Method for preparing anticorrosive paint and coating thereof

An anti-corrosion coating and coating technology, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of being unable to withstand rapid changes in cold and heat, containing pores, easy to crack and fall off, etc., to improve thermal stability and corrosion resistance, Improve the anti-corrosion and high-temperature performance and avoid the effect of high-temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

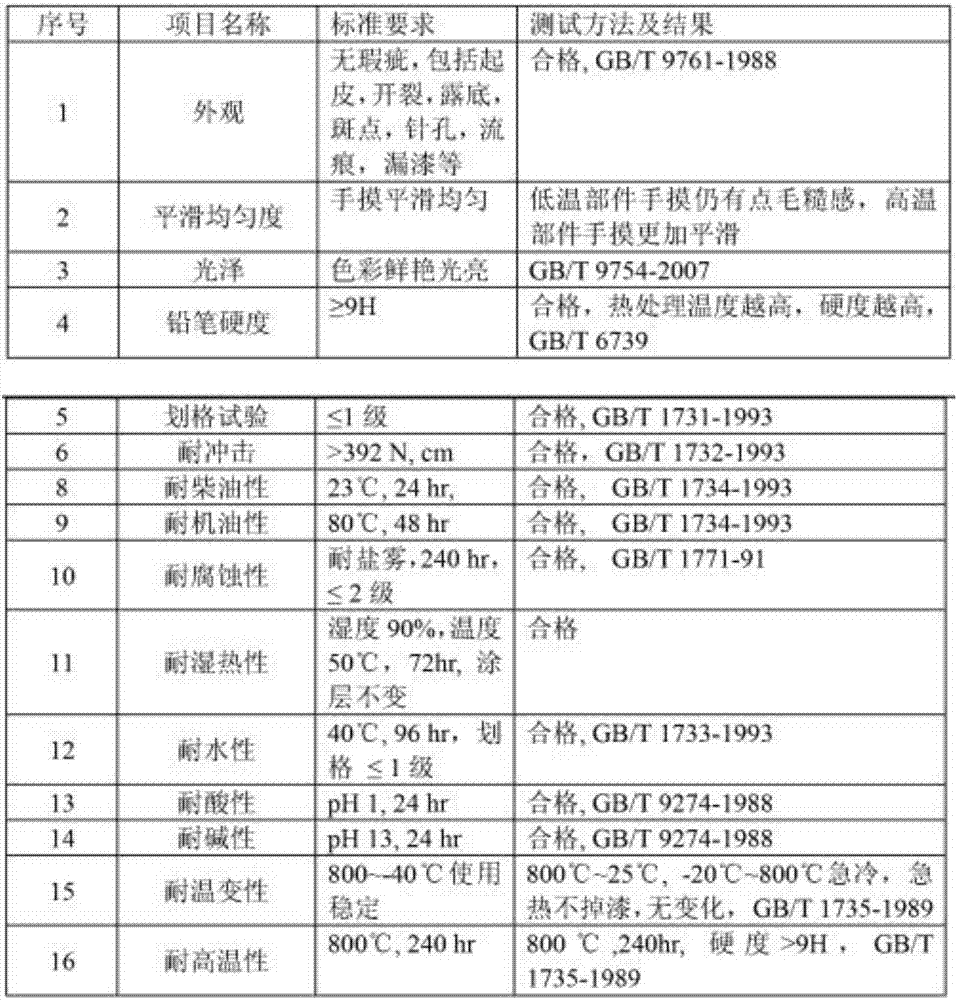

Examples

preparation example Construction

[0045] The preparation method of the above-mentioned high temperature resistant coating.

[0046] The first step: the silica sol (or silica-aluminum composite sol) in the base material undergoes a hydrolysis reaction with the silane coupling agent to form a polymer network structure. The pH of the reaction system is 3-7, and the water required for the hydrolysis reaction comes from silica sol or aluminum sol, and can also be added separately. Organic solvents can be used as auxiliary agents, such as one or more of methanol, ethanol, isopropanol, butanol and propylene glycol methyl ether, to assist the hydrolysis reaction of the silane coupling agent. That is, the solvent is water or a mixture of water and an organic solvent, and the amount of the solvent is 10% to 50% of the total weight of the hydrolysis system before the reaction; acetic acid, sulfuric acid, hydrochloric acid or nitric acid can also be used as a catalyst for the hydrolysis reaction, and the amount of the cat...

Embodiment 1

[0050] The first step: the neutral silica sol with a solid content of 30% (Suzhou Nadi Microelectronics Co., Ltd., ND-0201) and methyltrimethoxysilane 1:1 are hydrolyzed at room temperature, and acetic acid is added to adjust the pH to 4. The reaction time is 6 hours, as the base material.

[0051] The second step: crush the ceramic powder material with an ultra-fine ball mill to obtain a ceramic slurry with an average particle size D50 of about 4 μm. The solvent is isopropanol, the powder is 1000 mesh quartz sand, α-alumina powder, talcum powder, copper chromium black powder, ball milled according to the ratio of 1:1:0.5:1, the total solid content is 60%, as a ceramic Filler for coatings.

[0052] The third step: put the filler slurry into the base material at a ratio of 1:1, cool the mixed product to room temperature, and then filter through 200-mesh gauze to remove super-large particles and other impurities to obtain a high-temperature resistant coating.

[0053] When usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com