Patents

Literature

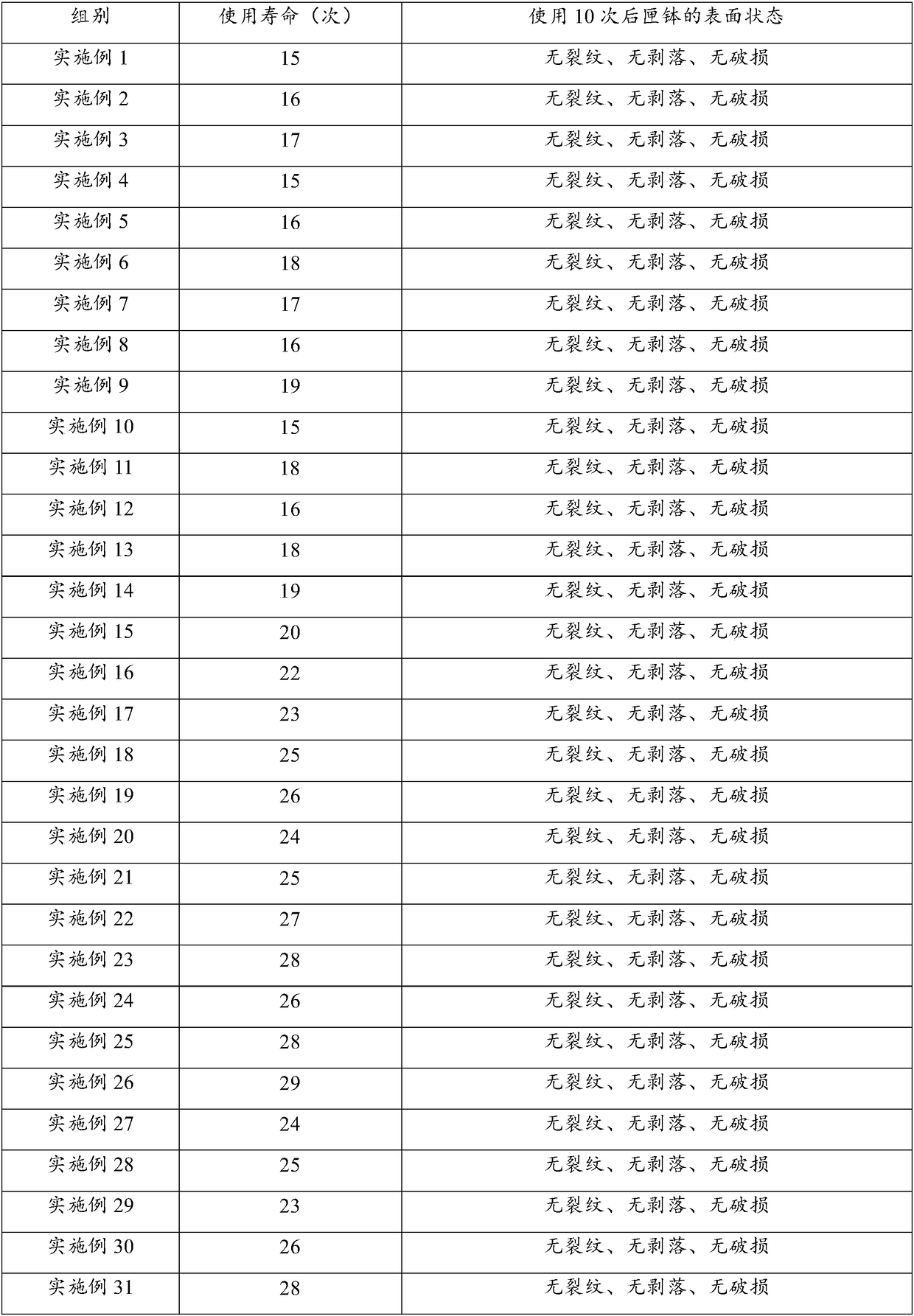

86results about How to "Coefficient of thermal expansion matching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polyurethane-nano kaolin composite material

InactiveCN102002141AGood for uniform dispersionGood for product performancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDimethyl formamideEthyl acetate

The invention relates to a preparation method of a polyurethane-nano kaolin composite material. The composite material mainly comprises polyurethane and nano kaolin. The preparation method is as follows: firstly, carrying out organic intercalation modification on the nano kaolin to obtain organically modified nano kaolin with larger interlamellar spacing; and then using a body-(in-situ) intercalative polymerization method to prepare the polyurethane-nano kaolin composite material. The preparation method is characterized in that the nano kaolin with lower price and better performance is utilized, the composite material is a novel efficient halogen-free retardant agent, and no benzene, toluene, N,N'-dimethyl formamide, ethyl acetate and other harmful solvents are used, therefore environmental requirements are met. By adding a small amount of kaolin, the mechanical property, heat insulation performance and heat resistance of the polyurethane elastomer can be significantly improved. In addition, the material has simple preparation process, low cost and excellent integrated performance, and can be widely applied to mining equipment, sports equipment, area pavement materials and other industries, thereby having wide market prospects.

Owner:ANHUI UNIVERSITY

Production method of once-fired super-spar ceramic tile and ceramic tile

The invention relates to a production method of once-fired super-spar ceramic tile and the ceramic tile. The production method of the once-fired super-spar ceramic tile comprises the following steps: preparing green body powder; pressing a tile body; cleaning the green body; pouring ground glaze; printing; pouring overglaze; firing a glaze body at a high temperature; polishing; performing surface treatment; performing edge polishing; and packaging to obtain a finished product, wherein the overglaze comprises the following components in parts by weight: 5 to 13 parts of quartz powder, 3 to 20 parts of potassium feldspar, 20 to 28 parts of soda feldspar, 12 to 18 parts of dolomite, 3 to 6 parts of fired talc, 3 to 8 parts of kaolin, 14 to 22 parts of calcined kaolin, 3 to 8 parts of zinc oxide, 7 to 14 parts of barium carbonate and 3 to 6 parts of grammite. According to the invention, the problems that microlite has low wear resistance and is difficult to process in the prior art are solved, and the defect of water ripples caused by the situations that fully-polished glaze absorbs dirt, bottom is easy to expose and the tile surface is uneven is also solved. The super-spar product produced with the method has the advantages that the microlite is transparent, bright and smooth like a mirror and does not absorb dirt completely; and the fully-polished glaze is light, thin and wear-resistant.

Owner:周予

Low temperature ceramic color without lead on glaze, and preparation method

This invention relates to a low-temperature lead-free overglaze pigment, which is composed of lead-free pigment 8-30 wt.%, and lead- and cadmium-free flux 70-92 wt.%. The flux is composed of: SiO2 30-60 wt%, B2O3 5-35 wt.%, Al2O3 1.5-15 wt.%, K2O 1.5-10 wt.%, Na2O 1.5-10 wt.%, Li2O 0-8 wt.%, ZnO 0-15 wt.%, CaO 0-5 wt.%, CoO 0-10 wt.%, BaO 0-5 wt.%, MgO 1-5 wt.%, ZrO2 0-10 wt.%, SnO2 0-10 wt.%, and TiO2 0-5 wt.%. The low-temperature lead-free overglaze pigment has such advantages as no toxic or side effects, compact structure, high chemical stability, low baking temperature, beautiful color, high resistance to acid and base, appropriate thermal expansion coefficient, good luster, good decoration effect, and simple preparation.

