Patents

Literature

235results about How to "Avoid high temperature oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

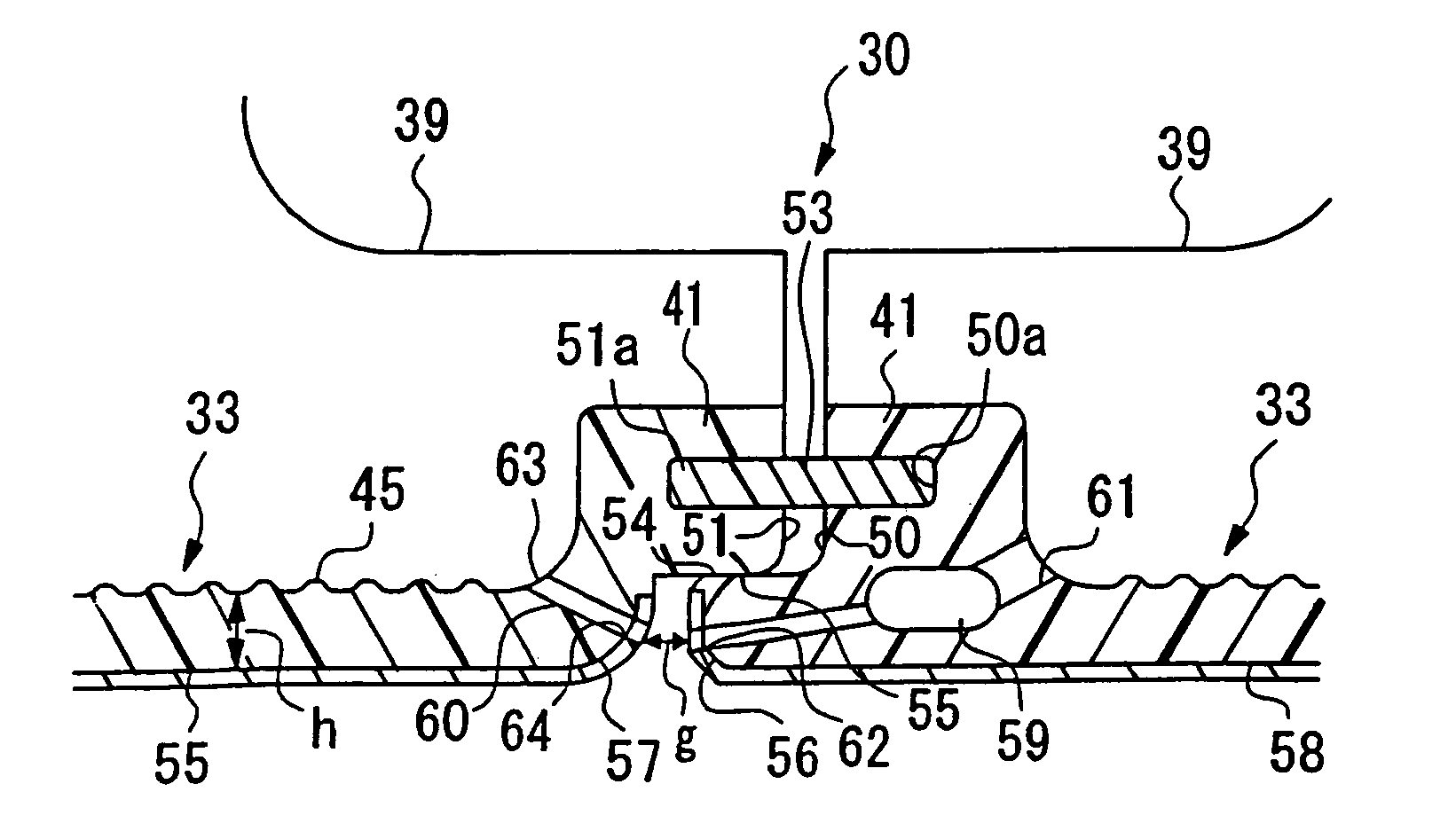

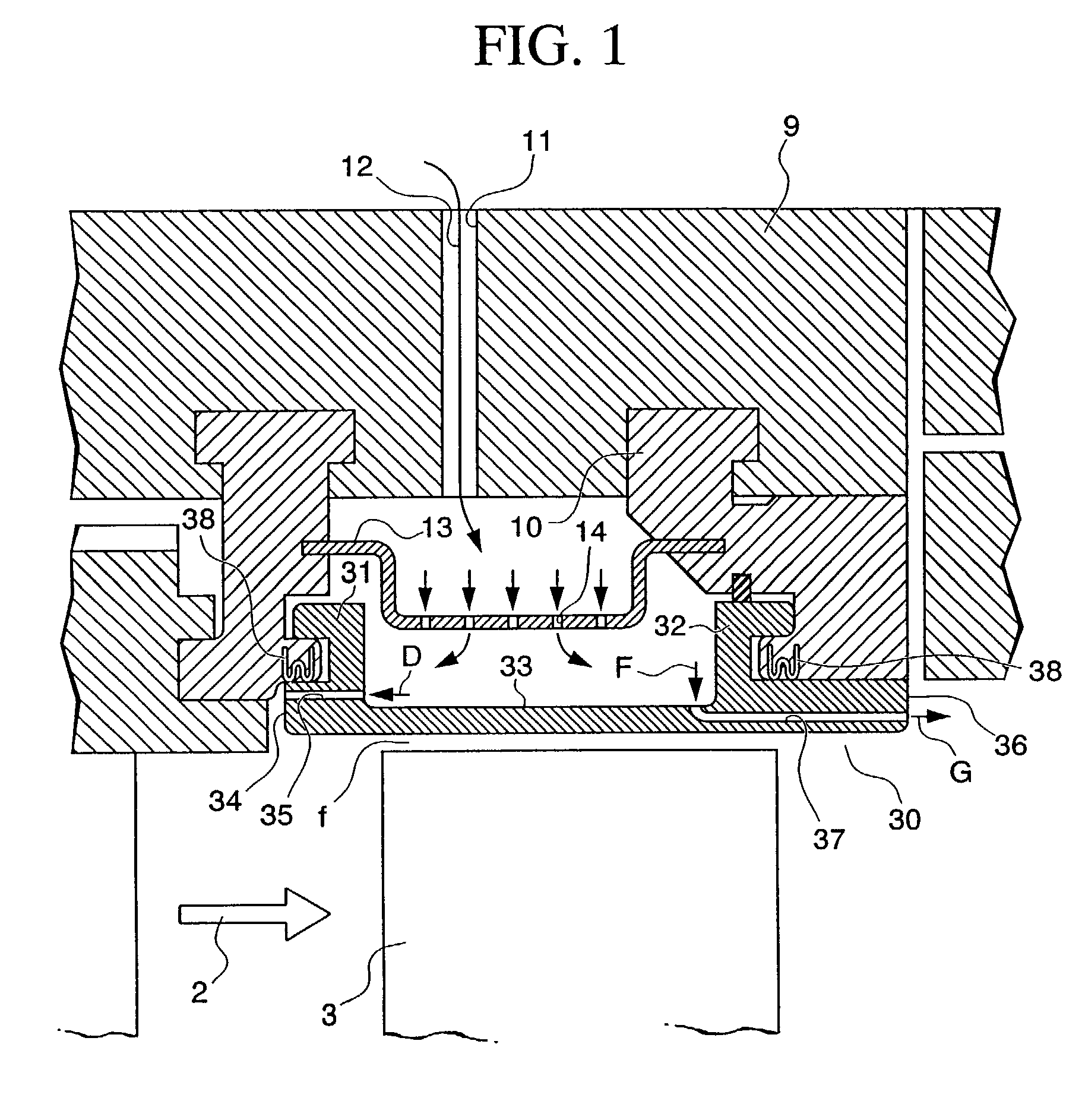

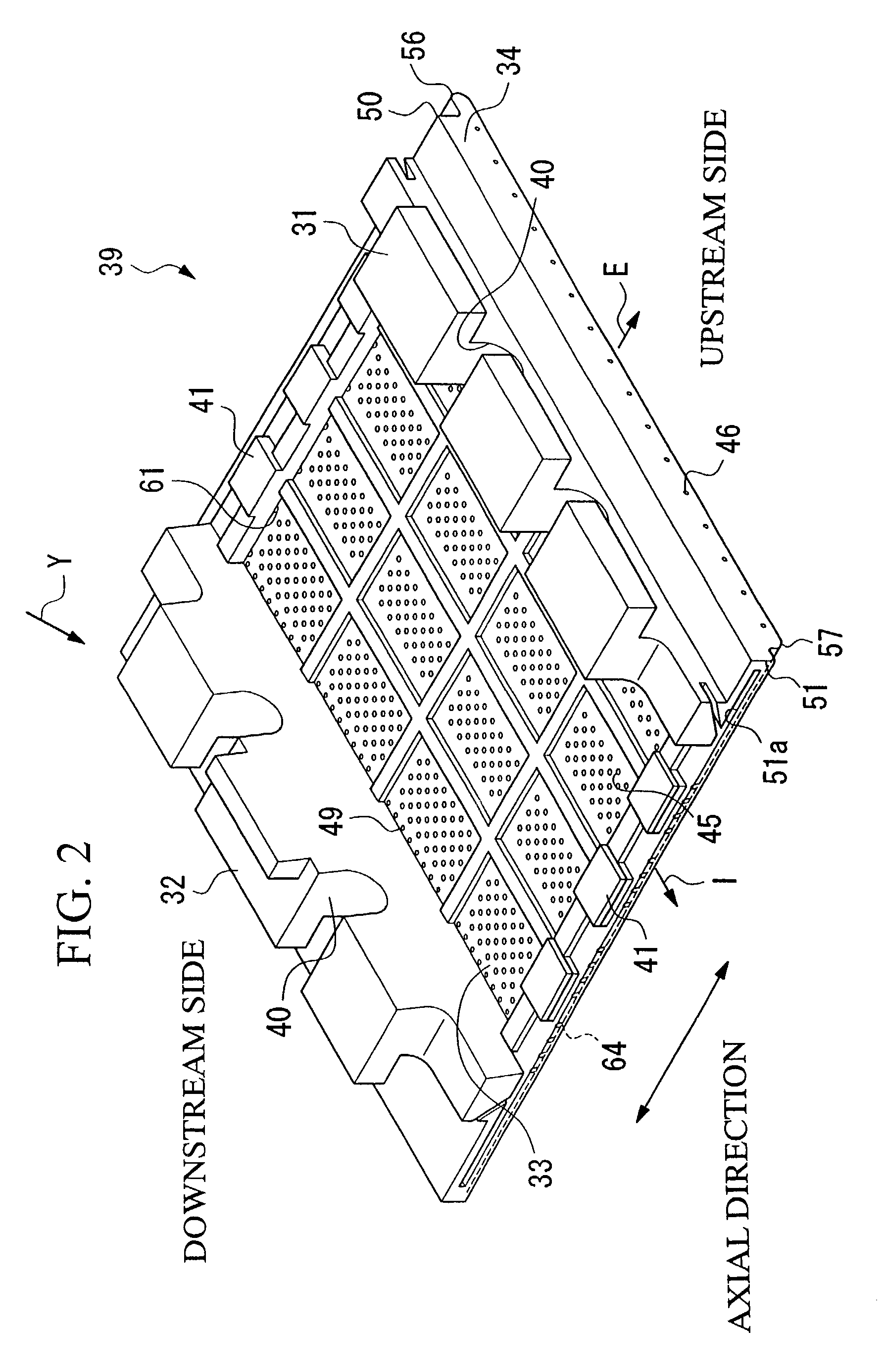

Ring segment of gas turbine

An object of the present invention is to provide a ring segment of a gas turbine in which the temperature is maintained low, damage due to high temperature oxidation is prevented, and high temperature deformation is prevented. In order to achieve the object, the present invention provides a ring segment of a gas turbine which comprises a blade ring, a main shaft and moving blades comprising a plurality of individual units which define an annular form by being arranged around the peripheral direction of the main shaft, and disposed so that its inner peripheral surface is maintained at a constant distance from the tips of the moving blades, wherein grooves which extend along the axial direction of the main shaft of the turbine are formed upon of the individual units so as mutually to confront one another; a seal plate which is inserted into each mutually confronting pair of the grooves so as to connect together the adjacent pair of individual units; and contact surfaces which are formed at positions more radially inward than the seal plates, which extend in the axial direction and the peripheral direction and which mutually contact one another.

Owner:MITSUBISHI HEAVY IND LTD

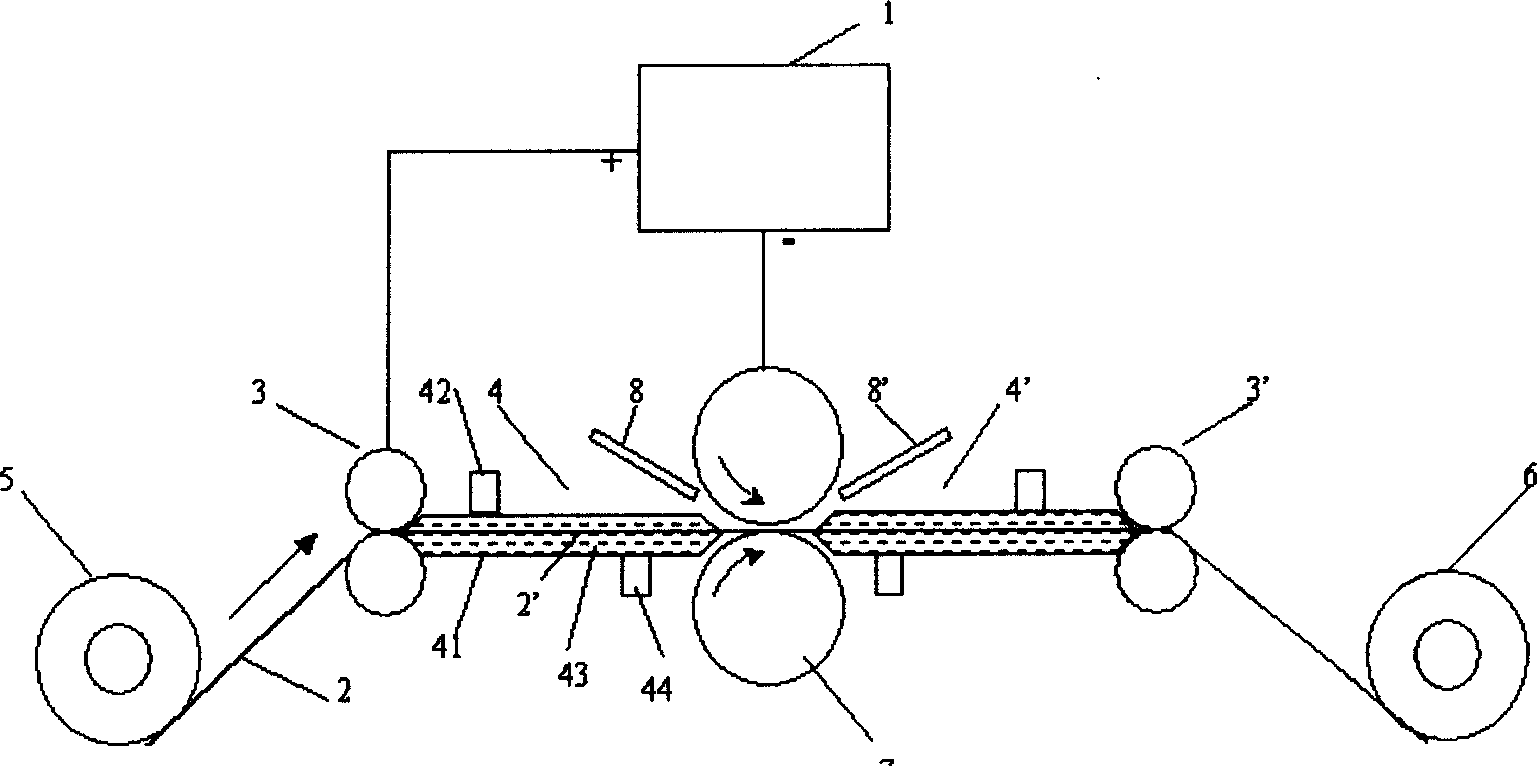

Electroplastic rolling method and apparatus for deformable magnesium alloy sheet, band and wire rod

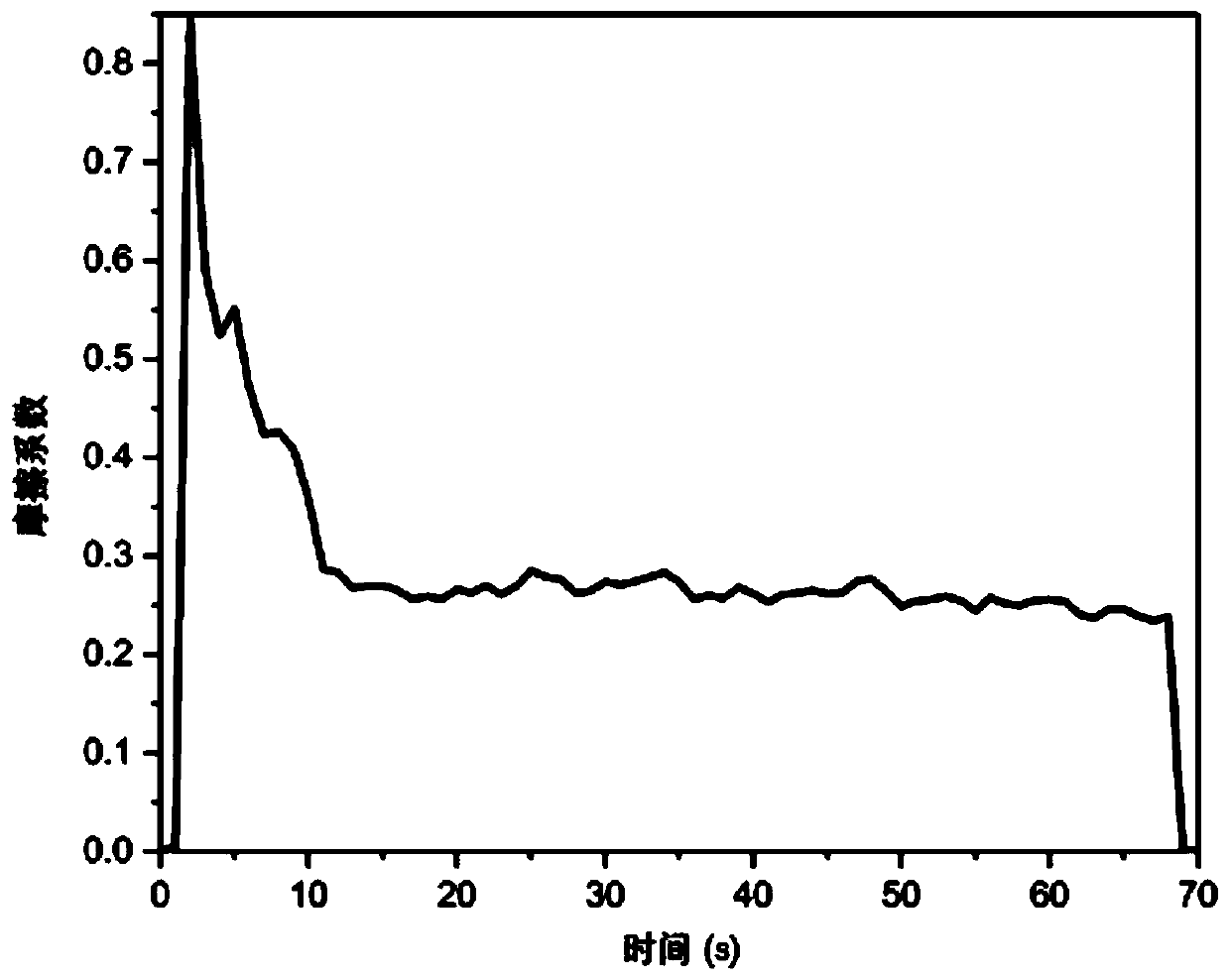

This invention relates to an electro-plastic rolling method and a device for deformed Mg alloy thin plates, strips and wires including: inducing the deformed Mg alloy plates, strips and wires in single-way instant high energy continuous pulse current directly in the process of rolling, the current passes through a pair of electric contact devices with their distance adjustable to apply on the moving Mg materials, and the roller is the negative in it, necessary cooling and lubrication measures should be taken when rolling, this time, the rolling deformation ability of the Mg material is increased greatly and the resistance is reduced to avoid high temperature oxidation and poor accuracy in size.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

