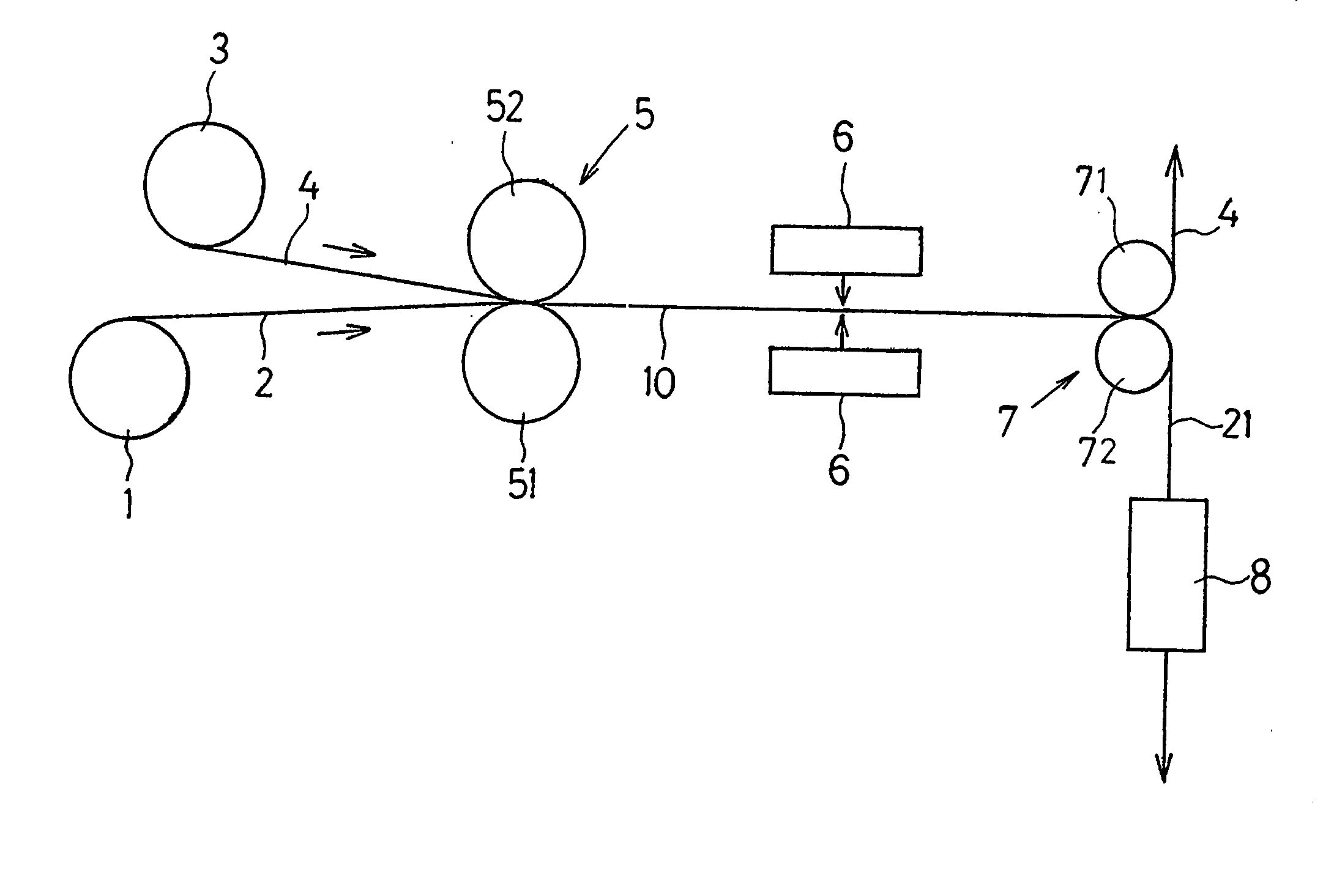

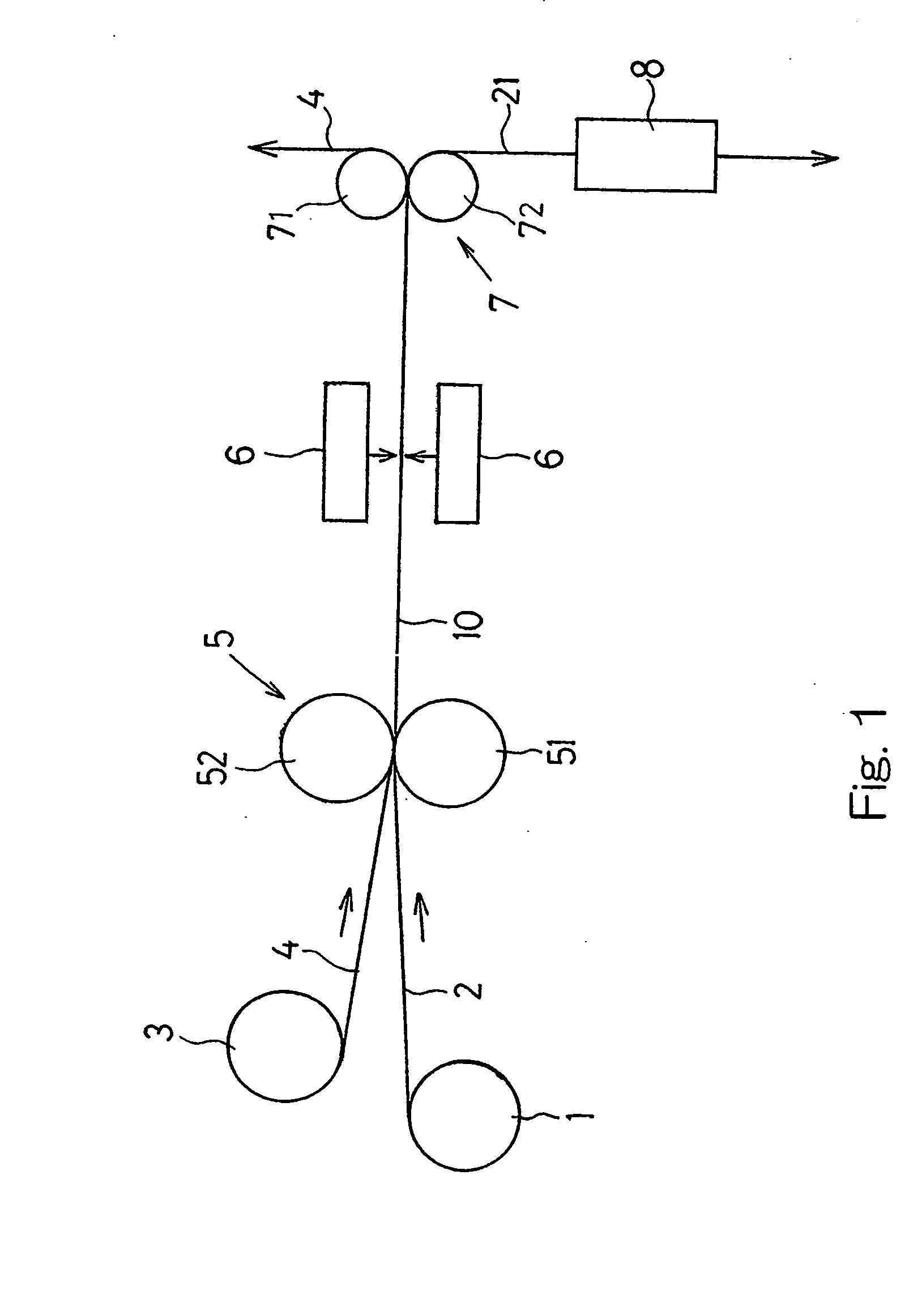

Method of making liquid crystal polymer films

ActiveUS20050067739A1Reduction of thermal expansion coefficientHigh coefficient of thermal expansionAdhesive processesLamination ancillary operationsPolymer scienceHeating time

A method of making a thermotropic liquid crystal polymer film includes continuously heat treating of the thermotropic liquid crystal polymer film 2 while the latter is jointed to a sheet-like support member 4, and subsequently separating the heat-treated thermotropic liquid crystal polymer film 2 from the support member 4. The continuous heat treatment of the thermotropic liquid crystal polymer film 2 then jointed to the support member 4 is carried out for a predetermined heating time within the range of 5 to 60 seconds at a predetermined heating temperature T° C. equal to or higher than the melting point Tm° C. of the thermotropic liquid crystal polymer film less 15° C. (i.e., Tm−15° C.), but lower than the melting point Tm° C. (thus, Tm−15° C.≦T° C.<Tm° C.), to thereby increase the thermal expansion coefficient of the thermotropic liquid crystal polymer film.