Owner:淄博华为颜料有限公司

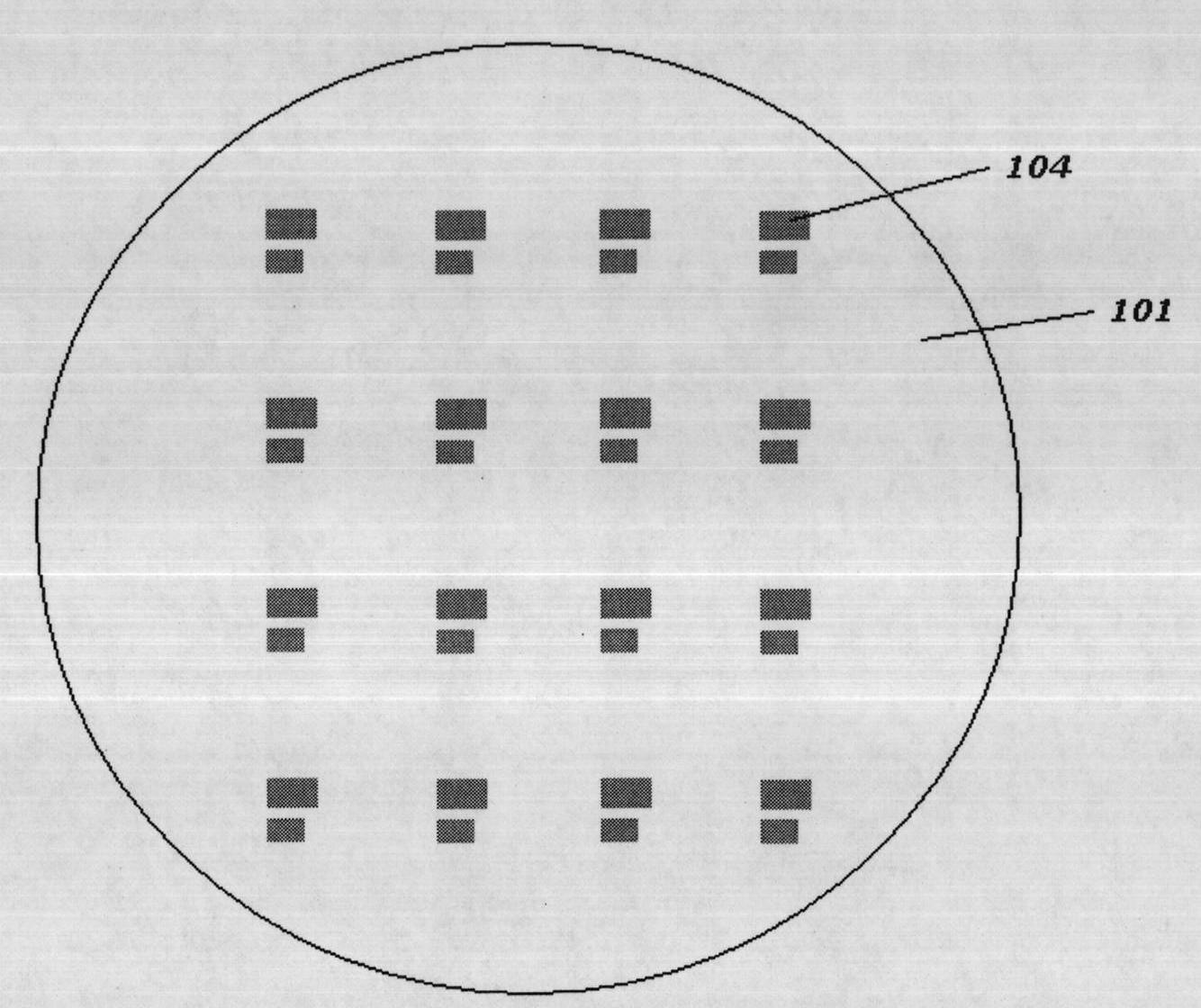

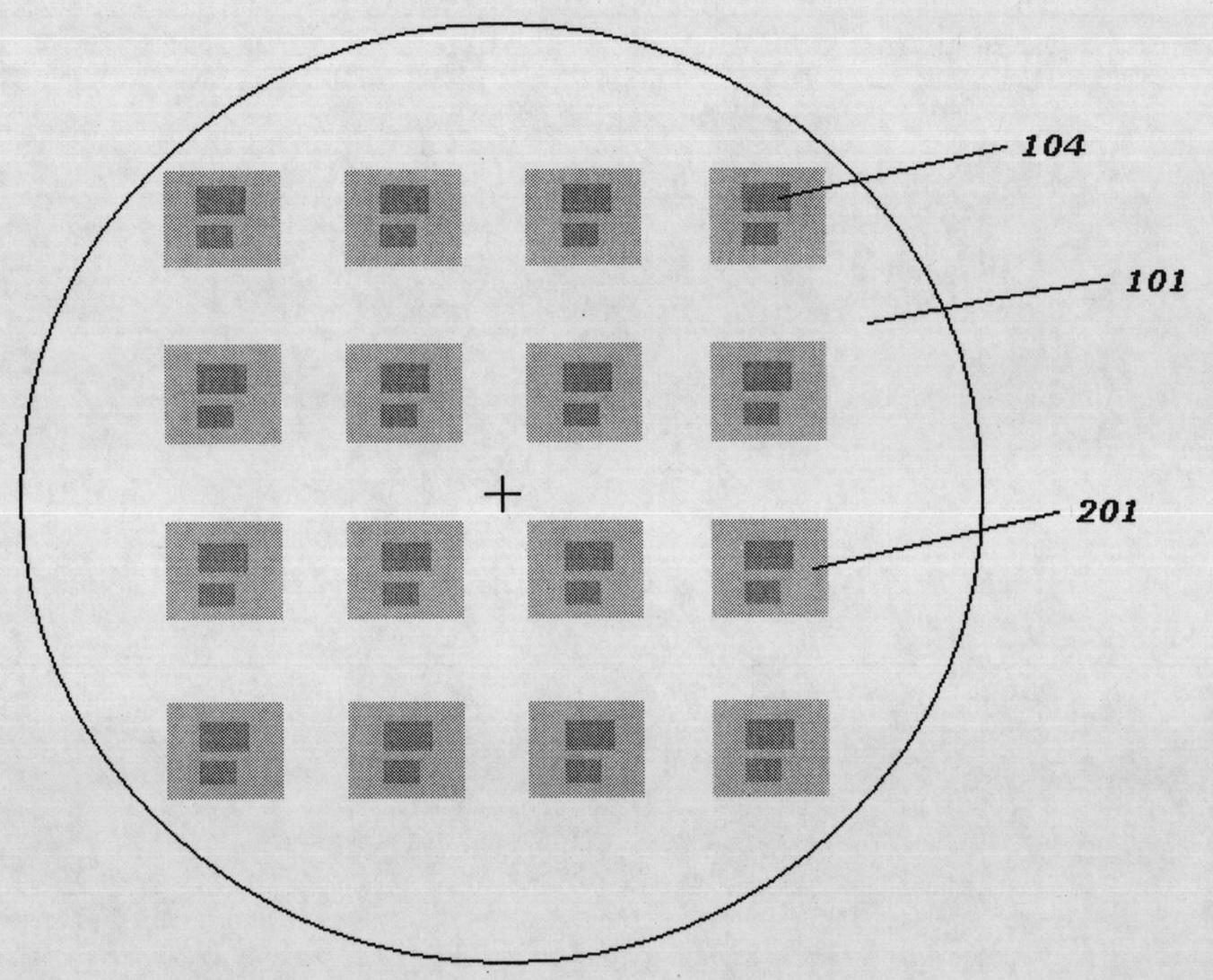

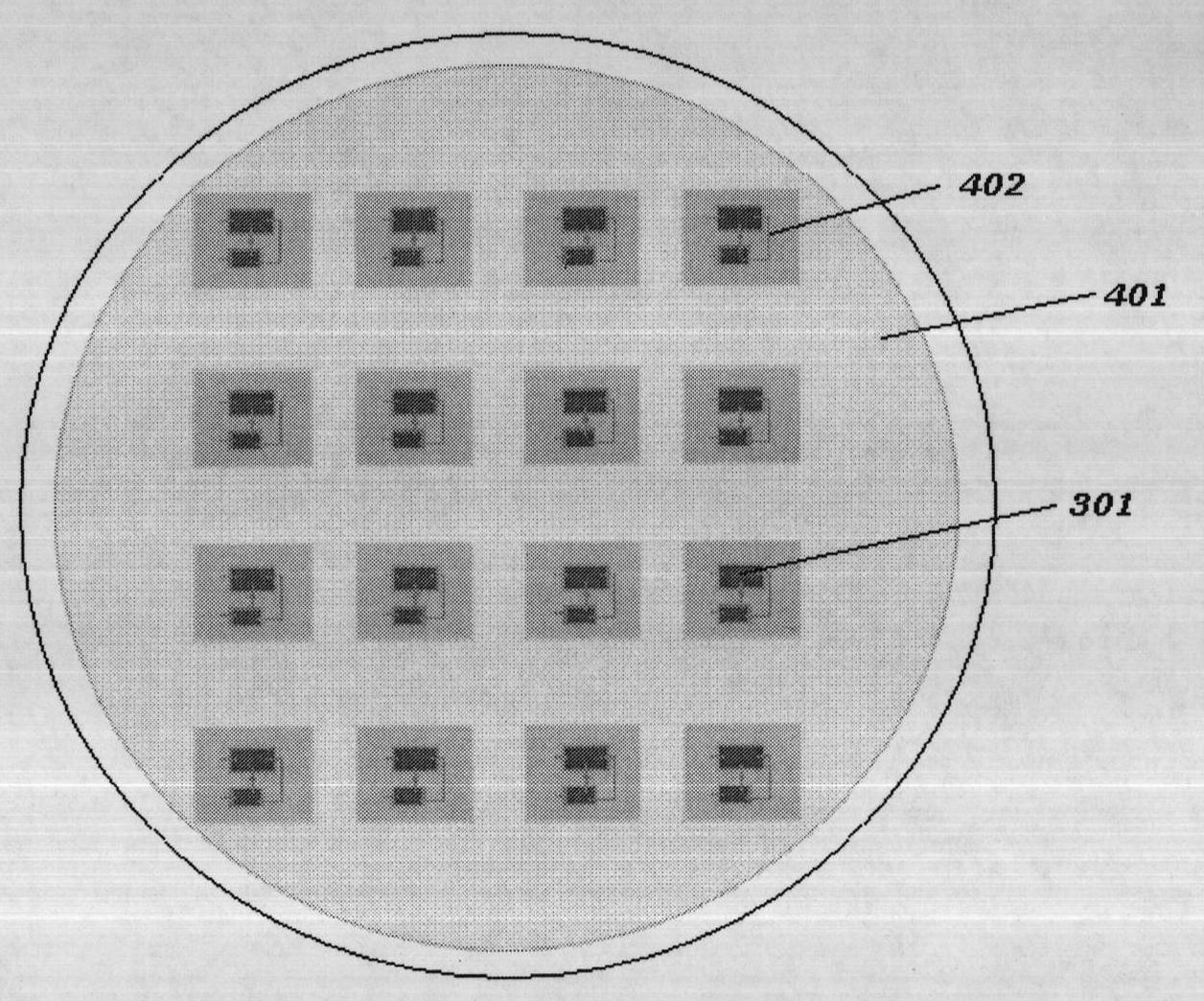

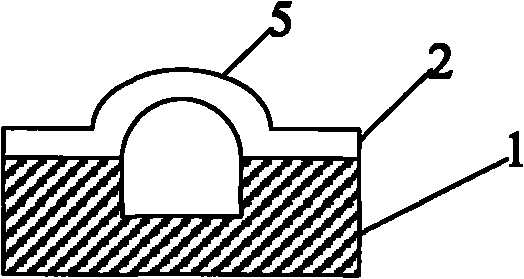

Wafer level MMCM (microwave multichip module) packaging structure using photosensitive BCB (benzocyclobutene) as dielectric layer and method

ActiveCN102110673ASolve the defect of large lossImprove performanceSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSurface-mount technology

The invention relates to a wafer level MMCM (microwave multichip module) packaging structure using photosensitive BCB (benzocyclobutene) as a dielectric layer and a method. The packaging structure is characterized by 1) manufacturing metal ground (GND) shielding layers on a silicon substrate with cavities for embedding; 2) using the photosensitive BCB as the dielectric layers and forming an interconnected through hole structure on the BCB by utilizing photoetching and developing processes; and 3) forming a multi-layer interconnection packaging structure through alternate occurrence of metal layers and the dielectric layers. The method is characterized by eroding or etching the cavities for embedding on the silicon substrate, sputtering a metal seed layer and carrying out electroplating to form the GND, embedding MMIC (monolithic microwave integrated circuit) chips, using conductive adhesives to bond the chips and the substrate, coating the photosensitive BCB and carrying out photoetching and developing to form the interconnected through hole patterns and carrying out curing to realize multi-layer MMCM package. The thickness of the dielectric layers is 20-35mu m. Capacitors, resistors, inductors, power dividers and antenna passive devices can be integrated in the multi-layer interconnection structure or discrete components are integrated through surface mount technology, thus realizing the functionalization of the module.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

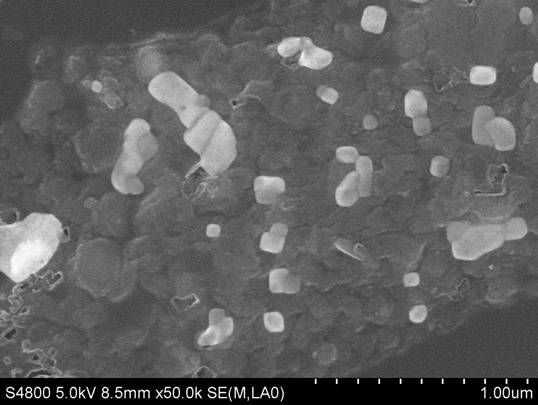

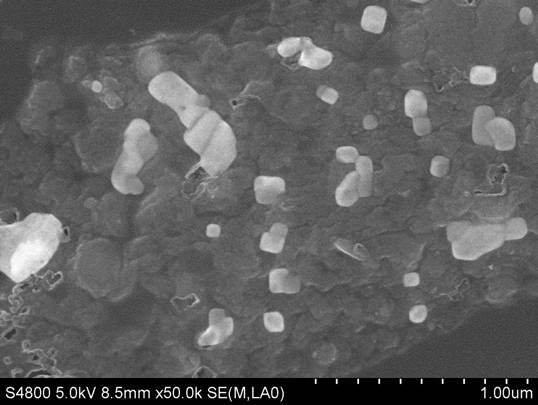

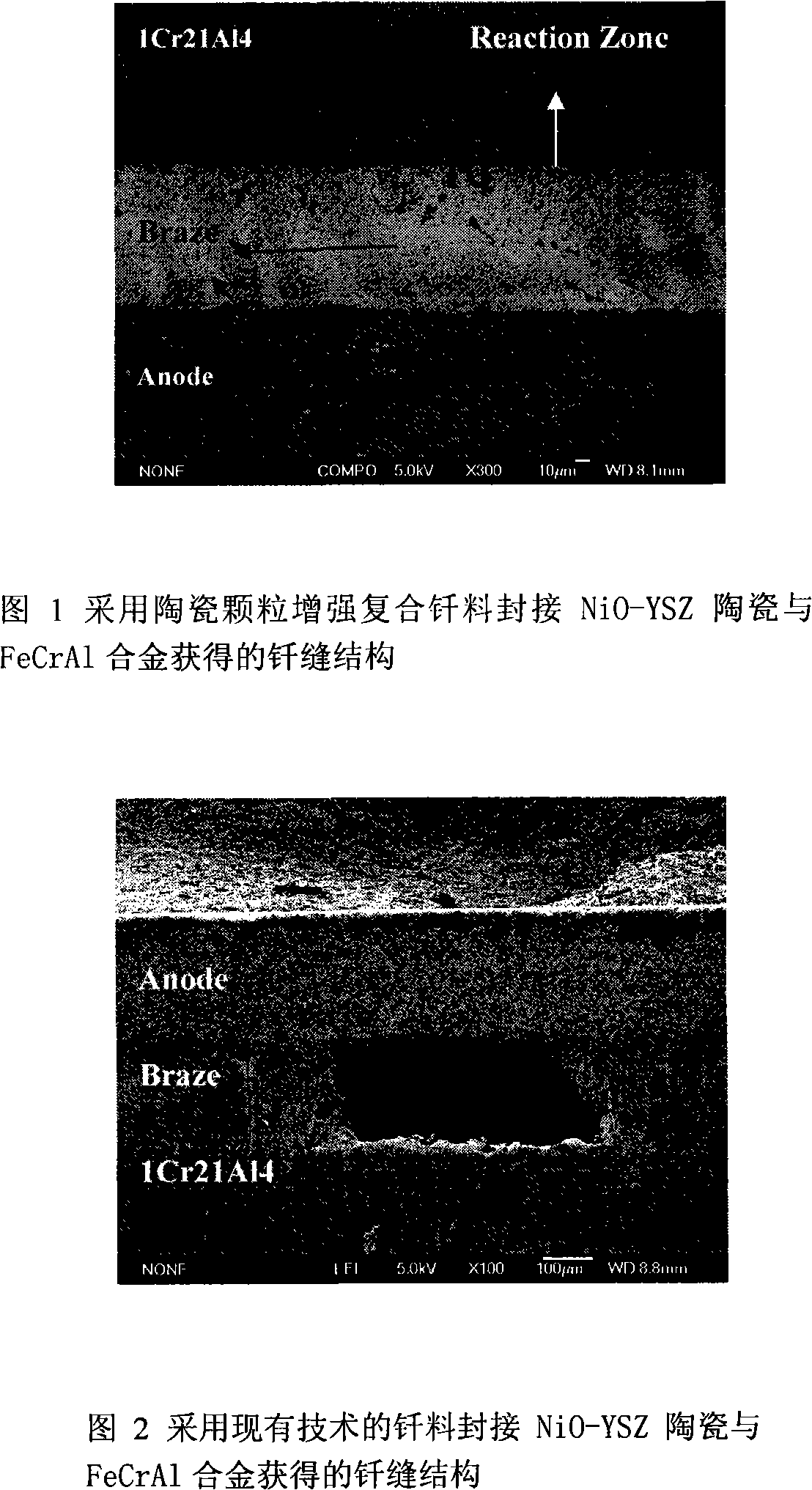

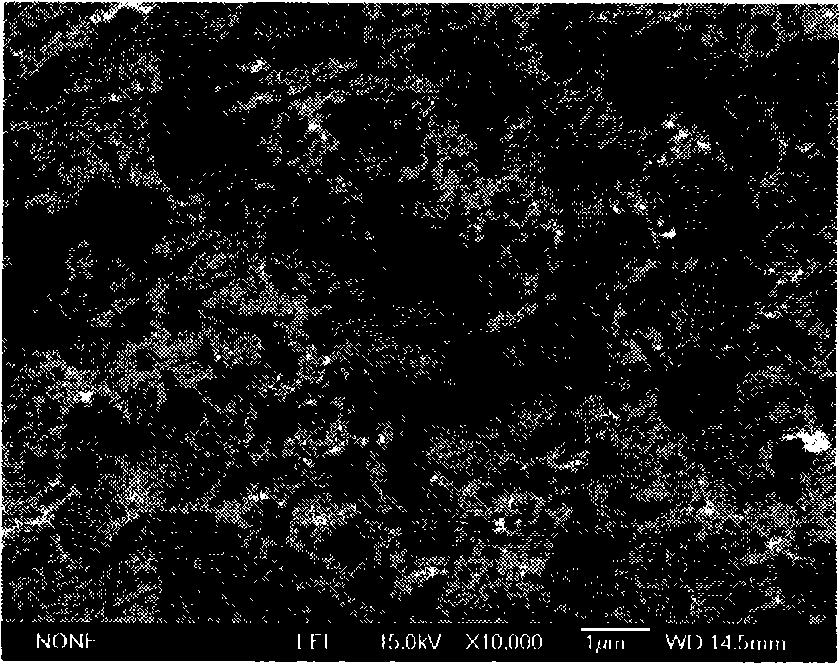

Ceramic granule reinforced composite material

InactiveCN101288928ACoefficient of thermal expansion matchingHigh Prepositioned Functional ViscosityWelding/cutting media/materialsSoldering mediaReducing atmosphereComposite solder

The present invention relates to a ceramic particle strengthening composite solder used for ceramic / ceramic or ceramic / metal solder. The ceramic particle strengthening composite solder consists of 90 to 99.8 percent of metal powder A and 0.2 to 10 percent of ceramic particle B according to the weight percentage; the metal powder A is formed by mixing Ag powder and Cu powder; relatively to the metal powder A, the mol rate of the Ag powder is 80 to 99.5 percent and the mol rate of the Cu powder is 0.5 to 20 percent. The ceramic particle strengthening composite solder provided by the present invention can reduce the generation of air holes in welding line, work at the high temperature of around 800 DEG C, and prolong the service life of the welding line at the high temperature and in the oxidizing atmosphere and the reducing atmosphere, thus obtaining the welding with high joint performance.