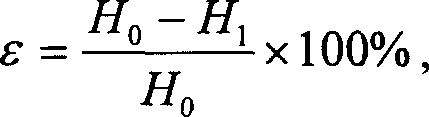

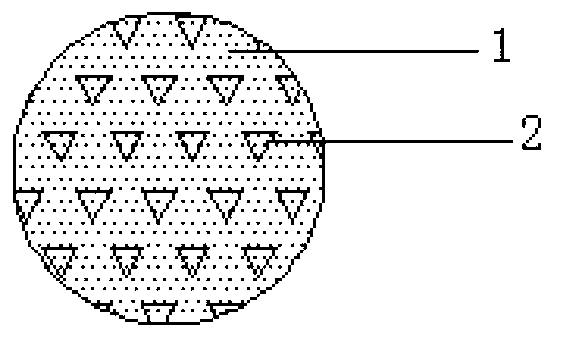

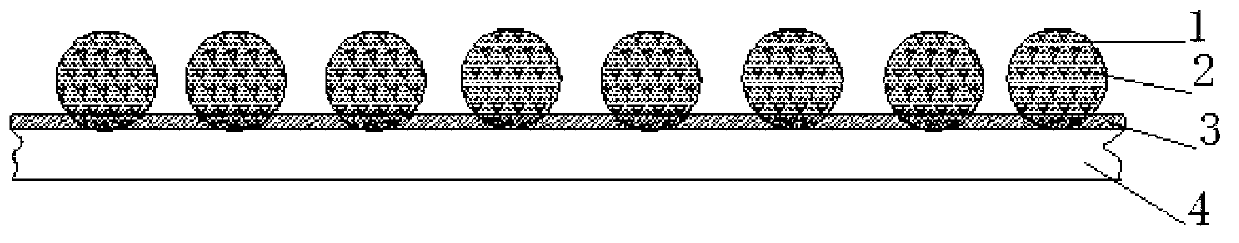

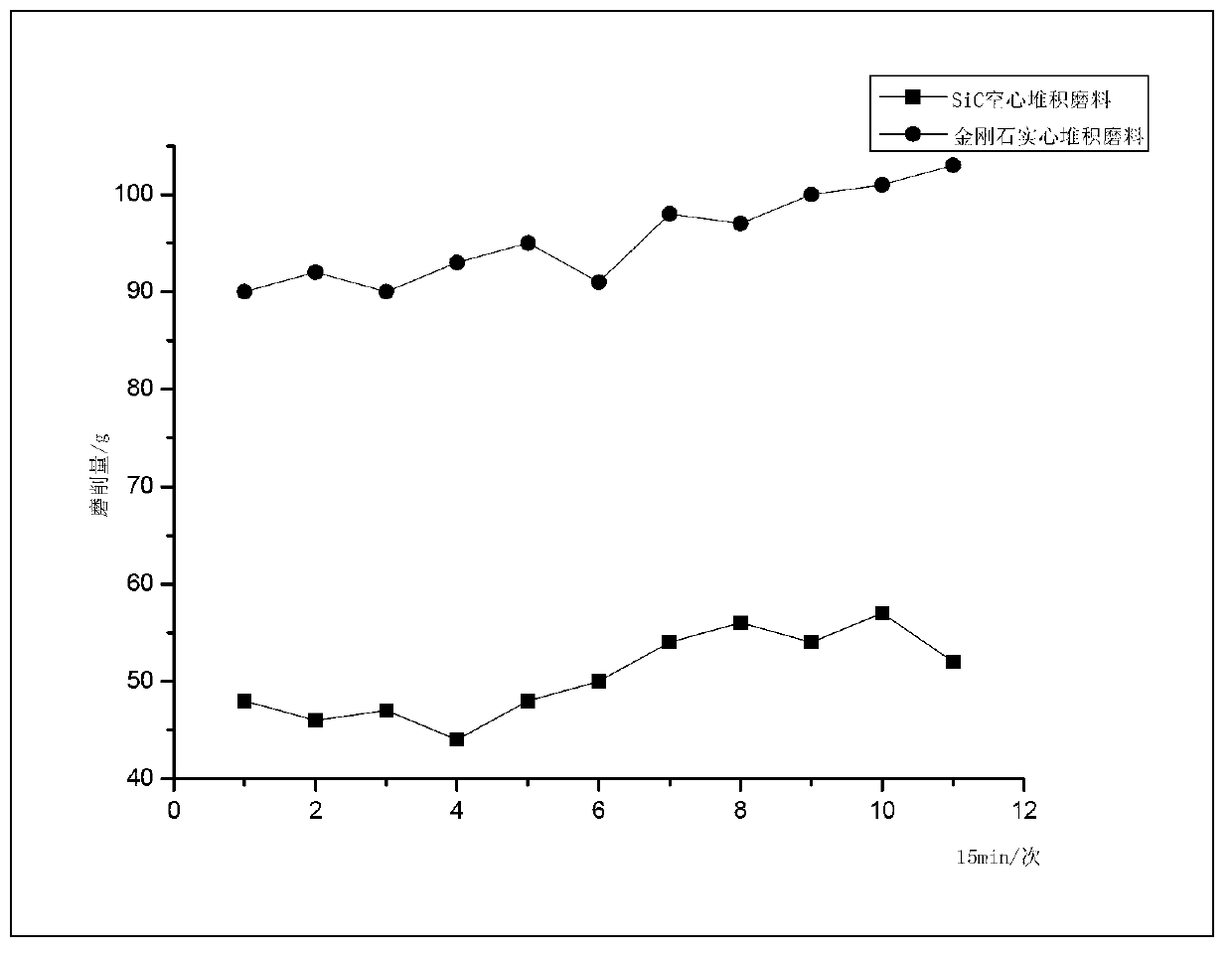

Ultrafine diamond and ceramic binding agent stacked abrasive materials and preparation method thereof

ActiveCN103273434AUniform internal structureBroaden the processing objectGrinding devicesCemented carbideSurface grinding

The invention relates to ultrafine diamond and ceramic binding agent stacked abrasive materials and a preparation method thereof. According to the ultrafine diamond and ceramic binding agent stacked abrasive materials, ultrafine diamond micro powder is added in the colloidal sol of a ceramic binding agent, a sizing agent is dried by spray mist, dry blank spherical stacked abrasive materials are obtained, and the ultrafine diamond and ceramic binding agent stacked abrasive materials can be obtained after calcinations. Stacked abrasive material particles are all spherical and even in particle size and internal organization structure. The ultrafine diamond and ceramic binding agent stacked abrasive materials can be used for preparing resin binder ultraprecise grinding wheels or diamond abrasive belts. A diamond abrasive material tool has high grinding efficiency and long grinding service life, and is mainly used for surface grinding and polishing of parts which are made of engineering ceramics, glass, hard alloy and the like.

Owner:HUNAN UNIV

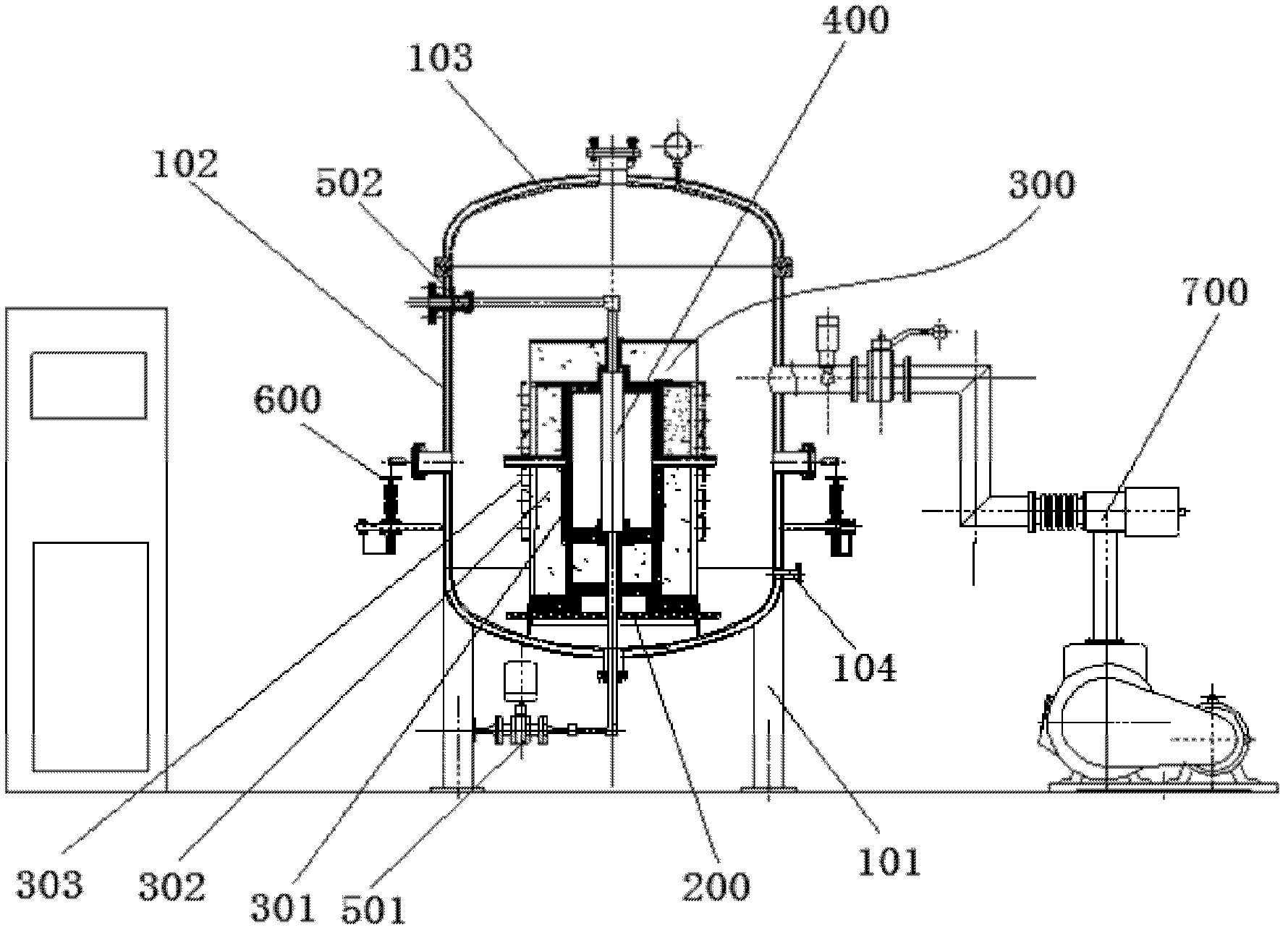

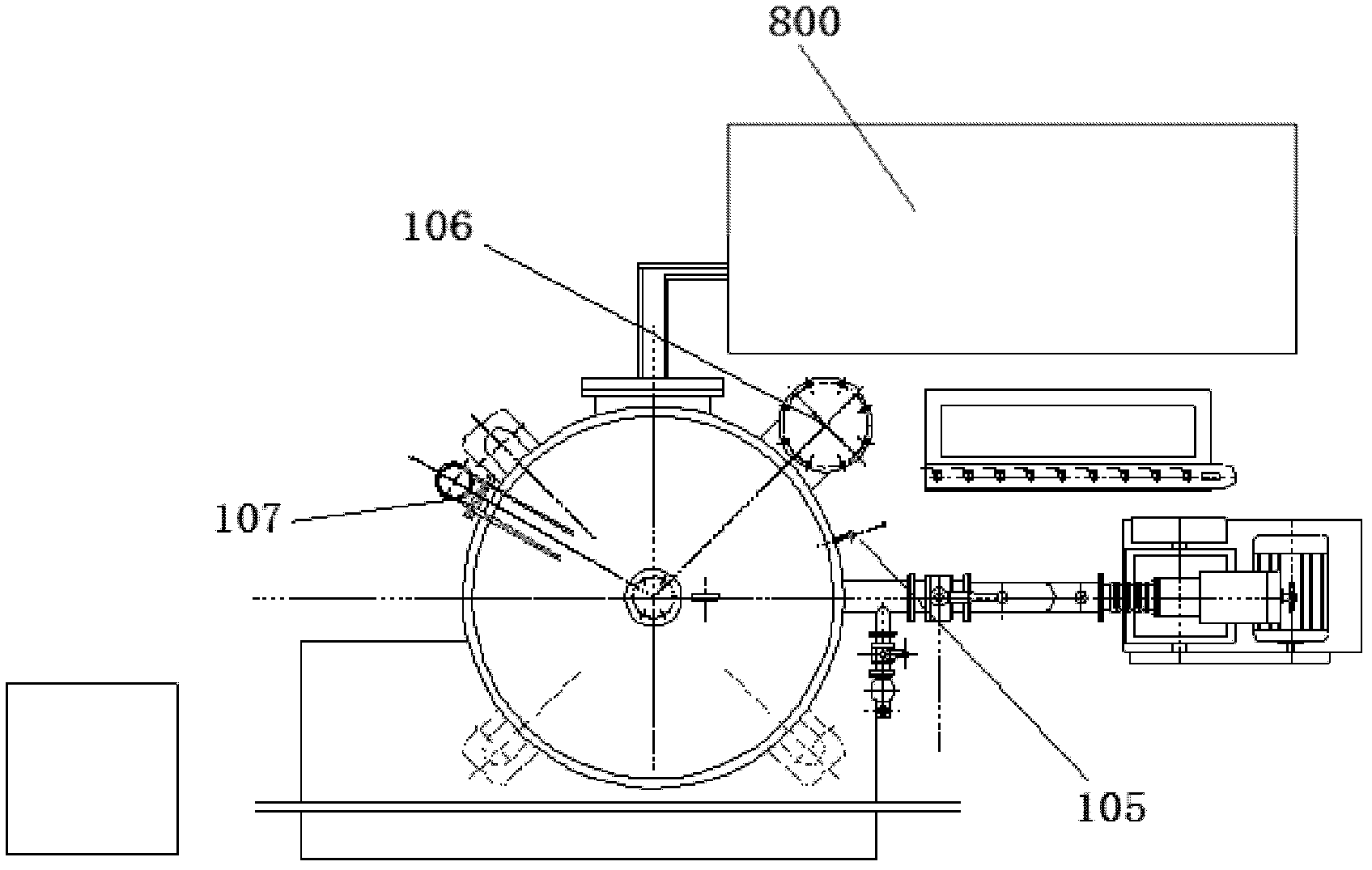

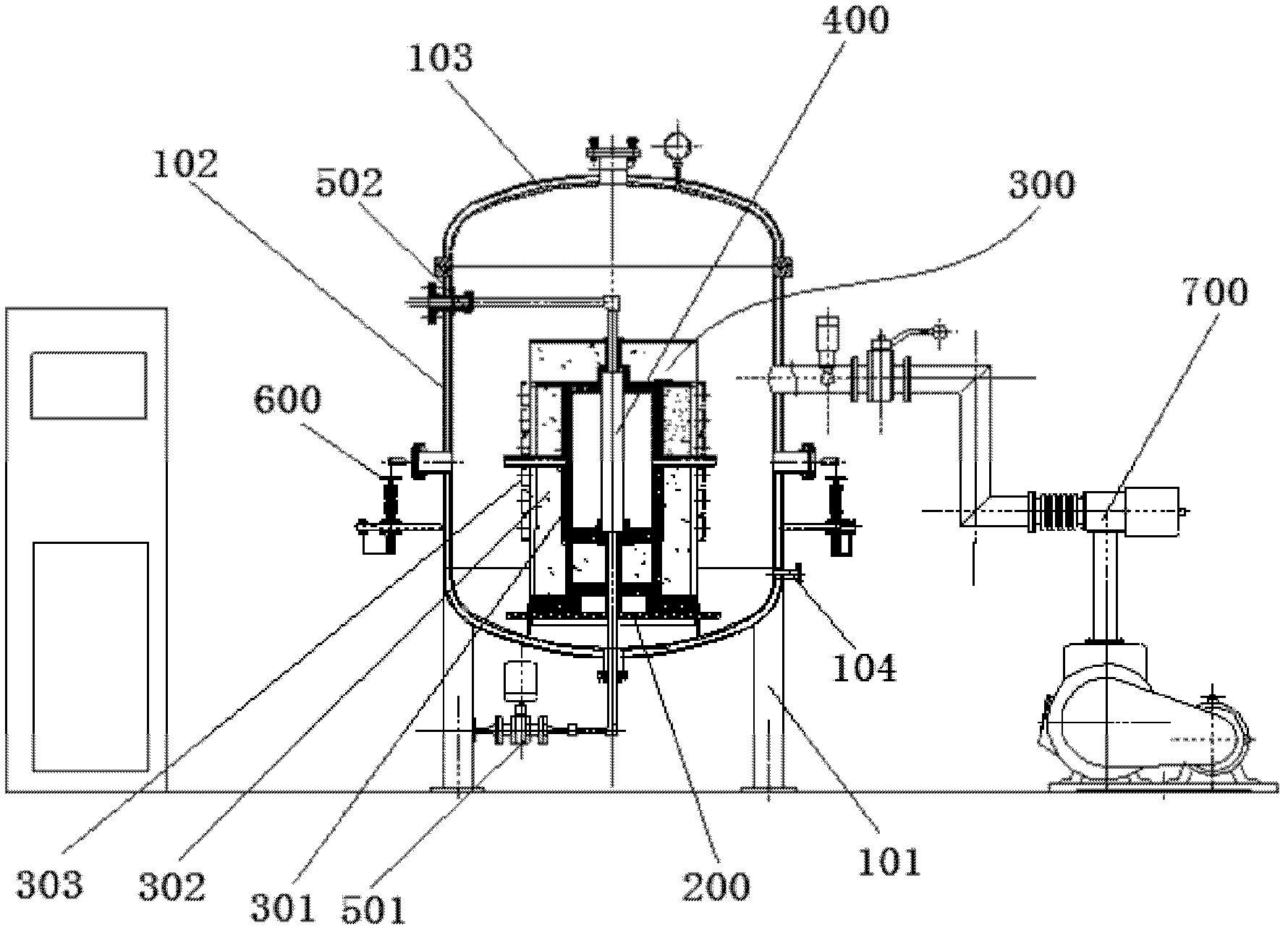

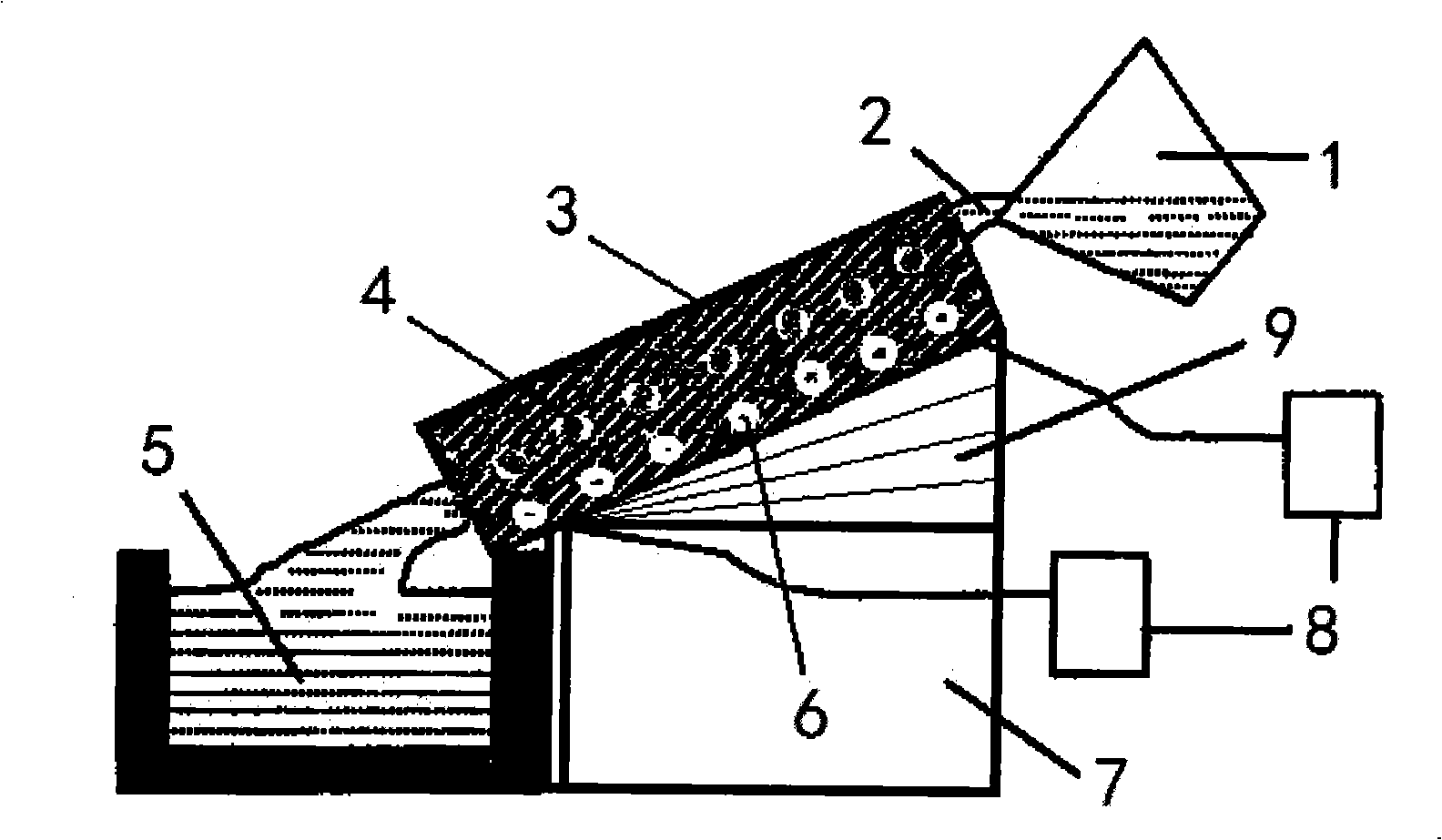

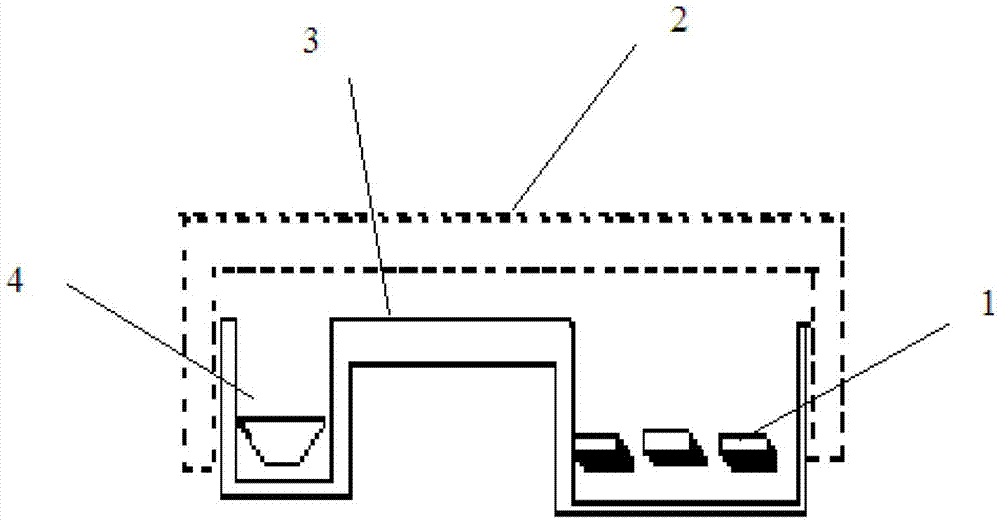

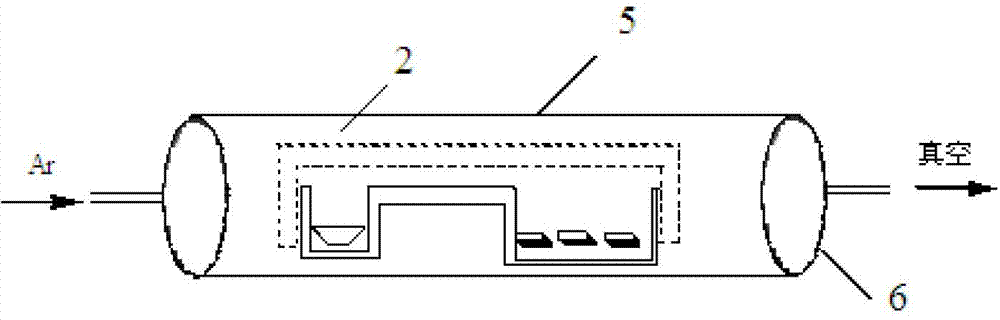

High heat flow thermal environment simulation device

ActiveCN102507194AEfficient and timely joinAvoid high temperature oxidationEngine testingInduction heating apparatusHeat flowMedium frequency

The invention discloses a high heat flow thermal environment simulation device, which comprises a support, a furnace body, a furnace cover, an insulation base, a heating body assembly, a test piece, a cooling medium inlet way, a cooling medium outlet way, a double-color integrated infrared temperature measurement meter, a vacuumizing device, an inflation opening, a pressure sensor, an explosion-proof opening and a power supply system. The high heat flow thermal environment simulation device of the embodiment adopts a medium frequency sensing mode for heating and can ensure heat to be added in time with high efficiency, and simultaneously, the structure of a cylinder ensures evenness of heating. The heating environment is protected by inert gas so as to prevent a graphite heating body from being oxidized by high temperature and enable the highest heating temperature to reach 2800 DEG C above so that the high heat flow thermal environment simulation device has the capacity of providing heat flow density of over 3MW / m2.

