Method for optimizing repaired tissue of large workpiece based on local heat treatment realized by induction heating

A local heat treatment and induction heating technology, applied in the field of metal parts repair, can solve the problems of difficult design and manufacture, out-of-tolerance deformation, complex dimensional accuracy, etc., and achieve the effect of small heat-affected zone, small deformation and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

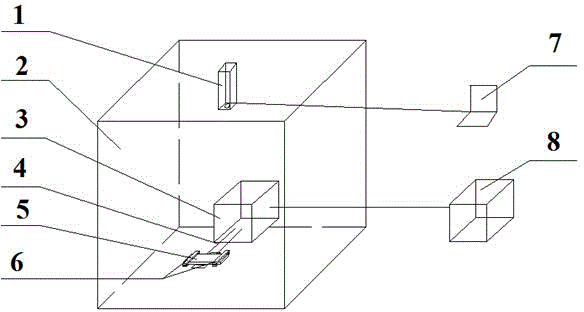

[0027] Such as figure 1 As shown, an induction heating local heat treatment device includes an infrared thermal imager 1, a protective gas box 2, an induction heating power supply auxiliary machine 3, an induction heater 4, repair parts 5, a special fixture 6, and a thermal imager measurement and control computer 7 and the induction heating power host 8, the infrared thermal imager 1 of the present invention, the protective gas box 2, the induction heating power auxiliary machine 3, the induction heater 4, the thermal imager measurement and control computer 7 and the induction heating power host 8 can be purchased commercially. Obtained, or prepared according to the method disclosed in the prior art, those skilled in the art can select and set according to the prior art. The thermal imaging camera 1 is arranged in the protective gas box 2, the input and output of the thermal imaging camera 1 is connected with the input and output of the measurement and control computer 7 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com