Owner:UNIV OF SCI & TECH OF CHINA +1

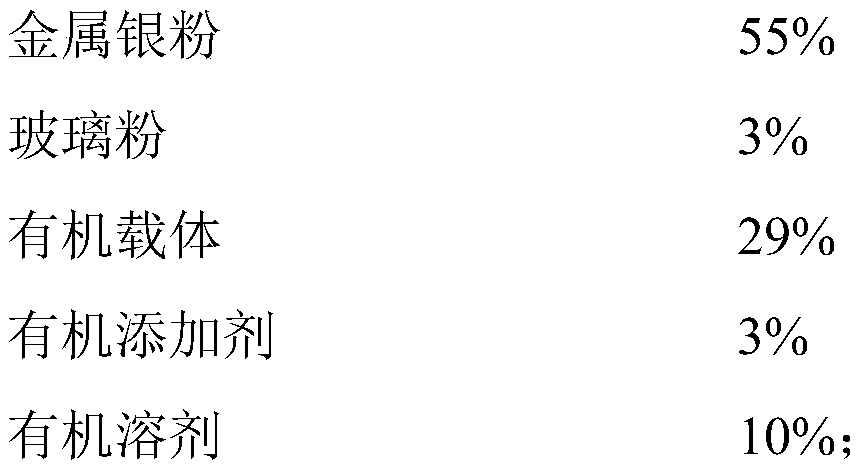

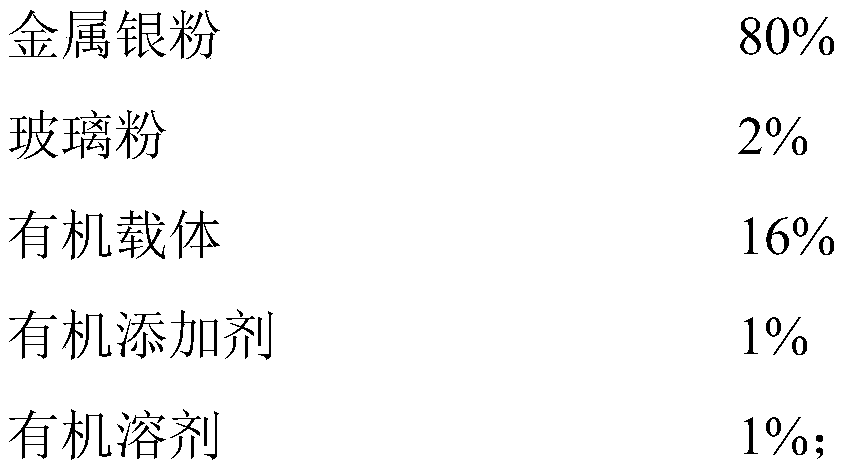

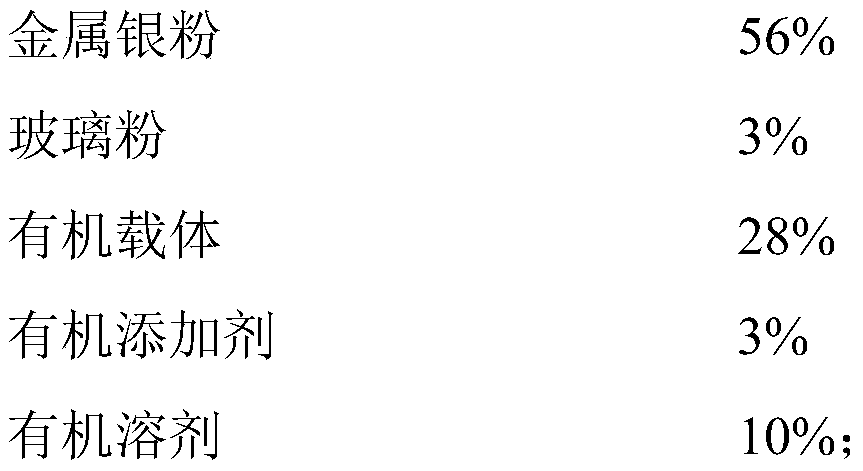

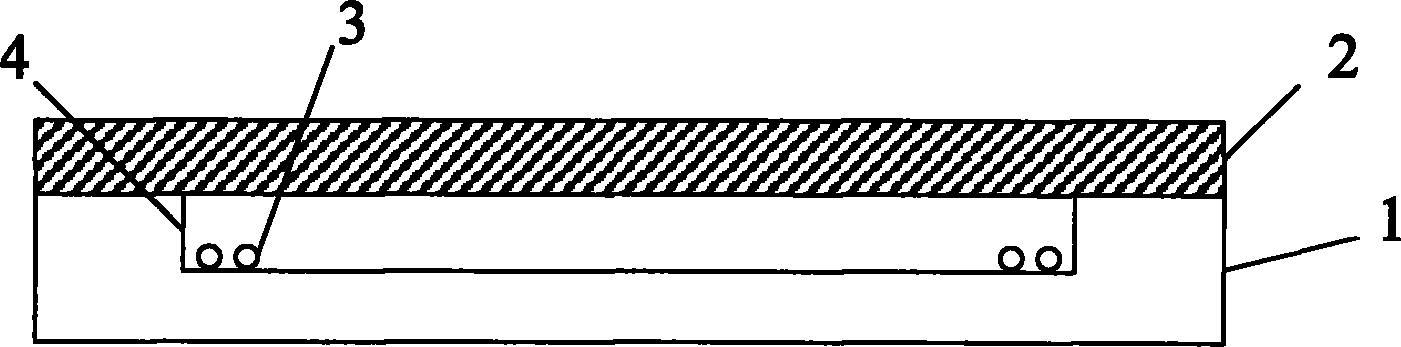

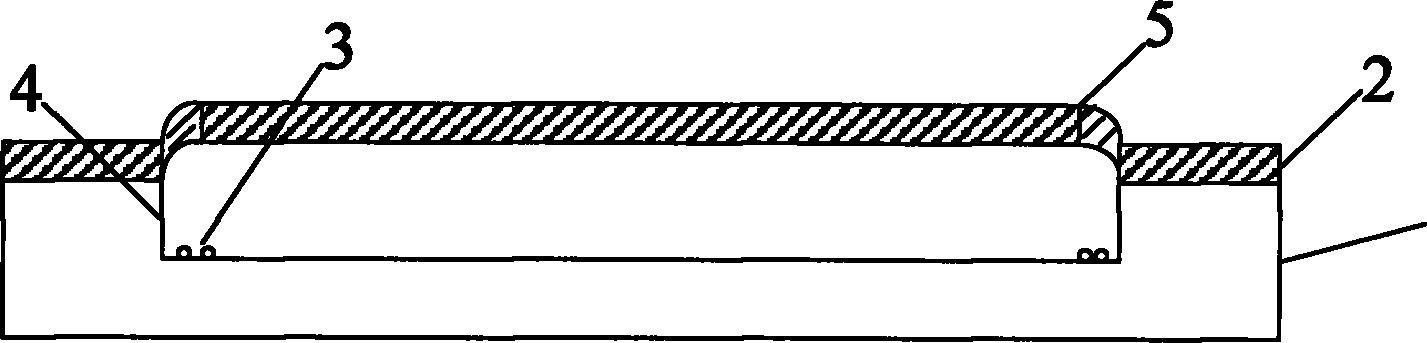

Conductive silver paste for ceramic filter and preparation method thereof

PendingCN111489848ASolve conductivity problemsSolve solder performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteThermal dilatation

The invention relates to conductive silver paste for a ceramic filter and a preparation method of the conductive silver paste. The conductive silver paste comprises the following components in parts by weight: 50-80 parts of metal silver powder, 2-5 parts of glass powder, 10-30 parts of an organic carrier, 1-3 parts of an organic additive and 1-10 parts of an organic solvent, wherein the glass powder is lead-free glass powder, the coefficient of thermal expansion is 110-120*10<-7> / DEG C, and the sintering temperature is 550-750 DEG C. The preparation method comprises the following steps: adding the organic carrier and the organic solvent into a mixer, adding the metal silver powder, the glass powder and the organic additive, fully mixing, transferring a mixture into a high-speed dispersionmachine, and uniformly dispersing at a high speed to obtain a conductive silver paste; and grinding the prepared conductive silver paste in a three-roller mill, and finely adjusting a roller to enable the fineness of the conductive silver paste to be less than 10mu m and the viscosity to be 30-50Pa.S, thereby obtaining the conductive silver paste for the ceramic filter. The conductive silver paste for the filter can form a conductive silver layer which is high in compactness, high in adhesive force, high in conductivity, good in weldability and stable in performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Preparation method of photocatalysis microreactor

ActiveCN101804315AImprove uniformityDoes not affect the photocatalytic effectPhysical/chemical process catalystsEnergy based chemical/physical/physico-chemical processesMicroreactorPhotocatalytic reaction

The invention discloses a preparation method of a photocatalysis microreactor, comprising the following steps of: forming a specific silicon micro-flow slot pattern on a silicon wafer by etching; locally placing the proper amount of high-temperature gas releasing agent at both ends or specific positions of a micro-flow slot; carrying out anodic bonding on the silicon wafer and a glass wafer in air or vacuum to enable the micro-flow slot on the silicon wafer to form a seal cavity body, and heating to 760-900 DEG C in the air and carrying out heat preservation for 5-10 min, wherein the high-temperature gas releasing agent releases gas to generate positive pressure after being heated to enable melted glass corresponding to the seal cavity body to be in a circular tube shape; cooling the melted glass to form a glass micro-flow channel; preparing an inlet and an outlet on the glass micro-flow channel; removing the decomposition residues of the high-temperature gas releasing agent; coating a photocatalyst on the inner tube wall of the glass micro-flow channel to form a thermal forming glass photocatalysis microreactor. In the invention, the cylindrical glass micro-flow channel is adopted to serve as the shell of the reactor, and thereby, a larger specific surface area is provided, the cost is low and the photocatalysis reaction efficiency is high.

Owner:NANTONG XIANGYANG OPTICAL ELEMENT +1

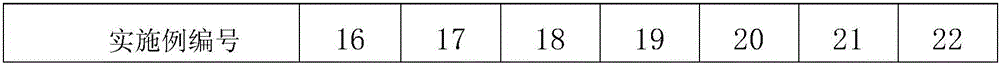

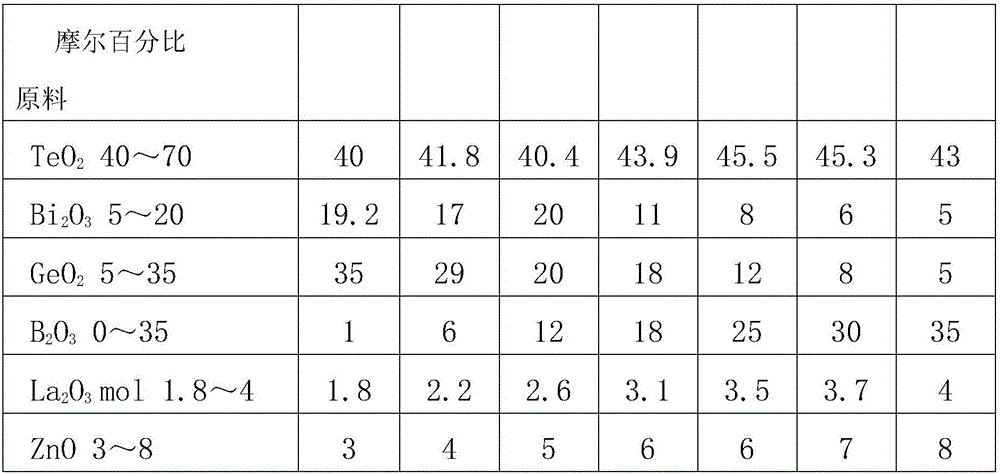

Preparation method of tellurite glass powder for silicon solar battery positive electrode silver paste

InactiveCN105800942ALower melting temperatureLow viscosityPhotovoltaic energy generationCable/conductor manufactureSilver pasteSilicon solar cell

The invention discloses a preparation method of tellurite glass powder for silicon solar battery positive electrode silver paste.The preparation method is characterized in that by molar percentage, 40-70% of TeO2, 5-20% of Bi2O3, 5-35% of GeO2, 0-30% of V2O5, 0-35% of B2O3, 1.8-4% of La2O3 and 3-8% of ZnO are weighed and blended, postprocessing steps including mixed material fine grinding and drying, glass melting, secondary fine grinding and the like are conducted, and the tellurite glass powder for silicon solar battery positive electrode silver paste is obtained.By the adoption of the prepared tellurite glass powder, no lead is contained, and it is beneficial to protect the environment and the human health; the tellurite glass powder is good in adaptation to a silicon substrate and silver, is matched with the silicon substrate and silver in coefficient of thermal expansion and is good in chemical stability, moderate in softening temperature and particularly suitable for a binding phase of the silicon solar battery positive electrode silver paste.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Transparent dielectric paste

InactiveCN101950600AHigh light transmittanceProper thermal transition temperatureLight-sensitive devicesSolid-state devicesOrganic solventThermal transition

The invention discloses a transparent dielectric paste, comprising an organic carrier and inorganic glass powder dispersed in the organic carrier, wherein the mass ratio of the inorganic glass powder to the organic carrier is 60:40-90:10; the inorganic glass powder comprises PbO, B2O and SiO2 based on the mass ratio of 60-80:6-15:10-30; and the organic carrier comprises an organic solvent with the boiling point of 150-300 DEG C and a resin with the decomposition temperature of 200-350 DEG C, and the mass ratio of the organic solvent to the resin is 85:15-97:3. The transparent dielectric paste provided by the invention is formed by evenly dispersing the inorganic glass powder with insulating performance in an organic medium. The transparent dielectric paste can form a transparent dielectric layer which has high transmittance and surface flatness, proper thermal transition temperature and thermal expansion coefficient matched with substrate glass.

Owner:IRICO

Matte glaze applied to sanitary ceramics, sanitary ceramics applying matte glaze and preparation method

The invention discloses a matte glaze applied to sanitary ceramics, the sanitary ceramics applying the matte glaze and a preparation method, and relates to the technical field of sanitary ceramics. The matte glaze applied to sanitary ceramics comprises the following raw materials by weight: 25-27 parts of potassium feldspar, 17-20 parts of quartz, 1-3 parts of zinc oxide, 8-12 parts of dolomite, 5-8 parts of wollastonite, 5-8 parts of kaolin, 6-8 parts of aluminum oxide, 7-9 parts of zirconium silicate, 1-4 parts of frit, 6-9 parts of barium carbonate, 5-9 parts of calcined talc and 0.5-1.5 parts of lithium carbonate. A certain quantity of lithium carbonate is introduced to achieve fluxing, the melting temperature of the raw materials is reduced, mutual fusion of the raw materials is facilitated, the viscosity of the frit is improved through lithium carbonate, the viscosity of the matte glaze is reduced, the flowing property of the matte glaze at high temperature is improved, flowing of crystals separated out of the matte glaze is facilitated, the crystals are arranged more uniformly and orderly, the glaze surface flatness is conveniently controlled, and the sanitary ceramic firingefficiency is improved.