Owner:BEIJING POWER MACHINERY INST

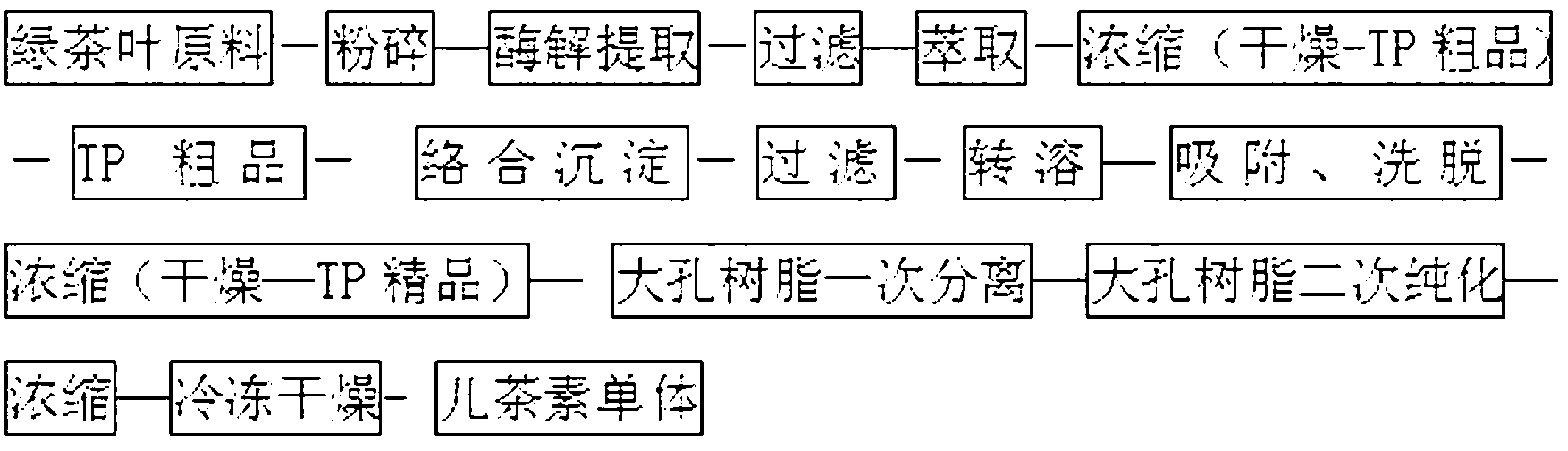

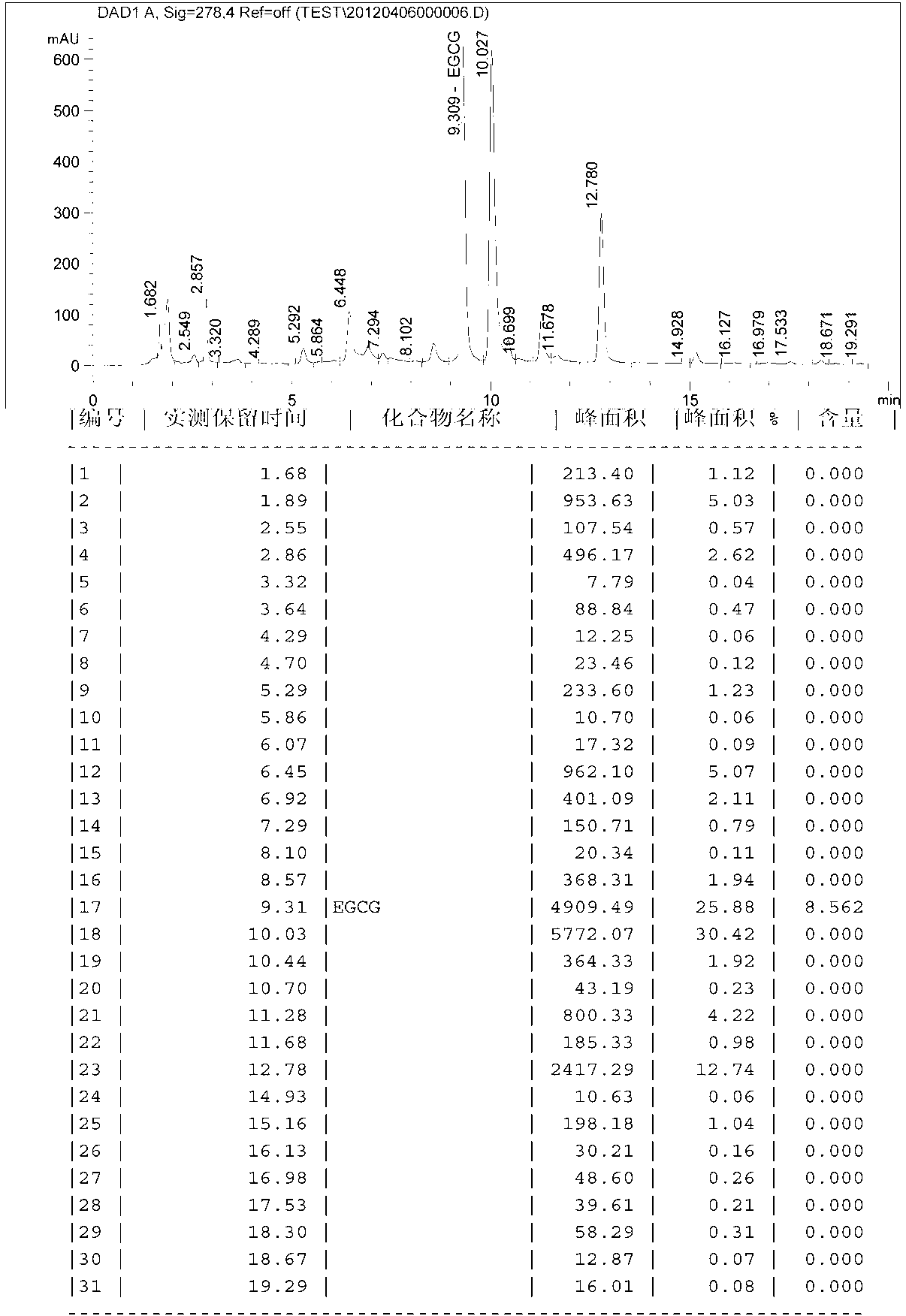

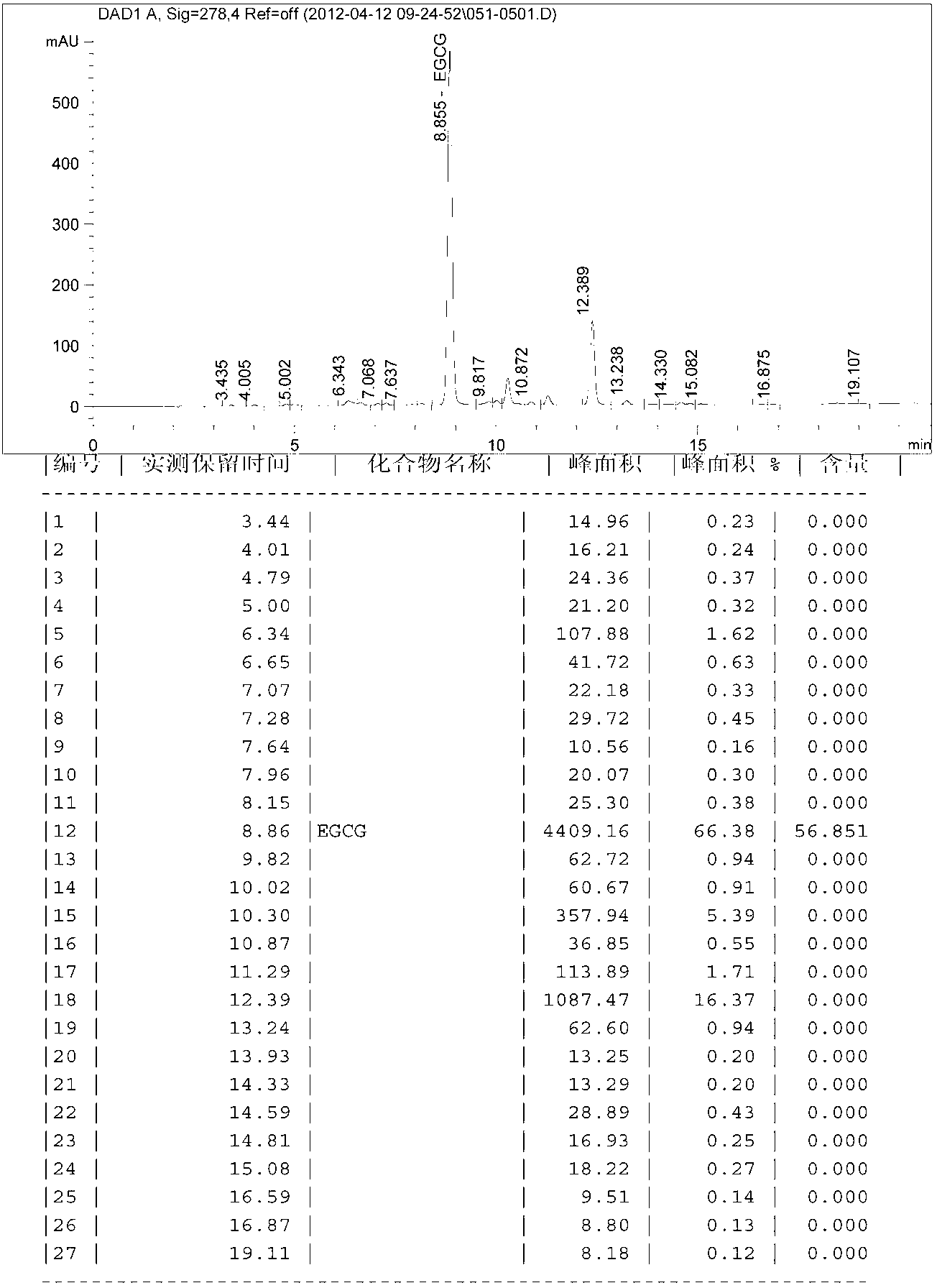

Method for preparing high-purity monomer epigallocatechin gallate from processed leftovers of tea leaves

The invention relates to a method for preparing high-purity monomer epigallocatechin gallate from processed leftovers of tea leaves. The method comprises the following steps of: extracting tea polyphenol, namely performing enzymolysis of the processed leftovers, which serve as raw materials, of fresh tea leaves, pruned tea leaves and non-fermented tea leaves by adding complex enzyme which consists of cellulose, protease and pectinase to extract the tea polyphenol; and separating a catechin out for purifying, namely precipitating the tea polyphenol by using a mixed precipitant which consists of CaCl2 and ZnCl2, performing primary separation by a macroporous resin chromatographic column, and performing secondary purification by the macroporous resin chromatographic column to obtain the high-purity monomer epigallocatechin gallate (EGCG). According to the method, chloroform is not used, the join from the extraction process to the refining and purification processes is compact, and the quality and yield of the product are high.

Owner:GUANGXI JIKANG BIO TECH

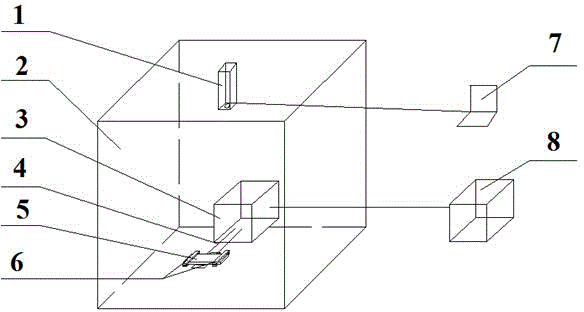

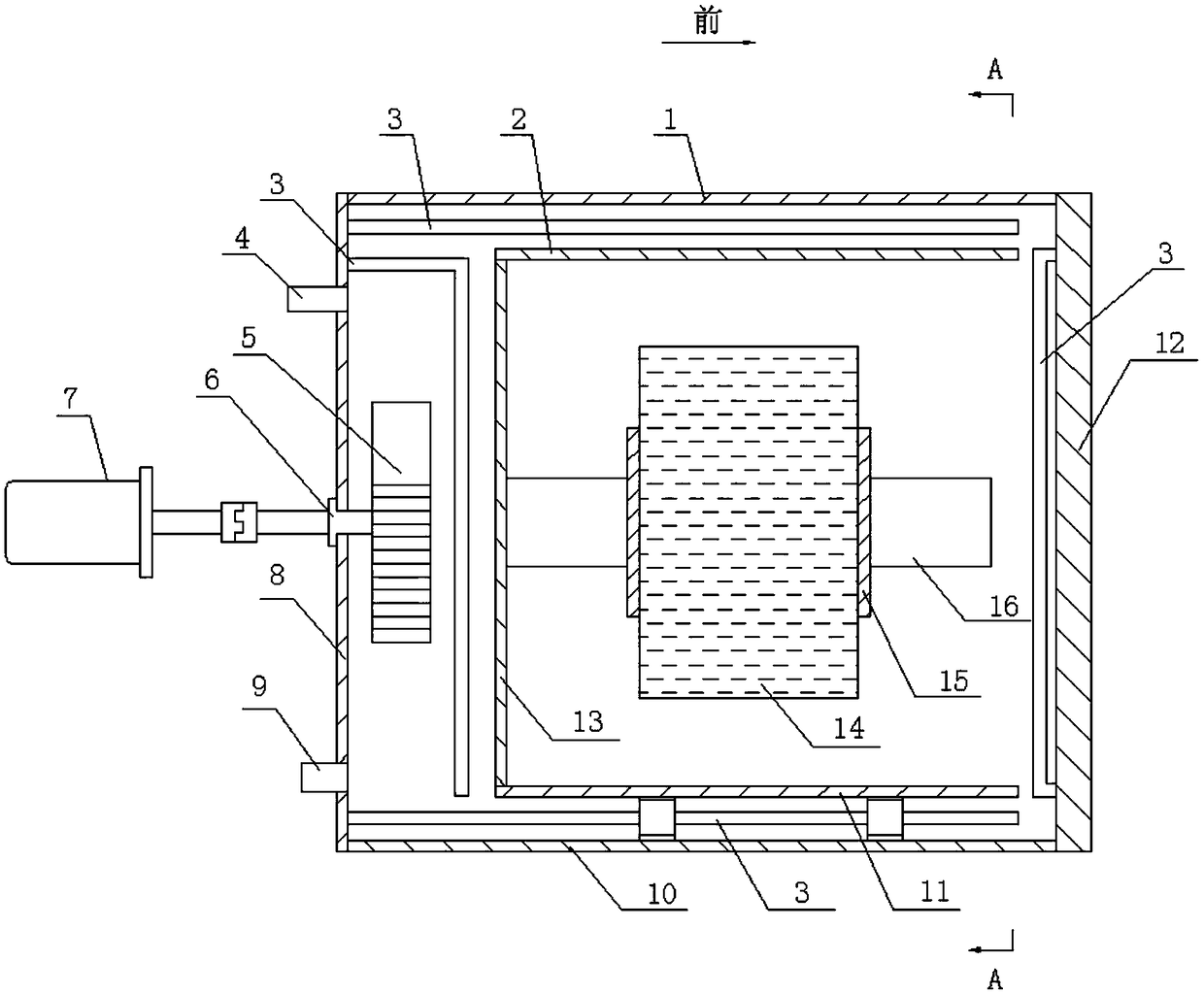

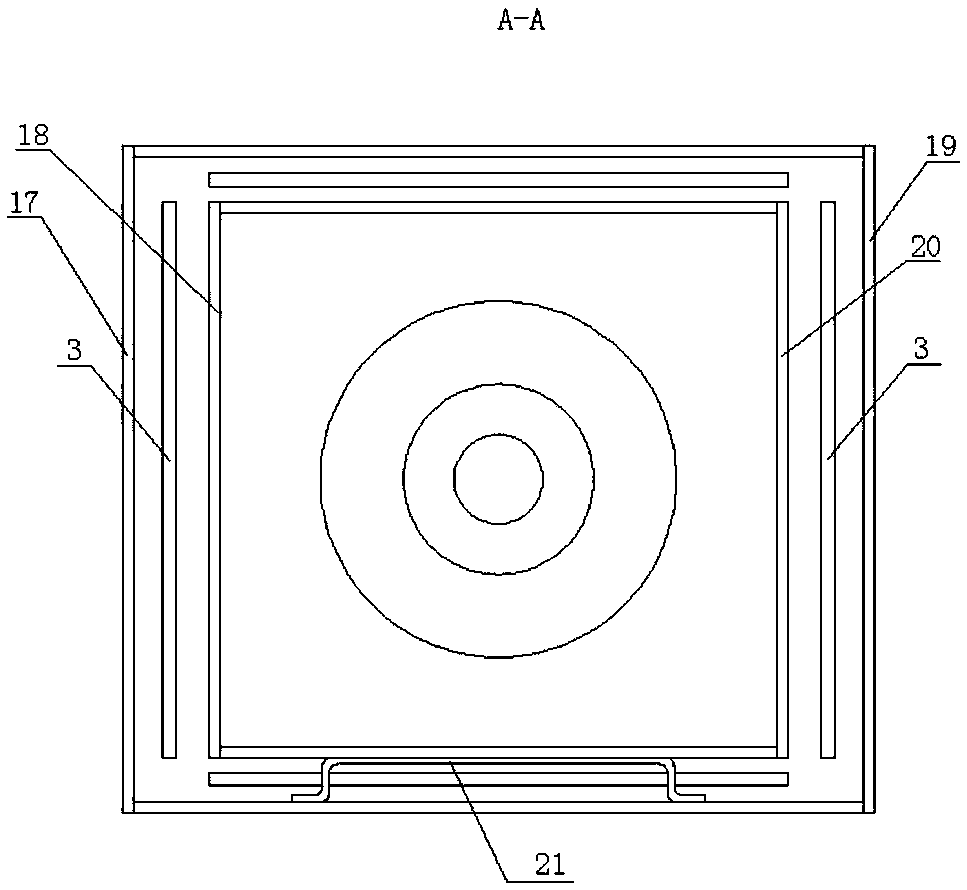

Method for optimizing repaired tissue of large workpiece based on local heat treatment realized by induction heating

The invention aims at providing a method for optimizing a repaired tissue of a large workpiece based on local heat treatment realized by induction heating, wherein the method can be used for realizing local heat treatment on an arbitrary-shape repaired part of a large repaired workpeice, meeting the requirements for regulating and controlling a heat treatment system for regulating repaired tissues of different materials, not only avoiding high-temperature oxidation caused during local heat treatment of the repaired workpiece, but also avoiding super-poor heat deformation of the repaired workpiece. The method comprises the steps of 1, calibrating the infrared emissivity of a part and a clamp material; 2, clamping a workpiece by using a special clamp; 3, purifying the atmosphere in an inert gas protecting box; 4, heating a repaired body by using an induction heating device; and 5, regulating and optimizing the repaired tissue subjected to local heat treatment realized by induction heating.