Owner:KURARAY CO LTD

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

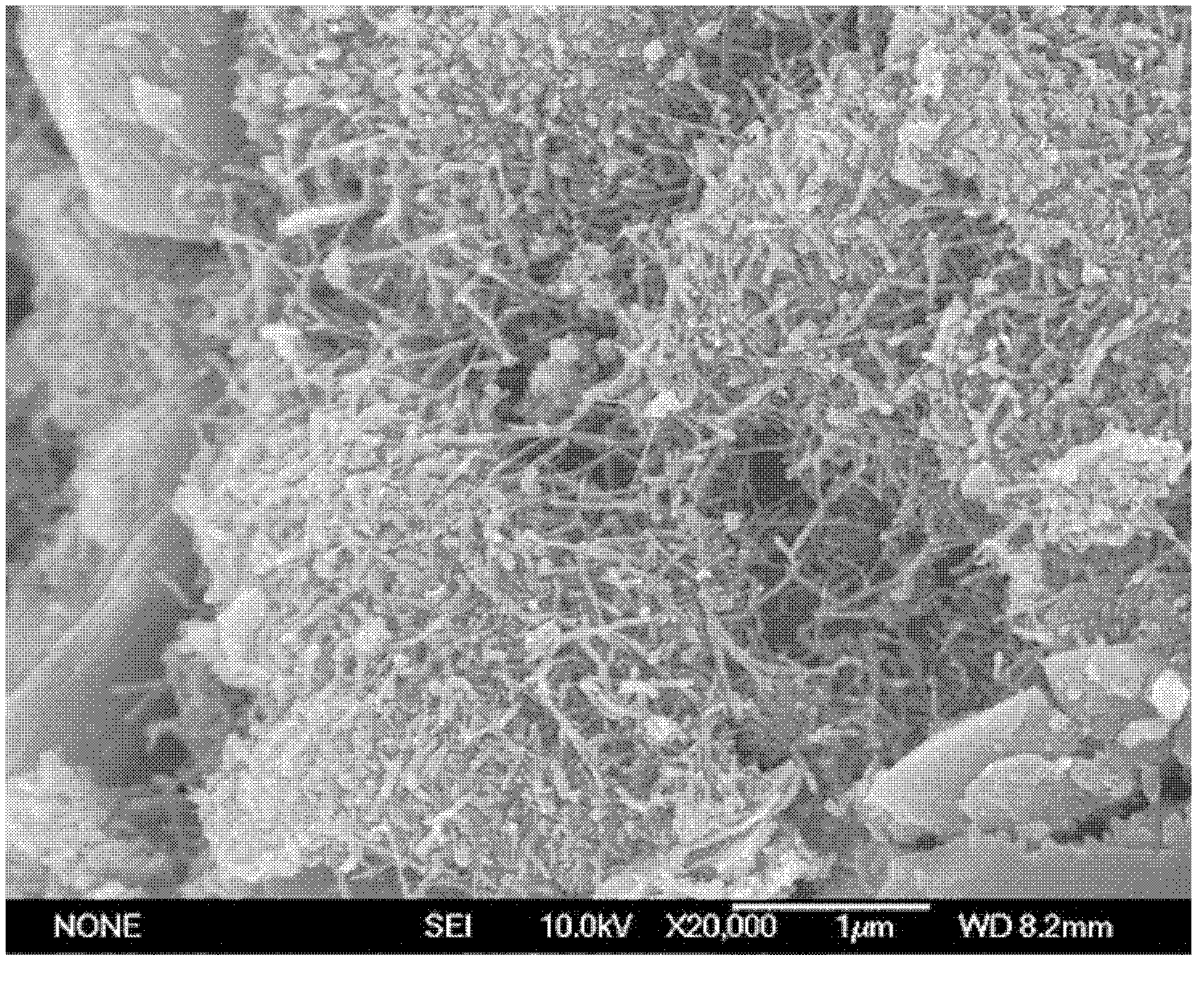

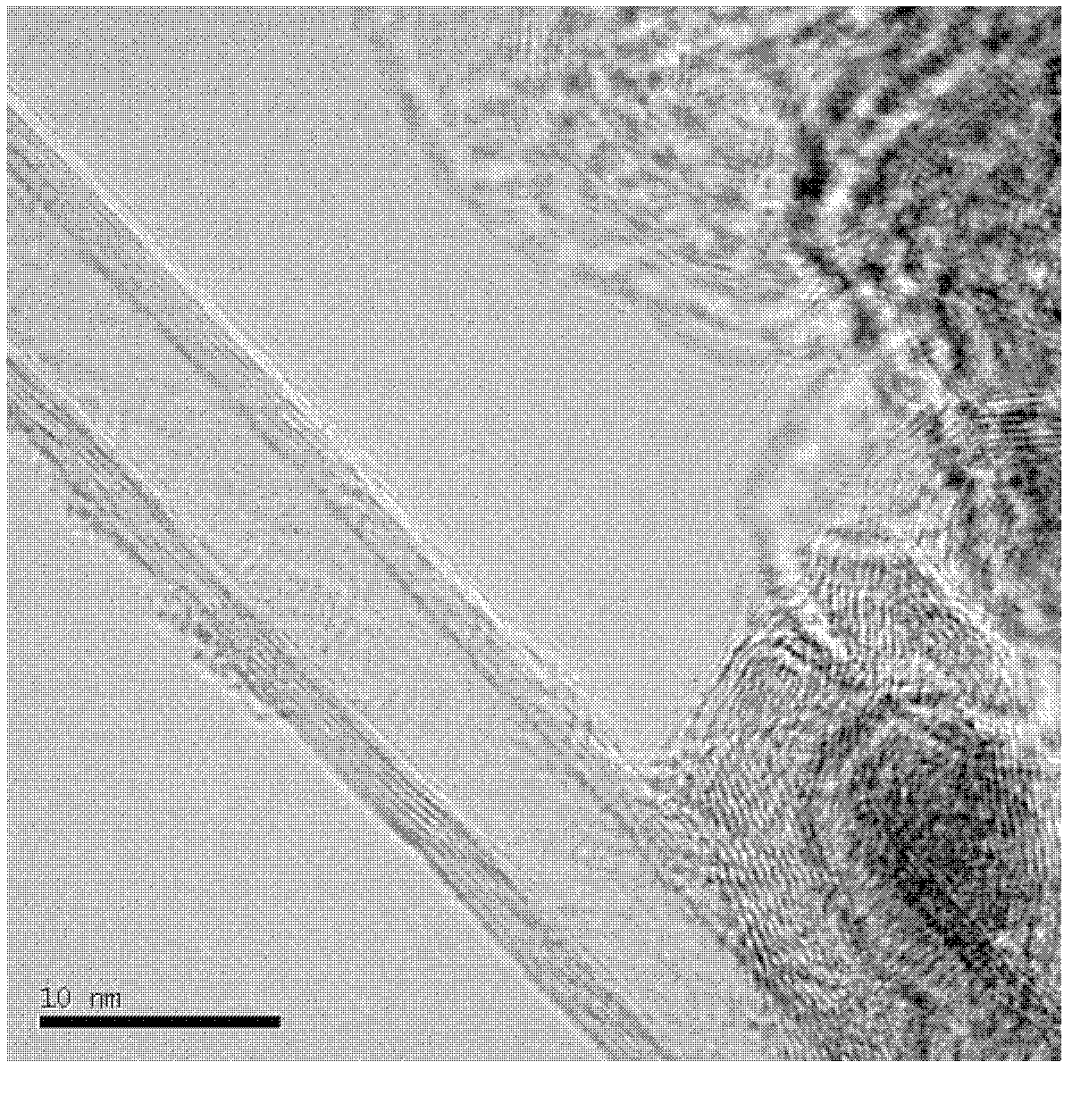

InactiveCN102206793AHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

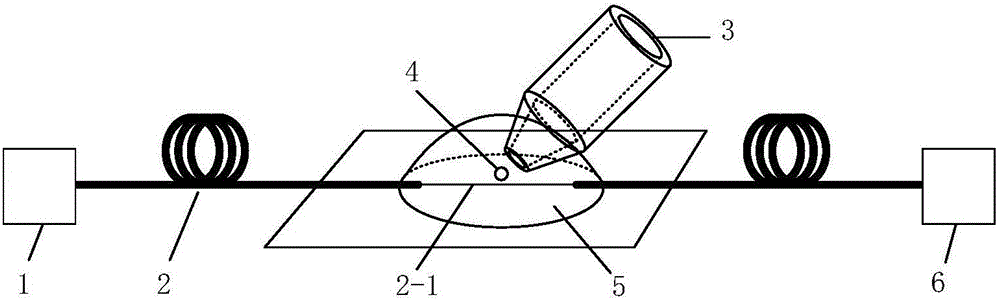

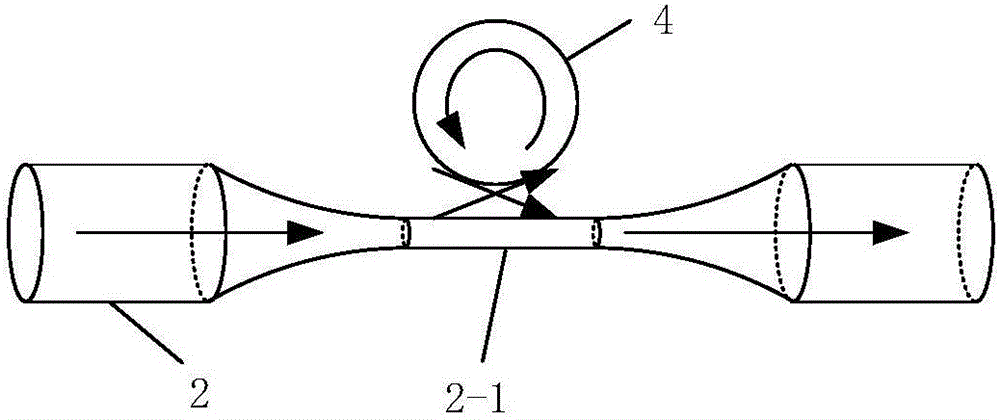

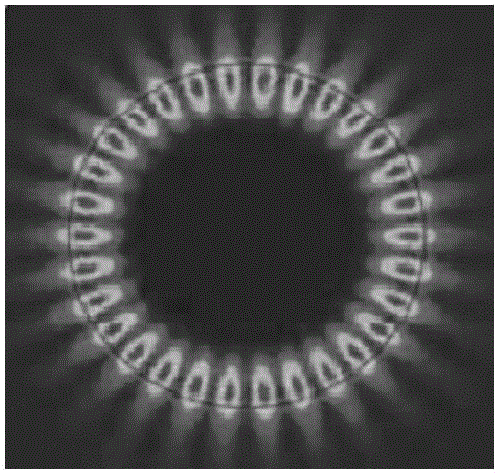

Micro-droplet sensing device and method using same to measure refractivity

InactiveCN106053389AHigh coefficient of thermal expansionSolve the problems caused by unevennessPhase-affecting property measurementsThermometers using physical/chemical changesResonance wavelengthSpectrograph

The invention provides a micro-droplet sensing device and a method using the same to measure refractivity. A single mode fiber forms a taper area through tapering, two ends of the single mode fiber are connected with a wide-spectrum light source and a spectrograph respectively, the taper area is placed in environment liquid, and annular core fiber optical tweezers control a micro-droplet to be close to the taper area; light emitted by the wide-spectrum light source is transmitted in the single mode fiber, is coupled into the micro-droplet by means of an evanescent field when going through the taper area and generates resonance in the mode of an echo wall, transmission light intensity at a resonance wavelength is reduced sharply to form a resonance valley, and the spectrograph is used to collect transmission light for spectrum analysis. The annular core fiber optical tweezers are utilized to control the micro-droplet to enable the same to form a perfect ball cavity, so that the problem that a solid ball echo wall sensor cannot form echo wall resonance due to unsmooth and defective surface of a solid ball is solved, and the micro-droplet is more sensitive to environment changing. The micro-droplet sensing device has wide application in the aspect of environment monitoring.