Owner:JIANGXI DONGPENG BATHROOM CO LTD +1

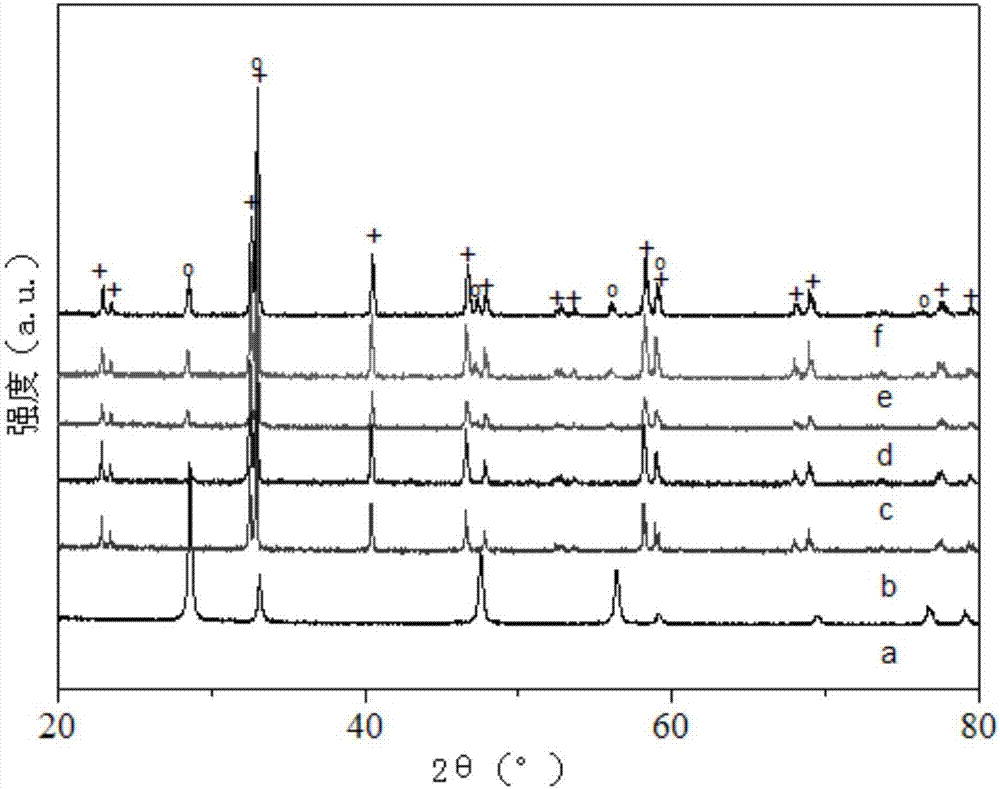

Rapid diffusion welding connection method for skutterudite thermoelectric material and electrode

ActiveCN111014929AImprove thermoelectric conversion efficiencyGuaranteed thermoelectric conversion efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusSkutteruditeElectroplating

The invention discloses a rapid diffusion welding connection method for a skutterudite thermoelectric material and an electrode, and relates to a diffusion welding connection method. The method aims to solve the problems of Sb element volatilization and element diffusion when the existing skutterudite thermoelectric material is connected with an electrode. The method comprises the steps of takingan electrode, cleaning a to-be-welded surface, electroplating an alloy barrier layer on the surface of the to-be-welded surface of the electrode, cleaning the to-be-welded surface of the skutteruditethermoelectric material, and performing diffusion welding. The barrier layer is prepared on the electrode side through an electroplating method, diffusion welding is achieved between the barrier layerand the skutterudite thermoelectric material under the relatively low pressure and at the relatively low temperature, element diffusion of weld joint elements and skutterudite does not exist in the process, and Sb element volatilization and element diffusion can be prevented. The method is suitable for welding the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

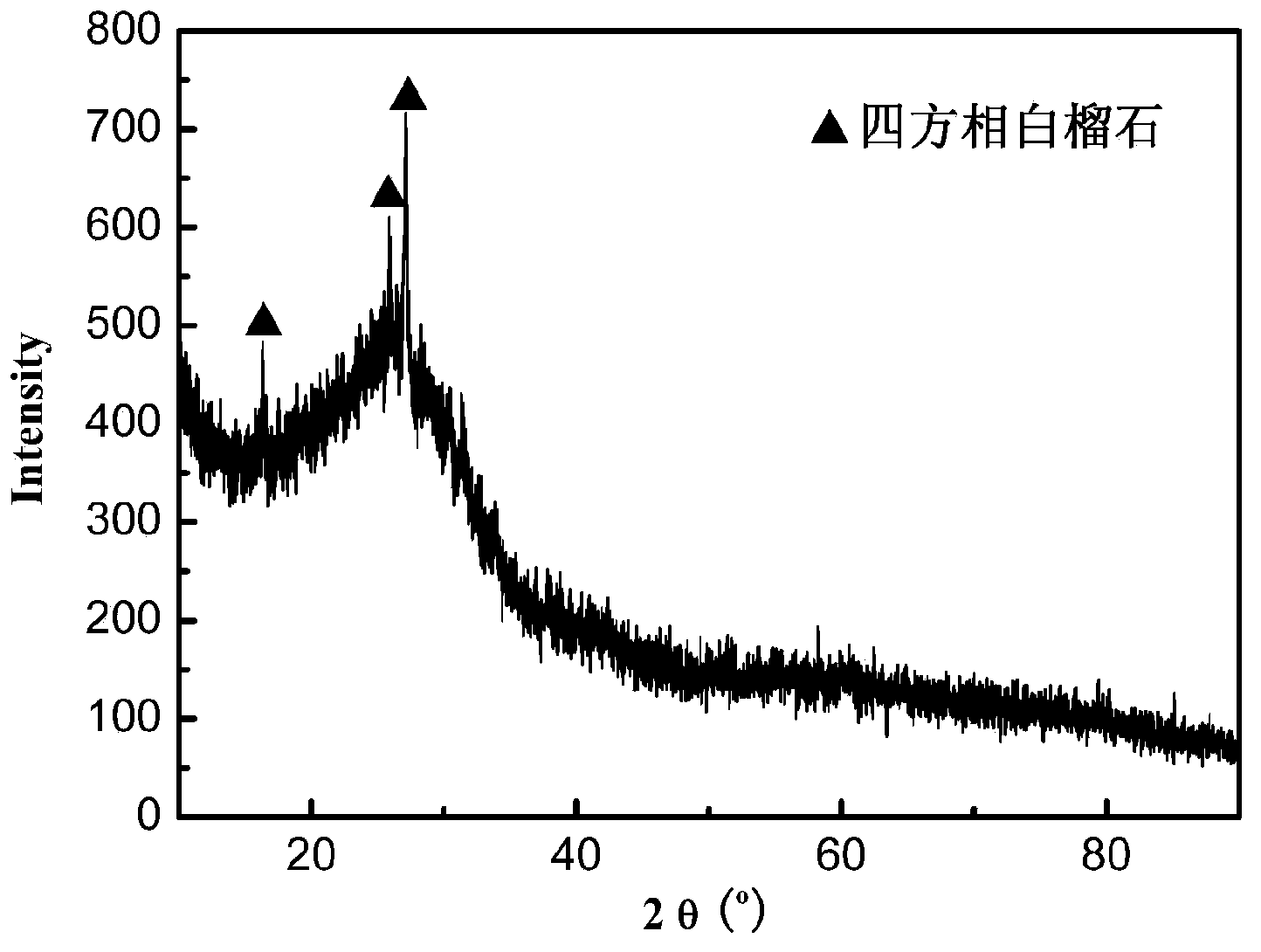

Glass used as dental veneering porcelain, preparation method and application thereof

ActiveCN103910489APorcelain low temperaturePorcelain temperature loweredGlass productionDental Veneer MaterialLeucite

The invention relates to a glass used as a dental veneering porcelain. The glass comprises, by mass, 50%-70% of SiO2, 6%-17% of B2O3, 6%-25% of Al2O3, 1%-10% of Na2O, and 17%-30% of K2O. The glass undergoes heat treatment at 700DEG C-1100DEG C, and leucite microcrystalline glass with different thermal expansion coefficients can be obtained. The microcrystalline glass only contains tetragonal phase leucite crystals, the size of which is less than 4 micrometers. The leucite microcrystalline glass has very good thermal stability, after experiencing a porcelain fusing program 10 times, the thermal expansion coefficient change of the leucite microcrystalline glass is less than 2%, and in a 120min process of heat preservation at a porcelain fusing temperature of 850DEG C, the size and number of the leucite crystals do not have obvious change. The leucite microcrystalline glass can be used as a transparent porcelain and incisal porcelain in the veneering porcelain, and also can be used as a body porcelain if a pigment is added.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Multi-particle ceramic/metal compound heat dissipation substrate and preparation method thereof

InactiveCN103968345AHigh thermal conductivitySmall coefficient of thermal expansionPoint-like light sourceLighting heating/cooling arrangementsHeat sinkStress level

The invention discloses a multi-particle ceramic / metal compound heat dissipation substrate and a preparation method thereof. The heat dissipation substrate comprises a ceramic / metal compound material formed by compounding a plurality of ceramics with metal, an insulation layer and a circuit layer, wherein each ceramic and metal compound part is a particle in the ceramic / metal compound material; the total area of particles accounts for 10%-80% that of the ceramic / metal compound material. The heat dissipation substrate has the characteristics of high heat conduction rate, small heat expansion coefficient, low cost, convenience in use and the like, and is applied to the aspects of lamp decorations, communication electronic equipment, power modules, computers, automotive electronics and the like; the stress level of the connection layer of a chip or device substrate and the heat dissipation substrate can be greatly reduced, that the heat dissipation substrate is in close contact with heat sinks of lamps, machine cases and the like can be kept, a heat transfer passage is kept unblocked for a long term, the weight of the metal heat sinks can be reduced, and a heat transfer technology guarantee is provided for greatly prolonging the service lives of components and economically utilizing heat sink materials.

Owner:襄阳新瑞源科技信息有限公司 +1

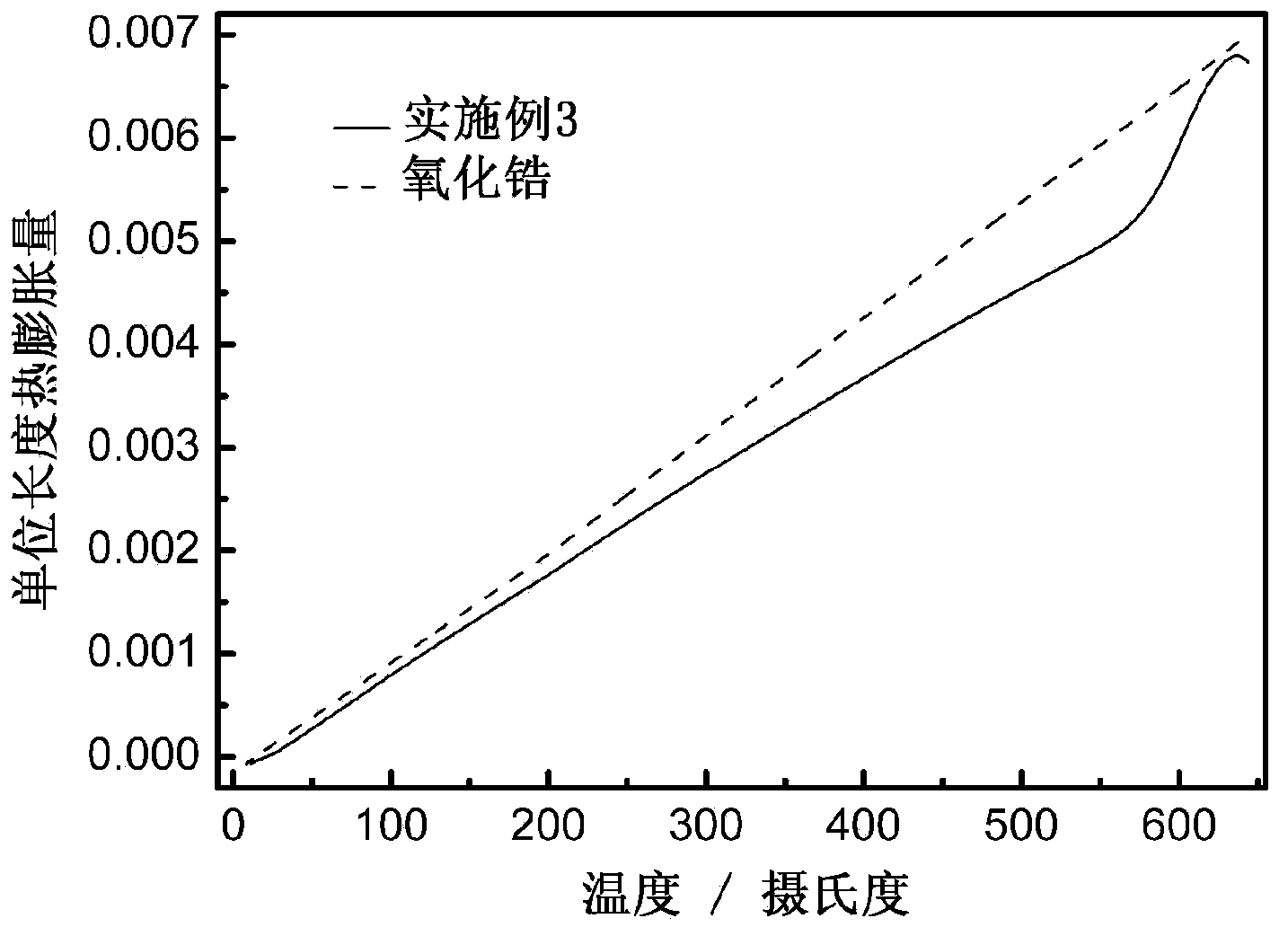

Glass powder for PERC aluminum paste and preparation method thereof

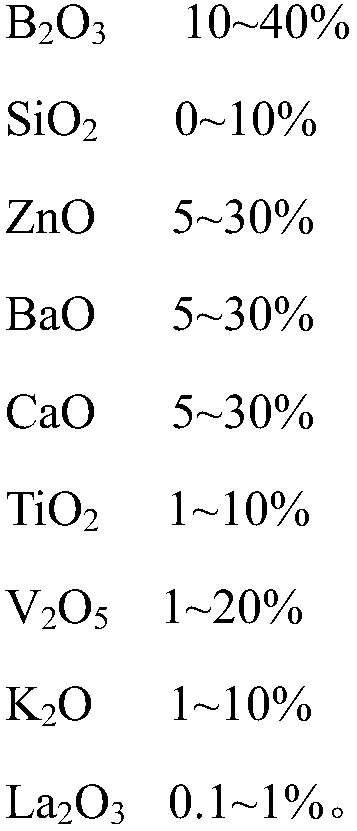

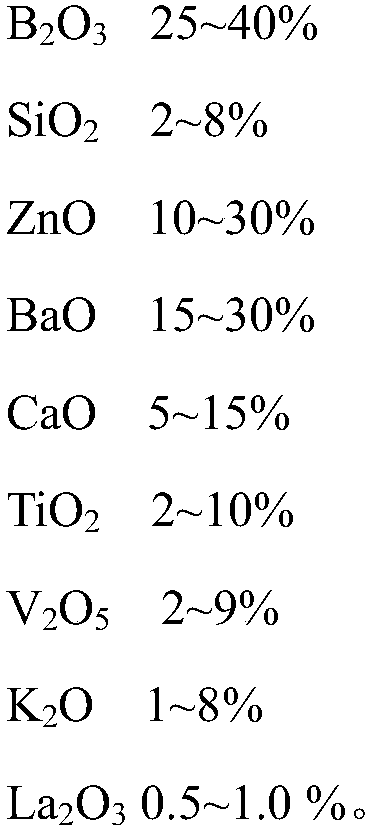

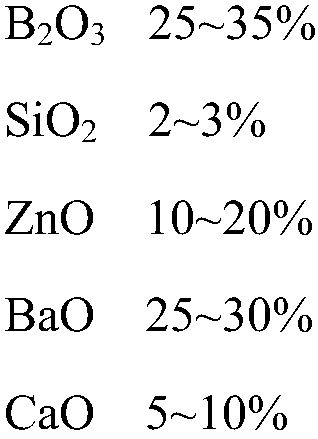

The invention discloses glass powder for PERC aluminum paste. The glass powder is mainly prepared from the following raw materials by mass: 10 to 40% of B2O3, 0 to 10% of SiO2, 5 to 30% of ZnO, 5 to 30% of BaO, 5 to 30% of CaO, 1 to 10% of TiO2, 1 to 20% of V2O5, 1 to 10% of K2O and 0.1 to 1% of La2O3. When applied to the PERC aluminum paste, the glass powder can reduce corrosion of the aluminum paste to a passive film layer at a high temperature and promote formation of alloy in local contact areas. The invention also discloses a preparation method for the glass powder applied to the PERC aluminum paste.