Owner:SHENYANG AEROSPACE UNIVERSITY

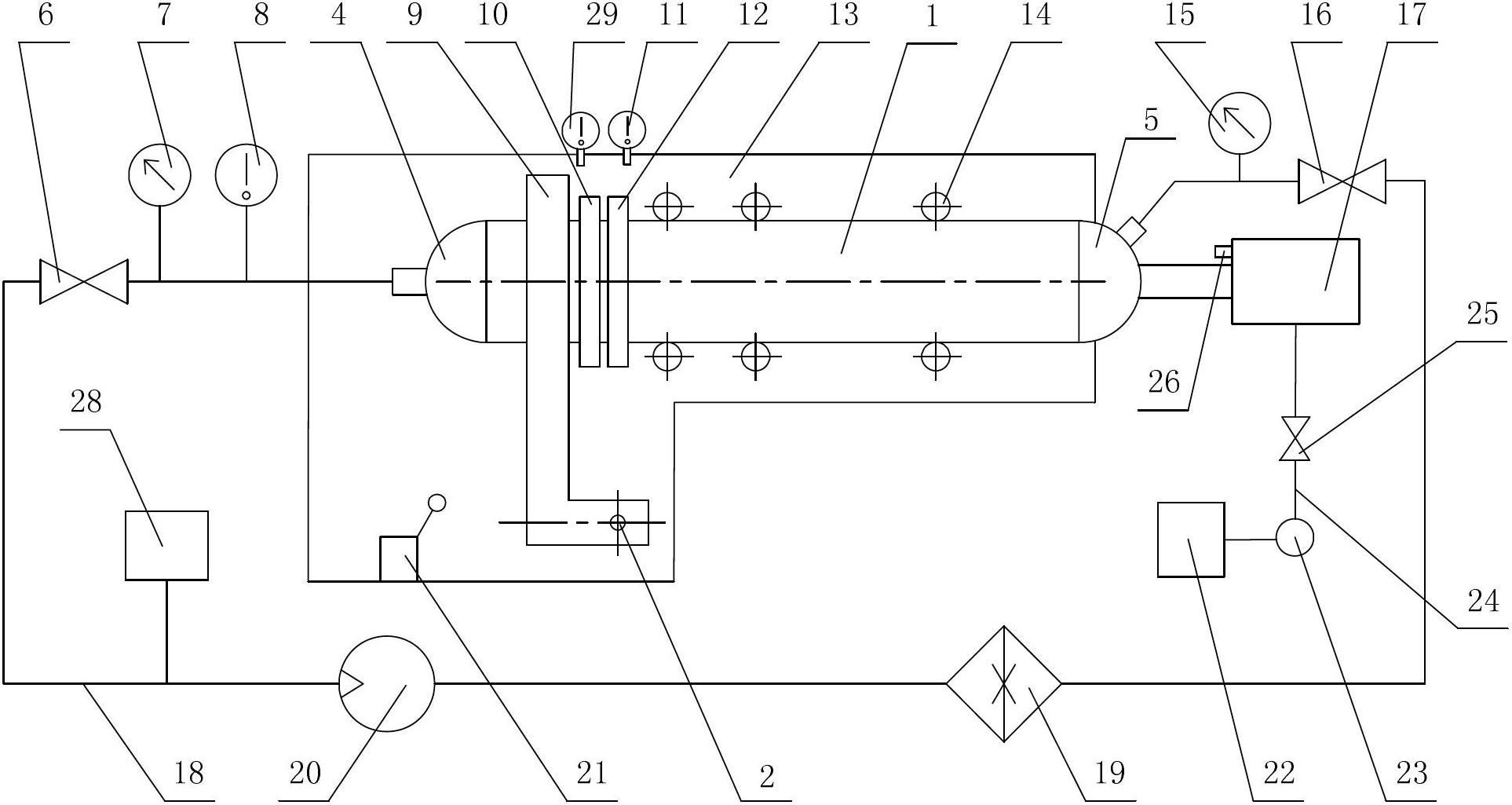

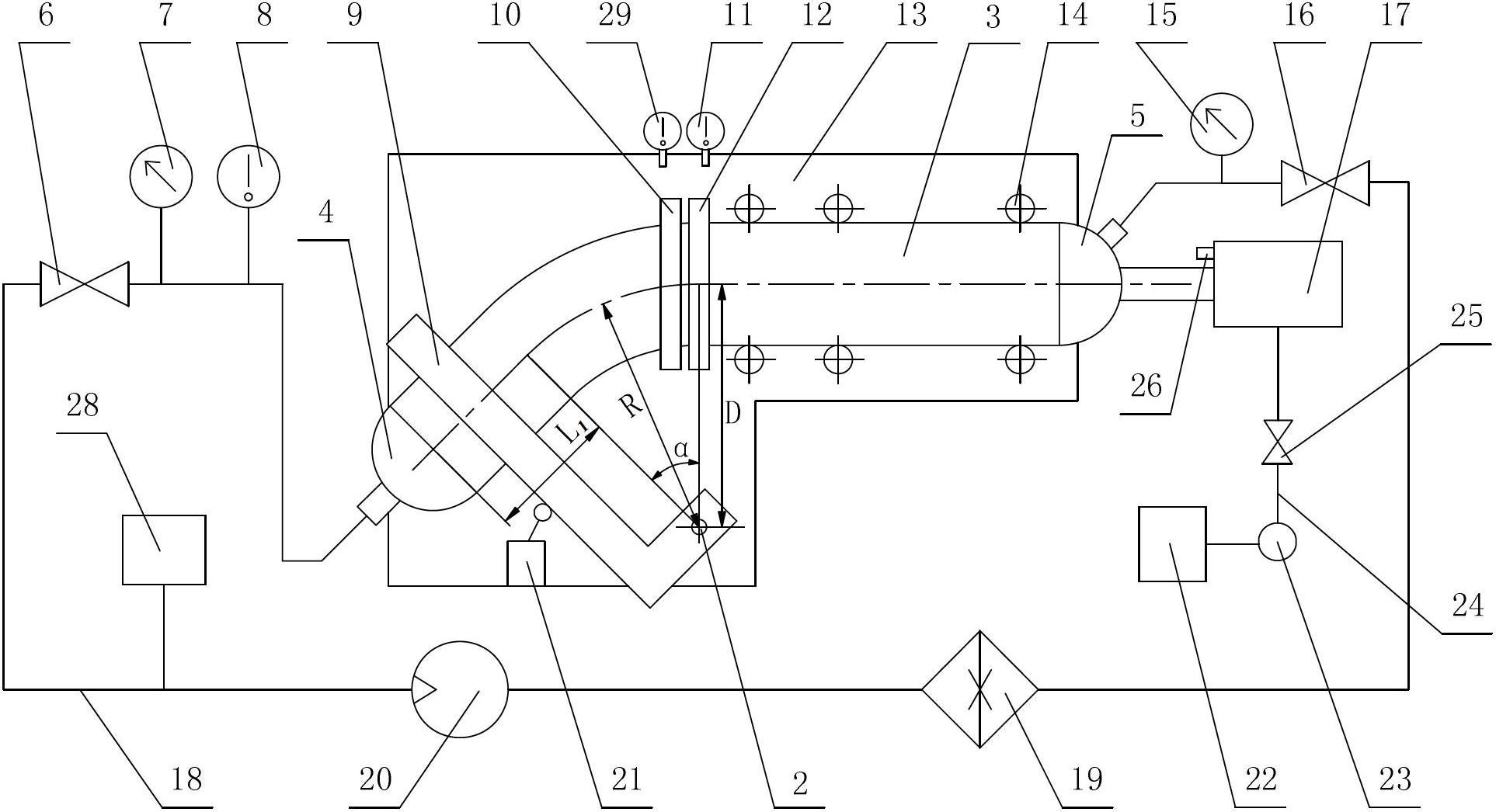

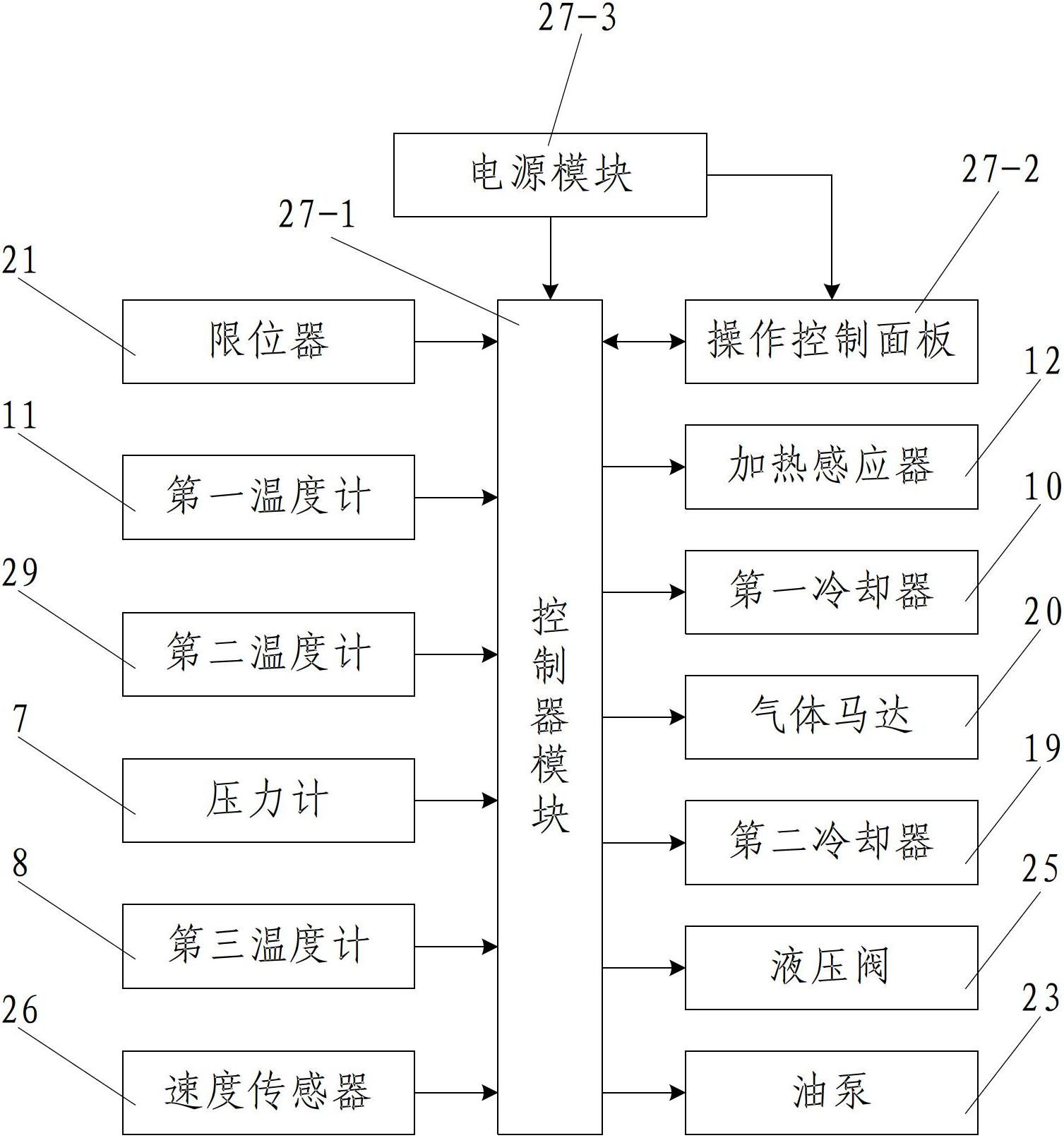

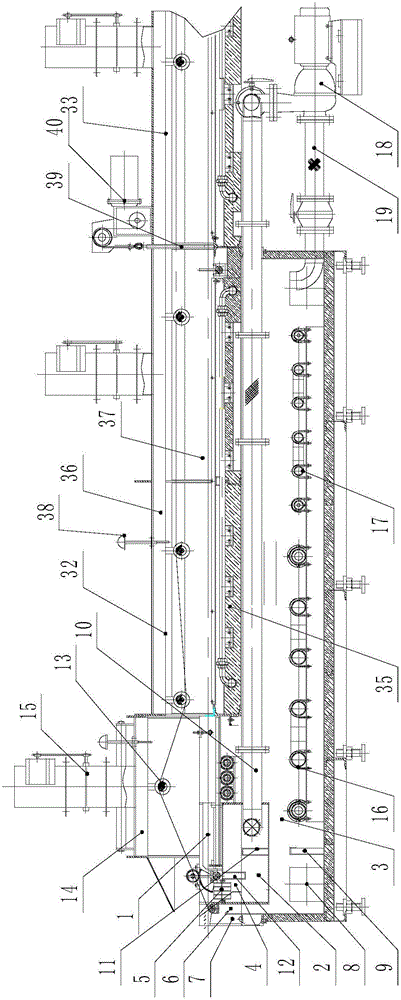

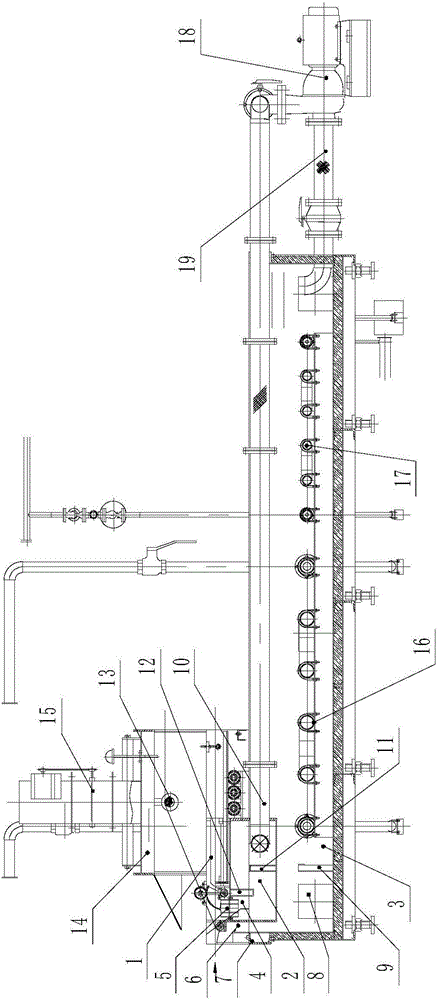

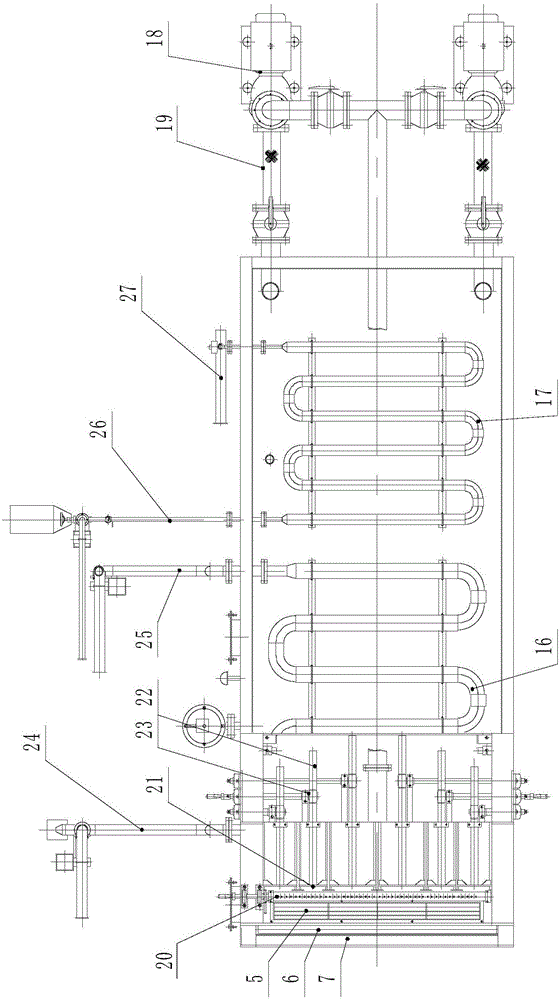

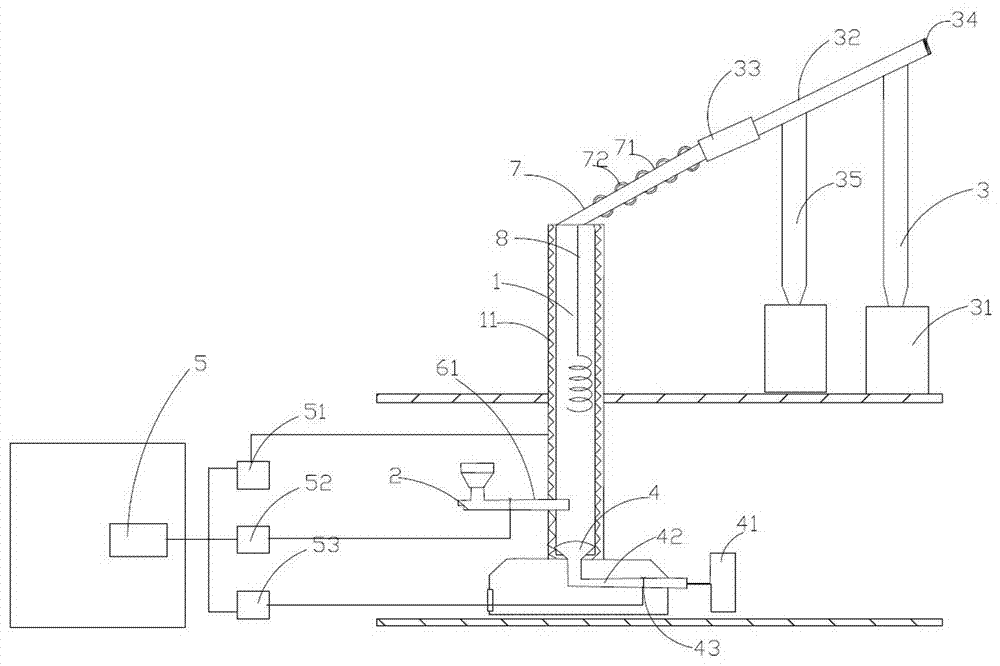

Manufacturing device and method for bimetal composite hot bend

The invention discloses a manufacturing device and a method for a bimetal composite hot bend. The device comprises a thermal induction bend mechanism, an inert gas protecting system and an automatic control system, wherein the thermal induction bend mechanism comprises a rack, a hydraulic cylinder and a hydraulic control system, a rolling wheel, a heating inductor, a limiting stopper, a rotating clamp and a first cooler are arranged on the rack, the inert gas protecting system comprises a gas inlet end socket, an exhausting end socket and a gas circulating pipeline, and a gas inlet end valve, an exhausting end valve, a gas concentration tester, a gas motor and a second cooler are mounted on the gas circulating pipeline. The method includes the steps of intercepting a required bimetal composite pipe, sealing the bimetal composite pipe, installing the bimetal composite pipe on the thermal induction bend mechanism, connecting the inert gas protecting system and roasting and bending. The manufacturing device and the method for the bimetal composite hot bend are reasonable in design, high in intelligent degree, applicability, rate of finished products, product qualities and practicability, and convenient to popularize and apply.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

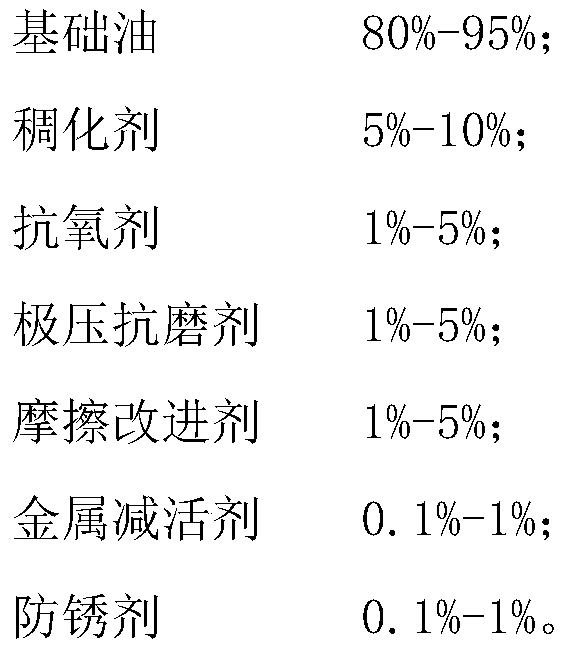

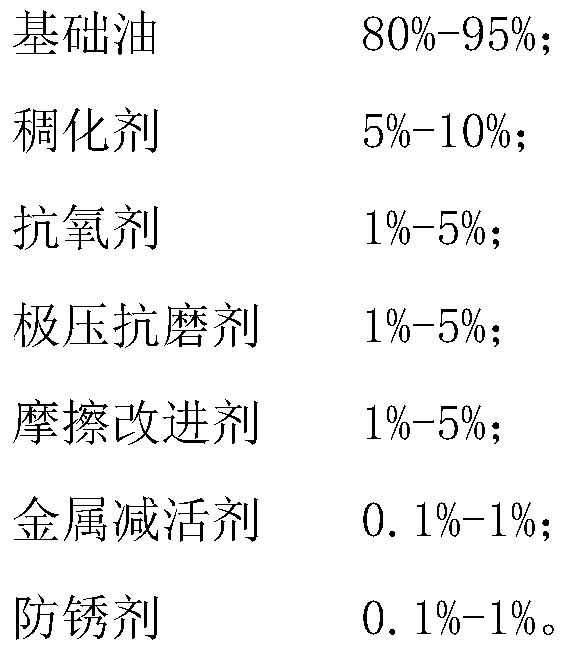

Long-life industrial robot RV reducer lubricating grease and preparation method thereof

InactiveCN109810768AIncrease frictionImprove Oxidation StabilityLubricant compositionLithium soapLithium hydroxide

The invention provides long-life industrial robot RV reducer lubricating grease and a preparation method thereof. According to the long-life industrial robot RV reducer lubricating grease, synthetic oil is used as base oil, fatty acid lithium soap is used as a thickening agent, an antioxidant, an anti-wear reagent at extreme pressure, a friction modifier, a metal deactivating agent and an antirusting agent are added and the long-life industrial robot RV reducer lubricating grease is prepared through modulation by a special technology, and the thickening agent is a thickening agent generated from the reaction of fatty acid and lithium hydroxide; and the antirusting agent is one type or multiple types of sulfonate, hydroxyl and salts of the hydroxyl, organic amine, esters, organic phosphoricacid and salts of the organic phosphoric acid and a heterocyclic compound. The long-life industrial robot RV reducer lubricating grease has excellent mechanical stability and oxidation stability, excellent abrasion resistance, low-temperature resistance and protection performance. Lubricating requirements of an industrial robot RV reducer are met. According to the preparation method of the long-life industrial robot RV reducer lubricating grease, a certain amount of antioxidant addition agents are added before high-temperature refining to effectively prevent high-temperature oxidation, and the service life of the lubricating grease is prolonged; and petroleum calcium sulfonate is added, and the tribology performance is effectively improved.