Owner:HARBIN ENG UNIV

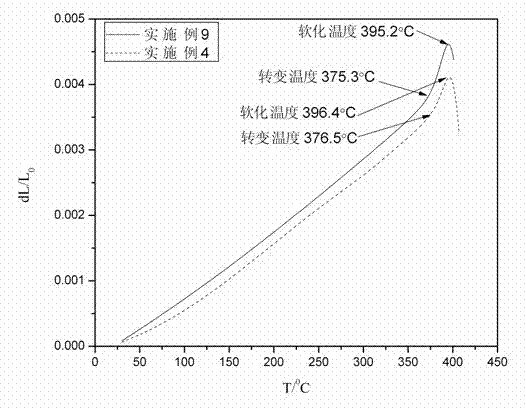

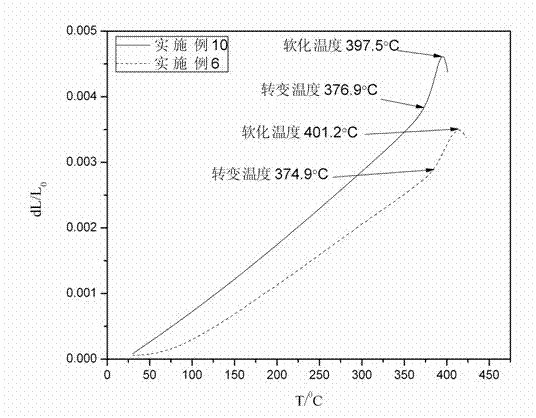

Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

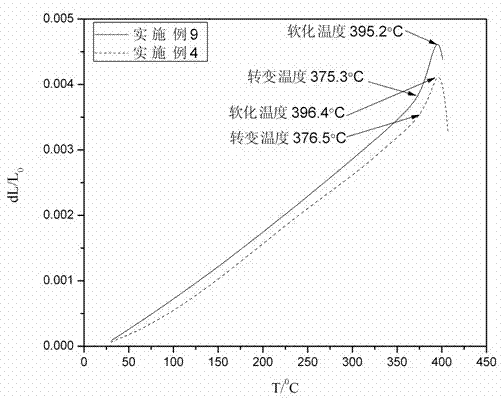

The present invention discloses a bismuthate low-melting point and lead-free sealing grass and a preparation method thereof. The bismuthate low-melting point and lead-free sealing grass powder comprises, by mass, 75-90% of base glass and 10-25% of a filler, wherein the filler is a zirconium phosphate salt with an expansion coefficient of -5*10<-6>k<-1>-5*10<-6>k<-1>. The bismuthate low-melting point and lead-free sealing grass of the present invention has characteristics of lead-free property and green environmental protection, can replace the lead-containing glass so as to eliminate the pollution due to the lead, and has excellent chemical stability. The production process is simple and the cost is low. Compared to other filler-doped sealing glass powders, the sealing temperature of the present invention is low, the glass transition temperature of the present invention is 330-370 DEG C, the softening temperature of the present invention is 370-410 DEG C, the sealing temperature of the present invention is less than 450 DEG C. With adjusting the proportion of the filler, the adjustable expansion coefficient can be realized at the low sealing temperature, wherein the adjustment range is (70-90)*10<-7> / DEG C, such that different requirements of the sealing device to the expansion coefficient of the sealing material can be met, and the sealing for VFD, PDP, CRT and other glass products can be directly performed.

Owner:CHINA JILIANG UNIV

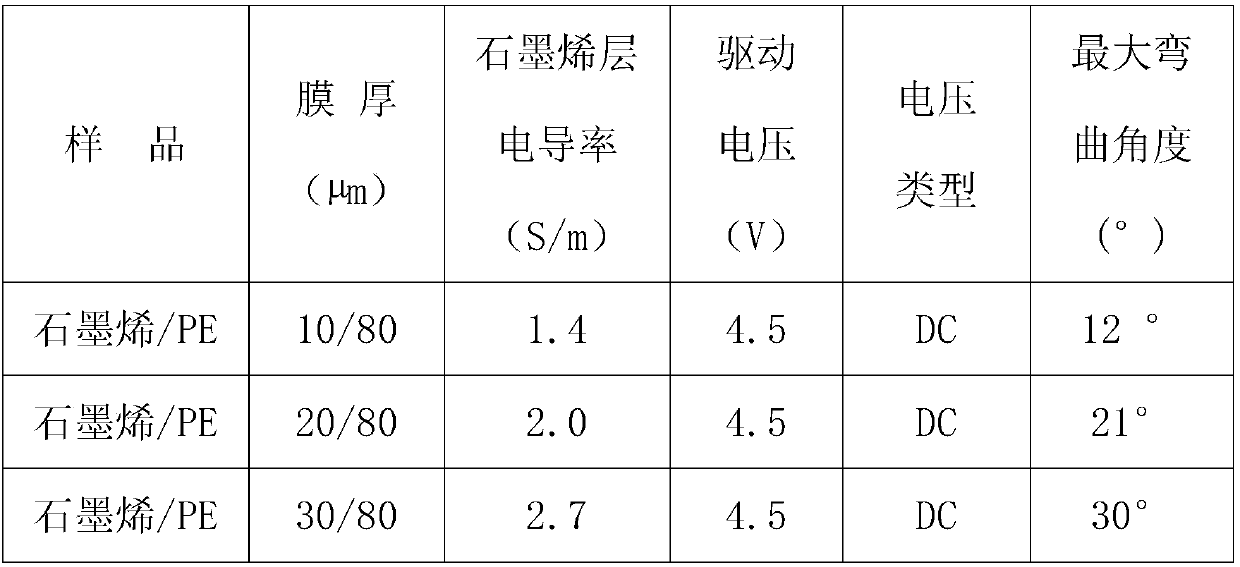

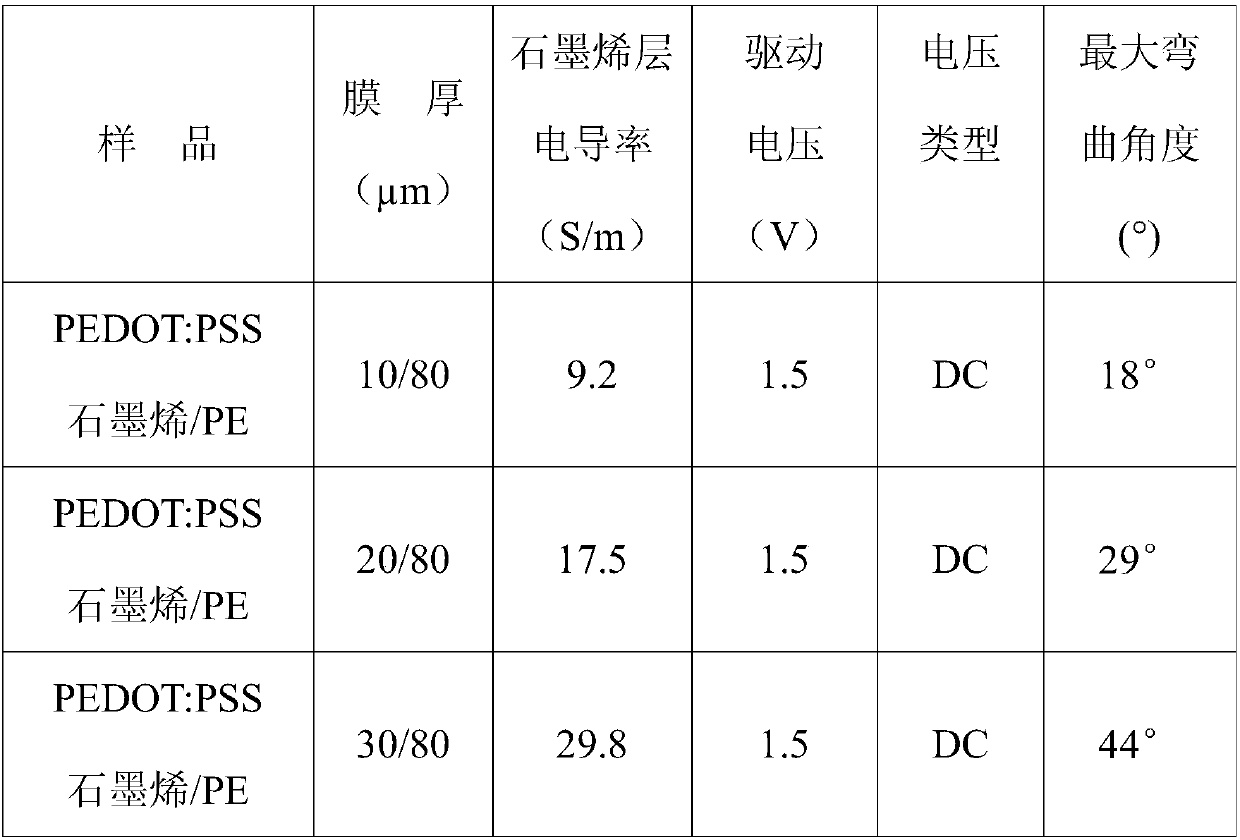

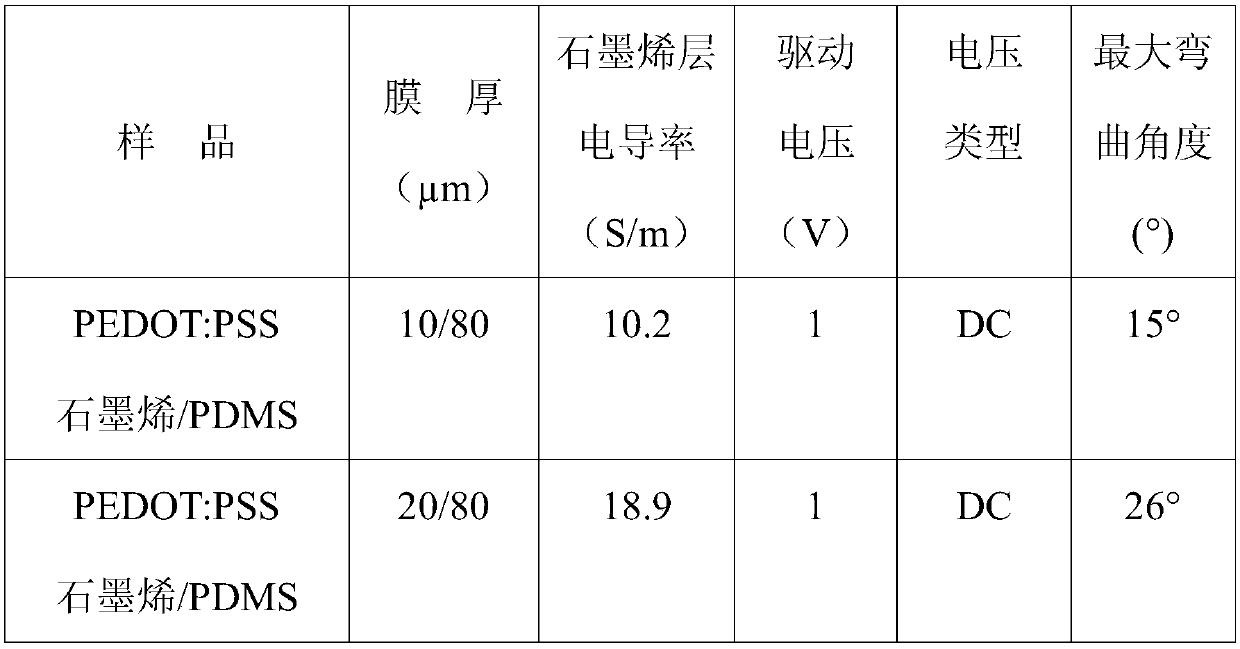

Graphene double-layer electroactive membrane and preparation method thereof

InactiveCN107778514AImprove flexibilityLarge coefficient of linear expansionGrapheneElectrically-conductive paintsPolymer thin filmsActuator