Owner:GUANGZHOU RUXING TECH DEV +1

Connection method for carbon/carbon composite materials

InactiveCN108329048AImprove cohesionImprove the bonding strength of the interfaceCarbon compositesGas phase

The invention provides a connection method for carbon / carbon composite materials. The method comprises the following steps: performing pre-oxidation treatment on surfaces of the carbon / carbon composite materials to form as many gullies as possible on the surfaces of the composite materials, wherein the gullies facilitate formation of a tortuous connection interface between a connecting layer and the carbon / carbon composite materials; growing carbon nanotubes in situ on the surfaces of the pre-oxidized carbon / carbon composite materials by adopting a chemical vapor deposition process; and enabling the carbon / carbon composite materials with the grown carbon nanotubes to be embedded together, performing fixing by using a graphite clamp, and depositing pyrolytic carbon among the carbon / carbon composite materials with the grown carbon nanotubes by adopting a chemical vapor infiltration process, so as to obtain a C / C composite material connected with a carbon nanotube / pyrolysis carbon middlelayer. The method provided by the invention has the main technical effects that compared with ceramic-based, glass-based and metal-based connecting layers, the carbon-based connecting layer prepared by the method provided by the invention has thermal expansion coefficient matched with that of the C / C composite material, and has the characteristics of excellent thermal shock resistance and high connection strength.

Owner:SHAANXI UNIV OF SCI & TECH

Composite saggar as well as preparation method and application thereof

ActiveCN108083823AStrong corrosion resistanceLow costElectrode manufacturing processesSecondary cellsSillimaniteSaggar

The invention relates to the field of refractory materials and particularly provides a composite saggar as well as a preparation method and an application thereof. The composite saggar comprises a bottom material and a surface material. The bottom material is mainly prepared from kaolin, sillimanite with specific particle size, aluminum oxide with specific particle size, corundum with specific particle size, andalusite with specific particle size and mullite with specific particle size. The raw materials of the base material have rich source and low cost, so that the cost of the bottom material is lower. The surface material is mainly prepared from a corundum surface material, a spinel surface material, a zirconium oxide surface material, a zirconium silicate-zirconium oxide surface material or a corundum-spinel surface material. All the raw materials of the surface material cooperate with one another, so that the surface material has good corrosion resistance. The composite saggar haslower cost, good corrosion resistance and the advantage of long service life.

Owner:ZHEJIANG UNIV

Enamel coating with function of resisting sulfuric acid and hydrochloric acid dew point corrosion and preparation technology thereof

ActiveCN108409138AThe preparation process is non-toxicNo pollution in the processMetallic materialsBoron trioxide

The invention relates to the field of inorganic protection coatings, and particularly provides an enamel coating with the function of resisting sulfuric acid and hydrochloric acid dew point corrosionand a preparation technology thereof. The enamel coating can serve as Q235 steel, BTC1 steel, 304 stainless steel and other metal material parts. Micron oxide particles are uniformly dispersed and distributed in an enamel glaze substrate parent phase, wherein enamel glaze is formed by mixing and melting the analytical pure raw materials (such as: silicon dioxide, aluminum sesquioxide, diboron trioxide, sodium oxide, potassium oxide, nickel oxide, cobalt oxide and calcium fluoride) at the high temperature and water quenching, and the micron oxide particles are one or arbitrary combination of analytical pure aluminum sesquioxide, silicon dioxide, titanium dioxide and zirconium dioxide. The enamel coating is prepared from the raw materials which can be purchased in the market directly, and the preparation technology is free of toxicity and pollution in the process, and conforms to the energy-saving and environment-friendly development trend. The enamel coating is compact and free of pores, has higher strength, fracture toughness, good binding force with a steel substrate and a matched coefficient of thermal expansion.

Owner:NORTHEASTERN UNIV

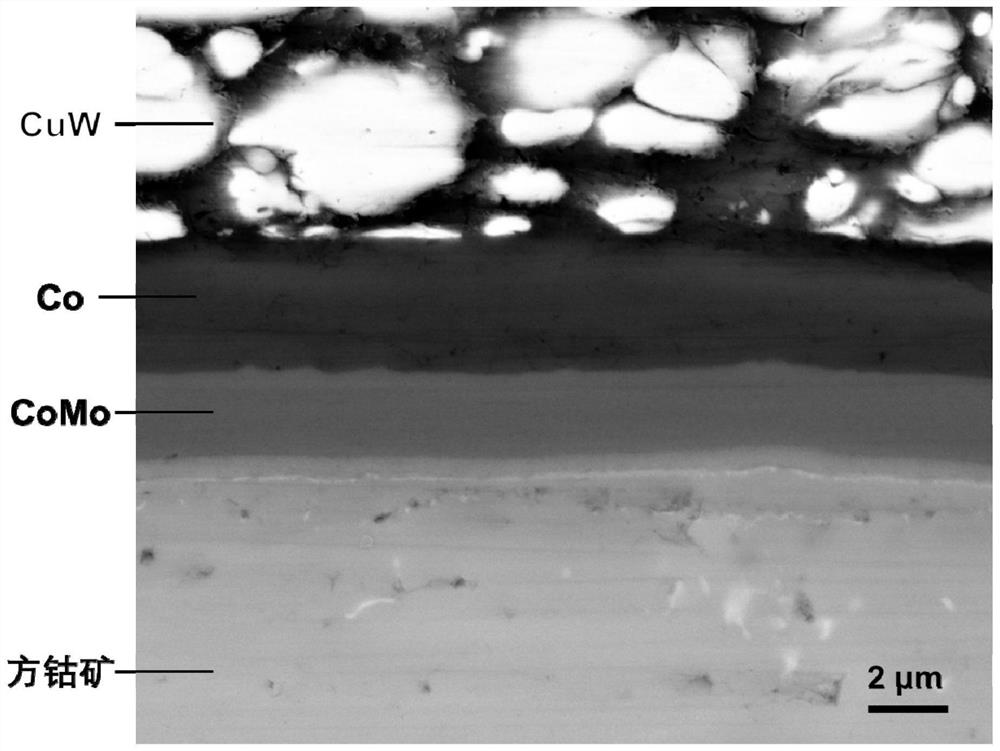

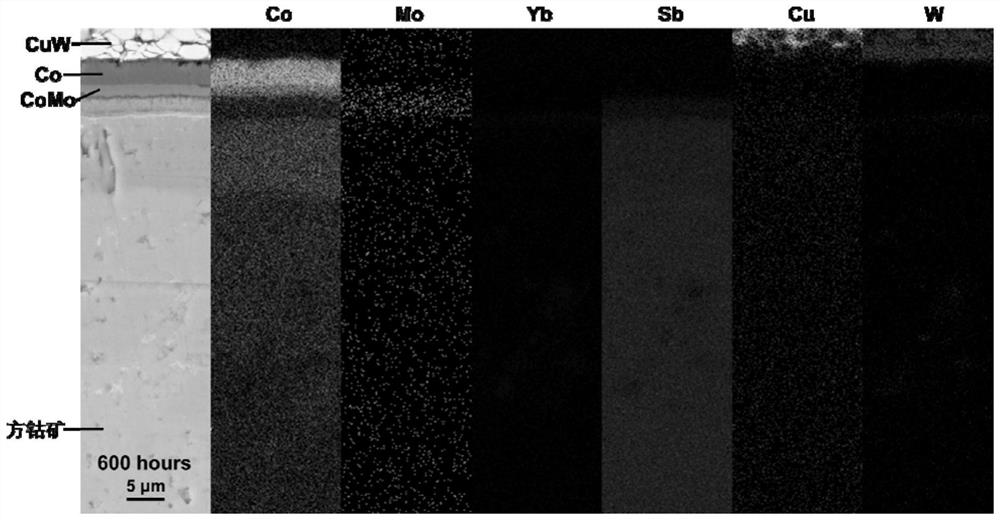

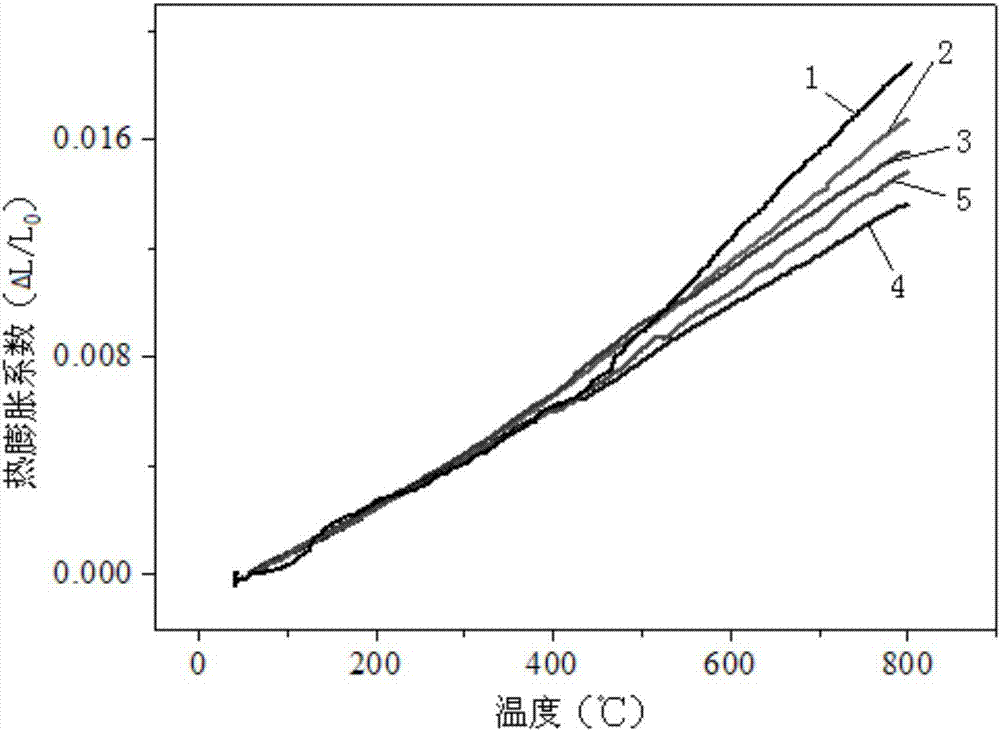

Method for connecting skutterudite thermoelectric material and electrode by using high-thermal-stability alloy composite intermediate layer

ActiveCN112276275ABarrier interdiffusionReduce contact resistivityThermoelectric device manufacture/treatmentSoldering apparatusHeat stabilityAlloy composite

The invention relates to a method for connecting a skutterudite thermoelectric material and an electrode by using a high-thermal-stability alloy composite intermediate layer, in particular to the method for connecting the skutterudite thermoelectric material and the electrode. The method aims to solve the problems of poor thermal stability and large contact resistance of a joint obtained by the existing skutterudite thermoelectric material welding method. The method comprises the following steps of 1, cleaning the skutterudite thermoelectric material and the electrode; and 2, preparing the intermediate connecting layer and a diffusion barrier layer by using an electroplating or physical vapor deposition method, and carrying out diffusion welding, wherein the intermediate connecting layer is made of Co, Fe or Ni, and the diffusion barrier layer is made of CoMo, CoW, FeMo or FeW. According to the method, the joint obtained by utilizing the intermediate connecting layer and the diffusionbarrier layer has low contact resistivity, and the thermal stability of the joint is high. The method is suitable for connecting the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

Preparation method of lightweight thermal-insulation decoration surface material for outer wall

The invention provides a preparation method of a lightweight thermal-insulation decoration surface material for outer wall, and the method is characterized by comprising the following steps: firstly, adopting ceramic green body waste material, Laiyang soil, sedimentation tank waste material, polished tile waste residue and the like as raw materials respectively at different mass ratios to obtain four types of pellet granules, namely A pellet granule, B pellet granule, C pellet granule and D pellet granule; then uniformly mixing the A pellet granule, the B pellet granule and the C pellet granule according to a mass ratio of A pellet granule to B pellet granule to C pellet granule of 1:2:1, then uniformly distributing the pellet granules in the concavo-convex mold, and paving the surface with a layer of D pellet granule as a base material, obtaining a green body under a pressure of 220 MPa after the process of second material distributing, wherein the mass ratio of the base material D pellet granule to the other three pellet granules is 1-3:10; and sequentially performing the process of drying, jet drawing patterns and sintering so as to obtain the lightweight thermal-insulation decoration surface material for outer wall. Test results show that the lightweight thermal-insulation decoration surface material for outer wall has characteristics of low specific gravity, uniform pore size distribution, low water absorption, high bending strength and low thermal conductivity. The decoration surface material has high wear resistance and enables demonstration of the appearance of stone.