Owner:辽宁海华科技股份有限公司

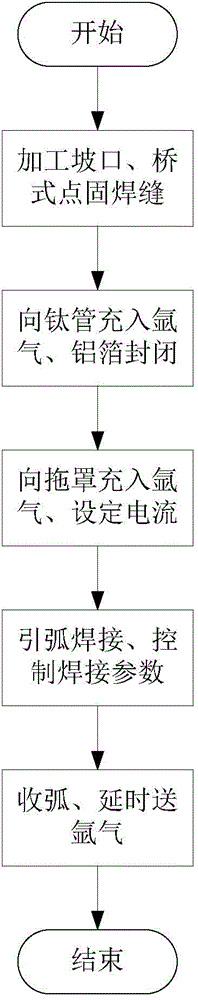

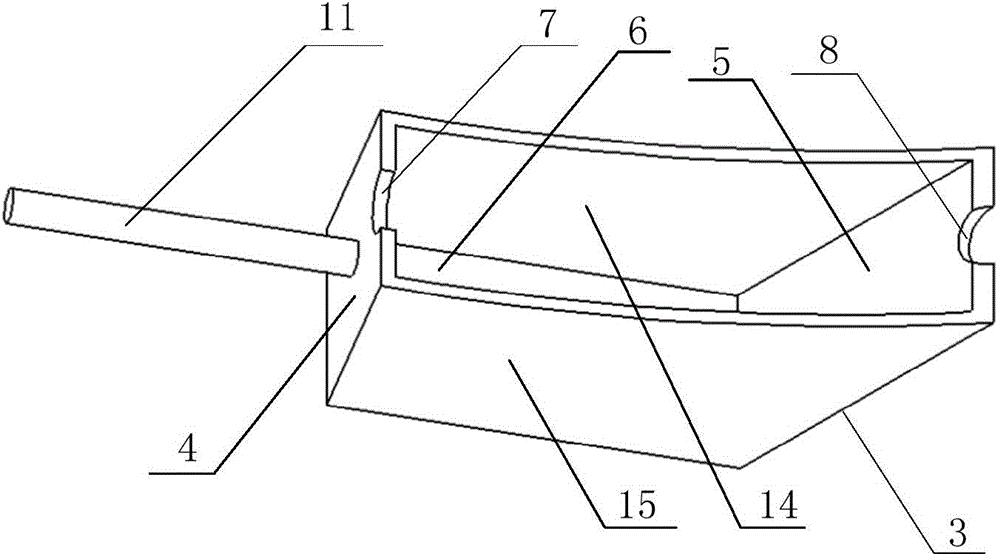

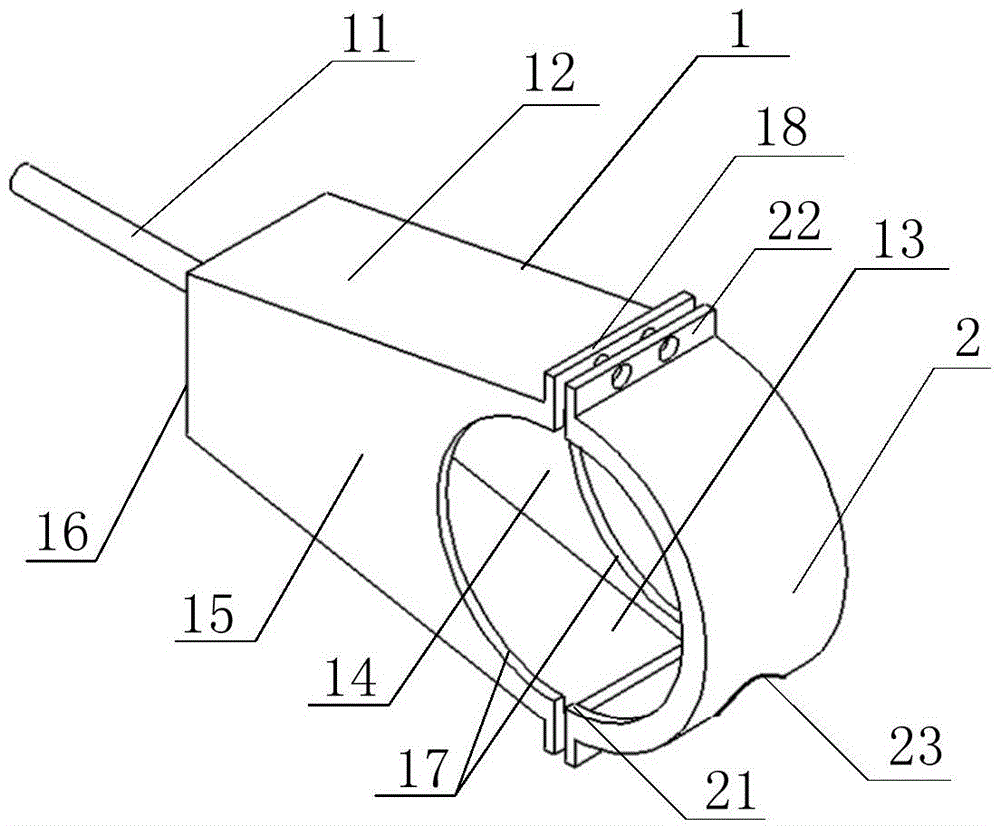

Titanium pipeline argon arc welding process method

InactiveCN104128696APrevent oxidationAvoid high temperature oxidationWelding/soldering/cutting articlesTubular articlesSurface oxidationBridge type

The invention provides a titanium pipeline argon arc welding process method. The process method includes the steps: processing a groove, fixing a welding seam through a bridge-type point, filling argon into a titanium pipe, using an aluminum foil to close the welding seam, filling argon into a dragging cover, controlling welding parameters, and feeding argon in a delayed manner during arc extinguishing. By the process method, strength, plasticity and tenacity of a welding joint can be improved effectively, and the defects of generation of cracks and air holes and surface oxidation at the welding seam can be prevented.

Owner:CHINA NAT CHEM ENG NO 14 CONSTR

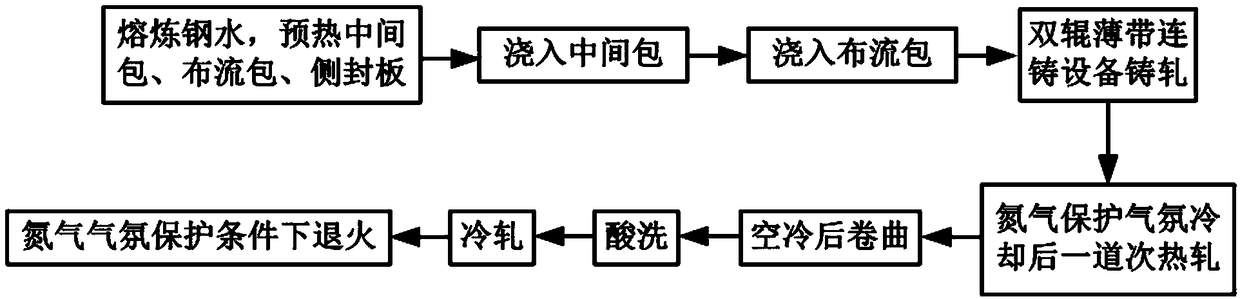

Short-process preparation method of thin specification high-manganese steel plate

ActiveCN108796190AReduce conversionReduce processing stepsMetal rolling arrangementsAlloyNitrogen gas

The invention belongs to the technical field of steel alloy materials and particularly relates to a short-process preparation method of a thin specification high-manganese steel plate. Elements of thethin specification high-manganese steel plate comprise, by mass percent, larger than or equal to 0.015% and smaller than or equal to 0.3% of C, larger than or equal to 15% and smaller than or equal to 25% of Mn, larger than or equal to 1% and smaller than or equal to 3% of Si, larger than or equal to 1.5% and smaller than or equal to 3% of Al, smaller than or equal to 0.003% of P, smaller than orequal to 0.002% of O, smaller than or equal to 0.002% of N, smaller than or equal to 0.003% of S and the balance Fe. The preparation method comprises the following steps that molten steel is smelted,and a tundish, a flow distribution bag and a side sealing plate are preheated; 2, the tundish is poured in; 3, the flow distribution bag is poured; 4, double-roller thin-strip casting equipment is utilized for cast rolling; 5, one-pass hot rolling is carried out after cooling is carried out in nitrogen protective atmosphere; 6, curling is carried out after air cooling; 7, acid pickling is carriedout; 8, cold rolling is carried out; and 9, annealing is carried out on the nitrogen atmosphere protecting condition. The thickness of the thin specification high-manganese steel plate is 0.47-1.2 mm, the width is 500-2000 mm, the extension strength is 750-1400 MPa, and the break ductility is 30-80%. The technology is a short-process near-end forming technology, and the method has the beneficialeffects of being low in cost, low in energy consumption and the like.

Owner:NORTHEASTERN UNIV

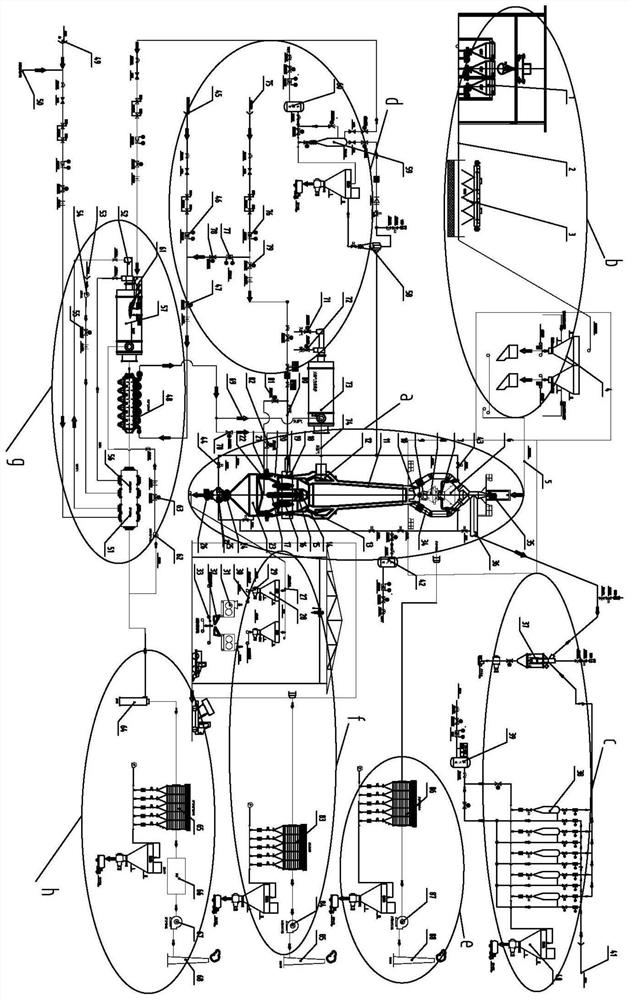

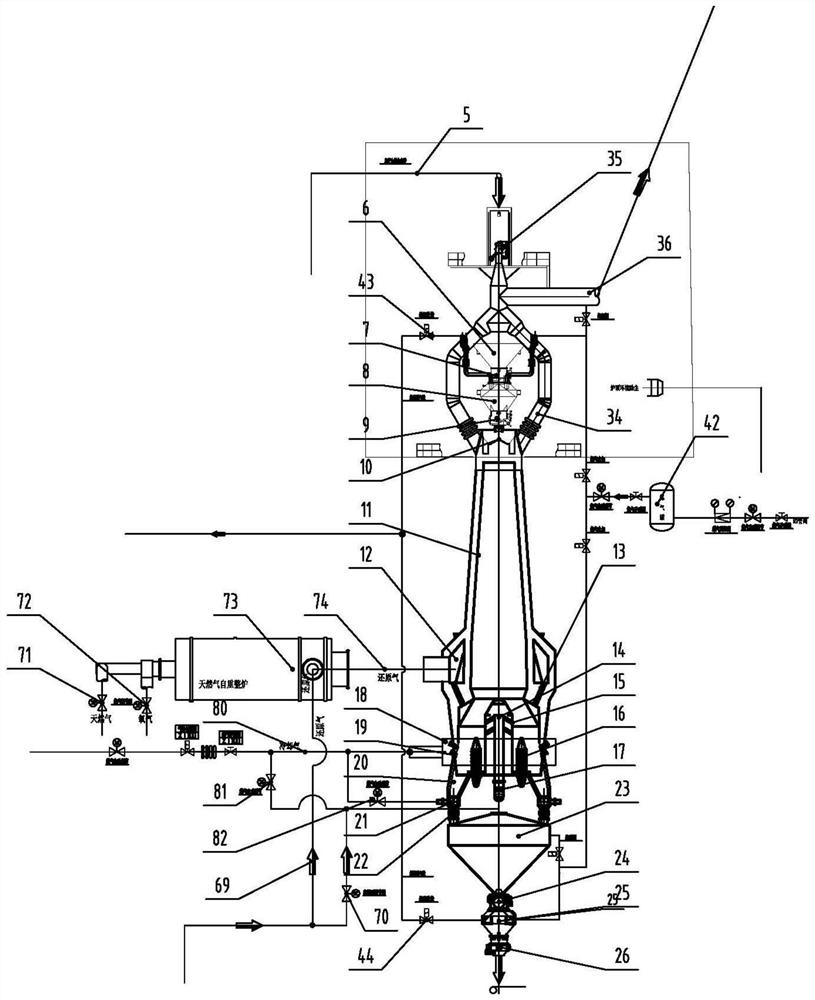

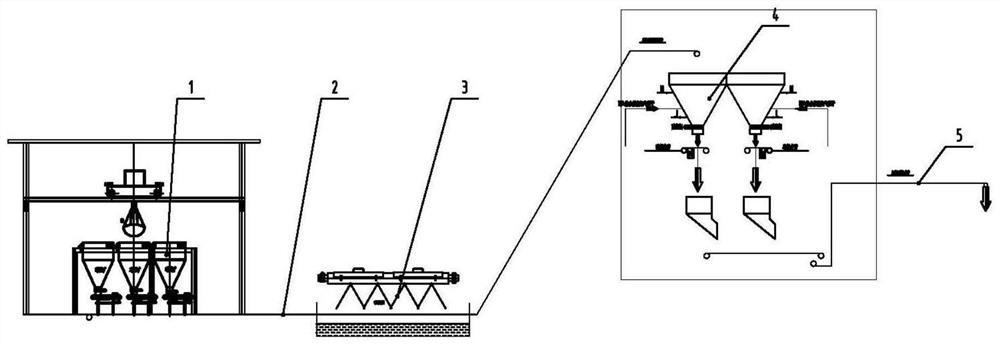

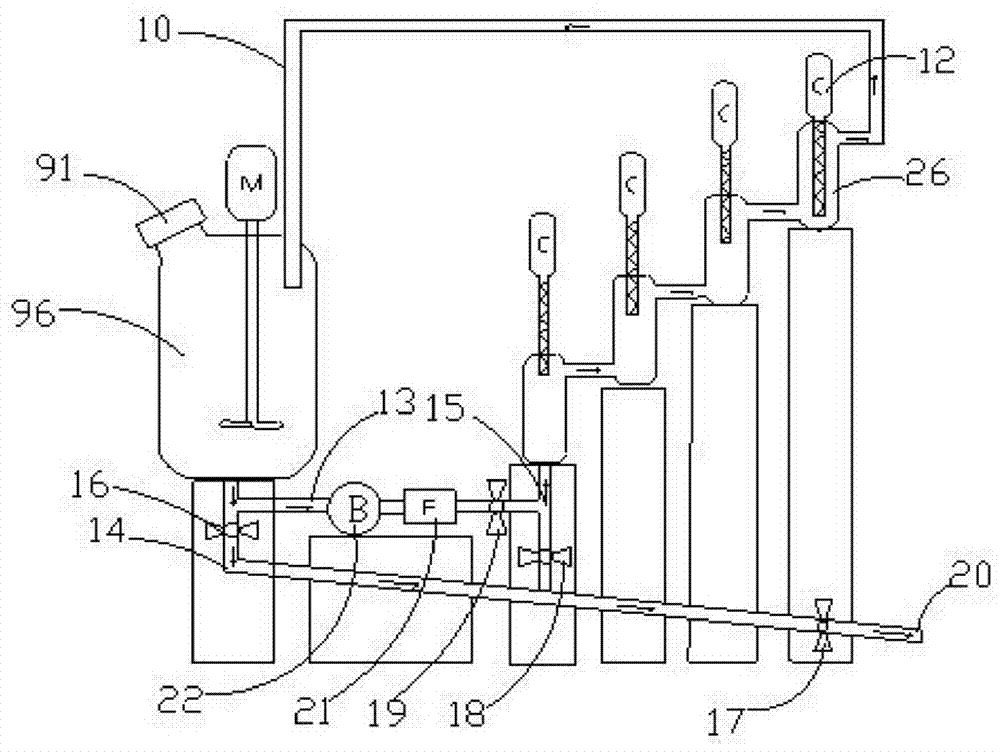

Hydrogen radical shaft furnace direct reduction system and method

ActiveCN111926135AAvoid the problem that the pressure balance point is difficult to controlSimple processShaft furnaceGas heaterCooling chamber

The invention relates to a hydrogen radical shaft furnace direct reduction system and method, belongs to the technical field of shaft furnace reduction, and solves the technical problems that when anexisting shaft furnace is adopted for reduction of oxidized pellets, reduction is not uniform, and a cooling circulating system is complicated, high in cost and large in energy consumption. The hydrogen radical shaft furnace direct reduction system comprises a shaft furnace body and a hydrogen-rich reduction gas heater; the hydrogen-rich reduction gas heater is used for heating hydrogen-rich reduction gas to 950-1000 DEG C; the shaft furnace body comprises an oxidized pellet reduction unit and a metal pellet in-furnace cooling unit; the oxidized pellet reduction unit comprises a shaft furnacereduction section, a reduction gas mixing section and a hollow shaft furnace central cone; the metal pellet in-furnace cooling unit comprises a cooling chamber; and the cooling chamber is formed belowthe reduction gas mixing section. According to the hydrogen radical shaft furnace direct reduction system, hydrogen-rich cooling gas with the same compositions as hydrogen-rich reduction gas is adopted to cool metal pellets, after heat exchange, high-temperature hydrogen-rich cooling gas and high-temperature hydrogen-rich reduction gas are mixed in the shaft furnace to be used for reduction of the oxidized pellets, and the technology is concise and obvious in energy-saving effect.

Owner:钢研晟华科技股份有限公司

Silicon solar cell electrode silver coated copper sizing agent and preparing method thereof

ActiveCN104157331AImprove stabilityImprove reliabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureCeriumSilicon solar cell

The invention relates to a silicon solar cell electrode silver coated copper sizing agent and a preparing method of the silicon solar cell electrode silver coated copper sizing agent. Conductive component micro silver coated copper powder is the spherical micro metal powder with copper serving as the core, silver serving as the shell, and copper-tin-silver alloy serving as the middle layer, the copper content is 50 percent to 60 percent, the silver content is 30 percent to 40 percent, the tin content is 3 percent to 10 percent, the particle size is 1-3 microns, the tap density is 4.0-5.5 g / ml, the specific surface area is 0.5-1.5 m<2> / g, and the conductive component micro silver coated copper powder is prepared under the alkaline condition with glyoxylic acid or glyoxal serving as a reducing agent to conduct step-by-step reduction on copper sulfate, tin sulfate and a silver nitrate solution. A bismuth-silicon-boron-zinc-cerium-molybdenum system is adopted in lead-free glass powder, the softening temperature of the glass powder is 400-600 DEG C, the micro silver coated copper powder serves as the conductive component, a large amount of silver powder is saved, and the raw material cost of the conductive sizing agent is greatly reduced.