The invention discloses a graphene double-layer electroactive membrane and a preparation method thereof. The graphene double-layer electroactive membrane is composed of a flexible conducting layer anda flexible polymer layer. The preparation method comprises mixing and reacting flake graphite powder, NaNO3, sulfuric acid, KMnO4 and deionized water, and performing washing and drying processes to obtain graphene oxide; mixing and ultrasonic-dispersing the graphene oxide, hydrazine hydrate, ammonium hydroxide and deionized water for reaction to obtain reduced graphene oxide dispersion liquid; dropwise or rotatingly applying the reduced graphene oxide dispersion liquid onto a flexible polymer layer-polymer membrane and performing a drying process to form the flexible conducting layer onto thepolymer membrane to obtain the graphene double-layer electroactive membrane. The graphene double-layer electroactive membrane has the advantages of high responsiveness, low power, broad pressure range and the like when being electrically driven, and can be applied to the fields of flexible wearable equipment, micro motor actuators and micro-robots.

Owner:SOUTHWEAT UNIV OF SCI & TECH

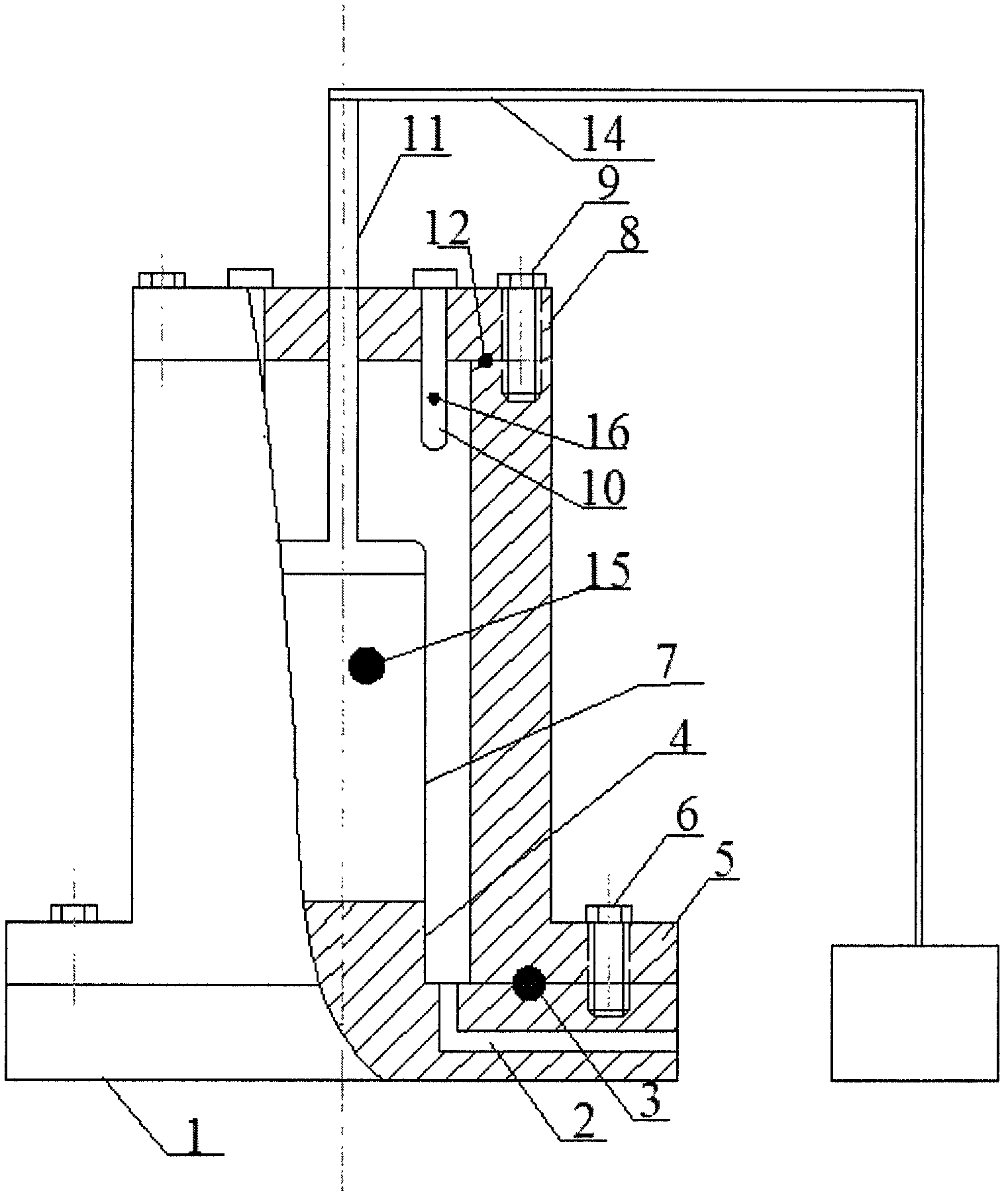

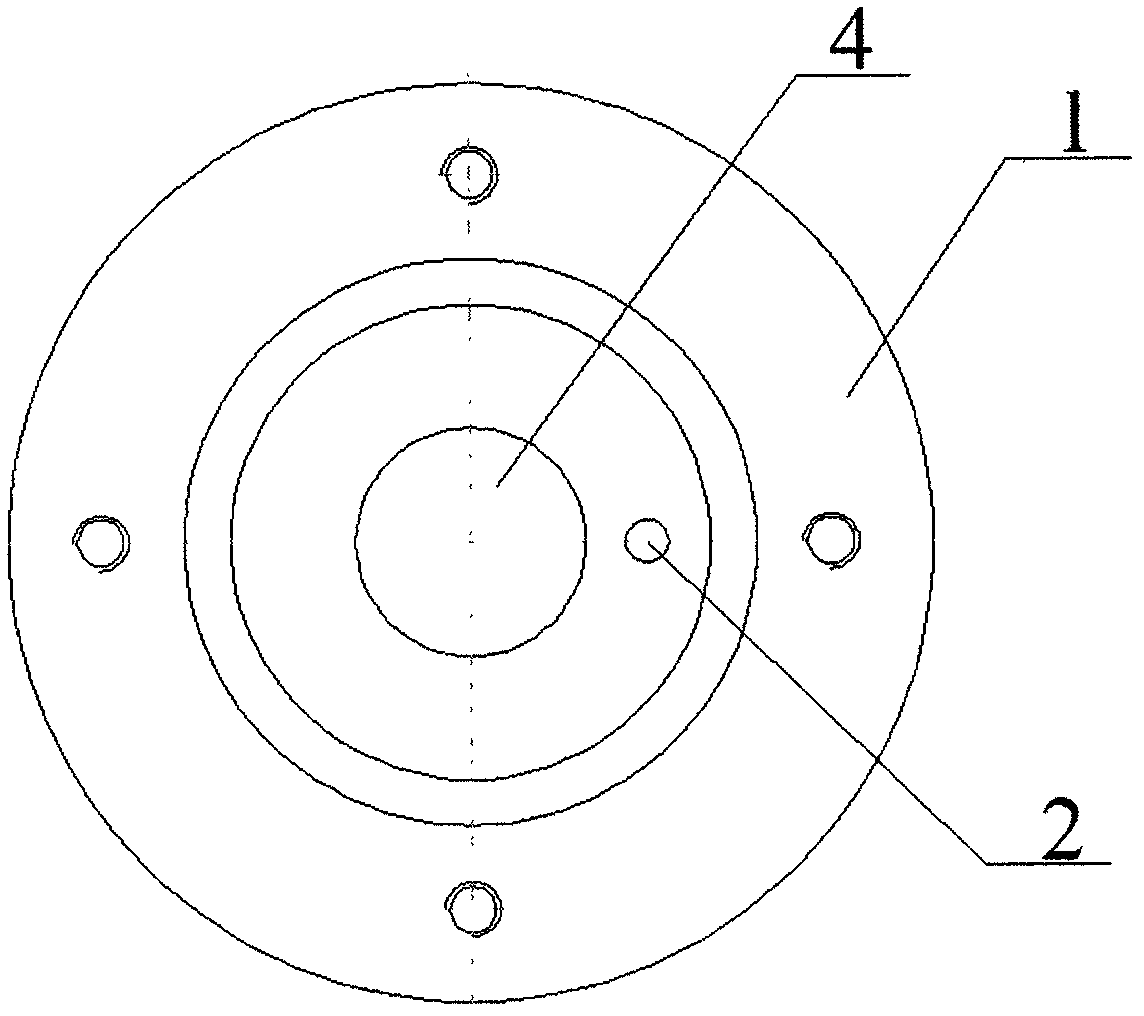

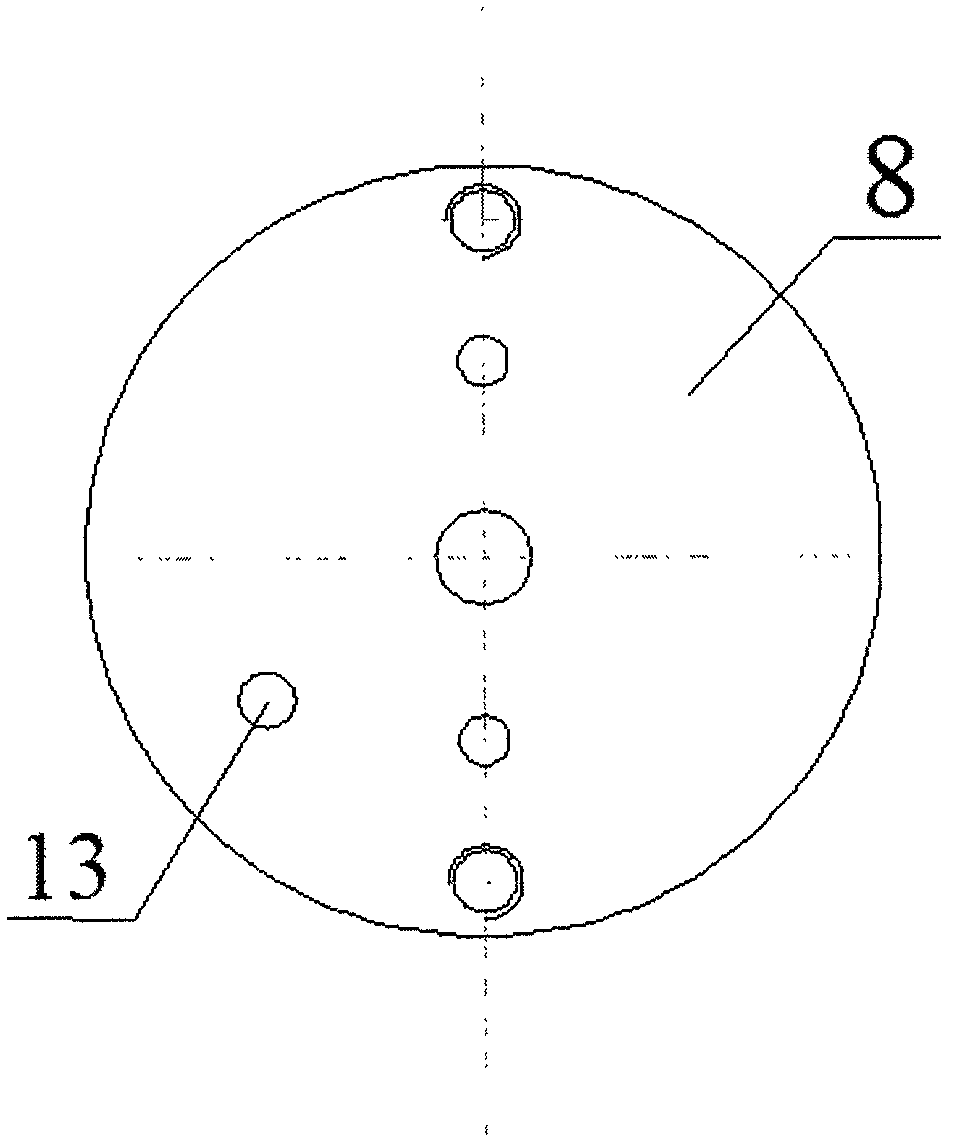

Indoor testing apparatus for thermal expansion coefficient of rock sample

InactiveCN103235002AEasy to installHeating evenlyMaterial thermal coefficient of expansionEngineeringThermal expansion