Owner:ZIBO GOLD LION KING TECH CERAMICS CO LTD

Method for reducing content of residual silicone in SiCf/SiC composites prepared by infiltration process

The invention belongs to the technical field of preparation of ceramic matrix composites, and particularly relates to a method for reducing the content of residual silicone in SiCf / SiC composites prepared by an infiltration process. According to the method, silicon carbide fibers, serving as fiber reinforcements, and paste containing Ti powder or TiC powder are prepared into prepregs, and after hot press molding, carbonization and infiltration, the silicon carbide fiber reinforced silicon carbide composites are prepared. After introduction, Ti or TiC can react with the residual silicone in matrixes to generate TiSi2. The method can overcome the defect that silicone remains in the matrixes of the ceramic matrix composites prepared by the infiltration process, and can improve the high temperature stability of the composites without affecting the original mechanical properties of the composites.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

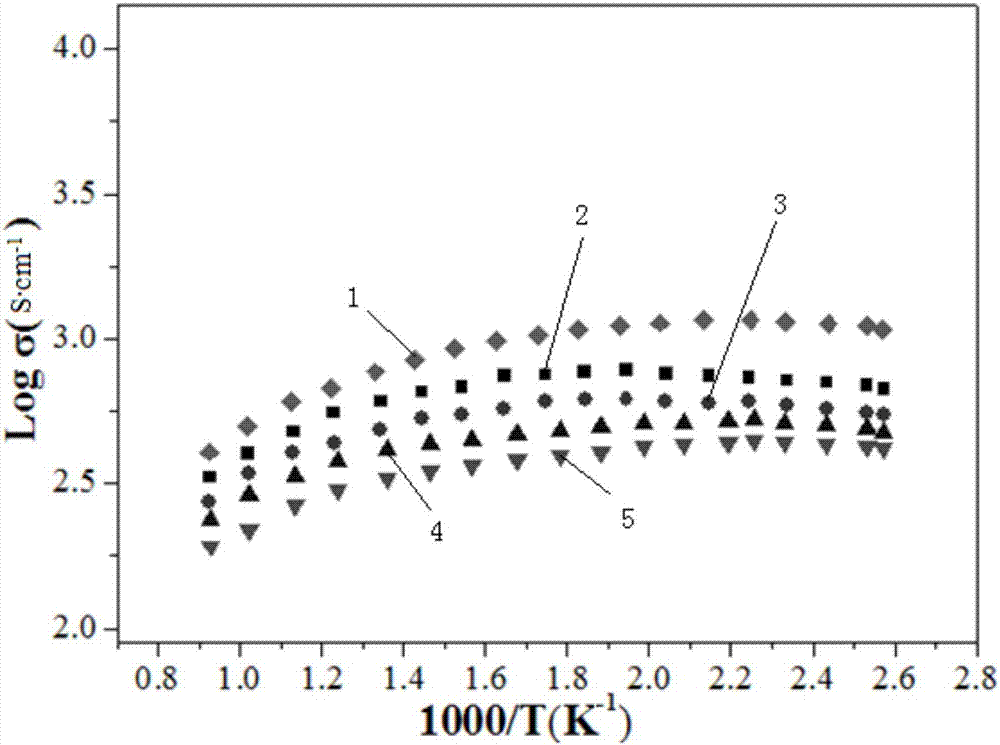

Method for preparing composite cathode materials RBCO-xCGO of SOFC by in-situ colloidal composite method

ActiveCN106856242AImprove the preparation effectGuaranteed uniformityCell electrodesComposite cathodeFuel cells

The invention discloses a method for preparing composite cathode materials RBCO-xCGO of SOFC by an in-situ colloidal composite method, belongs to the field of SOFCs, particularly relates to the method for preparing the composite cathode materials RBCO-xCGO of SOFC by the in-situ colloidal composite method, and aims at solving the problems of poor mixing uniformity of the conventional mechanical mixing method and nonuniform distribution of impregnated particles of a sol impregnation method. The method comprises the following steps: 1, preparing ReBaCo2O6-delta precursor sol; 2, preparing CGO hydrosol; 3, preparing RBCO-XCGO composite materials. The cathode materials and electrolyte materials are once compounded in situ in a liquid phase system, without the step of secondary impregnation to ensure the uniformity of the composite materials. CGO nanoparticles effectively prevent agglomeration of the cathode materials in the high-temperature sintering process, thereby being beneficial to improving electrode performances.

Owner:HEILONGJIANG UNIV

Thermal sprayed protective layer for metallic substrates

InactiveCN101328569ACrystallization behavior is strongly influenced byCoefficient of thermal expansion matchingMolten spray coatingThin material handlingPhysical chemistrySilicate minerals

The invention relates to a hot spraying air-tight protection coating for metal matrix, especially for Fe, Ni, Al, Mg and / or Ti basis metal matrix, wherein the spraying power comprises at least two components, wherein the first component is silicate mineral or igneous rock, and the second component is metal power and / or another silicate mineral or igneous rock, the alkali content in silicate mineral or igneous rock in the spraying power is less than 6 weight percentage.

Owner:MARKISCHES WERK

Thermoelectric modules

InactiveCN102237486ACoefficient of thermal expansion matchingGuaranteed stabilityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentElectrical conductorMetal matrix composite

The present invention relates to thermoelectric modules, in particular for use as thermoelectric generators. A thermoelectric module (300) includes: thermoelectric semiconductor elements (302, 304); printed metal conductors (308) for interconnecting the semiconductor elements; and at least one base support (310) for the printed conductors, the base support including a metal matrix composite.

Owner:ROBERT BOSCH GMBH

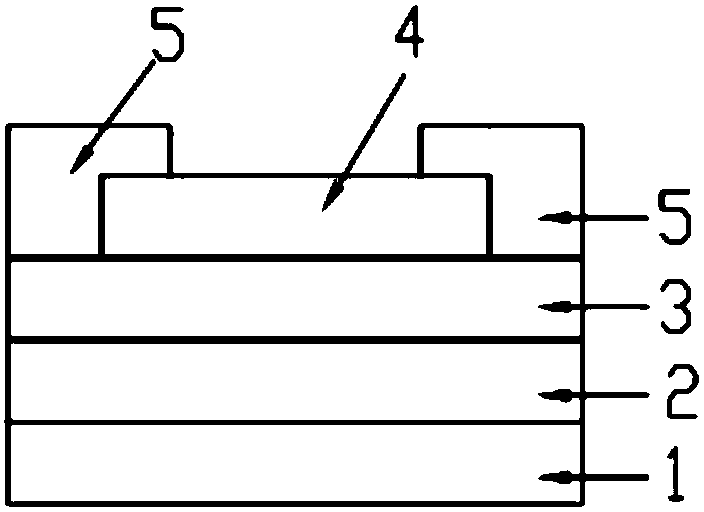

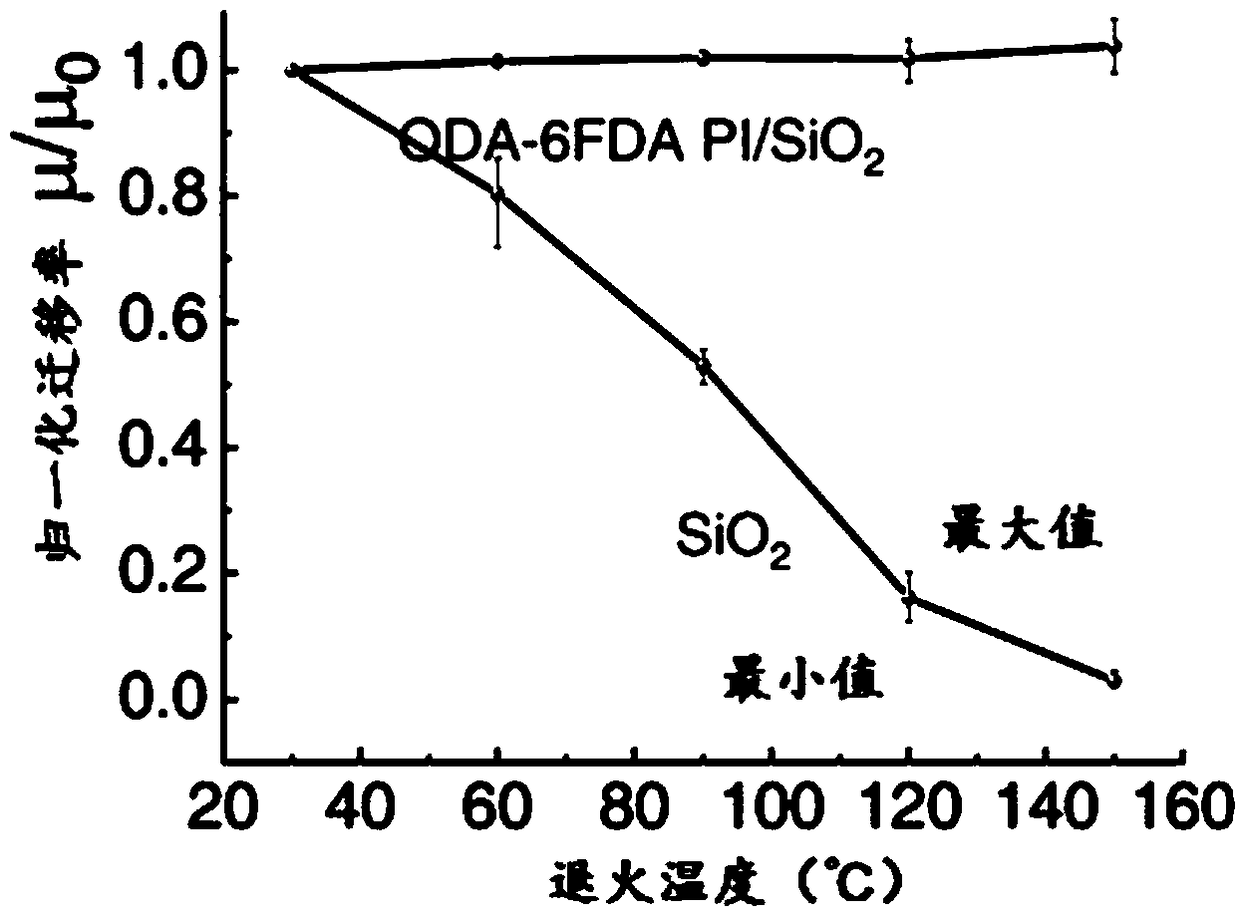

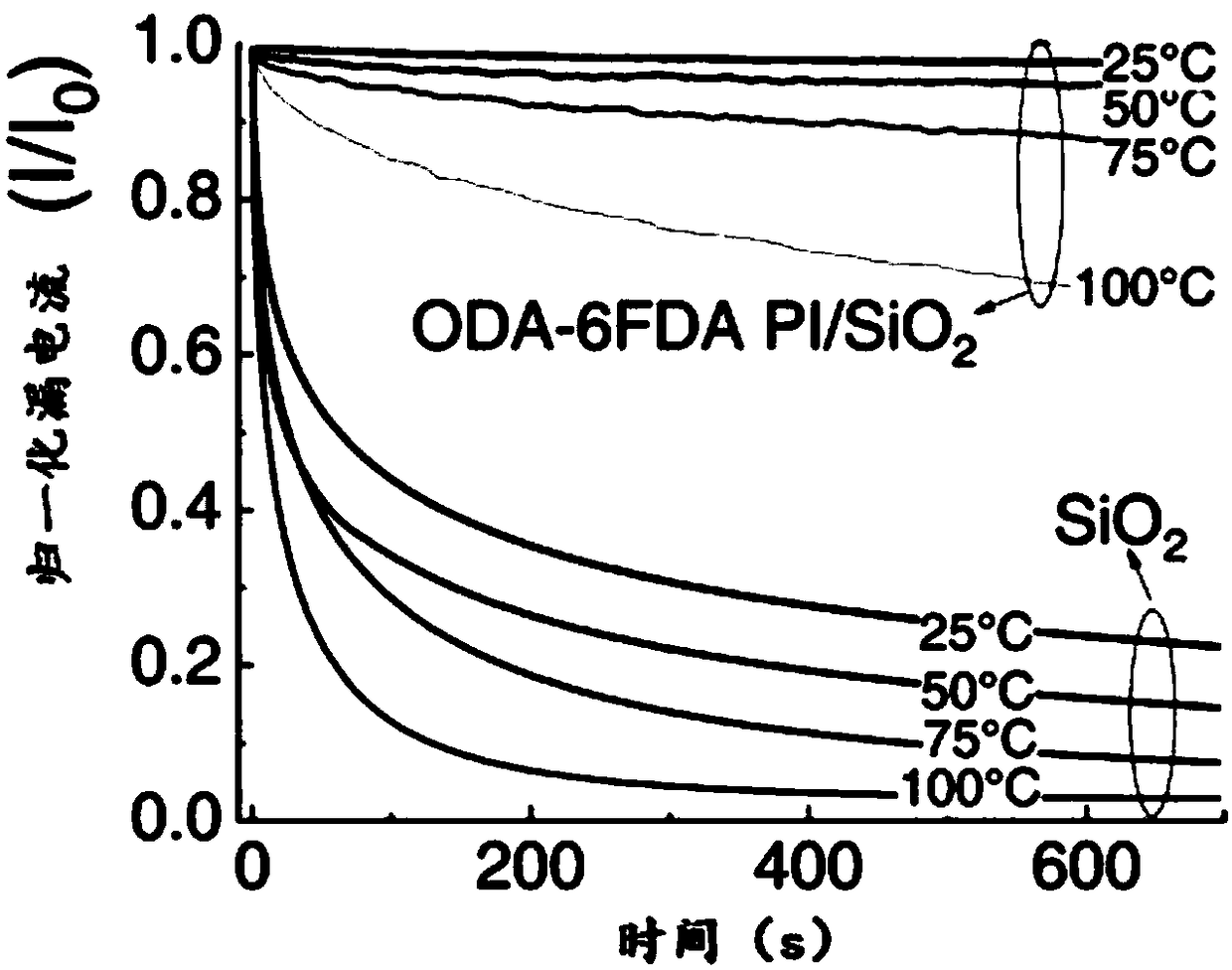

Organic thin film transistor containing dual dielectric layers and fabrication method of organic thin film transistor

PendingCN108417713AImprove thermal stabilityReduce the chance of captureSolid-state devicesSemiconductor/solid-state device manufacturingThermal expansionPolymer

The invention discloses an organic thin film transistor containing dual dielectric layers and a fabrication method of the organic thin film transistor. The organic thin film transistor sequentially comprises a gate substrate, a first dielectric layer, a second dielectric layer, an organic semiconductor layer and an electrode from bottom to top, wherein the material of the first dielectric layer isan inorganic dielectric material or a polymer material with a dielectric constant larger than 5, the material of the second dielectric layer is fluorine-containing polyimide, and the organic semiconductor layer and the second dielectric layer both are in overlapped joint with the electrode. The probability of charge trapped by a pit is reduced by hydrophobicity of the fluorine-containing polyimide at an upper layer, and meanwhile, the thermal stability of the transistor is improved by thermal expansion coefficient and favorable extensibility which are relatively matched of the fluorine-containing polyimide; the dielectric layer at a lower layer is used for reducing a dark current of the device, and positive drift of a threshold voltage is prevented; and by designing dual dielectric layers, the thermal stability and the electrical stability of the organic thin film transistor are improved.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