Owner:TIANJIN ZHONGKE CHEM

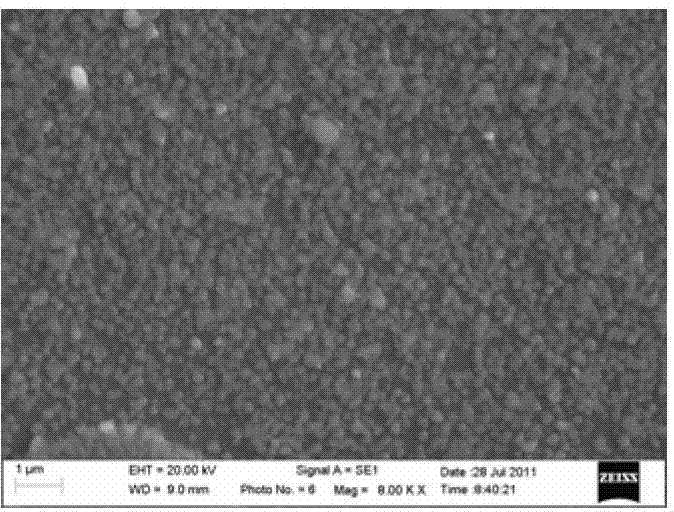

Method for preparing core-shell type copper-based alloy powder capable of resisting high-temperature oxidization

InactiveCN102528025AAvoid high temperature oxidationSimple processLiquid/solution decomposition chemical coatingMg alloysChemical plating

The invention discloses a method for preparing core-shell type copper-based alloy powder capable of resisting high-temperature oxidization, which is characterized by including steps of: (1) performing activation, filtering, deionization washing and drying on the surface of copper-based alloy; (2) performing chemical nickel plating processing in a plating tank with prepared nickel plating solution, and performing filtering, deionization washing and drying after the chemical nickel plating is finished; (3) performing chemical chromeplating processing in a plating tank with prepared chromeplating solution, and performing filtering, deionization washing and drying after the chemical chromeplating processing. The method for preparing core-shell type copper-based alloy powder capable of resisting high-temperature oxidization has the advantages of being simple in process, convenient to operate, high in processing efficiency and low in production cost. Prepared copper-based alloy powder has a core-shell structure, starting oxidation temperature of the powder is improved by 400-700 DEG C compared with unprocessed copper-based alloy powder, high-temperature oxidization of the copper-based alloy can be effectively avoided, and the method has wide application prospect in the field for cladding high-strength high-conductivity copper-based alloy coatings in laser mode on surfaces of copper crucibles, electromagnetic gun guide rails, aluminum alloy, magnesium alloy and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

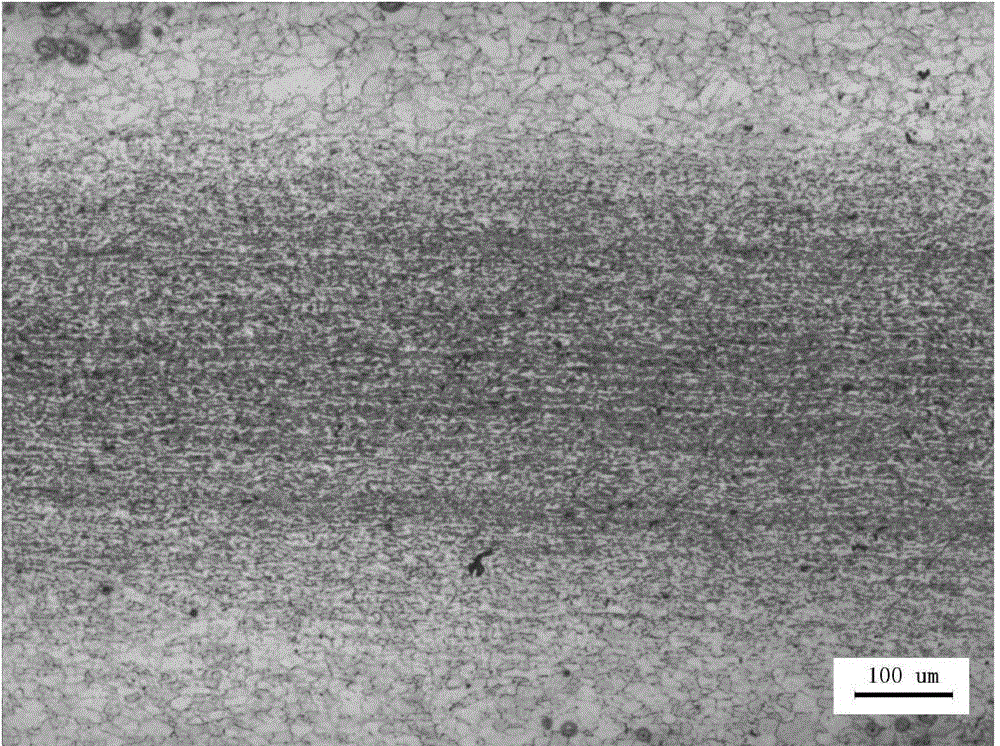

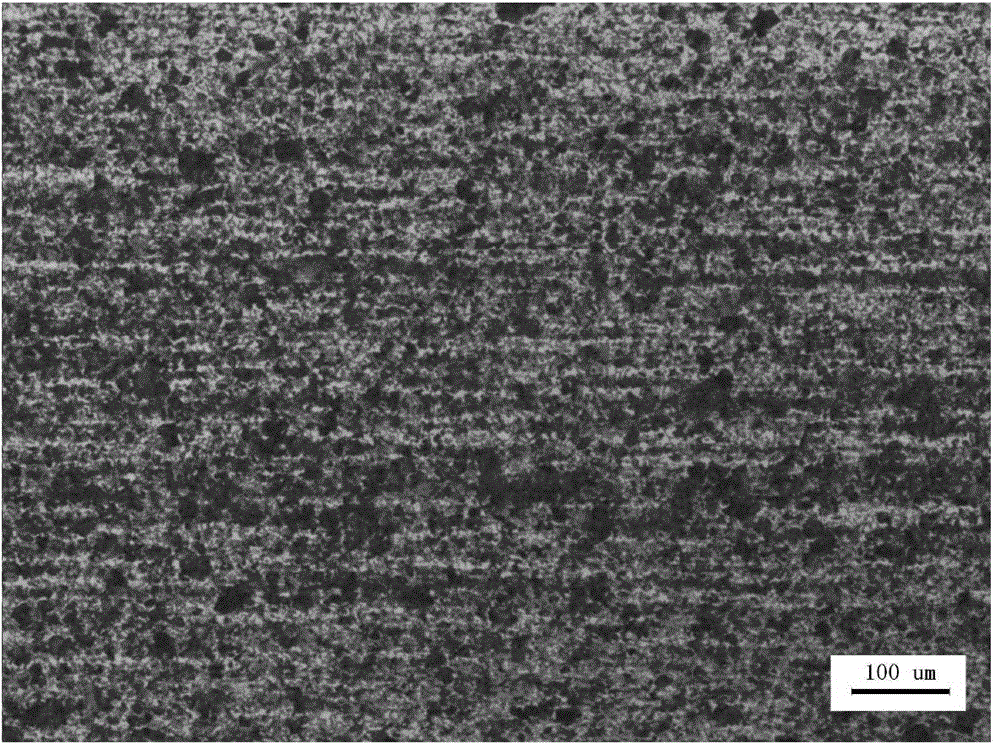

MCrAlY alloy and preparation method thereof

InactiveCN106987755AImprove mechanical propertiesImprove antioxidant capacityMechanical propertyVacuum induction melting

The invention provides a MCrAlY alloy and a preparation method thereof. The MCrAlY alloy adds Zr, Si, Ti, Hf and Ta to the existing MCrAlY alloy to improve the mechanical properties and oxidation resistance of the MCrAlY alloy. The preparation method of the MCrAlY alloy uses a combination of vacuum induction melting and vacuum casting technology to obtain an MCrAlY alloy with a relatively uniform and fine microstructure.

Owner:北京普瑞新材科技有限公司

Highly efficient drying device for pole coils and drying method thereof

PendingCN109186197AImprove temperature uniformityImprove heating efficiencyDrying solid materials without heatDrying gas arrangementsEngineeringContact heat

The invention provides a highly efficient drying method and device for a pole coil. The drying device mainly comprises an outer box body, a drying cavity, heaters, a horizontal metal mandrel, a pole coil winding drum, an air conveying motor, a wind wheel and the like. The heaters are fixed to the upper portion, the lower portion, the left side, the right side, the rear portion of the drying cavityand a box door of the outer box body, and the horizontal metal mandrel is internally provided with a heating device, so that synchronous heating of the six surfaces of the drying cavity and the horizontal metal mandrel is realized. Before heating, air in the outer box body is replaced with dry air, efficient convection heat exchange between the pole coil and the gas medium is realized through horizontal circulating air conveying, and contact heat conduction and temperature rise of an inner ring of the pole coil are realized through the pole coil winding drum. Compared with the prior art, thehighly efficient drying method for the pole coil has higher efficiency, reduces the temperature difference at different coil diameters of the pole coil, and has better temperature uniformity.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

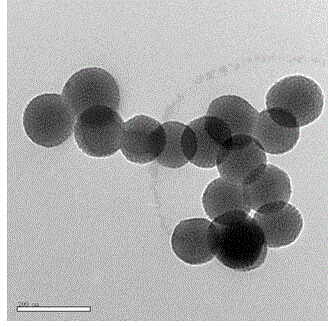

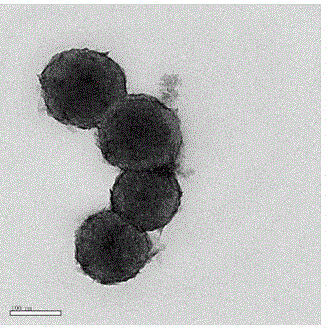

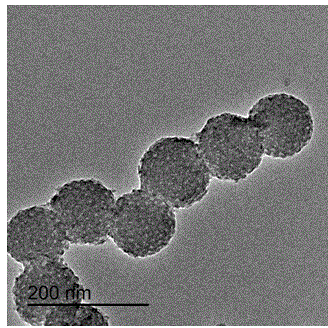

Preparation method of nickel oxide/carbon sphere composite material

InactiveCN104900421ALow priceEasy to storeMaterial nanotechnologyHybrid capacitor electrodesNickel oxide hydroxideSupercapacitor

A preparation method of a nickel oxide / carbon sphere composite material relates to the technical field of nano-material production. Backflow processing is carried out on ordered meso-pore carbon spheres, as carriers, in a NaOH solution, and a nickel hydroxide / carbon sphere precursor material is synthesized via hydrolysis of metal ions. The precursor is calcined in the atmosphere of nitrogen, nickel hydroxide is deposited to nickel oxide, and finally the nickel oxide / carbon sphere composite material is obtained. The preparation method provided by the invention is simple in technology and low in cost, and the prepared nickel oxide / carbon sphere composite material has good prospects in the field of super capacitors.

Owner:YANGZHOU UNIV

Coating graphite protective lubricant, and preparation method and application method thereof

ActiveCN103820198AAvoid high temperature oxidationStrong adhesionLubricant compositionDiacetone alcoholCarvacryl acetate

The invention discloses a coating graphite protective lubricant, and a preparation method and application method thereof. The coating graphite protective lubricant comprises the following ingredients by mass: 1.5-2 parts of monoethanolamine, 2.2-3 parts of sodium silicate, 1.8-2 parts of gelatins, 4.7-5 parts of sodium borate, 0.4-0.5 part of oxazolidine, 1.3-1.5 parts of sodium methylene bis-naphthalene sulfonate, 4.2-5 parts of ethylene-vinyl acetate copolymer, 0.8-1 part of crylic acid-2-ethylhexyl, 2.2-3 parts of diacetone alcohol, 14-15 parts of graphite and 60-62 parts of distilled water or deionized water. According to the invention, the coating graphite protective lubricant doesn't fall off, can't be oxidized, and has a good lubricating property and rejection capability.

Owner:QINGDAO YUANDA GRAPHITE

Camellia seed cold pressing oil making process

ActiveCN105602715AFull of flavorAvoid high temperature oxidationFatty-oils/fats productionAcid valueEngineering

The invention discloses a camellia seed cold pressing oil making process. The camellia seed cold pressing oil making process includes the following steps of camellia seed taking, cleaning and impurity removing, deshelling and shell and kernel separating, cold pressing, crude oil cold pressing, coarse filtering, clear filtering, refining and high-quality camellia oil obtaining. The acid value of a product is 0.03 mgKOH / g, and the peroxidation value of the product is 0.3-1 mmol / kg. Through treatment of a freezing test, the product is still kept in a clear and transparent state after being kept for 10 hours at the temperature of -8 DEG C.

Owner:JIANGXI WUYUAN ECOLOGICAL AGRI CO LTD

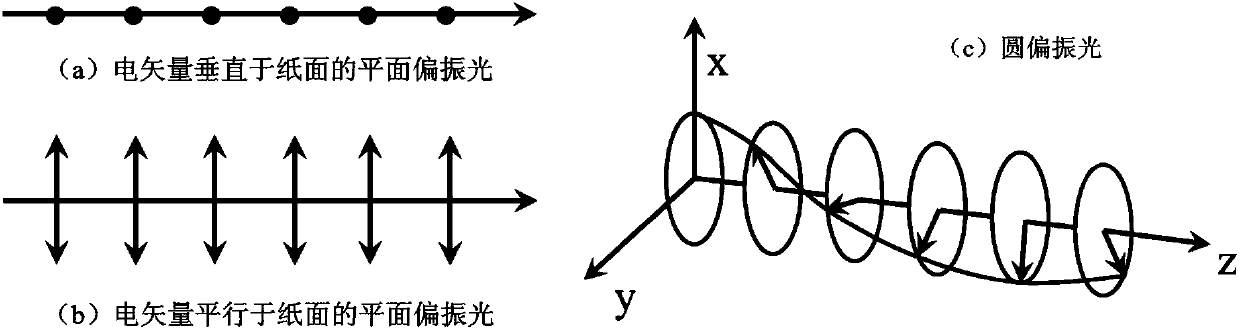

Preparation method of cellulose circular polarization thin film and cellulose linear polarization thin film and thin film products thereof

The invention discloses a preparation method of a cellulose circular polarization thin film and a cellulose linear polarization thin film and thin film products thereof. The preparation method is characterized in that cellulose cholesteric liquid crystals are obtained by using an ultrasonic method and are dried under a certain condition so as to prepare the cellulose circular polarization thin film; and meanwhile, cellulose macromolecular chains are effectively oriented by dissolving and regenerating celluloses, so that the cellulose linear polarization thin film is prepared. The polarization thin films prepared by the invention can be applied to optical display devices or auxiliary components and the like. Compared with conventional polaroids, the polarization thin films have the advantages that the used raw materials are rich, low in cost and environment-friendly; and the preparation method is simple and controllable and can be used for industrial production.

Owner:QINGDAO UNIV OF SCI & TECH

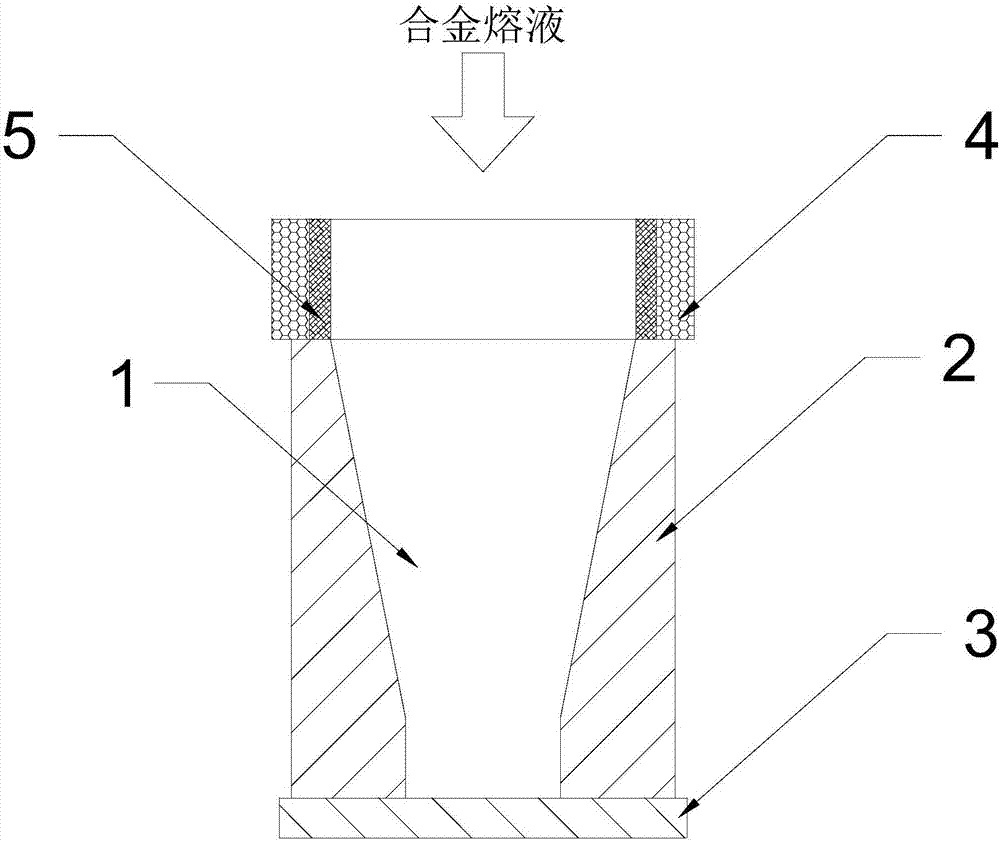

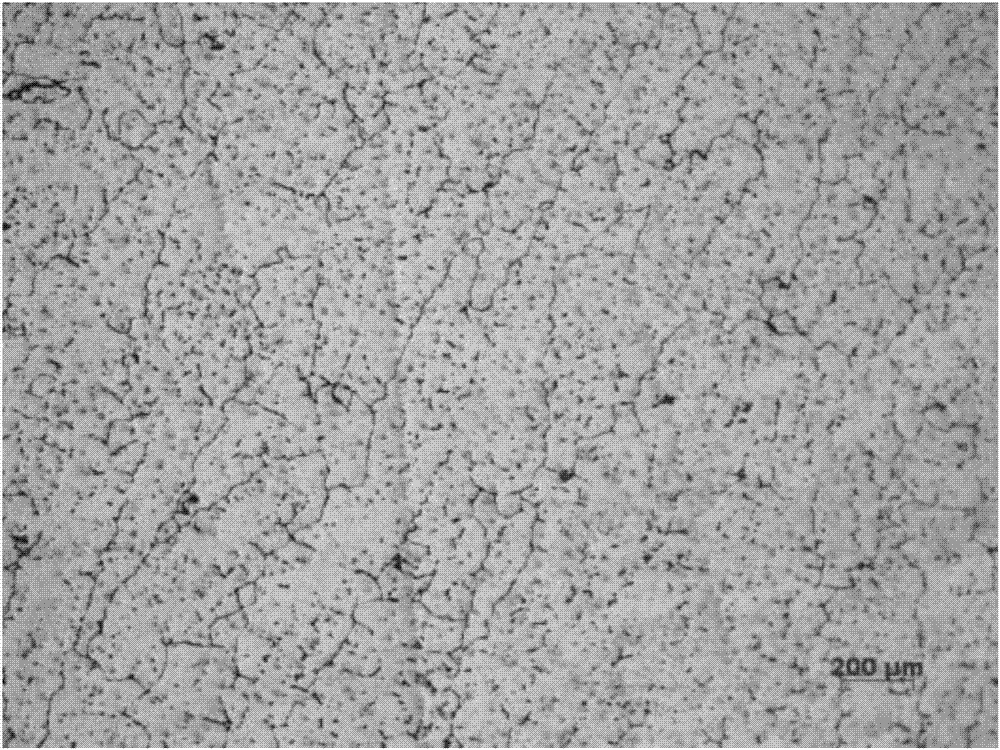

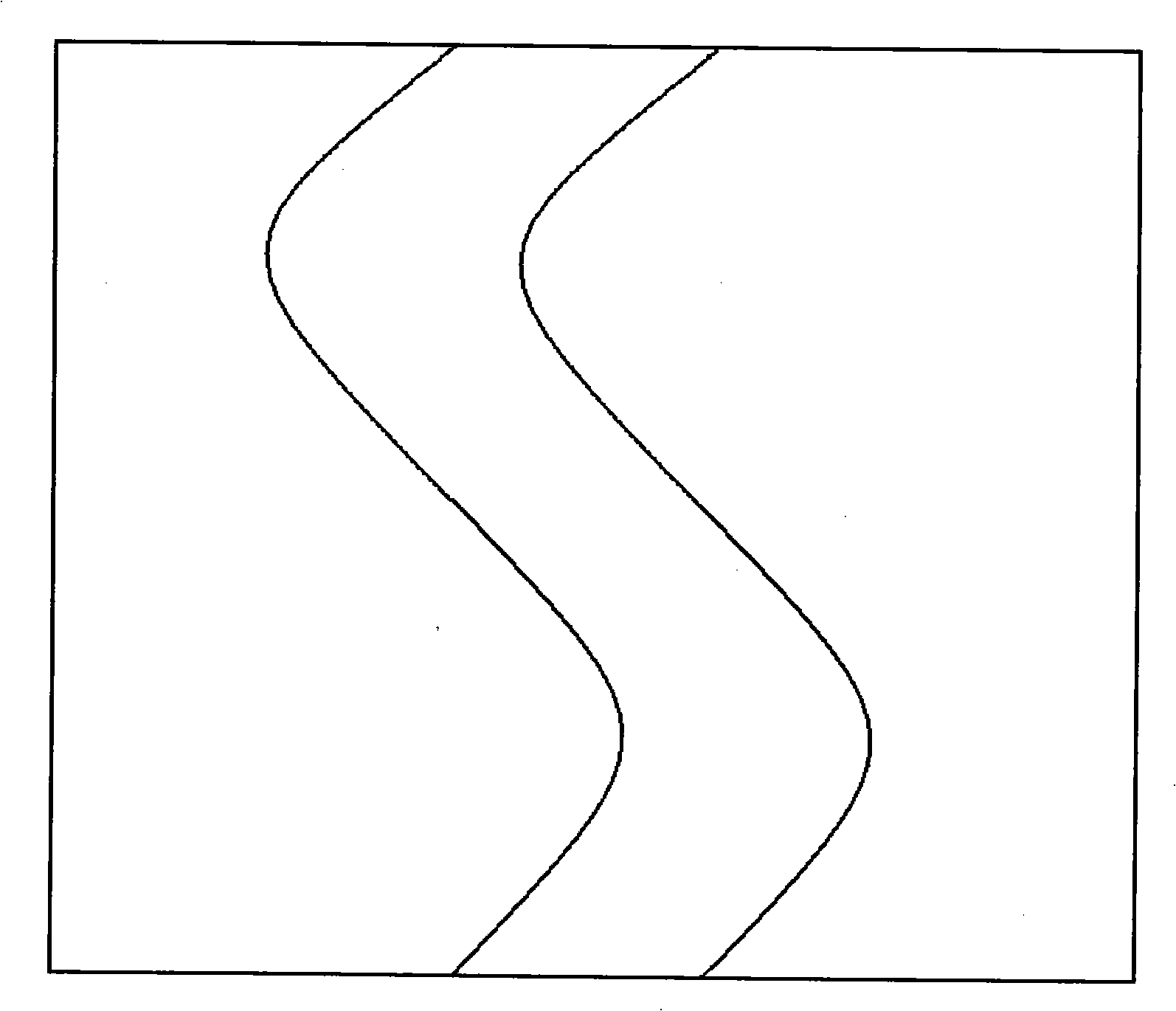

Sine waveform device for preparing semi-solid metal slurry

InactiveCN101347833AHomogeneous strong self-stirringPrevent crust stickingMolten metal conveying equipmentsCooling effectSemi solid