The invention relates to a testing apparatus for the thermal expansion coefficient of a rock sample, which belongs to the field of test instruments. The testing apparatus comprises a pedestal, an oil delivery channel, a furnace wall, a top cover, an electrical bar and a strain rod, wherein the furnace wall is hollow, an objective table is arranged on the pedestal, the pedestal is in fixed connection with the lower end surface of the furnace wall through a fastening screw, the upper end of the furnace wall is provided with the top cover, the top cover is provided with the electrical bar, and the lower end of the electrical bar is placed in a furnace chamber. The testing apparatus provided by the invention employs an assembling connection structure and a built-in oil heating mode, uniform heating of a to-be-tested rock sample can be realized through usage of the built-in oil heating mode, and since the strain rod is provided with a matching high precision strain gage, axial expansion strain of the to-be-tested rock sample after heating can be sensitively measured. The testing apparatus has the advantages of a reasonable structure, convenience in assembling connection, simple operation and capacity of measuring the thermal expansion coefficient of a rock; the built-in oil heating mode enables a high heating temperature to be obtained; and the high precision strain gage is cooperatively used for the testing apparatus, which facilitates measurement of the thermal expansion coefficient of the rock and enables high test precision to be obtained.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

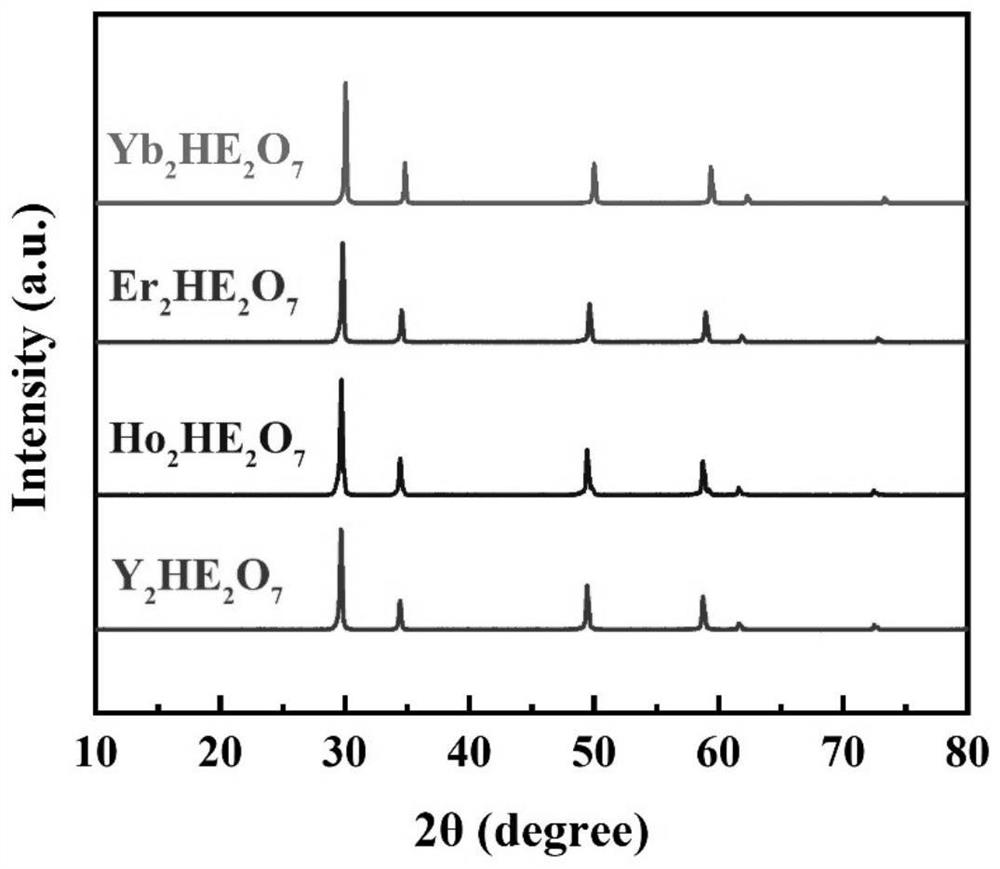

Fluorite structure high-entropy oxide powder for thermal barrier coating and preparation method of fluorite structure high-entropy oxide powder

ActiveCN113023776AHigh coefficient of thermal expansionShortened mean free pathThermal dilatationRare-earth element