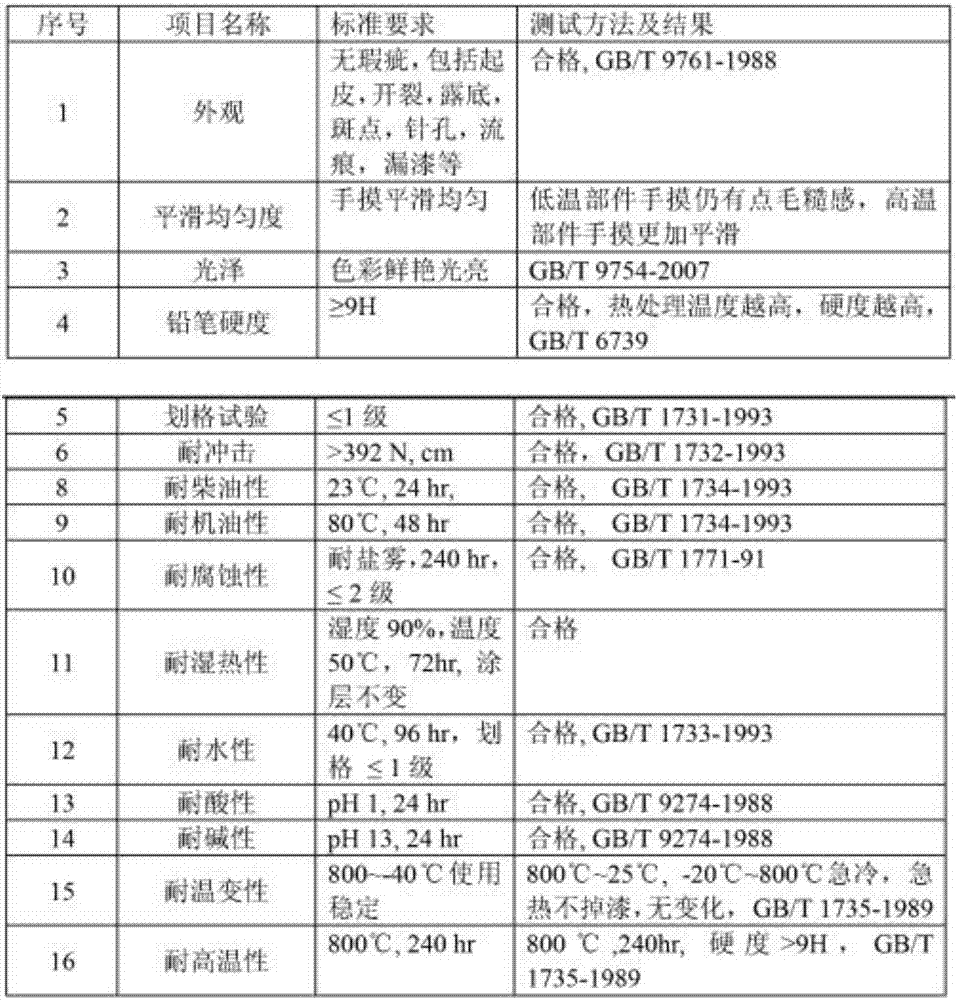

Method for preparing anticorrosive paint and coating thereof

InactiveCN107216804AImprove adhesionAvoid high temperature oxidationFireproof paintsSilencing apparatusSlurryMaterials science

The invention discloses a method for preparing anticorrosive paint and a coating thereof. The method comprises the following steps: preparing a base material and filling slurry, and mixing the base material with the filling slurry in a weight ratio of 1:1-1:4; and uniformly stirring to prepare the paint. The coating is constructed by spraying, brushing, rolling and other processes, and the constructed part can be cured at the temperature of 150-200 DEG C, and a completely compact imporous coating can be formed after secondary heat treatment at high temperature of over 600 DEG C.

Owner:SUZHOU NANODISPERSIONS

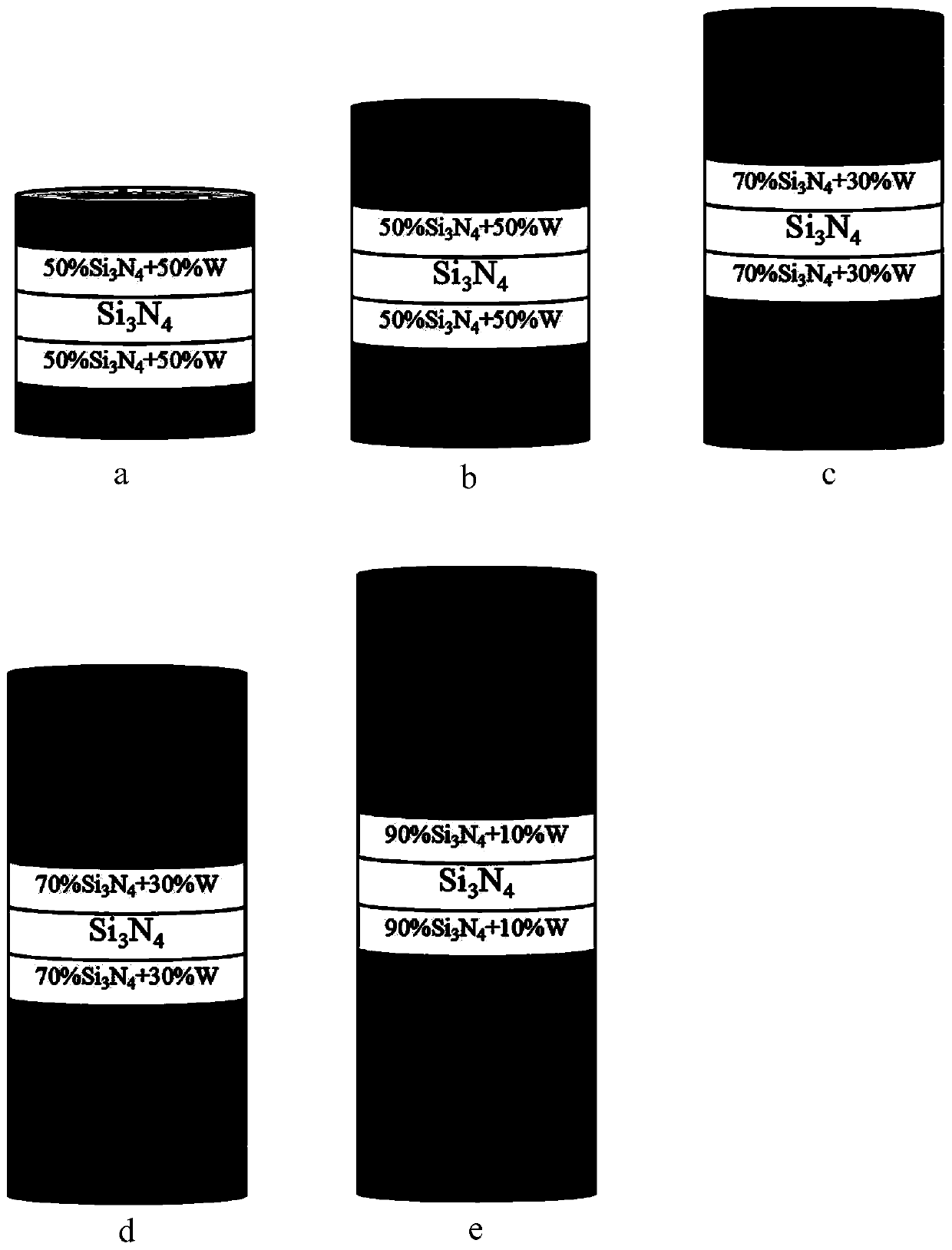

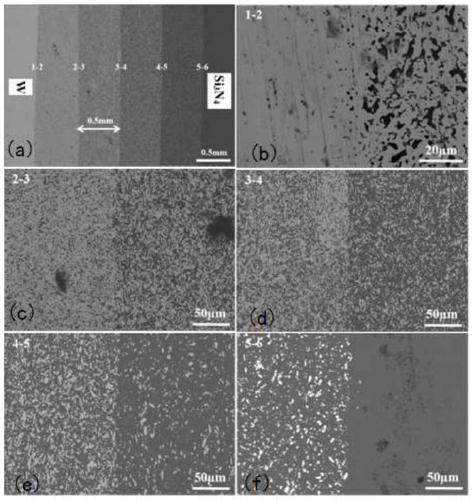

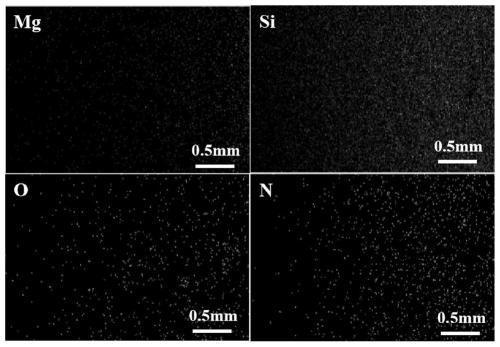

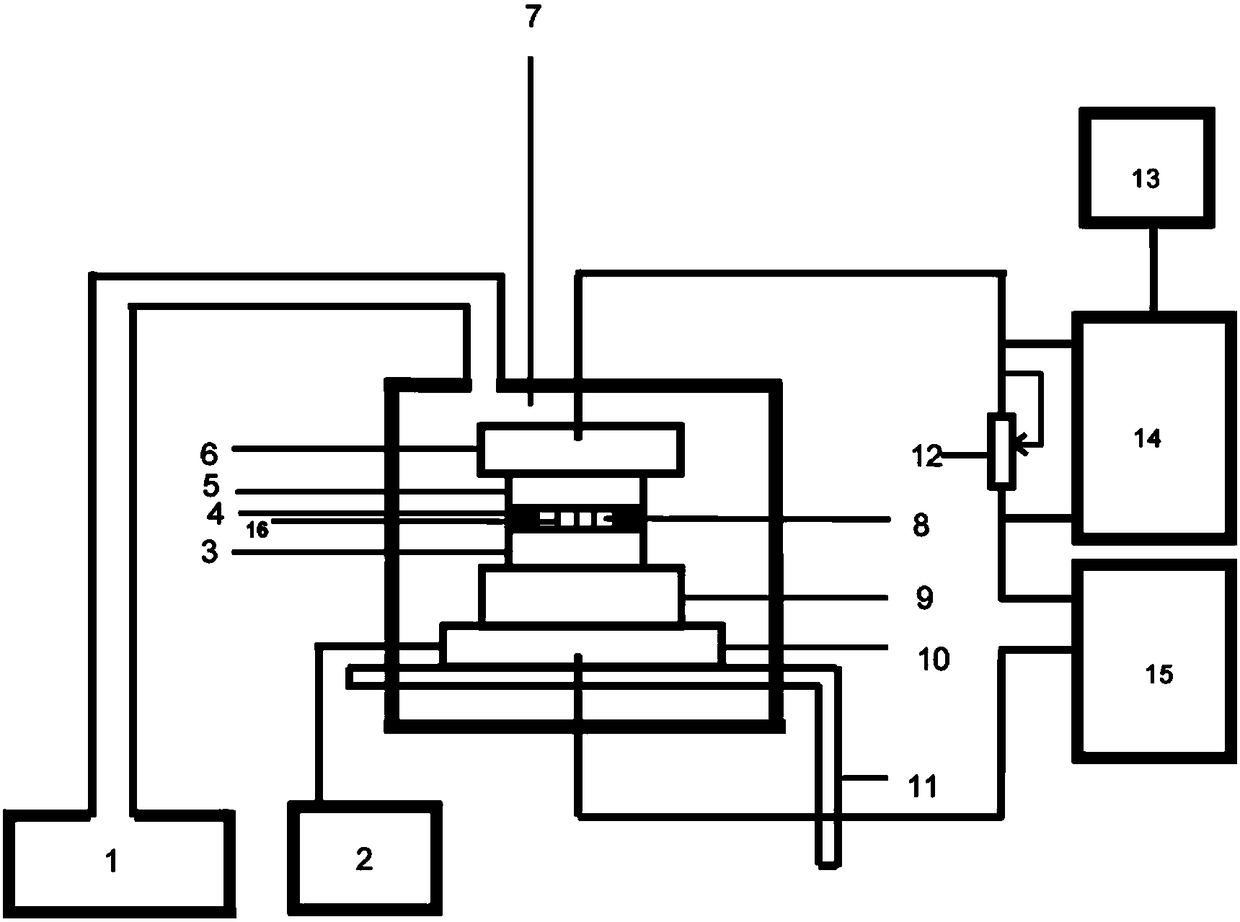

Tungsten/silicon nitride/tungsten symmetrical laminated gradient composite material as well as rapid preparation method and application thereof

ActiveCN111085688AExcellent high temperature mechanical propertiesImprove thermal shock resistanceIncreasing energy efficiencyCell sealing materialsComposite ceramicPlasma activation

The invention discloses a W / Si3N4 / W symmetrical laminated gradient composite material as well as a rapid preparation method and an application thereof, and belongs to the technical field of preparation for ceramic matrix composite materials. According to the tungsten / silicon nitride / tungsten symmetrical laminated gradient composite material as well as the rapid preparation method and the application thereof, the W / Si3N4 / W symmetrical laminated gradient composite material is prepared through an SPS sintering technology; in the method, an electric field is further introduced on the basis of a temperature field and a pressure field, a plasma activation effect on raw materials can be acted, so that a compact composite ceramic material can be rapidly prepared under the conditions of a low sintering temperature and a short heat-insulation time; and meanwhile, the activation effect of plasmas also contributes to the diffusion of atoms, then the interlayer bonding of W and Si3N4 can be promoted, and the high-performance connection between W and Si3N4 is realized. The method has the advantages of being high in heating speed, low in sintering temperature and short in heat-insulation time, and the W / Si3N4 / W symmetrical laminated gradient composite material with high compactness, low impurity content and good interface bonding can be rapidly prepared via the method.

Owner:XI AN JIAOTONG UNIV

Preparation method of SiB6 modified self-healing SiCf/SiC composite material

InactiveCN111410548AImprove high temperature oxidation resistanceDecreased high temperature oxidation resistanceCeramicwareThermal dilatationCrazing

The invention belongs to the technical field of preparation of ceramic matrix composite materials, and particularly relates to a preparation method of a SiB6 modified self-healing SiCf / SiC composite material. According to the invention, SiB6 self-healing components are uniformly dispersed and distributed in a matrix; under an oxidation condition, an oxidation reaction is carried out at a micro-crack of a matrix to generate glass-phase B2O3, so that the interior of the material is protected from being invaded by an oxidizing medium, and the influence of inherent defects such as pores and cracksin the composite material on the high-temperature service life of the material is solved; due to the good high-temperature oxidation resistance of SiB6, the high-temperature oxidation resistance of the prepared SiCf / SiC composite material is greatly improved. SiB6 is subjected to an oxidation reaction at a high temperature to generate B2O3 and SiO2 at the same time, the melting point is increasedthrough the borosilicate glass phase, no other gas by-products are generated, and cracks can be effectively healed; siB6 has excellent mechanical properties, and SiB6 and SiC have matched thermal expansion coefficients, so that the mechanical properties of the modified material are only reduced to a small extent.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Anodic bonding method and anodic bonding device for vacuum glass sealing

ActiveCN108328912ASimple preparation processLow costGlass reforming apparatusEnvironmental resistanceThermal expansion

The invention discloses an anodic bonding method and an anodic bonding device for vacuum glass sealing. The anodic bonding method includes selecting appropriate glass powder with a low melting point and manufacturing sealing materials; coating edge sealing layers and intermediate support dot matrixes on glass substrates at one step; laminating each glass substrate with another blank glass substrate, placing the glass substrates and the blank glass substrates in the anodic bonding device, vacuumizing the anodic bonding device until the pressure of the anodic bonding device reach 5.0*10<-2>-1.0*10<-4> Pa and carrying out effective anodic bonding in states of bonding temperatures of 300-500 DEG C and bonding voltages of 400-800 V. The anodic bonding method and the anodic bonding device have the advantages that vacuum glass can be vacuumized and sealed in the anodic bonding device at the low bonding temperatures at one step, and accordingly vacuum glass with excellent performance can be prepared by the aid of the anodic bonding method and the anodic bonding device; glass composition with the low melting point is free of lead, is green and environmentally friendly and is matched with thermal expansion coefficients of the glass substrates; preparation processes are simple and are low in cost and high in efficiency, the anodic bonding method and the anodic bonding device are suitablefor industrial production and high in efficiency, and energy can be saved; the vacuum glass is high in sealing strength, good in stability and long in service life as compared with the traditional vacuum glass sealing methods.