The invention discloses a sine waveform device used for preparing semi-solid metal slurry and a preparation method thereof. A flow channel of liquid metal is designed into sine waveform in the device. The flow direction of the liquid metal can be changed constantly and realize automatic even agitation when low superheat liquid metal flows through. In addition, due to the cooling effect at the bottom and the sidewall, a large number of primary crystals are produced from the liquid metal, the primary crystals which do not grow up yet detach from the container wall to enter into the liquid metal under the impact of the subsequent liquid metal, and finally form semi-solid slurry with large amount of globular crystals at the outlet of the channel of a sine waveform container. By adjusting the number of waveform and the inclination angle of the sine waveform container, and the indenter height of the liquid metal inside an inlet container, the number of nucleation can be controlled, as well as grain refinement and equiaxial effect can also be affected. The sine waveform device of the invention has the advantages of simple structure, compact process, high efficiency on energy saving, short process, wide application range, and can realize the preparation of semi-solid metal slurry such as iron and steel materials, aluminum alloy, magnesium alloy, etc.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

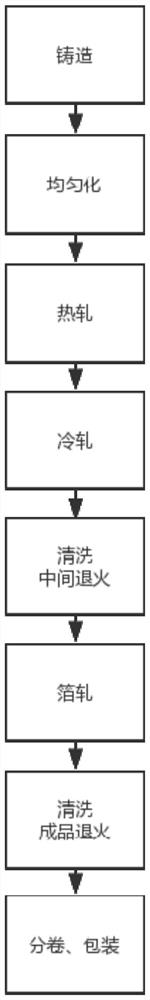

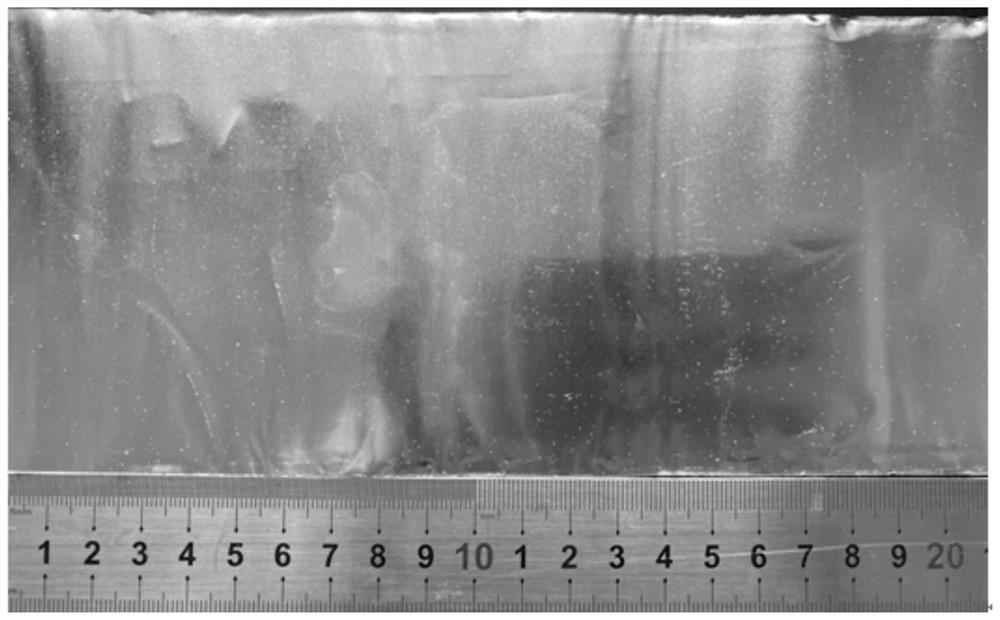

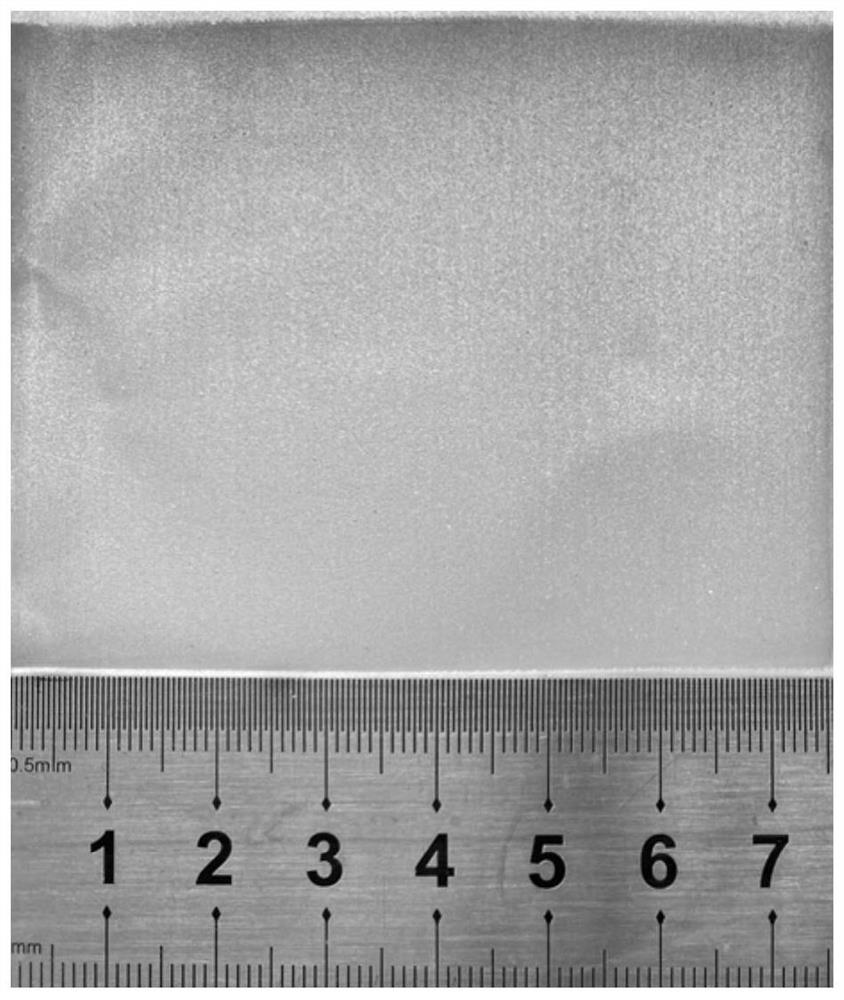

Medium-high-voltage electronic aluminum foil for high-capacity and high-strength capacitor and preparation method thereof

ActiveCN113234907AIncrease capacityIncrease the proportionElectrolytic capacitorsFurnace typesAluminum foilCapacitor

The invention discloses a medium-high-voltage electronic aluminum foil for a high-capacity and high-strength capacitor and a preparation method thereof. Through the production modes of casting and a continuous air cushion furnace, the specific volume is increased, and the production period is shortened; and the continuous air cushion furnace is used for multiple times for homogenization and annealing, and the problem that a casting structure is not uniform is solved, so that the performance and the cubic texture are improved, and the medium-high-voltage high-purity aluminum foil for the high-capacity and high-strength capacitor is obtained.

Owner:广西广投正润新材料科技有限公司

Water-based graphite-based high-temperature bonding solid lubricant and preparation method and application thereof

ActiveCN110982604AImprove the lubrication effectEasy to operateLubricant compositionPolyamideSodium sulfate

The invention discloses a water-based graphite-based high-temperature bonding solid lubricant and a preparation method and application thereof. The water-based graphite-based high-temperature bondingsolid lubricant is prepared from the following components in percentage by weight: 8 to 25% of a lubricating main agent, 1 to 5% of a dispersing agent, 4 to 16% of a bonding agent and 60 to 80% of water, wherein the lubricating main agent comprises graphite and silicon dioxide; the dispersing agent comprises at least one selected from the group consisting of a silane coupling agent, hexadecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium bromide, lauryl sodium sulfate and sodium dodecyl sulfate; and the bonding agent comprises at least one selected from the group consisting of water-based polyamideimide, inorganic phosphate and water glass. The water-based graphite-based high-temperature bonding solid lubricant has the characteristics of excellent antifriction and antiwear properties, wide temperature application range, normal-temperature curing, simple post-treatment of coating, environmental friendliness, avoidance of high-temperature oxidation of workpieces and the like.

Owner:TSINGHUA UNIV

Apparatus and method for carrying out selenylation treatment on CIGS (copper indium gallium selenide) thin films and CIGS thin-film device

InactiveCN103088301AReduce leakageHigh Selenization EfficiencyVacuum evaporation coatingSputtering coatingIndiumThermal insulation

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

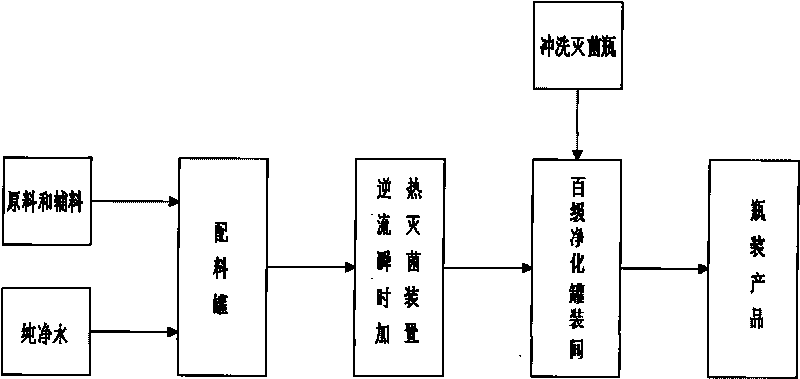

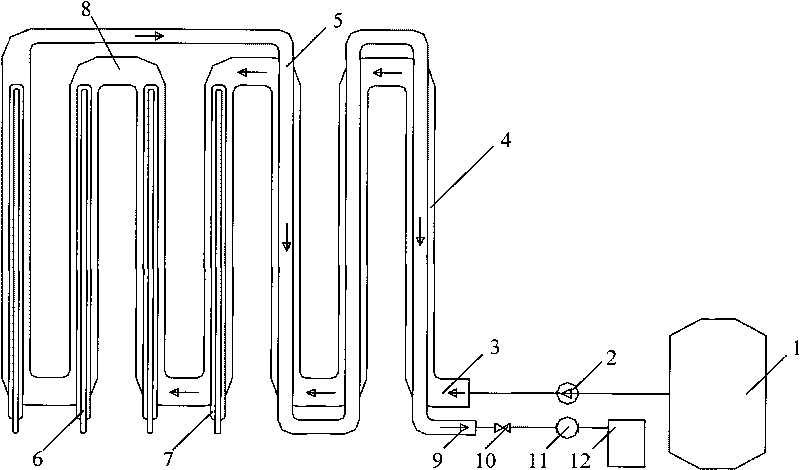

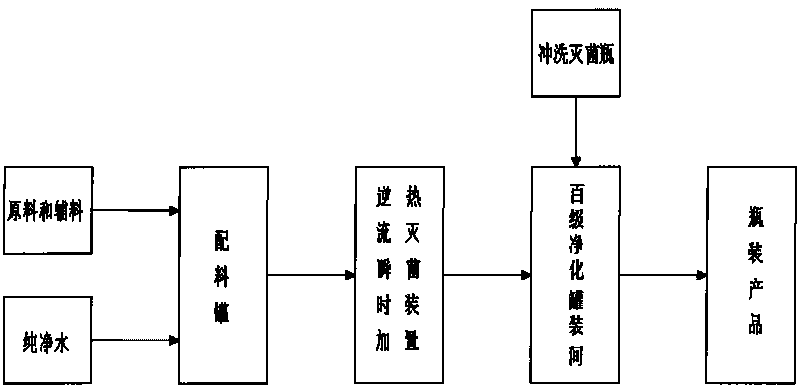

Low-temperature aseptic system and process for filling plastic bottled drink

The invention discloses a low-temperature aseptic system and a low-temperature aseptic process for filling plastic bottled drink, and belongs to the technical field of food processing. The system and the process are technically characterized in that: the heating sterilization adopts a countercurrent instantaneous heating sterilization device, and the device comprises a countercurrent heat exchange pipeline and an instantaneous heating sterilization pipeline; and a material is heated and sterilized in the instantaneous heating sterilization pipeline, the heated and sterilized material performs heat exchange and temperature reduction in the countercurrent heat exchange pipeline, the heating sterilization temperature is between 150 and 155 DEG C, the time is between 8 and 12 seconds, and the outlet temperature is between 25 and 30 DEG C. A countercurrent heat exchange structure and a countercurrent heat exchange process are adopted, so the system and the process have less heat loss and short heating time, avoid the high-temperature oxidation of the drink, effectively maintain nutritional components of finished products, and reduce the energy consumption. The system and the process adopt normal-temperature filling, have low filling temperature, effectively overcome the 'cooked soup taste' caused by high-temperature filling, and maintain the original flavor of tea and fruit juice. The system has the advantages of simple structure, steady operation and convenient maintenance.