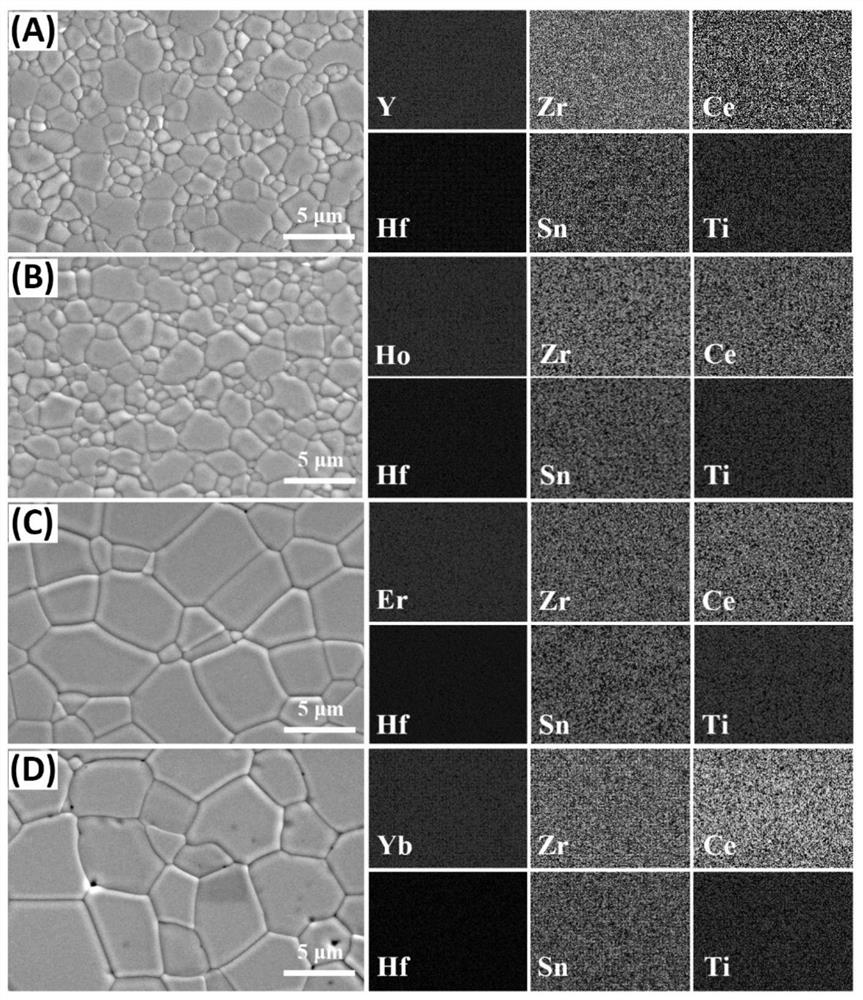

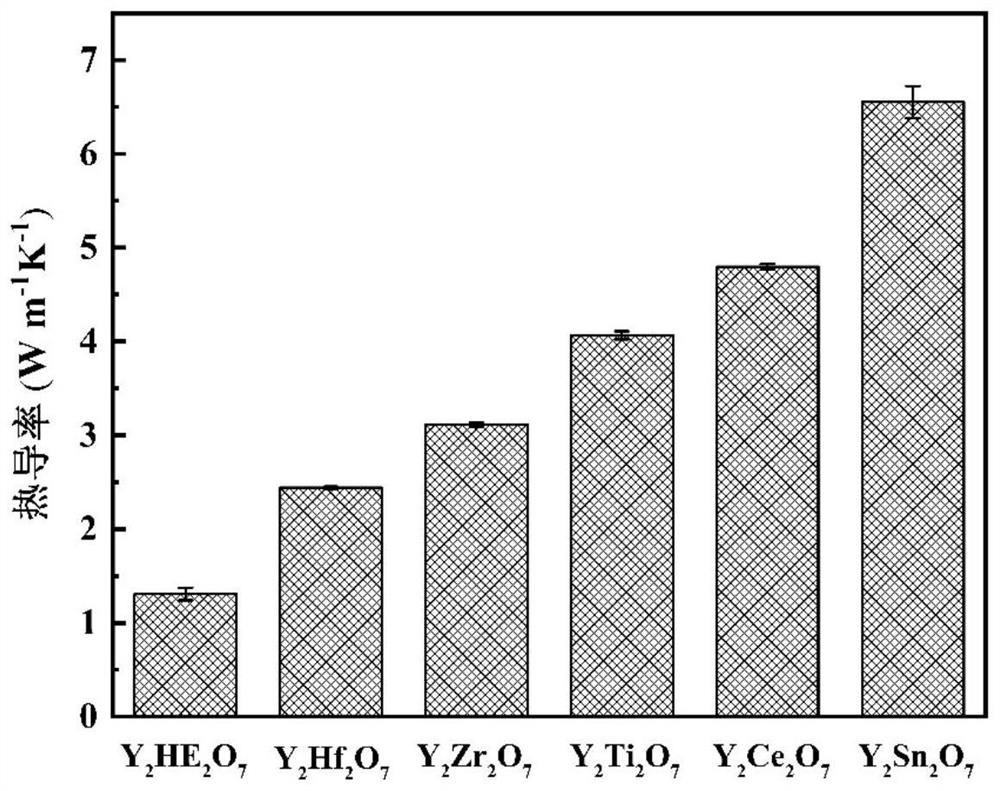

The invention relates to fluorite structure high-entropy oxide powder for a thermal barrier coating and a preparation method of the fluorite structure high-entropy oxide powder. The powder has a single fluorite structure, and the chemical formula is RE2HE2O7, wherein RE is one of rare earth elements Y, Ho, Er, Yb and Lu, HE is at least three elements of Ce, Zr, Hf, Sn and Ti, and the mole number of each HE element accounts for 10%-30% of the total mole number of all the HE elements. The preparation method comprises the following steps of: mixing original powder of RE2O3 and HEO2 in proportion, heating the mixed powder to a certain temperature to carry out solid-phase reaction, and carrying out ball milling, drying and sieving to obtain the high-entropy ceramic powder. Compared with the prior art, a ceramic material prepared from the high-entropy oxide powder has the advantages of extremely low thermal conductivity, high thermal expansion coefficient, excellent comprehensive mechanical properties, simple process and wide application range, and can be applied to the field of ceramic thermal barrier coating materials.

Owner:SHANGHAI JIAO TONG UNIV

Casting mixture for epoxy casting transformer and preparation method thereof

The invention discloses a casting mixture for an epoxy casting transformer, which comprises the following raw materials in part by weight: 1 part of epoxy resin, 2.5 to 3.1 parts of silicon micropowder, 0.1 to 0.2 part of toughening agent, 0 to 0.02 part of color paste, 0.6 to 0.7 part of curing agent, and 0.001 to 0.003 part of accelerating agent. The preparation method for the casting mixture comprises the following steps: melting the materials; adding the silicon micropowder, the toughening agent, the color paste, the curing agent, and the accelerating agent in the melted epoxy resin in turn under the conditions of heating and stirring; and then performing vacuum defoamation. Due to the adoption of mixed glue prepared from the components of the casting mixture by the preparation method thereof, the crack ratio of a cast casting body can be reduced, and the quality of the product can be improved.

Owner:PINGGAO GRP +2

Metal anticorrosive coating and preparation method and application thereof

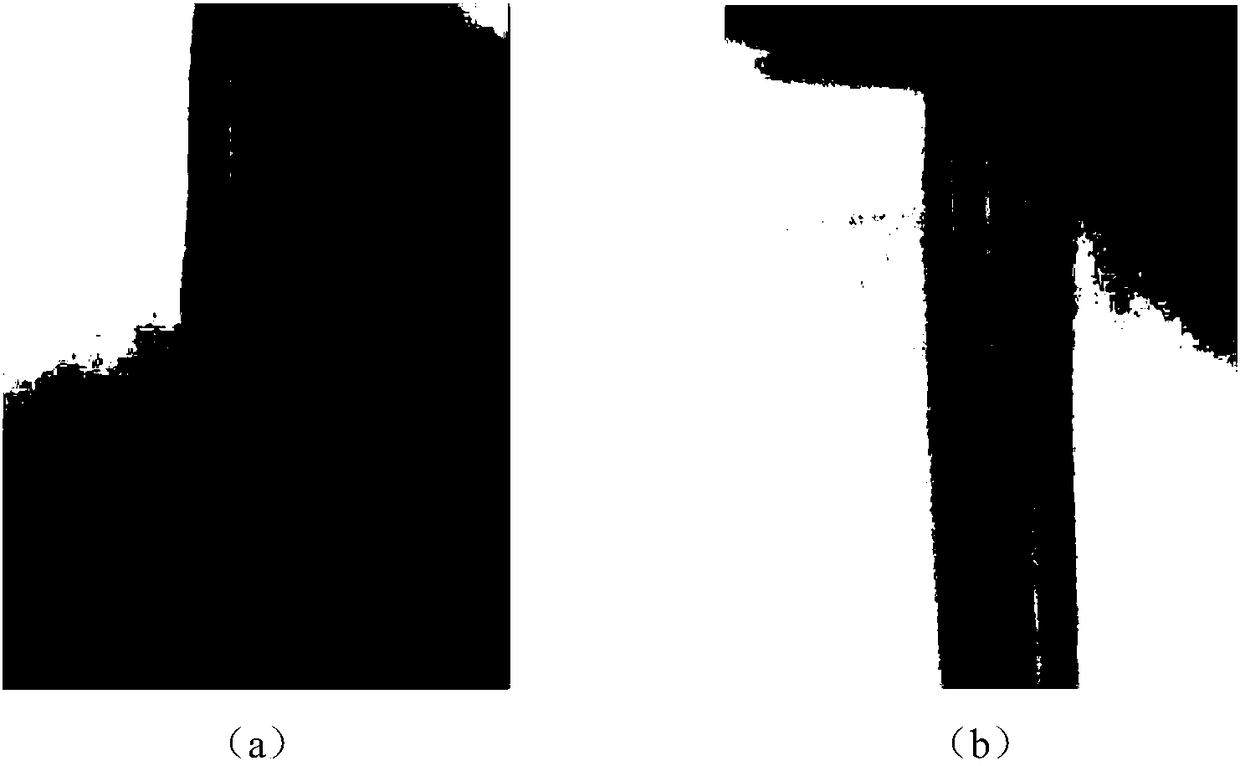

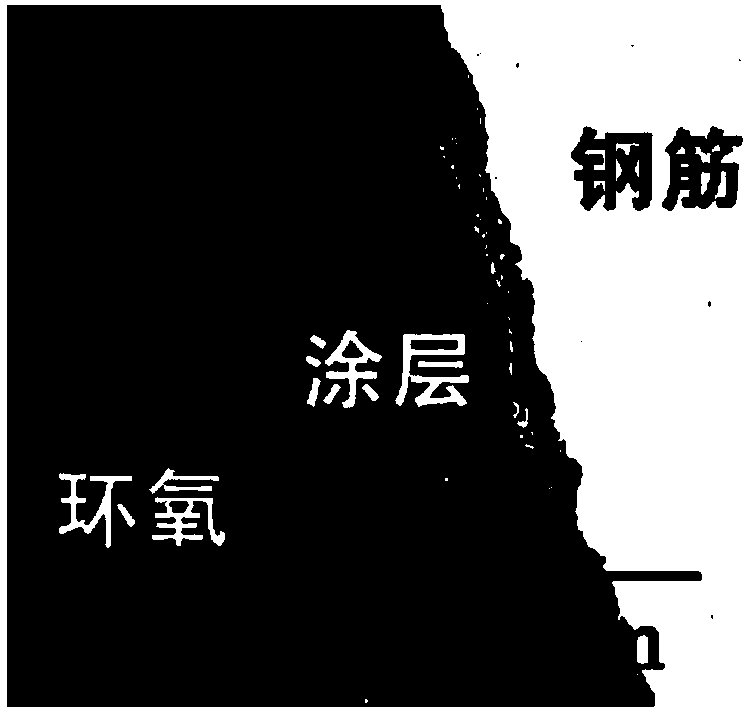

ActiveCN108531908AImprove performanceHigh coefficient of thermal expansionBuilding reinforcementsPotassiumMixed materials

The invention discloses a metal anticorrosive coating. The coating is an inorganic coating for metal anticorrosion. The coating is of a double-layer structure, and comprises an enamel coating on the outer layer and a matrix oxide coating on the inner layer. At the same time, the content of matrix metal oxide is decreased progressively from the inner layer to the outer layer, and therefore it is caused that the thermal expansion coefficient of the coating is increased progressively from the inner layer to the outer layer, and it is guaranteed that the overall thermal expansion coefficient of the coating is coherent with various matrix metals. The components of the enamel coating on the outer layer comprise, by weight, 1-40 parts of silicon, 1-30 parts of sodium, 1-20 parts of potassium, 2-20 parts calcium, 0.5-15 parts of fluorine, 0.3-10 parts of cobalt, 0.2-10 parts of nickel, 1-18 parts of boron, 0.5-10 parts of phosphorus, 0.1-8 parts of magnesium and the balance oxygen. The components of the matrix oxide coating on the inner layer comprise matrix metal and oxygen. The invention further discloses a preparation process of the double-layer compact metal anticorrosive coating formed by low-temperature sintering. The preparation process includes the following steps of (1) grinding; (2) mixed material preparing; (3) grinding; (4) high-temperature reaction; (5) grinding; (6) coating and (7) sintering. The coating has the advantage that the corrosion resisting performance is improved by 14 times or above, and the coating has the advantages that ductility is high, and coordinative stretching deformation with steel bars can be achieved; and the coating has the beneficial effects that a thermal expansion coefficient gradient is achieved, and the coating can be applicable to different metal and same metal in different models.