Owner:WUHAN UNIV OF TECH

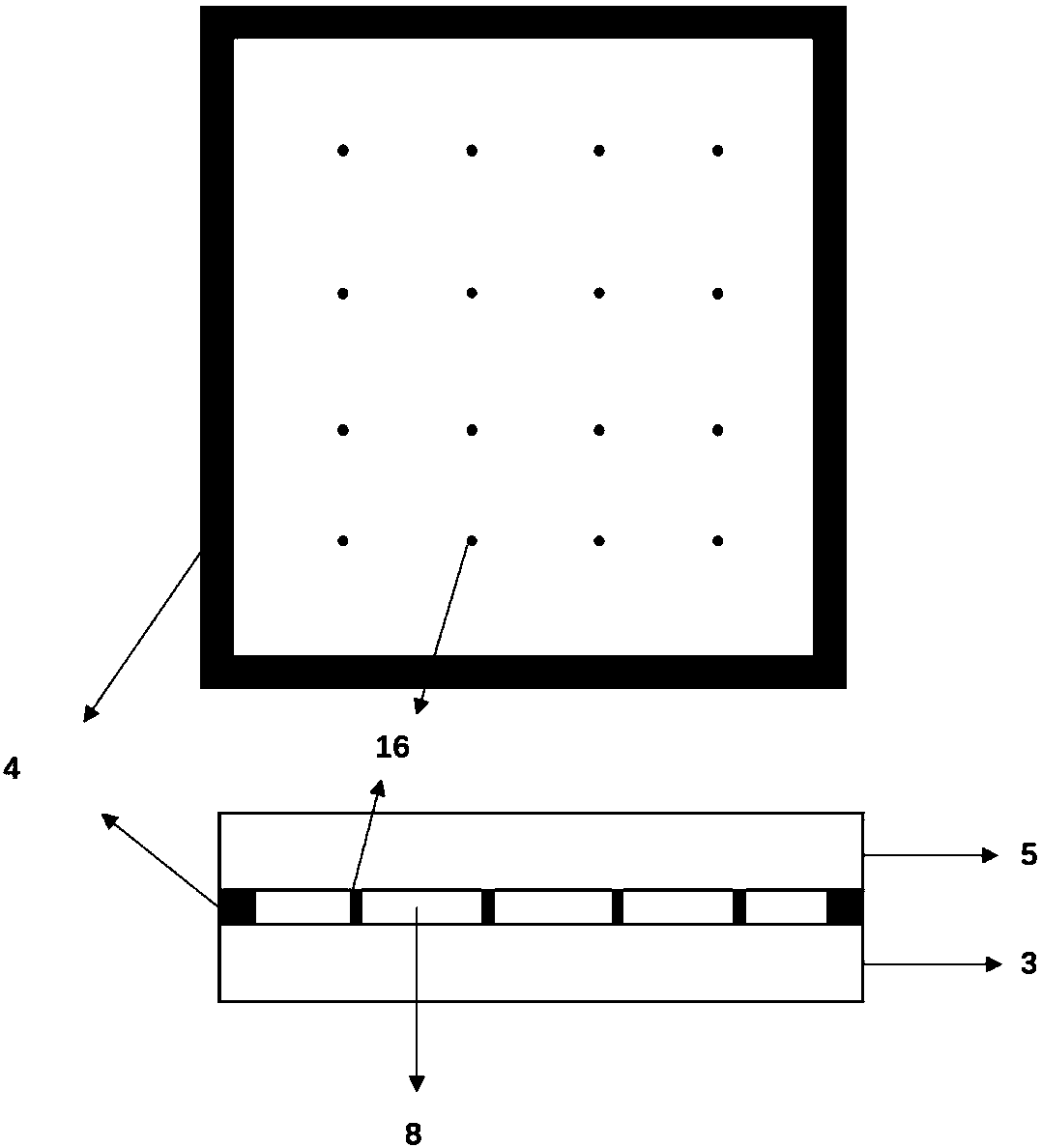

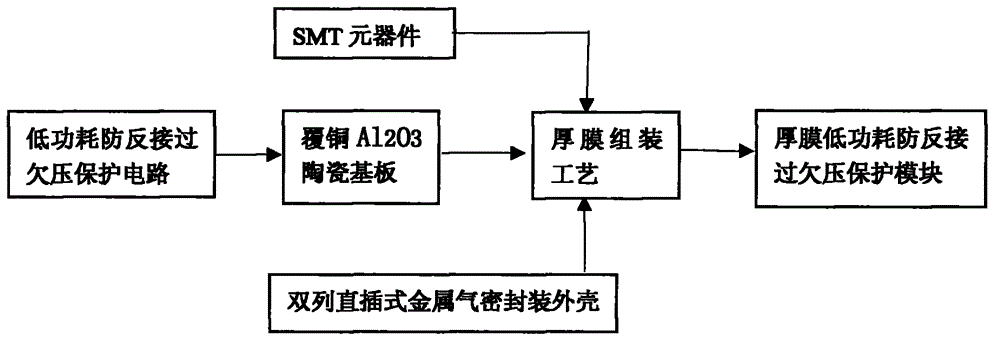

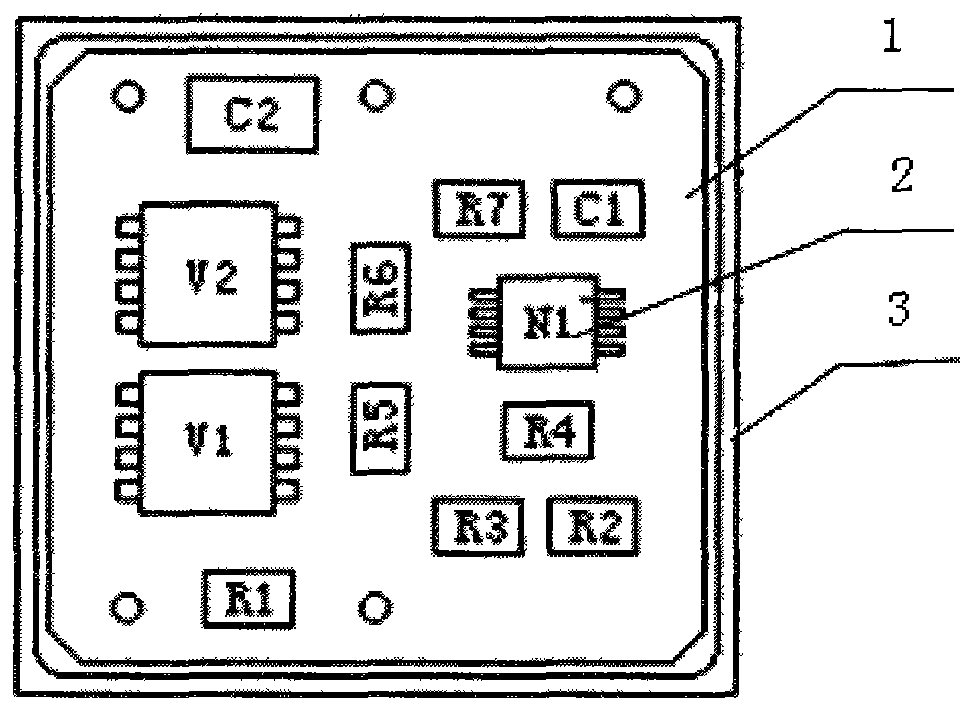

Thick film low power consumption counter-attack under-voltage protection module

InactiveCN104393558ALow costShort cycleArrangements responsive to excess voltageArrangements responsive to undervoltageElectrical conductorComputer module

The invention relates to the electronic technique and micro electronic technique, and in particular relates to a thick film low power consumption counter-attack under-voltage protection module. The thick film low power consumption counter-attack under-voltage protection module comprises a low power consumption counter-attack under-voltage protection circuit, an SMT element, copper-covering Al2O3 ceramic substrate and a dual in-line type metal hermetic encapsulation shell; the low power consumption counter-attack under-voltage protection circuit is designed by plane conversion and the copper conductive pattern is formed on the copper-covering Al2O3 ceramic substrate; the thick film assembly technology is adopted for assembling the surface-sticking SMT element, the copper-covering Al2O3 ceramic substrate and the dual in-line type metal hermetic encapsulation shell together. The thick film low power consumption counter-attack under-voltage protection module overcomes the defect of big power dissipation of the series diode, avoids the inconvenience of manual work replacing operation of parallel connection diode, increases the under-voltage protection function and realizes the multifunction combination.

Owner:程信羲

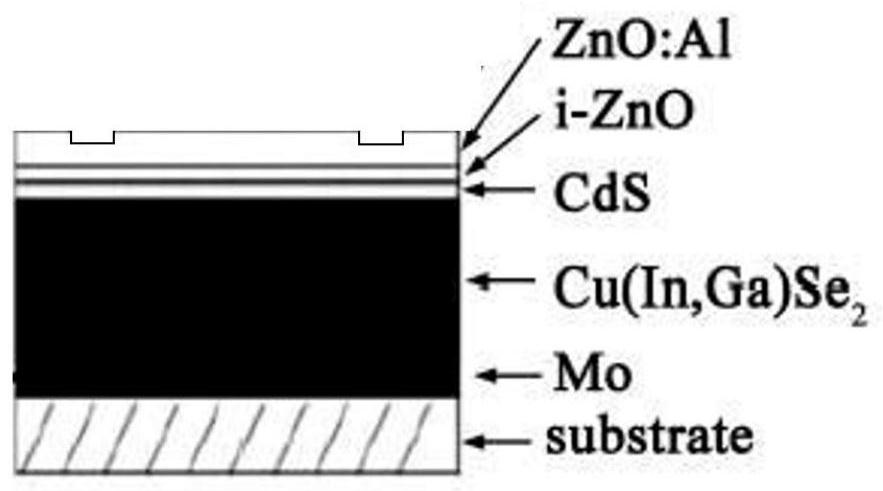

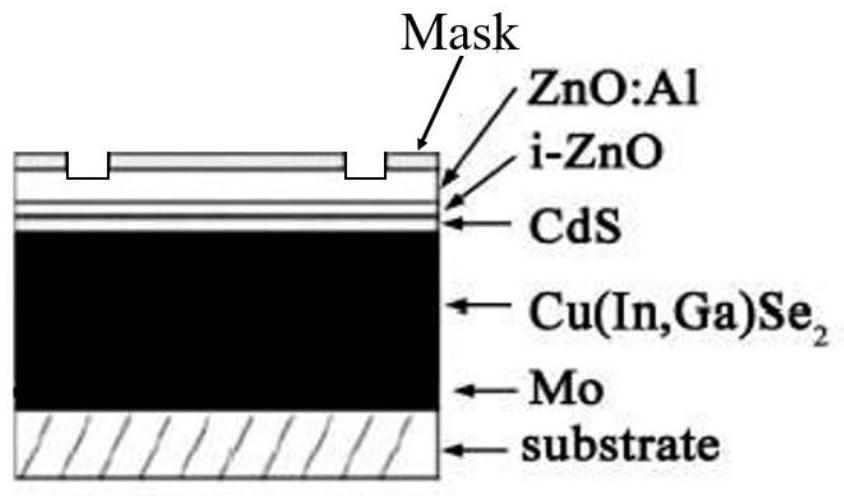

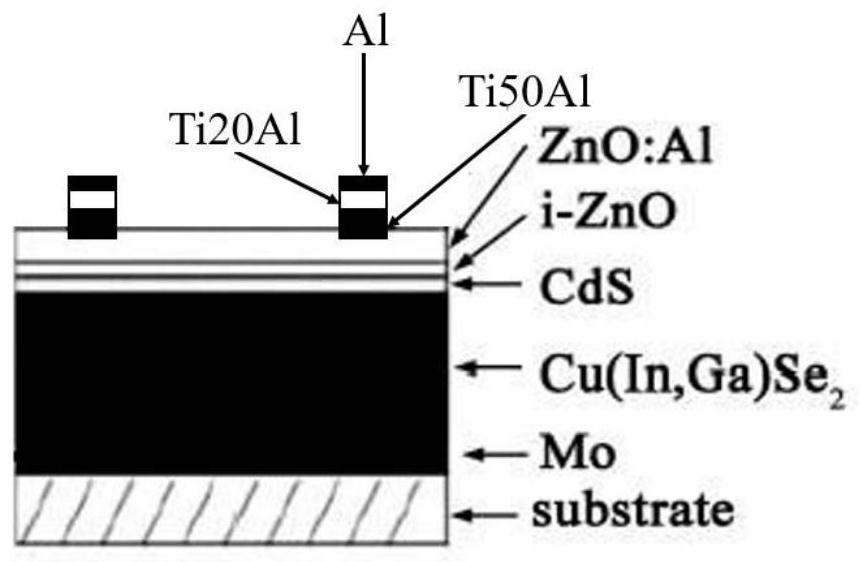

Electrode of flexible CIGS solar cell and manufacturing method

InactiveCN111769165ANot easy to break circuit failureLow resistivityFinal product manufacturePhotovoltaic energy generationEvaporation (deposition)Sputtering

The invention discloses an electrode of a flexible CIGS solar cell, which comprises an alloy layer, and one side of the alloy layer is connected with an aluminum layer. A preparation method of an electrode of a flexible CIGS solar cell is characterized by comprising the following steps: (1) taking a CIGS cell plated with an AZO film layer, and scribing a wire groove on the AZO film layer by usinglaser; (2) covering the top of the battery with the engraved wire groove with a mask plate, wherein the mask plate is hollowed out in a position corresponding to the wire groove; (3) then feeding intoa magnetron sputtering / evaporation process for physical vapor deposition, gradually decreasing the content of titanium in the titanium-aluminum alloy in the physical vapor deposition process, takingout the battery after the vapor deposition is finished, and removing the mask plate to obtain the battery passing through the physical vapor deposition electrode; and (4) bonding the electrode subjected to physical vapor deposition on the battery with the assembly bus bar. A composite transition multi-film-layer electrode design is adopted. And under the condition of ensuring that the Schottky barrier is relatively low, a relatively matched coefficient of thermal expansion is achieved.

Owner:宣城开盛新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com