Owner:万政豪

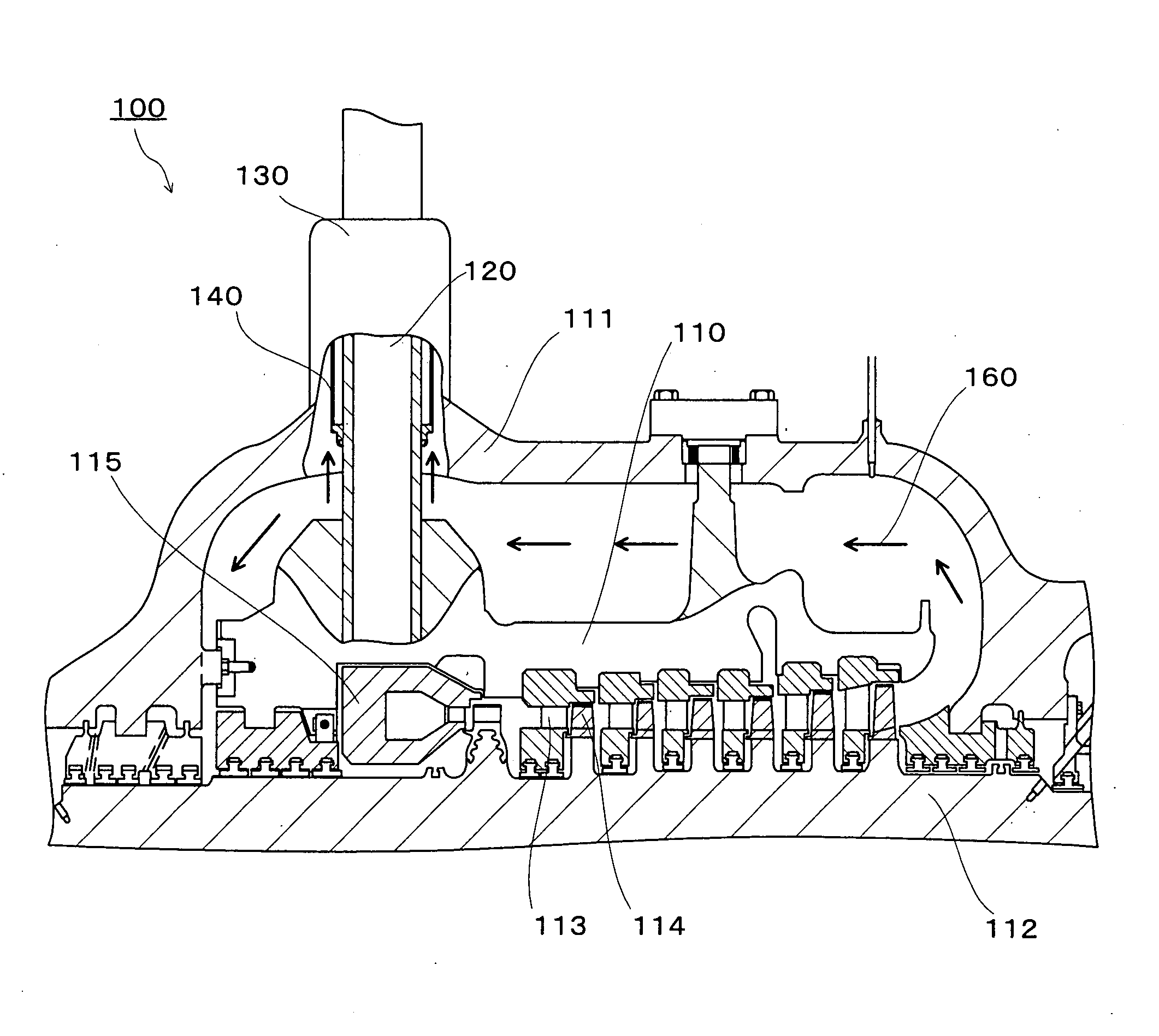

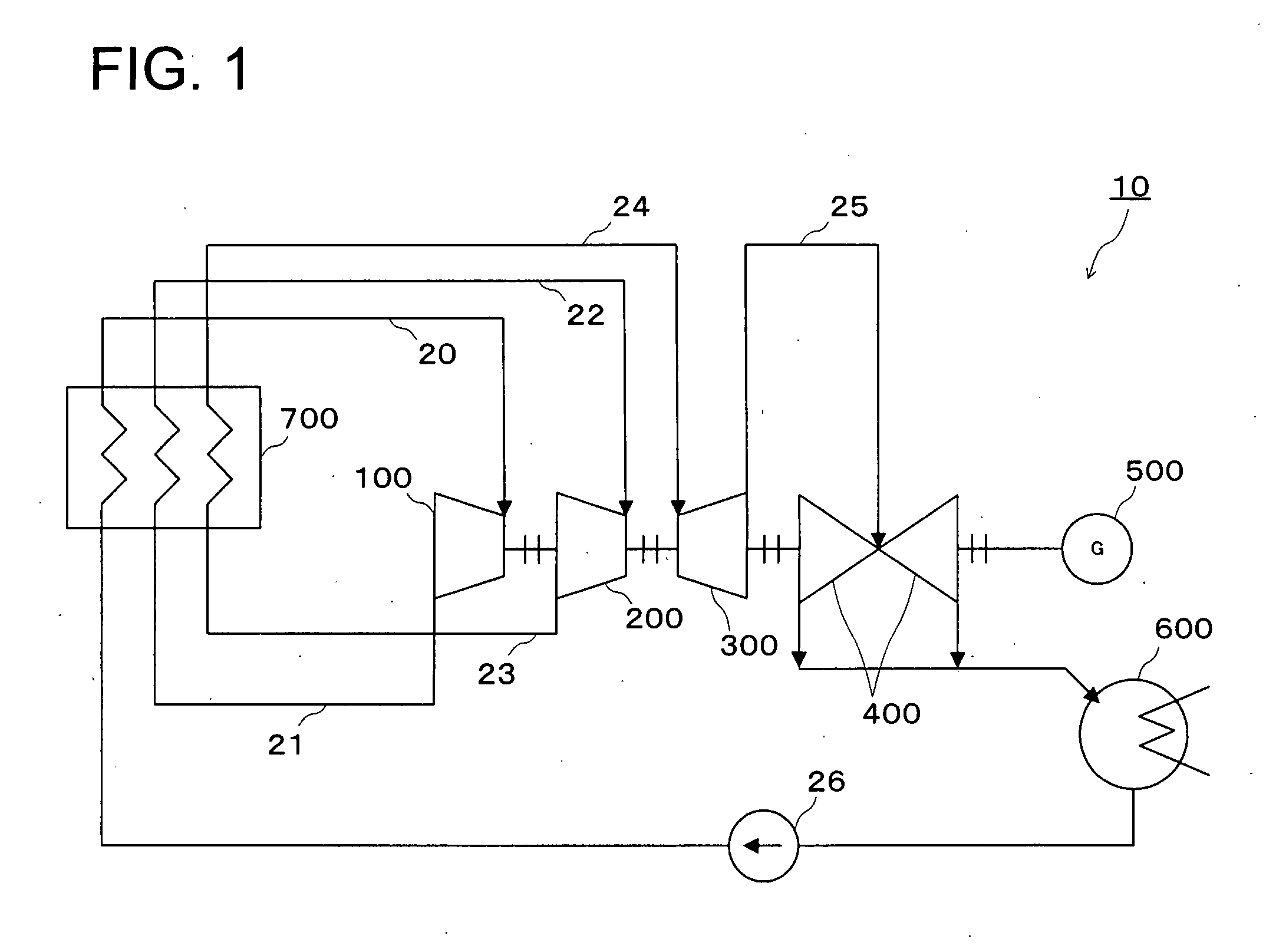

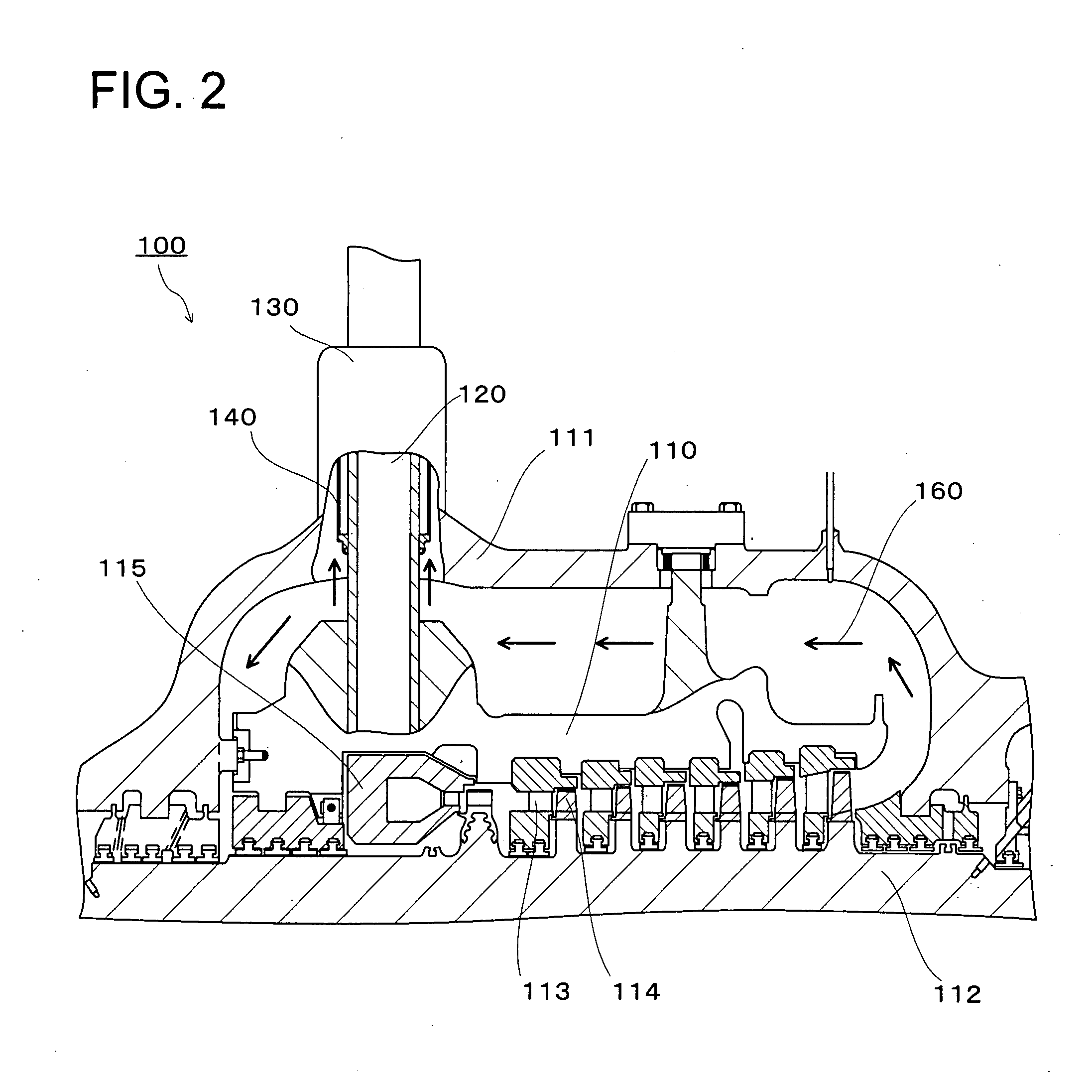

Steam turbine

ActiveUS20070253811A1Secure strengthAvoid high temperature oxidationPump componentsEngine fuctionsChemical compositionEngineering

A super steam turbine (100) into which high-temperature steam of 650° C. or more is introduced is provided with an inner steam pipe (120) which is disposed through an inner casing (110) and an outer casing (111), an outer steam pipe (130) which is welded to the outer casing (111) and disposed outside of the inner steam pipe (120) along the inner steam pipe (120) with a prescribed space therebetween, and a radiation heat shielding pipe (140) which is disposed along the inner steam pipe (120) between the inner steam pipe (120) and the outer steam pipe (130) to face a welded portion of at least the outer steam pipe (130), wherein cooling steam (160) is flown between the inner steam pipe (120) and the outer steam pipe (130), respective component parts are made of a suitable heat-resisting steel having prescribed chemical composition ranges.

Owner:KK TOSHIBA

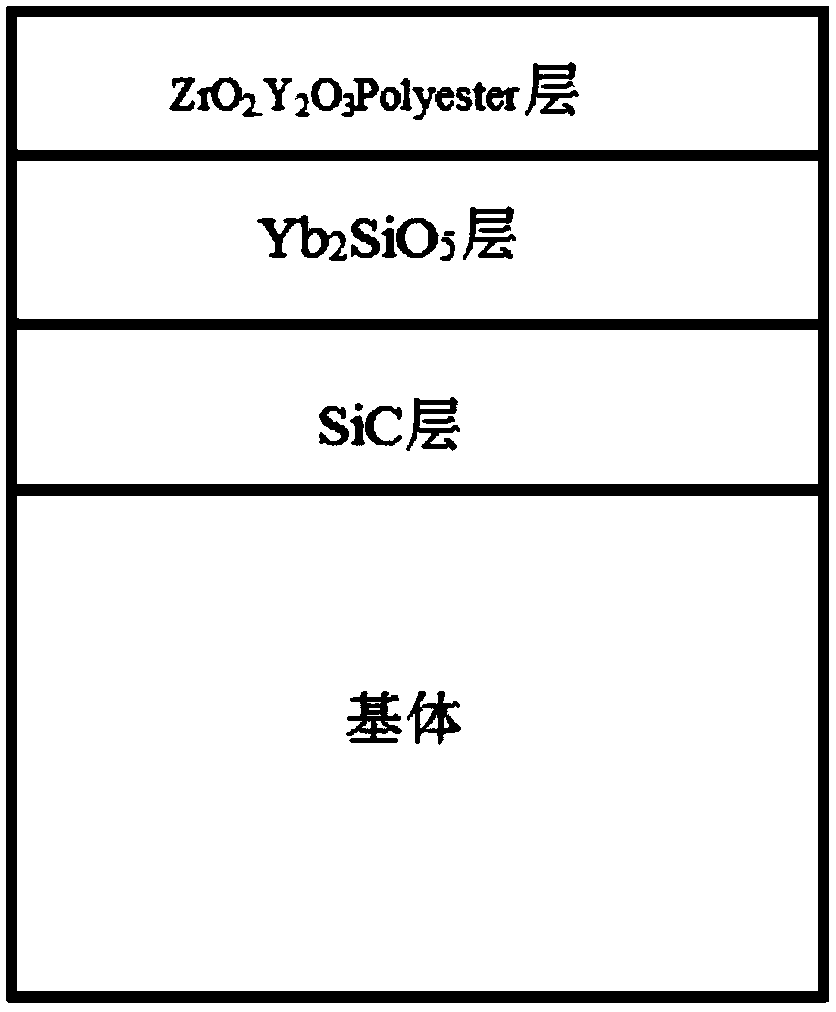

Ceramic-based composite turbine outer ring high-temperature sealing coating and preparation process thereof

InactiveCN109371353AAchieve lifeAchieve reliabilityMolten spray coatingPlasma technologyCeramic coating

The invention relates to the technical field of aero-engines, in particular to a ceramic-based composite turbine outer ring high-temperature sealing coating and a preparation process thereof. The ceramic-based composite turbine outer ring high-temperature sealing coating comprises a bonding layer, a transition layer and a wearing layer coating from inside to outside in sequence. The bonding layercomprises SiC. The transition layer comprises Yb2SiO5. The wearing layer coating comprises ZrO2.Y2O3Polyester. The coating provided by the invention is a composite coating capable of being matched with a SiC / SiC ceramic-based composite and has the advantages of 1200-DEG C wear consumption sealing and heat insulation. The problems that mechanical damage caused by mutual friction between SiC / SiC ceramic-based composite turbine components, and high-temperature oxidation, structure degradation and other damages to a ceramic-based composite can be solved. The plasma technology has the advantages ofhigh-energy density, high production efficiency, low cost, little equipment investment and the like and belongs to the optimal process for preparing high-temperature-resistant ceramic coating materials.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

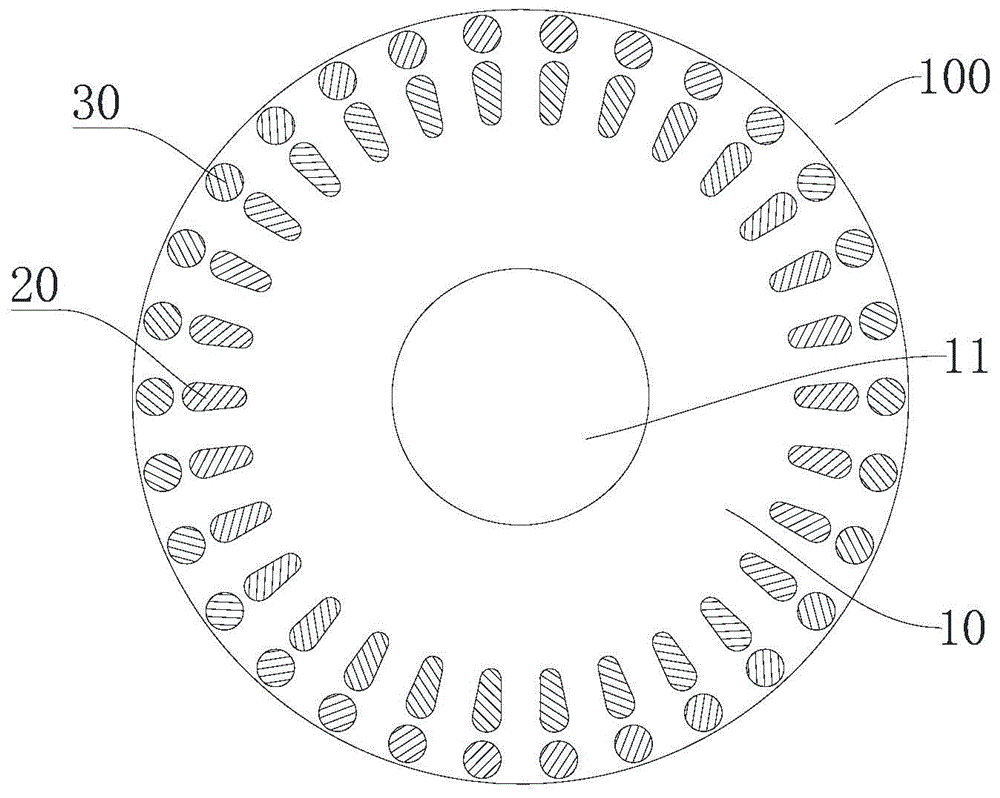

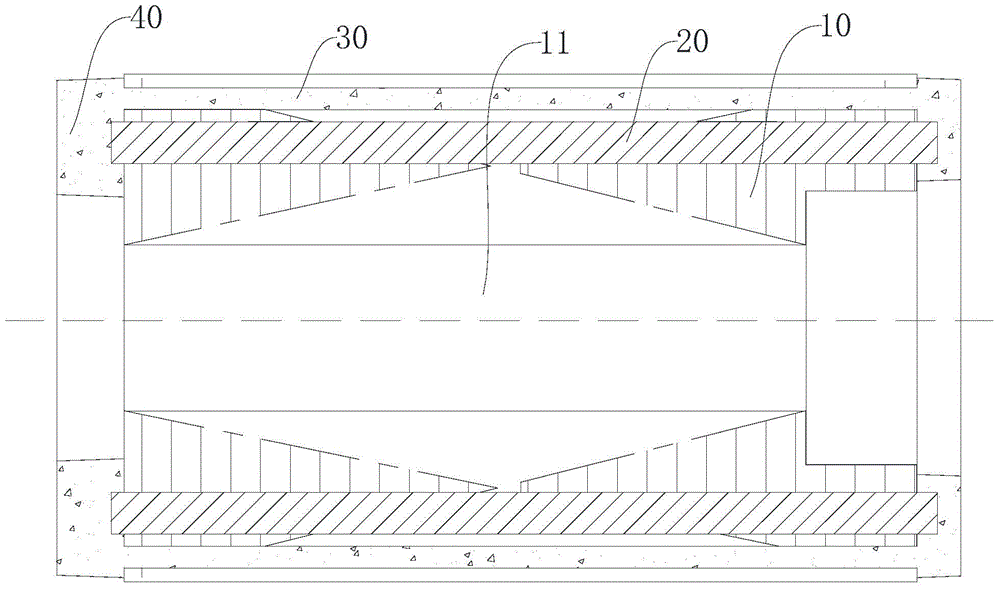

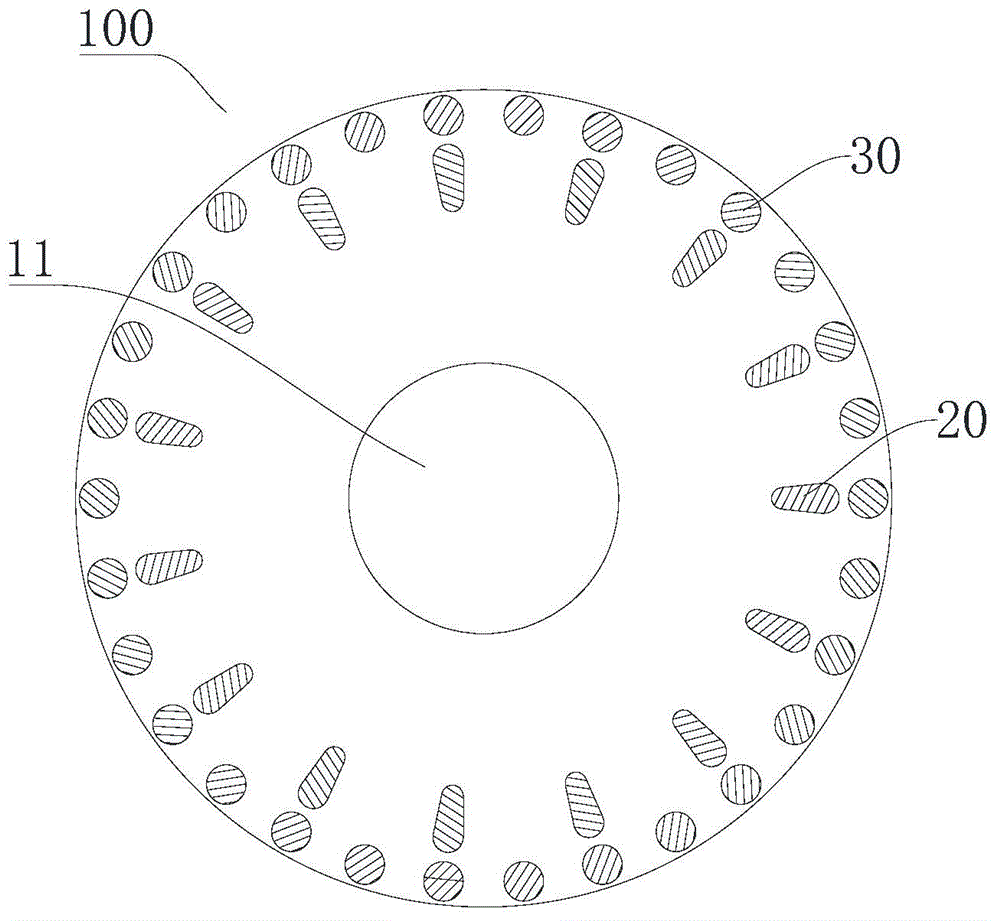

Motor rotor

InactiveCN104600932AImprove boot performanceImprove operational efficiencyMagnetic circuit rotating partsAsynchronous induction motorsEngineeringForming processes

The invention discloses a motor rotor. The motor rotor comprises a rotor core in which an axle hole is arranged, wherein the periphery of the axle hole is provided with multiple inner rotor slots and multiple outer rotor slots all which are spaced along the radial direction of the rotor core and along the circumferential direction of the rotor core, and each inner rotor slot is arranged inside the outer rotor slot along the radial direction of the rotor core; the motor rotor further comprises multiple inner conductive strips, multiple outer conductive strips and an end short-connection ring; said multiple inner conductive strips are respectively inserted in said multiple rotor slots, said multiple outer conductive strips are respectively inserted in said multiple outer rotor slots, and the electrical conductivity of each outer conductive strip is different from that of the inner conductive strip; the end short-connection ring is arranged on both ends of the rotor core, and said inner conductive strips and said outer conductive strips are respectively connected through the end short-connection ring. According to the motor rotor, the motor is better in start ability, and higher in operation efficiency, meanwhile high-temperature oxidation can be effectively avoided in a formation process, and the process can be simply and conveniently realized.

Owner:GUANGDONG MEIZHI COMPRESSOR

Steel wire water bathing and air cooling quenching unit

ActiveCN105803166AImprove water bath quenching effectImprove stabilityFurnace typesHeat treatment process controlQuenchingAir cooling

The invention discloses a steel wire water bathing and air cooling quenching unit which comprises a water bathing quenching unit body and an air cooling quenching unit body. The air cooling quenching unit body is arranged on the downstream portion of the water bathing quenching unit body, and the air cooling quenching unit body and the water bathing quenching unit body are in mutual linkage. The water bathing quenching unit body is provided with a plurality of water baths, the length of the water baths is controlled through movable baffles capable of moving, and accordingly the water bathing quenching time for steel wires is controlled. The air cooling quenching unit body can control the temperature independently and intelligently, and the influences of the environment temperature on air cooling are reduced. According to the water bathing and air cooling quenching unit, the quenching time and quenching length can be adjusted freely, and products with different specifications and strengths can be produced at the same time; and in addition, the water bathing and air cooling quenching unit can control the temperature independently, so that the steel wires are quenched within the required quenching temperature range all the time, the quenching effect of the steel wires is improved, and the stability of mechanical properties of the steel wires is guaranteed.

Owner:ZHANGJIAGANG DONGHANG MACHINERY

Method for preparing graphene from microcrystalline graphite

The invention belongs to the technical field of preparation of materials and particularly relates to a method for preparing graphene from expanded graphite. Microcrystalline graphite serving as a raw material is subjected to first chemical intercalation treatment, first high-temperature expansion treatment, second intercalation treatment and second high-temperature expansion treatment sequentially, second expanded microcrystalline graphite is obtained and subjected to ultrasonic treatment twice, and a peeling material is obtained and subjected to press filtering, separation and washing, and graphene is obtained. According to the method, the microcrystalline graphite is taken as the raw material, the production technology process is short, and the method is low in cost, produces no sulfur and can be used for mass production of graphene materials.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

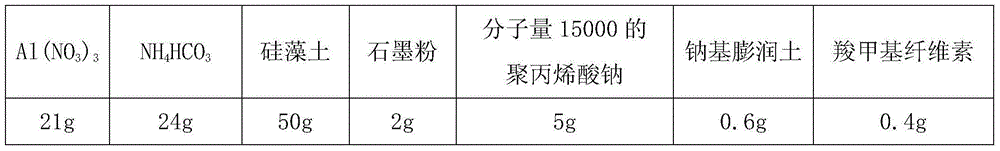

Anti-shedding carbon nano paint and preparation method thereof

InactiveCN105315821AHigh mechanical strengthImprove vitrification abilityPolyether coatingsNano al2o3Slurry

The invention provides an anti-shedding carbon nano paint and a preparation method thereof. The paint is composed of the following components in percentage by weight: 5 to 20 wt% of nano Al2O3, 50 to 80 wt% of diatomite, 2 to 10 wt% of graphite powder, 5 to 20 wt% of binder, 1 to 3 wt% of suspended dispersing agent, and the balance being solvent and impurities. The preparation method comprises the following steps: preparing an Al(NO3)3 water solution and a NH4HCO3 water solution from Al(NO3)3 and NH4HCO3 respectively; adding the Al(NO3)3 water solution into turbid liquid of diatomite and NH4HCO3, filtering and washing generated Al(OH)3 precipitate to obtain a mixture of nano Al(OH)3 and diatomite; heating to dehydrate the mixture to form nano Al2O3; adding a solvent, graphite powder, binder and a suspended dispersing agent into the mixture of nano Al2O3 and diatomite, and evenly mixing to obtain the nano level anti-shedding carbon slurry. The provided paint has the advantages that the size of nano particles is uniform, the size is small, the dispersibility is good, the cost is low, the preparation and painting technologies are simple and feasible, the natural peeling ability is strong, the high temperature oxidation and decarbonization of steel plate can be effectively avoided, and the paint is suitable for precision machining of metal workpiece with complicated shapes.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com