Owner:ZHEJIANG UNIV

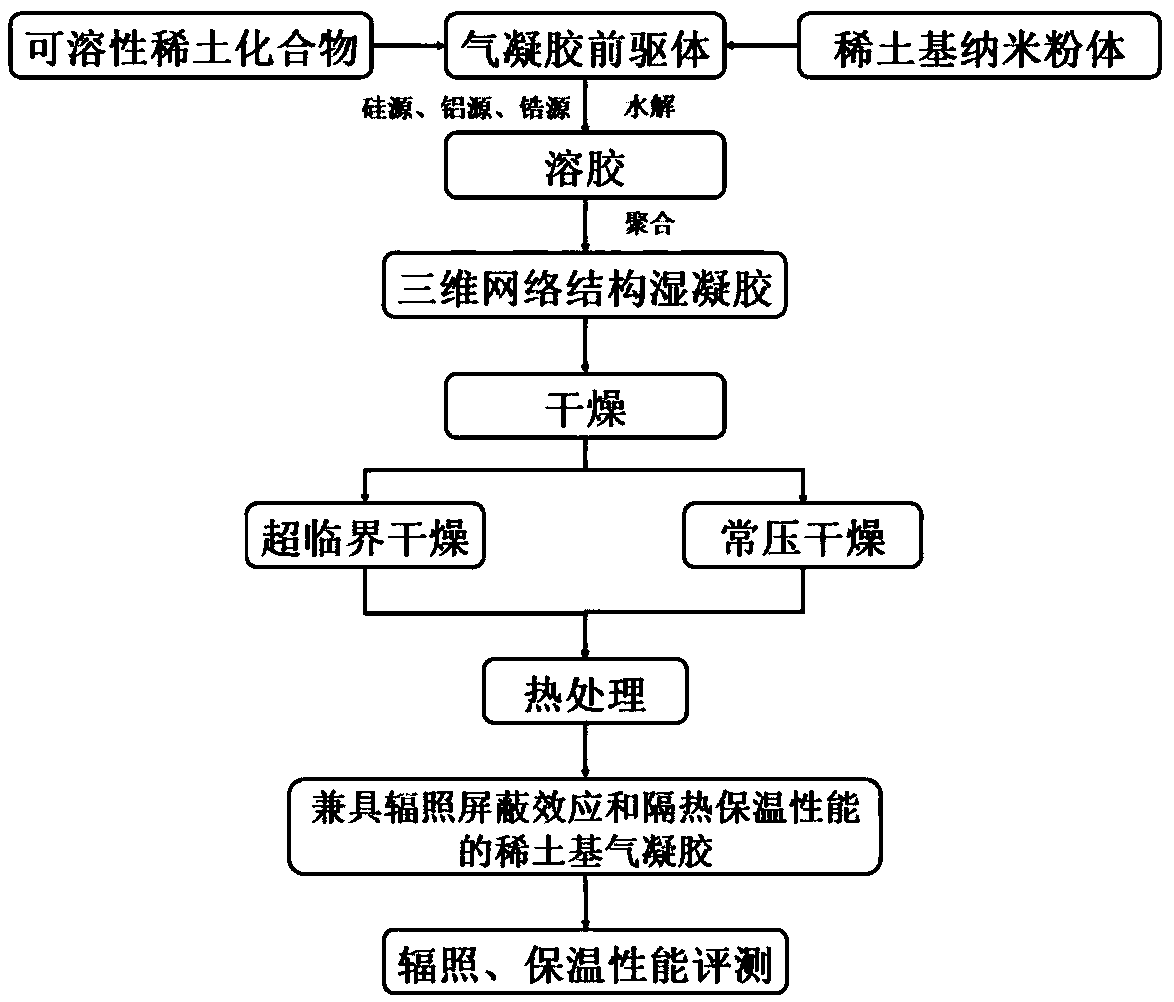

Rare-earth-based aerogel material with radiation shielding effect and heat insulation property as well as preparation and application of rare-earth-based aerogel material

The invention provides a rare-earth-based aerogel material with a radiation shielding effect and heat insulation property and preparation and application of the rare-earth-based aerogel material. Thematerial comprises an aerogel matrix material and a rare-earth-based material, wherein the rare-earth-based material is compounded with the aerogel matrix material; the rare-earth-based material is selected from one or more of rare earth zirconate, rare earth titanate, rare earth tungstate and rare earth cerate; and the content of the rare-earth-based material ranges from 1wt% to 45wt%. The radiation shielding property and the fireproof heat insulation property are effectively combined by compounding the rare-earth-based material in aerogel, and the prepared material particularly meets the requirements of radiation shielding and fireproof heat insulation in the field of nuclear engineering.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

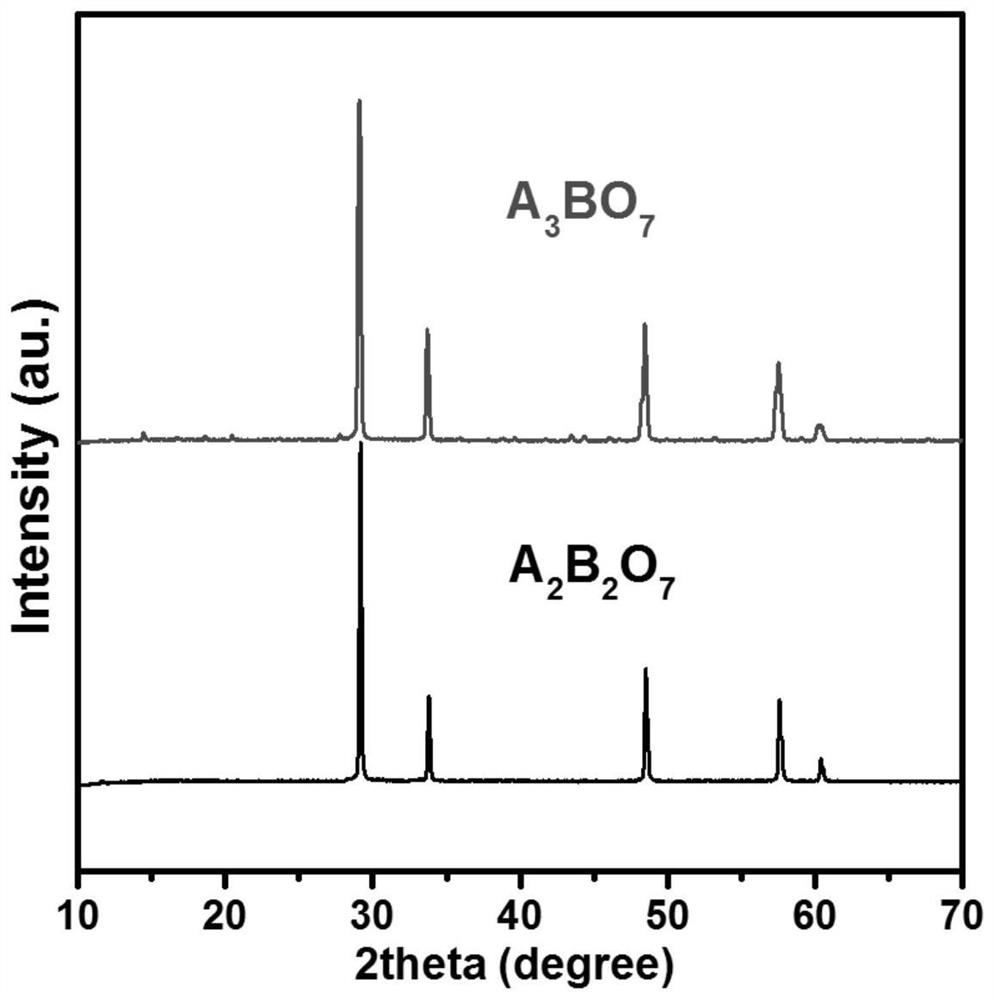

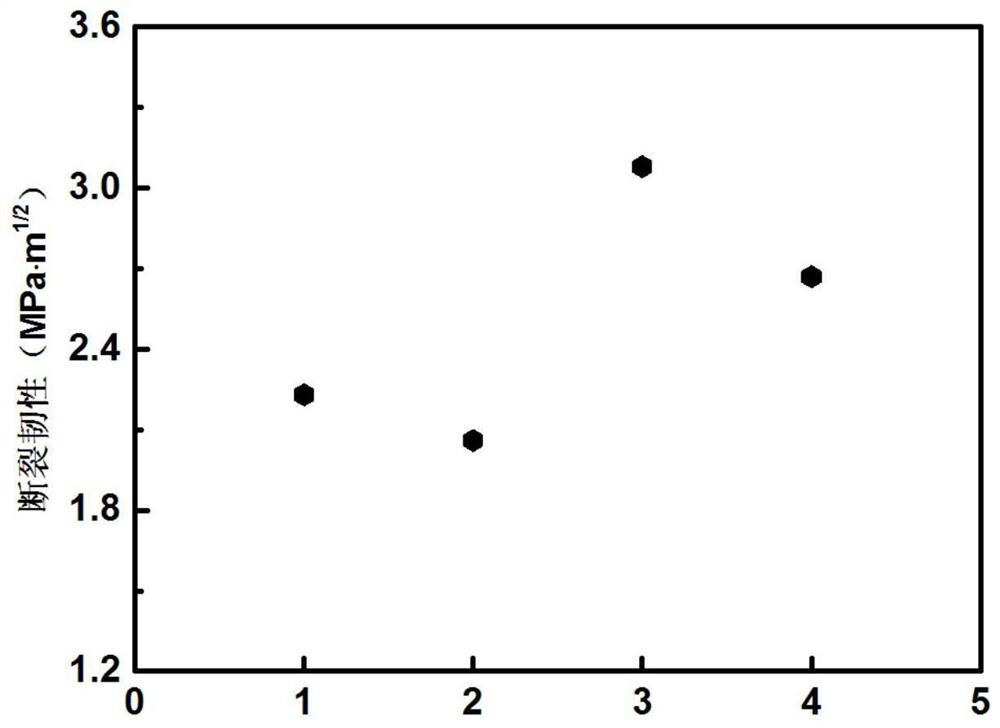

High-entropy stable rare earth tantalate/niobate ceramic and preparation method thereof

The invention discloses a high-entropy stable rare earth tantalate / niobate ceramic and a preparation method thereof, and the preparation method comprises the following steps: taking rare earth oxide RE2O3, tantalum oxide Ta2O5, niobium oxide Nb2O5 and MO2 oxide as raw materials, and taking A3BO7 type rare earth tantalate / niobate RE<3>Ta<1-x> Nb<x>O<7> ceramic as a matrix, and adding three or more MO2 oxides to equivalently replace rare earth and tantalum / niobium elements at positions A and B to obtain the novel high-entropy stable rare earth tantalate / niobate ceramic material RE < 3-y > Ta < 1-y / 2-x > Nb < x-y / 2 > M < 2y > O<7>. The ceramic material prepared by the invention has the characteristics of low thermal conductivity, high thermal expansion coefficient, high hardness, high fracture toughness, controllable crystal structure and the like, and can be used as a high-temperature protection material for thermal barrier coatings, environmental barrier coatings, nuclear material storages and the like.

Owner:KUNMING UNIV OF SCI & TECH

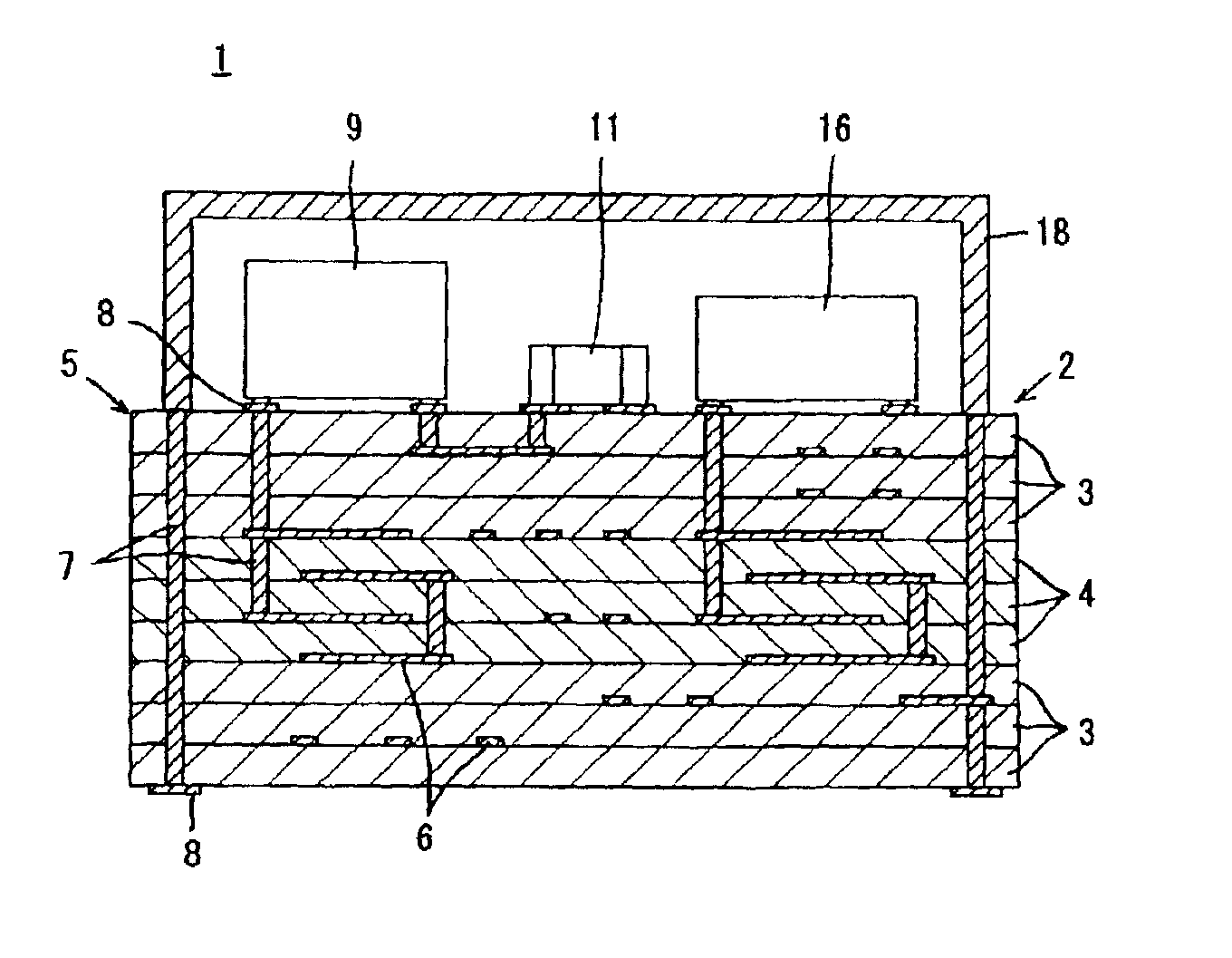

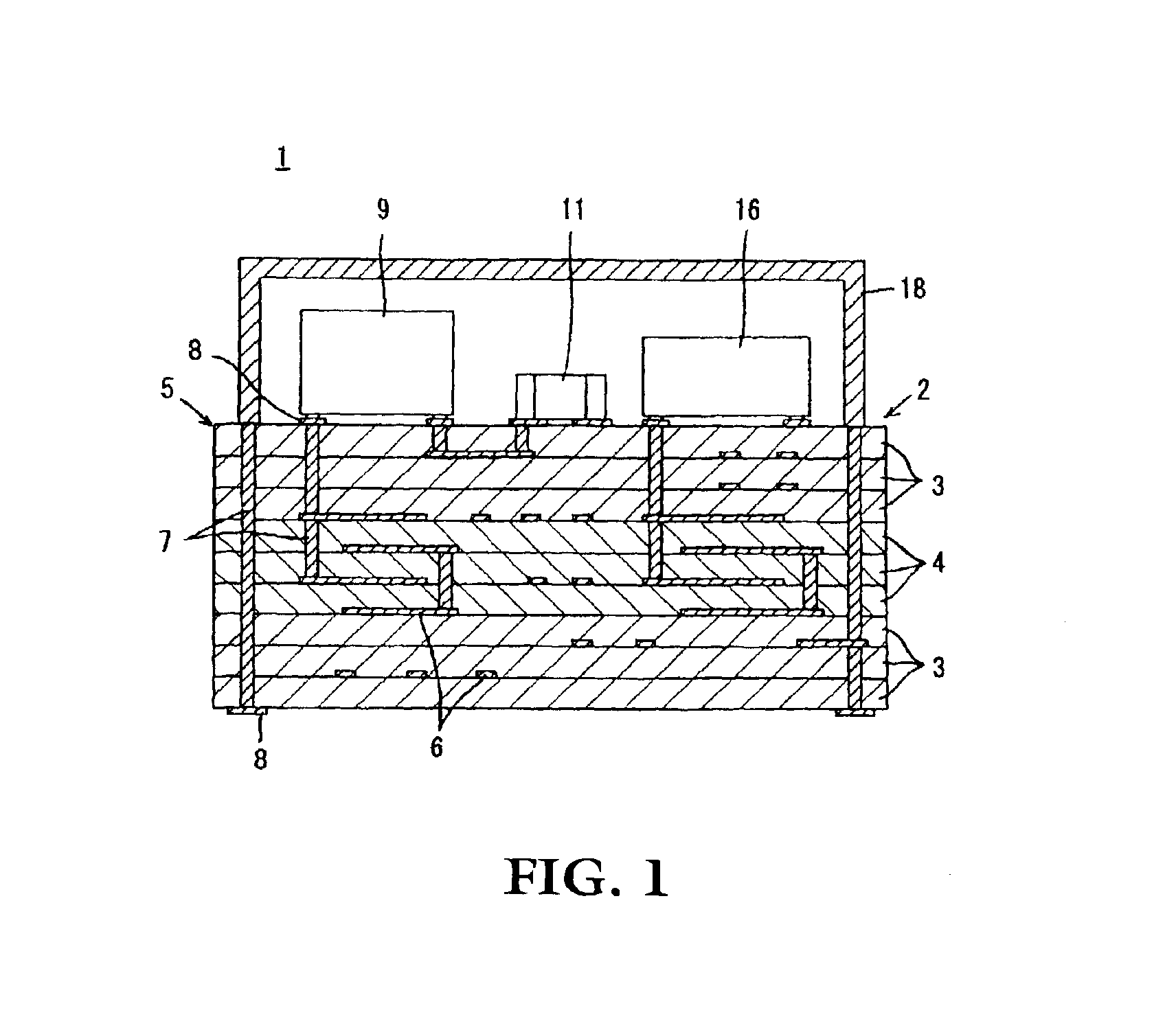

Glass-ceramic composite material and multilayered circuit substrate

InactiveUS6878464B2Low dielectric constantHigh coefficient of thermal expansionSemiconductor/solid-state device detailsSolid-state devicesCeramic compositeThermal expansion

A glass-ceramic composite material for use in forming a multilayered circuit substrate is provided which has a low dielectric constant, but exhibits a relatively high thermal expansion coefficient. Specifically, the glass-ceramic composite material comprises a glass power and a ceramic powder. The glass powder contains: about 30 to 60 mol % of SiO2, about 20 to 40 mol % of BaO, 0 to about 40 mol % of MgO, 0 to about 40 mol % of ZnO, 0 to about 20 mol % of B2O3, with the total content of MgO and ZnO being about 10 to 40 mol %. The ceramic powder contains an alumina powder. The content of the glass powder is set to be at least about 50 wt %. A sintered compact formed by sintering the above glass powder and the above ceramic powder contains a BaO.Al2O3.2SiO2 (BaAl2Si2O8) crystal, and its Q value becomes about 400 or more when a measured frequency is 10 GHz.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com